Ruthenium dioxide-based composite nano-material and preparation method thereof

A technology of composite nanomaterials and ruthenium dioxide, which is applied in the field of ruthenium dioxide/metal nanoparticles/carbon composite electrode materials and its preparation for supercapacitors, and can solve problems such as reducing electrochemical adsorption, affecting proton transfer, and dangerous production operations , to achieve the effect of improving energy density and power density, fast charging and discharging, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Ultrasonically disperse 4.14mg of activated carbon matrix in 20mL of water, then add 2.74mg of chloroauric acid and 4.14mg of ruthenium chloride, adjust the pH of the solution to 3, stir and absorb for 2 hours, react in an oil bath at 90°C for 2 hours, and then centrifuge , washed with ethanol and distilled water three times respectively, placed in a nitrogen-protected muffle furnace, and calcined at 350° C. to obtain the composite electrode material.

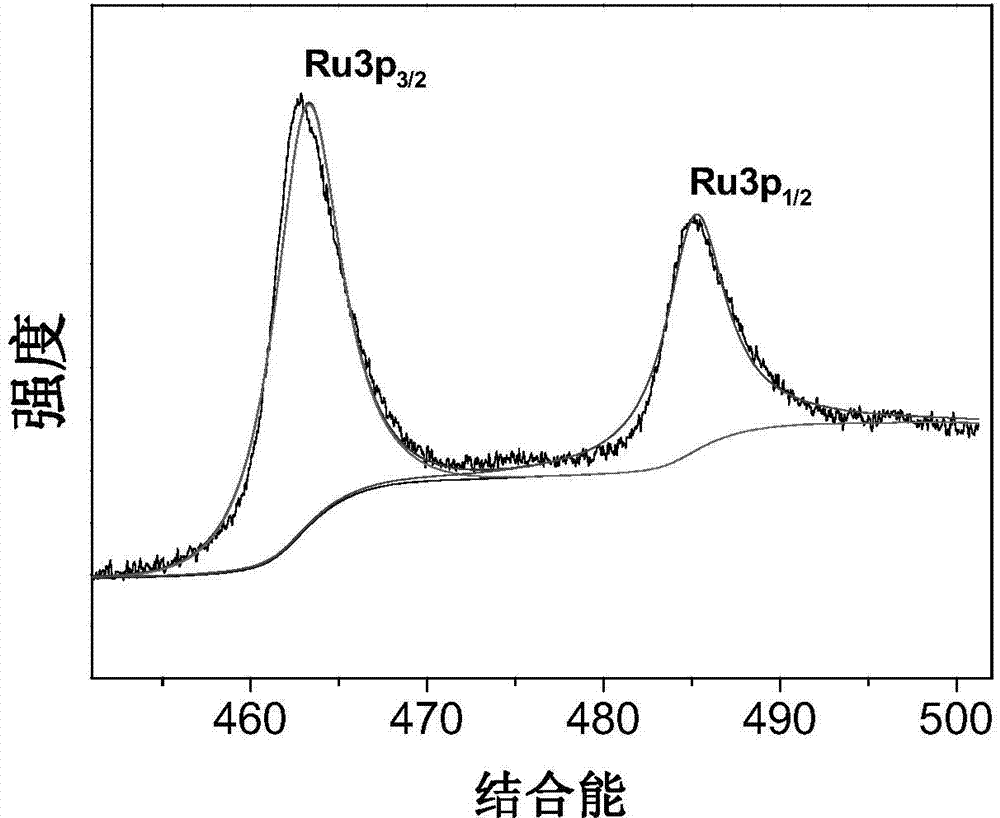

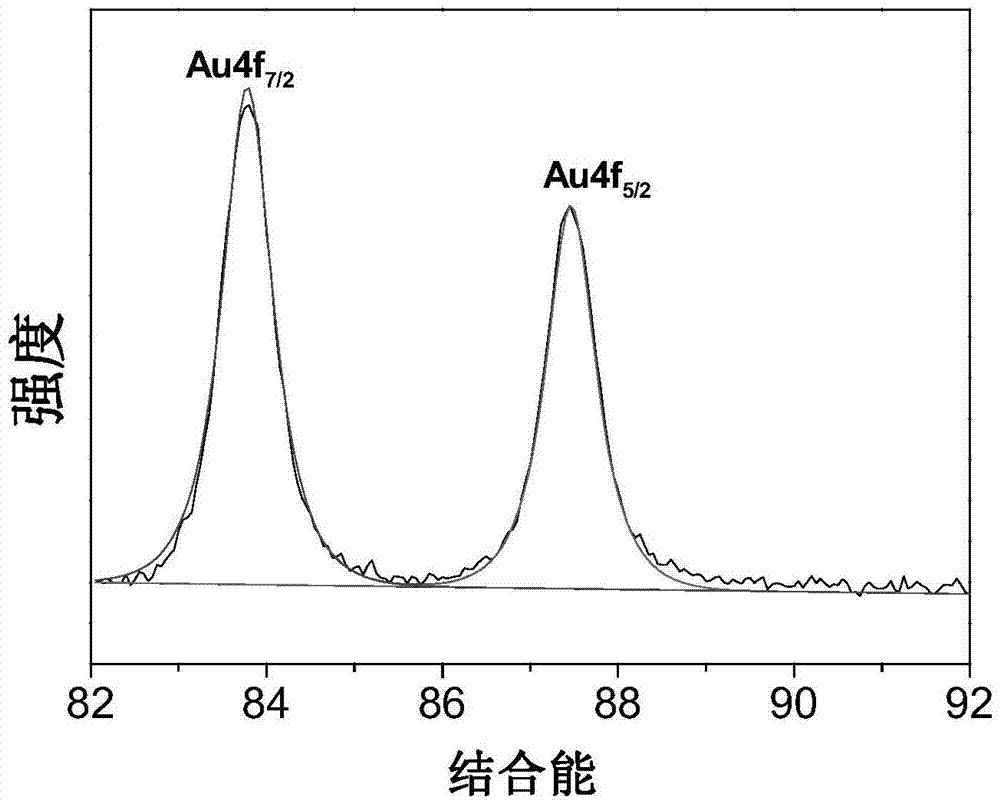

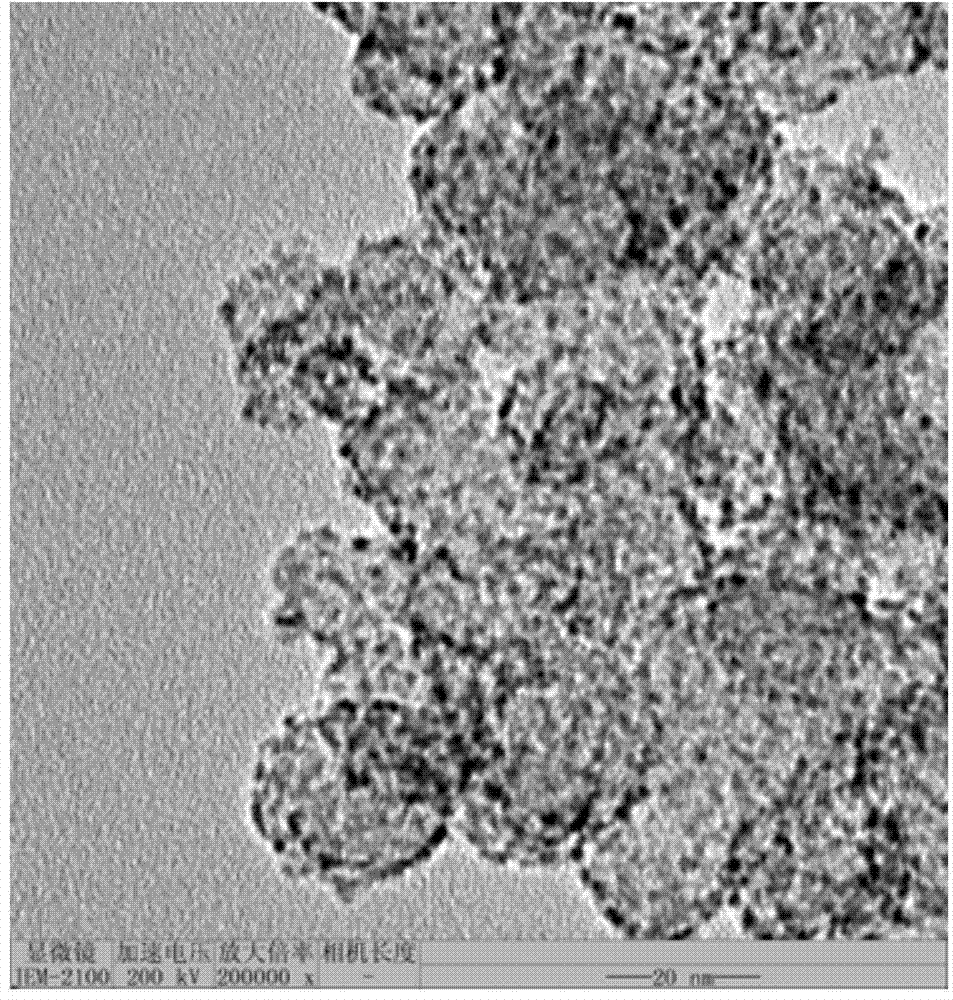

[0040] figure 1 The X-ray photoelectron spectrum of the ruthenium dioxide / metal nanoparticle / carbon composite material was obtained for this example, and the Ru3p orbital fitting results can indicate that the obtained material is a ruthenium dioxide material. figure 2 It is the fitting result of Au4f orbital, indicating that there are elemental gold particles in the composite material. image 3 It is the transmission electron microscope picture of the ruthenium dioxide / metal nanoparticle / carbon composite material. It c...

Embodiment 2

[0042] Ultrasonically disperse 0.3105 mg of activated carbon matrix in 20 mL of water, then add 0.4932 mg of chloroauric acid and 0.621 mg of ruthenium chloride to adjust the pH of the solution to 5, stir and absorb for 4 hours, react in an oil bath at 40 ° C for 3 hours, and then centrifuge , washed with ethanol and distilled water three times respectively, placed in a nitrogen-protected muffle furnace, and calcined at 200° C. to obtain the composite electrode material.

Embodiment 3

[0044] Ultrasonically disperse 2.07mg of activated carbon matrix in 20mL of water, then add 2.59mg of chloroplatinic acid and 2.07mg of ruthenium chloride, adjust the pH of the solution to 3, stir and absorb for 6 hours, react in an oil bath at 60°C for 4 hours, and then centrifuge , washed with ethanol and distilled water three times respectively, placed in a nitrogen-protected muffle furnace, and calcined at 250° C. to obtain the composite electrode material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com