Patents

Literature

355 results about "Ruthenium chloride" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Process for preparing an anode catalyst for fuel cells and the anode catalyst prepared therewith

InactiveUS6797667B2High activityHigh oxidation stateActive material electrodesCatalyst activation/preparationCarboxylic acidRuthenium chloride

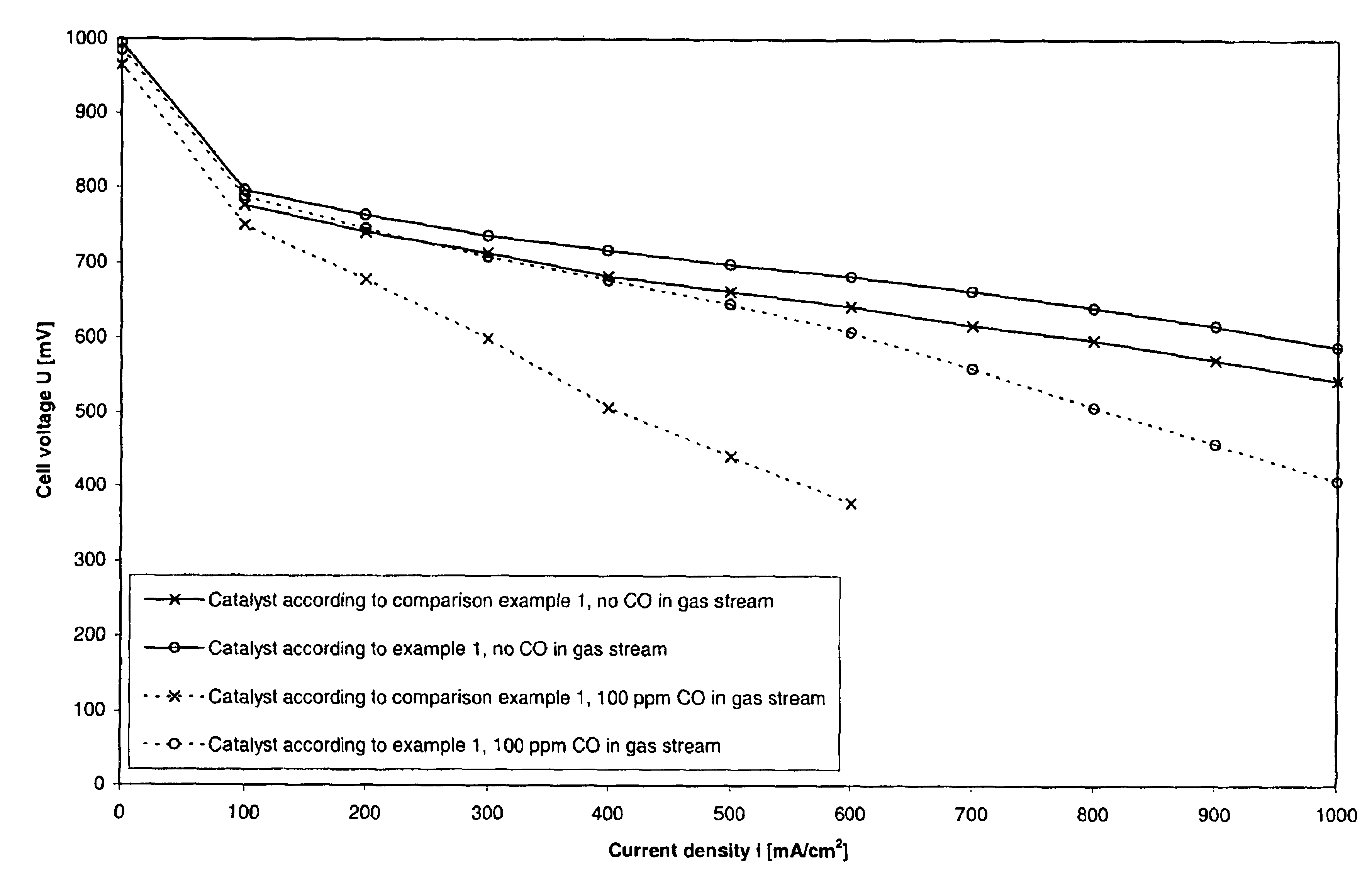

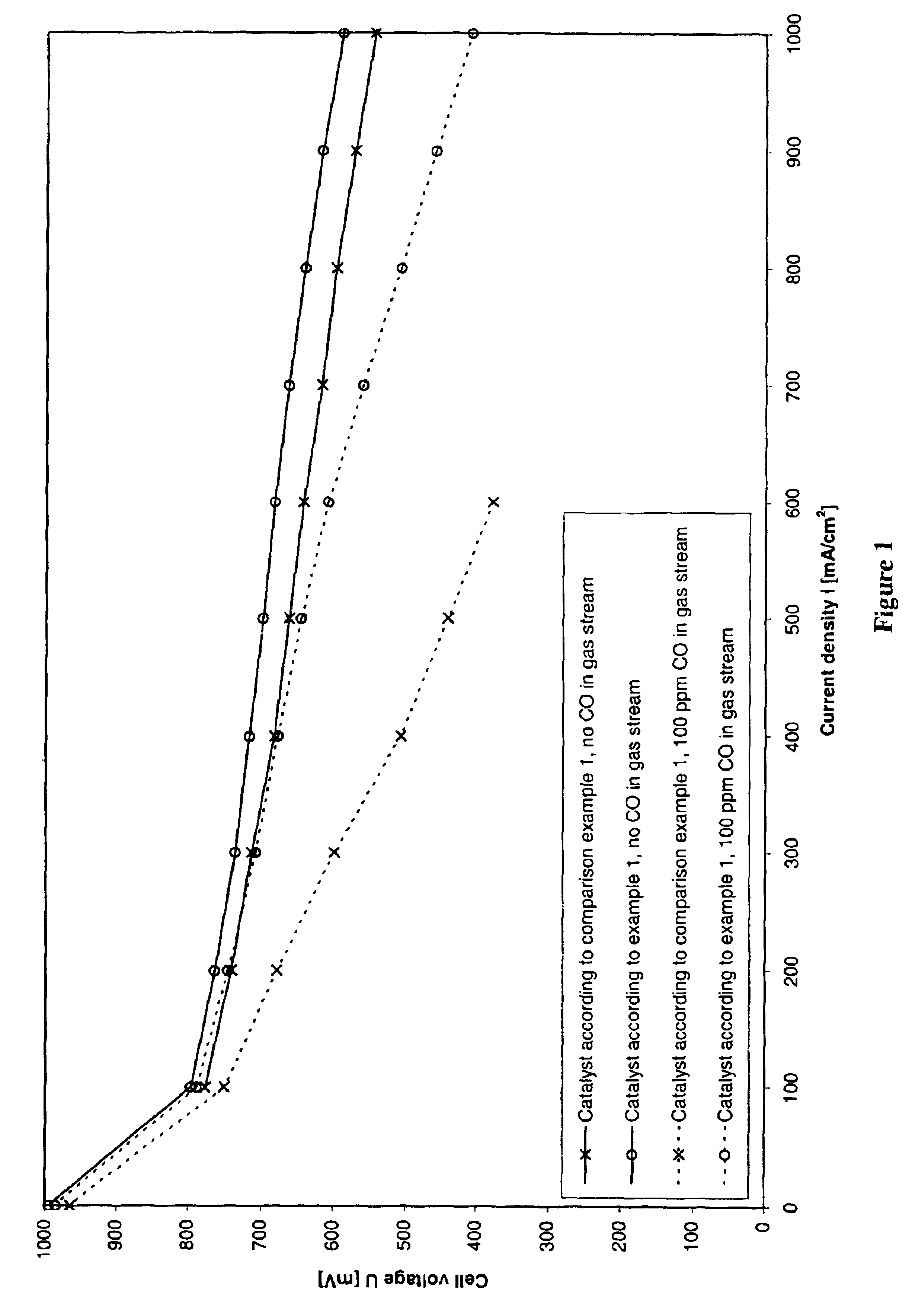

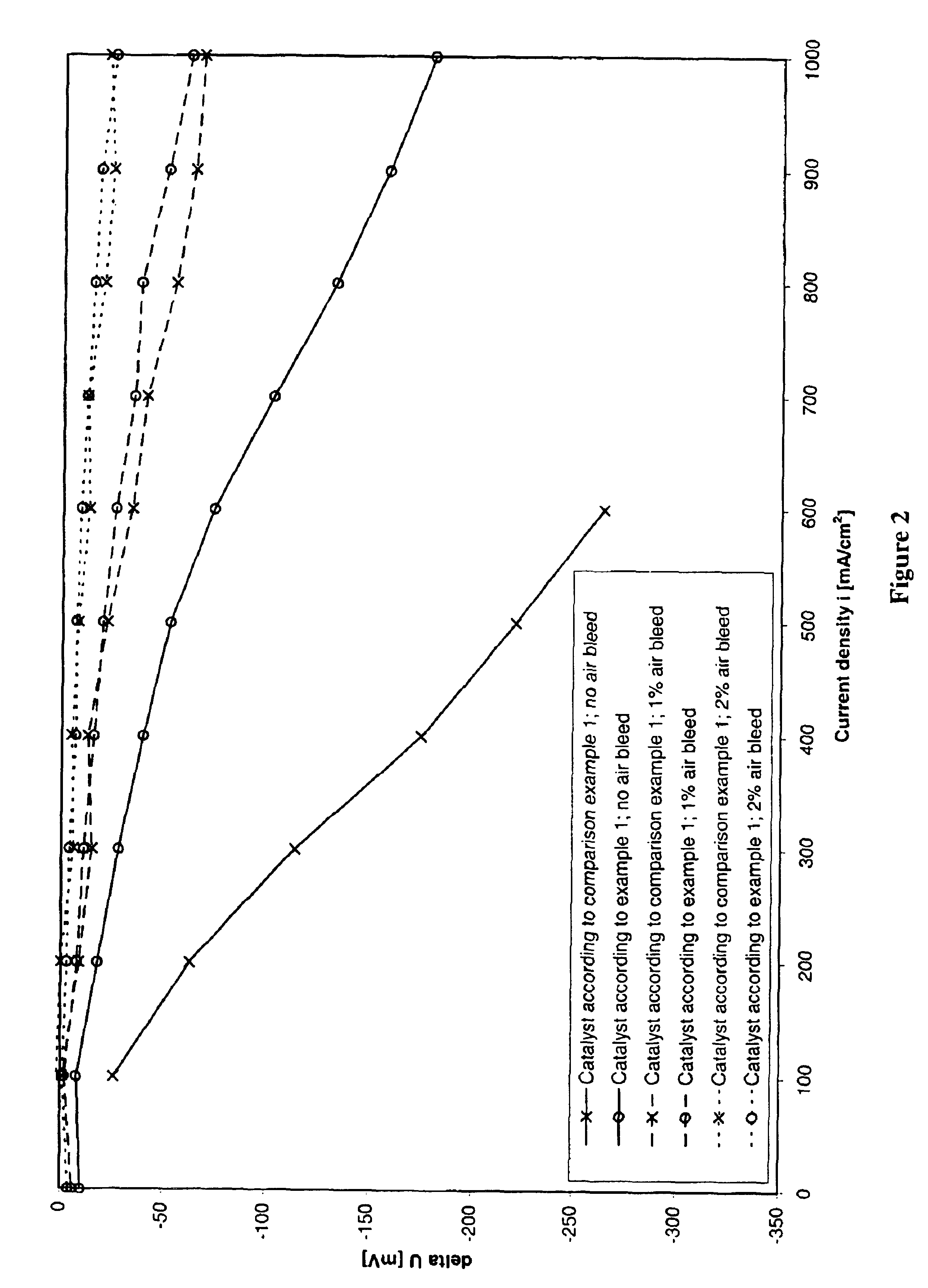

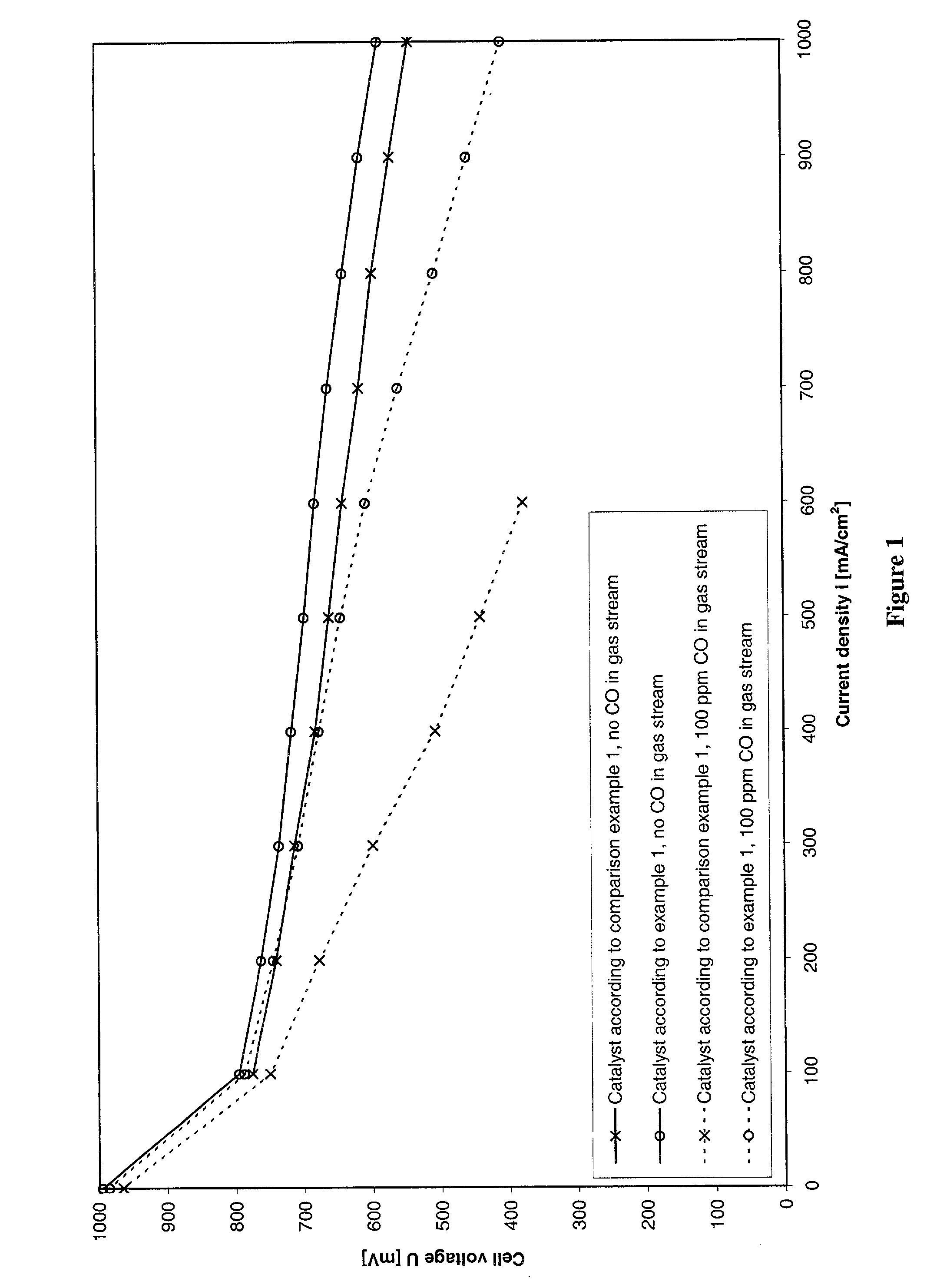

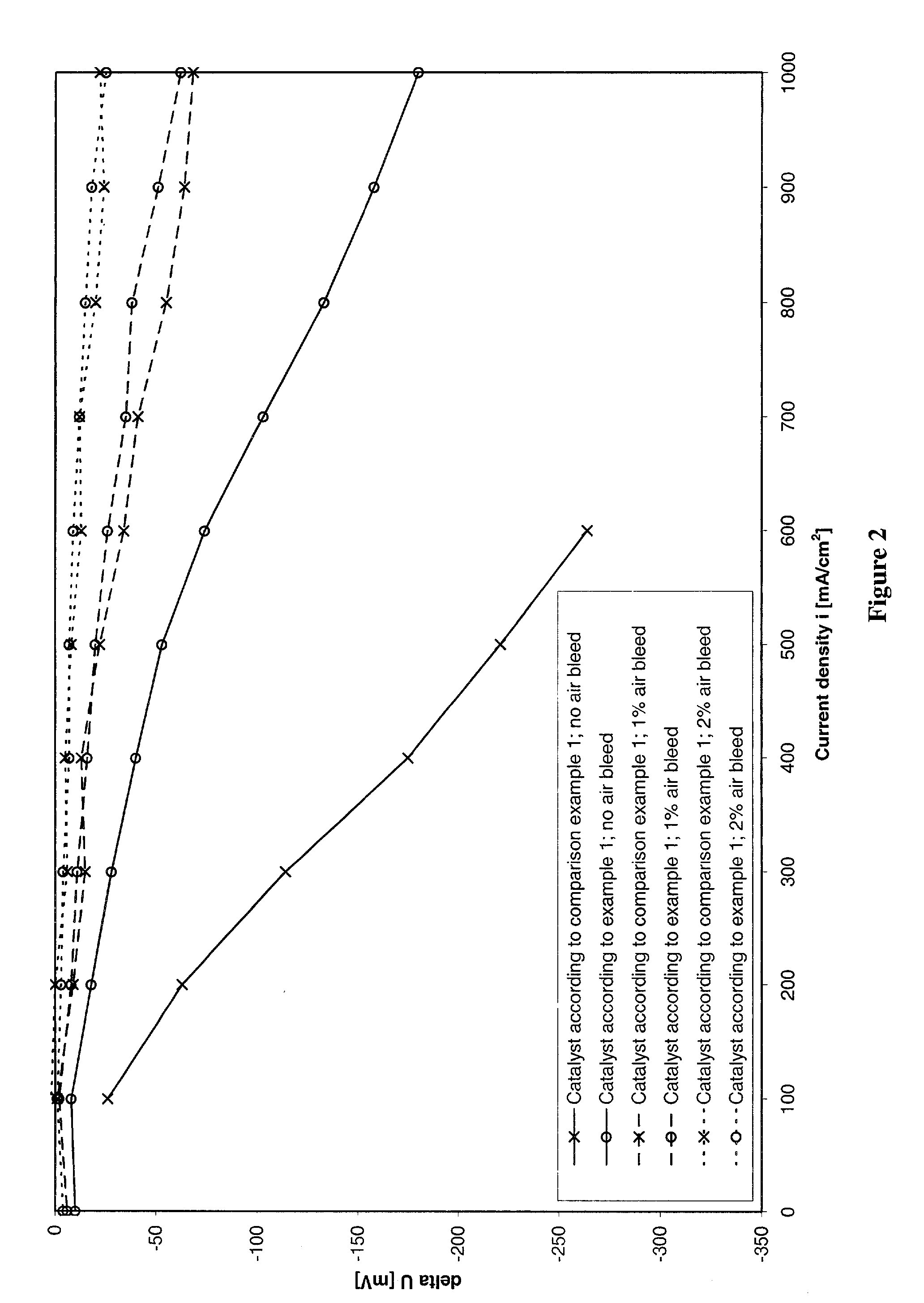

The invention provides a process for preparing a platinum-ruthenium catalyst and the catalyst prepared therewith. The catalyst can be supported on a support material in powder form or may also be unsupported. To prepare the supported catalyst, the support material is suspended in water and the suspension is heated to at most the boiling point. While keeping the temperature of the suspension the same, solutions of hexachloroplatinic acid and ruthenium chloride are then added to the suspension, then the pH of the suspension is increased to a value between 6.5 and 10 by adding an alkaline solution and the noble metals are thus precipitated onto the support material. Afterwards, one or more organic carboxylic acids and / or their salts are added to the suspension and the catalyst is chemically reduced, washed, dried and optionally subsequently calcined under an inert or reducing atmosphere at a temperature between 300 und 1000° C. The catalyst is characterised by a high tolerance to carbon monoxide poisoning in the fuel cell.

Owner:UMICORE AG & CO KG

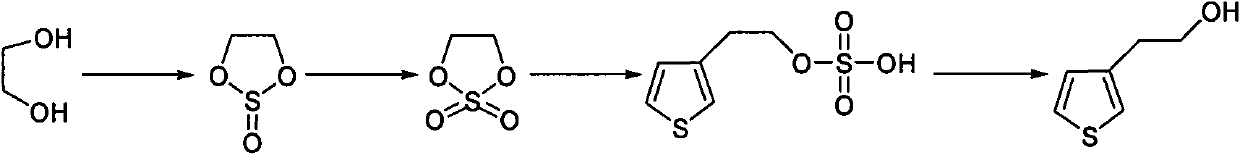

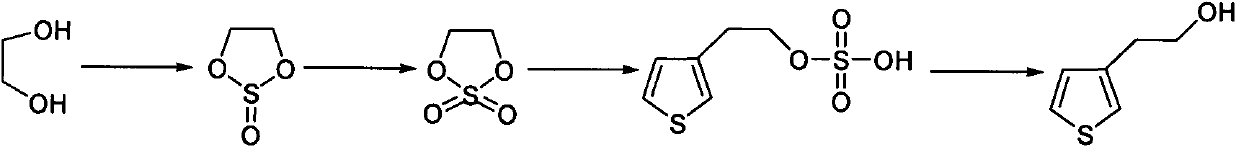

Synthetic method of thiophene-3-ethanol

The invention discloses a synthetic method of thiophene-3-ethanol. The method comprises the following steps of: adding a halogenated hydrocarbon solvent and ethylene glycol into a reaction kettle, dropwise adding thionyl chloride and preserving heat for reacting; separating liquid and extracting to obtain an organic phase containing a substance shown in the specifications; adding a ruthenium trichloride aqueous solution and a sodium bicarbonate aqueous solution in the presence of the halogenated hydrocarbon solvent and dropwise adding a sodium hypochlorite aqueous solution; after detecting that a system does not have oxidizing property, performing liquid separation, concentration, devitrification and drying to obtain a substance shown in the specifications, adding an ester solvent and butyl lithium into a reaction kettle, adding a prepared ester solution of tribromothiofuran and a prepared ester solution of the substance, separating the liquid and extracting to obtain a system containing a substance shown in the specifications; and adding a dilute sulfuric acid into the system containing the substance shown in the specifications, concentrating, neutralizing, extracting and concentrating to obtain an end product. The method has the advantages of high reaction purity and yield, stable process condition, easiness for operation and mass production capability; and the thiophene-3-ethanol is prepared from tribromothiofuran by performing low-temperature lithiation, so that the use of epoxy ethane serving as an explosive hazard is avoided, and mass production becomes possible.

Owner:ASYMCHEM LAB TIANJIN +4

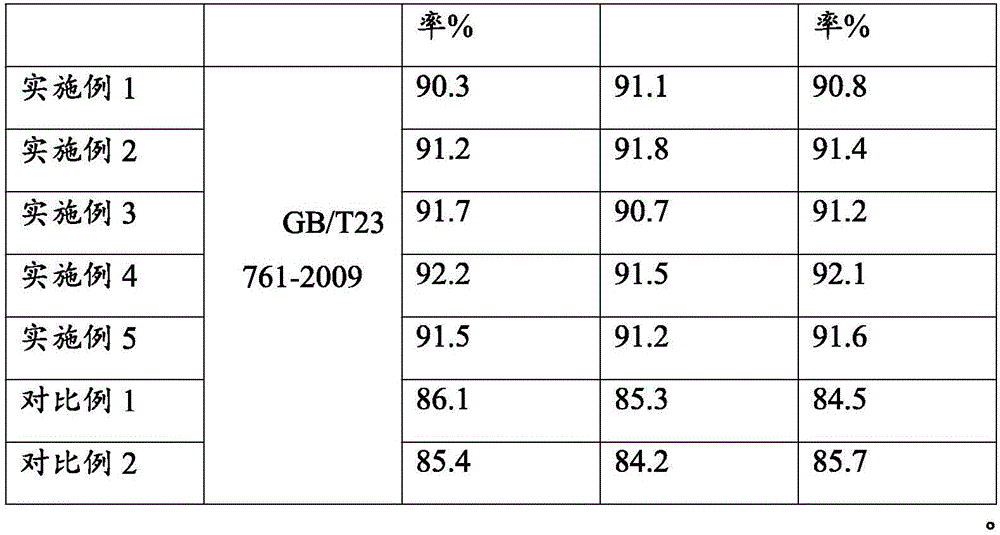

PtRu/graphene nano electro-catalyst and preparation method thereof

InactiveCN101740786AReductiveGood dispersionCell electrodesMetal/metal-oxides/metal-hydroxide catalystsSodium acetrizoateSodium acetate

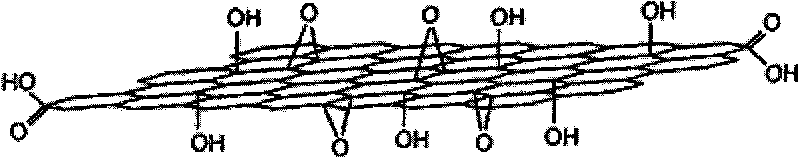

The invention discloses a preparation method of PtRu / graphene nano electro-catalyst, comprising the following steps of: ultrasonically dispersing oxidized nano graphite sheets into liquid polylol; then adding a chloroplatinic acid solution and a sodium acetate solution, sufficiently mixing, wherein the content of the oxidized nano graphite sheets contained in a mixture is 0.3-1.1 g / L, the concentration of chloroplatinic acid is 0.0004-0.002 mol / L, the concentration of ruthenium chloride is 0.0004-0.0013 mol / L, and the concentration of sodium acetate is 0.005-0.027 mol / L; transferring the mixture to a microwave hydro-thermal reaction kettle for microwave hydro-thermal reaction for 5-10 minutes; and filtering, washing and drying to obtain the PtRu / graphene nano electro-catalyst, wherein the mass fraction of a PtRu alloy contained in the PtRu / graphene nano electro-catalyst is 20-40 percent, the mass fraction of graphene is 80-60 percent, the atomic ratio of the PtRu alloy is Pt:Ru=1:2-1.5:1, and the liquid polylol is propanetriol or glycol. The preparation method has energy saving, fastness, simple process, and the like; and in addition, the prepared PtRu / graphene nano electro-catalyst has good electrocatalysis property for the oxidation of methanol and ethanol and is widely used as anode catalysts of direct methanol fuel cells.

Owner:ZHEJIANG UNIV

Method for preparation of phenolic compound by direct hydrogenolysis of lignin

InactiveCN104276930AHigh yieldSimple processOrganic chemistryOrganic compound preparationFiltration4-propylphenol

The invention relates to a method for preparation of a phenolic compound by lignin direct hydrogenolysis adopting hydrogen produced in situ by a solvent as a hydrogen donor under catalysis effects. The method comprises the following steps of adding lignin, catalysts and a solvent into a pressure-resistant container, carrying out a reaction process at a temperature of 150-350 DEG C for 1-20h and carrying out filtration and extraction separation. The method has a lignin conversion rate of more than 50% and phenol selectivity of more than 85% and can produce main products such as 4-propylguaiacol, 4-propylsyringol, 4-propylphenol, propenylguaiacol, syringol and allylphenol. The catalysts used by the method comprise palladium chloride, ruthenium chloride, cobaltous chloride, phospho-tungstic acid, nickel molybdate, barium molybdate, Pd / TiO2, Ru / TiO2 and Au / TiO2, a mass ratio of lignin to the catalysts is in a range of 1: 0.03 to 1: 1 and a mass ratio of lignin to the hydrogen donor is in a range of 1: 50 to 1: 150. The related lignin hydrogenolysis process has a simple technology and can be used for production of high-added value phenolic compounds by a biomass route.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

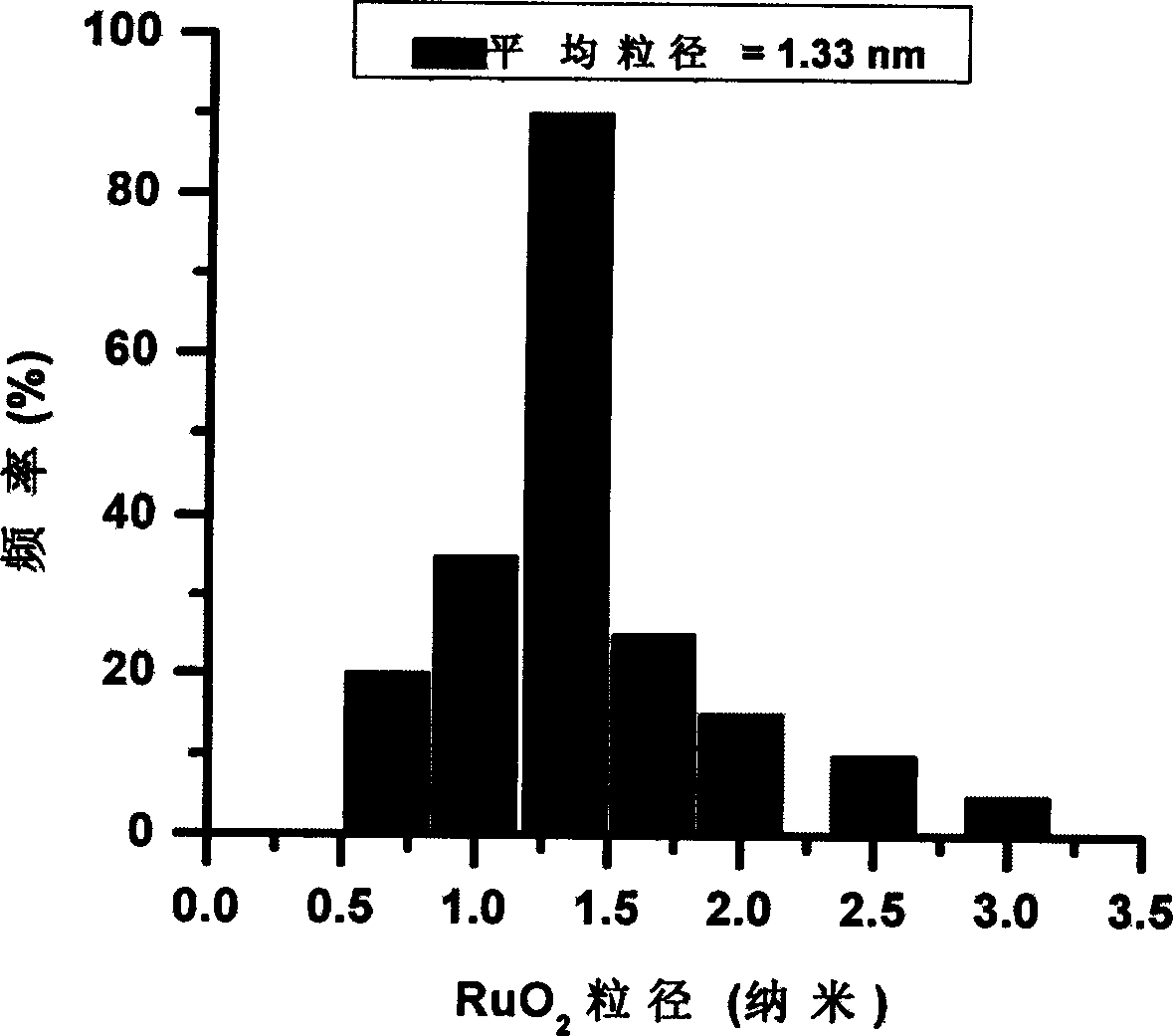

Method for preparing carbon nanotube supported nanometer hydrated ruthenium oxide

InactiveCN1806914AAvoid influenceMild preparation conditionsCatalyst carriersCatalyst activation/preparationCapacitanceAlcohol

The invention provides the method for preparation of hydrated nanometer ruthenium oxide loaded on carbon nanometer tube, comprising the following steps: putting the carbon nanometer tube into ruthenium chloride solution, vibrating with ultrasonic sound, at room temperature, adding hydrogen dioxide solution, carrying out heating-up reversed flow reaction, filtering, washing, drying and getting the product. The method is simple, and the hydrated ruthenium oxide has high dispersion degree on the carbon nanometer tube, small and homogeneous particles, good stability and high load capacity. The hydrated nanometer ruthenium oxide loaded on carbon nanometer tube has wide application in super capacitance and alcohol oxidative catalyst.

Owner:SOUTH CHINA UNIV OF TECH

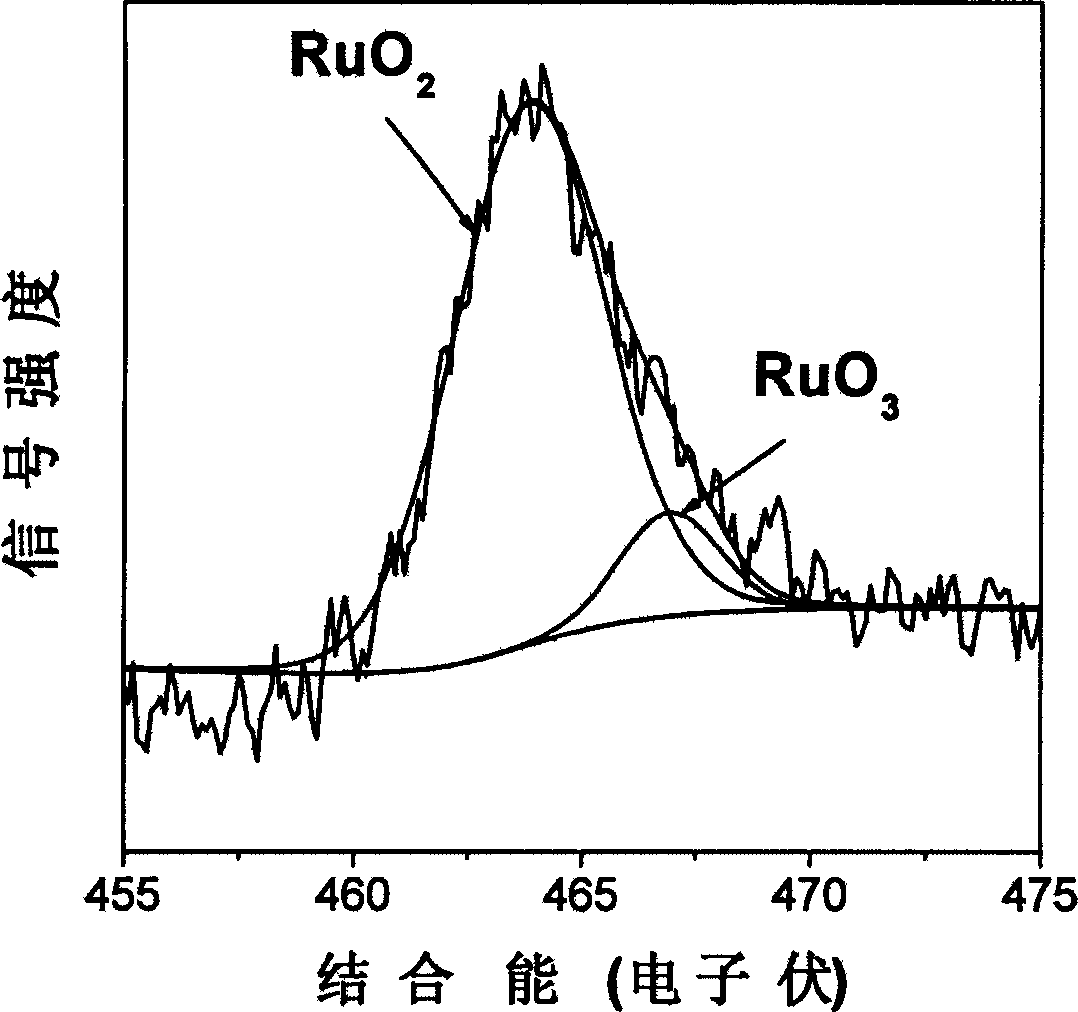

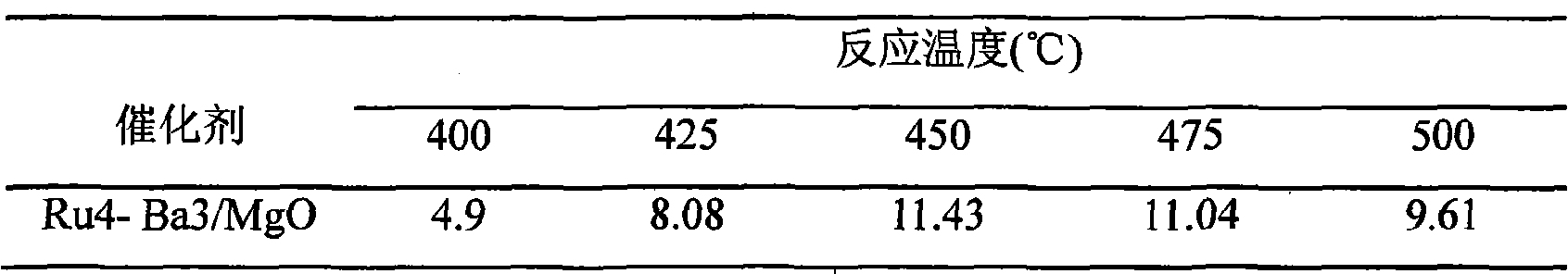

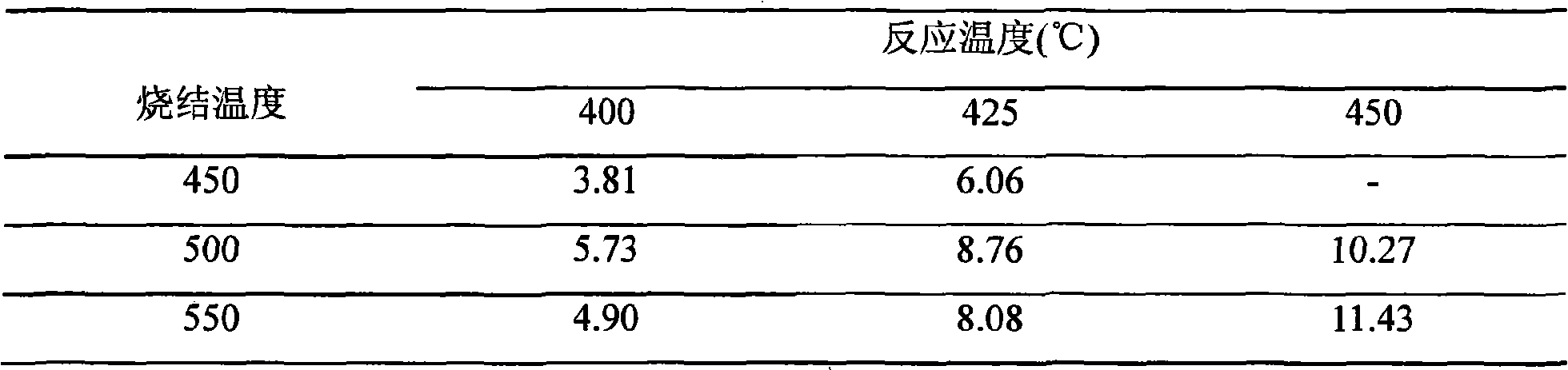

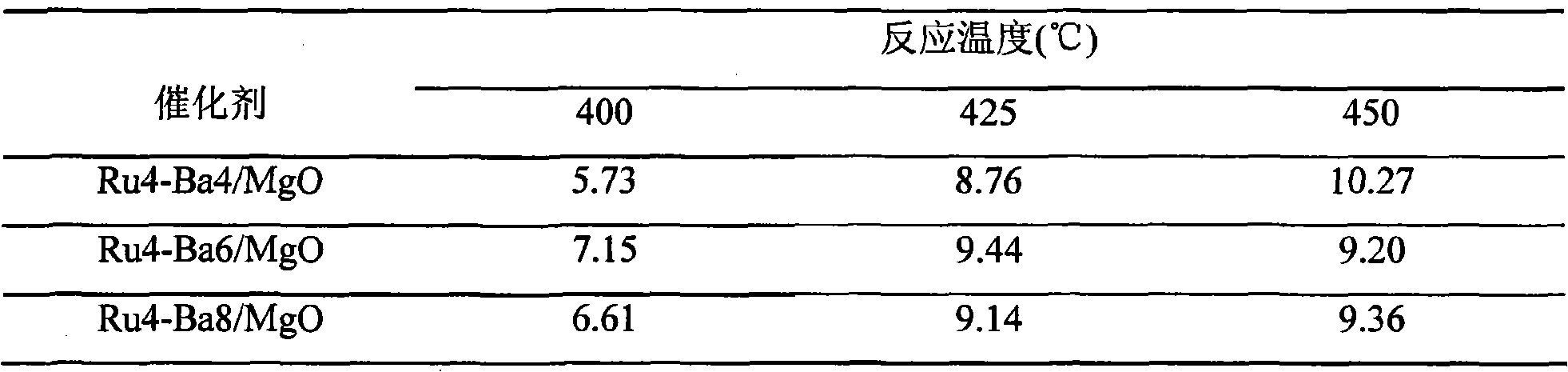

Ruthenium-based ammonia synthetic catalyst and preparation thereof

InactiveCN101322938ASimple processImprove production efficiencyMetal/metal-oxides/metal-hydroxide catalystsBulk chemical productionAlkaline earth metalRare earth

The invention provides a Ru-based ammonia synthesis catalyst and a preparation method thereof. The catalyst takes magnesium oxide as a carrier, metal ruthenium as an active constituent and at least one of alkali metal, alkaline earth metal or rare earth metal as an assistant; the composition is Ru-M1 / MgO, Ru-M2 / MgO, Ru-M1-M2 / MgO or Ru-(M1+M2) / MgO and the preparation method is as follows: the precursor, Ru-magnesium hydroxide catalyst, is prepared by a coprecipitation and dipping method: magnesium nitrate and ruthenium chloride are dissolved in water; the mixed solution is added into an alkaline solution to generate a precipitation; the precipitation is centrifugally washed, dried, sintered by reduction or soaked by equivoluminal soaking auxiliary after sintering, thus obtaining the catalyst that is required. The catalyst prepared by the synthesis method of the invention has good performance, relatively cheap raw material that is required, low energy consumption as well as simple devices and flow; besides, the catalyst is beneficial to reducing the cost and realizing mass production.

Owner:FUZHOU UNIV

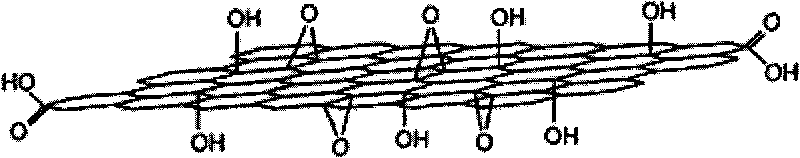

Graphene/Ru nano-composite material for supercapacitor and preparation method thereof

InactiveCN101714463AHigh specific capacitanceGood chemical stabilityElectrolytic capacitorsHybrid capacitor electrodesSodium acetateCapacitance

The invention discloses a graphene / Ru nano-composite material for a supercapacitor. The mass fraction of Ru is between 10 and 50 percent, and the mass fraction of graphene is between 90 and 50 percent. A preparation method comprises the steps of: ultrasonically dispersing oxidized graphite nano-plates into liquid polylol, and then adding solution of ruthenium chloride and solution of sodium acetate into the liquid polylol, wherein in the mixture, the content of the oxidized graphite nano-plates is between 0.5 and 1.5g / L, the concentration of the ruthenium chloride is between 0.0008 and 0.006mol / L, and the concentration of the sodium acetate is between 0.003 and 0.013mol / L; and transferring the mixture into a microwave hydrothermal reaction kettle, performing a microwave heating reaction for 5 to 10 minutes, and then obtaining the graphene / Ru nano-composite material through filtration, washing and drying. The preparation method has the advantages of energy conservation, quickness, simple process and the like; and the graphene / Ru nano-composite material which is taken as an electrode material of an electrochemical supercapacitor has high specific capacitance.

Owner:ZHEJIANG UNIV

Ruthenium system ammonia synthesis catalyst using graphitization activated carbon as carrier and preparation method of catalyst

ActiveCN104084197AImprove thermal stabilityImprove resistance to methanationMetal/metal-oxides/metal-hydroxide catalystsBulk chemical productionActivated carbonPotassium nitrate

The invention discloses a ruthenium system ammonia synthesis catalyst using a graphitization activated carbon as a carrier and a preparation method of the catalyst. The ruthenium system ammonia synthesis catalyst is as shown in Ru-X-K / AC, wherein Ru represents that a precursor is a water-soluble chloride-free ruthenium complex or ruthenium chloride; X represents a metal adjuvant and is one or more of nitrate, acetate, carbonate, metallic oxide and hydroxide of rare-earth metal or alkaline-earth metal; AC represents a graphitization activated carbon carrier, and K represents a kalium adjuvant, namely potassium hydroxide, potassium nitrate, potassium acetate and potassium carbonate; the graphitization activated carbon which has the advantages of high specific surface area, high graphitization and low oxygen content is utilized as the carrier, and the ammonia synthesis catalyst is prepared through steps such as secondary graphitization of graphitization activated carbon, preparation of precursor and preparation of catalyst. The ruthenium system ammonia synthesis catalyst has the advantages that the graphitization activated carbon has large specific surface area and pore volume, enough place is provided for metal segregation, the graphitization degree is high, the oxygen content is low, the methanation resisting capacity of the catalyst is strong, and the stability is good.

Owner:FUZHOU UNIV ASSET MANAGEMENT CO LTD

Active carbon supported ruthenium-based ammonia synthetic catalyst and preparation thereof

InactiveCN101322947AImproved size distributionSimple processOrganic-compounds/hydrides/coordination-complexes catalystsBulk chemical productionPotassium hydroxideRuthenium chloride

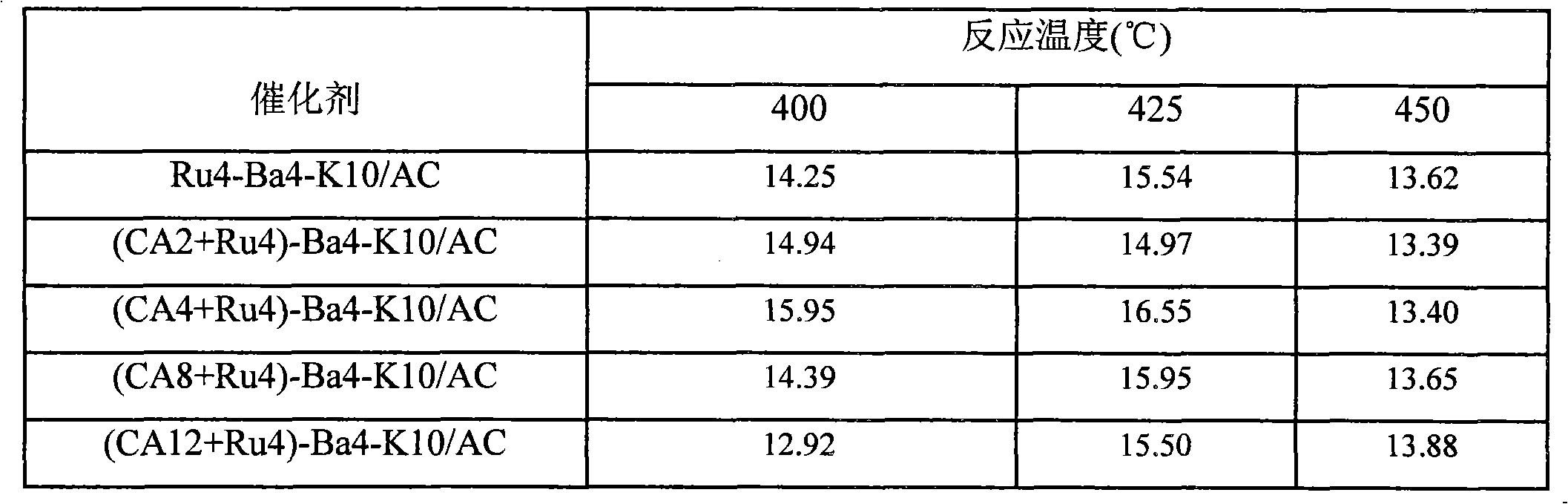

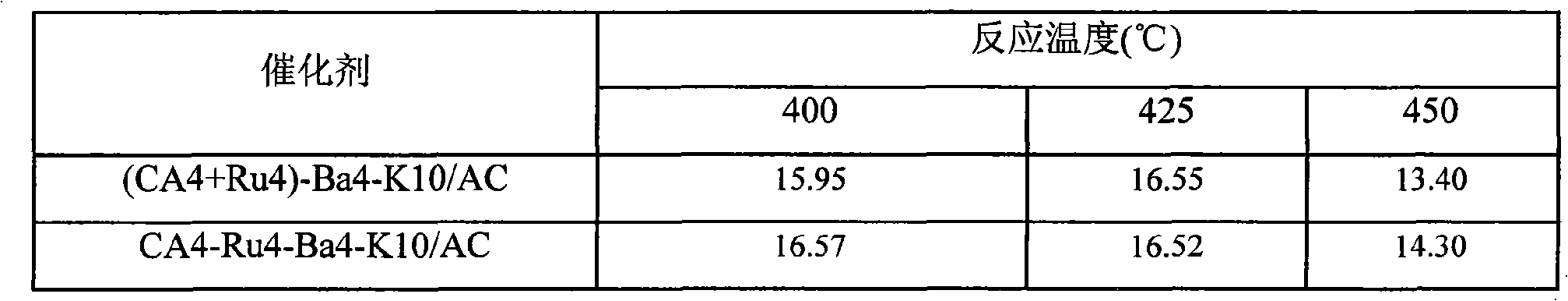

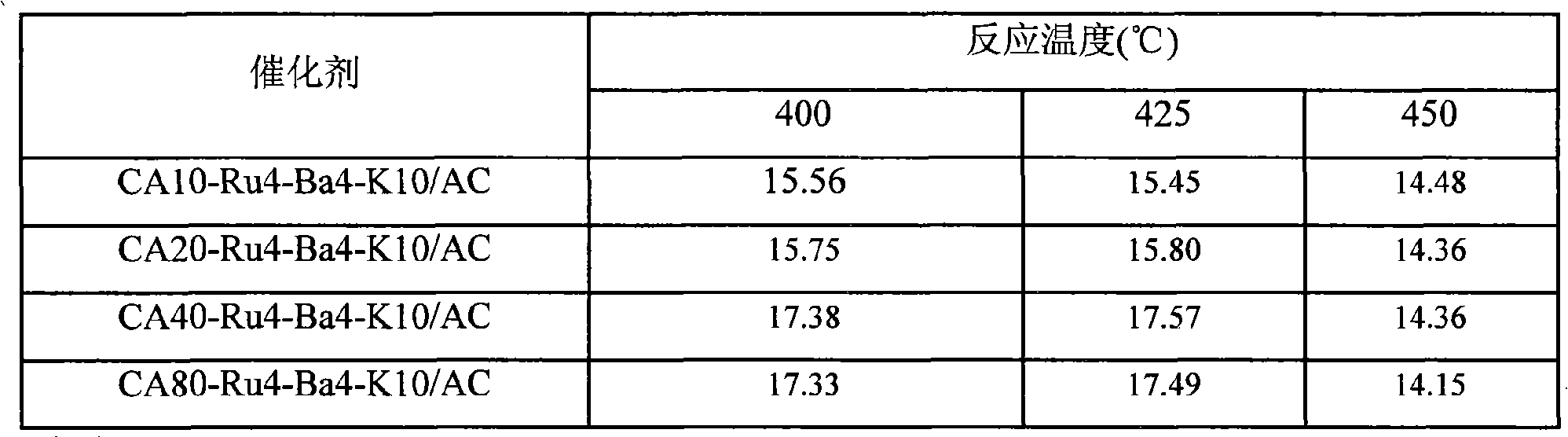

The invention provides an active carbon-supported ruthenium ammonia synthesis catalyst and a preparation method thereof. The catalyst takes active carbon as a carrier and takes ruthenium as an active component; the components of the catalyst are (CA+Ru)-Ba-K / AC and CA-Ru-Ba-K / AC, wherein, CA represents citric acid and AC represents the active carbon; in preparation of the catalyst, the citric acid is selected to carry out the pretreatment of the active carbon and ruthenium chloride; one or more of barium nitrate, potassium hydroxide or potassium nitrate is or are selected as an assistant; the equivalent-volumetric impregnation method is adopted in the preparation method for preparing the catalyst. Compared with the sol-gel method or the oxidation method in the prior art, the invention adopts the citric acid method and has the advantages of simple technique, high preparation efficiency, little energy consumption, cheap raw material and less material consumption, thus being beneficial to greatly lowering the production cost. The devices required by the invention are simple, are easy to be operated, do not need to change the original devices and are easy to realize mass production. The catalyst prepared by the invention has good performance and strong catalytic activity.

Owner:FUZHOU UNIV

Preparation method of recyclable and reusable hydrogenation catalyst

ActiveCN103418439AEasy to makeEasy to storeCatalyst carriersOrganic-compounds/hydrides/coordination-complexes catalystsHydrogenation reactionNitrogen

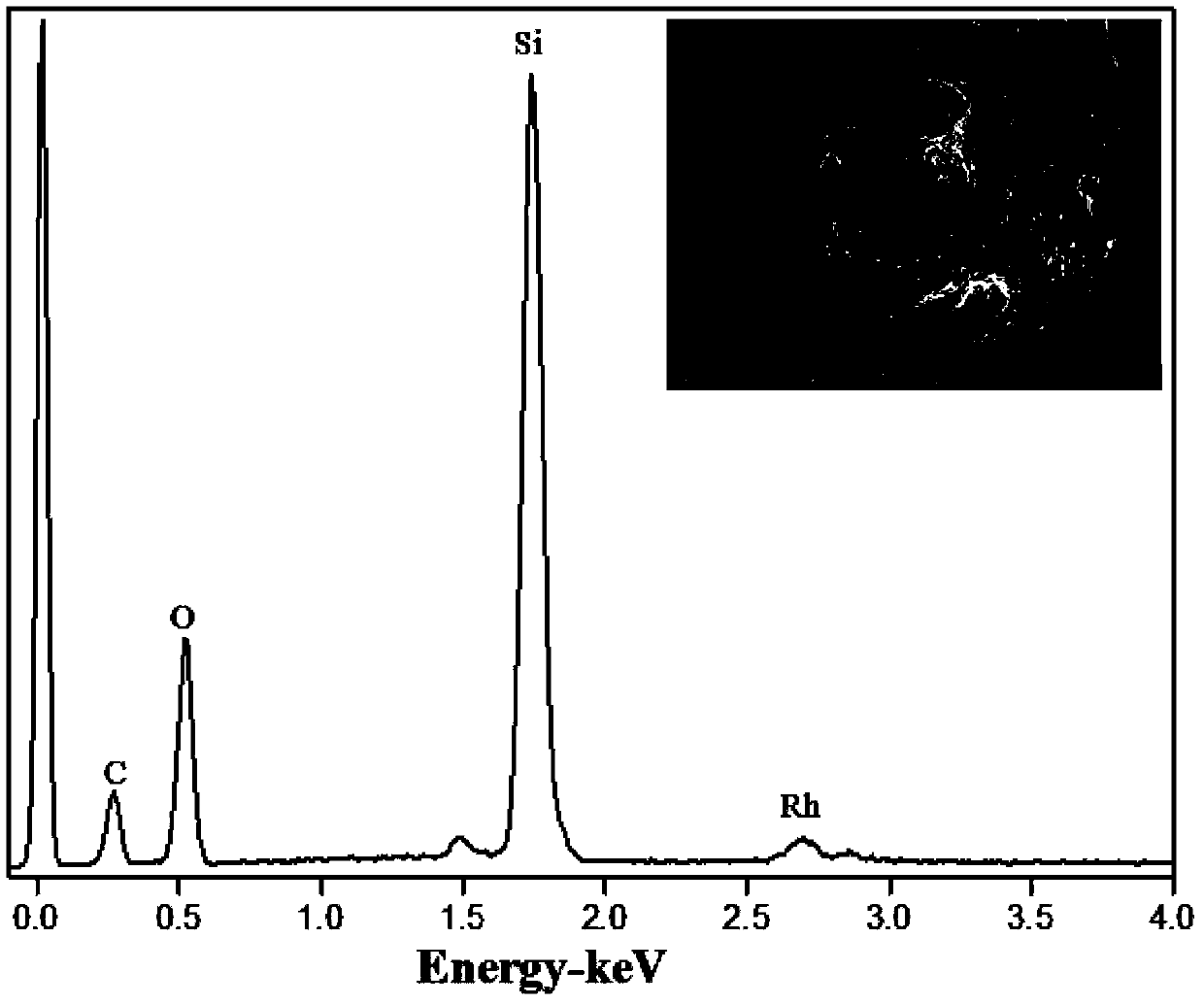

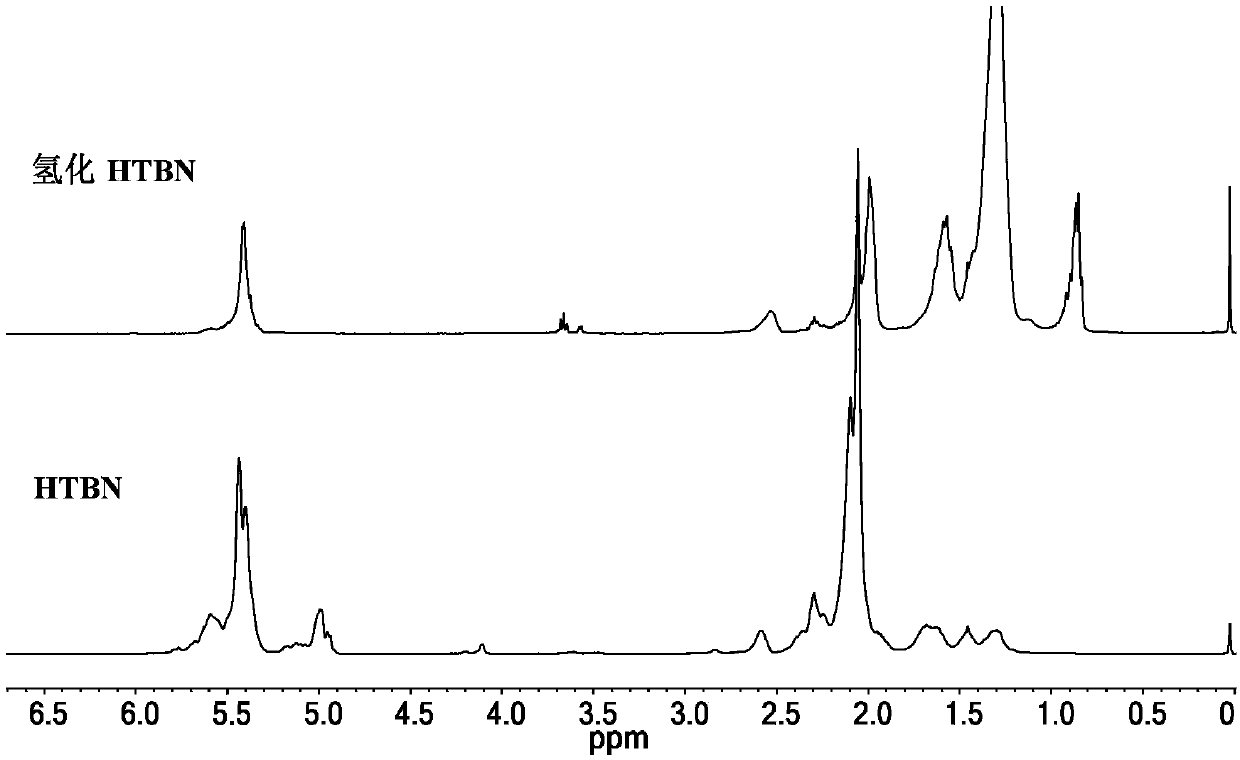

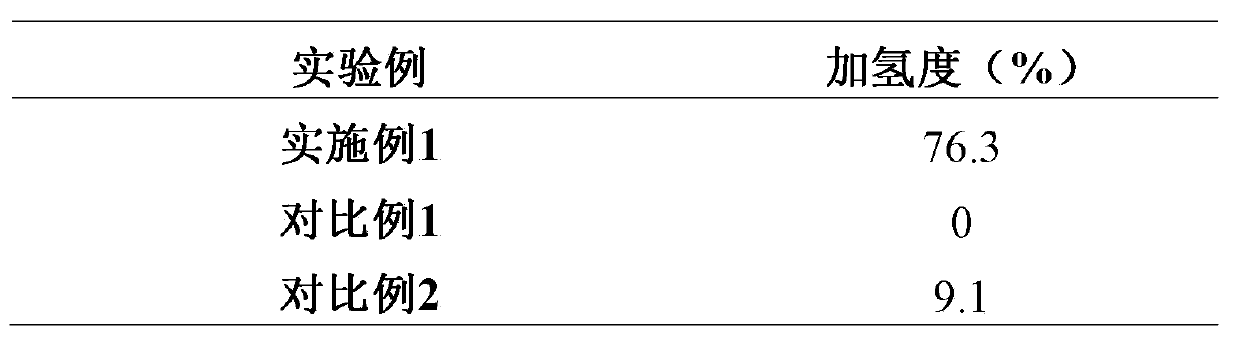

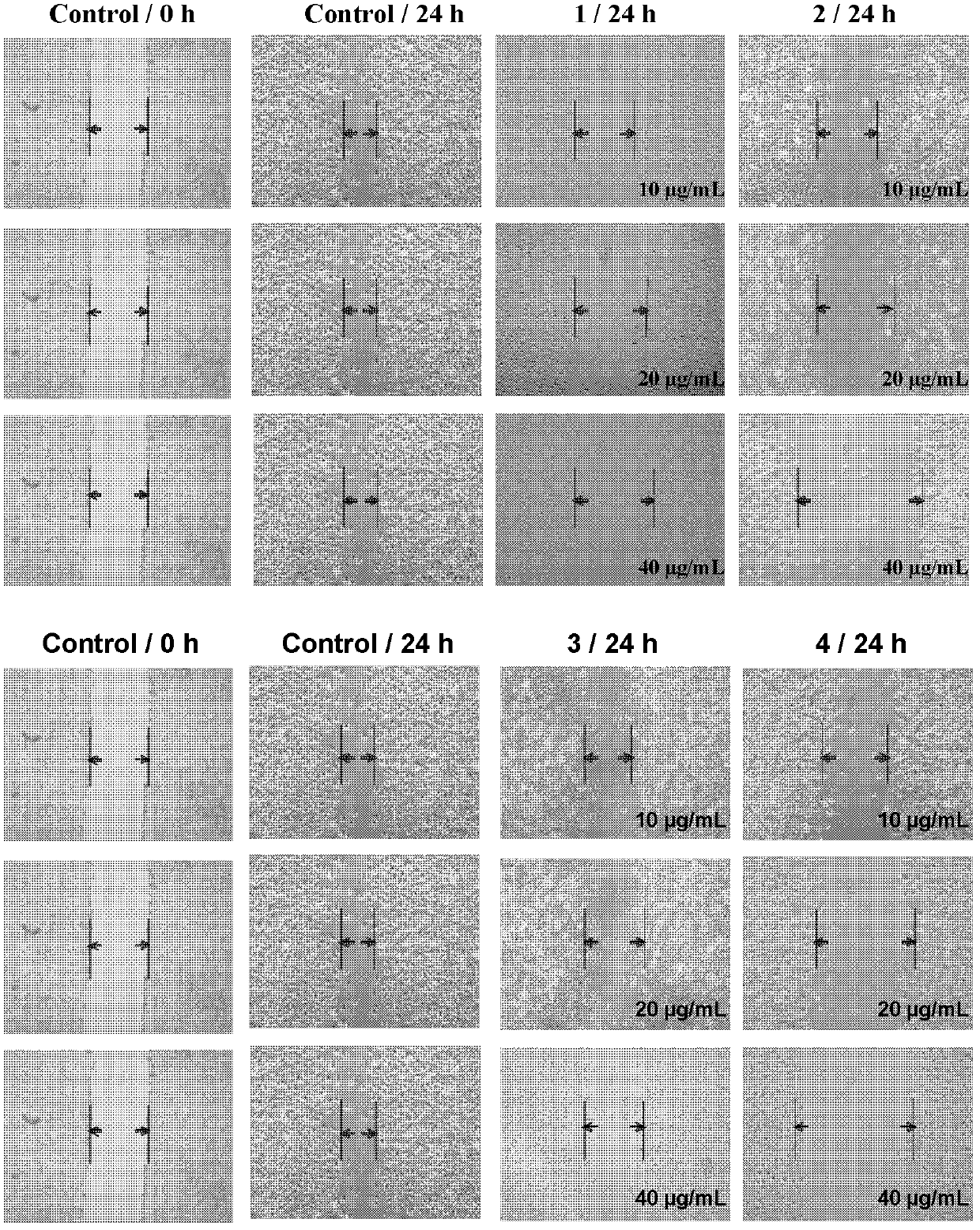

The invention relates to a preparation method of a recyclable and reusable hydrogenation catalyst. The preparation method is characterized by comprising the following steps: using a layer of poly dopamine to coat the surface of silicon dioxide, then adding an appropriate amount of deionized water as well as 0.5-500 mM rhodium chloride or ruthenium chloride or palladium chloride aqueous solution, performing reaction for 2-32 hours at the temperature of 20-100 DEG C, and performing oven-drying for 2-48 hours at the temperature of 25-75 DEG C to obtain a catalyst precursor; then adding 0.1%-20% of sodium borohydride aqueous solution, performing reaction for 1-24 hours at the temperature of 10-90 DEG C, and then performing oven-drying for 6-48 hours at the temperature of 10-90 DEG C to obtain the hydrogenation catalyst. The preparation method is simple in process, mild in reaction conditions and easy to operate; the hydrogenation catalyst has good stability to mediums such as air and water, and is simple in storage and processing manner; the operation of the hydrogenation catalyst does not need nitrogen protection; moreover, the hydrogenation reaction can be performed at lower temperature, the hydrogenation catalyst has a better hydrogenization effect after being used for 5 times in a recycling manner, and the recovery rate of the hydrogenation catalyst is more than 90%.

Owner:BEIJING UNIV OF CHEM TECH

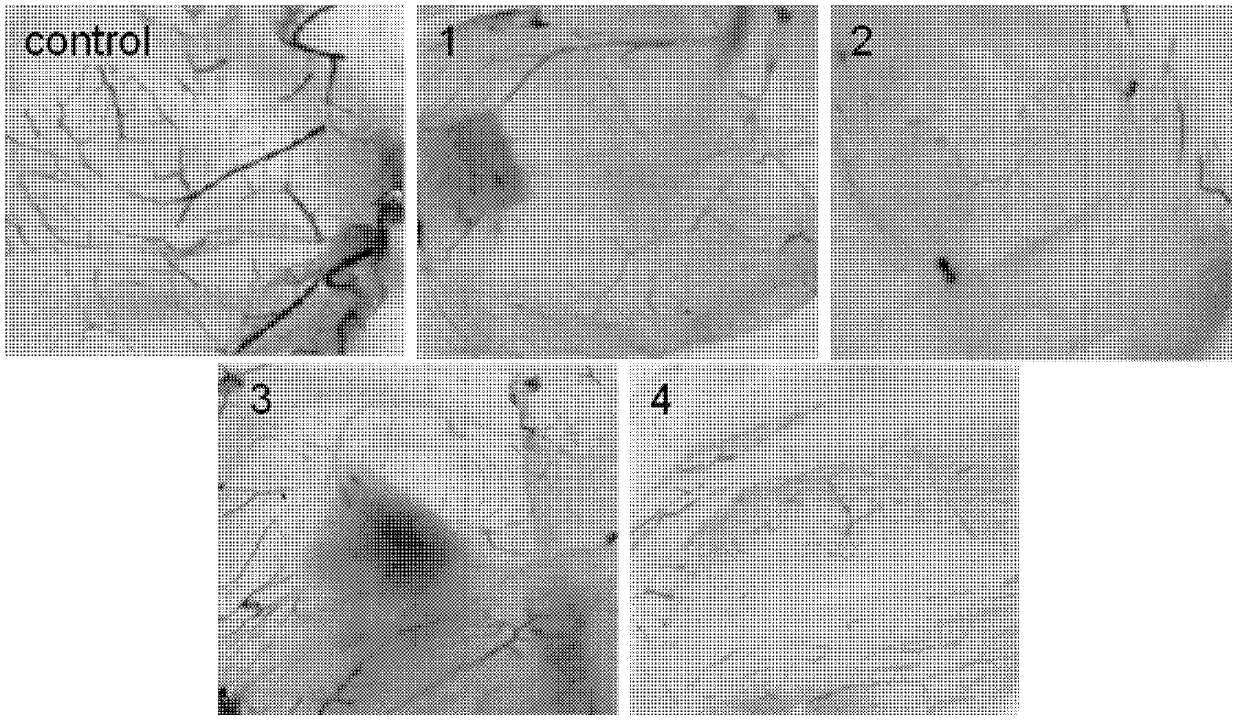

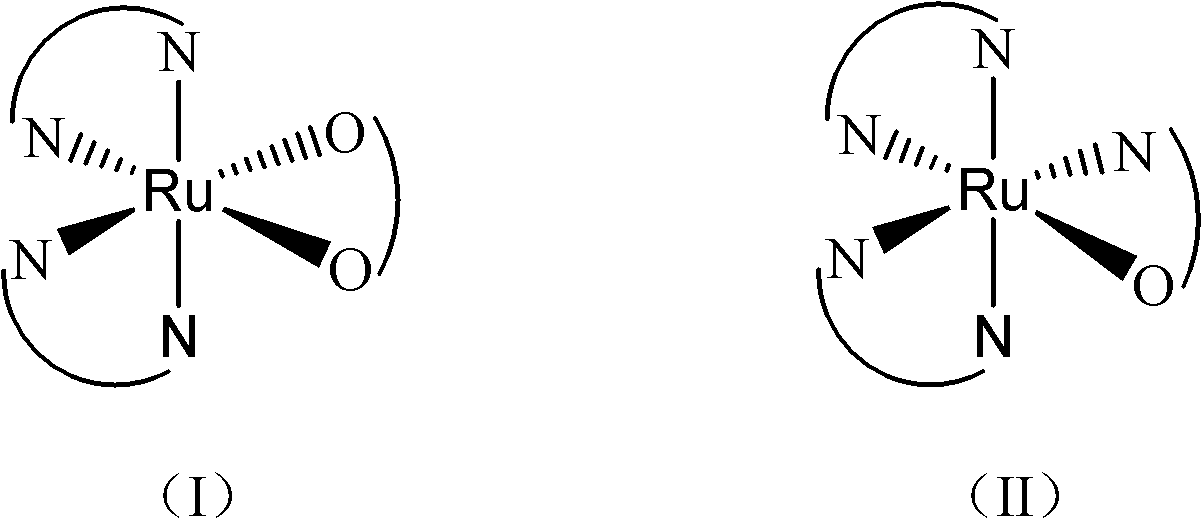

Ruthenium complex capable of inhibiting tumor angiogenesis and preparation method and application thereof

InactiveCN102516309AImprove stabilityImprove solubilityOrganic active ingredientsGroup 8/9/10/18 element organic compoundsSolubilityLithium chloride

The invention belongs to the field of chemical drugs, and discloses a ruthenium complex capable of inhibiting tumor angiogenesis and a preparation method and application thereof. The ruthenium complex provided by the invention has a structure shown in a formula I or II. The preparation method comprises the following steps of: dropwise adding a silver nitrate solution to a sodium salt solution, stirring and reacting, then filtering, washing and vacuum drying a precipitate, and thereby obtaining a ligand O-O; taking ruthenium chloride, L, and lithium chloride to be dissolved in N-, N-dimethyl formamide, heating and refluxing under the protection of argon atmosphere to obtain an intermeidate Ru (L2) Cl22 +; allowing the ligand O-O and the Ru (L2) Cl22 + to be dissolved in an ethanol / water mixed solvent, heating and refluxing to obtain the ruthenium complex shown in the formula I; and allowing the Ru (L2) Cl22 +, 8- hydroxyquinoline, and ammonium acetate to be dissolved in ethanol, and heating and refluxing under the protection of argon atmosphere to obtain the ruthenium complex shown in the formula II. The ruthenium complex has the advantages of good stability, uneasiness in hydrolysis, good solubility, low toxicity, and the ability to inhibit tumor angiogenesis, and is easily absorbed by the human body.

Owner:JINAN UNIVERSITY

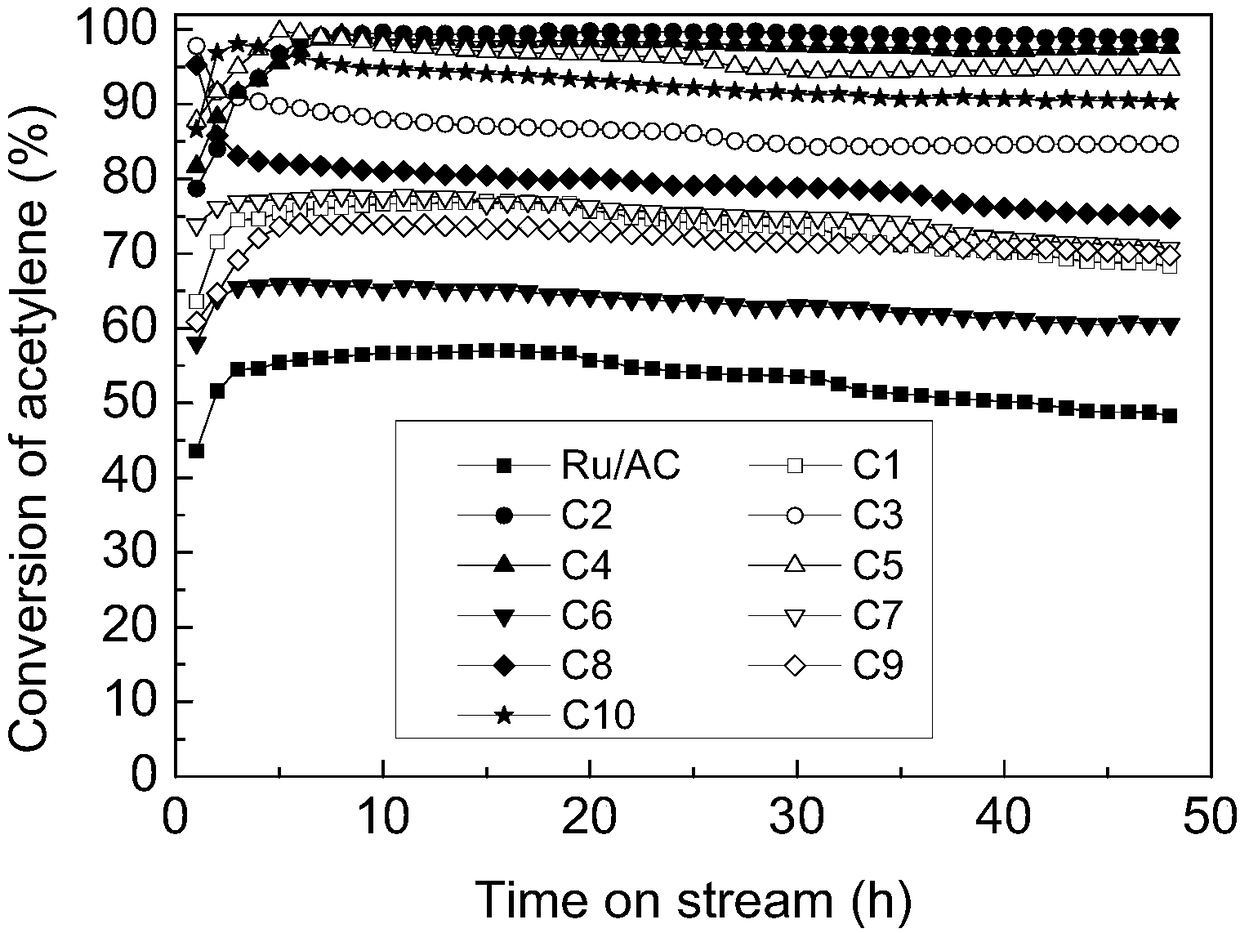

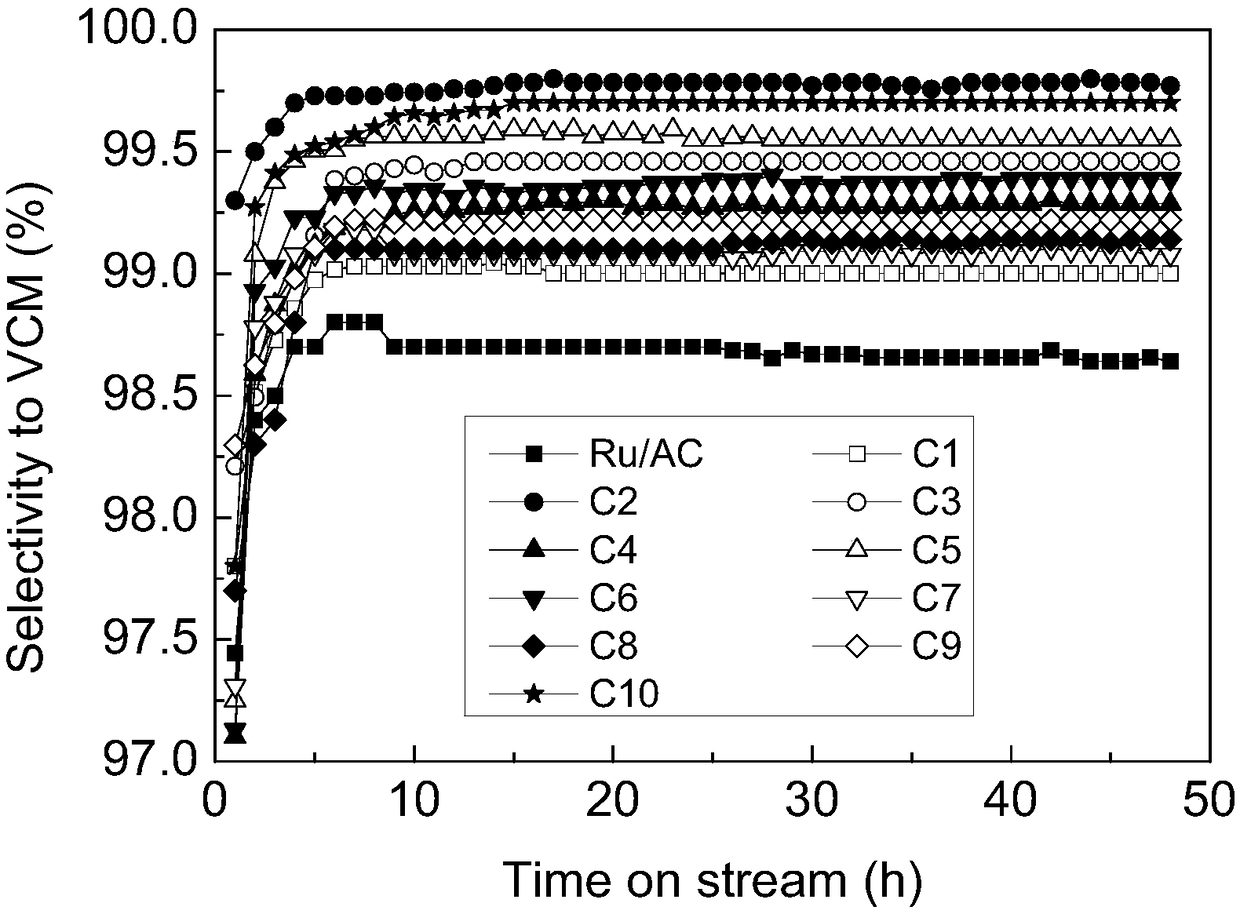

Ruthenium complex catalyzer for acetylene hydrochlorinate and preparation method and application thereof

ActiveCN108262072AImprove economyIncrease contentPreparation by halogen halide additionOrganic-compounds/hydrides/coordination-complexes catalystsChlorobenzeneRuthenium chloride

The invention discloses a ruthenium complex catalyzer for acetylene hydrochlorinate and a preparation method and application thereof. The catalyzer is characterized in that active carbon serves as catalyst support, and is loaded with ruthenium chloride and an organic ligand; the molar ratio of the ruthenium chloride and organic ligand is 1:1-6, and ruthenium accounts for 0.1-5.0% of the total weight of the catalyzer; the organic ligand is one or more of triphenylphosphine, pyridine, 2,2'-dipyridyl, acetylacetone, chlorodiphenylphosphine, chlorobenzene, cyclopentadiene, 4-methyl isopropyl benzene and 1,5-cyclooctadiene. The ruthenium complex catalyzer for the acetylene hydrochlorinate and the preparation method and application thereof have the advantages that the preparation process is simple, the catalytic activity and stability of the catalyzer are greatly improved, the catalyzer is more environmentally friendly, and the economy is high.

Owner:浙江天麟环境工程有限公司

Process for preparing an anode catalyst for fuel cells and the anode catalyst prepared therewith

InactiveUS20030017378A1High activityHigh oxidation stateActive material electrodesCatalyst activation/preparationCarboxylic acidRuthenium chloride

The invention provides a process for preparing a platinum-ruthenium catalyst and the catalyst prepared therewith. The catalyst can be supported on a support material in powder form or may also be unsupported. To prepare the supported catalyst, the support material is suspended in water and the suspension is heated to at most the boiling point. While keeping the temperature of the suspension the same, solutions of hexachloroplatinic acid and ruthenium chloride are then added to the suspension, then the pH of the suspension is increased to a value between 6.5 and 10 by adding an alkaline solution and the noble metals are thus precipitated onto the support material. Afterwards, one or more organic carboxylic acids and / or their salts are added to the suspension and the catalyst is chemically reduced, washed, dried and optionally subsequently calcined under an inert or reducing atmosphere at a temperature between 300 und 1000° C. The catalyst is characterised by a high tolerance to carbon monoxide poisoning in the fuel cell.

Owner:UMICORE AG & CO KG

Preparation method of L-carnitine

ActiveCN102633664AReduce pollutionRaw materials are easy to getOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsSpecific rotationEthyl Chloride

The invention relates to a method for preparing L-carnitine by asymmetric catalytic hydrogenation reduction. Alkyl 4-chloroacetoacetate is used as a raw material, [RuCl(cymene)(S-BINAP)]Cl[chloro[(S)-(-)-2,2'-di(diphenylphosphine)-1,1'-binaphthyl](p-cymene)ruthenium chloride(II))] is used as a catalyst, and amination and hydrolysis reaction are carried out to obtain the L-carnitine product. The amination reaction does not need any solvent or virulent cyanide. The chemical purity of the L-carnitine product is higher than 97%, and the specific rotation [alpha]20D is -29 -32. The invention has the advantages of high reaction speed, stable catalytic system, low pressure required by the reaction process, high conversion rate, no need of solvent in the amination reaction, and is convenient to operate, thereby lowering the cost, reducing the environmental pollution and being convenient for large-scale production.

Owner:GUANGXI XINJING TECH +2

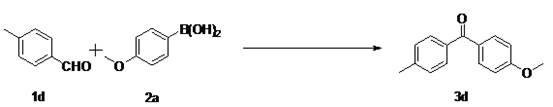

Method for preparing aryl ketone

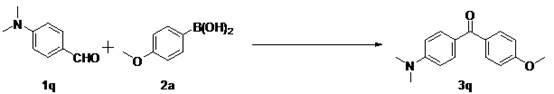

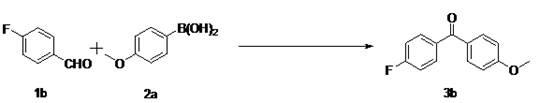

ActiveCN102153434AMild reaction conditionsReduce usageCarboxylic acid nitrile preparationOrganic compound preparationPtru catalystRuthenium Compounds

The invention relates to the field of catalysis, in particular to a method for preparing aryl ketone through reacting aldehyde with aryl boric acid under the catalysis of a ruthenium catalyst. In the method, an organic phosphide is used as a ligand, potassium phosphate is used as alkali, pinacolone or acetone is used as an additive, toluene or / and water is (are) used as a solvent(s), aldehyde and aryl boric acid which are used as reaction substrates react at 95-100 DEG C for 10-24h in the presence of a ruthenium compound used as a catalyst to prepare aryl ketone, wherein the catalyst is one of [Ru(cymene)Cl2]2, [Ru(CO)3Cl2]2, RuH2(CO)PPh3, Ru2(OAc)4, [Ru(benzene)Cl2]2, Ru(S-BINAP)Cl2 or Ru3(CO)12. In the invention, the used catalyst has relatively low price and low toxicity, thereby reducing the preparation cost and being more environmentally friendly.

Owner:铜陵市官作文化有限公司

Phthalate hydrogenation catalyst, preparation method thereof and application of catalyst

InactiveCN110052266AGood dispersionHigh yieldOrganic compound preparationCarboxylic acid esters preparationActivated carbonActive component

The invention relates to a phthalate hydrogenation catalyst which is characterized by comprising an active component, a composite support and auxiliaries, wherein the active component comprises ruthenium chloride, the composite support comprises a first support and a second support, the first support is optional one or two of shell activated carbon or coconut shell activated carbon, and the secondsupport is optional one or two of SiO2, ZrO2 or TiO2. The activated carbon and solid oxide composite support is used for supporting precious metal Ru and provided with activated carbon micropores andmesopores in solid oxide, so that a microporous-mesoporous hierarchical pore structure is formed, high dispersion of the active component is facilitated, diffusion of reactants can be improved, and the use efficiency of the catalyst is improved. The transformation rate of the catalyst in reaction of cyclohexane phthalate preparation by phthalate hydrogenation is 100%, and cyclohexane phthalate selectivity reaches up to 99.9%. The catalyst is simple in preparation technology, the support is low in price and easy to obtain, the active component is low in precious metal loading capacity, the catalyst is high in activity and product yield, by-products are almost avoided, reaction conditions are mild, and reaction can be performed under lower pressure and at lower temperature.

Owner:TIANJIN UNIV

Process for recovery of ruthenium from a ruthenium-containing supported catalyst material

InactiveUS20080287282A1High purityHigh purity gradeCell electrodesFinal product manufactureHydrogen halideRuthenium Compounds

Process to recover ruthenium in the form of ruthenium halide, particularly ruthenium chloride, from a ruthenium-containing supported catalyst material comprising:a) chemically decomposing the ruthenium-containing supported catalyst material;b) producing a raw ruthenium salt solution;c) purifying the raw ruthenium salt solution and optionally stripping gaseous ruthenium tetroxide from the raw ruthenium salt solution; andd) treating the purified ruthenium compound obtained in c), particularly the ruthenium tetroxide, with hydrogen halide or hydrohalic acid to obtain ruthenium halide, particularly with hydrogen chloride or hydrochloric acid to obtain ruthenium chloride.

Owner:BAYER MATERIALSCIENCE AG

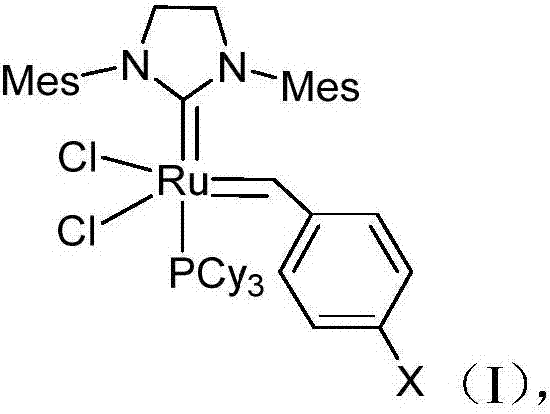

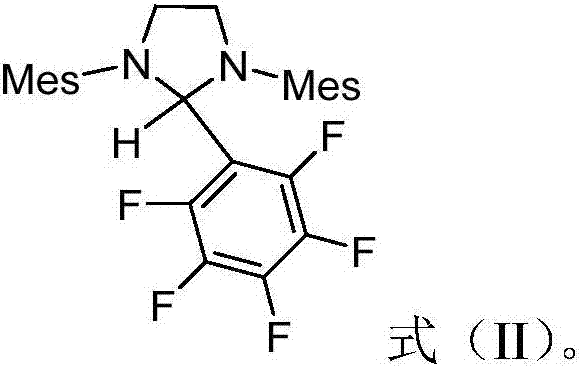

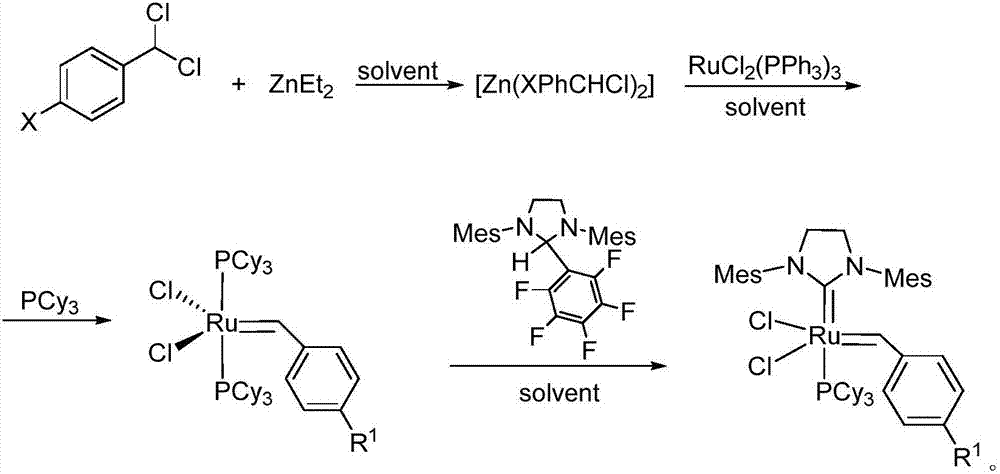

Ruthenium carbene complex, preparation method and application thereof

InactiveCN107216355AEasy to manufactureStable in natureRuthenium organic compoundsCarbeneRuthenium chloride

The invention relates to a ruthenium carbene complex, a preparation method and an application thereof. The chemical formula of the ruthenium carbene complex is shown as formula (I), wherein X is selected from trifluoromethyl, nitryl, dimethylamino or cyanogroup. In a preparation process, firstly, chloromethyl benzene ligand reacts with zinc alkyls so as to synthesize a chloromethyl benzene-zinc alkyls compound, and then the chloromethyl benzene-zinc alkyls compound reacts with tris (triphenylphosphine) ruthenium chloride and tricyclohexylphosphine in turn so as to acquire a catalyst precursor, and lastly, the catalyst precursor and N-heterocyclic carbene are subjected to ligand replacement. The prepared ruthenium carbene complex is used as a catalyst for catalyzing the olefin metathesis. Compared with the prior art, the ruthenium carbene complex provided by the invention has the advantages of convenience in preparation, property stability and capability of effectively catalyzing the olefin metathesis. The preparation method is characterized by simple operation, technology stability, controllability, environment-friendly effect, high yield, suitability for industrial amplification production and wide application prospect.

Owner:ZHONGYOU HAIKE GAS CO LTD +1

Active carbon loaded ruthenium-platinum bimetallic composite catalyst, and preparation method and applications thereof

ActiveCN106391001ASimple preparation processHigh catalytic activityCatalyst carriersOrganic compound preparationRuthenium chlorideVacuum drying

The invention provides an active carbon loaded ruthenium-platinum bimetallic composite catalyst. A preparation method comprises following steps: active carbon is added into a nitric acid solution for stirring dipping; an obtained solution is filtered; an obtained filter cake is washed with deionized water until pH value is increased to be 7, and is delivered into a tube furnace for calcination under N2 protection for further processing; trihydrate ruthenium chloride, chloroplatinic acid, and propylene carbonate are mixed, a reducing agent is added for reduction so as to obtain ruthenium-platinum nanoparticle sol; the active carbon obtained via pretreatment is added, an obtained mixture is subjected to stirring adsorption, and then is subjected to filtering, water washing, acetone washing, and vacuum drying so as to obtain the active carbon loaded ruthenium-platinum bimetallic composite catalyst. According to the preparation method, active carbon is taken as a carrier, the carrier is cheap and easily available. The preparation method is simple; catalytic activity is high; stability is high; hydrogenation of L-aminopropionic acid is realized at a relatively low temperature at a relatively low pressure in water phase; preparation of L-alaninol is realized; cost is low; yield is high; process is sample; and the preparation method is capable of according with green chemical principles.

Owner:ZHEJIANG UNIV OF TECH

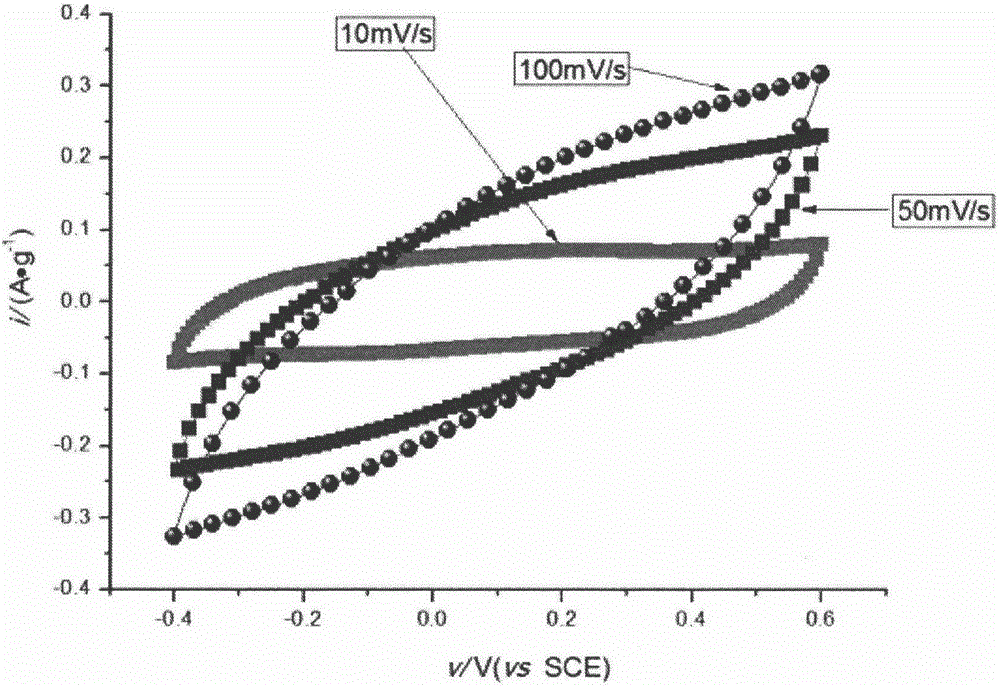

Porous ruthenium dioxide and manganese dioxide combined electrode and preparation method and application thereof

InactiveCN104868094ASimple preparation processReduce energy consumptionFuel and primary cellsChemical electrode manufacturingArgon atmosphereManganese

The invention discloses a preparation method of a porous ruthenium dioxide and manganese dioxide combined electrode. The preparation method of the porous ruthenium dioxide and manganese dioxide combined electrode comprises the following steps of mixing potassium permanganate, thick sulfuric acid and deionized water, obtaining mixed solution after evenly stirring, immersing substrate and obtaining a substrate-loaded precursor comprising manganic after hydrothermal reaction of 60 to 110 DEG C water; roasting the substrate-loaded precursor comprising manganic under 200 to 500 DEG C under argon atmosphere and obtaining manganese dioxide which is loaded on the substrate after cooling; mixing ruthenium chloride and water to obtain ruthenium salt solution, immersing the manganese dioxide which is loaded on the substrate to the ruthenium salt solution and performing aftertreatment to obtain the porous ruthenium dioxide and manganese dioxide combined electrode. According to the porous ruthenium dioxide and manganese dioxide combined electrode, the porous manganese dioxide directly grows on the substrate, nano ruthenium dioxide particles are loaded on the porous manganese dioxide, and a porous structure is maintained after loading of the ruthenium dioxide.

Owner:ZHEJIANG UNIV

Catalytic agent for synthesizing succinic acid through maleic acid hydrogenation and preparation method thereof

InactiveCN102430404AImprove stabilityHigh activityCarboxylic preparation by ozone oxidationMetal/metal-oxides/metal-hydroxide catalystsActive componentDistilled water

The invention relates to a catalytic agent for synthesizing succinic acid through maleic acid hydrogenation; the catalytic agent comprises the following components in percent by weight: 0.1-10% of active component ruthenium and 80-99.9% of acid resistance carrier. A preparation method of the catalytic agent comprises the following steps of: uniformly mixing a ruthenium chloride solution with the concentration of 0.1-50.0mg / ml and the carrier, adding an alkaline solution into mixed liquor under stirring at the temperature of 15-95 DEG C, adjusting pH value to be 6-14, and then maintaining for 0.5-24h; filtering the mixed liquor, washing solid precipitates by using distilled water till Cl <-> does not exist, drying naturally, and then feeding reducing gas at the temperature of 150-450 DEG C and reducing for 1-24h, wherein space velocity of the reducing gas is 200-100h<-1>, and obtaining the ruthenium catalytic agent. The catalytic agent has the advantages of good stability, low cost, high activity and high selectivity.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Electrocatalyst for electrochemical conversion of carbon dioxide

InactiveUS20130256123A1Readily apparentMaterial nanotechnologyMultiple component coatingsCopper nitrateCarbon nanotube

An electrocatalyst for the electrochemical conversion of carbon dioxide to hydrocarbons is provided. The electrocatalyst for the electrochemical conversion of carbon dioxide includes copper material supported on carbon nanotubes. The copper material may be pure copper, copper and ruthenium, copper and iron, or copper and palladium supported on the carbon nanotubes. The electrocatalyst is prepared by dissolving copper nitrate trihydrate in deionized water to form a salt solution. Carbon nanotubes are then added to the salt solution to form a suspension, which is then heated. A urea solution is added to the suspension to form the electrocatalyst in solution. The electrocatalyst is then removed from the solution. In addition to dissolving the copper nitrate trihydrate in the deionized water, either iron nitrate monohydrate, ruthenium chloride or palladium chloride may also be dissolved in the deionized water to form the salt solution.

Owner:KING FAHD UNIVERSITY OF PETROLEUM AND MINERALS +1

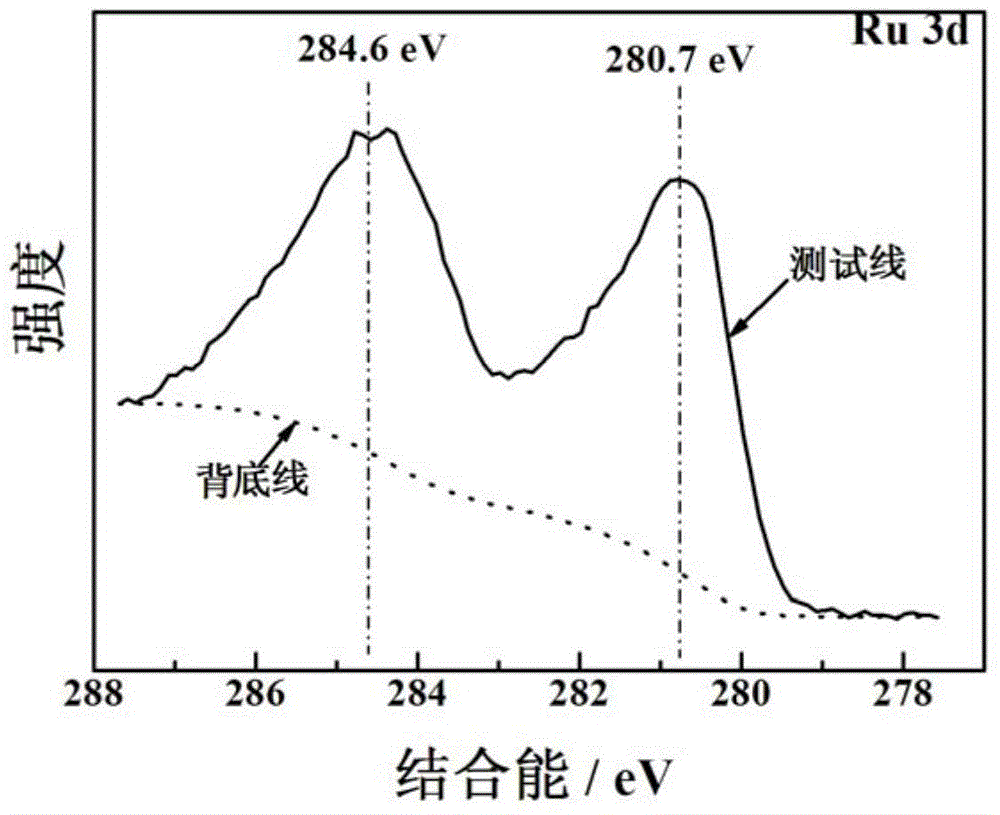

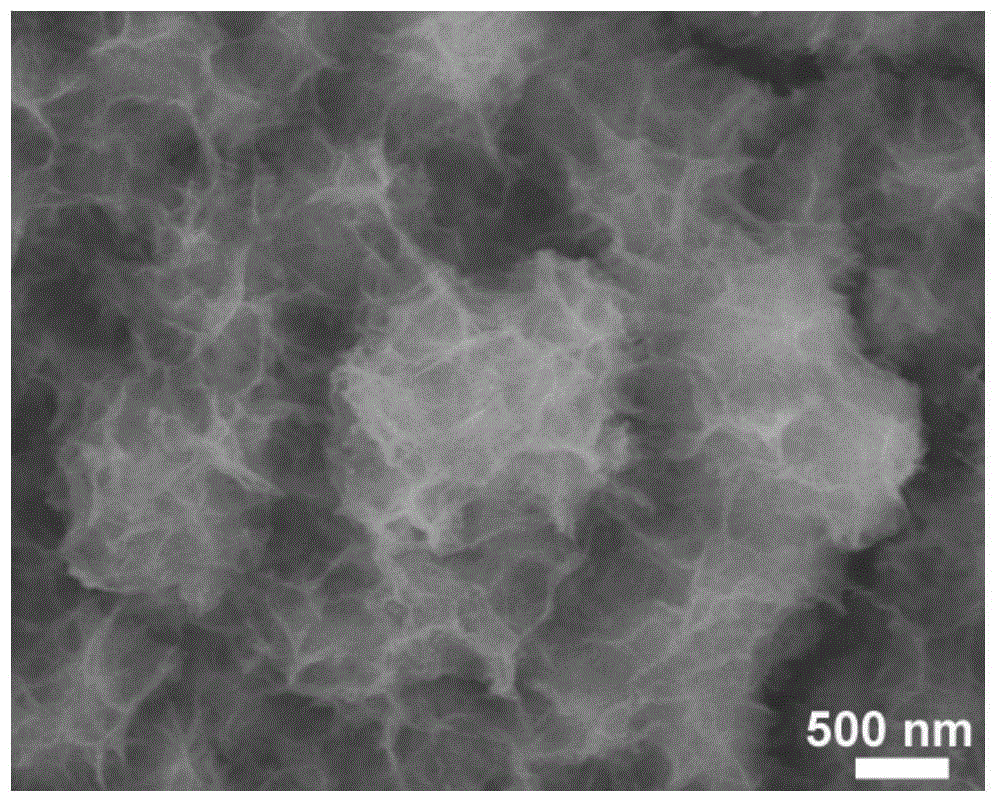

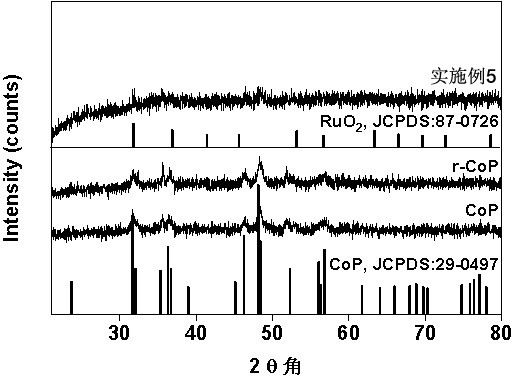

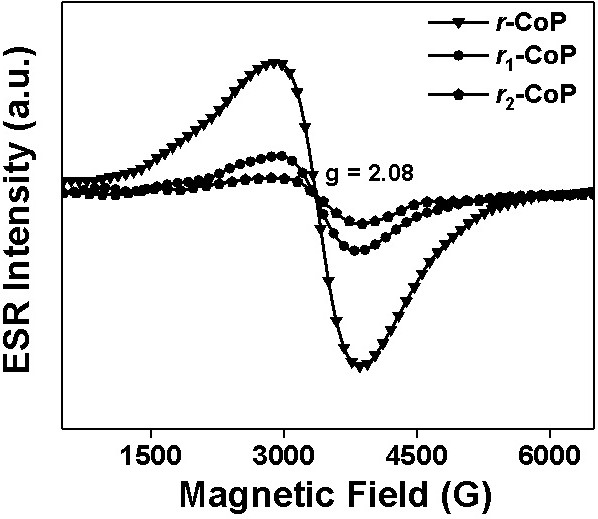

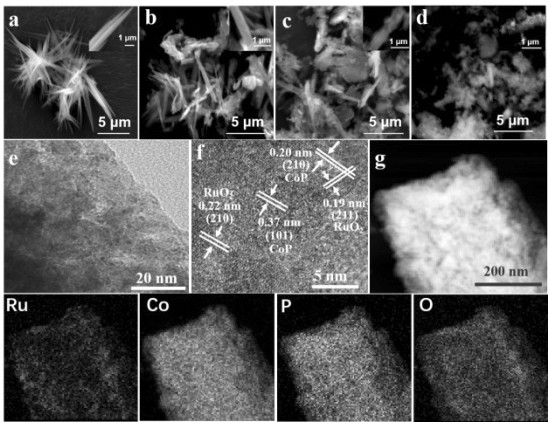

Preparation method of catalyst for hydrogen production based on Ru/r-CoP composite material hydrolysis

ActiveCN111905782AGood dispersionImprove conductivityPhysical/chemical process catalystsHydrogen productionHydration reactionPtru catalyst

The invention belongs to the field of chemical hydrogen evolution energy, and particularly relates to a preparation method of a catalyst for hydrogen production based on Ru / rCoP composite material hydrolysis, which comprises the following steps: preparing a cobalt-based precursor, a cobalt phosphide (CoP) precursor and a phosphorus hole precursor (r-CoP); dispersing the phosphorus hole precursor (r-CoP) in water, adding a proper amount of ruthenium trichloride hydrate, and adding a sodium borohydride solution for reduction; performing centrifuging, washing and drying to obtain a phosphorus hole precursor loaded ruthenium composite material (Ru / r-CoP); by enriching the phosphorus hole loaded ruthenium nano composite material, the dispersity and conductivity of ruthenium loaded on a precursor are improved, so that the intrinsic catalytic activity is improved, and the Ru / r-CoP composite material shows efficient hydrogen evolution performance in an alkaline sodium borohydride aqueous solution; and an effective synthetic route is provided for preparing an efficient sodium borohydride hydrolysis hydrogen evolution catalyst.

Owner:GUANGXI NORMAL UNIV

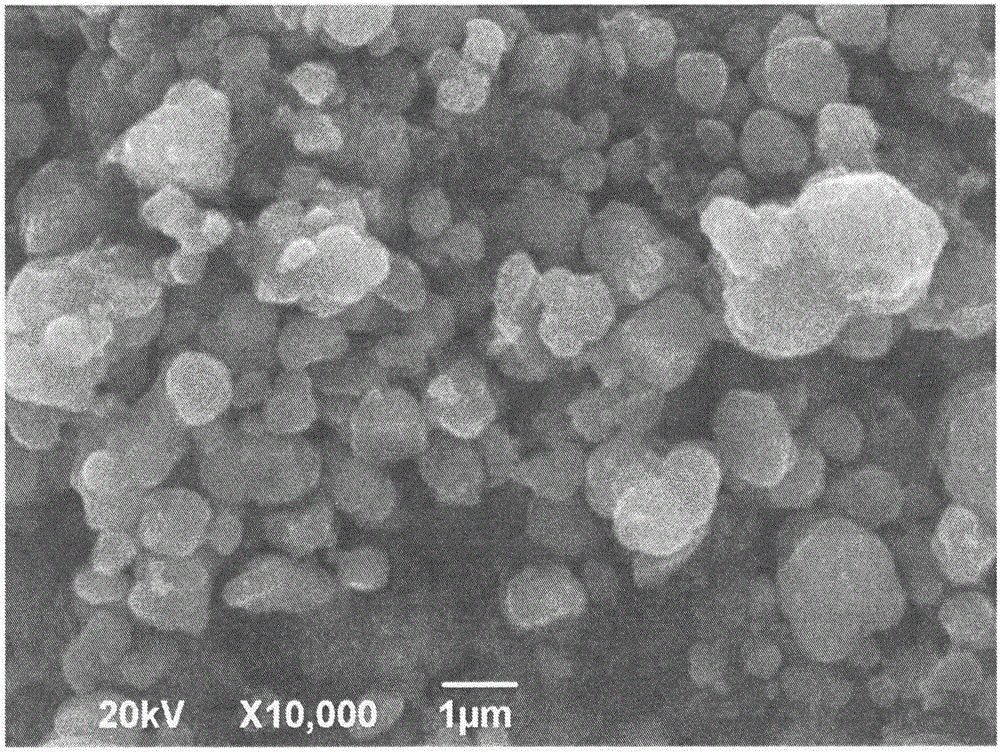

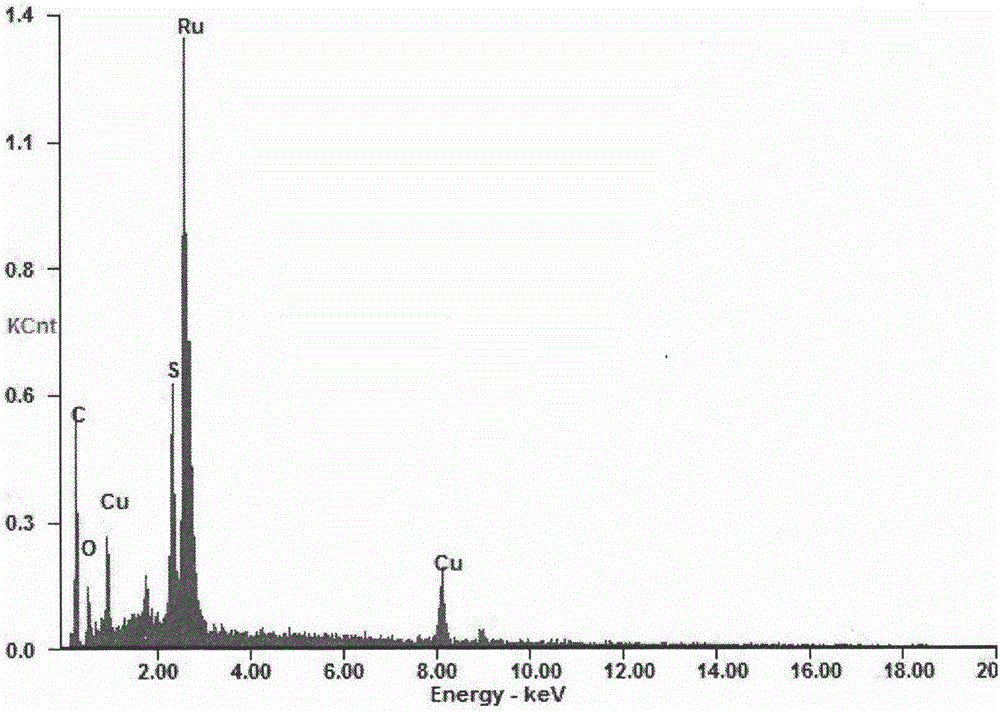

Ruthenium oxide-copper sulfide composite material, application thereof and electrode plate for supercapacitor

InactiveCN106024408AOvercoming costly problemsHigh specific capacitanceHybrid capacitor electrodesHybrid/EDL manufactureAlcoholFiltration

The invention discloses a ruthenium oxide-copper sulfide composite material, which solves defects of high price and less application in industrial production of ruthenium oxide in the prior art. A preparation method of the ruthenium oxide-copper sulfide composite material comprises the steps of (1) ultrasonic dissolving hydrous copper chloride into ethylene glycol, adding thiourea into the above reaction system, stirring for 0.5h-1h, carrying out a hydro-thermal reaction for 8h-12h under a condition of 150 DEG C-200 DEG C after stirring, performing suction filtration, washing and alcohol washing, and drying for 24h at a temperature of 150 DEG C-200 DEG c so as to acquire a copper sulfide nano material; (2) dissolving hydrous ruthenium trichloride into 40ml-60ml of water so as to acquire a ruthenium trichloride solution with the concentration being 10mg / ml-20mg / ml; and (3) adding the copper sulfide nano material prepared in the step (1) into the ruthenium trichloride solution prepared in the step (2), stirring for 0.5h-1h, then carrying out a hydro-thermal reaction for 8h-12h under a condition of 150 DEG C-200 DEG C, performing suction filtration, washing and alcohol washing, and drying for 24h under the condition of 150 DEG C-200 DEG C so as to acquire a ruthenium oxide-copper sulfide composite material.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

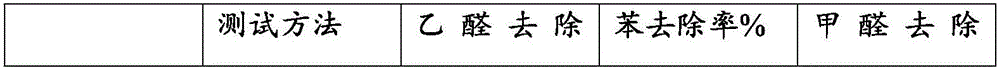

Efficient air purification type photocatalyst filter screen and preparation method thereof

ActiveCN106110885AGood adhesionImprove stabilityOrganic-compounds/hydrides/coordination-complexes catalystsDispersed particle separationTin dioxidePlatinum oxide

The invention discloses an efficient air purification type photocatalyst filter screen. The efficient air purification type photocatalyst filter screen comprises a filter screen base material; a photocatalyst is arranged on the filter screen base material; the photocatalyst is prepared from the following components: titanium dioxide, molybdenum oxide, cerium oxide, lanthanum oxide, nickel oxide, platinum oxide, silicon dioxide, nano tin dioxide, silica gel power, aluminum oxide, sepiolite, iron acetylacetonate and terpyridine ruthenium chloride. The photocatalyst filter screen prepared by the invention has a good adhesion property and a relatively large reaction contact area; the removing rates of acetaldehyde, benzene and formaldehyde are more than 90 percent and the photocatalytic property is very good; the efficient air purification type photocatalyst filter screen is high in utilization rate of catalyst and stable in property and has very good application value.

Owner:苏州健龙环保科技有限公司

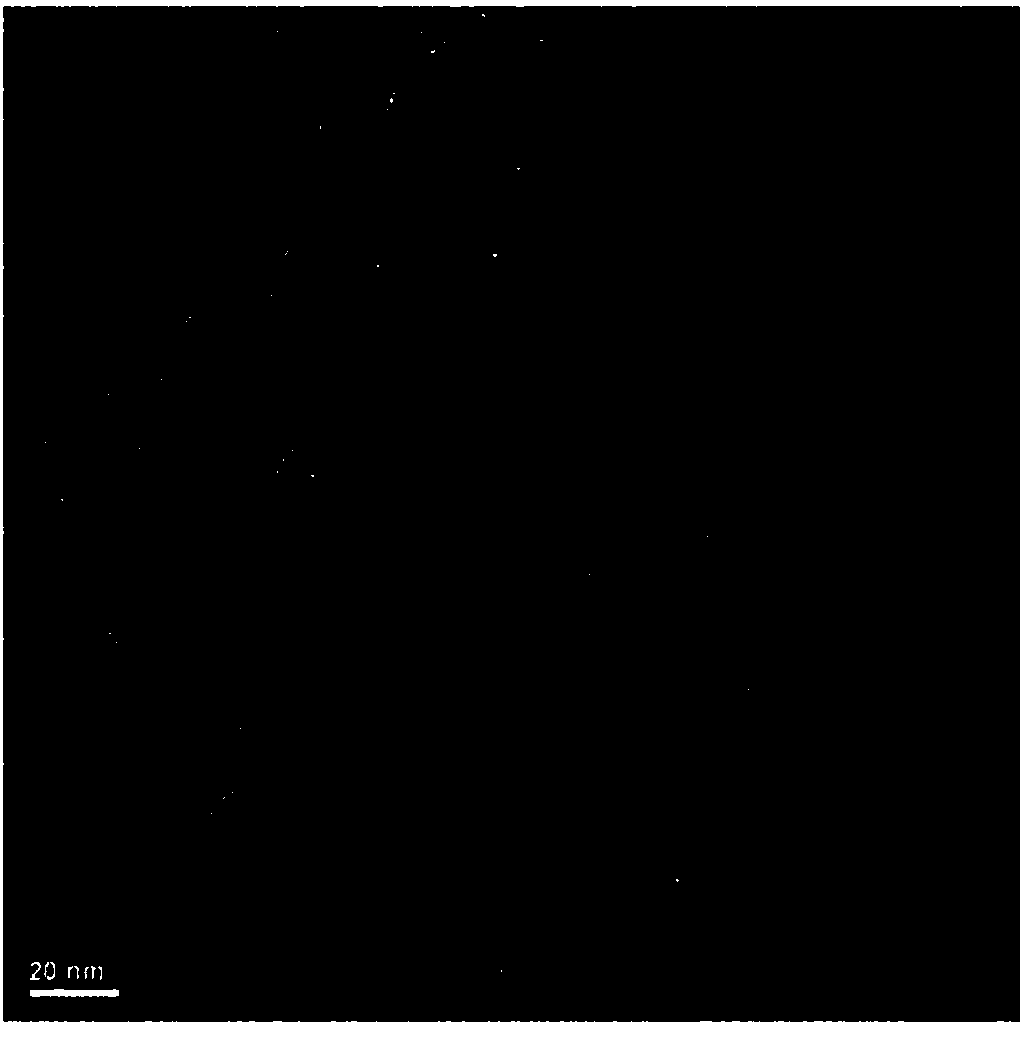

PtRu/C catalyst and its preparation method

InactiveCN104209122AHigh activityImprove stabilityCell electrodesMetal/metal-oxides/metal-hydroxide catalystsRoom temperatureSodium borohydride

The invention provides a preparation method of a PtRu / C catalyst, and belongs to the field of catalyst preparation methods. The method comprises the following steps: dispersing a carbon carrier in water to obtain a first suspension; adding a chloroplatinic acid solution and a ruthenium chloride solution to the first suspension to obtain a second suspension; and pouring the second suspension into a sodium borohydride solution, and stirring at room temperature to obtain the PtRu / C catalyst. The invention also provides the PtRu / C catalyst. The PtRu / C catalyst has the characteristics of small particle size, uniform dispersion, and good methanol electrooxidation reaction catalysis performance. Experiments show that when the capacity of the PtRu / C catalyst prepared through the method is 30wt%, the mass activity of the catalyst in a methanol solution with sulfuric acid as an electrolyte reaches 447mA / mg, and is 1 time higher than the mass activity of commercial PtRu / C catalysts.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Aromatic ruthenium complex and synthetic method thereof

InactiveCN103408597AHas anti-cancer synergistic effectGroup 8/9/10/18 element organic compoundsAntineoplastic agentsSynthesis methodsRuthenium

The invention relates to an aromatic ruthenium complex and a synthetic method thereof. According to the technical scheme, the aromatic ruthenium complex has a structure as shown in formulas (I), (II), (III) and (IV). The method comprises the following steps of: a, placing an aromatic dichloride ruthenium dimer and a chelating diamine ligand into a methanol solution to obtain the aromatic ruthenium complex; b, placing the aromatic dichloride ruthenium dimer and a schiff bases chelating diamine ligand into the methanol solution to obtain the aromatic ruthenium complex; c, placing aromatic dichloride ruthenium dimer and 5-fluorouracil containing schiff bases chelating diamine ligand into the methanol solution to obtain the aromatic ruthenium complex; and d, reacting an aldehyde group containing anti-cancer drug or an anti-cancer drug with the aldehyde group introduced by drug modification with a chelating diamine compound to obtain the schiff bases chelating diamine ligand; and then hitching into the aromatic ruthenium complex. According to the scheme, a 5-fluorouracil aromatic ruthenium complex with anticancer synergistic effect can be prepared.

Owner:WENZHOU UNIVERSITY

Preparation method and application of hyaluronic acid modified ruthenium nano photo-thermal material

InactiveCN108126200AEasy to prepareGood water solubilityEnergy modified materialsNanomedicineCancer cellCD44

The invention discloses a preparation method and application of a hyaluronic acid modified ruthenium nano photo-thermal material. The preparation method comprises the following steps: firstly, enabling hyaluronic acid and cysteine hydrochloride to carry out an amidation reaction so as to obtain cysteine modified hyaluronic acid; secondly, enabling the cysteine modified hyaluronic acid to react with ruthenium chloride under reaction of sodium borohydride, thereby obtaining a water-soluble hyaluronic acid modified ruthenium nano photo-thermal material. The preparation method is easy in preparation raw material obtaining, simple in process and small in environment pollution; meanwhile, the hyaluronic acid has the property of targeting cancer cells with over-expressed CD44, so that a high-efficiency photo-thermal material with a targeting function can be prepared, and the material has an application value in cancer treatment; due to targeting photo-thermal treatment of the hyaluronic acidmodified ruthenium nano photo-thermal material, the cancer cell killing rate is increased, and the material has wide application prospects in photo-thermal treatment, functional materials, tissue engineering, and the like.

Owner:GUANGXI NORMAL UNIV

Preparation method of RuCl3/Cu-MOF-based composite catalyst and application

InactiveCN110354890ASimple preparation processShort timePhysical/chemical process catalystsElectrodesArgon atmosphereNitrogen gas

The invention discloses a preparation method of a RuCl3 / Cu-MOF-based composite catalyst and application of the catalyst in catalyzing room temperature nitrogen reduction to ammonia, belonging to the technical fields of nanomaterials and catalysis. The method mainly comprises the following steps: mixing a copper acetate solution, a ruthenium trichloride solution and a ligand solution to prepare RuCl3 / Cu-MOF nanocrystals; placing the RuCl3 / Cu-MOF nanocrystals in a tube furnace, and pyrolyzing at 700 DEG C for 2 hours under an argon atmosphere to obtain a carbon-nitrogen matrix nano-porous composite material co-doped with CuO nanoparticles and Ru nanoparticles, namely the RuCl3 / Cu-MOF-based composite catalyst; the catalyst is used in catalyzing room temperature nitrogen reduction to ammonia,and has simple preparation process, low cost and good industrial prospect.

Owner:UNIV OF JINAN

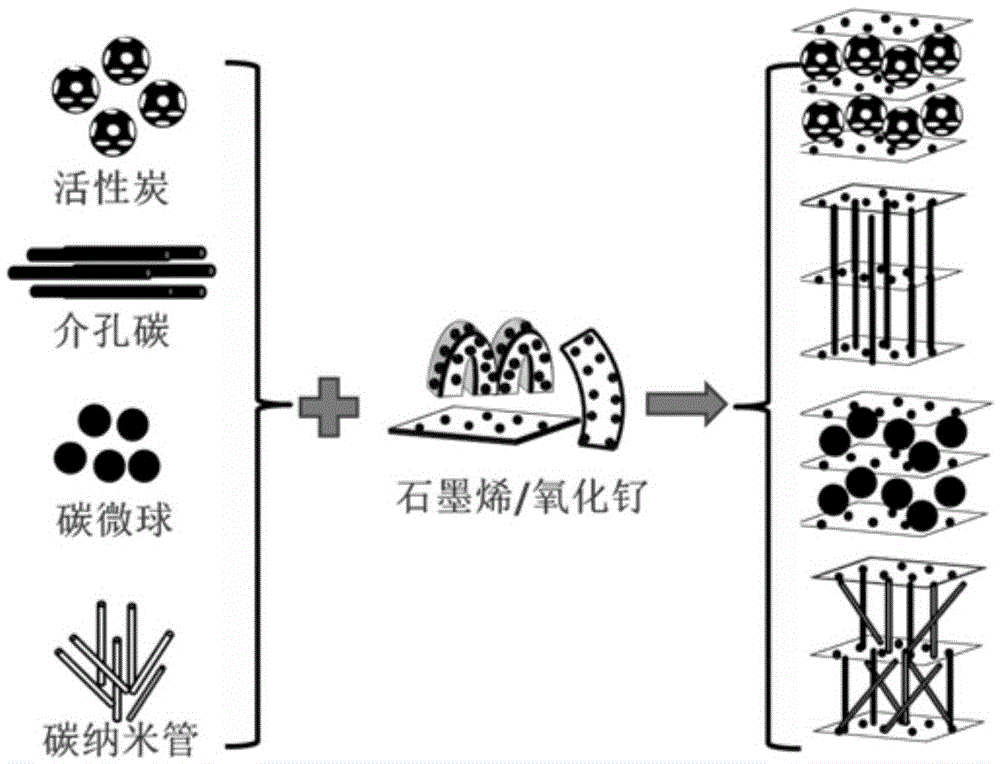

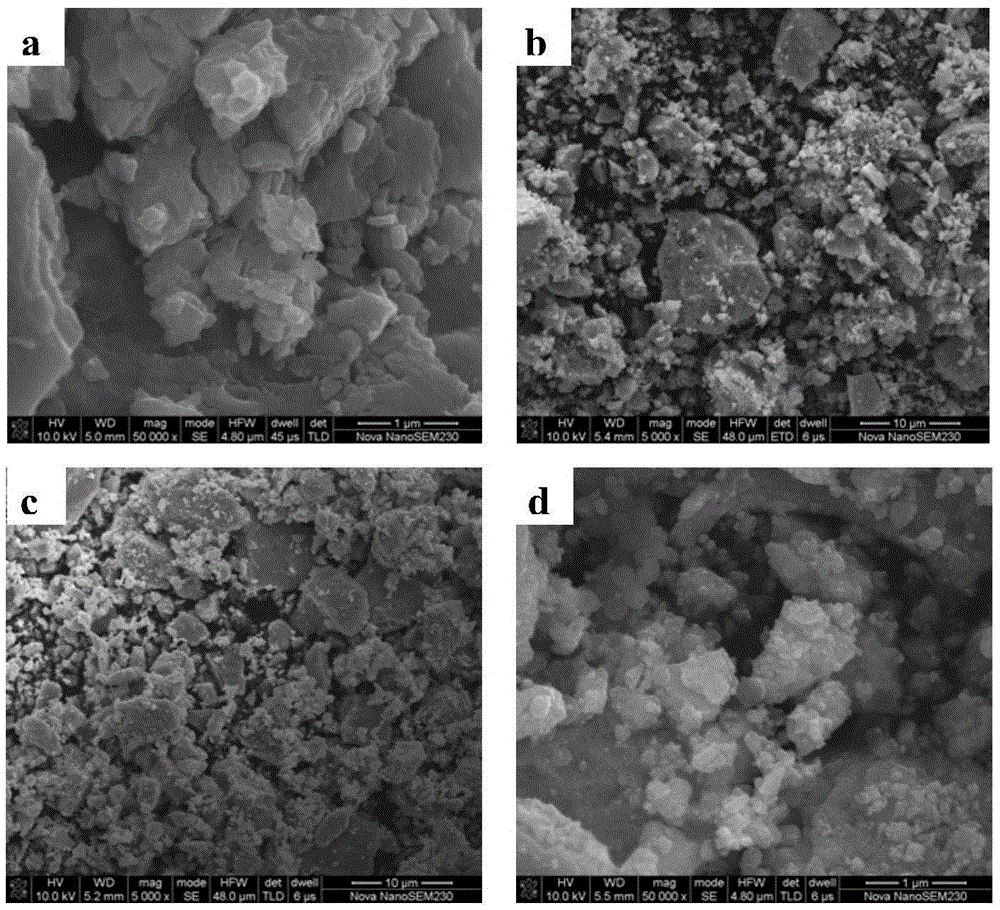

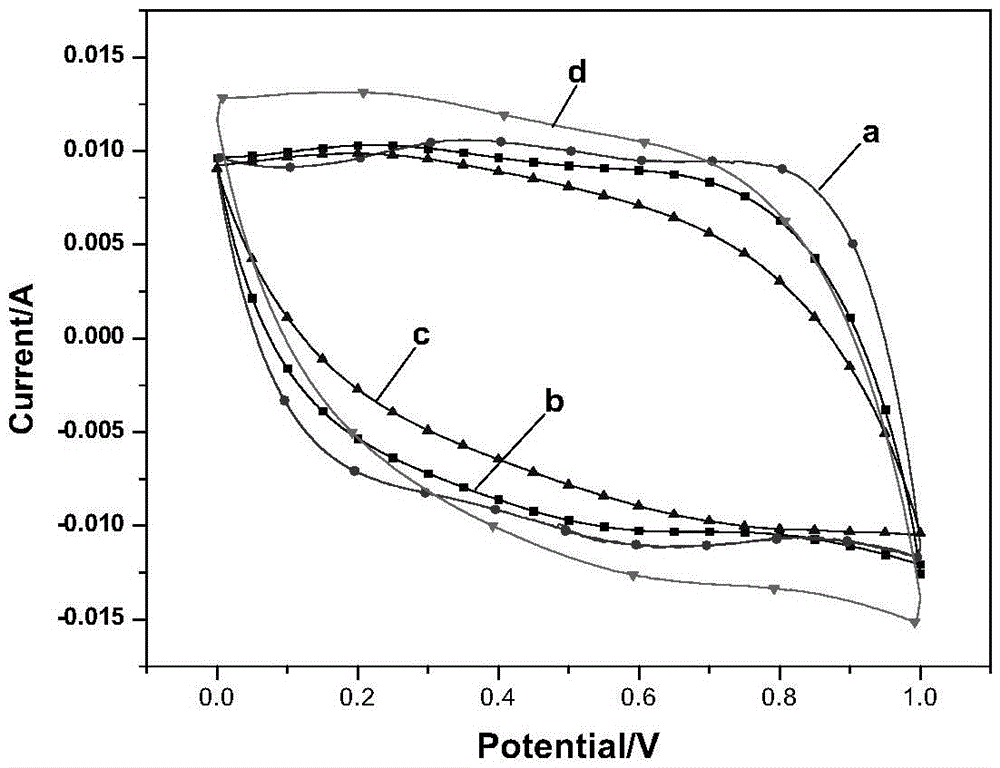

Preparation method and application of chemically-modified carbon material/graphene/RuO2 ternary composite material

InactiveCN105489397AImprove stabilityImprove conductivityHybrid capacitor electrodesHybrid/EDL manufactureModified carbonHigh pressure

The invention discloses a preparation method and application of a chemically-modified carbon material / graphene / RuO2 ternary composite material. The ternary composite material is prepared by mixing a dispersion liquid containing a chemically-modified carbon material and graphite oxide and a ruthenium chloride solution, placing the mixture liquid in a high-pressure reaction kettle for hydrothermal reaction to obtain a solid product, washing and drying the solid product, and then carrying out annealing processing. The prepared ternary composite material has the characteristics of high electrochemical activity, favorable stability, conductivity and cycle performance; and when the ternary composite material is used for preparing a capacitor electrode, the capacity of a capacitor can be improved, the power density is increased, and the rate performance is improved.

Owner:CENT SOUTH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com