Patents

Literature

628 results about "Ruthenium oxide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ruthenium oxide might refer to either of the following: Ruthenium oxide, RuO₂ Ruthenium oxide, RuO₄

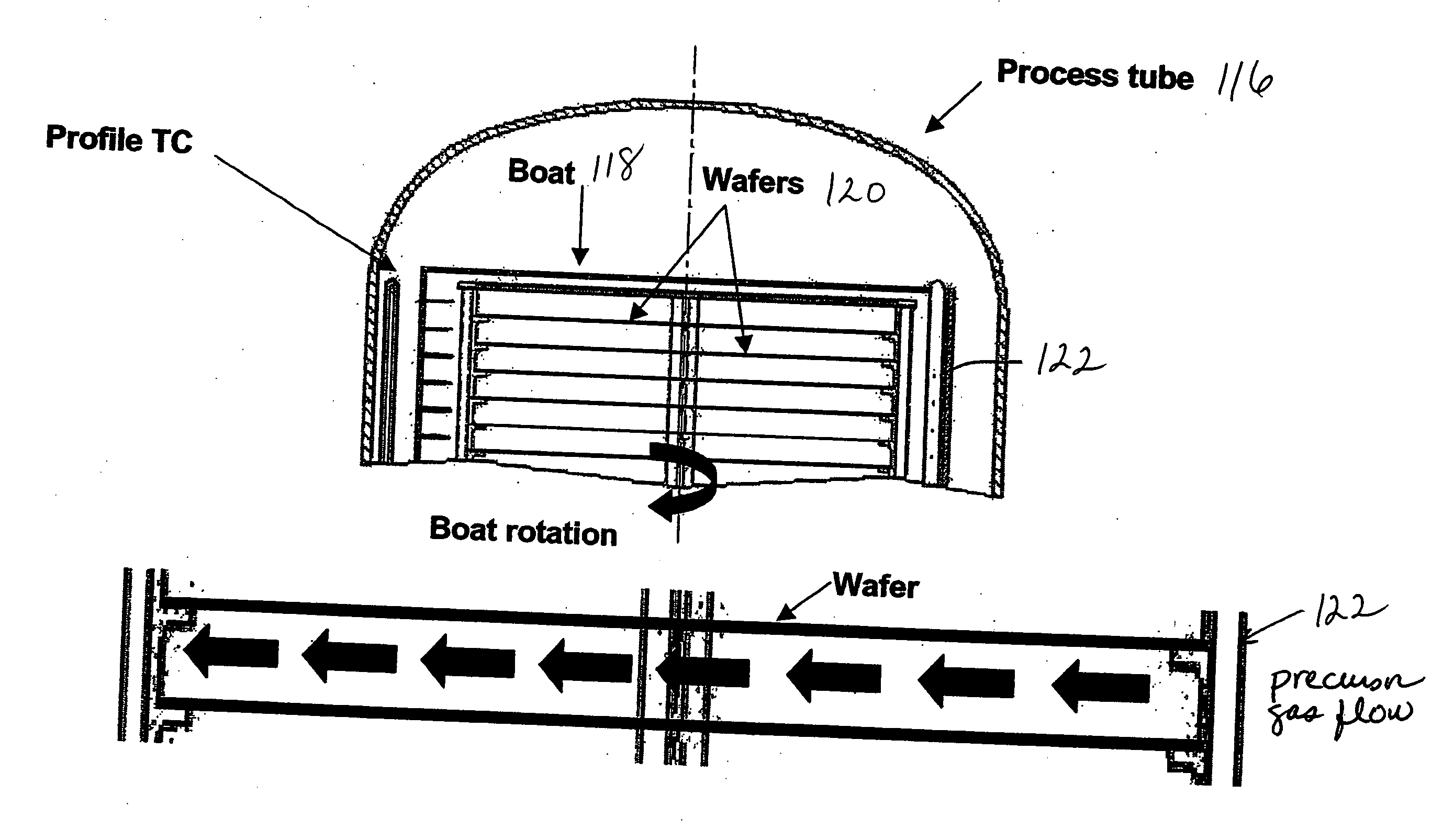

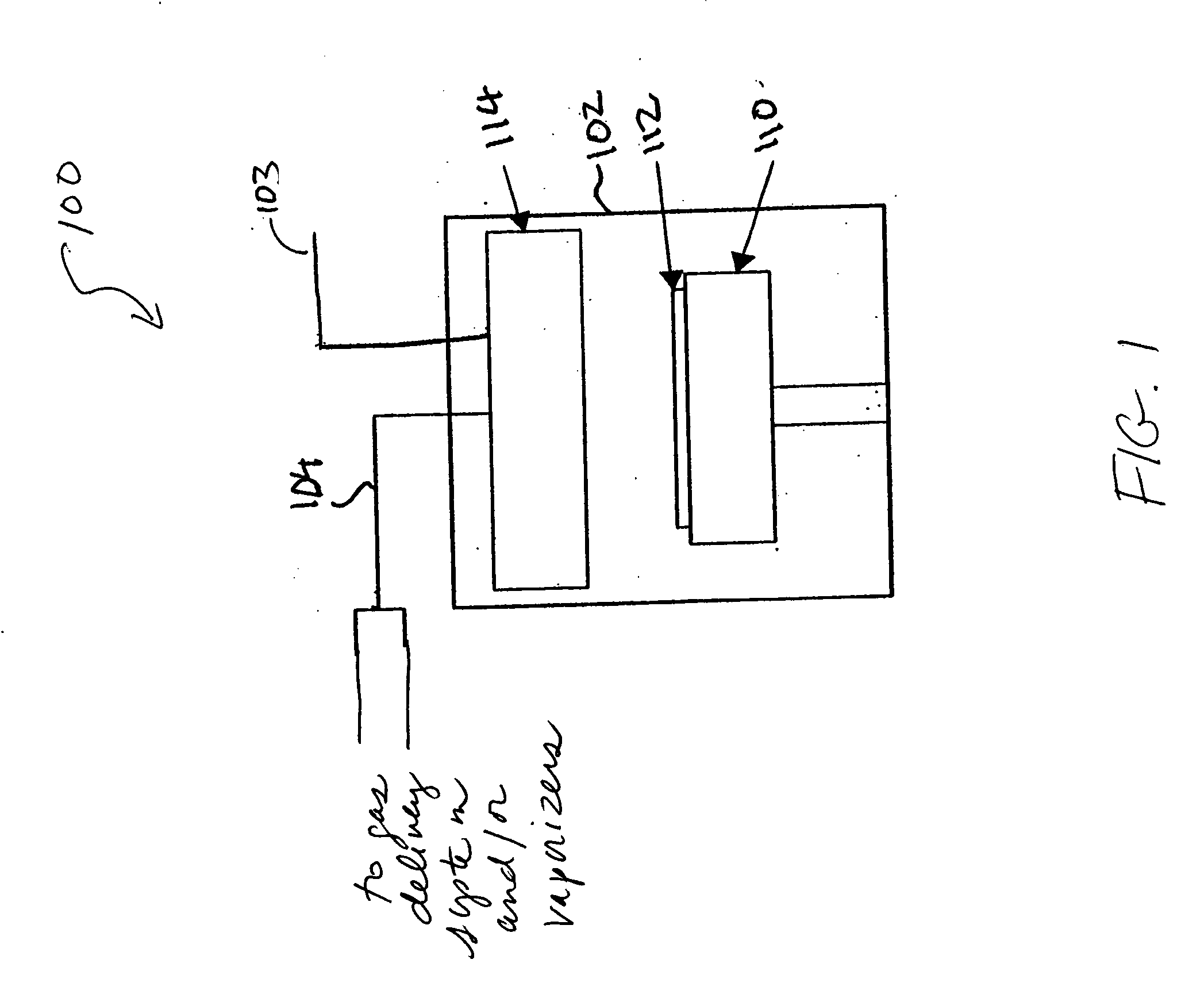

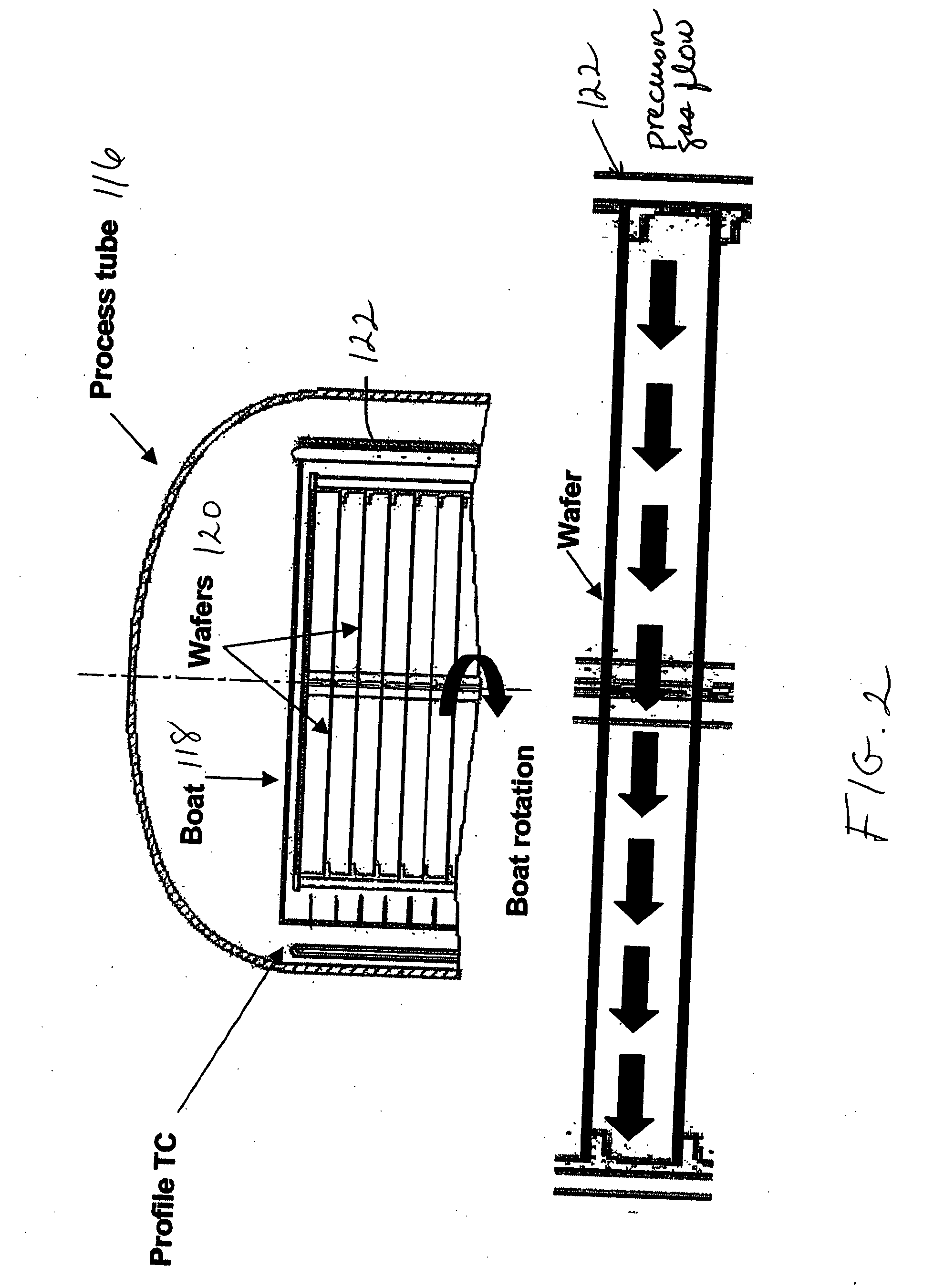

IN SITU GENERATION OF RuO4 FOR ALD OF Ru AND Ru RELATED MATERIALS

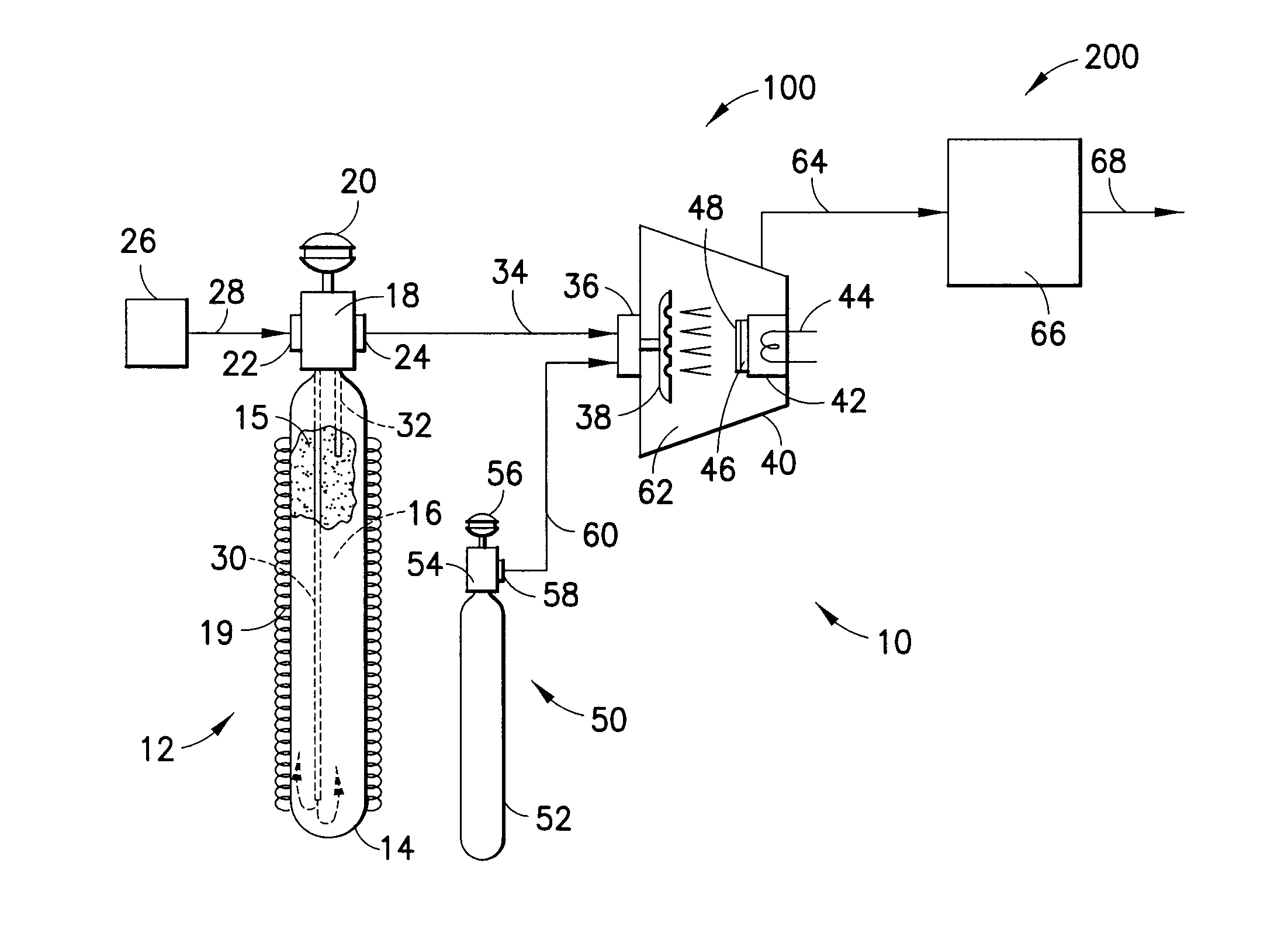

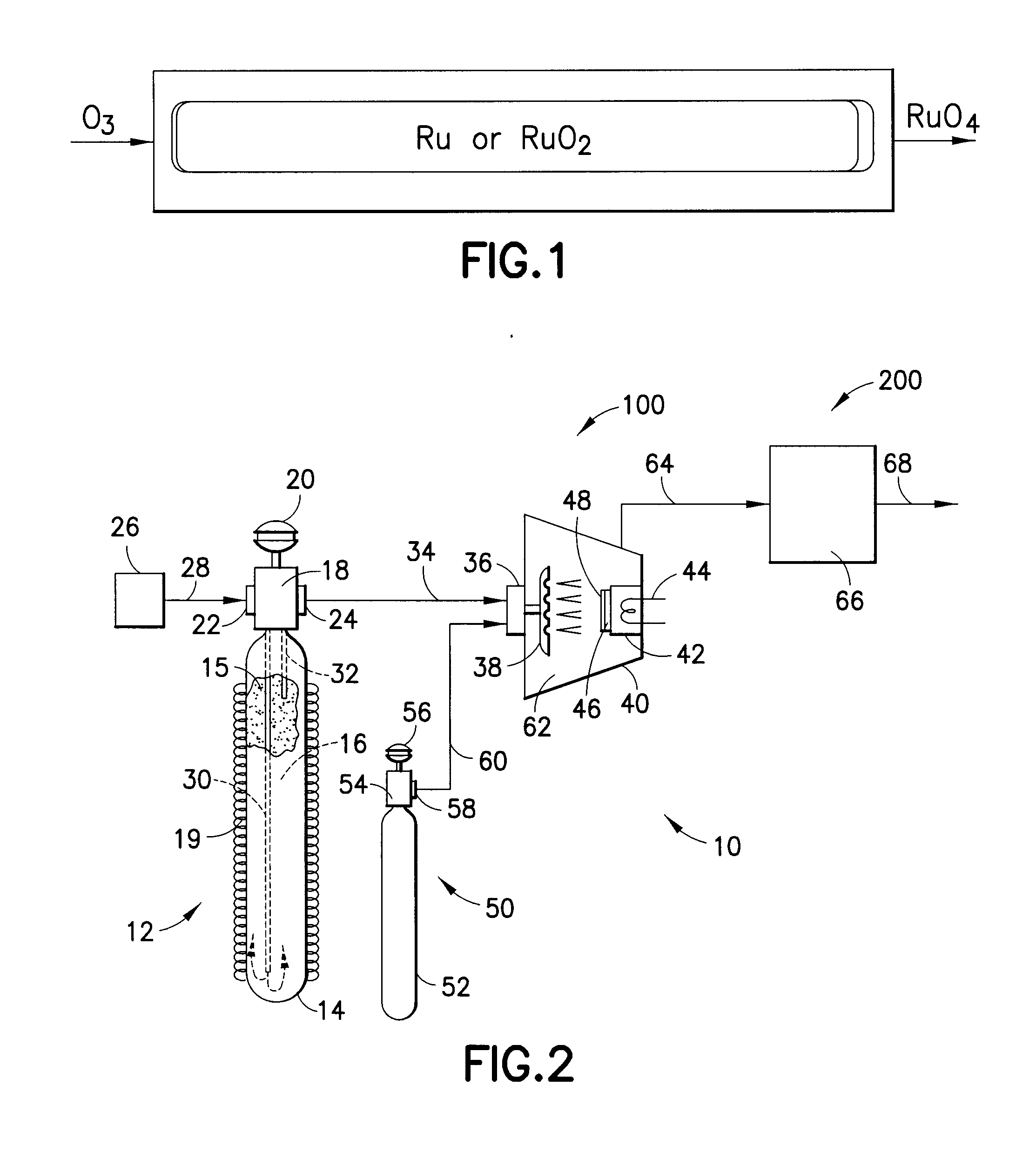

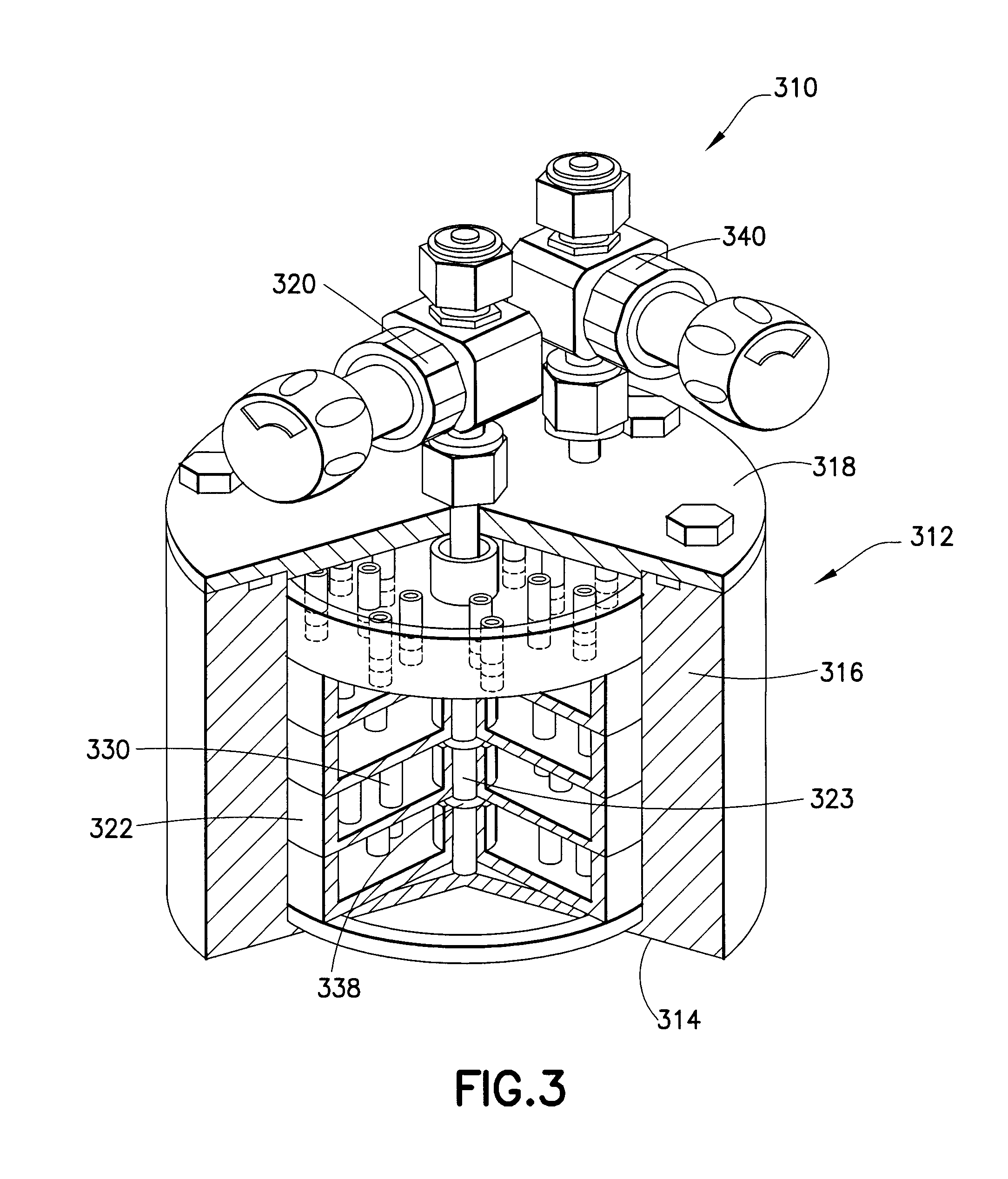

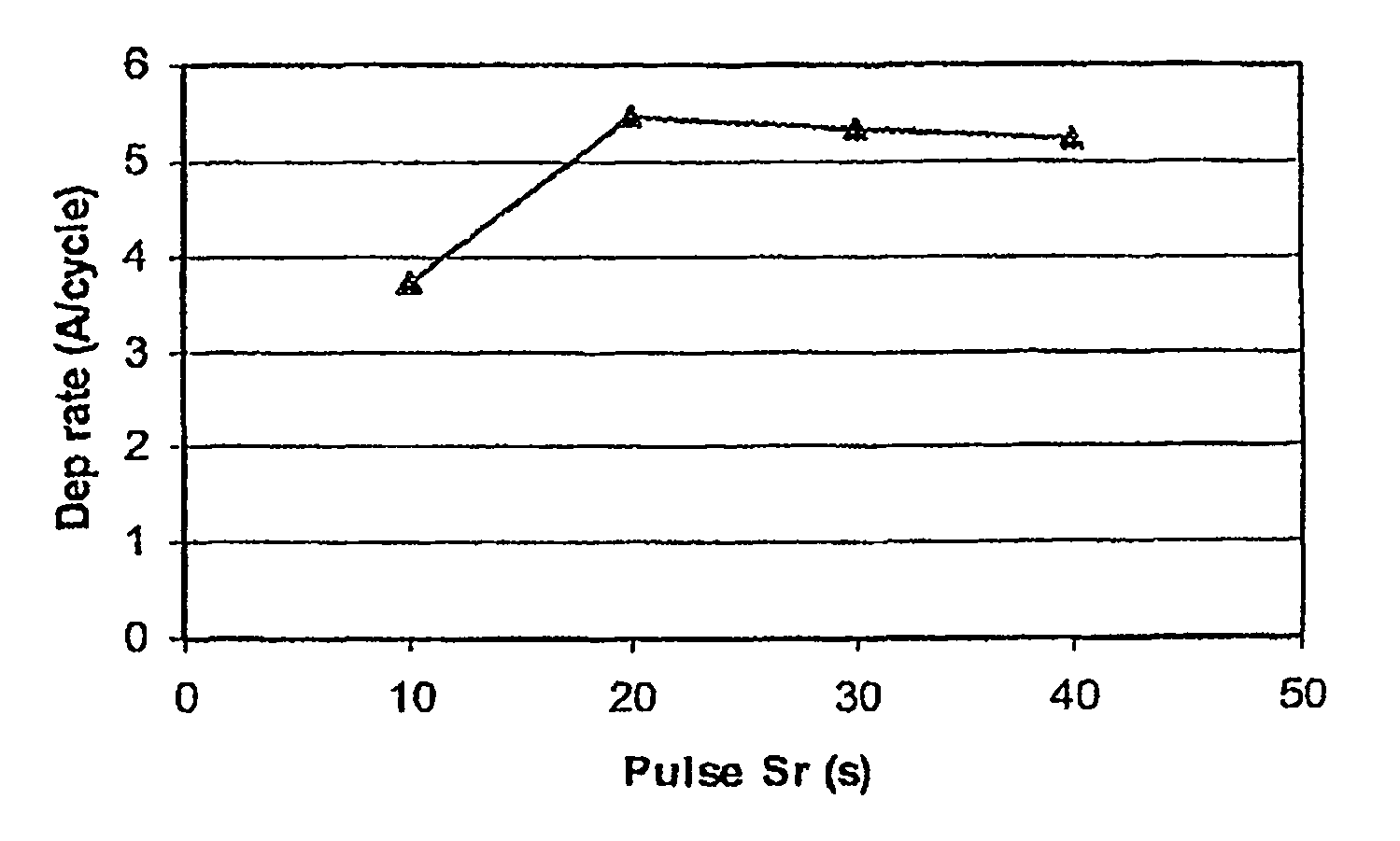

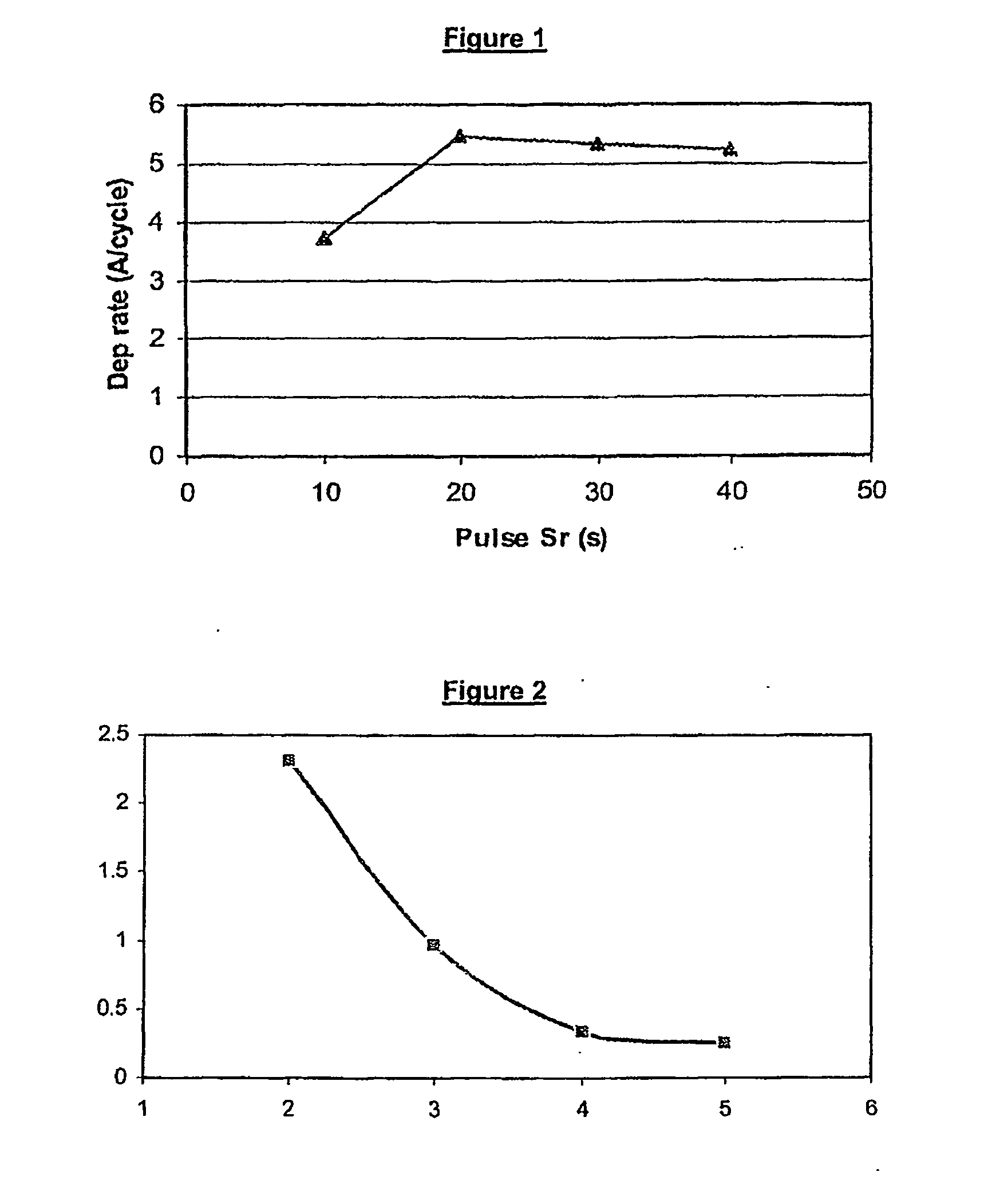

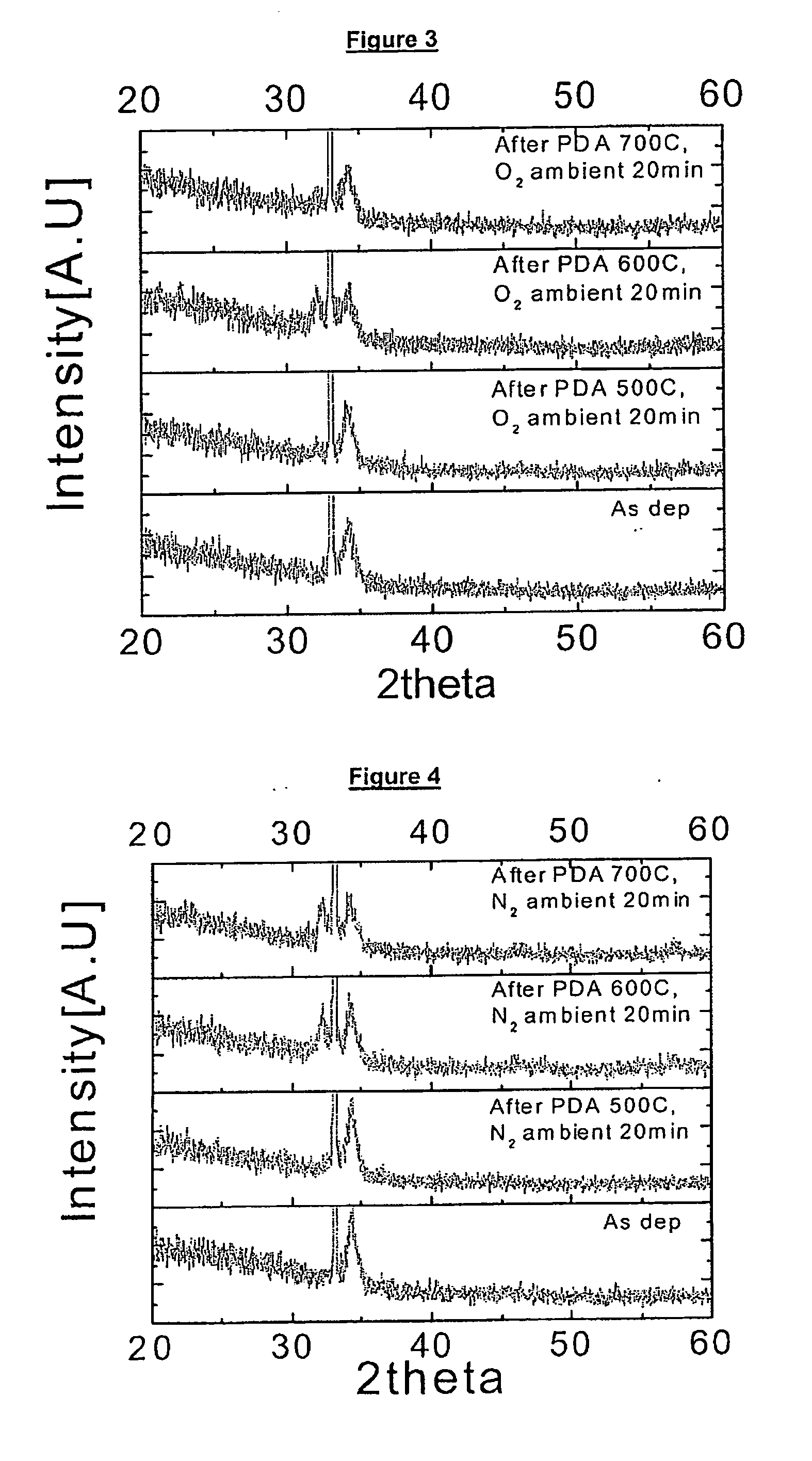

Apparatus and method for generating ruthenium tetraoxide in situ for use in vapor deposition, e.g., atomic layer deposition (ALD), of ruthenium-containing films on microelectronic device substrates. The ruthenium tetraoxide can be generated on demand by reaction of ruthenium or ruthenium dioxide with an oxic gas such as oxygen or ozone. In one implementation, ruthenium tetraoxide thus generated is utilized with a strontium organometallic precursor for atomic layer deposition of strontium ruthenate films of extremely high smoothness and purity.

Owner:ENTEGRIS INC

Use of ruthenium tetroxide as a precursor and reactant for thin film depositions

ActiveUS20130059078A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingAtomic layer depositionSemiconductor

Disclosed are atomic layer deposition methods using ruthenium-containing precursors to form ruthenium-containing films for use in the manufacture of semiconductor, photovoltaic, LCD-TFT, or flat panel type devices.

Owner:AIR LIQUIDE AMERICA INC +1

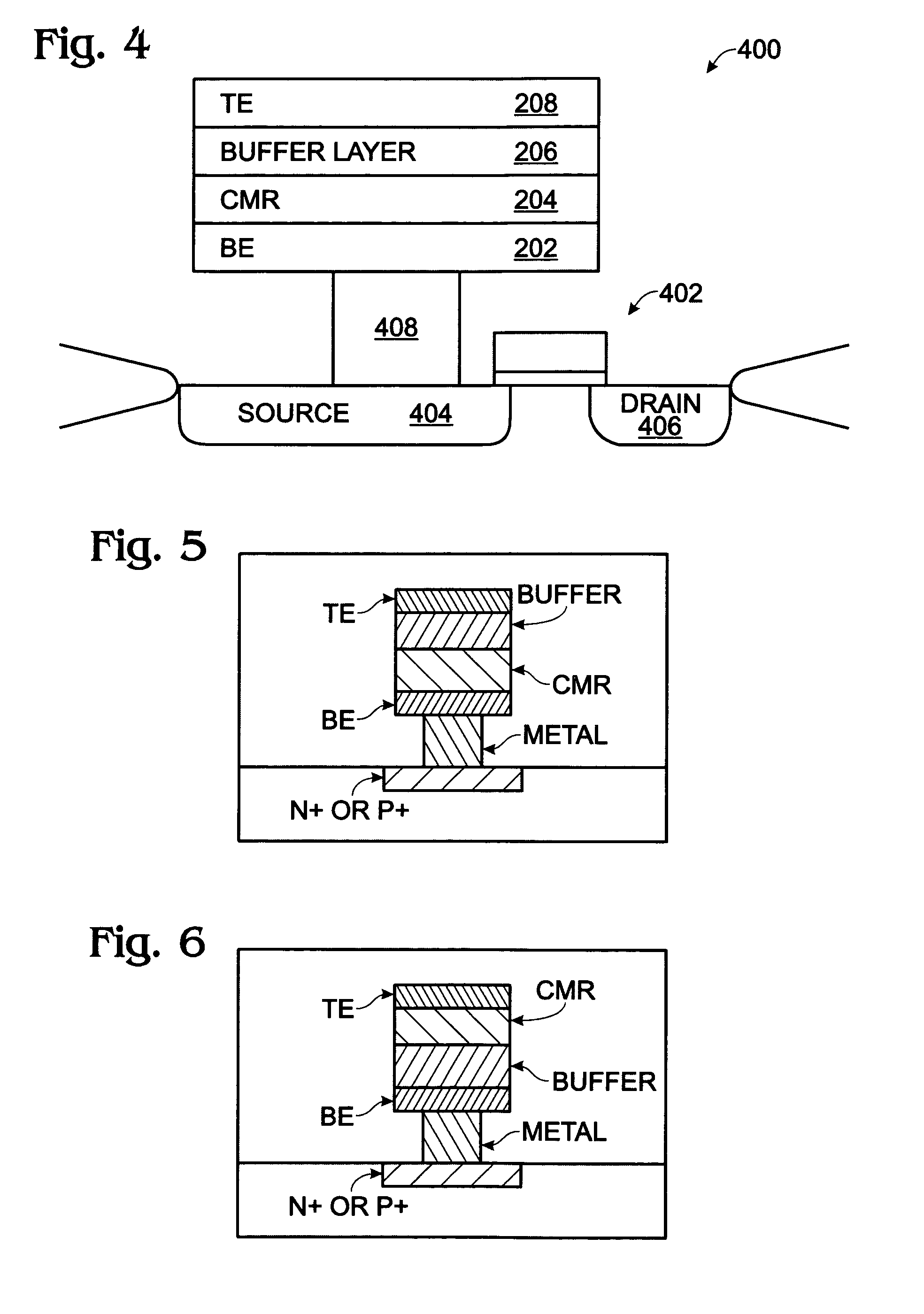

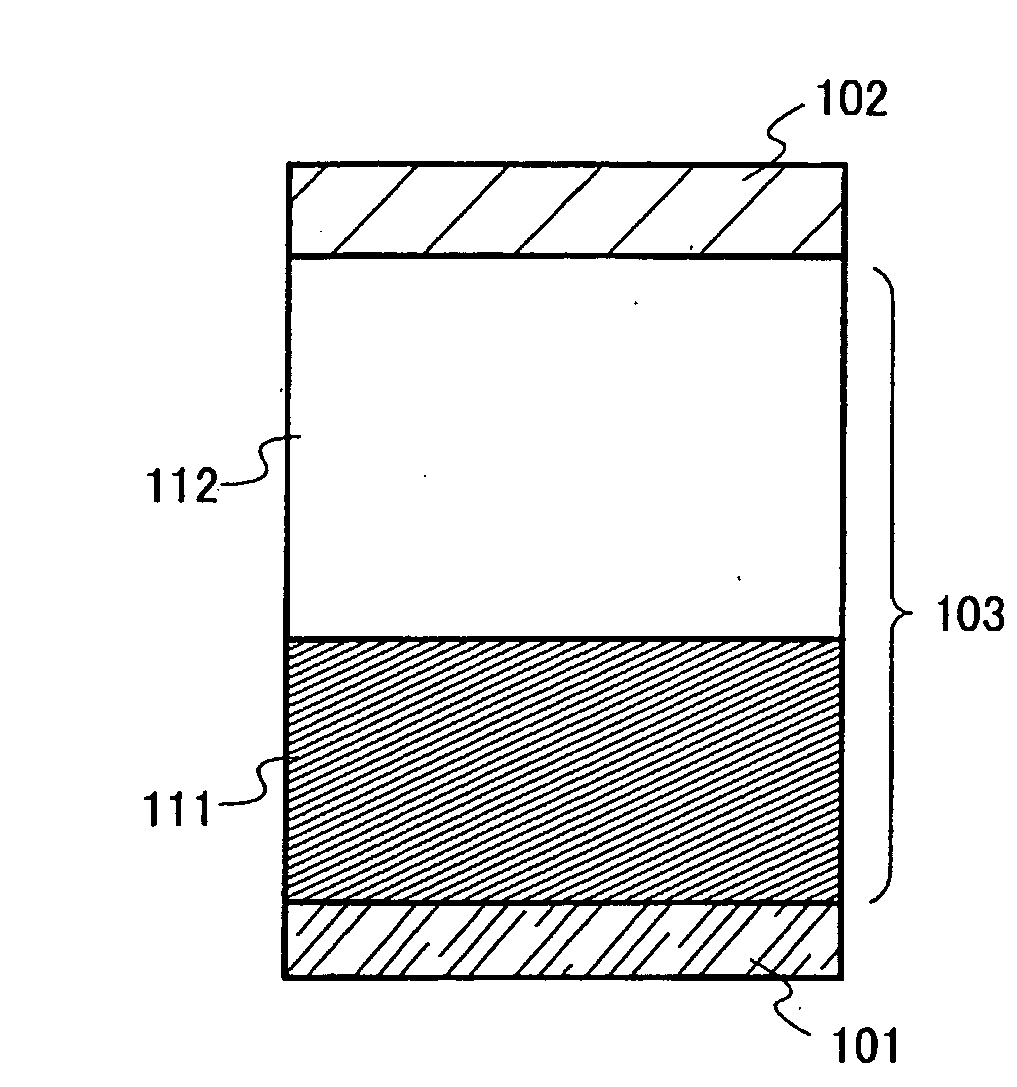

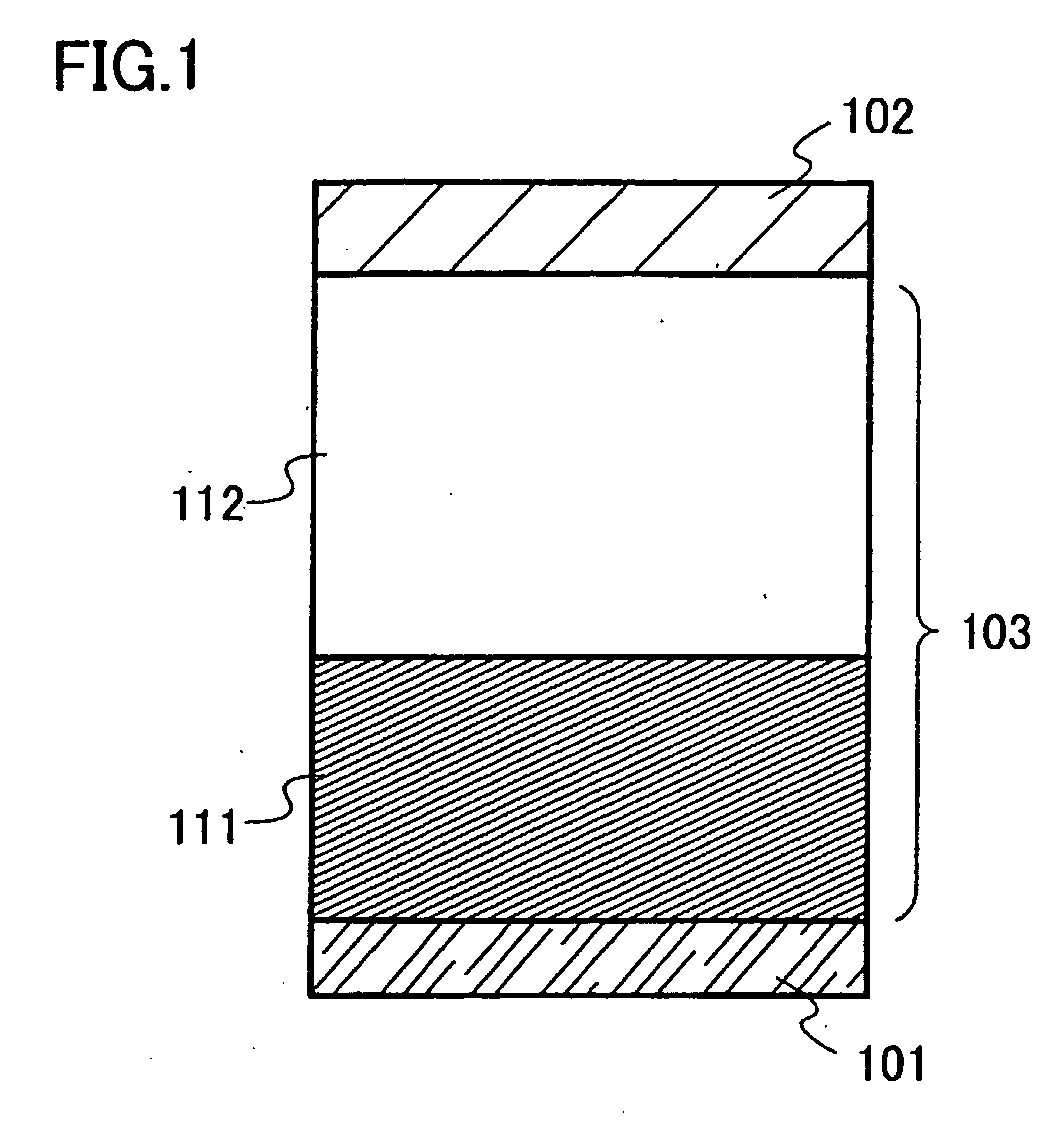

Buffered-layer memory cell

InactiveUS7029924B2Reliably programmedSolid-state devicesSemiconductor/solid-state device manufacturingIndiumSemiconductor

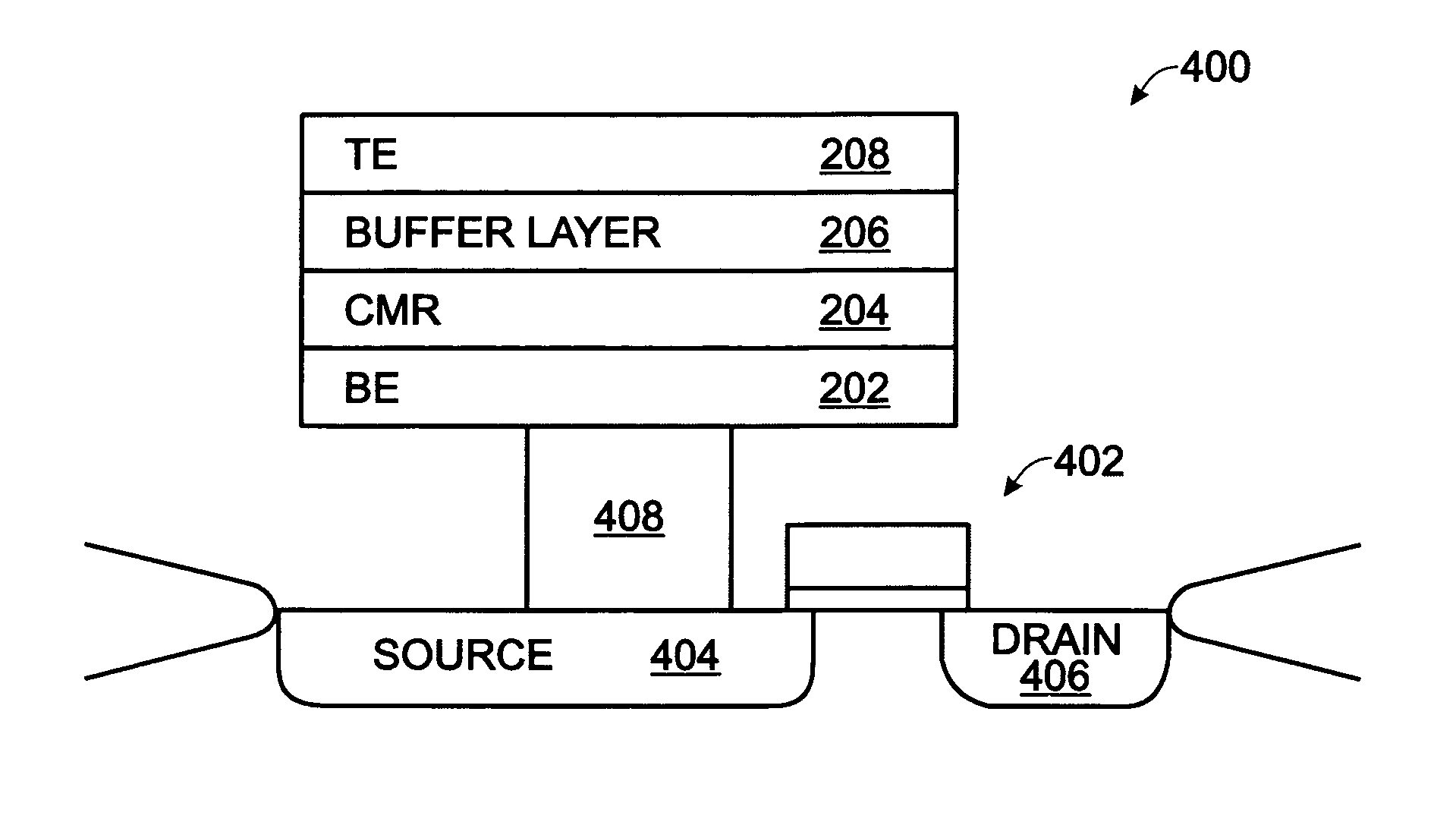

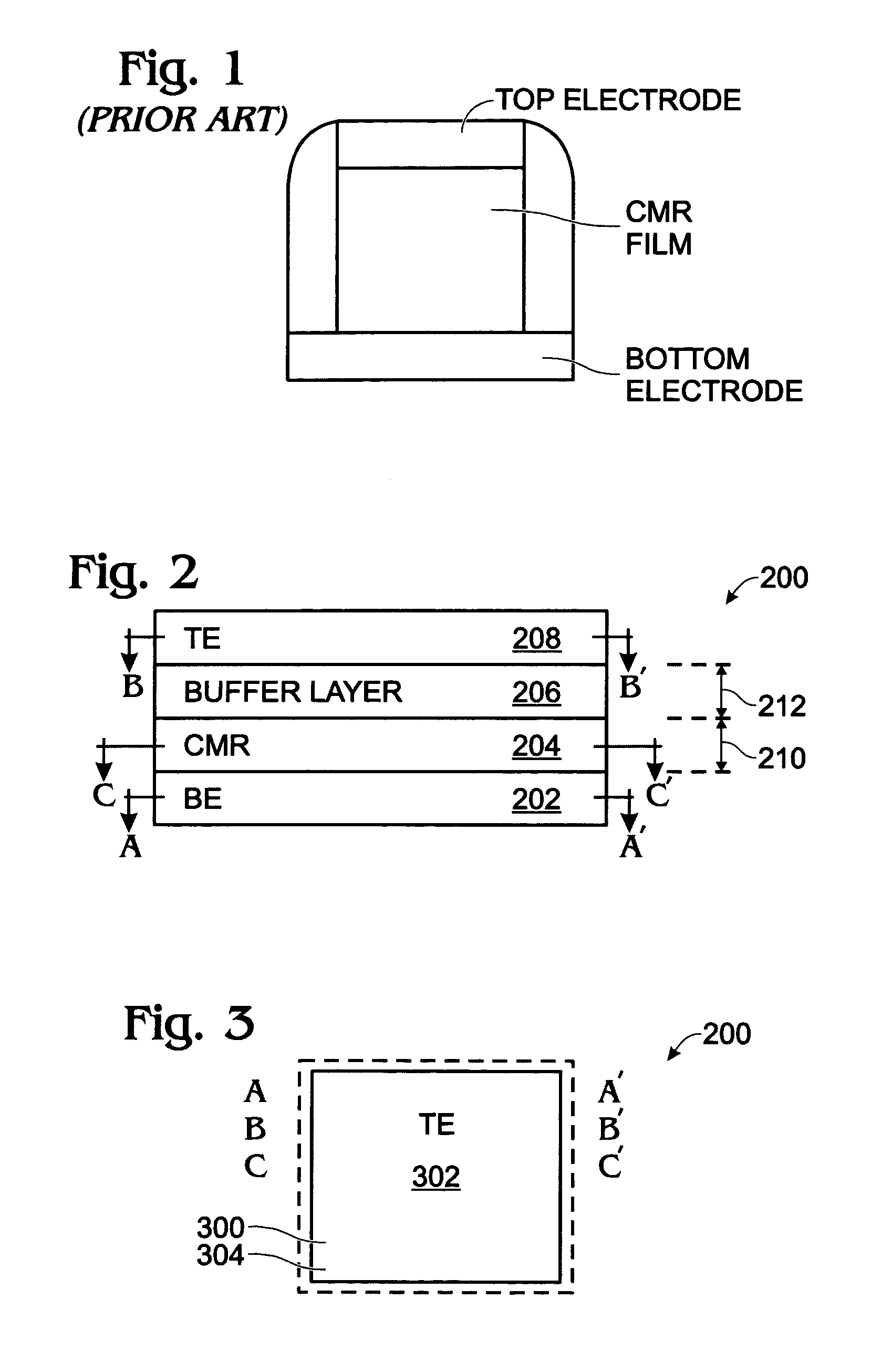

A method is provided for forming a buffered-layer memory cell. The method comprises: forming a bottom electrode; forming a colossal magnetoresistance (CMR) memory film overlying the bottom electrode; forming a memory-stable semiconductor buffer layer, typically a metal oxide, overlying the memory film; and, forming a top electrode overlying the semiconductor buffer layer. In some aspects of the method the semiconductor buffer layer is formed from YBa2Cu3O7-X (YBCO), indium oxide (In2O3), or ruthenium oxide (RuO2), having a thickness in the range of 10 to 200 nanometers (nm). The top and bottom electrodes may be TiN / Ti, Pt / TiN / Ti, In / TiN / Ti, PtRhOx compounds, or PtIrOx compounds. The CMR memory film may be a Pr1-XCaXMnO3 (PCMO) memory film, where x is in the region between 0.1 and 0.6, with a thickness in the range of 10 to 200 nm.

Owner:XENOGENIC DEV LLC

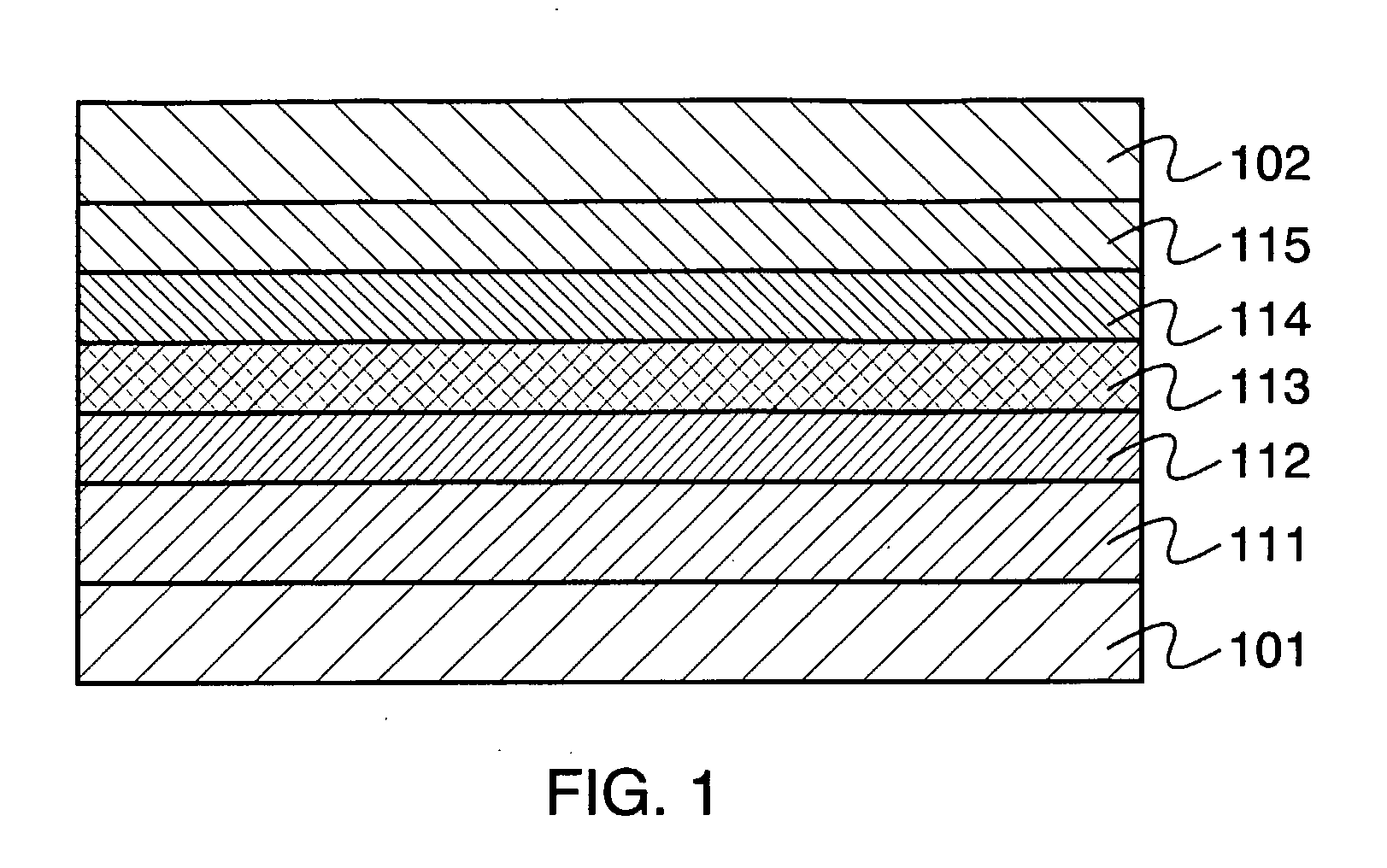

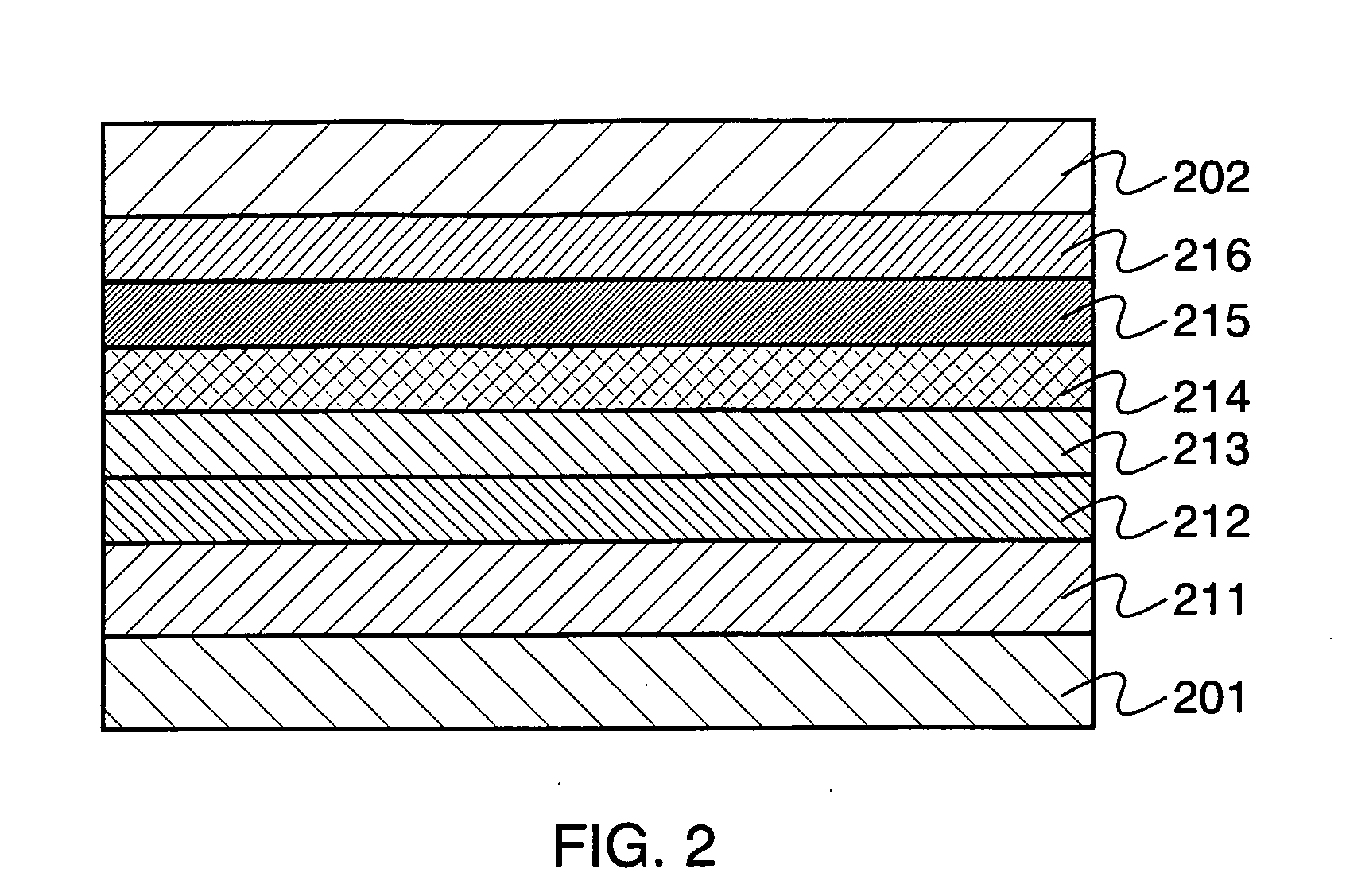

Light emitting device and electronic appliance using the same

InactiveUS20060292394A1Easy to changeDistanceDischarge tube luminescnet screensElectroluminescent light sourcesVanadium oxideOrganic compound

A light emitting device comprises a pair of electrodes and a mixed layer provided between the pair of electrodes. The mixed layer contains an organic compound which contains no nitrogen atoms, i.e., an organic compound which dose not have an arylamine skeleton, and a metal oxide. As the organic compound, an aromatic hydrocarbon having an anthracene skeleton is preferably used. As such an aromatic hydrocarbon, t-BuDNA, DPAnth, DPPA, DNA, DMNA, t-BuDBA, and the like are listed. As the metal oxide, molybdenum oxide, vanadium oxide, ruthenium oxide, rhenium oxide, and the like are preferably used. Further, the mixed layer preferably shows absorbance per 1 μm of 1 or less or does not show a distinct absorption peak in a spectrum of 450 to 650 nm when an absorption spectrum is measured.

Owner:SEMICON ENERGY LAB CO LTD

Electrode for electrolysis, preparation method of electrode and electrolytic bath

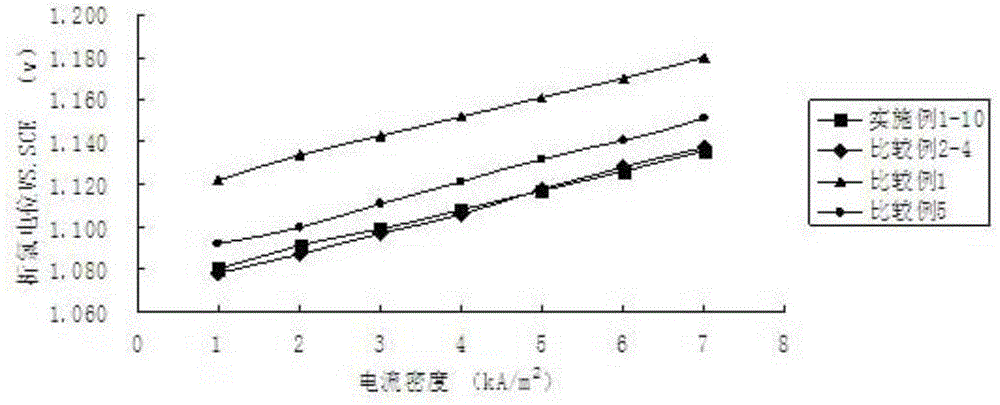

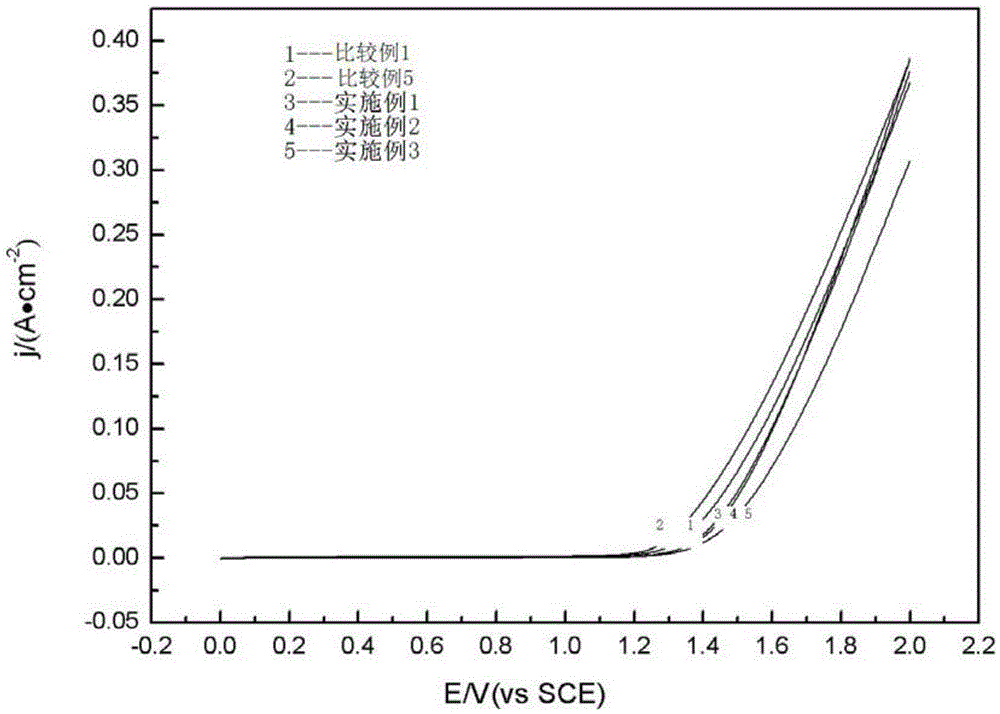

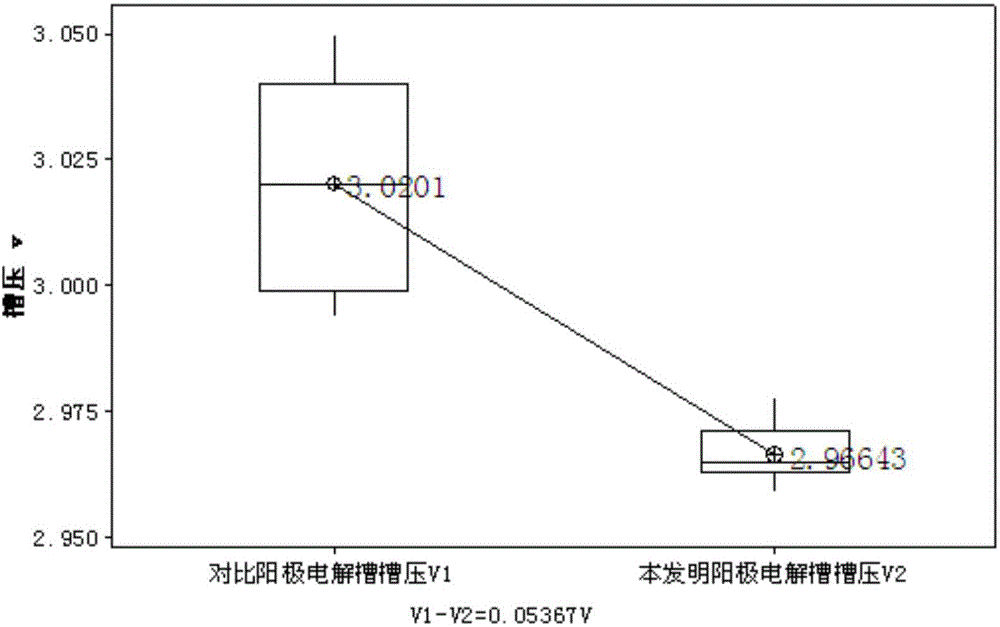

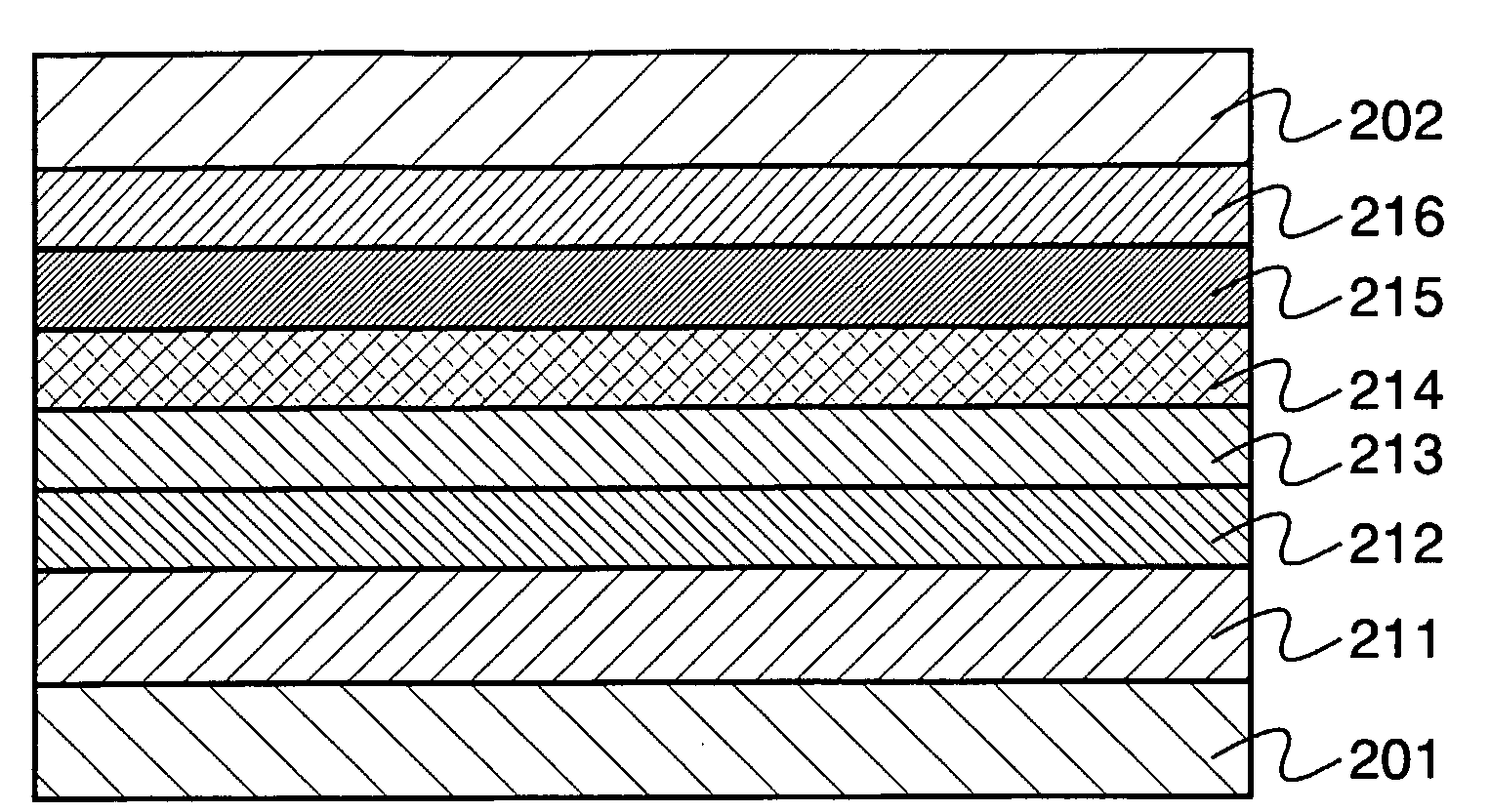

ActiveCN104562078AChlorine evolution potential is lowExtended service lifeElectrodesIridiumElectrolysis

The invention provides an electrode for electrolysis, a preparation method of the electrode and an electrolytic bath. The electrode for electrolysis comprises a conductive base material and an active coating, wherein the conductive base material is a base material containing titanium or titanium alloy; the active coating at least comprises a bottom coating layer and a surface coating layer; the bottom coating layer is prepared from titanic oxide, iridium oxide and ruthenium oxide; the surface coating layer is prepared from iridium oxide, ruthenium oxide, titanium oxide and a metal or an oxide of one of two of palladium and platinum. According to the electrode for electrolysis disclosed by the invention, the double coating layers are adopted; compared with the single coating layer only containing ruthenium, iridium and titanium, the electrode is better in activity, the chlorine evolution potential of the electrode is low, the oxygen evolution potential is high, the service life of the electrode is longer, and the electrolysis stability is better.

Owner:BLUESTAR BEIJING CHEM MACHINERY

Light emitting element, light emitting device, and electronic device

InactiveUS20090026922A1Operation failureEasy to changeDischarge tube luminescnet screensLamp detailsVanadium oxideTert butyl

One aspect of the present invention is a light emitting element having a layer including an aromatic hydrocarbon and a metal oxide between a pair of electrodes. The kind of aromatic hydrocarbon is not particularly limited; however, an aromatic hydrocarbon having hole mobility of 1×10−6 cm2 / Vs or more is preferable. As such aromatic hydrocarbon, for example, 2-tert-butyl-9,10-di(2-naphthyl)anthracene, anthracene, 9,10-diphenylanthracene, tetracene, rubrene, perylene, 2,5,8,11-tetra(tert-butyl)perylene, and the like are given. As the metal oxide, a metal which shows an electron-accepting property to the aromatic hydrocarbon is preferable. As such metal oxide, for example, molybdenum oxide, vanadium oxide, ruthenium oxide, rhenium oxide, and the like are given.

Owner:SEMICON ENERGY LAB CO LTD

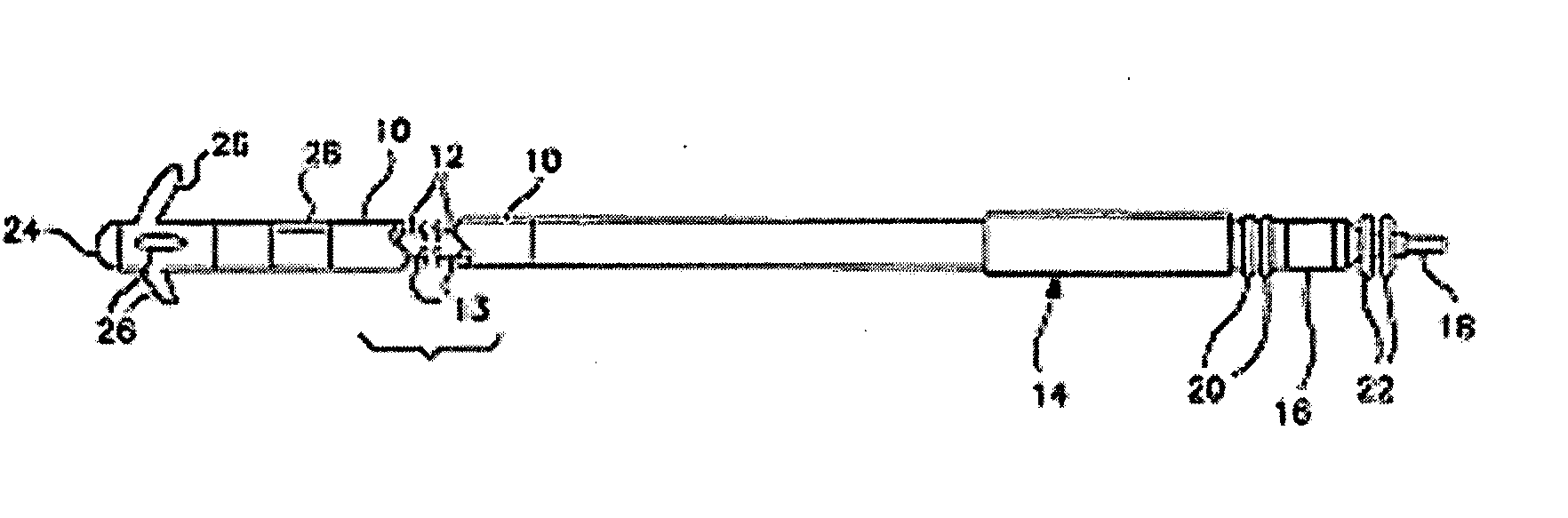

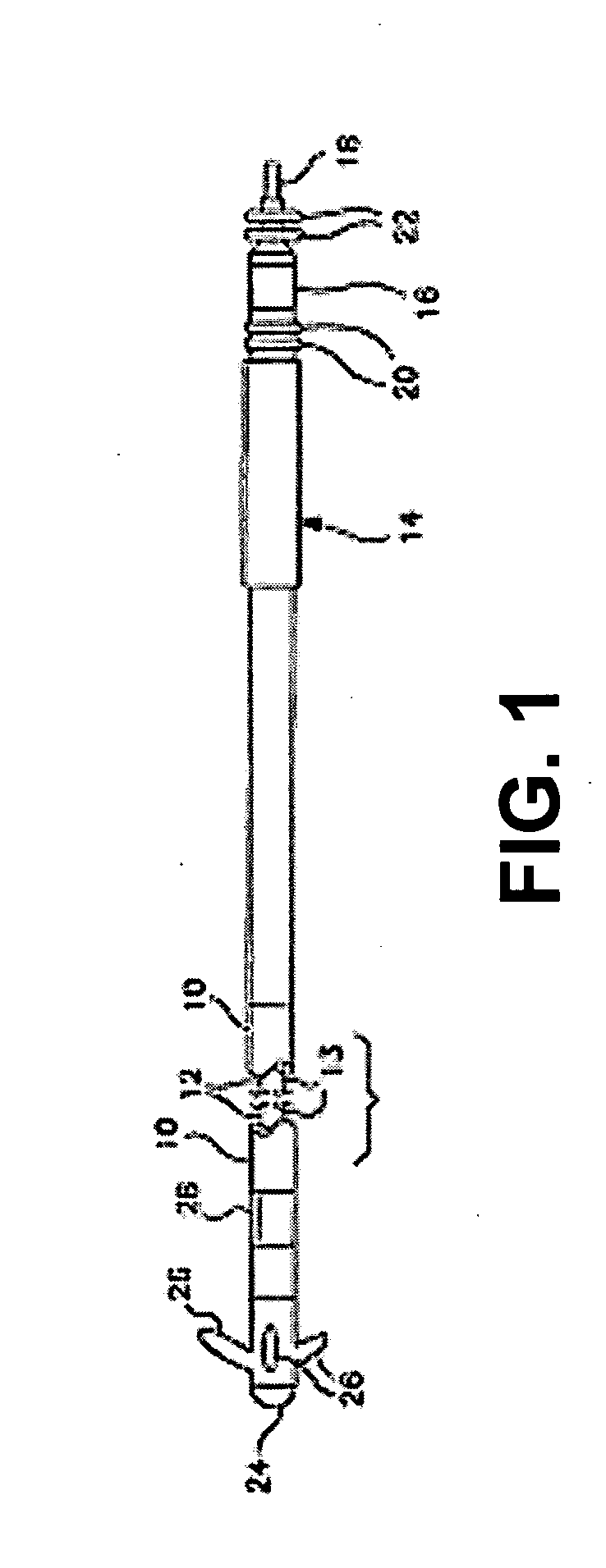

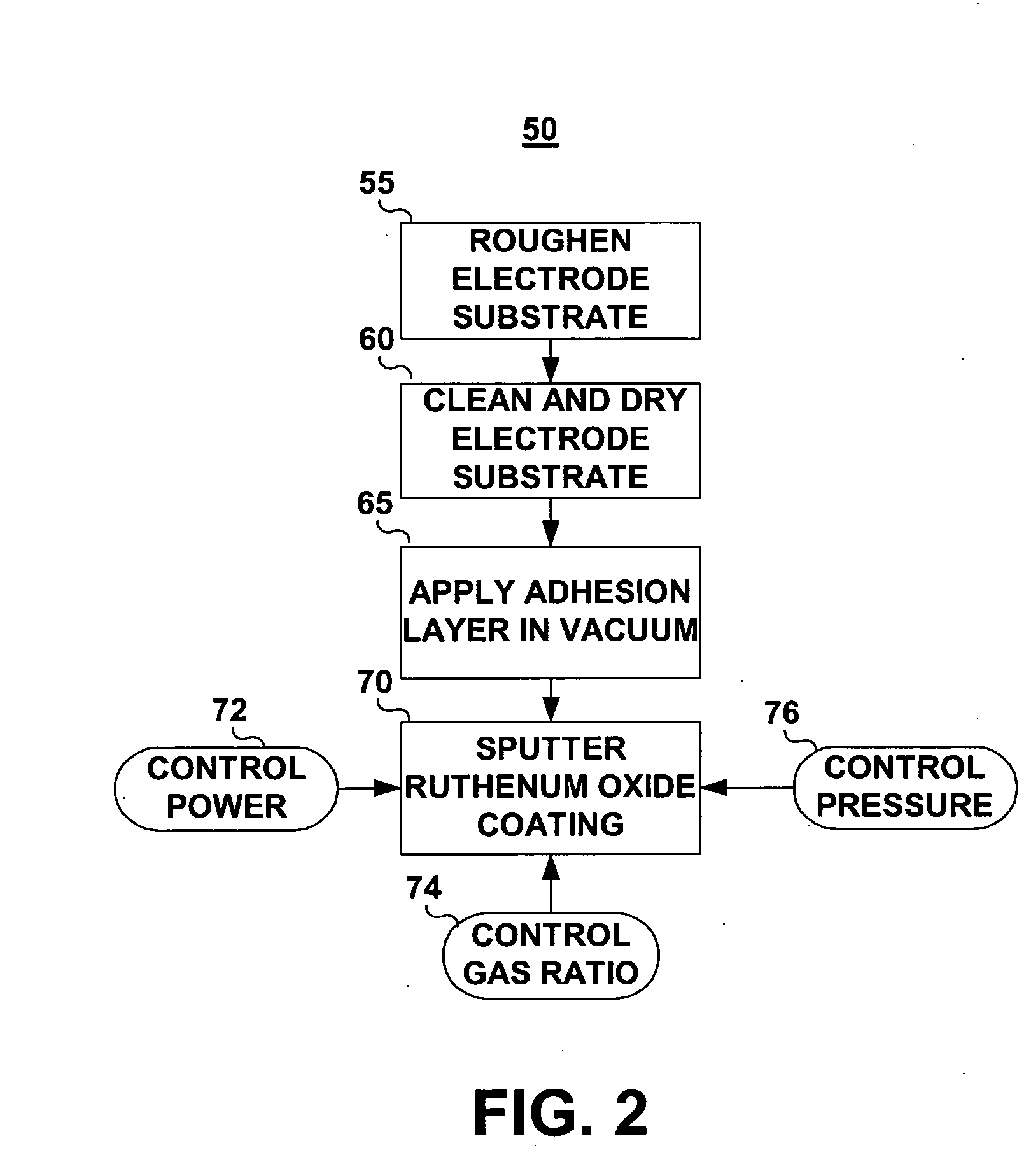

Method for fabrication of low-polarization implantable stimulation electrode

InactiveUS20060167536A1Avoid layeringPrevent oxidationInternal electrodesExternal electrodesIridiumImplantable Stimulation Electrodes

A method for fabricating an implantable medical electrode includes roughening the electrode substrate, applying an adhesion layer, and depositing a valve metal oxide coating over the adhesion layer under conditions optimized to minimize electrode impedance and post-pulse polarization. The electrode substrate may be a variety of electrode metals or alloys including titanium, platinum, platinum-iridium, or niobium. The adhesion layer may be formed of titanium or zirconium. The valve metal oxide coating is a ruthenium oxide coating sputtered onto the adhesion layer under controlled target power, sputtering pressure, and sputter gas ratio setting optimized to minimize electrode impedance and post-pulse polarization.

Owner:MEDTRONIC INC

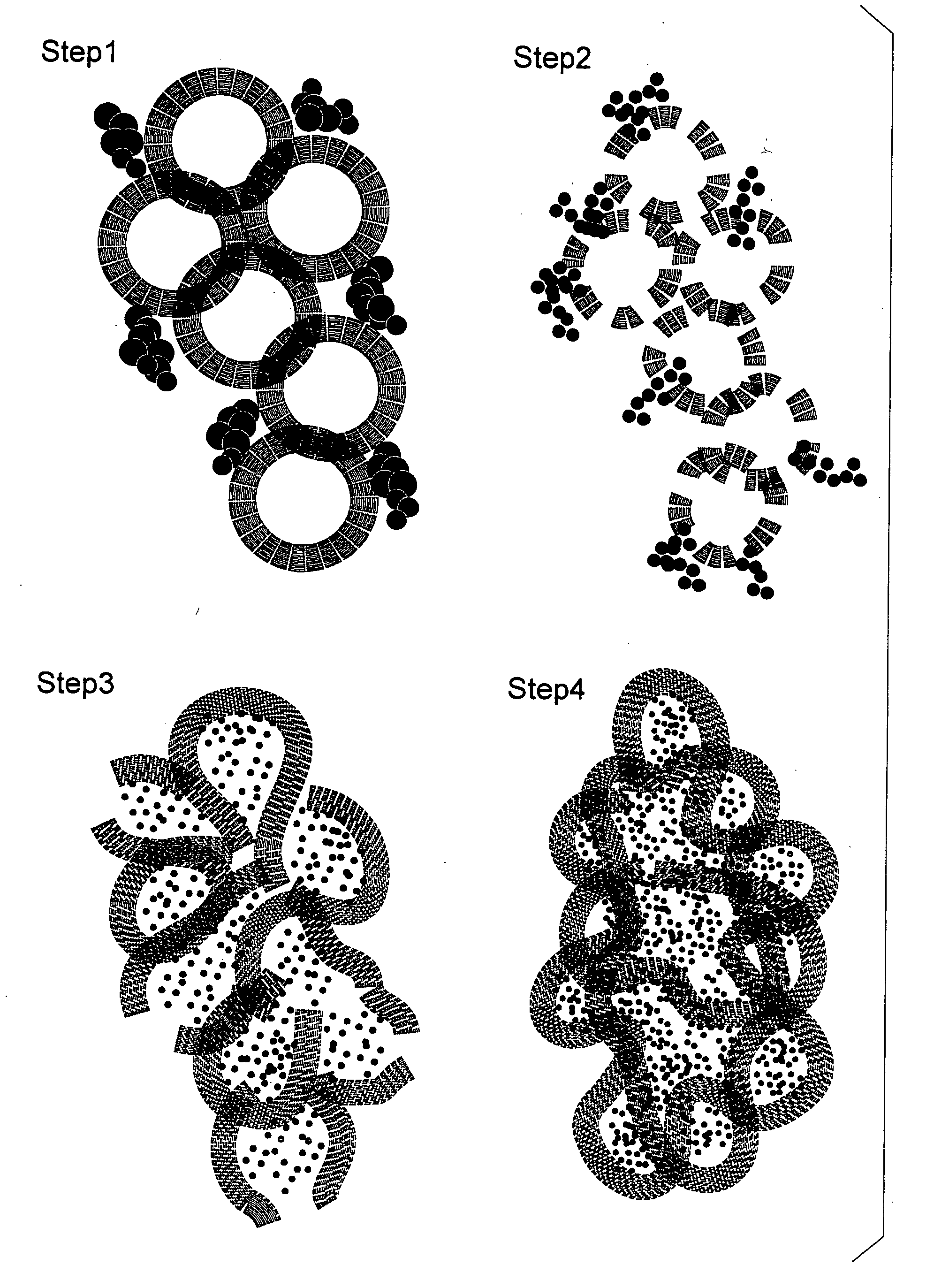

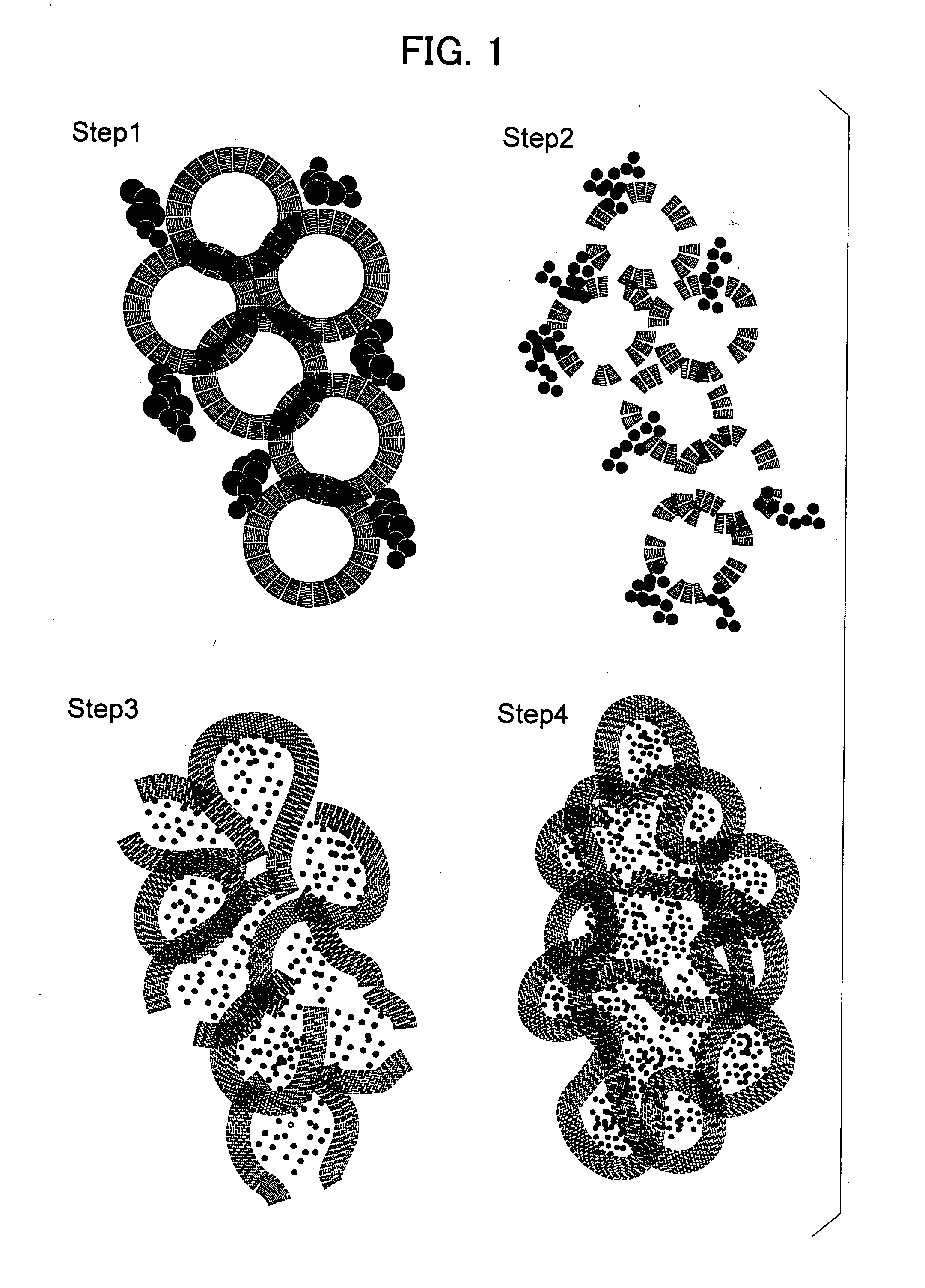

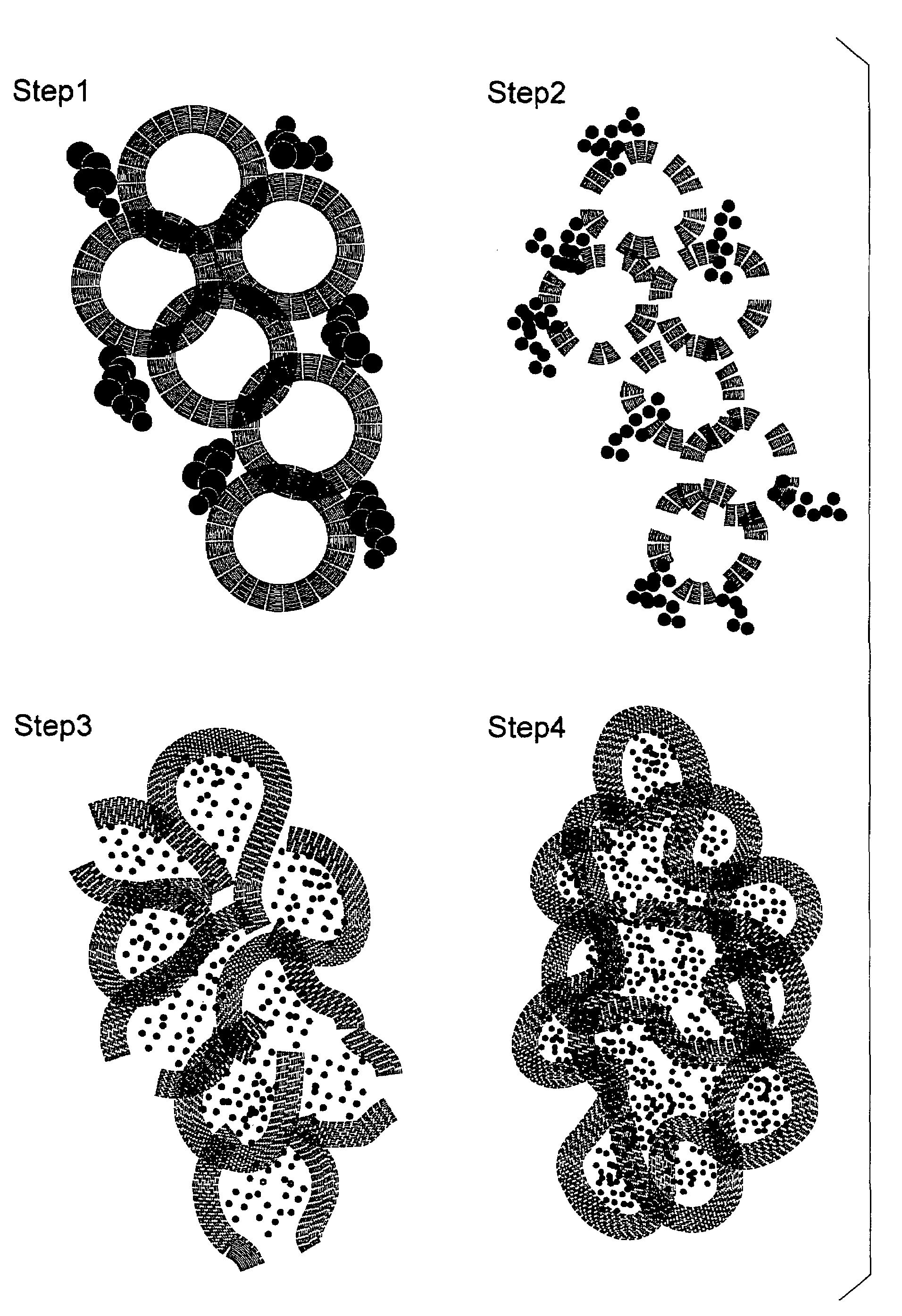

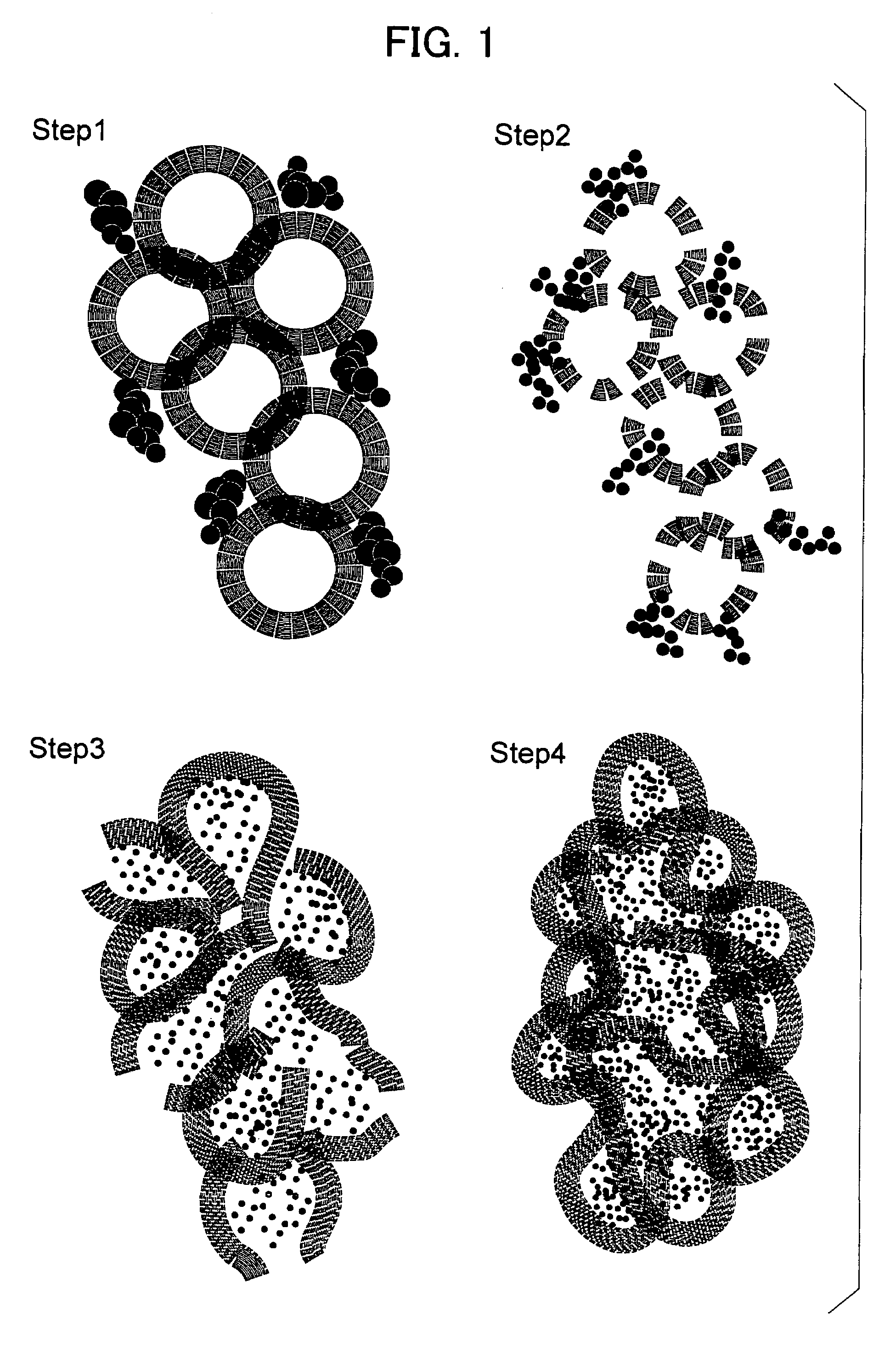

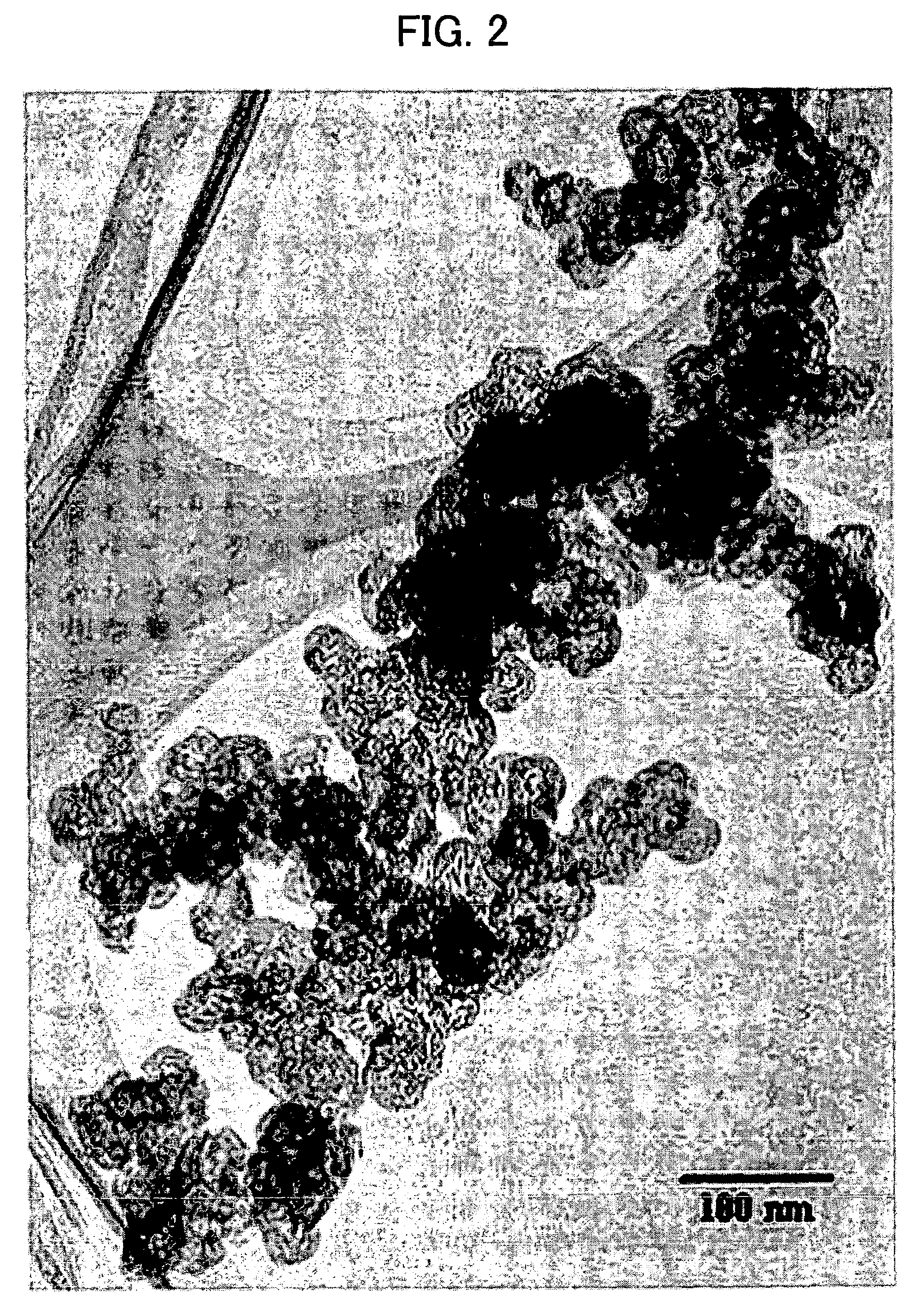

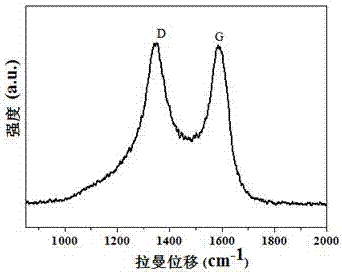

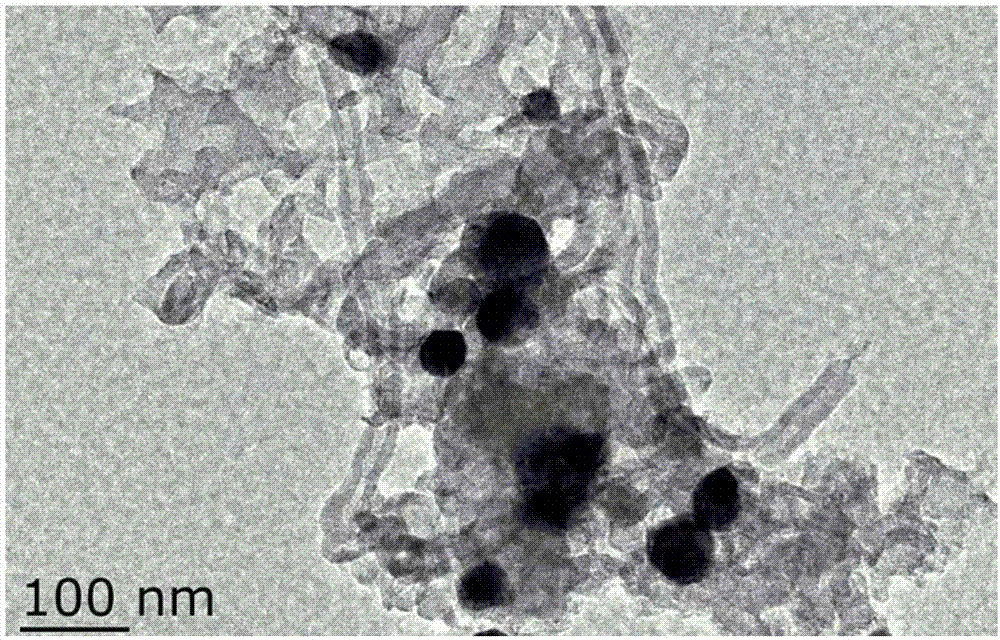

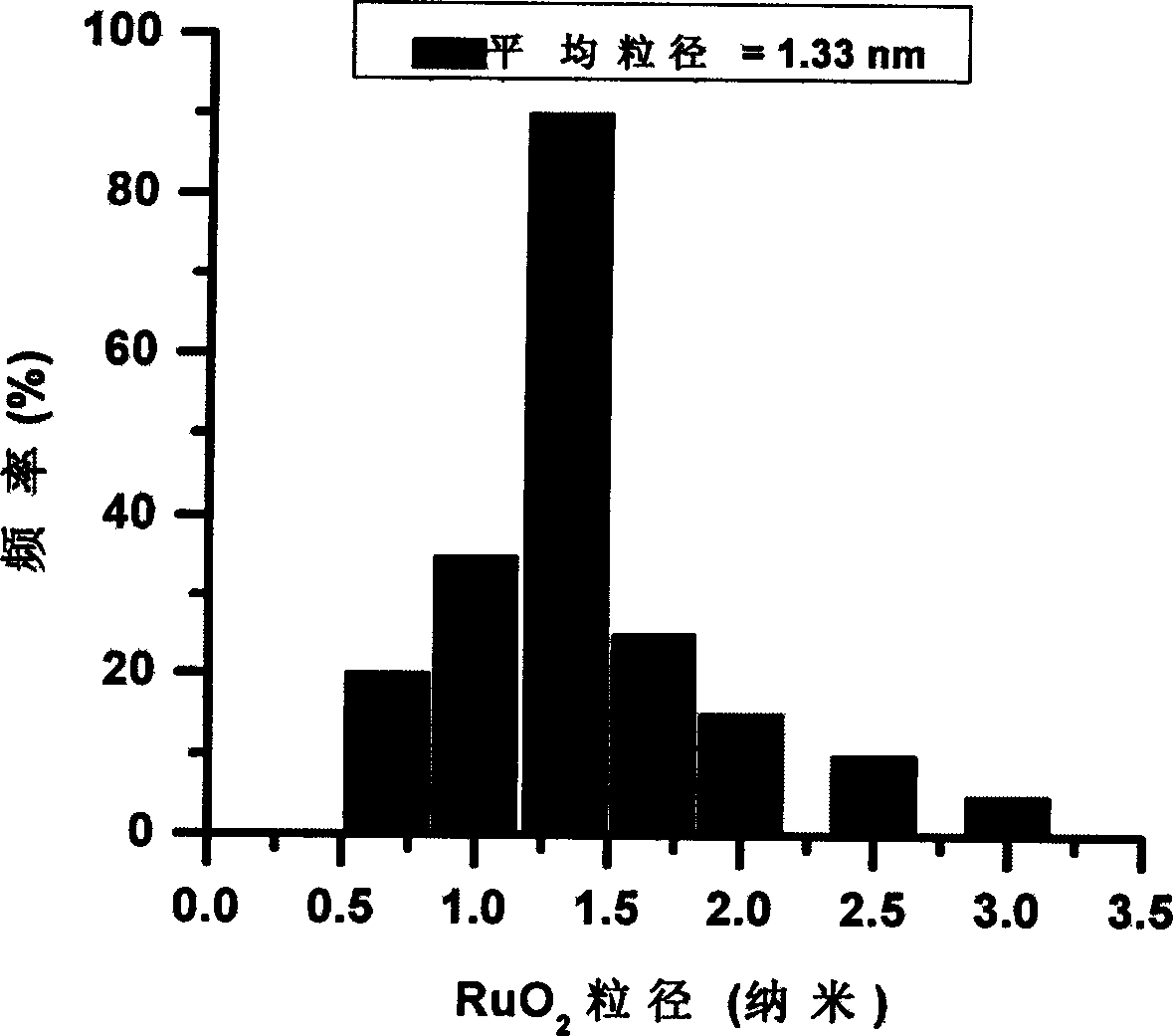

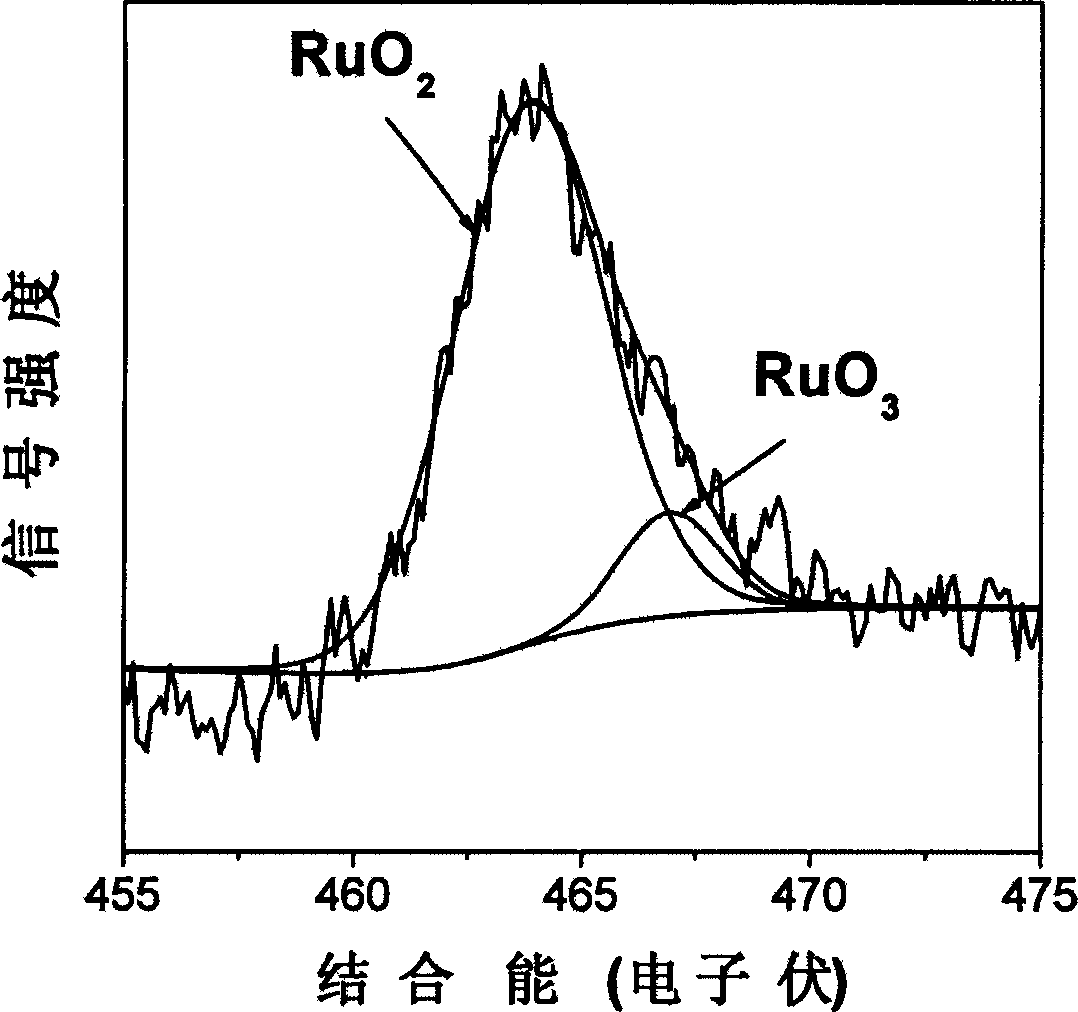

Nanocarbon Composite Structure Having Ruthenium Oxide Trapped Therein

InactiveUS20080048153A1Increase capacitanceImprove electrochemical activityMaterial nanotechnologyCarbon compoundsReaction fieldNanoparticle

A novel nanocarbon composite structure is provided having trapped ruthenium oxide. By using Ketjen black, and through chemical-mechanical effect utilizing an ultracentrifugal reaction field, both the specific surface area of ruthenium oxide and space of electrode material are expanded to have nanoparticles of ruthenium oxide highly dispersed in a graphene layer. This nanocarbon composite structure having trapped ruthenium oxide exhibits high electrochemical activity and is suitable for use as an electrical energy storing device, such as a large-capacity capacitor.

Owner:NAT UNIV CORP TOKYO UNIV OF AGRI & TECH

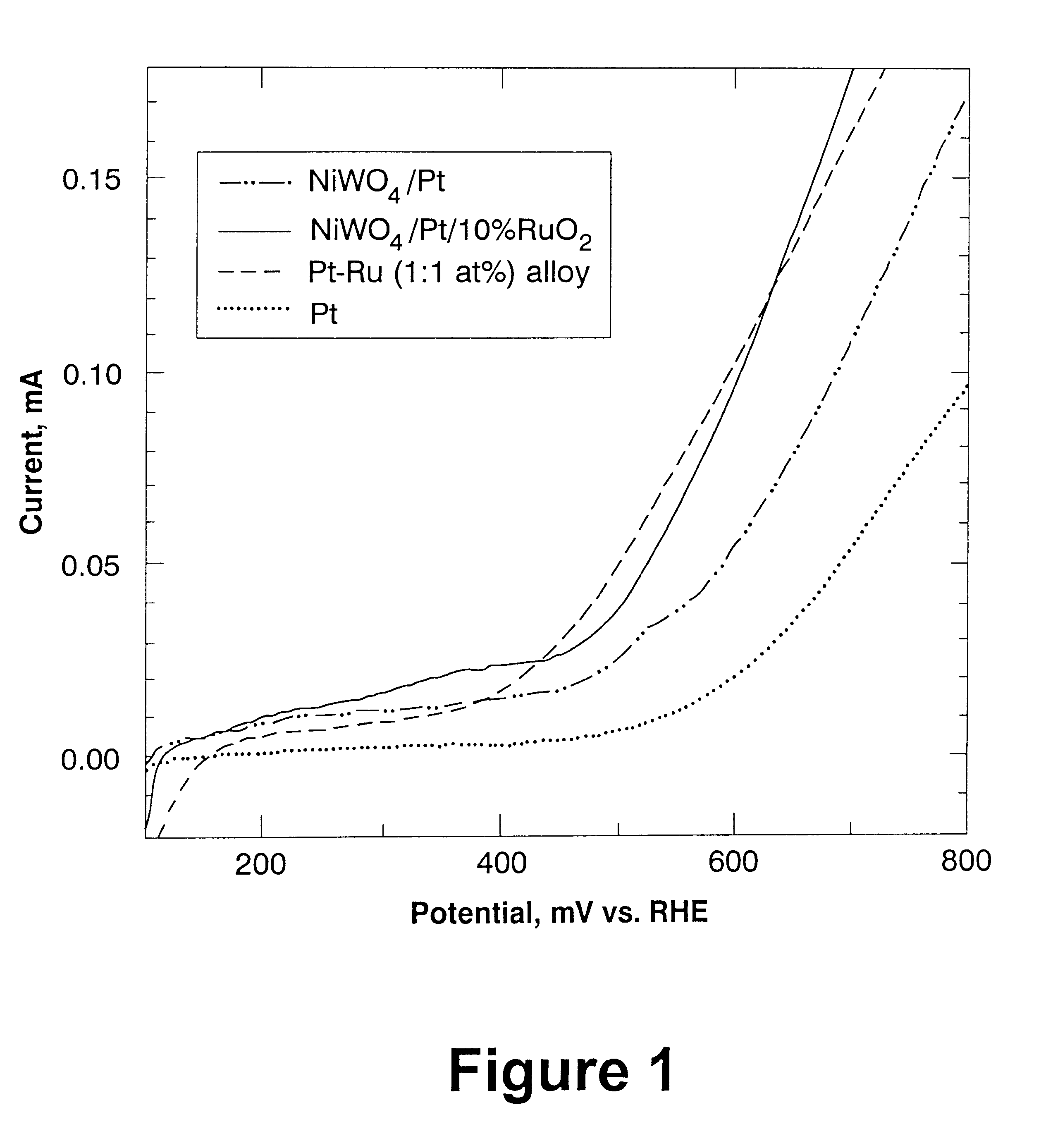

Electrocatalyst for alcohol oxidation in fuel cells

InactiveUS6183894B1Low costImprove stabilityElectrolysis componentsBreech mechanismsPtru catalystFuel cells

Binary and ternary electrocatalysts are provided for oxidizing alcohol in a fuel cell. The binary electrocatalyst includes 1) a substrate selected from the group consisting of NiWO4 or CoWO4 or a combination thereof, and 2) Group VIII noble metal catalyst supported on the substrate. The ternary electrocatalyst includes 1) a substrate as described above, and 2) a catalyst comprising Group VIII noble metal, and ruthenium oxide or molybdenum oxide or a combination thereof, said catalyst being supported on said substrate.

Owner:BROOKHAVEN SCI ASSOCS

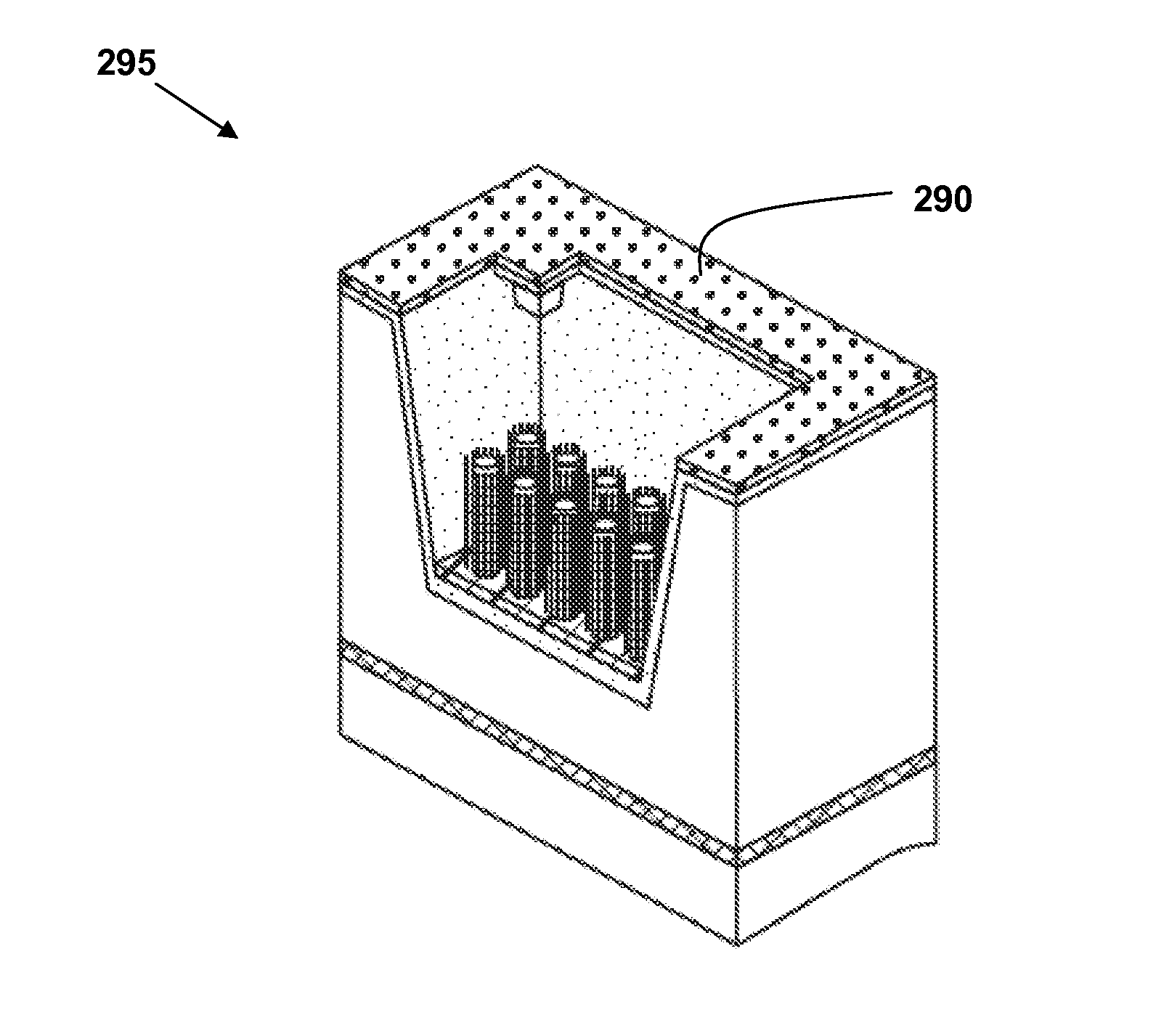

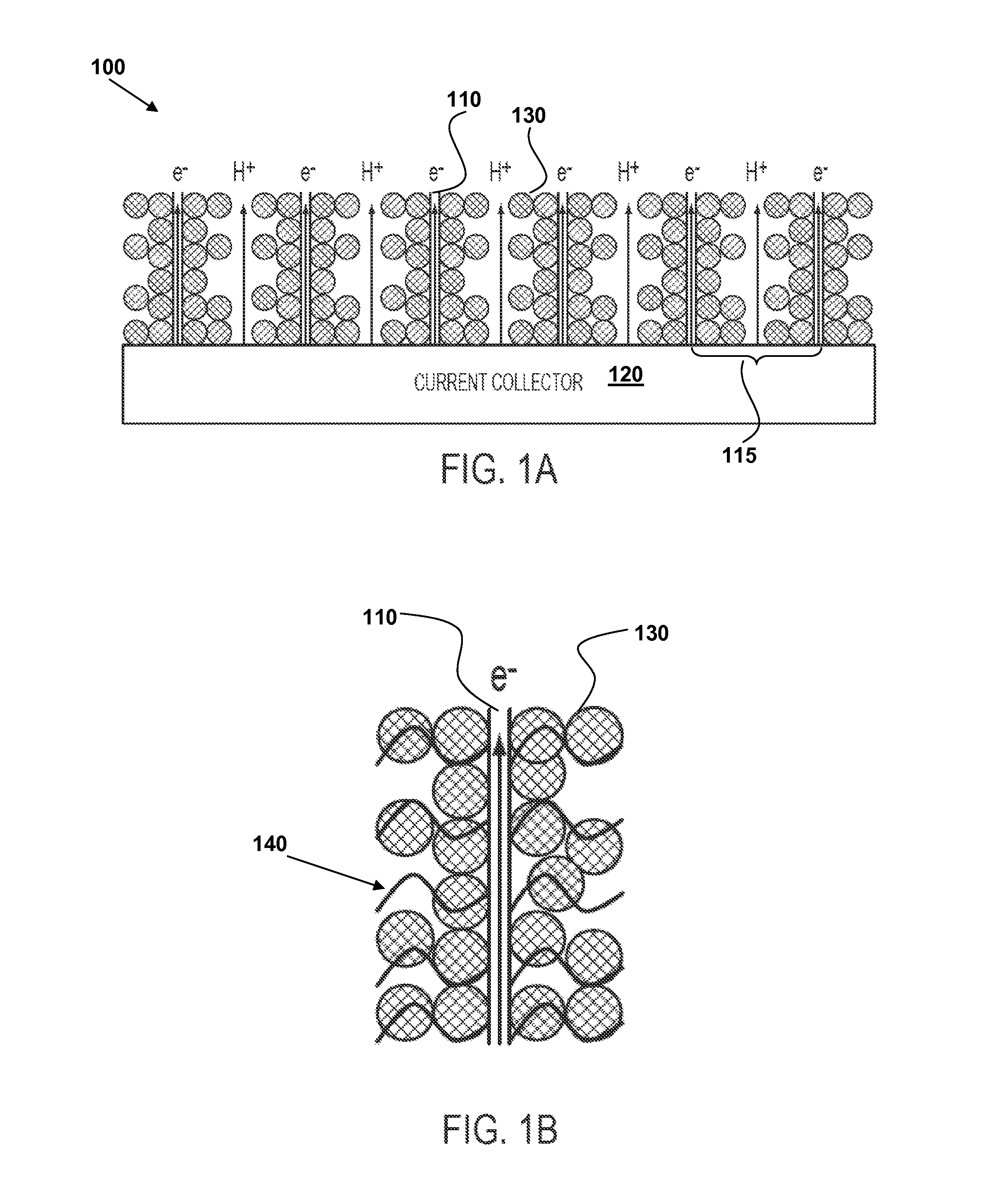

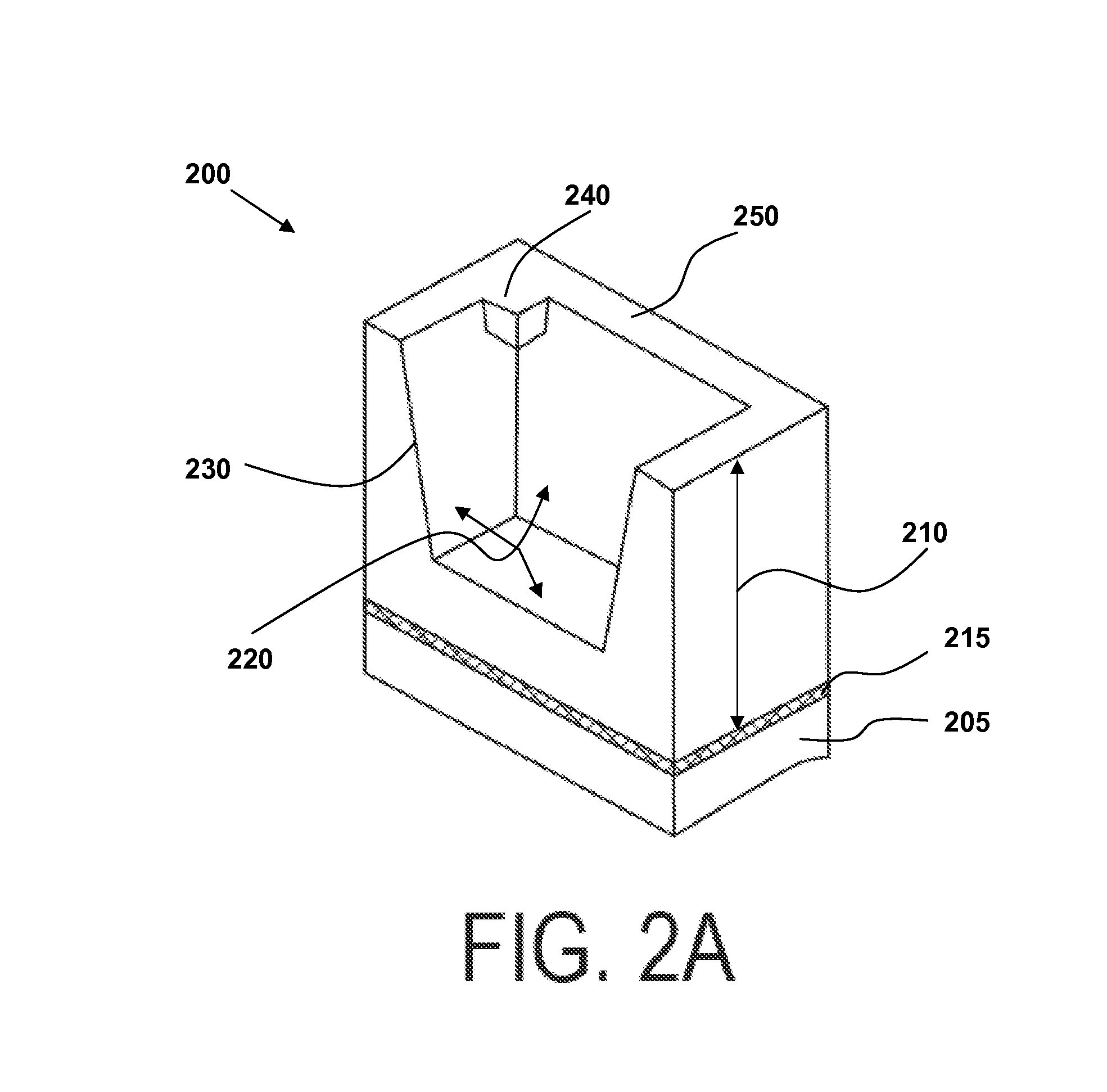

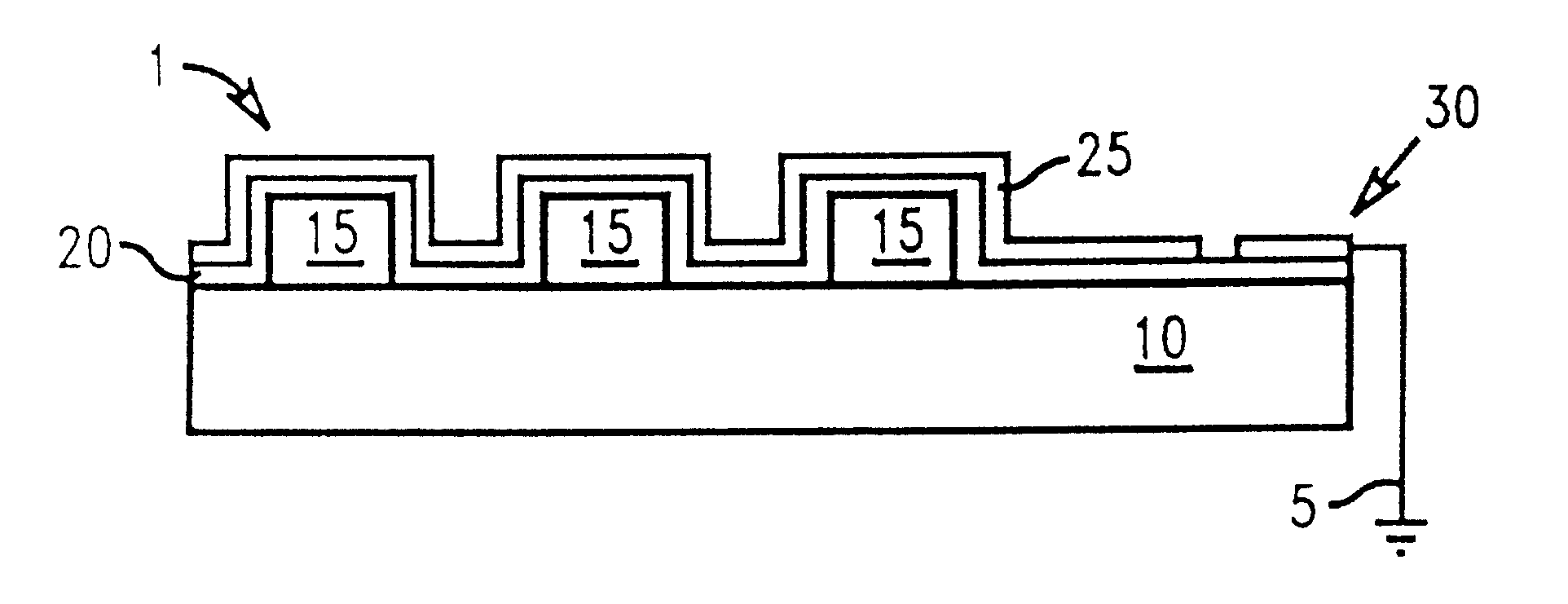

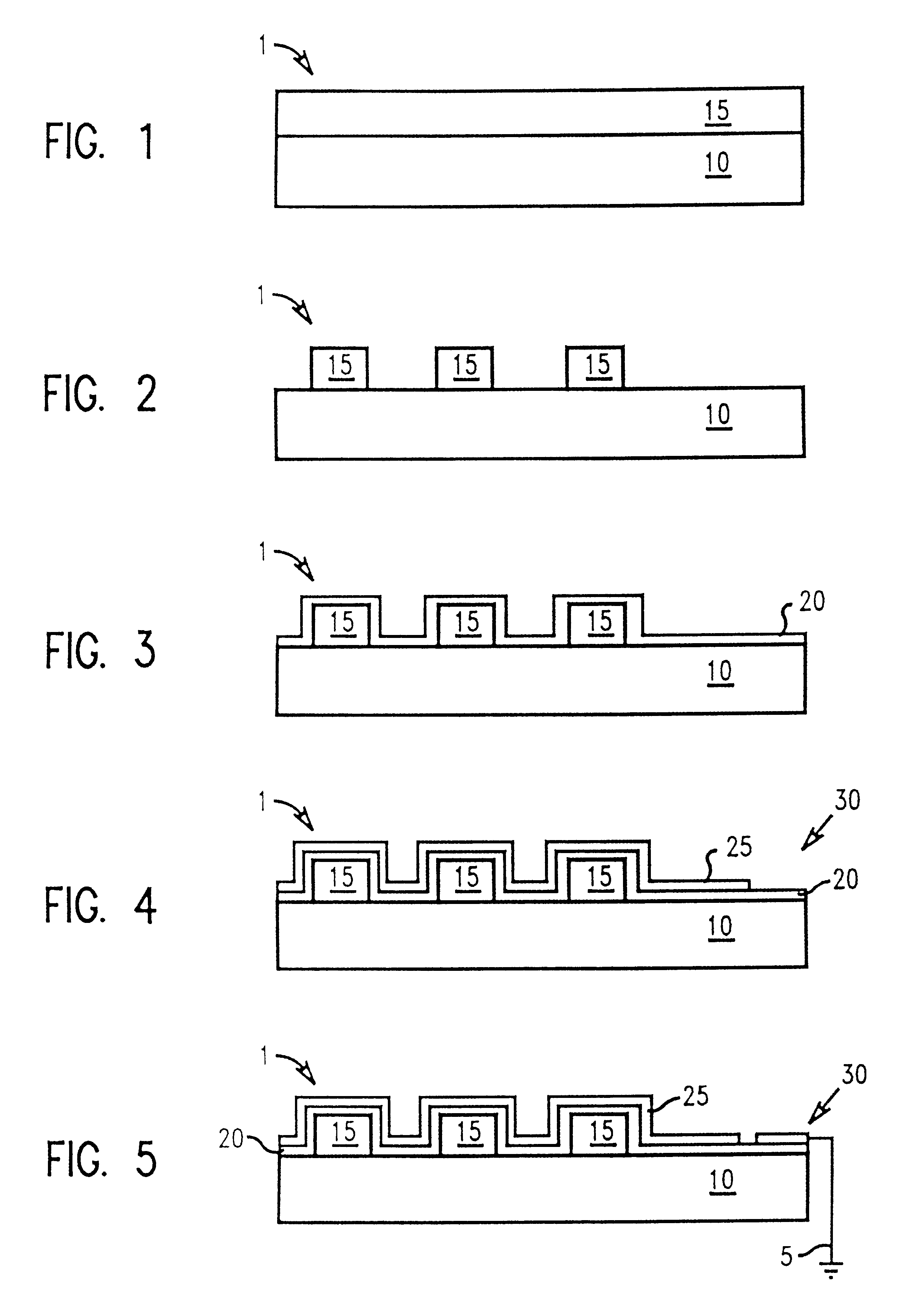

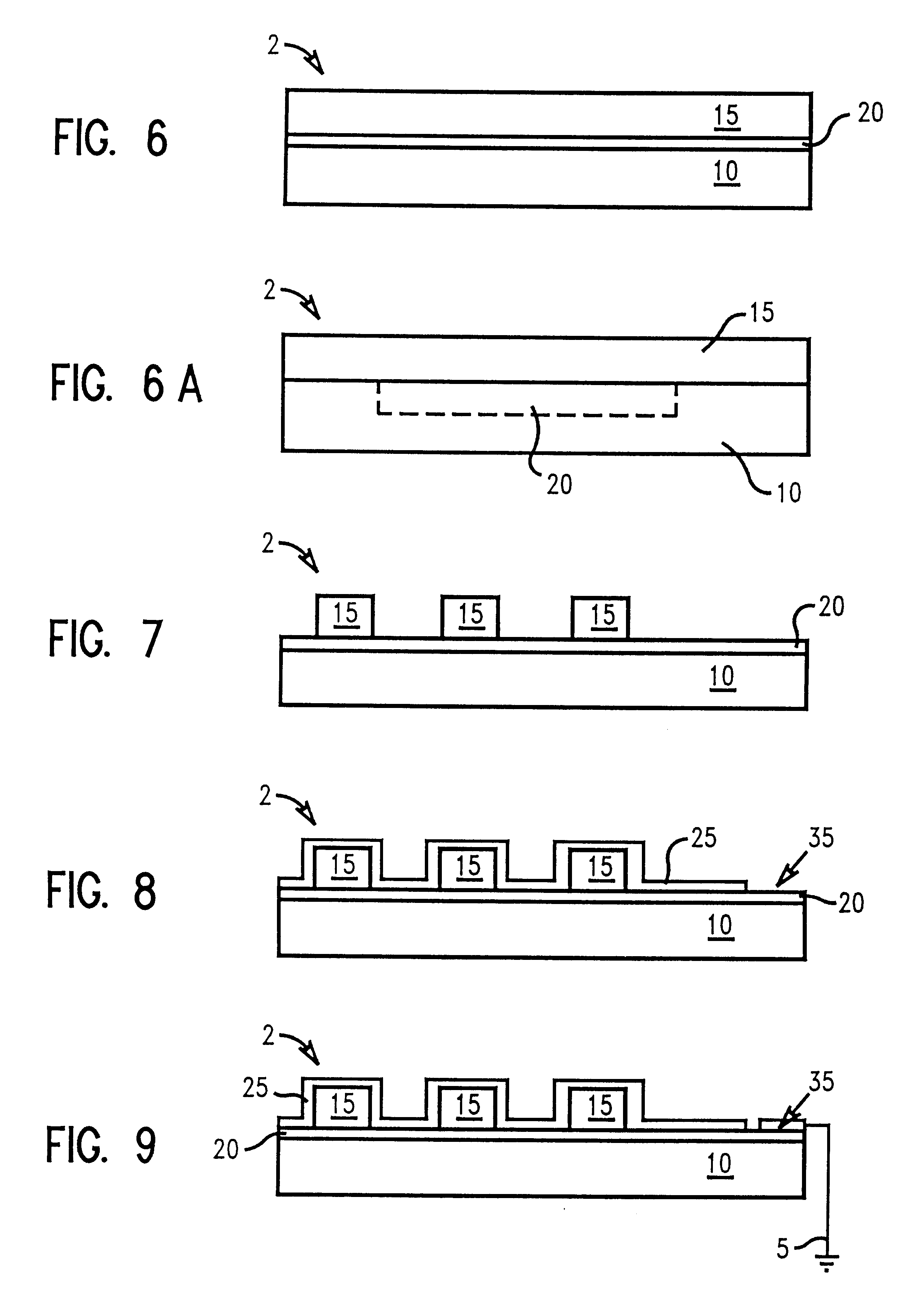

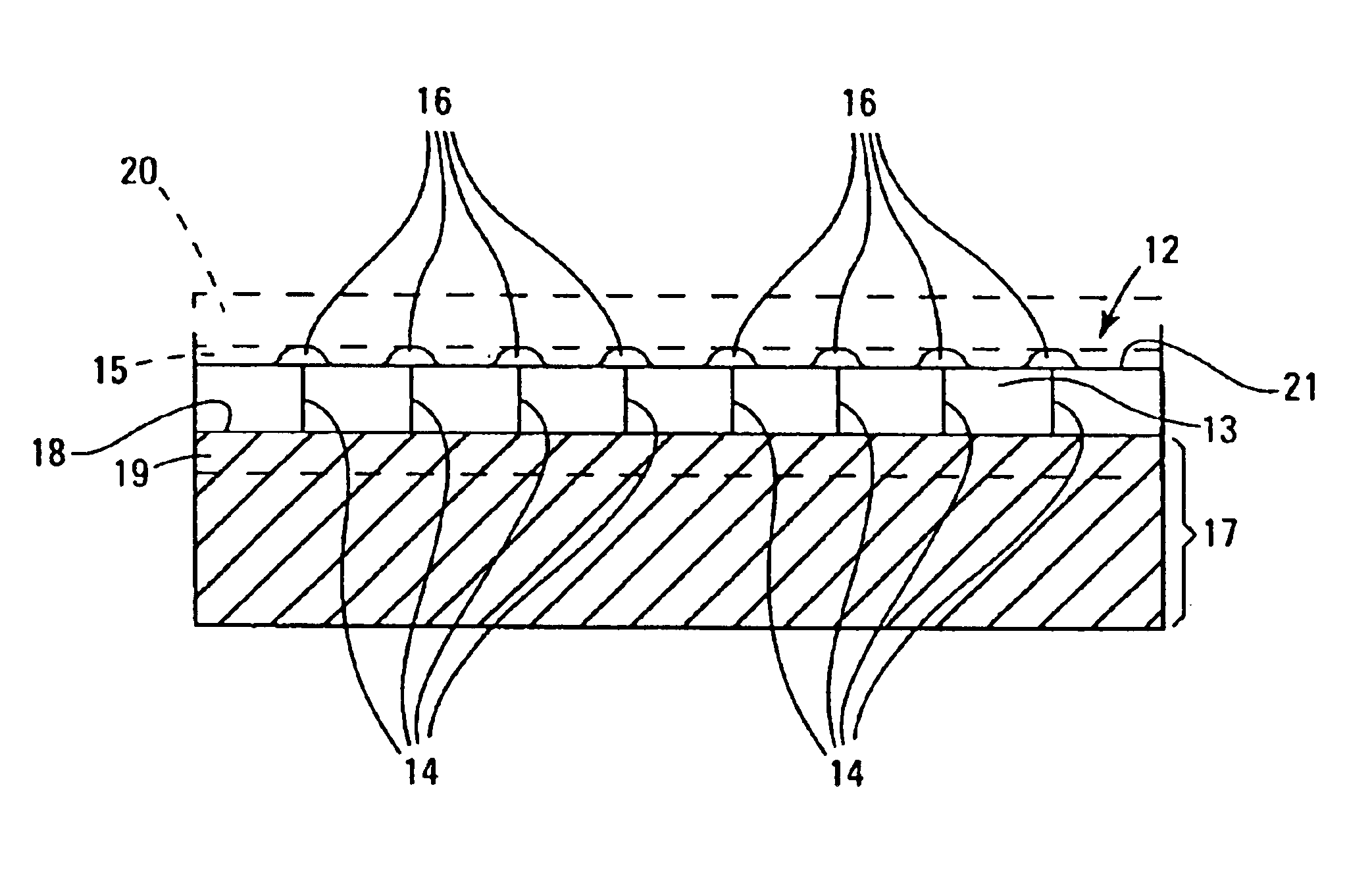

Supercapacitor cells and micro-supercapacitors

This invention provides a micro-supercapacitor with high energy density and high power density. In some variations, carbon nanostructures, such as carbon nanotubes, coated with a metal oxide, such as ruthenium oxide, are grown in a supercapacitor cavity that contains no separator. A lid is bonded to the cavity using a bonding process to form a hermetic seal. These micro-supercapacitors may be fabricated from silicon-on-insulator wafers according to the disclosed methods. An exemplary micro-supercapacitor is cubic with a length of about 50-100 μm. The absence of a separator translates to higher energy storage volume and less wasted space within the supercapacitor cell. The energy density of the micro-supercapacitor may exceed 150 J / cm3 and the peak output power density may be in the range of about 2-20 W / cm3, in various embodiments.

Owner:HRL LAB

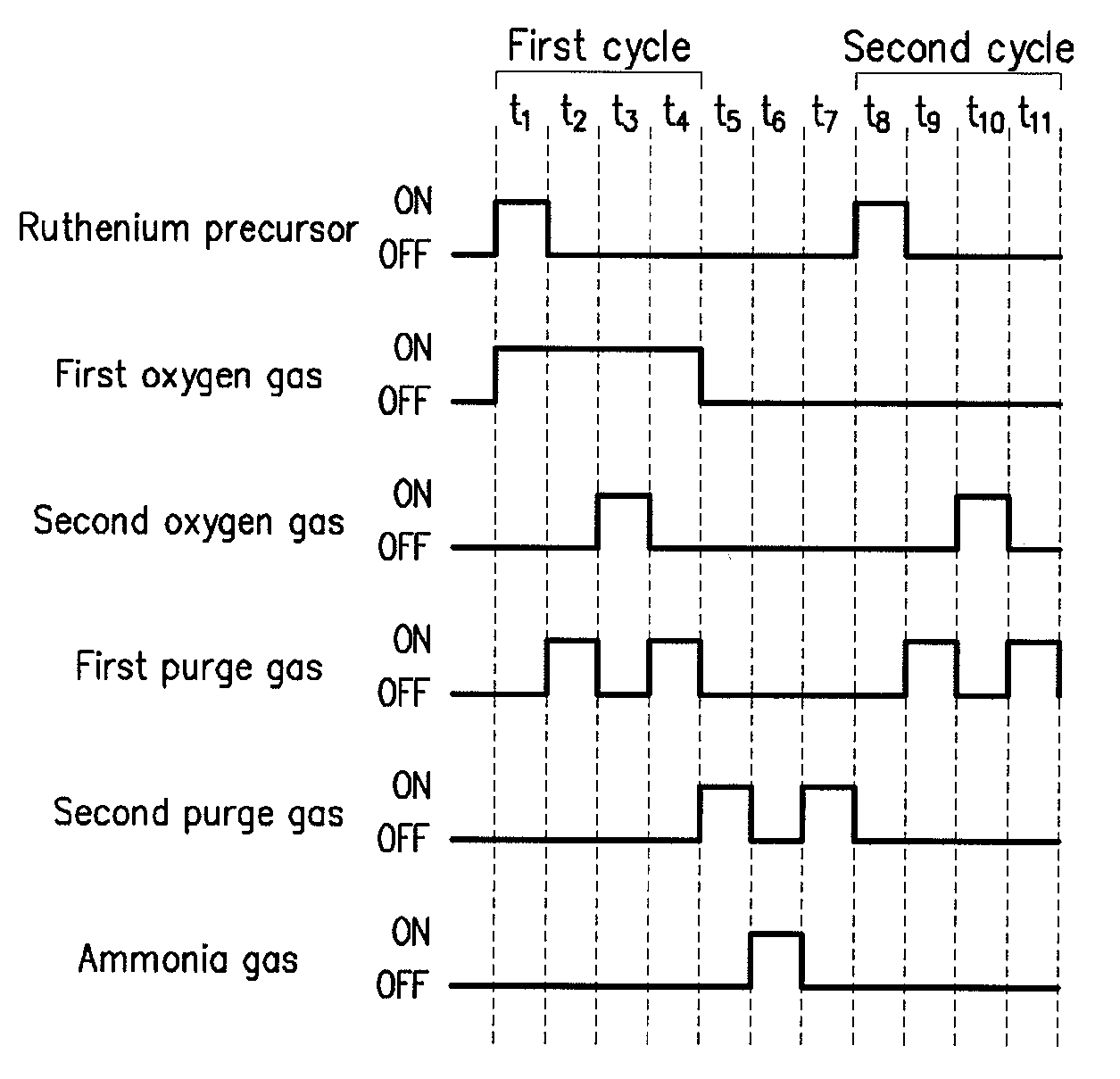

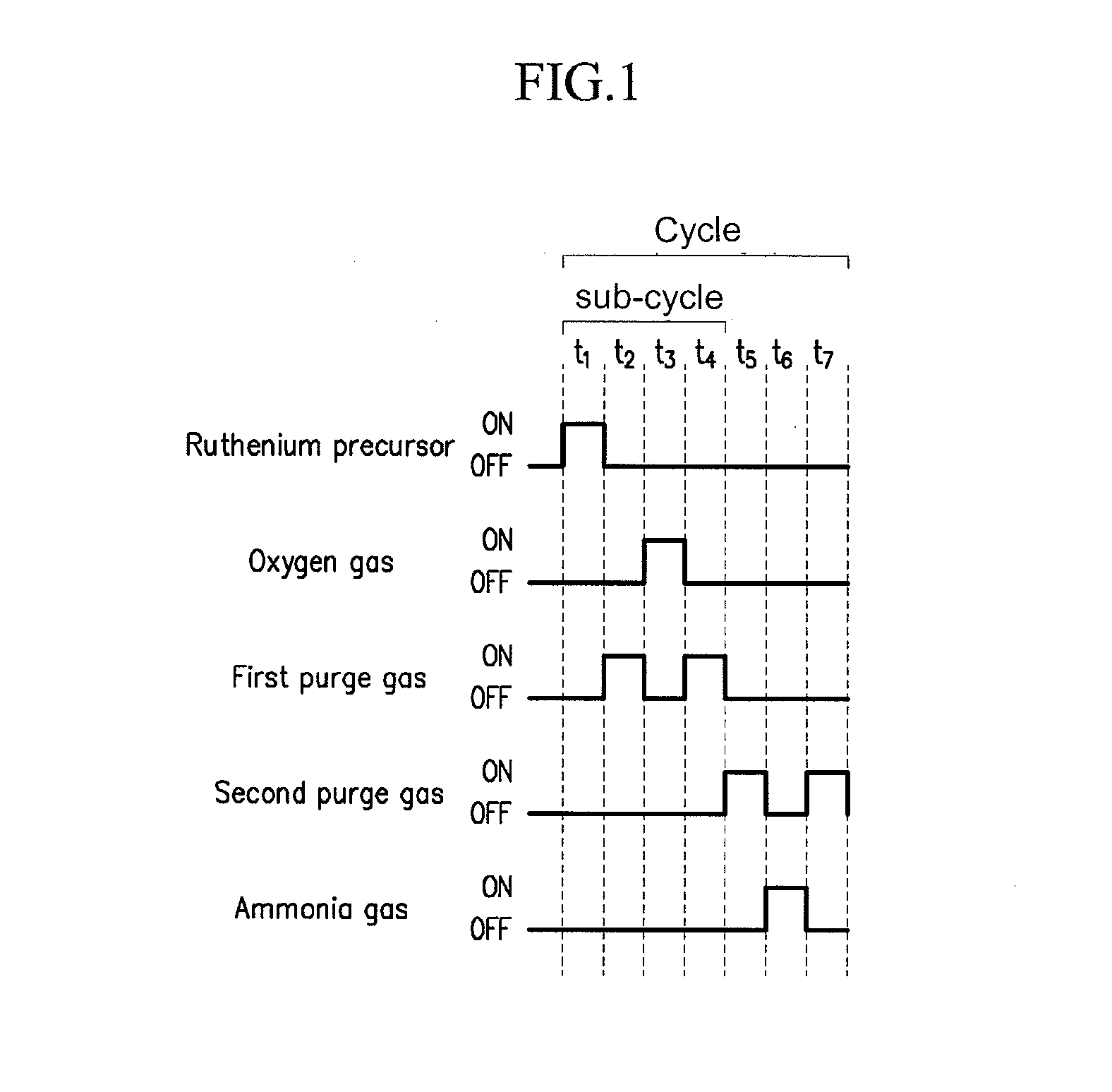

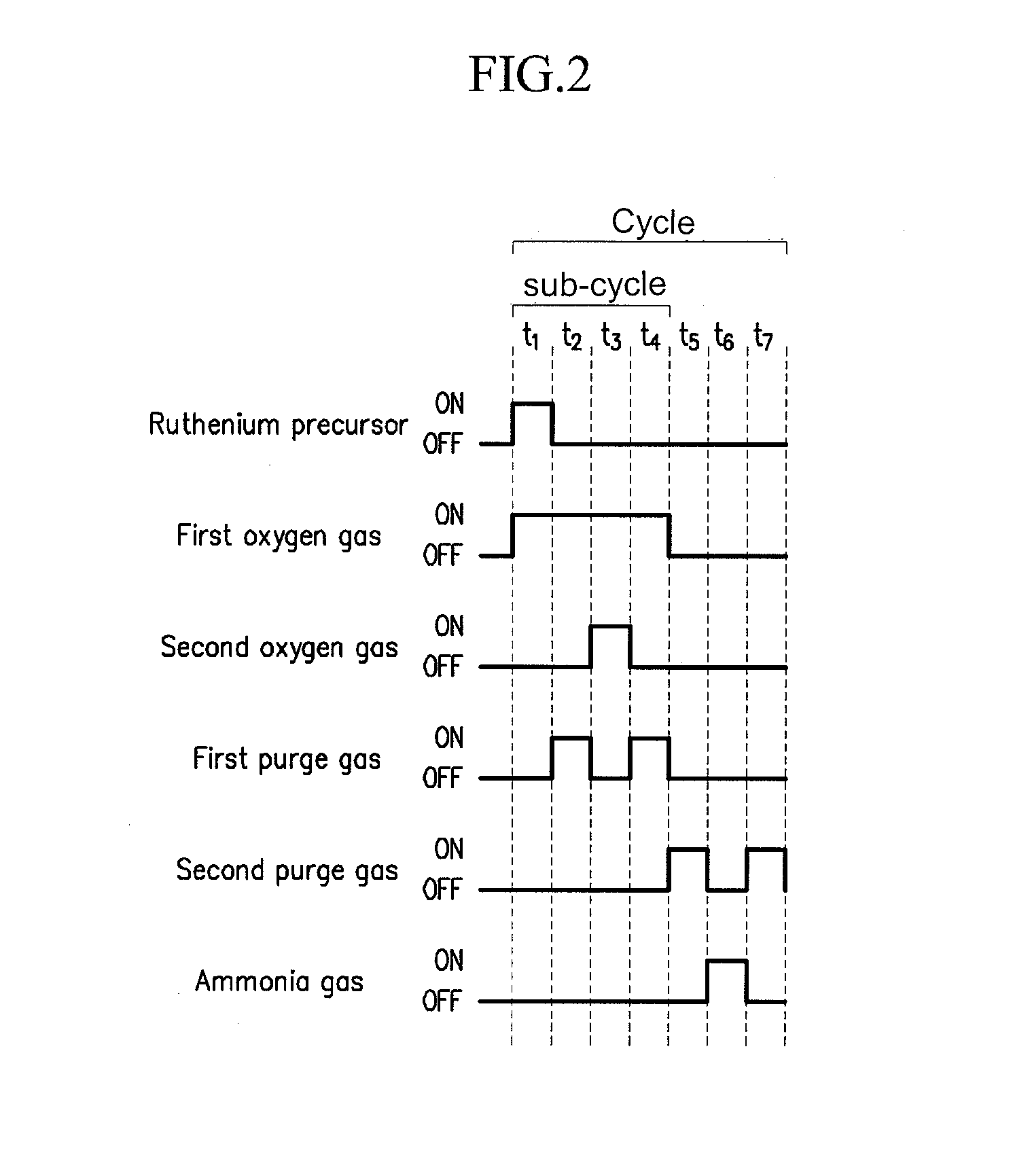

Methods of depositing a ruthenium film

Cyclical methods of depositing a ruthenium layer on a substrate are provided. In one process, initial or incubation cycles include supplying alternately and / or simultaneously a ruthenium precursor and an oxygen-source gas to deposit ruthenium oxide on the substrate. The ruthenium oxide deposited on the substrate is reduced to ruthenium, thereby forming a ruthenium layer. The oxygen-source gas may be oxygen gas (O2). The ruthenium oxide may be reduced by supplying a reducing agent, such as ammonia (NH3) gas. The methods provide a ruthenium layer having good adherence to an underlying high dielectric layer while providing good step coverage over structures on the substrate. After nucleation, subsequent deposition cycles can be altered to optimize speed and / or conformality rather than adherence.

Owner:ASM KOREA LTD

Deposition of ruthenium and/or ruthenium oxide films

InactiveUS20060013955A1Limited vapor pressureReduce carbon pollutionChemical vapor deposition coatingOxygenSemiconductor

The present invention relates generally to methods for depositing ruthenium and / or ruthenium oxide films in the formation of semiconductor devices. More specifically, the present invention provides methods for deposition of ruthenium containing metal and metal-oxygen based films on the surface of a substrate.

Owner:AVIZA TECHNOLOGY INC

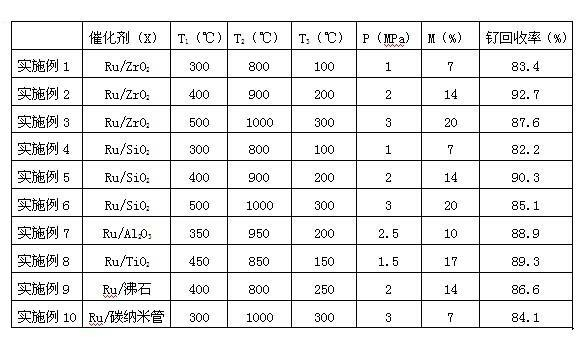

Method for recycling ruthenium in supported type ruthenium catalyst

ActiveCN102108444AReduce recycling stepsEasy to recycleProcess efficiency improvementEconomic benefitsNitrogen

The invention discloses a method for recycling ruthenium in a supported type ruthenium or ruthenium oxide catalyst. The method comprises the following technological steps: (1) placing a supported type ruthenium catalyst or a supported type ruthenium oxide catalyst in an airtight container, heating to 300-500 DEG C, and roasting for 1-2 hours; and feeding nitrogen for protection during roasting process; (2) stopping the feeding of nitrogen stream in the step (1), continuing to heat to 800-1000 DEG C, and roasting for 2-10 hours; and obtaining black solids after cooling; (3) grinding black solids into powder, placing in the airtight container, and heating to 100-300 DEG C; and feeding oxygen / ozone to oxidize solid powder and generate ruthenium tetroxide gas; and (4) feeding the ruthenium tetroxide gas into diluted hydrochloric acid, and restoring the acid combined with the gas into a red and brown ruthenium trichloride solution. According to the device, the step of recycling the catalyst is reduced; not only is the cost reduced during the recycling process of ruthenium catalyst, but also the recycling process is simplified; and economic benefit and the environment benefit are greatly improved.

Owner:KAILUAN ENERGY CHEM

Process and catalysts for the oxidation of methanol and/or ethanol

InactiveUS20050059839A1Good choiceIncrease surface densityOrganic compound preparationCarboxylic acid esters preparationOxygenProcess conditions

A process for oxidation of methanol, ethanol, or a mixture of methanol and ethanol comprising contacting the methanol and / or ethanol with an oxygen-containing gas and a supported catalyst comprising one or more platinum group oxides. The process conditions and / or catalyst may be selected to as to selectively produce methyl formate from methanol or diethoxyethane from ethanol. The invention also includes certain novel supported platinum group metal oxide catalysts. Preferred catalysts include one or more ruthenium oxides.

Owner:RGT UNIV OF CALIFORNIA

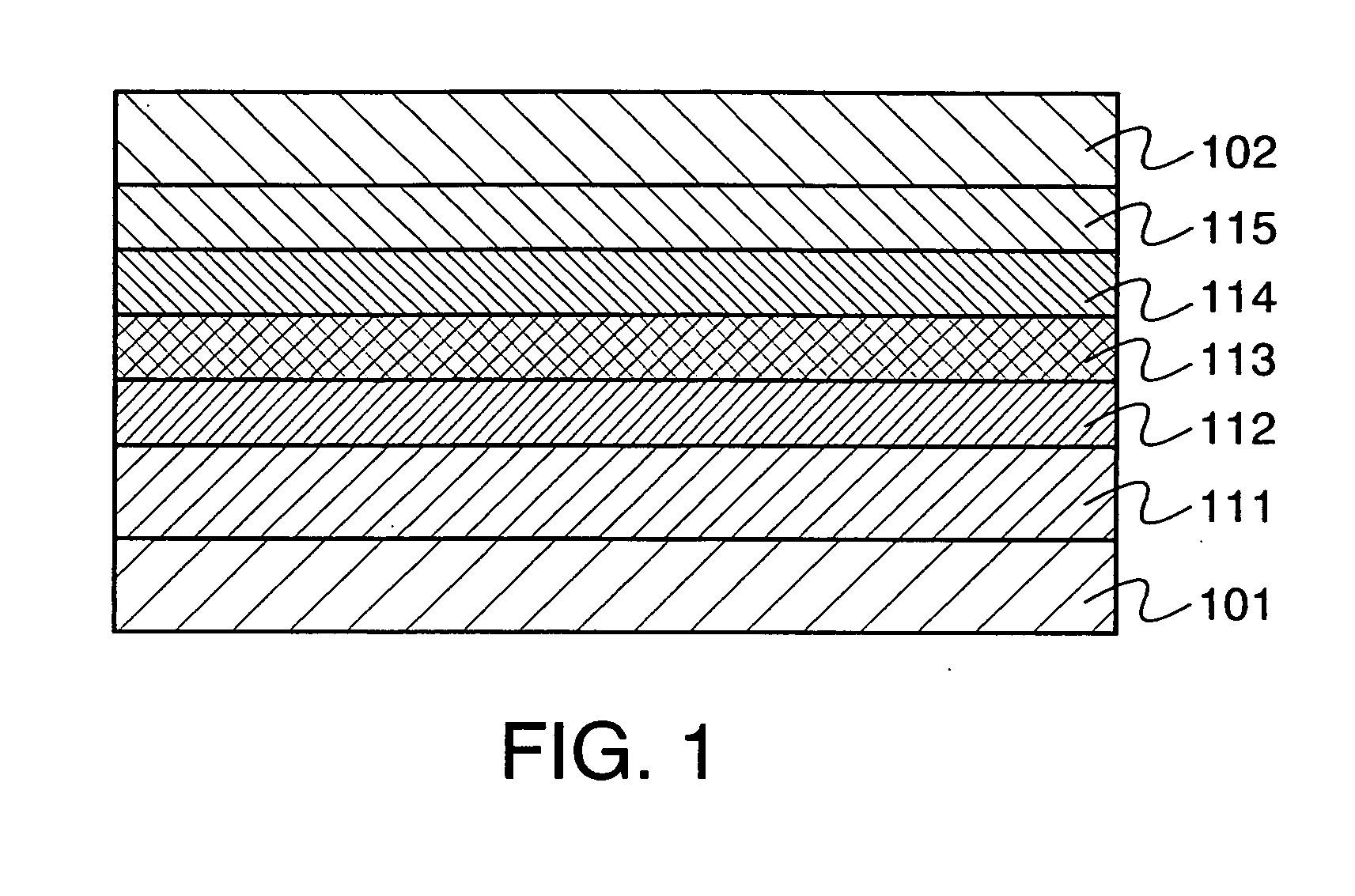

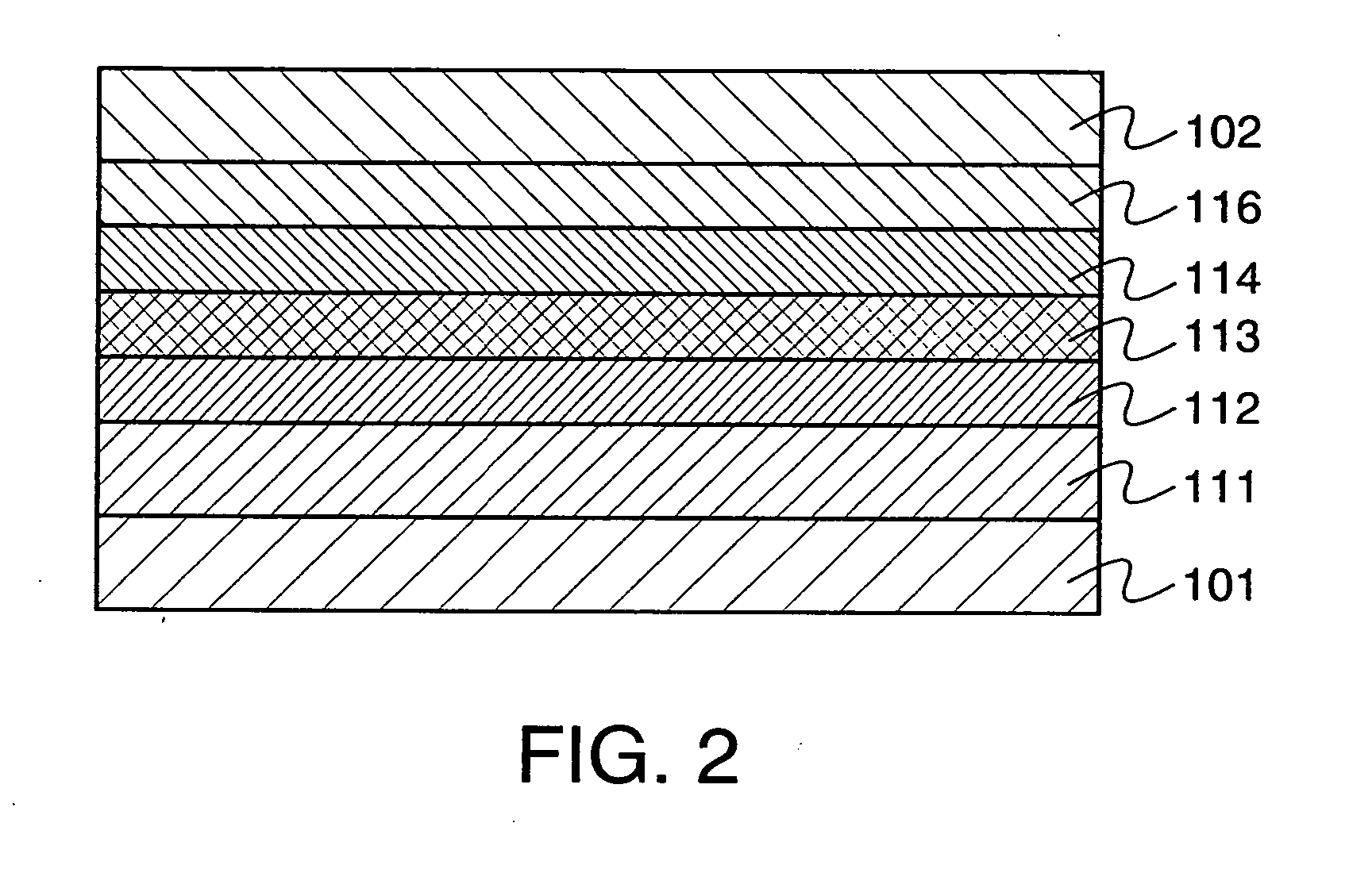

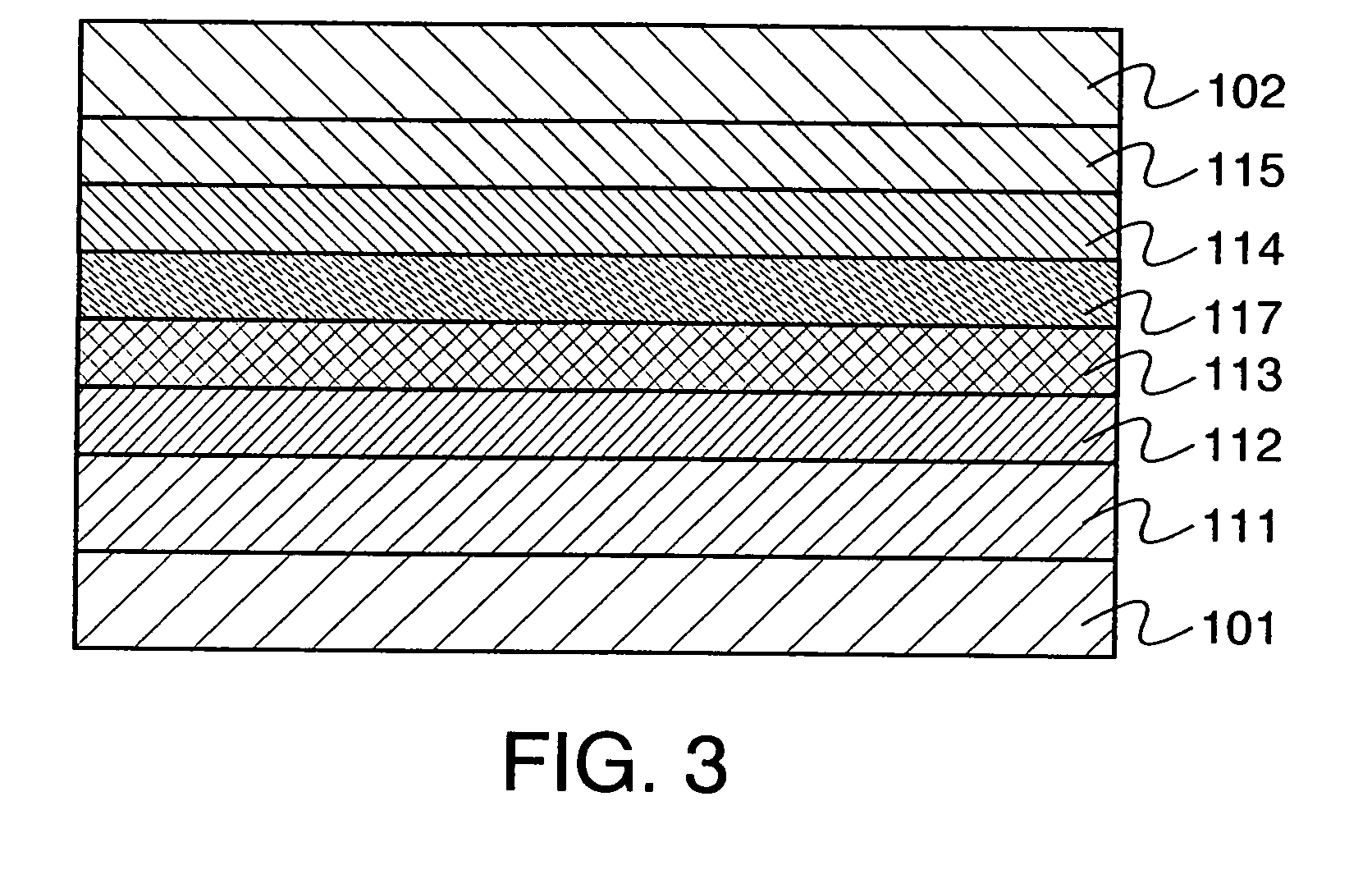

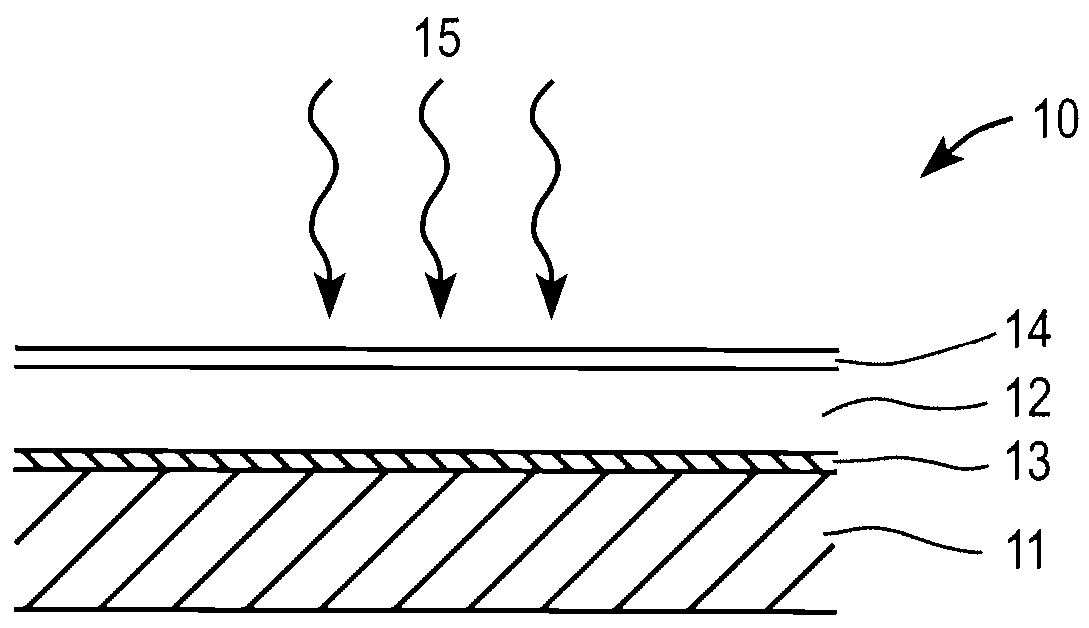

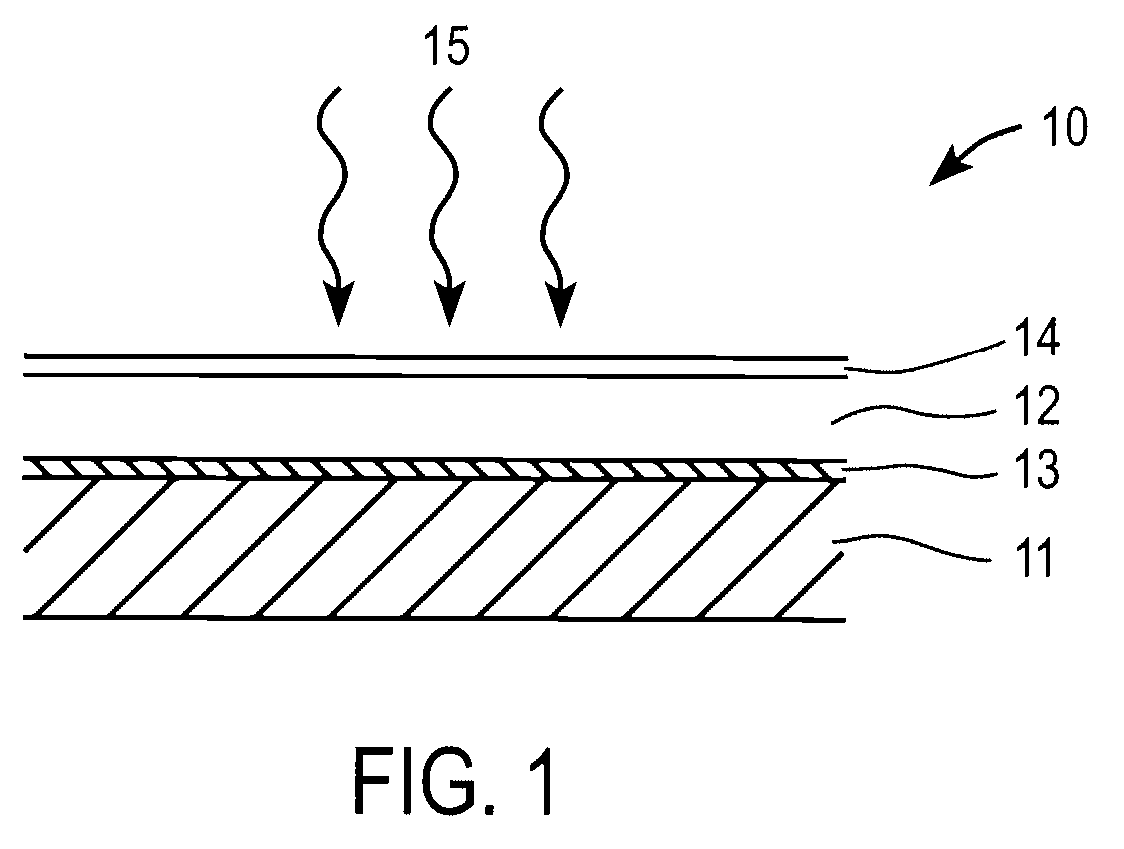

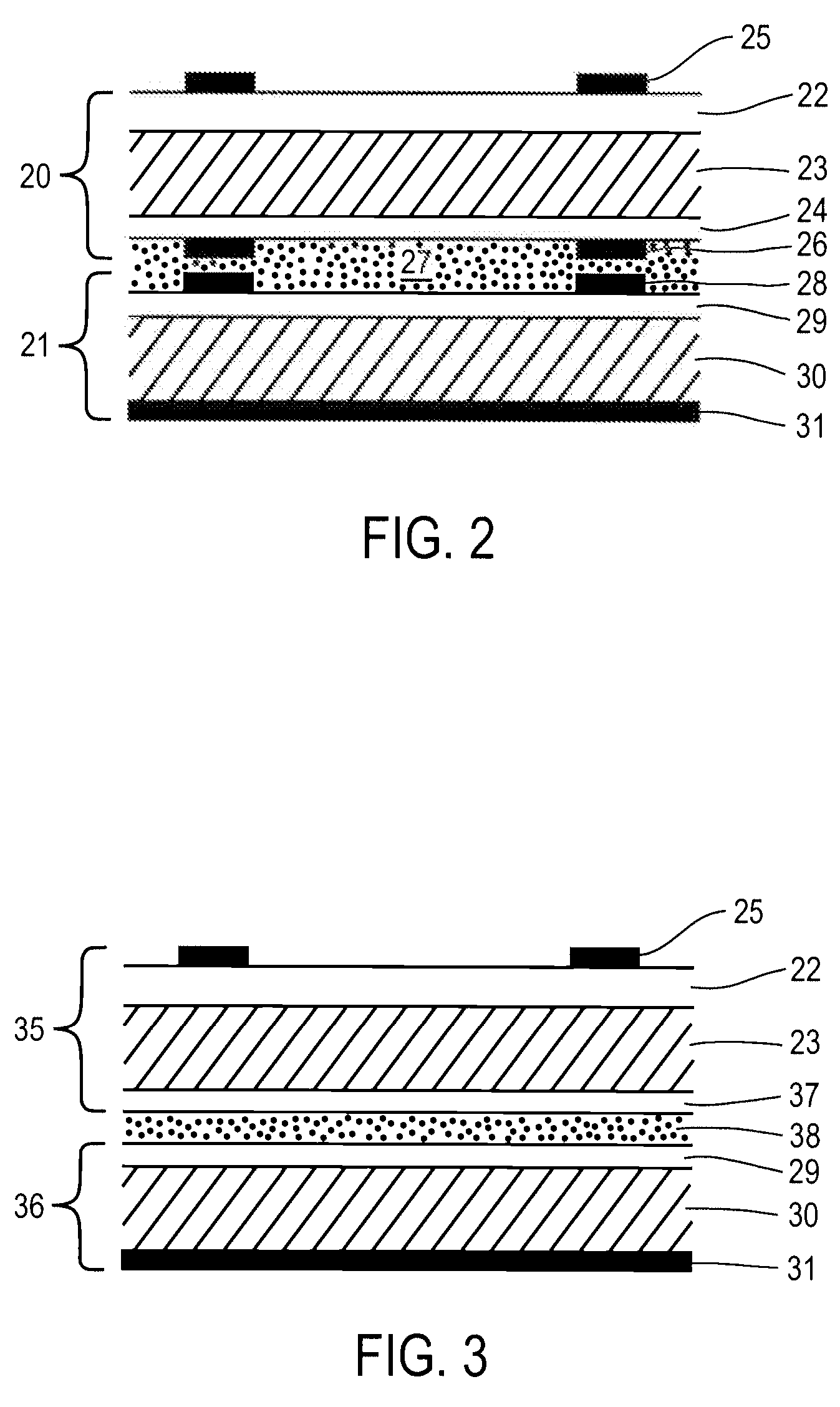

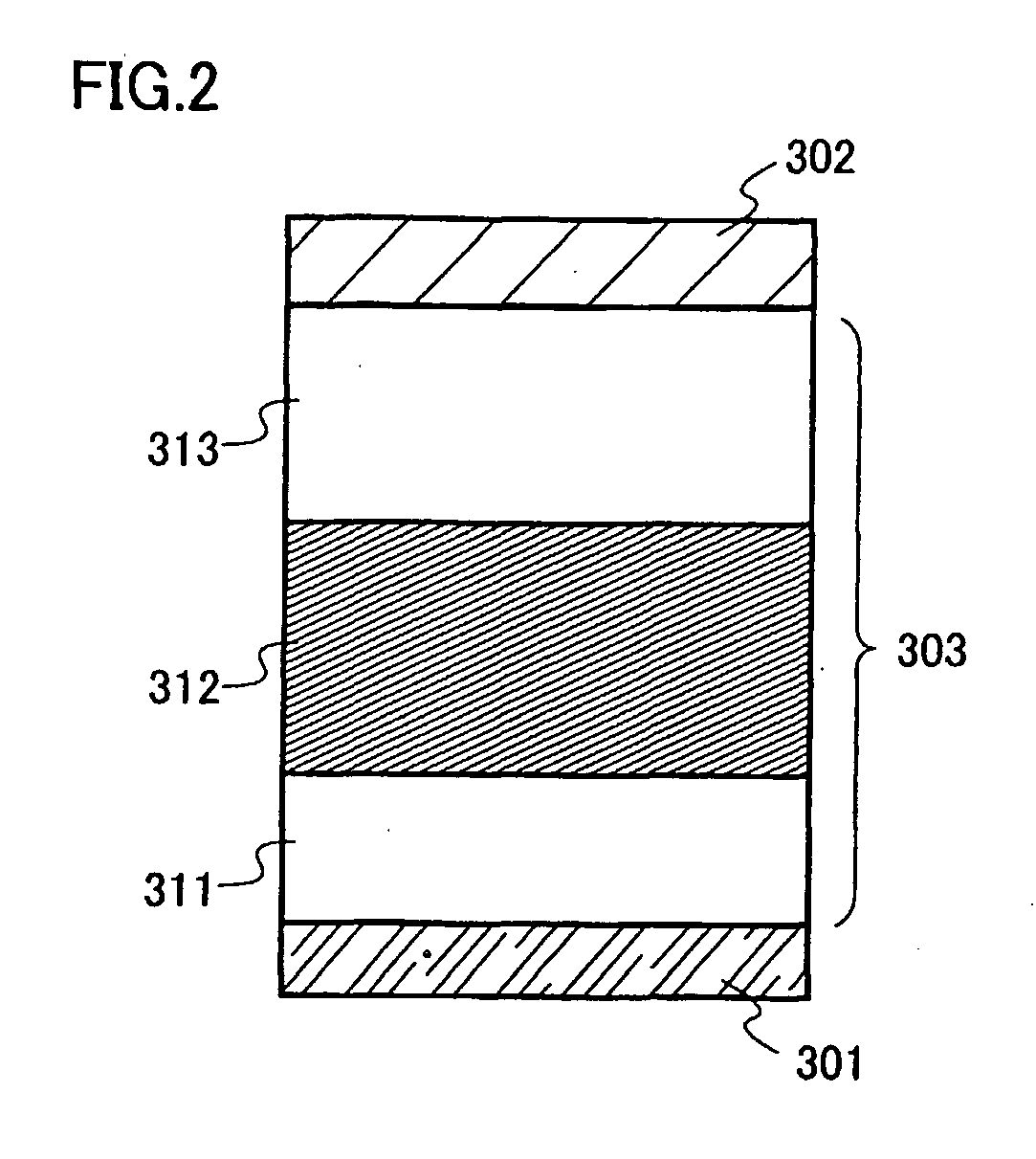

Tandem solar cell structures and methods of manufacturing same

The present invention relates to thin film solar cell structures and methods of manufacturing them, particularly tandem cell structures and components thereof. In one aspect there is provided a polycrystalline thin film solar cell structure that is semi-transparent and allows a predetermined wavelength range of light to pass therethrough, in which a bottom semi-transparent conductive layer includes at least one of a ruthenium oxide, an osmium oxide and an iridium oxide. In another aspect there is provided a tandem cell structure in which a top cell bottom contact layer includes at least one of a ruthenium oxide, an osmium oxide and an iridium oxide. In a preferred aspect, the tandem cell structure contains a single contact layer between the absorber layer of the top cell and the absorber layer of the bottom cell. In a particular aspect, this single contact layer is a ruthenium oxide layer.

Owner:SOLOPOWER

Nanocarbon composite structure having ruthenium oxide trapped therein

InactiveUS7572542B2Increase capacitanceImprove electrochemical activityMaterial nanotechnologyCarbon compoundsReaction fieldNanoparticle

A novel nanocarbon composite structure is provided having trapped ruthenium oxide. By using Ketjen black, and through chemical-mechanical effect utilizing an ultracentrifugal reaction field, both the specific surface area of ruthenium oxide and space of electrode material are expanded to have nanoparticles of ruthenium oxide highly dispersed in a graphene layer. This nanocarbon composite structure having trapped ruthenium oxide exhibits high electrochemical activity and is suitable for use as an electrical energy storing device, such as a large-capacity capacitor.

Owner:NAT UNIV CORP TOKYO UNIV OF AGRI & TECH

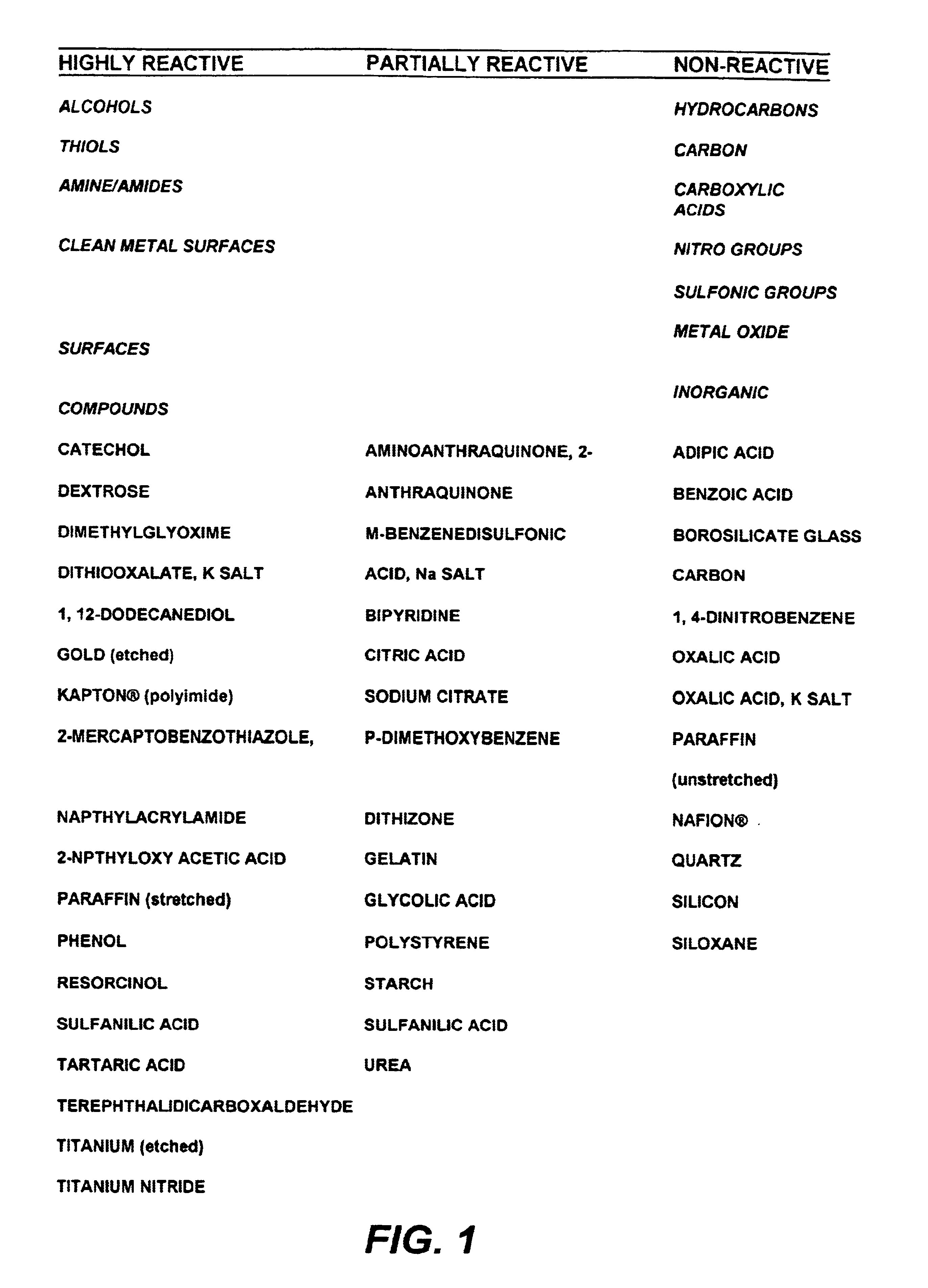

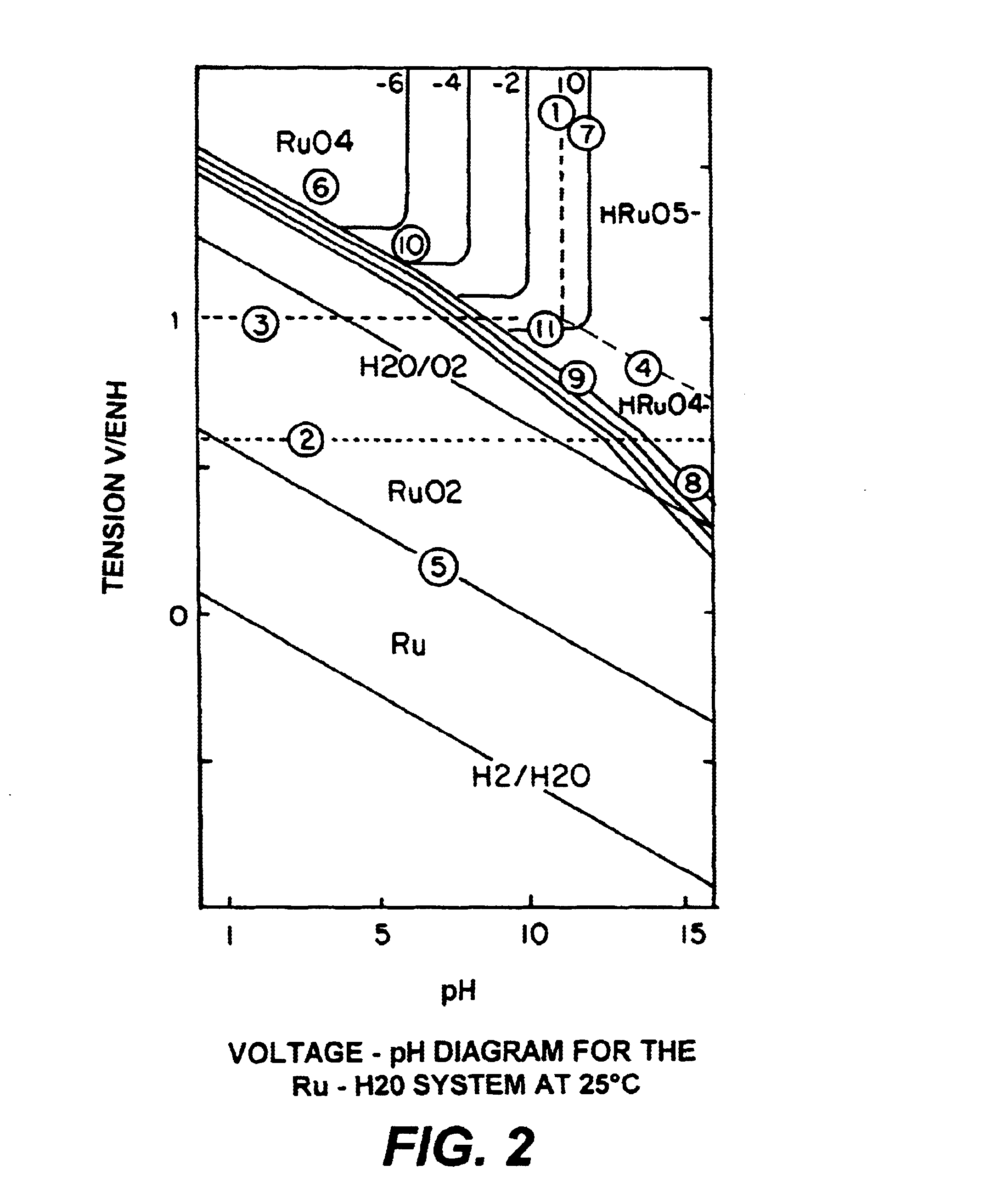

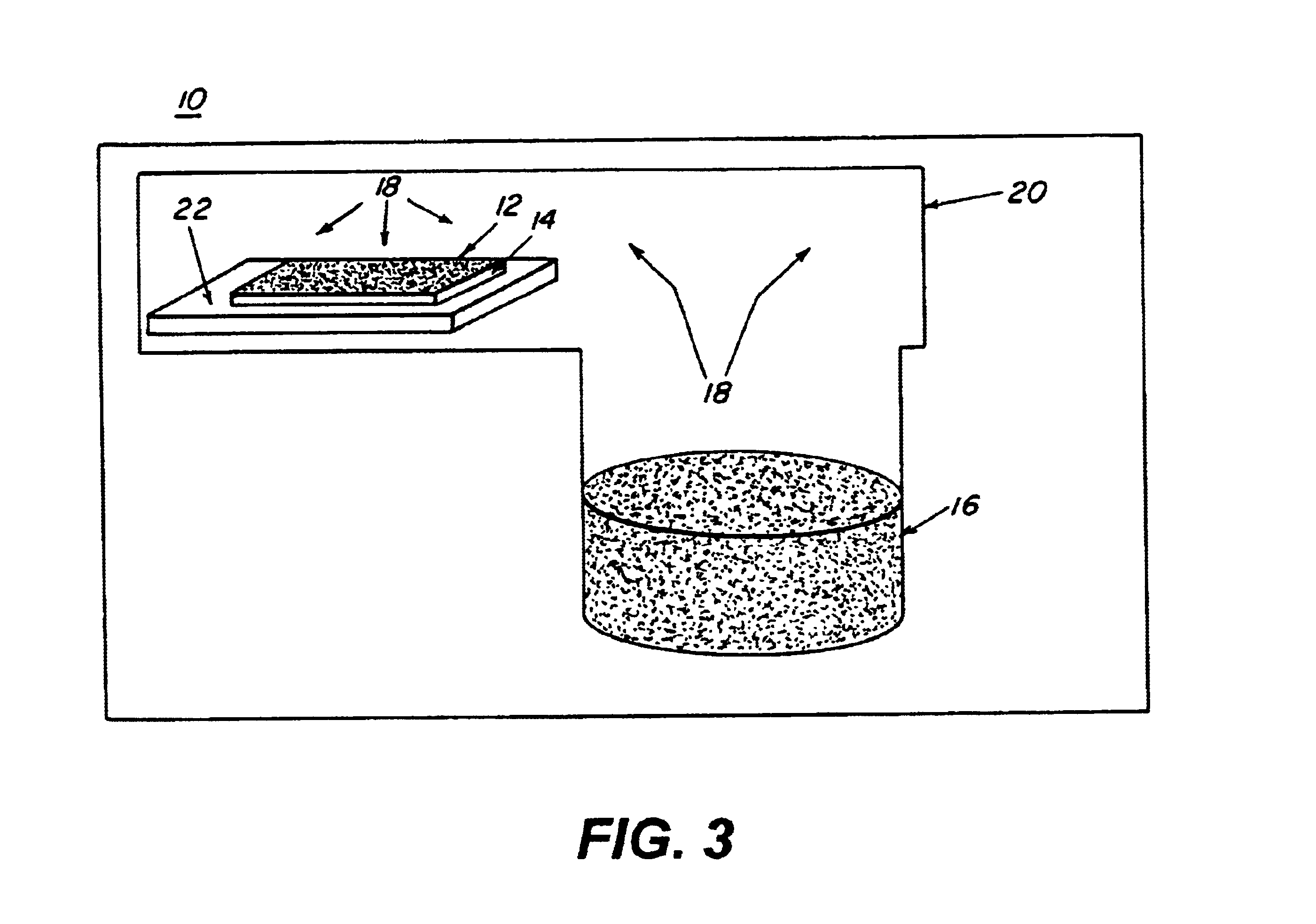

Selective deposition of hydrous ruthenium oxide thin films

InactiveUS6649211B2Solving the Insufficiency of ElasticityMaintain conductivityPretreated surfacesSpecial surfacesAutocatalysisSelective deposition

A method for selectively depositing a film of hydrous ruthenium oxide on a substrate, the method comprising the steps of:selectively functionalizing a substrate surface;preparing an oxidizing aqueous solution of a Ru-containing composition;generating RuO4(g) from said oxidizing solution;selectively depositing a film of hydrous ruthenium oxide from said vapor of said oxidizing solution on said functionalized surface of said substrate; anddepositing by autocatalysis hydrous ruthenium oxide from said vapor of said oxidizing solution on said previously deposited hydrous ruthenium oxide. RuO2.xH2O films are uniformly deposited on substrates that have been selectively surface-modified with or already contain the RuO4-reactive functional groups.

Owner:US SEC THE NAVY CHIEF OF NAVAL RES OFFICE OF COUNSEL THE

Fuel cell and anode catalyst therefor

InactiveUS20040115515A1High catalytic activityLess expensiveActive material electrodesCatalyst activation/preparationPtru catalystIndium

An anode catalyst contains gold fine particles, and / or at least one member selected from the group consisting of titanium, vanadium, gallium, zirconium, niobium, cerium, tantalum, indium, and the oxides of these metals, and / or at least one member selected from the group consisting of platinum, ruthenium, and ruthenium oxides are coated on a conductive support.

Owner:NAT INST OF ADVANCED IND SCI & TECH

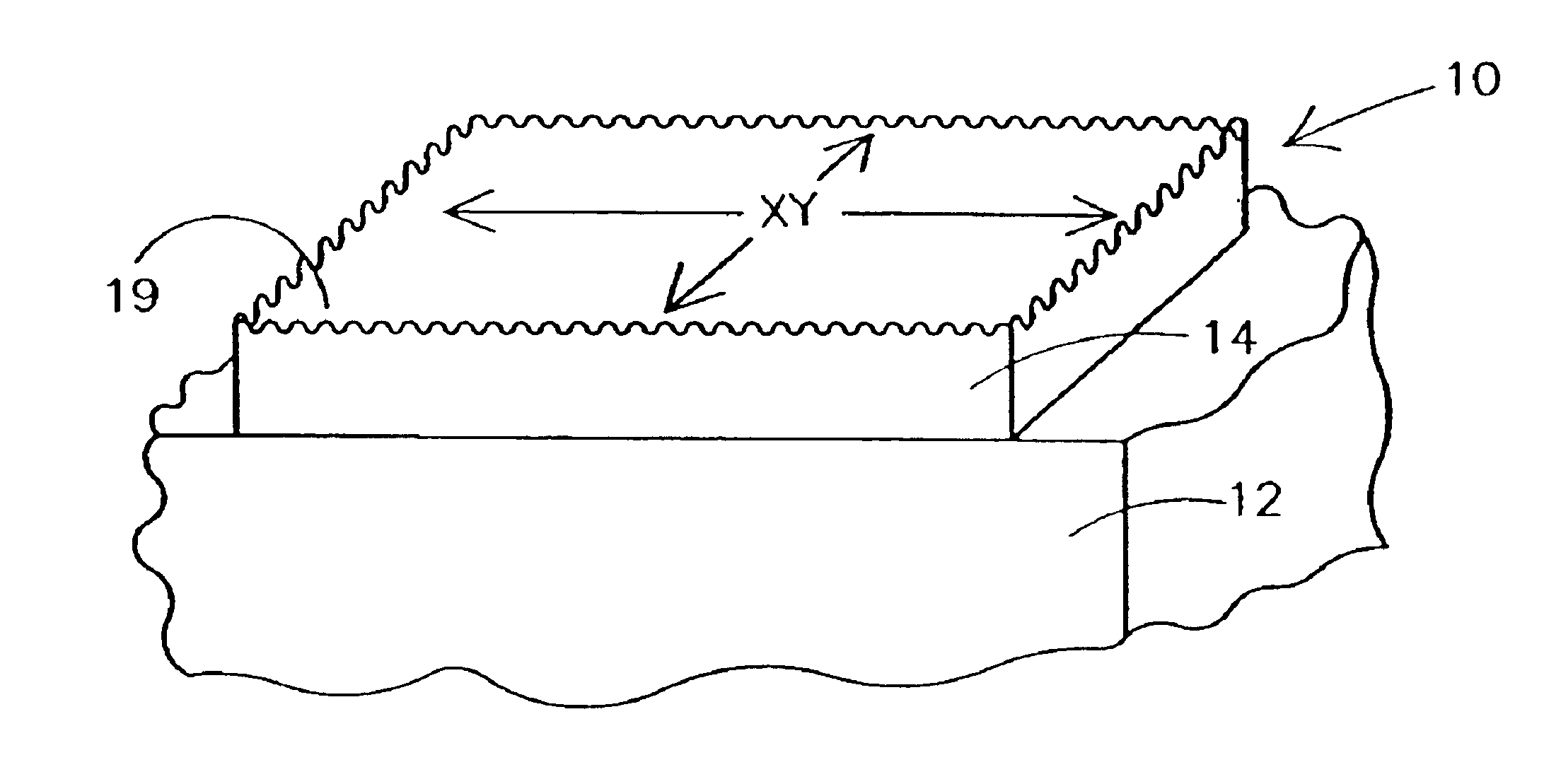

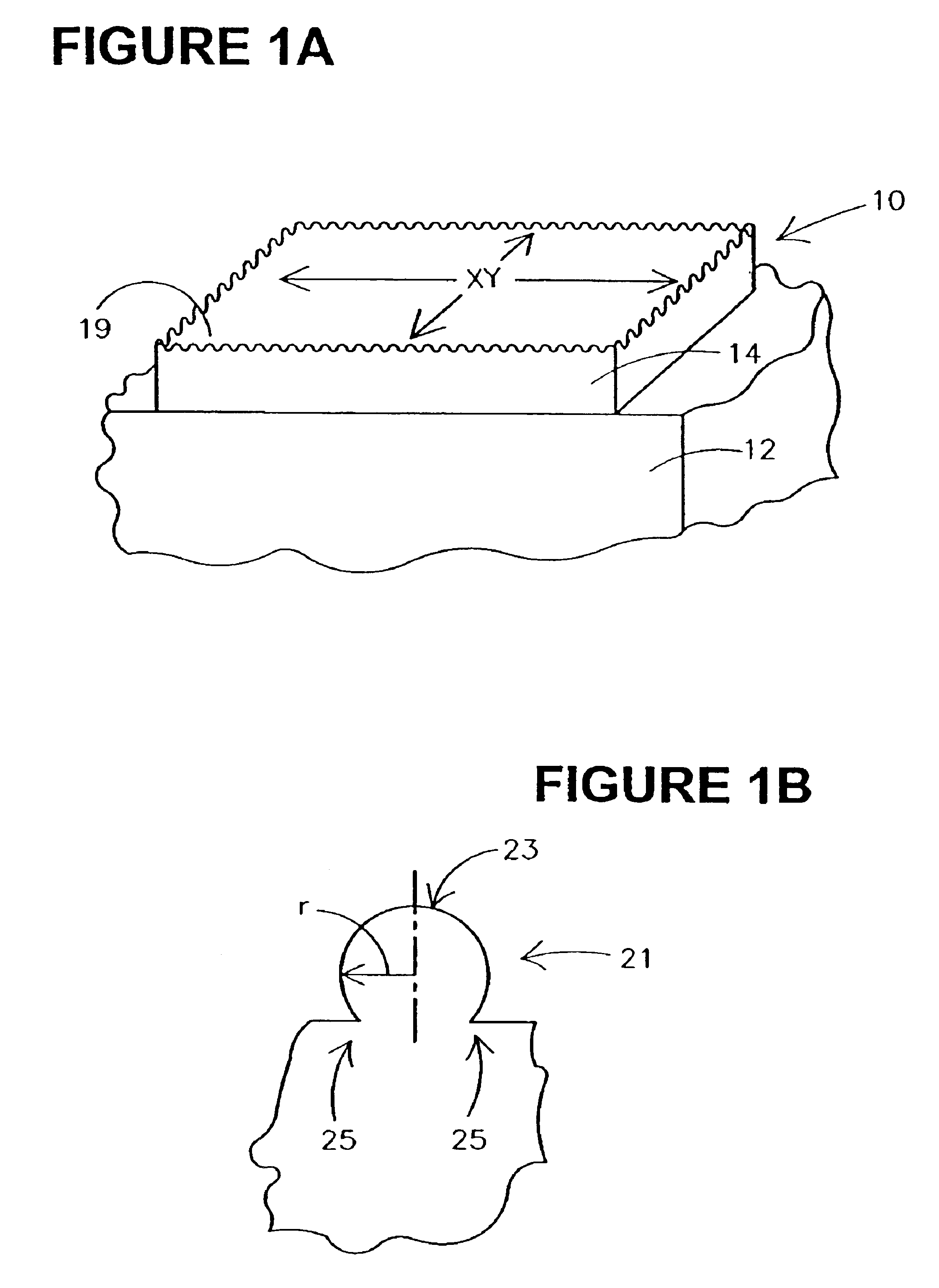

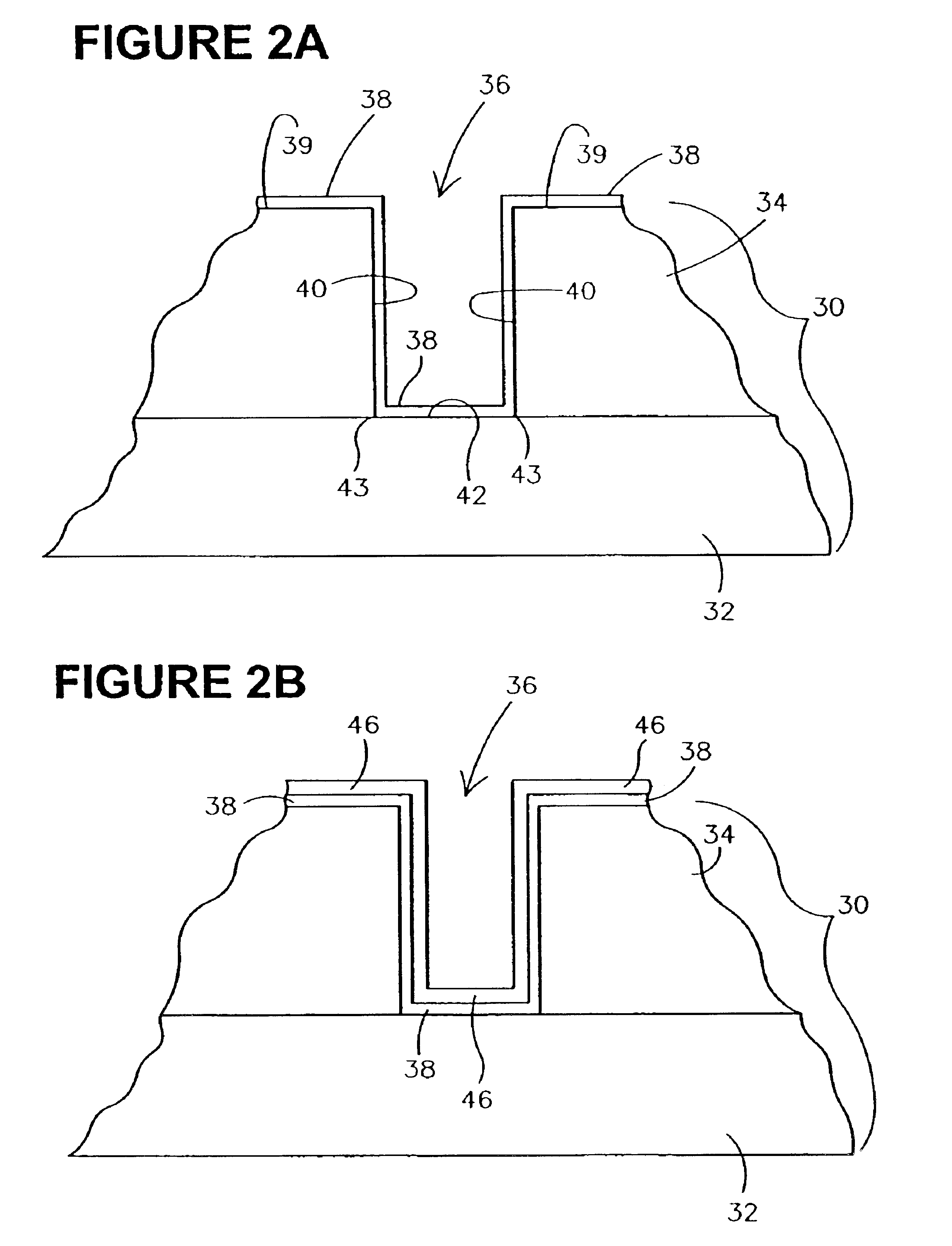

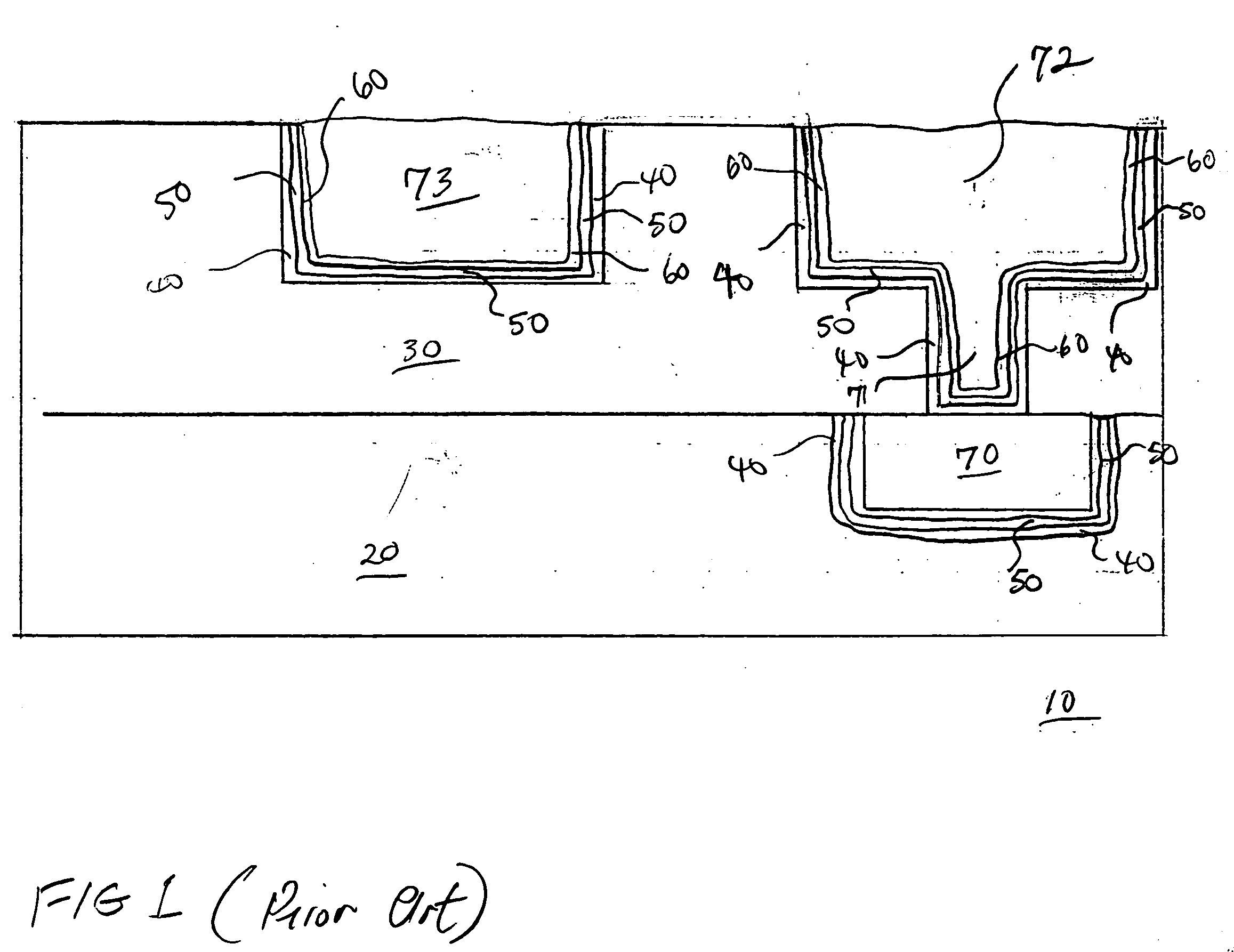

Methods for forming rough ruthenium-containing layers and structures/methods using same

InactiveUS6897160B2Reduce processing costsIncrease surface areaTransistorSolid-state devicesCombined useOxygen

A method for forming a rough ruthenium-containing layer on the surface of a substrate assembly includes providing a ruthenium-containing precursor into the reaction chamber. A rough ruthenium layer may be deposited on the surface of the substrate assembly at a rate of about 100 Å / minute to about 500 Å / minute using the ruthenium-containing precursor. Further, a rough ruthenium oxide layer may be formed by providing a ruthenium-containing precursor and an oxygen-containing precursor into the reaction chamber to deposit the rough ruthenium oxide layer on the surface of the substrate assembly at a rate of about 100 Å / minute to about 1200 Å / minute. An anneal of the layers may be performed to further increase the roughness. In addition, conductive structures including a rough ruthenium layer or a rough ruthenium oxide layer are provided. Such layers may be used in conjunction with non-rough ruthenium and / or non-rough ruthenium oxide layers to form conductive structures. For example, such structures may be part of a capacitor structure, e.g., bottom electrode of a capacitor.

Owner:STEVENS INSTITUTE OF TECHNOLOGY

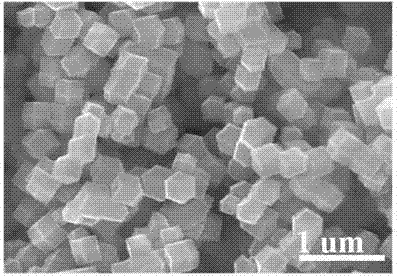

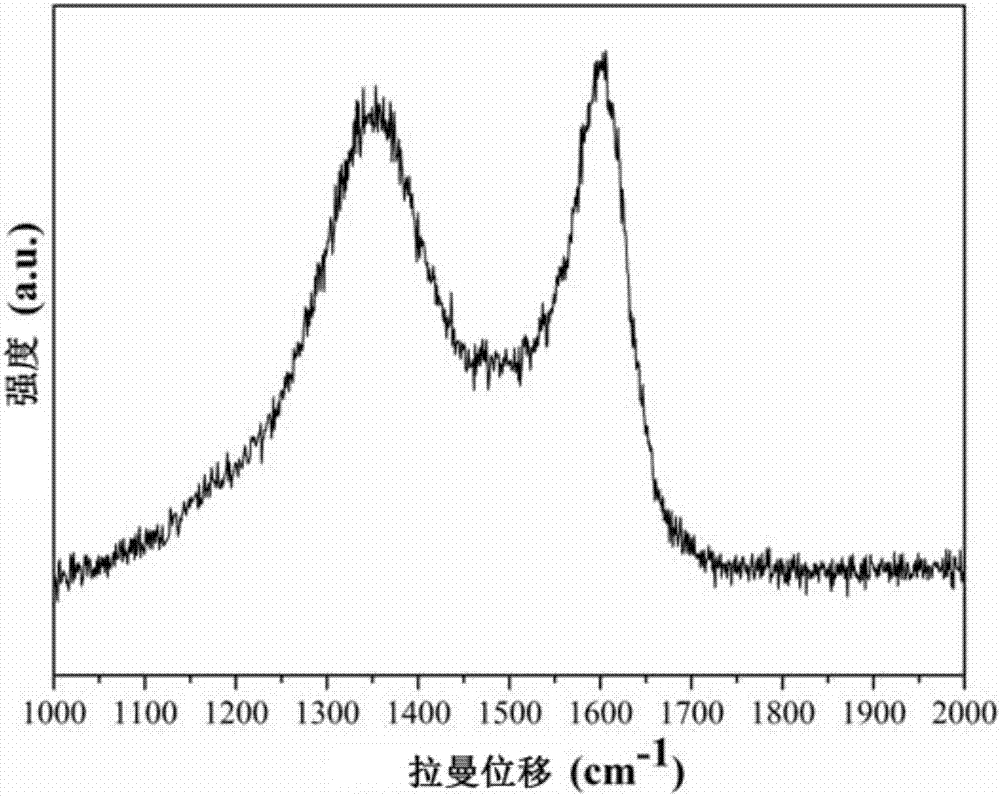

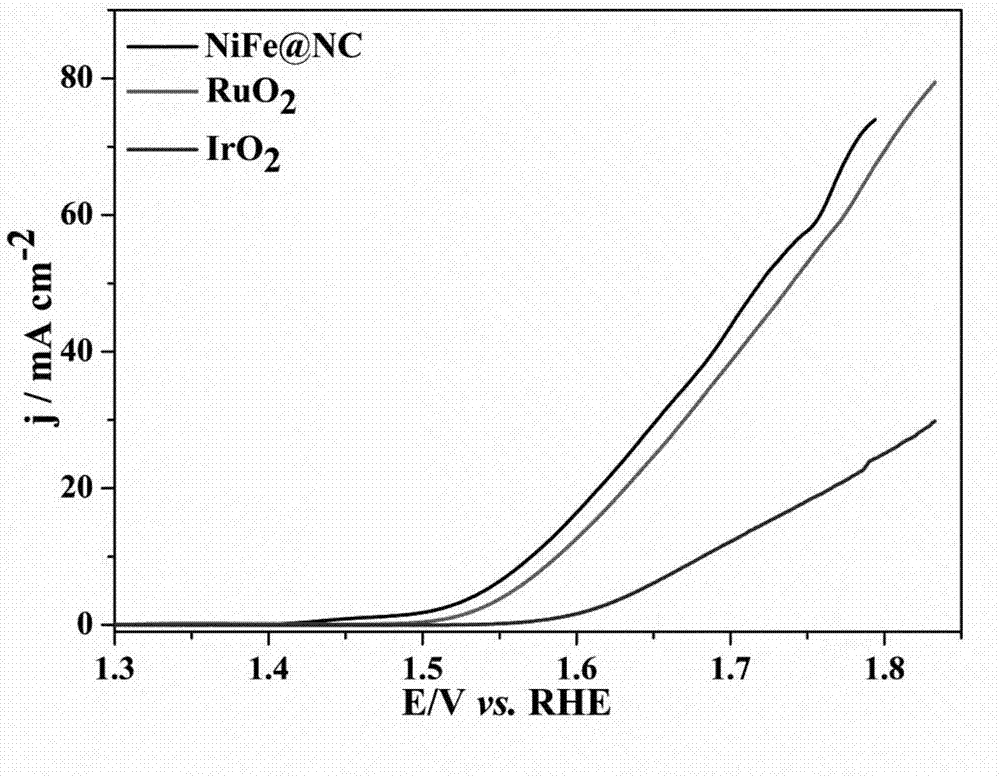

Nitrogen-containing graphitized carbon material adopting double-metal MOFs (metal organic frameworks)

InactiveCN107399729ALarge specific surface areaImprove performanceMaterial nanotechnologyPhysical/chemical process catalystsElectrolysisPorous carbon

The invention provides a nitrogen-containing graphitized carbon material adopting double-metal MOFs (metal organic frameworks). The material is prepared with a method as follows: S1, 2-methylimidazole is dissolved to form a solution A, cobalt salt and zinc salt are mixed to form a solution B, the solution A and the solution B are mixed, left to stand, centrifugalized, washed and dried, and double-metal MOF precursors are obtained; S2, the double-metal MOF precursors formed in S1 are calcined in an inert gas atmosphere, and the calcined double-metal MOF precursors are obtained; S3, the calcined double-metal MOF precursors formed in S2 are mixed with triphenylphosphine or tributyl phosphate in a solution, the mixture is calcined in an inert gas atmosphere, washed and dried, and the nitrogen-containing graphitized carbon material adopting the double-metal MOFs is obtained. The invention provides a highly-graphitized porous carbon material which is high in specific surface area and hierarchically porous, realizes uniform nitrogen doping and contains rich metal-nitrogen structures, the activity of the product in oxygen evolution through water electrolysis is more excellent than that of commercial ruthenium oxide, and the material has great application prospects in energy storage materials.

Owner:SUN YAT SEN UNIV

Static resistant reticle

InactiveUS6180291B1Facilitate transmissionReduce electrostatic dischargeOriginals for photomechanical treatmentGrain treatmentsAnti-reflective coatingRefractive index

A static resistant reticle for use in photolithography having optimal transmission and reduced electrostatic discharge. The reticle comprises a substrate, a patterning layer, and two layers of material having a first refractive index and a second refractive index wherein the first refractive index is greater than the second refractive index and at least one of the layers is conductive. The refractive indices and thickness of the layers are matched to create an anti-reflective coating. The anti-reflective coating optimizes transmission of light through the reticle substrate to about 98.0% to about 99.5% at a wavelength of about 360 nm to about 370 nm. The conductivity of at least one of the layers reduces electrostatic discharge further improving delineation of the pattern projected onto a silicon wafer of a semiconductor device. Preferably, the anti-reflective coating comprises two or more layers of cermet material. The layer of material having a first refractive index is most preferably ruthenium oxide or ruthenium oxide with alumina. The second layer of material having a second refractive index is most preferably silica. A method of fabricating a static resistant reticle, and a method of patterning a silicon wafer using the reticle of the present invention is also described.

Owner:IBM CORP

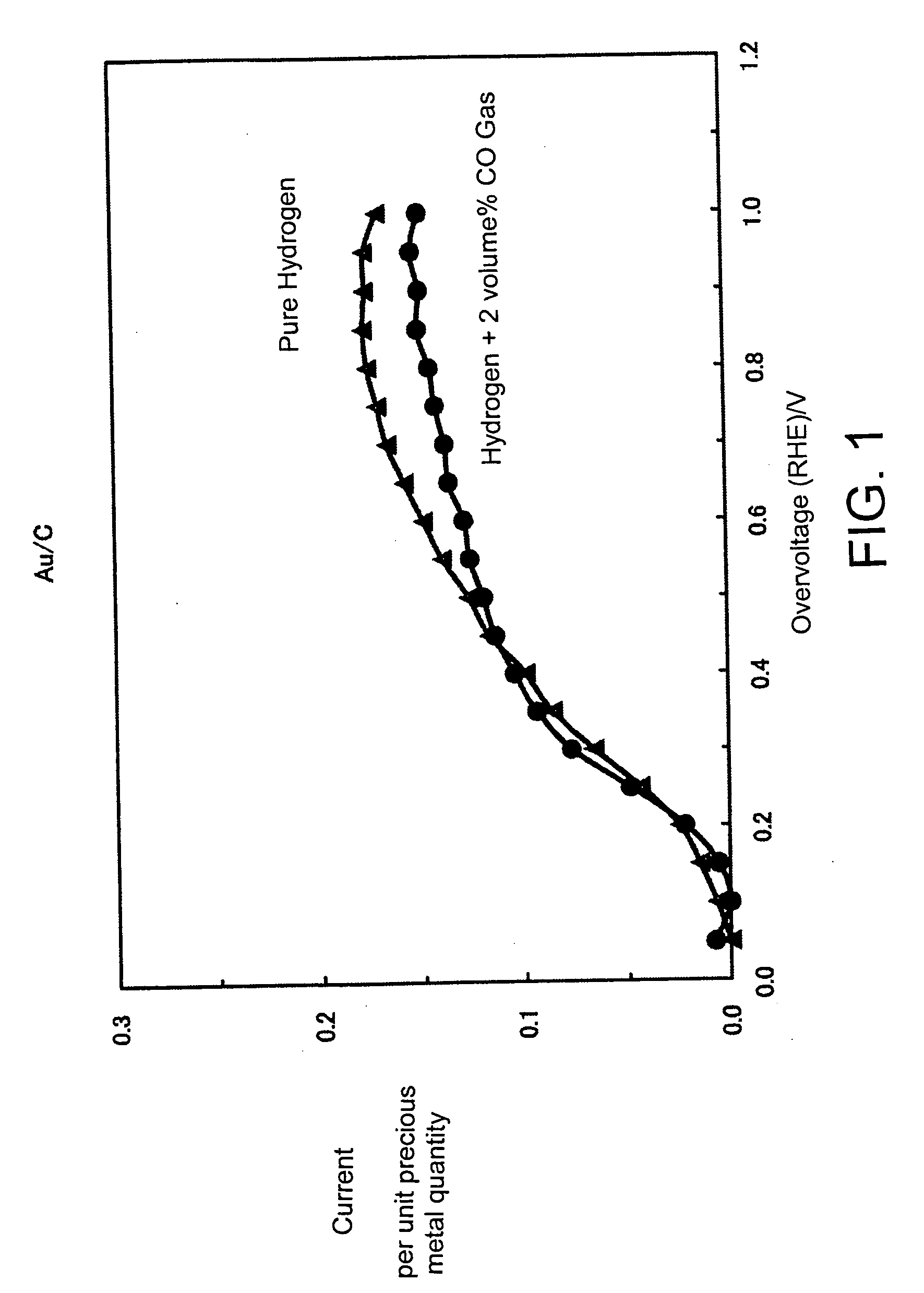

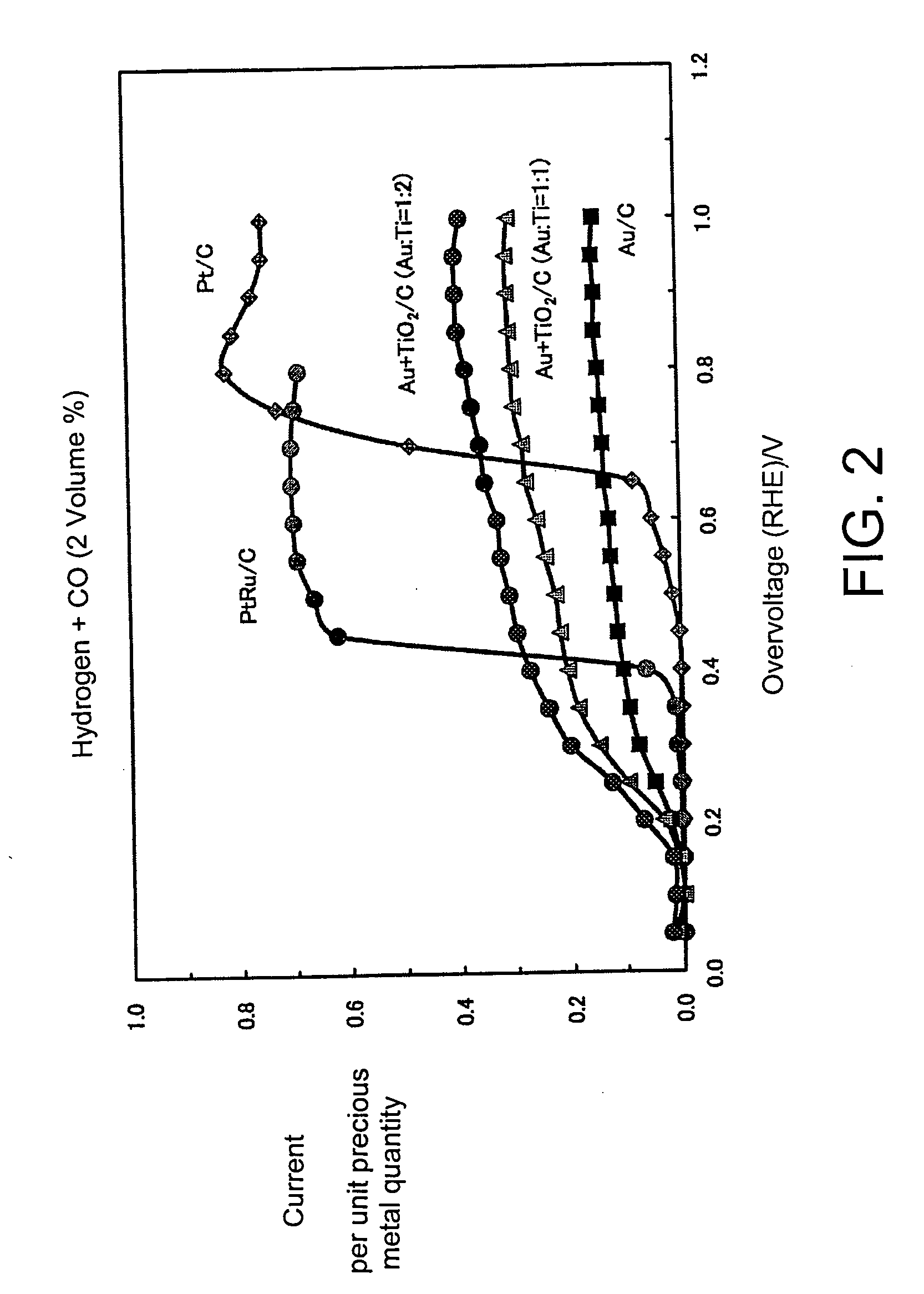

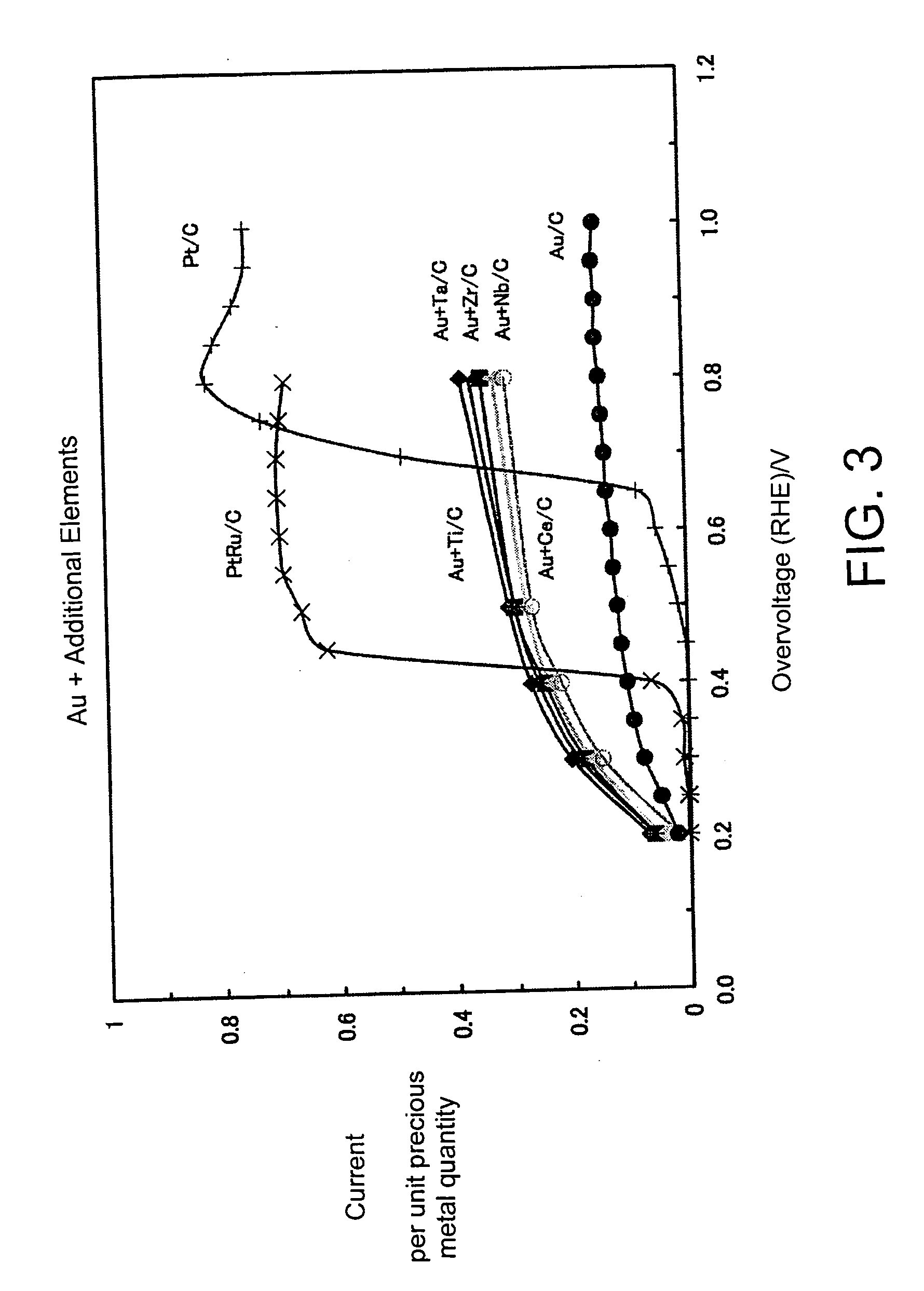

Precious metal oxide catalyst for water electrolysis

InactiveUS20140322631A1High densityLow precious metal loadingCellsActive material electrodesHigh current densityElectrolysis

Owner:UMICORE AG & CO KG

Conductive semiconductor structures containing metal oxide regions

InactiveUS6917112B2Process stabilityIncrease heightTransistorSemiconductor/solid-state device detailsPlatinumSemiconductor structure

A method for forming a metal / metal oxide structure that includes forming metal oxide regions, e.g.. ruthenium oxide regions, at grain boundaries of a metal layer, e.g., platinum. Preferably, the metal oxide regions are formed by diffusion of oxygen through grain boundaries of the metal layer, e.g., platinum, to oxidize a metal layer thereon, e.g, ruthenium layer. The structure is particularly advantageous for use in capacitor structures and memory devices, such as dynamic random access memory (DRAM) devices.

Owner:MICRON TECH INC

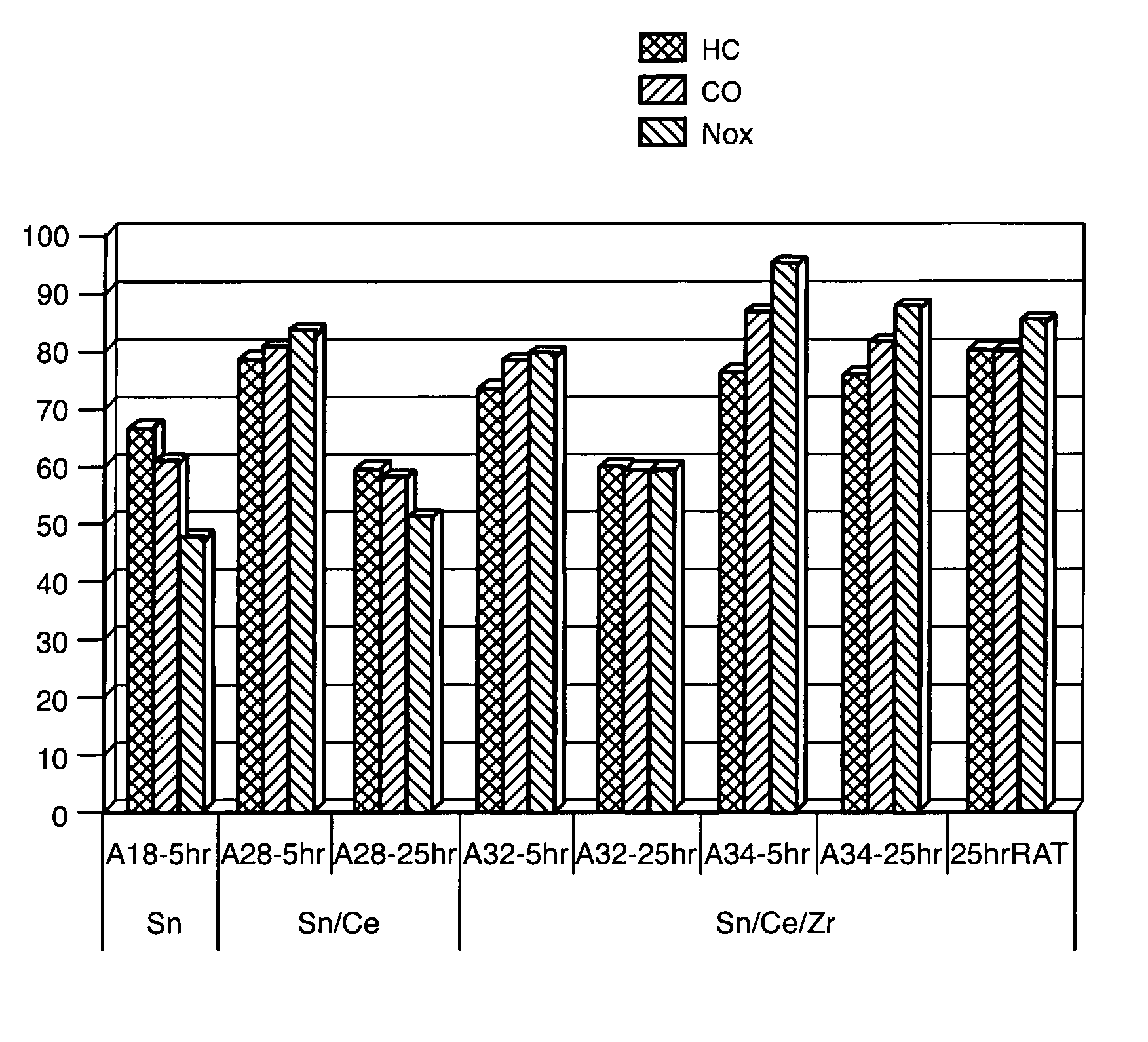

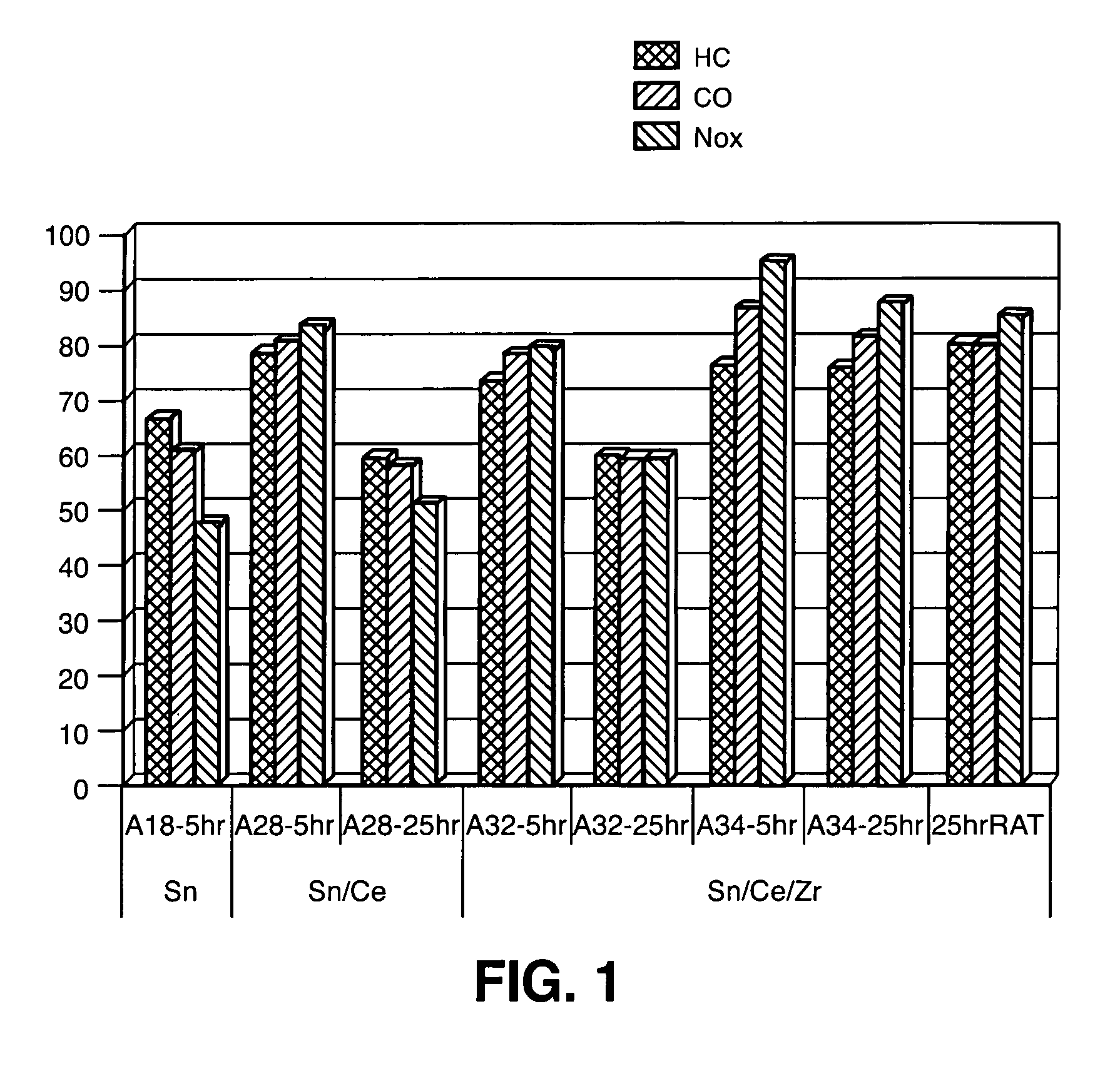

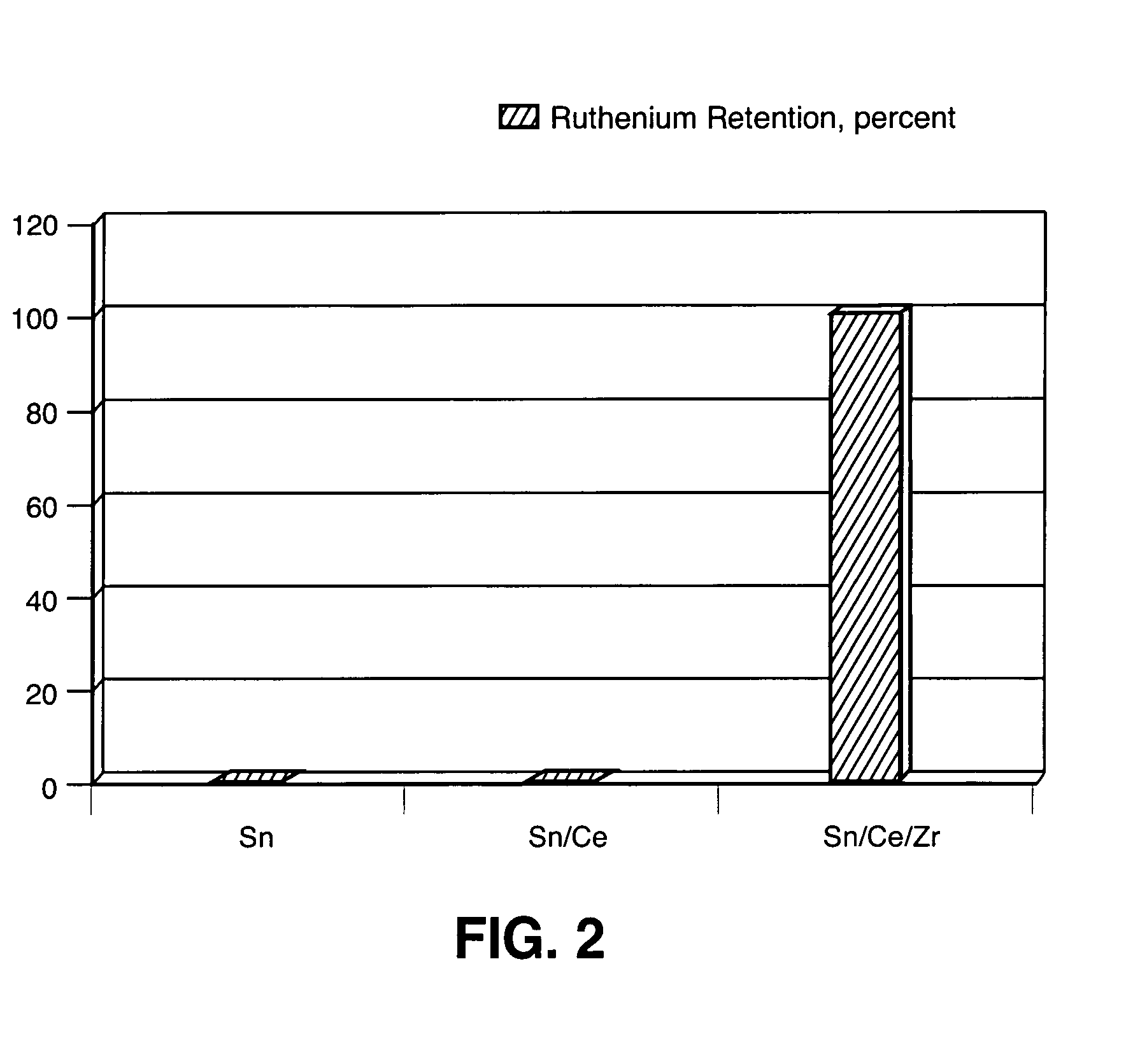

Oxidation-reduction catalyst and its process of use

InactiveUS7318915B2Improve thermal stabilityCost-effectiveOrganic chemistryInternal combustion piston enginesNitrogen oxideRedox catalyst

This invention relates generally to a ruthenium stabilized oxidation-reduction catalyst useful for oxidizing carbon monoxide, and volatile organic compounds, and reducing nitrogen oxide species in oxidizing environments, substantially without the formation of toxic and volatile ruthenium oxide species upon said oxidizing environment being at high temperatures.

Owner:NAT AERONAUTICS & SPACE UNITED STATES OF AMERICA AS REPRESENTED BY THE +1

Precious Metal Oxide Catalyst for Water Electrolysis

ActiveUS20070292744A1Low oxygen overvoltageReduce energy consumptionMachining electrodesCellsOvervoltageSolubility

The invention is directed to iridium oxide based catalysts for use as anode catalysts in PEM water electrolysis. The claimed composite catalyst materials comprise iridium oxide (IrO2) and optionally ruthenium oxide (RuO2) in combination with a high surface area inorganic oxide (for example TiO2, Al2O3, ZrO2 and mixtures thereof). The inorganic oxide has a BET surface area in the range of 50 to 400 m2 / g, a water solubility of lower than 0.15 g / l and is present in a quantity of less than 20 wt. % based on the total weight of the catalyst. The claimed catalyst materials are characterised by a low oxygen overvoltage and long lifetime in water electrolysis. The catalysts are used in electrodes, catalyst-coated membranes and membrane-electrode-assemblies for PEM electrolyzers as well as in regenerative fuel cells (RFC), sensors, and other electrochemical devices.

Owner:UMICORE AG & CO KG

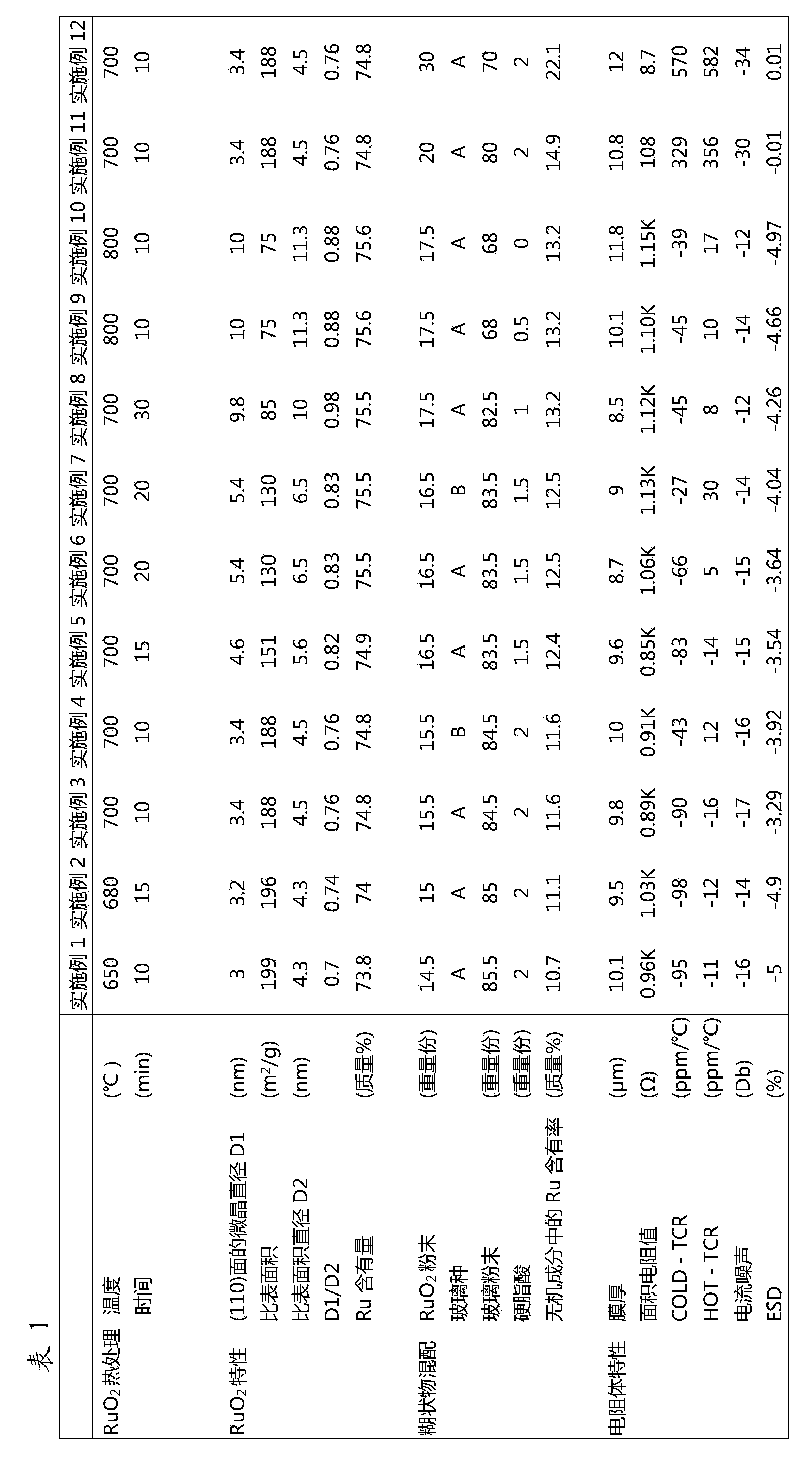

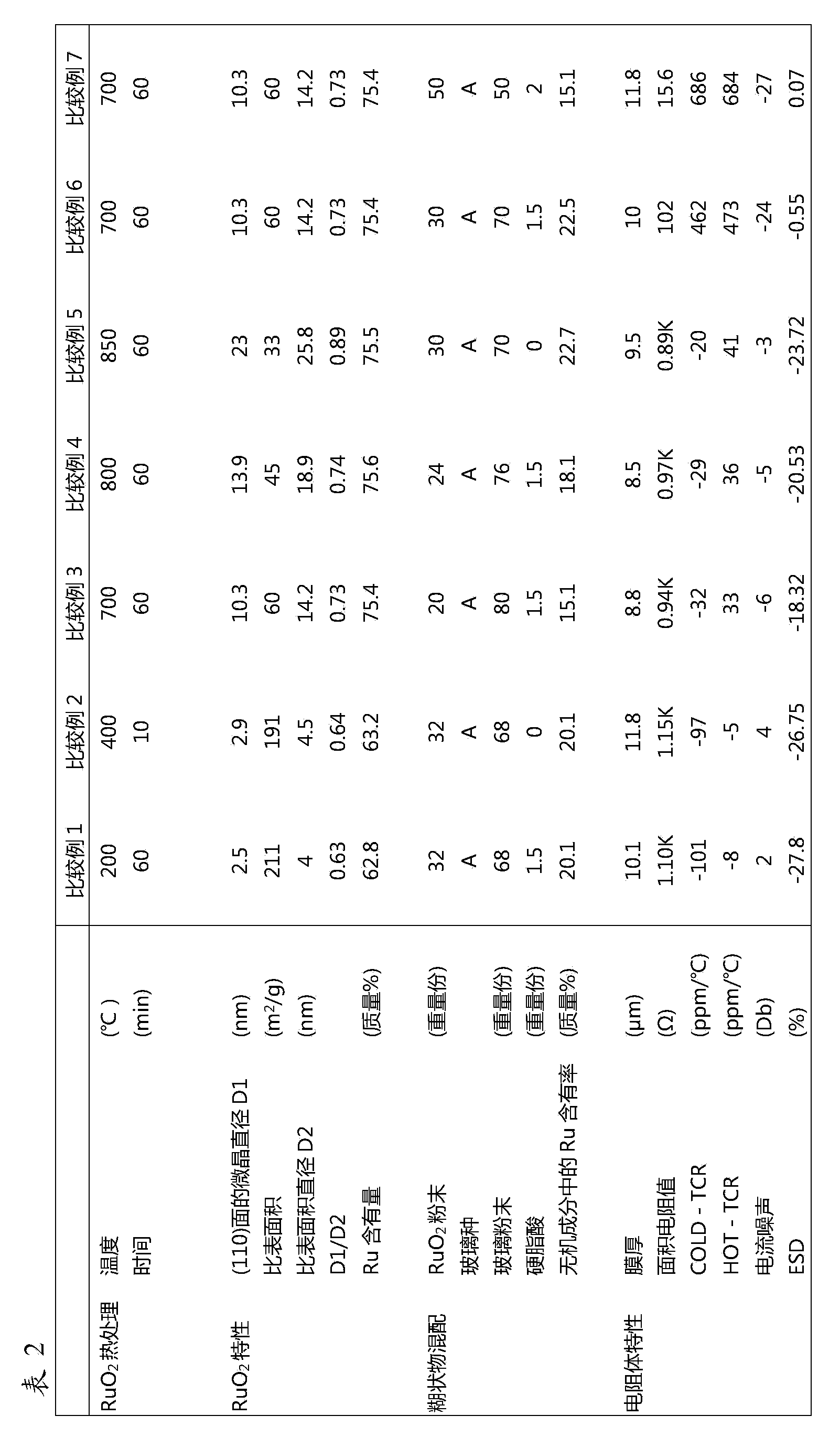

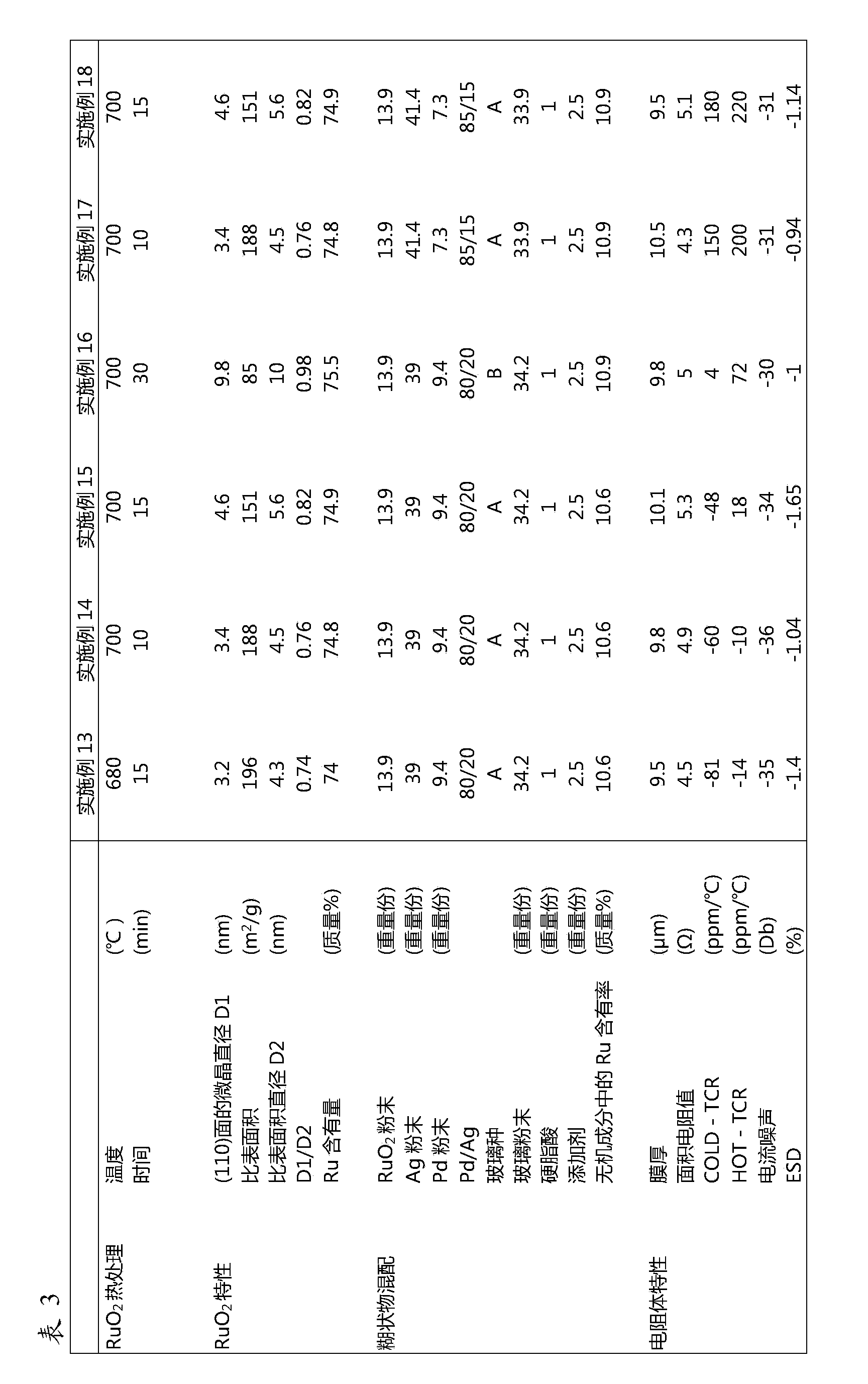

Ruthenium oxide powder, composition for thick film resistor elements using same, and thick film resistor element

ActiveCN103429537AInhibit growthHigh crystallinityRuthenium/rhodium/palladium/osmium/iridium/platinum oxides/hydroxidesThick film resistorsX-rayEngineering

Provided are: a ruthenium oxide powder which is produced, at low cost, as a material for electronic components such as a chip resistor, a hybrid IC and a resistive network each having a sufficient performance, even if the ruthenium content thereof is low; a composition for thick film resistor elements, which uses the ruthenium oxide powder; and a thick film resistor element. Specifically provided are: a ruthenium oxide (RuO2) powder having a rutile crystal structure, which is characterized in that the crystallite diameter of the (110) plane as determined by an X-ray diffraction method is 3-10 nm and the Ru content is 73% by mass or more; a composition for thick film resistor elements, which is obtained by blending a glass powder and conductive particles that are formed of the ruthenium oxide powder as main constituent elements; and a thick resistor element paste, which is obtained by dispersing the composition for thick film resistor elements in an organic vehicle that contains a fatty acid, and which is characterized in that the content of the fatty acid is 0.1-10 parts by weight per 100 parts by weight of the ruthenium oxide.

Owner:SUMITOMO METAL MINING CO LTD

Composite Material, Light Emitting Element and Light Emitting Device

ActiveUS20080191611A1Maintain good propertiesGood property of carrier injectionOrganic chemistryDischarge tube luminescnet screensInorganic compoundOrganic compound

An object of the present invention is to provide a composite material formed of an organic compound and an inorganic compound, and has an excellent carrier transporting property, an excellent carrier injecting property to the organic compound, as well as excellent transparency. A composite material of the present invention for achieving the above object is a composite material of an organic compound represented in the general formula below, and an inorganic compound. For the inorganic compound, an oxide of a transition metal, preferably an oxide of a metal belonging to groups 4 to 8 of the periodic table, in particular vanadium oxide, tantalum oxide, molybdenum oxide, tungsten oxide, rhenium oxide, and ruthenium oxide, can be used.

Owner:SEMICON ENERGY LAB CO LTD

Ni/Fe bimetal-containing MOFs nitrogen-containing graphitized carbon material

ActiveCN107267124ALarge specific surface areaHigh activityHeat-exchange elementsElectrode shape/formsElectrolysisIron salts

The invention provides a Ni / Fe bimetal-containing MOFs nitrogen-containing graphitized carbon material. A preparation method of the Ni / Fe bimetal-containing MOFs nitrogen-containing graphitized carbon material comprises that S1, 2-aminoterephthalic acid, an iron salt and a nickel salt are dissolved in N, N-dimethylformamide and undergo a solvothermal reaction, then the mixed solution is centrifuged, and the centrifuged product is washed, dried and activated to form a Ni / Fe bimetal-containing MOFs precursor, and S2, the Ni / Fe bimetal-containing MOFs is calcined in inert gas to form the Ni / Fe bimetal-containing MOFs nitrogen-containing graphitized carbon material. The invention provides the porous carbon material having a high specific surface area, rich metal nitrogen structures and a high graphitization degree. The Ni / Fe bimetal-containing MOFs nitrogen-containing graphitized carbon material has good material activity, stable performances and a low price and utilizes double non-noble metals. Compared with the commercial ruthenium oxide and iridium oxide, the product has excellent water electrolysis oxygen evolution activity and has a great application prospect in energy storage materials.

Owner:SUN YAT SEN UNIV

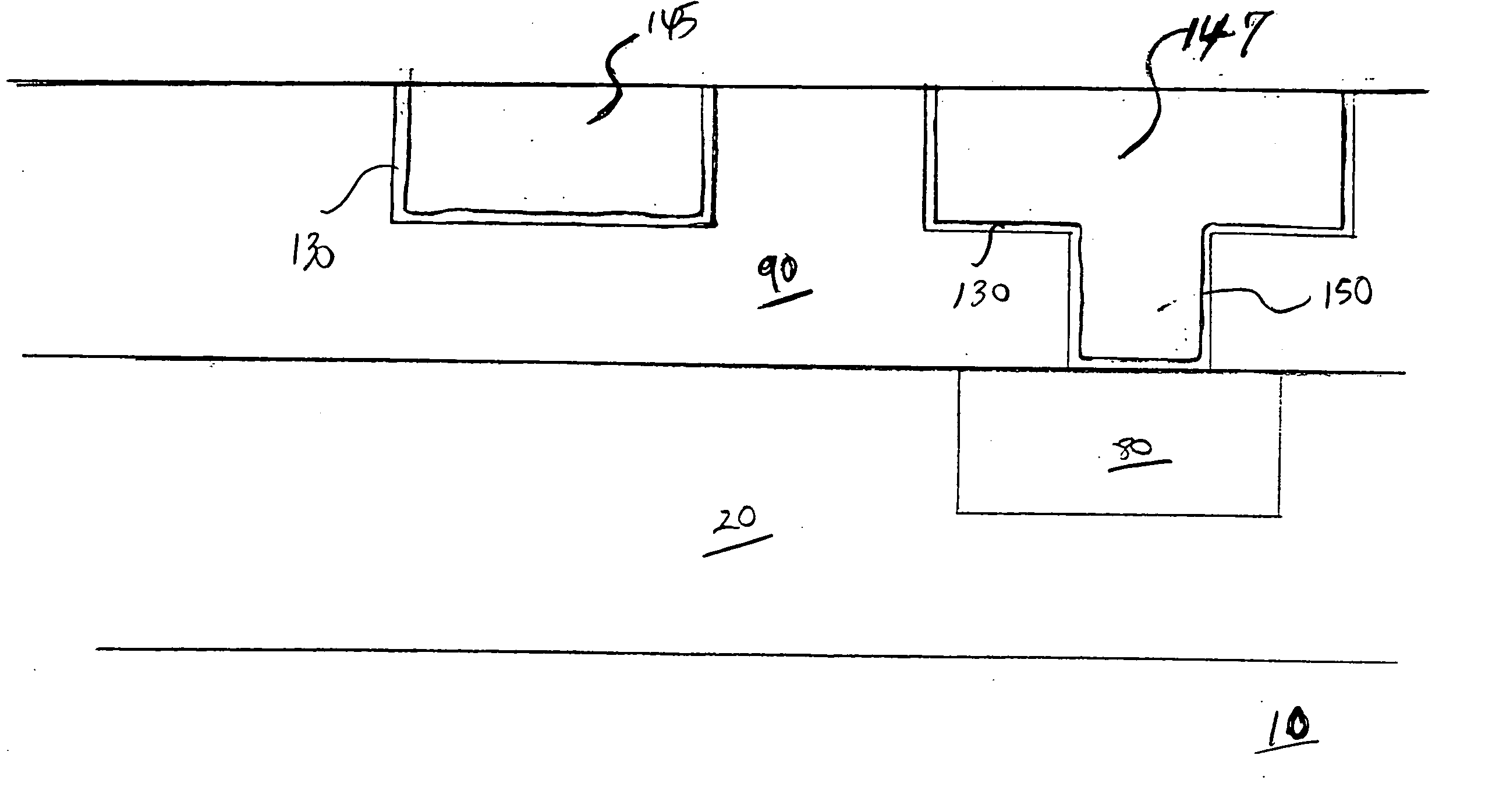

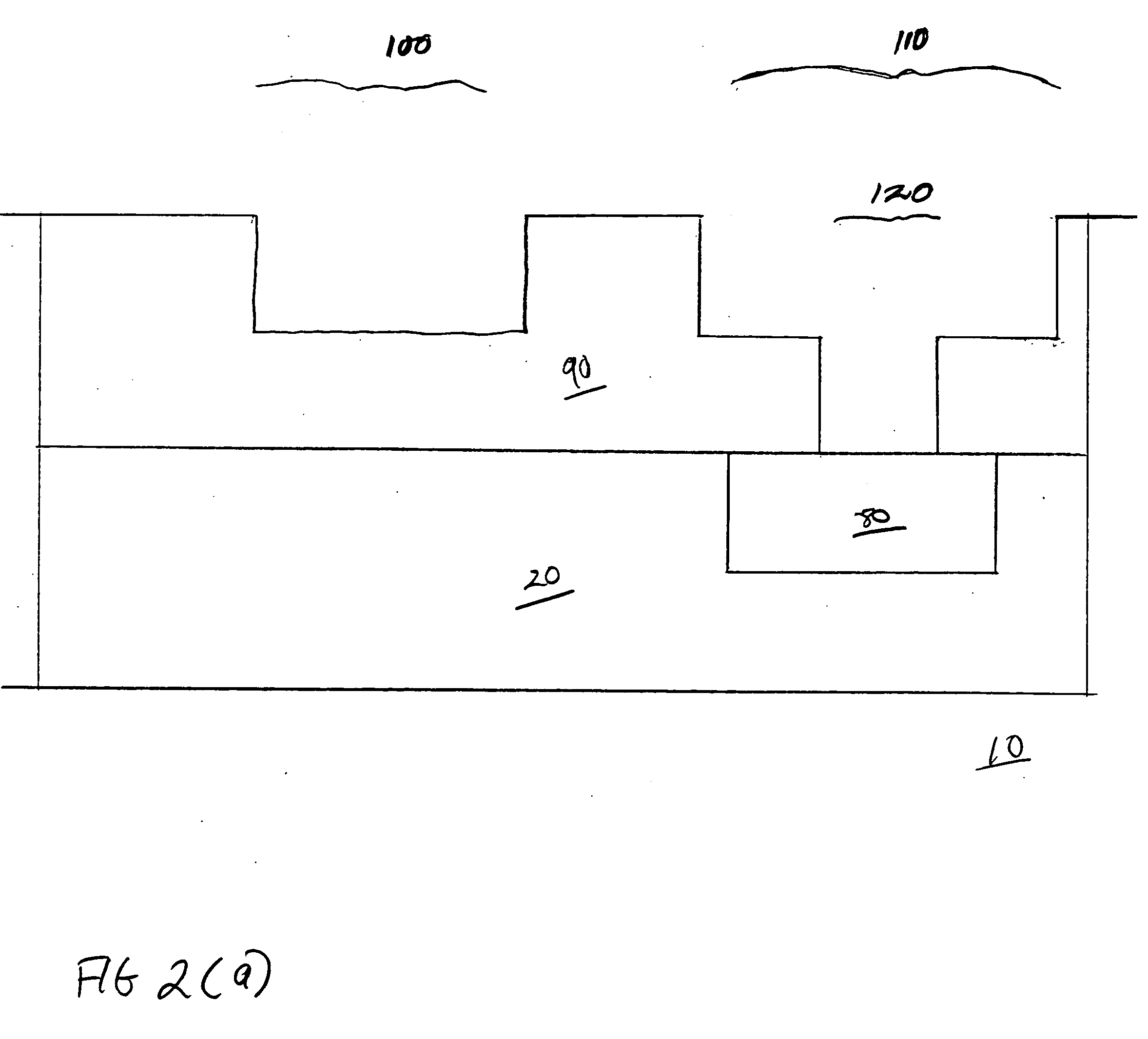

Barrier for copper integrated circuits

An integrated circuit copper interconnect structure is formed by forming a dielectric layer (90) over a semiconductor substrate (10). Trenches (110) and vias (120) are formed in the dielectric layer (90) and a barrier layer (130) is formed in the trenches (110) and vias (120) using material such as iridium, iridium oxide, ruthenium, ruthenium oxide, rhodium, rhodium oxide, rhenium, rhenium oxide, platinum, platinum oxide, palladium and palladium oxide. Copper (147) is then used to fill the remaining area in the trenches (110) and vias (120).

Owner:TEXAS INSTR INC

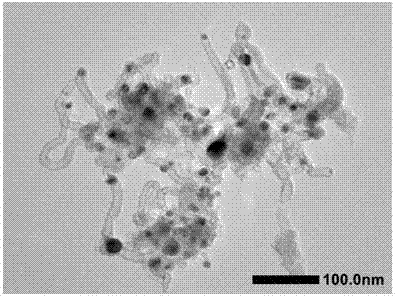

Method for preparing carbon nanotube supported nanometer hydrated ruthenium oxide

InactiveCN1806914AAvoid influenceMild preparation conditionsCatalyst carriersCatalyst activation/preparationCapacitanceAlcohol

The invention provides the method for preparation of hydrated nanometer ruthenium oxide loaded on carbon nanometer tube, comprising the following steps: putting the carbon nanometer tube into ruthenium chloride solution, vibrating with ultrasonic sound, at room temperature, adding hydrogen dioxide solution, carrying out heating-up reversed flow reaction, filtering, washing, drying and getting the product. The method is simple, and the hydrated ruthenium oxide has high dispersion degree on the carbon nanometer tube, small and homogeneous particles, good stability and high load capacity. The hydrated nanometer ruthenium oxide loaded on carbon nanometer tube has wide application in super capacitance and alcohol oxidative catalyst.

Owner:SOUTH CHINA UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com