Patents

Literature

265 results about "Double coating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A double coat is a type of coat that consists of two layers. Double coated dogs have a dense undercoat of short hairs, typically with a wooly texture, over a top coat of longer hairs called guard hairs. The denser the undercoat, the fluffier the coat will appear to be and the more grooming the dog will require.

Electrode for electrolysis, preparation method of electrode and electrolytic bath

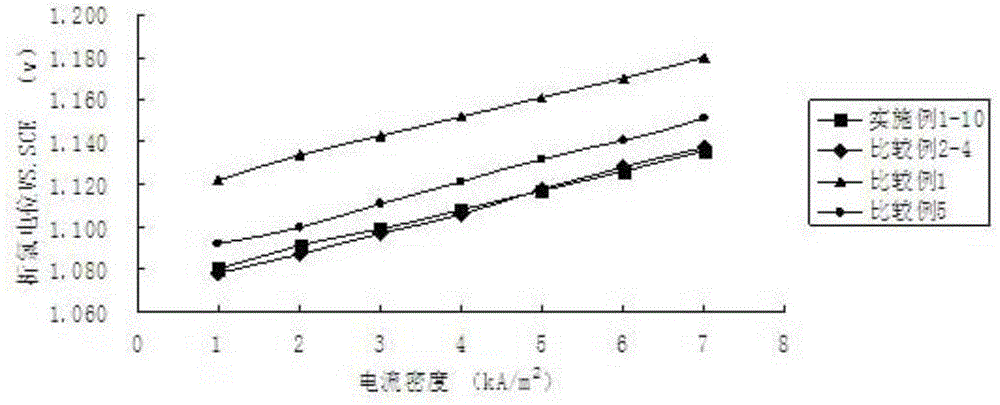

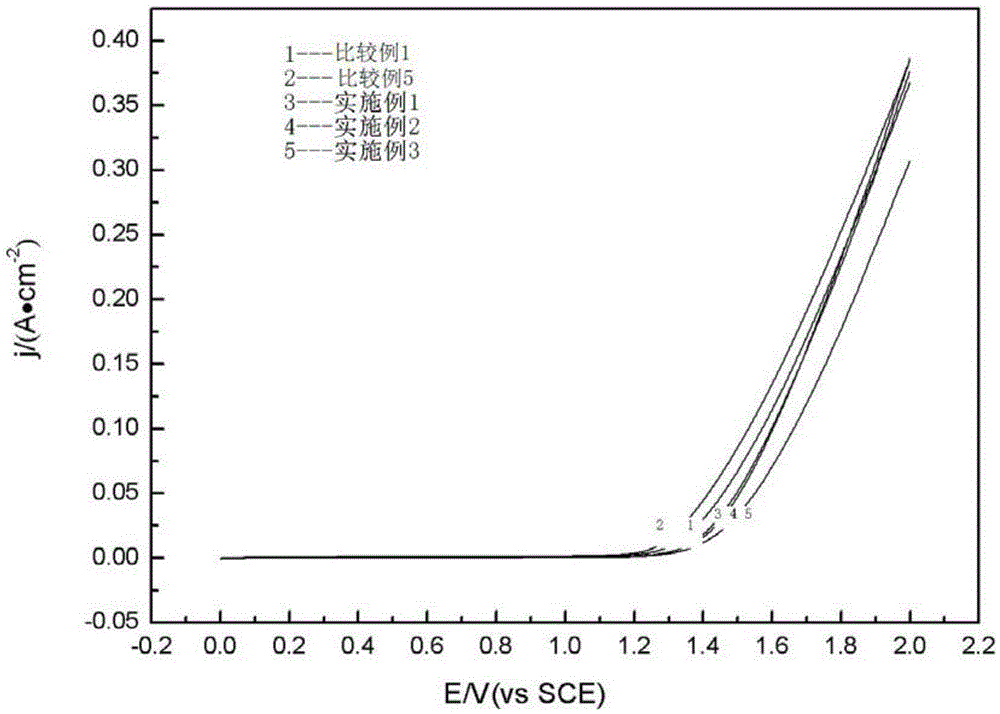

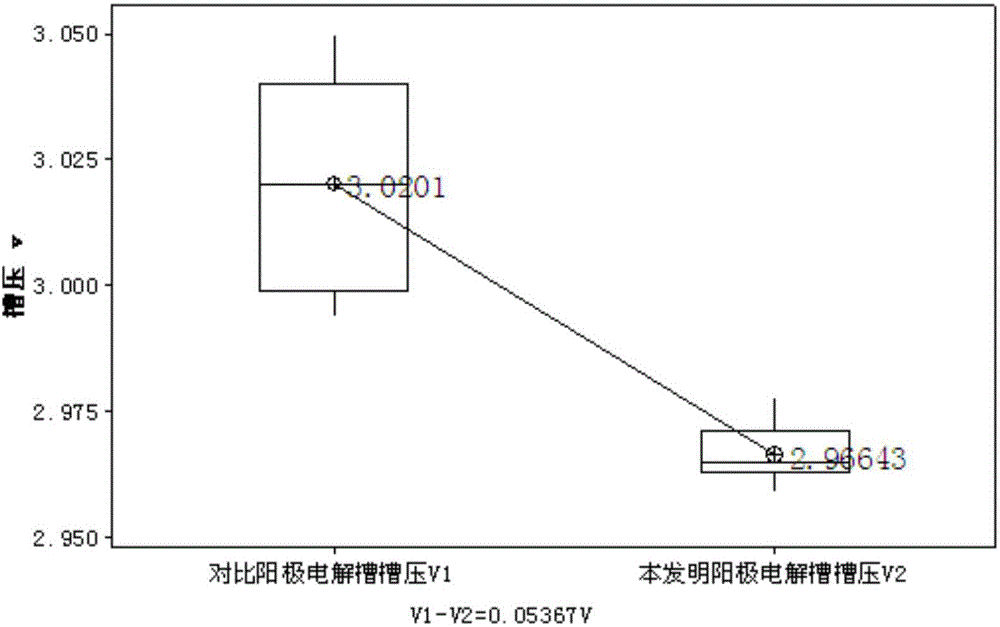

ActiveCN104562078AChlorine evolution potential is lowExtended service lifeElectrodesIridiumElectrolysis

The invention provides an electrode for electrolysis, a preparation method of the electrode and an electrolytic bath. The electrode for electrolysis comprises a conductive base material and an active coating, wherein the conductive base material is a base material containing titanium or titanium alloy; the active coating at least comprises a bottom coating layer and a surface coating layer; the bottom coating layer is prepared from titanic oxide, iridium oxide and ruthenium oxide; the surface coating layer is prepared from iridium oxide, ruthenium oxide, titanium oxide and a metal or an oxide of one of two of palladium and platinum. According to the electrode for electrolysis disclosed by the invention, the double coating layers are adopted; compared with the single coating layer only containing ruthenium, iridium and titanium, the electrode is better in activity, the chlorine evolution potential of the electrode is low, the oxygen evolution potential is high, the service life of the electrode is longer, and the electrolysis stability is better.

Owner:BLUESTAR BEIJING CHEM MACHINERY

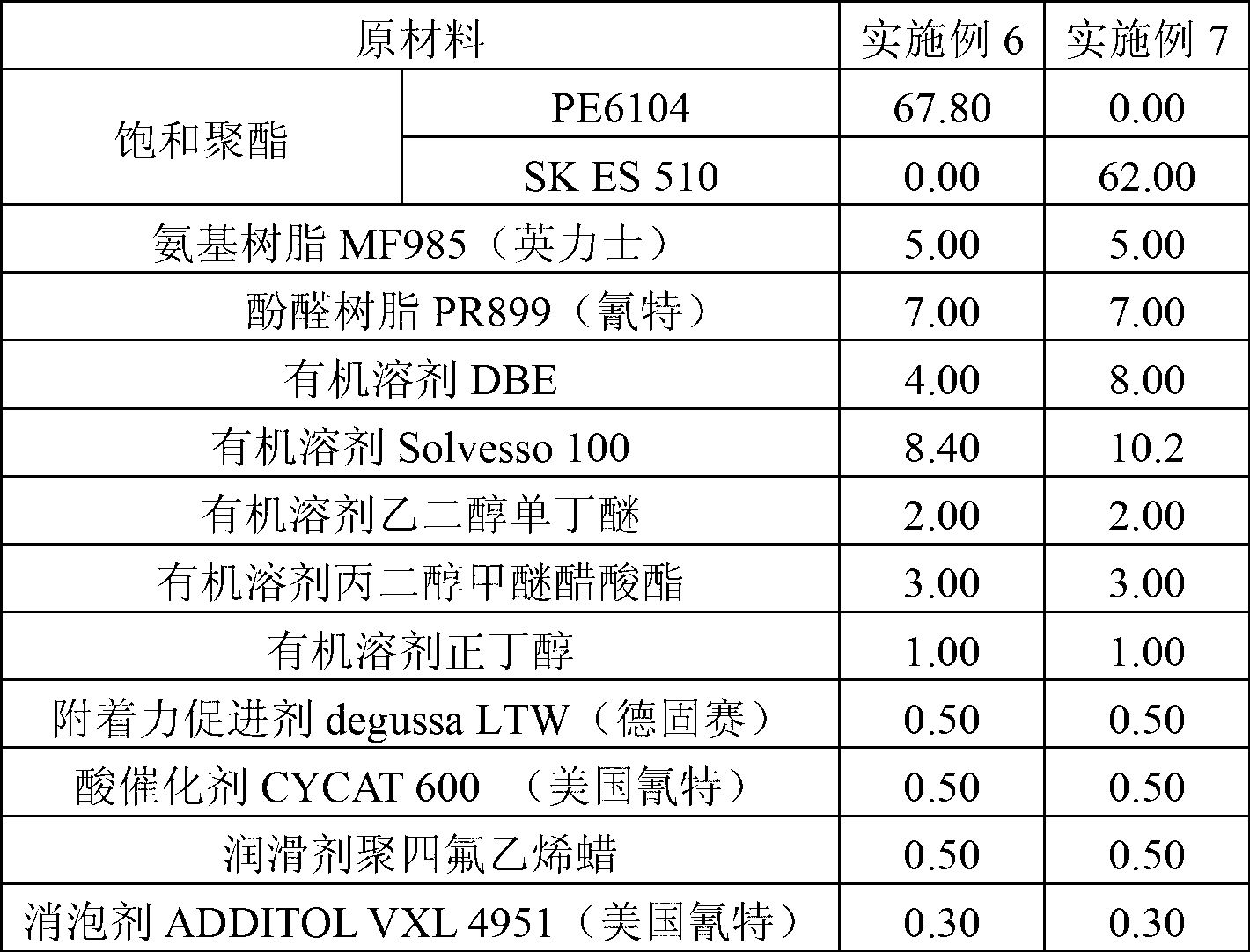

Inner paint of metal beverage food can and preparation method and application thereof

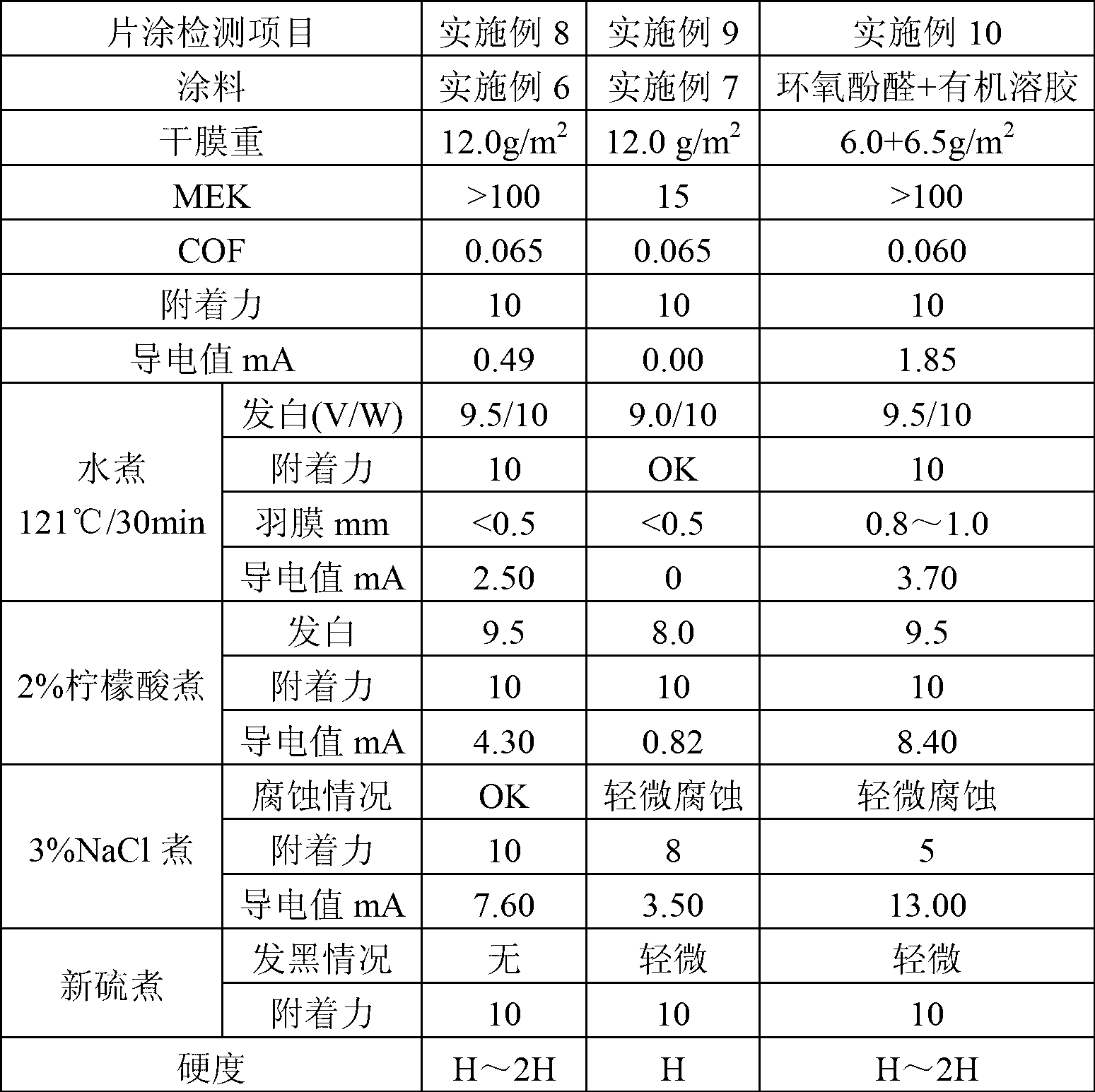

ActiveCN103013303AGood flexibilityCook without turning whiteAnti-corrosive paintsLinings/internal coatingsPolyesterEpoxy

The invention discloses inner paint of a metal beverage food can, a preparation method and an application thereof. The paint comprises the following components by mass: 35-70% of saturated polyester, 1-15% of amino resin, 3-20% of phenolic resin, and 1.8-2.5% of an additive. The components are mixed to obtain the paint provided by the invention. The paint has the following advantages that: no toxic monomer is contained; a coating prepared by the paint can resist high-temperature sterilization and acid boiling, has very good flexibility, thus can be used as an inner coating of easy-drawing lids, an inner coating of two-sheet deep drawing food cans, and an inner wall coating of three-sheet beverage cans, is suitable for storage of carbonated beverages, beer, sardine, pork luncheon meat, tomato sauce, and the like; the paint realizes a single coating weight of up to 13 g / m2, can replace double coating process by epoxy primer and organosol finish in a sheet coating mode, does not turn white during boiling, has excellent adhesive force, and cause no feather film.

Owner:清远慧谷新材料技术有限公司

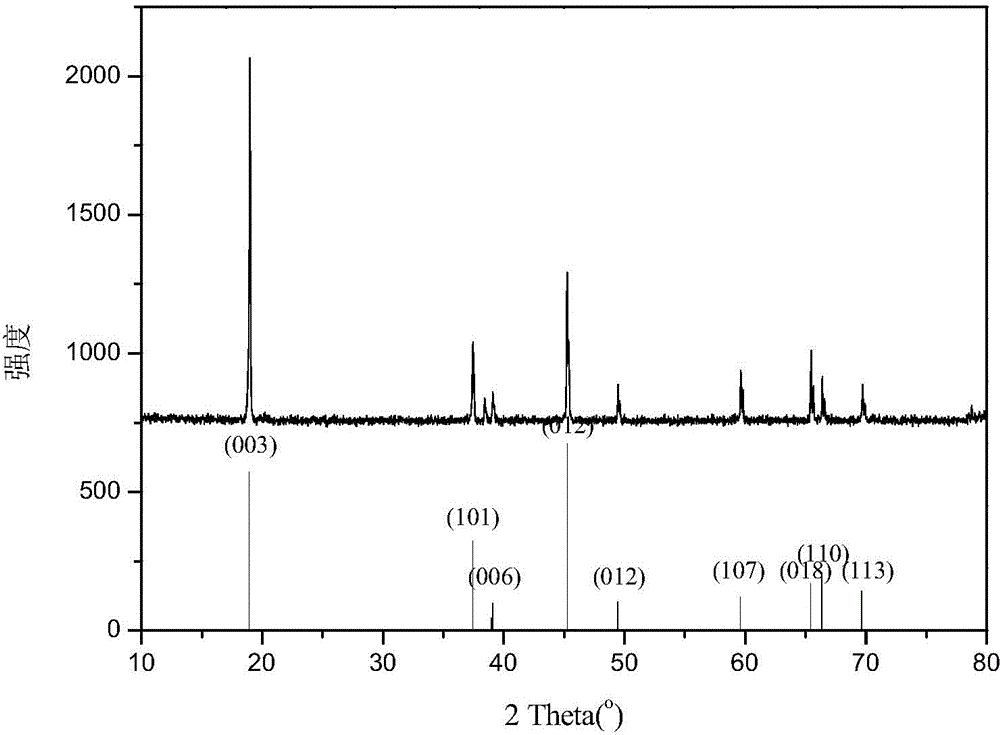

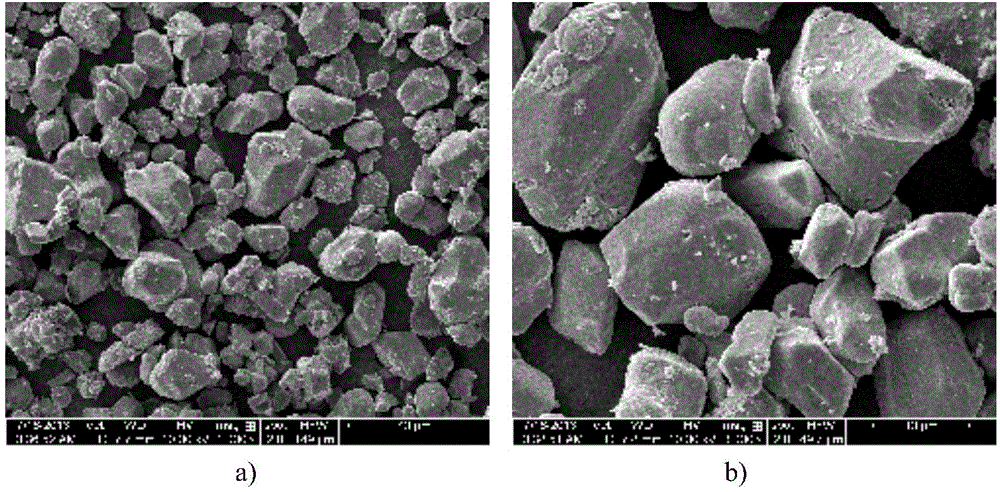

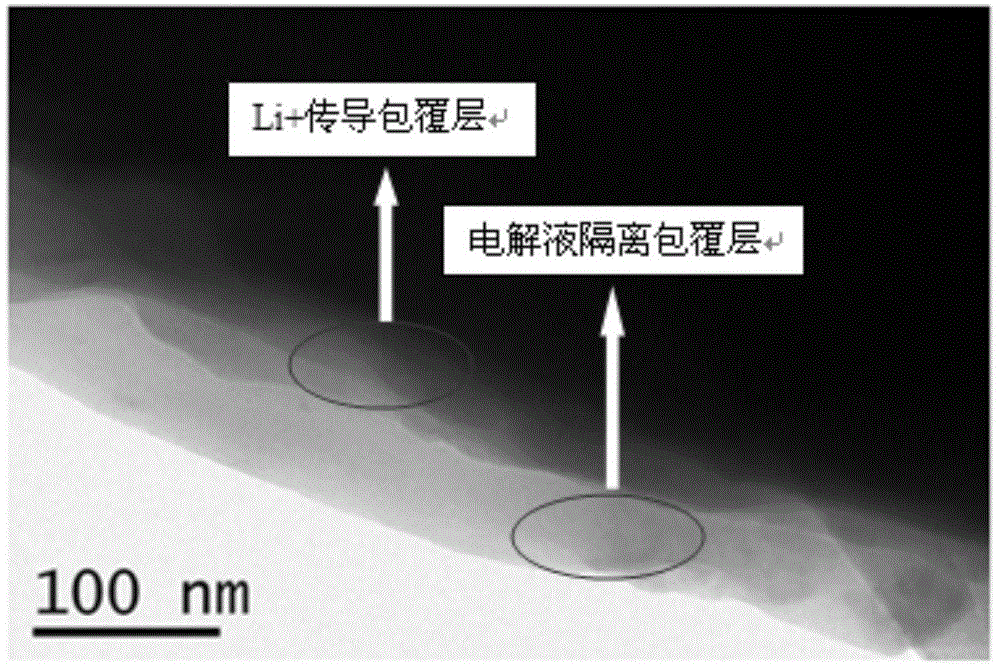

Surface-modified lithium cobaltate material and preparation method thereof

ActiveCN103606674AHigh discharge specific capacityLess side effectsCell electrodesLithiumDouble coating

The invention discloses a surface-modified lithium cobaltate material and a preparation method thereof. The lithium cobaltate material comprises a core particle and a surface-modified layer coating the core particle, wherein the core particle is a lithium cobaltate-based positive material with a structural formula as follows: LixCo(1-y)MyO2, wherein x is greater than 1 and not greater than 1.2, y is not less than 0 and not greater than 0.1, M is a doping element; the surface-modified layer comprises a Li<+1> conducting layer and an electrolyte isolating layer; the core particle is coated by the Li<+1> conducting layer and the electrolyte isolating layer in sequence. According to the invention, by sufficiently utilizing dynamic characteristic that different substances react with residual Li salt on the surface of the lithium cobaltate, and characteristic of final reaction product performance, the lithium cobaltate material with double coating layers is prepared. The material is high in comprehensive performances, has high discharge capacity, high cycling stability and the like. The preparation method disclosed by the invention is simple in process and easily realizes industrial production.

Owner:QINGHAI TAIFENG XIANXING LITHIUM ENERGY TECH CO LTD

Moisture-retention sustained and controlled release fertilizer and method of preparing the same

InactiveCN101508616AThe synthesis process is simpleUniform thicknessFertilizer mixturesHigh absorptionDouble coating

The invention discloses a water holding slow-controlled releasing fertilizer and a preparation method thereof, belonging to the technical field of agricultural fertilizers and preparation thereof. Macromolecule coating fertilizer is taken as an inner core and a water holding layer is taken as an outside layer to form a double-coating water holding slow-controlled releasing fertilizer; an inner coating is macromolecule protective layer coating material with nutrition controlling and releasing property; an outside coating is the water holding layer with excellent water holding property. Water retention agent suspension liquid is sprayed to the surface of macromolecule coating fertilizer grains for outside coating; wherein the water retention agent is prepared by taking cyclohexane, emulsifier, acrylic acid, acrylamide, sodium hydroxide, cross linker and evocating agent and adopting the method of opposite phase suspension polymerization. The fertilizer has the function of controlled releasing, drought resistance, water saving, water holding and soil improving and the advantages of high absorption percentage, wear resistance, difficult falling and the like; utilization ratio of liquid manure is improved and the fertilizer can be widely used to desert control, lawn plant, soil improvement, gardening, agriculture and forestry and the like.

Owner:CHINA AGRI UNIV

High-quality strawberry planting dedicated slow-release compound fertilizer

InactiveCN104030800AImprove the phenomenon of single fixationGood release effectFertilizer mixturesMicrobial agentGluconates

The invention relates to the compound fertilizer field, and particularly relates to a high-quality strawberry planting dedicated slow-release compound fertilizer. The fertilizer is prepared from the following raw materials in parts by weight: 10-15 parts of a 1250-2000 mesh diatomite, 4-5 parts of borax, 2-3 parts of ammonium molybdate heptahydrate, 10-12 parts of sodium humate, 20-25 parts of urea, 18-22 parts of potassium nitrate, 25-28 parts of organic compost, 2-4 parts of fish meal, 1-3 parts of sesame leaves, 8-10 parts of alfalfa meal, 15-18 parts of corn distiller grains, 2-4 parts of brine, 8-10 parts of an erythromycin fungi residue, 1-2 parts of an EM microbial agent, 4-6 parts of a fern root residue, 1-3 parts of nano silver, 1-2 parts of a semen ginkgo powder, 4-6 parts of 1,6-hexanediol diacrylate, 10-12 parts of an acrylic resin dispersion liquid, 1-2 parts of isocyanate, 1-2 parts of calcium stearoyl lactate, 2-4 parts of zinc gluconate, 6-8 parts of table vinegar, and 4-5 parts of an auxiliary agent. The compound fertilizer has multiple nutrients, is low in production cost and good in slow-release effect, allows double coating to be formed on the nutrients by utilizing diatomite and a coating agent in the process, also contains various trace elements, has no toxicity and no pollution, and is excellent in quality of planted strawberry and obvious in yield and income increasing effects.

Owner:ANHUI SUNSON CHEM

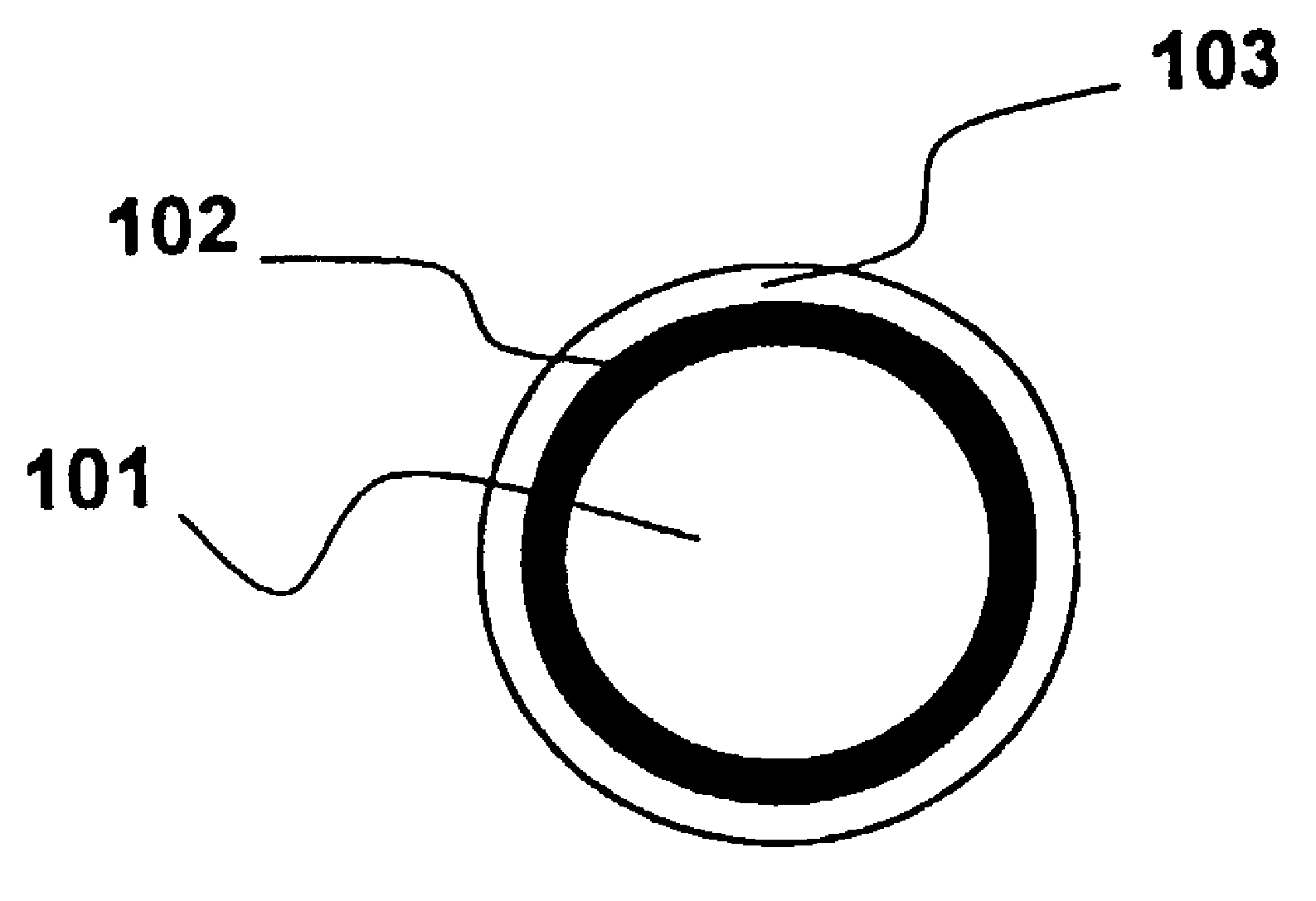

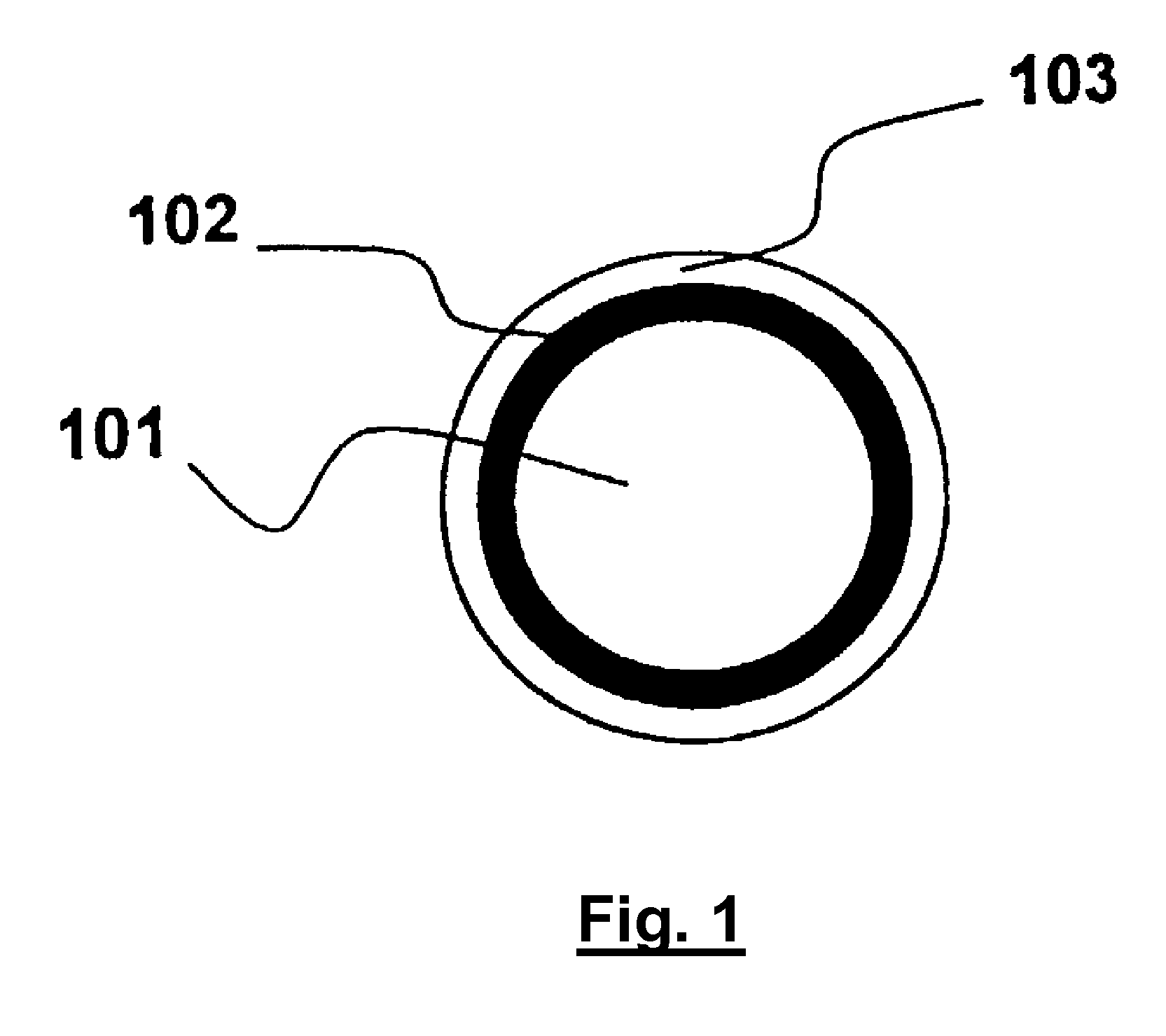

Optical fiber with double coating

ActiveUS20120321265A1Good resistance to mechanical stressAccelerated agingGlass optical fibreOptical fibre with multilayer core/claddingAlcoholDouble coating

An optical fiber includes an optical waveguide, a first coating layer disposed to surround the optical waveguide and a second coating layer disposed to surround the first coating layer, wherein the first coating layer is formed by a cured polymeric material obtained by curing a radiation curable composition including at least one (meth)acrylate monomer esterified with at least one branched alcohol having from 9 to 12 carbon atoms, and the second coating layer is formed by a cured polymeric material obtained by curing a radiation curable (meth)acrylate composition including from 0.8% to 1.5% by weight of silica, based on the total weight of the composition.

Owner:PRYSMIAN SPA

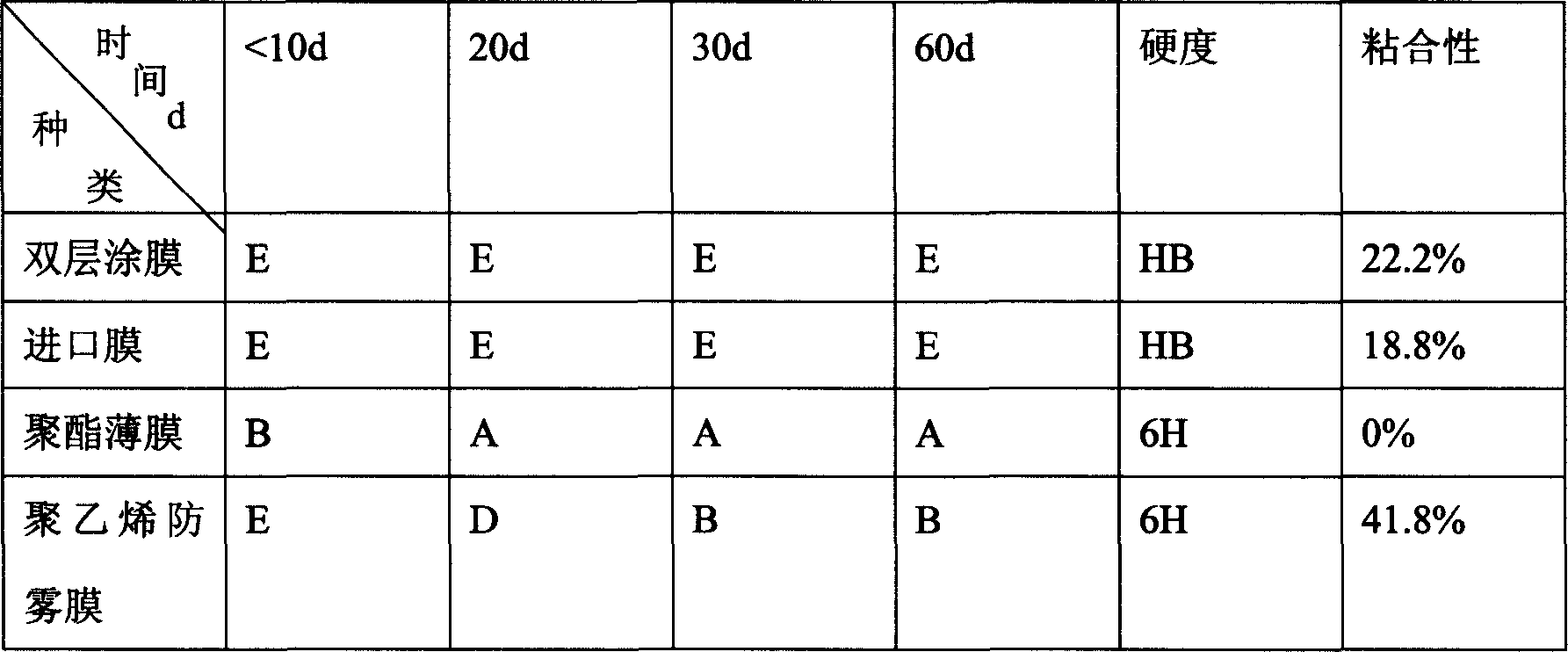

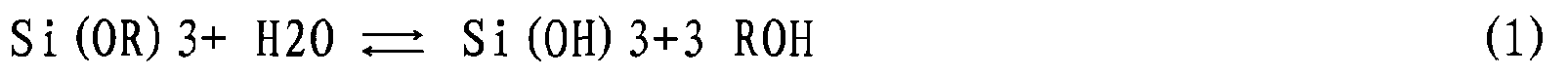

Exterior coating antifogging film and preparation method

InactiveCN1687199ACoating method is simple and easyCuring method is simpleCoatingsLight irradiationDouble coating

The present invention provides a new externally-coated fog-resisting film and its preparation method. It is characterized by that said invention adopts inorganic-organic coating process on the plastic film surface to prepare fog-resisting film. The described fog-resisting film has a double-coating structure, first coating layer is coated on the base film, it is a mixture obtained by using silane coupling agent and one or two kinds of ethyl orthosilicate and butyl titanate through hydrolysis reaction, after the first coating layer is solidified by means of heating or UV-light irradiation, on said layer of solidified film a second coating layer is coated, and said second coating layer also is a mixture formed from silane coupling agent and one or two kinds of ethyl orthosilicate and butyl titanate through hydrolysis reaction, and also is solidified by means of heating or UV-light irradiation.

Owner:EAST CHINA UNIV OF SCI & TECH

Flake pigment, coating material and powder coating composition each containing the same and surface-treating agent for flaky particle for use therein

InactiveUS20060063004A1Good metal effectEasy to separateMaterial nanotechnologySynthetic resin layered productsPhosphatePhosphoric acid

A flake pigment preferably usable in a powder paint, supplying a film with excellent metallicity and high brightness and further providing excellent secondary adhesiveness is provided. The flake pigment comprises base particles composed of flake particles and a single-layer or double-layer coat covering the surface of each base particle, and at least one layer of the said single-layer or double-layer coat is made of a resin composition containing a copolymer comprising a bond unit arising from a fluoric polymerizable monomer having alkyl fluoride groups and a bond unit arising from a polymerizable monomer having phosphate groups.

Owner:TOYO ALUMINIUM KK

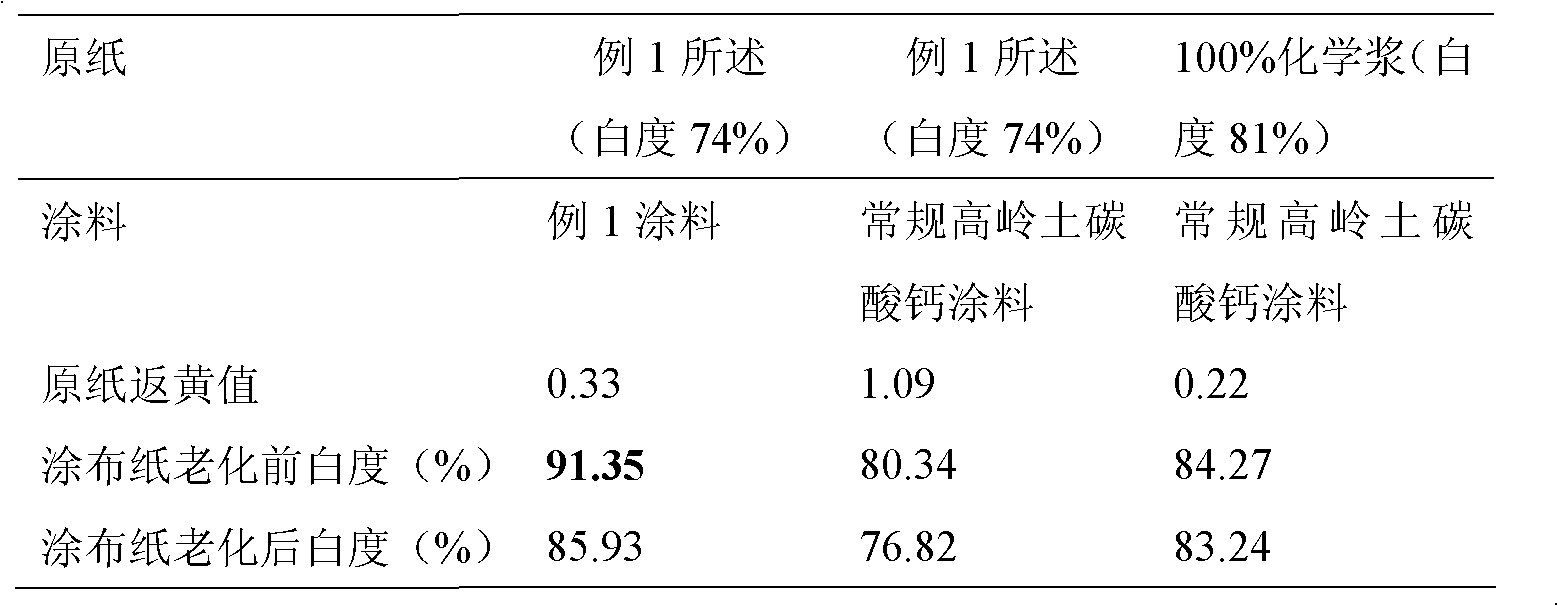

High-whiteness coated paper coated by using raw paper with medium whiteness, coating method and coating

InactiveCN102199897AReduce whitenessFulfil requirementsCoatings with pigmentsReinforcing agents additionCardboardManufacturing technology

The invention relates to high-whiteness coated paper coated by using raw paper with medium whiteness, a coating method and a coating. The coating method is mainly characterized by greatly reducing the whiteness of the raw paper for producing conventional high-grade coated paper such as copper plate paper and coated white cardboards. The coating mode is a common single-side or double-side two-layer (double-coating) or multi-layer coating mode in a papermaking plant. By using the mechanical property of the raw paper, the printing property of coatings and the synergetic whitening effect between the coatings, yellowing of the raw paper is inhibited, and the whiteness of the coated paper is improved to over 86 percent so as to meet the requirements of national standards on the high-grade copper plate paper. The raw paper of the high-grade coated paper can be made by using various kinds of environment-friendly and resource-saving pulp of medium whiteness more widely, and is favorable for promoting the development of the low-carbon manufacturing technology of the pulping papermaking industry. The newly invented coated paper can substitute the traditional high-grade paper such as the copper plate paper, the coated white cardboards and the like in the fields of printing and packing.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

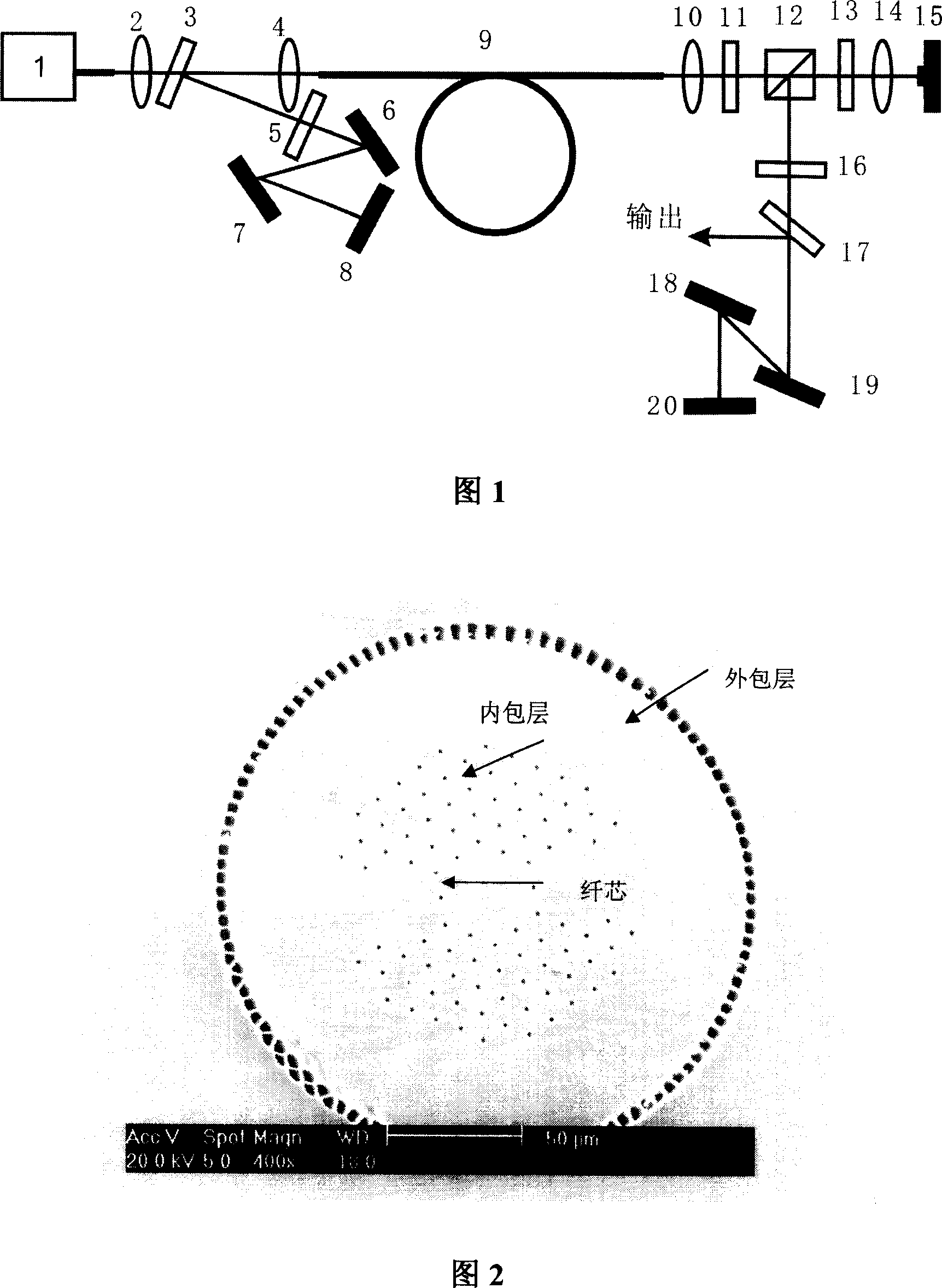

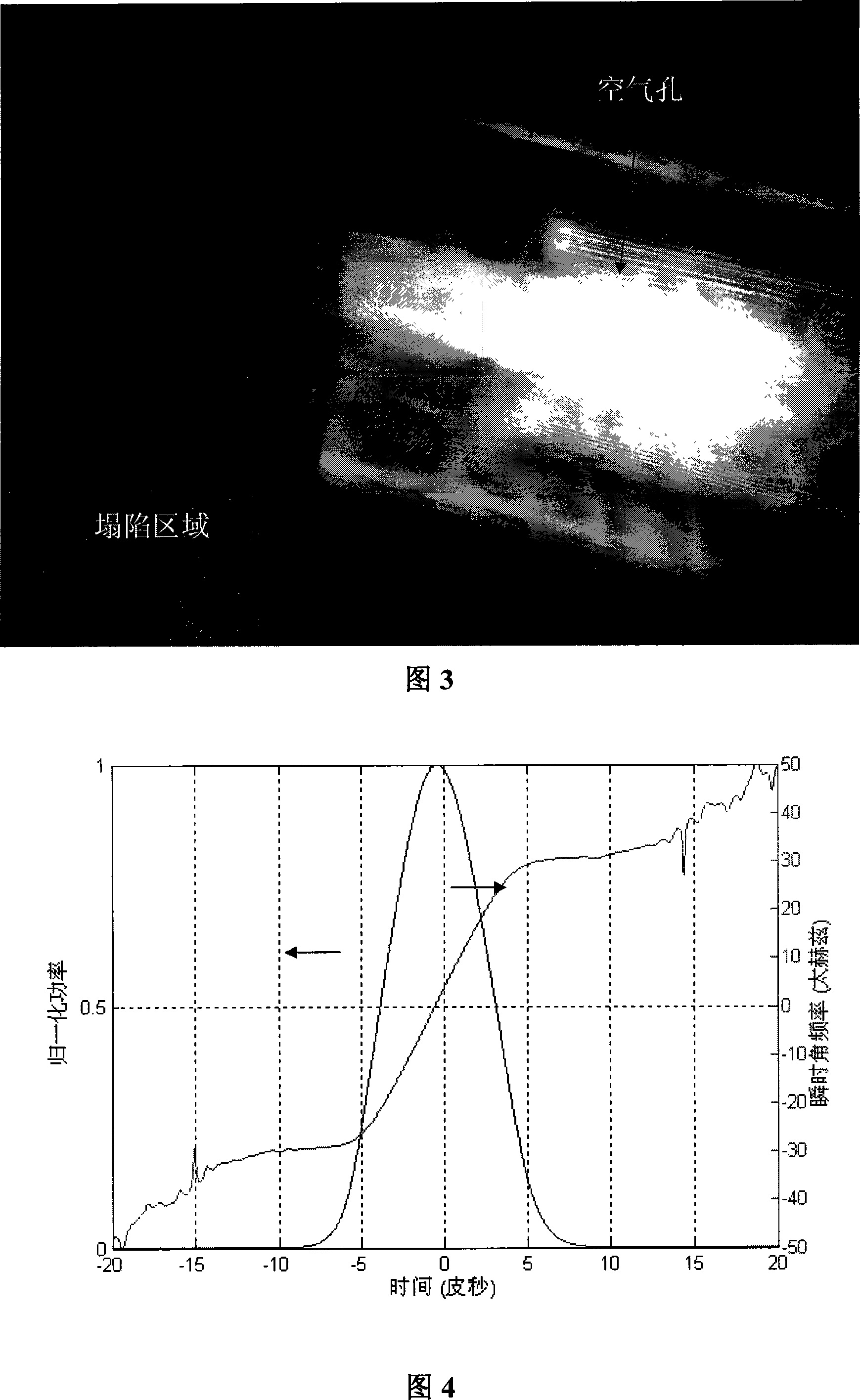

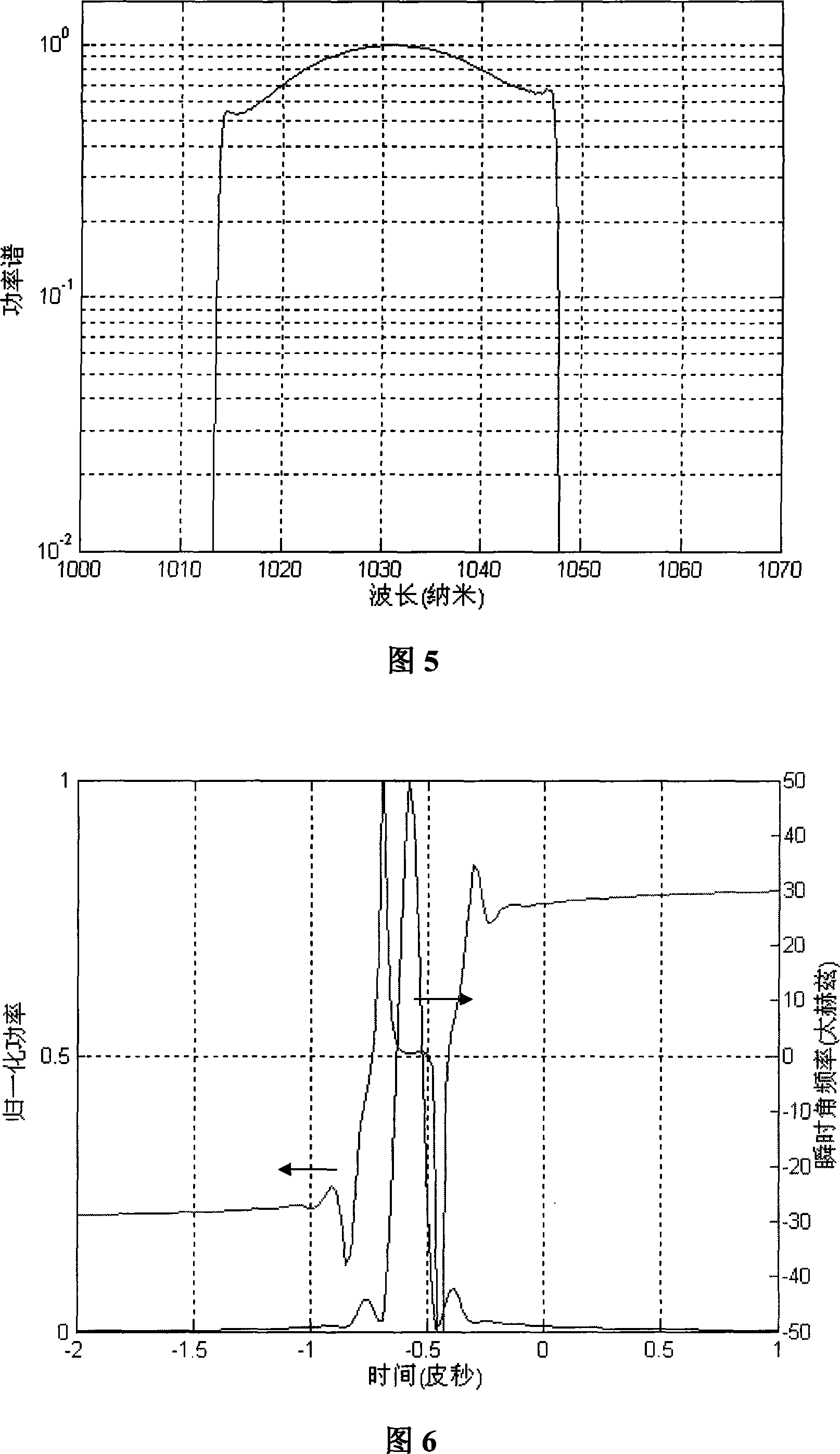

Double cladding large mode field area Yb-doped photon crystal optical fiber femtosecond laser

InactiveCN101101427AGood Polarization Maintaining PropertiesImprove stabilityCladded optical fibreOptical waveguide light guideFrequency spectrumNonlinear optics

The invention discloses a double-coating large-mode-area photon crystal flysecond laser directly obtaining micro joule-level single pulse energy, belonging to the field of laser technique and nonlinear optics, where the laser main body is based on double-coating large-mode-area photon crystal optical fiber of polarization-protection structure and adopts high-power LD laser to directly pump; the laser uses grating pair to compensate dispersion, starts mode locking with the help of semiconductor saturable absorber mirror (SESAM), and controls polarization by wave plate and polarization beam splitter and implements tunable output; laser resonant cavity keeps net positive dispersion inside and runs in self-similar mode locking mode and outside-cavity dispersion compensation is made on the output pulse and the pulse is 100-200fs wide. And the advantages: the laser has good stability, and the output pulse has high energy and high repeating frequency. And the invention can effectively avoid split of pulse running at high energy.

Owner:TIANJIN UNIV

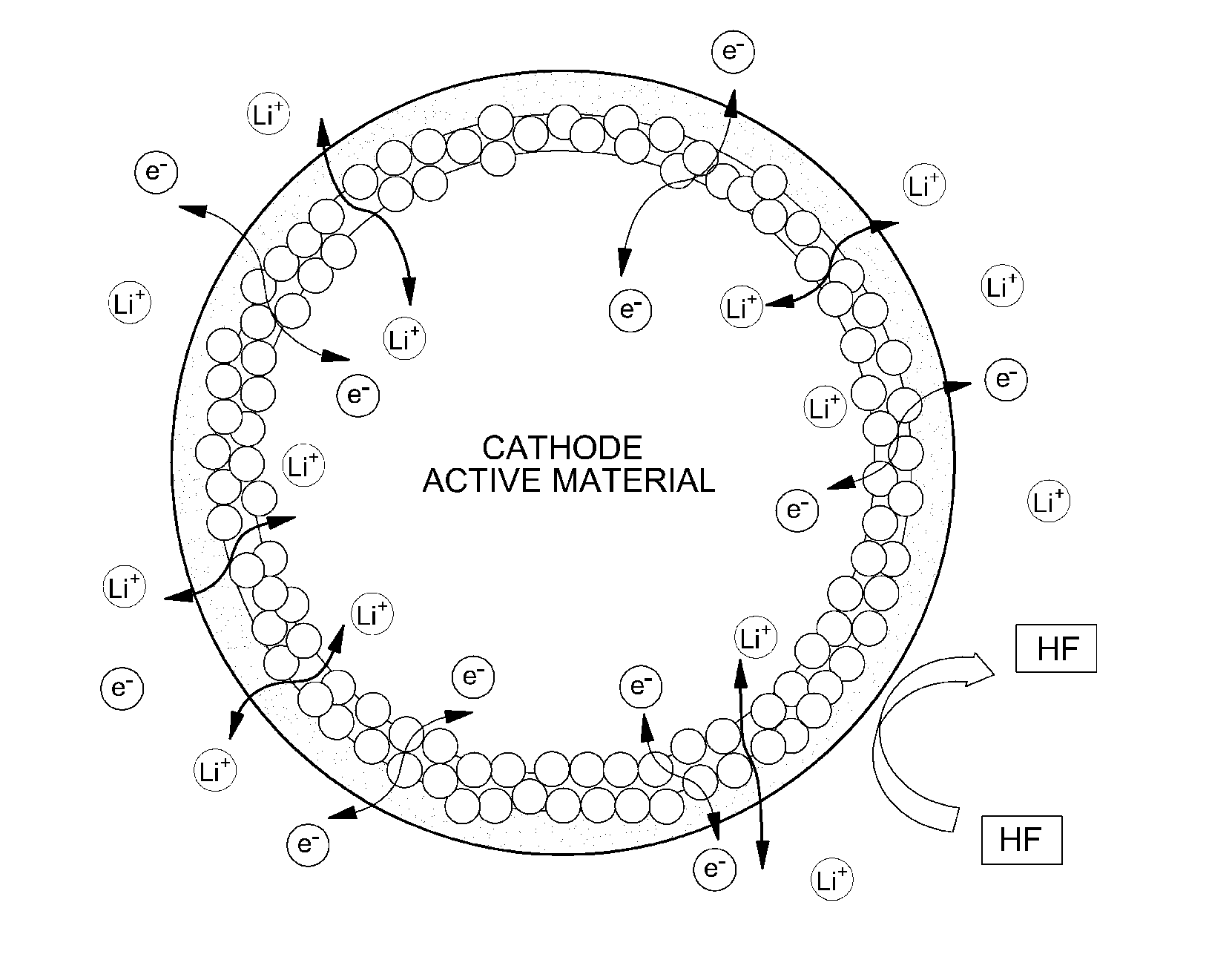

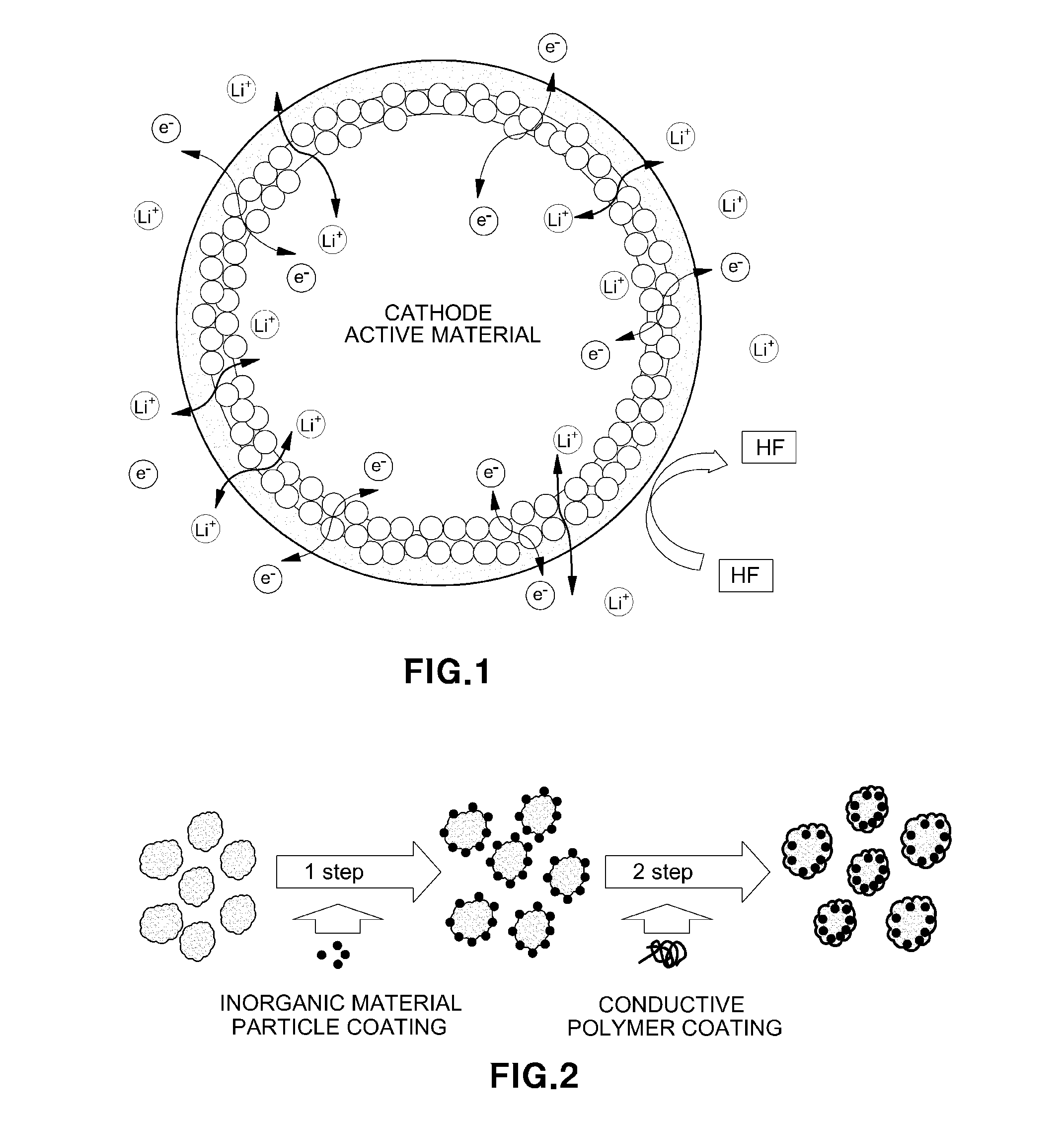

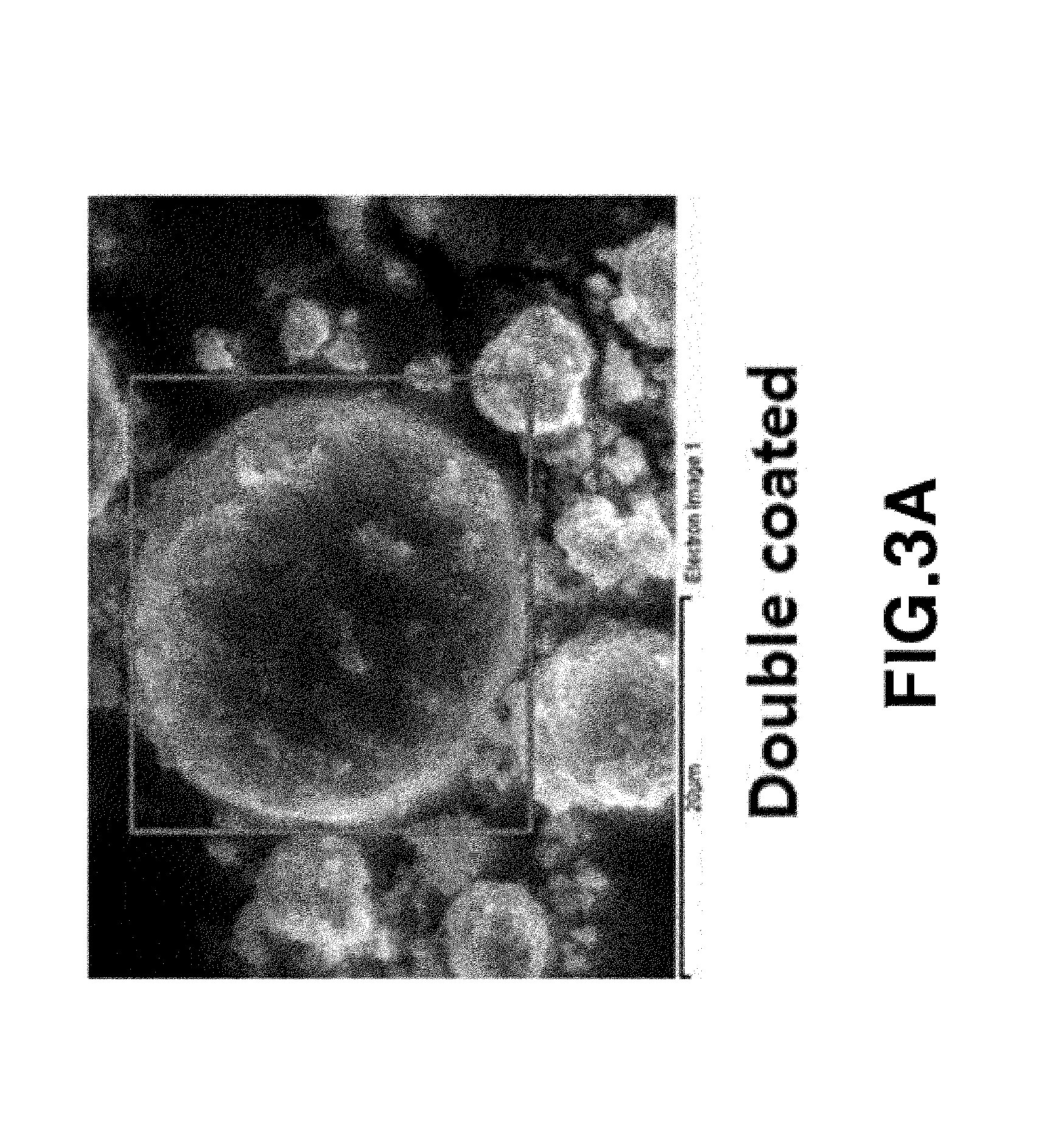

Surface-treated cathode active material and lithium secondary battery using the same

ActiveUS20150188144A1Enhance high voltageEnhance service life characteristicElectrode manufacturing processesPositive electrodesDouble coatingElectrochemistry

A surface-treated cathode active material useful for manufacturing a lithium secondary battery have excellent output characteristics by performing a double coating with metal oxide and an electron and ion conductive polymerized copolymer on a surface of a cathode active material for a lithium secondary battery to enhance electrochemical properties and thermal stability of the cathode active material.

Owner:HYUNDAI MOTOR CO LTD +1

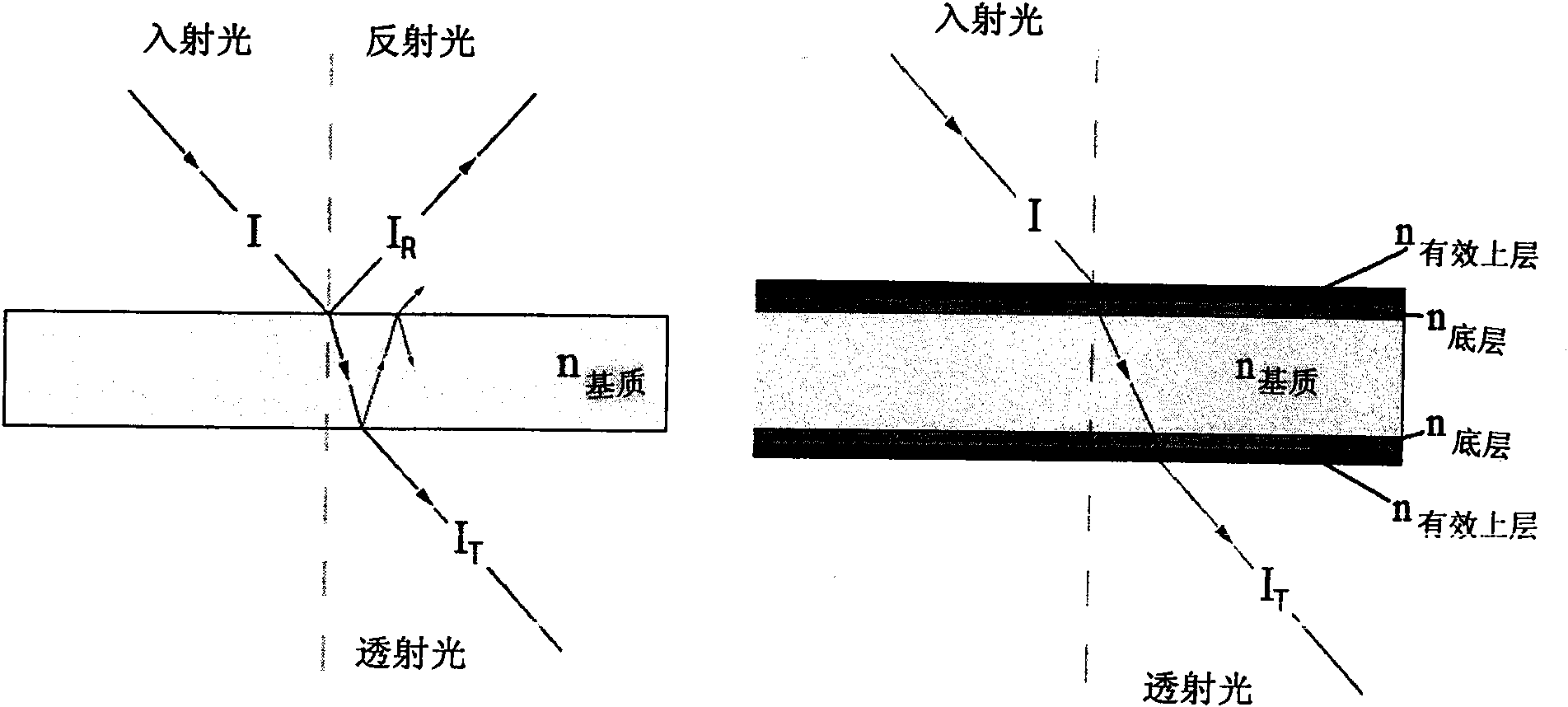

Double layer coating, its preparation and its use for rendering ultra water-repellent and antireflective the surfaces to which it is applied

The present invention relates to a double layer coating formed of a first layer (lower layer) of photo / thermosetting resin and a second later (upper layer) comprising hydrophobic microparticles partially incorporated in a matrix of photo / thermosetting resin. The application of said coating is an effective method for generating ultra water-repellent and antireflective surfaces.

Owner:IGUZZINI ILLUMINAZIONE

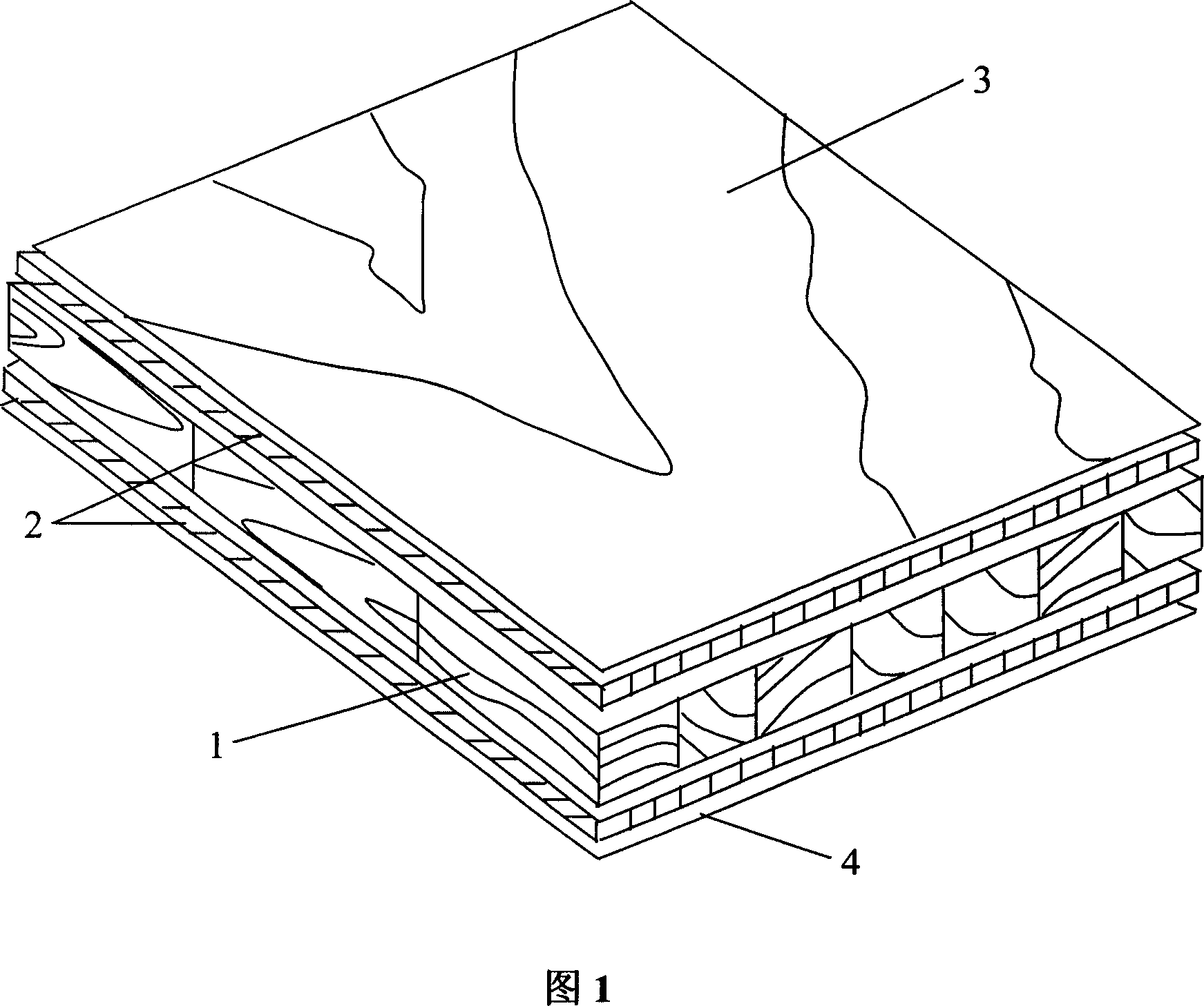

Formaldehydeless fine wooden board and its preparing method

InactiveCN101058197AMoisture-proofWaterproofPlywood pressesVeneer pressesDouble coatingPulp and paper industry

The invention relates to processing technique for ornament material and building laminated fine wood board. It adjusts the glue and applies to the gluing machine, sending the wood chip to double coating machine then to the working platform and cold press on the cold forging machine. Putting the laminated wood board on the hot press, it forms into the blank made of wood chip and wooden jobbing sheet. It cut off its irregular parts, sanding both surface smooth, then coating the plate blank for double faces coating, spreading bottom and surface plates on the working platform, then cold and hot pressing, trimming and sanding to get the laminated wood board. The laminated wood board is moisture proof, water proof, durable and good in stability.

Owner:戴武兵 +1

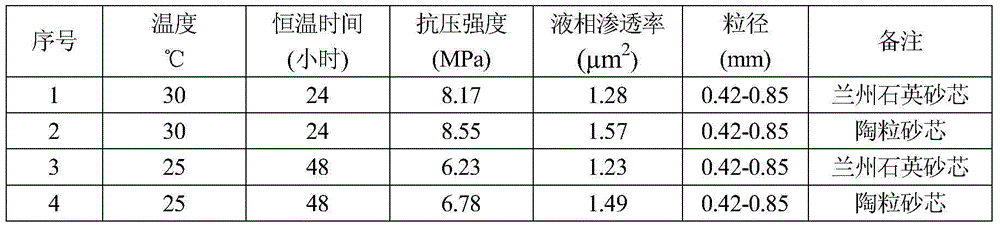

Double-coating gel-coated sand-preventing particle and preparation method thereof

InactiveCN104592965ASolve the problem of low consolidation strengthDoes not affect the consolidation effectDrilling compositionEpoxyExpanded clay aggregate

A double-coating gel-coated sand-preventing particle and a preparation method thereof are disclosed. In order to overcome the disadvantages that sand prevention effect cannot be realized when a conventional resin solution, a sand solidifying agent and other solution type sand-preventing products, and plastic pre-coated sand and other artificial well-wall sand-preventing products are used in an oil well with a relatively low well temperature. The double-coating gel-coated sand-preventing particle comprises an A type particle and a B type particle, and the A type particle and the B type particle are mixed according to the weight ratio of 1:1 for usage in on-site sand-preventing operation. The A type particle is formed by successively coating a quartz sand / ceramsite matrix with a resin coating membrane and an outer isolating agent. The B type particle is formed by successively coating a quartz sand / ceramsite with an epoxy resin curing agent coating membrane and an outer isolating agent. The particle size of quartz sand / ceramsite is 0.4-0.8 mm or 0.6-1.1 mm. The beneficial effects comprise that the double-coating gel-coated sand-preventing particle can be slowly dissolved in a water environment, prevents advanced cementation solidification, and satisfies sand-preventing construction requirements on oil, gas and water injection wells with a low temperature (<=30 DEG C) during oil gas exploitation, and the technology is simple, easy to control, safe and reliable.

Owner:DRILLING TECH DEV CO LTD OF TIANJIN DAGANG OILFIELD PETROLEUM ENG INST +1

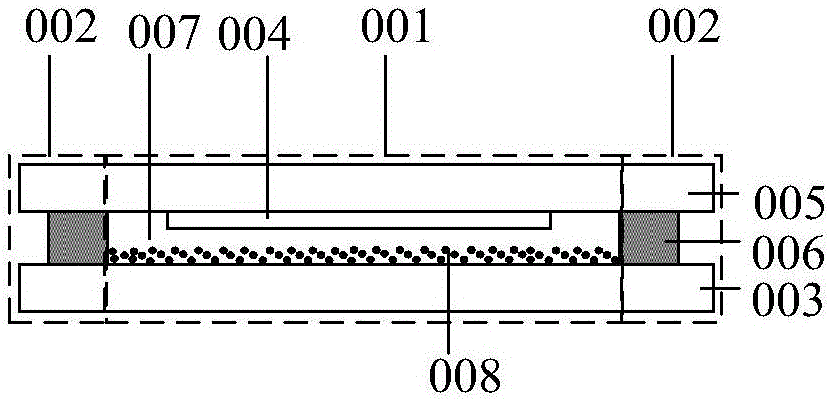

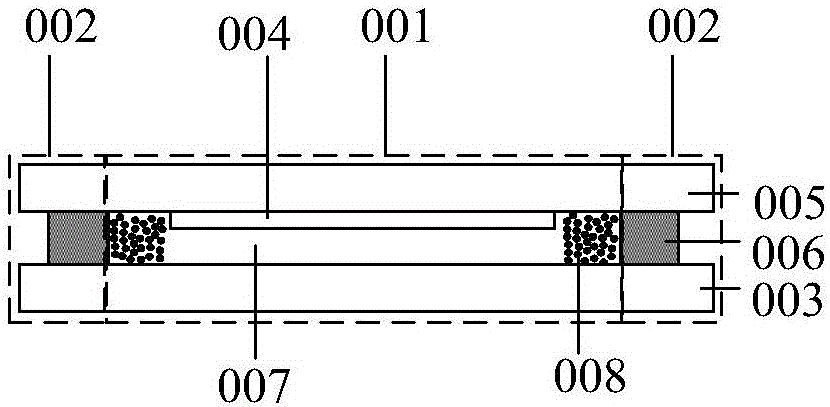

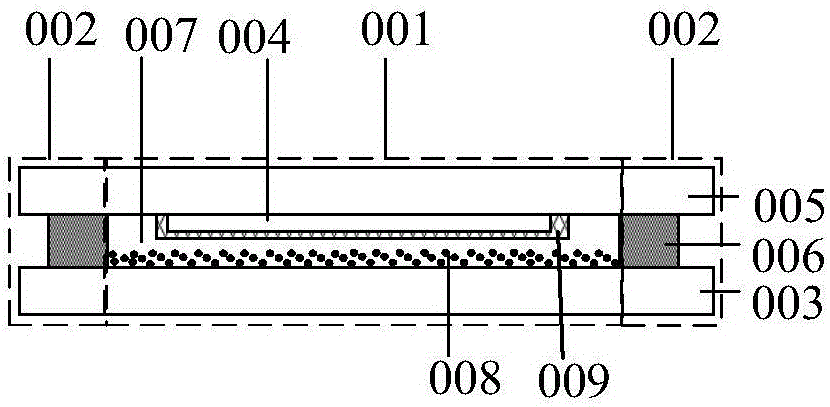

Display panel and manufacturing method thereof

ActiveCN106848105AImplement encapsulationRealize functionSolid-state devicesSemiconductor/solid-state device manufacturingState of artMagnetite Nanoparticles

The embodiment of the invention discloses a display panel and a manufacturing method thereof. According to the scheme, on one hand, magnetic nanoparticles with water absorption are distributed on the side, away from an OLED device, in the perpendicular film direction in a packaging layer or on the periphery of the area where the OLED device is located in the film direction; on the other hand, due to the fact that the magnetic nanoparticles with the water absorption have magnetism, in the packaging waterproofing technology, the magnetic nanoparticles with the water absorption can be doped in packaging materials, the magnetism is applied to induce the magnetic nanoparticles to the side away from an OLED device or the periphery of the area where the OLED device is located, and therefore a person only needs to conduct one-time coating on the packaging materials doped with the magnetic nanoparticles with the water absorption; compared with the double coating mode in the prior art, the technology is simple, and the technology complexity is lowered.

Owner:BOE TECH GRP CO LTD

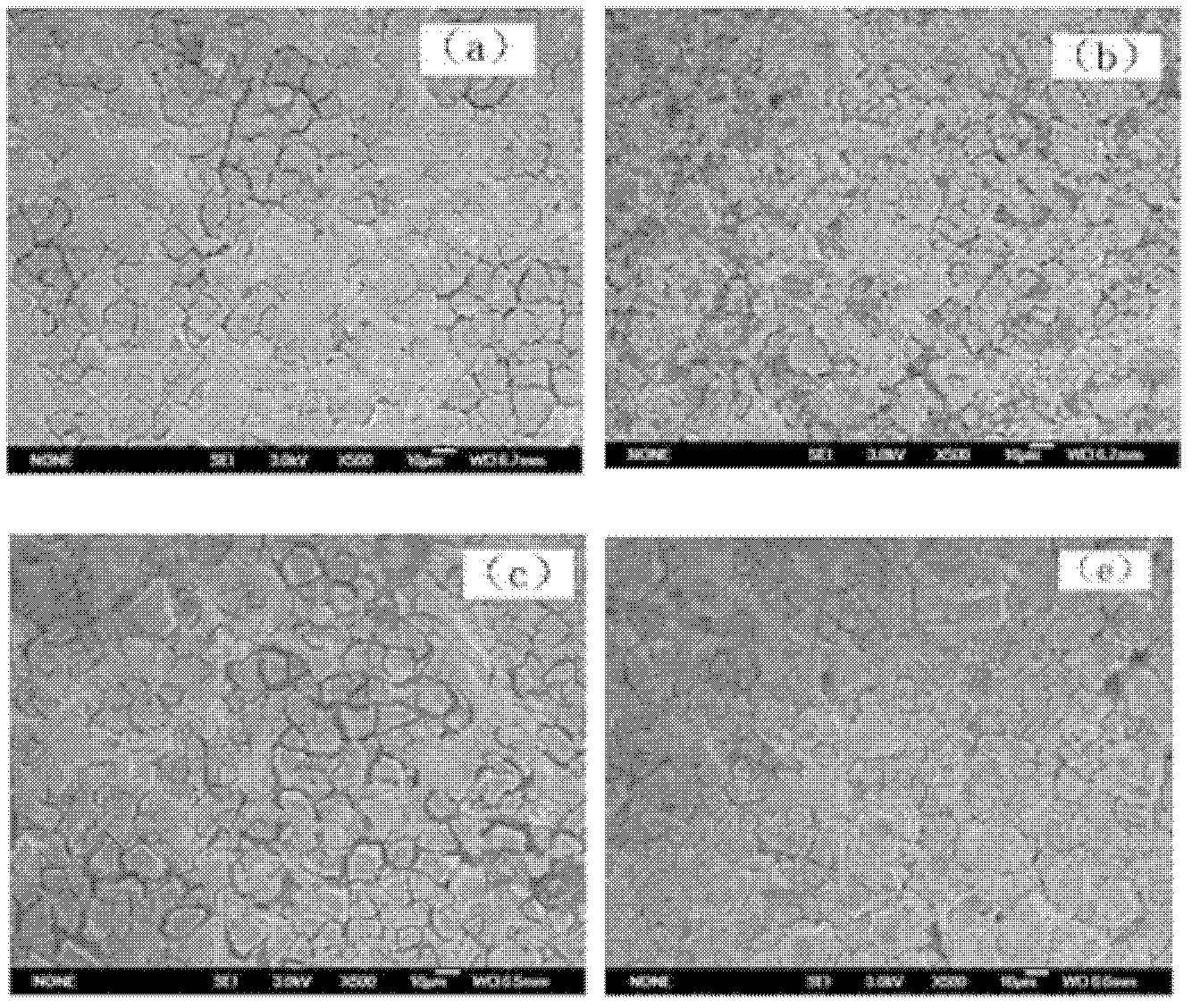

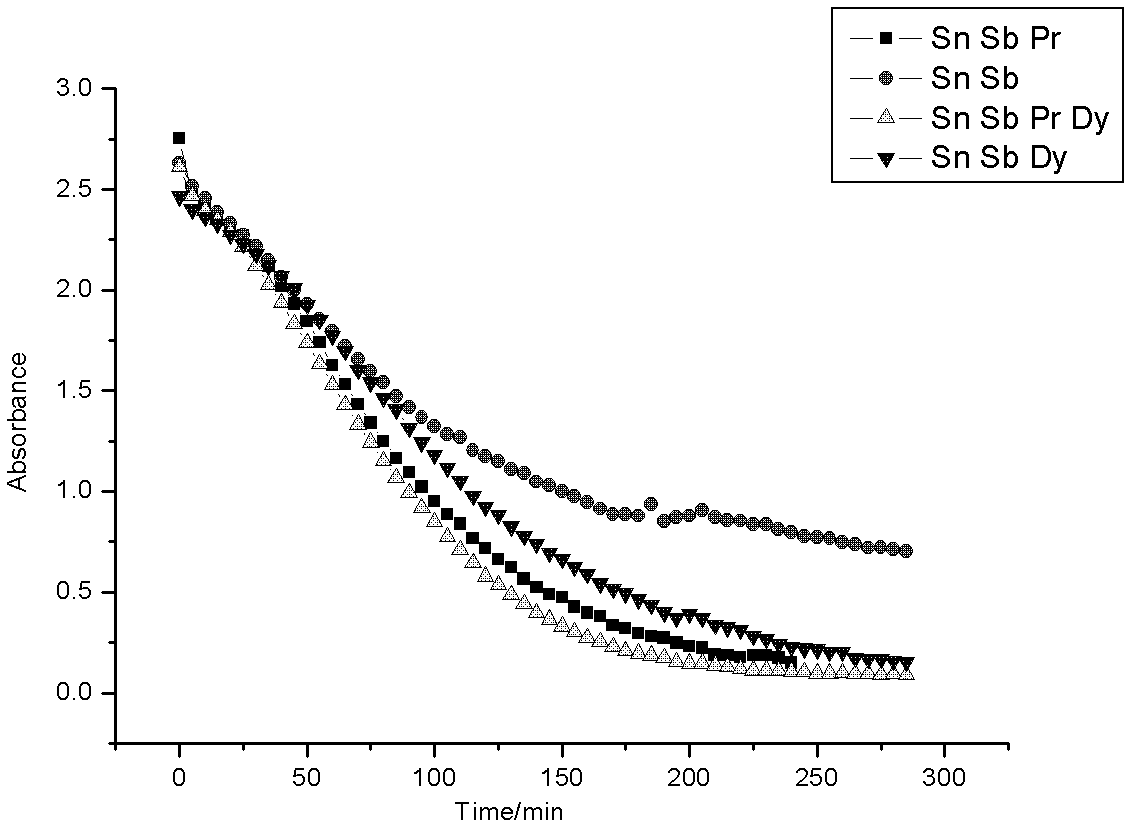

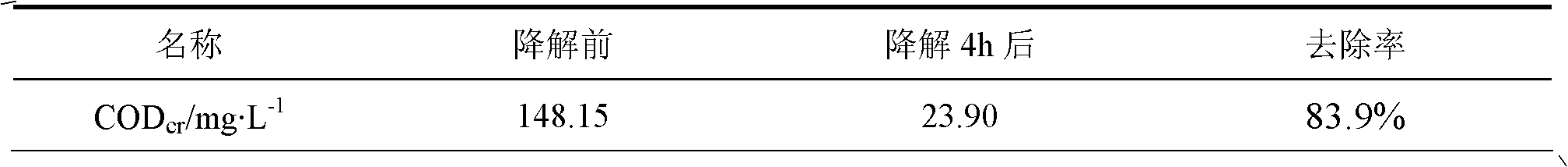

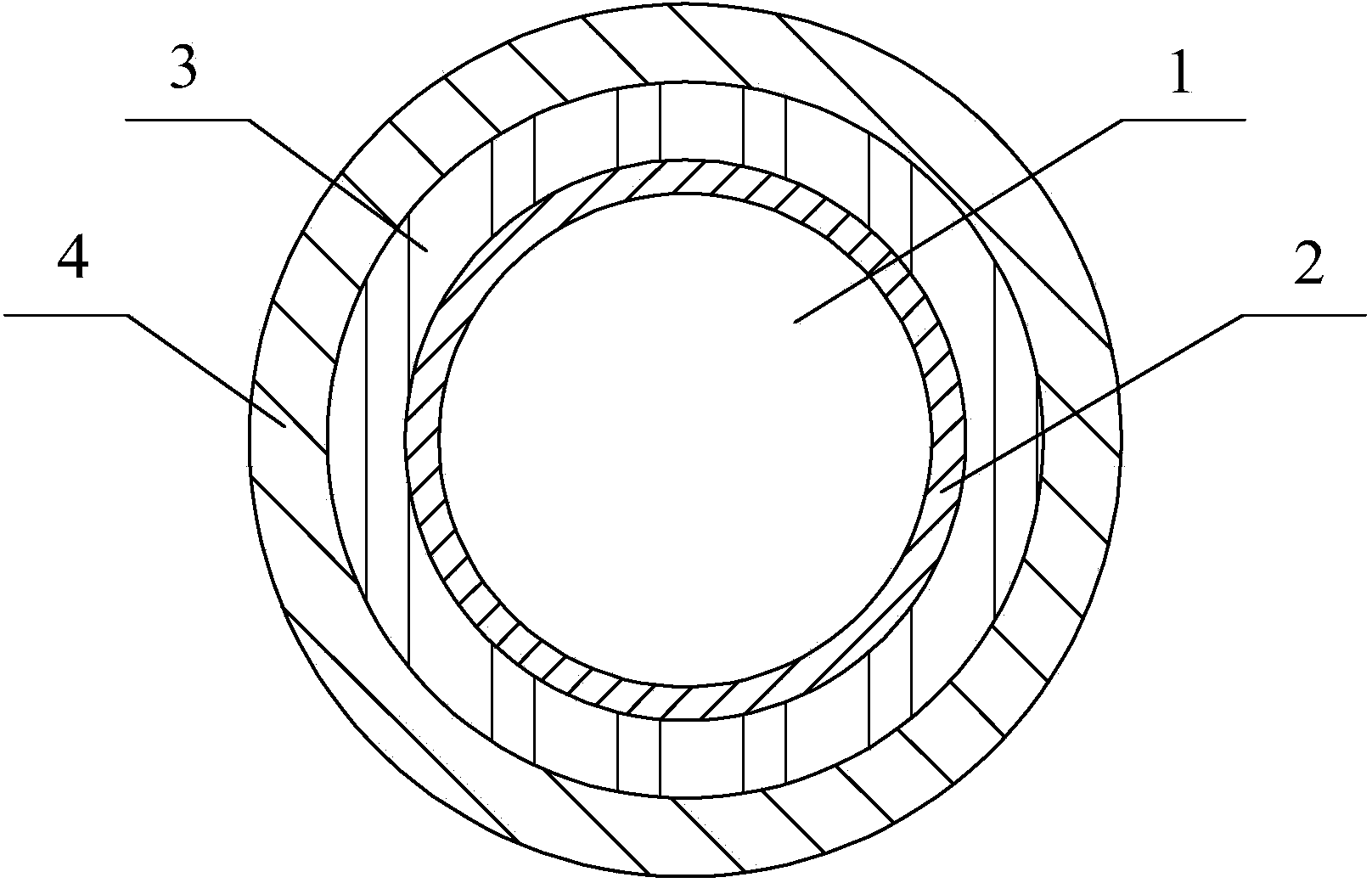

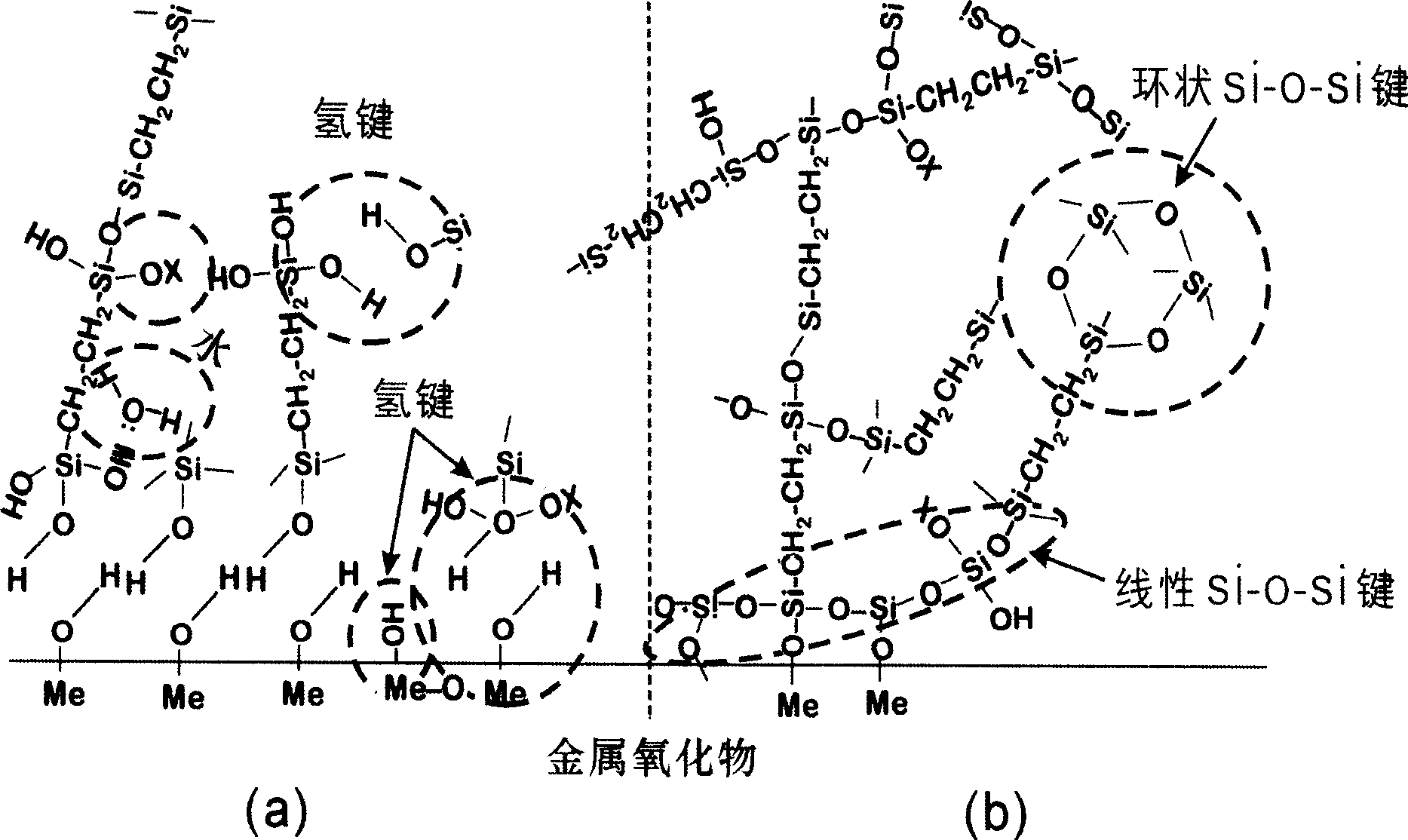

Preparation method of rare earth Pr (praseodymium)-Dy (dysprosium) doped nanometer titanium-based tin dioxide-antimony double coating electrode

InactiveCN102304724AImprove catalytic performanceReduce clumpingWater/sewage treatmentElectrodesTin dioxideDouble coating

The invention relates to a preparation method of a rare earth Pr (praseodymium)-Dy (dysprosium) Pr-Dy doped nanometer titanium-based tin dioxide-antimony (Ti / Sb-SnO2) double coating electrode, belonging to the technical field of electrochemical water treatment. The sol-gel technology is adopted to coat the Pr-Dy doped Sn-Sb sol on the surface of a pretreated electrode substrate; and the heat treatment technology combining soaking-bottom low temperature sintering and temperature programming is adopted to prepare the nanometer Ti / Sb-SnO2 double coating electrode with a Pr doped Sn-Sb intermediate layer and a Dy doped Sn-Sb catalyst layer. The electrode is characterized by high oxygen evolution potential, high catalytic performance, high conductivity, durability and the like.

Owner:SHANDONG UNIV

High-temperature-resistance optical fiber

ActiveCN103777269AIncrease temperatureImprove the attenuation effectCladded optical fibreOptical waveguide light guideUltrasound attenuationDouble coating

Disclosed is a high-temperature-resistance optical fiber which relates to the field of optical-fiber manufacturing. The optical fiber includes an optical-fiber body and coatings which cover the optical-fiber body. The optical-fiber body is covered with three coatings from inside to outside. A third coating at the outermost layer is a polyimide with a Young modulus higher than 3GPa. When a first coating is carbon, a second coating is a polyimide with a Young modulus lower than 1GPa. When the first coating is a polyacrylic resin with a Young modulus lower than 1.5MPa, the second coating is a high-temperature-resistance polyacrylic resin with a Young modulus higher than 1GPa. Compared with conventional double-coating optical fibers, the high-temperature-resistance optical fiber has transmission characteristics of better temperature performance and better attenuation and the like under a high-temperature environment so that global properties of the optical fiber meet demands of a high-temperature environment and the optical fiber is capable of standing a temperature up to 350 DEG C.

Owner:FENGHUO COMM SCI & TECH CO LTD

Silicone hydride and polyaniline hybridized polymer watersoluble metal heavy anticorrosion paint

The invention relates to an industrial paint which is used for manufacturing metal water-borne heavy-duty anticorrosion base coating and top coating capable of being matched to form systems after hybrid and polymerization of silane, doping-polyaniline and conductive polyaniline. As no organic solvent is used, the manufactured metal water-borne anticorrosion base coating and the manufactured metal water-borne anticorrosion top coating are non-solvent metal anticorrosion heavy-duty industrial paints which are used on the surfaces of metal bases, contain very little VOC (organic volatile) and are friendly to the environment. The theories that common sacrificial anticorrosion paint protects cathodes of metal surfaces and polyaniline protects the anodes of metal surfaces are comprehensively used, so that the metal water-borne heavy-duty anticorrosion coating made by the hybrid and polymerization of silane and polyaniline has very excellent double-coating anticorrosion property on metal surfaces. By adopting the industrial paint, application of double-coating systems having excellent anticorrosion and substitution for metal anticorrosion three-coating systems which are traditional and used at present become feasible.

Owner:傅晓平 +1

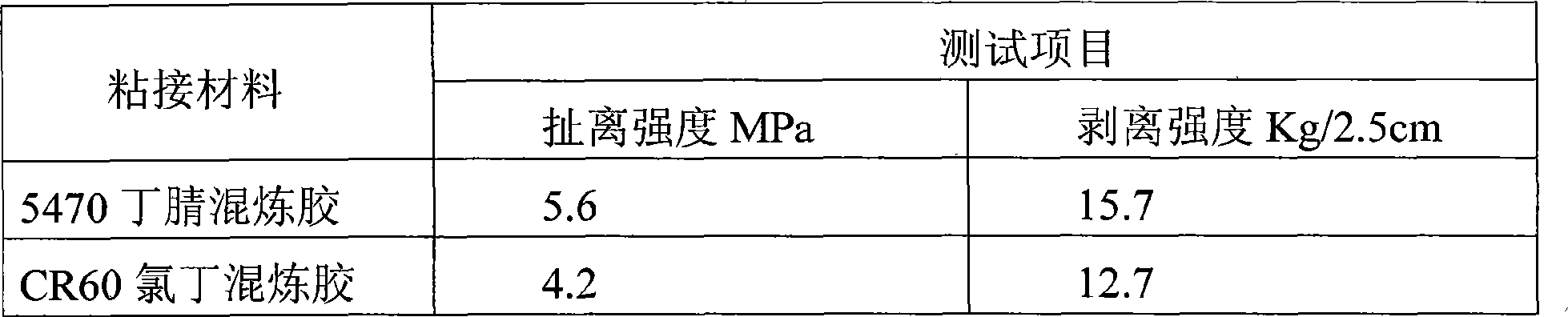

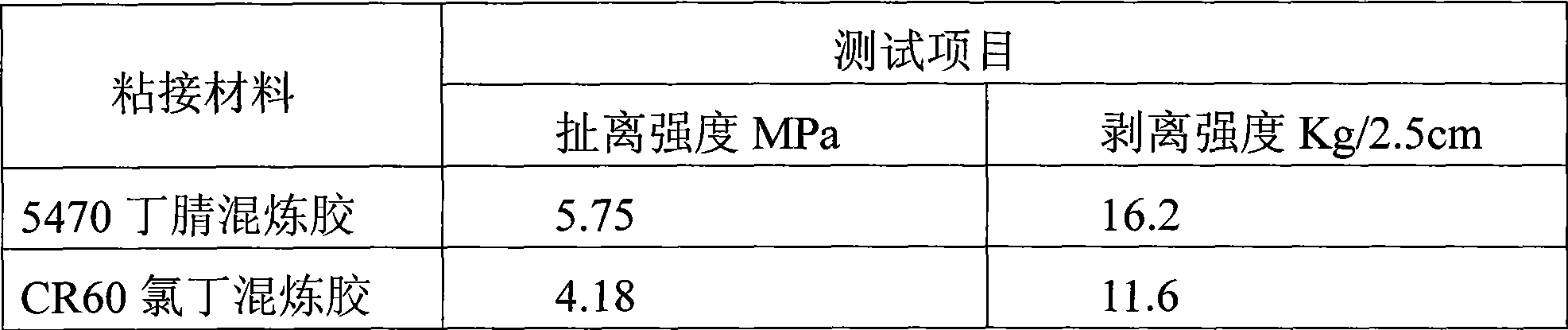

Undercoat adhesive for bonding hot vulcanization and preparation thereof

InactiveCN101497773AImprove heat resistanceGood heat resistance and ablation resistanceAldehyde/ketone condensation polymer adhesivesPolymer scienceVulcanization

The invention relates to pre-coating adhesive used for heat cure bonding and a preparation method thereof, belonging to adhesive and a preparation method thereof and solving the problems of poor heat resisting property and poor ablation resistance of the prior adhesive and the problems of poor bonding stability and low reliability of the prior adhesive. The pre-coating adhesive is made from matrix resin, filmerformer, coupling agent, filling agent and solvent. The preparation method comprises the following steps: firstly, weighting raw materials; secondly, respectively stirring and dissolving the raw materials in a dissolution reactor; thirdly, putting the raw materials in a mixing reactor for mixing uniformly; fourthly, dispersing the mixed raw materials by a high-speed shear dispersion machine and grinding the mixed raw materials by a colloid. The pre-coating adhesive has better heat resisting property and excellent ablation resistance, not only can be used as single-coating adhesive adhering with metal or composite material and rubber in a hot cure way, but also can be used as double-coating adhesive adhering with the metal or composite material and rubber in a hot cure way, has high adhering strength and stable and reliable adhering property, and can be applied to munitions industry, constructional engineering, and the like.

Owner:INST OF PETROCHEM HEILONGJIANG ACADEMY OF SCI

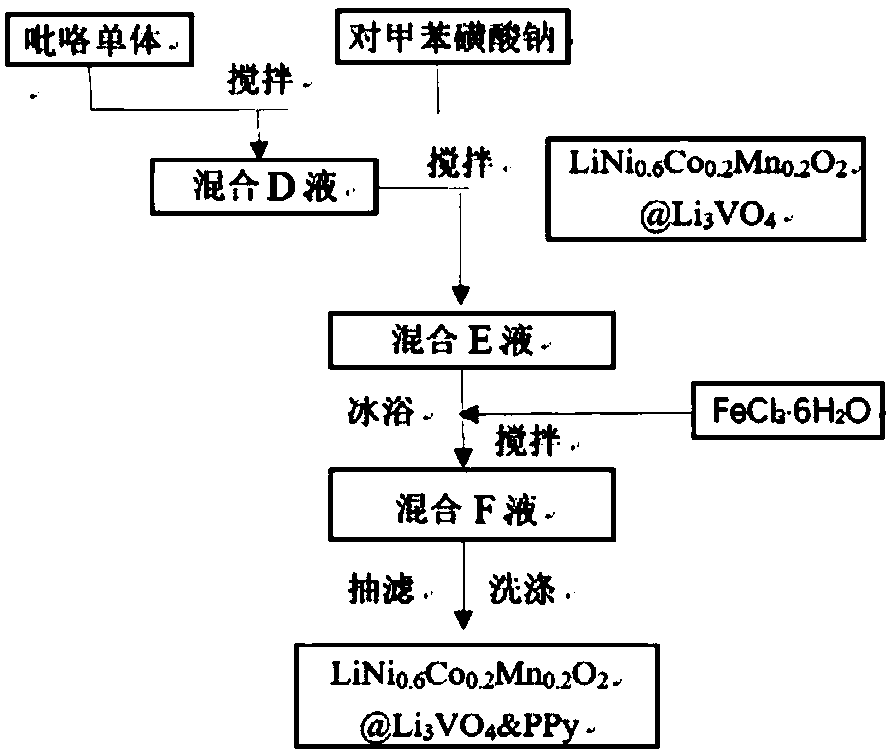

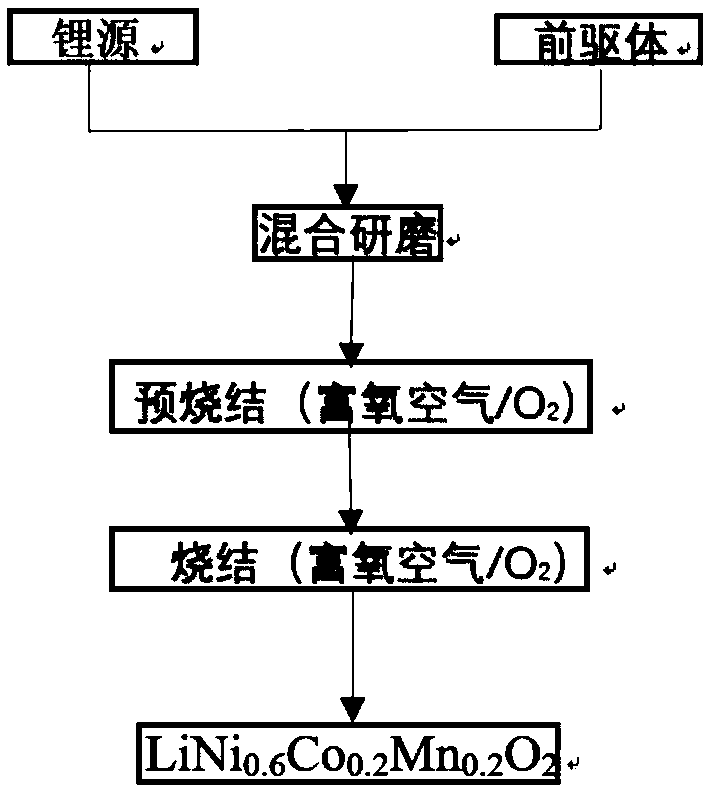

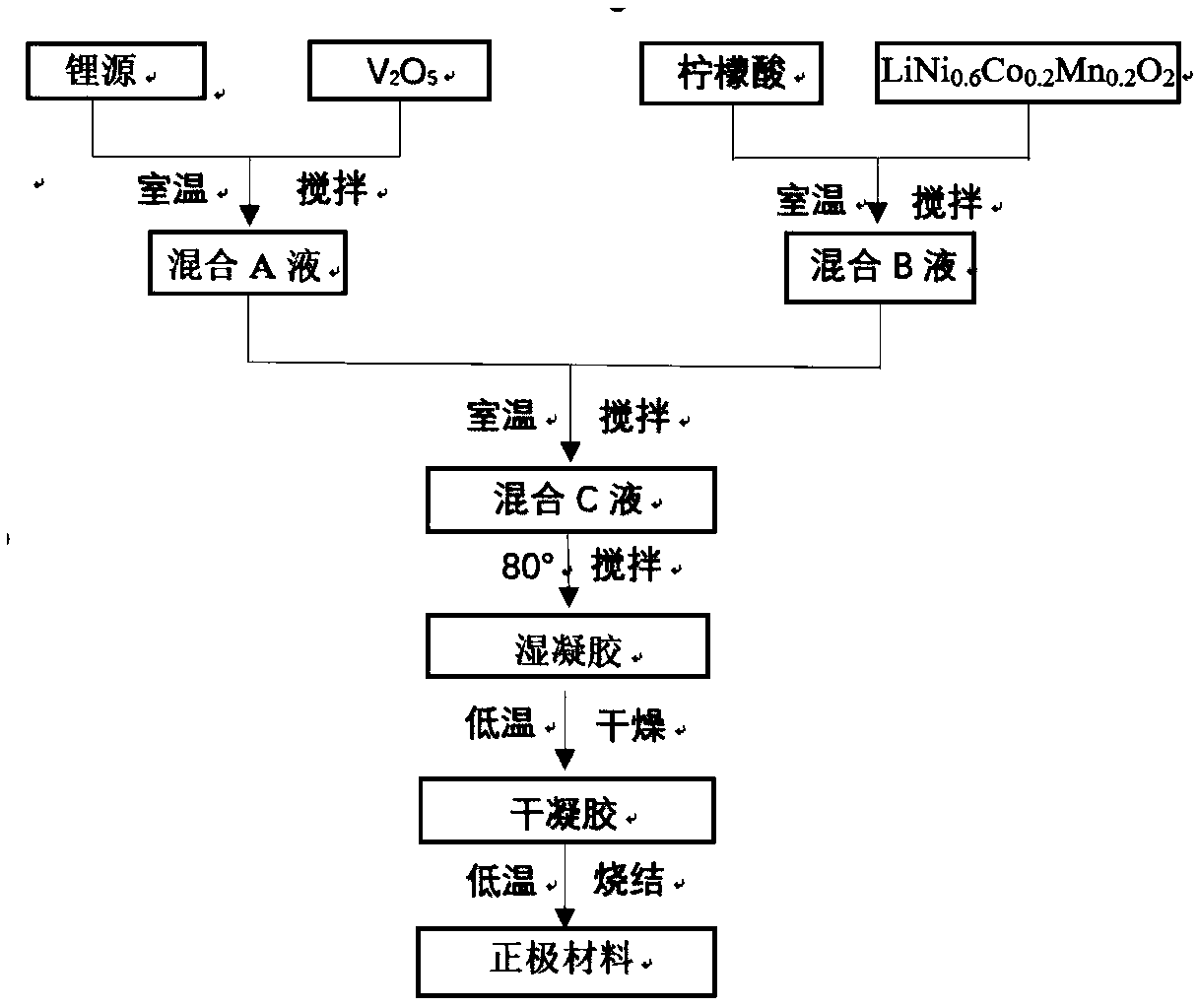

Double-layer coated cathode material LiNi0.6Co0.2Mn0.2O2 for lithium-ion battery and preparation method of double-layer coated cathode material

InactiveCN108807886AImprove ionic conductivityInhibition of erosionCell electrodesSecondary cellsDouble coatingConductive materials

The invention belongs to the technical field of preparation of cathode materials for lithium-ion batteries and specifically provides a double-layer coated cathode material LiNi0.6Co0.2Mn0.2O2 for a lithium-ion battery, wherein the coating amounts of Li3VO4 and PPy are 1 to 5 weight percent; Li3VO4 is a lithium fast ion conductor; by coating Li3VO 4, a protective layer can be provided and the lithium fast ion conductor also can be provided, so that ionic conductivity of the material is enhanced; in addition, lithium ions consumed during the formation of SEI and CEI films are made up and the cycle performance of the material is improved. The PPy is a fast electronic conductive material; by coating PPy, a second protective layer can be provided and the electronic conductivity of the materialcan be improved. Through double-layer coating of Li3VO4 and the PPy, the ionic conductivity is improved and the electrical conductivity is also improved; the cathode material is enabled to have super-high magnification discharge performance and higher discharge specific capacity; besides, double coating layers can more effectively inhibit the erosion effect of HF on the cathode material and enablethe cathode material to have excellent high voltage cycle stability.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

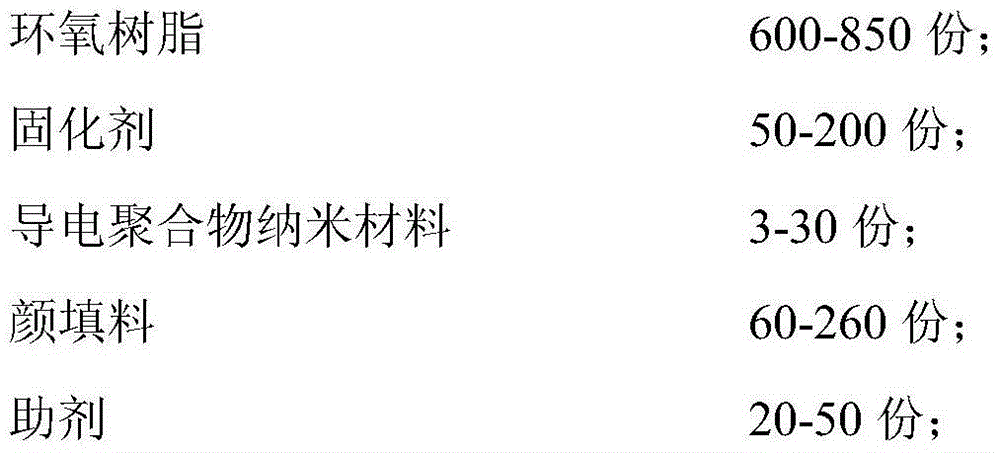

Powder coating used for heavy-duty corrosion-resistant high-bounding stress double-coating thin layer steel bar, heavy-duty corrosion-resistant high-bounding stress double-coating thin layer steel bar, and manufacturing method and applications of heavy-duty corrosion-resistant high-bounding stress double-coating thin layer steel bar

InactiveCN104893494AReduce corrosionWith self-healing functionPretreated surfacesAnti-corrosive paintsEpoxyCrack resistance

The invention relates to a powder coating used for heavy-duty corrosion-resistant high-bounding stress double-coating thin layer steel bar. The powder coating comprises a heavy-duty anticorrosive undercoat and a super-toughness epoxy finishing coat; the heavy-duty anticorrosive undercoat is composed of, by weight, 650 to 850 parts of epoxy resin, 50 to 200 parts of a curing agent, 3 to 30 parts of a conducting polymer nano material, 60 to 260 parts of a pigment and filler, and 20 to 50 parts of an auxiliary agent; the super-toughness epoxy finishing coat is composed of, by weight, 650 to 850 parts of a special toughness epoxy resin, 50 to 200 parts of a curing agent, 60 to 300 parts of a pigment and filler, and 20 to 50 parts of an auxiliary agent. The powder coating is capable of delaying metal corrosion, inducing gradual repairing of oxide films, providing heavy-duty anticorrosive undercoat coating with self repair functions, providing steel bar with super corrosion resistance, increasing adhesion of steel bar finishing coat coating, providing steel bar finishing coat coating with stretch resistance, cracking resistance, and peeling resistance, and prolonging service life of steel bar.

Owner:天津翔盛伟业粉末涂料有限公司

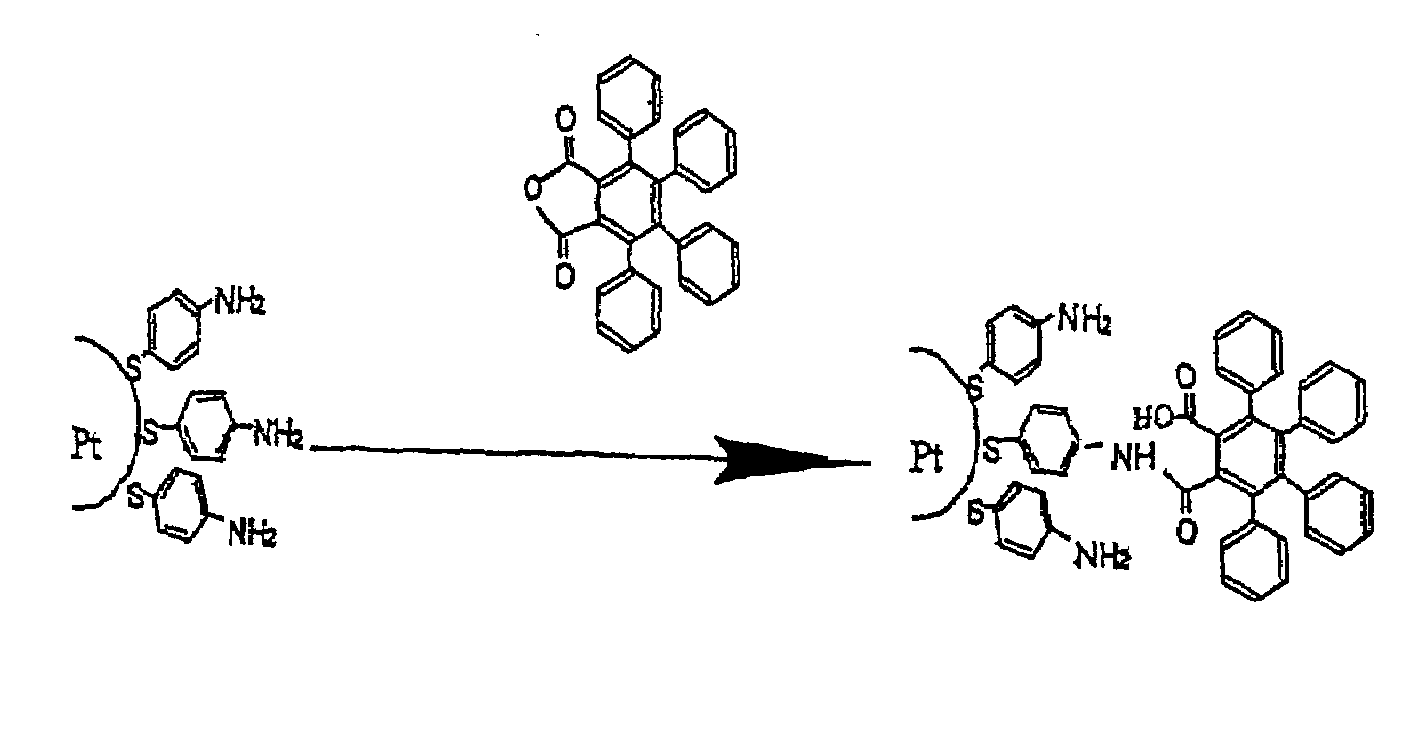

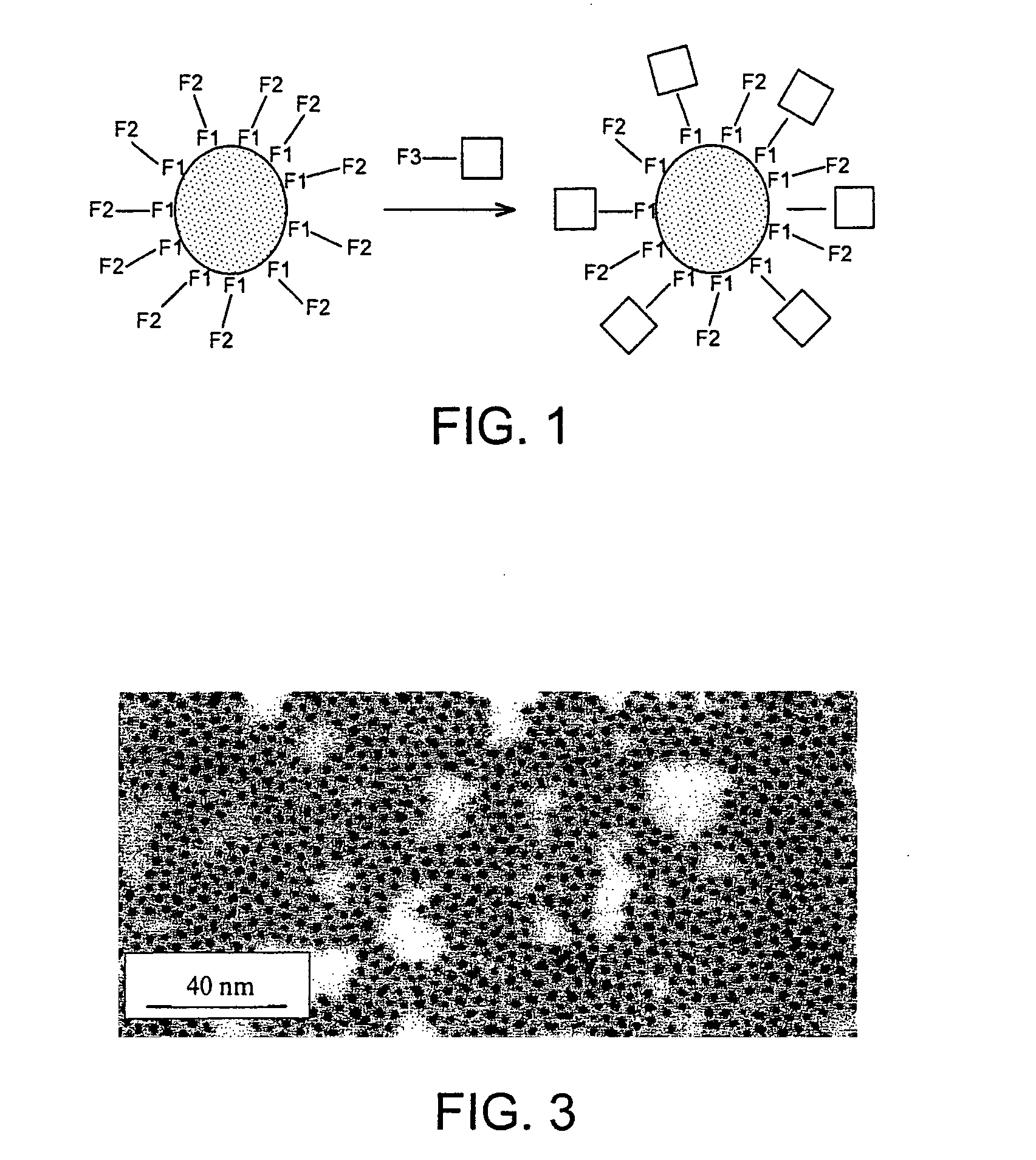

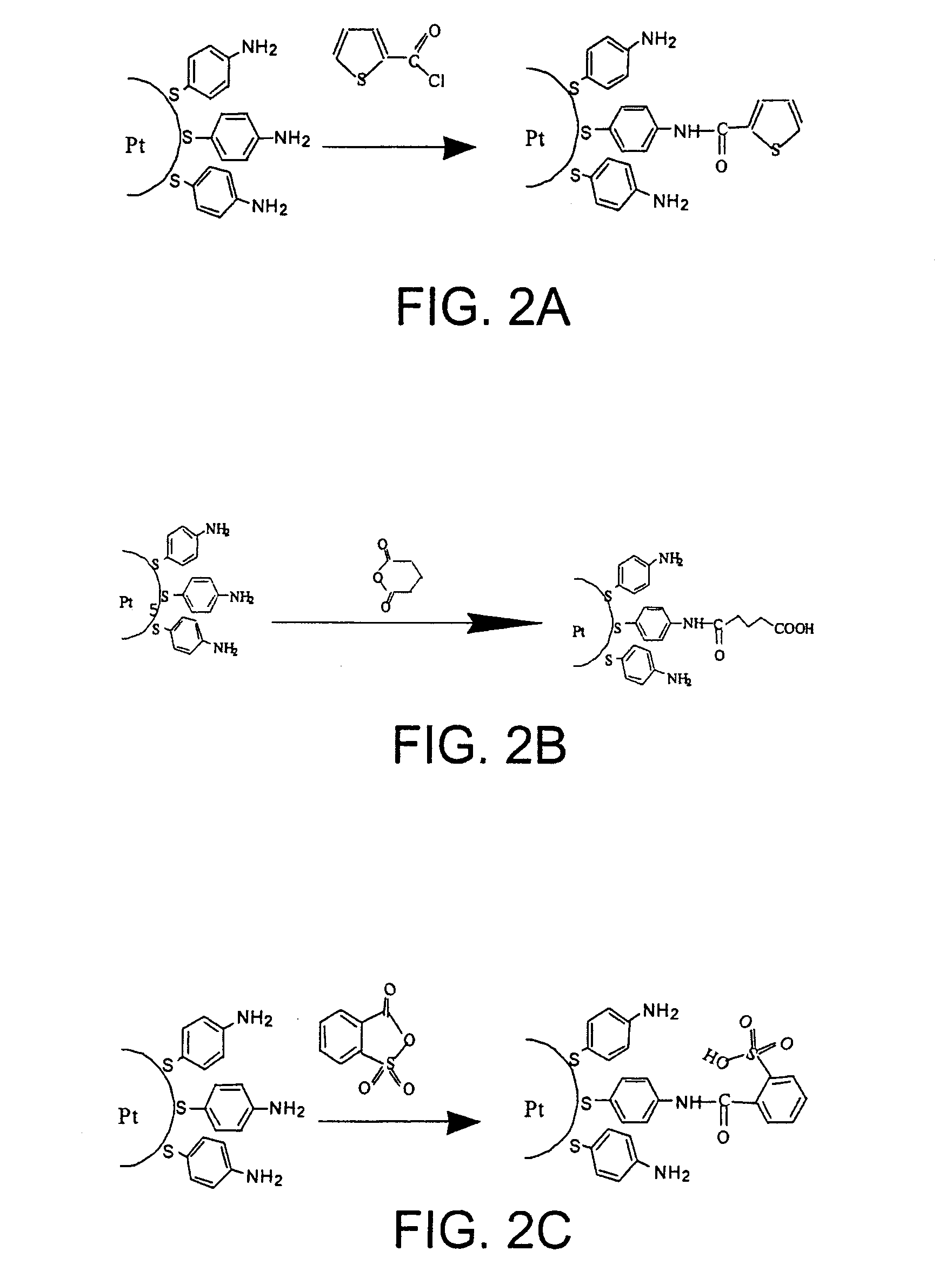

Nanoparticles comprising a metal core and an organic double coating useful as catalysts and device containing the nanoparticles

InactiveUS7595108B2Improve stabilitySimple toMaterial nanotechnologyOrganic-compounds/hydrides/coordination-complexes catalystsPlatinumFuel cells

The invention relates to novel nanoparticles comprising a metal core containing at least one platinoid or an alloy of a platinoid, a first organic coating formed from molecules attached to the surface of the metal core, and a second organic coating formed from molecules different from the molecules forming the first organic coating, and which are grafted onto molecules of the first organic coating. The invention also relates to the use of the nanoparticles as catalysts. The fields of application include devices for producing electrical energy, in particular in fuel cells, devices for detecting or assaying one or more chemical or biological species, in particular in sensors or multisensors, etc.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

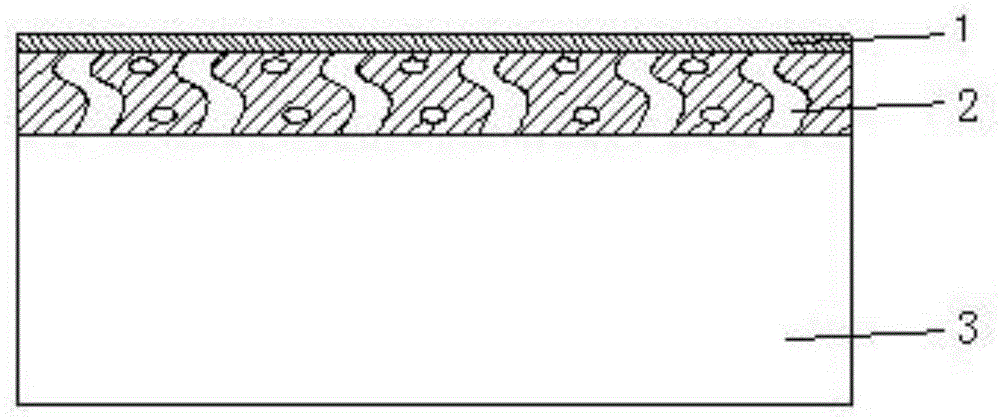

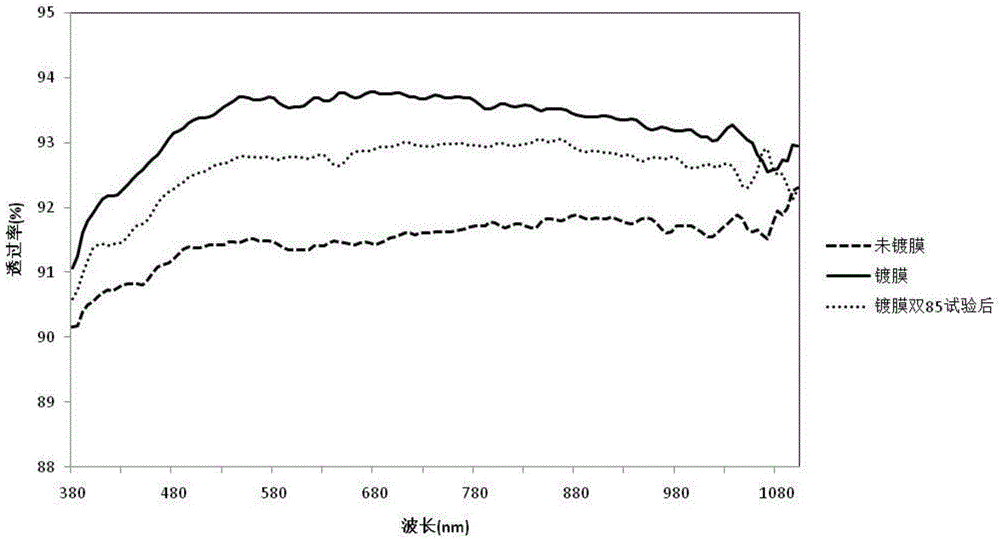

Glass substrate containing silica anti-reflection film and manufacturing method of glass substrate

ActiveCN106277825AHigh light transmittanceImprove adhesionSilicon compoundsWater vaporDouble coating

The invention relates to the technical field of an anti-reflection film, particularly to a glass substrate containing a silica anti-reflection film and a manufacturing method of the glass substrate. The glass substrate comprises glass and a silica anti-reflection film, wherein the silica anti-reflection film has a composite structure and includes a mesoporous silica film arranged on the glass and a compact silica film arranged on the mesoporous silica film. The method comprises steps of preparation of prepolymer sol and coating sol, double coating and high-temperature calcination. The transmissivity of the glass substrate is ensured, the phenomenon that the transmissivity is reduced due to water vapor in the air adsorbed by the mesoporous silica film is prevented, and the environmental stability is improved. The manufacturing method is simple to operate, equipment is easy to achieve, and the prepared film is good in adhesive force and high in hardness.

Owner:HENAN ANCAI HI-TECH +1

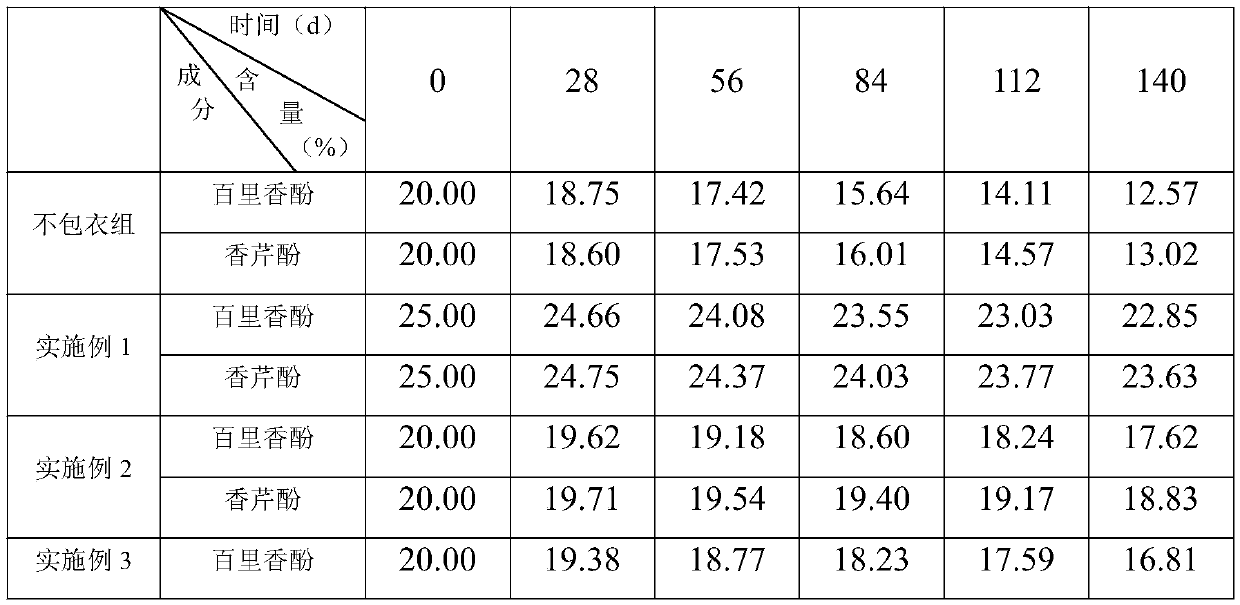

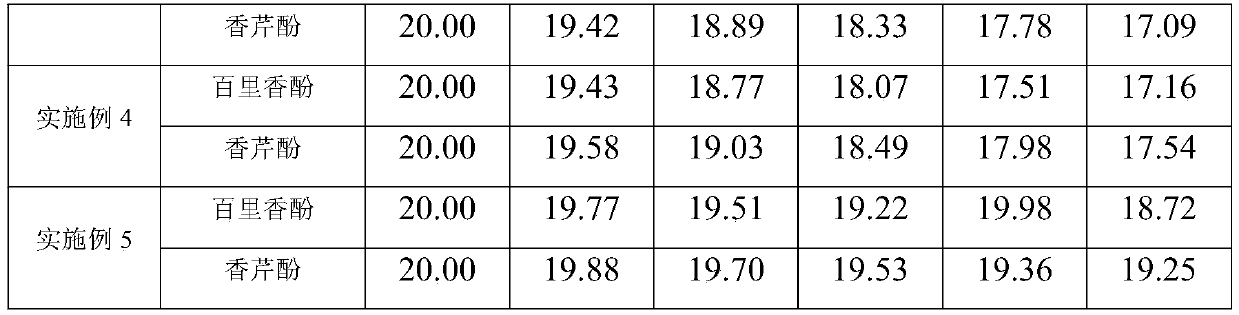

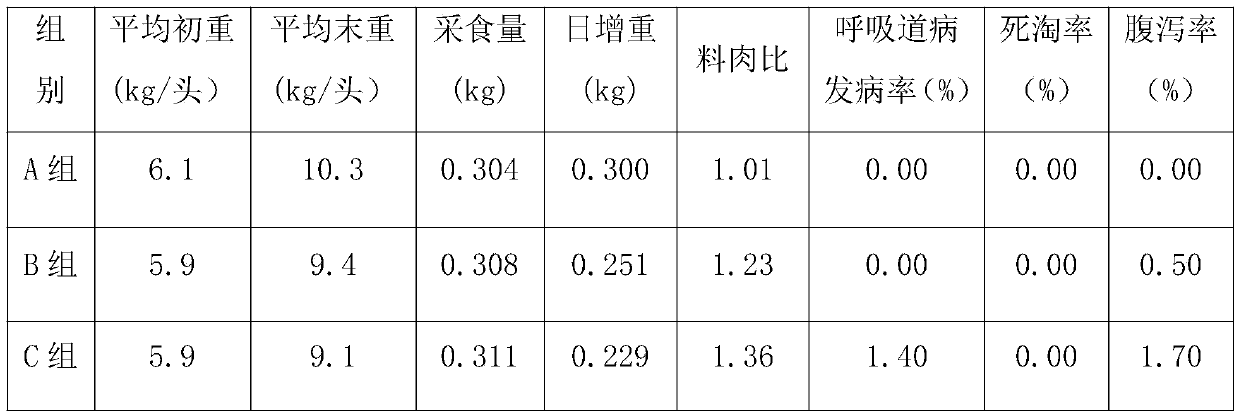

Plant essential oil feed additive and preparation method and application thereof

InactiveCN109645241AImprove function and effectReduce volatile lossAccessory food factorsWorking-up animal fodderMethacrylic acid-ethyl acrylate copolymerDouble coating

The invention provides a plant essential oil feed additive. The additive comprises a core material and a wrapping material wrapping the core material; the core material is prepared from thymol, carvacrol, microcrystalline cellulose and silicon dioxide; the wrapping material is a single coating layer formed by any kind of coating of methacrylic acid-ethyl acrylate copolymer aqueous dispersion, ethyecellulose or hydroxypropyl methyl cellulose, or a double coating layer formed by coating ethyl cellulose and hydroxypropyl methyl cellulose respectively. Accordingly, microcrystalline cellulose serves as an insoluble framework material, different materials of the methacrylic acid-ethyl acrylate copolymer aqueous dispersion, ethyecellulose and hydroxypropyl methyl cellulose serve as the wrapping material, and a fluidized bed is adopted for coating thymol and carvacrol, volatilization loss of thymol and carvacrol is reduced, the effectiveness of the effective ingredients in the additive to foodanimals is guaranteed, and the effect of improving the action of the additive is improved.

Owner:WUHAN HUAYANG ANIMAL PHARMA

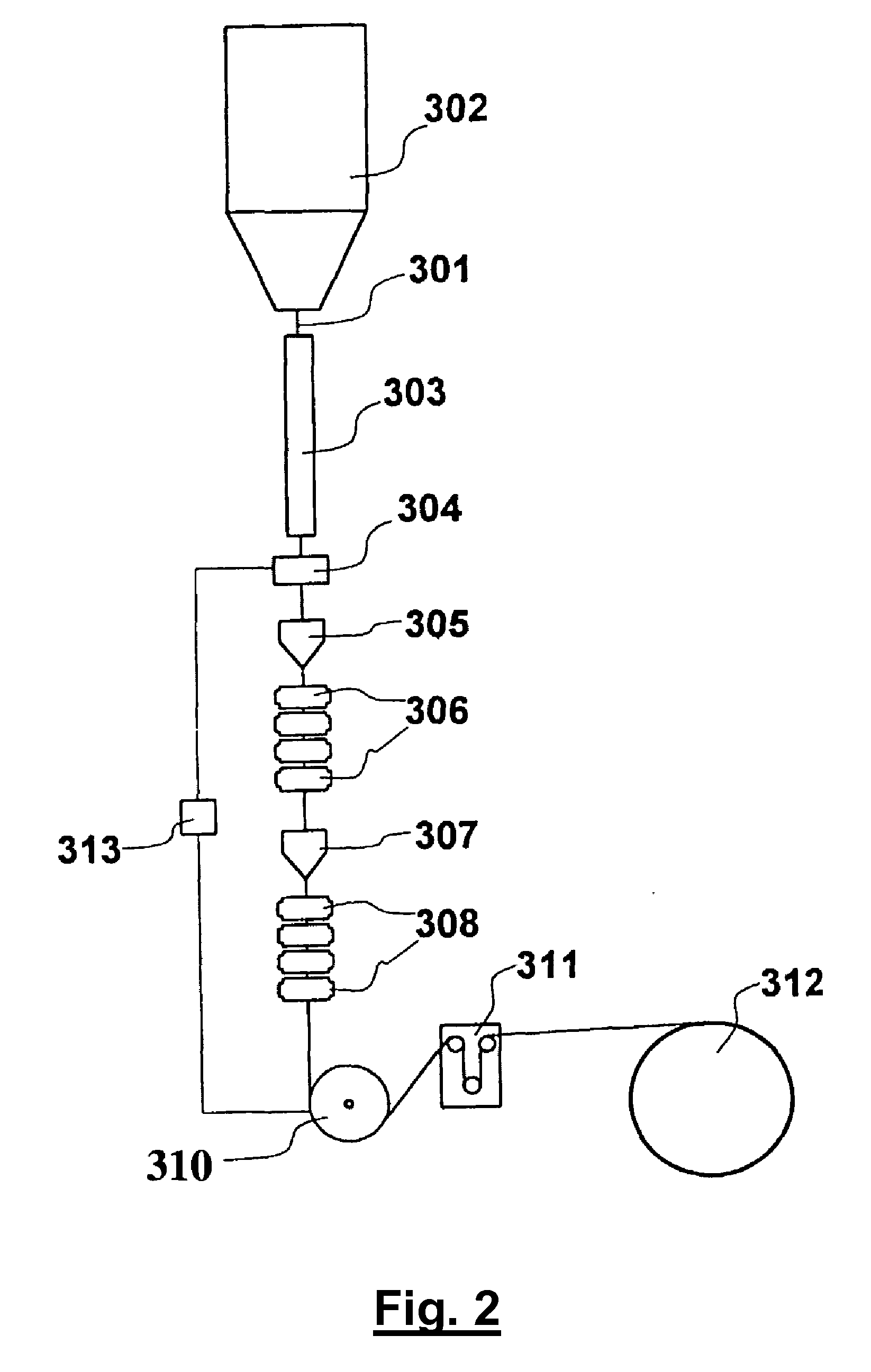

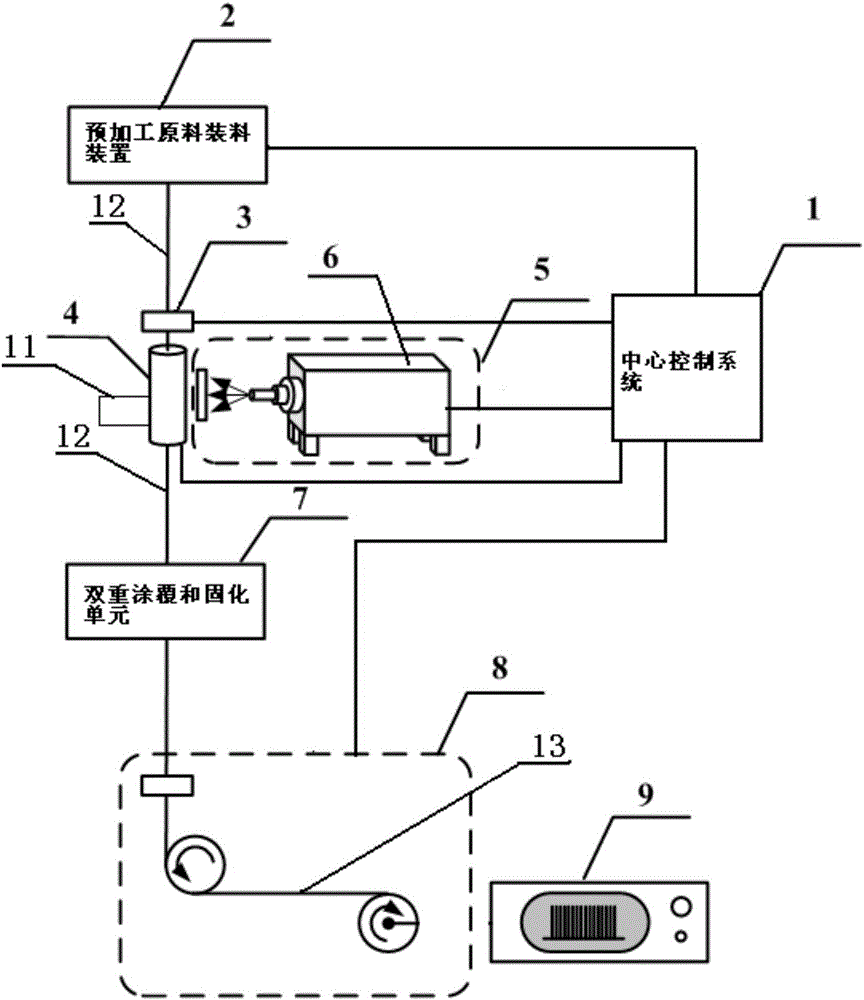

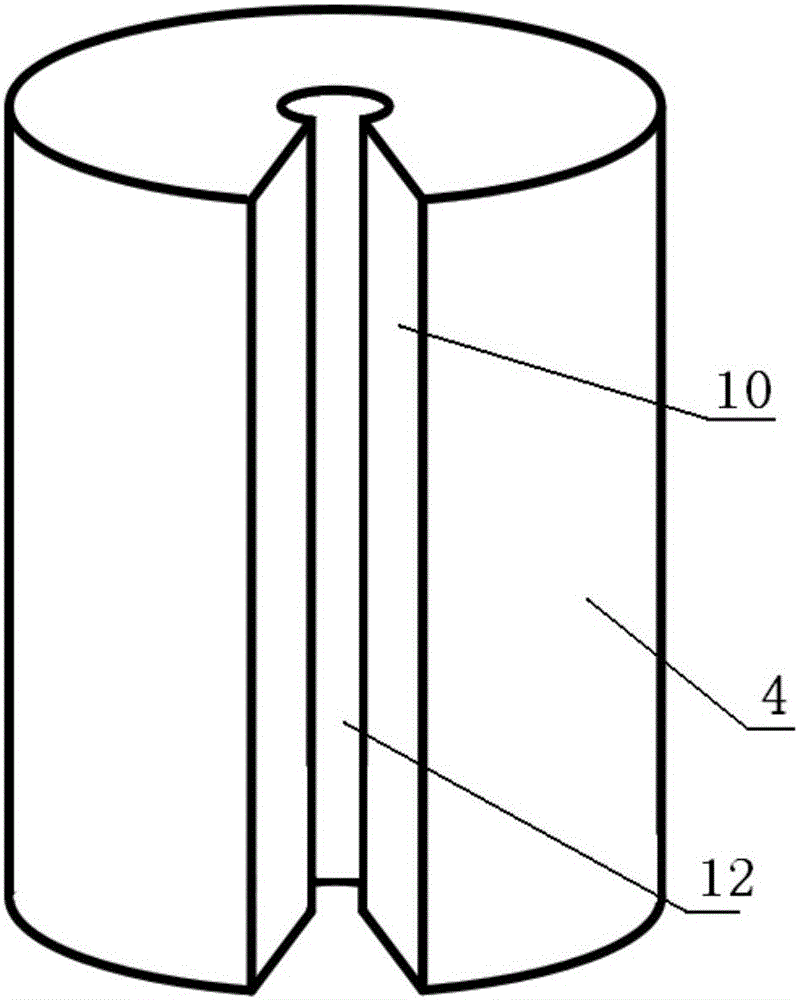

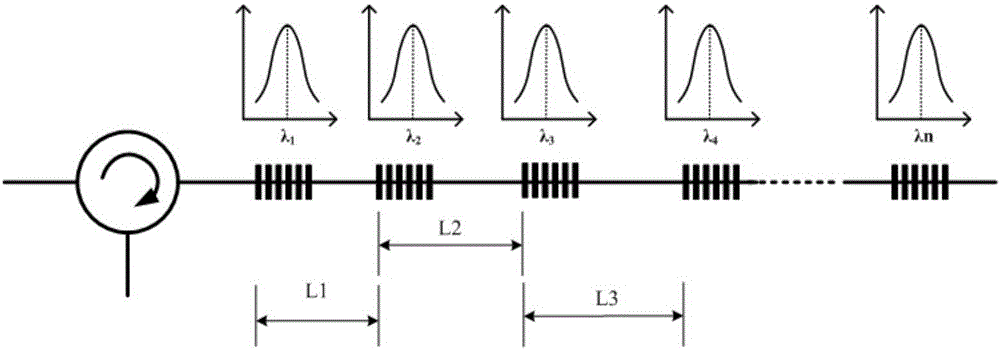

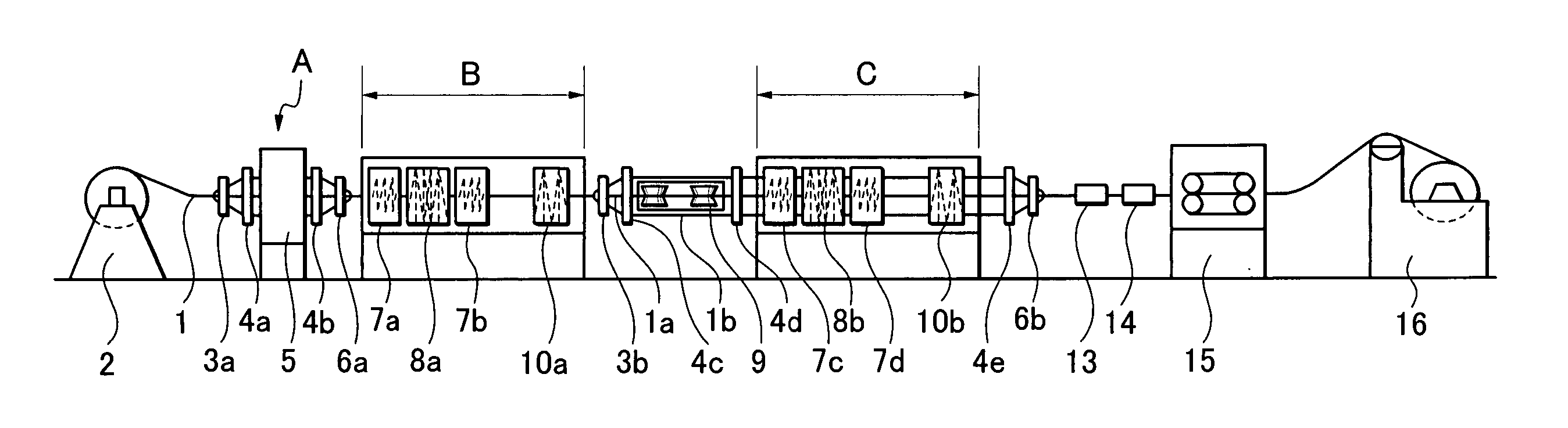

Large-capacity weak grating array processing apparatus and method

ActiveCN105783956AIncrease sensing distanceIncrease multiplexing capacityConverting sensor output opticallyFiberGrating

The invention discloses a large-capacity weak grating array processing apparatus. The large-capacity weak grating array processing apparatus is characterized in that the large-capacity weak grating array processing apparatus includes a central control system, a pre-processed raw material feeding device, a bare fiber diameter monitoring device, an optical fiber processing temperature control device, an FBG writing platform, a double-coating and curing unit and an FBG winding device; the material feeding control signal output end of the center control system is connected with the control signal input end of the pre-processed raw material feeding device; the signal output end of the bare fiber diameter monitoring device is connected with the bare fiber diameter monitoring result input end of the central control system; the temperature control signal output end of the central control system is connected with the control signal input end of the optical fiber processing temperature control device; the fiber grating writing control signal output end of the center control system is connected with the control signal input end of a laser writing device; and the FBG winding control signal output end of the center control system is connected with the control signal input end of the FBG winding device. With the large-capacity weak grating array processing apparatus of the invention adopted, the multiplexing capacity of a distributed sensing system can be greatly improved.

Owner:WUHAN UNIV OF TECH

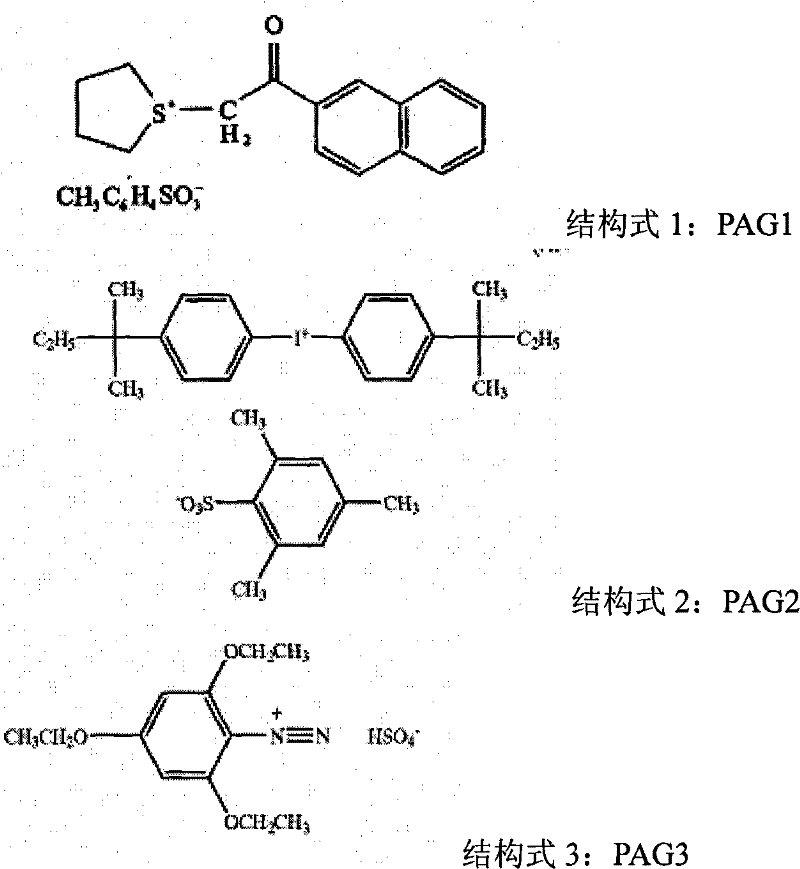

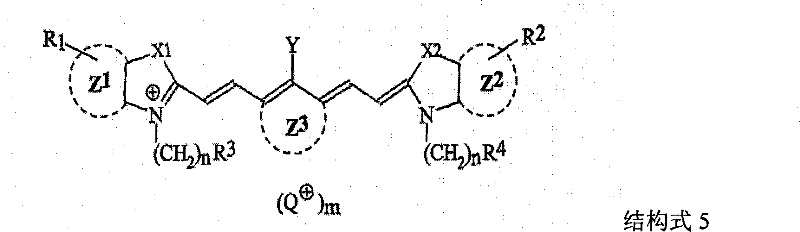

Positive image thermosensitive lithographic printing plate

InactiveCN102540728AImprove developmentIncreased sensitivityPhotosensitive materials for photomechanical apparatusForme preparationComputer to plateDouble coating

The invention relates to a positive image thermosensitive lithographic printing plate. A resin layer and a thermosensitive layer are successively coated onto a support with hydrophilic surface, wherein the resin layer comprises alkali-soluble resin, and the thermosensitive layer comprises alkali-soluble resin and infrared absorbent. The resin layer of the positive image thermosensitive lithographic printing plate contains an acid generator and an infrared absorbent. In the invention, the acid generator and the infrared absorbent are added into the resin layer of the double-coating positive image CTP (Computer-to-Plate) plate into heat, so that the acid generator generates acid, and the exposed portion is easily dissolved or dispersed in a developing liquid and removed by the developing liquid. As long as the upper layer is removed, the lower layer is very easy to remove. Unexposed portion does not generate acid and is not easy to remove by the developing liquid, the sensitivity of the plate is increased, the development of the plate is accelerated, and the sensitive and the development latitude of the plate are also improved.

Owner:LUCKY HUAGUANG GRAPHICS

Combination type full dummy brightness transferring aluminum-plating paper coating and preparing method thereof

ActiveCN101408015AThere will be no phenomenon such as uneven extinctionSimplify the batching processCoatings with pigmentsCoatingsAcrylic resinThermoplastic polyurethane

The invention relates to combination type total matte luster shift aluminum-plated paper paint and a preparation method thereof. The combination type total matte luster shift aluminum-plated paper paint consists of double coating type total matte luster shift aluminum-plated paper paint and separating paint used together with the aluminum-plated paper paint, the double coating type total matte luster shift aluminum-plated paper paint adopts the following components and contents (weight percentage) as raw materials: 6 to 8 percent of solid thermoplastic acrylic resin, 4 to 5 percent of thermoplastic polyurethane resin, 4 to 5 percent of chlorovinyl ether, 0 to 2 percent of nitrocotton, 0.5 to 1 percent of dye, 0.05 to 0.1 percent of auxiliary agent and 80 to 82 percent of solvent. Compared with the prior art, the invention has the following advantages: the batching procedure is simple, the delustering degree is high, the total matte effect of aluminum foil can be reached, and the difficulty that the shift aluminum-plated paper can not be made like matte aluminium-foil paper is solved; the difficulty of the fold foil break of the aluminium-foil card paper is overcome, the cost is lowered; the made products have better printing adaptability and good binding property with paper, aluminum plating luster is soft and simple but elegant, the aluminum plating fastness is good, and the application range is wide.

Owner:SHANGHAI WEIKAI CHEM

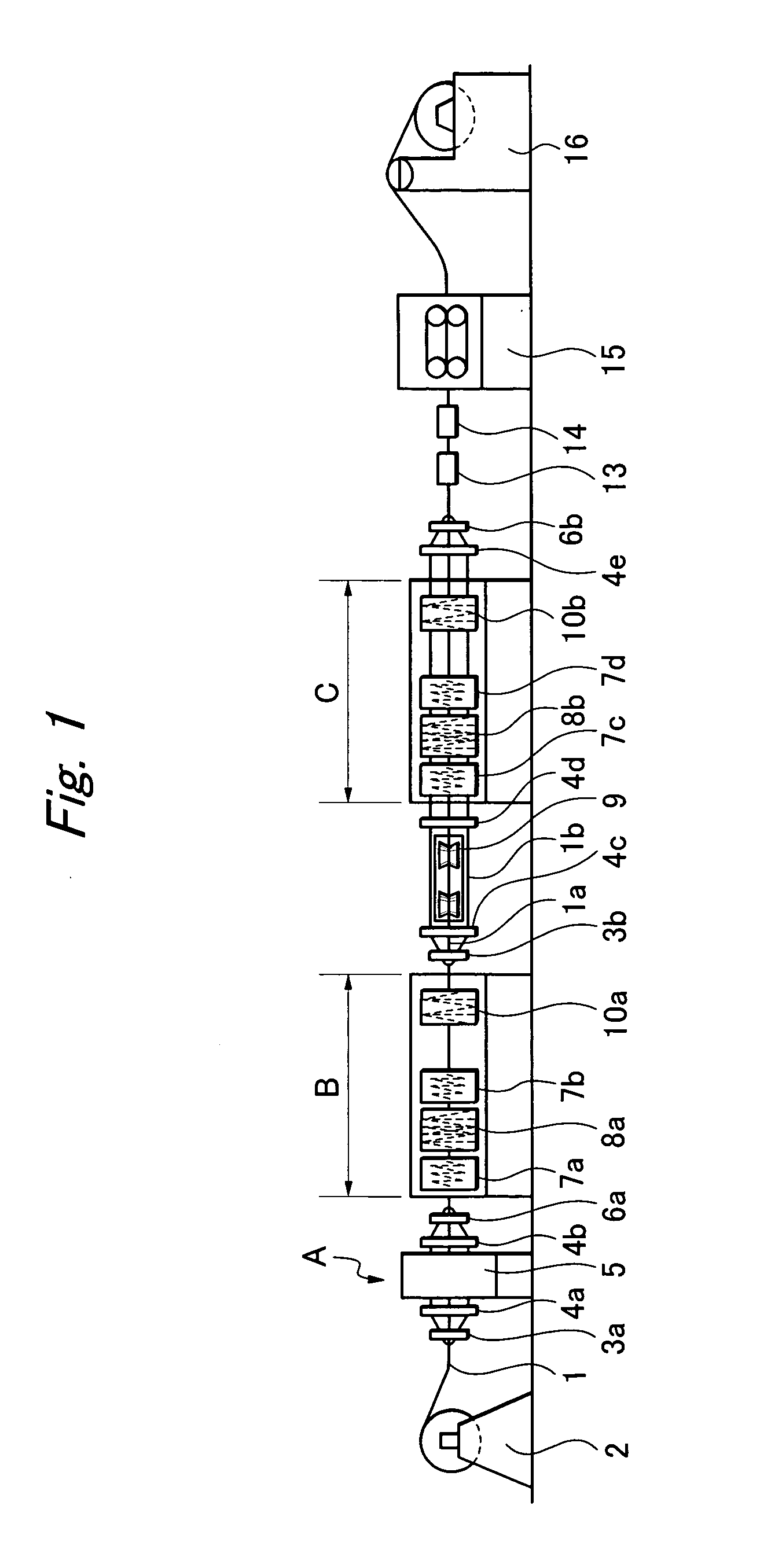

Method of forming corrosion protection double coatings on prestressing strand and prestressing strand produced by the method

To improve a tensile strength without impairing flexibility and adhesion strength to concrete, and to form thick coating in a surface layer part for preventing a basis material from being exposed by a damage of the coating, a method of forming double coatings on a prestressing strand includes a primary painting process after a pre-treatment process, in which a resin coating is formed only in the surface layer, a secondary painting process in which respectively individual state resin coating is formed on outer peripheral face of each of the core wire and the surrounding wires under a loosened and separated state, thereby forming a double coating in each surrounding wire, and a finishing process of tightening and retwisting the surrounding wires about the core wire to an original state. The obtained prestressing strand has the double coating portions only in the surface layer thereof and enough flexibility and adhesion strength to concrete.

Owner:KUROSAWA CONSTR CO LTD

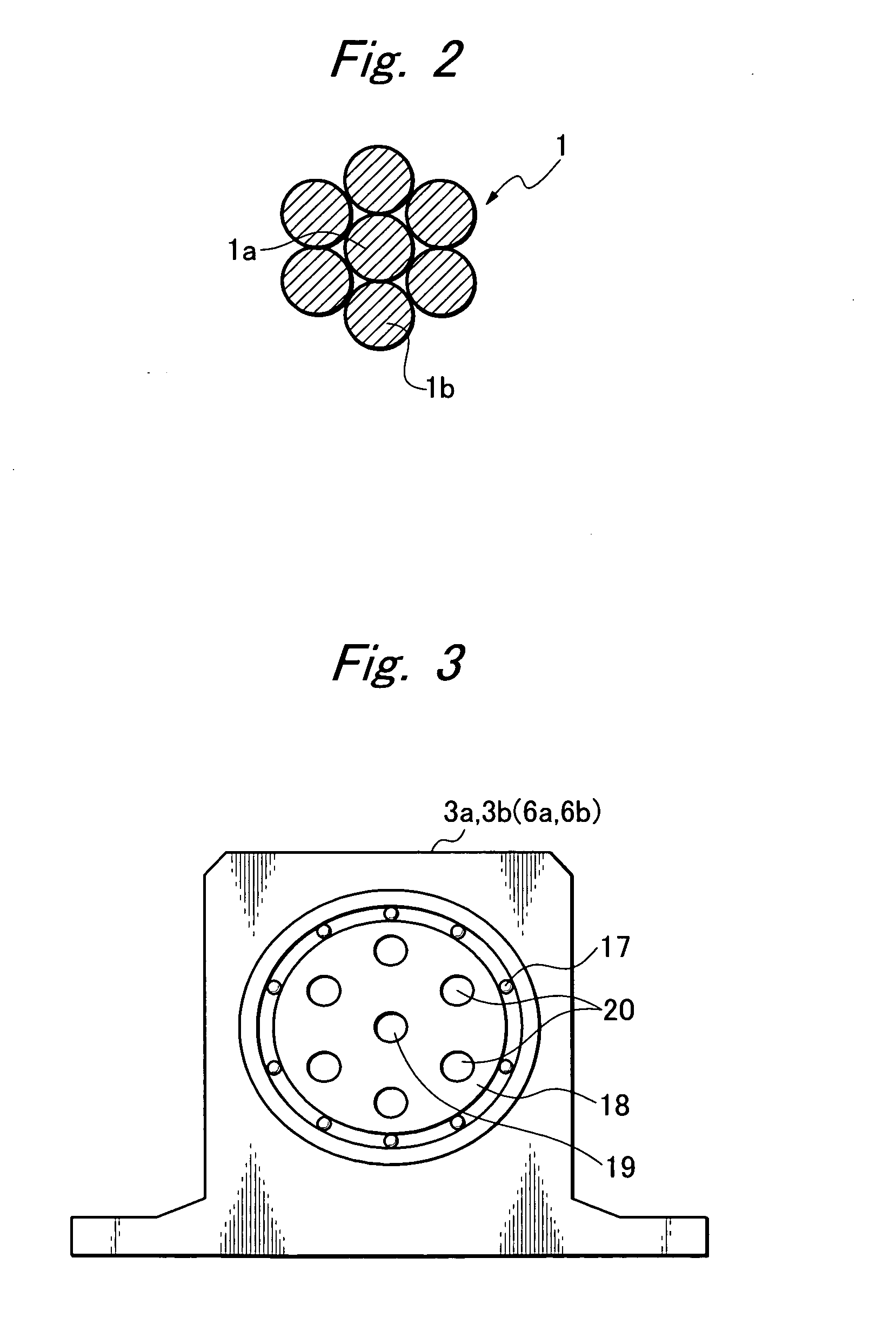

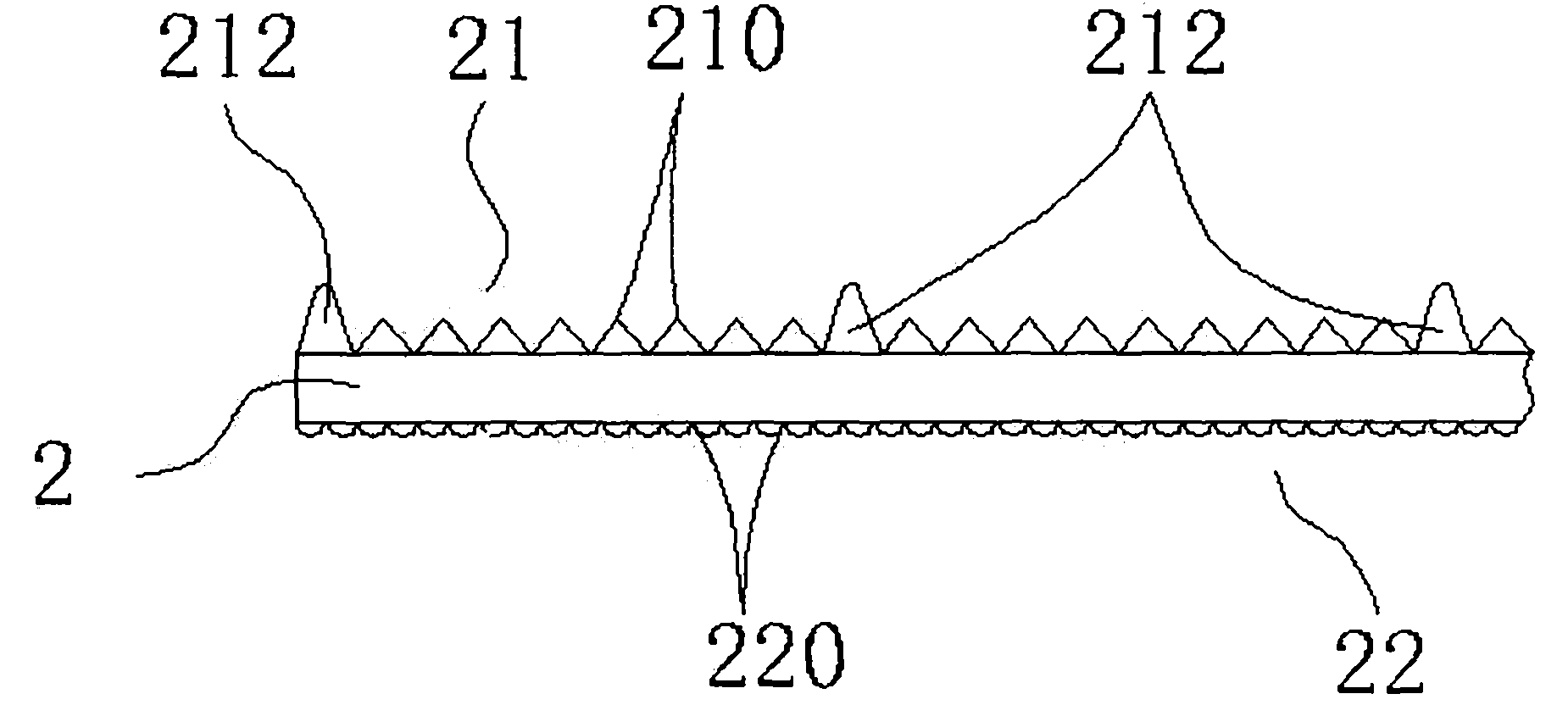

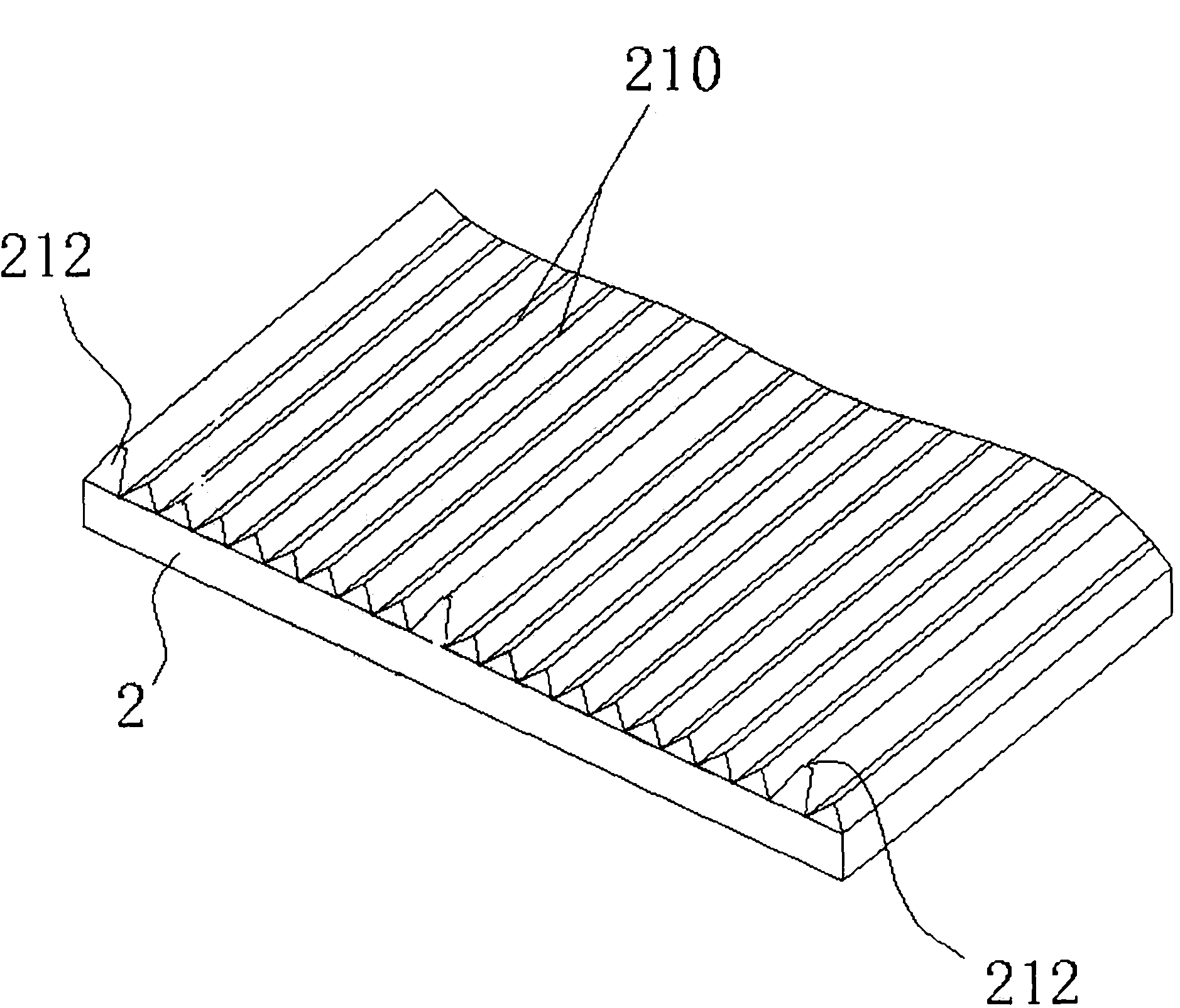

Composite bright enhancement film

ActiveCN102062891ATo achieve the effect of brighteningTo achieve the effect of atomization and diffusionPrismsDiffusing elementsDouble coatingOptoelectronics

The invention discloses a composite bright enhancement film, comprising a transparent film layer, a light collecting layer and an atomizing layer, wherein the light collecting layer, the atomizing layer and the transparent film layer are integrally arranged; the light collecting layer and the atomizing layer are integrally arranged. The composite bright enhancement film adopts a single-layer structure design, and uses a saw-tooth shaped refraction surface of the light collecting layer to enhance the bright. The light is diffracted by beads with different convex hemisphere grain sizes arranged on the atomizing layer, thereby achieving atomizing and diffusing effects. Compared with the traditional backlight module, the composite bright enhancement film can reduce more than one diffusion film, and can reduce the manufacturing steps of double coating the multi-layer diffusion films in the traditional manufacturing process, thereby greatly reducing the cost and improving the operating quality.

Owner:四川省维奇新材料股份有限公司

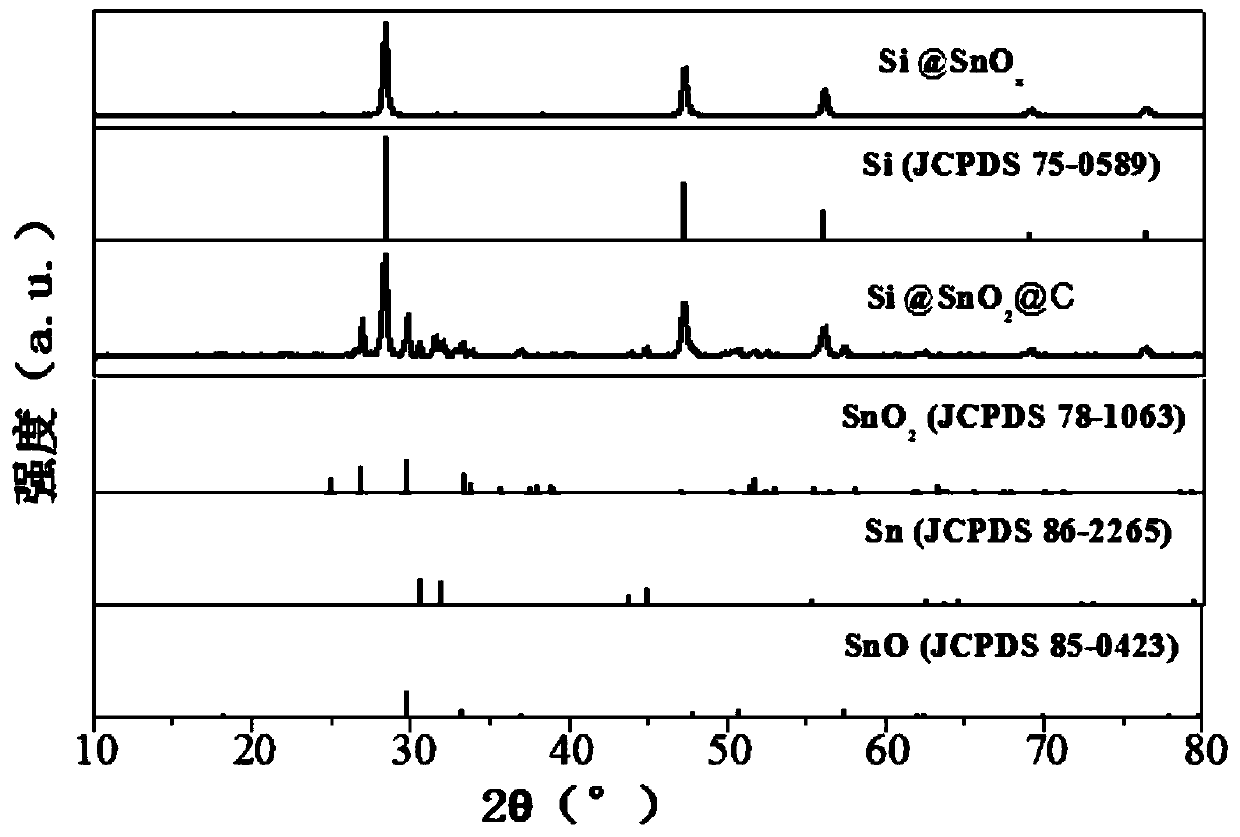

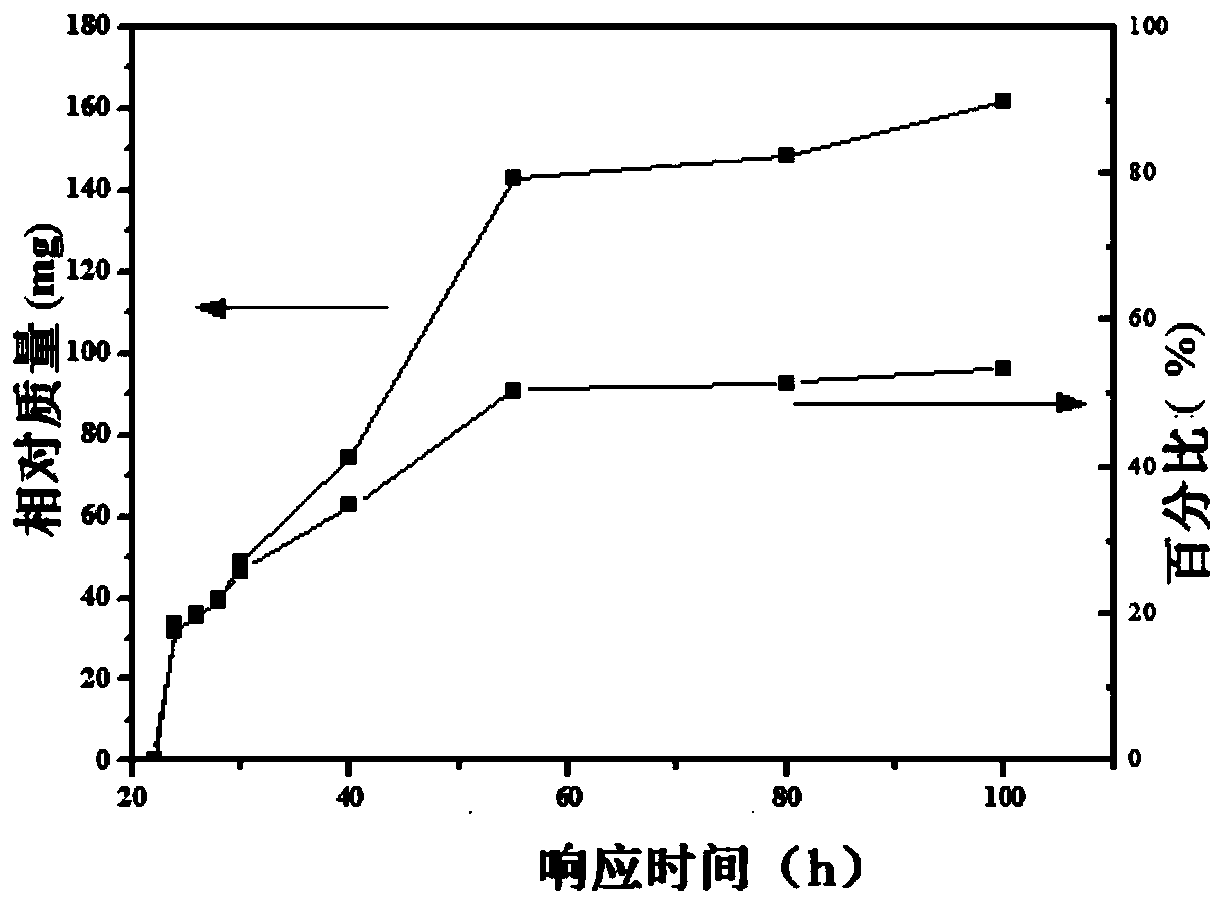

High-performance Si@SnO2@C composite material and preparation method and application thereof

ActiveCN109713257AImprove lithium storage performanceImprove electrochemical performanceCell electrodesSecondary cellsCarbon layerIn situ polymerization

The invention discloses a high-performance Si@SnO2@C composite material and a preparation method and application thereof. The method comprises firstly introducing a functional group into the surface of high-capacity nano-silicon by surface modification; in-situ depositing a uniform SnO2 layer; introducing a uniform carbon layer precursor by in-situ polymerization of phenolic resin; and obtaining ahigh-performance multilayer core-shell structure composite material by high-temperature calcinations. The invention also discloses a high-performance Si@SnO2@C composite material and application thereof. The method improves the electrochemical performance of the electrode material by coating the outer side of the intermediate layer of an active material with a double coating layer according to the characteristics that a volume effect is liable to occur in the charge and discharge cycle of the lithium battery Si negative electrode material. The SnO2 layer is not limited to the use as an inertcoating medium, can also be used as a lithium storage material at a wider potential of 0.01 to 3V. The SnO2 layer also has a volume effect, and can provide a sufficient buffer space for the silicon having a significant volume effect. Such design structure is advantageous for improving the cycle performance of the silicon-based material and increasing a reversible capacity.

Owner:YANCHENG INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com