Preparation method of rare earth Pr (praseodymium)-Dy (dysprosium) doped nanometer titanium-based tin dioxide-antimony double coating electrode

A technology of tin dioxide and nano-titanium, applied in chemical instruments and methods, electrodes, electrolytic components, etc., can solve the problems of large grain size of the coating, poor bonding force between the coating and the substrate, and low service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The preparation method of rare earth praseodymium and dysprosium joint doping nano-titanium-based tin dioxide-antimony double-coated electrode, the steps are as follows:

[0019] (1) Prepare mixed solution I with crystalline tin tetrachloride, antimony trichloride and praseodymium oxide according to the ratio of ion molar concentration Sn:Sb:Pr=100:5~7:0.75~1.25, and ultrasonic 10 at 70~100Hz ~30min, standing and aging for 1~2h to prepare Pr-doped sol I;

[0020] (2) Prepare mixed solution II with crystallized tin tetrachloride, antimony trichloride and dysprosium oxide according to the ratio of ion molar concentration Sn:Sb:Dy=100:5~7:0.75~1.25, and ultrasonicate at 70~100Hz for 10 ~30min, standing and aging for 1~2h to obtain Dy-doped sol II;

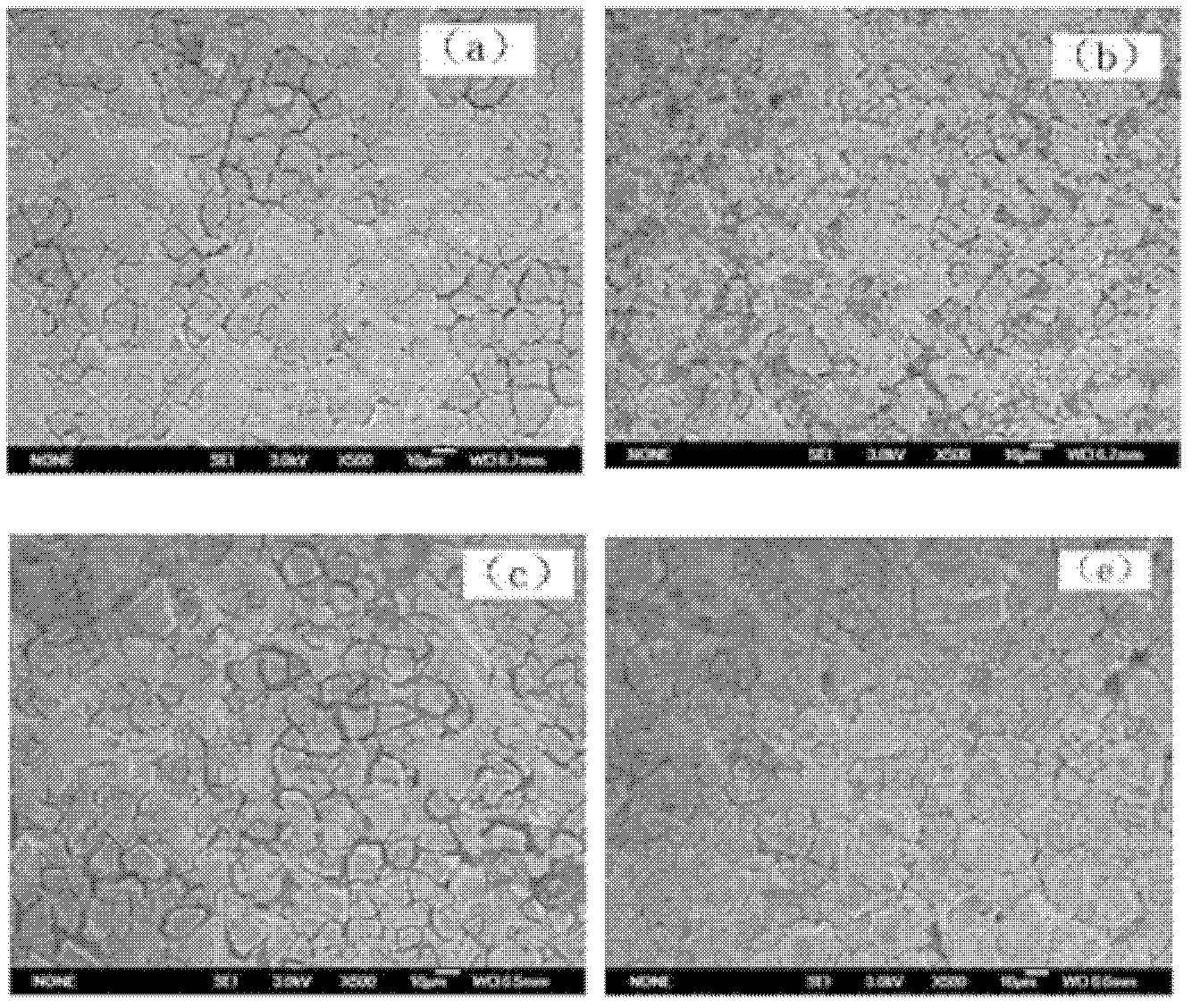

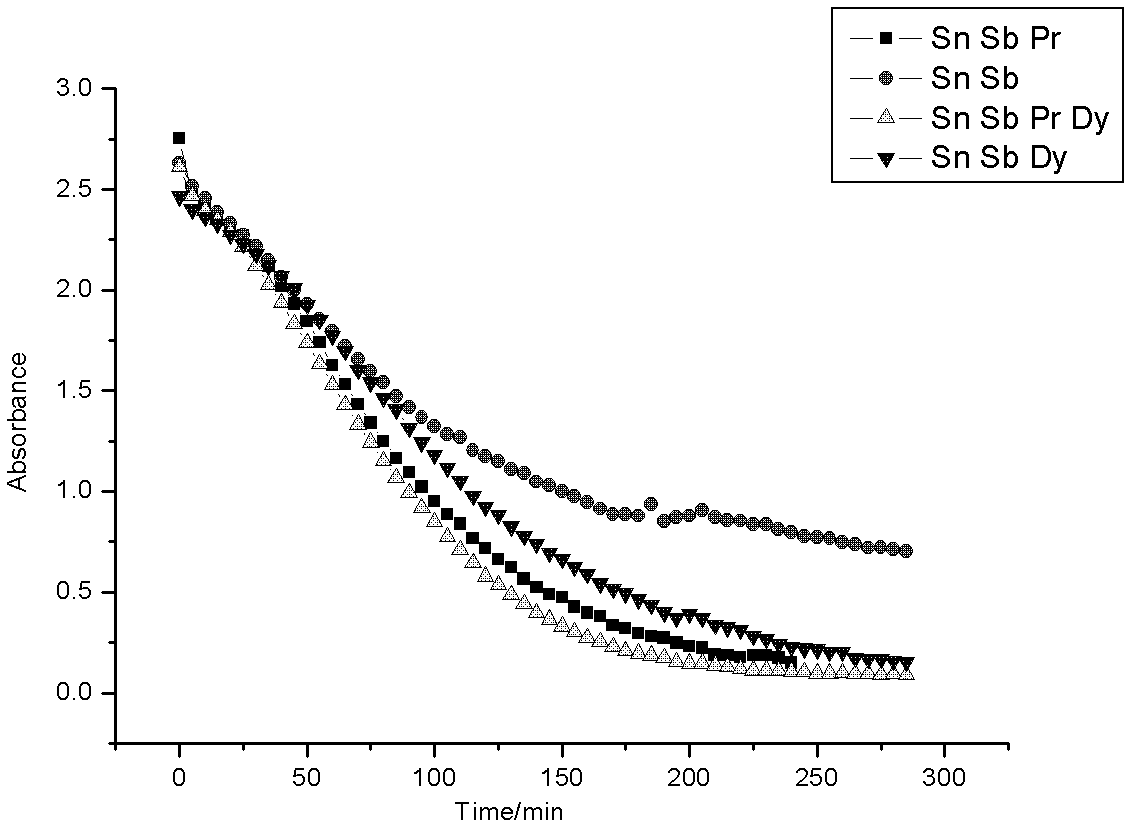

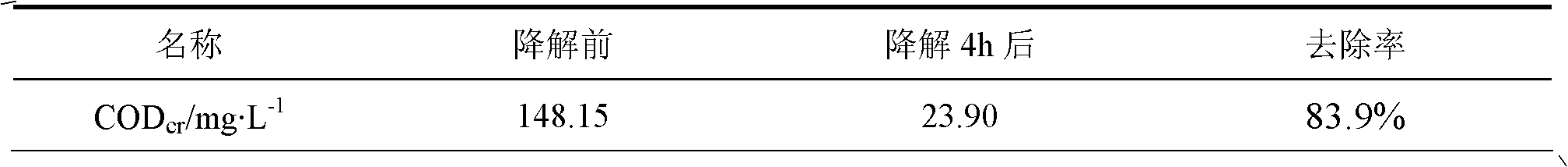

[0021] (3) Put the treated electrode matrix into the Pr-doped sol I prepared in step (1), let it stand for 4 to 8 minutes, dry, repeat 3 to 5 times, and then put the coated electrode matrix into Carry out pre-sintering in a m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com