Biomass magnetic carbon material for degrading organic dye

A technology of organic dyes and carbon materials, applied in the direction of inorganic chemistry, alkali metal compounds, chemical/physical processes, etc., can solve the problems of unsuitable for mass production, complex process, high production cost, etc., achieve good reusable effect and excellent preparation process Simple, high specific surface area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

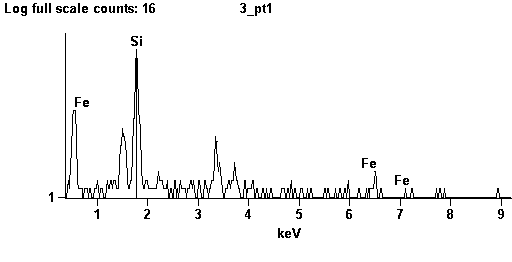

Image

Examples

Embodiment 1

[0038] Example 1 A biomass magnetic carbon material for degrading organic dyes, which is made by mixing biological raw materials and iron precursors at a ratio of 15kg:1kg.

[0039] Wherein: the iron precursor is ferric ammonium oxalate. Biological raw material refers to peanut shells.

[0040] The preparation method of the biomass magnetic carbon material of the degradation organic dye comprises the following steps:

[0041] ⑴ Weigh according to the ratio.

[0042] ⑵ Grinding the biological raw material to 100-200 mesh to obtain the crushed raw material;

[0043] (3) dissolving the iron precursor in water at a ratio of 1kg:70L to obtain an aqueous solution containing the iron precursor;

[0044] (4) fully immersing the pulverized raw material in the aqueous solution containing the iron precursor, and obtaining the soaked raw material after 10 hours;

[0045] (5) The impregnated raw materials are dried at a temperature of 80° C. to constant weight to obtain dried raw ...

Embodiment 2

[0049] Example 2 A biomass magnetic carbon material for degrading organic dyes, which is made by mixing biological raw materials and iron precursors at a ratio of 10kg:1kg.

[0050] Among them: the iron precursor is a mixture of ferric ammonium oxalate and copper nitrate, and the mass ratio of ferric ammonium oxalate to copper nitrate is 90 kg:10 kg. Biological raw material refers to straw.

[0051] The preparation method of the biomass magnetic carbon material of the degradation organic dye comprises the following steps:

[0052] ⑴ Weigh according to the ratio.

[0053] ⑵ Grinding the biological raw material to 100-200 mesh to obtain the crushed raw material;

[0054] (3) dissolving the iron precursor in water at a ratio of 1kg:40L to obtain an aqueous solution containing the iron precursor;

[0055] (4) fully immersing the pulverized raw material in the aqueous solution containing the iron precursor, and obtaining the soaked raw material after 8 hours;

[0056] (5) ...

Embodiment 3

[0060] Example 3 A biomass magnetic carbon material for degrading organic dyes, which is made by mixing biological raw materials and iron precursors at a ratio of 2kg:1kg.

[0061] Among them: the iron precursor is a mixture of ferric ammonium oxalate and manganese nitrate, and the mass ratio of ferric ammonium oxalate to manganese nitrate is 90 kg:10 kg. Biological feedstock refers to corn cobs.

[0062] The preparation method of the biomass magnetic carbon material of the degradation organic dye comprises the following steps:

[0063] ⑴ Weigh according to the ratio.

[0064] ⑵ Grinding the biological raw material to 100-200 mesh to obtain the crushed raw material;

[0065] (3) dissolving the iron precursor in water at a ratio of 1kg:10L to obtain an aqueous solution containing the iron precursor;

[0066] (4) fully immersing the pulverized raw material in the aqueous solution containing the iron precursor, and obtaining the soaked raw material after 6 hours;

[0067...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com