Patents

Literature

611 results about "Ammonium oxalate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ammonium oxalate, C₂H₈N₂O₄ – more commonly written as (NH₄)₂C₂O₄ – is an oxalate salt with ammonium (sometimes as a monohydrate). It is a colorless (white) salt under standard conditions and is odorless and non-volatile. It is the ammonium salt of oxalic acid, and occurs in many plants and vegetables.

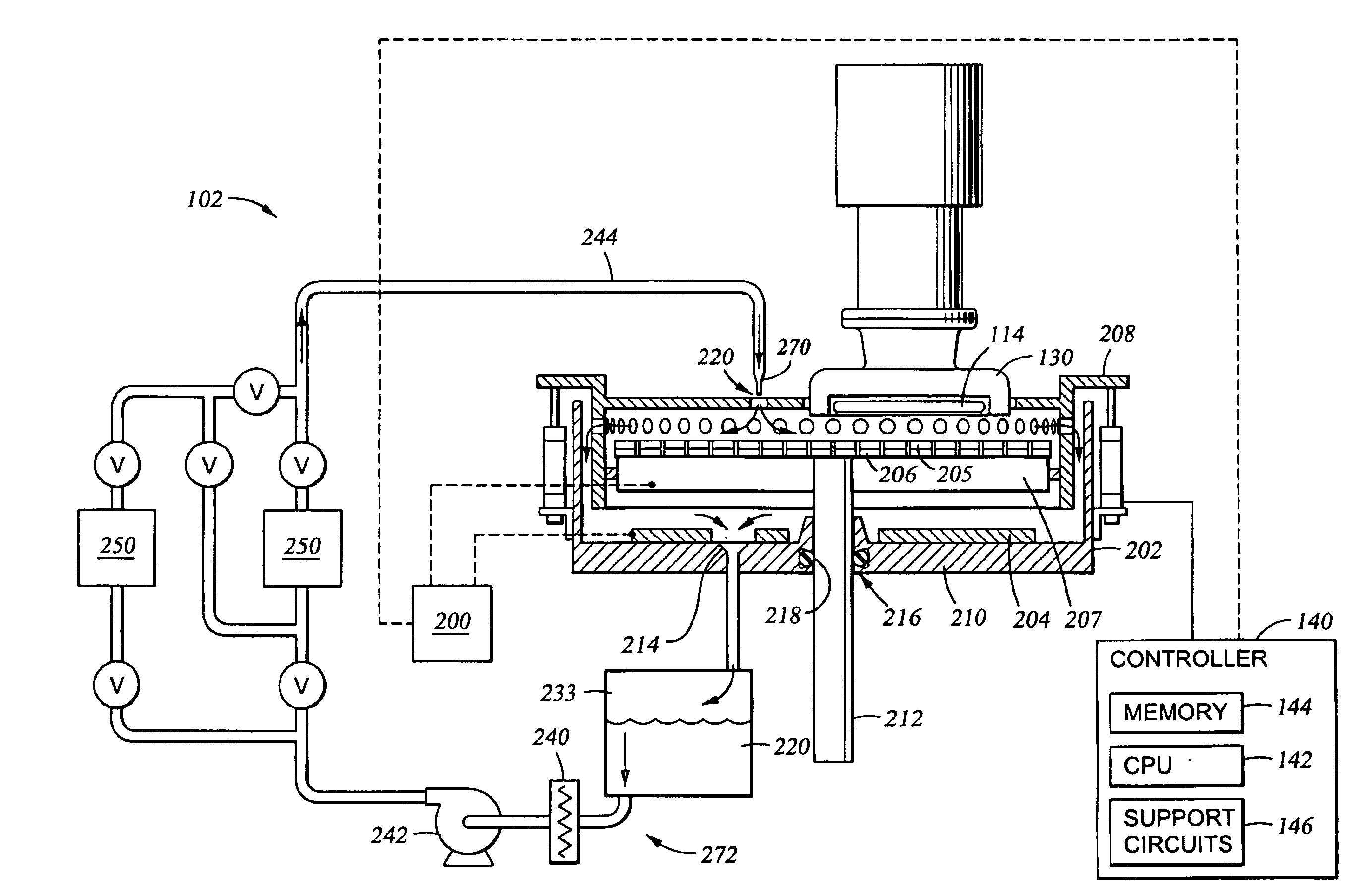

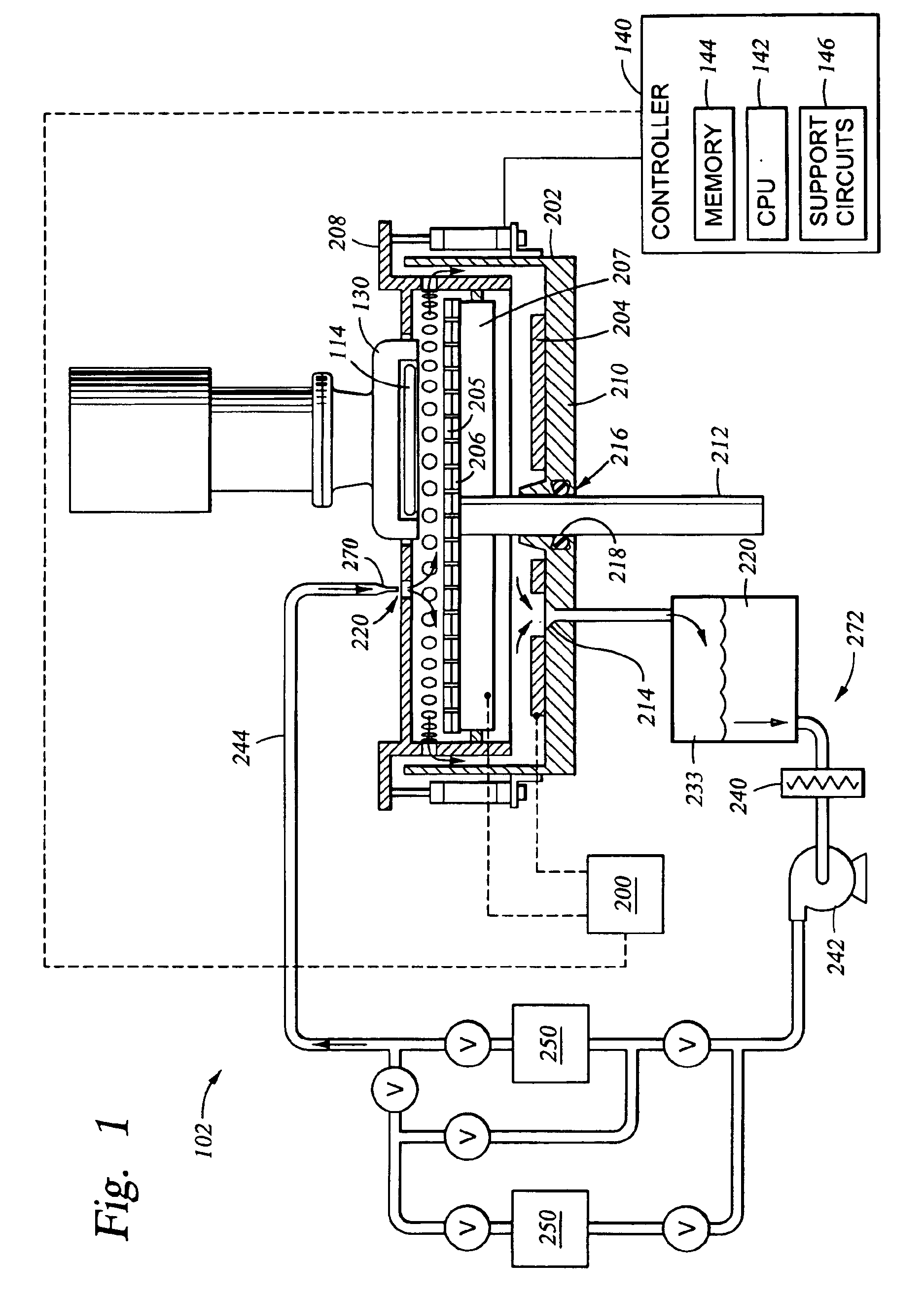

Electrolyte composition and treatment for electrolytic chemical mechanical polishing

Owner:APPLIED MATERIALS INC

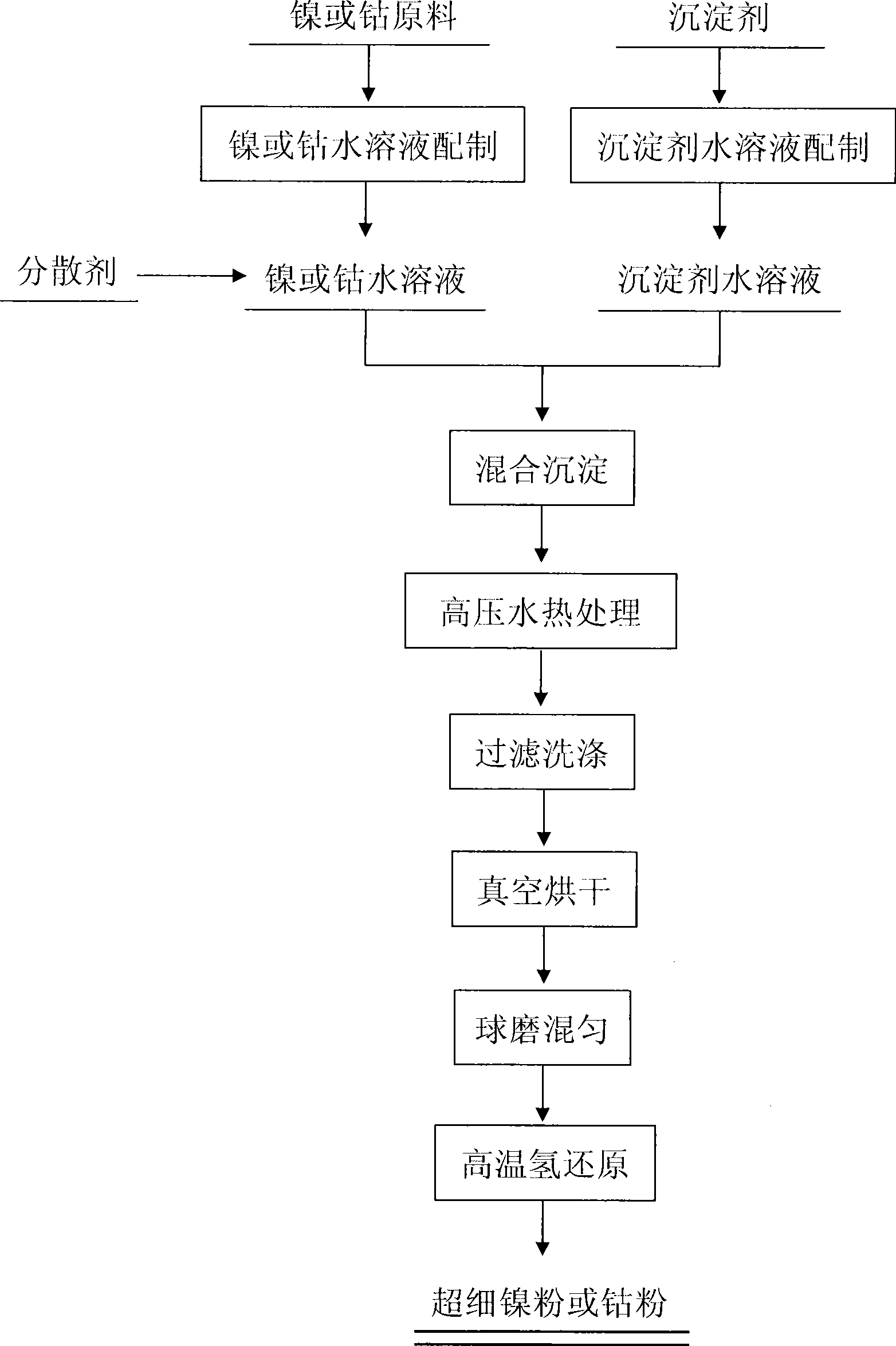

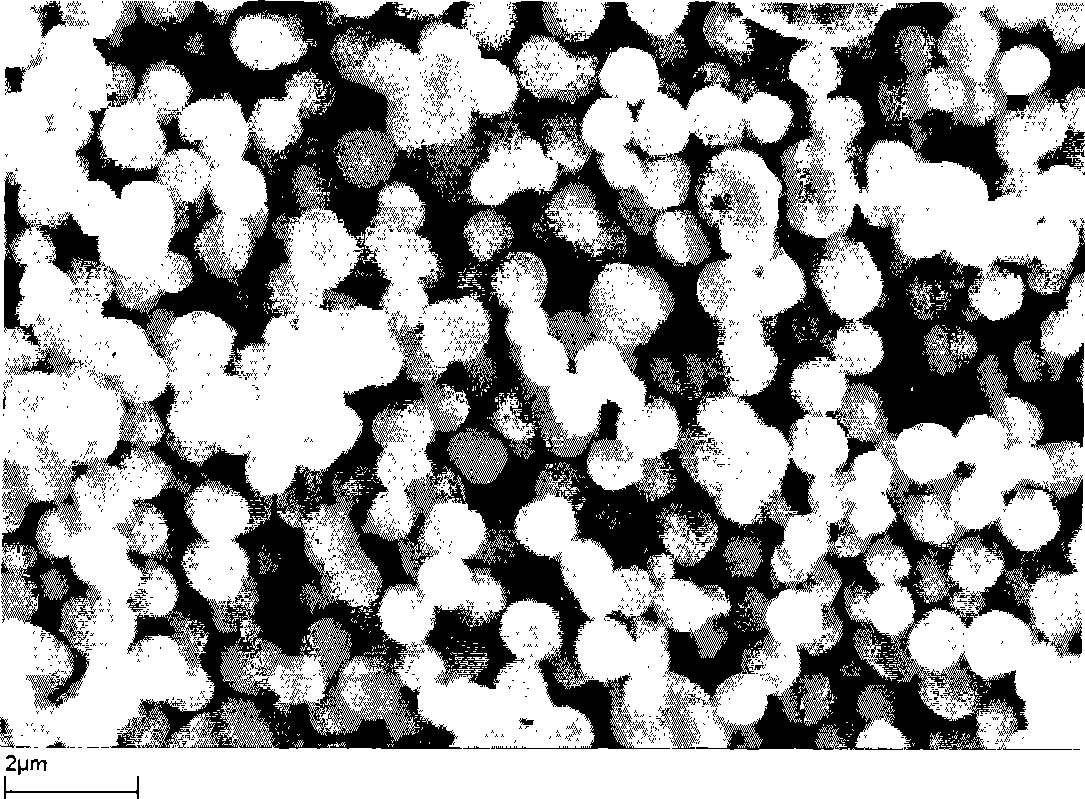

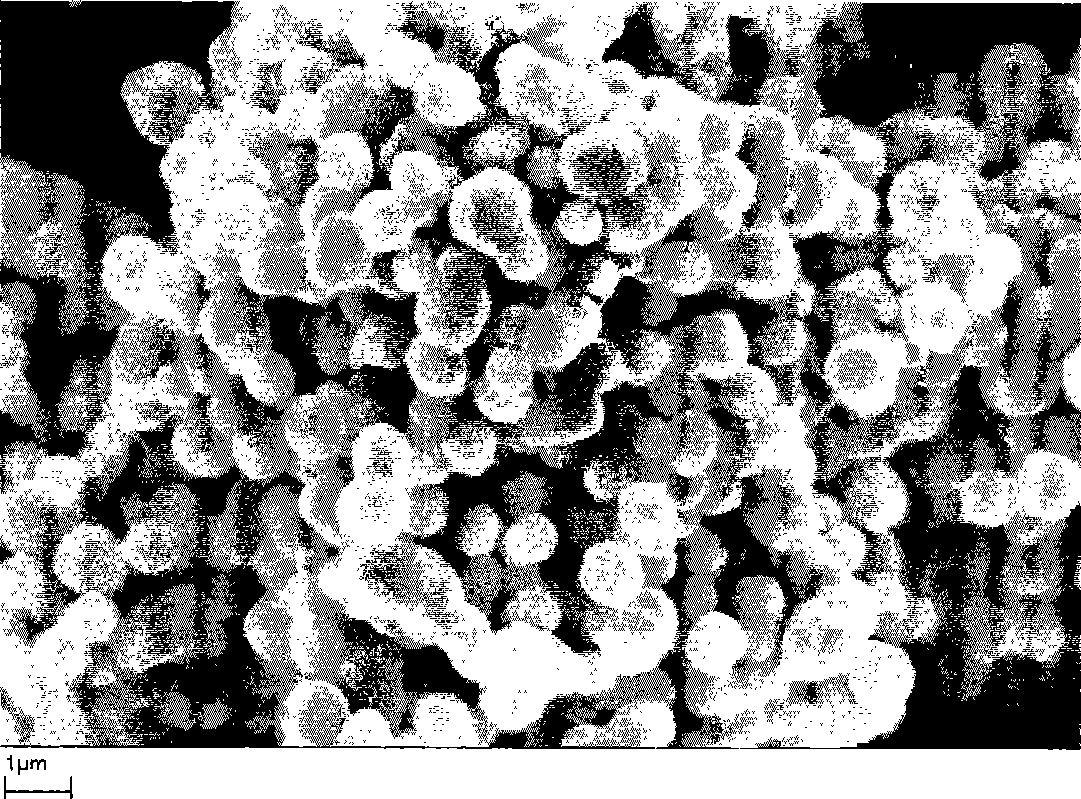

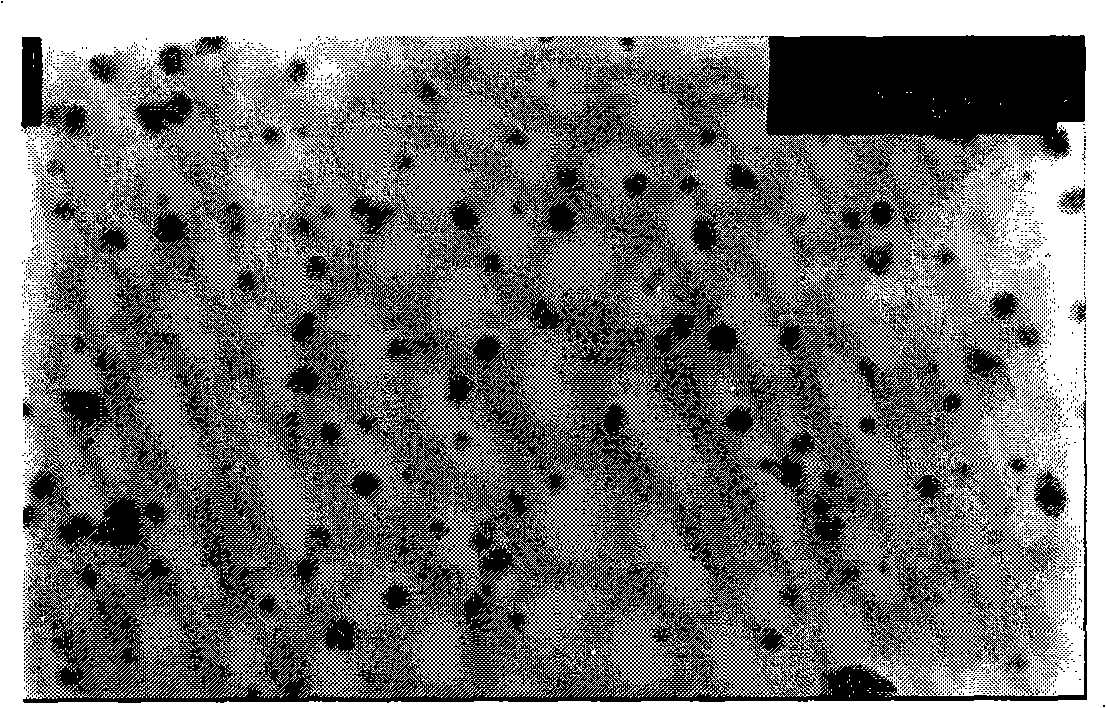

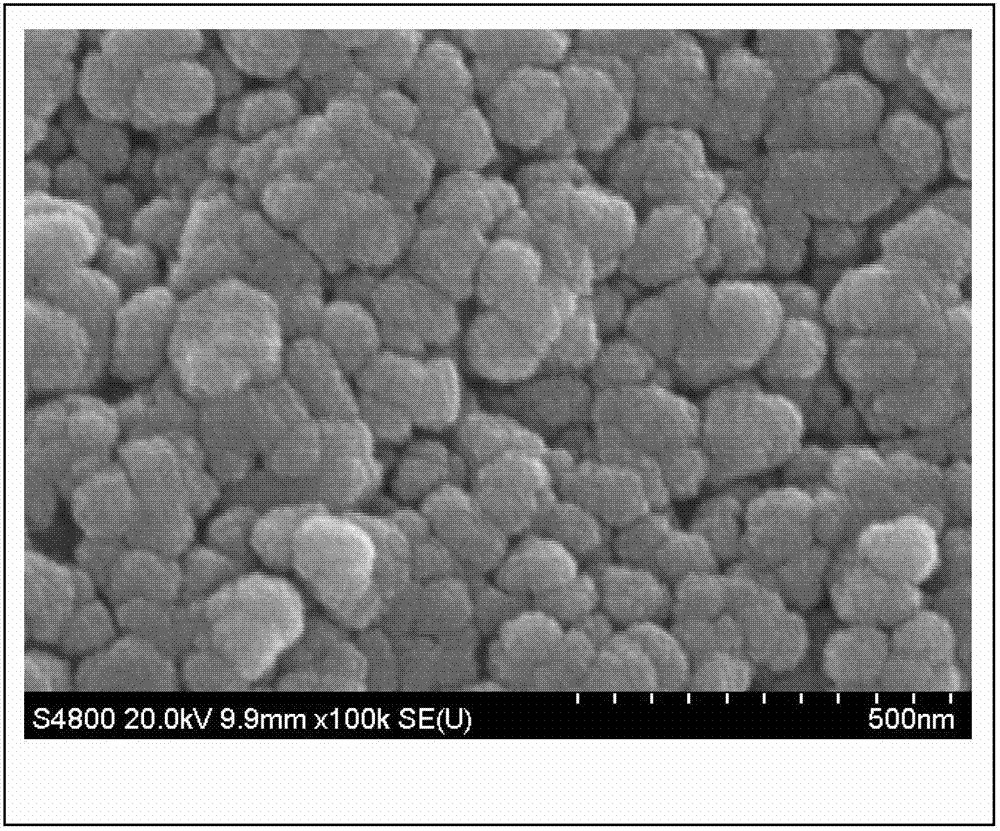

Process for producing spherical submicron metal with hydro-thermal treatment

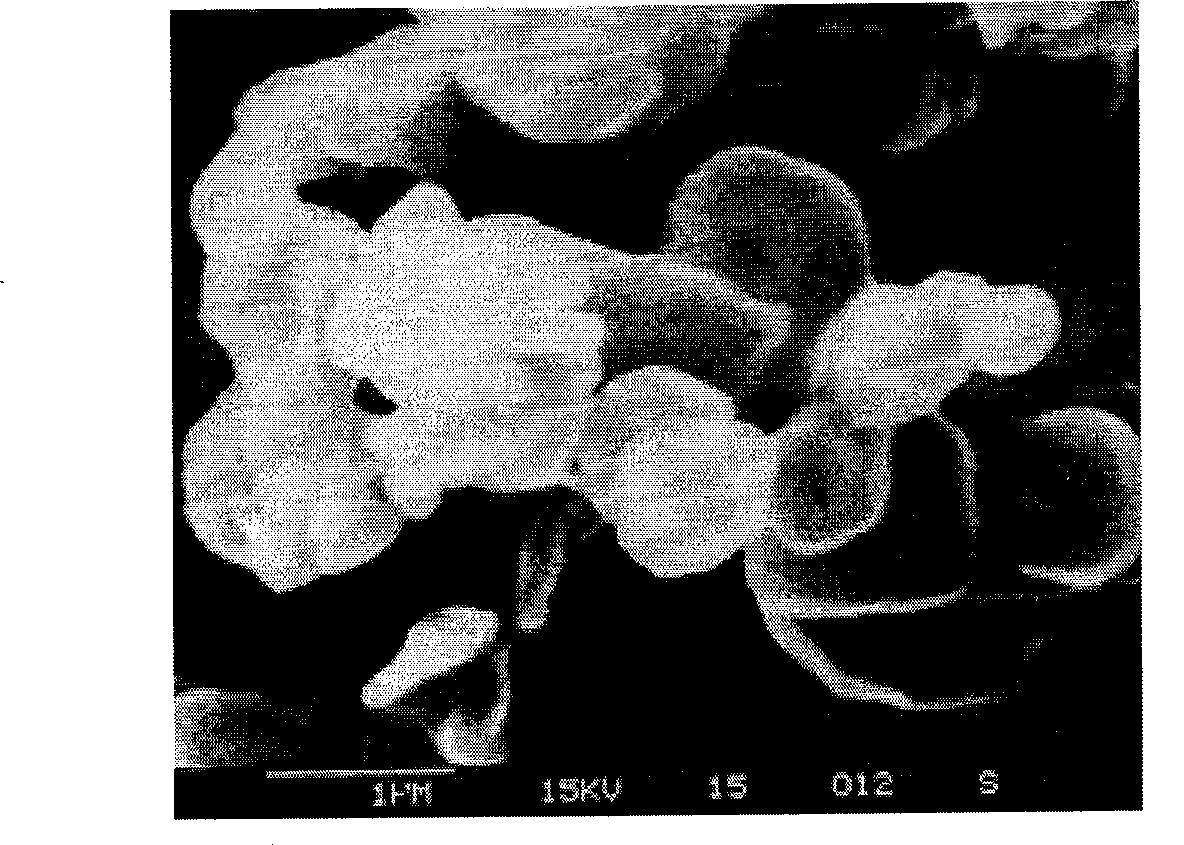

The invention discloses a technological method for preparation of sphere-shaped ultrafine metallic powders through hydro-thermal treatment, which relates to a technological method for preparation of sphere-shaped ultrafine nickel powders or ultrafine cobalt powders through the procedures such as precipitation, dispersing agent surface finish, high-pressure hydro-thermal treatment, washing, drying and high-temperature hydrogen reduction and the like, and which belongs to the technical field for preparation of metal powder materials. The technological method adopts water soluble salts with nickel and cobalt, cobalt oxide, sub-carbonate, carbonate or hydroxide as raw materials, which are prepared into water solution after processing, the dispersing agent is added, then nickel ion and cobalt ion in the water solution are precipitated through alkali, carbonate, oxalic acid or ammonium oxalate and the like, the hydro-thermal treatment of water pulp of the precipitate is performed in an autoclave, and products of sphere-shaped ultrafine nickel powders or ultrafine cobalt powders with even graininess and good dispersibility can be obtained through washing, drying and high-temperature hydrogen reduction. The technological method is not only suitable for medium- and small-scale discontinuous-type manufacture, but also used for large-scale continuous manufacture, and the manufacturing cost is low.

Owner:张建玲

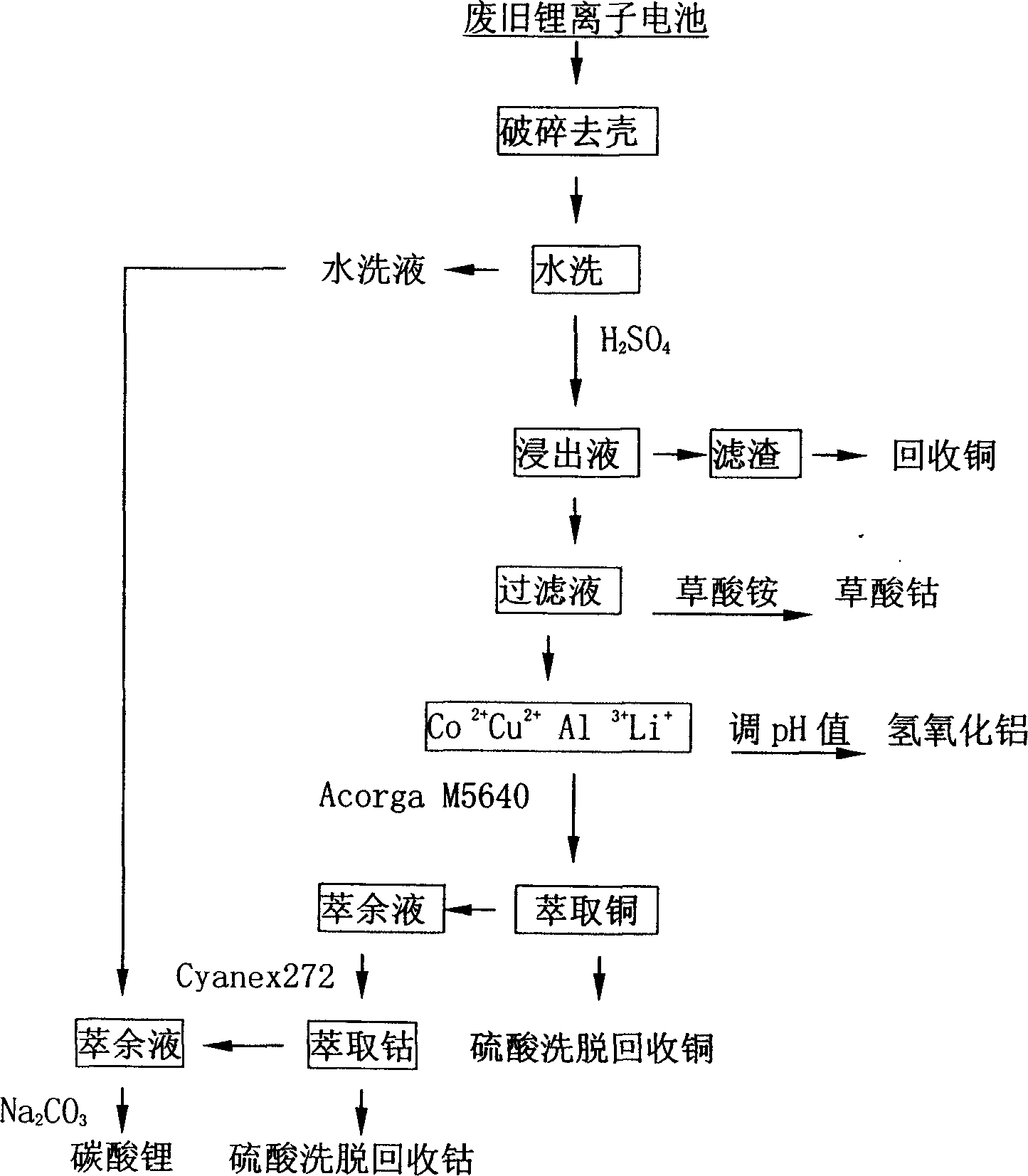

Recovery and treatment method for waster lithium ion cell

InactiveCN1601805AAvoid it happening againEasy to recycleSolid waste disposalWaste accumulators reclaimingSolventCobalt

The method for recycling and processing worn-out lithium ion battery includes steps: (1) taking out pack of worn-out battery; (2) using crushing facilities to open up case of battery, and segregation through magnetic method; (3) dissolving wastes of pole core of battery by using acid, and separating out most of cobalt through ammonium oxalate depositing method; (4) cobalt and copper deposited in residual liquid is extracted through solvent extraction method. Adding sodium carbonate generates deposition to retrieve lithium. Advantages are: simple technique, on solving pollution of worn-out batteries, and reclaining resources at same time.

Owner:SOUTH CHINA NORMAL UNIVERSITY

Method for preparing environment-friendly micro-arc oxidation black ceramic film on aluminum alloy surface

ActiveCN102154673AUniform colorImprove corrosion resistanceAnodisationPlasma electrolytic oxidationMicro arc oxidation

The invention discloses a method for preparing an environment-friendly micro-arc oxidation black ceramic film on an aluminum alloy surface, and the method comprises the following steps: firstly, pouring deionized water into an oxidation tank, weighing 1-10g / L of sodium hexametaphosphate, 1-3g / L of sodium silicate, 0.5-2g / L of potassium hydroxide, 0.2-2g / L of sodium fluoride and 0.5-20g / L of ferric ammonium oxalate in terms of the volume of the added deionized water, and uniformly stirring and mixing the sodium hexametaphosphate, the sodium silicate, the potassium hydroxide and the sodium fluoride to obtain a micro-arc oxidation base electrolyte; adding the weighed ferric ammonium oxalate into the base electrolyte, and stirring and mixing uniformly to obtain an aluminum alloy micro-arc oxidant solution; and then, sequentially carrying out surface deoiling and cleaning, water washing, aluminum alloy micro-arc oxidation, sealing and drying on the aluminum alloy to prepare the environment-friendly micro-arc oxidation black ceramic film on the aluminum alloy surface. By means of the preparation method disclosed by the invention, the problems of single color, limited application range, and environment pollution caused by a vanadate electrolyte, of the existing aluminum alloy ceramic film layer, are solved.

Owner:CSIC NO 12 RES INST

High precision rare earth polishing powder and preparation thereof

ActiveCN101475777AEasy to control abrasion resistanceImprove control stabilityOther chemical processesPolishing compositions with abrasivesCerium oxalateGranularity

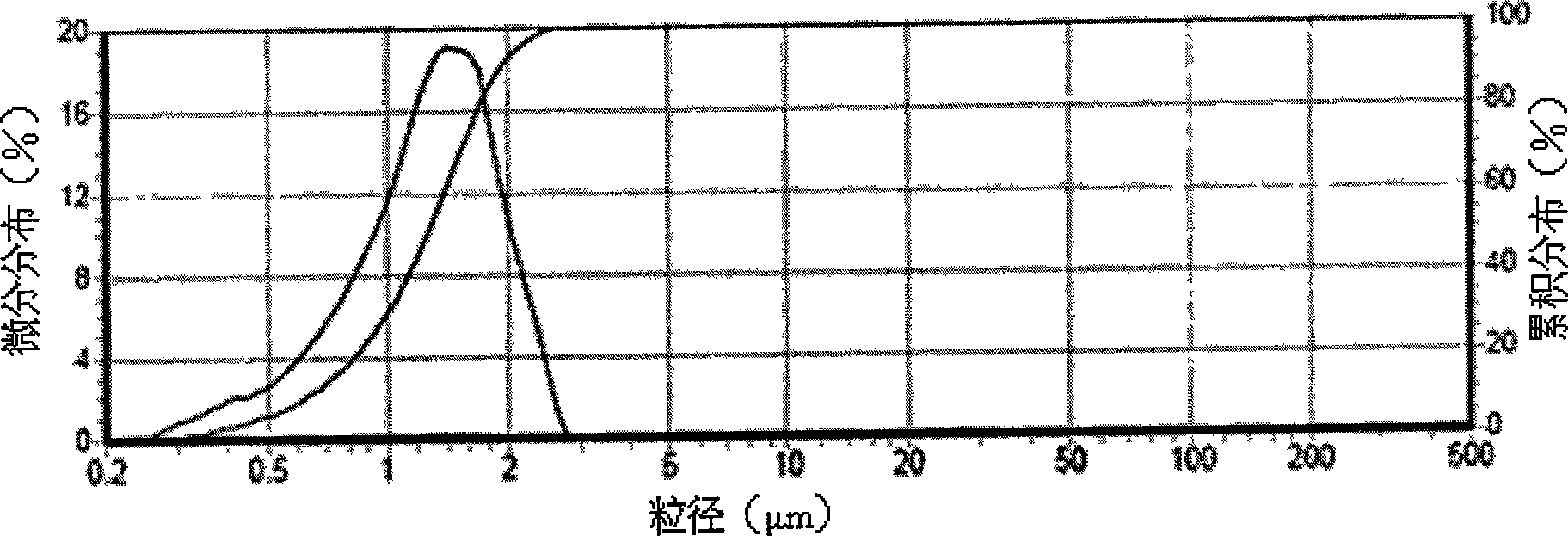

The invention discloses a high-precision rare-earth polishing powder and a method for preparing the same. The high-precision rare-earth polishing powder is characterized in that D50 particle diameter is between 0.5 and 1.80 mu m; the powder also meets the conditions that D10 is more than or equal to 0.5D50, D90 is less than or equal to 2D50, and D100 is less than or equal to 3D50; a cerium lanthanum nitrate or cerium lanthanum chloride solution is added to an ammonium oxalate solution with PH value of between 4.5 and 5.5 to generate monodisperse lanthanum cerium oxalate or lanthanum cerium praseodymium oxalate deposit; and the deposit is used as a crystal seed to prepare the high-precision rare-earth polishing powder. The high-precision rare-earth polishing powder prepared by the method does not need airflow pulverization and precise classification and has the characteristics of small median particle diameter and narrow granularity distribution range; the stability of the wearing resistance and polishing precision is easy to control; and the quality of a product has small fluctuation.

Owner:上海华明高纳稀土新材料有限公司

Method for recycling cobalt from waste and old lithium ion battery

InactiveCN101318712AMeet product quality requirementsEasy to manufactureCobalt oxides/hydroxidesEngineeringCobalt

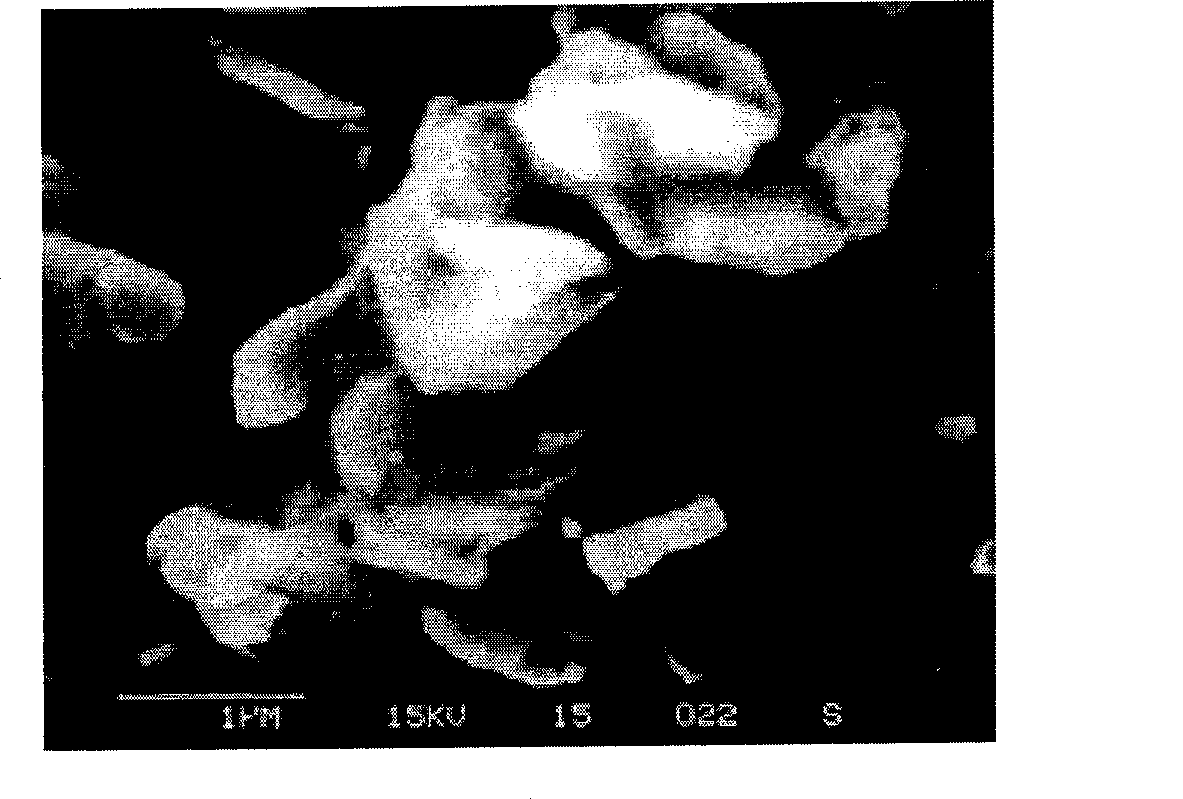

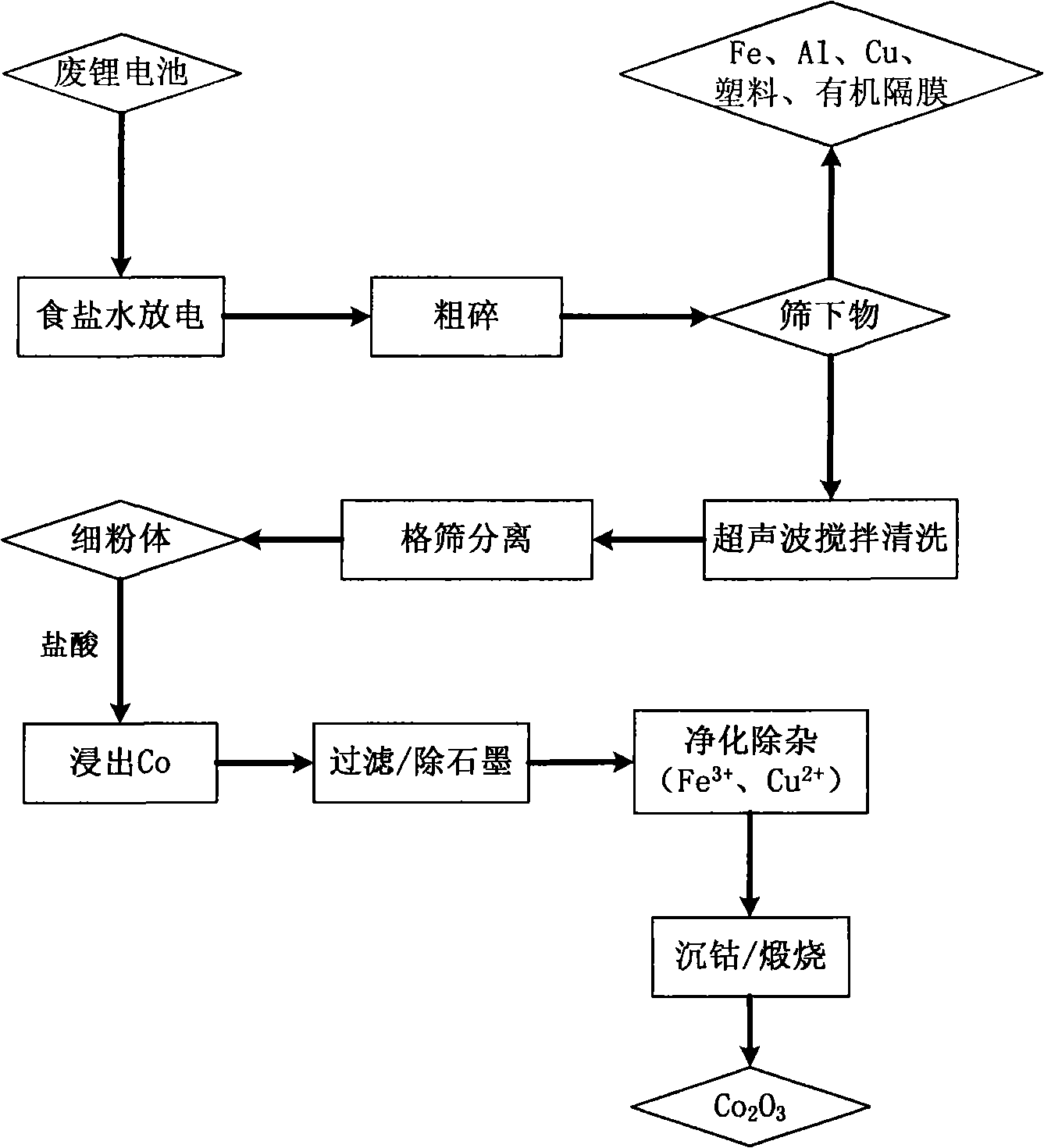

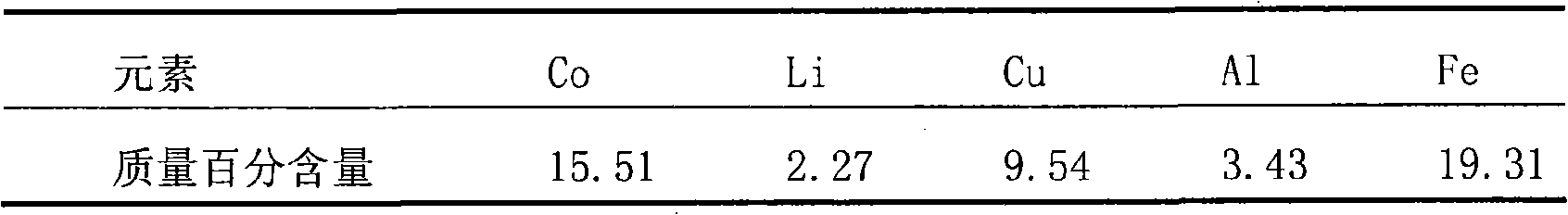

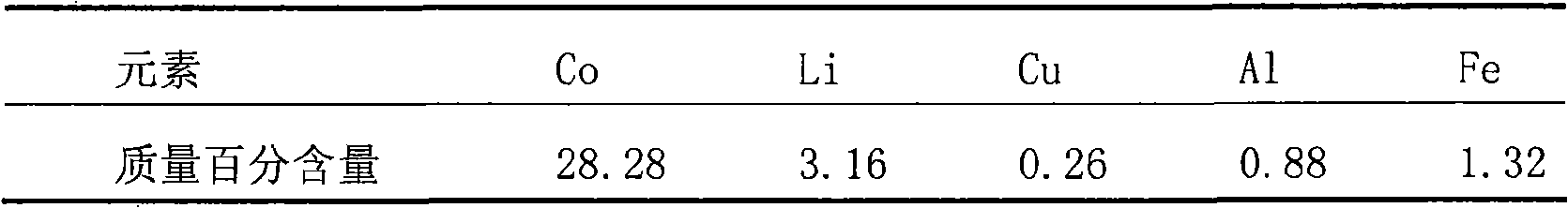

The invention discloses a method for recovering cobalt from a waste lithium ion battery. The method comprises the following steps that: the waste lithium ion battery is placed into salt solution to be discharged; the discharged waste lithium ion battery is mechanically crushed; the crushed waste lithium ion battery is stirred and cleaned by ultrasonic wave; a grizzly screen is used to separate after the cleaning; the leaching of filtrate Co and Li is performed; Fe<3+> is removed through purification; Cu<2+> is removed through purification; the cobalt is precipitated by ammonium oxalate; and finally a filtered cobalt oxalate precipitate is cleaned by de-ionized water, is dried in a drying box, and then is placed into a muffle furnace for heat treatment for 2 hours at a temperature of 600 DEG C to produce Co2O3 powder. The method has simple and convenient and feasible preparation process, the produced Co2O3 can meet the requirement of product quality of Co2O3-Y1(GB6518-86), and the recovery rate of the Co during the whole process is more than 89 percent.

Owner:TSINGHUA UNIV

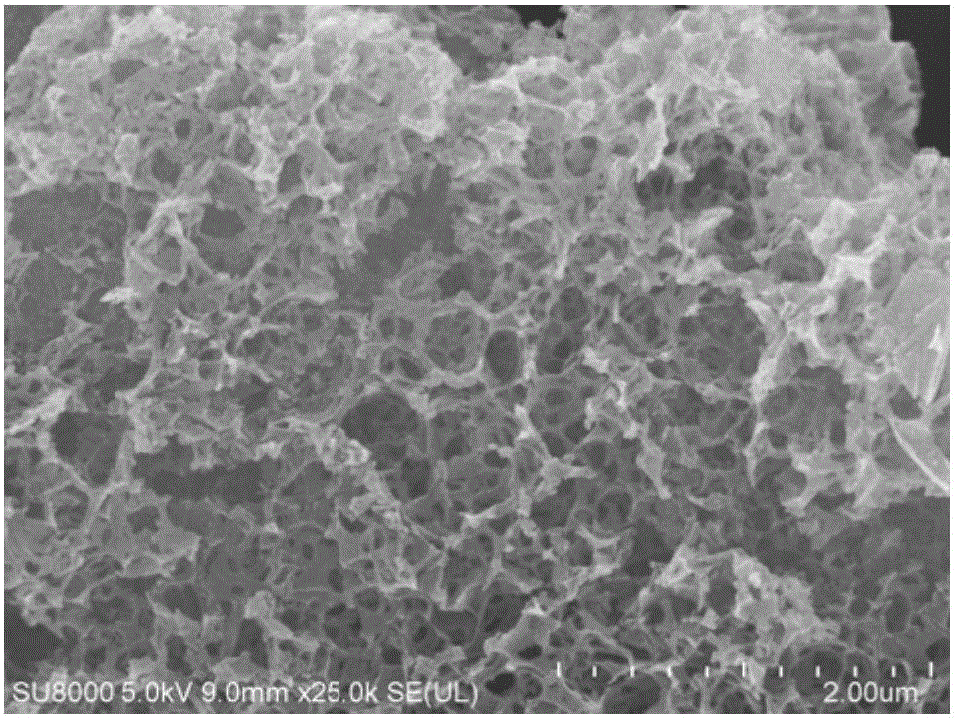

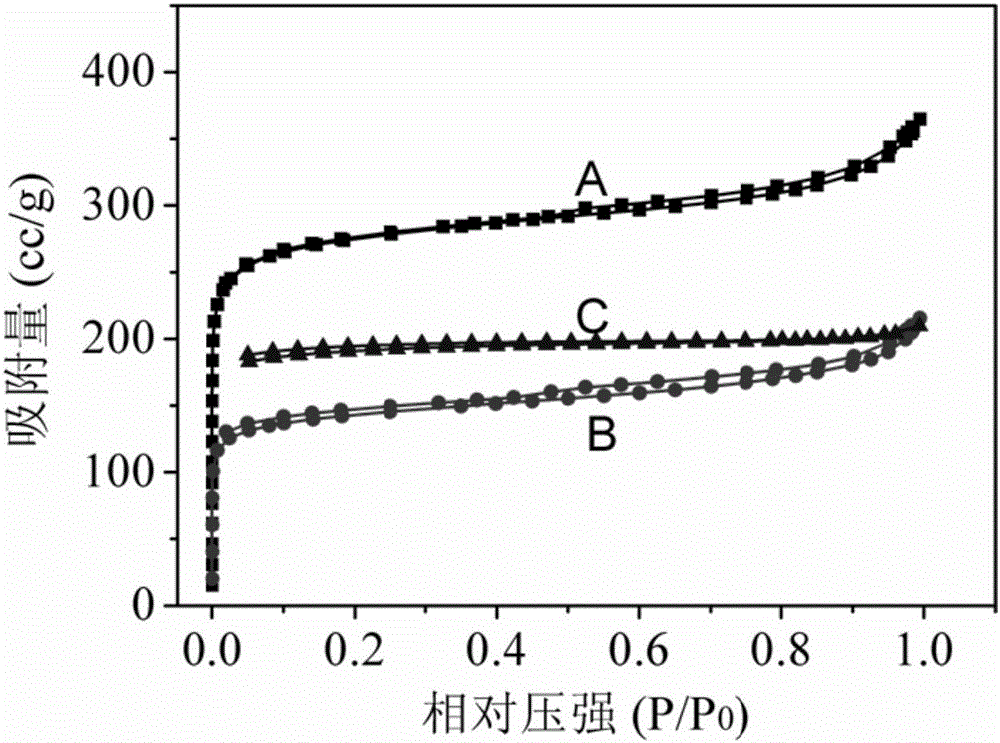

Preparation method and product of multistage porous carbon material

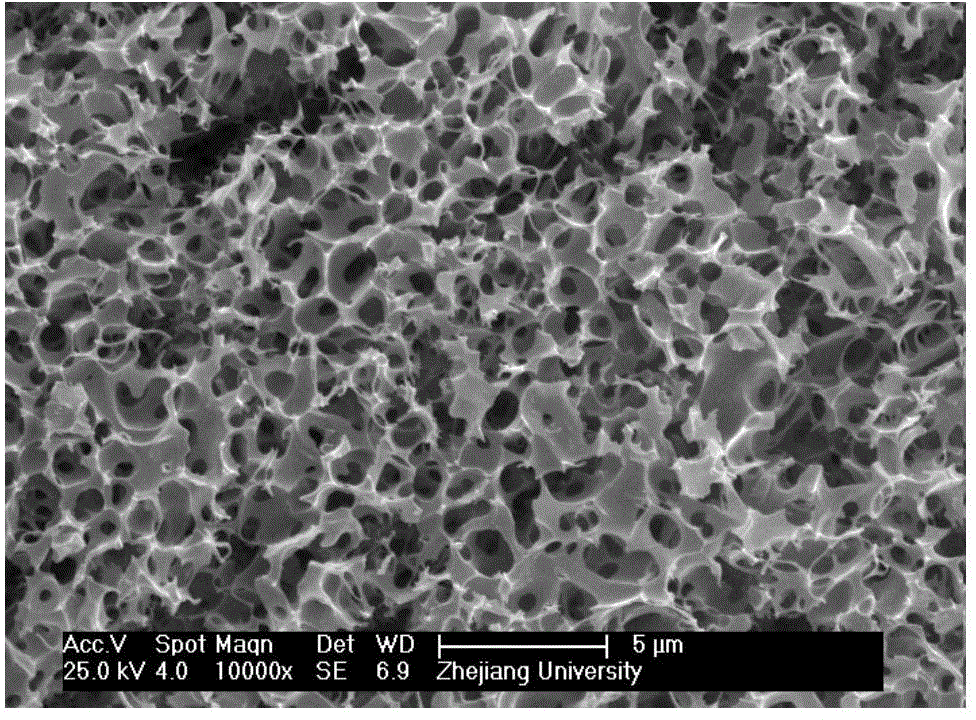

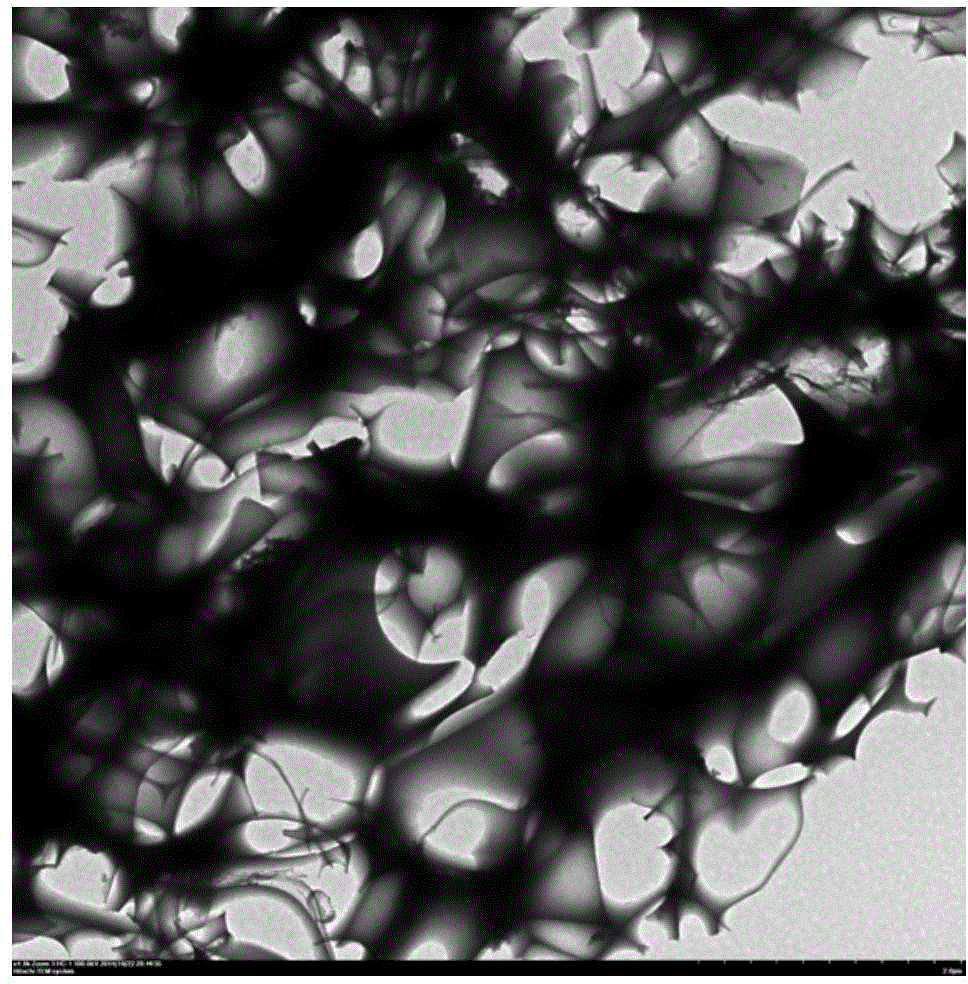

The invention discloses a preparation method of a multistage porous carbon material. The preparation method comprises the following steps: blending a carbon source with an activator, and performing two-step carbonization and after treatment to obtain the multistage porous carbon material, wherein the two-step carbonization comprises low-temperature carbonization and high-temperature carbonization, the temperature of the low-temperature carbonization is 200-400 DEG C, and the temperature for the high-temperature carbonization is 800-1200 DEG C; the carbon source is a biomass, monosaccharide, disaccharide or polysaccharide of which the cellulose content is more than 20%; and the activator is selected from ammonium oxalate, potassium oxalate, potassium hydrogen oxalate, potassium tetroxalate, sodium oxalate, sodium hydrogen oxalate, sodium tetroxalate, sodium hydrogen carbonate or potassium hydrogen carbonate. The invention provides the preparation method of the multistage porous carbon material rich in macropore, and according to the preparation method, physical expansion and chemical activation are utilized, and a carbon source is used as a raw material to match with a specific activator in order to prepare the multistage porous carbon material rich in macropore; and the raw material is low in price and easy to obtain, the method is simple and strong in sustainability and has a potential for large-scale production.

Owner:ZHEJIANG UNIV

Method for preparing vanadium oxide

InactiveCN103146930AAchieve recyclingReduce consumptionProcess efficiency improvementHigh phosphateSlag

The invention provides a method for preparing vanadium oxide, which comprises the following steps of: mixing vanadium slag with calcium oxide or limestone to form a mixed material; roasting the mixed material to obtain calcified clinker; leaching the calcified clinker by using C2O4<2-> and 35-70 g / L of oxalate solution at 80-95 DEG C; after leaching, carrying out solid-liquid separation to obtain vanadium-containing leachate and residues; removing silicon from the vanadium-containing leachate, so that the silicon concentration in the vanadium-containing leachate is less than 0.1 g / L, then adding ammonium oxalate into the vanadium-containing leachate, adjusting the mol ratio of NH4<+> to TV to 2-3.5, precipitating ammonium metavanadate, and filtering to obtain ammonium metavanadate and vanadium precipitation wastewater; and oxidizing, roasting and deaminizing ammonium metavanadate to prepare vanadium pentoxide or reducing to prepare vanadium trioxide. According to the invention, on the premise of satisfying environment-friendly requirements, preparation of vanadium oxide from ordinary vanadium slag and high-calcium and high-phosphate vanadium slag is realized; furthermore, consumption of reagents can also be reduced; and the production cost is reduced.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

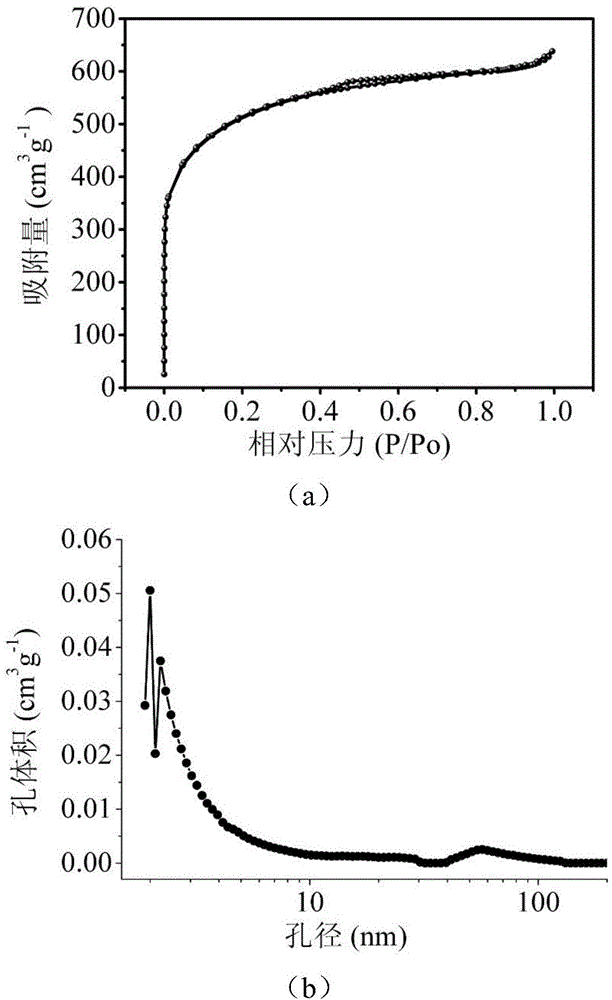

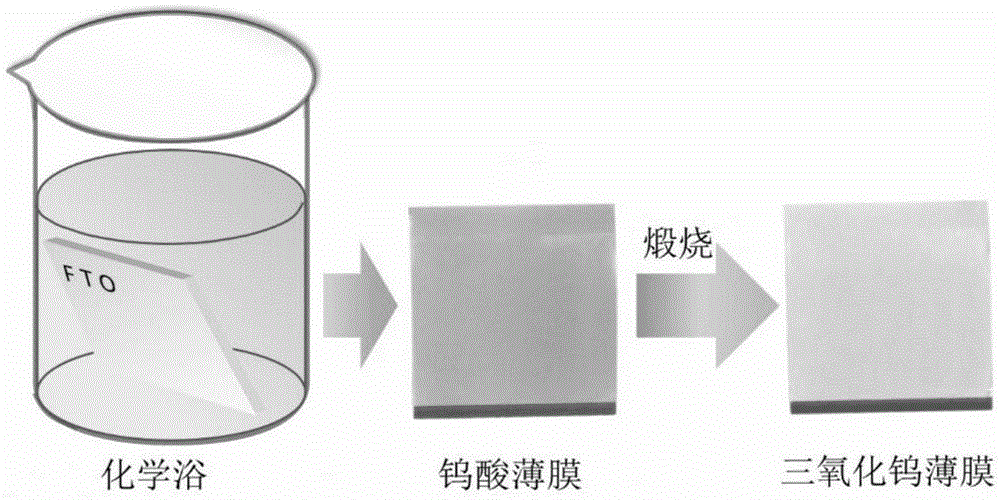

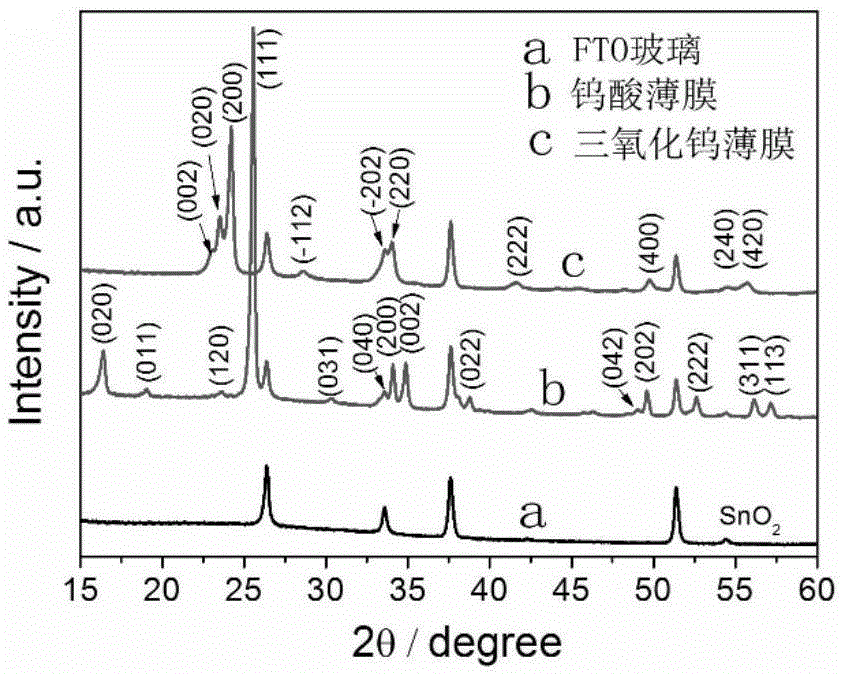

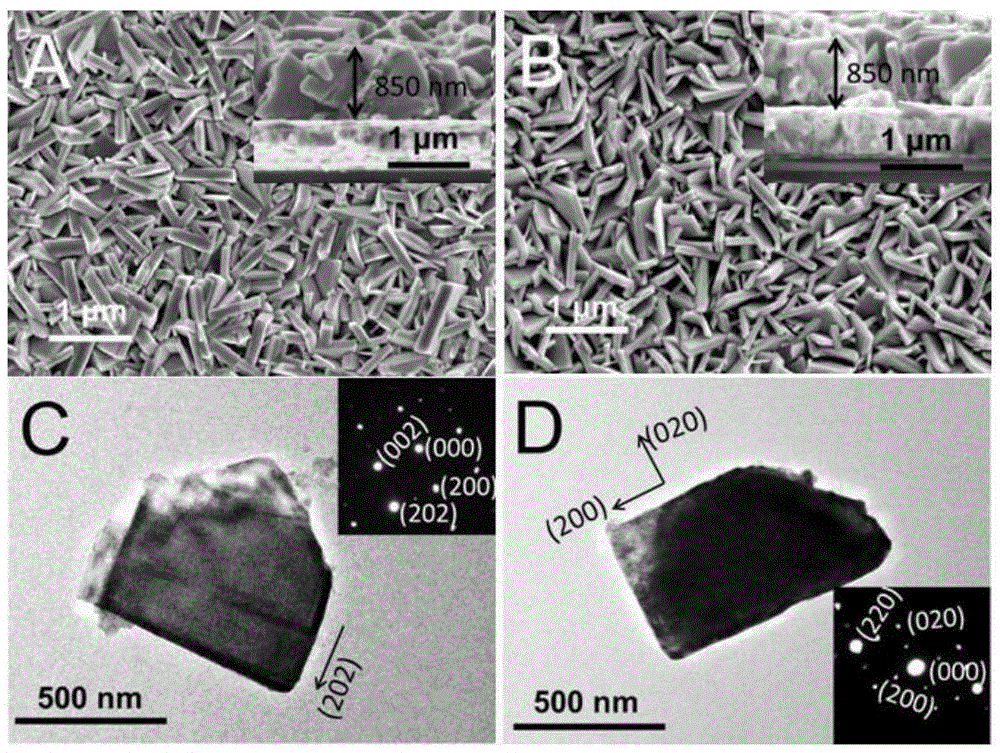

Preparation method and application research of WO3 nanosheet array film

InactiveCN105384358AThe preparation process is simpleThe preparation process is mildCoatingsWater bathsLight response

The invention discloses a preparation technology of a visible-light response WO3 nanosheet array film electrode. The preparation technology comprises the following steps that Na2WO4.2H2O and ammonium oxalate are dissolved in deionized water to react with hydrochloric acid to obtain tungstic acid precipitates, and the tungstic acid precipitates react with H2O2 to obtain a clear peroxotungstic acid solution; an ethyl alcohol reducing agent is added into the peroxotungstic acid solution, fluorine-doped tin oxide (FTO) conducting glass serves as a substrate to be placed in the solution, under the water bath condition, the peroxotungstic acid is slowly reduced into tungstic acid, the tungstic acid is slowly separated out on an FTO film, and then a tungstic acid film is obtained; after being cleaned and dried, the tungstic acid film is calcined to obtain the WO3 nanosheet array film electrode. The preparation technology has the advantages of being simple, convenient, mild, efficient and suitable for large-scale preparation. The prepared WO3 nanosheet array film electrode has the good visible-light absorption property and good stability and is high in photoelectric efficiency, good in photoelectrocatalytic degradation effect on organic matter and capable of being applied to the fields of photoelectrocatalysis hydrogen production and organic matter degradation, and the better effect is achieved.

Owner:SHANGHAI JIAO TONG UNIV

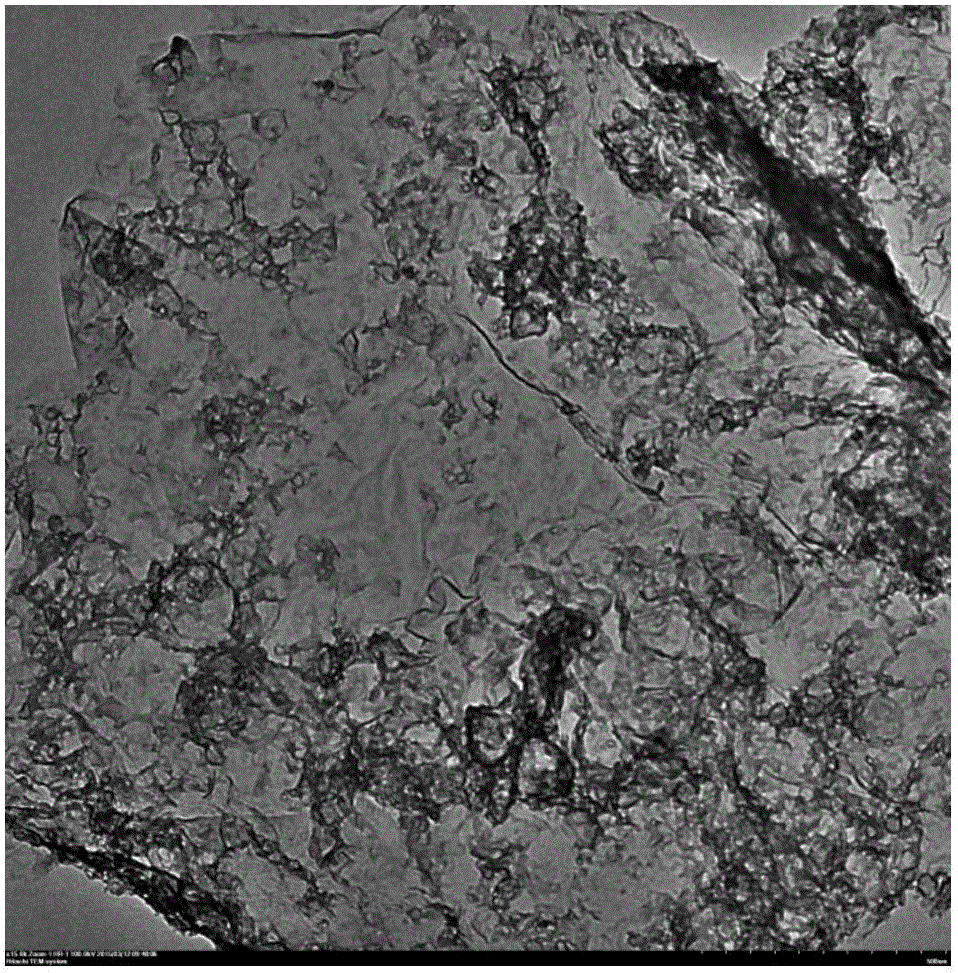

Nitrogen-doped hierarchical pore carbon and preparation method and application thereof

ActiveCN106179440AImprove usabilityLarge specific surface areaOrganic reductionPreparation by hydroxy compound hydrogenationNano catalystSodium bicarbonate

The invention discloses a preparation method of nitrogen-doped hierarchical pore carbon. The preparation method includes: using biomass as a raw material, and mixing the biomass with a composite activator; heating for calcining, mixing a calcining product with deionized water, standing for precipitation, and filtering to obtain precipitate; performing after-treatment to obtain the nitrogen-doped hierarchical pore carbon, wherein the composite activator is sodium hydrogen carbonate / nitrogen-containing compound, a mass ratio of sodium hydrogen carbonate to the nitrogen-containing compound is 0.25-4:1, the nitrogen-containing compound comprises at least one of ammonium oxalate, ammonium hydrogen carbonate, ammonium chloride and ammonium nitrate, and a mass ratio of the biomass to the composite activator is 1:2-16. The composite activator is utilized to activate the biomass to obtain a functionalized nitrogen-doped hierarchical pore carbon material, the preparation method is simple and easy to operate, the biomass existing in nature can be utilized directly, the obtained carbon material has rich hierarchical pore structure and can be used as a catalyst carrier to prepare high-performance nano catalysts, and utilization value of the biomass is increased greatly.

Owner:ZHEJIANG UNIV

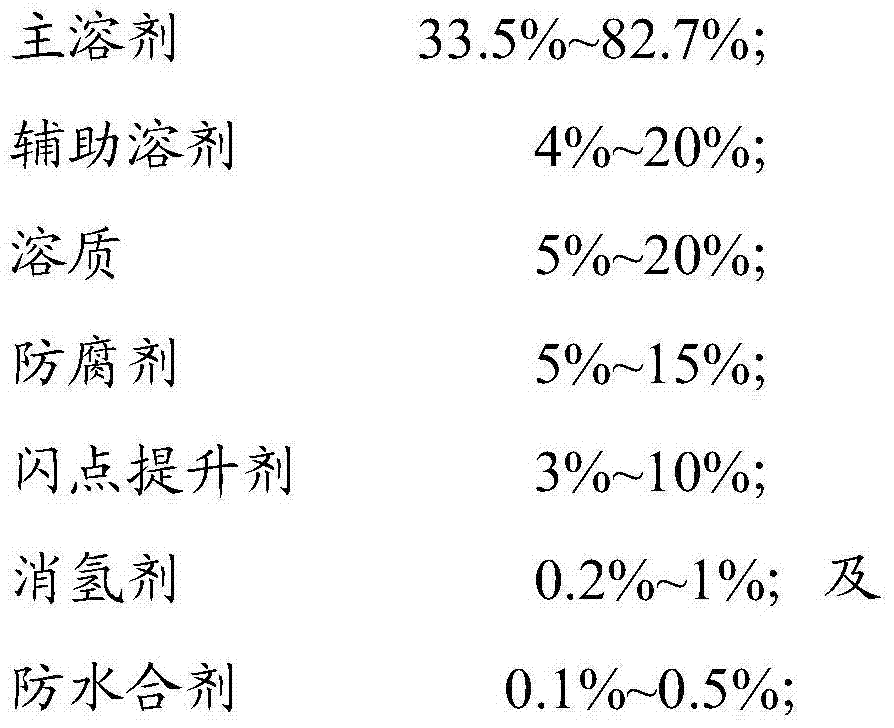

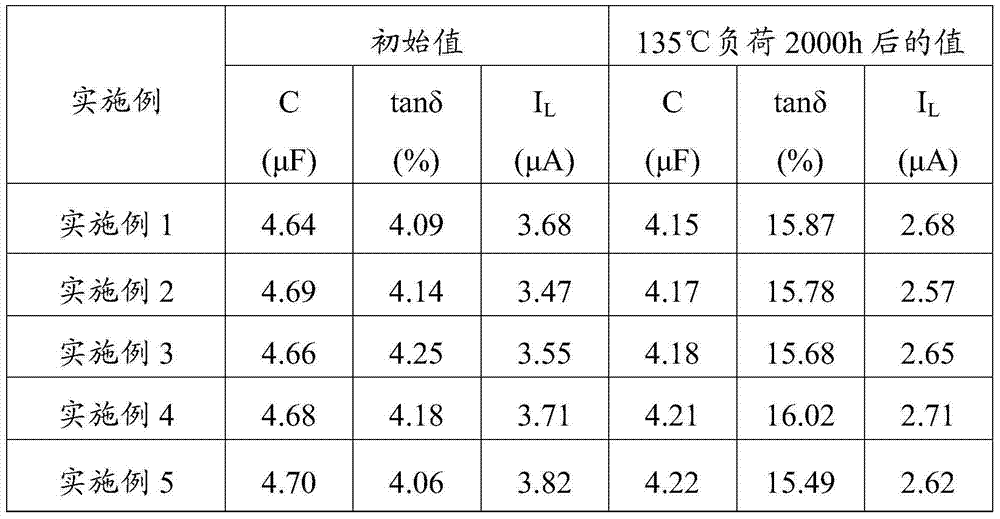

Electrolyte of aluminum electrolytic capacitor, preparation method thereof and aluminum electrolytic capacitor

The invention relates to electrolyte of an aluminum electrolytic capacitor, a preparation method thereof and the aluminum electrolytic capacitor. The electrolyte of the aluminum electrolytic capacitor includes the following components by mass: 33.5-82.7% of a main solvent, 4%-20% of an auxiliary solvent, 5%-20% of a solute, 5%-15% of a corrosion remover, 3%-10% of flash point promotion agent, 0.2%-1% of hydrogen elimination agent and 0.1%-0.5% of water-mixture-proof agent, wherein the solute is at least one of isodecyl ammonium sebate, 2-butyl-cork-acid-ammonium, 2- ethyl ammonium oxalate, 5, 6-ammonium sebate, potassium sebate, sebacic acid, azelaic acid, ammonium azelate, ammonium pentaborate and potassium carboxylate with chains with the number of carbon chains as 24-35. Experiments show that the aluminum electrolytic capacitor using the electrolyte has good high temperature resistance, the service life can be 2000 hours under the environment with the temperature high as 135 DEG C, and the service life is longer.

Owner:GUANGDONG FENGHUA ADVANCED TECH HLDG

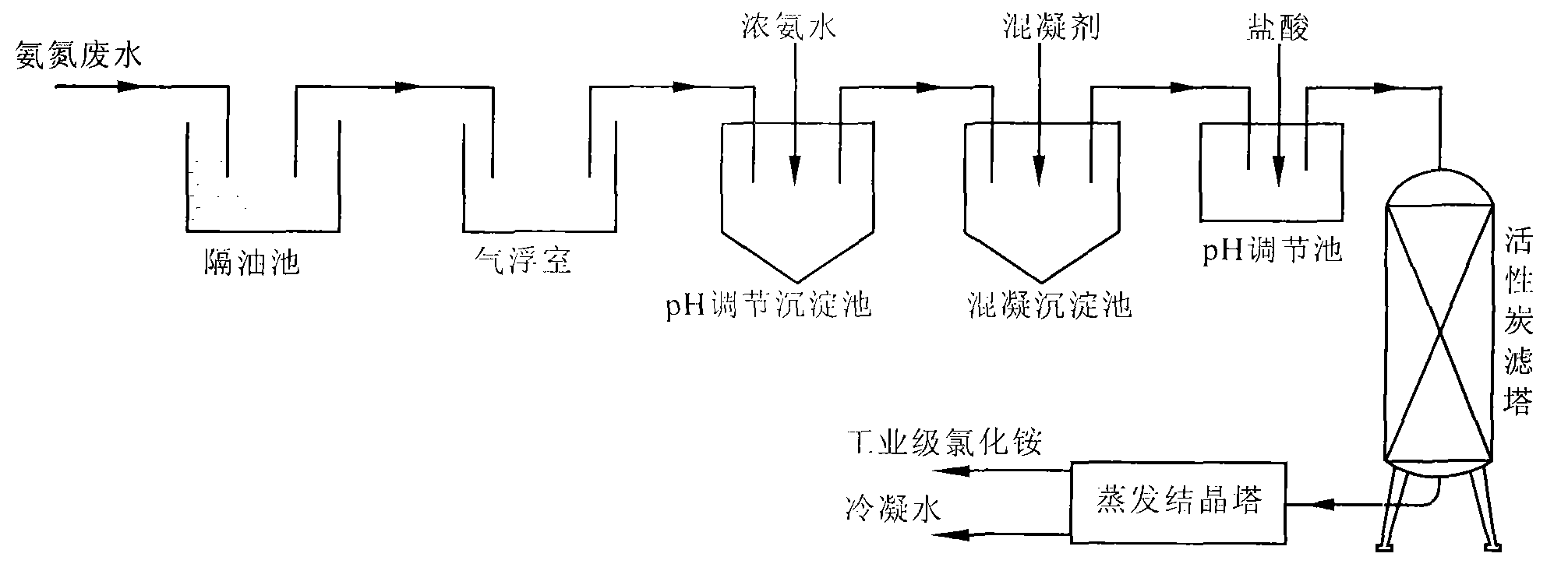

Compound coagulant used for treating rare-earth highly concentrated ammonian wastewater to recover industry ammonium chloride and treatment method

InactiveCN101555053ASimple processing methodLow costFatty/oily/floating substances removal devicesMultistage water/sewage treatmentRare earthPolyacrylamide

The invention provides a compound coagulant used for treating rare-earth highly concentrated ammonian wastewater to recover industry ammonium chloride and a treatment method, belonging to the technical field of chemical environment protection and resource recovery. The compound coagulant is a mixed liquor of ammonium oxalate, ammonium sulphate, heavy metal precipitator DTCR and polyacrylamide (PAM). The treatment method for treating wastewater by using the compound coagulant comprises the following steps: firstly, oil substances in the wastewater are removed through a separation tank and an air floating chamber; secondly, the wastewater enters a pH adjusting precipitation tank to adjust the pH value to be 7.5-8.5; thirdly, the wastewater enters a coagulative precipitation tank, the compound coagulant is added, the wastewater after being coagulated and precipitated enters the pH adjusting precipitation tank to adjust the pH value to be 2.5-4, the wastewater after being adjusted the pH value enters an active carbon filter tower to be absorbed and filtered and then is evaporated and concentrated under the condition of negative pressure. The compound coagulant has simple treatment method, low cost and good effect. The treatment method has short process and simple and easy treatment, not only solves the problem of the pollution of the highly concentrated ammonian wastewater, but also achieves the purpose of recovering valuable materials.

Owner:GUANGZHOU INST OF GEOCHEMISTRY - CHINESE ACAD OF SCI

Process for preparing active aluminium oxide

InactiveCN1425612AUniform temperatureUniform concentrationAluminium hydroxide preparationAluminium oxides/hydroxidesAluminium chlorideAluminium hydroxide

The present invention relates to the preparation process of active gamma-Al2O3. The mixed water solution of materials including aluminum chloride, ammonia water, pore expander ammonium oxalate or ammonium citrate, etc. is heated and concentrated to produce aluminum hydroxide precipitate; the precipitate is dried and heated to obtain solid powder and to decompose its NH4Cl, which is recovered from hot gas flow through cooling and crystallization; and the solid powder is roasted at 400-800 deg.c for 3-6 hr to convert into gamma-Al2O3. The present invention produces aluminum hydroxide through evaporation and concentration, rather than neutralization, and aluminium hydroxide is precipitated and separated in a stable and balanced solid-liquid state, and this is favorable to producing aluminium hydroxide grains with homogeneous size.

Owner:XIAMEN UNIV

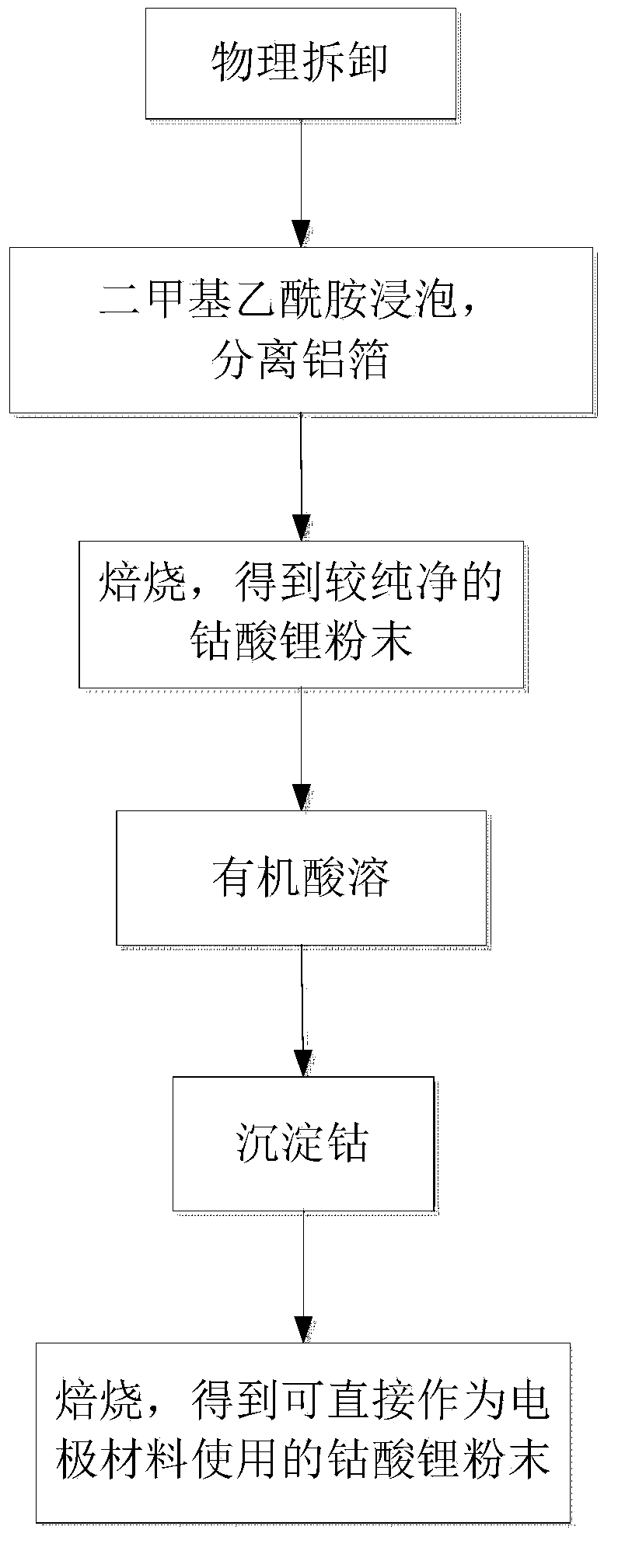

Method for recovering cobalt from lithium battery anode material

ActiveCN103474718AHigh recovery rateLow powder impurity contentWaste accumulators reclaimingBattery recyclingSolid matterAmmonium oxalate

The invention discloses a method for recovering cobalt from a lithium battery anode material. The method is characterized by comprising the following steps of: (1) removing aluminum foil from the anode material, obtaining a black solid matter containing lithium cobalt oxide, roasting the black solid matter to form lithium cobalt oxide powder, (2) weighing and adding the lithium cobalt oxide powder into 119-240g / L of citric acid according to a solid-to-liquid ratio of (20-30):1g / L, adding hydrogen peroxide at a mass fraction of 30% according to a mole ratio of 2:(1-1.05), performing stirring leaching for 5-7h at 80-90 DEG C, filtering to form filtrate containing the cobalt, (3) adding an ammonium oxalate solution into the filtrate to form a cobalt oxalate precipitate, and (4) after drying the cobalt oxalate precipitate, adding lithium carbonate powder according to a mole ratio (1:(1-1.05)) of the cobalt to lithium, grinding uniformly, roasting for 6-8h at 800-850 DEG C, and obtaining lithium cobalt oxide powder capable of directly serving as the electrode material. The method is easy to operate and high in recovery rate, equipment is simple, waste liquid is easy to treat, and the pollution of waste lithium batteries to an environment can be effectively reduced.

Owner:HUAZHONG UNIV OF SCI & TECH WUCHANG BRANCH

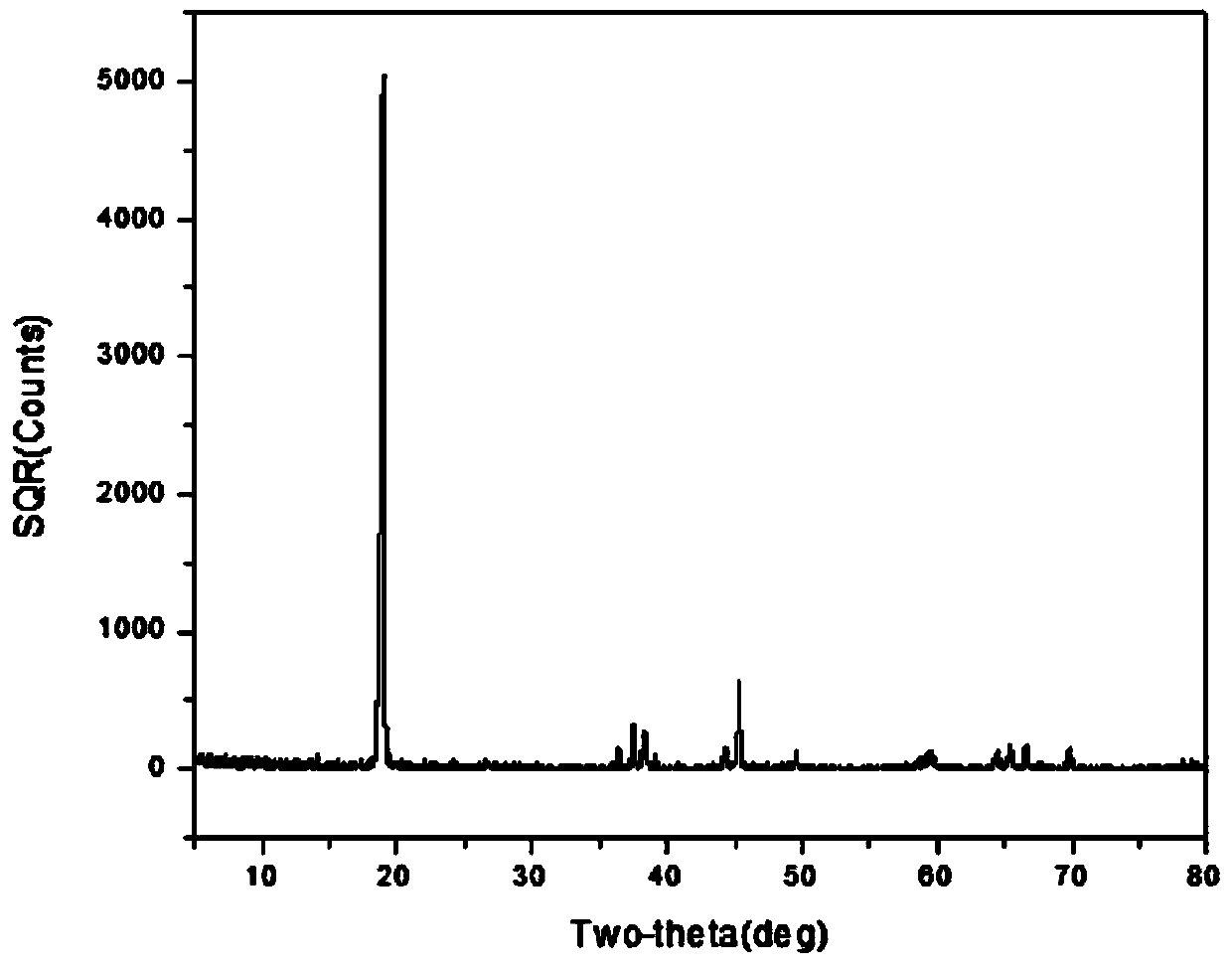

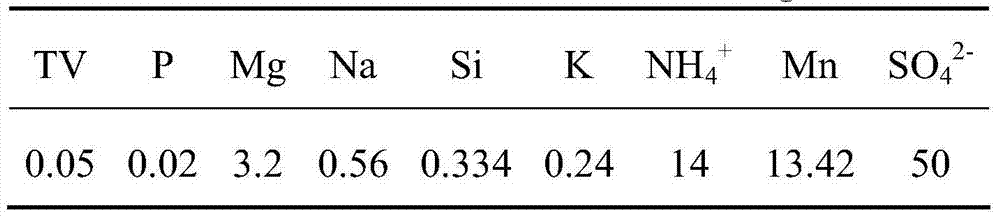

Method for removing manganese from acidic molybdenum precipitation wastewater

InactiveCN103922454AEfficient use ofHigh in manganeseWaste water treatment from metallurgical processWater/sewage treatmentWastewaterEconomic benefits

The invention discloses a method for removing manganese from acidic molybdenum precipitation wastewater. The method comprises the steps of adjusting the pH value of the acidic molybdenum precipitation wastewater to be 5-7, adding ammonium oxalate, and filtering to obtain ammonium oxalate deposits and supernatant liquor, wherein the supernatant liquor contains less than 0.05g / L of Mn<2+>. The method has the advantages of being simple in process, easy and convenient to operate, capable of recovering manganese resources, low in equipment requirement, environment-friendly and the like, and has very good social and economic benefits. In addition, ammonium sulfate obtained after manganese removal can be used for molybdenum precipitation, condensed water can be directly recycled, and the resources can be effectively utilized.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

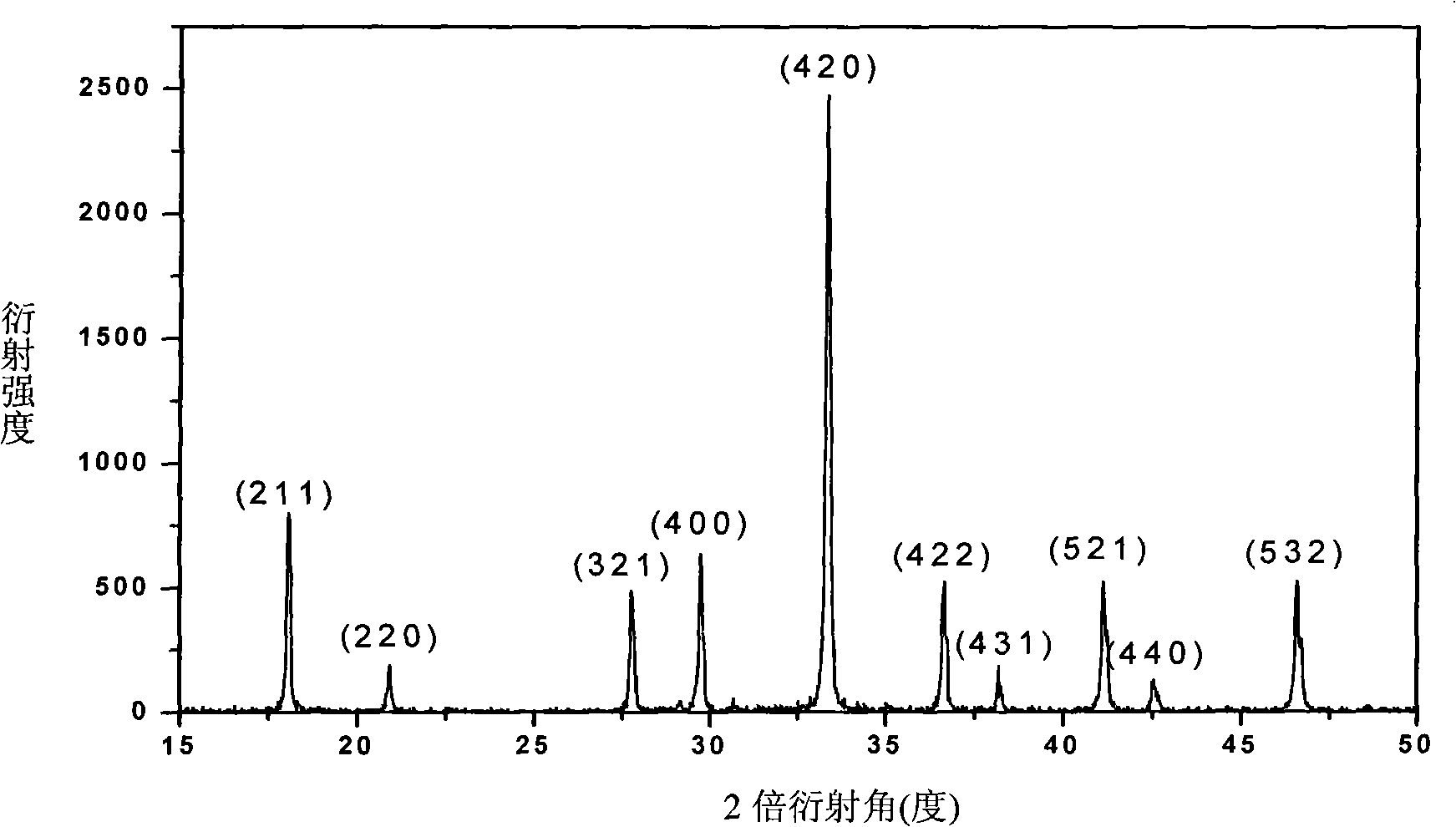

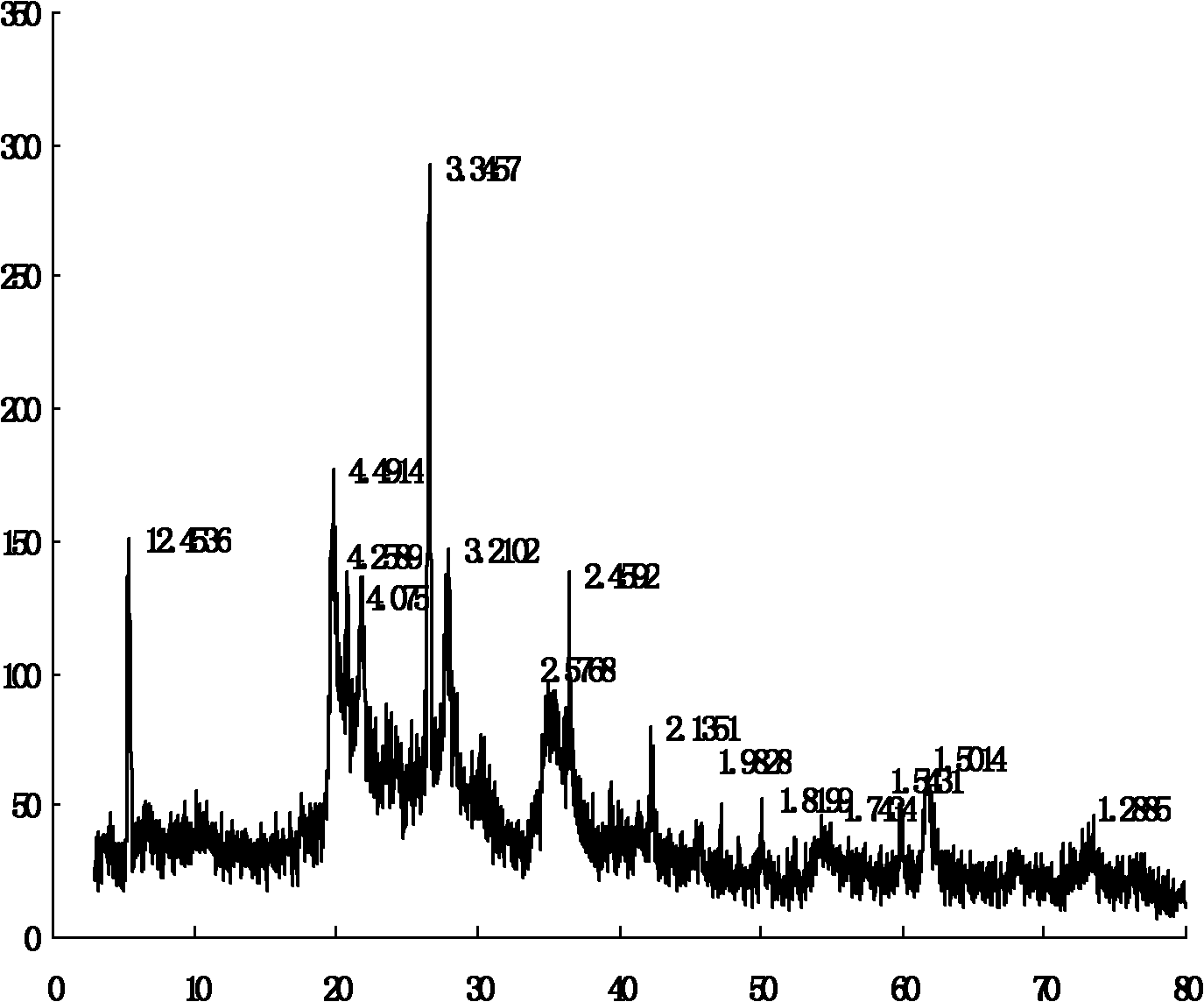

Method for preparing rare earth-doped yag nano-powder by partial liquid phase precipitation method

ActiveCN101302019AEvenly dopedEvenly distributedRare earth metal compoundsAluminium oxides/hydroxidesRare-earth elementMetallurgy

The invention relates to a method for preparing a rare earth doped yttrium aluminum garnet nanometer powder body by a partial liquid phase precipitation method. Y(NO3)3 and Al2O3 are used to synthesize the yttrium aluminum garnet nanometer powder body; and Nd, Yb, Cr and other rare earth elements are used for ion doping. Ammonium oxalate, NH4HCO3 or urea is adopted as a precipitant. Sediment is aged, fully washed, dried and calcined for 15 to 120 minutes at a temperature of between 1000 and 1600 DEG C under the aerobic condition, thereby acquiring the rare earth doped YAG powder body with a grain diameter between 80 to 200 nm. The method can realize the uniform doping of the rare earth elements, also avoid forming a colloidal substance which is unfavorable for washing, and prepare the rare earth doped YAG nanometer powder body material in high efficiency.

Owner:SHANDONG UNIV

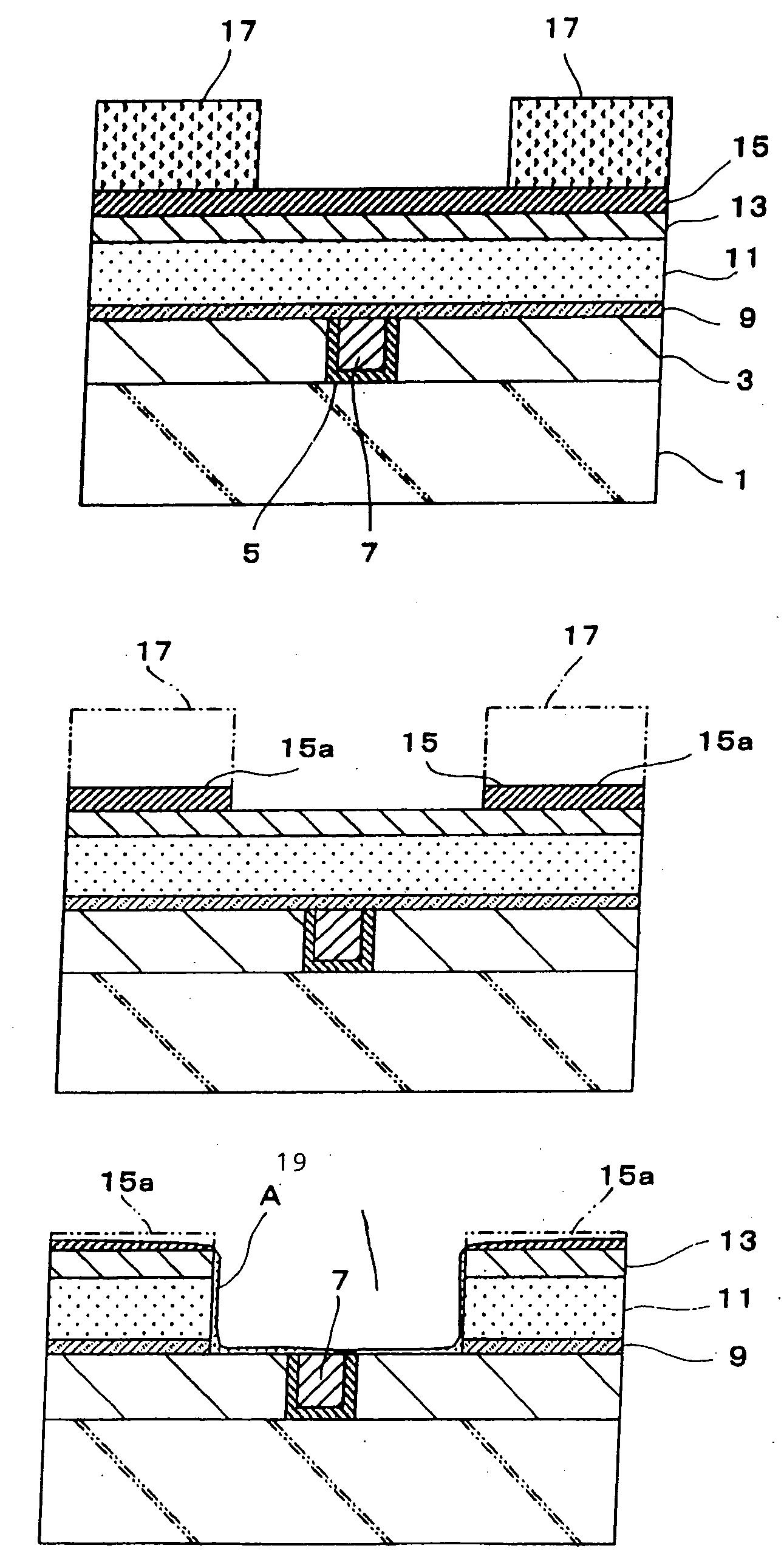

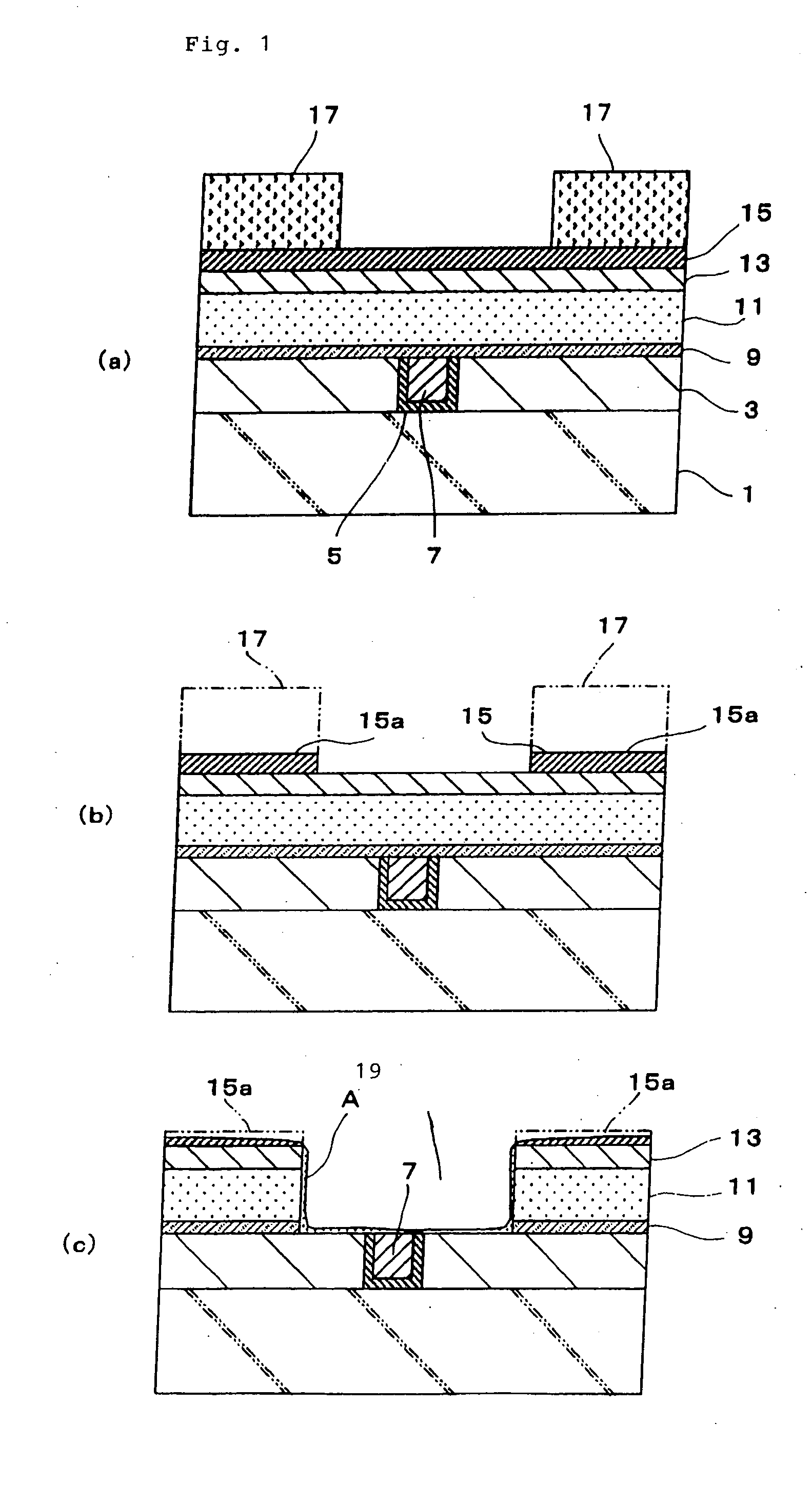

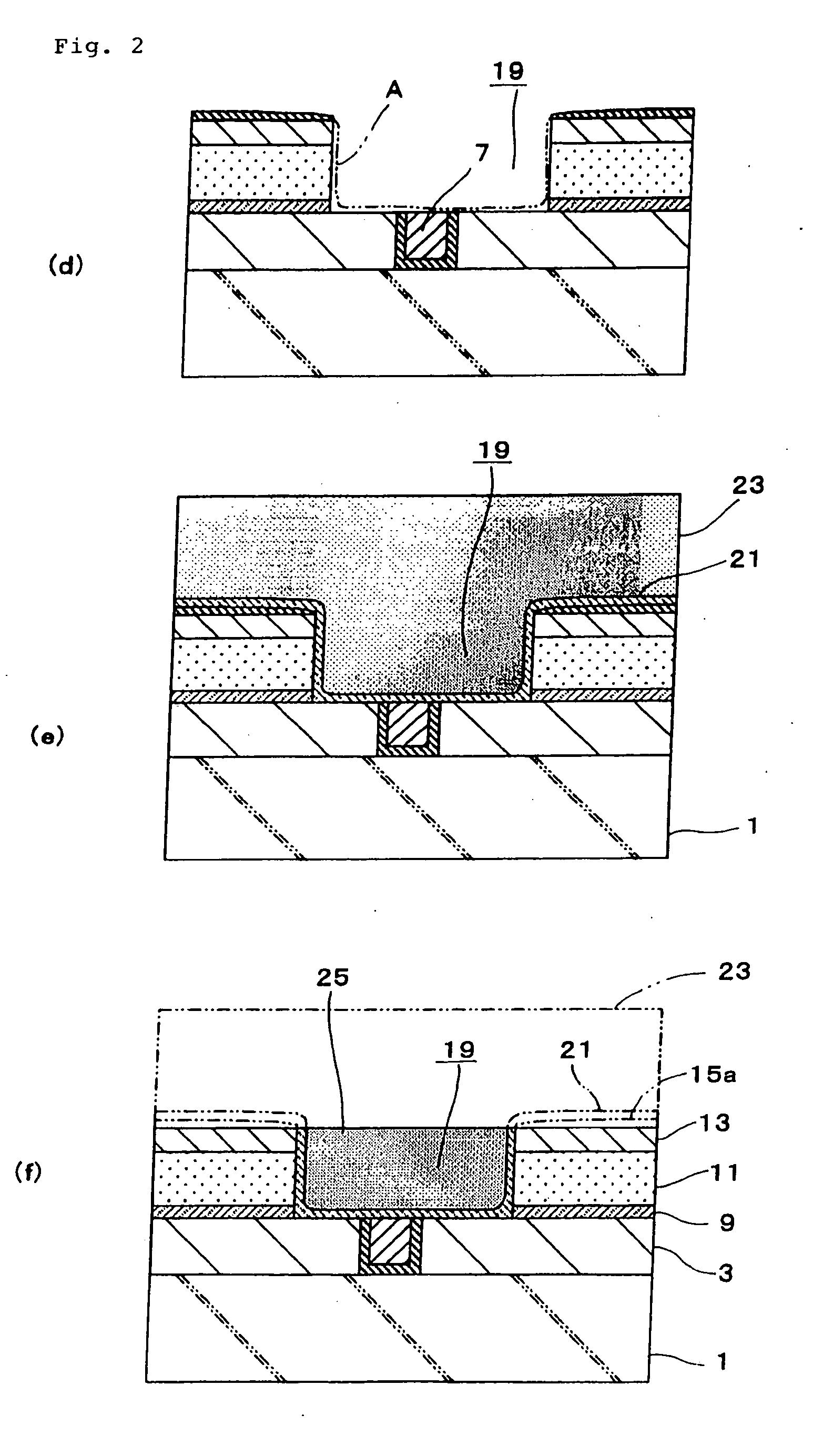

Post-dry etching cleaning liquid composition and process for fabricating semiconductor device

InactiveUS20060019201A1Avoid corrosionReduce the burden onInorganic/elemental detergent compounding agentsSemiconductor/solid-state device detailsDevice materialAmmonium oxalate

A post-dry etching cleaning liquid composition for cleaning a substrate after dry etching is provided, the cleaning liquid composition containing at least one type of fluorine compound, glyoxylic acid, at least one type of organic acid salt, and water. With regard to the fluorine compound, ammonium fluoride may be used. With regard to the organic acid salt, at least one of ammonium oxalate, ammonium tartarate, ammonium citrate, and ammonium acetate may be used.

Owner:SONY CORP +2

Method for leaching extracted vanadium from vanadium-containing raw material roasted clinker through ammonium oxalate

The invention provides a method for leaching extracted vanadium from vanadium-containing raw material roasted clinker through ammonium oxalate. The method includes the steps that a mixture of a vanadium-containing raw material and an additive is roasted to obtain a vanadium-containing raw material clinker; the vanadium-containing raw material clinker leaches extracted vanadium in an ammonium oxalate solution, and extracted vanadium tailings and a vanadium-containing leaching solution are obtained after solid-liquid separation. The method is high in vanadium selective leaching rate which can reach 90% or above, the content of vanadium-containing solution impurities obtained after leaching is small, the acidity and the alkalinity are proper, the purification and impurity removal process can be simplified or omitted, and subsequent vanadium precipitation and preparation of high-purity vanadium products are facilitated. No salt-containing waste water is generated. A leaching agent, namely the ammonium oxalate solution, used in the method does not volatilize, and the problem of ammonia volatilization is avoided. Besides, the leaching technology is simple in process, the method is friendly to the operation environment, and production cost is low.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

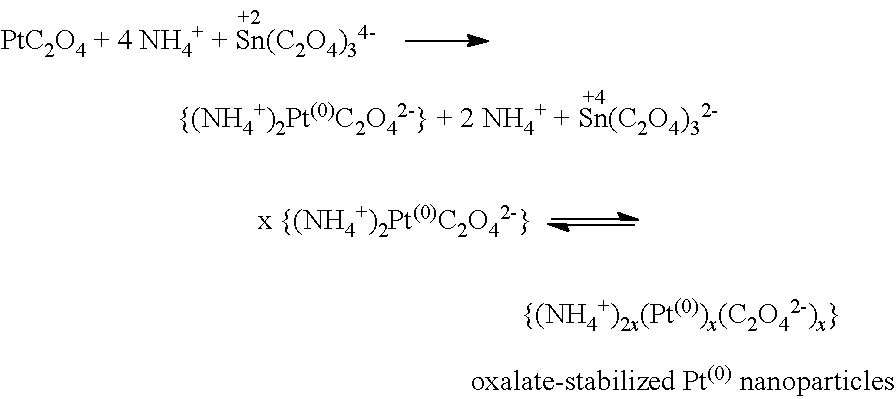

Processes for making tin-containing catalysts

InactiveUS8211821B2Promote solubilizationOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsOxalateSolvent

A process for producing a catalyst comprising the steps of contacting a support with a mixed metal precursor comprising tin oxalate, a second metal precursor, a solubilizing agent such as ammonium oxalate, and water to form an impregnated support and heating the impregnated support under conditions effective to remove at least a weight majority of the water and reduce the tin from the tin oxalate and the second metal from the second metal precursor and thereby form the catalyst.

Owner:CELANESE INT CORP

Method for separating and preparing high loose ratio and high purity cobalt oxalate from asbolite

InactiveCN101792855AHigh recovery rateReduce pollutionOrganic chemistryProcess efficiency improvementOxalateKerosene

The invention relates to a method for separating and preparing high loose ratio and high purity cobalt oxalate from asbolite. The method is characterized by comprising the following steps of: 1. carrying out reduction leaching and deironization by utilizing sodium sulfite; 2. extracting: carrying out copper extraction by utilizing a Li*984N and No.260 kerosene mixing solution, extracting and removing impurities by utilizing P204, and extracting and separating nickel and cobalt by utilizing P507; and 3. carrying out acidification by utilizing an oxalate solution on a solution after back extraction by utilizing the P507 in the step 2, then reacting the acidified solution with an ammonium oxalate solution and synthesizing to prepare the high loose ratio and high purity cobalt oxalate. The invention has the advantages of simple process flow, advanced technology, high metal recovery rate, low production cost, less environment pollution and excellent prepared product quality.

Owner:江苏雄风科技有限公司

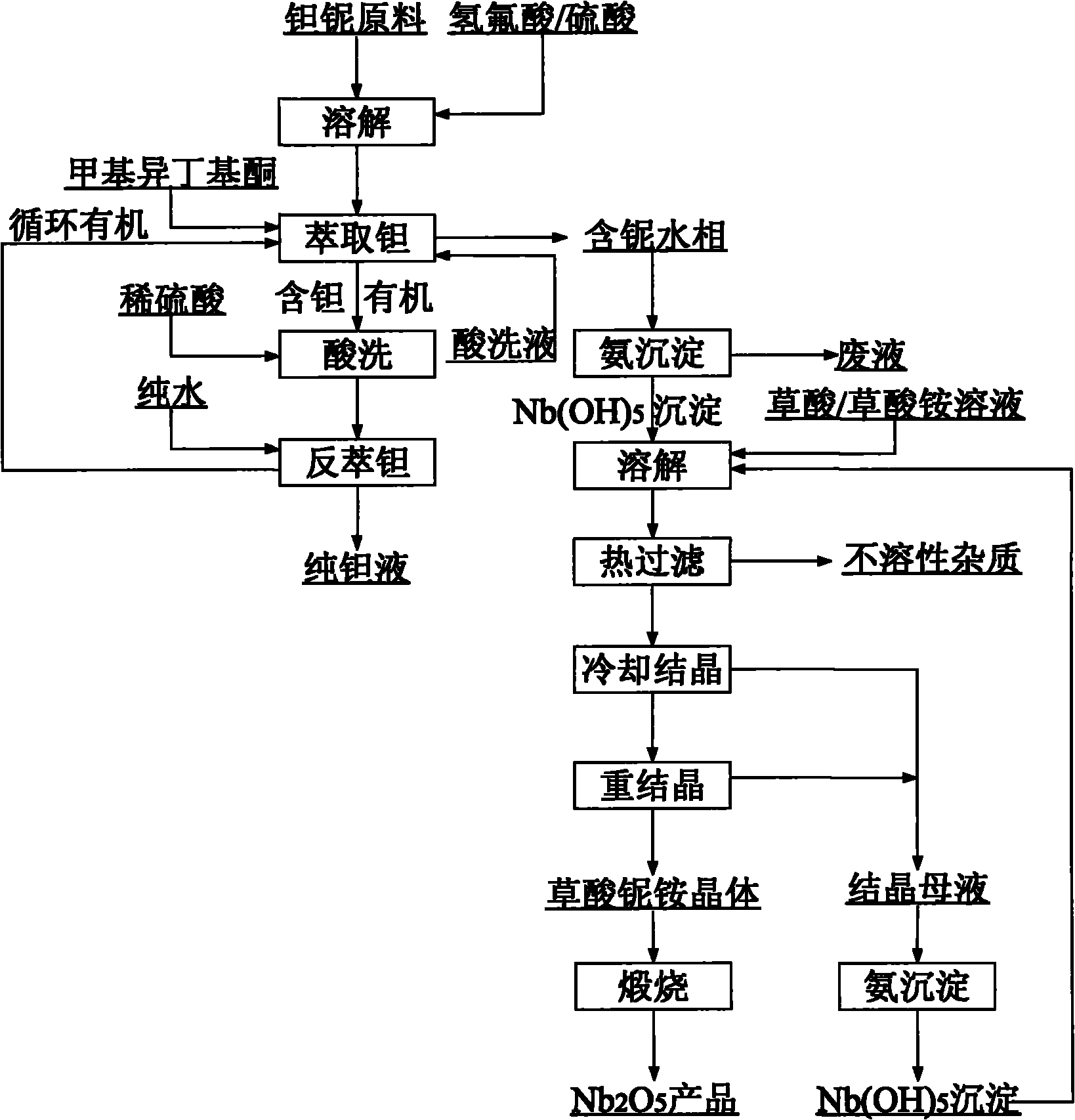

Method for separating tantalum and niobium

InactiveCN101955228AReduce concentrationReduce productionTantalum compoundsNiobium compoundsCoordination complexAmmonium oxalate

The invention relates to a method for separating tantalum and niobium from a raw material containing the tantalum and the niobium, comprising the following steps: dissolving the raw material containing the tantalum and the niobium by utilizing hydrofluoric acid or the mixing solution of the hydrofluoric acid and sulfuric acid to obtain the solution containing tantalum and niobium fluorine coordination compounds; extracting the tantalum by utilizing methyl isobutyl ketone to obtain a tantalum-containing organic phase and a niobium-containing aqueous phase; washing the tantalum-containing organic phase by dilute sulphuric acid, and performing back-extracting by pure water to obtain the pure tantalum liquid; precipitating the niobium-containing aqueous phase to obtain the Nb (OH)5 precipitation; dissolving the obtained Nb (OH)5 precipitation by utilizing an oxalic acid and ammonium oxalate mixing solution to obtain an oxalic acid niobium ammonium solution; carrying out hot filtering, crystallizing, and recrystallizing process to obtain the oxalic acid niobium ammonium crystal; and calcining the crystal to obtain the pure niobium pentaoxide. The method can realize extraction and separation of the tantalum and the niobium at low hydrofluoric acid concentration, and solves the problems that a large amount of fluorine-containing waste liquid and waste residue are generated in the extracting and separating process at the high hydrofluoric acid concentration, and F content in the final product is higher.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

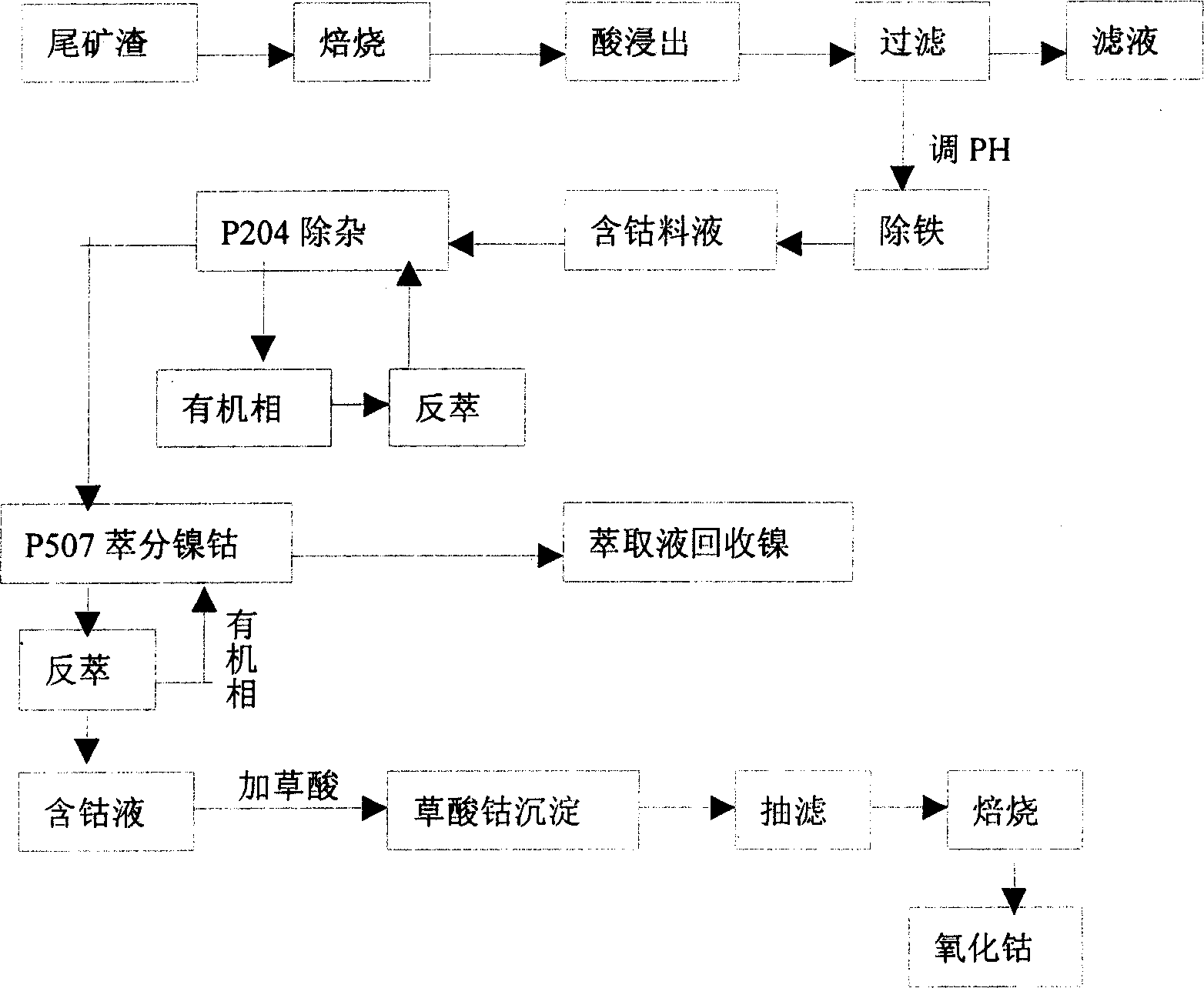

Tech. of extracting metallic cobait from magnetic-iron ore tailing slag

This invention discloses a technology to extract the cobalt from the tailing of magnetic iron ore. Its characteristics are as follows: (1) calcining the pretreatment magnetic iron ore at high temperature, (2) prophyrizing the magnetic iron ore which is handed as (1), (3) extracting the ore by sulfuric acid, (4) eliminating the rare-earth, iron, calcium and magnesium by chemical neutralization, (5) eliminating the copper, manganese, zinc and other substance with extraction reagent P204, then we can get cobalt solution by separating nickel and cobalt with extraction P507, (6)back-extracting, (7)depositing the cobalt with ammonium oxalate, (8) calcining the ammonium oxalate to high lever cobalt dioxide. The quality of cobalt dioxide recovered by this way can achieve to the lever of international Y0, the recovery ratio of cobalt can be above 85%.

Owner:HENAN UNIV OF SCI & TECH

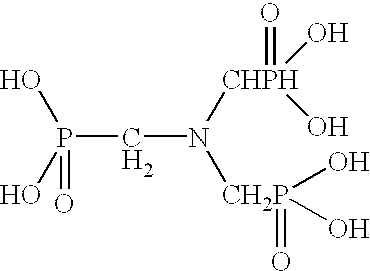

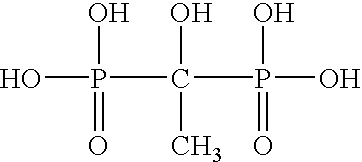

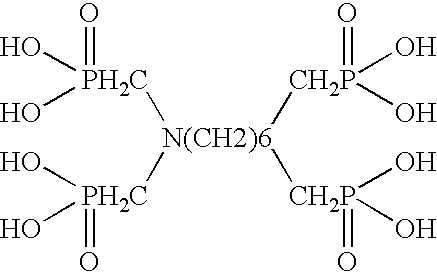

Ammonium polyphosphate solutions containing multi-functional phosphonate corrosion inhibitors

InactiveUS6846437B2Reduce corrosionOther chemical processesLiquid fertilisersSuspending AgentsFerrous Gluconate

A corrosion-inhibited fire retardant composition is provided that comprises at least one ammonium polyphosphate, at least one suspending agent, at least one phosphonate selected from a group consisting of aminotri(methylenephosphonic acid), 1-hydroxyethylidene-1,1-diphosphonic acid, hexamethylenediaminetetra(methylenephosphonic acid), diethylenetriaminepenta(methylenephosphonic acid), salts thereof, and mixtures thereof and a corrosion inhibiting system. The corrosion inhibiting system is comprised of at least one corrosion inhibiting compound selected from a group consisting of azoles, insoluble ferric pyrophosphate, soluble ferric pyrophosphate, ferrous oxalate, ferric citrate, ferrous sulfate, ferric ammonium citrate, insoluble ferric orthophosphate, soluble ferric orthophosphate, ferric ammonium oxalate, ferric ammonium sulfate, ferric bromide, ferric sodium oxalate, ferric stearate, ferric sulfate, ferrous acetate, ferrous ammonium sulfate, ferrous bromide, ferrous gluconate, ferrous iodide, ferric acetate, ferric fluoroborate, ferric hydroxide, ferric oleate, ferrous fumarate, ferrous oxalate, ferrous oxide, ferric lactate, ferric resinate, and any combination thereof. Methods of making and using the same are also described. In addition, agricultural plant nutrients comprising the same are provided.

Owner:PERIMETER SOLUTIONS LP

Fire retardant compositions with reduced aluminum corrosivity

InactiveUS6905639B2Reduced-tendency to corrode various metalBroaden applicationFireproof paintsAntifouling/underwater paintsBiopolymerFerrous Gluconate

Corrosion-inhibited fire retardant compositions and methods of making and using the same are provided. The corrosion-inhibited fire retardant compositions are comprised of at least one fire retardant component, at least one biopolymer having a particle size diameter of less than about 100 microns, and a corrosion inhibiting system. The corrosion inhibiting system is comprised of at least one corrosion inhibiting compound selected from a group of compounds including azoles, insoluble ferric pyrophosphate, soluble ferric pyrophosphate, ferrous oxalate, ferric citrate, ferrous sulfate, ferric ammonium citrate, soluble ferric orthophosphate, insoluble ferric orthophosphate, ferric ammonium oxalate, ferric ammonium sulfate, ferric bromide, ferric sodium oxalate, ferric stearate, ferric sulfate, ferrous acetate, ferrous ammonium sulfate, ferrous bromide, ferrous gluconate, ferrous iodide, ferric acetate, ferric fluoroborate, ferric hydroxide, ferric oleate, ferrous fumarate, ferrous oxide, ferric lactate, ferric resinate and any combination thereof. In a specific embodiment, the corrosion-inhibited fire retardant composition includes a xanthan biopolymer.

Owner:PERIMETER SOLUTIONS LP

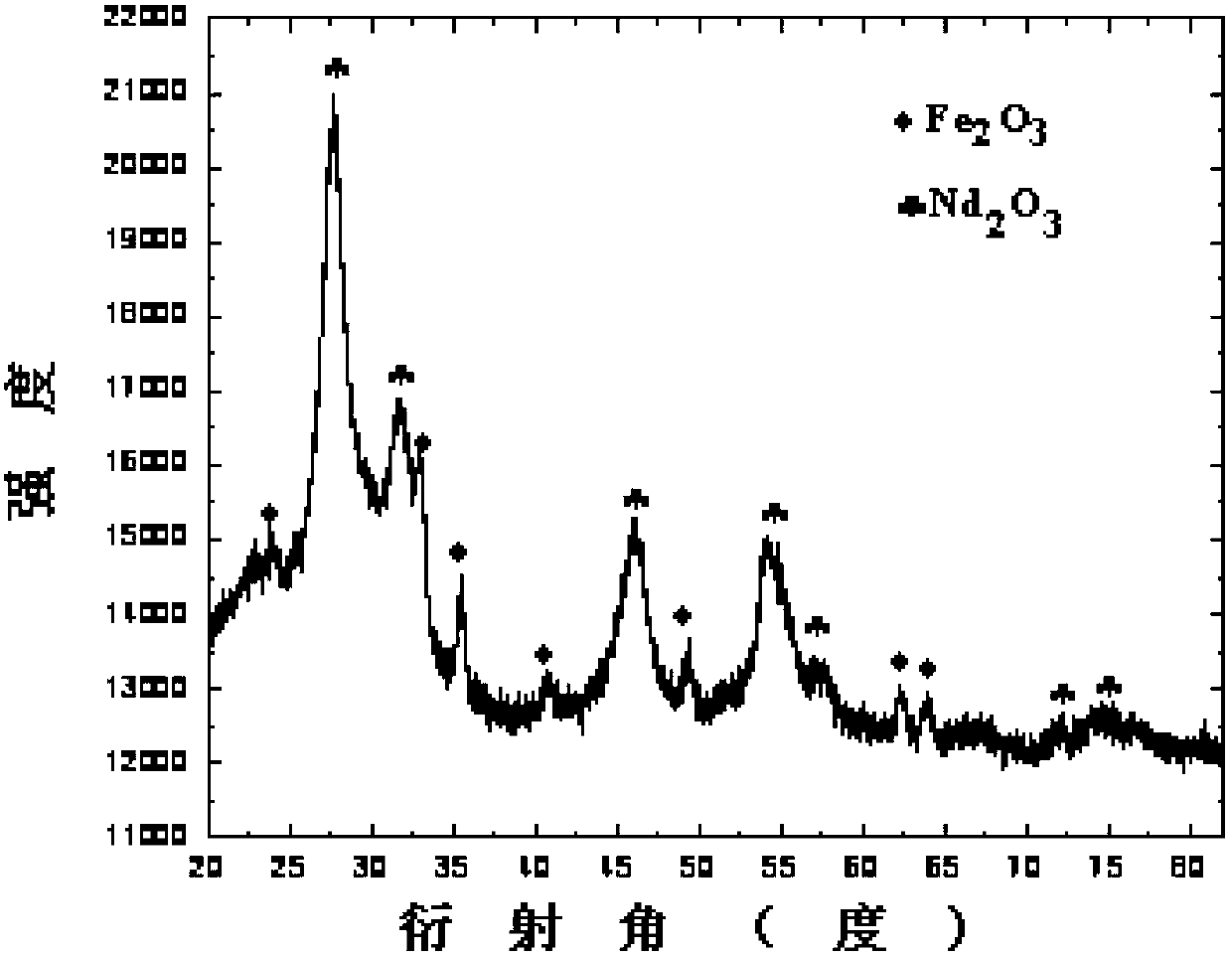

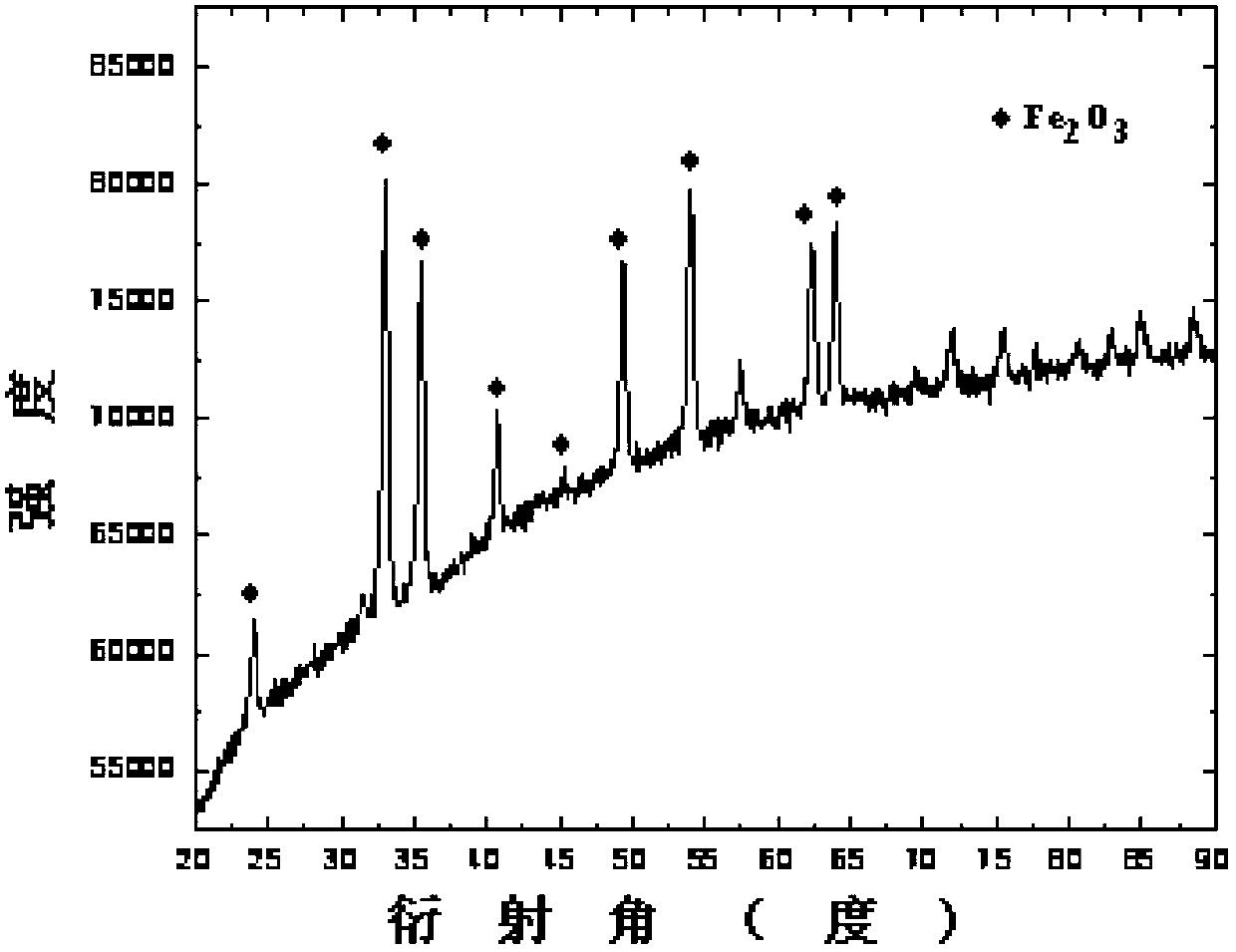

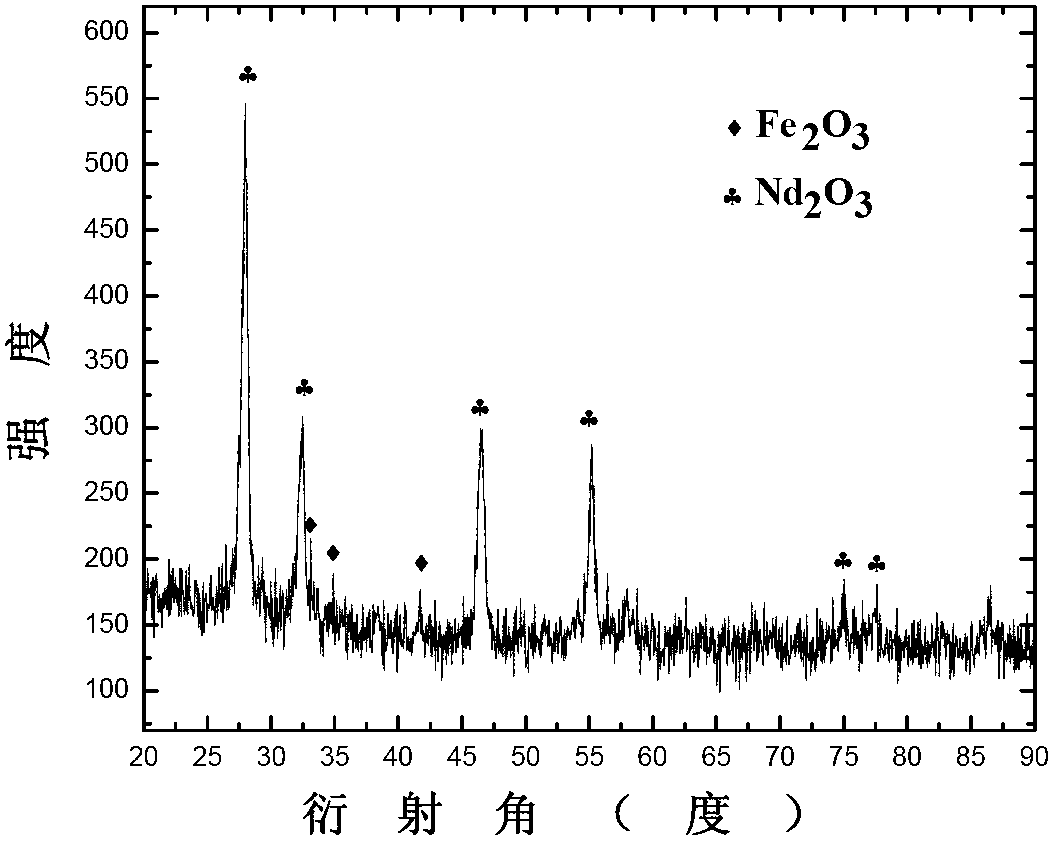

Method for recovering neodymium and iron from neodymium iron boron oil sludge through two-step co-precipitation

ActiveCN103343235AHigh recovery rateIncrease flexibilityProcess efficiency improvementDecompositionRare earth

The invention relates to a method for recovering neodymium and iron from neodymium iron boron oil sludge through two-step co-precipitation, belonging to the technical field of recycling of neodymium iron boron oil sludge. The method comprises the following steps of: dissolving the neodymium iron boron oil sludge by using hydrochloric acid and filtering undissolved substances, and then, controlling a certain pH value and reaction temperature after oxidizing through adding hydrogen peroxide; adding oxalic acid-ammonium bicarbonate and ammonium oxalate-ammonium hydroxide precipitating agent; co-precipitating a neodymium and iron sediment mixture in two steps; and respectively roasting a filtered product at the proper decomposition temperature to obtain neodymium and iron oxides. The neodymium and iron oxides can be used for re-preparing regenerated neodymium iron boron through reducing, forming, sintering and thermal treatment. A complex wet-method process for obtaining single high-purity rare earth in recovery is avoided, and the method is a key step for forming a cycle industry.

Owner:BEIJING UNIV OF TECH

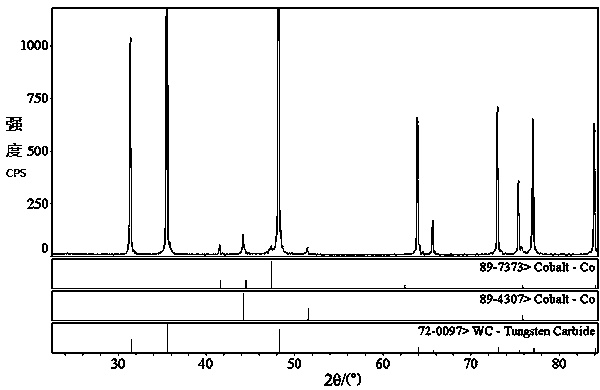

Extra-coarse hard alloy parcel powder and preparation method thereof

The invention discloses extra-coarse hard alloy parcel powder and a preparation method thereof. The preparation method comprises the steps of adding tungsten carbide powder of which the average Fisher particle size is 3-8 microns and other hard phase carbide powder of which the average Fisher particle size is 0.5-1.5 microns into a soluble cobalt salt solution, wherein the tungsten carbide powder and the hard phase carbide powder are used as a nucleating agent; performing chemical coprecipitation wrapping reaction on ammonium oxalate serving as a precipitator to enable the produced cobalt oxalate to be precipitated to the surfaces of the tungsten carbide powder and the hard phase carbide powder, and performing filtration, washing, drying and hydrogen reduction to obtain hard alloy parcel powder. The extra-coarse hard alloy parcel powder comprises the following components in percentage by weight: 6-12 percent of cobalt, 0-2 percent of crystalline grain inhibitor and the balance being tungsten carbide, wherein the average Fisher particle size of the tungsten carbide is 3-8 microns.

Owner:CENT SOUTH UNIV

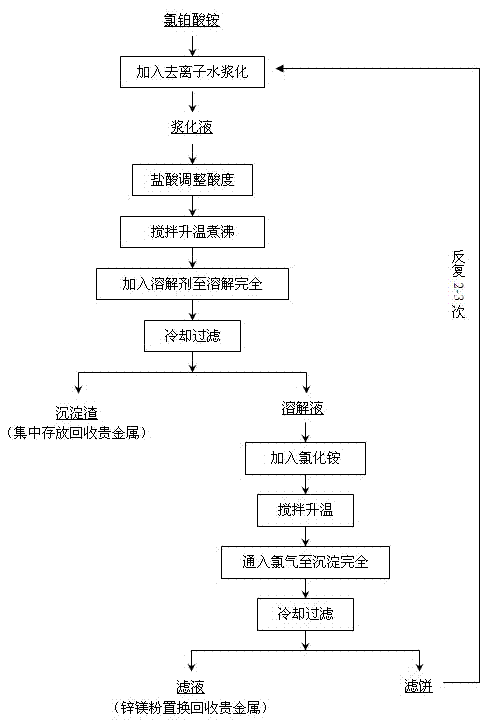

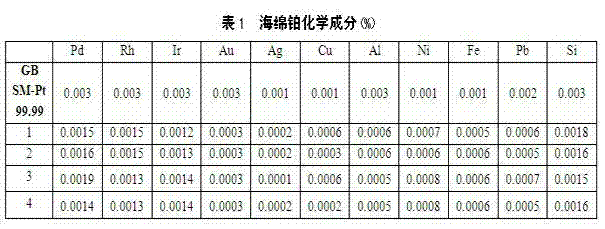

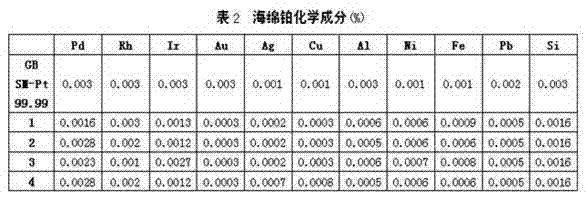

Platinum refining technology

A platinum refining technology comprises the steps of platinum family metal contained concentrate (slag, secondary resources and the like) chlorination dissolving, dissolved solution acidity adjustment, organic reducing agent ammonium oxalate precipitation, and precious metal filtering separation. The technology has the characteristics of wide material adaptability and simple operation, allows ammonium chloroplatinate of a platinum family metal contained material containing ammonium chloroplatinate to be efficiently and rapidly dissolved and precipitated, and allows the dissolving efficiency, the precipitation rate and the refining recovery efficiency to reach 95-99%, 99% and 90-95% respectively in the whole refining process; and compared with a traditional ammonium chloride repeated-precipitation method, the technology effectively solves a problem that nitrogen oxide cannot be discharged in a standard reaching mode, and eliminates the problems of large labor intensity of a aqua regia dissolved solution nitrate removing process and low production efficiency. The reducing agent ammonium oxalate is an organic reagent, and reacts to generate a pollution-free gas which can be directly discharged in the reaction process, so a solution system is not changed, thereby no influences on subsequent platinum precipitation by ammonium chloride are caused, and the yield and the quality of platinum family metal products are substantially improved.

Owner:JINCHUAN GROUP LIMITED

Preparation method for alumina carrier

ActiveCN105709711APrevent collapseStable supportCatalyst carriersRefining to eliminate hetero atomsO-Phosphoric AcidPtru catalyst

The invention discloses a preparation method for an alumina carrier. The preparation method comprises the following steps: (1) weighing a certain amount of pseudo-boehmite dry glue powder and impregnating the pseudo-boehmite dry glue powder with a proper amount of an aqueous solution containing polyol and / or carbohydrate substances; (2) subjecting a material obtained in the step (1) to hydro-thermal carbonizing treatment; and (3) subjecting a material obtained in step (2) to extrusion moulding, then subjecting the dried carrier to nonsaturated spraying and impregnation with a mixed solution of phosphoric acid and ammonium oxalate, carrying out hermetic heating treatment on the impregnated carrier and then carrying out drying and roasting so as to obtain the alumina carrier. The alumina carrier prepared by using the method has a great pore volume and great pore sizes; macro pores are nonuniformly distributed in the alumina carrier along a radial direction; and the carrier is applicable to the field of preparation of hydrogenation demetalization catalysts for heavy oil and residual oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

Bentonite binder and preparation method thereof

InactiveCN102070153AReduce usageImprove bindingFoundry mouldsFoundry coresSodium BentoniteHexamethylenetetramine

The invention relates to a bentonite binder and a preparation method thereof, belonging to the processing field of bentonite, and aiming at providing a bentonite binder with a better sodiumizing modification effect and a preparation method of the bentonite binder. The preparation method of the bentonite binder comprises the following steps: using bentonite ore as raw material, adding a sodiumizing agent accounting for 2-5wt% of bentonite ore and an accelerator accounting for 0.35-1.2wt% of bentonite ore, wherein the accelerator is at least one of ammonium oxalate, sodium polyacrylate, hexamethylenetetramine and tripolycyanamide; evenly mixing and carrying out sodiumizing modification, drying, smashing to obtain the bentonite binder. In the preparation method, required equipment is simple and is convenient for maintenance, the production efficiency is high, and energy-saving effect is obvious, and the bentonite binder is suitable for continuous production. The bentonite binder of the invention has higher water absorption rate and is a bentonite binder with high adhesive property; and the bonding force of the iron ore concentrate is greatly increased after the bentonite binder is used in the iron ore pelletizing metallurgy industry, thus improving the pelletizing rate of the iron ore concentrate.

Owner:PANZHIHUA UNIV

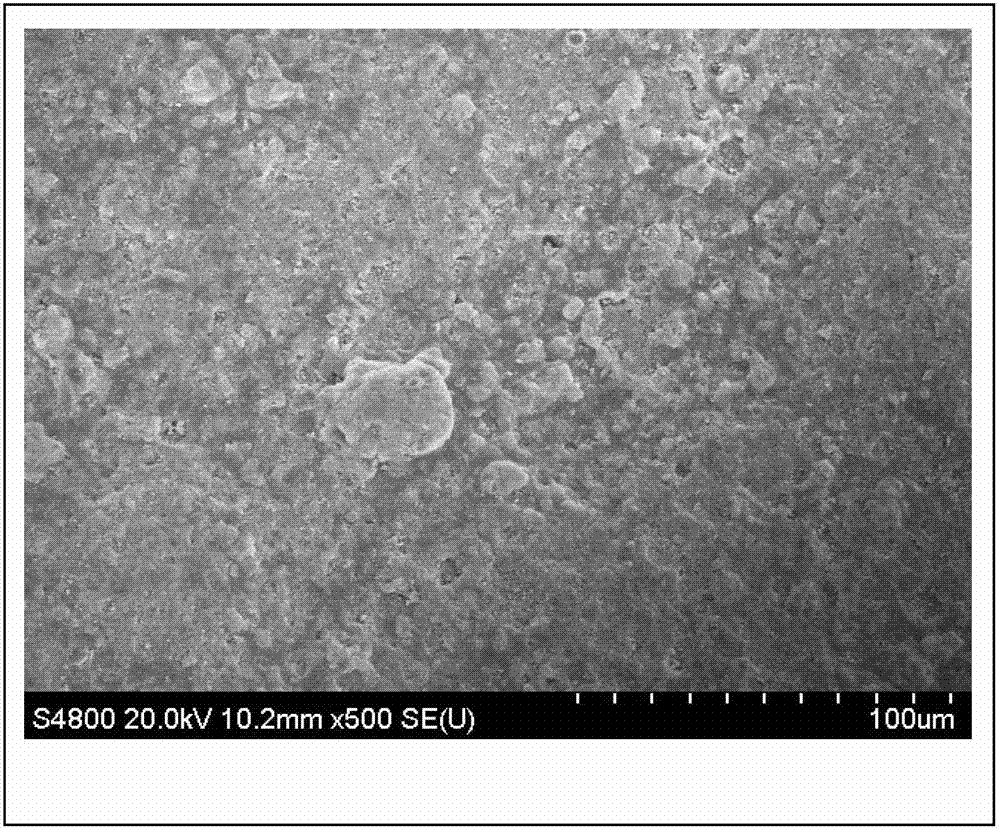

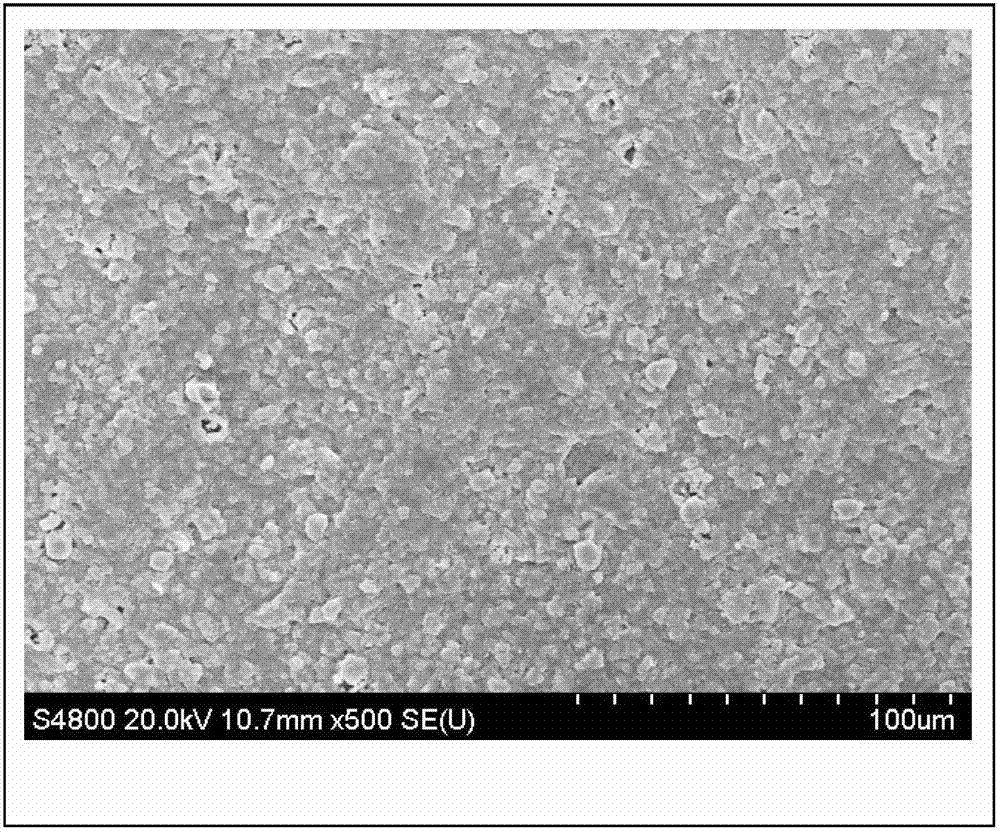

Method for lower-temperature sintering to prepare acid and alkali-resistant titanium dioxide ceramic ultrafiltration membrane

ActiveCN102806018AReduce manufacturing costGood acid and alkali resistanceSemi-permeable membranesUltrafiltrationSolid particle

The invention relates to a method for lower-temperature sintering to prepare an acid and alkali-resistant titanium dioxide ceramic ultrafiltration membrane. The method takes titanyl sulfate, ammonium oxalate or oxalic acid as a raw material, is combined with a technology of preparing small nanometer materials through a sol-gel method and a solid particle sintering technology, so the technology for preparing the acid and alkali-resistant titanium dioxide ceramic ultrafiltration membrane under the low-temperature sintering condition is obtained. The layer pore size distribution scope of the ceramic ultrafiltration membrane which is produced by the method is between 10-30nm, and the water flux under the operation condition of 0.1MPa is 400-600L / m<3>h; and the prepared ceramic ultrafiltration membrane has very good acid resistance and alkali resistance and brighter application prospect. The method uses inorganic titanium salt with lower price as the raw material for synthetizing titanium dioxide, so the preparation cost of the ceramic membrane is lowered; and moreover, compared with a solid particle high-temperature sintering technology of the existing ceramic membrane industrial production, the method adopts a lower-temperature sintering technology, so the energy consumption is reduced, and the produced product has higher cost performance.

Owner:SUNTAR MEMBRANE ENVIRONMENT TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com