Patents

Literature

95results about How to "High in manganese" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-nickel-series and full-concentration gradient lithium ion battery positive electrode material and preparation method thereof

InactiveCN105609759AStable structureImprove securityCell electrodesSecondary cellsManganeseConcentration gradient

The invention provides a high-nickel-series and full-concentration gradient lithium ion battery positive electrode material and a preparation method thereof and belongs to the field of lithium ion battery positive electrode materials. The structural formula of the positive electrode material is LiNixCoyMnzO2@LiNiaCobMncO2, wherein x is more than or equal to 0.7 and smaller than or equal to 1.0, y is more than or equal to 0.1 and smaller than or equal to 0.3, z is more than or equal to 0.05 and smaller than or equal to 0.1, a is more than or equal to 0.4 and smaller than or equal to 0.5, b is more than or equal to 0.1 and smaller than or equal to 0.3 and c is more than or equal to 0.25 and smaller than or equal to 0.3; the sum of the x, the y and the z is equal to 1, and the sum of the a, the b and the c is equal to 1; the positive electrode material is spherical and has a core-shell-type structure; in a process from a core of an inner core to the surface of a shell, the contents of nickel, cobalt and manganese are distributed in linear concentration gradient; the content of the nickel is gradually reduced, and the content of the cobalt is not changed or is gradually increased; and the content of the manganese is gradually increased. The invention further provides the preparation method of the high-nickel-series and full-concentration gradient lithium ion battery positive electrode material. The positive electrode material provided by the invention has high capability, high circulating performance and high safety performance.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Rare earth boron micro-alloyed high manganese steel

One kind of rare earth boraxium alloying high manganese steel that has the mass ratio of ingredient: C 0.9-1.6, Mn 13-30, B 0.0005-0.02, Re 0.01-0.05, Si 0.3-1.0, Cr<3, Mo<2, Ni<1, Cu<1, V+Ti+Nb+Zr+N+Al+Ca<2 S<0.04, P<0.07, the residue is Fe. Its process includes blending, melting, tapping of molten steel, adding alterant, packing. Its advantages include a good abradability of more than two fold than formal high manganese steel.

Owner:NORTHEASTERN UNIV

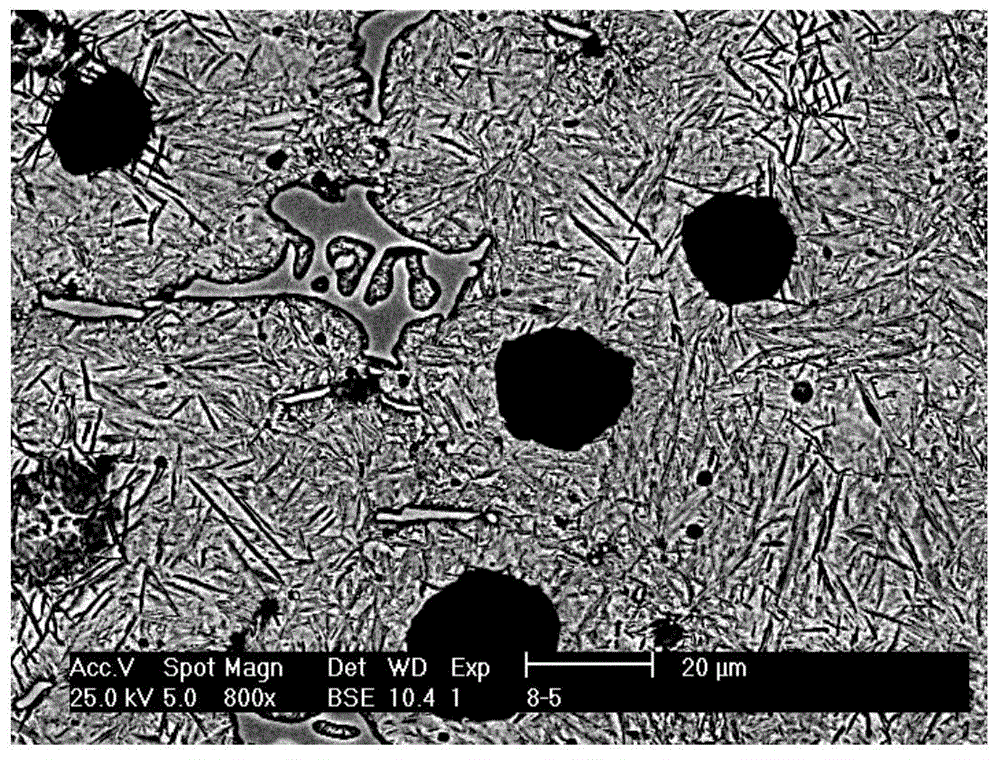

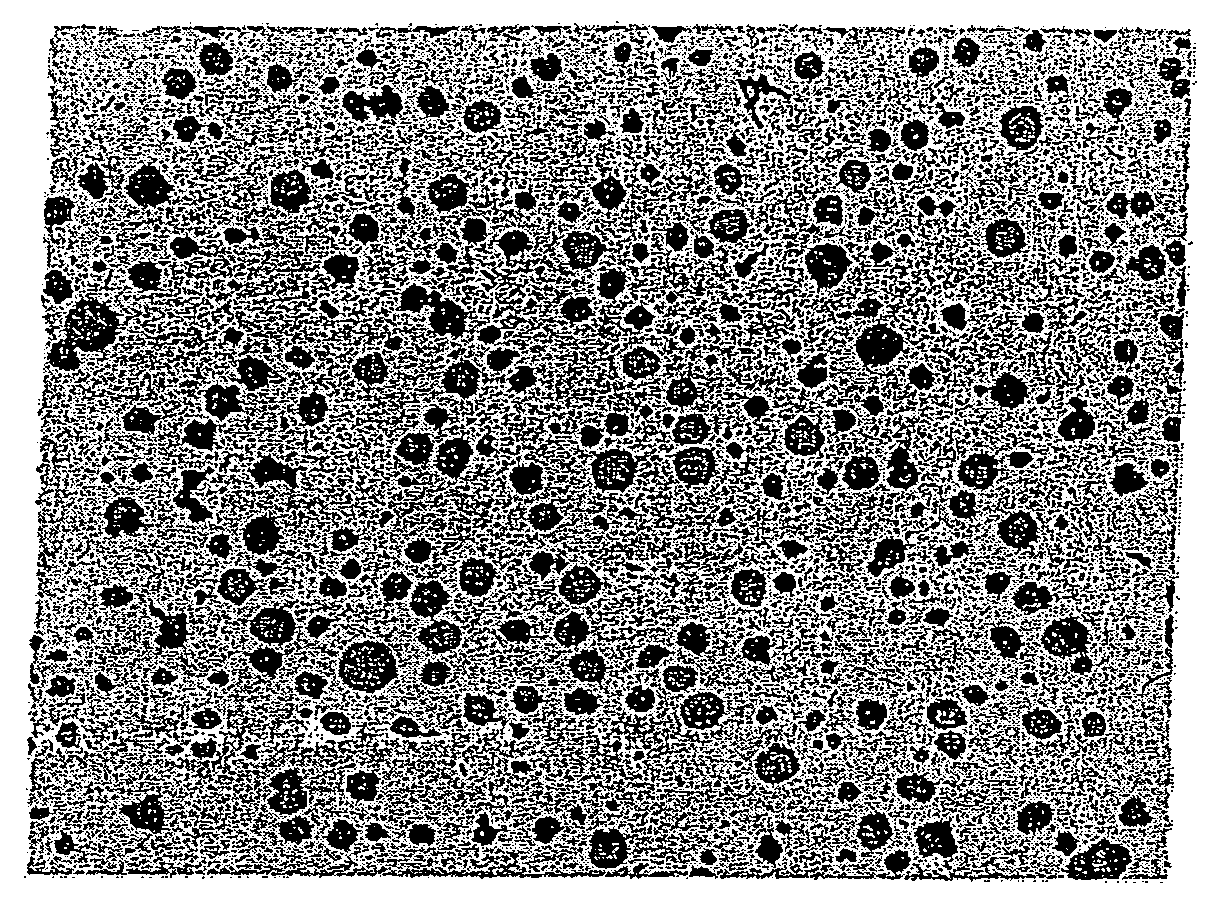

Ausferrite ductile cast iron grinding ball

ActiveCN104152792AHighlight substantive featuresImprove absorption rateGrain treatmentsAlloyDuctile iron

The invention discloses an Ausferrite ductile cast iron grinding ball, and relates to a spherulitic graphite-contained cast iron alloy. The Ausferrite ductile cast iron grinding ball comprises the following chemical elements in percentage by mass: 3.3-3.7% of C, 2.0-3.0% of Si, 1.0-2.5% of Mn, 0.7-3.0% of Cr, 0.1-1.0% of Mo, 0.1-1.0% of Cu, 0.04-0.08% of P, 0.01-0.020% of S, 0.03-0.05% of Mg, 0.02-0.04% of Ce, 0.03-0.07% of B, 0.06-0.12% of Ti, 0.03-0.2% of V, and the balance of Fe. The Ausferrite ductile cast iron grinding ball is prepared by the steps of preparation and smelting of raw materials, spheroidizing treatment, inoculation treatment and microalloying treatment, and isothermal quenching heat treatment. The Ausferrite ductile cast iron grinding ball overcomes the defects of low production efficiency and high consumption of electric energy of a ball mill due to easy surface stripping and crushing and shorter fatigue life of an existing grinding ball product in the service process.

Owner:HEBEI UNIV OF TECH

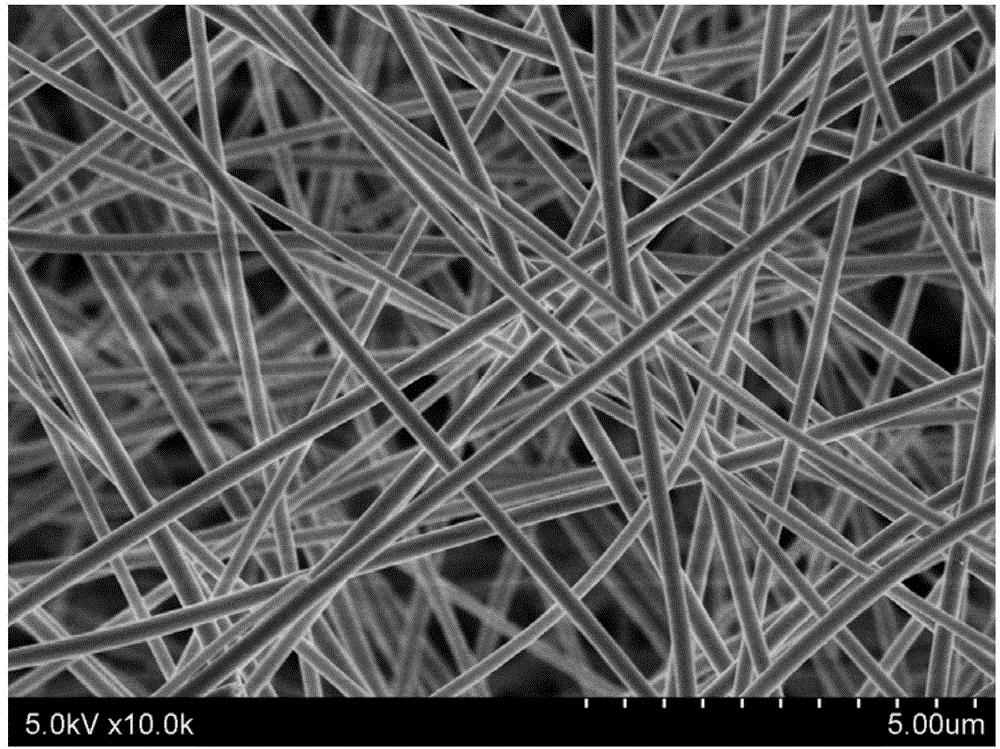

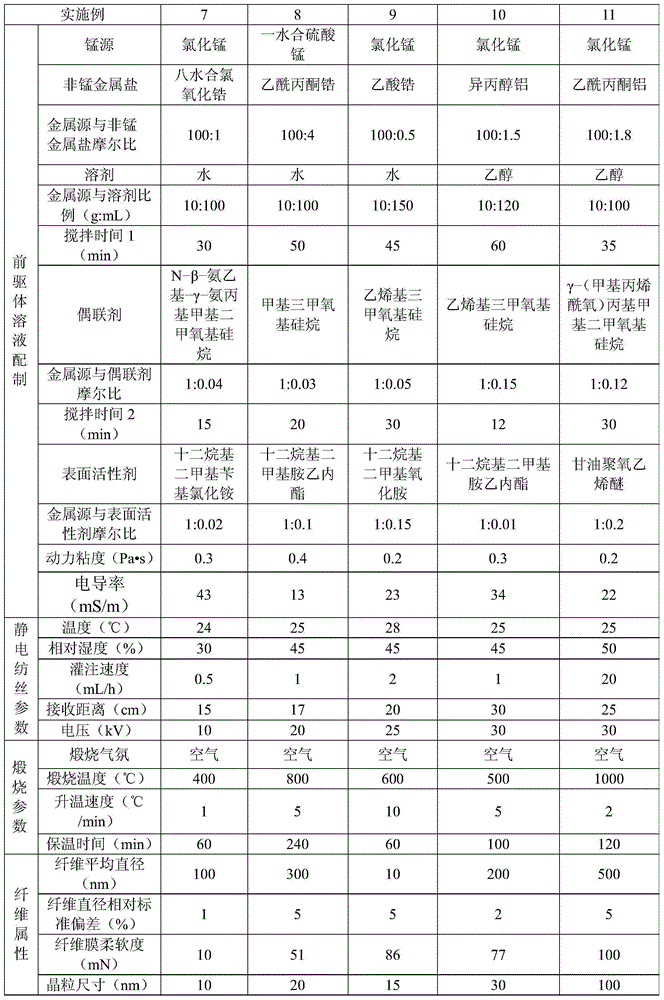

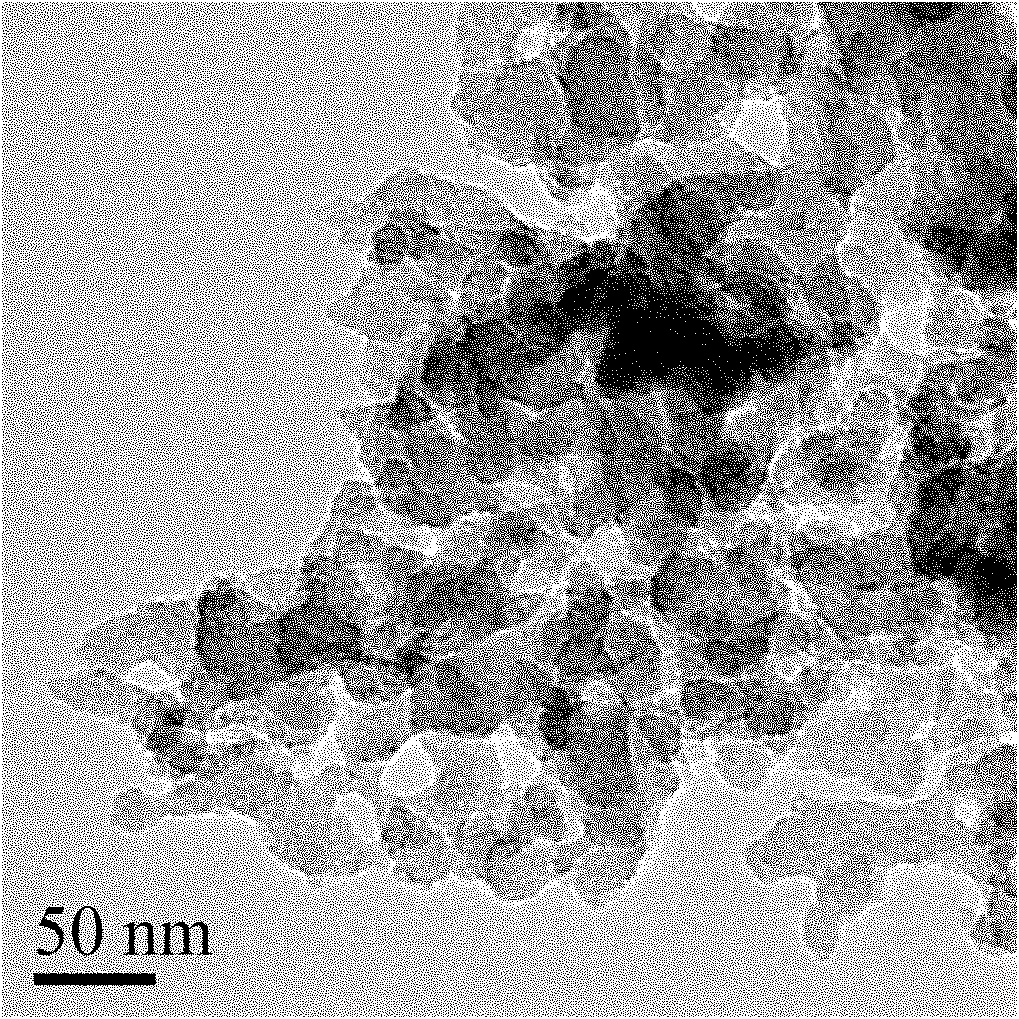

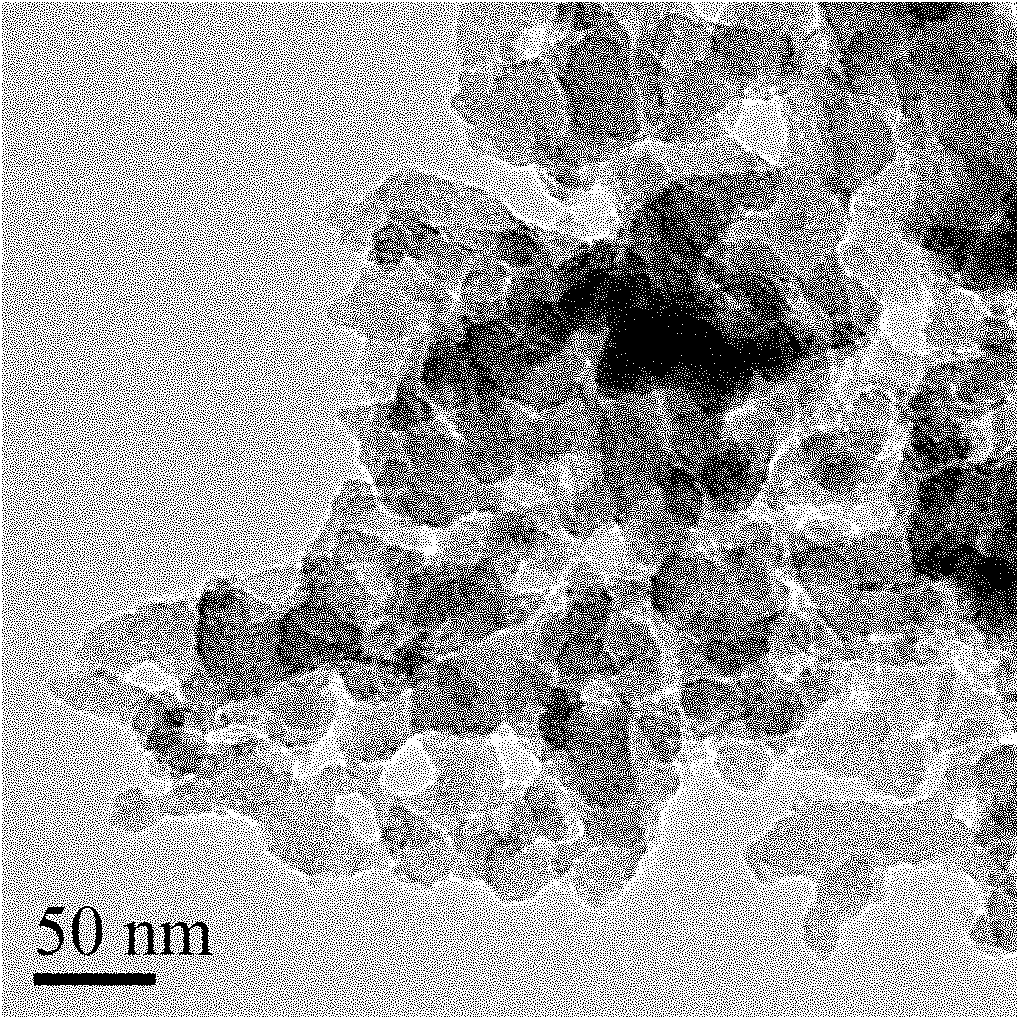

Flexible manganese oxide nano fibrous membrane and preparation method thereof

The invention relates to a flexible manganese oxide nano fibrous membrane and a preparation method thereof. The preparation method comprises the following steps: dissolving a manganese source a non-manganese metal salt in a solvent, sequentially adding a coupling agent and a surfactant, and uniformly mixing to obtain a uniform and stable precursor solution with a three-dimensional interpenetrating network structure; delivering the precursor solution into a spinneret of an electrostatic spinning device, and connecting the spinneret to a high-voltage power supply to perform electrostatic spinning, thereby obtaining a precursor nano fibrous membrane; and putting the precursor nano fibrous membrane into a box-type resistance furnace, and calcining in an air atmosphere to finally obtain the flexible manganese oxide nano fibrous membrane. The method has the advantages of simple preparation technique and low cost; the obtained manganese oxide nano fibrous membrane has the advantages of favorable flexibility, environment friendliness, low price, higher electrochemical catalytic activity and the like, and thus, can be made into oxidizers, catalysts, adsorbents and other products; and the manganese oxide nano fibrous membrane has wide application prospects in the field of chemical industry.

Owner:嘉兴富瑞邦新材料科技有限公司

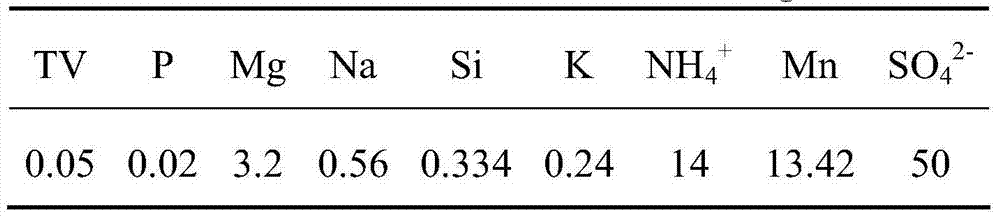

Method for removing manganese from acidic molybdenum precipitation wastewater

InactiveCN103922454AEfficient use ofHigh in manganeseWaste water treatment from metallurgical processWater/sewage treatmentWastewaterEconomic benefits

The invention discloses a method for removing manganese from acidic molybdenum precipitation wastewater. The method comprises the steps of adjusting the pH value of the acidic molybdenum precipitation wastewater to be 5-7, adding ammonium oxalate, and filtering to obtain ammonium oxalate deposits and supernatant liquor, wherein the supernatant liquor contains less than 0.05g / L of Mn<2+>. The method has the advantages of being simple in process, easy and convenient to operate, capable of recovering manganese resources, low in equipment requirement, environment-friendly and the like, and has very good social and economic benefits. In addition, ammonium sulfate obtained after manganese removal can be used for molybdenum precipitation, condensed water can be directly recycled, and the resources can be effectively utilized.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Austenic stainless steel

A high manganese nickelous austenic stainless steel consists of carbon is less than or equal to 0.10wt%, silicon is less than or equal to 0.80wt%, manganese 8.5-10.00wt%, chromium 14.00-15.00wt%, nickel is less than or equal to 1.20wt%, phosphorus is less than or equal to 0.050wt%, sulfur is less than or equal to 0.030wt%, nitrogen is less than or equal to 0.20wt%, iron residue. Its advantages include low cost, good mechanics and manufacturing machining performance.

Owner:CHANGHONG SPECIAL STEEL SCI INST JIANGSU PROV

Material for aluminum electrolysis crust-breaking hammer

The invention relates to a material for an aluminum electrolysis crust-breaking hammer, which is characterized by comprising the following components in percentage by weight: 0.5%-3.0% of carbon, 3.5%-10.0% of manganese, 0.5%-1.0% of silicon, less than 0.05% of phosphorus, less than 0.05% of sulphur, 5.0%-20.0% of chromium, less than 0.05% of Ni and the balance of ferrum. The material for the aluminum electrolysis crust-breaking hammer is an iron alloy material and is prepared by using a lost foam casting or sand casting process. In the invention, The manganese content in the material for the crust-breaking hammer is increased and the chromium content is optimized, thereby the material effectively improves the strength and wear resistance of the aluminum electrolysis crust-breaking hammer, prolongs the service life of the hammer, extends the replacement period, reduces the production cost and effectively relieves the labor intensity.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

Method for preparing white carbon black and manganese fertilizer from manganese leaching residue

The invention discloses a method for preparing white carbon black and manganese fertilizer from manganese leaching residue. The method comprises the following steps: 1, washing the manganese leaching residue with dilute sulphuric acid solution and running water in turn to obtain the residue; 2, conducting reaction between the residue and 25 to 40% strong base solution by mass at 90 to 120 DEG C for 2 to 5 h, and filtering to obtain filtrate; 3, decoloring the filtrate with active carbon and then carboxyl-terminated hyperbranched polyester at 100 to 120 DEG C to obtain the aqueous solution of silicate; 4, adding water and then inorganic acid and carboxyl-terminated hyperbranched polyester for reaction at 40 to 90 DEG C for 0.5 to 2 h to obtain the white carbon black; and 5, drying and dehydrating the residue obtained in step 2 and adding into a high-speed mixer, adding phosphoric acid, anticaking agent and manganese sulfate into the high-speed mixer, and mixing at room temperature for 10 to 20 min to obtain the manganese fertilizer. The method is simple in process and low in cost and is suitable for industrial production; and the silicon dioxide content of the prepared white carbonblack is more than 95% by mass, the specific area is more than 270 m<2> / g and the particle size is less than 50 nm.

Owner:SOUTH CENTRAL UNIVERSITY FOR NATIONALITIES

Aluminum-magnesium alloy welding wire for improving Mn content

ActiveCN102886618AHigh strengthImprove corrosion resistanceWelding/cutting media/materialsSoldering mediaSolubilityChemical composition

The invention discloses an aluminum-magnesium alloy welding wire for improving the Mn content. The aluminum-magnesium alloy welding wire is characterized in that the Mn content in the welding wire is improved by 1.0-2.0 wt%; if calculated in percentage by weight, the other chemical components of the welding wire comprise 4.5-5.5% of Mg, less than or equal to 0.15% of Si, less than or equal to 0.25% of Fe, less than or equal to 0.15% of Cr, less than or equal to 0.15% of Ti, less than or equal to 0.10% of Cu, less than or equal to 0.10% of Zn and less than or equal to 0.15% of Zr; and the balance are Al and inevitable impurity elements. The optimal addition quantity of Mn in the welding wire is 1.5 wt%. Because the Mn content in the aluminum-magnesium alloy welding wire provided by the invention is reached about the maximum solubility of Mn in a solid solution in an aluminum-magnesium alloy phase diagram, the Mn Al6 dispersoid particle is furthest separated out in the aluminum-magnesium alloy, so that the strength of a welded joint can be improved. After a lot of tests are carried out, compared with Al-5Mg alloy welding wires, such as 5356, 5183 and 5087 welding wires imported from a foreign country, the percentage elongation of the welding joint of the welding wire provided by the invention is approximate to that of the imported welding wires, while the yield strength and the tensile strength of the welding wire provided by the invention are improved and are more approximate to the level of an aluminum-magnesium alloy base metal.

Owner:NORTHEASTERN UNIV

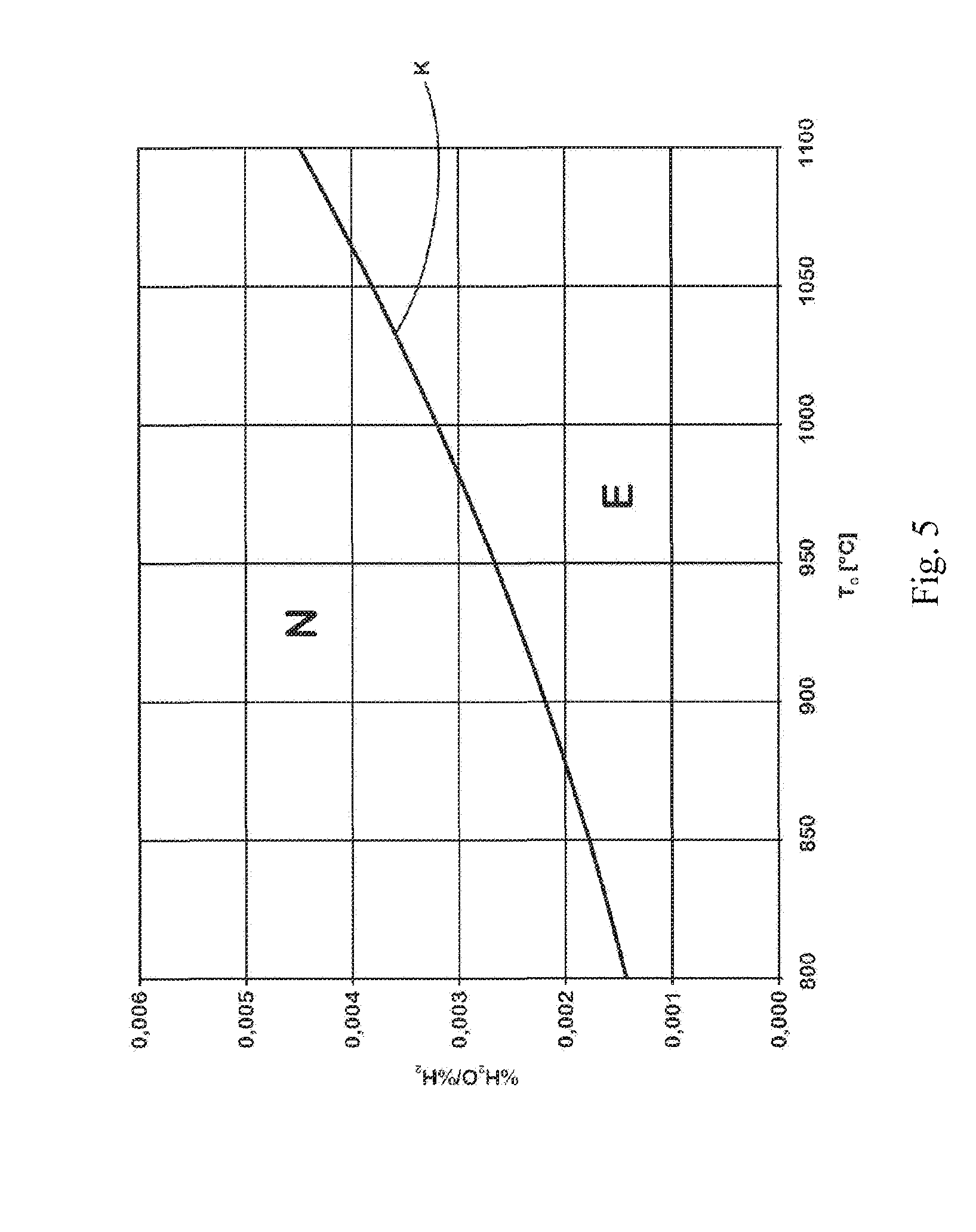

Process for coating a hot- or cold- rolled steel strip containing 6 - 30% by weight of MN with a metallic protective layer

ActiveUS20100065160A1High in manganeseHigh strengthHot-dipping/immersion processesFurnace typesWater contentSheet steel

A method for coating hot-rolled or cold-rolled steel strip containing 6-30 wt %. Mn with a metallic protective layer, includes annealing the steel strip at a temperature of 800-1100° C. under an annealing atmosphere containing nitrogen, water and hydrogen and then subjecting the steel strip to hot dip coating. The method provide an economical way of hot dip coating a high manganiferous sheet steel in that, in order to produce a metallic protective layer substantially free from oxidic sub-layers on the steel strip, the % H2O / % H2 ratio of the water content % H2O to the hydrogen content % H2 in the annealing atmosphere is adjusted as a function of the respective annealing temperature TG as follows: % H2O / % H2≦8·105·TG3.529.

Owner:THYSSENKRUPP STEEL EURO AG

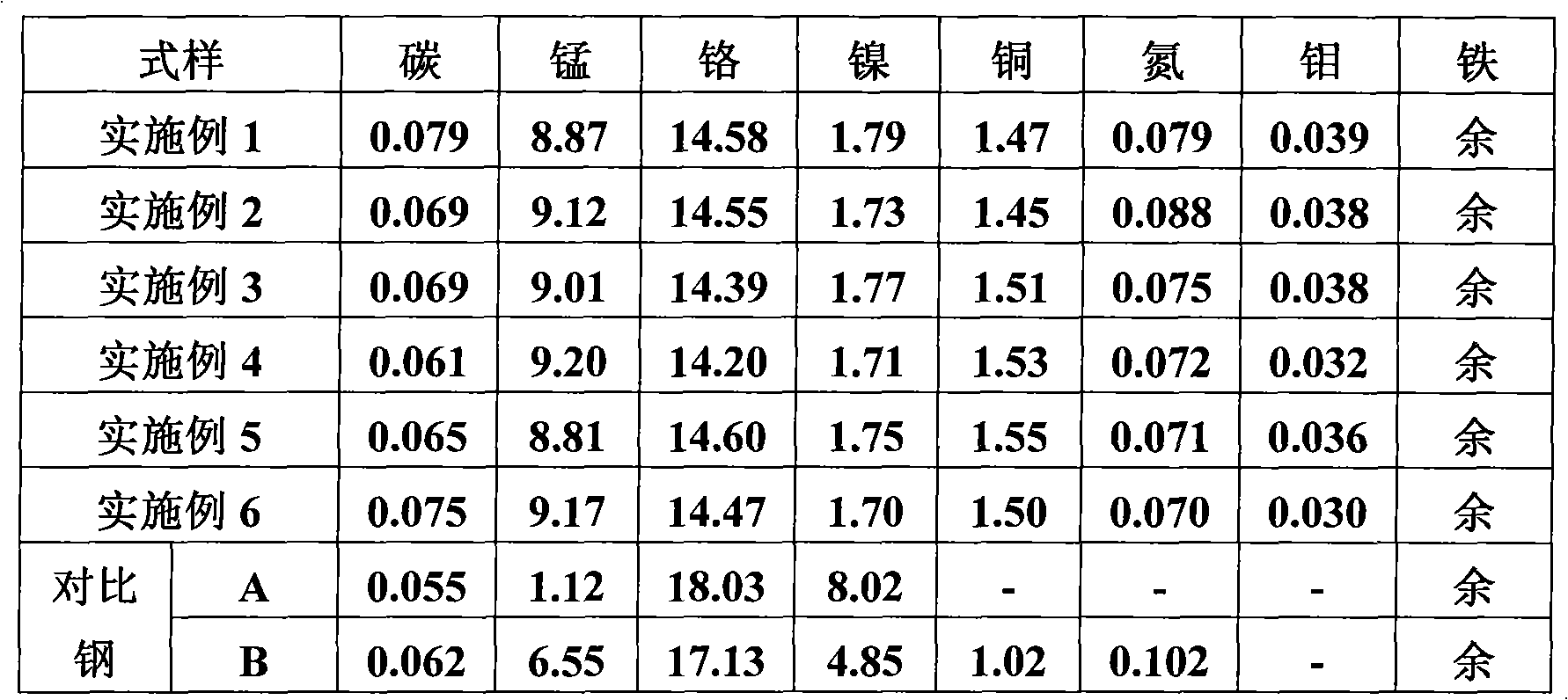

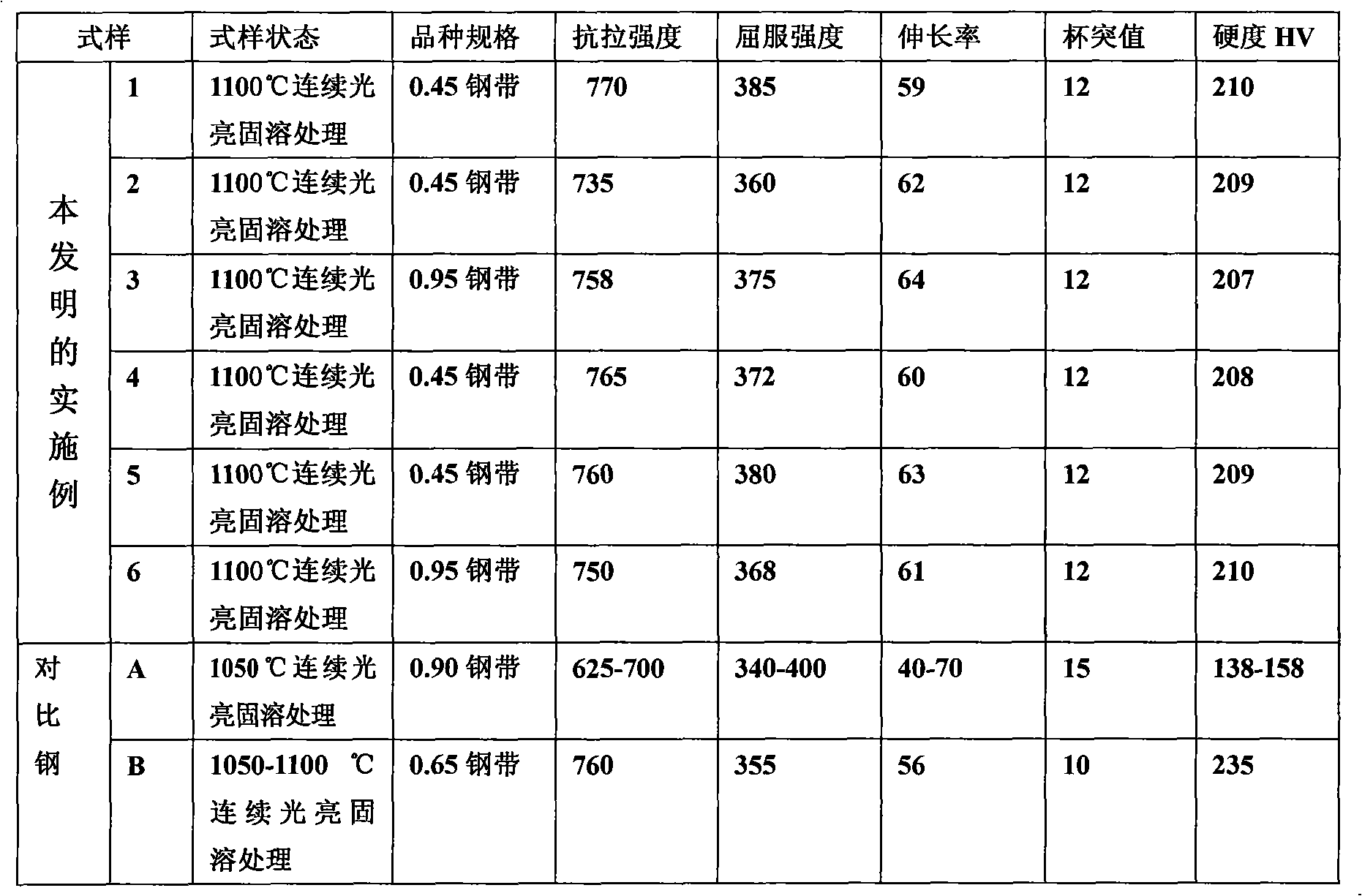

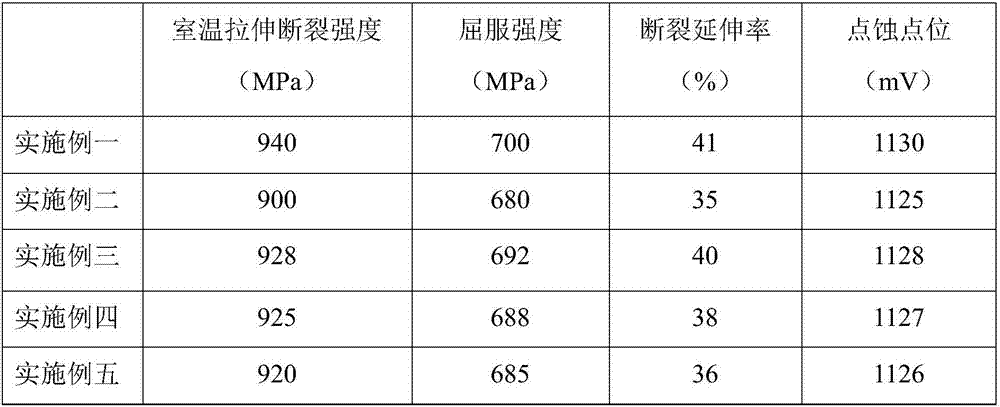

Austenitic stainless steel

The invention relates to an austenitic stainless steel, in particular to an austenitic stainless steel used for the deep punching of high manganese and low nickel. The chemical components of the invention according to the weight percentage are: 0.06 to 0.08 percent of C, 8.80 to 9.20 percent of Mn, 14.20 to 14.60 percent of Cr, 1.70 to 1.80 percent of Ni, 1.45 to 1.55 percent of Cu, 0.030 to 0.040 percent of Mo, 0.070 to 0.090 percent of N and the rest is Fe. The austenitic stainless steel has the advantages of: 1) being suitable for being used under the weak-corrosion environments such as the fields of hardware fitting, kitchenware, tableware etc. and being able to replace the austenitic stainless steels like 304 and 201; 2) having excellent mechanical properties and excellent manufacture processing prosperities (the total deformation capacity of cold rolling is 70 to 80 percent) and deep punching properties (the cupping test value of 0.50mm is larger than 12); 3) improving the content of Mn so as to save nickel which is expensive caused by energy lack; thereby reducing the price of the austenitic stainless steel; 4) adding a certain amount of Mo to increase the anti-corrosion property of the steel.

Owner:SUZHOU CHANGHONG SPECIAL STEEL

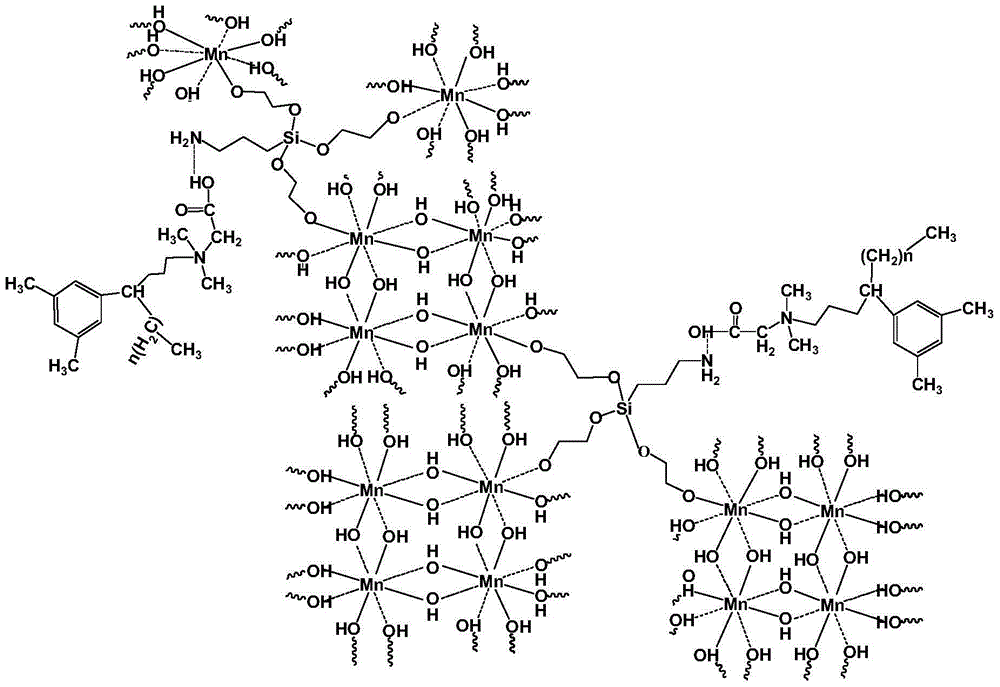

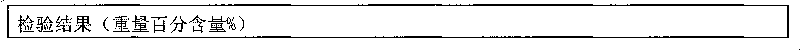

Organic additive for production of electrolytic manganese and preparation method thereof

ActiveCN101717957ANon-pollutingNot corrosivePhotography auxillary processesOrganic sulfide compoundManganese

The invention relates to an electrolytic additive free of selenium dioxide for production of electrolytic manganese and a preparation method thereof. The organic additive for production of the electrolytic manganese is characterized by being prepared from the following raw materials in percent by weight: 2-5% of organic sulfide, 6-10% of surfactant, 15-20% of polyethylene glycol and 65-77% of water, wherein the sum of the weight percent of the raw materials is 100%. The organic additive of the invention can be used for replacing the traditional selenium dioxide for the production of the electrolytic manganese, has the characteristics of environmental protection, no toxicity, simple processes and the like, and has higher electrolytic efficiency, low content of selenium impurities in products and high product quality.

Owner:WUHAN SUNEN TECH

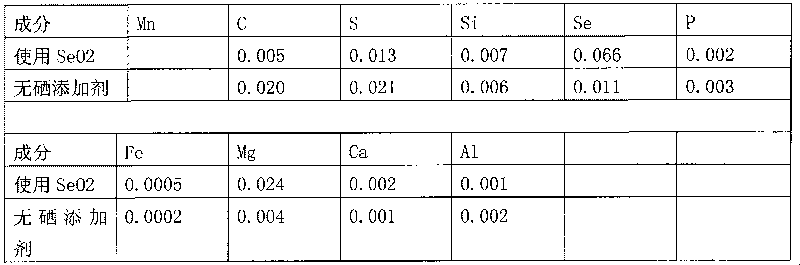

Organic additive for electrolytic manganese production and preparation method thereof

The invention relates to an organic additive without selenium dioxide for electrolytic manganese production and a preparation method thereof. The organic additive for electrolytic manganese production is characterized by being prepared from the following raw materials by the weight percentage: 1%-2% of polyacrylamide, 2%-5% of acetate, 5%-13% of auxiliary agent and 80%-92% of water, and the sum of the weight percentage of each raw material is 100%. The organic additive does not contain selenium dioxide, can replace the existing selenium dioxide to be used for electrolytic manganese production, and has the advantages of environment protection, no poison, simple technology and the like. By using the additive, the electrolytic efficiency is high. The content of selenium impurities in the product is low, and the product quality is high.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

Preparing method for electric-conduction and anti-corrosion cobalt and manganese spinel coating

ActiveCN105332029AHigh in manganeseImprove adhesionElectrolytic coatingsFinal product manufactureThermal transitionManganese

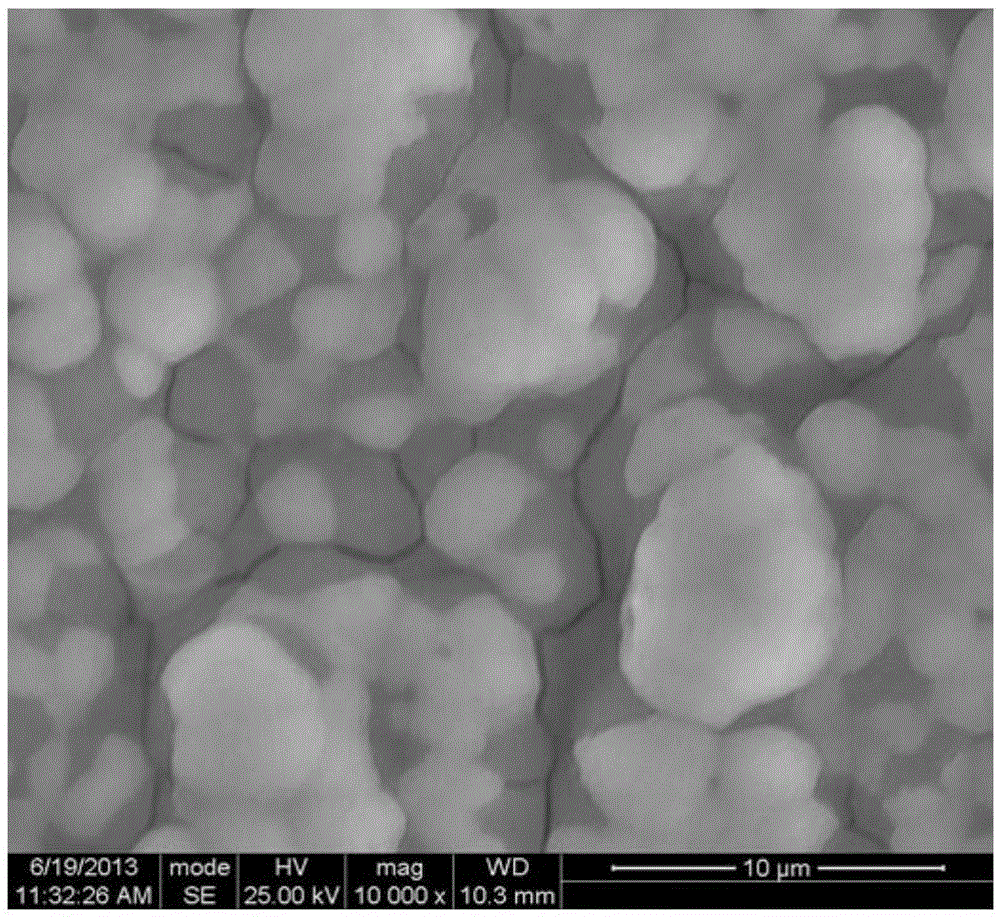

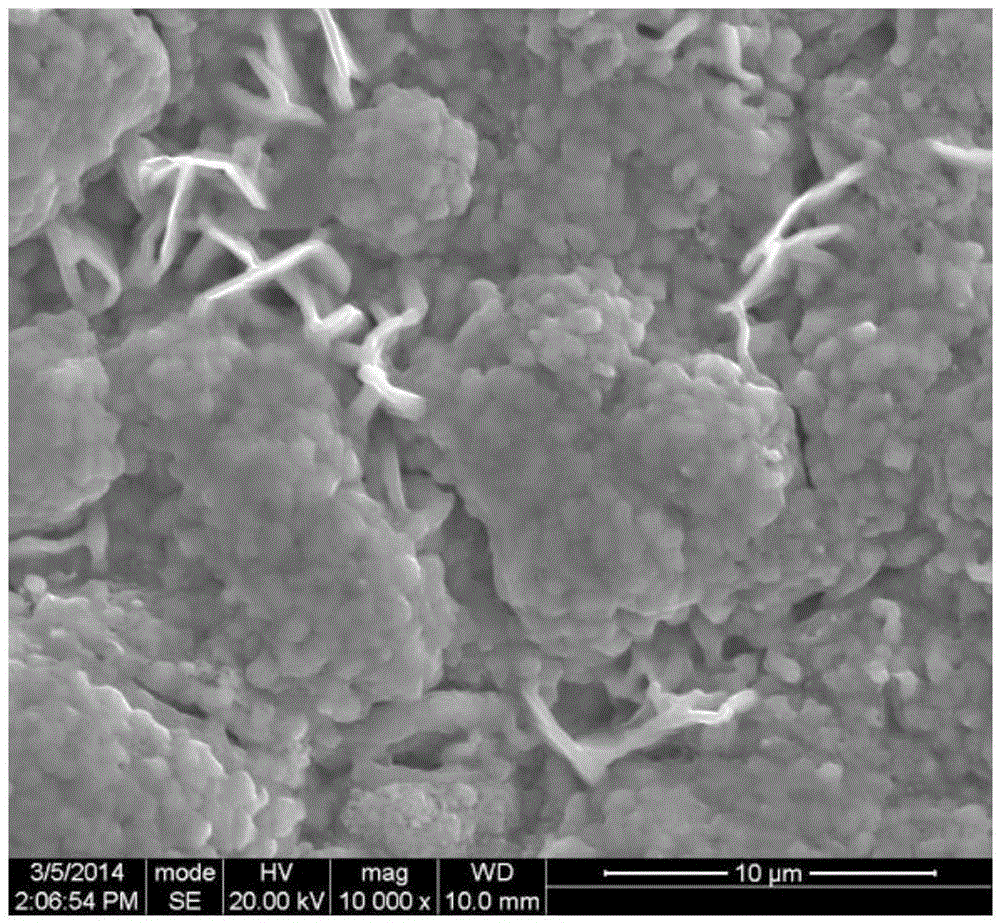

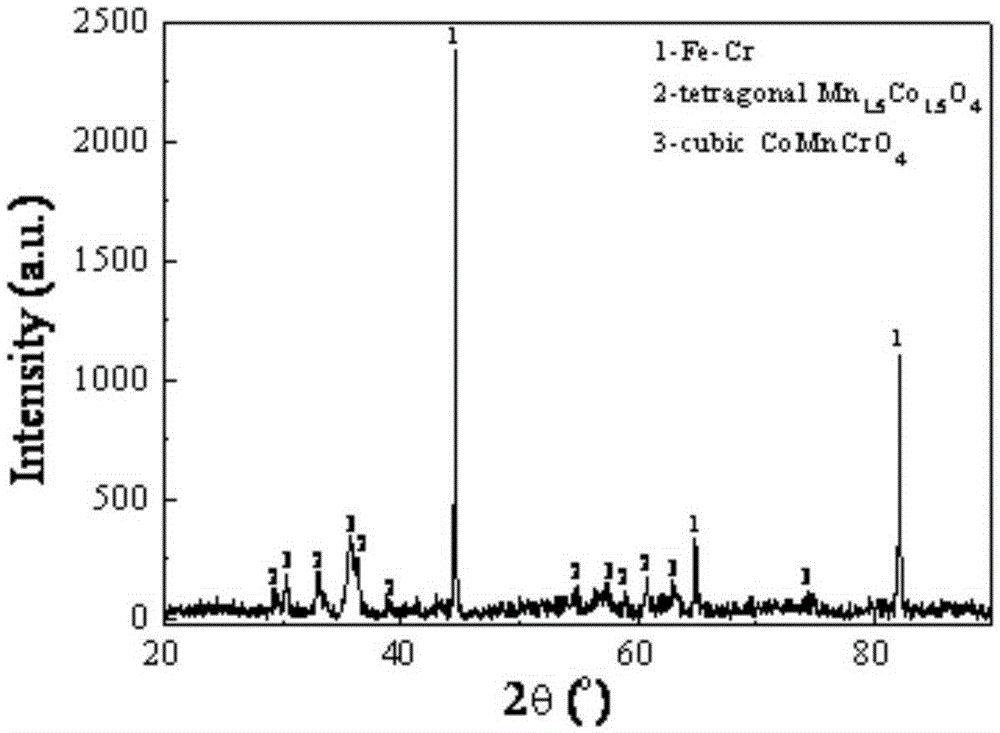

The invention provides a preparing method for an electric-conduction and anti-corrosion cobalt and manganese spinel coating. The preparing method includes the following steps that firstly, surface pretreatment is conducted on a ferrite stainless steel base body; secondly, a cobalt and manganese alloy-manganese hydroxide compound coating is prepared on the surface of the ferrite stainless steel base body on which surface pretreatment is conducted in the first step through a double-electrode electrochemical deposition method; thirdly, first thermal transition treatment is conducted, and the cobalt and manganese alloy-manganese hydroxide compound coating is obtained; and fourthly, second thermal transition treatment is conducted, and the electric-conduction and anti-corrosion cobalt and manganese spinel coating is obtained. The preparing method is simple in technology and low in equipment requirement and cost, the adhesion force between the prepared coating and the base body is good, density is high, the coating comprises an Mn1.5Co1.5O4 spinel layer highest in electric conductivity in a cobalt and manganese spinel system, and harsh working conditions of the surface of a solid oxide fuel cell metal connector can be better met.

Owner:XIAN UNIV OF SCI & TECH

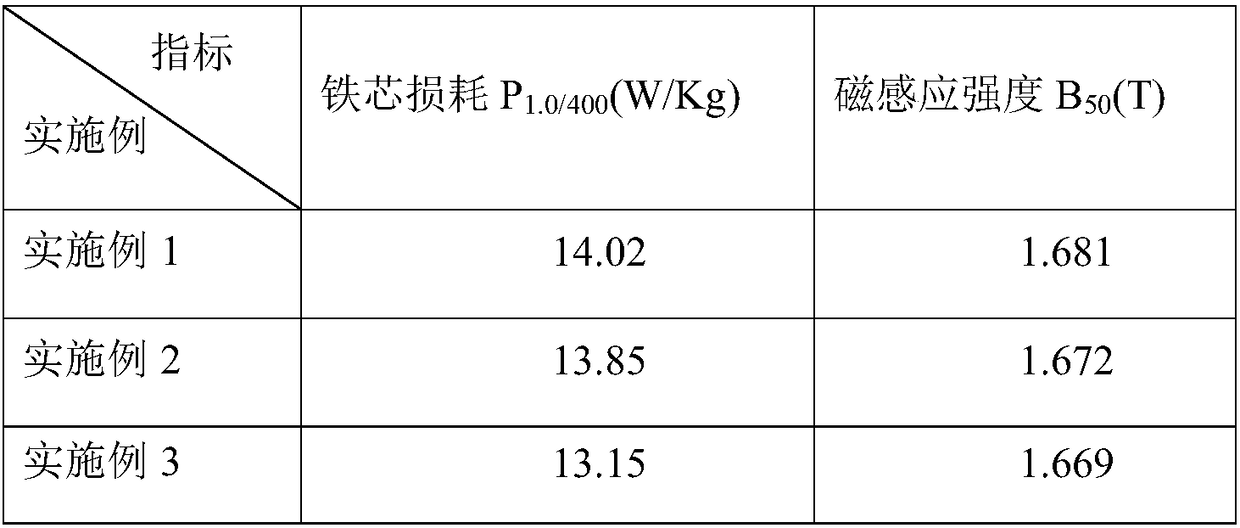

Non-oriented electrical steel for new energy vehicle and manufacture method thereof

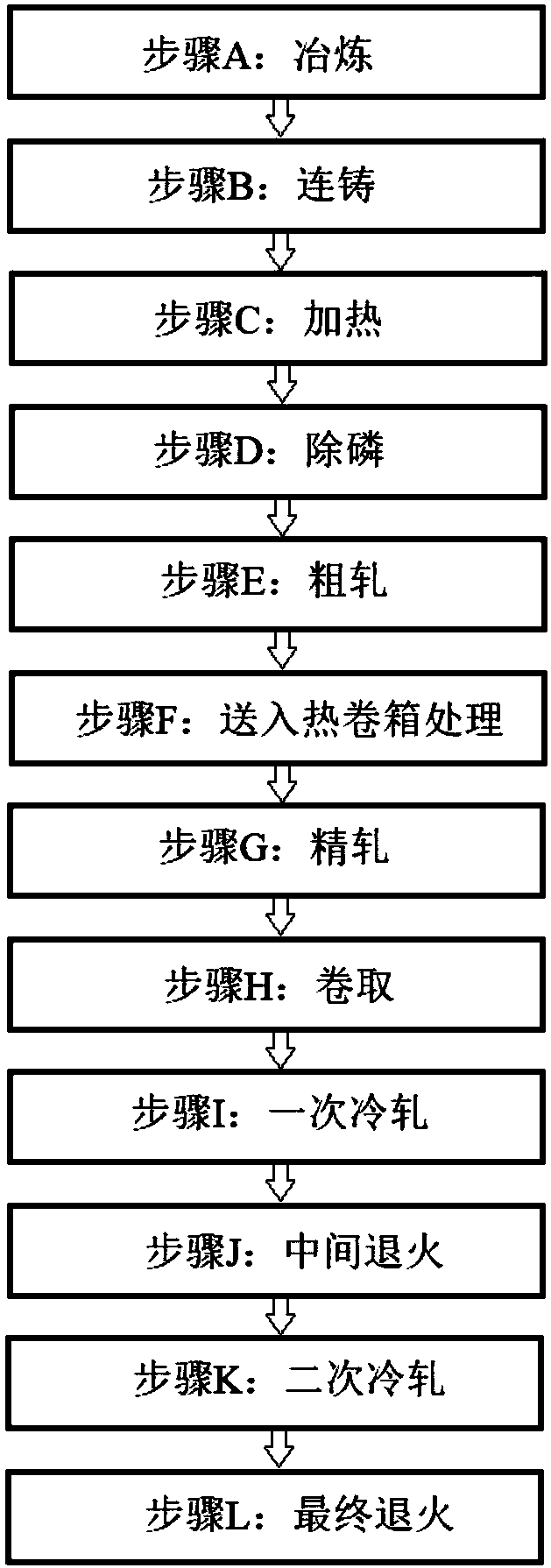

The invention discloses non-oriented electrical steel for a new energy vehicle and a manufacture method thereof, and relates to non-oriented electrical steel and the production method thereof. The production method comprises the following steps: step A, smelting; step B, continuous casting; step C, heating; step D, phosphorus removal; step E, rough rolling; step F, feeding into a hot rolling box to process; step G, finish rolling; step H, rolling; step I, primary cold-rolling; step J, intermediate annealing; step K, secondary cold-rolling; and step L, final annealing. The non-oriented electrical steel aims to overcome the defects that an existing production process has difficulty in meeting using requirements of the non-oriented electrical steel for the new energy vehicle, provides the non-oriented electrical steel for the new energy vehicle and the production method thereof which can produce the ultrathin non-oriented electrical steel for the new energy vehicle, and the ultrathin non-oriented electrical steel is low in iron loss under high frequency, and is good in high magnetic induction and surface quality.

Owner:INNER MONGOLIA UNIV OF TECH

Converter slag fluoride-free fusing agents and method for producing the same

ActiveCN102839252AHigh activityReduce ton consumption costManufacturing convertersSteelmakingMetallic aluminum

The invention relates to converter slag fluoride-free fusing agents and a method for producing the converter slag fluoride-free fusing agents. The converter slag fluoride-free fusing agents comprise metallic aluminum, manganese oxide, aluminum oxide, iron and iron oxide, silica, calcium oxide, magnesium oxide and other unavoidable impurities, and are suitable for slagging in the process of converter steelmaking. Used raw materials are common, balling process is advanced and reliable, and the fluoride-free fusing agents are convenient to use. The converter slag fluoride-free fusing agents and the method for producing the converter slag fluoride-free fusing agents have the advantages of obviously improving reaction kinetics conditions of a molten pool, being high in slag activity, well resolving the problems of steel-bonding of an oxygen lance, metal splashing and poor capacity of sulphur (S)-removing and phosphorus (P)-removing of slag due to re-drying of the slag, lowering tetrafluoroethylene (TFe) content of the slag, increasing yield of ferrum (Fe) in liquid steel, reducing cost of the liquid steel per ton, shortening smelting time, improving content and yield of manganese in the liquid steel, reducing corrosion to a furnace lining, having good slag-splashing and furnace-protection effects, being favorable for environment protection and achieving fluoride-free steel-making due to the fact that fluoride (F-) does not exist, and meeting the requirements for cleaning in the converter steel-making production process.

Owner:西峡县恒基冶材有限公司

Industrial ultra-pure iron and production method thereof

InactiveCN110747395ASmall sizeReduce in quantityManufacturing convertersElectro-slag remeltingDeoxygenation

The invention belongs to the technical field of metal smelting, and particularly relates to industrial ultra-pure iron and a production method thereof. The industrial ultra-pure iron comprises the following components of, less than or equal to 0.25 wt% of C, less than or equal to 0.005 wt% of Si, less than or equal to 0.005 wt% of Mn, less than or equal to 0.0008 wt% of S, less than or equal to 0.003 wt% of P, less than or equal to 0.005 wt% of Al, less than or equal to 0.003 wt% of Ti, 0.003-0.007 wt% of Ce, 0.001-0.004 wt% of La, trace of Nd and Pr and the balance Fe and inevitable impurities; and the preparation method comprises the following procedures of KR molten iron pre-desulfurization, converter deep dephosphorization, LF deep desulfurization, RH deep deoxygenation, continuous casting and electroslag remelting in sequence. The purity of the iron prepared by the method is high.

Owner:CHENGDU ADVANCED METAL MATERIALS IND TECH RES INST CO LTD

Ni—Fe—Cr—Mo alloy

ActiveUS9228250B2Easy to processDiminishing resistance of alloyWelding/cutting media/materialsRigid pipesAlloy

Owner:VDM METALS INT GMBH

Manufacturing method of high manganese high nitrogen low nickel non-magnetic stainless steel and product thereof

ActiveCN106868423AHigh symmetrical stabilityIncreased symmetrical stabilityFoundry mouldsElectric furnaceNiobiumNon magnetic

The invention provides a manufacturing method of a high manganese high nitrogen low nickel non-magnetic stainless steel and a product thereof. The stainless steel is single phase austenite stainless steel which comprises the following chemical components in percentages by mass: greater than 0 but less than or equal to 0.1% of C, less than or equal to 0.01% of S, less than or equal to 0.015% of P, greater than 0 but less than or equal to 1.0% of Si, greater than or equal to 16% but less than or equal to 18% of Mn, greater than 0 but less than or equal to 2% of Ni, greater than or equal to 10% but less than or equal to 14% of Cr, greater than or equal to 1% but less than or equal to 2% of N, greater than or equal to 0.3% but less than or equal to 1% of Cu, greater than or equal to 0.3% but less than or equal to 5% of Mo, greater than or equal to 0.3% but less than or equal to 1% of Nb and the balance of Fe. The manufacturing method comprises the following steps: heating and smelting raw materials, and performing decarbonization, desulfuration and deoxygenation; raising the temperature to 1600 DEG C and adding nickel; adjusting the temperature of a bath to 1550 DEG C, and adding ferromolybdenum, ferrocolumbium and a metal copper; adding a desoxidant for secondary deoxidization, introducing nitrogen, adjusting the temperature of the bath to 1610-1620 DEG C, and adding nitrogen containing ferrochromium; adjusting the temperature of the bath to 1150-1250 DEG C, introducing nitrogen, adding nitrided ferromanganese, pouring, quenching and air cooling, and machining to form a panel, heating the panel to 650-700 DEG C, keeping the temperature for 30min, and performing furnace cooling to room temperature. The stainless steel through deep punching is still non-magnetic, and needs not to be annealed and demagnetized. The manufacturing method is high in nitrogen-increasing efficiency and low in loss of equipment.

Owner:宁波市博祥新材料科技有限公司

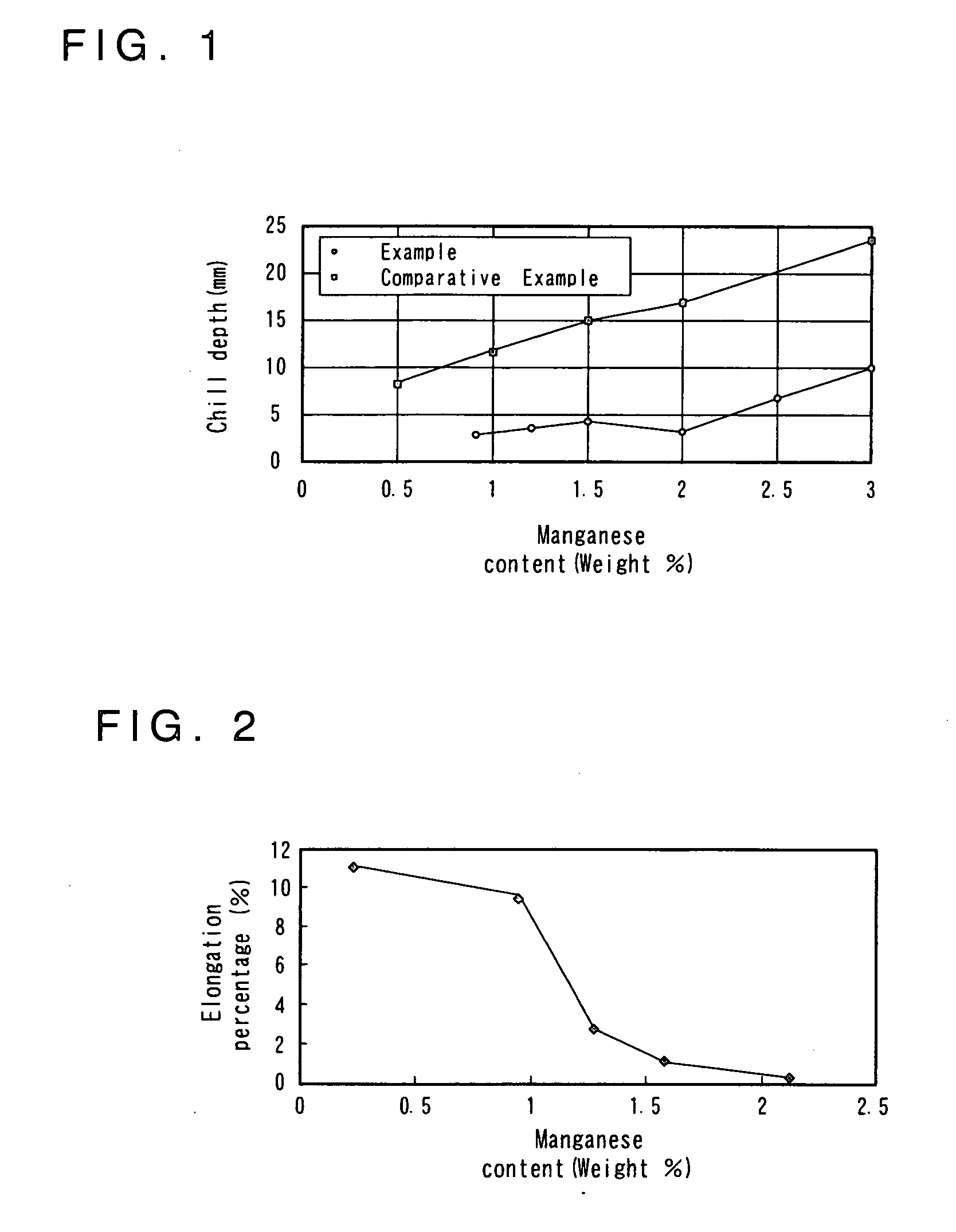

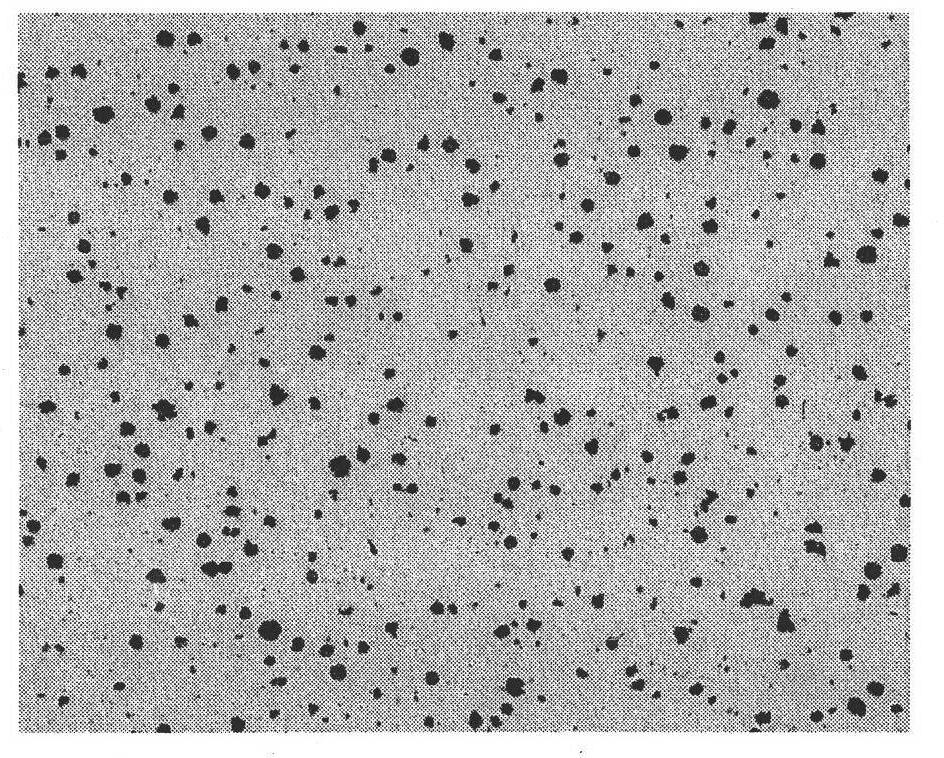

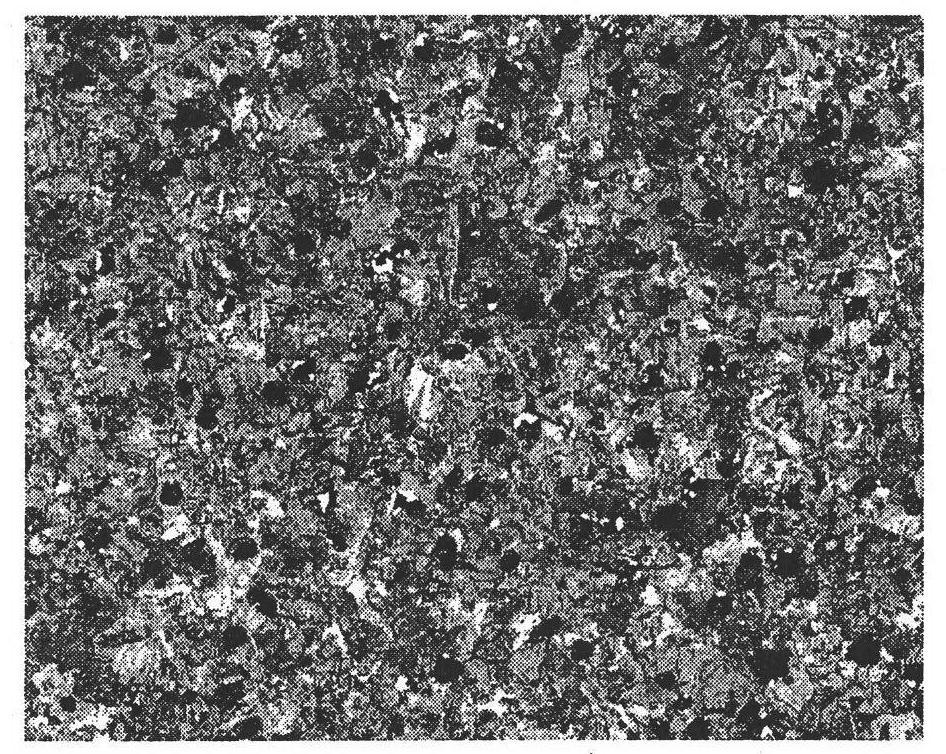

Method for reuse of steel sheet scrap

InactiveUS20050103161A1High mechanical strengthQuality improvementProcess efficiency improvementRare-earth elementMisch metal

A recycling method of scrap steel plate that can recycle scrap steel plates including scrap of high-tensile steel plate to produce good quality of cast iron efficiently, while avoiding unnecessary cost increase. In the recycling method, scrap of high-tensile steel plate and scrap of ordinary steel plate are collected together in a batch collecting process and, then, in a preparing process, the scrap steel plates collected are melted and if not less than 0.7 weight % manganese is contained in the hot metal, then the hot metal is prepared so that a sulfur content in the range of 0.02 to 0.2 weight % in the hot metal and rare earth element or misch metal which is two times as much as the sulfur content is added to the hot metal. To obtain spheroidal graphite cast iron, spheroidizing agent (which preferably comprises no rare-earth element but comprises bismuth) is added further to the hot metal after that.

Owner:DAIHATSU MOTOR CO LTD +2

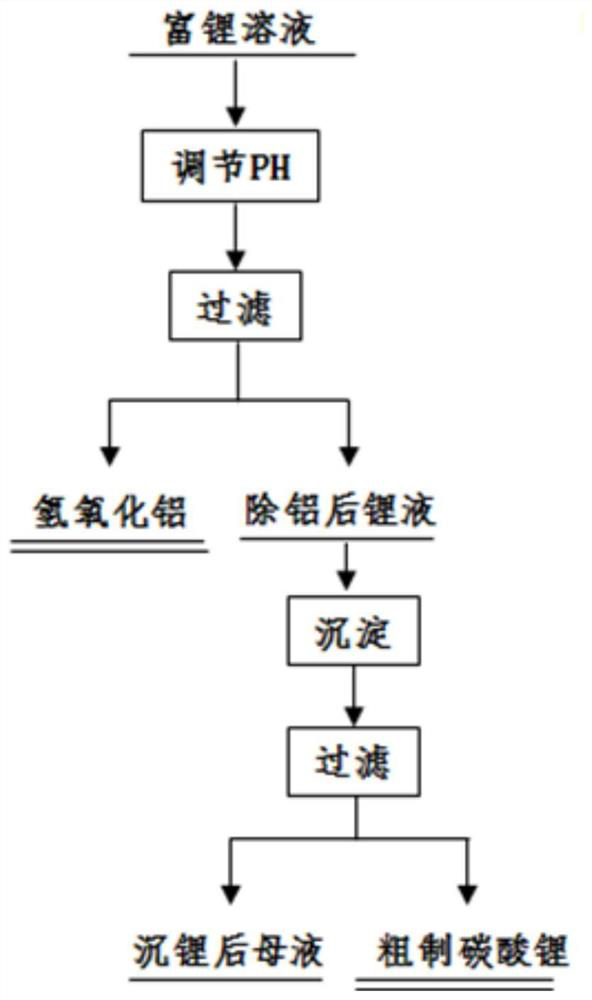

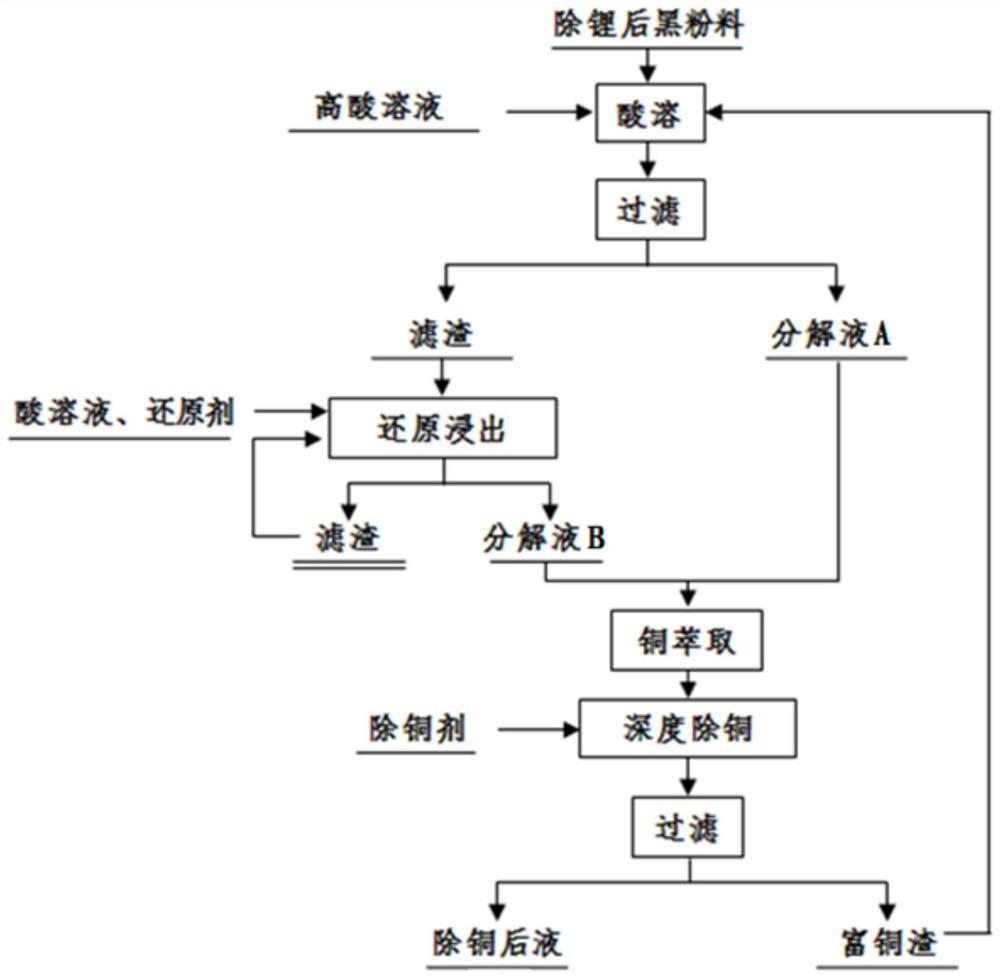

Lithium battery waste recycling method and application thereof

ActiveCN113106257AHigh recovery rateNo lossProcess efficiency improvementBattery recyclingAluminium hydroxidePhysical chemistry

The invention provides a lithium battery waste recycling method and application thereof, and relates to the technical field of waste battery recycling. The method comprises the following steps that firstly, reflux extraction is carried out on lithium battery waste by utilizing a countercurrent washing method to obtain a lithium-rich solution and lithium-removed black powder; then the lithium-rich solution and the lithium-removed black powder are treated respectively, aluminum hydroxide and crude lithium carbonate are extracted from the lithium-rich solution through precipitation and reduction methods, and meanwhile, the lithium-removed black powder is subjected to acid dissolution leaching before reduction leaching; metal impurity ions except cobalt, nickel and manganese in a leaching solution are removed by combining the oxidation-reduction property of metal with the modes of extraction, precipitation and the like; and finally, concentrating and crystallizing are carried out, and cobalt-nickel-manganese mixed salt crystals with high manganese content and cobalt-nickel-manganese mixed salt crystals with high cobalt and nickel contents are respectively prepared by utilizing a hot filtering method and a cooling filtering method. The recycling method has the advantages of being simple in technological process and easy to operate, and the purpose of comprehensively recycling valuable metal from the lithium battery waste is achieved.

Owner:GUANGDONG JIANA ENERGY TECH CO LTD +1

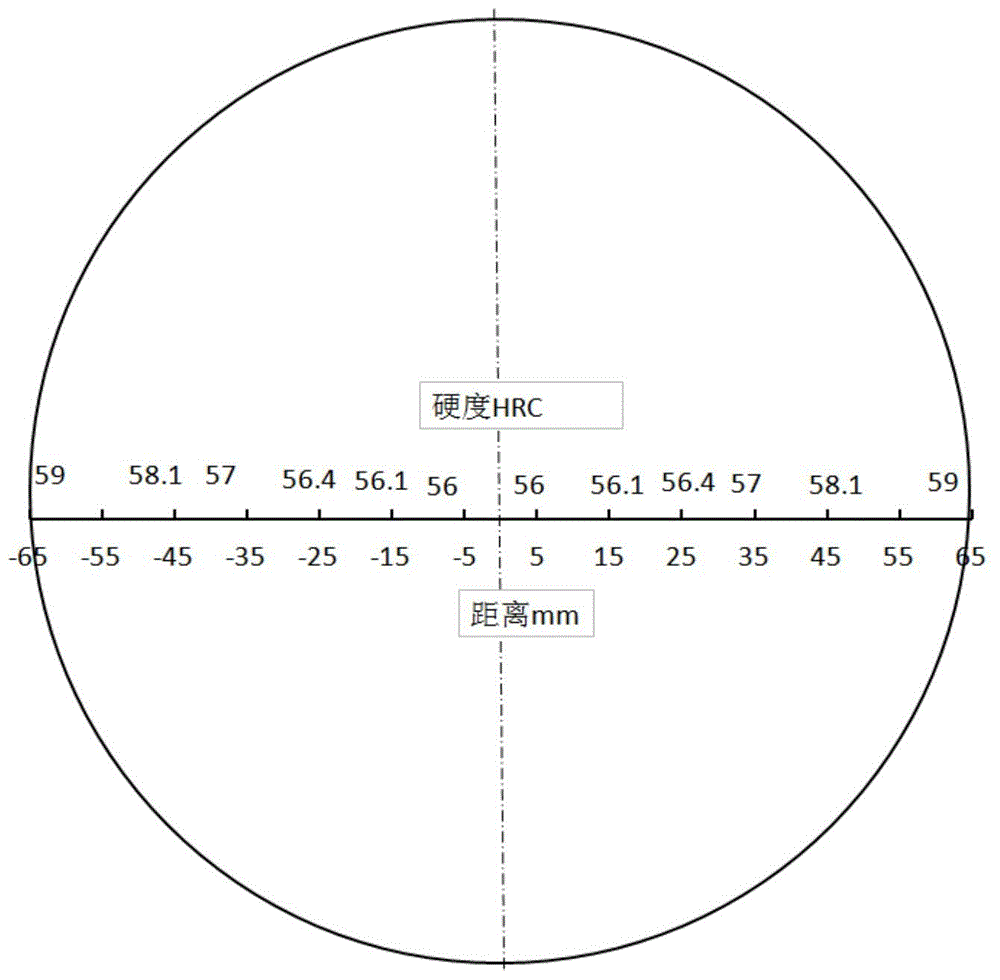

Wear-resisting cast steel

The invention provides wear-resisting cast steel. The cast steel comprises the following chemical components by weight percent: 0.3-0.4% of C, 1.8-2.2% of Mn, 0.8-1.2% of Cr, 0.6-1.0% of Si, 0.02-0.05% of Mo, 0-1.0% of Ni, 0-1.0% of V, 0-1.0% of Ti, 0-1.0% of Re, less than or equal to 0.04% of P, less than or equal to 0.04% of S, and the balance of Fe. Compared with the existing wear-resisting cast steel, the wear-resisting cast steel has the advantages that the content of manganese is improved and the content of molybdenum is lowered, thus the cost is lowered under the premise of guaranteeing the hardenability of the cast steel; the content of manganese is improved but the content of silicon is lowered, so that the wear-resisting cast steel is improved in thermal conductivity so as to avoid generating cracks in water quenching; furthermore, by regulating the content of carbon, manganese, chrome, silicon and molybdenum, the wear-resisting cast steel is improved in impact toughness and hardness, is not easy to break and has excellent wear-resisting property.

Owner:湖南华民控股集团股份有限公司

Manganese doped inorganic halogen perovskite quantum dots and preparation method thereof

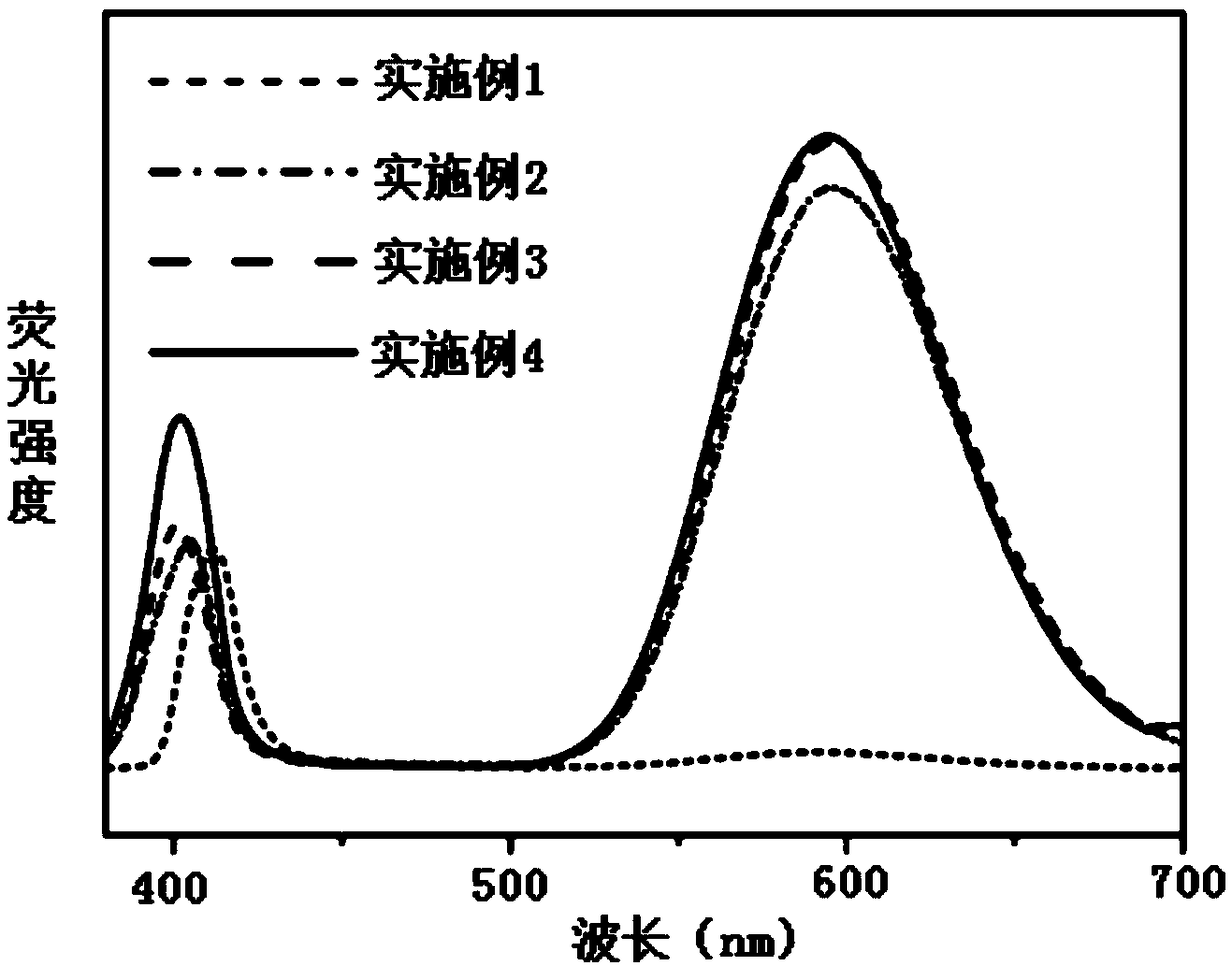

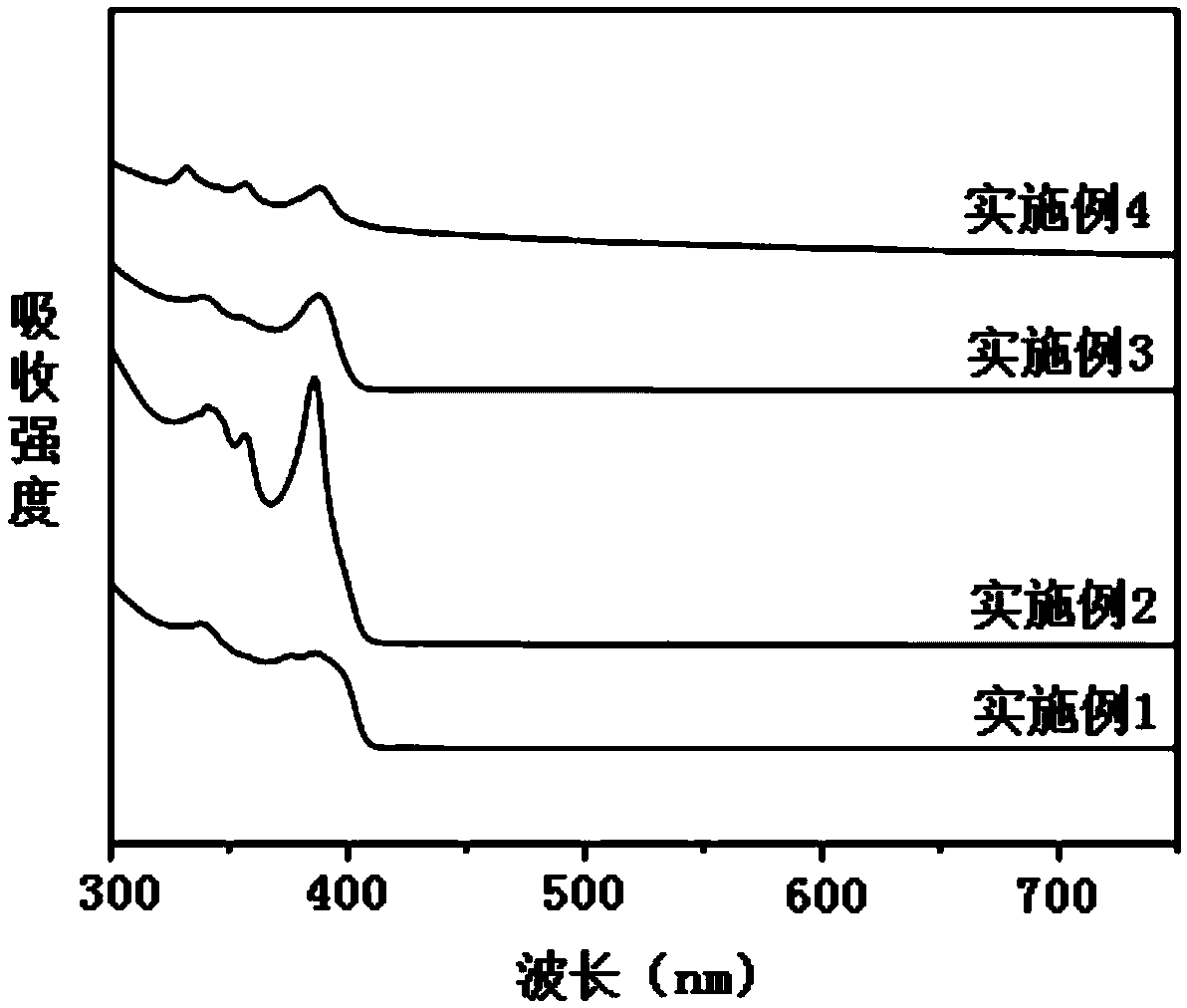

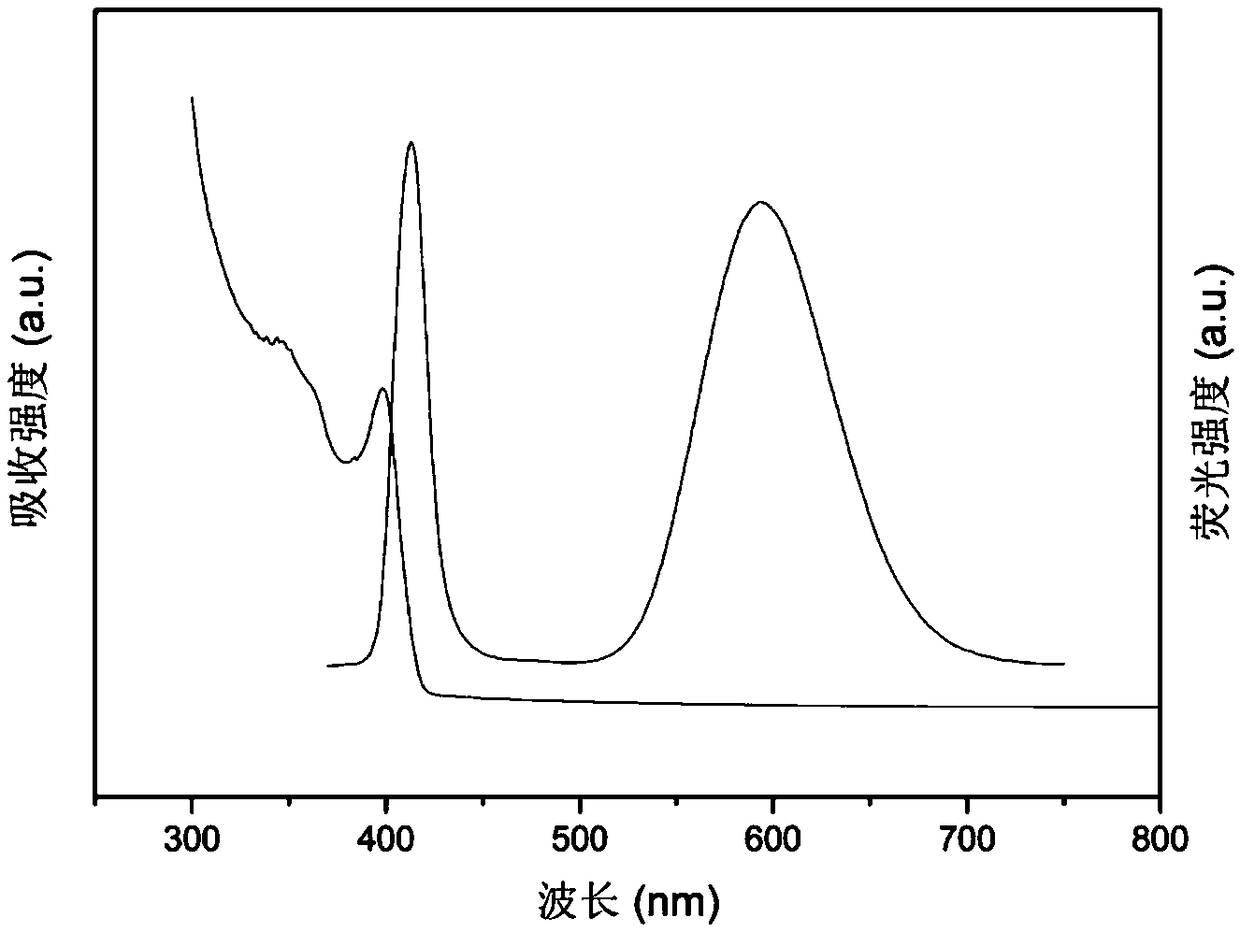

ActiveCN108728089AReduce manufacturing costImprove production efficiencyMaterial nanotechnologyNanoopticsQuantum yieldHalogen

The invention discloses manganese doped inorganic halogen perovskite quantum dots and a preparation method thereof. The preparation method comprises the following steps: lead salt and manganese chloride are dissolved and heated at 80-110 DEG C, and a halogen precursor is obtained; cesium salt is dissolved, and a cesium precursor is obtained; the cesium precursor is added to the halogen precursor,the mixture is heated at 80-110 DEG C, and the manganese doped inorganic halogen perovskite quantum dots are obtained. The method for preparing the manganese doped inorganic halogen perovskite quantumdots with high yield at lower temperature needs no inert gas protection, preparation cost is reduced, preparation efficiency is improved, quantum yield is as high as 62.41% which is 12.41% higher than the current highest quantum yield of 54% with a hot injection method, and the method can be applied to mass production.

Owner:HUAZHONG UNIV OF SCI & TECH

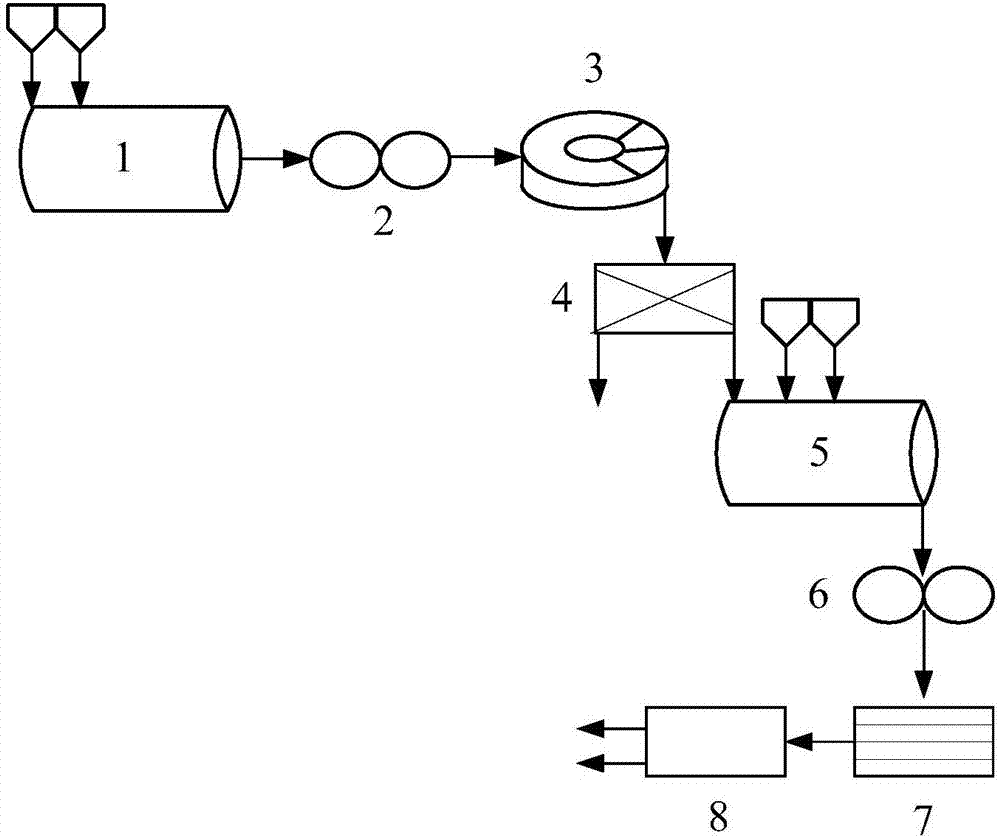

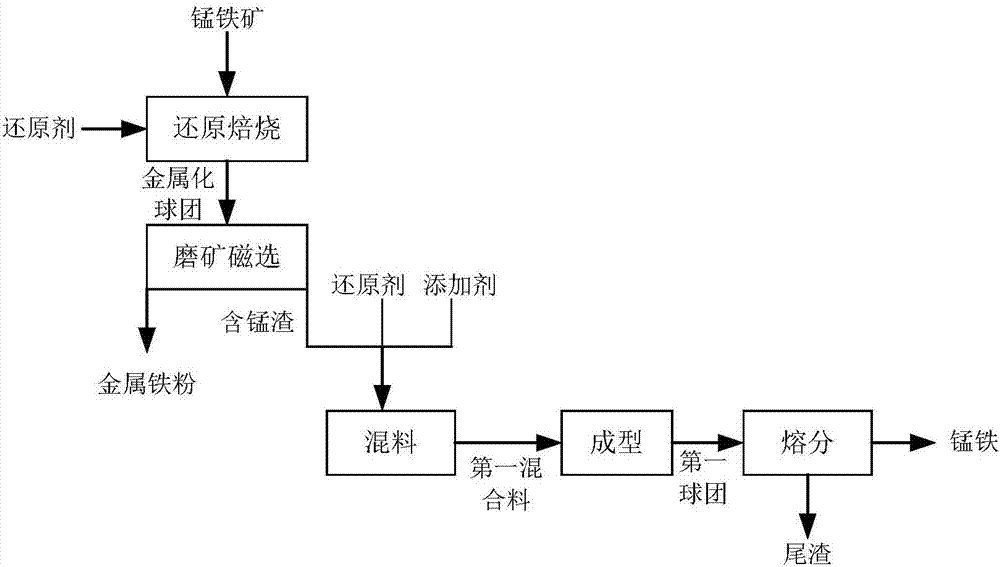

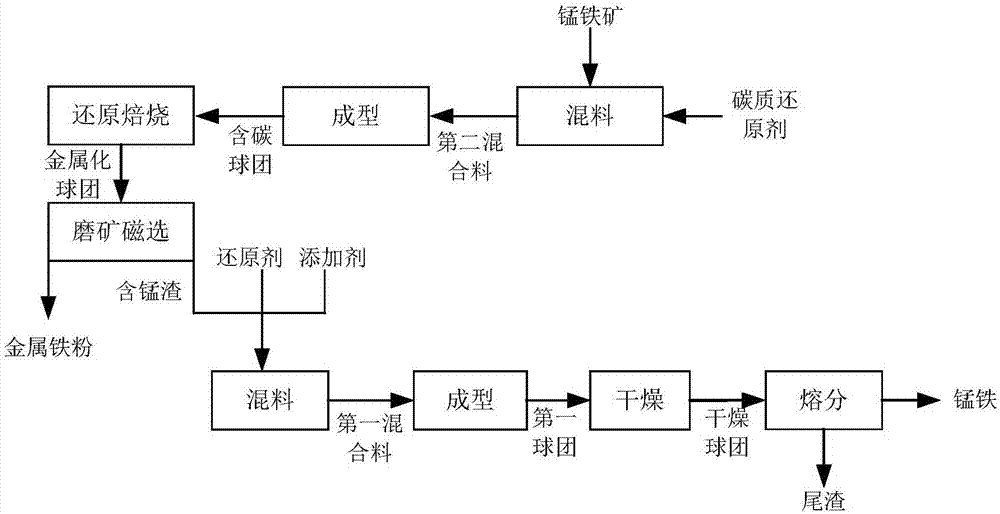

Treatment system and treatment method of ferrous manganese ore

The invention provides a processing system and processing method of ferromanganese ore. The system includes: reduction device, with raw material inlet and metallized pellet outlet; grinding device, with metallized pellet inlet, metal iron powder outlet and manganese slag outlet, metallized pellet inlet and metallization of reduction device The pelletizing outlet is connected; the first mixing device is provided with manganese slag inlet, reduced coal inlet, additive inlet and the first mixture outlet, and the manganese slag inlet is connected with the manganese slag outlet of the grinding device; the first forming device is equipped with The first mixture inlet and the first pellet outlet, the first mixture inlet is connected with the first mixture outlet of the first mixing device; the melting device is provided with the first pellet inlet and the ferromanganese alloy outlet, the first pellet The inlet is connected to the first pellet outlet of the first forming device. The invention can comprehensively recover the manganese and iron in the ferromanganese ore to obtain metal iron powder and ferromanganese.

Owner:JIANGSU PROVINCE METALLURGICAL DESIGN INST

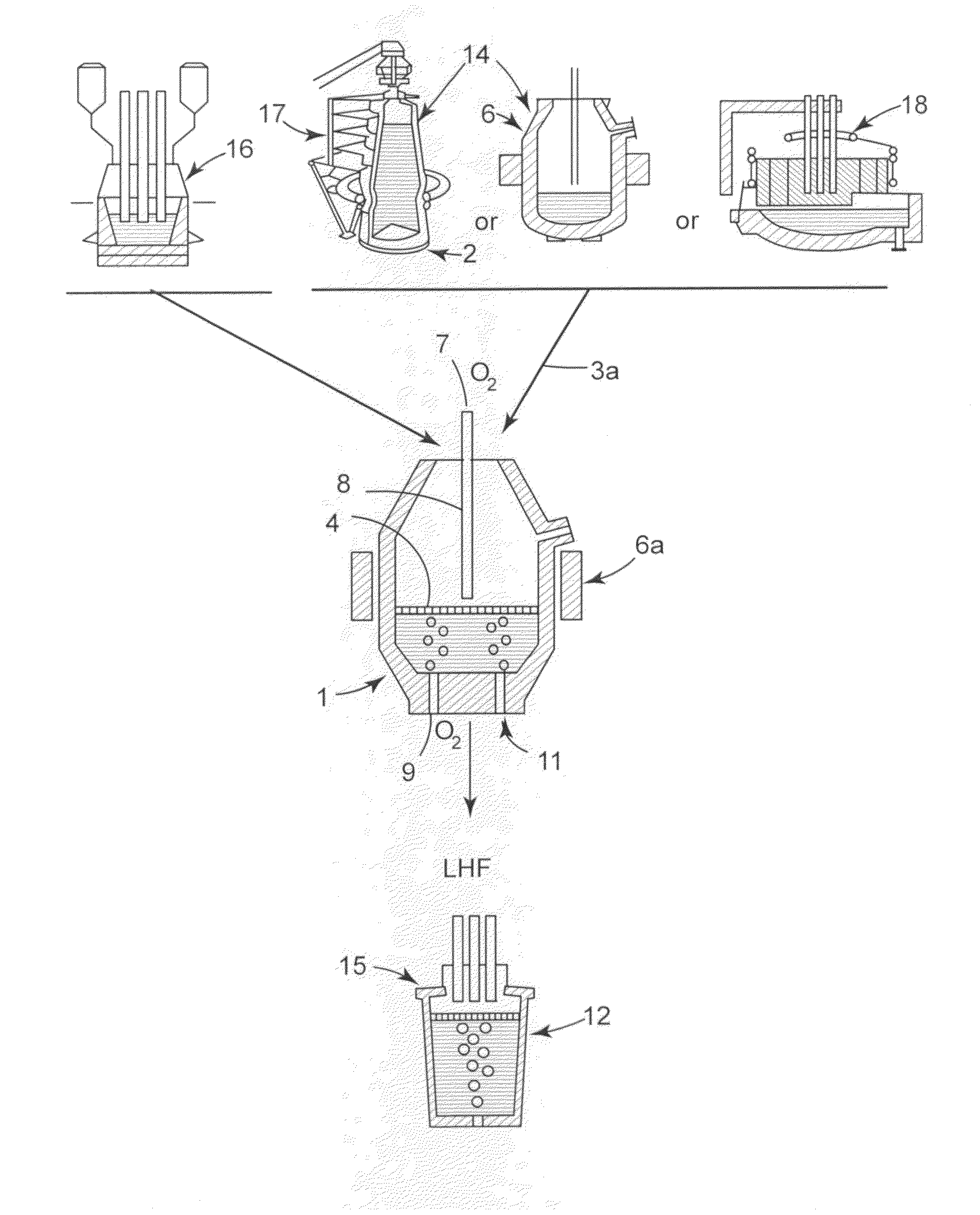

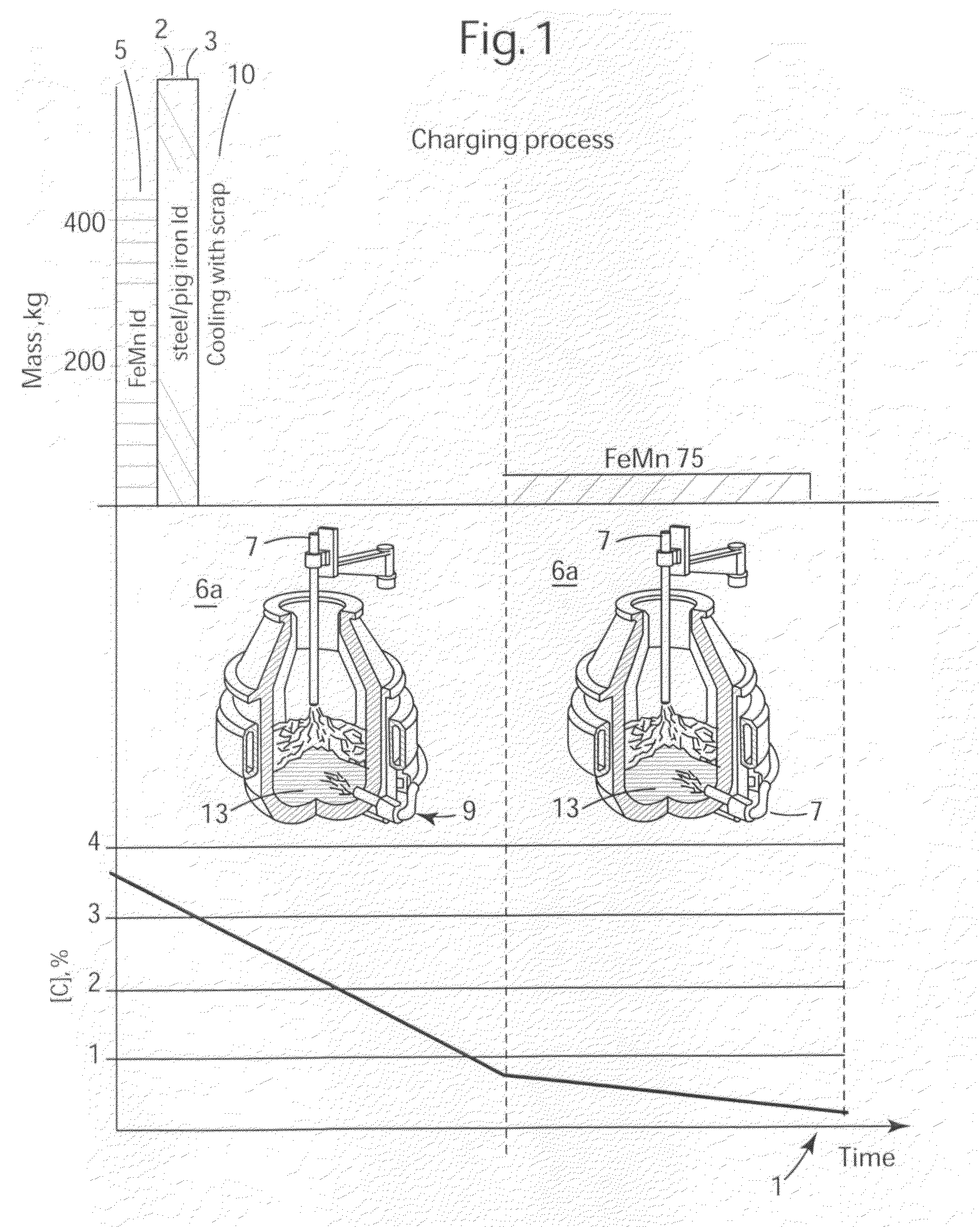

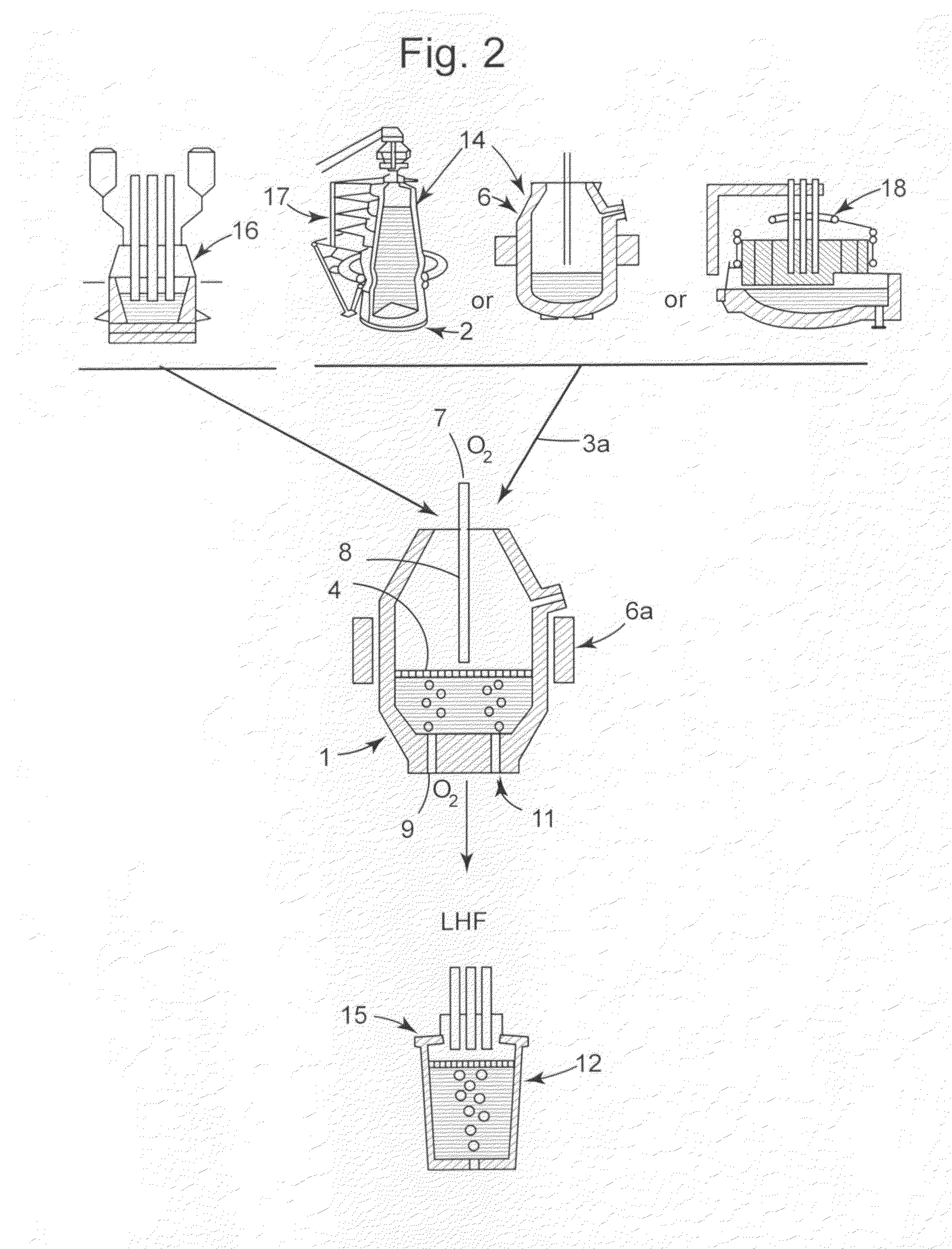

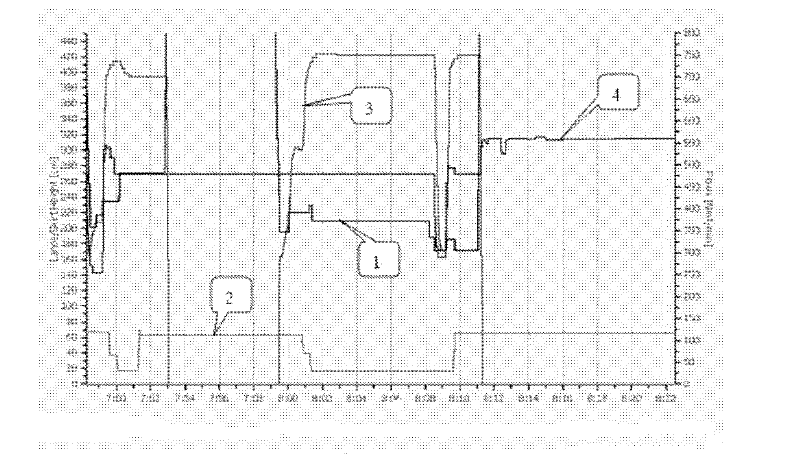

Method of producing steel with high manganese and low carbon content

ActiveUS20110000339A1Drawback can be obviatedHigh in manganeseBlast furnace detailsManufacturing convertersElectric arc furnaceLiquid steel

A method of producing steel (1) with a high manganese and low carbon content on the basis of liquid pig iron (2) or liquid steel (3) and slag-forming constituents (4) with the object of preventing existing drawbacks of process route in vessels other than, e.g., electrical arc furnaces (18). With steel produced with a high manganese and low carbon content, in a process, the carbon component is reduced to about 0.7-0.8% by a combined blowing of oxygen (7) through top lances (8) and underbath nozzles (9) after feeding of liquid ferro-manganese (50 and liquid steel (3a) in a FeMn-refining converter (6a), wherein a component of a cold end product from premelt is added as cooling means (10), and wherein the carbon component is reduced to about 0.05-0.1% C by a continuous blowing of oxygen (7) through the underbath nozzles.

Owner:SMS DEMAG AG

High-hardness alloyed nodular iron die material and preparation method thereof

ActiveCN102168222AReasonable and advancedImprove hardenabilityHigh volume manufacturingIntermediate frequency

Owner:宝武特种冶金有限公司

Converter manganese ore direct alloying steelmaking method

ActiveCN110527786AHigh in manganeseReduce the cost of converter smeltingManufacturing convertersManganiteSmelting

The invention relates to a converter manganese ore direct alloying steelmaking method, and belongs to the technical field of steelmaking. According to the method, a converter double-slag smelting method is adopted, a slagging material is added for primary slagging blowing, carbon drawing and deslagging are conducted after early dephosphorization, then secondary slagging blowing is conducted, the slagging material, a temperature raising agent and manganese ore are added in the secondary slagging blowing process for alloying, blowing is conducted till the final molten steel temperature is 1640-1670 DEG C, and tapping is conducted. According to the method, the dephosphorization effect of the converter is guaranteed, meanwhile, the manganese content of the end point molten steel is increased,and the manganese yield is high.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Method for removing manganese from molten iron in top and bottom combined blown convertor

InactiveCN102559982AHigh efficiency of manganese removalWide variety of sourcesProcess efficiency improvementSlagScrap

The invention discloses a simple, efficient and low-cost method for removing manganese from molten iron in a top and bottom combined blown convertor. The final manganese content of the convertor is controlled to be less than 0.05 weight percent. The method comprises the following specific steps of: adding steel scrap into the convertor, adding the molten iron into the convertor, adding a demanganization agent into the liquid level of the molten iron, supplying oxygen to the liquid level of the molten iron by using an oxygen lance from the top, supplying stirring gas into the molten iron from the bottom, monitoring the CO content of converter gas, and pouring initial slag out when the inhibition of the carbon oxidation is converted into intense carbon oxidation, wherein the amount of poured slag is not less than 60 percent of the total slag amount; and adding the demanganization agent into the liquid level of the molten iron. Compared with the conventional method for removing manganese by a common blowing process or a convertor duplex manganese removal process, the method has the advantages that: special manganese removal equipment is not required, a mature top and bottom combined blown convertor blowing technology is fully utilized, and the dynamical condition for removing manganese from the molten iron is fully met, the common demanganization agent used as the raw material is used, sources are wide, and price is low.

Owner:HEBEI SHOUGANG QIAN AN IRON & STEEL CO LTD +1

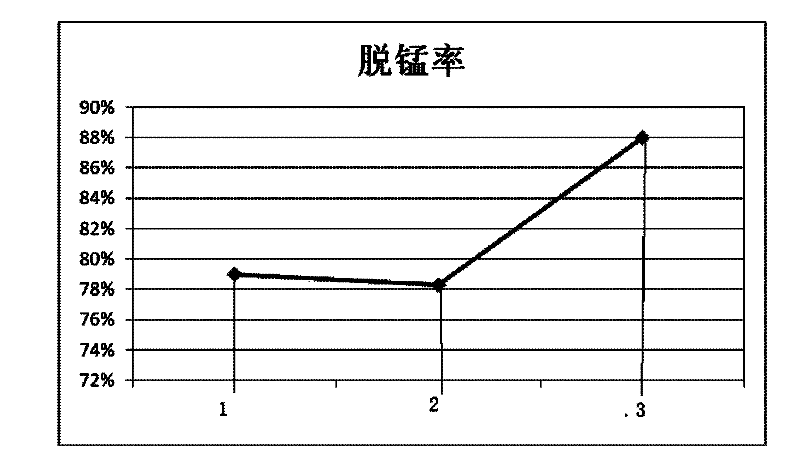

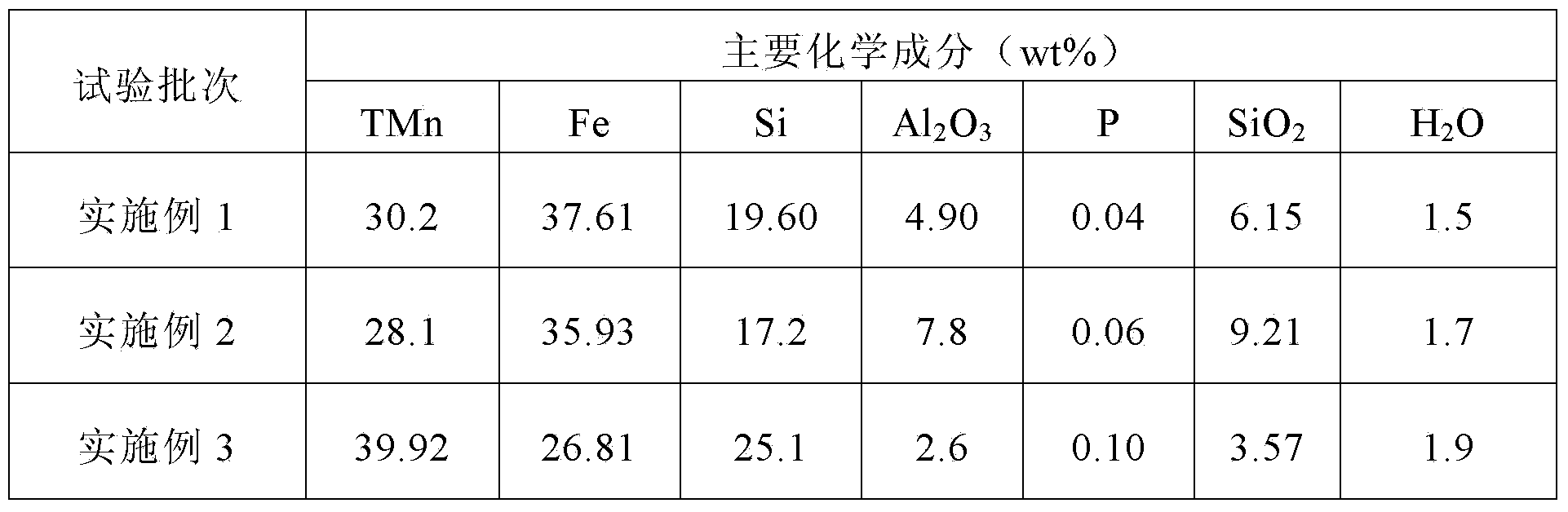

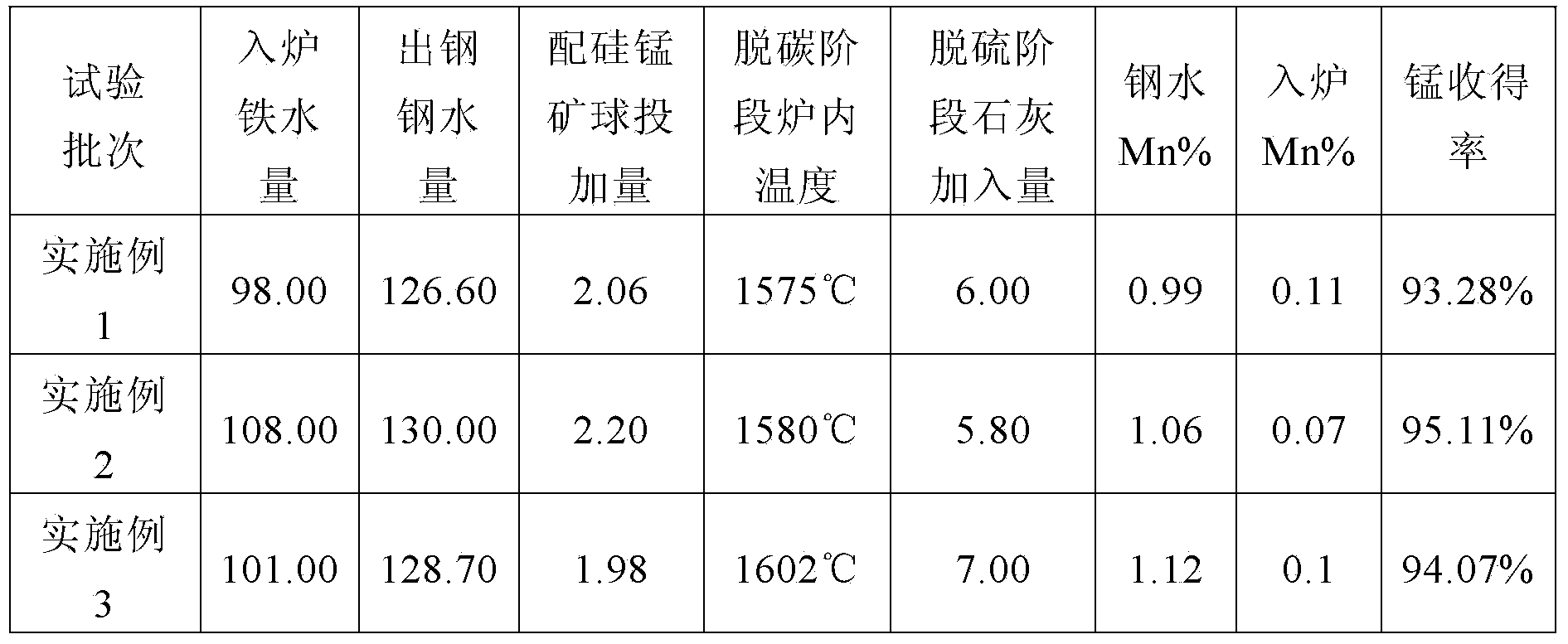

304 stainless steel smelting method by AOD (argon oxygen decarburization) Converter

A 304 stainless steel smelting method by an AOD (argon oxygen decarburization) converter comprises 1) a silicon aluminum oxidation stage; 2) a main decarbonization stage; 3) a dynamic decarburization stage; 4) a reduction stage; and 5) desulfurization alloying; and is characterized in that: silicon mixed manganese ore balls are added in the reduction stage, the silicon mixed manganese ore balls are prepared by mixing and pressing manganese ore powder with a manganese percent content of 25-40% and ferrosilicon powder in a ratio of 7:3, the dosage of the silicon mixed manganese ore balls is 0.01-0.02 ton / ton steel, the silicon mixed manganese ore balls are averagely added in 2 to 3 times at intervals of 2 to 3 minutes; the decarbonization stage smelting temperature of the AOD converter is 1560 to 1620 DEG C; in the desulfurization alloying stage, lime is supplemented, and the lime adding amount is 0.04-0.06 ton / ton steel. According to the method, silicon mixed manganese ore is used for replacing manganese alloy, the production cost can be effectively reduced, the purity of molten steel can be ensured, manganese alloy production link can be directly omitted, and the pollution of the environment can be reduced.

Owner:BAOSTEEL STAINLESS STEEL

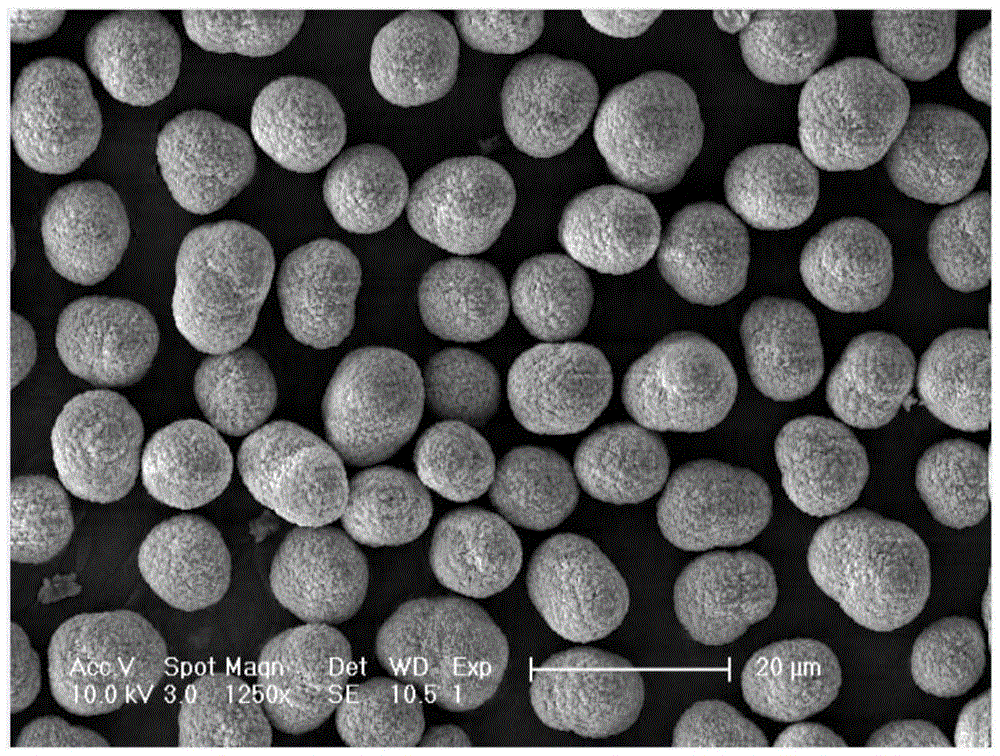

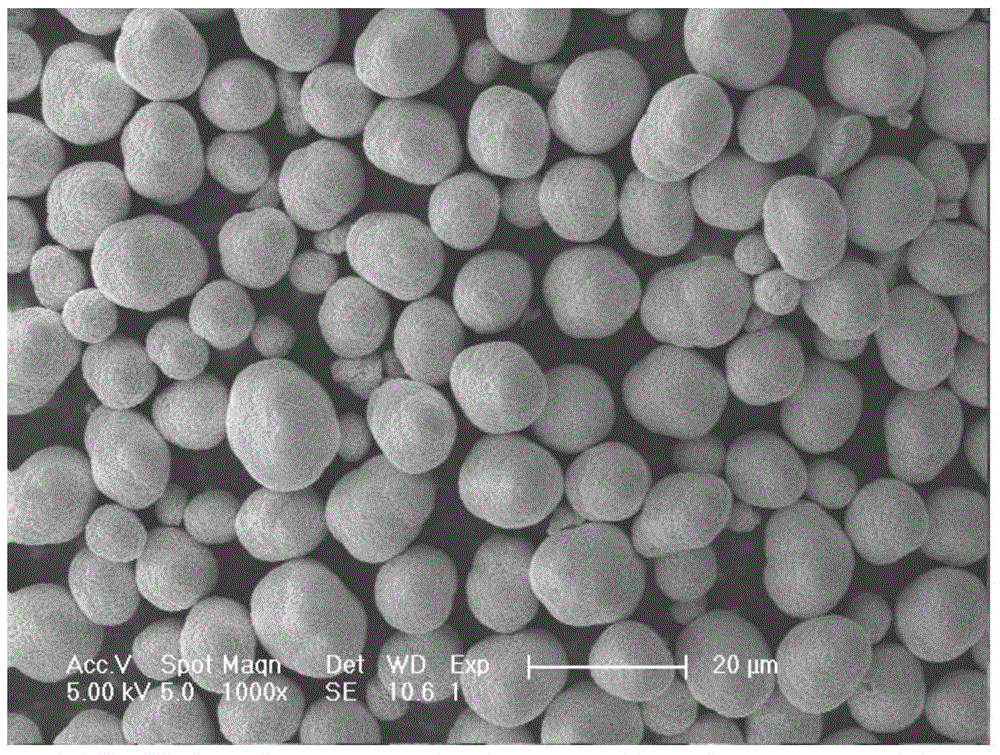

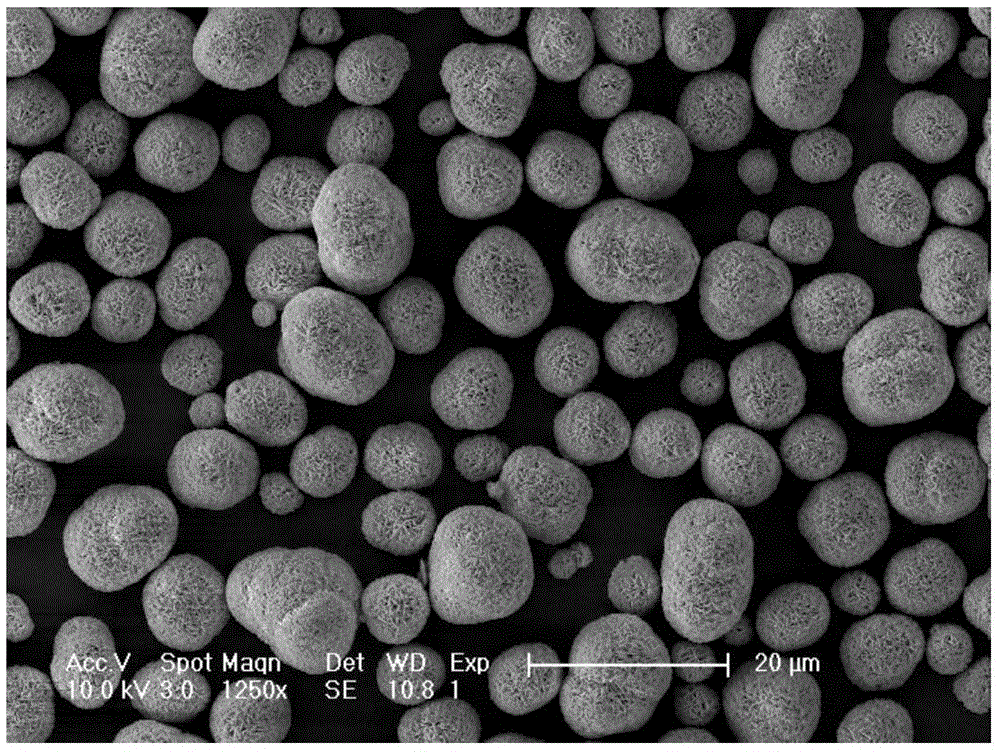

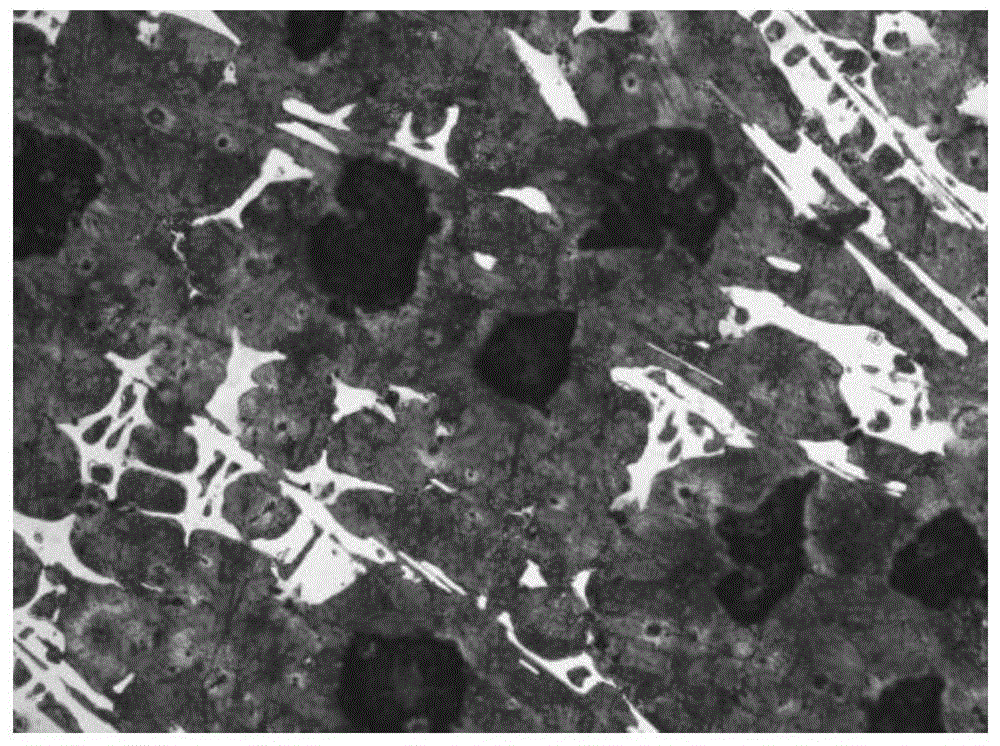

Process method for producing high-pure spherical heavy manganese carbonate

InactiveCN102795669AHigh in manganeseHigh content of impuritiesManganese compoundsManganese(II) carbonateSulfate

The invention relates to a process method for producing high-pure spherical heavy manganese carbonate. The process method comprises the following steps of a. preparing a manganese carbonate solution; b. preparing an ammonium hydrogen carbonate solution, filling ammonia into the ammonium bicarbonate solution to form an ammonium bicarbonate solution; c. adding water and crystal seeds of manganese carbonate into a reactor, stirring and heating to a temperature of 40-90 DEG C; and d. dropwise adding a manganese sulfate solution and the ammonium bicarbonate solution with equal molar ratio at the same time into the reactor, controlling reaction time for 4-8 hours, washing and suction filtering, and thus high-pure spherical heavy manganese carbonate is obtained, wherein the heavy manganese carbonate is in spherical shapes; average particle size is 10-20 micrometers; manganese content is larger than 44.5% (weight percentage); a tap density is 2.0-2.4 g / cm3, the content of Ca is no more than 100 PPm; the content of Mg is no more than 150 PPm; and the content of Pb is no more than 50 PPm. The high-pure spherical heavy manganese carbonate prepared by the process has high manganese content of manganese carbonate and low content of impurities. Chemical manganese dioxide produced by the high-pure spherical heavy manganese carbonate can effectively increase chemical performance of batteries.

Owner:湖北开元化工科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com