High-hardness alloyed nodular iron die material and preparation method thereof

A mold material and alloy ball technology, applied in the field of alloy ductile iron material manufacturing process, can solve problems such as wear and adhesion, and achieve the effect of improving comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

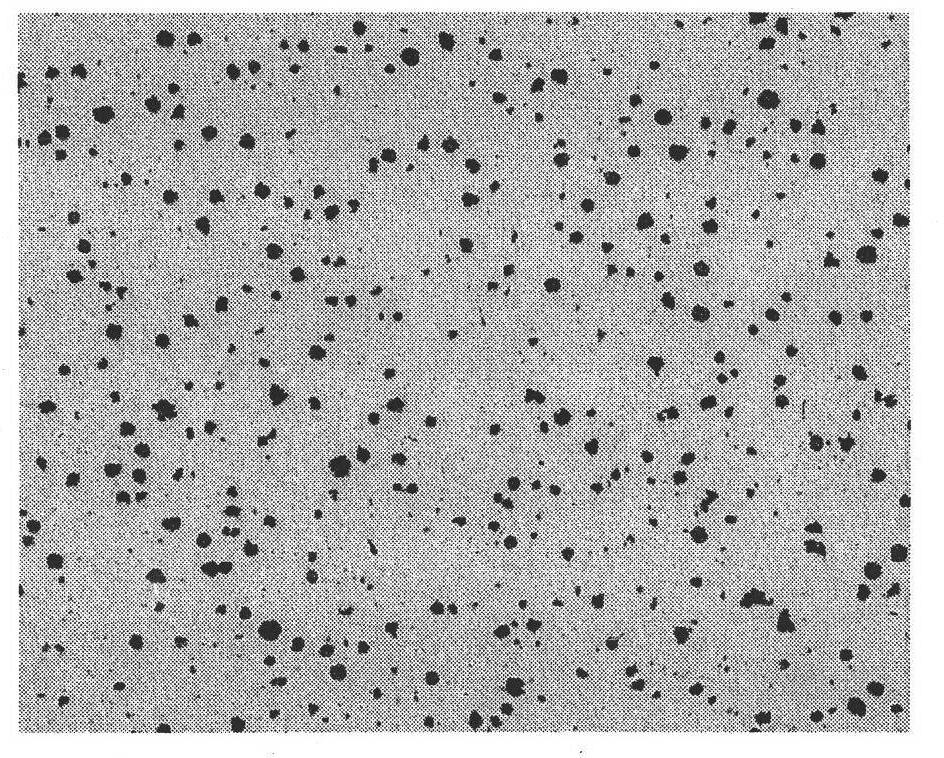

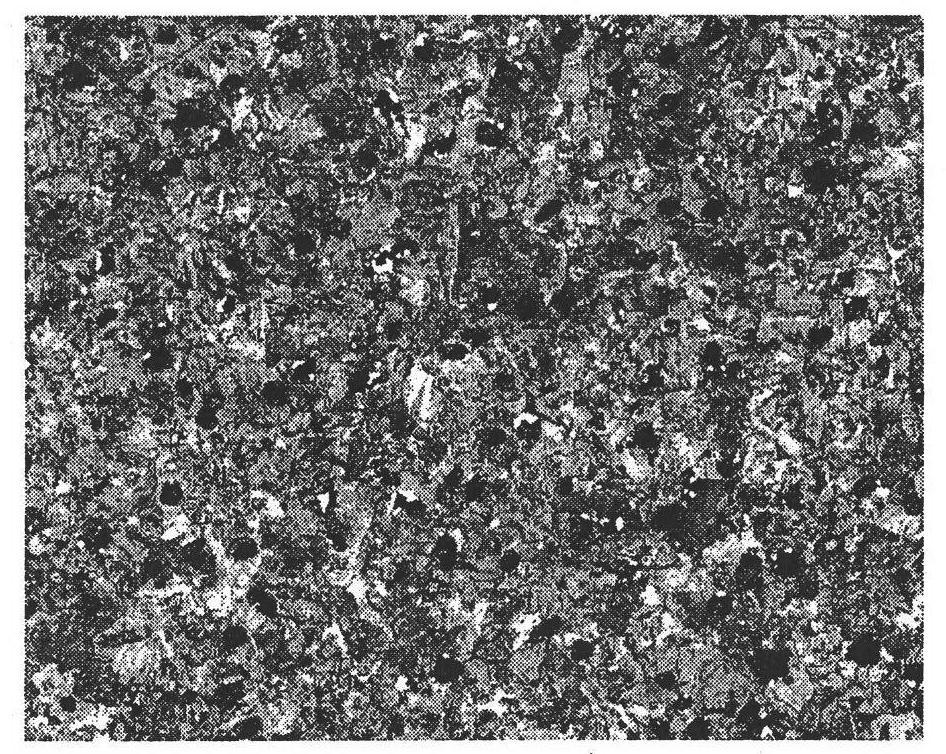

Image

Examples

Embodiment 1

[0042] See Table 1 for chemical composition. According to the chemical composition in Table 1, the ingredients were placed in an intermediate frequency induction melting furnace for melting, the melting temperature was controlled at 1400°C, and the temperature was kept for 0.8 hours after complete melting. The poured Y-shaped sample is subjected to surface intermediate frequency induction quenching treatment with a mobile induction hardening equipment, the output power is 24KW, the quenching temperature is controlled at 880°C, the quenching time is controlled at 2min / mm (thickness of ductile iron), and the quenching cooling method is air cooled.

[0043] Performance test: the surface hardness is 61HRC, the depth of the hardened layer is 2.78mm, and the tensile strength is 740MPa. See Table 2.

Embodiment 2

[0045] See Table 1 for chemical composition. According to the chemical composition, the ingredients are placed in a medium-frequency coreless induction melting furnace for melting. The melting temperature is controlled at 1300 ° C, and the temperature is kept for 0.5 hours after complete melting. The poured Y-shaped sample is subjected to surface intermediate frequency induction quenching treatment with a mobile induction hardening equipment, the output power is 20KW, the quenching temperature is controlled at 850°C, the quenching time is controlled at 2min / mm (thickness of ductile iron), and the quenching cooling method is air cooled.

[0046] Performance test: the surface hardness is 60HRC, the depth of the hardened layer is 2.71mm, and the tensile strength is 733MPa.

Embodiment 3

[0048] See Table 1 for chemical composition. According to the chemical composition, the ingredients are placed in a medium-frequency coreless induction melting furnace for melting. The melting temperature is controlled at 1500 ° C, and the temperature is kept for 0.9 hours after complete melting. The surface of the cast Y-shaped sample is quenched with a mobile induction hardening device, the output power is 28KW, the quenching temperature is controlled at 950°C, the quenching time is controlled at 4min / mm (thickness of ductile iron), and the quenching cooling method is air cooled.

[0049] Performance test: the surface hardness is 63HRC, the depth of the hardened layer is 2.85mm, and the tensile strength is 752MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com