Patents

Literature

68results about How to "Increase chromium content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-entropy alloy powder for laser cladding and preparation method of cladding layer

InactiveCN106086580AHigh bonding strengthEasy to diluteMetallic material coating processesHigh entropy alloysHardness

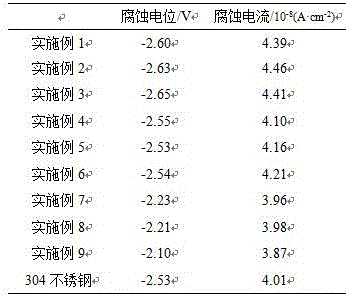

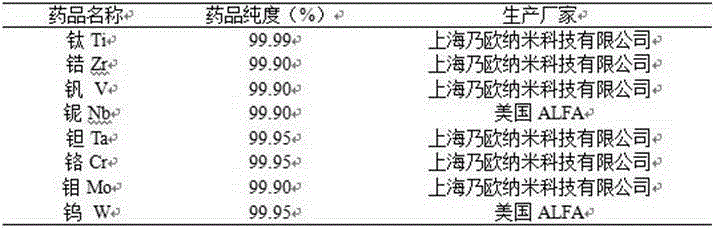

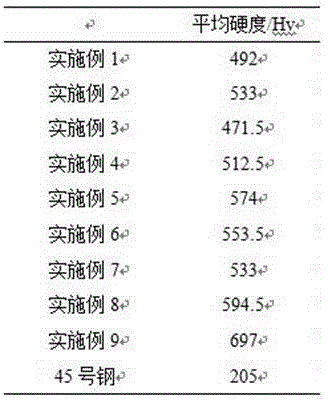

The invention discloses high-entropy alloy powder for laser cladding and a preparation method of a cladding layer. The high-entropy alloy powder comprises Ti, Zr, V, Nb, Ta and Mo. In addition, high-entropy alloy powder which comprises Ti, Zr, V, Nb, Ta, Mo and W, high-entropy alloy powder which comprises Ti, Zr, V, Nb, Ta, Mo, W and Cr and the preparation method of the cladding layer of the high-entropy alloy powder for laser cladding are provided. The high-entropy alloy powder mainly comprises two characteristics, namely, the high-entropy effect and the cocktail effect, each kind of powder exerts respective advantages, and therefore the cladding layer with high hardness, high corrosion resistance, excellent tempering softening resisting performance and excellent structure performance is obtained. Metallurgical bonding is formed by an alloy layer and a matrix through laser cladding; the bonding strength of the cladding layer and the matrix is greatly improved, and the heating speed is high; metal of the cladding layer is not prone to being diluted by the matrix; little heat deformation is generated; and therefore the part rejection rate is low.

Owner:KUNMING UNIV OF SCI & TECH

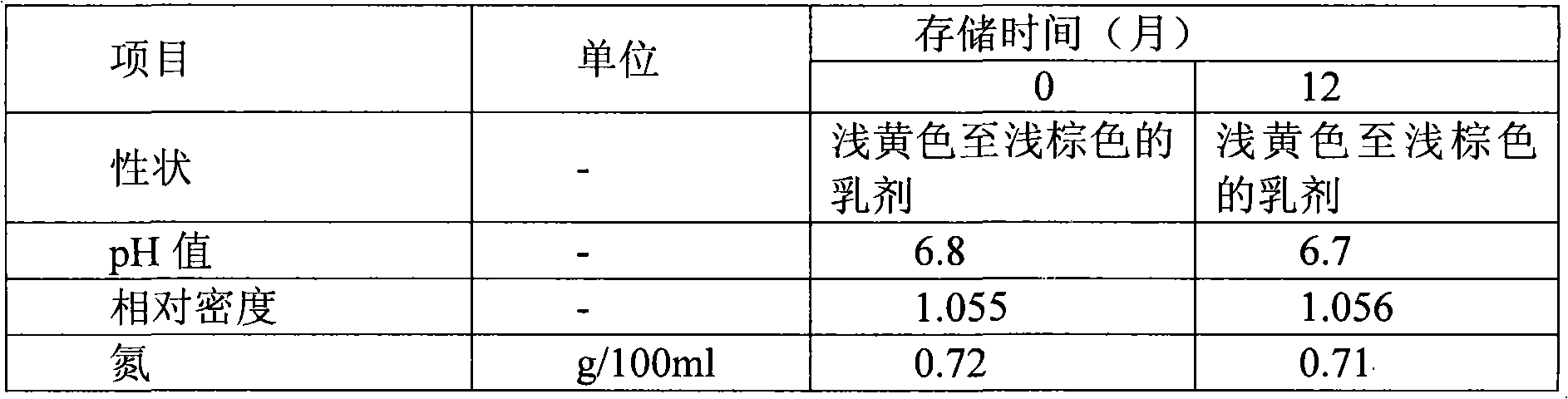

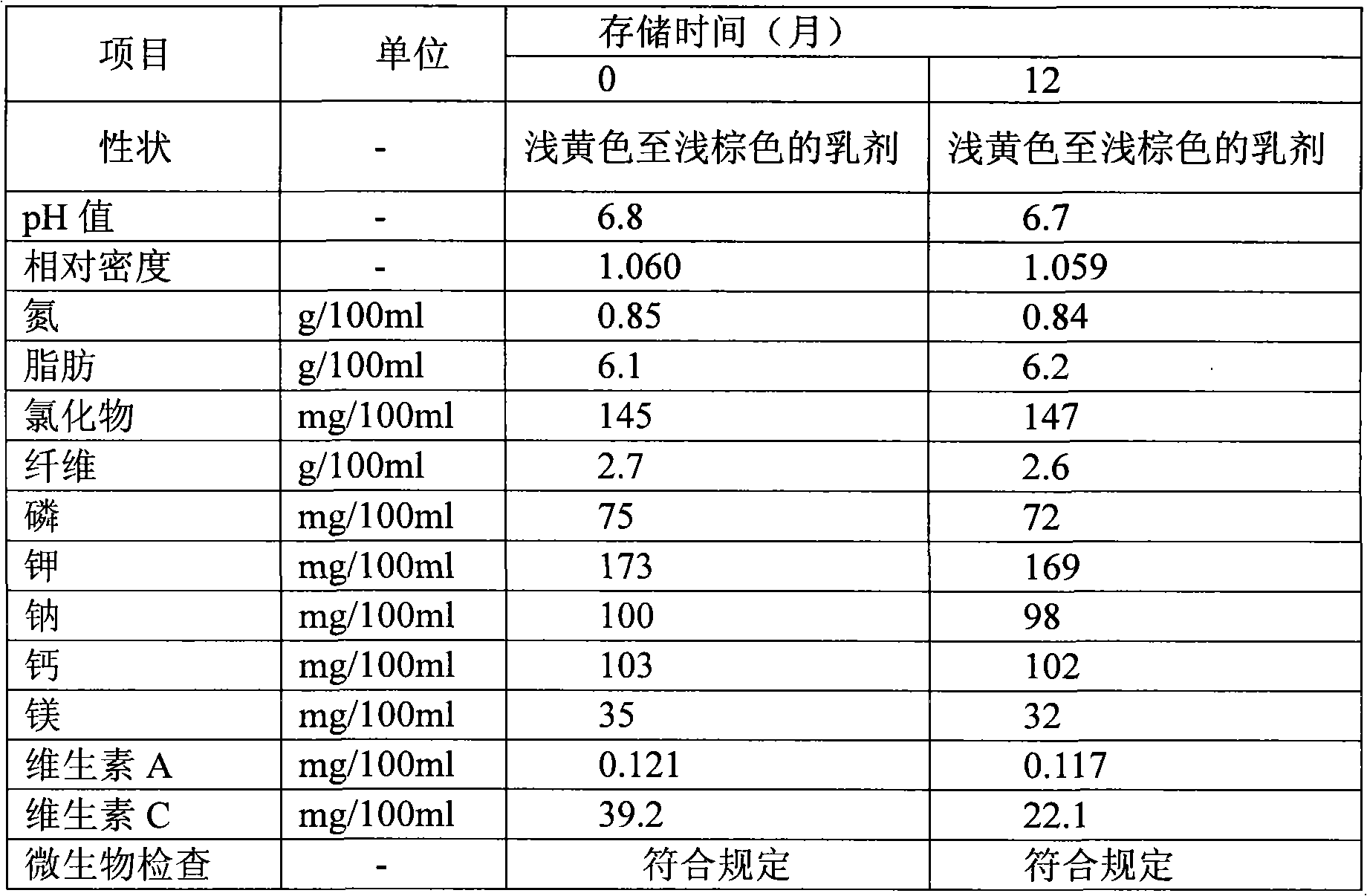

Eternal nutrition emulsion and preparation method thereof

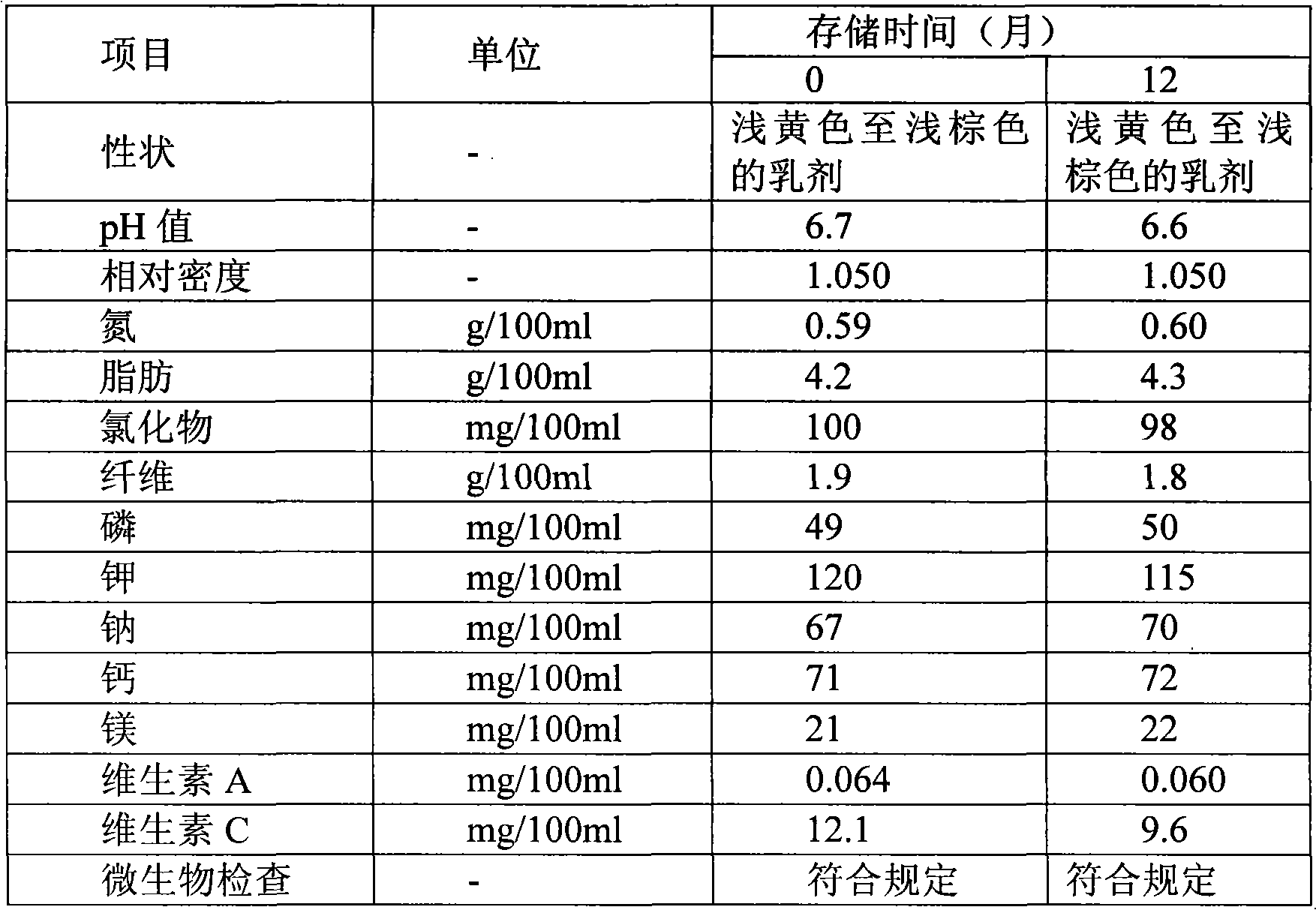

The invention discloses eternal nutrition emulsion for diabetics and a preparation method thereof. On the basis of the technical scheme provided by the invention, 1000ml of eternal nutrition comprises the following components of protein, carbohydrate, fat, dietary fiber, mineral substances of sodium, potassium, chlorine, calcium, magnesium and the like, microelements and vitamins. The invention has the following advantages of optimization of fat composition and carbohydrate composition, high chromium content, and rich antioxidant vitamins and dietary fiber.

Owner:费森尤斯卡比华瑞制药有限公司

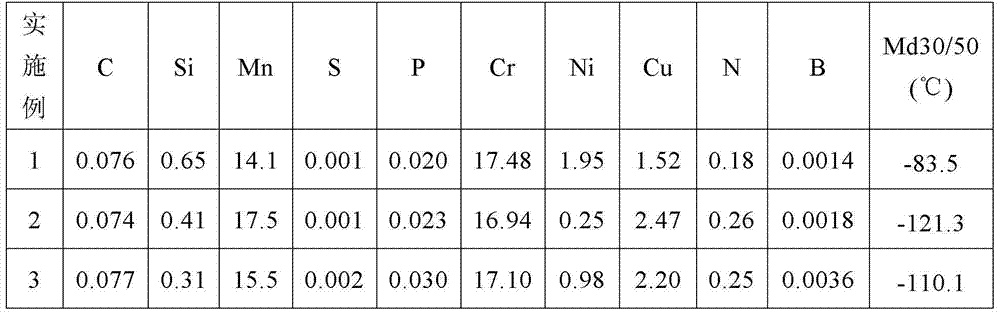

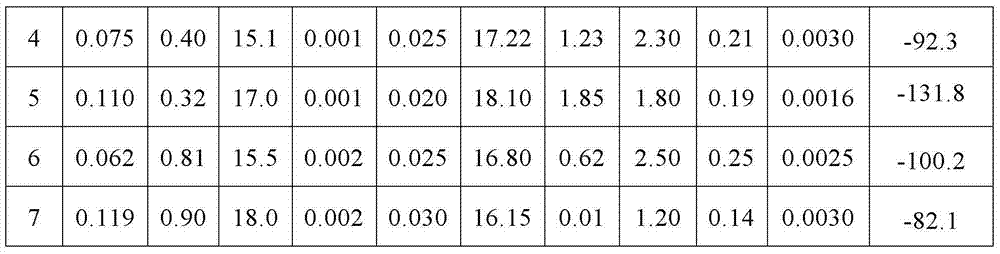

Inexpensive non-magnetic stainless steel and manufacturing method thereof

InactiveCN104513933AReasonable ingredient controlEase of mass productionElectrical devicesNon magnetic

The invention relates to an inexpensive non-magnetic austenite stainless steel and a manufacturing method thereof. The components comprise, by weight, 0.05-0.12% of C, 0.2-1.0% of Si, 14.0-18.0% of Mn, 16.0-19.0% of Cr, 0-2.0% of Ni, 1.0-3.0% of Cu, 0.1-0.3% of N, 0.001-0.004% of B, and the balance of Fe and unavoidable impurities. According to the present invention, the finished product can maintain the non-magnetic state after 80% of the finished product is subjected to cold rolling reduction; low nickel pig iron with a nickel content of 1-2 wt% and produced by using inexpensive laterite-nickel ore can be adopted as the nickel resource raw material without application of other nickel-containing resources, such that the consumption of the high nickel iron or pure nickel can be substantially saved, and the low cost characteristic is provided; and the inexpensive non-magnetic austenite stainless steel of the present invention has characteristics of no magnetism, high strength, and excellent cold processing performance, and can be widely used in the industries of electrical devices, electronics, instrumentations, springs, zippers and the like.

Owner:BAOSTEEL STAINLESS STEEL

Manufacturing technique for alloy mold

InactiveCN105671371AIncrease chromium contentImprove performanceElectrode potentialElectrical conductor

A manufacturing process of an alloy mold according to the present invention is characterized in that the manufacturing process includes the following steps: firstly weigh and batch the raw materials according to the weight ratio, then add the prepared raw materials into the smelting furnace, and after complete melting, the alloy aluminum liquid Transfer to the holding furnace for refining and degassing, then die-casting production, then preheating, cooling, injection, final molding, preheating, and heat preservation. When in use, the present invention increases the chromium content in the mold material, increases the chromium content, can increase the electrode potential of the iron in the mold steel, and improves the corrosion resistance. At the same time, the alloy aluminum liquid is poured into the production cavity through the side pouring method of double-layer runners, which realizes smooth filling and good feeding effect, and the produced conductor castings meet the process requirements of air tightness and conductivity at the same time. The filling time of alloy aluminum liquid is 0.01-0.2 seconds, and the cavity can be filled, and high-quality castings with good appearance and internal quality can be produced stably, rhythmically and efficiently.

Owner:SHANGHAI YADELIN NONFERROUS METAL

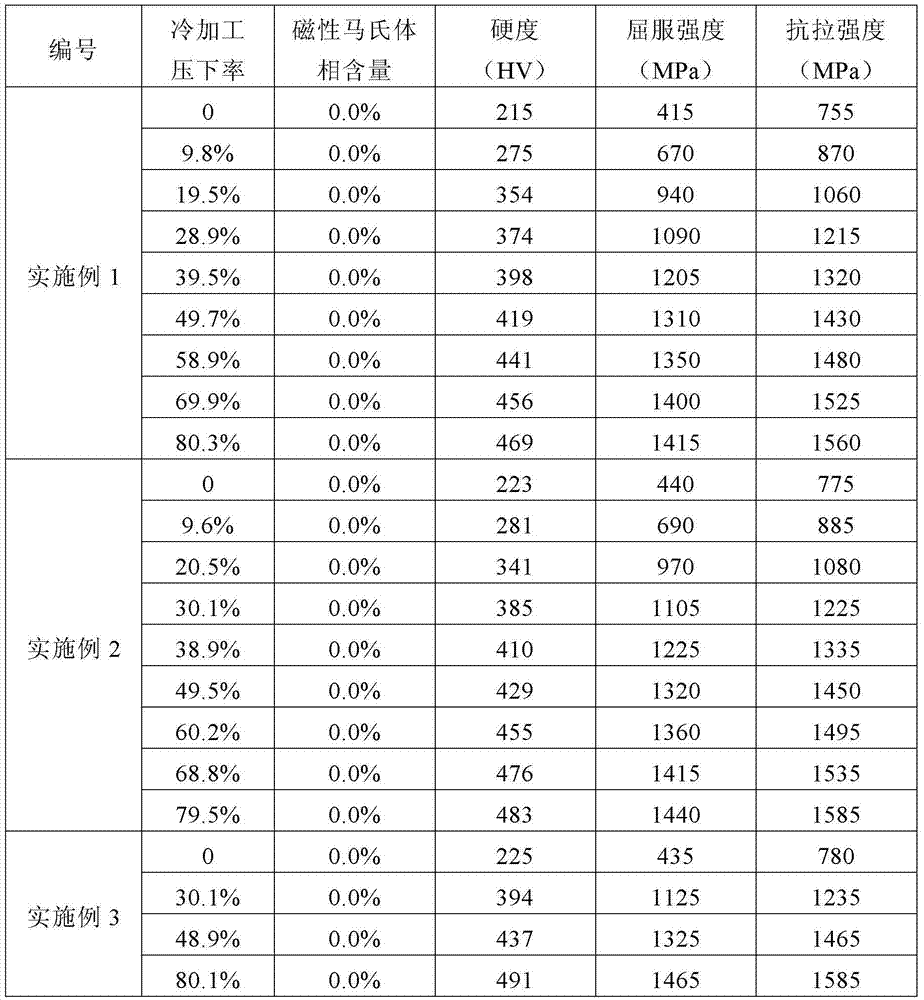

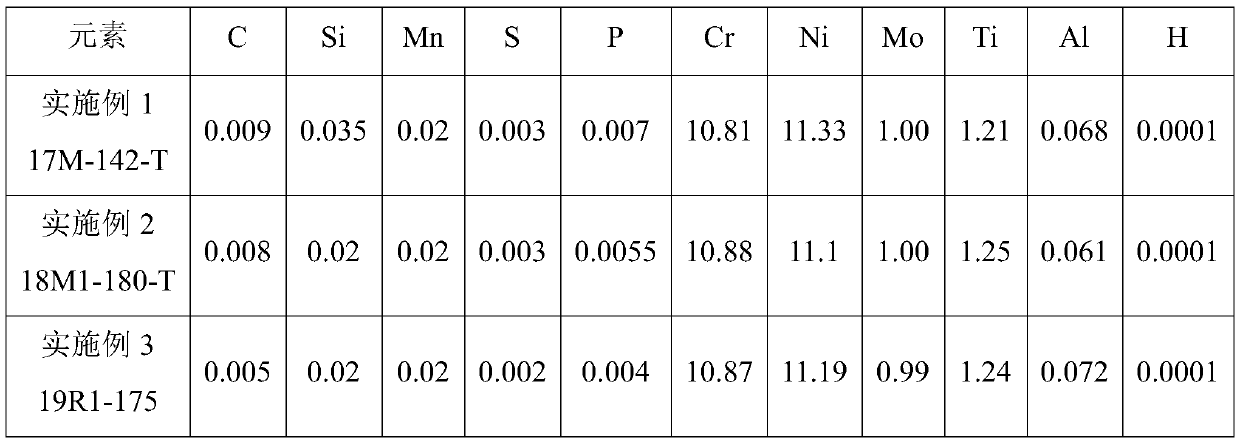

Anti-hydrogen embrittlement, high-strength and high-toughness stainless steel bar for fastener, and manufacturing method thereof

ActiveCN111218618AIncrease chromium contentImprove hydrogen embrittlement resistanceMetallic materialsSS - Stainless steel

The invention relates to an anti-hydrogen embrittlement, high-strength and high-toughness stainless steel bar for a fastener, and a manufacturing method thereof, belongs to the technical field of metal materials, and solves the problem of low matching degree of anti-hydrogen embrittlement property and high toughness of a fastener used in an aerospace environment. The anti-hydrogen embrittlement, high-strength and high-toughness stainless steel bar for the fastener comprises the following elements in mass fraction: 0.0001%-0.01% of C, 0%-0.10% of Si, 0.01%-0.15% of Mn, 0%-0.005% of S, 0%-0.015%of P, 10.50%-12.50% of Cr, 10.70%-11.50% of Ni, 0.75%-1.25% of Mo, 1.20%-1.70% of Ti, 0%-0.10% of Al, not greater than 1.5ppm of H, and the balance iron and inevitable impurities. The stainless steelbar meeting the comprehensive performance of high strength, high toughness and anti-hydrogen embrittlement property simultaneously is prepared, and the use requirement of the fastener making contactwith a corrosive medium and used for the aerospace environment is met.

Owner:CENT IRON & STEEL RES INST

Method for treating vanadium industrial wastewater by aid of semi-dry flue gas desulfurization ash

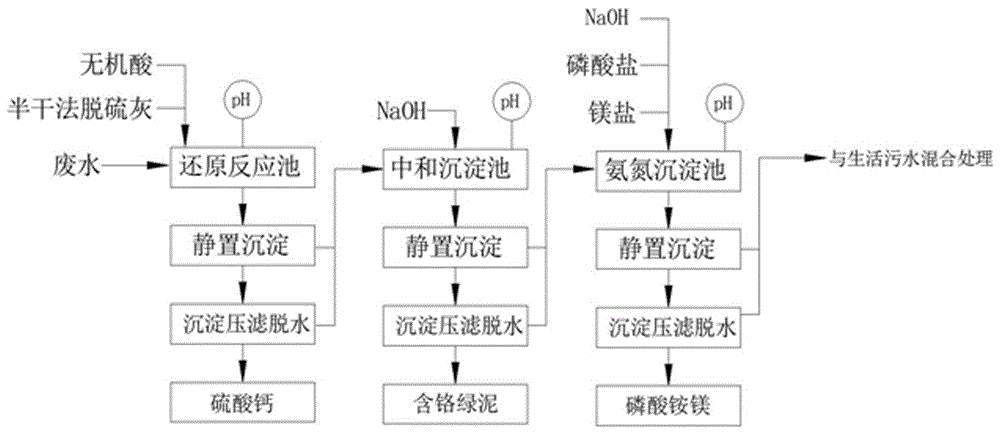

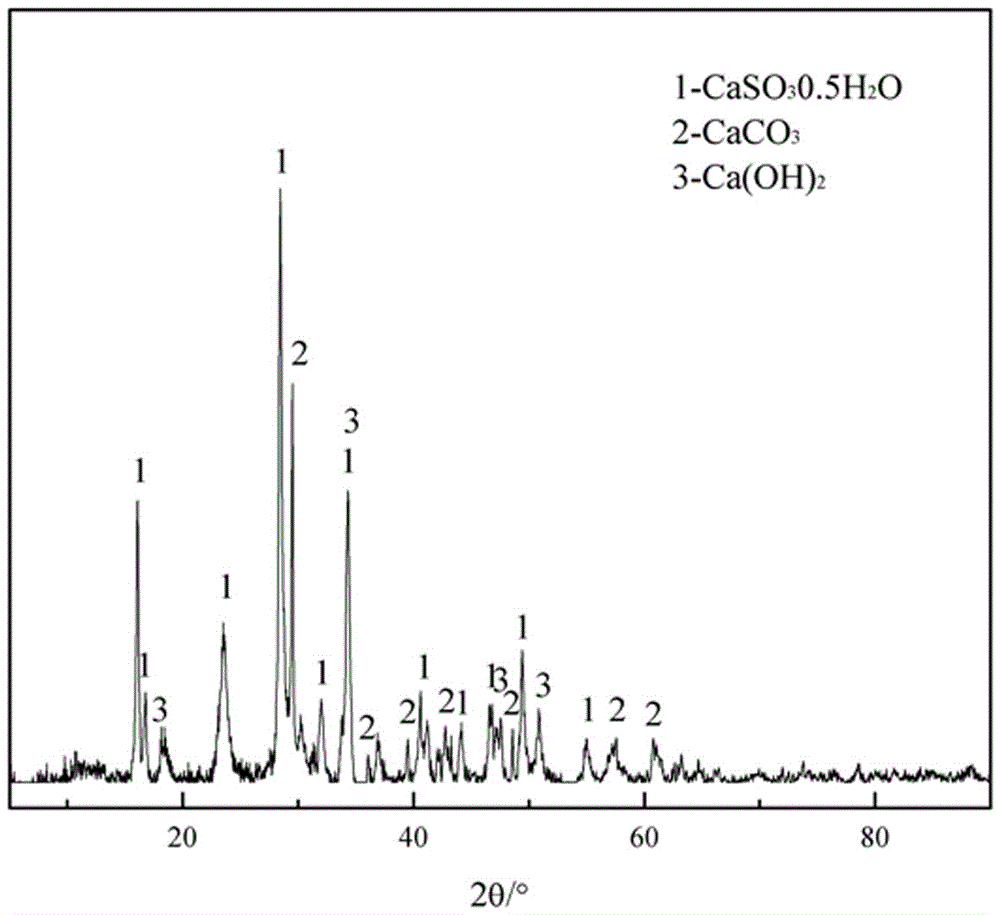

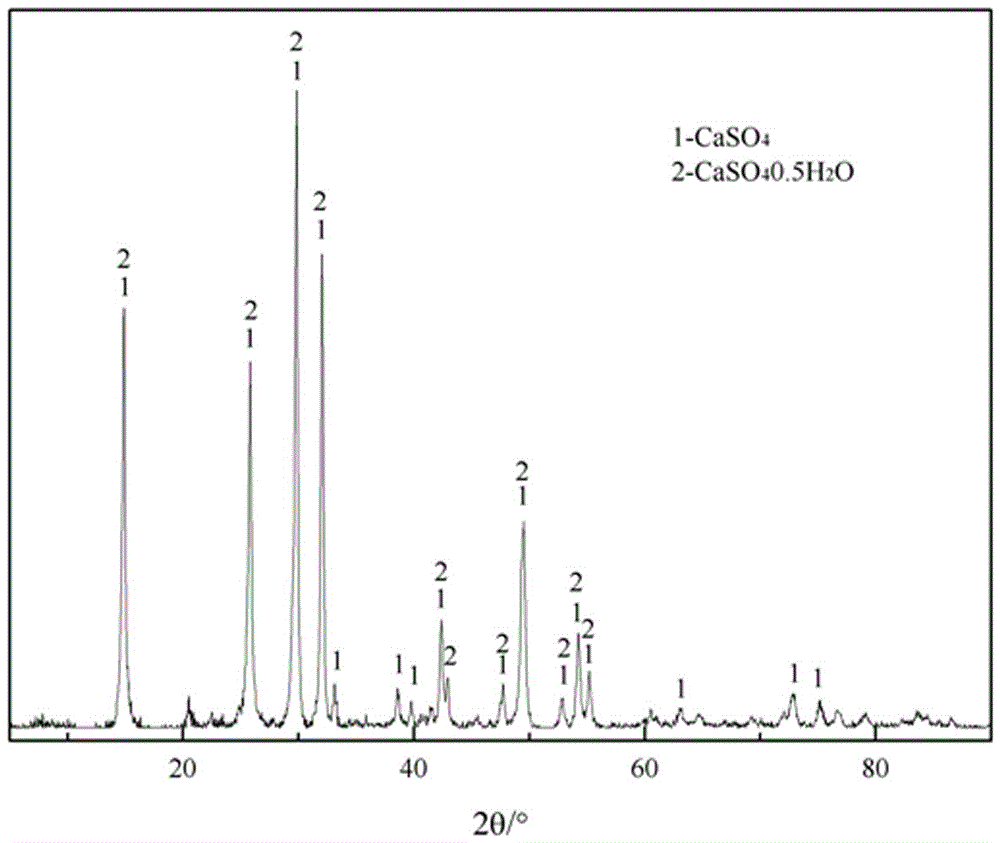

ActiveCN106809989AAmmonia nitrogen and phosphorus reductionIncrease chromium contentCalcium/strontium/barium sulfatesMultistage water/sewage treatmentMagnesium saltFiltration

The invention discloses a method for treating vanadium industrial wastewater by the aid of semi-dry flue gas desulfurization ash. The method includes steps of (1), adding the semi-dry flue gas desulfurization ash into the vanadium industrial wastewater; (2), adding inorganic acid into the vanadium industrial wastewater to regulate a pH (potential of hydrogen) value of the vanadium industrial wastewater and stirring the inorganic acid and the vanadium industrial wastewater to obtain mixtures; (3), allowing the mixtures to stand still, separating supernatant from precipitates, carrying out pressure filtration on the precipitates to obtain calcium sulfate and mixing filter liquid and the supernatant with each other to obtain first mixed liquid; (4), adding sodium hydroxide into the first mixed liquid, stirring the first mixed liquid and the sodium hydroxide to obtain second mixed liquid, adding flocculating agents into the second mixed liquid and continuing to stir the flocculating agents and the second mixed liquid to obtain third mixed liquid; (5), allowing the third mixed liquid to stand still, separating supernatant from precipitates, carrying out pressure filtration on the precipitates to form chromium-containing green mud and mixing filter liquid and the supernatant with each other to obtain fourth mixed liquid; (6), leading the fourth mixed liquid into an ammonia nitrogen precipitating tank, stirring the fourth mixed liquid, adding magnesium salt and phosphate into the fourth mixed liquid to obtain fifth mixed liquid, regulating a pH value of the fifth mixed liquid and then continuing to stir the fifth mixed liquid; (7), allowing the fifth mixed liquid to stand still and separating supernatant from precipitates. The method has the advantages that semi-dry desulfurization solid waste can be recycled, accordingly, the wastewater treatment cost can be reduced, the problems of secondary pollution and land occupation of semi-dry desulfurization ash can be solved, and the method has high environmental benefits, economic benefits and social benefits.

Owner:NORTHEASTERN UNIV

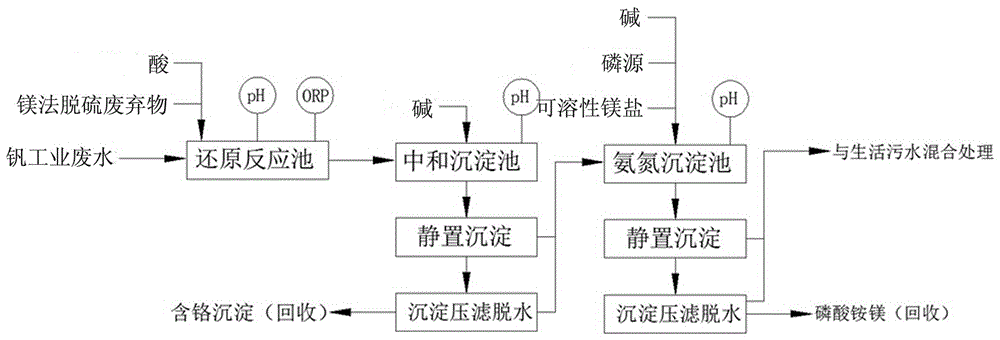

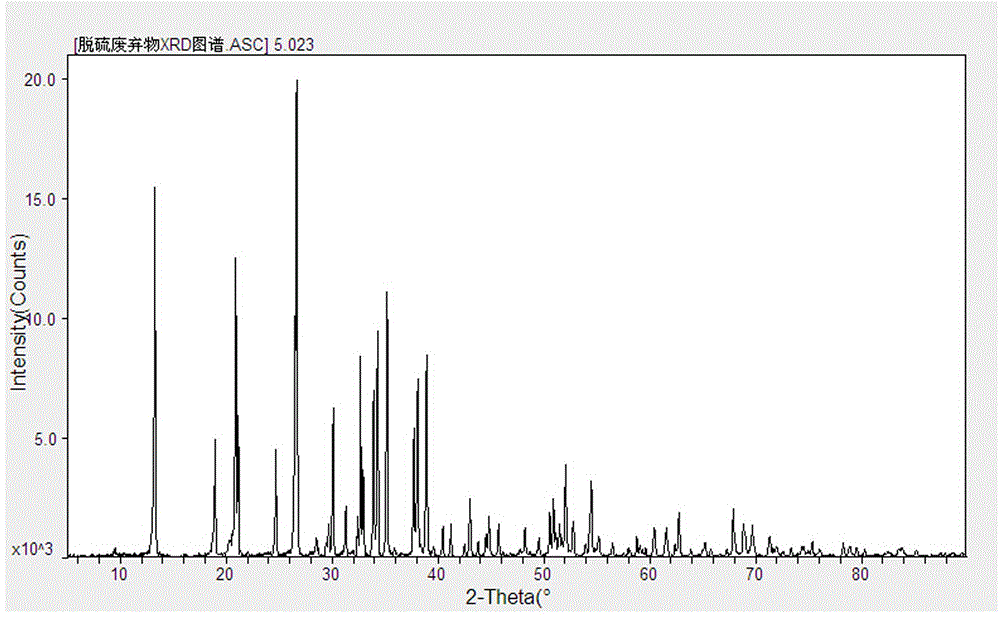

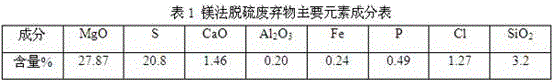

Method for treating vanadium industrial wastewater through magnesium-process desulfurization waste

ActiveCN105923836AEfficient removalIncrease chromium contentWater contaminantsMultistage water/sewage treatmentMagnesium saltTherapeutic effect

The invention belongs to the technical field of wastewater and solid waste treatment and particularly relates to a method for treating vanadium industrial wastewater through magnesium-process desulfurization waste, comprising: adding magnesium-process desulfurization waste into vanadium industrial wastewater, reducing high-valence vanadium and chromium in the wastewater into low-valence vanadium and chromium during reacting, continuing to stir the reduced wastewater, adjusting pH with alkali, adding a flocculant, and standing and precipitating to obtain precipitate, and press-filtering and dewatering the precipitate to form primary chromium hydroxide precipitate, charging the obtained filtrate and precipitate into an ammonia nitrogen precipitating tank, adding an easily-soluble magnesium salt into the ammonia nitrogen precipitating tank, continuing to stir and adding a phosphorus source after the easily-soluble magnesium salt dissolves, forming magnesium ammonium phosphate precipitate from ammonia nitrogen during reacting, standing for 20-50 min, press-filtering and dewatering precipitate to obtain slow-release fertilizer material for recycling, and using obtained filtrate and supernate as effluent. The method has good treatment effect, short process, high treatment speed and low cost and may be applied via existing equipment with no additional capital expenditure.

Owner:NORTHEASTERN UNIV

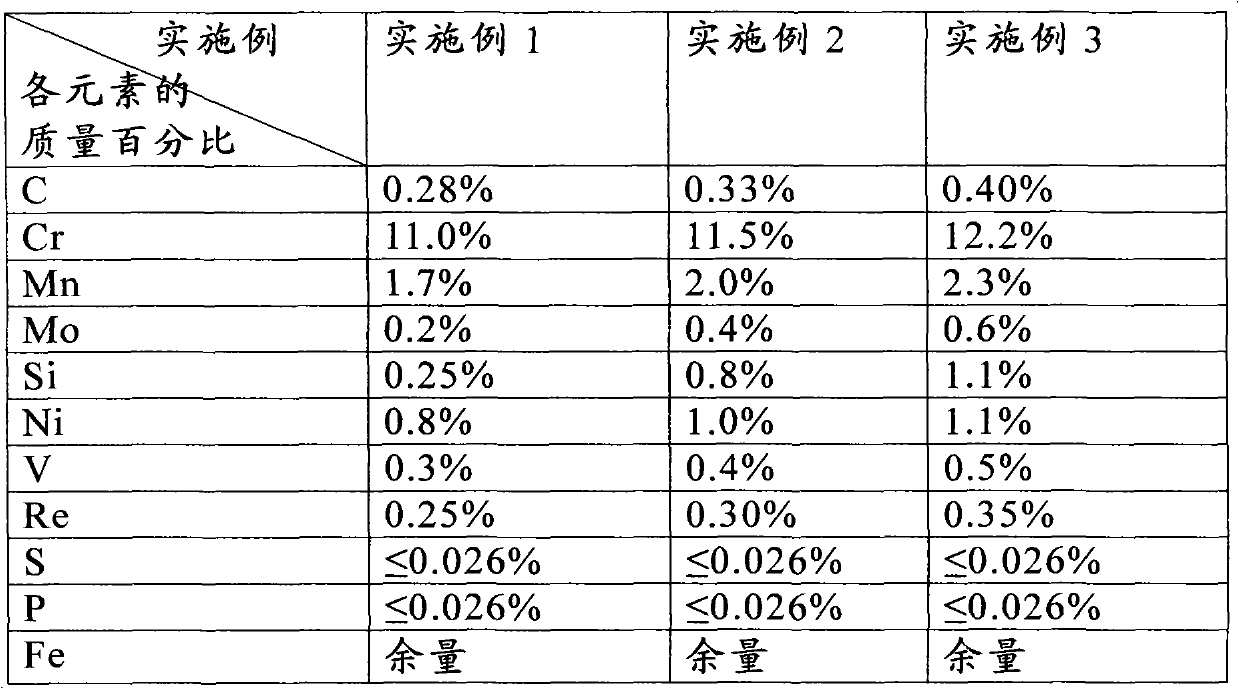

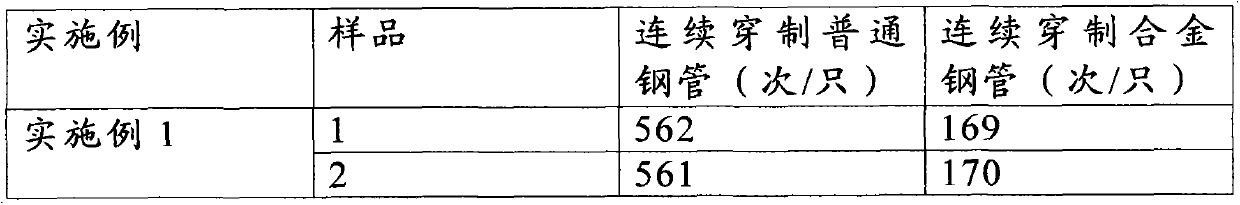

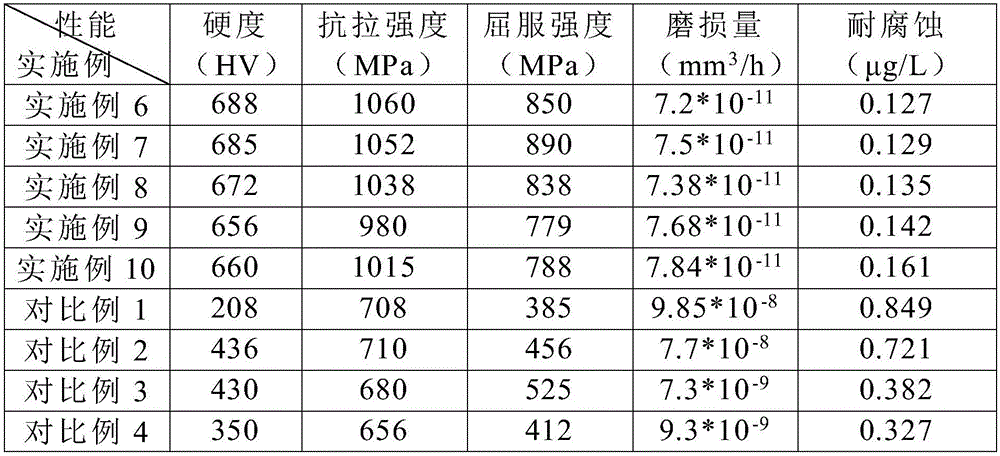

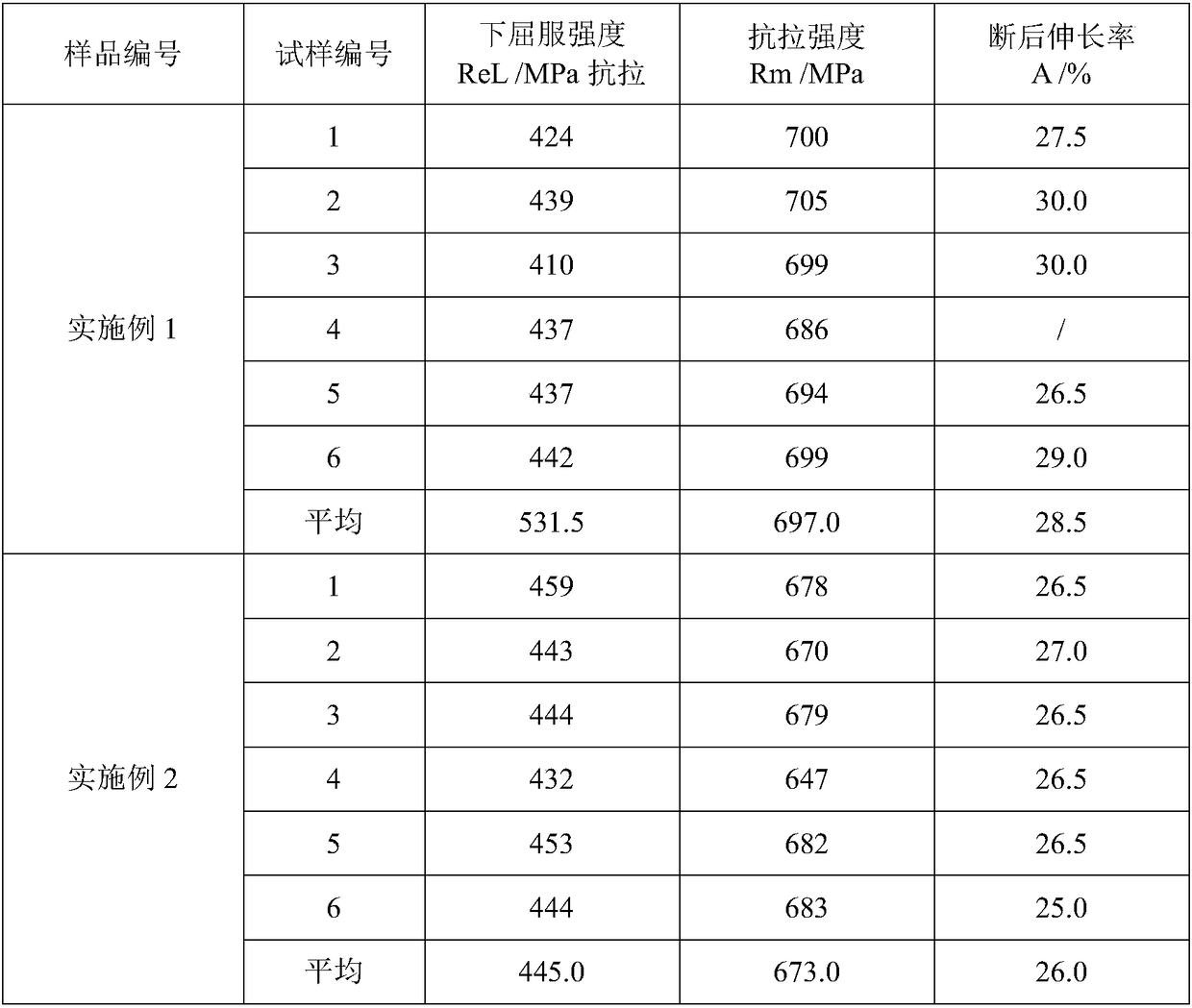

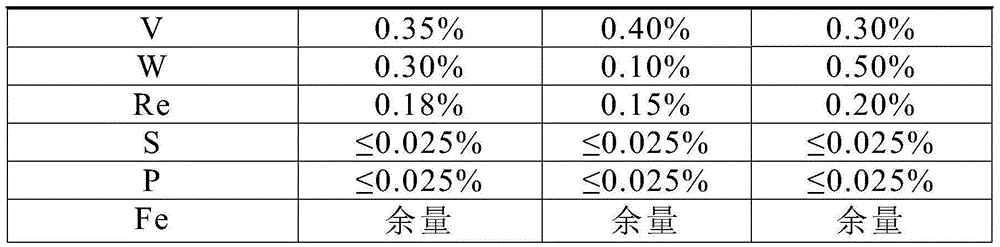

Steel tube piercing point and preparation method thereof

ActiveCN103131966AImprove wear resistanceExtended service lifeMandrelsMetal rolling arrangementsRheniumSurface oxidation

The invention discloses a steel tube piercing point and a preparation method thereof. The invention solves the problems of insufficient wear resistance, short service life and the like in the steel tube piercing point in the prior art. The steel tube piercing point disclosed by the invention comprises the following component elements in percentage by mass: 0.28%-0.40% of carbon (C), 11.0%-12.2% of chromium (Cr), 1.7%-2.3% of manganese (Mn), 0.2%-0.6% of molybdenum (Mo), 0.25%-1.10% of silicon (Si), 0.8%-1.1% of nickel (Ni), 0.3%-0.5% of vanadium (V), 0.25%-0.35% of rhenium(Re) and the balance of iron (Fe) and inevitable impurities. The invention also provides a preparation method of the steel tube piercing point, which comprises the following steps: proportioning, forging, annealing heat treatment and surface oxidation treatment. The steel tube piercing point disclosed by the invention has the advantages of favorable wear resistance and long service life.

Owner:宁波文而昌新材料科技有限公司

Pre-prepared alloy powder type flux-cored wire and self-protection open arc surfacing welding method of high-chromium alloy

ActiveCN106041361AIncreased welding deposition efficiencyRemarkable effect of energy saving and consumption reductionArc welding apparatusWelding/cutting media/materialsHigh carbonFerrosilicon

The invention discloses a pre-prepared alloy powder type flux-cored wire and a self-protection open arc surfacing welding method of a high-chromium alloy. The adopted technical scheme lies in that a cold rolled thin steel strip manufactured through low-carbon steel H08A as an outer coating, high carbon ferro-chrome, ferrosilicon, graphite and other metal powder are blended inside the coating to form a powder core of the flux-cored wire, and high carbon ferro-chrome, ferroboron, ferrosilicon and reduced iron powder are blended to form pre-prepared alloy powder; and before welding, the alloy powder is placed on a welding bead in advance, the surfacing welding current control value is set, a regulating melt mode combined with the mass of the pre-prepared alloy powder type flux-cored wire is set, a nonhomogeneous melt containing liquid high carbon ferro-chrome atom clusters formed through melting high carbon ferro-chrome particles is formed, and the concretionary high-chromium alloy which adopts the liquid high carbon ferro-chrome atom clusters as component donors, nucleates and grows into primary M7C3 abrasion-resistance phases is formed. According to the method, the problems that the source of components of surfacing welding alloys is single and the chromium content of the surfacing welding alloys is not liable to increase are solved, and the method is widely applied to surfacing welding manufacturing and repairing of parts with the requirement of abrasive wear resistance.

Owner:XIANGTAN UNIV

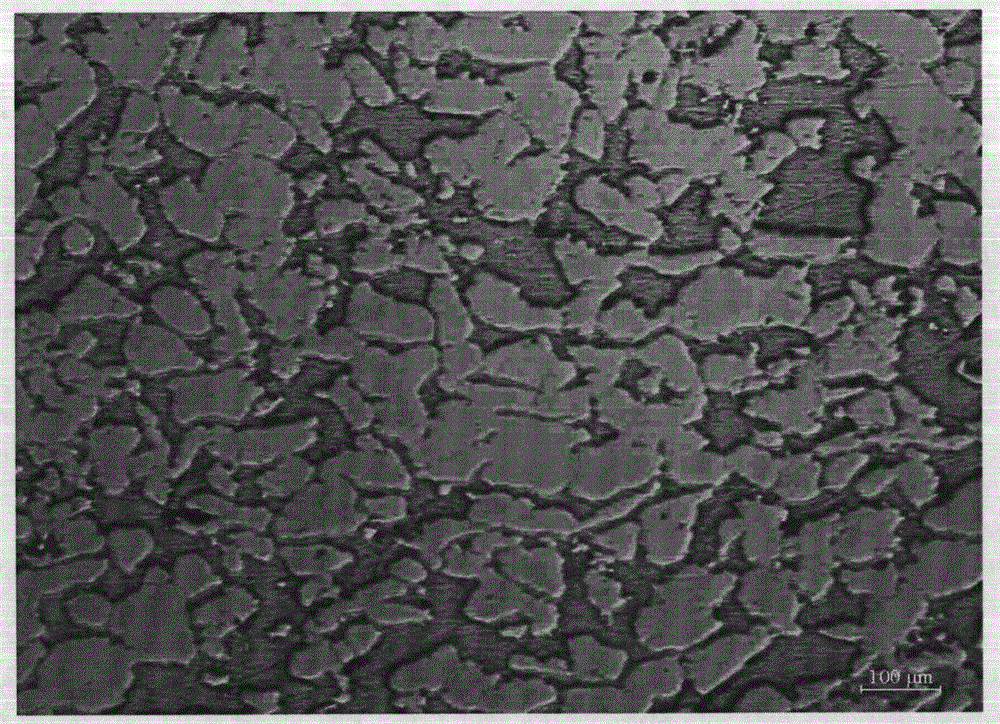

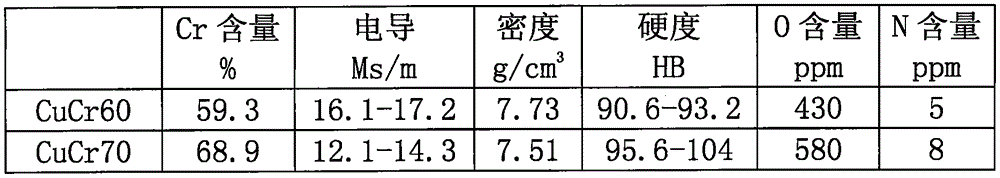

High-Cr-content high-pressure-resistance copper-chromium contact material and manufacturing method thereof

The invention relates to a high-Cr-content high-pressure-resistance copper-chromium contact material and a manufacturing method thereof. The copper-chromium contact material comprises, by weight percentage, 60%-70% of Cr and the balanced Cu. The manufacturing method includes the steps of raw material selection, powder mixing, blank pressing, infiltration and annealing. On the basis that only CuCr1 to CuCr50 materials can be manufactured on the basis of an existing powder metallurgy, casting and electric arc melting process, the high-performance contact material with the Cr content higher than 70% is developed, and therefore the requirement of the high-voltage stage for the pressure-resistant performance is met. According to the high-Cr-content high-pressure-resistance copper-chromium contact material, the high-melting-point Cr serves as a basic framework, Cu powder is doped to form a CuCr pressing blank with a certain strength, and then vacuum infiltration is carried out to obtain the high-Cr-content copper-chromium contact material.

Owner:SHAANXI SIRUI ADVANCED MATERIALS CO LTD

Hex screw and manufacturing method thereof

ActiveCN106089913ALower sintering temperatureAvoid crackingScrewsMetallic material coating processesLaser scanningEngineering

The invention relates to a hex screw and belongs to the technical field of alloy materials. The hex screw comprises a main body and a connecting bolt arranged at one end of the main body, a connecting hole is formed in the other end of the main body, the connecting bolt is provided with an external thread structure, and the connecting hole is provided with an internal thread structure. The connecting bolt, the connecting hole and the main body are coaxial in the extending direction of the main body. The hex screw is made of an alloy steel composite which comprises an alloy steel base body and a ceramic layer arranged on the surface of the alloy steel base body in a laser cladding mode. According to the hex screw, the surface of the alloy steel base body is coated with the ceramic layer in a laser scanning mode, and the mechanical properties, such as strength, abrasion resistance and corrosion resistance, of the hex screw are further improved.

Owner:NINGBO YINZHOU HAISHENG MACHINERY

Preparation method of Q420-grade hot-rolling weather-resistant angle steel

The invention relates to a preparation method of Q420-grade hot-rolling weather-resistant angle steel. The preparation method of the Q420-grade hot-rolling weather-resistant angle steel comprises thefollowing steps: smelting a steel billet, rolling the steel billet, cooling the steel billet and straightening the angle steel. The Q420-grade hot-rolling weather-resistant angle steel can be producedon a large scale for use of a power transmission line iron tower.

Owner:CHONGQING YUHUANG ELECTRIC POWER EQUIP MFG

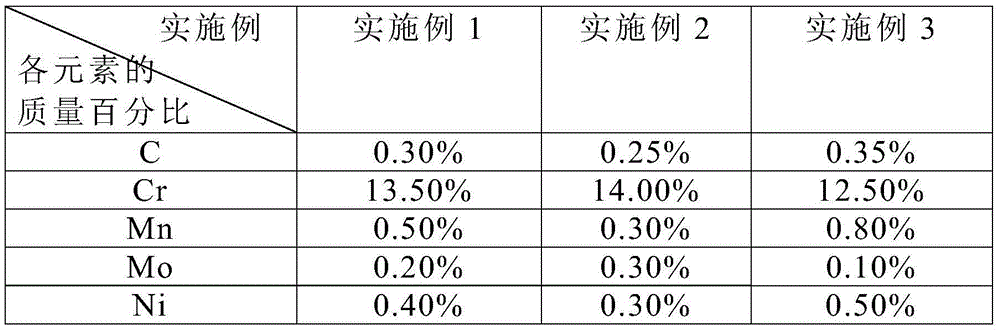

Piercing plug of steel pipe and preparation method thereof

ActiveCN104099529AImprove wear resistanceWide temperature rangeFurnace typesHeat treatment furnacesRheniumMetallic materials

The invention relates to a piercing plug of a steel pipe and a preparation method thereof, and belongs to the field of metal materials. The piercing plug of the steel pipe comprises the following elements in percentage by mass: 0.25-0.35% of carbon (C), 12.5-14.0% of chrome (Cr), 0.3-0.8% of manganese (Mn), 0.1-0.3% of molybdenum (Mo), 0.3-0.5% of nickel (Ni), 0.3-0.4% of vanadium (V), 0.1-0.5% of tungsten (W), 0.15-0.2% of rhenium (Re), with the balance being iron (Fe) and inevitable impurities. The invention particularly relates to the preparation method of the piercing plug of the steel pipe. The piercing plug of the steel pipe has good mechanical property, and has the advantages of higher hardness, toughness and tensile strength and long service life when having higher wear resistance and temperature tolerance.

Owner:宁波文而昌新材料科技有限公司

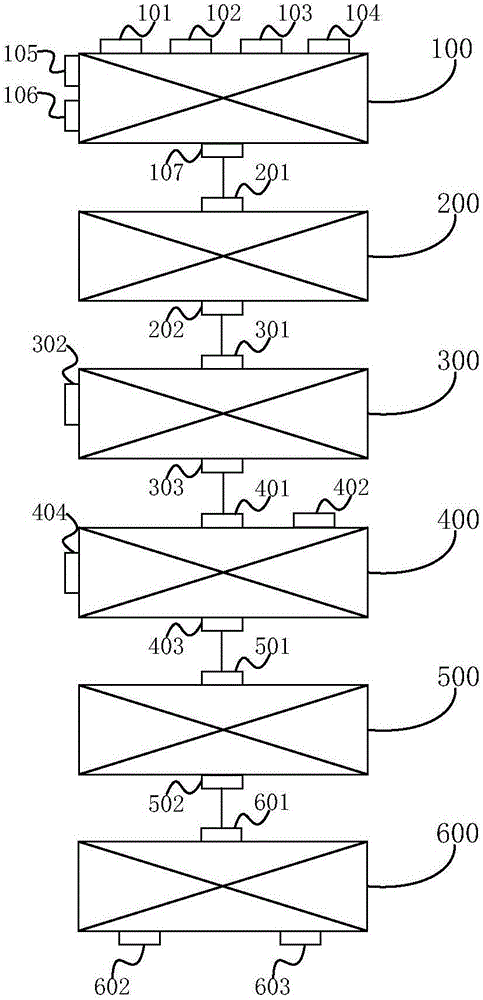

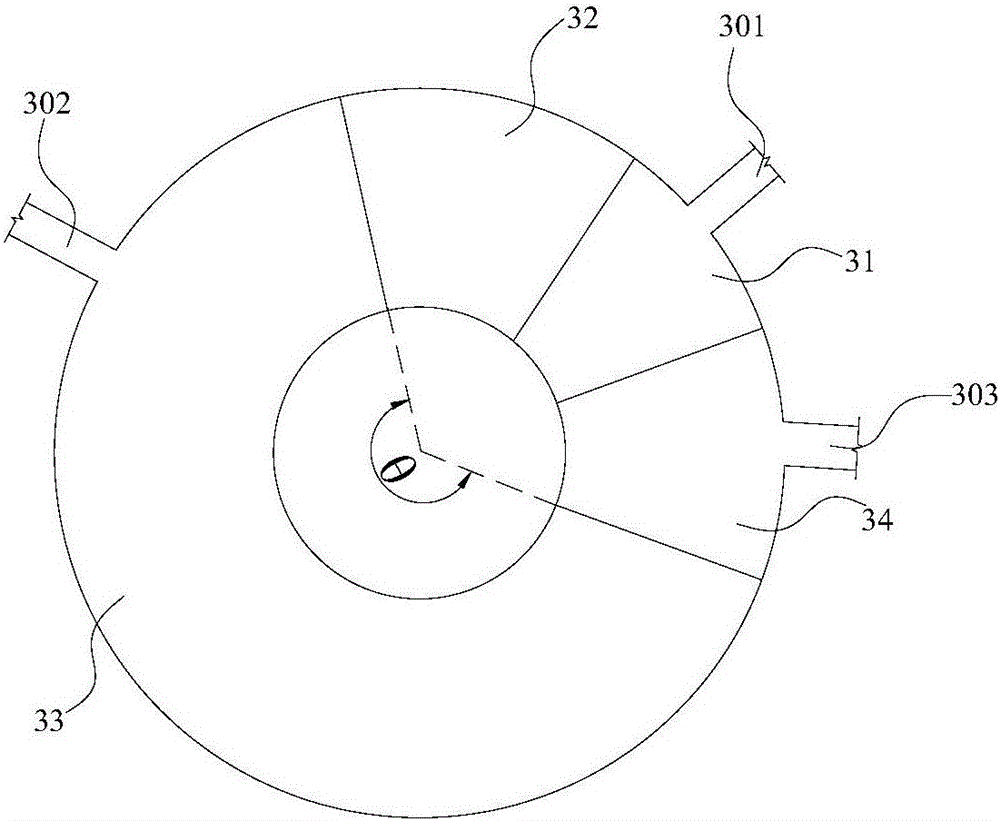

System and method for preparing ferrochrome

ActiveCN105969978AReduce manufacturing costImprove responseProcess efficiency improvementPolymer scienceMaterial distribution

The invention discloses a system and method for preparing ferrochrome. The system comprises a mixed forming device, a pellet drying device, a rotary hearth furnace, a cooling acid leaching device, a leaching cinder drying device and a smelting device, wherein the mixed forming device is provided with a carbonic material inlet, a silica inlet, a fluxing agent inlet, a binder inlet, a ferrochromium mineral powder inlet, a water inlet and a mixed wet pellet outlet; the pellet drying device is provided with a mixed wet pellet inlet and a dried pellet outlet; a material distribution area, a pre-heating area, a reduction area and a discharging area are sequentially formed in the rotary hearth furnace in the rotation direction of a furnace bottom, a dried pellet inlet is formed in the material distributing area, and a solid reduzate outlet is formed in the discharging area; the cooling acid leaching device is provided with a solid reduzate inlet, a dilute acid inlet, a leaching cinder outlet and a leaching liquid outlet; the leaching cinder drying device is provided with a leaching cinder inlet and a dried cinder outlet; the smelting device is provided with a dried cinder inlet, a ferrochrome outlet and a cinder outlet. By means of the system, the production cost of the ferrochrome can be reduced while the raw material source of the ferrochrome is expanded.

Owner:JIANGSU PROVINCE METALLURGICAL DESIGN INST

Chromium rich liquid and its application in producing chromium (Cr3+) rich pumpkin

InactiveCN1948230AIncrease chromium contentRaise the ratioHorticulture methodsMaterials scienceChromium

The present invention discloses a chromium-rich liquor for producing chromium-rich pumpkin and its application for producing chromium-rich pumpkin. Its raw material composition includes Cr2O3:500mg / kg-3000mg / kg,KH2(PO4):5g / kg-10g / kg,K2MnO4:1g / kg- 5g / kg,Tween 20 2ml / L and the rest is water. Said invention also provides the concrete method and steps for applying said chromium-rich liquor.

Owner:NORTHWEST A & F UNIV

Manufacturing method of auto tire mold

InactiveCN106626163AIncrease chromium contentIncrease contentTyresElectrode potentialElectrical conductor

The invention discloses a manufacturing method of an auto tire mold. The manufacturing method comprises the following steps that (A), the mold molded face is designed through a combination method of CAD and CAE; (B), materials are prepared, specifically, the raw materials are weighed and prepared from the raw materials including, by weight, 60-65% of Al, 5-10% of Cr, 2-3% of Si, 3-4% of Cu, 5-9% of Fe, 0.5-1.0% of Mn, 1-2% of Zn, 1-3% of Mg, 0.5-1.0% of Ni, 1.0-3.0% of Sn, 0.1-0.13% of Ti and 0.1-0.18% of Pb; and (C), smelting is conducted, specifically, the prepared raw materials are added into a smelting furnace, the temperature of the smelting furnace is controlled to be 850-900 DEG C, and after complete smelting, the temperature falls to 650-700 DEG C. According to the manufacturing method of the auto tire mold, the chromium content in the mold materials is increased; through increasing of the chromium content, electrode potential of iron in mold steel and corrosion resistance can be improved; and meanwhile, alloy molten aluminum is poured into a fabrication mold cavity in a double-layer pouring way side pouring mode, so that smooth and steady mold filling and the good feeding effect are achieved, the technical requirements of air impermeability and electrical conductivity of a produced conductor casting are simultaneously met, and the service life of the mold is remarkably improved.

Owner:JIANGSU YUYAN MOLDING CO LTD

Seedling strengthening cultivation method of chromium-rich pumpkins

InactiveCN106613157AIncrease chromium contentGood health effectSeed and root treatmentPlant cultivationIonGermination

The invention belongs to the technical field of agricultural planting, and particularly relates to a seedling strengthening cultivation method of chromium-rich pumpkins. The method includes the following steps: seedling raising shed preparation, seed soaking, germination accelerating, sowing, seedling stage management, field planting, field management and harvesting. Compared with the prior art, the method has the following advantages that the cultivation method provides corresponding nutrition for pumpkin seedling growth and improves the seedling strengthening rate of seedling cultivation, corresponding treatment is conducted on the seed soaking stage and the germination accelerating stage respectively, the germination vigor of seeds can be effectively improved, the endoenzyme activity and metabolic activity of seed embryos are improved, and the seeds are made to absorb a certain chromium ion solution; corresponding management in the seedling stage and the growth stage is conducted respectively, the natural resistance of plants is improved, the chromium content of the pumpkins is increased significantly, the health care effect is strengthened, taste is good, commodity characteristics are increased, and planting benefits of farmers are improved.

Owner:蚌埠市涂山绿园蔬菜科研专业合作社

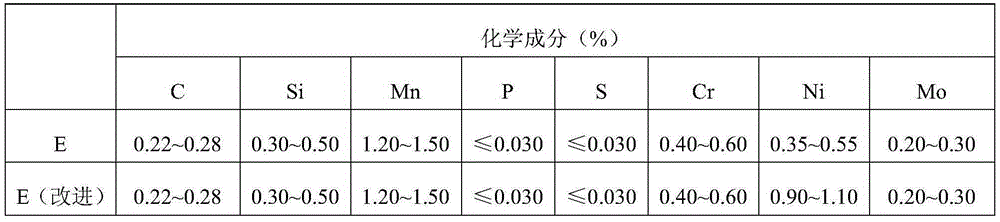

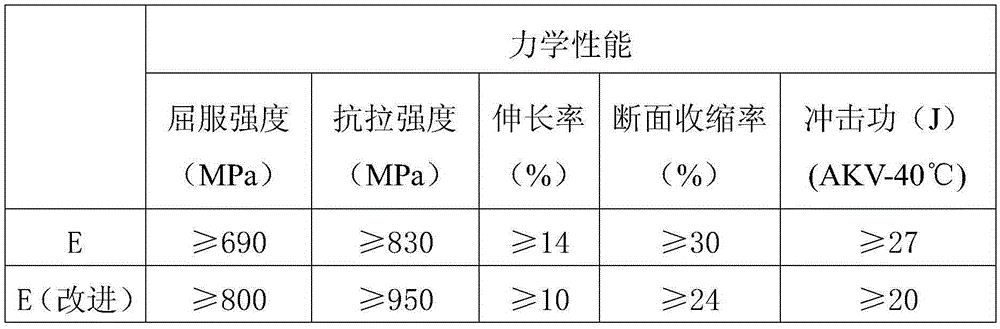

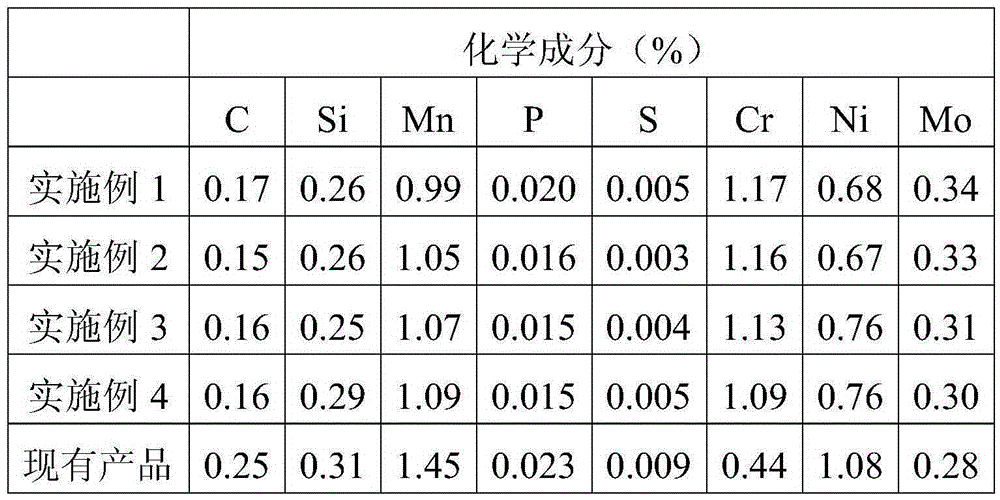

High-strength high-tenacity alloy cast steel material used for draw gears of railway vehicles

The invention discloses a high-strength high-tenacity alloy cast steel material used for draw gears of railway vehicles. The alloy caste steel material is composed of, by weight, 0.14-0.20 part of C, 0.20-0.40 part of Si, 0.90-1.20 parts of Mn, 1.00-1.20 parts of Cr, 0.60-0.90 part of Ni, 0.20-0.40 parts of Mo, 0-0.030 part of S, 0-0.030 part of P and the balance Fe and inevitable impurities. According to the alloy caste steel material, the yield strength is equal to or larger than 800 MPa, the tensile strength is equal to or larger than 920 MPa, the elongation is equal to or larger than 14%, the percentage reduction of area is equal to or larger than 40%, and the ballistic work at the temperature of-40 DEG C is equal to or larger than 35 J.

Owner:CRRC YANGTZE CO LTD

Device and method for processing chromium-containing wastewater

ActiveCN104773866AReduce dripping and leakingLower requirementWater/sewage treatment by centrifugal separationWater treatment compoundsWastewaterChromium

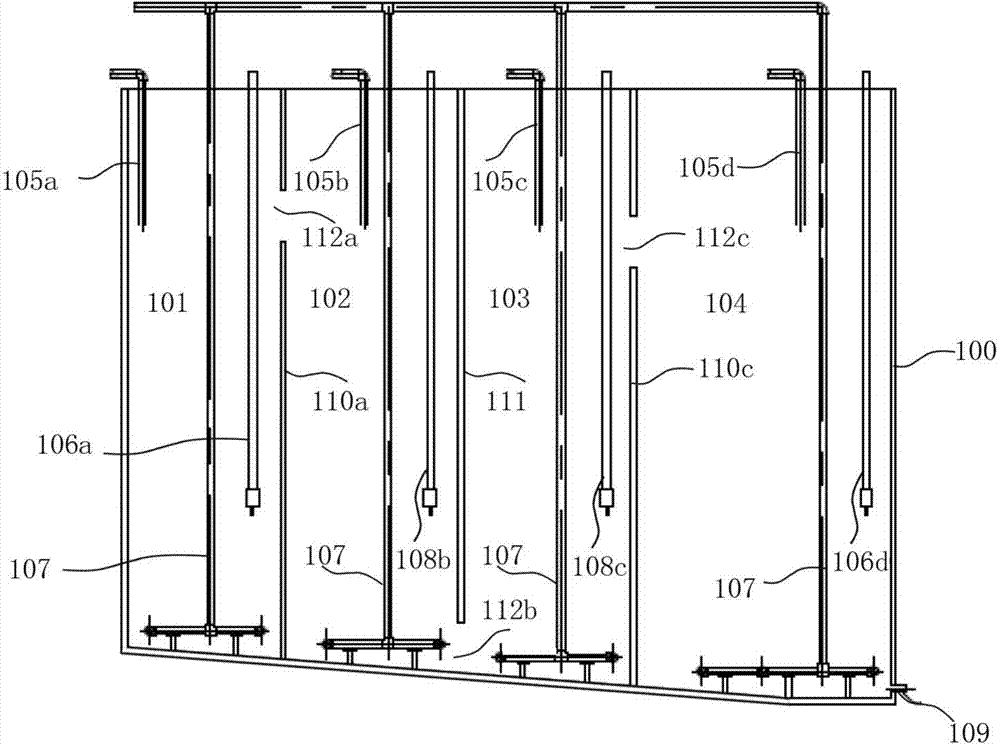

The invention provides a device and method for processing chromium-containing wastewater. The device comprises a tank, a first partition plate, a second partition plate, and a third partition plate; the tank is divided by the first partition plate, the second partition plate, and the third partition plate into a pH adjusting tank, a primary reduction tank, a secondary reduction tank, and a neutralizing tank in the horizontal direction in sequence; a water outlet is arranged in the bottom of the neutralizing tank, a solid / liquid separating device is arranged in the water outlet; the bottom surface of the tank is inclined, each partition plate is provided with a water outlet, and the chromium-containing wastewater in the pH adjusting tank can flow through the primary reduction tank, the secondary reduction tank, and the neutralizing tank in sequence. Through the provided device and method, the wastewater with a small discharge amount can be processed by a less dosage, and the processing procedure can be simplified.

Owner:NEW METALLURGY HI TECH GRP

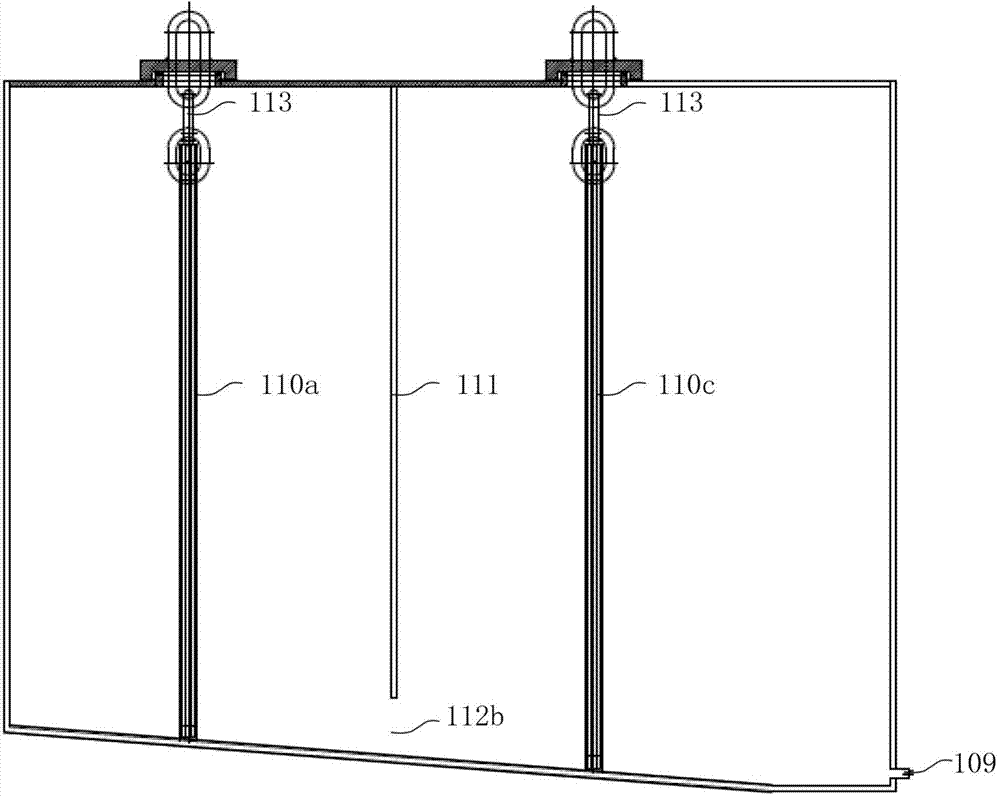

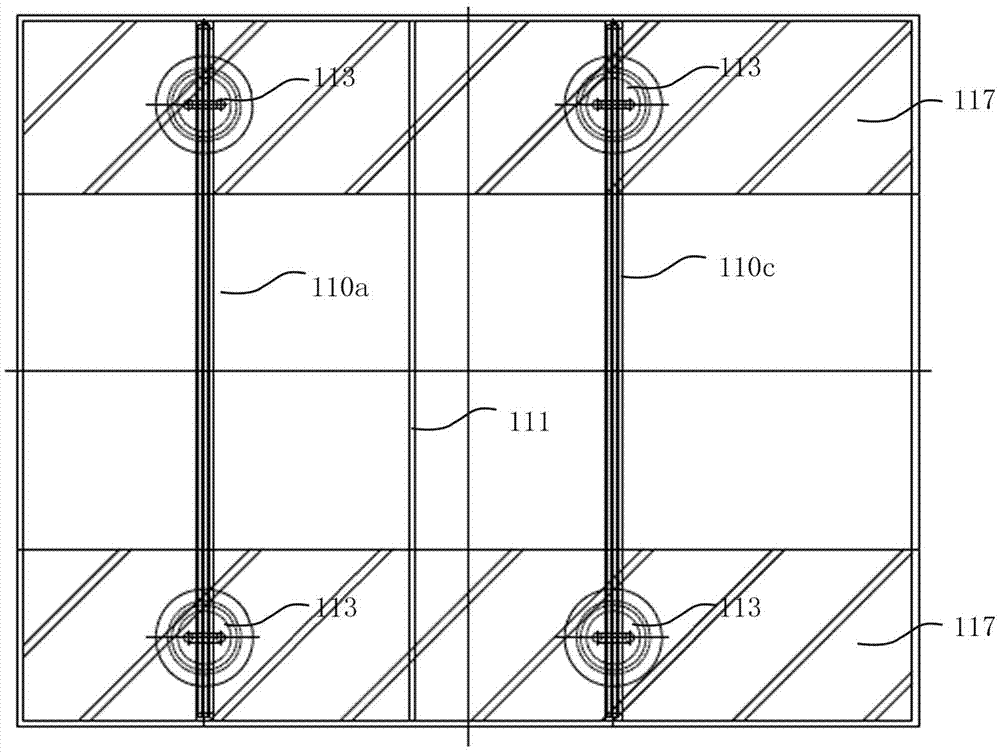

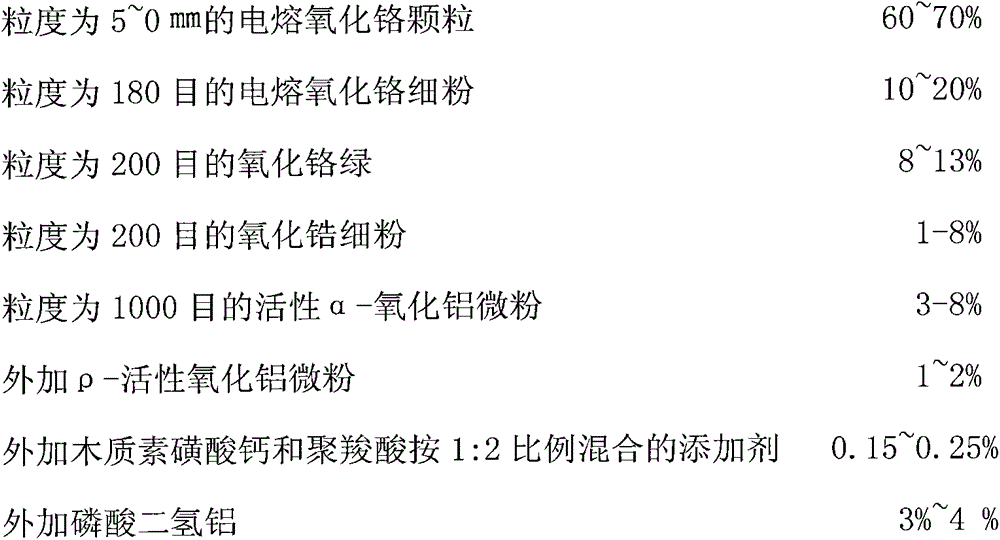

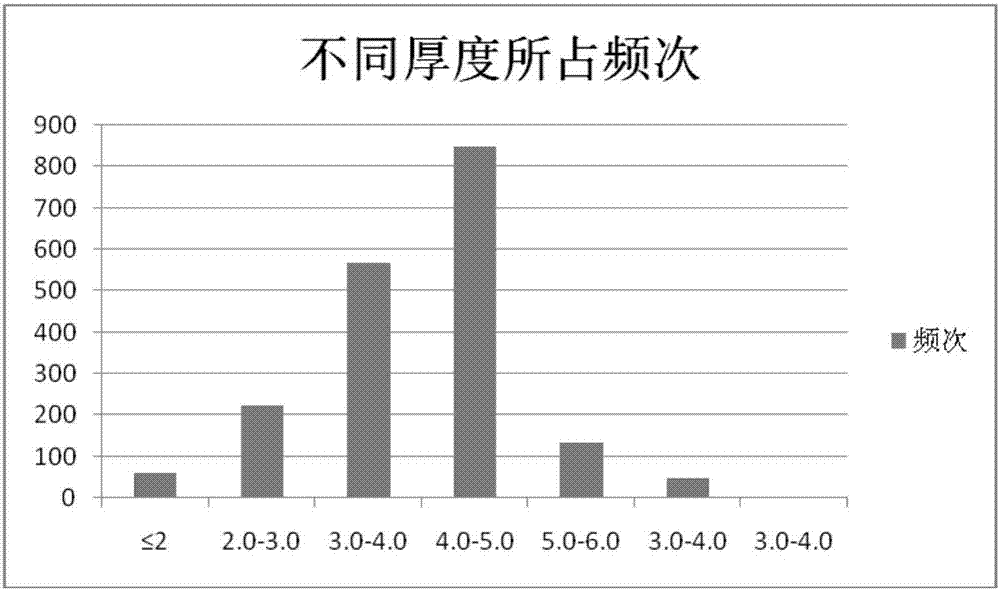

Plugging brick for top opening of water-coal slurry gasification furnace and preparation process thereof

The invention relates to a plugging brick for the top opening of a water-coal slurry gasification furnace and a preparation process thereof. The plugging brick comprises 60-70% of 0-5-millimeter particles of fused chromium oxide, 10-20% of 180-mesh fine powder of fused chromium oxide, 8-13% of 200-mesh chromium oxide green, 1-8% of 200-mesh fine powder of zirconium oxide and 3-8% of 1,000-mesh micro powder of active alpha-alumina, and the plugging brick further comprises 1-2% of micro powder of active rho-alumina, 0.15-0.25% of a compound additive in which the ratio of calcium lignosulphonate to polycarboxylic acid is 1:2 and 3-4% of solution of aluminium dihydrogen phosphate, wherein the specific surface area of the micro powder of active rho-alumina is 200m<2> / g, and the specific gravity of the solution of aluminium dihydrogen phosphate is more than or equal to 1.85. The preparation process of the plugging brick comprises the following steps: premixing fine powder, mixing aggregates, ageing, molding, drying, sintering, assembling and processing. The plugging brick has high compressive strength and excellent corrosion and erosion resistance, is reusable, basically has the same volume as a plugging brick which has a high content of chromium of 90% and is used for the top opening of a water-coal slurry gasification furnace and is beneficial to prolonging the service life of the top opening of a water-coal slurry gasification furnace and keeping the top opening of a water-coal slurry gasification furnace intact.

Owner:宜兴瑞泰耐火材料有限公司 +1

Processing method of SCR denitration catalyst

ActiveCN106319223AReduce pollutionTake advantage ofProcess efficiency improvementAfter treatmentSlag

The invention discloses a processing method of an SCR denitration catalyst, and belongs to the field of waste recycling. The processing method comprises the steps of firstly, preparing molten iron; secondly, adding molten iron into the SCR denitration catalyst; thirdly, carrying out slagging, and maintaining the temperature of the molten iron to range from 1300 DEG C to 2100 DEG C; fourthly, pouring out a slag system, obtaining the molten iron, adjusting the components of the molten iron, pouring and mould entering, and obtaining a wear-resisting steel ball after heat treatment. The molten iron is prepared through waste steel and / or pig iron in a melting manner, through slagging, vanadium is converted into stable and nontoxic vanadate, the pollution of a waste SCR denitration catalyst to the environment is reduced, the molten iron obtained after treatment of the SCR denitration catalyst can be used for manufacturing the wear-resisting steel ball, the treatment cost is low, practicability is high, and economic benefits are good.

Owner:马鞍山艺诚机电有限公司

Heat-resisting and oxidation-resisting stainless iron

Owner:常州凯翔医用不锈钢有限公司

Low-cost and high-performance SPA-H hot rolled steel coil and preparation method thereof

InactiveCN106947915AImprove plasticityImprove toughnessManufacturing convertersProcess efficiency improvementLaminar coolingPre treatment

The invention relates to a low-cost and high-performance SPA-H hot rolled steel coil and a preparation method thereof. The low-cost and high-performance SPA-H hot rolled steel coil comprises, by mass, 0.07%-0.095% of C, 0.25%-0.35% of Si, 0.38%-0.48% of Mn, 0.085%-0.105% of P, 0.007% of S or the less, 0.25%-0.35% of Cu, 0.08%-0.20% of Ni, 0.50%-0.60% of Cr, 0.015%-0.045% of Als and the balance Fe and inevitable impurities. The preparation method comprises the steps of composition design, hot metal pretreatment, converter smelting, ladle furnace treatment, continuous casting, hot continuous rolling, laminar cooling and reeling, and the SPA-H hot rolled steel coil is obtained. The SPA-H hot rolled steel coil has excellent plasticity and toughness, cold processing performance is improved, the problem of bending cracking of large deformation in the using process of the SPA-H steel coil is avoided, quality objections are reduced, and comprehensive performance of SPA-H steel is improved.

Owner:NINGBO IRON & STEEL

Powder metallurgy brake caliper iron alloy and manufacturing method thereof

Provided are powder metallurgy brake caliper iron alloy and a manufacturing method thereof. The powder metallurgy brake caliper iron alloy is characterized by comprising, by weight, 95-99 parts of iron powder, 1.4-1.8 parts of chromium powder, 1.2-1.4 parts of boron nitride, 0.12-0.15 part of bismuth, 0.4-0.6 part of graphite, 0.02-0.04 part of Sb, 0.9-1.2 parts of Bi, 0.01-0.02 part of Yb, 1.2-1.4 parts of ZnO, 0.4-0.6 part of boric oxide, 1.2-1.4 parts of nanometer bentonite, 0.2-0.4 part of chromium boride, 3-3.6 parts of microcrystalline wax, and 2-3 parts of dispersing agents. The powder metallurgy brake caliper iron alloy increases the chromium content, performance is good, and brake caliper performance requirements can be met; a powder metallurgy process is adopted, and cost is greatly reduced.

Owner:ANHUI RUITAI AUTO PARTS

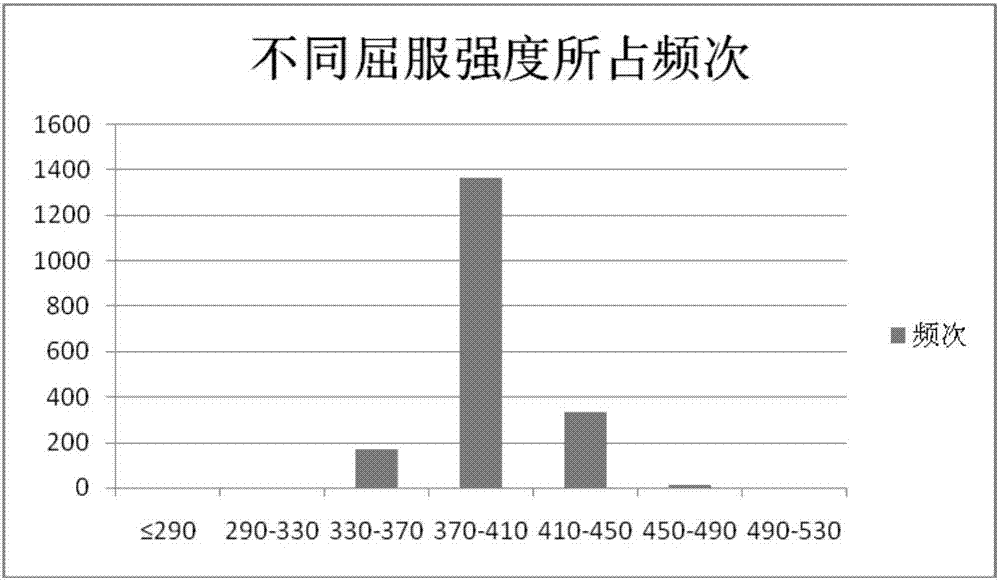

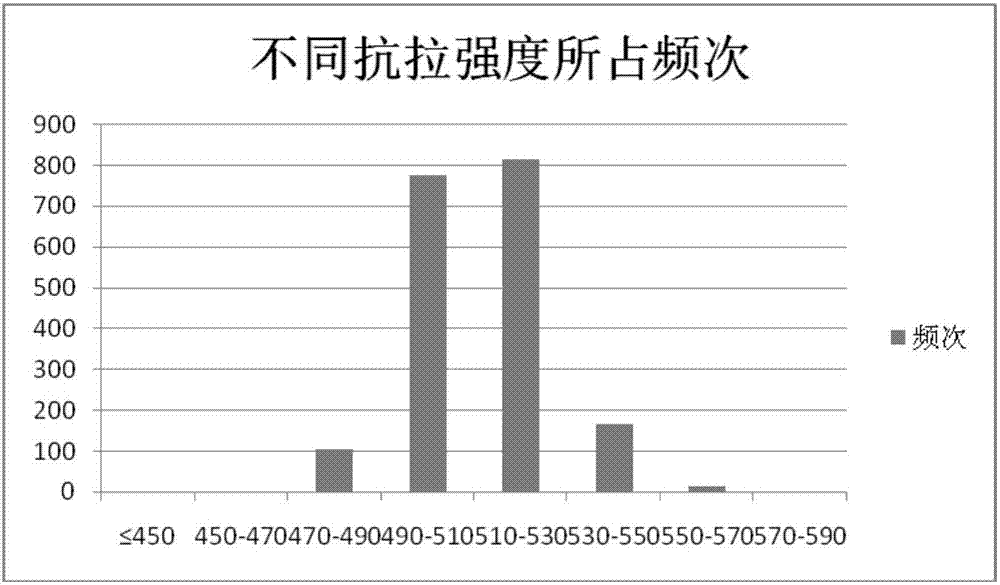

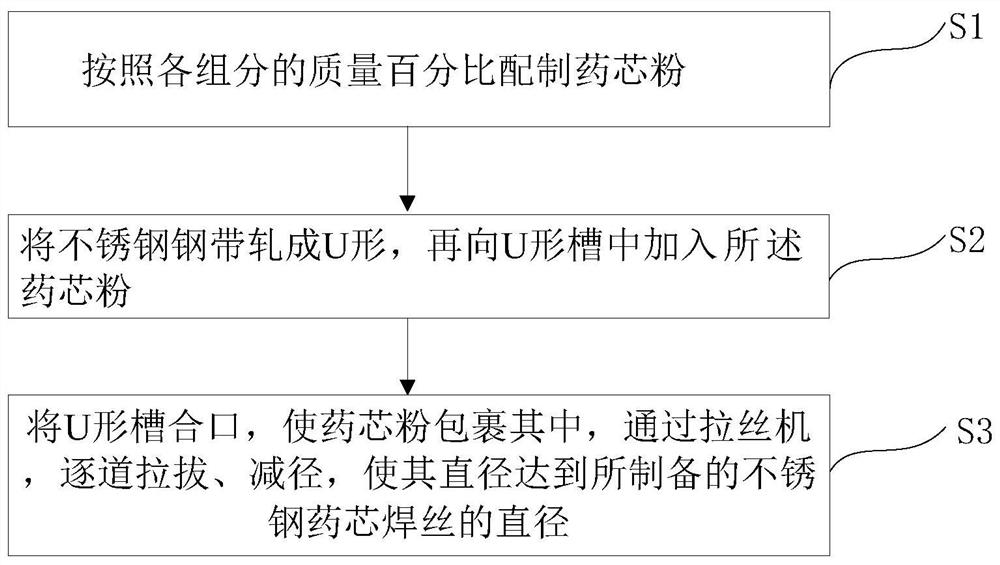

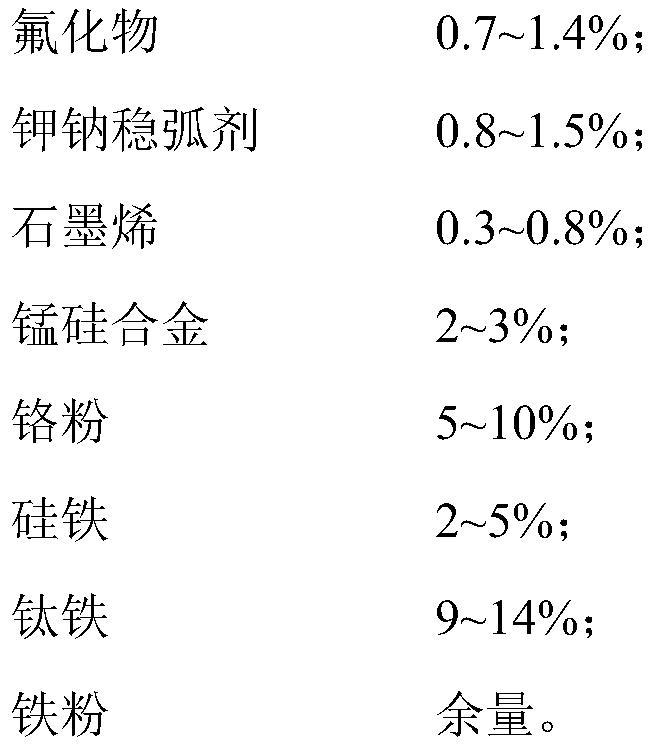

Stainless steel flux-cored wire

ActiveCN112643243ASimple welding processImprove wear resistanceWelding/cutting media/materialsSoldering mediaSilicon alloyFerrosilicon

The invention provides a stainless steel flux-cored wire. The stainless steel flux-cored wire comprises a stainless steel strip and a flux core, and the stainless steel strip is filled with the flux core. The flux core comprises, by mass, 0.7-1.4% of fluoride, 0.8-1.5% of a potassium-sodium arc stabilizer, 0.3-0.8% of graphene, 2-3% of manganese-silicon alloy, 5-10% of chromium powder, 2-5% of silicon iron, 9-14% of ferrotitanium and the balance iron powder. When the stainless steel flux-cored wire is used for welding, electric arcs are soft and stable, weld joints are attractive in appearance and small in splashing after welding, small air holes do not exist in the weld joints, and meanwhile weld joint metal has excellent abrasion resistance, corrosion resistance and high-temperature resistance.

Owner:山东聚力焊接材料有限公司

Antibacterial medical stainless steel

InactiveCN105316584AImprove protectionLow priceVacuum evaporation coatingSputtering coatingChemical compositionCorrosion

The invention discloses an antibacterial medical stainless steel. The antibacterial medical stainless steel comprises, by weight, 0.06 to 0.08% of C, 6 to 10% of Mn, 18 to 22% of Cr, 0.5 to 1% of Ti, 0.5 to 1% of Mo, 0.3 to 0.5% of N, 3 to 5% of Cu, less than 0.03% of P, less than 0.03% of S, and the balance impurities and iron. The surface of the antibacterial medical stainless steel is coated with a TiO2 thin film. The antibacterial medical stainless steel has corrosion resistance.

Owner:常州凯翔医用不锈钢有限公司

Nickel-chromium-phosphorous brazing alloys

ActiveUS9970089B2Increase chromium contentPrevent excessive thermal stressWelding/cutting media/materialsWelding/soldering/cutting articlesImpurityMaterials science

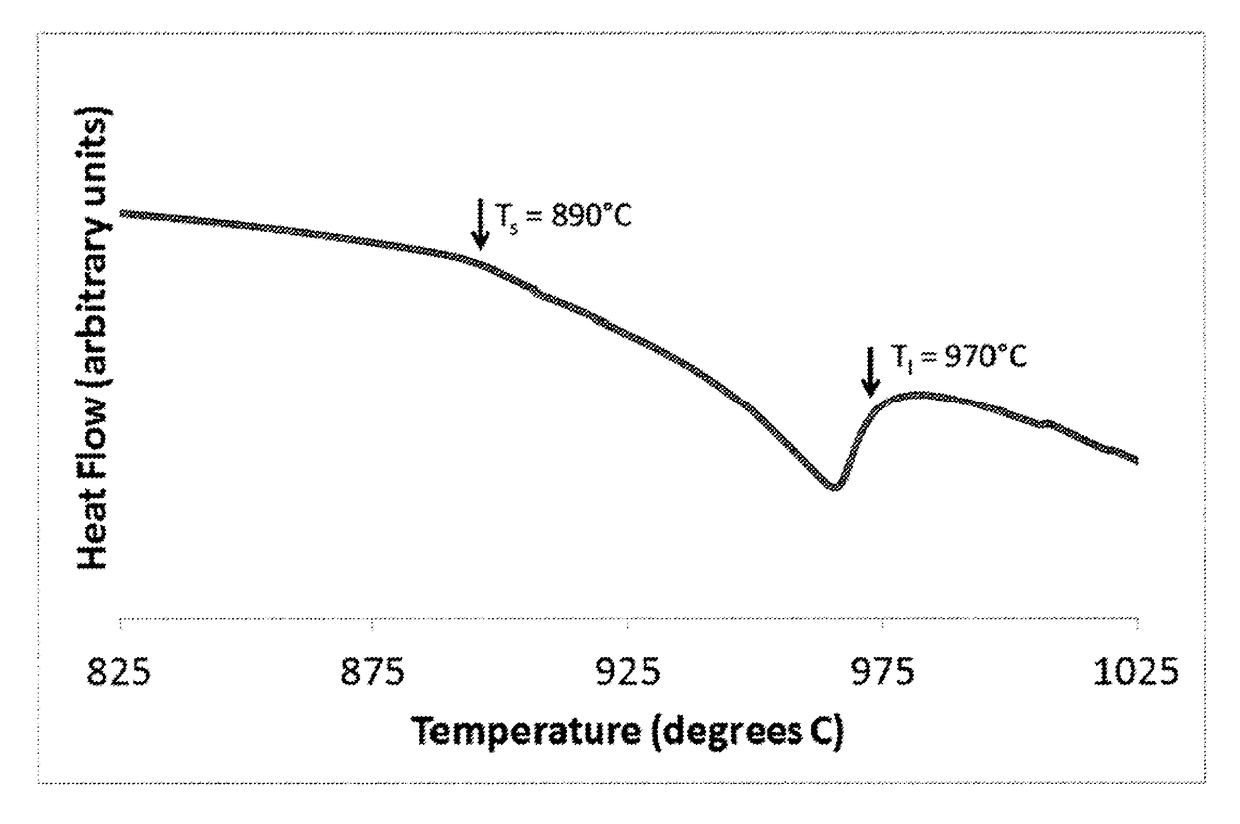

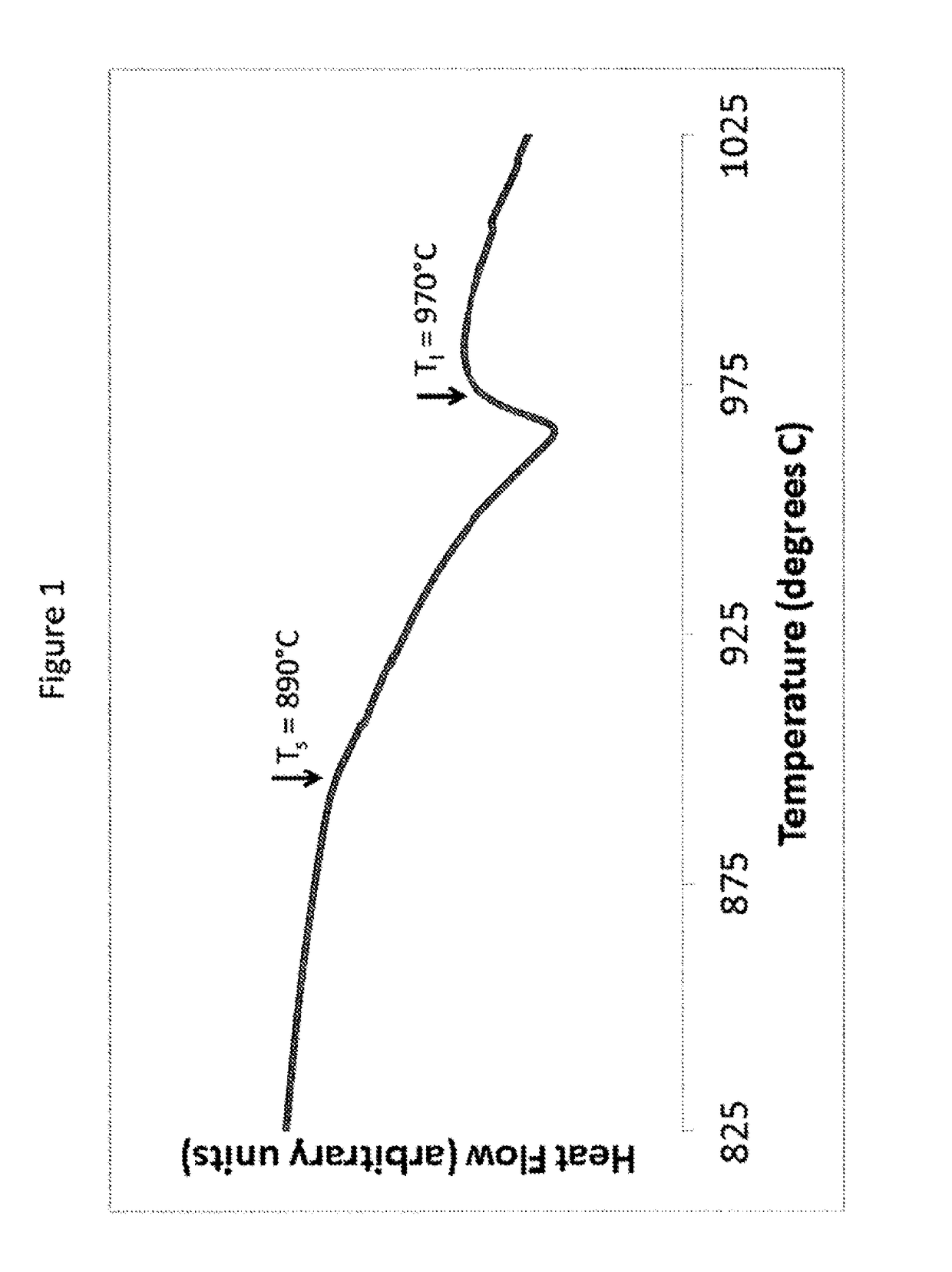

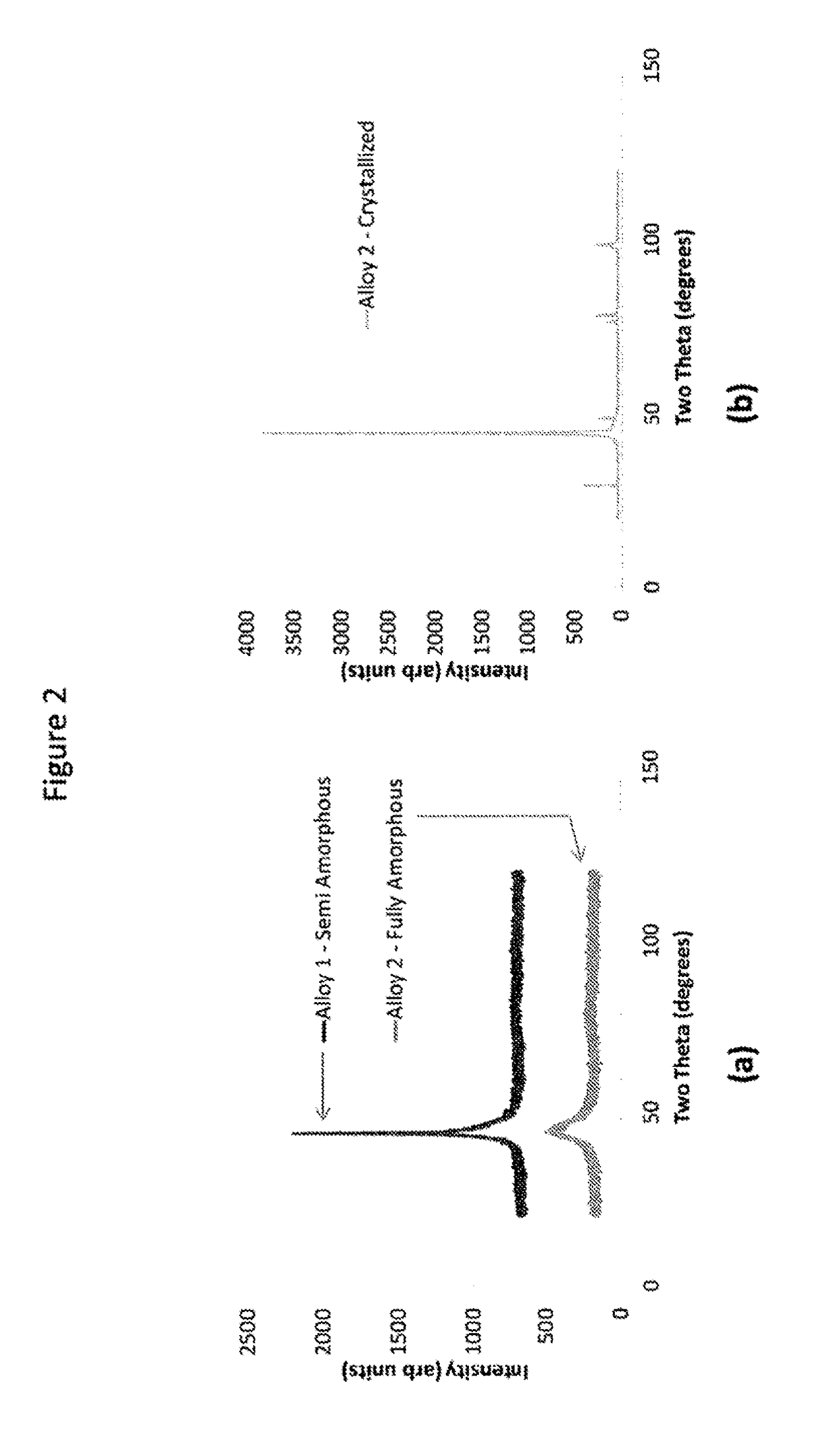

Disclosed is the semi-amorphous, ductile brazing foil with composition consisting essentially of NibalCraBbPcSidMoeFef with approximately 24 atomic percent≤a≤approximately 31 atomic percent; b≤approximately 3 atomic percent; approximately 9 atomic percent≤c≤approximately 11 atomic percent; approximately 2 atomic percent≤d≤approximately 4 atomic percent; e≤approximately 2 atomic percent; f≤approximately 1 atomic percent; and the balance being Ni and other impurities; where b+c+d<approximately 16 atomic percent.

Owner:METGLAS INC

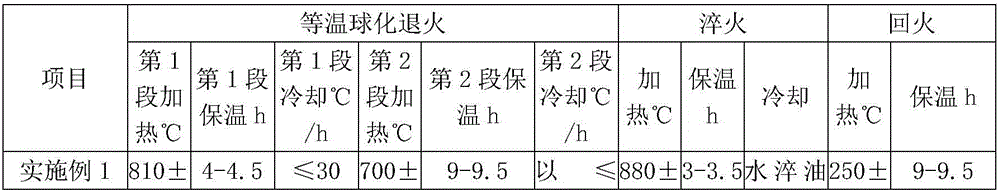

Steel used for quartering hammer piston rods, and thermal treatment method thereof

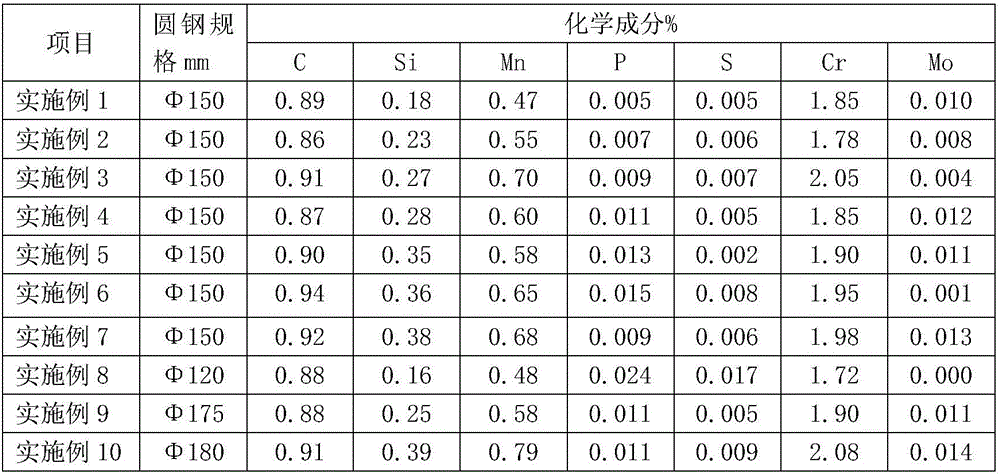

The invention provides a steel used for quartering hammer piston rods, and a thermal treatment method thereof. The steel comprises following ingredients, by weight, 0.85 to 0.95% of C, 0.15 to 0.40% of Si, 0.46 to 0.80% of Mn, P<=0.025%, S<=0.025%, 1.71 to 2.10% of Cr, 0 to 0.15% of Mo, and the balance Fe and inevitable impurity elements. The thermal treatment method is adopted to prepare the steel. The quartering hammer piston rods prepared from the steel possesses following advantages, compared with quartering hammer piston rods prepared via the prior art, the high cost of conventional 40CrNiMoa steel piston rods is avoided, occasionally caused piston rod deformation, diameter increasing, and cylinder damage are avoided, breakage of conventional GCr15 steel piston rods easily caused in applications is reduced greatly, and breakage rate in applications is lower than 0.3%.

Owner:MAGANG (GROUP) HOLDING CO LTD +1

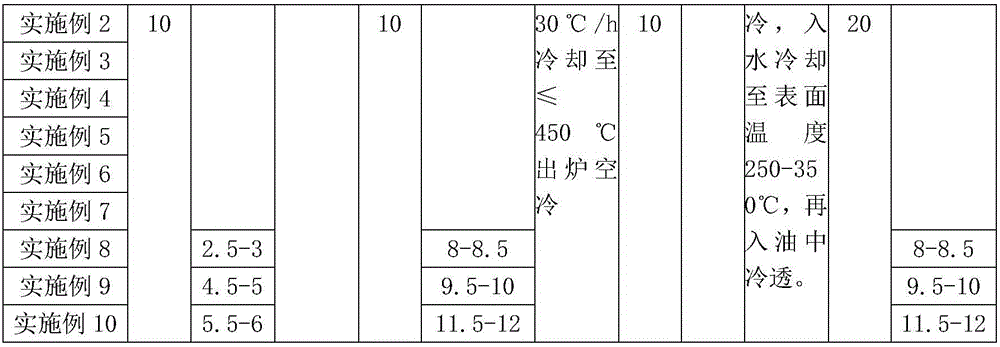

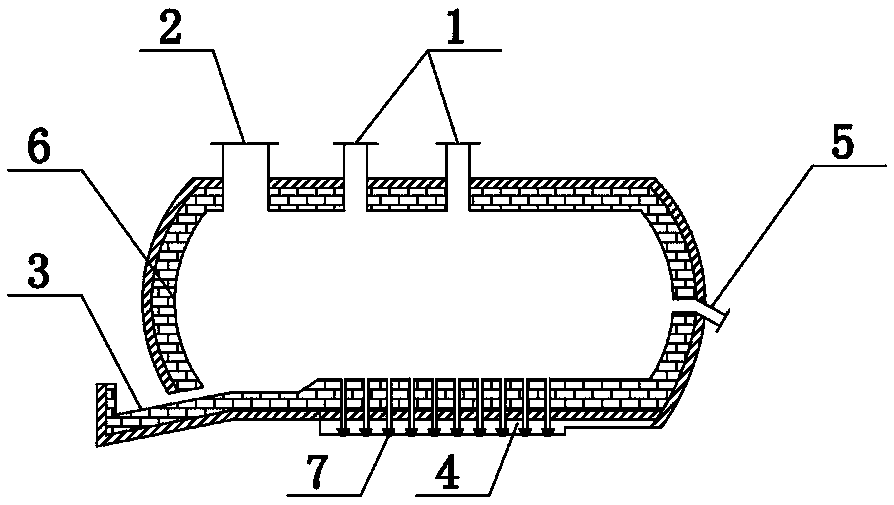

A kind of masonry method for inner lining of reduction furnace

The invention discloses a laying method for a lining of a reduction furnace. Laying of the lining is performed in the reduction furnace from bottom to top. The laying method for the lining comprises the following steps: a: the lower half part of the lining is laid in a staggered-joint manner, expansion joints are reserved in a spray gun area, after half of the lining is laid, an arch form is manufactured, and a support is prepared; and b: the upper half part of the lining is also laid in a staggered-joint manner, a filler is well filled, when laying reaches a lock brick, the lock brick needs to be processed in advance, after the lock brick is completely laid, a steel plate of 2-3 mm in thickness is adopted for strengthening and locking, flat laying is adopted at the broken part of a spherical arch and expansion joints are reserved. By adoption of the laying method, the service life of the lining of the reduction furnace is prolonged, the operation efficiency is improved, the maintenance cost of the reduction furnace is lowered, and high economic benefits are brought for enterprises.

Owner:岷山环能高科股份公司

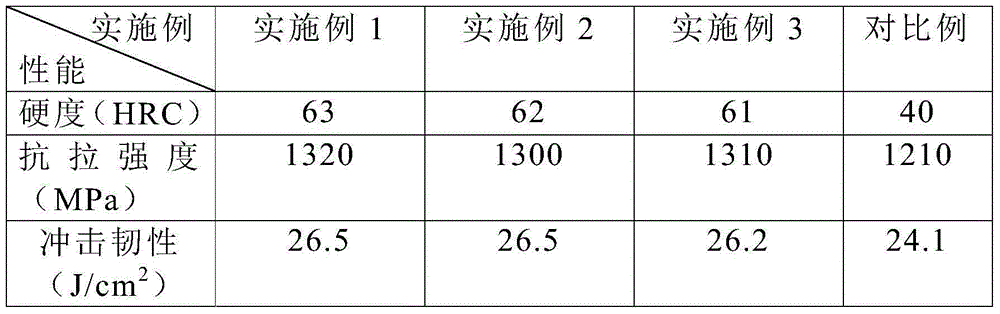

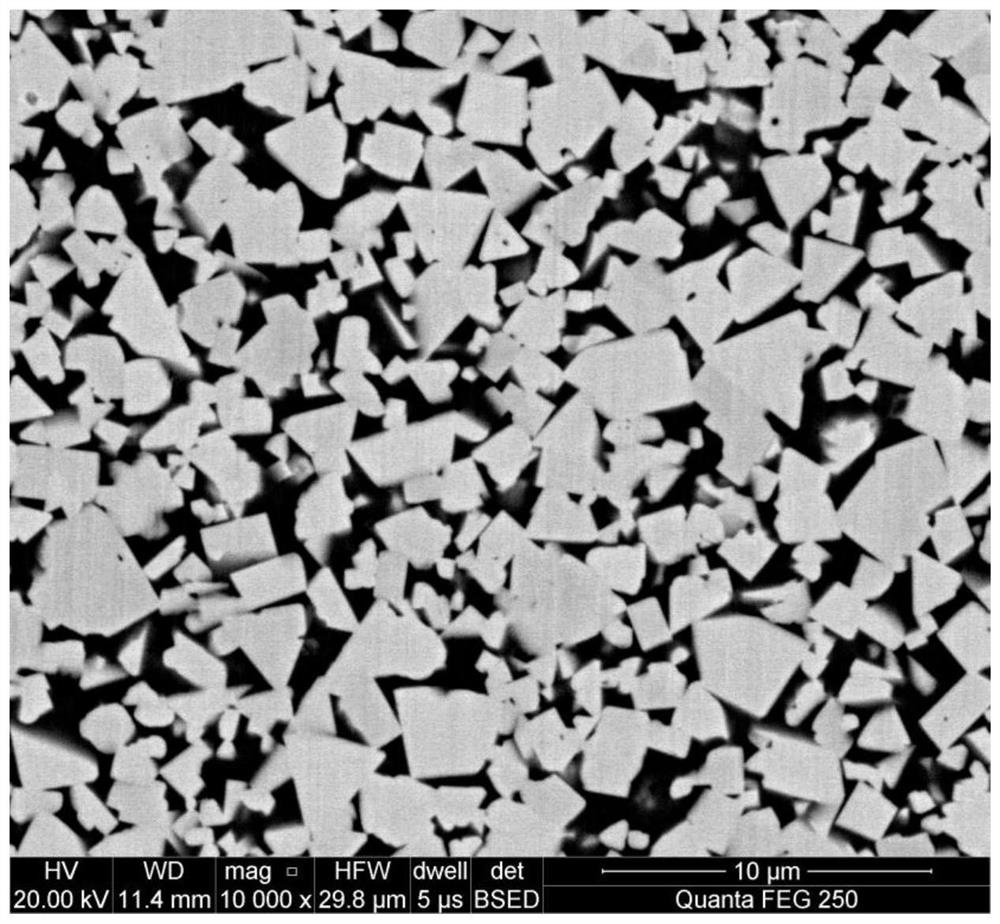

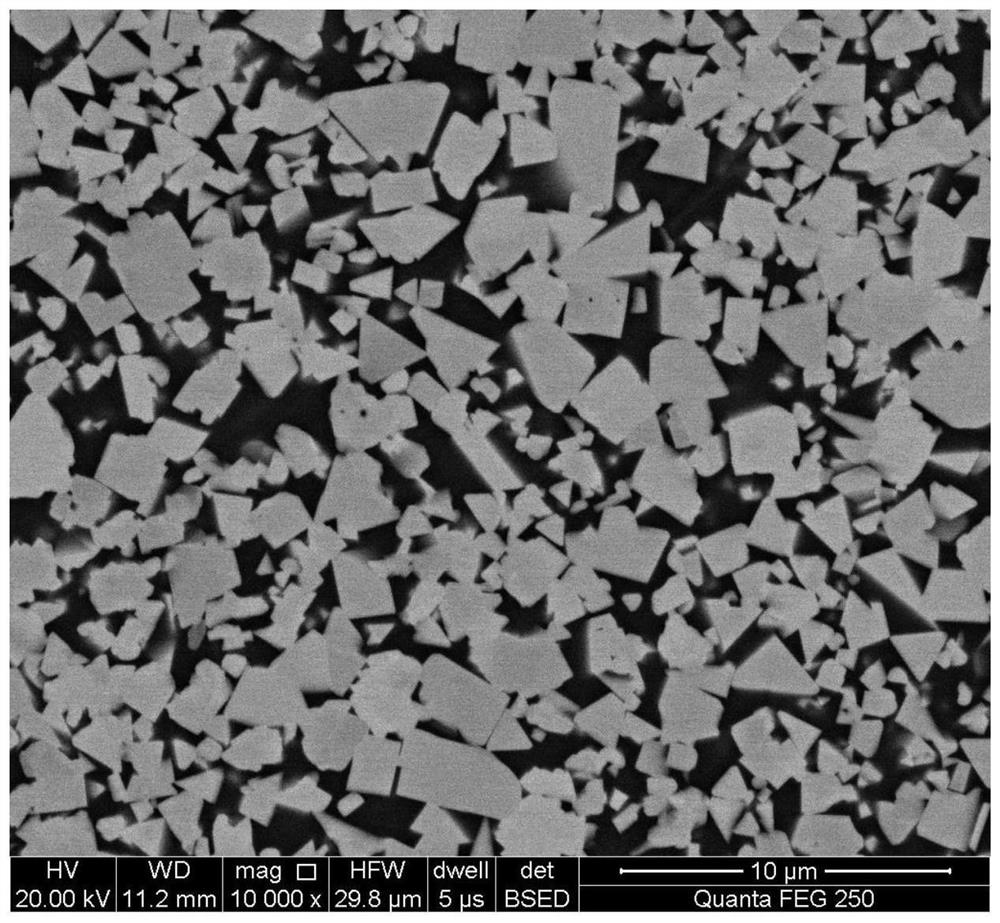

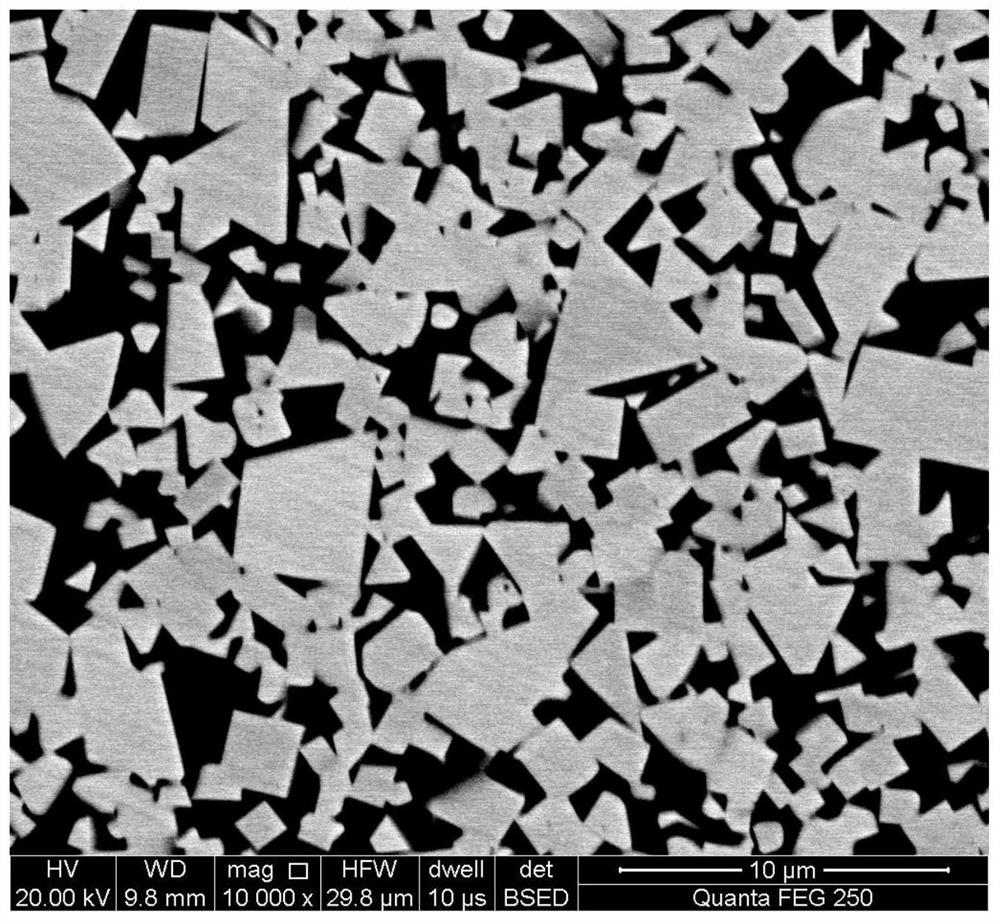

Cobalt-nickel-iron-chromium-based hard alloy material and preparation method thereof

The invention discloses a cobalt-nickel-iron-chromium-based hard alloy material and a preparation method thereof. Co, Ni, Fe and Cr are used as binder phases, W, V, Nb, Ta and the like are used as trace alloy elements, and Co, Ni, Fe, Cr or Cr3C2 powder, the alloy elements and carbide powder are subjected to mixing, ball milling, drying granulation, press forming, dewaxing and sintering to prepare a series of novel binder hard alloys which are low in cost and high in performance. The high-quality cobalt-nickel-iron-chromium-based hard alloy is obtained by adopting the tungsten carbide powder with the average particle size of 1.5-2.5 [mu]m, the particle size distribution of 0.7-4.2 [mu]m and the content of 65-95% (weight ratio) and carrying out low-pressure sintering for 0.5-2 hours at the temperature of 1350-1480 DEG C and the pressure of 5-10 MPa. The hardness of the cobalt-nickel-iron-chromium-based hard alloy material prepared by the method reaches the level of a hard alloy with Co as a binder phase, the bending strength and the fracture toughness are improved by 10-20% compared with those of a pure cobalt hard alloy, and industrial requirements are met. The application range of the product can cover hard alloy cutters, mining tools, shield products and PCB micro drills.

Owner:CENT SOUTH UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com