Patents

Literature

44results about How to "Improve lattice distortion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-entropy alloy powder for laser cladding and preparation method of cladding layer

InactiveCN106086580AHigh bonding strengthEasy to diluteMetallic material coating processesHigh entropy alloysHardness

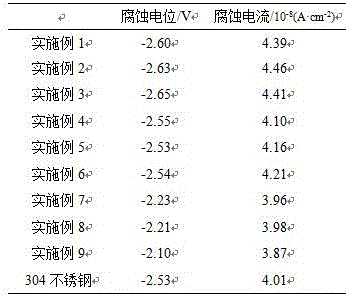

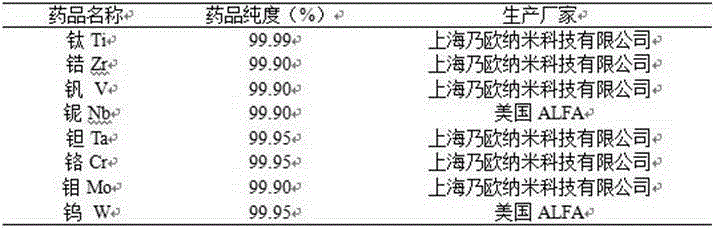

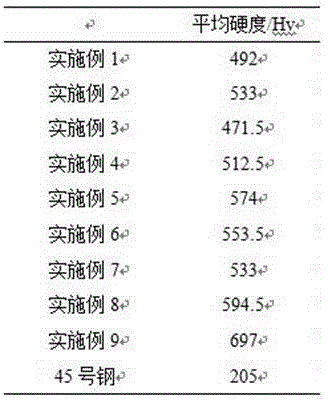

The invention discloses high-entropy alloy powder for laser cladding and a preparation method of a cladding layer. The high-entropy alloy powder comprises Ti, Zr, V, Nb, Ta and Mo. In addition, high-entropy alloy powder which comprises Ti, Zr, V, Nb, Ta, Mo and W, high-entropy alloy powder which comprises Ti, Zr, V, Nb, Ta, Mo, W and Cr and the preparation method of the cladding layer of the high-entropy alloy powder for laser cladding are provided. The high-entropy alloy powder mainly comprises two characteristics, namely, the high-entropy effect and the cocktail effect, each kind of powder exerts respective advantages, and therefore the cladding layer with high hardness, high corrosion resistance, excellent tempering softening resisting performance and excellent structure performance is obtained. Metallurgical bonding is formed by an alloy layer and a matrix through laser cladding; the bonding strength of the cladding layer and the matrix is greatly improved, and the heating speed is high; metal of the cladding layer is not prone to being diluted by the matrix; little heat deformation is generated; and therefore the part rejection rate is low.

Owner:KUNMING UNIV OF SCI & TECH

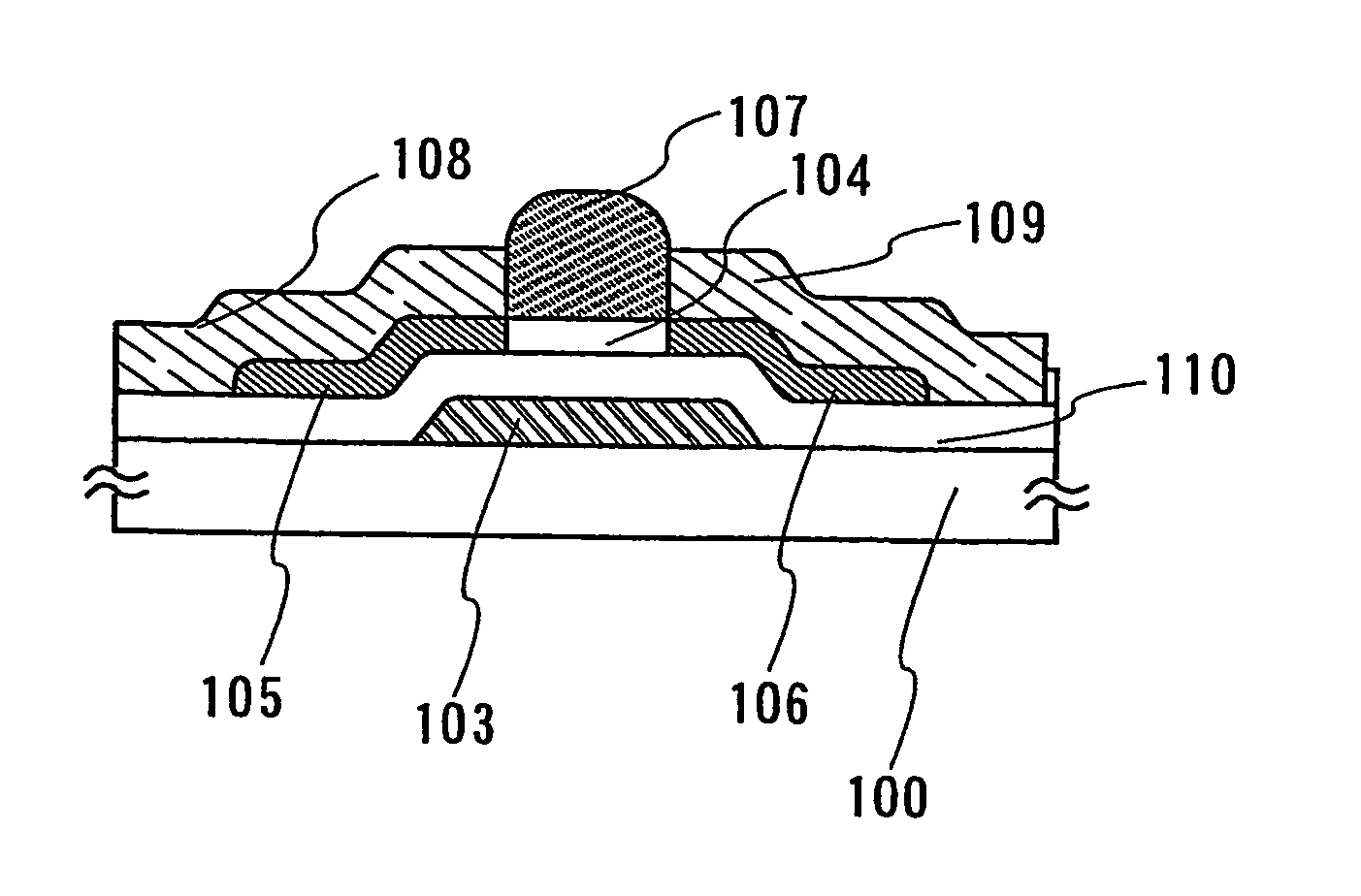

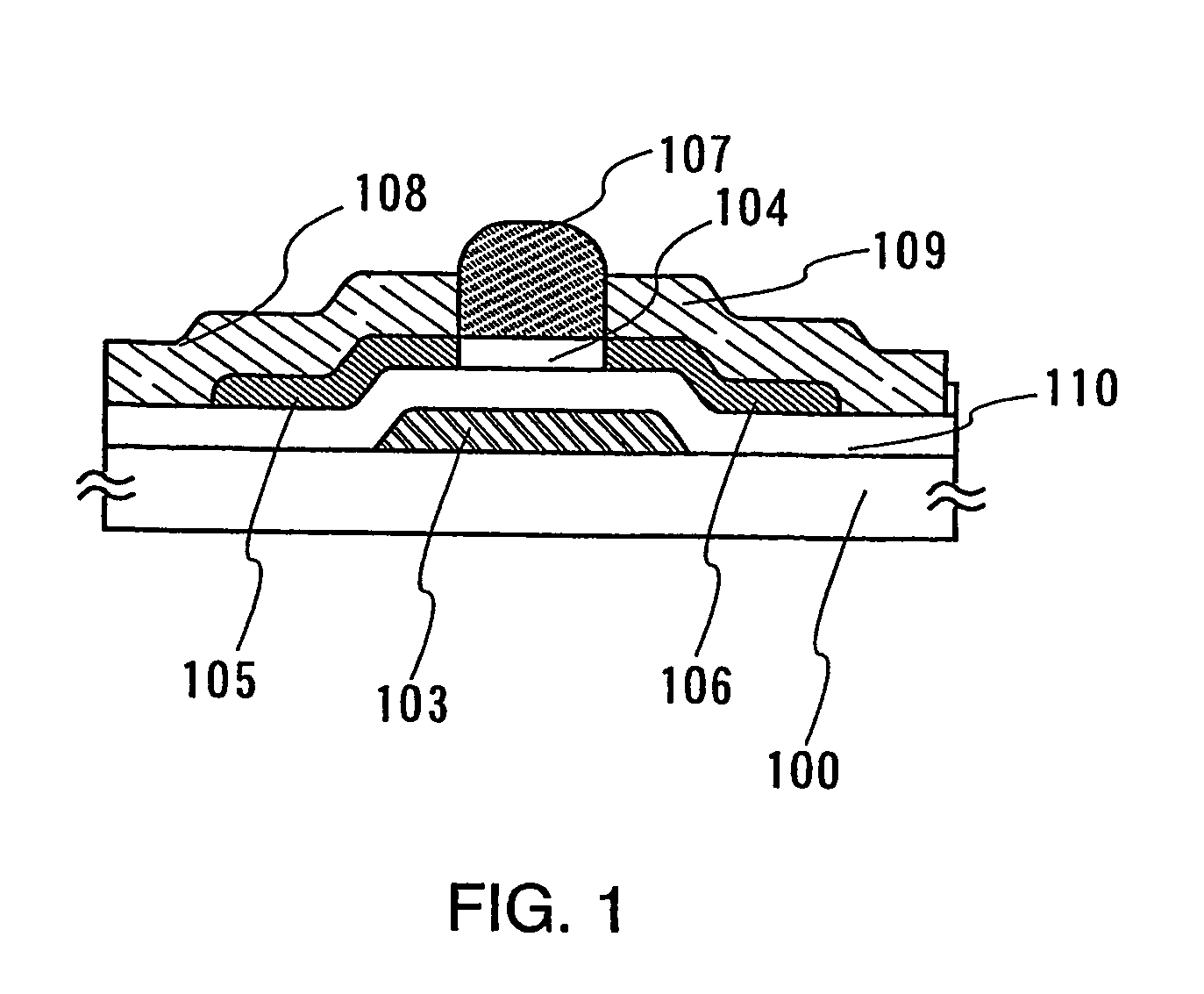

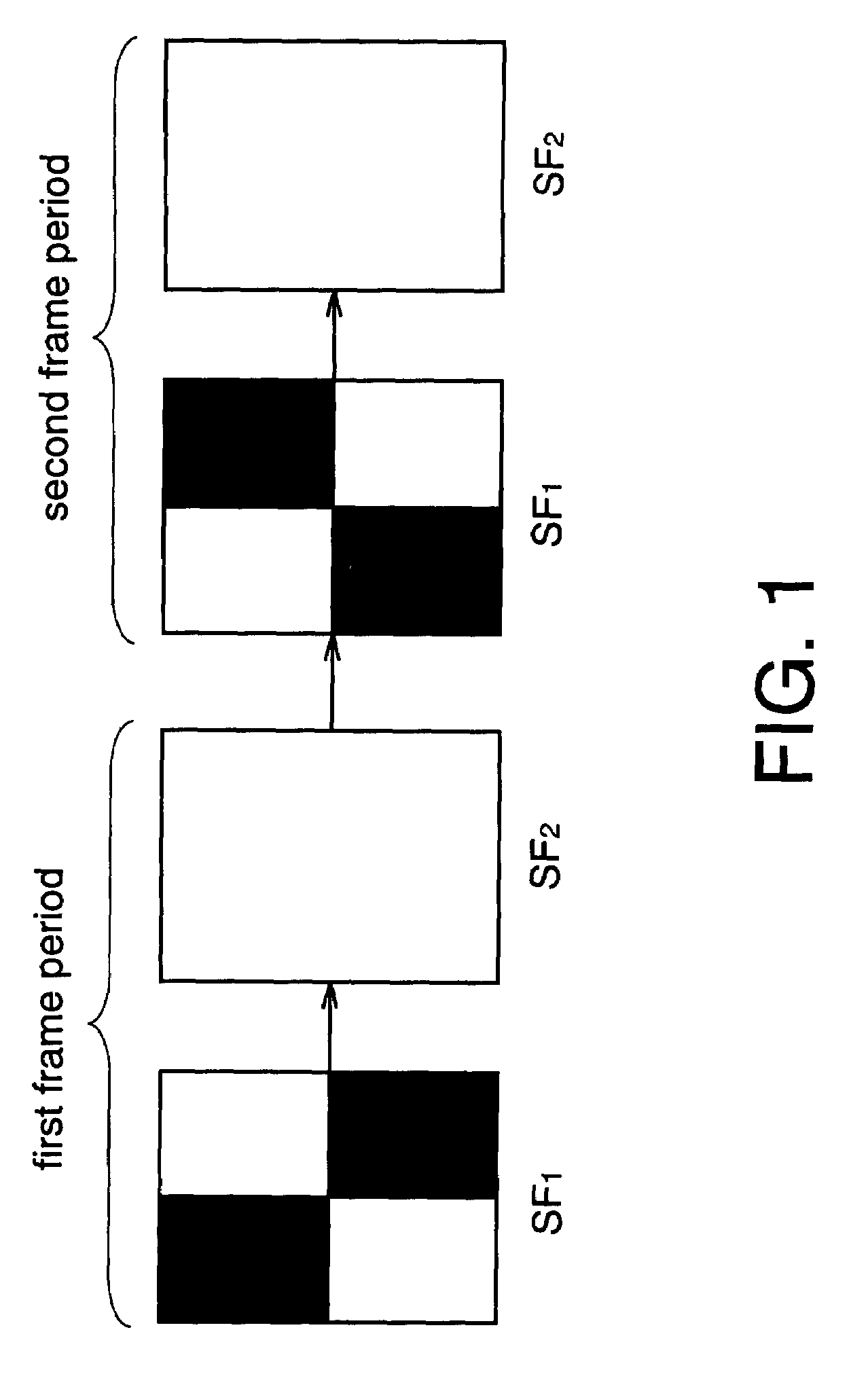

Light emitting device

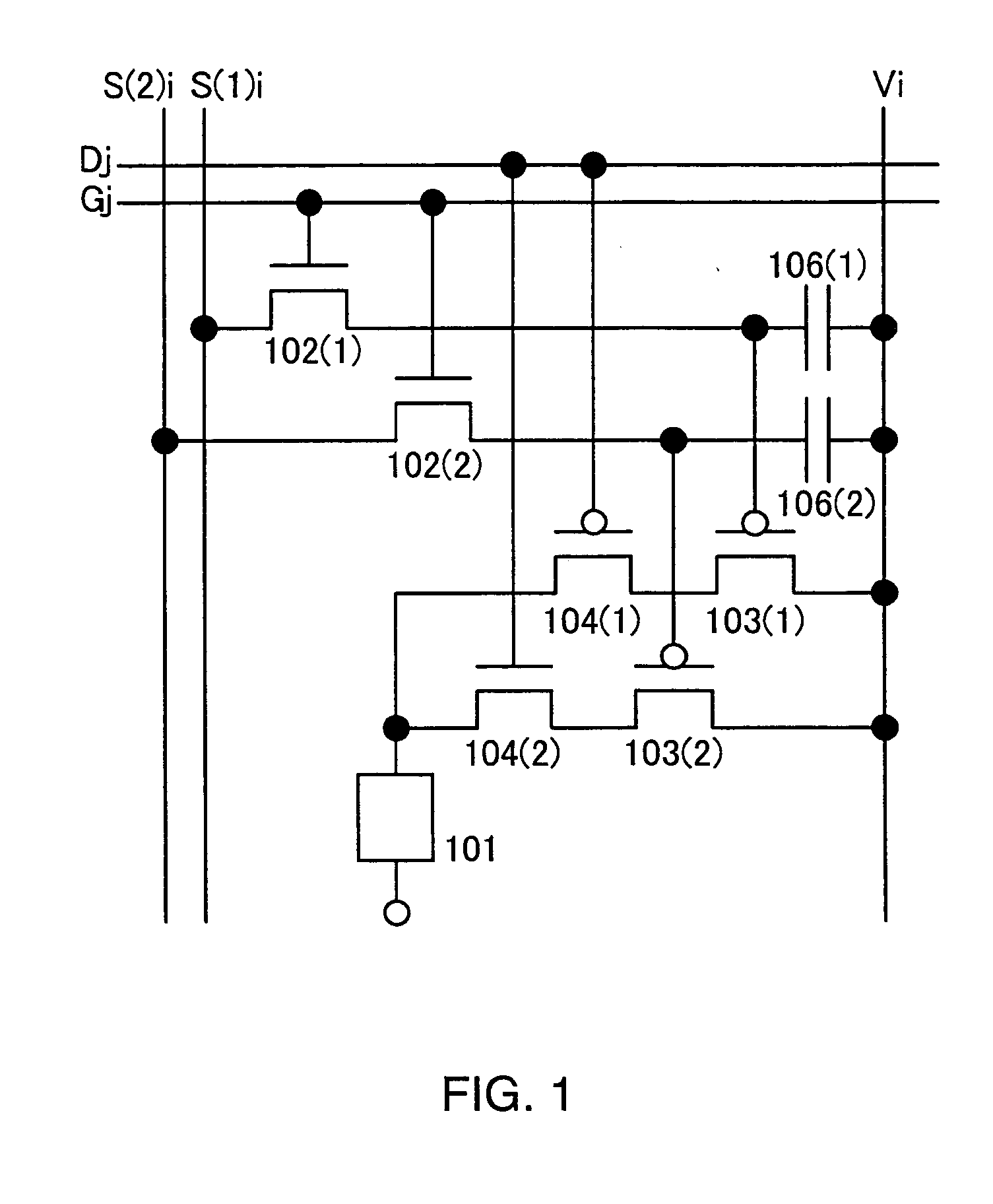

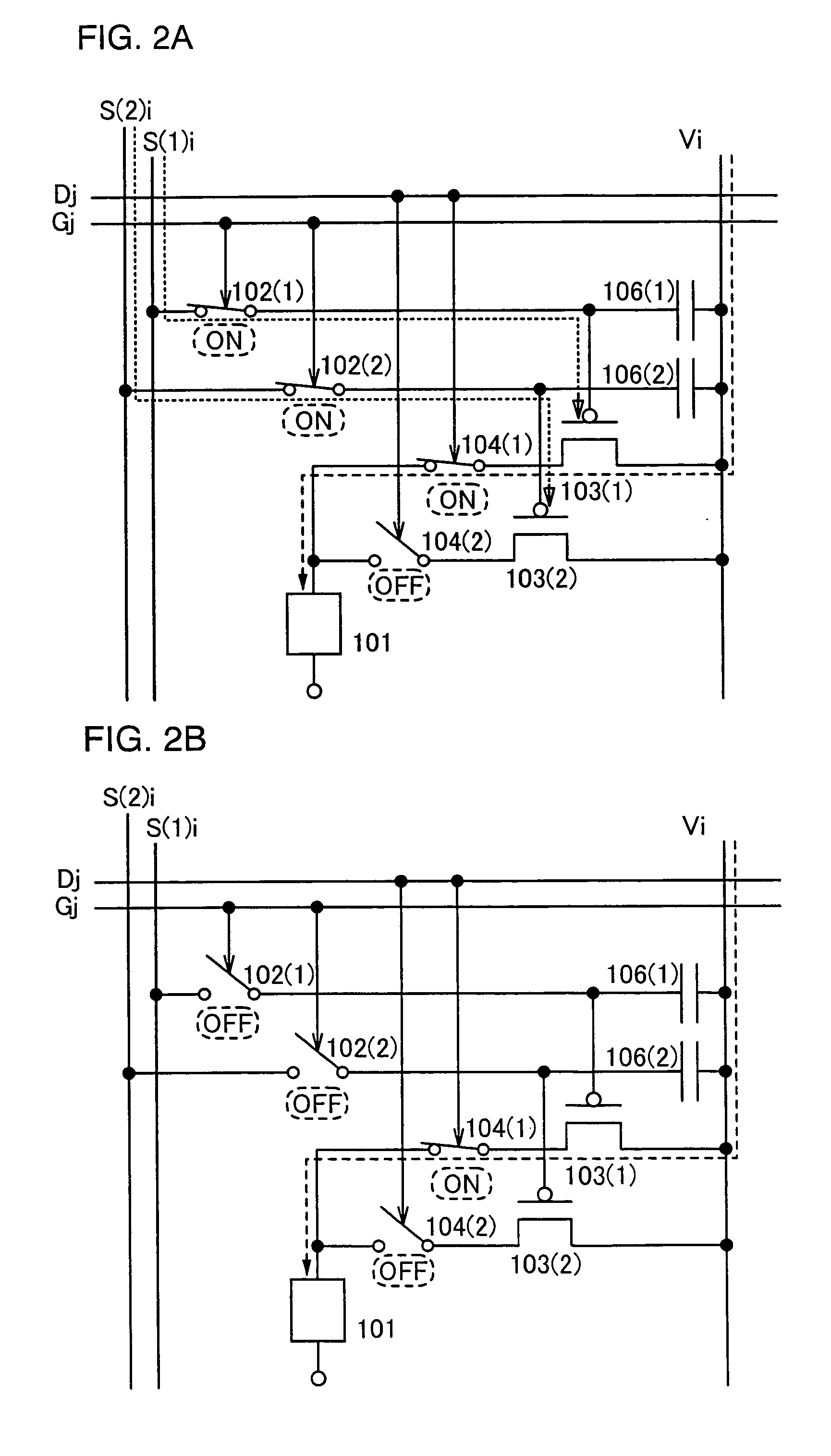

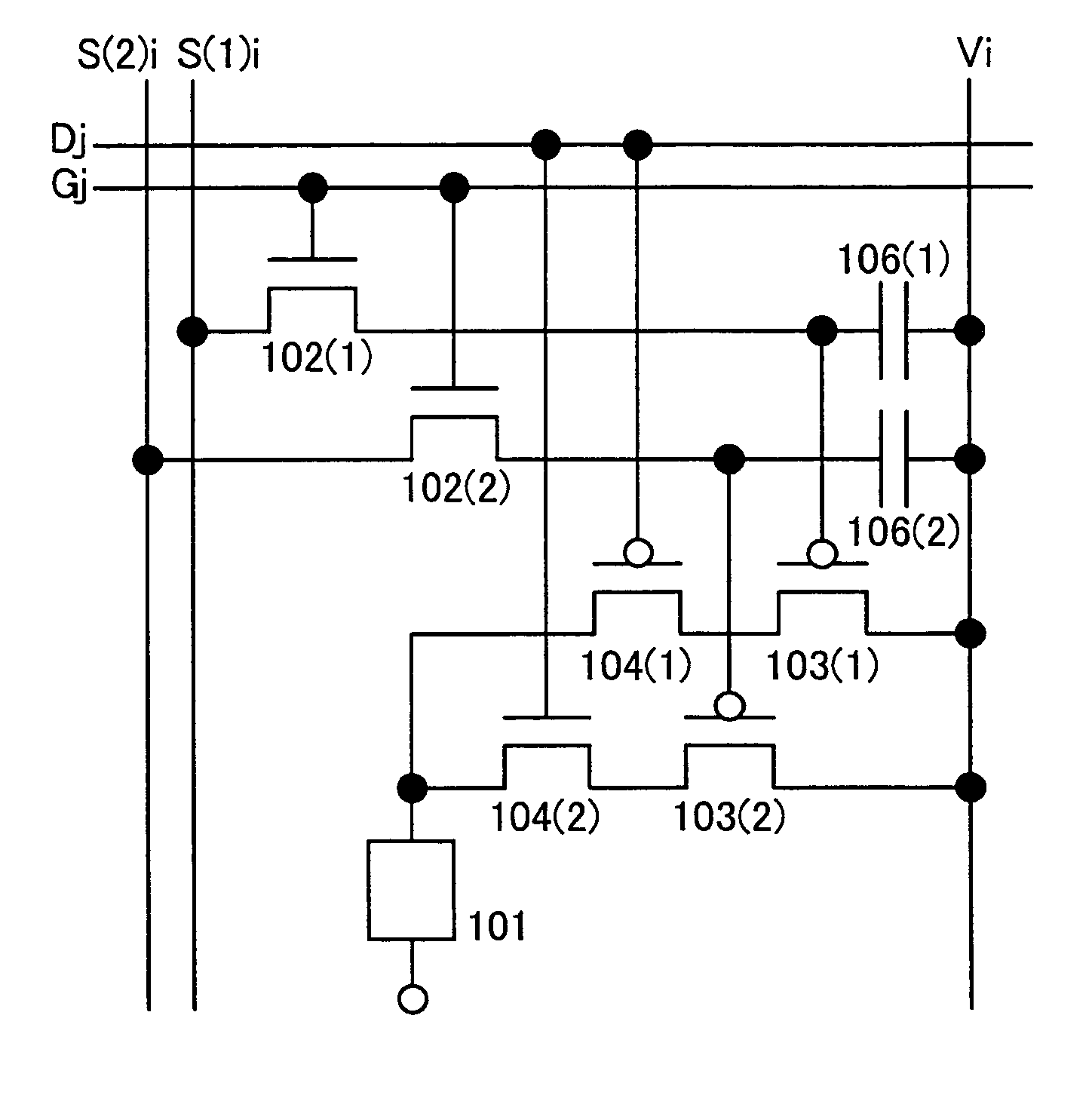

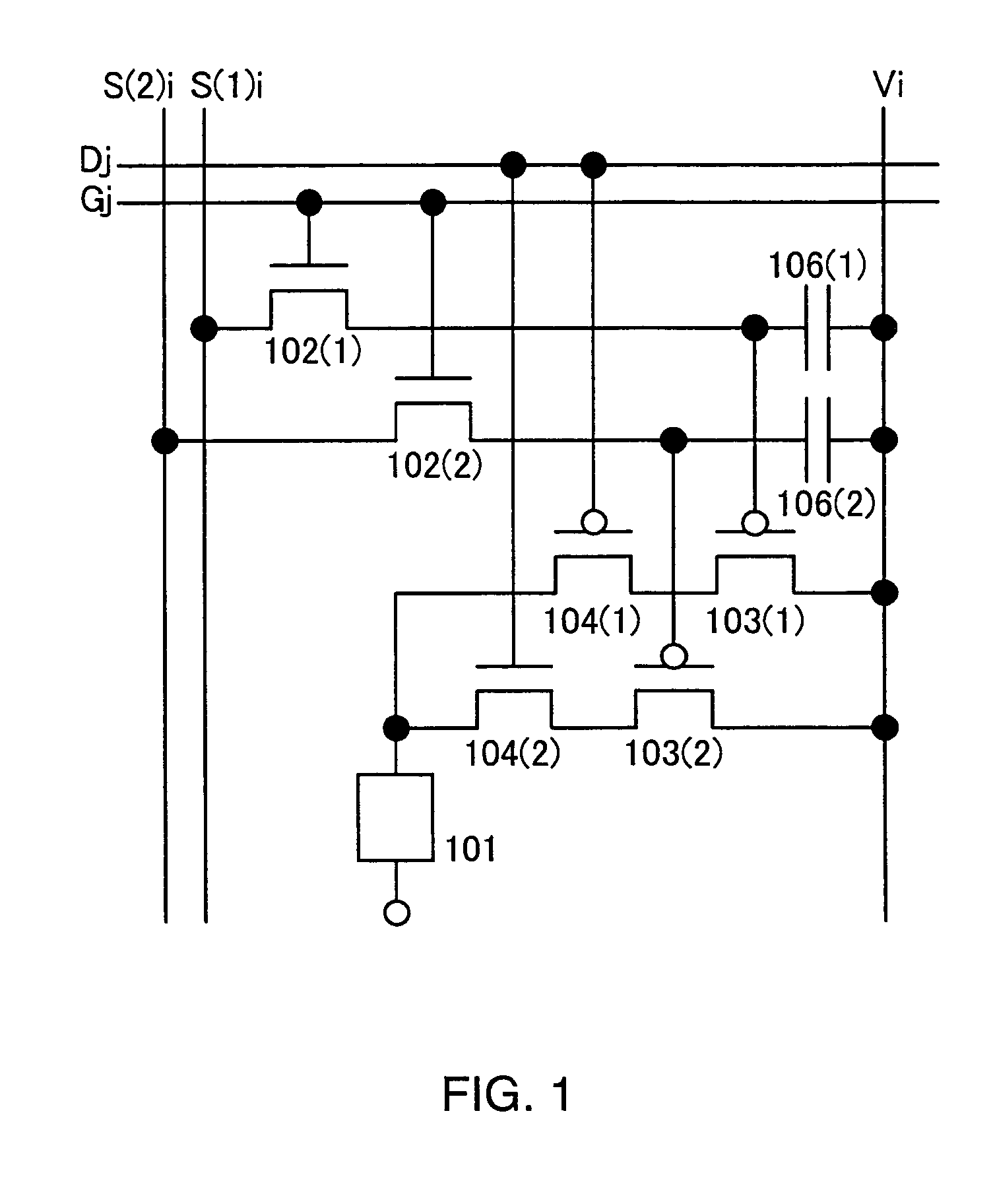

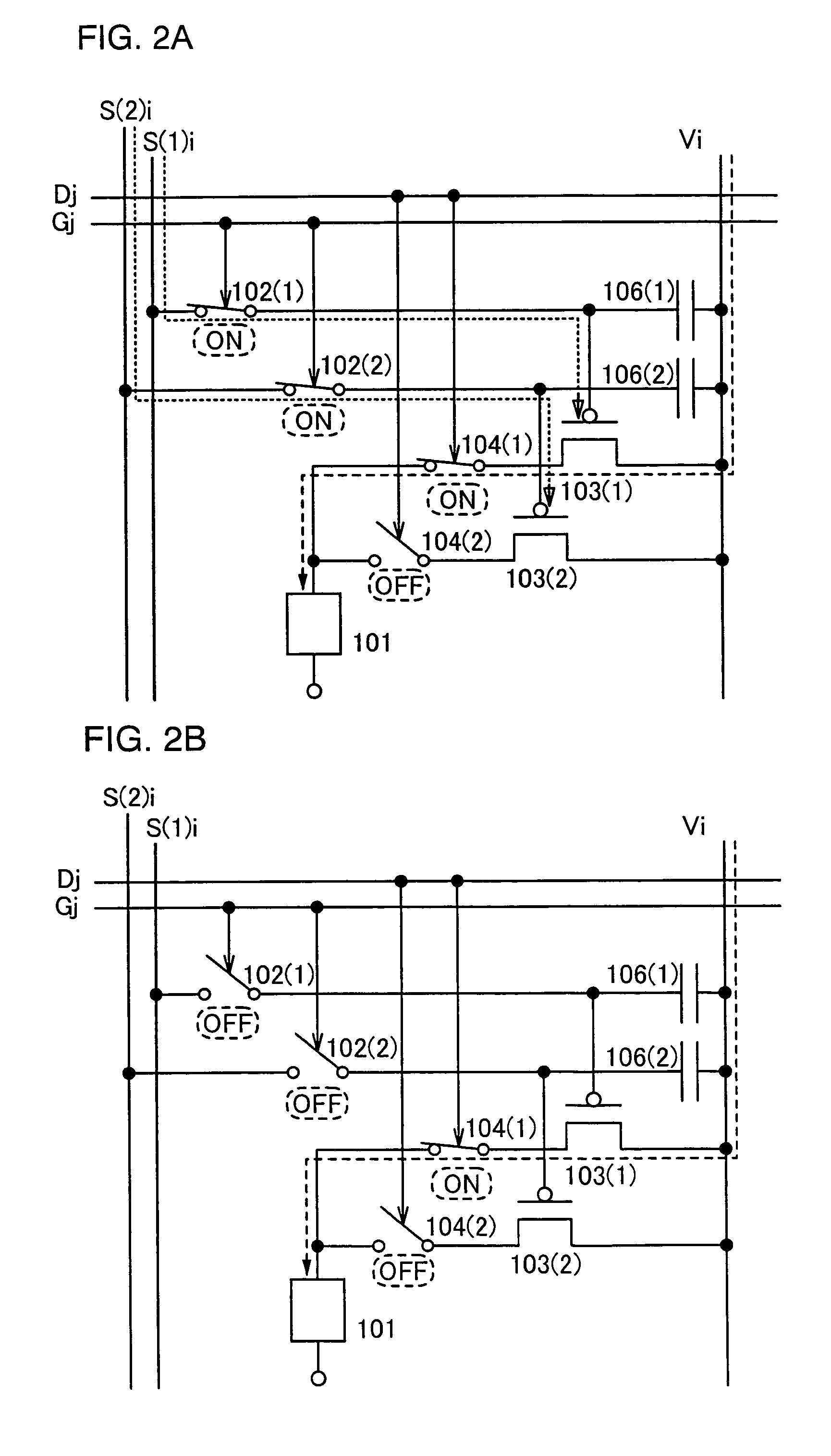

InactiveUS20050243079A1Improve stabilityEnergy stabilityElectrical apparatusElectroluminescent light sourcesDriver circuitDriver/operator

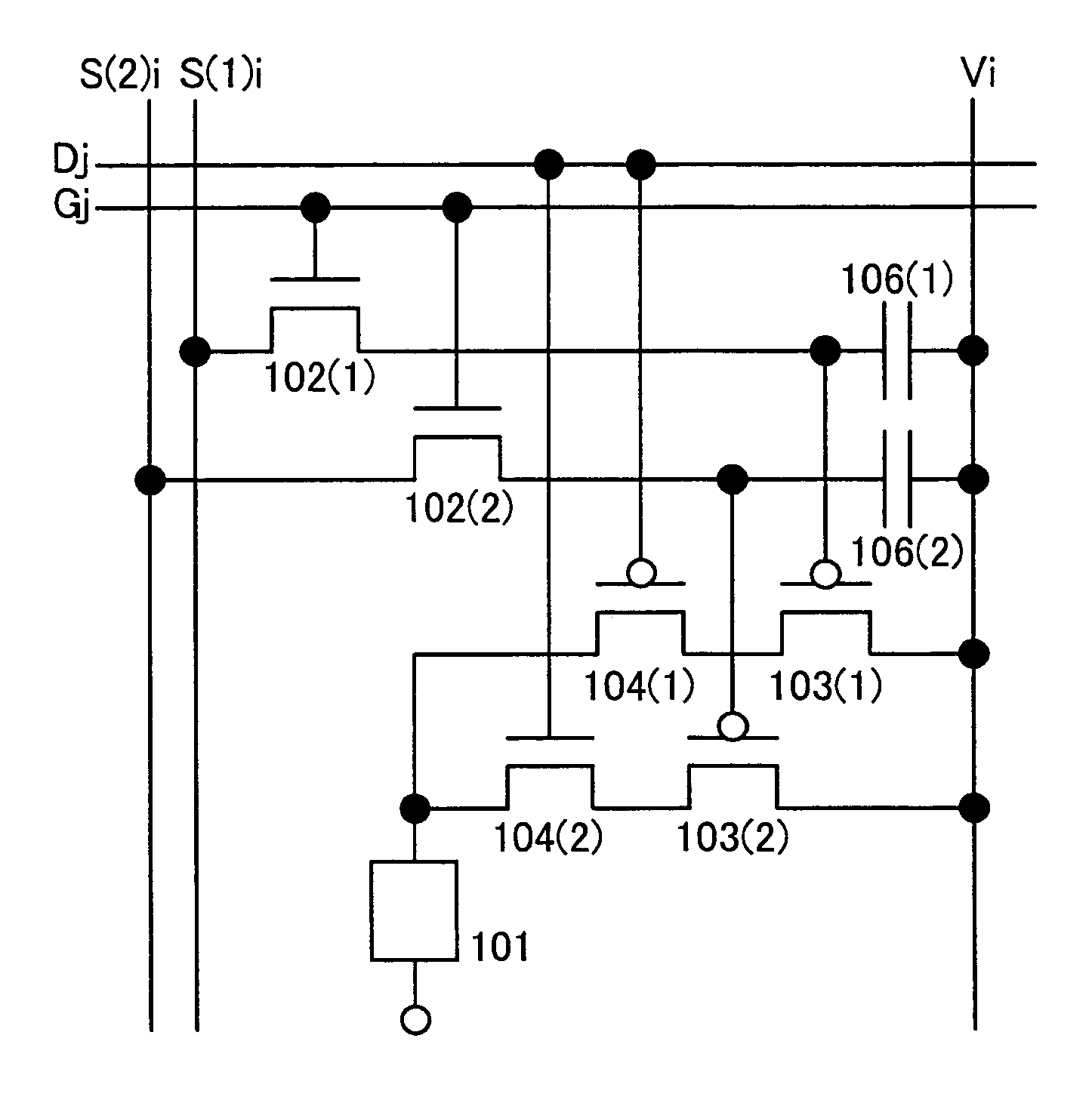

A light emitting device with generation of a pseudo contour suppressed is provided in which the drive frequency of a driver circuit is suppressed while the frame frequency is increased. In addition, a light emitting device with generation of a pseudo contour suppressed is provided in which the drive frequency of a driver circuit is suppressed while the dividing number of a subframe period is increased. To input plural bits of video signals into pixels in parallel, a switching transistor and a driving transistor are provided in each pixel in accordance with the number of the bits. In addition, a transistor for selecting a video signal (a data selecting transistor) is provided in each pixel in order to select each bit of a video signal within the pixel when display is actually performed at the pixels.

Owner:SEMICON ENERGY LAB CO LTD

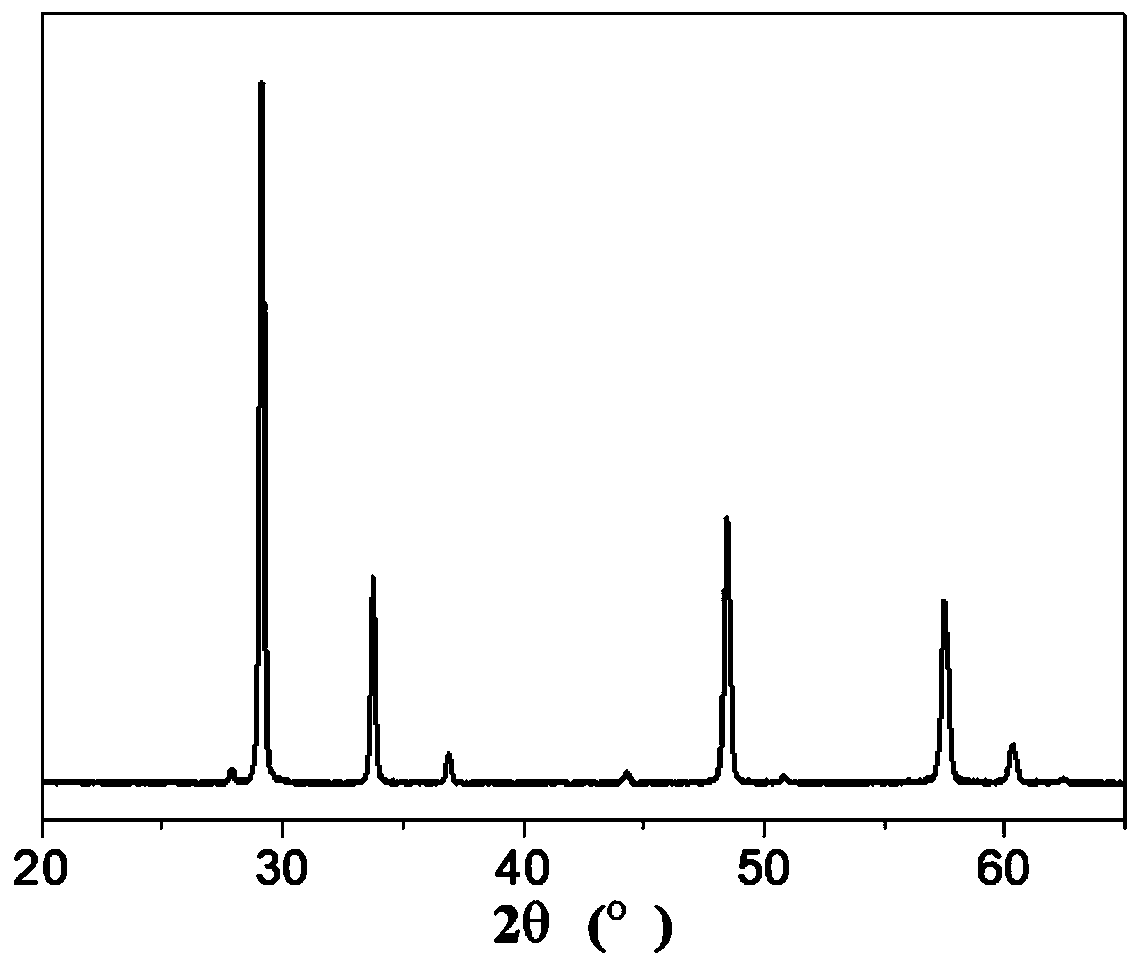

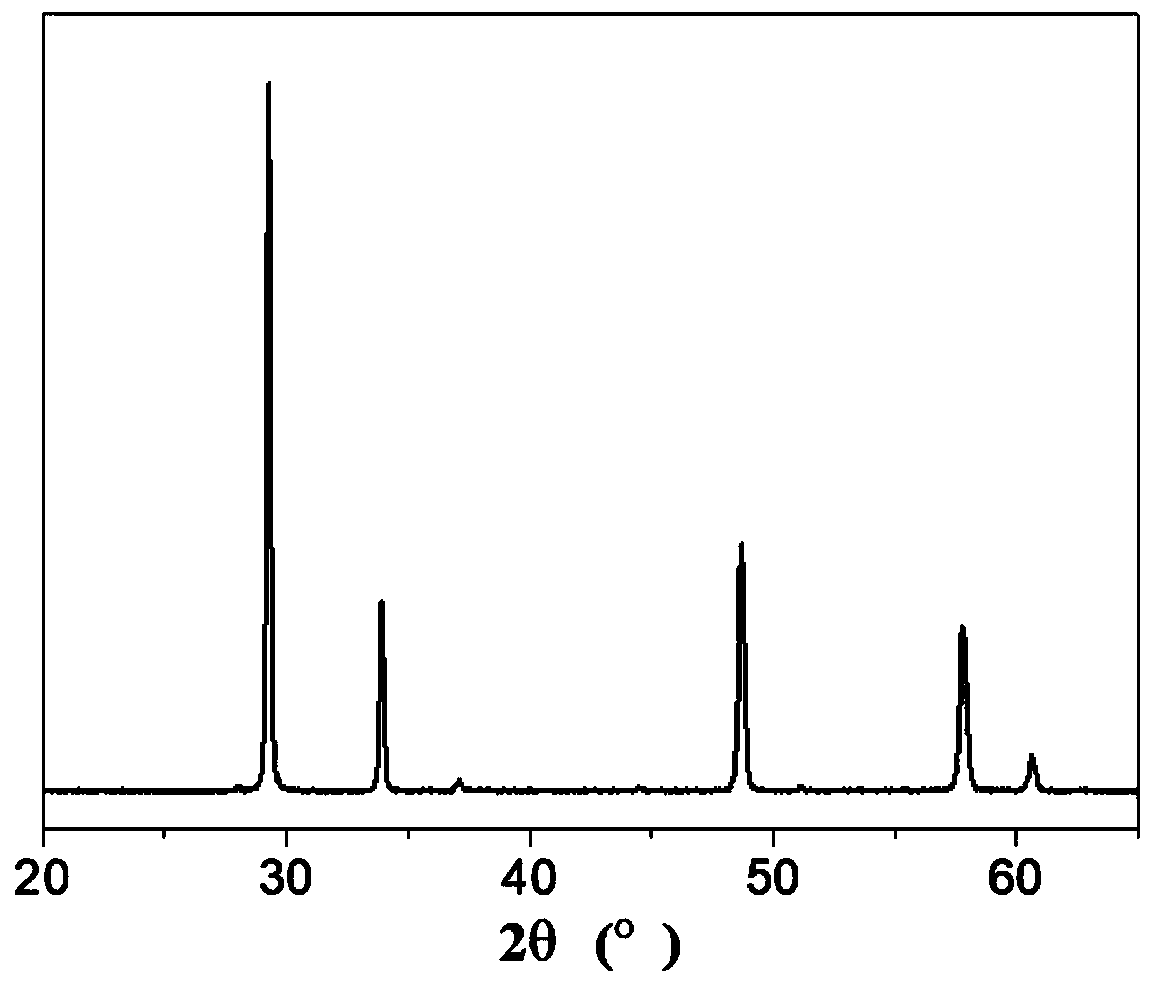

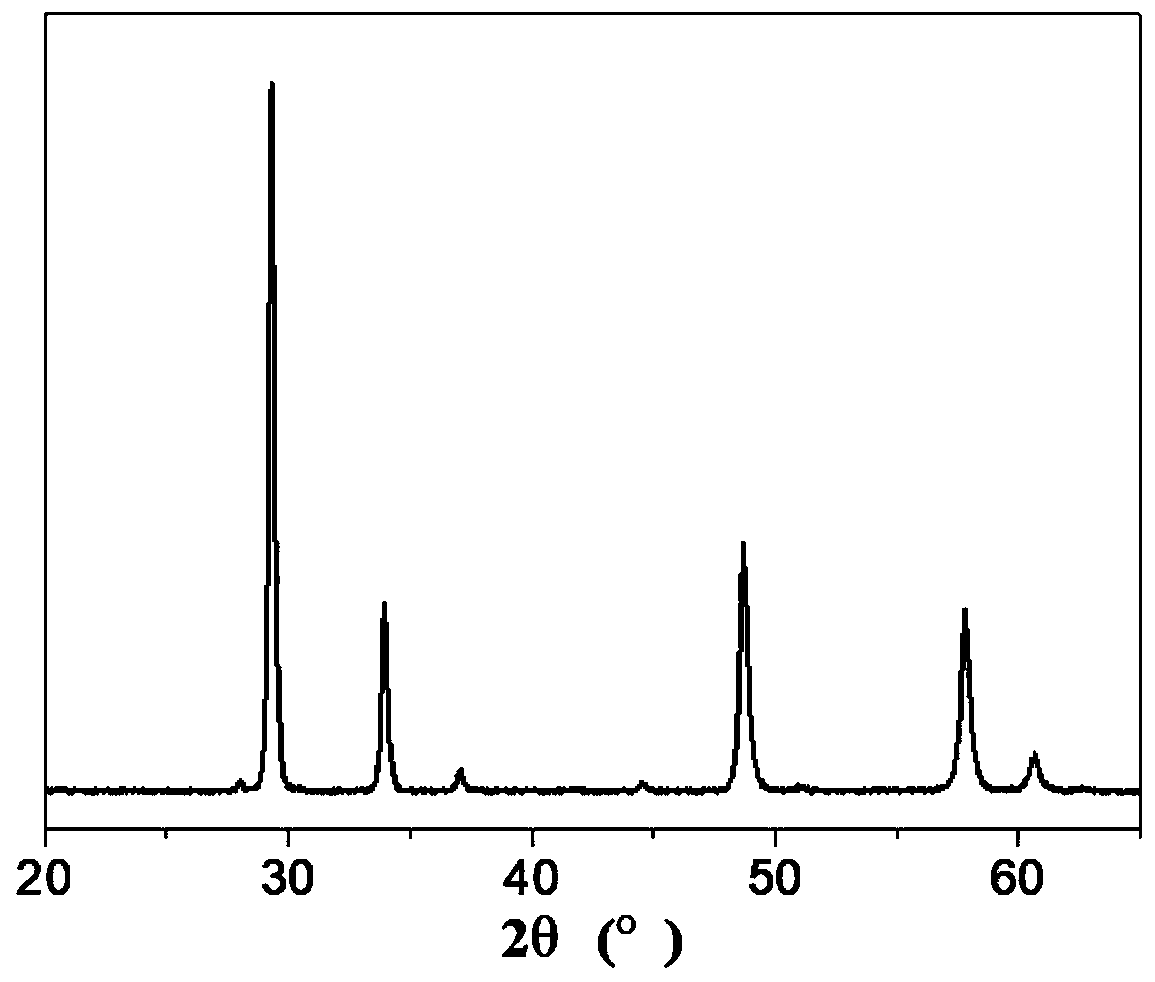

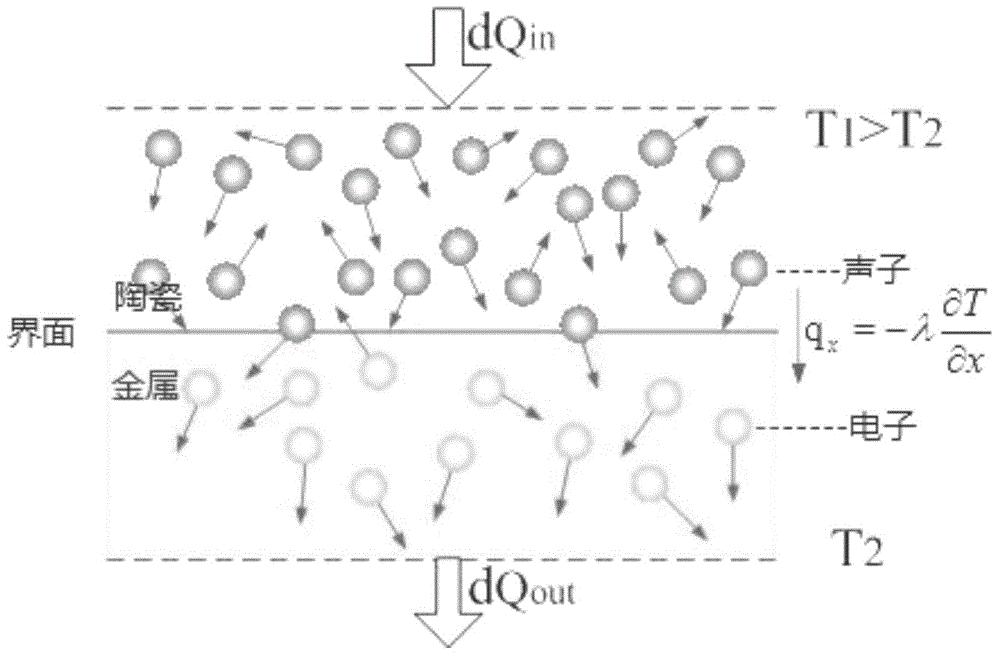

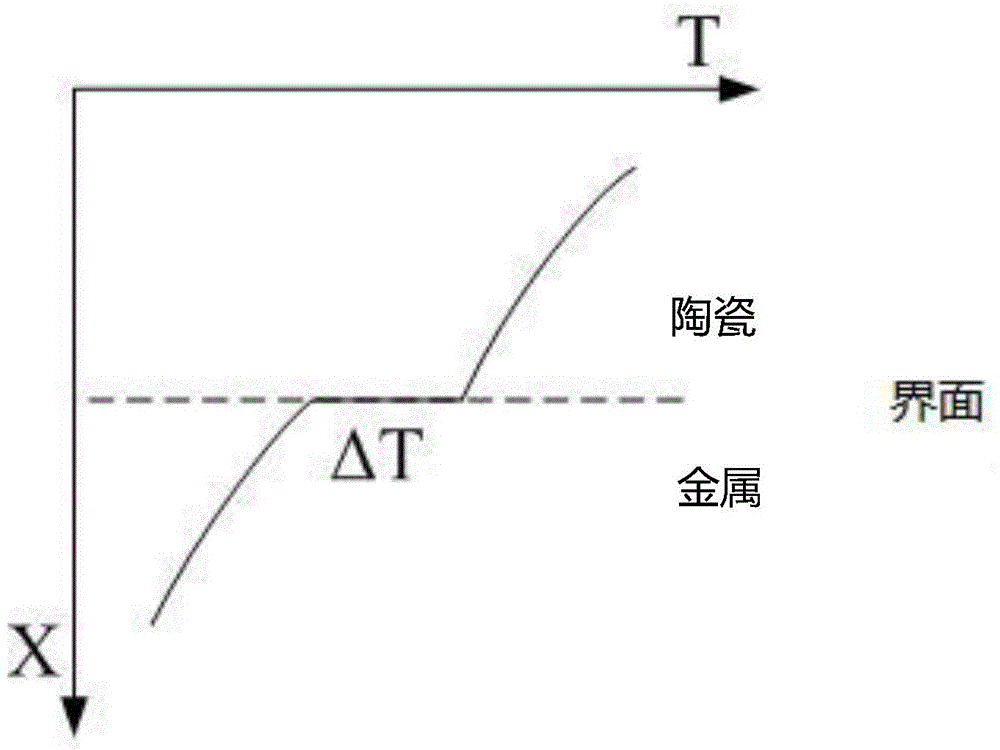

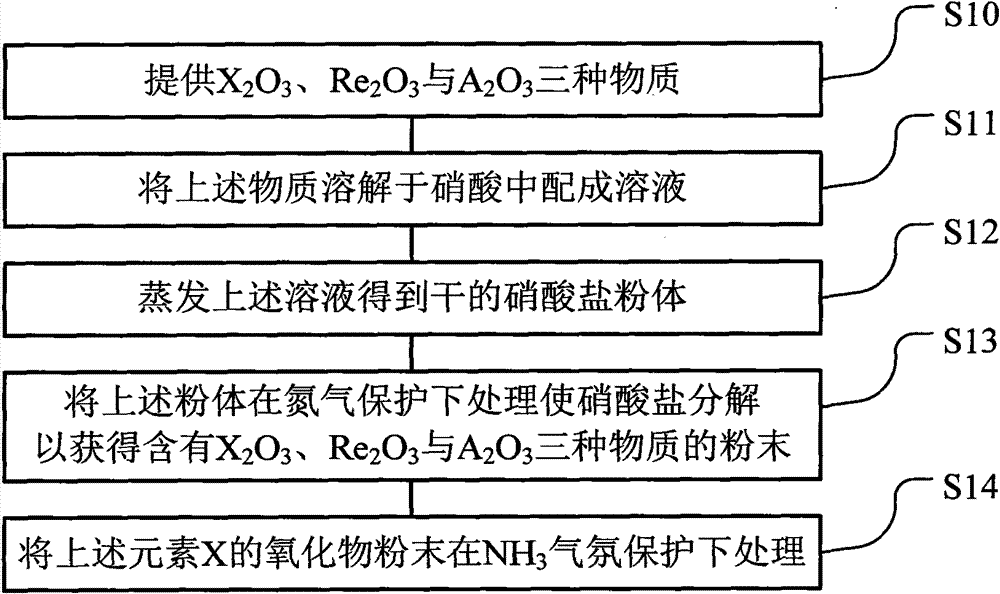

High-entropy ceramic powder used for thermal barrier coating and preparation method of ceramic powder

ActiveCN110272278ALow thermal conductivityImprove lattice distortionAir atmosphereRare-earth element

The invention discloses high-entropy ceramic powder used for a thermal barrier coating. The ceramic powder is characterized by having a pyrochlore structure and a chemical formula of RE2Zr2O7, wherein RE is any 3-7 different metal elements selected from rare earth elements including Y, La, Pr, Nd, Sm, Eu and Gd, and the percentage of one mole number of each RE element to the total mole number of all RE elements is 5%-35%. The preparation method comprises the following steps: mixing RE2O3 powder and ZrO2 powder, and heating the mixed powder under the heating condition of 1000-1700 DEG C for 1-10 h in an air atmosphere to obtain the high-entropy ceramic powder. According to the method provided by the invention, the high-entropy ceramic powder prepared by the method enriches a system of a thermal barrier coating material, has the advantages of low costs, simple and easy operation, a wide application range and the like, and is expected to be used in the field of thermal barrier coatings.

Owner:DONGHUA UNIV

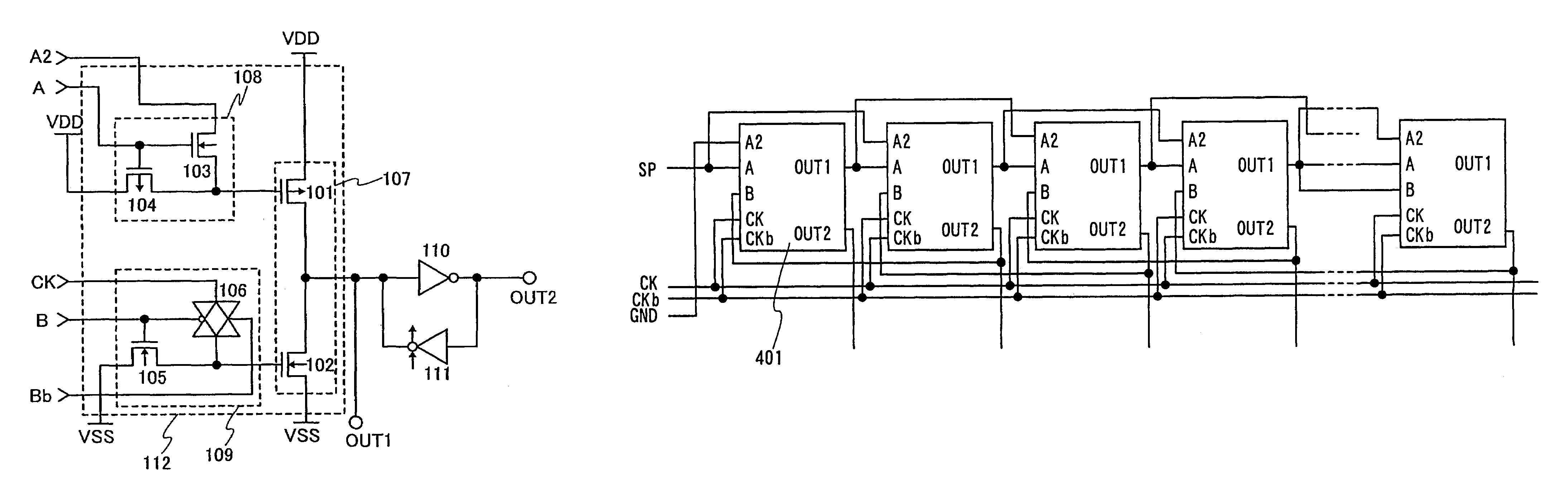

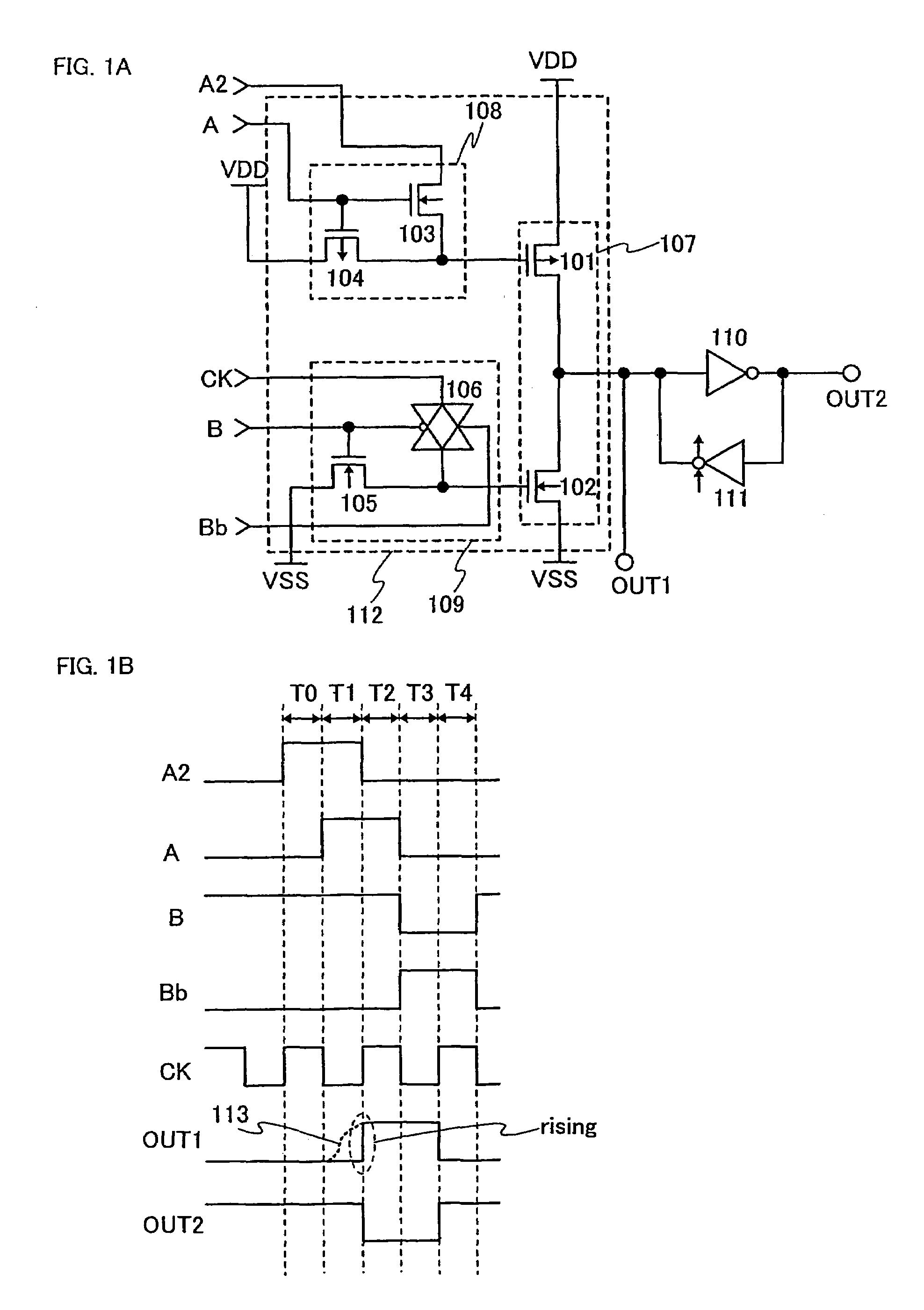

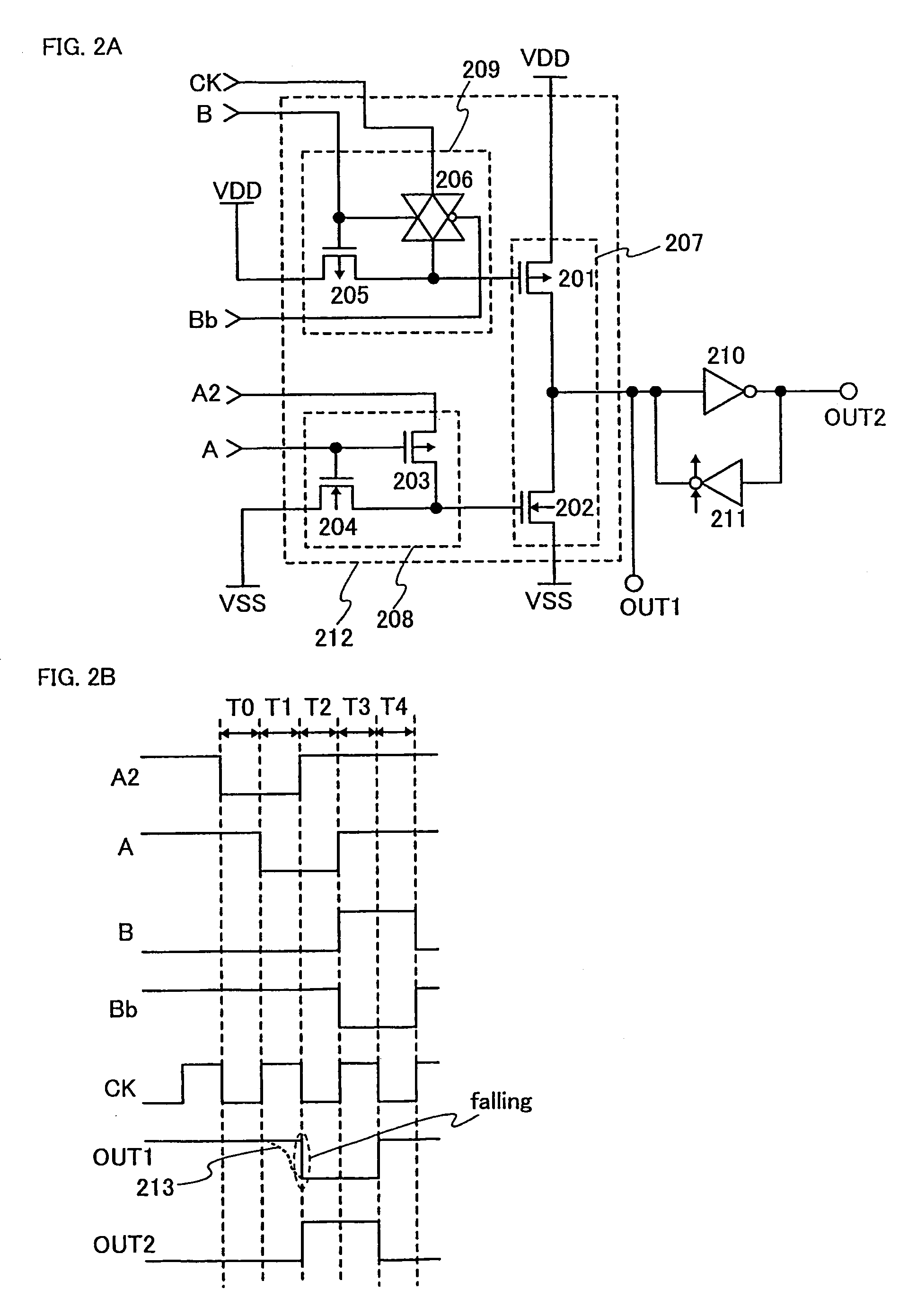

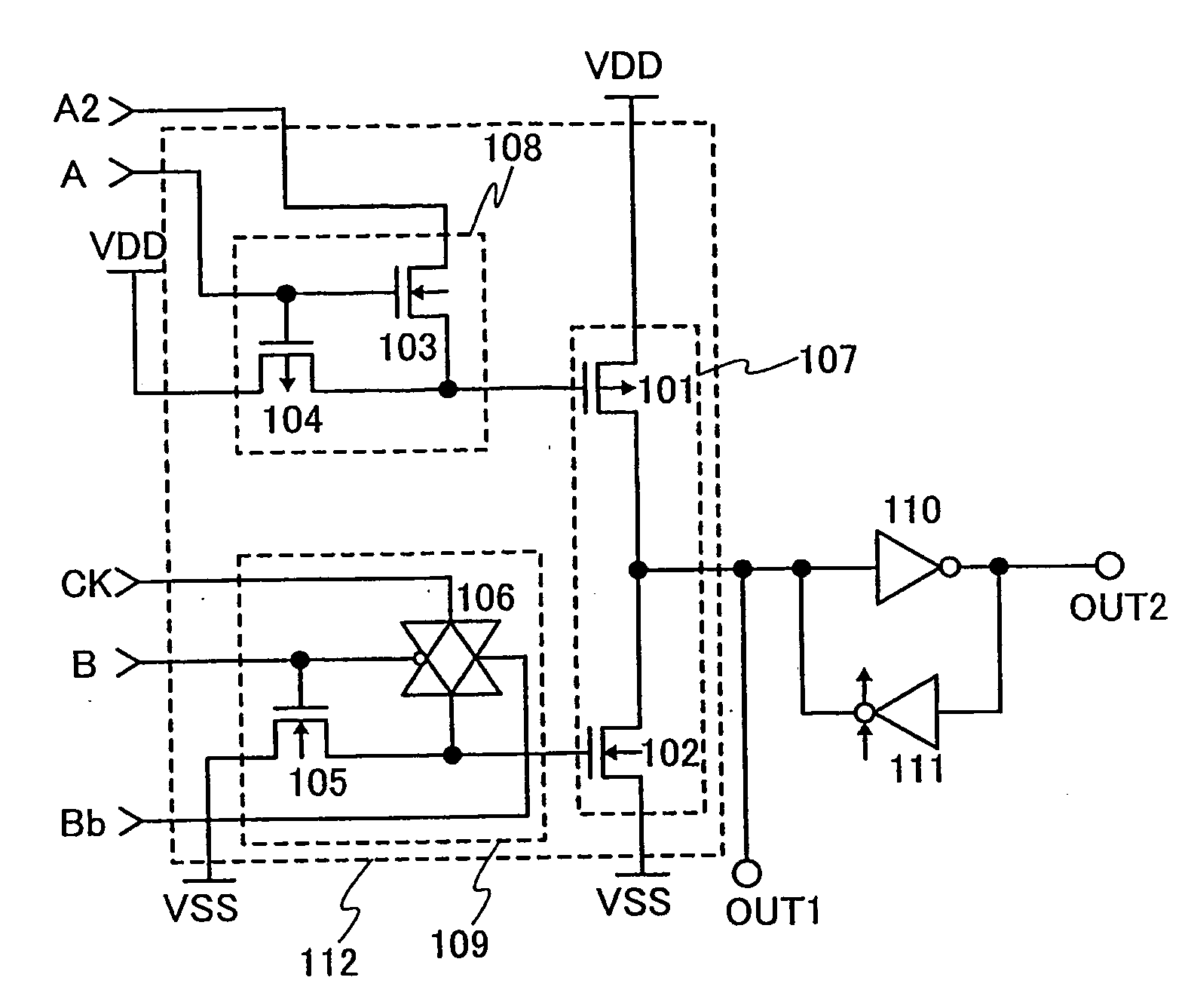

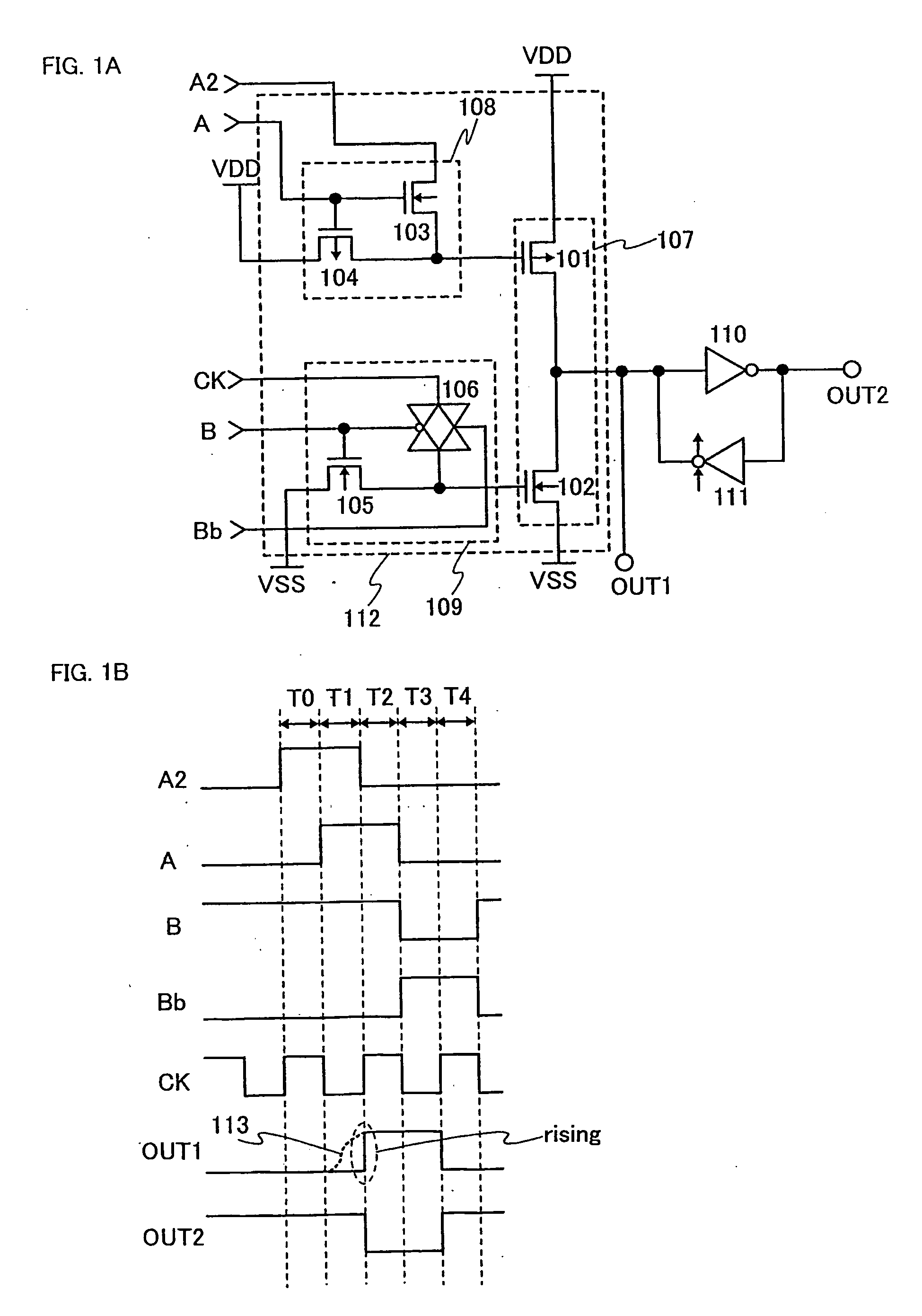

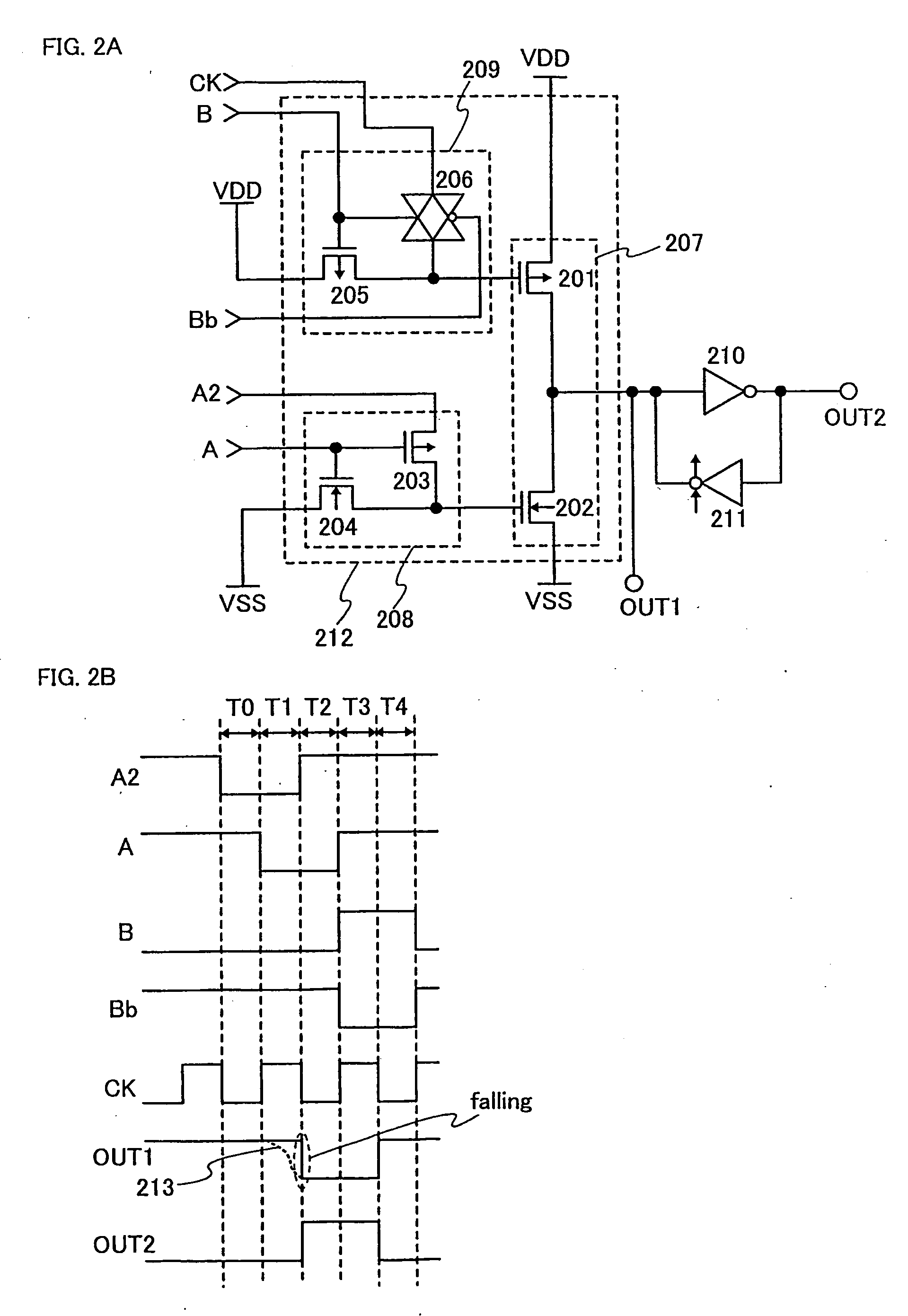

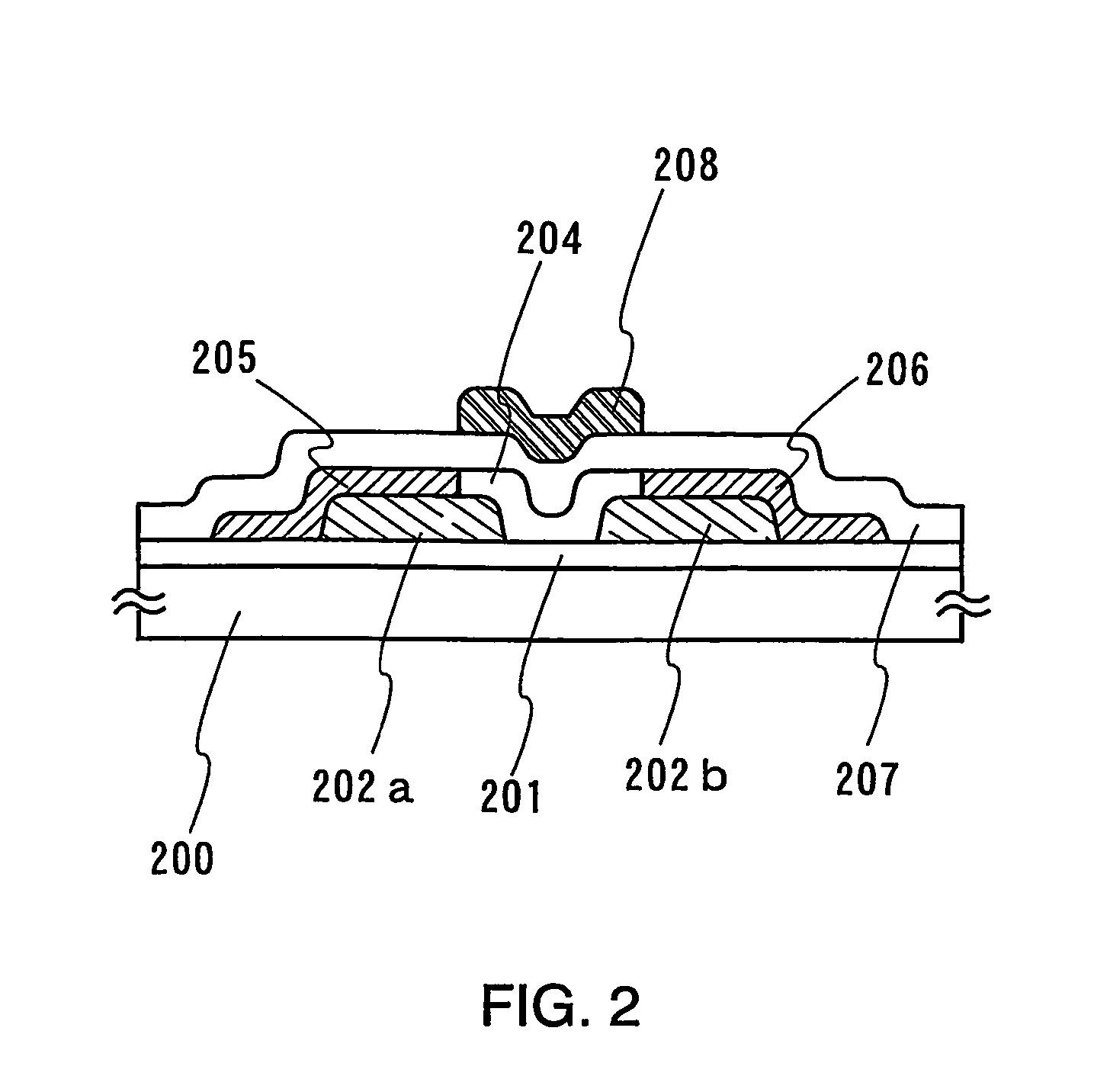

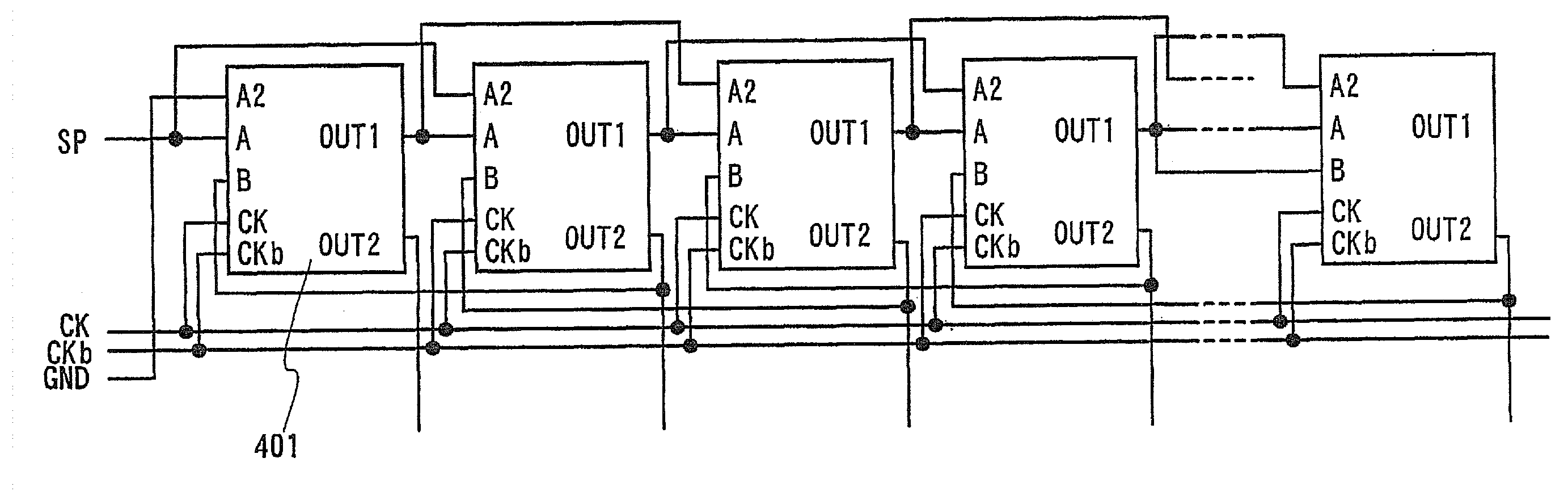

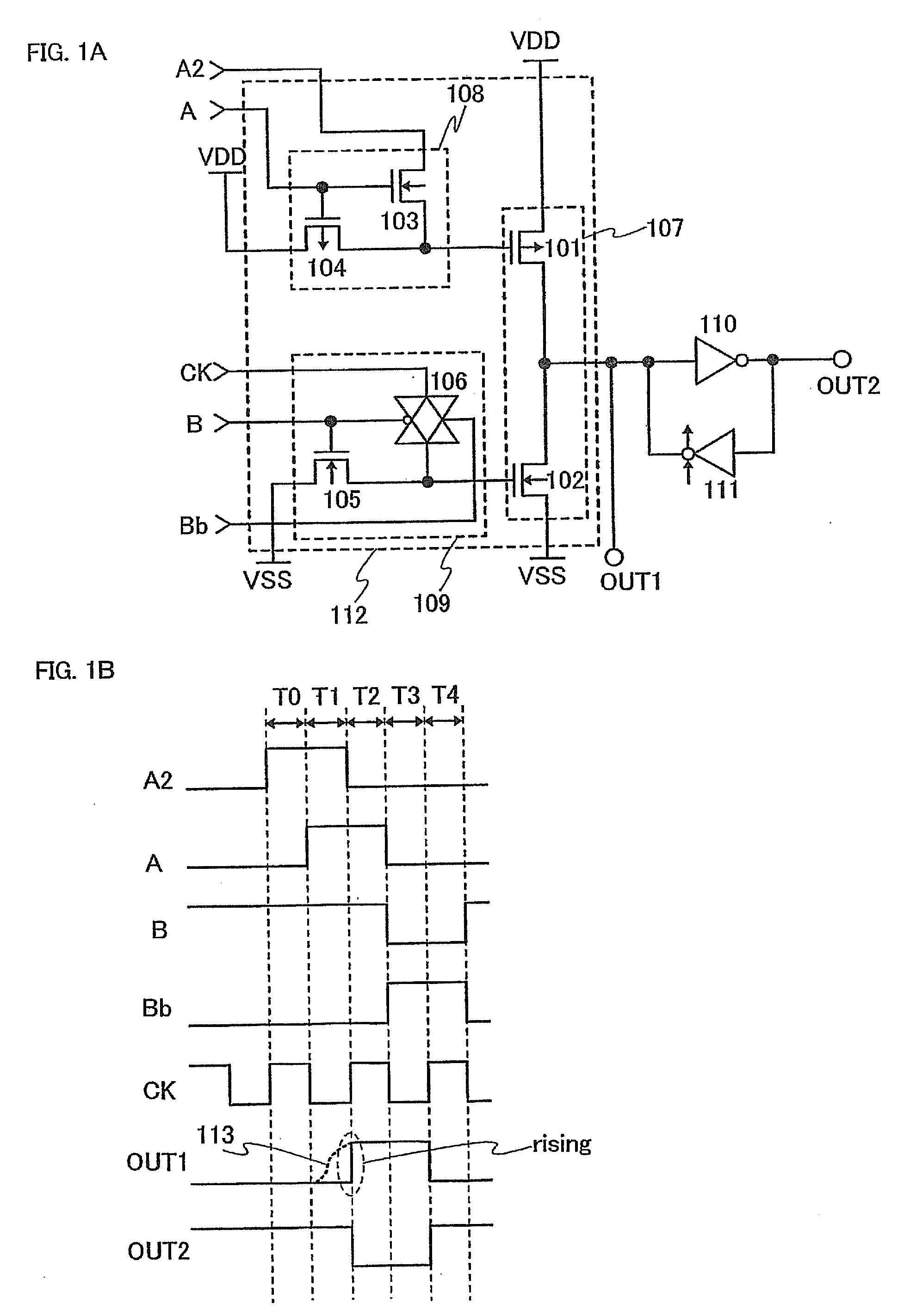

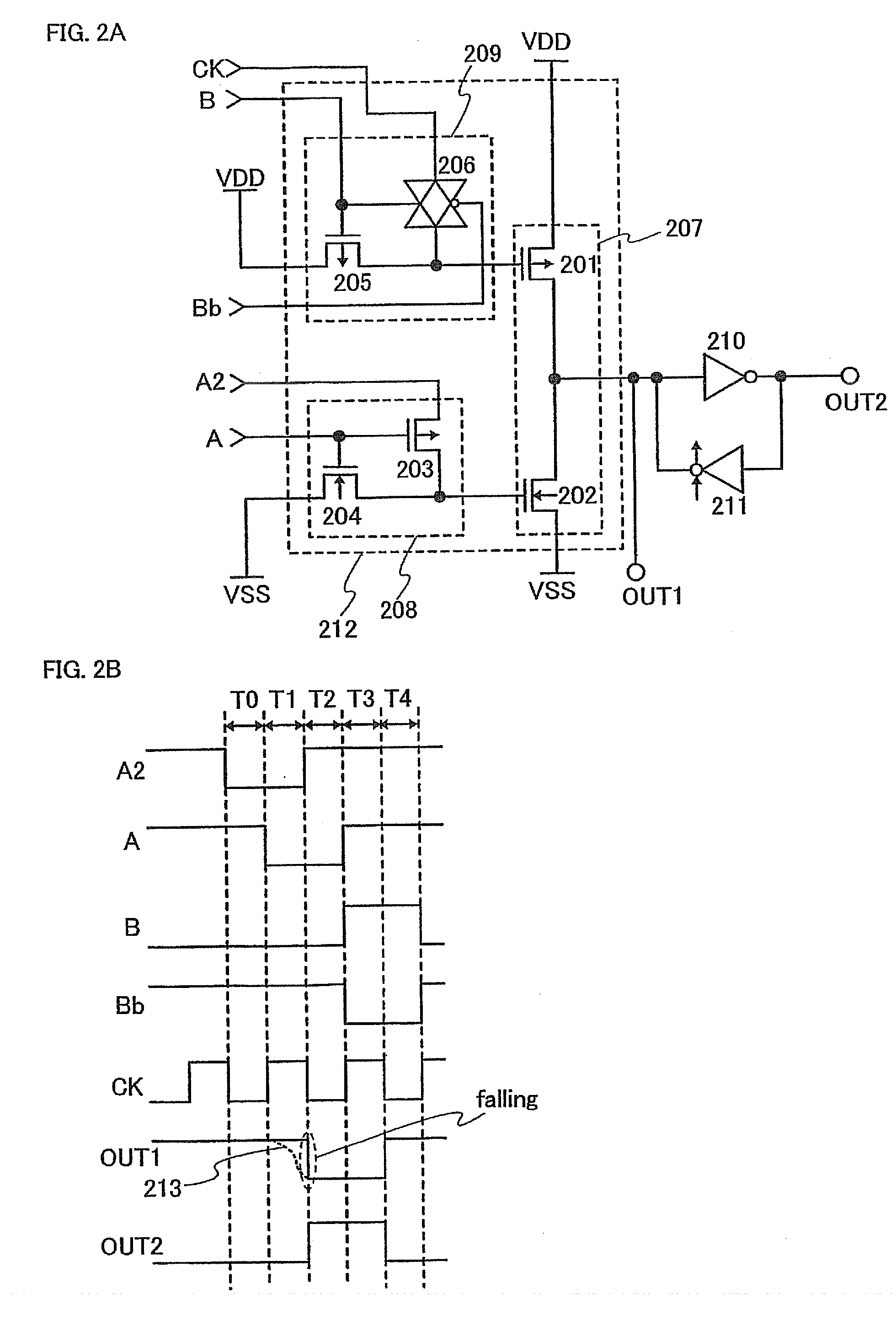

Shift register and semiconductor display device

ActiveUS7602215B2Reduce sizeSuppress signal delayStatic indicating devicesCounting chain pulse countersShift registerPower inverter

The invention provides a shift register which can operate normally while suppressing a delay of signal and a rounding of waveform. The shift register of the invention includes a plurality of stages of flip-flop circuits each of which includes a clocked inverter. The clocked inverter includes a first transistor and a second transistor which are connected in series, a first compensation circuit including a third transistor and a fourth transistor which are connected in series, and a second compensation circuit including a fifth transistor and a transmission gate. According to the first compensation circuit, a timing at which a signal outputted from the flip-flop circuit rises or falls can be controlled in synchronization with an output of two stages before. The second compensation circuit can control a clock signal input can be controlled.

Owner:SEMICON ENERGY LAB CO LTD

Shift Register and Semiconductor Display Device

ActiveUS20080273004A1Stable in free energyImprove lattice distortionStatic indicating devicesCounting chain pulse countersShift registerTransmission gate

The invention provides a shift register which can operate normally while suppressing a delay of signal and a rounding of waveform. The shift register of the invention includes a plurality of stages of flip-flop circuits each of which includes a clocked inverter. The clocked inverter includes a first transistor and a second transistor which are connected in series, a first compensation circuit including a third transistor and a fourth transistor which are connected in series, and a second compensation circuit including a fifth transistor and a transmission gate. According to the first compensation circuit, a timing at which a signal outputted from the flip-flop circuit rises or falls can be controlled in synchronization with an output of two stages before. The second compensation circuit can control a clock signal input can be controlled.

Owner:SEMICON ENERGY LAB CO LTD

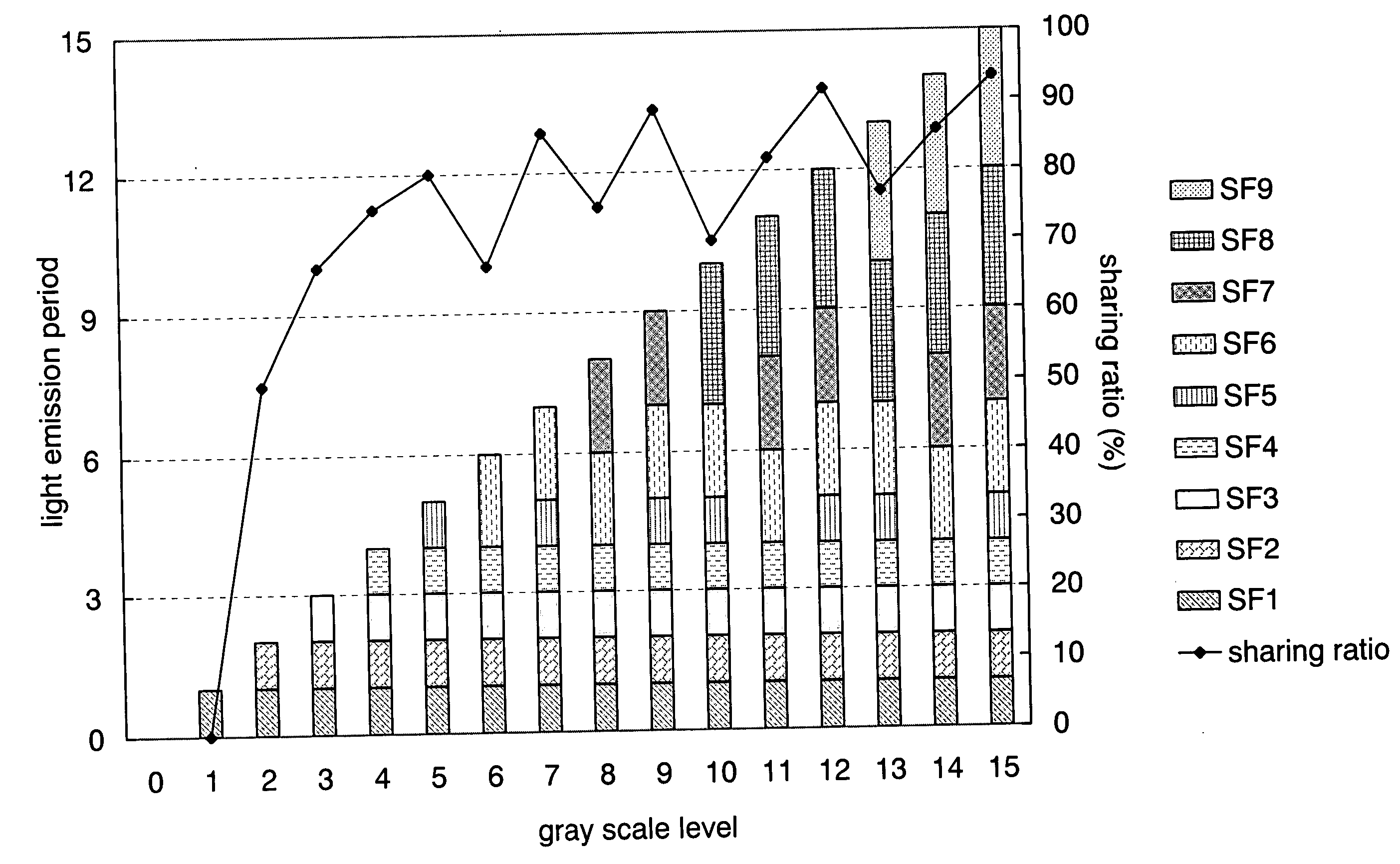

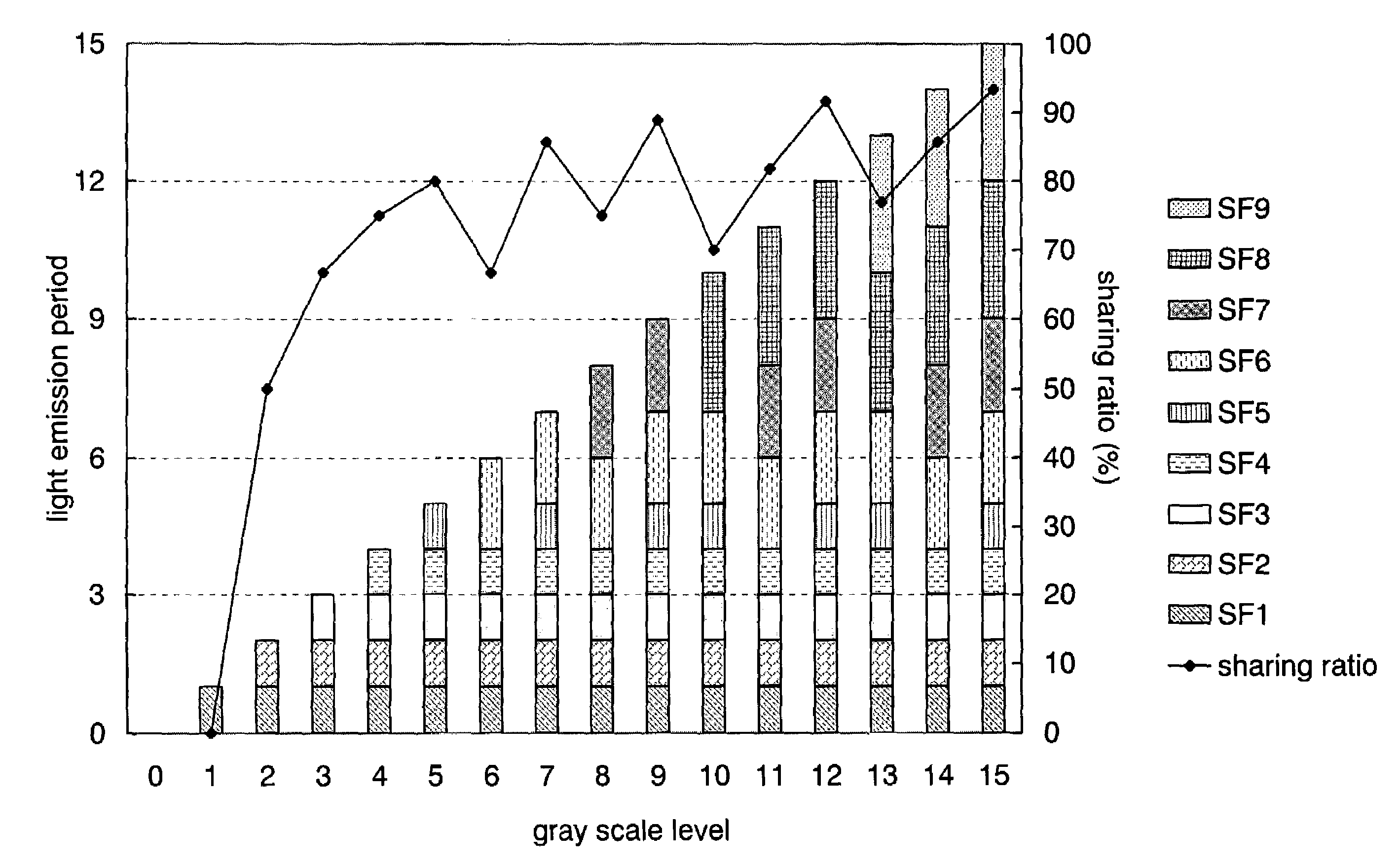

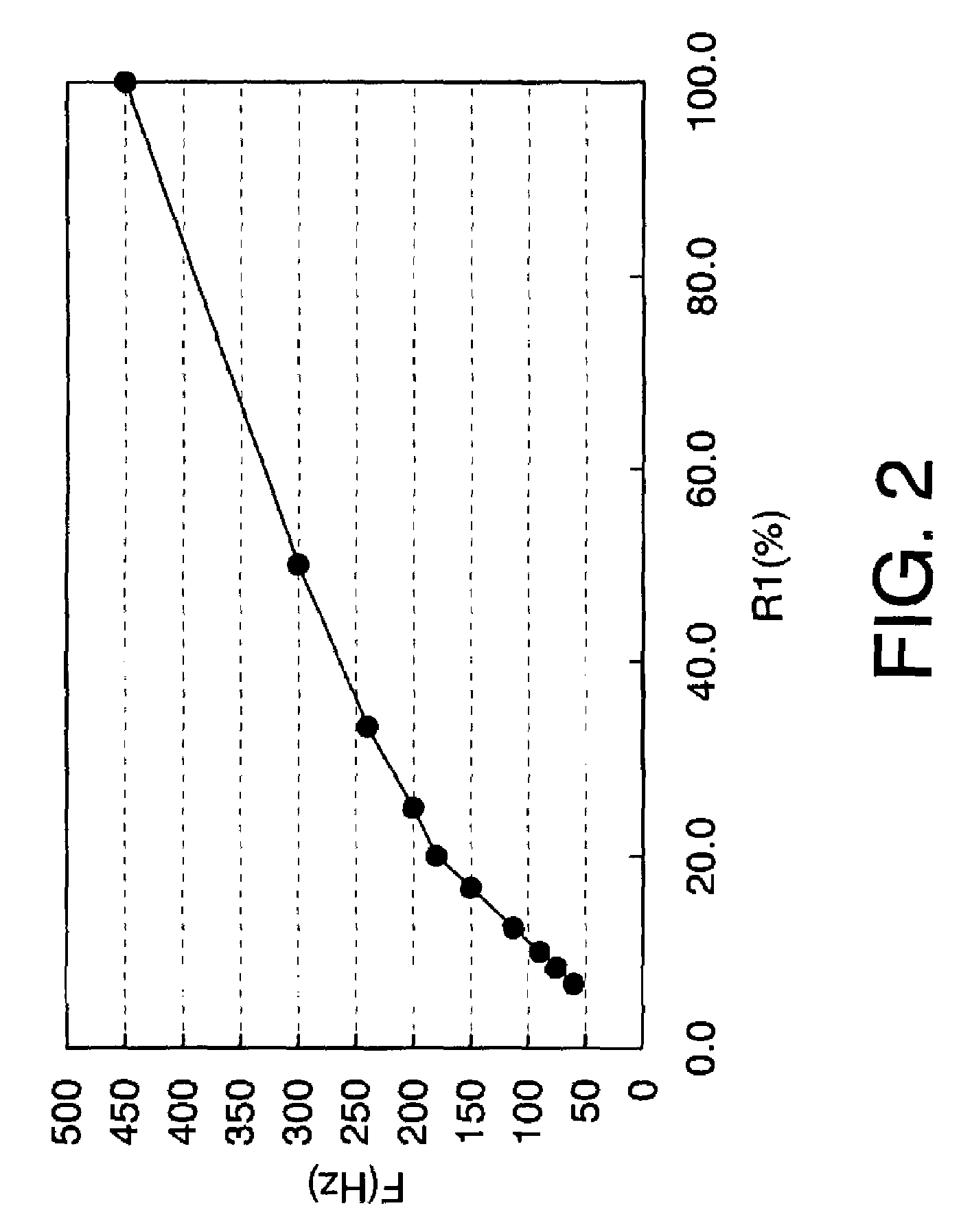

Semiconductor display device and driving method

InactiveUS20050259121A1Improve stabilityReduce distanceCathode-ray tube indicatorsInput/output processes for data processingDriver circuitImaging quality

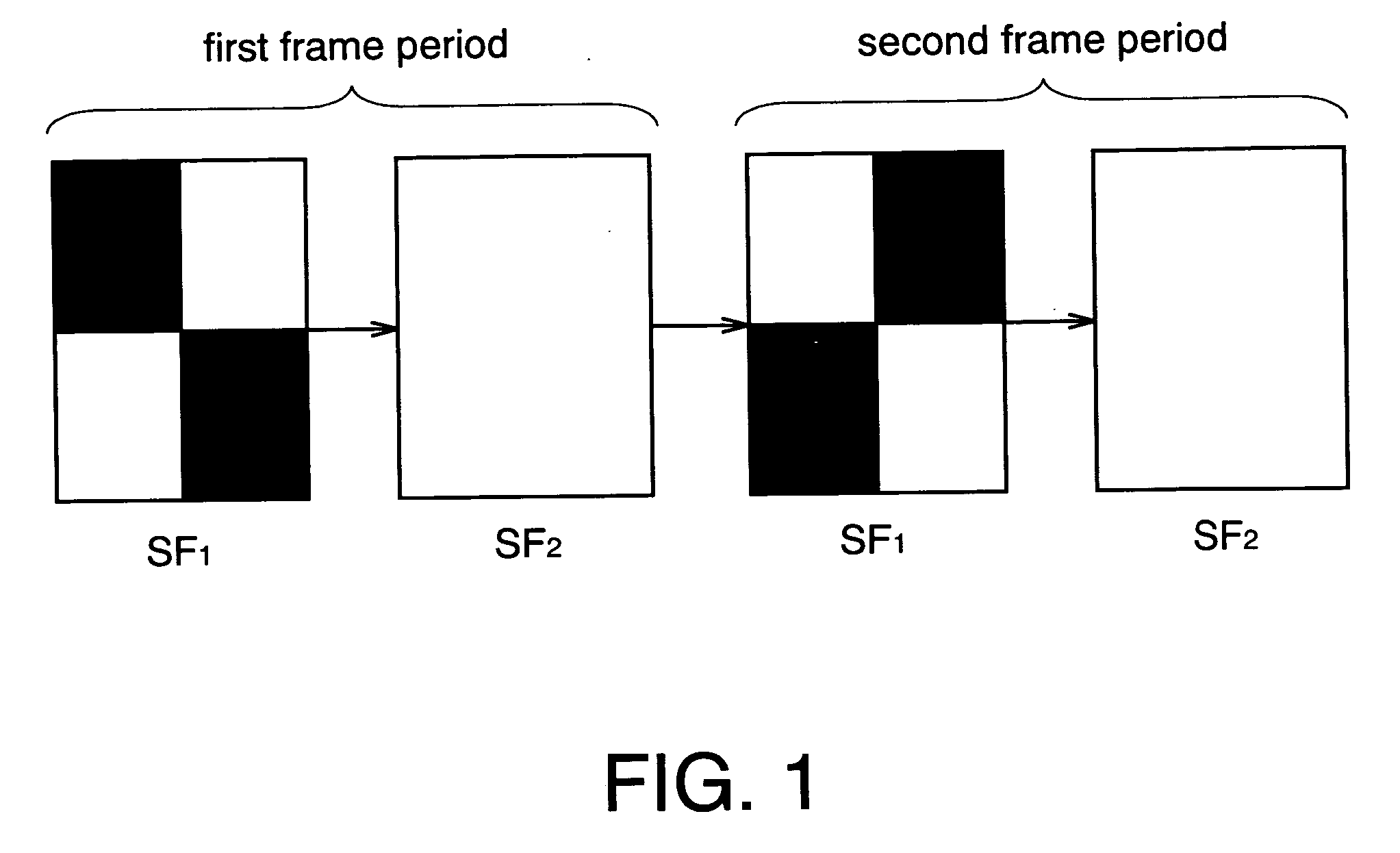

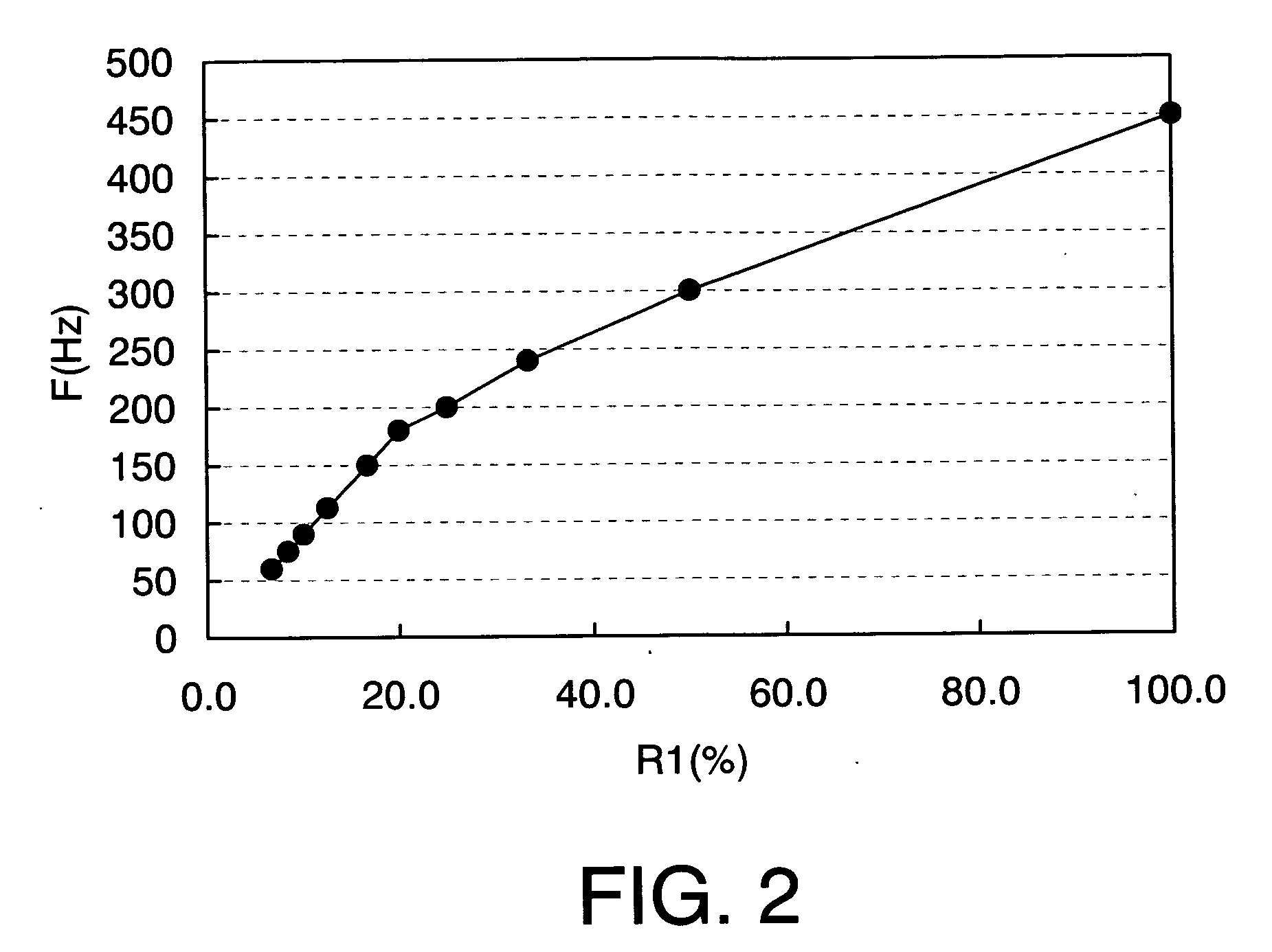

The invention provides a semiconductor display device with less generation of a pseudo contour while the drive frequency of a driver circuit is suppressed. Furthermore, the invention provides a semiconductor display device with less generation of a pseudo contour while the decrease in image quality is suppressed. A semiconductor display device comprises a table storing data for determining a relationship between the gray scale level of a video signal and a subframe period for light emission in the plurality of subframe periods, a controller for changing a video signal in accordance with the data and outputting, and a panel whose pixel gray scale level is controlled in accordance with the outputted video signal. The number and the length of the plural subframe periods for each gray scale level of 2 or more are determined in accordance with a subframe ratio RSF which is calculated in accordance with a sharing ratio Rsh determined by the frame frequency.

Owner:SEMICON ENERGY LAB CO LTD

Reverse osmosis compound scale inhibitor

InactiveCN101973644AExcellent chelating solubilizationExtended shelf lifeScale removal and water softeningReverse osmosisCarboxylic acid

The invention provides a reverse osmosis compound scale inhibitor and belongs to the field of reverse osmosis water treatment. The scale inhibitor comprises the following components in percentage by weight: 10 to 20 percent of 1-hydroxyethylidene-1,1-diphosphonic acid, 30 to 40 percent of hydrolytic polymaleic anhydride, 30 to 40 percent of polyacrylic acid and 10 to 20 percent of sulfonated styrene-maleic anhydride copolymer, and the scale inhibitor comprises also comprises a bactericide. The reverse osmosis compound scale inhibitor fully utilizes the synergistic effect among organic phosphorous scale inhibitors, polycarboxylic acid scale inhibitors and sulfonic acid scale inhibitors, has good scale inhibition and dispersion performance; and when used in a reverse osmosis water inflow system, the scale inhibitor can effectively lighten pollution of calcium carbonate, calcium sulfate and silicate to reverse osmosis membranes and prolongs the cleaning period and service life of the reverse osmosis system.

Owner:NANJING UNIV

Pretreatment method of refractory gold ore

ActiveCN102560138AHigh activityLarge specific surface areaProcess efficiency improvementGrain treatmentsPretreatment methodDecomposition

The invention discloses a pretreatment method of refractory gold ore, which is characterized by comprising the following steps of: adopting a dry-wet two-level ball grinder activating and impregnation process; carrying out first-level dry grinding by adopting a vibratory ball grinder and efficiently improving the mineral activity on the basis of energy conservation through adjusting the content of quartz in a ball grinding sample; carrying out second-level wet grinding by adopting a stirred ball grinder, simultaneously carrying out the mineral grain size reduction and the acid addition and preimpregnation, further damaging a mineral structure, realizing the complete oxidation and decomposition of sulfide ore at a lower temperature and a pressure through controlling the content of sulfuricacid, the solid-to-liquid ratio and the oxygen partial pressure in a reaction vessel and restraining the generation of elemental sulfur. The pretreatment method has the advantages of low extraction temperature, short time and low energy consumption.

Owner:SHANGHAI MORIMATSU CHEMICAL EQUIPMENT CO LTD

Light emitting device

InactiveUS7928937B2Improve stabilityEnergy stabilityElectrical apparatusElectroluminescent light sourcesDriver circuitData selection

A light emitting device with generation of a pseudo contour suppressed is provided in which the drive frequency of a driver circuit is suppressed while the frame frequency is increased. In addition, a light emitting device with generation of a pseudo contour suppressed is provided in which the drive frequency of a driver circuit is suppressed while the dividing number of a subframe period is increased. To input plural bits of video signals into pixels in parallel, a switching transistor and a driving transistor are provided in each pixel in accordance with the number of the bits. In addition, a transistor for selecting a video signal (a data selecting transistor) is provided in each pixel in order to select each bit of a video signal within the pixel when display is actually performed at the pixels.

Owner:SEMICON ENERGY LAB CO LTD

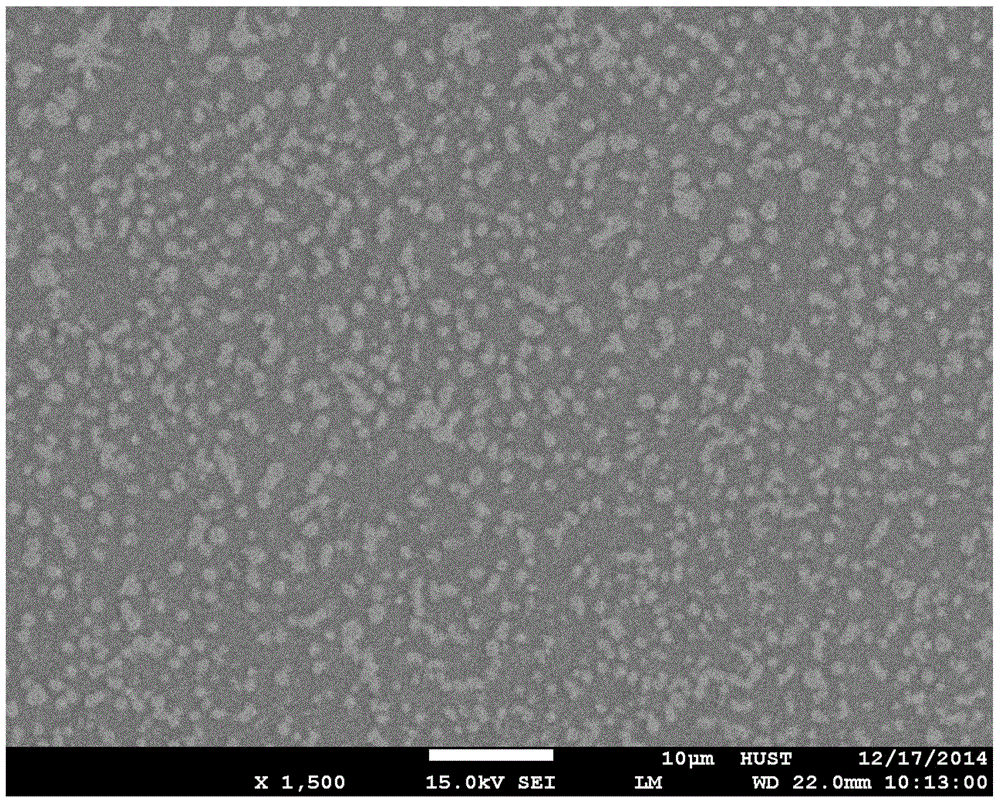

Method for preparing gradient thermal barrier coating

ActiveCN104630688AImprove wettabilityImprove bindingMolten spray coatingNanoparticleThermal insulation

The invention discloses a method for preparing a gradient thermal barrier coating and the method is used for preparing the gradient thermal barrier coating on the surface of a metal. 40-80mu m ceramic particles are bound on the surface of a metal substrate by virtue of a thermal spraying or laser cladding method to prepare the nano-ceramic particle-reinforced thermal barrier coating, wherein the nano-ceramic particles are uniformly dispersed and have a particle size of 100-500nm, the 40-80mu m ceramic particles are obtained by agglomerating initial nanoparticles and comprise Al2O3 particles, ZrO2 particles and rare earth zirconate particles and the component of the rare earth zirconate particles is A2Zr2O7, wherein A is one or more of Ln, La, Gd and Nd. The gradient thermal barrier coating prepared by the method is good in thermal-insulation effect and is firmly bound with the metal substrate and the problems that the existing gradient thermal barrier coating is difficult to be successfully applied and is easy to fall off to cause failure under thermal cycling conditions are solved.

Owner:HUAZHONG UNIV OF SCI & TECH

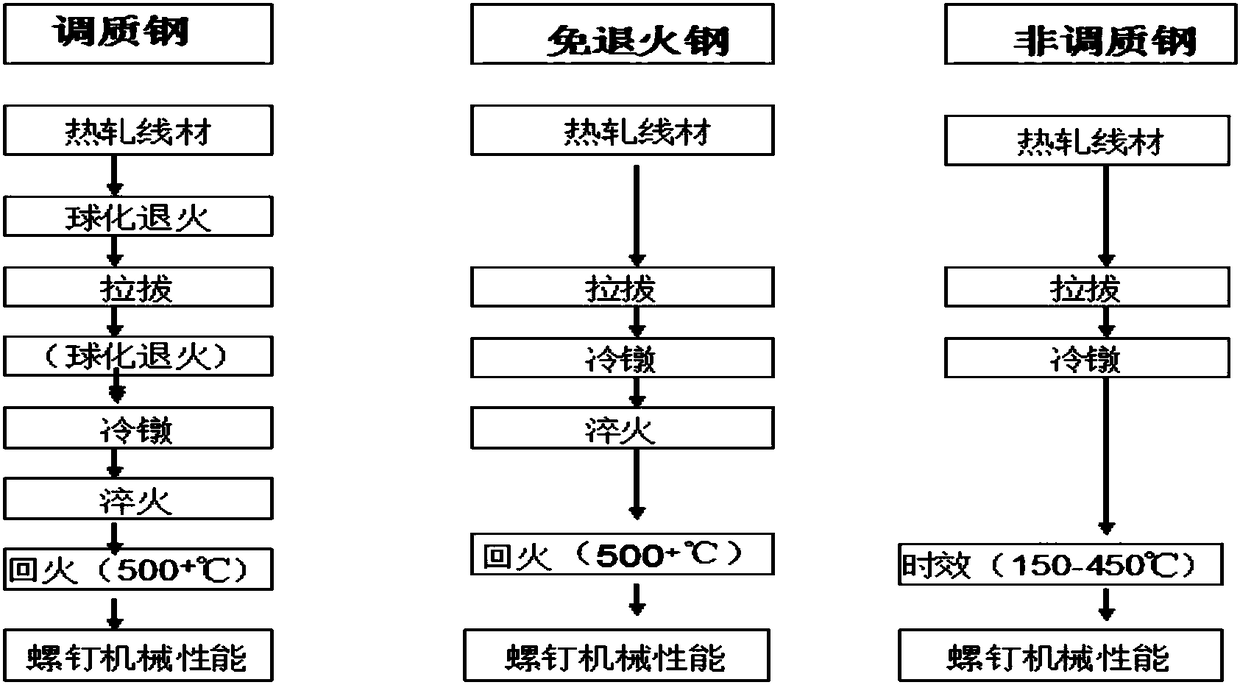

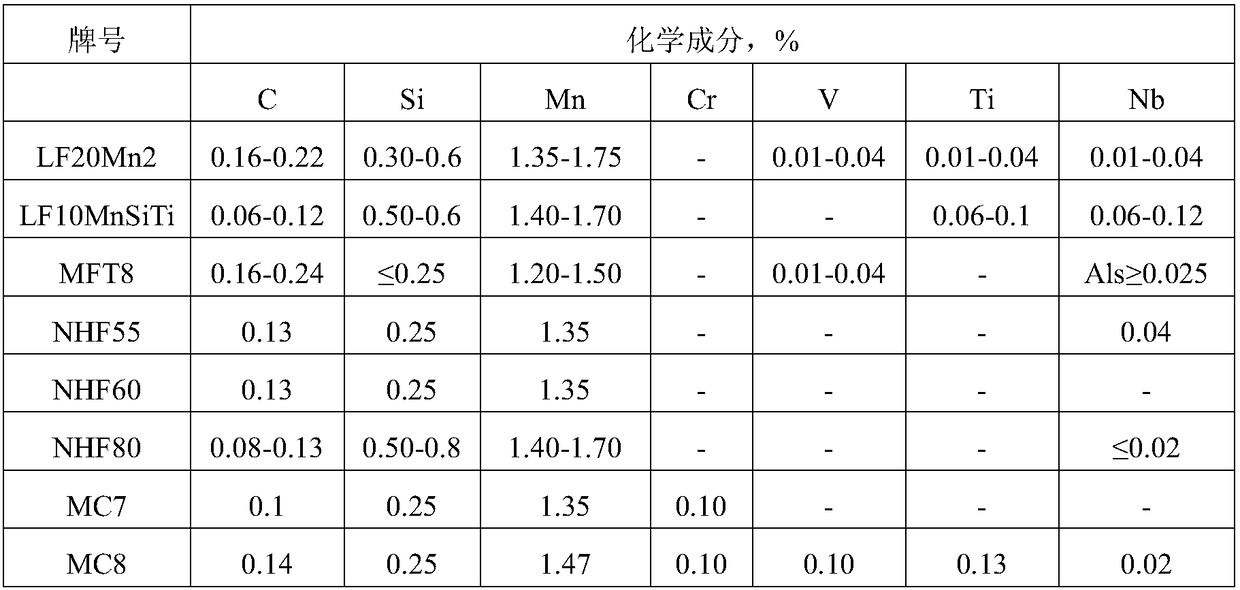

Heat-treatment-free grade 8.8 fastener-use cold forging steel and manufacturing method thereof

The invention relates to heat-treatment-free grade 8.8 fastener-use cold forging steel and a manufacturing method thereof. The heat-treatment-free grade 8.8 fastener-use cold forging steel is preparedfrom the following chemical ingredients in percentage by weight: 0.13 to 0.20 percent of C, 0.10 to 0.35 percent of Si, 1.40 to 1.80 percent of Mn, 0.03 to 0.10 percent of V, 0.01 to 0.03 percent ofTi, 0.008 to 0.02 percent of N, at most 0.02 percent of P, at most 0.015 percent of S and the balance of Fe and impurities, wherein the Ti and N meets the requirement that N-0.15Ti-0 .1V is greater than or equal to 0 .003 percent; the ratio of V to N is smaller than or equal to 10. In the rolling steps, the low-temperature heating is performed; the low-temperature rolling does not need to be executed; the equipment requirement and the production cost are reduced; the obtained grade 8.8 fastener-use cold forging steel has good cold deformation capability; after the drawing, cold forging and aging treatment, the high-intensity grade of a 8.8 fastener can be reached; the use requirement of the fastener can be met.

Owner:BAOSHAN IRON & STEEL CO LTD

Thin film transistor, manufacturing method for thin film transistor and manufacturing method for display device

InactiveUS20070164280A1Simple manufacturing processReduce processing timeSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceEngineering

The present invention provides a thin film transistor that can be manufactured at lower cost and at higher yield by simplifying a manufacturing process, a manufacturing method thereof, and a manufacturing method of a display device using the thin film transistor. According to this invention, a pattern used in a pattering process is formed by using a droplet discharging method. The pattern is formed by selectively discharging a composition comprising an organic resin. By using the pattern, an electrically conductive material, an insulator or semiconductor constituting a semiconductor element, are patterned into a desired shape by a simple process.

Owner:SEMICON ENERGY LAB CO LTD

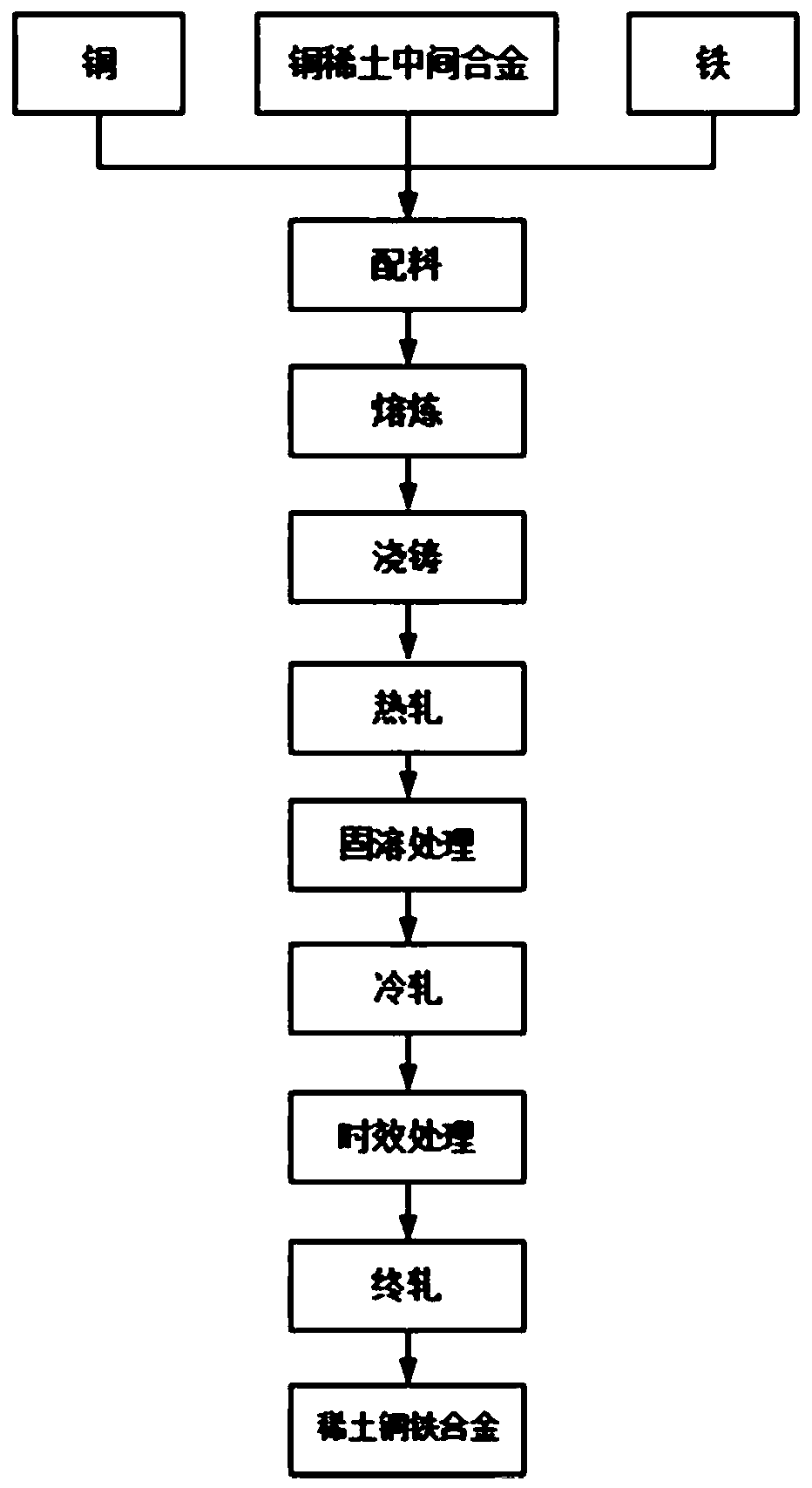

Rare earth copper and iron alloy and preparation method and application

The invention provides a rare earth copper and iron alloy and a preparation method and an application, belonging to the technical field of nonferrous metal materials. The rare earth copper and iron alloy provided by the invention, in percentage by mass, comprises 0.25-0.5% of rare earth elements, 8-20% of Fe and the balance Cu. According to the invention, the rare earth elements are added in the Cu-Fe alloy, functions of purifying the alloy, refining crystalline grains and prompting separation of a Fe phase are realized, and conductivity of the Cu-Fe alloy is improved; in the alloy, content ofan iron element is high, dosage of copper is low, and thus, production cost is reduced; and dosage of the rare earth elements is relatively higher, and thus, affection of the iron element on conductivity of the alloy can be reduced. A result of an embodiment shows that the rare earth copper and iron alloy provided by the invention has conductivity of more than 56% IACS, strength of extension of more than 768 MPa and rate of elongation of more than 2.9%.

Owner:INST OF APPLIED PHYSICS JIANGXI ACADEMY OF SCI

Shift register and semiconductor display device

InactiveUS20100034338A1Reduce sizeSuppress signal delayMultiple input and output pulse circuitsStatic indicating devicesShift registerTransmission gate

The invention provides a shift register which can operate normally while suppressing a delay of signal and a rounding of waveform. The shift register of the invention includes a plurality of stages of flip-flop circuits each of which includes a clocked inverter. The clocked inverter includes a first transistor and a second transistor which are connected in series, a first compensation circuit including a third transistor and a fourth transistor which are connected in series, and a second compensation circuit including a fifth transistor and a transmission gate. According to the first compensation circuit, a timing at which a signal outputted from the flip-flop circuit rises or falls can be controlled in synchronization with an output of two stages before. The second compensation circuit can control a clock signal input can be controlled.

Owner:SEMICON ENERGY LAB CO LTD

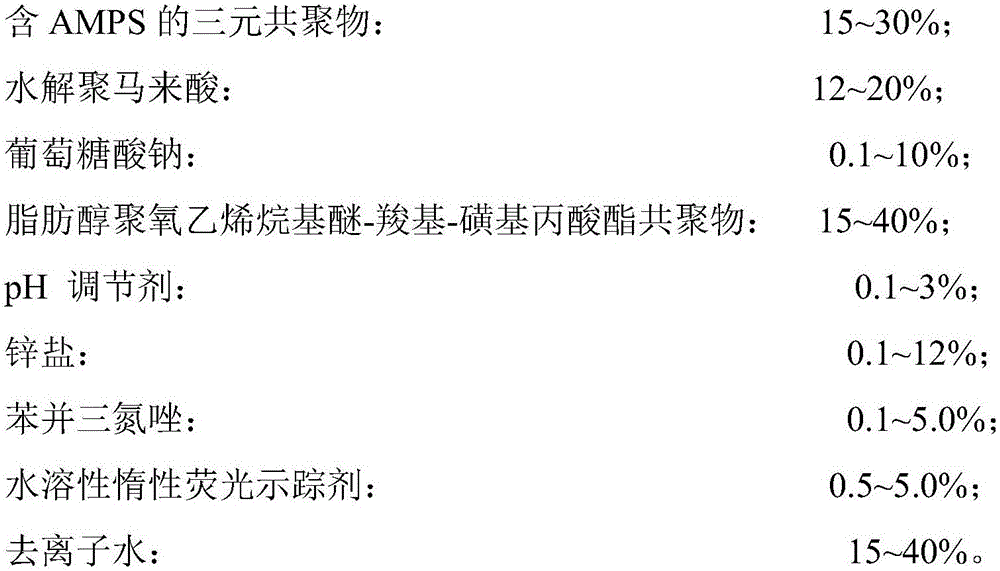

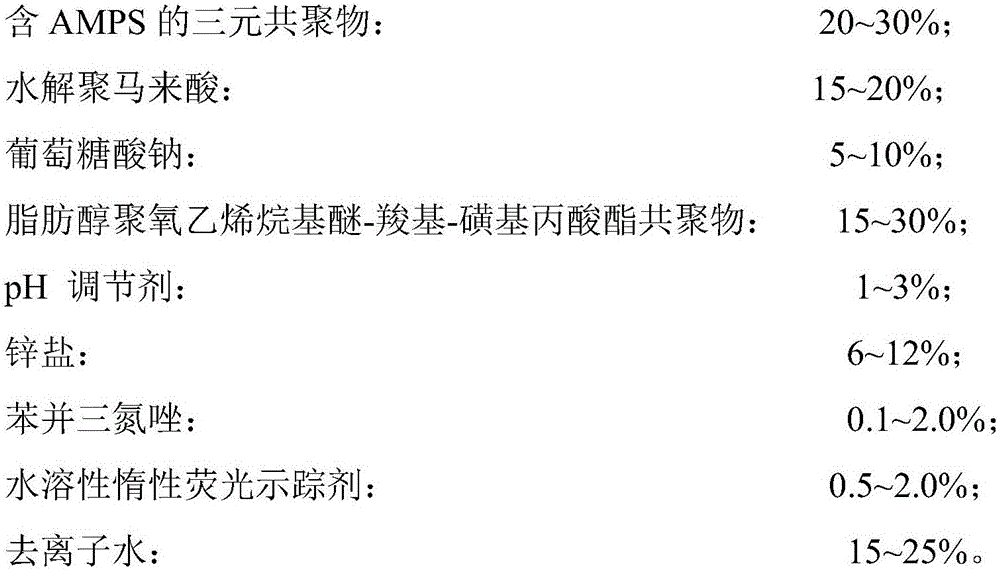

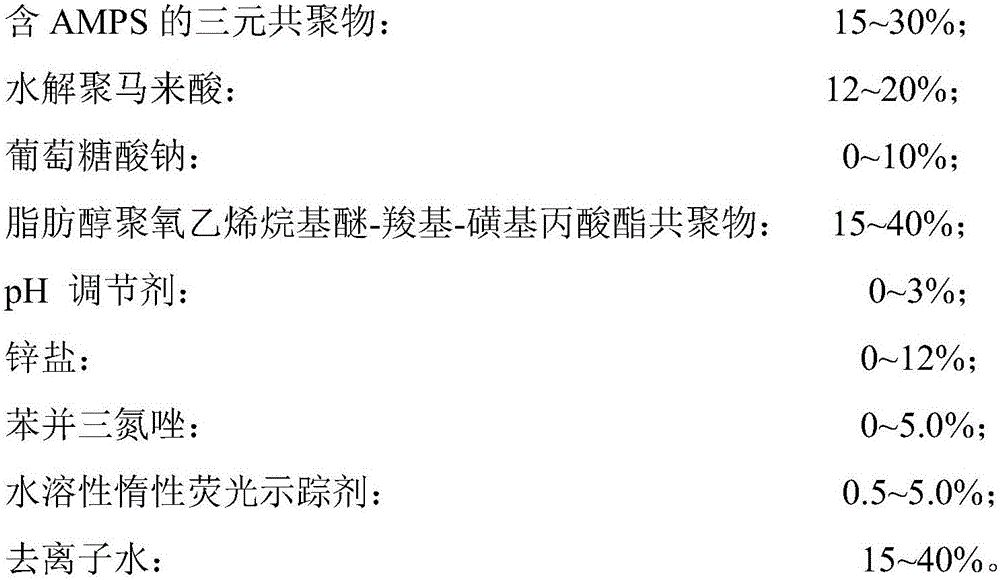

Non-phosphorus corrosion and scale inhibitor suitable for medium-and-low-hardness and strong-corrosion water and application of non-phosphorus corrosion and scale inhibitor

ActiveCN106082457AGood corrosion inhibitionGood synergySpecific water treatment objectivesTreatment using complexing/solubilising chemicalsWater qualityGluconic acid

The invention relates to a non-phosphorus corrosion and scale inhibitor suitable for medium-and-low-hardness and strong-corrosion water and application of the non-phosphorus corrosion and scale inhibitor. The non-phosphorus corrosion and scale inhibitor is prepared from the following ingredients by weight percent: 15-30% of an AMPS-containing terpolymer, 12-20% of hydrolyzed polymaleic acid, 0.1-10% of sodium gluconate, 15-40% of a fatty alcohol polyoxyalkylene alkyl ether-carboxyl-sulfopropionate copolymer, 0.1-3% of a pH regulator, 0.1-12% of zinc salt, 0.1-5.0% of benzotriazole, 0.5-5.0% of a water-soluble inert fluorescent tracer and 15-40% of deionized water. Compared with the prior art, the non-phosphorus corrosion and scale inhibitor provided by the invention solves the problem that a common non-phosphorus corrosion and scale inhibitor cannot draw the corrosion and scale inhibition function into consideration during concentration of a circulating water system. The non-phosphorus corrosion and scale inhibitor is favorable in performance and good in stability, has general applicability to medium-and-low-hardness and strong-corrosion water, and has the characteristics of no phosphorus, environmental friendliness and high efficiency.

Owner:SHANGHAI EMPEROR OF CLEANING HI TECH

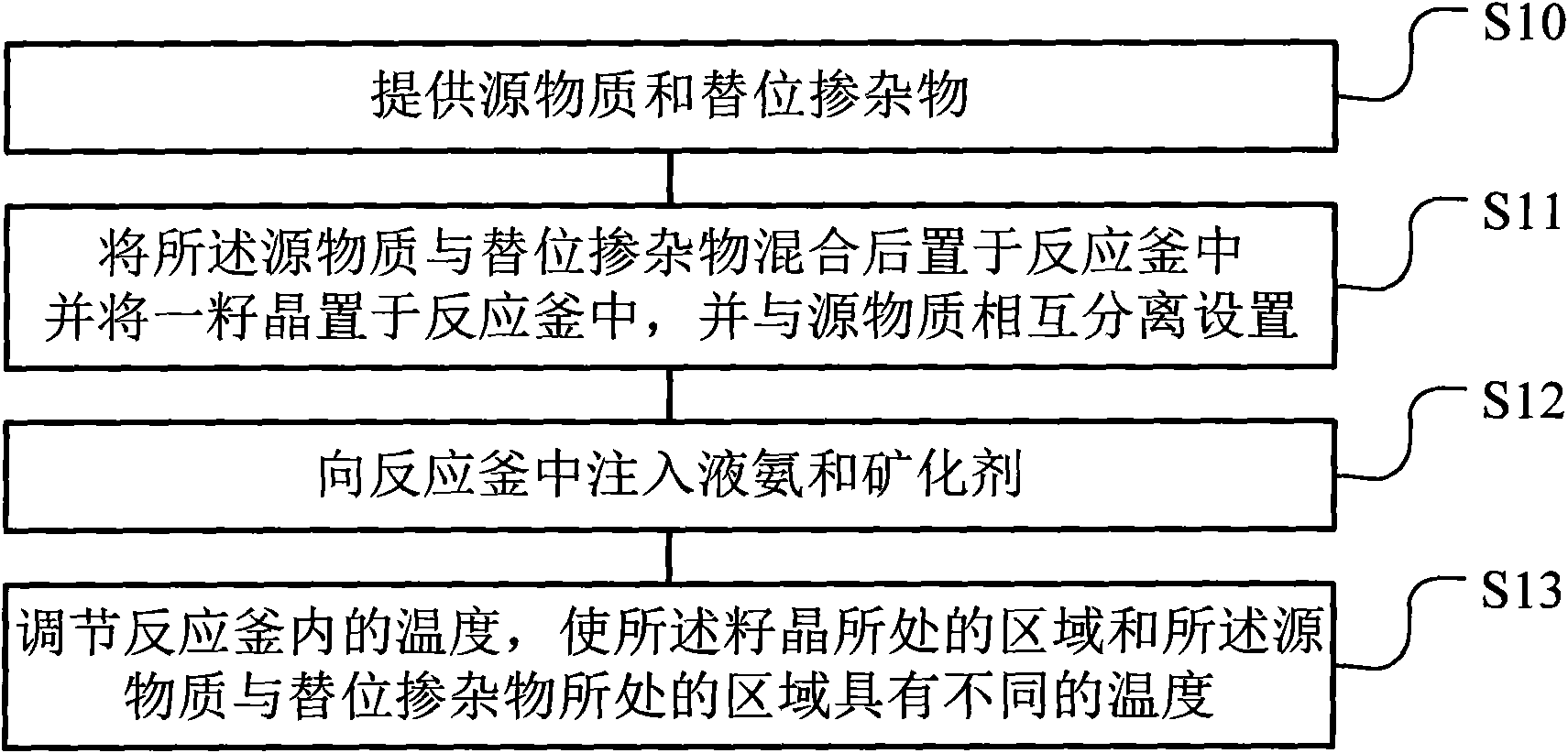

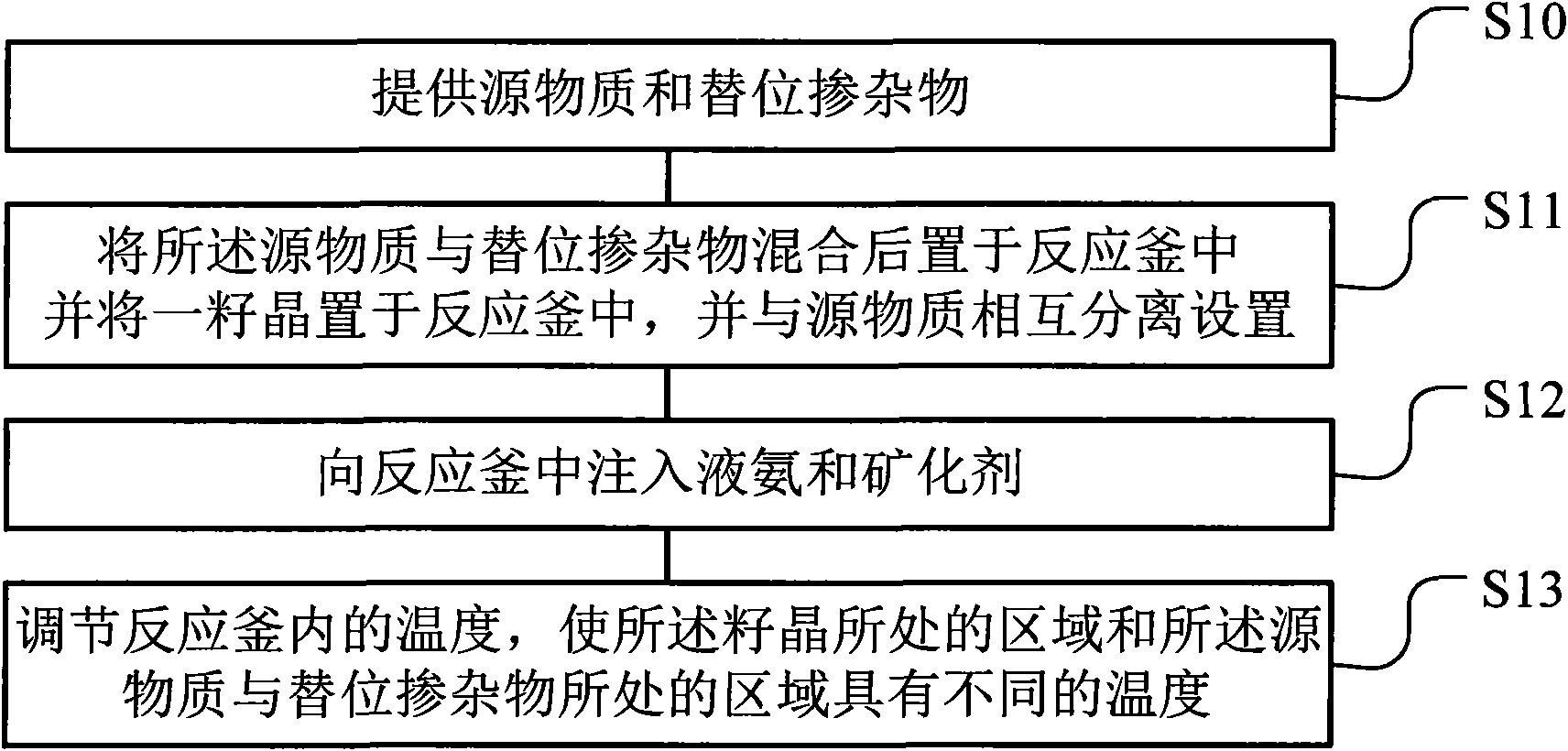

Compound semiconductor material doped with rare-earth elements and growth method thereof

InactiveCN101775658AImprove luminous efficiencyImprove lattice distortionPolycrystalline material growthSemiconductor/solid-state device manufacturingRare-earth elementSemiconductor materials

The invention discloses a compound semiconductor material doped with rare-earth elements, which is a crystal material being composed of III group elements and V group elements and doped with the rare-earth elements. The crystal material further comprises displacement adulterant which is an III group element or the combination of a plurality of III group elements, the atomic numbers of the III group elements contained in the displacement adulterant are smaller than those of the III group elements forming the crystal material, and the displacement adulterant substitutes original III group elements in crystal to form a displacement defect. The invention also provides a preparation method of the material. The invention has the advantages that the displacement defect is formed by doping elements with smaller atomic numbers in the material so as to improve the lattice deformation of the semiconductor material caused by doping the rare-earth element, thus improving the luminous efficiency of the material.

Owner:SUZHOU NANOWIN SCI & TECH

Method of growing GaN-based luminescent crystalline membrane for molecular beam epitaxy

InactiveCN101748382AImprove lattice distortionImprove luminous performanceChemical vapor deposition coatingAluminiumMetal

The invention discloses a method of growing GaN-based luminescent crystalline membrane for molecular beam epitaxy, which dopes rare earth ions in the growth process to replace part of lattice site of Ga3+ and is characterized by comprising the following steps: doping III group element boron or aluminum in the raw material formula of the GaN crystalline membrane according to a certain ratio, wherein the III group element boron or aluminum enters into GaN lattice site via a mode of trivalent ion in the growth process; preparing ion radius difference between the rare earth ion and the Ga3+, wherein the molar ratio of the raw material formula is as follows: Ga:Re:A=(1-x-y):x:y, x represents rare earth metal, A represents III group element boron or aluminum, x is more than or equal to 0.1% and less than or equal to 10.0%, and y is more than or equal to 0.1x and less than or equal to x. In the invention, III group element boron or aluminum is doped with rare earth metal together according to a certain ratio so as to greatly improve lattice deformation of the GaN crystalline membrane caused by larger radius mismatch of Re3+ and Ga3+, and increase luminescent performance of the GaN crystalline membrane.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

Preparation method for high-performance modified fluorgypsum

ActiveCN104177049AShort setting timeTurn waste into treasureSolid waste managementSlagPolyvinyl alcohol

The invention discloses a preparation method for high-performance modified fluorgypsum. The preparation method comprises the following steps of: carrying out thermal treatment after grinding, smashing and screening fluorgypsum waste residue; then, adding calcium hydroxide, portland cement, carbide slag, oxalic acid, sodium gluconate, bone glue, phosphogypsum, semi-hydrated gypsum, bauxite, modified rice straw fiber, coal ash, redispersible latex powder, corn straw fiber, wheat straw fiber, polyvinyl alcohol and rosin milk, drying and smashing, wherein the modified rice straw fiber is modified by virtue of hydrogen peroxide and sodium hydroxide; the redispersible latex powder is formed as follows: adding methyl methacrylate and butyl acrylate into ammonium chloride, sodium persulfate and lauryl sodium sulfate to react to obtain initial emulsion; and adding sodium hydroxide into the initial emulsion for alkalization, then, adding polyvinyl alcohol, and spraying and drying to obtain the redispersible latex powder. The modified fluorgypsum obtained by the method is short in setting time, high in tensile strength and breaking strength after being hydrated, and capable of changing fluorgypsum into things of value.

Owner:ANHUI JINYANG FLUORINE CHEM

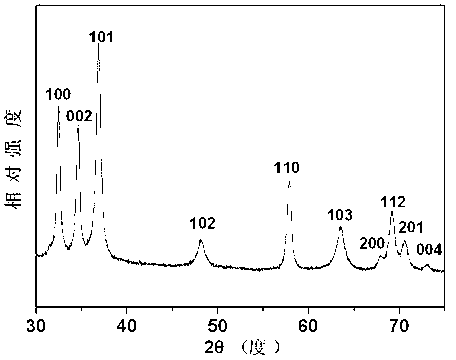

Thermal treatment method for rare earth nickel based AB5 type hydrogen storage alloy

InactiveCN101429636AEliminate and improve composition segregationEliminates and improves compositional uniformityRare earthElectrochemistry

The invention relates to a thermal processing method for rare earth nickel base AB5 type hydrogen storage alloy for the negative electrode of a nickel hydrogen cell. A staged thermal processing method using low-temperature treatment before high-temperature treatment is adopted for the rare earth nickel base AB5 type hydrogen storage alloy in the inert or reducing atmosphere after smelting and casing the rare earth nickel base AB5 type hydrogen storage alloy into ingots. The staged thermal processing method comprises the following steps: firstly keeping the rare earth nickel base AB5 type hydrogen storage alloy within the temperature range of 400 to 800 DEG C for 2 to 5 hours; and then increasing the temperature to 950 to 1100 DEG C and keeping the rare earth nickel base AB5 type hydrogen storage alloy for 0.3 to 5 hours. The staged thermal processing of the rare earth nickel base AB5 type hydrogen storage alloy can remove and improve the component segregation, the lattice stress and the lattice distortion of the hydrogen storage alloy without the merging and growing of the crystal grains of the alloy, thereby improving the anti-atomization capability of the alloy, improving the gradient of the P-C-T curve of the hydrogen storage alloy, reducing the platform pressure, improving the hydrogen absorption and desorption amount, the electrochemical content and the cycle life of the alloy, and consequently truly improving the electrochemical performance and the cycle life of the cell.

Owner:BYD CO LTD

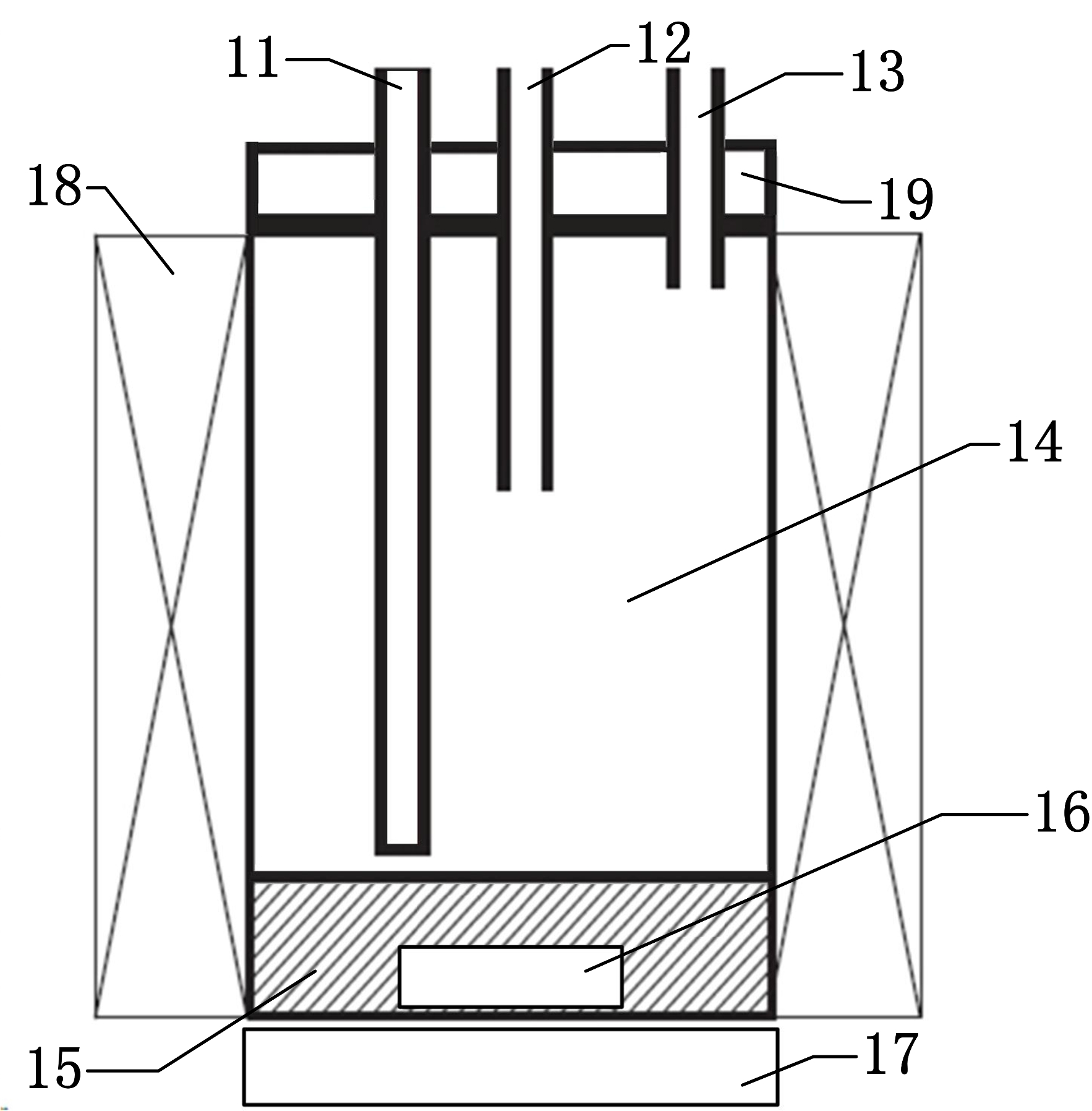

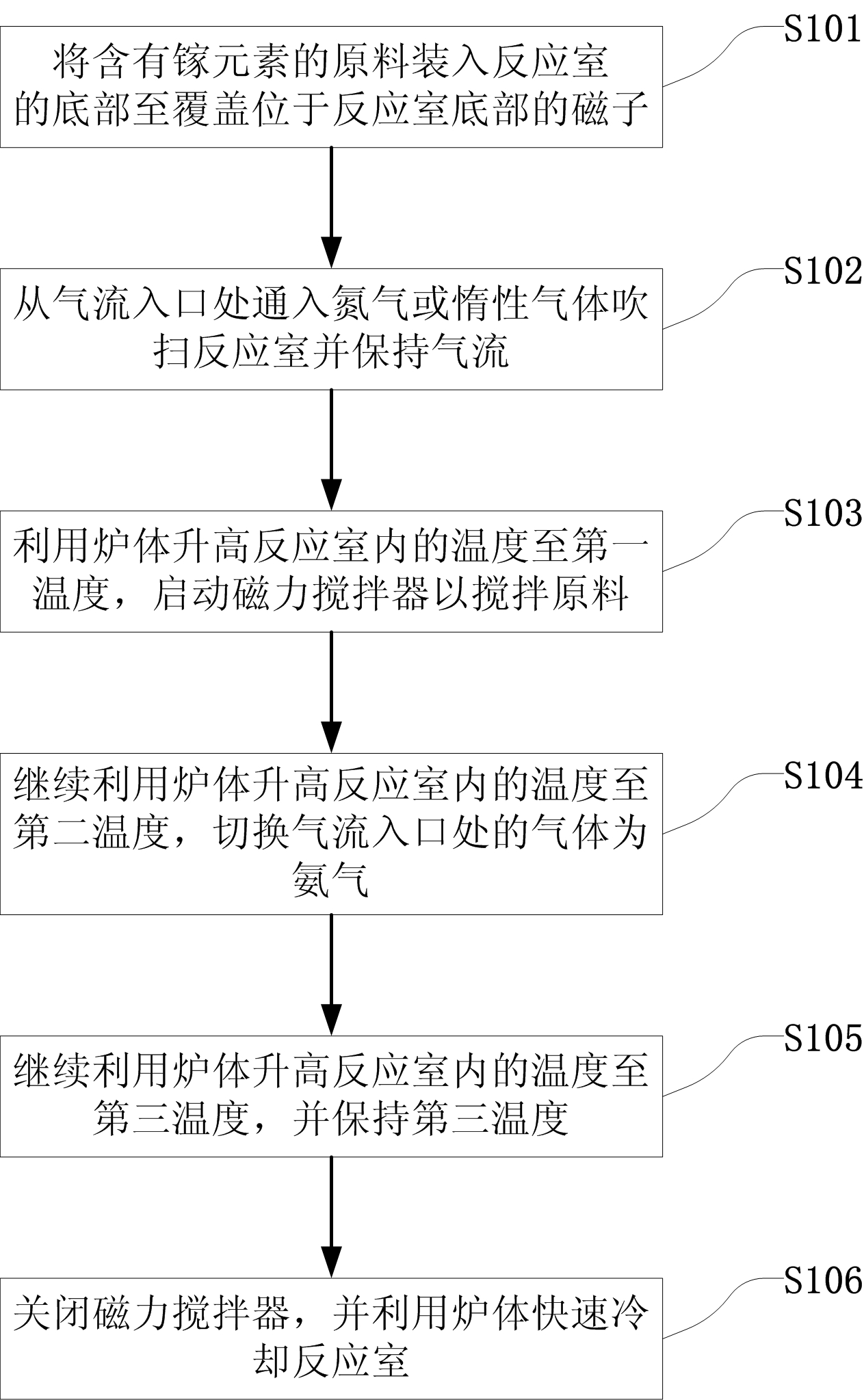

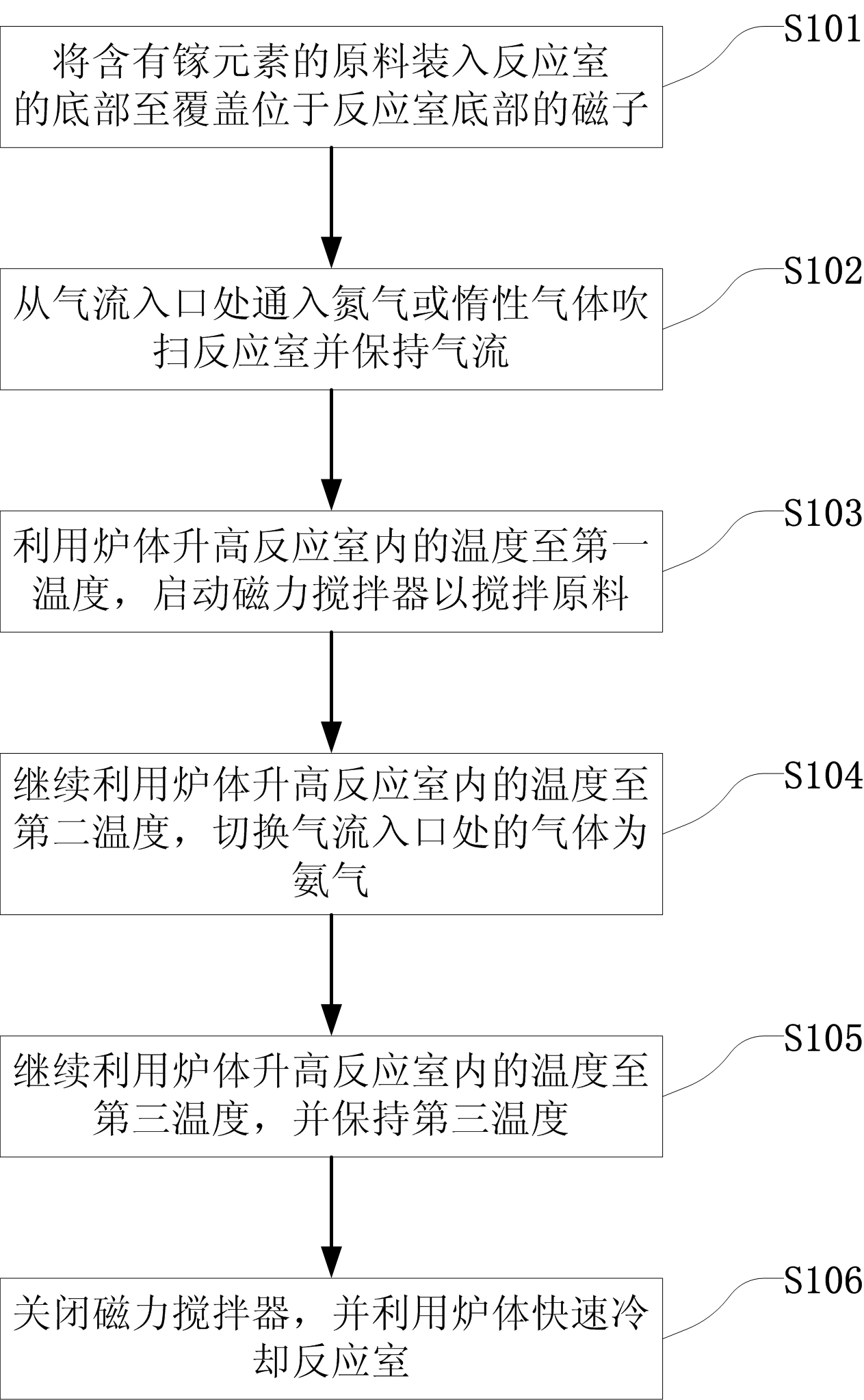

Preparation method and apparatus for rare earth element dopped gallium nitride powder material

InactiveCN102660282AImprove liquidityAvoid formingLuminescent compositionsRare-earth elementNitrogen gas

The invention provides a preparation method for a rare earth element dopped gallium nitride powder material, including the following steps: filling a gallium-containing raw material at bottom of an apparatus to cover magnetons at bottom of the apparatus; letting in nitrogen or inert gas from an airflow inlet to purge a reaction chamber and keeping airflow; rising a temperature in the reaction chamber to a first temperature by utilizing a furnace body and starting a magnetic stirring apparatus; rising the temperature continually in the reaction chamber to a second temperature by utilizing the furnace body and switching the gas in the airflow inlet to ammonia gas; rising the temperature continually in the reaction chamber to a third temperature by utilizing the furnace body and keeping the third temperature; closing the magnetic stirring apparatus and cooling the reaction chamber rapidly by utilizing the furnace body. The invention also provides an apparatus, comprising a reaction chamber, which includes magnetons at bottom of the apparatus and a magnetic stirring apparatus at external bottom of the apparatus. The magnetic stirring apparatus is opposite to the magnetons at position and used for cooperating with the magnetons in stirring material in the reaction chamber.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI +1

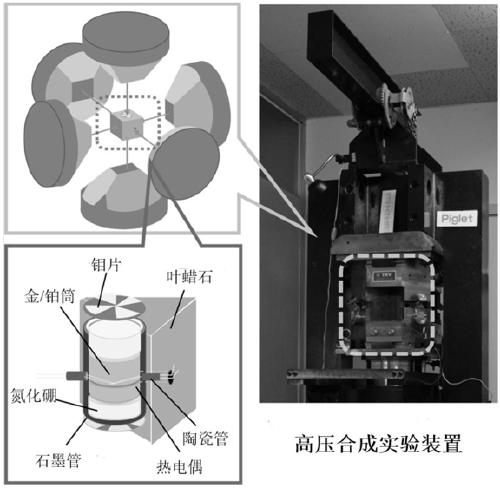

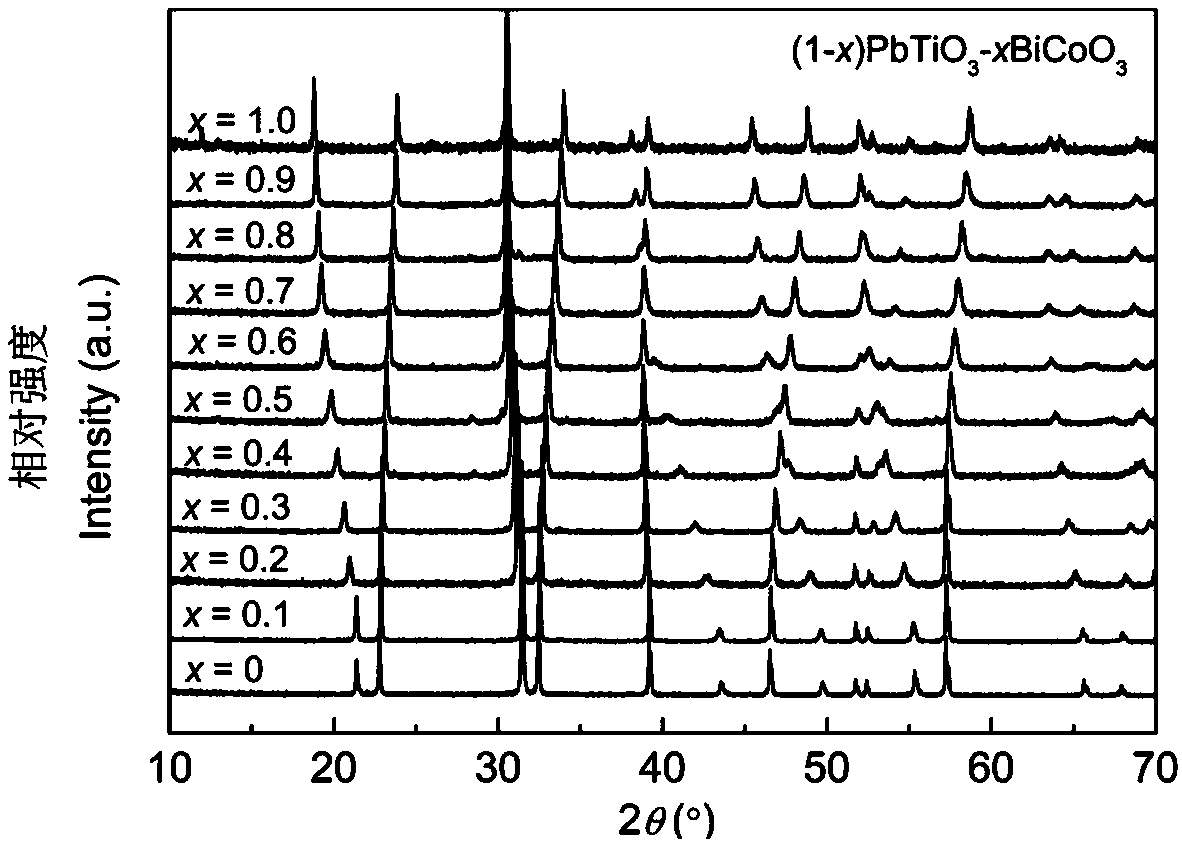

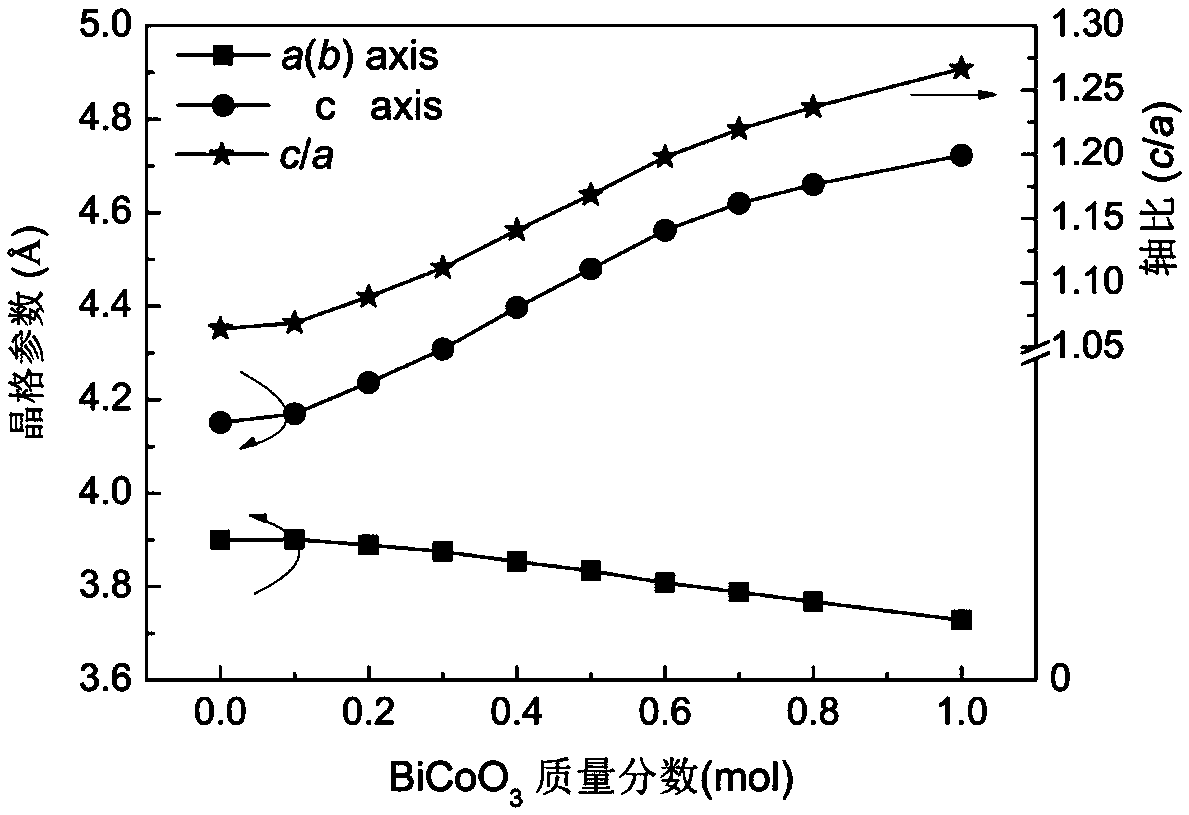

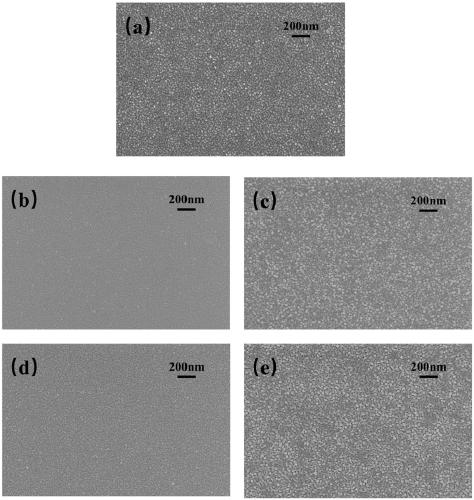

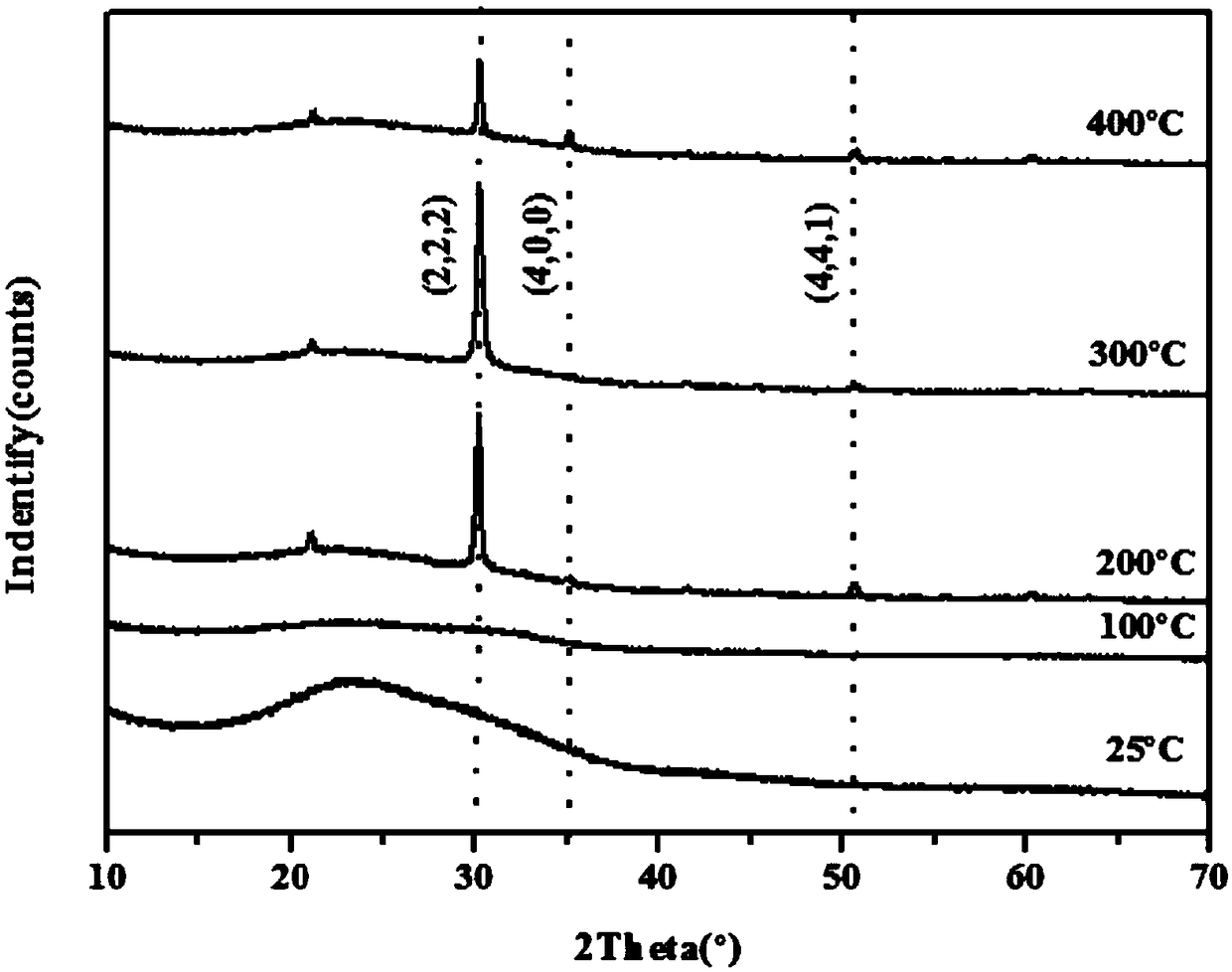

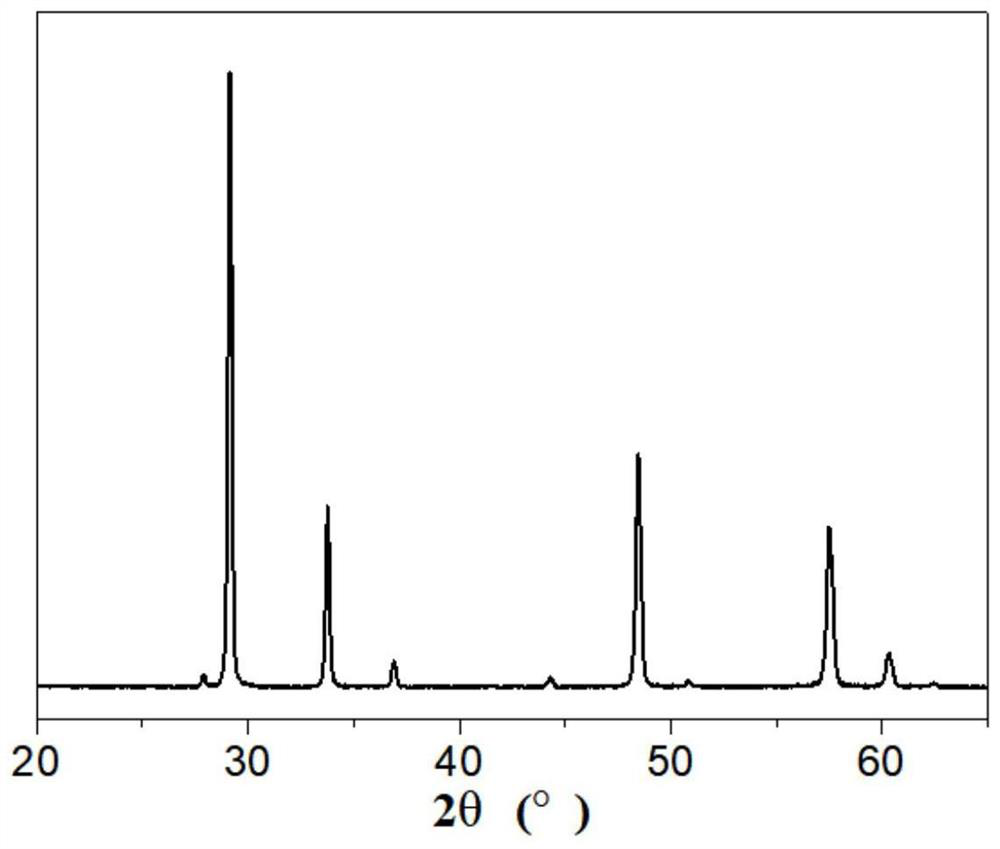

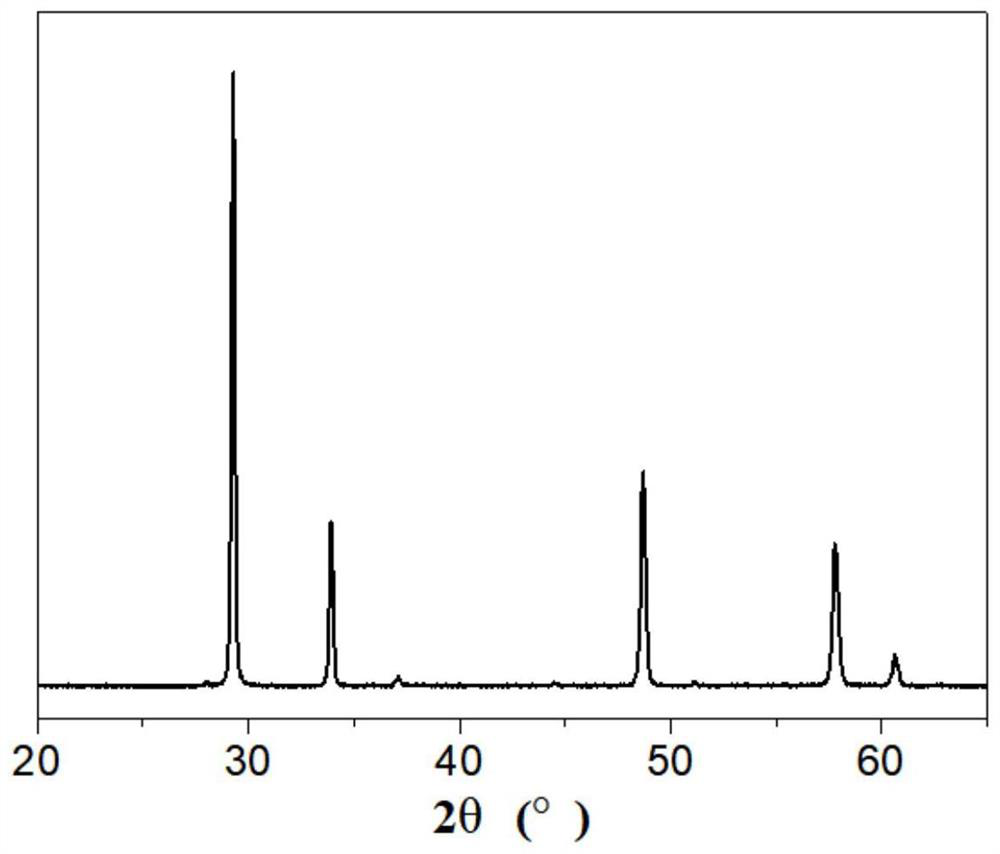

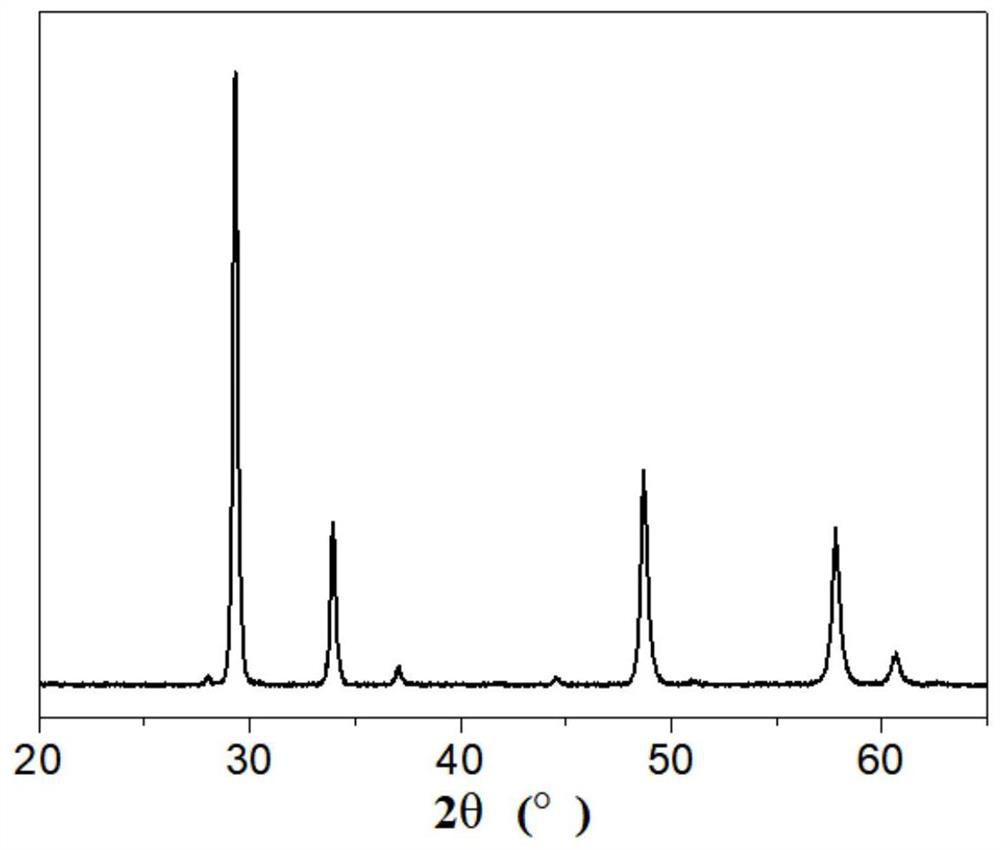

Material with negative thermal expansion performance and preparation method thereof

The invention relates to a material with negative thermal expansion performance and a preparation method thereof. The method is characterized by comprising the steps that 1, PbO, TiO2, Bi2O3 and Co3O4samples are mixed and blended uniformly according to a preset ratio, and pre-processing is conducted; 2, the mixed samples are added to a tube crucible, an antioxidant is added, and the tube cruciblecontaining the mixed samples is placed into a sealed mold; 3, the sealed mold is placed in high-pressure synthesis equipment, temperature and pressure are increased, heat and pressure preserving areconducted, and the temperature and the pressure are reduced to a room temperature and normal pressure; 4, the processed samples are taken out and demolded, the processed samples are washed, the samples are dried, and the novel material (1-x)PbTiO3-xBiCoO3 with the negative thermal expansion performance is obtained, wherein 0.0<=x<=1.0. Compared with a traditional material with the negative thermalexpansion performance, the material, with the negative thermal expansion performance, prepared through the method has high purity, high repeatability, significantly enhanced negative thermal expansion performance and broadened negative expansion temperature zone, and therefore the material has wide scientific researching and practical value.

Owner:WUHAN UNIV OF SCI & TECH

Method for developing crystal of yttrium aluminate with cerium doped

InactiveCN1563515AImprove flicker performanceImprove lattice distortionPolycrystalline material growthBy pulling from meltCeriumCe element

A doped Ce yttrium aluminic acid crystal growing method characterizes in doping CeO2 and Lu2O3 in the raw material formula at the same time and is determined by the following formula: Al2O3+(1-X-Y) Y2O3+2XCeO2+YLu2O3=2Y1-x-y Cex Luy AlO3 + x / 2O2, in which X is greater or equal to 0.1% but less than or equal to 2.0%, y is greater than or equal to x but less than or equal to 3x. The crystal is grown in an IF inducing furnace with a pulling method. The dislocation density is reduced to 100-10000 / sq.cm, its scintillation output performance increases 5%-10%.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

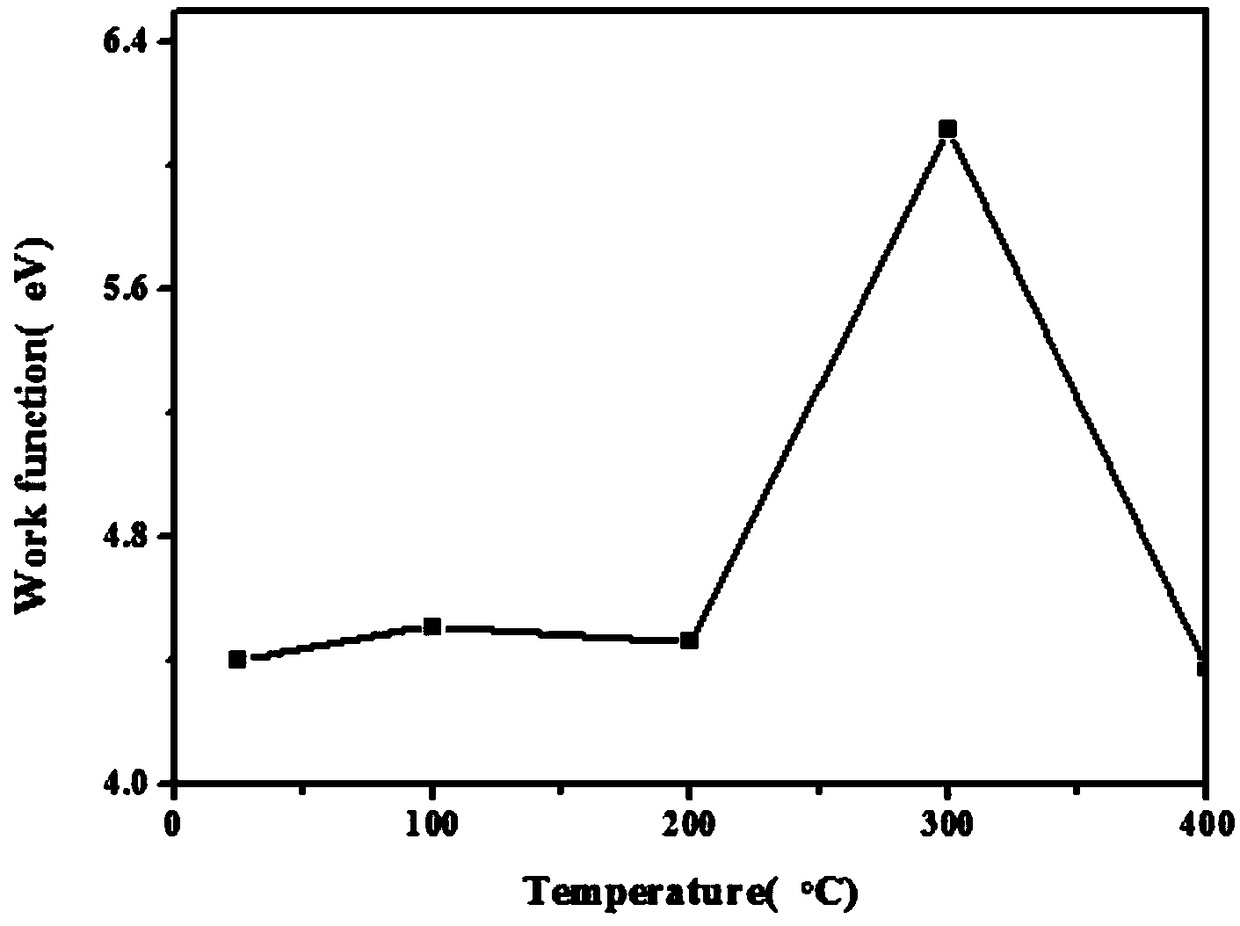

Method for increasing work functions of thin transparent conductive oxide films

InactiveCN109371378AImprove work functionImprove adhesionVacuum evaporation coatingSputtering coatingWork functionCrystallization temperature

The invention relates to a method for increasing work functions of thin transparent conductive oxide films. According to the method, the thin transparent conductive oxide films are prepared with a physical vapor deposition method, during preparation of the thin films, substrates are heated, and heating temperatures are secondary crystallization temperatures of the thin transparent conductive oxidefilms. According to the method, the technology is simple, all that is required is to heat the substrates in situ in the deposition processes of the thin films, other surface treatments are not required to be performed on the thin films or the substrates, the modulation amplitude of the work functions of the thin films is large, and the method is not only applicable to one kind of thin transparentconductive oxide films.

Owner:WUYI UNIV

Semiconductor display device and driving method

InactiveUS7466325B2Suppress generationImprove stabilityCathode-ray tube indicatorsInput/output processes for data processingDriver circuitImaging quality

The invention provides a semiconductor display device with less generation of a pseudo contour while the drive frequency of a driver circuit is suppressed. Furthermore, the invention provides a semiconductor display device with less generation of a pseudo contour while the decrease in image quality is suppressed. A semiconductor display device comprises a table storing data for determining a relationship between the gray scale level of a video signal and a subframe period for light emission in the plurality of subframe periods, a controller for changing a video signal in accordance with the data and outputting, and a panel whose pixel gray scale level is controlled in accordance with the outputted video signal. The number and the length of the plural subframe periods for each gray scale level of 2 or more are determined in accordance with a subframe ratio RSF which is calculated in accordance with a sharing ratio Rsh determined by the frame frequency.

Owner:SEMICON ENERGY LAB CO LTD

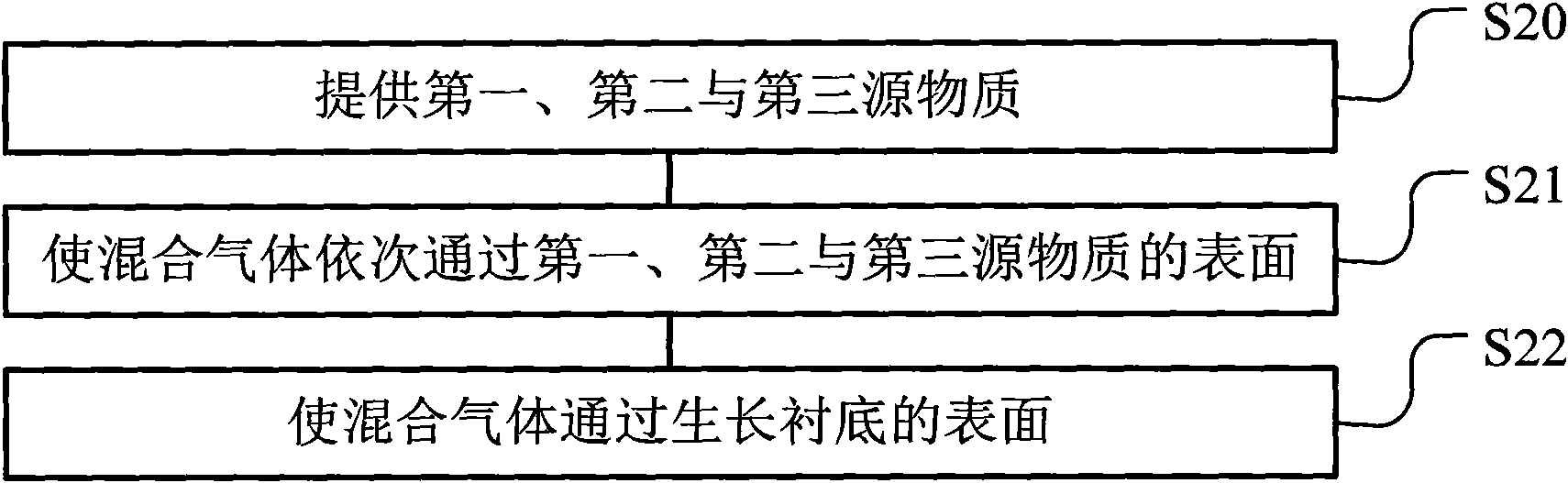

Method for growing GaN-based luminous crystal film by metal organic chemical vapor deposition

InactiveCN101736400BImprove lattice distortionImprove luminous performancePolycrystalline material growthFrom chemically reactive gasesRare-earth elementChemical vapor deposition

The invention discloses a method for growing a GaN-based luminous crystal film by metal organic chemical vapor deposition. The method is characterized in that: trimethylborine or trimethylaluminium are doped in a raw material formula of the GaN crystal film in proportion, and boron or aluminum enter a GaN crystal lattice in a mode of trivalent ion in a growing process to regulate the ionic radiusdifference between rare-earth ions and Ga3+; the molar ratio of the raw material formula is that: Ga (CH3)3 to rare-earth organic complex to A(CH3)3 is (1-x-y):x:y, wherein the rare-earth organic complex is Re(TMHD)3 or Re (i-PrCp)3 taking rare-earth element Re as a core; A represents III group element boron or aluminum; x is more than or equal to 0.1 percent and less than or equal to 10.0 percent; and y is more than or equal to 0.1 time of the x and less than or equal to x. Because the organic complex of the III group element boron or aluminum and the rare-earth organic complex are co-doped in a certain proportion, the method can improve lattice distortion of the GaN crystal film caused by larger radius mismatch between Re3+ and Ga3+ to a large extent so as to improve the luminous performance of the GaN crystal film.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

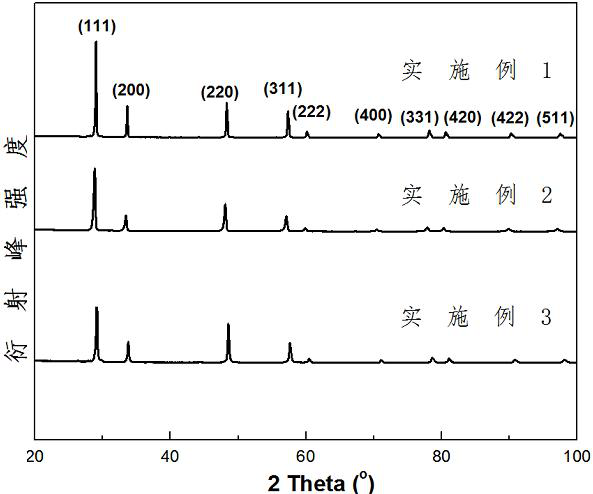

High-entropy ceramic powder for thermal barrier coating and preparation method thereof

ActiveCN110272278BLow thermal conductivityImprove lattice distortionRare-earth elementAir atmosphere

The invention discloses a high-entropy ceramic powder for thermal barrier coating, which is characterized in that the ceramic powder has a pyrochlore structure, and the chemical formula is RE 2 Zr 2 o 7 , wherein RE is any 3 to 7 different metal elements among the rare earth elements Y, La, Pr, Nd, Sm, Eu and Gd, and the percentage of the moles of each RE element to the total moles of all RE elements is 5%~ 35%. The preparation method is: the RE 2 o 3 Powder and ZrO 2 The powders are mixed, and the mixed powders are heated at 1000-1700° C. in an air atmosphere for 1-10 hours to prepare high-entropy ceramic powders. The high-entropy ceramic powder prepared by the present invention enriches the system of thermal barrier coating materials, has the advantages of low cost, simple operation, wide application range, etc., and is expected to be applied in the field of thermal barrier coatings.

Owner:DONGHUA UNIV

Rare-earth doped GaN luminescent powder and preparation method thereof

InactiveCN103224793AImprove lattice distortionImprove luminous performanceLuminescent compositionsRADIUSThermal insulation

The invention relates to a rare-earth doped GaN luminescent powder and preparation method thereof. The chemical formula of the luminescent powder is Ga(1-x-y)RexAyn, wherein Re refers to one of Ce<3+>, Pr<3+>, Nd<3+>, Pm<3+>, Sm<3+>, Eu<3+>, Gd<3+>, Tb<3+>, Dy<3+>, Ho<3+>, Er<3+>, Tm<3+> and Yb<3+>, and A refers to B<3+> or Al<3+>, x refers to the content of Re, y refers to the content of B<3+> or Al<3+>, x is greater than or equal to 0.1% and less than or equal to 10.0%, and y is greater than or equal to 0.1x and less than or equal to x. After raw materials are mixed, the obtained mixture is subjected to thermal insulation in a vacuum quartz tube at a temperature of 500-1000 DEG C for 8-16h; and after the obtained mixture is ground, the ground mixture is subjected to thermal insulation in an ammonia gas atmosphere in a temperature of environment of 1000-1150 DEG C 10-20h, thereby obtaining the luminescent powder material. According to the invention, lattice distortion caused by the radius mismatching between Re<3+> and Ga<3+> is improved, and the luminescent property of GaN powder material is effectively increased.

Owner:SUZHOU UNIV OF SCI & TECH

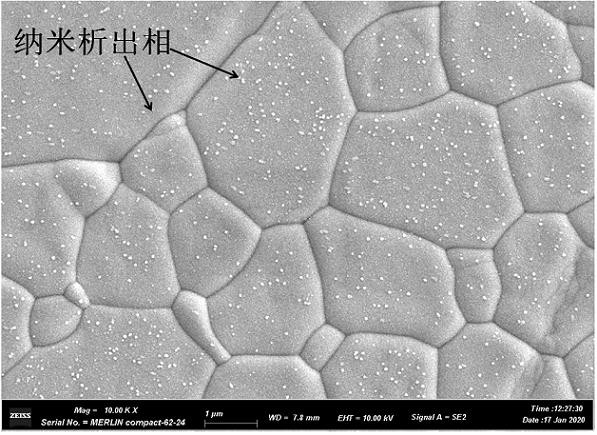

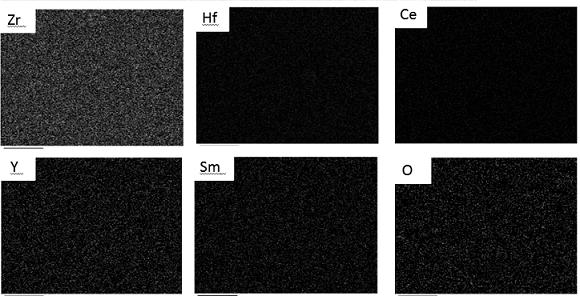

A low thermal conductivity, high fracture toughness aerospace thermal barrier material and its preparation

The invention relates to a thermal barrier material for aerospace with low thermal conductivity and high fracture toughness. The composition of the material in terms of atomic ratio is (ZrO 2 )a(CeO 2 )b(HfO 2 )c(Y 2 o 3 )d(A 2 o 3 )e, corresponding to (Zr a Ce b f c Y 2d A 2e )O f , where A is Sm or Nd, a=0.75~1.25, b=0.75~1.25, c=0.75~1.25, d+e=0.75~1.25, d and e are near equiatomic ratios, f=2(a+b +c)+3(d+e). The invention also discloses a preparation method of the thermal barrier material. While ensuring high lattice distortion solid solution, the invention reduces grain size and promotes the formation of nano-precipitated phase, so as to realize the improvement of fracture toughness and the reduction of thermal conductivity.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Rare earth element doped fluorescent powder and preparation method thereof

ActiveCN101735815BImprove lattice distortionImprove luminous performanceLuminescent compositionsRare-earth elementRADIUS

The invention discloses rare earth element doped fluorescent powder and a preparation method thereof. The rare earth element doped fluorescent powder comprises polycrystal powder formed by rare earth element doped III group nitride, wherein the III group nitride consists of nitrogen atoms and an III group element; the polycrystal powder further comprises a substitutional dopant which is one III group element or the combination of a plurality of III group elements; the atomic number of a substitutional element is less than that of the III group element forming the polycrystal powder; and the substitutional dopant replaces the traditional III group element in the polycrystal powder to form the substitutional defect. The invention further provides a preparation method of the fluorescent powder. The invention has the advantages that: the lattice distorsion of the polycrystal powder, caused by the mismatching of the larger atom radius, between the III group element and rare earth element is improved by introducing the substitutional dopant to replace the traditional III group element in the polycrystal powder to form the substitutional defect, thereby improving the luminous performance of the powder.

Owner:SUZHOU NANOWIN SCI & TECH

Refined crystalline strengthening method for silver magnesium nickel alloy

ActiveCN108893690AImprove diffusion abilityImprove lattice distortionSurface reaction electrolytic coatingSolid state diffusion coatingOxygenPt element

The invention discloses a refined crystalline strengthening method for a silver magnesium nickel alloy and belongs to the technical field of an electric contact material. The method disclosed by the invention comprises the following steps: placing raw materials into a vacuum induction furnace in proportion and smelting, thereby acquiring a silver magnesium nickel alloy cast ingot, and then cold-rolling the cast ingot into a sheet; taking a silver magnesium nickel alloy sheet as a cathode, taking a platinum sheet as an anode and adding a hydrogenating inhibitor into a hydrogenated electrolyte which is an acidic system; performing direct current hydrogeneration for a period of time, and then taking out the silver magnesium nickel alloy sheet, cleaning and drying; taking out, performing finish rolling and shaping; placing into an atmosphere sintering furnace; keeping temperature for a period of time under the conditions of vacuum and low temperature; aerating and rising temperature; thermally oxidizing under high temperature and then cooling with the furnace. The material prepared according to the method disclosed by the invention has high strength, high hardness, high plasticity, high elasticity, excellent conductivity and excellent electric arc resistance.

Owner:KUNMING UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com