High-entropy ceramic powder used for thermal barrier coating and preparation method of ceramic powder

A technology of ceramic powder and thermal barrier coating, which is applied in the field of high-entropy ceramic powder for thermal barrier coating and its preparation, can solve the problem of high thermal conductivity of rare earth zirconate, achieve excellent low thermal conductivity, and is easy to realize The effect of large-scale and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A preparation method of high-entropy ceramic powder for thermal barrier coatings:

[0026] La 2 o 3 、Nd 2 o 3 、Sm 2 o 3 、Eu 2 o 3 、Gd 2 o 3 The original powder (particle size 1μm, purity 99wt%) and ZrO 2 (Particle diameter 0.2 μm, purity 99 wt%) were compounded in a molar ratio of 1:1:1:1:1:5 (the molar ratio of rare earth elements was 0.2:0.2:0.2:0.2:0.2:1). With ethanol as the medium, ZrO 2 The ball is a grinding ball, and the ball mill is mixed at a speed of 560 rpm for 8 hours on a planetary ball mill, and a dry mixed powder with a uniform composition is obtained through rotary evaporation; the obtained mixed powder with a uniform composition is put into an alumina crucible, and then Put it in a muffle furnace, in an air atmosphere, raise the temperature at a rate of 1°C / min, and keep it at 1000°C for 1h to prepare high-entropy ceramic powder.

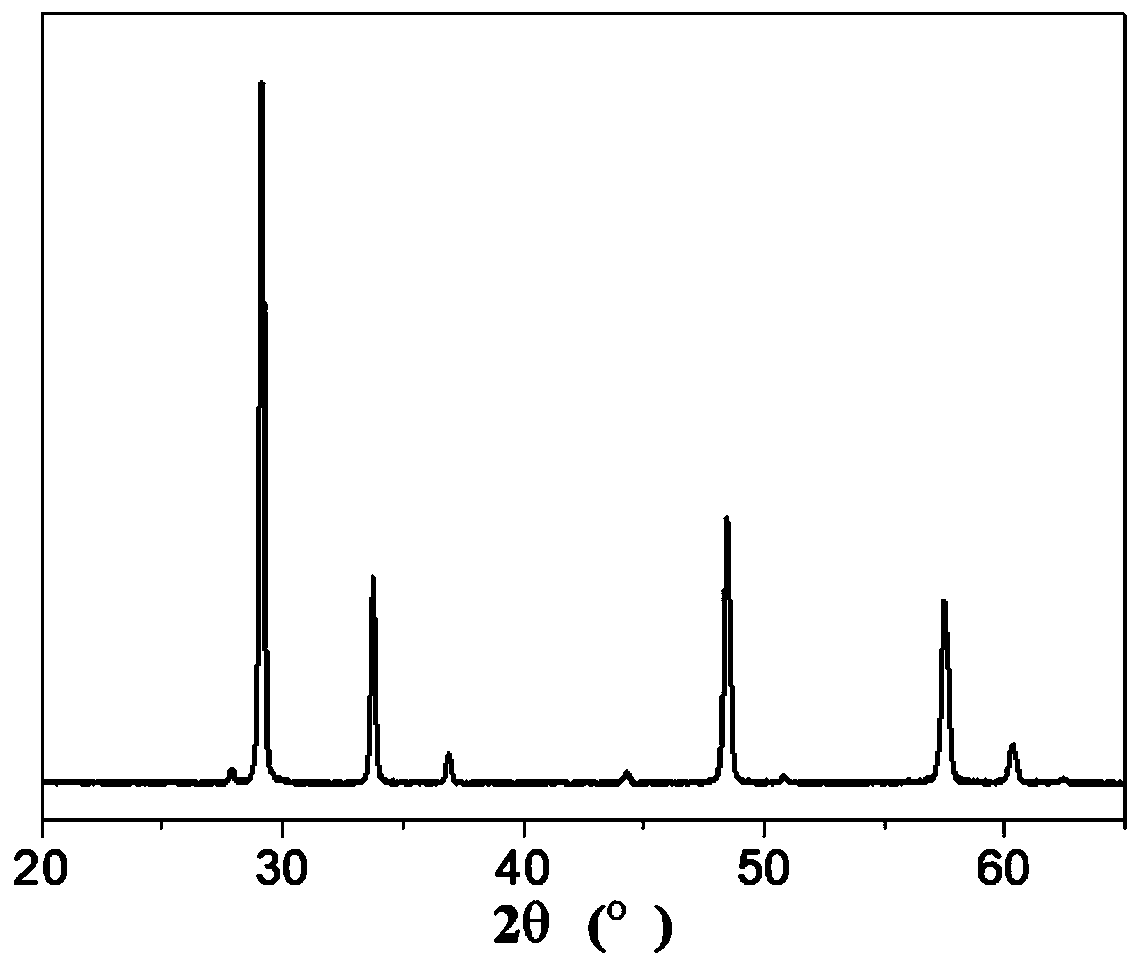

[0027] After analysis: the XRD pattern of the prepared high-entropy ceramic powder is as follows figure 1show...

Embodiment 2

[0029] A preparation method of high-entropy ceramic powder for thermal barrier coatings:

[0030] Will Y 2 o 3 , La 2 o 3 、Sm 2 o 3 、Eu 2 o 3 、Gd 2 o 3 The original powder (particle size 5μm, purity 99wt%) and ZrO 2 Powder (particle diameter 0.5 μm, purity 99wt%) carries out batching in molar ratio 1:1:1:1:1:5 (the molar ratio of rare earth element is 0.2:0.2:0.2:0.2:0.2:1), with ethanol as Medium, ZrO 2 The ball is a grinding ball, and the ball mill is mixed at a speed of 500 rpm for 16 hours on a planetary ball mill, and a dry mixed powder with a uniform composition is obtained through rotary evaporation; the obtained mixed powder with a uniform composition is put into an alumina crucible, and then Put it in a muffle furnace, raise the temperature at a rate of 10°C / min in an air atmosphere, and keep it at 1200°C for 3 hours to prepare high-entropy ceramic powder.

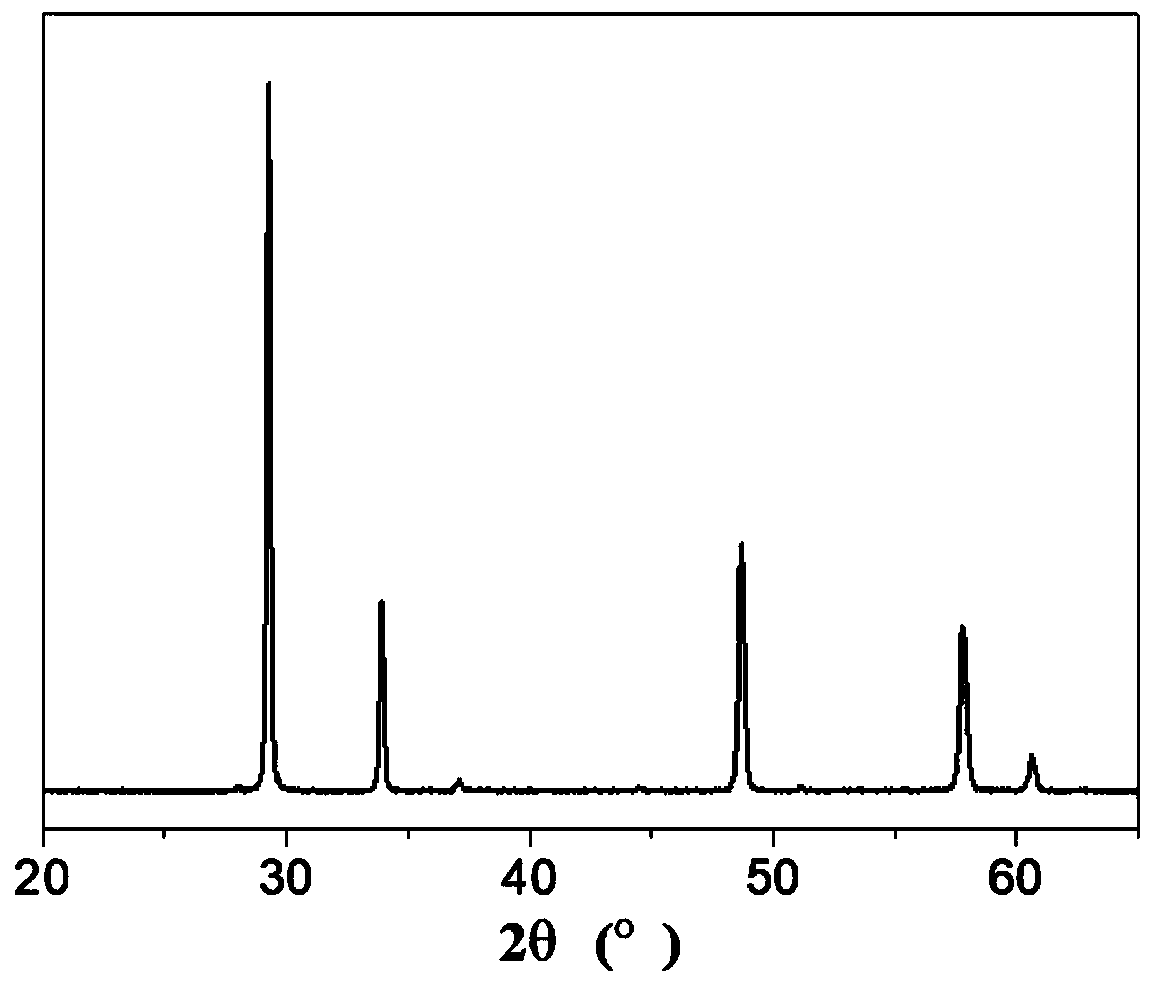

[0031] After analysis: the XRD pattern of the prepared high-entropy ceramic powder is as follows ...

Embodiment 3

[0033] A preparation method of high-entropy ceramic powder for thermal barrier coatings:

[0034] Will Y 2 o 3 , La 2 o 3 、Nd 2 o 3 、Sm 2 o 3 、Gd 2 o 3 The original powder (particle size 10μm, purity 99wt%) and ZrO 2 The powder (0.8 μm in particle size, 99 wt% in purity) is prepared in a molar ratio of 1:1:1:1:1:5 (the molar ratio of rare earth elements is 0.2:0.2:0.2:0.2:0.2:1) Medium, ZrO 2 The ball is a grinding ball, and the ball mill is mixed at a speed of 450 rpm for 20 hours on a planetary ball mill, and a dry mixed powder with a uniform composition is obtained through rotary evaporation; the obtained mixed powder with a uniform composition is put into an alumina crucible, and then Place it in a muffle furnace, raise the temperature at a rate of 15°C / min in an air atmosphere, and keep it at 1500°C for 8 hours to prepare high-entropy ceramic powder.

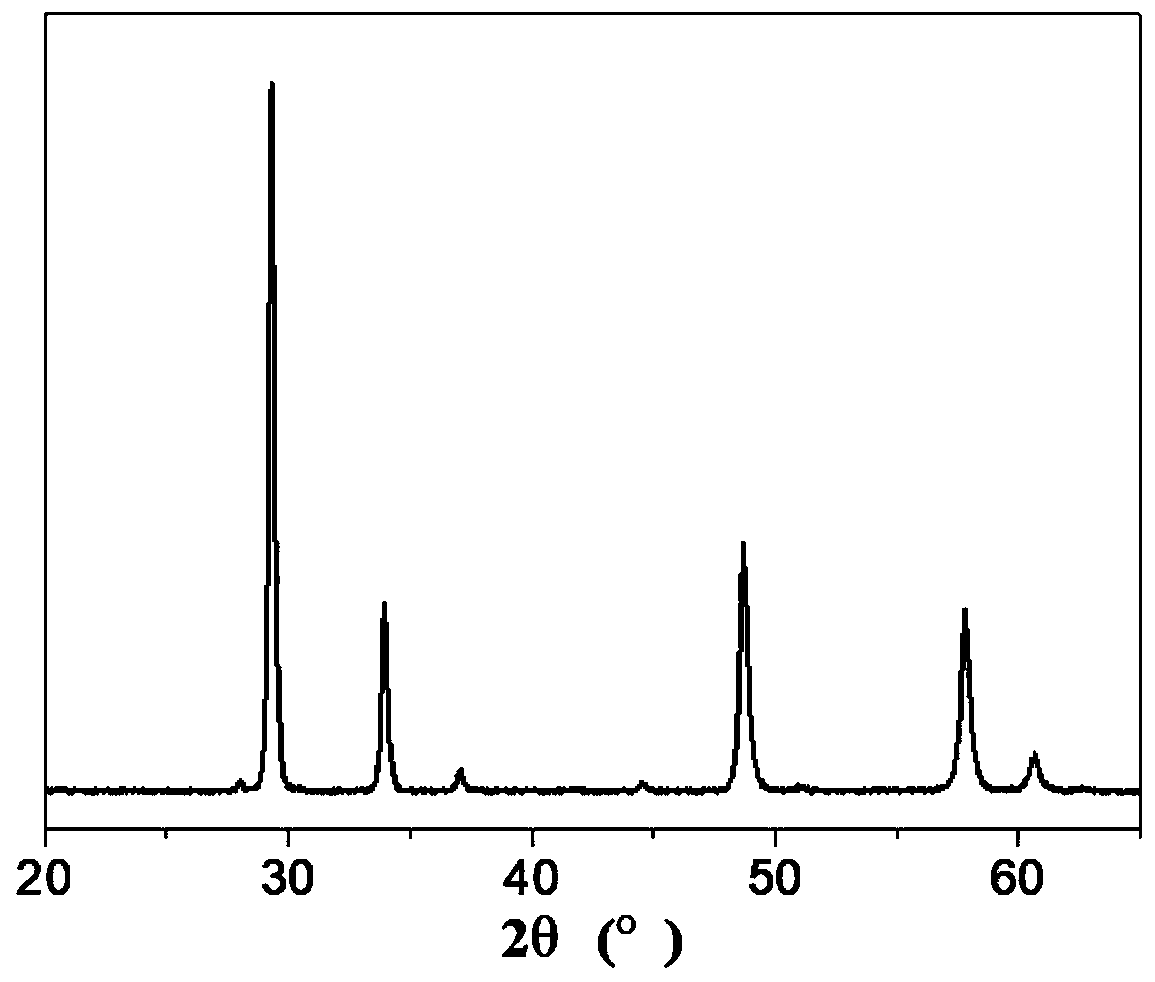

[0035] After analysis: the XRD pattern of the prepared high-entropy ceramic powder is as follows image 3 sh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com