Method for increasing work functions of thin transparent conductive oxide films

An oxide film, transparent conductive technology, applied in ion implantation plating, metal material coating process, coating and other directions, can solve problems such as work function decline, film surface etching, insufficient stability, etc., to achieve simple process, improved The effect of work function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

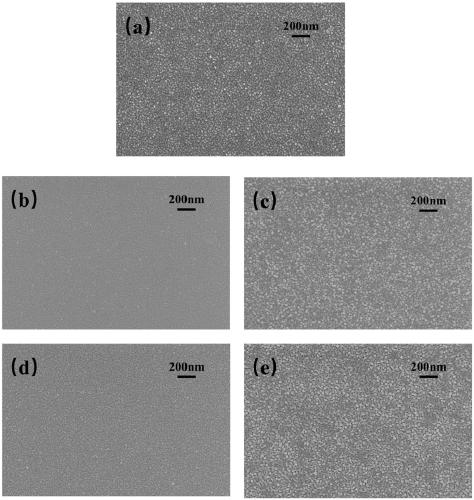

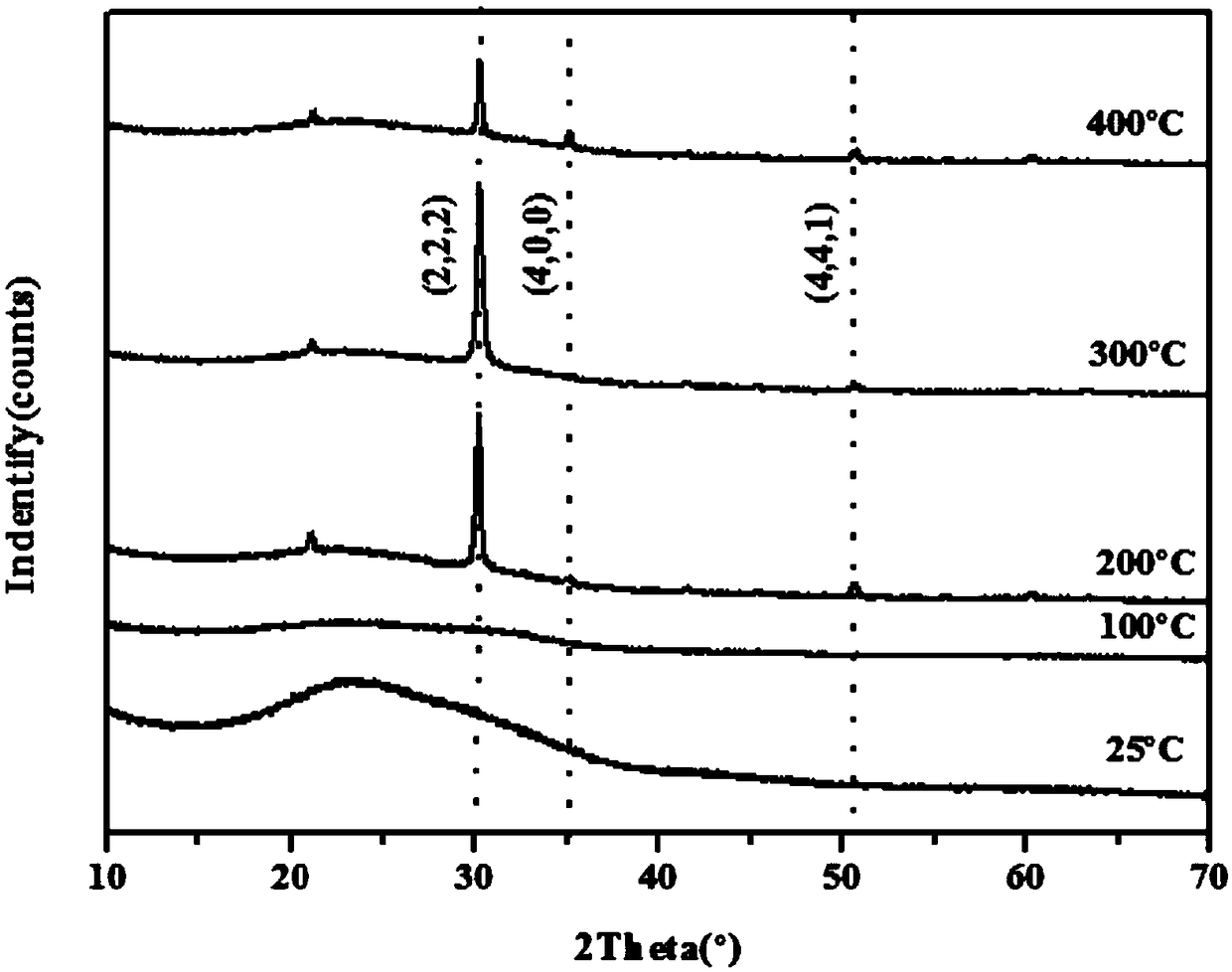

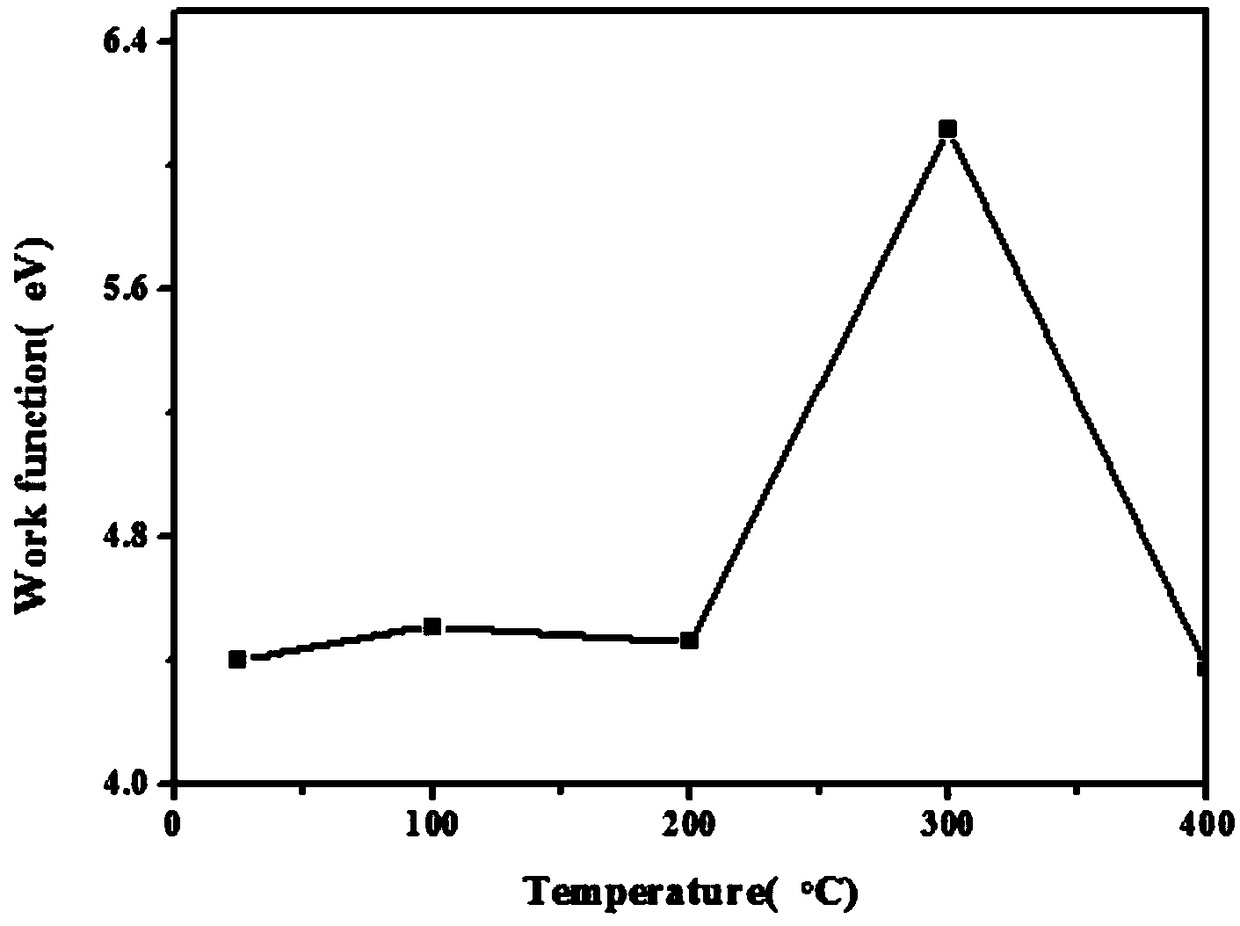

Image

Examples

Embodiment 1

[0033] In this example, ITO (In 0.9 sn 0.1 O) thin film, concrete process comprises the following steps:

[0034] (1) Use acetone, ethanol, and deionized water to perform ultrasonic cleaning on the silicon wafer substrate for 20 minutes each;

[0035] (2) Control the temperature of the oven at 70°C, and dry the substrate for 1 hour;

[0036] (3) Put the dried substrate into the magnetron sputtering chamber, and vacuum the chamber to 6×10 -4 Pa, the distance between the target and the substrate is set to the maximum value that the equipment can achieve, which is 12cm;

[0037] (4) Feed 30 sccm argon gas, control the bias power supply to 850V, wait for 15 minutes, and carry out the pre-cleaning process of the substrate;

[0038] (5) Turn off the bias power supply, set the argon gas flow rate to 0 sccm, set the substrate temperature to 300°C, set the heating rate to 55.2°C / min, and wait for 5 to 10 minutes to stabilize the temperature;

[0039] (6) The argon flow rate is set...

Embodiment 2

[0046] In this example, the magnetron sputtering method is used to prepare SnO on the n-type silicon substrate. 2 film, the specific process includes the following steps:

[0047] (1) Use acetone, ethanol, and deionized water to perform ultrasonic cleaning on the silicon wafer substrate for 20 minutes each;

[0048] (2) Control the temperature of the oven at 70°C, and dry the substrate for 1 hour;

[0049] (3) Put the dried substrate into the magnetron sputtering chamber, and vacuum the chamber to 6×10 -4 Pa, the distance between the target and the substrate is set to the maximum value that the equipment can achieve, which is 12cm;

[0050] (4) Feed 30 sccm argon gas, control the bias power supply to 850V, wait for 15 minutes, and carry out the pre-cleaning process of the substrate;

[0051] (5) Turn off the bias power supply, set the argon gas flow rate to 0 sccm, set the substrate temperature to 200°C, set the heating rate to 55.2°C / min, and wait for 5 to 10 minutes to st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electron work function | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| electron work function | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com