Patents

Literature

579 results about "Graphene electrode" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

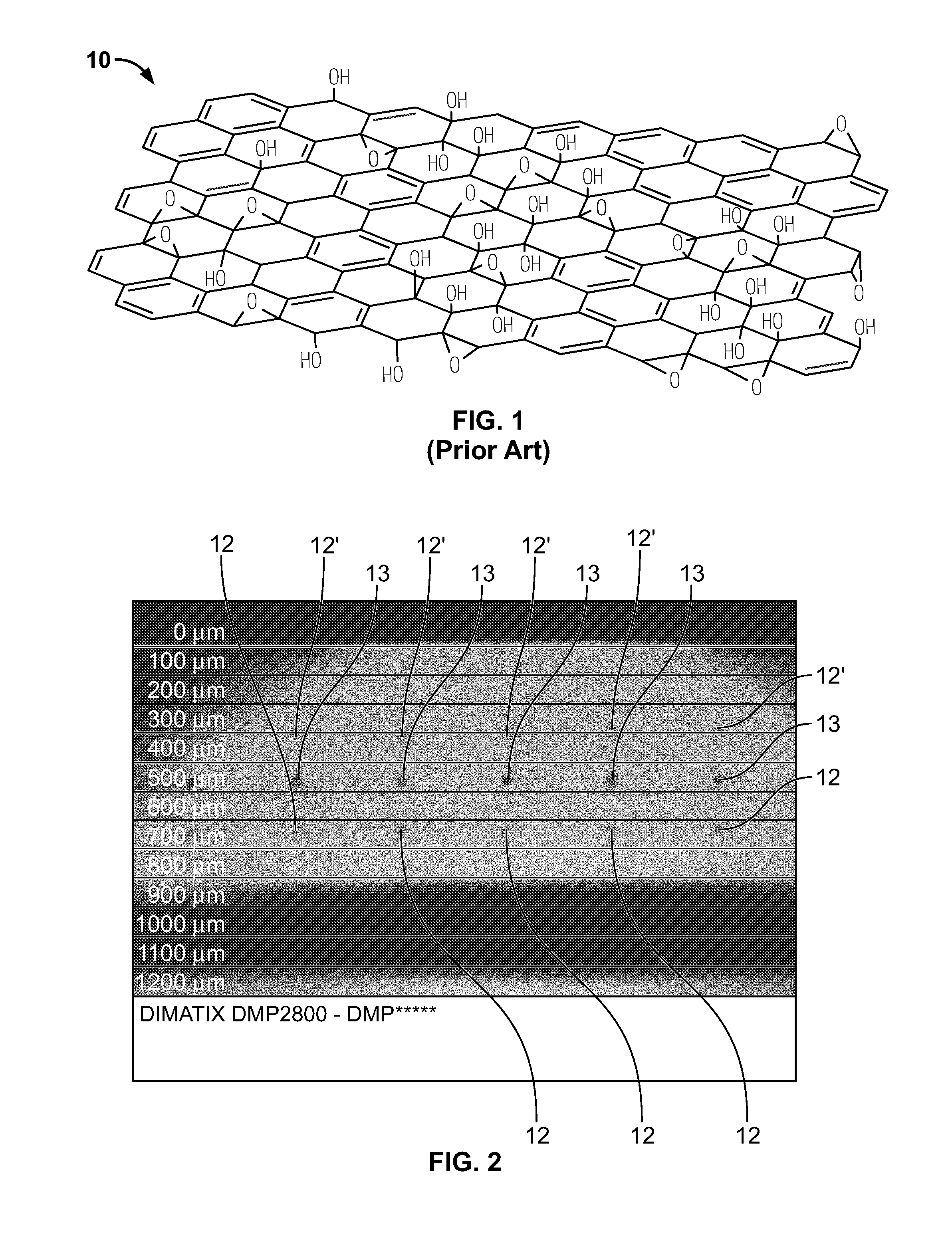

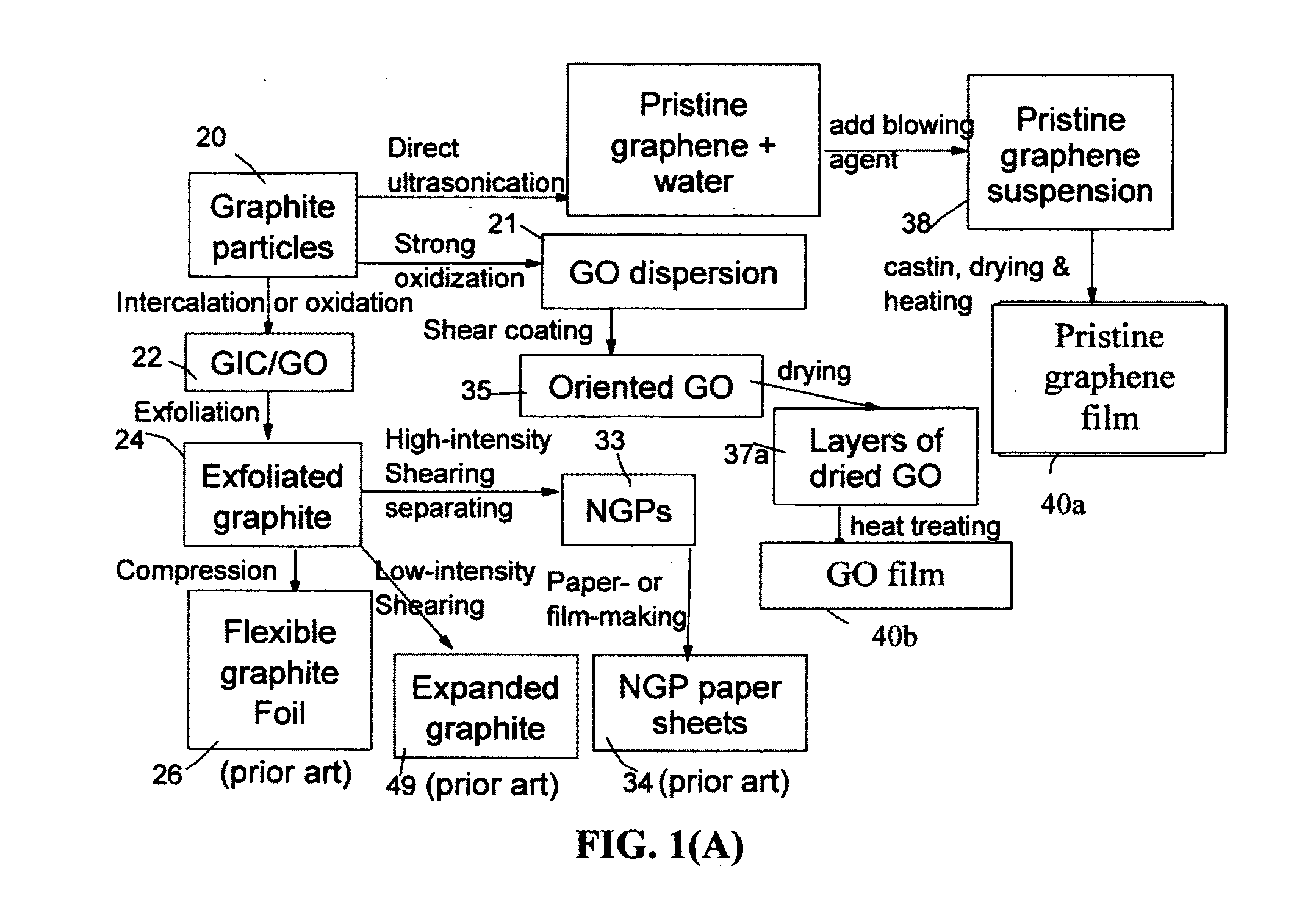

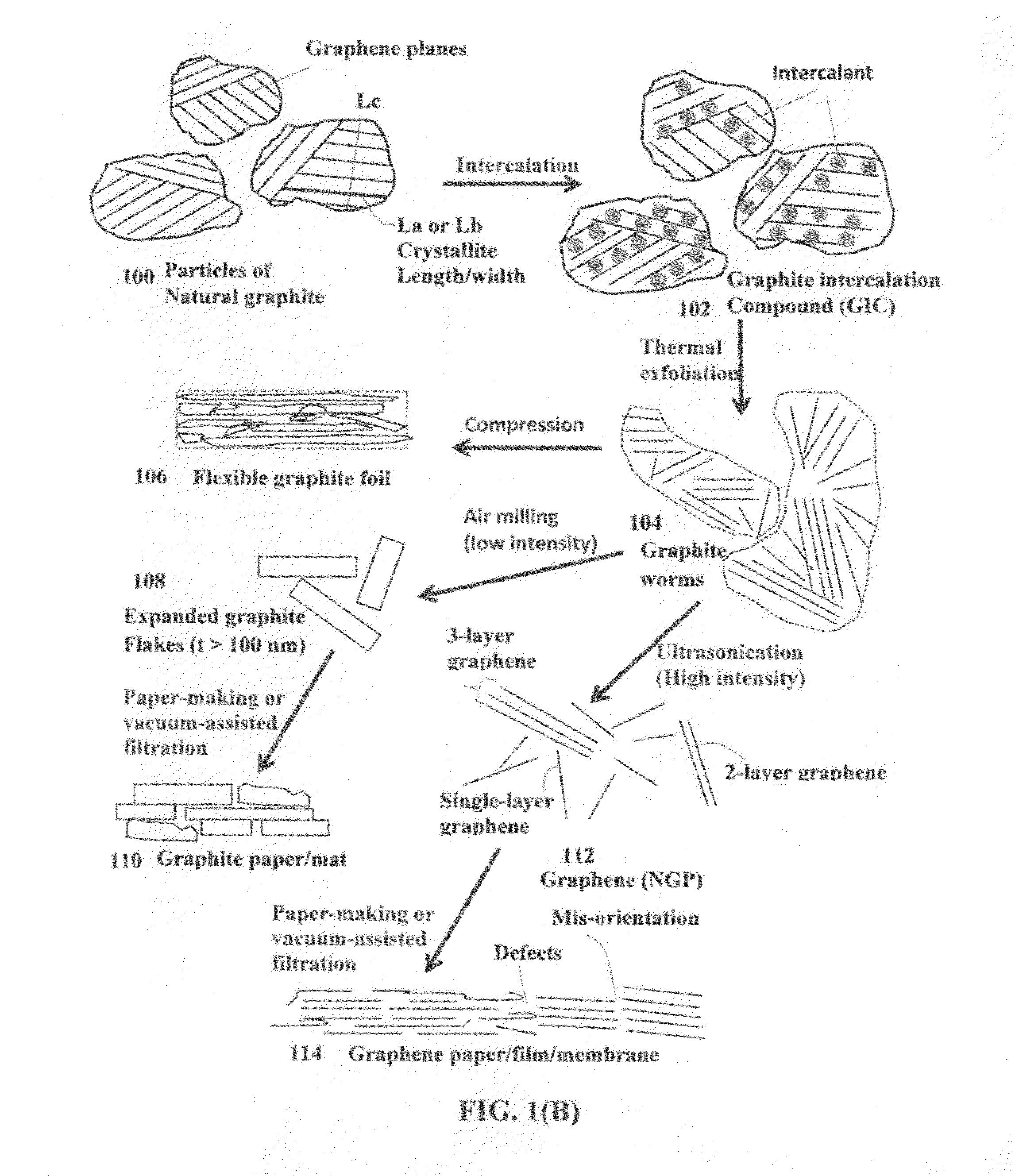

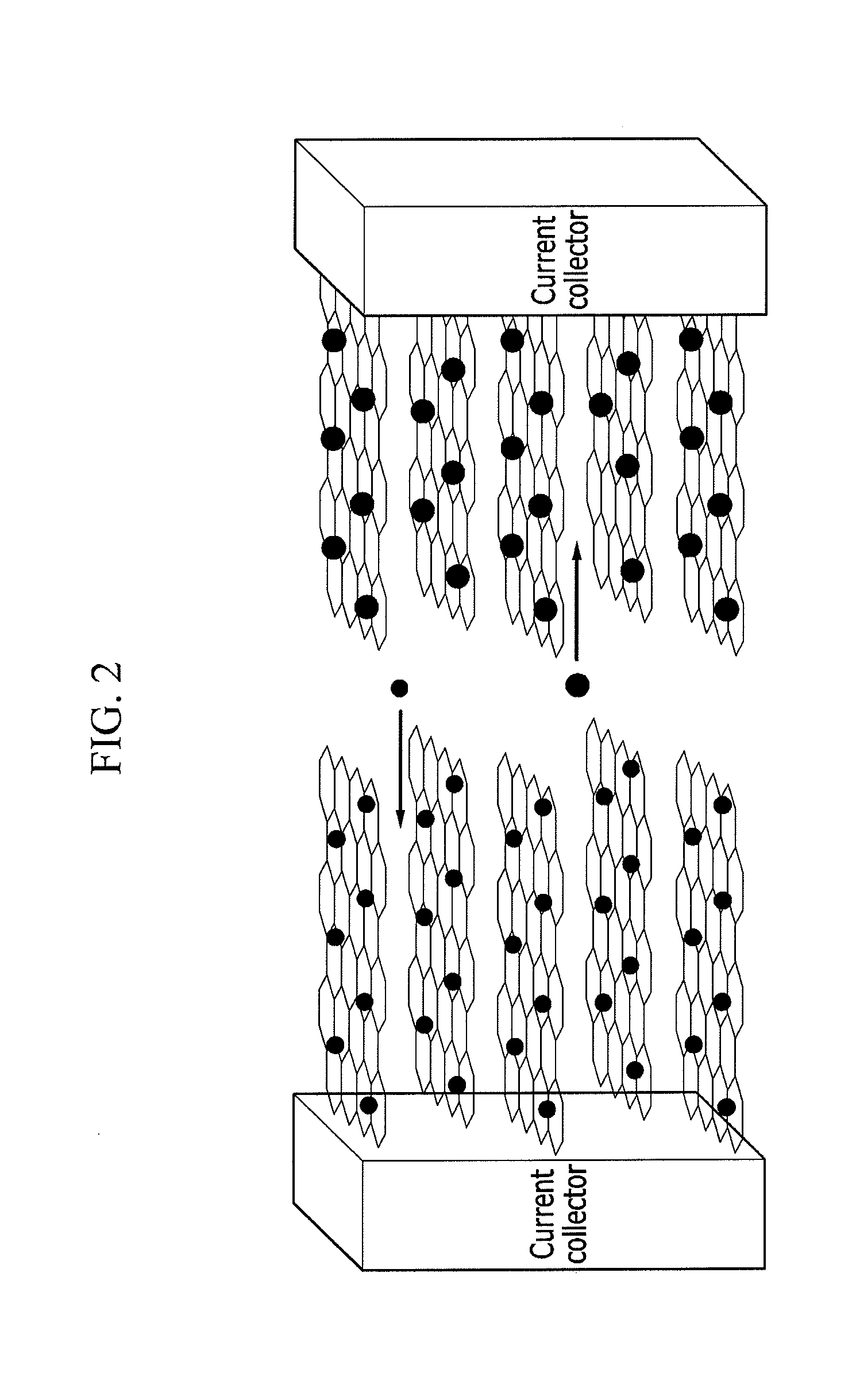

In electrodes, graphene works in two general ways, either as a composite/hybrid or as a support material. As a support material, graphene helps to keep metal ions in a regular order, which helps with electrode efficiency.

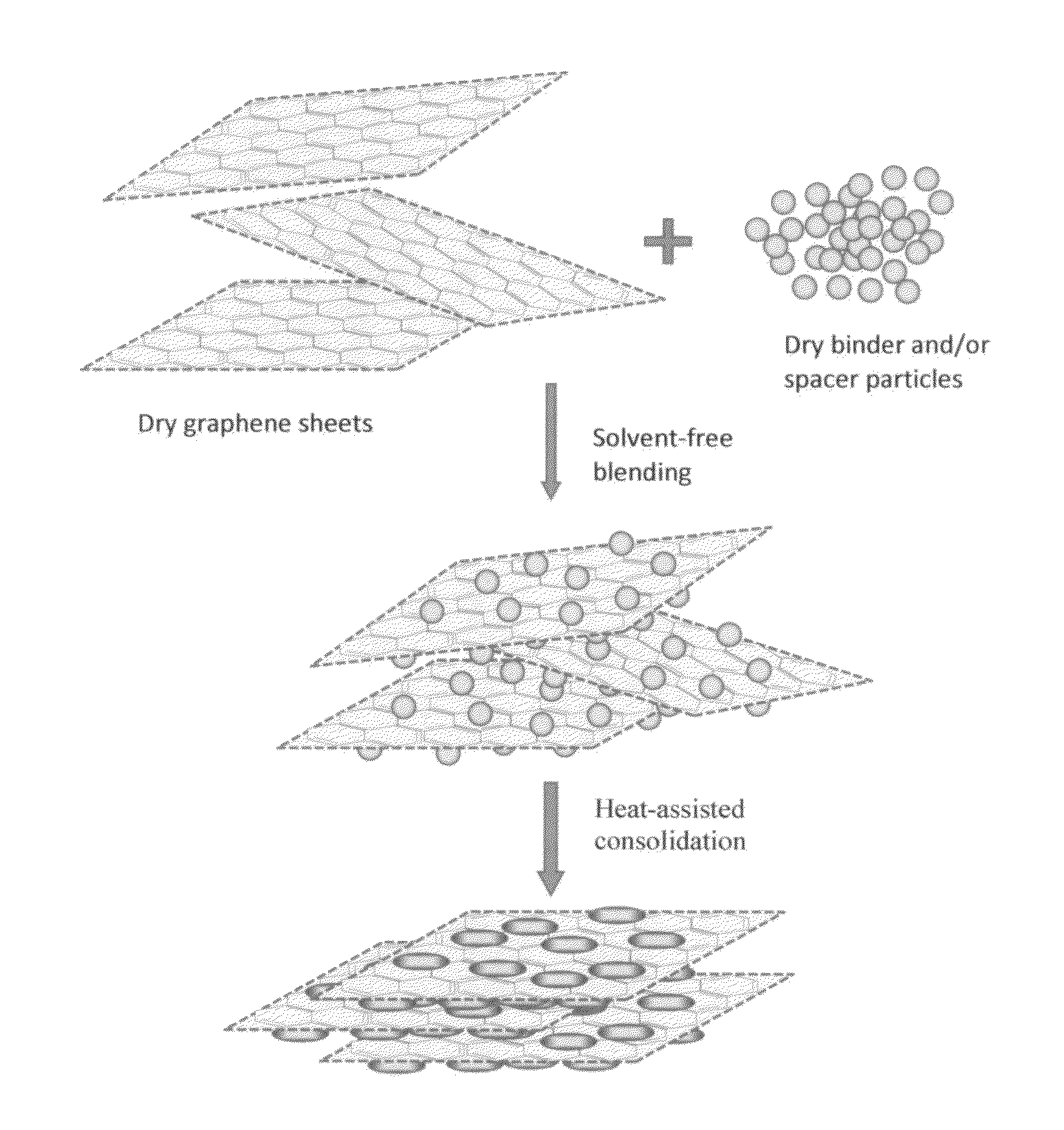

Solvent-free process based graphene electrode for energy storage devices

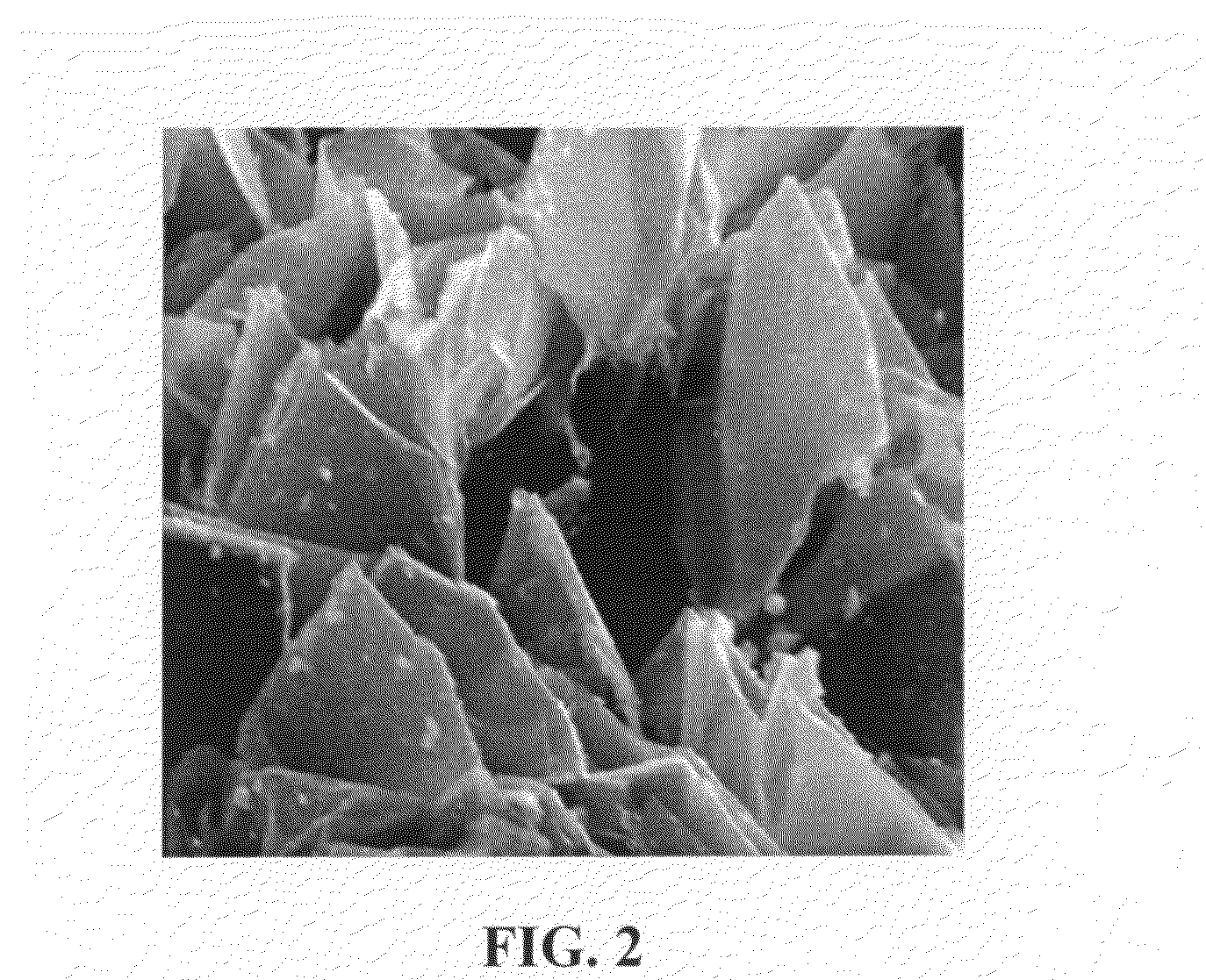

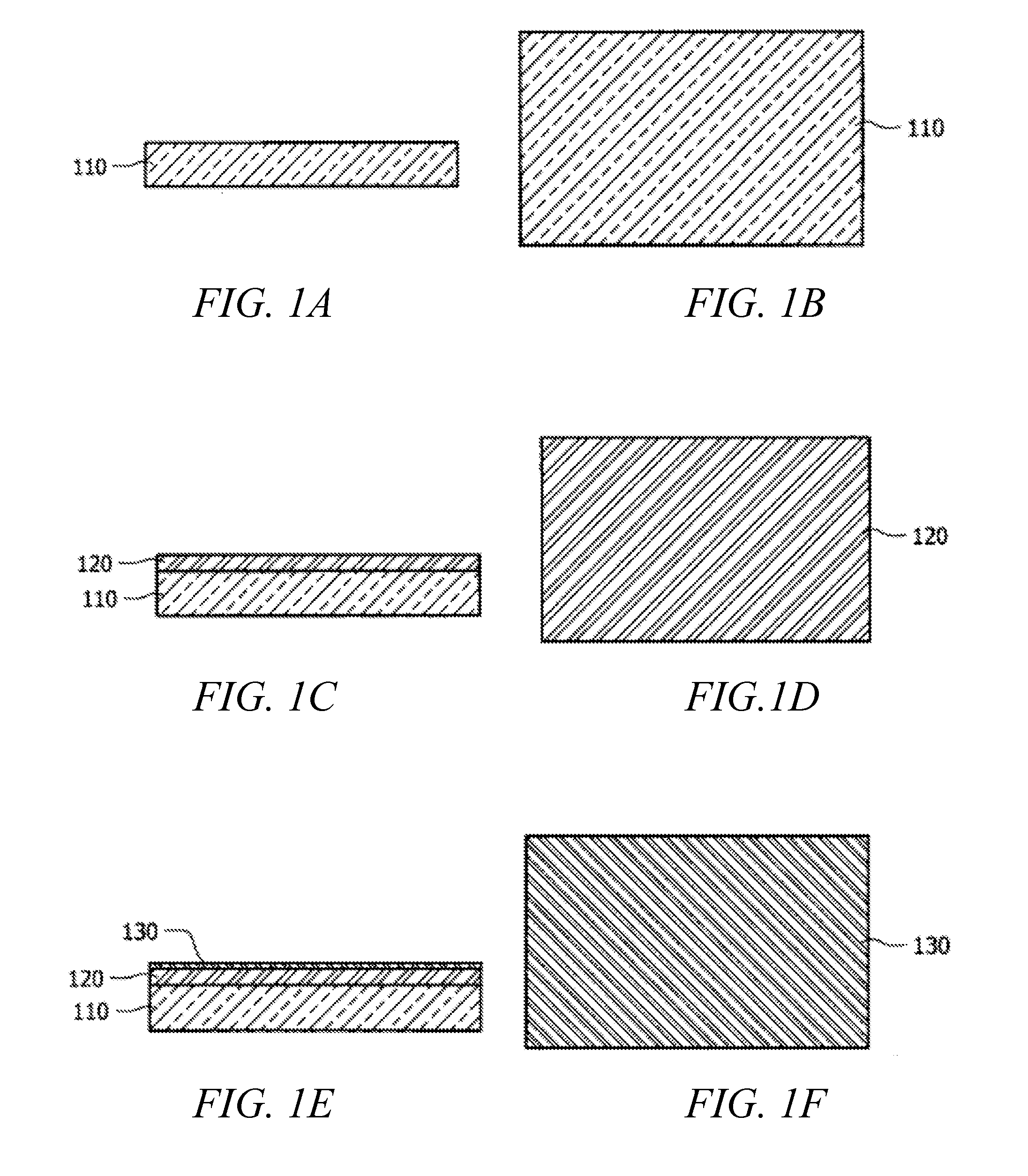

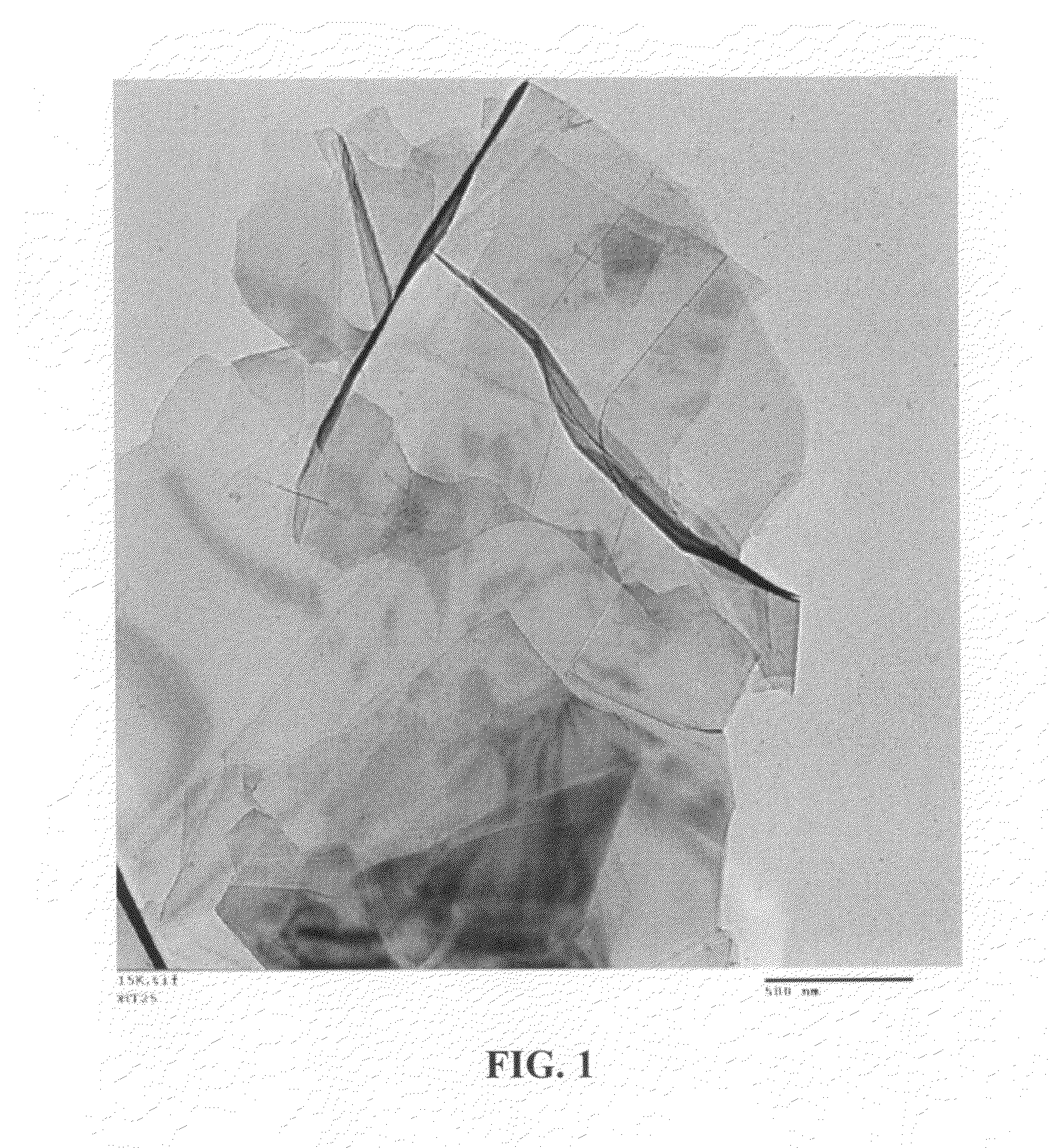

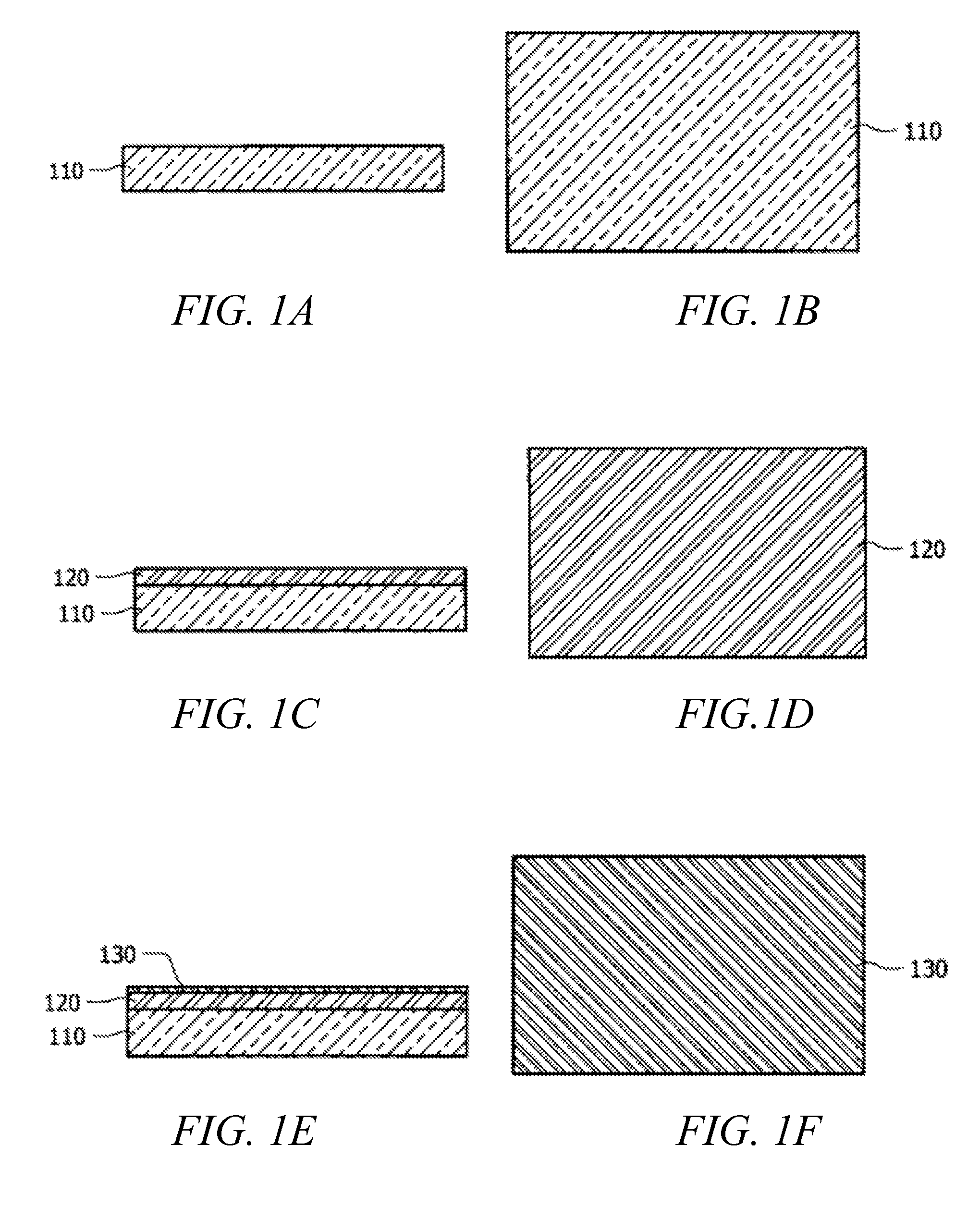

PendingUS20140030590A1Inexpensive and durable and highly reliableHigh capacitanceMaterial nanotechnologyHybrid capacitor electrodesGraphene flakeSolvent free

Disclosed is an electrode for an electrochemical energy storage device, the electrode comprising a self-supporting layer of a mixture of graphene sheets and spacer particles and / or binder particles, wherein the electrode is prepared without using water, solvent, or liquid chemical. The graphene electrode prepared by the solvent-free process exhibits many desirable features and advantages as compared to the corresponding electrode prepared by a known wet process. These advantages include a higher electrode specific surface area, higher energy storage capacity, improved or higher packing density or tap density, lower amount of binder required, lower internal electrode resistance, more consistent and uniform dispersion of graphene sheets and binder, reduction or elimination of undesirable effect of electrolyte oxidation or decomposition due to the presence of water, solvent, or chemical, etc.

Owner:GLOBAL GRAPHENE GRP INC

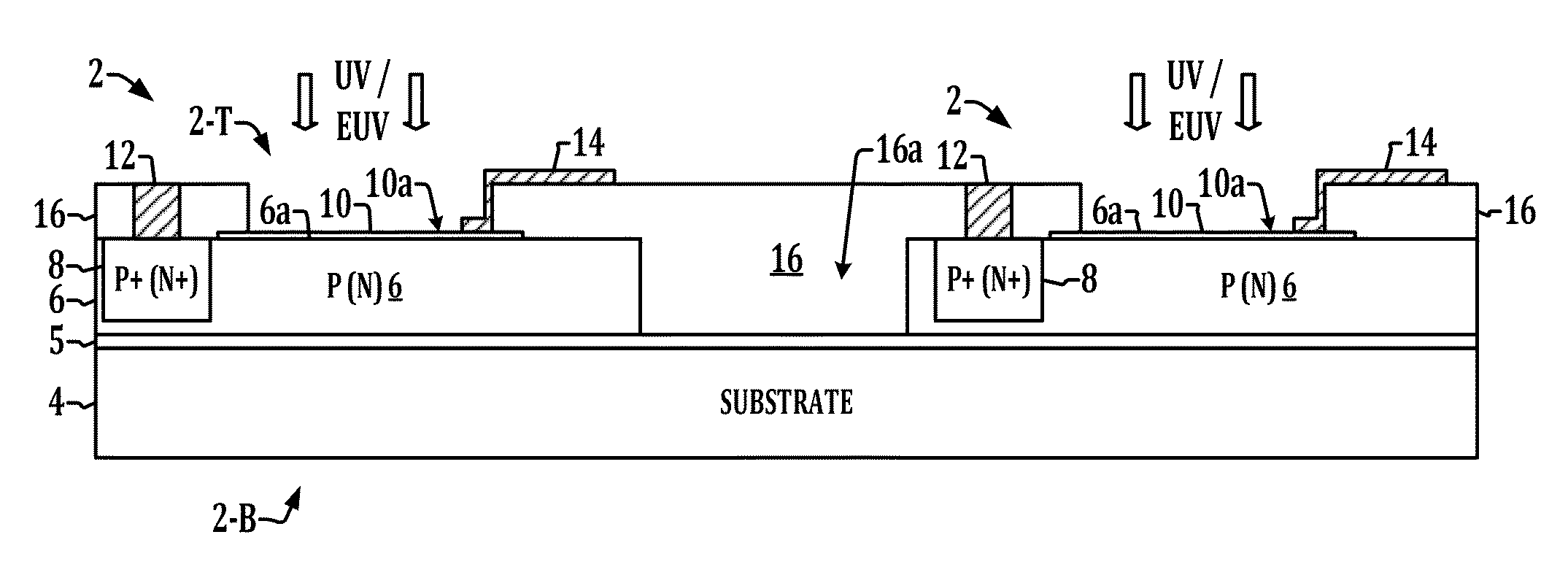

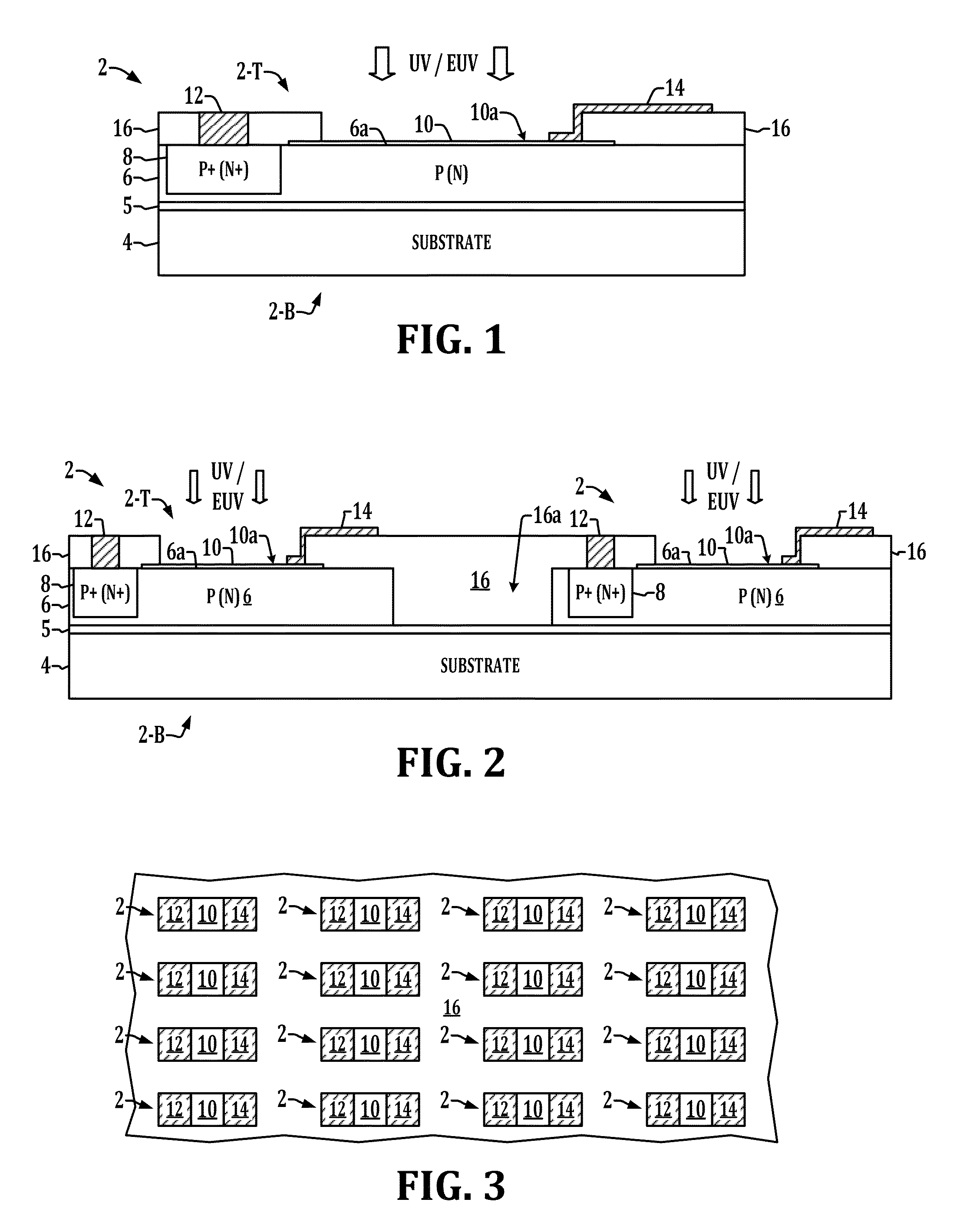

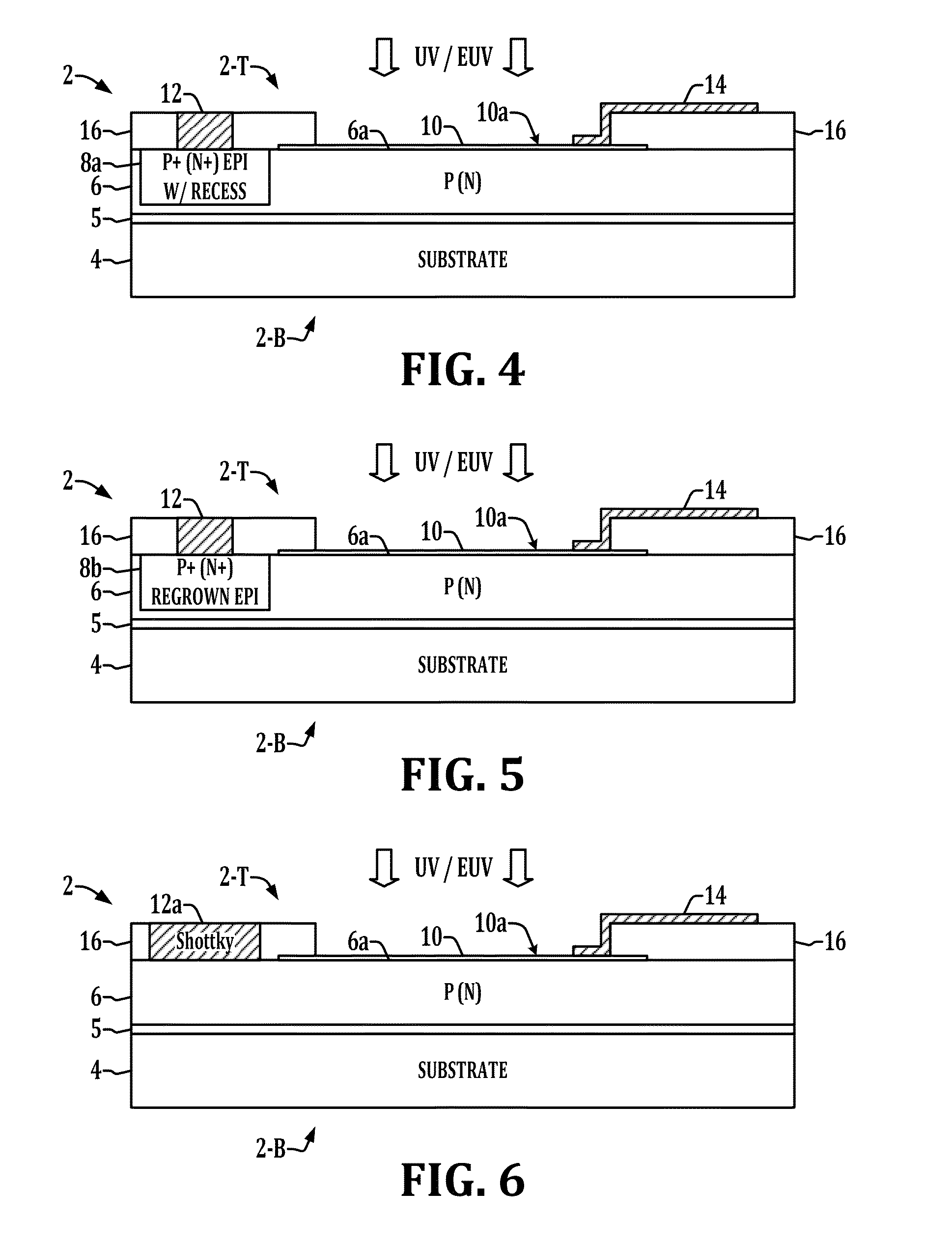

Graphene on Semiconductor Detector

InactiveUS20130082241A1Well formedReduce sheet resistanceSolid-state devicesSemiconductor/solid-state device manufacturingSemiconductor materialsManufacturing technology

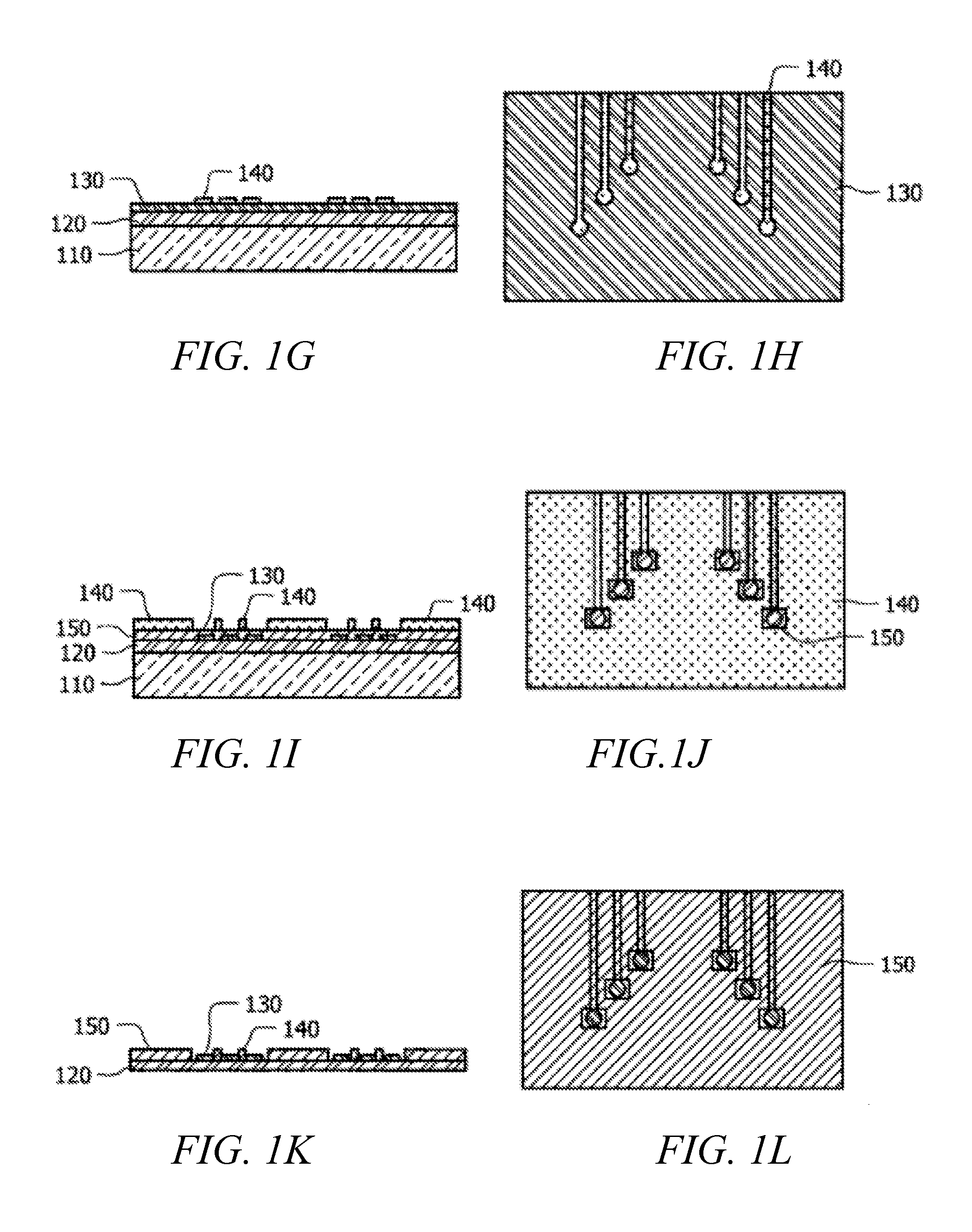

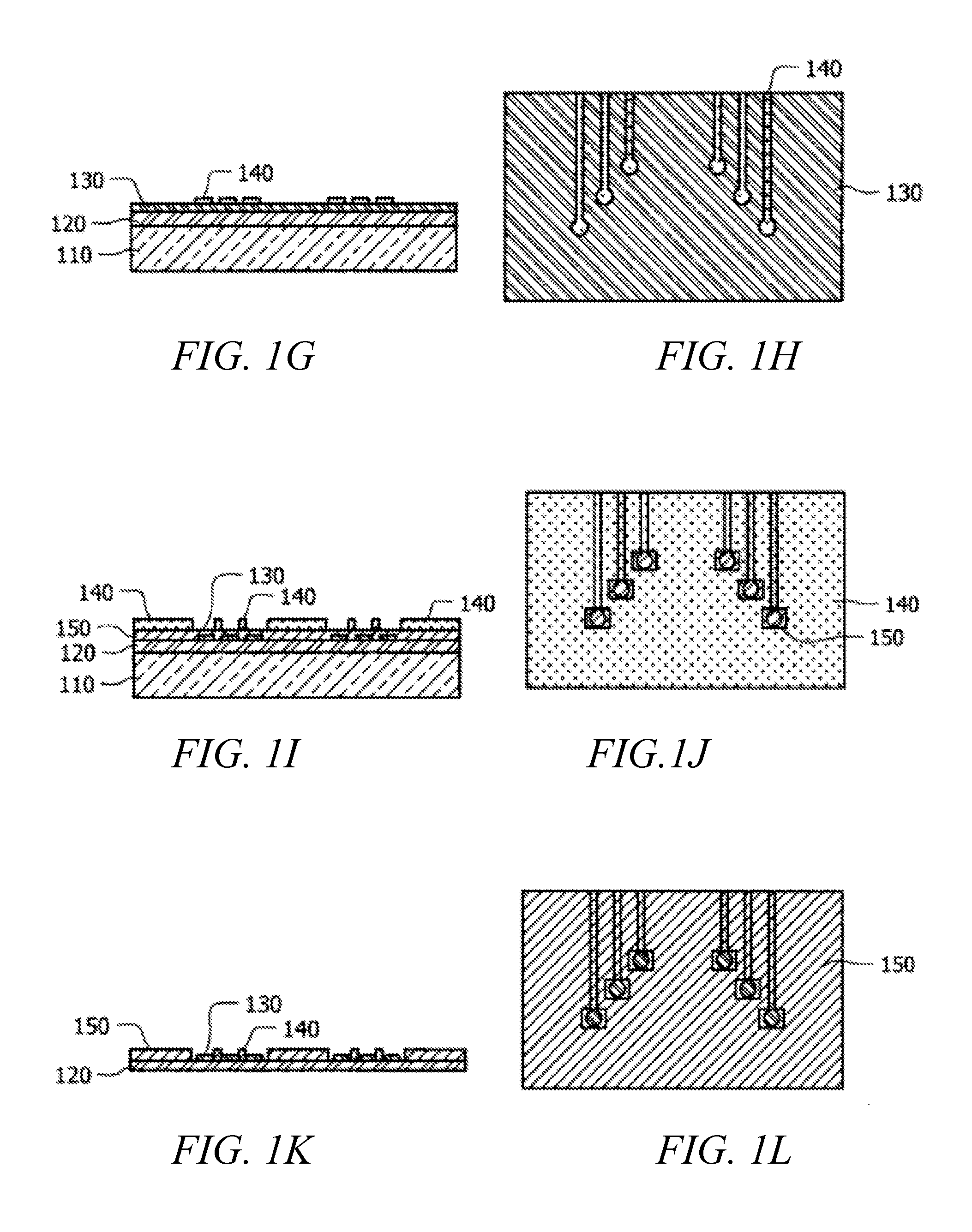

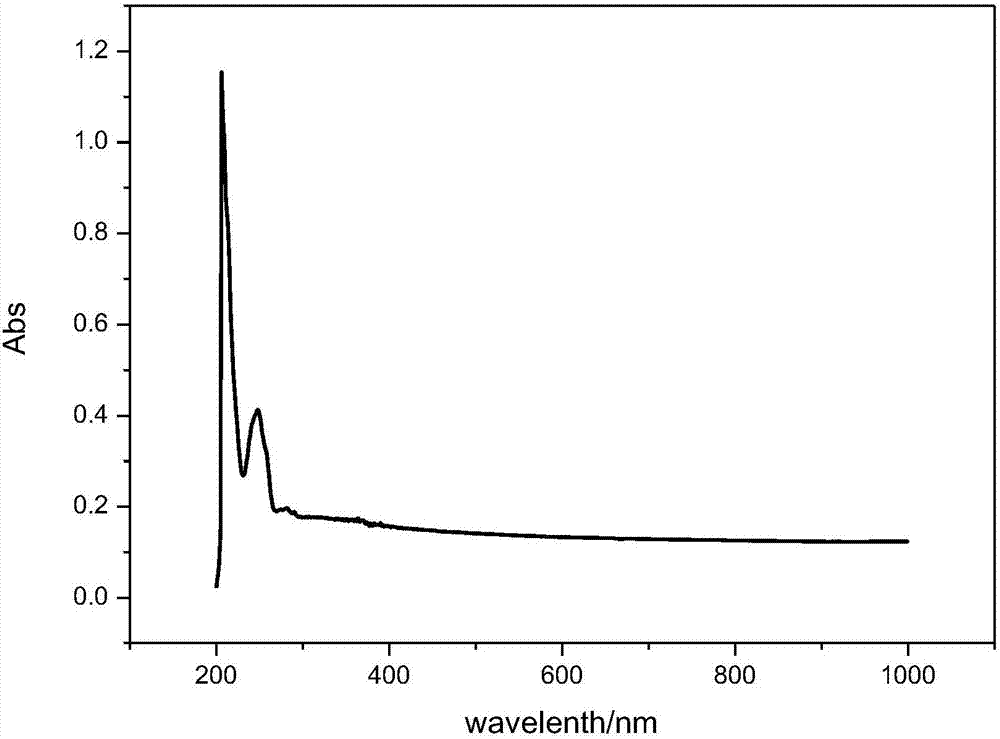

Ultraviolet or Extreme Ultraviolet and / or visible detector apparatus and fabrication processes are presented, in which the detector includes a thin graphene electrode structure disposed over a semiconductor surface to provide establish a potential in the semiconductor material surface and to collect photogenerated carriers, with a first contact providing a top side or bottom side connection for the semiconductor structure and a second contact for connection to the graphene layer.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

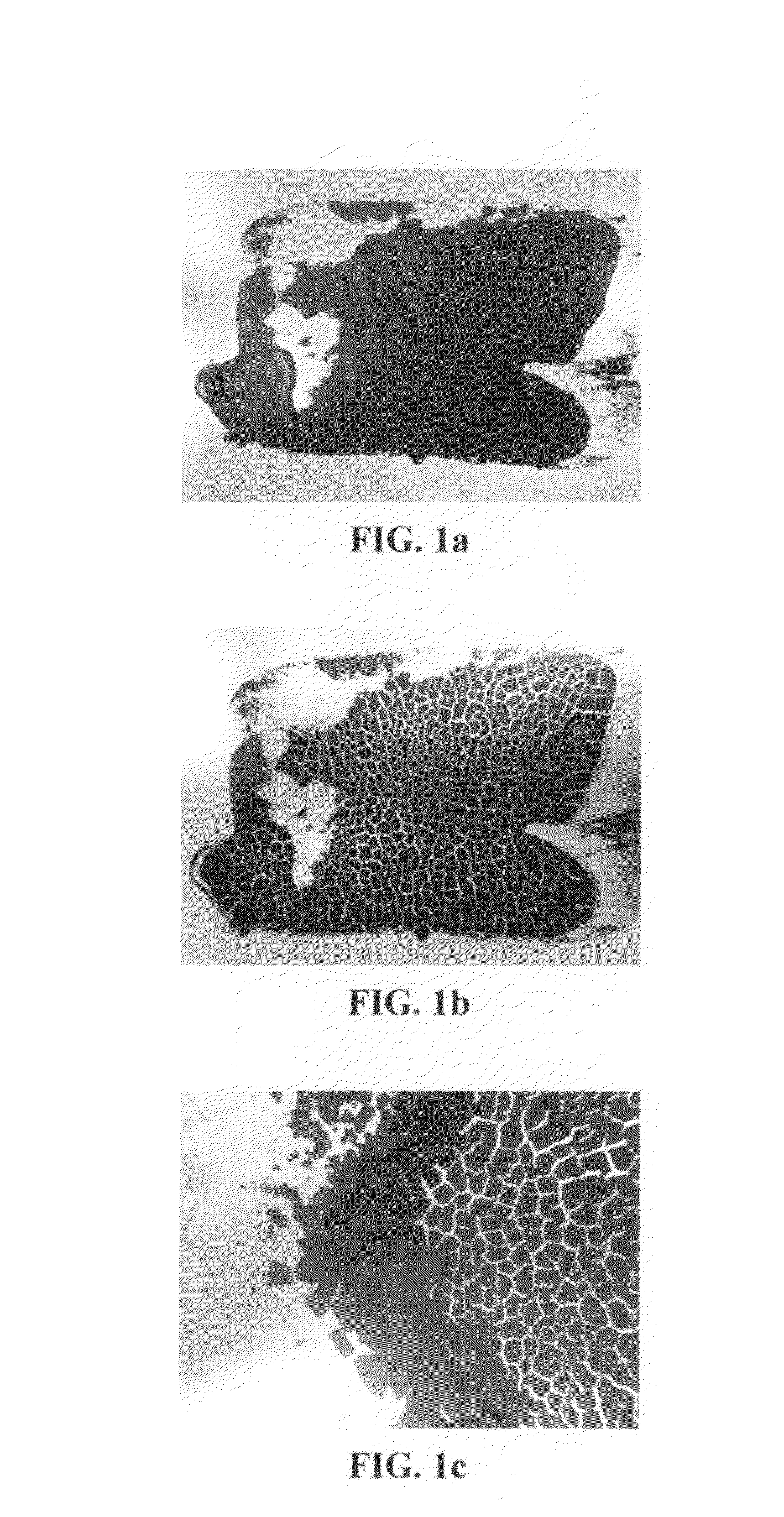

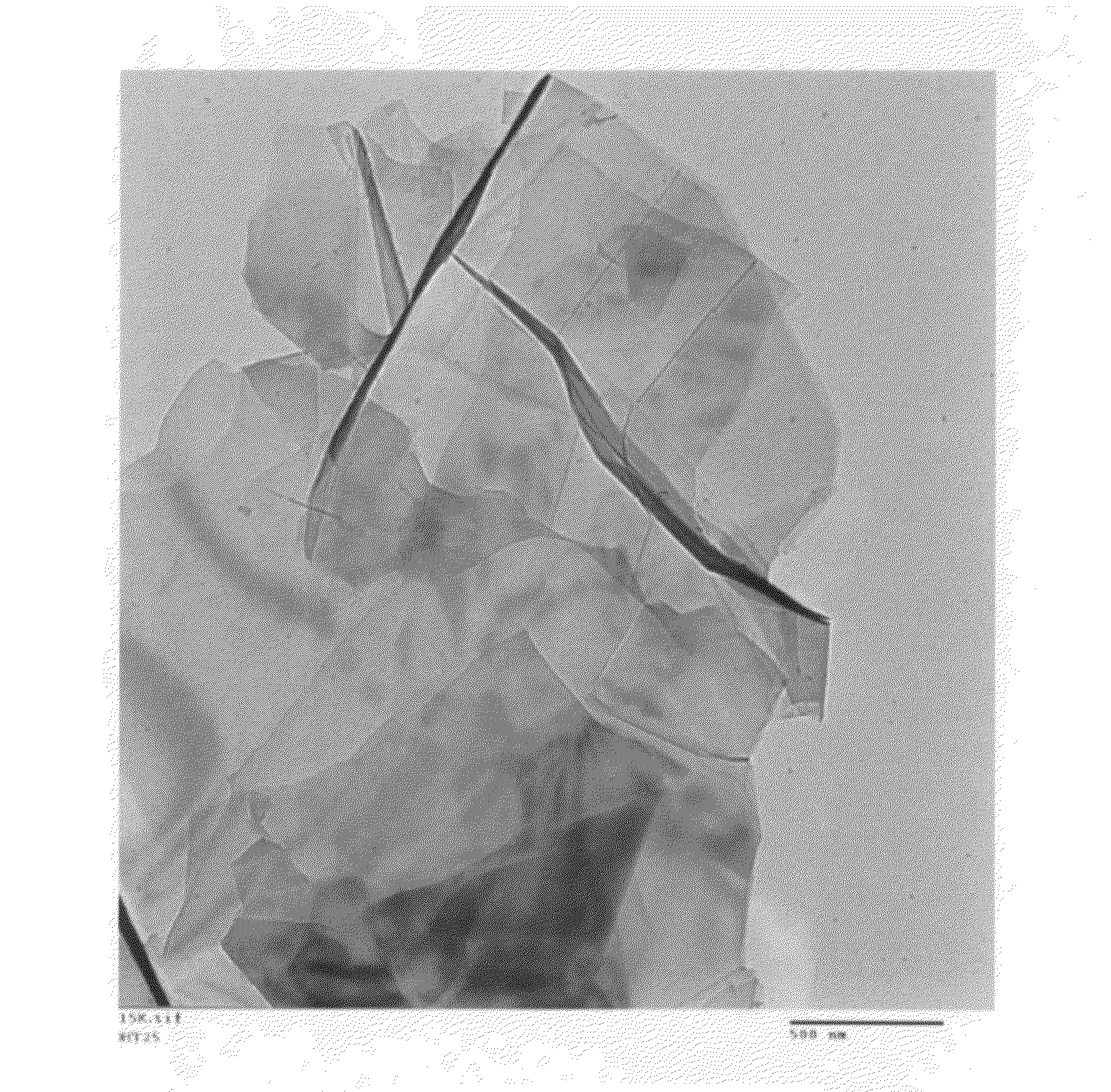

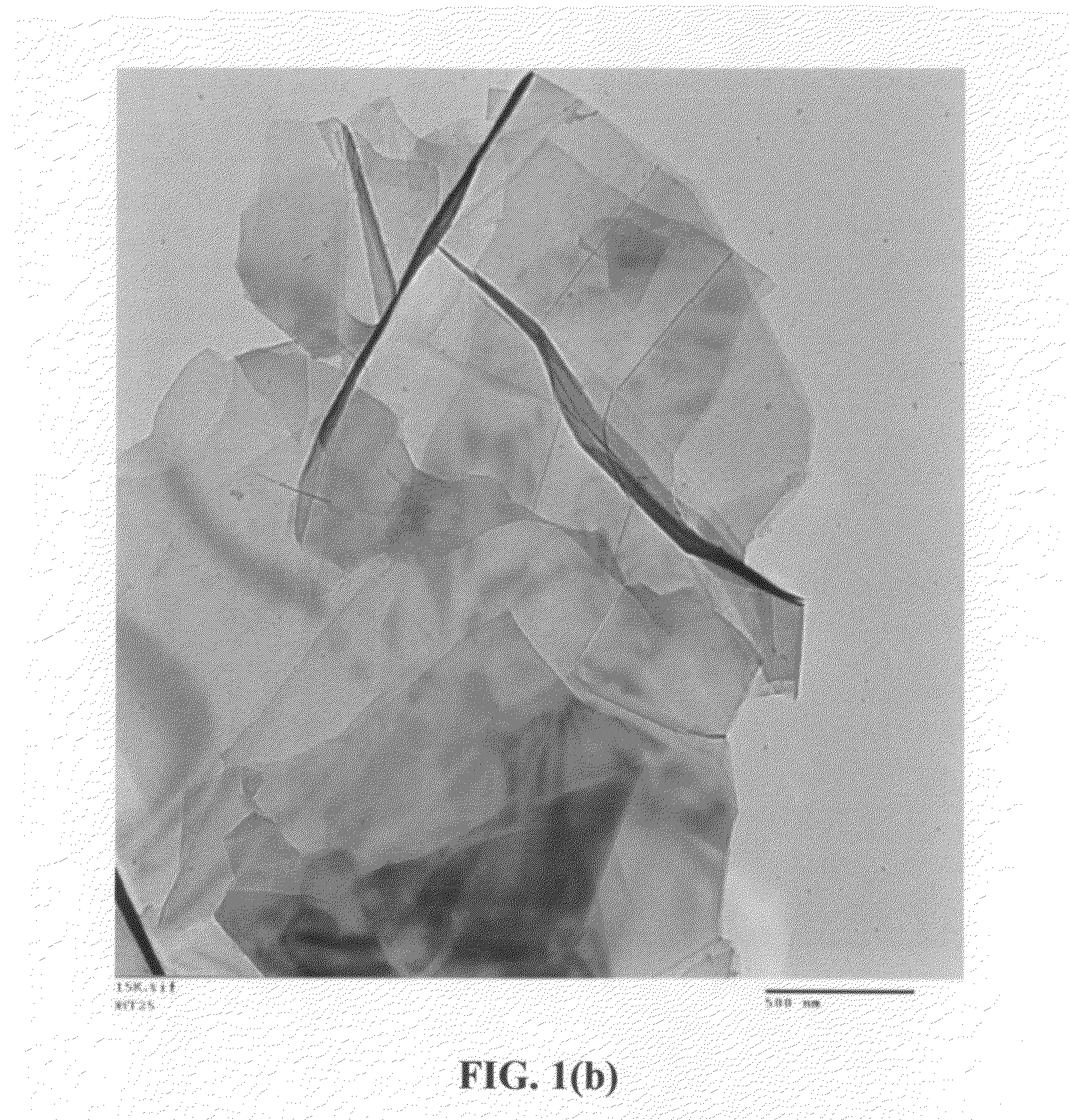

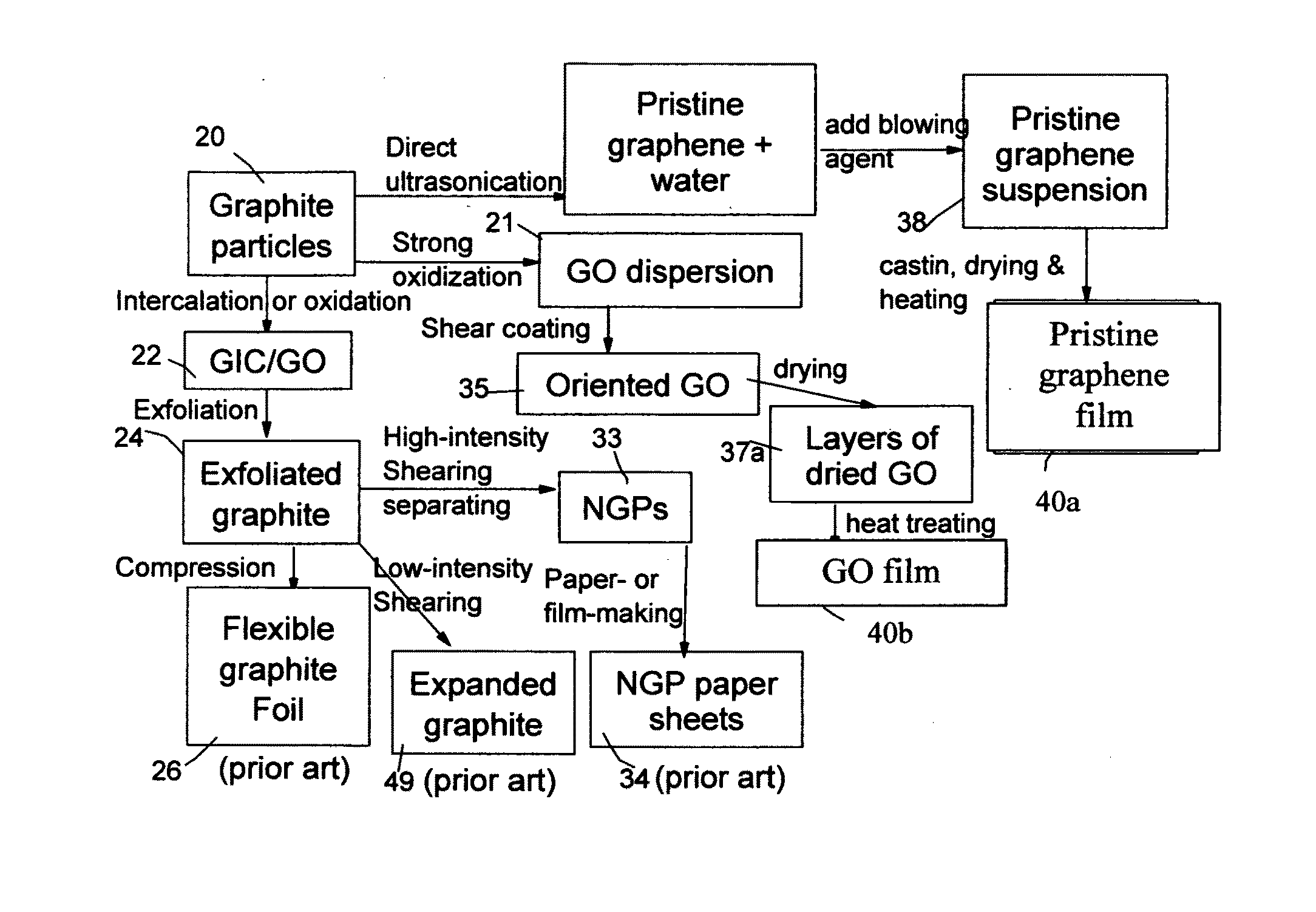

Continuous process for producing spacer-modified nano Graphene electrodes for supercapacitors

ActiveUS20110165321A1Increase surface areaMaterial nanotechnologyElectrolytic capacitorsSupercapacitorSolvent

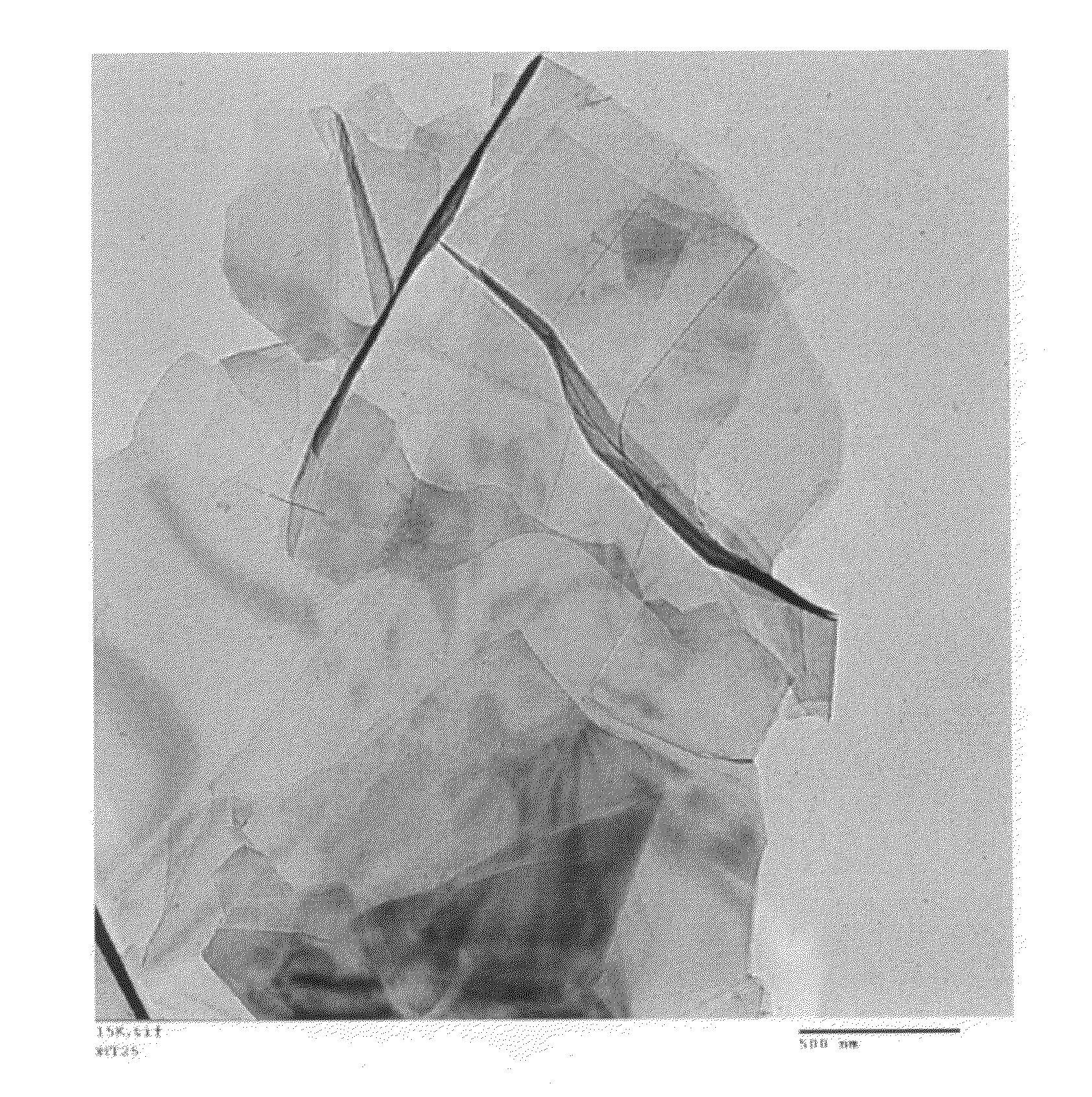

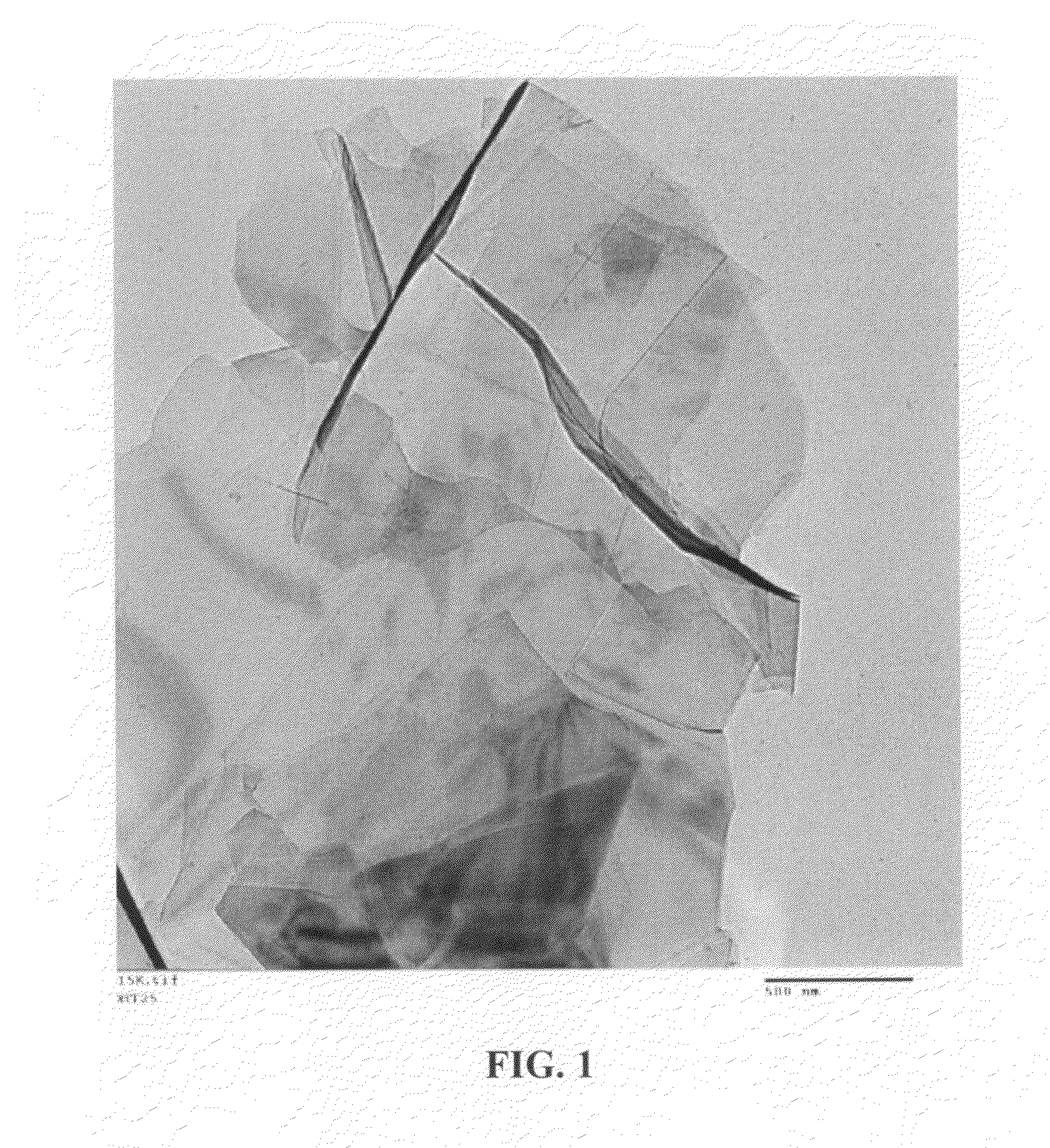

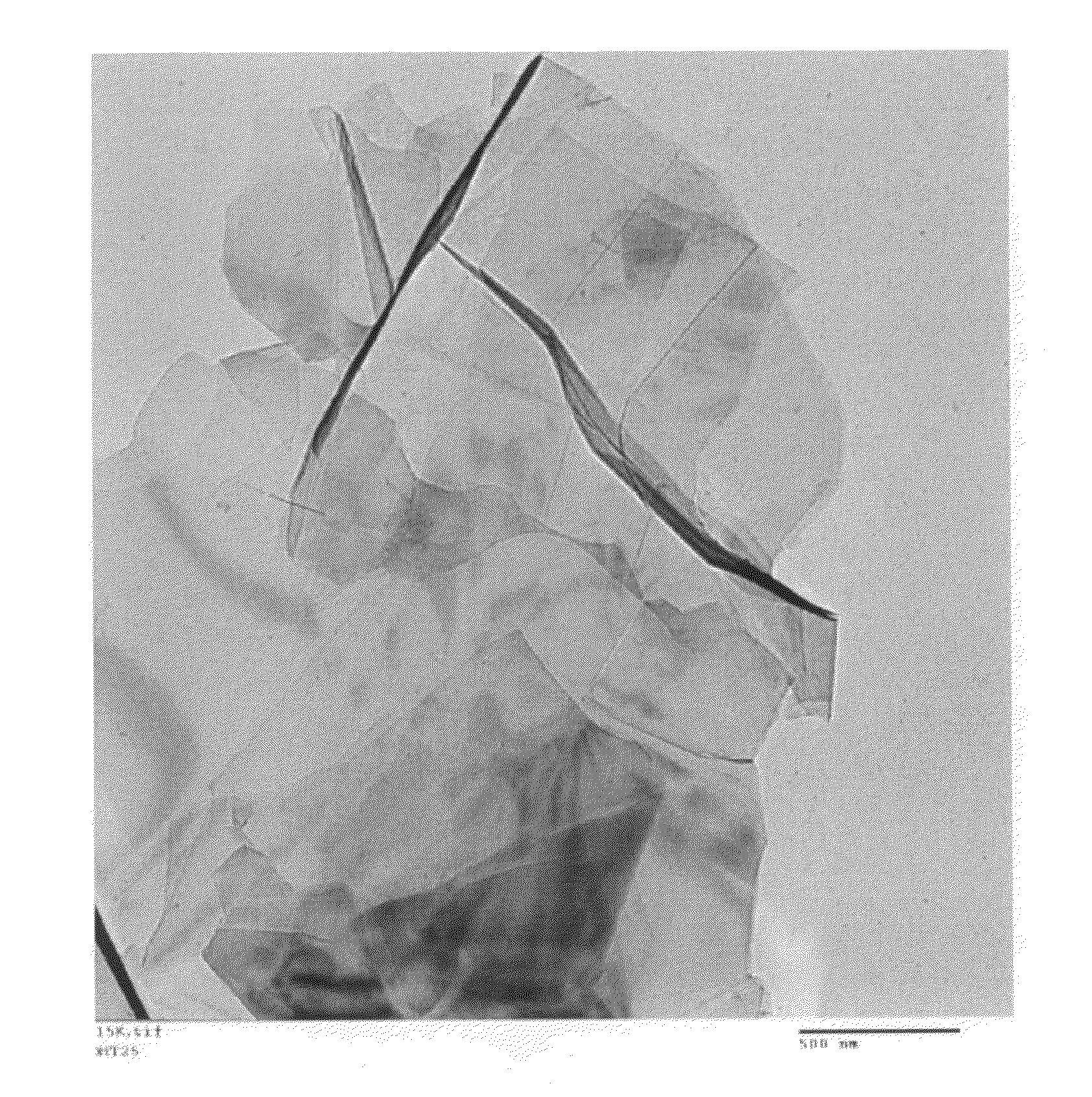

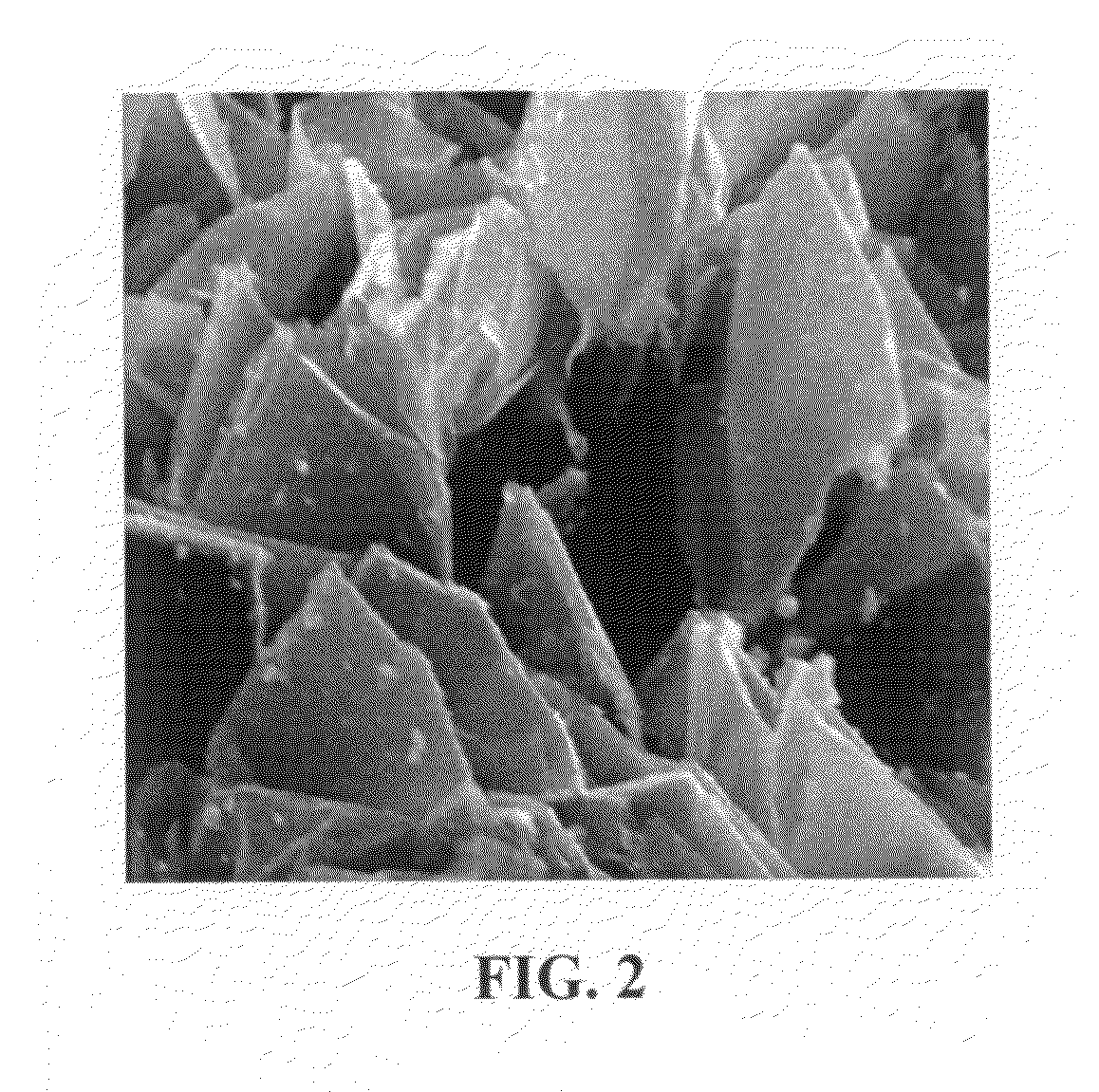

A specific embodiment of the present invention is a process for continuously producing a porous solid film of spacer-modified nano graphene platelets for supercapacitor electrode applications. This process comprises: (a) dissolving a precursor material in a solvent to form a precursor solution and dispersing multiple nano graphene platelets into the solution to form a suspension; (b) continuously delivering and forming the suspension into a layer of solid film composed of precursor material-coated graphene platelets overlapping one another, and removing the solvent from the solid film (e.g., analogous to a paper-making, mat-making, or web-making procedure); (c) continuously converting the precursor material into nodules bonded to surfaces of graphene platelets to form a porous solid film composed of spacer-modified graphene platelets; and (d) continuously collecting the porous solid film on a collector (e.g., a winding roller). The roll of porous solid film (mat, paper, or web) can then be cut into pieces for used as supercapacitor electrodes.

Owner:NANOTEK INSTR GRP LLC

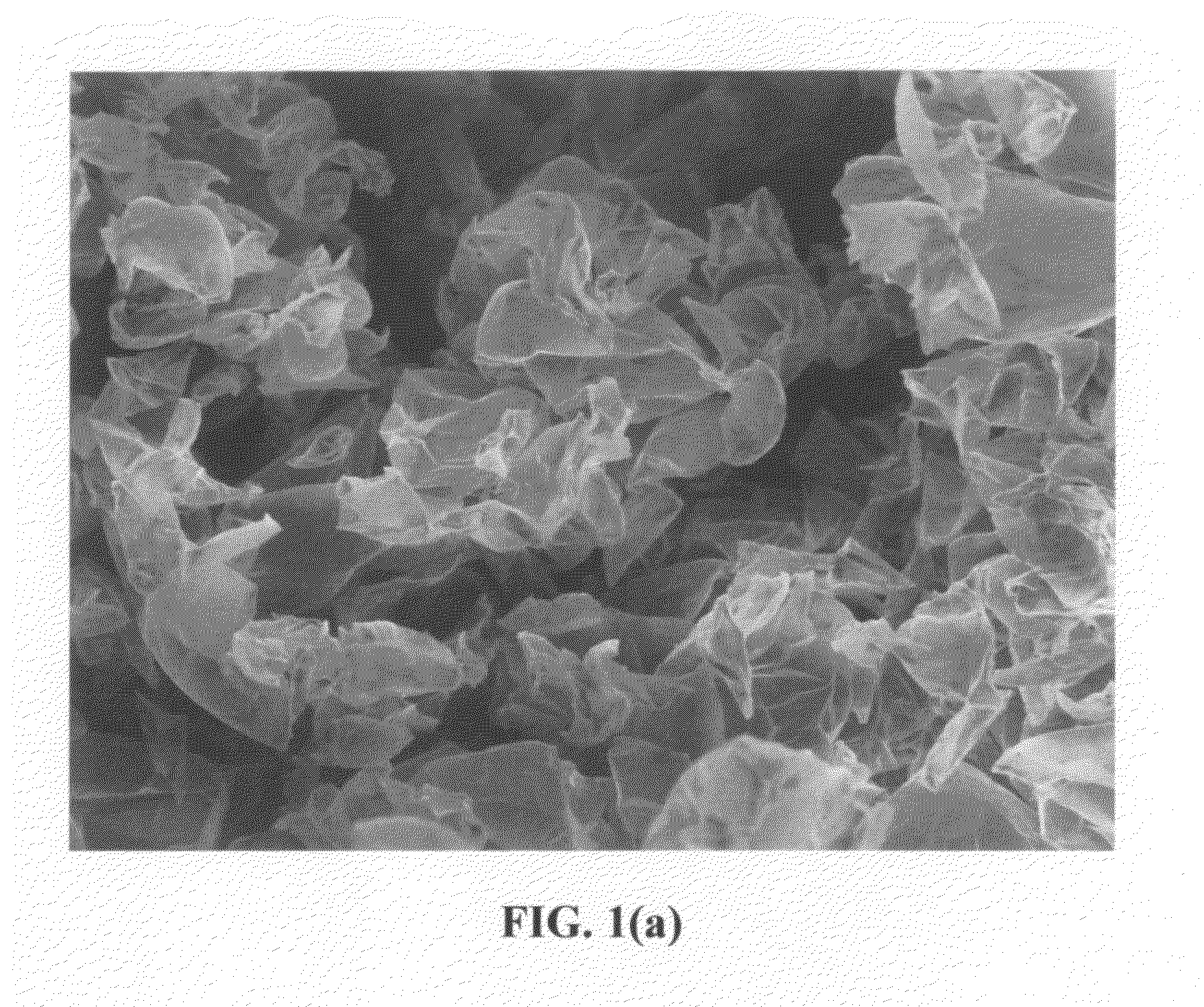

Supercapacitor with a meso-porous nano graphene electrode

ActiveUS20120026643A1Well formedHybrid capacitor electrodesElectrolytic capacitorsCapacitanceHigh energy

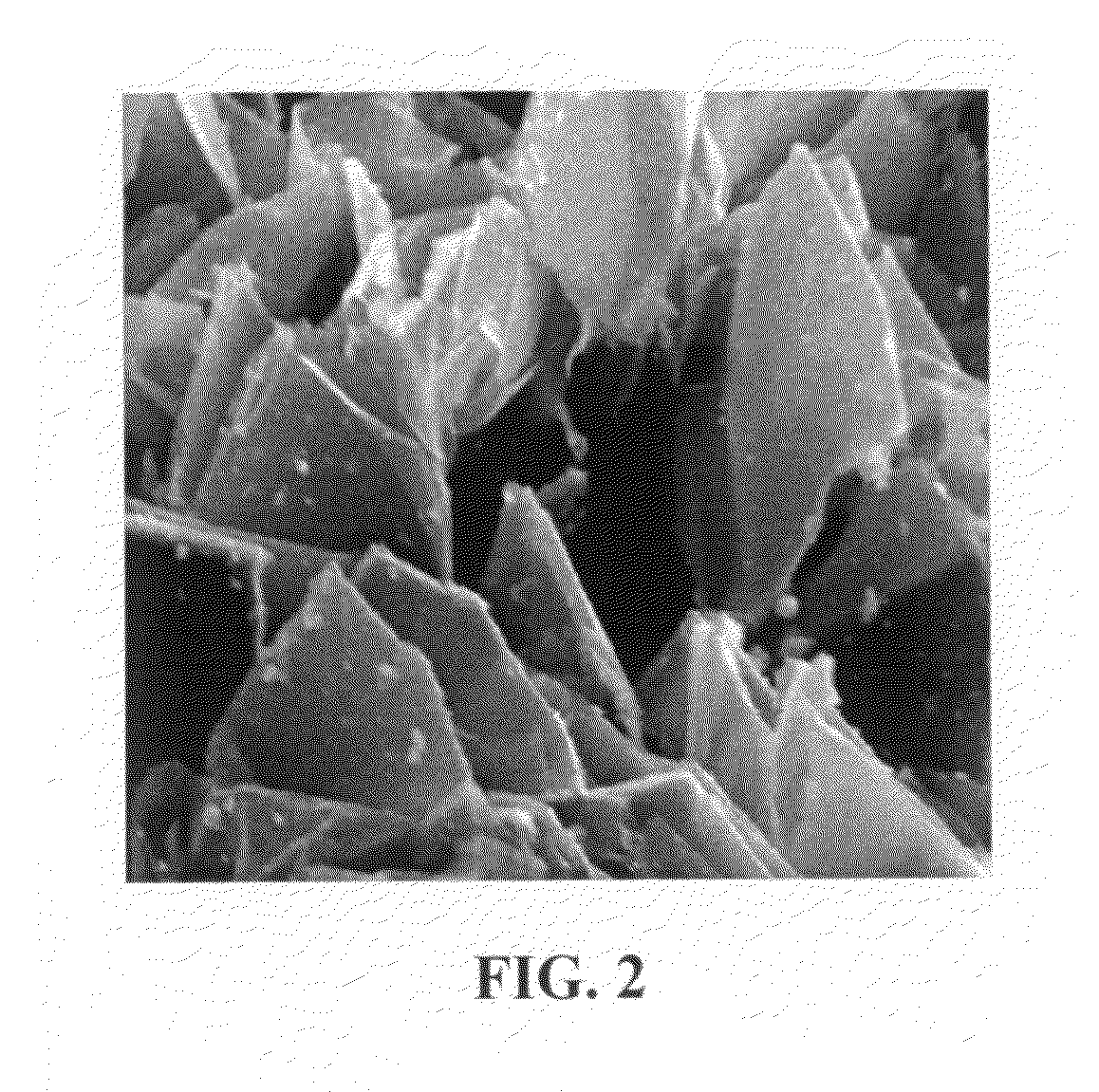

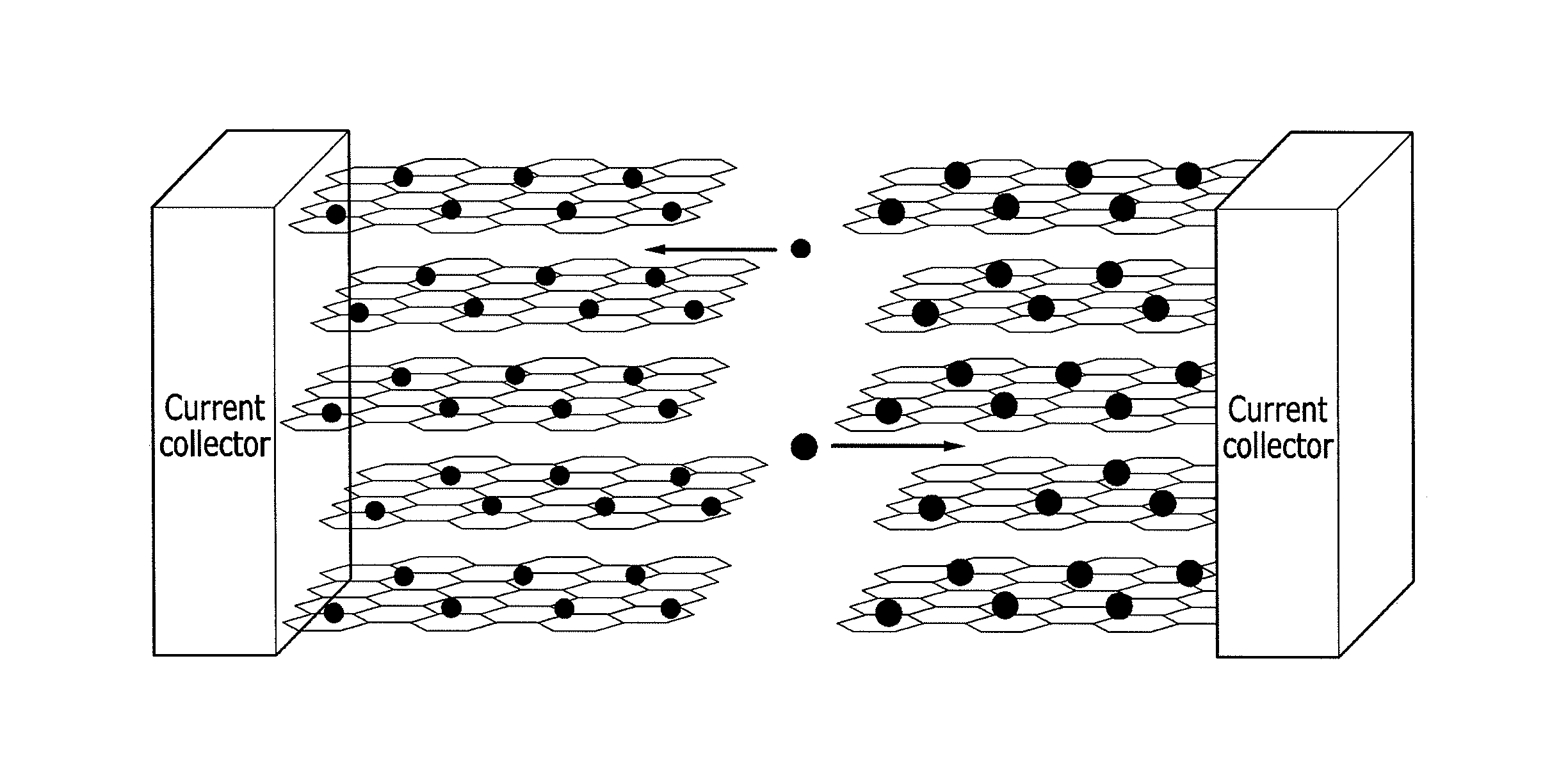

A supercapacitor comprising a two electrodes, a porous separator disposed between the two electrodes, and an ionic liquid electrolyte in physical contact with the two electrodes, wherein at least one of the two electrodes comprises a meso-porous structure being formed of a plurality of nano graphene platelets and multiple pores having a pore size in the range of 2 nm and 25 nm, wherein the graphene platelets are not spacer-modified or surface-modified platelets. Preferably, the graphene platelets are curved, not flat-shaped. The pores are accessible to ionic liquid molecules, enabling the formation of large amounts of electric double layer charges in a supercapacitor, which exhibits an exceptionally high specific capacitance and high energy density.

Owner:NANOTEK INSTR GRP LLC

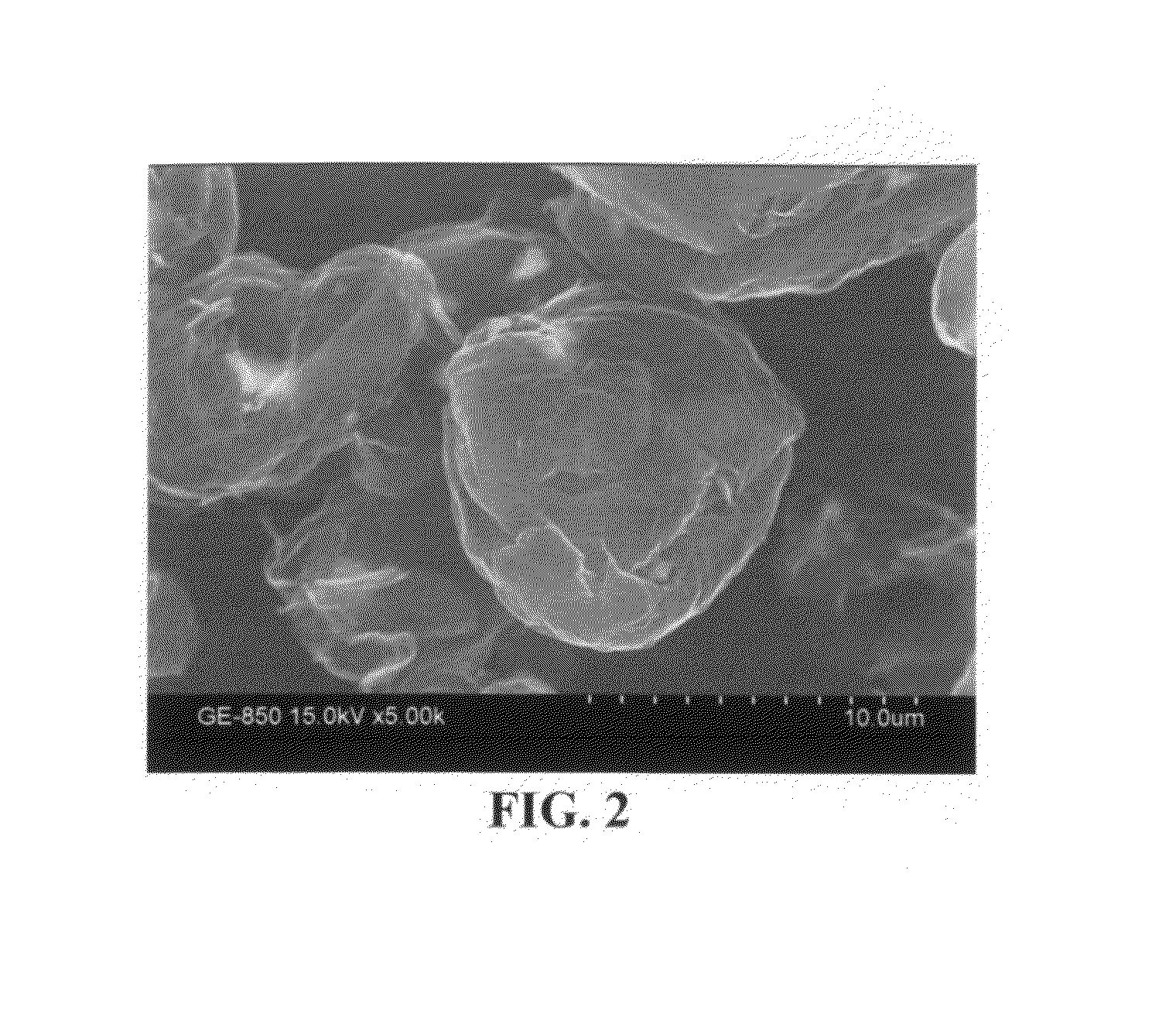

Spacer-modified nano graphene electrodes for supercapacitors

ActiveUS20110157772A1Increase surface areaMaterial nanotechnologyLiquid electrolytic capacitorsCapacitanceSupercapacitor

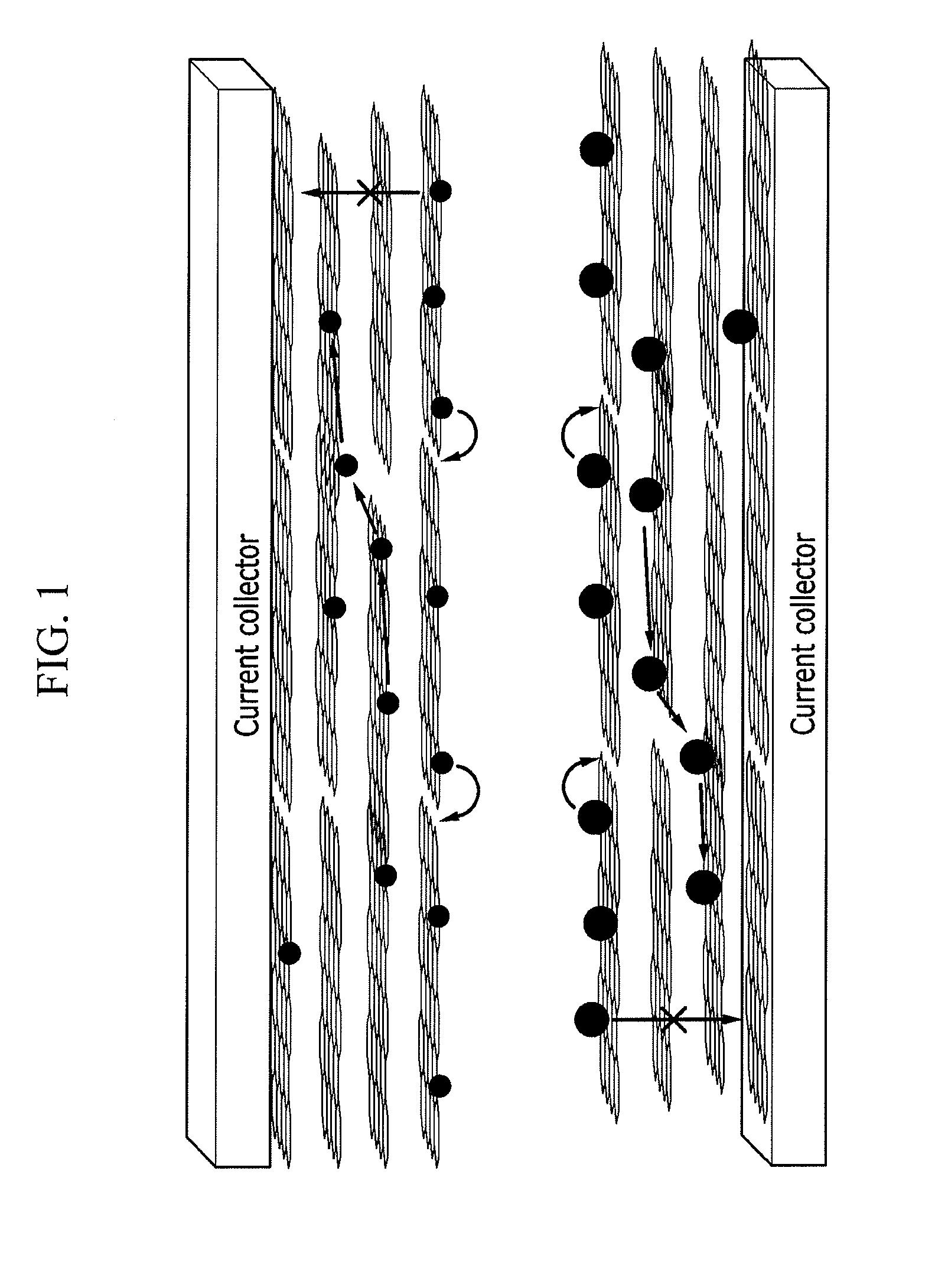

A surface-modified nano graphene platelet (NGP), comprising: (a) a nano graphene platelet having a thickness smaller than 10 nm; and (b) discrete, non-continuous, and non-metallic bumps or nodules bonded to a surface of the graphene platelet to serve as a spacer. When multiple surface-modified NGP sheets are stacked together to form an electrode, large numbers of electrolyte-accessible pores are formed, enabling the formation of large amounts of double layer charges in a supercapacitor, which exhibits an exceptionally high specific capacitance.

Owner:NANOTEK INSTR GRP LLC

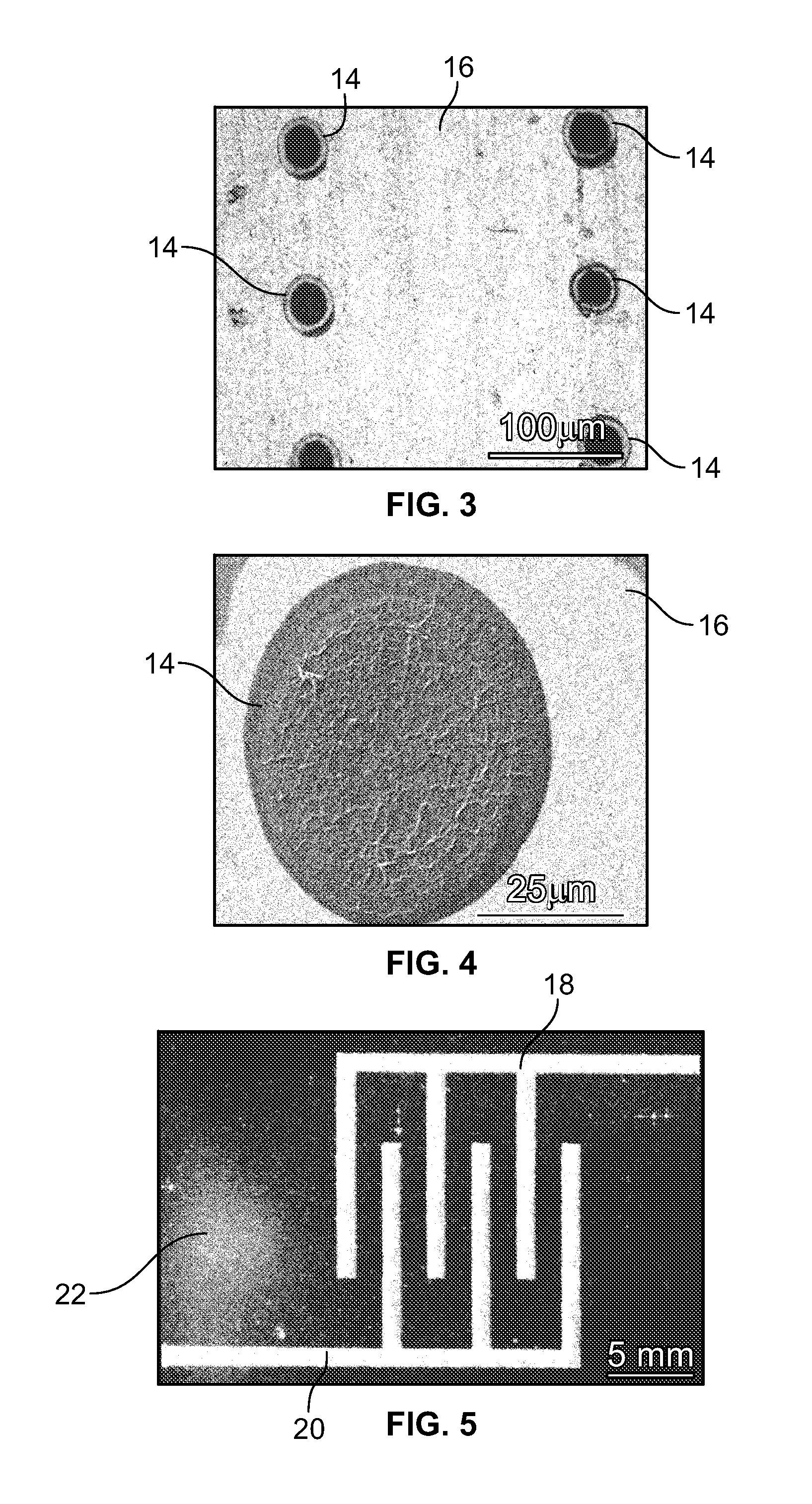

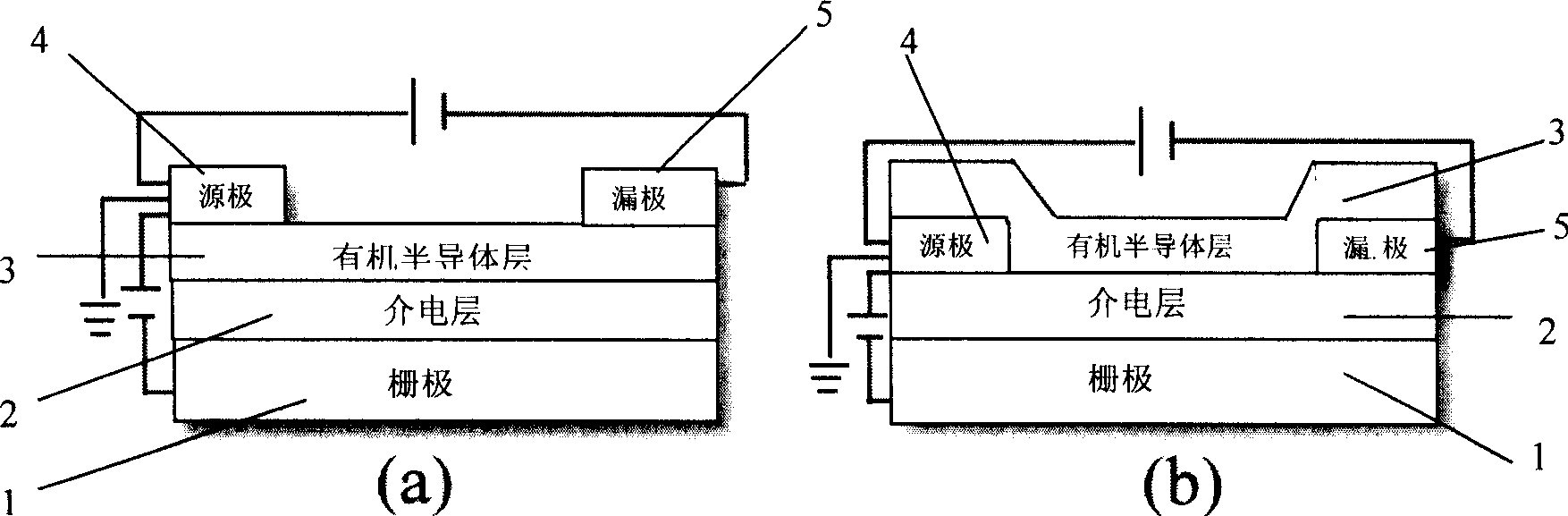

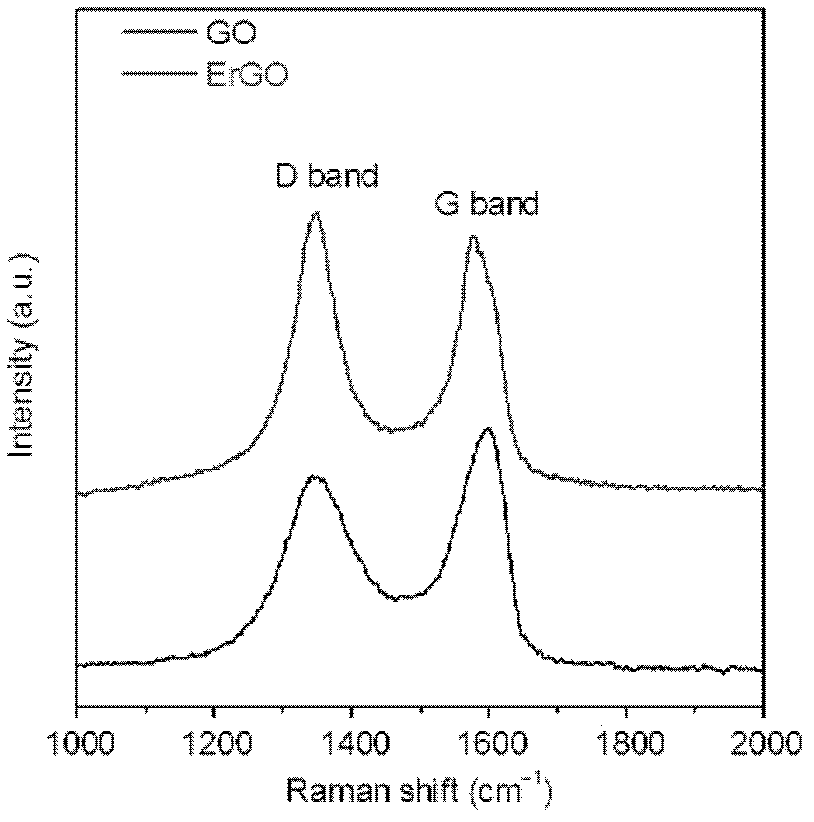

Inkjet-printed flexible electronic components from graphene oxide

InactiveUS20120170171A1Improve conductivityThermally degradedSolid electrolytic capacitorsHybrid capacitor electrodesCarbon nanotubeCharge separation

An electrical component includes an inkjet-printed graphene electrode. Graphene oxide flakes are deposited on a substrate in a graphene oxide ink using an inkjet printer. The deposited graphene oxide is thermally reduced to graphene. The electrical properties of the electrode are comparable to those of electrodes made using activated carbon, carbon nanotubes or graphene made by other methods. The electrical properties of the graphene electrodes may be tailored by adding nanoparticles of other materials to the ink to serve as conductivity enhancers, spacers, or to confer pseudocapacitance. Inkjet-printing can be used to make graphene electrodes of a desired thickness in preselected patterns. Inkjet printing can be used to make highly-transparent graphene electrodes. Inkjet-printed graphene electrodes may be used to fabricate double-layer capacitors that store energy by nanoscale charge separation at the electrode-electrolyte interface (i.e., “supercapacitors”).

Owner:STEVENS INSTITUTE OF TECHNOLOGY +1

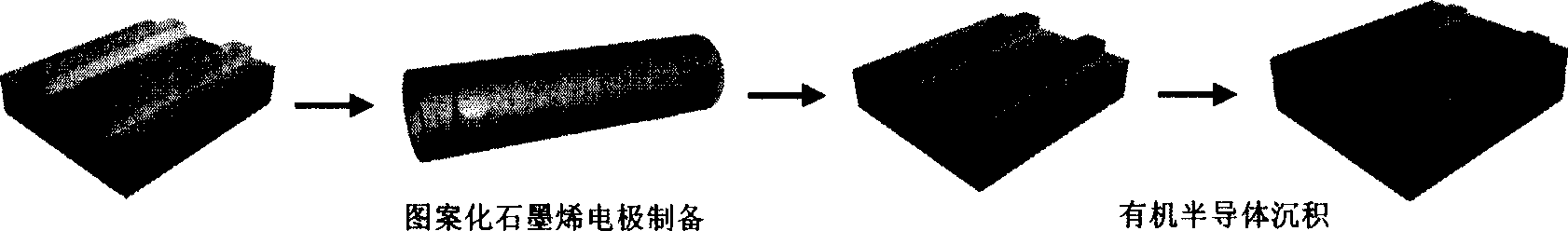

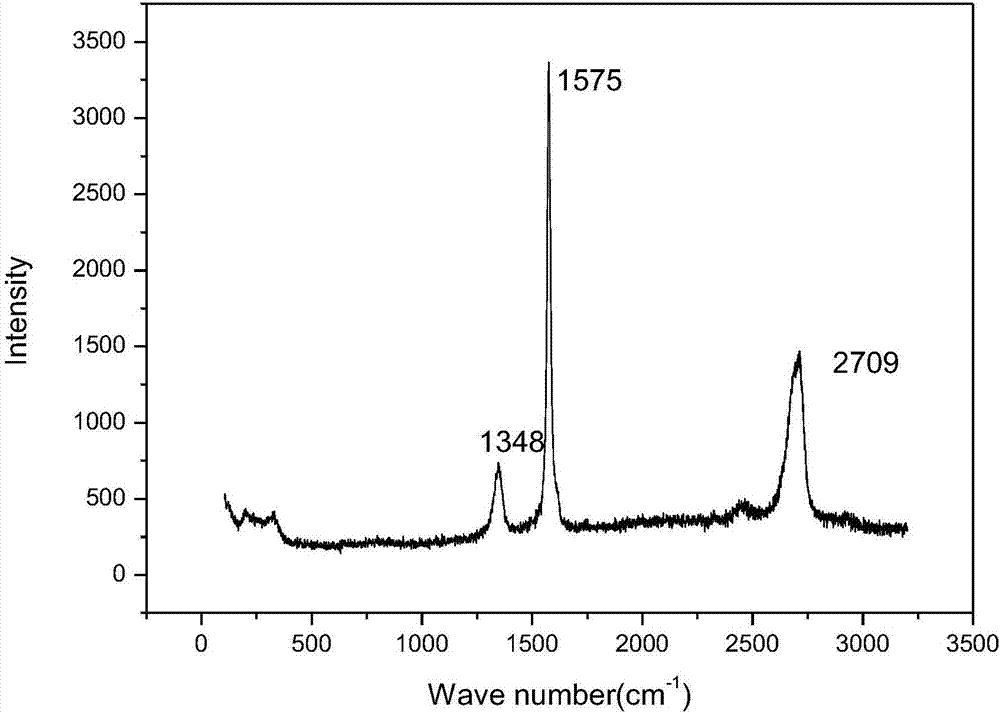

Organic field effect transistor and special source/drain electrode and preparation method thereof

InactiveCN101442105ALow costImprove performanceSolid-state devicesSemiconductor/solid-state device manufacturingOrganic field-effect transistorGas phase

The invention discloses an organic field effect transistor (FET), as well as a special source-drain electrode and a preparation method thereof. The organic FET with an electrode structure comprises a gate electrode, a dielectric layer, an organic semiconductor layer, a source electrode and a drain electrode, wherein the source electrode and the drain electrode are patterned Graphene electrodes. The method for preparing the patterned Graphene electrodes comprises the following steps: 1) a metal film is deposited on a substrate and is patterned; and 2) the substrate on which the patterned metal film is deposited is placed in a chemical vapor deposition system, and chemical vapor Graphene deposition is performed on the surface of a patterned metal electrode material, so as to obtain the patterned Graphene electrodes, wherein a carbon source used in chemical vapor deposition is methanol, ethanol, propanol, pentanol, benzene, toluene, xylene, methane and the like.

Owner:INST OF CHEM CHINESE ACAD OF SCI

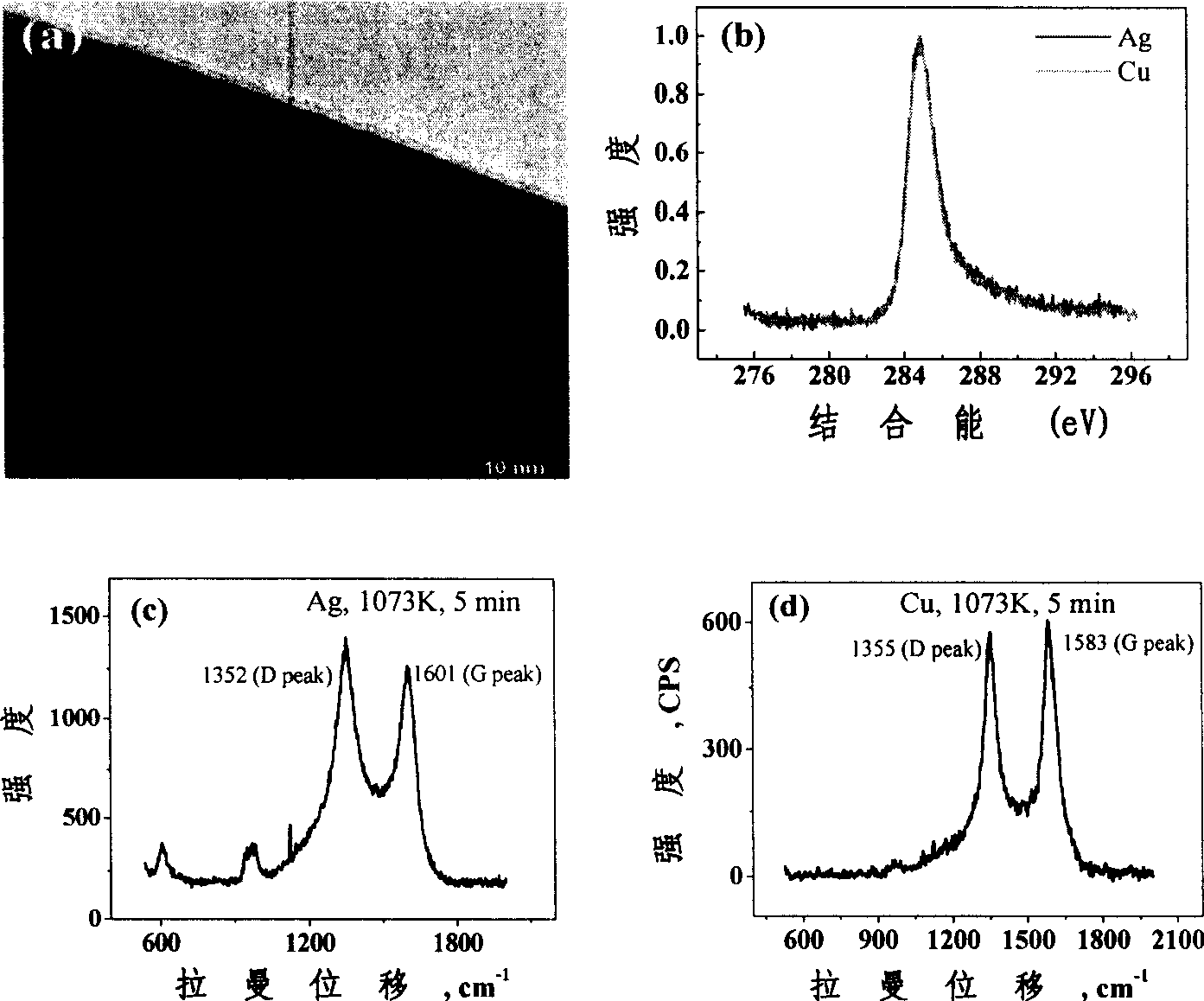

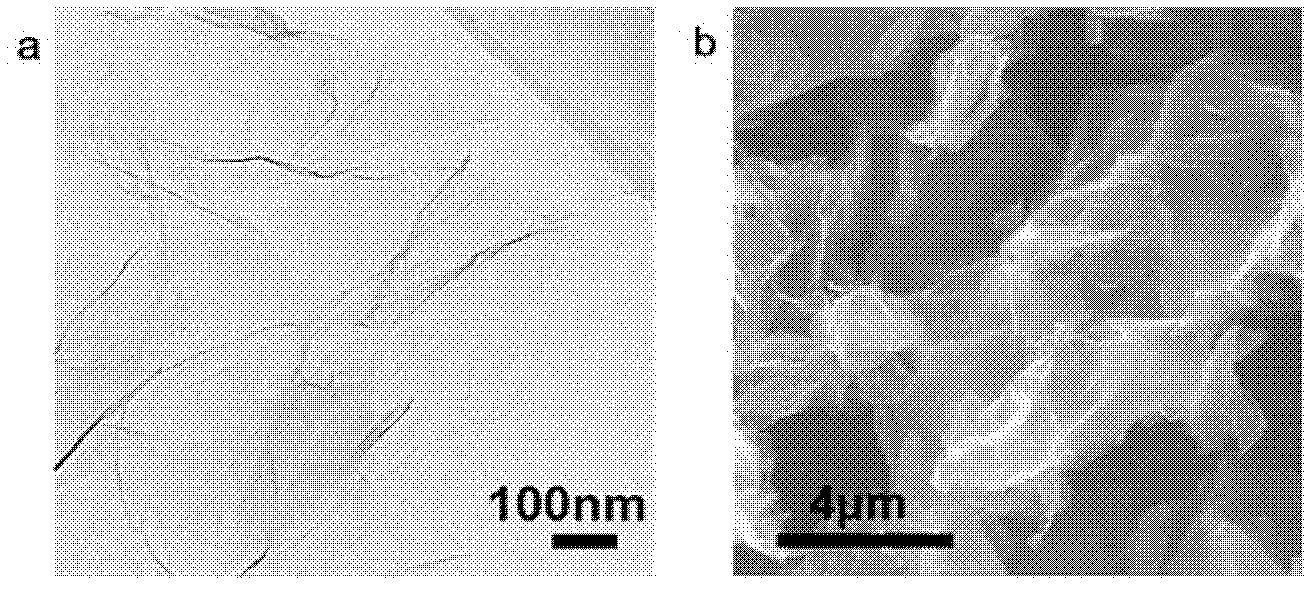

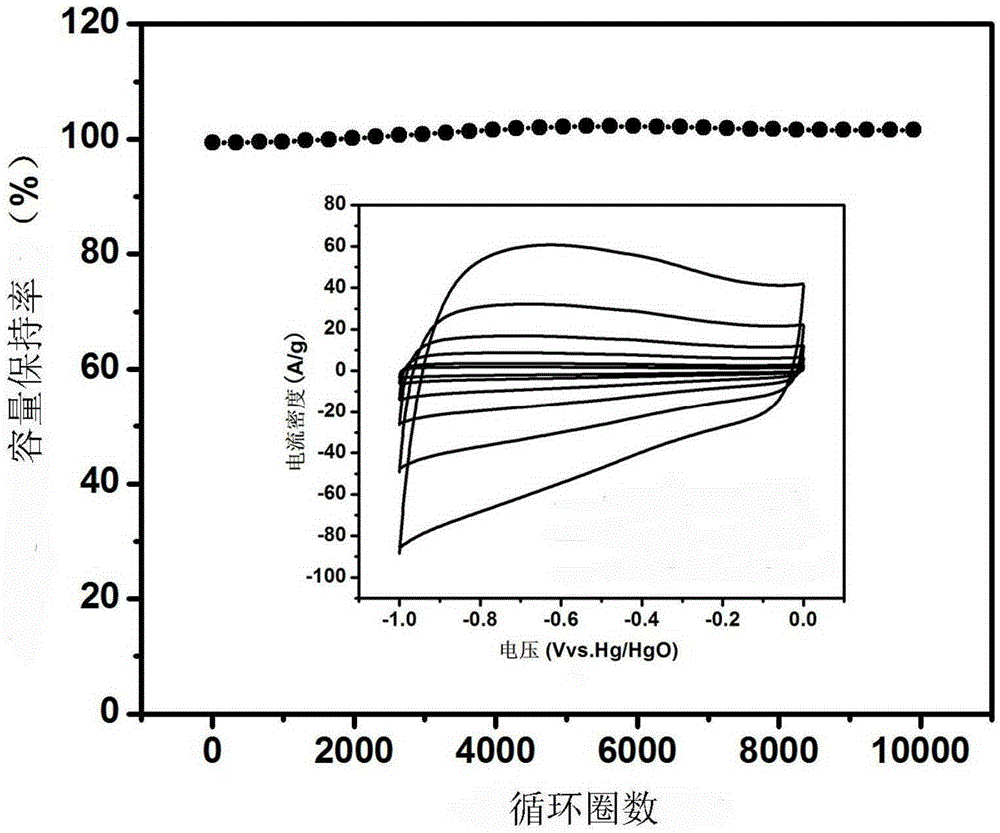

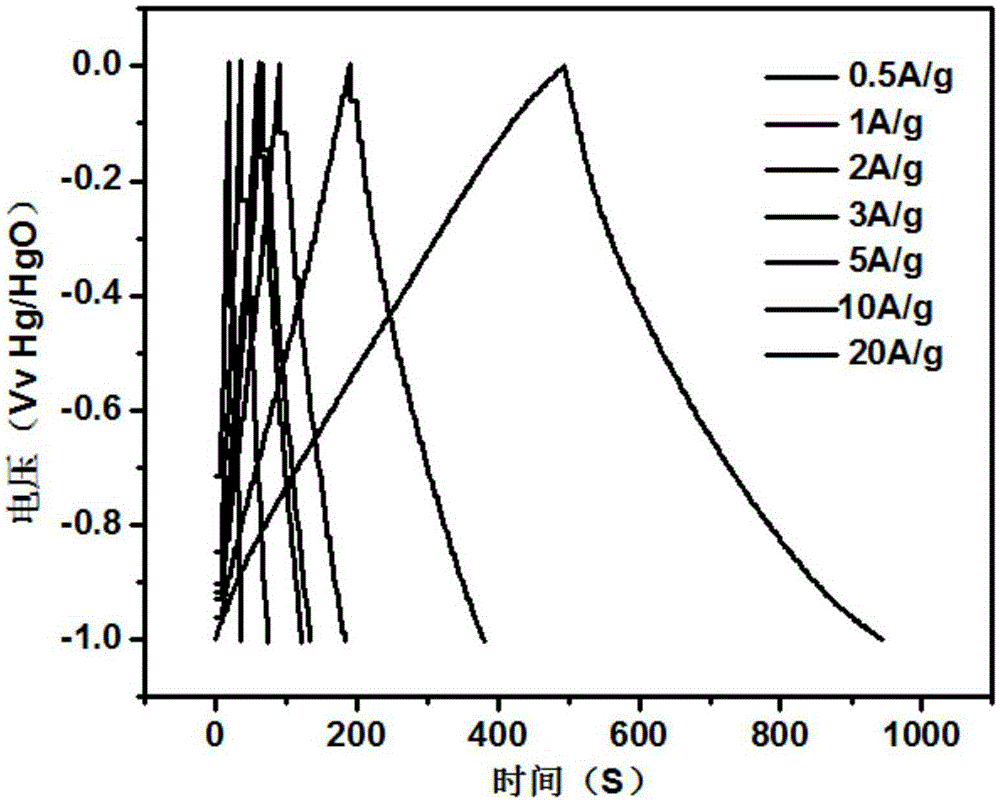

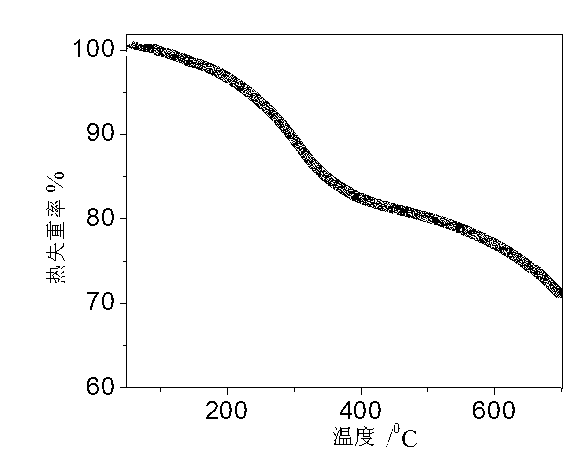

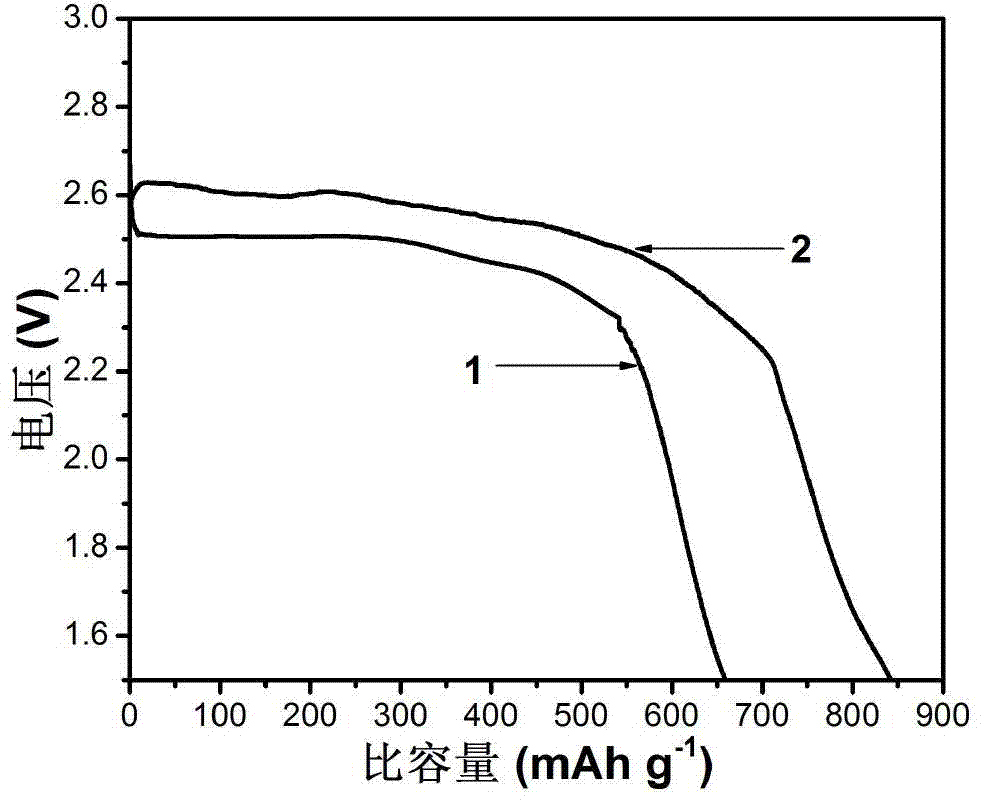

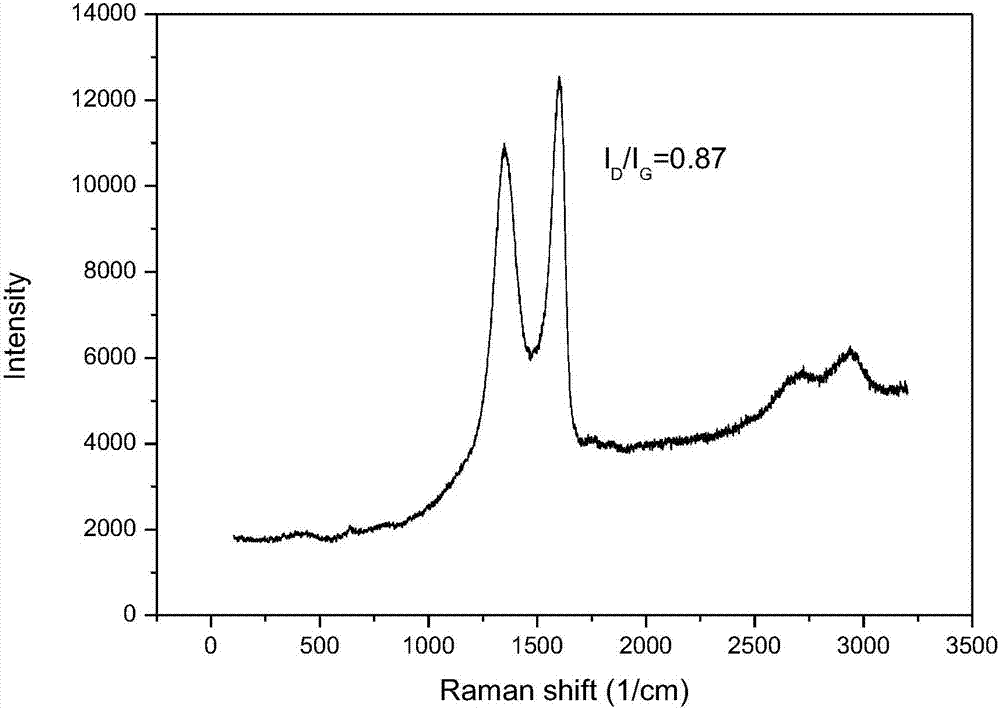

Doped graphene electrode material, macro preparation method and application of doped graphene electrode material

InactiveCN102306781AImprove conductivityGood thermal stabilityCell electrodesHigh current densityDoped graphene

The invention relates to the field of graphene electrode materials, and in particular relates to a doped graphene electrode material, a macro preparation method as well as an application of the doped graphene electrode material in a high-capacity high-multiplying-power lithium ion battery. In the invention, graphene is taken as a raw material. The preparation method comprises the following steps: controlling the temperature rising speed rate through shielding gas; introducing gas containing nitrogen or boron elements in different concentrations at high temperature so as to realize the doping of heteroatoms of the graphene, and get the nitrogen or boron doped graphene; mixing the doped graphene, conductive carbon black and a bonding agent; adding a solvent; coating the mixture on a current collector after grinding; taking the mixture after drying, shearing and tabletting as a working electrode; adding electrolyte containing a lithium salt by taking a lithium plate as a counter electrode / reference electrode; assembling into a button-type lithium ion half-battery in a glove box; and carrying out constant current charge and discharge tests under the condition of high current density. According to the invention, the electrode stability of the material under the condition of high current density is improved, and the fact that the doped graphene has higher specific capacity and excellent cycle performance in a shorter time is realized.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

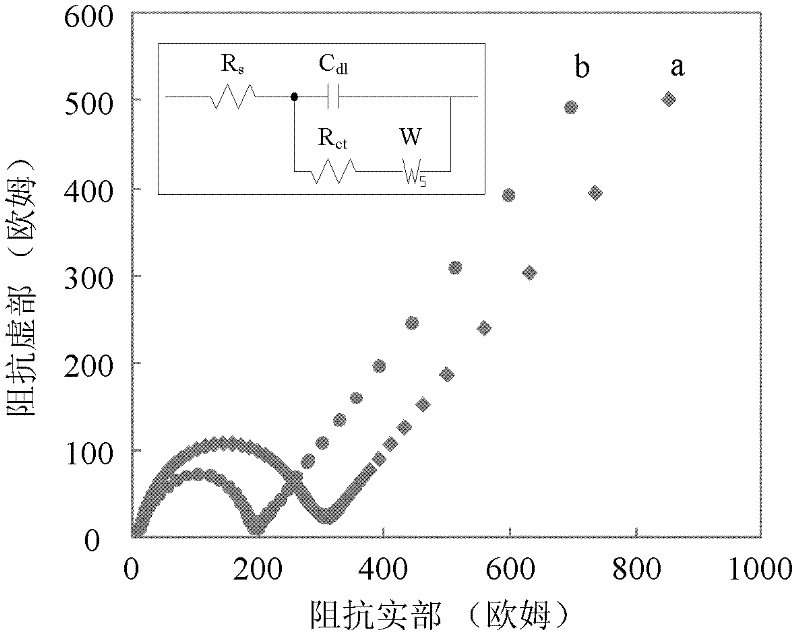

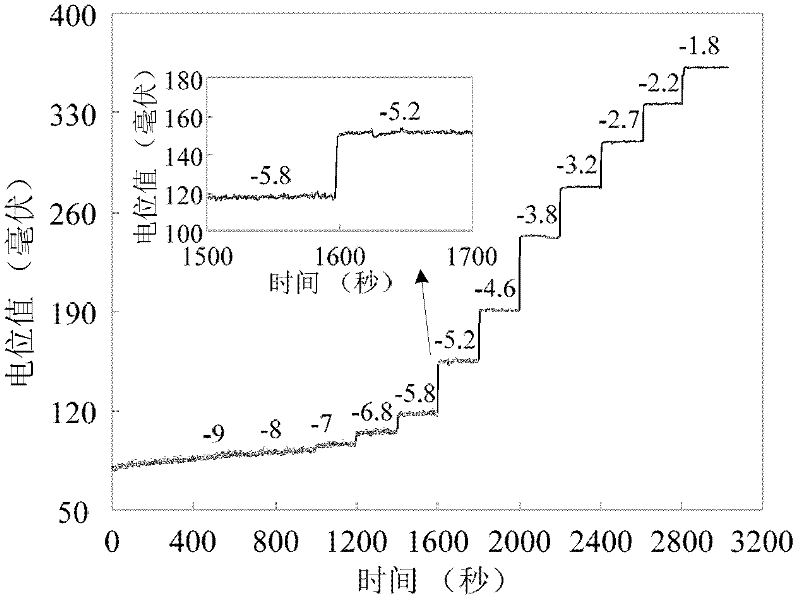

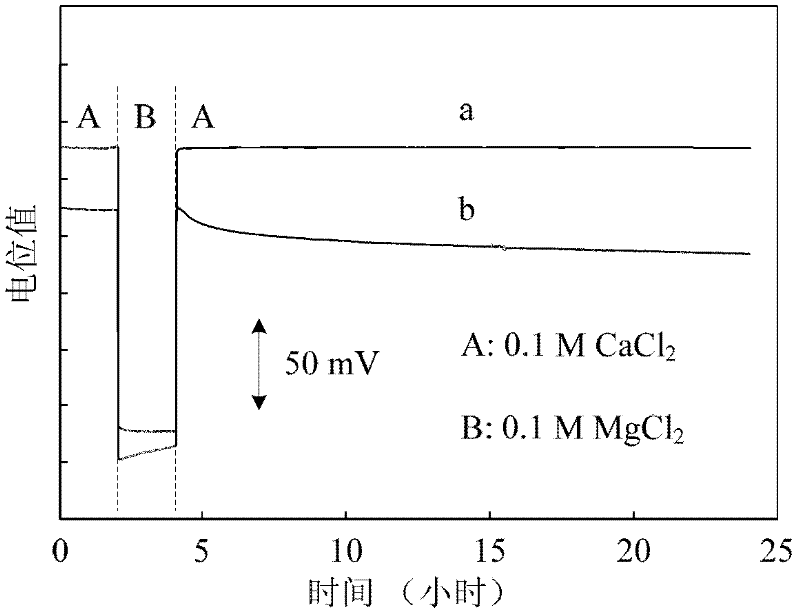

Ion-selective electrode based on graphene electrode and preparation method thereof

InactiveCN102507696AImprove featuresHigh Specific CapacitanceMaterial analysis by electric/magnetic meansMicroelectrodeGraphene electrode

The invention discloses an ion-selective electrode based on a graphene electrode, comprising an electrode base body and an ion-selective polymer film coated on the surface of the electrode base body, wherein the electrode base body is an electrode doped with graphene or decorated by a graphene film on the electrode surface by electro-deposition. The ion-selective electrode, provided by the invention, has the advantages of simple preparation, low cost, fast electron transfer, stable potential, high sensitivity, good selectivity and the like, is applied to detection of ion concentration in solution, and provides a new idea to development of the ion-selective electrode towards a microelectrode aspect.

Owner:ZHEJIANG UNIV

Graphene Electrode Based Ceramic Capacitor

ActiveUS20160079001A1Improve crystal structureGood physical propertiesFixed capacitor electrodesFixed capacitor dielectricDoped grapheneIodide

A ceramic capacitor comprising at least a dielectric ceramic layer and at least a graphene electrode layer deposited on the ceramic layer, wherein the graphene electrode layer has a thickness no less than 2 nm and consists of a graphene material or a graphene composite material containing at least 0.1% by weight of a graphene material dispersed in a matrix material or bonded by a binder material, wherein the graphene material is selected from (a) a plurality of single-layer or multi-layer pristine graphene sheets having less than 0.01% by weight of non-carbon elements, or (b) one or a plurality of a non-pristine graphene material having at least 0.01% by weight of non-carbon elements, wherein the non-pristine graphene is selected from graphene oxide, reduced graphene oxide, graphene fluoride, graphene chloride, graphene bromide, graphene iodide, hydrogenated graphene, nitrogenated graphene, doped graphene, chemically functionalized graphene, or a combination thereof.

Owner:GLOBAL GRAPHENE GRP INC

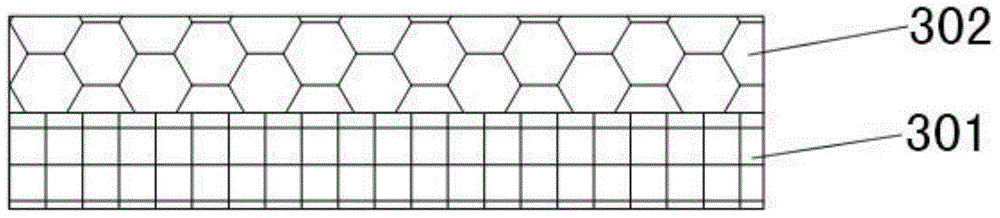

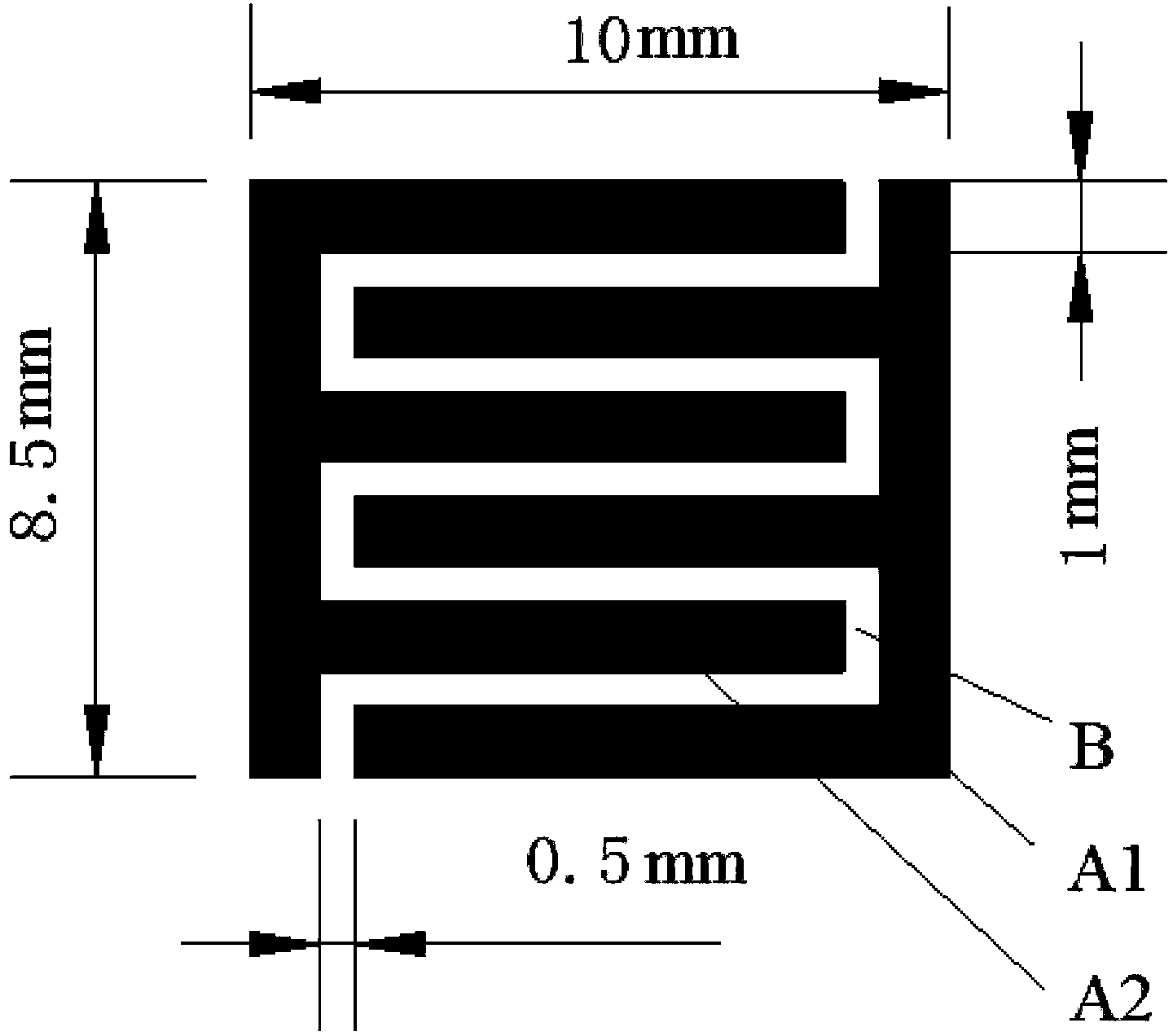

Film-type supercapacitor and manufacturing method thereof

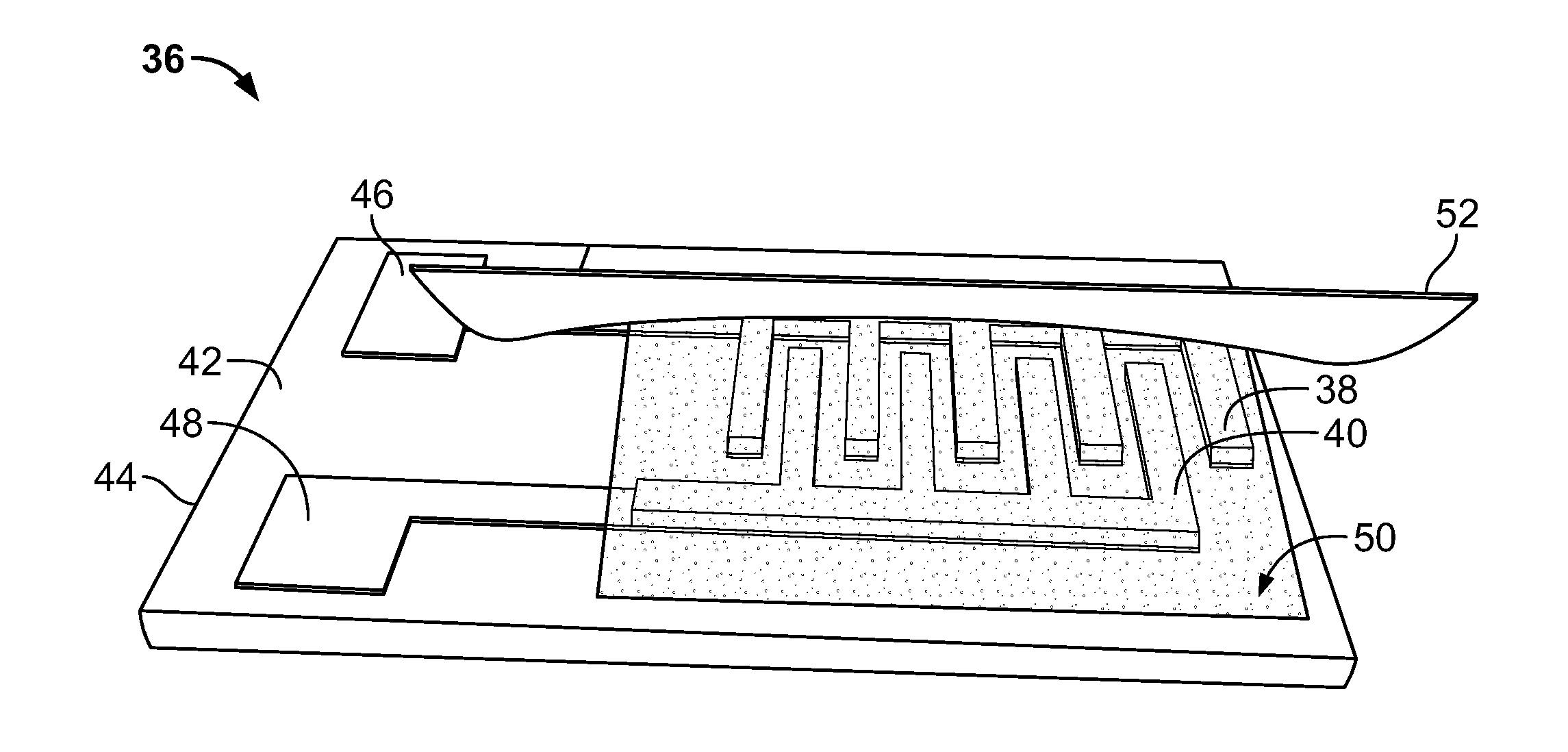

InactiveUS20130182373A1Small supplySolid electrolytic capacitorsDouble layer capacitorsIn planeMicrometer

The present invention relates to a film-type micro-supercapacitor and a manufacturing method thereof including a method for manufacturing an electrode film by using graphene or graphene oxide, a method for forming a two-dimensional electrode by separating a graphene or graphene oxide electrode film into two independent electrodes through patterning, a method for forming an in-plane structure of the two-dimensional electrode, a method for forming a current collector on an electrode, and a method for manufacturing a supercapacitor with a micrometer thickness by supplying an electrolyte to the two-dimensional electrode. The film-type micro-supercapacitor can efficiently replace or support the battery in the field of very small electronic devices such as microelectromechanical systems (MEMS), paper-like displays, or smartcards requiring a very small power supply.

Owner:KOREA ADVANCED INST OF SCI & TECH

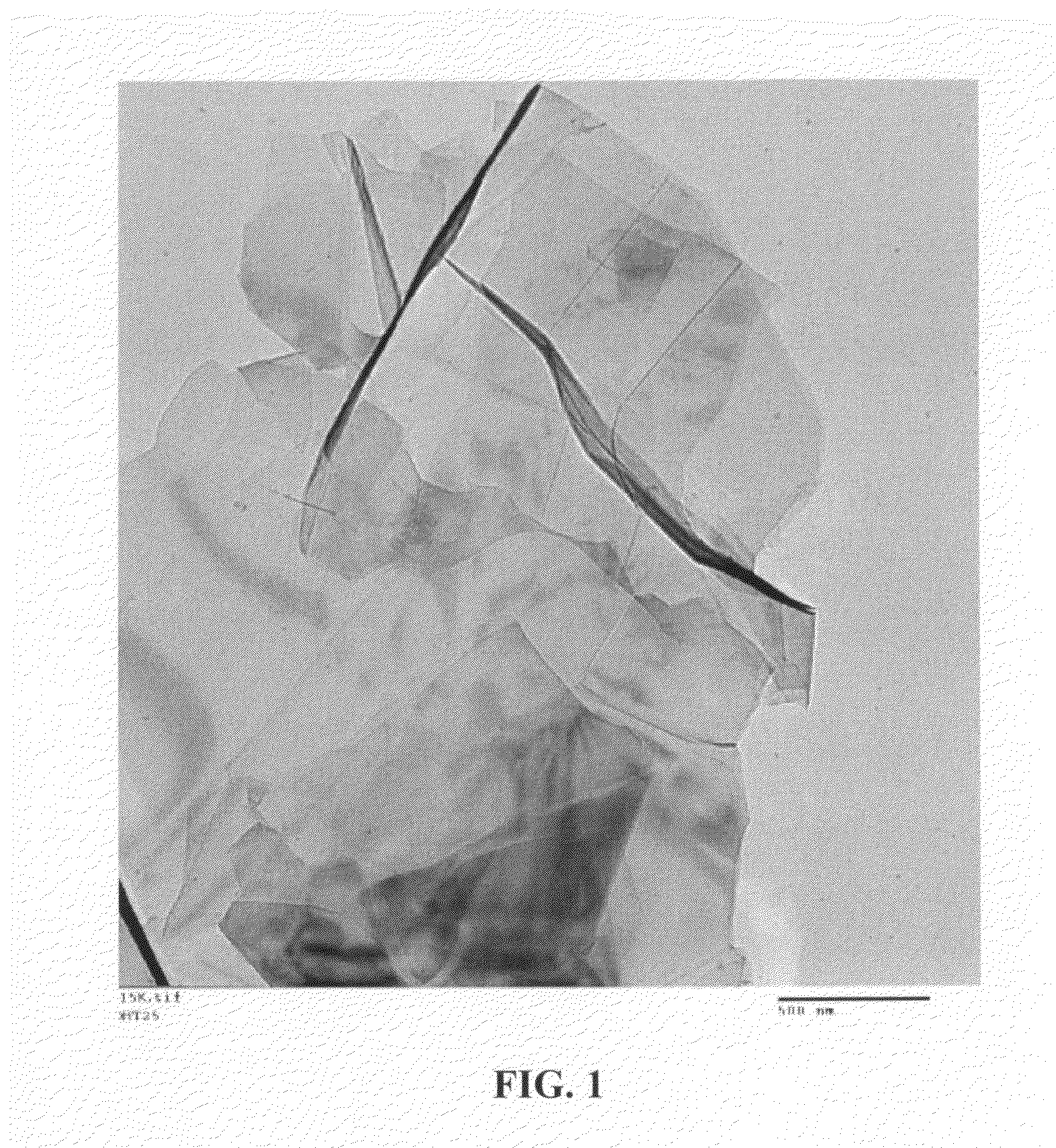

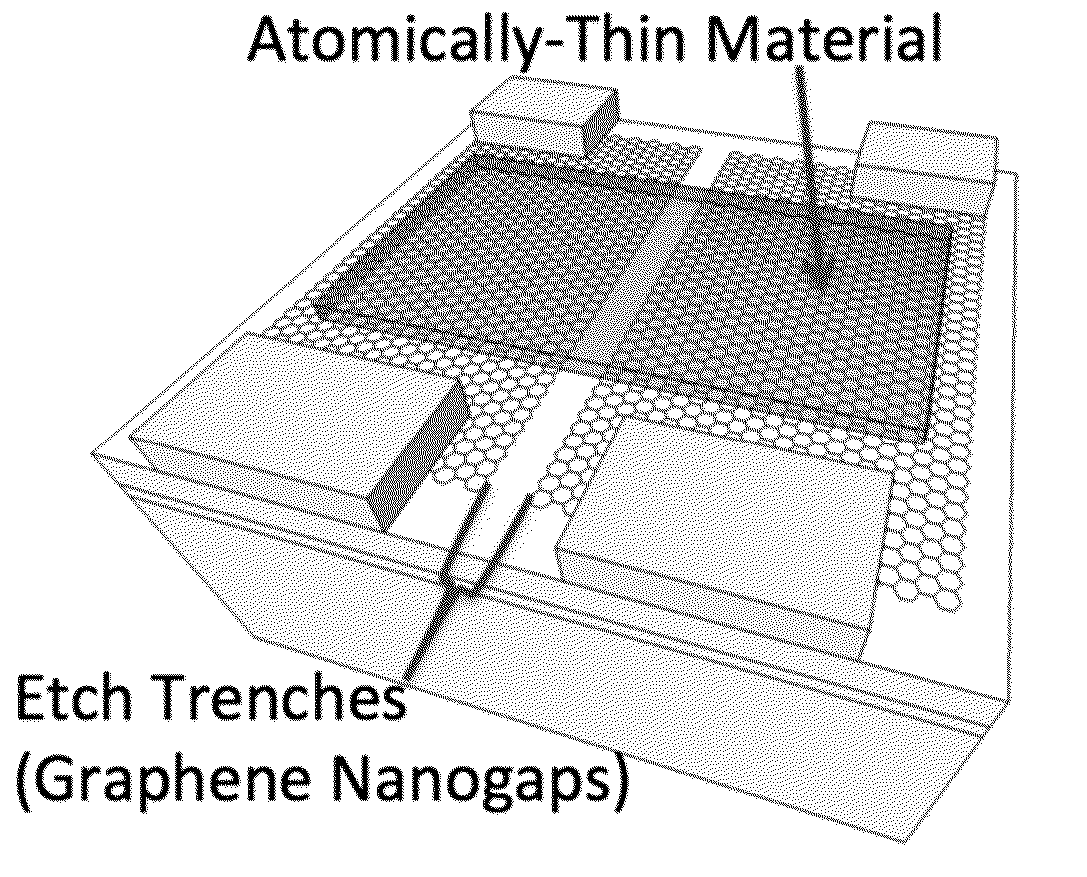

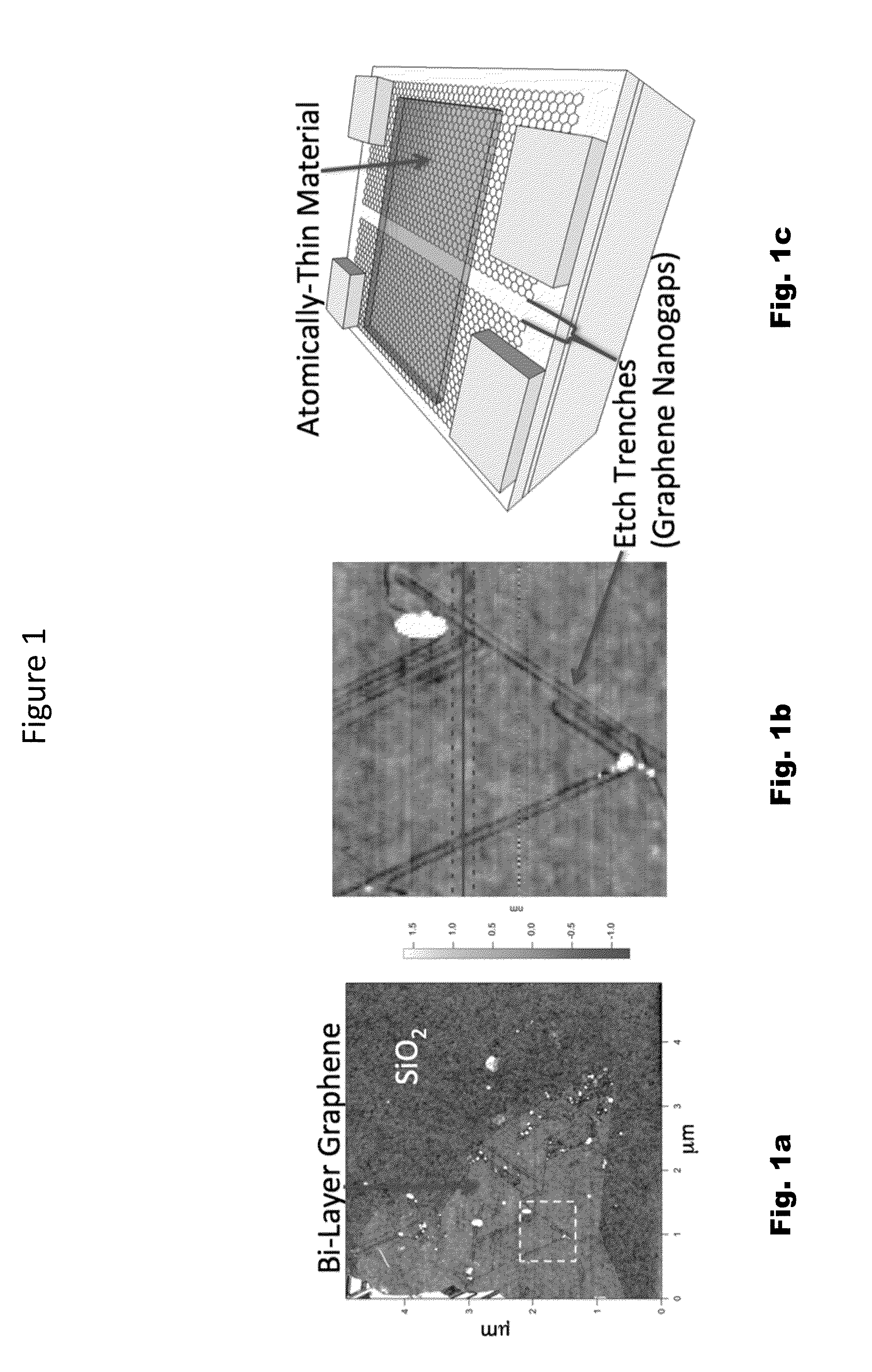

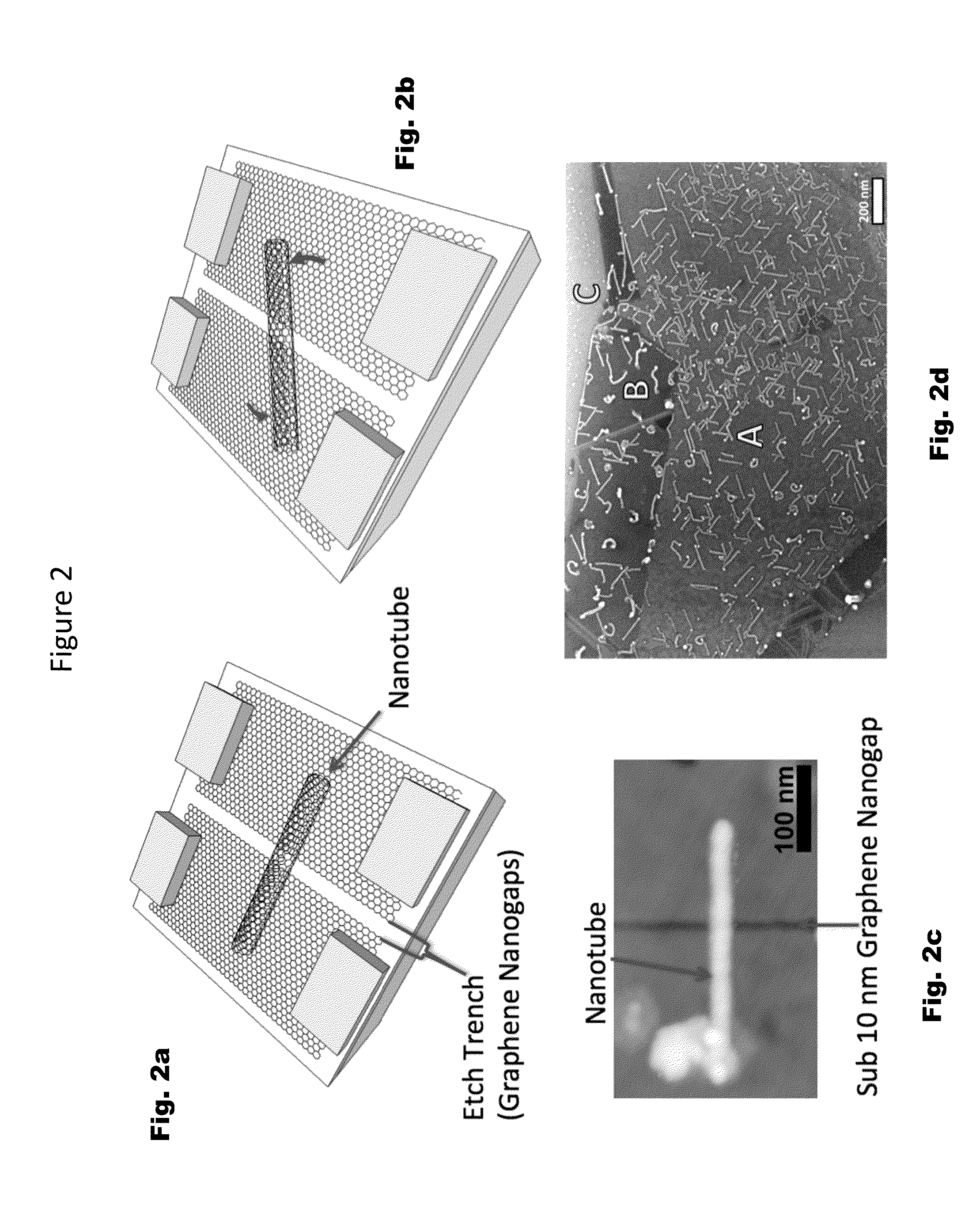

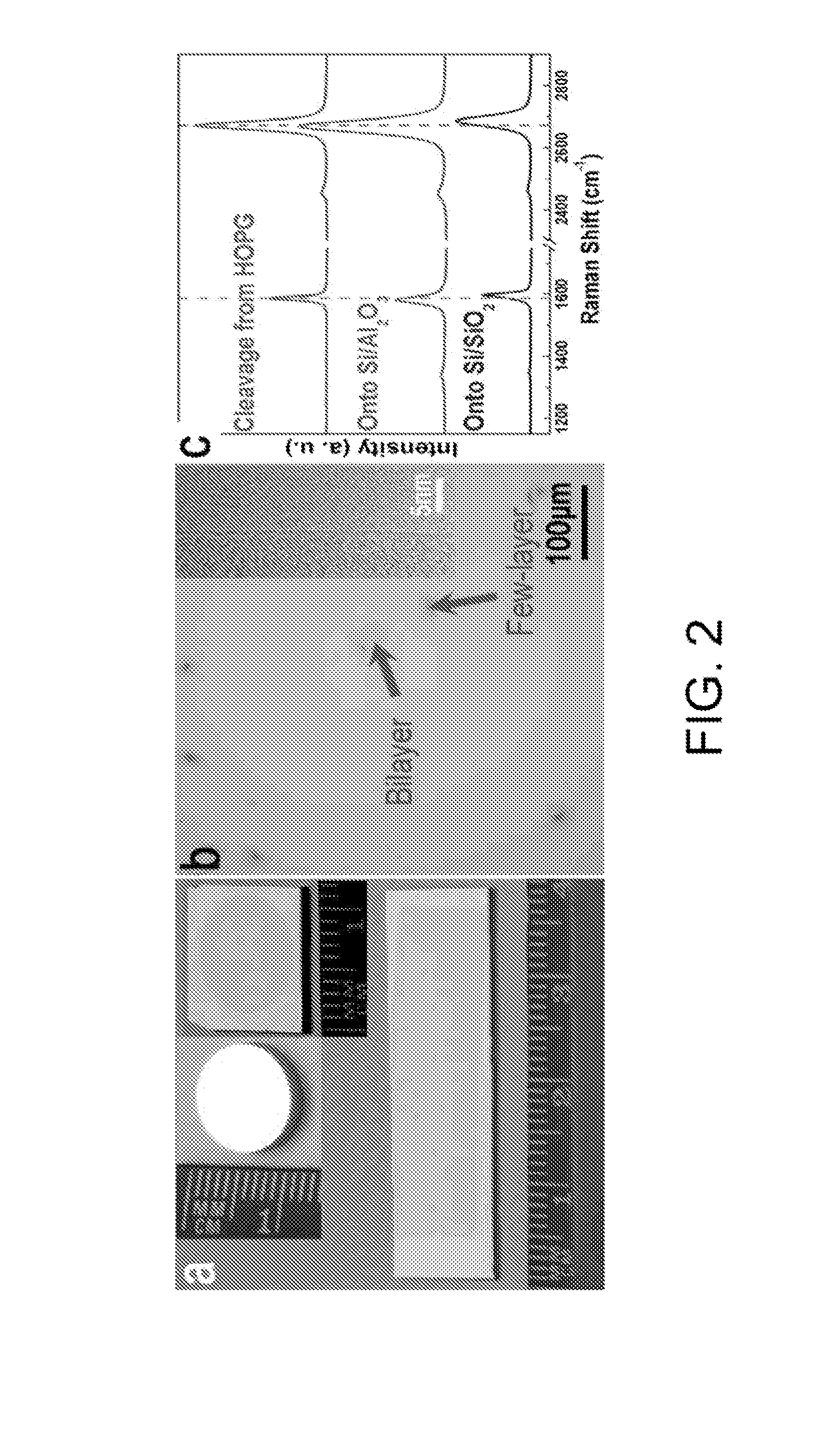

Integrated multi-terminal devices consisting of carbon nanotube, few-layer graphene nanogaps and few-layer graphene nanoribbons having crystallographically controlled interfaces

ActiveUS20160155971A1Solid-state devicesSemiconductor/solid-state device manufacturingQuantum transportGraphene nanoribbons

The present invention relates to atomically-thin channel materials with crystallographically uniform interfaces to atomically-thin commensurate graphene electrodes and / or nanoribbons separated by nanogaps that allow for nanoelectronics based on quantum transport effects and having significantly improved contact resistances.

Owner:UNIV OF KENTUCKY RES FOUND

Graphene electrodes on a planar cubic silicon carbide (3c-sic) long term implantable neuronal prosthetic device

InactiveUS20130338744A1Increase surface areaSpecific capacitanceSpinal electrodesConductive pattern formationCapacitanceCubic silicon carbide

Graphene, can be used to make an implantable neuronal prosthetic which can be indefinitely implanted in vivo. Graphene electrodes are placed on a 3C—SiC shank and electrical insulation is provided by conformal insulating SiC. These materials are not only chemically resilient, physically durable, and have excellent electrical properties, but have demonstrated a very high degree of biocompatibility. Graphene also has a large specific capacitance in electrolytic solutions as well as a large surface area which reduces the chances for irreversible Faradaic reactions. Graphene can easily be constructed on SiC by the evaporation of Si from the surface of that material allowing for mechanically robust epitaxial graphene layers that can be fashioned into electrodes using standard lithography and etching methods.

Owner:UNIV OF SOUTH FLORIDA

Spacer-modified nano graphene electrodes for supercapacitors

ActiveUS8315039B2Increase surface areaMaterial nanotechnologyLiquid electrolytic capacitorsCapacitancePlatelet

Owner:NANOTEK INSTR GRP LLC

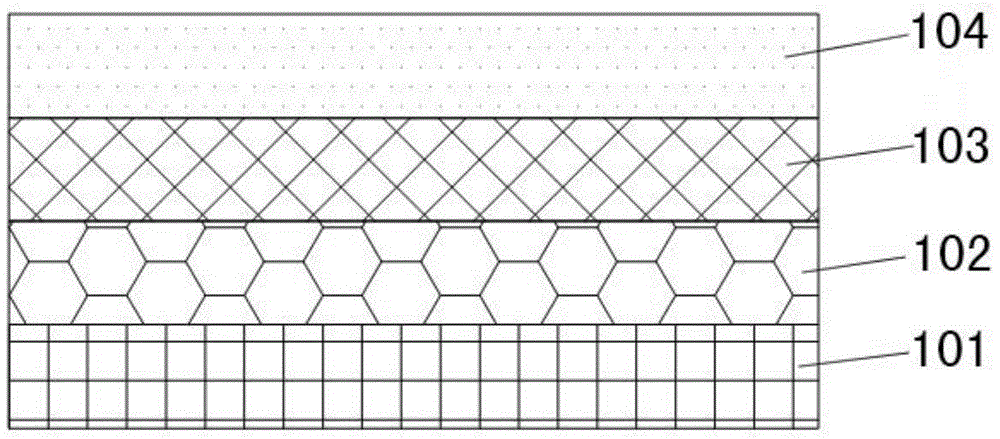

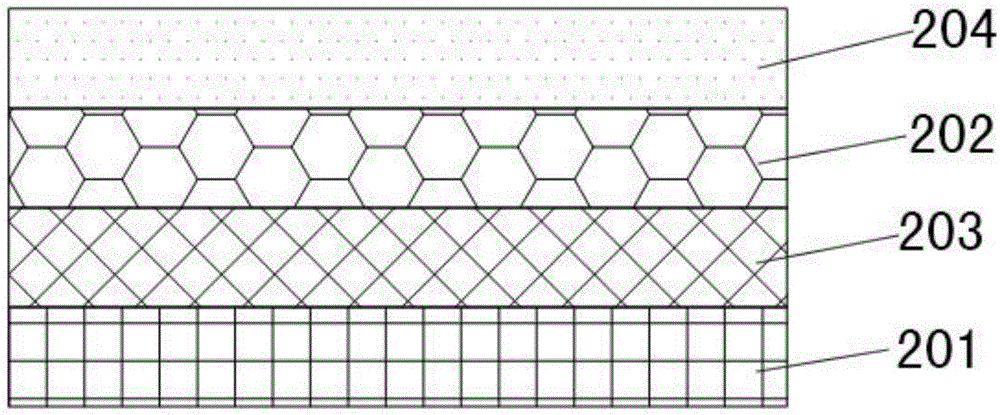

Organic semiconductor photoelectric device based on graphene electrode

ActiveCN104091892AHigh light transmittanceAchieve metal-freeSolid-state devicesSemiconductor/solid-state device manufacturingConductive polymerGraphene electrode

The invention relates to an organic semiconductor photoelectric device based on a graphene electrode. The organic semiconductor photoelectric device comprises a graphene anode, a graphene cathode and an organic functional layer. The graphene anode is composed of a graphene film, a metal mesh and a conductive polymer layer. The graphene cathode is a graphene film on which a surface modification layer is absorbed. The organic semiconductor photoelectric device based on the graphene electrode has excellent performance on the aspects of sheet resistance, light transmittance and work functions, is suitable for large-scale low-cost manufacturing and compatible with a reel-to-reel technology and the like, and lays a foundation for large-scale low-cost flexible device production in the future.

Owner:CHONGQING INST OF GREEN & INTELLIGENT TECH CHINESE ACADEMY OF SCI

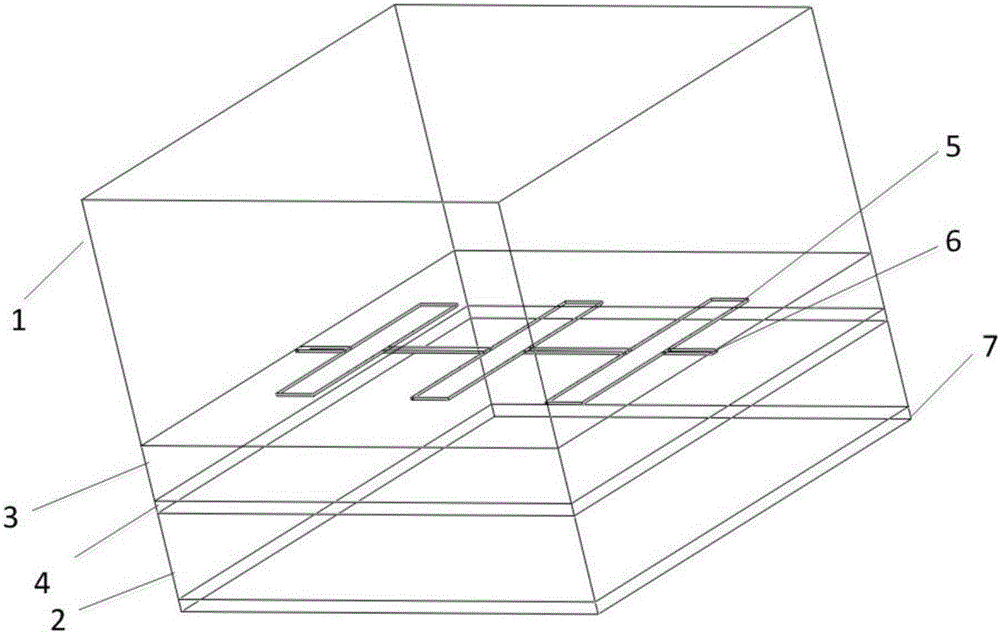

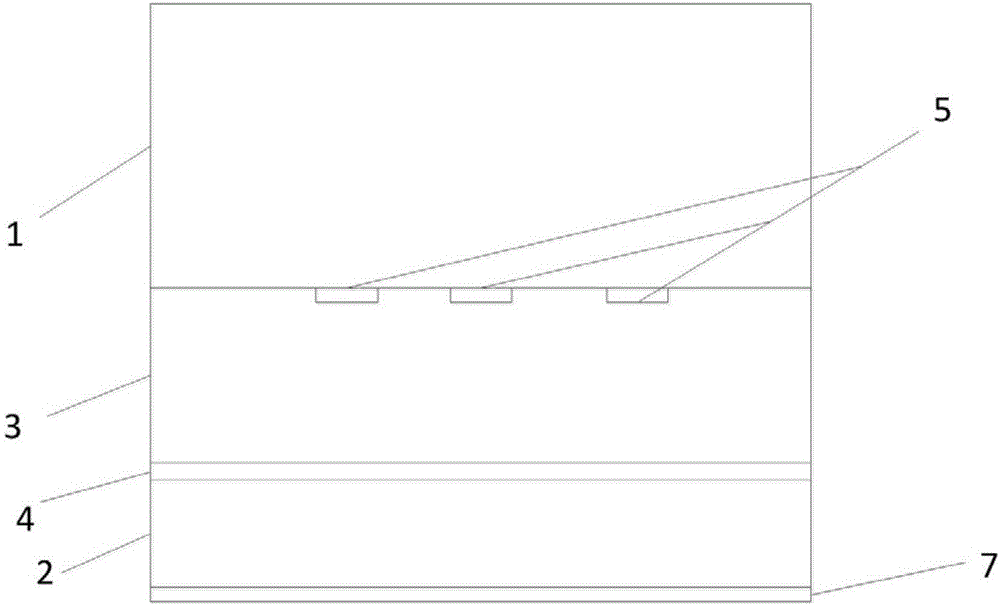

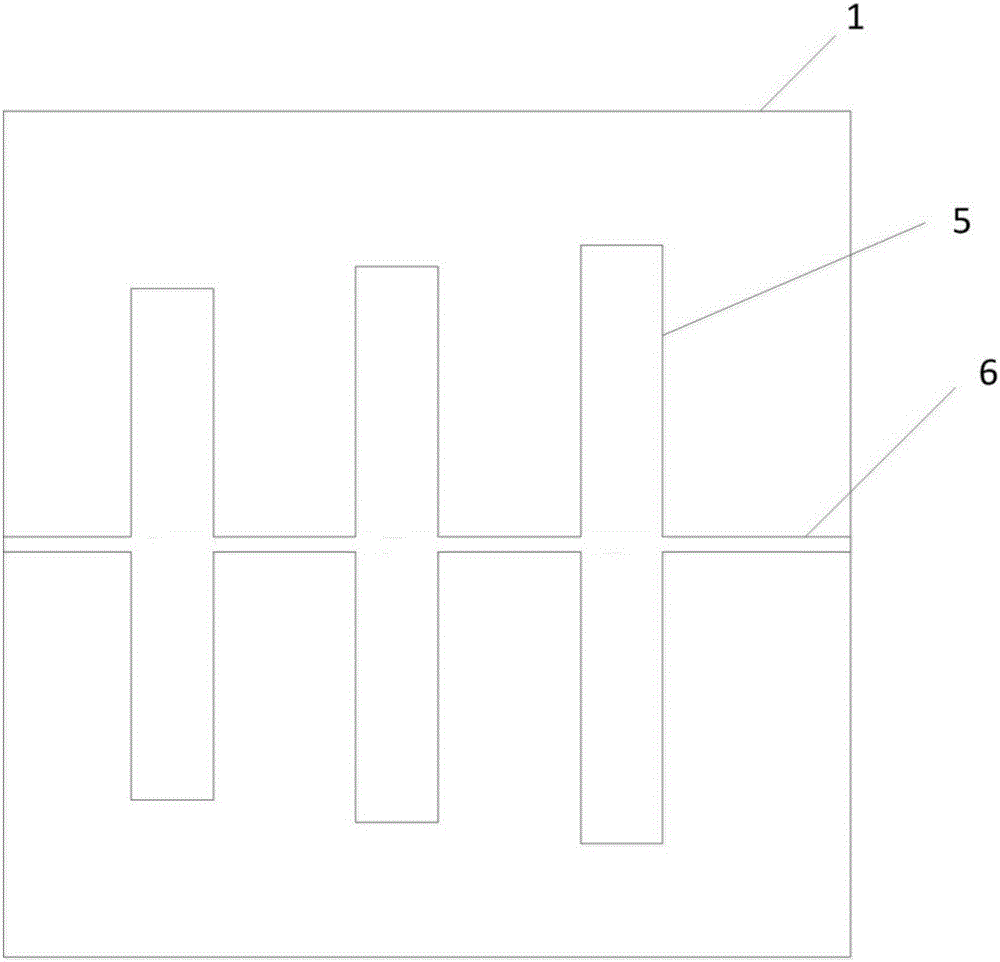

Graphene electrode-based reflecting liquid crystal phase shift unit

ActiveCN106532200AWorking bandwidthSimple structureWaveguide type devicesAntennasLiquid-crystal displayPhase shifted

The invention discloses a graphene electrode-based reflecting liquid crystal phase shift unit, which comprises two upper and lower layers of dielectric substrates, wherein a liquid crystal layer is injected into a gap between the two upper and lower layers of dielectric substrates; a plurality of metal patches which are sequentially connected in series through a connection line are arranged on the lower surface of the upper layer of dielectric substrate to form a layer of metal microstrip structure; a graphene layer completely covers the upper surface of the lower layer of dielectric substrate to form a graphene electrode; and a metal layer completely covers the lower surface of the lower layer of dielectric substrate to form a metal grounding electrode. The continuous phase shift characteristic is obtained within a broadband in an electric control manner; and the graphene electrode-based reflecting liquid crystal phase shift unit has the characteristics of being small and easy to process.

Owner:HEFEI UNIV OF TECH

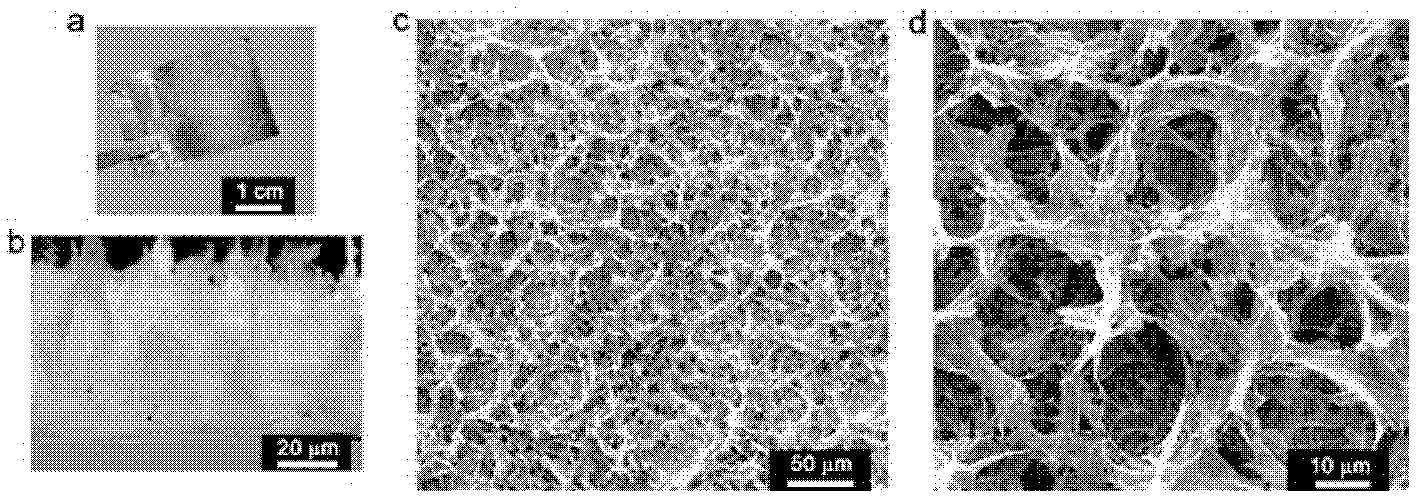

Flexible graphene composite film and preparation method thereof

ActiveCN103011150AIncrease holeIncrease concentrationCarbon compoundsEnergy inputComposite filmSolar battery

The invention discloses a flexible graphene composite film and a preparation method thereof. The preparation method comprises the following steps of: based on oxidized or reduced graphene and organic polymer or micromolecule with a special functional group as raw materials, forming a uniform composite material by utilizing the interaction of a surface functional group of graphene and an organic molecule group, and preparing the graphene composite film on the surfaces of different substrates through methods of spin coating, spraying and the like. According to the preparation method disclosed by the invention, by utilizing an electron withdrawing group, an electron-donating group or a conjugate group in the organic polymer or micromolecule, the hole or electron concentration on the surface of a graphene electrode is increased, the work function of the electrode is controlled, the conductivity of the graphene electrode is improved, and the application range of a device is widened. According to the flexible graphene composite film disclosed by the invention, because the interaction among the groups is utilized, the compatibility of the prepared composite film is better, the structure is uniform, and the flexible graphene composite film is suitable for the photoelectric field of solar batteries, sensors, organic light-emitting diodes, touch screens and the like.

Owner:SHANGHAI JIAO TONG UNIV

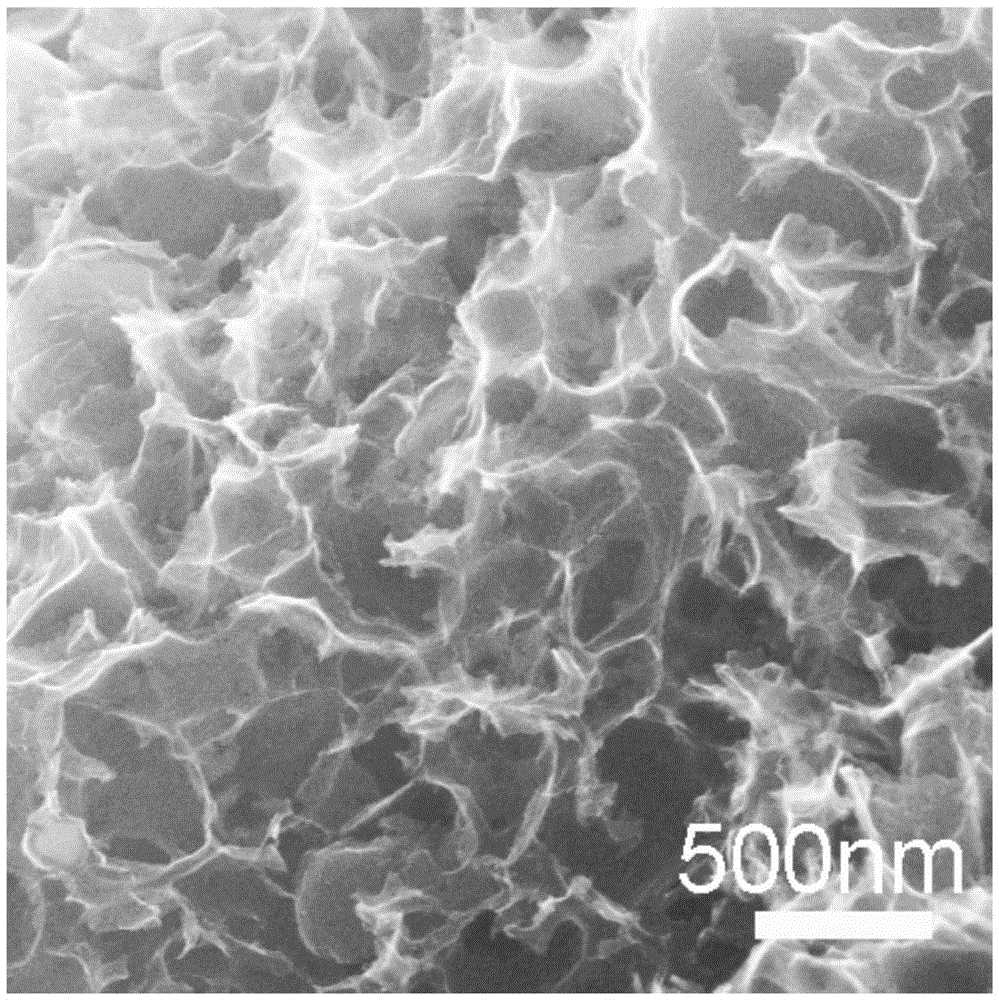

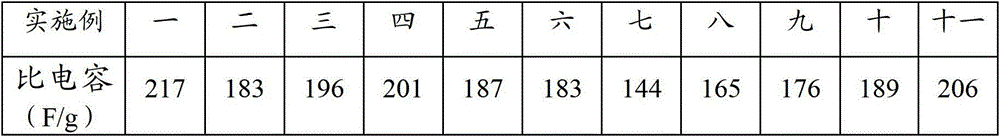

Method for directly preparing co-doping three-dimensional graphene electrode material through biomass carbon sources

The invention discloses a method for directly preparing a co-doping three-dimensional graphene electrode material through biomass carbon sources. The method mainly includes the steps that biomass such as eggshells of artemia cysts, bean pulp and shrimp shells are used as the carbon sources, red phosphorus or boric acid is added to serve as a stripping agent, metal nickel salt is added to serve as a catalyst, and oxygen-nitrogen-phosphor multi-atom co-doping three-dimensional porous graphene is synthesized in a roasted mode at the temperature of 700 DEG C to 900 DEG C under argon atmosphere; the obtained graphene is ground into powder, the graphene, acetylene black and PTFE are ultrasonically dispersed into absolute ethyl alcohol in the mass ratio of 85:10:5, the mixture is dried at the temperature of 80 DEG C to be pasty, 0.5 mg to 5 mg of the mixture is taken and evenly smeared on 1*1-cm foam nickel, vacuum drying is carried out at the temperature of 120 DEG C for 12 h, plate pressing is carried out at the pressure of 12 MPa, and an electrode plate is obtained. According to the method, the source of the required raw materials is wide, the price is low, devices are simple, repeatability is good, and low-cost large-scale industrial production can be achieved easily; the prepared graphene electrode material has the advantages of being good in electrochemical activity, large in specific area, not prone to repeated accumulation and the like; the broad application prospects are achieved in the aspects such as electrode materials and catalyst carriers of supercapacitors and lithium ion batteries.

Owner:YANSHAN UNIV

Graphene-ionic liquid composite electrode and preparation method thereof, and electrochemical capacitor

InactiveCN104008895AGood dispersionSingle layer rate is highHybrid capacitor separatorsHybrid capacitor electrodesAdhesiveGraphene electrode

The invention discloses a preparation method of a graphene-ionic liquid composite electrode. The method comprises adding chloride intercalated graphite into a molten ionic liquid for ultrasonic stripping for 0.5 to 24 hours with power being 400 to 800W, and obtaining a liquid mixture of graphene, the ionic liquid and chloride; putting the liquid mixture in an electric field environment for centrifugation for 1 to 10 minutes, removing the supernate, and obtaining a graphene-ionic liquid composite material; and putting the obtained graphene-ionic liquid composite material in a mould, applying pressure of 10 to 30Mpa to a mould cap, cooling the graphene-ionic liquid composite material to room temperature, and solidifying the graphene-ionic liquid composite material, and obtaining the graphene-ionic liquid composite electrode. According to the method, ultrasonic treatment is performed on the intercalated graphite suspended on the ionic liquid, and the graphene electrode is formed by directly compacting the prepared graphene-ionic liquid composite material. The preparation of the graphene-ionic liquid composite electrode needs not to use a conductive agent or an adhesive or to prepare a current collector separately, and therefore the efficiency of the graphene-ionic liquid composite electrode is improved, and the preparation method is also simplified.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +2

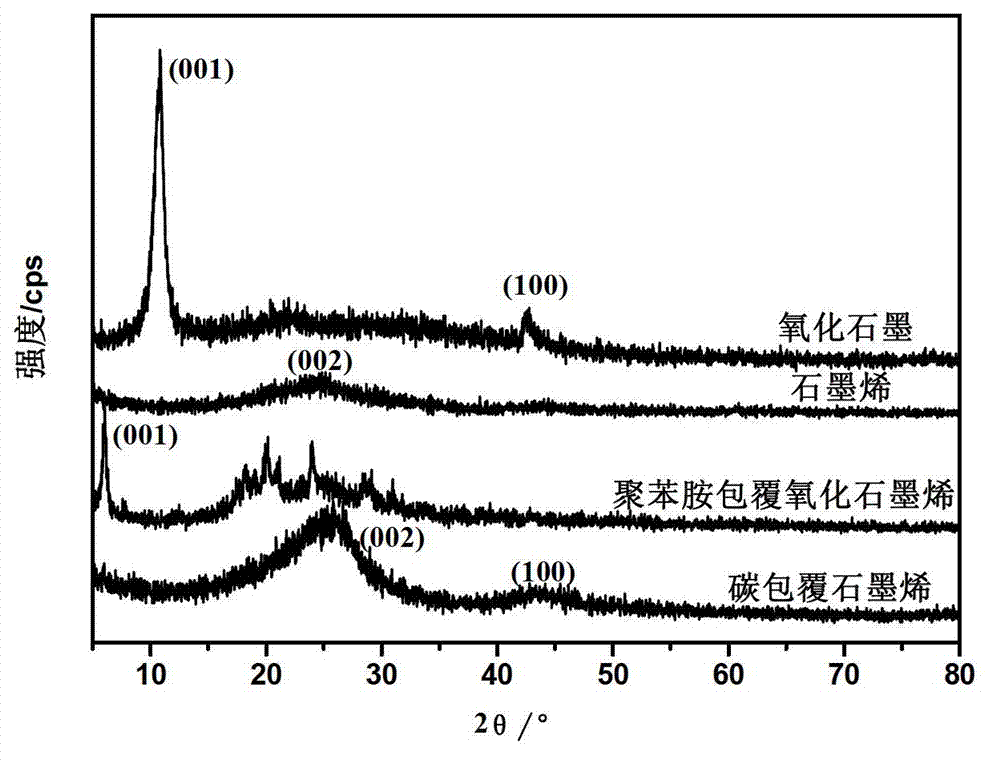

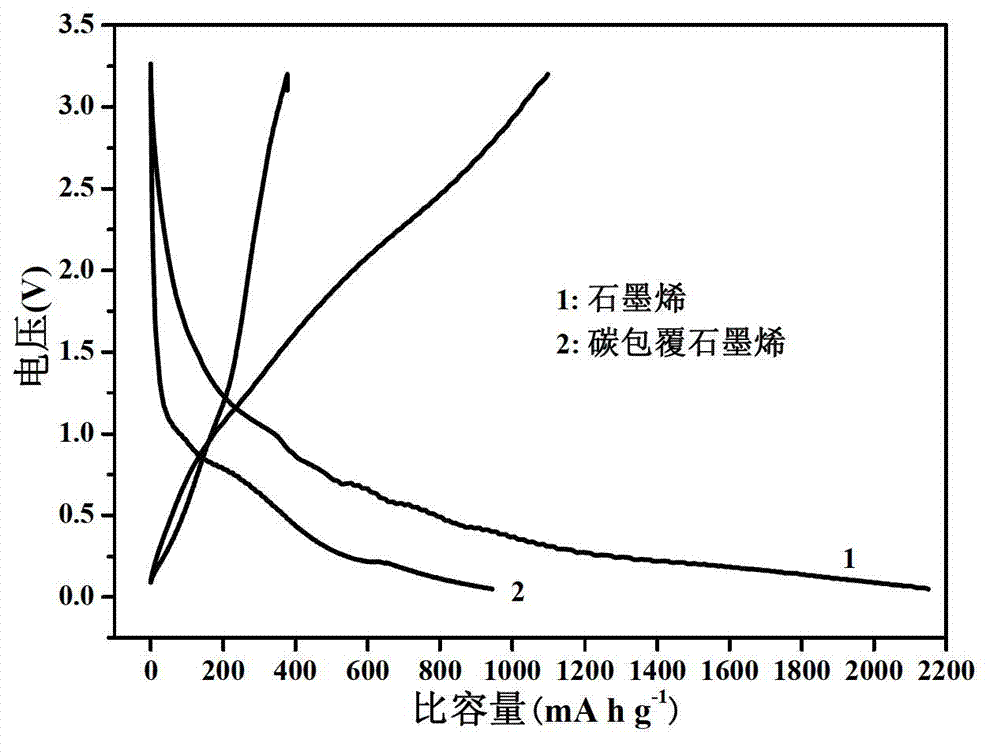

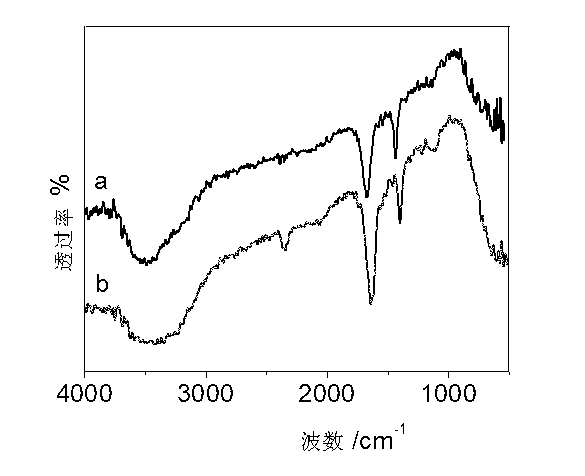

Preparation method and application of carbon-coated graphene composite material for lithium ion battery

The invention discloses a preparation method and an application of a carbon-coated graphene composite material for a lithium ion battery. The preparation method comprises the steps of: dispersing graphite oxide or graphene in a diluted acid solution, adding different amount of polymer monomers in the solution, continuously stirring the solution, slowly adding a polymer initiator for generating polymerization reaction, coating the graphite oxide or the graphene by a polymer generated through the polymerization reaction of deionized water and ethanol, and carrying out vacuum drying after alternate cleaning for multiple times; and grinding the graphite oxide or the graphene coated by the polymer, then placing the ground graphite oxide or graphene in flowing protective gas to heat for generating high temperature thermal reduction and carbonization reaction, and at last cooling the ground graphite oxide or graphene to be at room temperature in the flowing protective gas, so as to obtain the carbon-coated graphene material. The prepared carbon-coated graphene material has the advantages of high rate and long service life; for the present single graphene electrode material, the preparation technological problems caused by the overlarge specific surface, fast capacity fading problem caused by high rate, and the like are solved; and the carbon-coated graphene composite material can be adopted as a negative electrode material of the lithium ion battery.

Owner:SUZHOU UNIV

Preparation method of fluorosilane surface finished grapheme for supercapacitor

InactiveCN102701191ASimple processRaw materials are cheap and easy to getElectrolytic capacitorsHybrid capacitor electrodesFiltrationGraphene electrode

Owner:BOHAI UNIV

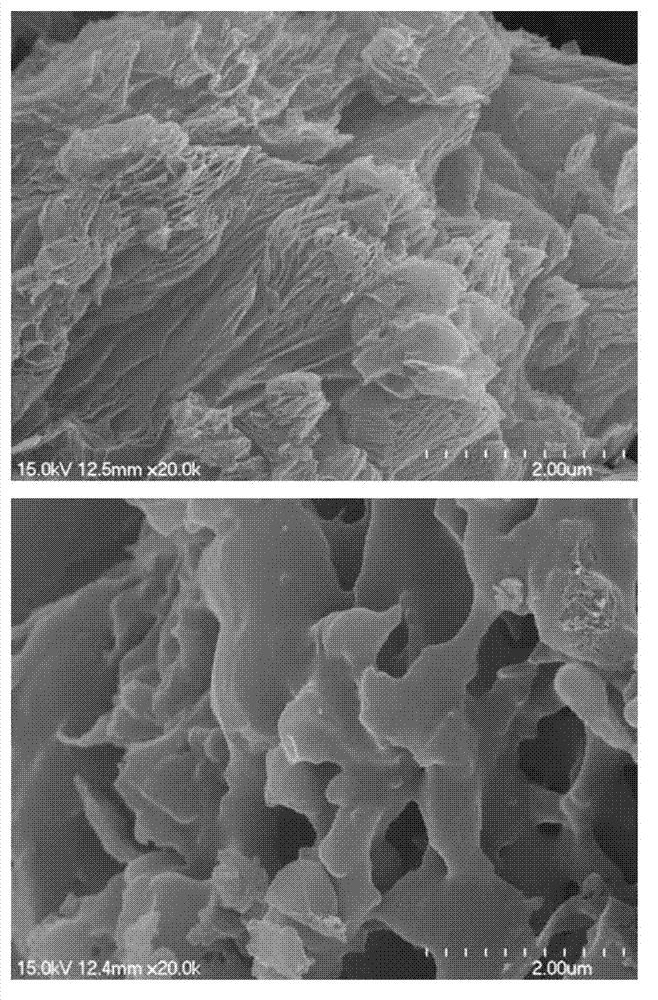

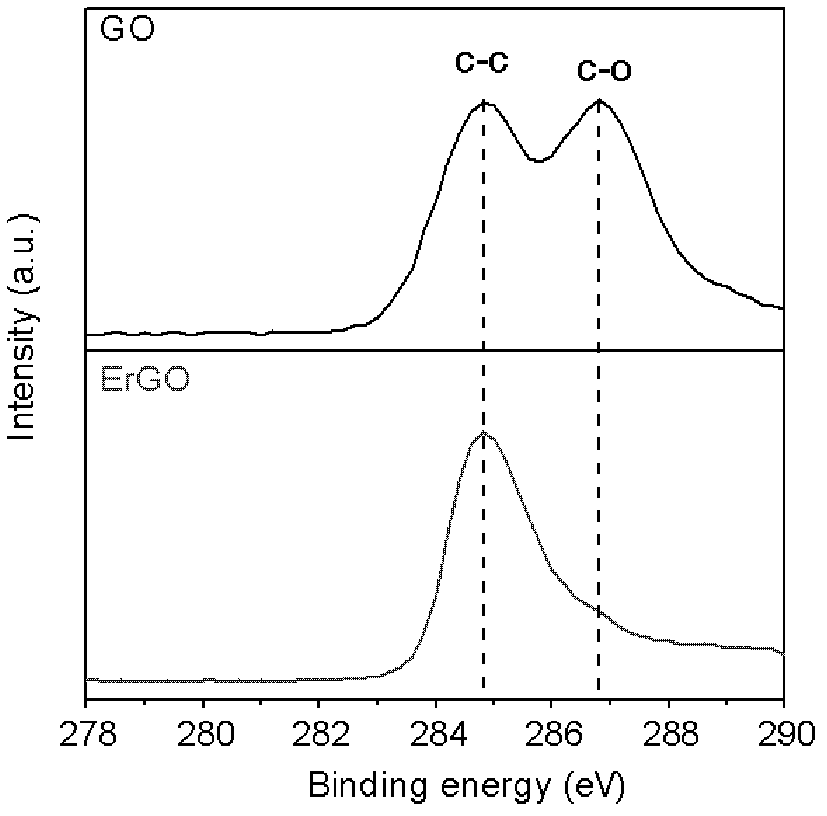

Grapheme electrode and preparation method and application thereof

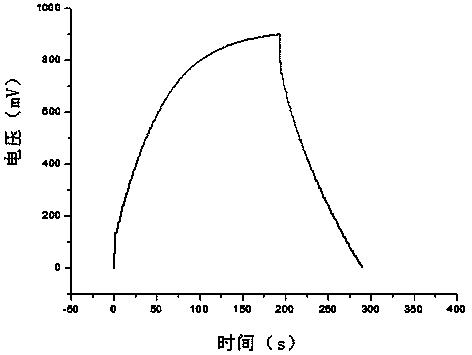

ActiveCN103208373AFast wayEfficient methodHybrid capacitor electrodesHybrid/EDL manufactureInternal resistanceGraphene electrode

The invention discloses a grapheme electrode and a preparation method and application thereof. A substrate of the grapheme electrode is a polished metal substrate, the aperture is 5-20 micrometers, and the thickness is 10-60 micrometers. The preparation method of the grapheme electrode includes that an electrolytic water solution of oxidized grapheme is electrolyzed through constant potentials in a three electrode method, electrochemical reduction grapheme is deposited on the metal substrate, reduction is further performed in a lithium perchlorate electrolyte solution, and the three-dimensional porous meshed electrode is obtained after deionized water washing. The preparation method of the grapheme electrode is environment-friendly, simple, convenient and easy to do, and can be used for volume production of the three-dimensional porous meshed electrodes. The obtained grapheme electrodes can be assembled to a super-capacitor with charge-discharge time to be 0.8-4 milliseconds and internal resistance to be 0.09-0.14 ohm, and can be used for alternating current filter by replacing aluminum electrolytic capacitors.

Owner:TSINGHUA UNIV

Flexible microelectrode for detecting neural signals and a method of fabricating the same

InactiveUS20130085359A1Improve conductivityGood biocompatibilityElectroencephalographyMaterial nanotechnologyLow noiseBiocompatibility Testing

A flexible microelectrode for detecting neural signals and a method of fabricating the same are disclosed. The method comprises steps: growing a graphene electrode layer on a temporary substrate; growing a flexible substrate on the graphene electrode layer and patterning the flexible substrate; removing the temporary substrate but preserving the graphene electrode layer and the flexible substrate to form an electrode body; and using an insulating layer to wrap the electrode body but exposing a bio-electrode end to contact a living body and detect the signals thereof. The graphene electrode layer features high electric conductivity, high biocompatibility and low noise. The flexible substrate is bendable. Thus is improved the adherence of the skin tissue to the bio-electrode end and decreased the likelihood of skin inflammation.

Owner:NATIONAL TSING HUA UNIVERSITY

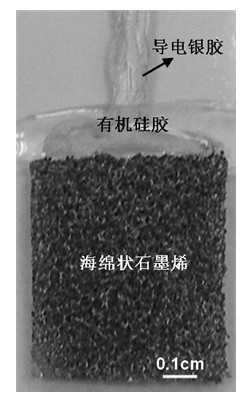

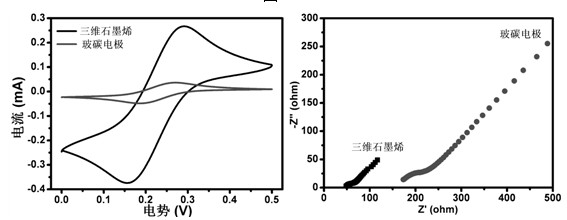

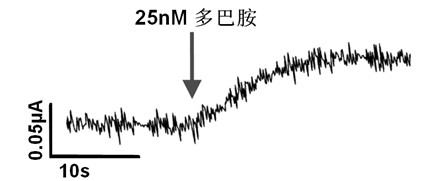

Preparation method and application of three-dimensional graphene electrode for electrochemical biosensor

InactiveCN102621208ASimple preparation processLow priceMaterial analysis by electric/magnetic meansElectrochemical biosensorFunctional modification

The invention discloses a preparation method and application of a three-dimensional graphene electrode for an electrochemical biosensor. The preparation method comprises the following steps of: fixing spongy graphene in which industrially produced foam nickel is taken as a substrate and which has a three-dimensional structure and is synthesized through chemical vapor deposition on a glass or quartz sheet; connecting the spongy graphene with the three-dimensional structure and a wire by using a silver conductive adhesive; and coating organic silica gel on a connection point of the metal wire and the graphene for insulation to obtain a spongy graphene electrochemical electrode with the three-dimensional structure. The three-dimensional spongy graphene electrode has the outstanding characteristics of high conductivity, high specific surface area, high electrochemical stability and the like, is easily subjected to surface functional modification, and has high detection sensitivity to dopamine and nicotinamide adenine dinucleotide; and a highly sensitive electrochemical biosensor for non-enzymatically and selectively detecting glucose can be obtained after the surface of the electrode is modified by Co3O4.

Owner:南京南工维明新材料科技有限公司

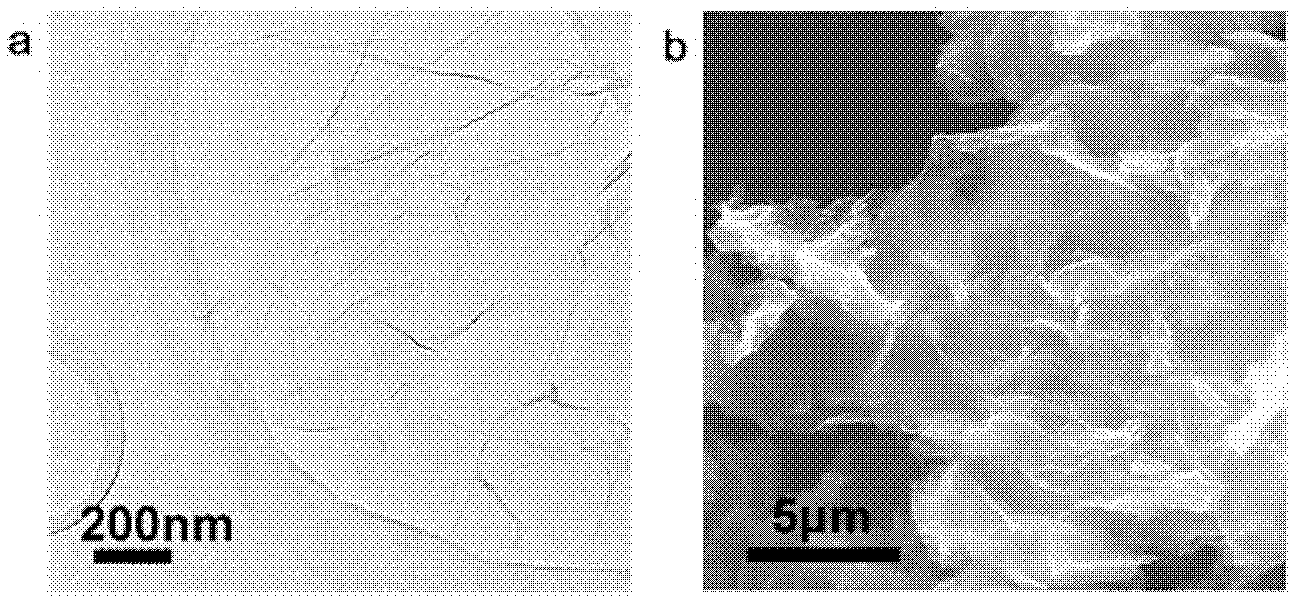

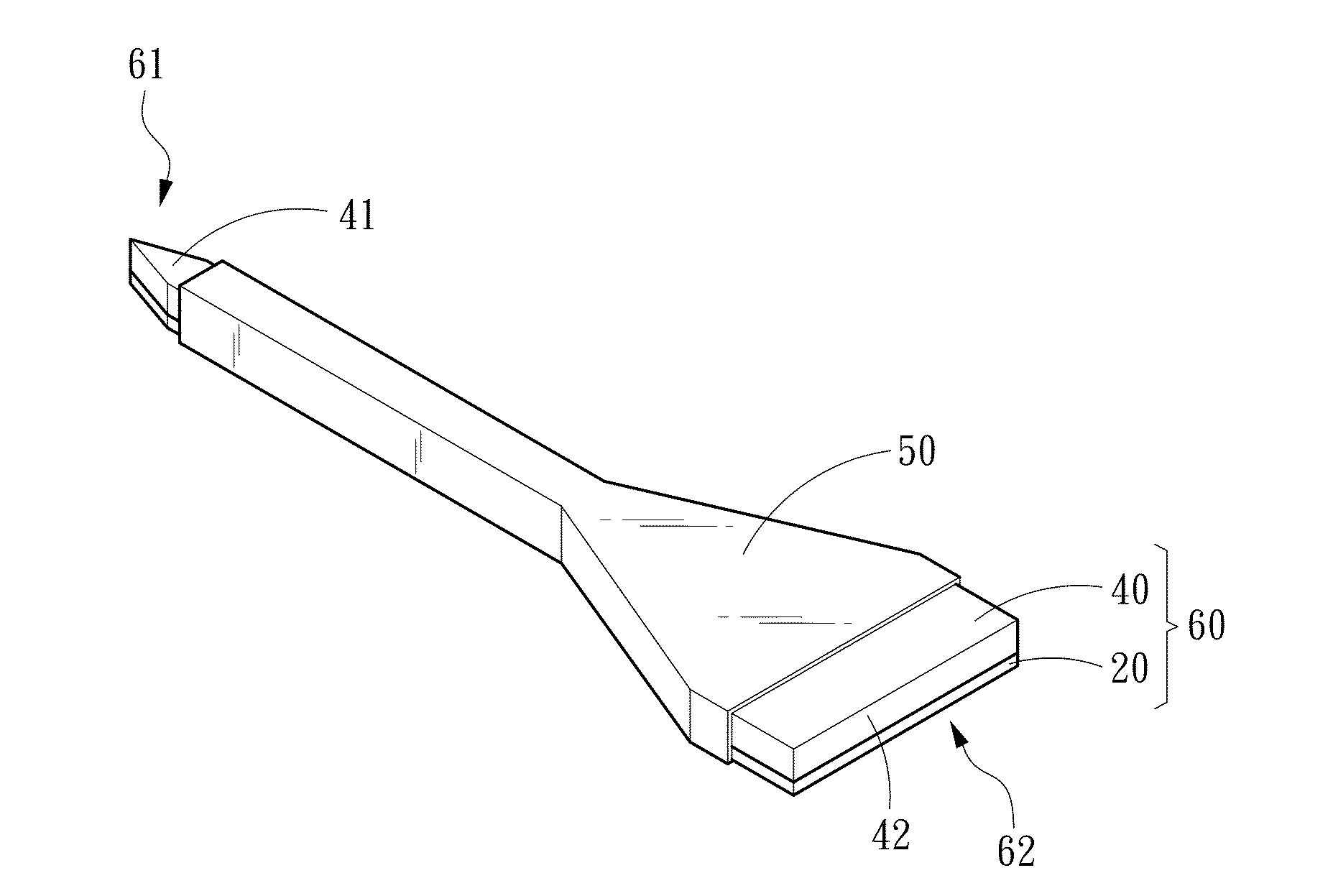

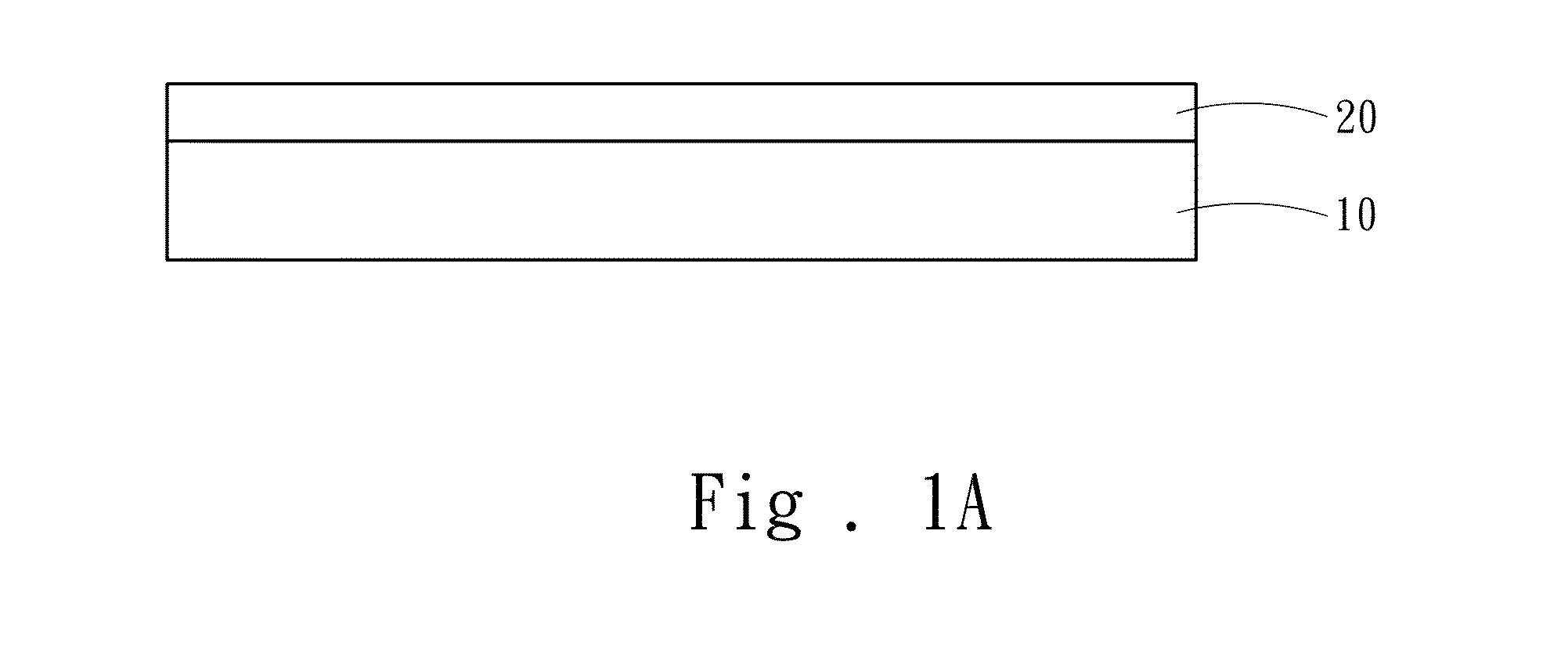

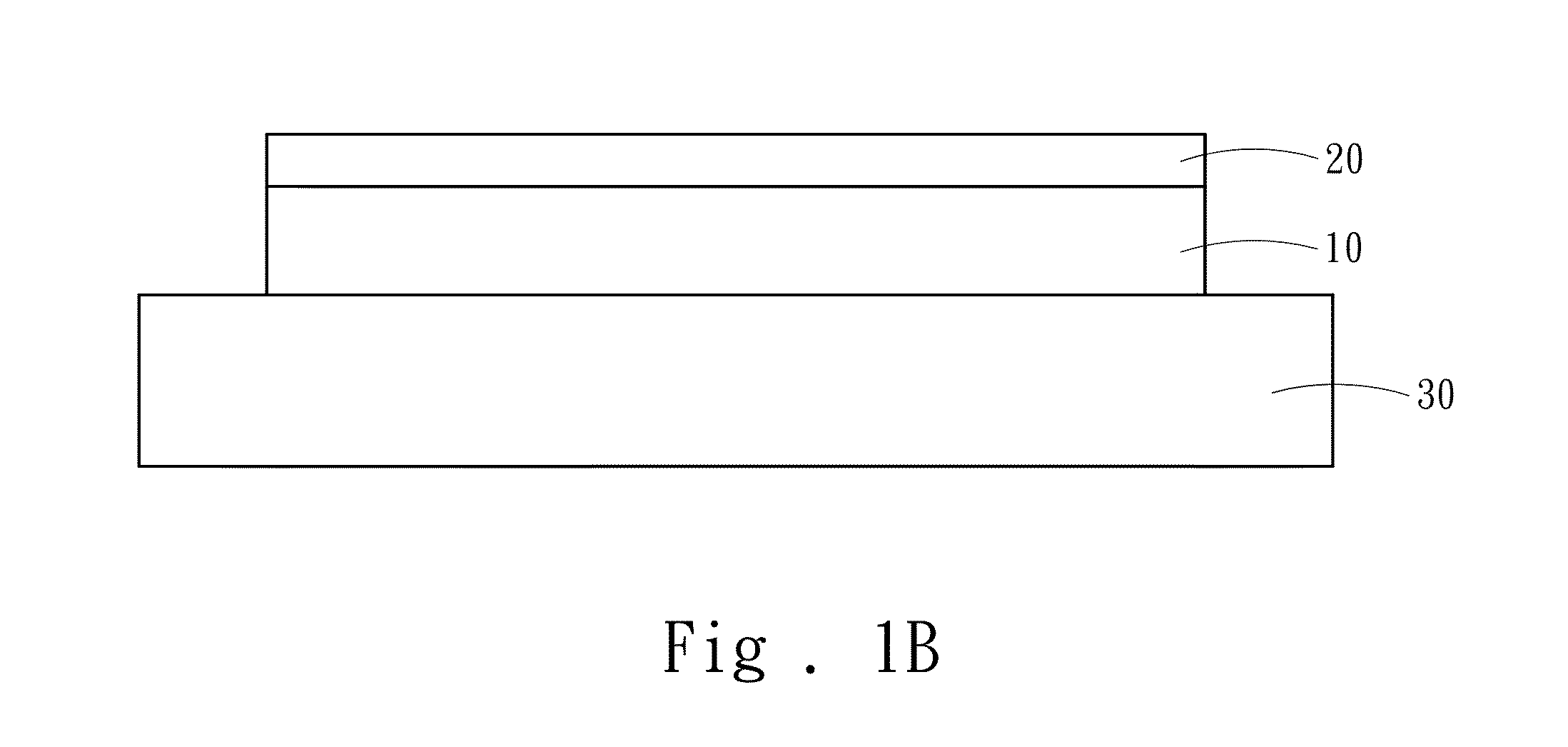

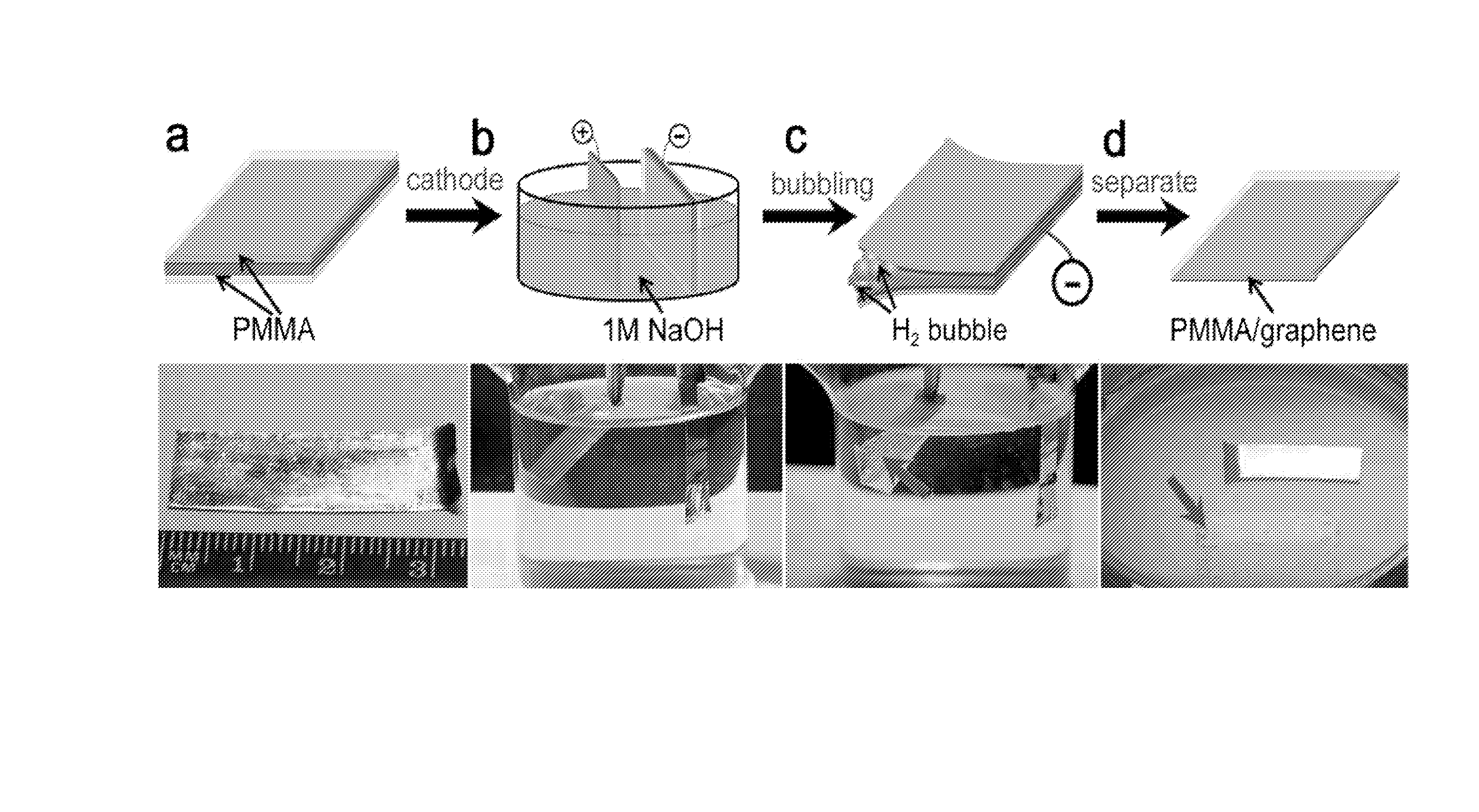

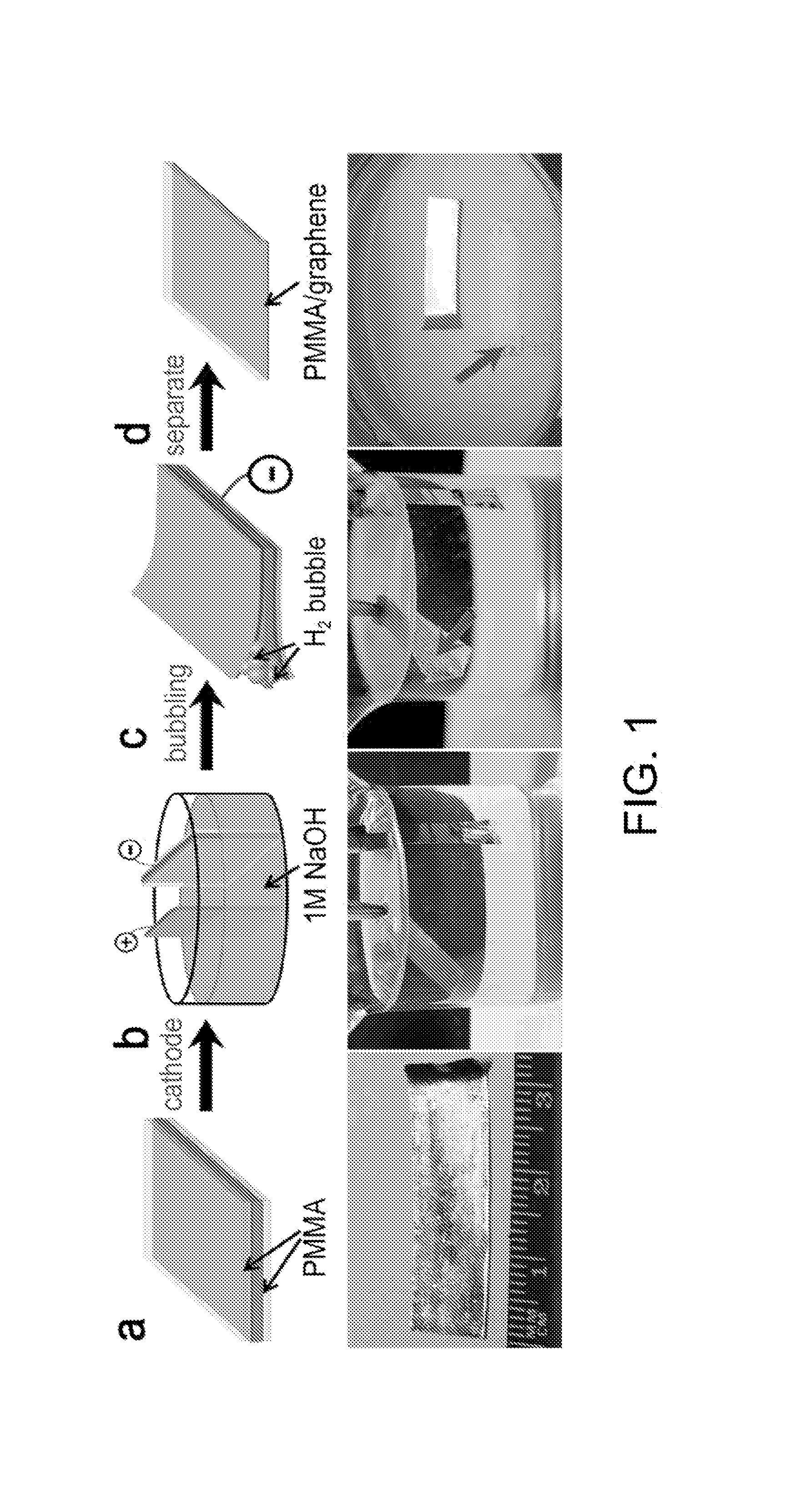

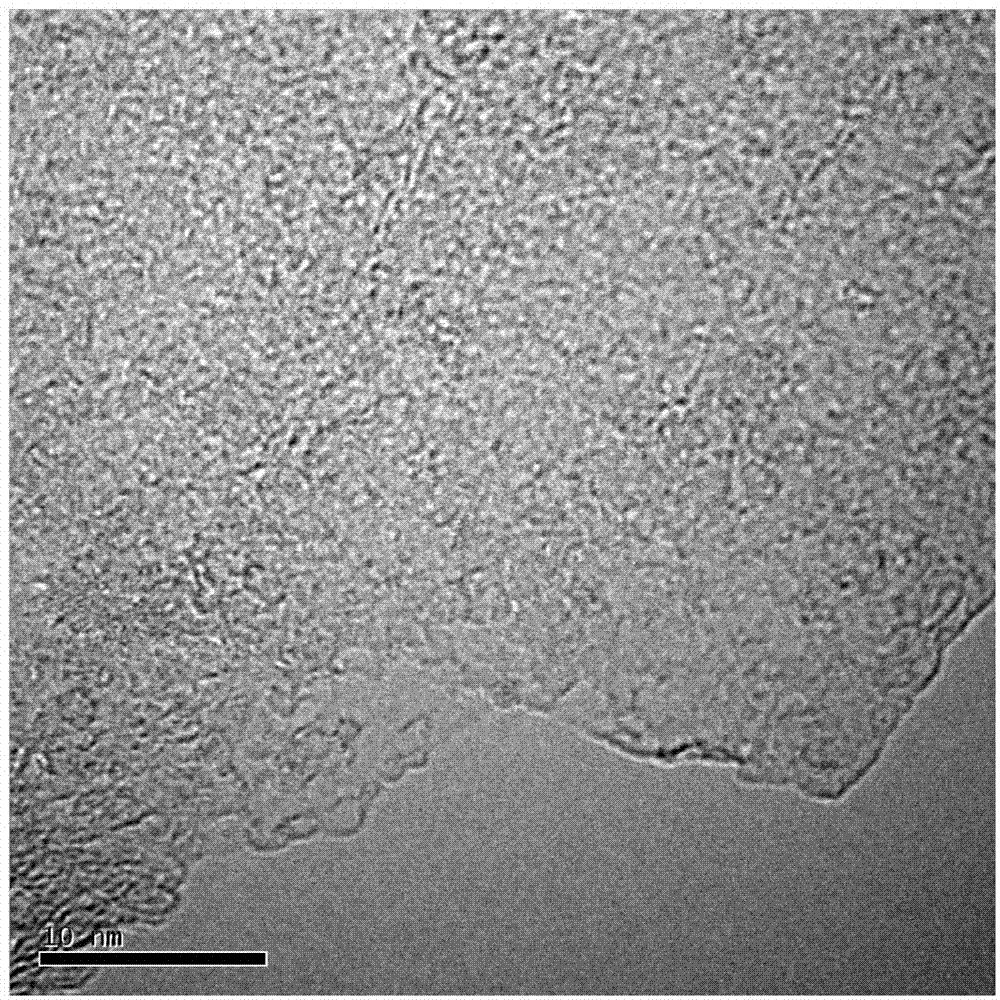

Method for Transferring Graphene Nondestructively with Low Cost

ActiveUS20140130972A1Easy to disassembleCheap and durableMaterial nanotechnologyElectrolysis componentsElectrolysisGraphene electrode

A method for transferring graphene nondestructively and at a low cost. In the method, a graphene is used whose surface is coated with transferring media and whose original substrate is an electrode, the electrode is placed into an electrolyte, and the graphene is separated from the original substrate by means of the driving force of bubbles and the gas intercalation produced on the graphene electrode surface during electrolysis. Then, the graphene coated with transferring media is nondestructively combined with a target substrate. The transferring media is removed so as to transfer the graphene to the target substrate nondestructively. The transferring method results in no damage or loss with respect to the graphene and the original substrate, and the original substrate can be re-used. Furthermore, the method is easy to perform, works quickly, is easy to control, and is pollution-free.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

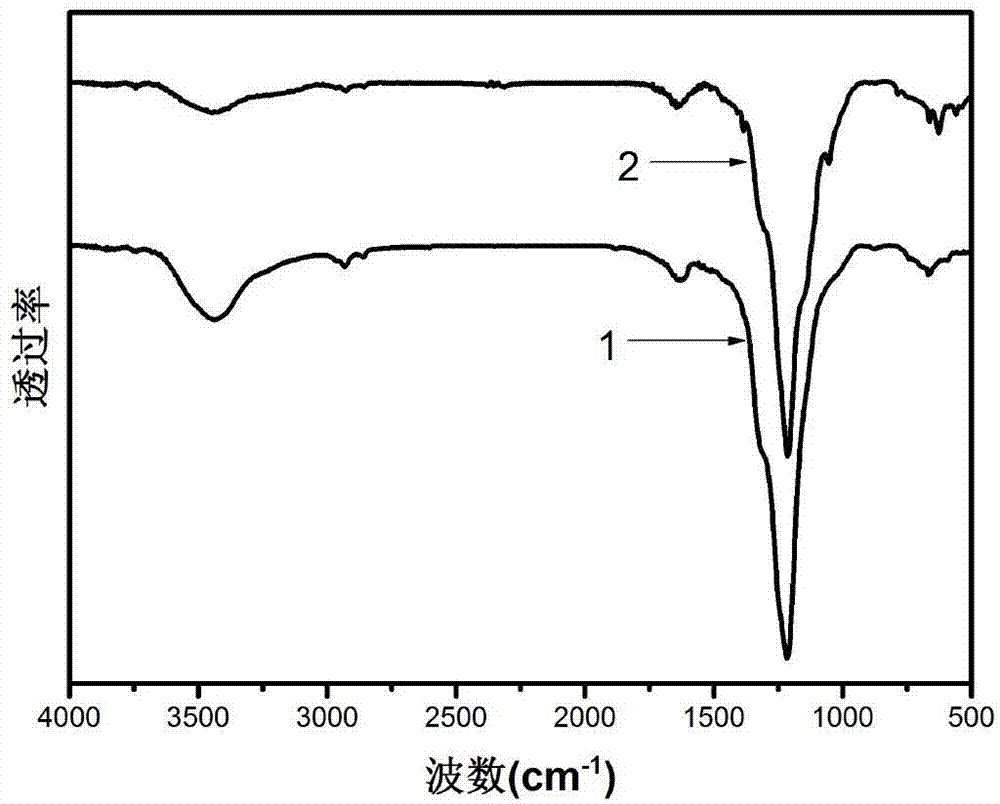

Fluorinated graphene electrode material and preparation method thereof

The invention discloses a fluorinated graphene electrode material and a preparation method thereof. The preparation method comprises the steps: carrying out thermal intercalation of graphite fluoride by using an organic solvent with low boiling point; carrying out ultrasonic stripping of graphite fluoride; centrifuging to remove graphite fluoride which is not stripped, carrying out suction filtration of the centrifuged upper solution to obtain fluorinated graphene, and adding a conductive agent and an adhesive into fluorinated graphene to obtain the fluorinated graphene electrode material. According to the technical scheme of the invention, the prepared composite material has the advantages of high specific capacitance and voltage platform and the like, and is suitable for use in electrode materials of lithium batteries.

Owner:TIANJIN UNIV

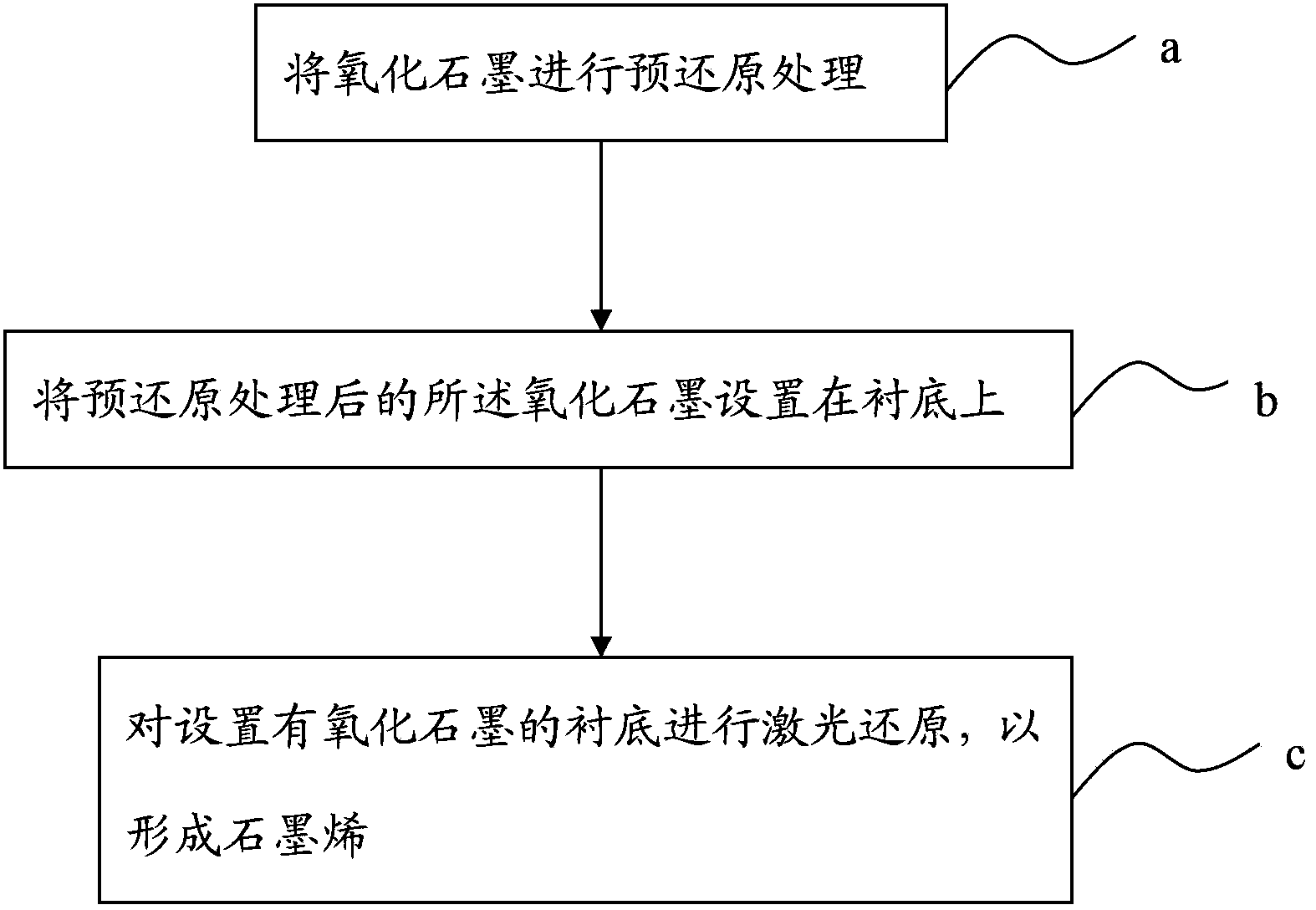

Graphene, graphene electrode, graphene supercapacitor and preparation method thereof

Disclosed are a graphene, a graphene electrode, a graphene super capacitor and preparation methods thereof. The preparation method of the graphene comprises the following steps: a) prereducing graphite oxide; b) setting the prereduced graphite oxide on a substrate; and c) laser-reducing the substrate having the graphite oxide set thereon to form graphene. According to the preparation method of graphene in the embodiment of the present invention, the prereduced graphite oxide can be reduced more easily into graphene via laser-reducing, since the graphite oxide has been prereduced in a certain degree prior to the laser reduction (namely, full reduction). The reducing effect of graphene obtained from the prereduced graphite oxide film after one photoetching is evidently superior to that of the graphene prepared without prereduction treatment. Therefore, the time of laser reduction can be apparently decreased and the production efficiency can be improved in the present invention.

Owner:NEWNAGY TANGSHAN

Graphene electrodes on a planar cubic silicon carbide (3C-SiC) long term implantable neuronal prosthetic device

InactiveUS8751015B2Increase surface areaIncrease capacitanceSpinal electrodesConductive pattern formationCapacitanceElectricity

Graphene, can be used to make an implantable neuronal prosthetic which can be indefinitely implanted in vivo. Graphene electrodes are placed on a 3C—SiC shank and electrical insulation is provided by conformal insulating SiC. These materials are not only chemically resilient, physically durable, and have excellent electrical properties, but have demonstrated a very high degree of biocompatibility. Graphene also has a large specific capacitance in electrolytic solutions as well as a large surface area which reduces the chances for irreversible Faradaic reactions. Graphene can easily be constructed on SiC by the evaporation of Si from the surface of that material allowing for mechanically robust epitaxial graphene layers that can be fashioned into electrodes using standard lithography and etching methods.

Owner:UNIV OF SOUTH FLORIDA

Preparation method of stable graphene colloid

The invention discloses a preparation method of stable graphene colloid. Inorganic nanoparticles (such as carbon nanometer quantum dot, oxidized graphene, acidified nanotube, and graphene quantum dot) are used, a surfactant (such as 3-[3-cholamidopropyl)dimethylammonium]-1-propanesulfonate, dihexadecyldimethylammonium bromide, cetyl dimethyl benzyl ammonium bromide, n-hexadecyl-beta-D-maltoside, and a polymer (octadecanol ethylene oxide polyether, cellulose nanometer crystal) and one or several kinds of additives are assisted; high speed mixing and shearing, ultrasonic exfoliation and dispersion of graphite or graphene are carried out, in order to obtain long-term stable graphene colloid. The method is simple, the graphene colloid is long-term stable, the graphene colloid can be divided into water-soluble colloid and oil soluble colloid, in order to facilitate practical application of graphene. After pumping filtration of the graphene colloid is carried out and film is formed, the film is hopeful to be used as a graphene electrode, a graphene composite material, a graphene coating, and a graphene fiber composite material.

Owner:SOUTH CENTRAL UNIVERSITY FOR NATIONALITIES

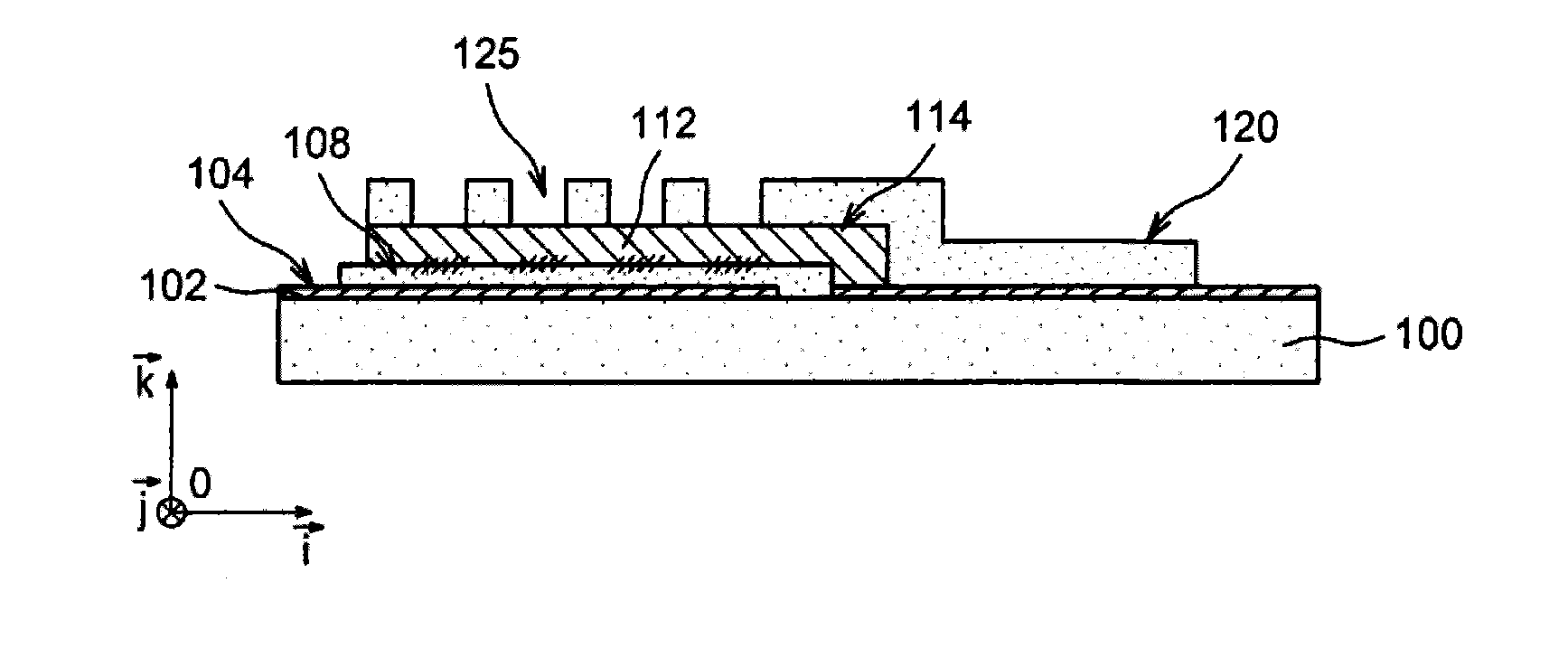

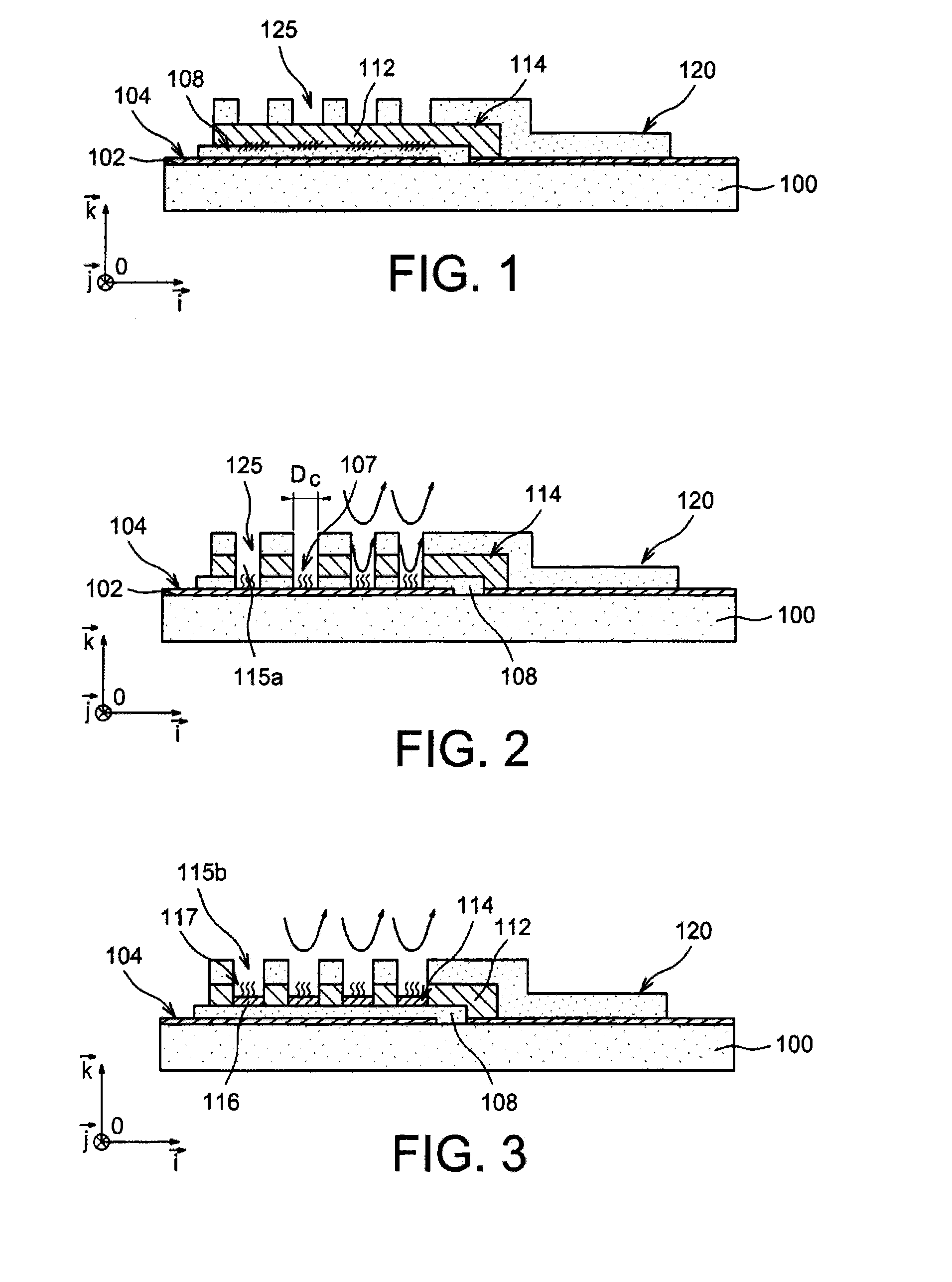

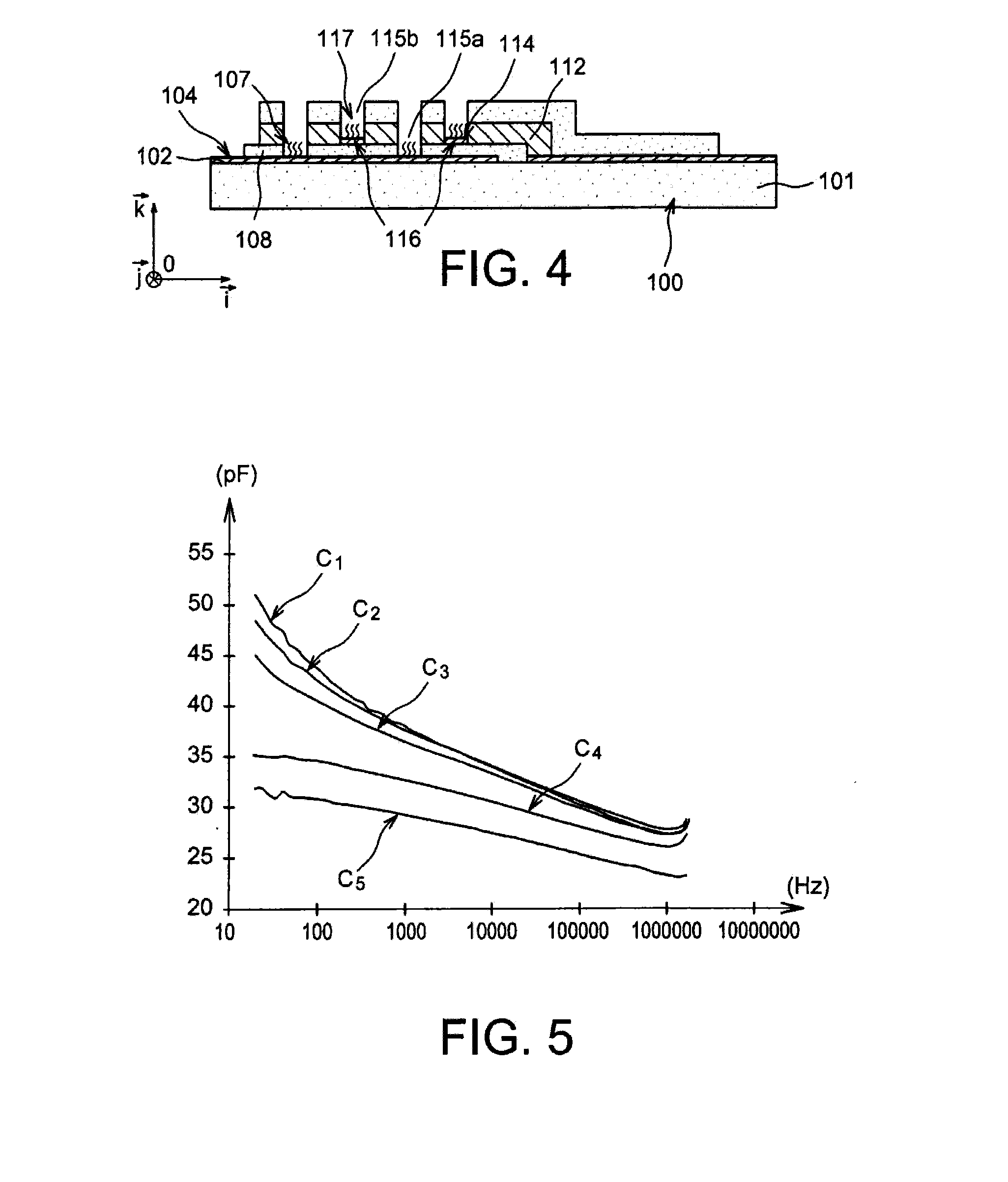

Capacitive humidity sensor with graphene electrode

ActiveUS20150153297A1High detection sensitivityHigh sensitivityUsing mechanical meansCoatingsGraphene electrodeMoisture sensor

A humidity-sensing device and a method of producing the humidity-sensing device. The humidity-sensing device is of capacitive type and includes a dielectric material with low permeability to moisture and an electrode with permeability to moisture greater than that of the dielectric material with which it is in contact.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com