Patents

Literature

67 results about "Cubic silicon carbide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Diamond/cubic boron nitride saw blade for cutting metal and fabricating method therefor

ActiveCN1669708ANo harmHuman and Environmental HazardsMetal sawing toolsSawing tools dressing arrangementsBoron carbideBoron nitride

This invention relates to a saw bit belonging to mechanical working field, which comprises metal base being alloy steel or carbon steel, with Phi8-Phi10mm radiating holes equispaced on its surface; Carcass including alumina, zircite, quartz, tungsten carbide, zirconium diboride, molybdenum disilicide; common abradant including brown fused alumina, carbofrax, green silicon carbide, cubic carbofrax, boron carbide; superhard abradant including diamond and cubic boron nitride. The produce process includes mixing carcass flour, working layered material batching-mixing process, welding layered material batching-mixing process, koldflo, thermal pressing-sintering formation, arc milling, welding, dressing and making edge. The invention has improved working efficiency, lowered product cost, and is suitable for cutting metal tube, plate such as this materials.

Owner:SF DIAMOND CO LTD

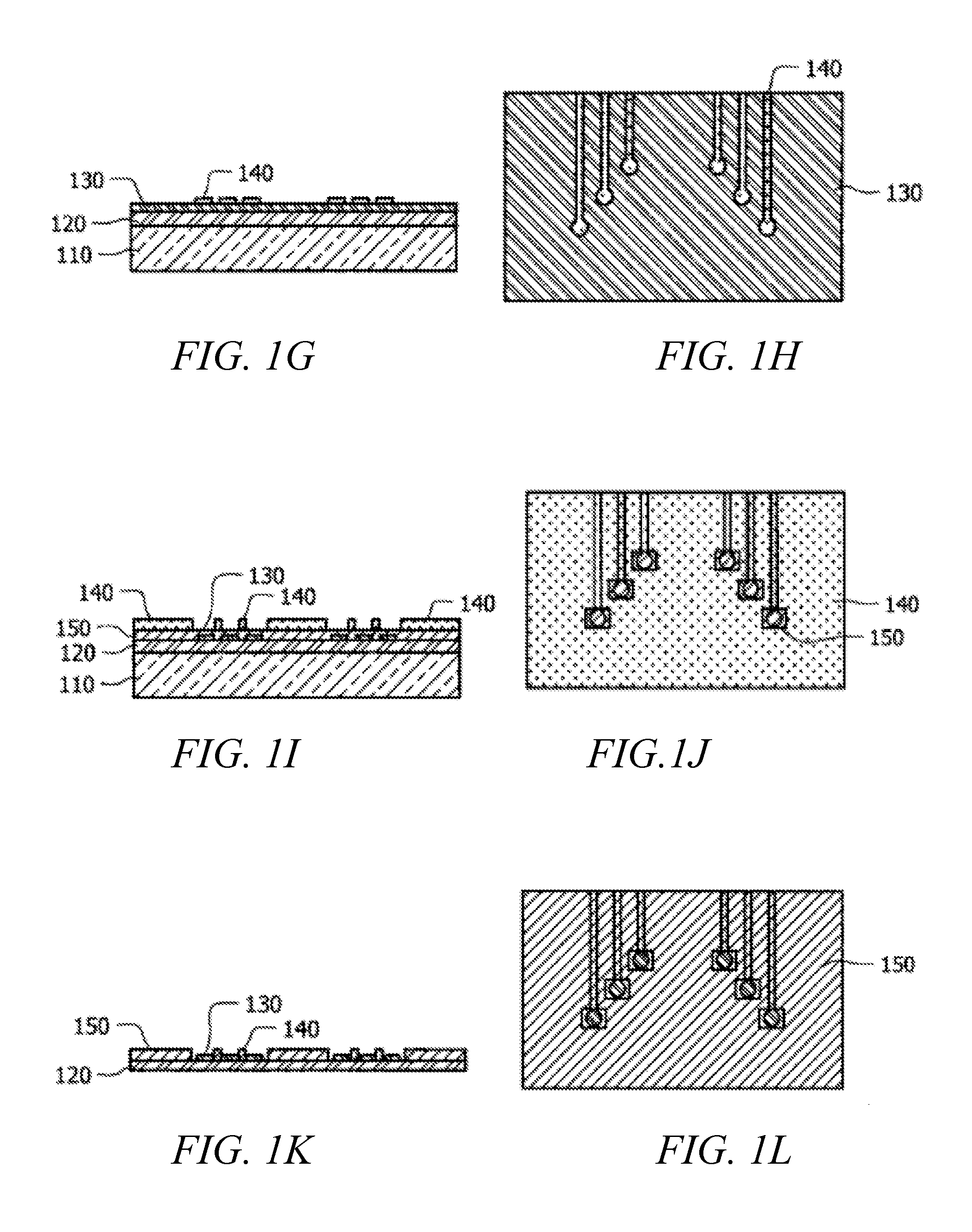

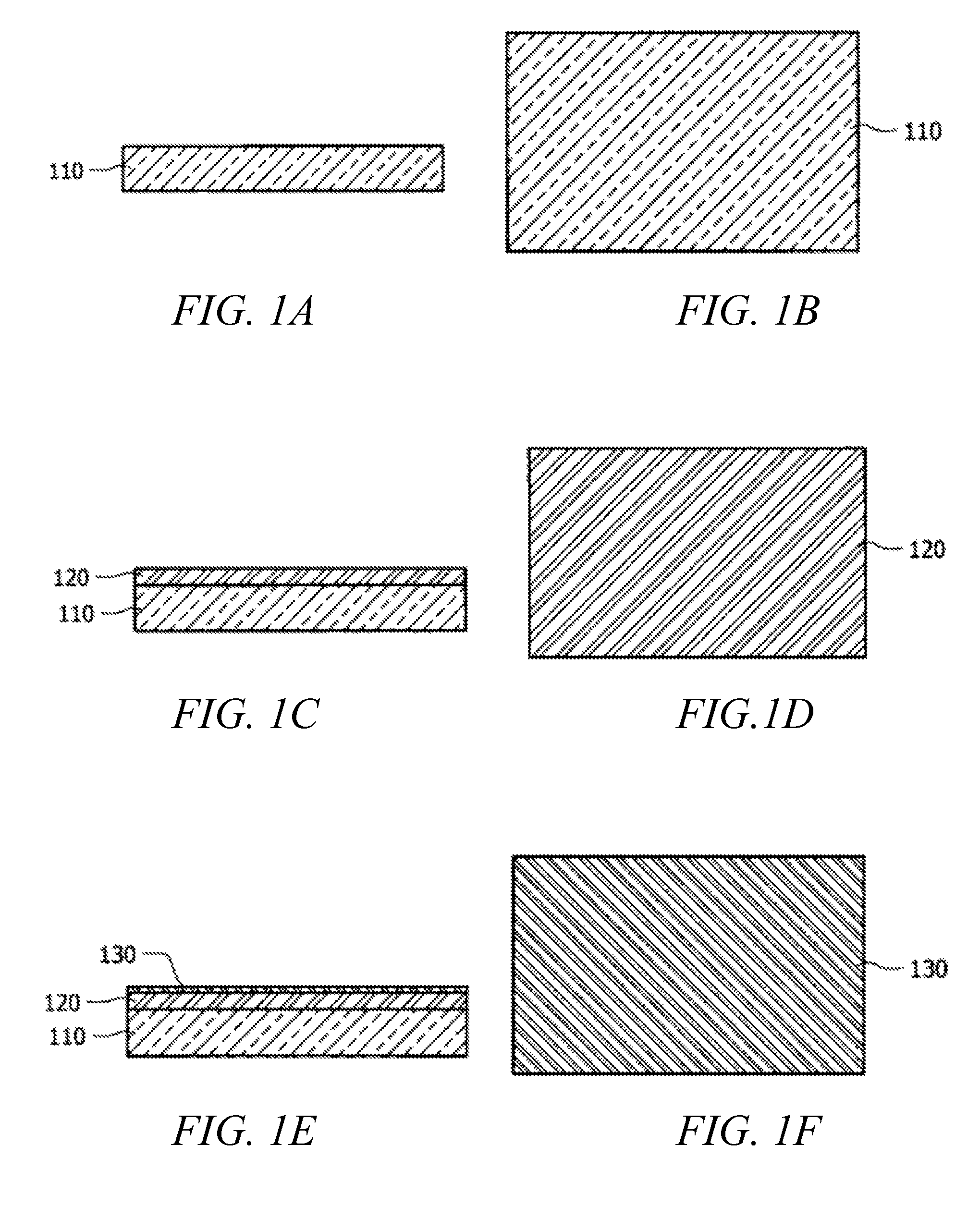

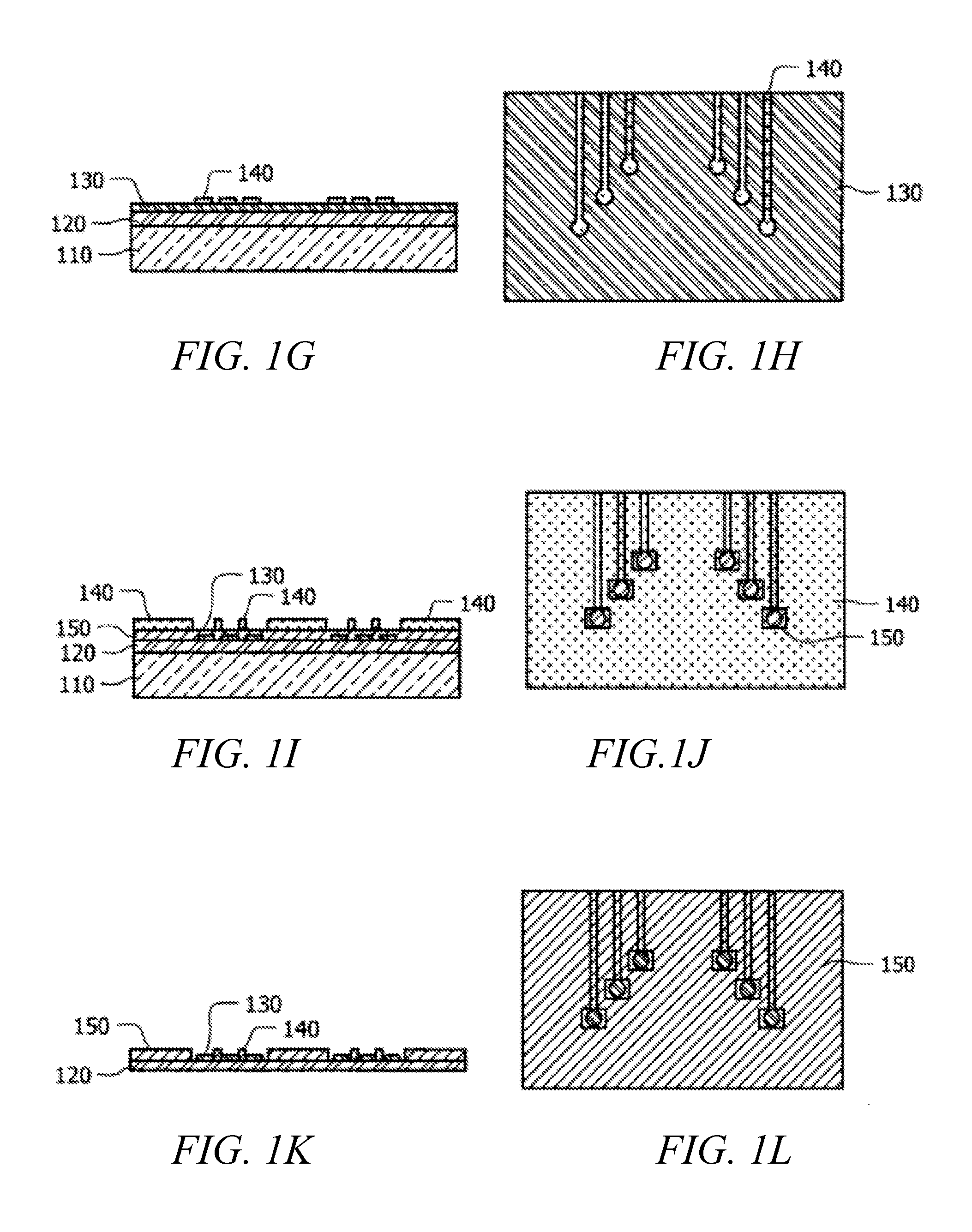

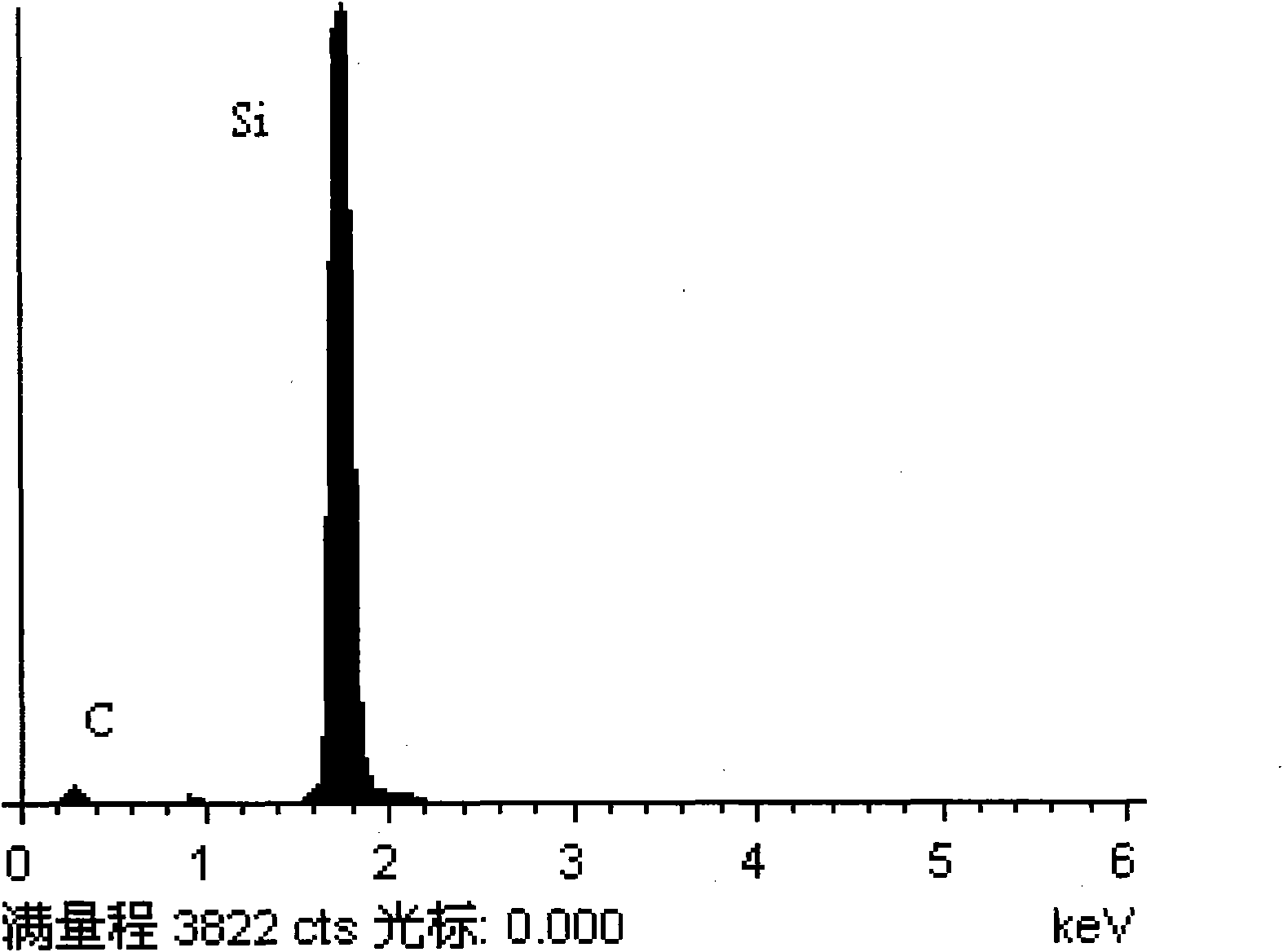

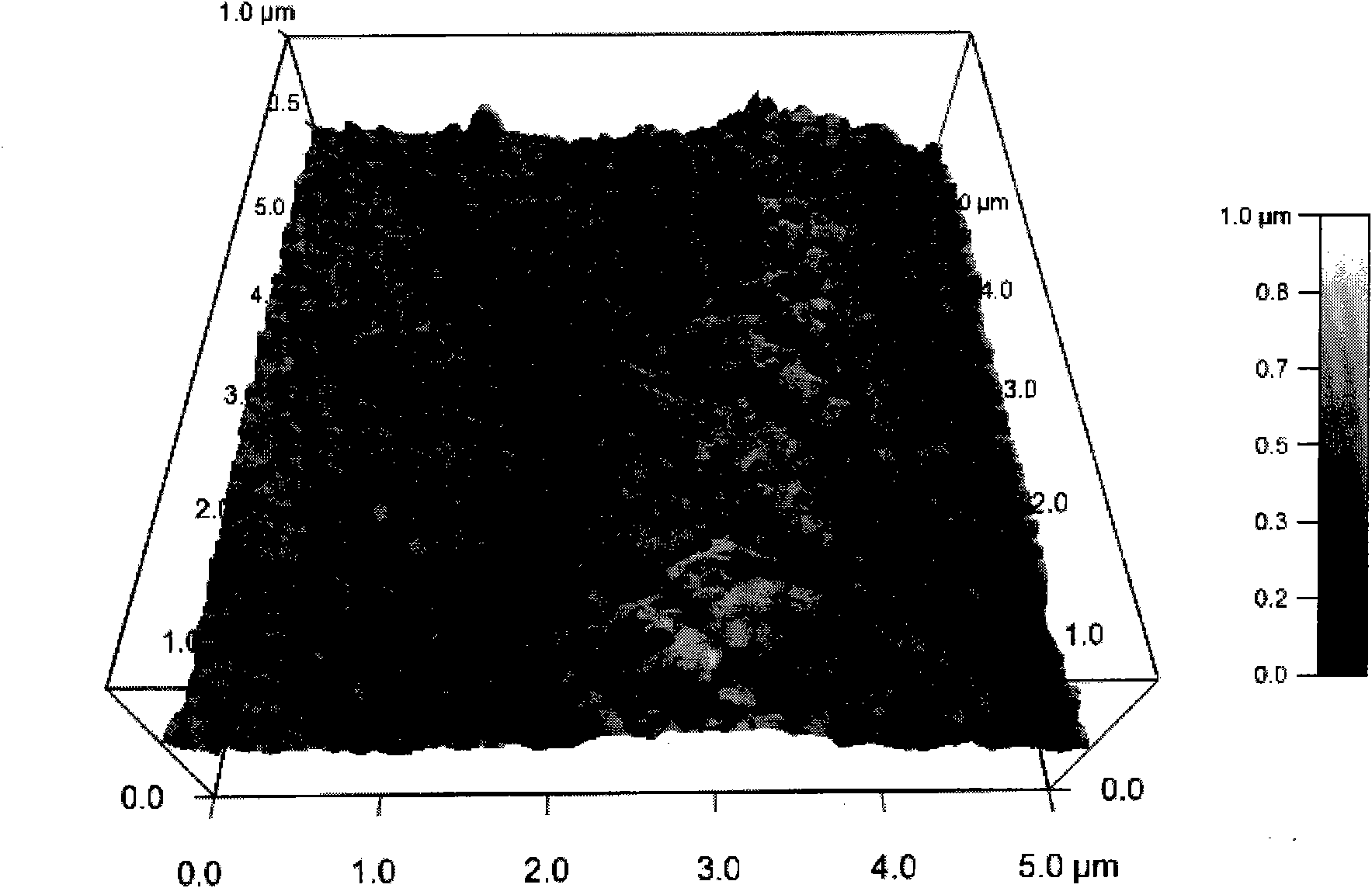

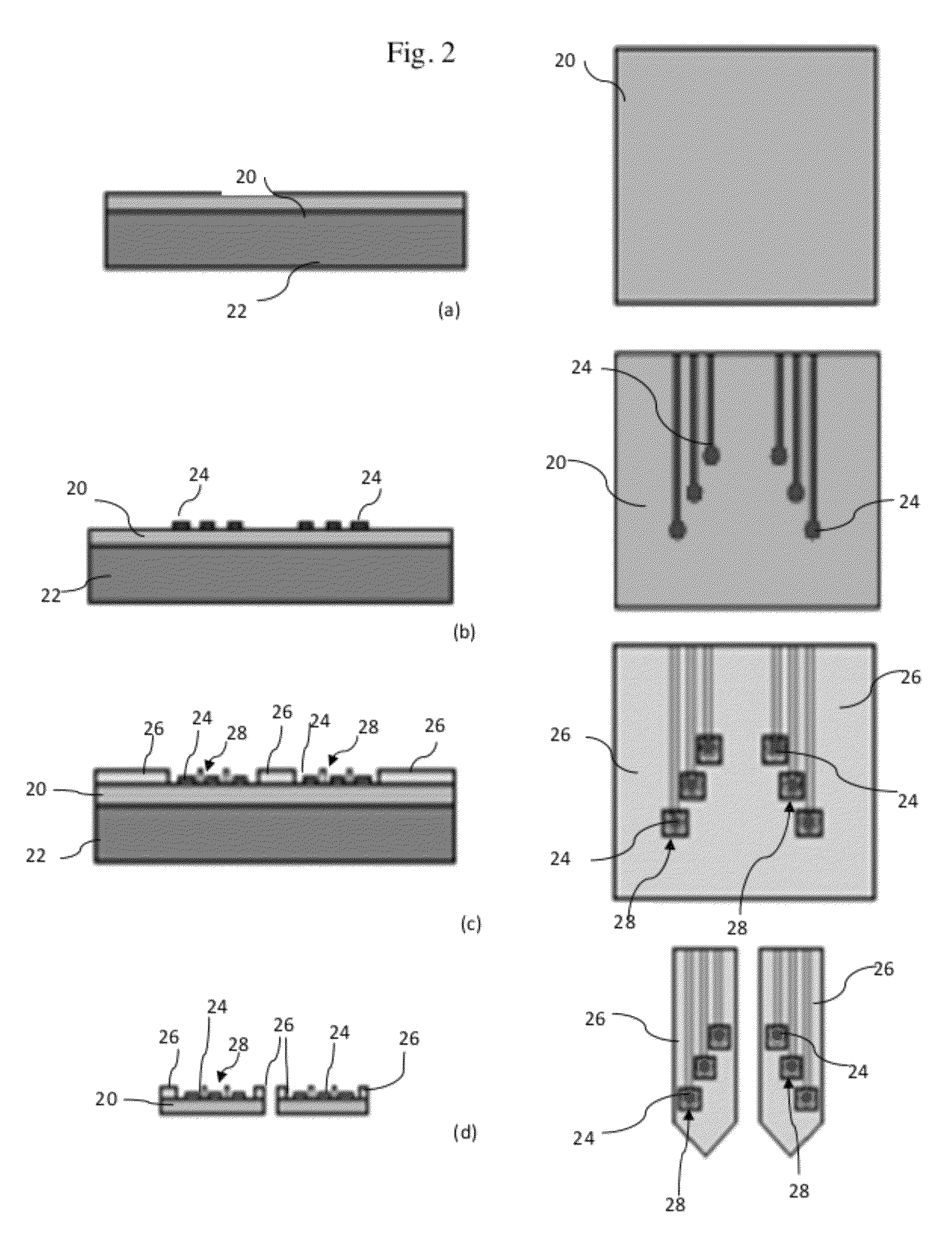

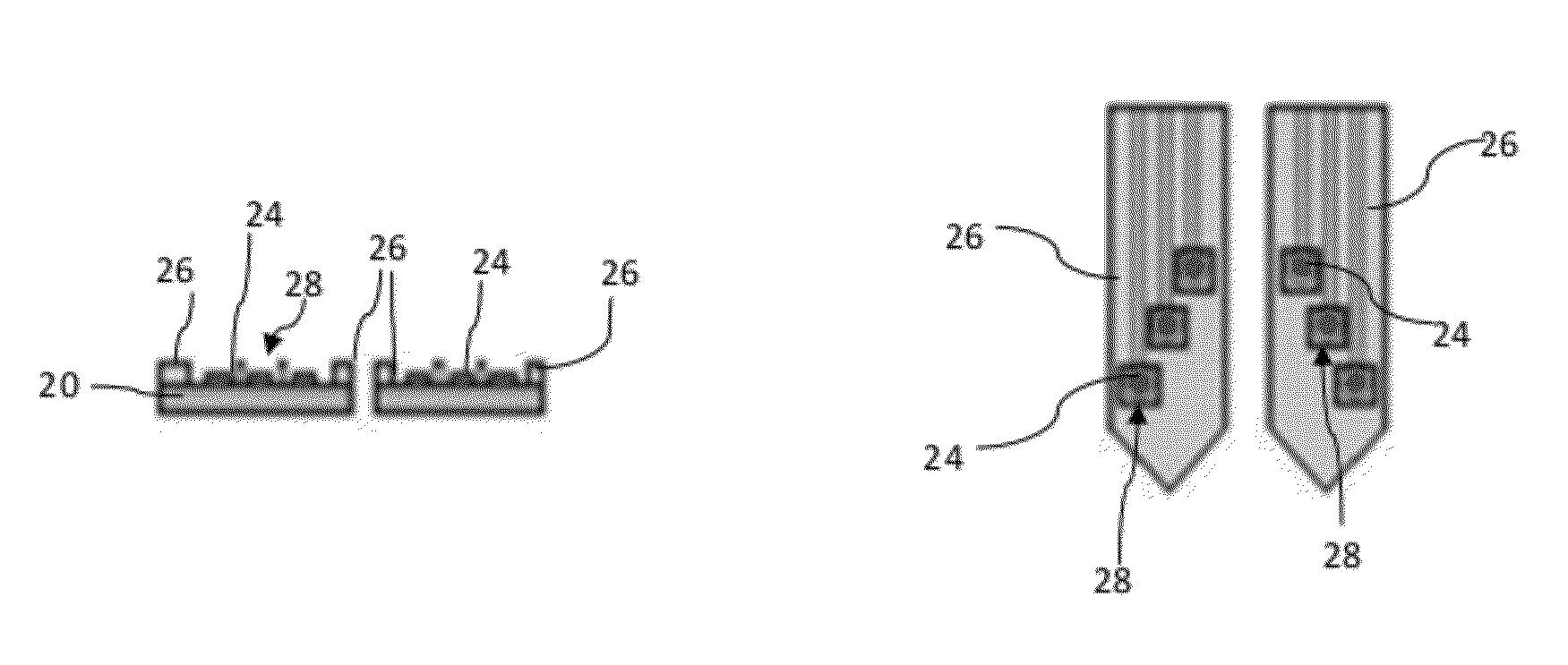

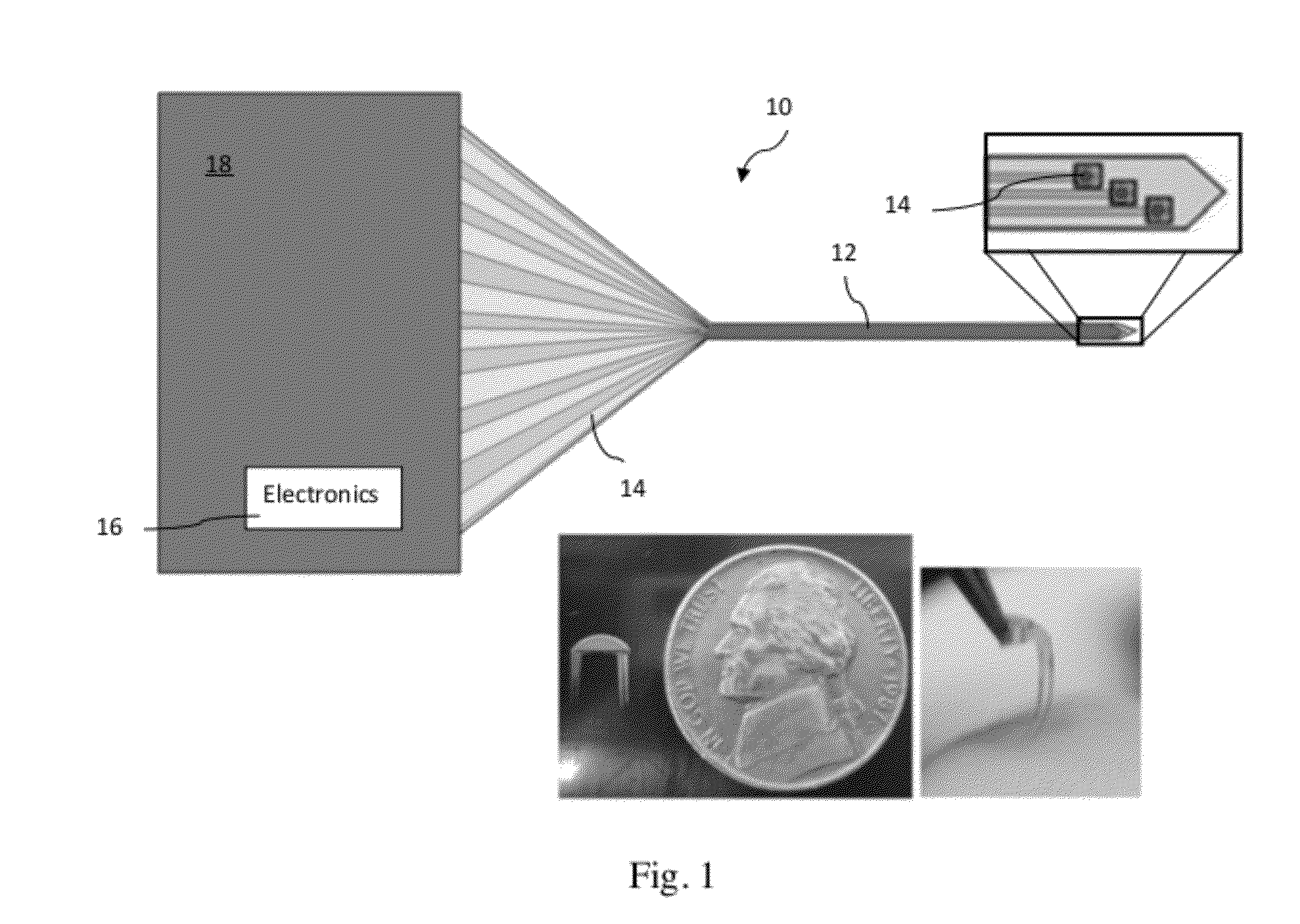

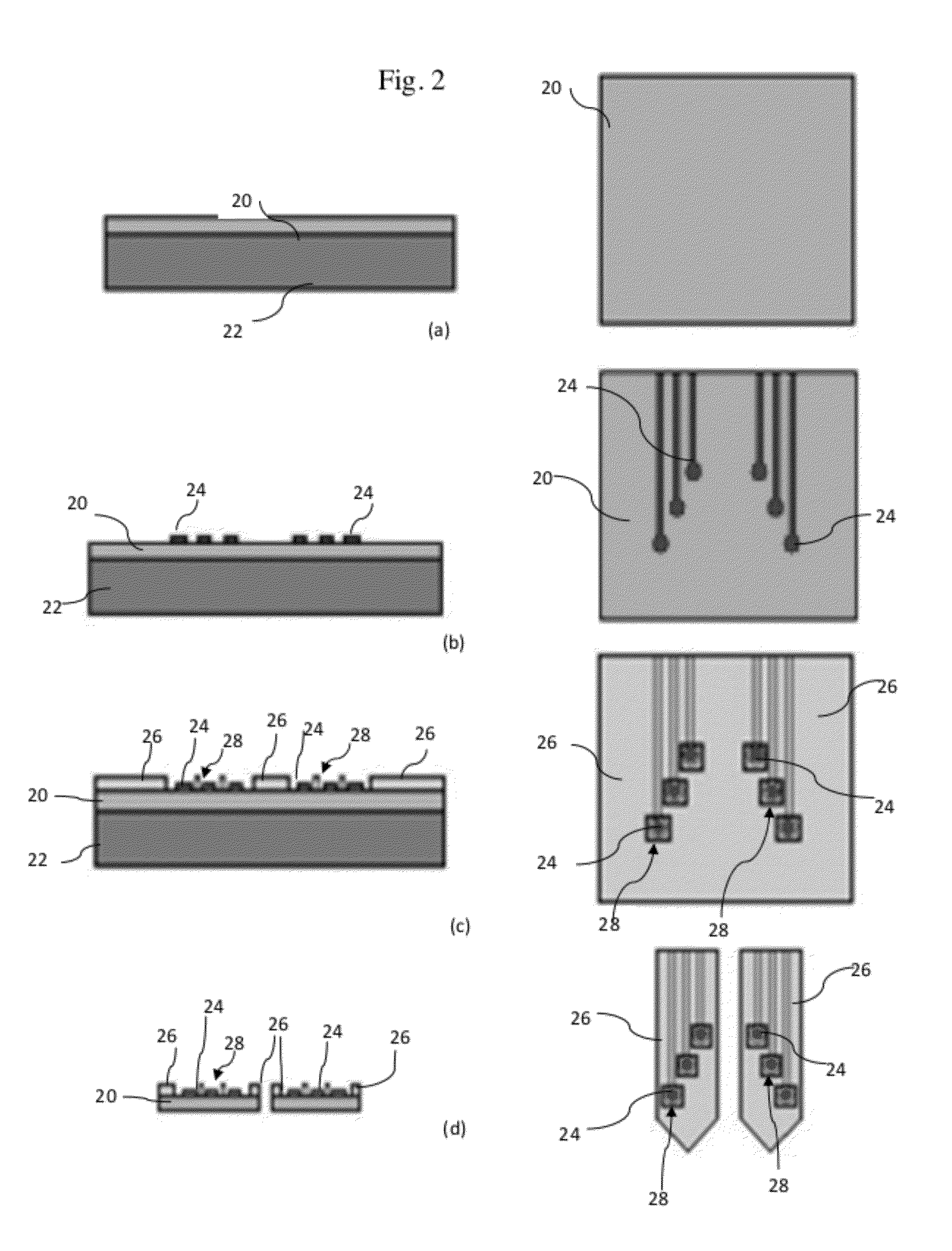

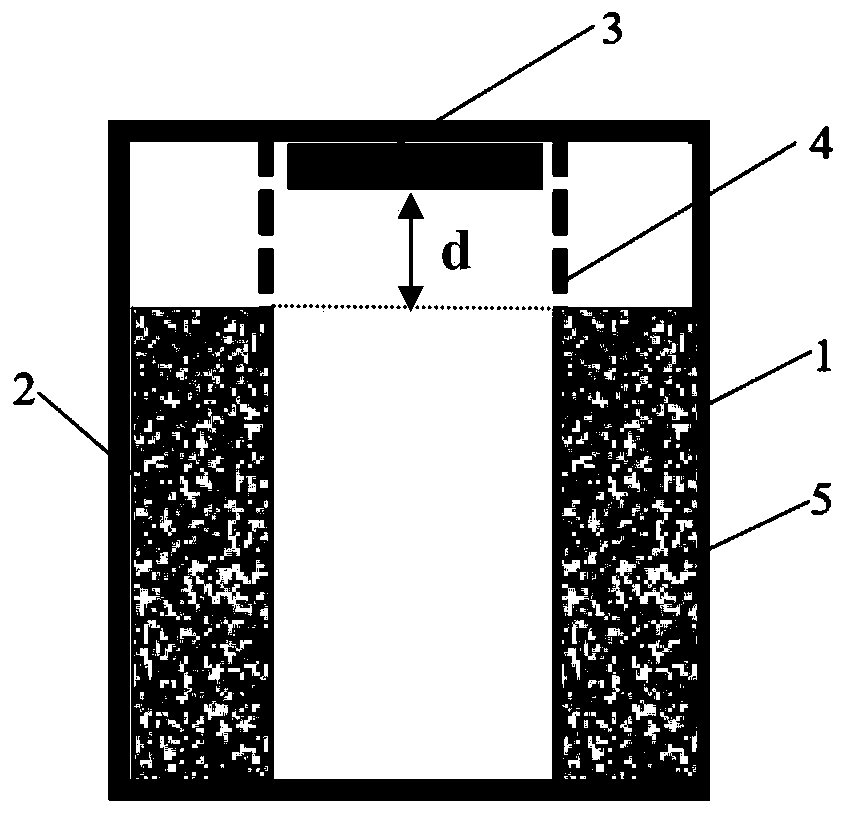

Graphene electrodes on a planar cubic silicon carbide (3c-sic) long term implantable neuronal prosthetic device

InactiveUS20130338744A1Increase surface areaSpecific capacitanceSpinal electrodesConductive pattern formationCapacitanceCubic silicon carbide

Graphene, can be used to make an implantable neuronal prosthetic which can be indefinitely implanted in vivo. Graphene electrodes are placed on a 3C—SiC shank and electrical insulation is provided by conformal insulating SiC. These materials are not only chemically resilient, physically durable, and have excellent electrical properties, but have demonstrated a very high degree of biocompatibility. Graphene also has a large specific capacitance in electrolytic solutions as well as a large surface area which reduces the chances for irreversible Faradaic reactions. Graphene can easily be constructed on SiC by the evaporation of Si from the surface of that material allowing for mechanically robust epitaxial graphene layers that can be fashioned into electrodes using standard lithography and etching methods.

Owner:UNIV OF SOUTH FLORIDA

Graphene electrodes on a planar cubic silicon carbide (3C-SiC) long term implantable neuronal prosthetic device

InactiveUS8751015B2Increase surface areaIncrease capacitanceSpinal electrodesConductive pattern formationCapacitanceElectricity

Graphene, can be used to make an implantable neuronal prosthetic which can be indefinitely implanted in vivo. Graphene electrodes are placed on a 3C—SiC shank and electrical insulation is provided by conformal insulating SiC. These materials are not only chemically resilient, physically durable, and have excellent electrical properties, but have demonstrated a very high degree of biocompatibility. Graphene also has a large specific capacitance in electrolytic solutions as well as a large surface area which reduces the chances for irreversible Faradaic reactions. Graphene can easily be constructed on SiC by the evaporation of Si from the surface of that material allowing for mechanically robust epitaxial graphene layers that can be fashioned into electrodes using standard lithography and etching methods.

Owner:UNIV OF SOUTH FLORIDA

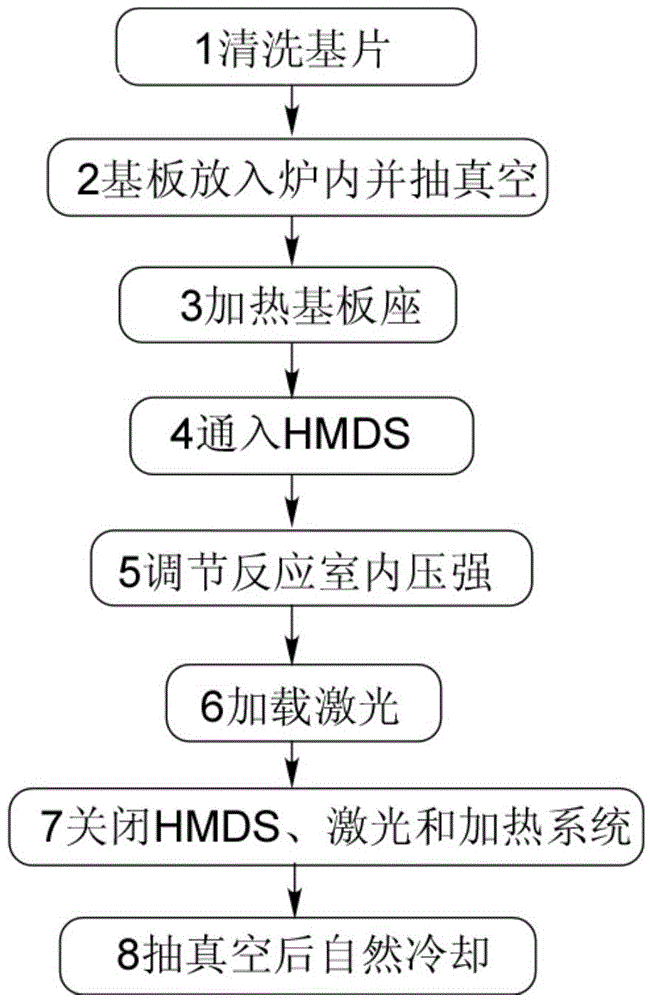

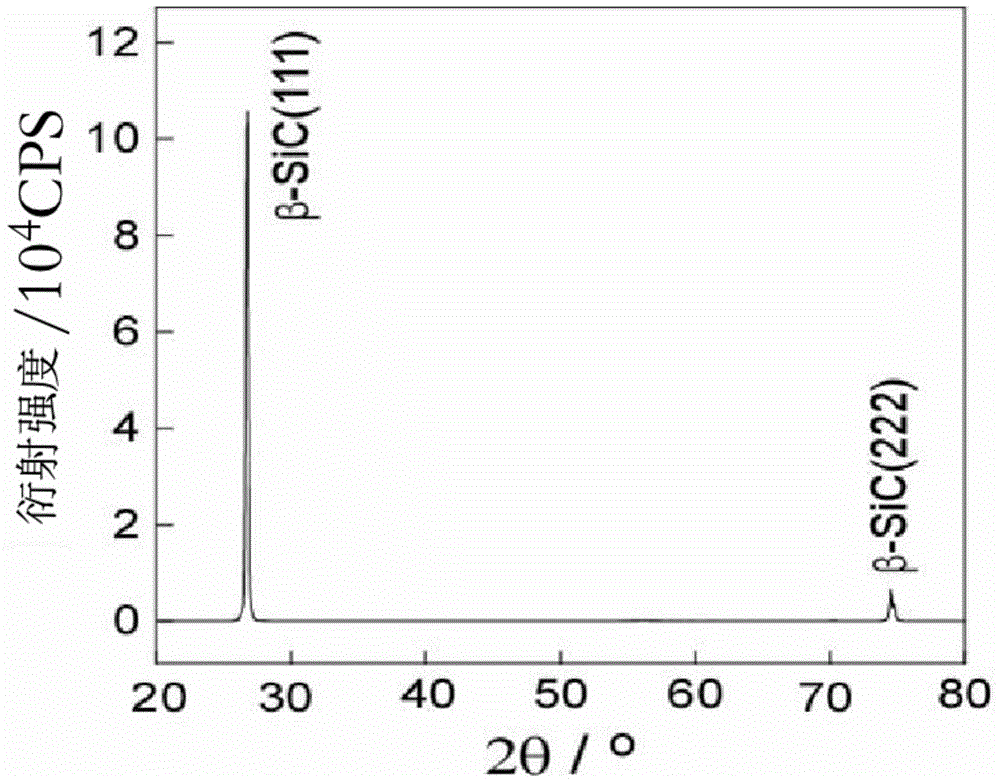

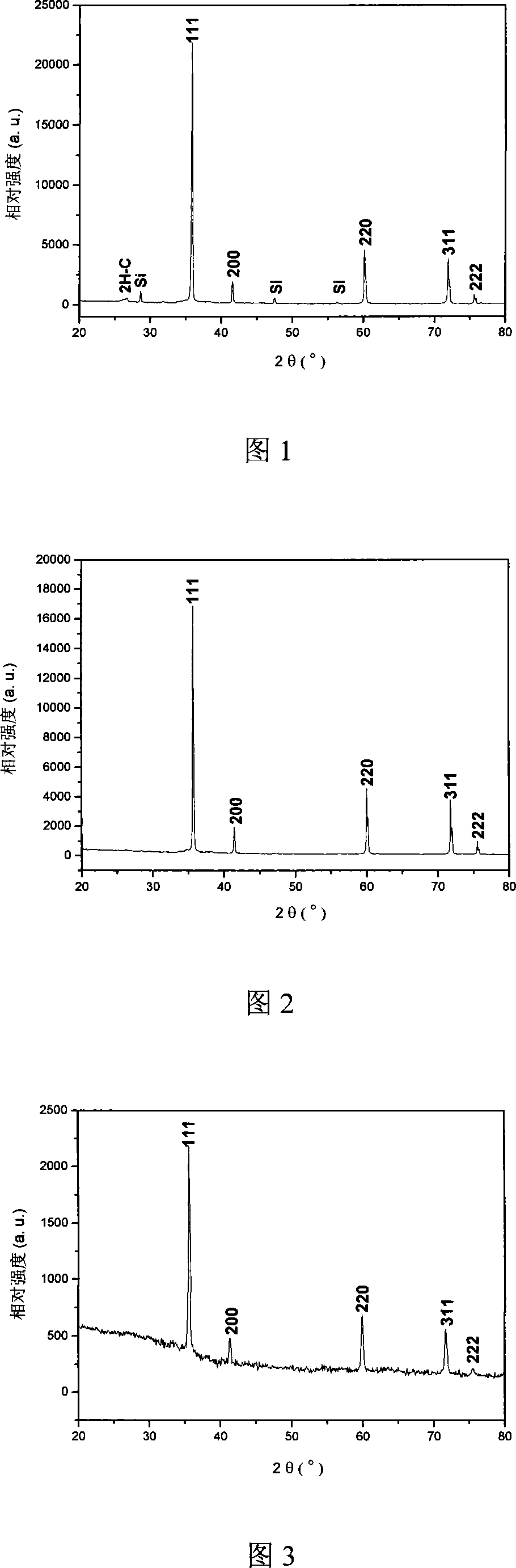

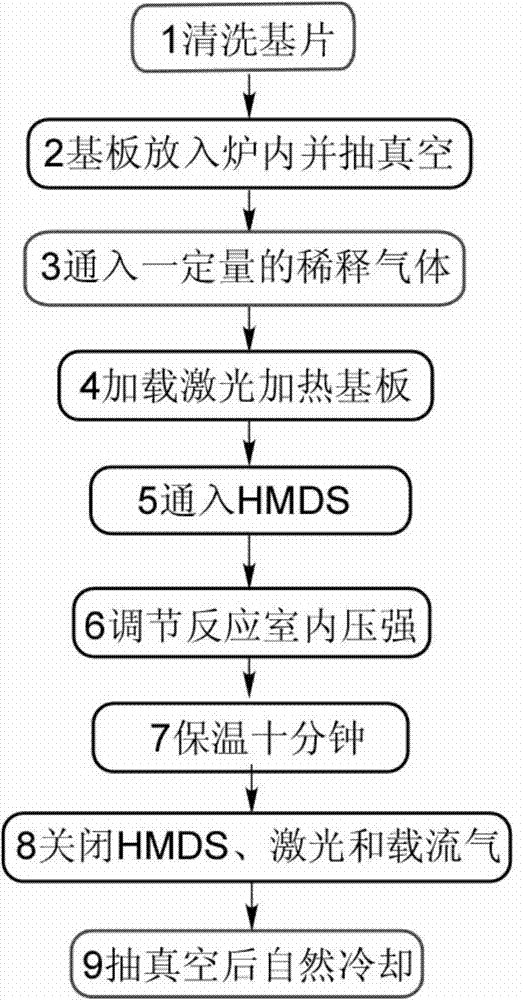

Preparation method of cubic silicon carbide film

ActiveCN104087909AReduce crystal defectsFast deposition rateChemical vapor deposition coatingCubic silicon carbideGas phase

The invention discloses a preparation method of a cubic silicon carbide film. The preparation method comprises the following steps of (1) placing a monocrystalline silicon substrate on a substrate seat of a cold-wall type laser induced chemical vapor deposition device, vacuumizing, and heating the substrate seat to 100-900 DEG C; (2) introducing HMDS-containing carrier gas to a reactor and regulating the vacuum degree to 10-10000Pa, wherein the flux of HMDS is 1-20sccm; (3) loading continuous laser to irradiate the surface of the silicon substrate at the wavelength of 750-1150nm and the power of 10-150W for 1-10min; (4) stopping the introduction of the HMDS-containing carrier gas, closing the laser, stopping heating, vacuumizing, and naturally cooling to room temperature to obtain the cubic silicon carbide film. A planar defect of the cubic silicon carbide film prepared by the invention trends to grow towards the growth direction of the film, and the self-disappearance phenomenon can be generated when adjacent defects meet, so that crystal defects in the material are effectively reduced.

Owner:武汉拓材科技有限公司

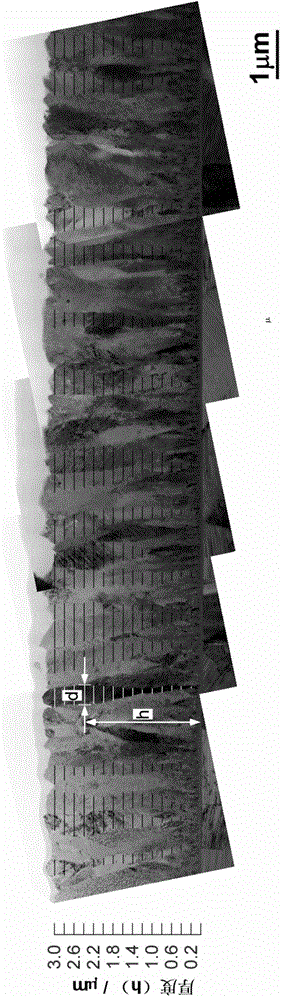

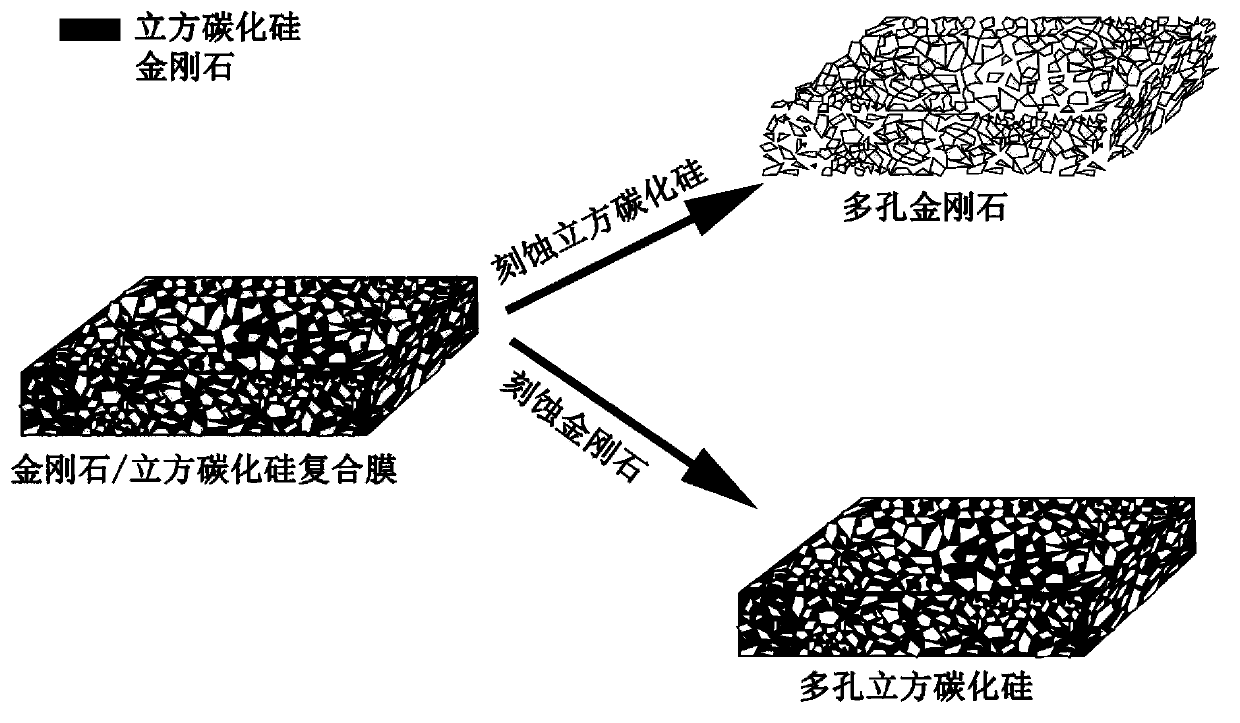

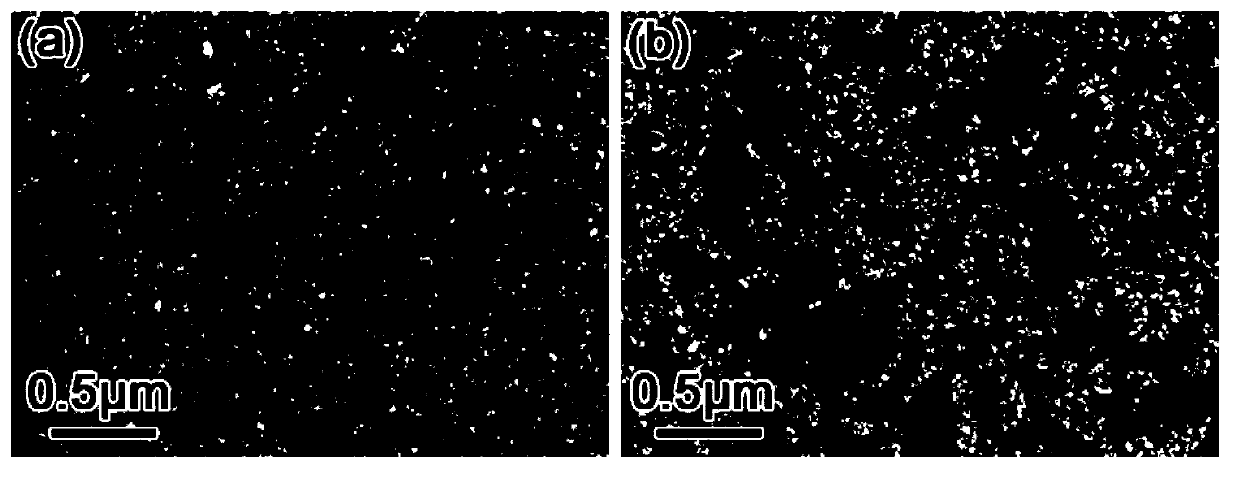

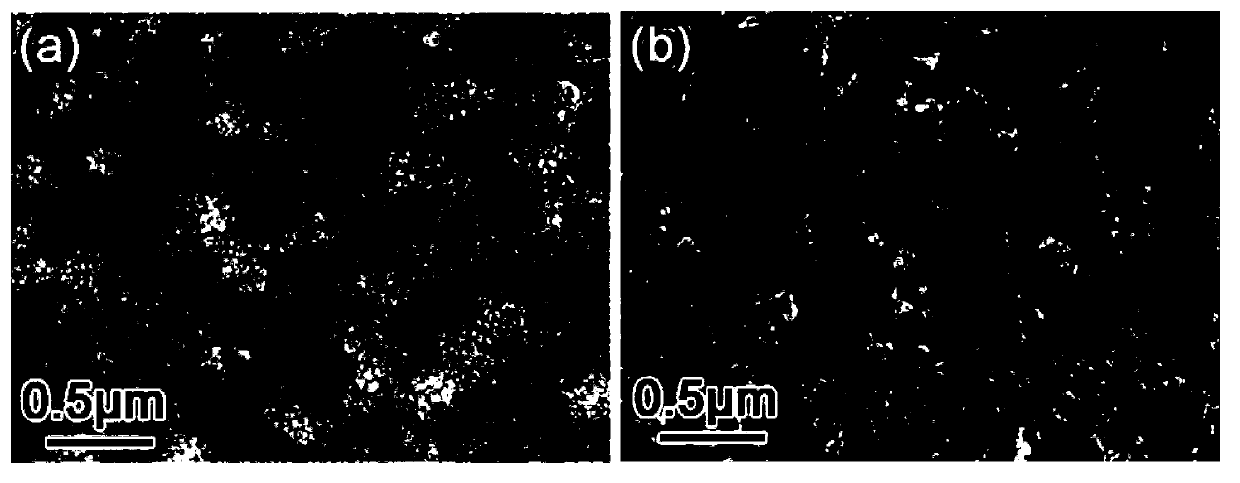

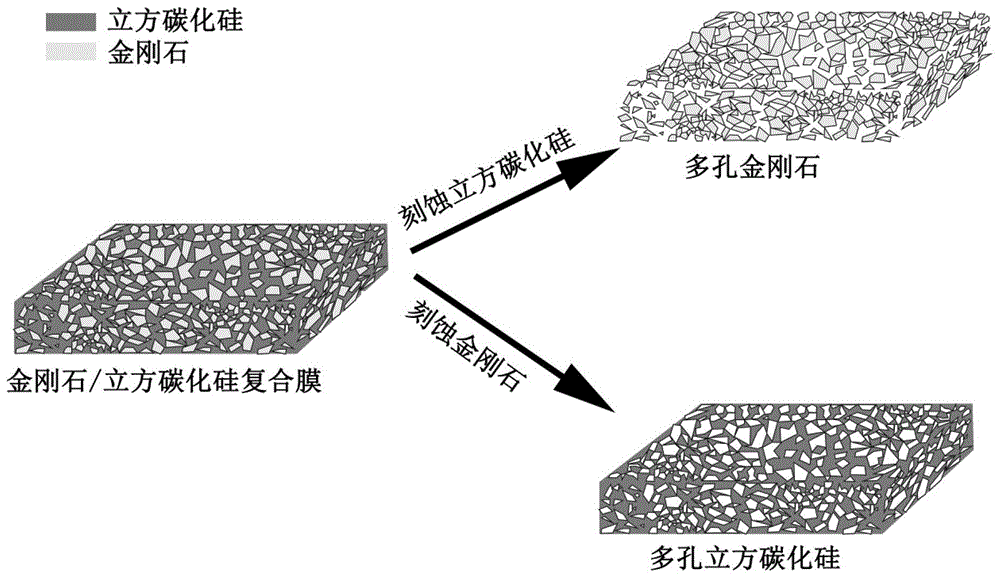

Method for manufacturing porous diamond or porous cubic silicon carbide self-supporting film

ActiveCN104178745AImprove stabilityControllable distributionChemical vapor deposition coatingPorosityComposite film

The invention discloses a method for manufacturing a porous diamond or porous cubic silicon carbide self-supporting film. The method comprises the steps that a base material is provided, and surface of the base material is pretreated to obtain a higher diamond-shaped nuclei rate; the pretreated base material is put into a microwave plasma chemical vapor deposition or hot filament chemical vapor deposition reactor, and at the temperature of 600 DEG C to 900 DEG C, a diamond / cubic silicon carbide composite film is manufactured; selective etching is performed on the obtained composite film, at the temperature above 70 DEG C, the composite film is etched in mixed corrosion liquid of hydrofluoric acid and nitric acid, and the porous diamond self-supporting film is obtained, at the temperature above 500 DEG C, the composite film is heated in the air containing oxygen gas, and the porous cubic silicon carbide self-supporting film is obtained. Under the condition that any template and any electrode material are not used, the obtained porous diamond self-supporting film and the porous cubic silicon carbide self-supporting film have the controllable aperture, the controllable porosity and the controllable thickness, and the method is suitable for industrial application and fundamental research.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

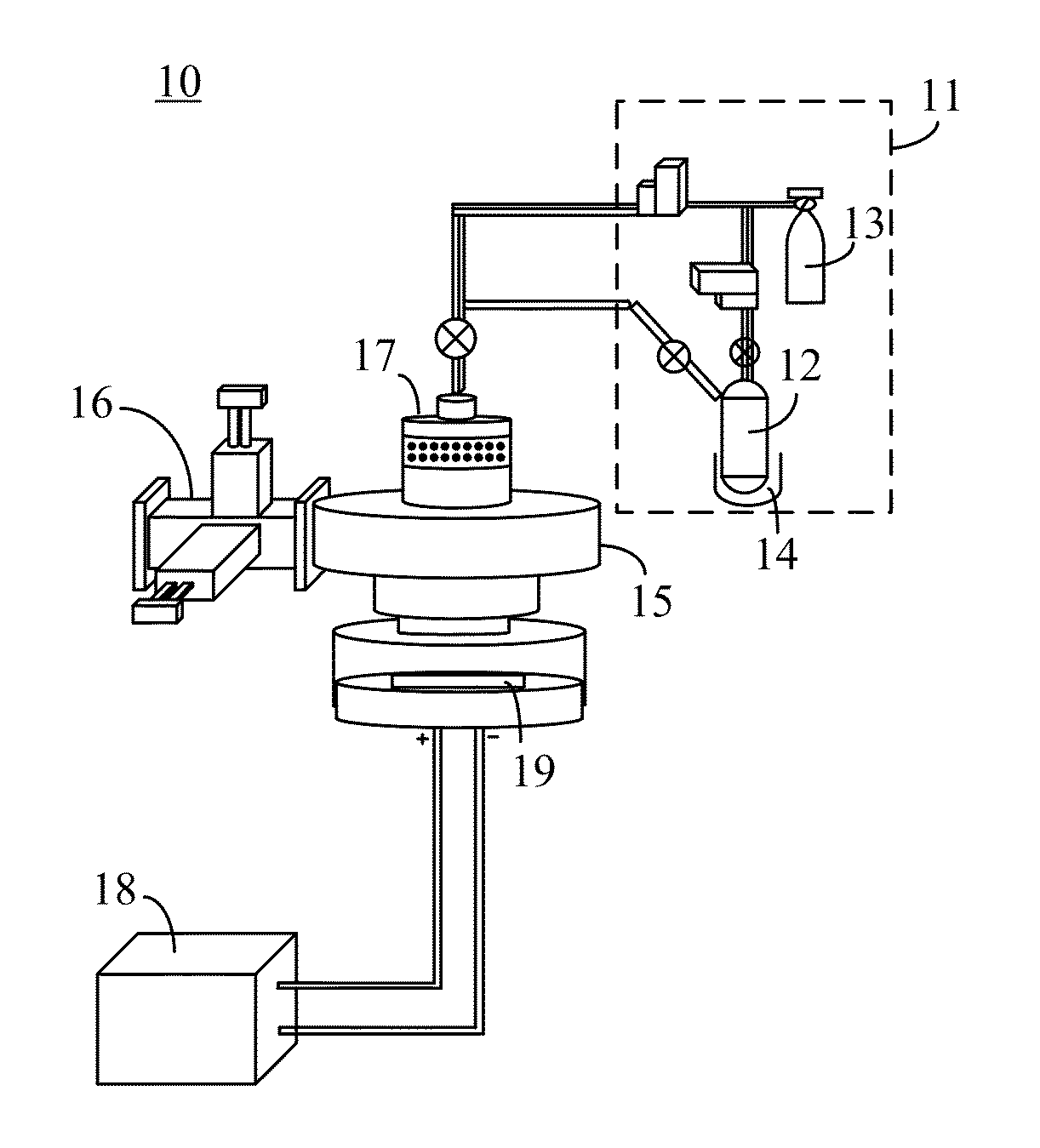

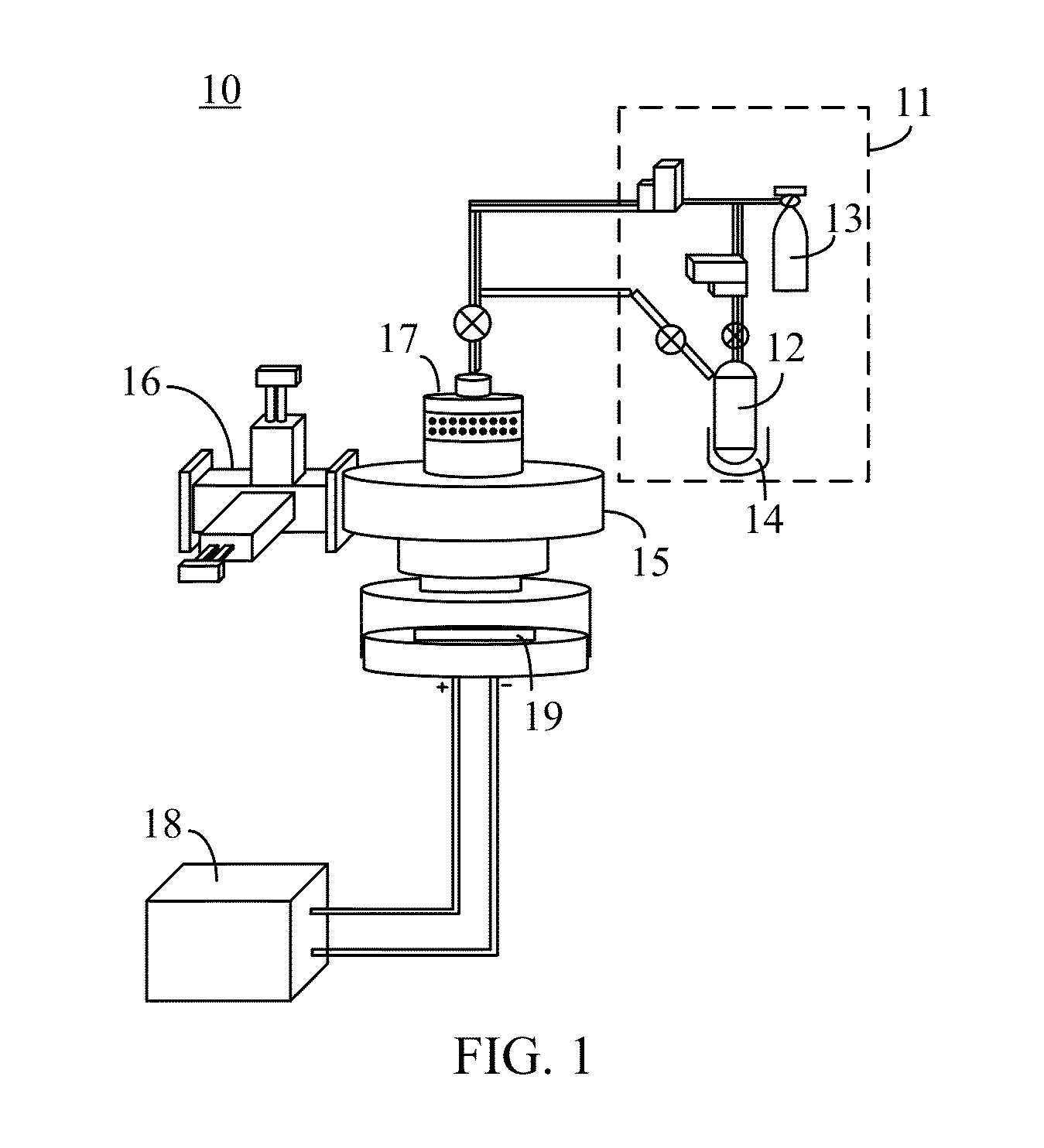

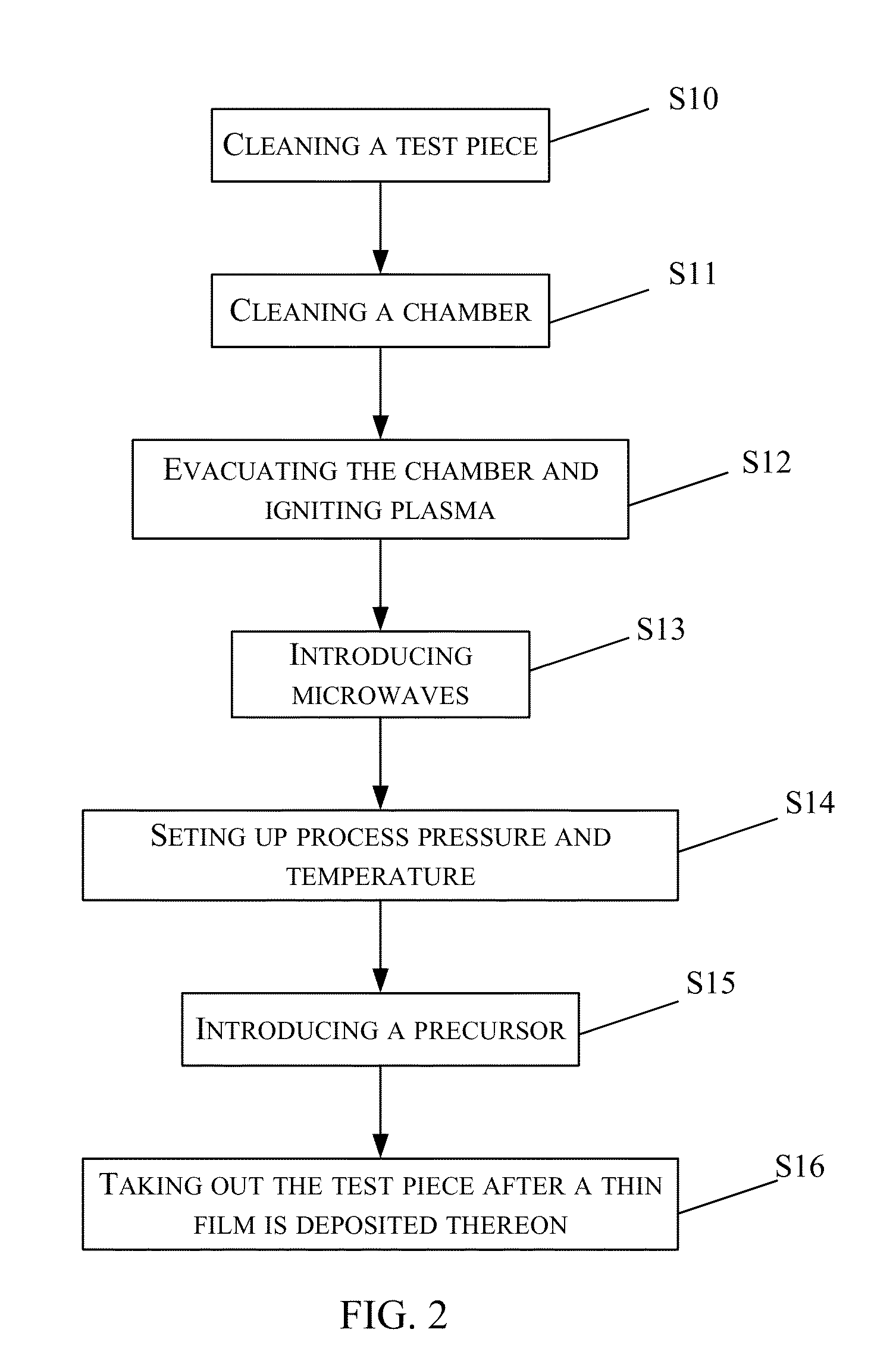

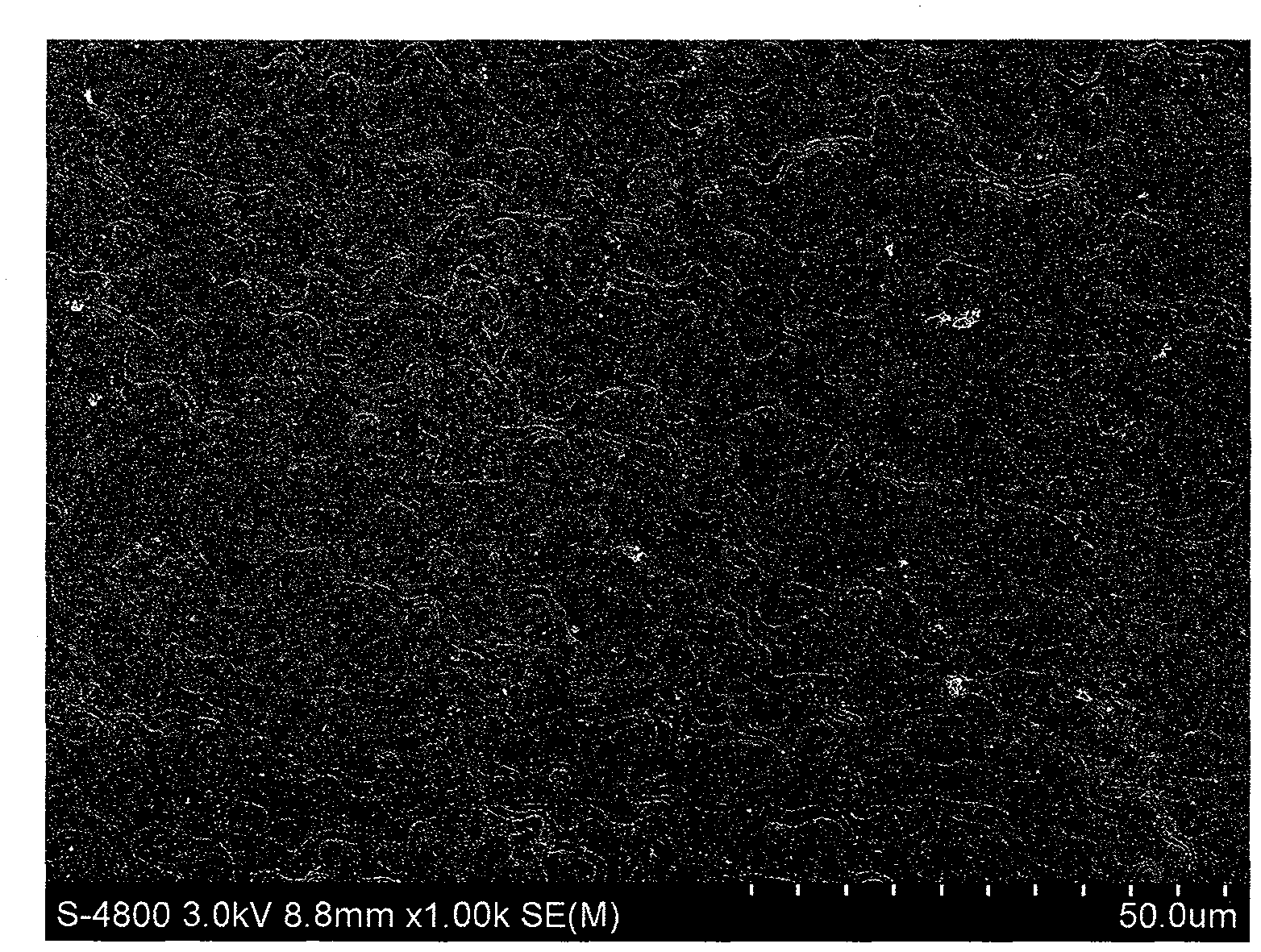

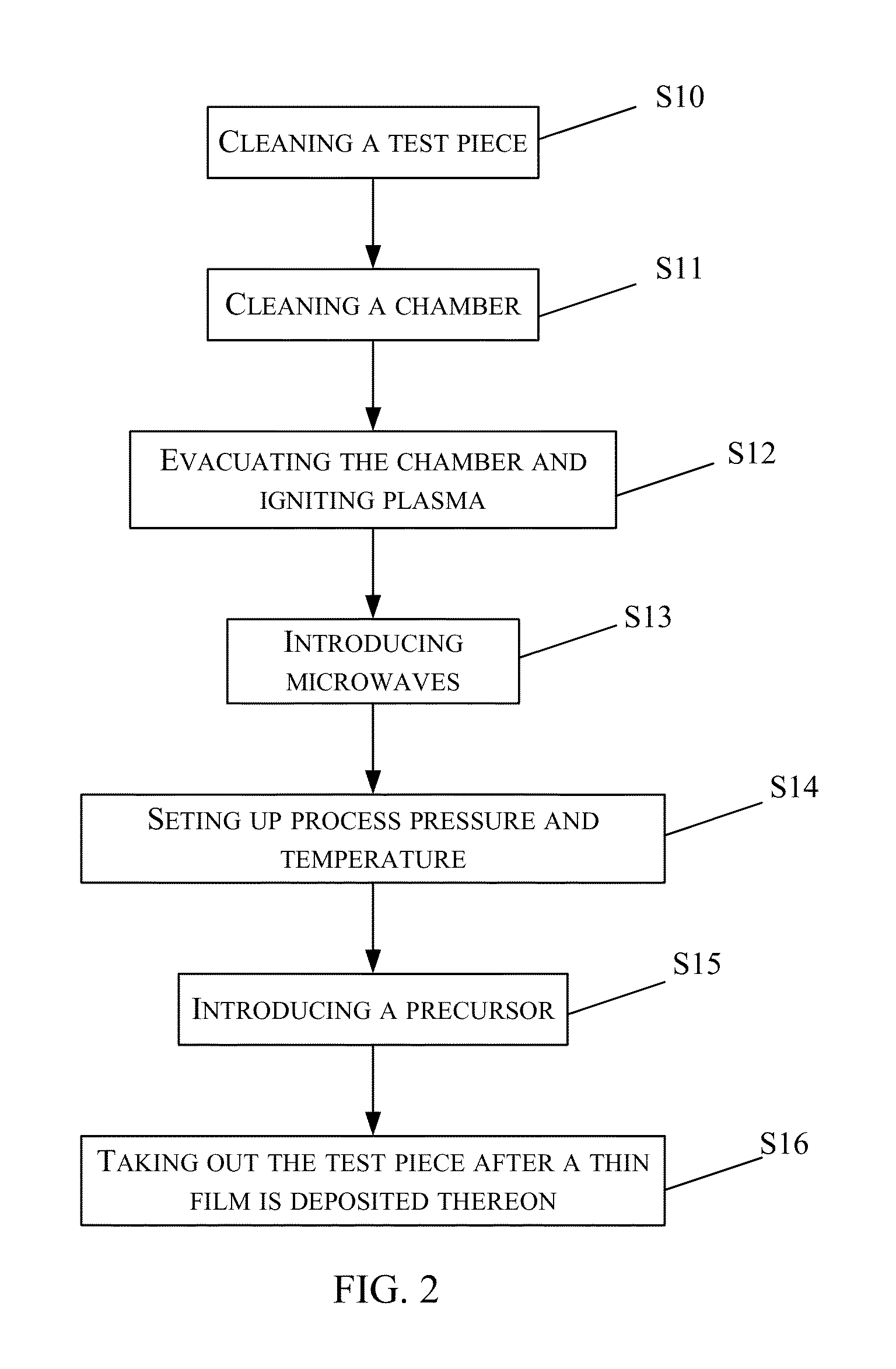

Method for manufacturing silicon carbide thin film

ActiveUS9371582B2High crystallinityLarge gran sizeChemical vapor deposition coatingPlasma techniqueCubic silicon carbideMicrowave

A method for manufacturing a silicon carbide thin film comprises steps of: (a) utilizing a mechanical pump to remove gases in a chamber such that the pressure in the chamber is reduced to a base pressure; (b) utilizing a microwave generator to generate microwaves at 1200 W to 1400 W so as to form microwave plasma inside the chamber; and (c) introducing into the chamber a silicon-based compound containing chlorine atoms that serve as a precursor, during the time that the temperature of a substrate disposed in the chamber is stable at 400° C. to 500° C., in which the temperature of the substrate is risen by the microwave plasma without heating the substrate additionally, so as to form a film of cubic silicon carbide on the substrate. In the present invention, the SiC thin film has good crystallinity and is manufactured by using MPECVD in a low temperature process.

Owner:NATIONAL TSING HUA UNIVERSITY

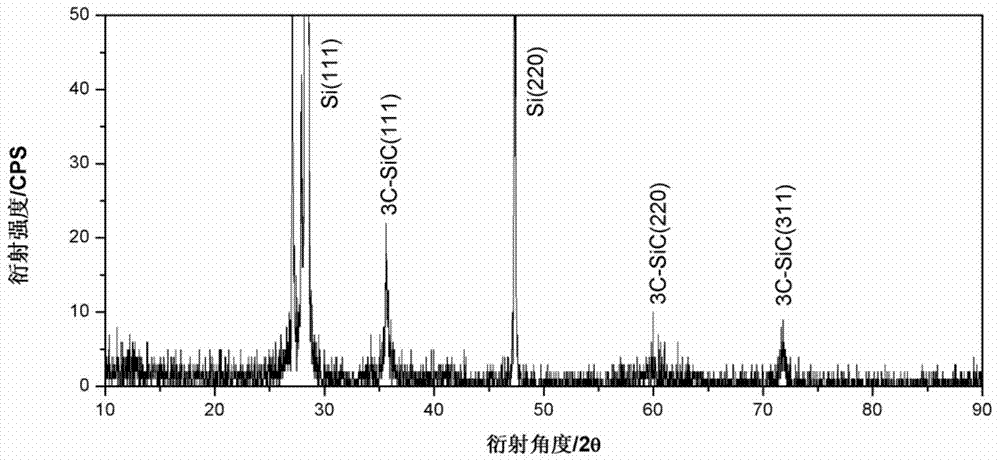

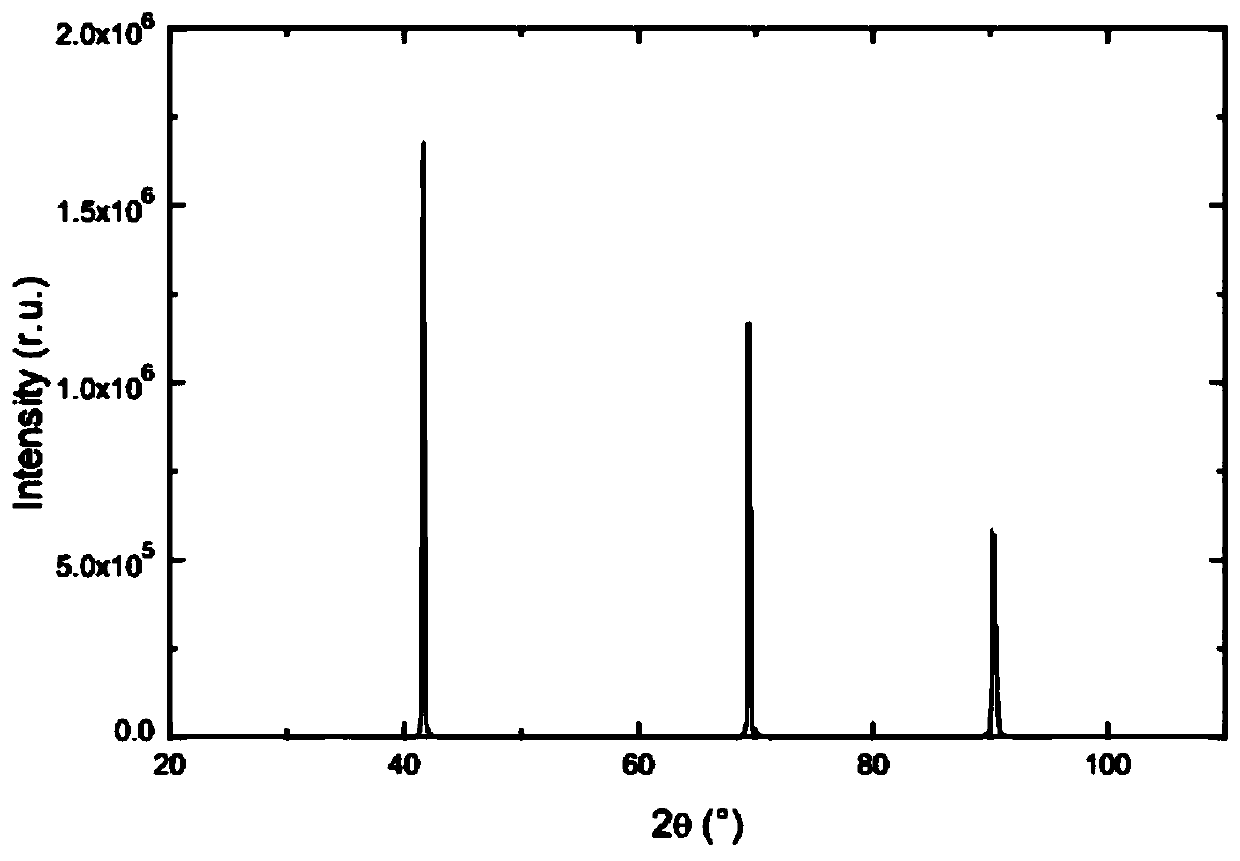

Si-base reversed extension 3C-SiC monocrystal film and preparation method thereof

InactiveCN101942696AEasy to operateAvoid difficultiesPolycrystalline material growthFrom chemically reactive gasesSemiconductor materialsSingle crystal

The invention relates to a cubic silicon carbide (3C-SiC) monocrystal film with reversed extension growth on a Si base and a preparation method thereof, belonging to the preparation field of novel Si-base wide band-gap semiconductors, wherein the cubic silicon carbide (3C-SiC) monocrystal film with reversed extension growth on the Si base is formed by diffusing carbon on the Si base to Si and reacting with the Si. The method adopts low-temperature chemical vapor deposition (LPCVD for short), comprising the following steps of: diffusing the carbon to the Si by utilizing methane decomposition at high temperature to effectively displace the Si, and forming the 3C-SiC monocrystal film with the stoichiometric ratio of 1:1 by using a reversed extension growth mechanism, wherein the thickness of the 3C-SiC monocrystal film can reach the micrometer level, the electronic Hall mobility at the room temperature reaches 1.22*10<3> cm<2> / (V.S), and the electronic Hall mobility in liquid nitrogen reaches 2.06*10<3> cm<2> / (V.S). The impurity concentration and the condition type of the 3C-SiC monocrystal film prepared in the method can be controlled through the impurity concentration and the condition type of a monocrystal silicon substrate, and the impurity concentration in the film is uniform. The preparation method can be used for obtaining the Si-base reversed extension 3C-SiC monocrystal film with low stress and high quality.

Owner:SICHUAN UNIV

Cubic silicon carbide implantable neural prosthetic

Owner:UNIV OF SOUTH FLORIDA

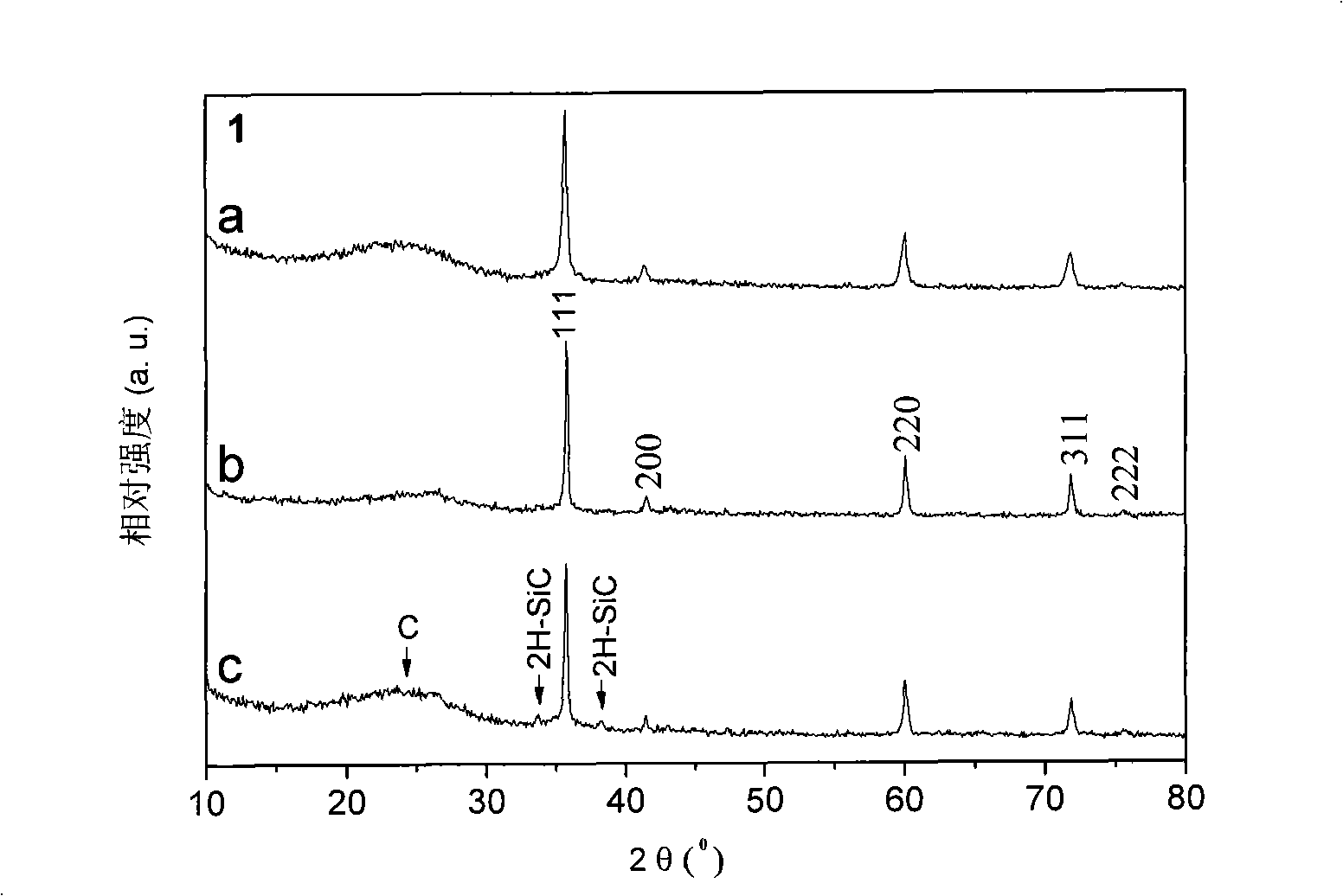

Method for preparing cubic silicon carbide ultrafine powder by using waste plastic at low temperature

InactiveCN101525134ALow costRealize resourcesPolycrystalline material growthSingle crystal growth detailsHigh pressureReducing agent

The invention relates to a method for preparing cubic silicon carbide ultrafine powder by using waste plastic at low temperature, which comprises the following steps: waste plastic is used as a carbon source to synthesize silicon carbide with silicon powder, sodium metal and magnesium metal powder are used as reducing agents, sulfur powder is used as an adjuvant, the mixture reacts for 10 to 30 hours under the condition of 0.5 to 10 MPa at the temperature of 350 to 500 DEG C in a high-pressure kettle, and the product of reaction is washed and purified to obtain the cubic silicon carbide ultrafine powder. The method can cheaply prepare 3C-SiC ultrafine powder with good crystal degree in a large scale at relatively lower temperature and enlarge the application of silicon carbide ceramics and relevant composite materials thereof; especially the method uses the waste plastic as the carbon source, thereby being beneficial to energy saving, consumption and cost of raw materials reducing and changing the waste into a resource and controlling the environmental pollution.

Owner:SHANDONG UNIV

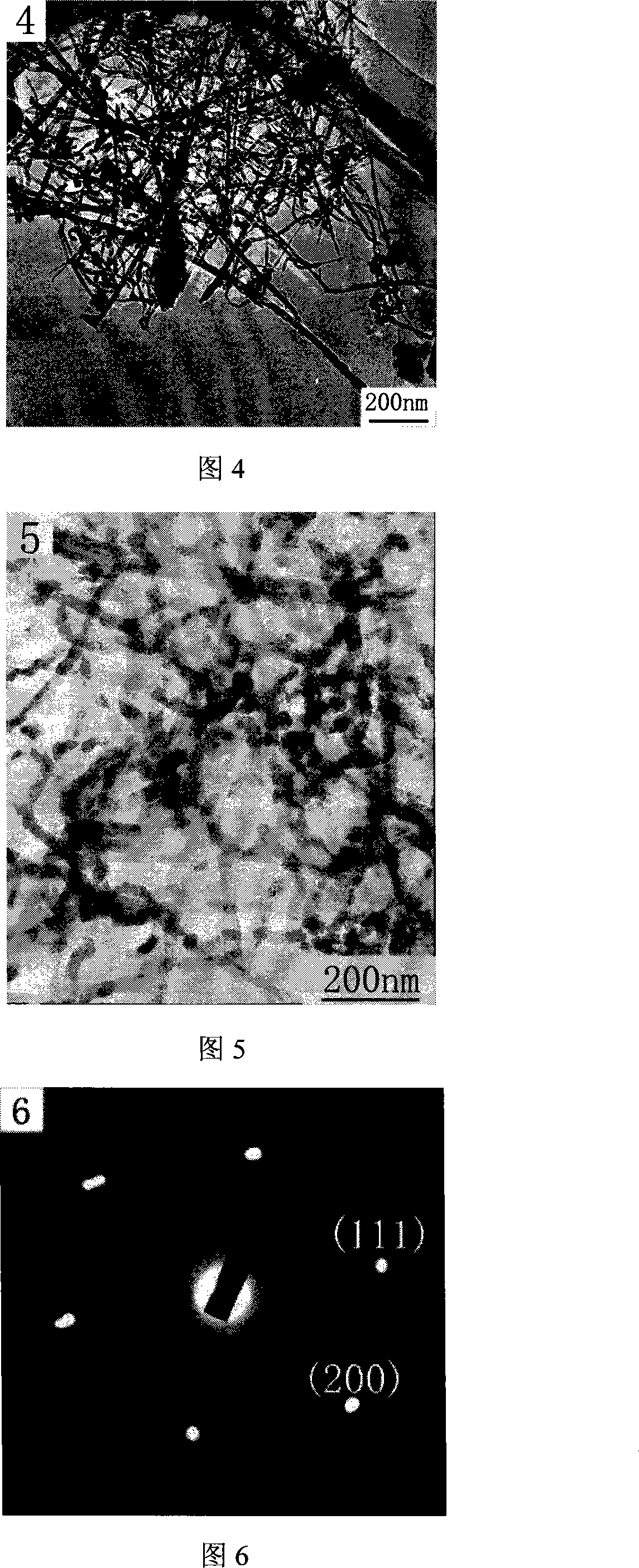

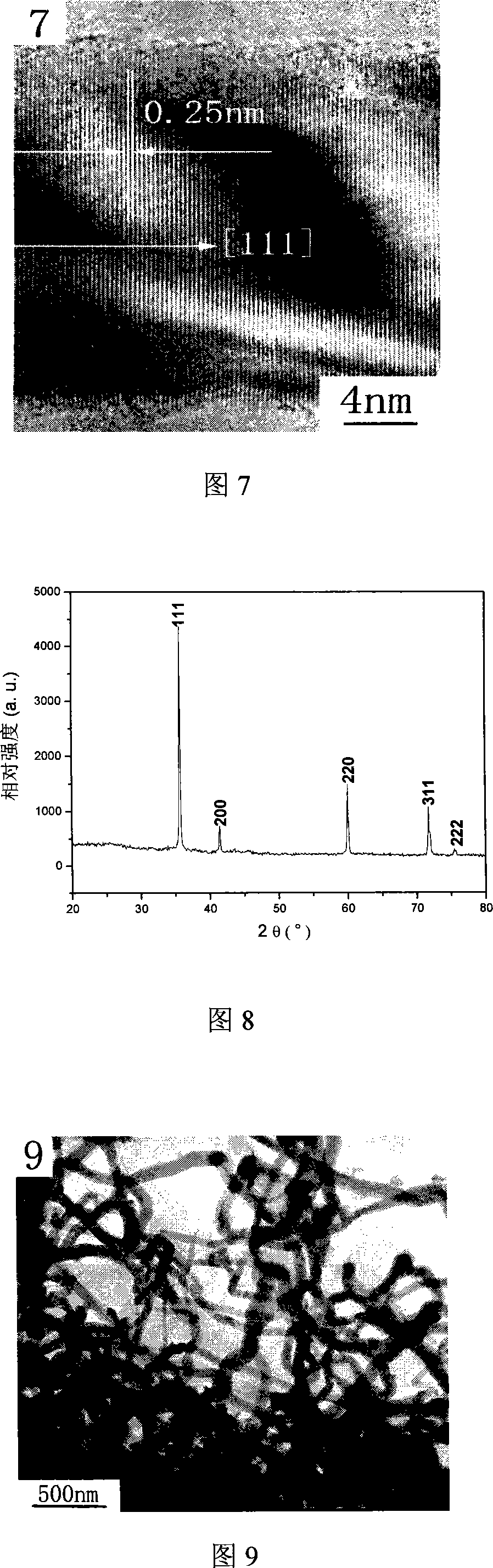

Method for low-temperature preparation of cubic silicon carbide nano wire

InactiveCN101177268AGood lookingImprove toughnessNanostructure manufactureAdditive ingredientReaction temperature

The invention discloses a low-temperature preparation method of cubic silicon carbide nano-wires, which comprises the following steps: silica flour, tetrachloroethylene, sodium and sublimed sulfur are mixed in a mol radio of 0.5 to 4 : 1 : 2 to 8 : 0.5 to 2 and then sealed in an autoclave for reaction under the condition of 120 to 260 DEG C and 5 MPa to 18 MPa for 10 to 55 hours, or under the condition of 260 to 600 DEG C and 7 MPa to 18 MPa for 10 to 55 hours, with the same ingredients and without adding sulfur. After alcohol washing, pickling or igniting, then the product is pickled and washed with water until the product shows a neutral pH, and finally the cubic silicon carbide mano-wires are obtained after conventional centrifugal separation and drying. Compared with the prior art, the method has the advantages of low reaction temperature, low material cost and easy availability, simple reaction, easy control for the size and dimension of the product, enhanced toughness of ceramic and easy realization for industrial production.

Owner:SHANDONG UNIV

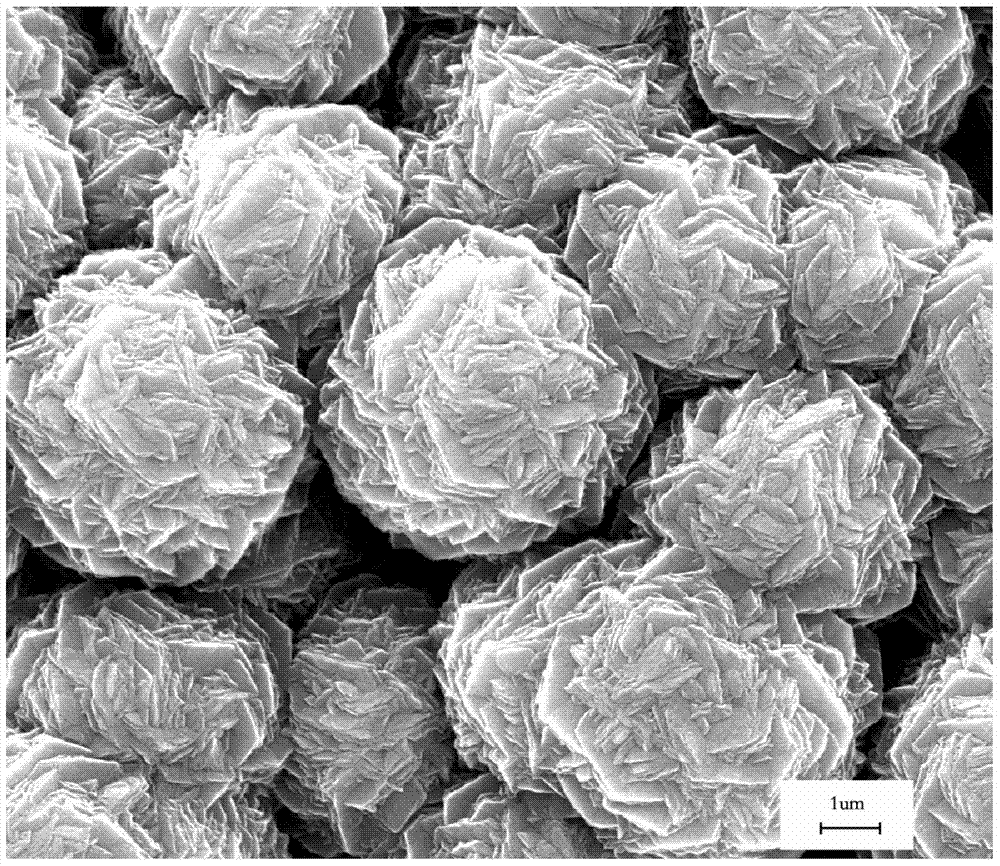

Preparation method of silicon carbide film

ActiveCN104498897ALarge specific surface areaRich Surface TopographyCatalyst carriersChemical vapor deposition coatingCubic silicon carbideGas phase

The invention relates to a preparation method of a cubic silicon carbide film, which comprises the following steps: putting a cleaned substrate onto a substrate seat of cold-wall laser chemical vapor deposition device, and vacuumizing; introducing a right amount of argon; starting the laser to radiate the substrate surface until the substrate temperature rises to the set temperature for depositing the silicon carbide film, and keeping the temperature stable; starting a current-carrying gas containing HMDS, adjusting the vacuum degree of the reaction chamber, and keeping for 5-30 minutes; and shutting down the current-carrying gas containing HMDS, shutting down the laser and diluting gas, vacuumizing, and naturally cooling to room temperature. The silicon carbide film has the advantages of higher specific area and abundant surface topography. Therefore, the catalyst can be attached to the silicon carbide support surface more easily, thereby enhancing the supporting capacity of the catalyst and the adhesive force of the support, prolonging the service life of the catalyst, increasing the contact area between the catalyst and reaction substance and enhancing the catalytic efficiency of the catalyst.

Owner:WUHAN UNIV OF TECH

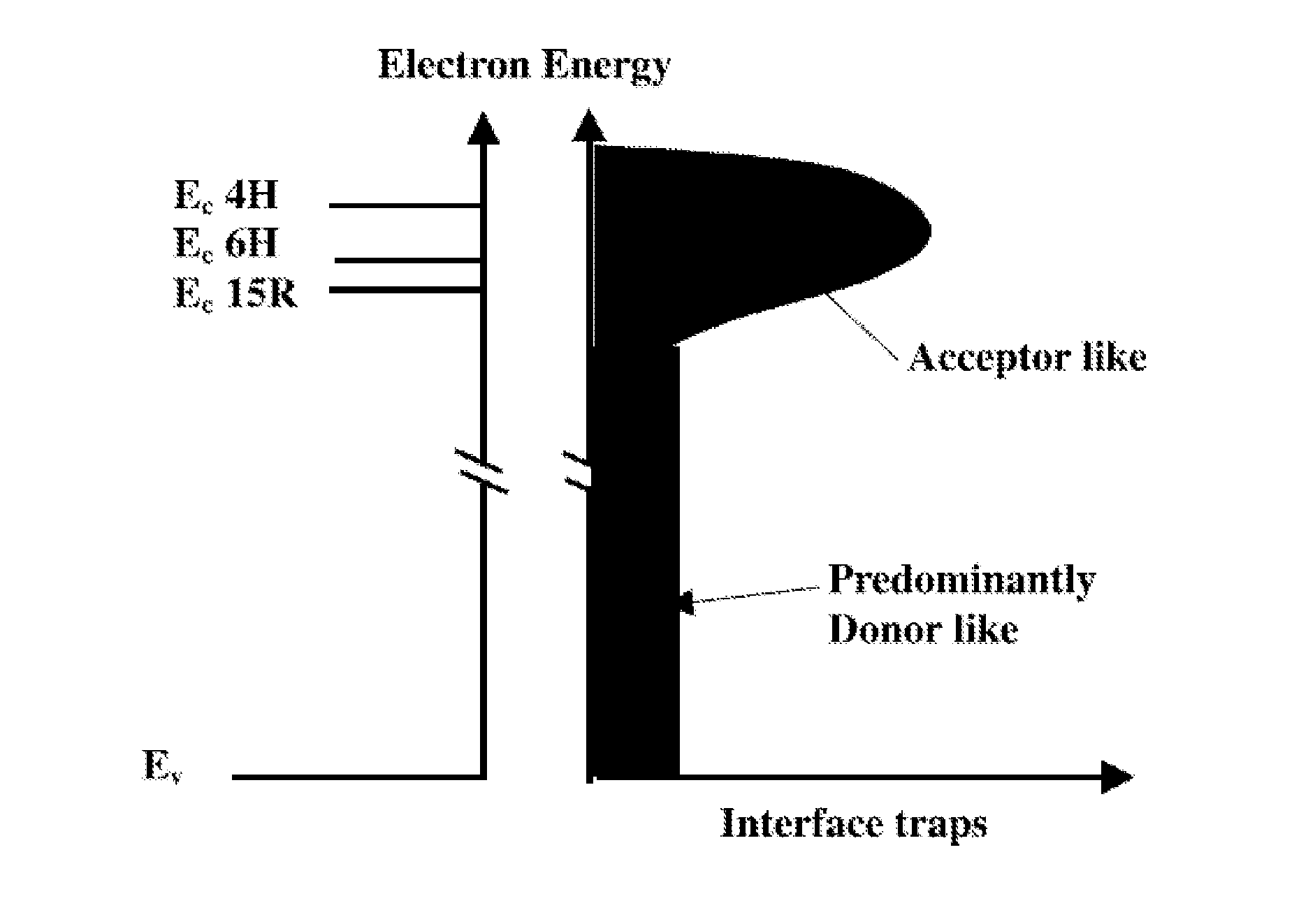

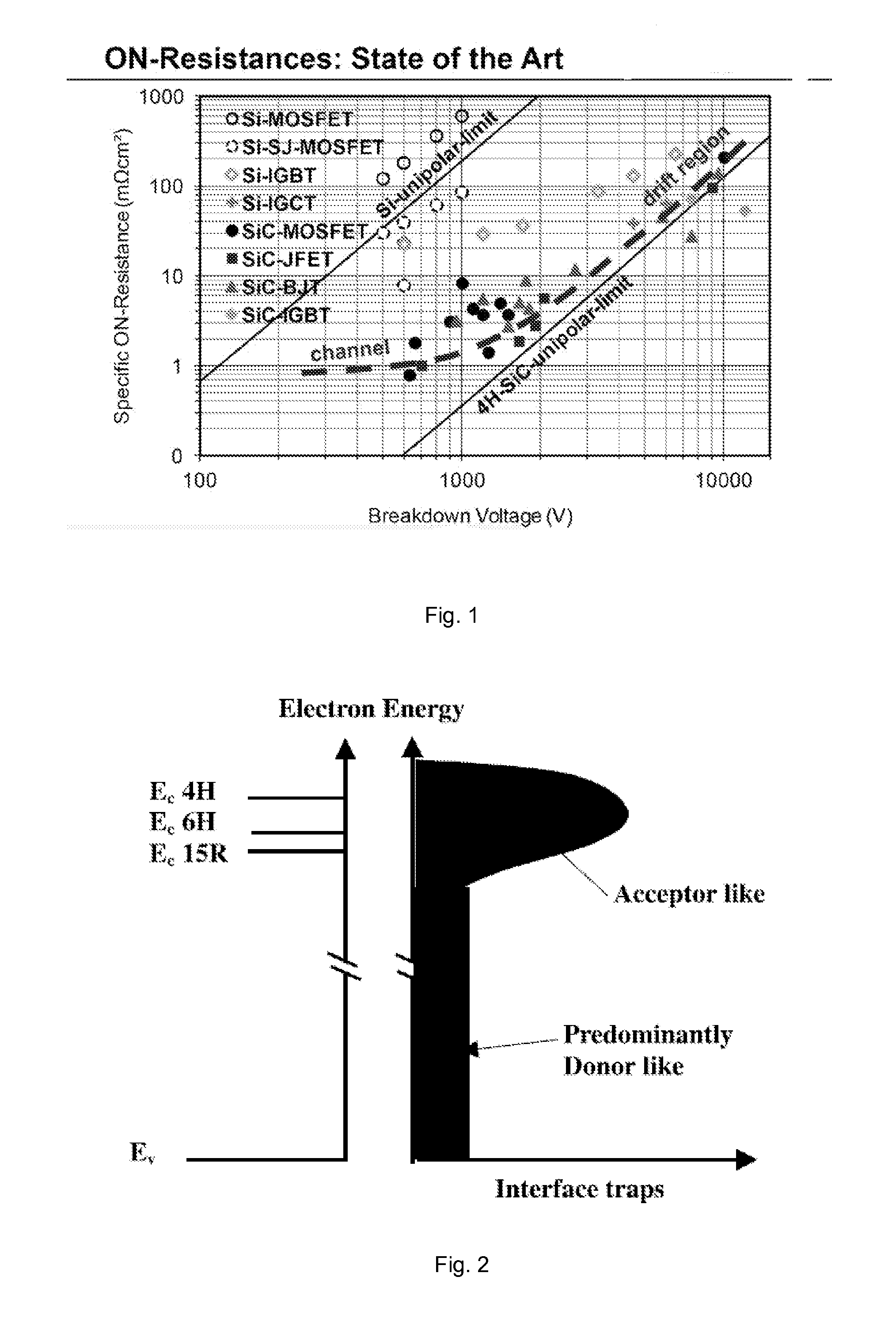

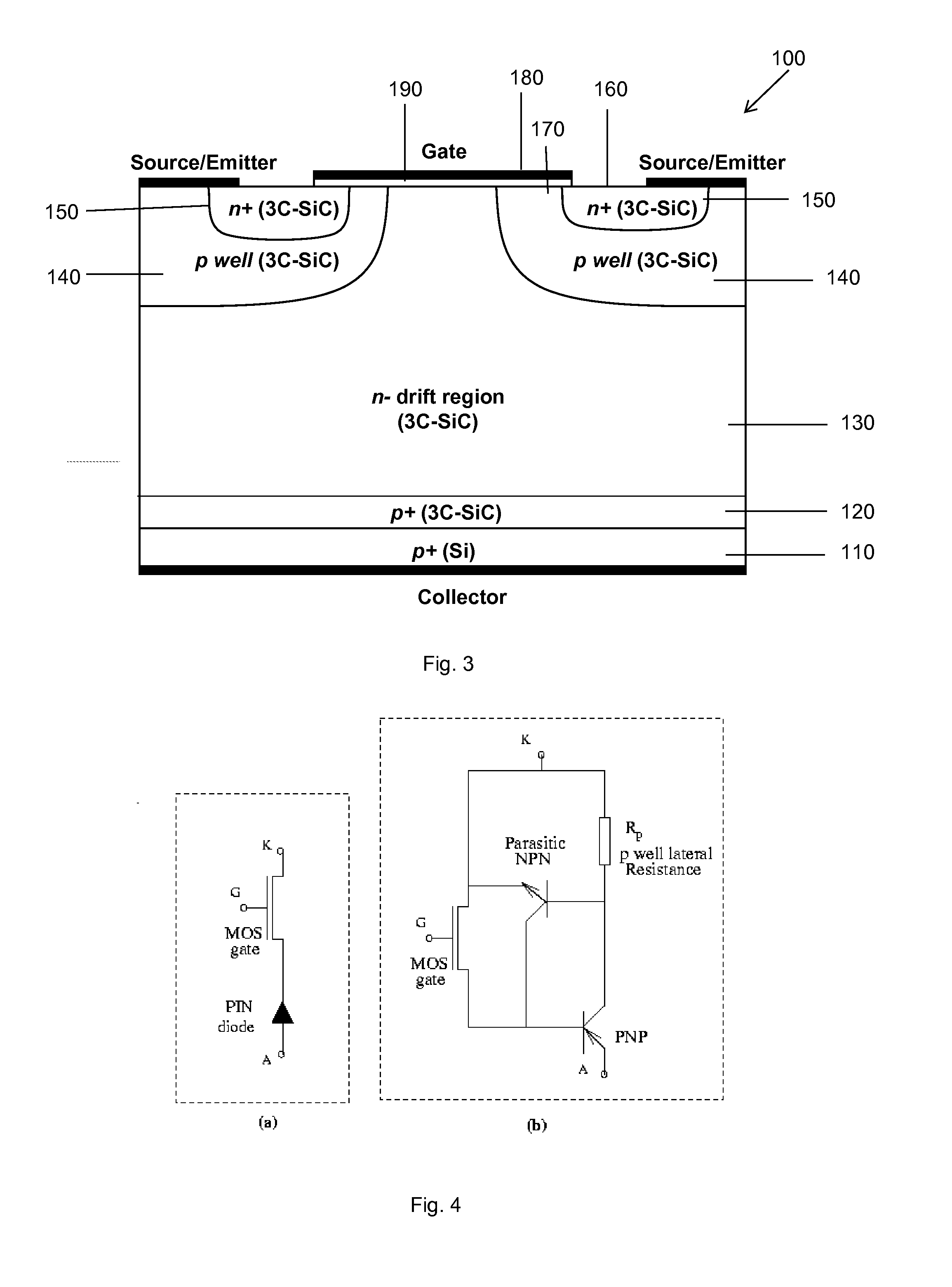

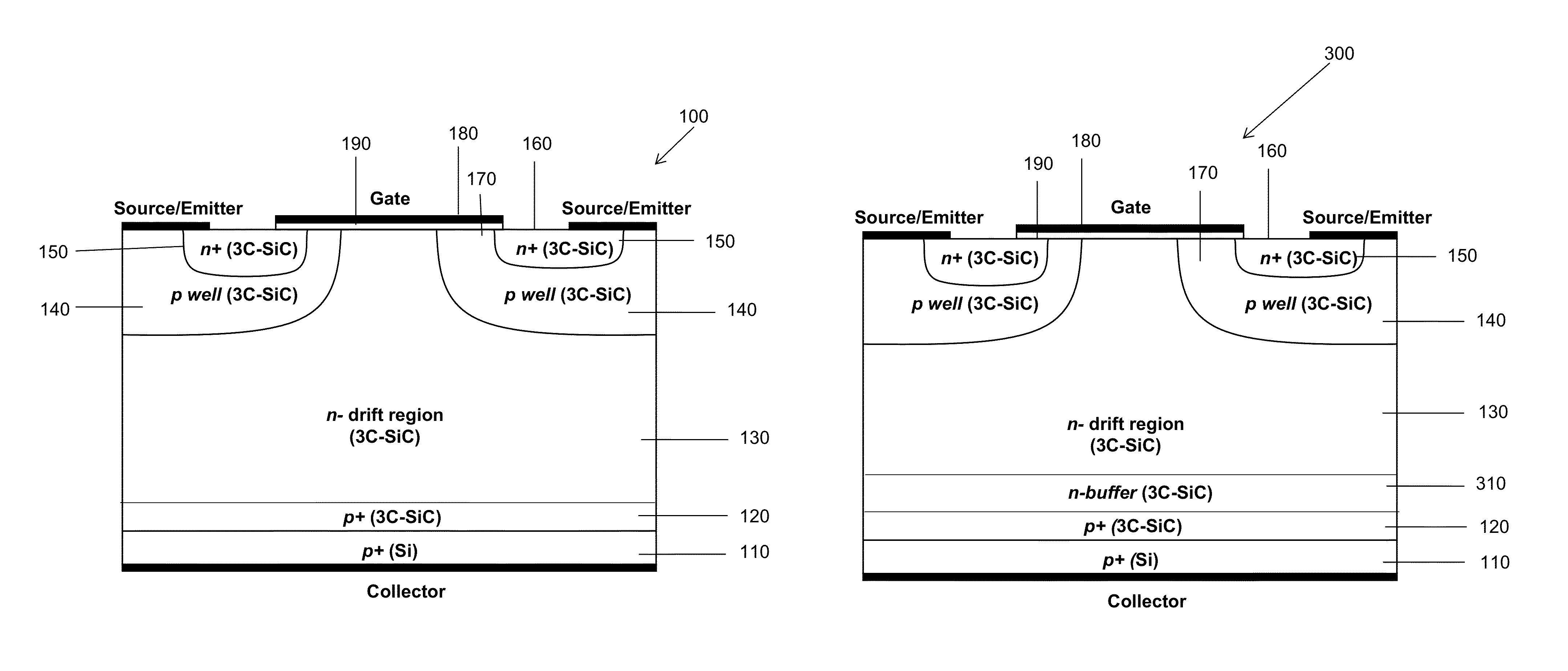

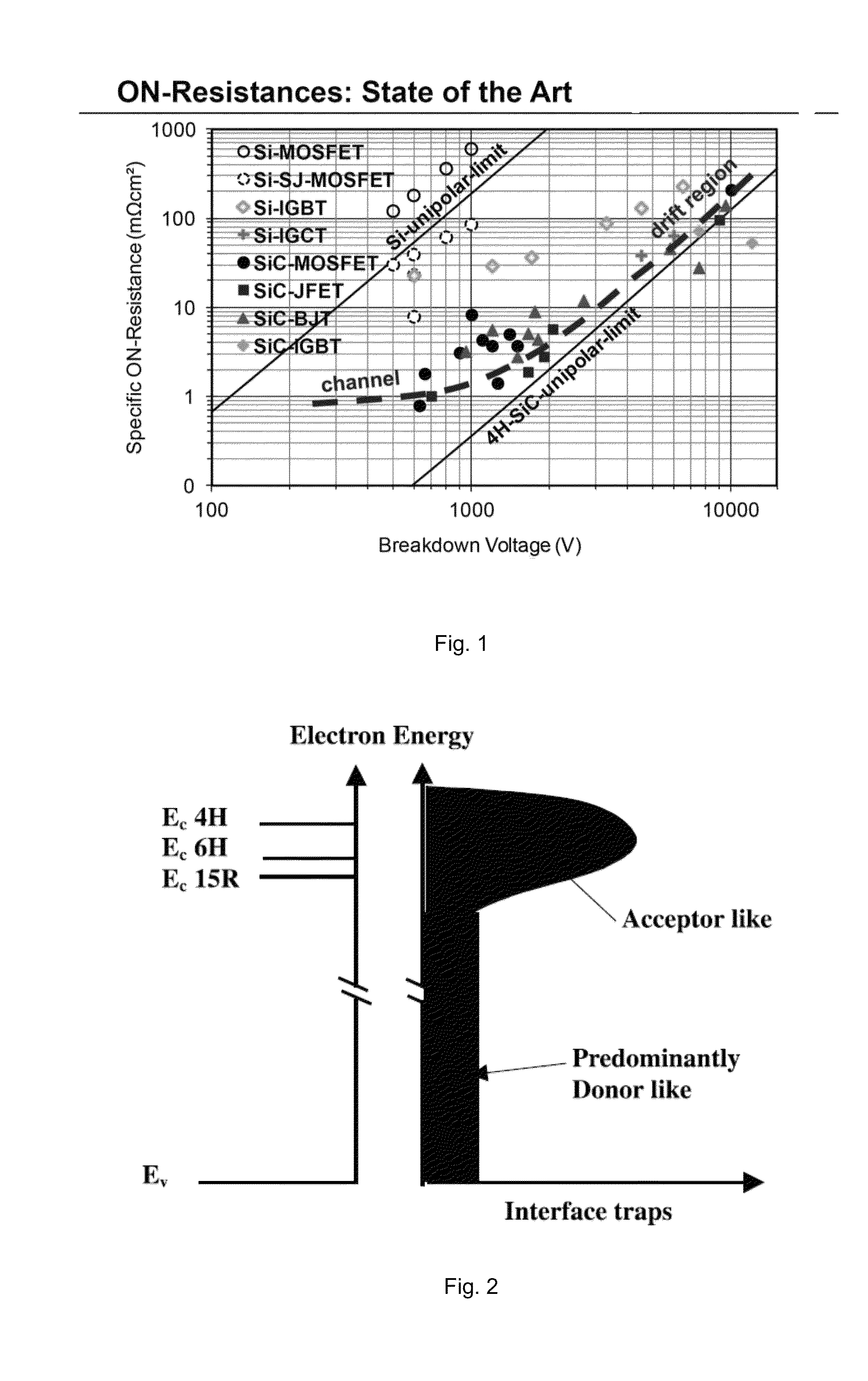

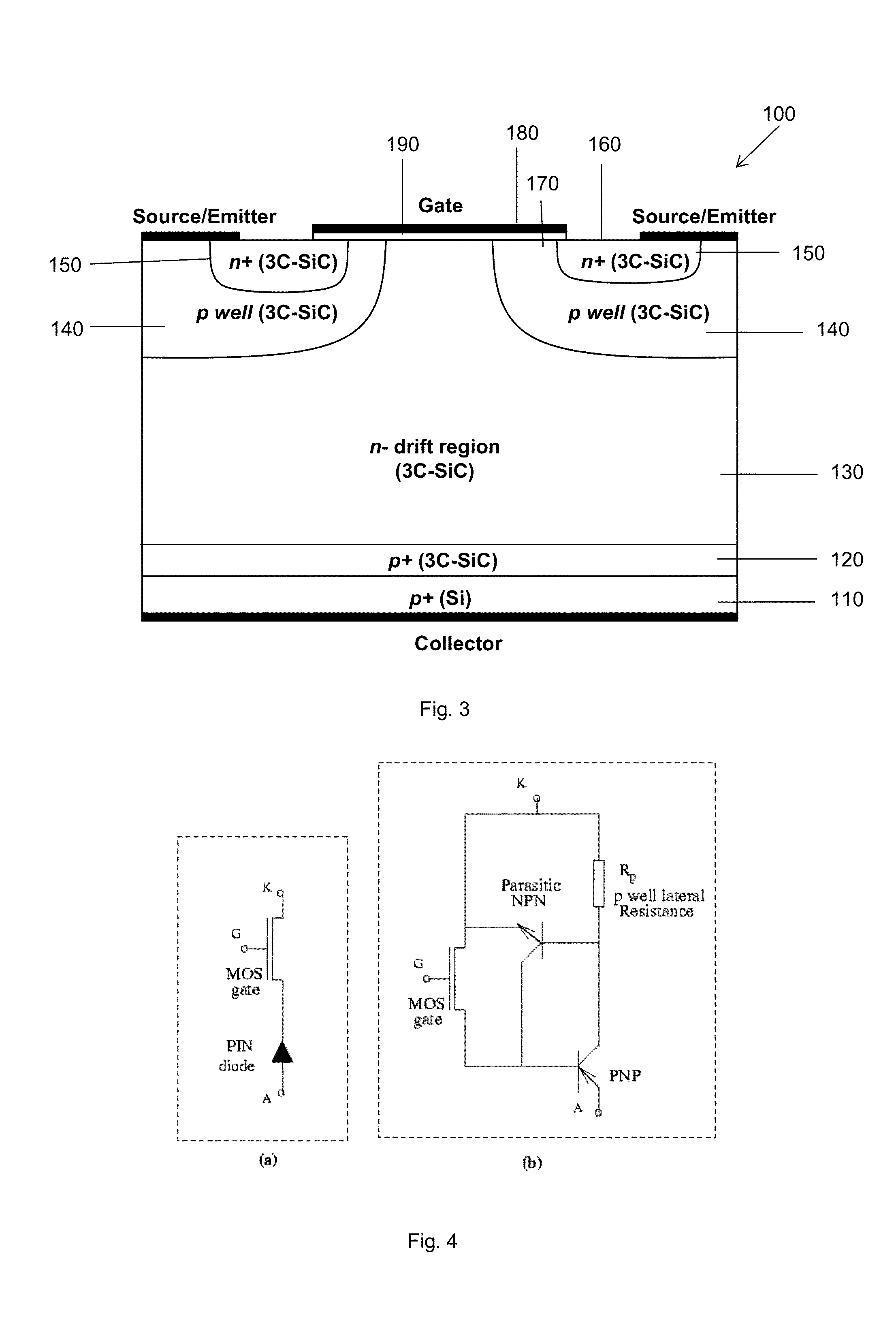

3C-SiC TRANSISTOR

InactiveUS20140014973A1Mitigate SiC unipolar drift region limitLower channel resistanceThyristorSemiconductor/solid-state device manufacturingCubic silicon carbideBody region

A bipolar power semiconductor transistor is disclosed. The transistor includes a semiconductor substrate of a first conductivity type, a first semiconductor region of the first conductivity type disposed on the semiconductor substrate; a semiconductor drift region of a second conductivity type, opposite the first conductivity type, disposed on the first semiconductor region, a body region of the first conductivity type located within the semiconductor drift region, a source region of the second conductivity type located within the body region, a gate placed above and in contact to the source region, the gate to control charge in a channel region between the semiconductor drift region and the source region and to thereby control flow of charge within the semiconductor drift region. The semiconductor substrate includes a material having silicon (Si) and the first semiconductor region includes a material having 3-step cubic silicon carbide (3C-SiC).

Owner:ANVIL SEMICON

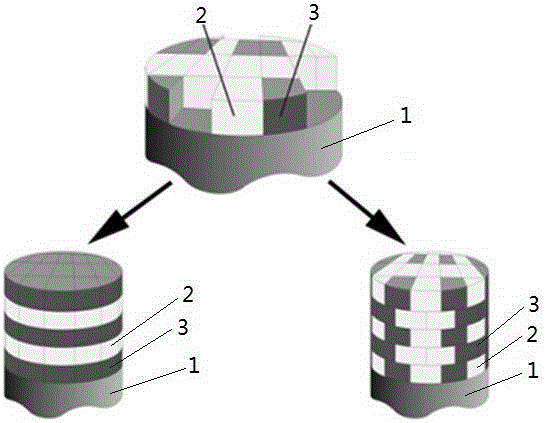

Preparation method of diamond/silicon carbide three-dimensional composite structure and prepared product

InactiveCN105039928AImprove adhesionImprove wear resistanceChemical vapor deposition coatingCatalytic effectGrowth time

The invention discloses a preparation method of a diamond / silicon carbide three-dimensional composite structure and a prepared product, and aims to solve the problem that a traditional micron crystal / nanometer crystal diamond multilayer film structure cannot be applied to a metal matrix containing a graphite phase catalytic effect due to strong dependence on the material type of the matrix. Under the condition of no need of additional matrix pretreatment, the preparation method realizes one-step intermittent growth of a diamond / cubic silicon carbide three-dimensional composite structure on multiple matrix materials (such as stainless steel, WC-Co, Si3N4 and the like), so that the treatment procedures are effectively reduced, the growth time is shortened, and the labor cost is saved. Meanwhile, the prepared three-dimensional composite structure can prominently improve the adhesivity, the wear resistance and the fracture toughness of coatings on the surface of the matrix, satisfies the application demands in the high-performance surface coating field, is better in application prospect, and is worthy of large-scale promotion and application.

Owner:姜辛 +2

3C-SiC transistor

InactiveUS9082811B2Improve mobilityThyristorSemiconductor/solid-state device manufacturingCubic silicon carbideBody region

A bipolar power semiconductor transistor is disclosed. The transistor includes a semiconductor substrate of a first conductivity type, a first semiconductor region of the first conductivity type disposed on the semiconductor substrate; a semiconductor drift region of a second conductivity type, opposite the first conductivity type, disposed on the first semiconductor region, a body region of the first conductivity type located within the semiconductor drift region, a source region of the second conductivity type located within the body region, a gate placed above and in contact to the source region, the gate to control charge in a channel region between the semiconductor drift region and the source region and to thereby control flow of charge within the semiconductor drift region. The semiconductor substrate includes a material having silicon (Si) and the first semiconductor region includes a material having 3-step cubic silicon carbide (3C-SiC).

Owner:ANVIL SEMICON

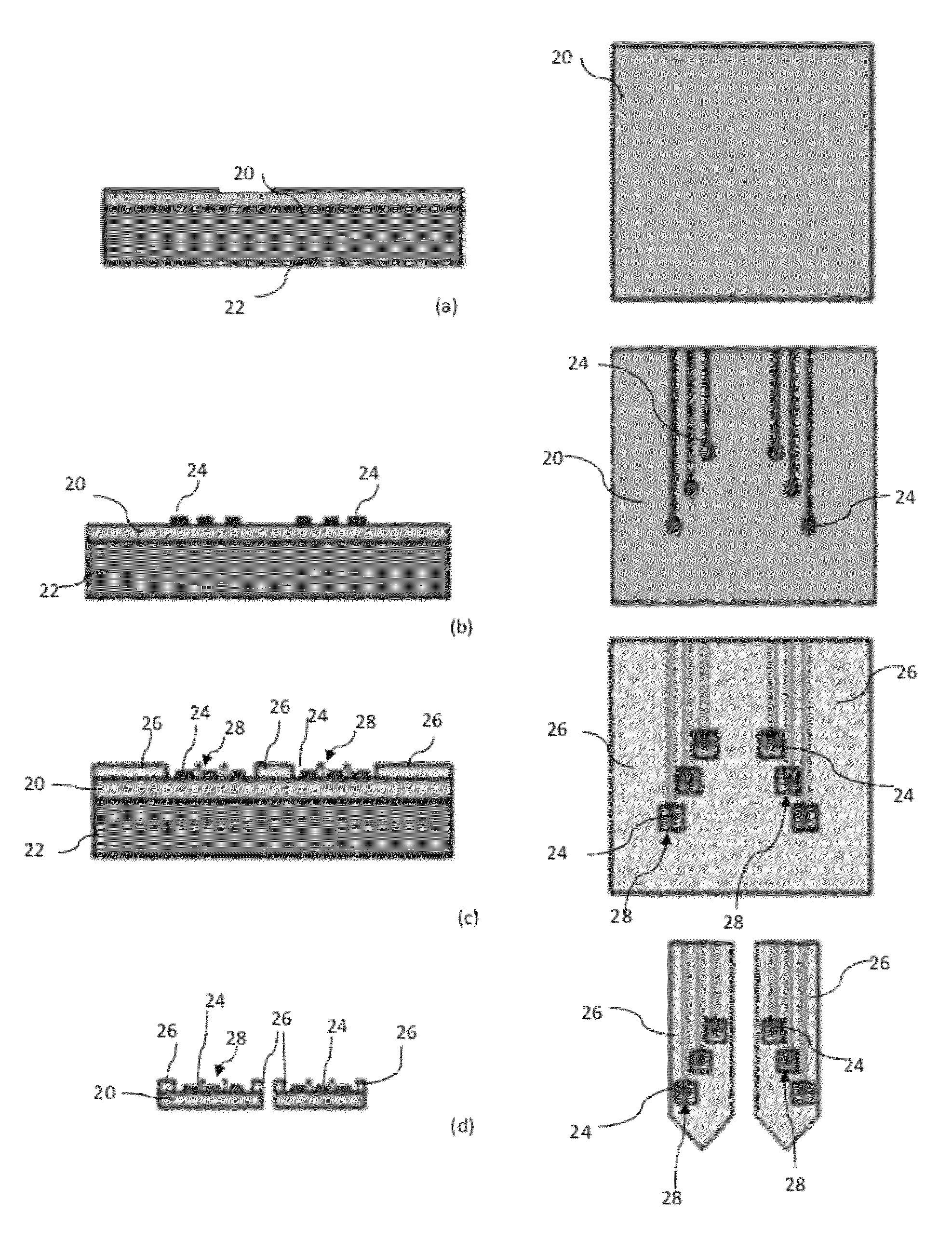

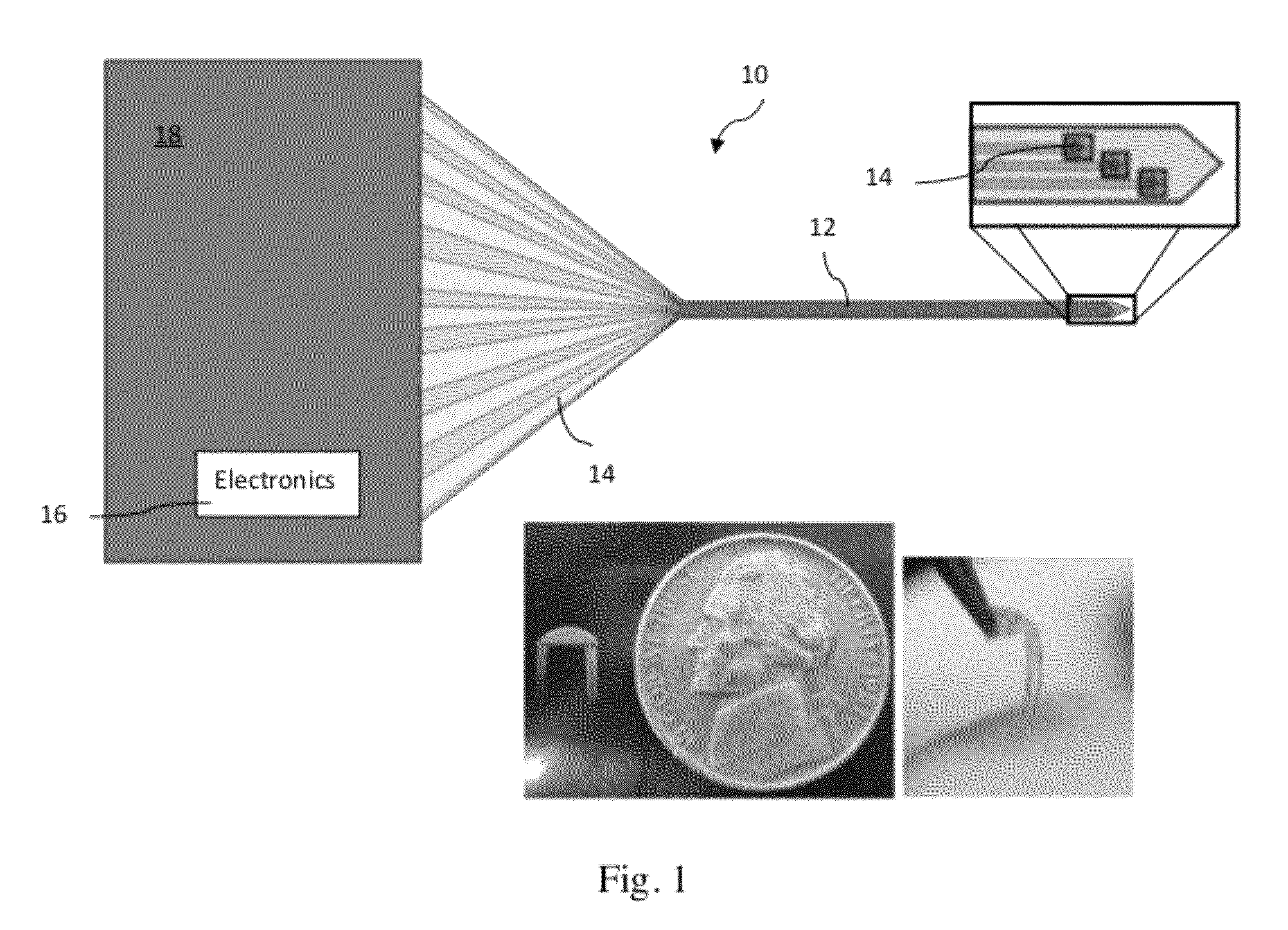

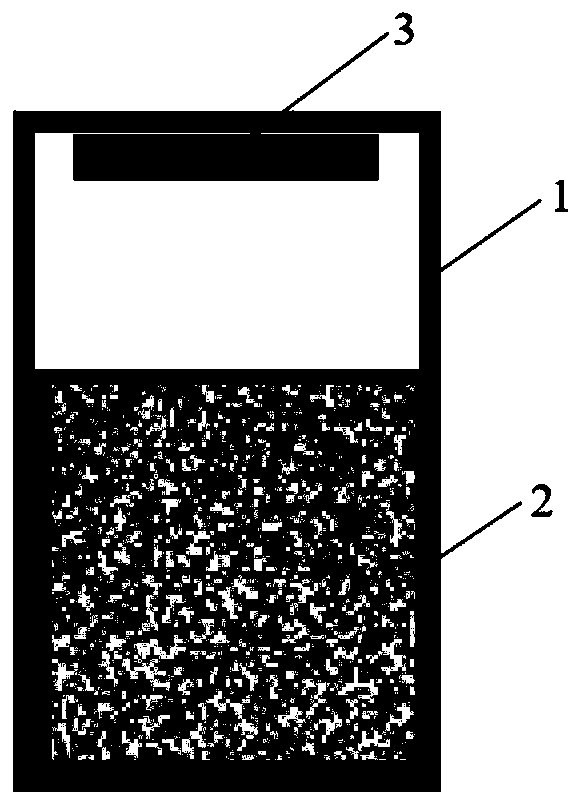

Cubic silicon carbide implantable neural prosthetic

ActiveUS20120232631A1Line/current collector detailsHead electrodesCubic silicon carbideCarbide silicon

An implantable neuronal prosthetic and method of manufacture thereof includes at least one elongated electrode shank adapted for arrangement in the brain having at least one electrode contact disposed on its surface and arranged to electrically couple with said brain. The at least one elongated electrode shank is formed form a single crystal cubic silicon carbide. An insulation layer of amorphous, polycrystalline, or single crystal silicon carbide is disposed over the elongated electrode shank; the insulation layer of amorphous, polycrystalline, or single crystal silicon carbide is removed from the at least one electrode contact. Signal control electronics are attached to the at least one elongated electrode shank and are in electrical communication with the at least one electrode contact. In an embodiment, a plurality of the at least one elongated electrode shanks are arranged into a matrix.

Owner:UNIV OF SOUTH FLORIDA

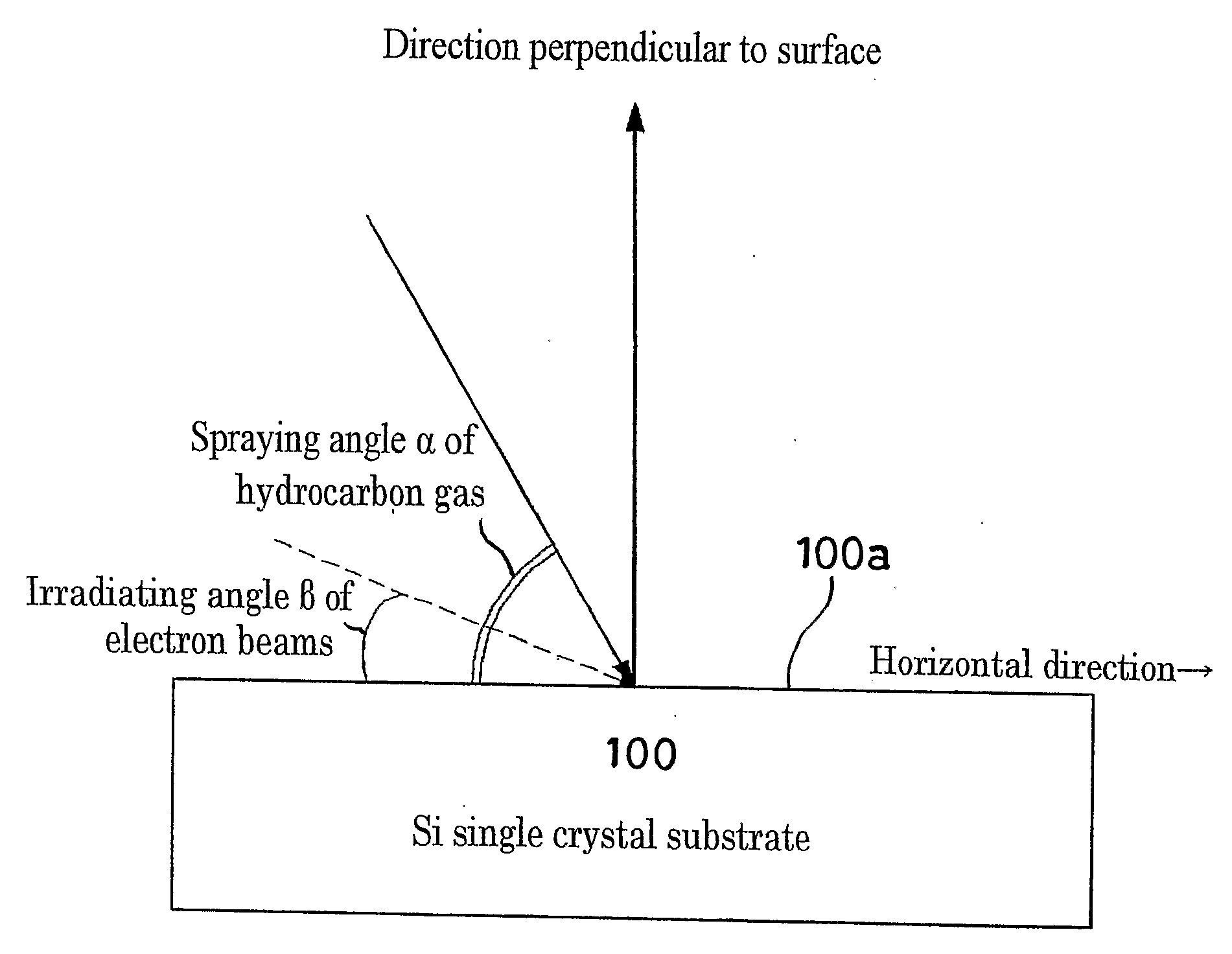

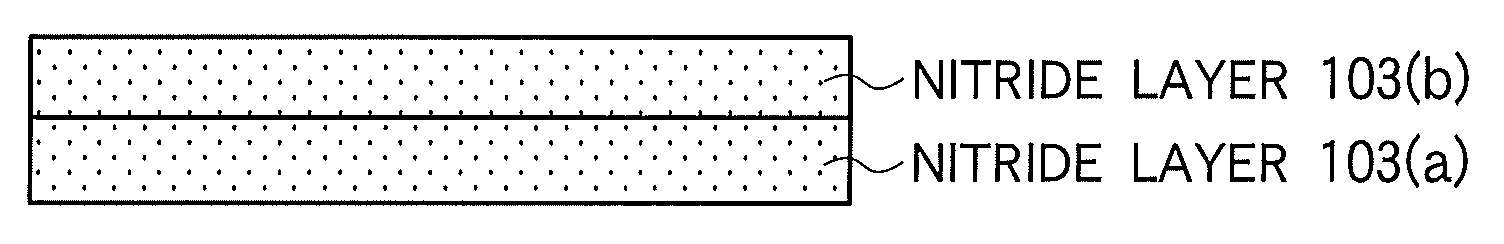

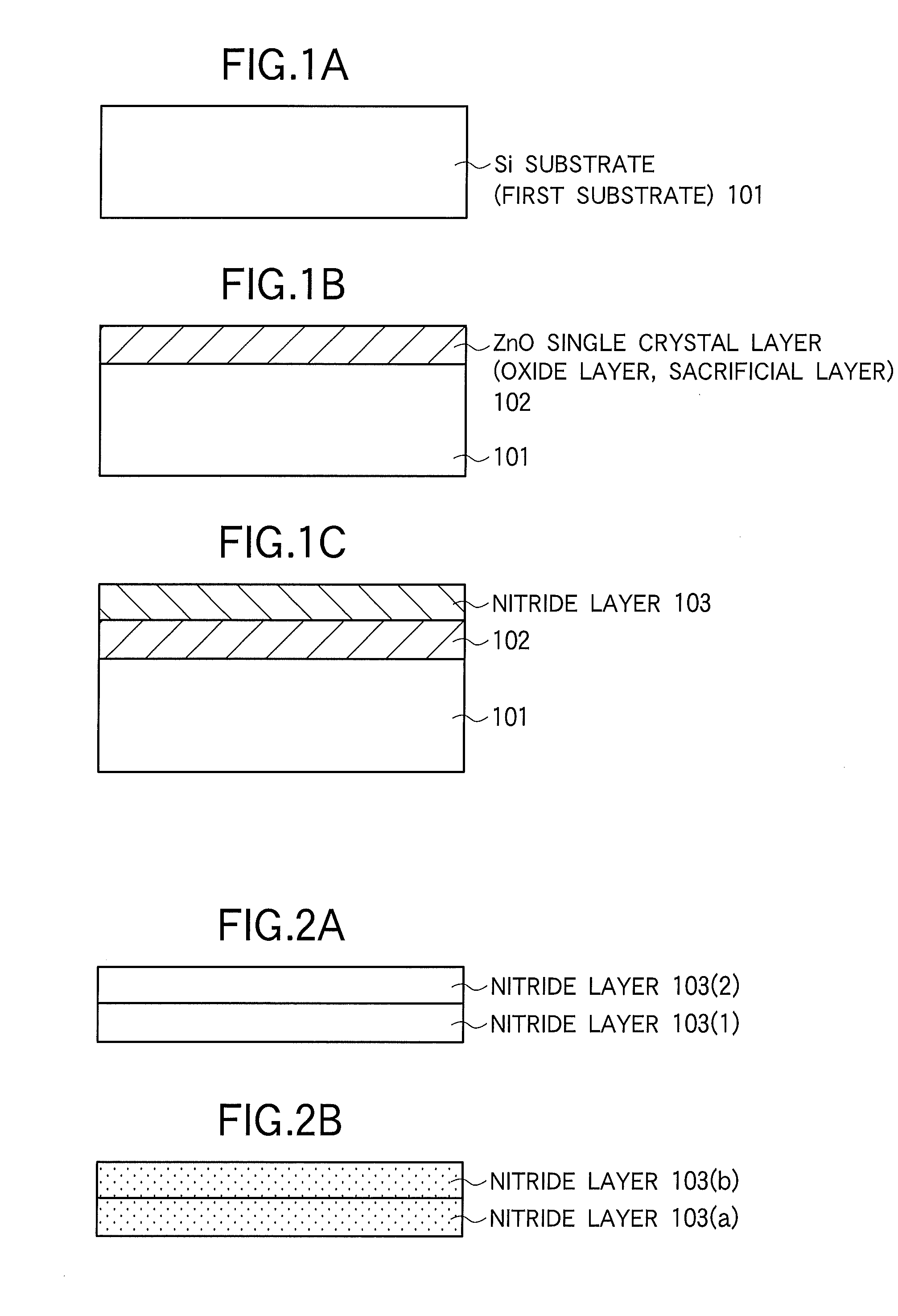

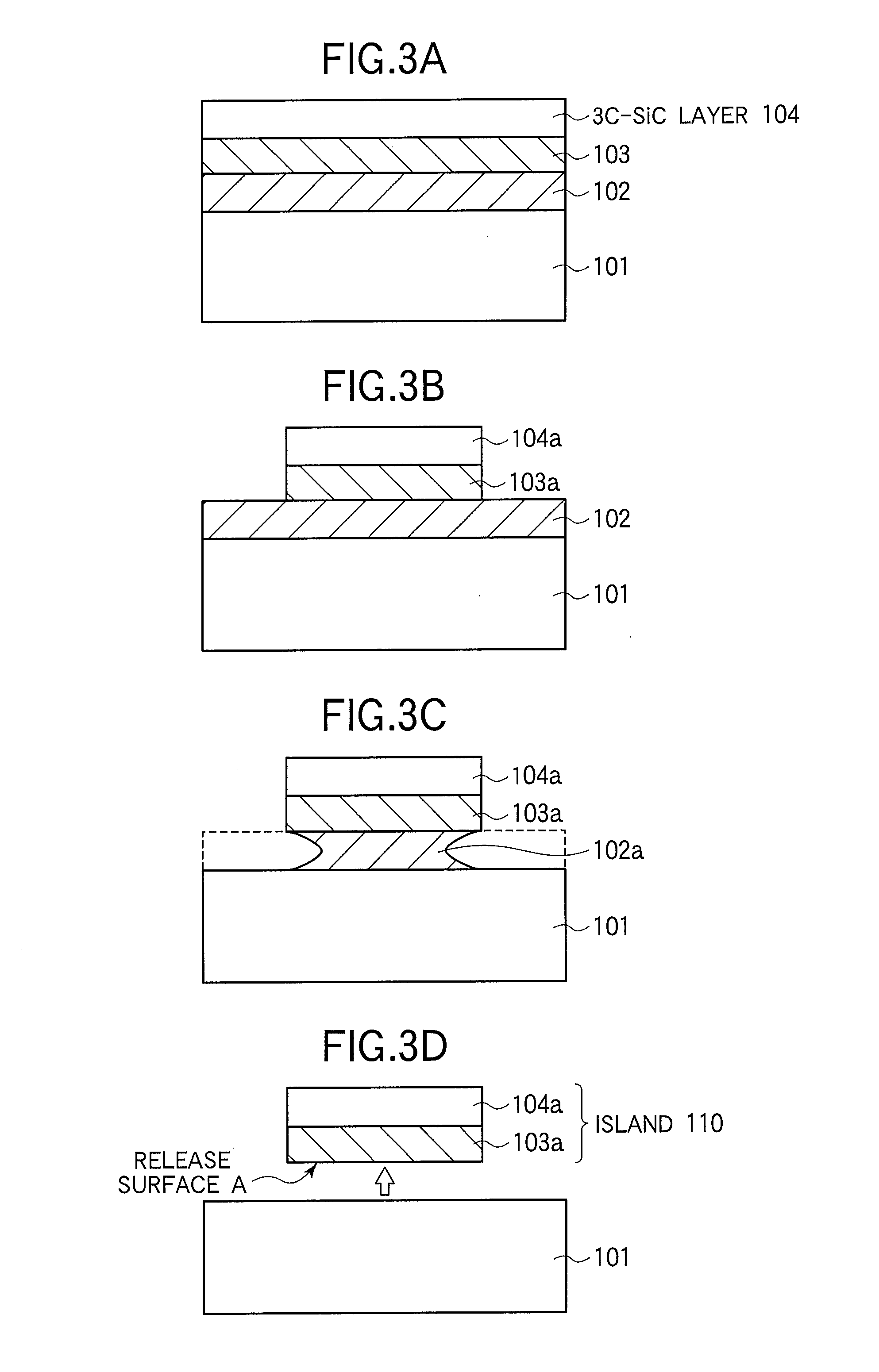

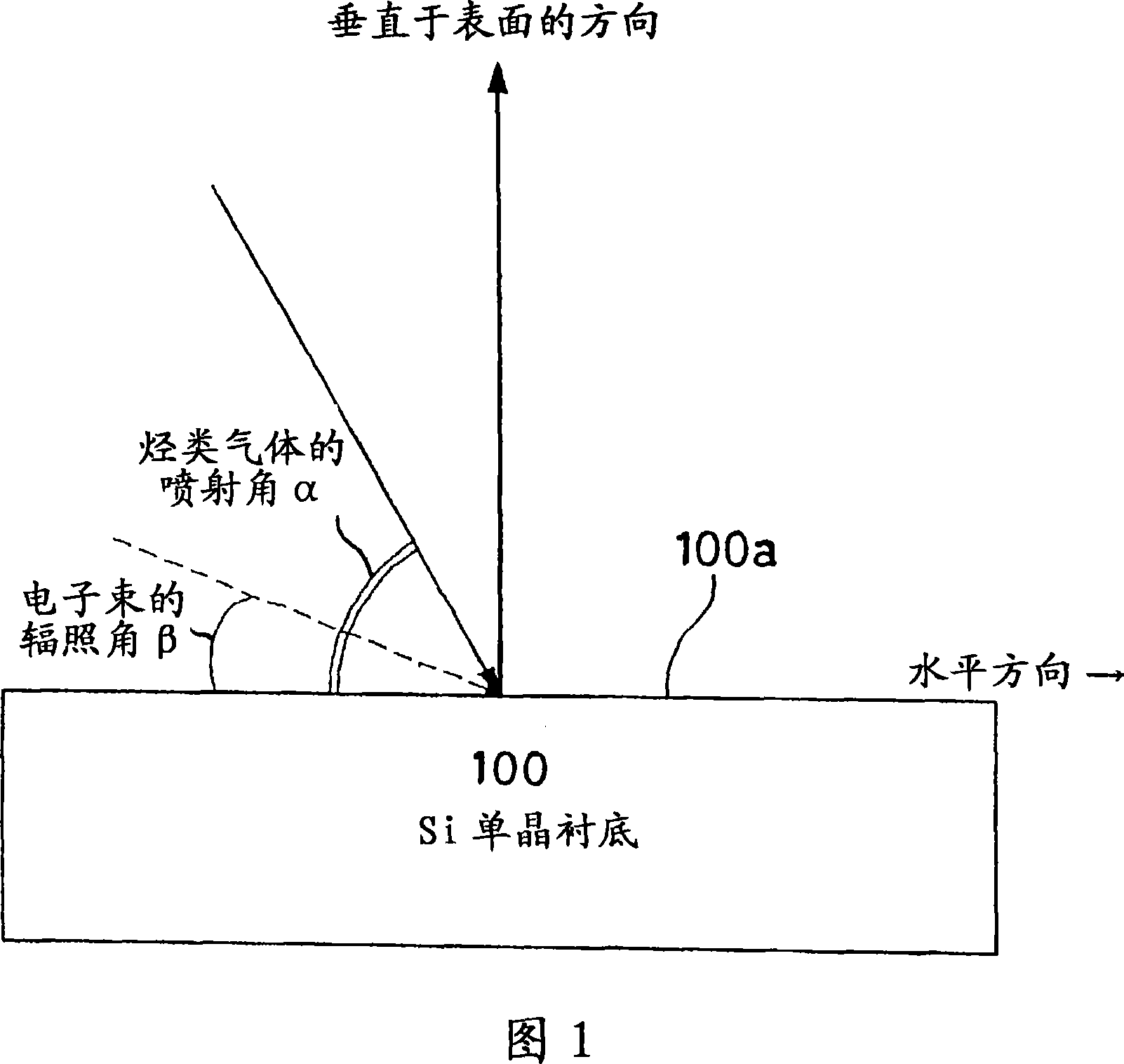

Method for production of silicon carbide layer, gallium nitride semiconductor device and silicon substrate

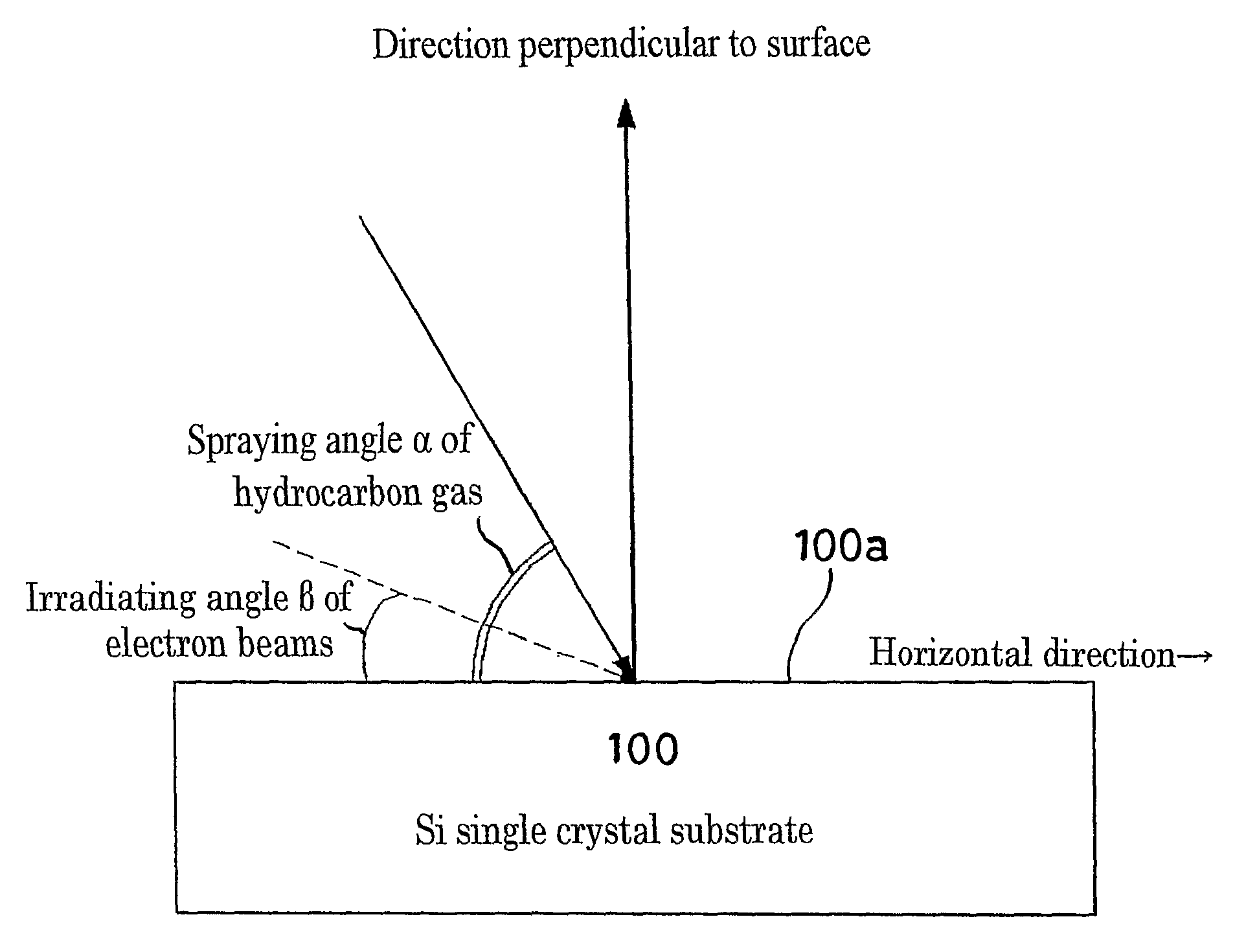

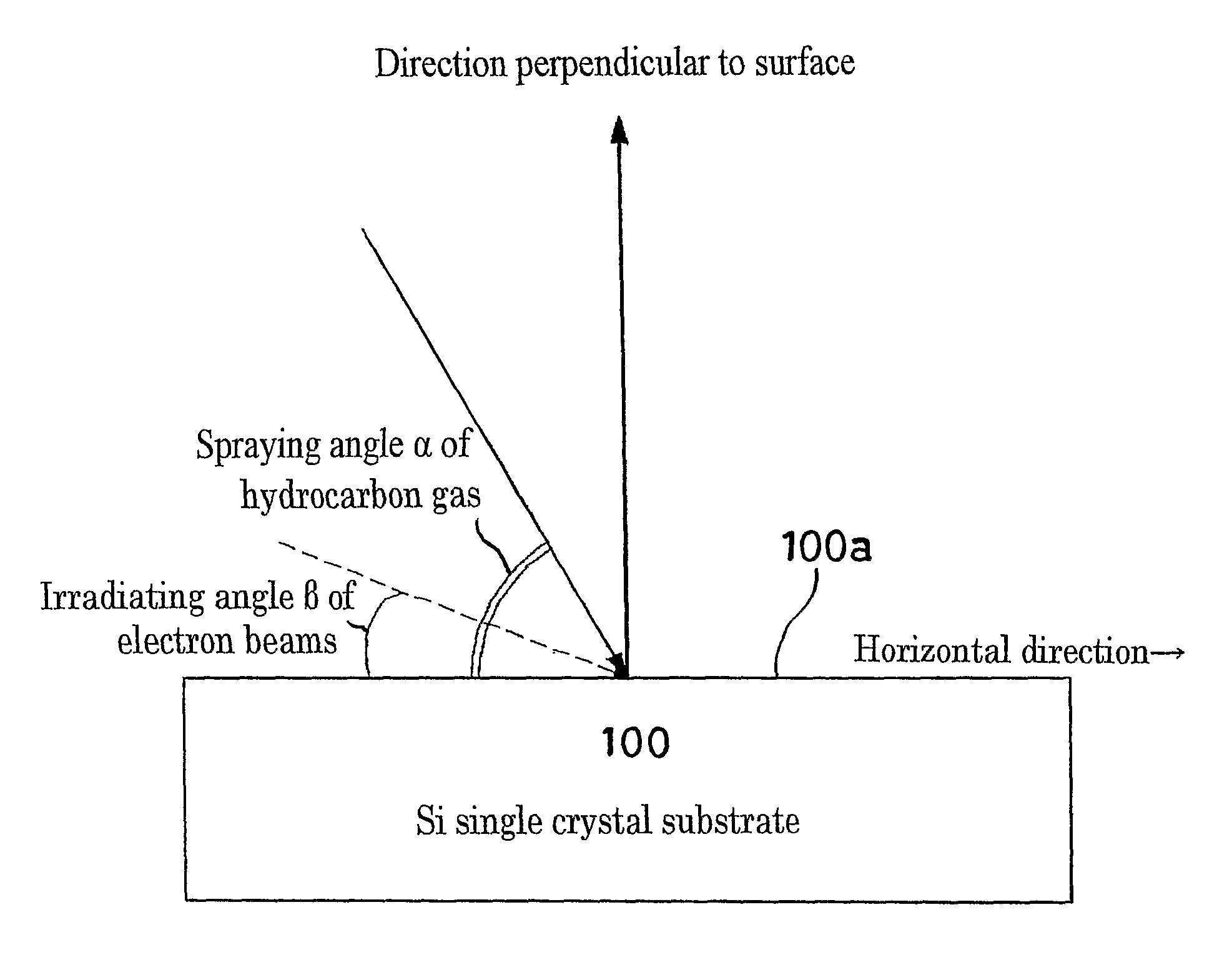

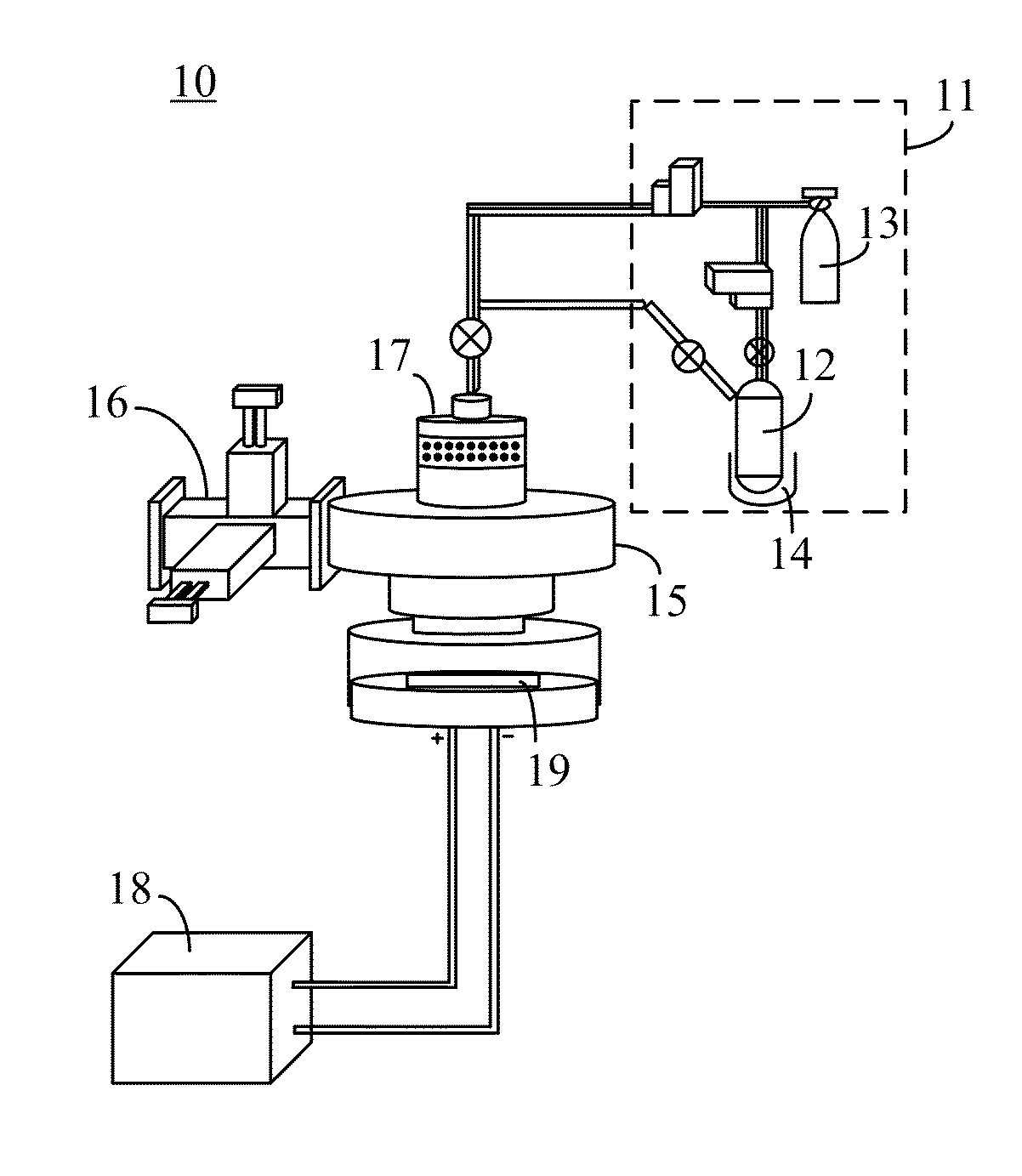

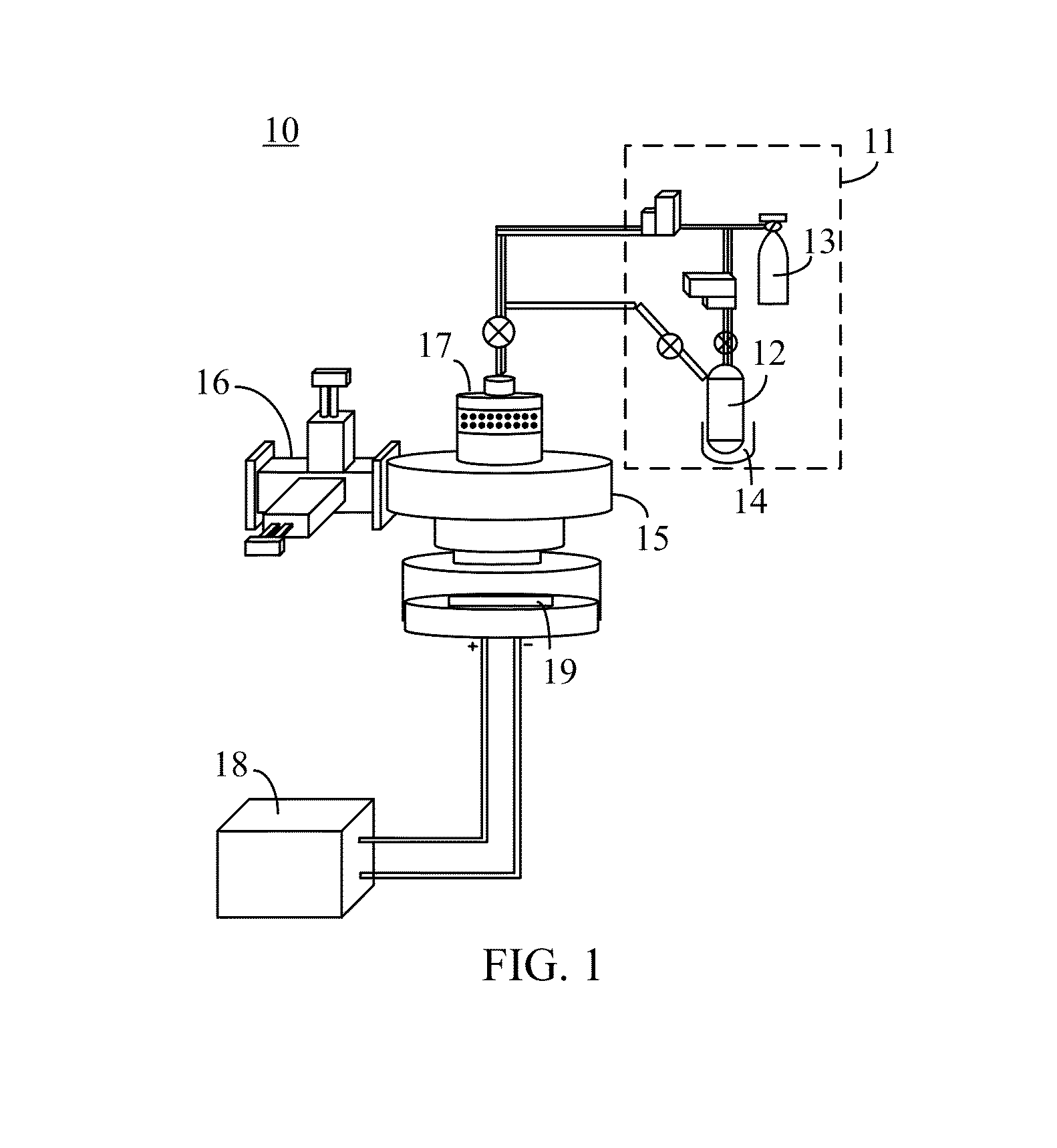

ActiveUS20090045412A1Few crystalline defectPromotion of unnecessary disintegration can be avoidedPolycrystalline material growthSemiconductor/solid-state device manufacturingGallium nitrideCubic silicon carbide

A method for producing a silicon carbide layer on a surface of a silicon substrate includes the step of irradiating the surface of the silicon substrate heated in a high vacuum at a temperature in a range of from 500° C. to 1050° C. with a hydrocarbon-based gas as well as an electron beam to form a cubic silicon carbide layer on the silicon substrate surface.

Owner:SHOWA DENKO KK

Semiconductor device based on the cubic silicon carbide single crystal thin film

ActiveUS20120241764A1Semiconductor/solid-state device manufacturingSemiconductor devicesCubic silicon carbideSingle crystal

A semiconductor apparatus includes a cubic silicon carbide single crystal thin film of a multilayer structure including an AlxGa1-xAs (0.6>x≧0) layer and a cubic silicon carbide single crystal layer. The apparatus also includes a substrate on which a metal layer is formed. The multilayer structure is bonded to a surface of the metal layer with the AlxGa1-xAs (0.6>x≧0) in direct contact with the metal layer.

Owner:OKI ELECTRIC IND CO LTD

A kind of preparation method of porous diamond or porous cubic silicon carbide self-supporting film

ActiveCN104178745BImprove stabilityControllable distributionChemical vapor deposition coatingBasic researchOxygen

The invention discloses a method for preparing a porous diamond or porous cubic silicon carbide self-supporting film, comprising: providing a matrix material, and pretreating the surface of the matrix material to obtain a higher diamond nucleation rate; placing the pretreated matrix In a microwave plasma chemical vapor deposition or hot wire chemical vapor deposition reactor, at a temperature of 600-900 ° C, a diamond / cubic silicon carbide composite film is prepared; the resulting composite film is selectively etched: 1) at 70 At a temperature above ℃, etch in a mixed etching solution of hydrofluoric acid and nitric acid to obtain a porous diamond self-supporting film; (2) at a temperature above 500°C, heat in an atmosphere containing oxygen to obtain a porous cubic Silicon carbide free-standing film. Without using any template and electrode materials, the obtained porous diamond and porous cubic silicon carbide self-supporting films have controllable pore size, porosity, and thickness, which are suitable for industrial applications and basic research.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Cubic silicon carbide anticorrosive wear-resistant coating and preparation method thereof

InactiveCN111040576AImprove corrosion resistanceImprove wear resistanceAnti-corrosive paintsEpoxy resin coatingsCubic silicon carbideCarbide silicon

The invention discloses a cubic silicon carbide anticorrosive wear-resistant coating. The cubic silicon carbide anticorrosive wear-resistant coating is prepared from the following raw materials in parts by mass: 40-60 parts of water-based resin, 10-20 parts of deionized water, 10-20 parts of titanium dioxide, 2-6 parts of cubic silicon carbide micro-powder, 5-10 parts of a filler, 0.1-0.5 part ofa defoaming agent, 0.1-0.5 part of a wetting agent, 0.05-0.2 part of a thickening agent and 0.2-0.6 part of a water-based drier. The invention also discloses a preparation method of the cubic siliconcarbide anticorrosive wear-resistant coating. The preparation method comprises the following steps: preparing a mixture by a step-by-step method, adding deionized water and assistants, and carrying out dispersing and filtering to obtain the coating. According to the coating, the water-based resin is used as a film-forming substance, so a curing agent is not required to be added, and the corrosionresistance and wear resistance of the coating are improved; the method provided by the invention is beneficial for full and uniform mixing of the components, ensures full play of the effects of the assistants, and does not need heating in the preparation process; and the coating can be used without blending, so the application range of the coating is enlarged.

Owner:XIAN BOER NEW MATERIAL CO LTD

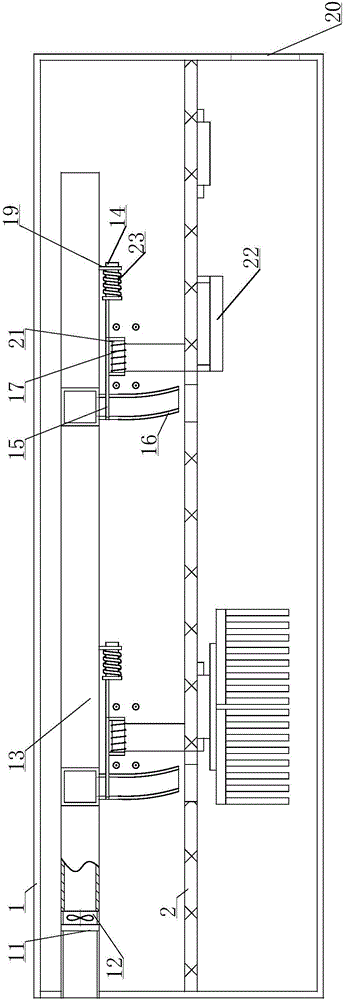

Square pipe cutting device

InactiveCN105345683ASimple structureHigh strengthBonded abrasive wheelsPolyvinyl chlorideEngineering

The invention discloses a square pipe cutting device which comprises a bottom supporting board. A supporting frame, an operation handle, a motor, a reduction gearbox connected with the motor and a grinding wheel saw web connected with the reduction gearbox are arranged on the bottom supporting board. The grinding wheel saw web comprises, by weight, 19 to 20 parts of white corundum, 18 to 19 parts of bauxite sintered alumina, 3 to 3.5 parts of polyvinyl chloride fibers, 1.9 to 2 parts of copper powder, 1.9 to 2 parts of tungsten carbide, 2 to 2.1 parts of potassium oxide, 2 to 2.5 parts of polytetrafluoroethylene powder, 2.5 to 3 parts of lignin fibers, 1 to 1.3 parts of calcium sulfide, 4.8 to 5 parts of cast stone, 5 to 5.8 parts of cubic silicon carbide, 1.9 to 2 parts of nitrile rubber, 3 to 4 parts of nano-boron fibers, 2 to 2.8 parts of epoxy resin and 3 to 3.5 parts of phenolic resin. In this way, the square pipe cutting device is simple and reasonable in structure, the strength of the grinding wheel saw web is high, and the cutting device is suitable for cutting square pipes.

Owner:无锡市锡山区仁景模具厂

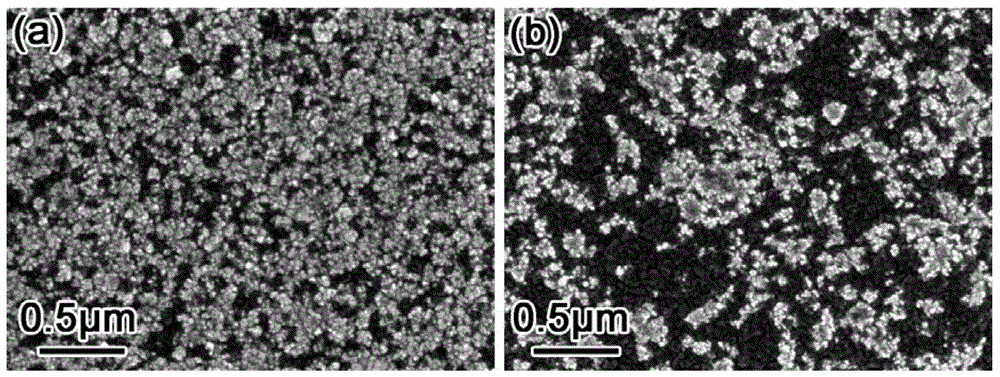

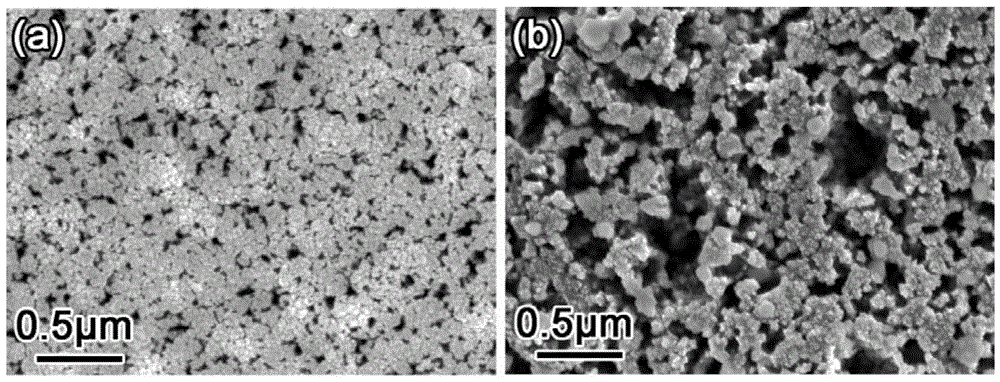

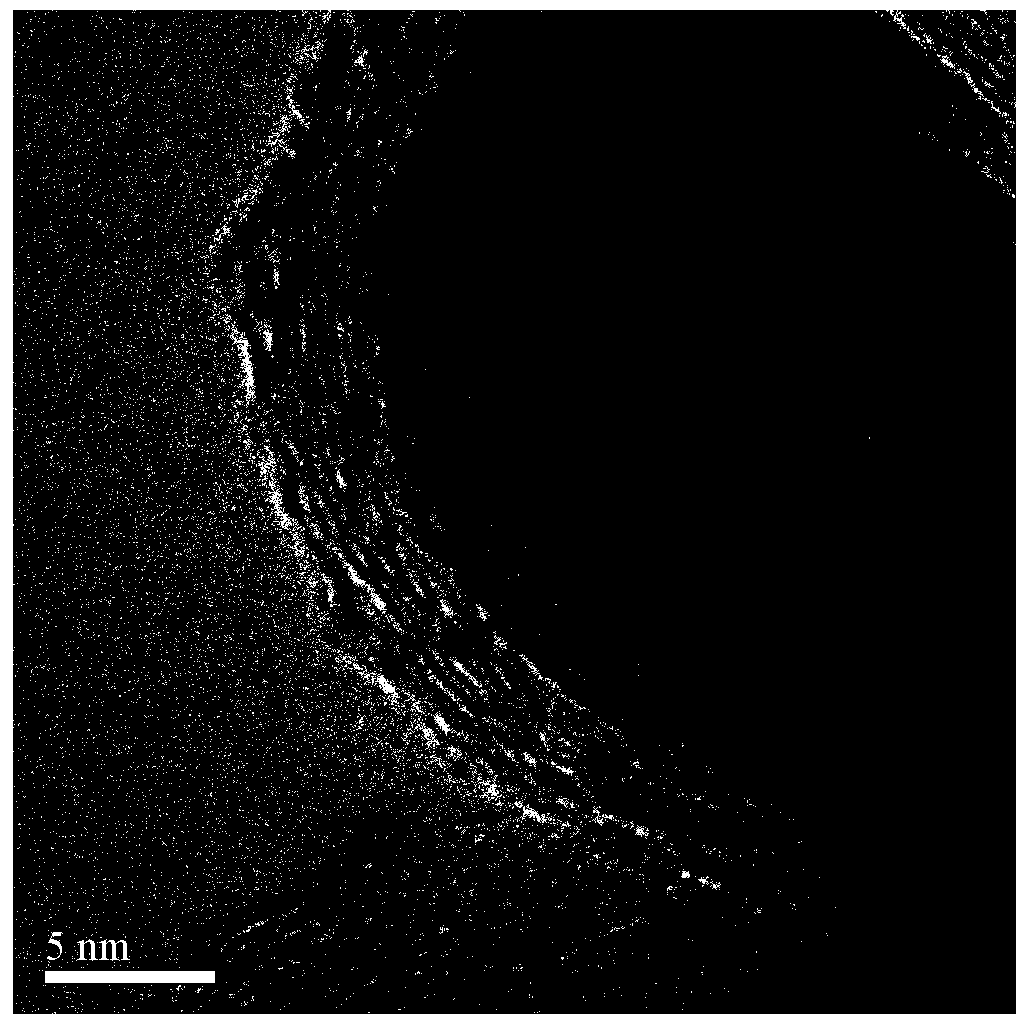

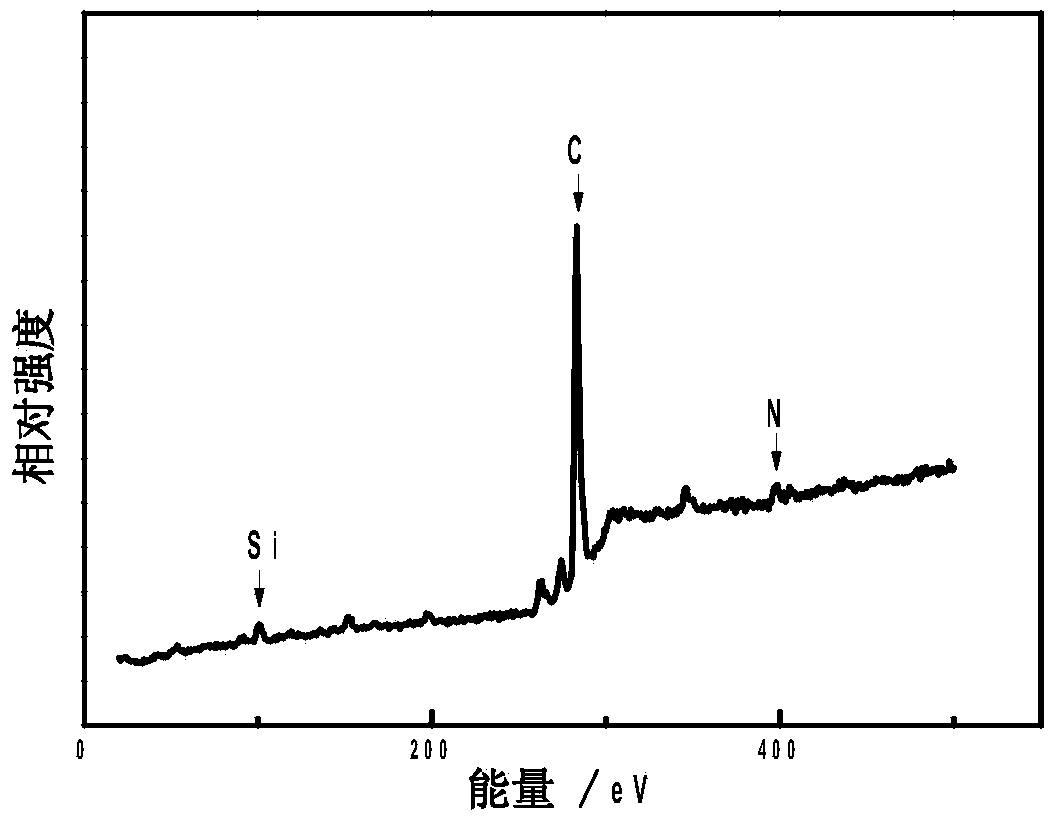

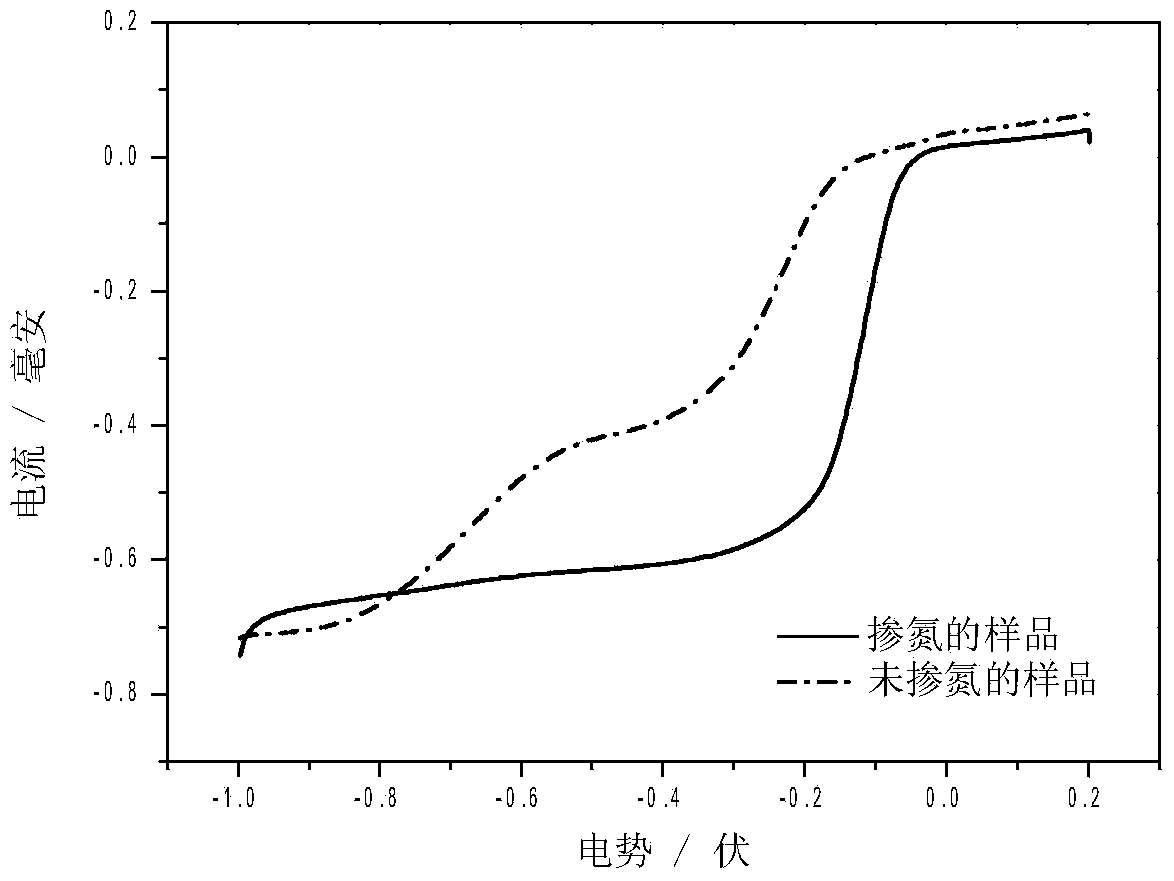

Silicon-carbide-core nano compound particle coated by nitrogen-doped carbon shell and preparation method of particle

InactiveCN103746124AExtended service lifeIncreased durabilityPhysical/chemical process catalystsCell electrodesNitrogen gasChemical stability

The invention discloses a silicon-carbide-core nano compound particle coated by a nitrogen-doped carbon shell. The silicon-carbide-core nano compound particle is formed by taking nano silicon carbide as the core and carbon generated on the surface of the silicon carbide in situ as the shell and doping nitrogen atoms into the carbon shell. The preparation method of the nano compound particle mainly comprises the following steps: dropping a saturated chloride solution into cubic silicon carbide particles or whiskers till the silicon carbide can be soaked by the solution completely; then drying after uniformly mixing, uniformly mixing the dried silicon carbide and tripolycyanamide or ammonium chloride, and then putting in a sintering furnace; heating to 1,000-1,500 DEG C in vacuum, argon gas or nitrogen gas atmosphere, and cooling to room temperature after preserving the heat for 0.5-3 hours; and soaking the powder after heat treatment with 37% concentrated hydrochloric acid, water-washing to neutrality, and drying. The preparation method of the nano compound particle disclosed by the invention is simple and safe, the nano compound particle which serves as a cathode catalyst of a fuel battery has high thermostability and chemical stability, so that the synthetic catalyst material has high durability, and the service life of the catalyst is prolonged.

Owner:YANSHAN UNIV

Method for production of silicon carbide layer, gallium nitride semiconductor device and silicon substrate

InactiveCN101203940AAvoid decompositionAvoid Facilitating DecompositionSemiconductor/solid-state device manufacturingPolycrystalline material growthCubic silicon carbideGallium nitride

A method for producing a silicon carbide layer on a surface of a silicon substrate includes the step of irradiating the surface of the silicon substrate heated in a high vacuum at a temperature in a range of from 500 DEG C to 1050 DEG C with a hydrocarbon-based gas as well as an electron beam to form a cubic silicon carbide layer on the silicon substrate surface.

Owner:SHOWA DENKO KK

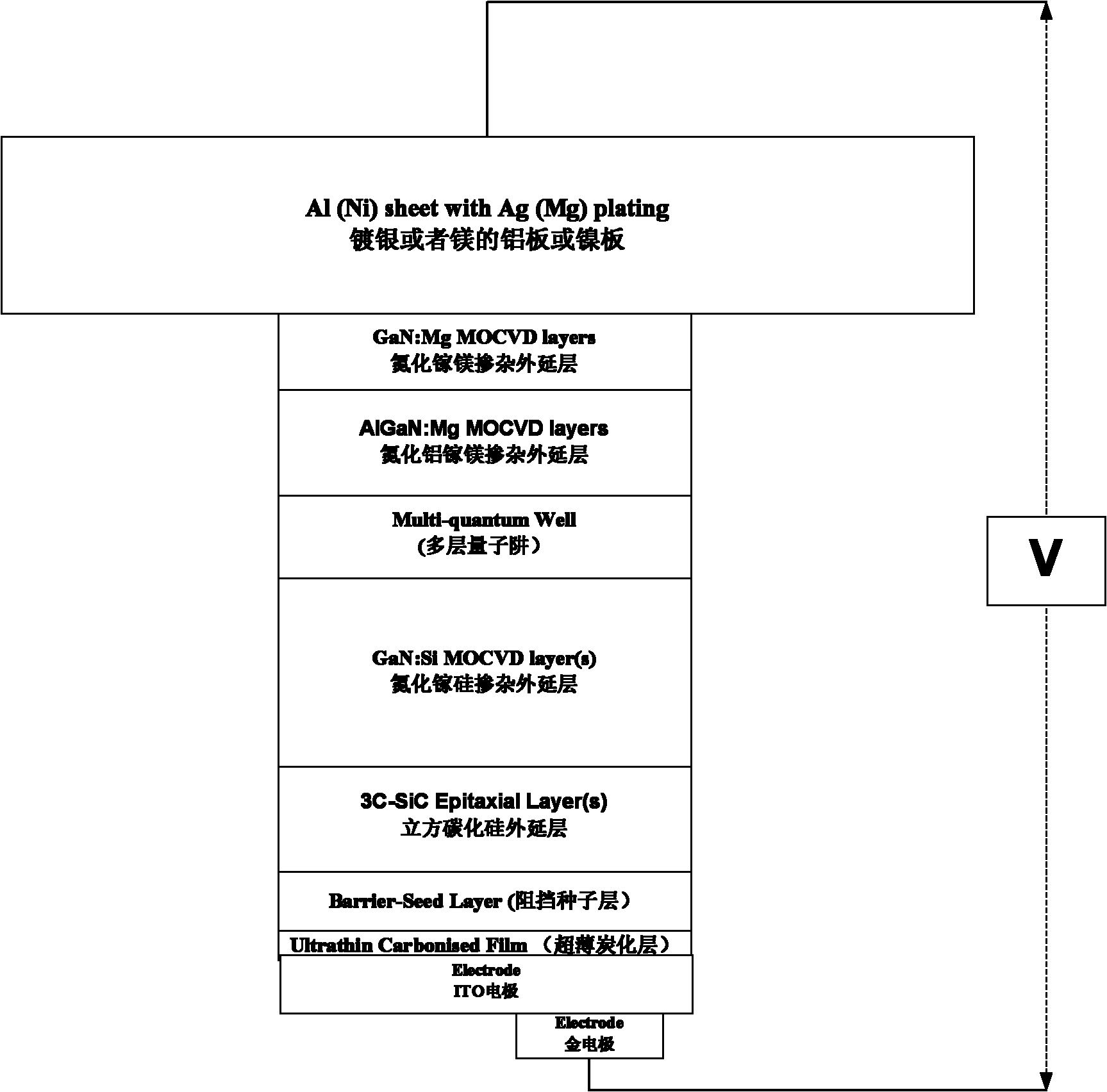

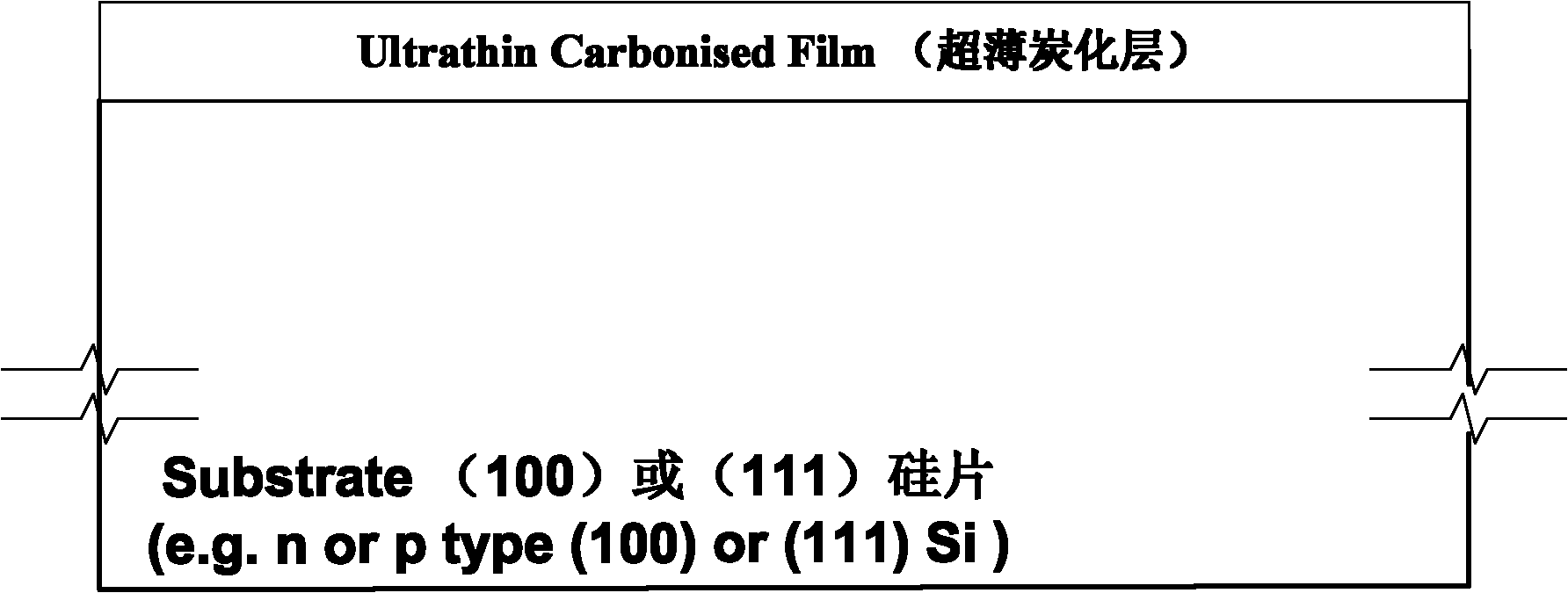

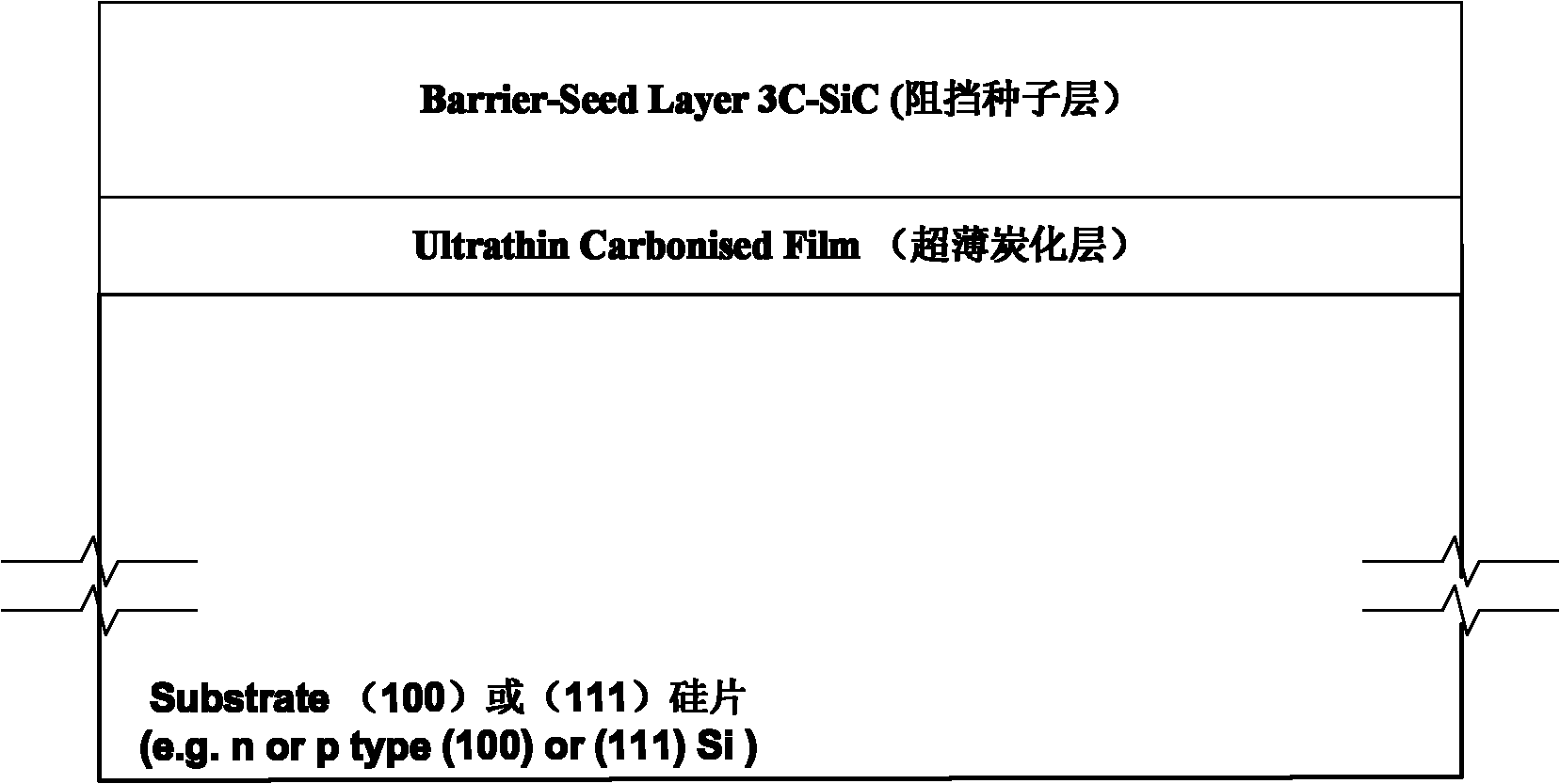

GaN blue light LED device using 3C-SiC-Si as substrate

InactiveCN102064256AIncrease brightnessImprove efficiencySemiconductor devicesTemperature stressCubic silicon carbide

The invention relates to a GaN blue light light-emitting diode (LED) device using 3C-SiC-Si as a substrate. A manufacturing method comprises the following steps of: preparing a silicon wafer, manufacturing a buffer layer, which consists of an ultrathin carbonizing layer, a blocking seed layer and a cubic silicon carbide epitaxial layer, of the device on a silicon wafer serving as a basic substrate layer; depositing GaN on the buffer layer to form a GaN structural layer; bonding an aluminum plate or a nickel plate plated with silver or magnesium on the GaN structural layer to form ohmic contact; and etching silicon to form the GaN blue light LED device with a self-support structure. By the implementation and application of the technology of the invention, diameters of LEDs wafers are increased (which can reach 12 maximally), the production cost and machining cost of LED chip materials are reduced greatly, the high-quality GaN depositing layer can be obtained effectively and also can be used as barrier layer with high chemical stability to etch the silicon, and the opportunity is created for the improvement on LED tube cores, the extraction of light and the elimination of high-temperature stress.

Owner:韩吉胜 +1

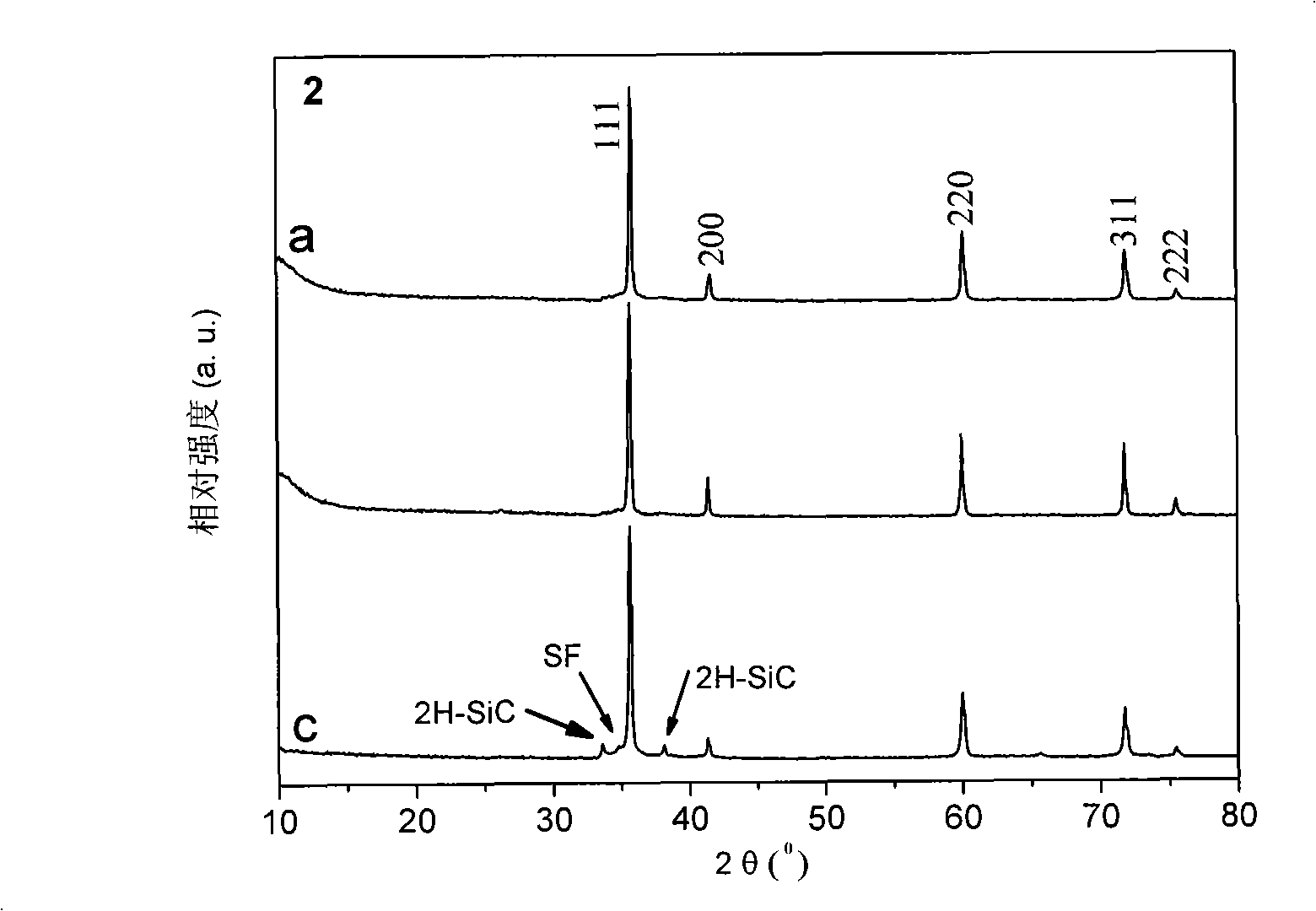

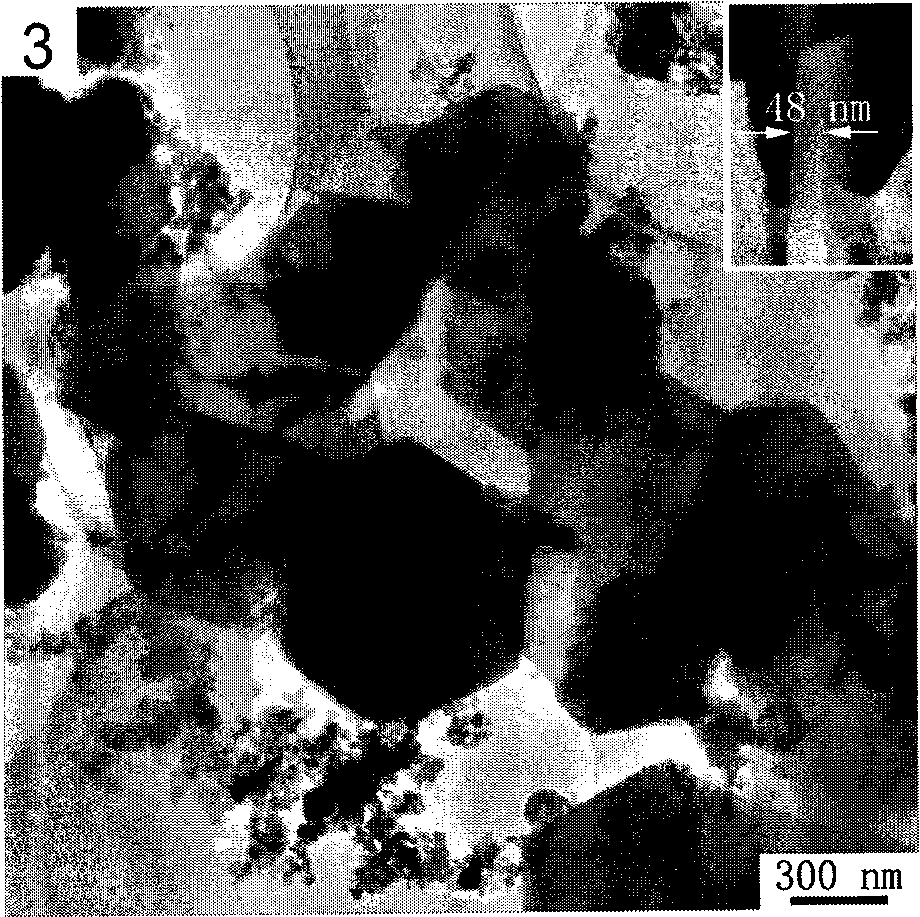

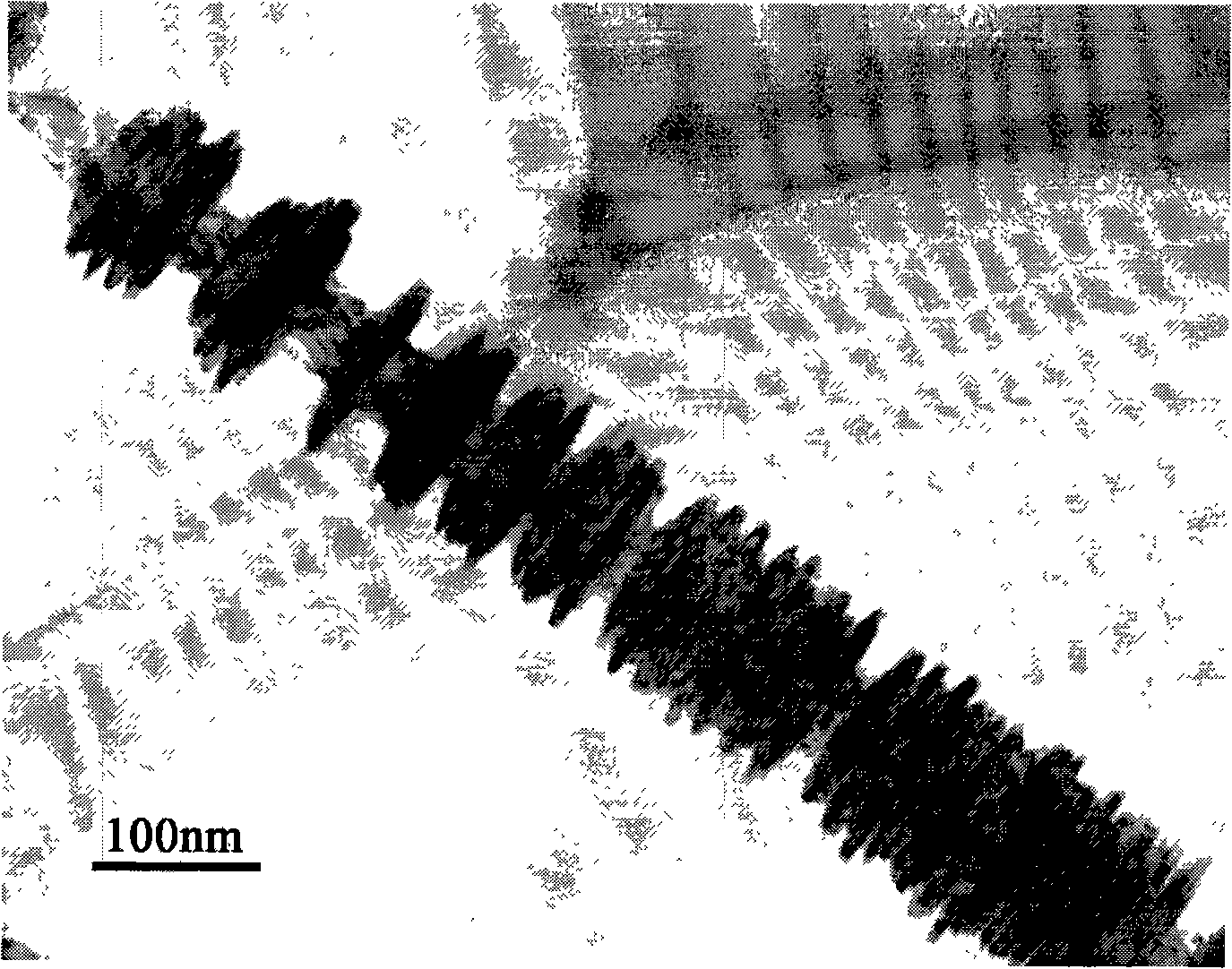

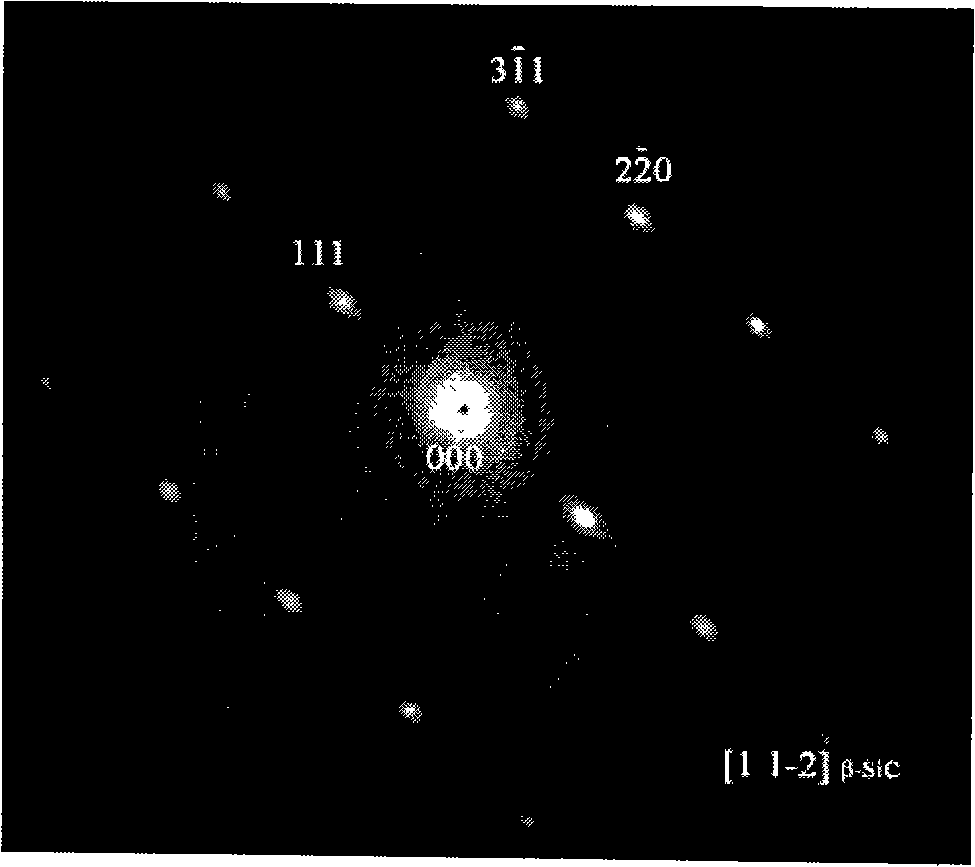

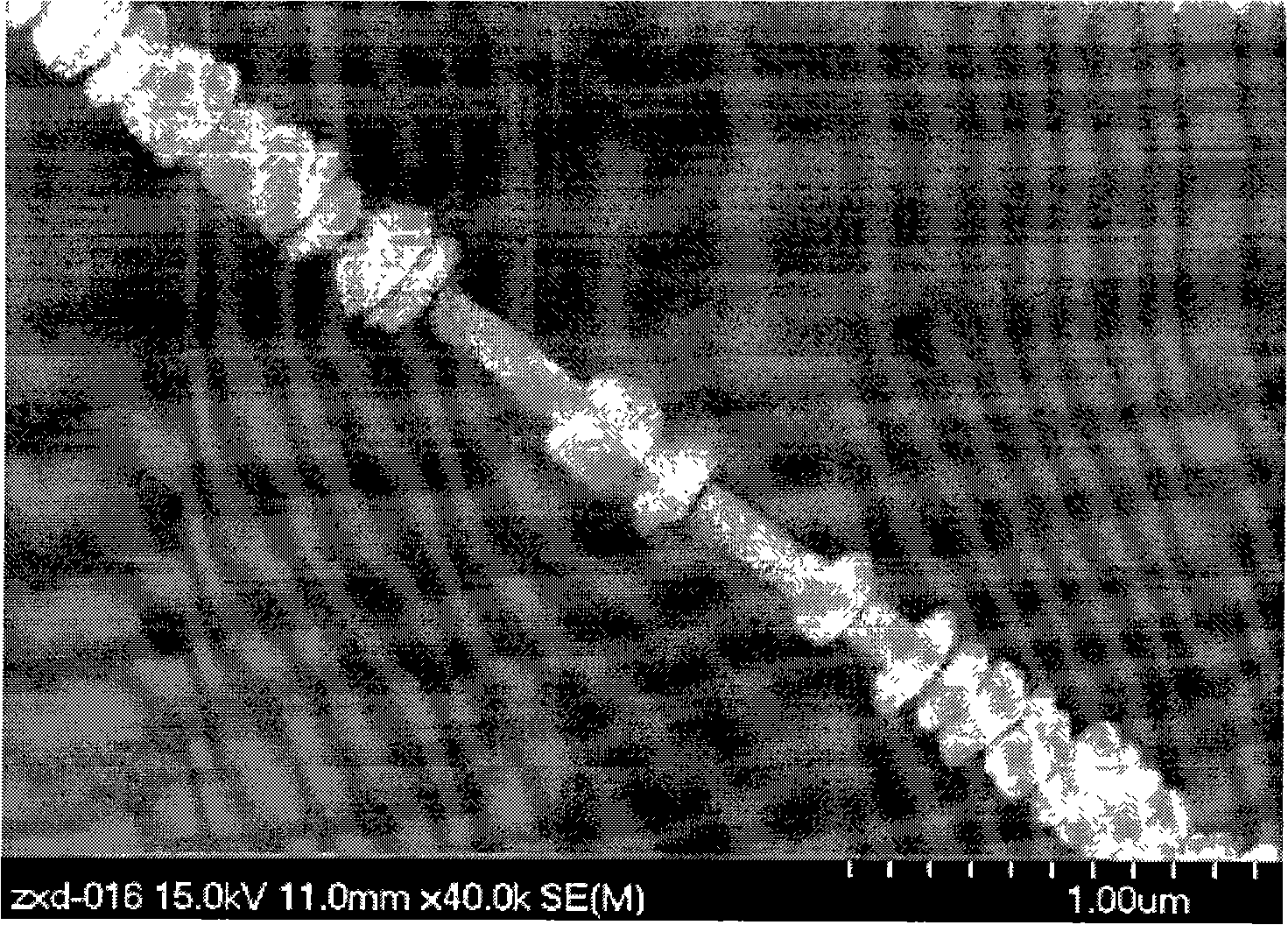

Silicon carbide nanometer line accompanied with string structure and preparation method thereof

InactiveCN101319399ALow costSimple preparation processPolycrystalline material growthSingle crystal growth detailsNanowireQuasi one dimensional

The invention provides a silicon carbide nanowire with a string-shaped structure and a preparation method thereof, and relates to a quasi-one dimensional nanostructure and a preparation method thereof. The silicon carbide nanowire with the string-shaped structure is a single crystal of cubic silicon carbide. The method comprises the following steps of: putting amorphous carbon / silicon dioxide nano composite powder into a crucible and place the crucible in an atmosphere sintering furnace; passing through argon into the furnace after the furnace is vacuumized to ensure that initial air pressure reaches between 0.1 and 2.0MPa; then, heating the furnace up to a temperature of between 1500 and 1800 DEG C at a rising speed of between 5 and 30 DEG C / minute for 0.5 to 6 hours; and cooling the powder to room temperature in the furnace to obtain the silicon carbide nanowire with the string-shaped structure. A diameter of a central line or a central rod is distributed in a range of between 50 and 100 nanometers, and a diameter of the silicon carbide nanowire with the string-shaped structure on the central line or the central rod is distributed in a range of between 100 and 500 nanometers. The silicon carbide nanowire with the string-shaped structure and the preparation method have the advantages of simple preparation process, low cost and short preparation period, and can realize control to the structure and the appearance of a product.

Owner:HARBIN INST OF TECH

Method for manufacturing cold end part of silicon carbide rod by cubic silicon carbide

InactiveCN101747043ALow resistivityLow costHeating element materialsSocial benefitsCubic silicon carbide

The invention provides a method for manufacturing a cold end part of a silicon carbide rod by cubic silicon carbide. In the method, an adhesive is added to the cubic silicon carbide to carry out extrusion forming, and then biscuit firing treatment is carried out so as to form a biscuit fired product; the biscuit fired product is buried by a burying material, then high-temperature siliconizing and silicifying are carried out under the temperature of 1,700 to 2,000 DEG C, protective gas is filled for protection at the same time, and the siliconizing and silicifying treatment of the biscuit fired product is finished after 1.5 to 2.5 hours so as to obtain the finished cold end part of the silicon carbide rod. The method for manufacturing the cold end part of the silicon carbide rod by the cubic silicon carbide can obviously lower the resistance rate of the cold end part, and has the characteristics of high finished product rate, low production cost, short production time and high economical as well as social benefits; moreover, the processing controllability is also improved.

Owner:郑州嵩山电热元件有限公司

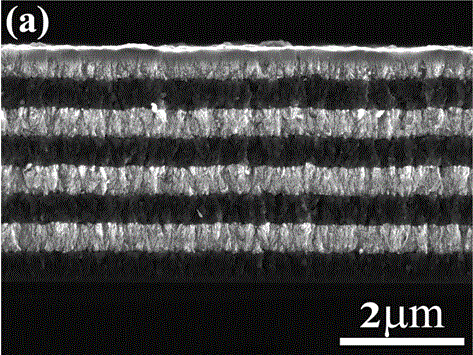

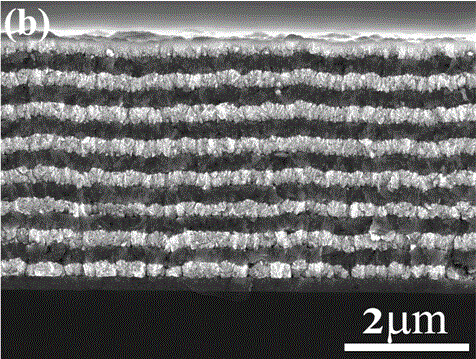

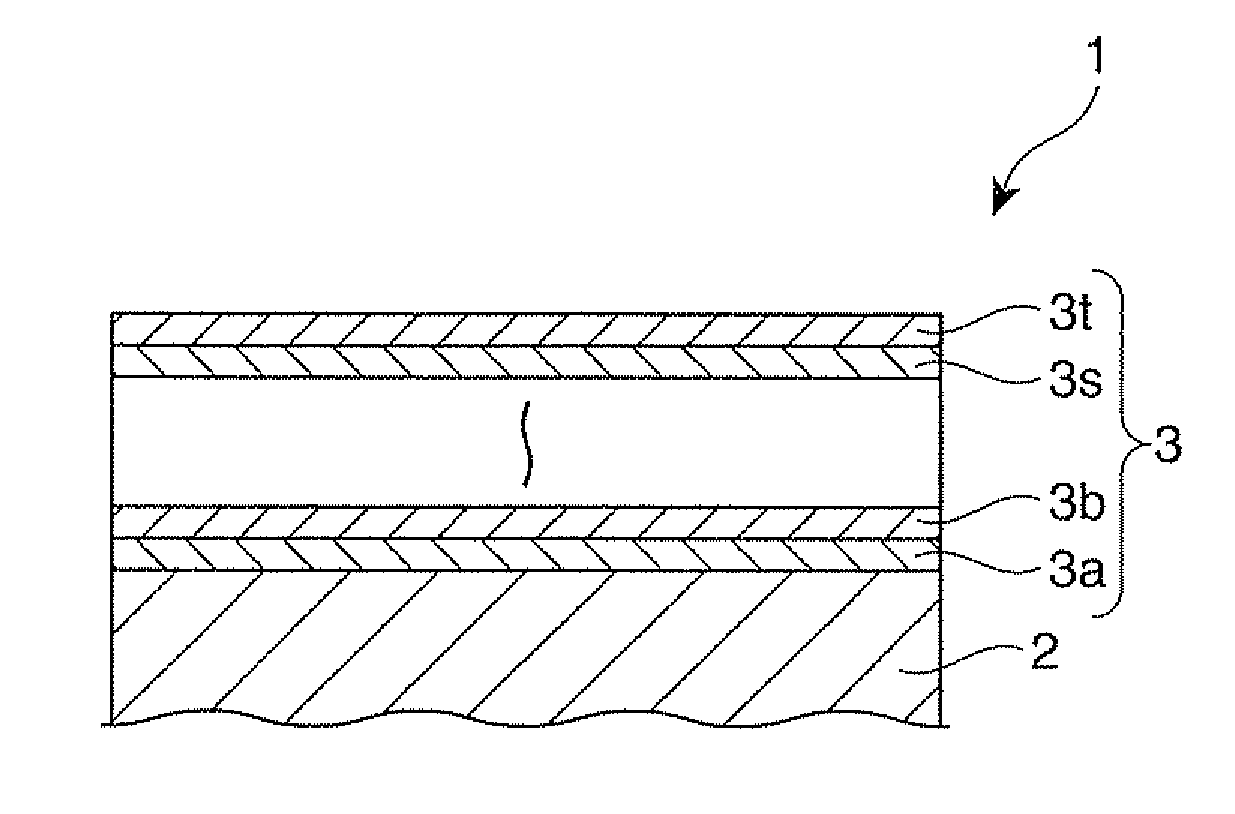

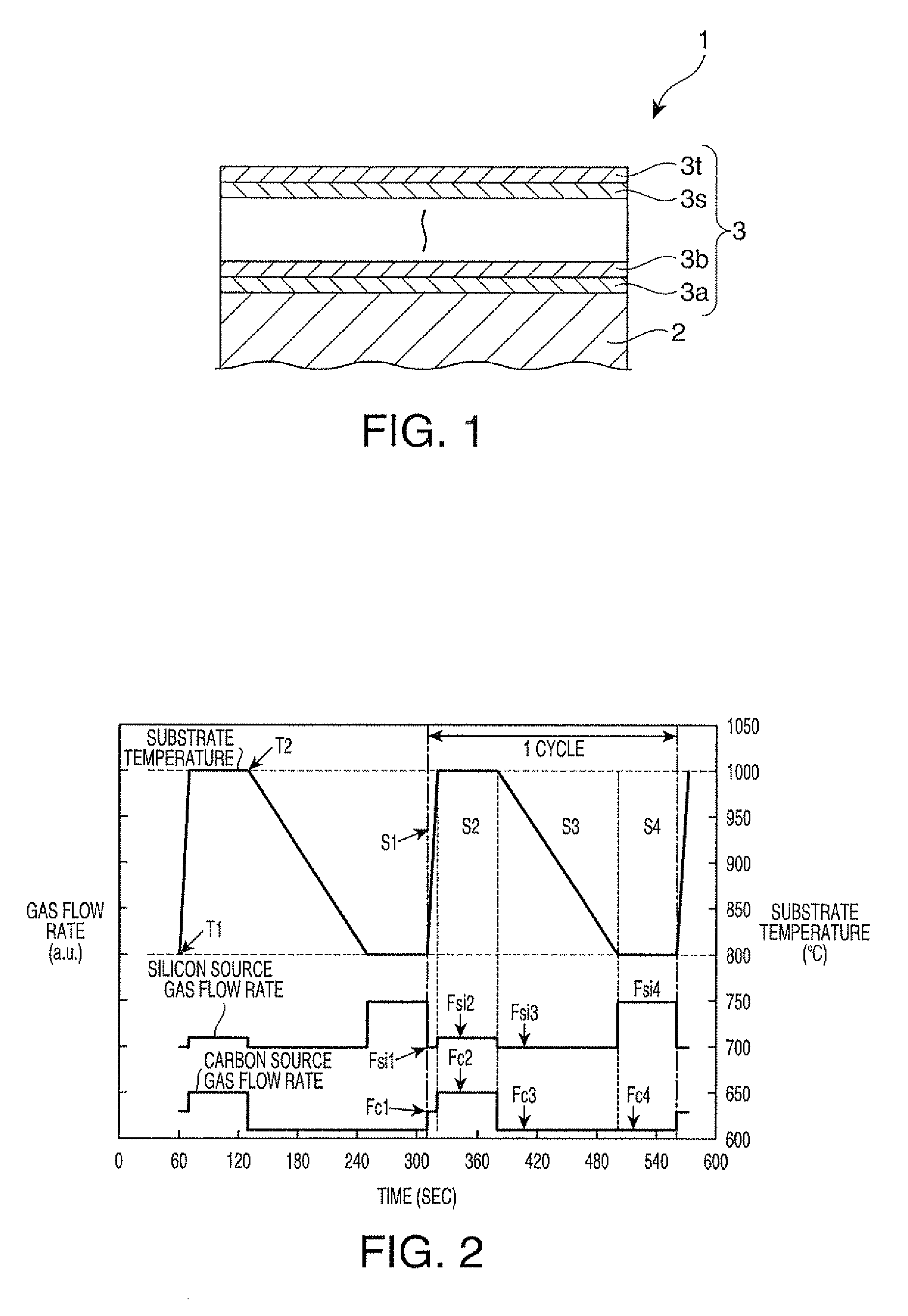

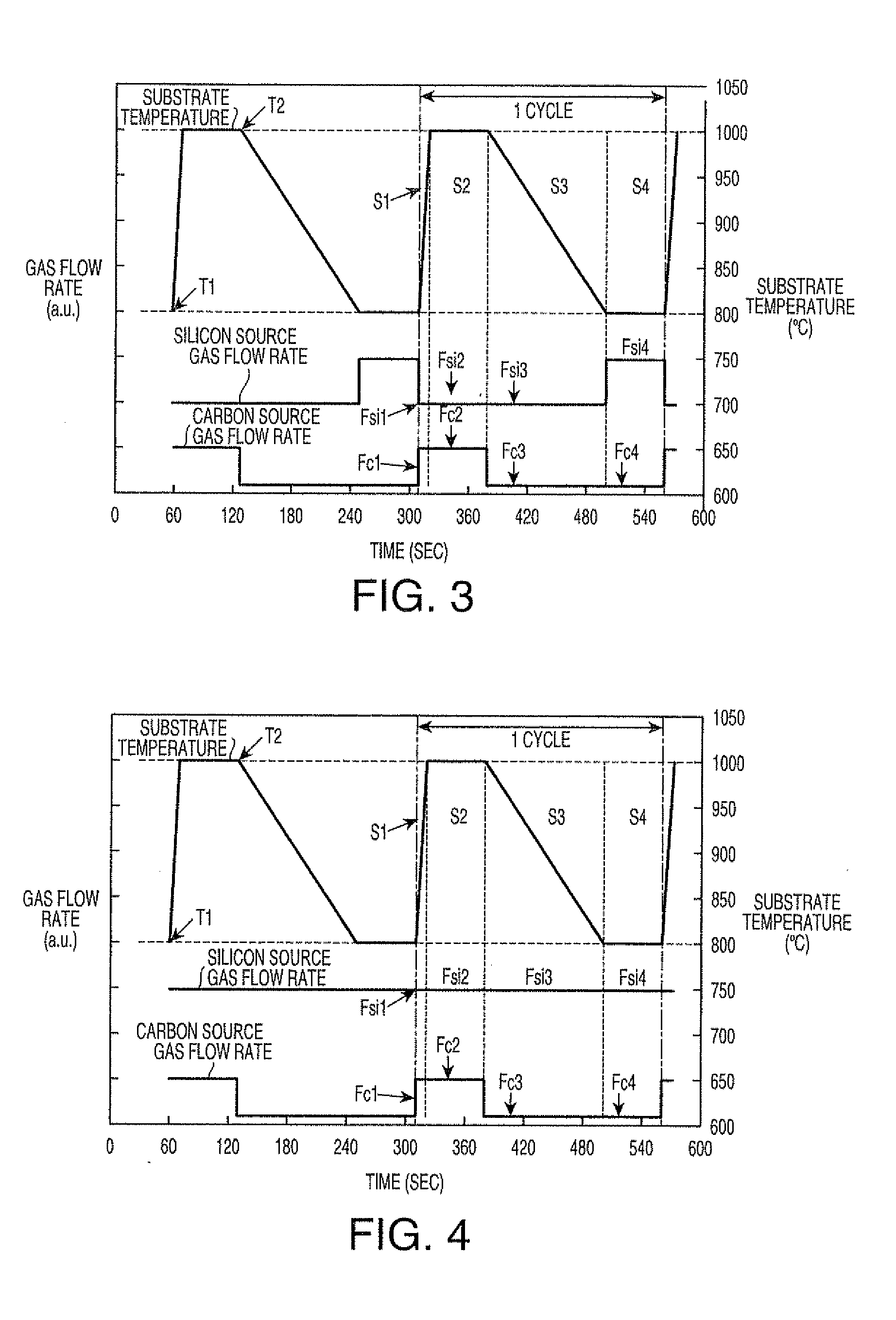

Cubic silicon carbide film manufacturing method, and cubic silicon carbide film-attached substrate manufacturing method

InactiveUS20120037067A1Increase speedPolycrystalline material growthFrom chemically reactive gasesCubic silicon carbideMaterials science

A method for manufacturing a cubic silicon carbide film includes: a first step of introducing a carbon-containing gas onto a silicon substrate and rapidly heating the silicon substrate to an epitaxial growth temperature of cubic silicon carbide so as to carbonize a surface of the silicon substrate and form a cubic silicon carbide film; and a second step of introducing a carbon-containing gas and a silicon-containing gas onto the cubic silicon carbide film while maintaining the cubic silicon carbide film at the epitaxial growth temperature of cubic silicon carbide, so as to allow further epitaxial growth of the cubic silicon carbide film.

Owner:SEIKO EPSON CORP

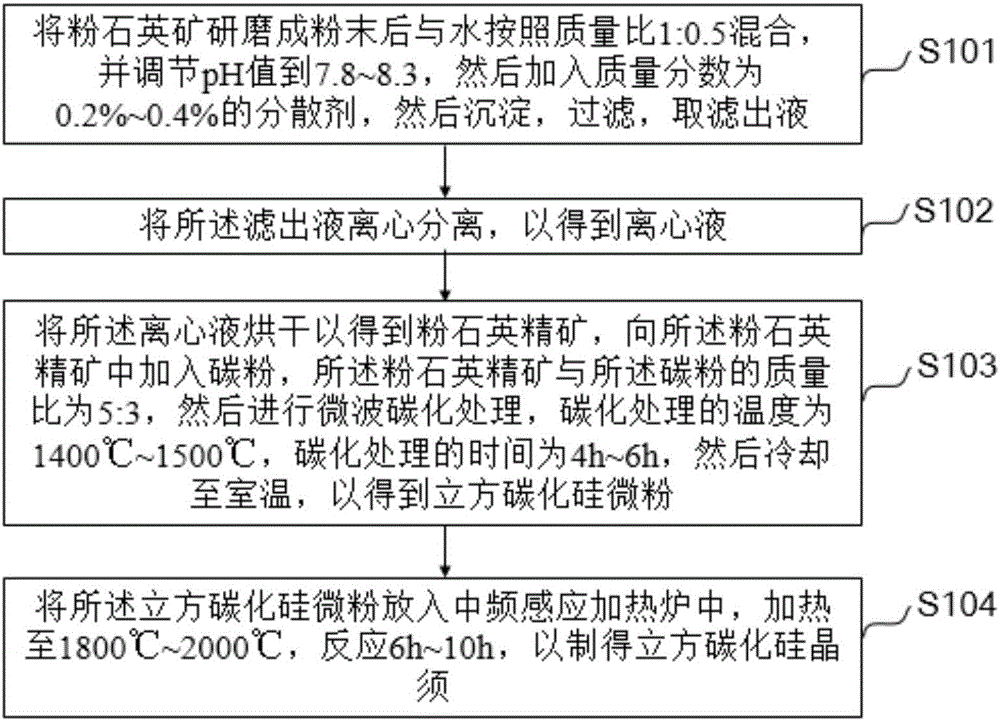

Method for processing cuboid silicon carbide whiskers through natural fine quartz

ActiveCN106087061AHigh yieldHigh purityPolycrystalline material growthFrom solid stateCubic silicon carbideMedium frequency

The invention relates to a method for processing cuboid silicon carbide whiskers through natural fine quartz. The method includes the steps of mixing natural fine quartz with water, adjusting the pH value to be 7.8-8.3, adding a dispersing agent, conducting sedimentation and filtering, taking out filtrate, centrifugally separating the filtrate to obtain centrifugate, drying the centrifugate to obtain natural fine quartz concentrate, adding carbon power to the natural fine quartz concentrate, conducting microwave carbonizing treatment, conducting cooling to the room temperature to obtain cuboid silicon carbide micro powder, putting the cuboid silicon carbide micro powder into a medium-frequency induction heating furnace, conducting heat to 1800-2000 DEG C, and conducting reaction for 6-10 h to obtain the cuboid silicon carbide whiskers. According to the method, reaction is complete, the impurity content is greatly reduced, the cuboid silicon carbide yield and purity are greatly improved, the processing method is simple, and cuboid silicon carbide can be easily prepared on a large scale.

Owner:武汉拓普准晶新材料有限公司

Method for preparing cubic silicon carbide crystals and device thereof

InactiveCN111394788AEffectively maintains carbonization growth rateMaintain the carbonation growth ratePolycrystalline material growthFrom condensed vaporsCubic silicon carbideCarbide silicon

The invention belongs to the technical field of crystal growth, and provides a method for preparing cubic silicon carbide crystals. The method comprises the following steps: silicon carbide powder andseed crystals are put into a closed graphite crucible; wherein the seed crystal is arranged in the center of the top of the graphite crucible, the silicon carbide powder is arranged on the outer sideof the seed crystal, the silicon carbide powder is isolated from the seed crystal by adopting a graphite ring, the silicon carbide powder is sublimated to the surface of the seed crystal, and coolingcrystallization is performed on the seed crystal to grow cubic silicon carbide crystals. According to the method for preparing the cubic silicon carbide crystal, traditional high-temperature and low-pressure growth conditions are avoided, the crystal growth space is greatly increased through an innovative vertical charging mode compared with a traditional method, and therefore the high-quality cubic silicon carbide crystal can be stably prepared under the low-temperature and high-pressure conditions.

Owner:江苏超芯星半导体有限公司

Method for production of silicon carbide layer, gallium nitride semiconductor device and silicon substrate

ActiveUS8216367B2Stably produce high-qualityFew crystalline defectsPolycrystalline material growthSemiconductor/solid-state device manufacturingCubic silicon carbideGallium nitride

A method for producing a silicon carbide layer on a surface of a silicon substrate includes the step of irradiating the surface of the silicon substrate heated in a high vacuum at a temperature in a range of from 500° C. to 1050° C. with a hydrocarbon-based gas as well as an electron beam to form a cubic silicon carbide layer on the silicon substrate surface.

Owner:RESONAC CORPORATION

Method for manufacturing silicon carbide thin film

ActiveUS20150252471A1High crystallinityLarge gran sizeChemical vapor deposition coatingPlasma techniqueCubic silicon carbideMicrowave

A method for manufacturing a silicon carbide thin film comprises steps of: (a) utilizing a mechanical pump to remove gases in a chamber such that the pressure in the chamber is reduced to a bass pressure; (b) utilizing a microwave generator to generate microwaves at 1200W to 1400W so as to form microwave plasma inside the chamber; and (c) introducing into the chamber a silicon-based compound containing chlorine atoms that serve as a precursor, during the time that the temperature of a substrate disposed in the chamber is stable at 400° C. to 500° C., in which the temperature of the substrate is risen by the microwave plasma without heating the substrate additionally, so as to form a film of cubic silicon carbide on the substrate. In the present invention, the SiC thin film has good crystallinity and is manufactured by using MPECVD in a low temperature process.

Owner:NATIONAL TSING HUA UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com