Preparation method of diamond/silicon carbide three-dimensional composite structure and prepared product

A three-dimensional composite, diamond technology, applied in gaseous chemical plating, metal material coating process, coating and other directions, can solve the problem that it cannot be used for metal matrix containing graphite phase catalytic effect, and achieve controllable and controllable growth conditions. High-quality, wide-ranging effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

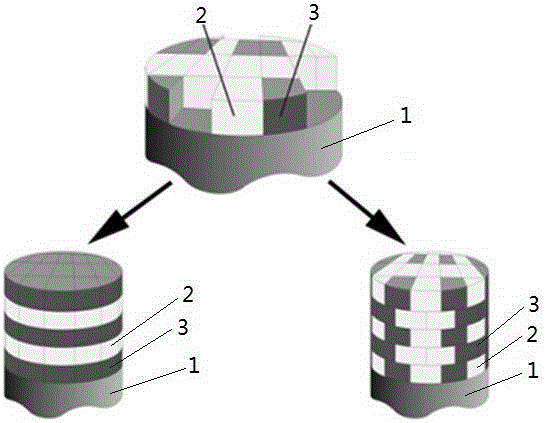

[0059] In the preparation method of the diamond / cubic silicon carbide three-dimensional composite structure established according to the present invention, the cleaned matrix material is put into chemical vapor deposition equipment, and the vapor deposition equipment includes: microwave plasma chemical vapor deposition and hot wire chemical vapor deposition .

[0060] In the preparation method according to the present invention, when the temperature of chemical vapor deposition is 600-1000°C, preferably 700-900°C, and more preferably 750-850°C. When the temperature is higher than 1000°C or lower than 600°C, the growth of diamond is inhibited, so that the diamond / cubic silicon carbide three-dimensional composite structure cannot be obtained.

[0061] In the preparation method of the diamond / cubic silicon carbide three-dimensional composite structure established according to the present invention, when microwave plasma equipment is selected for deposition, when the microwave pow...

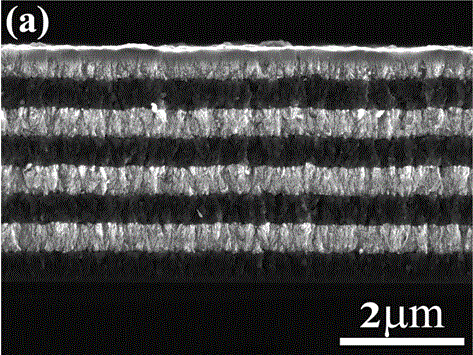

Embodiment 1

[0066] The 10×10mm Si substrate was ultrasonically cleaned with acetone, ethanol, and distilled water for 10 minutes, and then dried with high-purity nitrogen. Put the cleaned Si substrate into the microwave plasma vapor deposition equipment, and evacuate the equipment so that the pressure in the chamber is less than 1×10 -2 Torr, pass hydrogen to 40Torr, and heat the substrate to 850°C at the same time to trigger the reaction of gas molecules. Then the microwave power was fixed to 1800W, and 30 sccm of tetramethylsilane was passed through to deposit cubic silicon carbide. After 1 hour of deposition, turn off the tetramethylsilane, turn on the regulated DC power supply, adjust the voltage value to 200V, and pass 10 sccm of methane gas to start the nucleation of diamond. After 10 minutes, adjust the voltage value to 0V and turn off the DC power supply. Then adjust the flow of methane gas to 4 sccm, and start to deposit the diamond layer. After 1 h of deposition, the methane ...

Embodiment 2

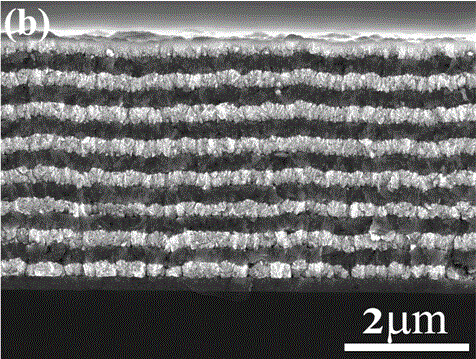

[0070] The 10×10mm Si substrate was ultrasonically cleaned with acetone, ethanol, and distilled water for 10 minutes, and then dried with high-purity nitrogen. Put the cleaned Si substrate into the microwave plasma vapor deposition equipment, and evacuate the equipment so that the pressure in the chamber is less than 1×10 -2 Torr, pass hydrogen to 25 Torr, while heating the substrate to 750°C. Then microwave plasma was excited, and the microwave power was fixed to 1000W, and 30 sccm of tetramethylsilane was passed through to deposit cubic silicon carbide. After 45 minutes of deposition, turn off the tetramethylsilane, turn on the regulated DC power supply, adjust the voltage value to 120V, and pass 8 sccm of methane gas to start the nucleation of diamond. After 12 minutes, adjust the voltage value to 0V and turn off the DC power supply. Then adjust the methane gas flow rate to 6 sccm, and start to deposit the diamond layer. After 45 minutes of deposition, the methane gas wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com