Patents

Literature

59 results about "Performance surface" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A performance surface is a flooring suitable for dance or sport. Performance surfaces are normally laid on top of, or are part of, a sprung floor to produce a complete dance floor or sports floor. Dance performance surfaces made of sheet vinyl are also called dance floors and marley floors. They are called marley-type floors from a very popular reversible vinyl flooring manufactured for years until about 1978 by Marley Floors Ltd.

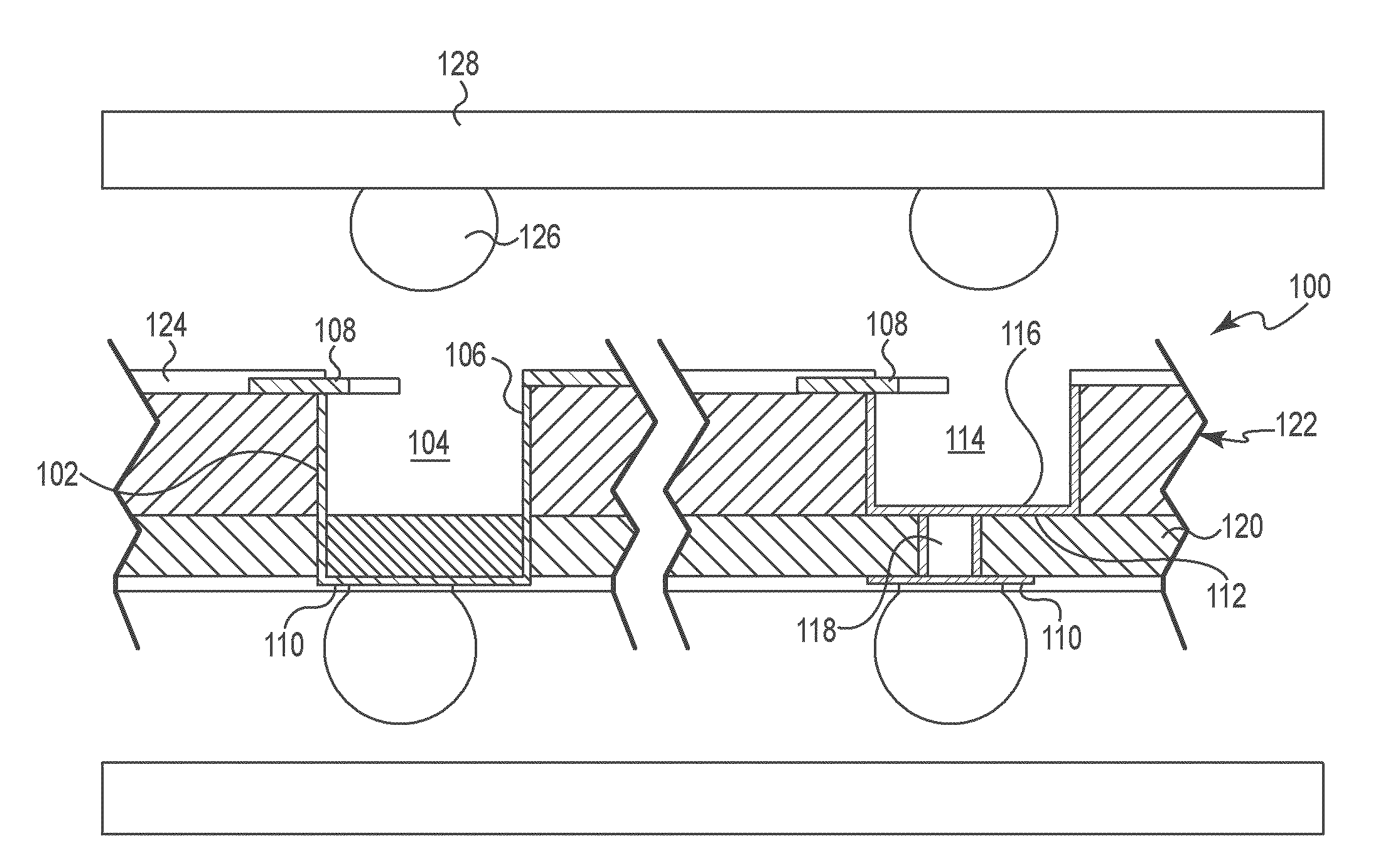

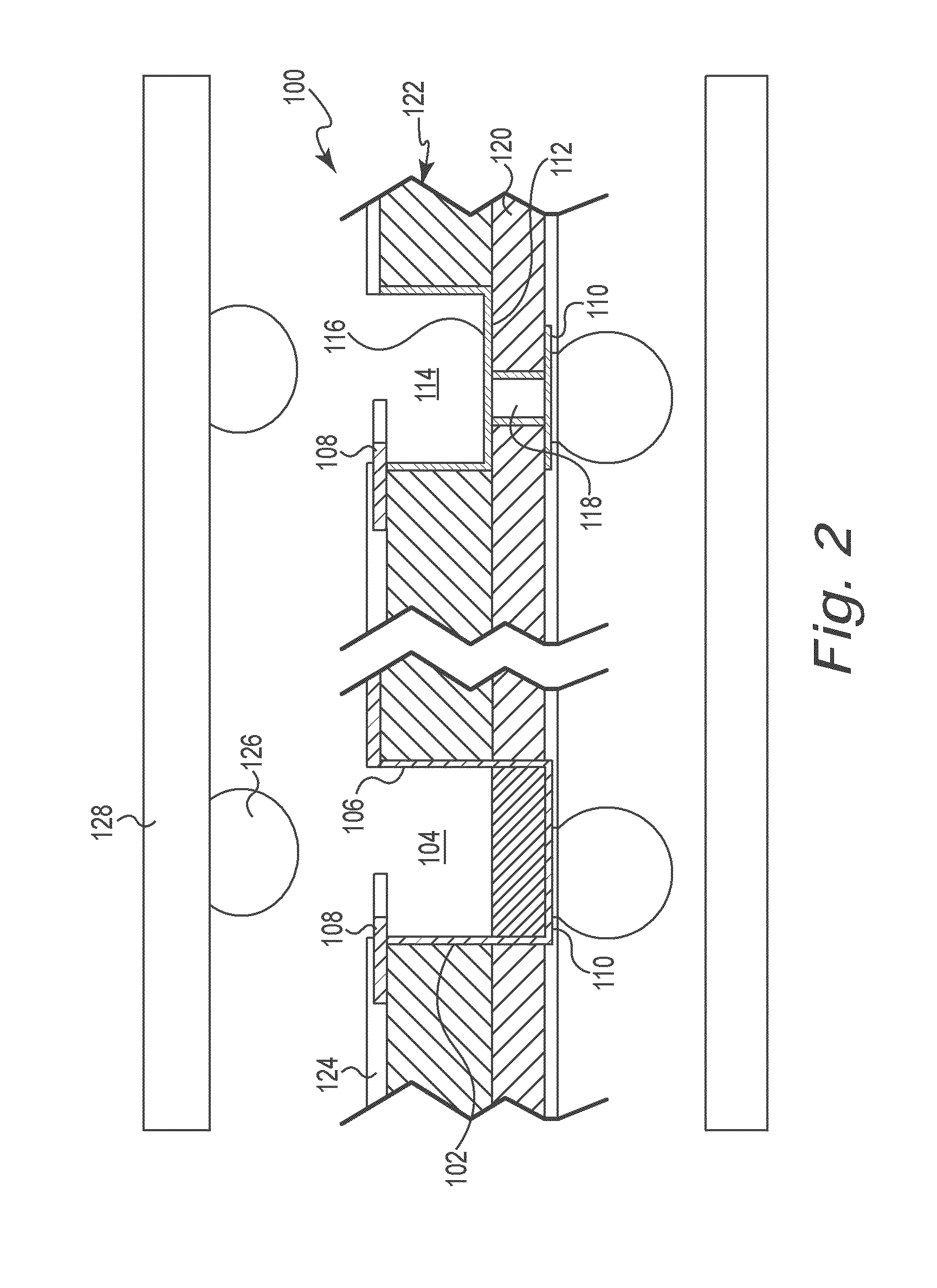

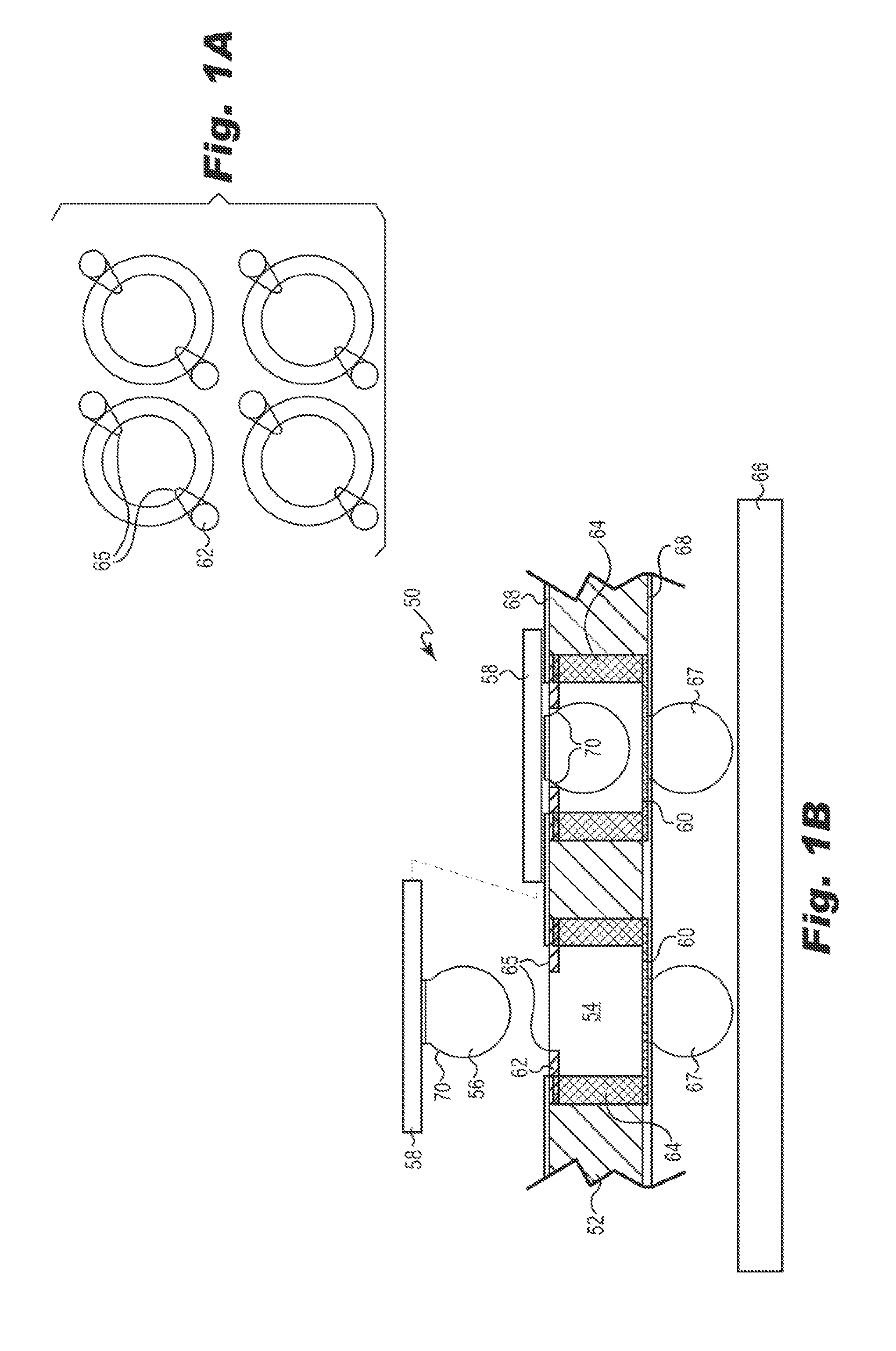

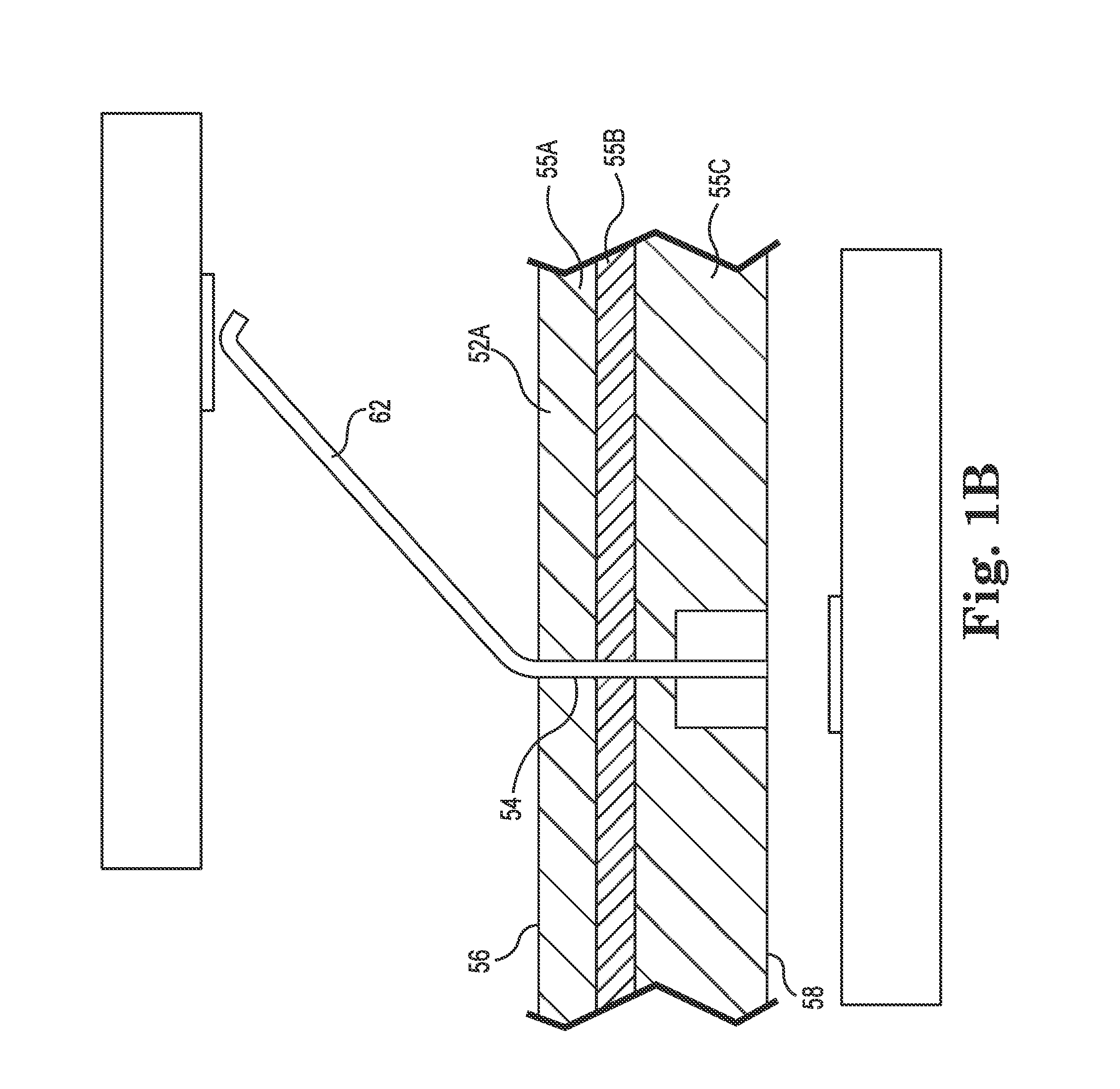

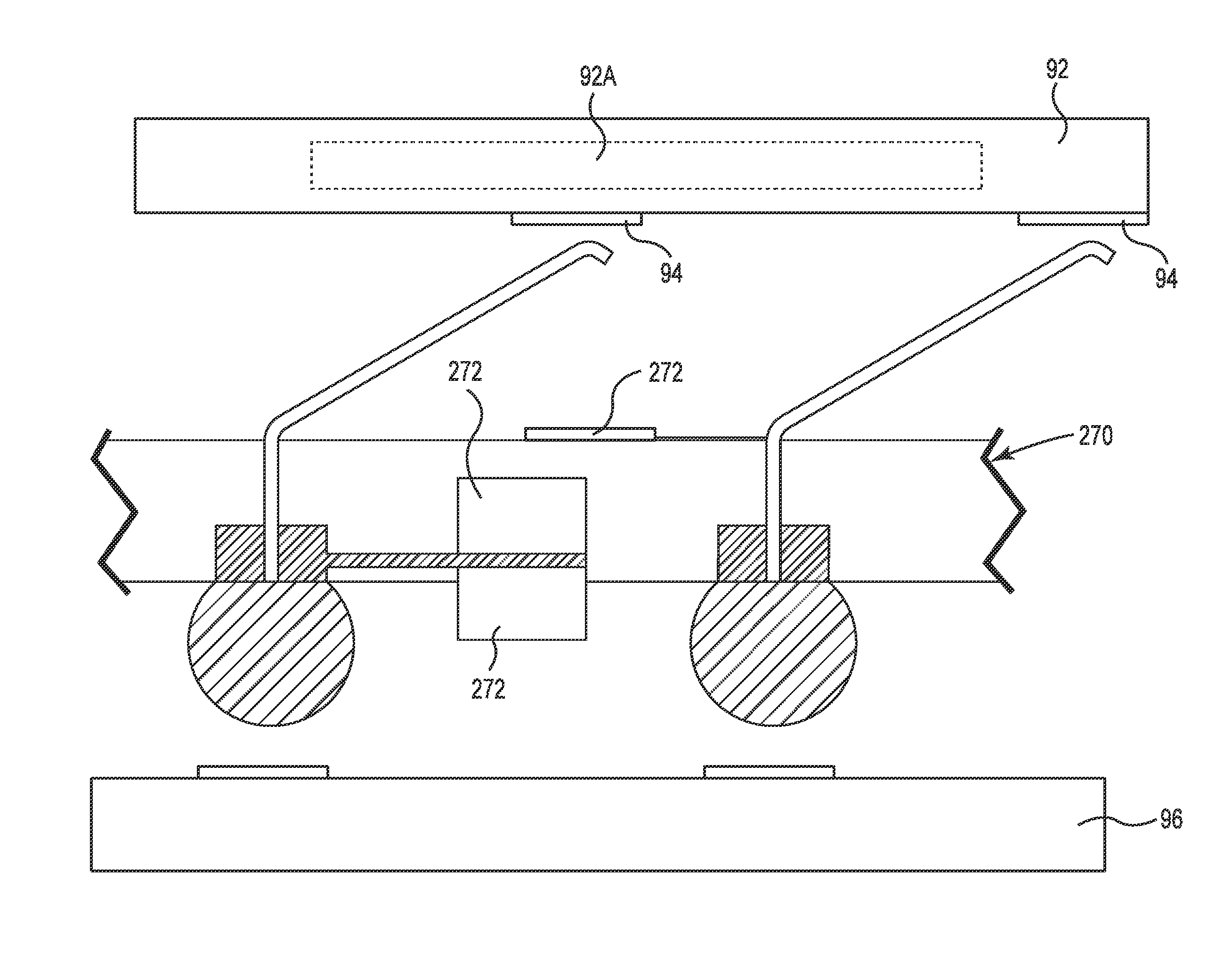

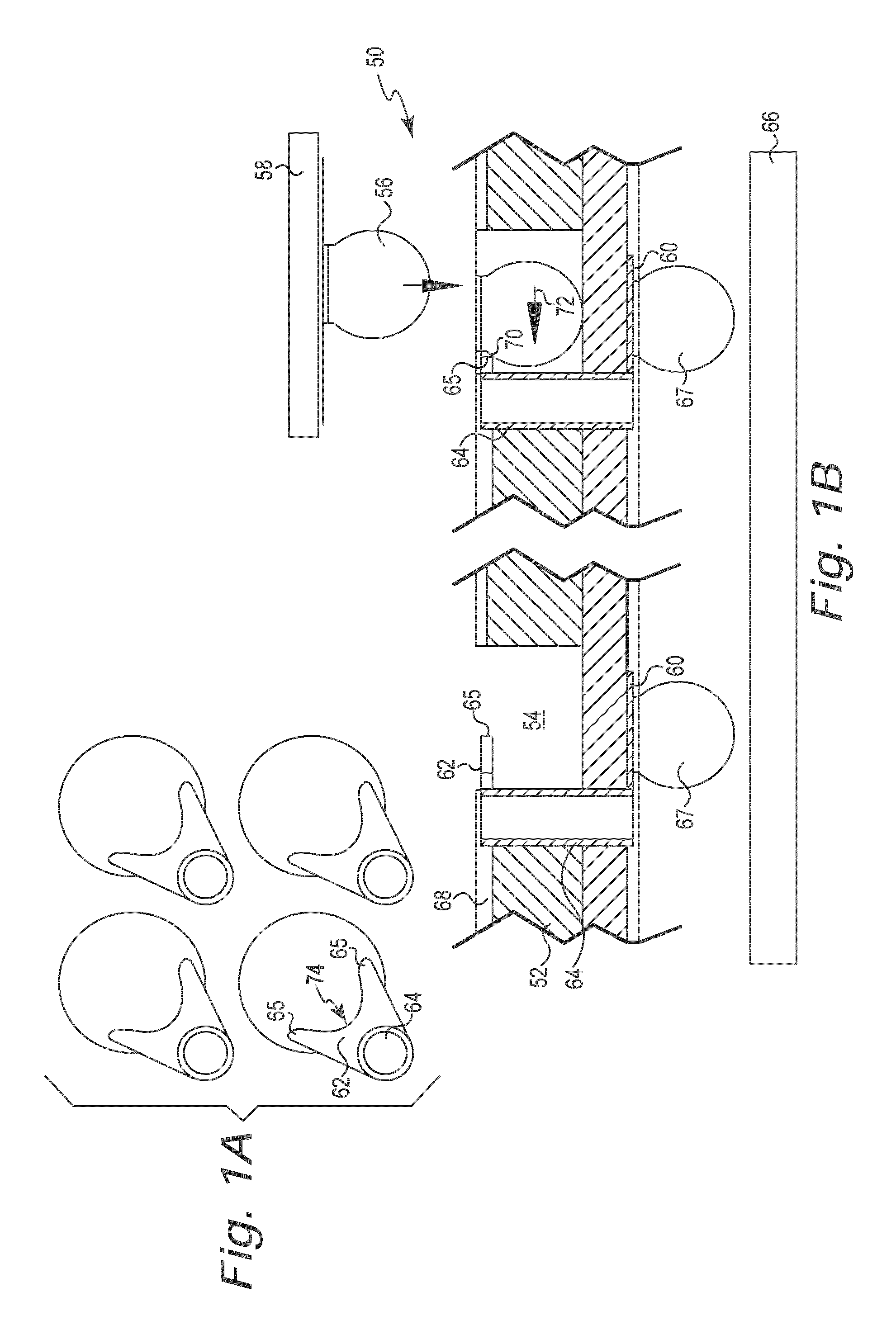

High performance surface mount electrical interconnect with external biased normal force loading

ActiveUS20120244728A1Low enough forceEasy to disassembleCoupling device connectionsContact member manufacturingContact padSurface mounting

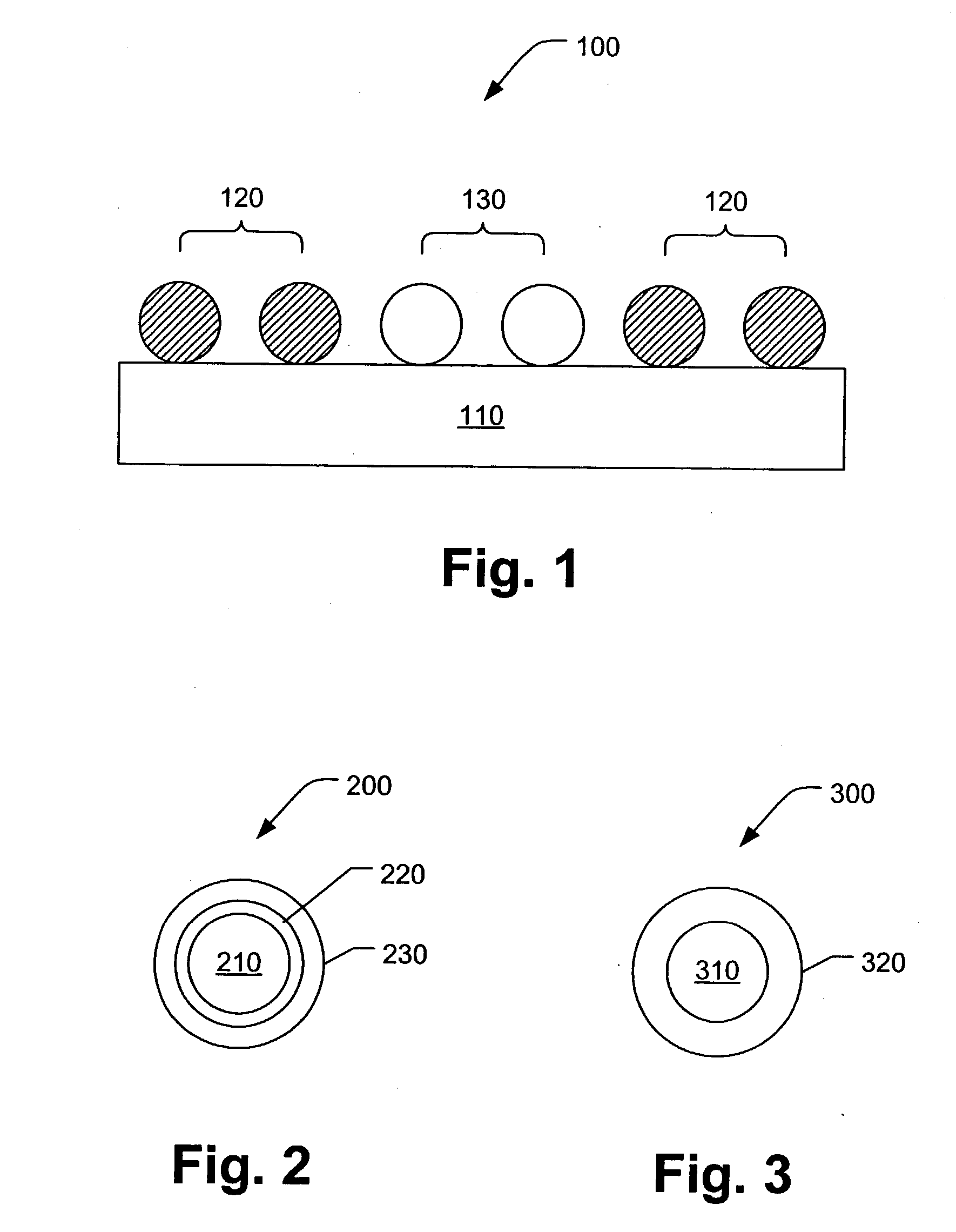

A surface mount electrical interconnect adapted to provide an interface between solder balls on a BGA device and a PCB. A socket substrate is provided with a first surface, a second surface, and a plurality of openings sized and configured to receive the solder balls on the BGA device. A plurality of electrically conductive contact tabs are attached to the socket substrate so that contact tips on the contact tabs extend into the openings. The contact tips electrically couple with the BGA device when the solder balls are positioned in the openings. Vias electrically couple the contact tabs to contact pads located proximate the second surface of the socket substrate. Solder balls are bonded to the contact pads to electrically and mechanically couple the electrical interconnect to the PCB.

Owner:HSIO TECH

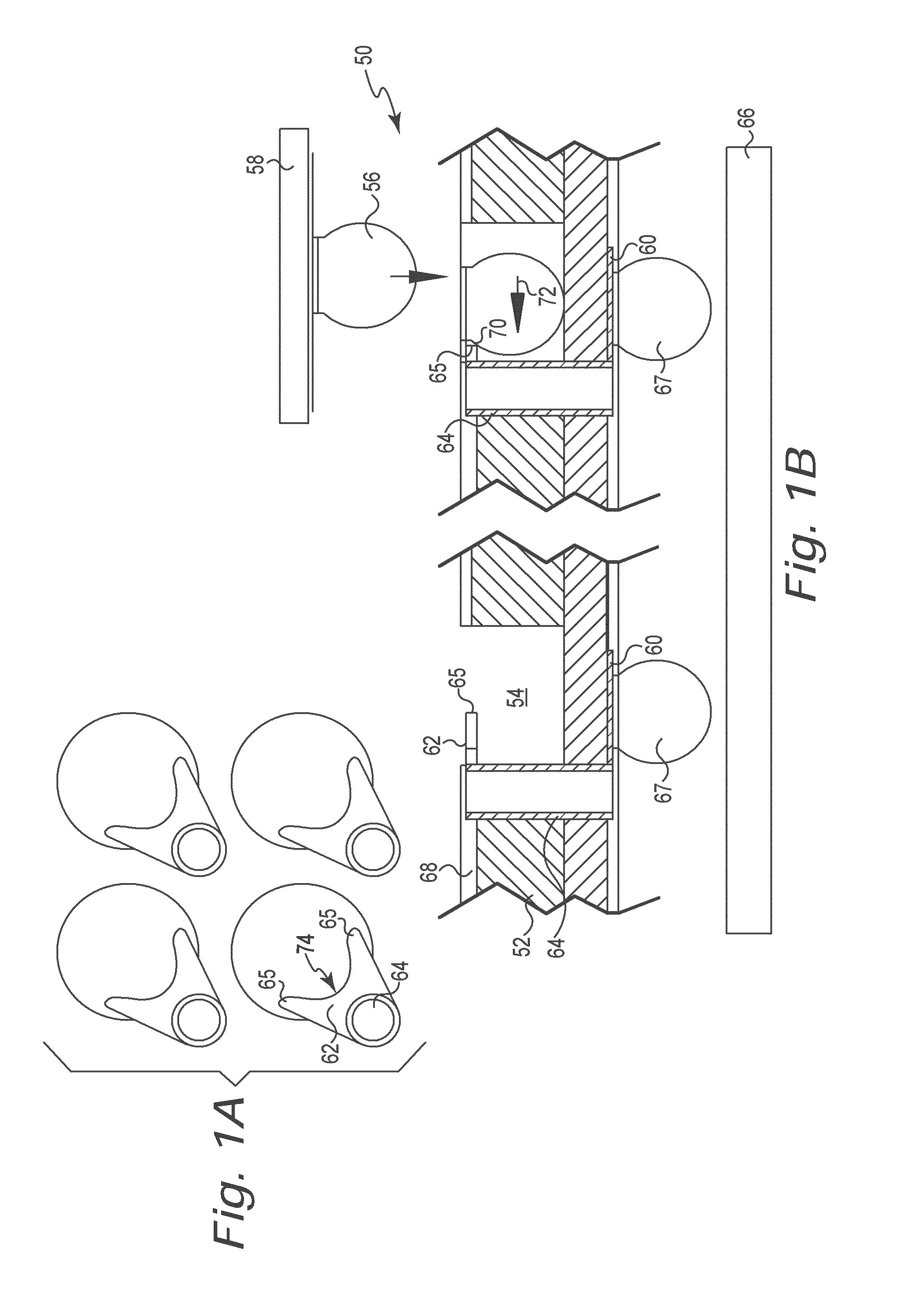

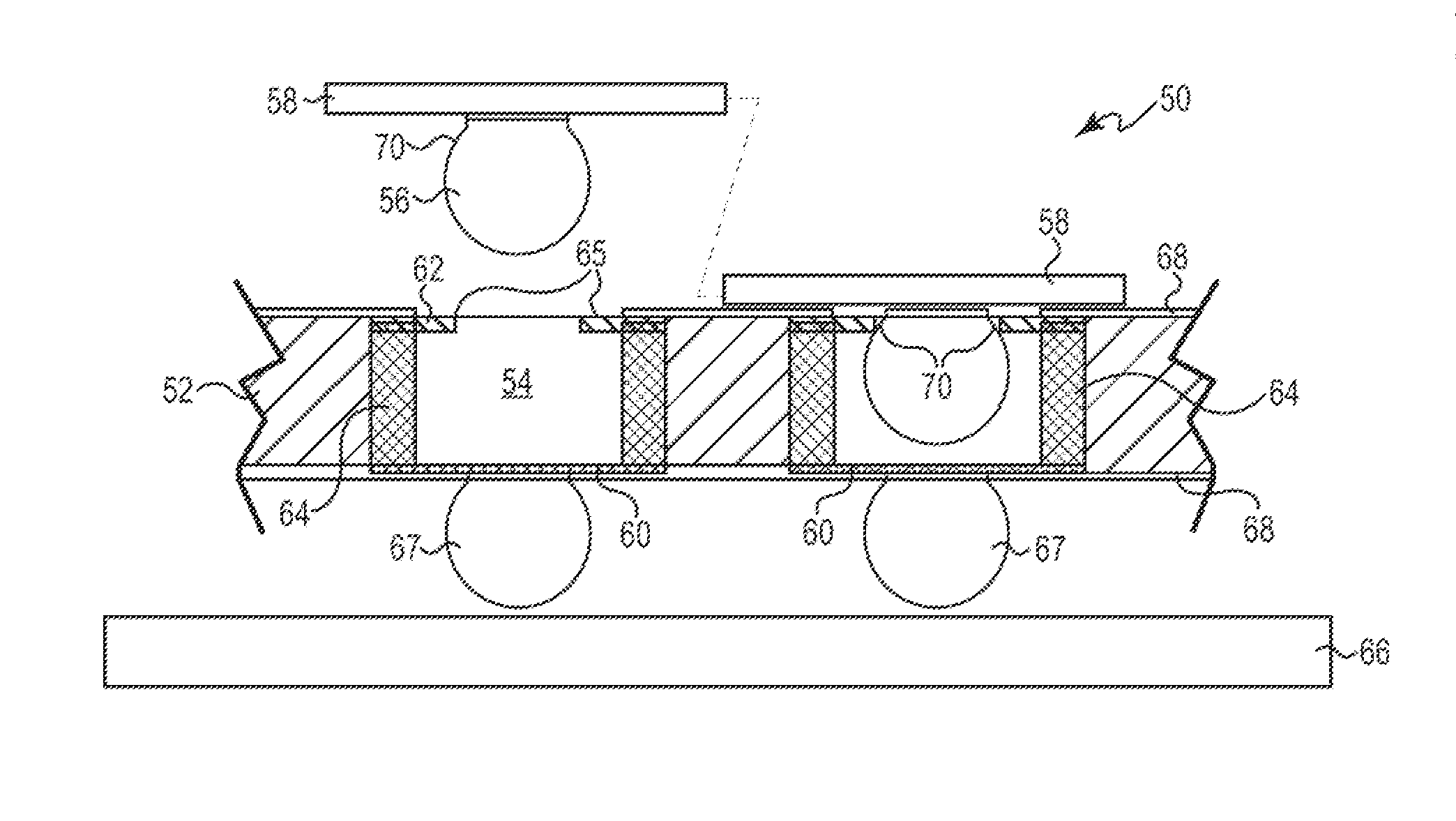

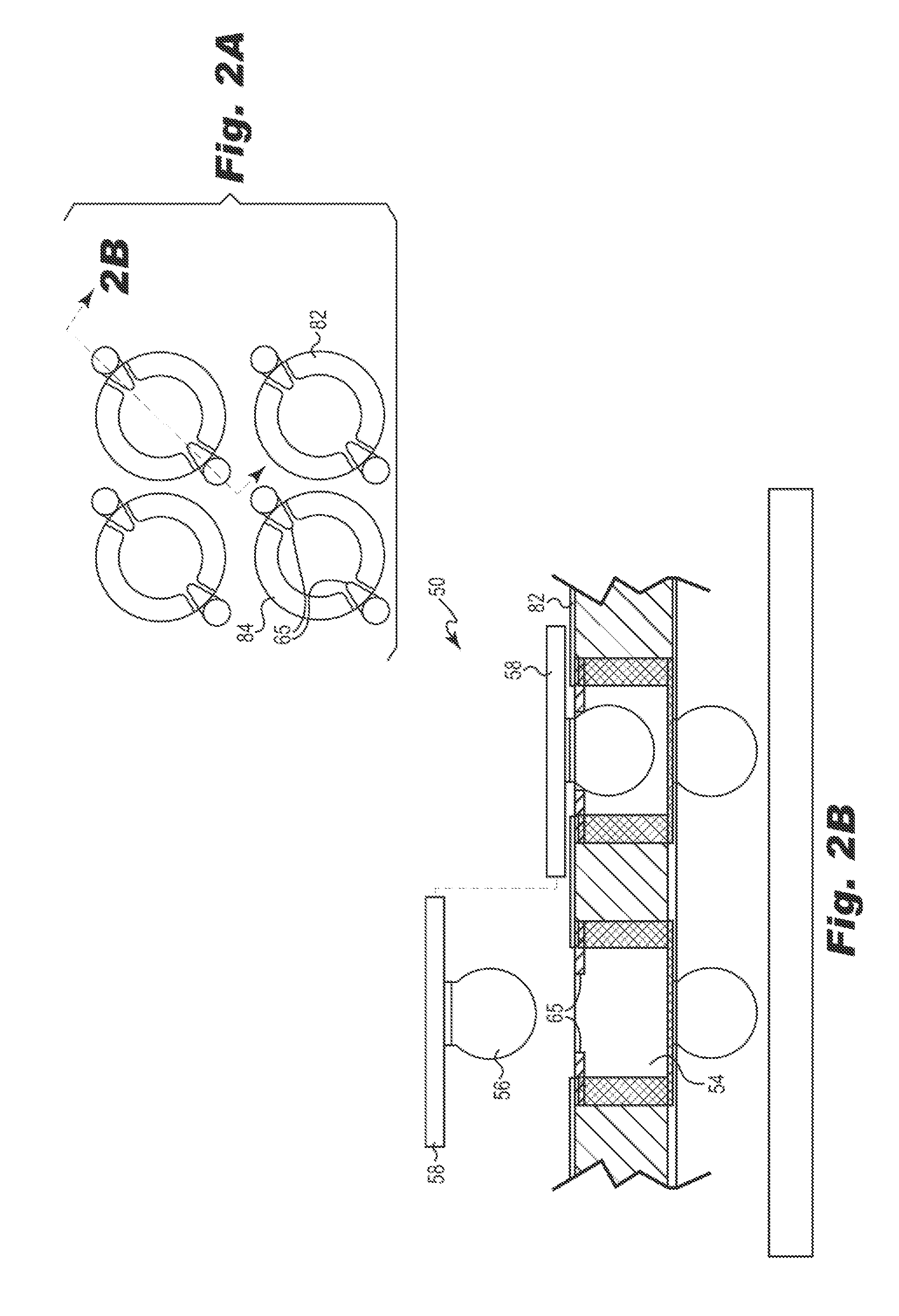

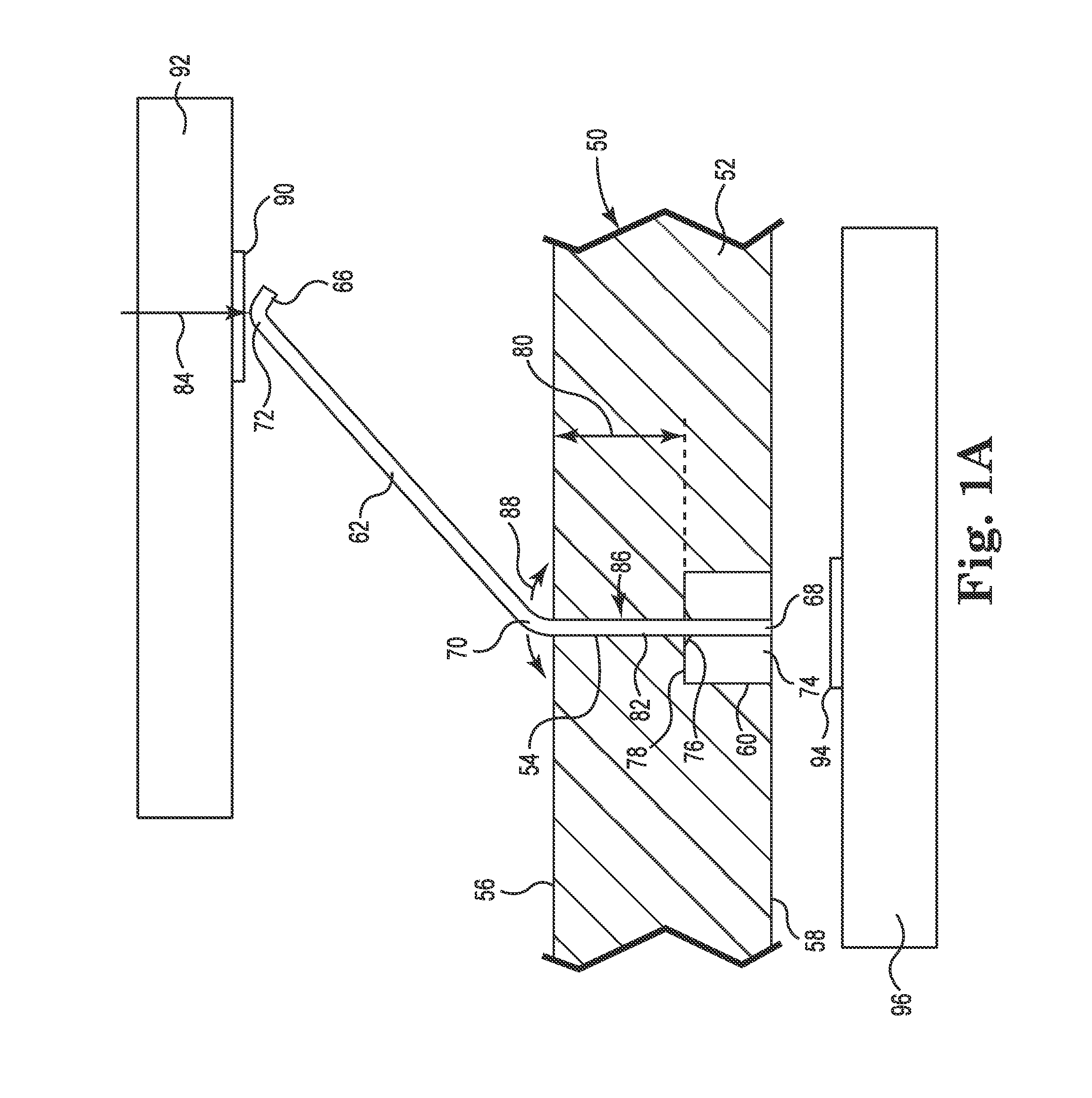

High performance surface mount electrical interconnect

ActiveUS20130244490A1Attractive cost of manufactureHigh densityPrinted circuit aspectsCoupling device detailsContact padSurface mounting

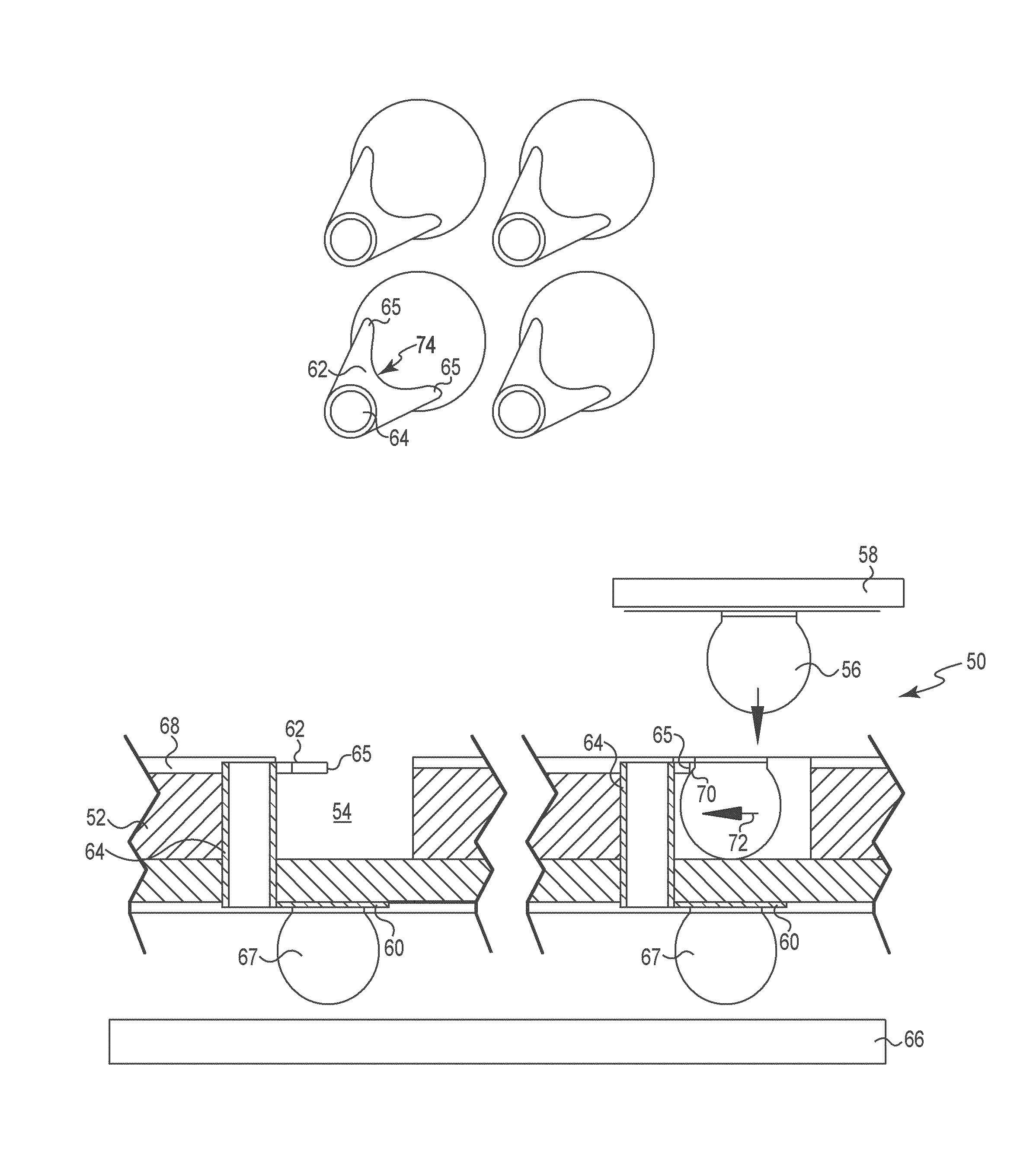

A surface mount electrical interconnect adapted to provide an interface between solder balls on a BGA device and a PCB. The electrical interconnect includes a socket substrate with a first surface, a second surface, and a plurality of openings sized and configured to receive the solder balls on the BGA device. A plurality of electrically conductive contact tabs are bonded to the first surface of the socket substrate so that contact tips on the contact tabs extend into the openings. The contact tips electrically couple with the BGA device when the solder balls are positioned in the openings. Vias are located in the openings that electrically couple the contact tabs to contact pads located proximate the second surface of the socket substrate. Solder balls are bonded to the contact pad that are adapted to electrically and mechanically couple the electrical interconnect to the PCB.

Owner:HSIO TECH

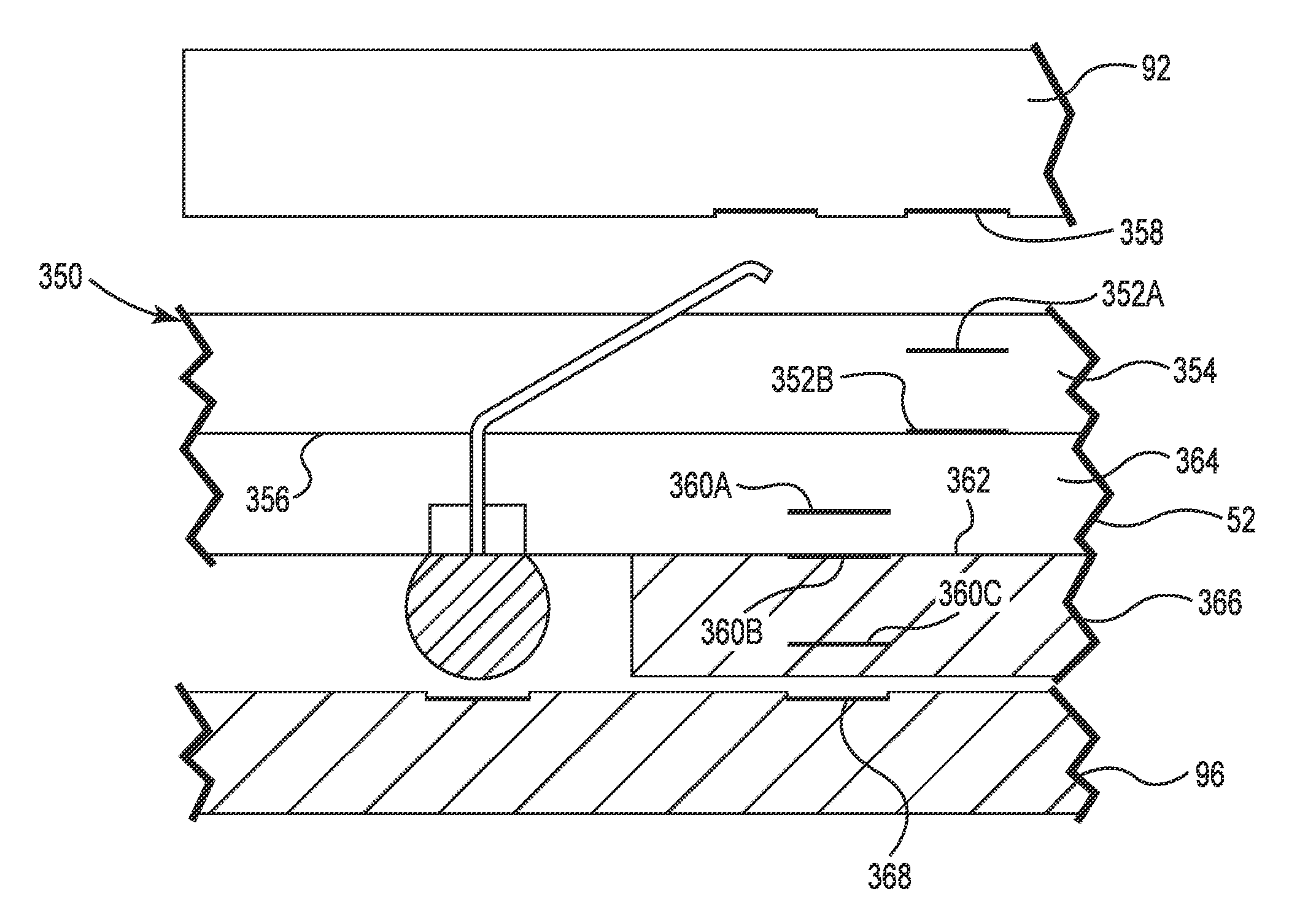

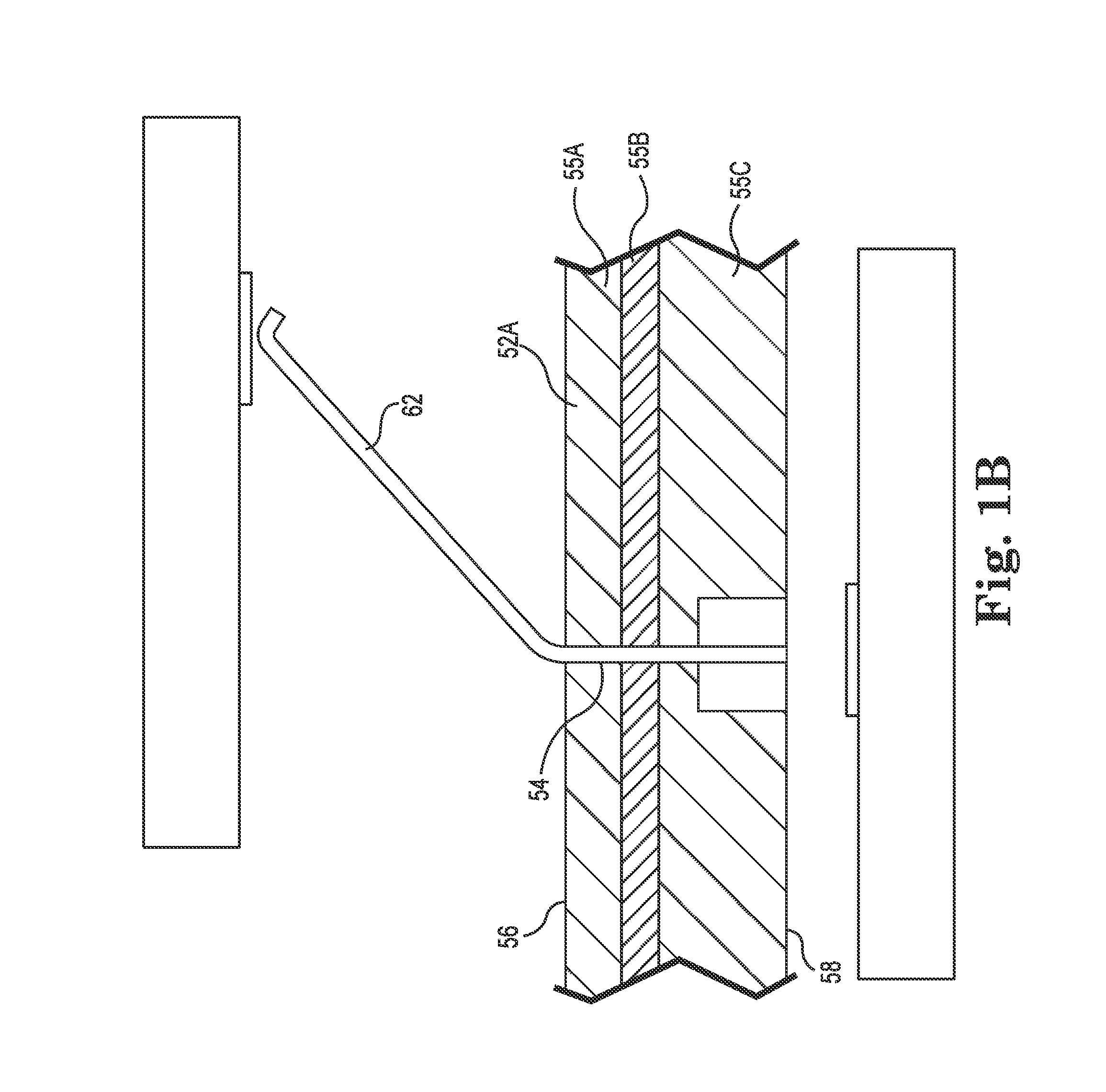

High performance surface mount electrical interconnect

ActiveUS20120055701A1Improve the substrateReduce complexityPrinted electric component incorporationFixed connectionsEngineeringMechanical engineering

An interconnect assembly including a substrate with a plurality of through holes extending from a first surface to a second surface. A plurality of discrete contact member are located in the plurality of through holes. The contact members include proximal ends that are accessible from the second surface, distal ends extending above the first surface, and intermediate portions engaged with an engagement region of the substrate located between the first surface and the recesses. Retention members are coupled with at least a portion of the proximal ends to retain the contact members in the through holes. The retention members can be made from a variety of materials with different levels of conductivity, ranging from highly conductive to non-conductive.

Owner:HSIO TECH

Method for forming high performance surface coatings and compositions of same

InactiveUS6410086B1Improve performanceHigh mechanical strengthPhotography auxillary processesElectrolysis componentsGas phaseCompound (substance)

A method of forming on an object a surface coating having a high mechanical strength and chemical and physical stability above 700° C. is disclosed. The method comprises (a) electrophoretically depositing at least one surface coating material on a surface of the object for obtaining a green coating on the surface; and (b) infiltrating into and depositing onto the green coating at least one additional surface coating material by a gas-phase infiltration / deposition method, thereby forming a high performance surface coating, wherein, the at least one surface coating material and the at least one additional surface coating material are chemically and physically stable above 700° C.

Owner:CEREL CERAMIC TECH +1

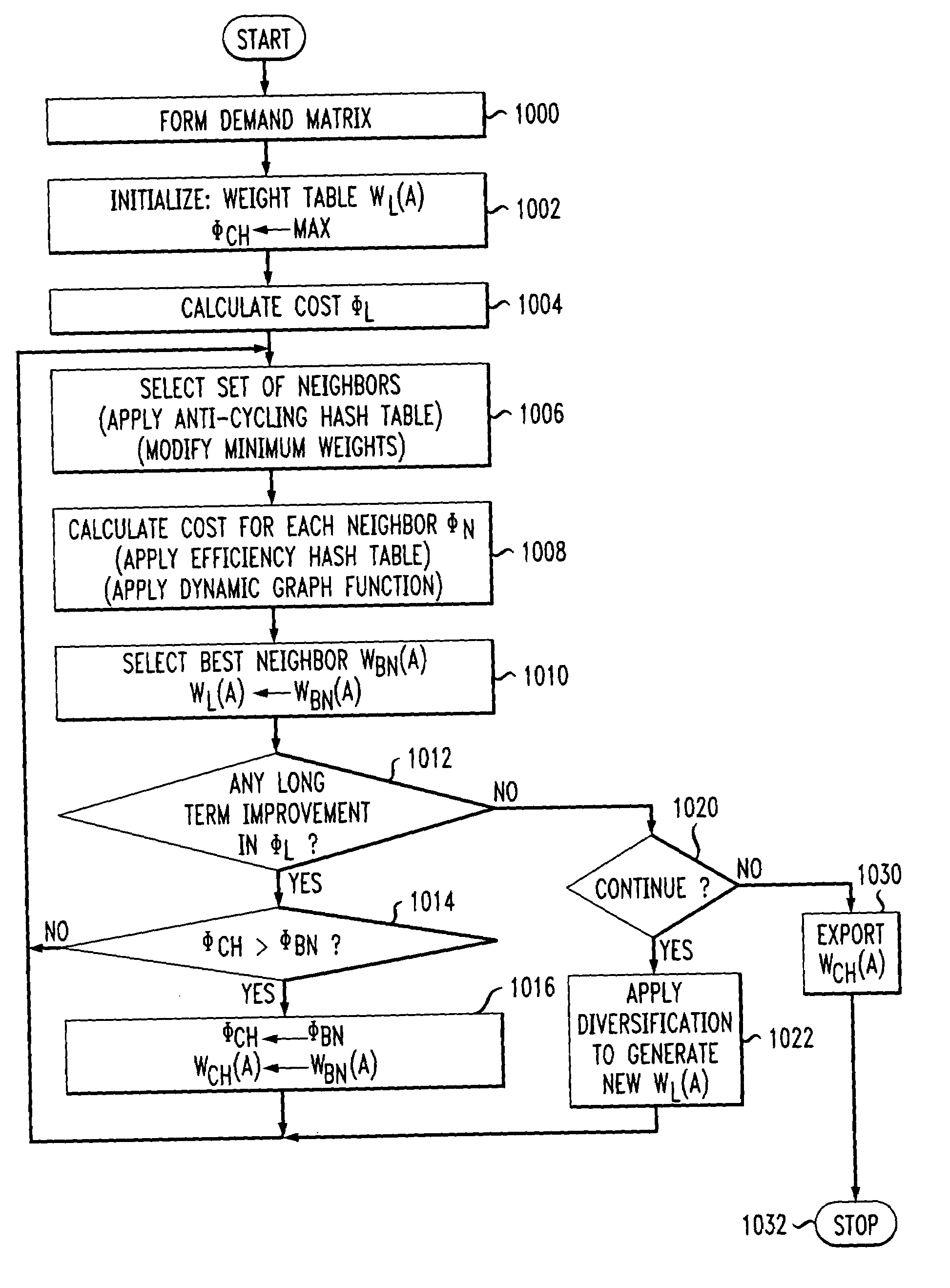

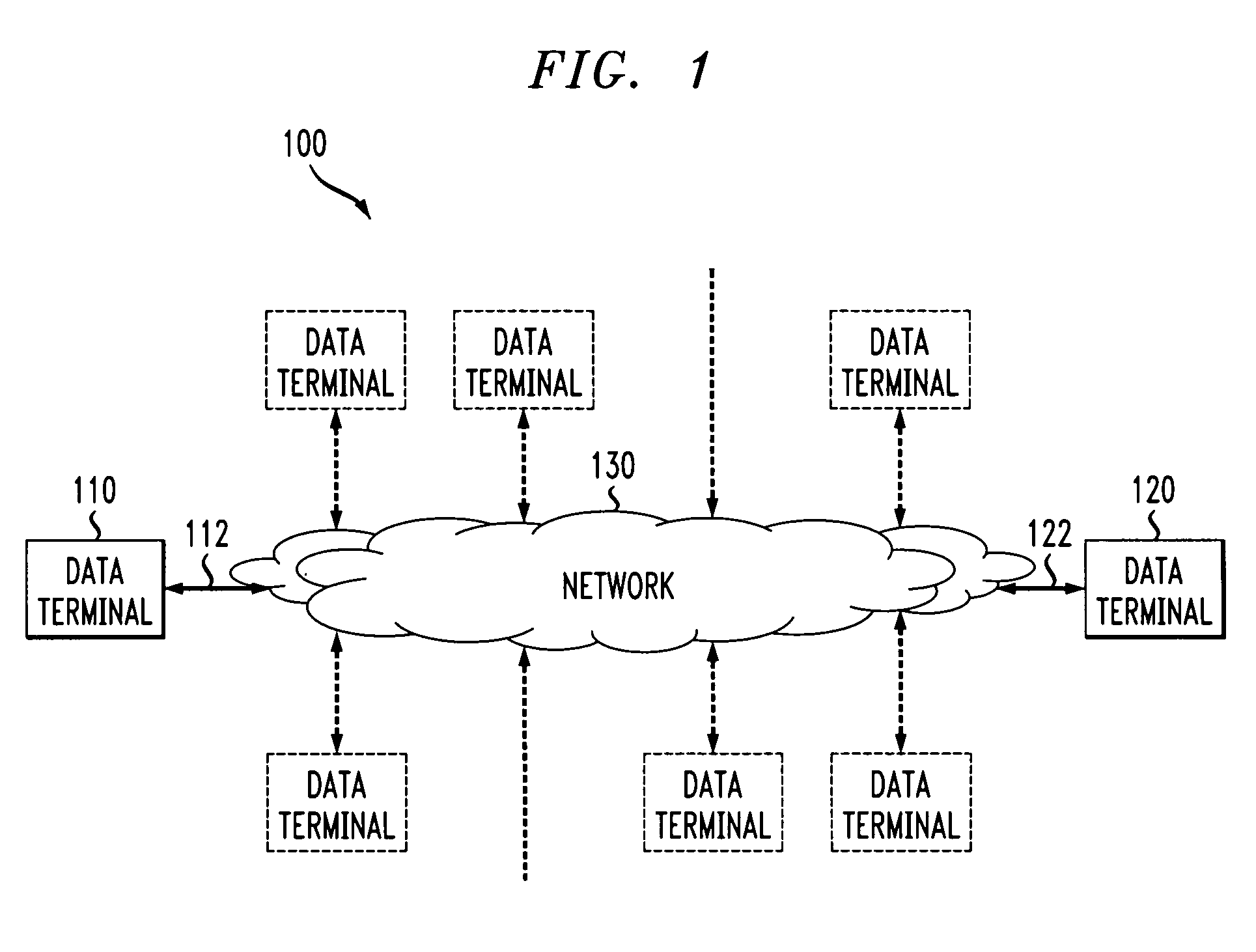

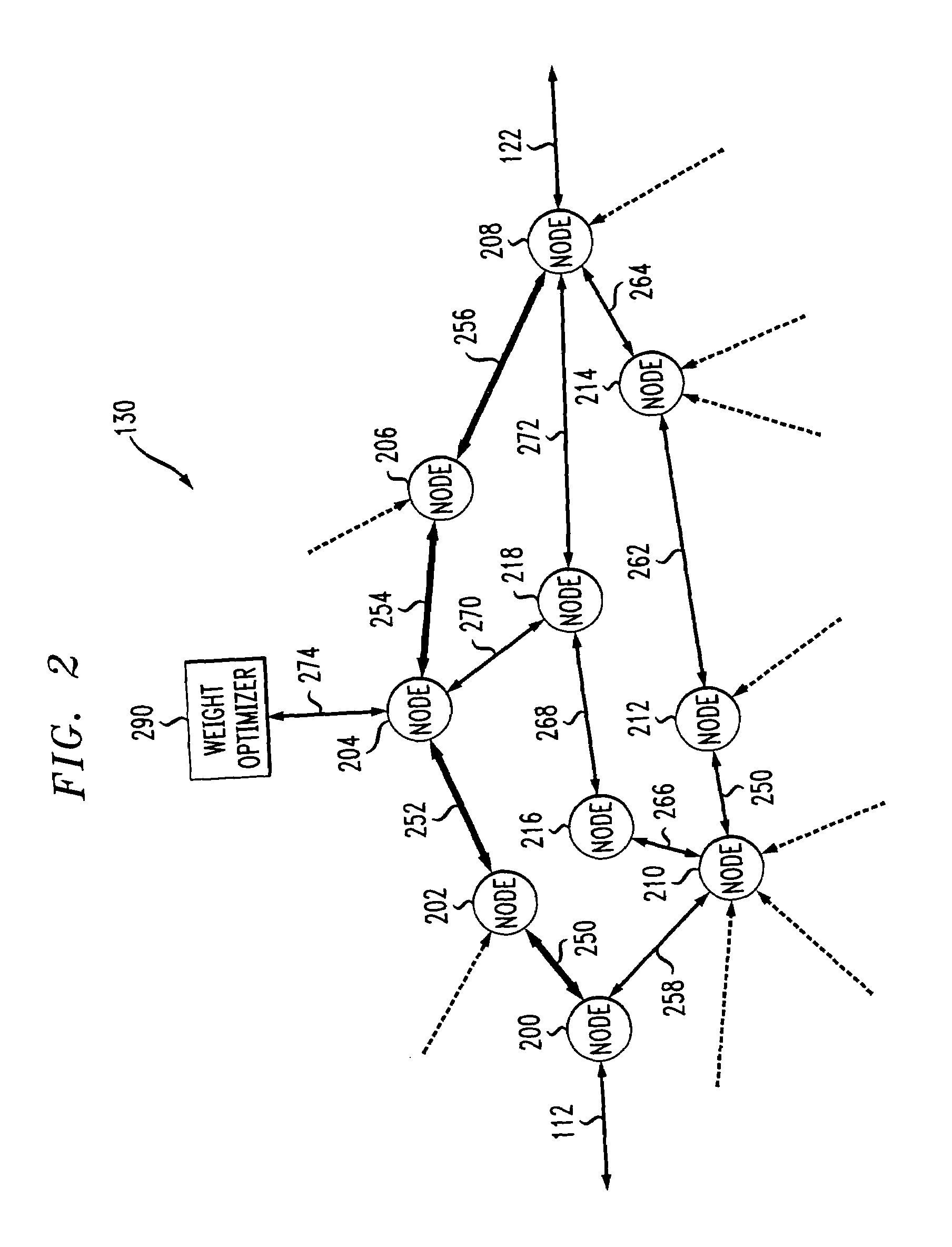

Methods and systems for optimizing network traffic

InactiveUS7185104B1Quickly and efficiently searchedError preventionTransmission systemsTraffic capacityGraphics

The present invention provides methods and systems for evaluating network traffic. By generating successive sets of weights relating to a performance surface using a variety of heuristic techniques, and then evaluating the weights using a piece-wise linear cost function, a number of performance minima can be found. By continuously searching the performance surface, a champion minimum can be extracted. Searching the performance surface can be quickly and efficiently accomplished using a variety functions such as an anti-cycling function, an impatience function, a dynamic graph technique and a diversity process.

Owner:AMERICAN TELEPHONE & TELEGRAPH CO

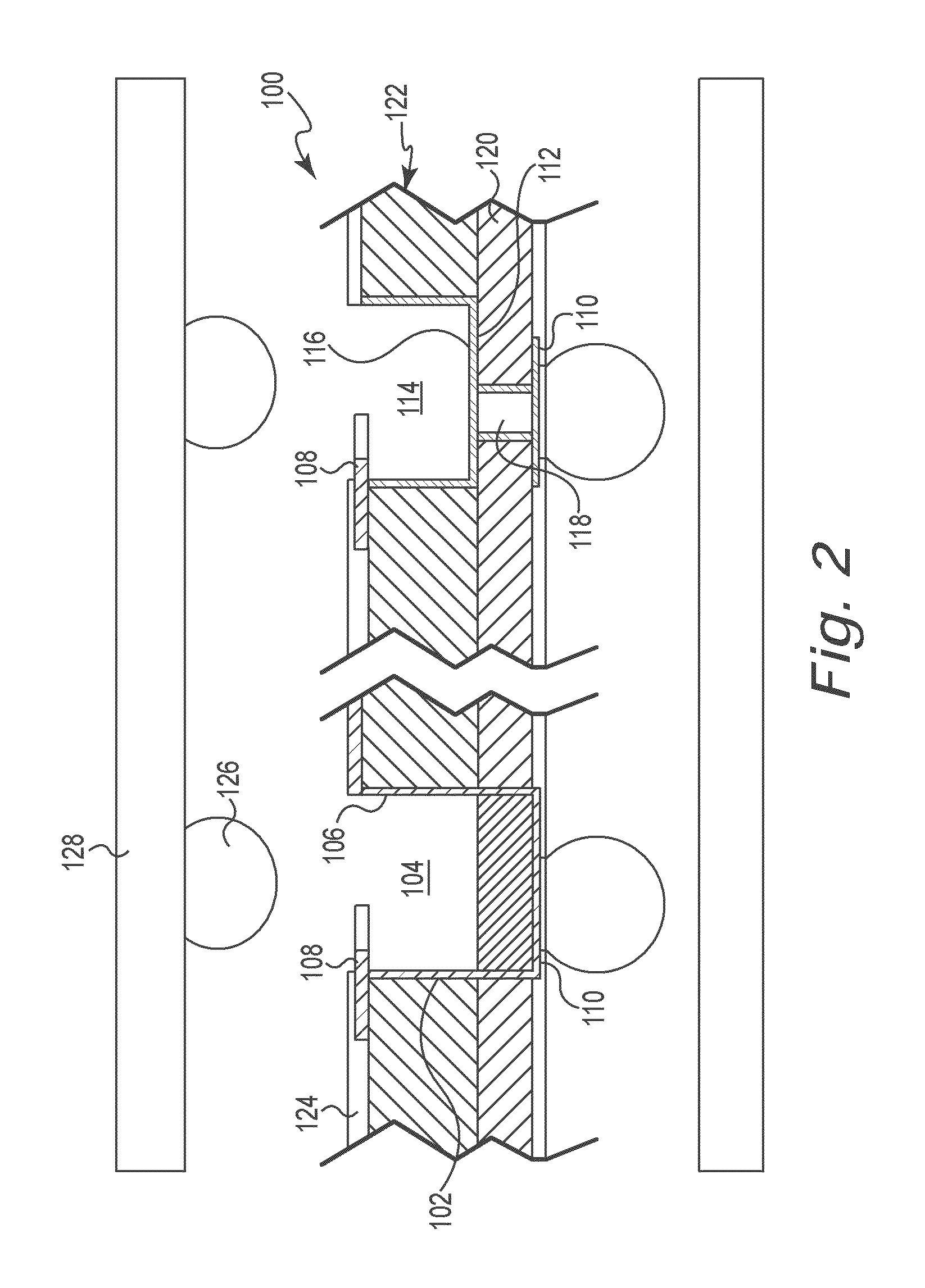

High performance surface mount electrical interconnect

ActiveUS8955215B2Reduce complexityFirmly connectedCoupling device connectionsPrinted circuit assemblingEngineeringMechanical engineering

A method of forming an interconnect assembly including forming a substrate with a plurality of through holes extending from a first major surface to a second major surface. A plurality of recesses are formed in the second major surface of the substrate that at least partially overlap with the plurality of through holes. The recesses have a cross-sectional area greater than a cross-sectional area of the through holes. At least one discrete contact member is inserted in a plurality of the through holes. The contact members include proximal ends extending into the recesses, distal ends extending above the first major surface, and intermediate portions engaged with an engagement region of the substrate located between the first major surface and the recesses. Retention members at least partially deposited in the recesses bond to the proximal ends to retain the contact members in the through holes.

Owner:HSIO TECH

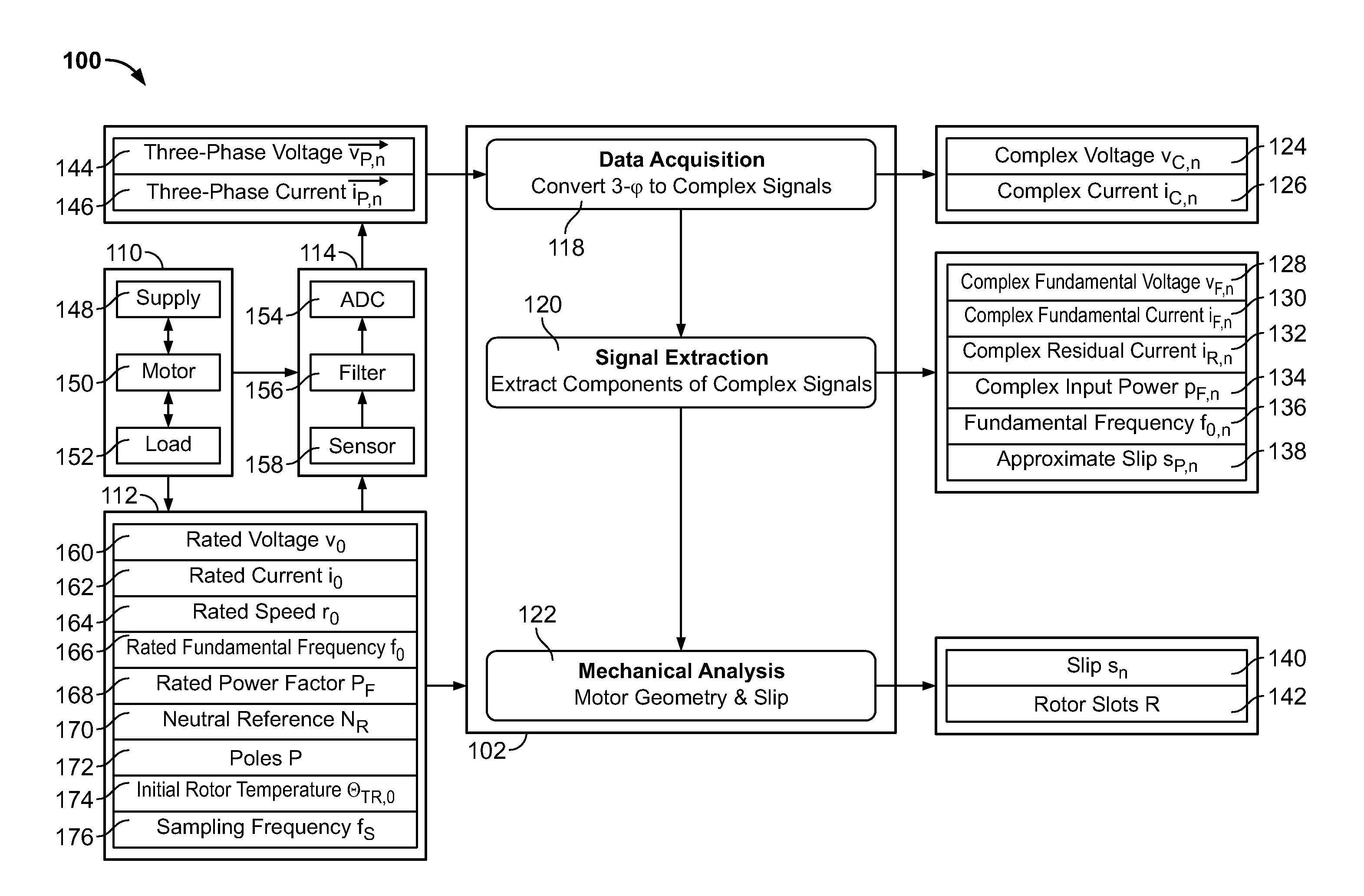

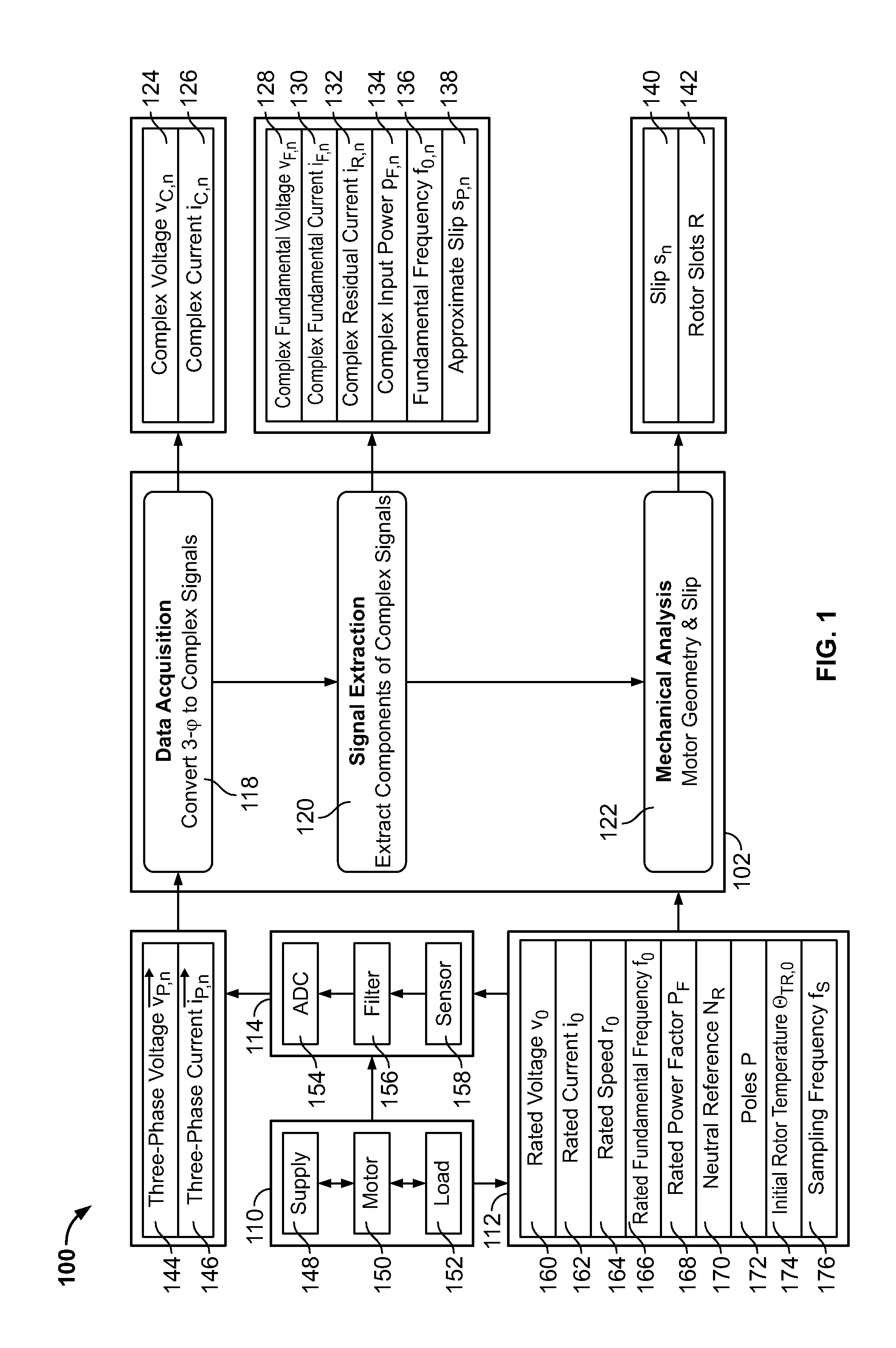

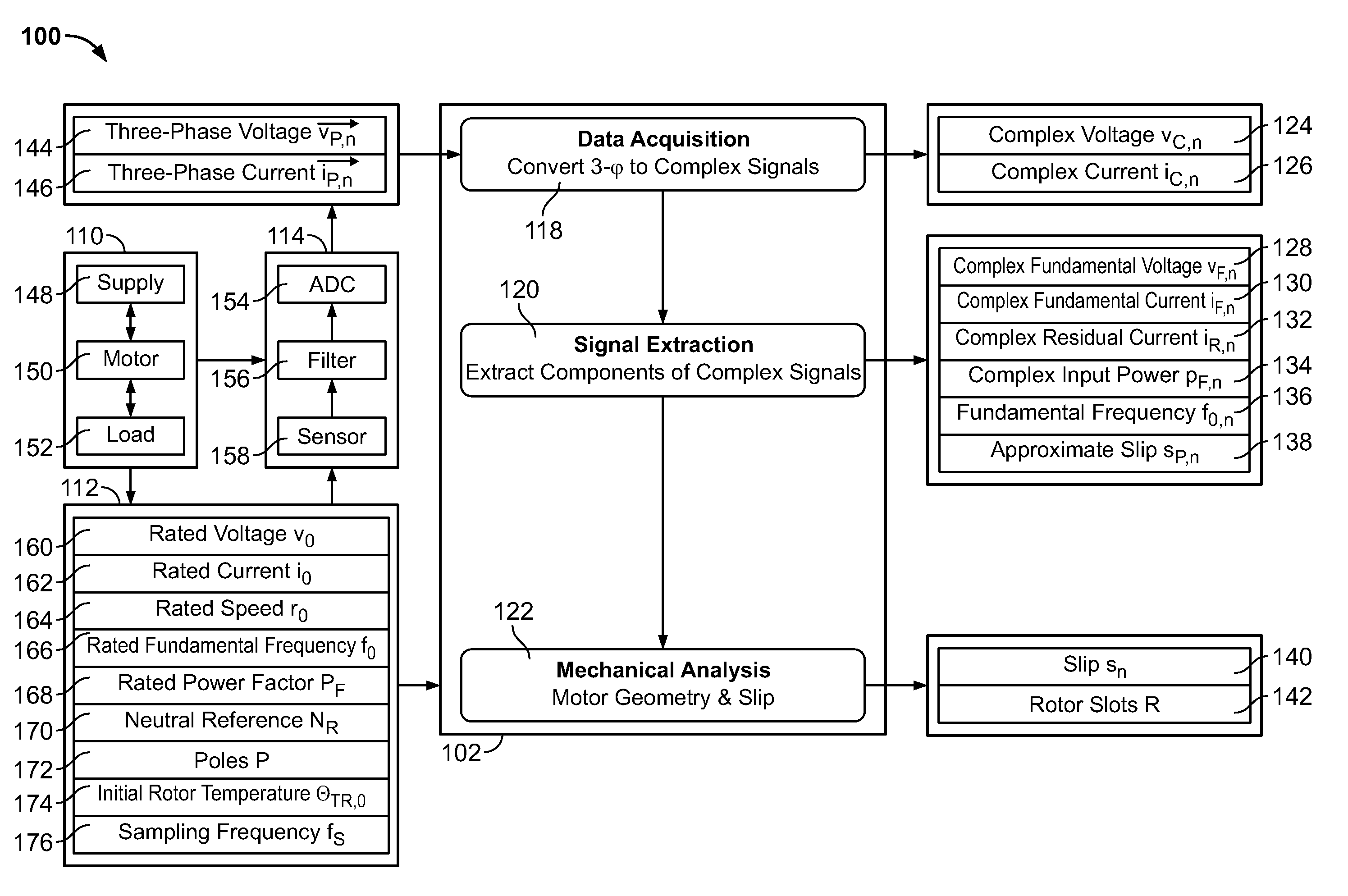

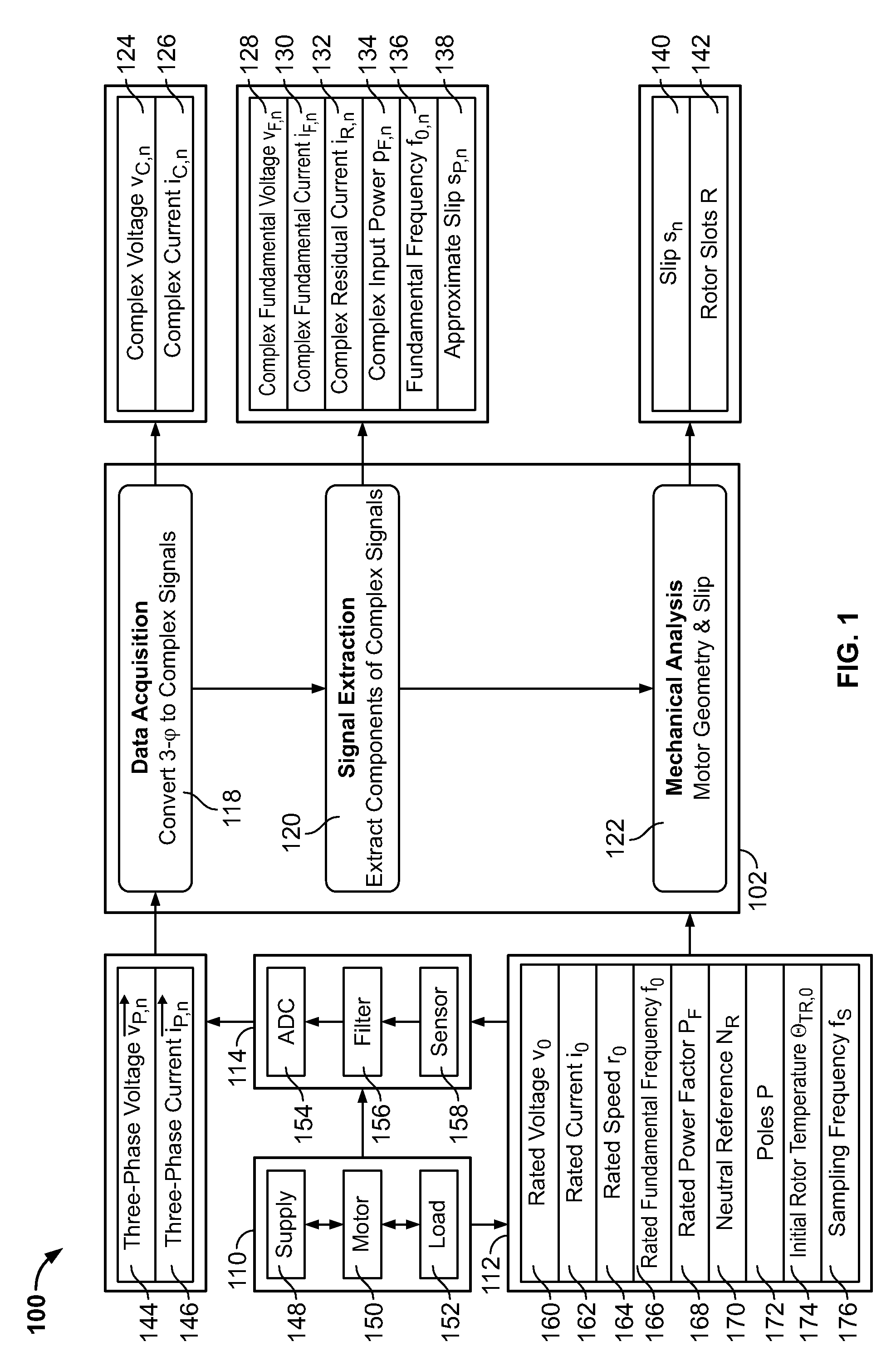

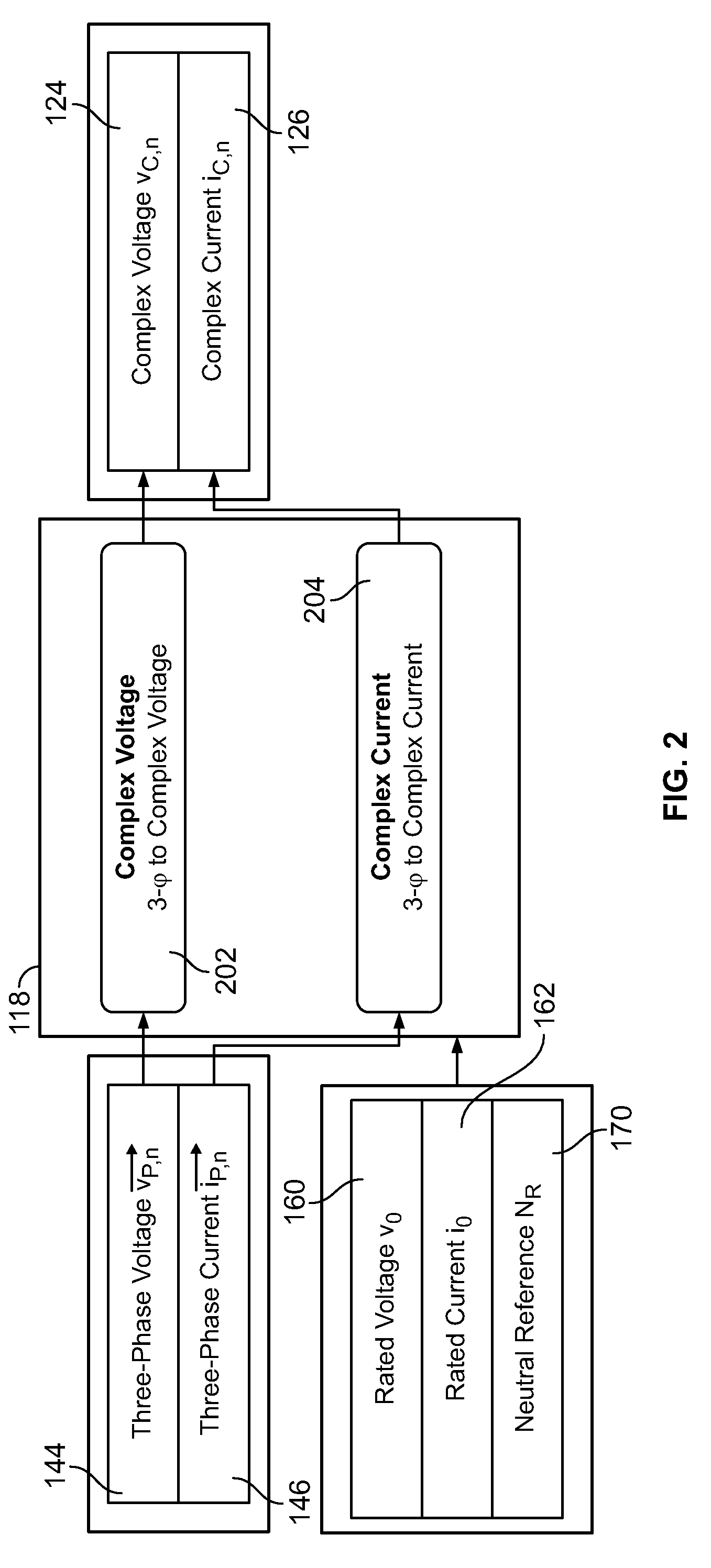

Methods and apparatus for estimating rotor slots

ActiveUS20090287463A1Robust and accurate estimationImprove transient responseElectrical testingComputation using non-denominational number representationInduction motorFundamental frequency

A method of determining a quantity of rotor slots in an induction motor through analysis of voltage and current signals. An approximate slip is calculated according to an approximate slip function that is independent of a rotor slots quantity. A fundamental frequency is calculated from a representation of the voltage signal. A saliency frequency is calculated from a representation of the current signal. For each rotor slots index in a set of rotor slots indices, a slip estimate is calculated according to a slip estimation function that includes the saliency frequency, a saliency order, the fundamental frequency, a rotor slots index in the set of rotor slots indices, and a quantity of poles of the motor, such that the slip estimate is evaluated at respective ones of the set rotor slots indices. A slip estimation error signal is calculated according to a slip estimation error function that includes a difference between the approximate slip and respective ones of the slip estimates. A rotor slots performance surface representative of an aggregate of the slip estimation error signals evaluated over the set of the rotor slots indices is calculated. A rotor slots quantity equal to the rotor slots index corresponding to a minimum of the rotor slots performance surface over at least a portion of the set of the rotor slots indices is defined.

Owner:SCHNEIDER ELECTRIC USA INC

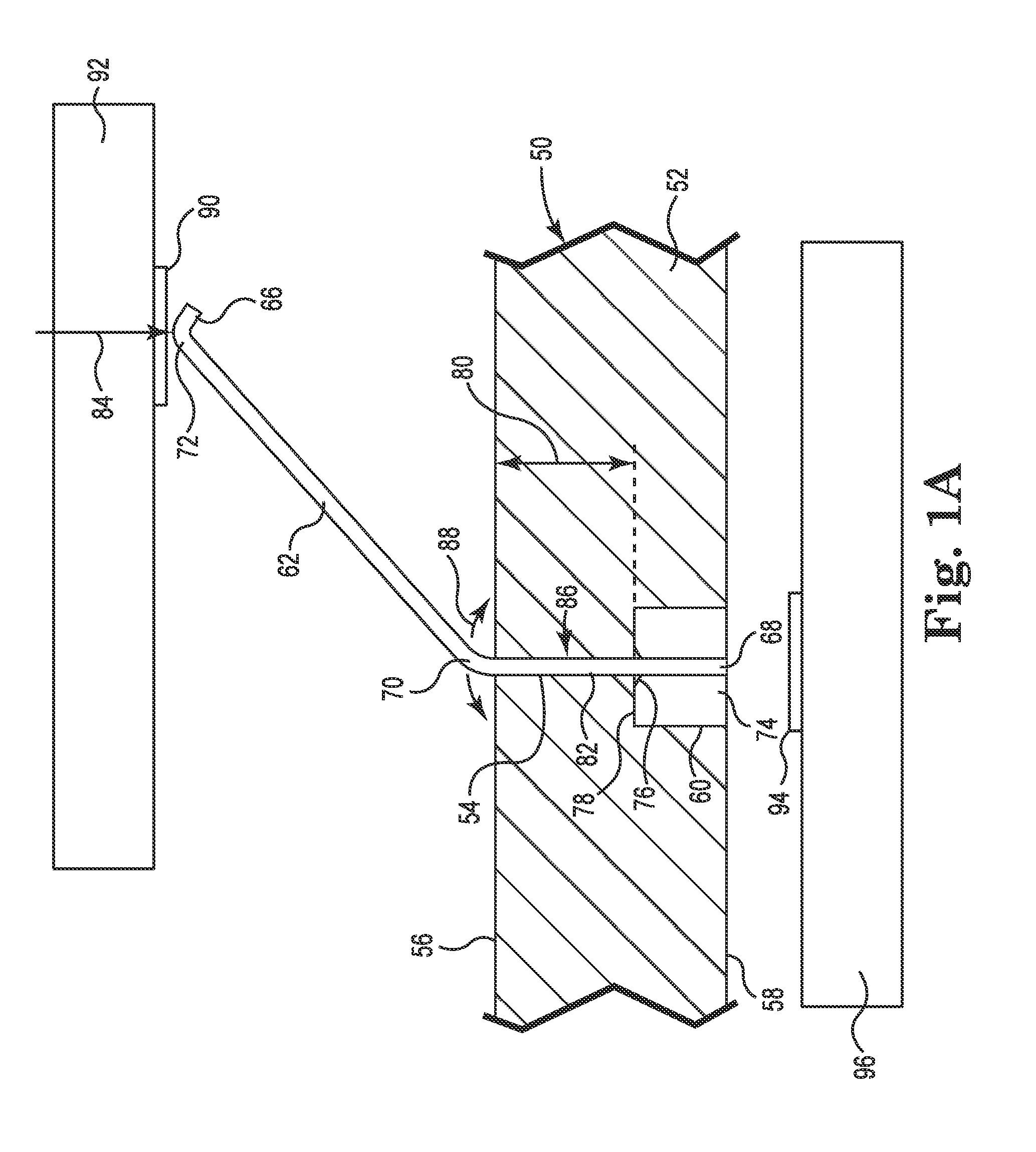

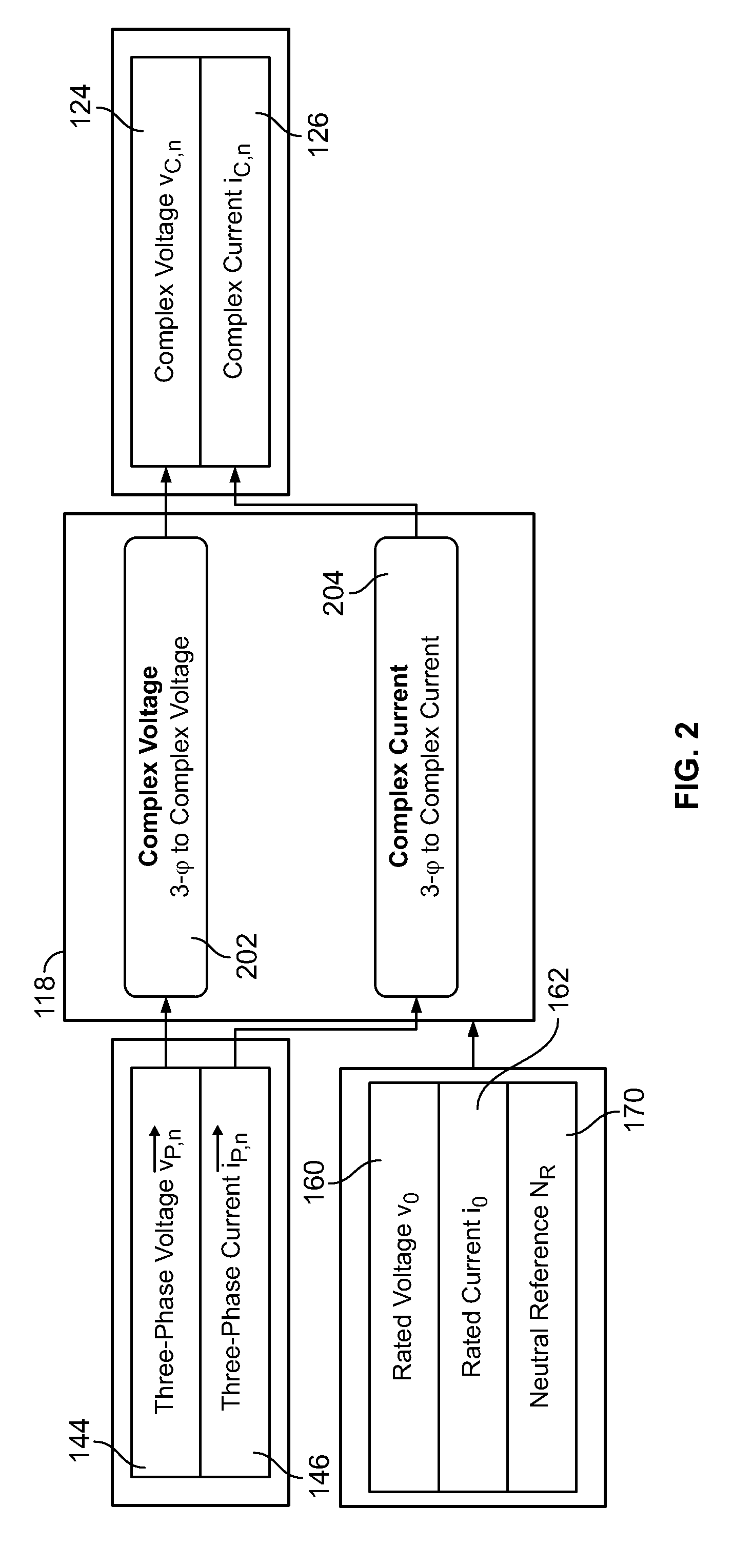

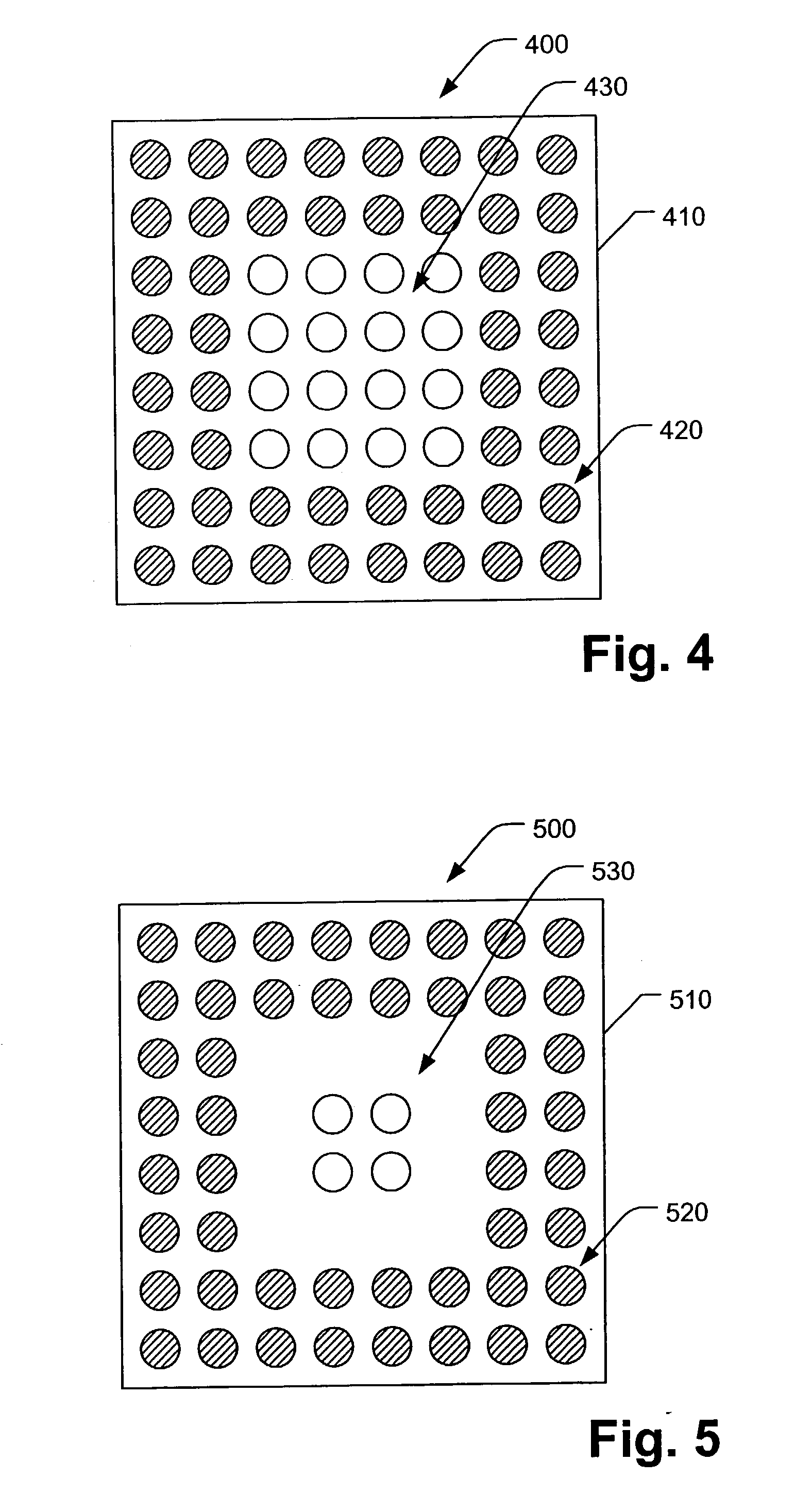

Second level packaging interconnection method with improved thermal and reliability performance

InactiveUS20030202332A1Improved reliability performanceImprove cooling effectPrinted circuit assemblingFinal product manufactureSurface mountingInterconnection

Surface mount packages having a plurality of polymer and metallic contacts (e.g., balls) applied thereon and methods of fabricating and utilizing such packages are provided. The polymer balls are employed to improve mechanical compliance of the package; and the metallic (e.g., copper) balls are employed to improve thermal conduction between the package and a substrate to which the package is attached. The polymer balls can be located on a periphery portion of a package where mechanical and thermal stresses are the highest; and the metallic balls can be located on a middle portion of the package. Thus the present invention improves both mechanical stresses and thermal conductivity of a second level packaging interconnection, which in turn improves reliability of an electronic device.

Owner:NOKIA CORP

Composite heating wire for electronic cigarettes

InactiveCN106072775AAffect the electrothermal performanceReasonable control of electric heating performanceVacuum evaporation coatingSputtering coatingChemical reactionMetal alloy

The invention provides a composite heating wire for electronic cigarettes. The composite heating wire comprises a core part and a shell part arranged on the outer surface of the core part; the core part is a linear metal heating wire; the shell part comprises at least one inorganic film layer. According to the composite heating wire, the inorganic film layer with chemical inertness covers on a metal alloy heating surface, so that oil fume is prevented from directly contacting metal alloy, chemical reactions between the metal alloy heating wire with chemical activity and oil fume can be effectively prevented, and charring gas and electrothermal property influencing the heating wire can be avoided; furthermore, the heating wire is only a diameter performance surface, and the thickness of the inorganic film layer is reasonably controlled, so that the heating efficiency and flexibility of the composite heating wire can be guaranteed, and the composite heating wire is highly compatible with an existing electronic cigarette structure.

Owner:杭州森翼科技有限公司

High performance surface mount electrical interconnect with external biased normal force loading

ActiveUS9196980B2Low enough forceEasy to disassembleCoupling device connectionsResistor terminals/electrodesContact padSurface mounting

Owner:RATHBURN JAMES

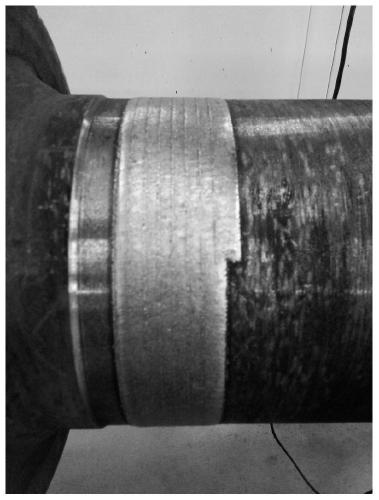

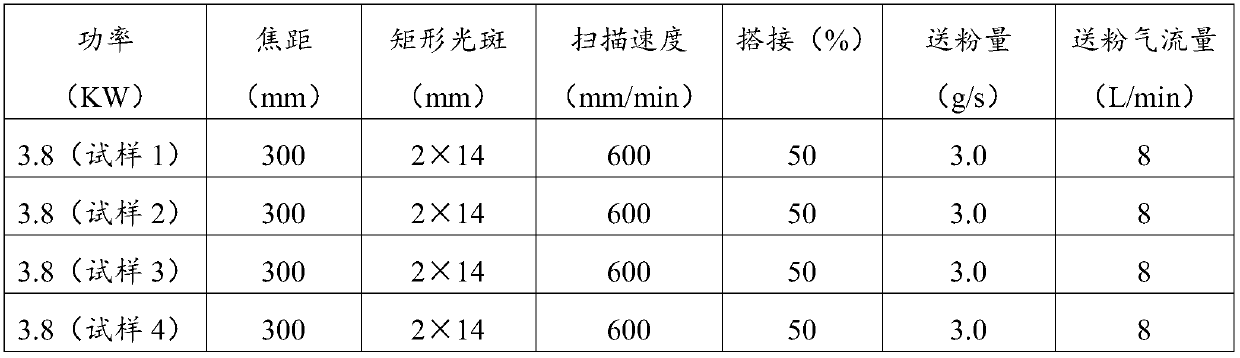

Laser cladding method for bearing position of cast iron roller and alloy powder for laser cladding

InactiveCN110257826AIncrease work intensityExtend working lifeMetallic material coating processesWorking lifeEconomic benefits

The invention relates to a laser cladding method for a bearing position of a cast iron roller and alloy powder for laser cladding, wherein the alloy powder for the laser cladding comprises, by mass: Mn: 0.32%-0.43%, B: 1.2%-1.3%, Cr: 12.5%-16.5%, C: 0.03%-0.08%, Si: 0.62-0.8%, and the balance Fe. The alloy powder can be used for preparing a high-performance surface alloy layer on a low-cost cast iron roller bearing position base material, metal is endowed with good wear resistance, corrosion resistance and other properties and the service life of the repaired bearing position is greatly prolonged. By adopting the alloy powder for the laser cladding and combining a cladding alloy layer formed by the corresponding laser cladding method for the bearing position of the cast iron roller, good metallurgical bonding can be formed between the alloy powder and the surface of a cast iron roller bearing position base body after laser cladding processing, good toughness, strength and wear resistance are achieved, laser cladding repair of the cast iron roll bearing position after wear is effectively realized, and defects of cracks, air holes and the like are avoided, therefore, the working strength and the working life of the cast iron roller are improved, and remarkable economic benefits are achieved.

Owner:YANSHAN UNIV

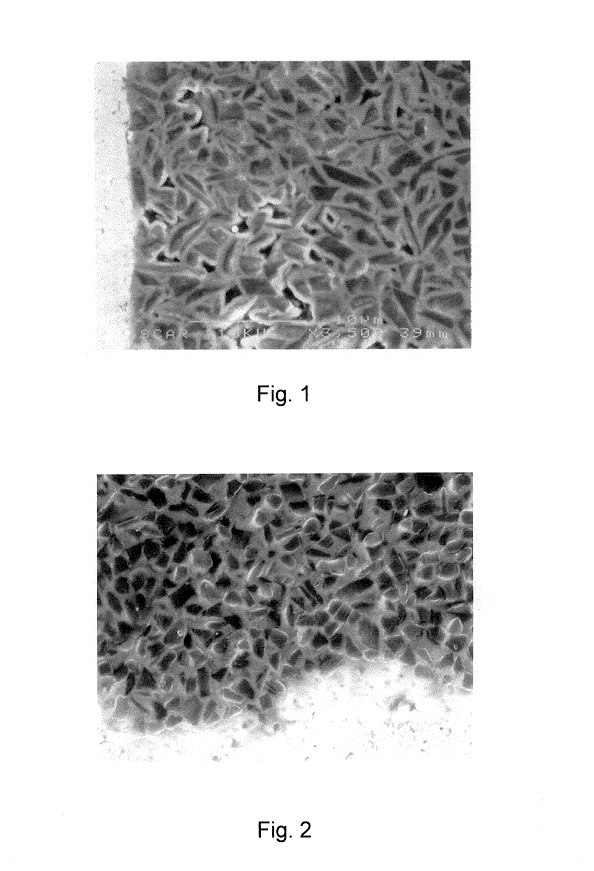

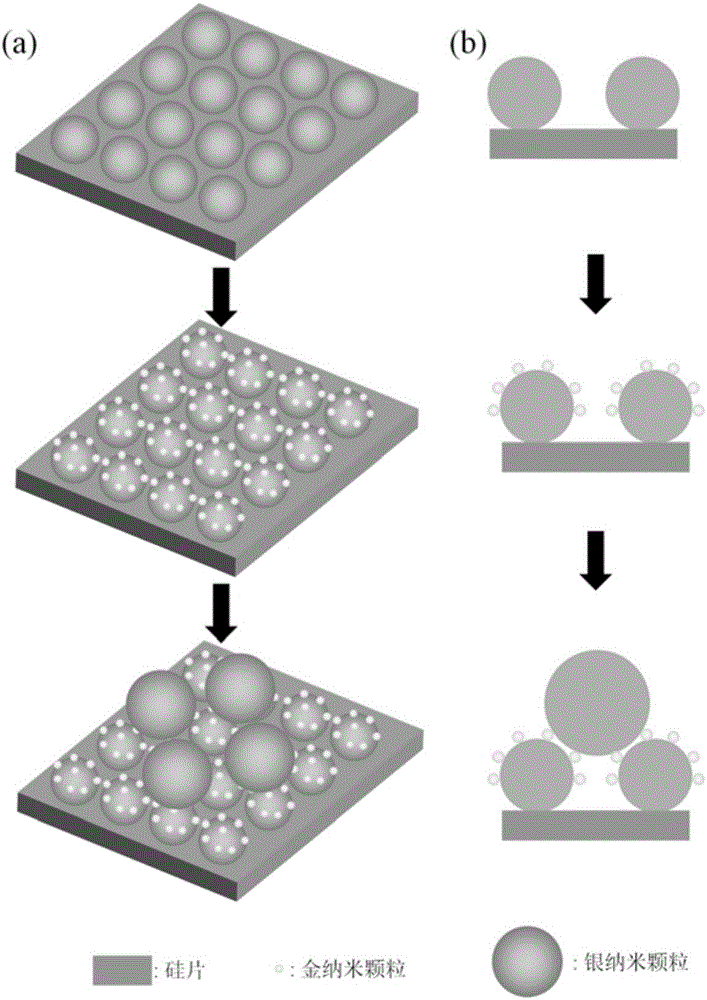

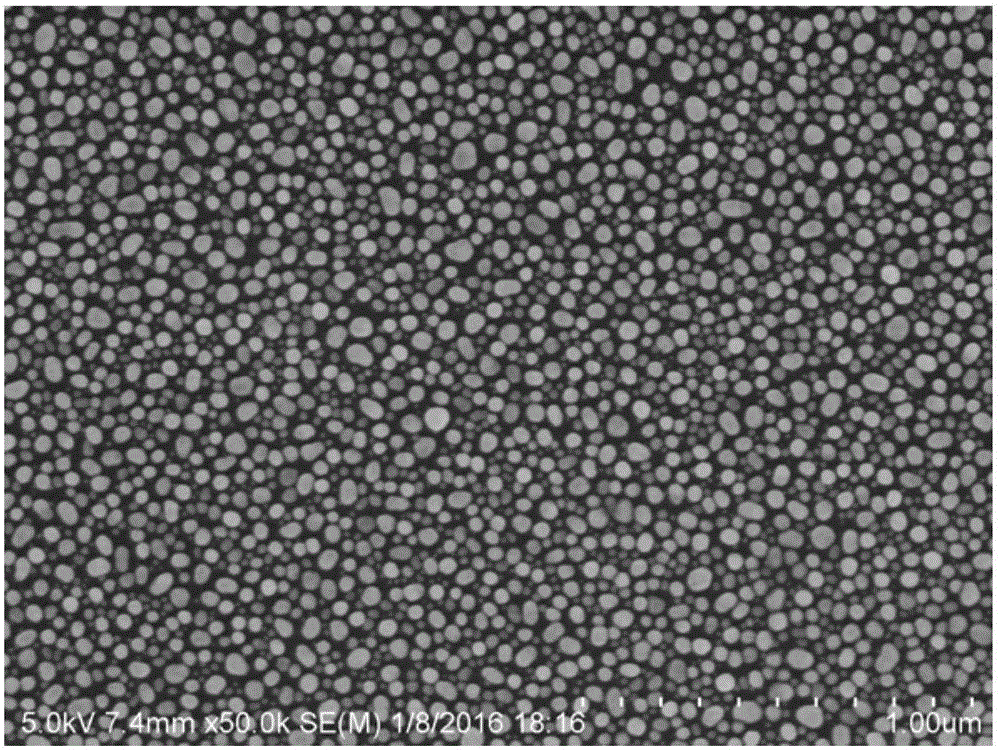

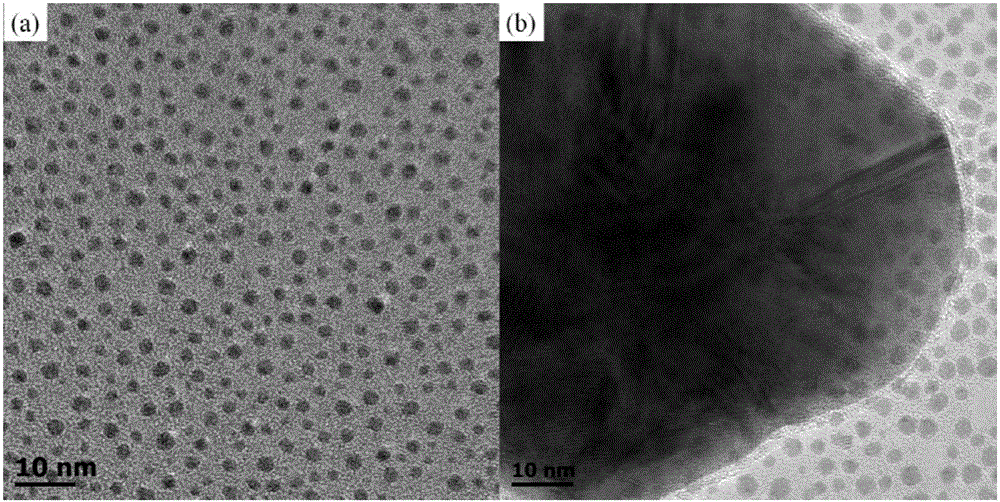

Surface enhanced Raman spectrum substrate with nano gap and preparation method thereof

ActiveCN105911044AHigh sensitivityMaterial nanotechnologyRaman scatteringSurface-enhanced Raman spectroscopySpins

The invention discloses a surface enhanced Raman spectrum substrate with a nano gap and a preparation method thereof. The surface enhanced Raman spectrum substrate with the nanometer gap is composed of first-layer silver nanoparticles attached on a monocrystal silicon slice and having the surface loaded with gold nanoparticles and second-layer silver nanoparticles spin-coated on the first-layer silver nanoparticles. By depositing a certain size and distribution of gold nanoparticles, the nano gap is formed between the two layers of silver nanoparticles. The surface enhanced Raman spectrum substrate with the nano gap is used for detecting 4-pyridinethiol molecules in an ethanol solution, the obtained Raman spectrum signal intensity is two times that of a substrate without gold nanoparticles. The invention provides a means for preparing the nano gap to enhance the surface enhanced Raman spectrum signal, and the reference significance is provided for preparation of the high-performance surface enhanced Raman spectrum substrate.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

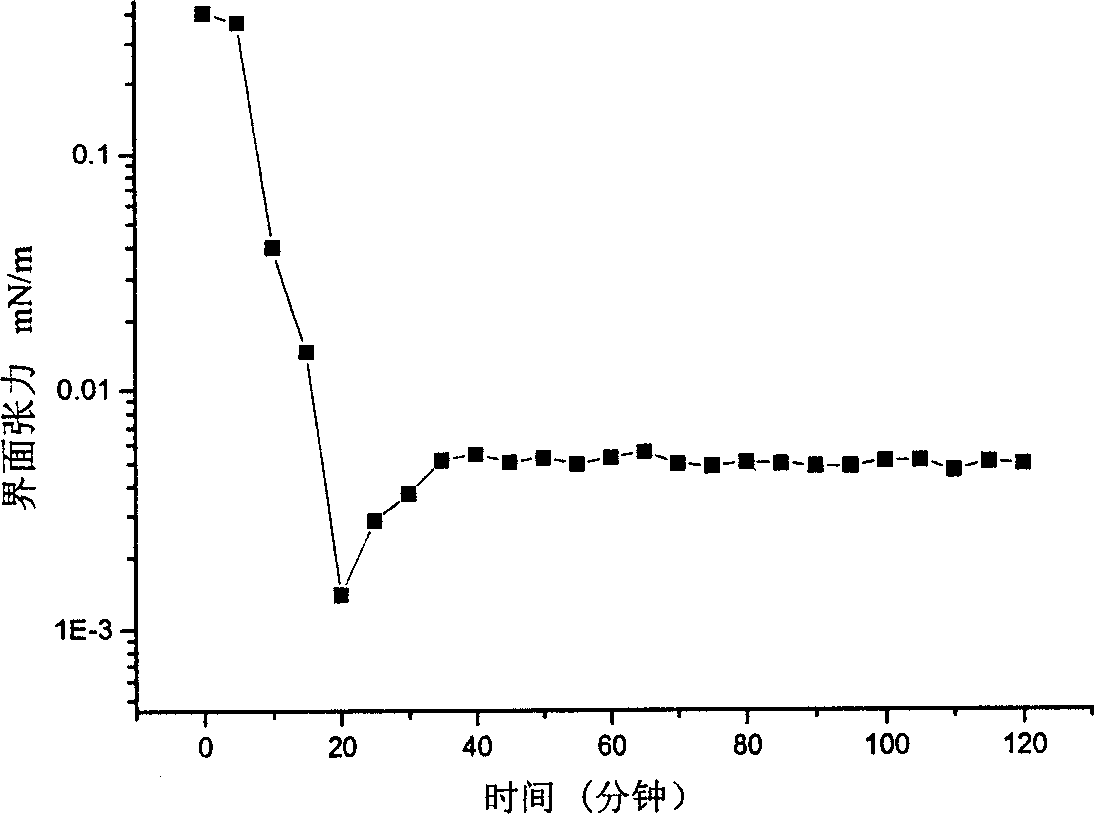

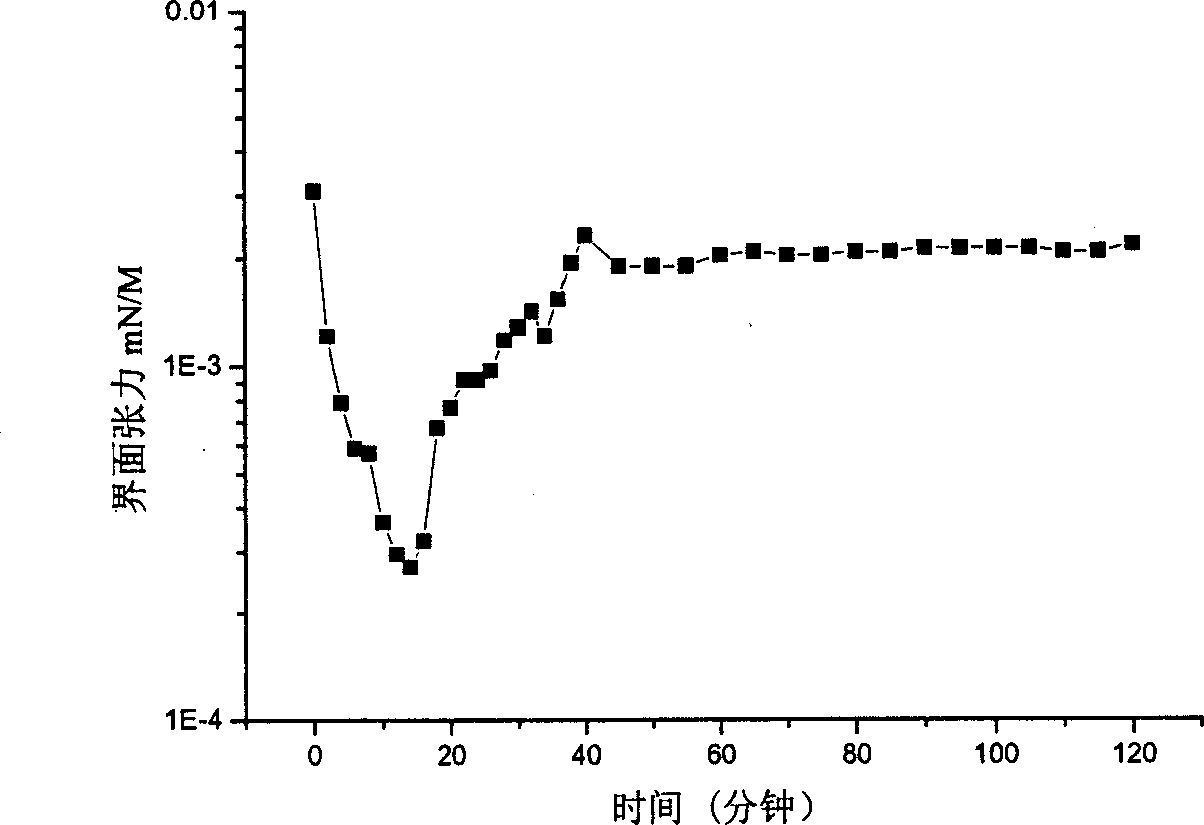

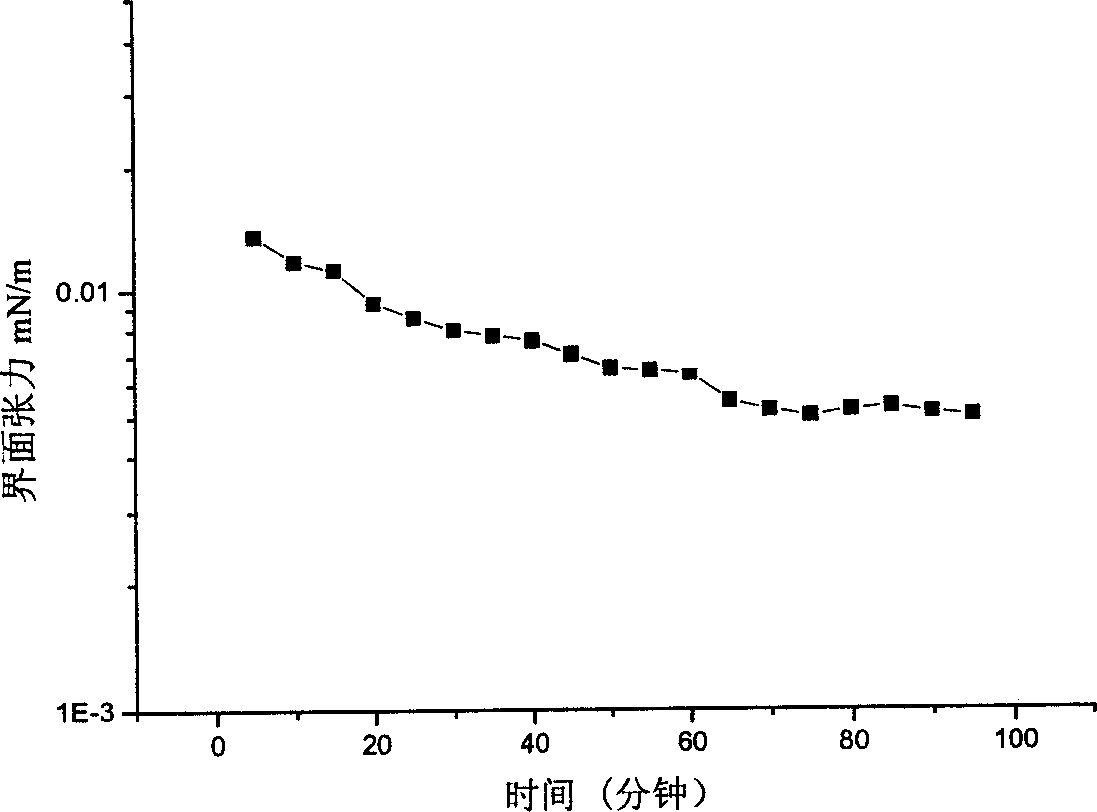

Guerbet anion surfactant, and its preparing method and use

InactiveCN1891807ASurface-active detergent compositionsTransportation and packagingAlkaline earth metalSulfate radicals

The invention relates to Guerbet cathode surface activating agent and the manufacture method and the application. Guerbet (carbon atom quantity is 12-20) mellow would form a cathode surface activating agent after a series of reaction. The agent has 12-20 carbon quantity hydrophobic group and different quantities C2H40 group. The feature of hydrophobic group is that Y shaped molecular structure is formed from the beta carbon atom with alkyl substituent. The hydrophilic group is sulphoacid radical, sulfate radical or alkali metal of carboxylic acid radical, alkali earth metal or ammonium salt. The good performance surface activating agent system would be gained after taking research to the aqueous solution, simulating oil, and the interfacial tension between raw oil.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

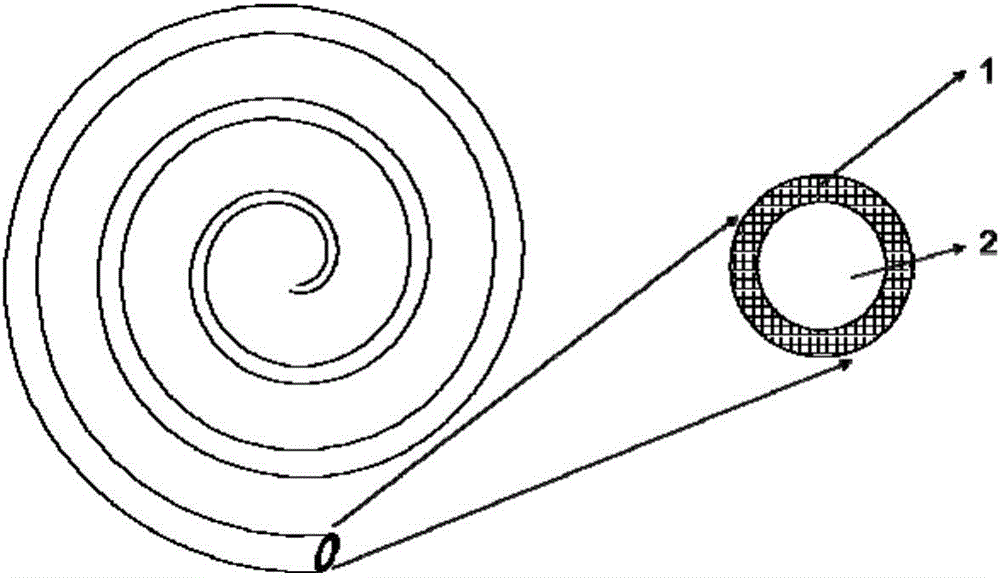

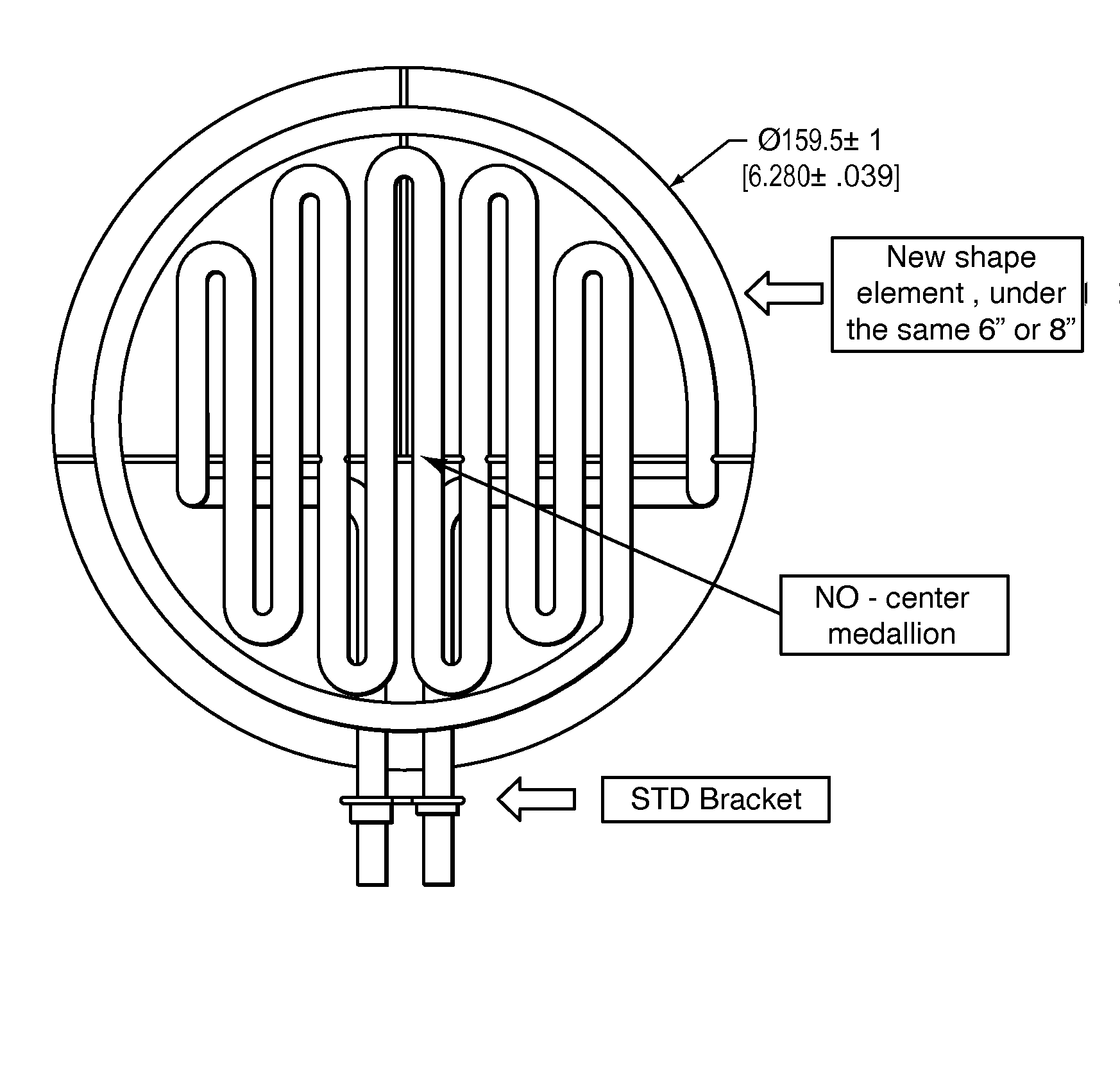

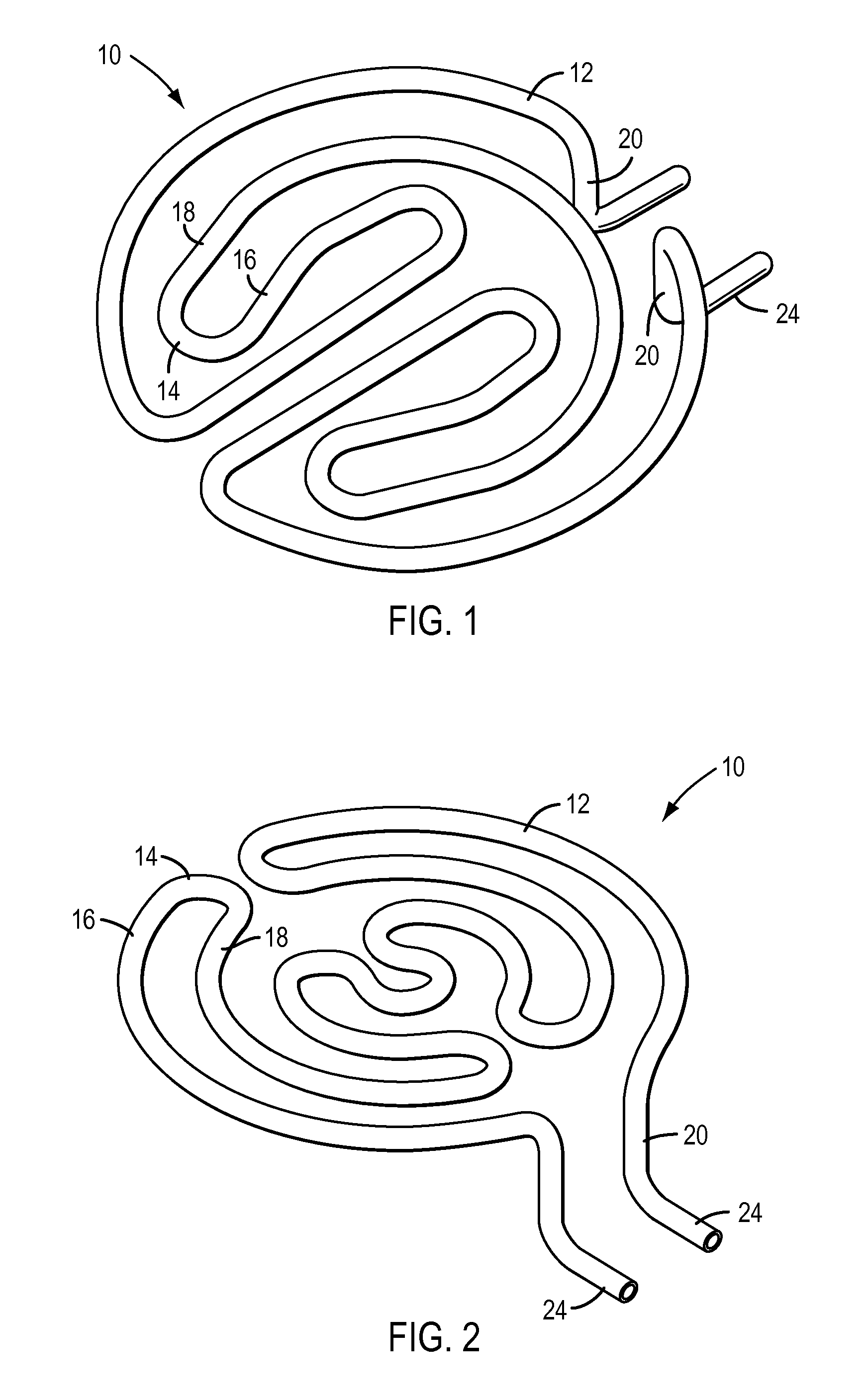

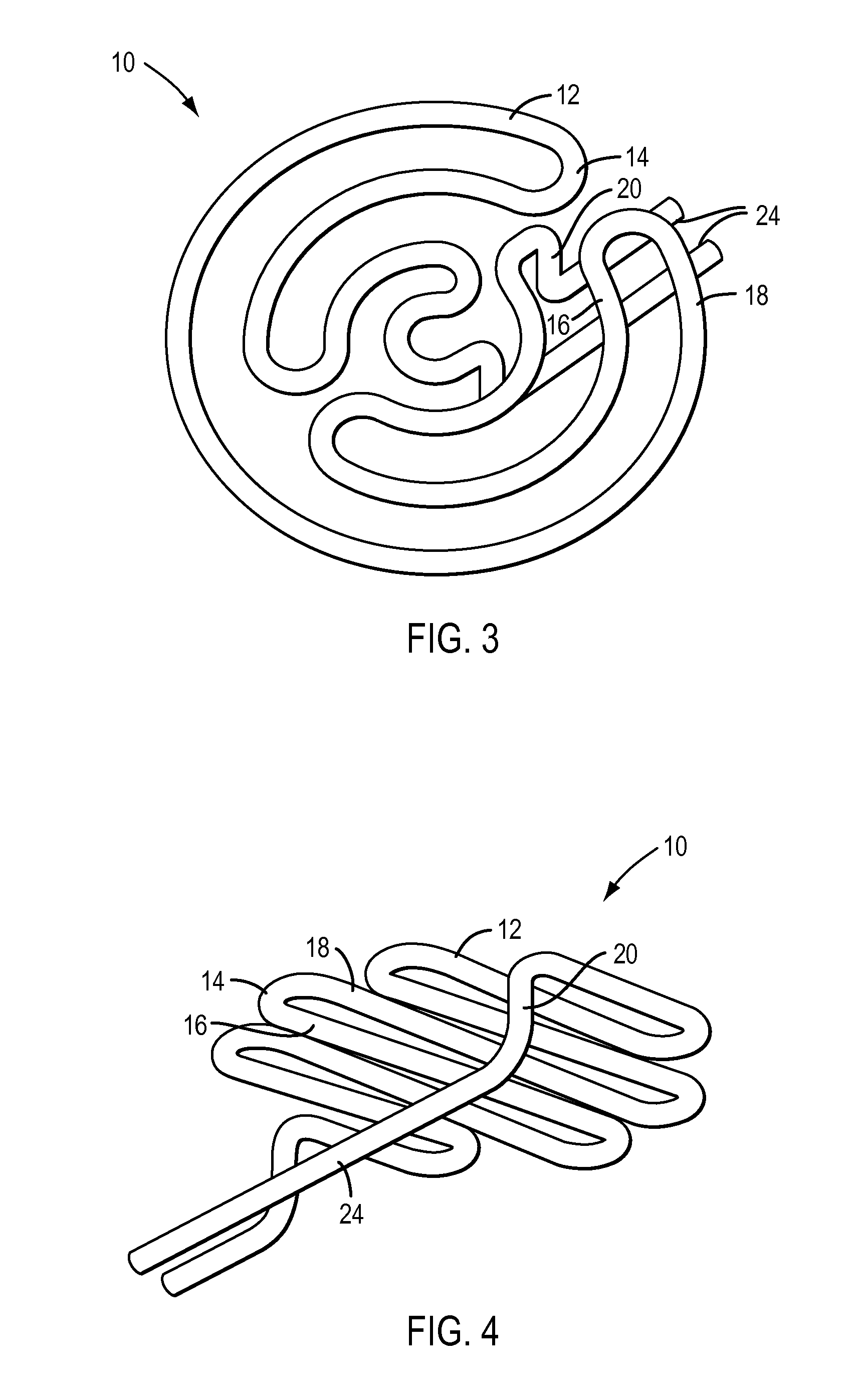

High performance surface unit for heating

InactiveUS20160010873A1Heating evenlyDomestic stoves or rangesLighting and heating apparatusElectrical resistance and conductanceEngineering

A horizontal electrical resistance heater is provided with an elongate wire heating element having a geometry with at least three turnarounds that change a direction of travel of the wire heating element. The turnarounds are integral sections of the heating element. Each turnaround couples a first section of a heating element to a second section of the heating element with at least portions of the first and second sections having a same parallel geometry which can include curved sections and linear sections. The wire heating element has a planar top surface and a planar bottom surface and provides uniform heating through the elongate wire heating element. First and second ends of the heating element are configured to be coupled to an electrical power source. At least one insulator can be included.

Owner:ZOPPAS IND DE MEXICO S A DE

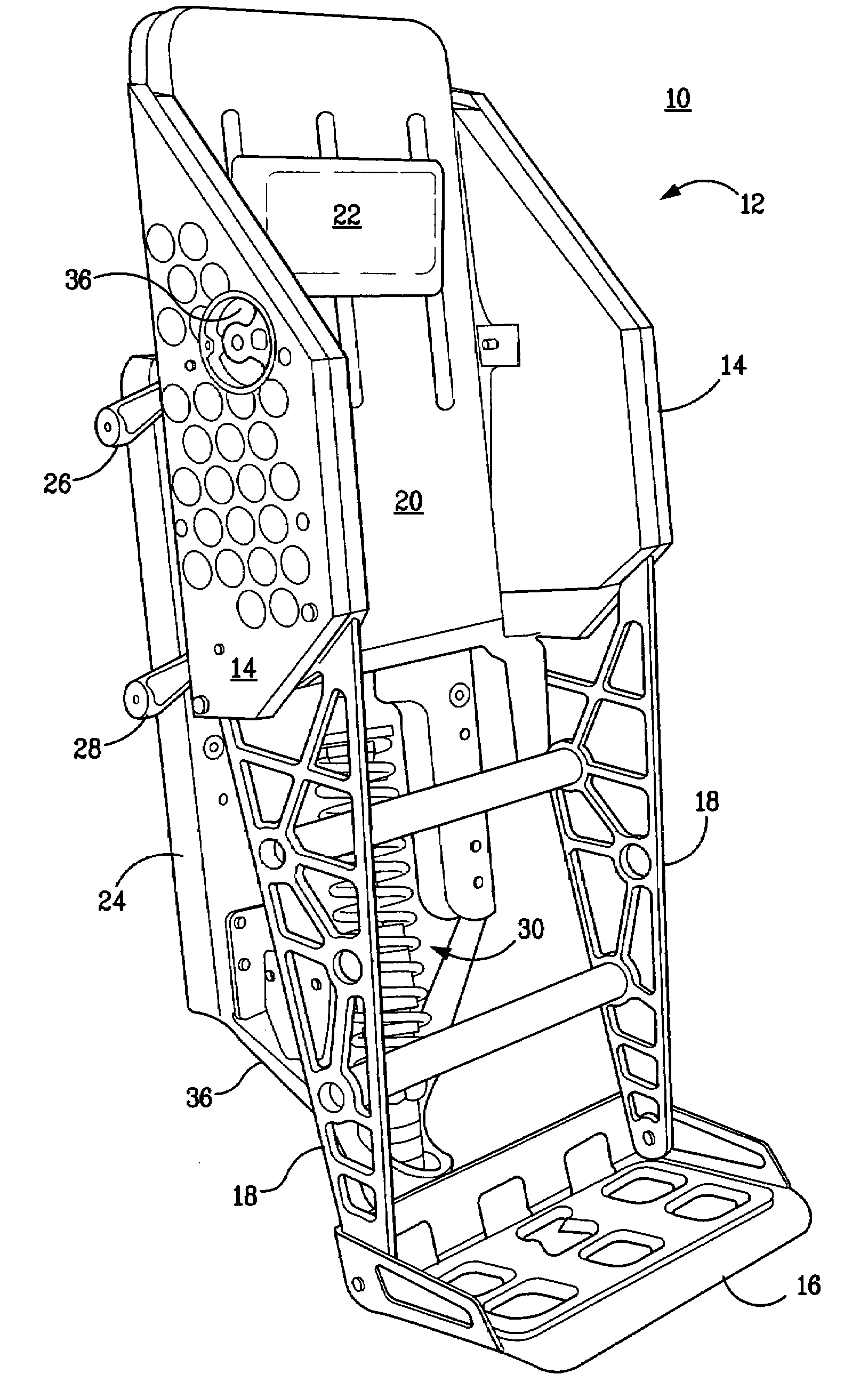

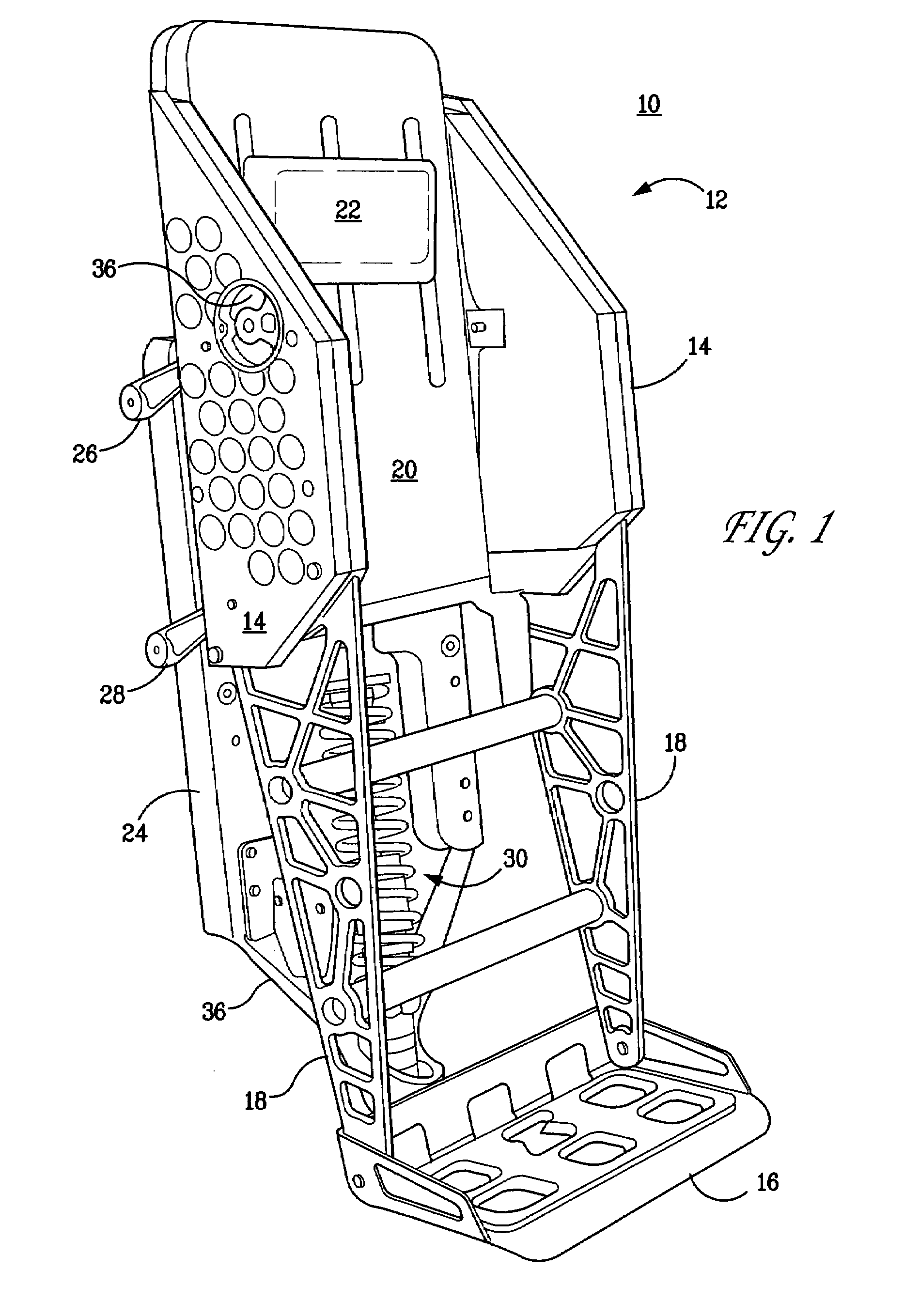

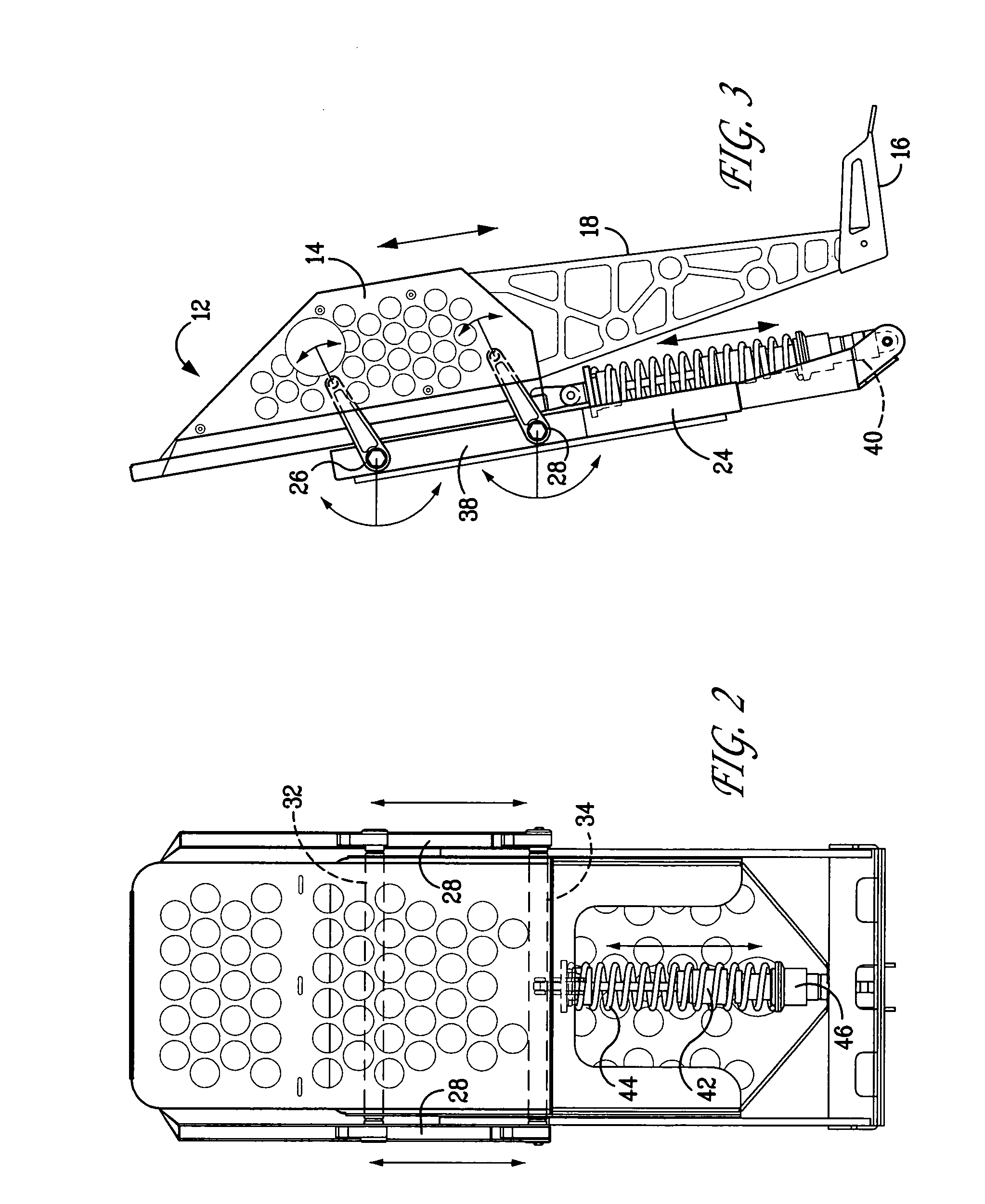

Shock-mitigating bolster

A personal support device having particular utility for use by personnel in high-performance surface watercraft comprises a bolster adapted and dimensioned to support an occupant for shock isolation from accelerations experienced by the vessel. The bolster is mounted by pivot means extending between the bolster and a back plate which is rigidly mounted to the vessel. The pivot means permit the bolster to pivot in an arc with respect to the back plate. A shock absorber extends between the back plate and bolster to dampen the accelerations which would otherwise be passed to the bolster by the pivot means from the back plate. The bolster is capable of supporting a user in a standing position or receiving a seat assembly to allow an occupant to be seated.

Owner:STIDD SYST

Preparation method of diamond/silicon carbide three-dimensional composite structure and prepared product

InactiveCN105039928AImprove adhesionImprove wear resistanceChemical vapor deposition coatingCatalytic effectGrowth time

The invention discloses a preparation method of a diamond / silicon carbide three-dimensional composite structure and a prepared product, and aims to solve the problem that a traditional micron crystal / nanometer crystal diamond multilayer film structure cannot be applied to a metal matrix containing a graphite phase catalytic effect due to strong dependence on the material type of the matrix. Under the condition of no need of additional matrix pretreatment, the preparation method realizes one-step intermittent growth of a diamond / cubic silicon carbide three-dimensional composite structure on multiple matrix materials (such as stainless steel, WC-Co, Si3N4 and the like), so that the treatment procedures are effectively reduced, the growth time is shortened, and the labor cost is saved. Meanwhile, the prepared three-dimensional composite structure can prominently improve the adhesivity, the wear resistance and the fracture toughness of coatings on the surface of the matrix, satisfies the application demands in the high-performance surface coating field, is better in application prospect, and is worthy of large-scale promotion and application.

Owner:姜辛 +2

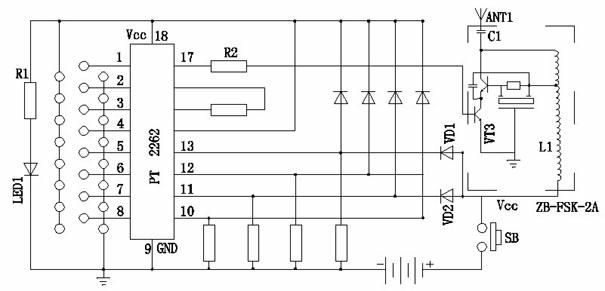

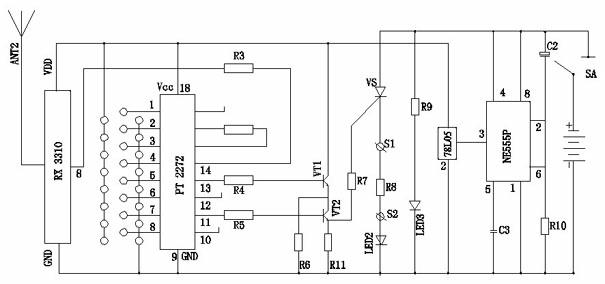

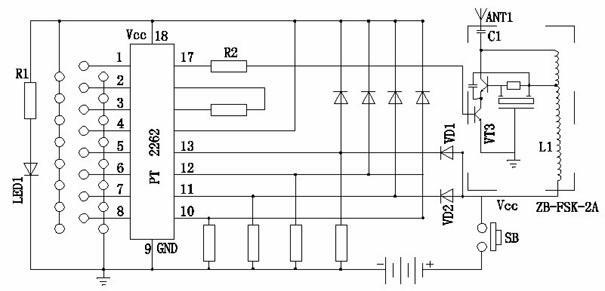

Household remote-control firework igniter

ActiveCN102175101AAvoid electromagnetic interferencePrevent false triggeringFireworksRemote controlTime delays

The invention relates to a household remote-control firework igniter, which consists of a wireless transmitter and a wireless receiving execution device. The wireless transmitter comprises a transmitting module ZB-FSK-2A, a coding chip PT2262, and a transmitting antenna ANT 1 installed at the top of a casing. The wireless receiving execution device comprises a receiving antenna ANT 2 installed at the top of the casing, a receiving integrated module RX3310, a decoding chip PT2272 and an execution circuit. The wireless receiving circuit and the execution circuit are integrated to share the same power supply. The household remote-control firework igniter employs a coding technology compounding address coding and data coding, a dual-data-channel output decoding technology, an automatic turnoff technology and a time-delay safety technology for preventing electromagnetic interference and improper triggering so as to improve the safety. Besides, the household remote-control firework igniter utilizes high-performance surface-mounted elements and uses an electric ignition head to ignite, thereby having the advantages of simple structure, excellent access to operate and good safety and reliability.

Owner:盐城市射阳荣港实业有限公司

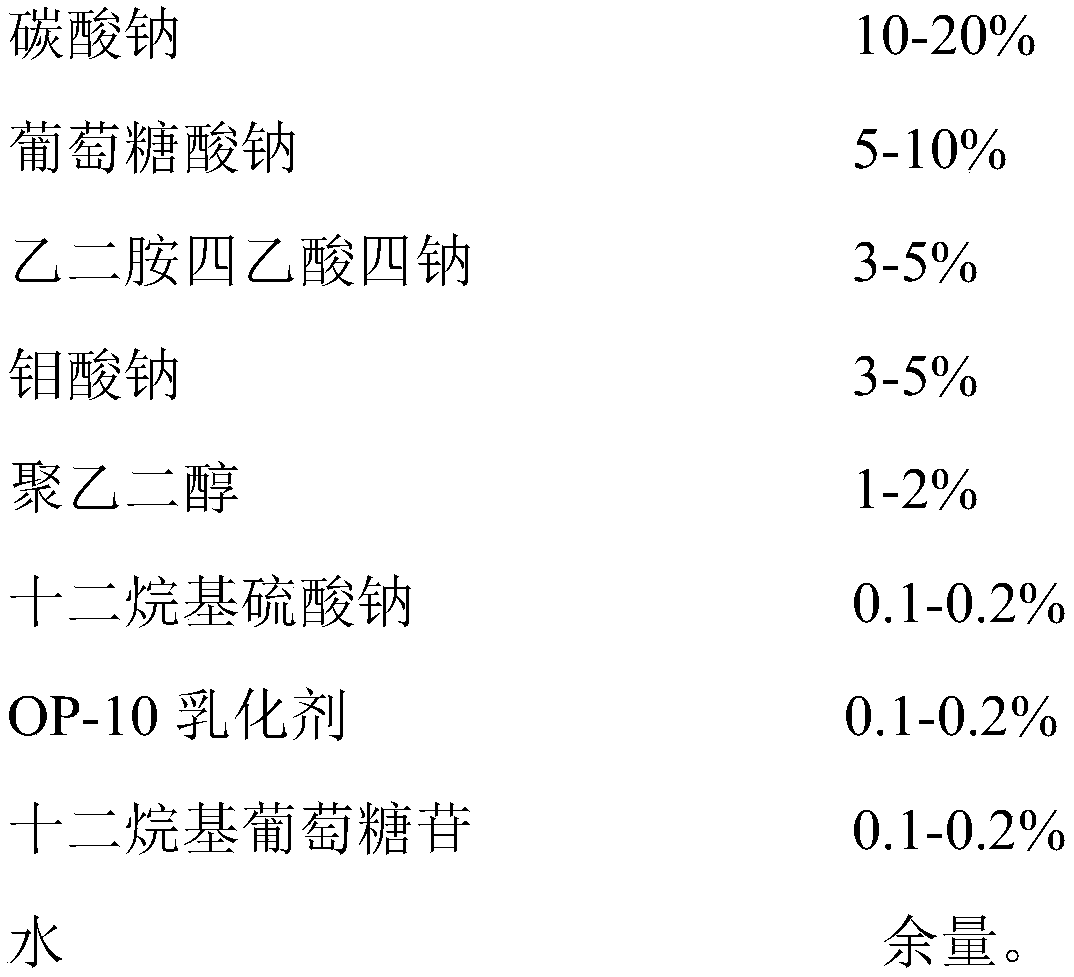

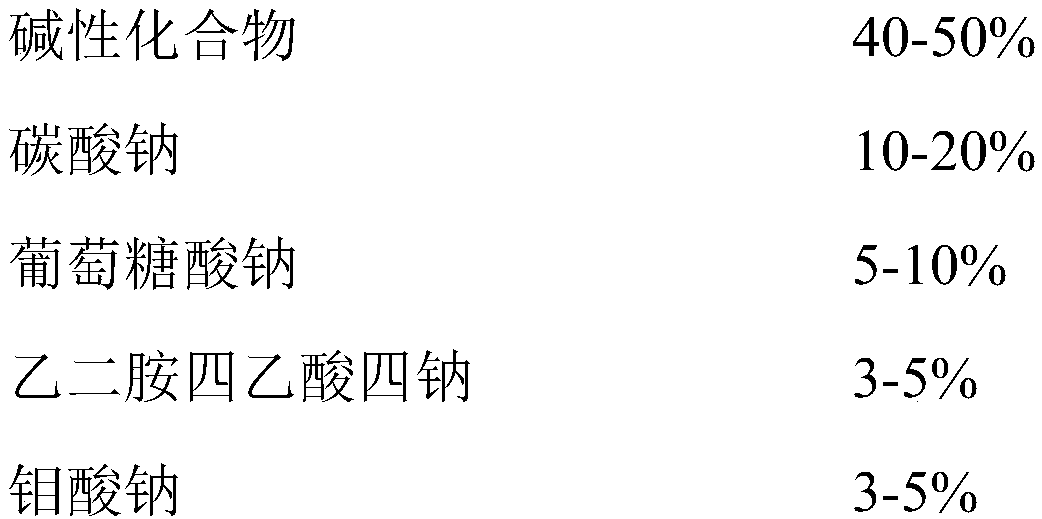

Four-in-one medium-low-temperature alkaline degreaser and preparation and use methods thereof

The invention discloses a four-in-one medium-low-temperature alkaline degreaser and preparation and use methods thereof. The four-in-one medium-low-temperature alkaline degreaser comprises the following components including, by weight, 40% to 50% of sodium methyl silicate, 10% to 20% of sodium carbonate, 5% to 10% of sodium gluconate, 3% to 5% of ethylenediamine tetraacetic acid tetrasodium salt,3% to 5% of sodium molybdate, 1% to 2% polyethylene glycol, 0.1%-0.2% lauryl sodium sulfate, 0.1%-0.2% of an op-10 emulsifier, 0.1%-0.2% of dodecyl glucoside and the balance water. The four-in-one medium-low-temperature alkaline degreaser is an alkaline bright cleaning degreaser without heavy metal, fluorine, phosphorus and ammonia nitrogen, has no toxic and side effects on the human body and an operating environment, and is a high-performance surface treatment additive integrating degreasing, alkali wash, polishing and neutralizing, and is very suitable for oxidation pretreatment of aluminumprofiles.

Owner:FOSHAN HAIHUA SURFACE TREATMENT TECH CO LTD

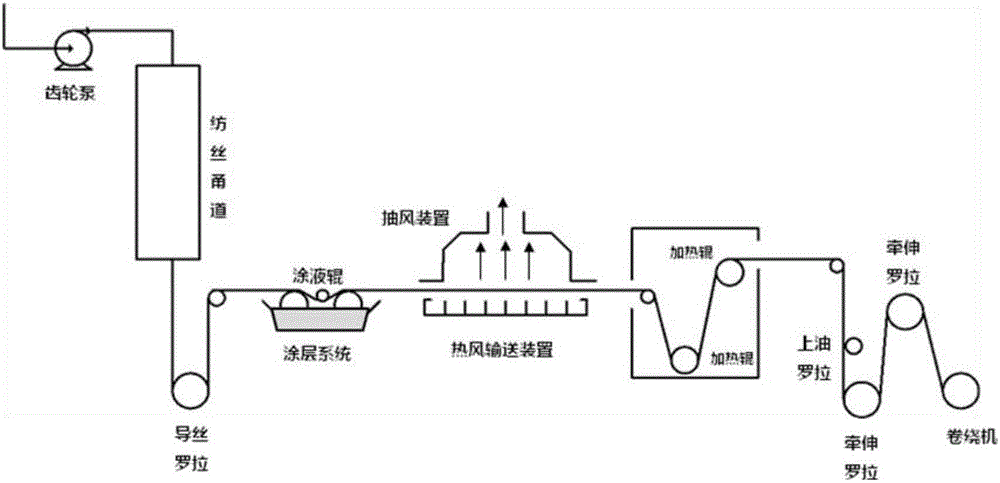

Control method of coating performance surface quality of double-phase steel cold-rolled high-strength automobile board

ActiveCN109136739AIncrease roughnessImprove surface qualityFurnace typesHeat treatment furnacesDouble phaseHigh pressure water

The invention discloses a control method of coating performance surface quality of a double-phase steel cold-rolled high-strength automobile board, which comprises smelting, continuous casting, hot rolling, descaling, acid rolling, continuous annealing and leveling. The descaling process uses a three-stage descaling process, wherein the descaling position comprises descaling after a heating furnace, descaling before rough rolling and descaling before finish rolling, the descaling pressure at each descaling point is greater than or equal to 24MPa, the rough rolling is reciprocating rolling, therolling is carried out for 5 times, and high-pressure water descaling is carried out for every time. By adjusting and optimizing a whole process production process, including controlling the chemicalcomposition of a continuous casting blank, improving the heating and cooling system of the continuous casting, hot rolling, and cold rolling, controlling the hot rolling and descaling processes and cold rolling and acid rolling processes, controlling the roughness of a leveled steel strip, and the like, the surface quality of the double-phase steel cold-rolled automobile board is improved, the element enrichment on the surface of the steel board is inhibited, the quality of a phosphating film is improved, the coating performance of the double-phase steel cold-rolled high-strength automobile board and the anti-corrosion performance of the double-phase steel cold-rolled high-strength automobile board after being coated are improved.

Owner:TANGSHAN IRON & STEEL GROUP +1

DMF-free and environmentally-friendly high performance silicone rubber polymer synthetic leather and manufacturing technology thereof

InactiveCN109023982AImprove flame retardant performanceGood weather resistanceTextiles and paperEnvironmental resistancePolymer science

The invention discloses a DMF-free and environmentally-friendly high performance silicone rubber polymer synthetic leather. The DMF-free and environmentally-friendly high performance silicone rubber polymer synthetic leather comprises a flame-retardant base, and the flame-retardant base is sequentially coated to form a DMF-free and environmentally-friendly high performance liquid silicone rubber layer and a DMF-free and environmentally-friendly high performance surface layer; and the DMF-free and environmentally-friendly high performance liquid silicone rubber layer comprises, by mass, 80-100parts of silicone rubber base rubber, 10-15 parts of low-viscosity vinyl silicone oil, 5-10 parts of vinyl MQ resin, 5-10 parts of hydrosilicone oil, 3-5 parts of a silane coupling agent, 1-3 parts ofa tackifier, 0.1-0.5 part of a platinum catalyst, 5-20 parts of a color paste pigment and 0.02-0.1 part of an inhibitor. The liquid silicone rubber is used as a raw material for manufacturing the synthetic leather, and no DMF is used in the production process, so the synthetic leather is harmless to human bodies or the environment, and has excellent resistance to flame, weather and hydrolysis. Aproduction technology of the synthetic leather has the advantages of simplicity, high production efficiency and low cost.

Owner:GUANGDONG TIANYUE NEW MATERIAL CO LTD

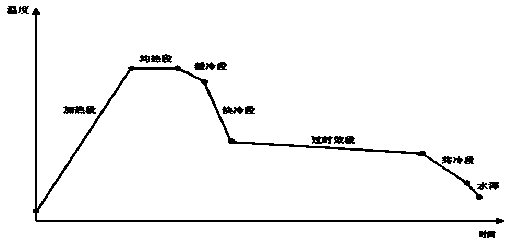

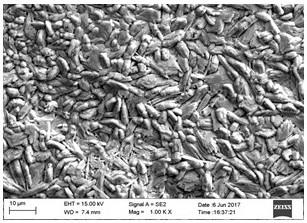

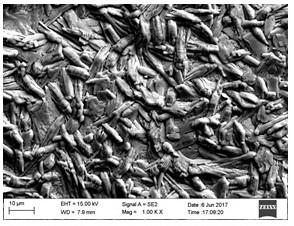

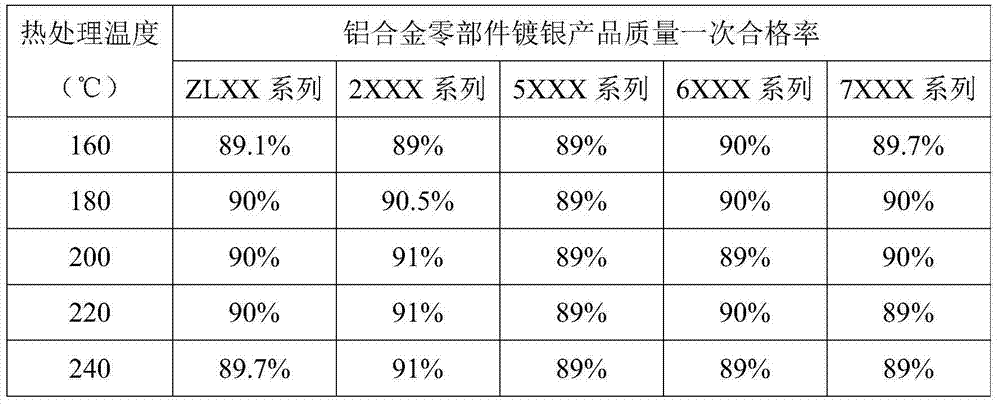

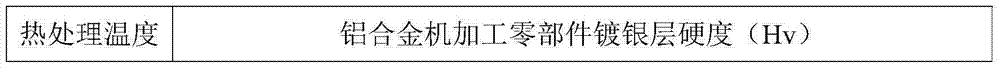

Aluminum alloy silver-plating pre-treatment method

InactiveCN104328466AImprove bindingAvoid the problem of bubbling and peelingSilver plateHigh pressure

The invention discloses an aluminum alloy silver-plating pre-treatment method including steps of firstly performing heat-treatment to aluminum alloy for removing a stress and then performance surface treatment. In the aluminum alloy silver-plating pre-treatment method, the aluminum alloy is firstly subjected to the heat-treatment for removing the stress and then is subjected to the surface treatment so that a bubbling and peeling phenomenon is maximumly avoided. A first qualification ratio of an aluminium alloy part silver-plating product can reach 89-91%, which is increased by about 5% with comparison of the first qualification ratio of a silver-plating product through a conventional technology. The method greatly increases the qualification ratio of the product, reduces numbers of repaired and scrapped parts, reduces a production cost and increases an economic benefit. A bonding force between a silver plating layer and an aluminum alloy base material is excellent and quality of the aluminium alloy silver-plating product is improved. A micro-hardness of the silver plating layer of the aluminum alloy part is higher than Hv120, which reaches or exceeds a usage requirement of a high-voltage switch, thereby ensuring safe operation of the high-voltage switch.

Owner:STATE GRID CORP OF CHINA +1

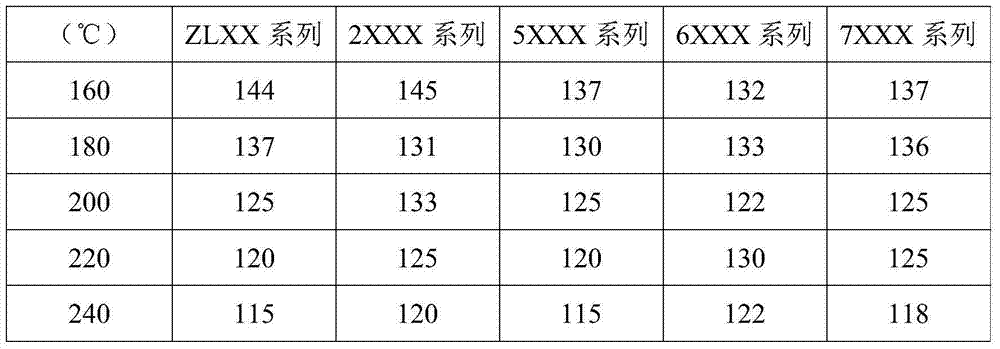

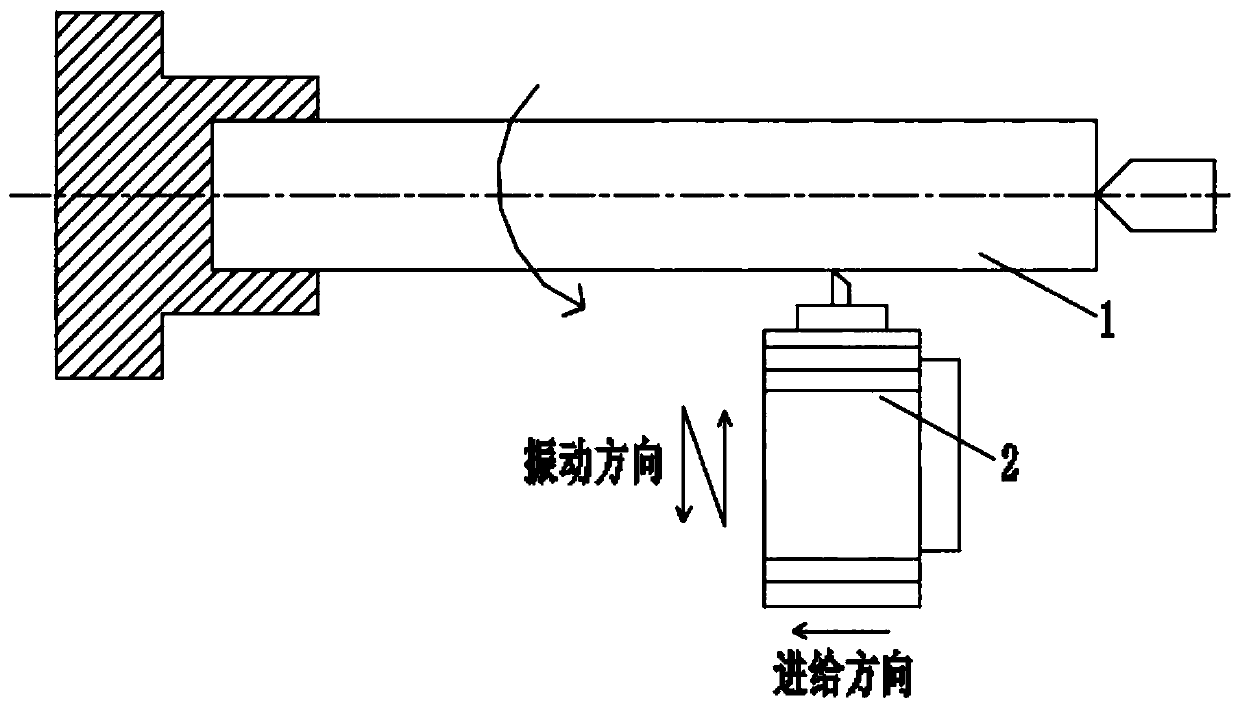

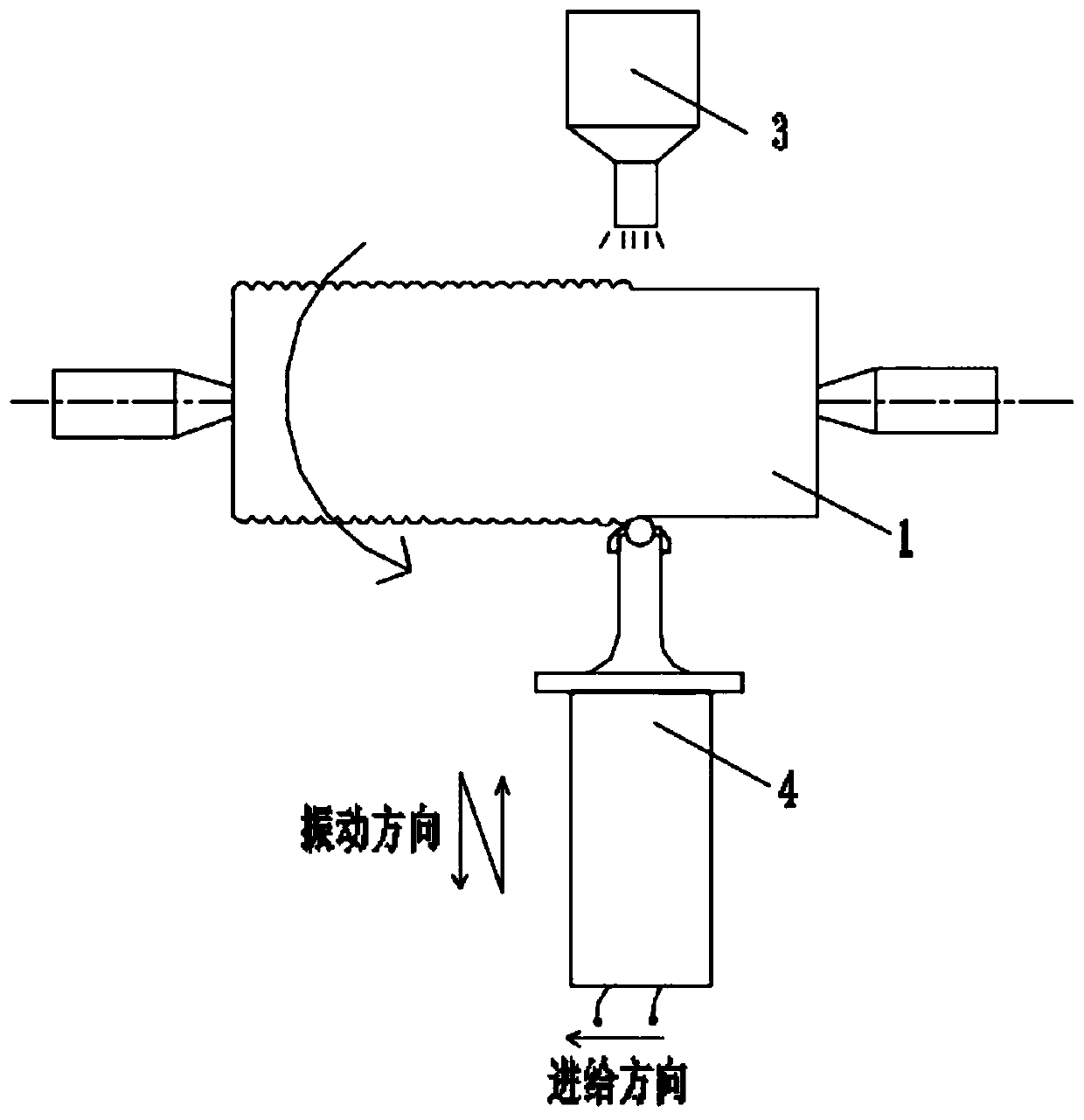

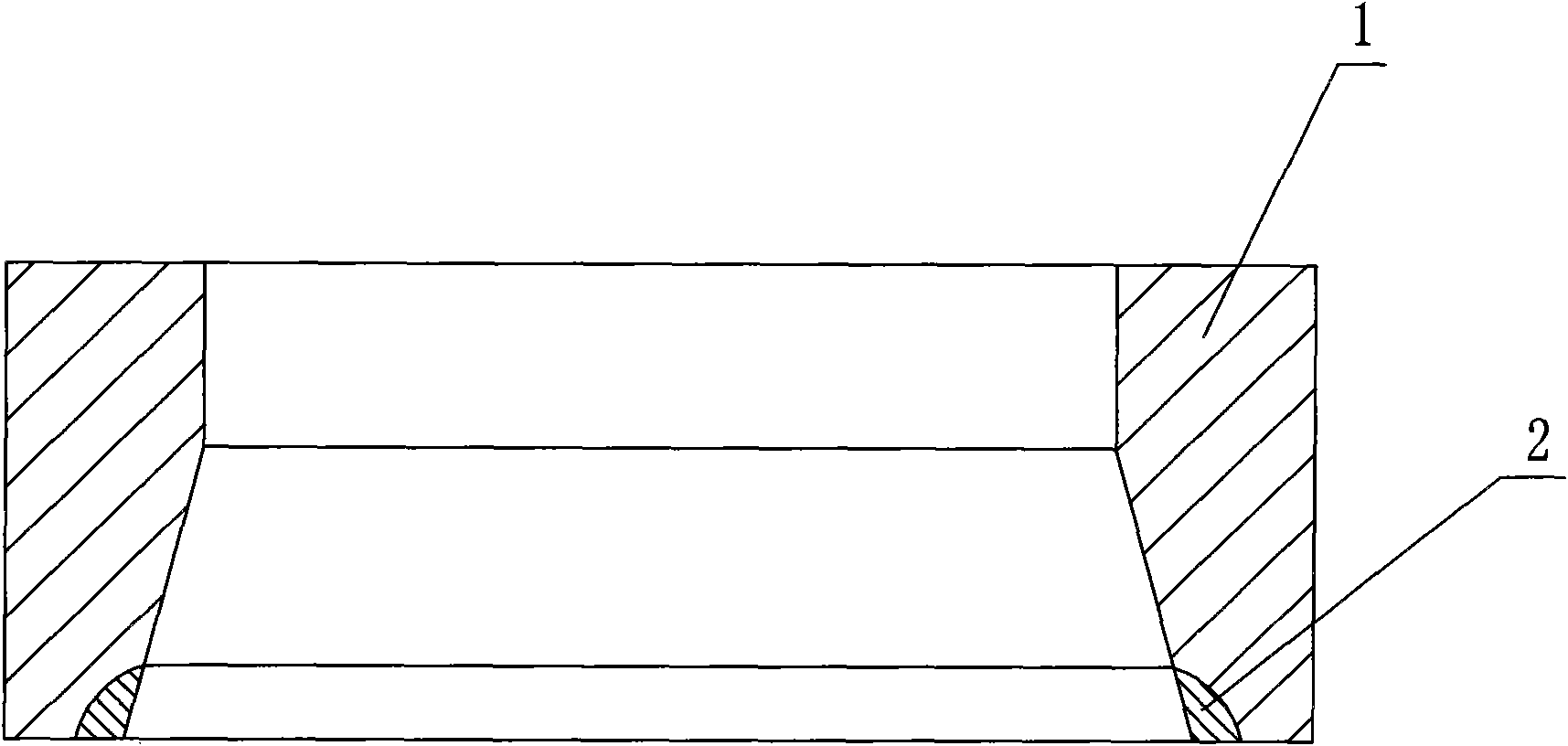

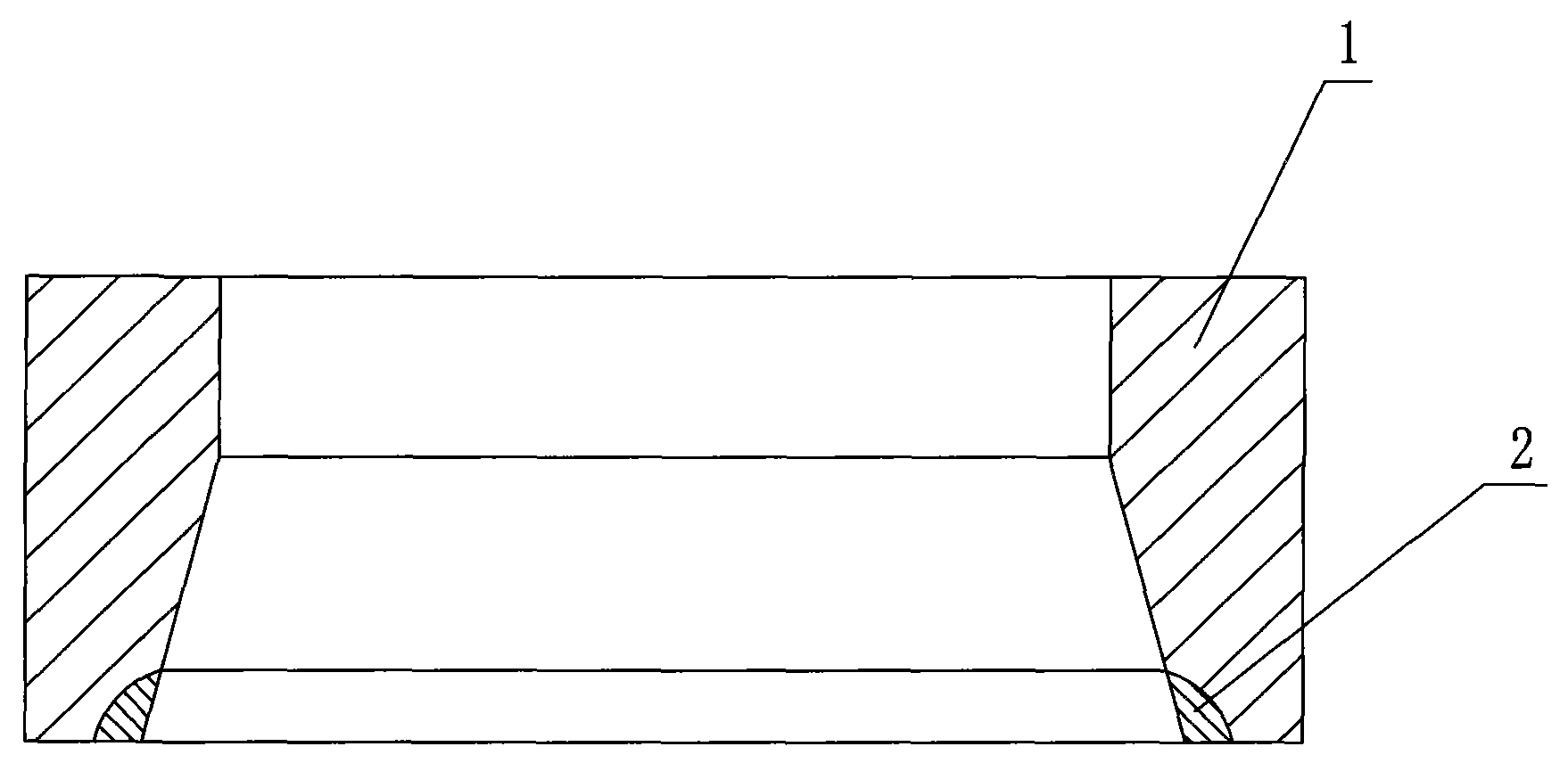

High-performance surface composite strengthening method for shaft parts

The invention discloses a high-performance surface composite strengthening method for shaft parts, and belongs to the field of surface machining of metal materials. The surface composite strengtheningmethod comprises the following steps that S1, carrying out radial vibration turning on the shaft parts, and forming a specific regular distributed micron scale / nano scale microcosmic geometrical morphology on the surfaces of the shaft parts; S2, coating the surfaces; and S3, carrying out mechanical reinforcement treatment on the coating surfaces by adopting an ultrasonic rolling processing technology. Compared with the prior art, the high-performance surface composite strengthening method for the shaft parts can greatly improve the bonding strength of a bonding interface of a base material and a coating layer, meanwhile, the hardness, the fatigue strength and the wear-resistant and corrosion-resistant shaft parts of the final forming surfaces are improved, and the method has good popularization and application values.

Owner:QILU UNIV OF TECH

Abrasion-resistant valve seat

The invention discloses an abrasion-resistant valve seat, and relates to the technical field of valve seat production. The abrasion-resistant valve seat comprises a valve seat main body made of a metal material, and a sealed conical surface of the valve seat main body is provided with a ceramic granule reinforced composite coating. The abrasion-resistant valve seat can realize high-performance surface modification on a low-grade material, and the composite coating is in firm metallurgical connection with an alloy cast iron base material. Meanwhile, the low-grade alloy cast iron material realizes high-performance surface modification; and the abrasion-resistant valve seat achieves optimal combination of low cost of a part and high performance of a working surface, saves resources, and has the advantages of prolonging of the integral service life of the valve seat and good technical stability of products.

Owner:江苏仪征威龙活塞环有限公司

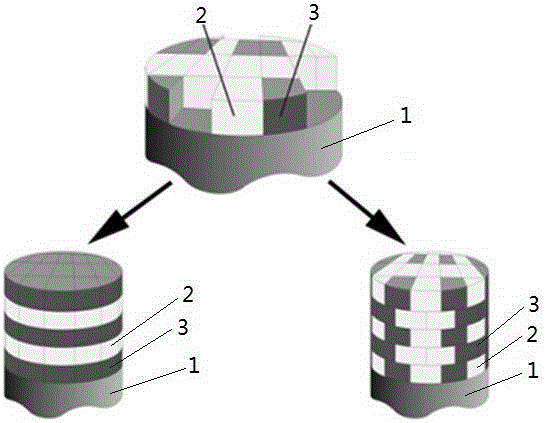

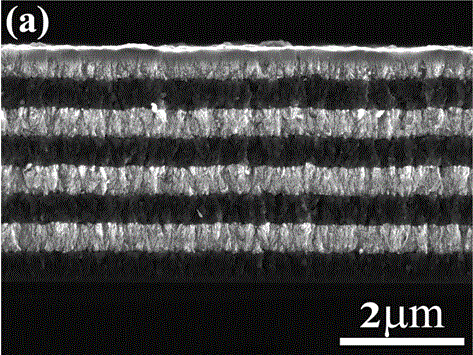

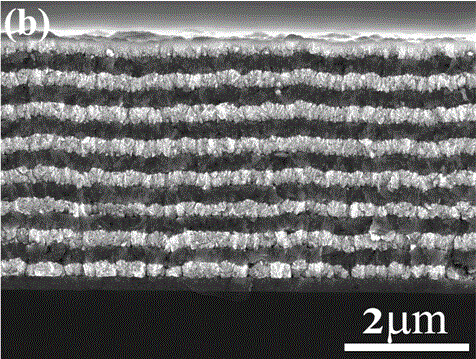

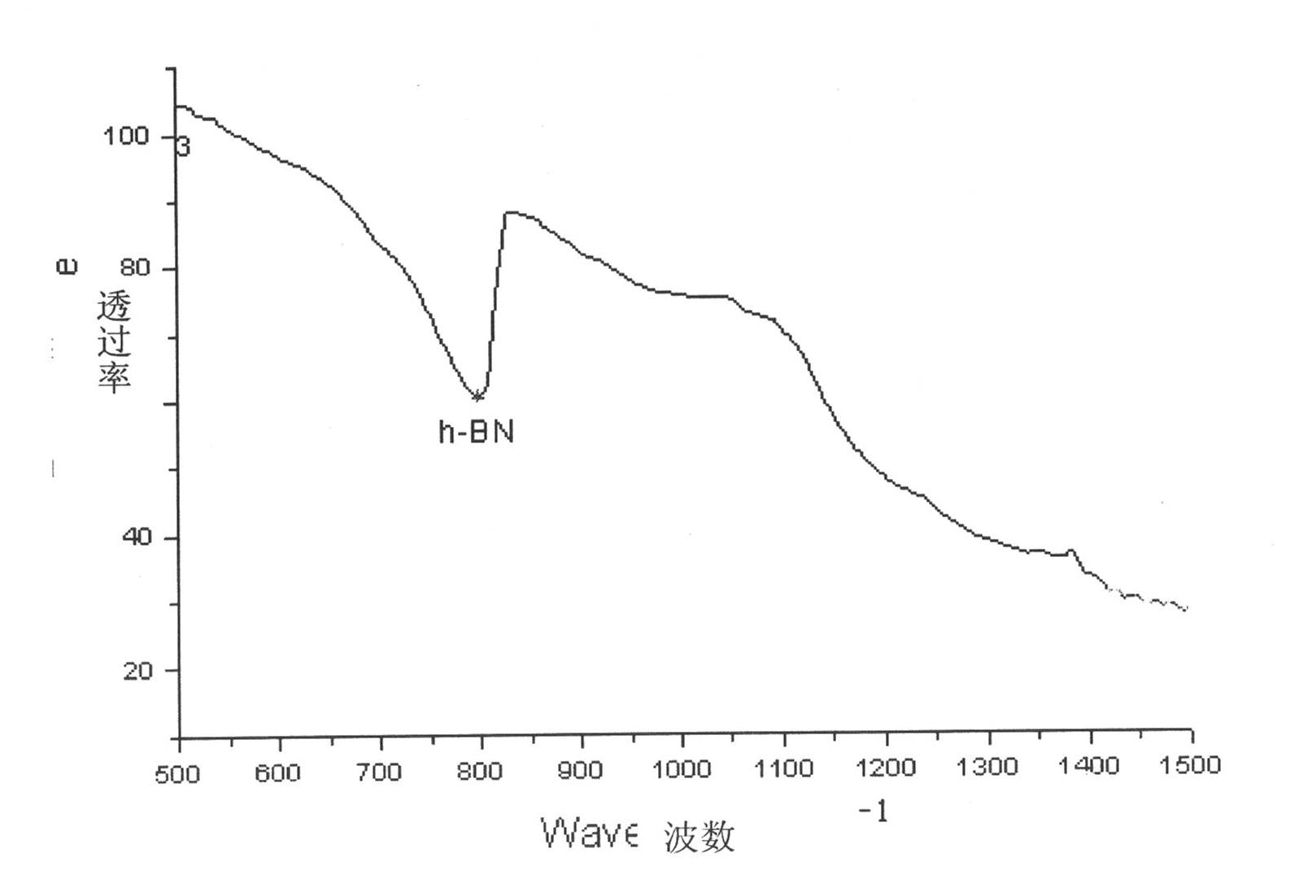

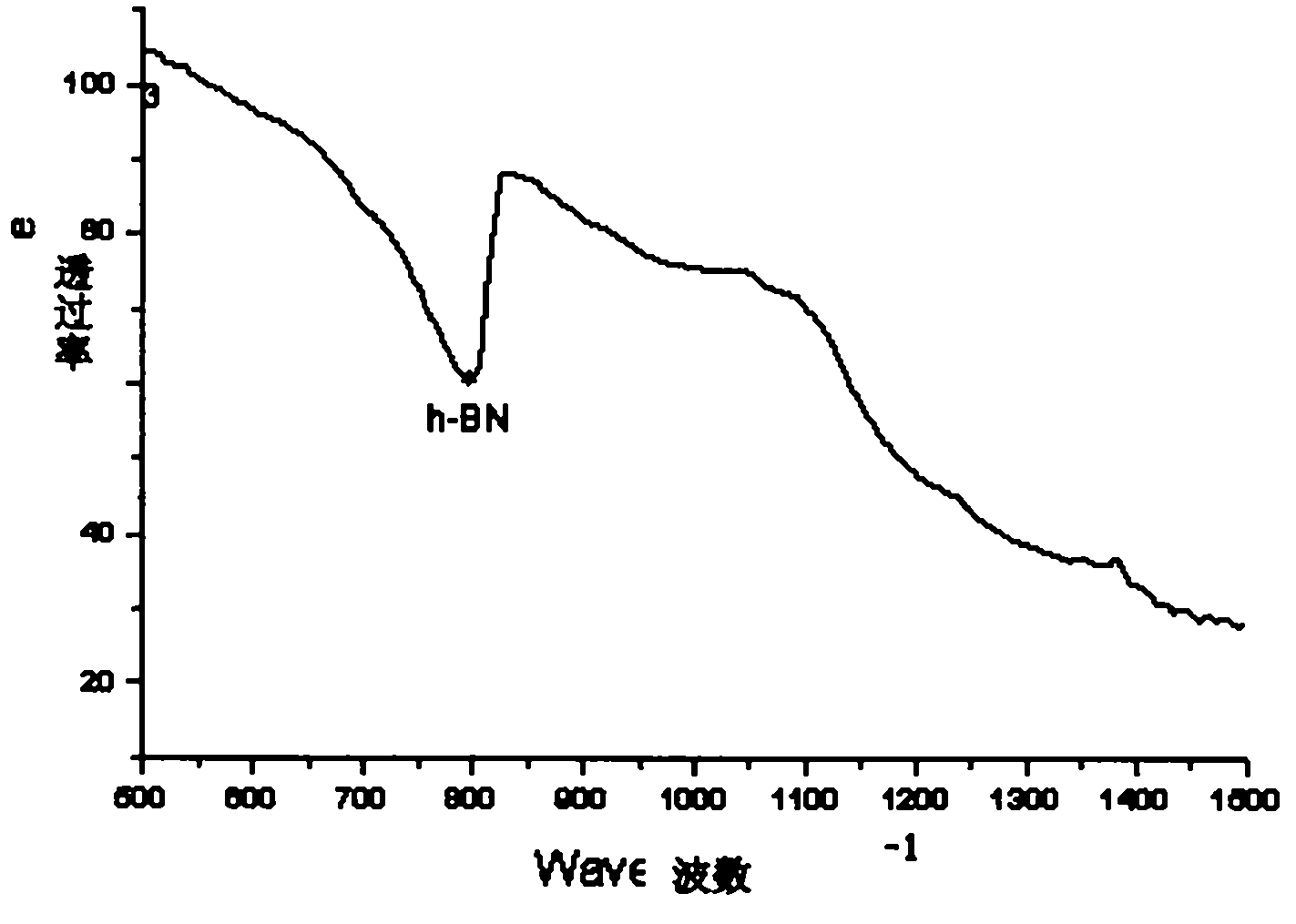

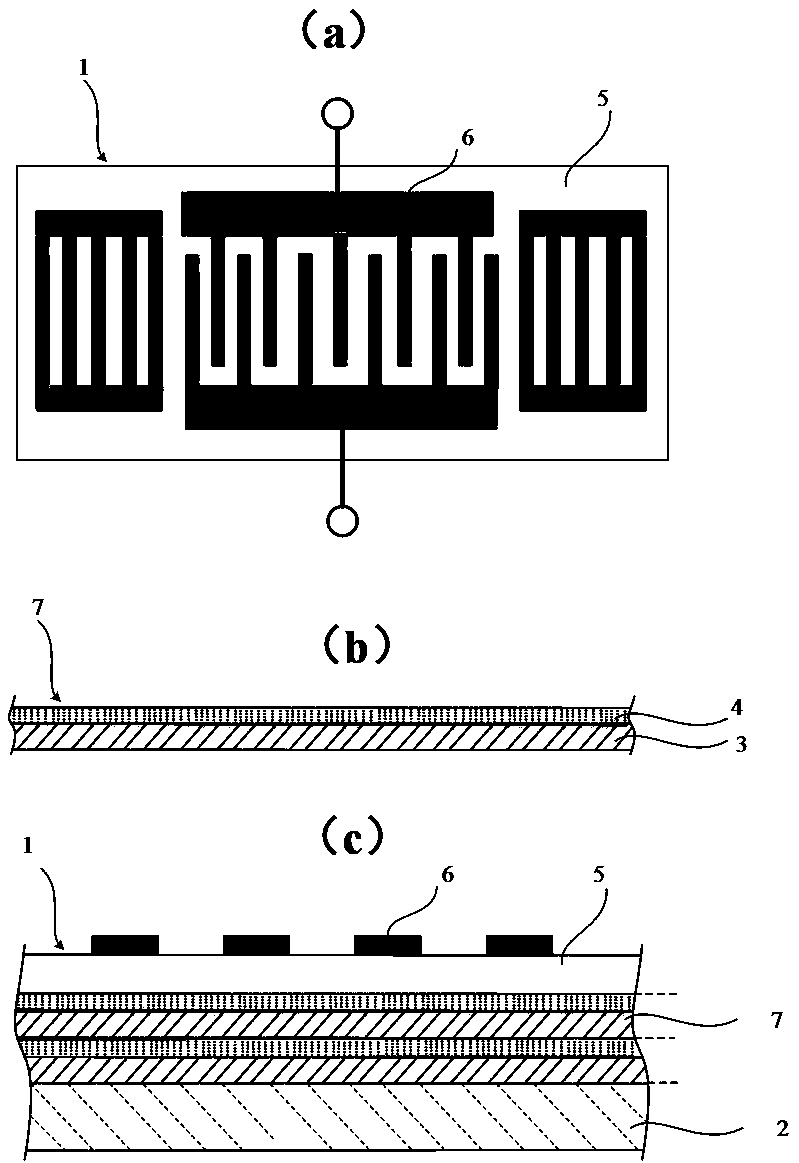

Method for preparing high-performance surface acoustic wave device with multilayer film structure

InactiveCN102094178AThe process conditions are convenient and easyVacuum evaporation coatingSputtering coatingHexagonal boron nitrideBoron nitride

The invention discloses a method for preparing a high-performance surface acoustic wave device with a multilayer film structure. In the invention, a substrate is a CVD (Chemical Vapor Deposition) diamond film, and the surface of the CVD diamond film forms a layer of h-BN (hexagonal boron nitride) film. The film is deposited by adopting a vacuum sputtering method, and the substrate of the film is a mirror polishing silicon substrate. The crystal face index is 100, the base pressure of a vacuum sputtering room is 5X10-4Pa, and the target material for sputtering is hot-pressed h-BN with purity of 99.99%, wherein the hot-pressed h-BN with purity of 99.99% comprises the preparation steps of: depositing a boron nitride underlayer rich in B, then changing the negative bias value of the substrate from 0V to 100V, and finally prolonging the sputtering deposition time to 80 minutes under the condition of keeping process conditions unchanged. Compared with the prior art, the method has the advantages that the equipment used in the preparation method is simple, the process conditions are convenient and easy, and the preparation method is beneficial to large-scale application and has important significance in both production and practice.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

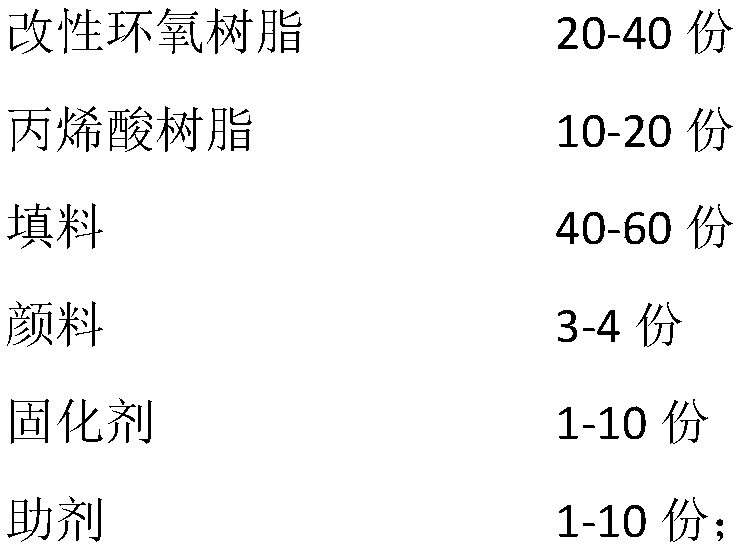

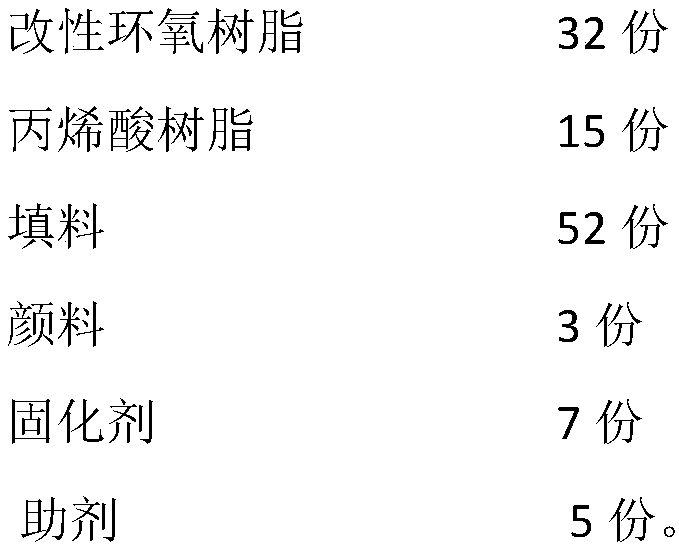

High-performance surface mounting ink and preparation method thereof

The invention provides a high-performance surface mounting ink. The high-performance surface mounting ink is prepared from the following raw materials in parts by weight: 20-40 parts of modified epoxyresin, 10-20 parts of acrylic resin, 40-60 parts of filler, 3-4 parts of pigment, 1-10 parts of curing agent, and 1-10 parts of auxiliaries; wherein the auxiliaries include a photosensitizer, a dispersing agent, a flatting agent, a promoter, a diluent, a defoamer, and a coupling agent.

Owner:广东科鼎新材料股份有限公司

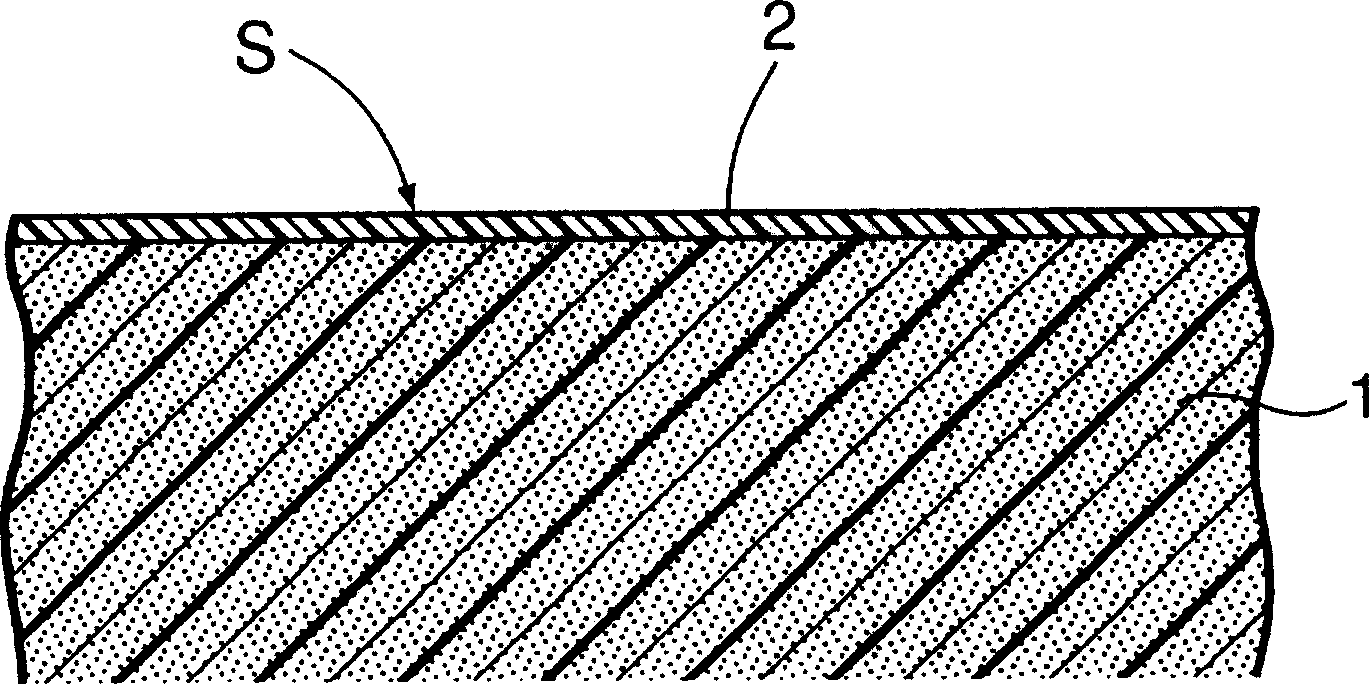

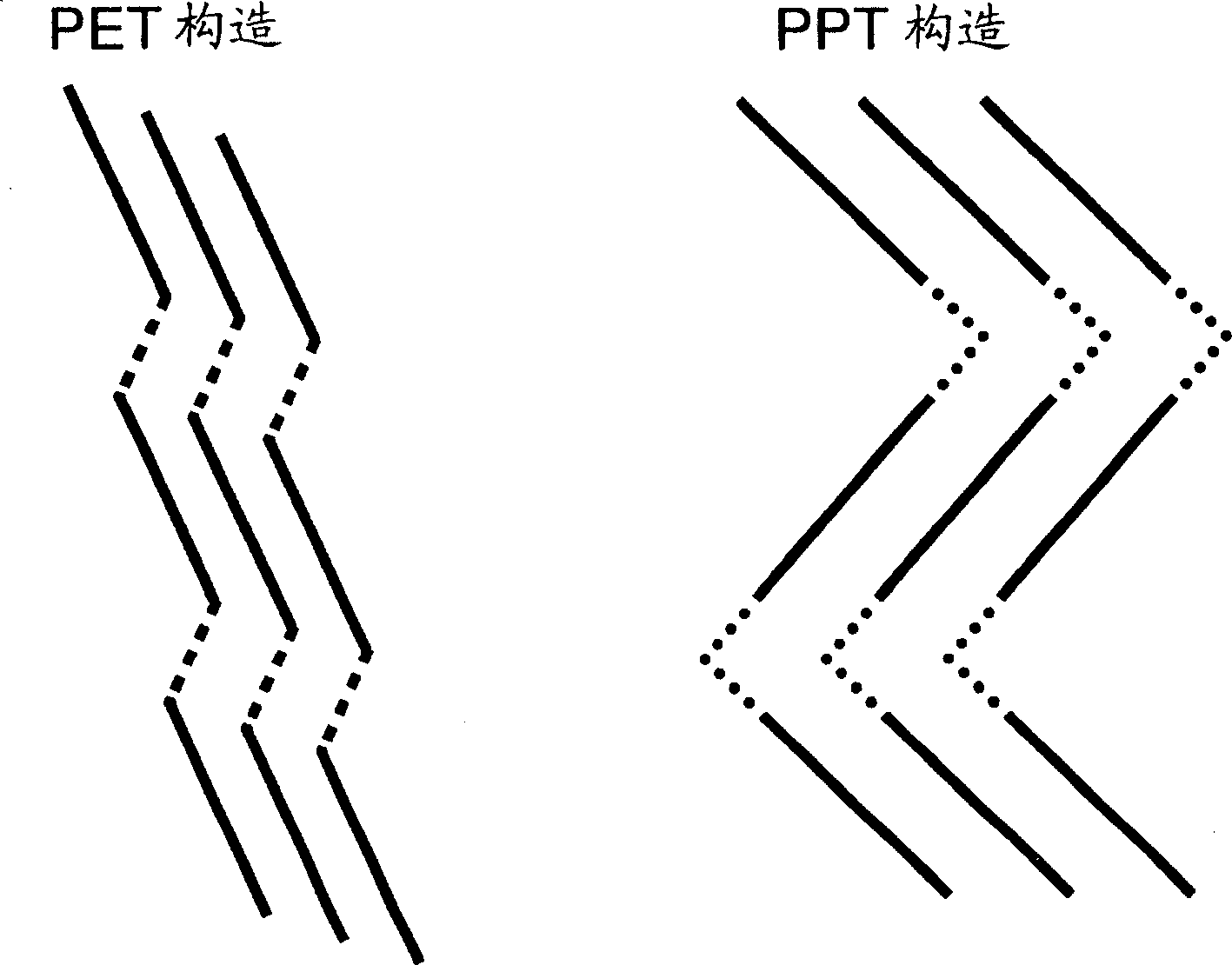

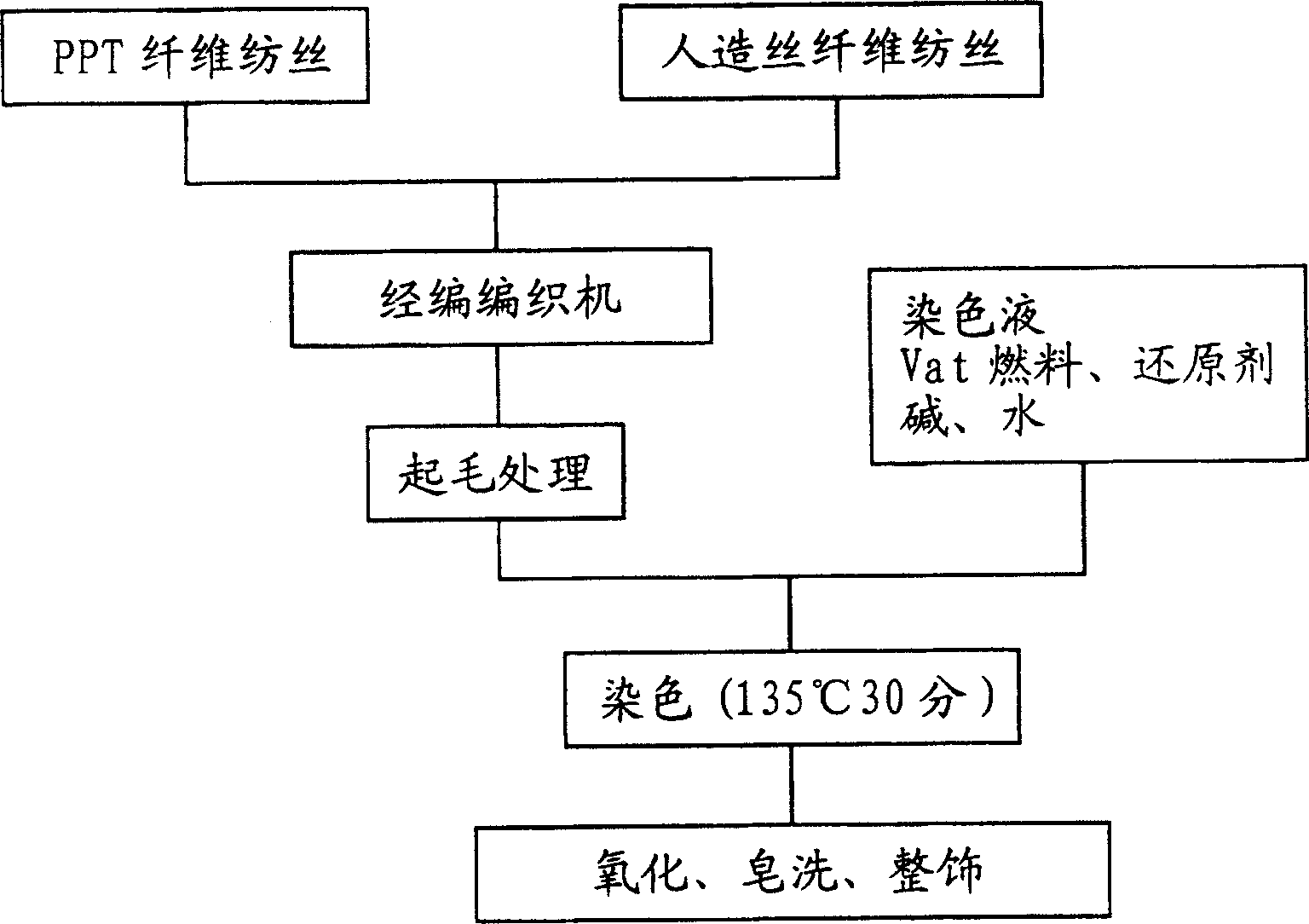

Surface material for vehicle use, producing method thereof, internal decorative material and seat material for automatic two-wheel and tricycle vehicles

InactiveCN1673427AFunctionalLow priceConjugated cellulose/protein artificial filamentsDyeing processCellulose fiberLightfastness

This invention provides an extremely high-performance surface skin material for vehicles which can readily and accurately be dyed at low cost and excellent in properties which both component fibers have and is relatively inexpensive by carrying out blended spinning of PPT fiber excellent in light resistance and fastness to abrasion and having good touch feeling with a cellulosic fiber excellent in hygroscopic property and flame retardance and dyeing the resultant blended fabric with a vat dye. The surface skin material for vehicles is composed of a blended fabric of PPT fiber and the cellulosic fiber and dyed with the vat dye.

Owner:HONDA MOTOR CO LTD

Methods and apparatus for estimating rotor slots

ActiveUS8131482B2Robust and accurate estimationImprove transient responseElectrical testingMotor parameters estimation/adaptationInduction motorEngineering

Owner:SCHNEIDER ELECTRIC USA INC

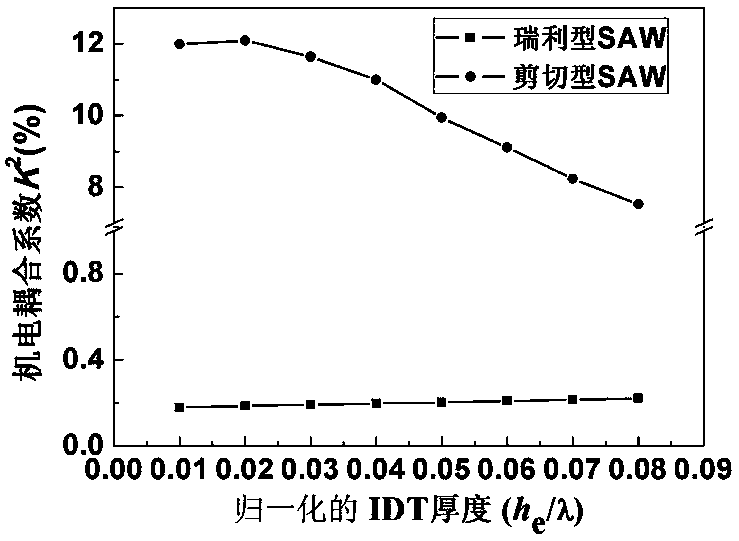

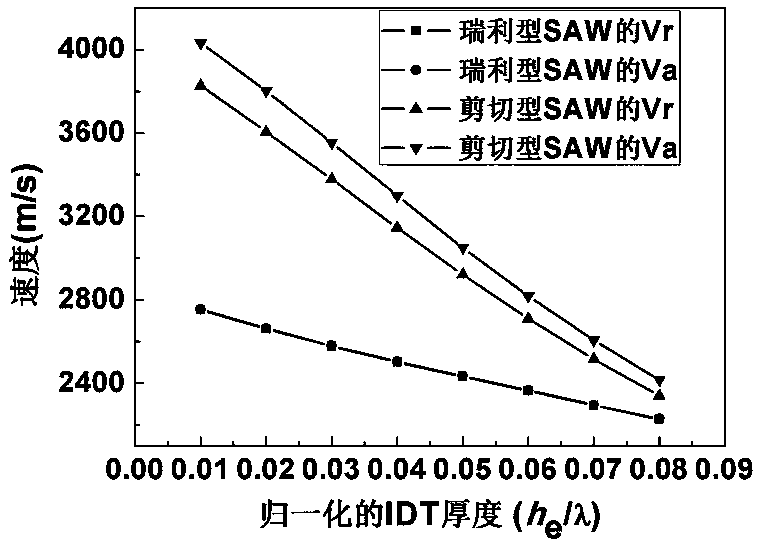

Resonator structure design for high-performance surface acoustic wave filter

InactiveCN108039872AHigh electromechanical coupling coefficientHigh quality factorImpedence networksSpecial data processing applicationsGratingSingle crystal

The invention provides a resonator structure design for a high-performance surface acoustic wave filter, which can be used for effectively inhibiting the clutter response caused by rayleigh waves andbody waves. The resonator structure (1) of the high-performance surface acoustic wave filter comprises a monocrystal Si substrate (2), a multi-layer film structure (7), a YX-theta LiTaO3 piezoelectricfilm (5), an interdigital electrode IDT mainly dominated by Al or Cu electrodes, a reflecting grating (6) and the like which are sequentially overlaid from bottom to top, wherein the multi-layer filmstructure (7) is formed by alternated sedimentation of high acoustic impedance films (3) and low acoustic impedance films (4); and the resonator structure (1) of the high-performance surface acousticwave filter has an optimized formula in the following way: the euler angle theta and standard thickness of the YX-theta LiTaO3 piezoelectric film respectively meet the following relationships: thetais more than or equal to 0 and less than or equal to 60, and hLT is more than or equal to 0.1 time lambda and less than or equal to 0.5 time lambda.

Owner:天通瑞宏科技有限公司

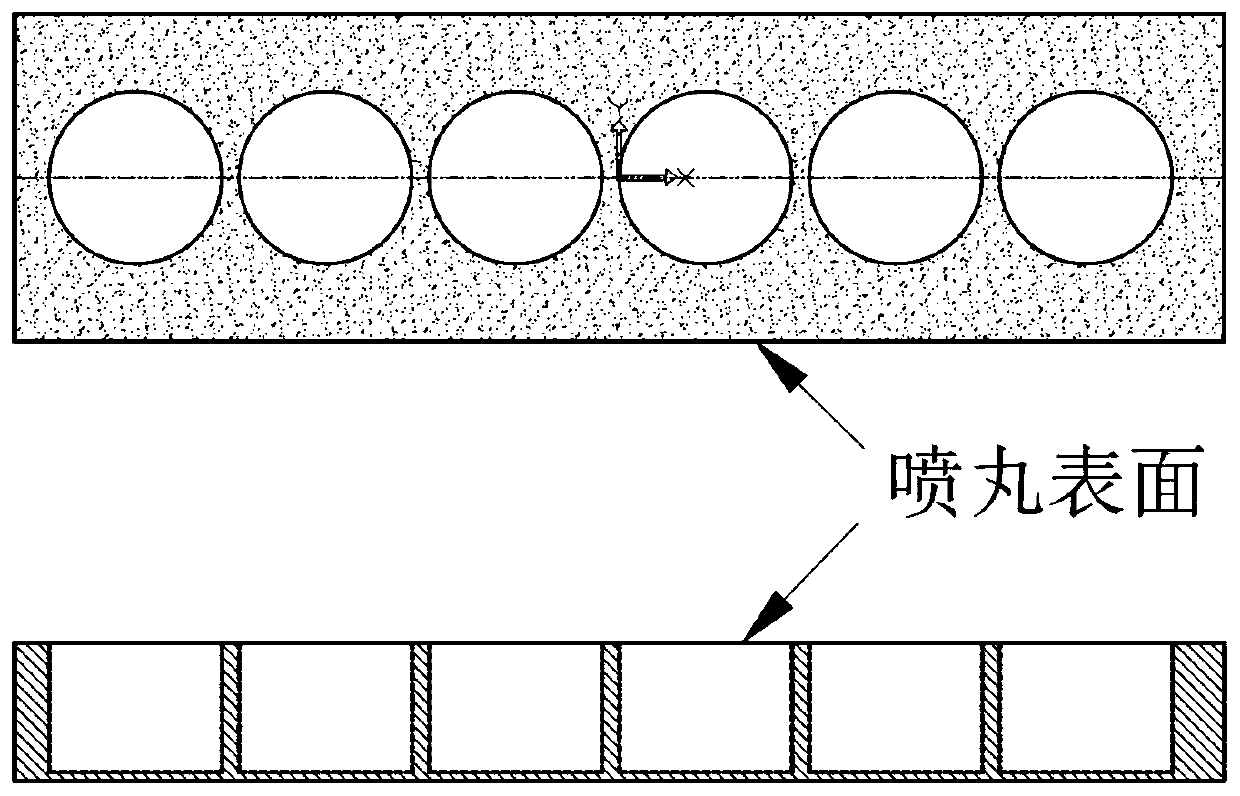

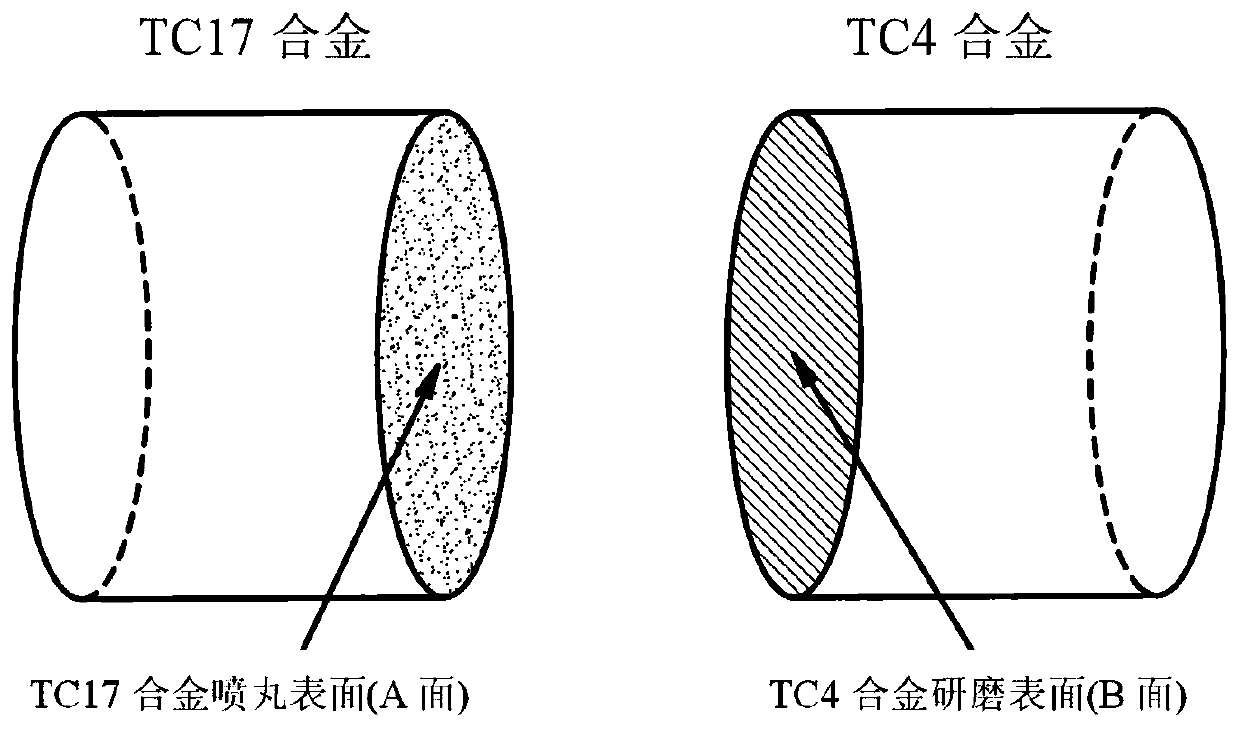

Solid-state connection method of surface self-nanocrystallization TC17 alloy and TC4 alloy

ActiveCN109746562AGood metallurgical bondNon-electric welding apparatusVacuum extractionMegasonic cleaning

The invention relates to a solid-state connection method of a surface self-nanocrystallization TC17 alloy and TC4 alloy. The solid-state connection method comprises the steps that shot blasting treatment is performed on the surface of a TC17 alloy by placing the TC17 alloy into a shot blasting chamber, then the TC17 alloy is placed in an anhydrous ethanol solution for ultrasonic cleaning and driedwith a blower for standby application, and further, SiC waterproof abrasive paper is used for grinding a TC4 alloy; then the ground TC4 alloy is placed in the anhydrous ethanol solution for ultrasonic cleaning for 15-25 min, and dried by a blower for standby application; the blasting surface of the TC17 alloy and the ground surface of the TC4 alloy are closely attached together and placed in a thermal simulation test machine, vacuum extraction is performed, pressurization at a constant temperature is performed for 10-30 min, and then pressure relief and cooling are performed; and finally, theconnected alloy test piece is air-cooled to the room temperature. The solid-state connection method enables a base layer of the TC 17 alloy to provide more diffusion channels for atomic diffusion atthe solid-state connection interface, promotes metallurgical bonding of a heterogeneous titanium alloy joint, and then obtains a high-performance surface layer surface self-nanocrystallization TC17 alloy and TC4 alloy joint.

Owner:南京三航智能制造科技有限公司

Preparing method for polyurethane elastic fiber with heat bonding performance

The invention discloses a preparing method for a polyurethane elastic fiber with the heat bonding performance. The preparing method includes the steps that waterborne polyurethane capable of being rapidly cured to form a film at the temperature of 80 DEG C to 100 DEG C is synthesized, then the surface of a common polyurethane fiber is evenly coated with the waterborne polyurethane, high-temperature drying, oil applying and drafting treatment are carried out, and then the composite polyurethane elastic fiber with a different-performance surface layer and a different-performance lining layer is obtained. The fiber-surface-layer polyurethane can be heated and fused at the temperature of 100 DEG C to 150 DEG C, and the fiber-surface-layer polyurethane and other fiber materials form high adhesive force; the lining-layer polyurethane is large in mechanical strength and high in elastic recovery rate.

Owner:ZHEJIANG HUAFENG SPANDEX

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com