Preparing method for polyurethane elastic fiber with heat bonding performance

A technology of polyurethane elasticity and polyurethane fiber, which is applied in fiber types, fiber treatment, textiles and papermaking, etc., can solve the problems of complex process, difficult control, high equipment precision requirements, etc., and achieve simple and easy process control, high elastic recovery rate, The effect of high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0049] The specific implementation of the technology of the present invention is as follows:

[0050] 1). Preparation of waterborne polyurethane

[0051] The diisocyanate and the polymer diol are reacted at 70-90° C. for 2-4 hours. Slowly add the mixture of the alcohol chain extender and the hydrophilic chain extender dropwise, and react at a constant temperature of 60-80° C. for 1-3 hours. After the reaction is completed, an organic solvent is added to adjust the viscosity of the polymer product. Next, add a neutralizing agent to react for 10-30 minutes, and control the pH of the system between 7-8. Afterwards, add a film-forming agent and deionized water, and use a high-speed emulsifier to perform emulsification for 30 to 60 minutes. Finally, the emulsified product is distilled under reduced pressure to remove the organic solvent therein to obtain water-based polyurethane with a viscosity of 50-500 poise.

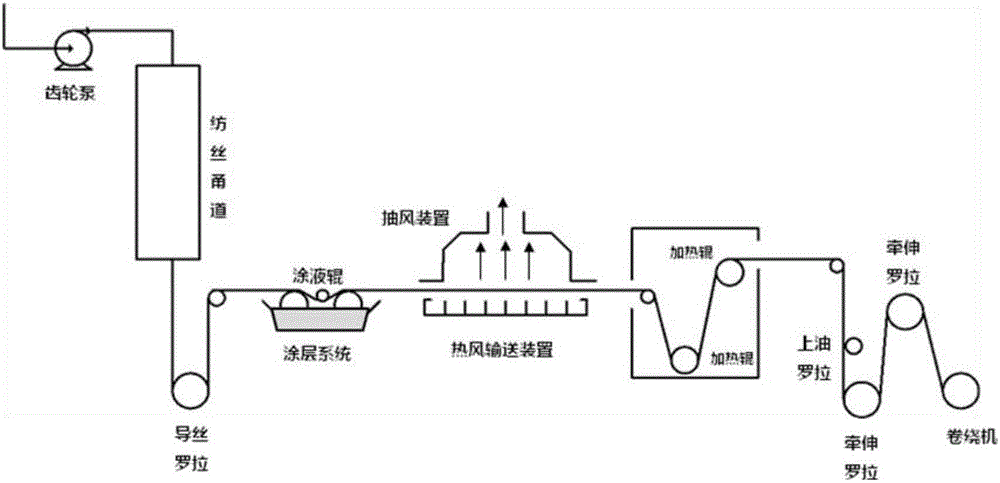

[0052] 2). Preparation of heat-adhesive polyurethane elastic fib...

Embodiment 1

[0055] 378g of 4,4'-diphenylmethane diisocyanate and 2000g of polybutylene adipate diol with a molecular weight of 2000 were mixed uniformly and heated to 90°C for 2 hours. The temperature was lowered to 70° C., and a mixture of 24.8 g of ethylene glycol and 17.8 g of sodium 1,2-dihydroxy-3-propanesulfonate was added dropwise to carry out a chain extension reaction for 1 hour. The polymer product was diluted by adding 500 ml of acetone. Add 10.4 g of triethylamine dropwise to carry out the neutralization reaction, and the pH value of the system is controlled at about 8. Add 24g ethyl alcohol butyl ether and 3500g deionization to carry out high-speed emulsification treatment for 30 minutes. Finally, the emulsion was heated to 60° C. for vacuum distillation to remove acetone to obtain water-based polyurethane with a viscosity of 85 poise.

[0056] Evaporate the solvent from the dry spinning stock solution to form a polyurethane fiber precursor, which is drawn through a grooved...

Embodiment 2

[0058] Mix 450g of 4,4'-diphenylmethane diisocyanate with 1800g of polyethylene adipate diol with a molecular weight of 1000, and heat to 75°C for 2 hours. A mixture of 48 g of 1,4-butanediol and 24 g of dimethylol propionic acid was added dropwise to carry out a chain extension reaction for 1.5 hours. The polymer product was diluted by adding 750 ml of acetone. Add 20.8 g of triethylamine dropwise to carry out the neutralization reaction, and the pH value of the system is controlled at about 7.5. Add 35.4g of ethylene glycol propyl ether and 4200g of deionization to carry out high-speed emulsification treatment for 45 minutes. Finally, the emulsion was heated to 50° C. for vacuum distillation to remove acetone to obtain water-based polyurethane with a viscosity of 100 poise.

[0059] Evaporate the solvent from the dry spinning stock solution to form a polyurethane fiber precursor, which is drawn through a grooved roller equipped with a water-based polyurethane coating, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com