Hyperbranched structure-containing asphalt pavement joint sealant and preparation method thereof

A technology for asphalt pavement and joint filler, which is applied in the direction of asphalt material adhesive, adhesive, adhesive type, etc. Increase road maintenance costs and other issues to achieve good market development prospects, low costs, and high elastic recovery rates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

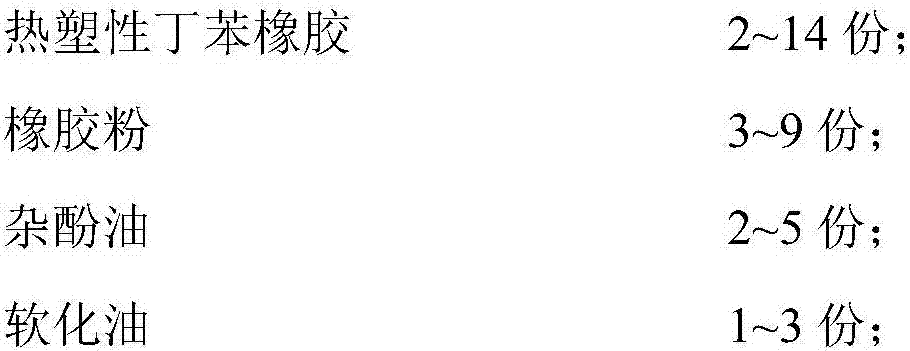

[0032] An asphalt pavement joint filler containing a hyperbranched structure, mainly made of the following components by weight: see Table 1.

[0033] Each component weight part of table 1 embodiment one

[0034]

[0035]

[0036] The above-mentioned asphalt pavement joint filler containing hyperbranched structure is prepared by the following method:

[0037] Measure the base asphalt and heat it to 130-150°C, transport it to the mixing tank, then add the measured auxiliary additives and stir for 30 minutes to obtain the mixture, then raise the temperature of the mixture to 150-170°C and send it to the colloid mill for grinding for 2- After 3 times, it is transported to the mixing tank, and the temperature of the ground mixture is raised to 190°C, then the metered composite modifier is added, and after stirring for 1 hour, the temperature of the mixture is lowered to 160-170°C, and the metered After the hyperbranched polymer is dissolved in an organic solvent, it is adde...

Embodiment 2

[0039] An asphalt pavement joint filler containing a hyperbranched structure, mainly made of the following components by weight: see Table 2.

[0040] Each component weight part of table 2 embodiment two

[0041]

[0042] The preparation method of the above-mentioned asphalt pavement joint filler containing hyperbranched structure is the same as that of Example 1.

Embodiment 3

[0044] An asphalt pavement joint filler containing a hyperbranched structure, mainly made of the following components by weight: see Table 3.

[0045] Each component weight part of table 3 embodiment three

[0046]

[0047] The preparation method of the above-mentioned asphalt pavement joint filler containing hyperbranched structure is the same as that of Example 1.

[0048] In the above-mentioned Examples 1-3, in order to make the present invention obtain better bonding properties, the hyperbranched polymer is a hydroxyl-terminated hyperbranched polyamide-ester, and the hydroxyl-terminated hyperbranched polyamide-ester is prepared by the following method :

[0049] (1) Add a certain amount of diethanolamine in a three-necked flask equipped with a thermometer, a stirrer, and a constant pressure funnel, and then add dimethylacetamide in the three-necked flask until the diethanolamine is completely dissolved; take a certain amount of phthalamide Put the acid anhydride in a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com