Patents

Literature

1112results about "Alkali metal silicates" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

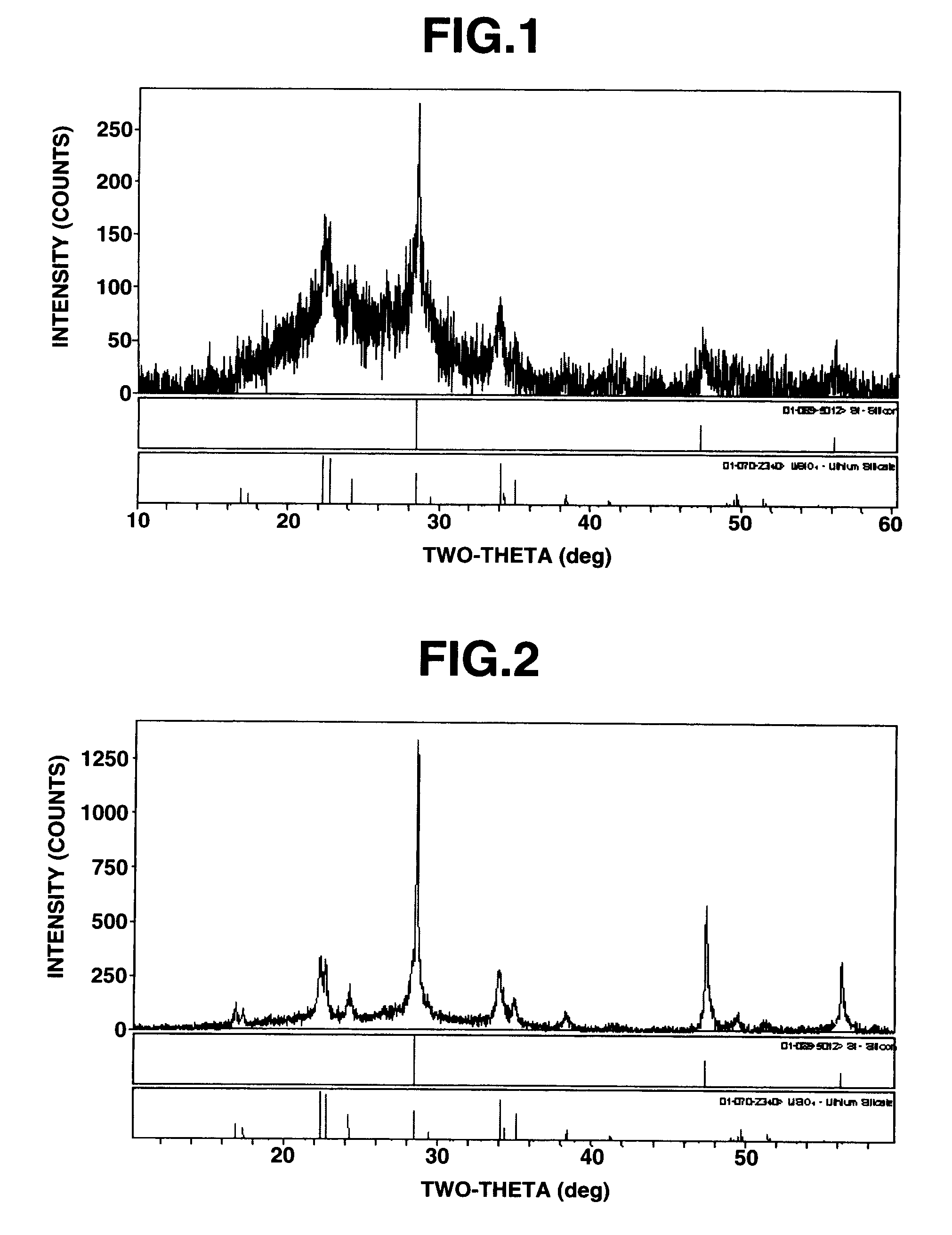

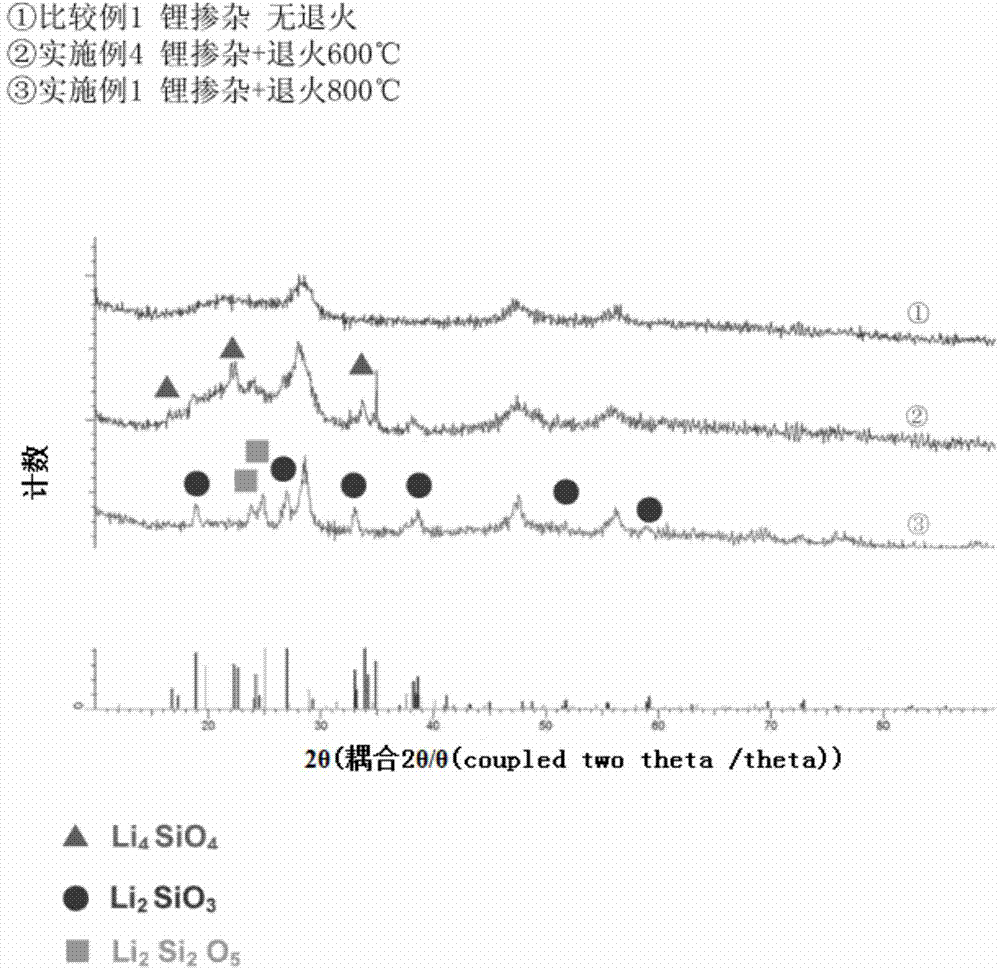

Silicon-silicon oxide-lithium composite, making method, and non-aqueous electrolyte secondary cell negative electrode material

ActiveUS20070224508A1Improve initial efficiencyImprove cycle performanceSecondary cellsNegative electrodesOxide compositeSilicon oxide

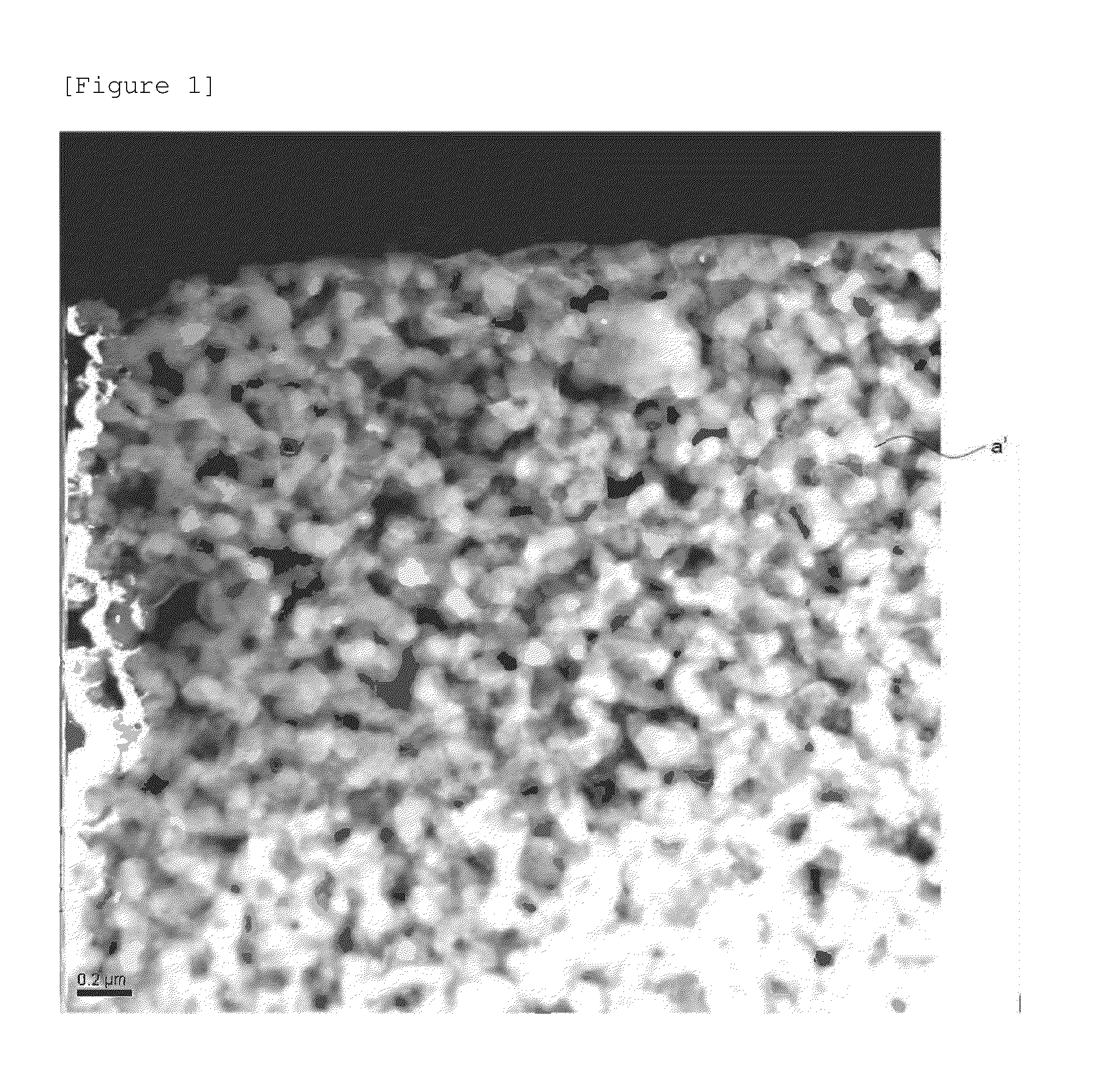

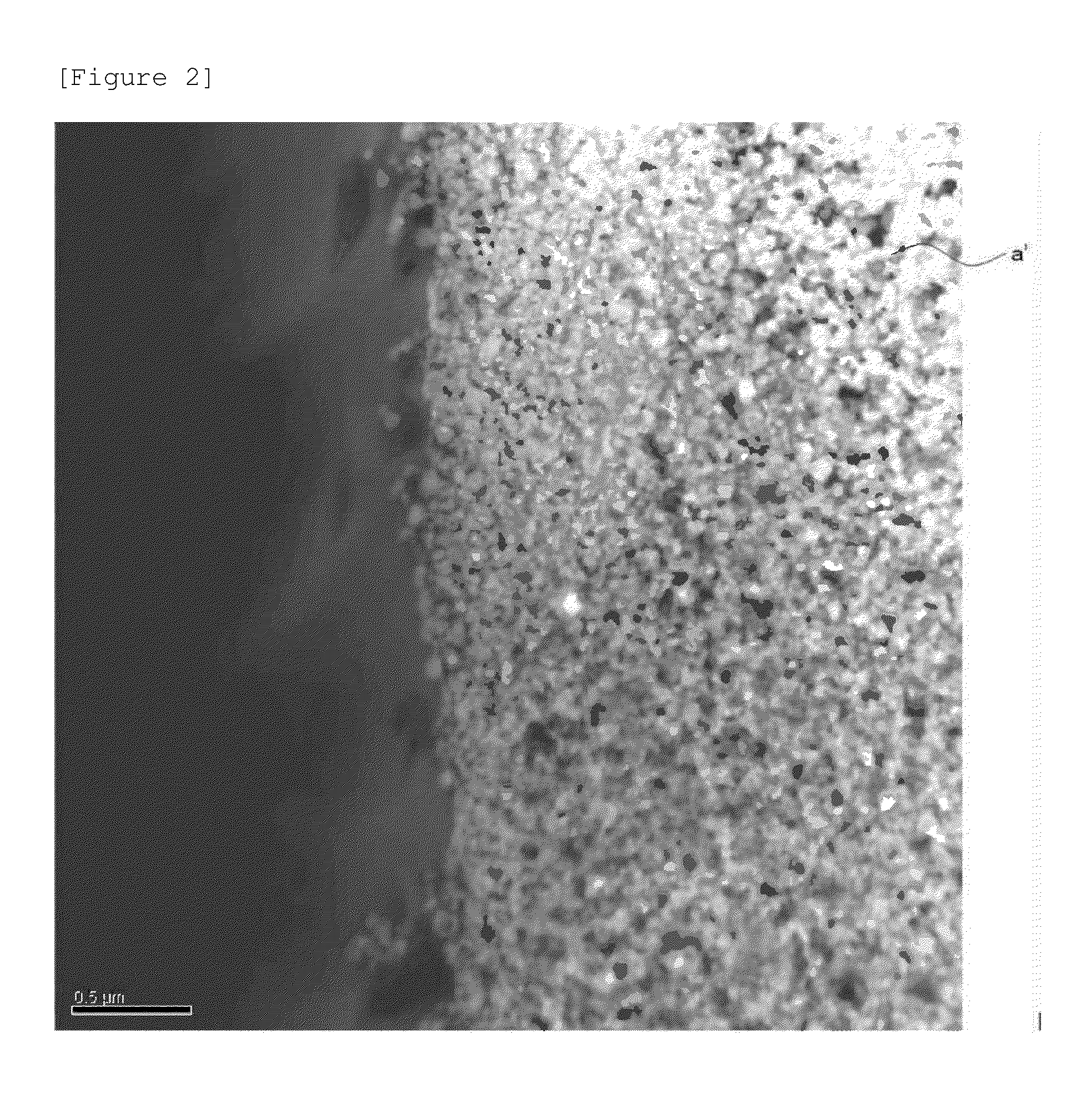

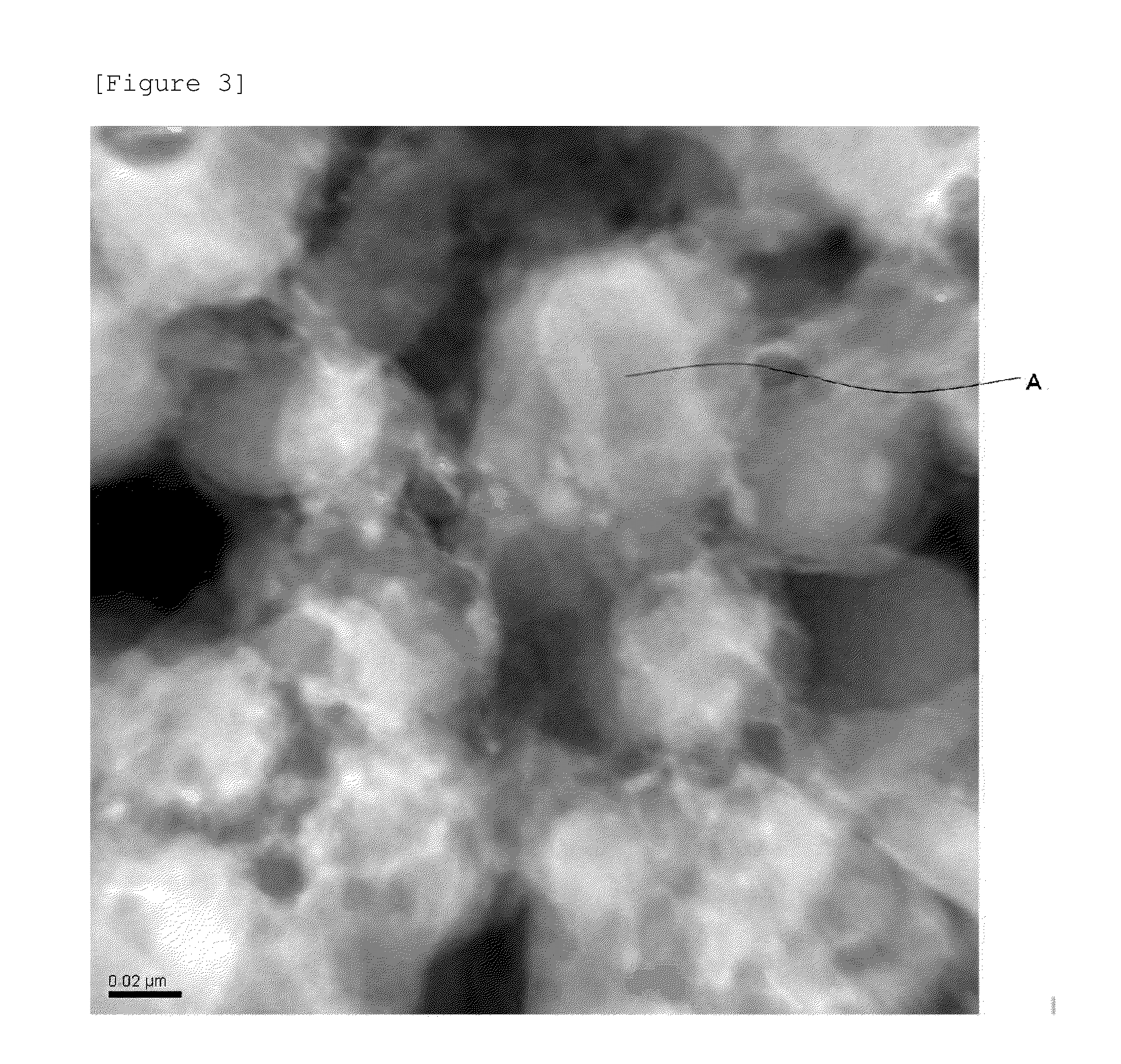

A silicon-silicon oxide-lithium composite comprises a silicon-silicon oxide composite having such a structure that silicon grains having a size of 0.5-50 nm are dispersed in silicon oxide, the silicon-silicon oxide composite being doped with lithium. Using the silicon-silicon oxide-lithium composite as a negative electrode material, a lithium ion secondary cell having a high initial efficiency and improved cycle performance can be constructed.

Owner:SHIN ETSU CHEM IND CO LTD

Method for quick-speed preparing aerogel by hydro-thermal synthesis at low cost

InactiveCN101456569AReduce surface tensionIntegrity guaranteedSilicaAlkali metal silicatesReaction temperatureHydrothermal synthesis

The invention discloses a method for preparing aerogel materials by combining hydrothermal synthesis technology and sol-gel technology. The prepared aerogel comprises one or more of alumina aerogel, silica aerogel, zirconia aerogel and titania aerogel. The method comprises the following steps: mixing a reactant and a structure-directing agent according to certain proportion, and adding a pH value control agent to adjust the pH value; sealing hydrothermal reaction equipment, heating the mixture to be between 50 and 280 DEG C, making the mixture stand for 0 to 72 hours, raising the temperature to be between 60 and 300 DEG C, and continuously reacting for 0.1 to 72 hours; and cooling gel, taking out the gel, drying the gel and obtaining the aerogel. Compared with the prior art, the method has low reaction temperature and pressure, small equipment investment and simple and controllable technology, reduces potential safety hazards, greatly improves the preparation speed of the aerogel, saves the production cost, and is favorable to realize commercial mass production.

Owner:纳诺科技有限公司 +1

Pharmaceutical excipient having improved compressibility

InactiveUS6217909B1Improve compression performanceReduce the amount requiredInorganic/elemental detergent compounding agentsPowder deliverySilica particleSilicon dioxide

Owner:J RETTENMAIER & SOEHNE GMBH CO KG ROSENBERG

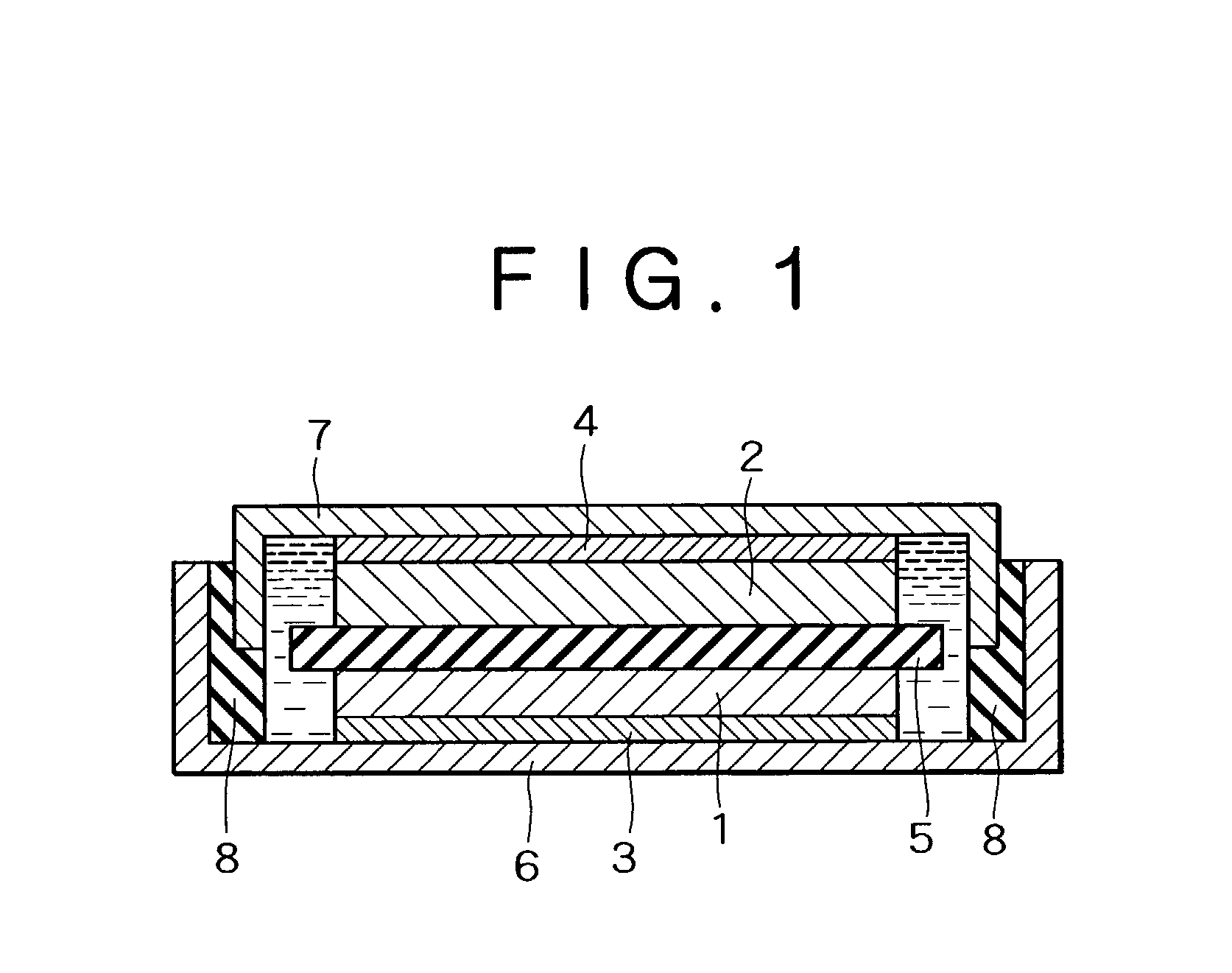

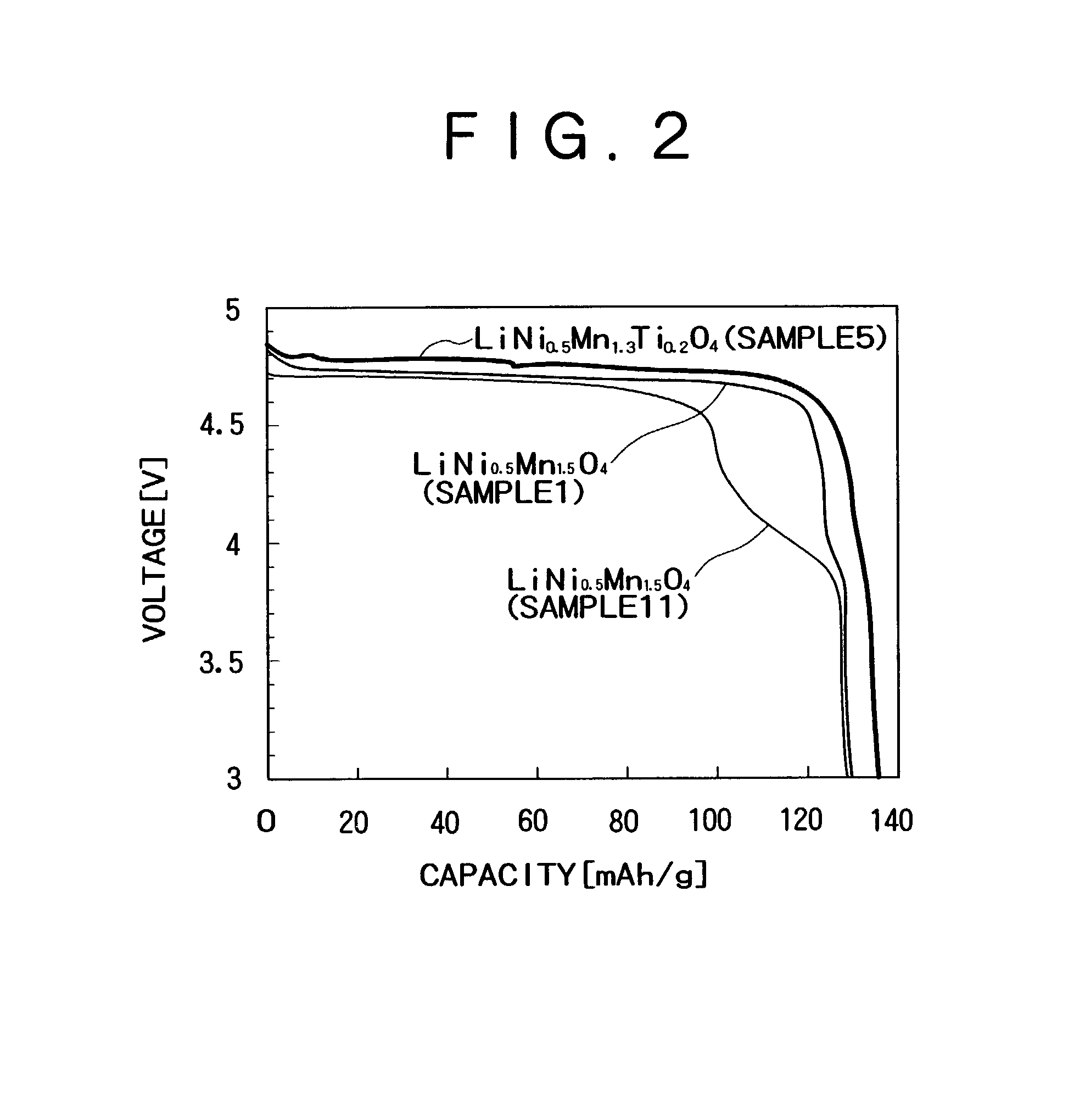

Positive electrode active material, positive electrode and non-aqueous electrolyte secondary battery using thereof

ActiveUS7026070B2Large capacityIncrease energy densityElectrode manufacturing processesSecondary cellsHigh energyManganese

A positive electrode active material for a secondary battery contains a spinel lithium manganese composite oxide expressed by a general formula of Lia(MxMn2−x−yAy)O4 where x and y are positive values which satisfy 0.4<x, 0<y, x+y<2, and 0<a<1.2. “M” denotes Ni and at least one metal element selected from the group consisting of Co, Fe, Cr and Cu. “A” denotes at least one metal element selected from the group consisting of Si and Ti. The ratio y of A has a value of 0.1<y in case where A includes only Ti. Accordingly, it is possible to acquire a material for the positive electrode of a lithium ion secondary battery, which has a high capacity and a high energy density with a high voltage of 4.5 V or higher with respect to Li.

Owner:NEC CORP

Silicon-silicon oxide-lithium composite, making method, and non-aqueous electrolyte secondary cell negative electrode material

ActiveUS7776473B2Improve efficiencyImprove cycle performanceNegative electrodesSecondary cellsOxide compositeSilicon oxide

A silicon-silicon oxide-lithium composite comprises a silicon-silicon oxide composite having such a structure that silicon grains having a size of 0.5-50 nm are dispersed in silicon oxide, the silicon-silicon oxide composite being doped with lithium. Using the silicon-silicon oxide-lithium composite as a negative electrode material, a lithium ion secondary cell having a high initial efficiency and improved cycle performance can be constructed.

Owner:SHIN ETSU CHEM CO LTD

Precipitated silicic acid

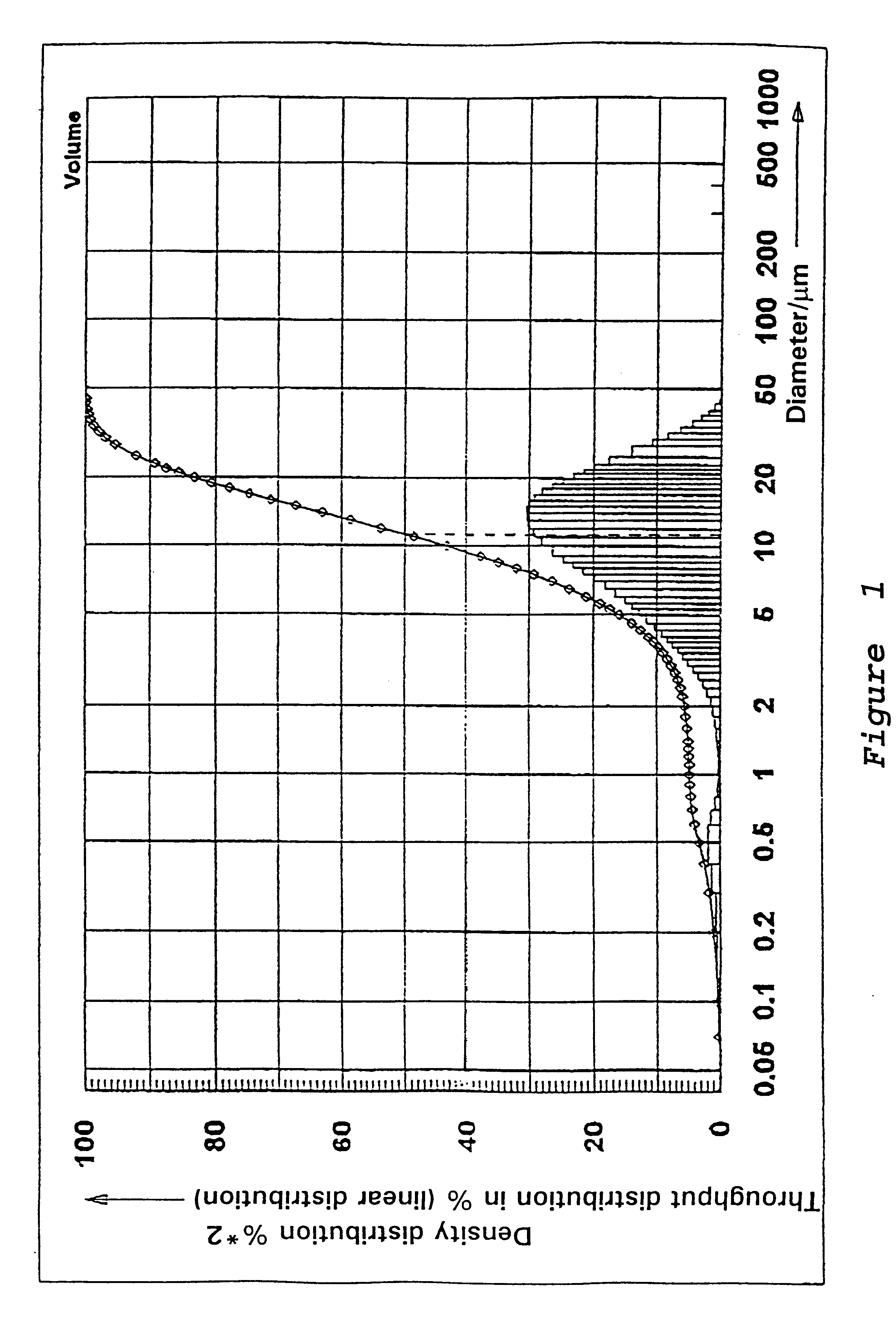

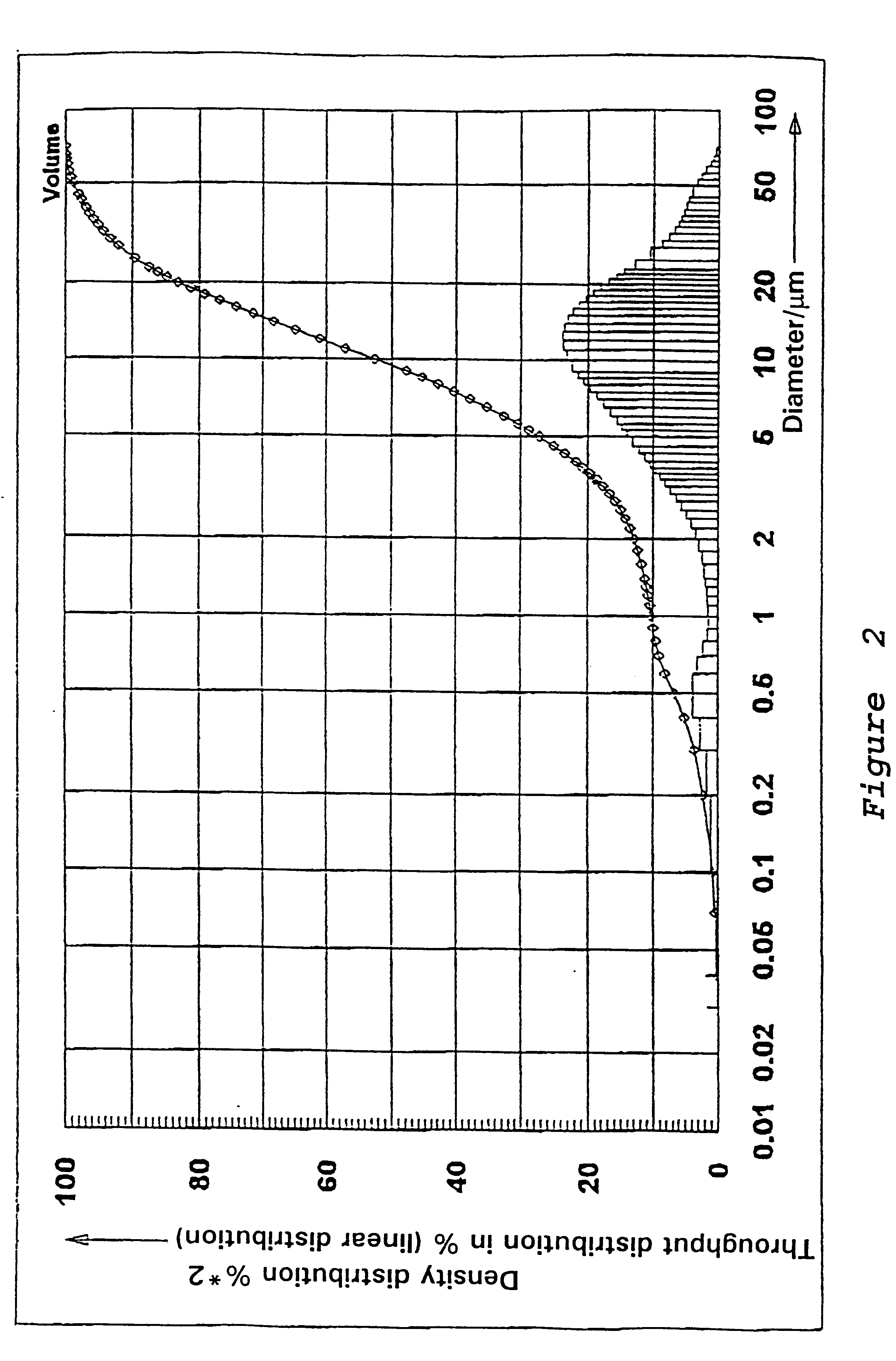

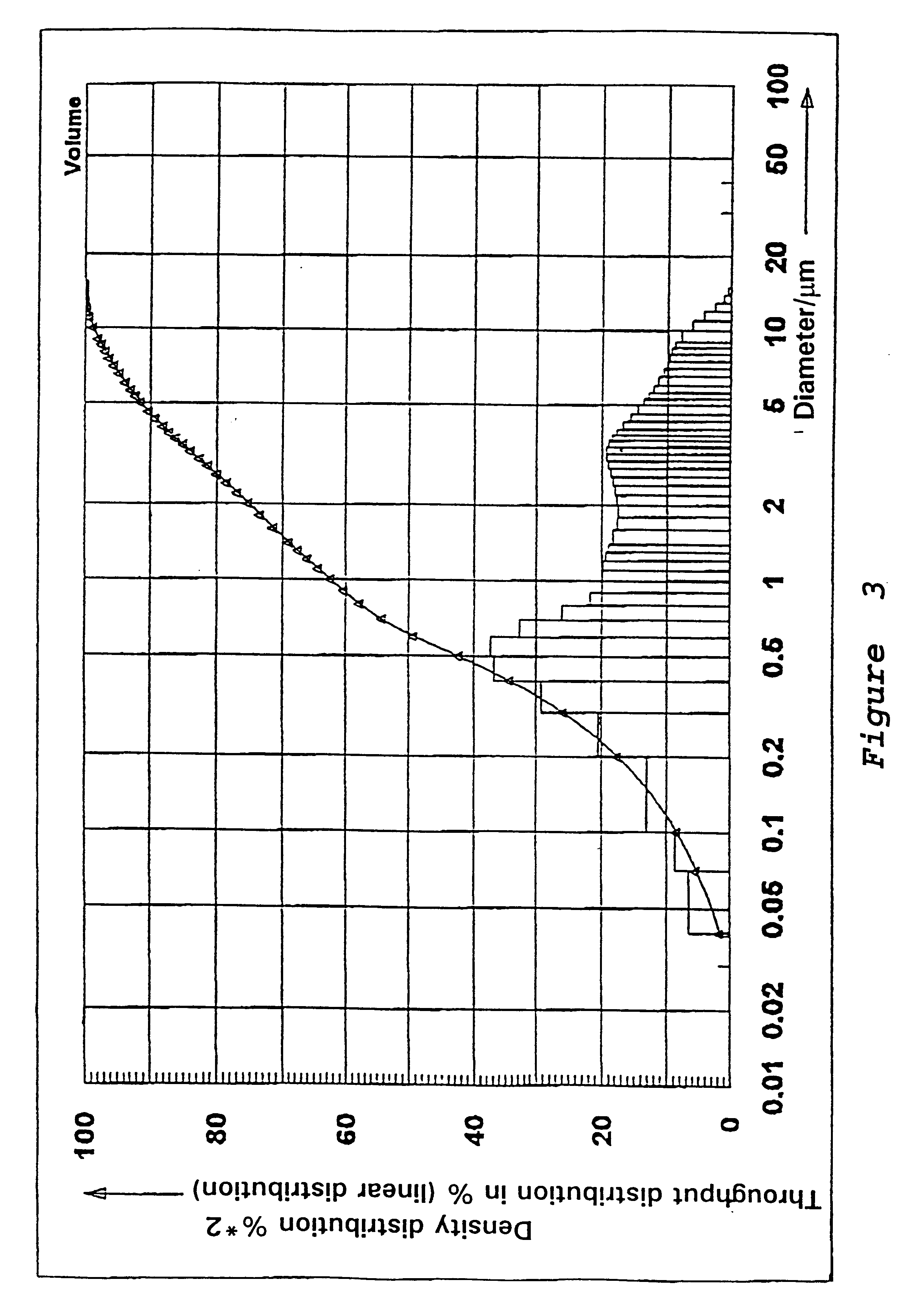

InactiveUS6268424B1Easily dispersible in tire carcassExtended service lifePigmenting treatmentSilicaSilicic acidPhysical chemistry

Precipitated silica having the following parameters:is prepared by reacting alkali silicate with mineral acids and aluminum sulfate solution at temperatures of 60-95° C. at a pH of 7.0-10.0 while stirring constantly, wherein the reaction is continued to a solids concentration of 40-110 g / l, the pH is adjusted to a value between 3 and 5, and the precipitated silica is filtered off, washed and then dried, and optionally ground or granulated.

Owner:EVONIK DEGUSSA GMBH

Lithium silicate glass ceramic

ActiveUS7867930B2Easy to shapeExcellent chemical durabilityDental implantsGlass drawing apparatusSilicate glassPhysical chemistry

Owner:IVOCLAR VIVADENT AG

Lithium silicate glass ceramic

ActiveUS7867933B2Easy to shapeExcellent chemical durabilityDental implantsAlkali metal silicatesLithiumSilicate glass

Owner:IVOCLAR VIVADENT AG

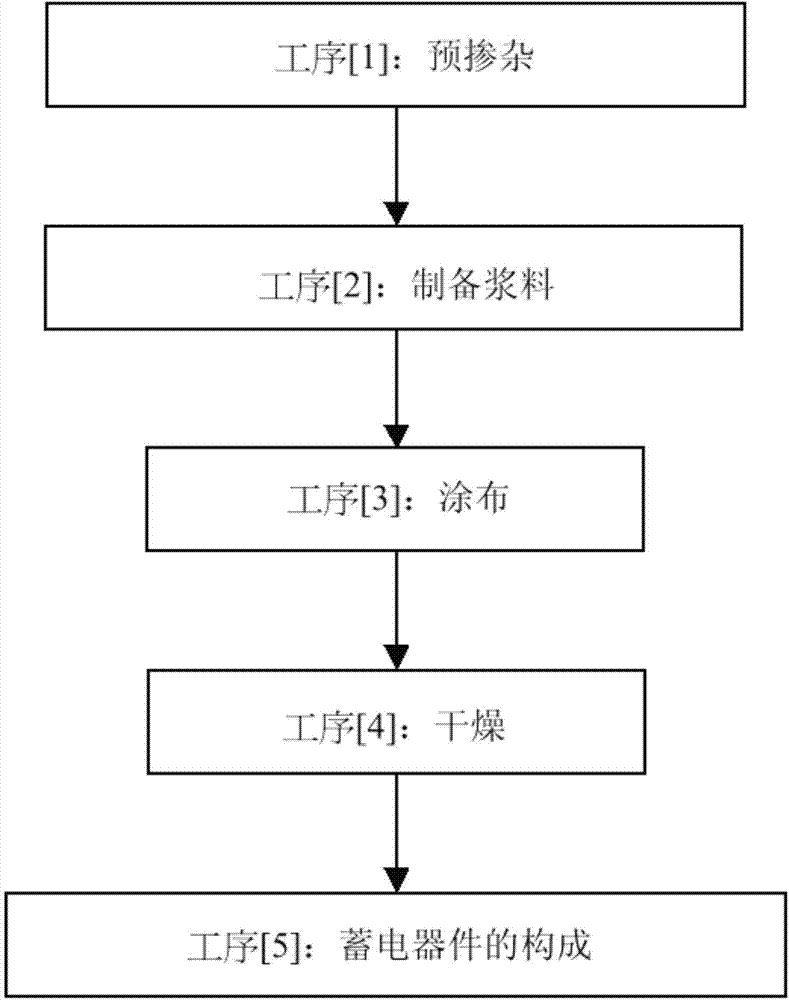

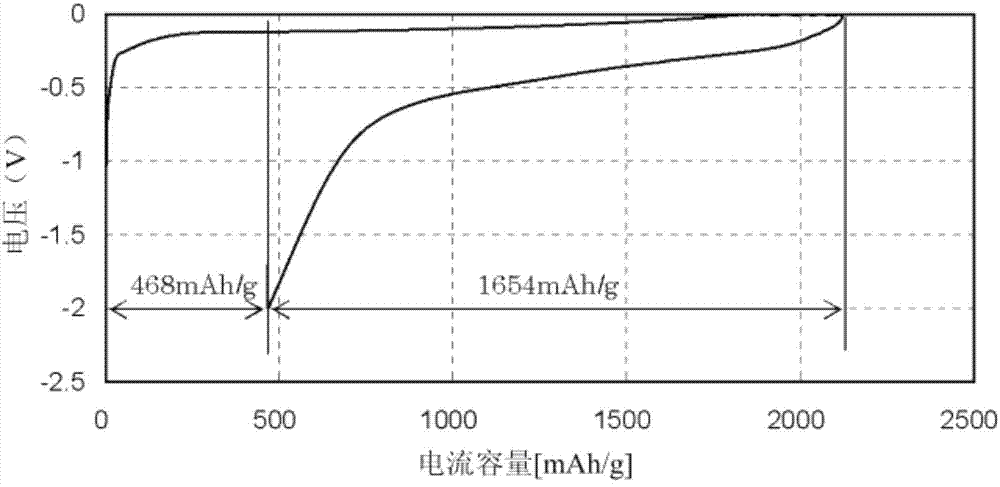

Cathode materials for electricity storage device, electrode for electricity storage device and electricity storage device, and method for manufacturing them

ActiveCN103840136AImprove initial charge and discharge efficiencyExcellent initial charge and discharge efficiencyElectrode thermal treatmentHybrid capacitor electrodesElectricityCharge discharge

The invention aims to provide a cathode materials for an electricity storage device and a method for manufacturing them; the cathode materials for the electricity storage device uses Si series material with excellent primary charge-discharge efficiency and stability in the atmosphere; furthermore, the invention also provides an electricity storage device electrode containing the cathode materials and the electricity storage device, and the method for making them; the making method of the cathode material for the electricity storage device is provided; the Si series material adsorbing releasing li-ions and Li metal can be mixed in solvent; and thermo processing is carried out after the mixture so as to form lithium silicate, thereby making the cathode material with pre-doped Li.

Owner:SHIN ETSU CHEM IND CO LTD

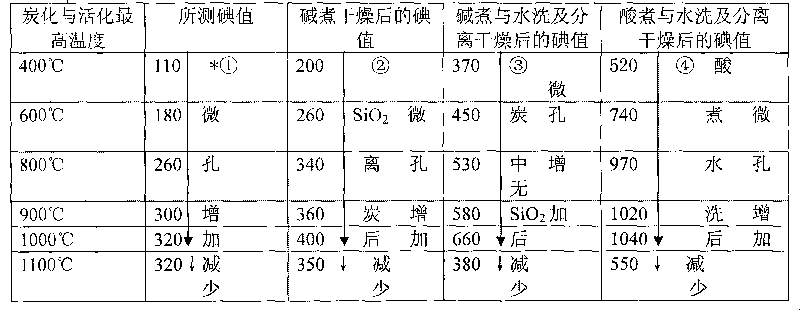

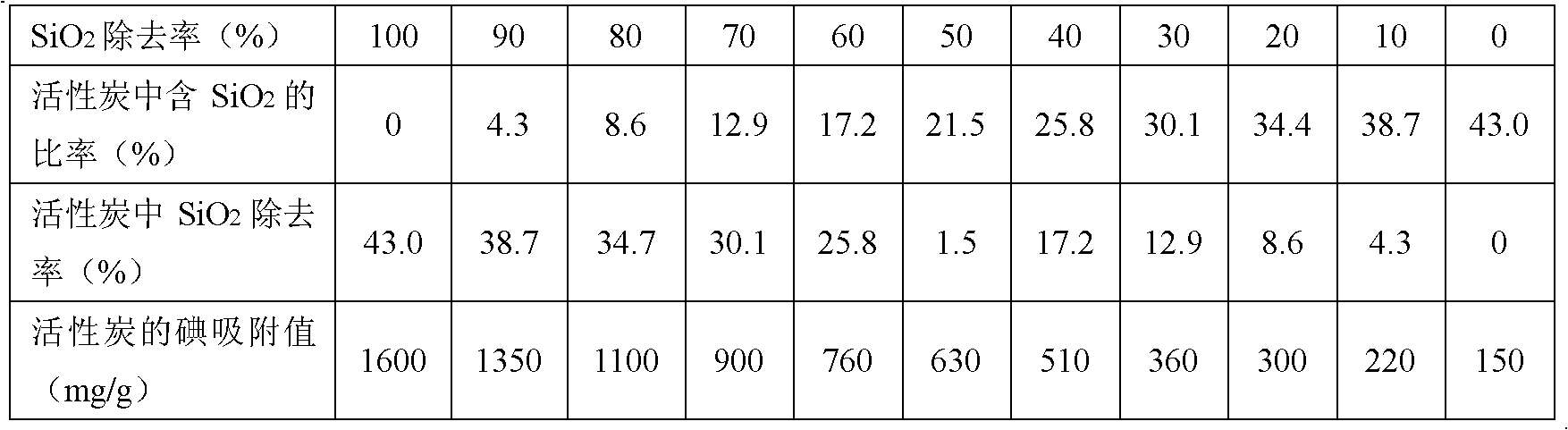

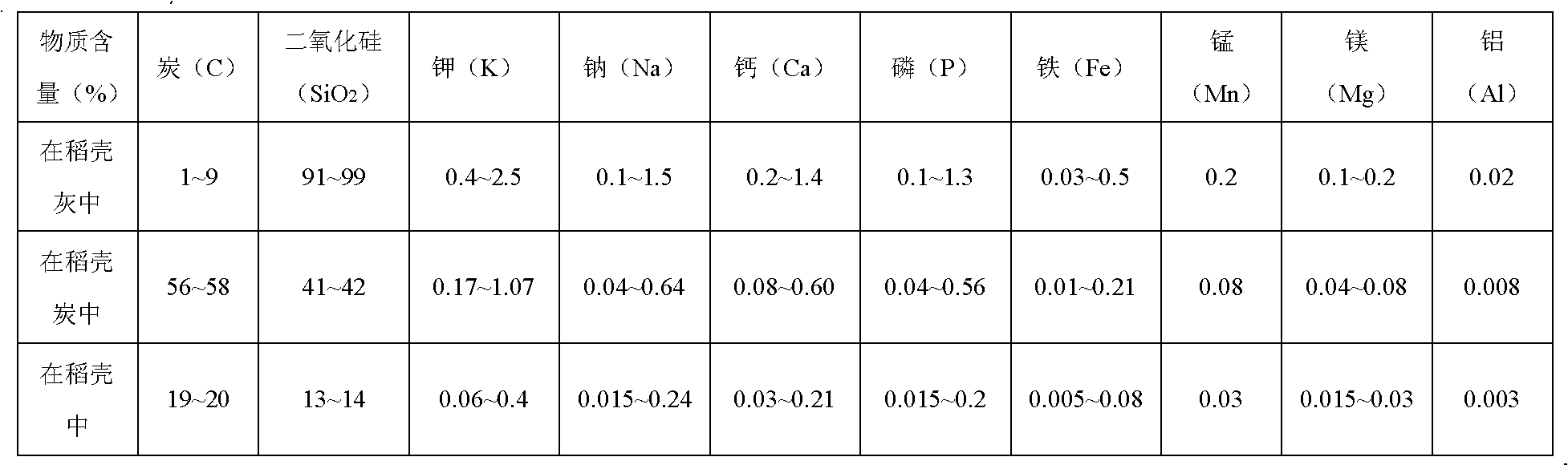

Method for preparing high mode number waterglass and active carbon by rice hull ash

The invention relates to a method for preparing high-mode water glass and activated carbon from rice husk ash, which is characterized by comprising: micro-milling, heating of an alkali liquor, reaction, filtration, washing by boiling water, acid leaching, filtration and washing, drying, secondary activation, water washing, drying, and crushing. The method has the advantages that the method adopts the rice husk ash as a raw material to prepare the activated carbon, and the rice husk ash not only has low cost but also dose not contain harmful substances, so that the method fully and comprehensively utilizes rice husks, and not only achieves the aim of using waste materials as resources but also protects the environment.

Owner:NANCHANG UNIV

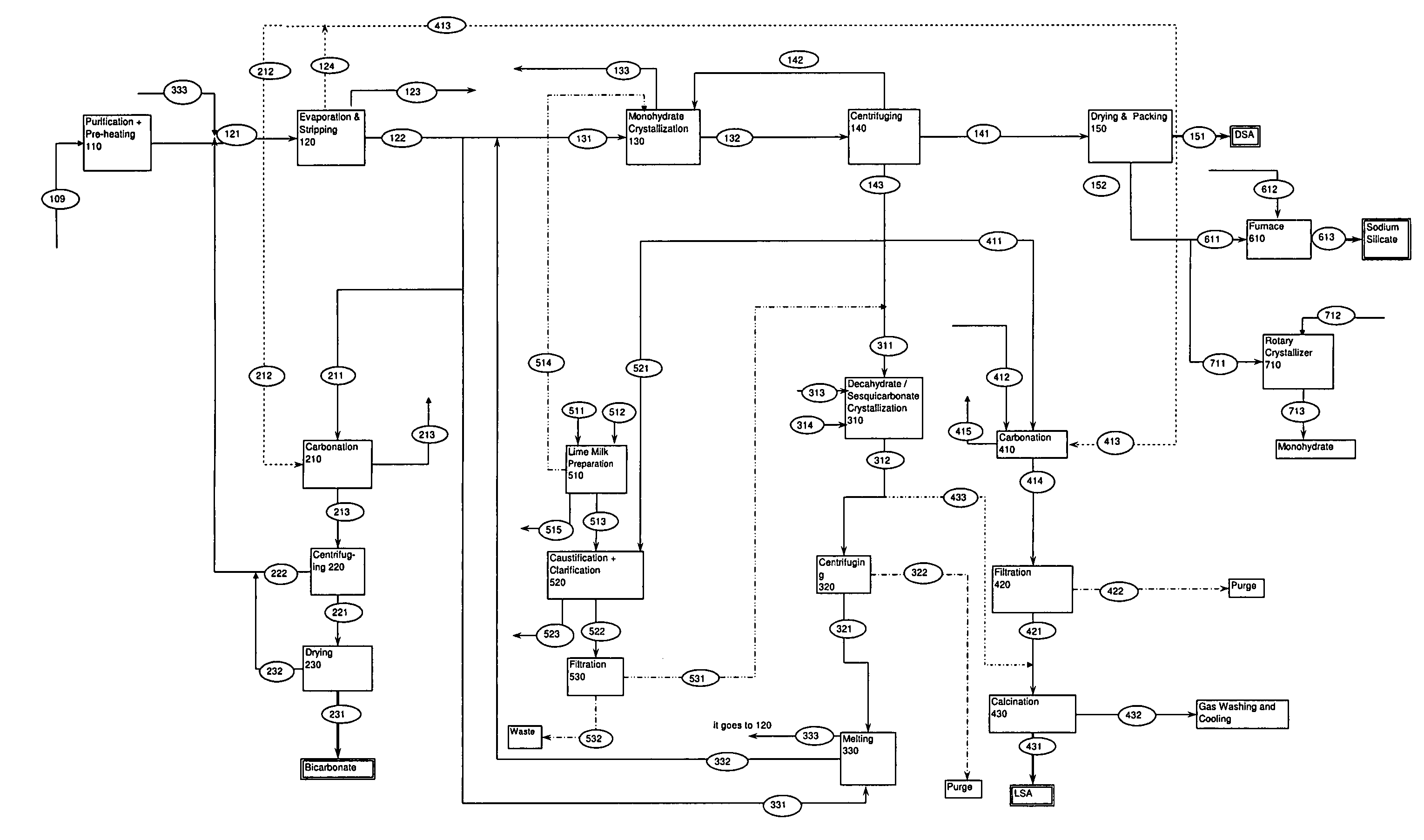

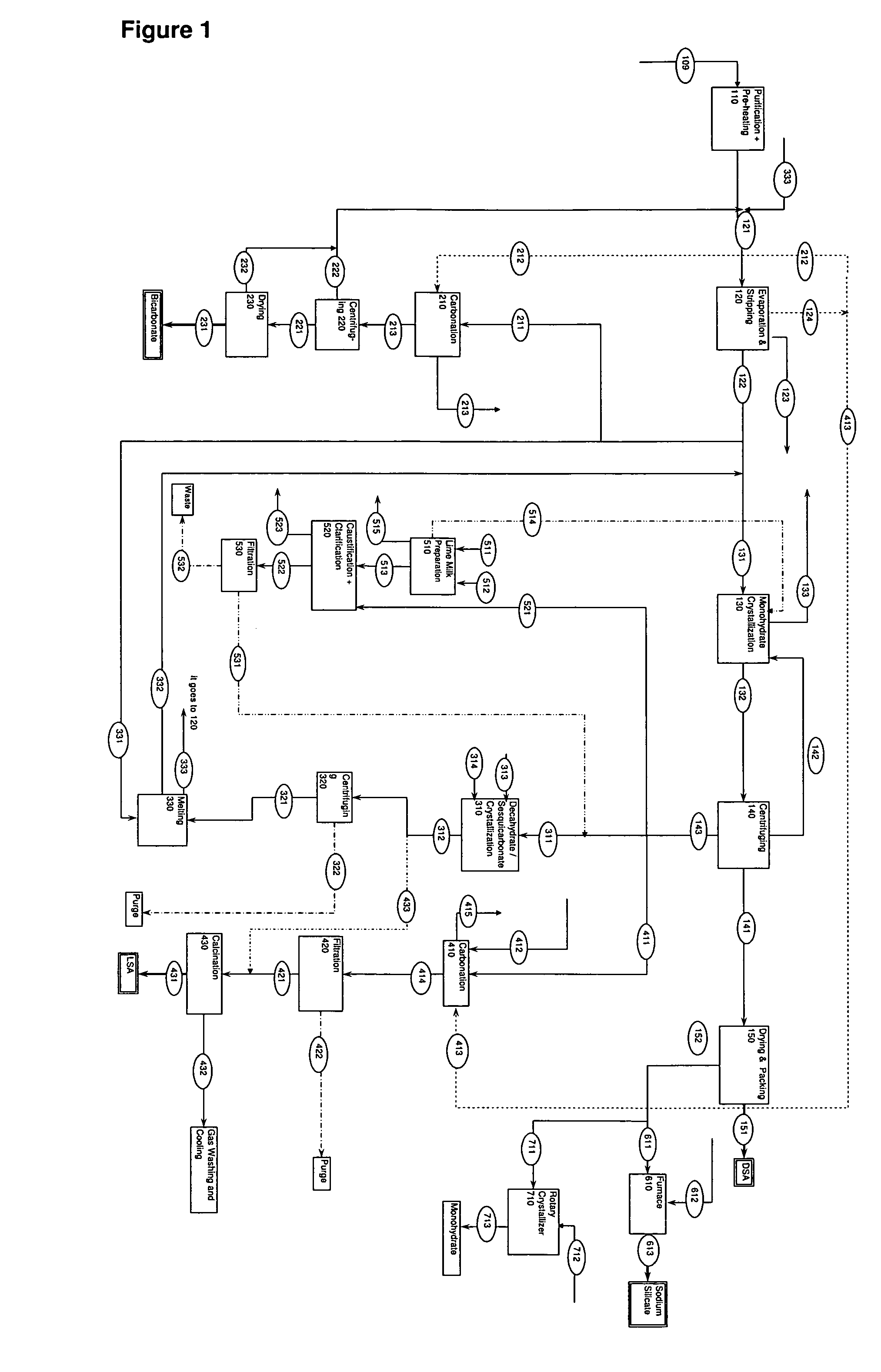

Process for production of dense soda, light soda, sodium bicarbonate and sodium silicate from solutions containing bicarbonate

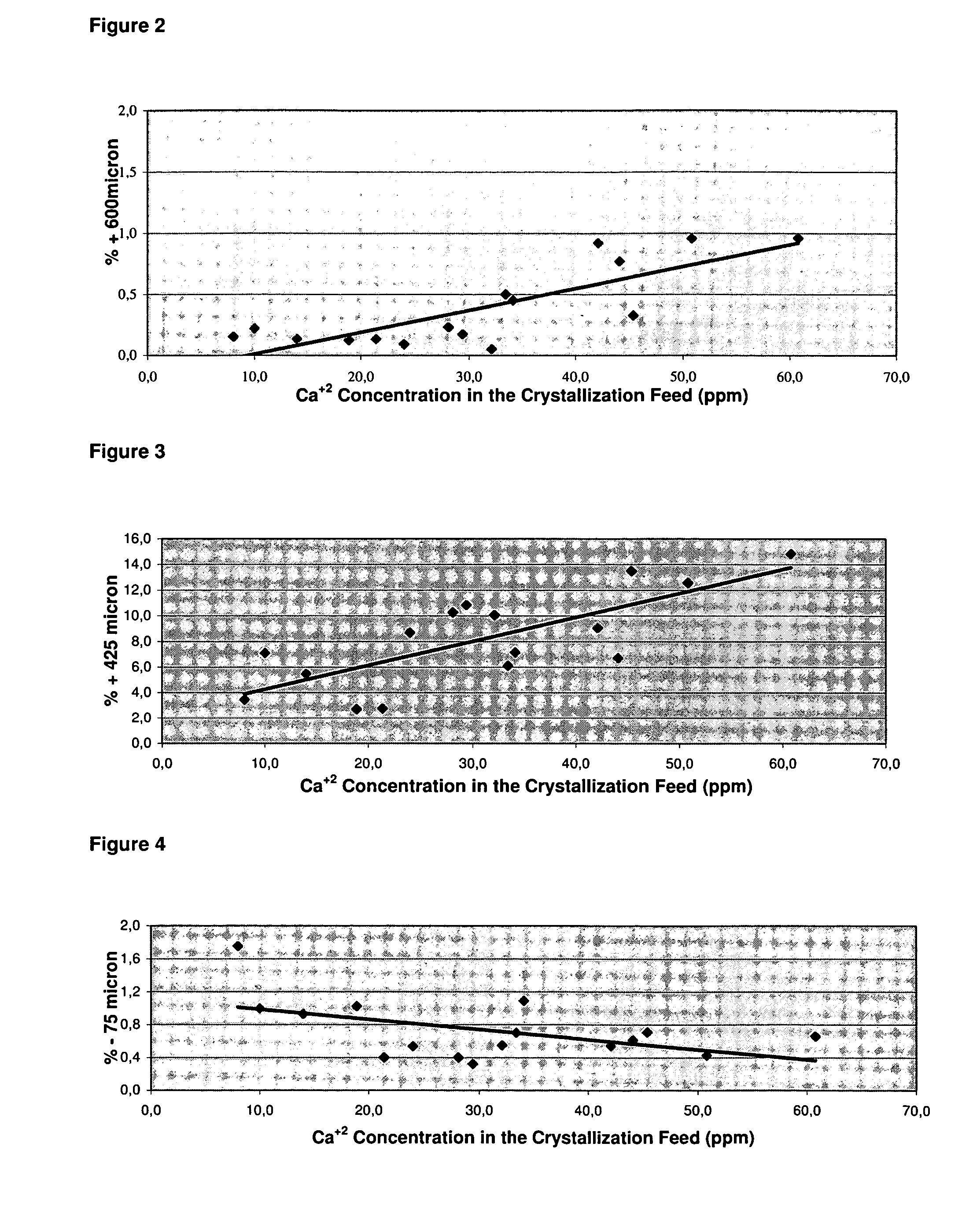

ActiveUS7507388B2Processing requirementLow production costCrystallization separationAlkali metal silicatesSodium bicarbonateEvaporation

A process related to sodium chemicals production, including the processing of bicarbonate containing solutions obtained by solution mining of trona, nahcolite or wegscheiderite reserves and the lake waters containing bicarbonates, includes the steps of purification, evaporation-decarbonation, crystallization, centrifuging, and drying.

Owner:ETI SODA URETIM PAZARLAMA NAKLIYAT & ELEKTRIK URETIM SANAYI & TICARET A S

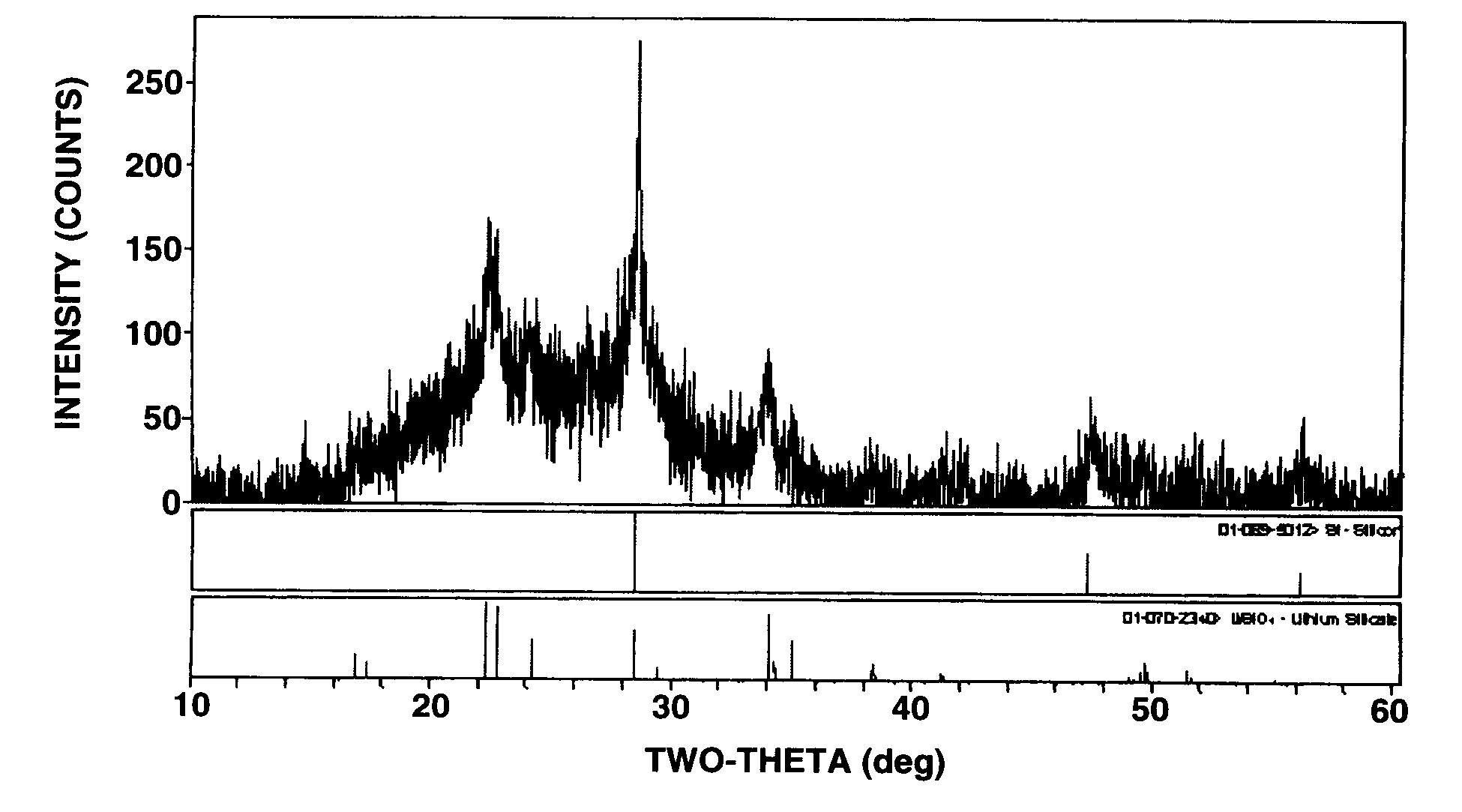

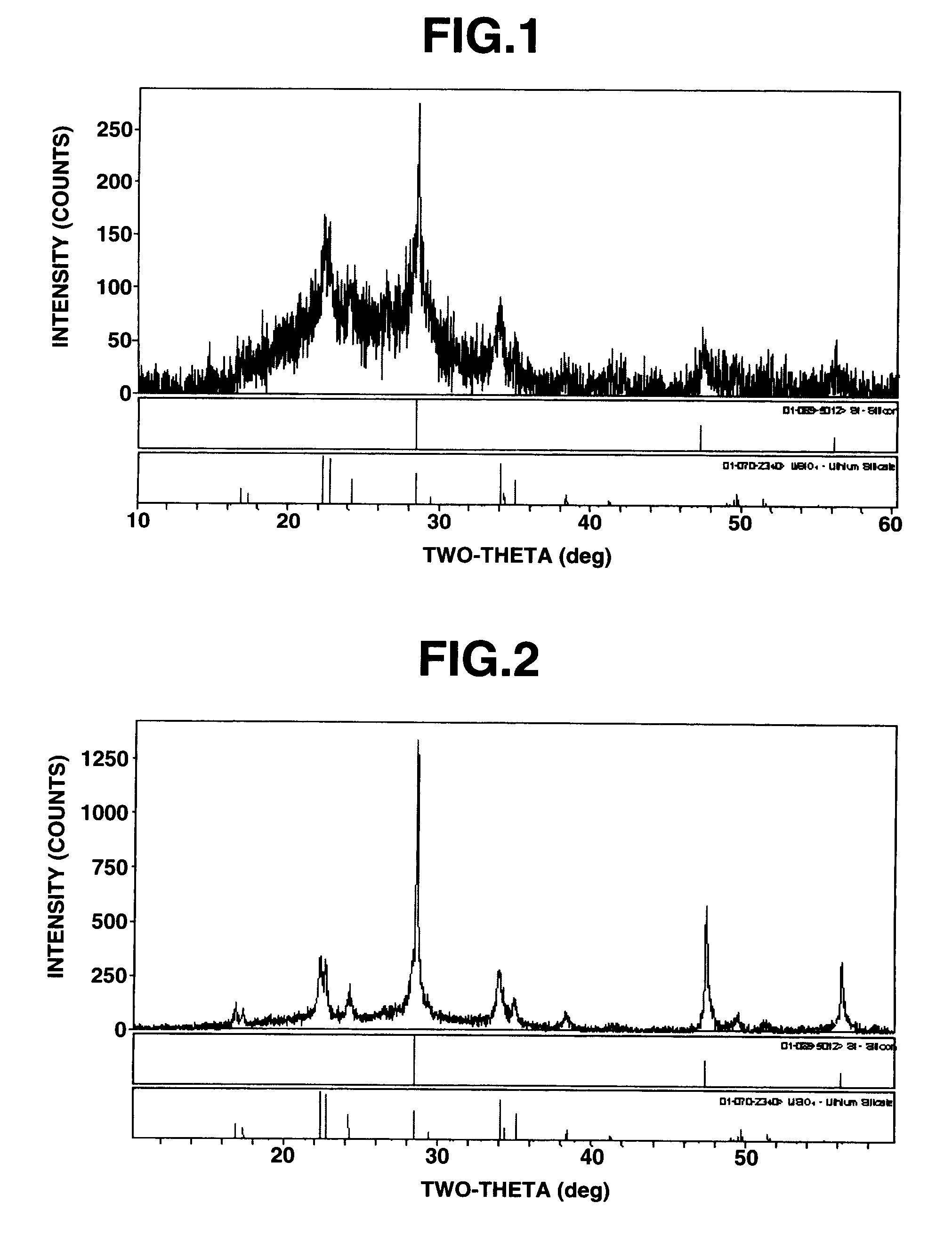

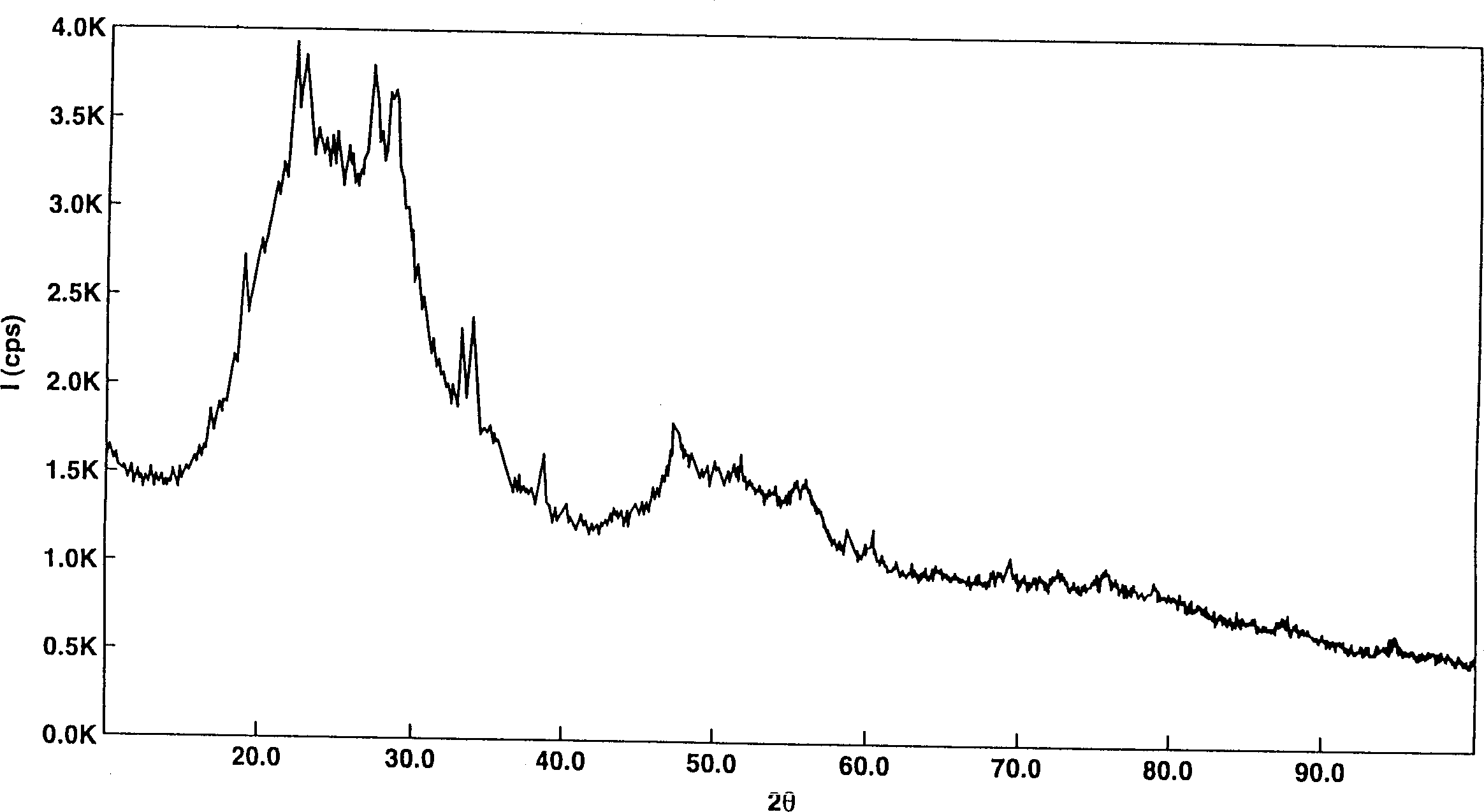

Cathode active material, cathode, secondary battery and manufacturing methods for the same

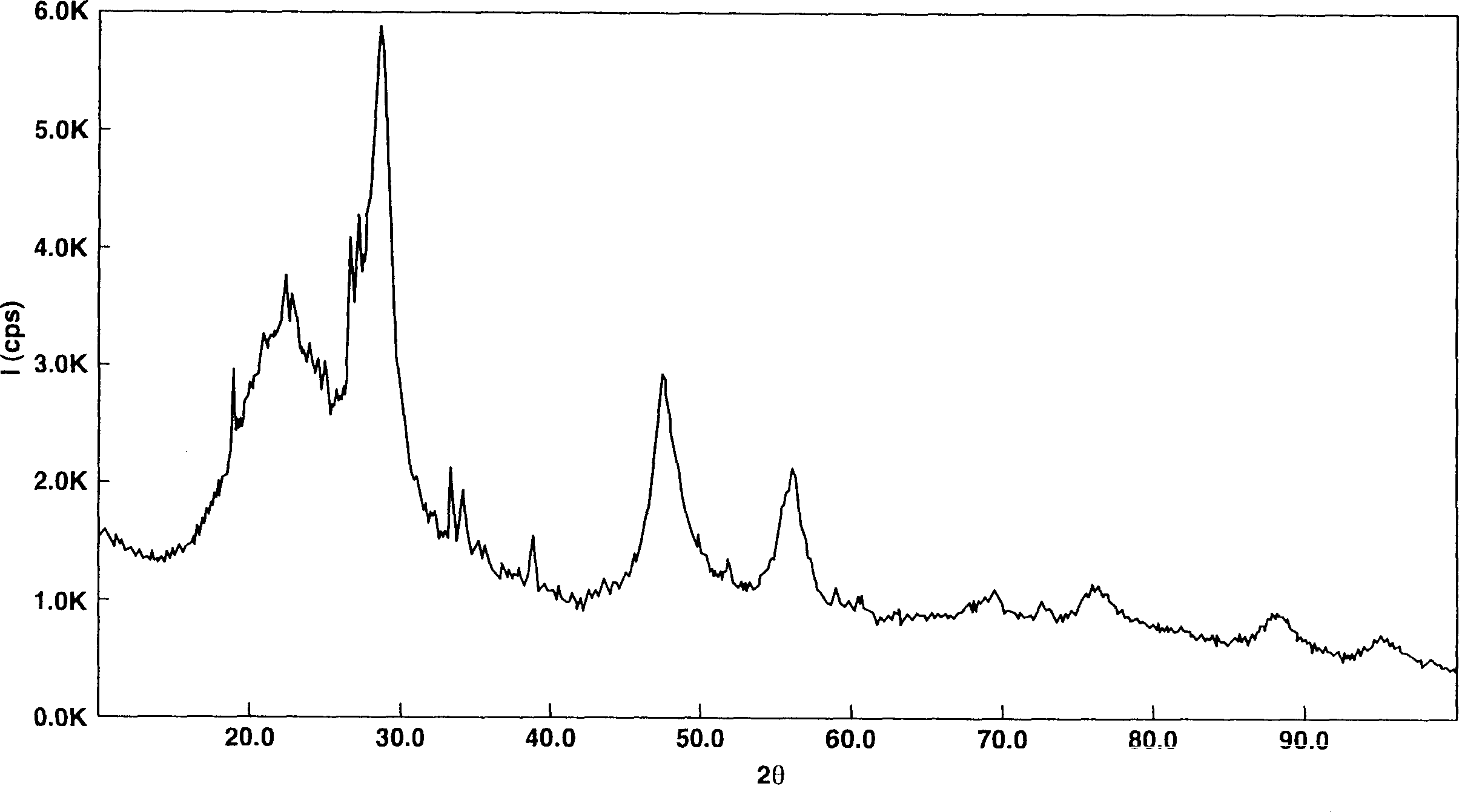

ActiveUS20130052544A1Improve discharge capacityIntercalation is facilitatedMaterial nanotechnologyPhosphatesX-rayRoom temperature

An object of the present invention is to provide a cathode active material which contains small-particle sized and low-crystalline lithium transition metal silicate and which undergoes charge-discharge reaction at room temperature.The cathode active material for a non-aqueous electrolyte secondary battery is characterized by containing a lithium transition metal silicate and exhibits diffraction peaks having half widths of 0.175 to 0.6°, the peaks observed through powder X-ray diffractometry within a 2θ range of 5 to 50°.

Owner:FURUKAWA ELECTRIC CO LTD +1

Preparation method of Li2FeSiO4 cathode material used for controlling Fe3P

InactiveCN101734675ALow costWide variety of sourcesCell electrodesAlkali metal silicatesPhosphorous acidWater baths

The invention relates to a preparation method of Li2FeSiO4 cathode material used for controlling Fe3P. The technical scheme comprises the following steps: weighting lithium salt or hydrate of lithium salt, ferrous salt or hydrate of ferrous salt, silicon compound and phosphorous acid or aqueous solution of phosphorous acid according to a molar ratio of the reactants that Li<+>:Fe<2+>:Si:H3PO3=0.95-1.10:0.95-1.10:0.70-0.999:0.001-0.429, mixing the reactants, then adding carbon-containing compound which accounts for 1wt%-20wt% of anhydrous reactants and wet grinding medium which accounts for 0.10-10 times of anhydrous reactants by volume, mixing with a ball mill, heating with water bath, mixing with a ball mill again, heating and drying in vacuum, and then using the two-stage sintering process or temperature programmed two-stage sintering process to prepare Li2FeSiO4 with controllable Fe3P under inert atmosphere or weak reduction atmosphere. The material prepared by the method of the invention has better discharge performance, the discharge capacity is significantly increased in 2.9V zone and the cycle performance is good under 0.3C current.

Owner:FUJIAN NORMAL UNIV

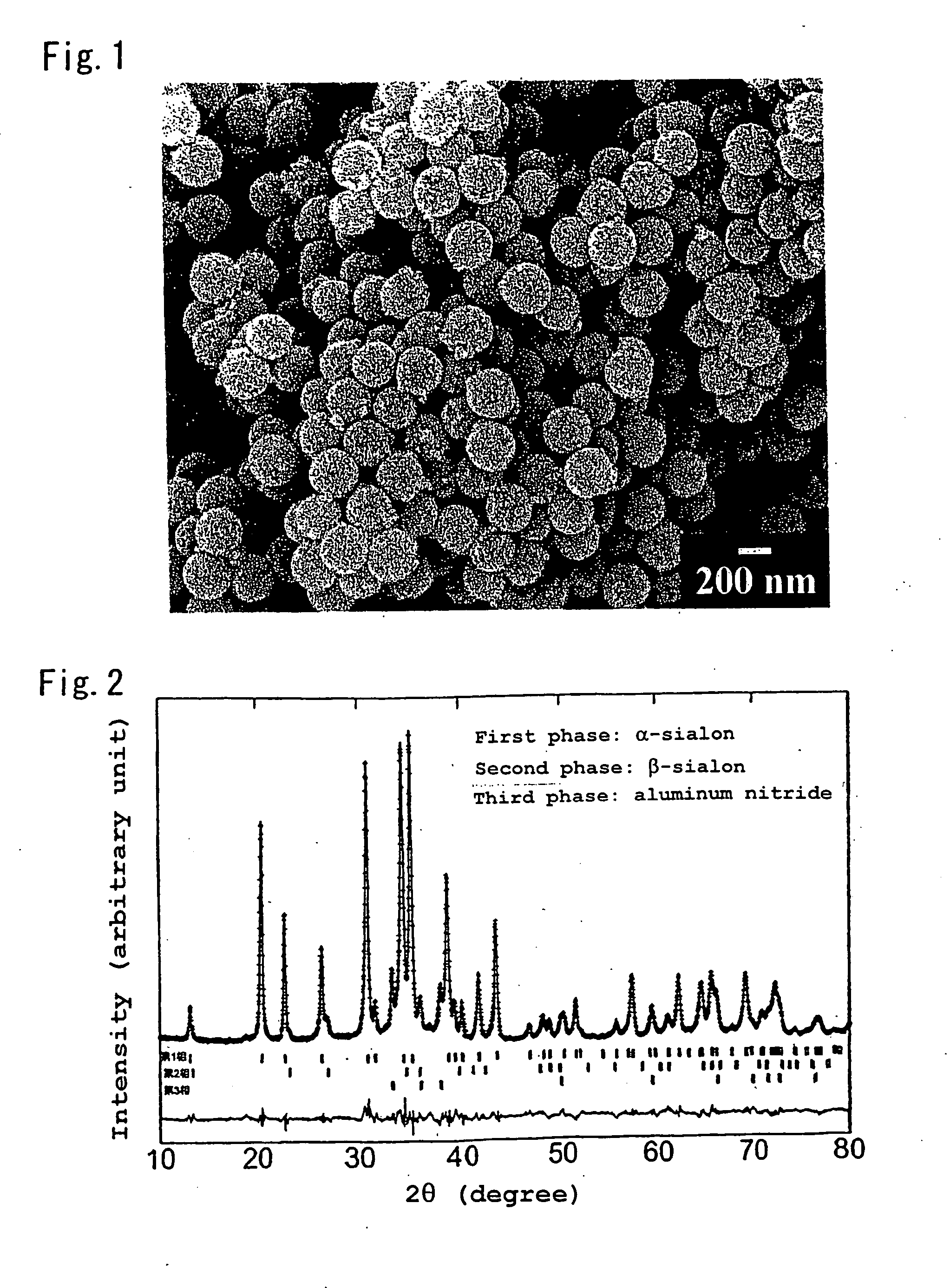

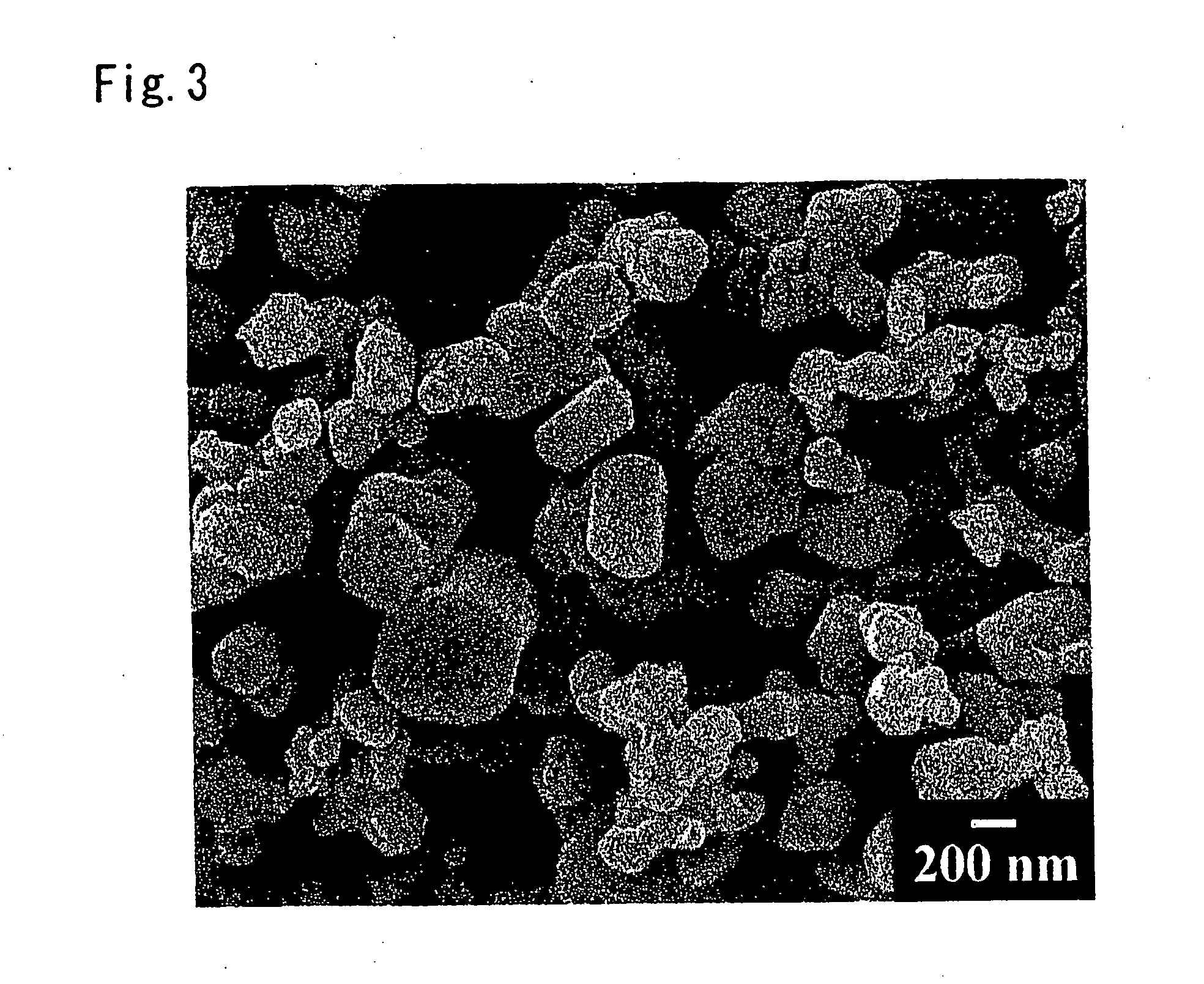

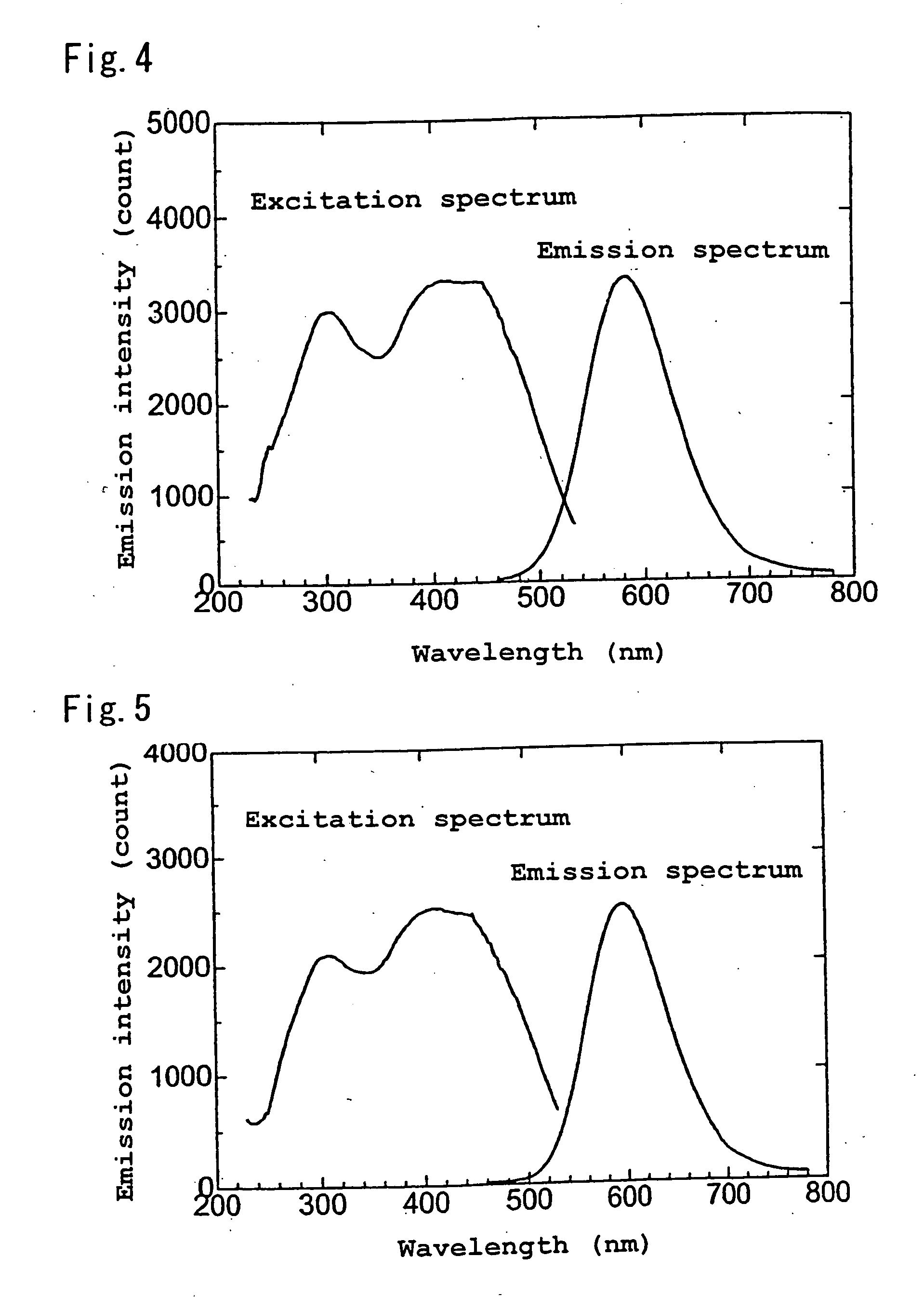

Oxynitride powder and production method thereof

ActiveUS20070166218A1Low oxygenHigh nitrogen contentAluminium compoundsAluminium silicatesPhosphorNitrogen

It is aimed at providing an oxynitride powder, which is suitable for usage as a phosphor, is free from coloration due to contamination of impurities, and mainly includes a fine α-sialon powder. An oxynitride powder is produced by applying a heat treatment in a reducing and nitriding atmosphere, to a precursor compound including at least constituent elements M, Si, Al, and O (where M is one element or mixed two or more elements selected from Li, Mg, Ca, Sr, Y, La, Ce, Pr, Nd, Sm, Eu, Gd, Tb, Dy, Ho, Er, Tm, Yb, and Lu), thereby decreasing an oxygen content and increasing a nitrogen content of the precursor.

Owner:NAT INST FOR MATERIALS SCI

Process for the produciton of synthetic magnesium silicate compositons

InactiveUS20060147367A1Improved rheological propertiesShort reaction timeAlkaline-earth metal silicatesAlkali metal silicatesSynthetic magnesium silicateCrystal structure

A method for the preparation of a synthetic magnesium silicate having a crystal structure similar to natural hectorite, includes the steps of a) forming a precursor slurry, b) subjecting the precursor slurry to a continuous hydrothermal reaction in a pipe reactor at a temperature of from 210° C. to 400° C. and under a pressure of at least 20 10 bar for 10 seconds to 4 hours, and e) washing and filtering to remove water soluble salts formed in the preparation of the precursor slurry. The precursor slurry is not washed and filtered before it is subjected to the continuous hydrothermal reaction.

Owner:ROCKWOOD ADDITIVES

Method for preparing high-modulus sodium silicate

InactiveCN101318663AWide variety of sourcesLow priceAlkali metal silicatesSilicic acidSODIUM SILICATE SOLN

The invention discloses a method for producing high-modulus sodium silicate at low temperature and normal pressure. The method comprises the following steps: the activated silicon dioxide from fly ash-typed industrial waste is leached by caustic lye of soda to produce low-modulus sodium silicate solution, the solution is decomposed by carbonation to prepare silicic acid (SiO2nH2O), then the silicic acid, the low-modulus sodium silicate and / or sodium hydroxide solution are mixed at the modulus index required by the final sodium silicate products and stirred to dissolve at temperature lower than liquid boiling point, therefore, the high-modulus sodium silicate is produced. Compared with the existing drying and wet methods for producing sodium silicate, the method of the invention has the advantages of wide raw material resources, low cost and energy consumption, no pollution; the method can be used for producing the sodium silicate with any modulus (M) from 1 to 4, in particular to the high-modulus sodium silicate, and has great industrialized generalization and application value.

Owner:PINGSHUO INDAL

Monox powder containing Li and its manufacture

A lithium ion secondary cell having a high capacity, improved first charge / discharge efficiency and improved cycle performance is obtainable using as the negative electrode material a lithium-containing silicon oxide powder having the formula: SiLixOy wherein x and y are 0 < x < 1.0 and 0 < y < 1.5, with the lithium being fused and partially crystallized.

Owner:SHIN ETSU CHEM IND CO LTD

Method for preparing aluminium sulphate, sodium silicate, and derivative products from coal slack

This invention relates to a method for producing aluminum sulfate, sodium silicate and their derivatives from gangue. The method comprises: crushing the gangue by a jaw crusher, torrefying to remove organic substances, pulverizing by a ball mill till 80% powder are 200 mesh or finer, placing the gangue powder in a reaction kettle, adding 46-60% sulfuric acid and reacting to obtain aluminum sulfate solution, filtering, sending into a refinery tank, adding BaS to remove iron, adding silicon dioxide residue and liquid alkali into a reaction kettle, reacting at 120-160 deg.C under 0.7-0.8 MPa for 3-5 h, and filtering to obtain liquid sodium silicate. The method does not produce harmful substances, thus is not pollutive to the environment.

Owner:刘希林

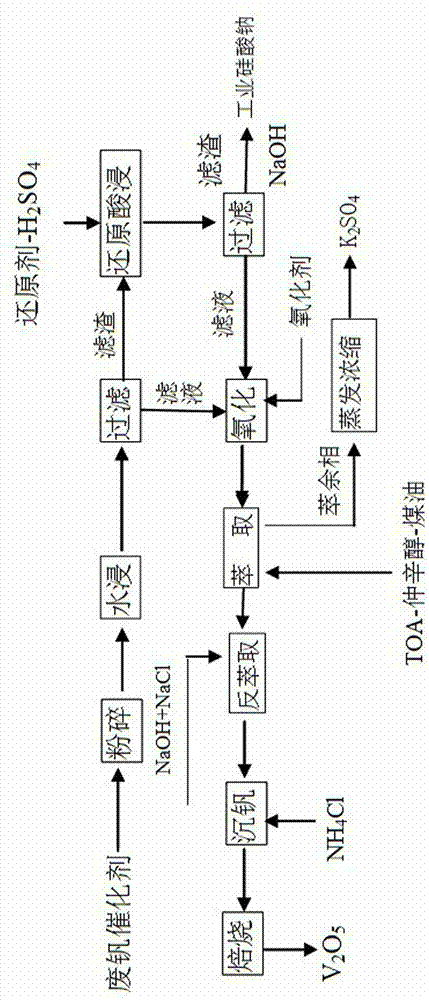

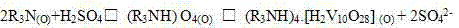

Method for recovering vanadium, potassium and silicon from waste vanadium catalyst

InactiveCN103789550AGood choiceLarge distribution ratioAlkali metal silicatesProcess efficiency improvementSlagMetal impurities

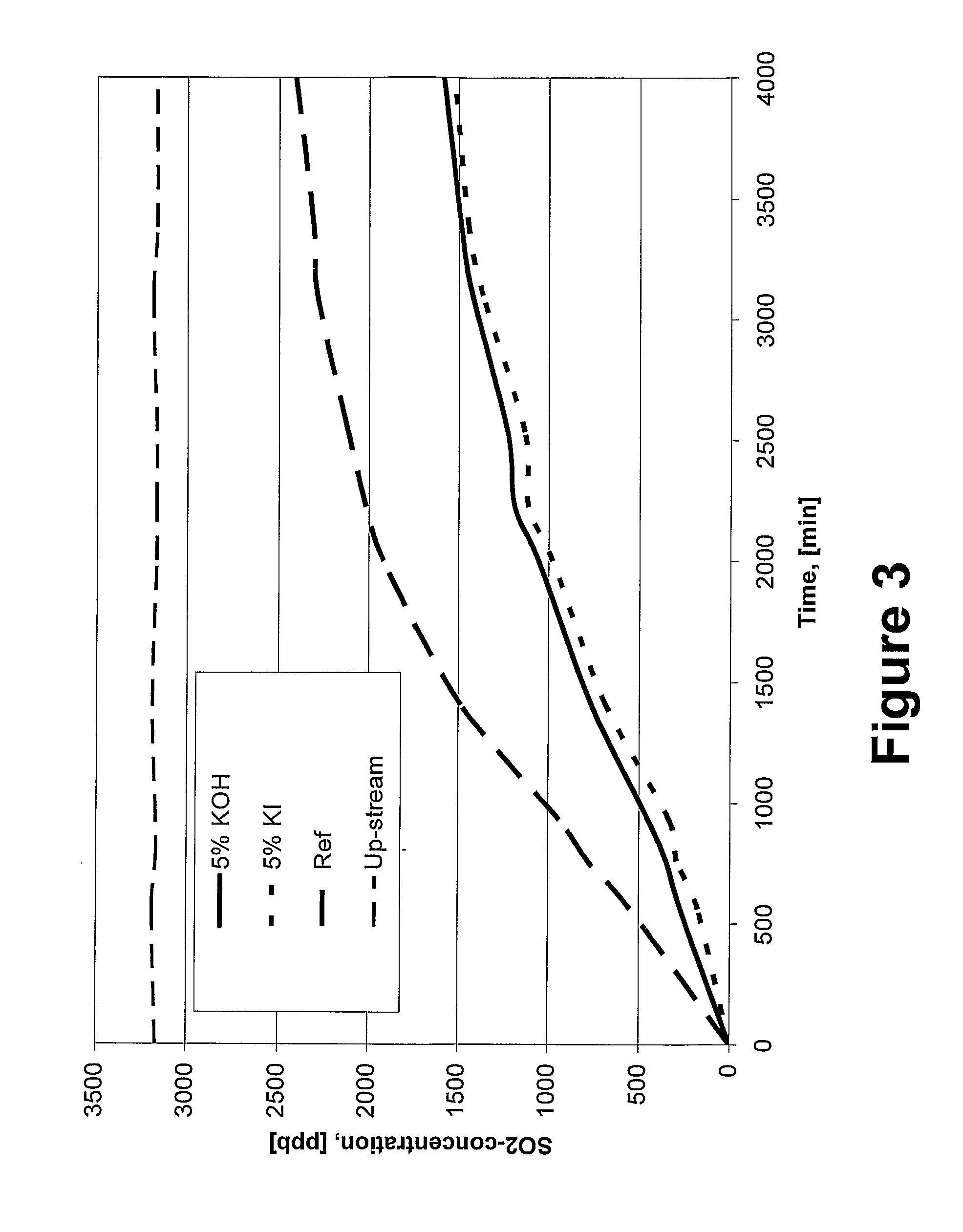

The invention discloses a method for recovering vanadium, potassium and silicon from a waste vanadium catalyst. The method comprises the following steps: firstly, leaching the waste vanadium catalyst in water, and leaching in a reductic acid, wherein the total leaching rate of vanadium is greater than or equal to 95.0%, separating the silicon from vanadium and potassium transferred to a leaching solution in a form of a leaching slag; preparing liquid sodium silicate to recover silicon from the leaching slag by alkali dissolution; separating the vanadium from potassium in the leaching solution in an extraction manner; preparing potassium sulphate to recover potassium from a raffinate phase in an evaporative crystallization manner; and preparing vanadium pentoxide from an extract phase by the procedures of re-extraction, molybdenum precipitation, calcination and the like. Meanwhile, the vanadium in the extract phase and the raffinate phase is larger in distribution ratio, and does not react with other metal impurities such as iron and the like due to excellent selectivity of an extraction agent TOA on vanadium, other metal impurity ions such as iron and the like do not need to be removed in advance, and the vanadium can be directly extracted. Thus, a part of edulcoration procedures are reduced, the raw material consumption is saved, and a high-purity product of vanadium can be directly prepared. By adopting the method disclosed by the invention, not only can the vanadium, potassium and silicon in the waste vanadium catalyst be comprehensively recovered, but also the targets of turning the waste into treasure and protecting the environment are achieved.

Owner:KAIFENG UNIV

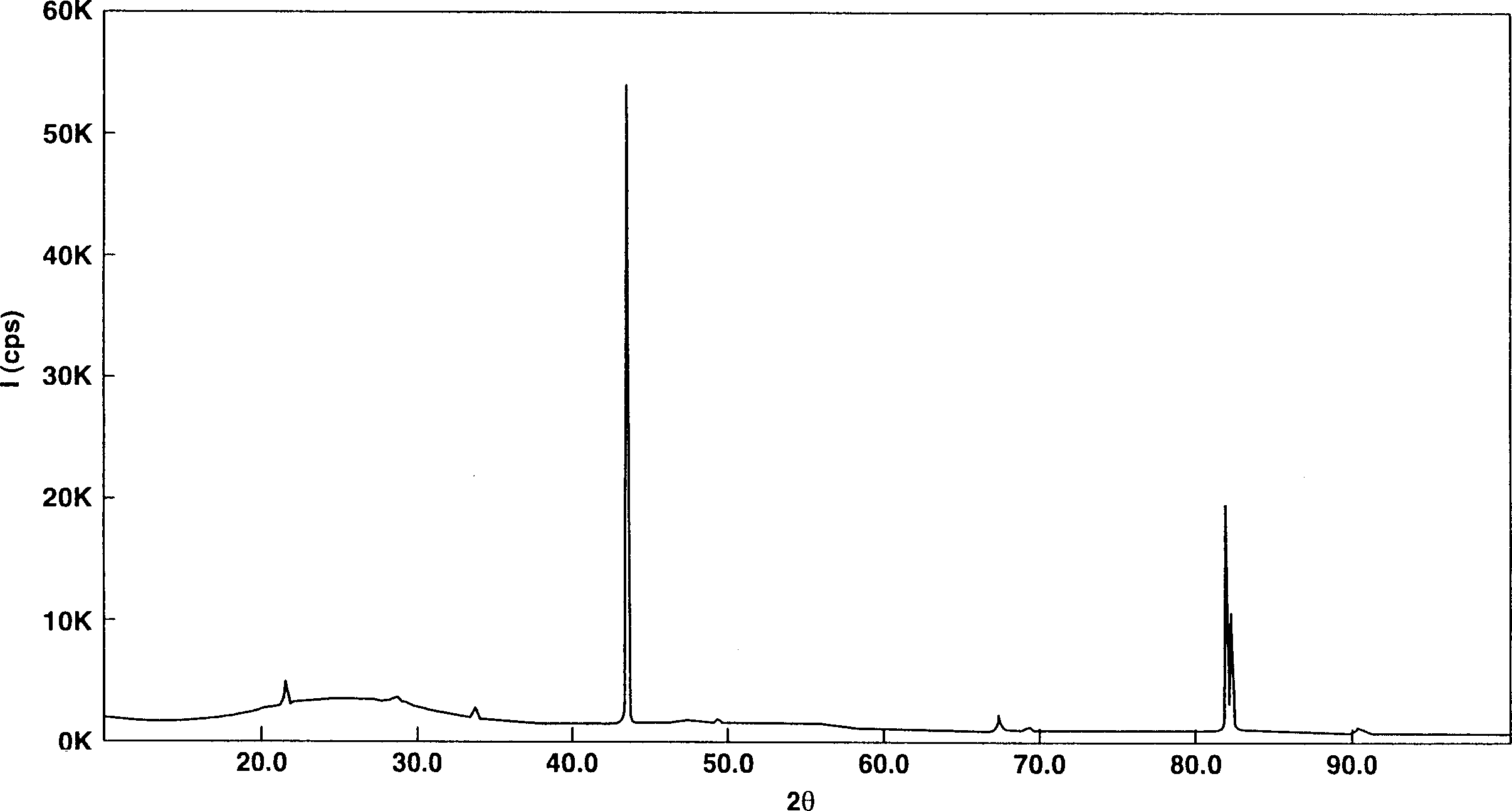

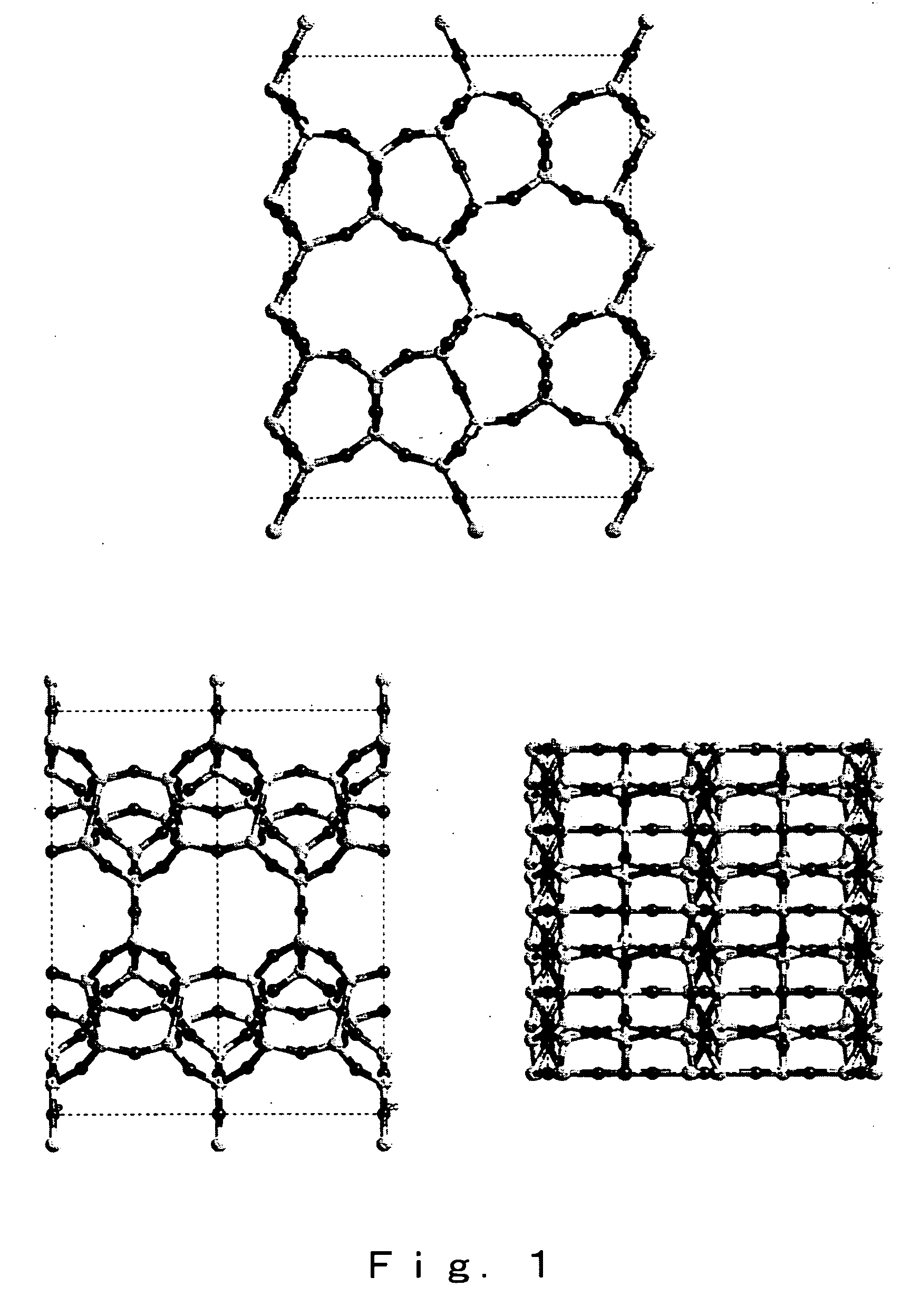

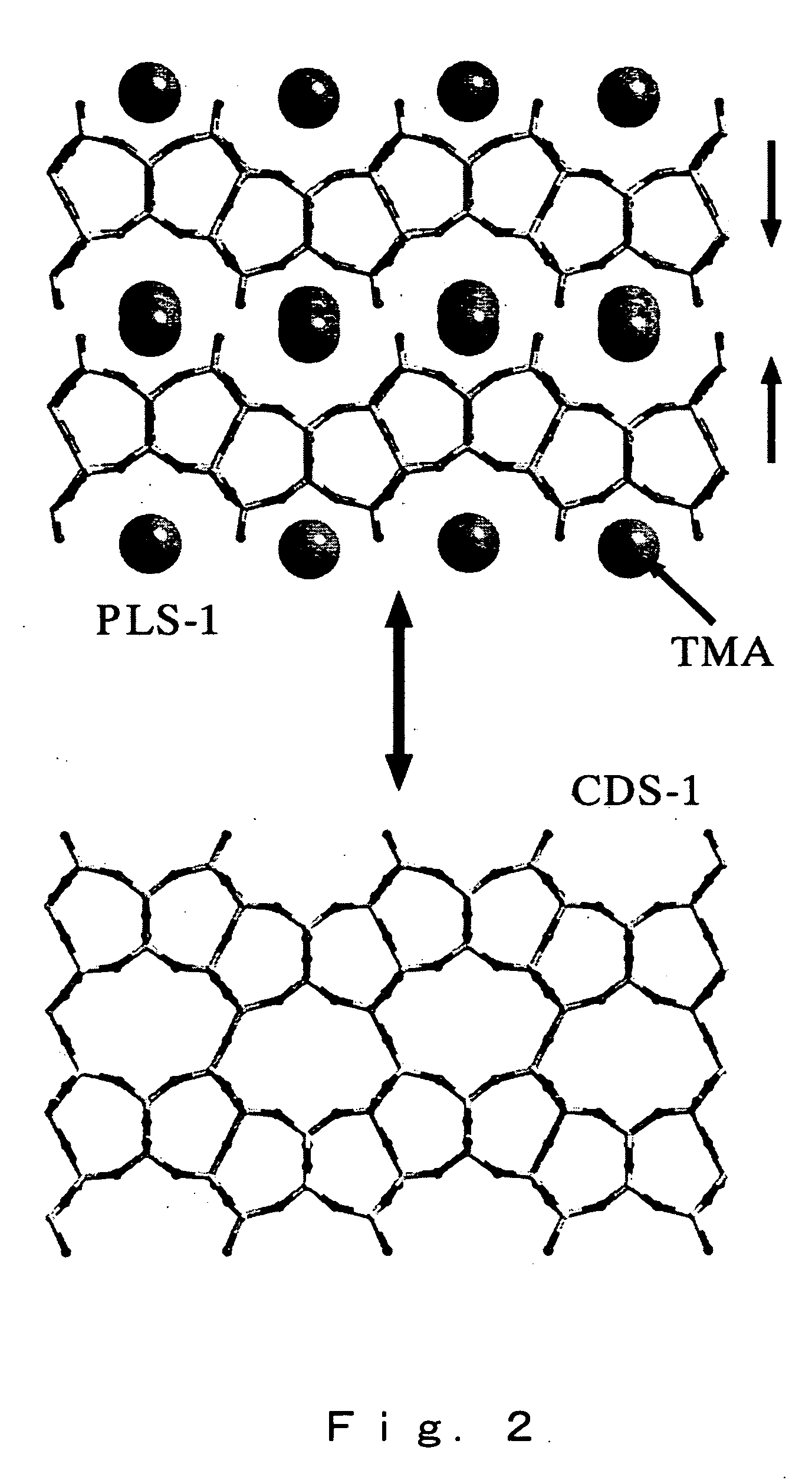

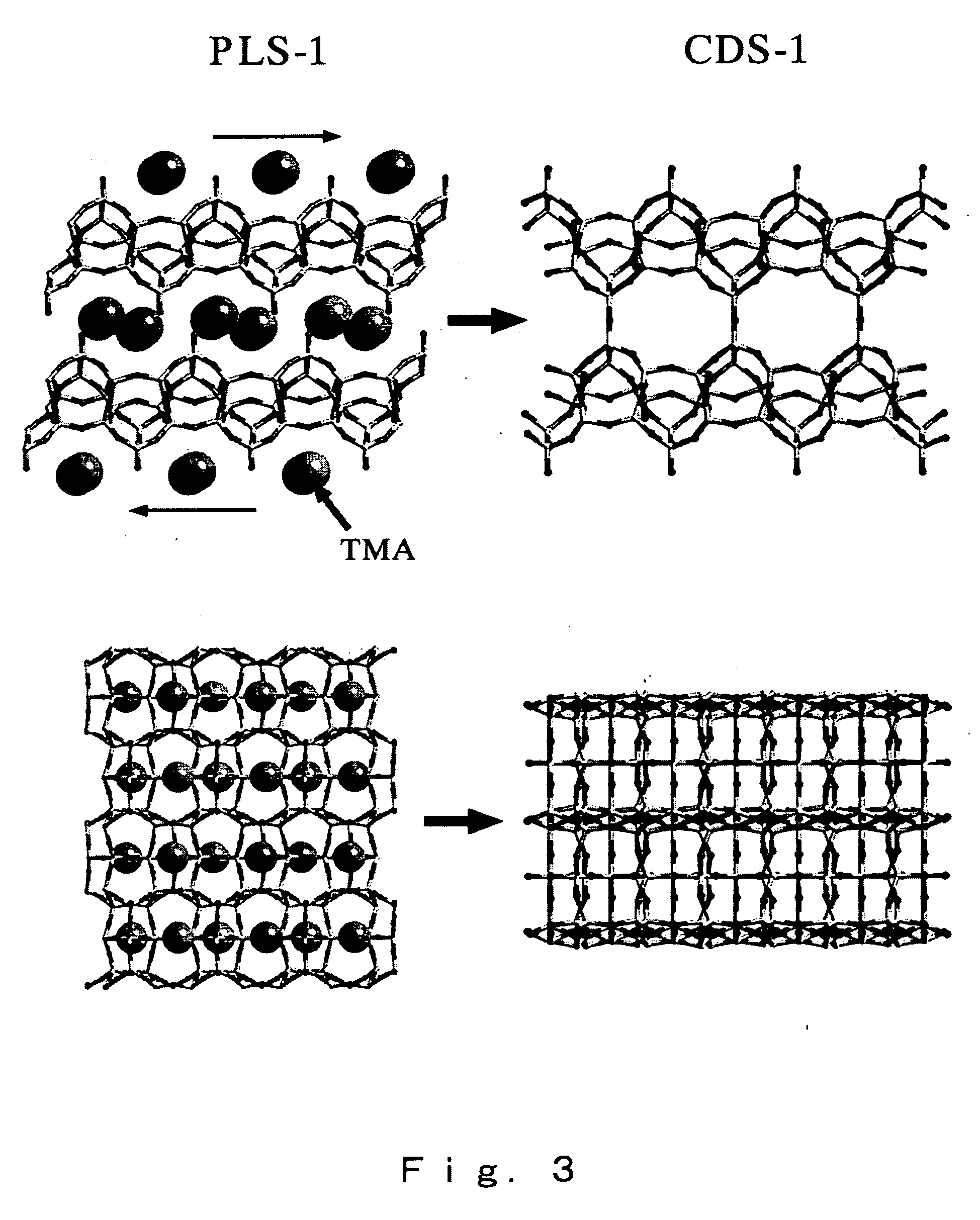

High silica cds-1 zeolite

InactiveUS20070112189A1Novel crystal structureHigh in silicaSemi-permeable membranesMembranesChemical compositionPhysical chemistry

A high-silica content zeolite having a novel crystal structure, a zeolite membrane and manufacturing methods for these are provided, and the present invention relates to a zeolite having the chemical composition represented by [(Si36-xTy.O72).Mz] (wherein M is a cation of an alkali metal such as Li, Na, K or Rb, T represents Al, Ga, Fe and Ce as skeleton substituting elements, x satisfies 0≦x≦3.0, y satisfies 0≦y≦1.0 and z satisfies 0≦z≦3.0), and having a micropore formed of covalent bonds between Si and O atoms, with a specific diffraction peak at 2θ in powder x-ray diffraction, together with a zeolite membrane and methods for manufacturing these.

Owner:NAT INST OF ADVANCED IND SCI & TECH

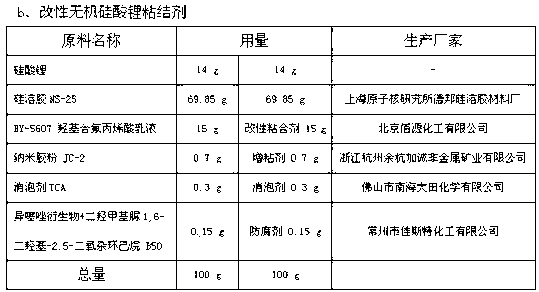

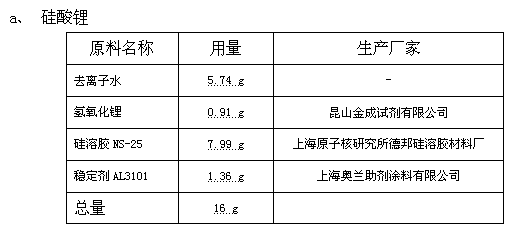

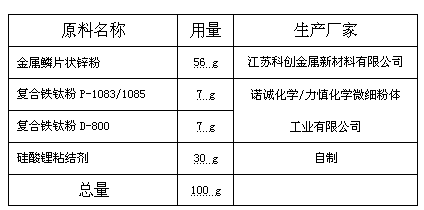

Modified water-based inorganic zinc rich coating and preparation method thereof

ActiveCN103305041ALow viscosityEasy to dryAlkali metal silicate coatingsAlkali metal silicatesWater basedAluminium

The invention relates to a modified water-based inorganic zinc rich coating and preparation thereof. The modified water-based inorganic zinc rich coating is produced by mixing a composite powder with a water-based inorganic binder in a weight ratio of (65-75): (35-25), wherein the composite powder comprises 40-70 parts of metal zinc powder, 3-15 parts of composite iron-titanium powder and 0-15 parts of an antirust agent; the water-based inorganic binder is a lithium silicate binder and comprises 10-25 parts of lithium silicate binder, 60-75 parts of silica sol, 10-15 parts of modified binder and 0.6-3 parts of other auxiliaries; and the modified binder is organic fluorine and / or an organic silicon modified acrylic emulsion. The water-based inorganic lithium silicate binder is used as the base stock of the modified water-based inorganic zinc rich coating, so that the coating is quick in air-drying, nontoxic, tasteless and non-combustible, and has excellent abrasive resistance, flexibility, impact resistance, bending resistance, high / low temperature resistance, electric welding resistance and chemical corrosion resistance, as well as high binding strength, resistance to heat and humidity, salt water resistance and long salt fog resistance time; therefore, the coating is suitable for various building steel structure as a heavy corrosion protective primer, and also can be used as a paint for closure of thermally sprayed zinc, thermally sprayed aluminium anticorrosion layers.

Owner:JIUQING PAINT SHANGHAI

Method for preparing lithium ferrous silicate or carbon ferrous silicate cathode material for lithium ion battery

InactiveCN102664262AEvenly mixedHigh tap densityCell electrodesAlkali metal silicatesCarbon sourceCarbon composites

The invention discloses a method for preparing a lithium ferrous silicate or carbon ferrous silicate cathode material for a lithium ion battery, relates to a method for preparing a cathode material for a lithium ion battery and aims to solve the problems that the conventional prepared lithium ferrous silicate or carbon ferrous silicate composite is low in purity, inhomogeneous in granularity, and poor in electrochemical cycling stability. The method comprises the following steps of: 1, weighing a lithium salt compound, a ferric salt compound, a nano silica and a carbon source compound; 2, dispersing the weighed materials in the step 1 into a dispersing agent by a ball mill or ultrasonic dispersion method to obtain mixed liquor; 3, drying the mixed liquor by a spray drying method to obtain precursor powder; and 4, heating, namely heating the precursor powder obtained in the step 3 under the protection of inert gas in a certain flow rate, cooling naturally to room temperature, and thus obtaining the lithium ferrous silicate or carbon ferrous silicate cathode material for the lithium ion battery. The method is mainly applied to preparation of the lithium ferrous silicate or carbon ferrous silicate cathode material for the lithium ion battery.

Owner:HARBIN INST OF TECH

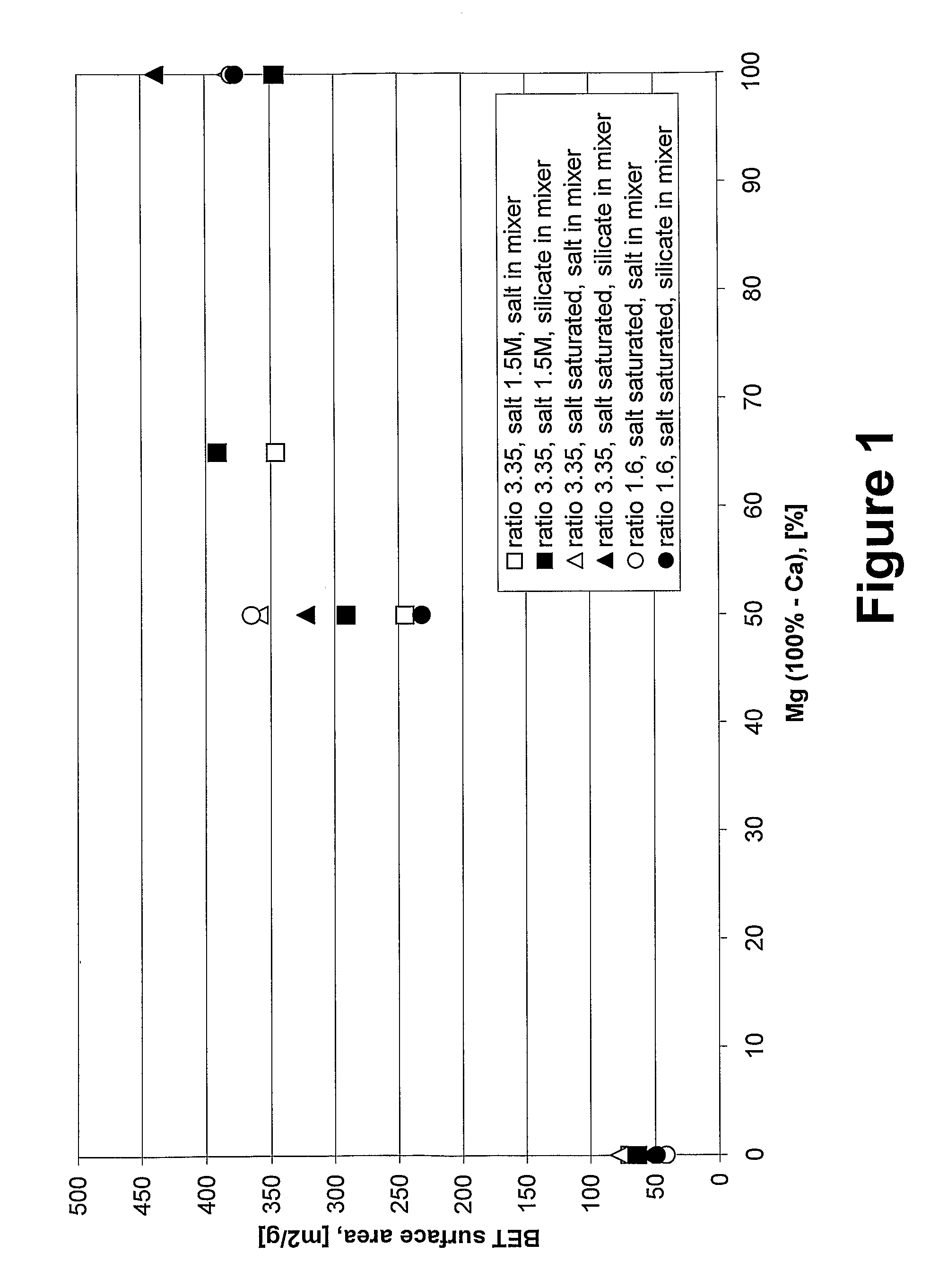

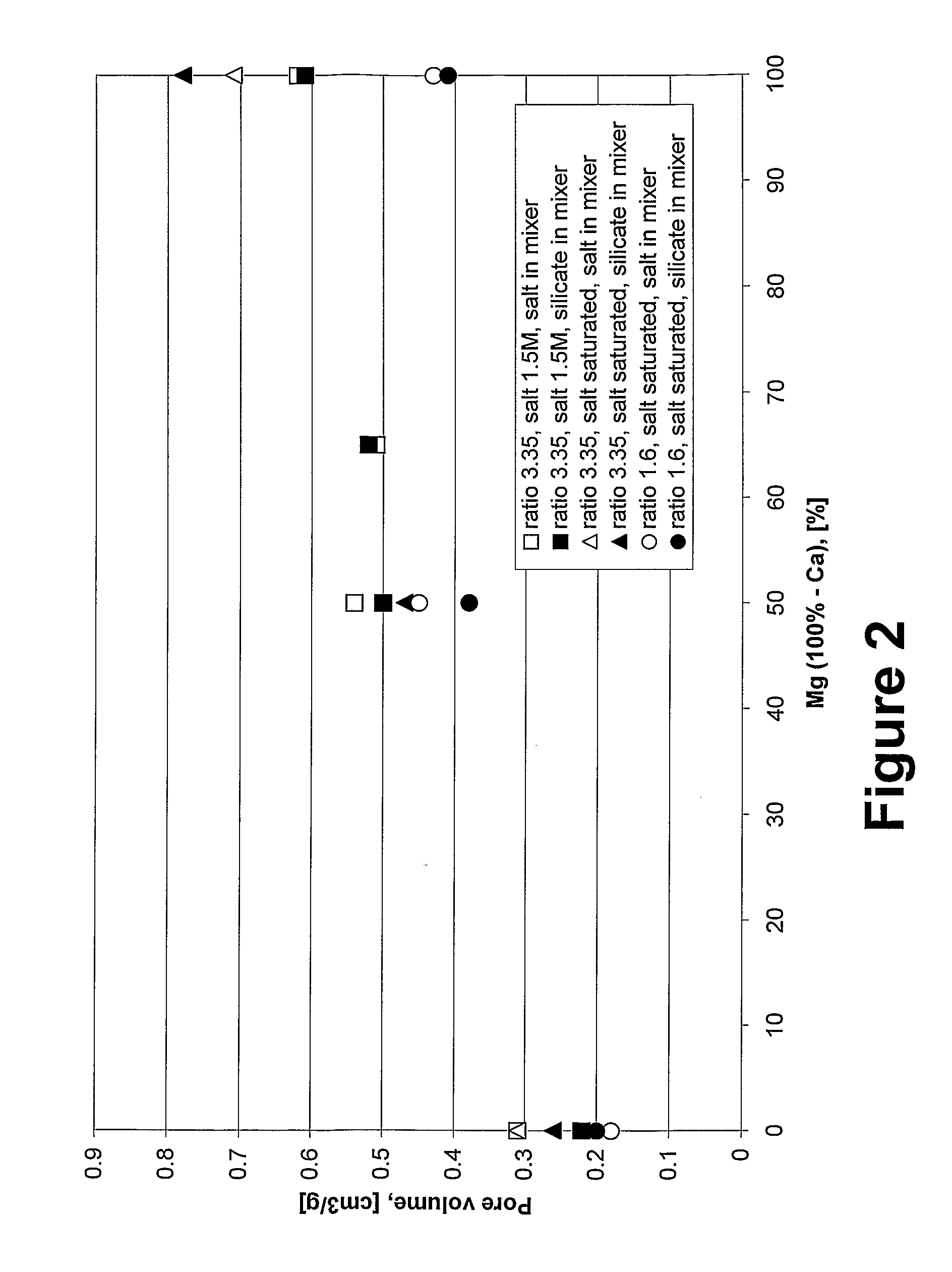

Agglomerates of Precipitated Silica, Method for Their Preparation and Their Use as Filter Medium for Gas Filtration

ActiveUS20080034968A1Improve performanceSimpler and cheapOther chemical processesAluminium silicatesFilter mediaSilicon dioxide

A method of producing a material including agglomerated particles of precipitated silica, including preparing a solution of at least two metal salts (Me), wherein the metal ions are divalent or polyvalent. A solution of alkali metal (M) silicate having a molar ratio SiO2 / M2O of 1-4 is prepared. The solutions are mixed and the mixture stirred, allowing a coagulum to immediately form. The coagulum is rinsed, collected, dewatered, impregnated and processed to provide a material having a dry matter content of >75%, preferably >97%. A material obtainable by the process is also provided.

Owner:SVENSKA AEROGEL

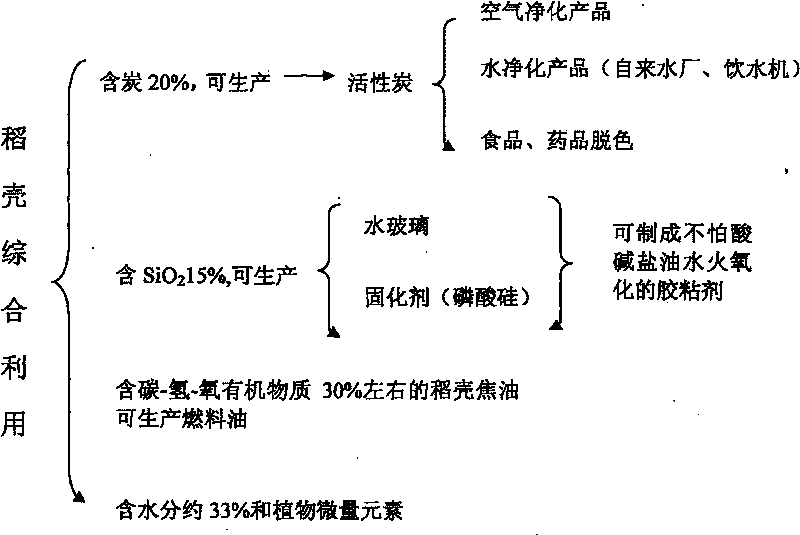

Method for preparing active carbon and rice hull tar by comprehensively utilizing rice hulls and co-producing water glass or silicon phosphate

InactiveCN101700883AIncrease profitSimple processCarbon compoundsBiofuelsHazardous substanceAdhesive

The invention provides a method for preparing active carbon with strong adsorptivity and rice hull tar by comprehensively utilizing rice hulls and co-producing water glass or silicon phosphate, comprising the following steps of: slowly sifting the rice hulls into an activated carbonization furnace; carbonizing and depositing in the activated carbonization furnace to form a carbon shell and generate a gas; condensing the gas to obtain the rice hull tar; and processing the carbon shell by sodium hydroxide or a phosphoric acid to obtain the active carbon and the water glass or a silicon phosphate curing agent. The method has simple process, and the produced products have good quality, high output, low cost and no pollution, thereby large-scale industrialized production can be realized. The obtained rice hull active carbon contains no heavy metal ion, i.e. lead, cadmium, arsenic, mercury, and the like which are toxic to human bodies and other toxic and harmful substances and is a purifying agent, a decolorizing agent and a catalyst which are urgently needed in the fields of foods, medicines and environmental protection; the rice hull curing water glass is a non-toxic harmless aqueous inorganic adhesive and has wide application range; in addition, the rice hull tar is renewable biological energy. The method has good social benefit and economic value.

Owner:成如山

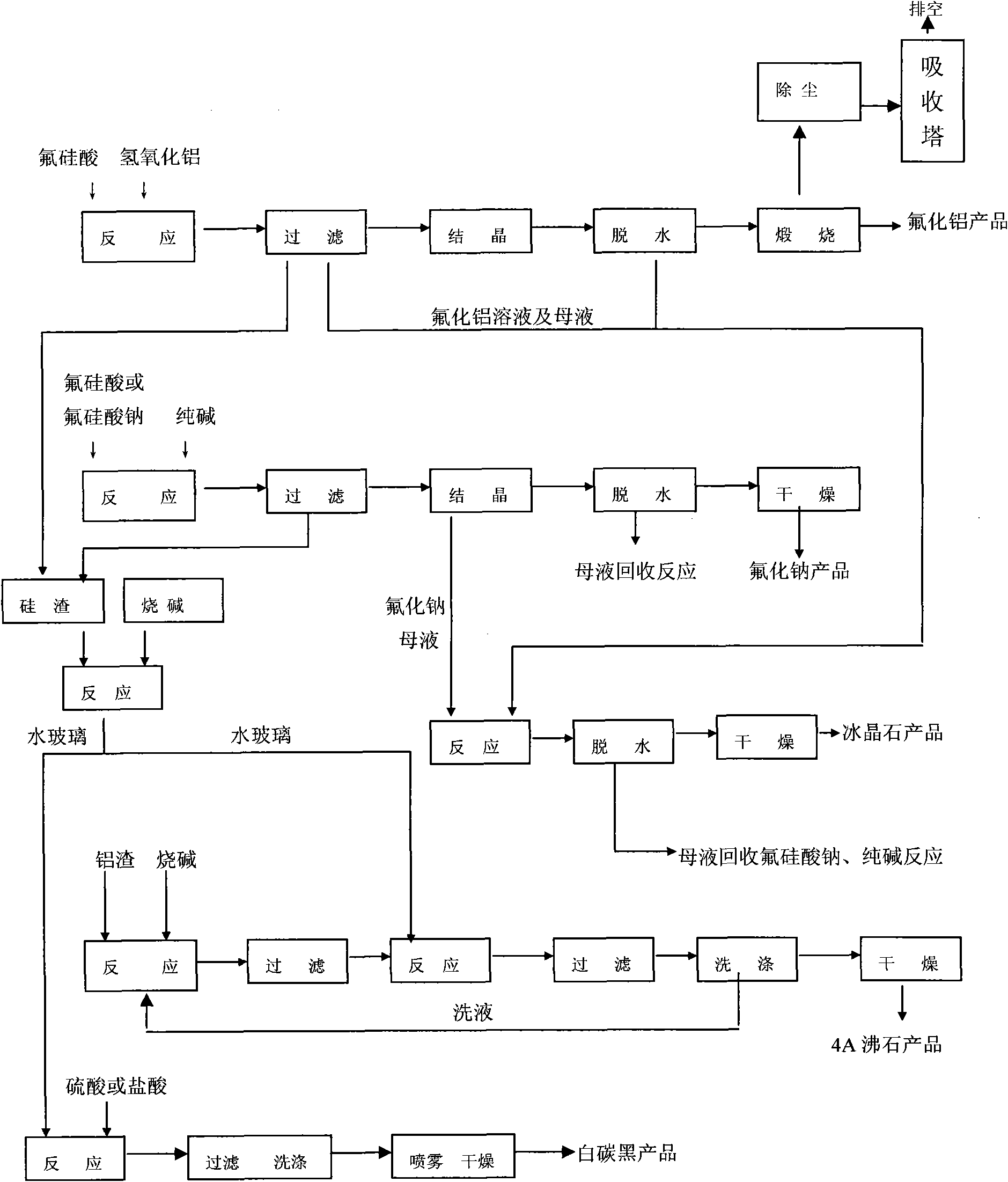

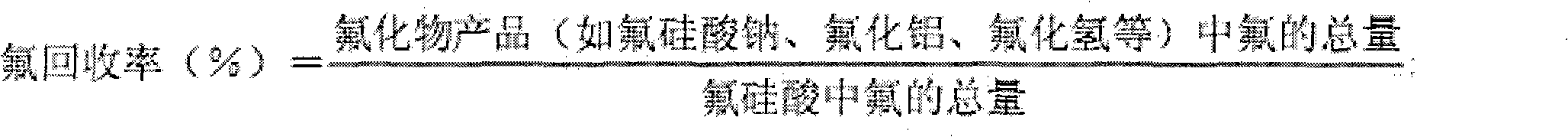

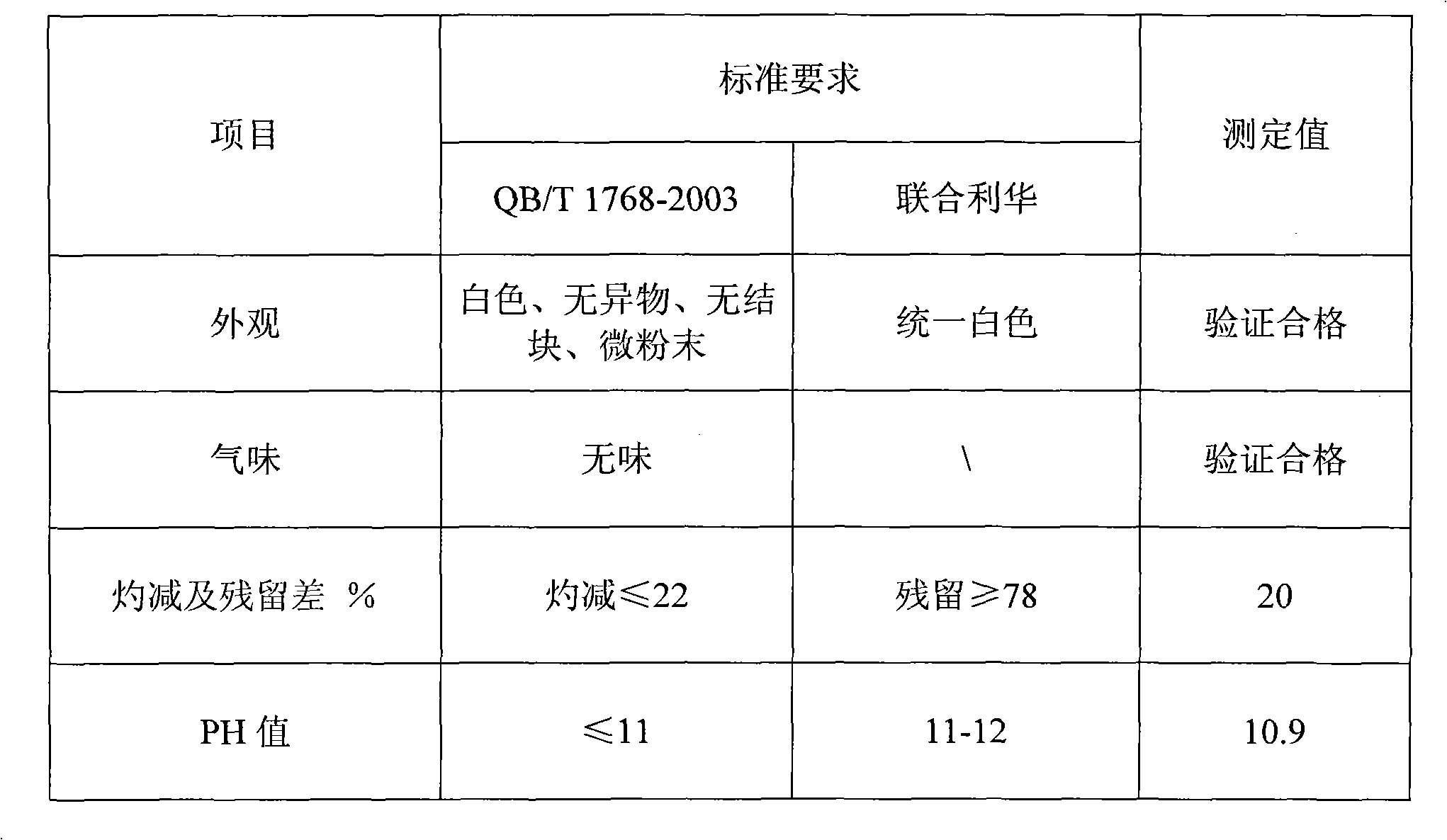

Process method for producing fluorine compounds and silicon compounds by cleanly utilizing fluosilicic acid

ActiveCN101913637AHigh recovery rateTake advantage ofSilicaAlkali metal silicatesChemical industrySlag

The invention discloses a process method for producing fluorine compounds and silicon compounds by cleanly utilizing fluosilicic acid. The process method comprises the following steps of: preparing fluosilicic acid as a phosphorus chemical by-product into an anhydrous aluminum fluoride product, a sodium fluoride product and a cryolite product, and combining with other industrial waste silicon slags and aluminum slags to prepare a 4A zeolite product. The process method comprehensively utilizes the fluosilicic acid and has high resource recovery rate, wherein the recovery rate of the fluorine element reaches higher than 90 percent. Waste silicon dioxide slags generated in the process can be recycled to produce white carbon black and the 4A zeolite, and a mother liquor, a cleaning solution and waste gas which are generated in the production process are all recycled, thereby the environmental pollution is reduced, and the purposes of zero emission and no pollution are truly achieved, thus the method completely meets the requirement for clean production. The invention has the advantages of advanced production process, good product quality and high value, wherein the fluorine content of the aluminum fluoride is high and between 63-65 percent; the quality index of the obtained white carbon black meets the requirement on the standard of the chemical industry; and the quality of the 4A zeolite product meets the requirements on the national standard and the standard of European and American developed countries.

Owner:四川励志环保科技有限公司

Synthetic clay compositions and methods for making and using

InactiveUS6890502B2Increase productionImprove propertiesPhysical/chemical process catalystsAluminium silicatesOrganoclayMedicine

Selected smectites may be synthesized from a wide variety of components. Morphology, purity, size, and / or shape of the selected smectite may be controlled by mixing the clay smectite formatives, and selectively controlling the pH during mixing. The selected smectites may be used in any applications in which naturally occurring smectite may be used. The selected smectite may also be formulated into an organoclay.

Owner:BYK ADDITIVES

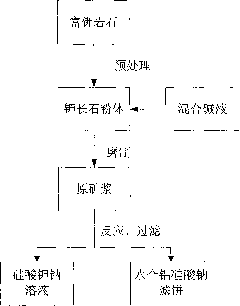

Process for preparing sodium potassium silicate solution by predesiliconizing potassium-rich rock

InactiveCN101798095ARaise the ratioReduce consumptionAluminium silicatesAlkali metal silicatesWater insolubleSlag

The invention discloses a process for preparing a sodium potassium silicate solution by predesiliconizing potassium-rich rock. The process comprises the following steps of: crushing and homogenizing potassium-rich rock to prepare potash feldspar powder; grinding the potash feldspar powder and an alkali solution together to prepare original ore pulp; carrying out a constant temperature reaction of the original ore pulp in a reaction at 180-250 DEG C for 1-4h to obtain reaction slurry; and diluting, filtering and reversely washing the reaction slurry to prepare a sodium potassium silicate solution and an Al-rich hydrated sodium aluminum filter cake. The sodium potassium silicate solution can be used as a raw material for preparing inorganic silicon compounds and sylvite products, and the Al-rich hydrated sodium aluminum filter cake is further processed to extract alumina therein. The process solves the problems of great silicon-calcium slag castoff emission and scaled production restriction existing in the potassium-extracting process from water-insoluble potassium ore.

Owner:昊青薪材(北京)技术有限公司

Process for preparing sodium silicate alkali solution depleted of sodium salt and enriched in silica

InactiveUS20040053773A1Economically and efficiently convertedSpeed up the processMolecular sieve catalystsAlkali metal silicatesMolecular sieveImproved method

The present invention relates to an improved process for obtaining sodium silicate alkali solution depleted of sodium salt and enriched in silica from a mother liquor recovered after isolation of molecular sieves and more particularly, the present invention relates to a process for recycling mother liquor obtained after the isolation of molecular sieves for the preparation of fresh molecular sieves or as a binder for producing Fluid Catalytic Cracking (FCC) catalyst.

Owner:INDIAN OIL CORPORATION

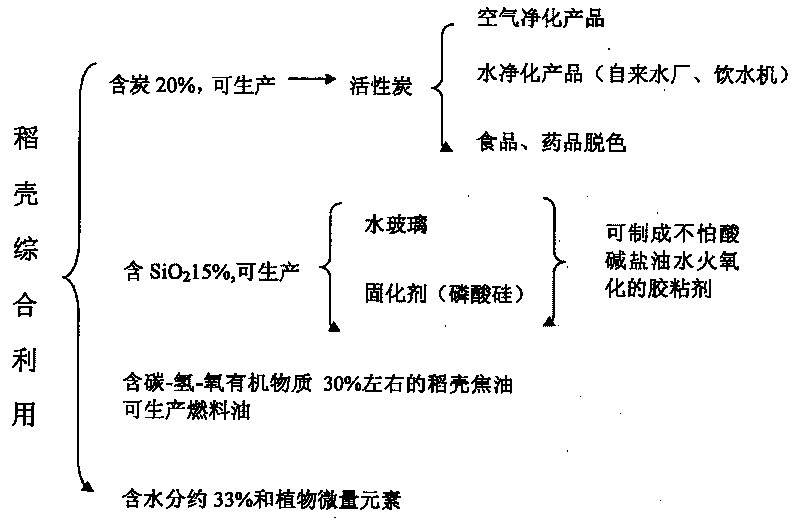

Method for preparing coal gas, top-grade active carbon, water glass and silicate phosphate from rice hulls

ActiveCN101891189AImprove qualityOvercome absorbencyPhosphatesAlkali metal silicatesPhosphateBiological activation

The invention relates to a method for preparing coal gas, high-grade active carbon, water glass and silicate phosphate from rice hulls, which comprises the following steps of: smouldering, carbonizing and activating the rice hulls to produce the coal gas for power generation and to obtain rice hull carbon; activating the rice hull carbon with acid and alkaline to obtain low-grade active carbon, packaging the low-grade active carbon in a dust-proof explosion-proof sealed mode, and activating at moderate temperature, secondary high temperature and high temperature to finally obtain the high-grade active carbon and produce the water glass and the silicate phosphate simultaneously. The defect of low-grade active carbon prepared from the rice hull carbon in the prior art is overcome. The invention has reasonable technological method and technological process, and solves the technical obstacles on moderate temperature and high temperature activation of the rice hull carbon. The rice hull carbon obtained after preparing the coal gas from the rice hulls can be directly used for producing the high-grade active carbon, the water glass and the silicate phosphate, and the economical benefits and the social benefits of the rice hulls are effectively increased. Large-scale industrial production can be realized, and a new approach is provided for realizing a complete industrial chain of agriculture industrialization and rice processing.

Owner:长沙稻香农业科技有限公司

Process for preparing water glass from silicon micropowder by using wet method

InactiveCN102424394ASolve bulk consumptionSolve technical barriers to high-value utilizationAlkali metal silicatesBuffer tankEconomic benefits

The invention provides a process for preparing water glass from silicon micropowder by using the wet method, belonging to the technical field of production of water glass. The process comprises the following steps: analyzing the content of SiO2 in silicon micropowder; mixing silicon micropowder and liquid alkali according to a mol ratio of 0.9-1.8:1; delivering obtained mixed liquor into a liquidphase reaction vessel under agitation; allowing steam to enter into the reaction vessel to heat the mixed liquor; carrying out a dwell reaction at a temperature of 70 to 220 DEG C for 0.5 to 6 h so as to prepare mixed liquor of water glass; discharging the mixed liquor of water glass out from the reaction vessel; adjusting the temperature of the mixed liquor of water glass to 50 to 95 DEG C in a feed liquid buffer tank; carrying out plate and frame pressurized filtering to obtain a filtrate which is water glass with a modulus of 1.80 to 3.20. The invention has the following advantages: since the water glass is prepared by using dust in the ferrosilicon alloy industry as a raw material and employing the characteristic that the reaction between amorphous SiO2 in silicon micropowder and alkali liquid has high activity, high conversion efficiency is obtained, the process is simple, the problem of dust pollution in the ferrosilicon alloy industry is overcome, and good economic benefits andsocial benefits are achieved.

Owner:UNIV OF SCI & TECH BEIJING +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com