Method for preparing coal gas, top-grade active carbon, water glass and silicate phosphate from rice hulls

A technology of activated carbon and silicon phosphate, applied in the direction of phosphate, phosphorus oxyacid, silicate, etc., can solve the problems of low utilization rate of gas, waste of resources, inability to process rice husk carbon deeply, etc., to expand the scope of application and market good prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

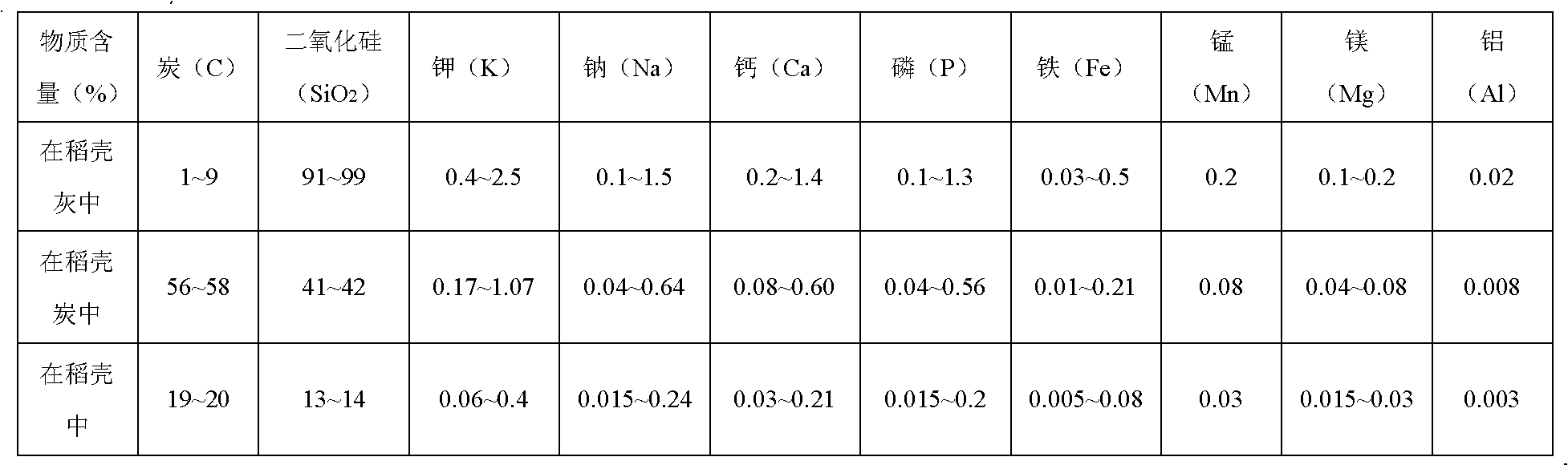

[0048] Embodiment 1: After 7.5 tons of rice husks are used to generate electricity, high-quality activated carbon, water glass primary product and silicon phosphate primary product are produced.

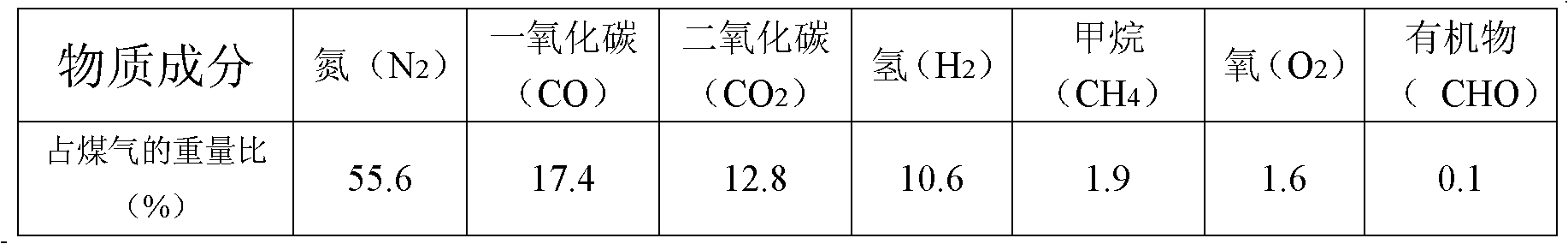

[0049] The first step: add 7.5 tons of rice husks to the gas generator in stages, smolder, carbonize and activate at 550-580 ° C to generate gas for power generation. After carbonization and activation, the husk is discharged from the bottom of the furnace to obtain 2.5 tons of rice husk charcoal, and its iodine adsorption value is 110mg / g;

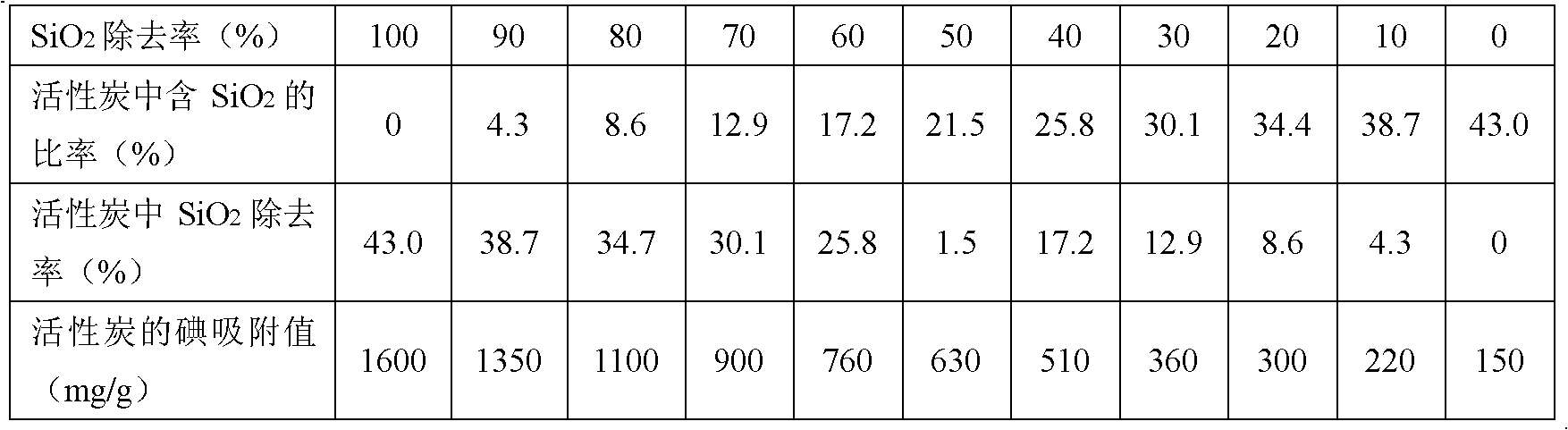

[0050] The second step: Add 2.5 tons of the obtained rice husk charcoal into 3.3 tons of sodium hydroxide solution with a concentration of 22%, pump it into the reaction kettle, stir and heat it to 130-140°C, and react for 4-5 hours. The solid-liquid mixture is filtered, the filtrate is water glass, and the filter residue is the first-grade activated carbon after drying, weighing about 1.8 tons (the activated carbon particles contain a large amo...

Embodiment 2

[0055] Embodiment 2: After 7.5 tons of rice husks are used to generate electricity, high-quality activated carbon and the first product of silicon phosphate and the first product of water glass are produced.

[0056] The first step: add 7.5 tons of rice husks to the gas generator in stages, smolder, carbonize and activate at 550-580 ° C to generate gas for power generation. After carbonization and activation, the husk is discharged from the bottom of the furnace to obtain 2.5 tons of rice husk charcoal, and its iodine adsorption value is 110mg / g;

[0057] The second step: Add 2.5 tons of the obtained rice husk charcoal to 2.5 tons of phosphoric acid solution with a concentration of 22%, pump it into the reaction kettle, stir and heat to 130-140°C, and react for 4-5 hours, and the solid-liquid obtained after the reaction The mixture is filtered, the filtrate is silicon phosphate, and the filter residue is primary activated carbon after drying, weighing about 1.8 tons (activated...

Embodiment 3

[0063] After generating electricity from 7.5 tons of rice husks, high-quality activated carbon, primary silicon phosphate and primary water glass are produced.

[0064] The first step: add 7.5 tons of rice husks to the gas generator in stages, smolder, carbonize and activate at 550-580 ° C to generate gas for power generation. After carbonization and activation, the husk is discharged from the bottom of the furnace to obtain 2.5 tons of rice husk charcoal, and its iodine adsorption value is 110mg / g;

[0065] The second step: add 2.5 tons of the obtained rice husk charcoal into 2.5 tons of phosphoric acid solution with a concentration of 22%, heat to 130-140°C, react for 4-5 hours, filter the solid-liquid mixture obtained after the reaction, and the filtrate is It is silicon phosphate, and after the filter residue is dried, it is the first-grade activated carbon, weighing about 1.8 tons (activated carbon particles contain a large amount of silicon phosphate), and its iodine ads...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Iodine adsorption value | aaaaa | aaaaa |

| Iodine adsorption value | aaaaa | aaaaa |

| Iodine adsorption value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com