Patents

Literature

1070results about How to "Reasonable process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Process for recovering rare earth element in waste florescent lamps

InactiveCN101307391AReasonable processProcess efficiency improvementRare-earth elementAlkaline earth metal

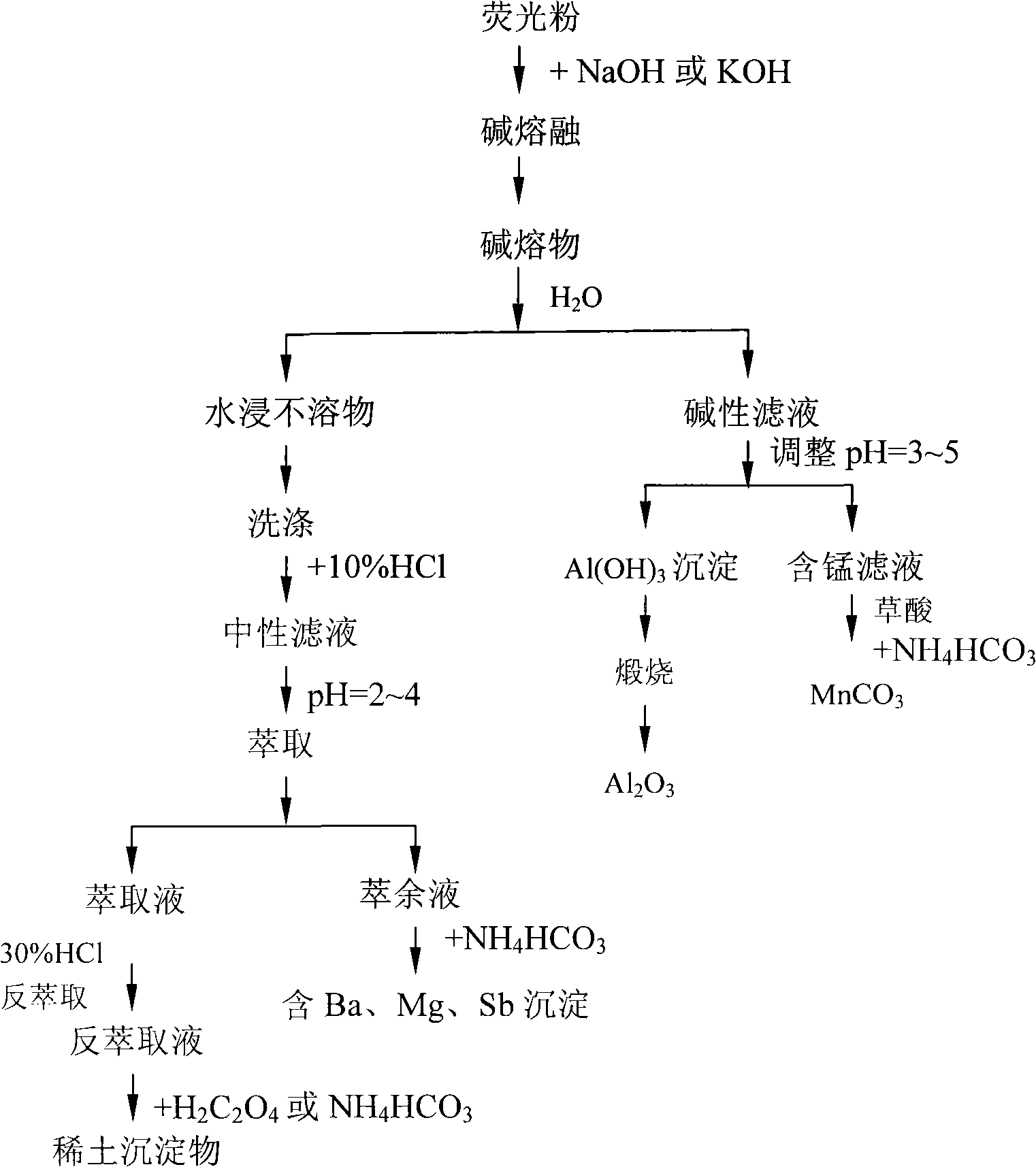

The invention provides a method for reclaiming a rare earth element from abandoned fluorescent lamp. The invention is characterized in that the method comprises the following steps of: melting fluorescent powder by NaOH or KOH and adding water into an alkali melted substance to produce water insoluble substances and alkaline filtrate; dissolving the water insoluble substances into hydrochloric acid to produce neutral filtrate; extracting the neutral filtrate by P204 or P507 to produce extraction liquid and raffinate; back extracting the extraction liquid by HCl to produce back-extraction liquid, and precipitating the back-extraction liquid by H2C2O4 or NH4HCO3 to produce rare earth precipitate containing mixed Y, Ce, Tb and Eu; precipitating the raffinate by the NH4HCO3 to produce precipitate containing Mg, Ba and Sb; adjusting the pH value of the alkaline filtrate to between 3 and 5 to produce Al(OH)3 precipitate and manganiferous filtrate; washing, filtering and calcining the Al(OH) precipitate to produce alumina; and adding oxalic acid into the manganiferous filtrate to produce manganous carbonate. The method realizes that the rare earth element, Eu, Tb, Ce and Y are separated from Mg, Ba, Ca and other alkaline-earth metals, ensures that resources are comprehensively reclaimed and used, and has the advantages of reasonable process flow, economy and practicality.

Owner:GUANGZHOU RES INST OF NON FERROUS METALS

Method for producing low-temperature cold-pressed and refined tea seed oil

InactiveCN103013651AReasonable processStrong maneuverabilityFatty-oils/fats refiningFatty-oils/fats productionChemistryPeroxide value

The invention discloses a method for producing low-temperature cold-pressed and refined tea seed oil, and belongs to the technical field of deep processing of agricultural products. The method for producing the cold-pressed and refined tea seed oil comprises the following main processes of: performing low-temperature storage on screened tea seeds, cleaning, grading, shelling, separating, drying, crushing, pressing at a low temperature, filtering, degumming, decolorizing, deodorizing, winterizing, and packing finished refined oil. By the new technology of low-temperature cold pressing and refining, overheating and excessive chemical treatment of the oil in the conventional processing are avoided, meanwhile, the residue of harmful substances produced in the conventional high-temperature processing is effectively reduced at the same time, the production cost is remarkably reduced, the purely natural property of the oil is kept, and physiological active substances in the oil are kept as much as possible. The tea oil produced by the method is light in color, low in acid value and peroxide value, low in phosphorus content, fragrant and rich in nutrition, and has a long storage period; and a feasible new path is provided for deep processing and utilization of the tea seed oil.

Owner:NANJING UNIV OF FINANCE & ECONOMICS +1

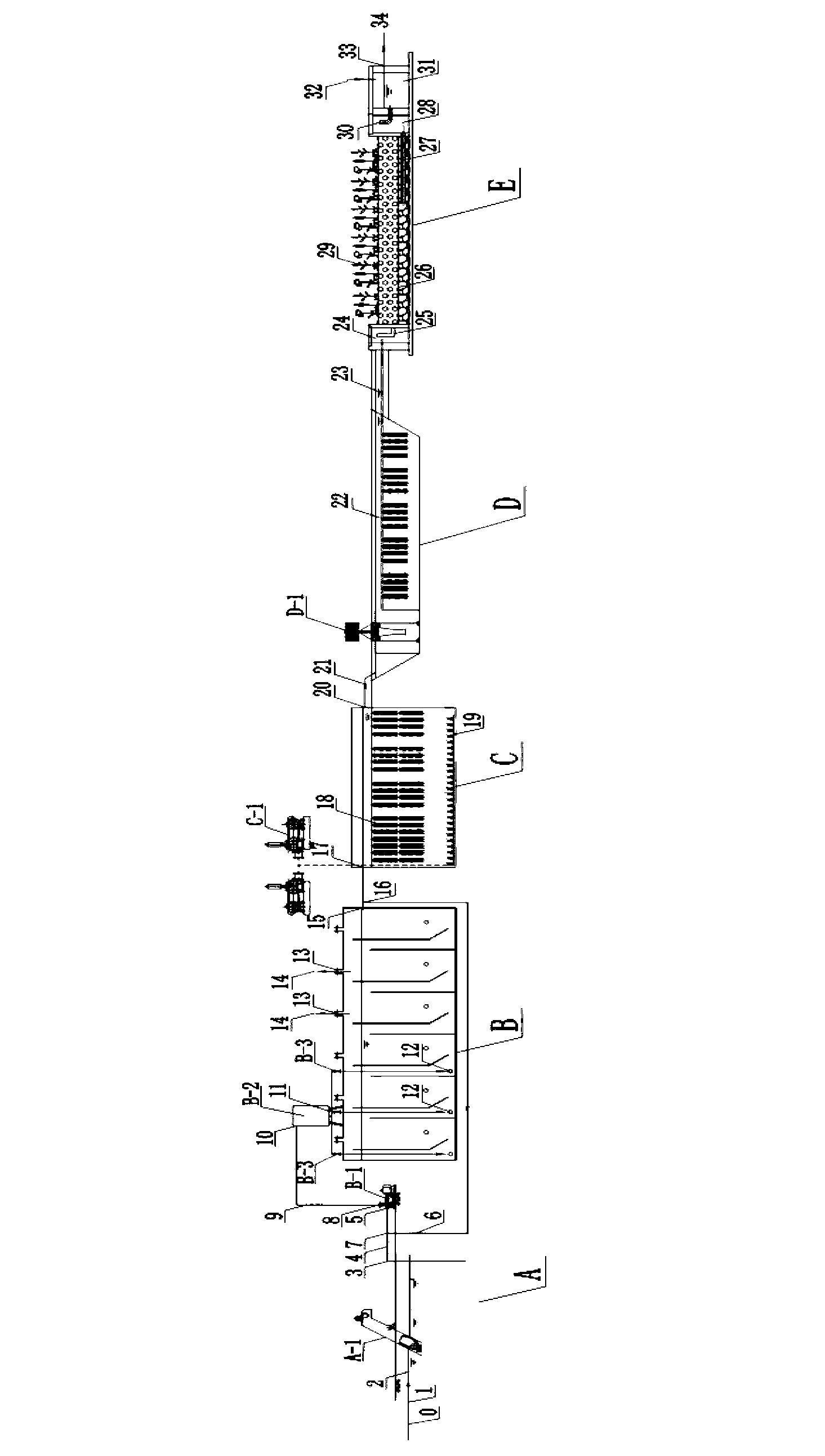

An integrated process of ecological dredging and sludge solidification and disposal

ActiveCN102267797AMeet the requirements of actual productionRich and perfect processing methodsSludge treatment by de-watering/drying/thickeningSludgeFirming agent

The invention discloses an integral process for ecologically desilting and curing sludge. The process comprises the following treatment steps of: I, absorbing riverbed sludge in an undistributed way; II, pretreating landed slurry based on high-frequency oscillation; III, decreasing and concentrating slurry-containing sewage while adding a flocculating agent A; IV, performing solid-liquid separation on the concentrated slurry, conveying the concentrated slurry in a decreasing and concentrating pond to a horizontal centrifuge, adding a flocculating agent B and centrifuging to obtain dehydrated slurry cakes; V, inputting the dehydrated slurry cakes into curing equipment, adding a curing agent to obtain cured sludge, introducing sewage drained from the centrifuge into an adjusting pond, adding a flocculating agent C, homogenizing, blending, elevating to a purifying tower through an elevating pump, and adding a flocculating agent D; and VI, making a purified liquid part drained from the purifying tower reflow for utilizing, and making precipitated concentrated slurry reflow to the decreasing and concentrating pond for retreating. The integral process has the advantages of high desilting efficiency, low cost, no secondary pollution, small floor area, and detachability and assembly for rapid transition.

Owner:中国船舶重工集团公司第七〇二研究所

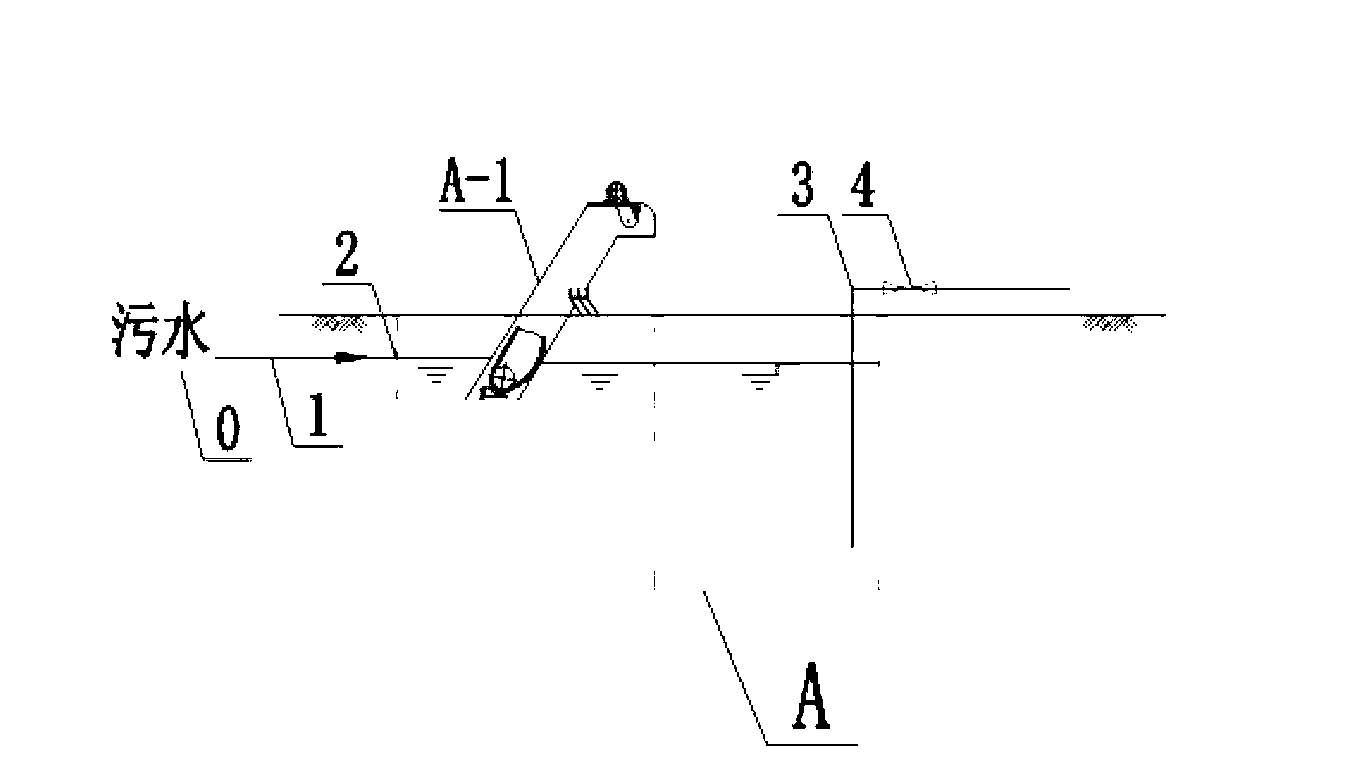

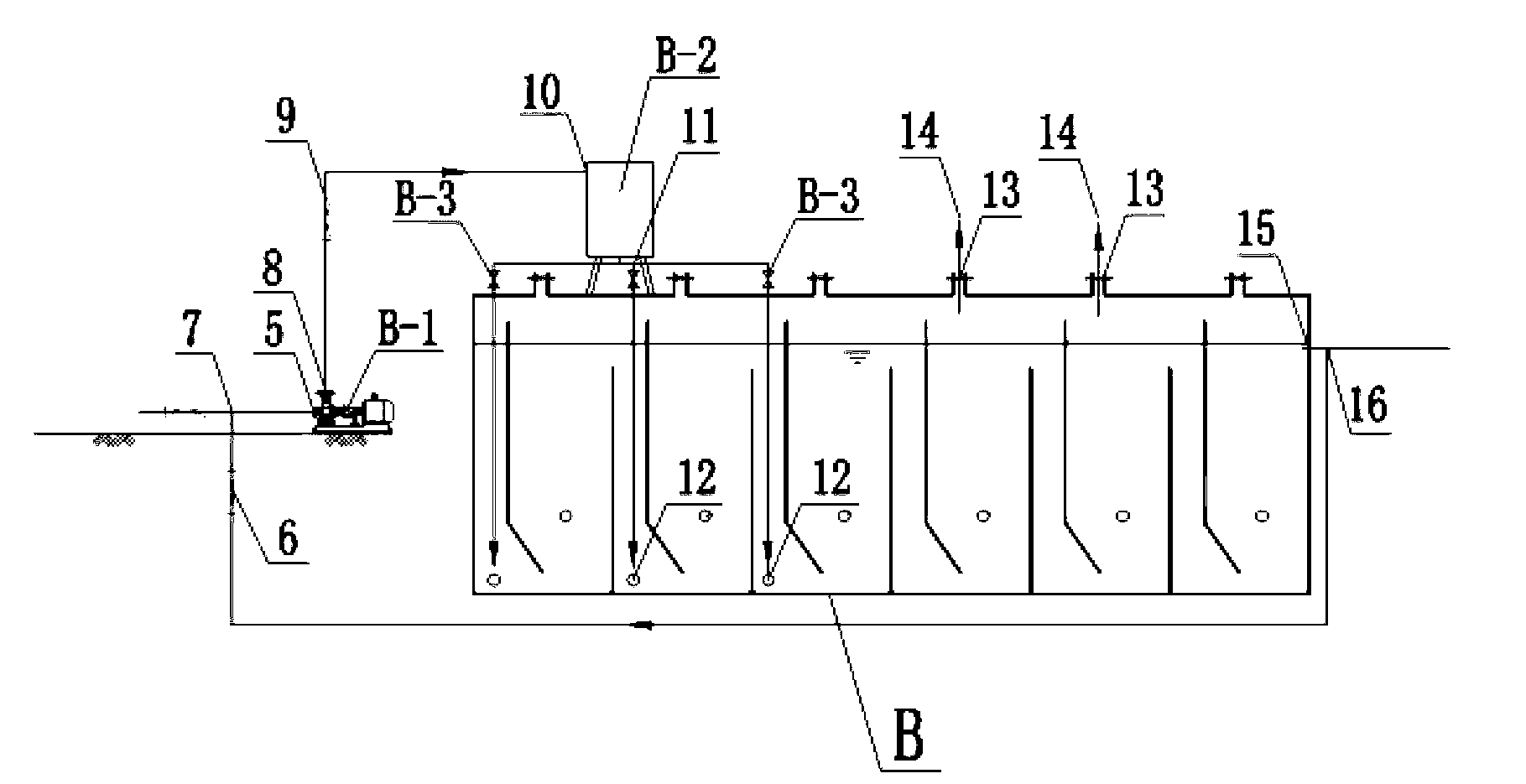

Low-energy-consumption low-carbon-emission economical energy-saving urban sewage treatment method

ActiveCN102701521AEasy to handleReduce load ratioEnergy based wastewater treatmentMultistage water/sewage treatmentConstructed wetlandRural area

The invention discloses a low-energy-consumption low-carbon-emission economical energy-saving urban sewage treatment method. The method comprises the steps that: 1, the to-be-treated wastewater is collected by a sewage pipe network and then is filtered by lattices, and is lifted by a pump to enter a pulse water distribution pot of a novel efficient turn-back anaerobic biochemical pool (ABR); 2, the swage subjected to the treatment in step 1 flows into a circulation-flow biological oxidization pool; 3 the effluent water from the step 2 flows into an artificial reinforced biological contact oxidization pool reconstructed by a water body from natural tunnels and reservoirs; and 4, the effluent water from the step 2 or the step 3 flows into constructed wetlands. After the sewage is treated by the above steps, the most pollutants in the water are effectively removed and the treated effluent water reaches the standard first-grade A in GB 18918-2002 ''Discharge standard of pollutants for municipal sewage treatment plant''. The energy-saving sewage treatment purification process with low cost, low energy consumption, low carbon emission and low operating cost is particularly suitable for the sewage treatment in small towns or rural areas.

Owner:武汉昌宝环保工程有限公司

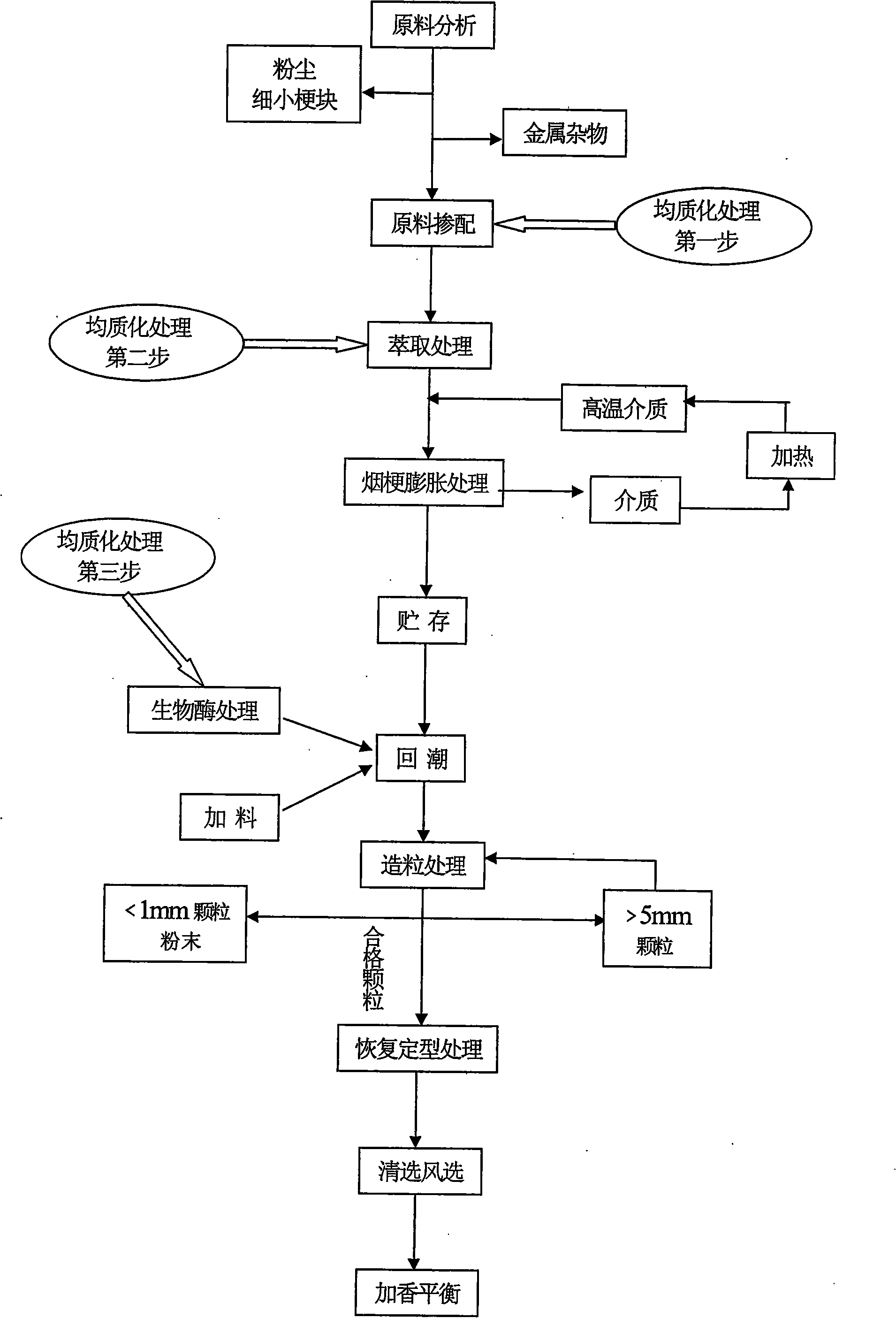

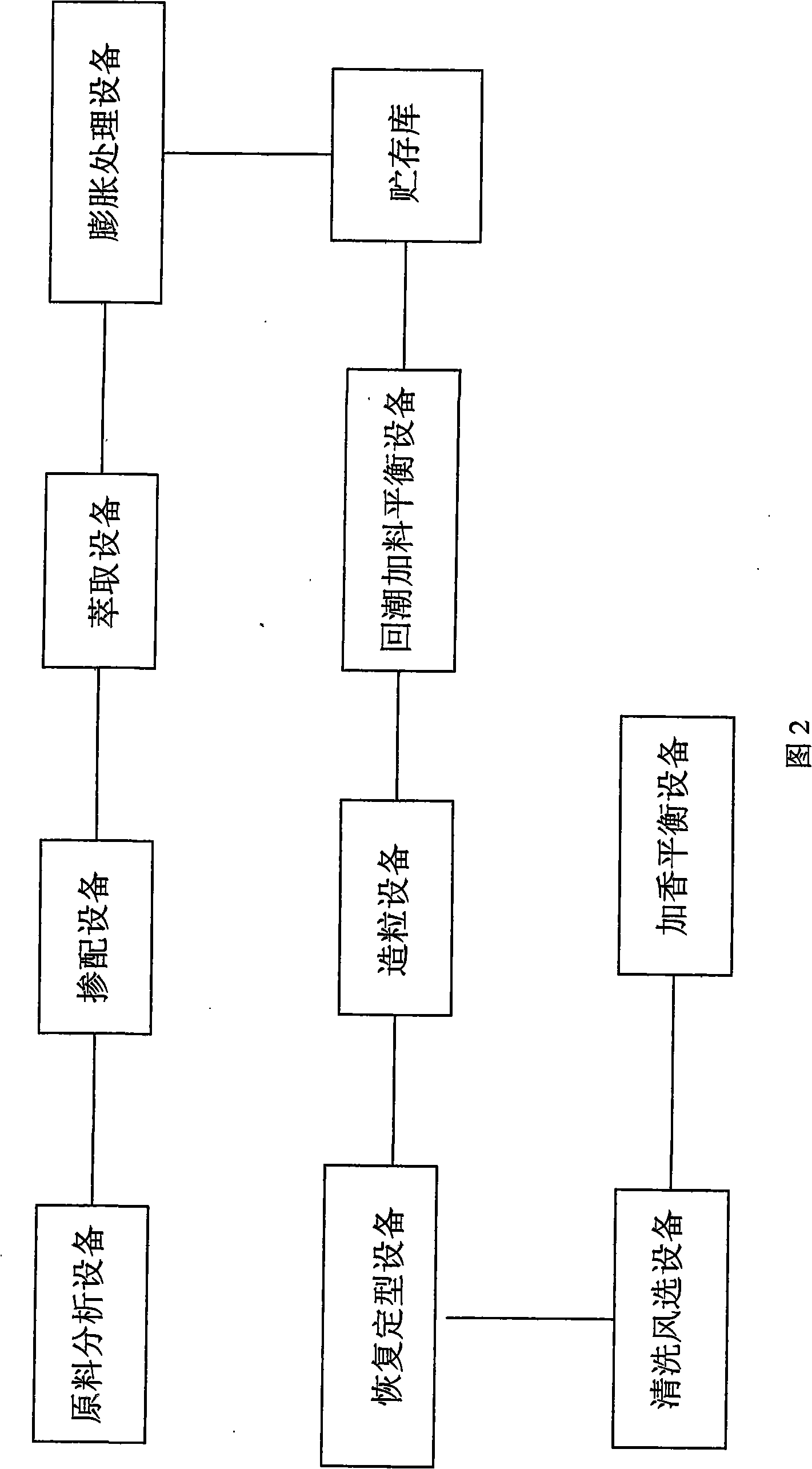

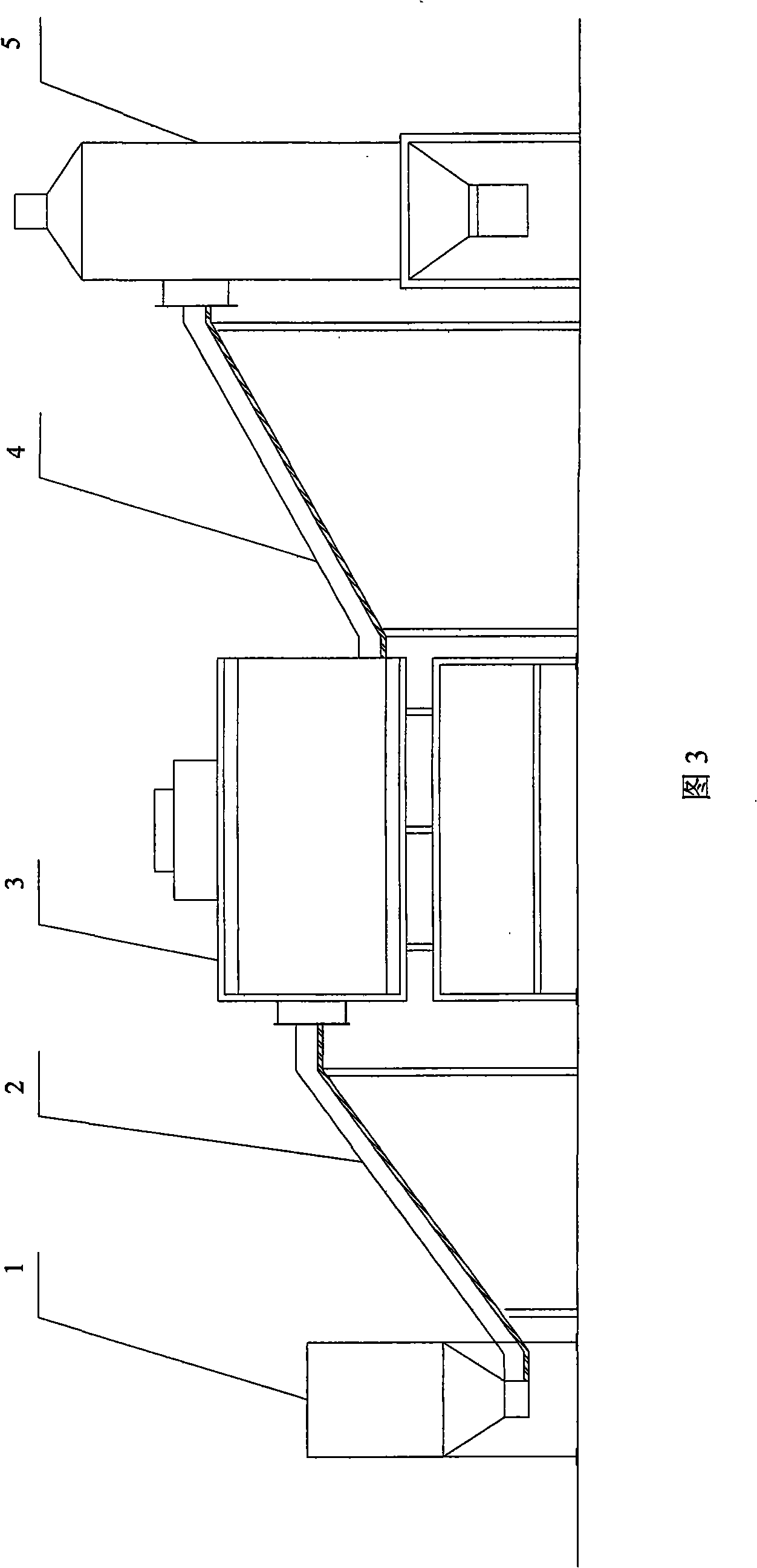

Method and device for preparing expanded stem granule

ActiveCN101305836AWide variety of sourcesAchieve expansionTobacco preparationTobacco treatmentTotal nitrogenSugar

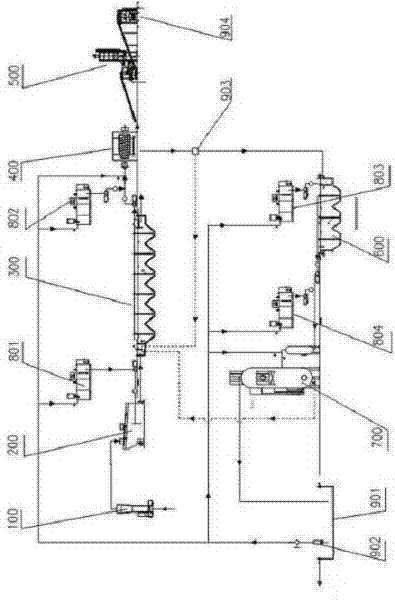

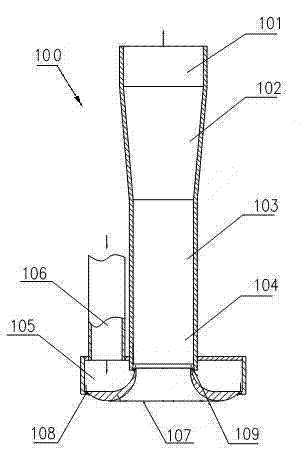

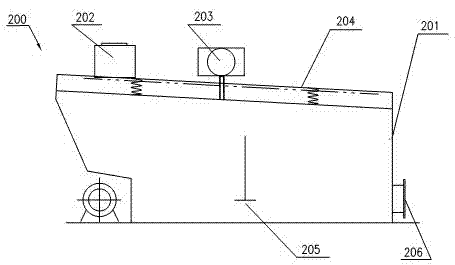

The invention discloses a method for preparing expanded tobacco stem particles and the equipment thereof. The method is characterized in that the method can control the mixed ratio of tobacco stems on the basis of raw material analysis. The method comprises the following steps: mixing materials to obtain tobacco stem containing 10 to 18%of total sugar, 8 to 16% of reduced sugar, 0.3 to 1.5% of nicotine, and 1.0 to 2.0% of total nitrogen, extracting, expanding, storing, regaining moisture, granulating, recovering, shaping, cleaning and air-sorting, flavoring, and balancing to obtain the required expanded tobacco stem particles. The invention eliminates the influences of material difference on the quality of the expanded tobacco stem particles to ensure the stability and the uniformity of the product quality, thus improving the utilization rate of the tobacco stem and further improving the production process of the expanded tobacco stem particles. The method has the advantages of simple, reasonable and easy process flow, stable equipment operation, high efficiency, low energy loss, and good application prospect.

Owner:YUNNAN REASCEND TOBACCO TECH GRP +1

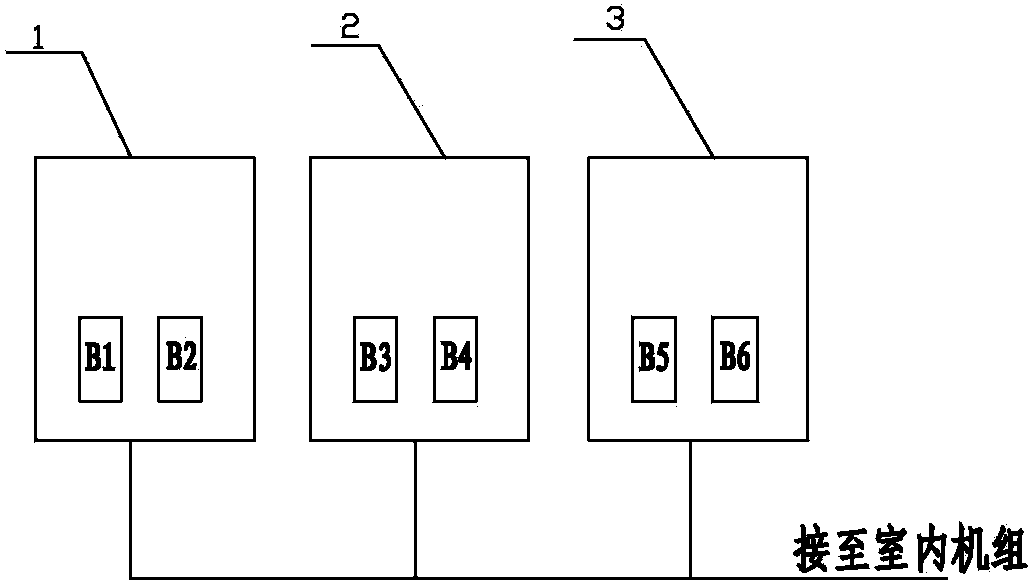

Modular multiple on-line control method

InactiveCN103512154AReasonable processMaximize energy saving potentialSpace heating and ventilation safety systemsLighting and heating apparatusEmbedded systemOperating frequency

The invention relates to a modular multiple on-line control method. Indoor units and outdoor units are included, wherein each outdoor unit comprises an inverter compressor. The control method includes the following steps that first, the capacity requirement Q of the indoor units is calculated; second, the number N of the outdoor units needing to be turned on is determined; third, the turned on outdoor units are allocated according to weight; fourth, all the outdoor units determine the number of the compressors to be turned on and the operating frequency of the inverter compressors according to the allocated capacity. The control method is reasonable in procedure, simple in control and capable of playing the multiple on-line energy-saving potential. Meanwhile, due to the fact that all the inverter compressors can operate within a high-efficiency range through the method, the phenomenon that because the operating frequency is too high, the compressors are lack of oil or burnt to be damaged can be avoided, and the operating reliability and the service life of all the compressors can be effectively guaranteed.

Owner:NANJING TICA AIR CONDITIONING CO LTD

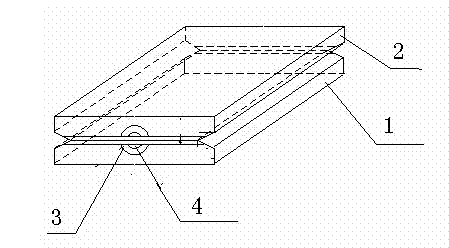

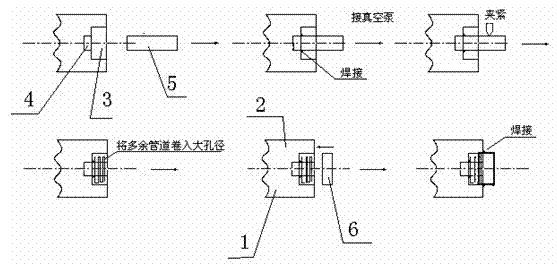

Composite manufacturing method of ultra-thick steel plate

InactiveCN102240894AOvercome the problems existing in the production of extra-thick steel plates above 100mmThe internal quality of the product is goodSheet steelHydrogen

The invention relates to a composite manufacturing method of an ultra-thick steel plate, which adopts a method of high-temperature hydrogen reduction and hot rolling for producing an ultra-thick steel plate and belongs to the field of steel rolling in the metallurgical industry. The technical scheme is as follows: the composite manufacturing method sequentially comprises the following process steps: preparing a base material and a covering material; carrying out surface treatment on the base material and the covering material; carrying out welding and combined blanking on the side part of a composite surface; carrying out high-temperature hydrogen reduction; vacuumizing and sealing a composite cavity; heating and rolling; carrying out hot straightening; cooling and inspecting; and collecting and warehousing the finished product. The composite manufacturing method has the following benefits: the ultra-thick steel plate with the thickness of greater than 100mm can be manufactured by the composite manufacturing method, stratification and cracking can be avoided during shearing, drilling and other processing operations, the method overcomes the problems existing in the production of ultra-thick steel plates with the thickness of greater than 100mm in the background art, and the composite manufacturing method has the characteristics of good internal quality of the product, reasonable process steps, high efficiency, low investment, convenient operation process and the like.

Owner:HEBEI IRON & STEEL GRP

Asbestos fiber reinforced thermoplastic base wood and plastic composite material and preparing method thereof

The invention belongs to the field of building material, in particular to a wood and plastic composite material, a preparing method and application thereof. The asbestos fiber reinforced thermoplastic base wood and plastic composite material is prepared from the following raw materials by weight percentage: 20%-45% of plastic, 30%-60% of wood powder, 5%-30% of asbestos fiber, 0.5%-3% of coupling agent, 0-2% of plastizer, 0-2% of stabilizer, and 0-4% of lubricant. The processed wood and plastic composite material has mechanical property higher than that of the wood and plastic material singly using the coupling agent, various mechanical property indexes being equal or exceeding that of the wood and plastic material simultaneously reinforced by using the coupling agent and the glass fiber, and cost greatly lower than that of the coupling agent and the glass fiber used at present, and can be widely applied to the fields of buildings, automobiles, transportation, aerospace and military; after discard, the product processed by the asbestos fiber reinforced thermoplastic base wood and plastic composite material can be used as a raw material to be reprocessed profiles through removing surface contaminants and crushing, therefore, the invention has the advantages of repetitive reutilization and wide popularization and application prospect.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

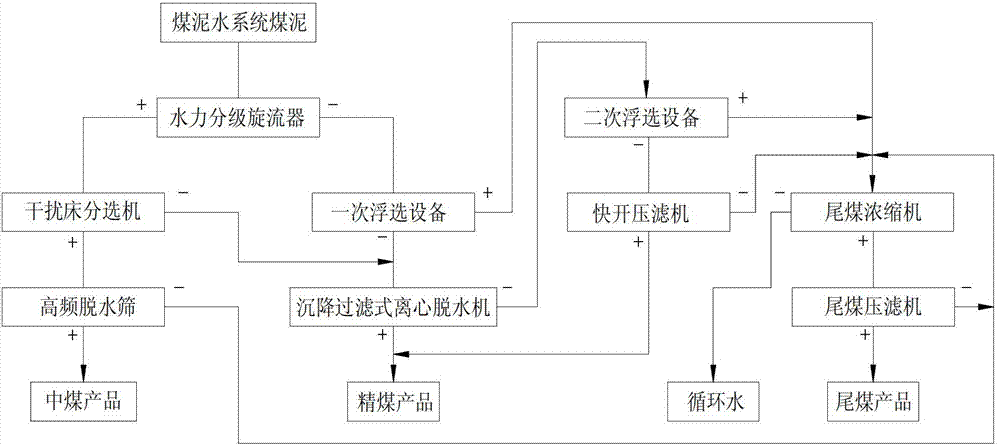

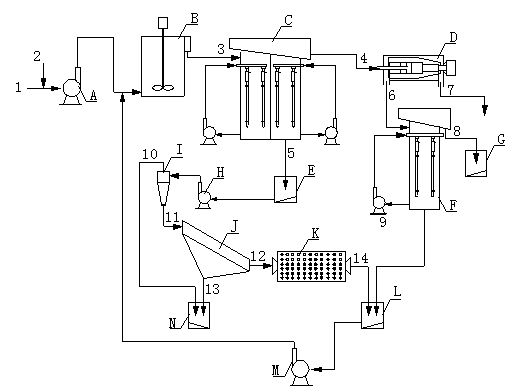

Classifying, separating and dewatering method for high-ash-content difficultly-separated coal slime

ActiveCN103240168AGive full play to the advantages of sortingRealize high-precision sortingFlotationWet separationCycloneFluidized bed

The invention discloses a classifying, separating and dewatering method for high-ash-content difficulty-separated coal slime. The classifying, separating and dewatering method includes: pumping a coal slime water system coal slime to a hydraulic classifying cyclone for classifying, enabling the coal slime to enter primary floatation equipment to separate by overflowing, subjecting bottom flow to entering a separating machine of a liquid-solid fluidized bed to separate, mixing and 'doping' primary floated fine clean coal and coarse-grain clean coal prior to entering a horizontal sedimentation perforated basket centrifuge to dewater and recycle, enabling filtrate and centrifugate of the horizontal sedimentation perforated basket centrifuge to enter secondary floatation equipment to separate, dewatering secondarily-separated clean coal by a quick-opening filter press, doping on-sieve products of coarse-grain tailing coal slime dewatered by a high-frequency sieve into coal products, and mixing backwater of the high-frequency sieve and primarily-separated tailing coal, the secondarily-separated tailing coal and filtrate of a clean coal quick-opening filter press into a tailing coal concentrator and the filter press to dewater and recycle. Therefore, high-quality clean coal low in ash content and water and high in recycling rate is obtained, the problem of 'loss of coarse coal' of floatation of tailing coal is solved, and the technical difficulty of high-precision separation of high-ash-content difficultly-separated coarse and fine coal slime is overcome.

Owner:CHINA UNIV OF MINING & TECH

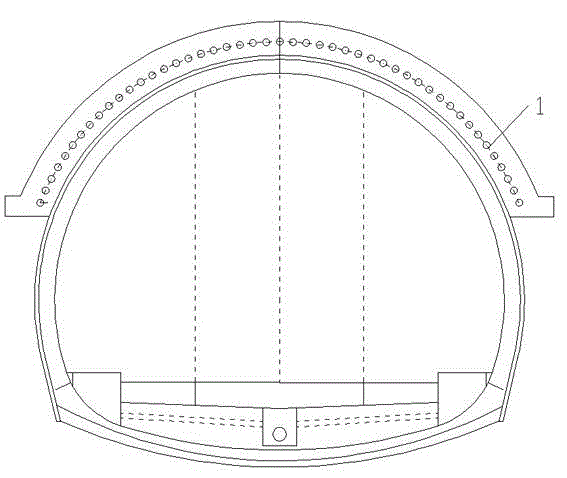

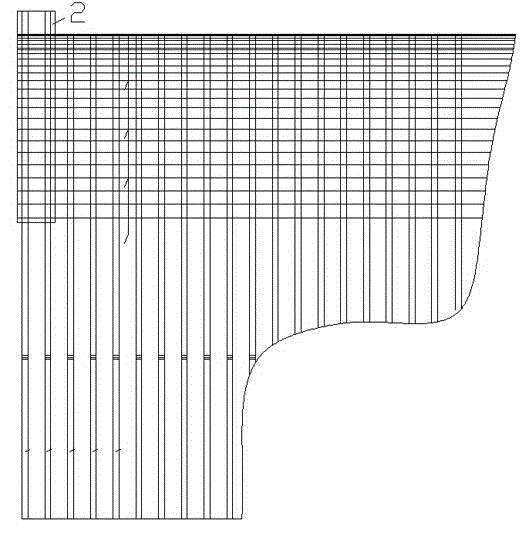

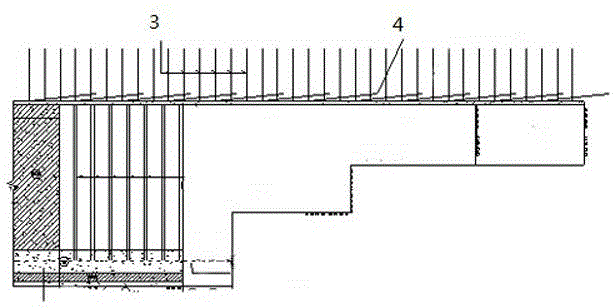

Construction method of residual slope wash tunnel with shallow cover and unsymmetrical pressure

ActiveCN104818991ASimple processReasonable processUnderground chambersExcavationsShotcreteEarth surface

The invention relates to a construction method of a residual slope wash tunnel with a shallow cover and the unsymmetrical pressure. The scheme with the step of ground surface grouting and shotcrete anchorage combined supporting, the step of pre-reinforcement of a long pipe shed and the step of correction three-stair four-step excavation construction is adopted, construction is conducted layer by layer from outside to inside, and operation that the deep-cover unsymmetrical pressure side is excavated, supporting is conducted, then the shallow-cover unsymmetrical pressure side is constructed, and an asymmetrical initial supporting structure is used for conducting construction according to the unsymmetrical pressure of surrounding rock is conducted, so that the supporting structure is optimized, the working procedure is more reasonable, and the construction speed is increased.

Owner:中铁二十四局集团福建铁路建设有限公司 +1

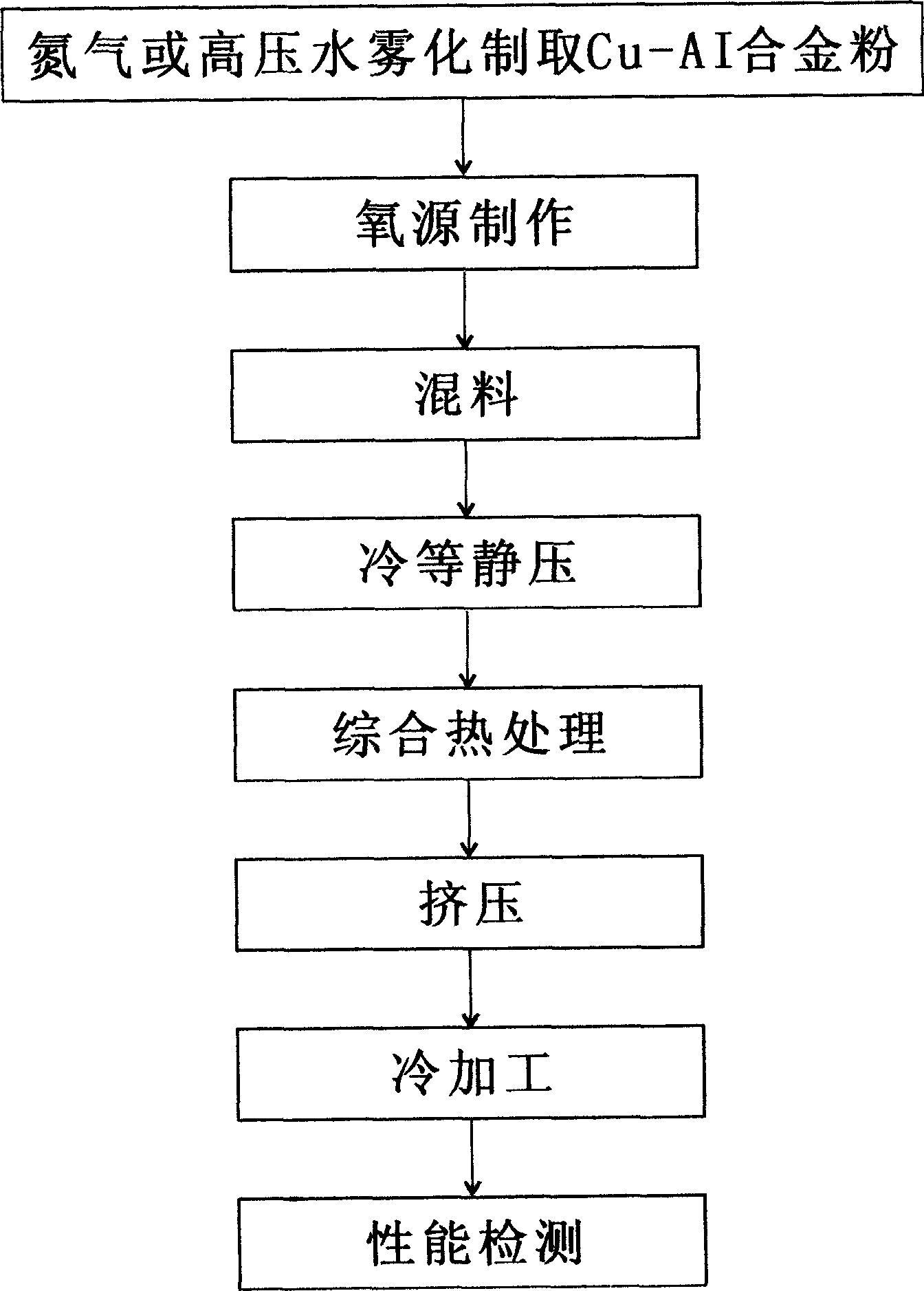

Dispersion strengthened copper alloy, and preparing technical method

A dispersion intensified copper alloy characterizes that the distribution ratio of the Al content is 0.05-0.6%, the rest is copper and the impurities are more than 0.5%, nitrogen or high pressure atomized water are utilized to prepare Cu-Al alloy powders by oxygen source preparation-materials mixing-cold isostatic pressure-comprehensive heat process-extrusion-cold process-performance test.

Owner:LUOYANG COPPER PROCESSING GROUP

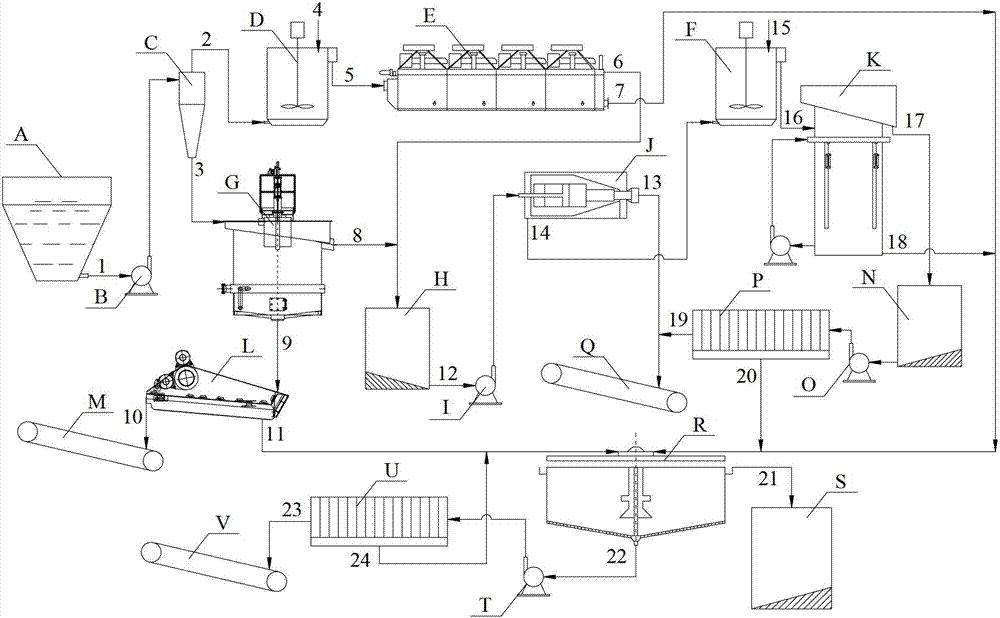

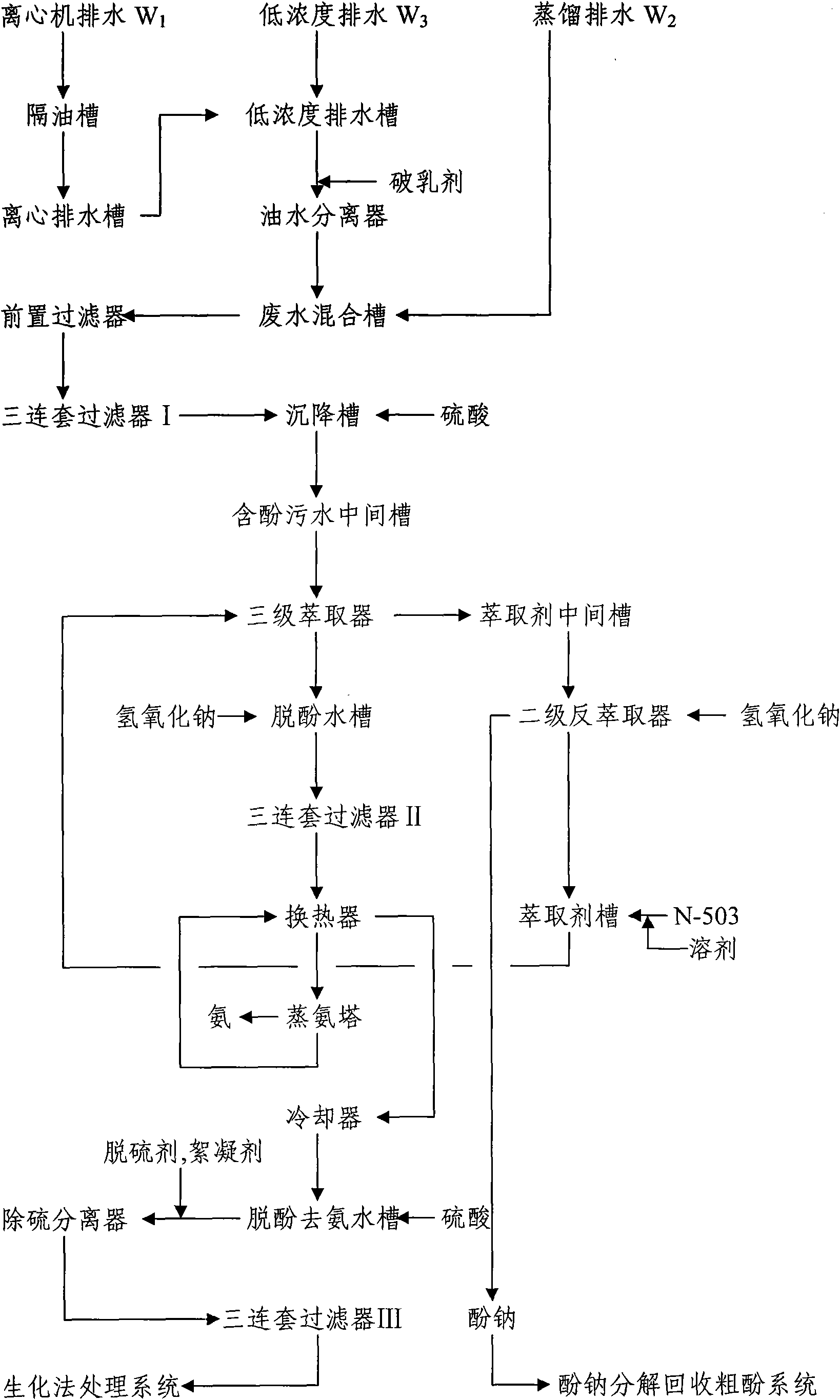

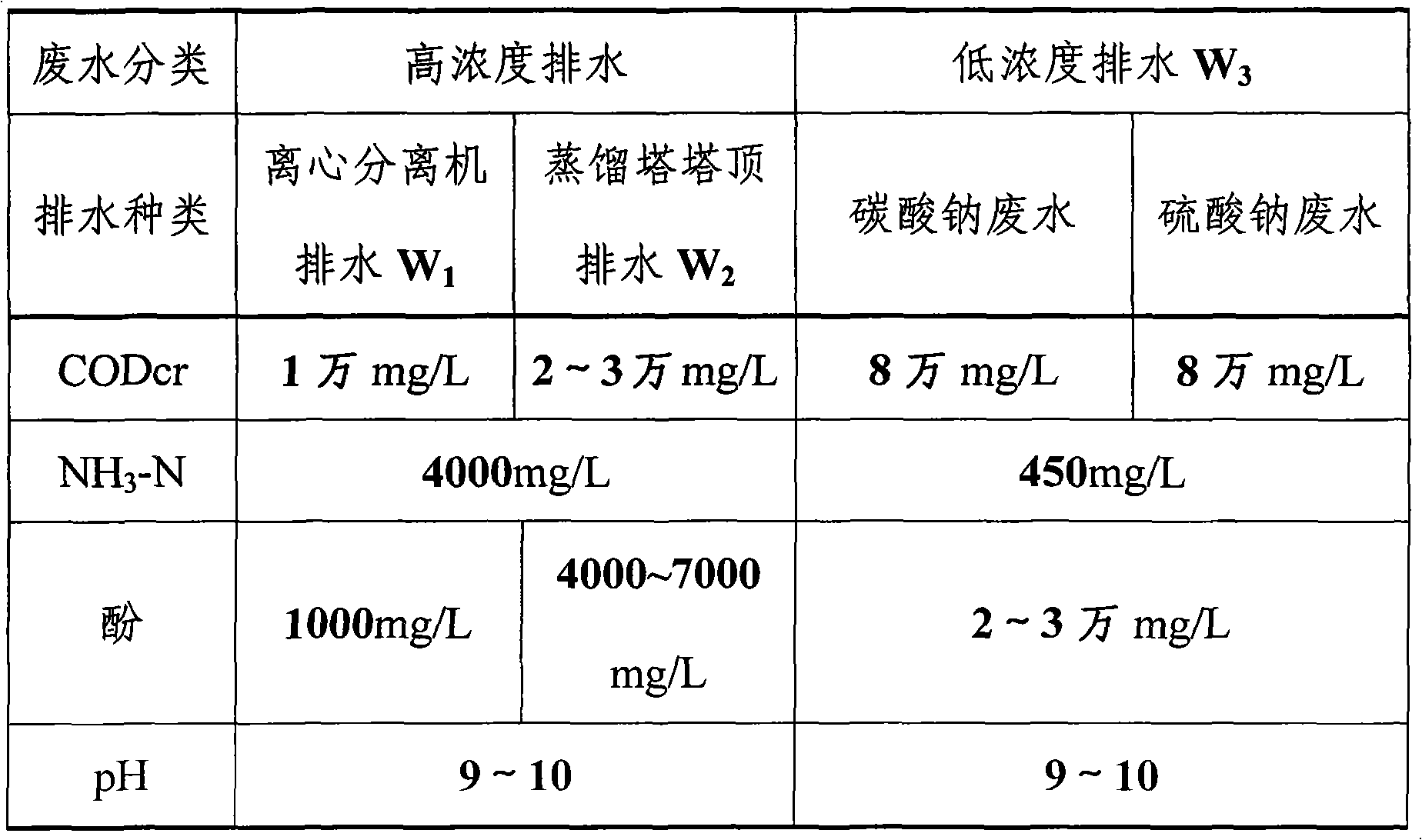

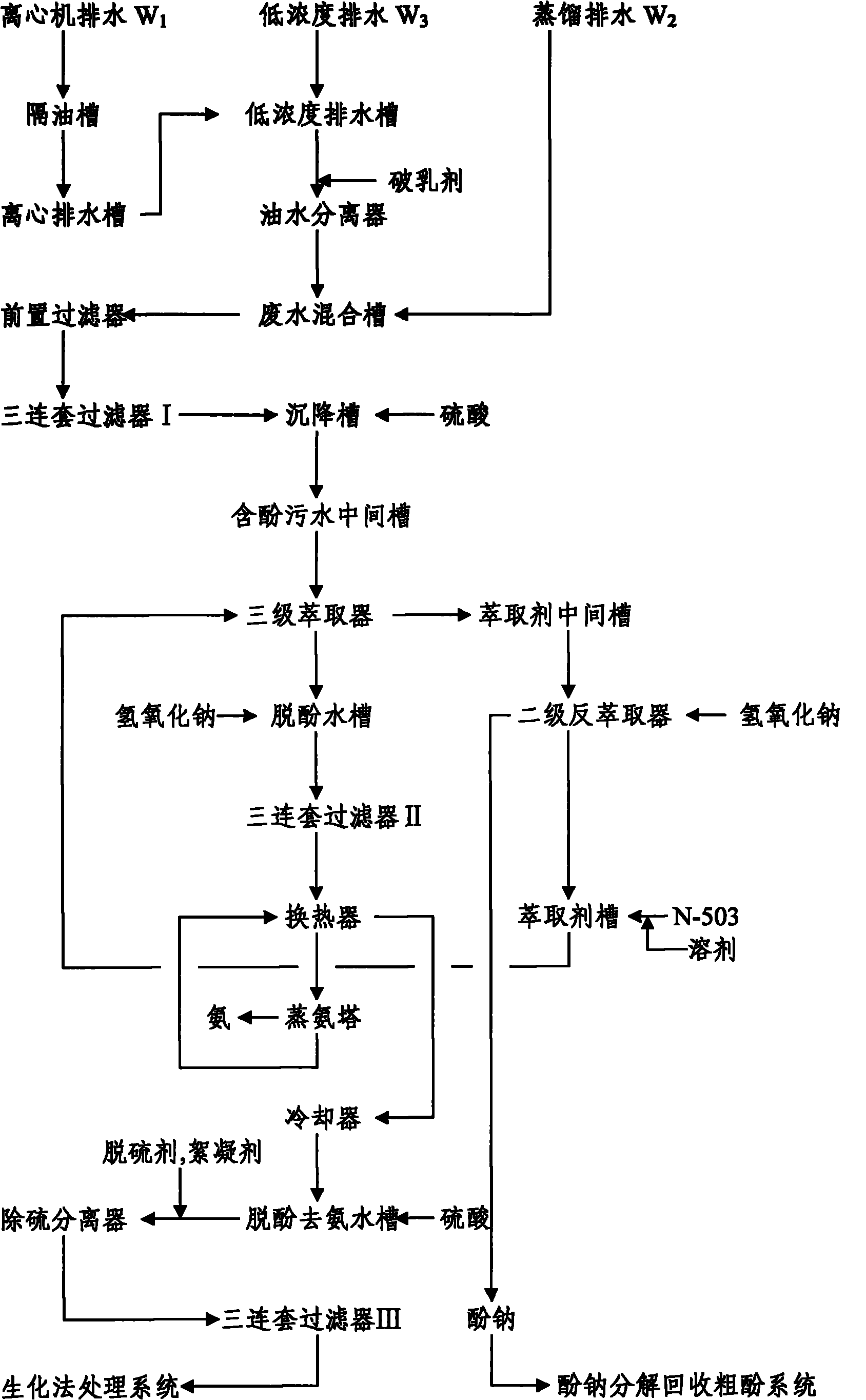

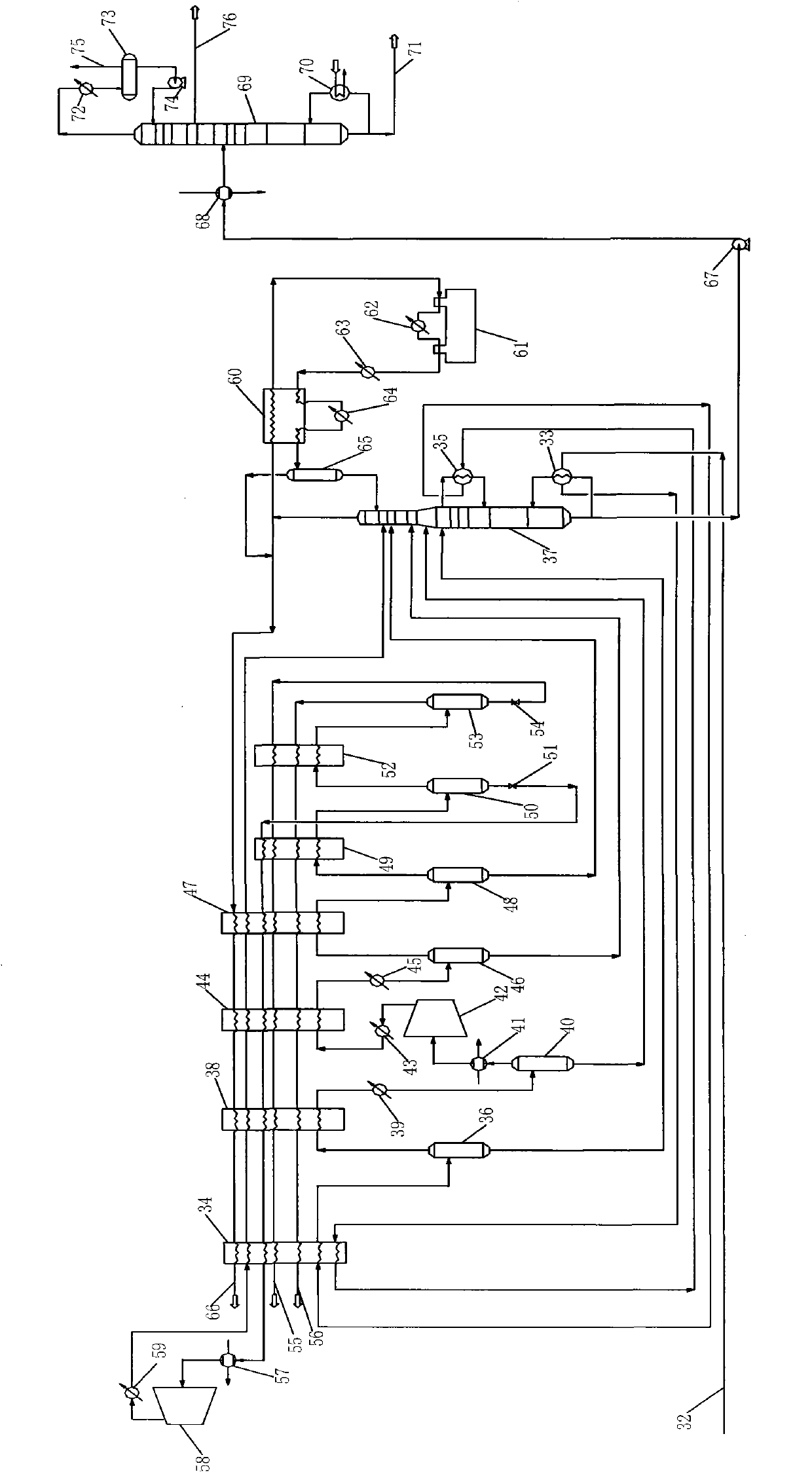

Coal tar processing wastewater treatment method and system

ActiveCN101875523AEfficient removalAchieve emission standardsFatty/oily/floating substances removal devicesMultistage water/sewage treatmentWater qualityEconomic benefits

The invention relates to coal tar processing wastewater treatment method and system. The treatment method comprises materialization treatment comprising the following steps of: (1) removing free oil and emulsified oil which are contained in wastewater, filtering, regulating the pH value of the wastewater to 3-4, and then separating out depositions; (2) extracting and dephenolizing; (3) regulatingthe pH value of the dephenolized wastewater to 9-10, filtering, then carrying out steam stripping and deaminization by using steam, and besides, carrying out reextraction on extract phase containing phenol to respectively recover an extracting agent and phenate, and then recycling the extracting agent and decomposing the phenate to obtain crude phenol; and (4) cooling the deaminized wastewater, regulating the pH value to 7-8, and then filtering after adding a desulfurizing agent to remove sulfides. The water quality of the materialized wastewater achieves the requirement of a biochemical treatment system; meanwhile, the invention can recover a given amount of useful matter comprising the phenol, ammonia and the like and make the extracting agent recycled so that the economic benefit of wastewater treatment is improved.

Owner:高科环保工程集团有限公司

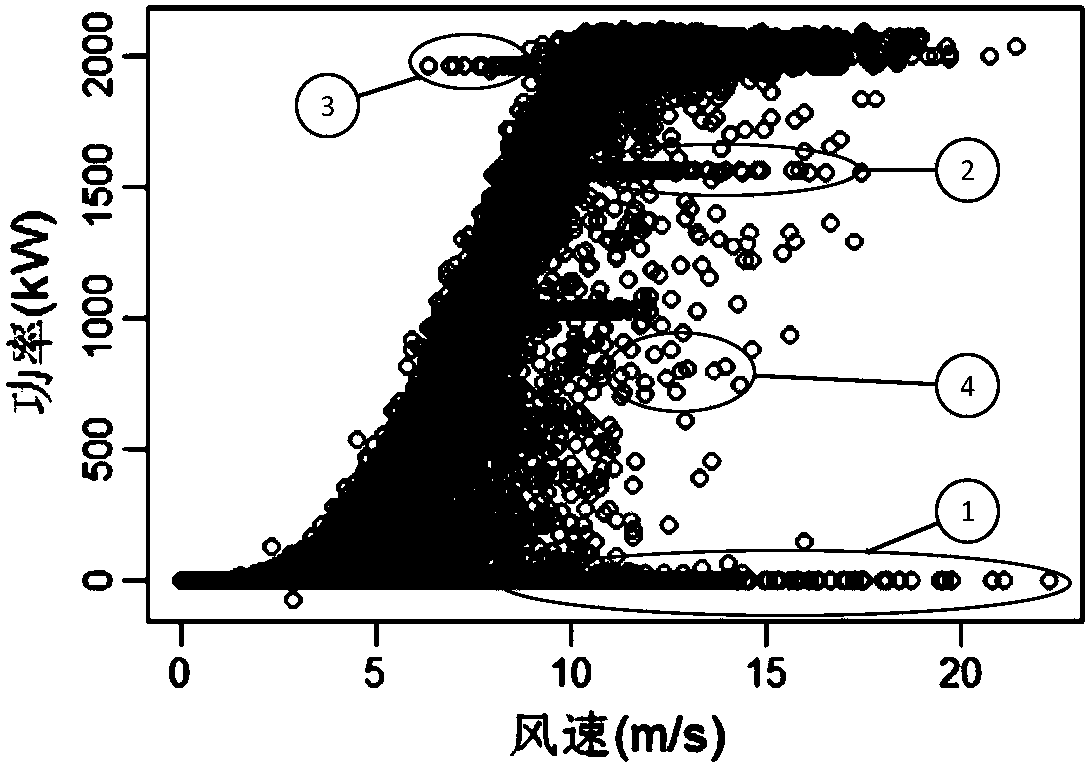

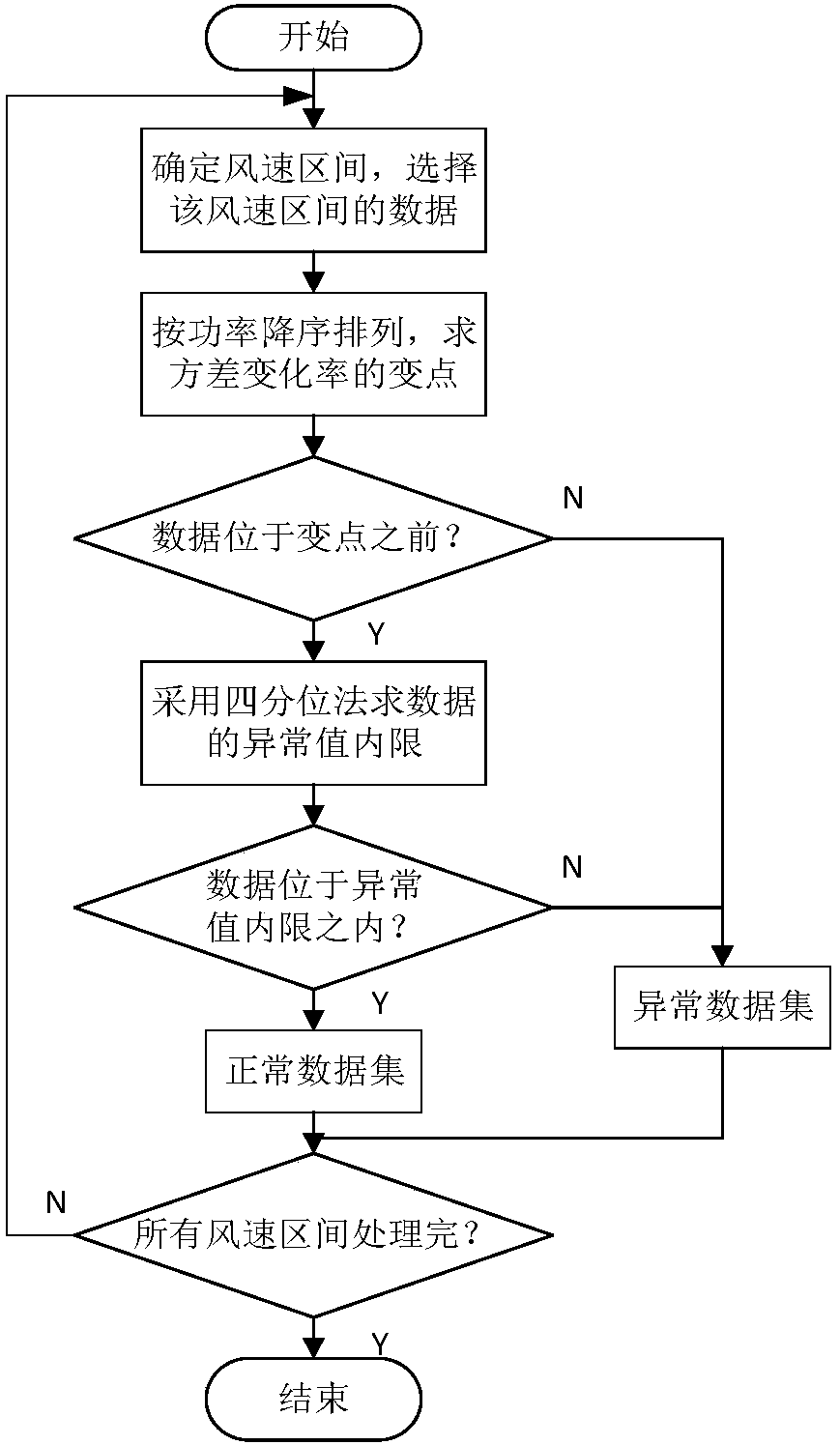

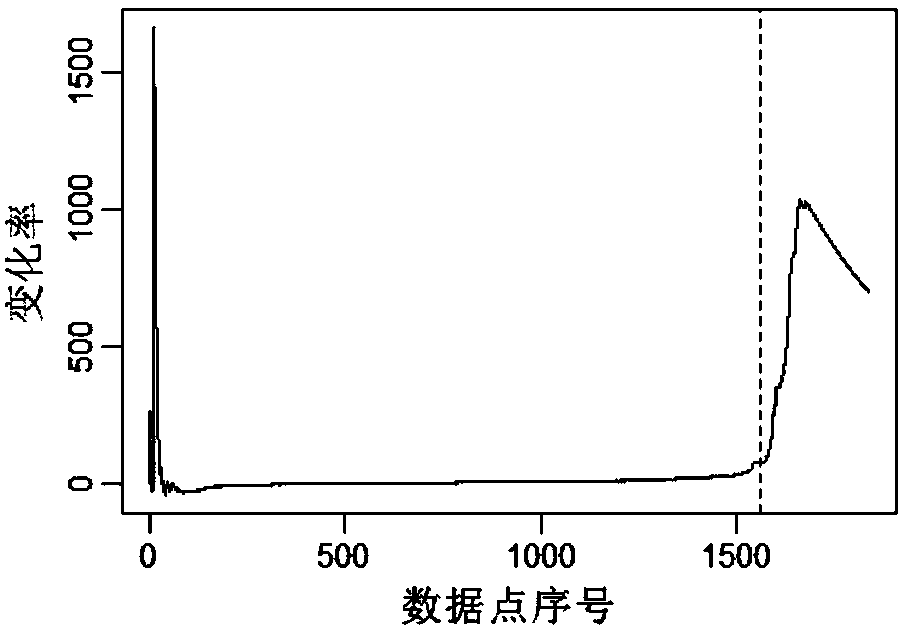

Cleaning method for wind power data of wind generating set

ActiveCN108412710AReasonable processEasy to cleanWind motor combinationsMachines/enginesElectricityCleaning methods

The invention relates to a cleaning method for the wind power data of a wind generating set. The method comprises the following steps that (1) the wind power data to be cleaned are divided into a plurality of data intervals according to the wind speed; (2) each data interval is subjected to data cleaning by adopting a variable-point grouping-quartile method, and abnormal data are removed; and (3)the cleaned data intervals are combined to obtain the cleaned wind power data. Compared with the prior art, the method has the advantages of being good in data cleaning effect, high in efficiency andhigh in universality.

Owner:TONGJI UNIV

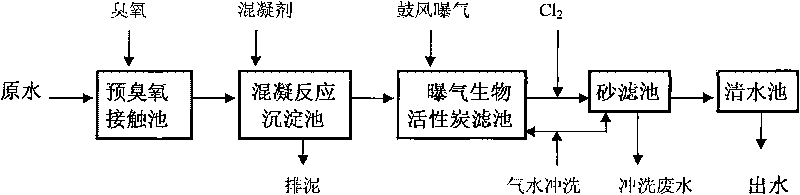

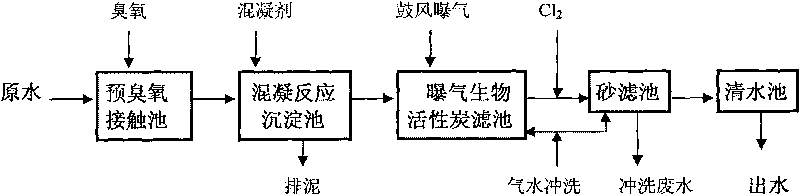

Feedwater treatment method by pre-ozonation and aerated biological activated carbon

InactiveCN101704609AAvoid breedingReduce qualityTreatment using aerobic processesMultistage water/sewage treatmentWater sourceWater quality

The invention discloses a method for applying pre-ozonation and aerated biological activated carbon processes to feedwater treatment. The method combines ozone pre-oxidation, an aerated biological activated carbon filter tank and a coagulation-sedimentation-sand filtering-disinfection conventional feedwater treatment process to produce drinking water, is a feedwater treatment process for improving water quality of feed water aiming at micro-polluted drinking water sources, and integrates the characteristics of an aerated biofilter biological pre-treatment process and an ozone biological activated carbon advanced water-purifying process. Raw water enters a pre-ozonation contact tank, a coagulation sedimentation tank and the aerated biological activated carbon filter tank orderly, is disinfected, enters a sand filtering tank, and finally flows into a clear water tank. Because the pre-ozonation contact tank and the aerated biological activated carbon filter tank are arranged in the conventional feedwater treatment process, the effect of removing organic matters, ammonia nitrogen, pathogenic microorganism, odor, chroma and the like is greatly improved, and the water quality safety of the method is obviously superior to that of the biological pre-treatment process and the ozone biological activated carbon advanced water-purifying process.

Owner:SOUTH CHINA UNIV OF TECH

Chromosome karyotype image cutting method

ActiveCN110533684AThe segmentation effect is clearReduce mistakesImage enhancementImage analysisImaging processingDomain analysis

The invention discloses a chromosome karyotype image cutting method, and belongs to the technical field of chromosome image processing. An existing image segmentation method is used for segmenting a chromosome image, due to the fact that the chromosome image has a lot of noise, the phenomenon of wrong segmentation can occur, and errors are caused to bring interference to subsequent analysis. According to the method, chromosome image segmentation is mainly carried out based on connected domain segmentation and skeleton extraction modes, after independent single chromosomes are extracted throughconnected domain analysis, skeleton extraction and skeleton analysis are carried out on remaining cross chromosomes to find possible segmentation points, and segmentation of the cross chromosomes isrealized through the segmentation points; compared with the prior art, direct segmentation of the preprocessed image is changed, the segmentation effect is clear, errors caused by segmentation are reduced to the maximum extent, the process is simple and reasonable, large-scale popularization and application can be conducted outwards, and deployment is simple.

Owner:HANGZHOU DIAGENS BIOTECH CO LTD

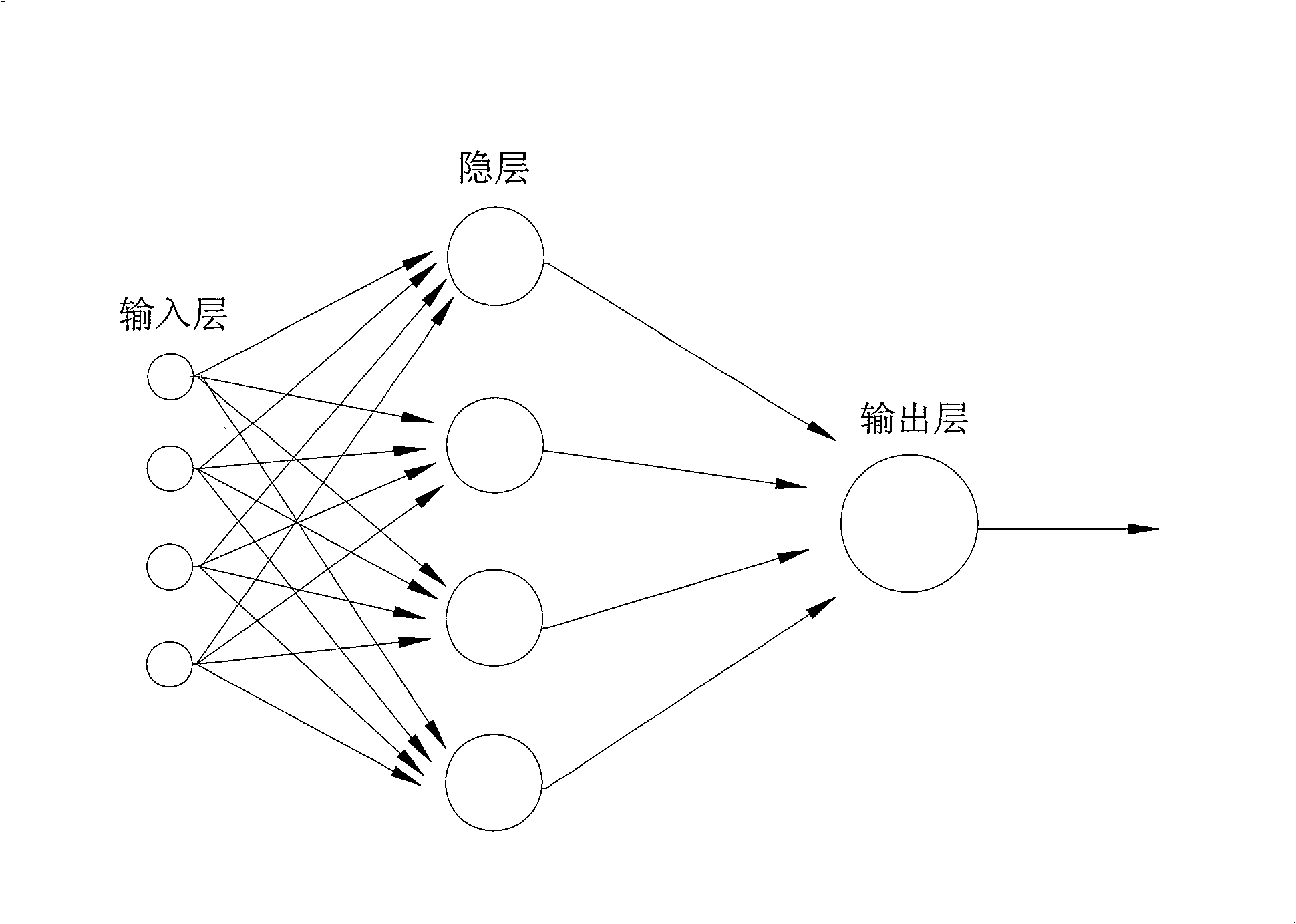

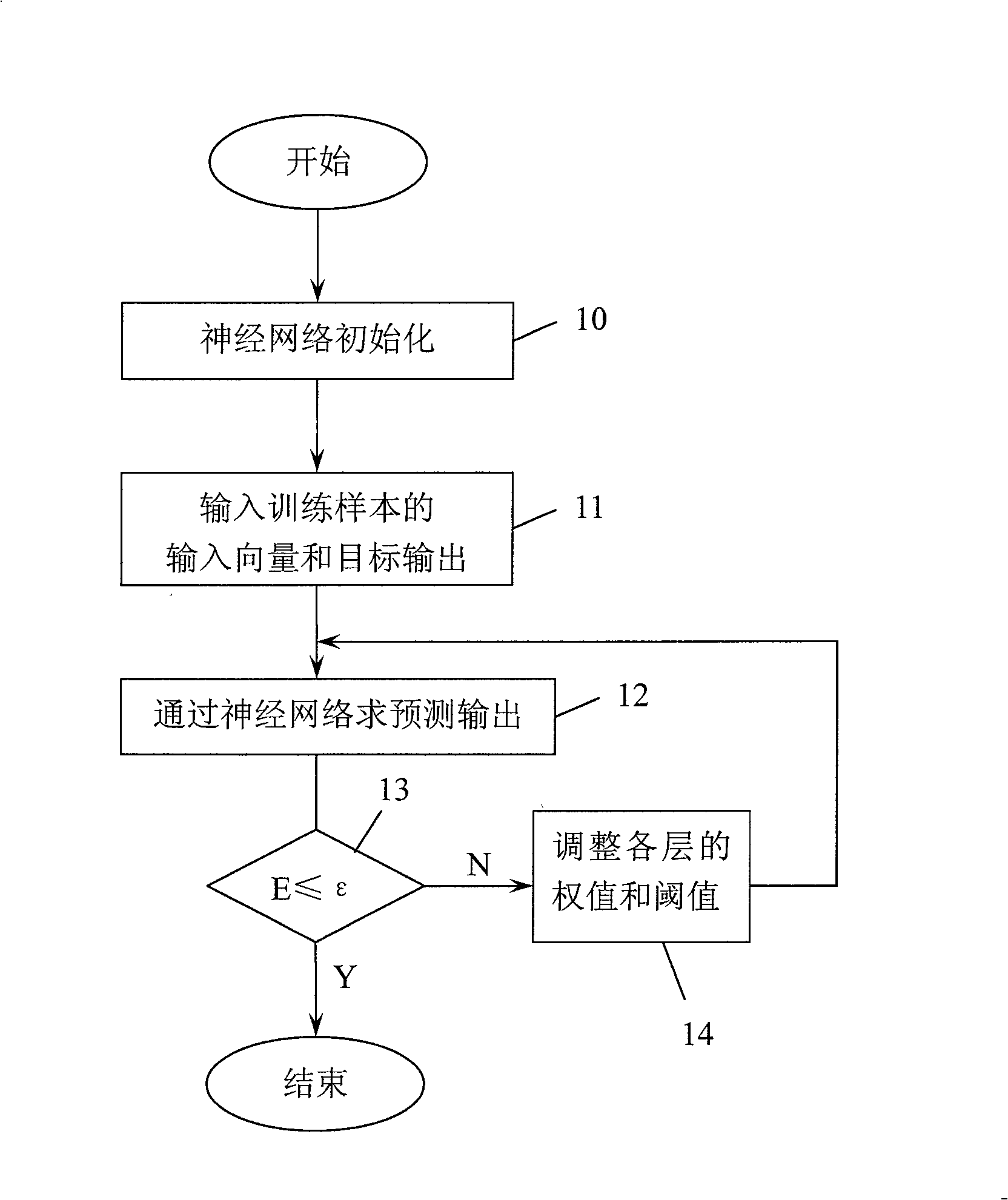

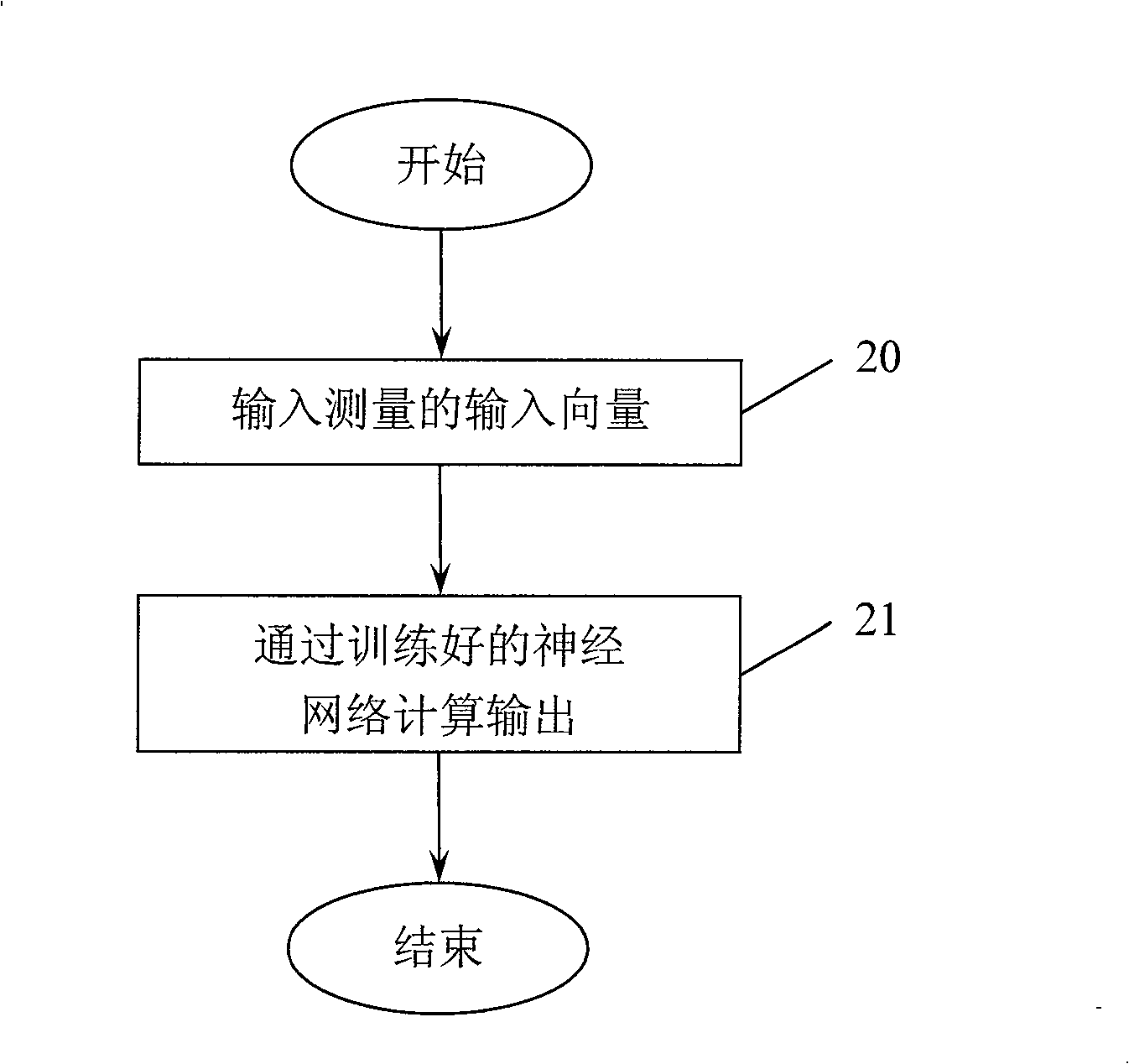

Method for estimating tunnel surrounding rock displacement by neural network

ActiveCN101344389AArrange the process reasonablyReasonable processMeasurement devicesPhysical realisationNetwork modelFeedback analysis

The invention discloses a method for forecasting the displacement of surrounding rocks of a tunnel by utilizing a neural network, which comprises the following steps: an appropriate neural network model is selected, a training sample of the displacement data of the surrounding rocks is input, training is carried out to the neural network , the neural network model with the precision which meets the requirements is obtained, the forecast of the displacement of the surrounding rocks is further carried out by utilizing the trained neural network, the neural network calculates and outputs the forecasted displacement of the surrounding rocks within the following 3 to 5 days of the construction time according to the input measuring point input vector, thereby realizing pre-warning of the displacement of the surrounding rocks. The method utilizes the credible monitoring data in the actual construction, considers the geological features and the related influencing factors of the construction region and carries out the forecast of the deformation and the internal force, etc., of the rocks in the next stage by the feedback analysis of the neural network, thereby guiding the construction, optimizing the construction parameters and reasonably arranging the working procedure.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

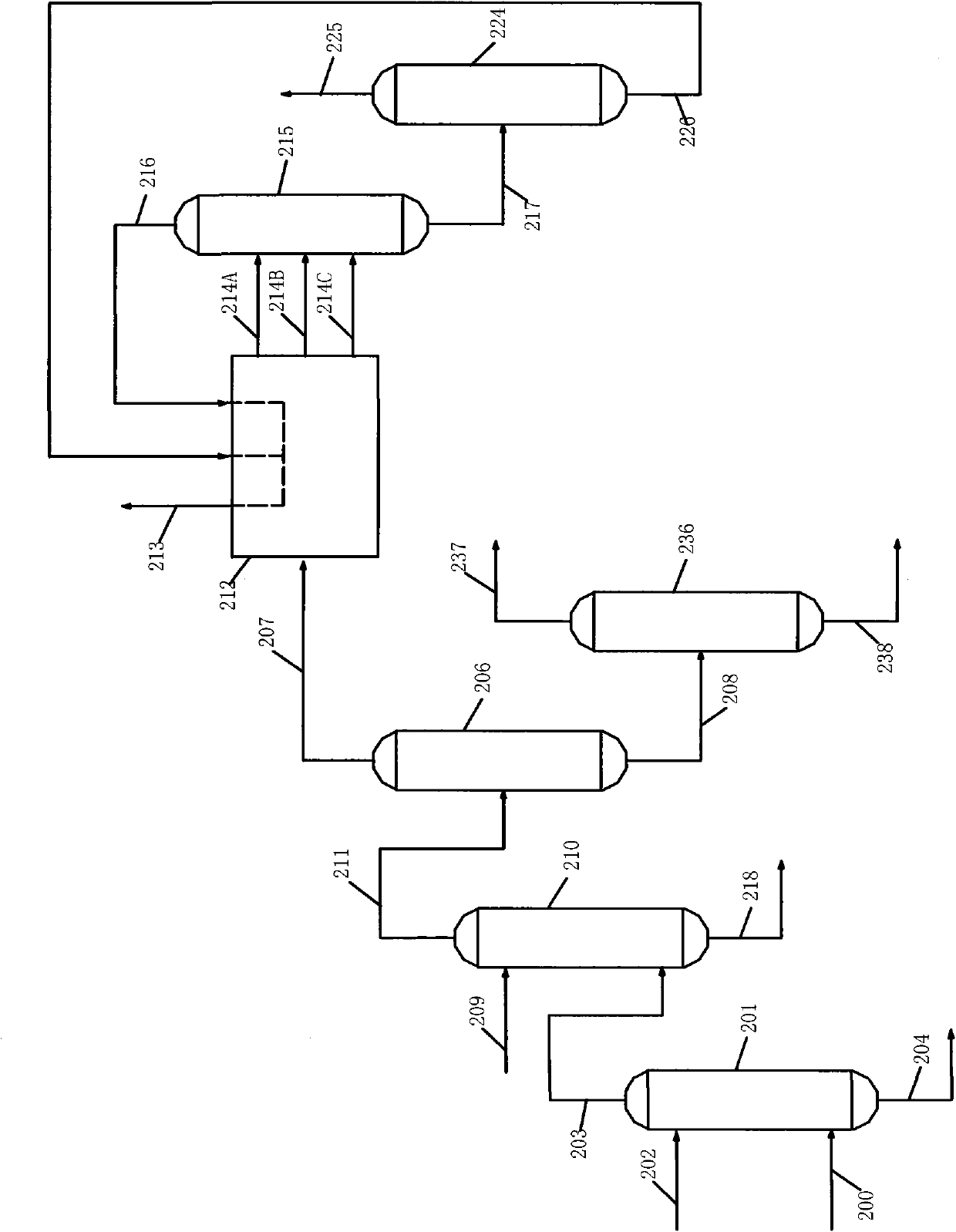

Technology for separating low carbon olefin gases

The invention discloses a technology for separating low carbon olefin gases, for solving the problems that hydrogen, methane, ethane and propane and other products with high purity can not be acquired and dimethyl ether and oxygen and carbon monoxide in impurities are not removed efficiently, etc. in the prior art. The technology is characterized in that a step of removing carbon monoxide and oxygen is added, methanol-to-olefin gas streams processed by removing carbon monoxide and oxygen enter into a deethanizing column, deethanizing column overhead streams successively pass through an ethene hydrogenation reactor, six separation pots, a low pressure demethanizing column and an ethene rectification column, etc. to separate to obtain ethene and ethane products, and deethanizing column bottom streams successively pass through a propyne hydrogenation reactor, a methane stripper and a propylene rectification column, etc. to separate to obtain propylene and propane products. According to the invention, polymer grade ethene and propylene products can be obtained, and hydrogen, methane, ethane and propane products, etc. with high purity can be obtained.

Owner:CHINA PETROLEUM & CHEM CORP +1

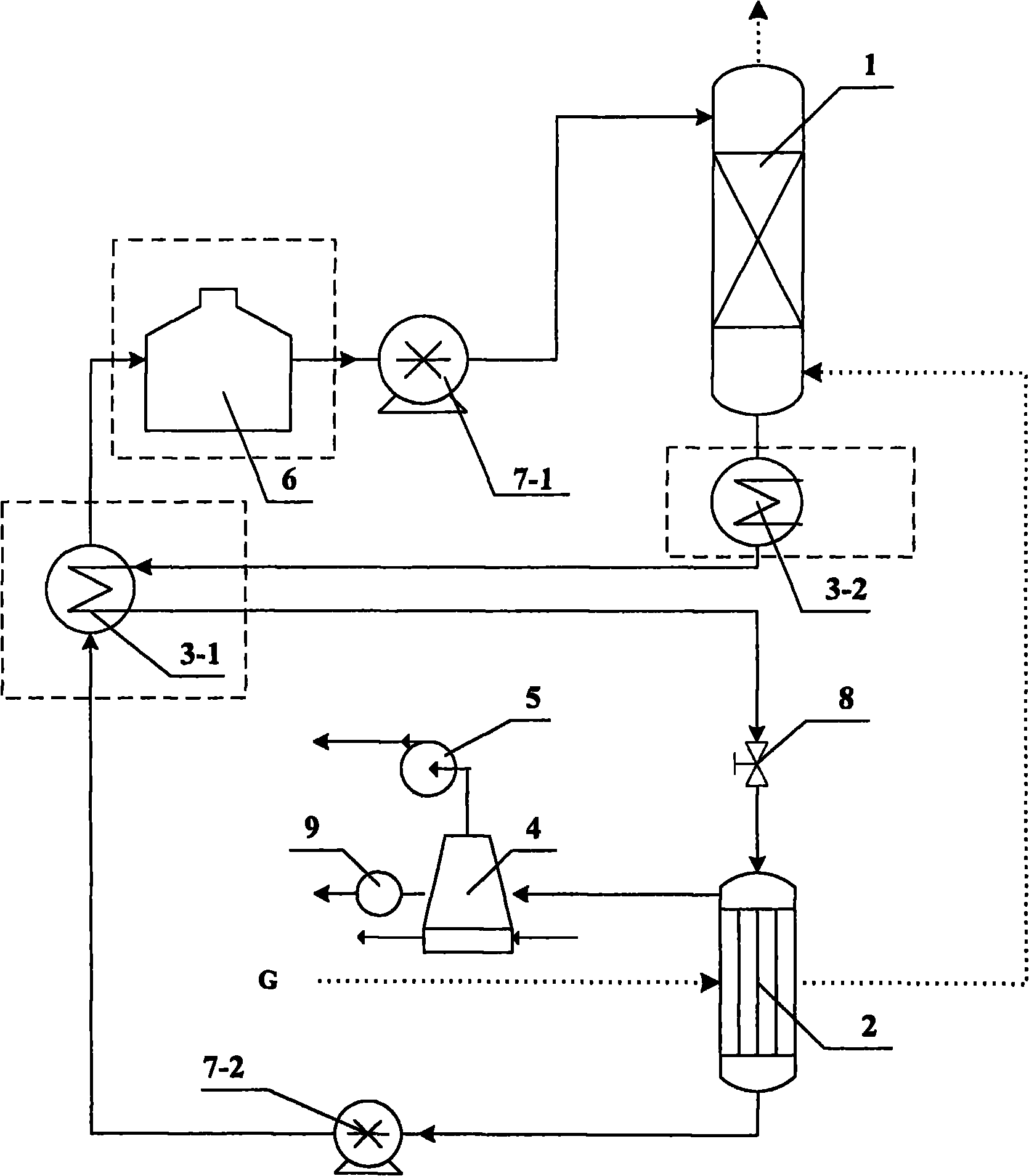

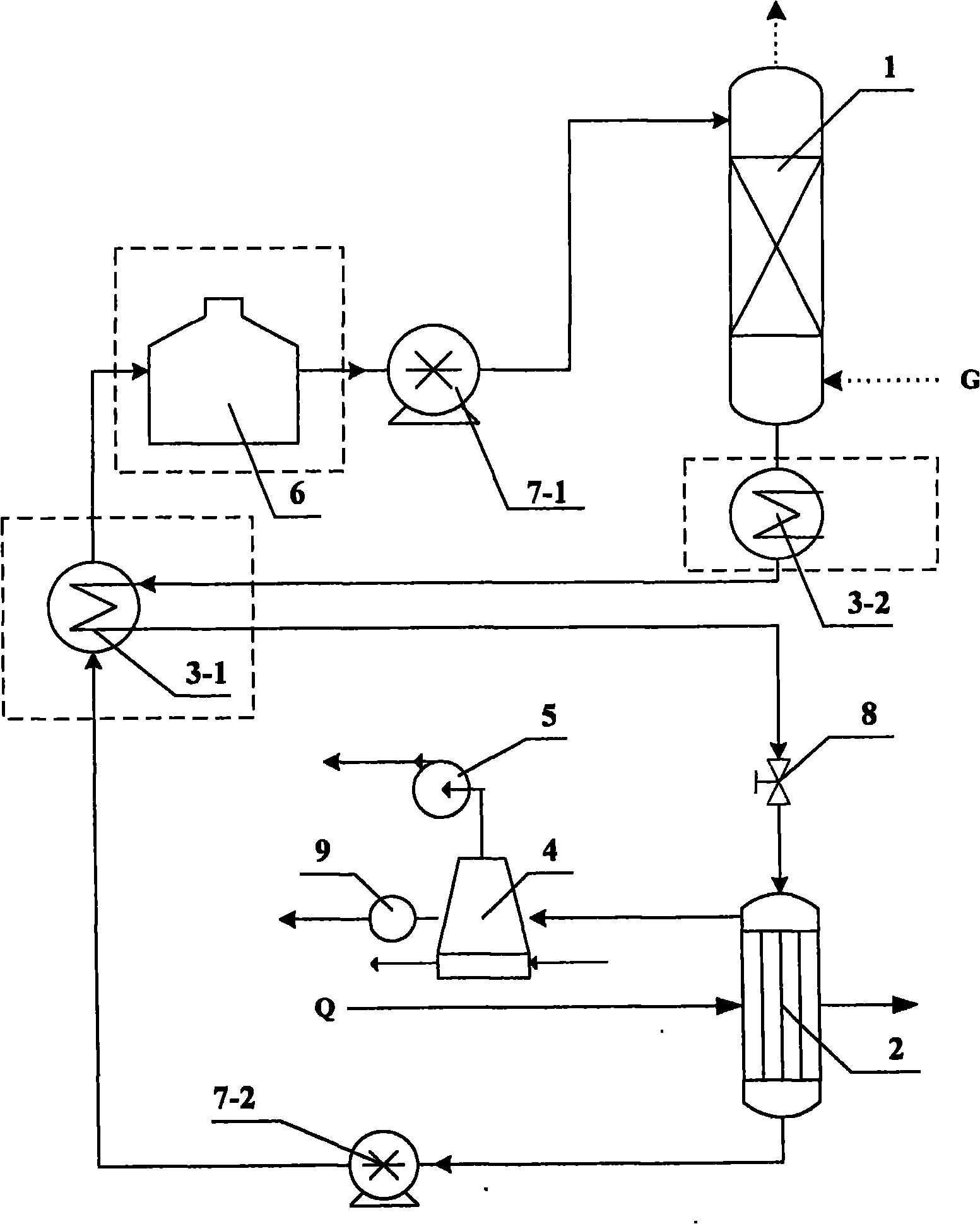

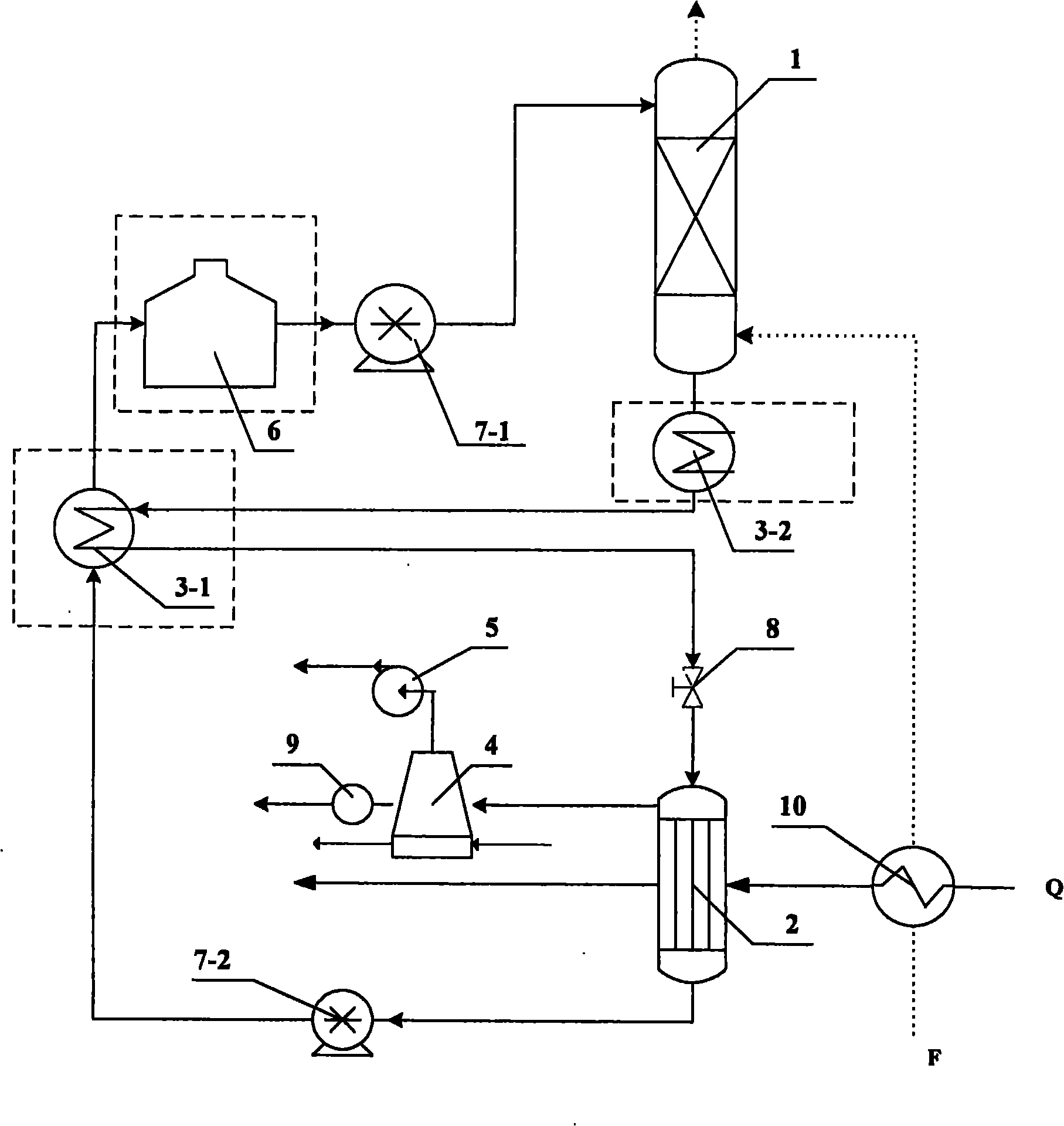

Method for simultaneously recovering water and latent heat in high-humidity flue gas and heat pump device

InactiveCN101922821AOptimizing Process ParametersLow costClimate change adaptationEnergy efficient heating/coolingHigh humidityFlue gas

The invention discloses a method for simultaneously recovering water and latent heat in high-humidity flue gas and a heat pump device, relating to the technique of energy-saving equipment. A heat exchanger is arranged in an absorber of the heat pump device, the top of the absorber is provided with a flue gas discharging pipe, the bottom of the absorber is provided with a dilute solution outlet, the side surface of the bottom is provided with a gas inlet pipe, the side surface of the top is provided with a concentrated solution inlet, and a concentrated solution pipeline is communicated with a spray head at the inner upper part of a cavity; the top of a regenerator is provided with a dilute solution inlet, the bottom of the regenerator is provided with a concentrated solution pipeline outlet, a gas-liquid heat exchanger is arranged in the regenerator, and an inlet and an outlet of the gas-liquid heat exchanger are communicated with a flue gas pipe; the flue gas pipe is communicated with the gas inlet pipe at the bottom of the absorber after passing through the regenerator; the bottom of the absorber is communicated with the regenerator through a dilute solution pipeline, in which a regulating valve is arranged; and the regenerator runs under negative pressure, and the bottom of the regenerator is communicated with the absorber through the concentrated solution pipeline, in which a solution pump is arranged. The method and the device directly recover the water and the latent heat in the flue gas and have the advantages of equipment simplification, better energy saving, environmental protection and economic benefit.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

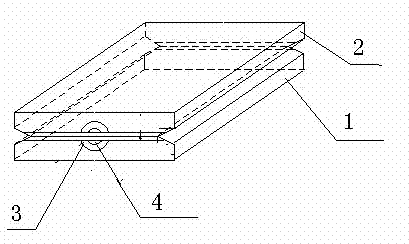

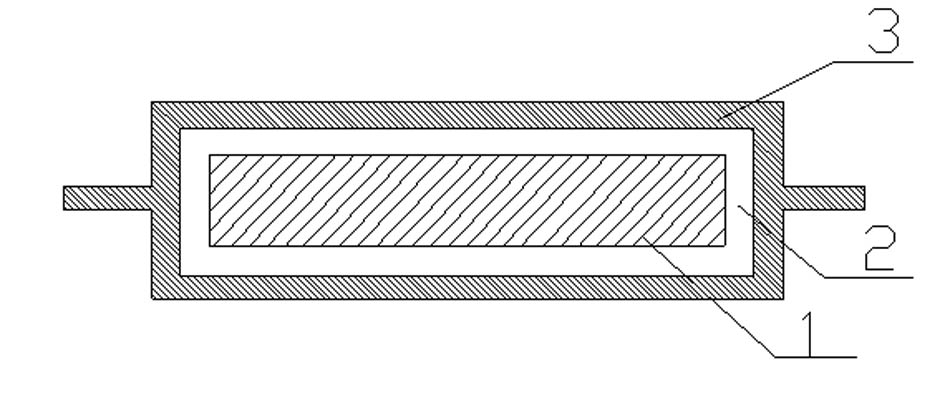

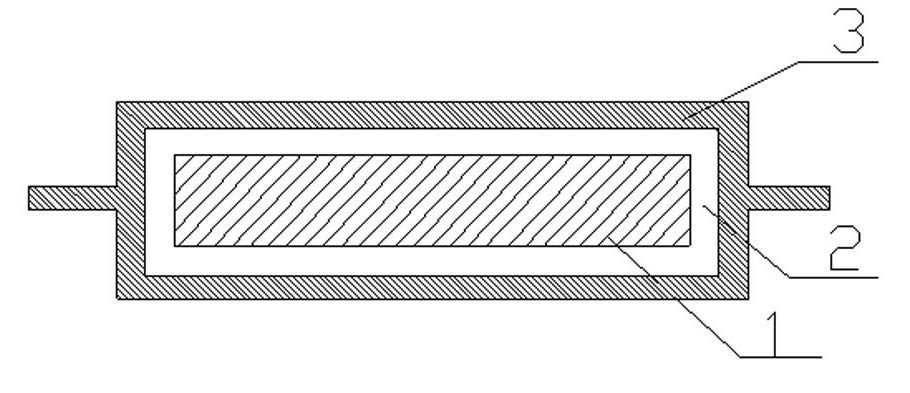

Vacuum insulated panel produced from superfine glass wool with wet process and method for producing same

ActiveCN102062277AReduce weightLow conductivityThermal insulationPipe protection by thermal insulationAging resistanceGlass wool

The invention discloses a vacuum insulated panel produced from superfine glass wool with a wet process. The vacuum insulated panel comprises a core material, a gas adsorption material layer and an isolating film layer, wherein the core material is in the innermost layer and is a core panel produced from superfine glass wool, the gas adsorption material layer wraps the outer surface of the core material, and the isolating film layer wraps the outer part of the gas adsorption material layer. The invention further discloses a method for producing the vacuum insulated panel. The vacuum insulated panel has light weight, low conductivity, good elasticity, corrosion resistance, aging resistance, high stability, good heat insulation effect and ideal sound-absorbing effect and is non-toxic, non-combustible and pollution-free. The vacuum insulated pane has the thickness of 8-30 mum, the service life of over 15 years, the use temperature of -50-70 DEG C and the conductivity of 0.0018-0.0028W / m.K at 20 DEG C.

Owner:许立江

New method for recycling iron minerals in magnetic separated gangues

The invention belongs to the technical field of mineral separation in iron and steel metallurgy industry, and particularly relates to a new method for recycling iron minerals in magnetic separated gangues, which adopts a method for recycling the magnetic separated gangues through staged magnetic separation, regrinding, fine screening and a magnetic separation column process: sending the magnetic separated gangues recycled by a recycling machine to a concentrated low-intensity magnetic separator; feeding the separated iron minerals into a ball mill for ball milling and discharging, and sendingthe minerals to a first segment of dehydration tank by a pump through a pump box; sending the dehydrated concentrate to a second segment of magnetic separator; sending the selected concentrate to a high frequency vibrating screen, returning substances on the screen to a feeding box of the concentrated low-intensity magnetic separator, and feeding the products under the screen into a third segmentof magnetic separator; sending the magnetic separated concentrate into a feeding box of a magnetic separation column to cause the concentrate to automatically flow to the magnetic separation column; and returning the gangues in each segment of magnetic separator to the gangue recycling machine. The concentrate at the magnetic separation column is the final concentrate, and the gangue at the firstsegment of magnetic separation recycling machine is the final gangue. The invention has reasonable process flow, can improve the grade of the reclaimed iron minerals in the magnetic separated ganguesthrough reasonable separation, fully utilize mineral resources, reduce the waste and loss of metals, obtain good indexes and simultaneously obtain remarkable economic benefit.

Owner:ANSTEEL GRP MINING CO LTD

Production method for ready-to-eat instant nutritive edible fungus soup

The invention discloses a production method for ready-to-eat instant nutritive edible fungus soup, which belongs to the technical field of deep processing of agricultural products. The production method mainly comprises the steps of selecting, cleaning, precise cutting, mixed boiling, spreading, pre-freezing and microwave vacuum freeze drying on screened raw materials such as edible fungi, thus obtaining the product which is subjected to nitrogen-filled packaging after being taken out of storage. The raw materials of the edible fungus soup is dewatered by a microwave vacuum freeze drying technology according to a modern food nutrition principle, so that the original color, aroma, taste and nutrients of the product are kept to the hilt, and compared with those of a conventional process, the drying efficiency is remarkably improved, the production cycle is shortened, the production cost is effectively reduced, and the special sterilizing effect of microwaves further guarantees the product quality at the same time. The edible fungus soup produced by the method is flat in shape, bright in color and luster, rich in nutrition, good in water regaining effect and long in storage time, and a feasible new way is provided for deep processing and utilization of the edible fungi.

Owner:NANJING UNIV OF FINANCE & ECONOMICS +1

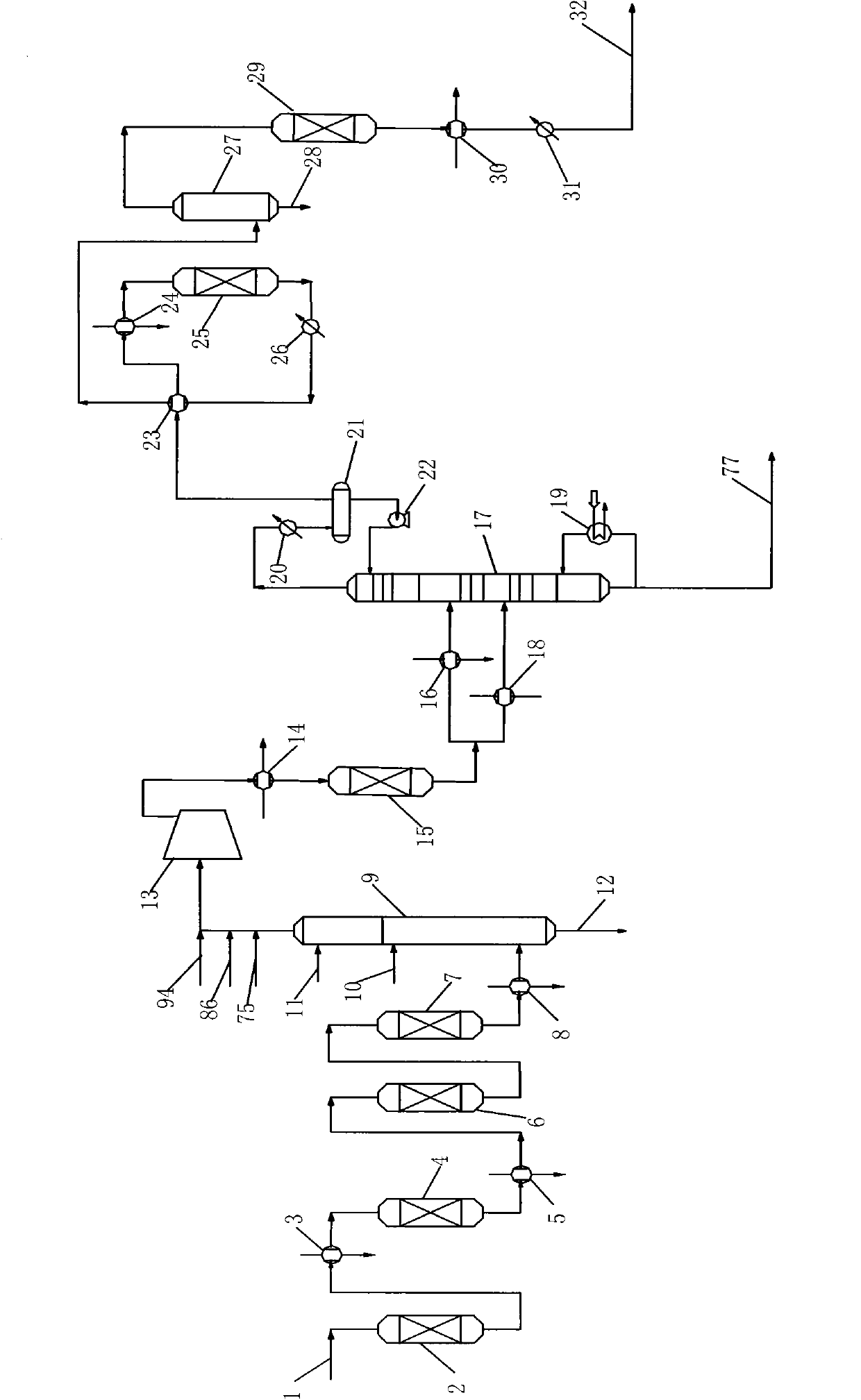

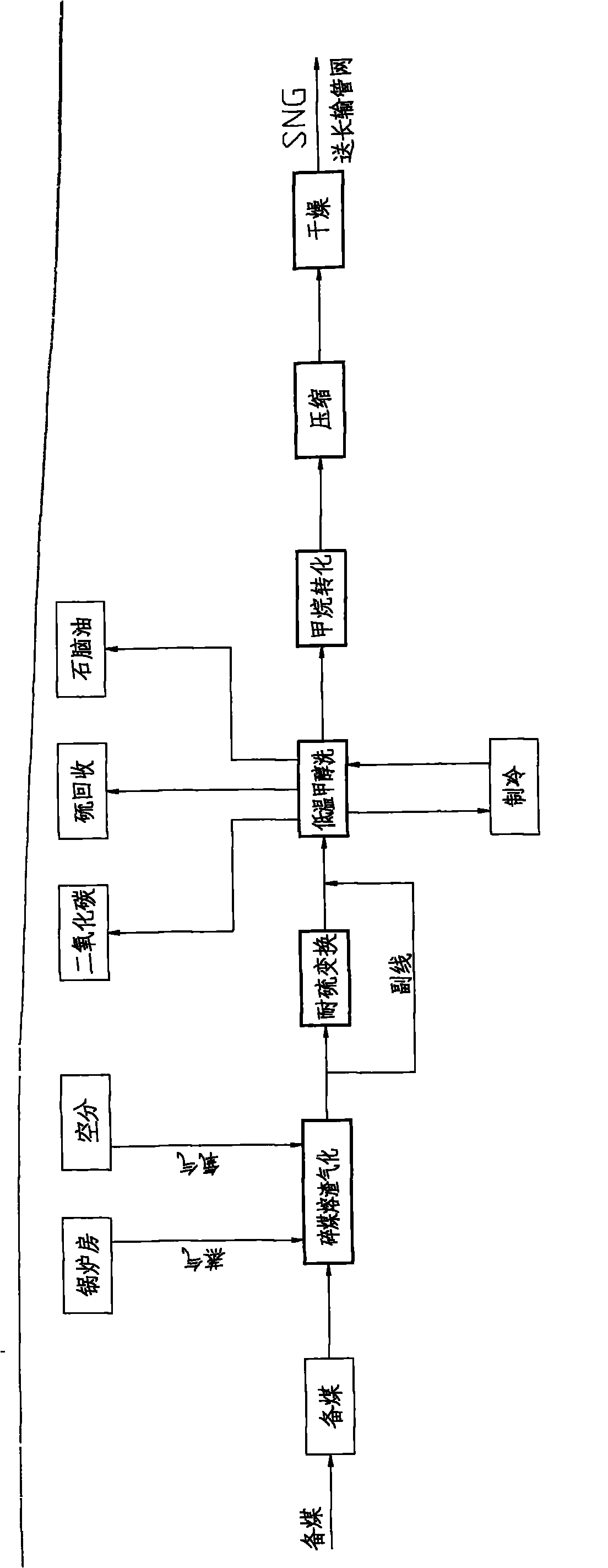

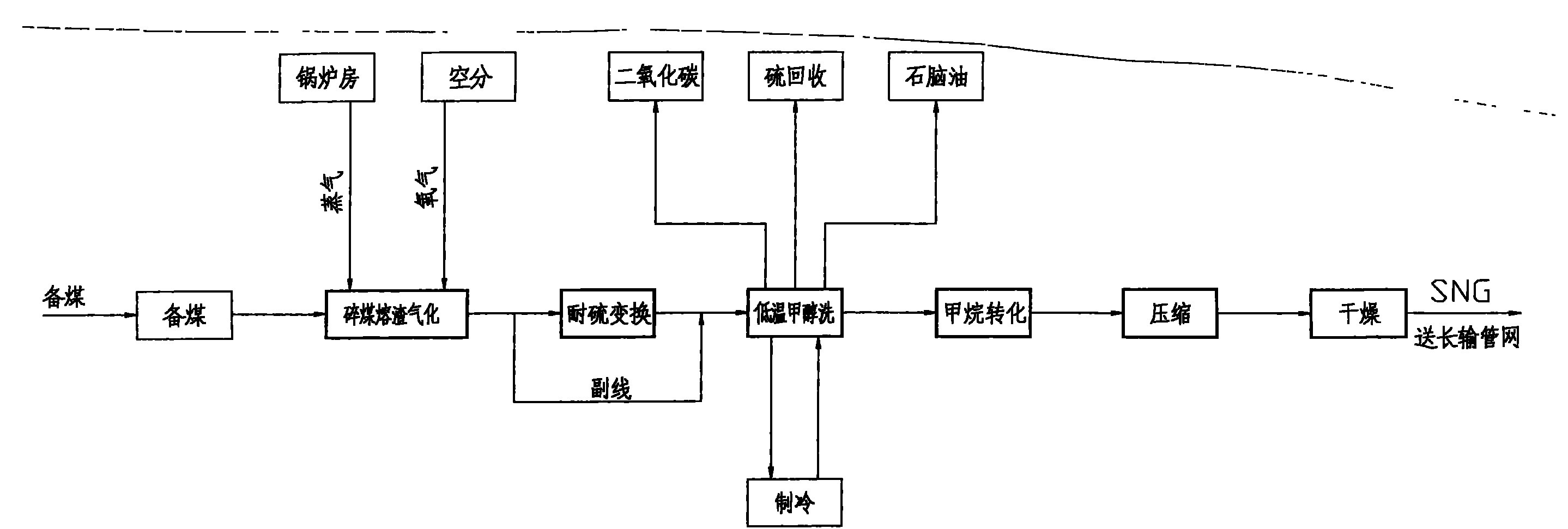

Technique for producing coal natural gas by utilizing crushed coal slag through gasification

ActiveCN101768488AMature and reliable technologyStable operation and maintenanceGaseous fuelsCombustible gas catalytic treatmentNaphthaSulfur

A technique for producing coal natural gas by utilizing crushed coal slag through gasification includes that part of crude coal gas containing CH4 produced by crushed coal slag through gasification receives sulfur tolerant shift, the other part of crude coal gas is conveyed in a sub-line and converges with the gas after sulfur tolerant shift to be cooled, the cooled gas is purified to remove CO2,H2S, naphtha and H2O and other impurities to obtain synthesis gas meeting the methane synthesis H / C ratio, the synthesis gas performs methane synthesis under the effect of methane conversion catalyst, and the methane-synthesis natural gas (SNG) is transmitted in long-distance pipeline network after compression and drying. The invention has the advantages of high gasification rate, high gasification intensity, low consumption and low water content of coal gas.

Owner:SEDIN ENG

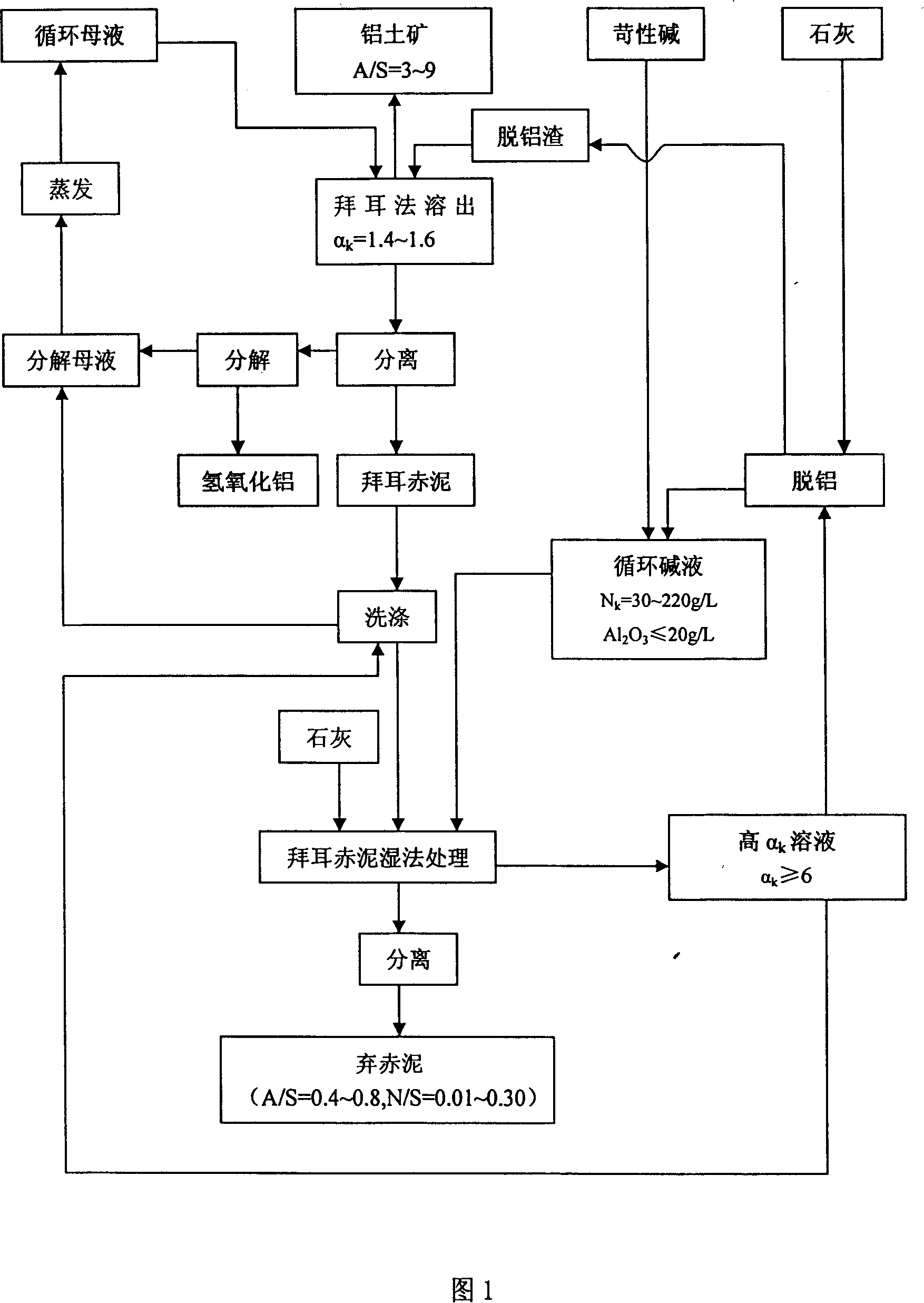

Method for producing aluminium oxide by middle-low grade alumyte

ActiveCN101113001AReduce energy consumptionReasonable processAluminates/aluminium-oxide/aluminium-hydroxide purificationAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationAluminateResource utilization

A method to produce aluminum oxide with middle-low bauxite relates to a method to produce aluminum oxide with middle-low bauxite by the means of Bayer-method. The invention is characterized in that: during the Bayer-method process, digestion process is to add dealuminization slag instead of lime as additive in middle-low bauxite to do Bayer process digestion; after digestion and backward washing of red mud, the red mud is mixed with recycle alkaline liquor, the lime is added, the digestion reaction is done, the red mud is separated from the slurry and discharged outside, the solution part obtained oppositely washes with Bayer-method, is sent to Bayer-method system to supplement alkali after digesting the red mud, the lime is added partly and is reacted, then, dealuminization slag and recycle alkaline liquor that goes through Bayer-method red mud wet treatment are gotten and dealuminization slag calcium aluminate hydrate instead of lime is added into the Bayer process digestion. The method of the invention belongs to all wet treatment, has simple process, low energy consumption, low alkali consumption and high recovery rate of aluminum oxide and is suitable for treating Chinese bauxite that is mainly middle-low bauxite; besides, the resource utilization is high, the amount of discharged red mud is low and the red mud is easy to be utilized comprehensively.

Owner:中铝郑州有色金属研究院有限公司

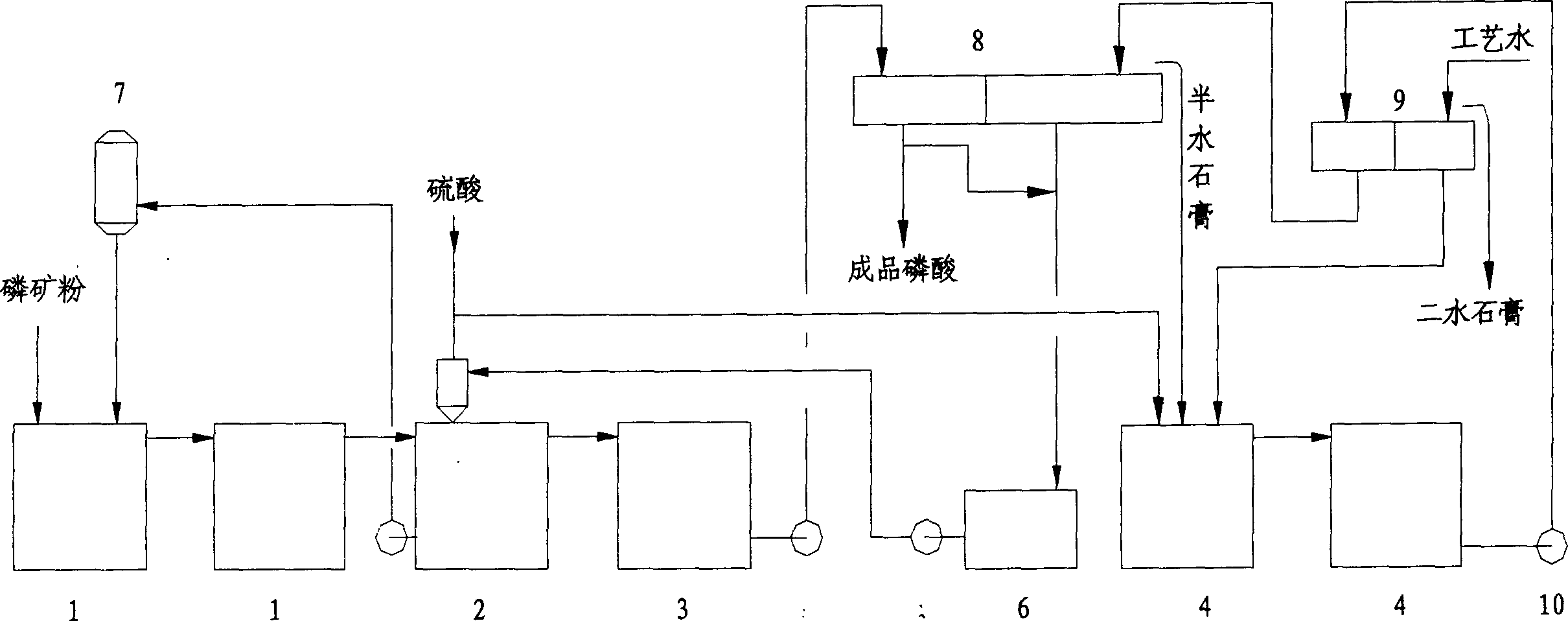

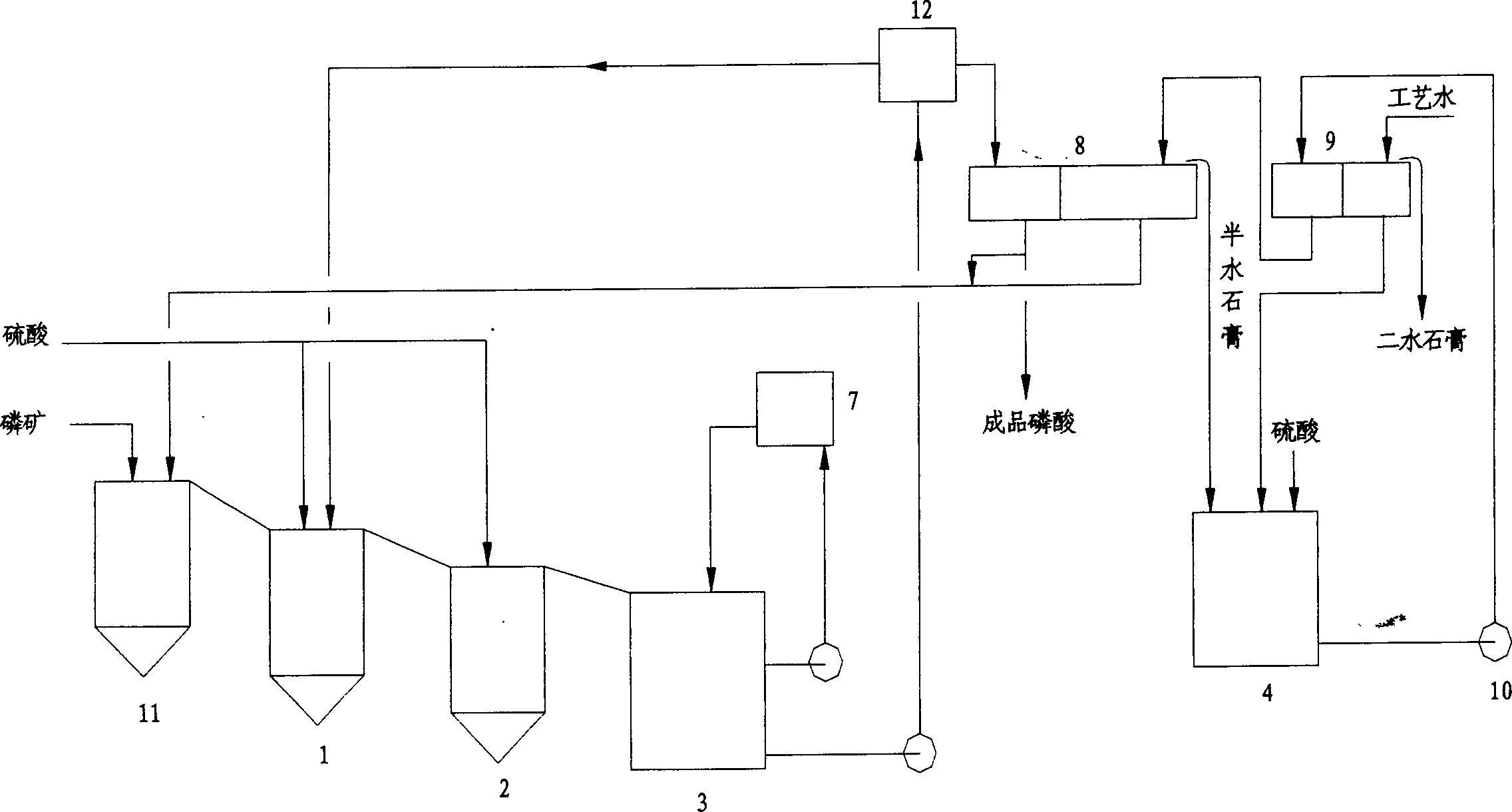

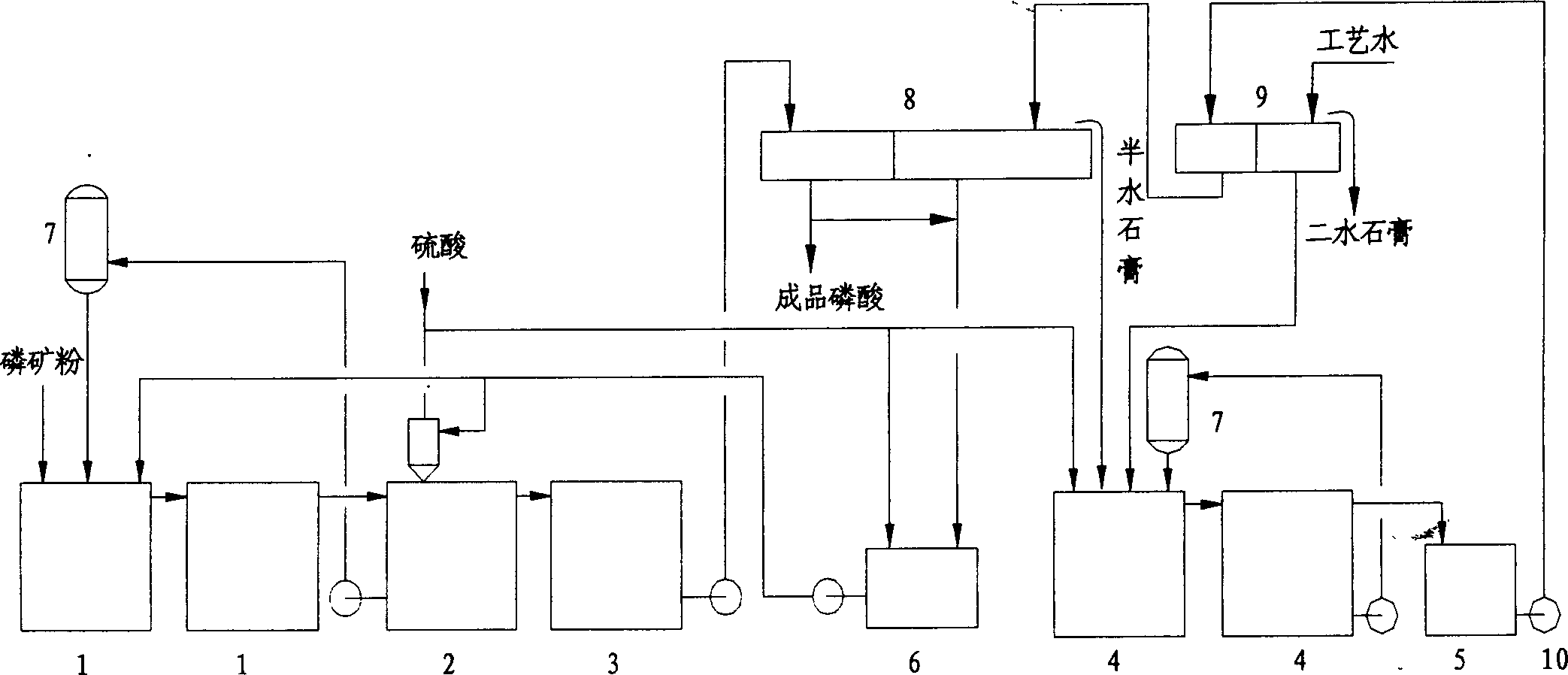

Production process of semiwater-diaquo phosphoric acid

InactiveCN1421385AWide adaptabilityReasonable processPhosphorus compoundsO-Phosphoric AcidSulfate radicals

Of the production process of semiwater-diaquo phosphoric acid, the technological keys include the calcium separating rate in the first reaction tank in the semiwater reaction part being controlled in50-60 %; the two-place addition of sulfuric acid in the semiwater reaction part including the partial addition to acid mixer for mixing with phosphoric acid and other partial addition to dilute phosphoric acid tank for controlling the concentration of sulfate radical in 8-10 %; pumping partial dilute phosphoric acid added with sulfuric acid into the first reaction tank while the other part being fed to acid mixer and the second reaction tank; and one increased vacuum flash distilling slurry cooler in the diaquo reaction part. The present invention has wide phosphate are adaptability.

Owner:YUNNAN RED PHOSPHORUS CHEM

Processing method of instant lightly baked spicy squid

The invention relates to a processing method of instant lightly baked spicy squid, and the method comprises the following steps that fresh squid, or fresh frozen and thawed squid is selected as a raw material and cleaned; the head and the internal organs are removed; then the squid is cut and sliced, cooked, uniformly mixed with seasoning and cured, dried and baked until the water content is 40 percent + / -0.8 percent; and the slices are packaged, sealed and sterilized to obtain an instant lightly baked spicy squid finished product. The processing method has reasonable procedures and is simple in preparation. The seasoning for curing is mixed scientifically, so that the dainty flavor and palatability of the squid food are improved. The lightly baked spicy squid food which is prepared through the method has soft texture, maintains the nutrition of the squid as well as the original color and the appearance of the fresh squid to the largest extent, has long storage life, can be eaten conveniently only after a package is opened, the taste is dainty in hardness, saline taste and sweetness and delicious, and has the special aroma of seafood.

Owner:RONGCHENG HONGWEI FOOD

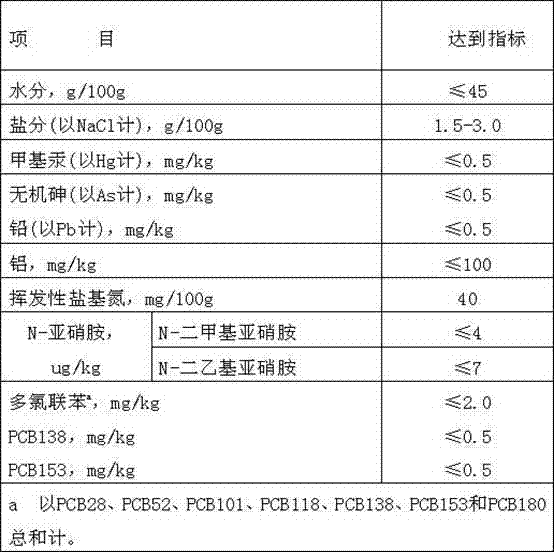

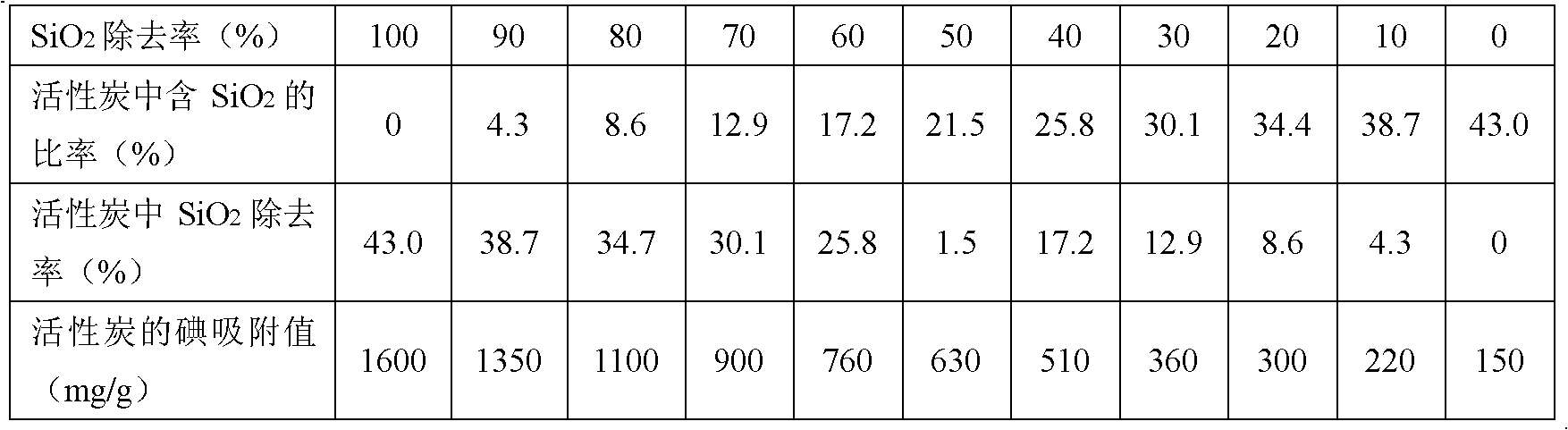

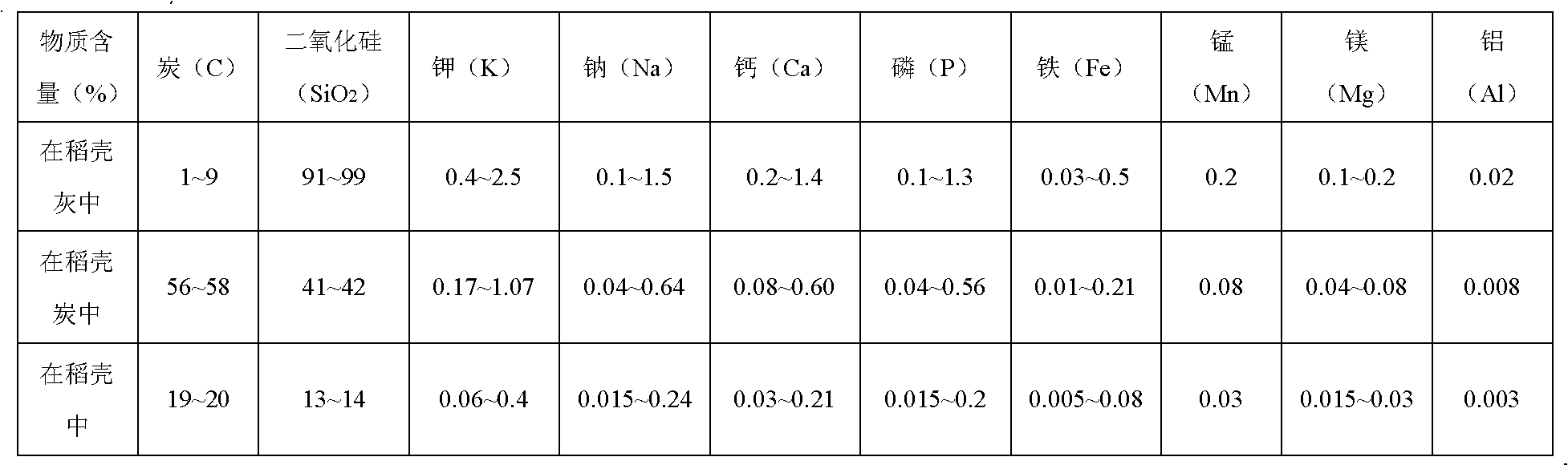

Method for preparing coal gas, top-grade active carbon, water glass and silicate phosphate from rice hulls

ActiveCN101891189AImprove qualityOvercome absorbencyPhosphatesAlkali metal silicatesPhosphateBiological activation

The invention relates to a method for preparing coal gas, high-grade active carbon, water glass and silicate phosphate from rice hulls, which comprises the following steps of: smouldering, carbonizing and activating the rice hulls to produce the coal gas for power generation and to obtain rice hull carbon; activating the rice hull carbon with acid and alkaline to obtain low-grade active carbon, packaging the low-grade active carbon in a dust-proof explosion-proof sealed mode, and activating at moderate temperature, secondary high temperature and high temperature to finally obtain the high-grade active carbon and produce the water glass and the silicate phosphate simultaneously. The defect of low-grade active carbon prepared from the rice hull carbon in the prior art is overcome. The invention has reasonable technological method and technological process, and solves the technical obstacles on moderate temperature and high temperature activation of the rice hull carbon. The rice hull carbon obtained after preparing the coal gas from the rice hulls can be directly used for producing the high-grade active carbon, the water glass and the silicate phosphate, and the economical benefits and the social benefits of the rice hulls are effectively increased. Large-scale industrial production can be realized, and a new approach is provided for realizing a complete industrial chain of agriculture industrialization and rice processing.

Owner:长沙稻香农业科技有限公司

Processing method of instant seasoning grilled squid strips

The invention relates to a processing method of instant seasoning grilled squid strips, and the method comprises the following steps that fresh squid, or fresh frozen and thawed squid is selected as a raw material and cleaned; the head and the internal organs are removed; then the squid is uniformly mixed with seasoning and cured, dried, aired and baked into grilled dried squid with the water content being controlled to be 17 percent + / - 1 percent; the grilled dried squid is torn into strips; and the grilled squid strips are detected by metal and packaged to obtain finished products. The processing method has reasonable procedures, is simple in preparation, and easily realizes large-scale production. The seasoning for curing is mixed scientifically, so that the freshness and the flavor of the squid product are improved, and the product is not dry, hard and crispy. The seasoning grilled squid strips which are prepared through the method maintain the nutrition of the squid, have golden color, and the special baking aroma of marine food products, and the product has tough texture, is chewy and dainty in saline taste and sweetness, has delicious taste and long storage life, can be eaten conveniently only after a package is opened, and is ideal leisure food.

Owner:RONGCHENG HONGWEI FOOD

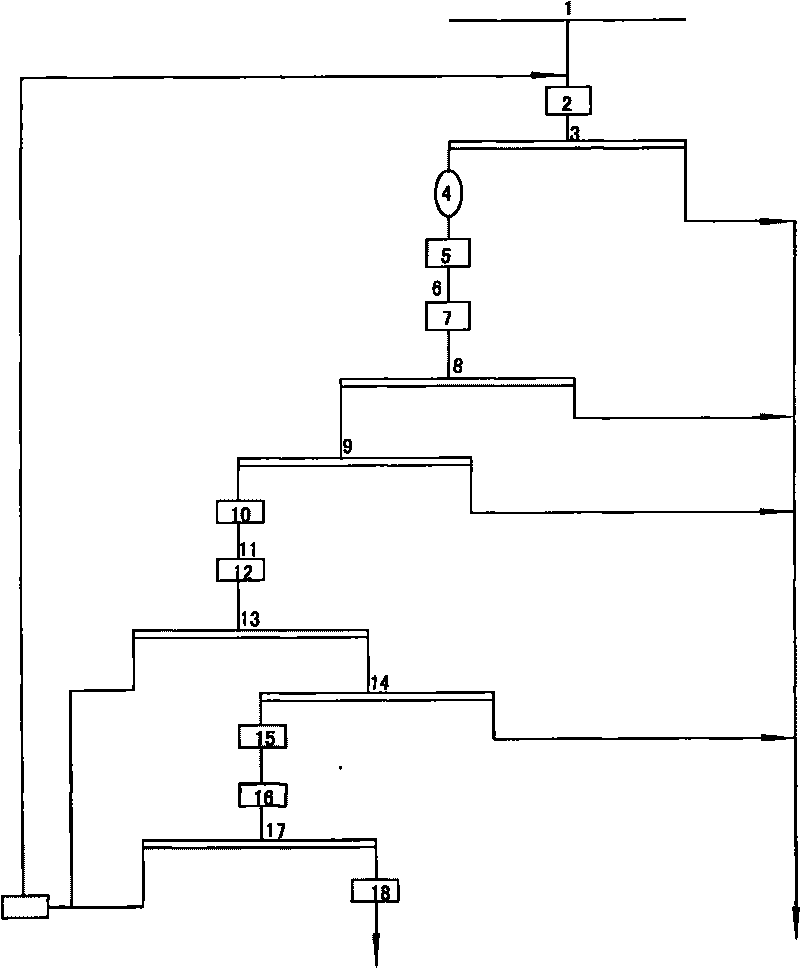

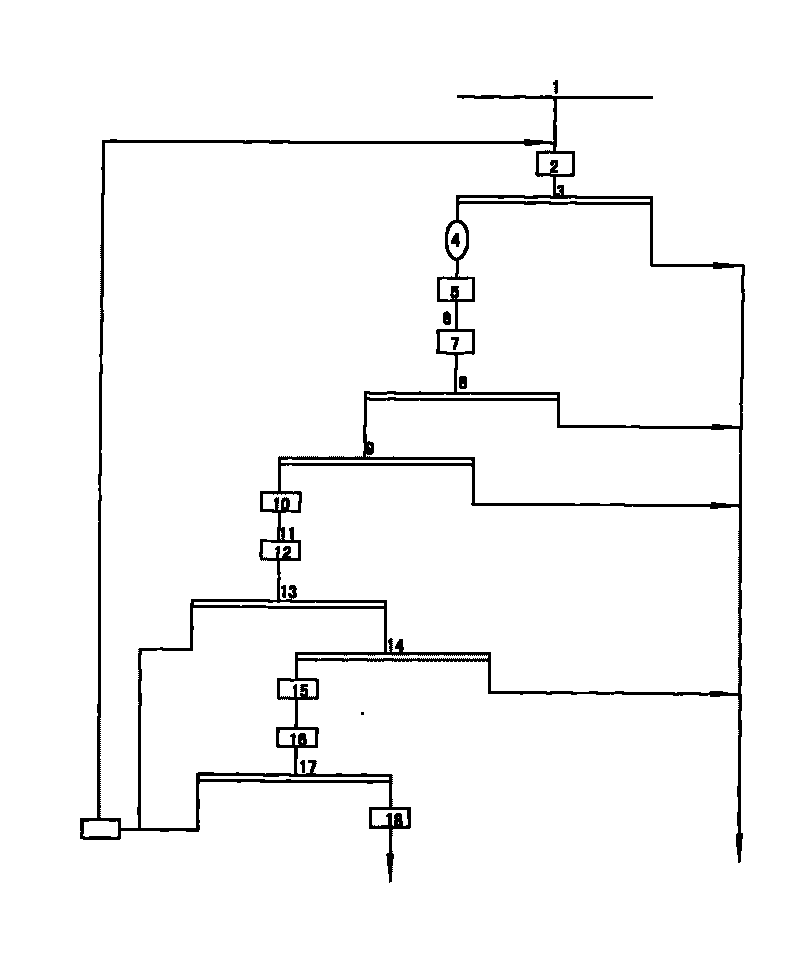

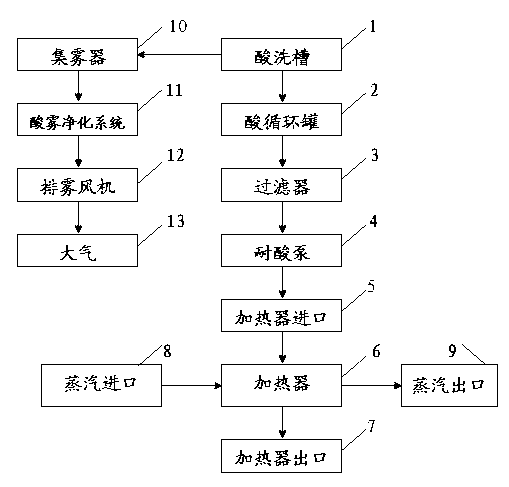

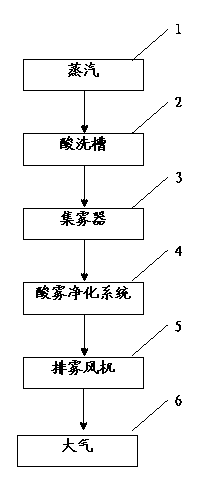

Method for heating acid washing solution

The invention discloses a method for heating acid washing solution. The method comprises: (1) the acid washing solution in an acid washing tank 1 flows back into an acid circulation tank 2, is filtered through a filter 3 and is pumped into a heater 6 by an acid-resistant pump 4 through an inlet 5 of the heater, the heated acid washing solution is pumped into the acid washing tank 1 through an outlet 7 of the heater to form circulation, and the circulation is repeated in the way; (2) heating steam enters through a steam inlet 8 and is discharged through a steam outlet 9, so that the acid washing solution is kept at normal technological temperature all the time; and (3) acid mist which is generated during the acid washing process is concentrated through a mist collector 10 under the action of a mist exhaust fan 12 and enters an acid mist purification system 11 to be purified, and the mist which meets the emission standards is discharged to the atmosphere 13 through the mist exhaust fan 12. By the method, heat exchange is indirectly realized, the acid washing solution cannot be diluted, excessive acid mist is not generated, the acid mist cannot be leaked during the heat exchange process, and the heating process of the acid washing solution and the temperature of the acid washing solution can be automatically controlled through adopting a heat exchanger.

Owner:TIANJIN YIBO STEEL MAKING

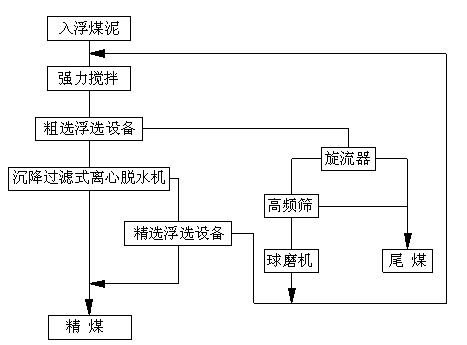

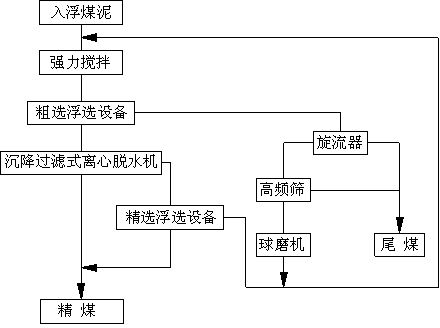

Sorting process for high-ash and difficult-separation coal slime

Disclosed is sorting process for high-ash and difficult-separation coal slime. Floatation coal slime is fed into a stirring barrel to be prepared into ore pulp with percentage concentration of 80g / L-120g / L, the ore pulp automatically flows to roughing and floatation equipment to be sorted, roughing tail coal enters a cyclone to be concentrated in a classified manner, concentrated bottom flow products enter a high-frequency screen to be dewatered, dewatered substances on the high-frequency screen return to roughing pulp mixing operation to be sorted again after being finely ground via a ball mill, floatation rough and fine ores are fed to a precipitation perforated basket centrifuge to be dewatered, after being dewatered via the precipitation perforated basket centrifuge, fine ore filter liquor is fed into concentration flotation equipment to be concentrated, and concentration tail coal and overflow of the ball mill return to roughing pulp mixing operation together via a pipeline to besorted again. Accordingly, low-ash and high-recovery-rate flotation clean coal is obtained. The sorting process not only avoids influence of high-ash content and fine particle slime and integrated ore to a floatation process, but also avoids contradiction between the quality and the recovery rate of a high-ash difficult-separation coal slime sorted product.

Owner:CHINA UNIV OF MINING & TECH

Preparation method of carbon grilled squid slices

ActiveCN103584188AReasonable processEasy to makeFood ingredient functionsFood preparationLiver and kidneyAngor pectoris

The invention relates to a preparation method of carbon grilled squid slices, which comprises the steps such as preprocessing of raw materials, primary flavoring and pickling, tenderization, injection, secondary flavoring and pickling, carbon grilling, stripping and packaging. The preparation method has the advantages of reasonable procedures, simple preparation and easy realization of scale production; the nutrition and the gold color of squids are retained; the special carbon grilled smell of marine products and the fresh lotus leaf scent are obtained; the meat quality is tender, properly sweet and salty, and delicious; raspberry juice is added in the squid slices for effectively relieving the cardiovascular diseases such as angor pectoris and achieving the effects of tonifying liver and kidney; the raspberry juice is added in flavoring liquid, so that appetites are satisfied after squid products are ate by human bodies, and more nutrition beneficial to the human bodies is absorbed. The squid slices prepared by the invention method are suitable for wide crowds such as children with weak teeth or the aged, and have the advantages of low cost, rich nutrition and long preservation time.

Owner:ZHEJIANG OCEAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com