Dispersion strengthened copper alloy, and preparing technical method

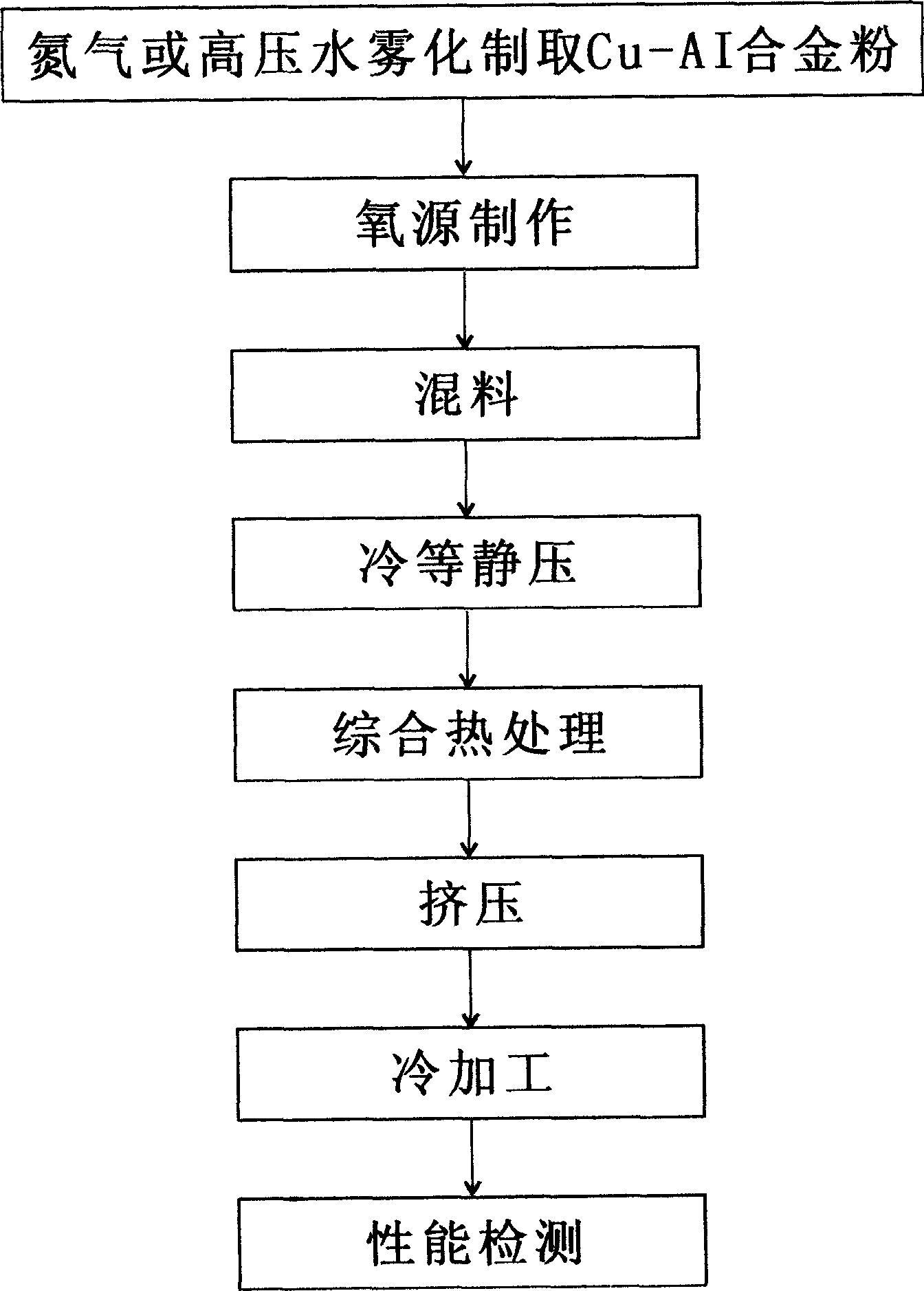

A technology for dispersion-strengthened copper and its preparation process, which is applied in the fields of integrated circuit lead frame materials, resistance welding electrodes, and microwave electron tubes, can solve the problems of long process flow, difficult quality control, and high labor intensity of dispersion-strengthened copper alloys, so as to improve the material quality. Strength and cold workability, avoid hydrogen expansion, good air tightness of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Take the production of TuMAI0.12 alloy for electric vacuum microwave tube as an example. The raw materials are high-purity oxygen-free electric copper, copper-30% aluminum master alloy, copper-13% phosphorus deoxidizer master alloy;

[0021] 1) Preparation of copper-aluminum alloy powder by nitrogen atomization: add high-purity electric copper into a 100Kw intermediate frequency melting furnace, melt for 15 minutes after melting, add 15 grams of copper-13% phosphorus master alloy for 1 minute, and then add copper - 30% aluminum master alloy melting for 5 minutes, then with 0.75N / mm 2 Nitrogen is atomized to make -40 mesh copper-aluminum alloy powder;

[0022] 2) Preparation of oxygen source: Take -100 mesh copper-aluminum alloy powder and heat it to 380°C in a resistance furnace, keep it warm for 50 hours, and then heat it at 840°C for 1.5 hours under the protection of nitrogen to make the required oxygen source;

[0023] 3) Mixing: Mix the prepared oxygen source and ...

Embodiment 2

[0030] Take the LCM115 alloy for the production of 110,000 high-voltage isolation switch conductive rods as an example, the raw materials are high-purity oxygen-free electric copper, copper-30% aluminum master alloy, copper-13% phosphorus deoxidizer master alloy;

[0031] 1) Preparation of copper-aluminum dispersion strengthened copper alloy powder by water atomization: add high-purity oxygen-free electric copper in a 100Kw intermediate frequency melting furnace, melt for 15 minutes after melting, then add 15 grams of copper-13% phosphorus master alloy for melting 1 minute, then add copper-30% aluminum master alloy for smelting for 5 minutes, and then use 8.5N / mm 2 High-pressure water is atomized to make -100 mesh copper-aluminum alloy powder;

[0032] 2) Production of oxygen source: Take -100 mesh copper-aluminum alloy powder and heat it in a resistance furnace to 380°C for 25 hours, then heat it at 840°C for 1.5 hours under the protection of nitrogen to make the required oxy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com