Vertical sinter ore cooling machine capable of efficiently recycling sensible heat of sinter ores

A sinter and cooling machine technology, which is applied in the direction of improving energy efficiency, waste heat treatment, and processing discharged materials, can solve the problems of heavy maintenance workload and low recovery rate of sinter waste heat, and achieve environmental quality degradation and comprehensive and efficient recovery Utilization, effect of improving heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

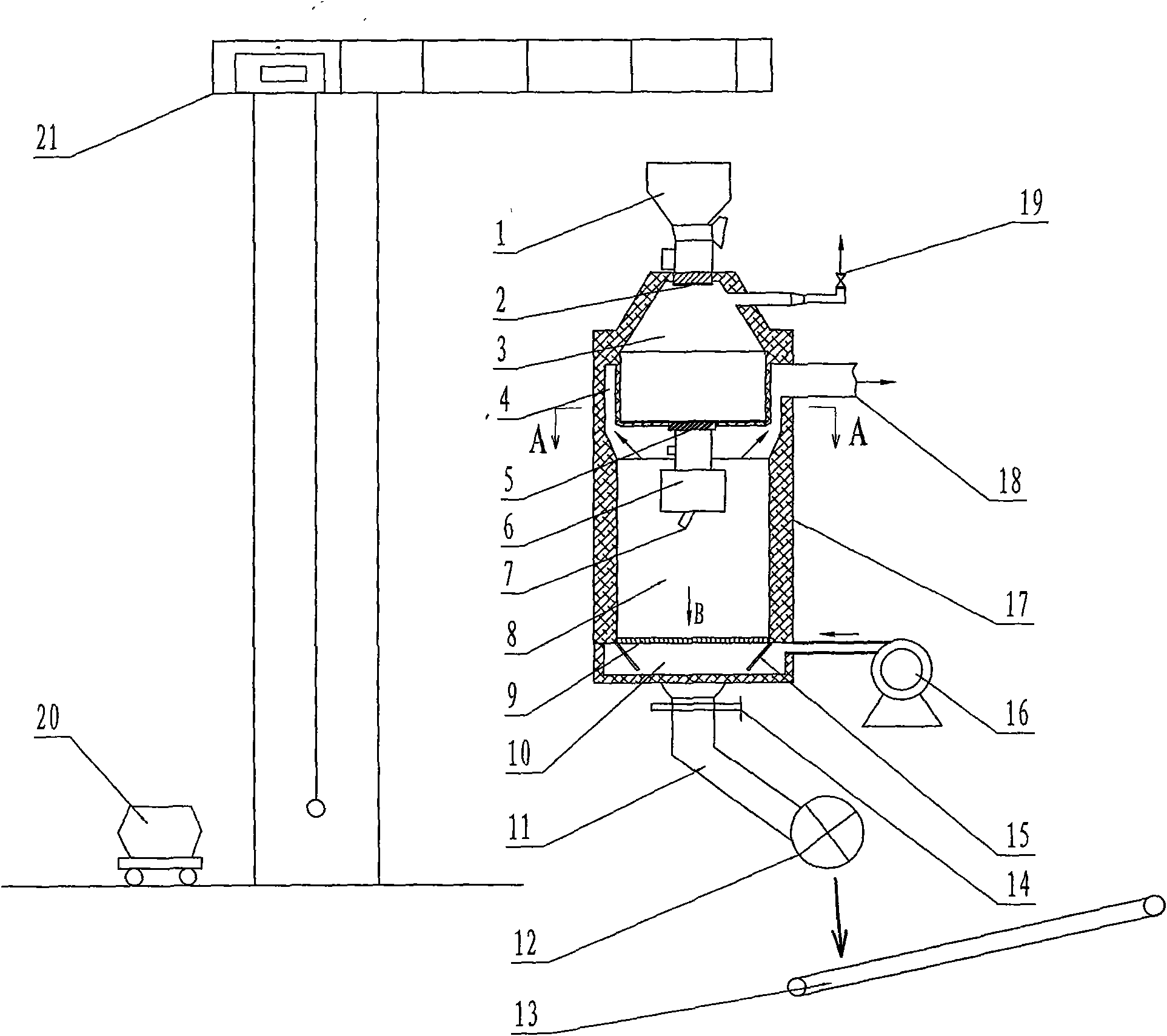

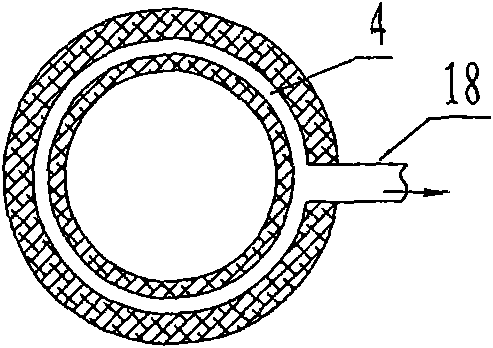

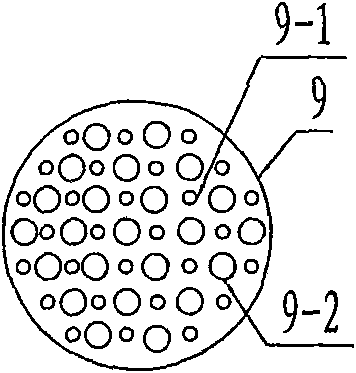

[0018] see figure 1 , figure 2 The vertical sinter cooler of the present invention is composed of a feeding part, a cooling part and a feeding part. The cooling part includes a vertical airtight body 17, a hot air pipeline 18, a fan 16 and a The hopper 1 of the body, the upper sealing valve 2, the pre-storage chamber 3, the lower sealing valve 5, the heat exchange chamber 8, the air distribution plate 9, the equal pressure air chamber 10 and the discharge channel 11, between the pre-storage chamber and the heat exchange chamber The annular air chamber 4 is connected to the hot air pipeline, and the equal-pressure air chamber is connected to the fan. The hot sintered ore is sent in from the hopper on the upper part of the main body, and discharged after being cooled by the pre-storage room and the heat exchange room. The cooling air sent by the fan enters from the air distribution plate at the lower part of the body, and after being heated up in the heat exchange chamber, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com