Spray type shell-and-tube heat exchanger adopting nonmetal heat exchange tubes

A technology of shell-and-tube heat exchanger and heat exchange tube, which is applied in the direction of heat exchanger type, indirect heat exchanger, heat exchange equipment, etc. Due to the high price of materials and other problems, the effect of light weight, low density and increased heat exchange area is achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In the following description, many technical details are proposed in order to enable readers to better understand the application. However, those skilled in the art can understand that without these technical details and various changes and modifications based on the following implementation modes, the technical solution claimed in each claim of the present application can be realized.

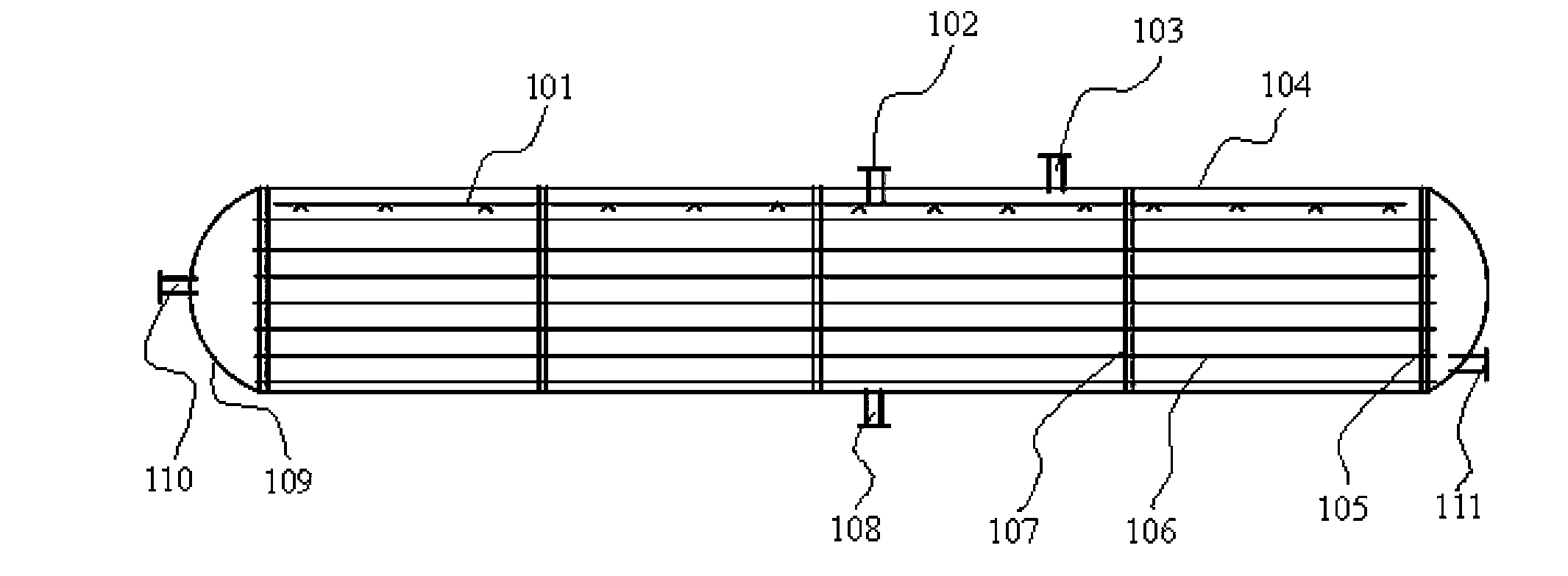

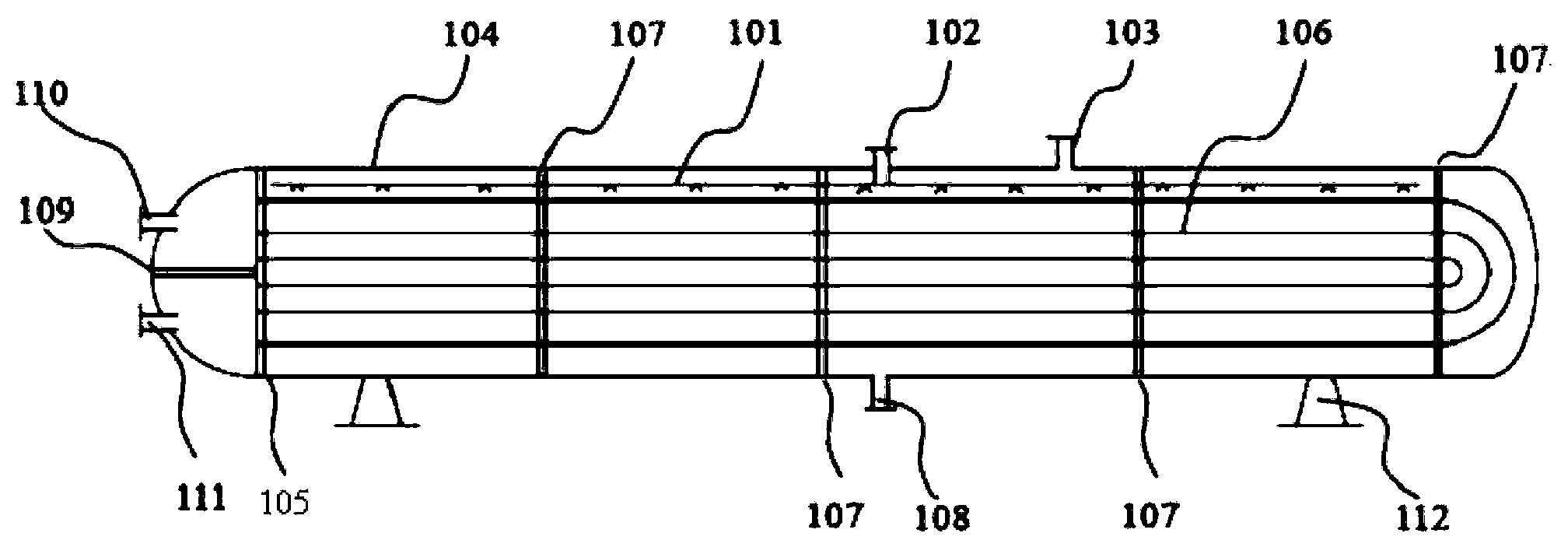

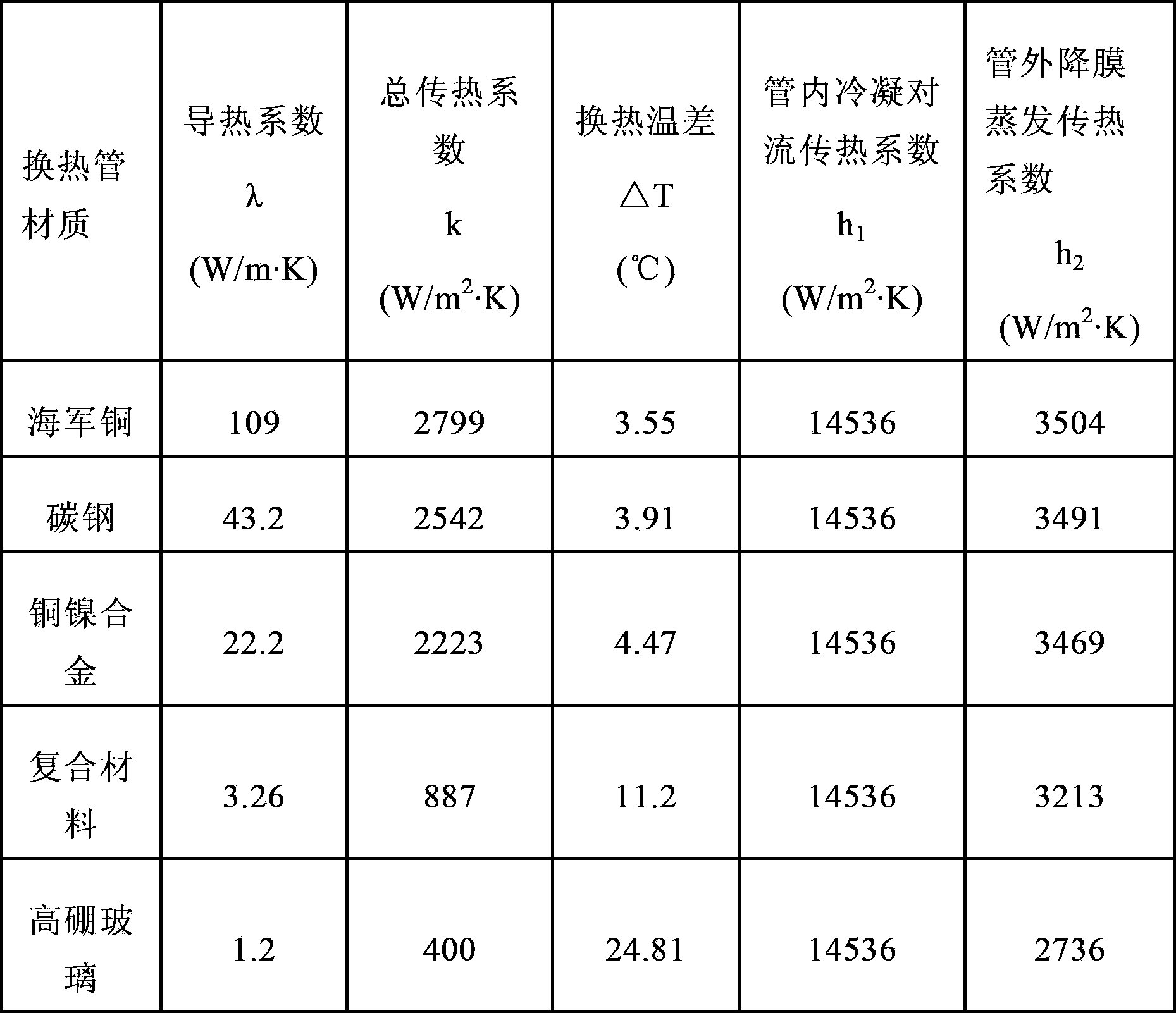

[0024] figure 1 An embodiment of the non-metallic spray shell-and-tube heat exchanger of the present invention is shown, the heat exchanger includes: a shell 104, a spray 101, a plurality of heat exchange tubes 106 placed in parallel in the shell, a supporting heat exchanger The support plate 107 of the heat pipe 106 and the tube plate 105 connected to the heat exchange pipe, wherein the heat exchange pipe 106 is made of a non-metallic material with a thermal conductivity of 0.5W / m·K~10W / m·K, and the heat exchange pipe 106 The outer diameter is 5~15mm.

[0025] Specifically, the heat ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com