Patents

Literature

1005 results about "Anodizing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

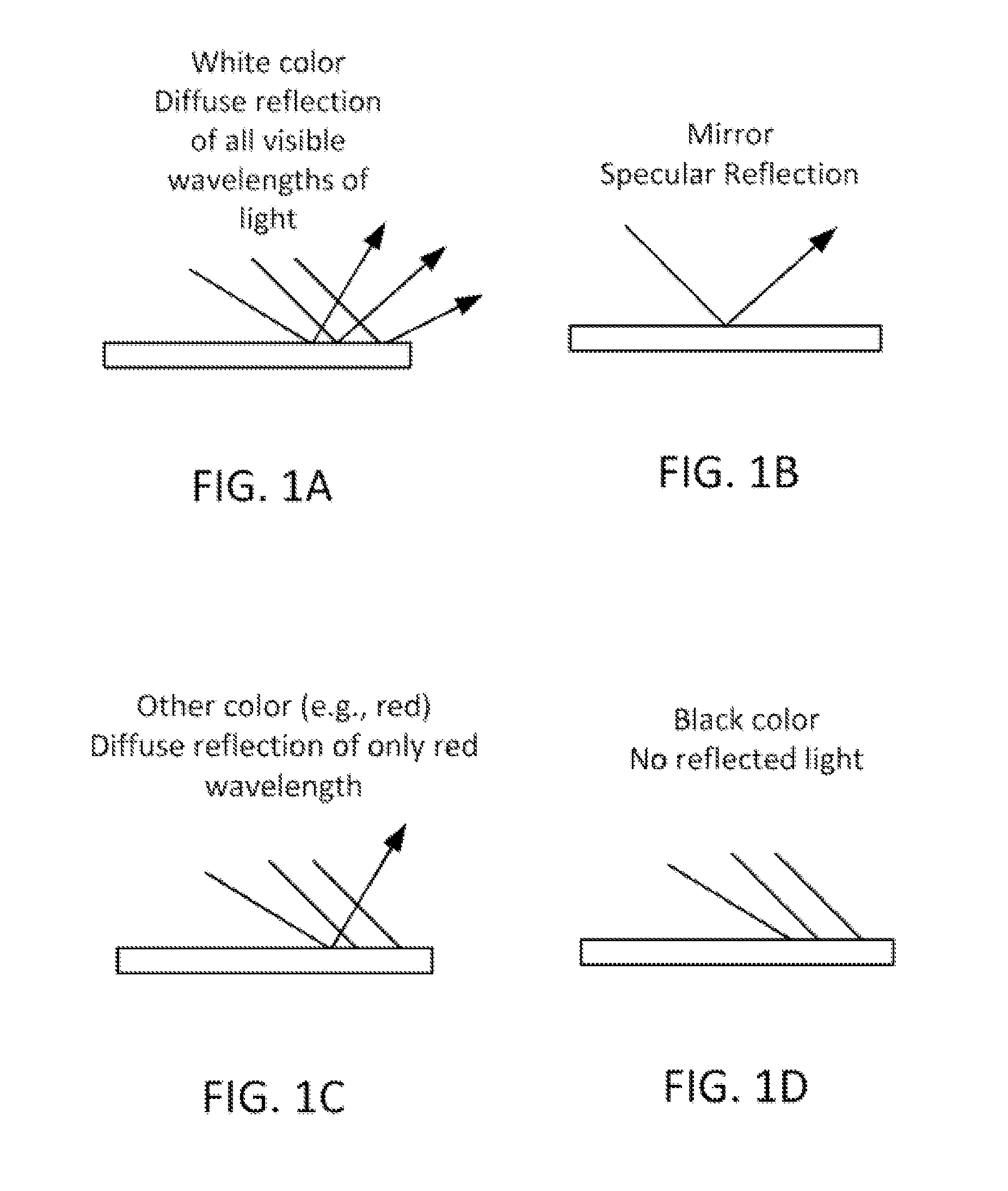

Anodising (also spelled anodizing in American English) is an electrolytic passivation process used to increase the thickness of the natural oxide layer on the surface of metal parts. The process is called anodising because the part to be treated forms the anode electrode of an electrolytic cell. Anodising increases resistance to corrosion and wear, and provides better adhesion for paint primers and glues than bare metal does. Anodic films can also be used for a number of cosmetic effects, either with thick porous coatings that can absorb dyes or with thin transparent coatings that add interference effects to reflected light.

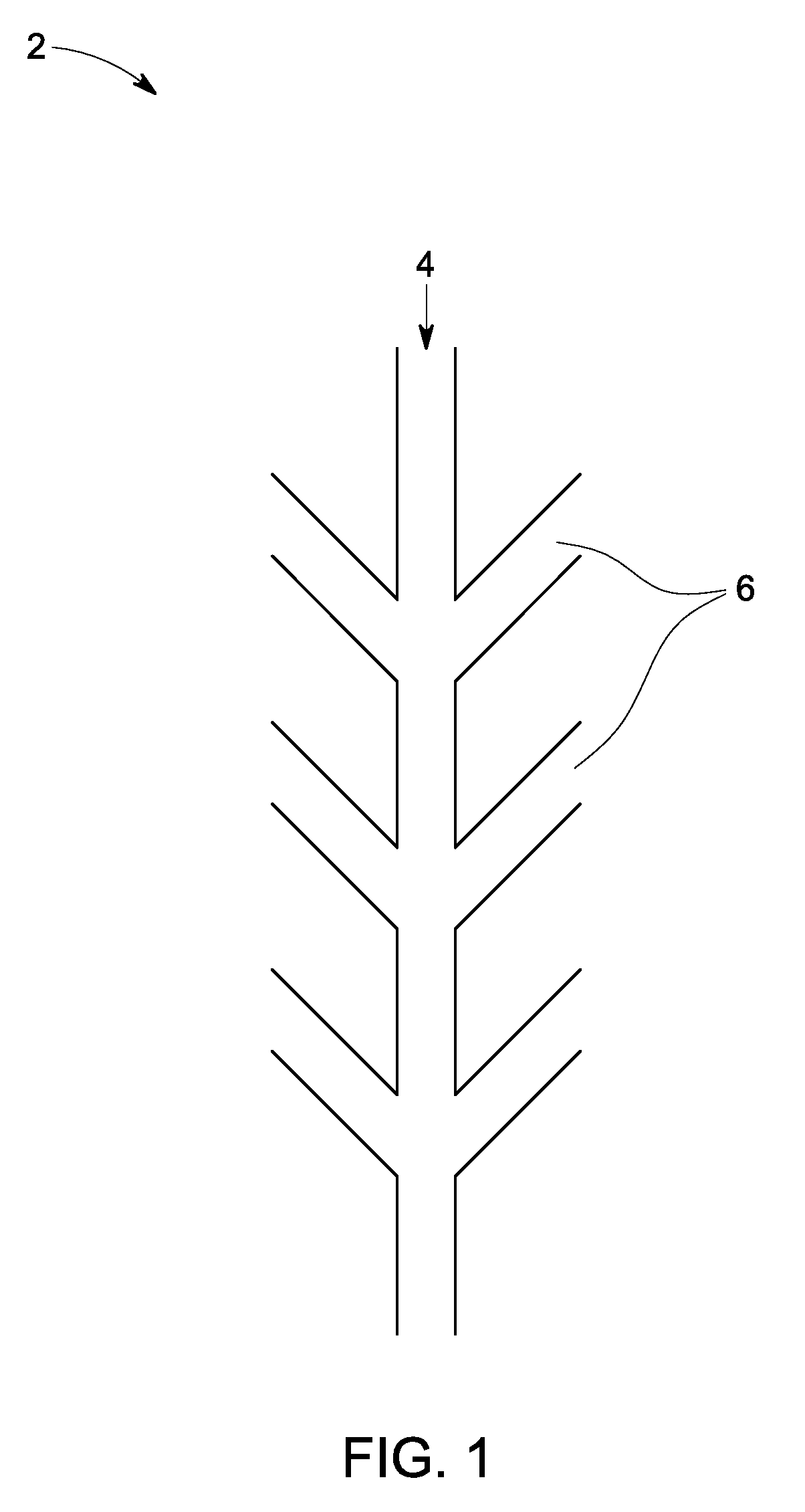

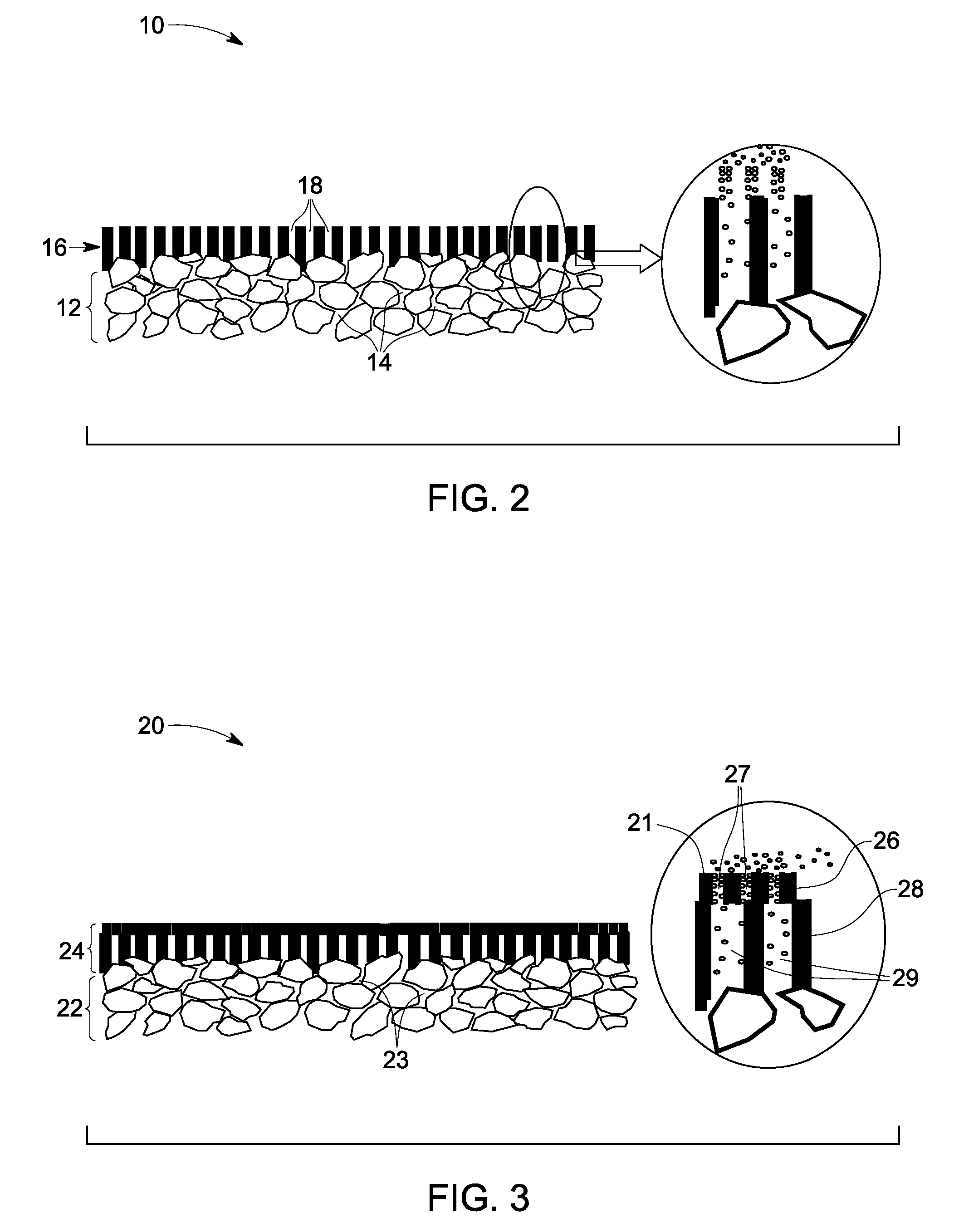

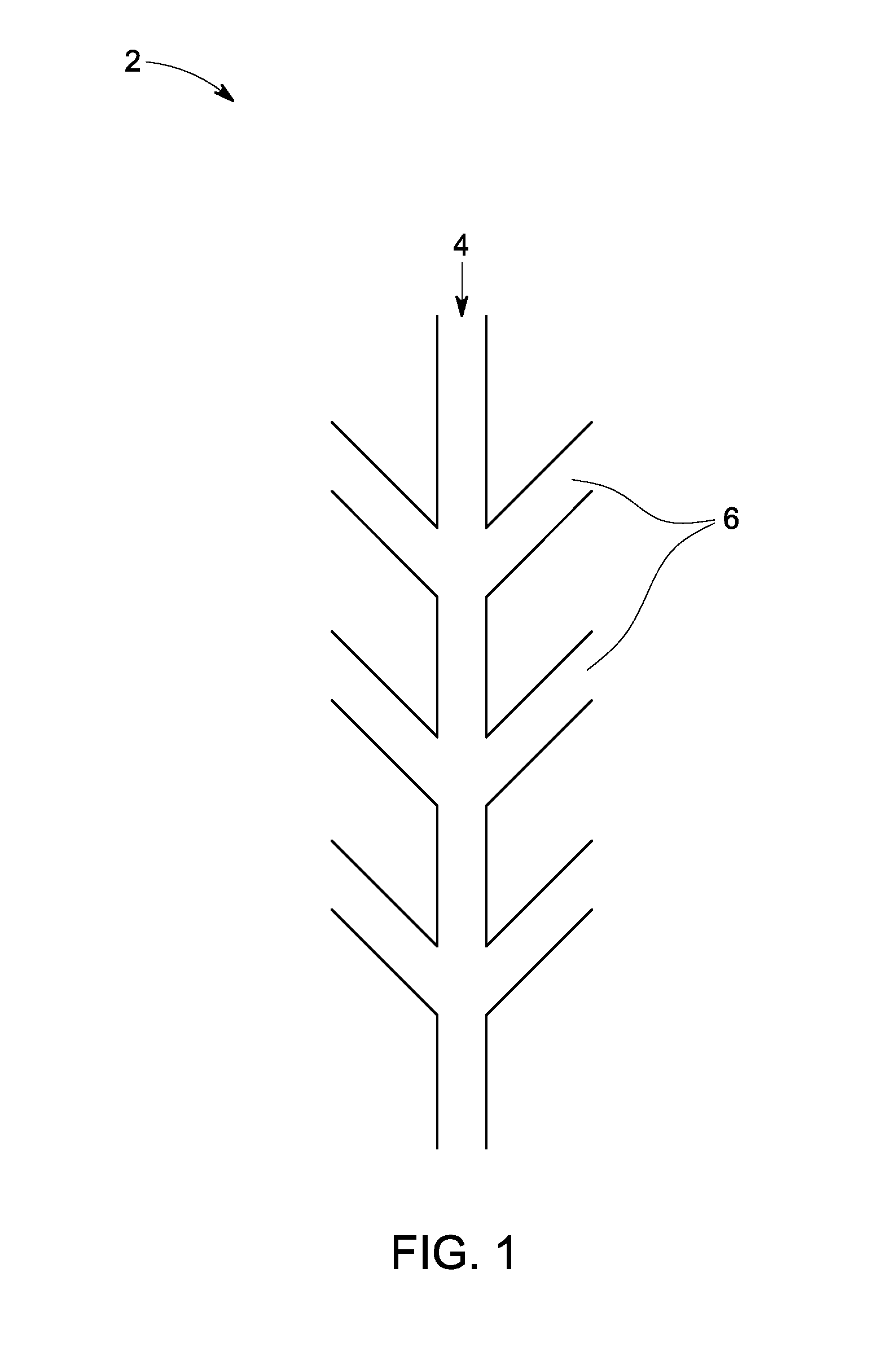

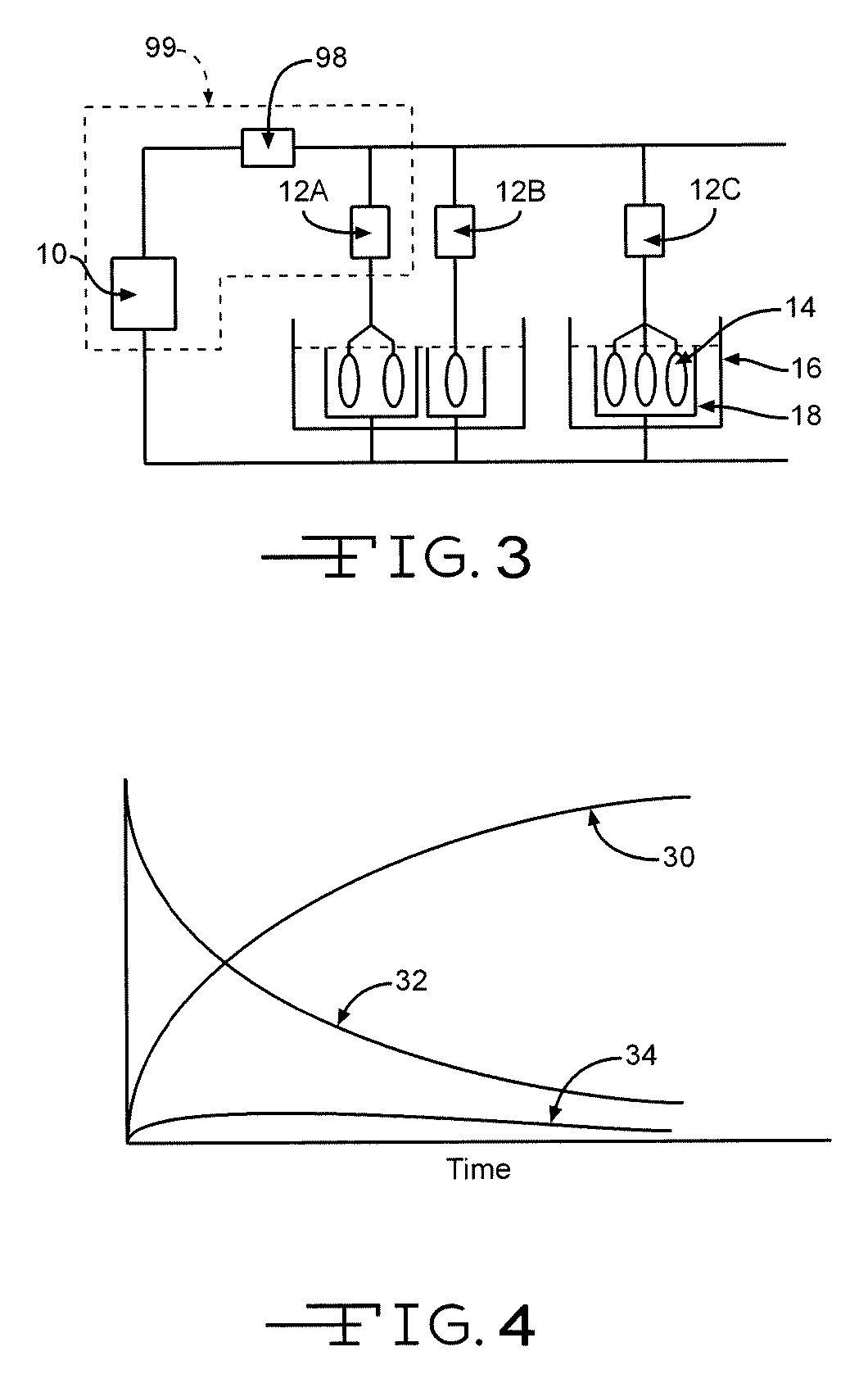

Method and apparatus for electrochemical processing

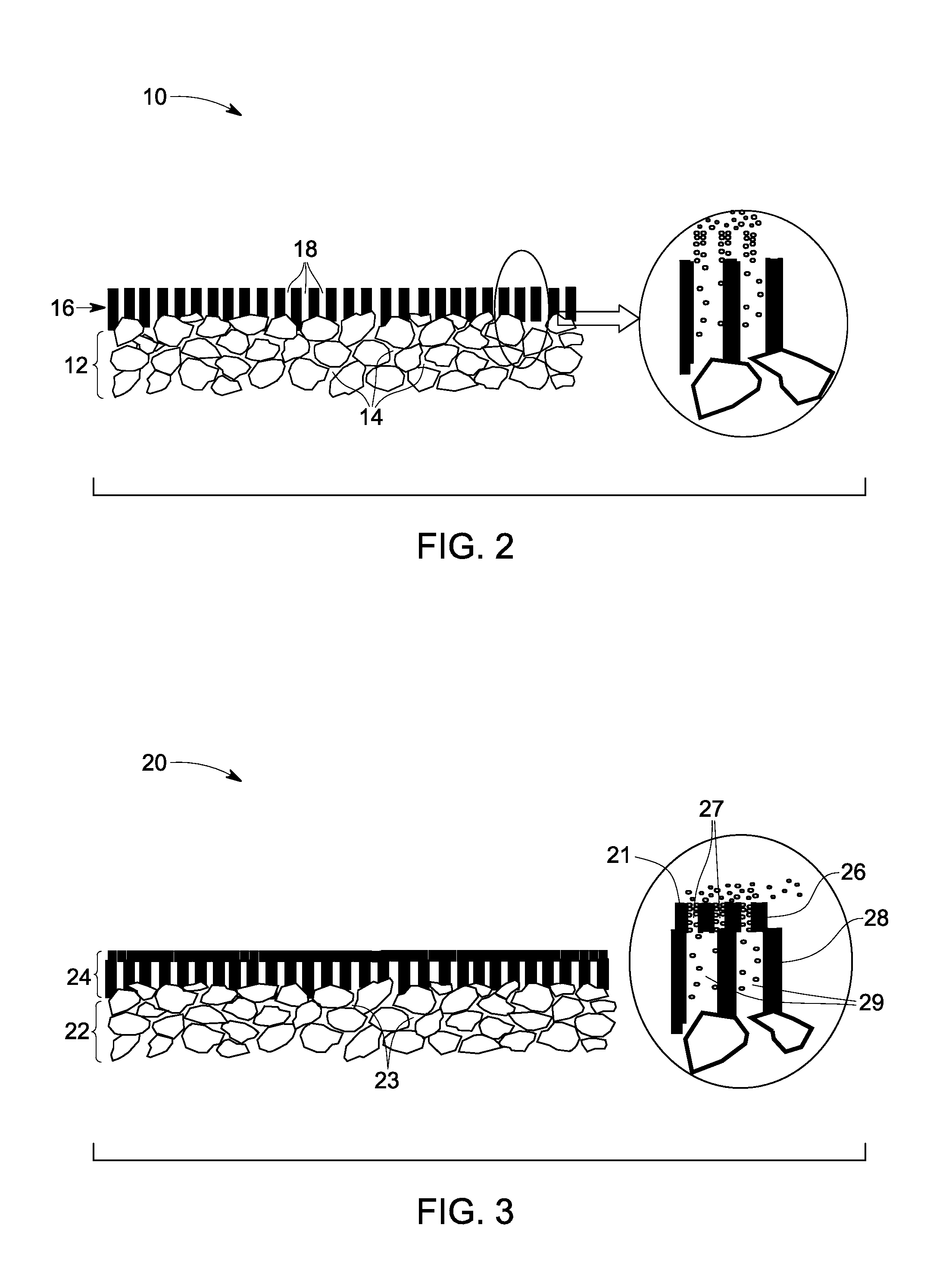

InactiveUS6149781AEffective expansionPreventing gradual depletionElectrolysis componentsDielectricAnodizing

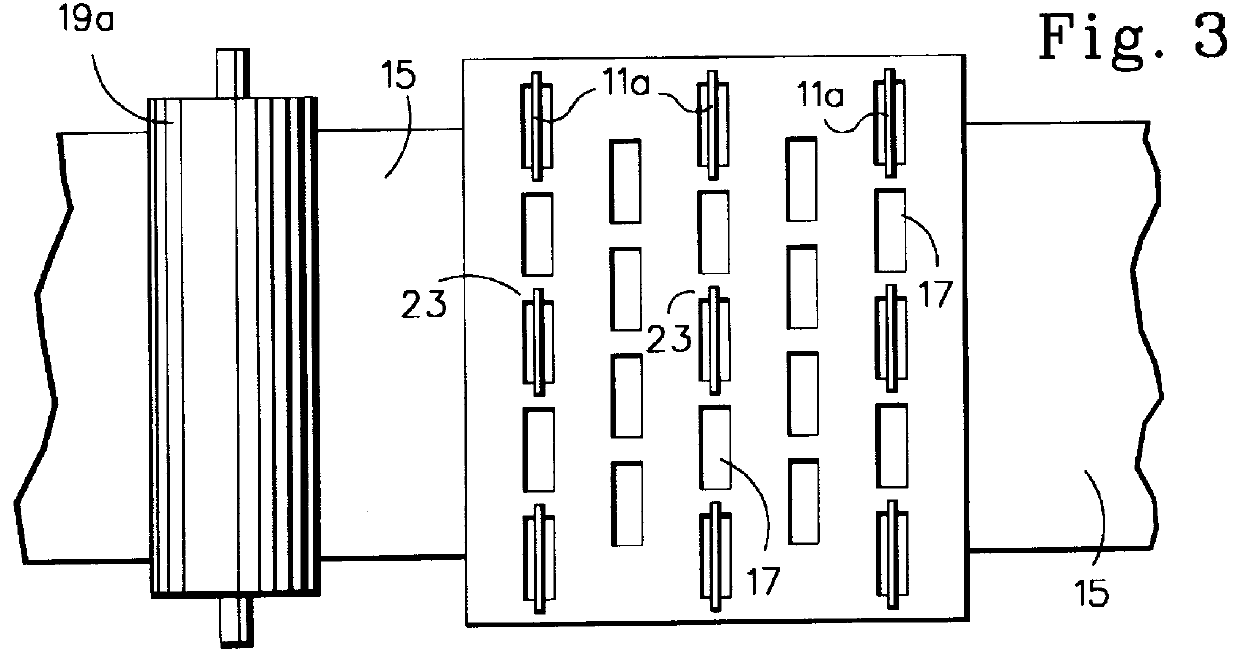

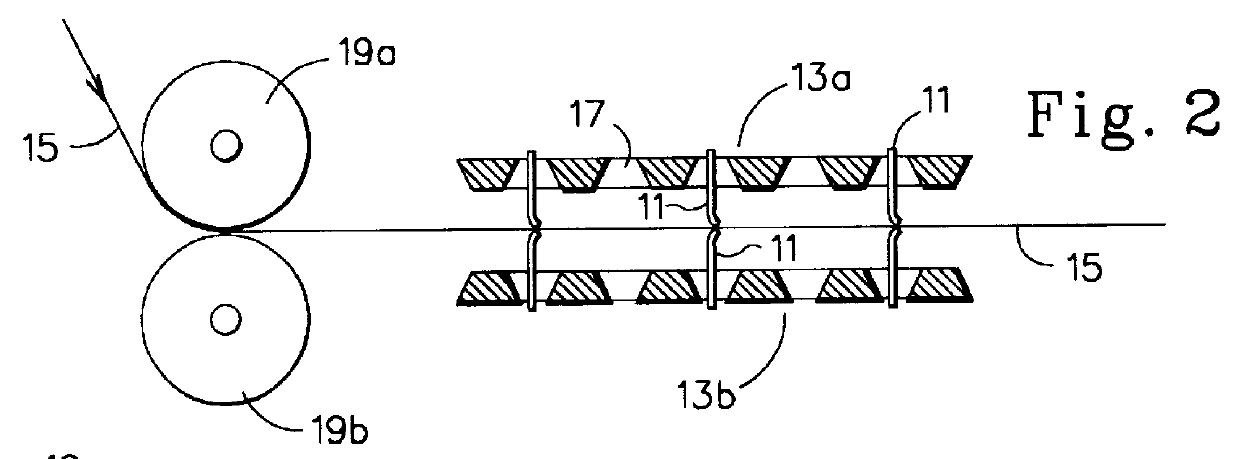

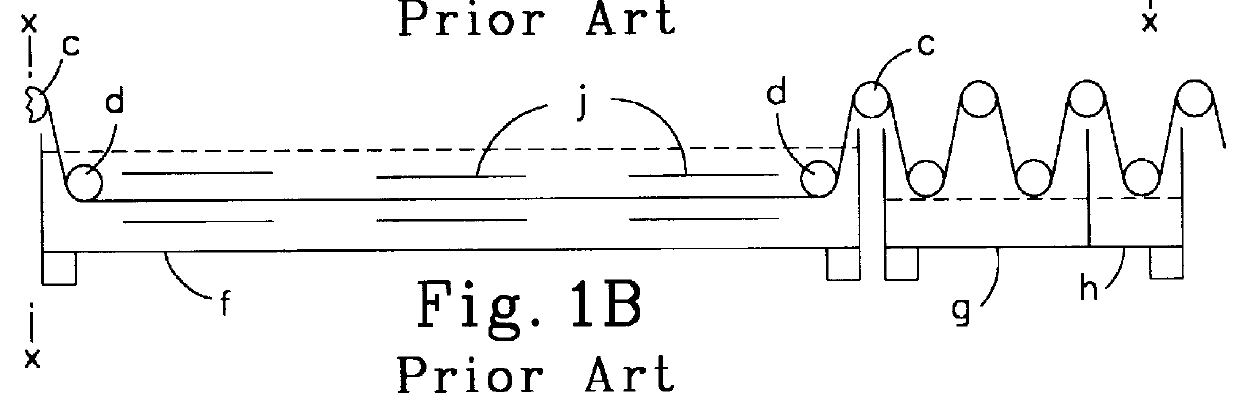

A continuous strip is electrochemically processed in an electrolytic processing bath using either a thin flexible or resilient dielectric wiping blade or an open web, plastic mesh to wipe bubbles of gas from the surface, sever dendritic material, if such is present, and to remove a surface layer of partially depleted electrolytic solution in the form of a barrier or depletion layer including a heat zone, replacing with fresh cooler solution and to stabilize strip portions extending between support rolls. The resilient dielectric wiper blade is preferably used with perforated anodes which allow fresh electrolytic solution to flow into the space between the anodes and the strip surface after being expelled by passage of the strip past the wiping blade. It may also be used with electrode baskets in electroplating, however. The open web, plastic mesh wiper is particularly effective as a separator to provide the best spacing between the strip and the electrodes to prevent arcing and also prevents any filter cloth used over the electrodes in electroplating from catching upon the strip. The resilient wiper blade and open web, plastic mesh are preferably used in combination, but may also be used separately in electroplating, anodizing or electrolytic cleaning.

Owner:ELECTROPLATING TECH

Anodizing Aluminum and Alloys Thereof

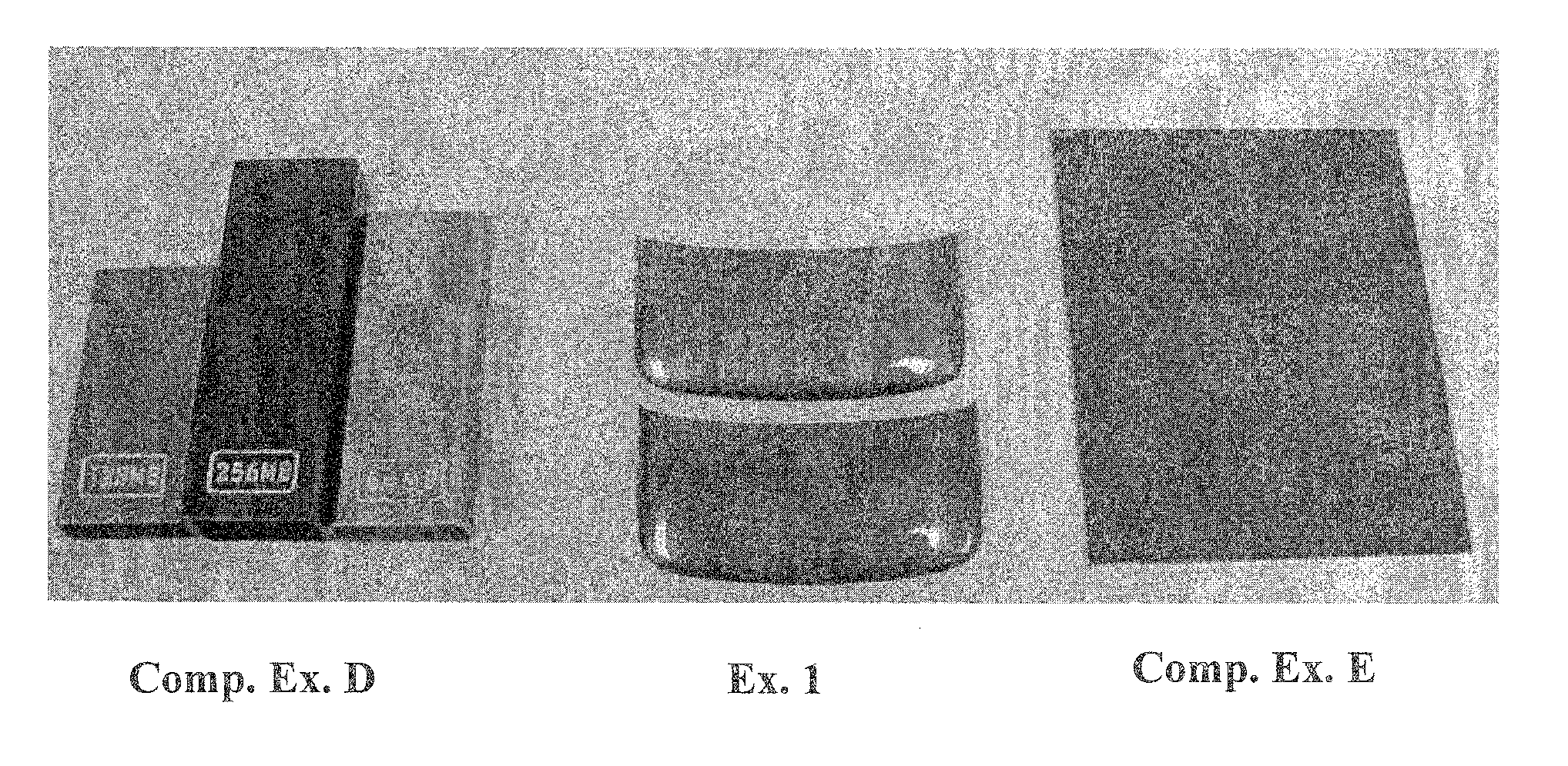

This invention encompasses methods of producing a colored oxide layer on an aluminum material by anodizing the aluminum material in an electrolyte comprising water, sulfuric acid and oxalic acid. The anodizing step comprises passing at least two sequential current densities through the electrolyte. Methods of making and using article with a colored oxide layer on an aluminum material make by the methods disclosed herein are also disclosed.

Owner:DURACOUCHE INT

Planographic printing plate

InactiveUS20010041305A1High purityReduce surface roughnessPhotosensitive materialsRadiation applicationsAnodizingSolubility

A planographic printing plate precursor comprising: an aluminum substrate which has been subjected to a roughening treatment and an anodizing treatment; and a photosensitive layer which provided on a surface of said substrate, and which contains an infrared absorbing agent and a water-insoluble and alkali aqueous solution-soluble polymer compound, and whose solubility in an alkali developing solution varies by infrared laser exposure, wherein said substrate is obtained by electrochemically roughening an aluminum alloy plate which contains a trace amount of certain elements to an aluminum alloy of high purity.

Owner:FUJIFILM CORP

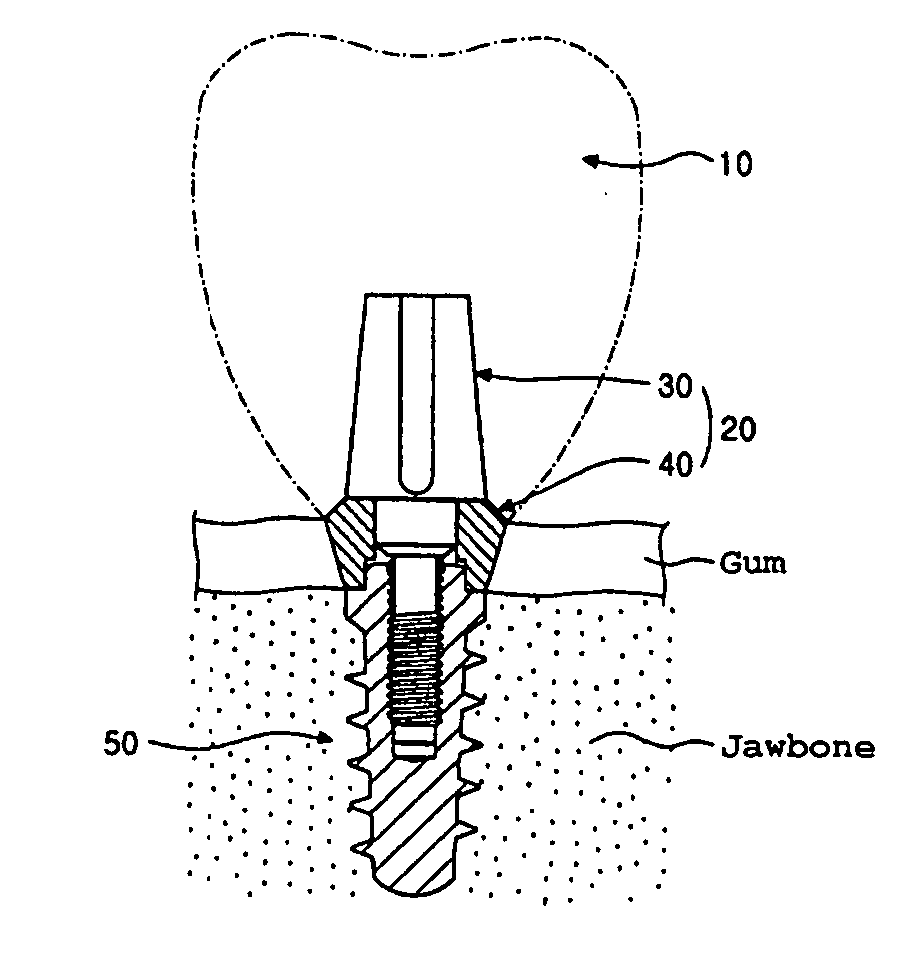

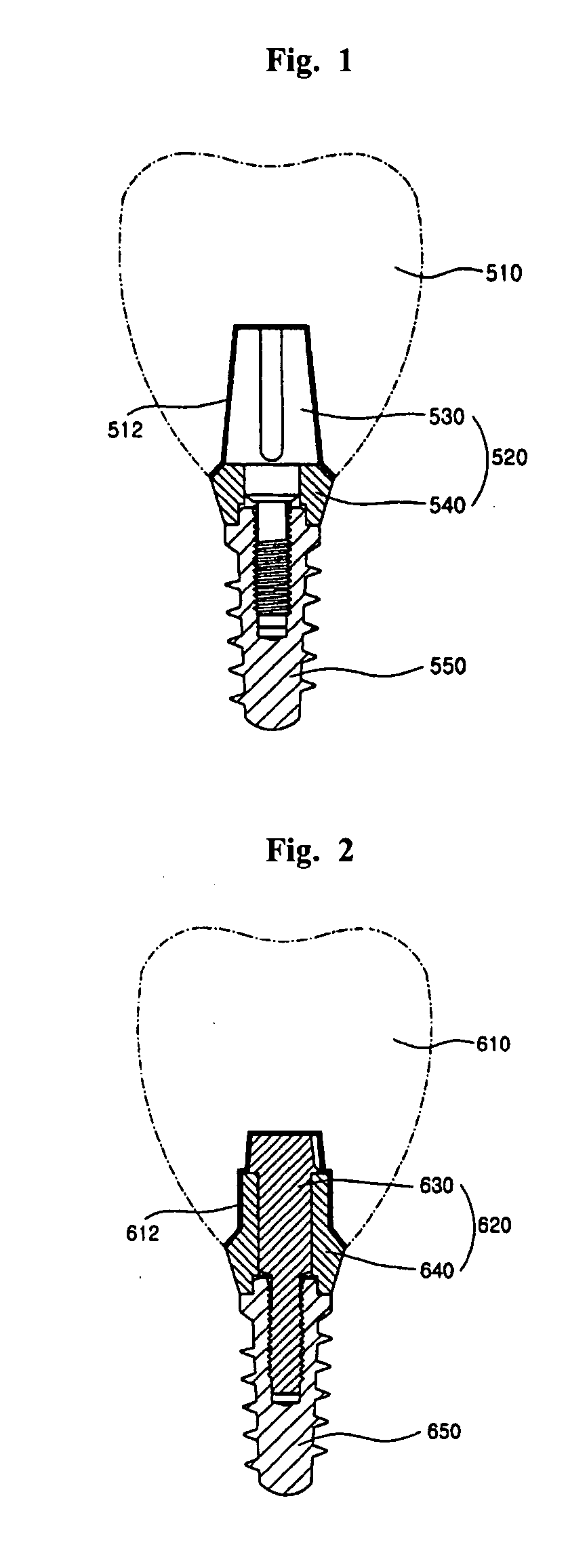

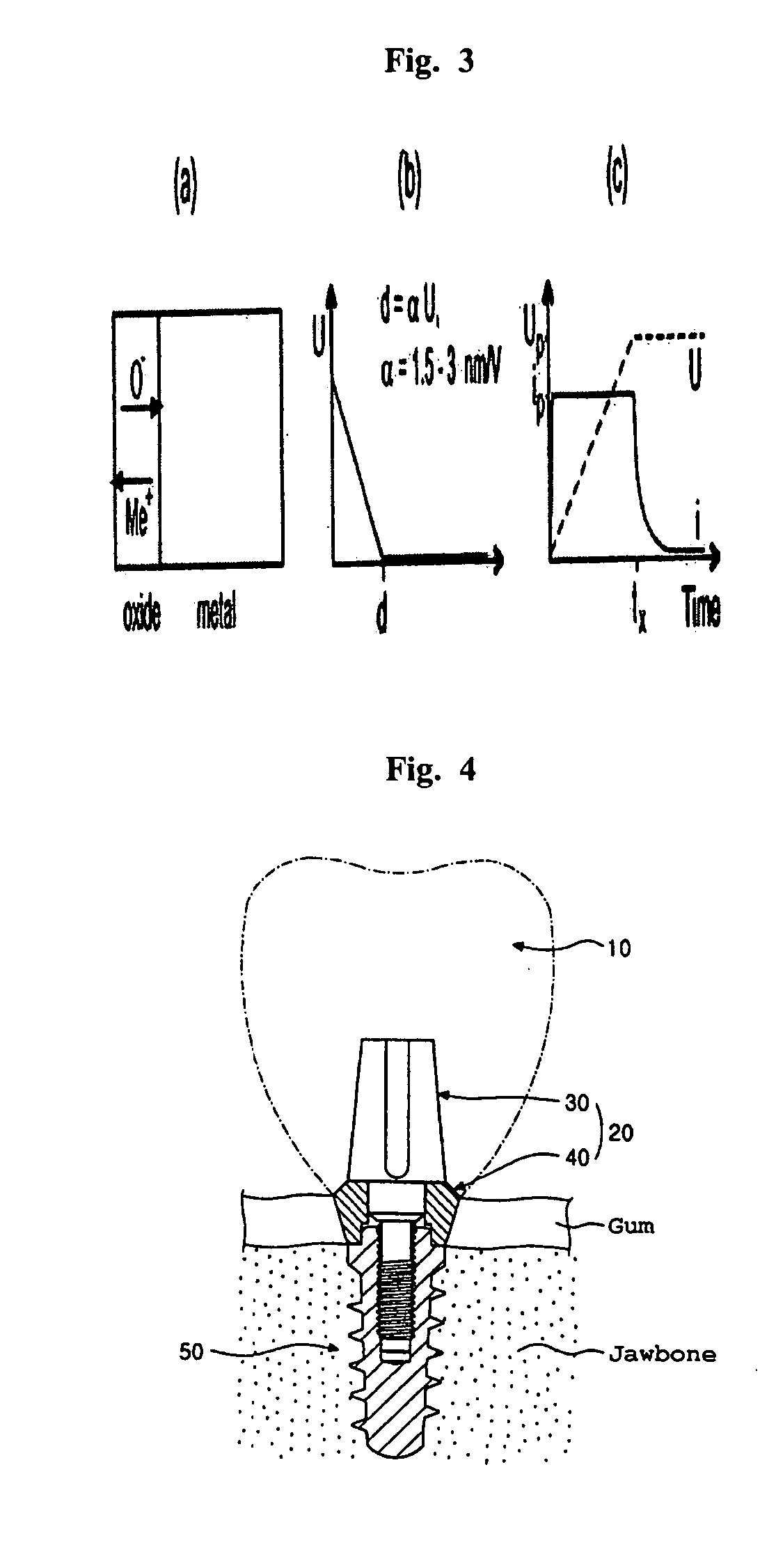

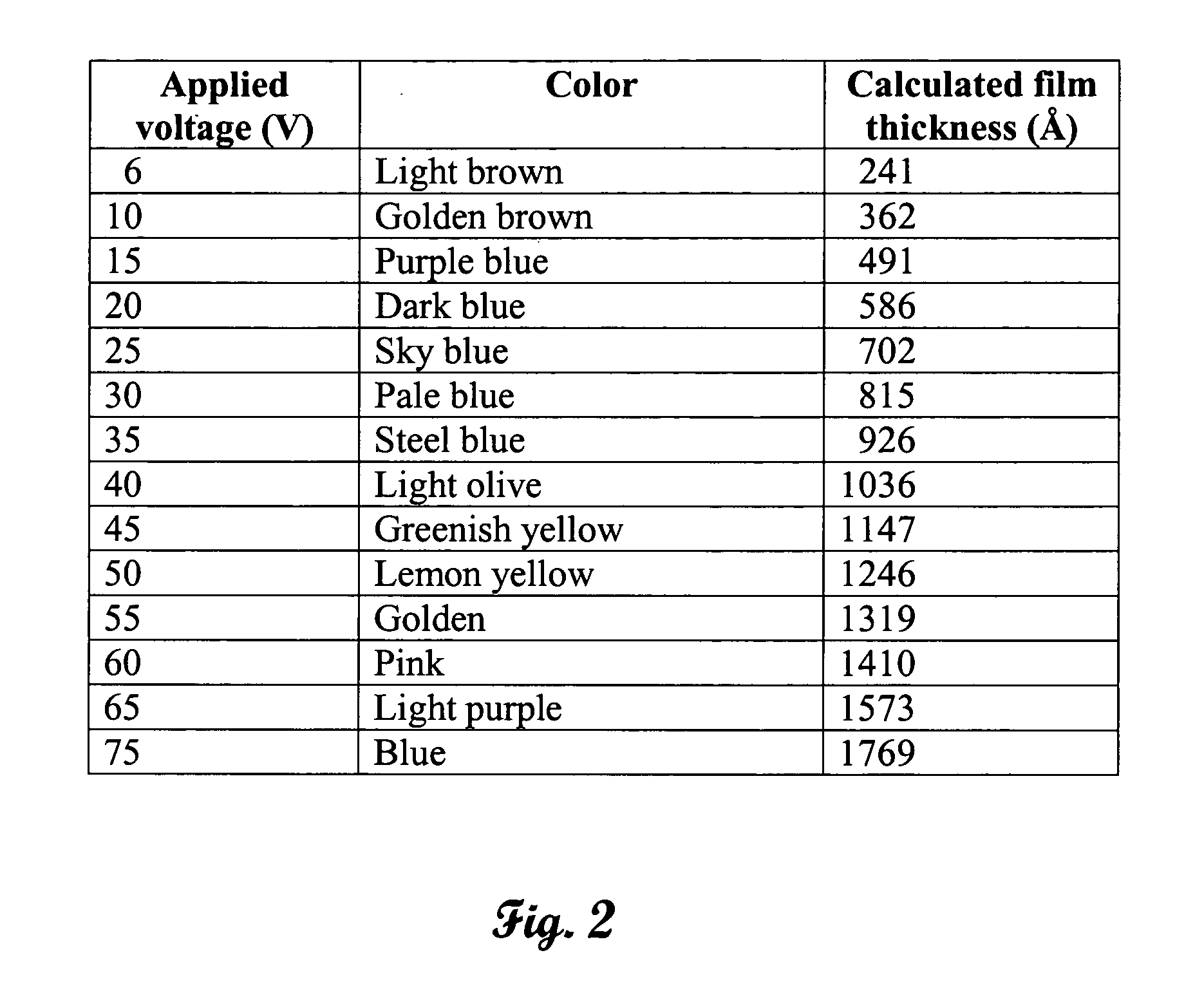

Abutment of dental implant and aesthetic surface treatment method of the same

InactiveUS20050181330A1Improve adaptabilityGood bio-compatibility with human bodyDental implantsSwitch operated by excess voltageTooth Supporting StructuresTitanium alloy

The present invention discloses an abutment of a dental implant consisting of an abutment screw and a shoulder surface. The upper structure of a crown or bridge abutment, i.e., the abutment screw is made of titanium alloy, and surface-treated in brown color by an anodizing process, and the connecting structure thereof, i.e., the shoulder surface is made of ceramic material containing zirconia of a white color, thereby providing an adequate mechanical strength, while maintaining the natural color of human teeth and light permeability. Further, the present invention discloses a method of aesthetically surface-treating the abutment screw of a dental implant abutment by using the anodizing process, and a method of fabricating the shoulder surface of a dental implant abutment.

Owner:COWELL MEDI CO LTD

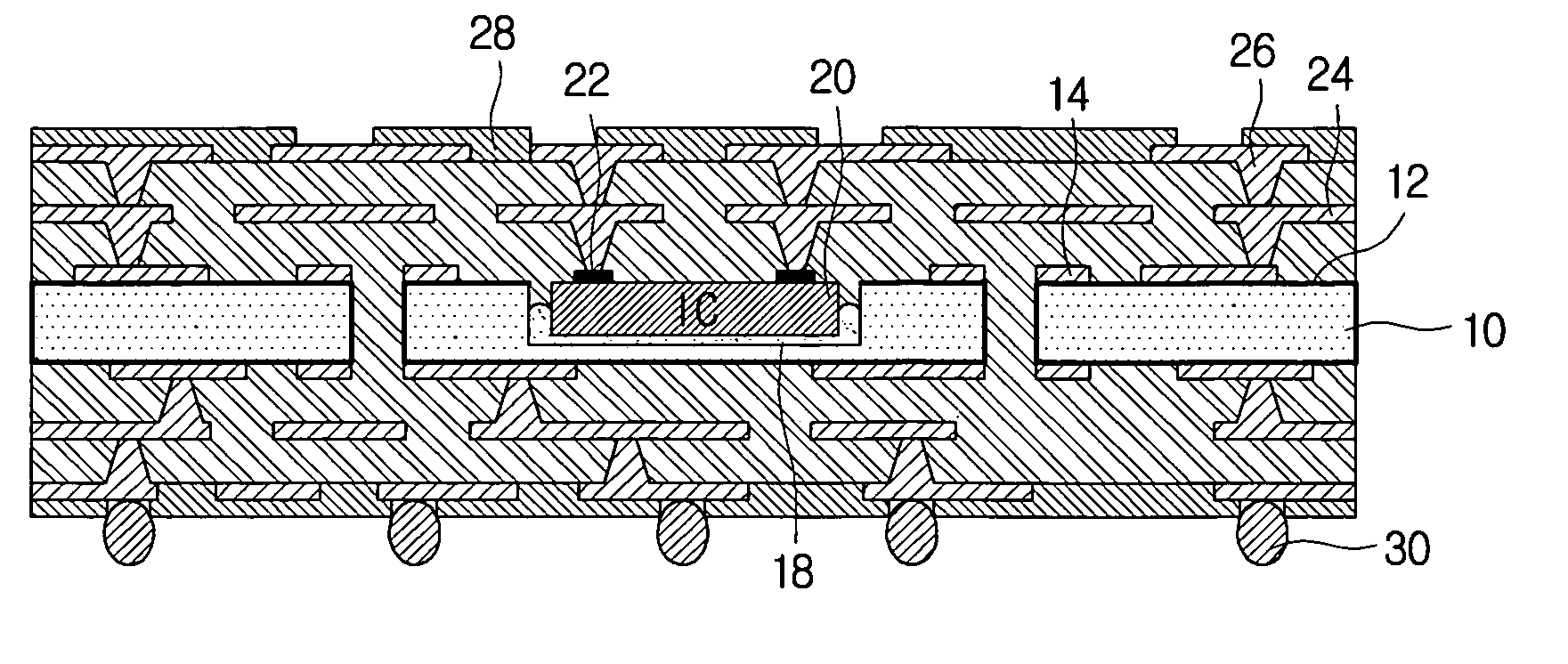

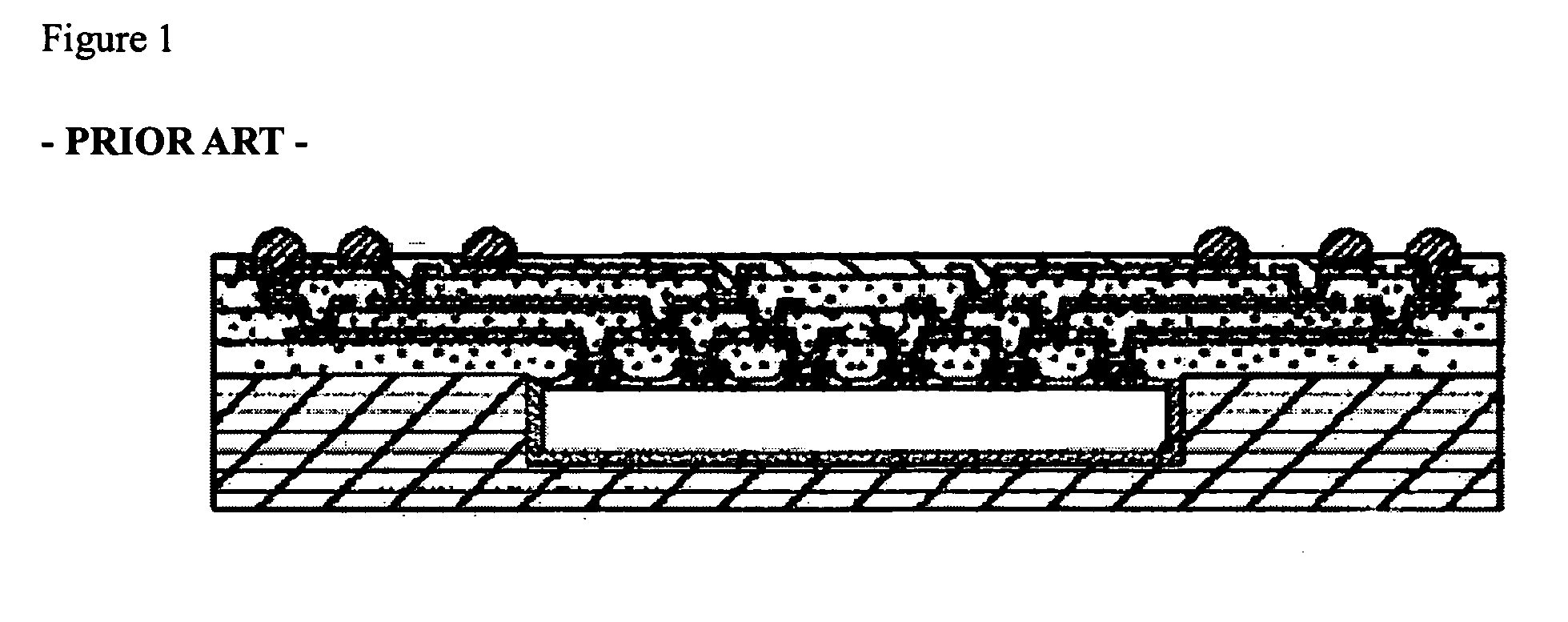

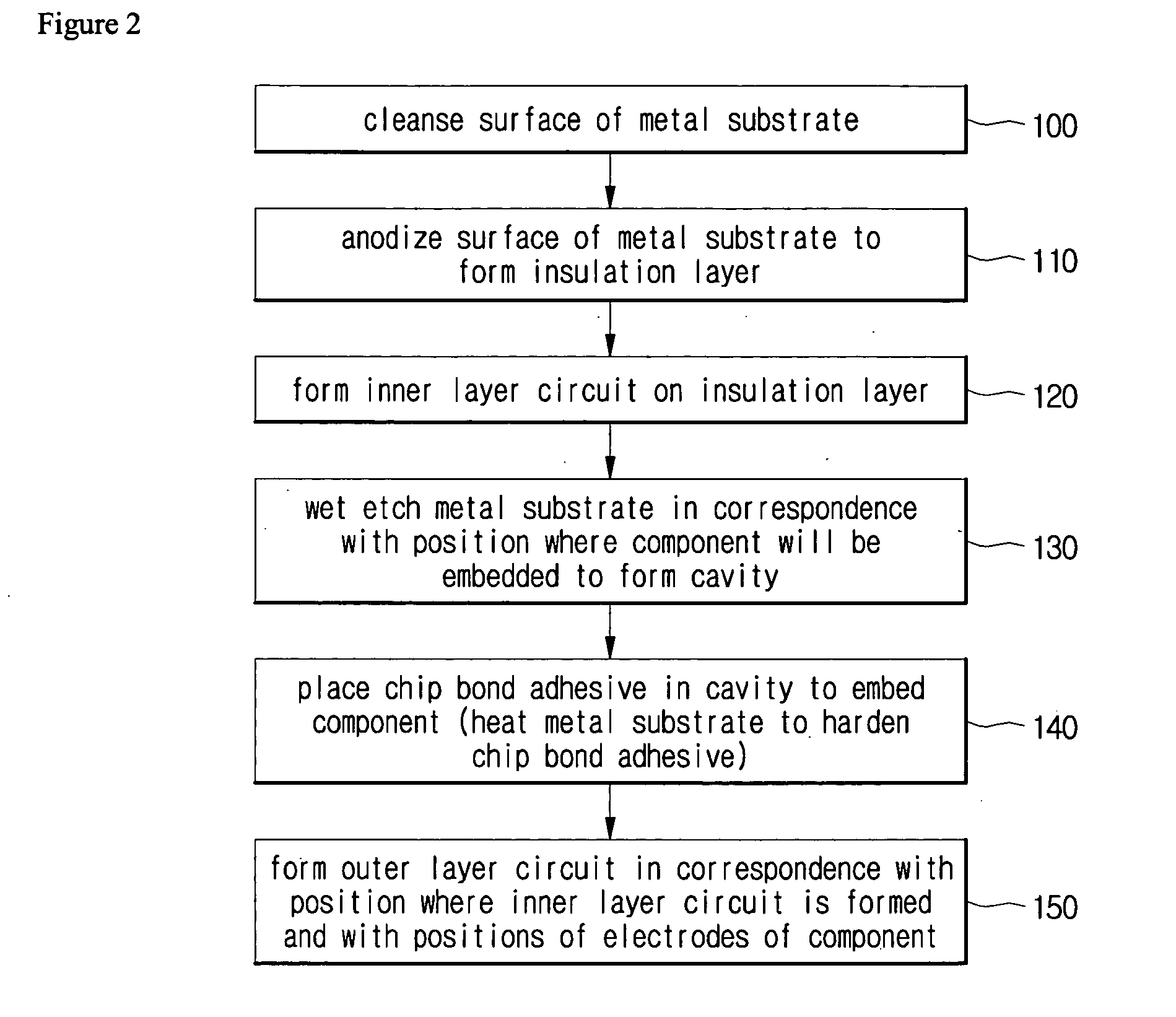

Printed circuit board and manufacturing method thereof

InactiveUS20070074900A1Increase stiffnessImprove heat-releasing propertyPrinted circuit assemblingPrinted electric component incorporationManufacturing cost reductionEtching

A printed circuit board and manufacturing method thereof are disclosed. By use of a method of manufacturing a printed circuit board, which uses a metal substrate as a core member and has an electronic component embedded in the metal substrate, mainly comprising: (a) anodizing at least one surface of the metal substrate to form at least one insulation layer, (b) forming an inner layer circuit on the at least one insulation layer, (d) placing chip bond adhesive in correspondence with a position where the electronic component is to be embedded and mounting the electronic component, and (e) forming an outer layer circuit in correspondence with a position where the inner layer circuit is formed and with positions of the electrodes of the electronic component, and which may further comprise an operation (c) of etching the metal substrate to form a cavity in correspondence with a position where the electronic component is to be embedded between the operations (b) and (d), a metal substrate, such as that of aluminum, etc., is rendered electrically insulating by applying an anodizing process and is used as a core member in a printed circuit board, so that bending stiffness and heat-releasing property are improved; wet etching can be applied, so that manufacturing costs are reduced; and a chip bond adhesive, die attach film, or nonconductive paste, etc., that is high in thixotropy is used in embedding the electronic component, so that the degree of precision may be increased for the position and height of the electronic component when embedding the electronic component.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

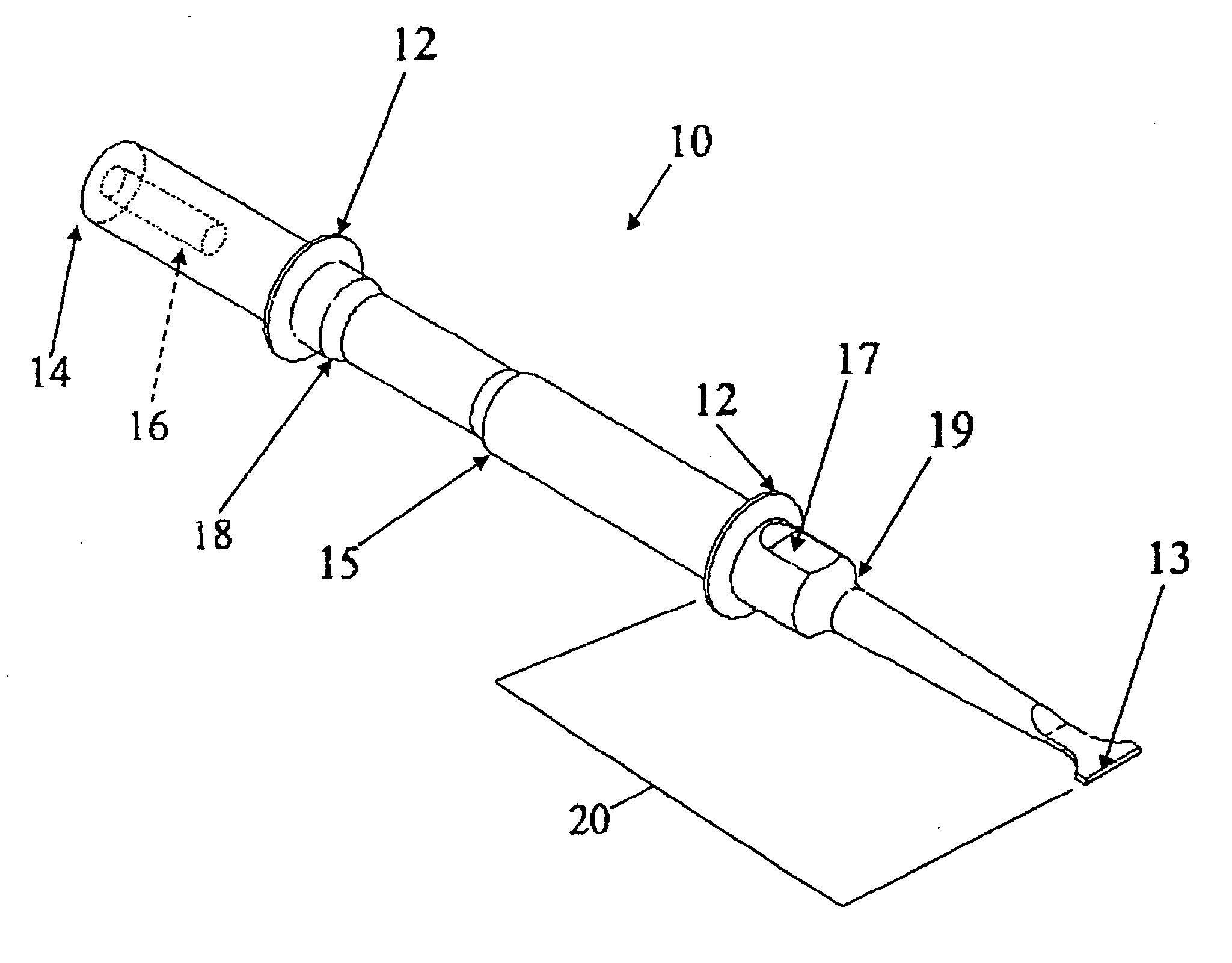

Color treated condition-indicating ultrasonic surgical device and method

Disclosed is a condition-indicating ultrasonic surgical device and method of making the same in which an ultrasonic surgical instrument (10) has at least a portion of which has an outer surface which includes a color layer formed by anodizing or chemical processing. The color layer has a predetermined thickness wherein the thickness, and thereby the color, of the layer is affected by damage to the instrument to provide an indication that would otherwise be imperceptible by visual inspection.

Owner:CRESCENDO TECH

Method for processing anode of aluminum or aluminum alloy surface

The invention relates to method for processing the anode of an aluminum or aluminum alloy surface, comprising the following steps: providing an aluminum or aluminum alloy base body which comprises aninner surface and an outer surface opposite to the inner surface; carrying out first machining processing on the outer surface of the aluminum or aluminum alloy base body so that the outer surface hasfirst machining surface effect; carrying out first-time anode processing on the aluminum or aluminum alloy base body so that the surface of the aluminum or aluminum alloy base body forms an oxidationfilm with a first color; removing a part or all of the oxidation film formed on the inner surface of the aluminum or aluminum alloy base body so that the aluminum or aluminum alloy base body is conductive; carrying out second machining processing on the outer surface of the aluminum or aluminum alloy base body; removing a part of the oxidation film positioned on the outer surface and enabling anarea the oxidation film of which is removed to have second machining surface effect; and carrying out second-time anode processing for the aluminum or aluminum alloy base body so that the area which has the second machining surface effect forms an oxidation film with a second color. The method can obtain different surface effects on a same base body.

Owner:SHENZHEN FUTAIHONG PRECISION IND CO LTD

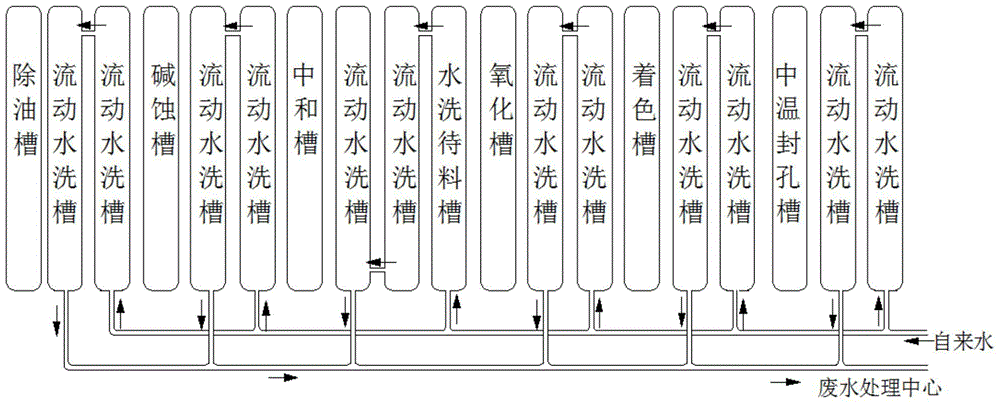

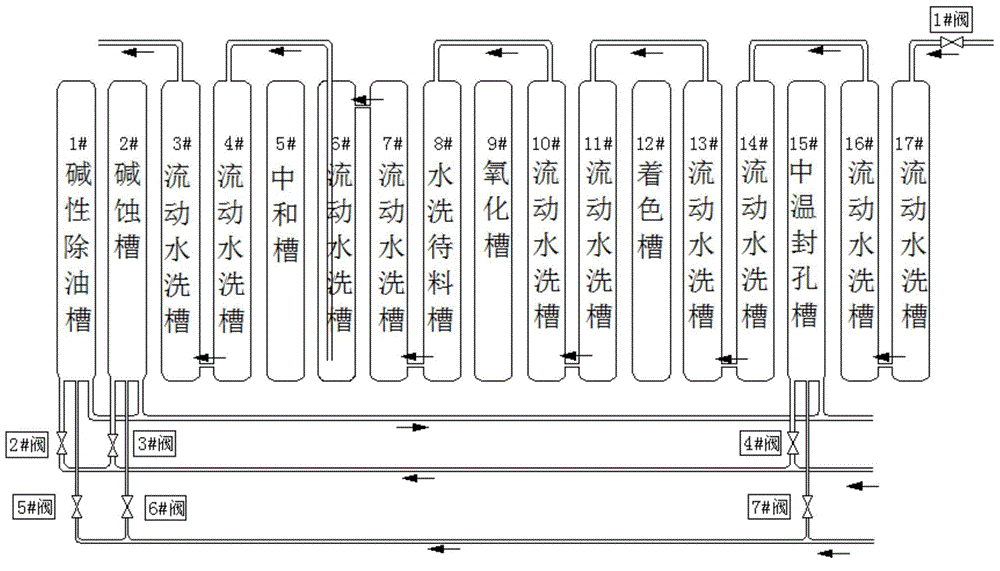

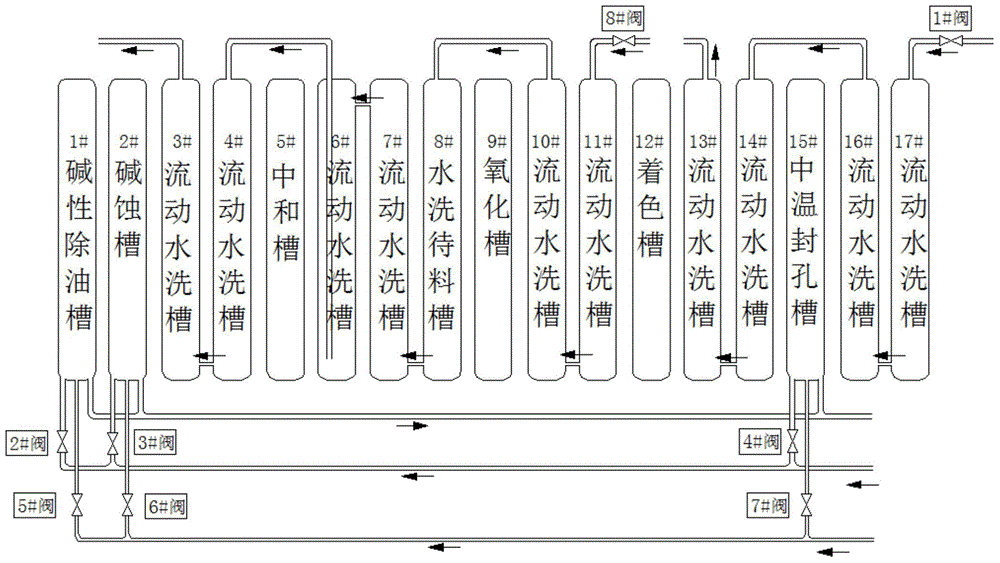

Aluminum alloy anodizing line treatment process

ActiveCN103952741AAchieve large-scale water conservationAvoid pollutionAnodisationAnodizingMaterials science

The invention relates to an aluminum alloy anodizing line treatment process. The aluminum alloy anodizing line treatment process comprises a functional trough system and water washing trough systems arranged between functional troughs. The functional trough system is arranged along the flow direction of washing water in a manner that an upstream functional trough is compatible with a downstream functional trough, and the water washing trough systems are arranged in an overall phase-reversing in-series-connection manner. According to the aluminum alloy anodizing line treatment process, a mode in which a flowing water washing tank is separately configured for each functional trough in the traditional anodizing line is changed. Since all water washing troughs are connected in series in a phase-reversing manner, the number of the water inlets and outlets is greatly reduced and the water consumption is decreased from 25.0-35.0 tons per ton material to 5.0-6.0 tons per ton material and the water is saved by more than 80%. The treatment process disclosed by the invention has the advantages of low production cost, high efficiency and environmental friendliness and is suitable for industrial application.

Owner:FOSHAN SANSHUI XIONGYING INNOVATION CENT FOR ALUMINUM SURFACE TECH

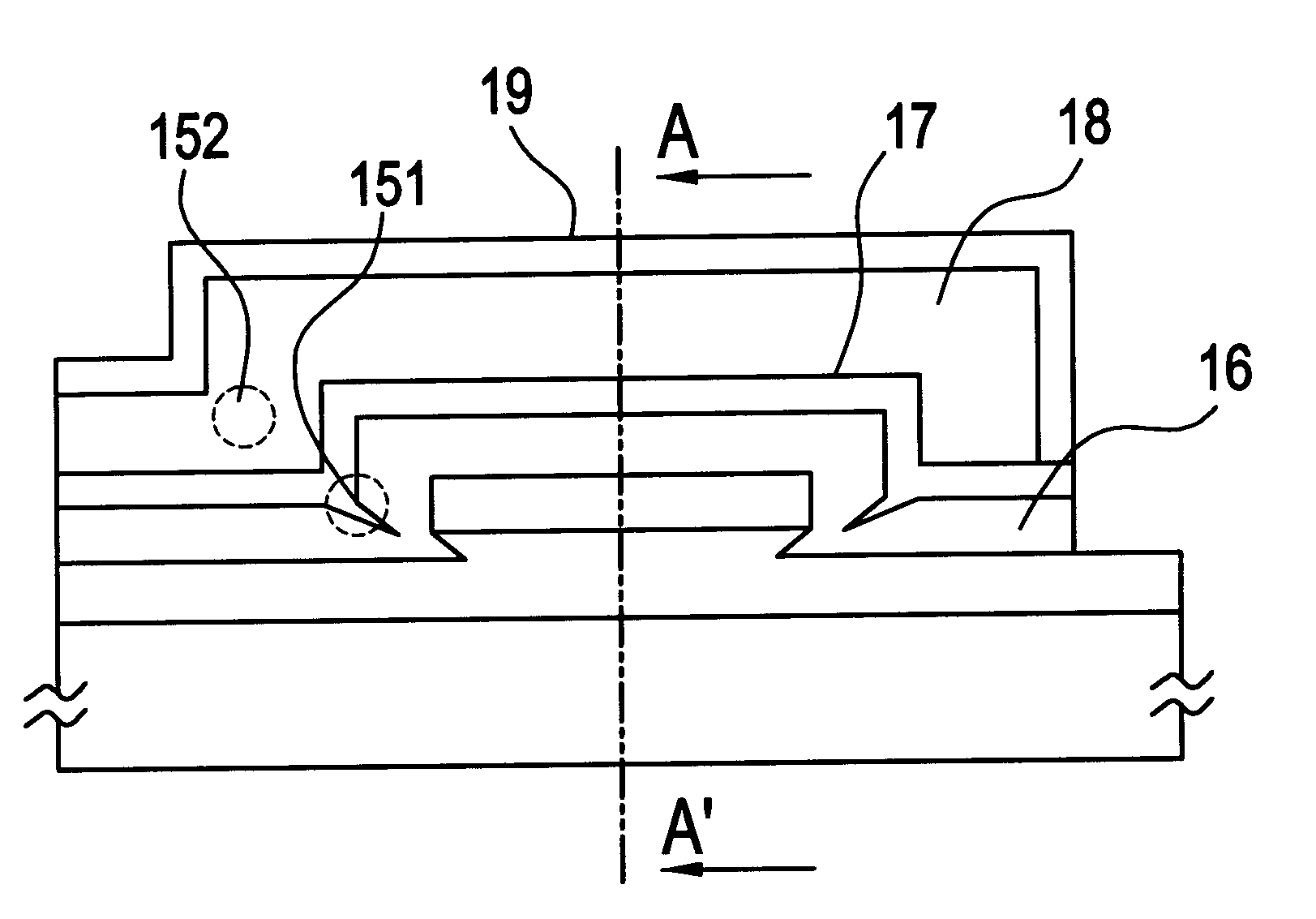

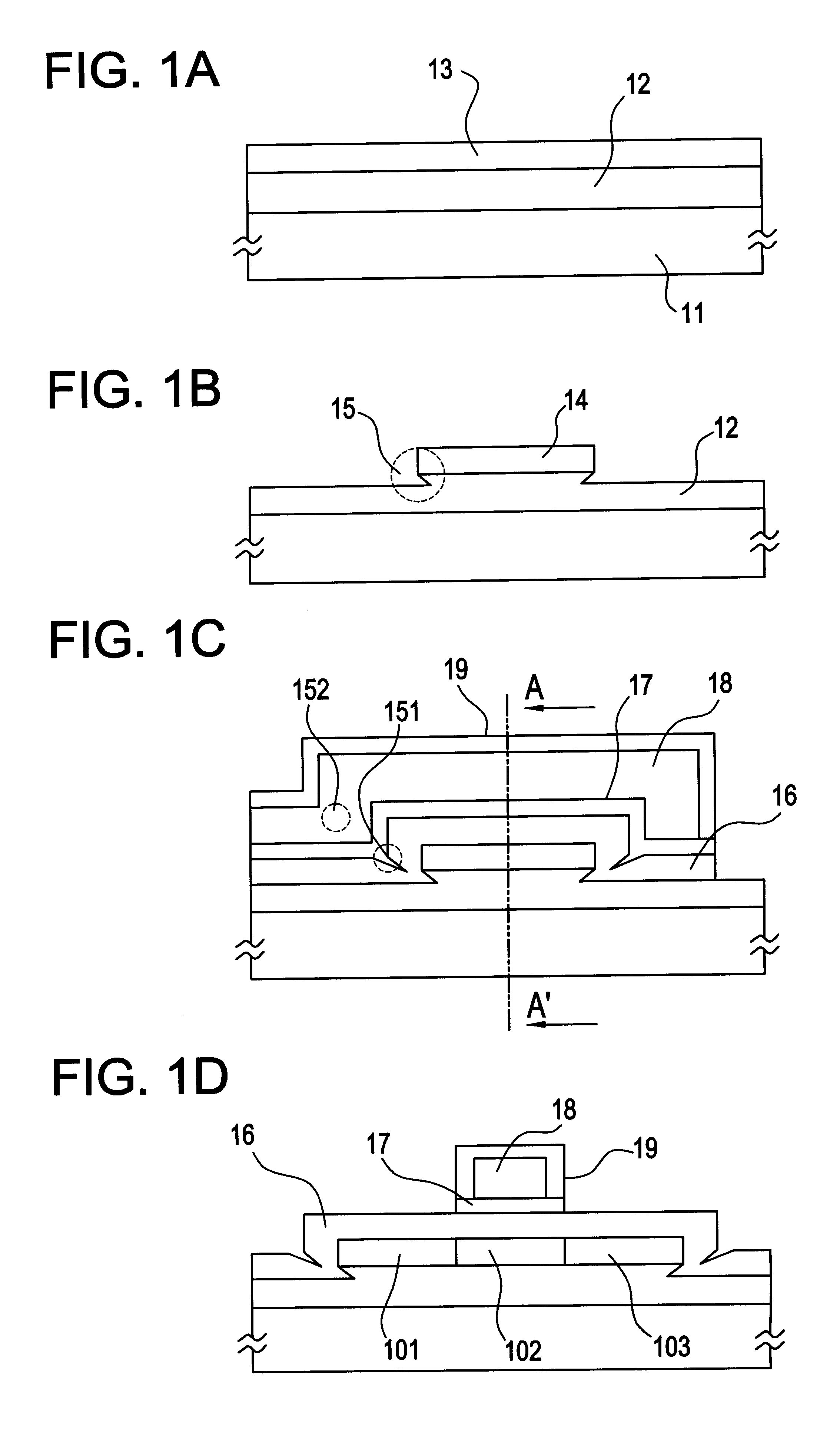

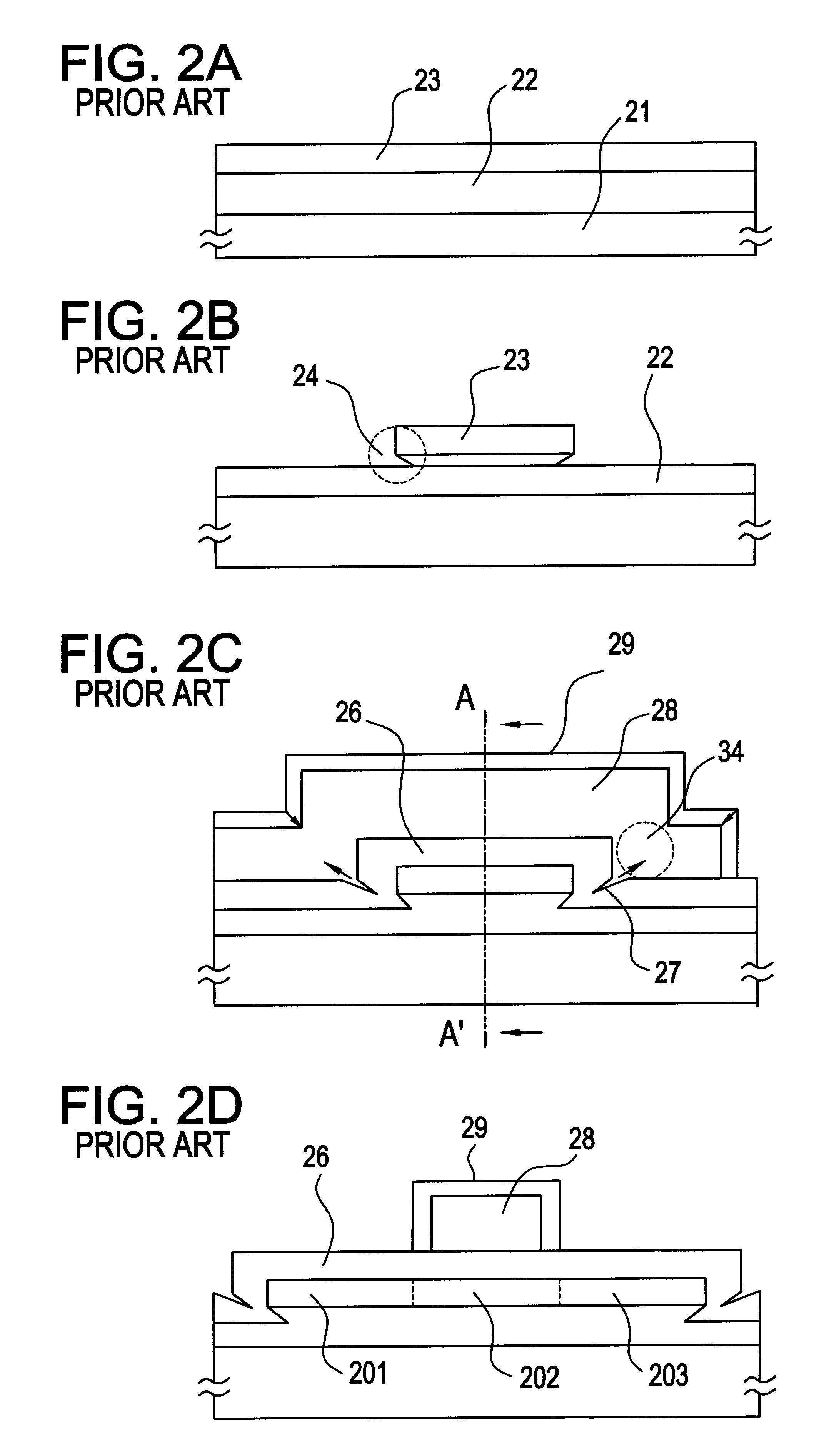

Semiconductor device and method for producing the same

In the production of thin film transistor (TFT), a gate insulating film is formed to cover an active layer, a titanium nitride film is formed on the gate insulating film, and an aluminum film used as the gate electrode is formed on the titanium nitride film. The resulted configuration prevents the etching of the aluminum film from the insulating film side even if the etchant of aluminum enters the recessed portion at the edge of the active layer during the patterning of the gate electrode. Also in the anodizing process, when an oxide film is formed on the surface of the aluminum film, the oxidation of aluminum from the gate insulating film side is prevented even when the electrolyte solution enters the recessed portion at the edge of the active layer.

Owner:SEMICON ENERGY LAB CO LTD

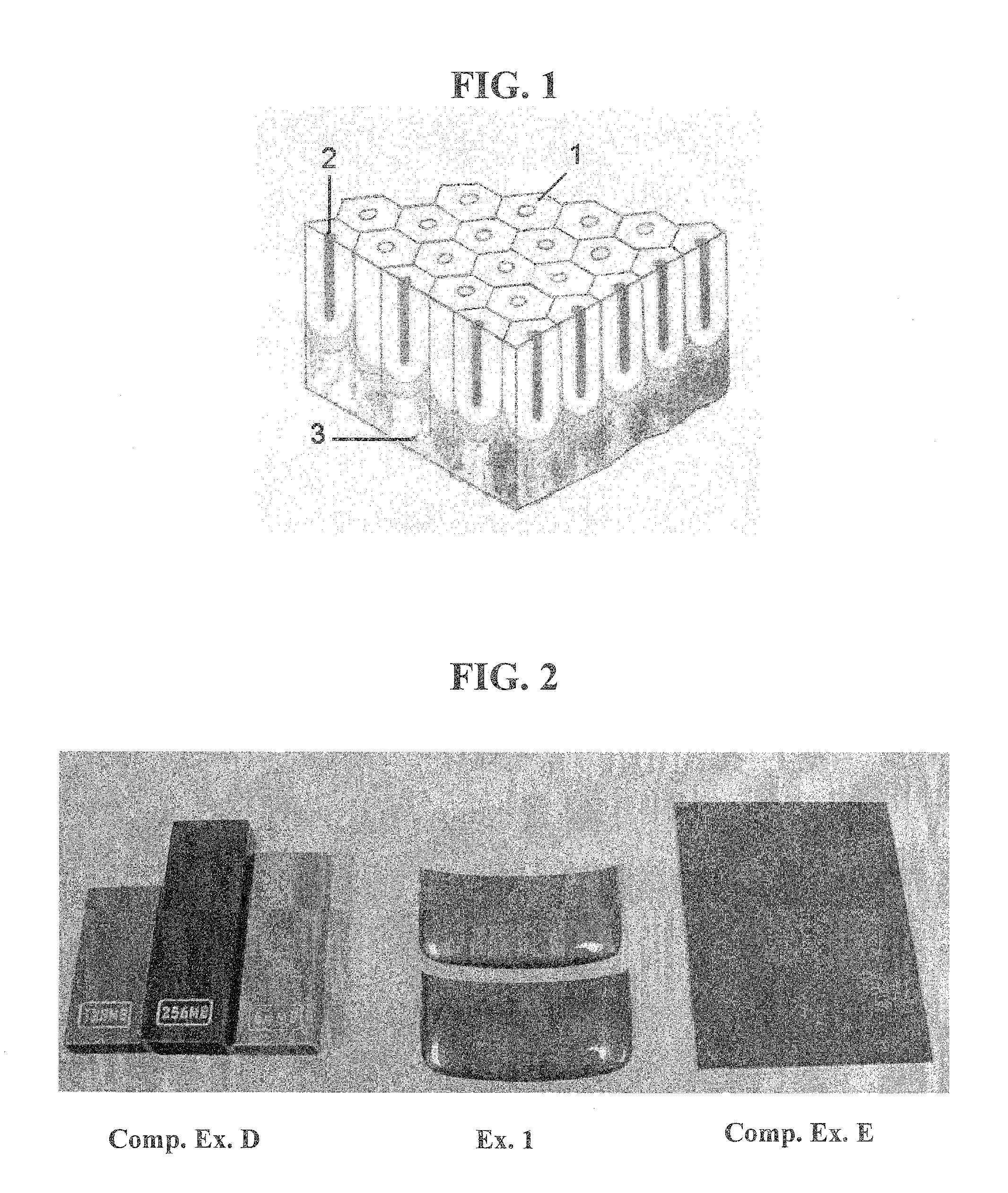

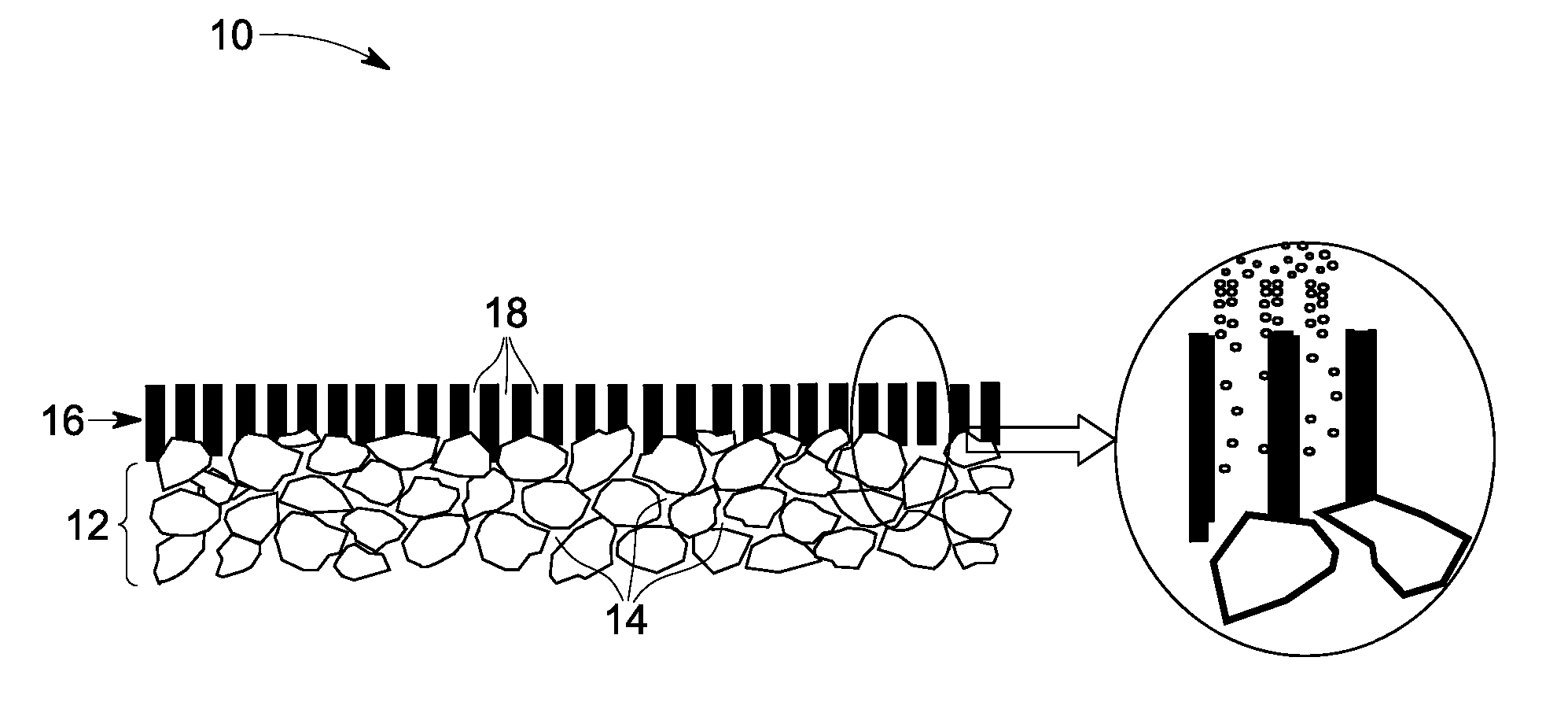

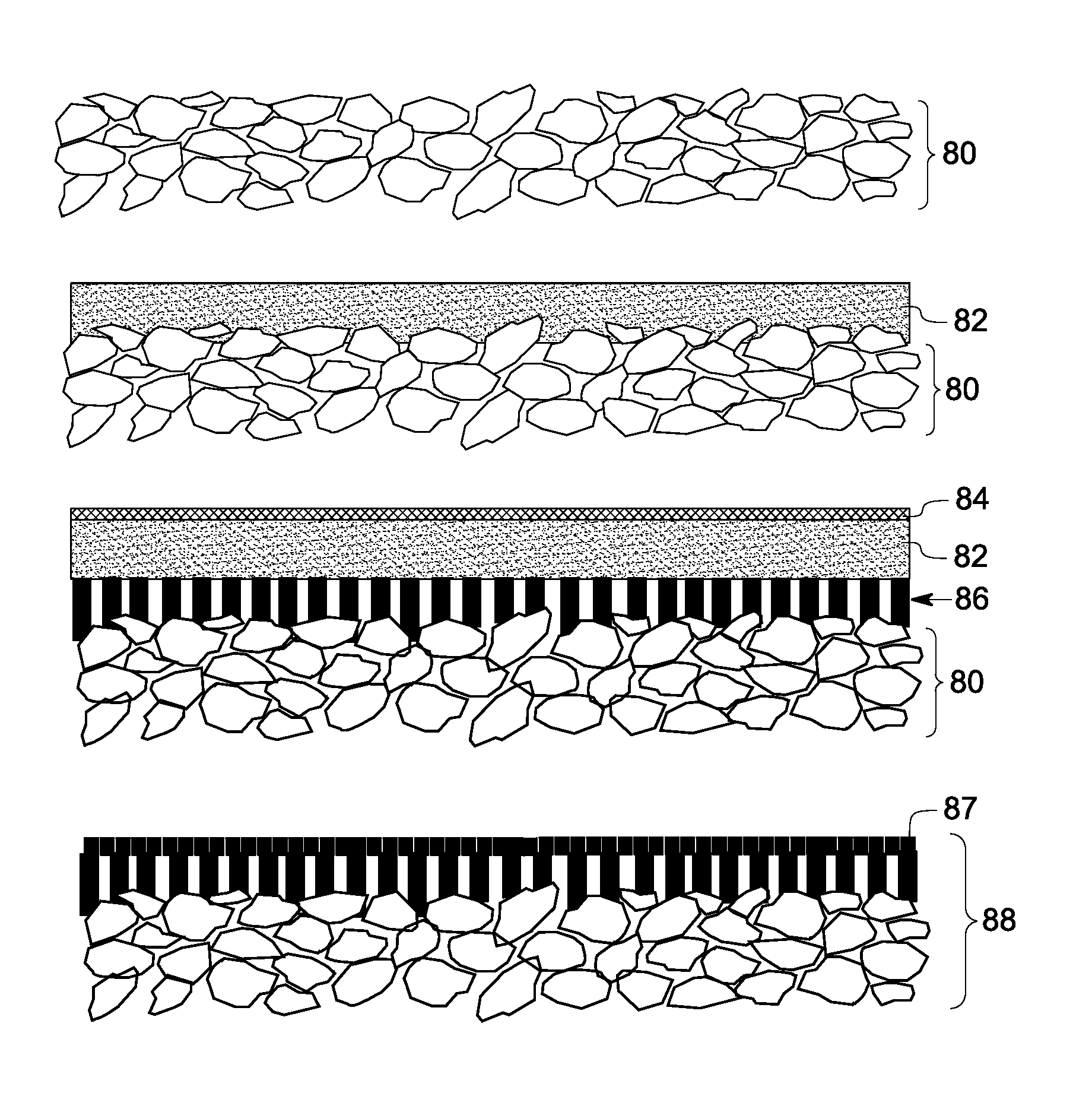

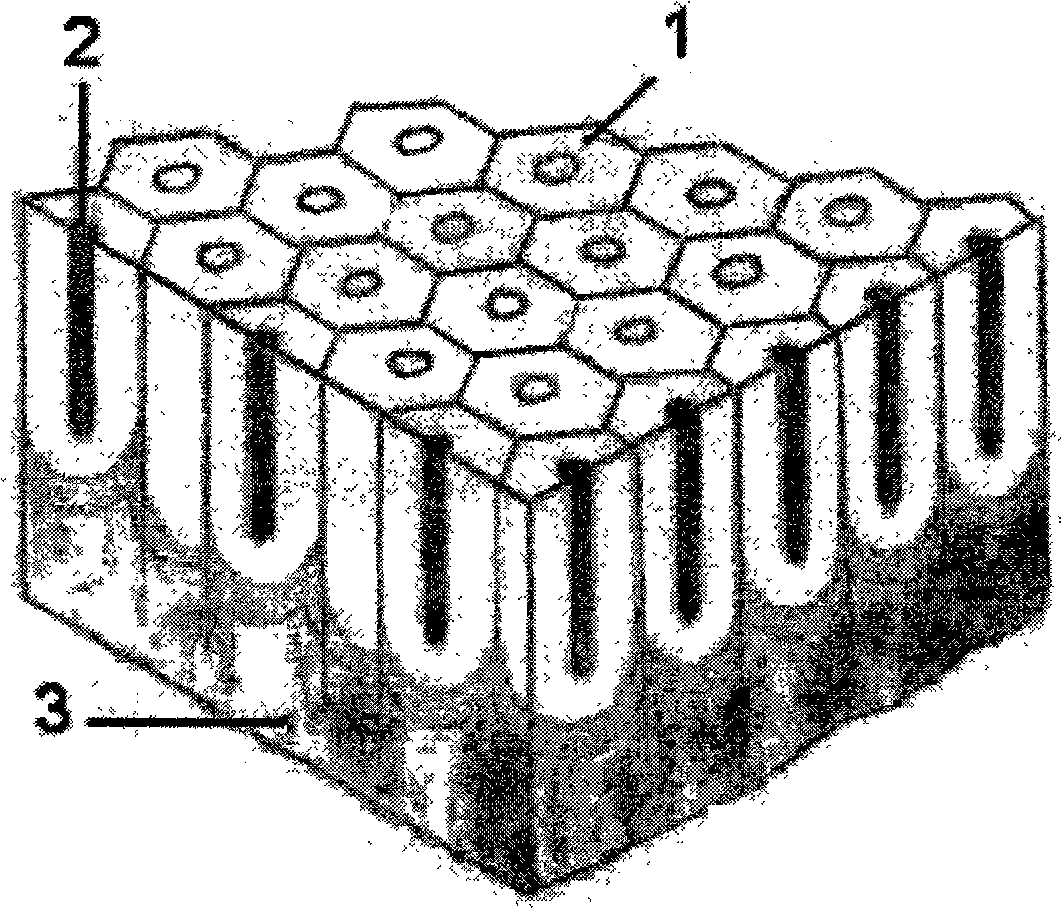

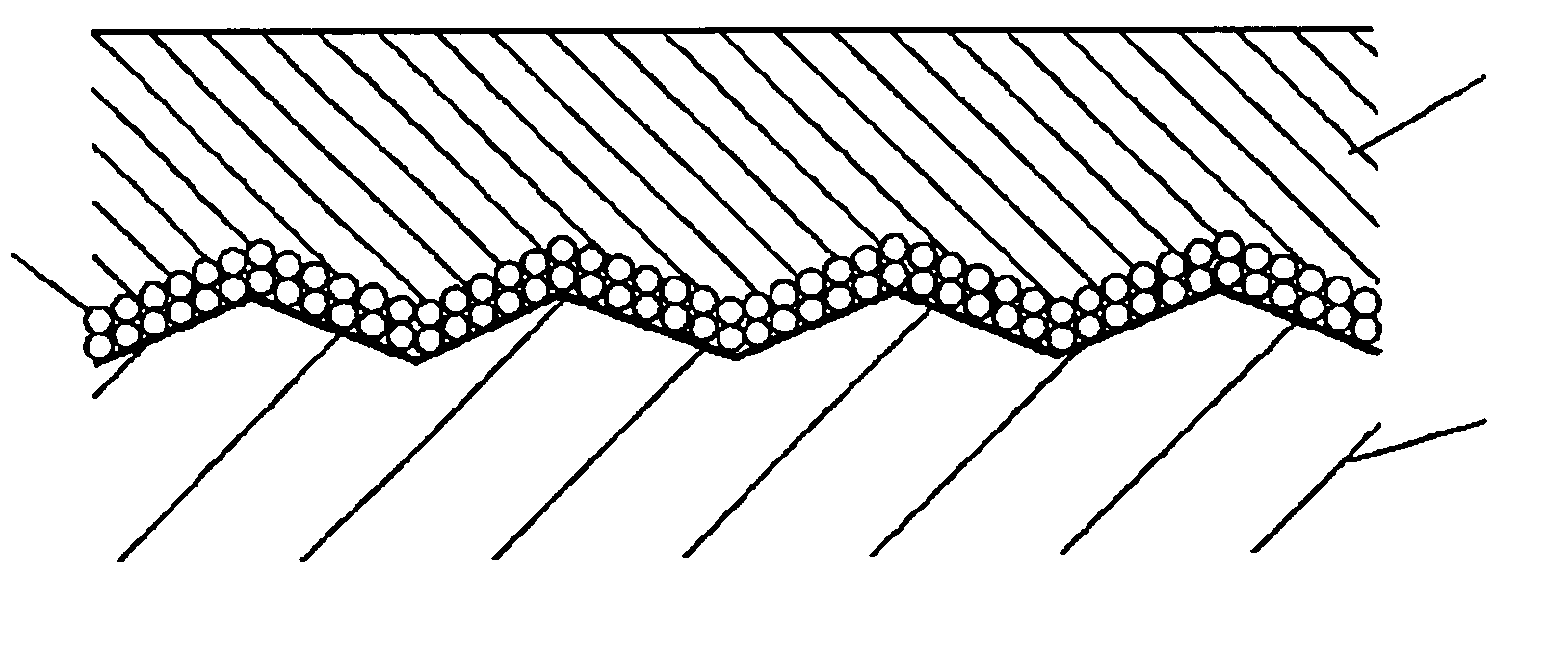

Membrane structure and method of making

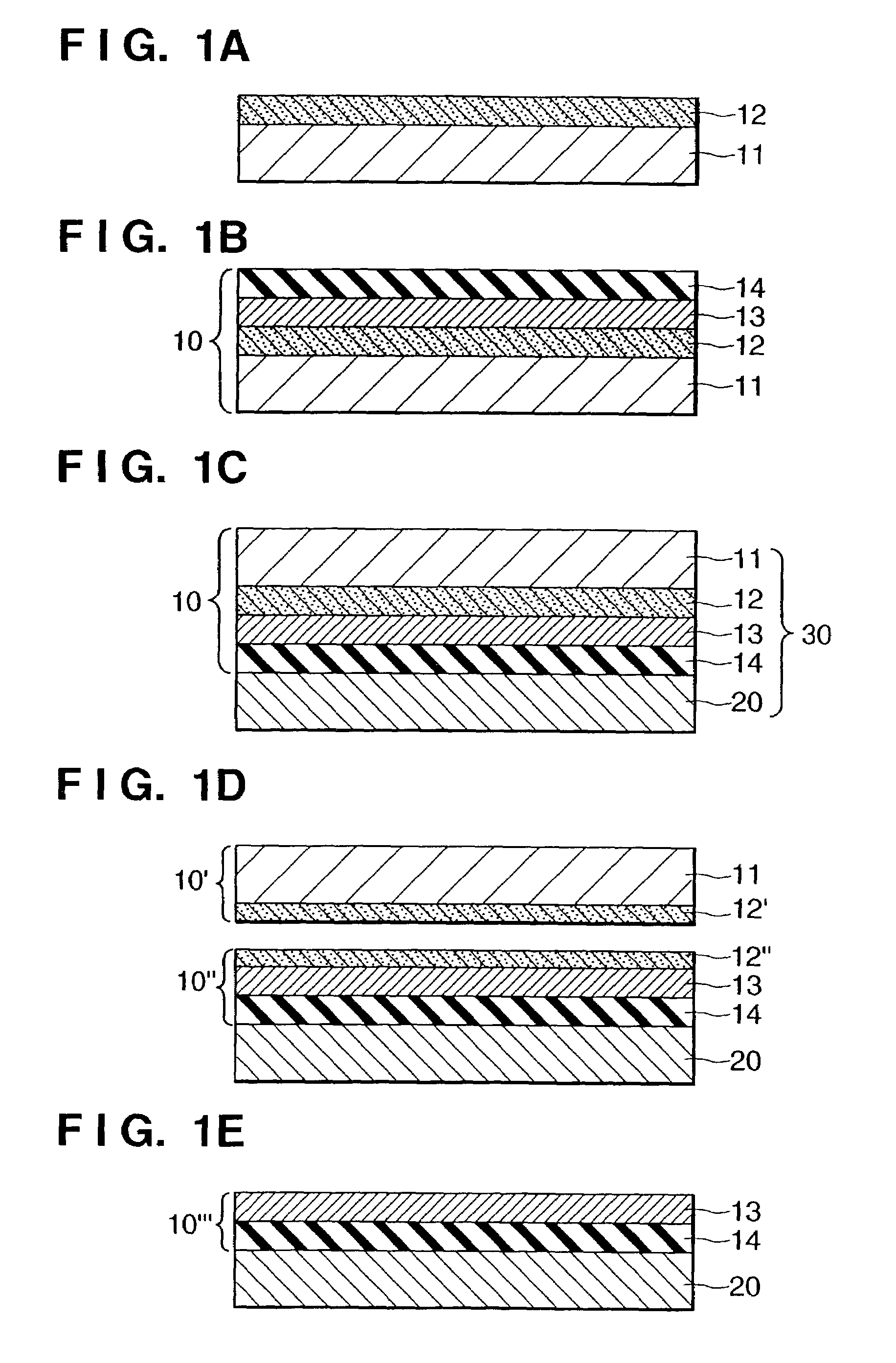

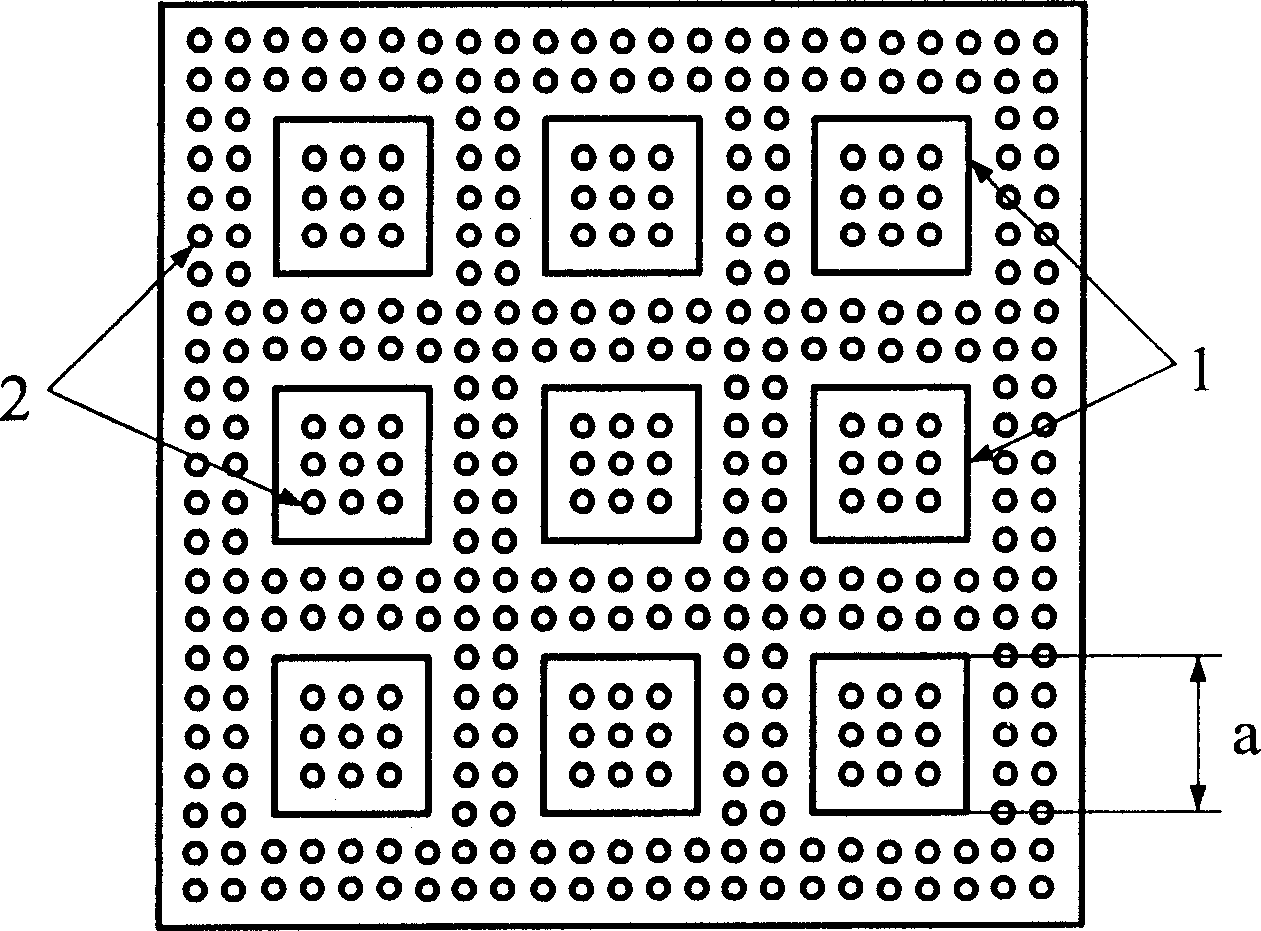

InactiveUS20070125702A1Improve throughputHigh selectivitySemi-permeable membranesSurface reaction electrolytic coatingAnodizingPolymer science

A membrane structure is provided. The membrane structure includes a polymer layer having a plurality of pores; and a ceramic layer disposed on the polymer layer. The ceramic layer has a plurality of substantially unconnected pores. Each of the substantially unconnected pores is in fluid communication with at least one of the pores of the polymer layer. A method of manufacturing a membrane structure is provided. The method includes the steps of providing a polymer layer having a plurality of pores; and disposing a ceramic layer on the polymer layer. Disposing a ceramic layer includes depositing a metal layer on the polymer layer; and anodizing the metal layer to convert the metal layer into a porous layer. At least one of the depositing step and the anodizing step is performed as a continuous process. Alternatively, at least one of the depositing and the anodizing step is performed as a batch process.

Owner:GENERAL ELECTRIC CO

Membrane structure and method of making

InactiveUS7547393B2Improve throughputHigh selectivitySemi-permeable membranesSurface reaction electrolytic coatingAnodizingPolymer science

A membrane structure is provided. The membrane structure includes a polymer layer having a plurality of pores; and a ceramic layer disposed on the polymer layer. The ceramic layer has a plurality of substantially unconnected pores. Each of the substantially unconnected pores is in fluid communication with at least one of the pores of the polymer layer. A method of manufacturing a membrane structure is provided. The method includes the steps of providing a polymer layer having a plurality of pores; and disposing a ceramic layer on the polymer layer. Disposing a ceramic layer includes depositing a metal layer on the polymer layer; and anodizing the metal layer to convert the metal layer into a porous layer. At least one of the depositing step and the anodizing step is performed as a continuous process. Alternatively, at least one of the depositing and the anodizing step is performed as a batch process.

Owner:GENERAL ELECTRIC CO

Anodizing aluminium and alloys thereof

This invention encompasses methods of producing a colored oxide layer on an aluminum material by anodizing the aluminum material in an electrolyte comprising water, sulfuric acid and oxalic acid. The anodizing step comprises passing at least two sequential current densities through the electrolyte. Methods of making and using article with a colored oxide layer on an aluminum material make by the methods disclosed herein are also disclosed.

Owner:DURACOUCHE INT

Metallic surface anode treatment method

Owner:SHENZHEN FUTAIHONG PRECISION IND CO LTD

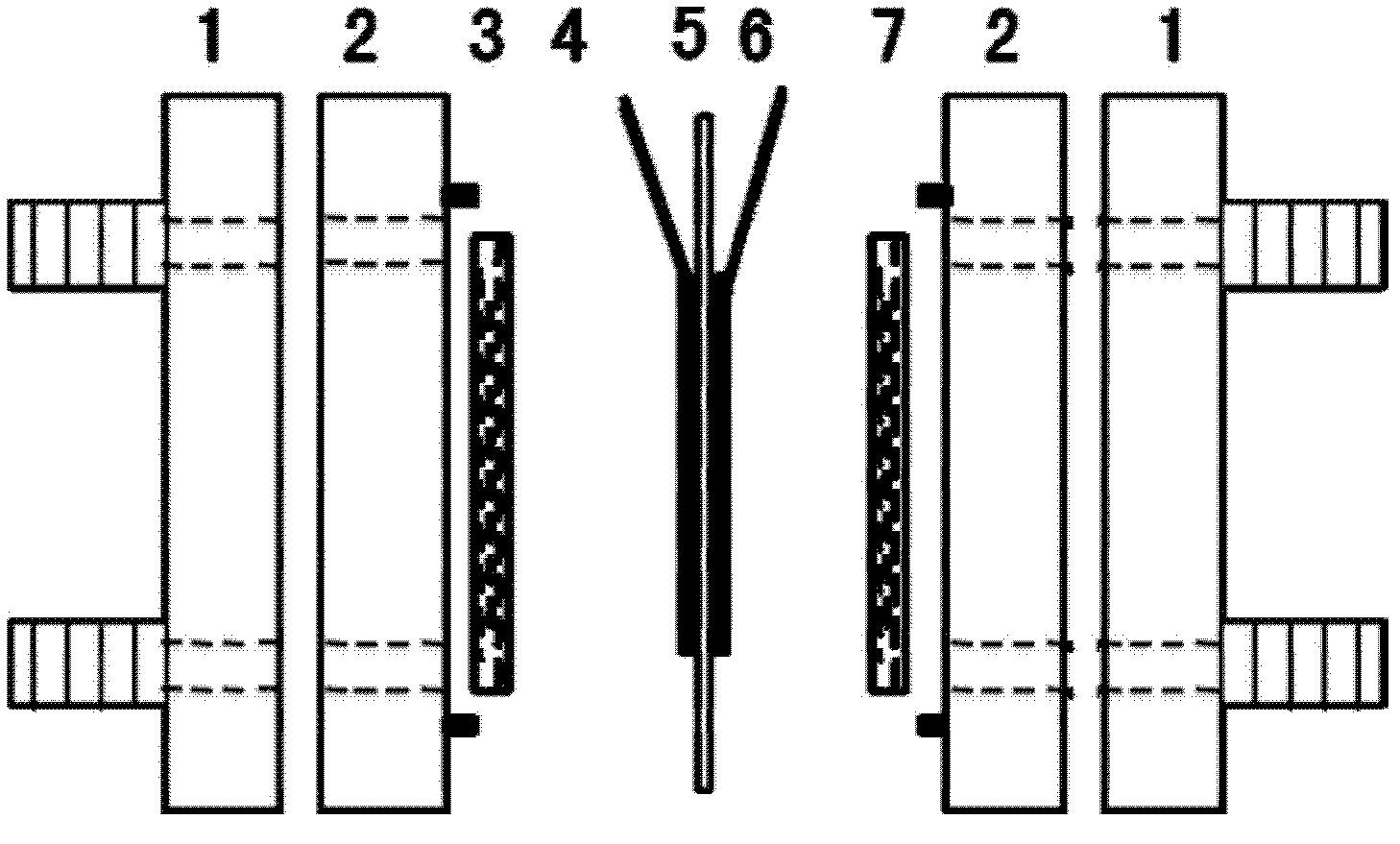

Anodizing method, substrate processing method, and substrate manufacturing method

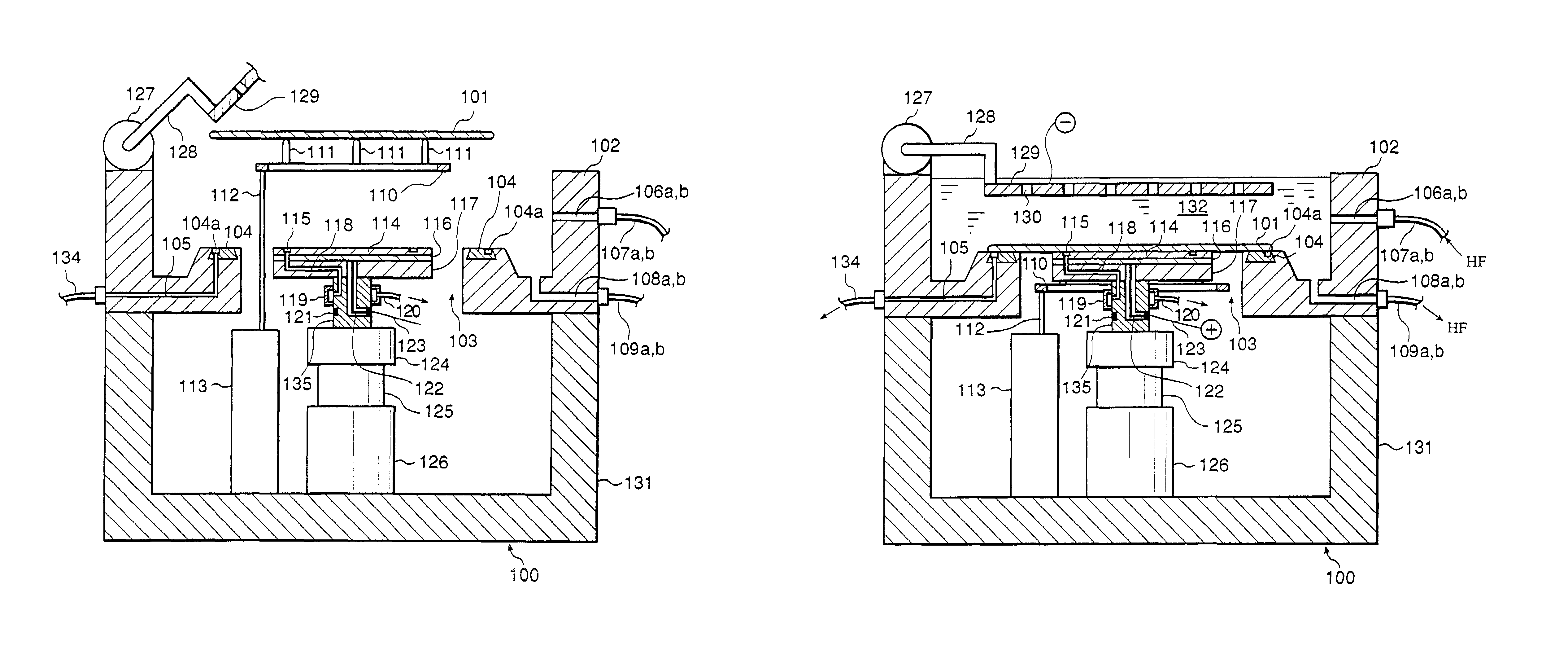

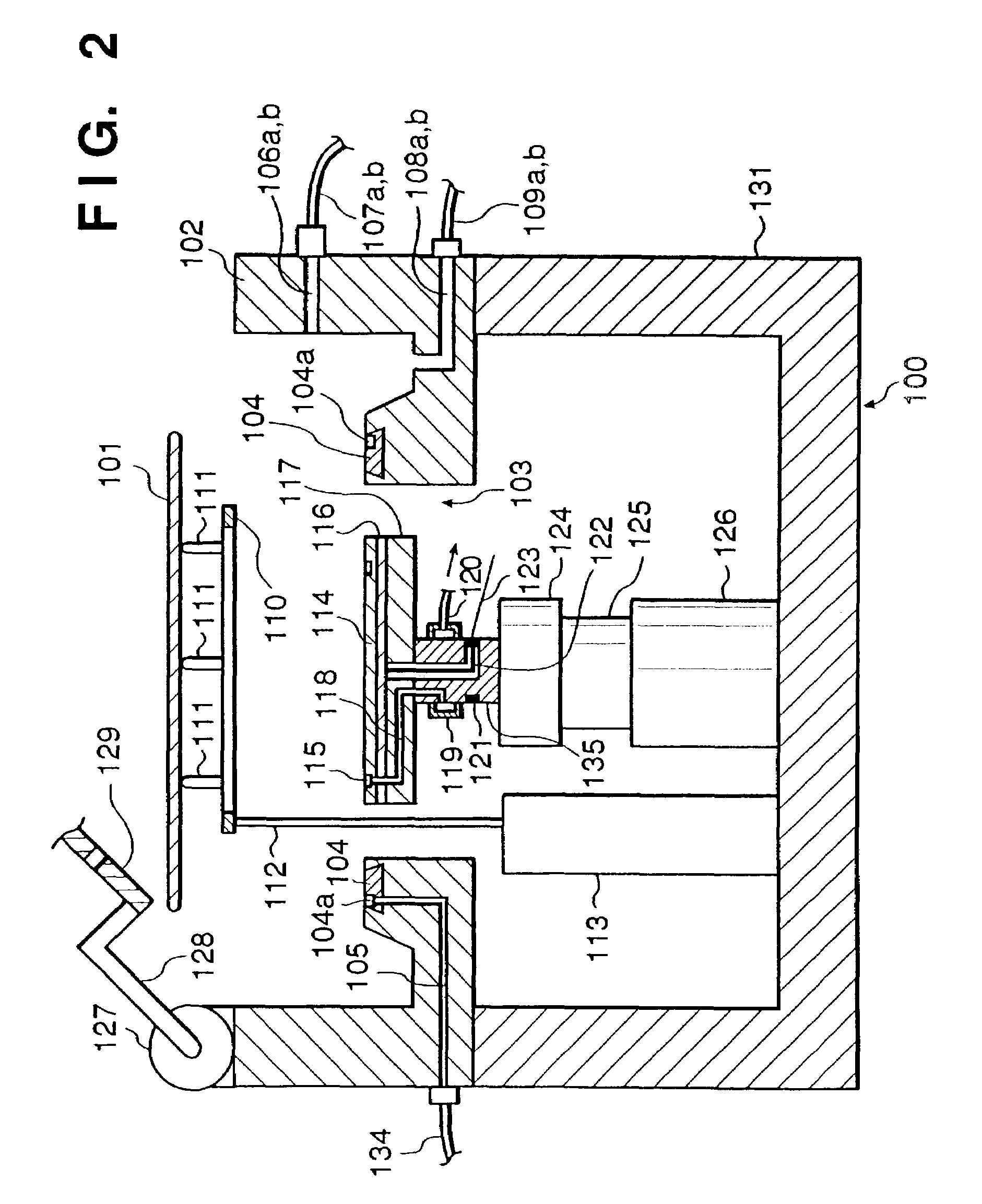

InactiveUS7014748B2Avoid influenceAvoid pollutionAnodisationSemiconductor/solid-state device manufacturingAnodizingElectrode

This invention is to reduce the influence of a gas generated by an anodizing reaction. A silicon substrate (101) to be processed is horizontally held. A negative electrode (129) is arranged on the upper side of the silicon substrate (101), and a positive electrode (114) is brought into contact with the lower surface of the silicon substrate (101). The space between the negative electrode (129) and the silicon substrate (101) is filled with an HF solution (132). The negative electrode (129) has a number of degassing holes (130) to prevent a gas generated by the anodizing reaction from staying on the lower side of the negative electrode (129).

Owner:CANON KK

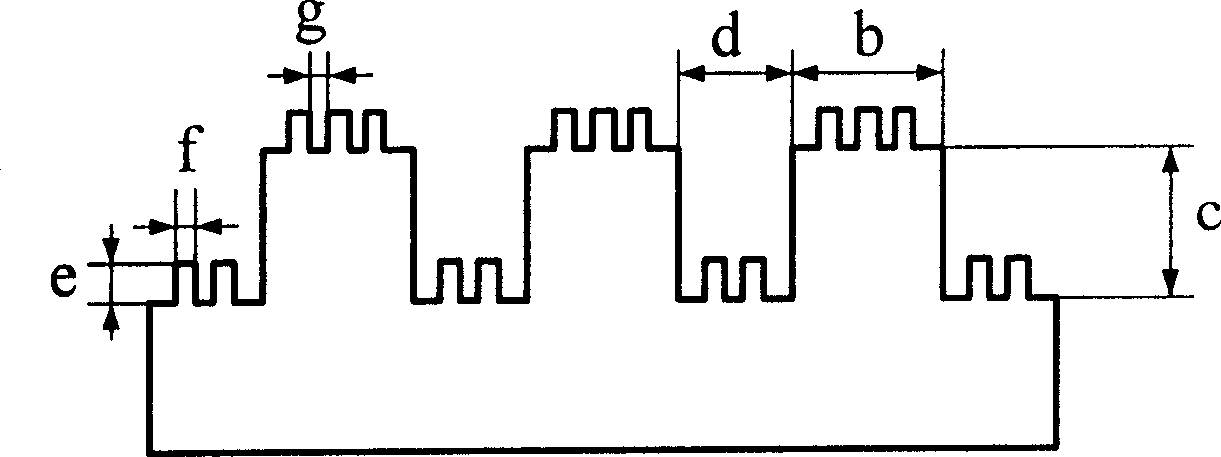

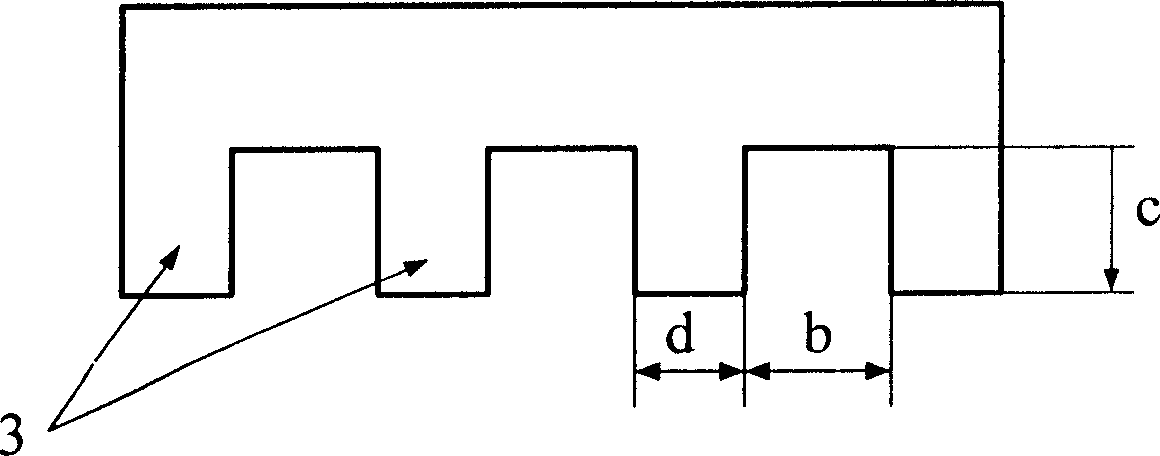

Super hydrophobic surface possessing dual microtexture and preparation method

InactiveCN1760112AAvoid surface frictionOvercoming wear and tearDecorative surface effectsIndividual molecule manipulationAnodizingNanopillar

A superhydrophobic surface with dual microscopic structures features that the micron-class arrays and nano-class arrays are prepared on the surface of polymer film through microprocessing and anodizing. The length, width, height and gap of microposts in array are 10-100 microns for micron array and 10-100 nm for nano-array. Its template can be cyclically used.

Owner:HUAZHONG UNIV OF SCI & TECH

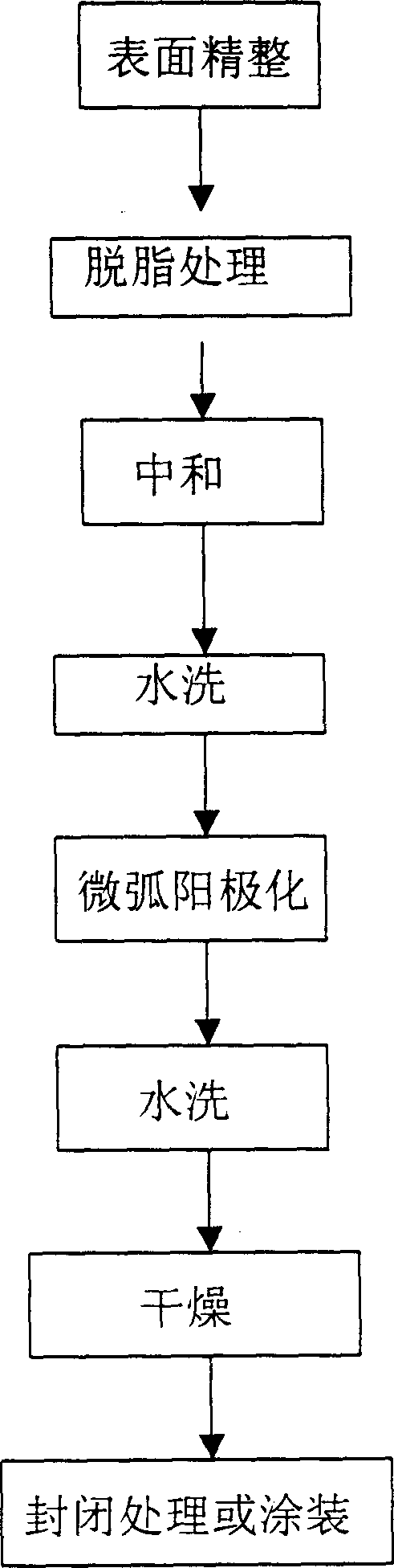

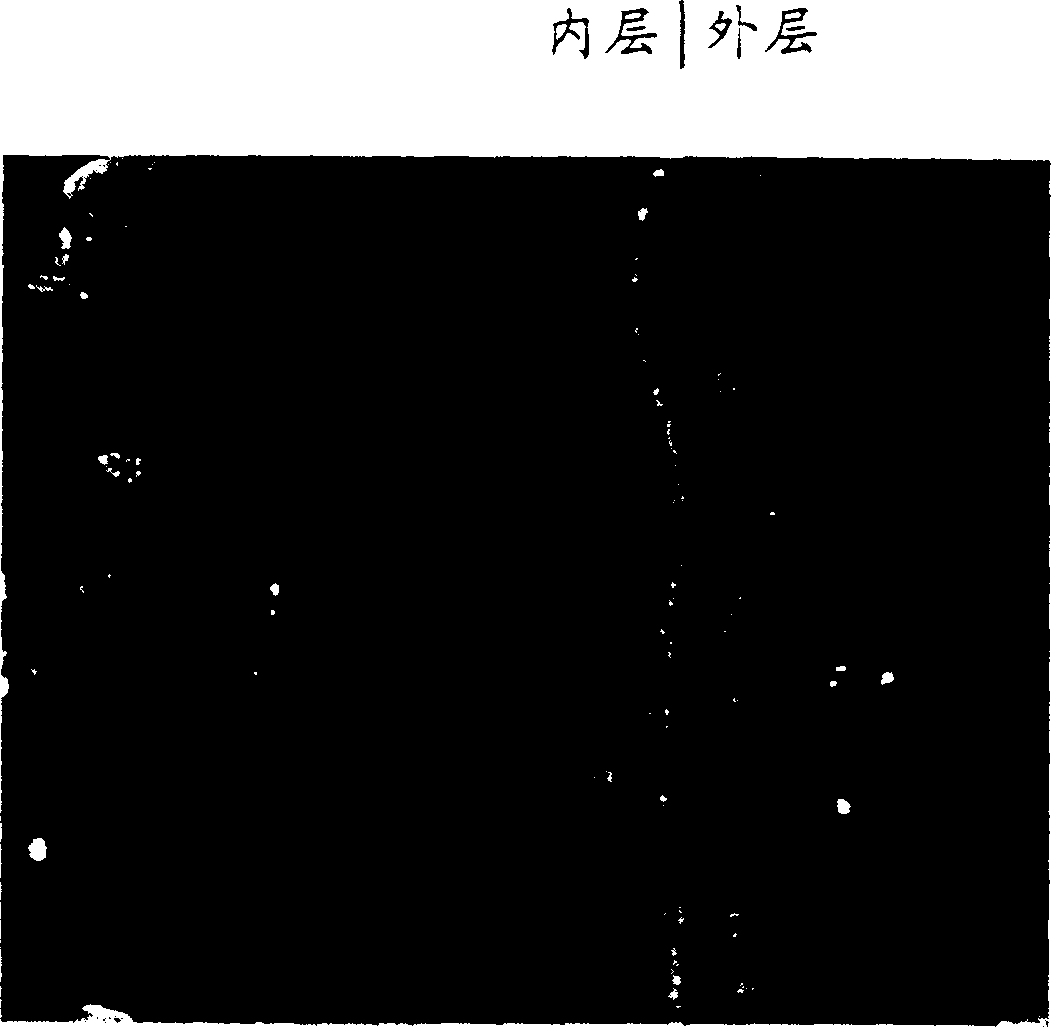

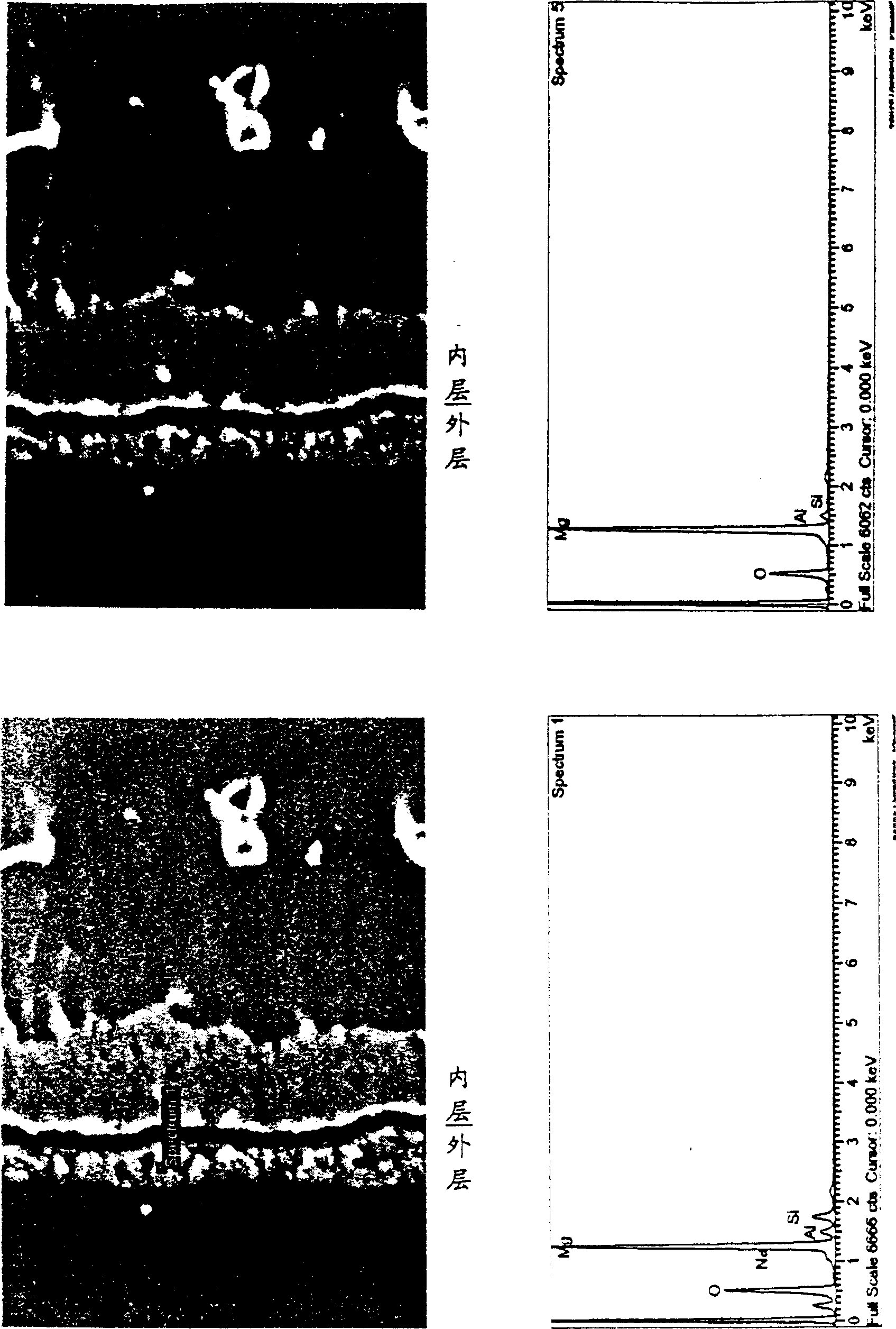

Composite ceramic film on surface of magnesium alloy and its forming process

InactiveCN1388272AOvercoming brittlenessOvercoming the formation of voids in the film layerAnodisationMicro arc oxidationPlasma electrolytic oxidation

The present invention features that the composite ceramic film consists of two layers, the inner layer film of silicon-containing composite Mg-Al oxide and the outer layer film of Mg-Al silico-oxide of 5-70 micron thickness each. The composite ceramic film is formed through surface treatment, degreasing, neutralizing, water washing, micro-arc anodizing, water washing, drying, closing treatment or painting. The composite ceramic film has no holes and cracks, high corrosion resistance, high wear resistance and smooth surface.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

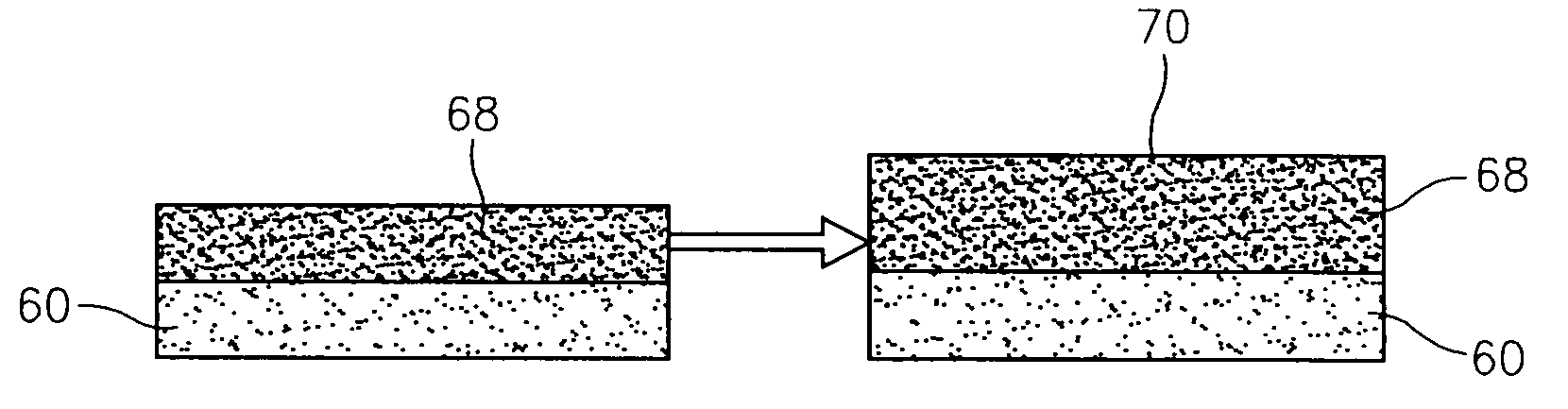

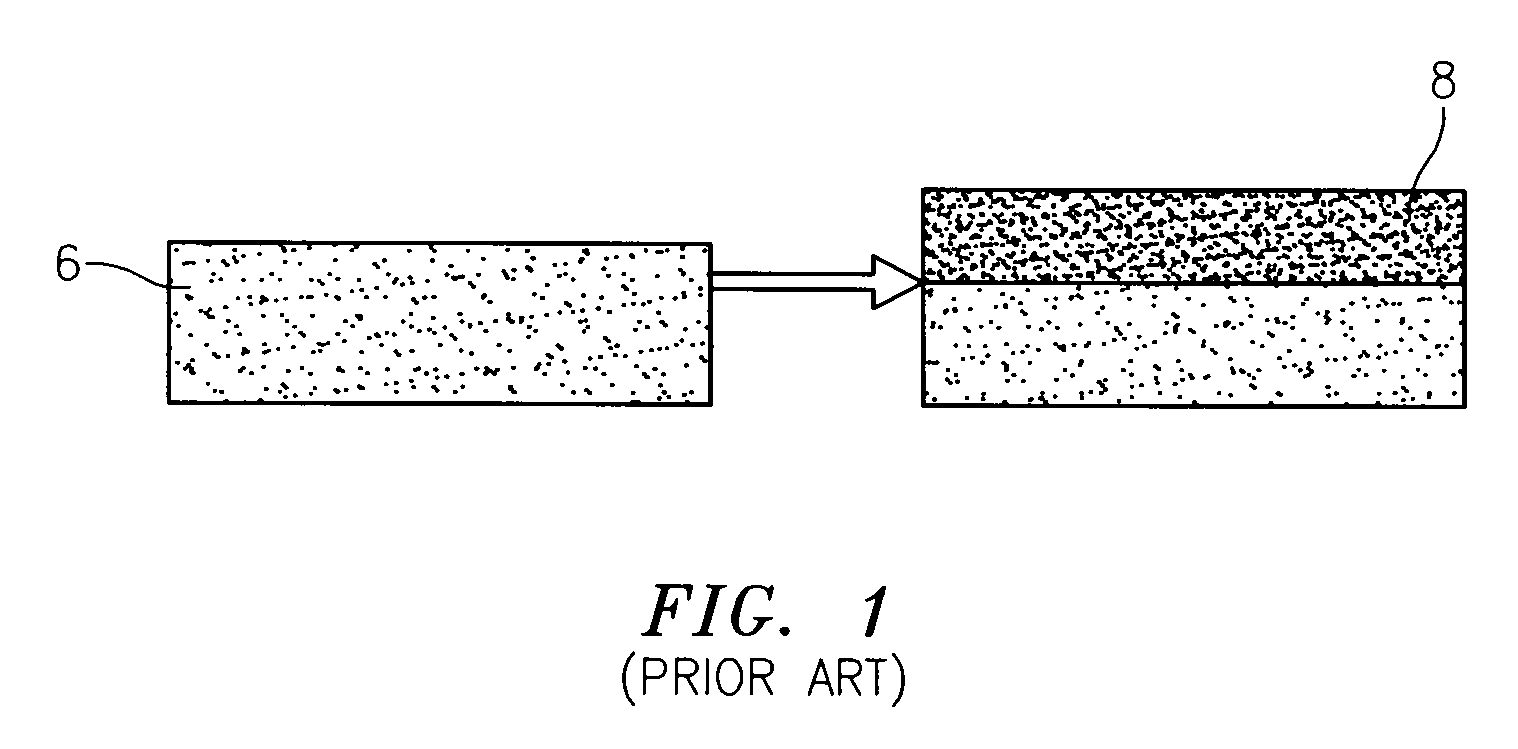

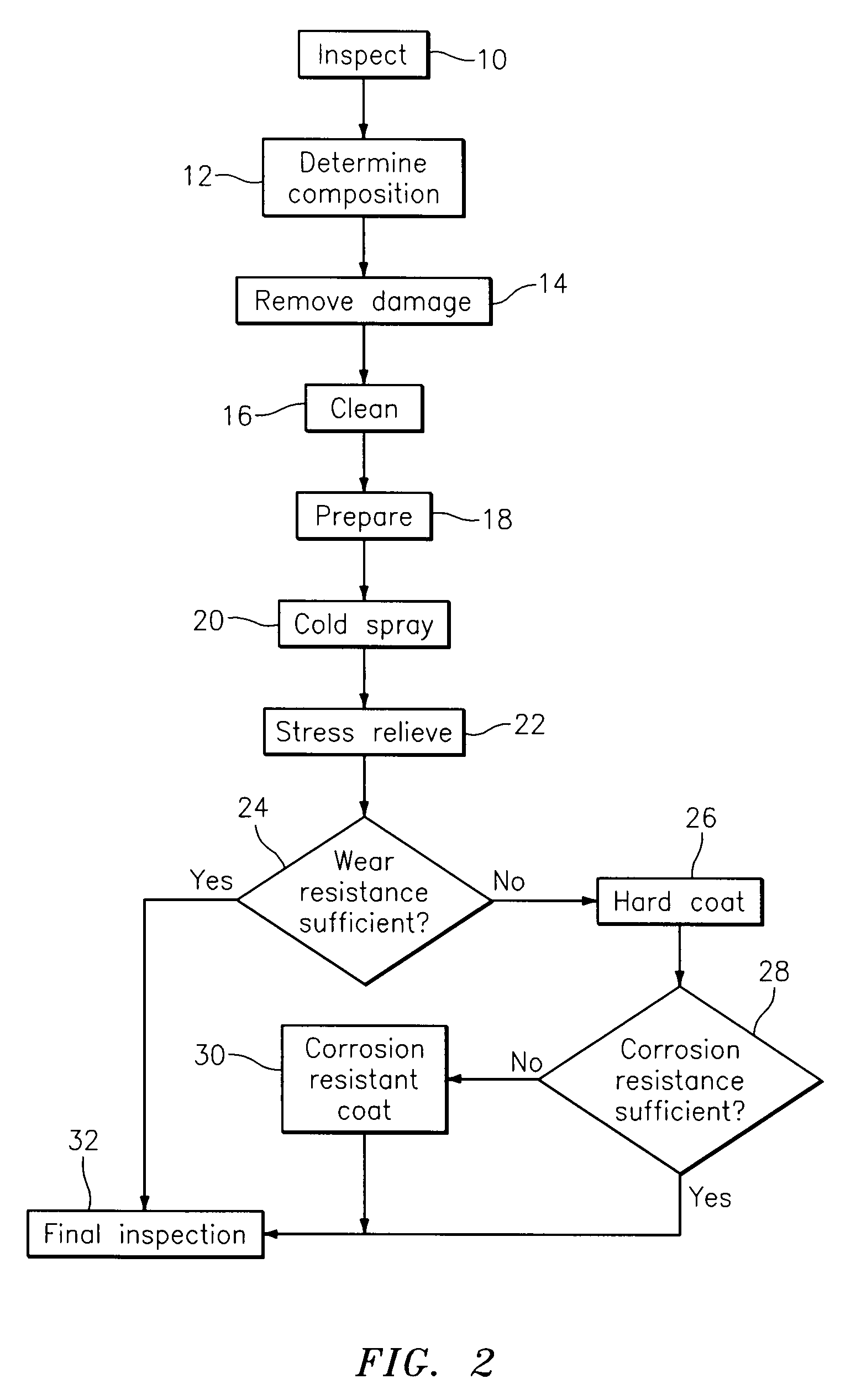

Hard anodize of cold spray aluminum layer

A process for repairing components includes the steps of providing a component having an affected area on a surface of a component to be repaired; depositing a repair material over the affected area on the surface of the component so that the repair material plastically deforms without melting and bonds to the affected area upon impact with the affected area and thereby covers the affected area; providing a sulfuric acid based anodizing solution; anodizing a deposited repair material on the surface of said component in the sulfuric acid based anodizing solution; consuming only a portion of the deposited repair material to form a hard anodized coating layer upon the deposited repair material to form a hard anodized coated component; providing a corrosion resistant sealant solution; and contacting a hard anodized coated component with the corrosion resistant sealant solution to form a corrosion resistant sealant coating on the hard anodized coated component.

Owner:UNITED TECH CORP

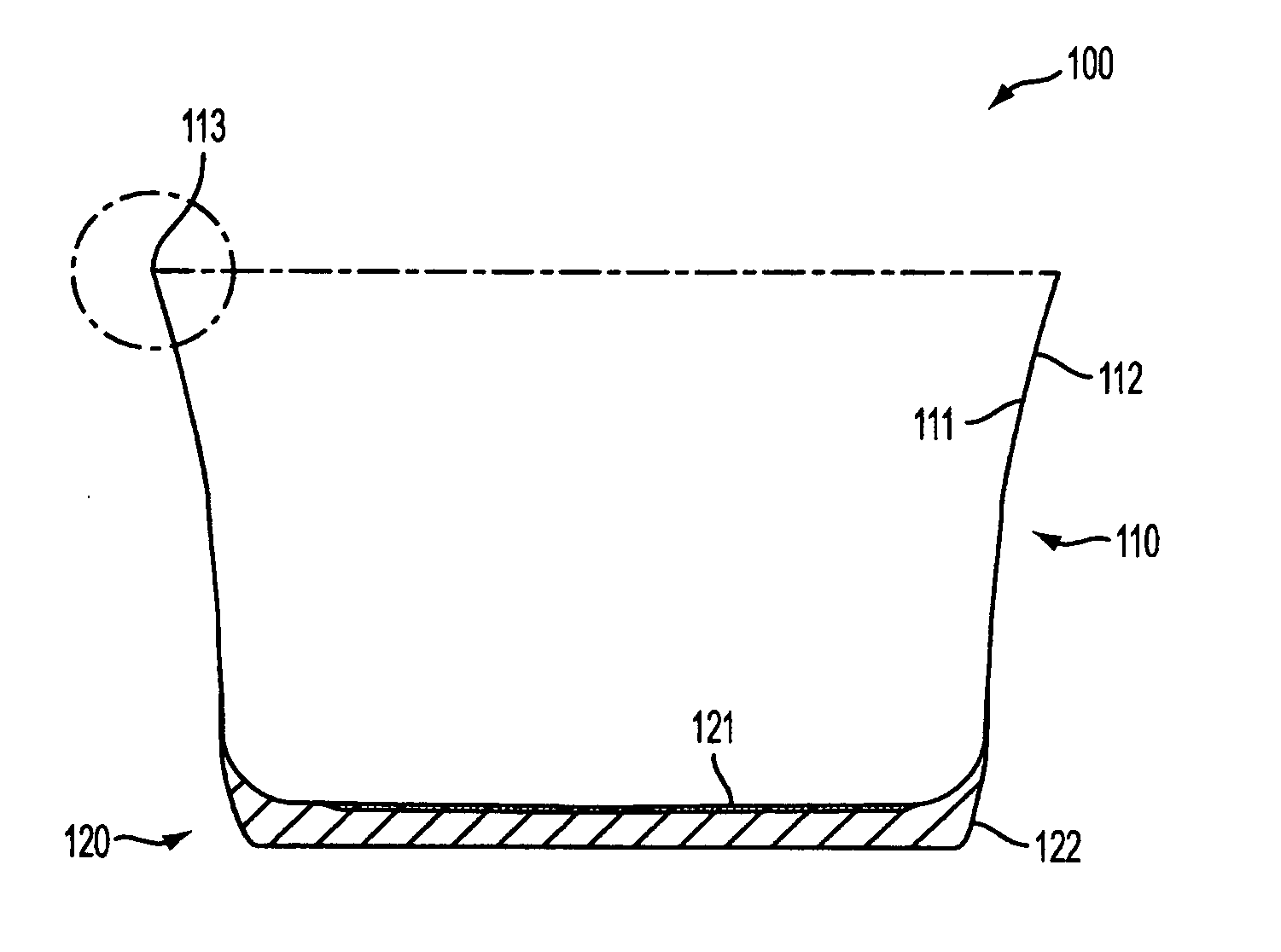

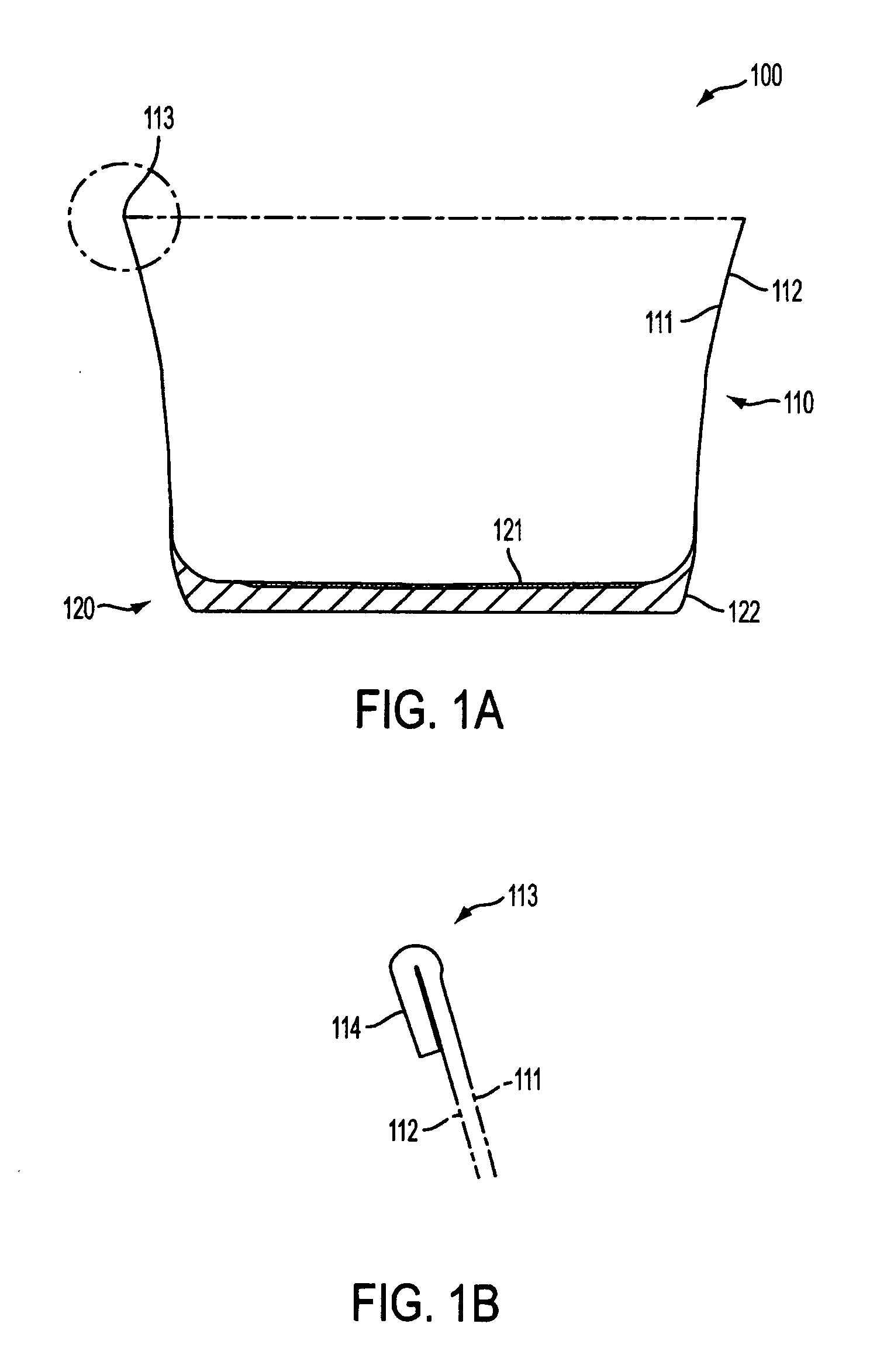

Titanium based composite cookware

InactiveUS20050205582A1Excellent heating characteristicLightweight maintenanceCooking-vessel materialsBaking vesselsAnodizingAlloy

Article of cookware has upright walls and surrounding bottom-cooking surfaces that are both formed from titanium or an alloy thereof at a first thickness. The cooking vessel also has a thicker bottom formed of a material more heat conductive than titanium, thus allowing the vessel to be of significantly lighter weight, or have superior uniformity of heating due to a thicker bottom formed of a more heat conductive materials. The bottom is optionally formed of anodized aluminum as the titanium walls withstand the corrosive environment of the anodizing bath.

Owner:MEYER INTPROPIS

Technique for preparing high-hardness large-aperture thick film by mixed acid anode oxidation

The invention relates to a technology of mixed acid anodizing high hardness wide-bore thick-film, first the anodizing solution is mixed with the phosphoric acid and the oxalic acid preparation; then the alkaline solution removes the oxide layer of specimen surface; and then acidic solution neutralizes the surface residue, followed by electrochemical polishing treatment; more the anode is oxidized to prepare the porous alumina, finally the specimen of anodization in the phosphoric acid solution process the reaming. The invention relates to a method of the mixed acid with the phosphoric acid and the oxalic acid as the electrolyte to form 20-45um porous alumina film; the anode is oxidized by the phosphoric acid to reaming, the aperture increased to 80-140nm; the temperature of the anodization mixed the oxalic acid is higher greatly, to save the energy; the micromesh of the mixed acid anodic alumina film fills in the PTFE, MoS2, carbon nano fibers, zinc stearate, and other solid lubricants, prepared to self-lubricating materials, the invention is worthy of spreading to application.

Owner:CHINALCO MATERIALS APPL RES INST CO LTD

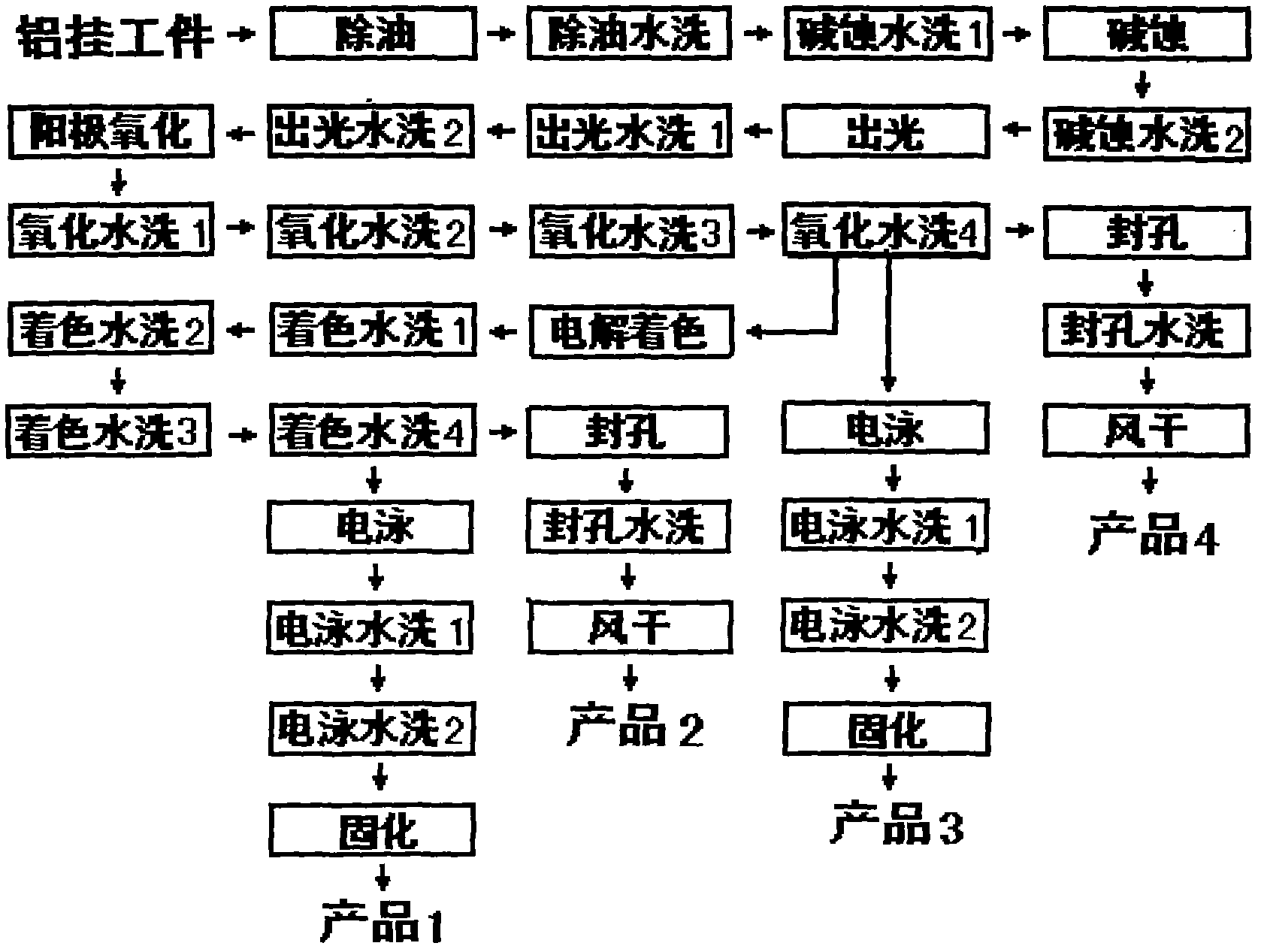

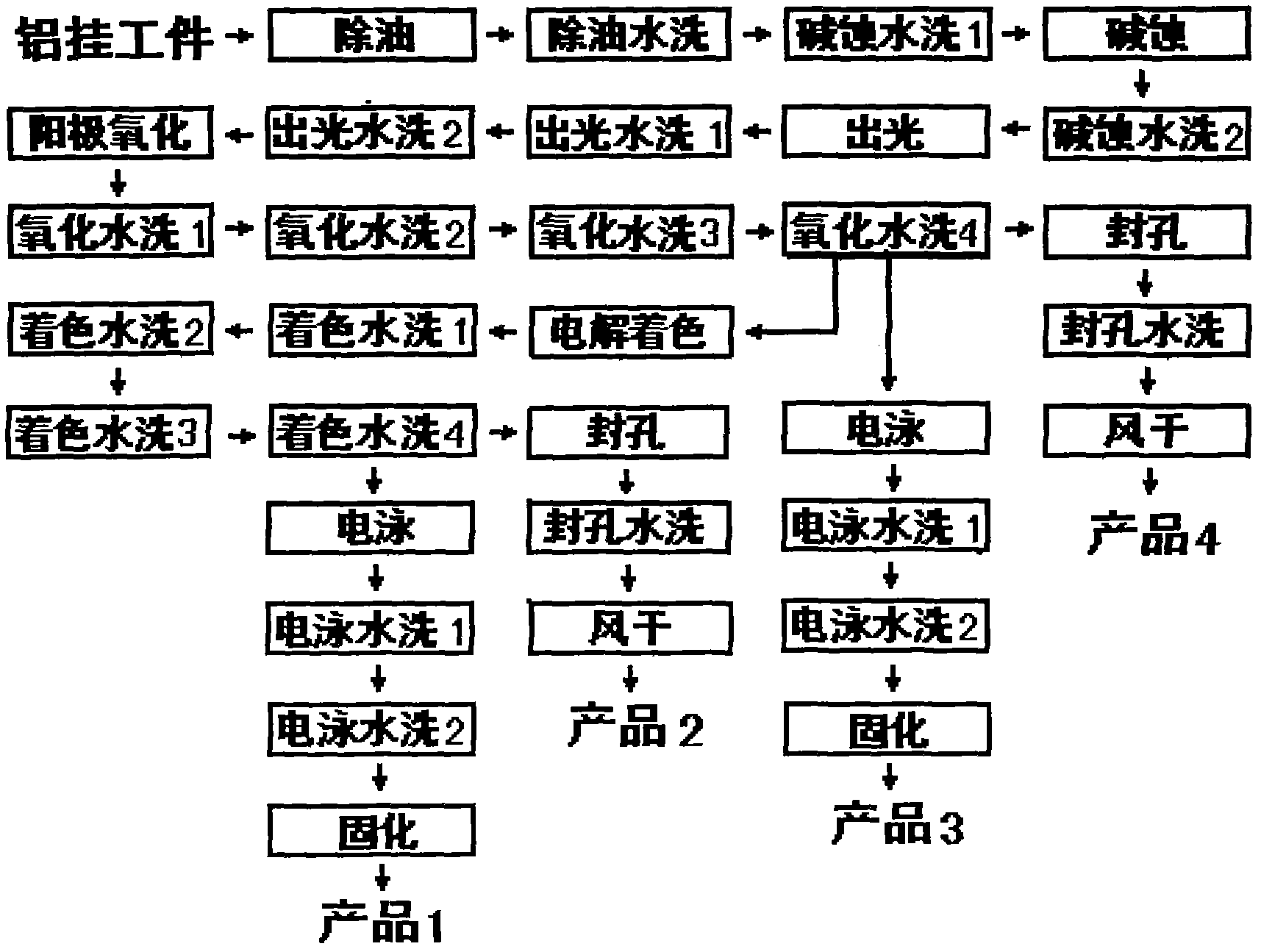

Method for anodizing aluminum pendants

ActiveCN102154674AAddressing the Effects of Oxidation QualitySolve the disadvantages of extremely fluctuating process parametersAnodisationAnodizingElectrophoresis

The invention discloses a method for anodizing aluminum pendants. The method is characterized in that: anodizing bath solution is used as a degreasing agent; a first rinsing step for alkaline degreasing is arranged between a degreasing rinsing step and an alkaline degreasing step. The method comprises the following process steps of: degreasing, performing degreasing rinsing, performing alkaline degreasing rinsing 1, performing alkaline degreasing, performing alkaline degreasing rinsing 2, performing bright dipping, performing bright dipping rinsing 1, performing bright dipping rinsing 2, anodizing, performing oxidation rinsing 1, performing oxidation rinsing 2, performing electrolytic coloring, performing coloring rinsing 1, performing coloring rinsing 2, performing coloring rinsing 3, performing coloring rinsing 4, performing electrophoresis, performing electrophoresis rinsing 1, performing electrophoresis rinsing 2, sealing, performing sealing rinsing, air-drying and curing to obtain anodized electrolytic colored electrophoresis aluminum pendants, anodized electrolytic colored aluminum pendants, anodized electrophoresis aluminum pendants or the anodized aluminum pendants. By themethod, the problem that the process parameters of alkaline degreasing baths are greatly fluctuated due to the influence of the particularity of an alkaline degreasing process is solved, and the influence of the aluminum incensement of anodizing baths on the oxidation quality of the aluminum pendants is thoroughly prevented, degreasing and alkaline degreasing cost is reduced, and the quality of products is ensured.

Owner:广西南南铝加工有限公司

Electrode foil for electrolytic capacitor and method for manufacturing the same

InactiveUS20060076243A1Less defectiveHigh capacitanceElectrolytic capacitorsSuperimposed coating processParticulatesAnodizing

A manufacturing method including: forming a boehmite film on a roughened surface of an aluminum foil; forming a particulate gel of a valve metal oxide on the surface of the aluminum foil on which the boehmite film is formed; then carrying out heat treatment for forming particulate valve metal oxide; and anodizing.

Owner:PANASONIC CORP

Treating method of metallic titanium material

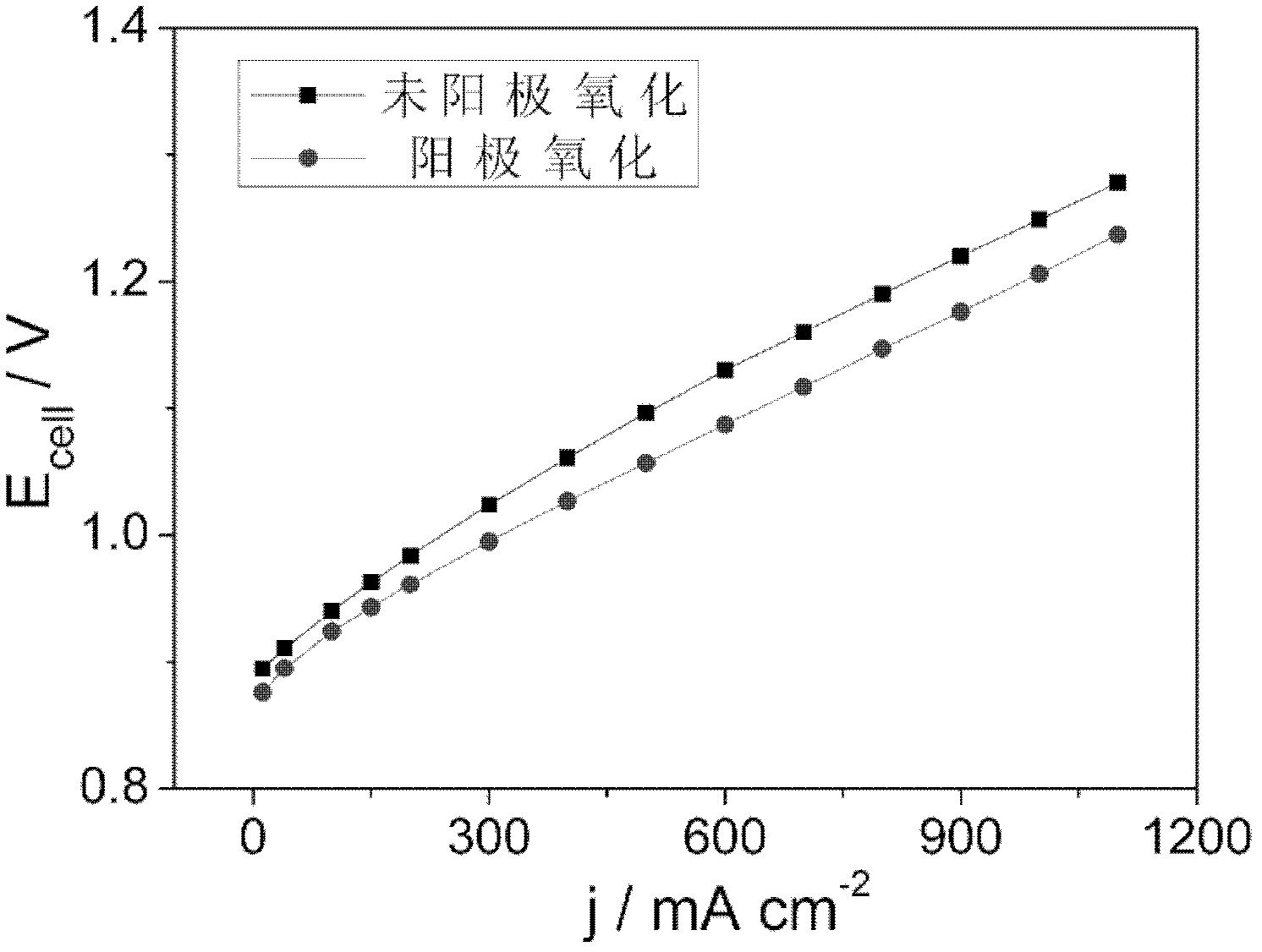

ActiveCN103173835ASimple preparation processNo complex equipment requiredElectrolytic inorganic material coatingCell electrodesAnodizingFuel cells

The invention provides a treating method of a metallic titanium material. The metallic titanium material is sintered porous titanium, a titanium felt, a titanium mesh or foaming titanium. The treating method of the metallic titanium material comprises the following steps of: purifying the surface of the titanium material; taking the titanium material after purification as an anode to carry out anodizing; and electro-depositing a layer of catalyst or coating a catalyst precursor on the surface of the titanium material after oxidation, and carrying out high-temperature roasting to obtain the titanium material with high catalytic activity. The prepared titanium material with the catalytic activity can be used as a diffusion layer and also an electrode, has the advantages that the preparation method is simple, the catalytic activity is high, the decomposition voltage is greatly lowered, the energy utilization ratio is increased, and the like, is applied to a hydrobromic acid electrolytic cell and can also be used as the diffusion layer or the electrode in a hydrobromic fuel cell and a hydrobromic reproducible energy storage cell.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

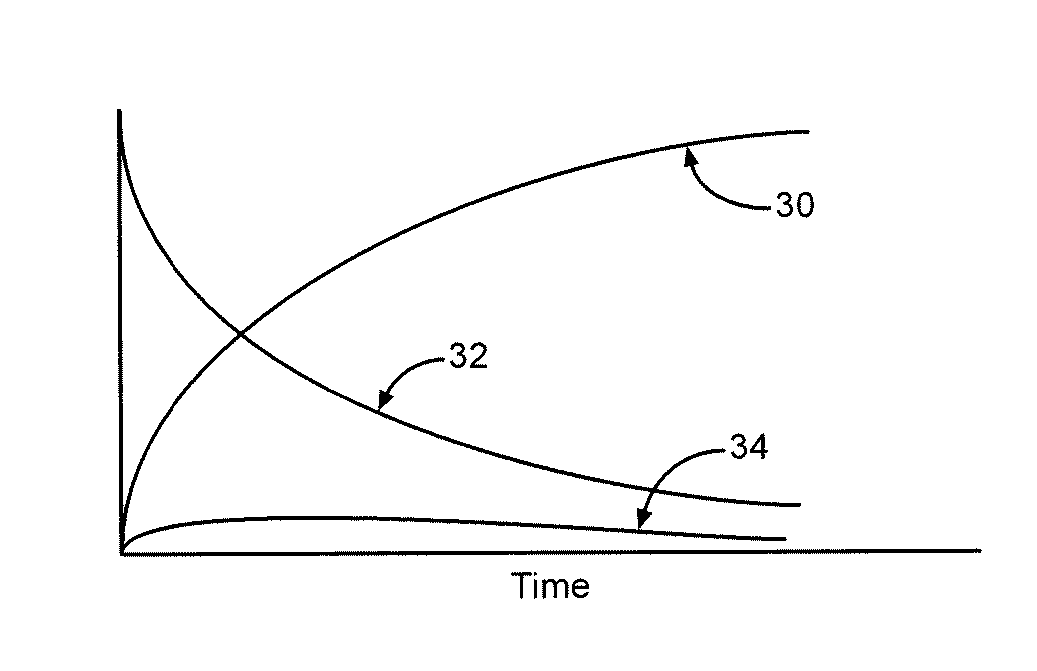

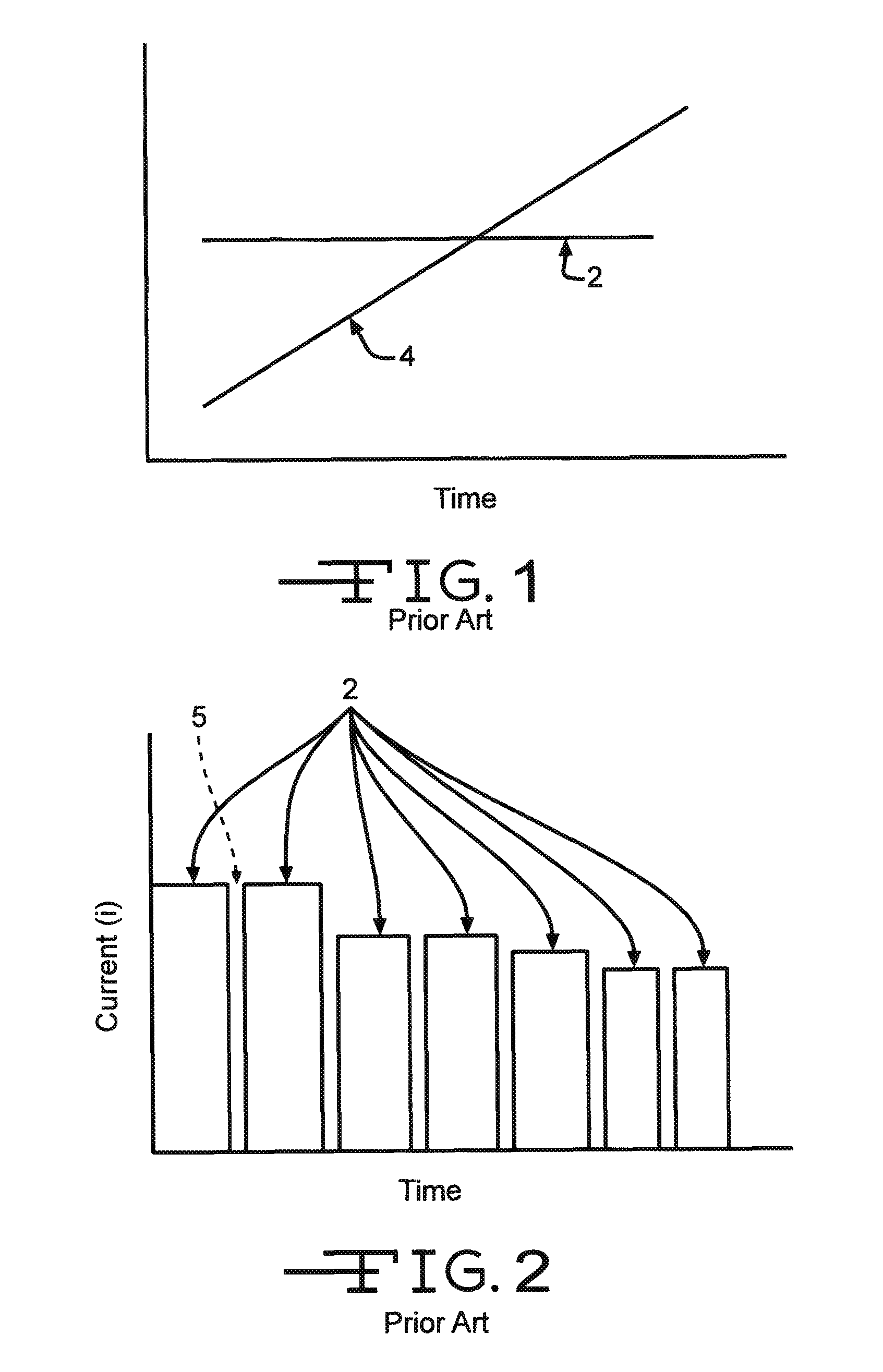

Anodizing valve metals by self-adjusted current and power

A method for anodizing valve metal structures to a target formation voltage is described. The valve metal structures are placed in an anodizing electrolyte and connected to a power supply that generates a source voltage to at least one current limiting device. If at least two current limiting devices are used, they are in series with the valve metal structures with the one current limiting device connected to at least one structure. The valve metal structures are then subjected to a current that decreases over time, a formation voltage that increases over time to a level below the voltage from the power supply and a power level that is self-adjusted to a level that decreases excessive heating in the structure. The invention also includes the components for the method.

Owner:WILSON GREATBATCH LTD

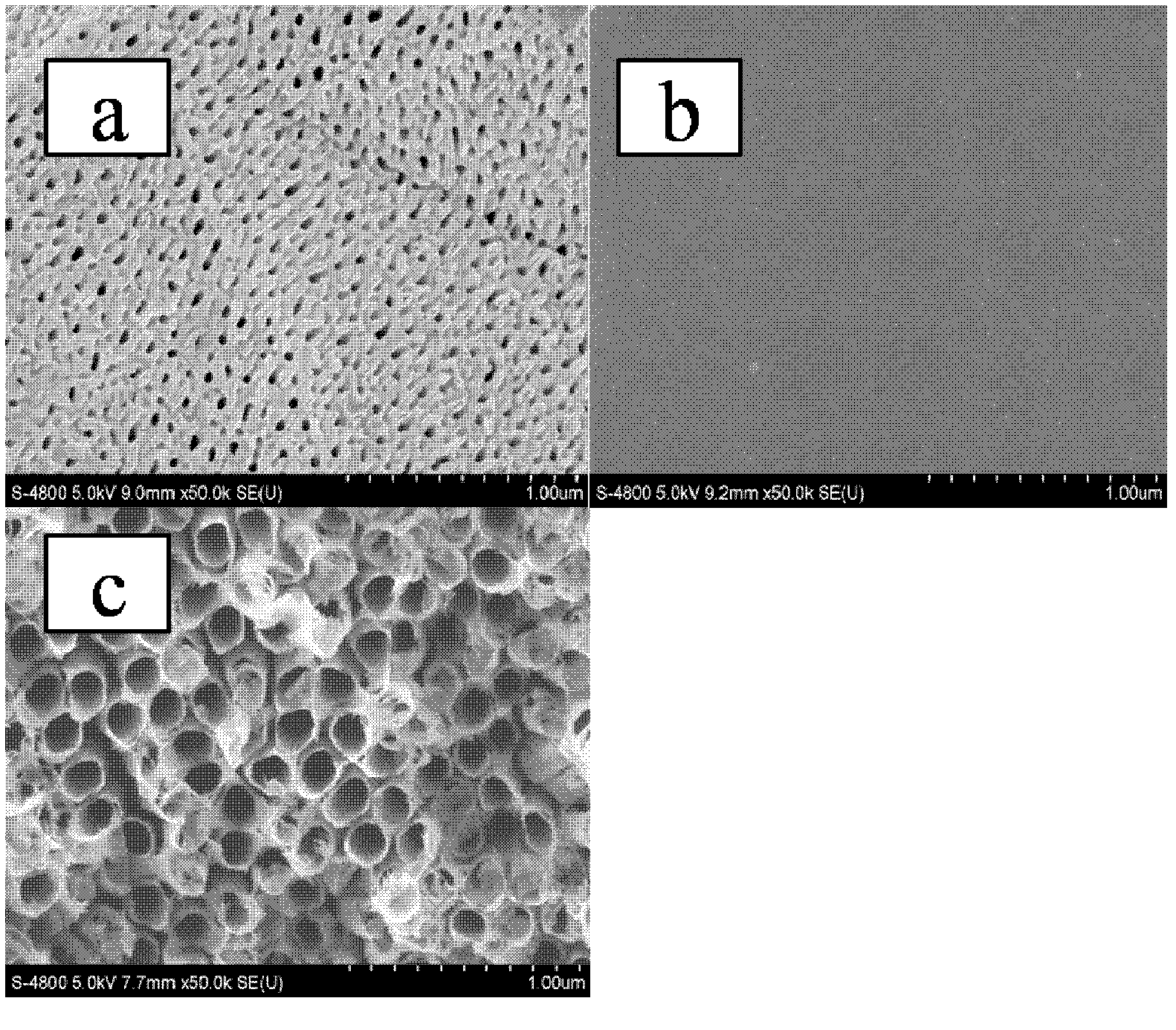

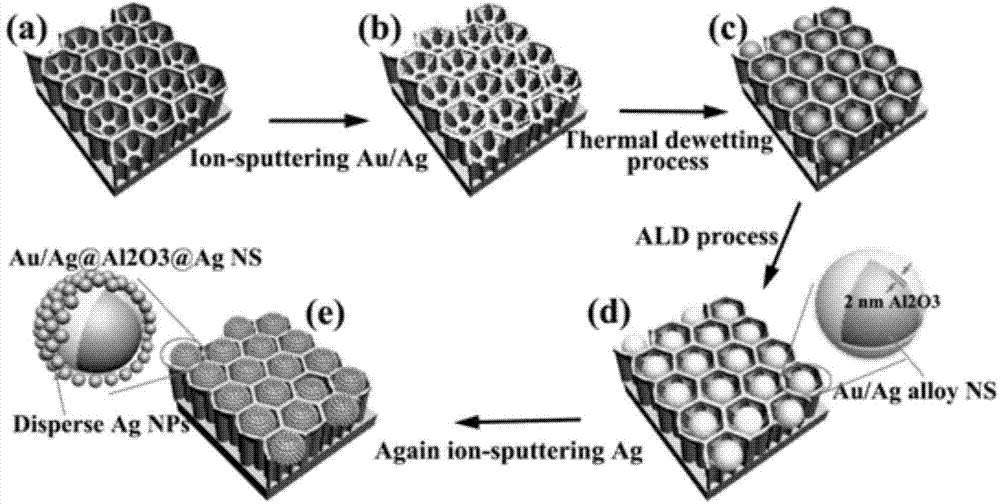

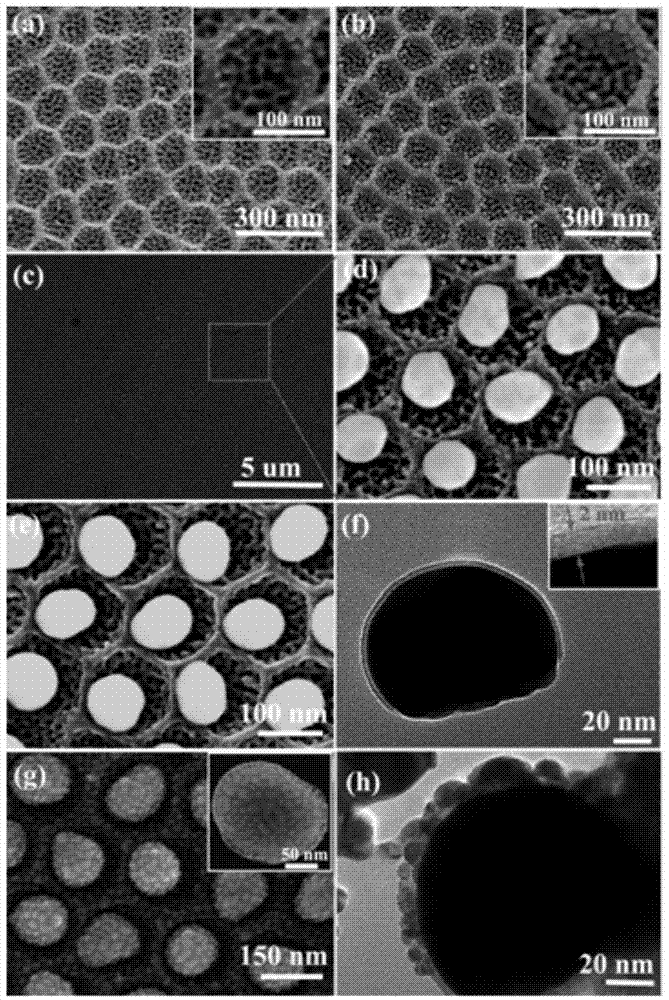

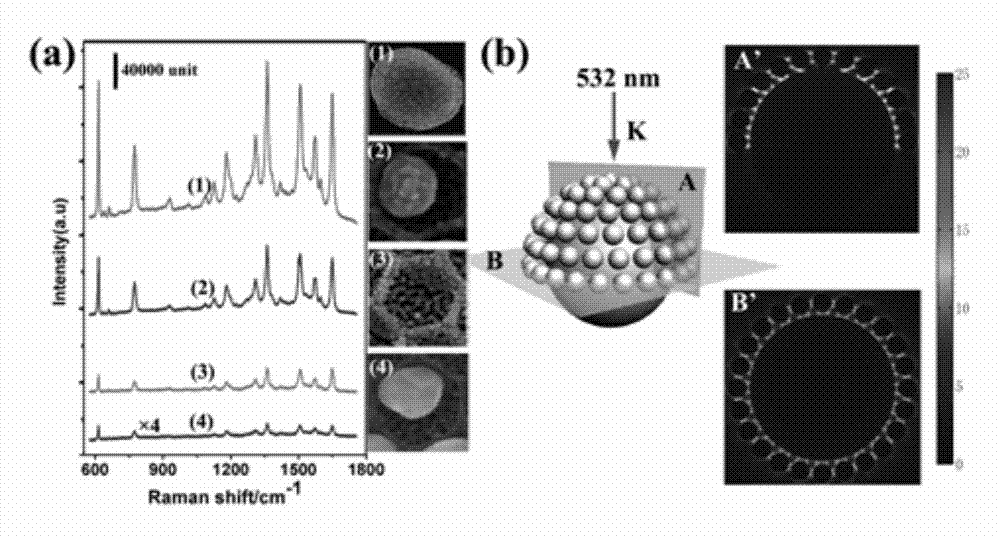

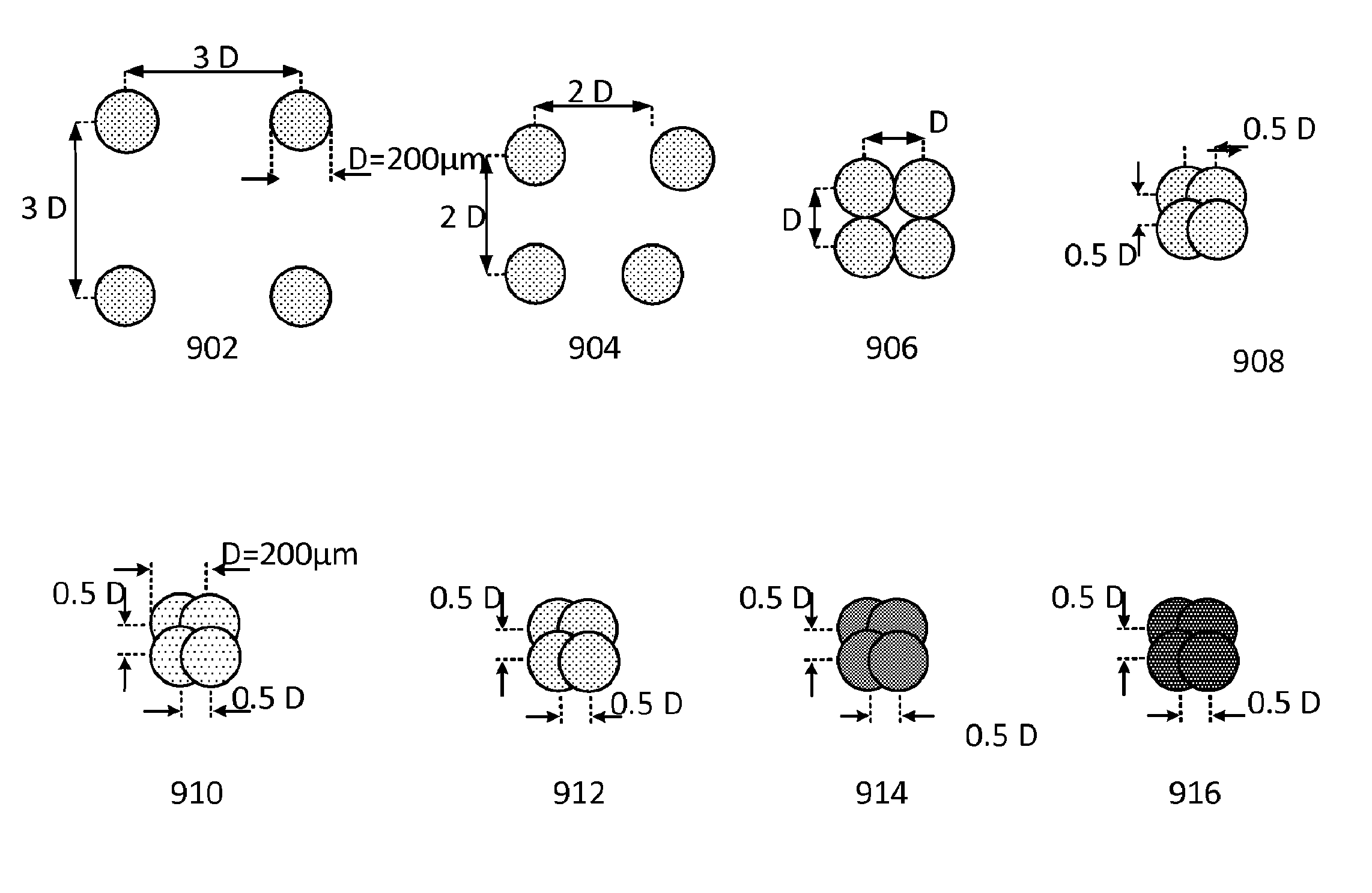

Preparation method for superstructure Au/Ag@Al2O3@Ag nanosphere array and SERS performance of superstructure Au/Ag@Al2O3@Ag nanosphere array

InactiveCN104707992APrecisely controlled formationGood repeatabilityMaterial nanotechnologyVacuum evaporation coatingAnodizingTitanium

The invention discloses a preparation method for a superstructure Au / Ag@Al2O3@Ag nanosphere array and the SERS performance of the superstructure Au / Ag@Al2O3@Ag nanosphere array. The anodizing method is implemented on a pure titanium sheet two times to prepare a titanium dioxide nanometer bowl array; the titanium dioxide nanometer bowl array serves as a template, and ion sputtering of Au and Ag nano-particles is carried out so as to form Au / Ag nano-particle film; annealing treatment is then carried out to agglomerate the Au / Ag nano-particle film so as to form an ordered Au / Ag alloy nanosphere array; an atomic layer deposition technology is adopted for wrapping the Au / Ag alloy nanosphere array with an ultra-thin aluminum oxide dielectric layer; finally an ion sputtering method is then adopted for sputtering the Ag nano-particles on Au / Ag alloy nanospheres forming wrapped with the aluminum oxide dielectric layer, and the Ag nano-particles are dispersed on the Au / Ag alloy nanospheres. The SERS activity of the superstructure Au / Ag@Al2O3@Ag nanosphere array is high, the SERS signal collecting repeatability is good, and the SERS activity is not influenced by changes of incident light angles.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

Casing of electronic device

InactiveCN1419404AWith metallic textureStrong corrosion resistanceMolten spray coatingSurface reaction electrolytic coatingAnodizingMetal

A casing of electronic devices comprises a plastic casing, a metal coating and an oxidized layer formed on the surface of the metal coating by anodizing. The method for manufacturing the casing of electronic devices, including the following steps: (1) ejecting and forming the above plastic casing; (2) forming in metal coating on the surface of the plastic casing; (3) anodizing the plastic casing with the metal coating. In such a way, the casing of electronic devices has a metal sense and a strong erosion resistance. The method can continue the tinctorial processing after the step (3) to acquire the required color or pattern.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

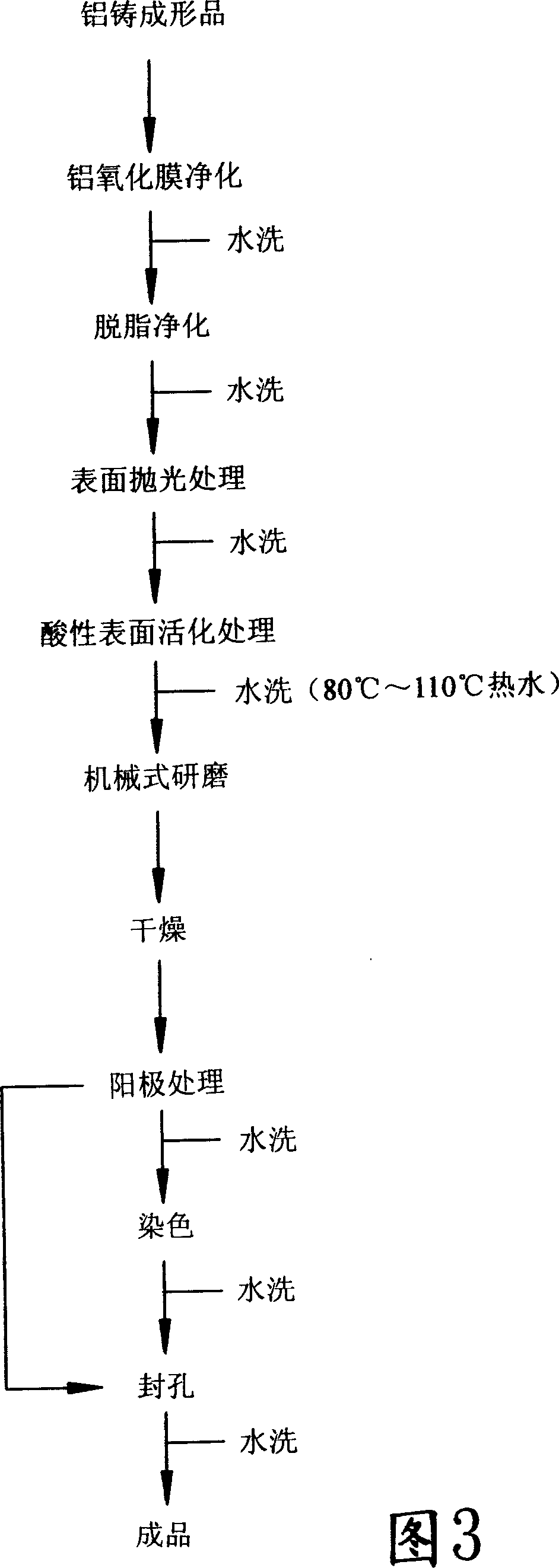

Method for anode treatment of aluminum casting profile

InactiveCN1566410AReduce the ratio of different concentrationsGood activation interfaceSurface reaction electrolytic coatingAnodizingThermal water

The invention discloses a method for anode treatment of aluminum casting profile which comprises anodic treatment, charging chemical agent, surface polishing, surface activating treatment, mechanical grinding, high temperature water scrubbing.

Owner:LEE CHI ENTERPRISES

Process for surface treating aluminum and aluminum alloy articles

A process for surface treating aluminum and aluminum alloy articles is provided. The method includes the steps of providing a substrate of aluminum or aluminum alloy material, the substrate having an internal surface and an external surface; machining the external surface of substrate, thereby forming a first surface appearance on the external surface; forming a first oxide coating with a first color on the substrate surface by a first anodizing process; removing at least a portion of the first oxide coating on the internal surface of the substrate to make the substrate electricity conductive; machining the external surface of the substrate, thereby removing at least a portion of the first oxide coating on the external surface and forming a second surface appearance thereon; forming a second oxide coating with a second color on the area of the external surface excluding the first oxide coating by a second anodizing process.

Owner:SHENZHEN FUTAIHONG PRECISION IND CO LTD +1

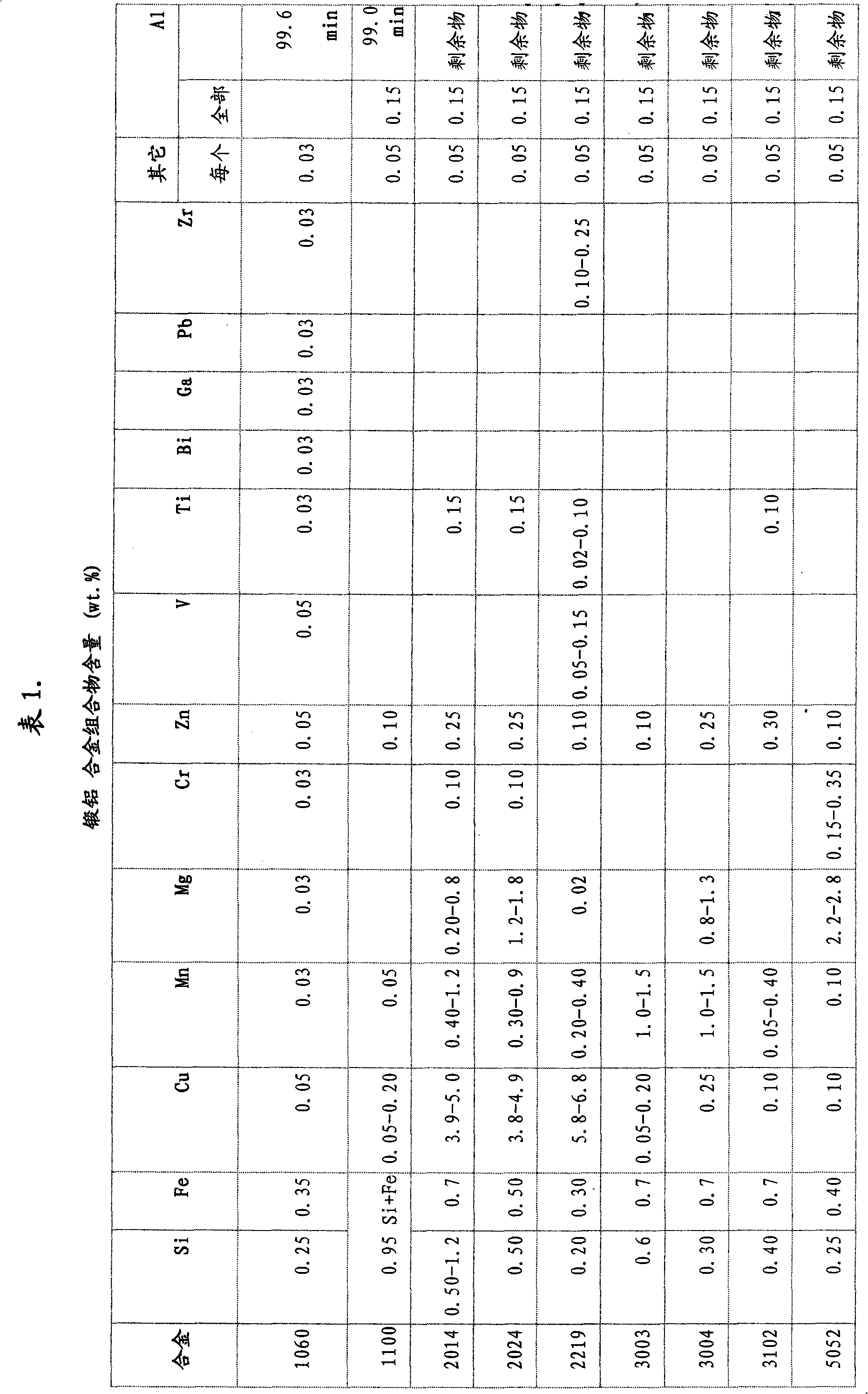

Production method of aluminum strip for cosmetic bottle cap

The invention discloses a production method of an aluminum strip for a cosmetic bottle cap. The production method comprises the steps of: (1) preparation of an ingot and adoption of a new alloy, wherein the ingot comprises the following elements in percentage by weight: not more than 0.08% of Si, not more than 0.1% of Fe, not more than 0.03% of Cu, not more than 0.02% of Mn, not more than 0.02% of Mg, not more than 0.02% and not less than 0.01% of Ti, and the balance of Al; (2) surface milling; (3) uniform heating; (4) hot rolling; (5) cold rough rolling; (6) cleaning; (7) intermediate annealing; (8) cold finish rolling; (9) stretching, bending, straightening and cleaning of trimmings; and (10) checking. The aluminum strip has such excellent characteristics as smooth and bright surface, stable mechanical performance, precise dimensional tolerance, easy punch forming, low earing ratio after punching of the bottle cap and good anodizing effect, and is suitable for producing top-grade cosmetic bottle cap.

Owner:DALISHEN ALUMINUM

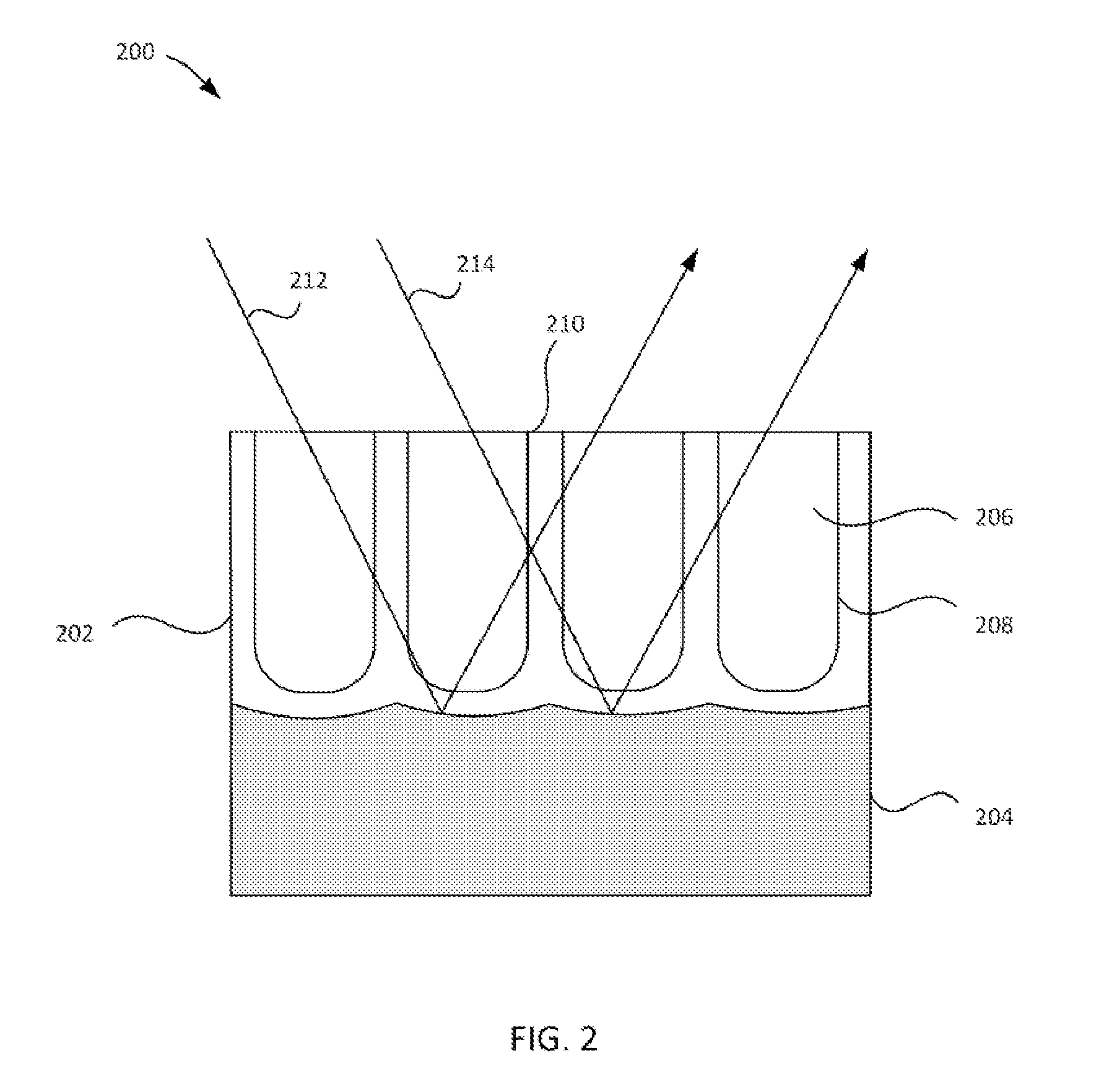

White appearing anodized films and methods for forming the same

The embodiments described herein relate to forming anodized films that have a white appearance. In some embodiments, an anodized film having pores with light diffusing pore walls created by varying the current density during an anodizing process is described. In some embodiments, an anodized film having light diffusing micro-cracks created by a laser cracking procedure is described. In some embodiments, a sputtered layer of light diffusing aluminum is provided below an anodized film. In some embodiments, light diffusing particles are infused within openings of an anodized layer.

Owner:APPLE INC

Surface treatment method for metal workpiece

InactiveCN101033553AImprove the shortcomings of poor conductivityImprove conductivityAnodisationAnodizingProcess region

This invention relates to a surface process method of a metal piece including the following steps: providing a metal workpiece with a region to be plated with a metal layer and an anode process region on the surface, and a veil is coated on the anode process region and a metal layer is plated on the metal layer region, then the veil on the anode process region is removed to expose said anode process region, a veil is coated on the metal layer coated on the surface of the metal workpiece and an anode oxidation layer is formed on the anode region to remove the veil on the plated metal layer of the metal workpiece to expose said metal layer.

Owner:SHENZHEN FUTAIHONG PRECISION IND CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com