Method for anodizing aluminum pendants

An anodizing and anodizing cell technology, which is applied in anodizing, electrolytic coating, surface reaction electrolytic coating, etc., can solve the problems of increased aluminum ions in anodizing tanks, difficulty in alkaline etching and water washing, and high cost of degreasing, etc. The effect of solving the increase of aluminum ions, solving the great fluctuation of process parameters and reducing the cost of oil removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

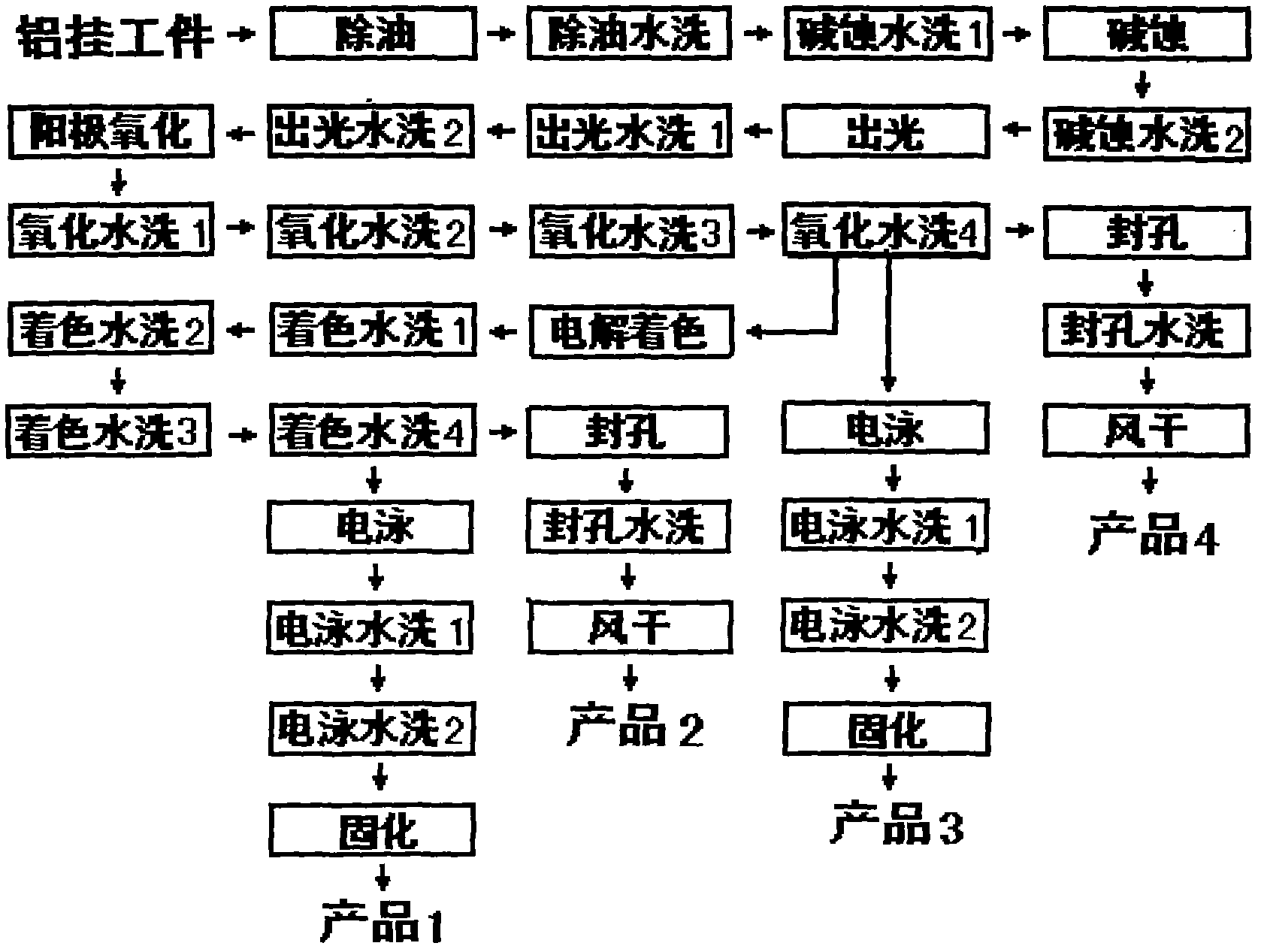

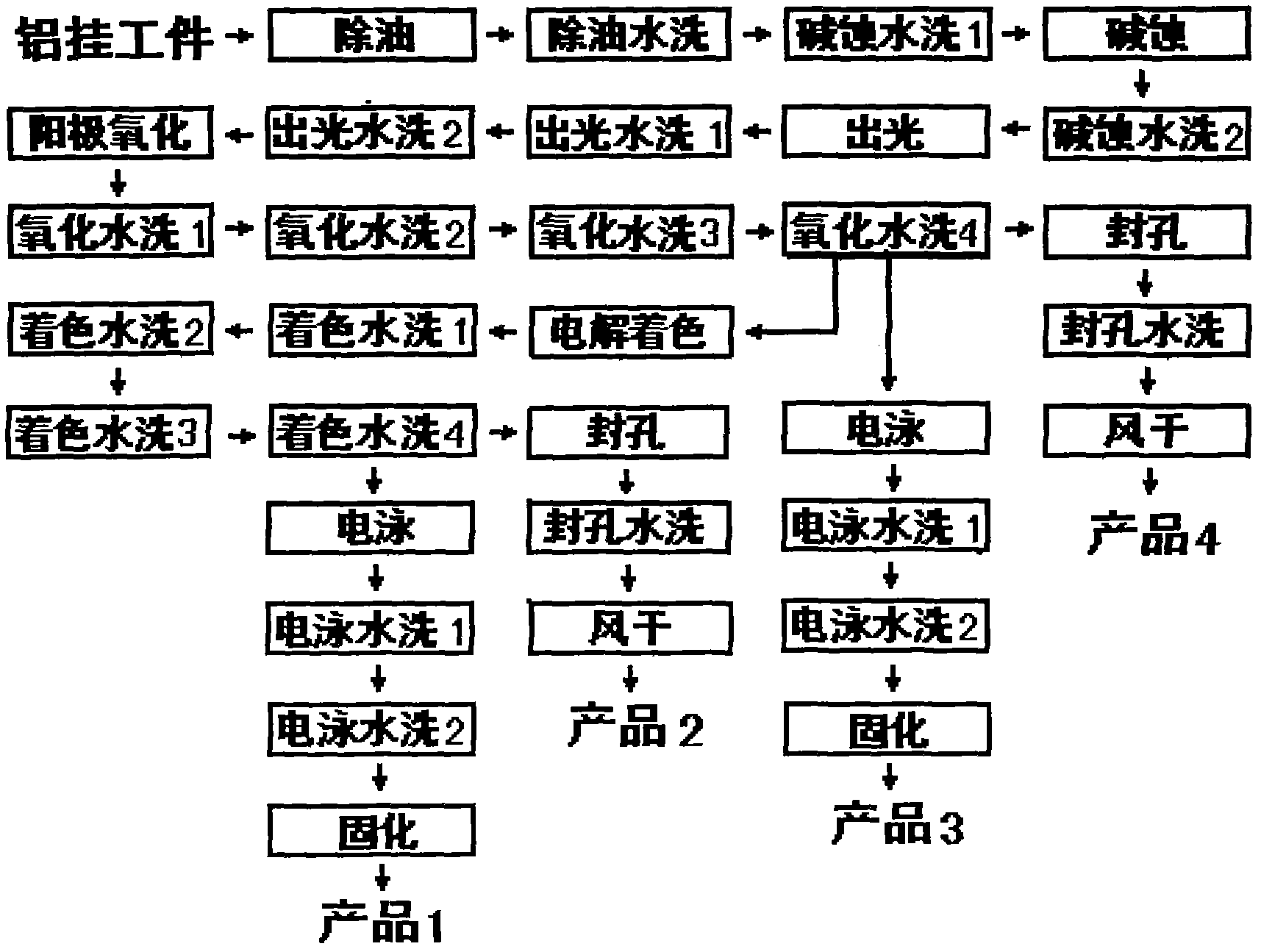

[0032] Product 1- Production of anodic oxidation and electrolytic coloring electrophoretic materials for aluminum pendants

[0033] Move the aluminum hanging workpiece into the degreasing working fluid with a sulfuric acid concentration of 90g / l prepared by anodizing bath liquid to remove oil, the temperature is normal temperature, and the working time is 4min, remove the degreasing aluminum hanging workpiece and wash it with water; Carry out water washing, then move the aluminum hanging workpiece into the liquid caustic soda with a concentration of 50g / l prepared by industrial sodium hydroxide and water, and press 1000m 2 Add 1kg of solid longevity alkali to the aluminum pendant, control the working temperature at 50°C, and work for 3 minutes. After the alkali etching of the aluminum hanging workpiece is completed, perform the second alkali etching wash; move the aluminum hanging workpiece after the second alkali etching to a concentration of 120g / l sulfuric acid aqueous sol...

Embodiment 2

[0036] Product 2- Production of anodizing and electrolytic coloring materials for aluminum parts

[0037] Move the aluminum hanging workpiece into the degreasing working fluid with a sulfuric acid concentration of 80g / l prepared by anodizing bath liquid to remove oil, the temperature is normal temperature, and the working time is 6min, remove the degreasing aluminum hanging workpiece and wash it with water; Carry out water washing, then move the aluminum hanging workpiece into the liquid caustic soda with a concentration of 30g / l prepared by industrial sodium hydroxide and water, and press 1000m 2 Add 1kg of solid longevity alkali to the aluminum pendant, control the working temperature at 60°C, and work for 4 minutes. After the alkali etching of the aluminum hanging workpiece is completed, perform the second alkali etching washing; move the aluminum hanging workpiece after the second alkali etching to a concentration of 120g / l sulfuric acid aqueous solution, and according to...

Embodiment 3

[0040] Product 3- Production of anodized electrophoretic materials for aluminum parts

[0041] Move the aluminum hanging workpiece into the degreasing working fluid with a sulfuric acid concentration of 110g / l prepared by anodizing bath liquid to remove oil. The temperature is normal temperature and the working time is 3min. Carry out water washing, then move the aluminum hanging workpiece into the liquid caustic soda with a concentration of 60g / l prepared by industrial sodium hydroxide and water, and press 1000m 2 Add 1kg of solid longevity alkali to the aluminum pendant, control the working temperature at 50°C, and work for 2 minutes. After the alkali etching of the aluminum hanging workpiece is completed, perform the second alkali etching washing; move the aluminum hanging workpiece after the second alkali etching to a concentration of 120g / l sulfuric acid aqueous solution, and according to 2000m 2 Add 1kg of light-emitting agent to the aluminum pendant to emit light in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com