Patents

Literature

951 results about "Anodic Aluminum Oxide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Surface coating for chamber components used in plasma systems

ActiveUS20170032942A1Low plasma surface recombination rateHigh trafficElectric discharge tubesVacuum evaporation coatingBlood plasmaPlasma chamber

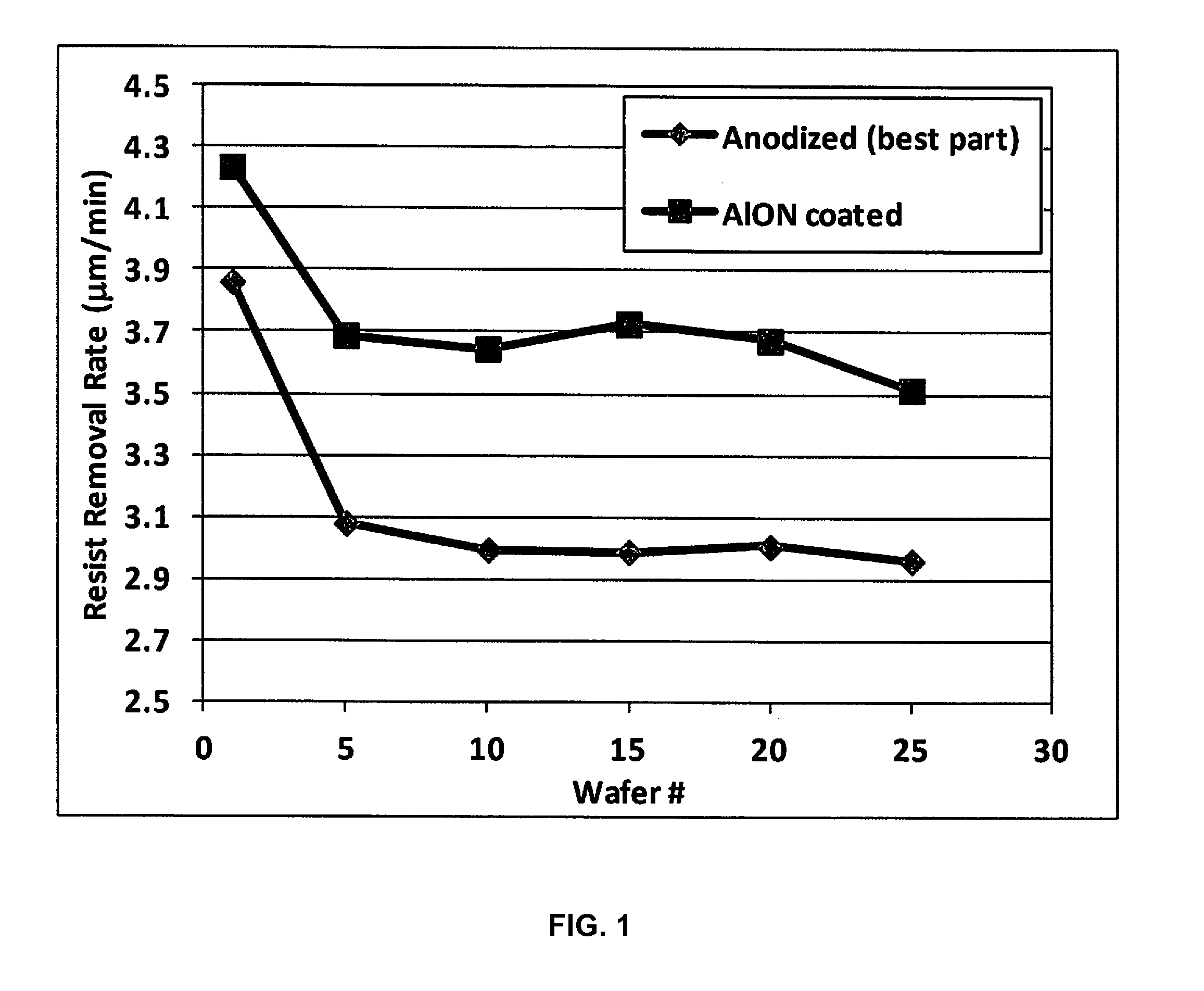

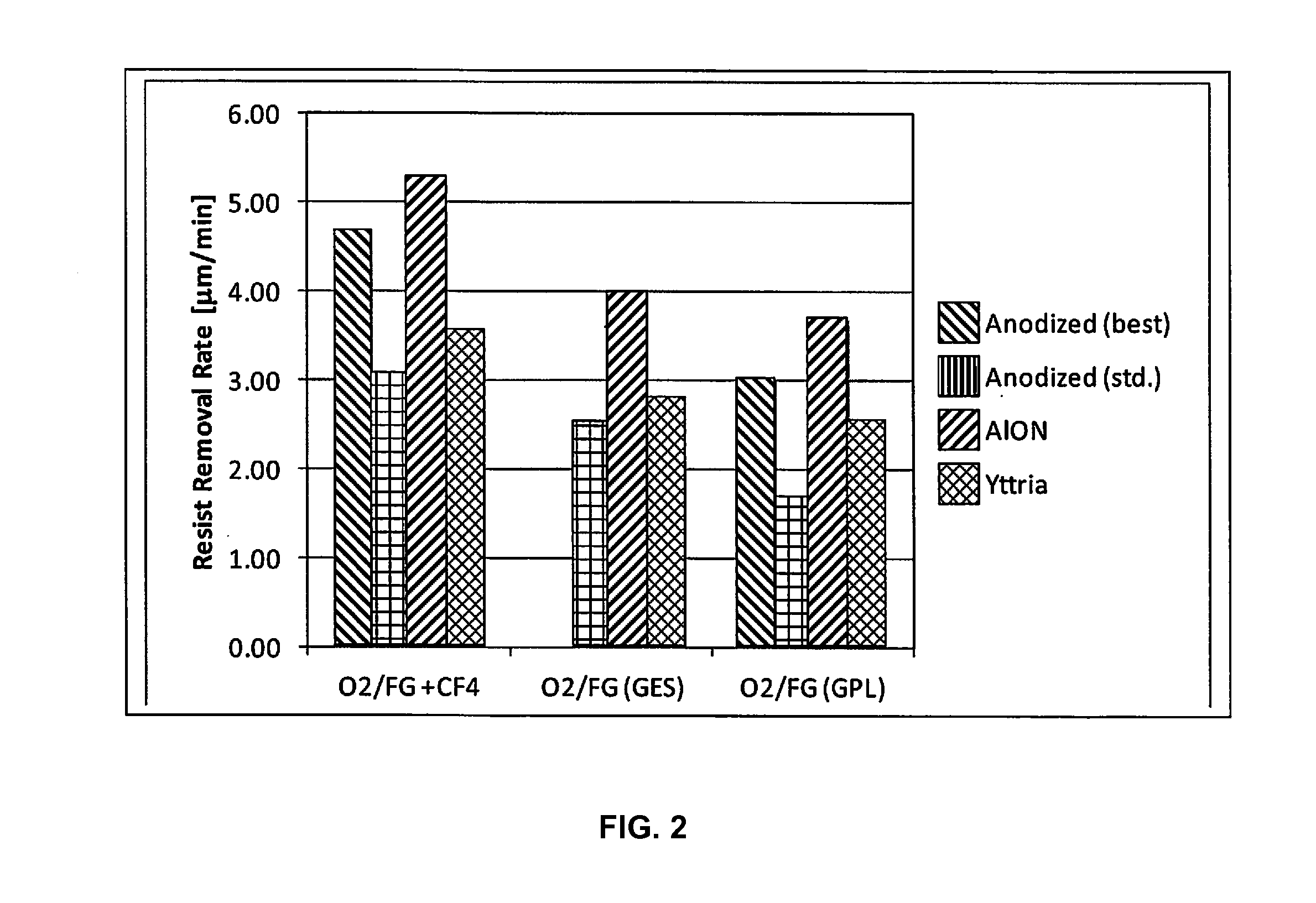

Disclosed herein are surface coatings for plasma components that have the benefit of being robust against chemical and plasma physical attack in aggressive (e.g., fluorine-based) plasma environments. The coatings also provide low plasma surface recombination rates for active oxygen, nitrogen, fluorine, and hydrogen species when compared with other known surface treatments. The coatings can be applied to any plasma system component not requiring etching or plasma cleaning including but not limited to materials like quartz, aluminum, or anodized aluminum. Additionally, the efficiency of the system is increased by applying a non-reactive coating to system components thereby increasing the flow of excited plasma species to the plasma chamber of the system.

Owner:ENTEGRIS INC

Negative Working, Heat-Sensitive, Lithographic Printing Plate Precursor

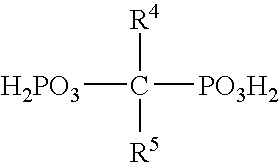

ActiveUS20080213696A1Number of defectSize of defectPhotosensitive materialsDuplicating/marking methodsSimple Organic CompoundsPhosphoric acid

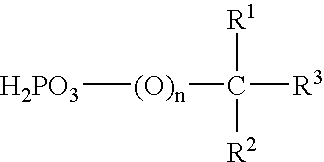

A heat-sensitive negative-working lithographic printing plate precursor includes on a grained and anodized aluminum support a coating including hydrophobic thermoplastic polymer particles, a hydrophilic binder, and an organic compound, wherein the organic compound includes at least one phosphonic acid group or at least one phosphoric acid group or a salt thereof.

Owner:AGFA OFFSET BV

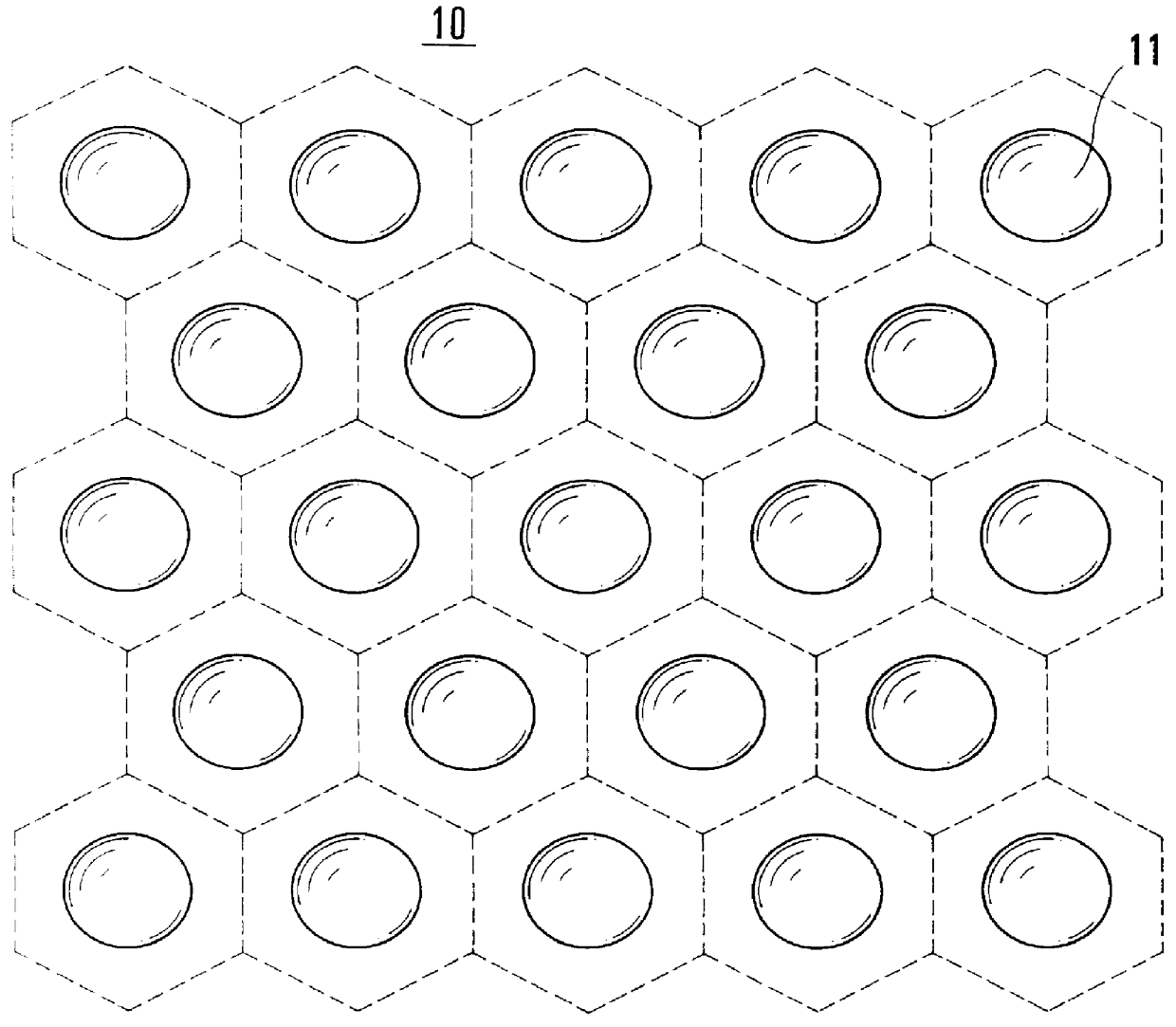

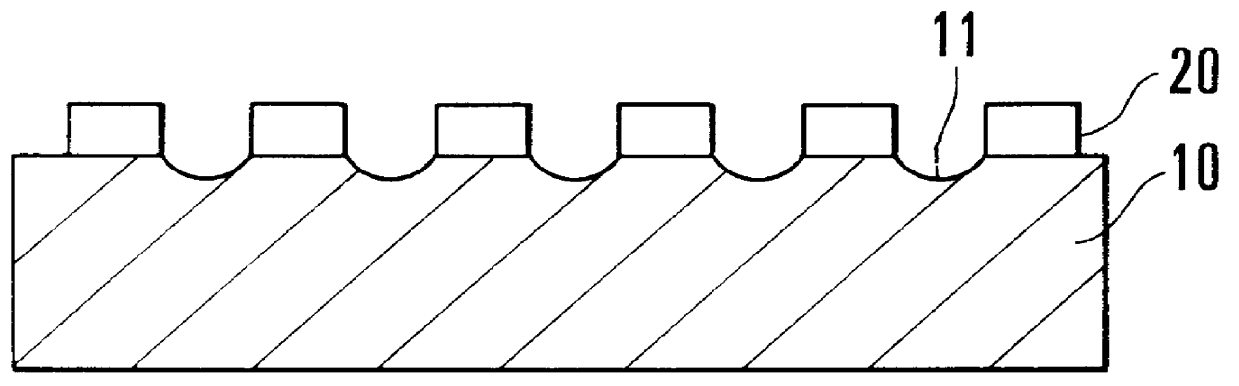

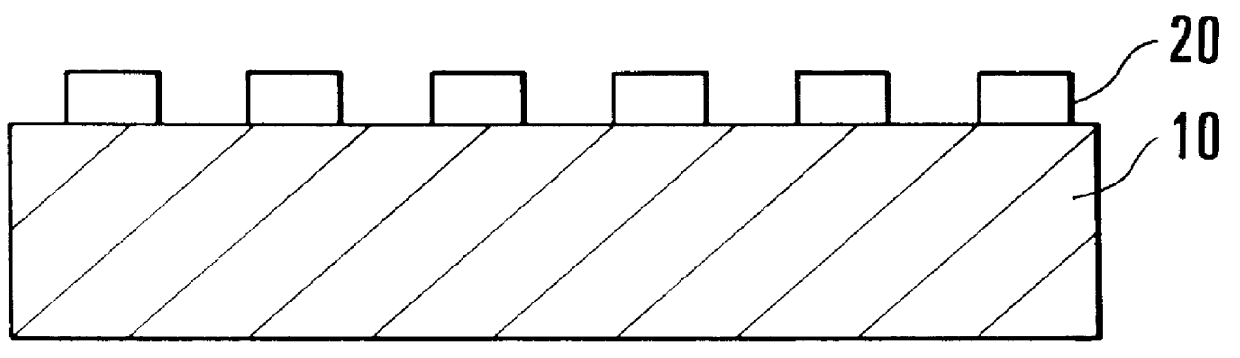

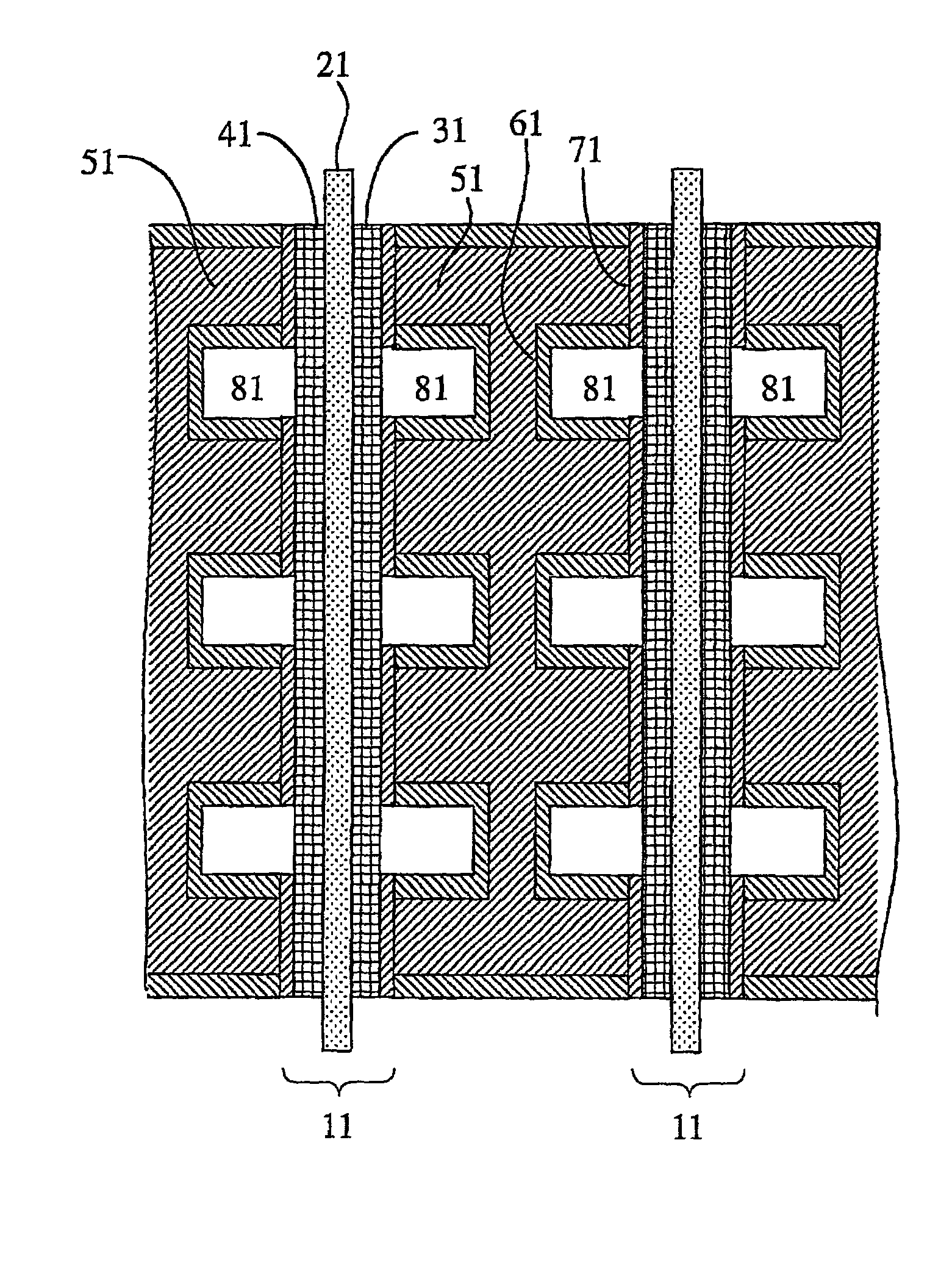

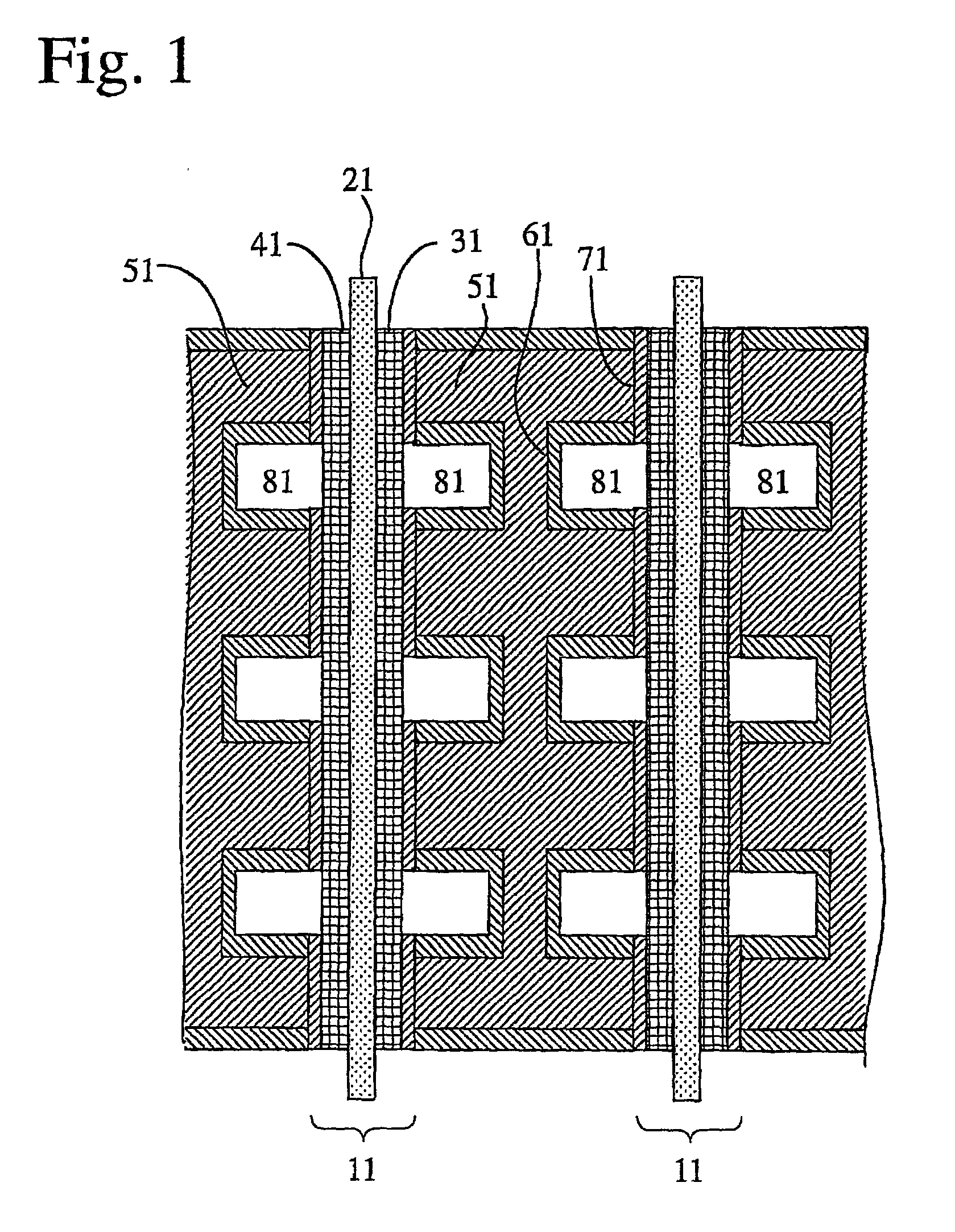

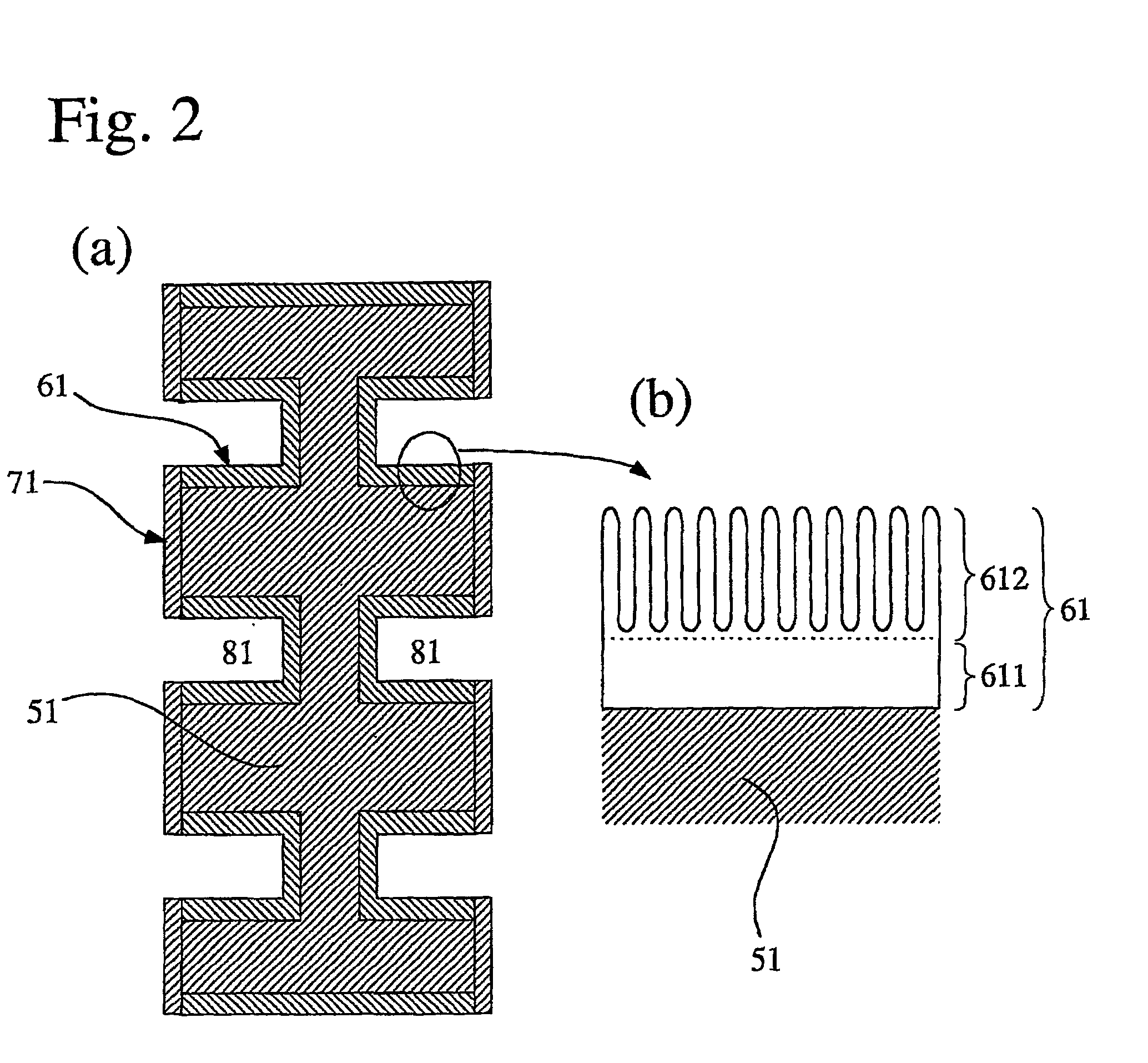

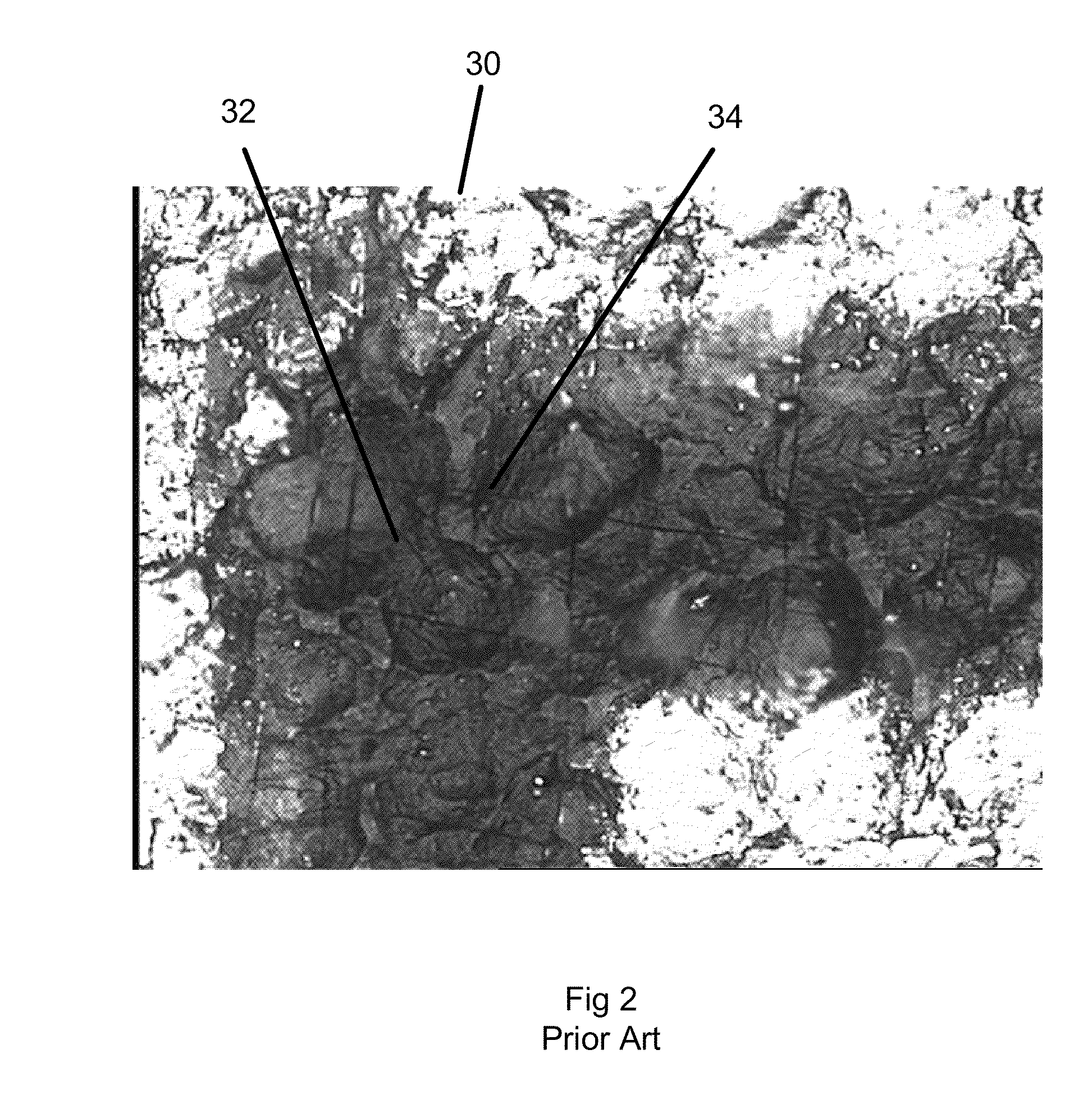

Method of manufacturing porous anodized alumina film

PCT No. PCT / JP97 / 02965 Sec. 371 Date Nov. 2, 1998 Sec. 102(e) Date Nov. 2, 1998 PCT Filed Aug. 26, 1997 PCT Pub. No. WO98 / 09005 PCT Pub. Date Mar. 5, 1998A plurality of recesses having the same interval and array as those of pores of an alumina film, which are to be formed in anodizing, are formed on a smooth surface of an aluminum plate in advance, and then, the aluminum plate is anodized. With this process, the roundness of the pores of the porous anodized alumina film and the uniformity of pore size are improved, and the pores are regularly arrayed at a predetermined interval. The recesses are formed by pressing a substrate having a plurality of projections on its surface against the aluminum plate surface to be anodized.

Owner:NIPPON TELEGRAPH & TELEPHONE CORP

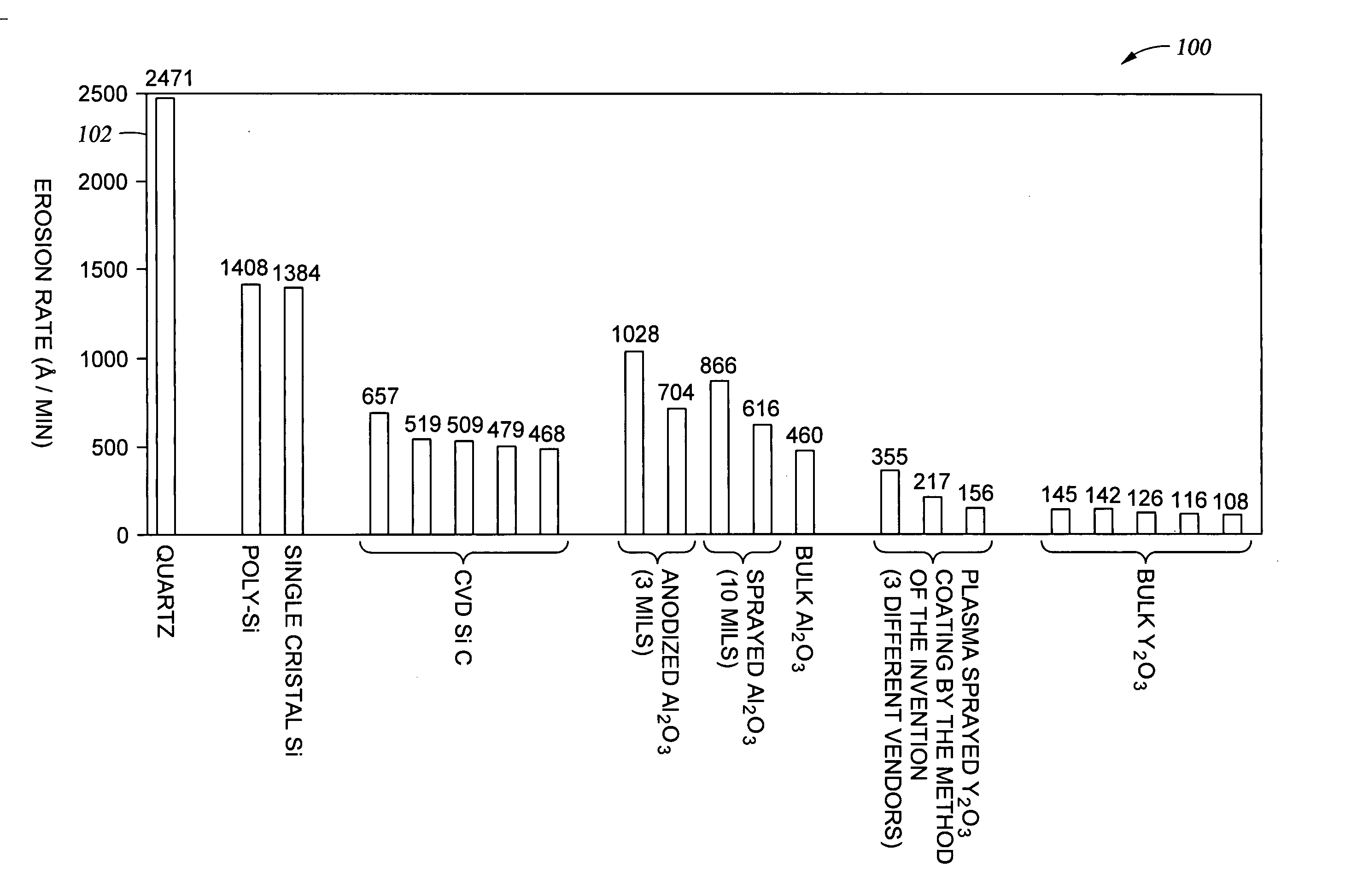

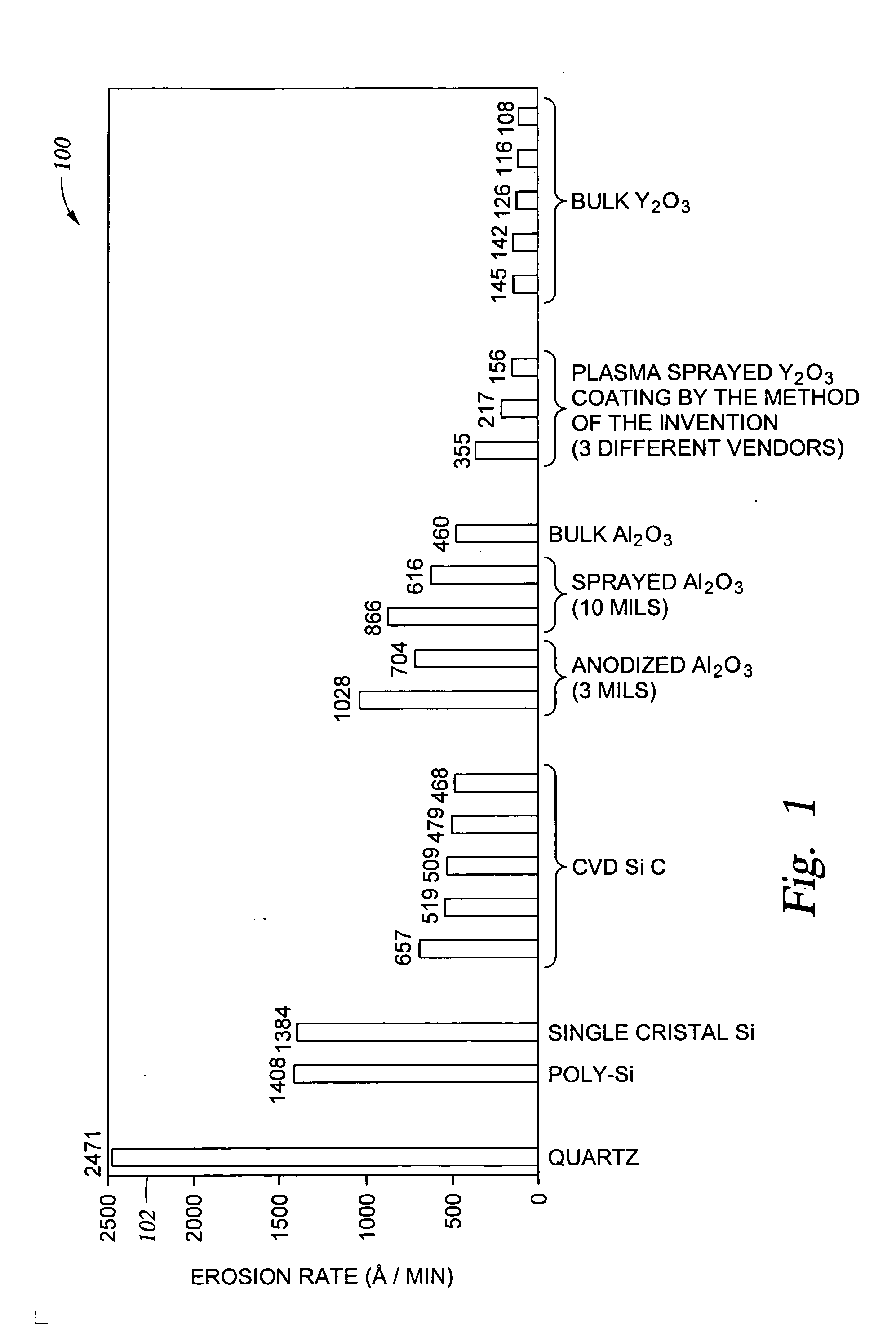

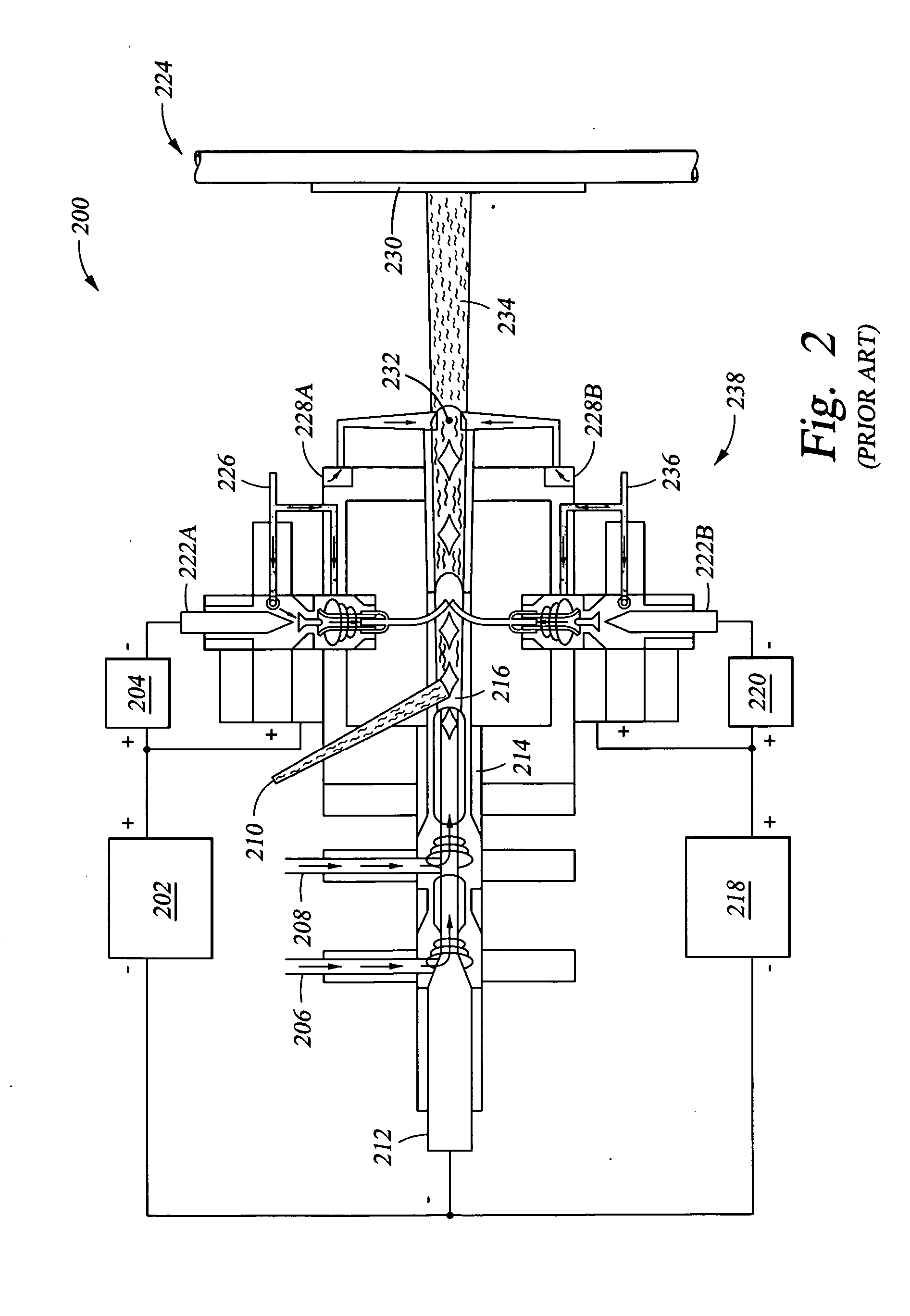

Clean, dense yttrium oxide coating protecting semiconductor processing apparatus

ActiveUS20050037193A1Extended service lifeExcellent plasma corrosion-resistanceLiquid surface applicatorsMolten spray coatingPlasma coatingChemical vapor deposition

Disclosed herein is a method for applying plasma-resistant coatings for use in semiconductor processing apparatus. The coatings are applied over a substrate which typically comprises an aluminum alloy of the 2000 series or the 5000 through 7000 series. The coating typically comprises an oxide or a fluoride of Y, Sc, La, Ce, Eu, Dy, or the like, or yttrium-aluminum-garnet (YAG). The coating may further comprise about 20 volume % or less of Al2O3. The coatings are typically applied to a surface of an aluminum alloy substrate or an anodized aluminum alloy substrate using a technique selected from the group consisting of thermal / flame spraying, plasma spraying, sputtering, and chemical vapor deposition (CVD). To provide the desired corrosion resistance, it is necessary to place the coating in compression. This is accomplished by controlling deposition conditions during application of the coating.

Owner:APPLIED MATERIALS INC

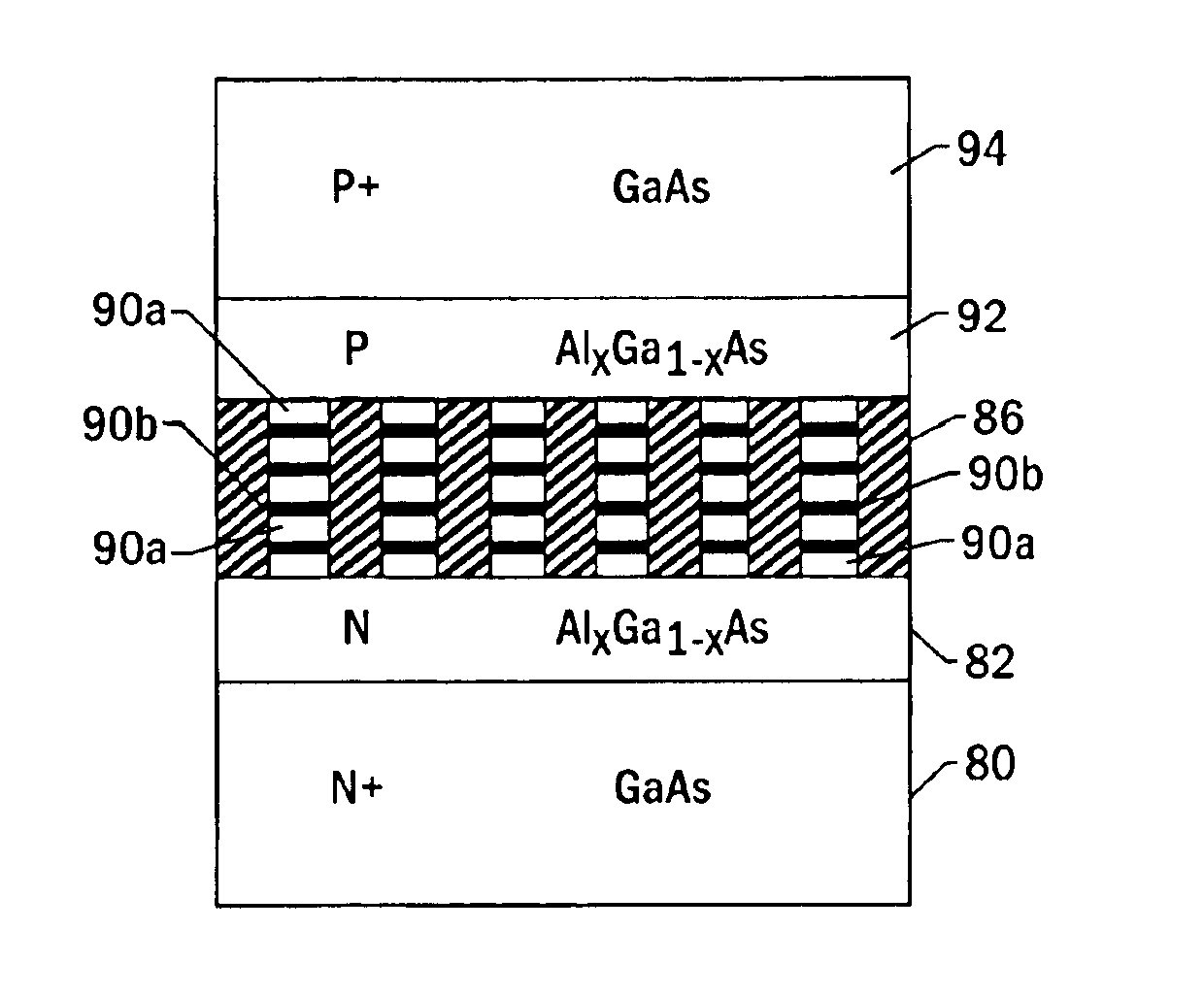

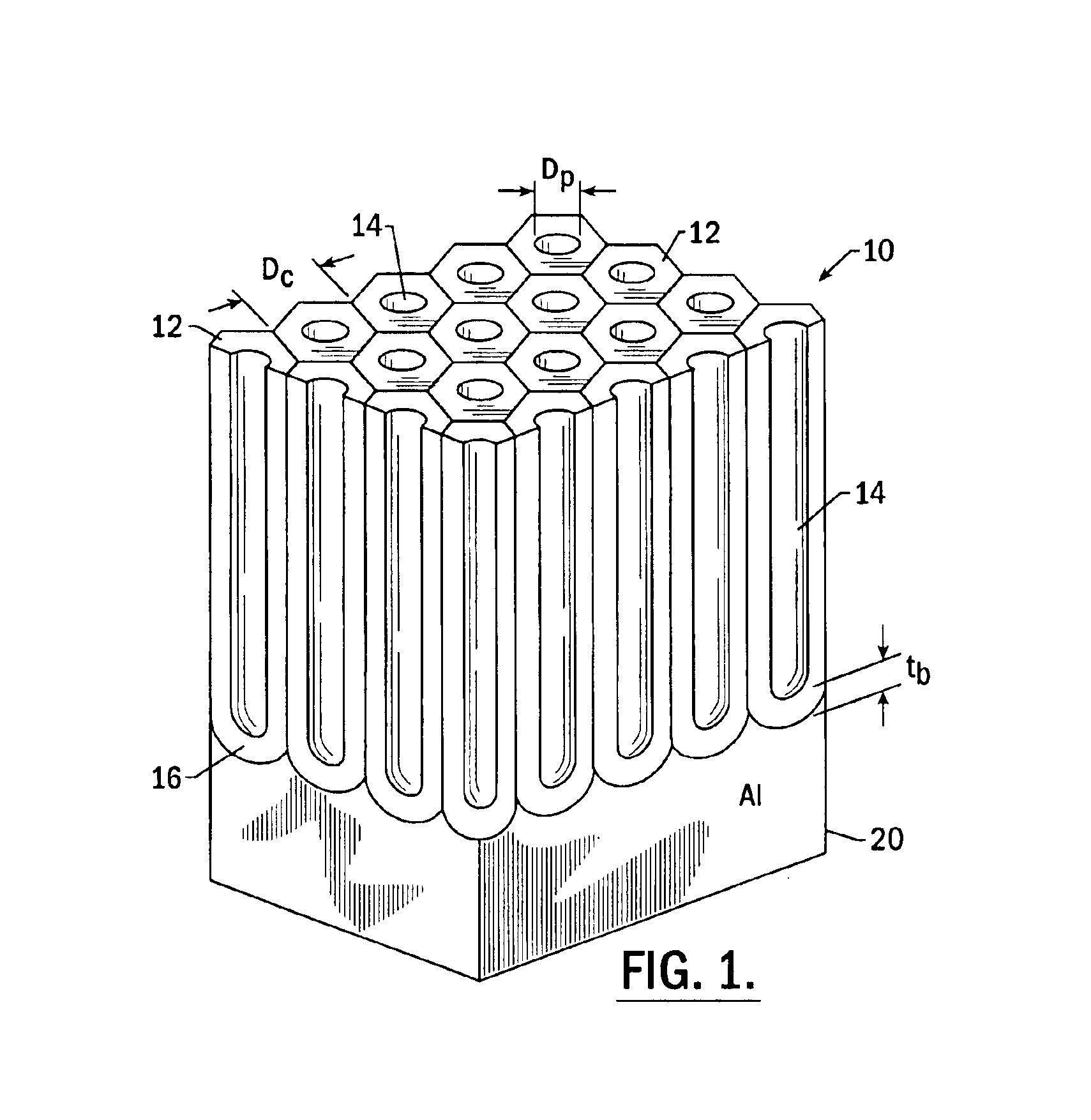

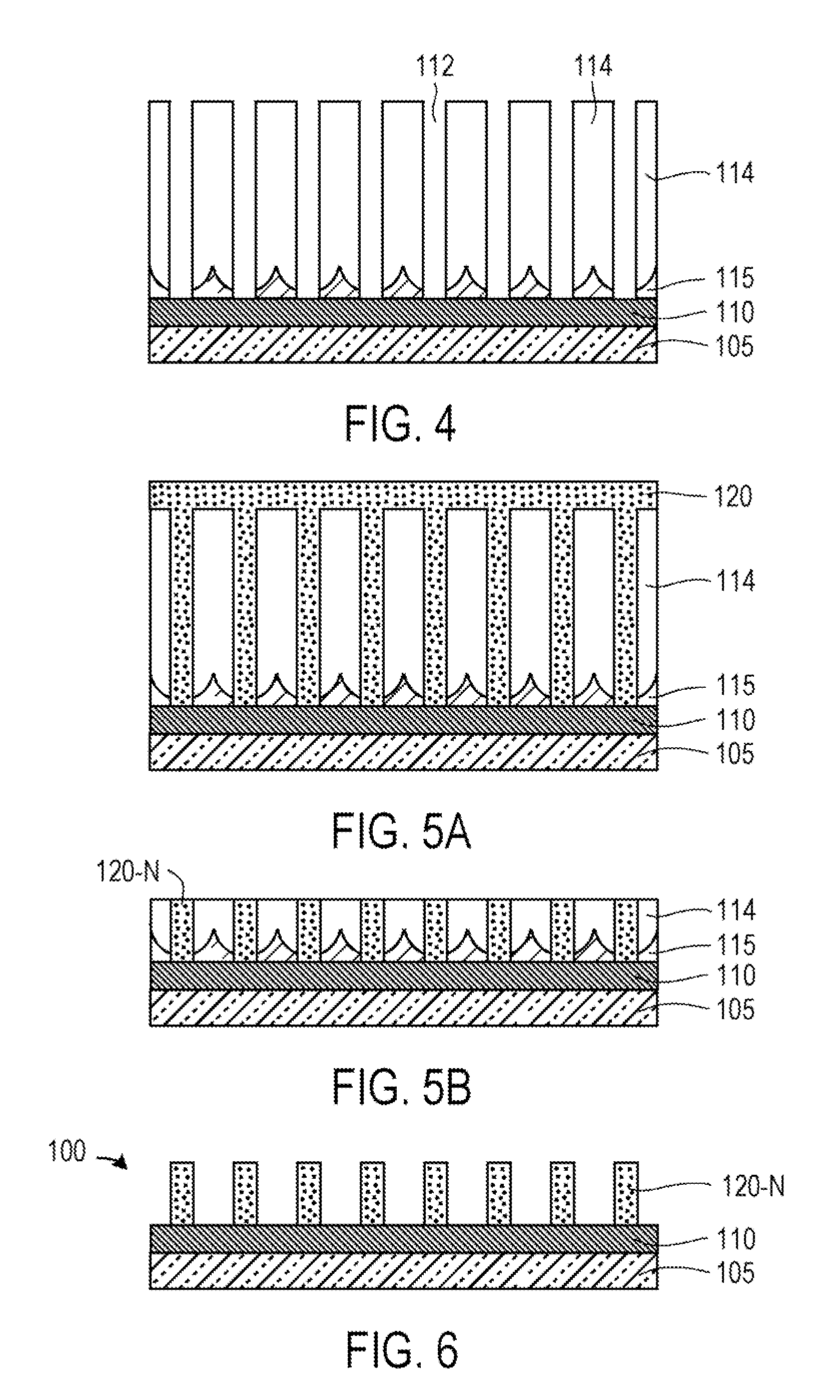

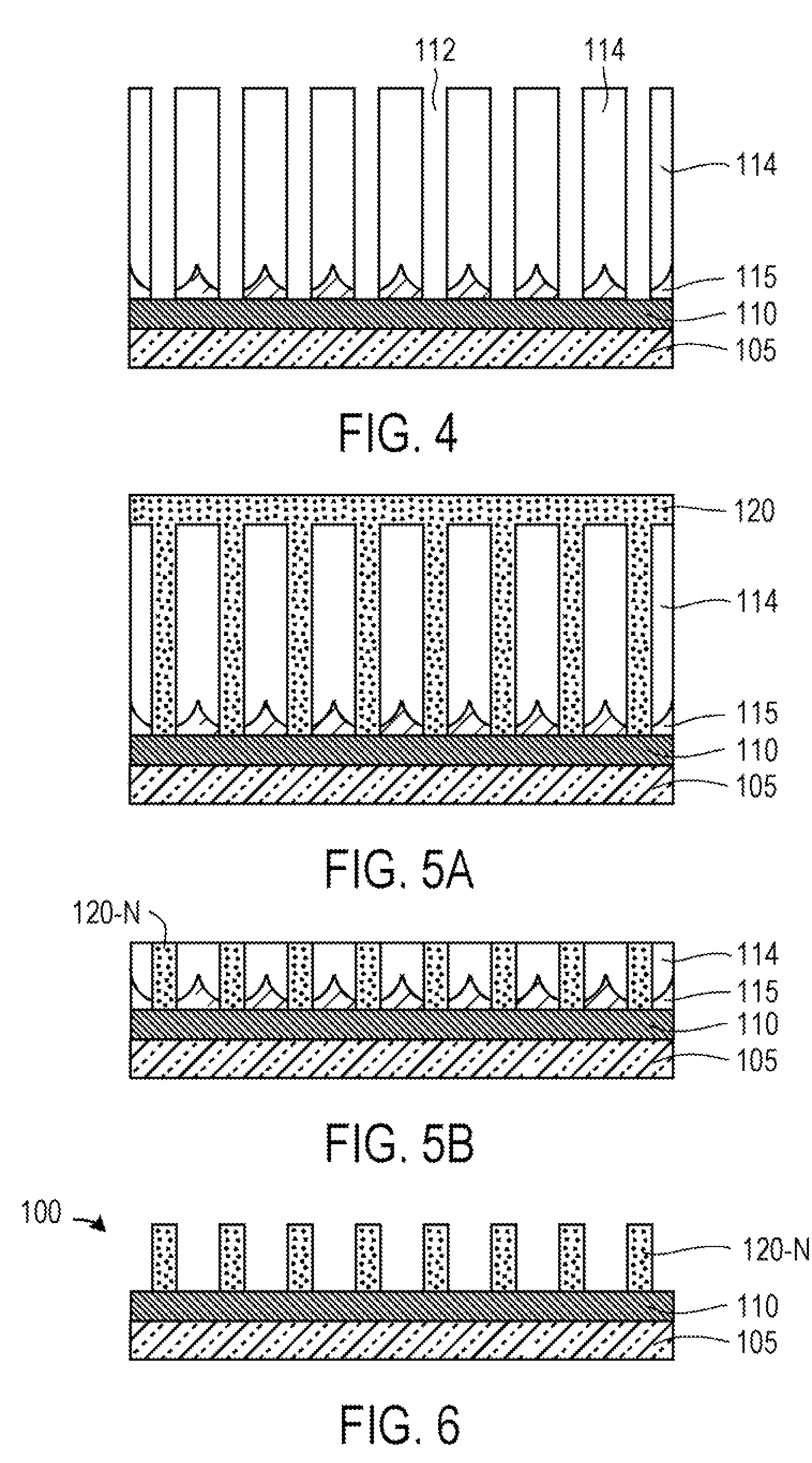

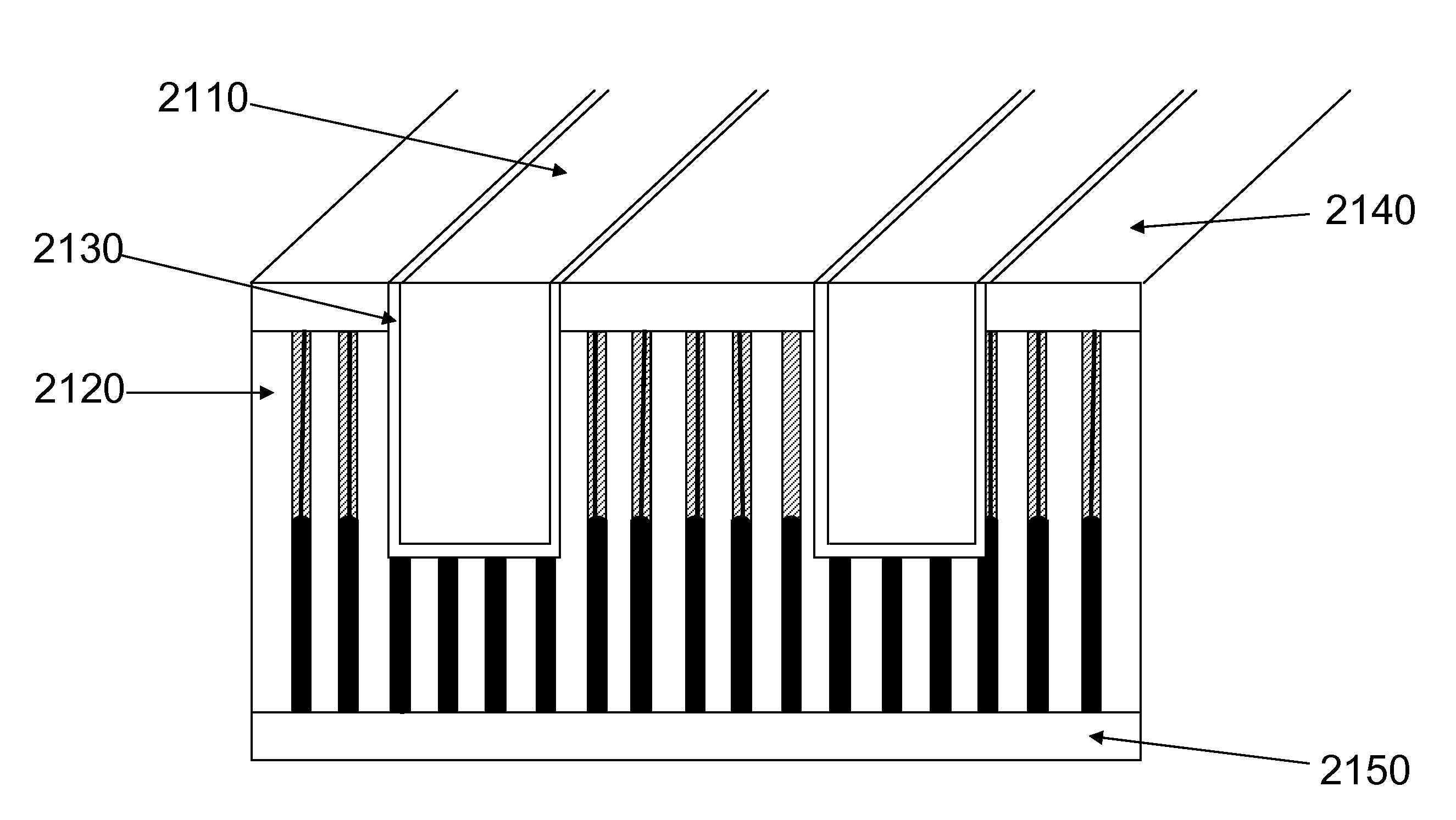

Optoelectronic devices having arrays of quantum-dot compound semiconductor superlattices therein

Methods of forming a nano-scale electronic and optoelectronic devices include forming a substrate having a semiconductor layer therein and a substrate insulating layer on the semiconductor layer. An etching template having a first array of non-photolithographically defined nano-channels extending therethrough, is formed on the substrate insulating layer. This etching template may comprise an anodized metal oxide, such as an anodized aluminum oxide (AAO) thin film. The substrate insulating layer is then selectively etched to define a second array of nano-channels therein. This selective etching step preferably uses the etching template as an etching mask to transfer the first array of nano-channels to the underlying substrate insulating layer, which may be thinner than the etching template. An array of semiconductor nano-pillars is then formed in the second array of nano-channels. The semiconductor nano-pillars in the array may have an average diameter in a range between about 8 nm and about 50 nm. The semiconductor nano-pillars are also preferably homoepitaxial or heteroepitaxial with the semiconductor layer.

Owner:NORTH CAROLINA STATE UNIV

Anodizing Aluminum and Alloys Thereof

This invention encompasses methods of producing a colored oxide layer on an aluminum material by anodizing the aluminum material in an electrolyte comprising water, sulfuric acid and oxalic acid. The anodizing step comprises passing at least two sequential current densities through the electrolyte. Methods of making and using article with a colored oxide layer on an aluminum material make by the methods disclosed herein are also disclosed.

Owner:DURACOUCHE INT

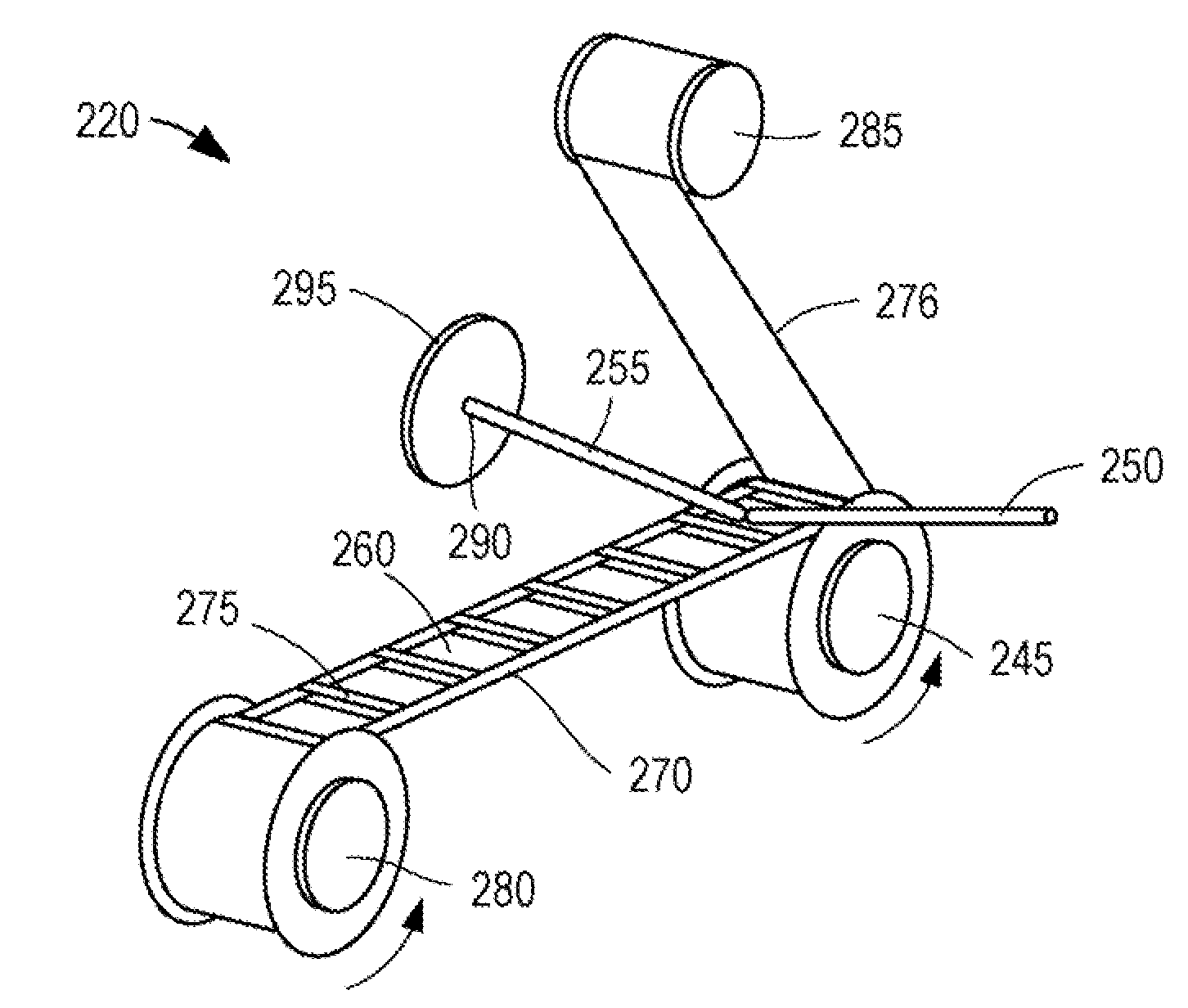

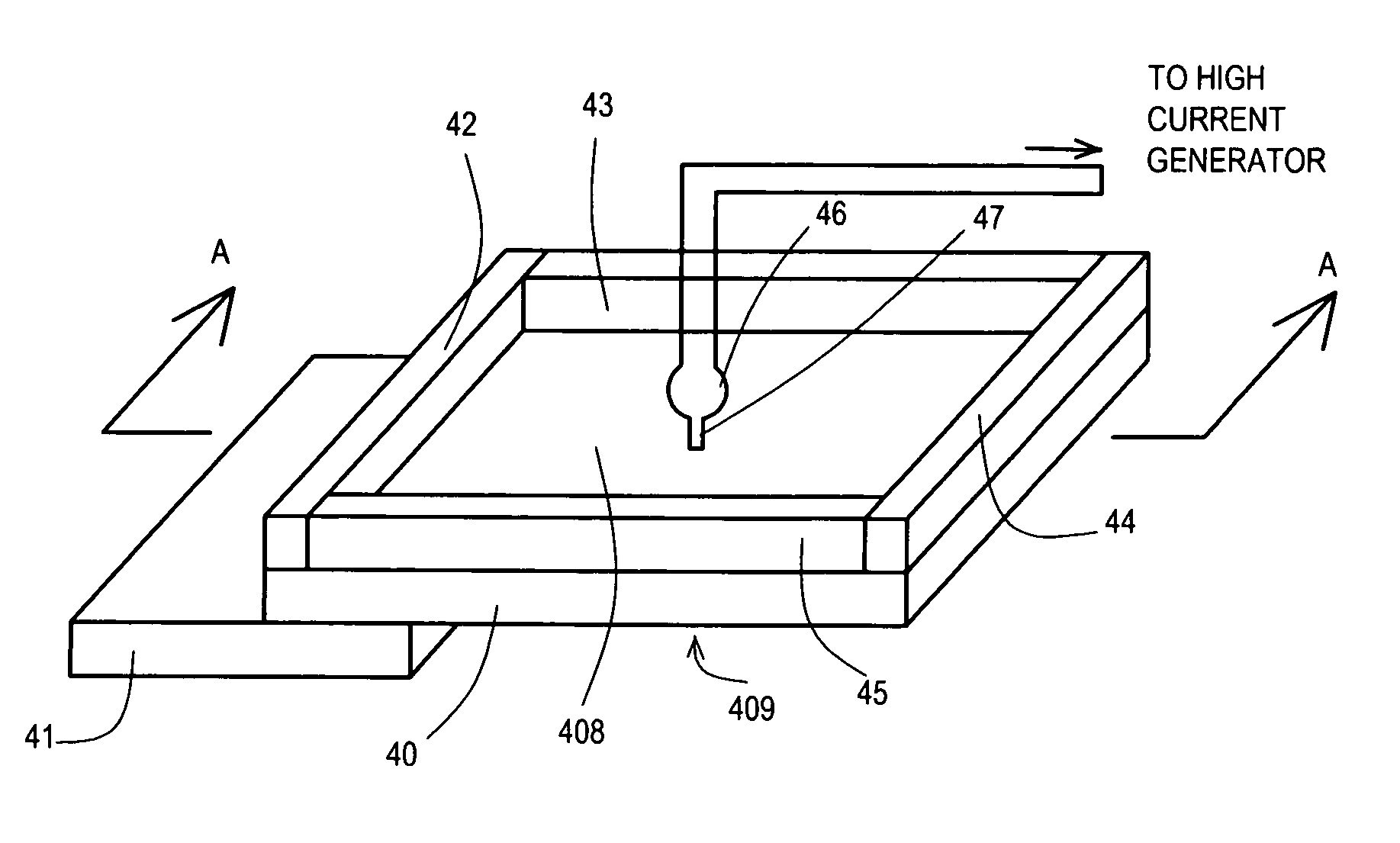

Embossed current collector separator for electrochemical fuel cell

InactiveUS20020009630A1Improve conductivityImprove corrosion resistanceElectrode carriers/collectorsSpecial surfacesFuel cellsEngineering

A bipolar current collector separator for a fuel cell composed of a metal plate having flow channels and contact faces that come into contact with electrodes or collectors, wherein a corrosion-resistant layer such as an anodized aluminum layer and a heat-resistant polymer layer is disposed on each of the flow channels.

Owner:RIKEN CO LTD

Nanotube Transistor and Rectifying Devices

InactiveUS20070001220A1Low yieldHigh densityNanostructure manufactureNanoinformaticsAudio power amplifierNanotube

Single-walled carbon nanotube transistor and rectifying devices, and associated methods of making such devices include a porous structure for the single-walled carbon nanotubes. The porous structure may be anodized aluminum oxide or another material. Electrodes for source and drain of a transistor are provided at opposite ends of the single-walled carbon nanotube devices. A gate region may be provided one end or both ends of the porous structure. The gate electrode may be formed into the porous structure. A transistor of the invention may be especially suited for power transistor or power amplifier applications.

Owner:ETAMOTA CORP

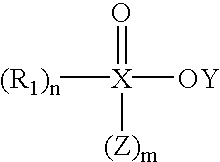

Ultrasonic assisted deposition of anti-stick films on metal oxides

InactiveUS20020130441A1Inhibit entry and adhesionLiquid surface applicatorsOptical articlesUltrasonic assistedCasting mold

A method and apparatus for ultrasonic assisted deposition of a release agent onto a workpiece is disclosed. The release agent can be any fluorinated or non-fluorinated phosphorous-containing organic acid. The workpiece can be any workpiece desired to be coated with the release agent, such as a surface needing an anti-stick coating required in a plastic casting or injection mold. Metal oxide workpiece surfaces strongly bond to fluorinated phosphorus-containing organic acids. In particular, the present invention can deposit anti-stick coatings onto smooth or porous surfaces, such as anodized aluminum and its alloys, using ultrasonic assisted deposition

Owner:KORRY ELECTRONICS

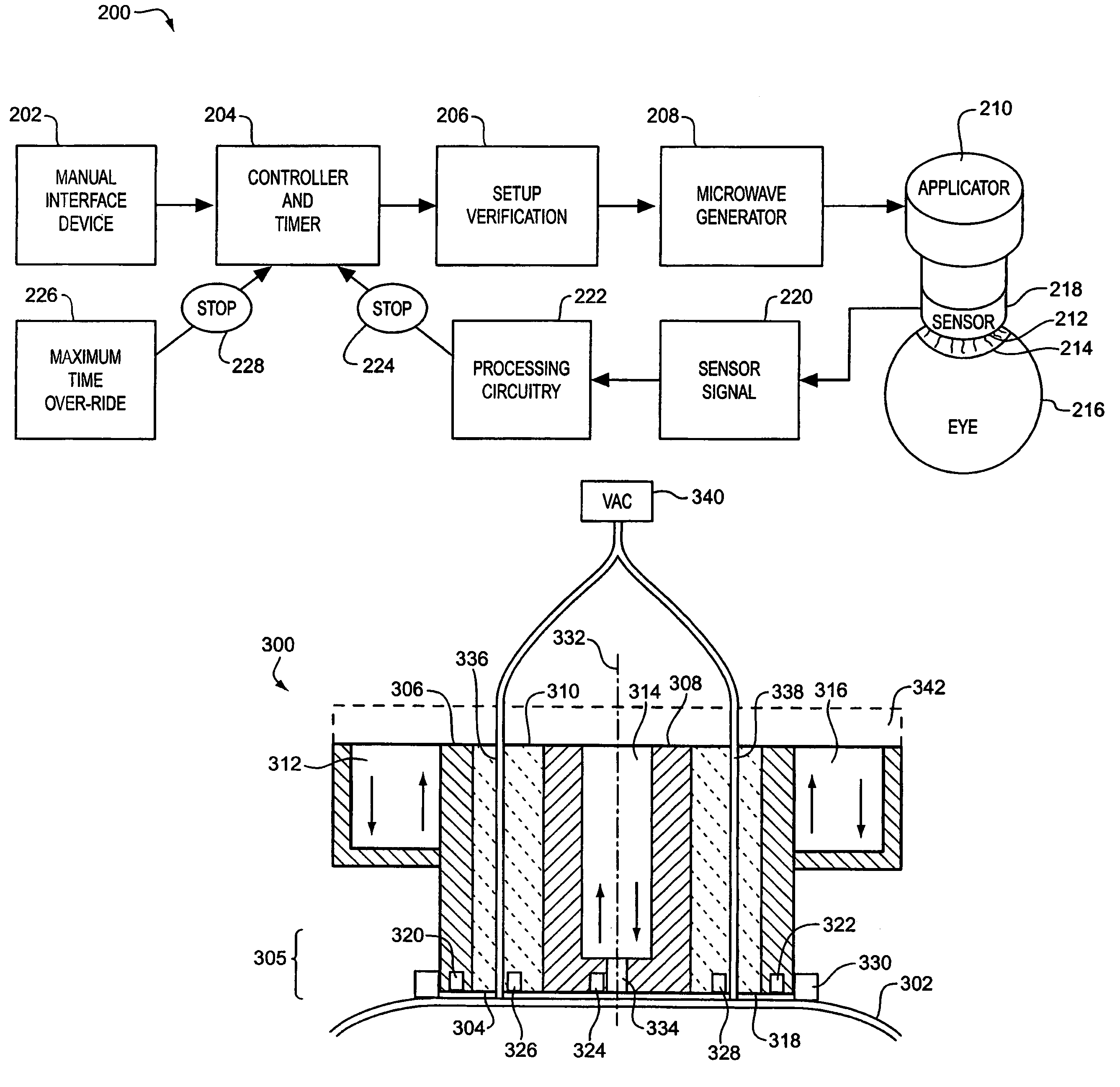

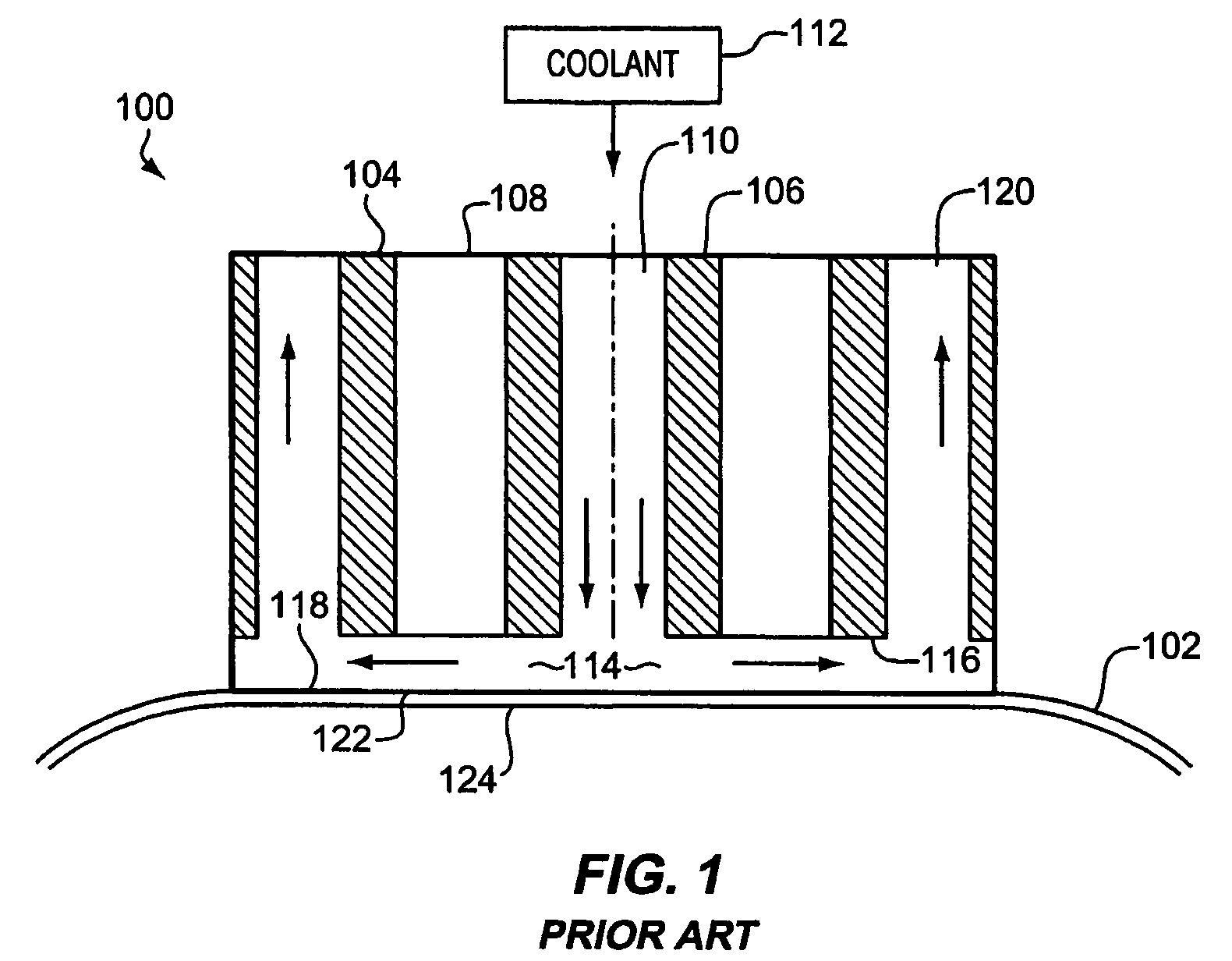

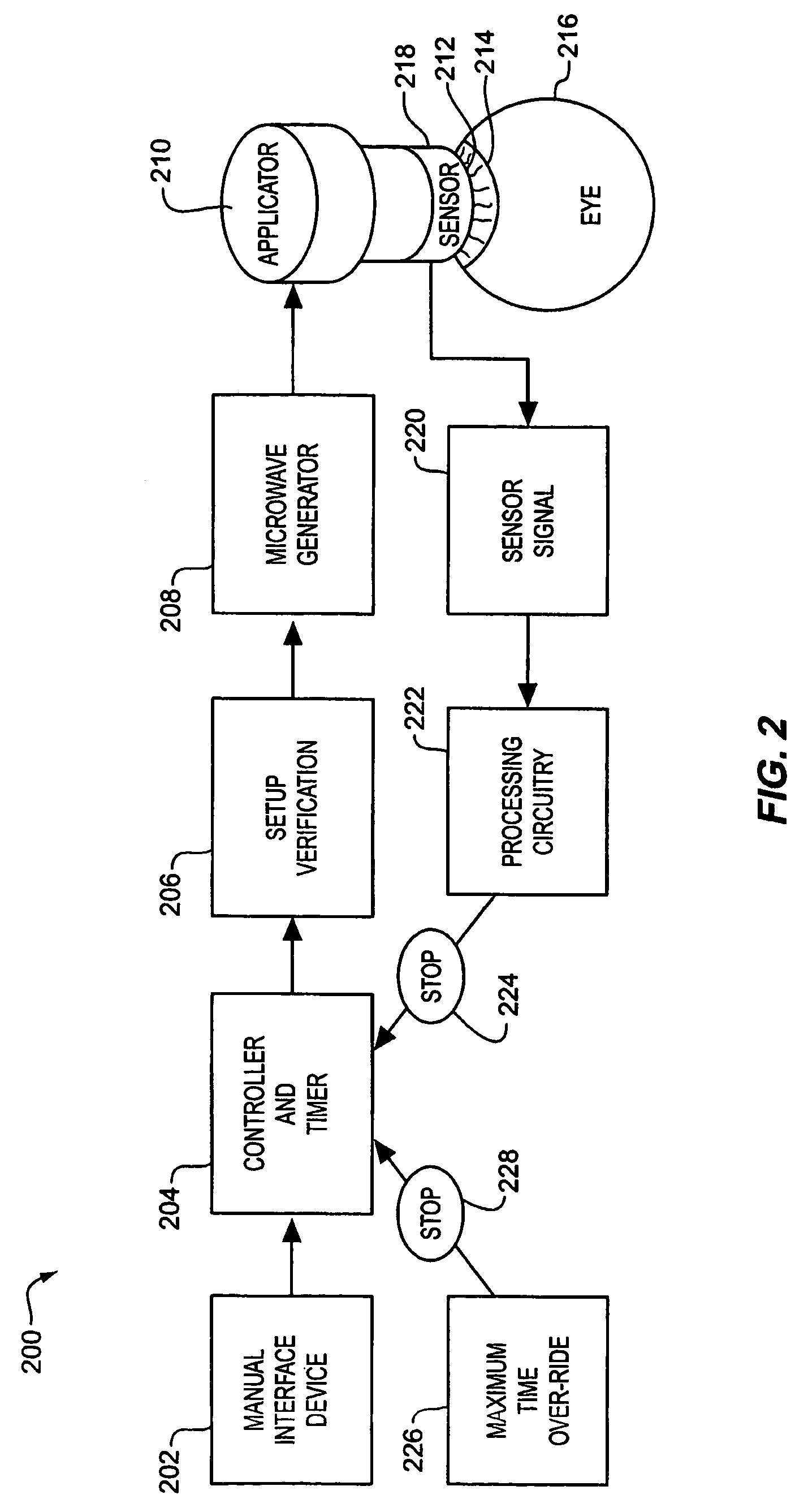

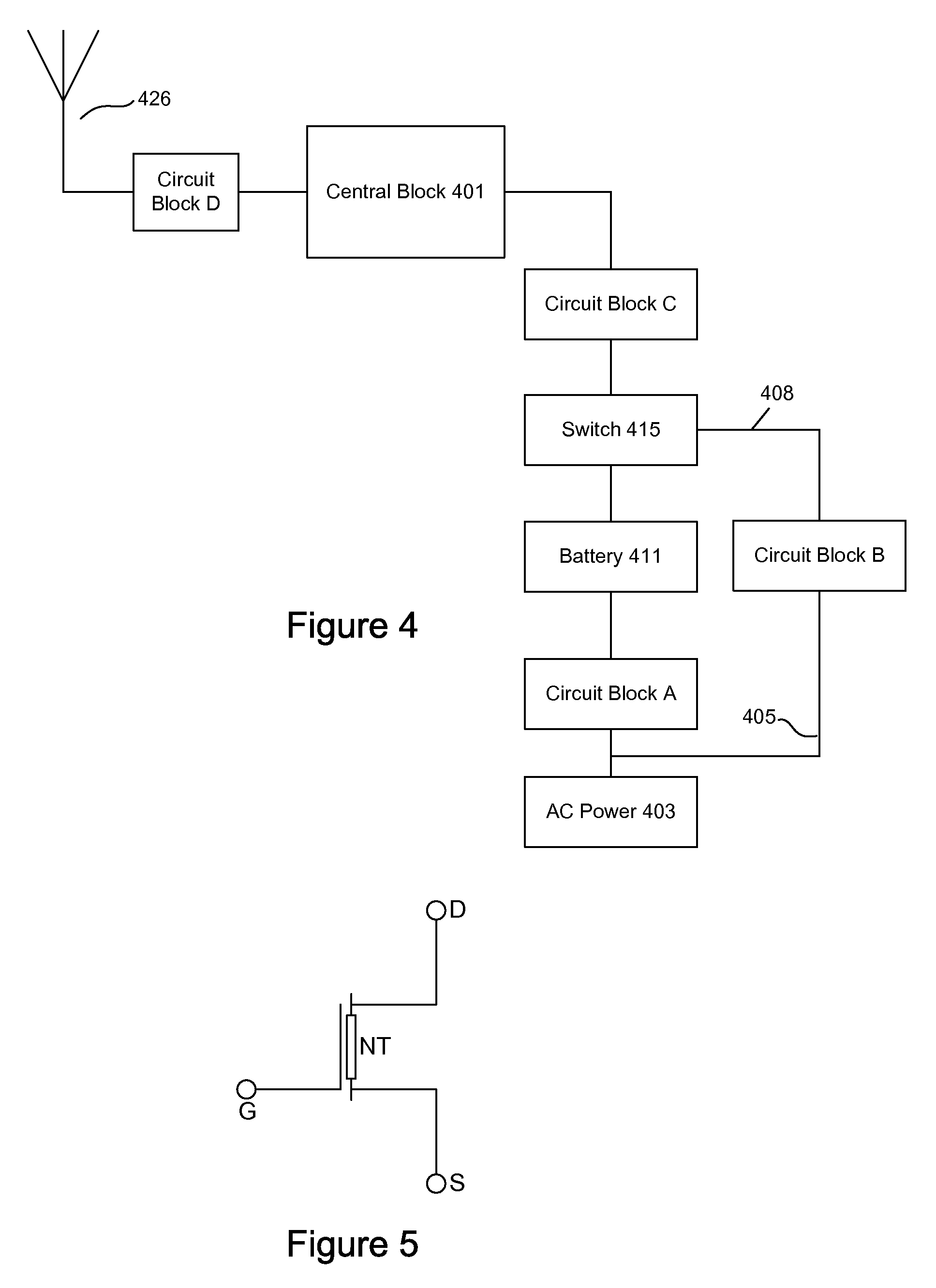

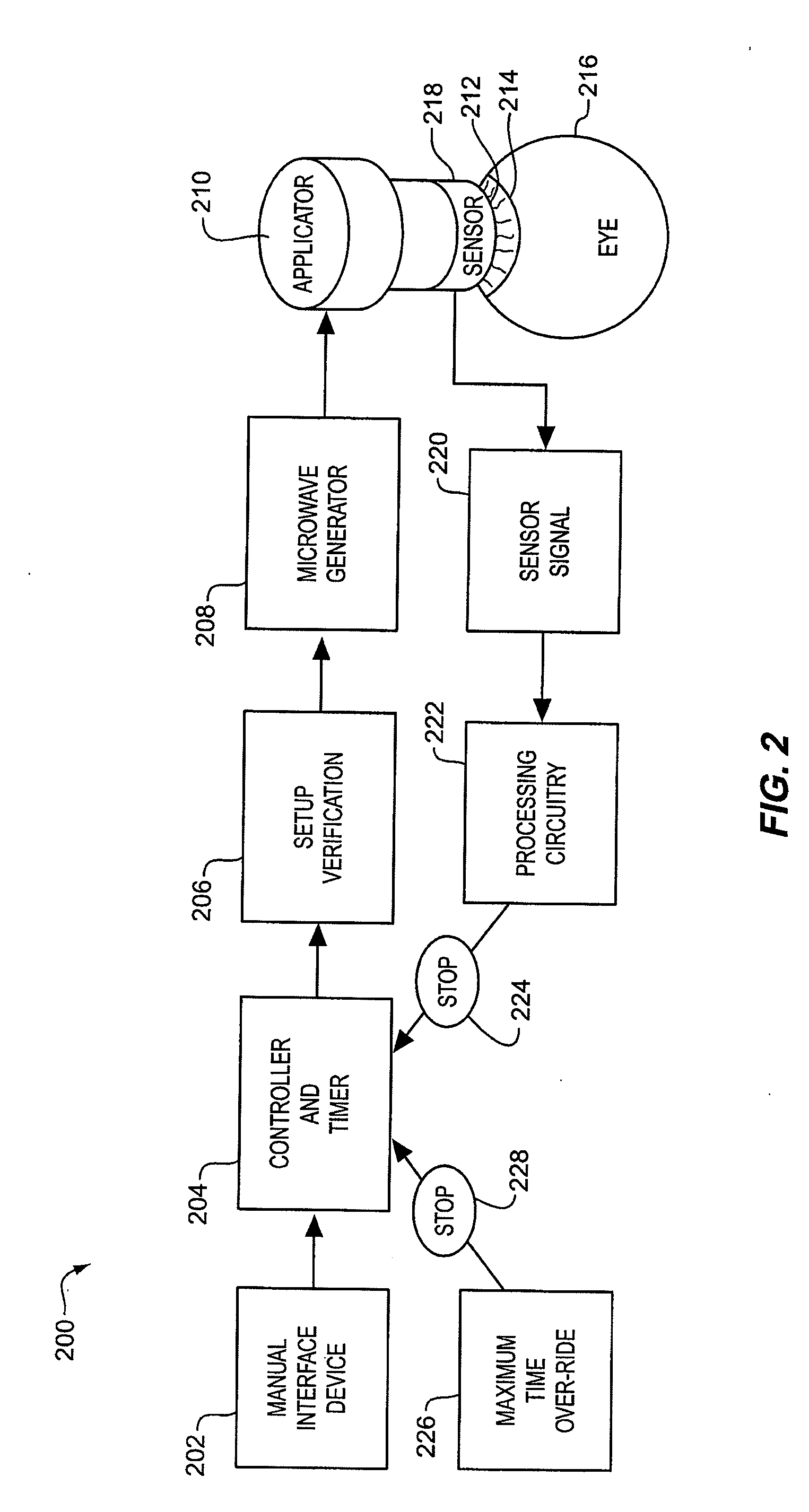

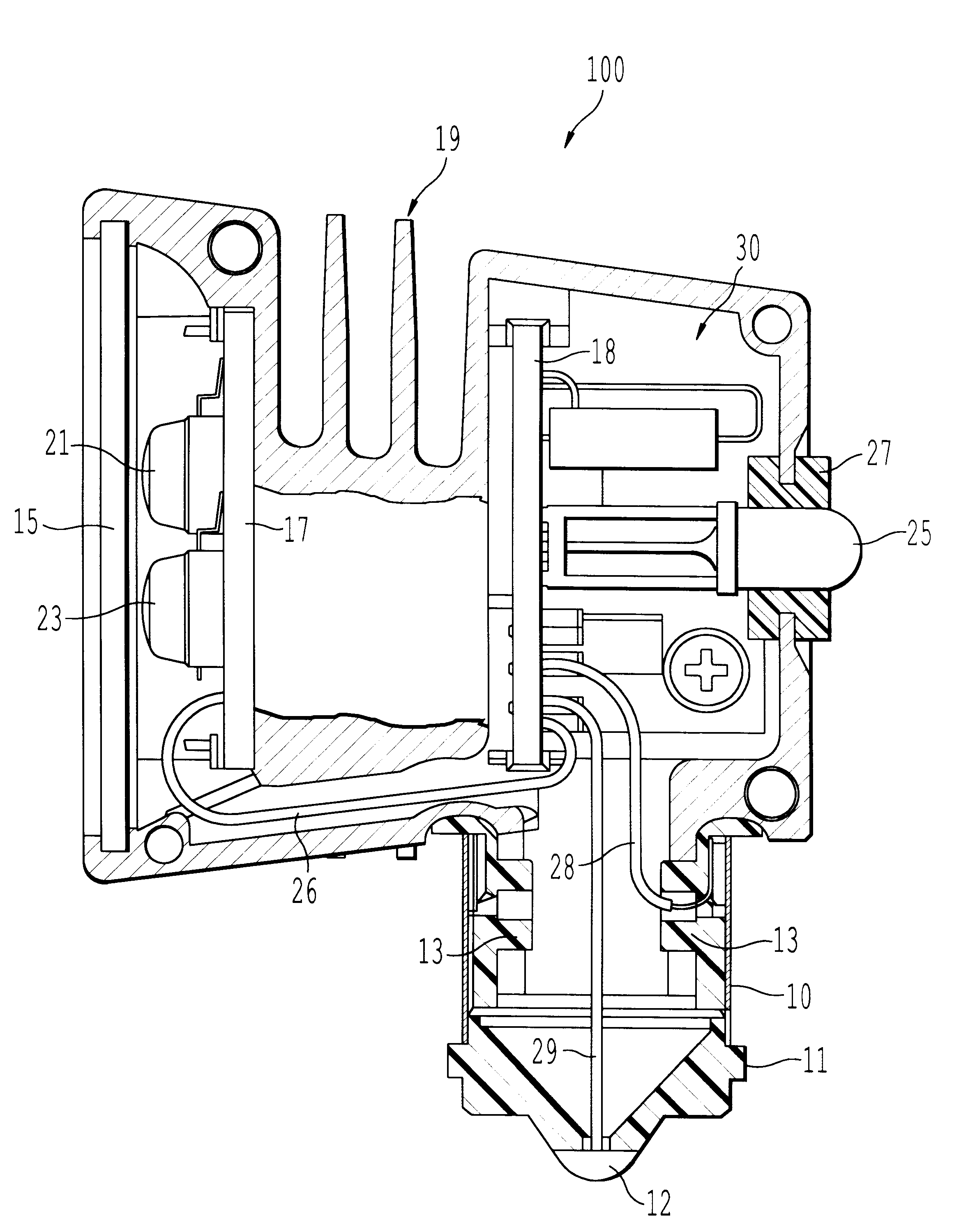

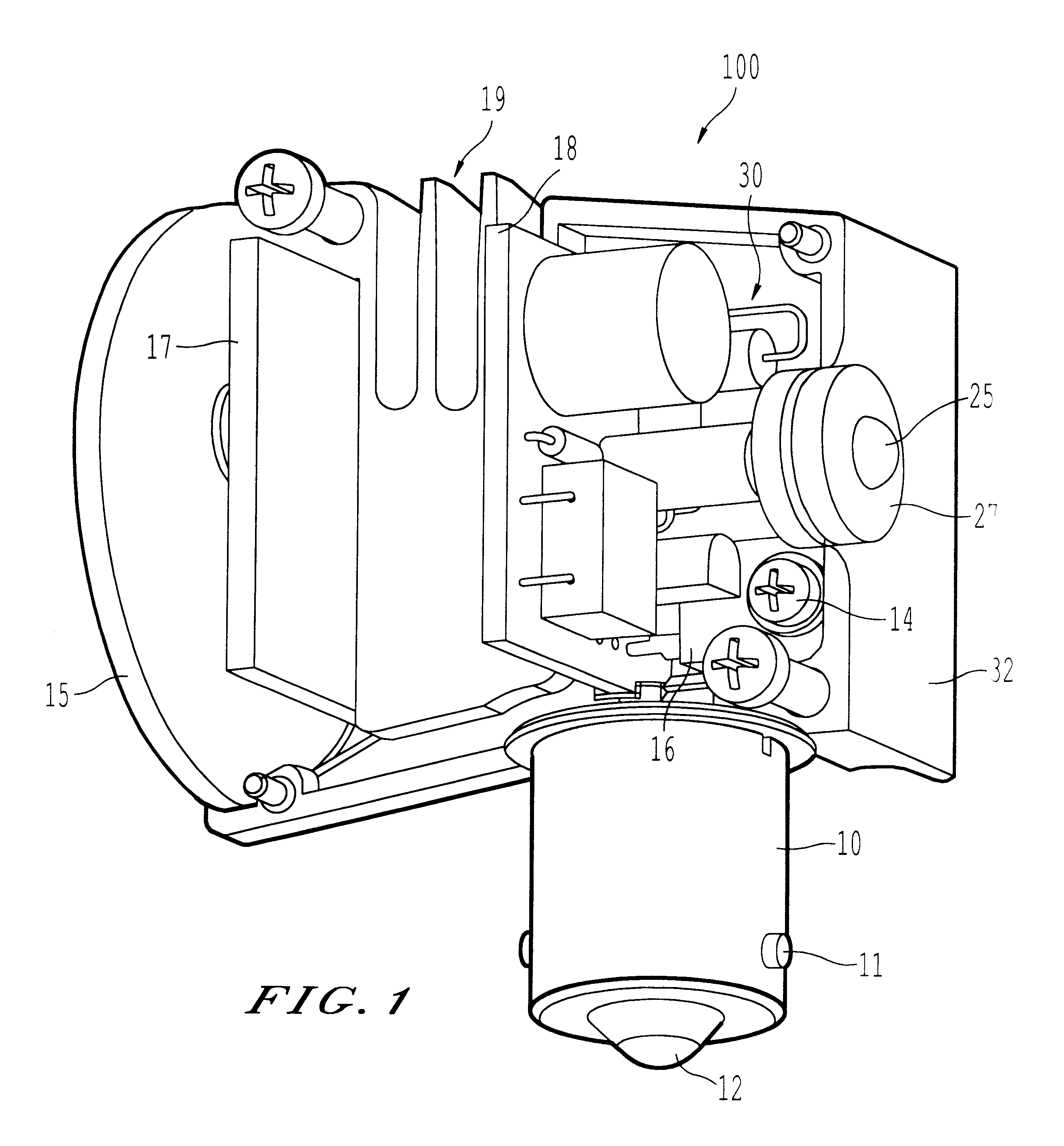

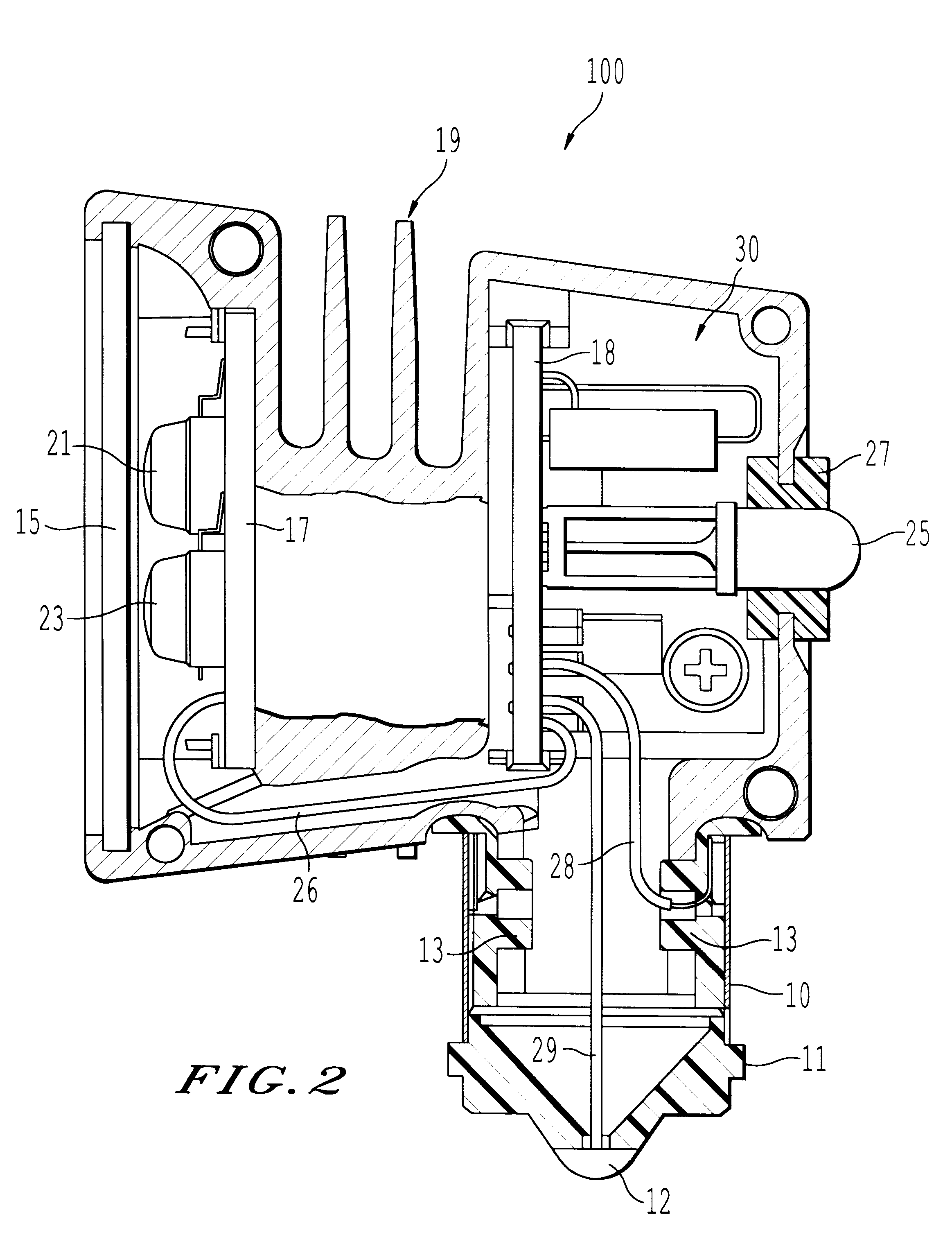

Thermokeratoplasty systems

InactiveUS7192429B2Damage to produceEliminate systematic errorsEye surgerySurgical instruments for heatingGonioplastyEngineering

The present invention provides applicators for performing thermokeratoplasty. One embodiment of such applicators includes two generally tubular electrical conducting elements coaxially disposed relative to one another and separated by an electrically insulating element having a selected thickness. At least a portion of each conducting tube is coated with an electrically insulating and thermally conductive material, e.g., anodized aluminum, so as to electrically insulate the conducting tubes from corneal tissue upon placement of the applicator on a subject's cornea while facilitating extraction of heat from the cornea.

Owner:TRUSTEES OF DARTMOUTH COLLEGE THE

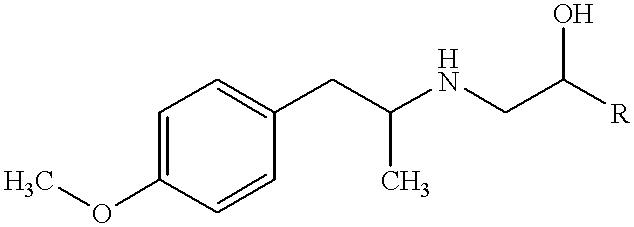

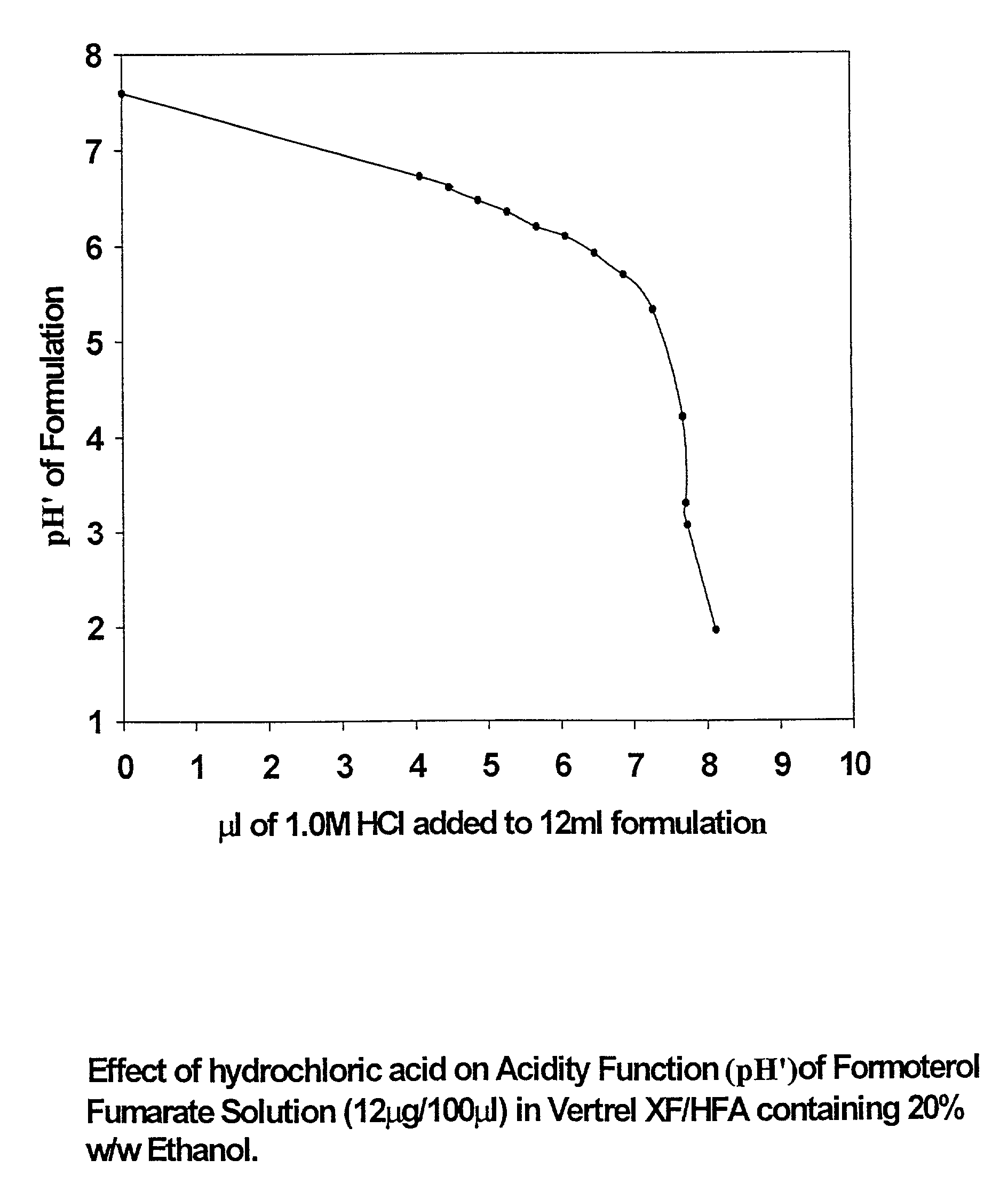

Stable pharmaceutical solution formulations for pressurised metered dose inhalers

An aerosol solution composition for use in an aerosol inhaler comprises an active material, a propellant containing a hydrofluoroalkane, a cosolvent and optionally a low volatility component to increase the mass median aerodynamic diameter (MMAD) of the aerosol particles on actuation of the inhaler. The composition is stabilized by using a small amount of mineral acid and a suitable can having part or all of its internal metallic surfaces made of stainless steel, anodized aluminium or lined with an inert organic coating.

Owner:CHIESI FARM SPA

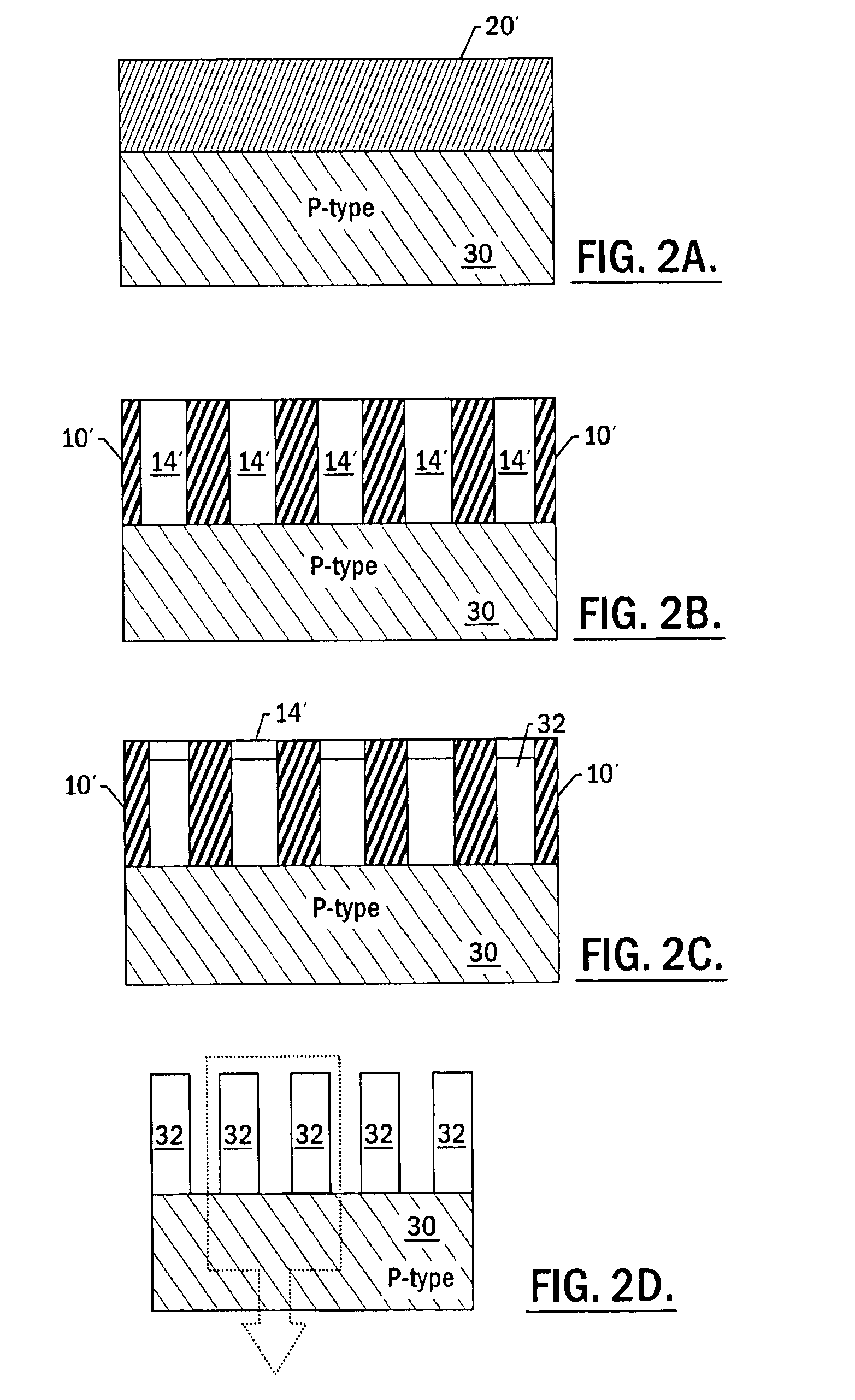

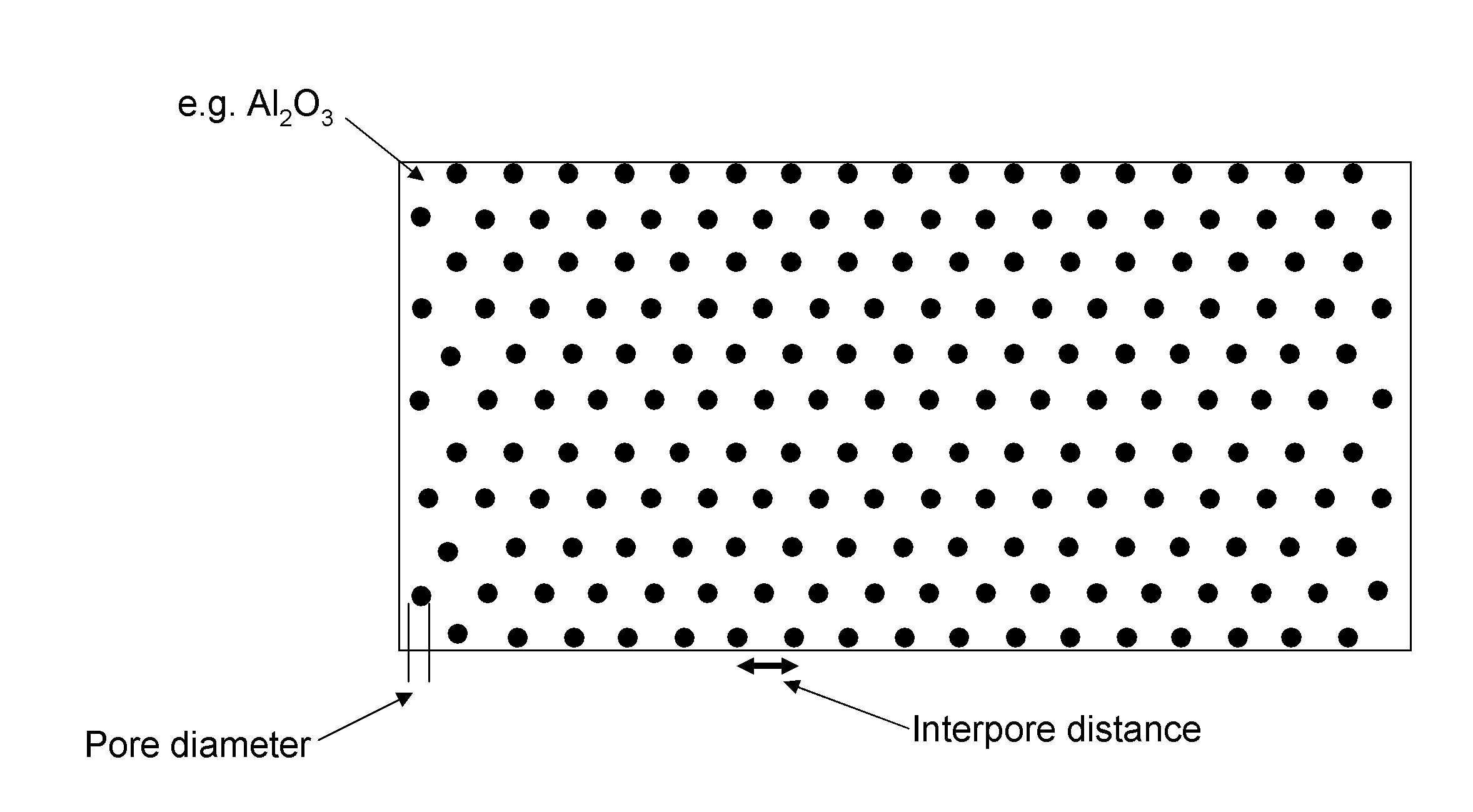

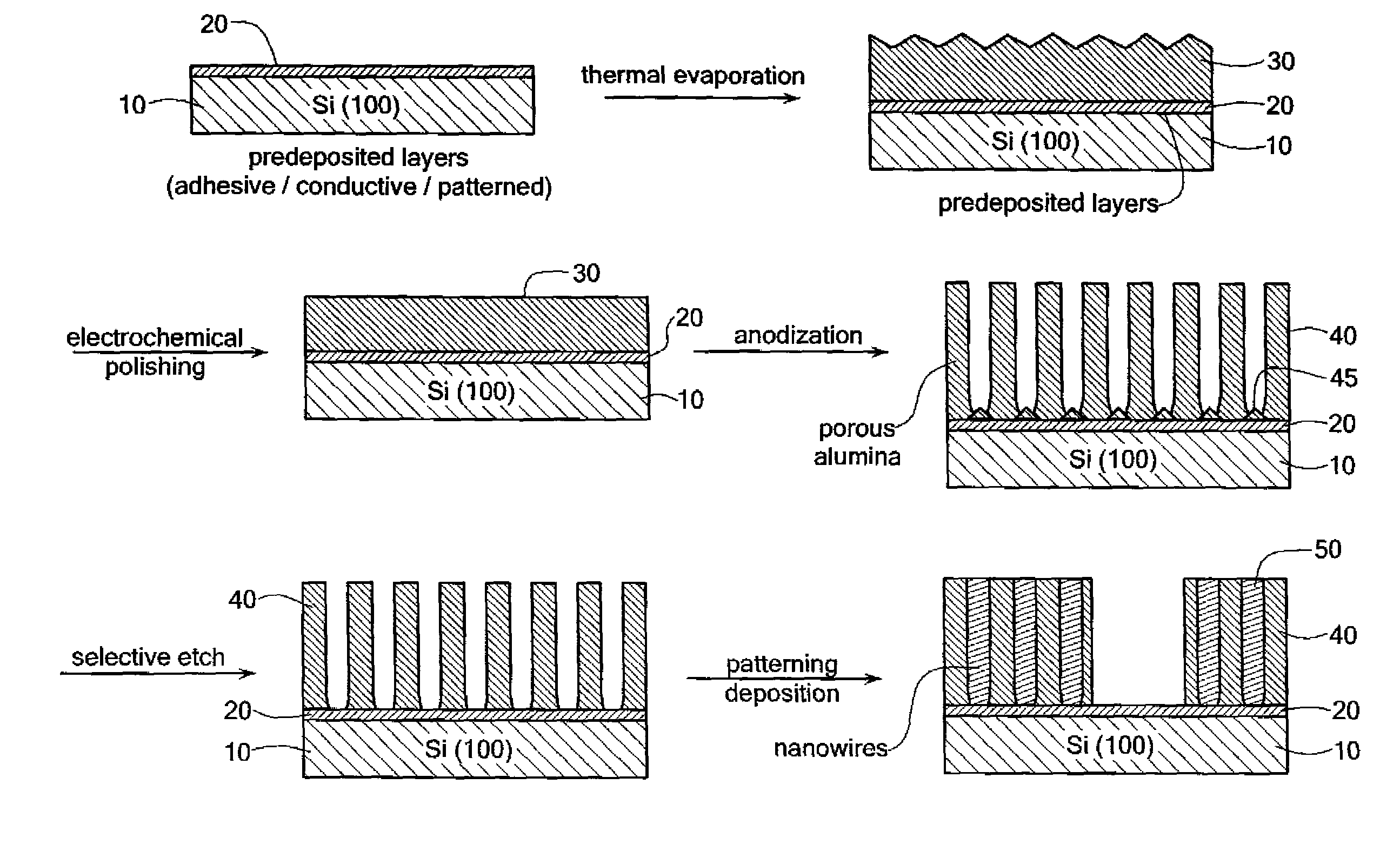

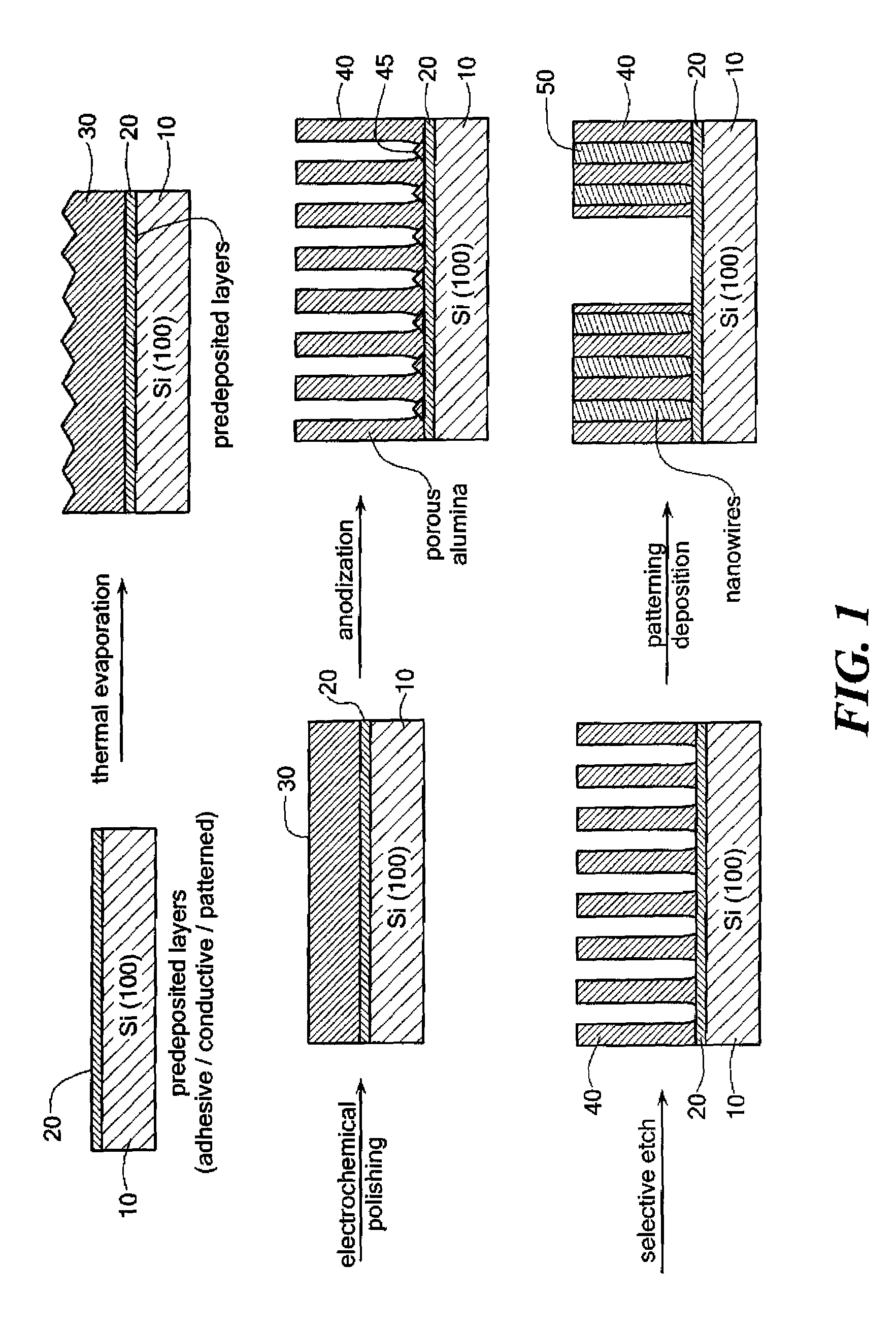

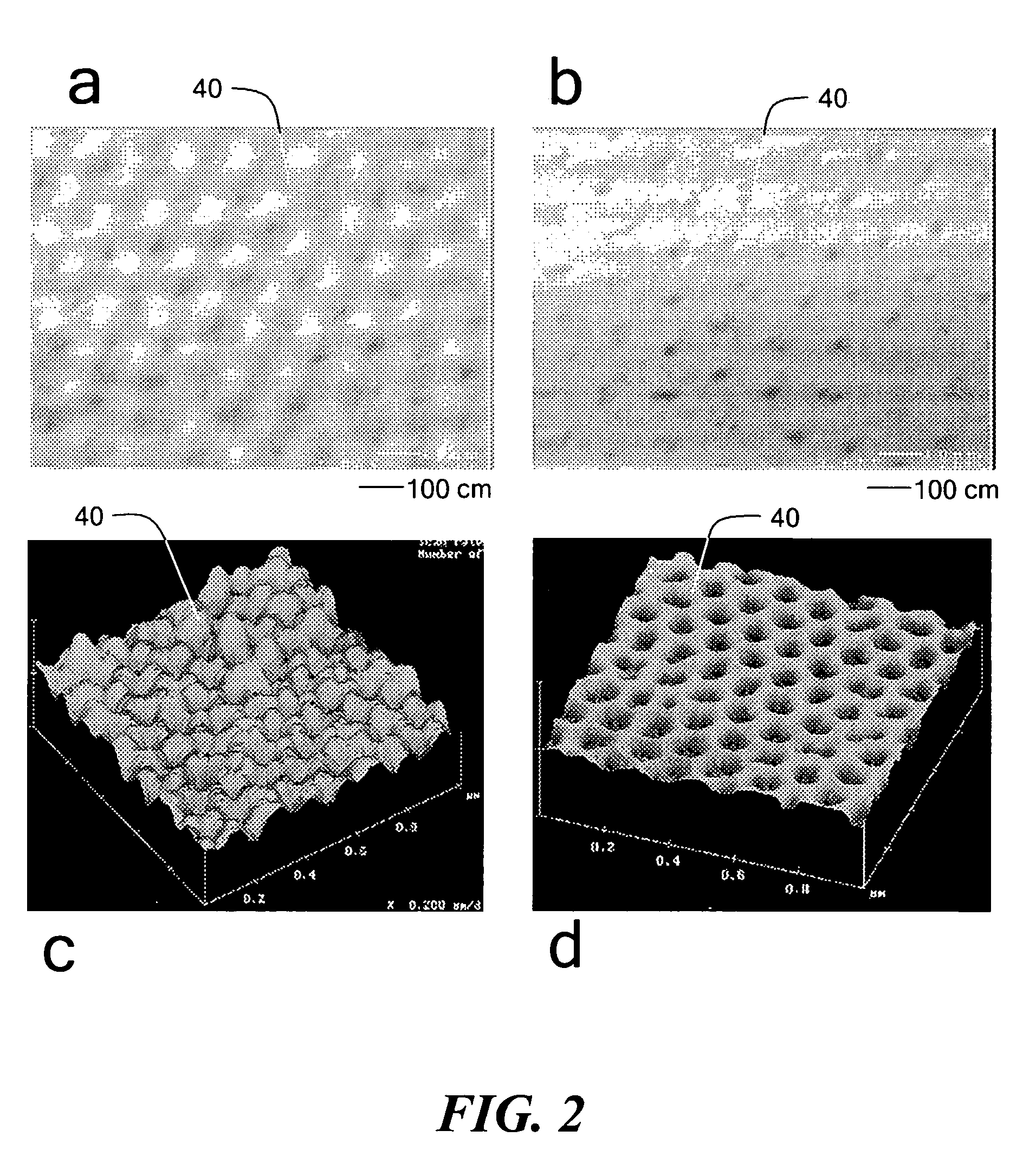

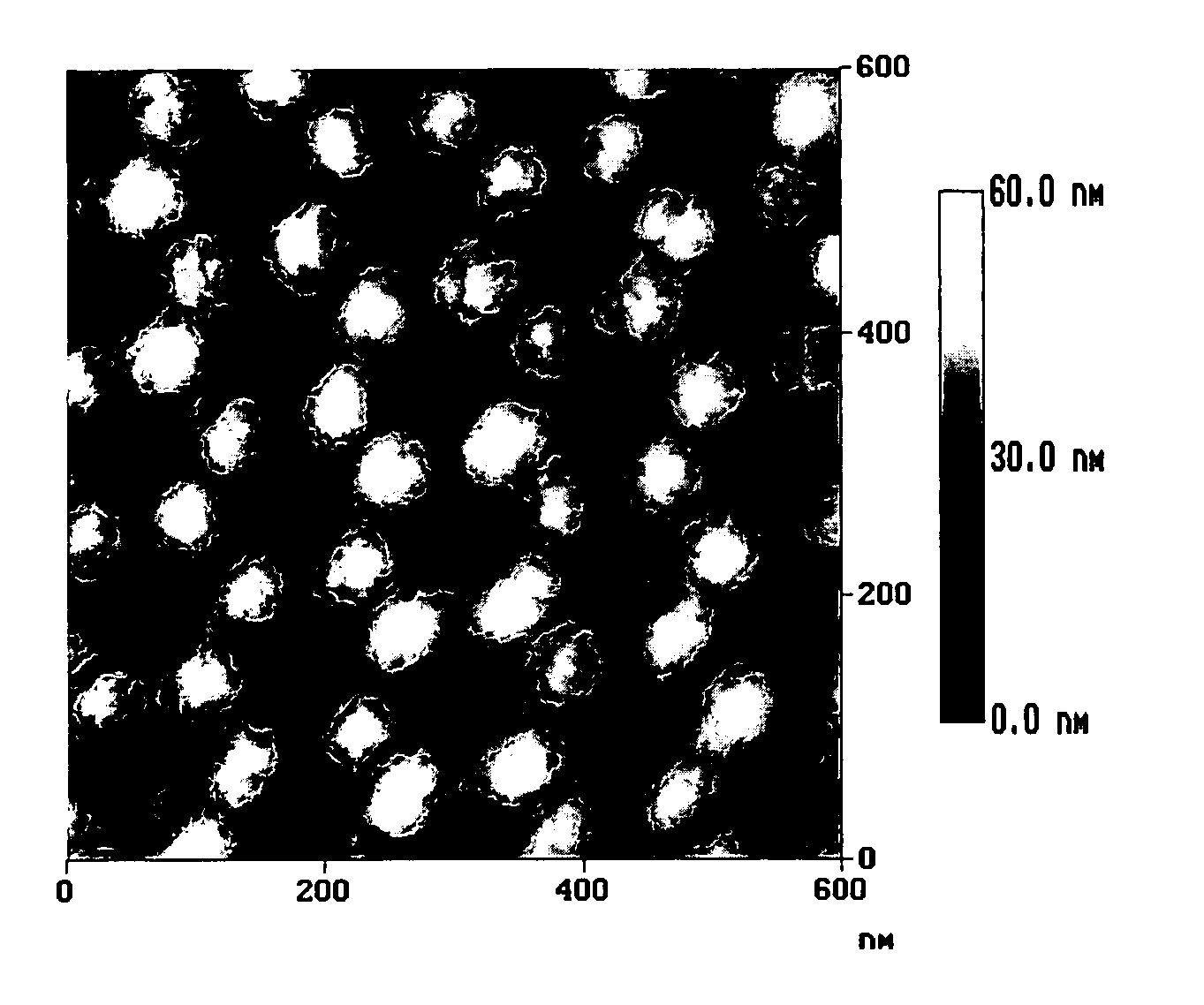

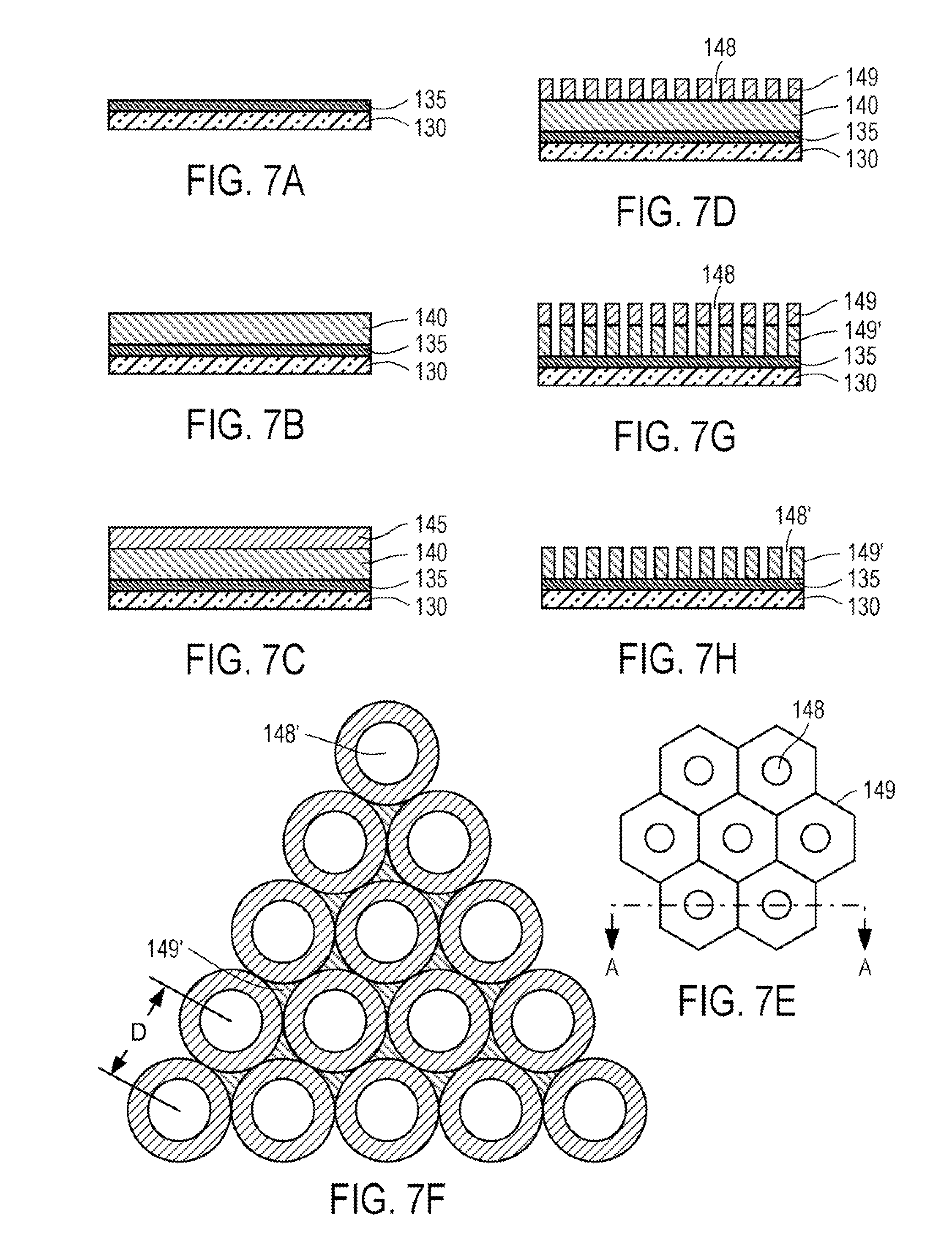

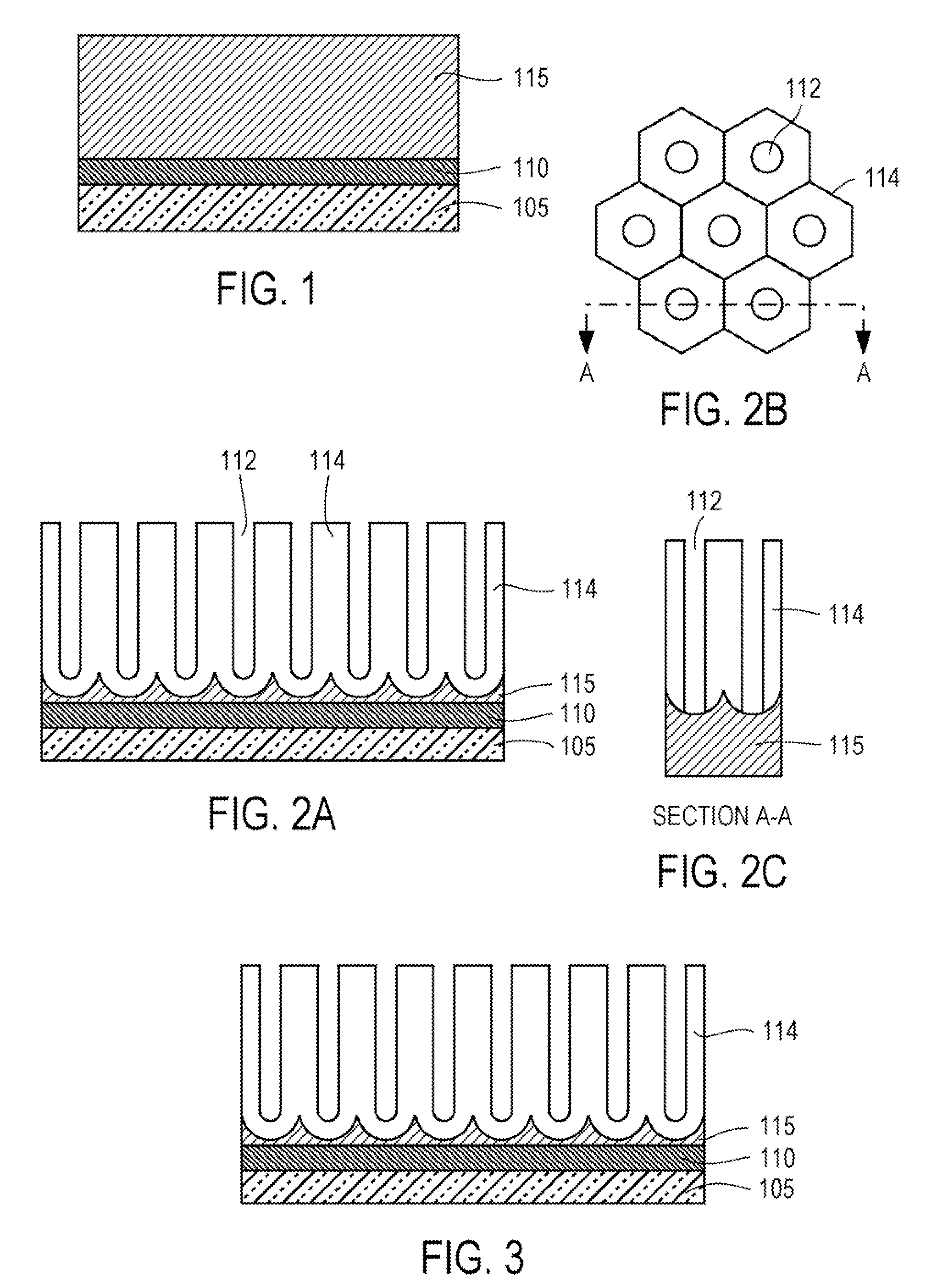

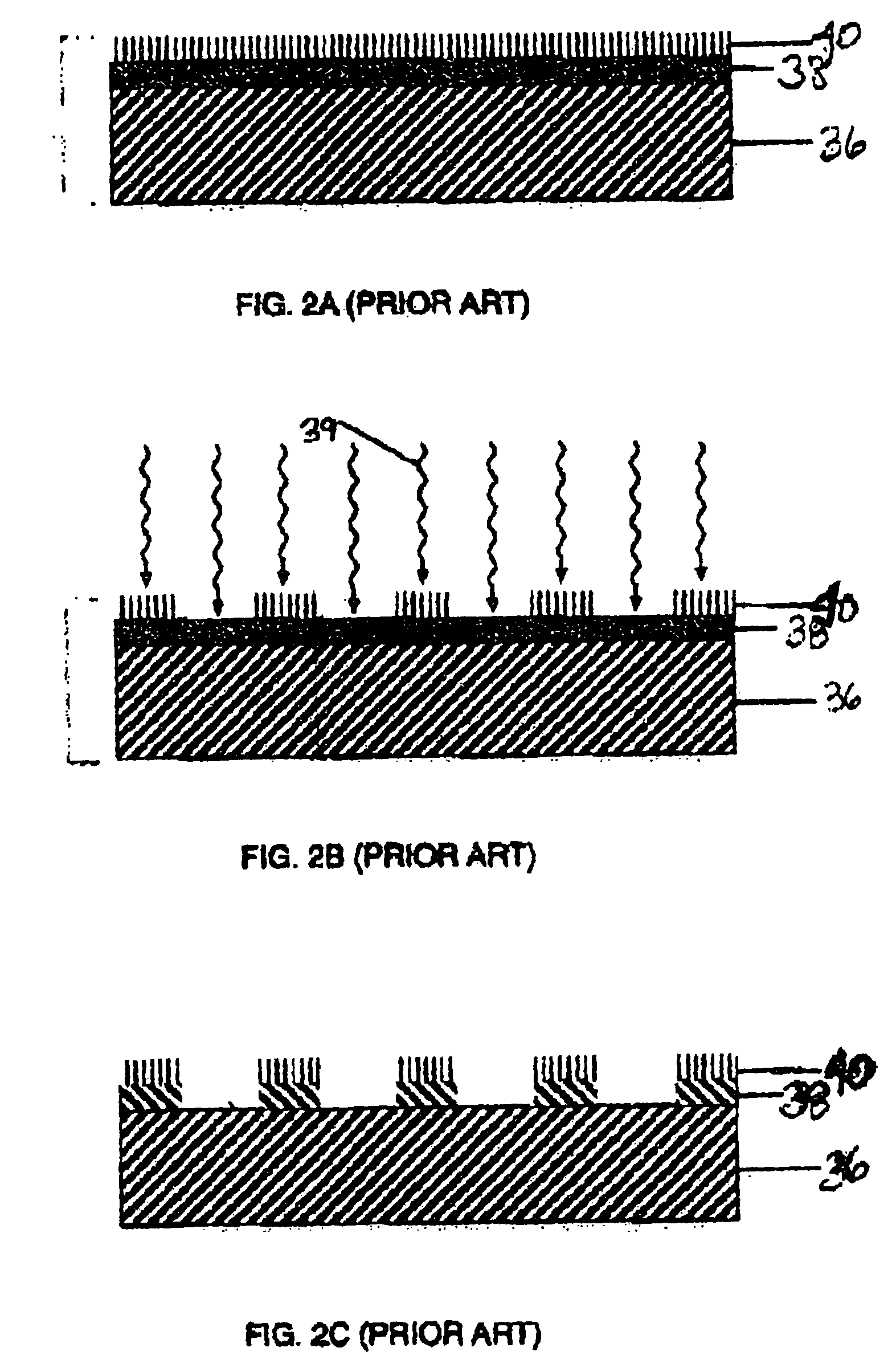

Thick porous anodic alumina films and nanowire arrays grown on a solid substrate

InactiveUS7267859B1Promote growthMore tractableMaterial nanotechnologyAnodisationSingle stageElectrochemistry

The presently disclosed invention provides for the fabrication of porous anodic alumina (PAA) films on a wide variety of substrates. The substrate comprises a wafer layer and may further include an adhesion layer deposited on the wafer layer. An anodic alumina template is formed on the substrate. When a rigid substrate such as Si is used, the resulting anodic alumina film is more tractable, easily grown on extensive areas in a uniform manner, and manipulated without danger of cracking. The substrate can be manipulated to obtain free-standing alumina templates of high optical quality and substantially flat surfaces PAA films can also be grown this way on patterned and non-planar surfaces. Furthermore, under certain conditions the resulting PAA is missing the barrier layer (partially or completely) and the bottom of the pores can be readily accessed electrically. The resultant film can be used as a template for forming an array of nanowires wherein the nanowires are deposited electrochemically into the pores of the template. By patterning the electrically conducting adhesion layer, pores in different areas of the template can be addressed independently, and can be filled electrochemically by different materials. Single-stage and multi-stage nanowire-based thermoelectric devices, consisting of both n-type and p-type nanowires, can be assembled on a silicon substrate by this method.

Owner:MASSACHUSETTS INST OF TECH

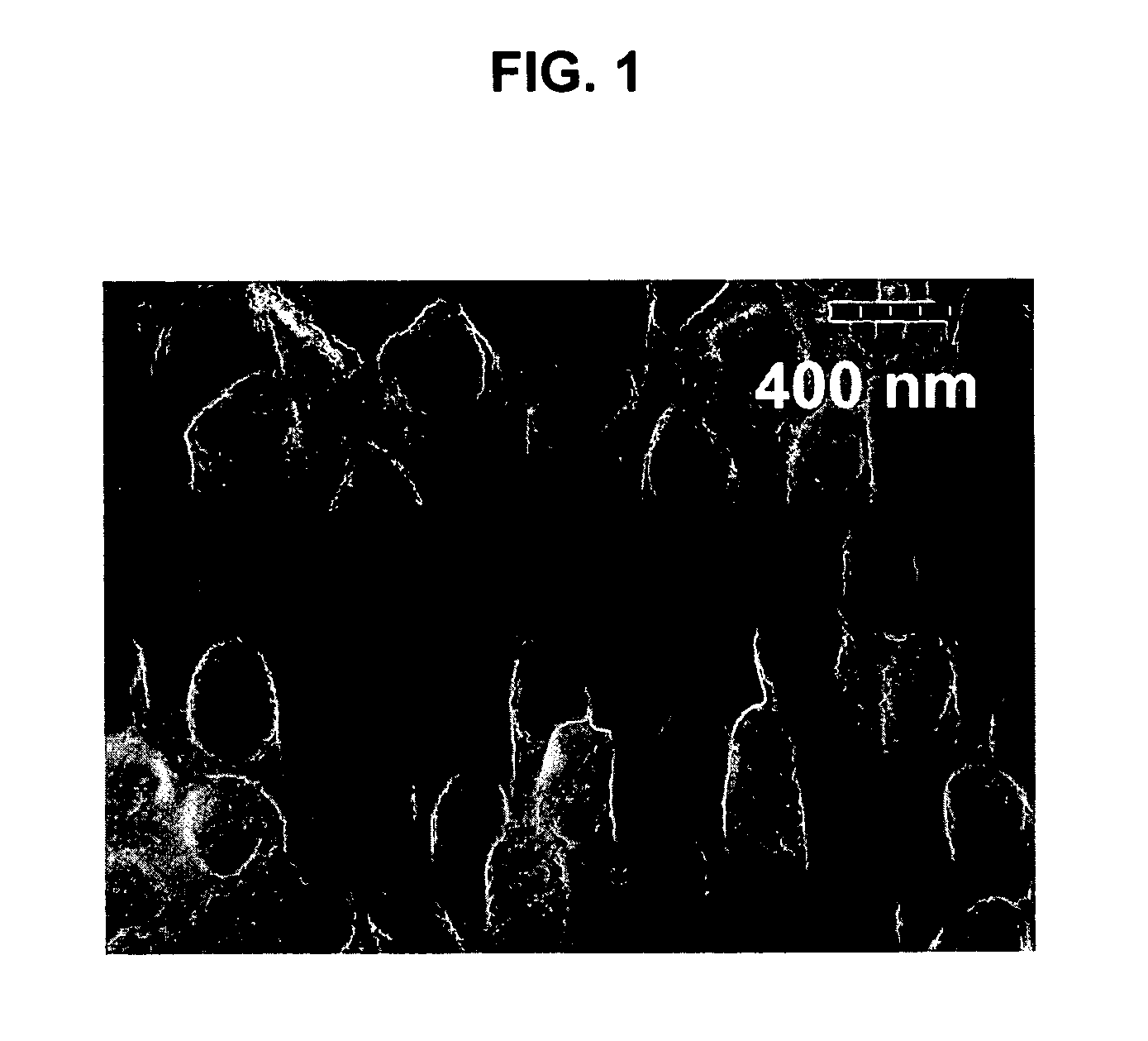

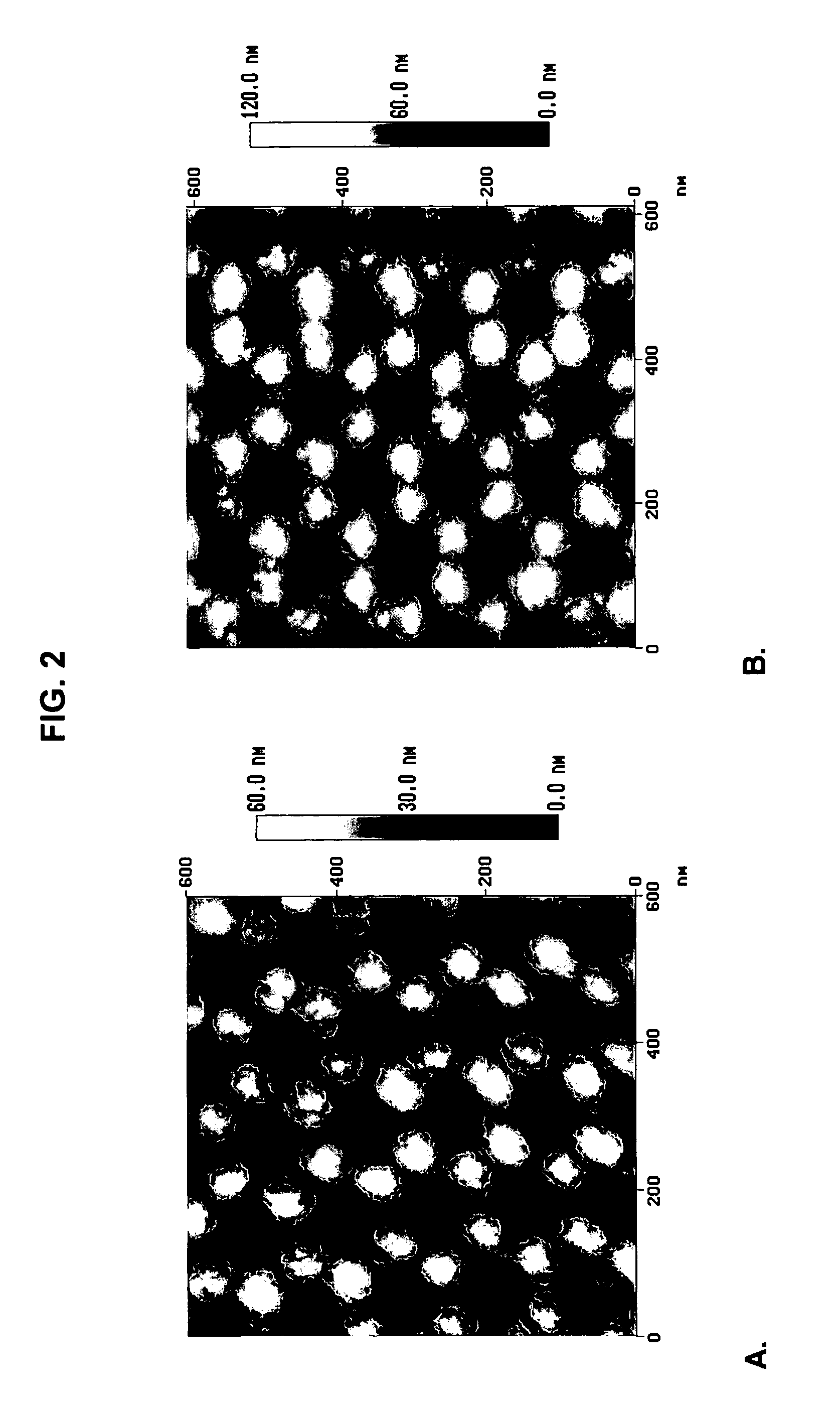

Nanostructures synthesized using anodic aluminum oxide

InactiveUS20060289351A1Simple methodEasy to makeMaterial nanotechnologyCoatingsHydrogen sensorNanostructure

This invention provides ways to fabricate nanotubes and nanobead arrays by utilizing nanopores in anodic aluminum oxide (AAO) membranes. Nanotubes of bismuth and other low melting point metals with controlled diameters and lengths can be fabricated by sintering AAO coated with appropriate metals at temperatures above their melting points. Carbon nanotubes may also be readily formed by carbonizing a polymer on the interior walls of the nanopores in AAO membranes. Palladium nanobead arrays which can be used as ultrafast hydrogen sensors are fabricated by coating the flat surface of AAO membranes with controlled pore-wall ratios.

Owner:UCHICAGO ARGONNE LLC

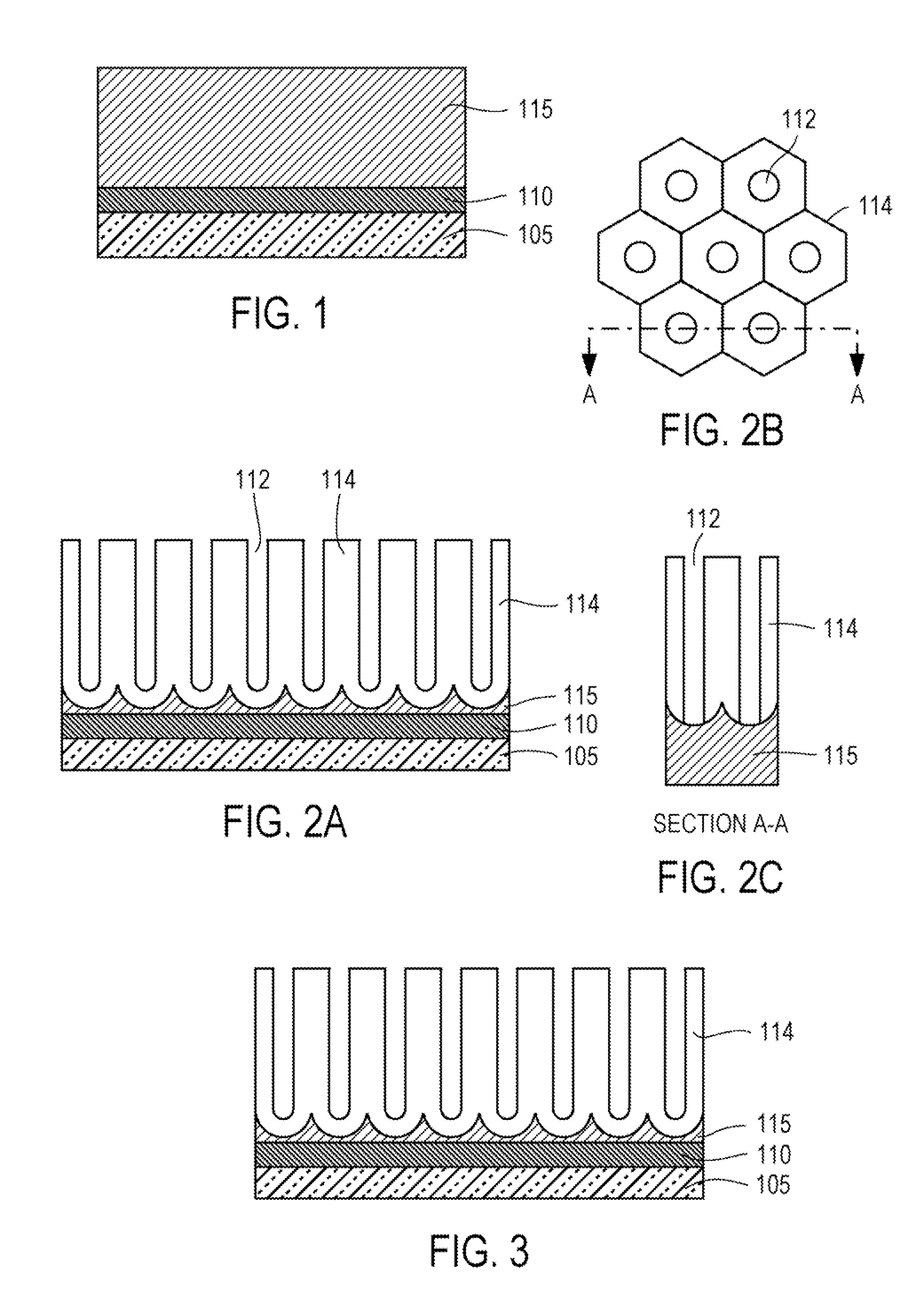

Micro structure for sensing trace chemicals

InactiveUS20070140900A1Increase surface adsorption capacityAvoid pollutionRadiation pyrometryAnalysis using chemical indicatorsMicro structureMaterials science

A method to fabricate an optical scattering probe and the method includes the steps of a) depositing an conductive layer on a substrate followed by depositing a noble metal layer on top of the conductive layer and then an aluminum layer on top the noble metal layer; b) anodizing the aluminum layer to form a porous aluminum oxide layer having a plurality of pores; and c) etching the plurality of pores through the aluminum oxide layer and the noble metal layer for forming a nano-hole array. In a preferred embodiment, the step of etching the plurality of pores through the aluminum oxide layer and the noble metal layer further comprising a step of widening the pores followed by removing the aluminum oxide layer for forming a plurality of noble metal column on top of the conductive layer.

Owner:EXCELLENT CAPACITY LTD

Method of fabricating nano-structured surface and configuration of surface enhanced light scattering probe

InactiveUS7384792B1Increase surface adsorption capacityAvoid pollutionRadiation pyrometryRaman scatteringNanostructureLight scattering

A method to fabricate an optical scattering probe and the method includes the steps of a) depositing an conductive layer on a substrate followed by depositing a noble metal layer on top of the conductive layer and then an aluminum layer on top the noble metal layer; b) anodizing the aluminum layer to form a porous aluminum oxide layer having a plurality of pores; and c) etching the plurality of pores through the aluminum oxide layer and the noble metal layer for forming a nano-hole array. In a preferred embodiment, the step of etching the plurality of pores through the aluminum oxide layer and the noble metal layer further comprising a step of widening the pores followed by removing the aluminum oxide layer for forming a plurality of noble metal column on top of the conductive layer.

Owner:OPTOTRACE TECH

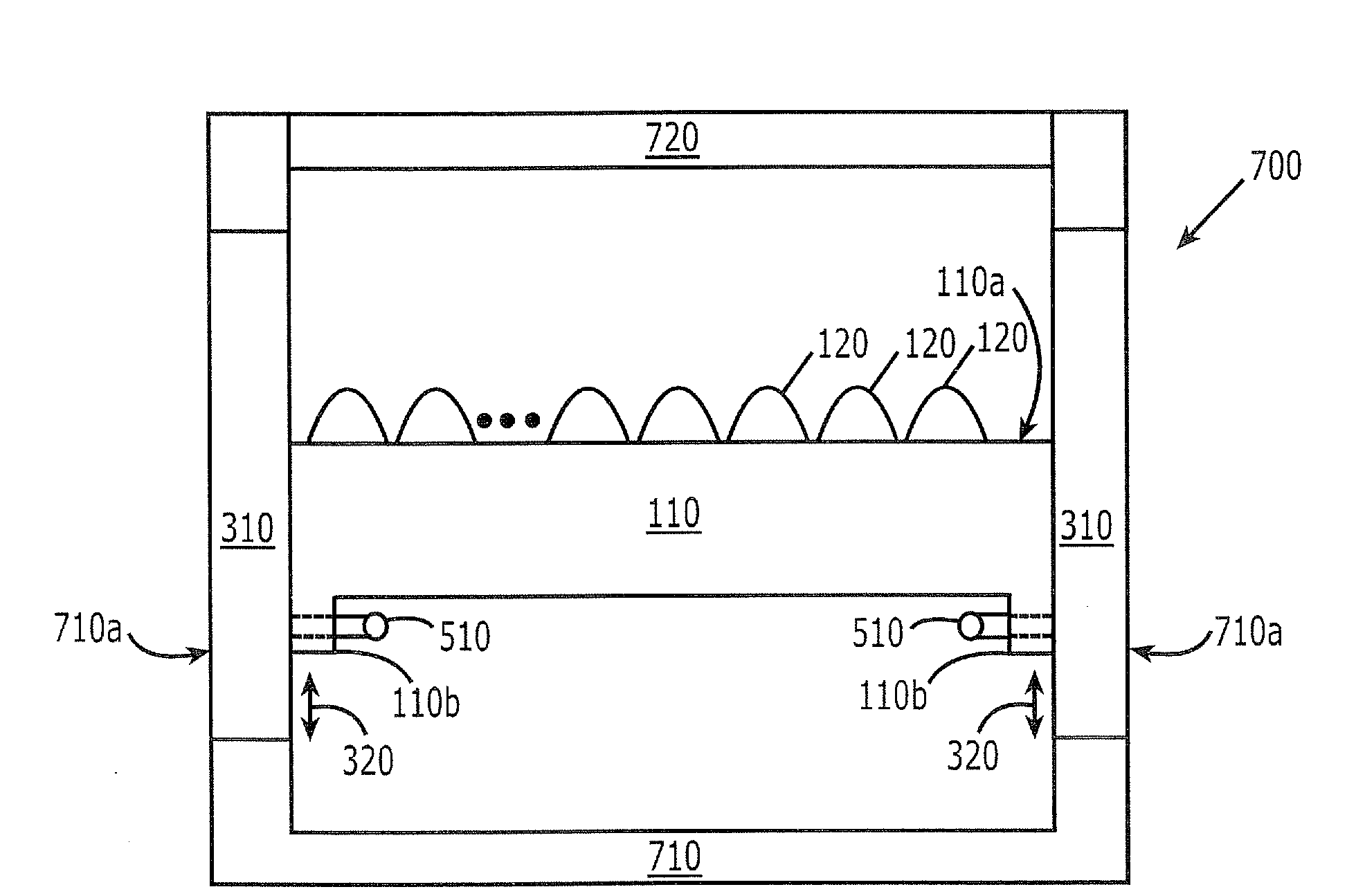

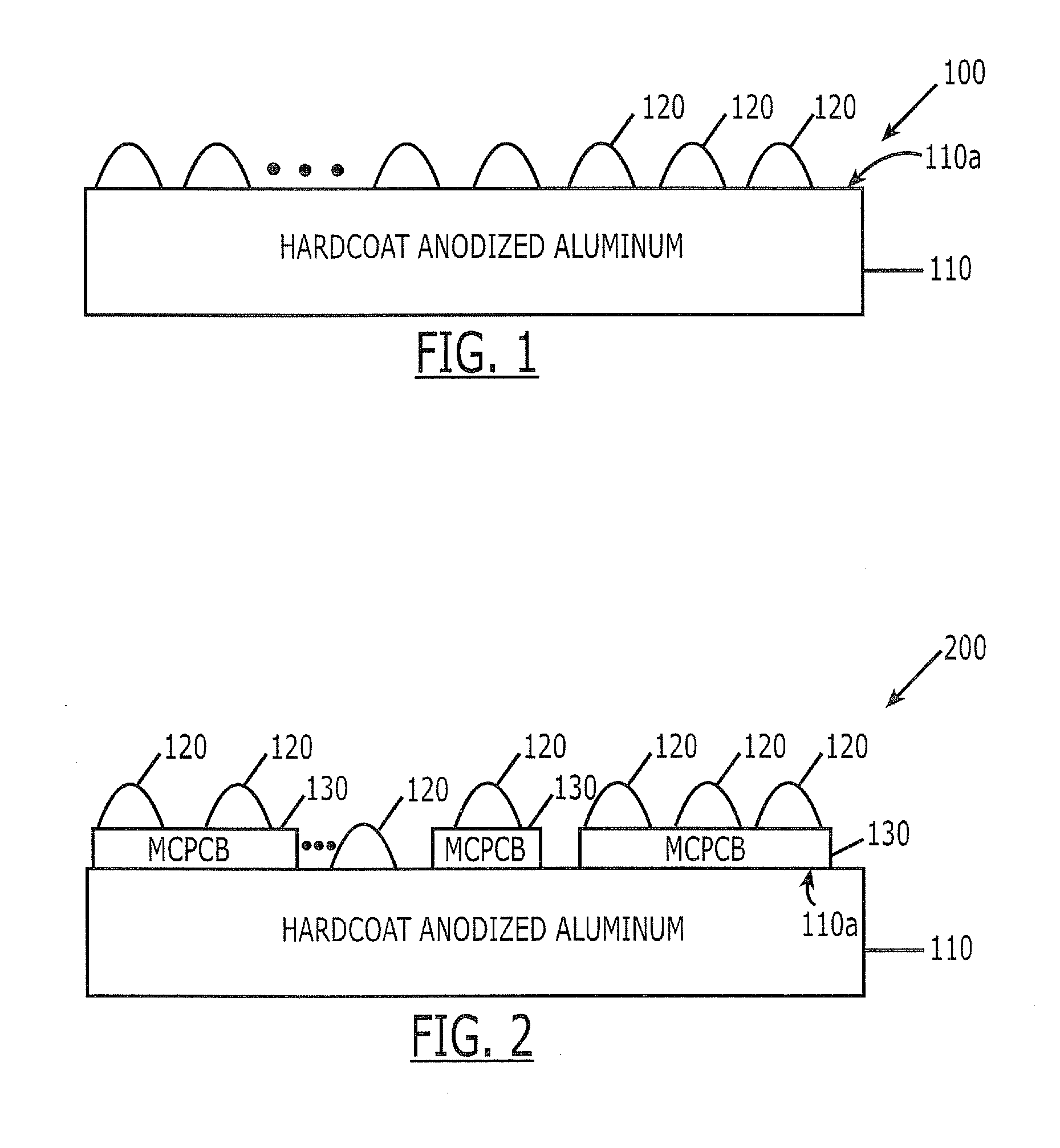

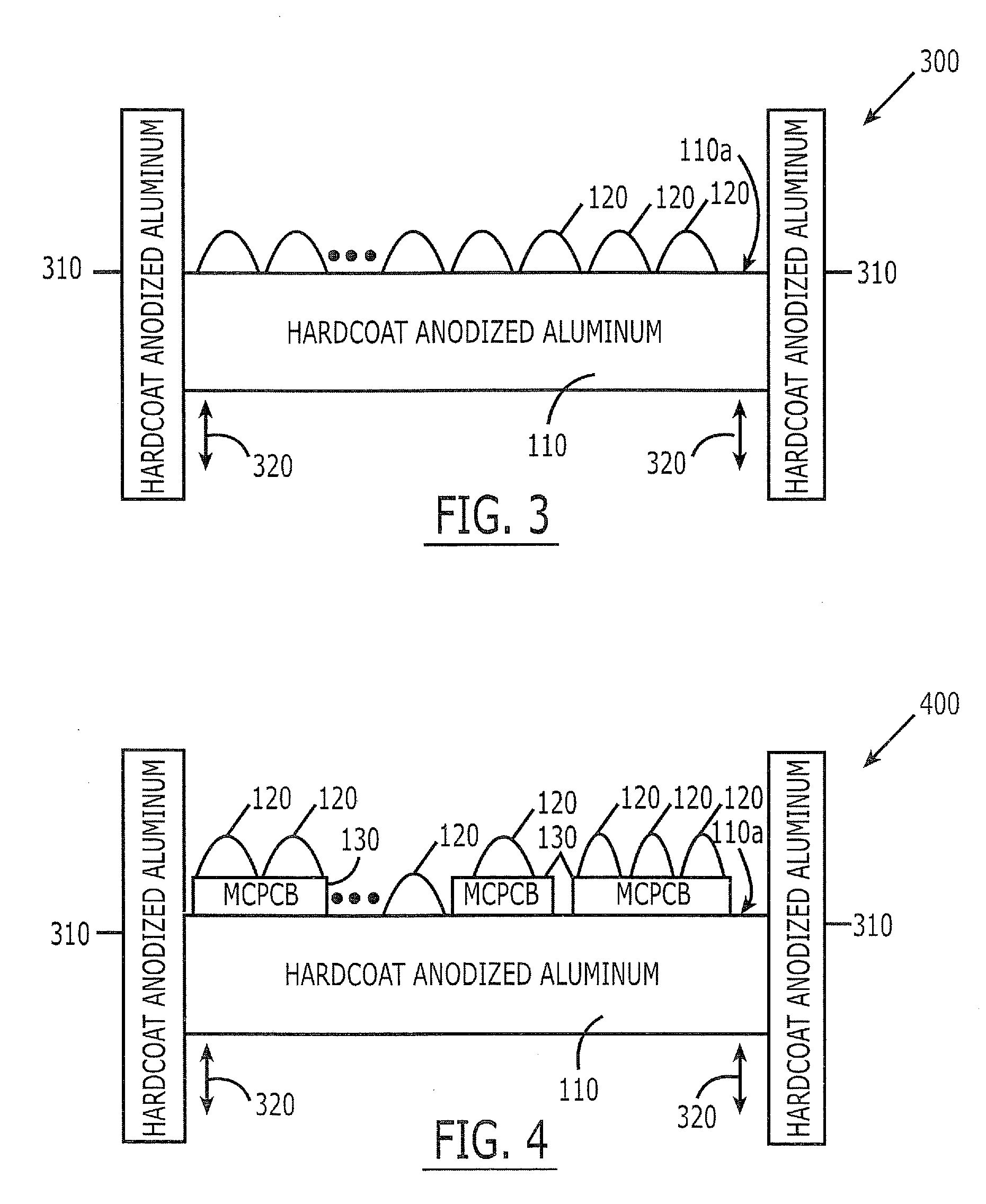

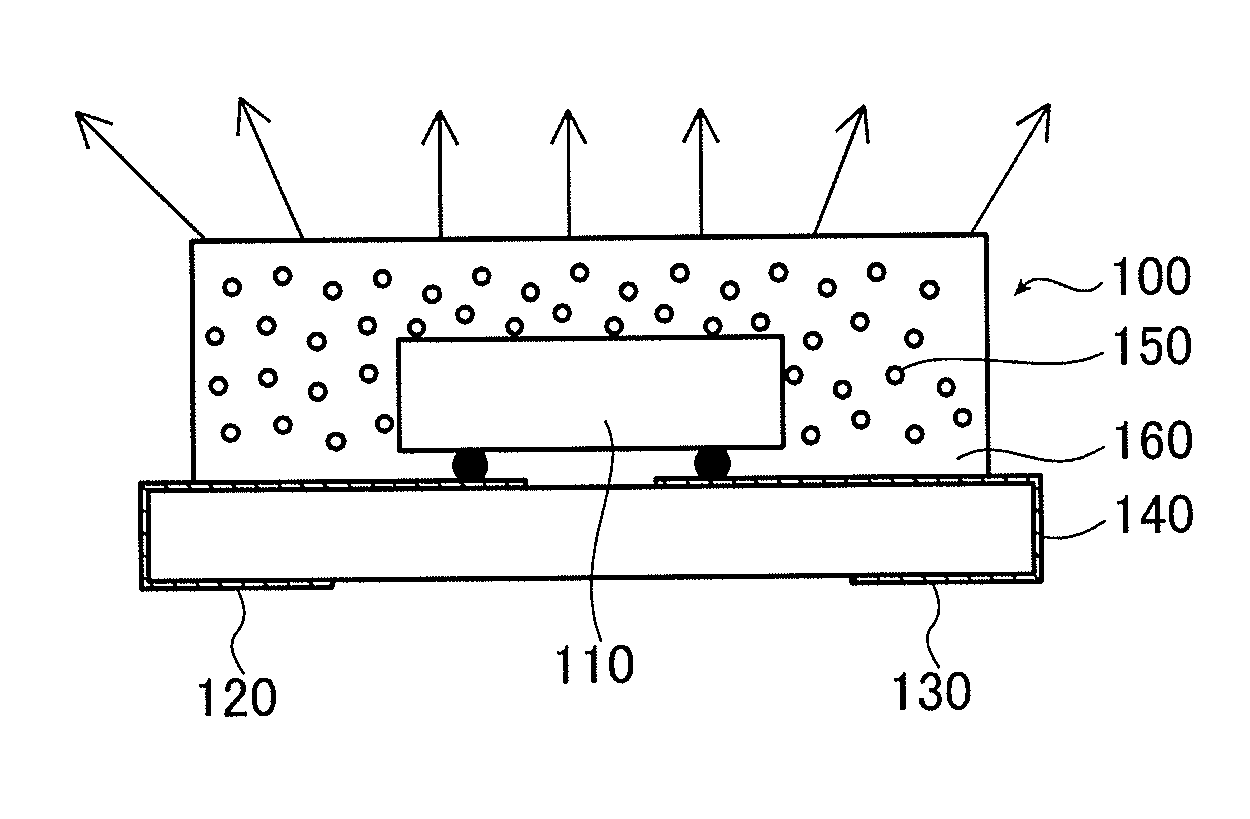

High thermal conductivity packaging for solid state light emitting apparatus and associated assembling methods

One or more solid state light emitting elements are mounted on a hardcoat anodized aluminum substrate. One or more bars also may be provided that slidably contact an edge of the hardcoat anodized aluminum substrate. The substrate and the bar(s) may be mounted in a housing with the bars mounted in apertures in the housing wall. Related assembling methods for solid state light emitting apparatus also are disclosed.

Owner:IDEAL IND LIGHTING LLC

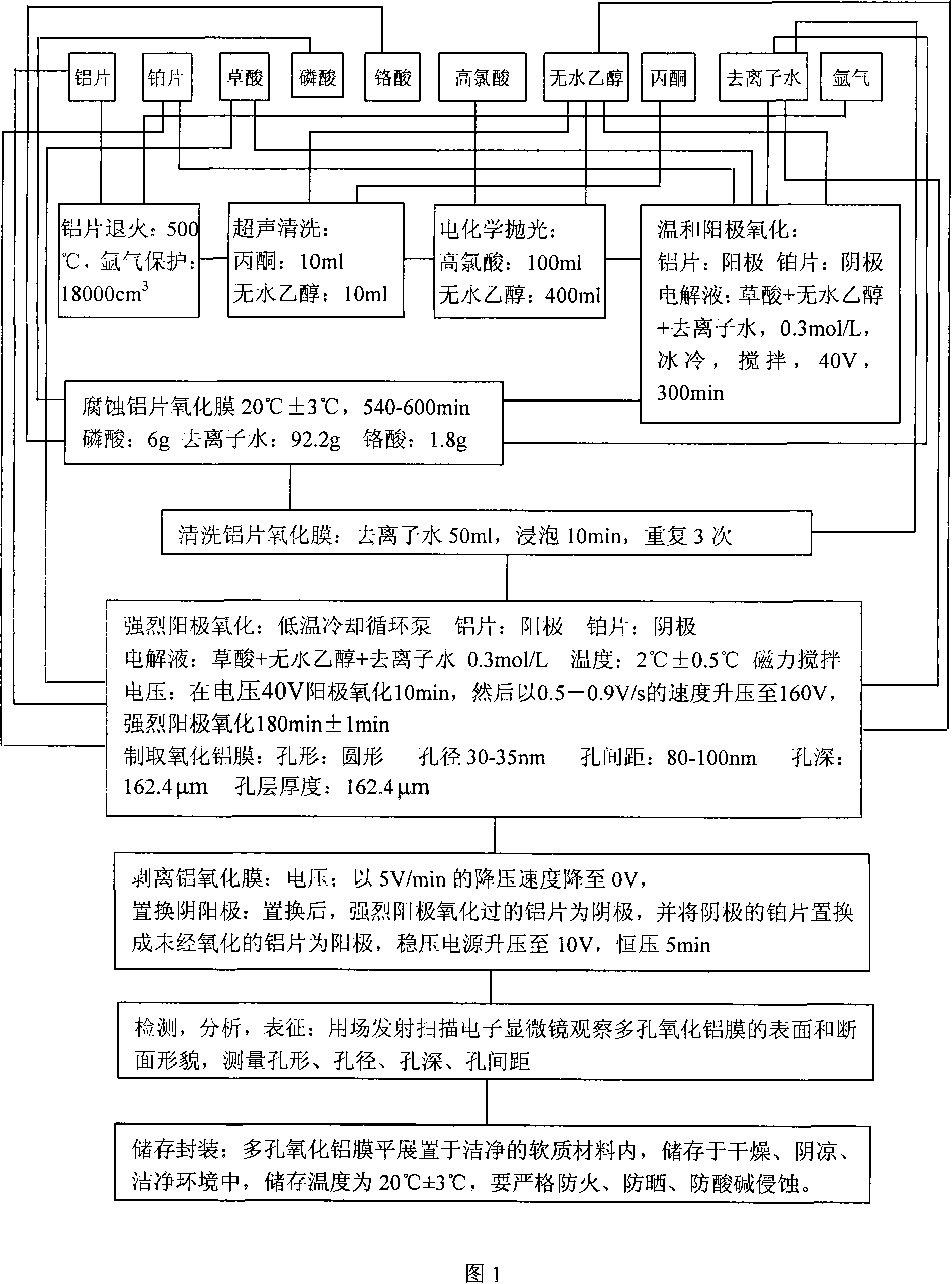

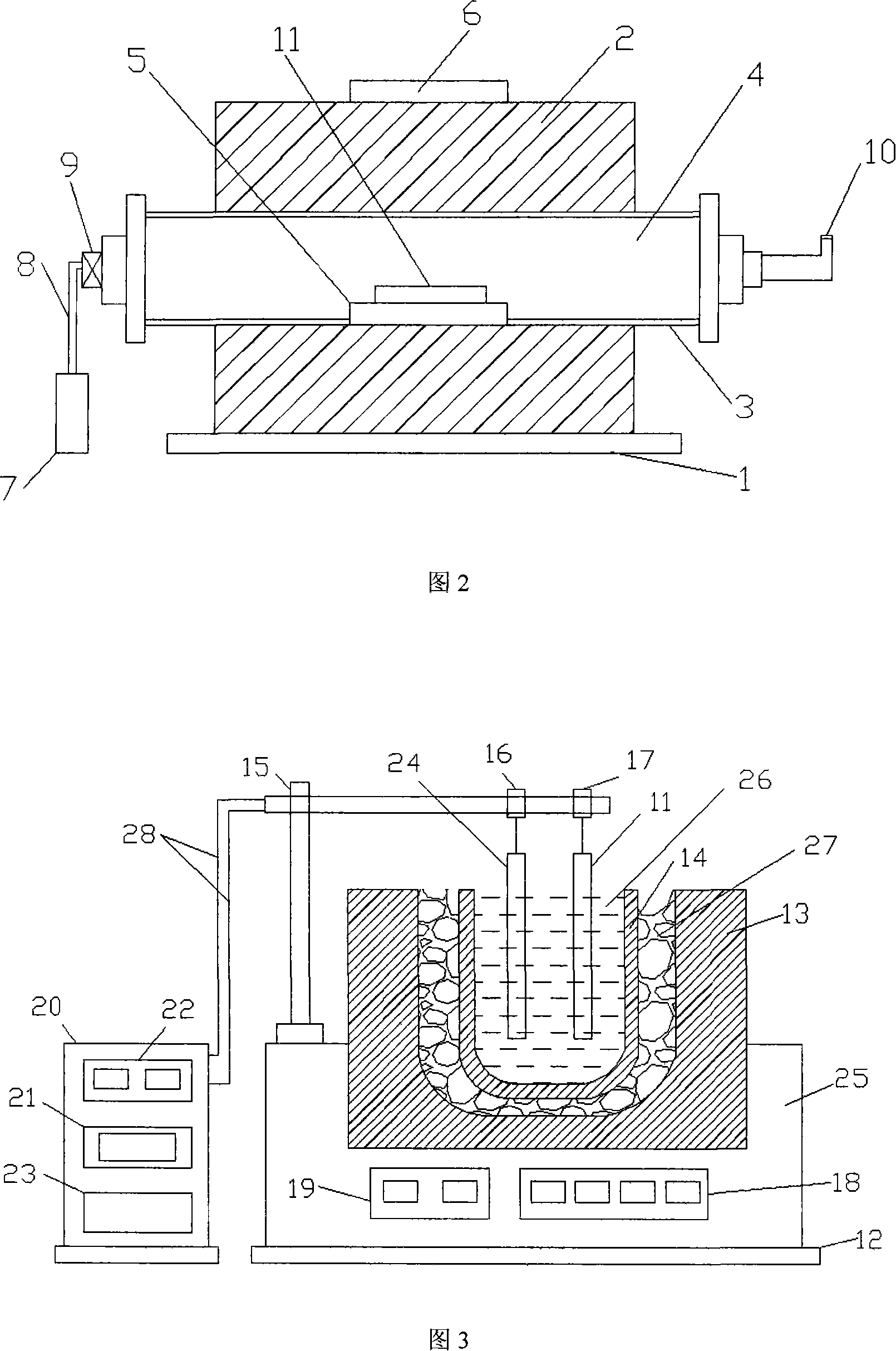

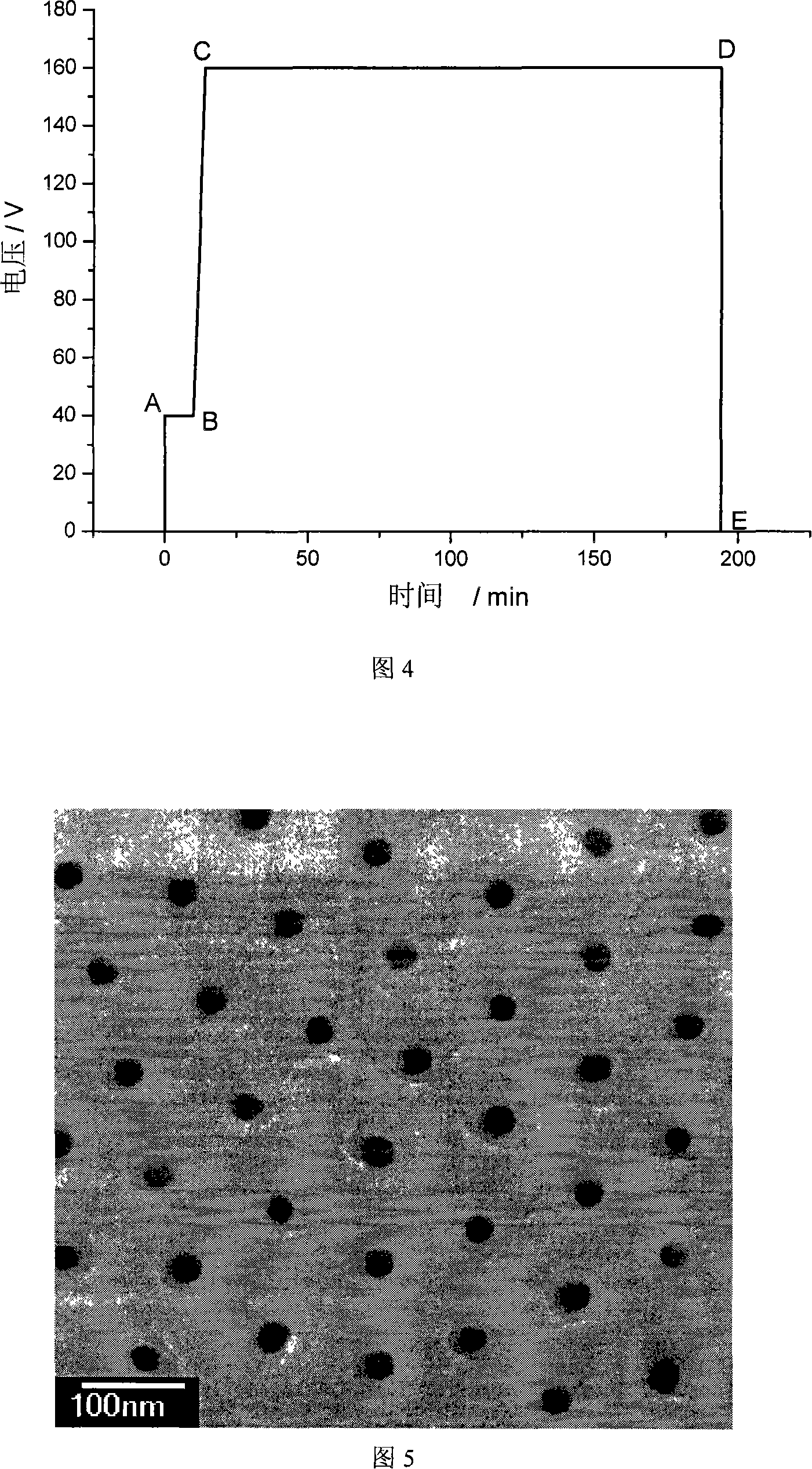

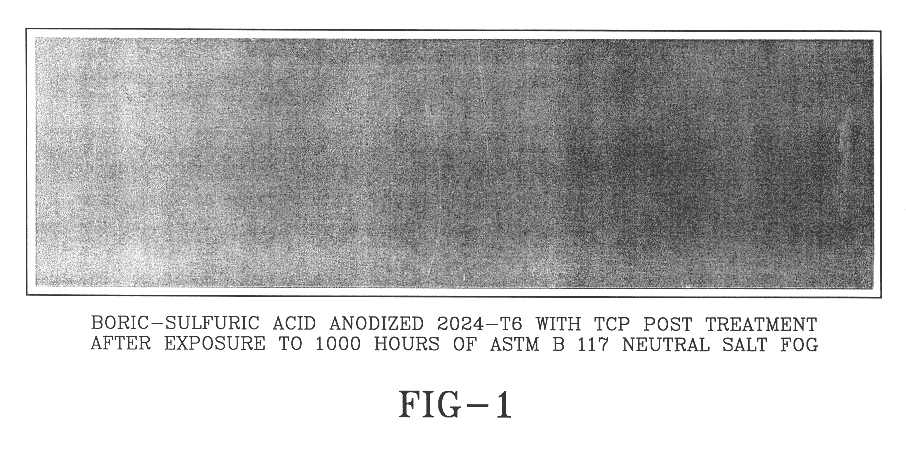

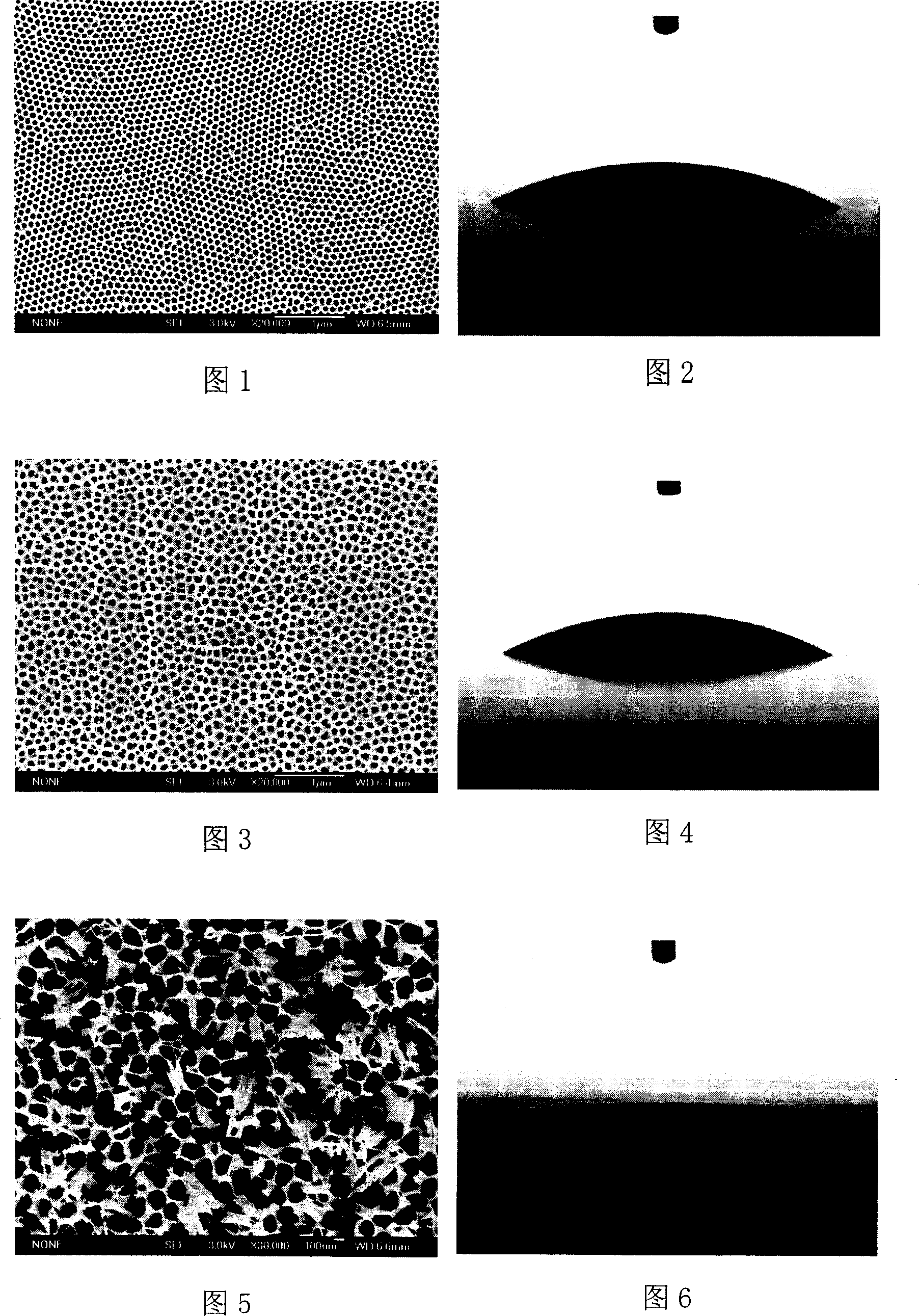

Strong anodic oxidation method for preparing porous pellumina

InactiveCN101139730AReduce pollutionRich sourcesSurface reaction electrolytic coatingShielding gasPhosphoric acid

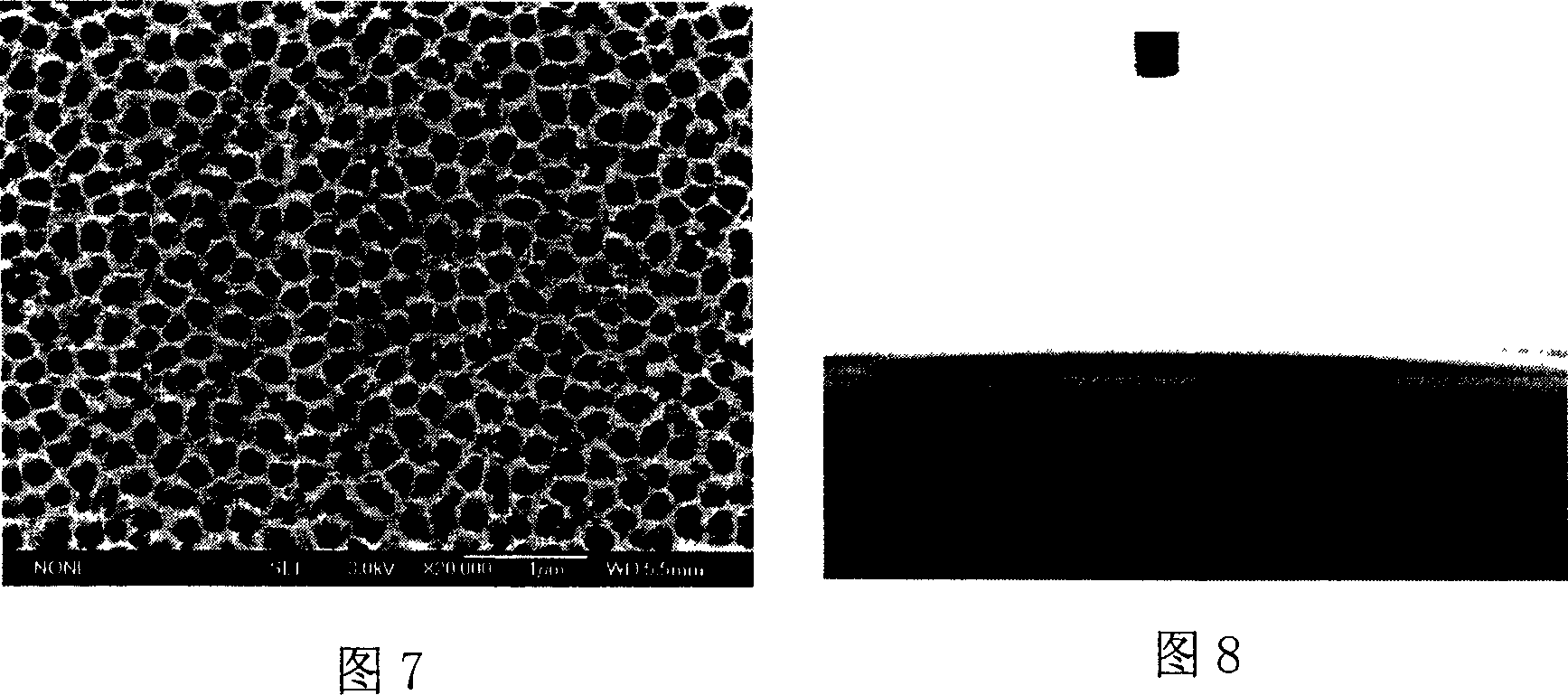

The invention relates to an intensive anodic oxidation process to prepare porous anodic alumina film. An aluminum sheet is as an anode; a platinum sheet as a cathode; argon as shielded gas; mixed solution of perchloric acid with absolute alcohol as electrochemical polishing compound for the aluminum sheet; mixed solution of oxalic acid, absolute alcohol and deionized water as electrolyte; and mixed solution of phosphoric acid, chromic acid and deionized water as alumina film corrodent. Through aluminum sheet annealing, purging, electrochemical polishing, mild anodic oxidation, corrosion on aluminum sheet oxide film, intensive anodic oxidation and stripping oxide film, and finally, pale yellow, high purity and ordered porous-structured nanometer-leveled alumina film is achieved; The alumina film pore is in circular shape sized in 30 to 35nm, pore distance in 80 to100nm and pore depth in 162.4 micrometers; growth rate of the alumina film is 54 micrometers / h, which is 27 times higher than 2 micrometers / h of growth rate of anodic oxidation aluminum film prepared through mild anodic oxidation process.

Owner:TAIYUAN UNIV OF TECH

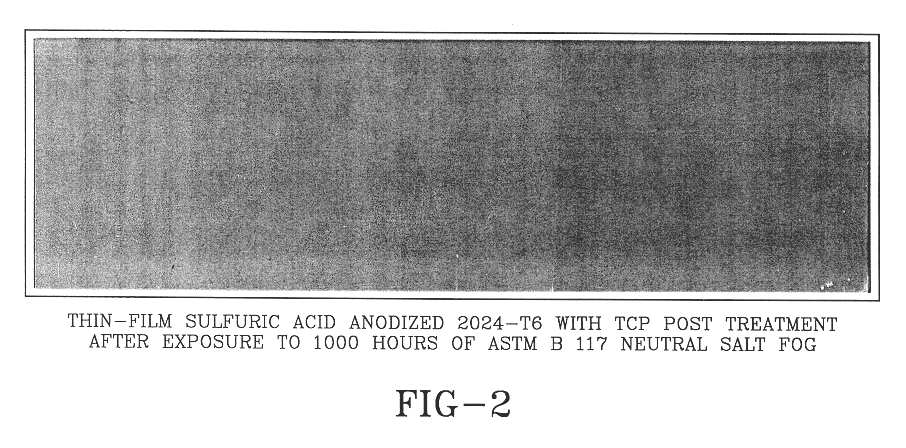

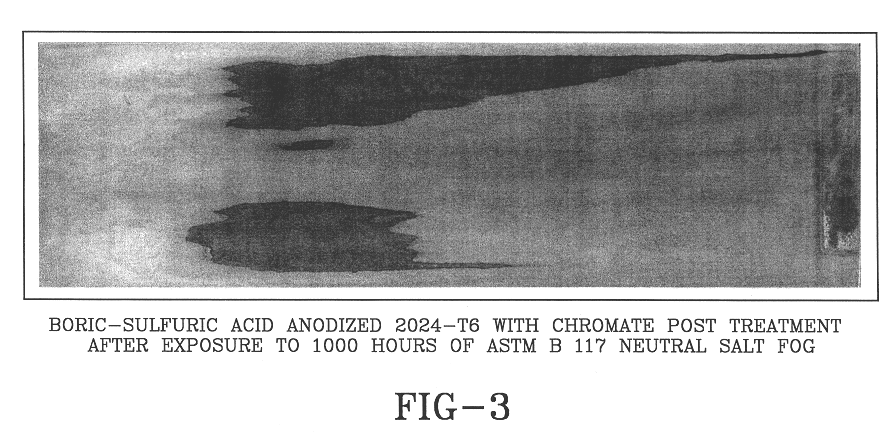

Post-treatment for anodized aluminum

InactiveUS6511532B2Improve corrosion-resistanceImprove adhesion bonding propertySurface reaction electrolytic coatingPretreated surfacesWater solubleSURFACTANT BLEND

Composition for post-treating anodized aluminum and aluminum alloys and the process for using said composition to improve the corrosion-resistance, abrasion, and adhesion bonding properties of the anodized aluminum and its alloys. The composition comprises an acidic aqueous solution having a pH ranging from about 2.5 to 4.5 containing effective amounts of trivalent chromium salts, alkali metal hexafluorozirconates, an alkali metal fluoro-compound e.g. fluoroborates and / or fluorosilicates, and effective amounts of water soluble thickeners and surfactants.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

LED bulb

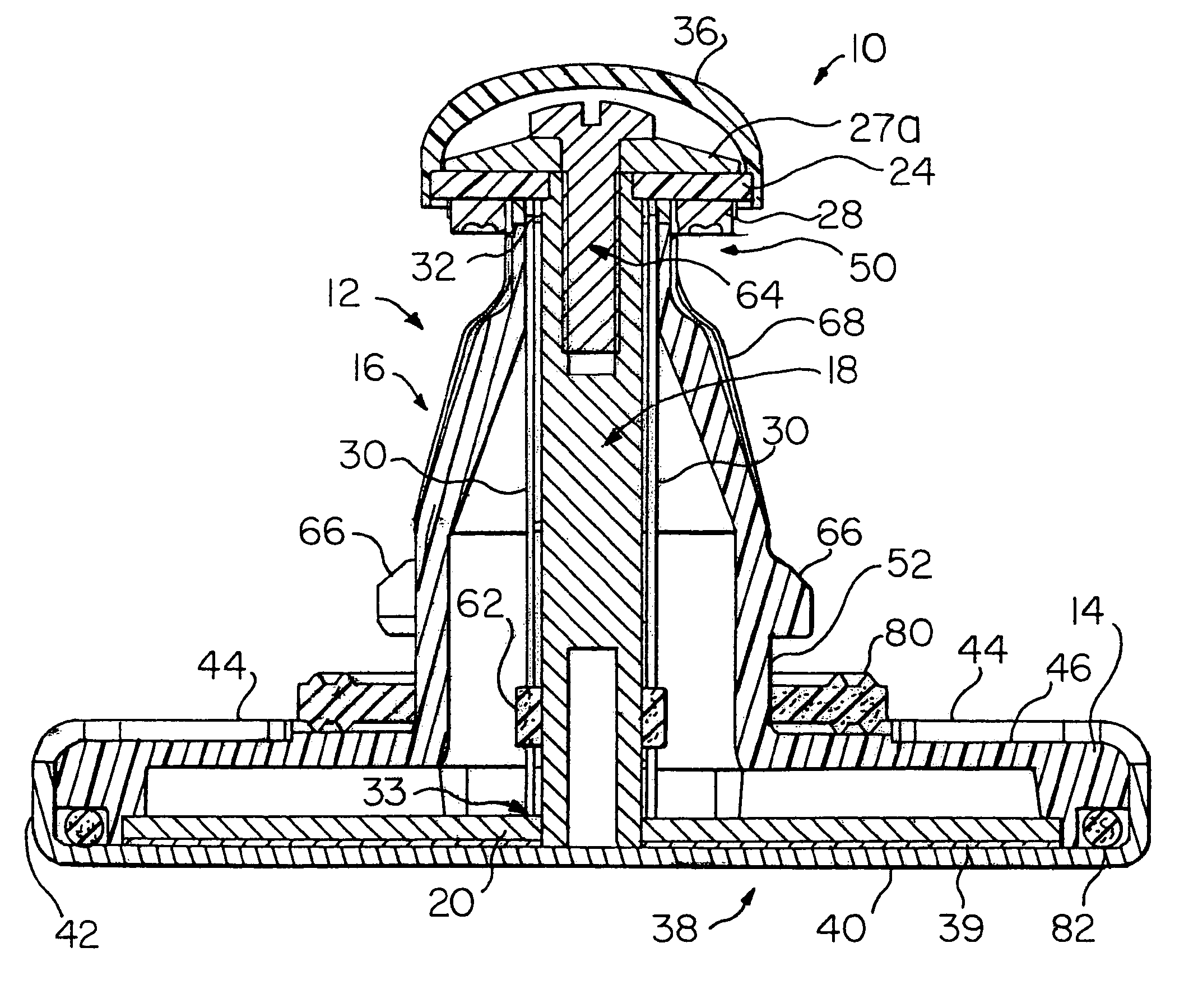

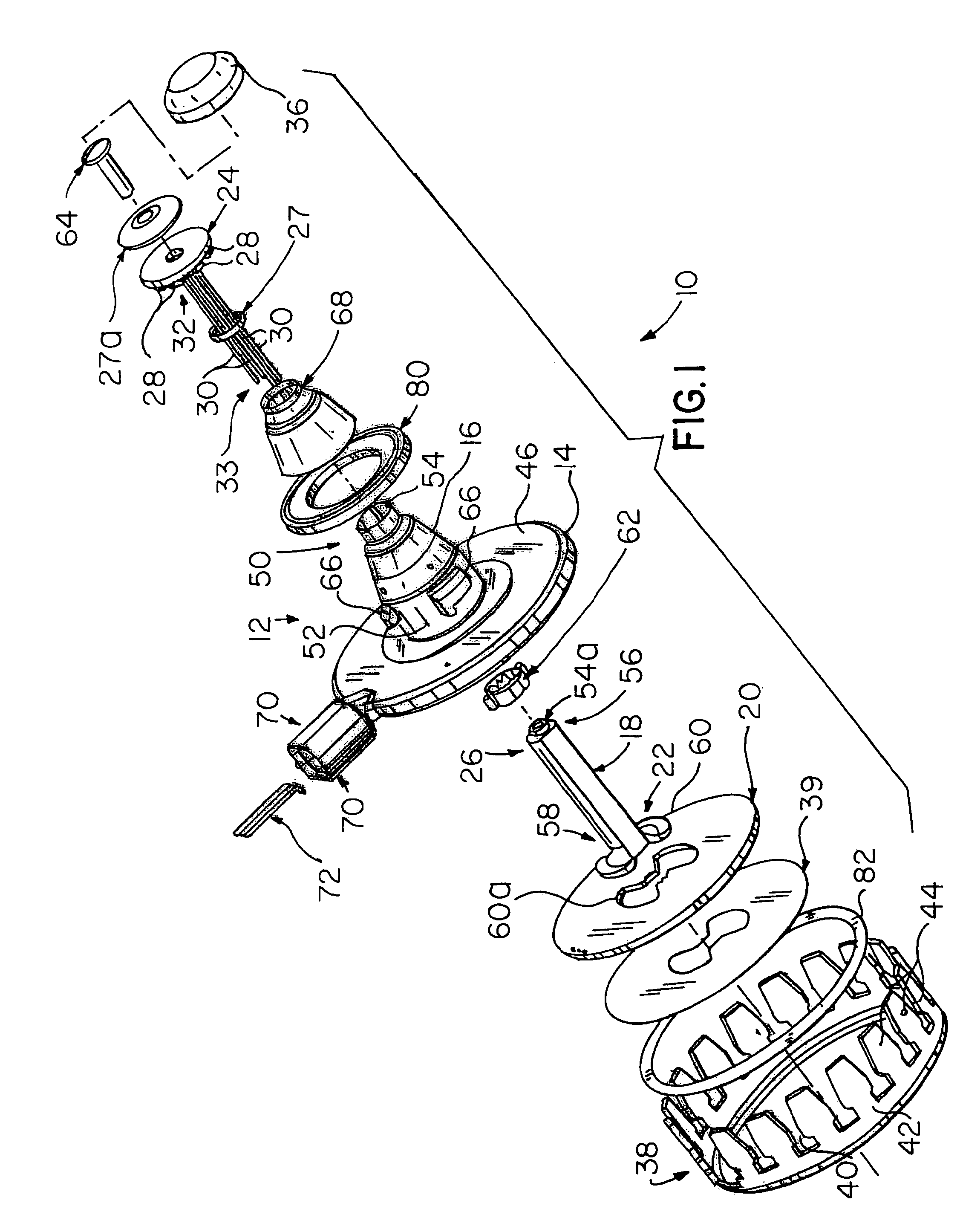

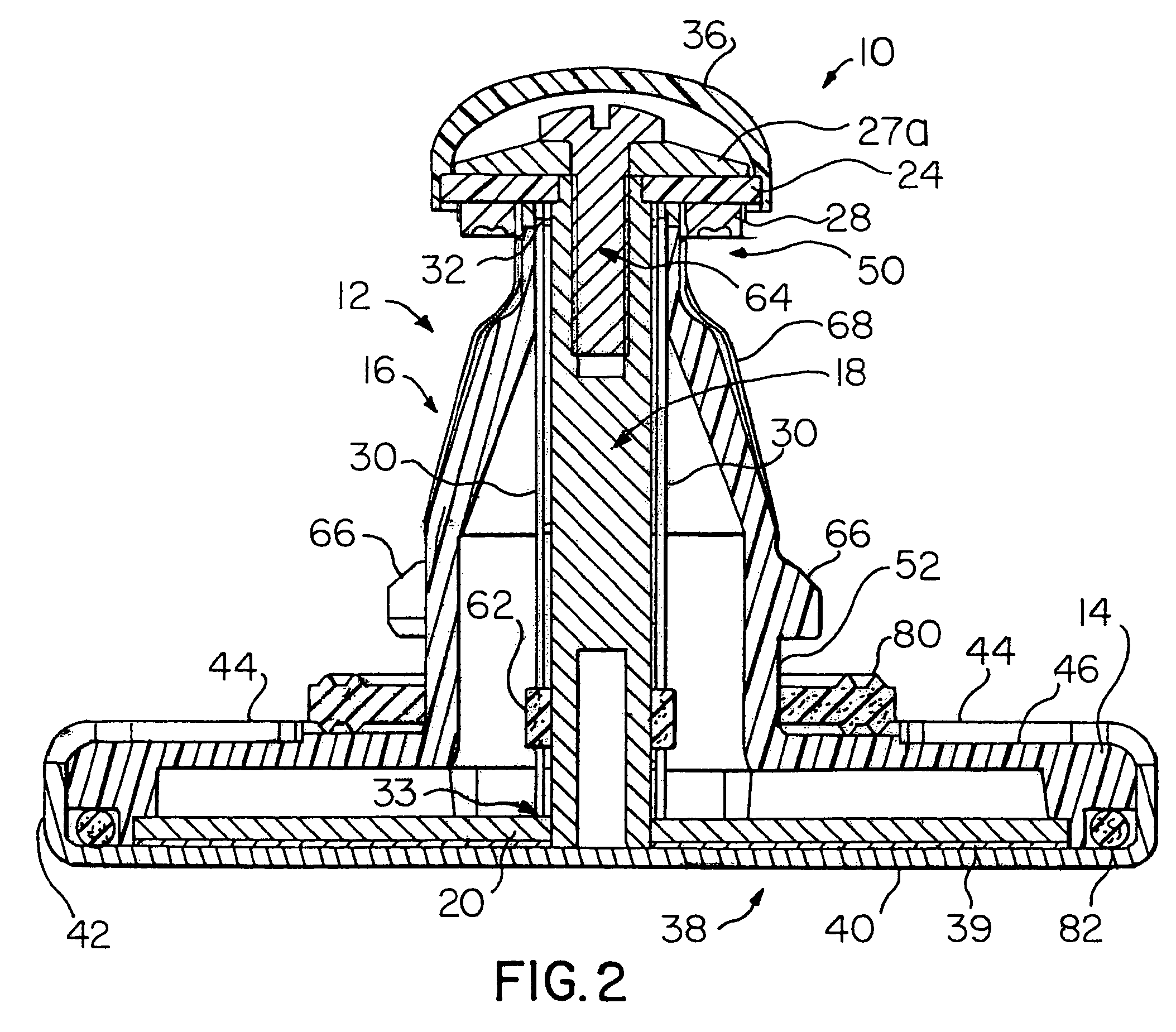

ActiveUS7059748B2Eliminate needVehicle headlampsData processing applicationsElectrical conductorHeat conducting

An LED light source (10) has a housing (12) with a base (14). A central heat conductor (18) is centrally located within the hollow core (16) and is formed of a suitable heat-conducting material, such as copper. A cap (36) is fitted over a second printed circuit board (24), and a heat sink (38) is attached to the base (14) and in thermal contact with a first printed circuit board (20). The heat sink (38) has a bottom (40) with an upstanding side wall (42) terminating in a plurality of fingers (44), the fingers (44) being formed to overlie an upper surface (46) of the base (14). The heat sink (38) is preferably formed from black-anodized aluminum.

Owner:OSRAM SYLVANIA INC

Fabricating carbon nanotube transistor devices

During fabrication of single-walled carbon nanotube transistor devices, a porous template with numerous parallel pores is used to hold the single-walled carbon nanotubes. The porous template or porous structure may be anodized aluminum oxide or another material. A gate region may be provided one end or both ends of the porous structure. The gate electrode may be formed and extend into the porous structure. A transistor of the invention may be especially suited for power transistor or power amplifier applications.

Owner:ETAMOTA CORP

Thermokeratoplasty systems

InactiveUS20070161976A1Damage to produceEliminate systematic errorsEye surgerySurgical instruments for heatingGonioplastyConductive materials

The present invention provides applicators for performing thermokeratoplasty. One embodiment of such applicators includes two generally tubular electrical conducting elements coaxially disposed relative to one another and separated by an electrically insulating element having a selected thickness. At least a portion of each conducting tube is coated with an electrically insulating and thermally conductive material, e.g., anodized aluminum, so as to electrically insulate the conducting tubes from corneal tissue upon placement of the applicator on a subject's cornea while facilitating extraction of heat from the cornea.

Owner:TRUSTEES OF DARTMOUTH COLLEGE THE

LED wayside signal for a railway

A wayside signal for a railway includes a plurality of light emitting diodes housed in a housing. The light emitting diodes output indication signals. Further, the light emitting diodes are configured on a first circuit board which is thermally coupled to the housing. The housing may also include heat sink fins to dissipate heat generated by the light emitting diodes and associated driving circuitry for driving the light emitting diodes also contained within the housing. An additional light emitting diode may also be contained within the housing to point in an opposite direction than the indication signal light emitting diodes, which additional light emitting diode may be formed on a second circuit board with the driving circuitry. The additional light emitting diode provides an indication to anyone behind the wayside signal as to the indication of the wayside signal. The wayside signal is further optimized for thermal efficiency and to be sealed against the elements. In regard to thermal efficiency, the first circuit board may be metal clad and the housing may be formed of black anodized aluminum. Also, a plastic insulator may be attached to the housing and covered with a lamp base. The lamp base may be configured to be inserted into a conventional socket for a wayside signal, so that the wayside signal of the present invention can be utilized with existing circuitry.

Owner:DIALIGHT CORP

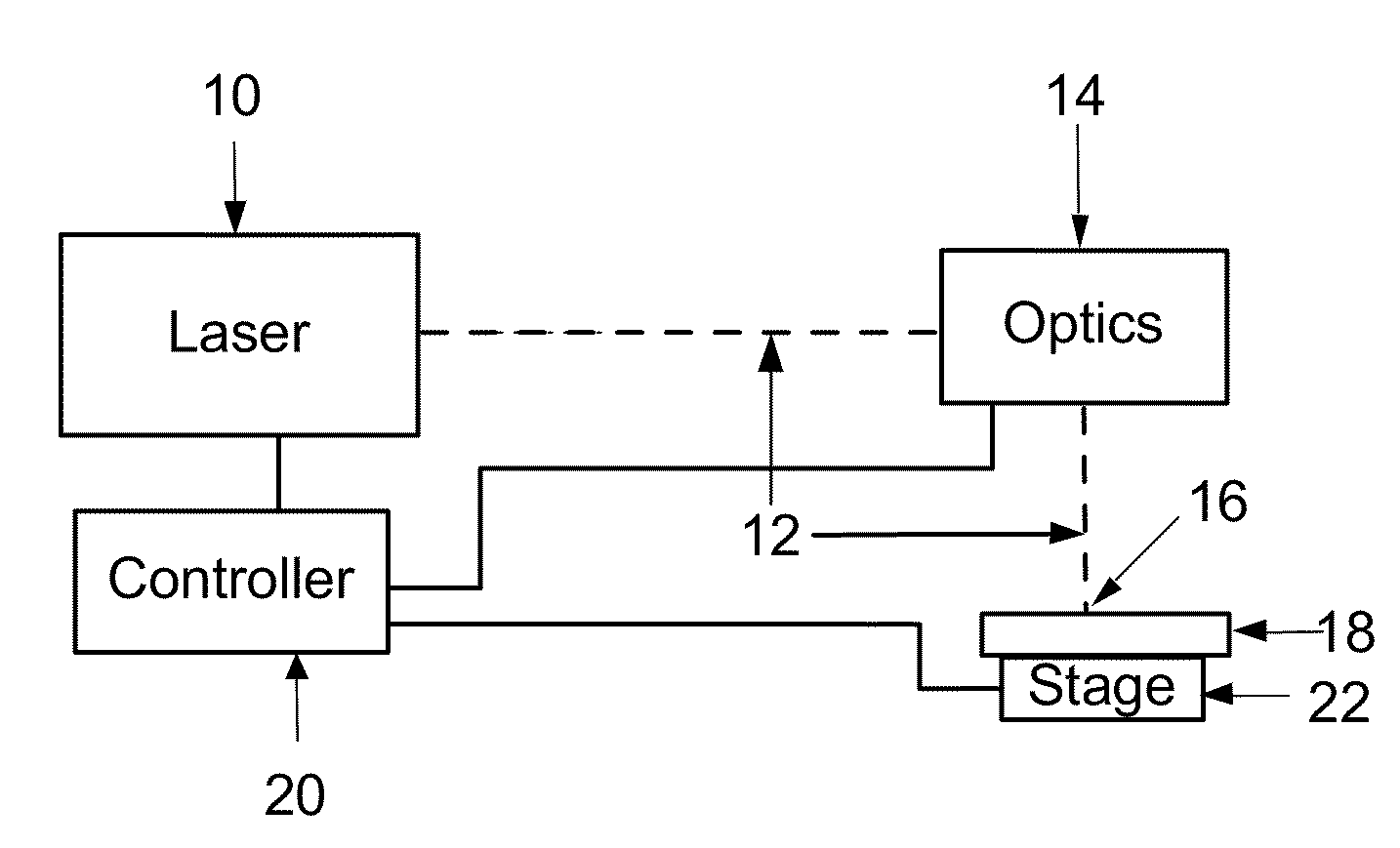

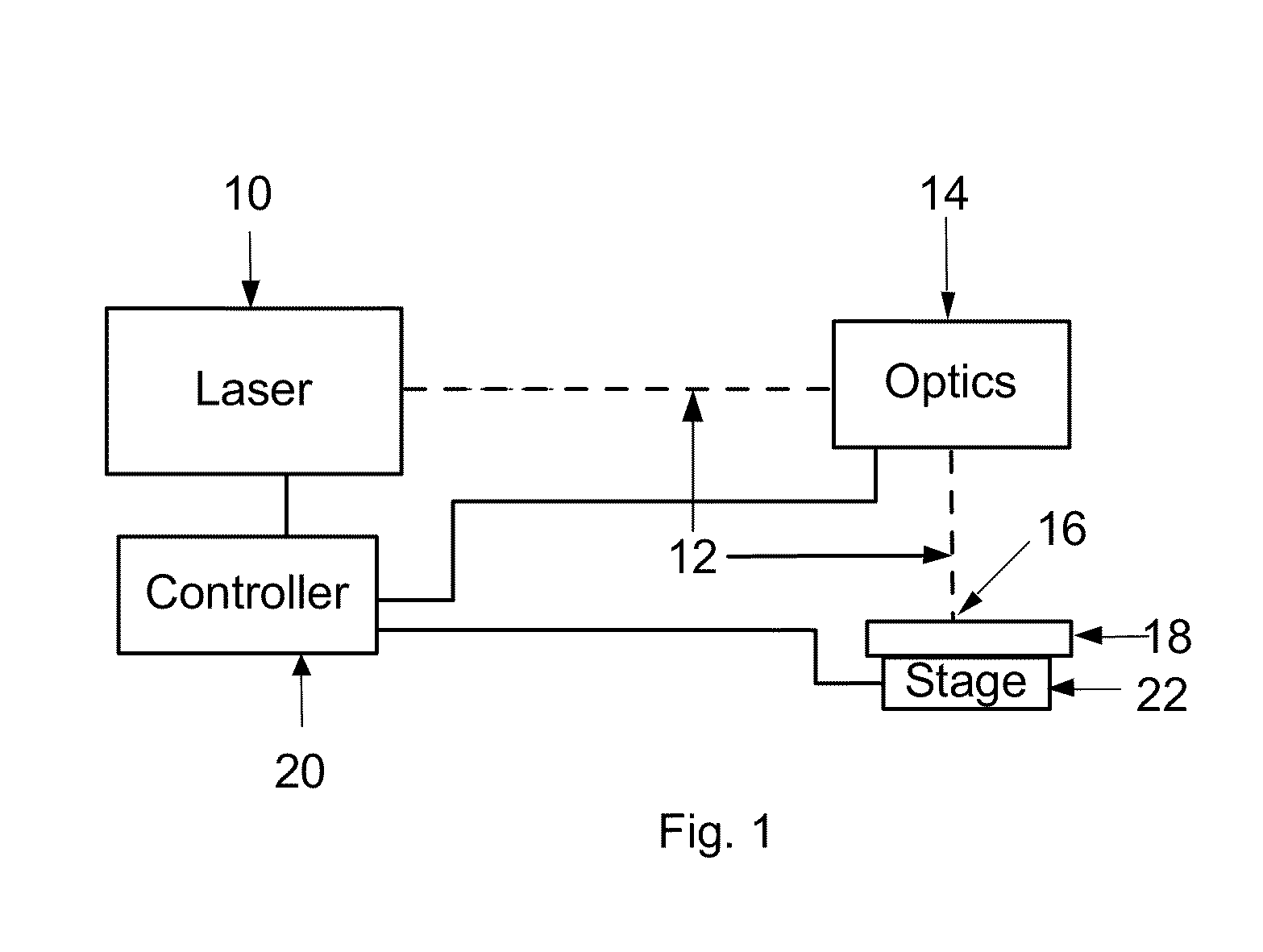

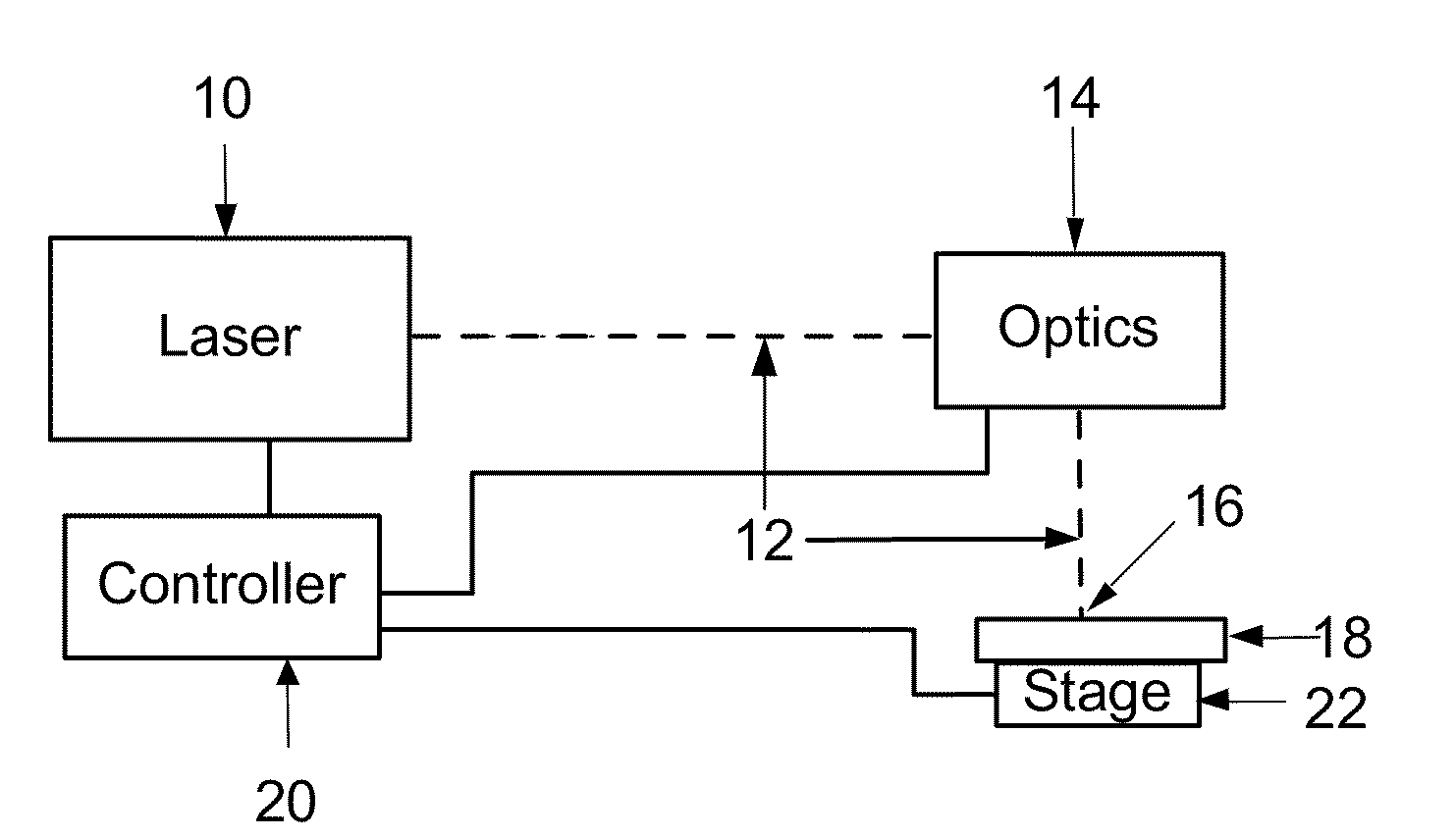

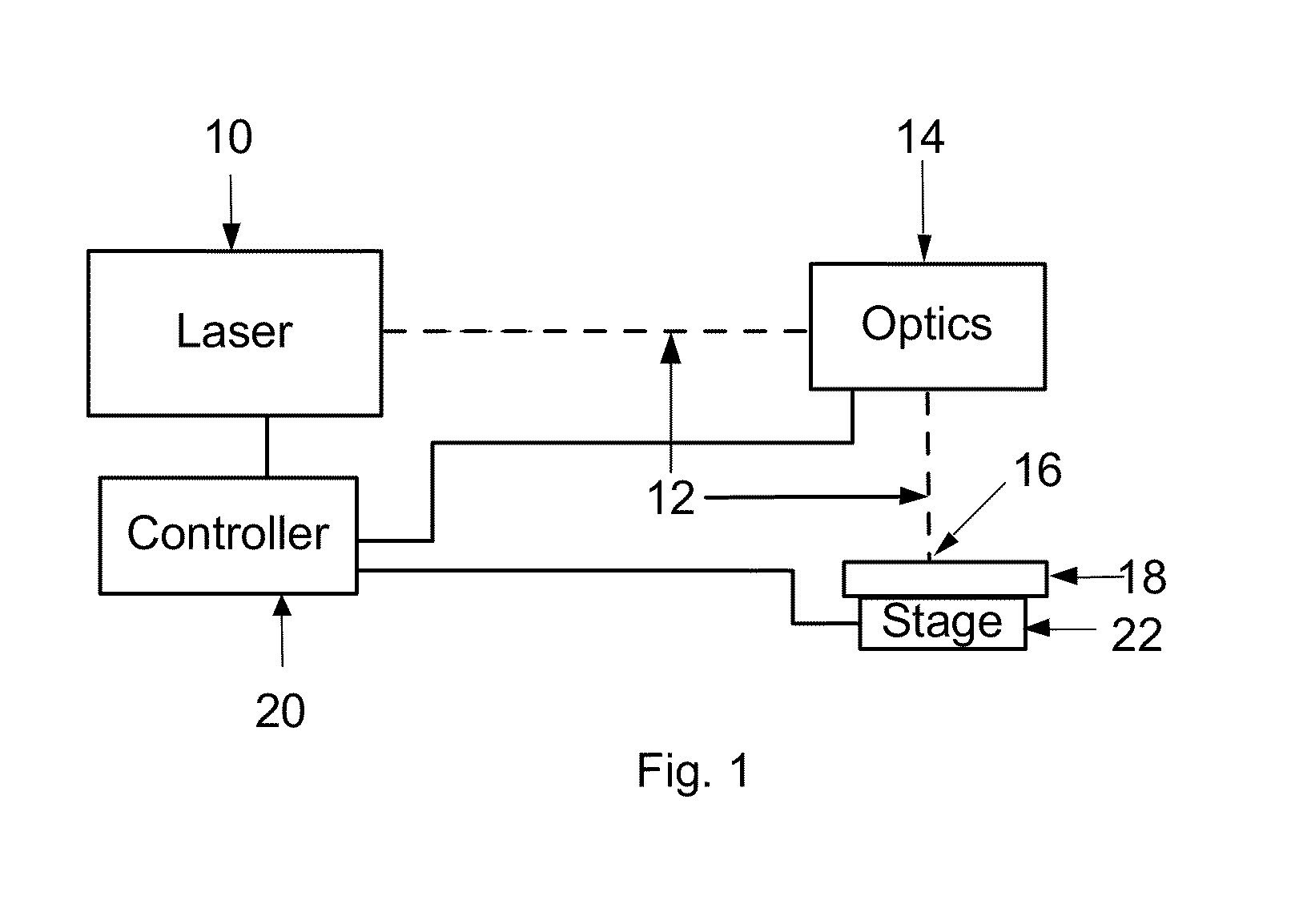

Method and apparatus for reliably laser marking articles

InactiveUS20110194574A1Desirable appearanceMarking is durableRecording apparatusLaser detailsPulse parameterPicosecond

The invention is a method and apparatus for creating a color and optical density selectable visible mark on an anodized aluminum specimen. The method includes providing a laser marking system having a laser, laser optics and a controller operatively connected to said laser to control laser pulse parameters and a controller with stored laser pulse parameters, selecting the stored laser pulse parameters associated with the desired color and optical density, directing the laser marking system to produce laser pulses having laser pulse parameters associated with the desired color and optical density including temporal pulse widths greater than about 1 and less than about 1000 picoseconds to impinge upon said anodized aluminum.

Owner:ELECTRO SCI IND INC

Process for preparing highly-hydrophilic alumina film material

InactiveCN101007645AImprove stabilityShape is easy to controlAluminium oxide/hydroxide preparationPhosphoric acidElectrochemistry

The invention discloses a making method of high-hydrophilicity alumina film, which comprises the following steps: adopting electrochemical polished aluminium foil as anode and platinum piece as cathode; selecting one of sulfuric acid, oxalic acid phosphoric acid with water or poor water (the composite solution of oxalic alcohol and water) as electrolyte solution; using electrochemical oxidizing method to strip aluminium base; removing damping layer; obtaining the product with different shapes and areas.

Owner:BEIJING ZHONGKE NANO THINK PRINT TECH

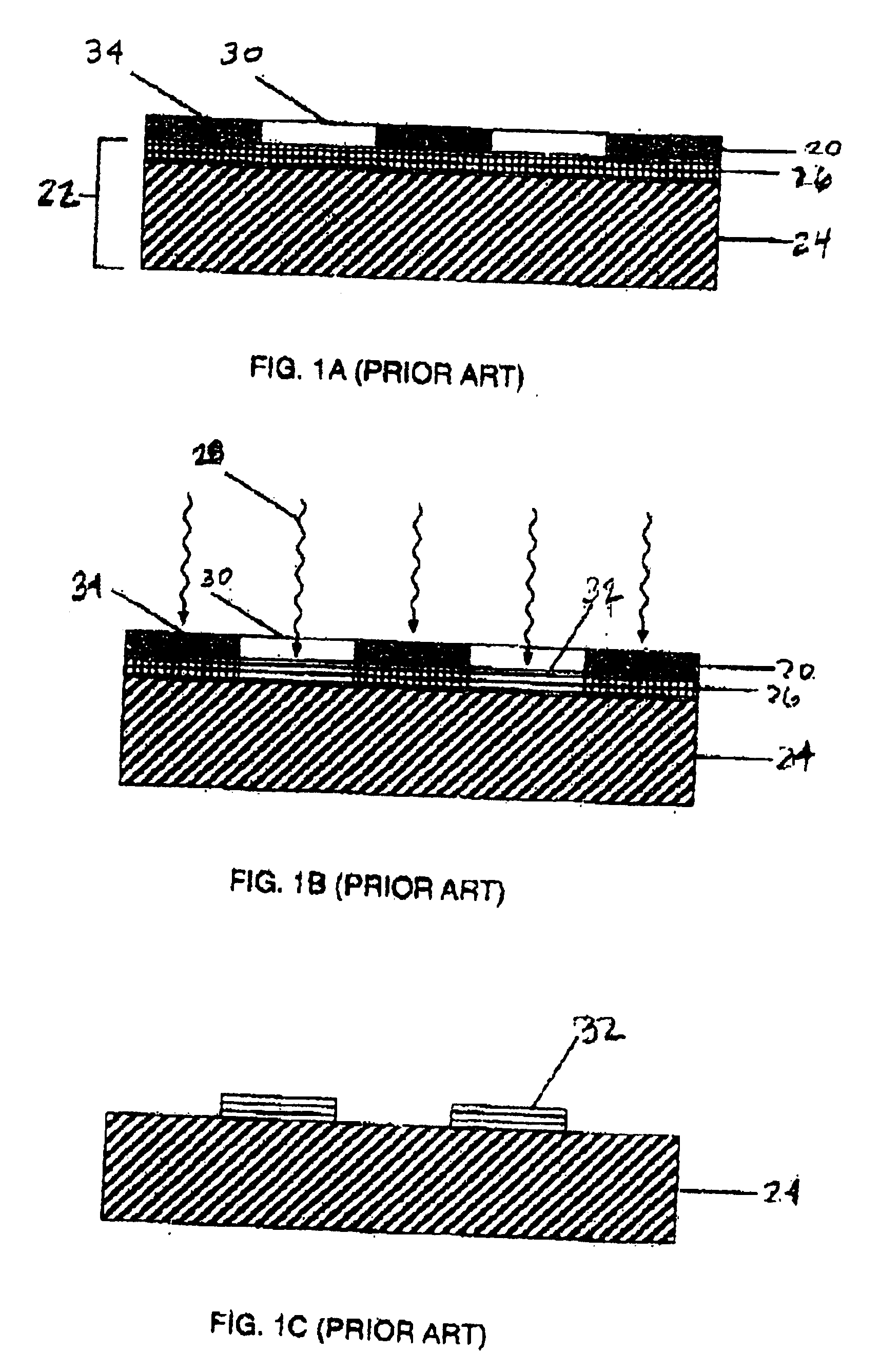

Pre-treatment liquid for use in preparation of an offset printing plate using direct inkjet CTP

InactiveUS6906019B2Improve image qualityFast plating speedSurface-active detergent compositionsDuplicating/marking methodsPre treatmentSurface chemical

A method of making a printing plate in which the uncoated surface of a substrate is treated with a pre-treatment solution prior to the deposition of ink on the surface. The pre-treatment liquid comprises a polyvalent metal salt, and at least one of an organic swelling reagent and / or a coalescence reagent. The pre-treatment liquid is applied to form a thin, homogenous layer of approximately 4 μm to the entire upper surface of the recording plate. The swelling reagent and / or the coalescence reagent and the polyvalent metal cations are physically well localized in the porous structure of the plate's surface. After partial drying of the pretreated anodized aluminum plate, CTP liquid is deposited onto the surface to form an image. The CTP liquid solids react with the pre-treatment liquid and are, therefore, chemically bound to the surface. This allows all data to be deposited in a single pass of the inkjet head without the problem of clustering.

Owner:HEWLETT PACKARD IND PRINTING LTD

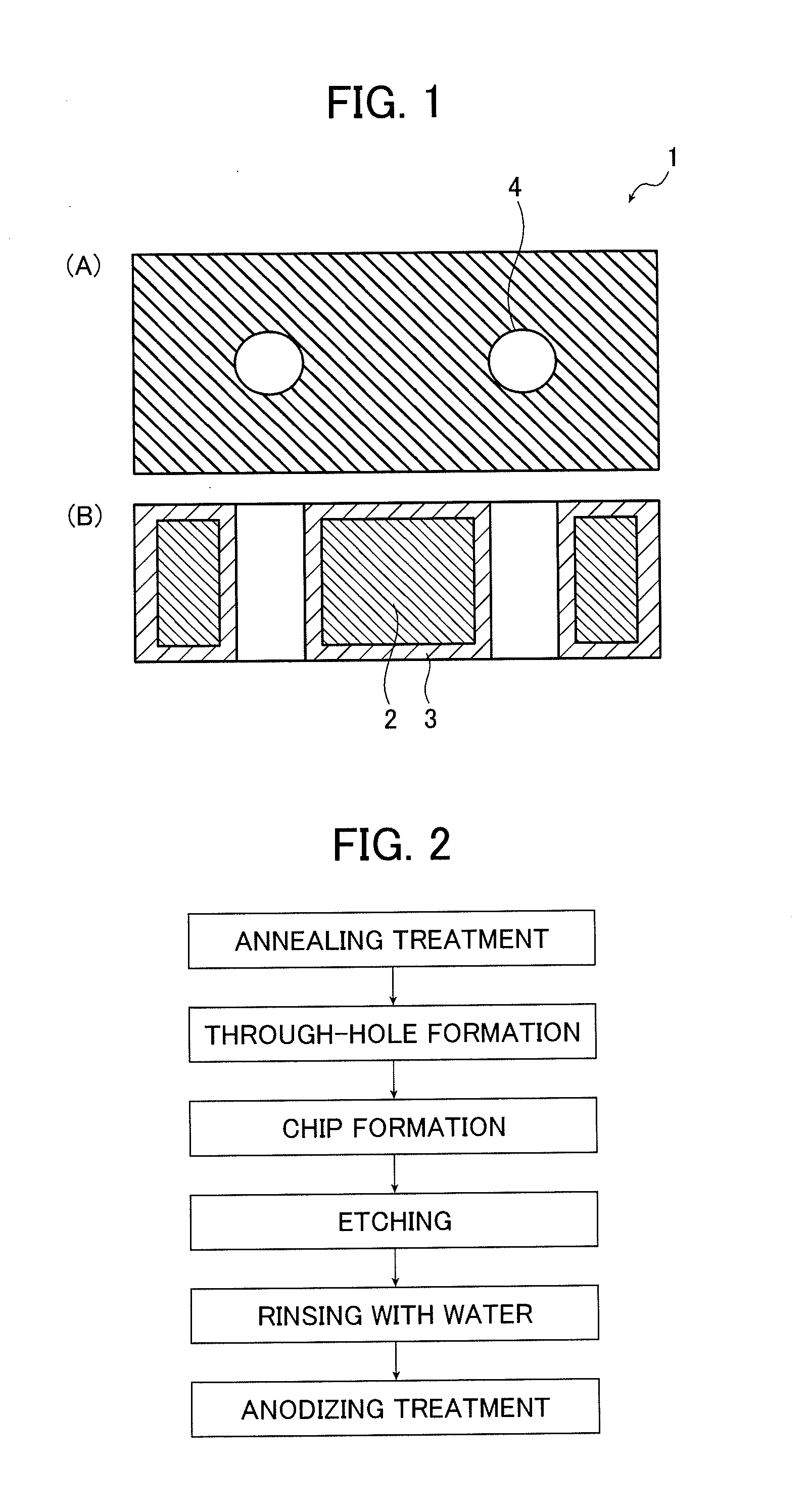

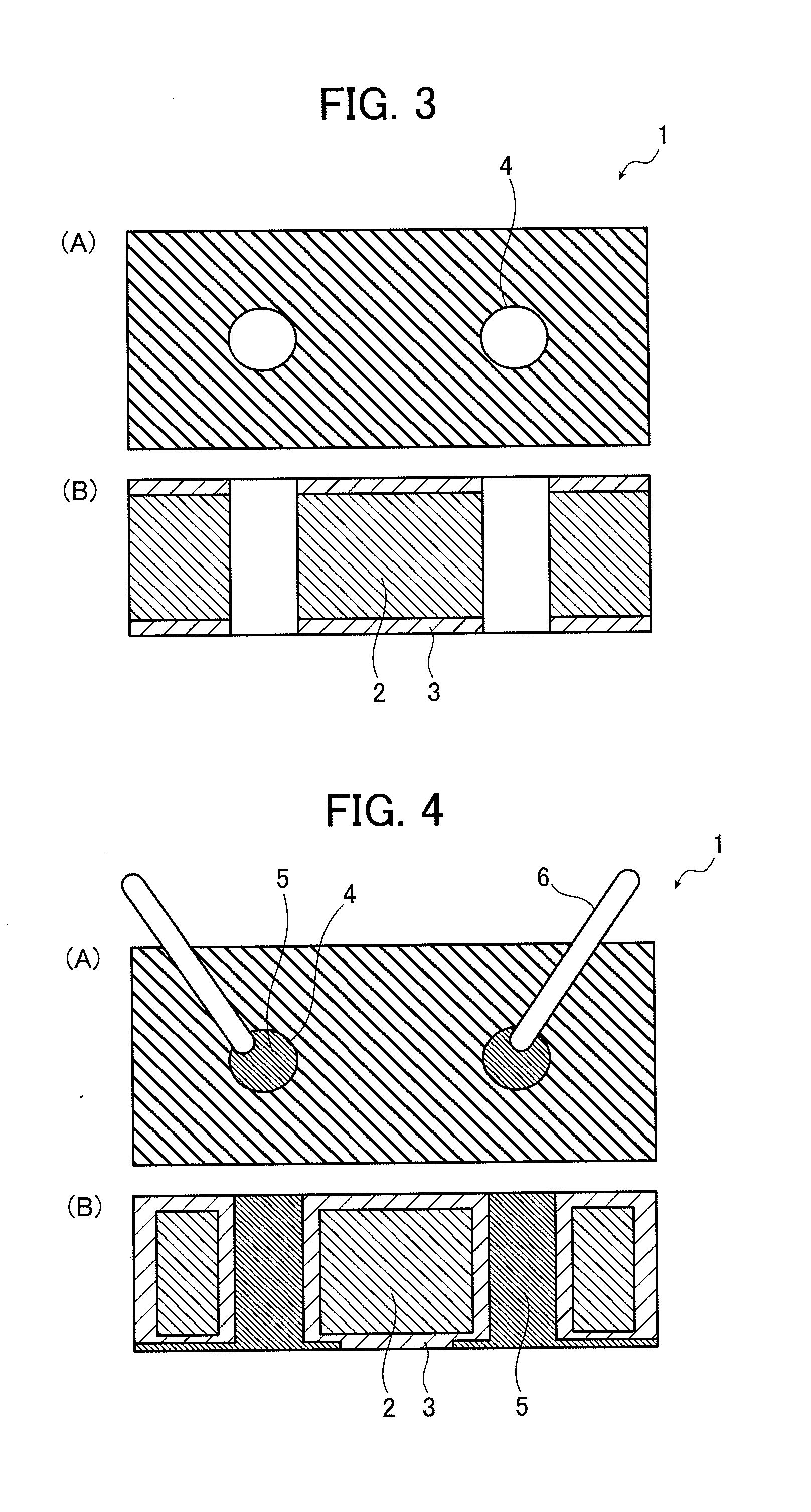

Insulated substrate, process for production of insulated substrate, process for formation of wiring line, wiring substrate, and light-emitting element

InactiveUS20120256224A1Improve insulation performanceImprove cooling effectAnodisationDuplicating/marking methodsOptoelectronicsAluminum substrate

Provided is an insulating substrate which includes an aluminum substrate and an anodized film covering a whole surface of the aluminum substrate and in which the anodized film contains intermetallic compound particles with a circle equivalent diameter of 1 μm or more in an amount of up to 2,000 pcs / mm3. Also provided is a method for manufacturing the insulating substrate which includes an anodizing treatment step for anodizing the aluminum substrate. The anodized film of the insulating substrate covering the whole surface of the aluminum substrate contains intermetallic compound particles with a circle equivalent diameter of 1 μm or more in an amount of up to 2,000 pcs / mm3.

Owner:FUJIFILM CORP

Method for preparing porous titanium dioxide nanotube array

InactiveCN101748463AControllable growthEffective peelingPolycrystalline material growthSurface reaction electrolytic coatingTio2 nanotubeTitanium oxide

The invention relates to a method for preparing an ordered porous anodic titanium dioxide nanotube array. The method can prepare an ultra-large area defect-free titanium dioxide nanotube array film, the surface layer is the porous shape like an anodic aluminum oxide template, and the lower layer is a nanotube ordered array, thereby overcoming the common problems of easy lodging and aggregation of tubes in the prior art of preparing the anodic titanium dioxide nanotube array and simultaneously solving the problems that the prepared nanotube array film has more surface defect corrosion pits and the sediment blocks tube mouths. The nanotube array can realize the controllable growth by controlling the preparation conditions and the process and obtain the ordered array films with different tube diameters, different wall thicknesses and different tube lengths. The diameter range of the nanotubes is 20-200nm, the wall thickness range is 5-30nm, and the length range of the titanium dioxide tubes is 100nm-1mm. The invention particularly relates to a technology which can effectively and completely strip the titanium dioxide array film, effectively strip a titanium substrate from the TiO2 nanotube array and obtain the different sizes of porous nanotube array self-support films.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

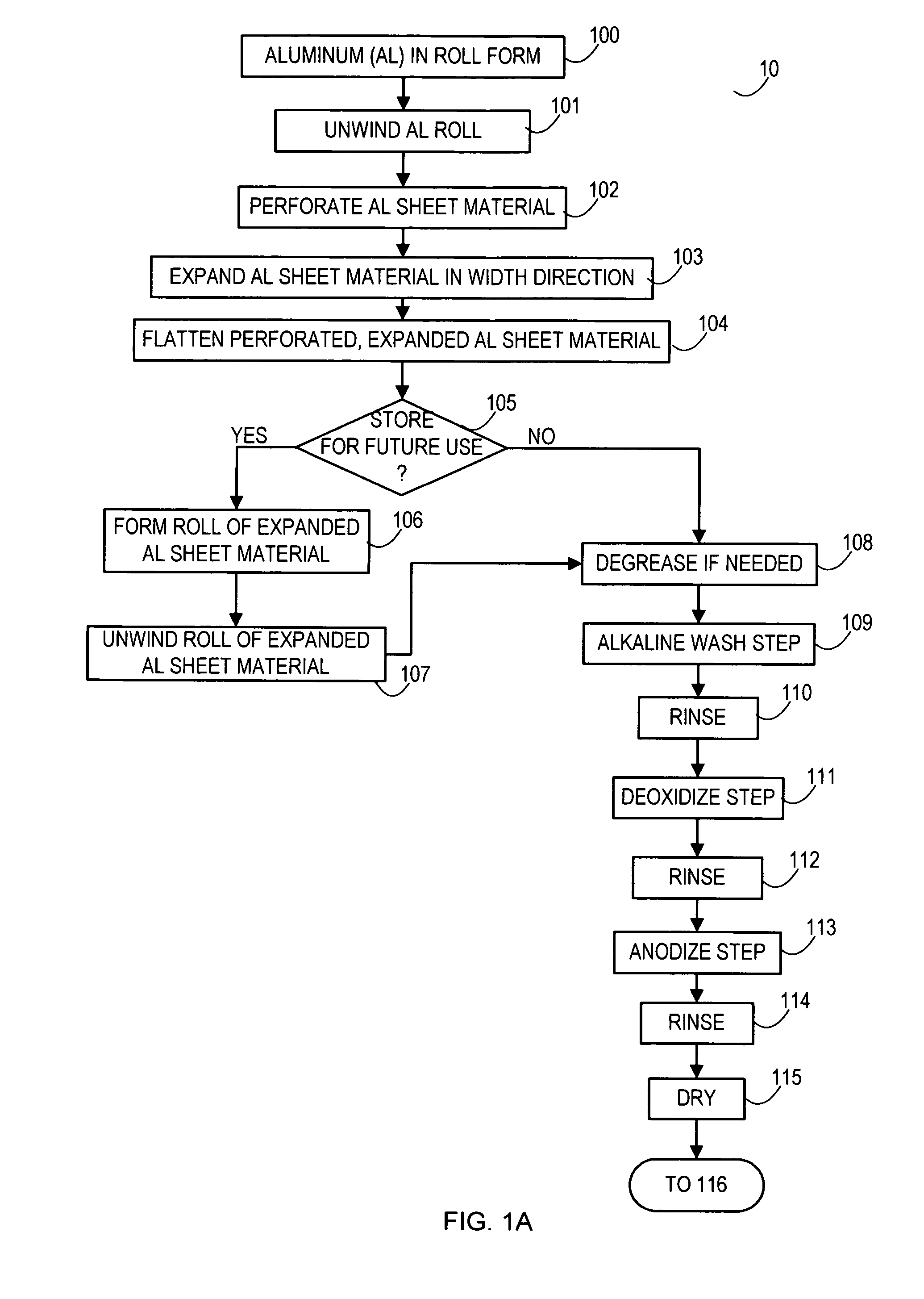

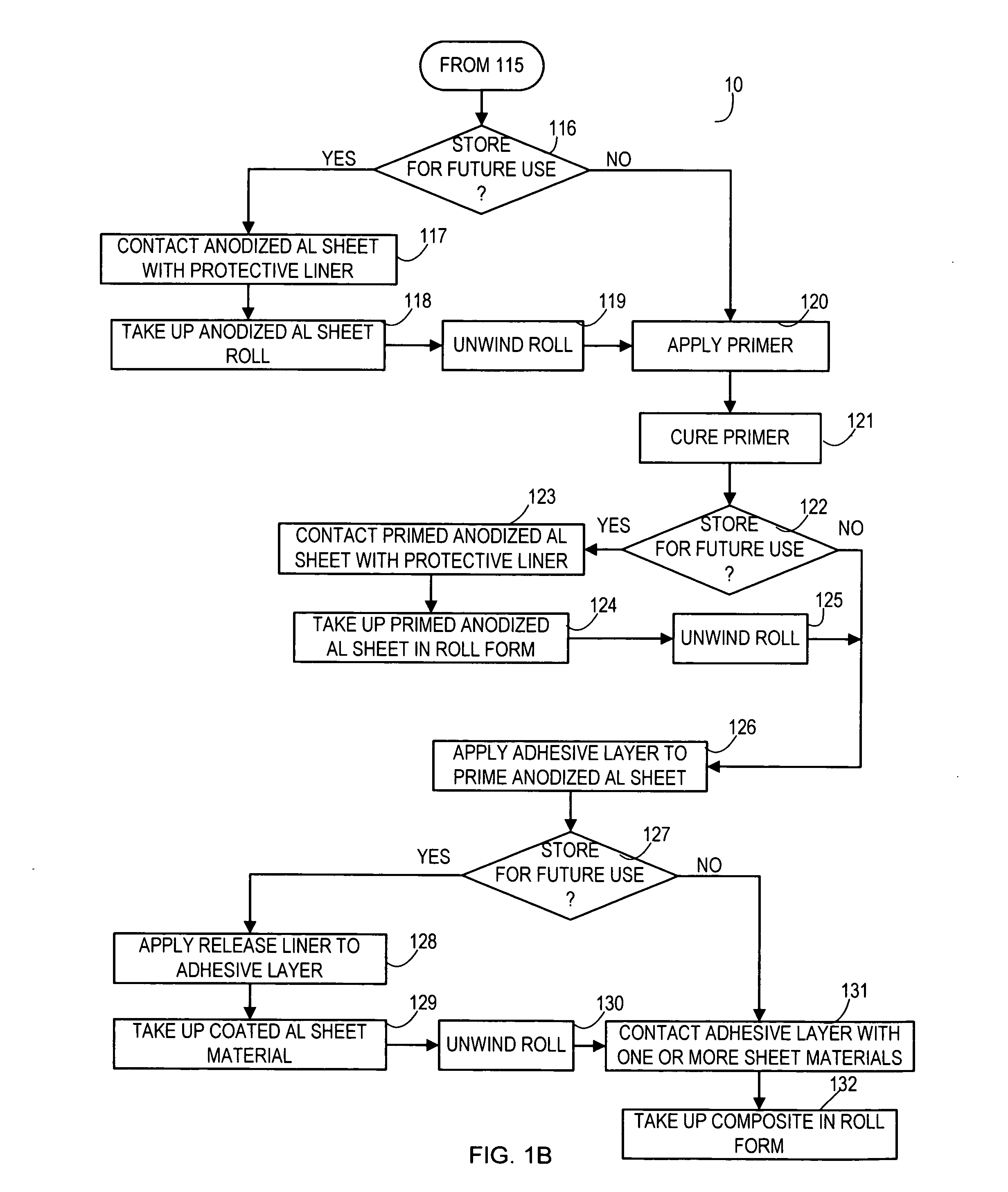

Anodized aluminum foil sheets and expanded aluminum foil (EAF) sheets and methods of making and using the same

Anodized aluminum foil sheets and expanded aluminum foil (EAF) and composites containing the same are disclosed. Methods of making anodized aluminum foil sheets and expanded aluminum foil (EAF) and composites containing the same are also disclosed. Methods of using anodized aluminum foil sheets and expanded aluminum foil (EAF) and composites containing the same are further disclosed.

Owner:HEXCEL

Anodized aluminum alloy material having both durability and low polluting property

InactiveUS20090050485A1High hardnessIncreased durabilityAnodisationDuplicating/marking methodsHardnessImpurity

An anodized aluminum alloy material is formed of an aluminum alloy having a Mg content between 0.1 and 2.0% by mass, a Si content between 0.1 and 2.0% by mass, a Mn content between 0.1 and 2.0% by mass, and an Fe, a Cr and a Cu content of 0.03% by mass or below and containing Al and unavoidable impurities as other components, and is coated with an anodic oxide film. Parts of the anodic oxide film at different positions with respect to thickness of the anodic oxide film have different hardnesses, respectively, and the difference in Vickers hardness between a part having the highest hardness and a part having the lowest hardness is Hv 5 or above.

Owner:KOBE STEEL LTD

Method and apparatus for reliably laser marking articles

InactiveUS20110193929A1Desirable appearanceHigh color densityRecording apparatusAblative recordingPulse parameterOptoelectronics

The invention is a method and apparatus for creating marks on an anodized aluminum specimen with selectable color and optical density. The method includes providing a laser marking system having a laser, laser optics and a controller operatively connected to said laser to control laser pulse parameters. The laser marking system is directed to produce laser pulses having laser pulse parameters associated with the desired color and optical density in the presence of a fluid directed to the surface of the anodized aluminum specimen while marking.

Owner:ELECTRO SCI IND INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com