Patents

Literature

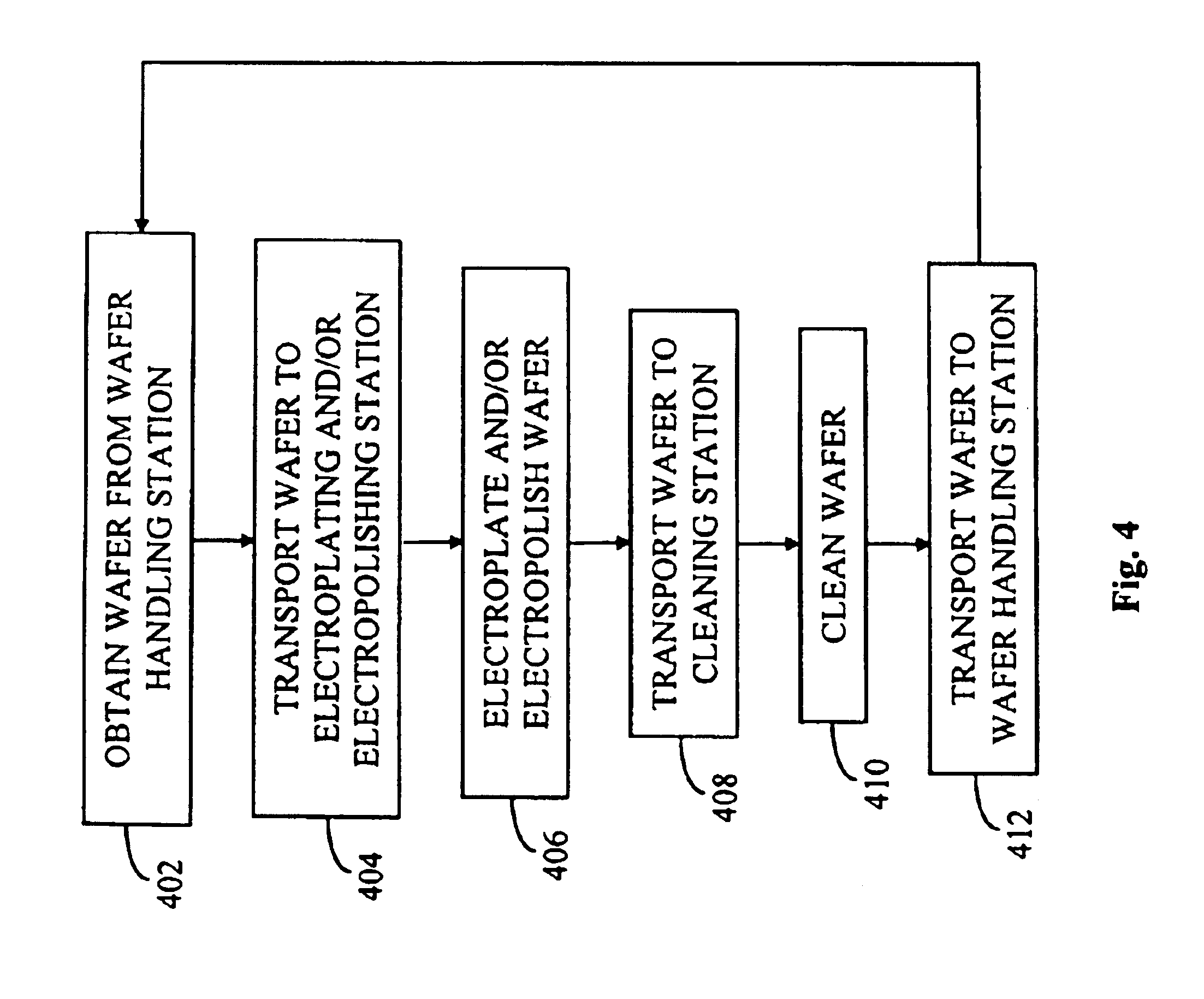

7472results about "Anodisation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

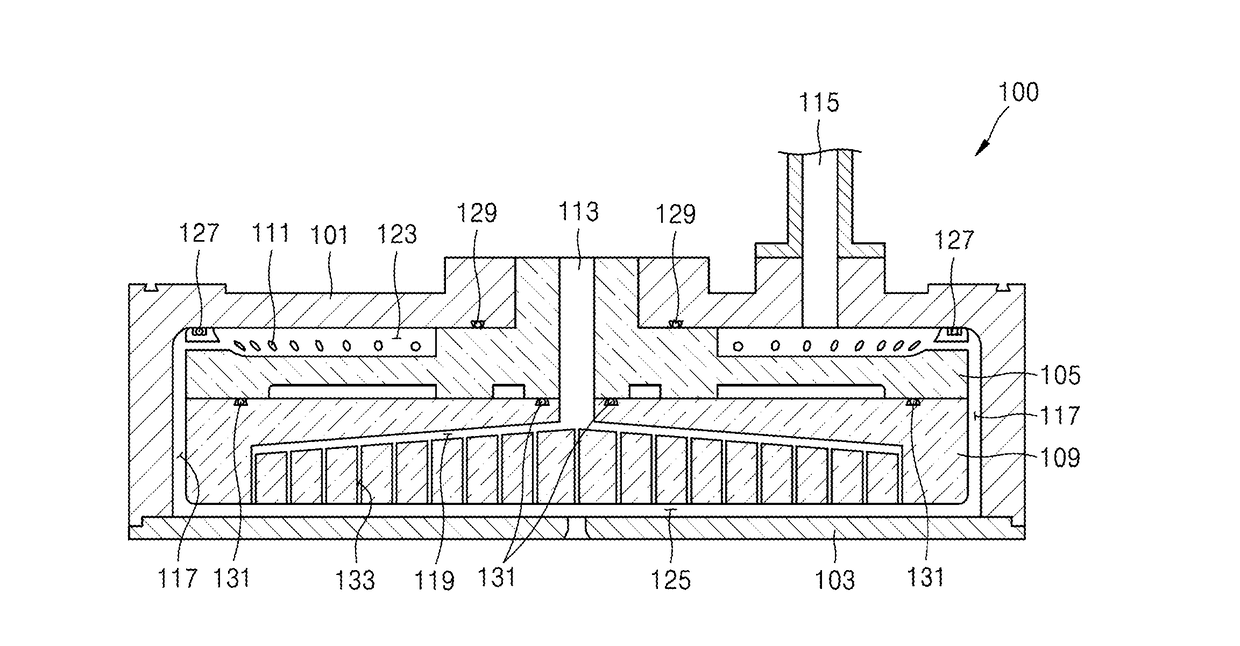

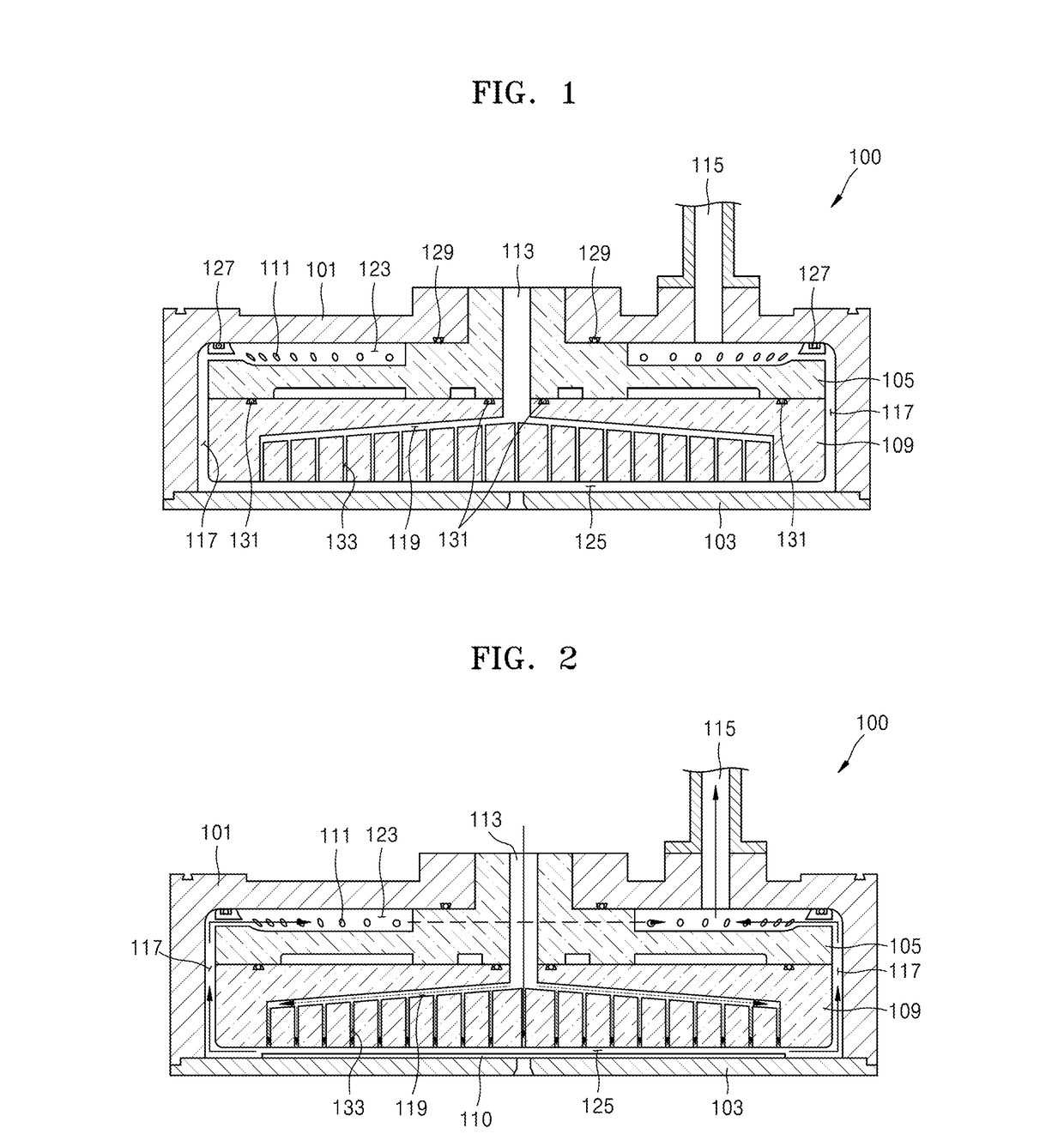

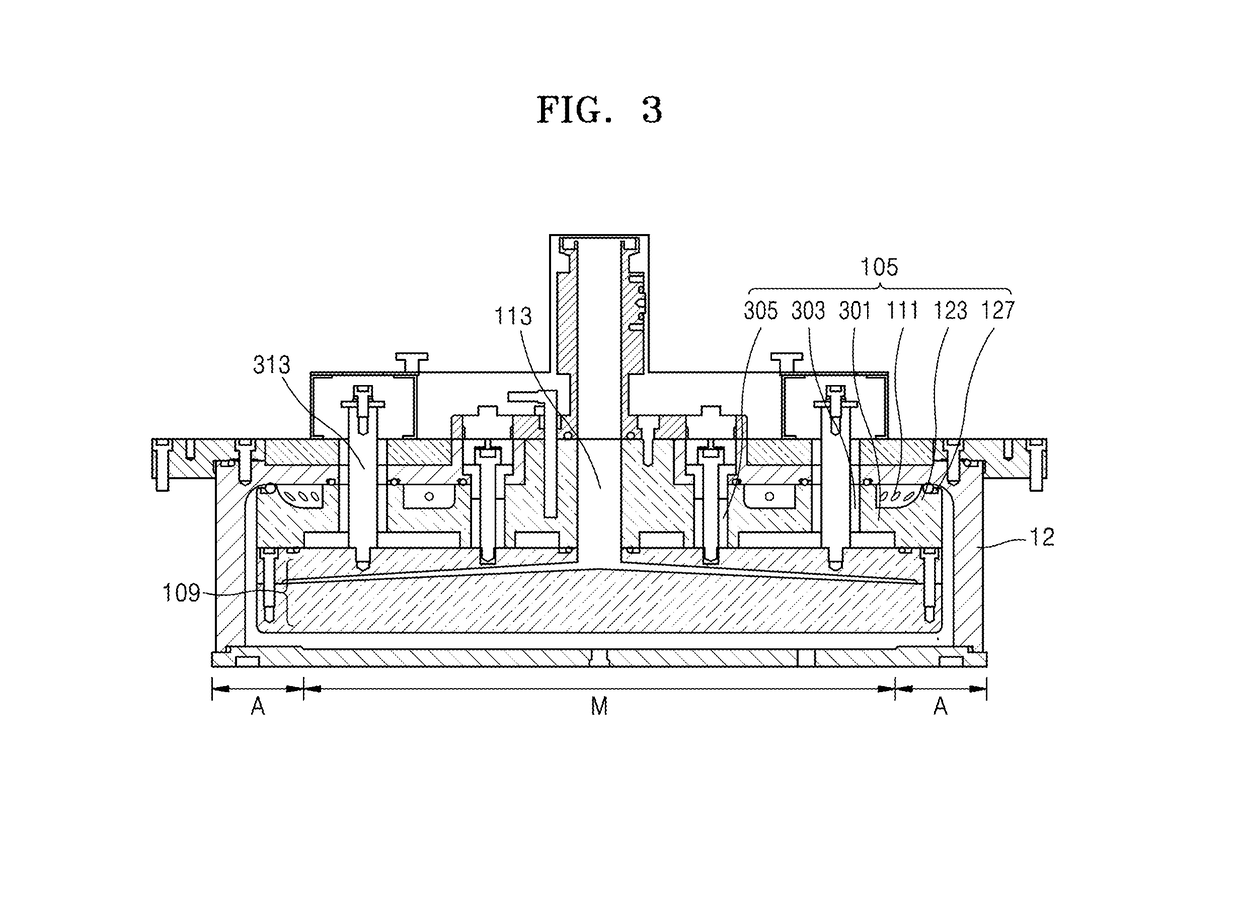

Substrate supporting plate, thin film deposition apparatus including the same, and thin film deposition method

A substrate supporting plate that may prevent deposition on a rear surface of a substrate and may easily unload the substrate. The substrate supporting plate may include a substrate mounting portion and a peripheral portion surrounding the substrate mounting portion. An edge portion of a top surface of the substrate mounting portion may be anodized. A central portion of the top surface of the substrate mounting portion may not be anodized.

Owner:ASM IP HLDG BV

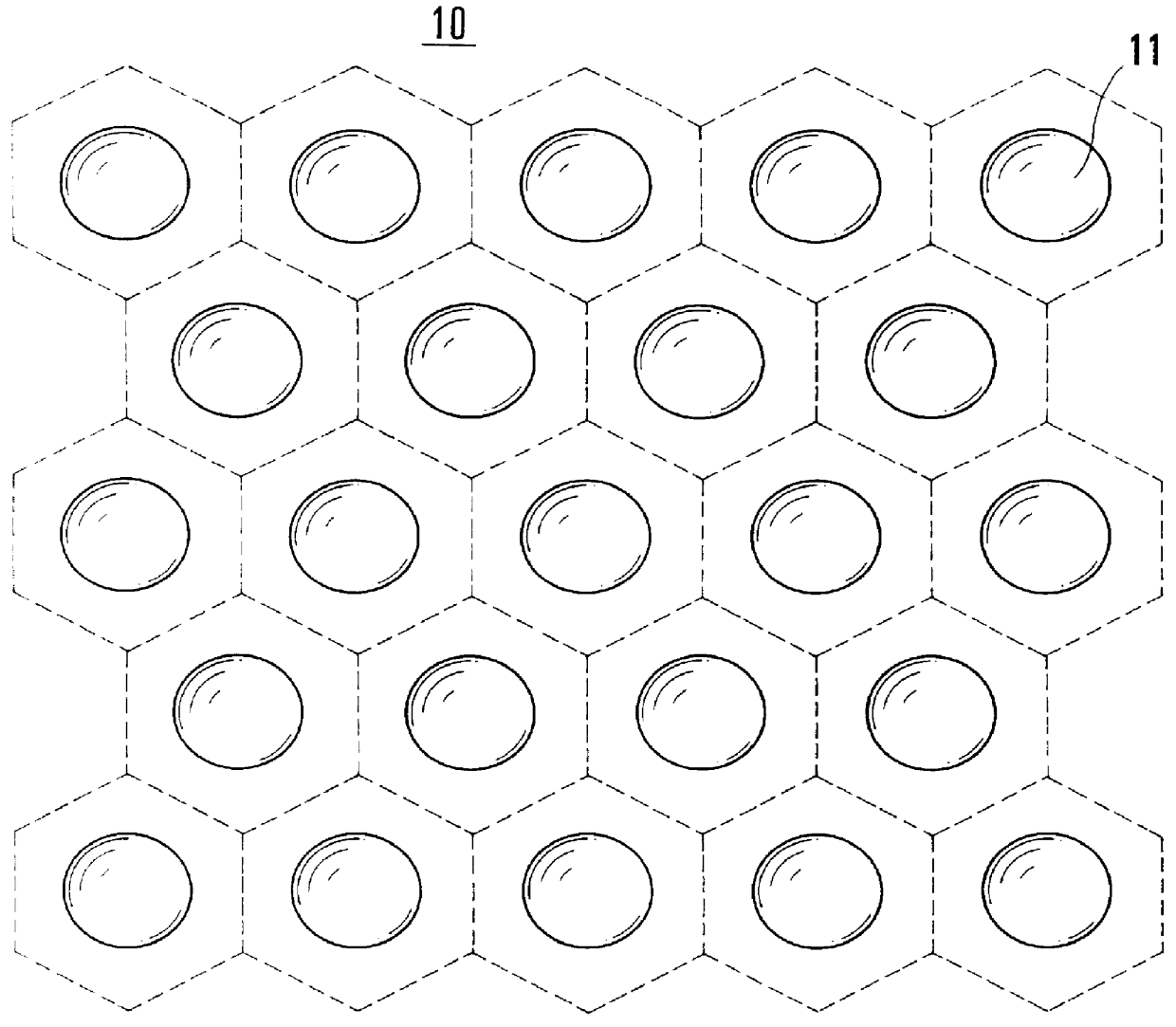

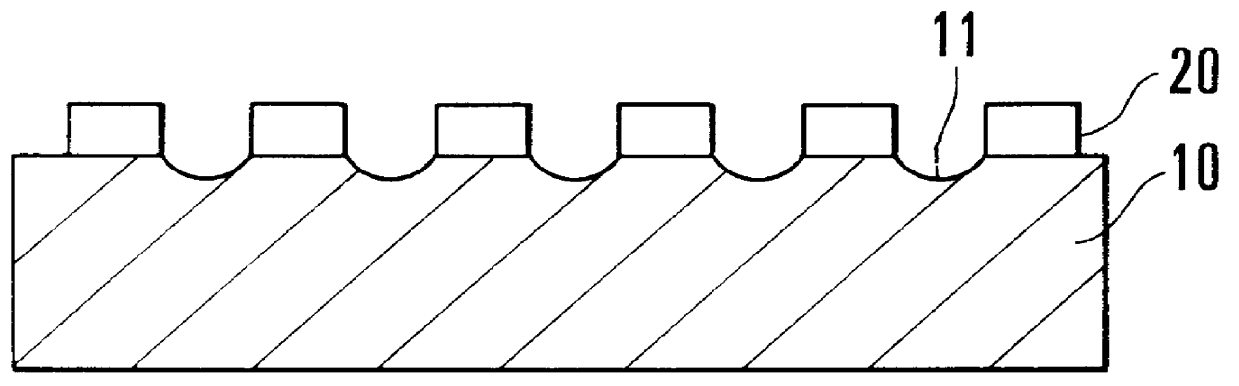

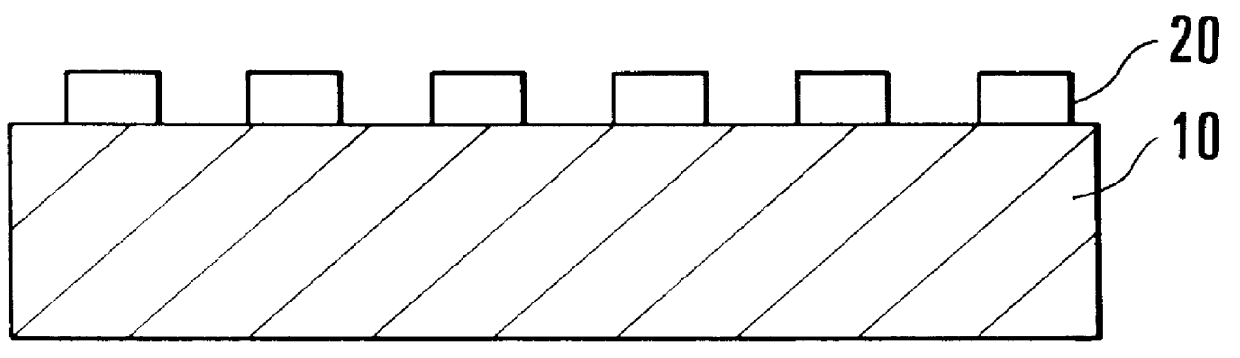

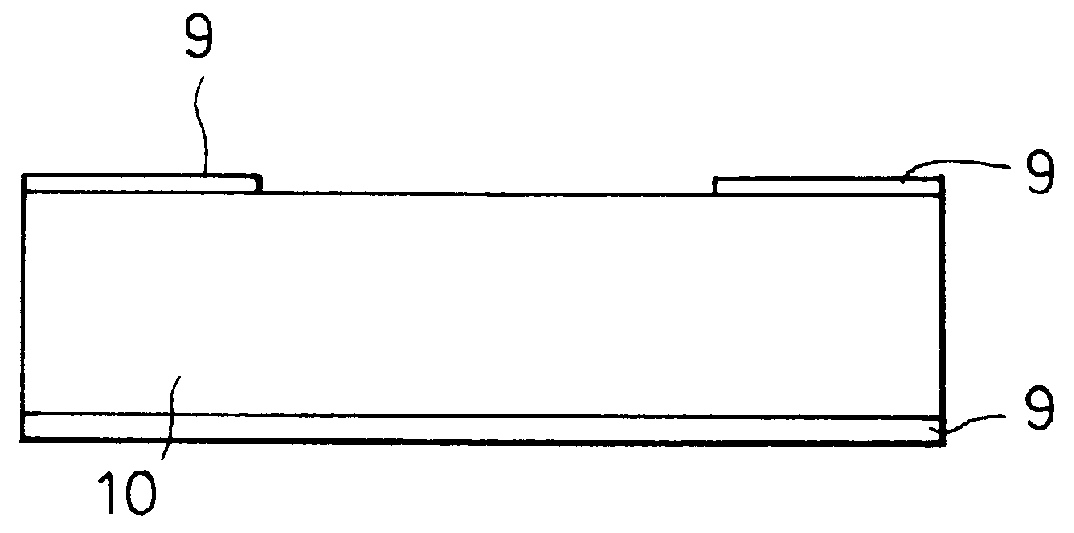

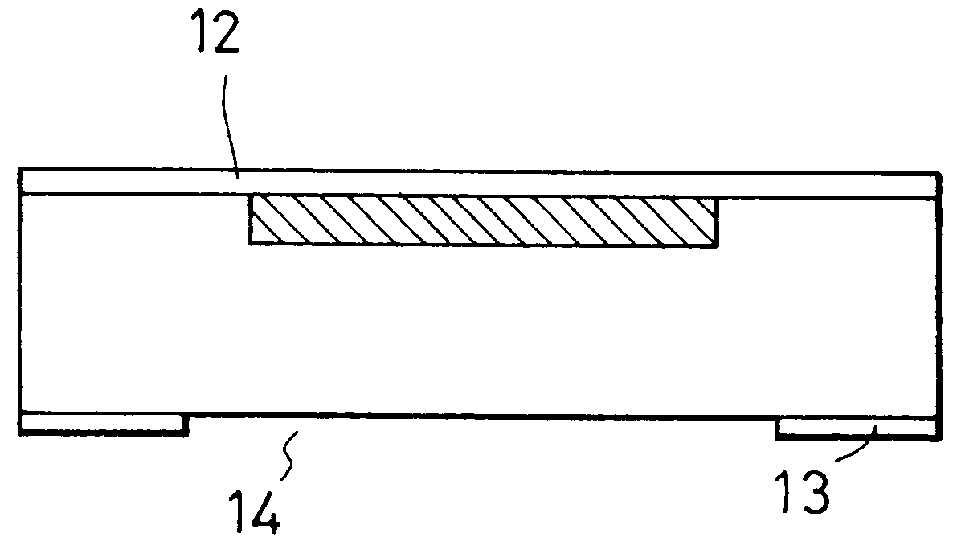

Method of manufacturing porous anodized alumina film

PCT No. PCT / JP97 / 02965 Sec. 371 Date Nov. 2, 1998 Sec. 102(e) Date Nov. 2, 1998 PCT Filed Aug. 26, 1997 PCT Pub. No. WO98 / 09005 PCT Pub. Date Mar. 5, 1998A plurality of recesses having the same interval and array as those of pores of an alumina film, which are to be formed in anodizing, are formed on a smooth surface of an aluminum plate in advance, and then, the aluminum plate is anodized. With this process, the roundness of the pores of the porous anodized alumina film and the uniformity of pore size are improved, and the pores are regularly arrayed at a predetermined interval. The recesses are formed by pressing a substrate having a plurality of projections on its surface against the aluminum plate surface to be anodized.

Owner:NIPPON TELEGRAPH & TELEPHONE CORP

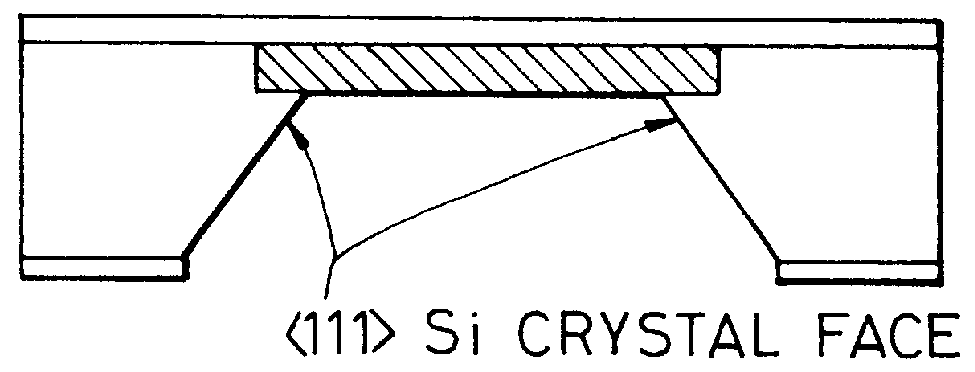

Method of producing a through-hole, silicon substrate having a through-hole, device using such a substrate, method of producing an ink-jet print head, and ink-jet print head

The invention provides a method of producing a through-hole, a substrate used to produce a through-hole, a substrate having a through-hole, and a device using such a through-hole or a substrate having such a through-hole, which are characterized in that: a through-hole can be produced only by etching a silicon substrate from its back side; the opening length d can be precisely controlled to a desired value regardless of the variations in the silicon wafer thickness, and the orientation flat angle, and also regardless of the type of a silicon crystal orientation-dependent anisotropic etchant employed; high productivity, high production reproducibility, and ease of production can be achieved; a high-liberality can be achieved in the shape of the opening end even if temperature treatment is performed at a high temperature for a long time; and a high-precision through-hole can be produced regardless of the shape of a device formed on the surface of a substrate.

Owner:CANON KK

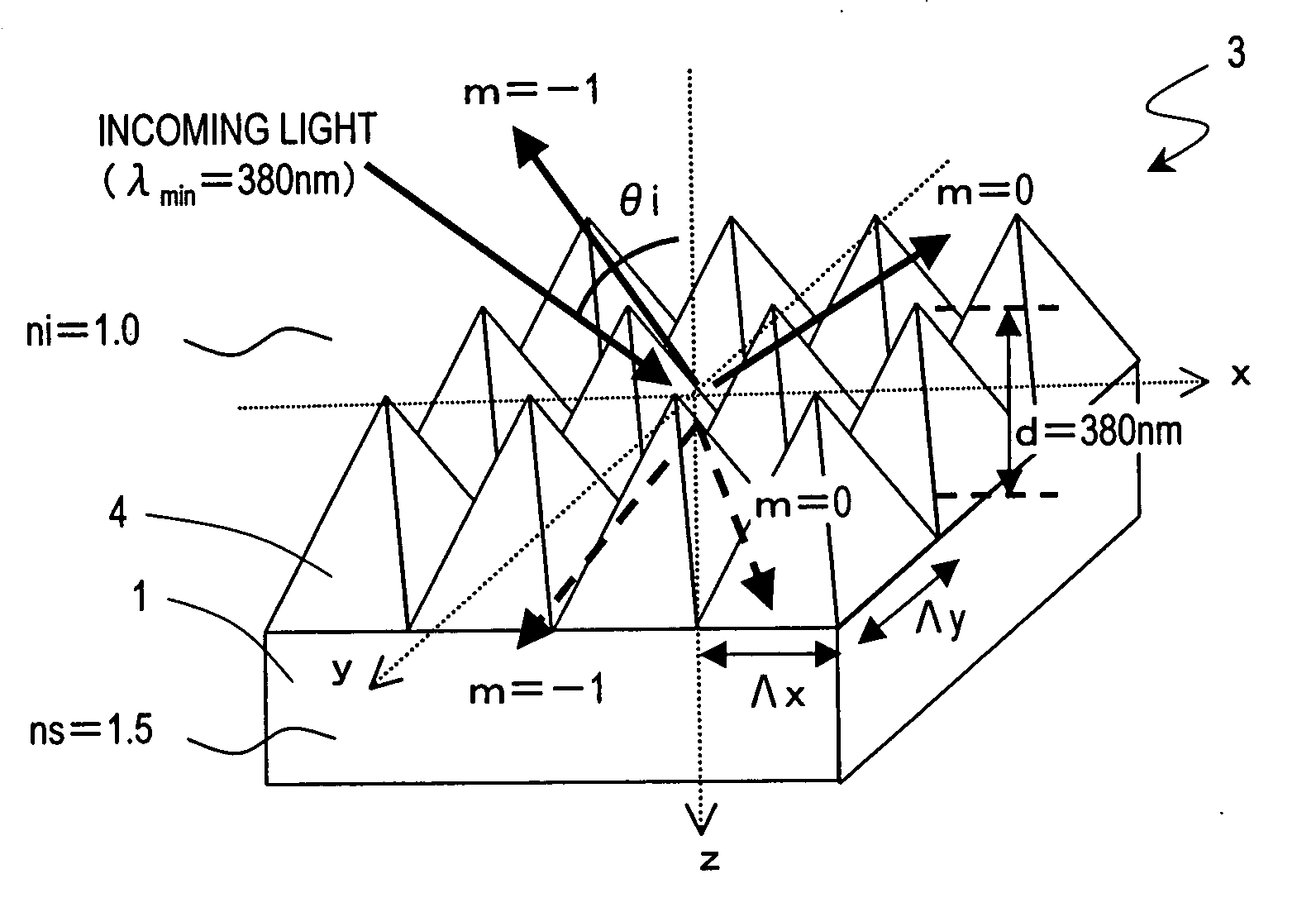

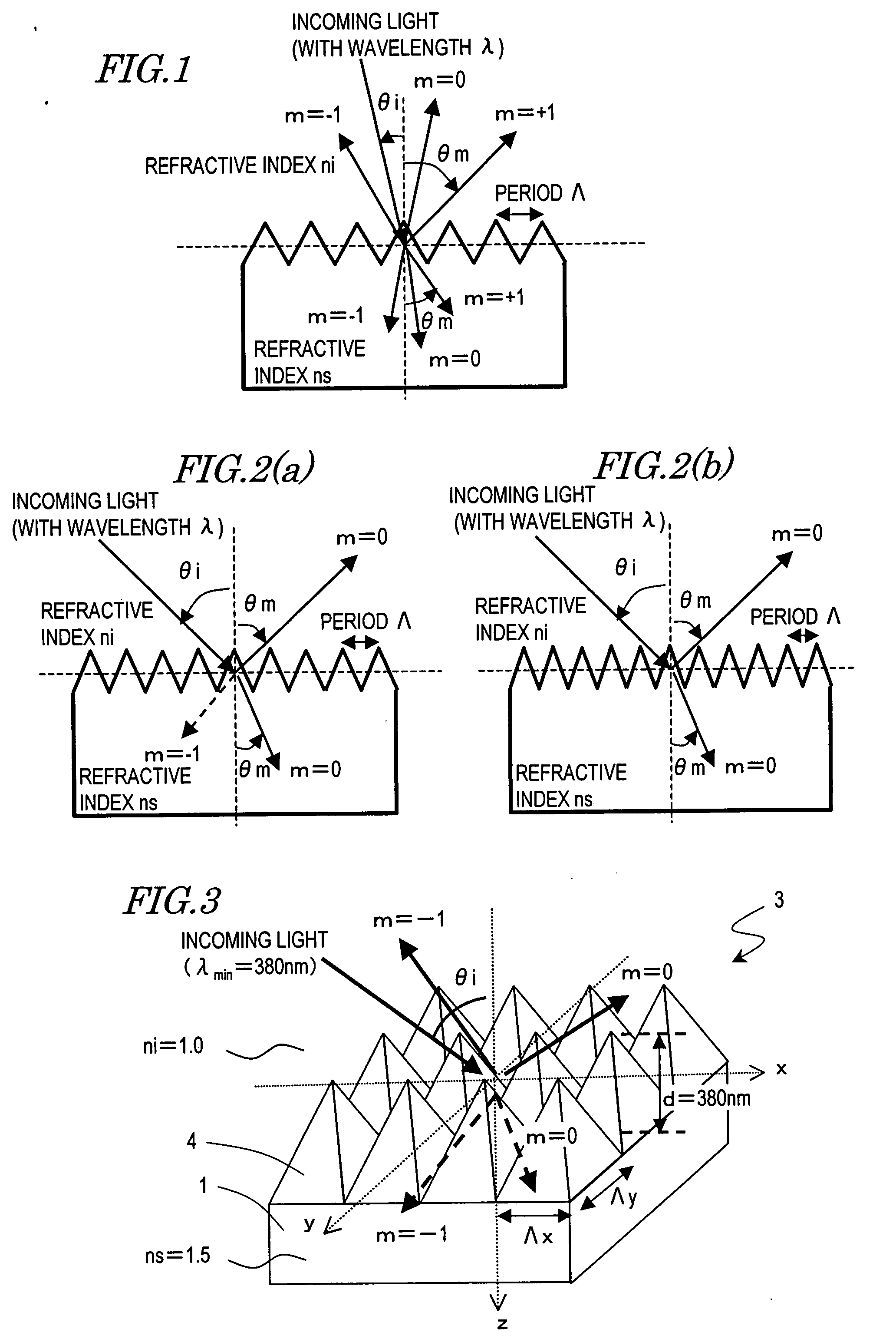

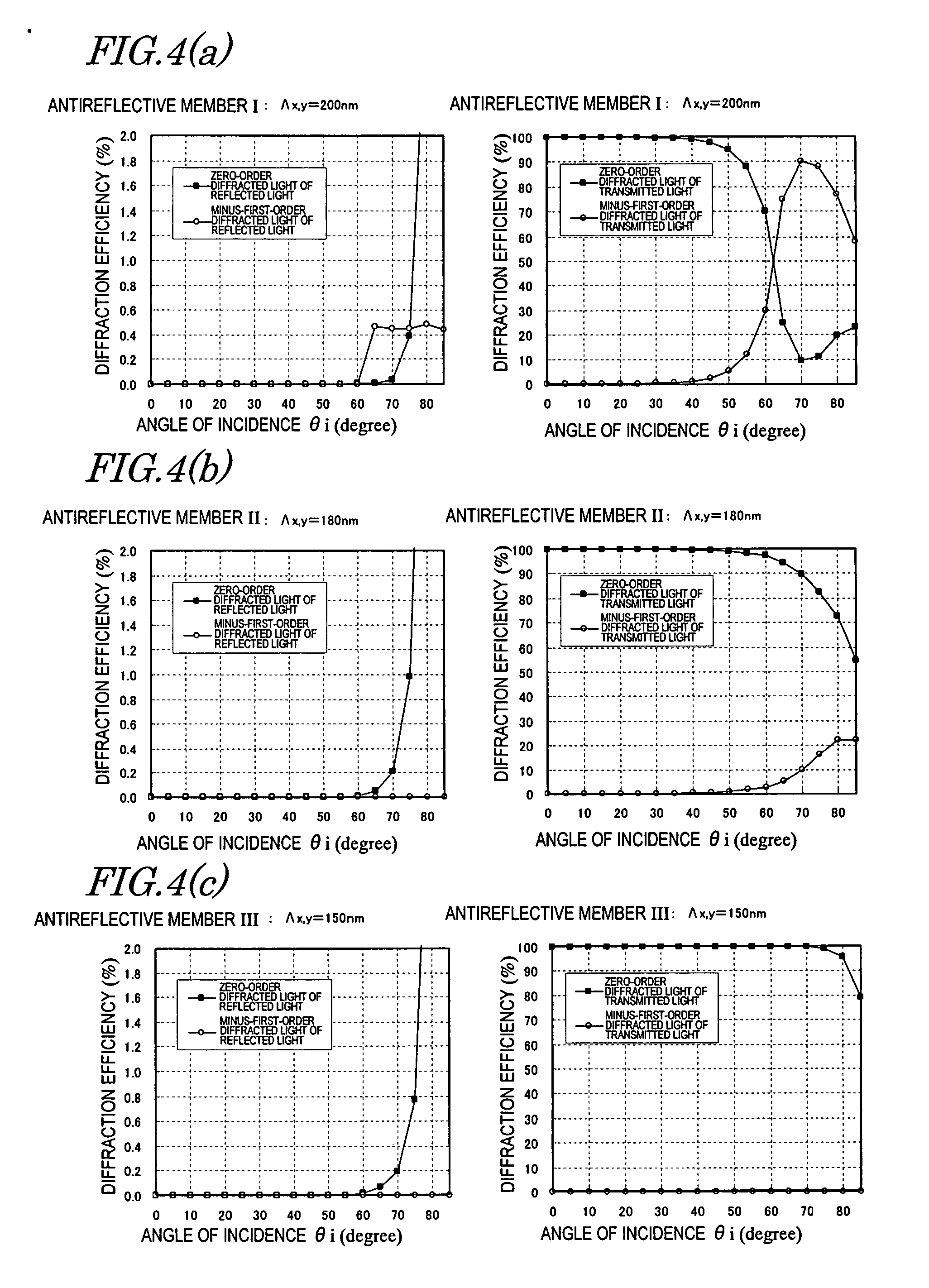

Antireflective member, optical element, display device, method of making stamper and method of making antireflective member using the stamper

ActiveUS20070159698A1Reduce regular reflectionLittle dependenceAnodisationElectric discharge tubesDisplay deviceRefractive index

An antireflective member according to the present invention has an uneven surface pattern, in which unit structures are arranged in x and y directions at respective periods that are both shorter than the shortest wavelength of an incoming light ray, on the surface of a substrate and satisfies the following Inequality (1): Λ x,yλmin<1ni+ni·sin θ imax(1)where λmin is the shortest wavelength of the incoming light ray, θimax is the largest angle of incidence of the incoming light ray, ni is the refractive index of an incidence medium, Λx is the period of the uneven surface pattern in the x direction, and Λy is the period of the pattern in the y direction. As a result, diffraction of short-wave light components can be reduced in a broad wavelength range.

Owner:SHARP KK

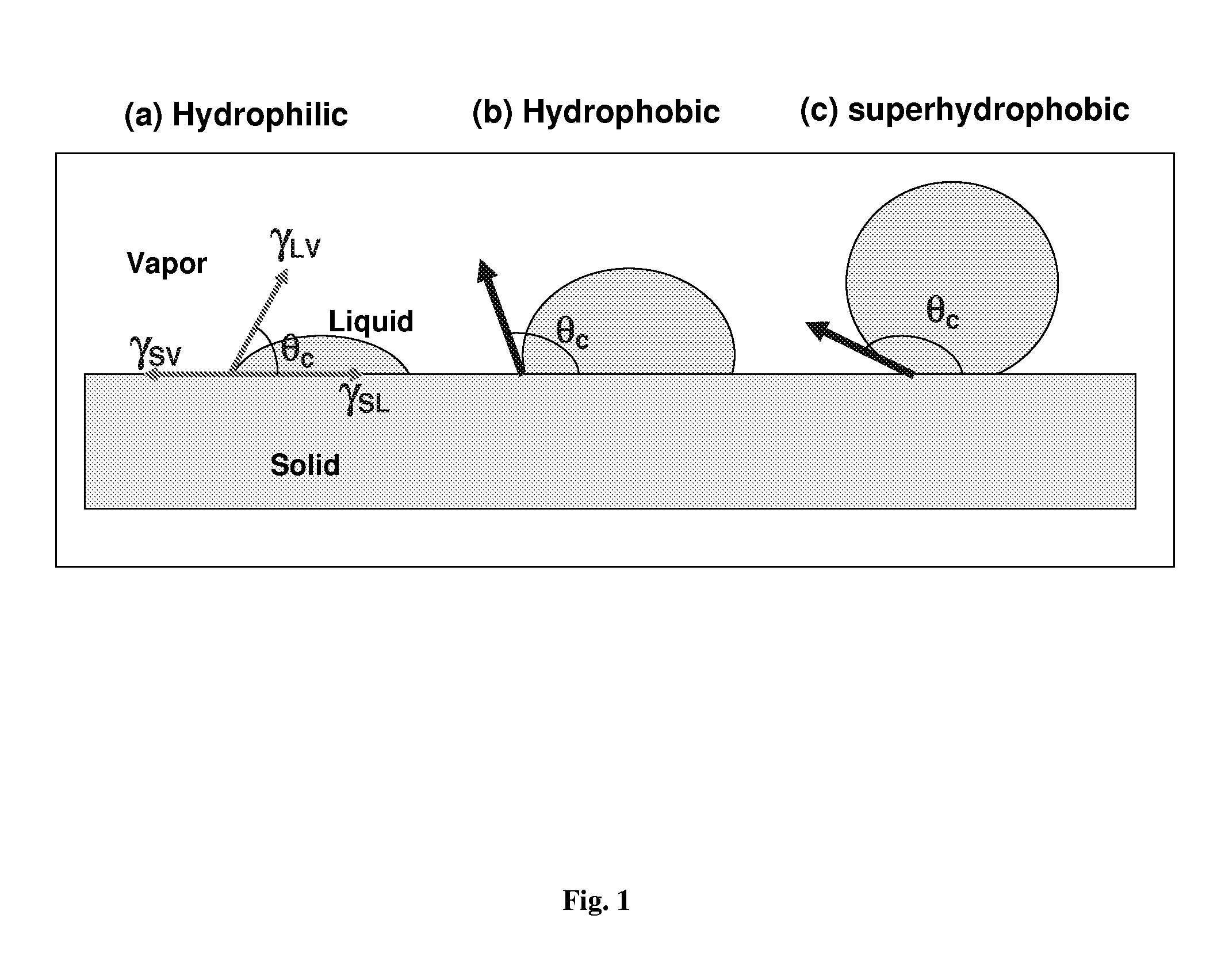

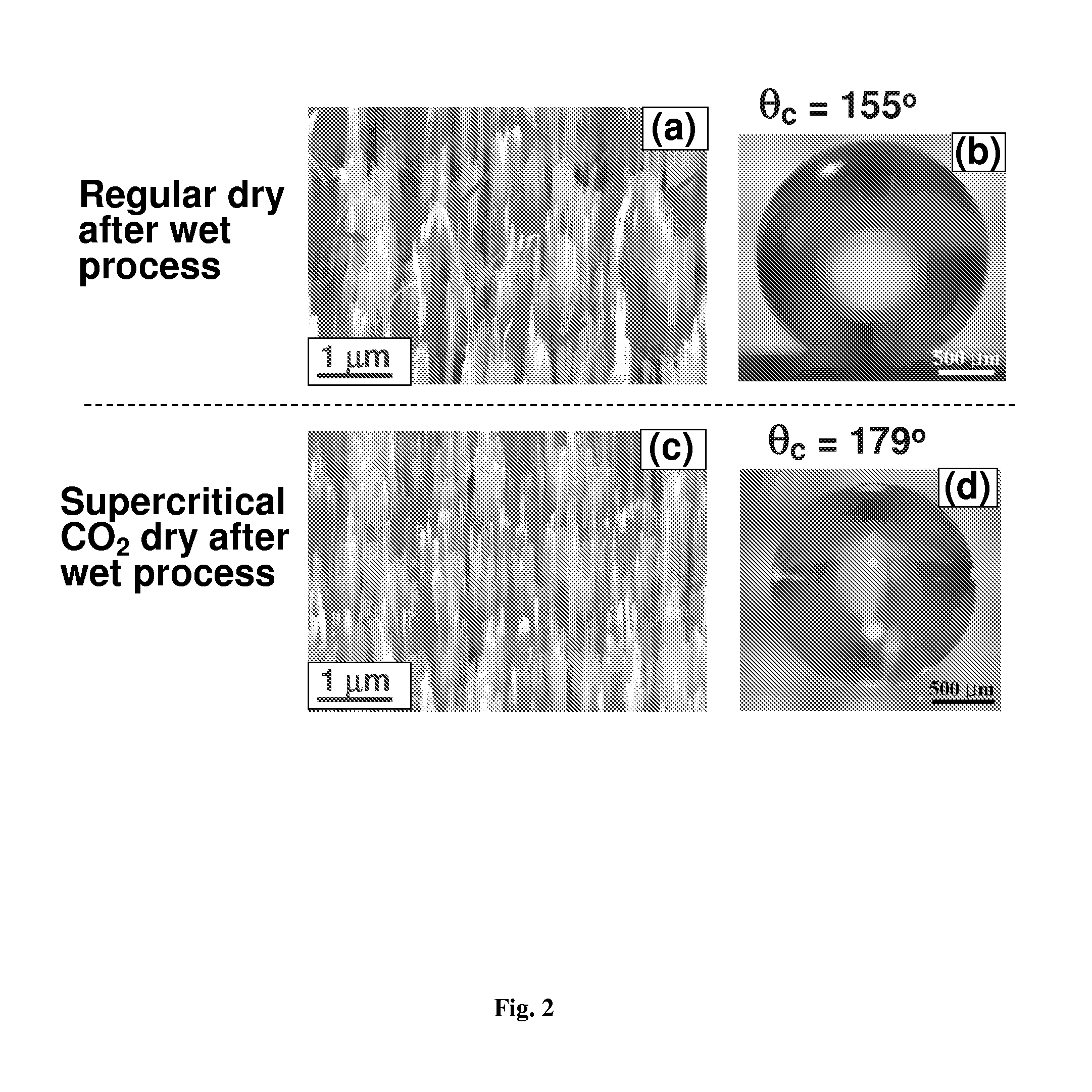

Articles having low wettability and methods for making

InactiveUS20070031639A1Low liquid wettabilityAnodisationMolten spray coatingEngineeringContact angle

Owner:GENERAL ELECTRIC CO

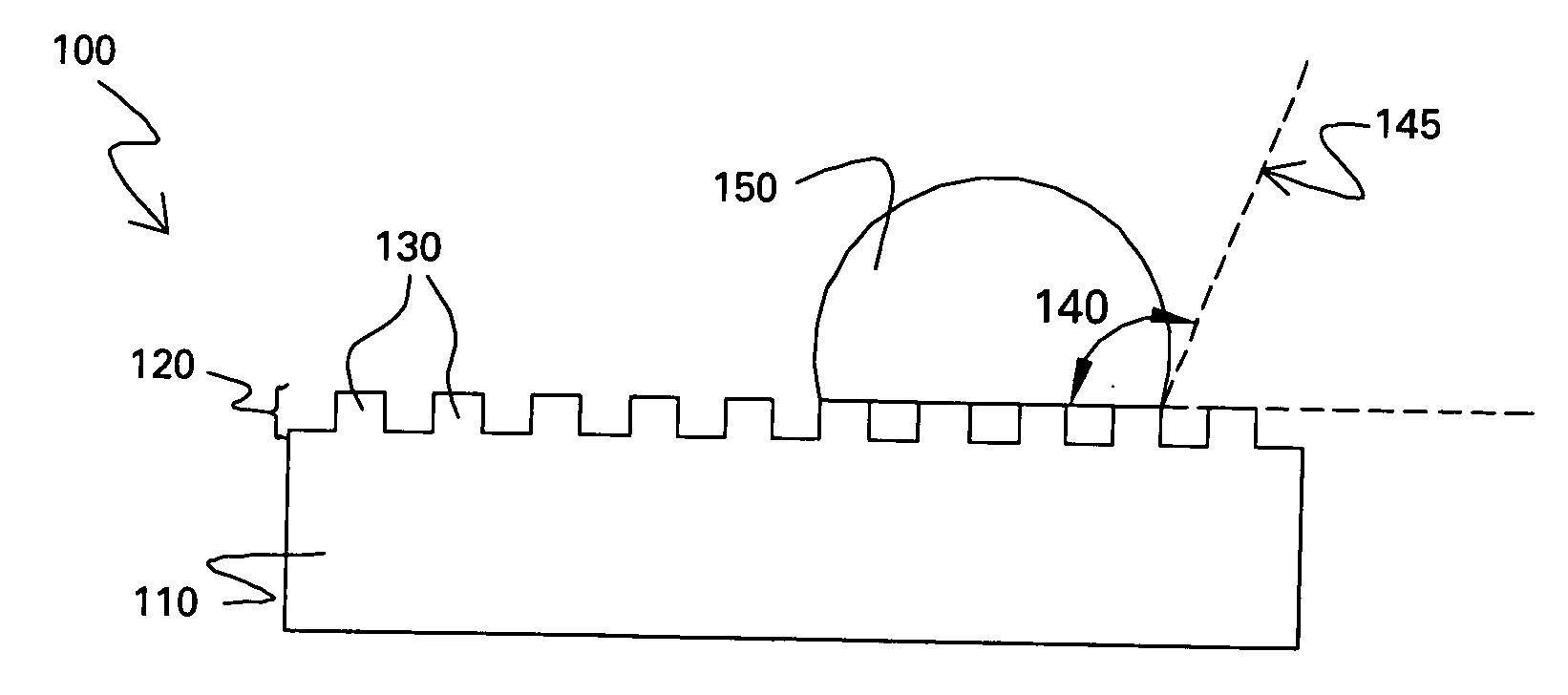

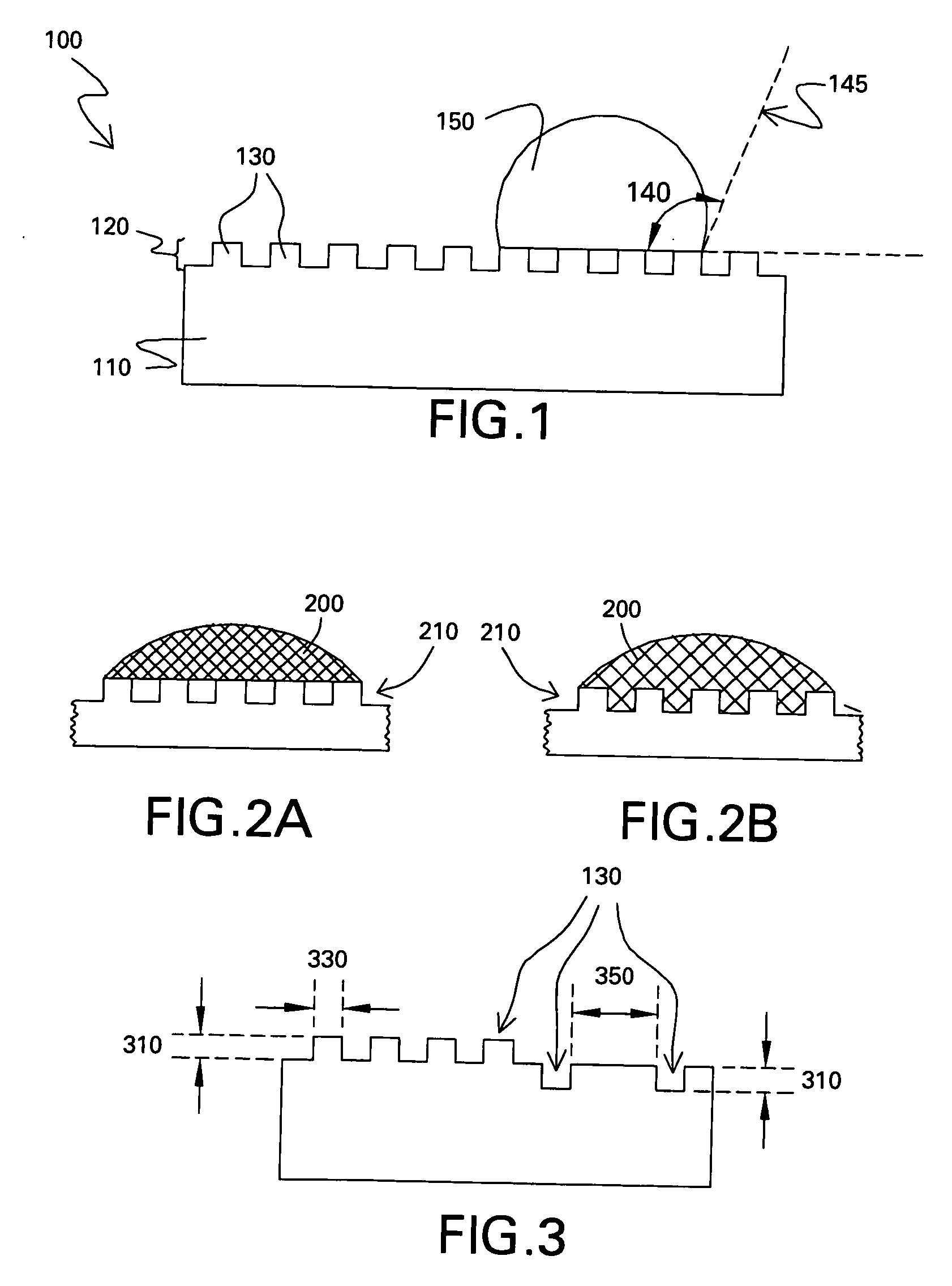

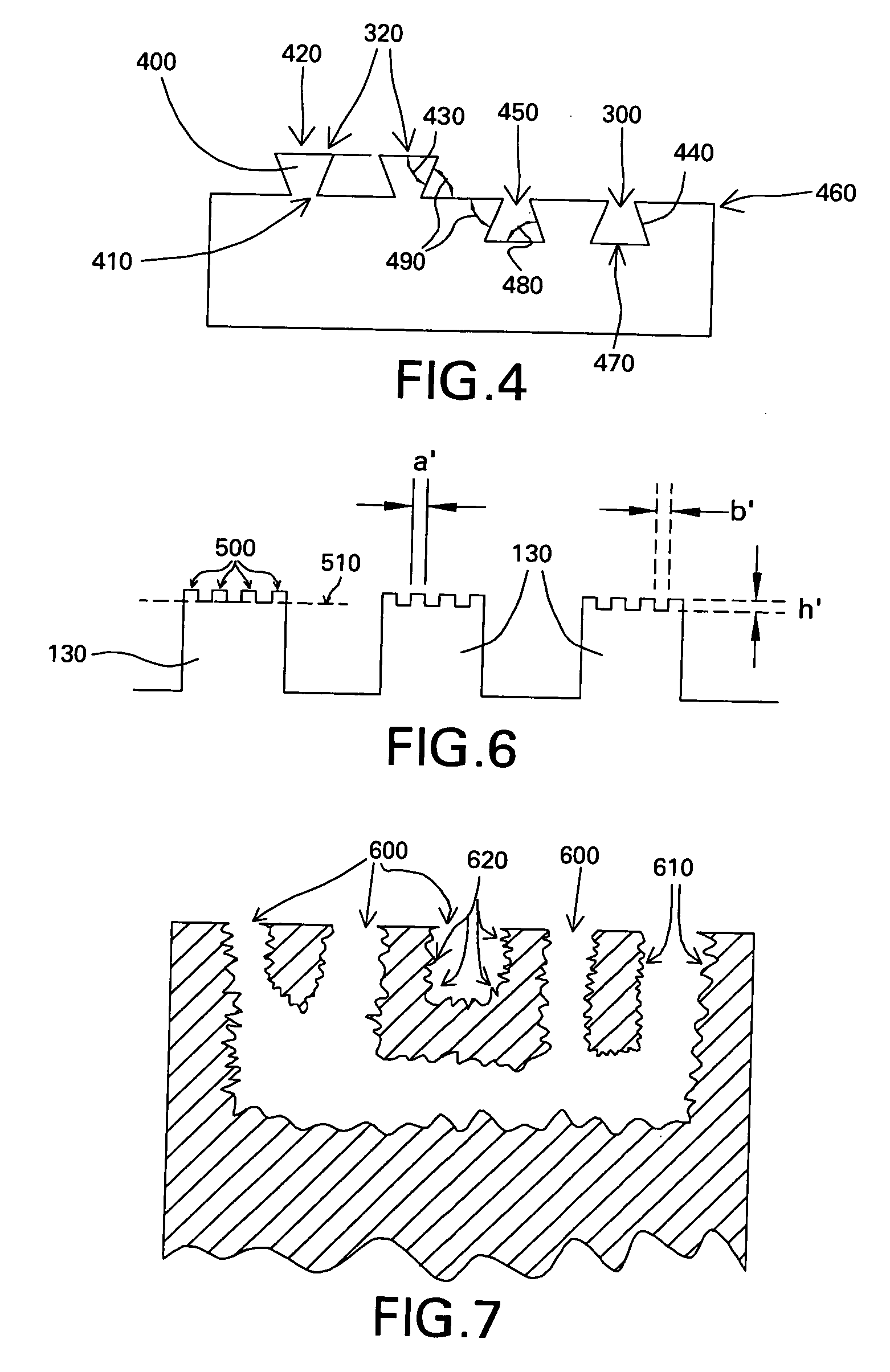

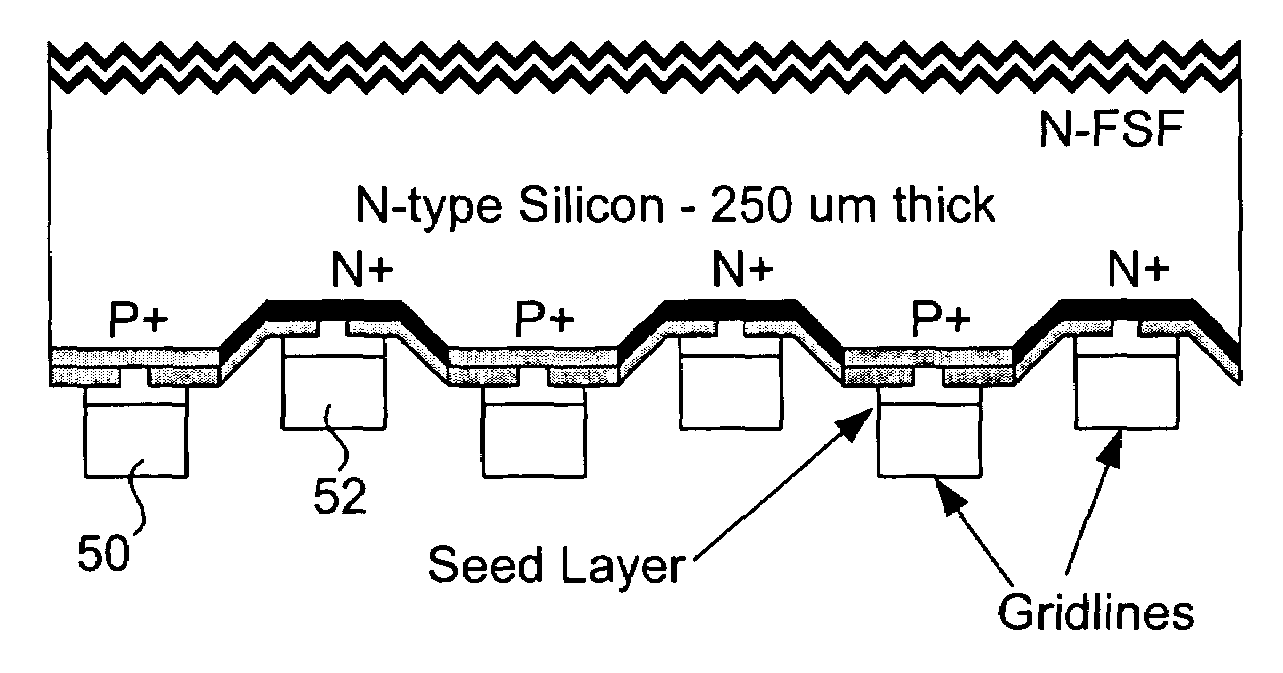

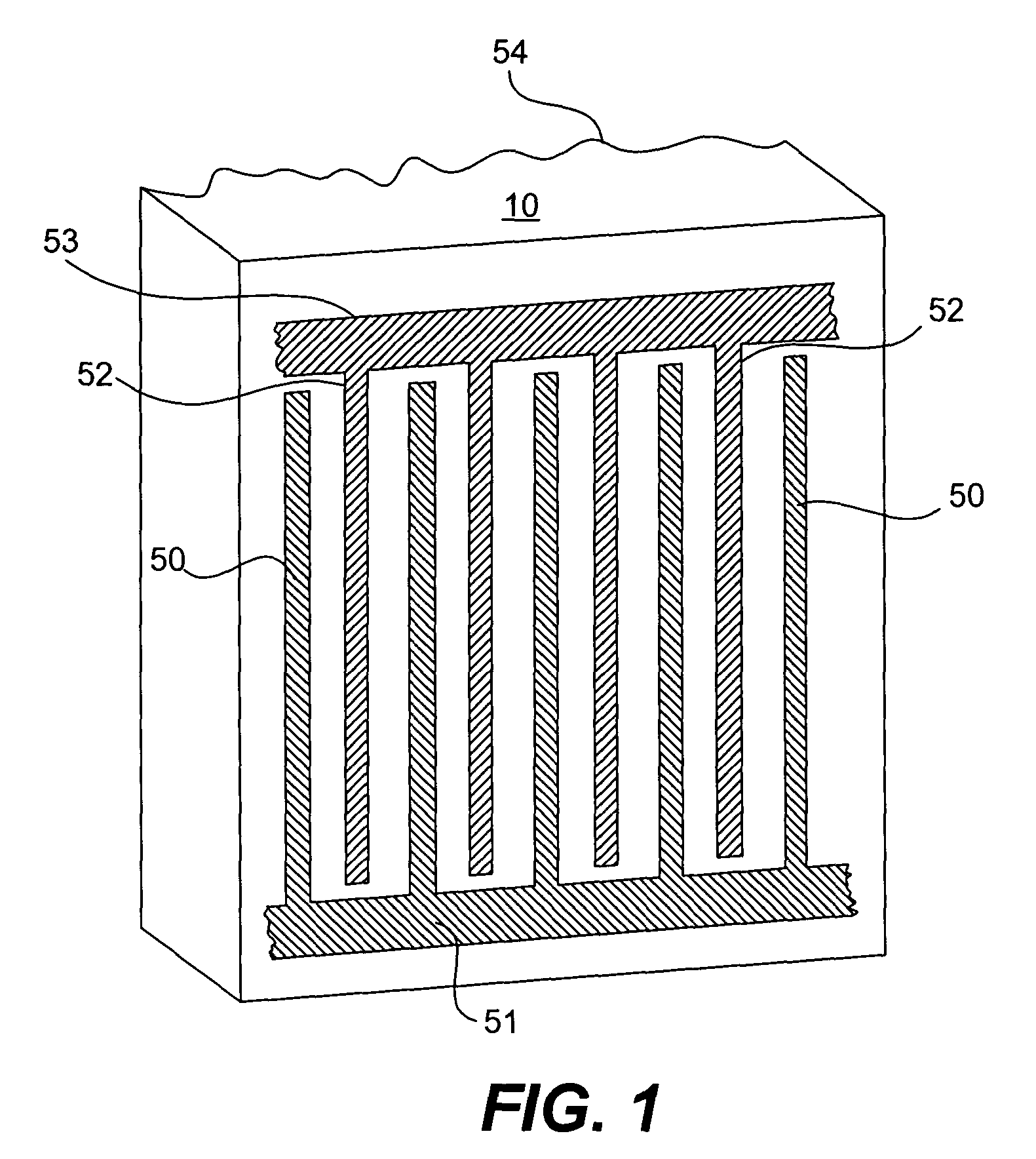

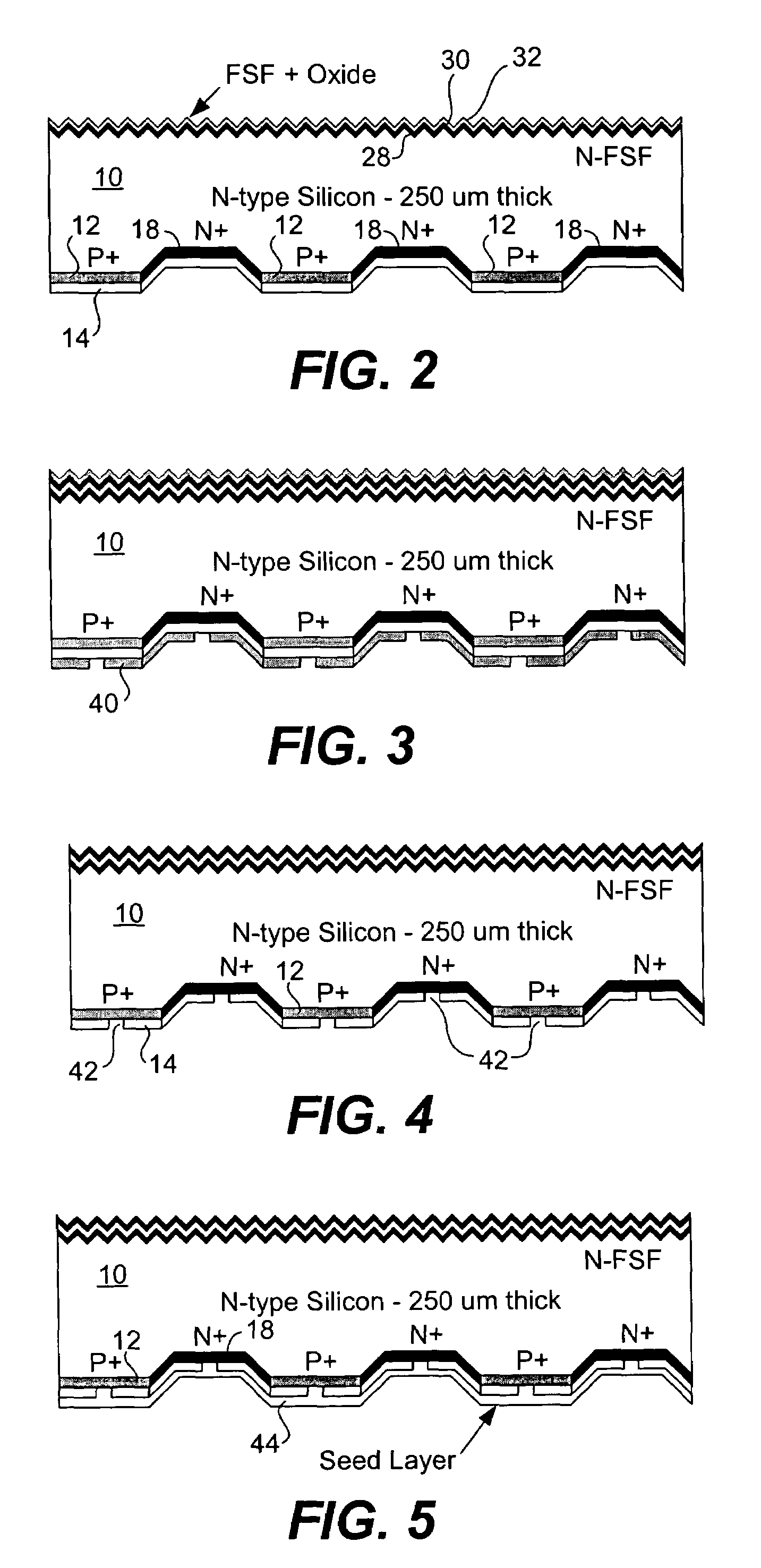

Metal contact structure for solar cell and method of manufacture

In a solar cell having p doped regions and n doped regions alternately formed in a surface of a semiconductor wafer in offset levels through use of masking and etching techniques, metal contacts are made to the p regions and n regions by first forming a base layer contacting the p doped regions and n doped regions which functions as an antireflection layer, and then forming a barrier layer, such as titanium tungsten or chromium, and a conductive layer such as copper over the barrier layer. Preferably the conductive layer is a plating layer and the thickness thereof can be increased by plating.

Owner:CREDIT SUISSE CAYMAN ISLANDS BRANCH +1

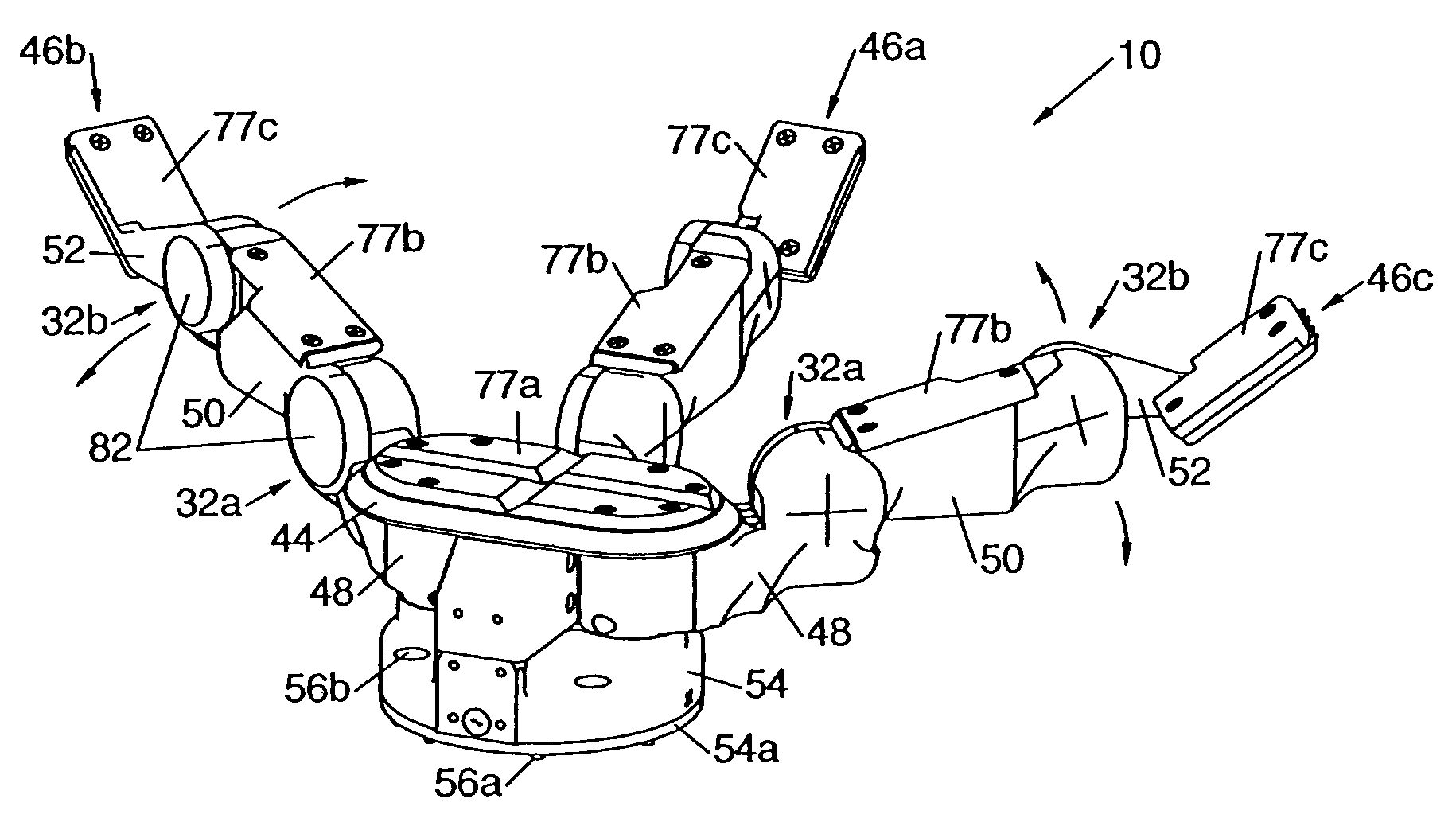

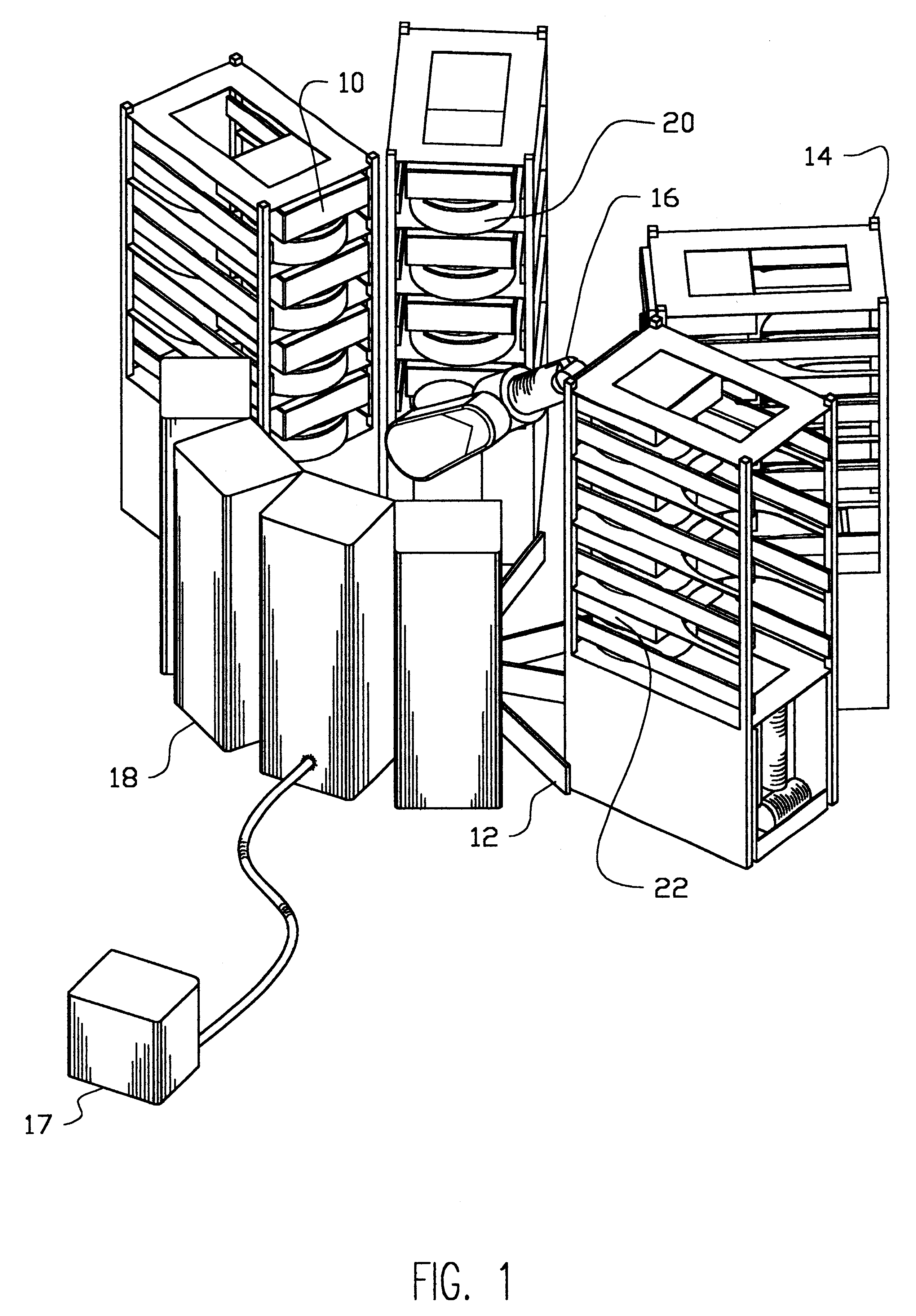

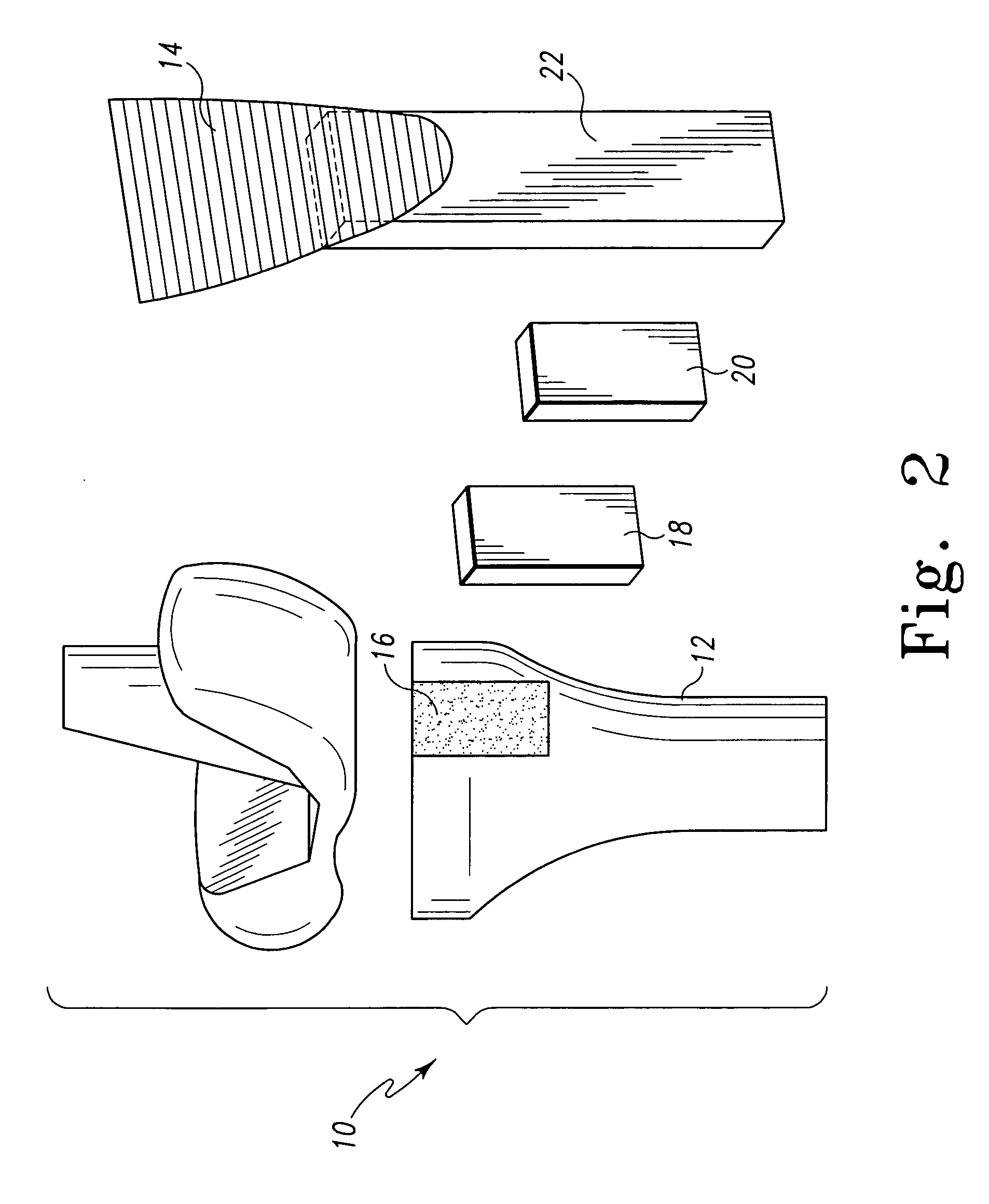

Intelligent, self-contained robotic hand

A robotic device has a base and at least one finger having at least two links that are connected in series on rotary joints with at least two degrees of freedom. A brushless motor and an associated controller are located at each joint to produce a rotational movement of a link. Wires for electrical power and communication serially connect the controllers in a distributed control network. A network operating controller coordinates the operation of the network, including power distribution. At least one, but more typically two to five, wires interconnect all the controllers through one or more joints. Motor sensors and external world sensors monitor operating parameters of the robotic hand. The electrical signal output of the sensors can be input anywhere on the distributed control network. V-grooves on the robotic hand locate objects precisely and assist in gripping. The hand is sealed, immersible and has electrical connections through the rotary joints for anodizing in a single dunk without masking. In various forms, this intelligent, self-contained, dexterous hand, or combinations of such hands, can perform a wide variety of object gripping and manipulating tasks, as well as locomotion and combinations of locomotion and gripping.

Owner:BARRETT TECH LLC

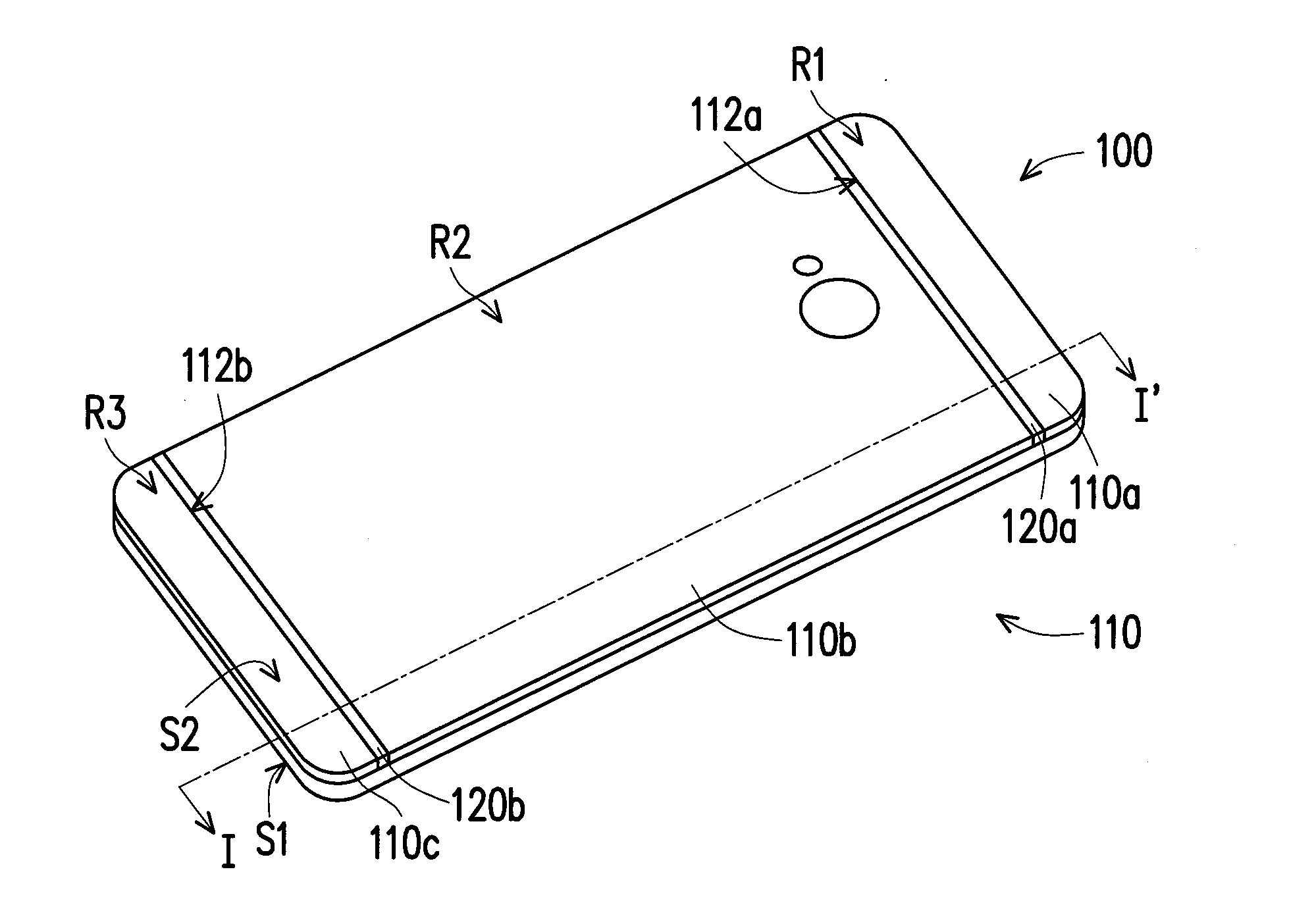

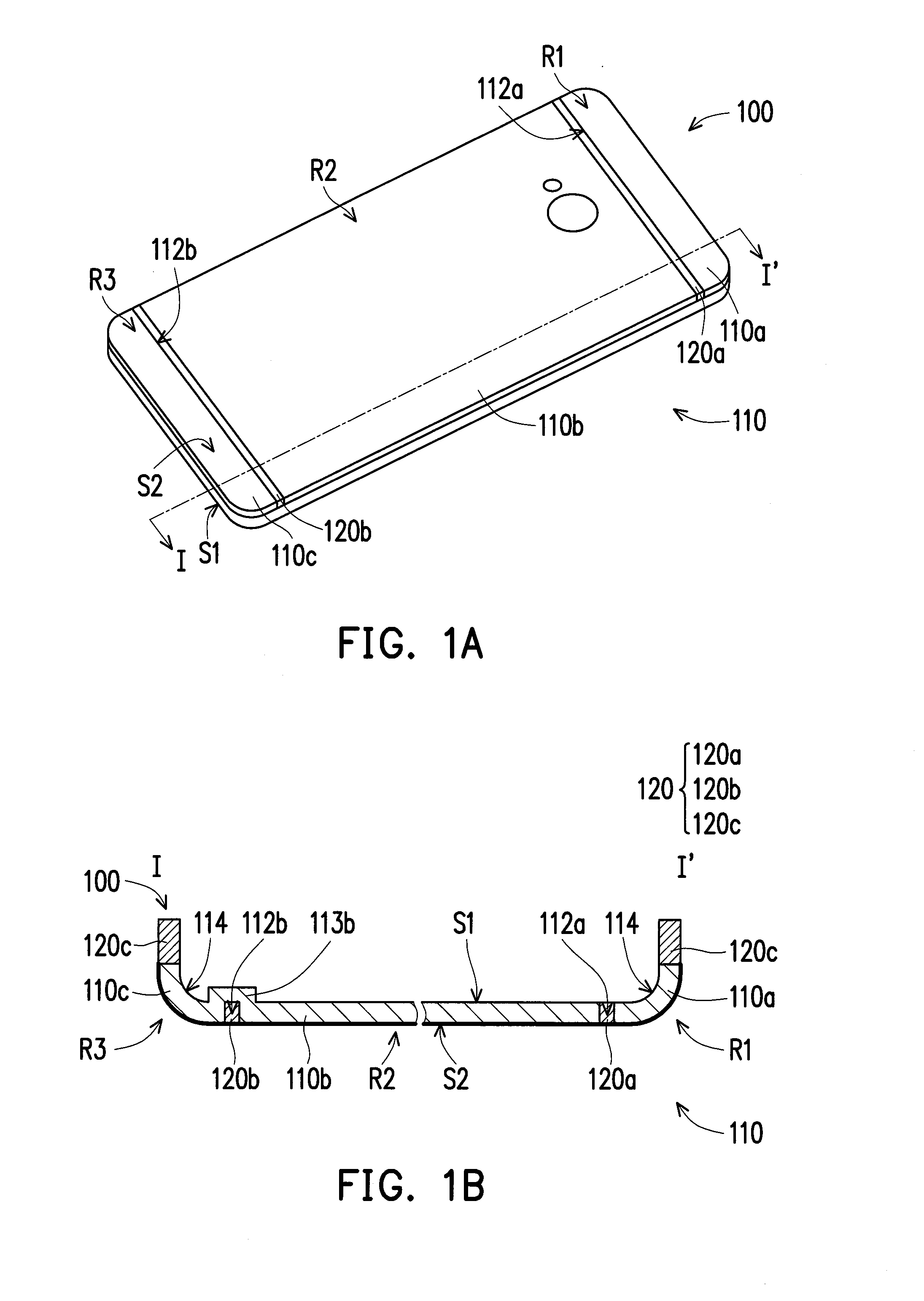

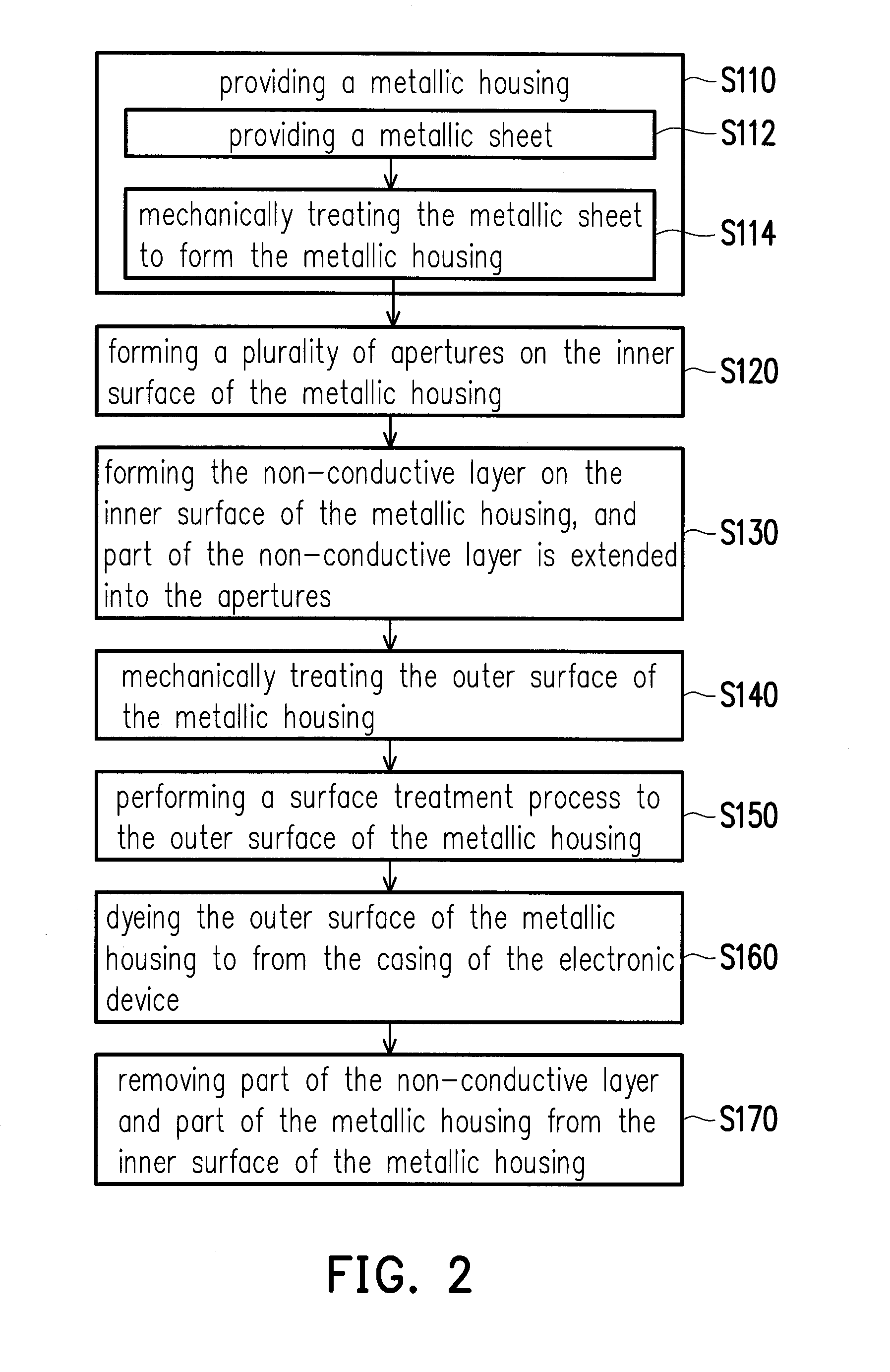

Casing of electronic device and method of manufacturing the same

ActiveUS20140284096A1Avoid residueSolve uneven dyeingAnodisationClosed casingsEngineeringElectronic equipment

Owner:HTC CORP

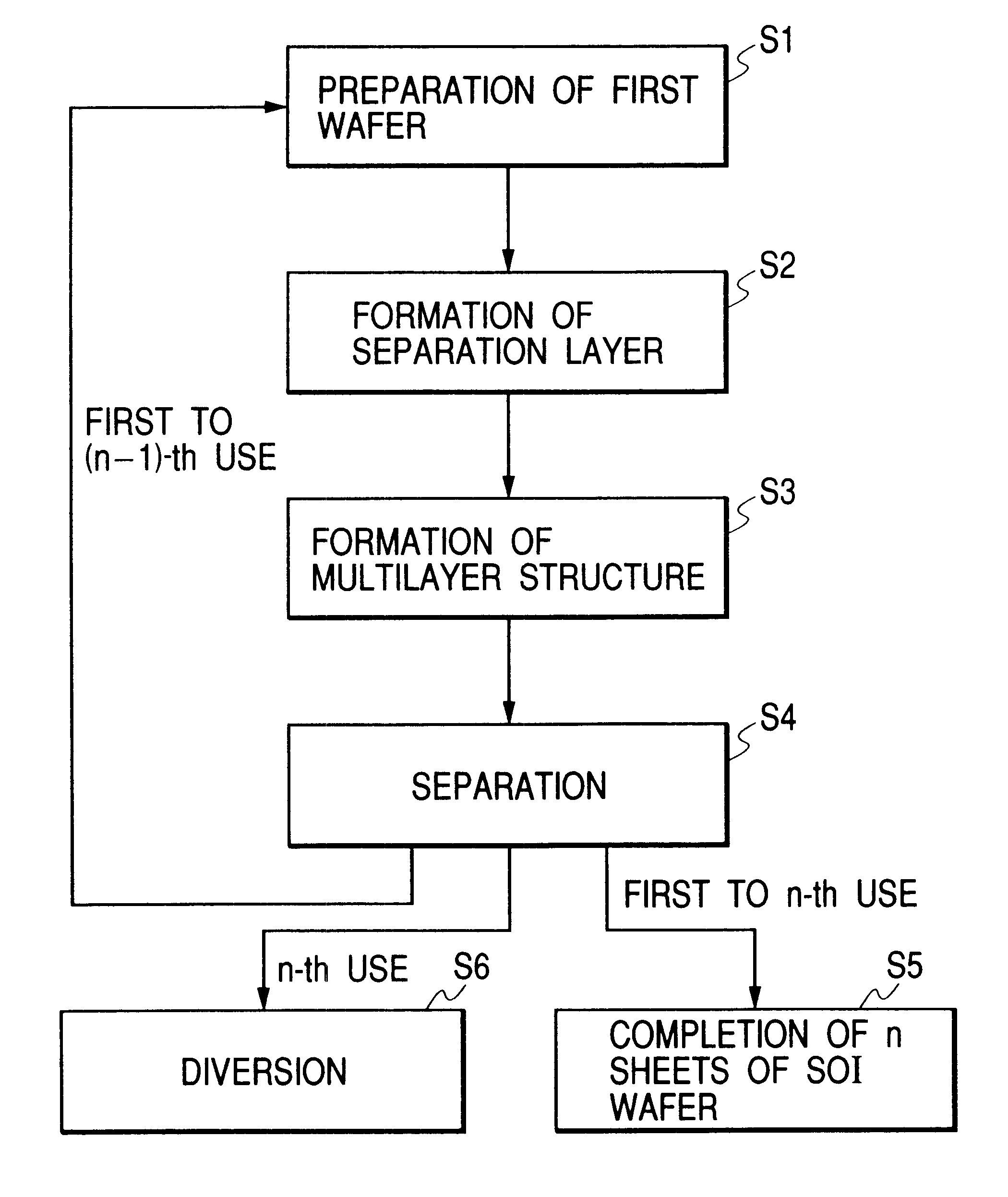

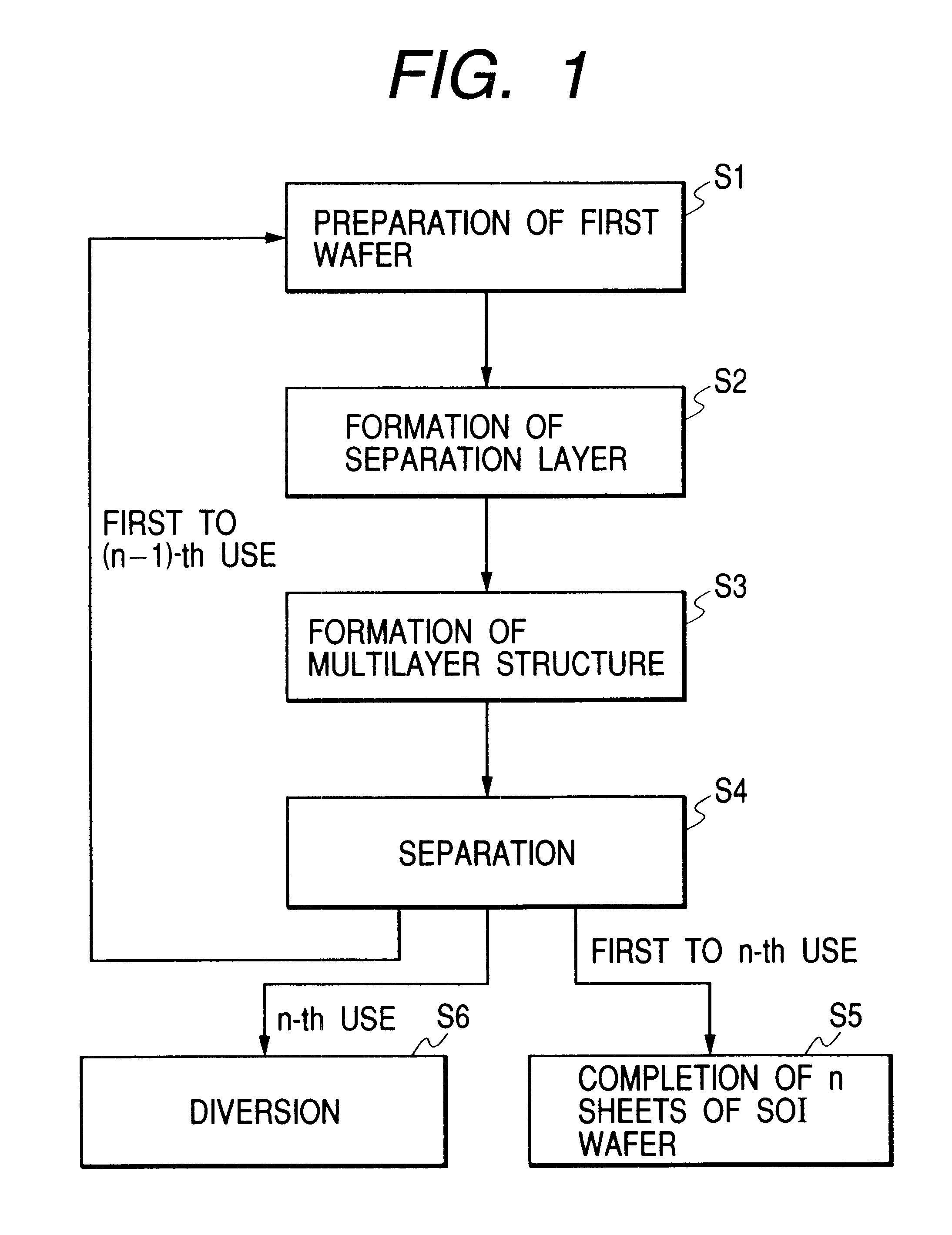

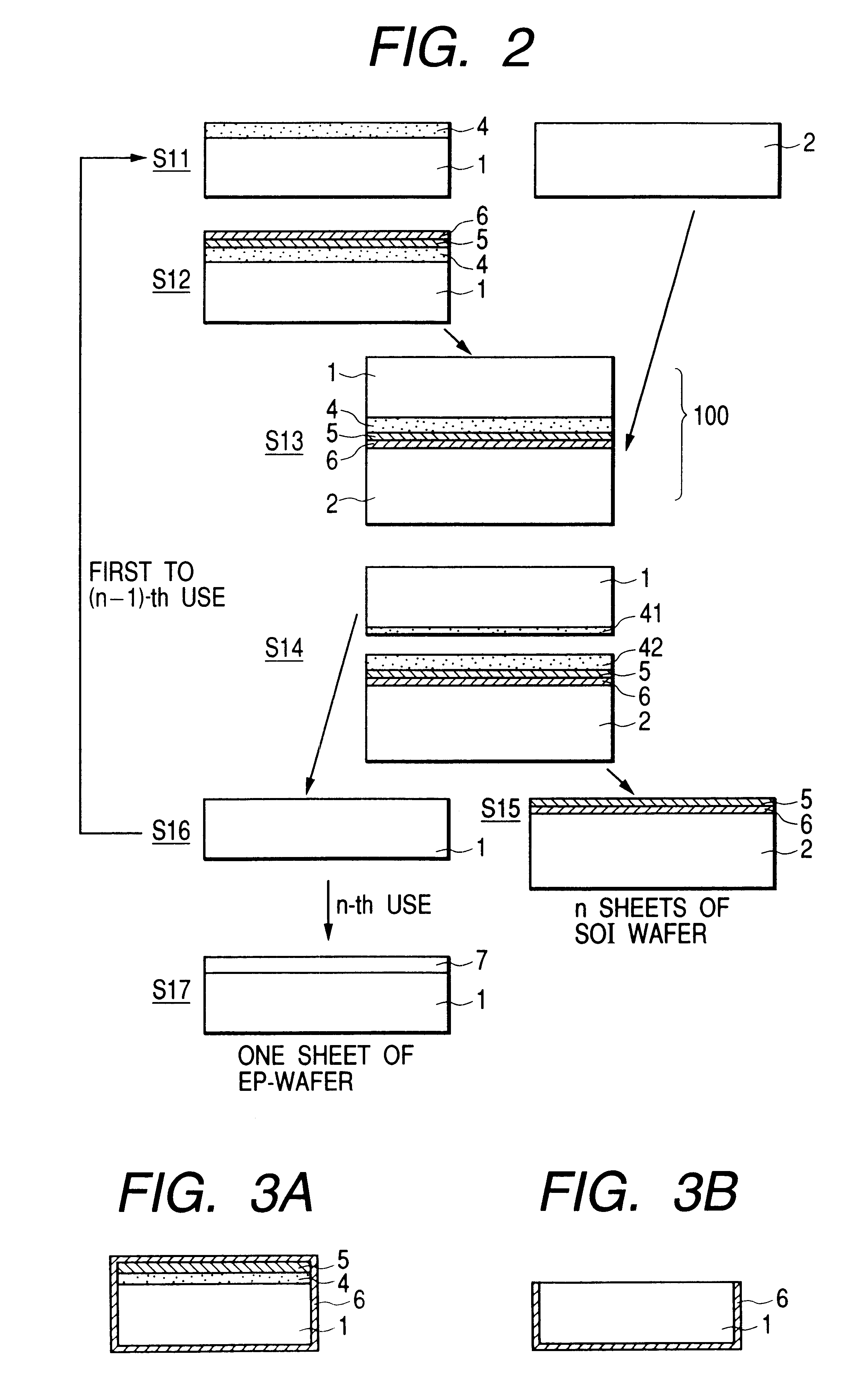

Method of producing semiconductor member

A method of producing a semiconductor member comprises a first step of preparing a first member having a non-porous layer on a semiconductor substrate, and a second step of transferring the non-porous layer from the first member onto a second member, wherein use of the semiconductor substrate from which the non-porous layer is separated in the second step as a constituent material of the first member in the first step is conducted (n-1) times ("n" is a natural number not less than 2), the first and second steps are repeated n times, the semiconductor substrate is separated in n-th use in the second step and the separated semiconductor substrate is used for an use other than that of the first and second steps.

Owner:CANON KK

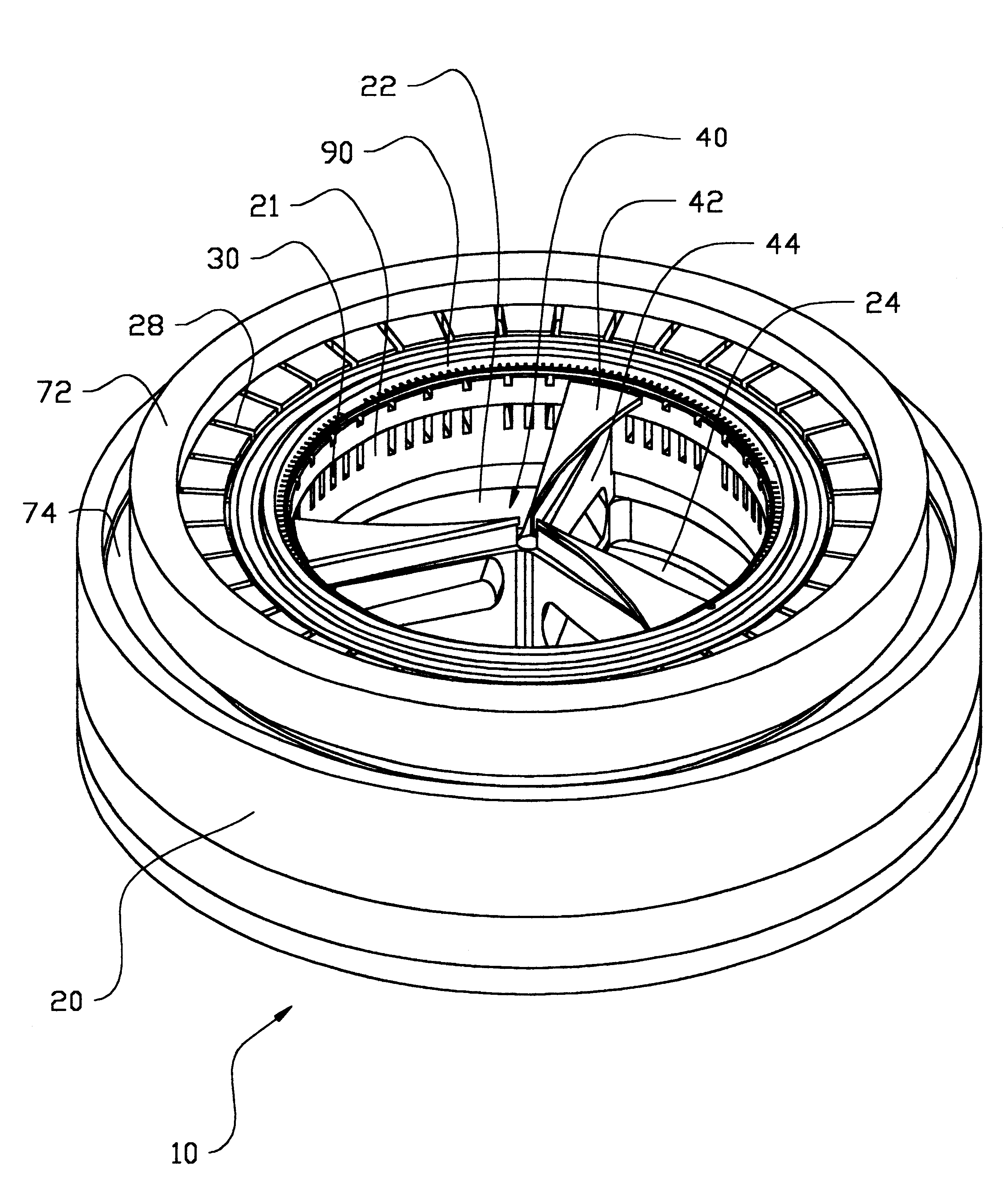

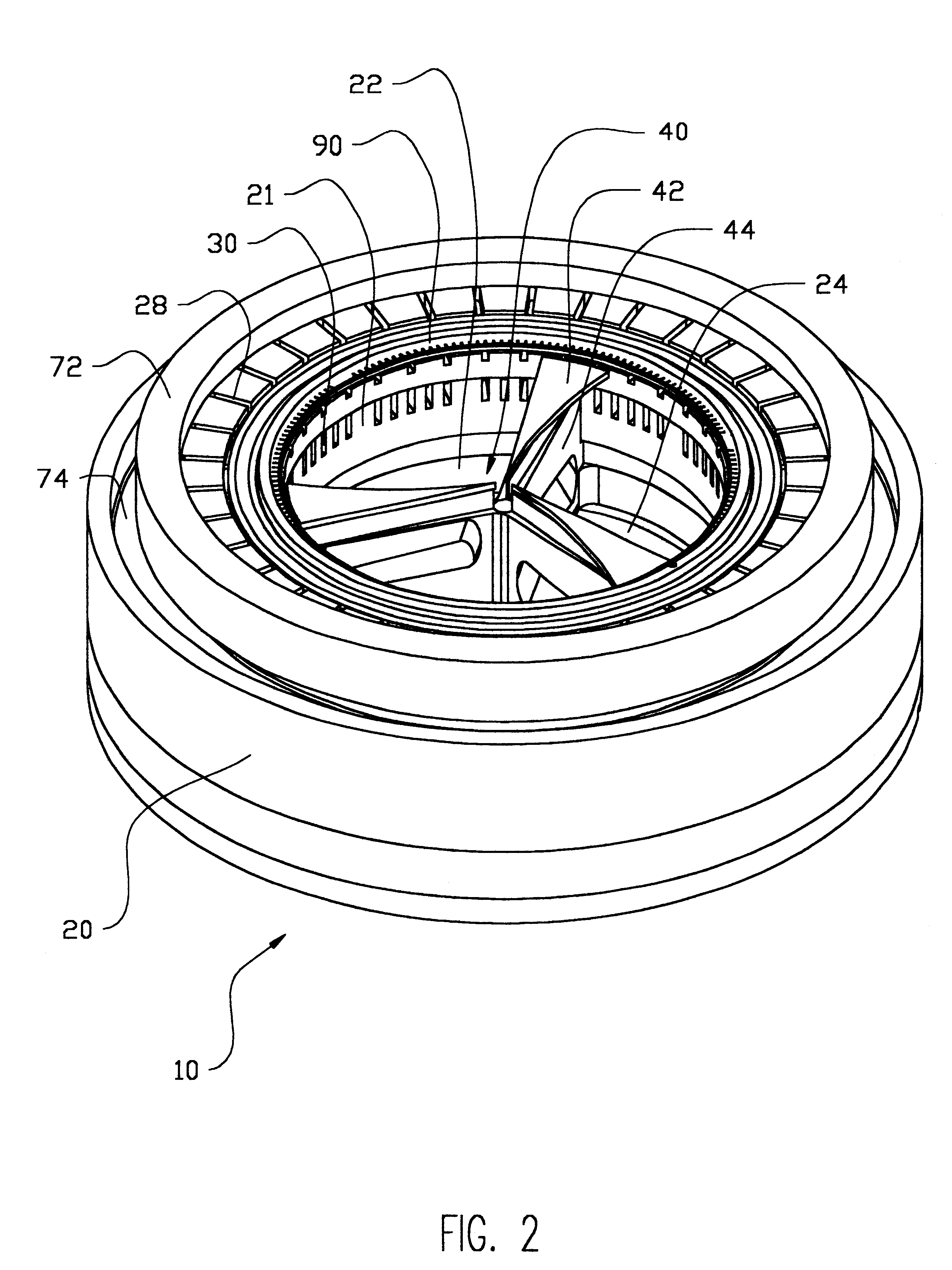

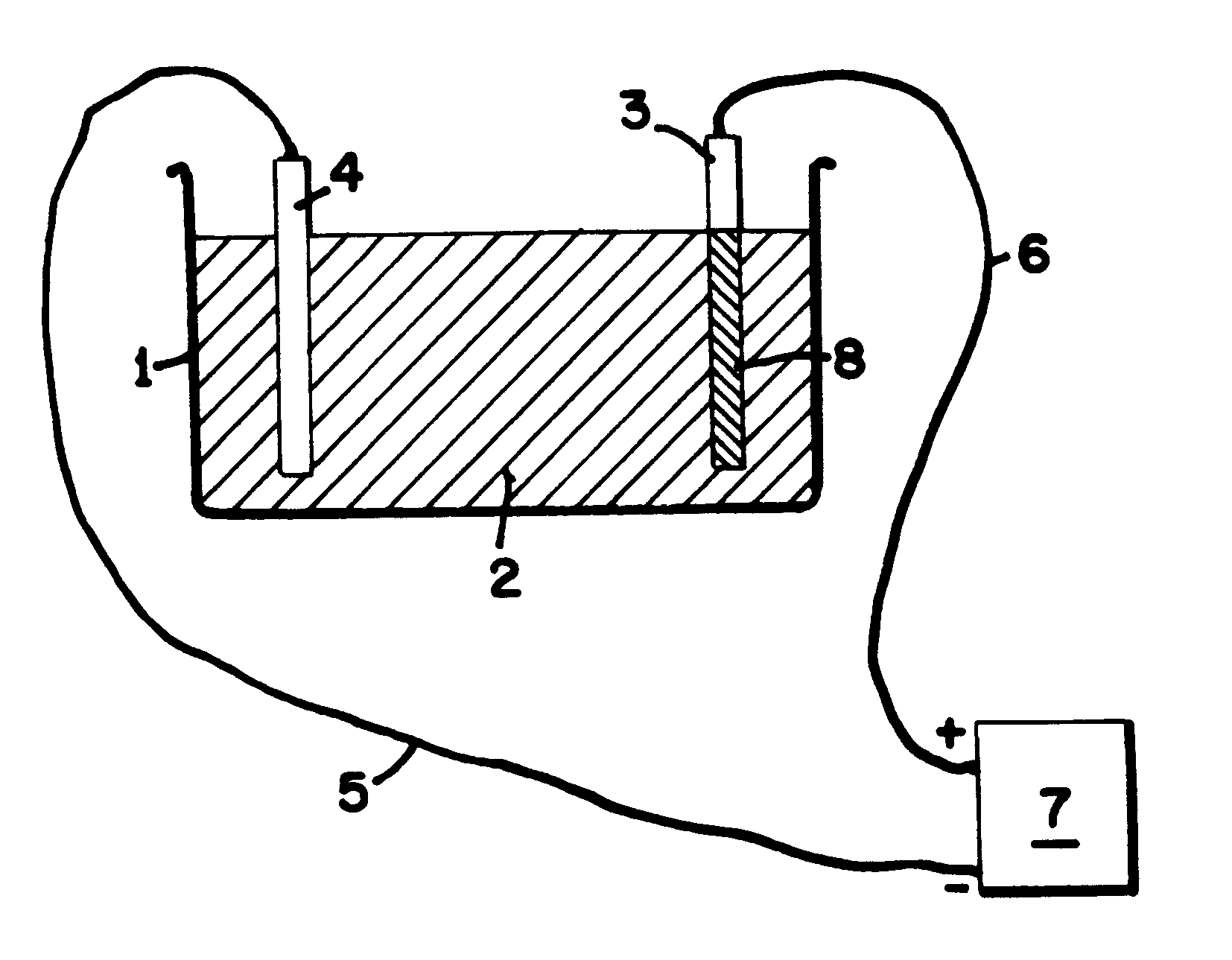

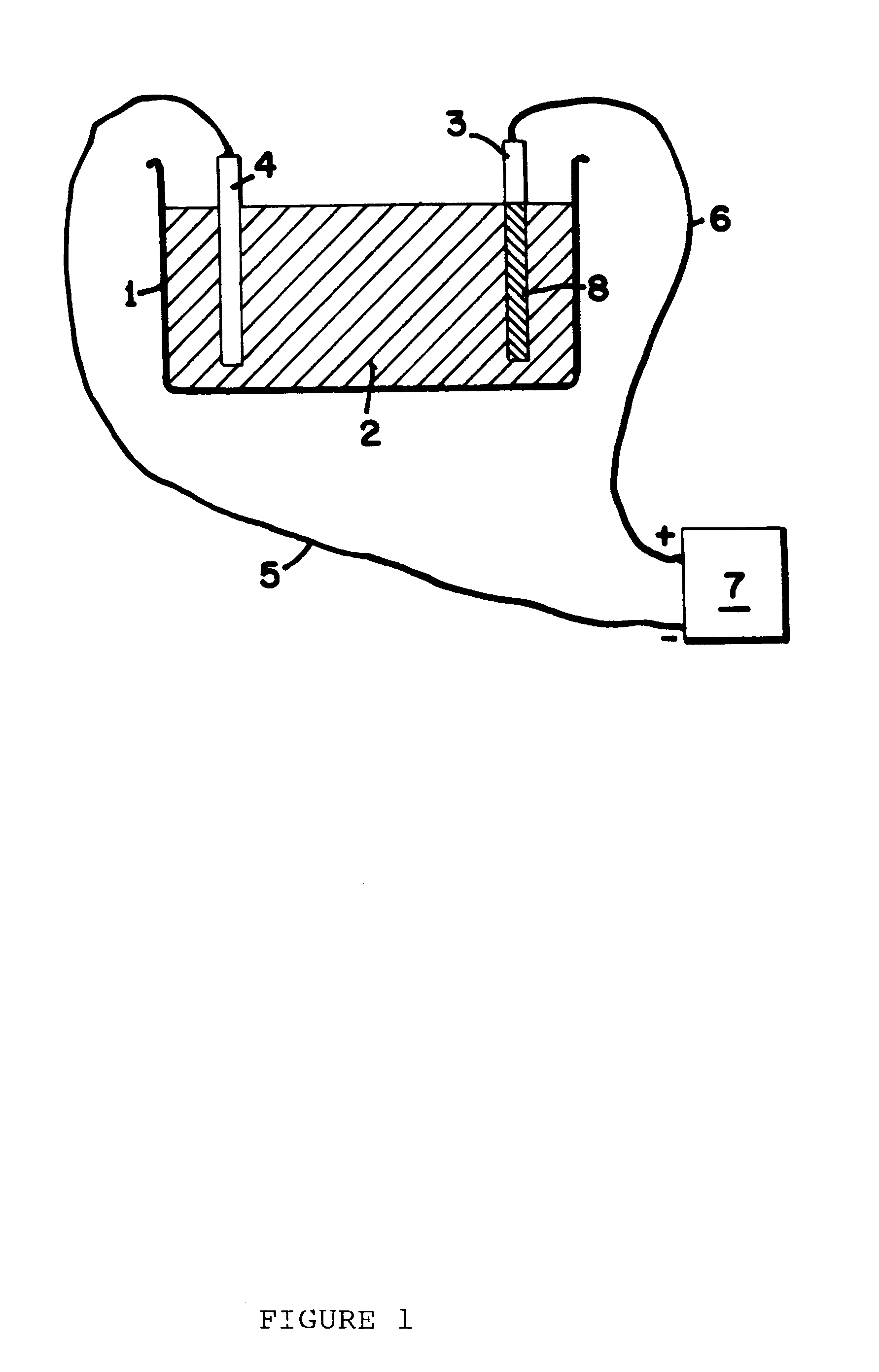

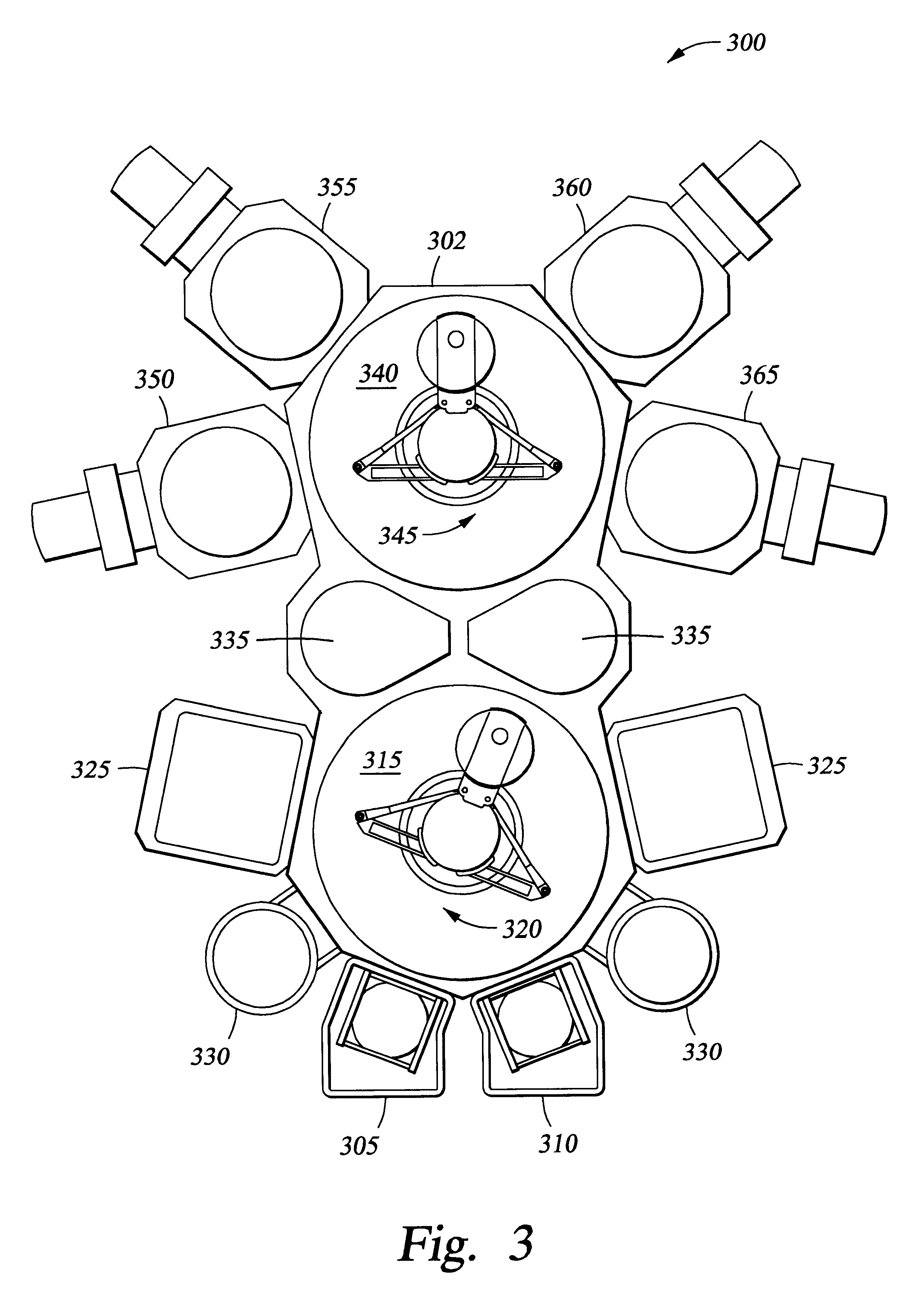

Method of and apparatus for controlling fluid flow and electric fields involved in the electroplating of substantially flat workpieces and the like and more generally controlling fluid flow in the processing of other work piece surfaces as well

A novel method and apparatus of wet processing workpieces, such as electroplating semiconductor wafers and the like, that incorporates reciprocating processing fluid agitation to control fluid flow at the workpiece, and where electric fields are involved as in such electroplating, controlling the electric field distribution.

Owner:HERCULES TECH GROWTH CAPITAL +1

Methods and apparatus for holding and positioning semiconductor workpieces during electropolishing and/or electroplating of the workpieces

A wafer chuck assembly for holding a wafer during electroplating and / or electropolishing of the wafer includes a wafer chuck for receiving the wafer. The wafer chuck assembly also includes an actuator assembly for moving the wafer chuck between a first and a second position. When in the first position, the wafer chuck is opened. When in the second position, the wafer chuck is closed.

Owner:ACM RES

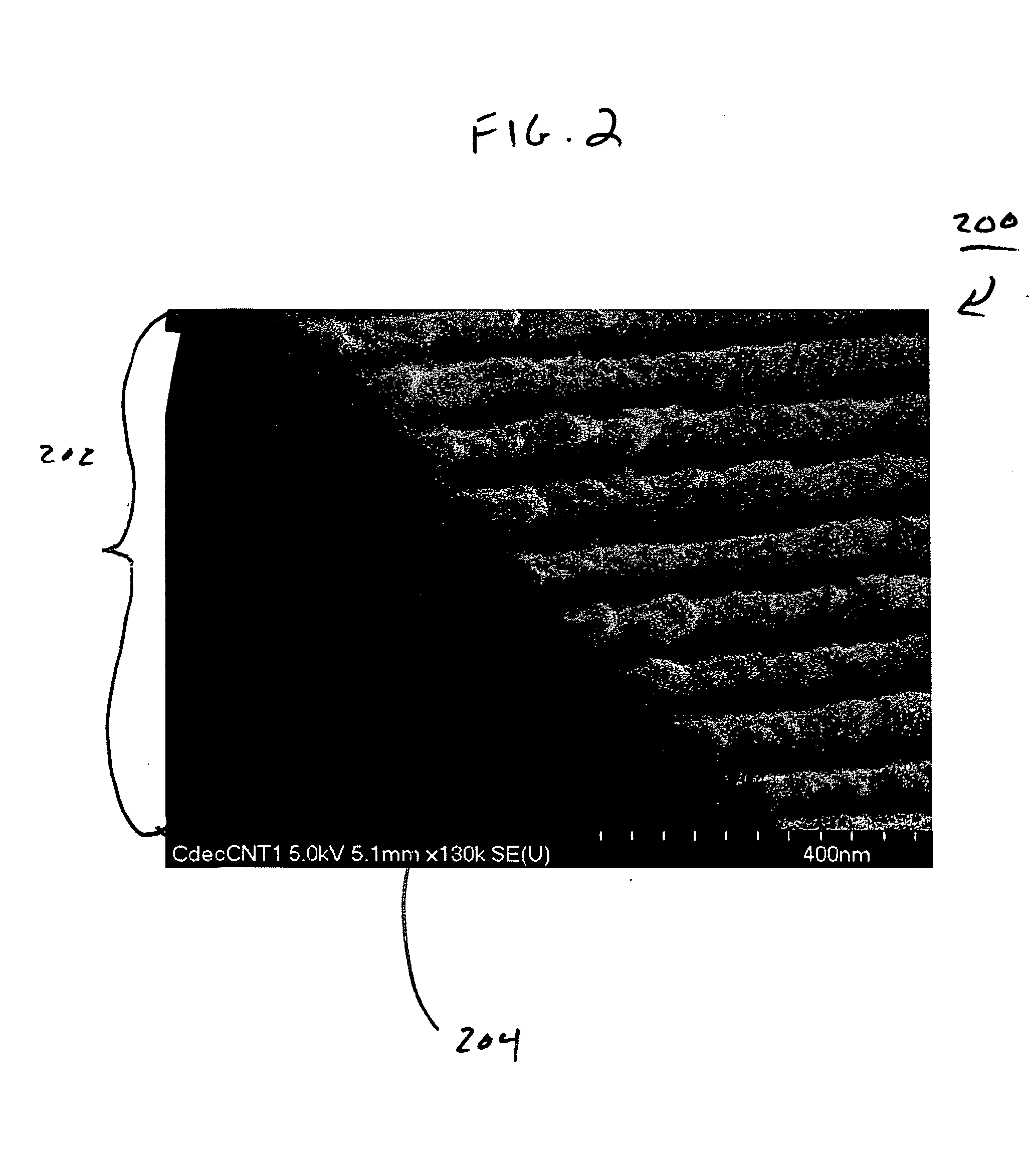

Method for fabrication of porous metal templates and growth of carbon nanotubes and utilization thereof

InactiveUS20050276743A1Large caliberSimple methodAnodisationMaterial nanotechnologyChemical speciesFuel cells

The present invention relates to controlled growth of carbon nanotube (CNT) arrays via chemical vapor deposition (CVD) using novel porous anodic aluminum oxide (AAO) templates, which have been seeded with transition metal catalysts. The resulting CNT bundles may be dense and long and can be used for numerous applications. Further, the porous AAO templates and the CNTs grown thereby, can be functionalized and used for separation of chemical species, hydrogen storage, fuel cell electrocatalyst and gas flow membranes, other catalytic applications, and as a bulk structural material.

Owner:BOARD OF RGT NEVADA SYST OF HIGHER EDUCATION ON BEHALF OF THE UNIV OF NEVADA RENO

Anodization of magnesium and magnesium based alloys

This invention provides a method for the anodization of magnesium or magnesium based alloys using an electrolytic solution containing ammonia, amines or both. The use of such an aqueous electrolytic solution in at least preferred forms alters the conditions under which anodization can occur to provide a more than satisfactory coating on the magnesium material with reduced cycle times.

Owner:MAGNESIUM TECHNOLOGY LIMITED

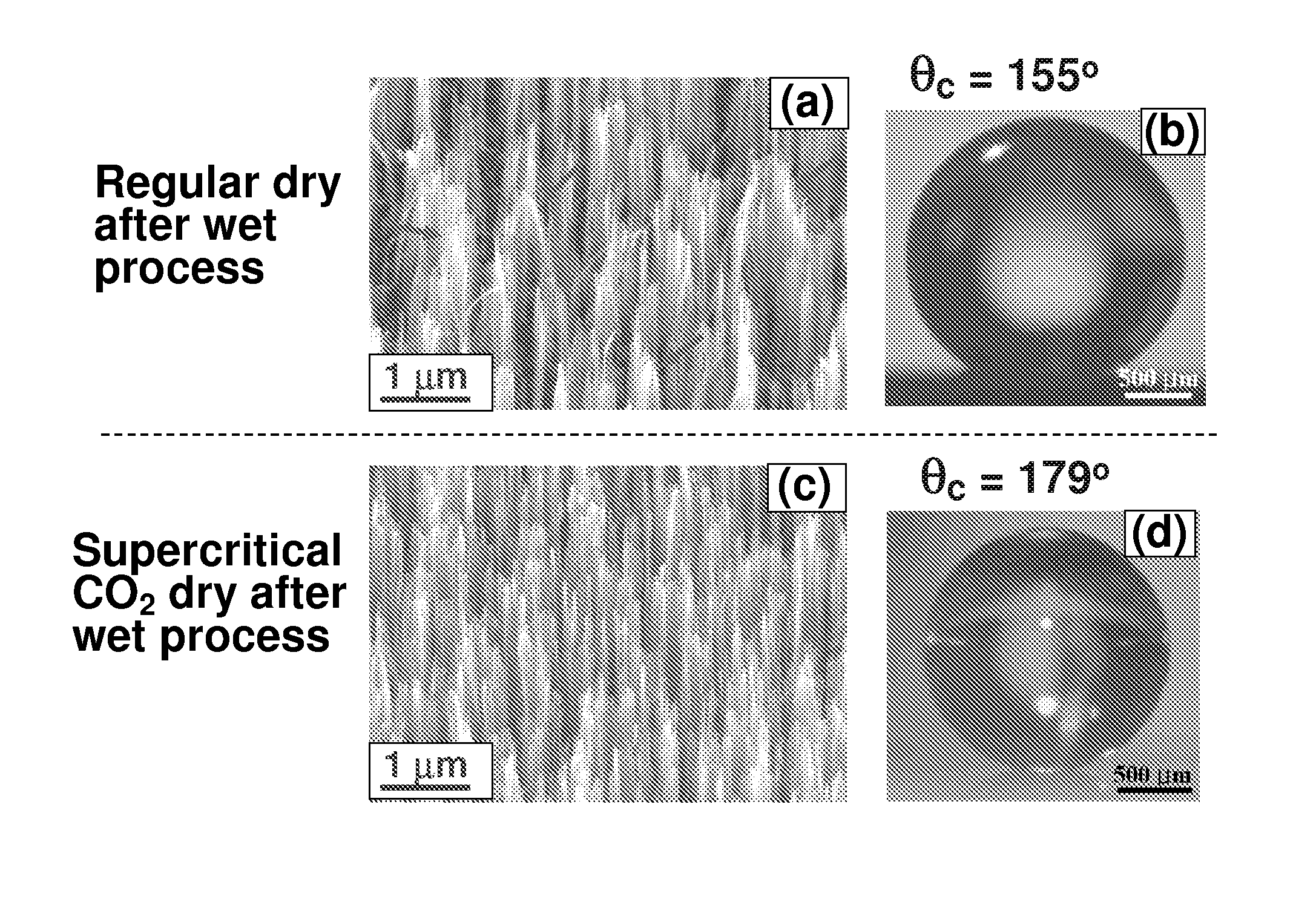

Nanostructured superhydrophobic, superoleophobic and/or superomniphobic coatings, methods for fabrication, and applications thereof

Systems, techniques and applications for nanoscale coating structures and materials that are superhydrophobic with a water contact angle greater than about 140° or 160° and / or superoleophobic with an oil contact angle greater than about 140° or 160°. The nanostructured coatings can include Si or metallic, ceramic or polymeric nanowires that may have a re-entrant or mushroom-like tip geometry. The nanowired coatings can be used in various self-cleaning applications ranging from glass windows for high-rise buildings and non-wash automobiles to pipeline inner surface coatings and surface coatings for biomedical implants.

Owner:RGT UNIV OF CALIFORNIA

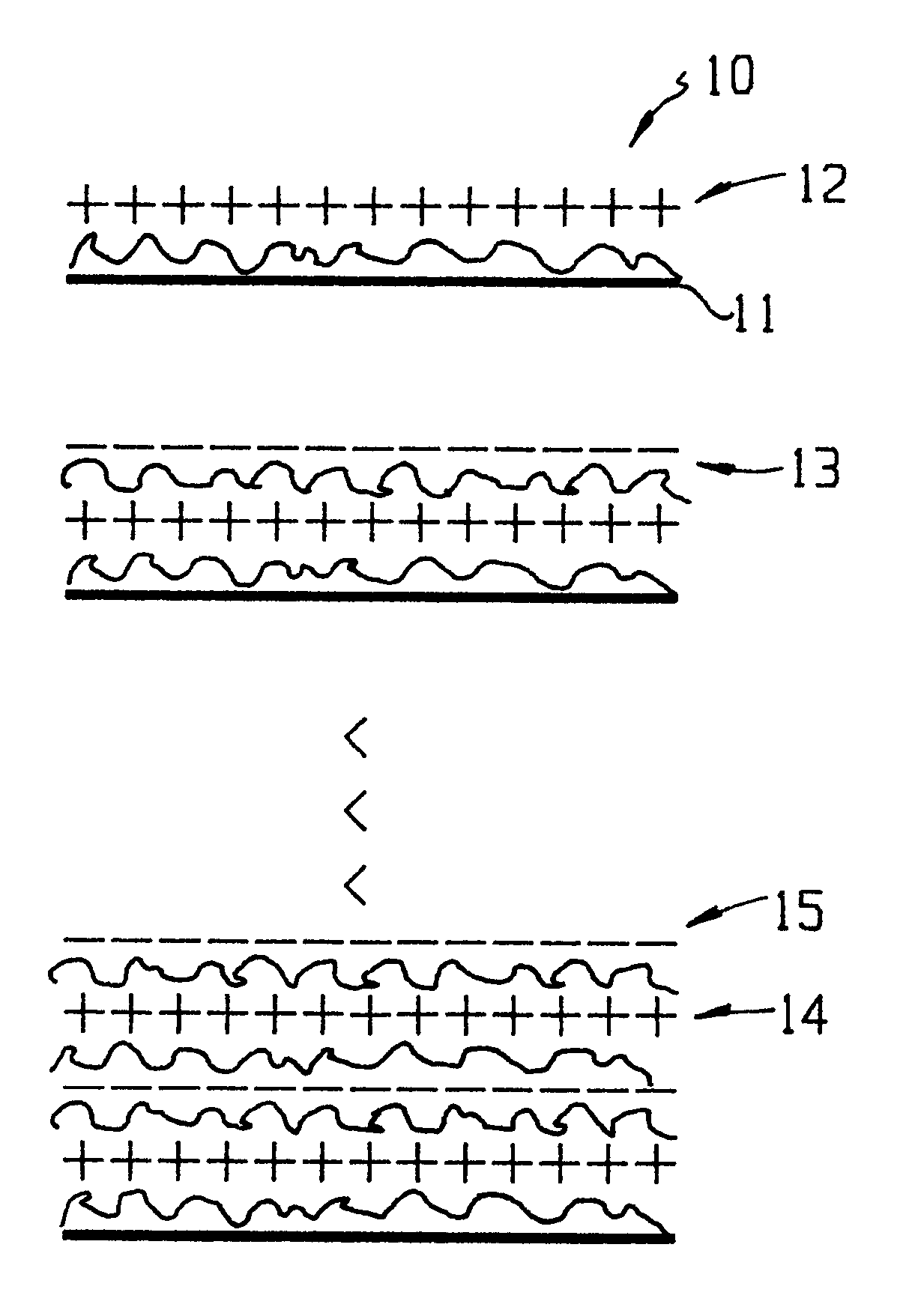

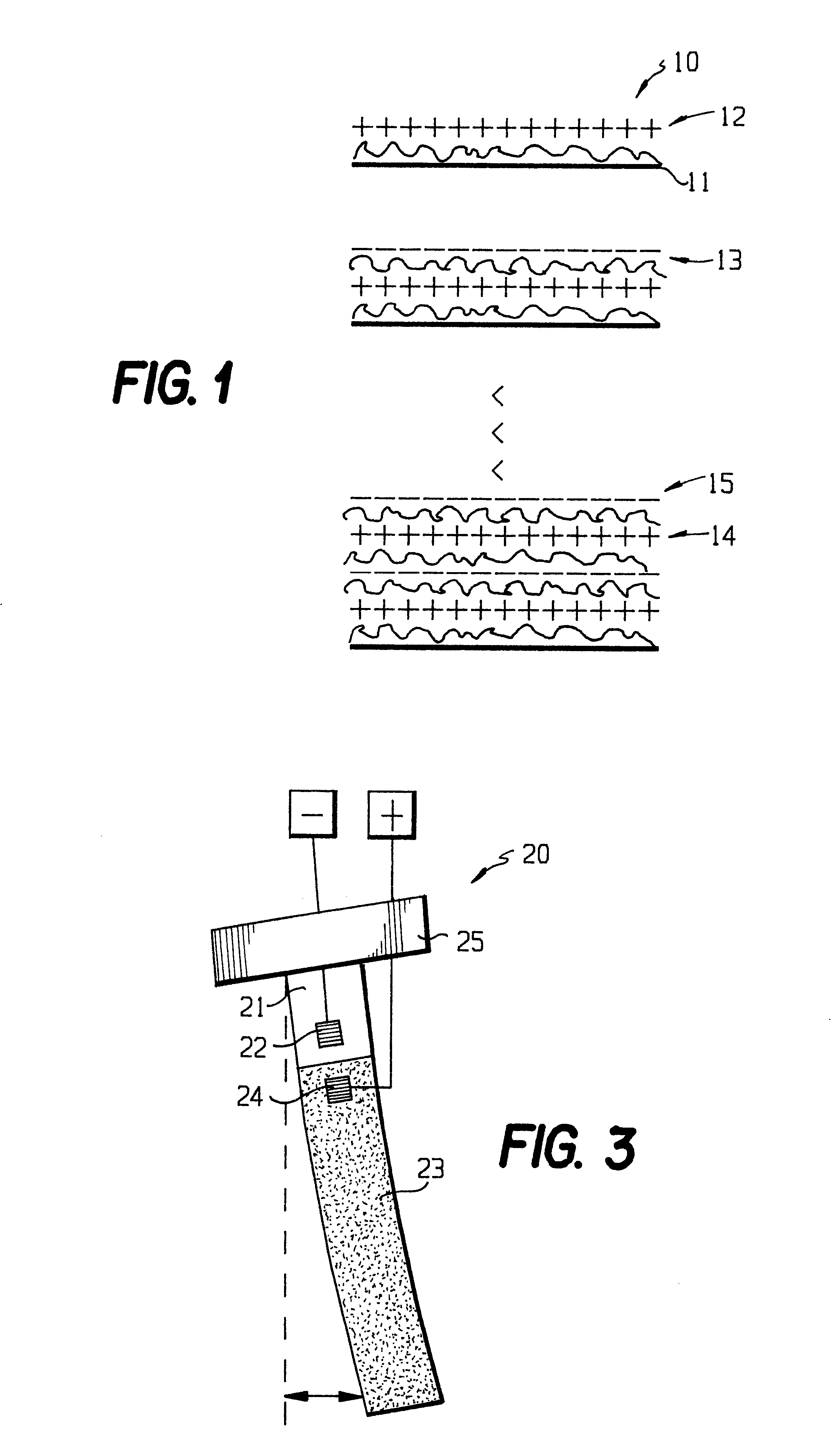

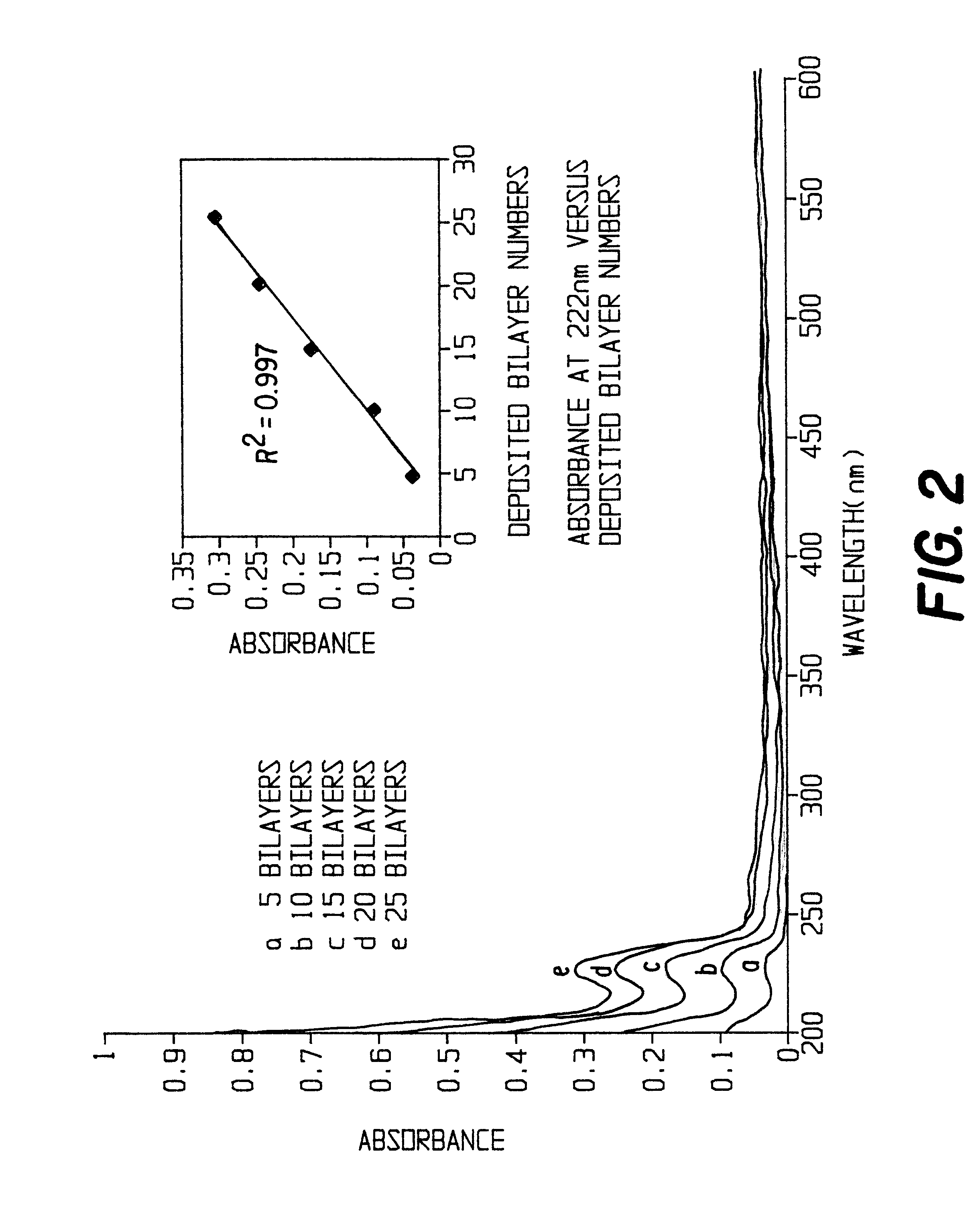

Electrostrictive and piezoelectric thin film assemblies and method of fabrication therefor

InactiveUS6447887B1Avoid misalignmentUniform propertyAnodisationMaterial nanotechnologyMolecular levelEngineering

An electrostatic self-assembly method of fabricating electrostrictive and piezoelectric thin film assemblies not only provides a thinner film than is attainable by conventional methods, but provides excellent molecular-level uniformity and precise structural control, and thus large, effective piezoelectric coefficients. The method produces a thin film assembly including (a) a substrate, and (b) a film having one or a plurality of layers disposed upon the substrate, wherein at least one of the layers includes a dipolar material, and this layer of dipolar material has a uniform thickness of at most 500 nm.

Owner:VIRGINIA TECH INTPROP INC

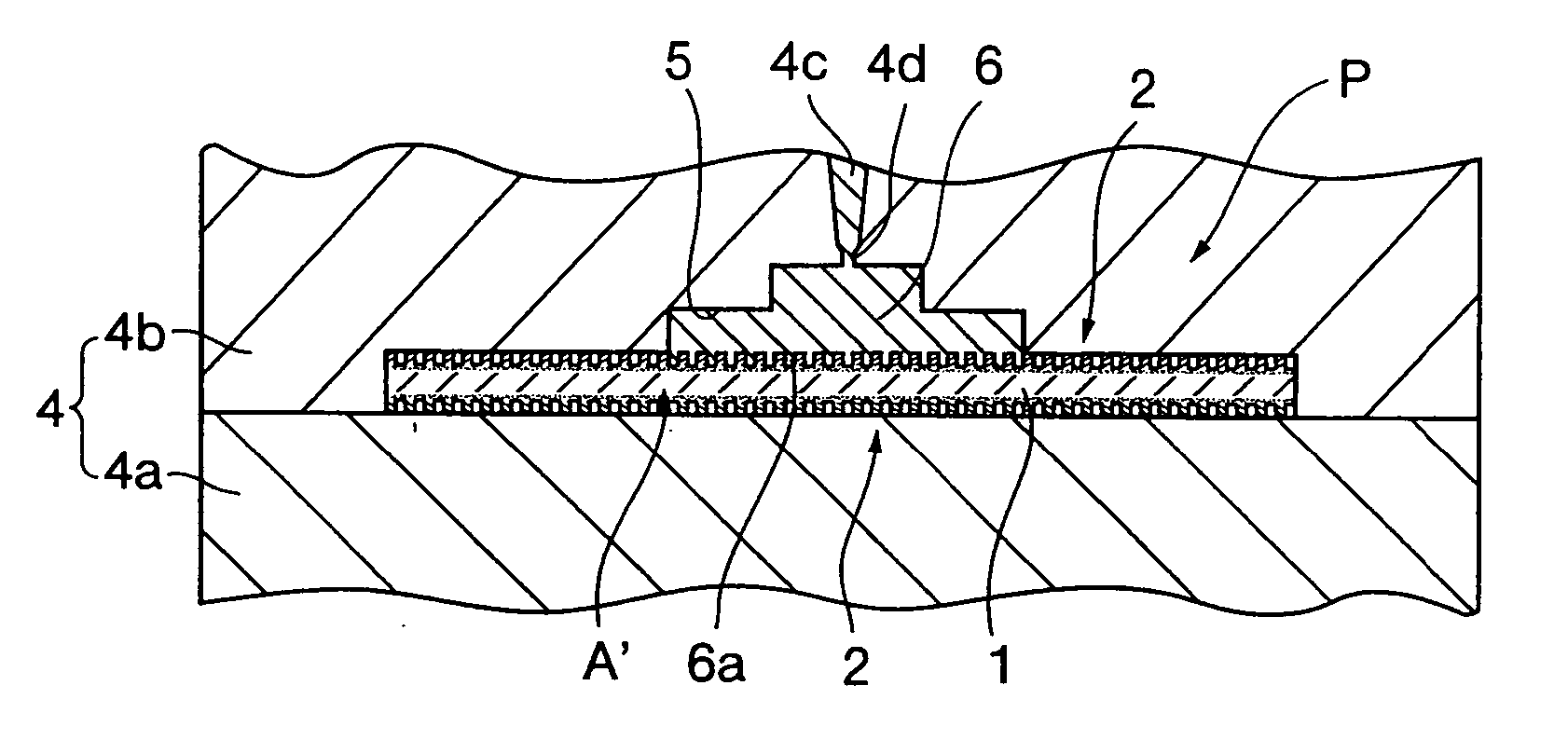

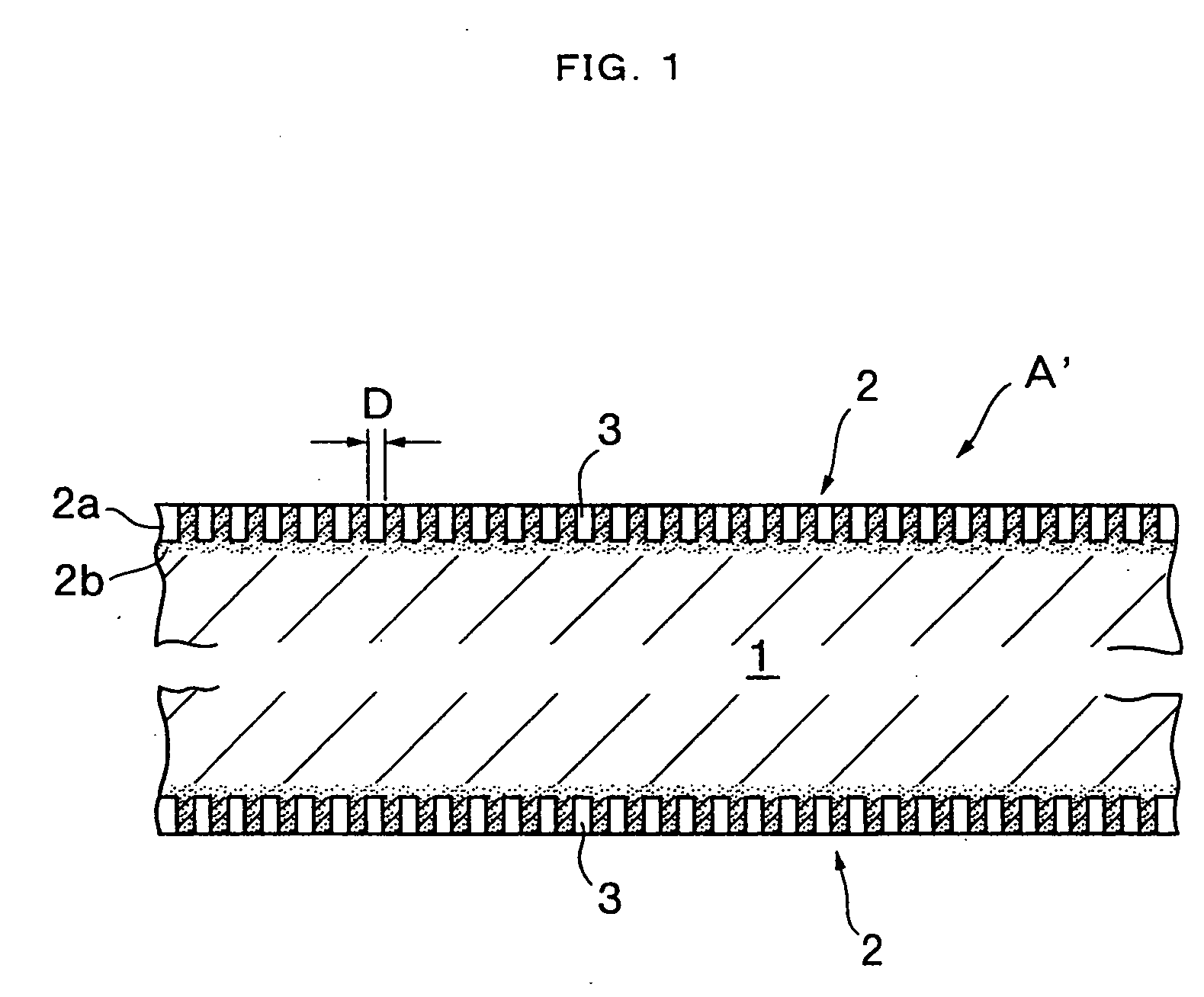

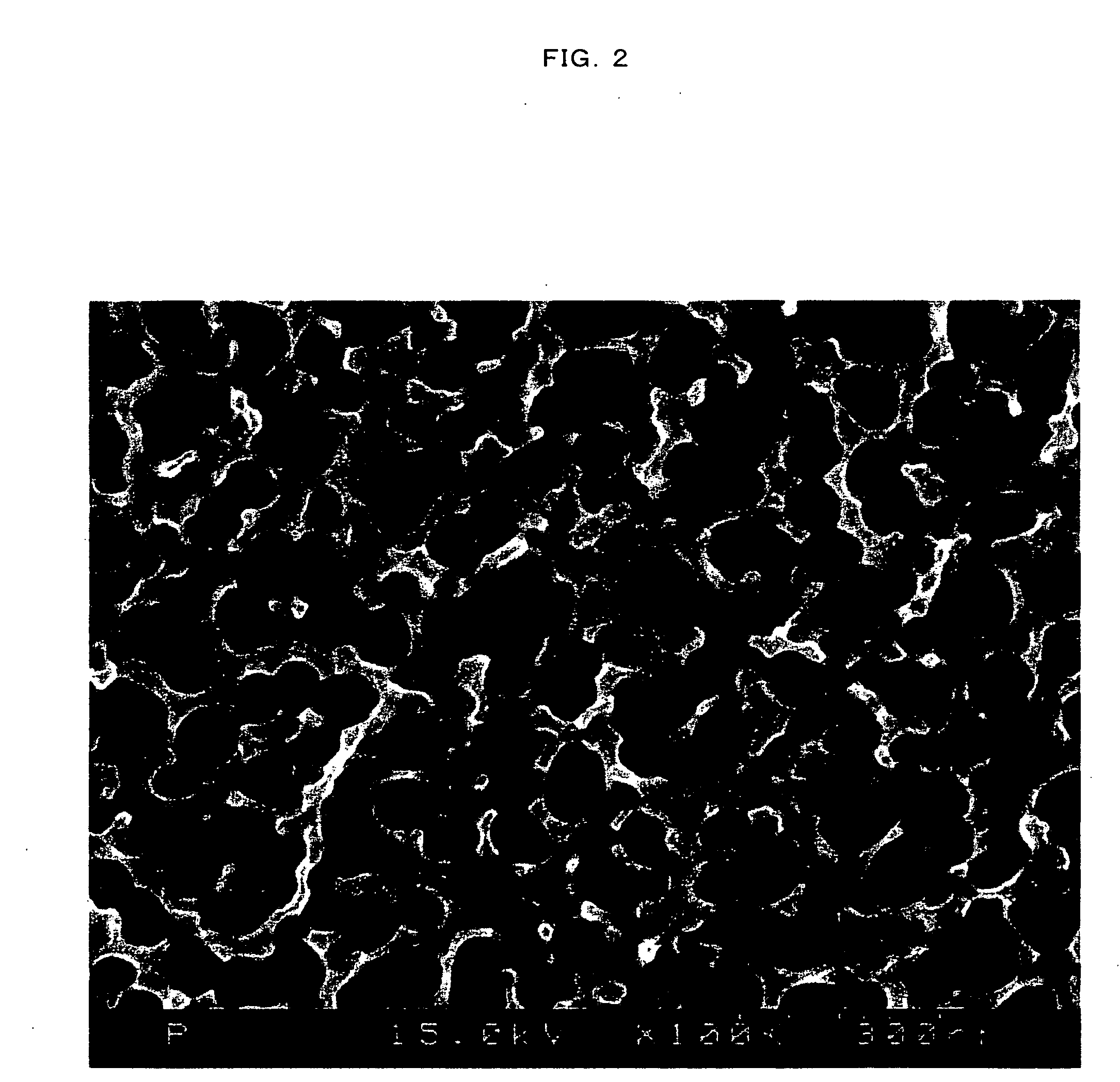

Composite of aluminium material and synthetic resin molding and process for producing the same

ActiveUS20060055084A1Stable and fast compositeHigh tensile strengthAnodisationNatural mineral layered productsO-Phosphoric AcidSynthetic resin

The present invention is to provide a process for producing a composite of an aluminum material and a synthetic resin molding that can be produced at a high efficiency and to provide a stable and fast composite that is large in a peel strength and a mechanical strength. The process for producing a composite according to the present invention is characterized in that an aluminum raw material is oxidized in an electrolytic bath of phosphoric acid or sodium hydride, thereby an anodic oxidation coating provided with innumerable pores 3 having a diameter of 25 nm or more made open in the surface thereof is formed thereon, and a synthetic resin mold 6 is coupled with the anodic oxidation coating 2 in such a condition that the part 6a thereof is intruded in the innumerable pores.

Owner:CHERRY CHIEF MAF CORP

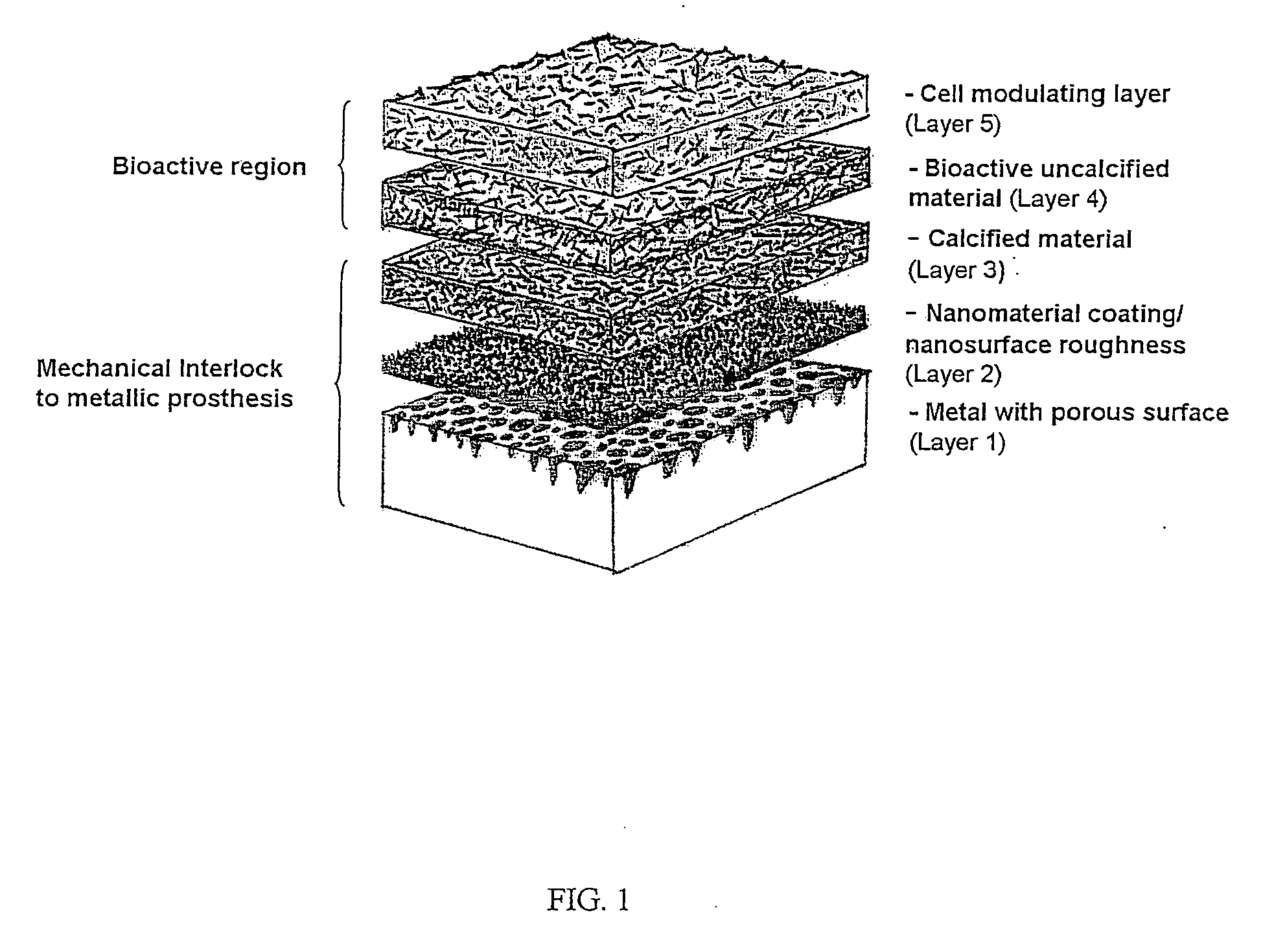

System and method for attaching soft tissue to an implant

ActiveUS20060105015A1Firmly connectedIncreased pull-out strengthAnodisationBiocideCell-Extracellular MatrixProsthesis

One embodiment of the present invention is directed to compositions and methods for enhancing attachment of soft tissues to a metal prosthetic device. In one embodiment a construct is provided comprising a metal implant having a porous metal region, wherein said porous region exhibits a nano-textured surface, and a biocompatible polymer matrix coating the nano-textured surface. The polymer matrix coating comprises a naturally occurring extracellular matrix with biocompatible inorganic materials distributed within the matrix, or a biocompatible polymer and an osteo-inductive agent.

Owner:DEPUY SYNTHES PROD INC +1

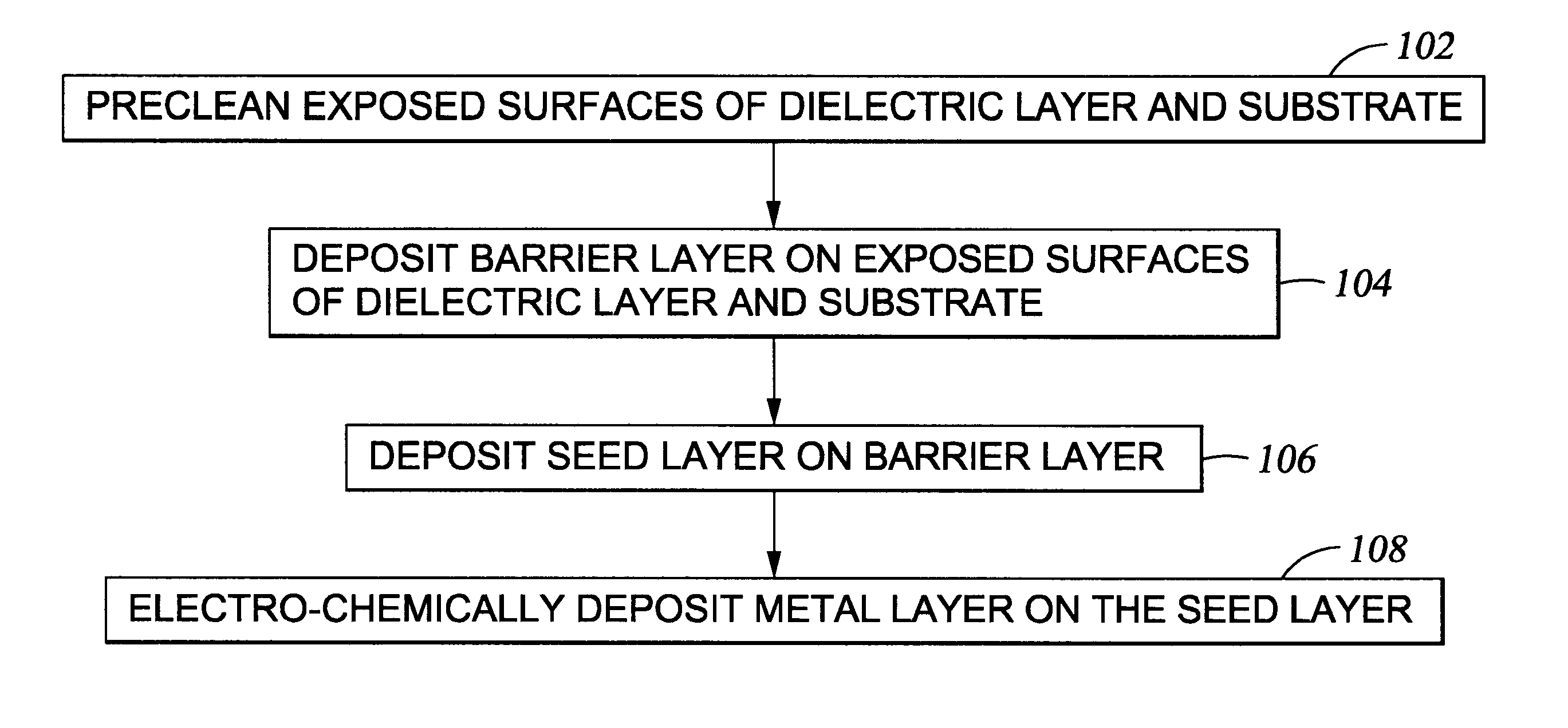

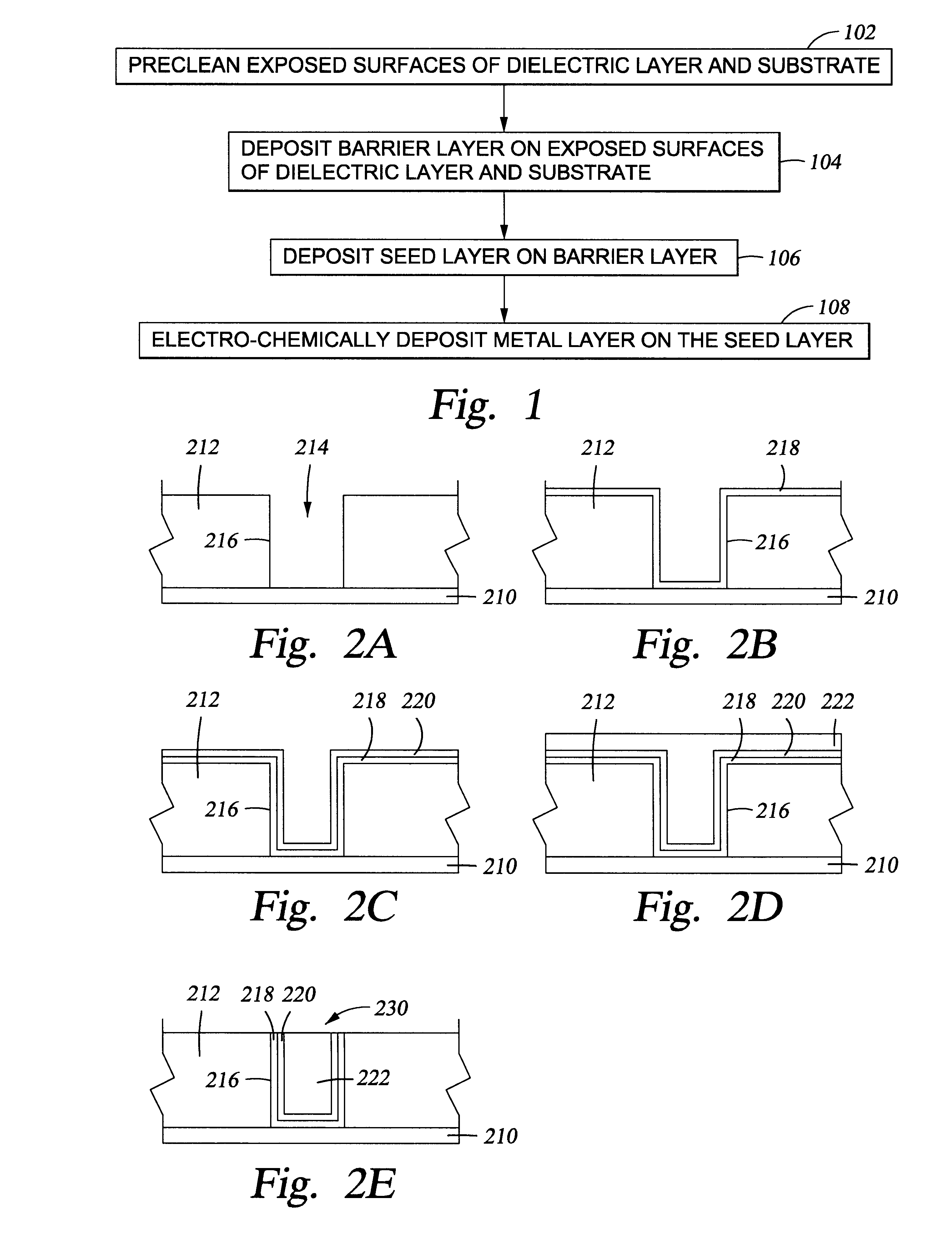

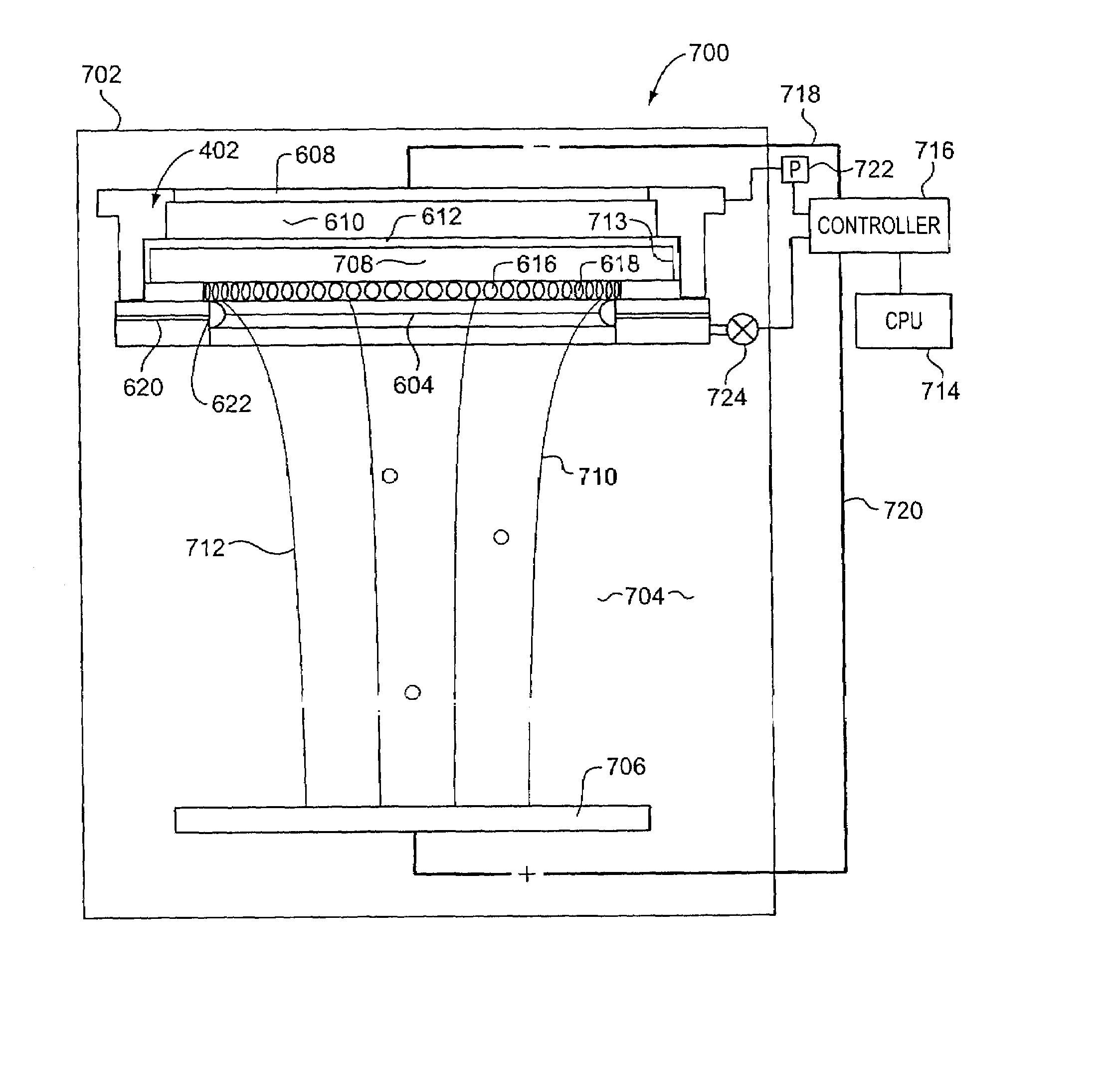

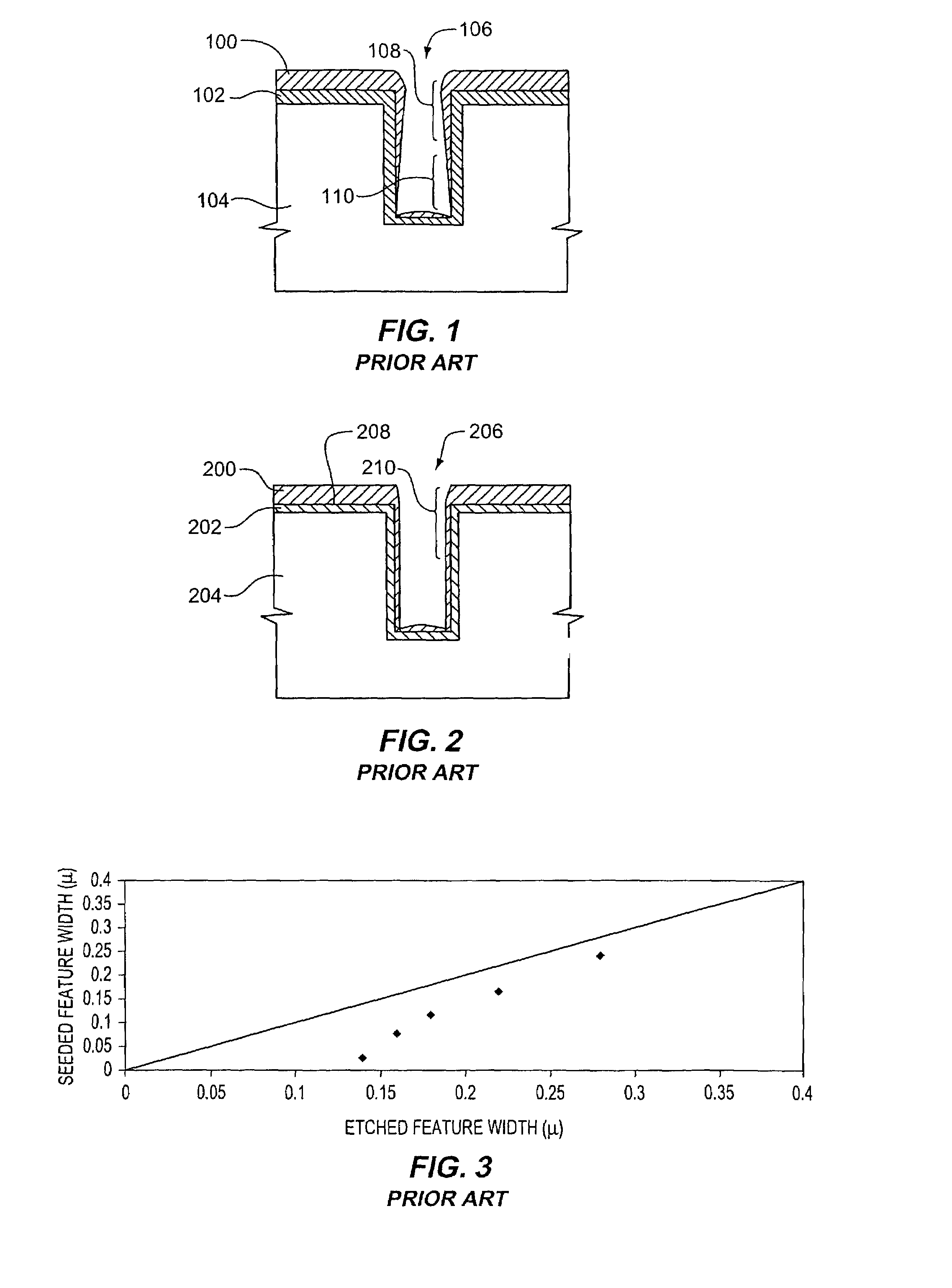

Method for achieving copper fill of high aspect ratio interconnect features

InactiveUS6436267B1AnodisationSemiconductor/solid-state device manufacturingMetal interconnectGas phase

One aspect of the invention provides a consistent metal electroplating technique to form void-less metal interconnects in sub-micron high aspect ratio features on semiconductor substrates. One embodiment of the invention provides a method for filling sub-micron features on a substrate, comprising reactive precleaning the substrate, depositing a barrier layer on the substrate using high density plasma physical vapor deposition; depositing a seed layer over the barrier layer using high density plasma physical vapor deposition; and electro-chemically depositing a metal using a highly resistive electrolyte and applying a first current density during a first deposition period followed by a second current density during a second period.

Owner:APPLIED MATERIALS INC

Anodizing Aluminum and Alloys Thereof

This invention encompasses methods of producing a colored oxide layer on an aluminum material by anodizing the aluminum material in an electrolyte comprising water, sulfuric acid and oxalic acid. The anodizing step comprises passing at least two sequential current densities through the electrolyte. Methods of making and using article with a colored oxide layer on an aluminum material make by the methods disclosed herein are also disclosed.

Owner:DURACOUCHE INT

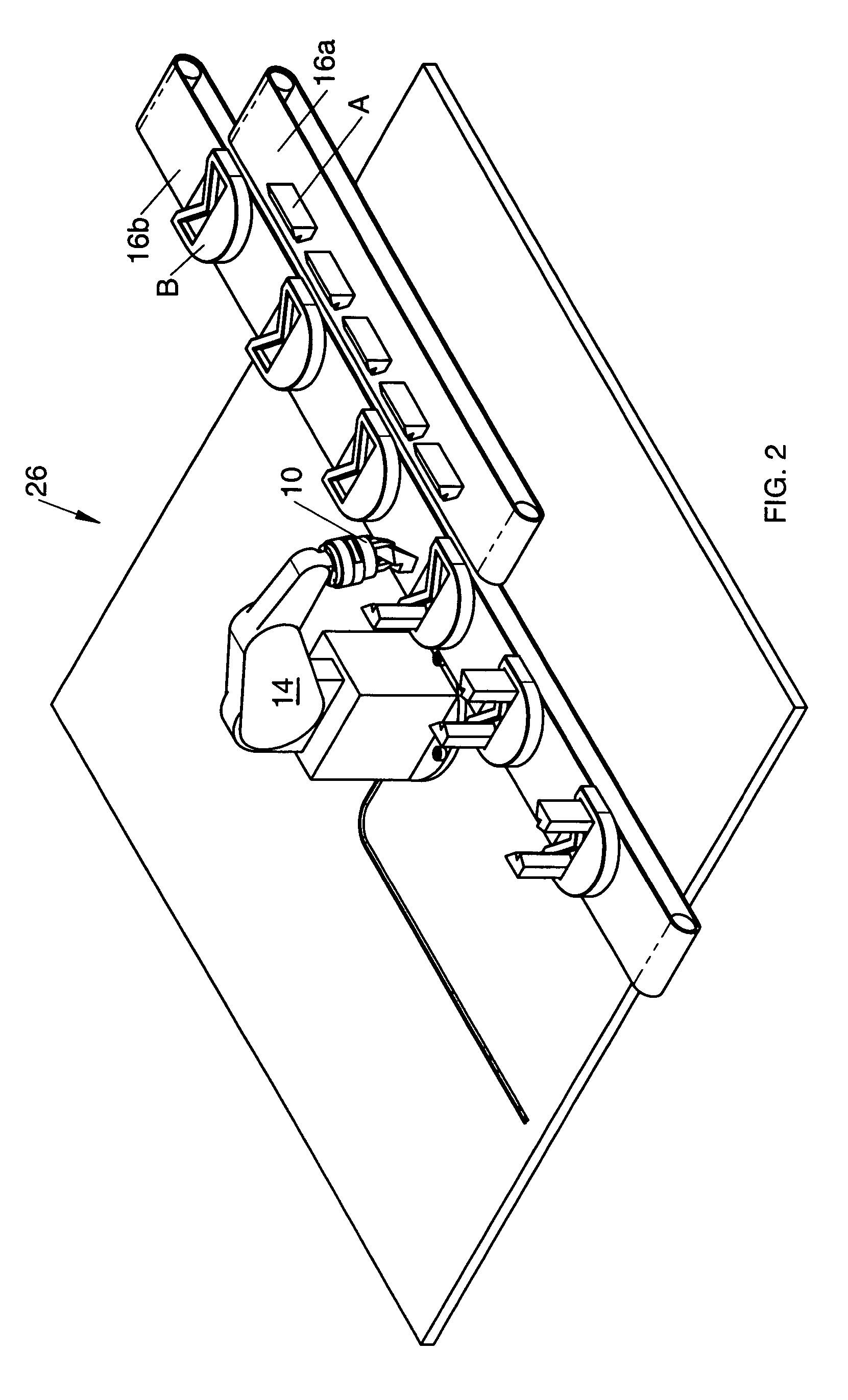

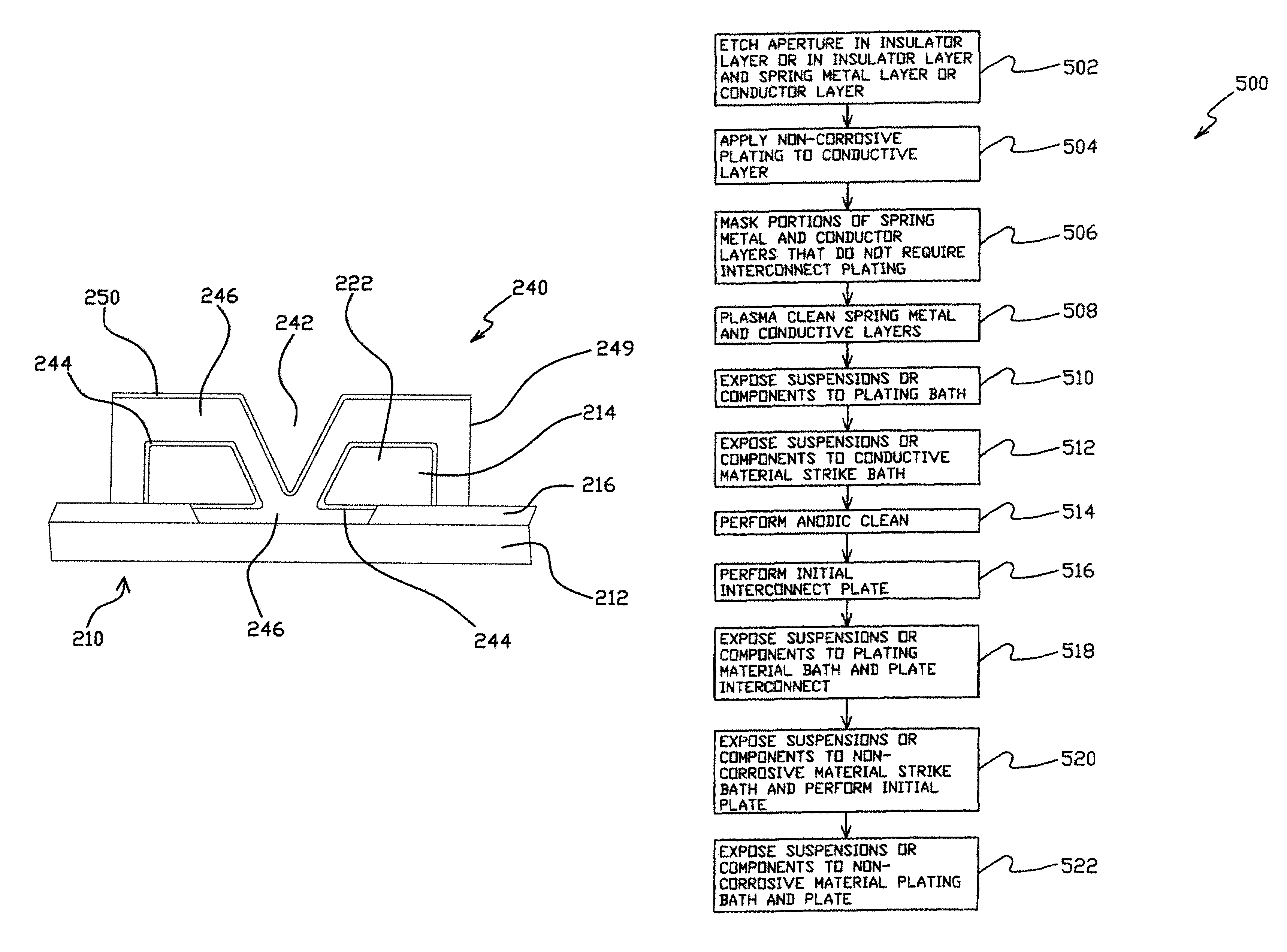

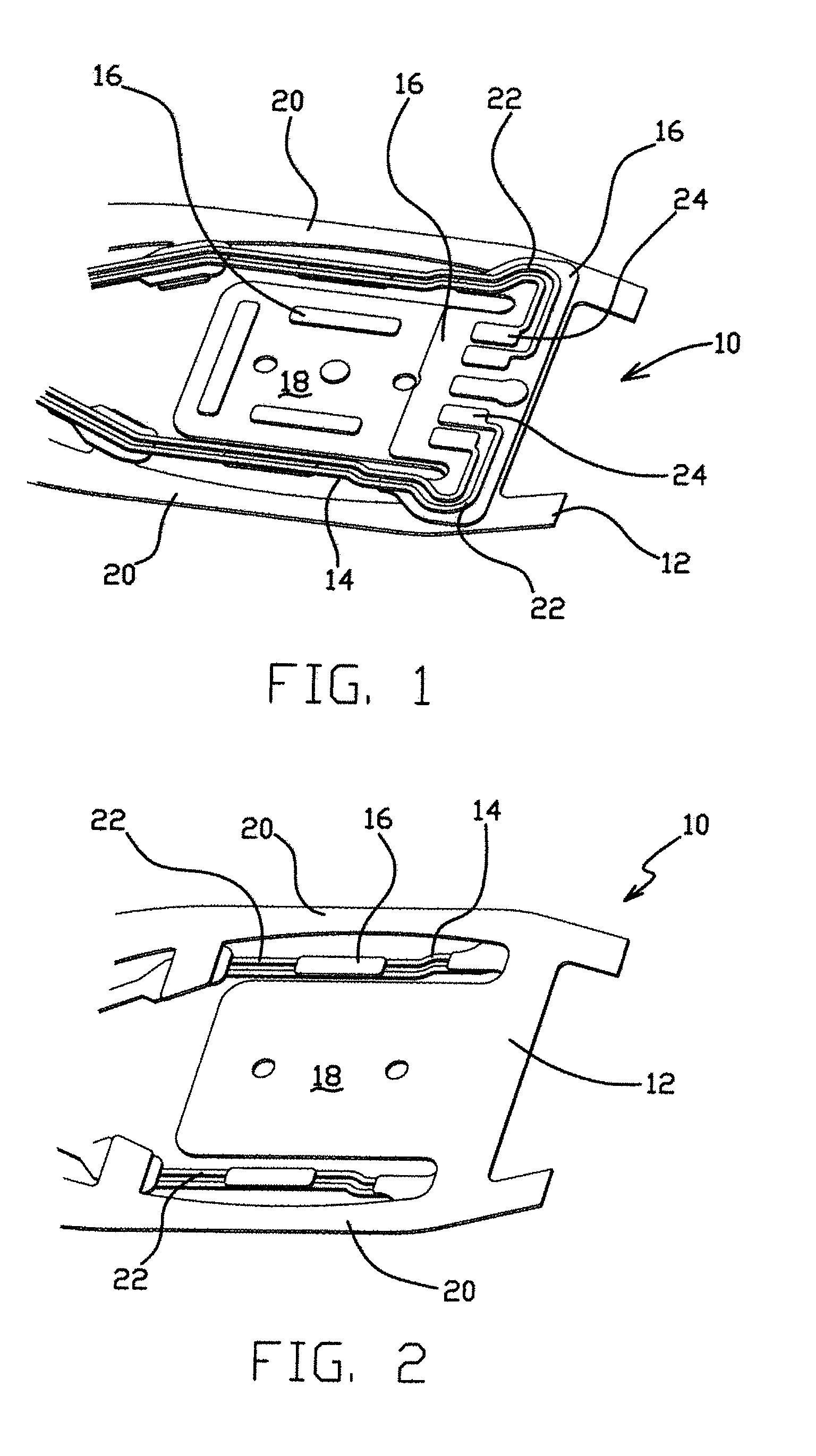

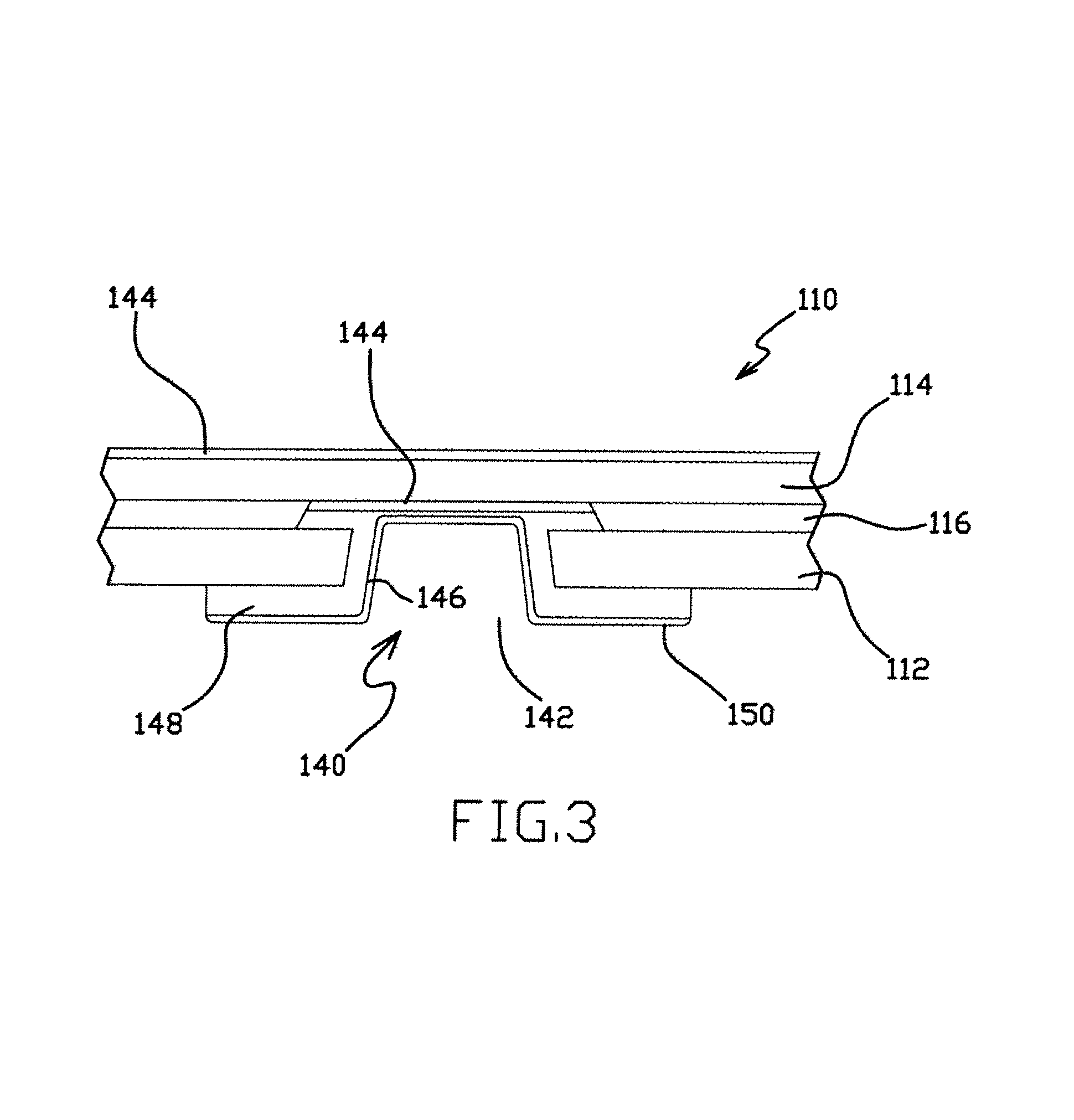

Plated ground features for integrated lead suspensions

ActiveUS7384531B1Quality improvementAnodisationElectrical connection between head and armConductive materialsElectroplating

A method for forming an electrical interconnect on an integrated lead suspension or suspension component of the type formed from a laminated sheet of material having a stainless steel layer, a conductive lead layer and an insulating layer separating the stainless steel and conductive lead layers. An aperture is formed through at least the insulating layer to expose the stainless steel layer at an interconnect site. An interconnect mask is applied around the interconnect site. Conductive material is electroplated onto the stainless steel layer at the interconnect site to form a plated interconnect. The mask is then removed. The method is used to form an interconnect bond pad on the same side of the stainless steel layer as the conductive lead layer in one embodiment. In another embodiment the aperture is formed through the insulator layer and the stainless steel layer, and conductive material is built up on the stainless steel layer during the electroplating step until it meets and plates onto the conductive lead layer to form a stainless steel side interconnect. In yet another embodiment the aperture is formed through the insulator layer and the conductive lead layer, and conductive material is built up on the stainless steel layer during the electroplating step until it meets and plates onto the conductive lead layer to form a conductive lead side interconnect.

Owner:HUTCHINSON TECH

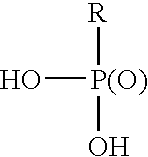

Electrodeposition coatings for use over aluminum substrates

A process for applying a coating on aluminum substrates by anionic electrodeposition of a phosphated epoxy resin made by phosphating a polyepoxide with both phosphoric acid and an organophosphonic acid and / or an organophosphinic acid. The coating has a reduced tendency to form pinholes.

Owner:PPG IND OHIO INC

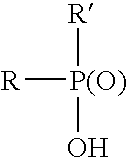

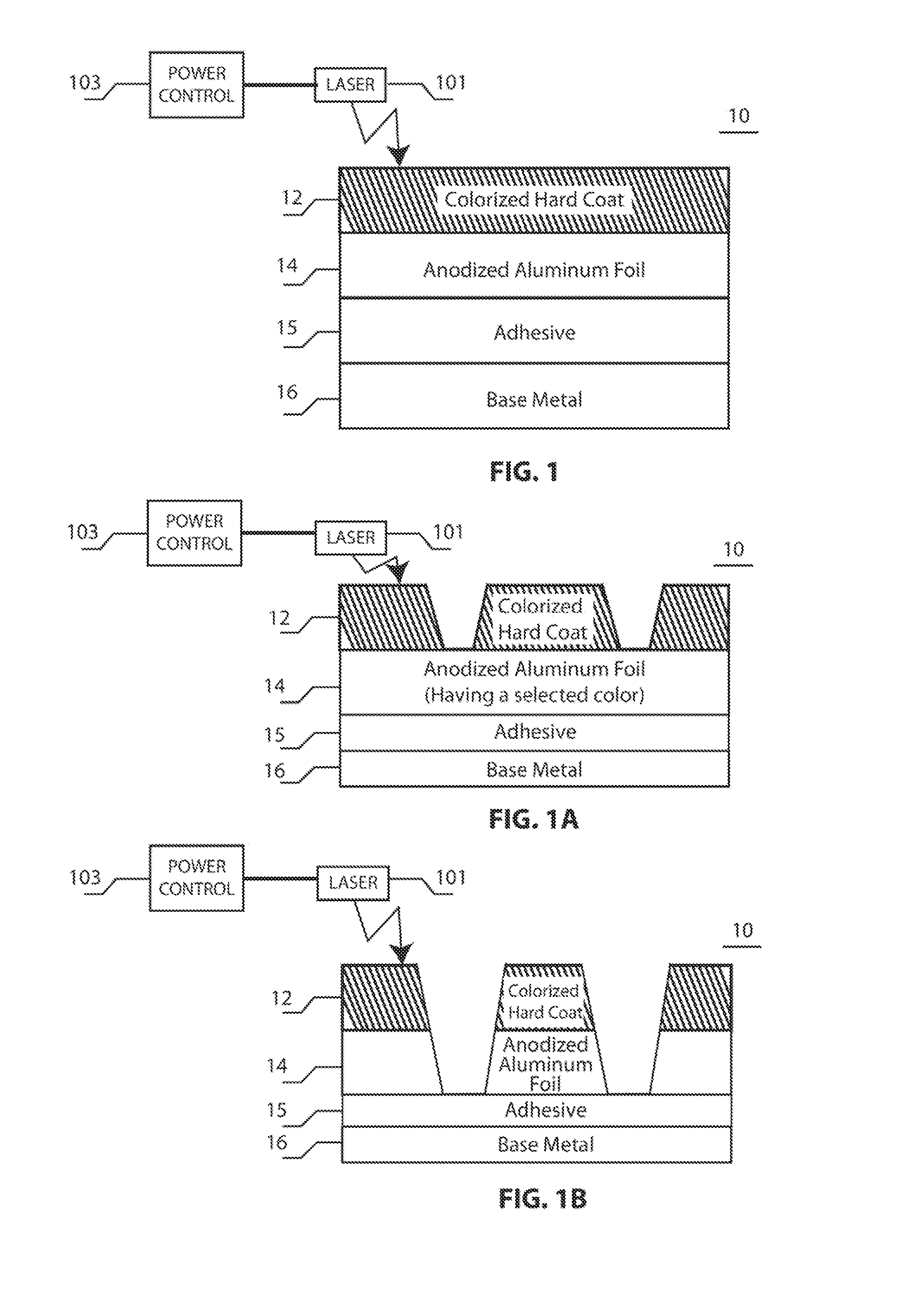

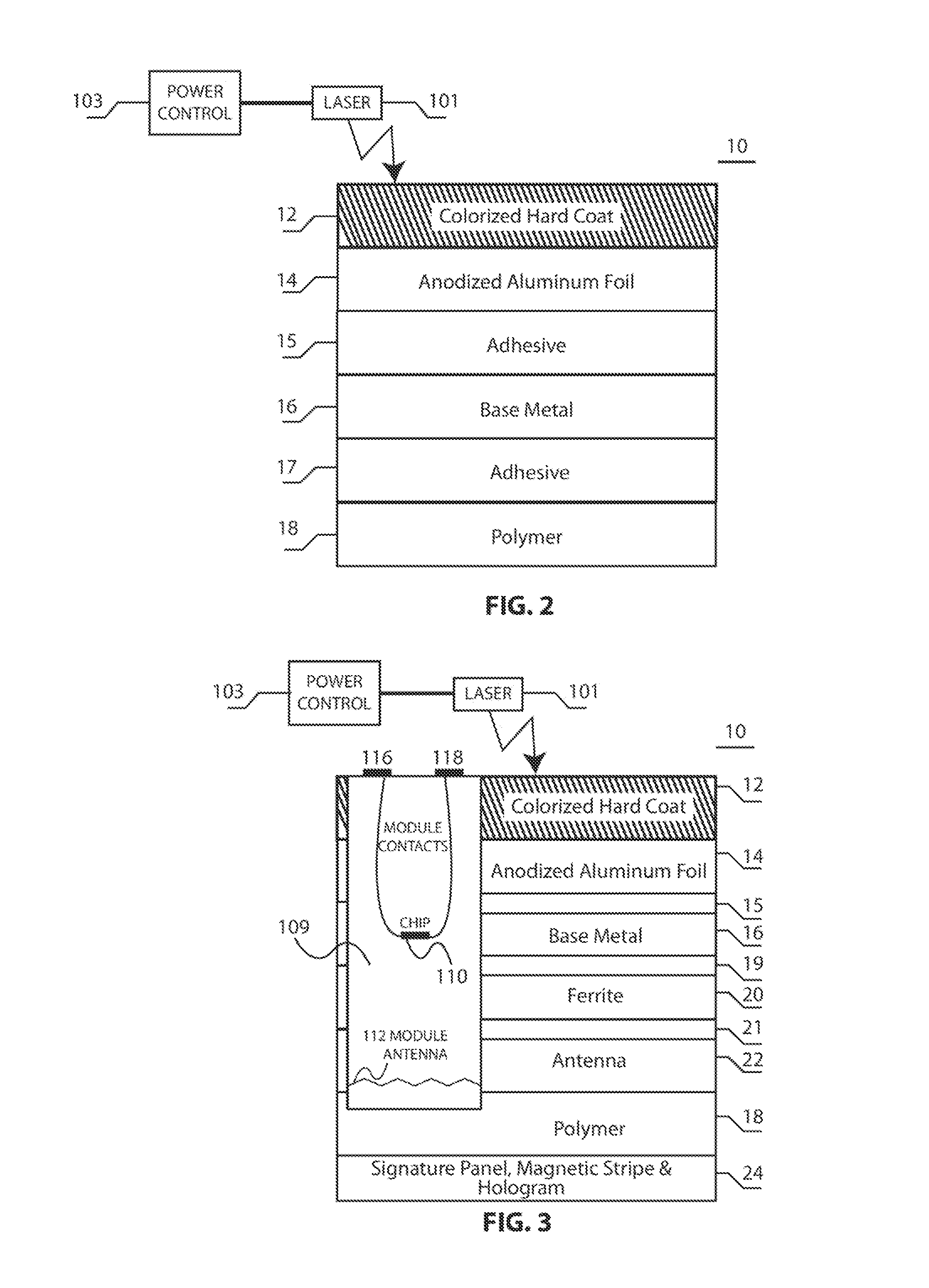

Transaction and id cards having selected texture and coloring

ActiveUS20150339564A1More costAvoid less flexibilityAnodisationWave amplification devicesEpoxyFinancial transaction

Cards made in accordance with the invention include a specially treated thin decorative layer attached to a thick core layer of metal or ceramic material, where the thin decorative layer is designed to provide selected color(s) and / or selected texture(s) to a surface of the metal cards. Decorative layers for use in practicing the invention include: (a) an anodized metal layer; or (b) a layer of material derived from plant or animal matter (e.g., wood, leather); or (c) an assortment of aggregate binder material (e.g., cement, mortar, epoxies) mixed with laser reactive materials (e.g., finely divided carbon); or (d) a ceramic layer; and (e) a layer of crystal fabric material. The cards may be dual interface smart cards which can be read in a contactless manner and / or via contacts.

Owner:COMPOSECURE LLC

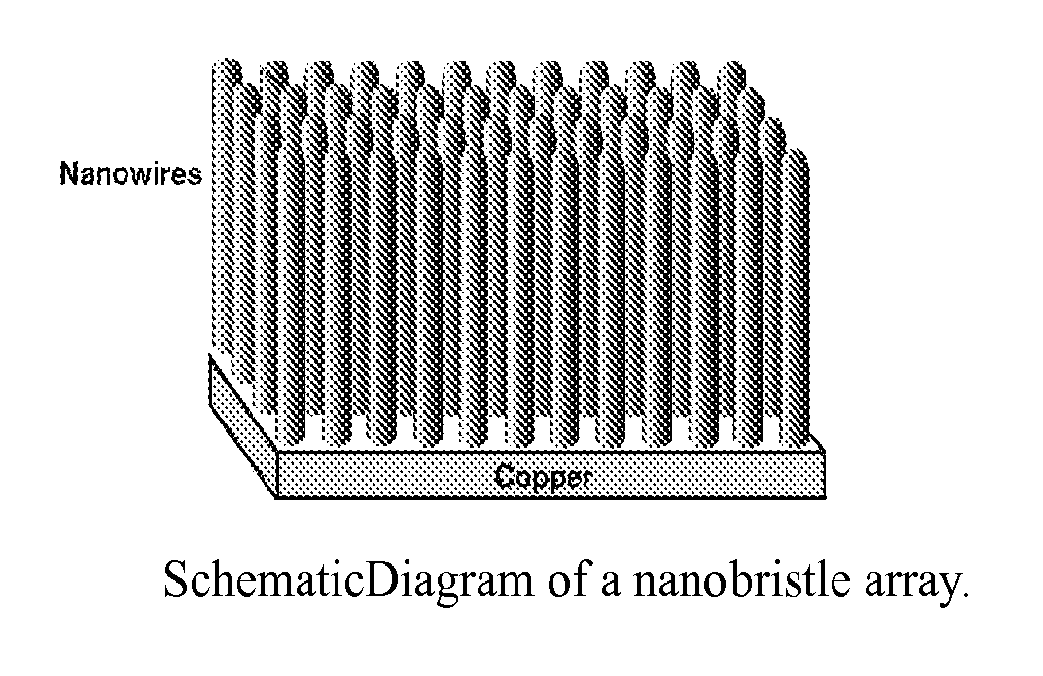

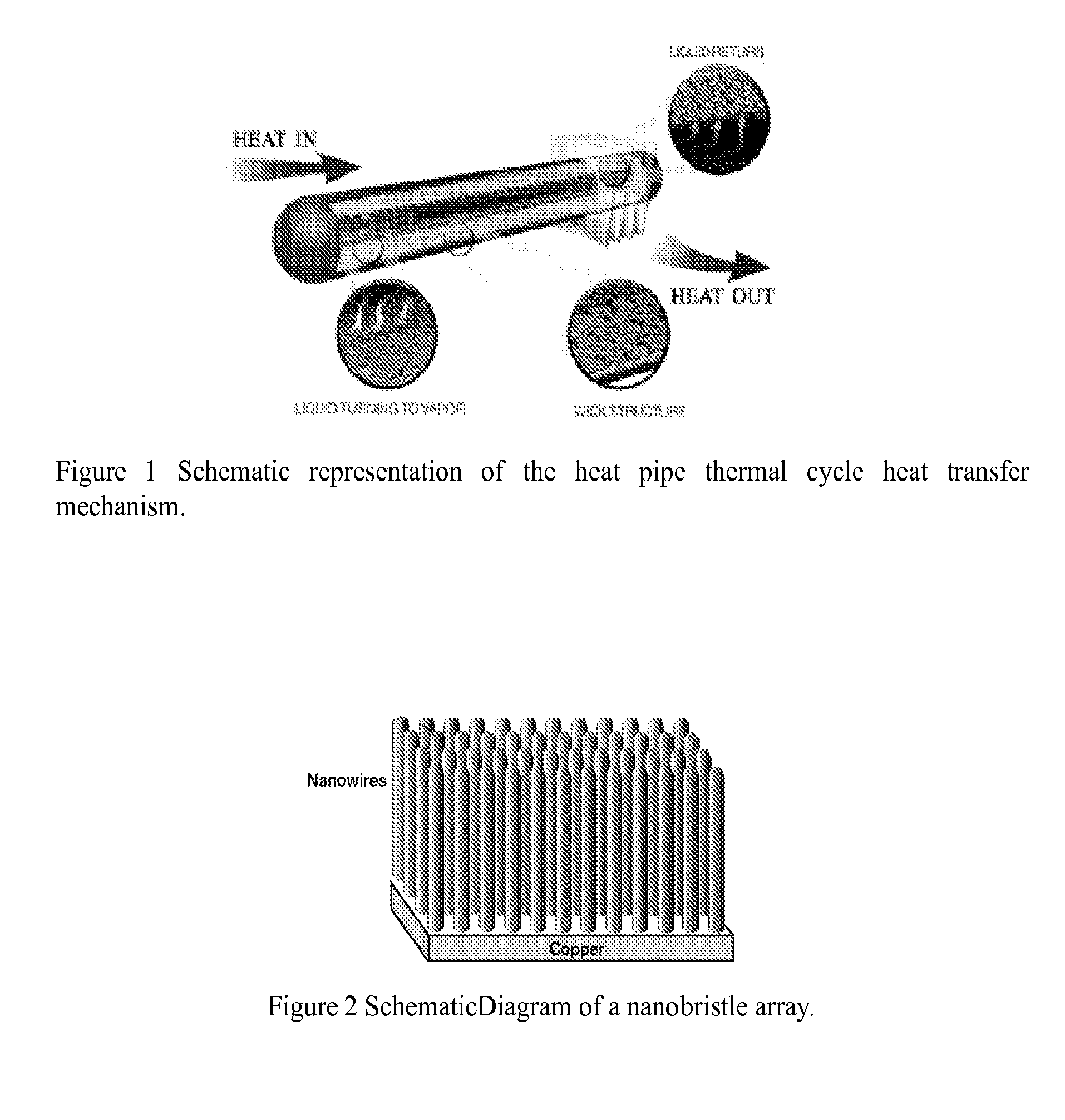

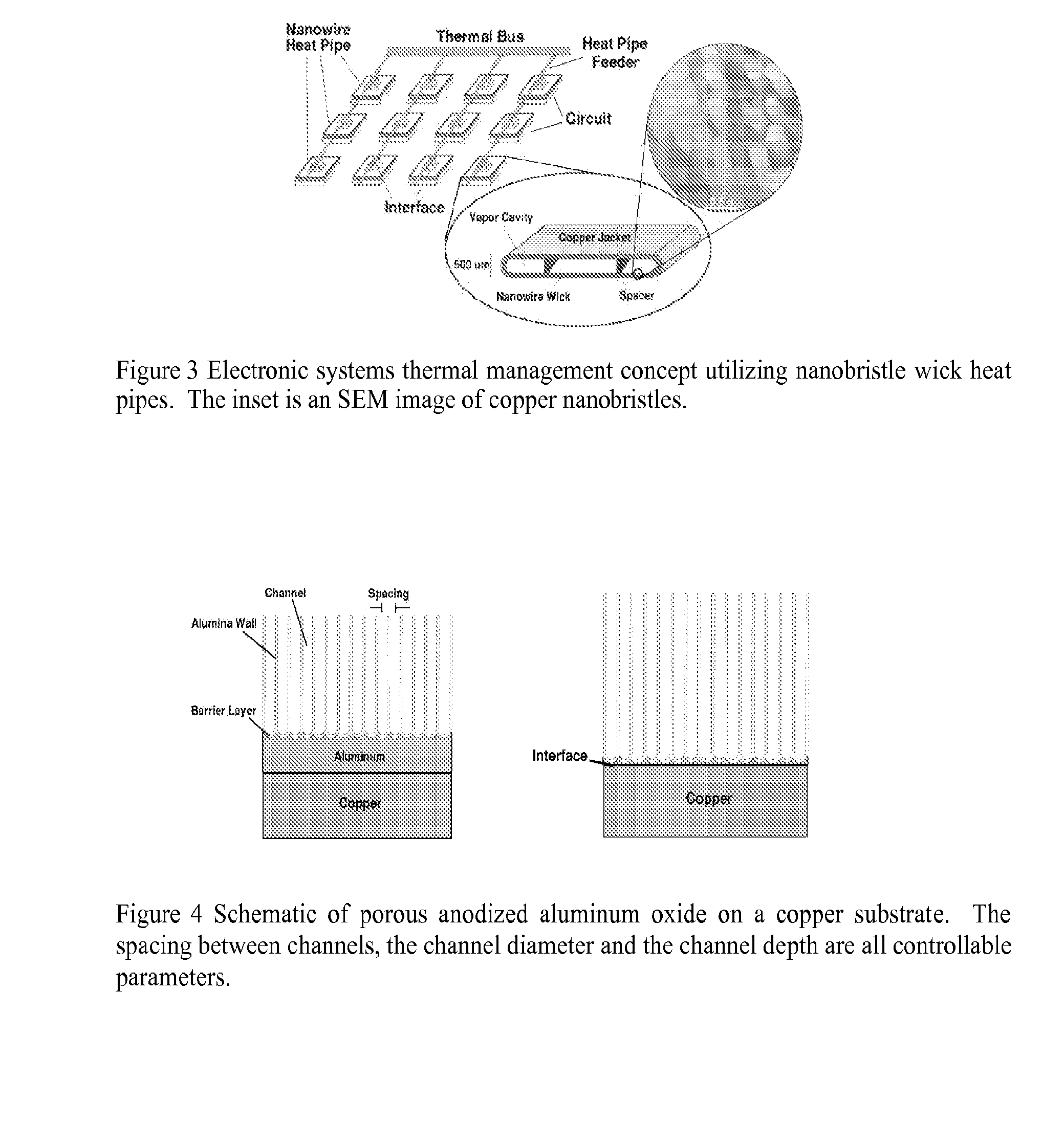

Heat Pipe with Nanostructured Wick

InactiveUS20100200199A1Improve efficiencyPerformance advantageMaterial nanotechnologyAnodisationNanowireBristle

A heat pipe with a nanostructured wick is disclosed, with the method of forming the nanostructured wick on a metal substrate. The wicking material is a pattern of metallic nanostructures in the form of bristles or nanowires attached to a substrate, where the bristles are substantially freestanding.

Owner:ILLUMINEX CORP

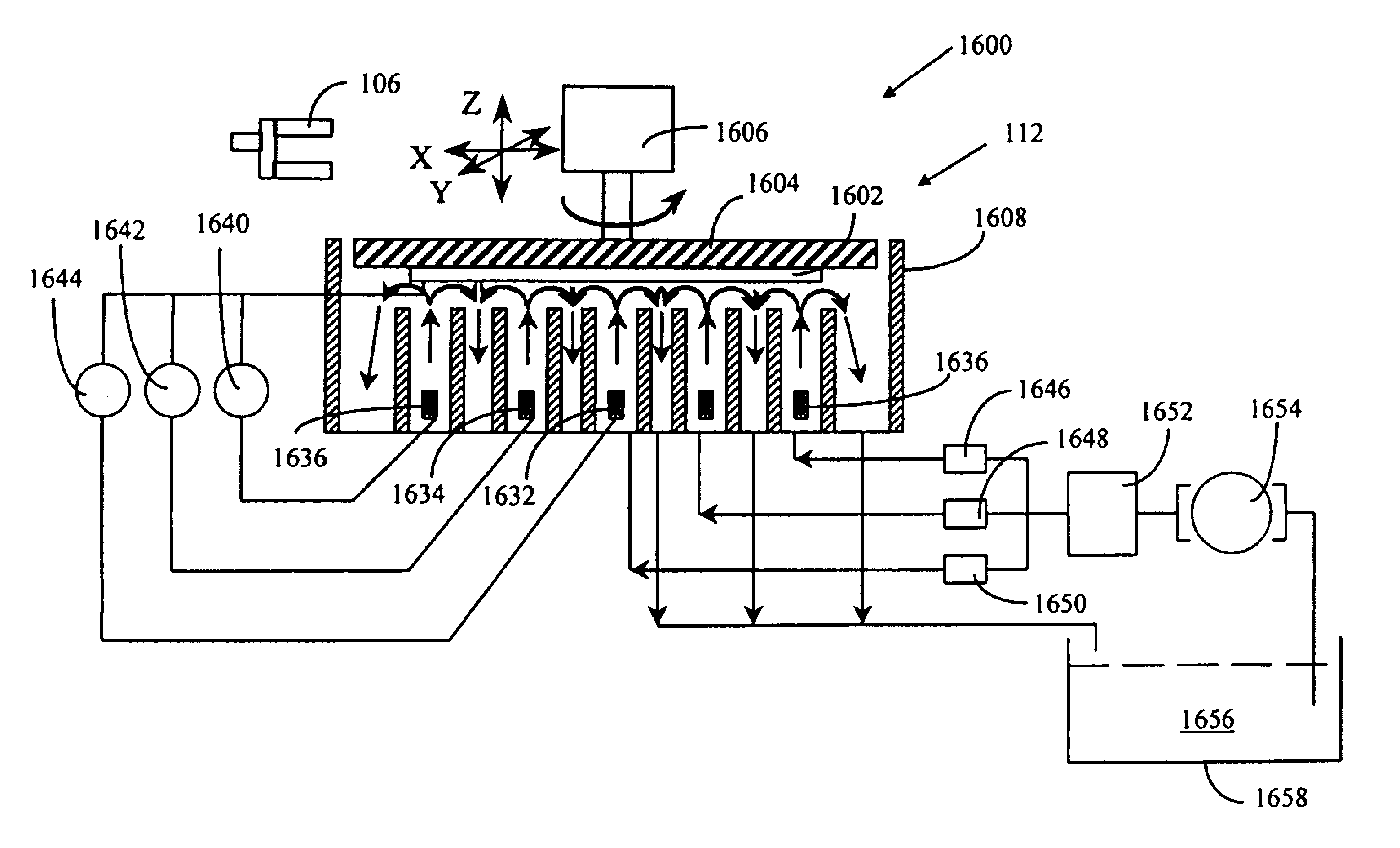

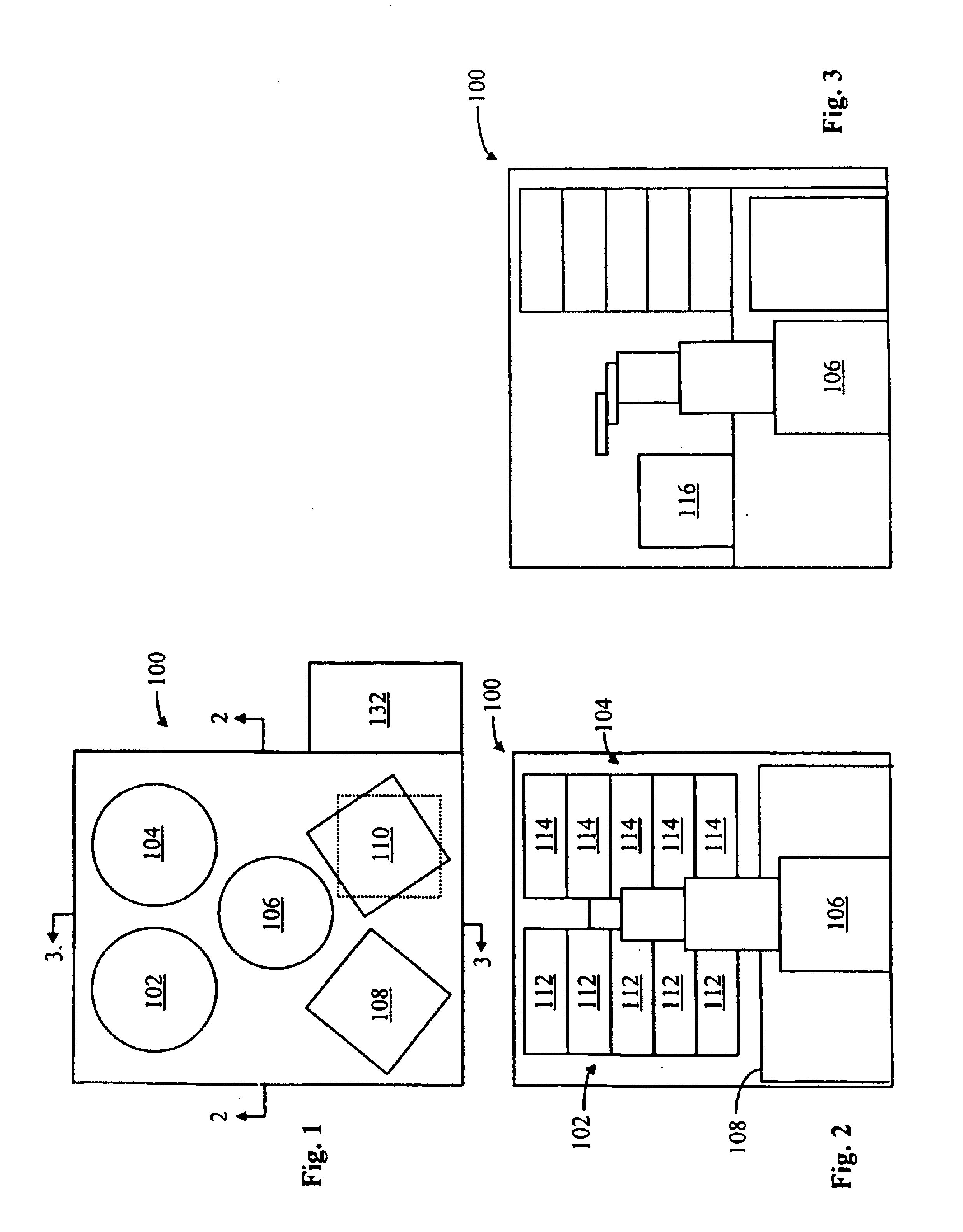

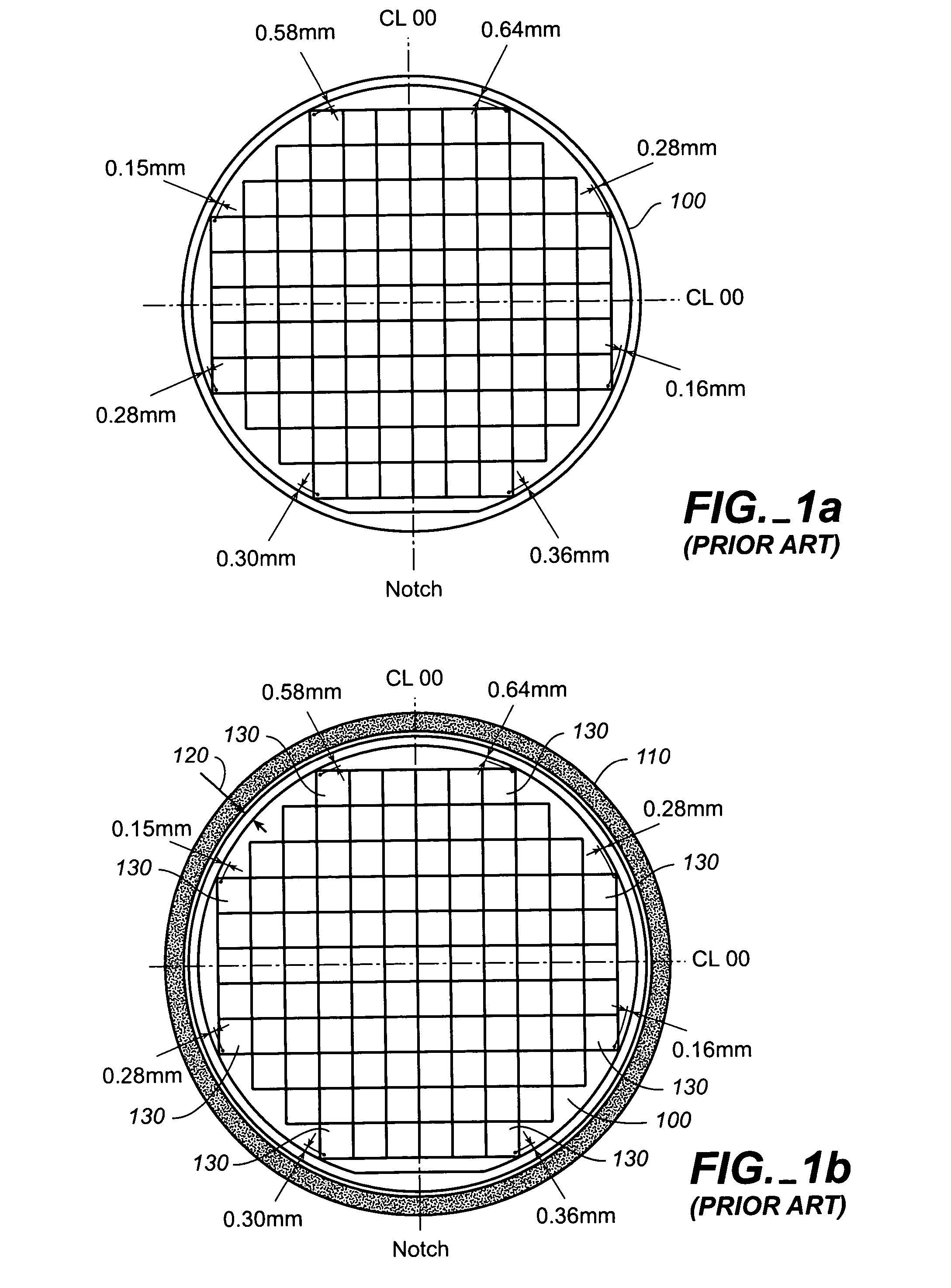

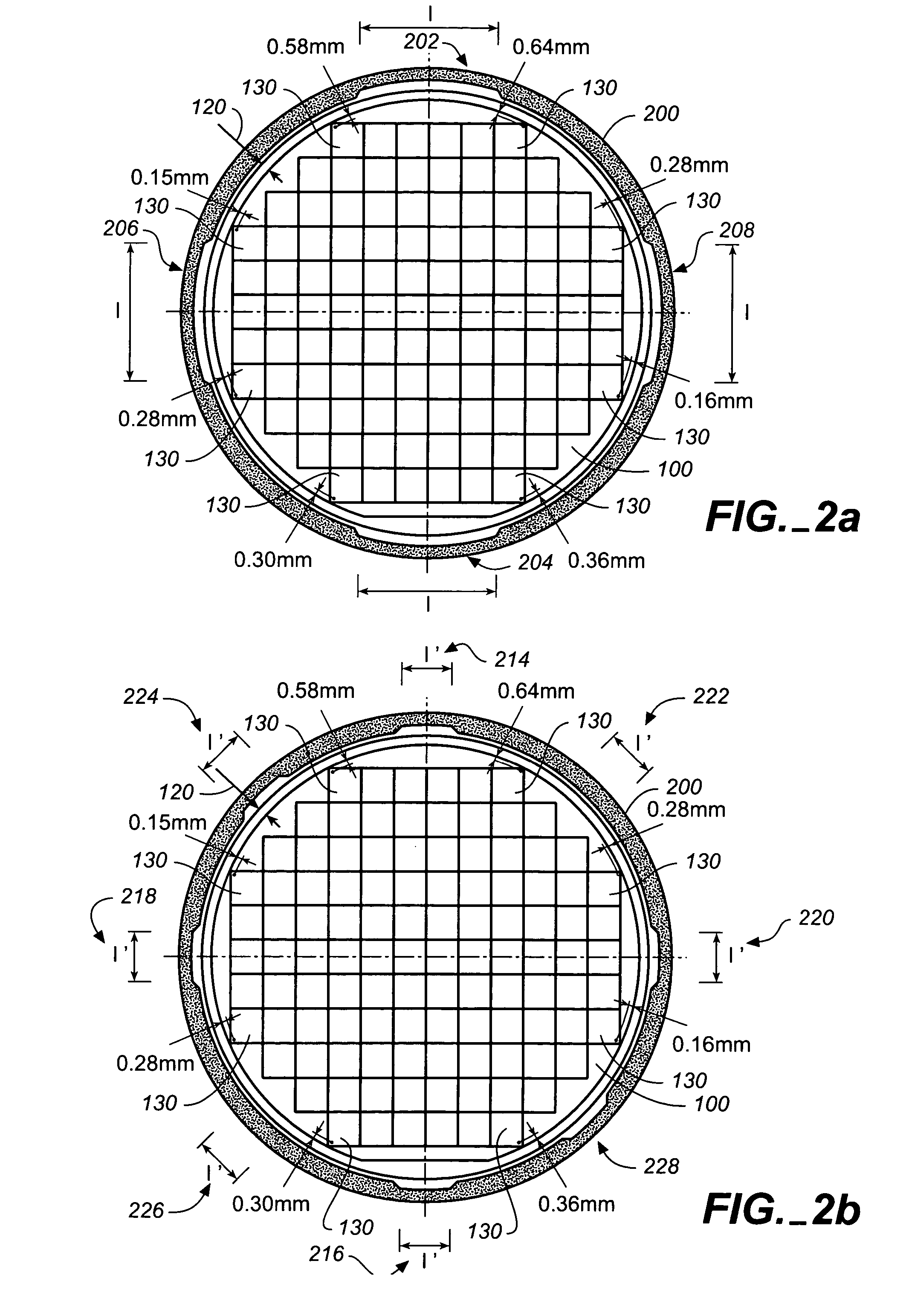

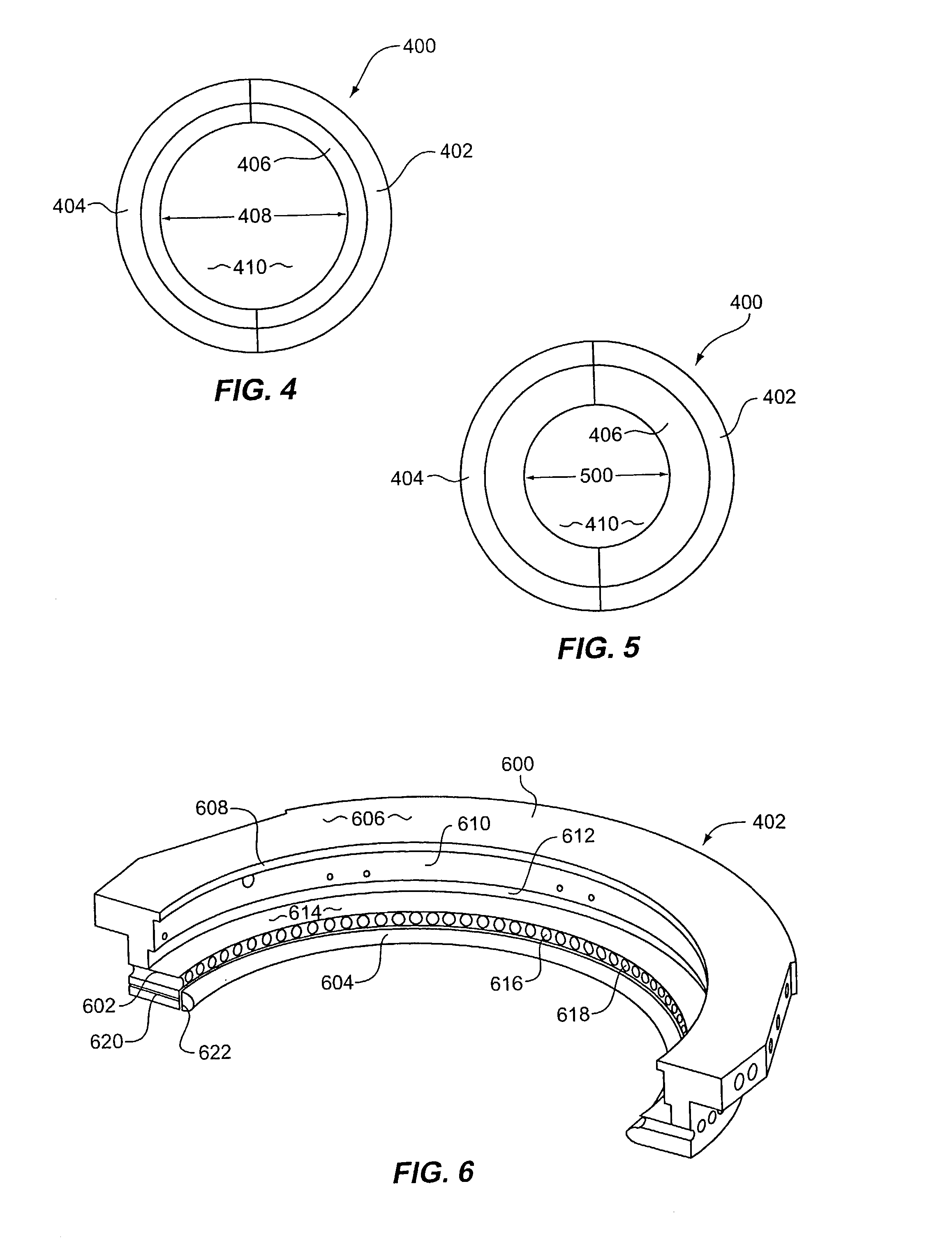

System and method for increasing yield from semiconductor wafer electroplating

ActiveUS7641776B2Potential for defects on the edge dies is reducedAvoid overlapCellsAnodisationEngineeringElectroplating

A system and method increase yield from semiconductor wafer electroplating. The aspects include a semiconductor wafer, the semiconductor wafer comprising a plurality of die areas. A plating ring for holding the semiconductor wafer in position during electroplating is also included, the plating ring substantially surrounding a circumference of the semiconductor wafer and having a width that varies in order to avoid overlap near edge die areas of the semiconductor wafer.

Owner:BELL SEMICON LLC

Dynamically variable field shaping element

InactiveUS7070686B2Uniform current distributionUniform currentAnodisationMachining electric circuitsElectrical resistance and conductanceElectrochemical response

In an electrochemical reactor used for electrochemical treatment of a substrate, for example, for electroplating or electropolishing the substrate, one or more of the surface area of a field-shaping shield, the shield's distance between the anode and cathode, and the shield's angular orientation is varied during electrochemical treatment to screen the applied field and to compensate for potential drop along the radius of a wafer. The shield establishes an inverse potential drop in the electrolytic fluid to overcome the resistance of a thin film of conductive metal on the wafer.

Owner:NOVELLUS SYSTEMS

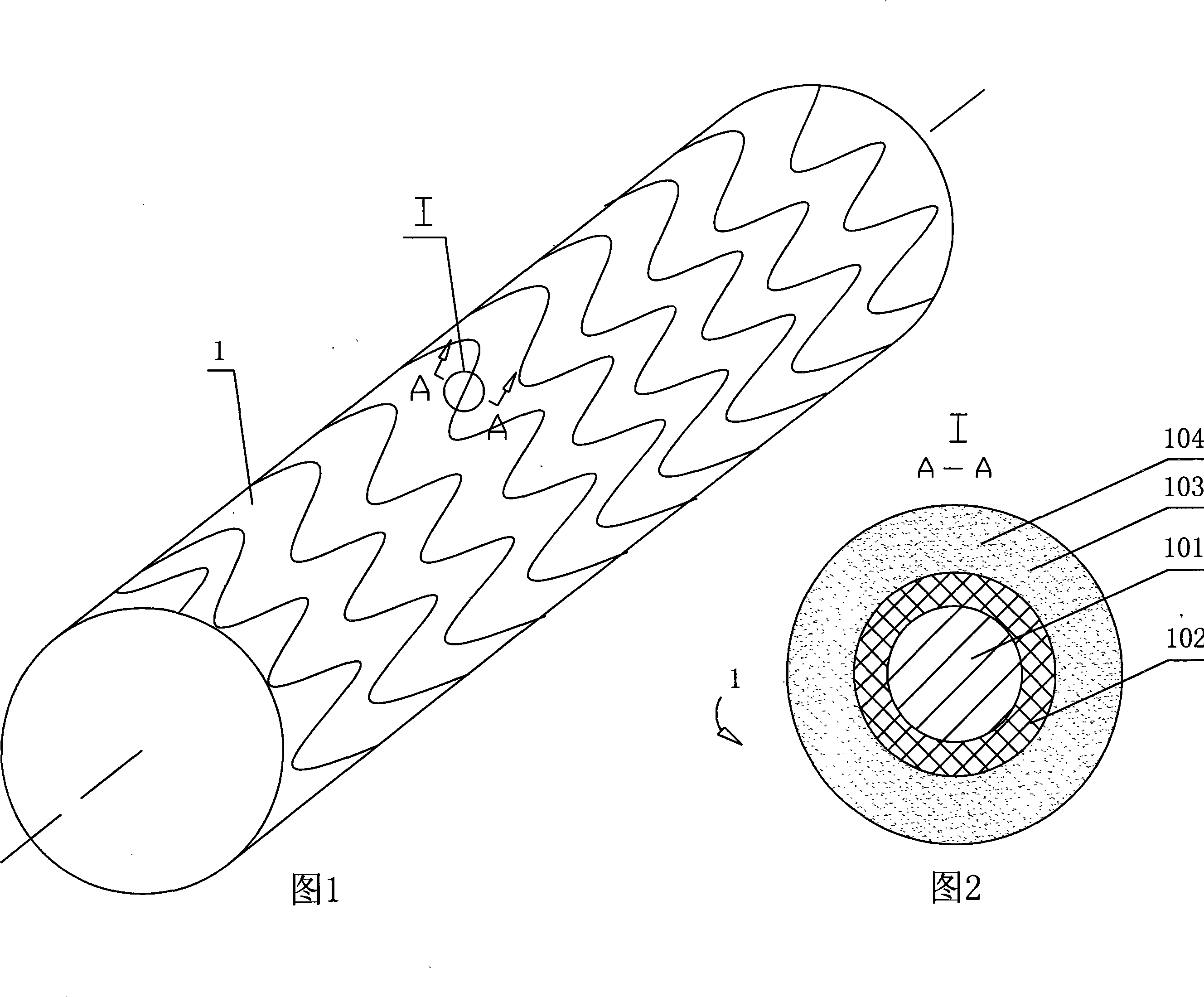

Controlled degradation magnesium alloy coating bracket and preparation thereof

InactiveCN101214396AImprove mechanical propertiesExcellent pharmacological propertiesAnodisationStentsSurface cleaningPolymer chemistry

The invention relates to a controlled degradation magnesium alloy coating stent and a preparation method. The stent body is made of medical high purity magnesium or magnesium alloy by mechanical processing or laser carving; the stent body is provided with a drug-loading coating which bears curative drug; the surface of the stent body is provided with an anti-corrosive coating; the surface of the anti-corrosive coating is provided with a degradable polymer film drug-loading coating; the preparation method includes surface cleaning, preparation of the degradable polymer film drug-loading coating, and application of curative drug; through (1)surface cleaning, (2)preparation of the degradable polymer film drug-loading coating, and (3)application of curative drug, an oxide film is formed on the surface; different drugs and dosage can be fixed by regulating the molecular weight and the thickness of the polymer layer, the drug-loading quantity is more than 30 percent, which improves the fixed stability of the drug, greatly reduces the degradation speed of the magnesium alloy and controls release of the drug, delays corrosion of the magnesium alloy, extends the service life of the stent, is safe in use, and meets the clinical requirement.

Owner:LEPU MEDICAL TECH (BEIJING) CO LTD

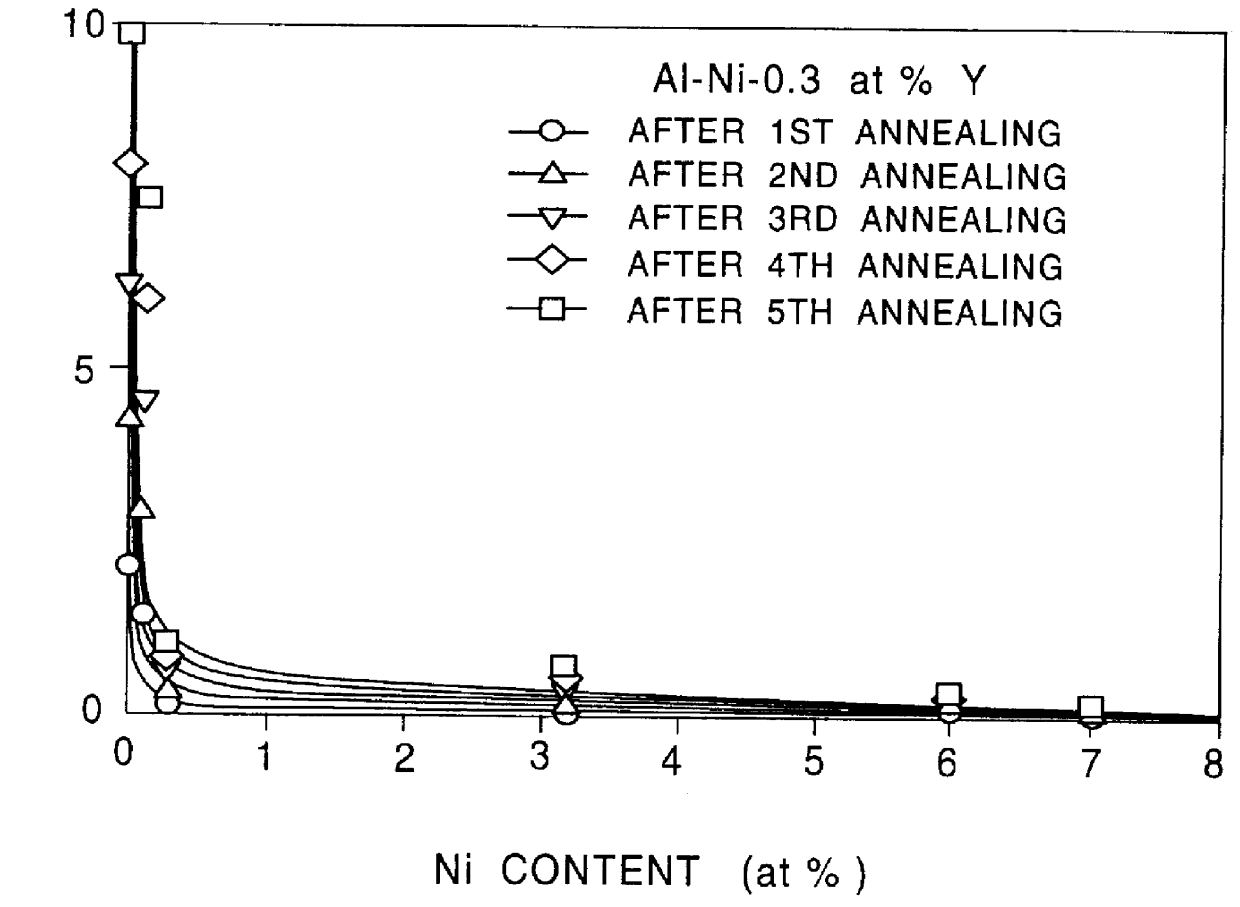

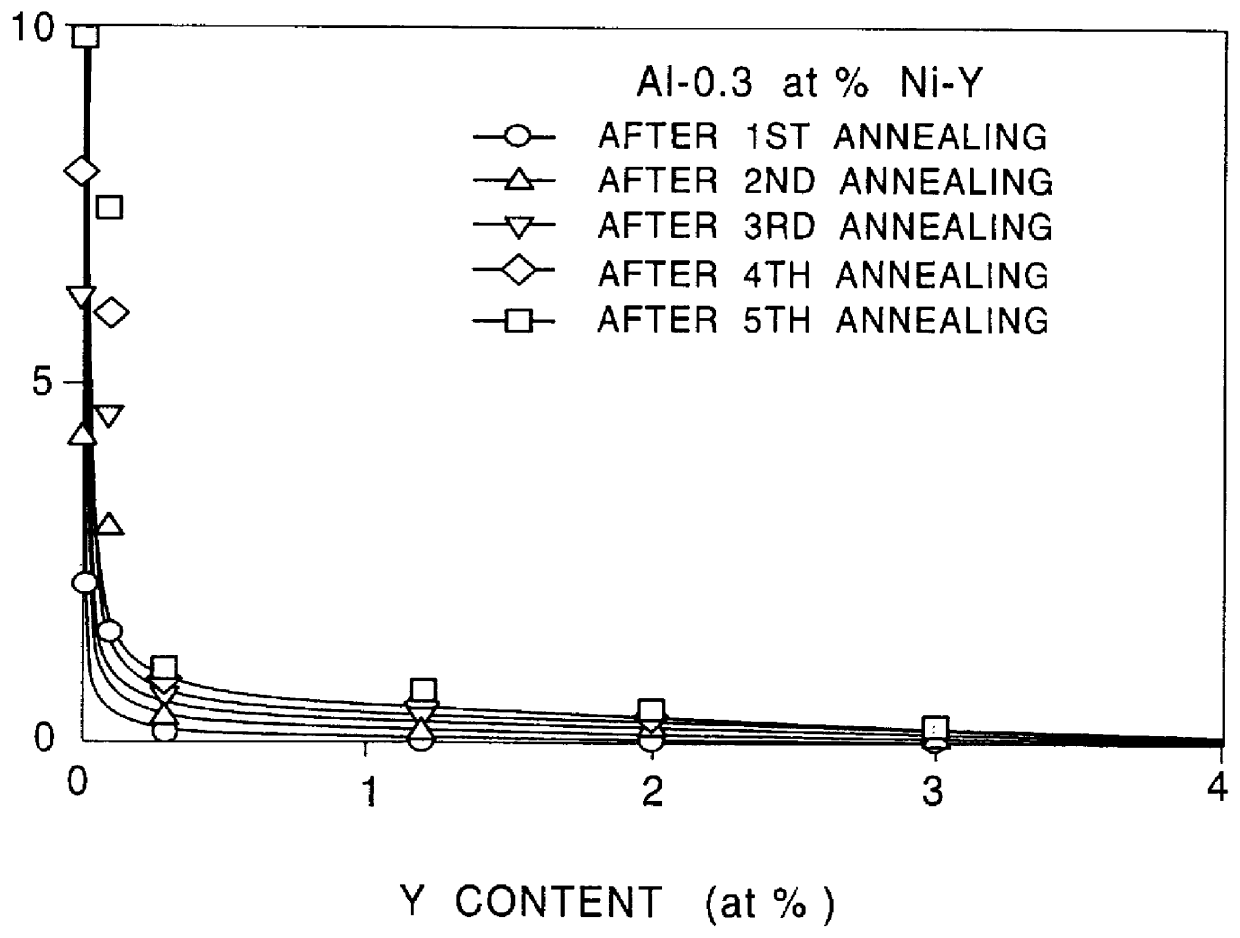

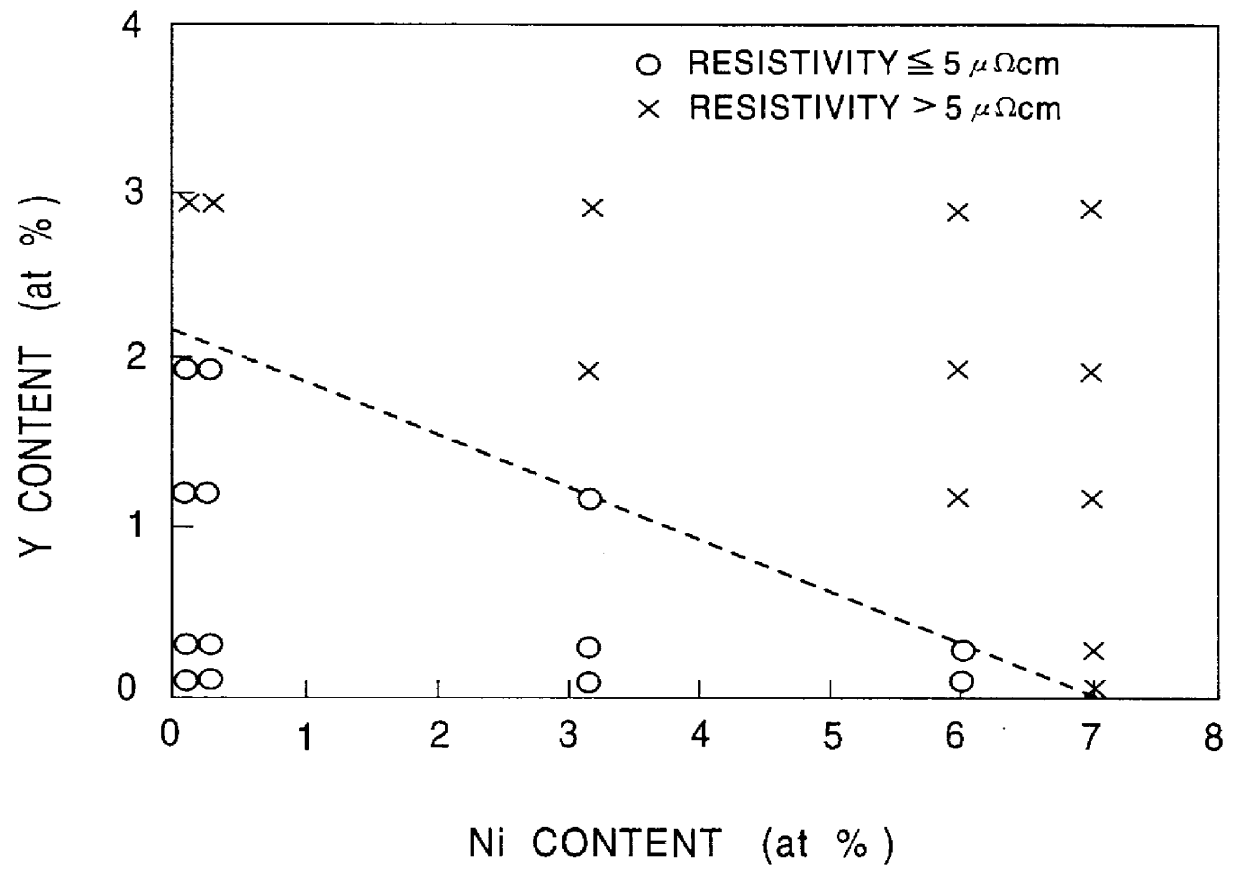

A1-N1-Y alloy films for electrodes of semiconductor devices and sputtering targets for depositing the A1-N1-Y alloy films

The invention provides an Al alloy film for use as an electrode of a semiconductor device and also provides an Al alloy sputtering target used to produce such an Al alloy film wherein the Al alloy film has not only a low resistivity equal to or less than 5 mu OMEGA cm and a high hillock resistance (property of hillock suppression) but also a high dielectric strength when it is anodized into an anodic oxide film and wherein the Al alloy film has a composition such that the Ni content is equal to or greater than 0.3 at % and the Y content is equal to or greater than 0.3 at % and such that 0.22 CNi+0.74 CY<1.6 at % where CNi denotes the Ni content (at %) and CY denotes the Y content (at %) and further wherein, in order to deposit the Al alloy film by sputtering, a spray forming Al alloy target containing Ni and Y is used.

Owner:KOBE STEEL LTD

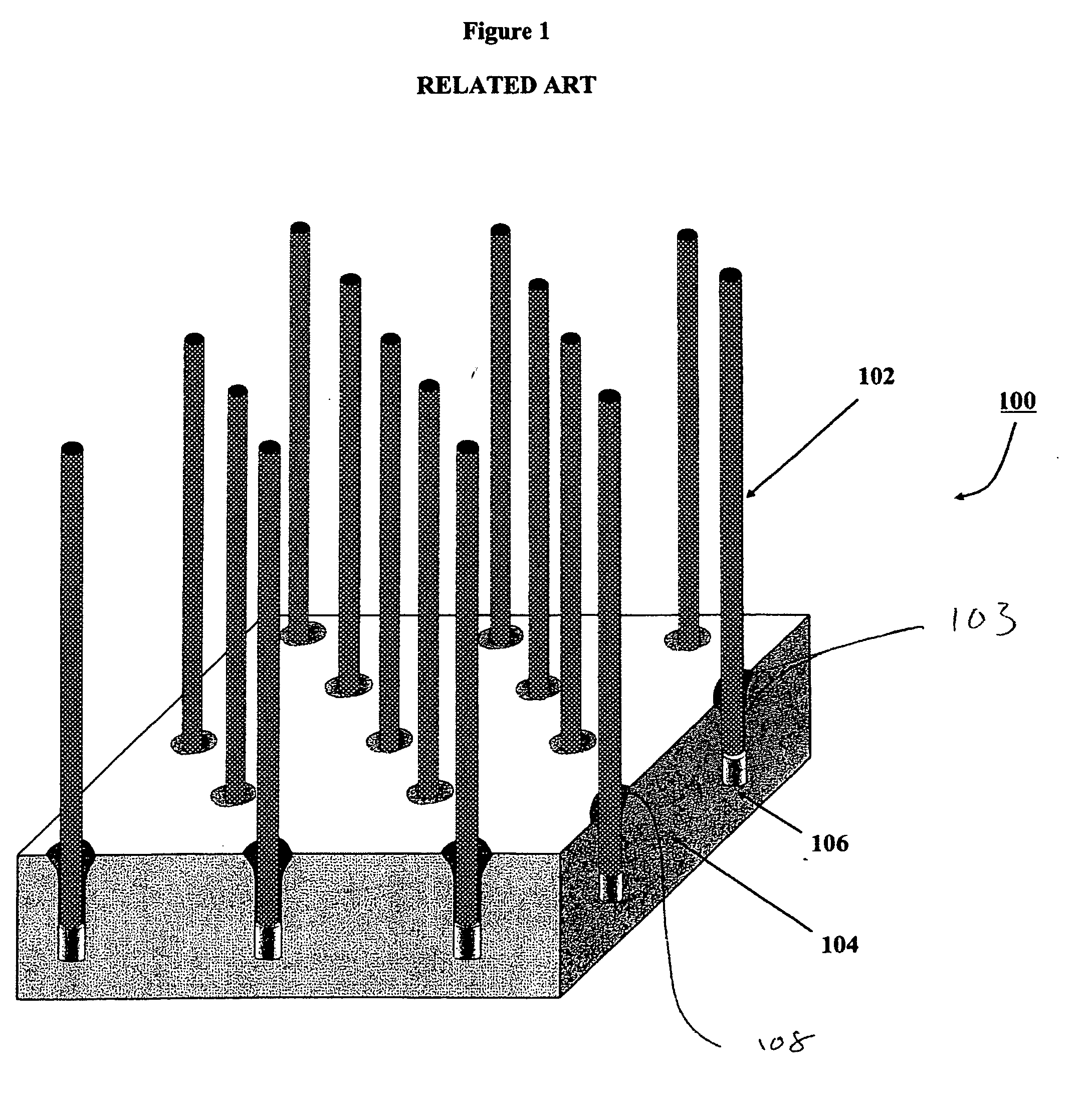

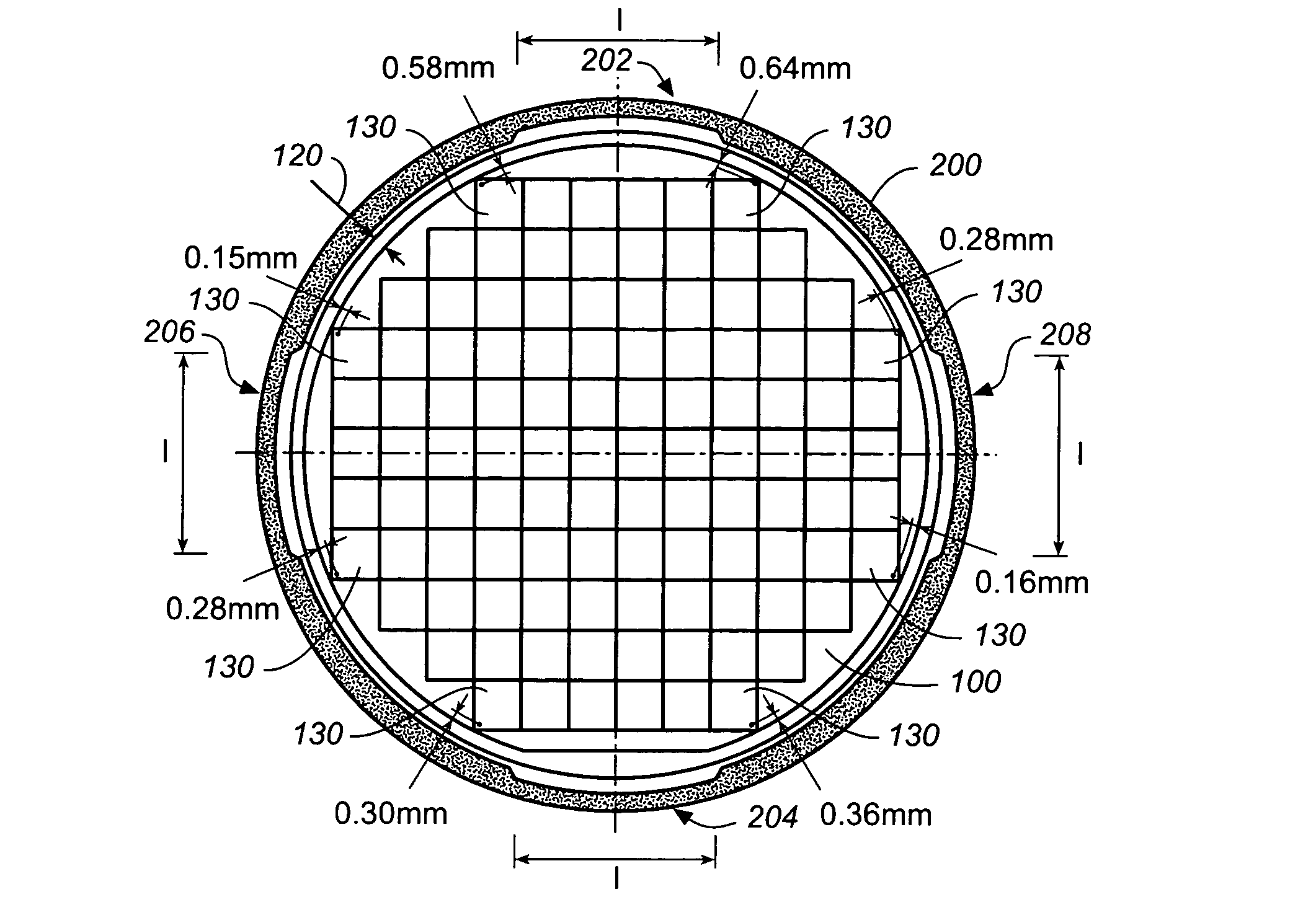

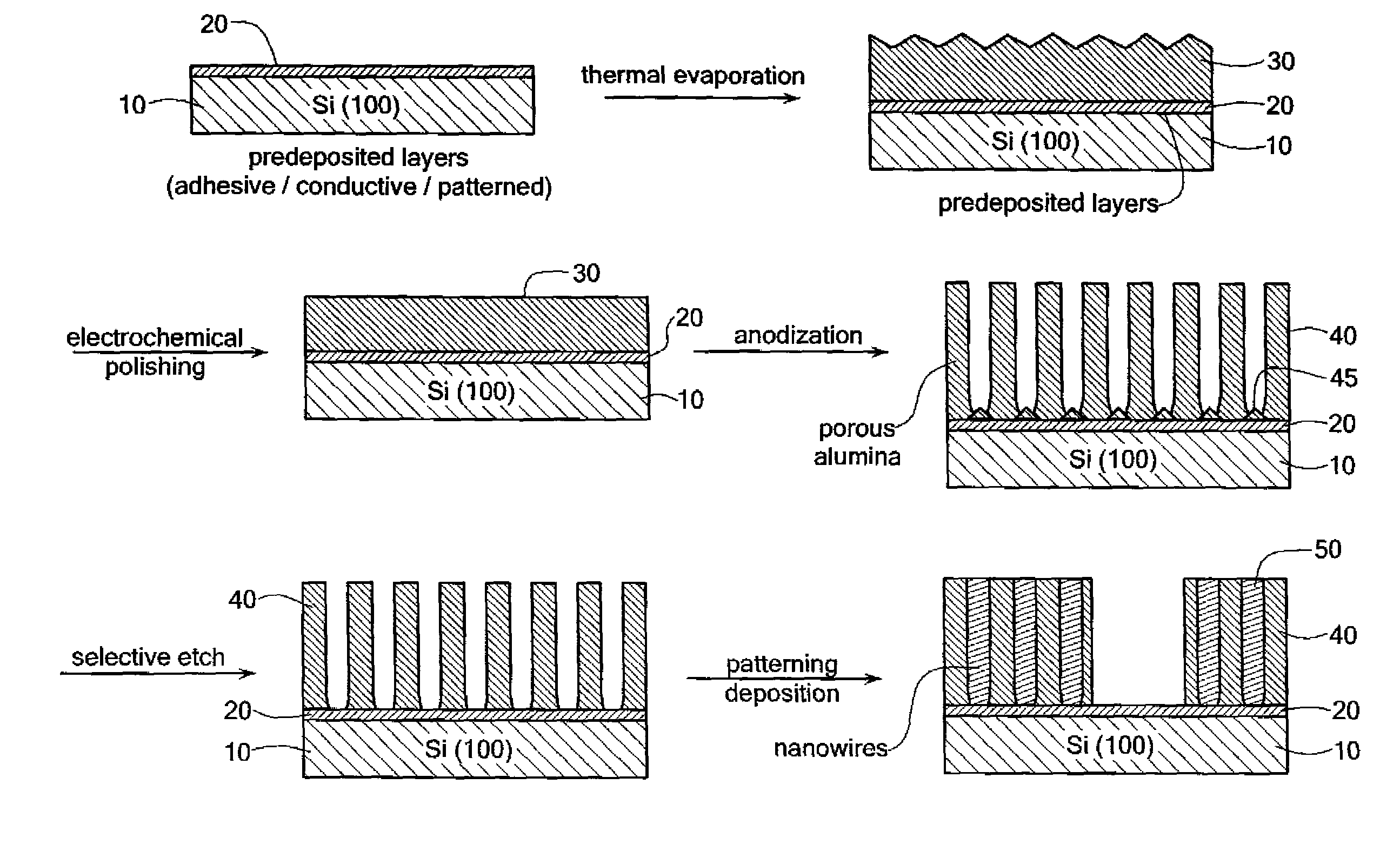

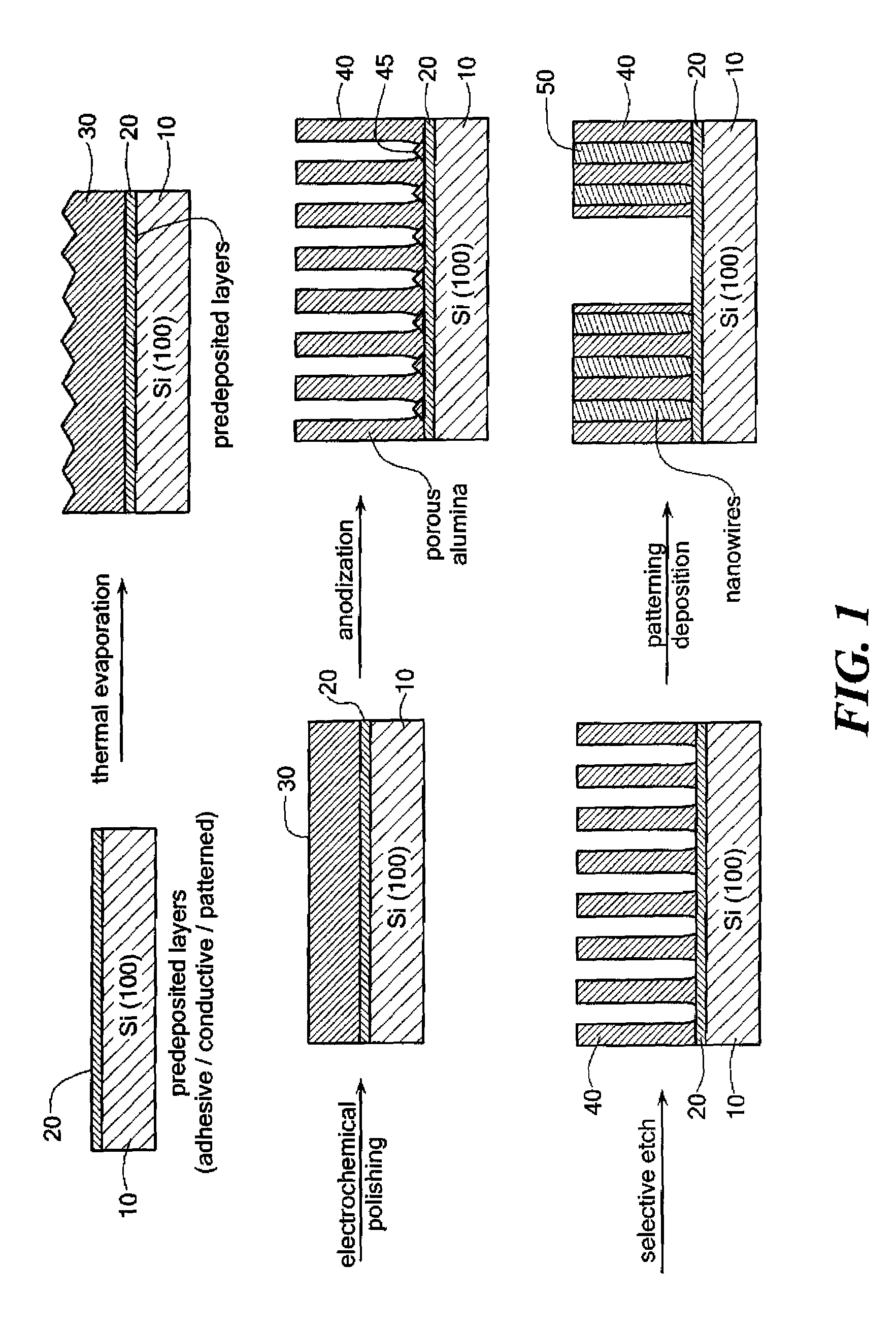

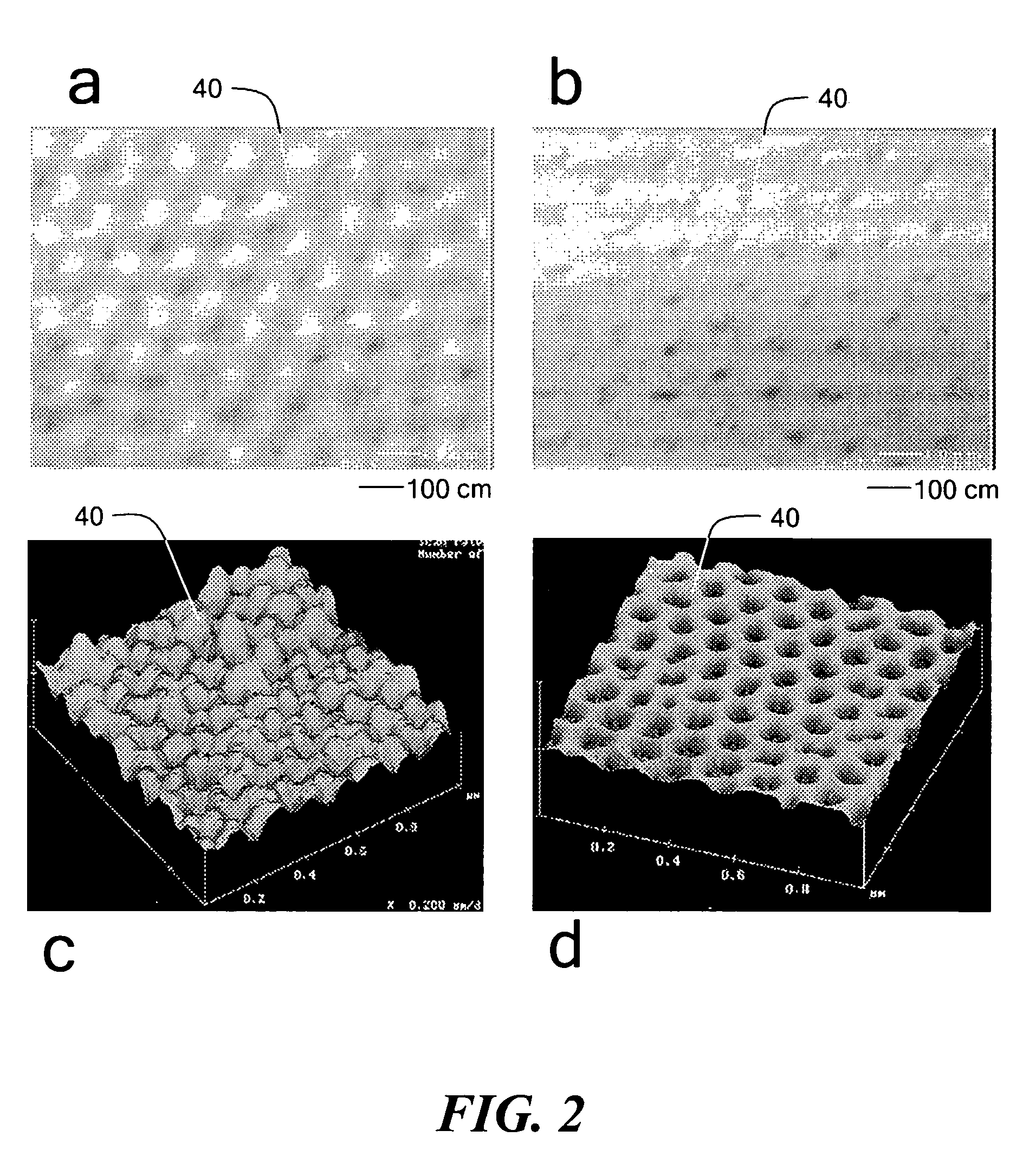

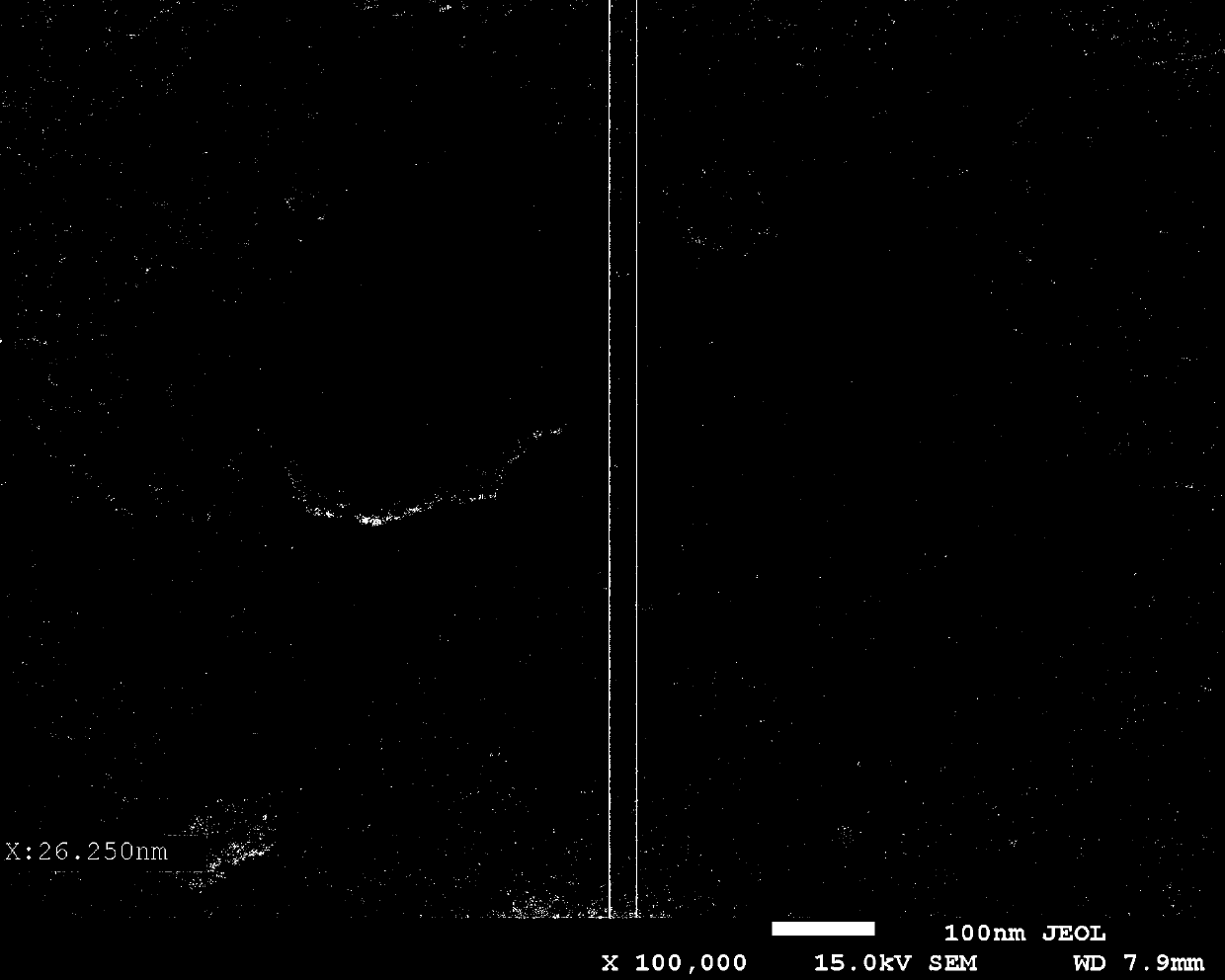

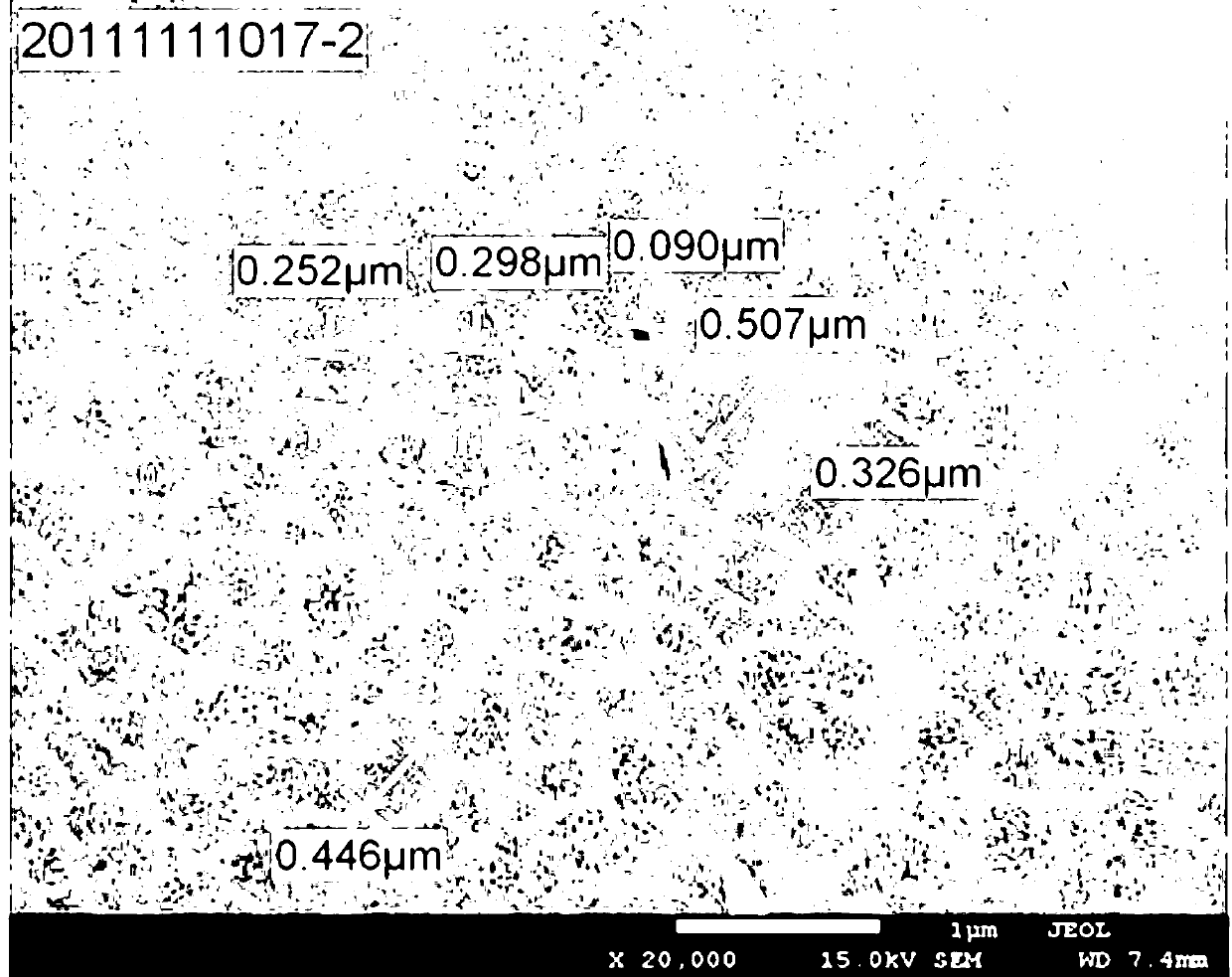

Thick porous anodic alumina films and nanowire arrays grown on a solid substrate

InactiveUS7267859B1Promote growthMore tractableMaterial nanotechnologyAnodisationSingle stageElectrochemistry

The presently disclosed invention provides for the fabrication of porous anodic alumina (PAA) films on a wide variety of substrates. The substrate comprises a wafer layer and may further include an adhesion layer deposited on the wafer layer. An anodic alumina template is formed on the substrate. When a rigid substrate such as Si is used, the resulting anodic alumina film is more tractable, easily grown on extensive areas in a uniform manner, and manipulated without danger of cracking. The substrate can be manipulated to obtain free-standing alumina templates of high optical quality and substantially flat surfaces PAA films can also be grown this way on patterned and non-planar surfaces. Furthermore, under certain conditions the resulting PAA is missing the barrier layer (partially or completely) and the bottom of the pores can be readily accessed electrically. The resultant film can be used as a template for forming an array of nanowires wherein the nanowires are deposited electrochemically into the pores of the template. By patterning the electrically conducting adhesion layer, pores in different areas of the template can be addressed independently, and can be filled electrochemically by different materials. Single-stage and multi-stage nanowire-based thermoelectric devices, consisting of both n-type and p-type nanowires, can be assembled on a silicon substrate by this method.

Owner:MASSACHUSETTS INST OF TECH

Mobile phone shell and preparation method thereof

ActiveCN103297565AImprove corrosion resistanceAppearance has no effectAnodisationSmall component housingsMobile phoneNanotechnology

The invention provides a mobile phone shell and a preparation method of the mobile phone shell. The mobile phone shell comprises a plastic piece and a metal shell body which is combined with the plastic piece, wherein the surface of a face, combined with the plastic piece, of the metal shell body is provided with an oxidation film layer, corrosion holes are formed in the surface layer of a face, opposite to the plastic piece, of the oxidation film layer, the hole diameter of each corrosion hole is 200 nanometers to 2000 nanometers, nanometer micro holes are formed in the inner layer of the oxidation film layer, the hole diameter of each nanometer micro hole is 10 nanometers to 100 nanometers, and resin compositions of the plastic piece are filled in the nanometer micro holes and the corrosion holes. The prepared mobile phone shell is resistant to abrasion, falling and corrosion.

Owner:BYD CO LTD

Super-hydrophobic and super-oleophobic surface preparation technology

The invention discloses super-hydrophobic and super-oleophobic surface preparation technology. In the preparation technology, aluminum or aluminum alloy sheets are subjected to two-step electrochemical treatment, and then are modified by using perfluorinated octadecyl trichlorosilane or perfluorinated polymethacrylate to prepare the super-hydrophobic and super-oleophobic surface. The surface has super-hydrophobic property on aqueous solution of which the pH value is between 1 and 14 and super-oleophobic property on various oil drops, wherein a contact angle of the surface on water is 171 degrees, and a rolling angle is less than 1 degree; the surface expresses the super-oleophobic property on various oil drops except for perfluorinated polymer liquid, and all contact angles between the oil drops and the surface are more than 150 degrees, and rolling angles are generally less than 10 degrees; and the surface can also be put in air for a long time and can still maintain the super-hydrophobic property and super-oleophobic property.

Owner:中科润泉(烟台)工业科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com