Patents

Literature

339results about "Small component housings" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

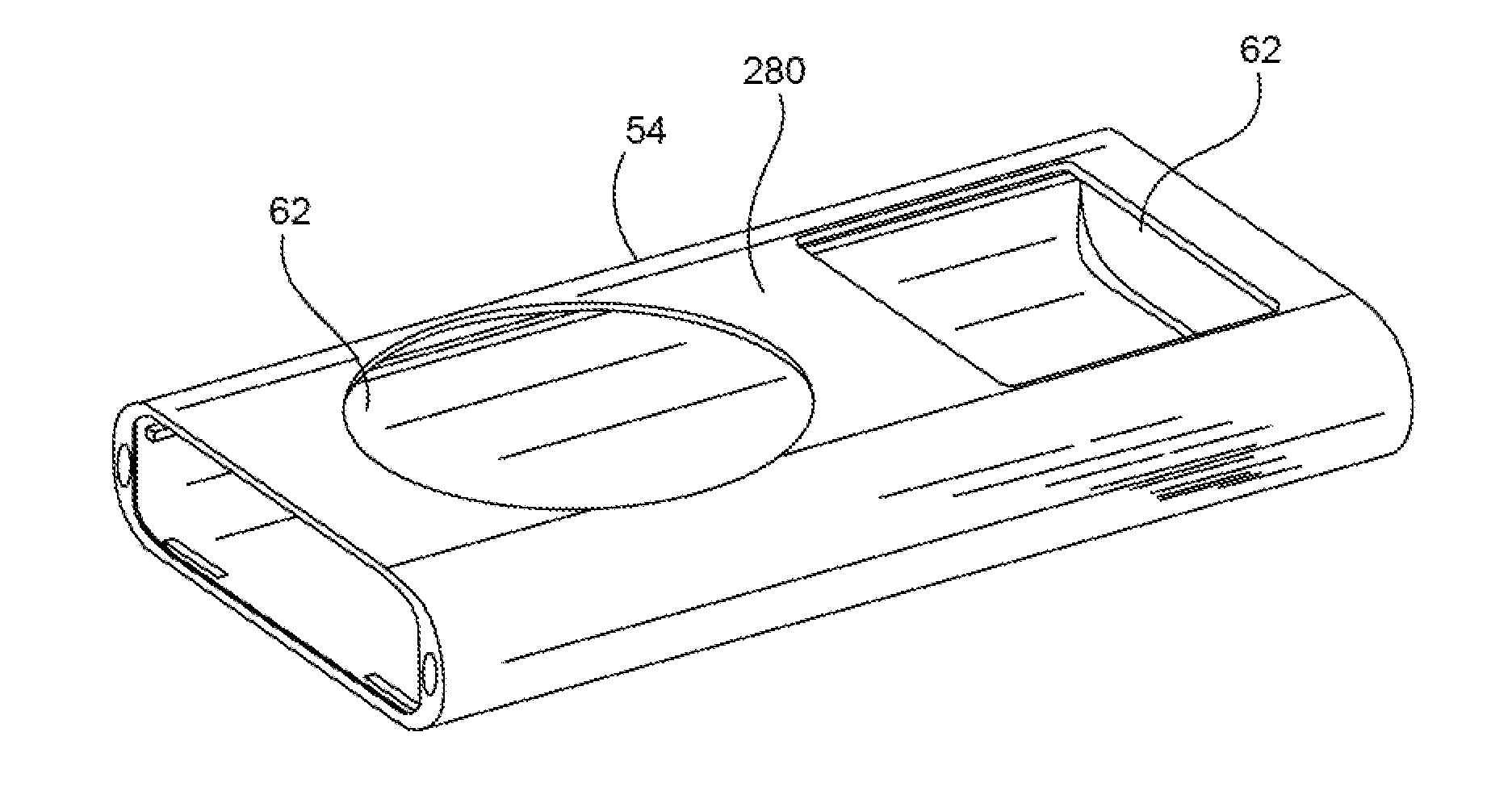

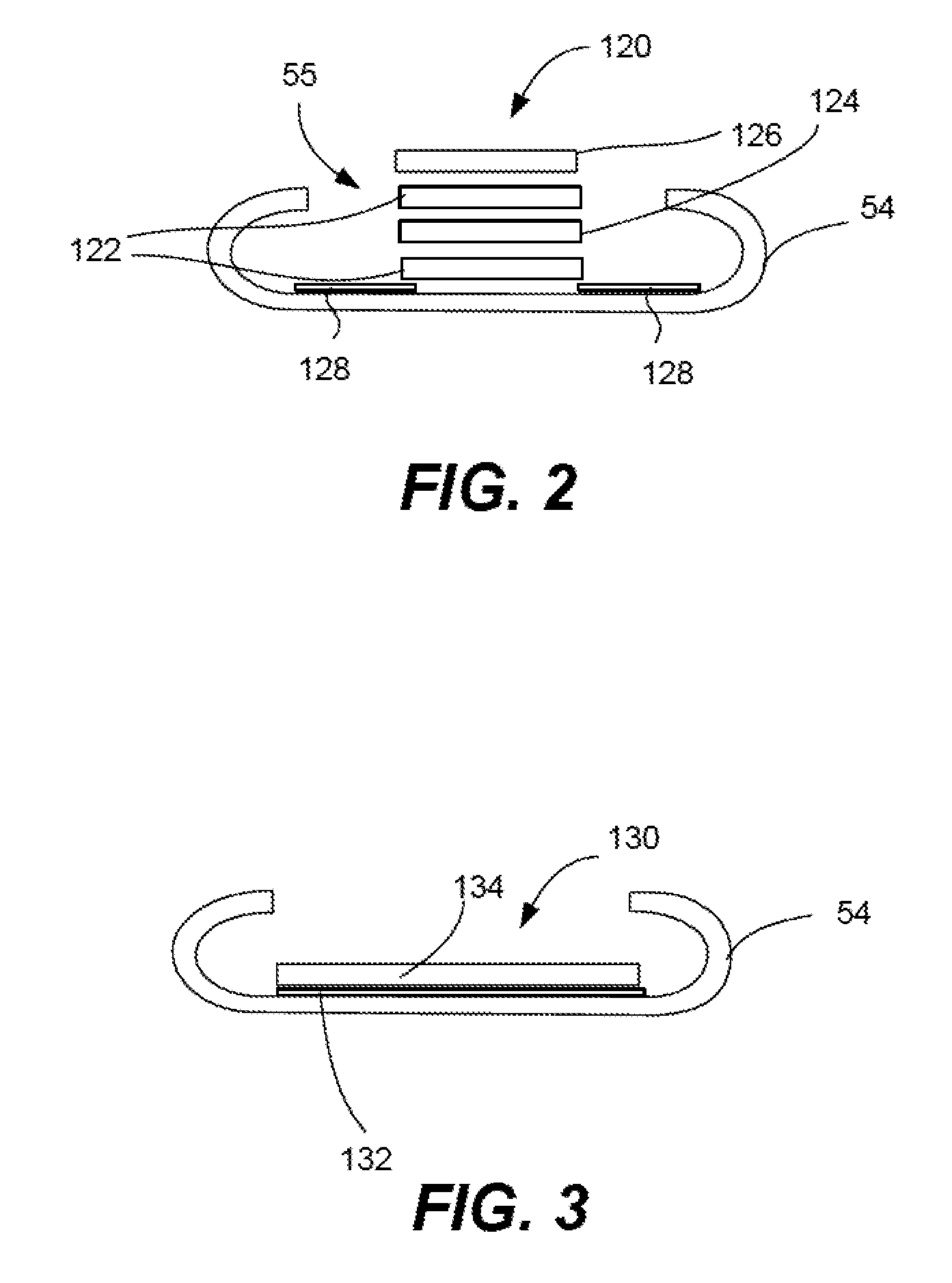

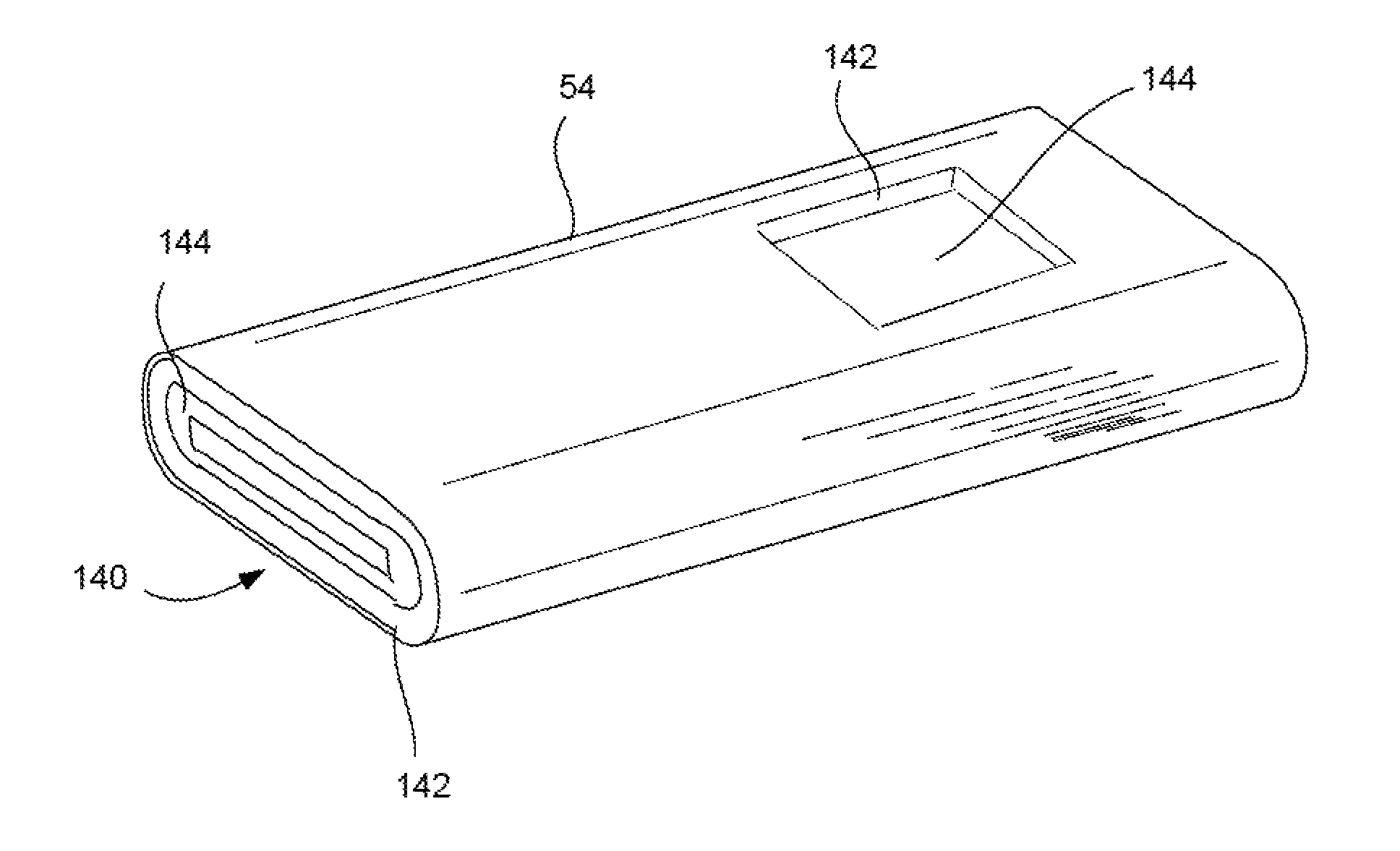

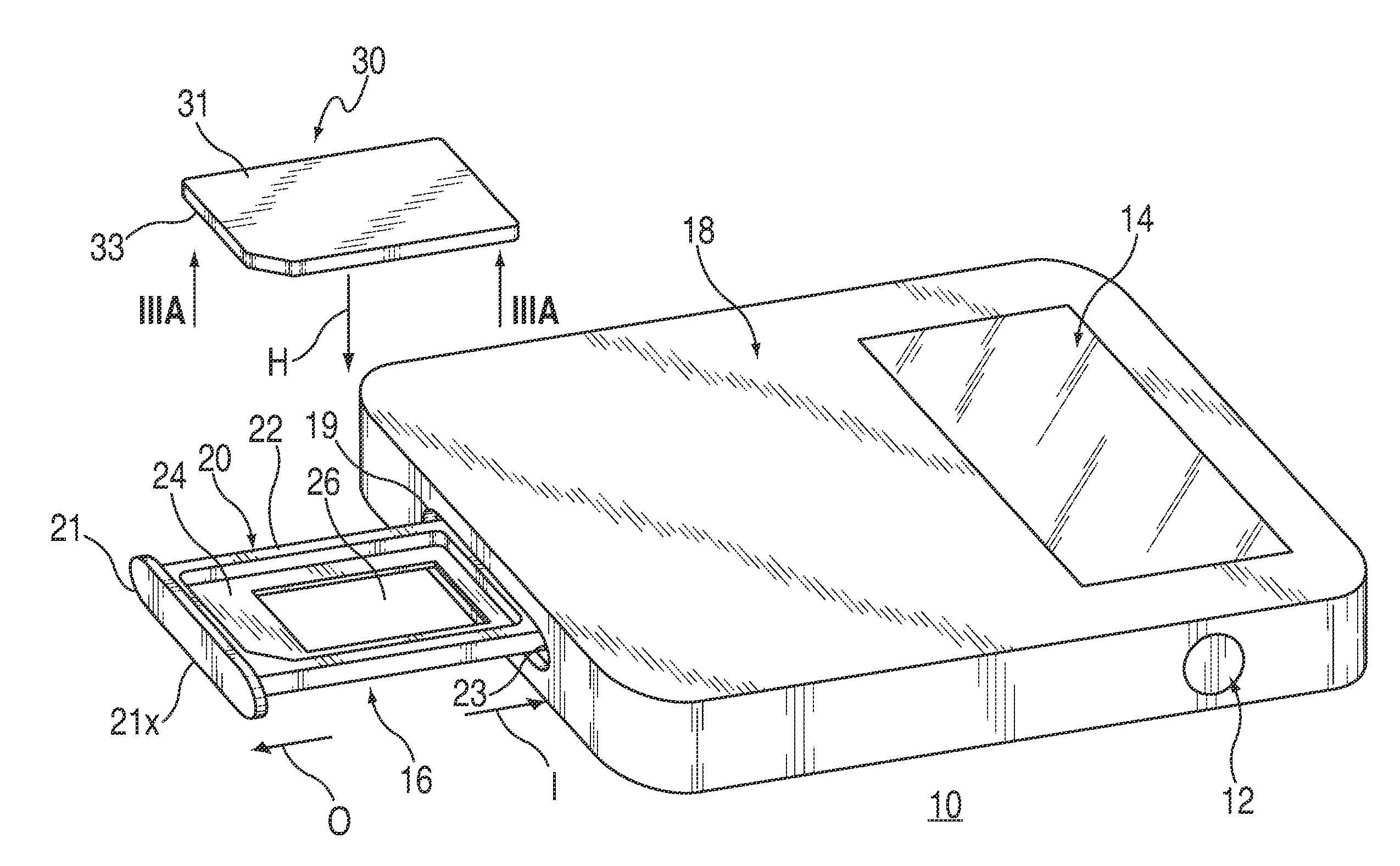

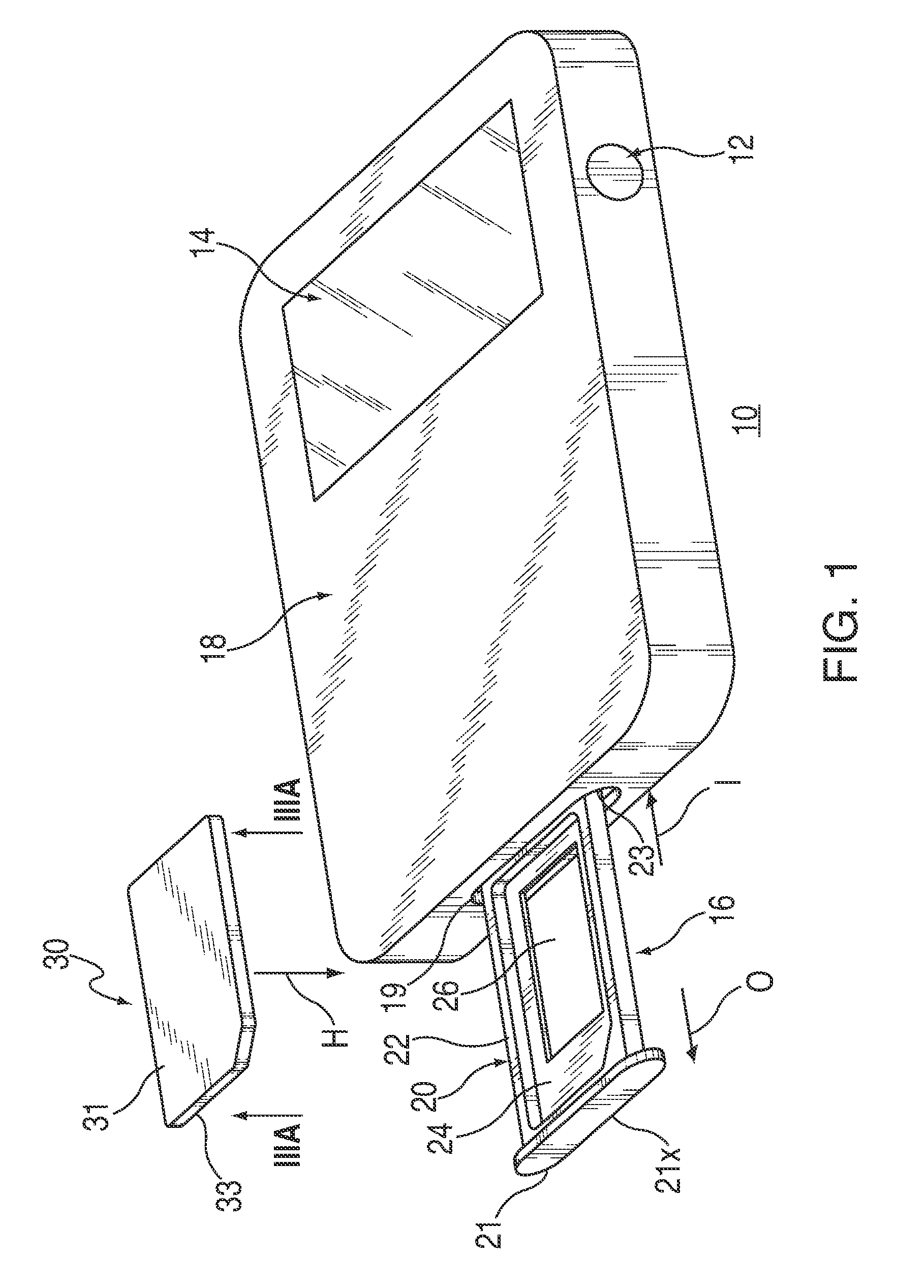

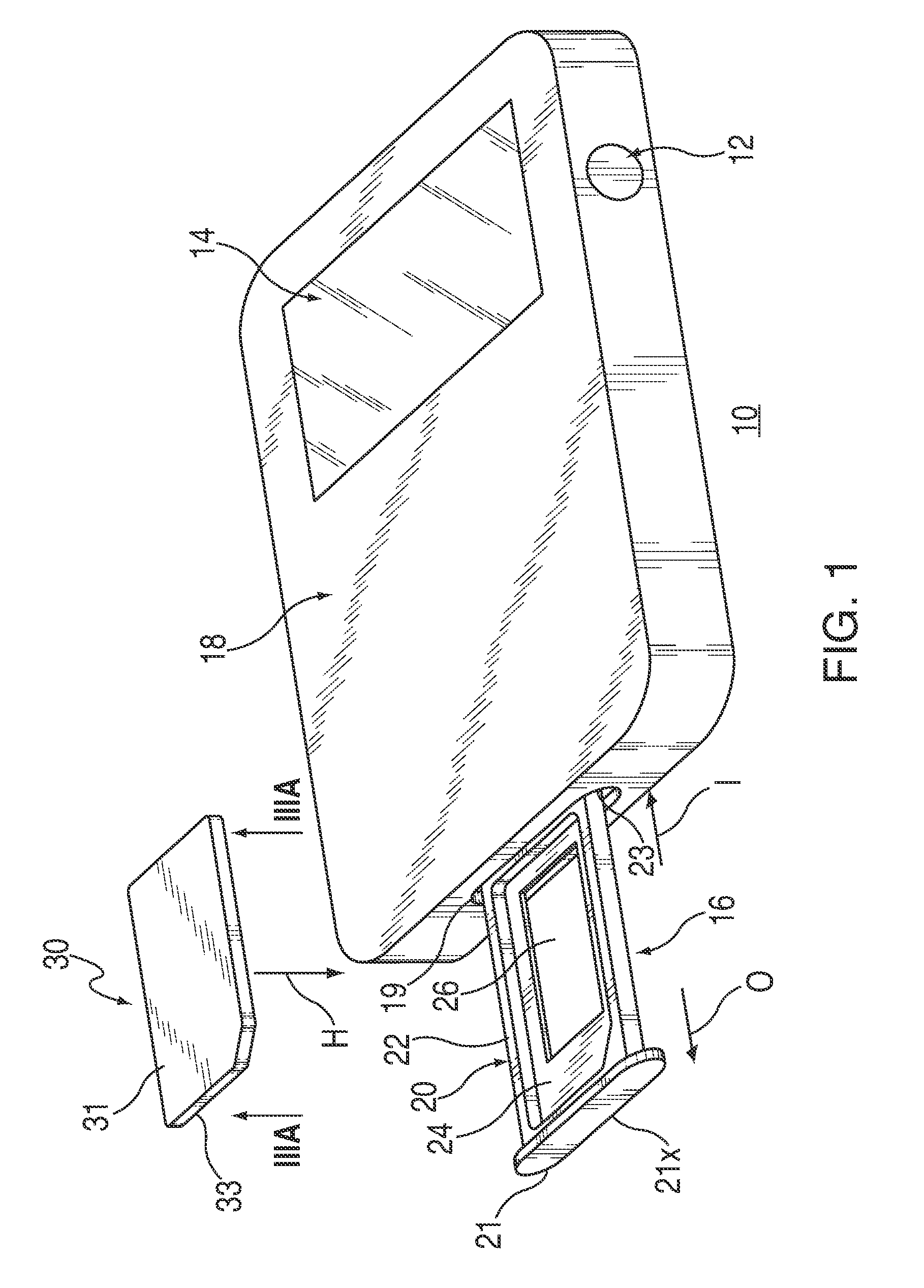

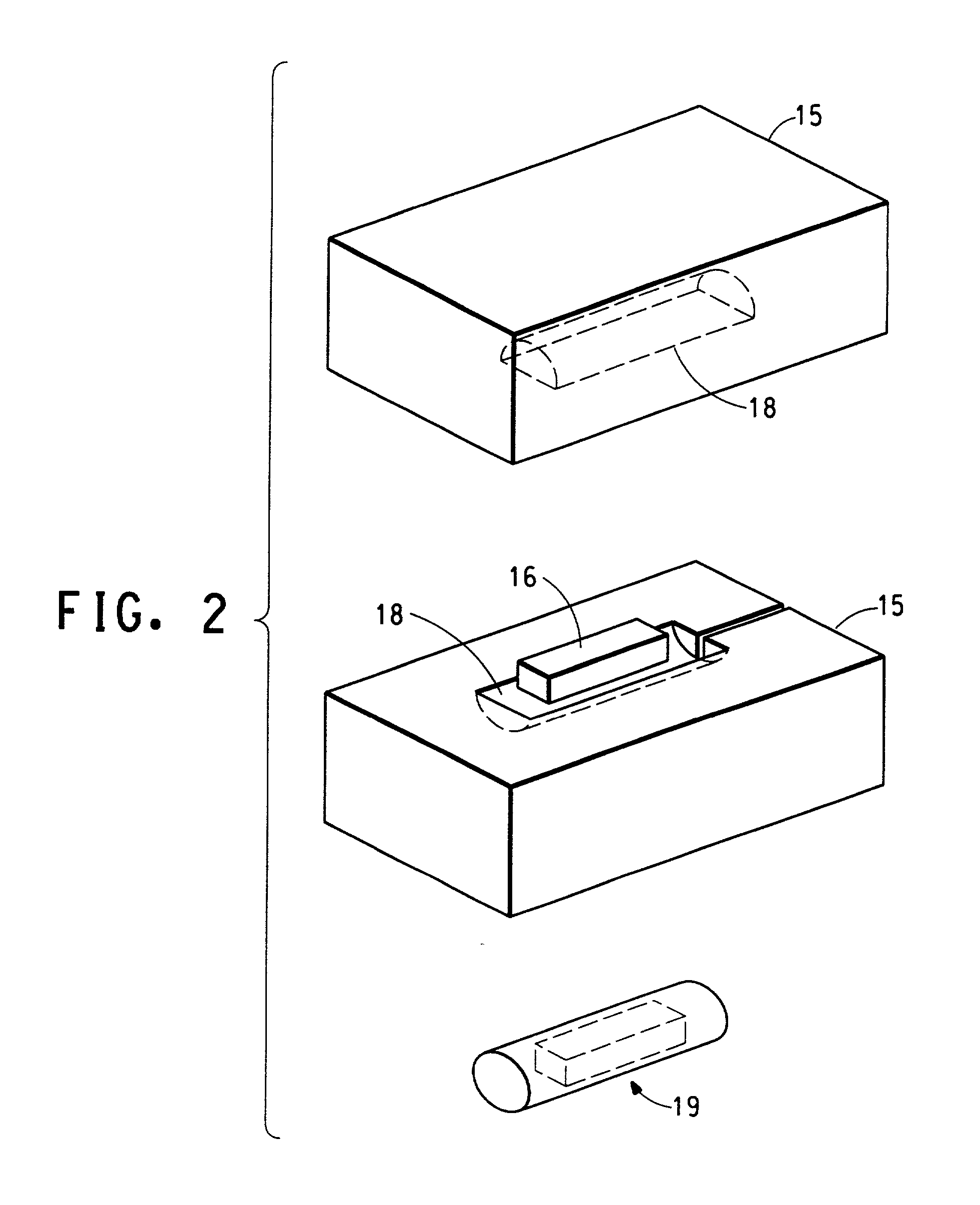

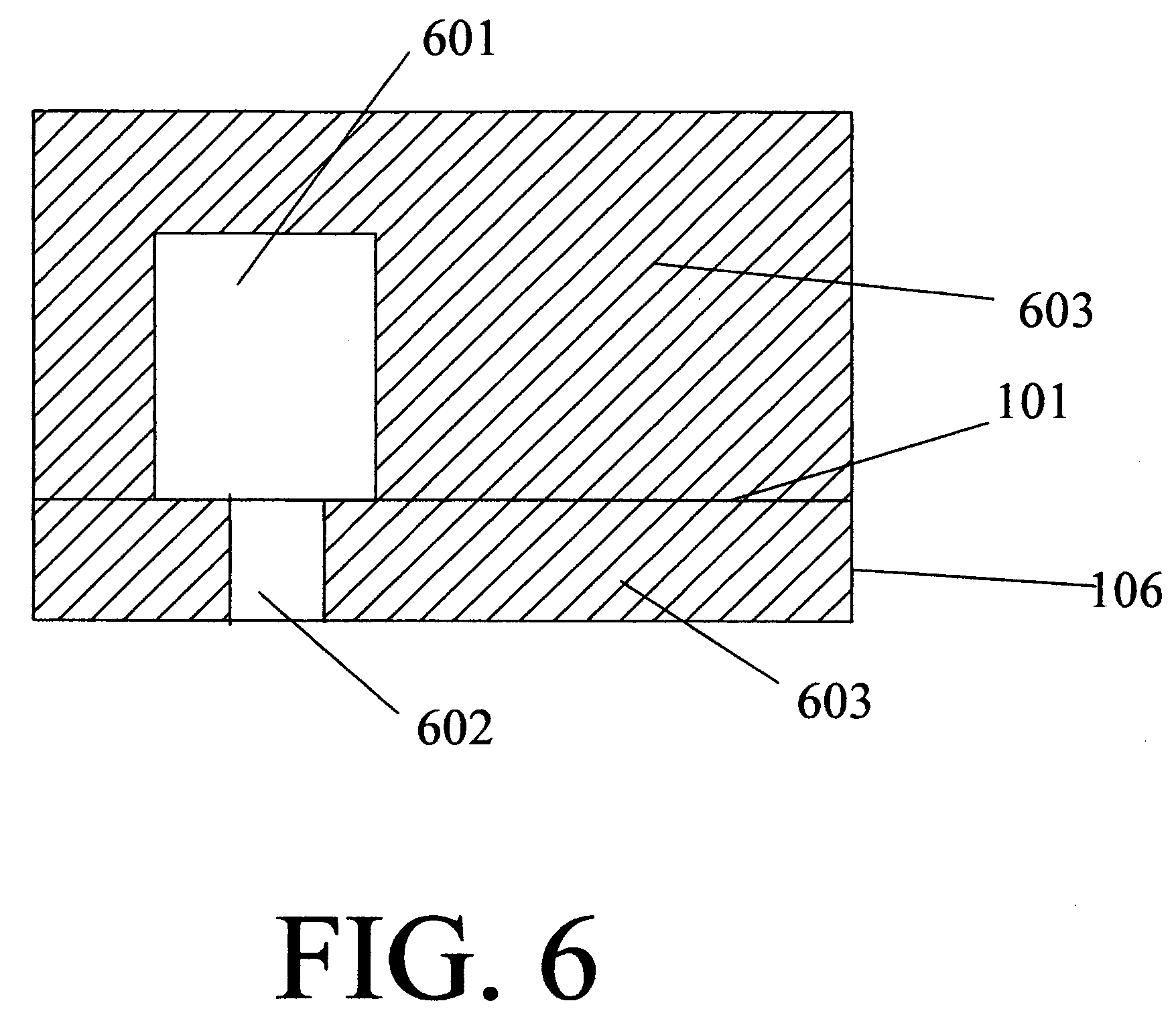

Glass enclosure

A handheld computing device that includes an enclosure having structural walls formed from a glass material that can be radio-transparent. The enclosure can be formed from a hollow glass tube or two glass members bonded together. A laser frit bonding process may be used to hermetically seal the two glass members together to create a water resistant electronic device.

Owner:APPLE INC

Glass enclosure

ActiveUS8824140B2Digital data processing detailsCasings with display/control unitsFritBonding process

Owner:APPLE INC

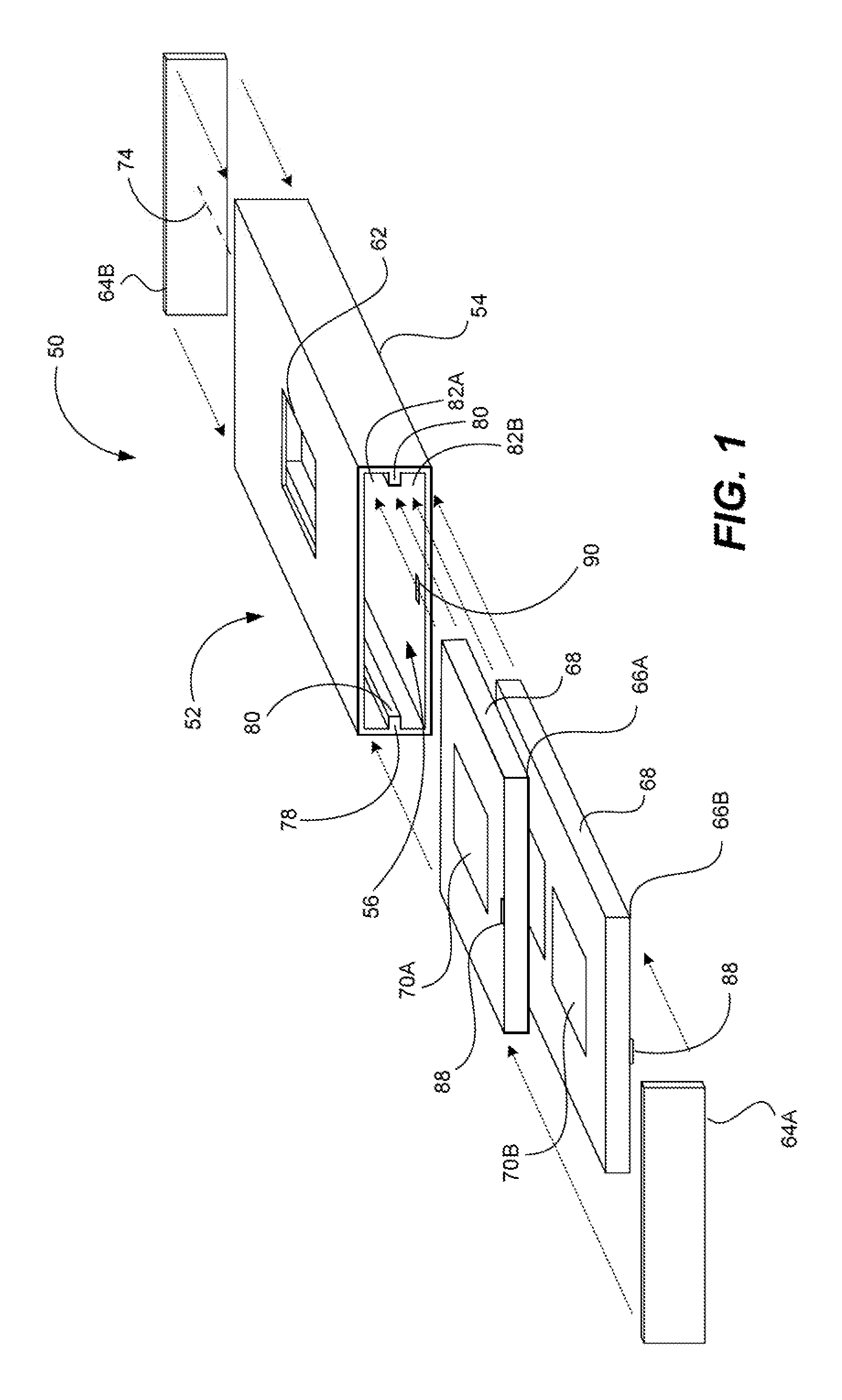

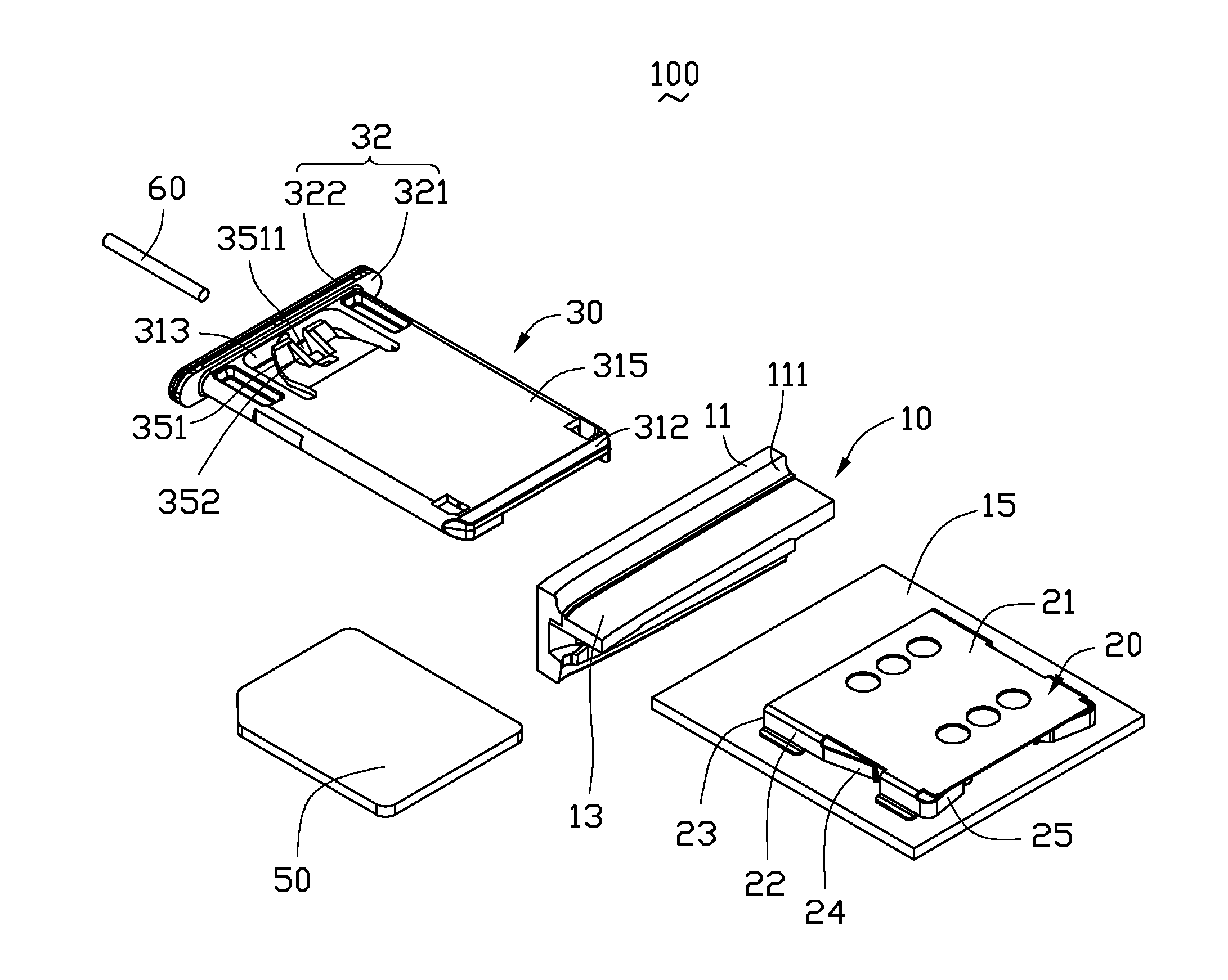

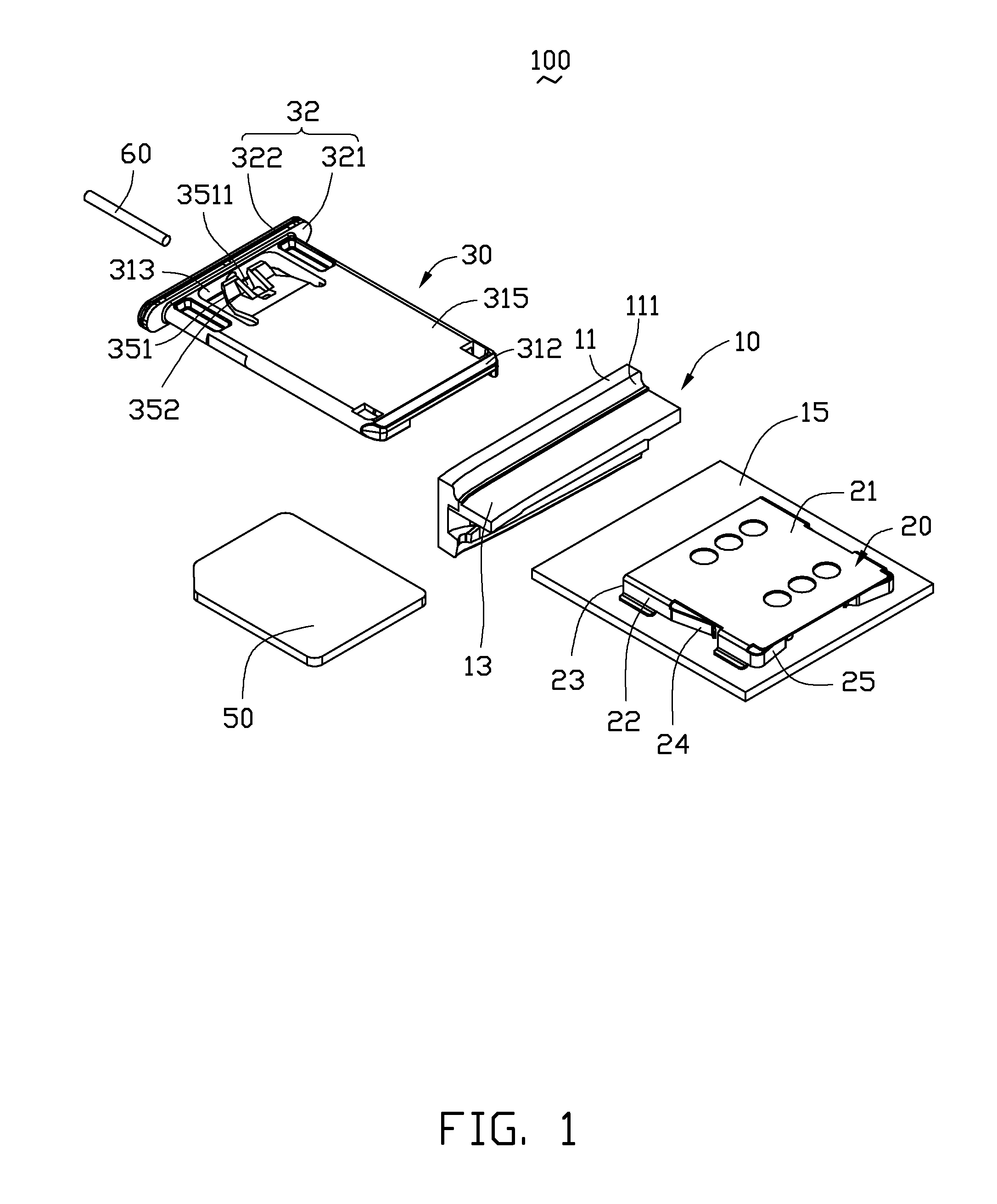

Compact ejectable component assemblies in electronic devices

ActiveUS20110255252A1Devices with card reading facilityConveying record carriersMechanical engineeringElectronic equipment

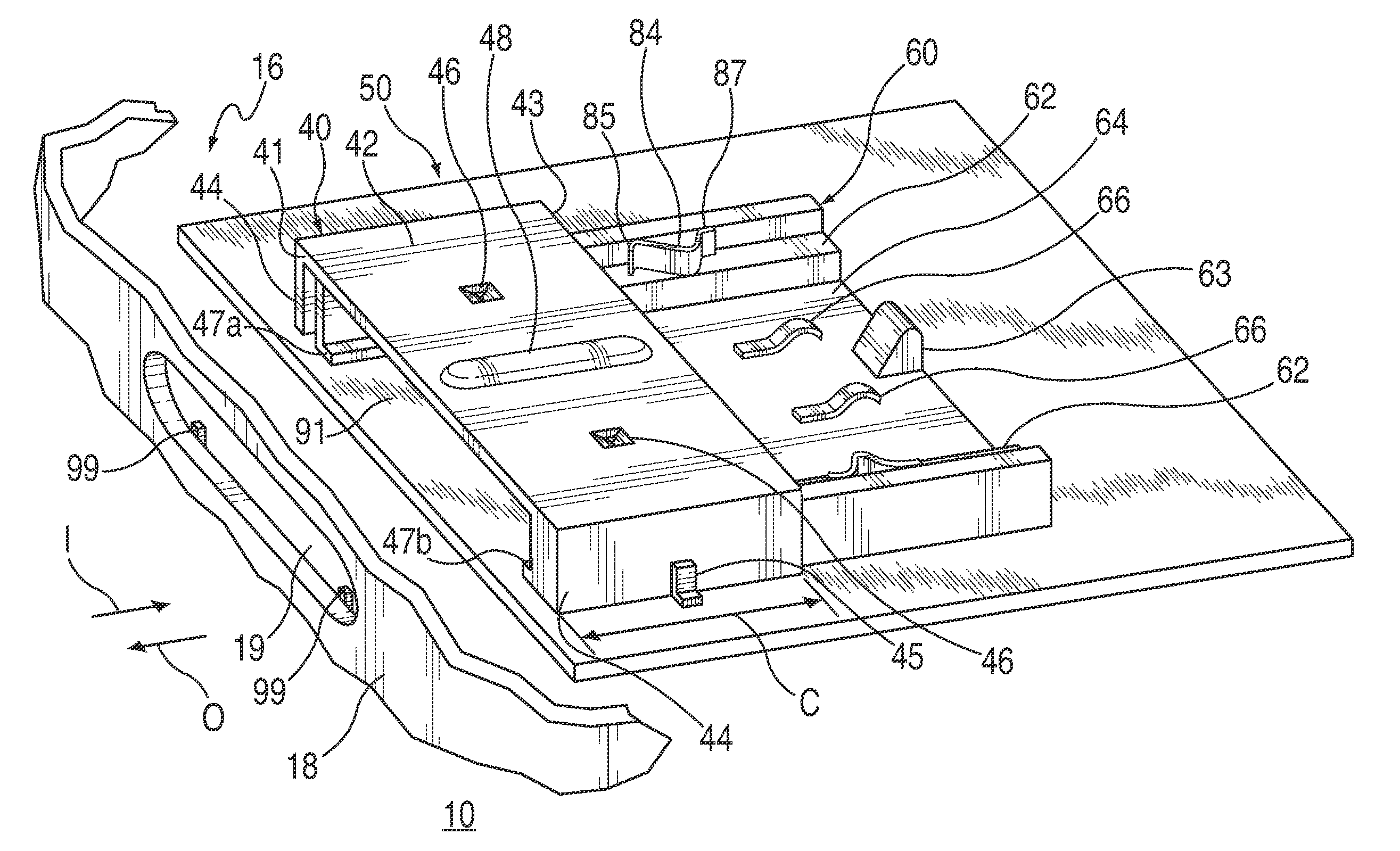

Electronic devices are provided with ejectable component assemblies. Each ejectable component assembly may include a tray that can be loaded with one or more types of removable module, such as a mini-SIM card and a micro-SIM card, and inserted into the device. Each assembly may also include a base coupled to a circuit board for electrically coupling with the removable module, a cage for biasing the module down against the base, and a guide for retaining the module at a functional insertion position within the device.

Owner:APPLE INC

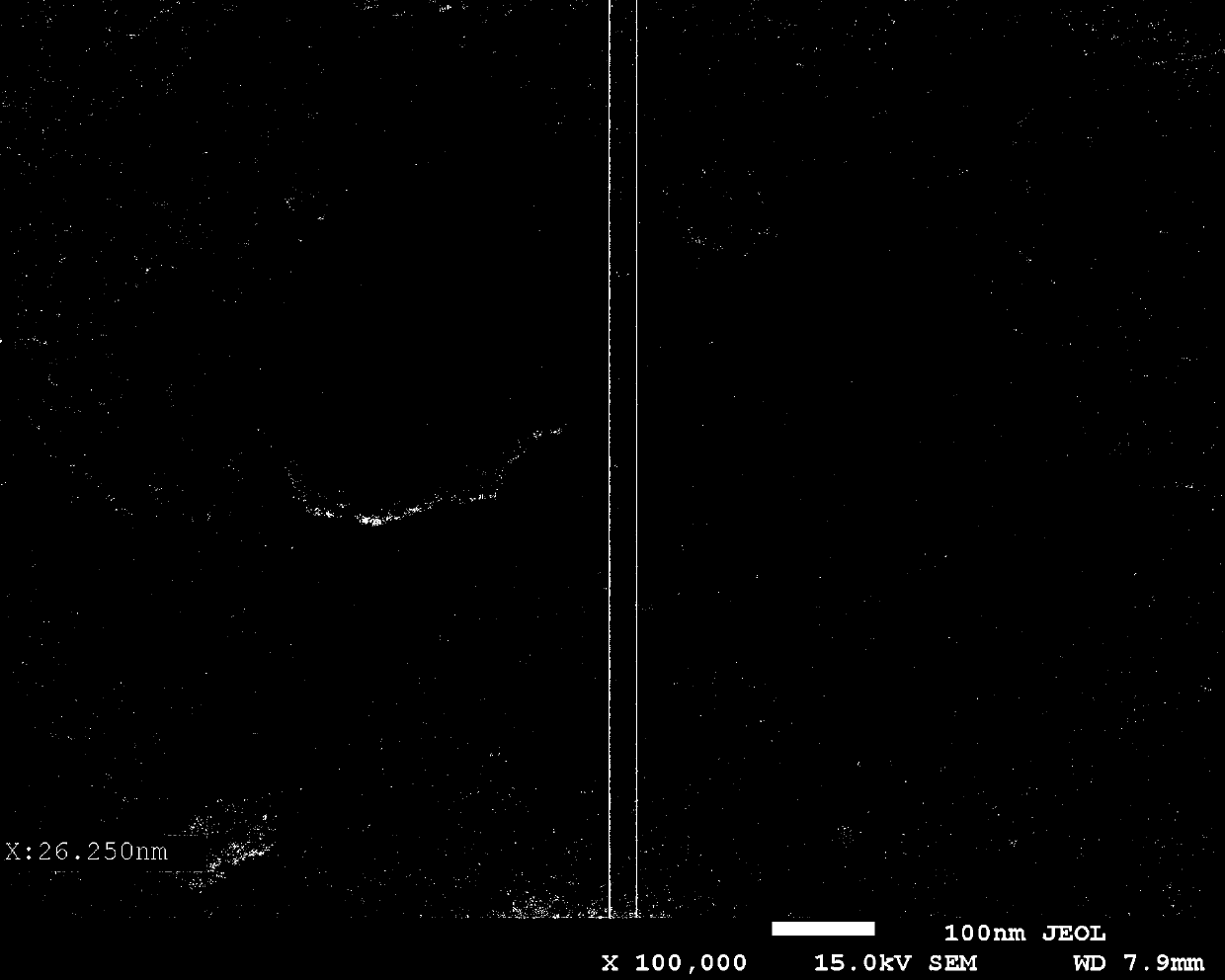

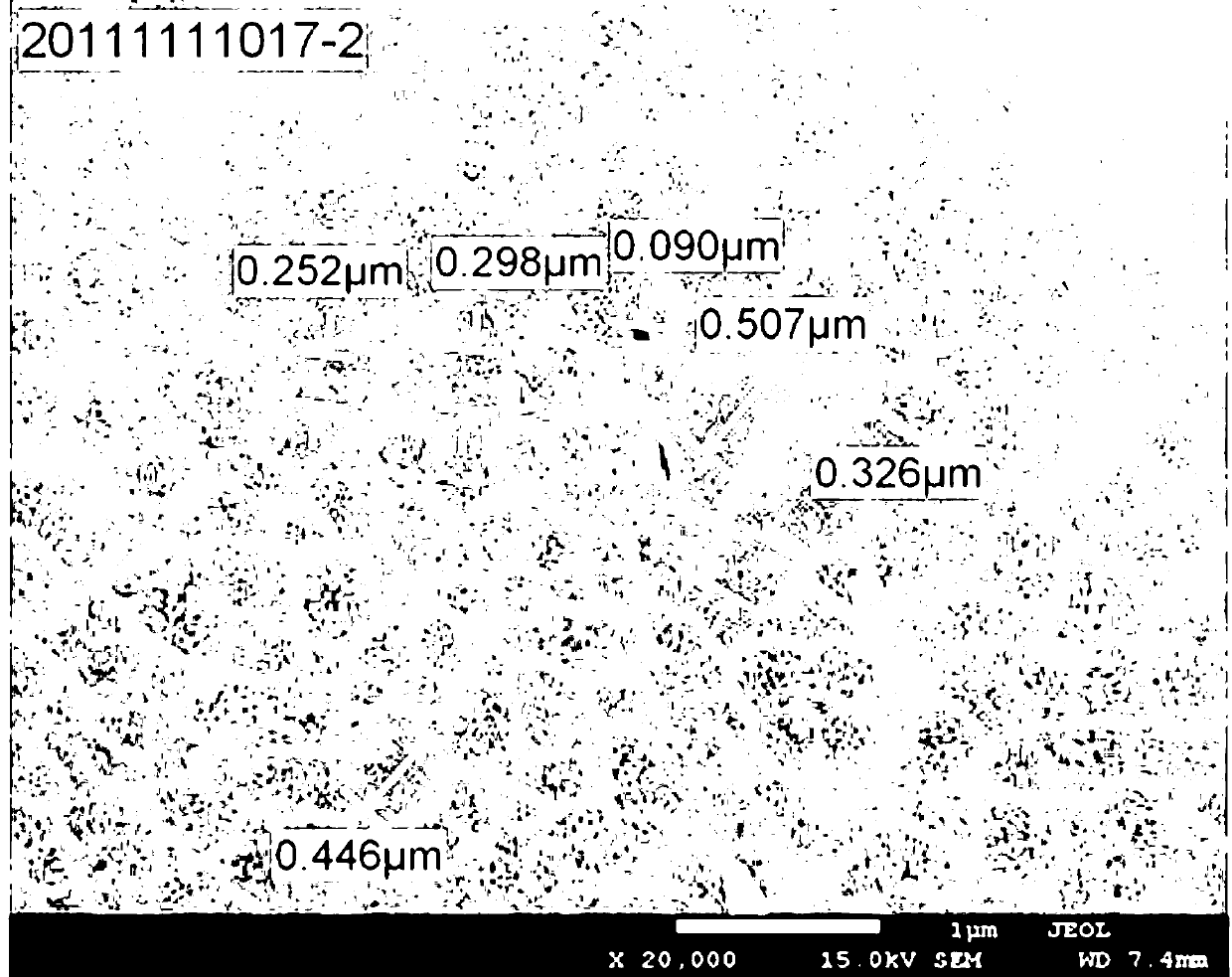

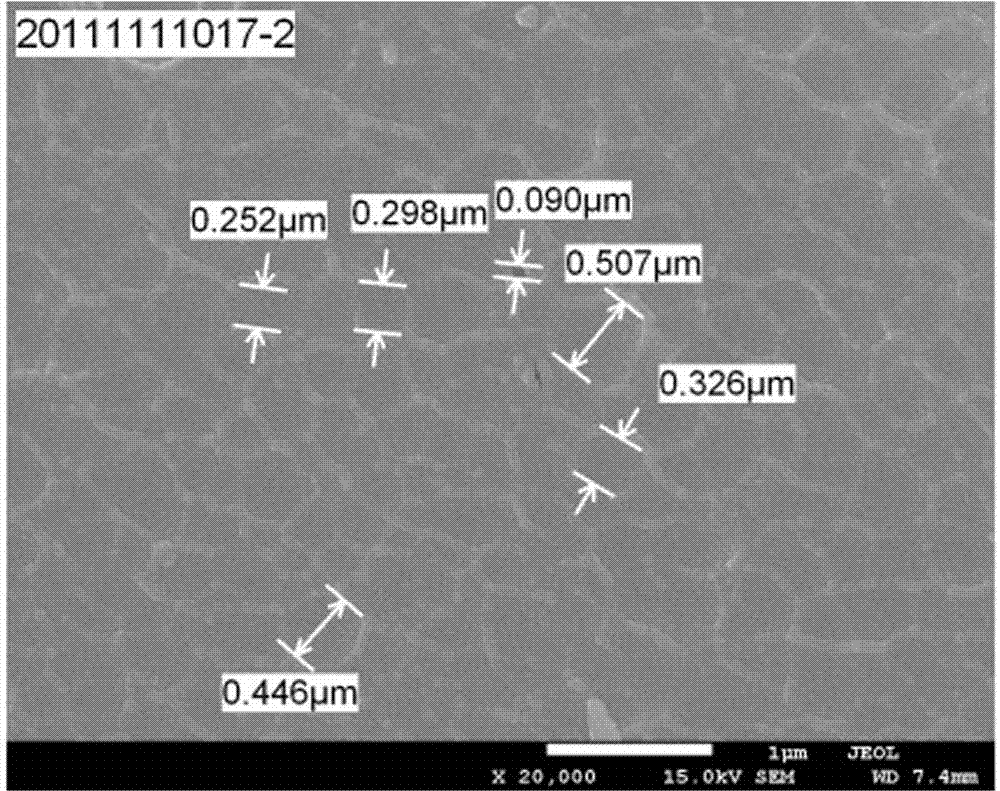

Mobile phone shell and preparation method thereof

ActiveCN103297565AImprove corrosion resistanceAppearance has no effectAnodisationSmall component housingsMobile phoneNanotechnology

The invention provides a mobile phone shell and a preparation method of the mobile phone shell. The mobile phone shell comprises a plastic piece and a metal shell body which is combined with the plastic piece, wherein the surface of a face, combined with the plastic piece, of the metal shell body is provided with an oxidation film layer, corrosion holes are formed in the surface layer of a face, opposite to the plastic piece, of the oxidation film layer, the hole diameter of each corrosion hole is 200 nanometers to 2000 nanometers, nanometer micro holes are formed in the inner layer of the oxidation film layer, the hole diameter of each nanometer micro hole is 10 nanometers to 100 nanometers, and resin compositions of the plastic piece are filled in the nanometer micro holes and the corrosion holes. The prepared mobile phone shell is resistant to abrasion, falling and corrosion.

Owner:BYD CO LTD

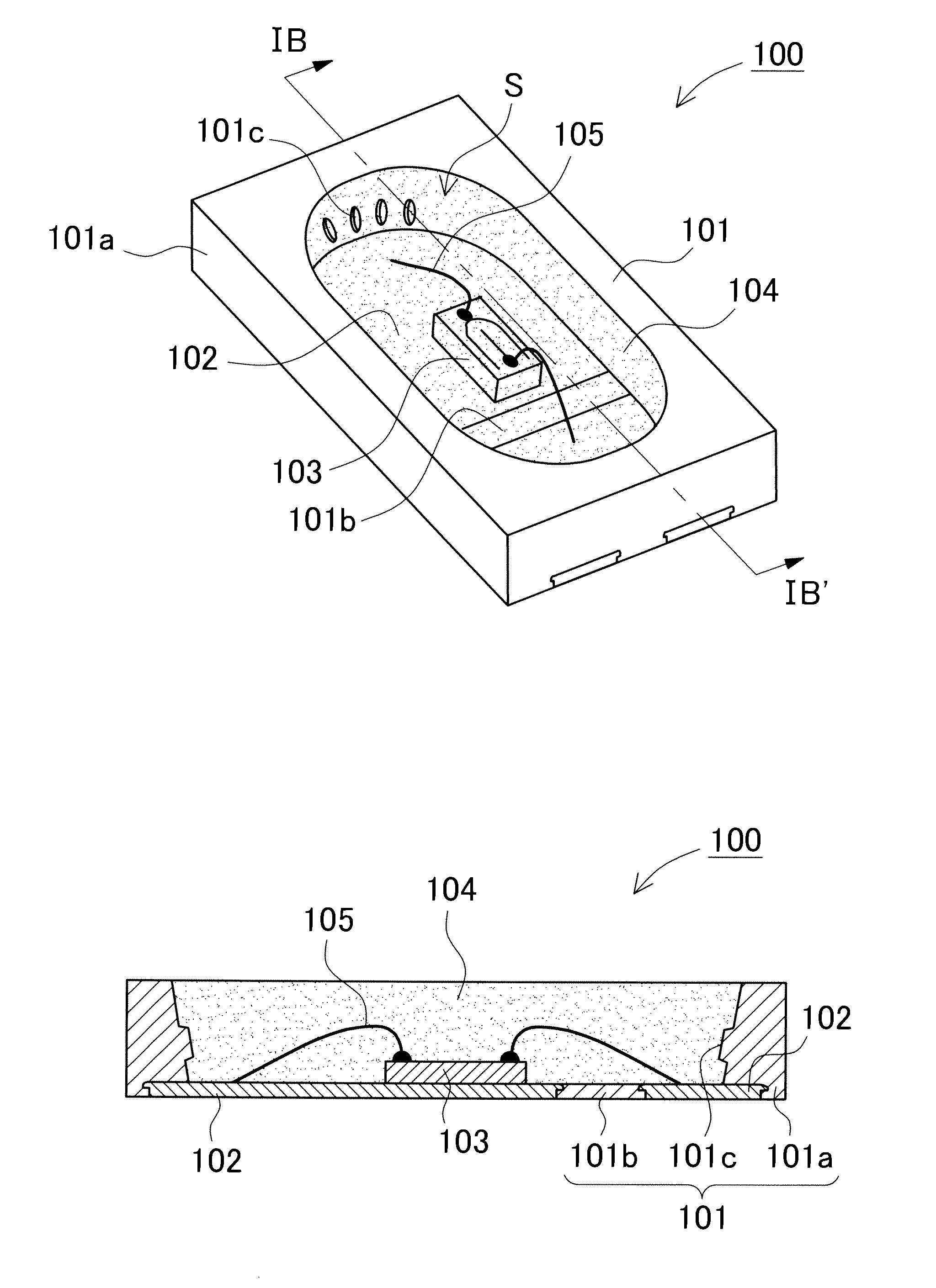

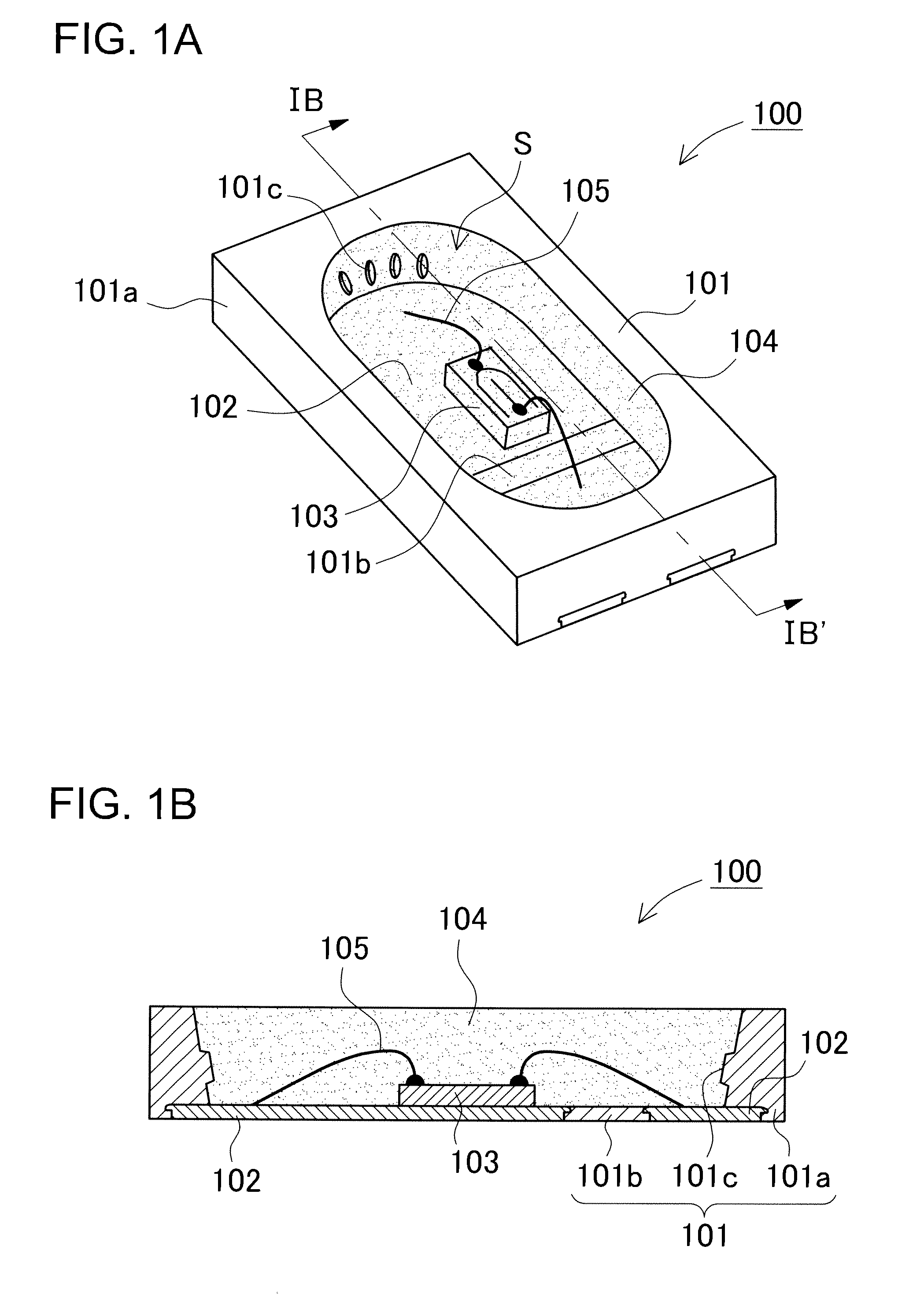

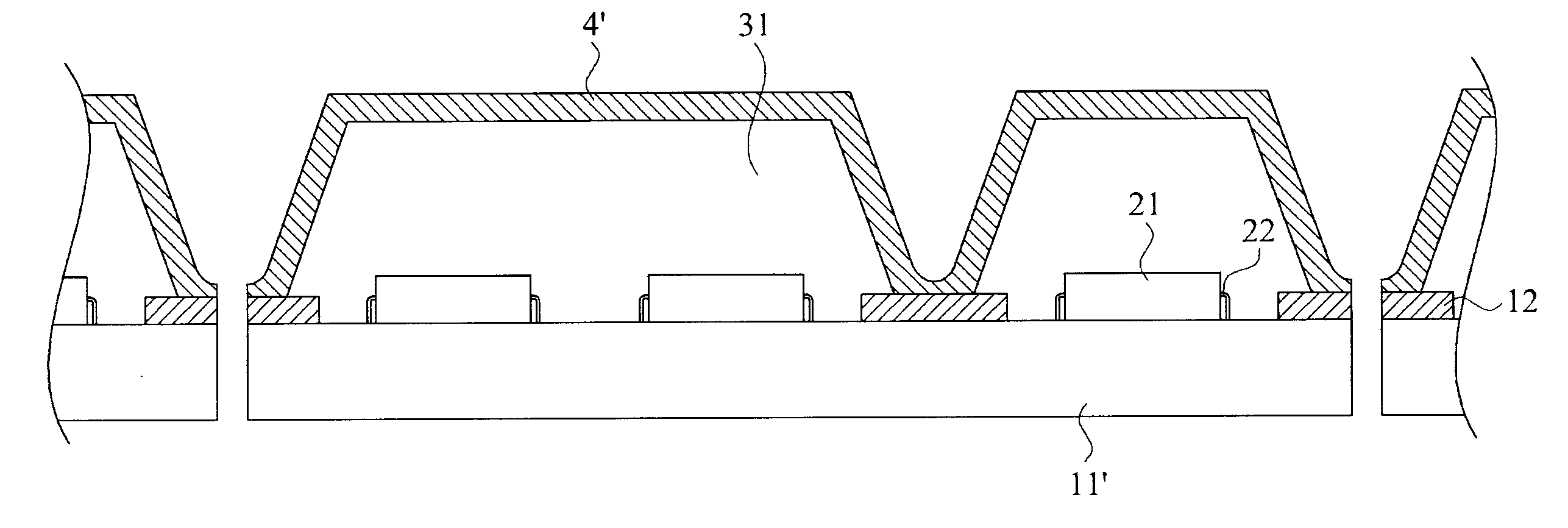

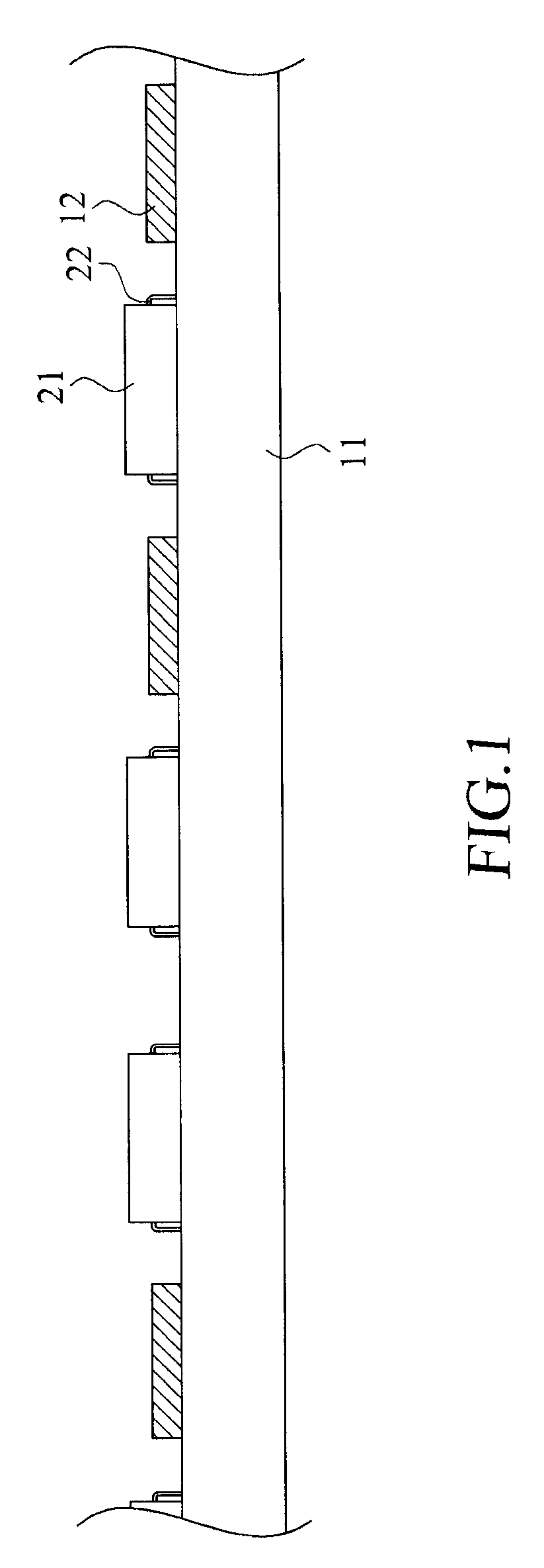

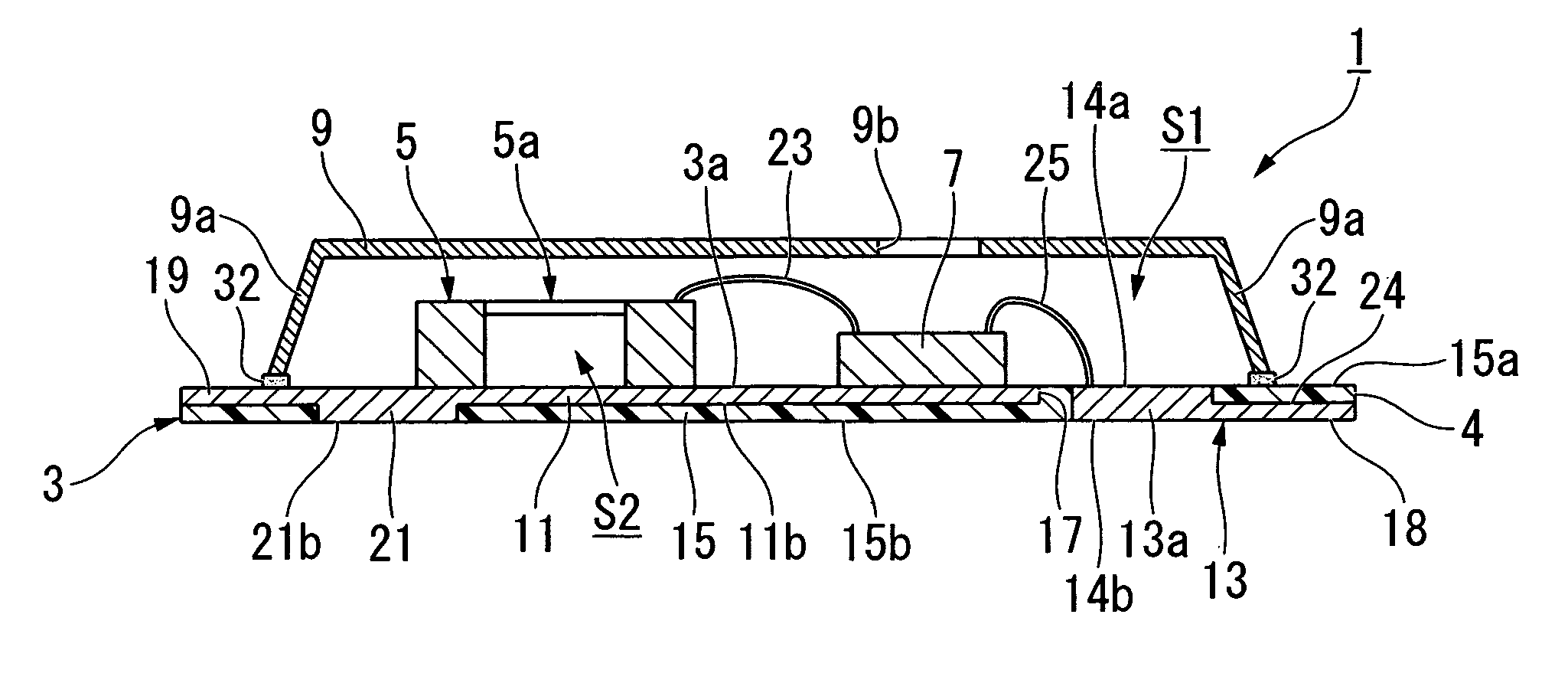

Light emitting device and method of manufacturing the light emitting device

ActiveUS20120018772A1Light extraction efficiency can be improvedImprove production yieldSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringLight emitting device

A light emitting device includes a base body forming a recess defined by a bottom surface and a side wall thereof, a conductive member whose upper surface being exposed in the recess and whose lower surface forming an outer surface, a protruding portion disposed in the recess, a light emitting element mounted in the recess and electrically connected to the conductive member, and a sealing member disposed in the recess to cover the light emitting element. The base body has a bottom portion and a side wall portion integrally formed of a resin, an inner surface of the side wall portion is the side wall defining the recess and has a curved portion, and the protruding portion is disposed in close vicinity to the curved surface. With this arrangement, a thin and small-sized light emitting device excellent in light extraction efficiency and reliability can be obtained.

Owner:NICHIA CORP

Combined packaging and storage apparatus having added functionality

InactiveUS20050243522A1Function increaseOther accessoriesSmall component housingsEmbedded systemCombination Package

Owner:MOTOROLA INC

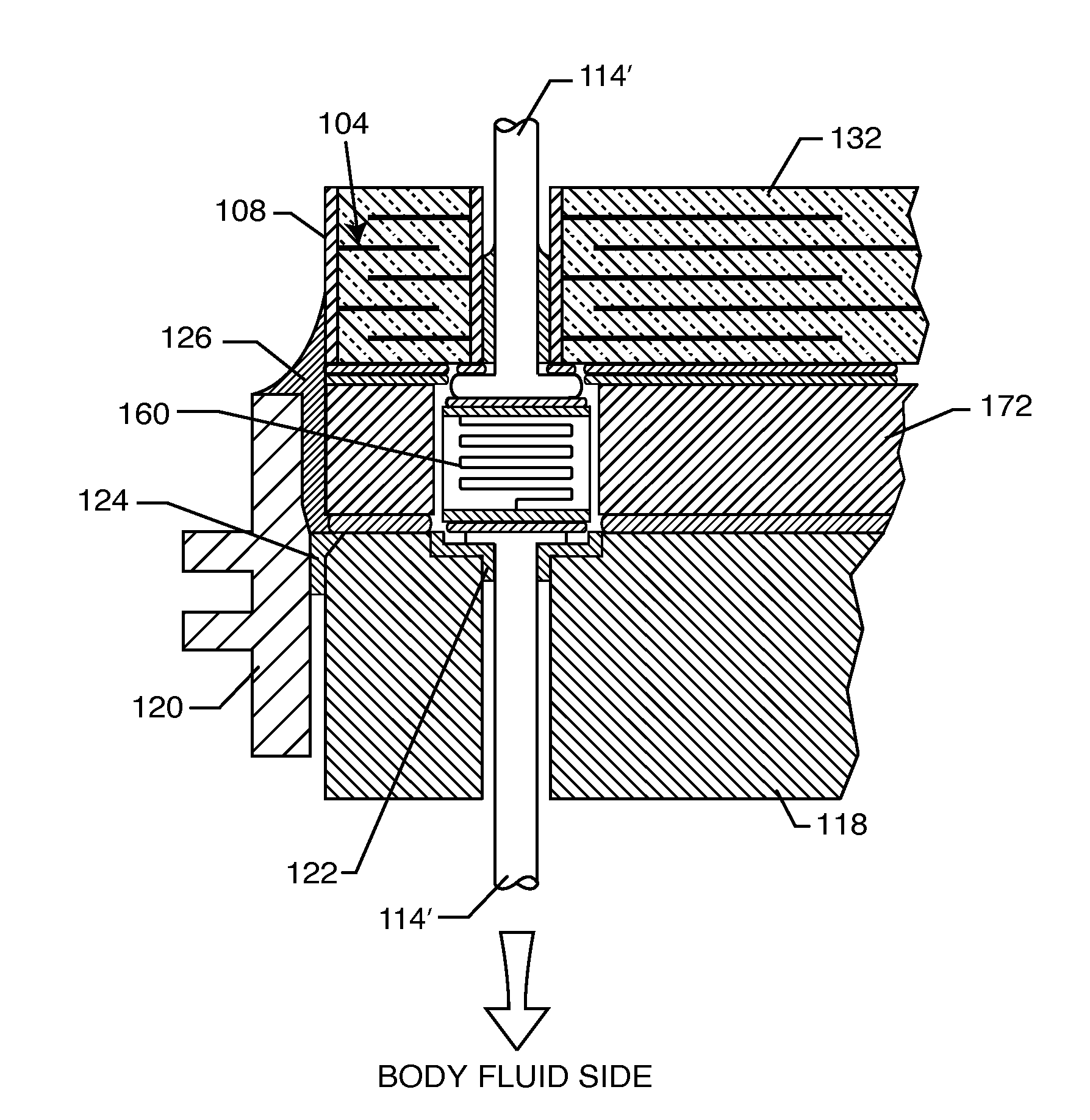

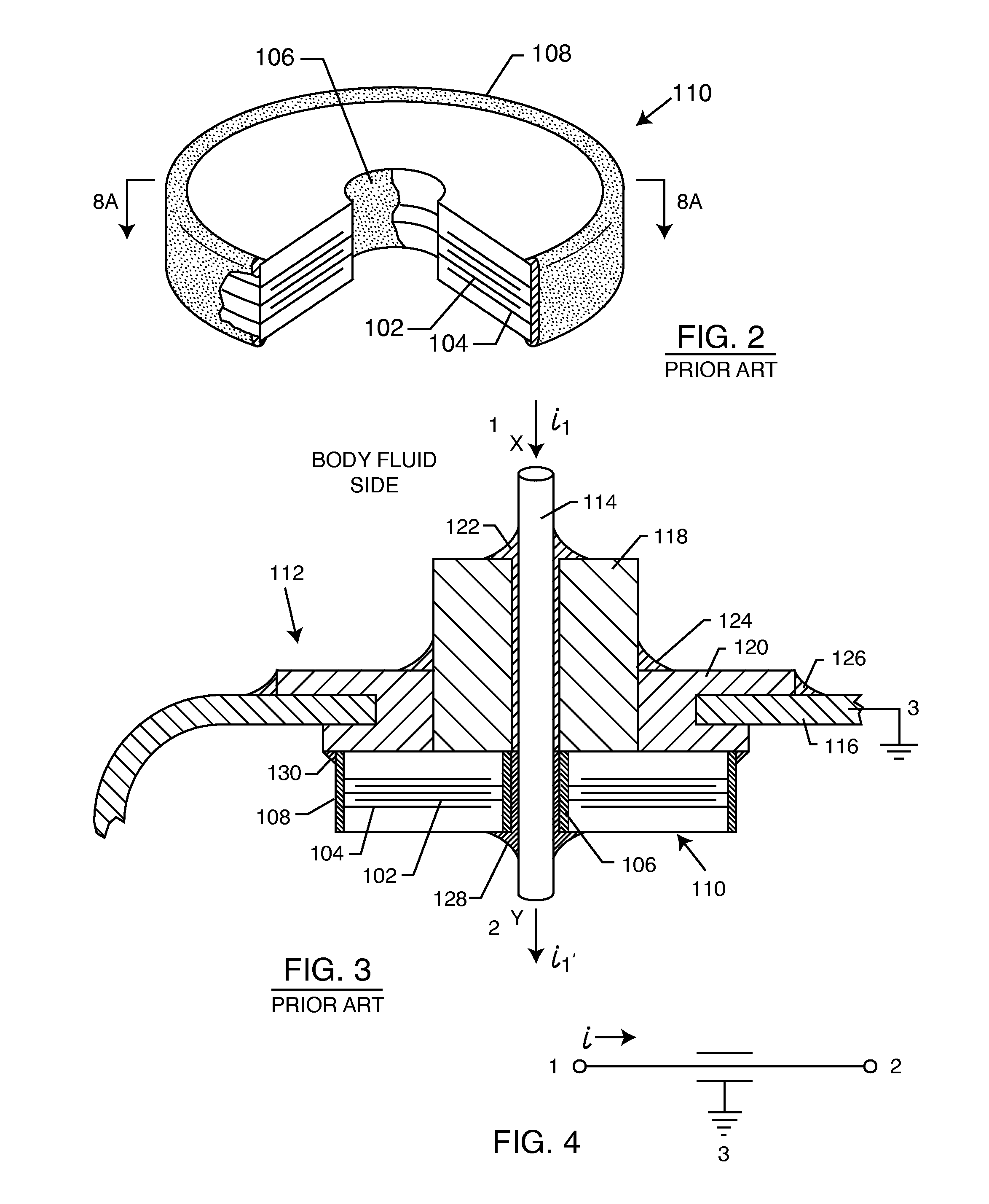

Shielded three-terminal flat-through emi/energy dissipating filter

InactiveUS20110004283A1Value maximizationDrag minimizationMultiple-port networksAnti-noise capacitorsEngineeringActive electrode

A shielded three-terminal flat-through EMI / energy dissipating filter includes an active electrode plate through which a circuit current passes between a first terminal and a second terminal, a first shield plate on a first side of the active electrode plate, and a second shield plate on a second side of the active electrode plate opposite the first shield plate. The first and second shield plates are conductively coupled to a grounded third terminal. In preferred embodiments, the active electrode plate and the shield plates are at least partially disposed with a hybrid flat-through substrate that may include a flex cable section, a rigid cable section, or both.

Owner:WILSON GREATBATCH LTD

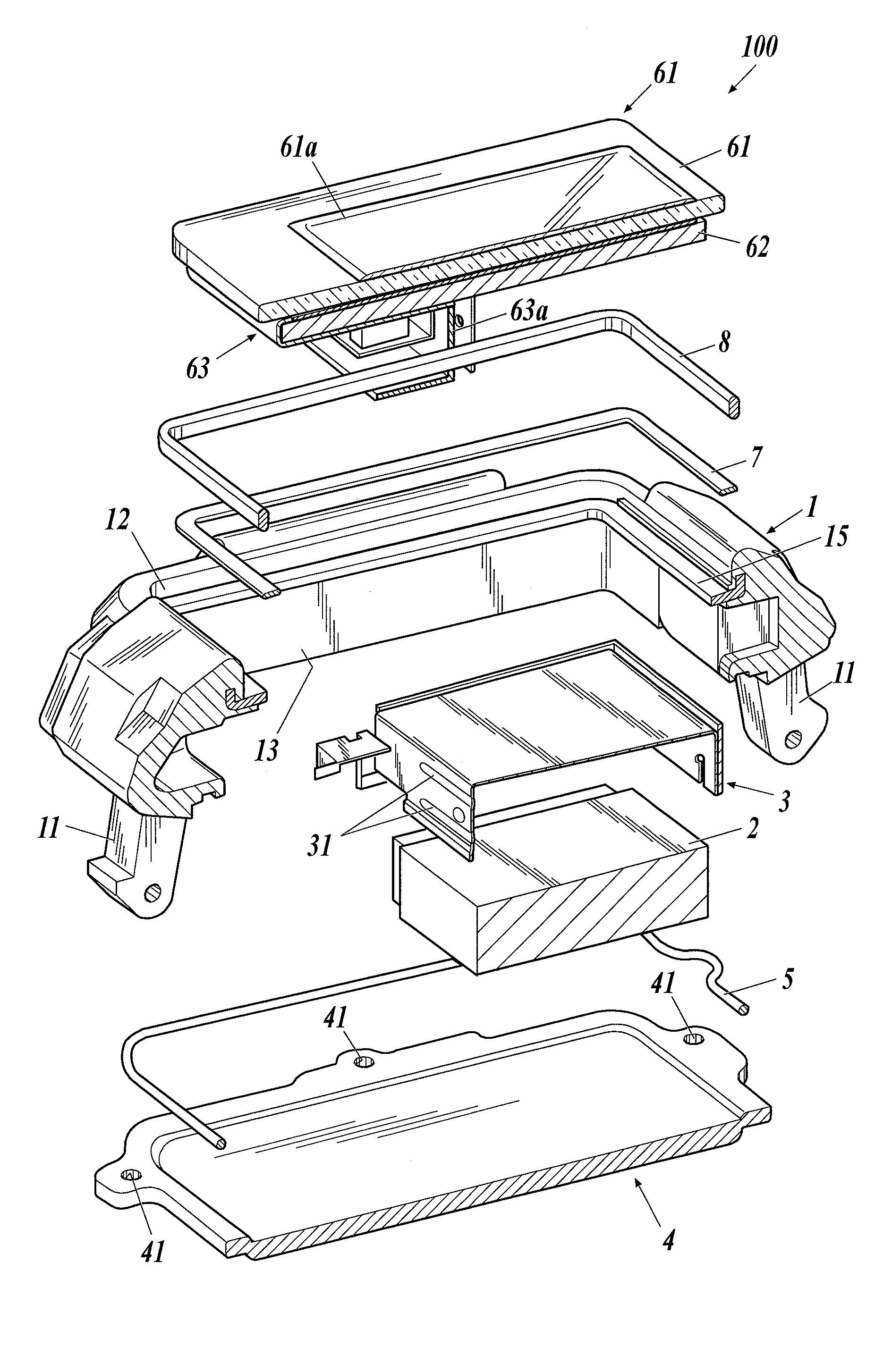

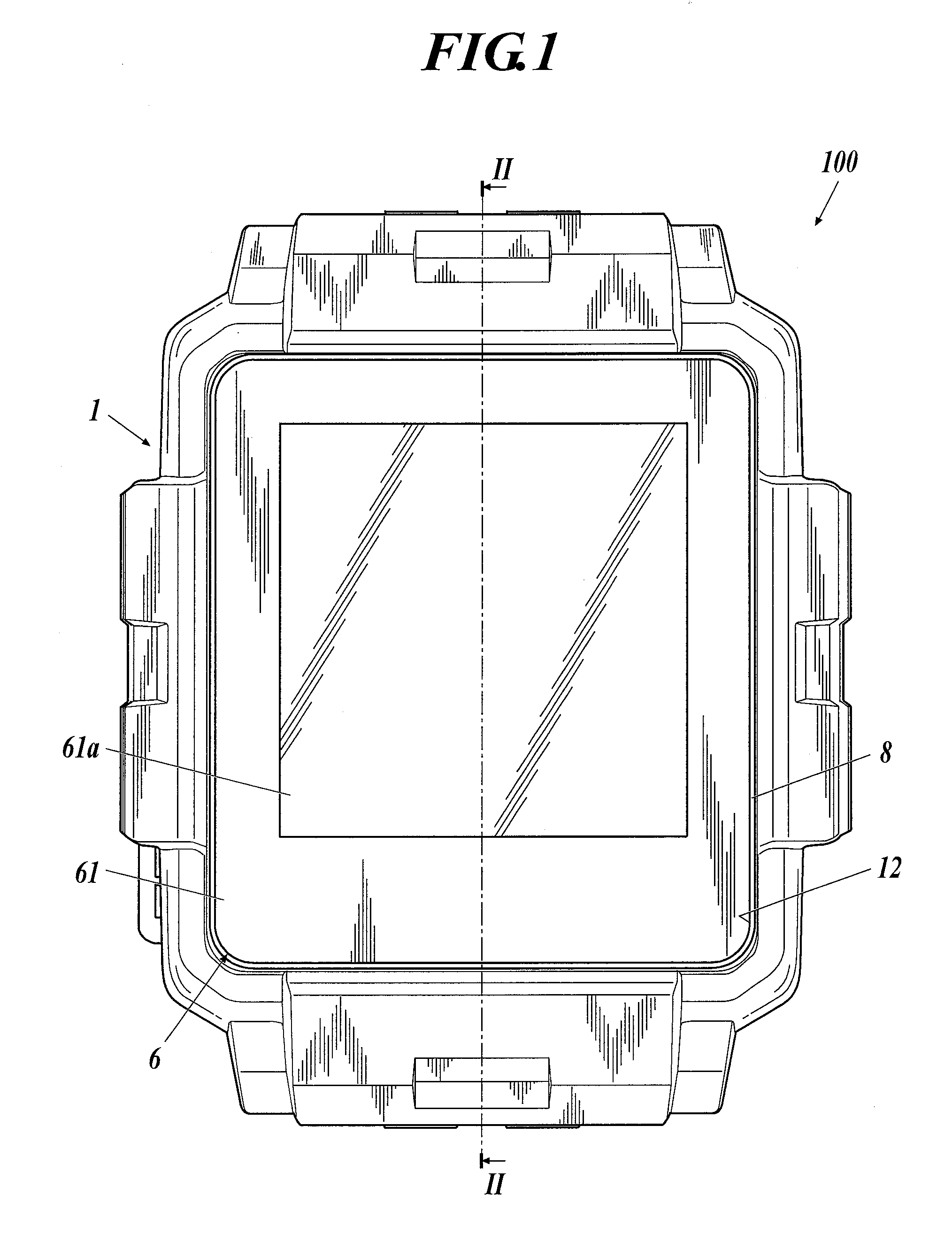

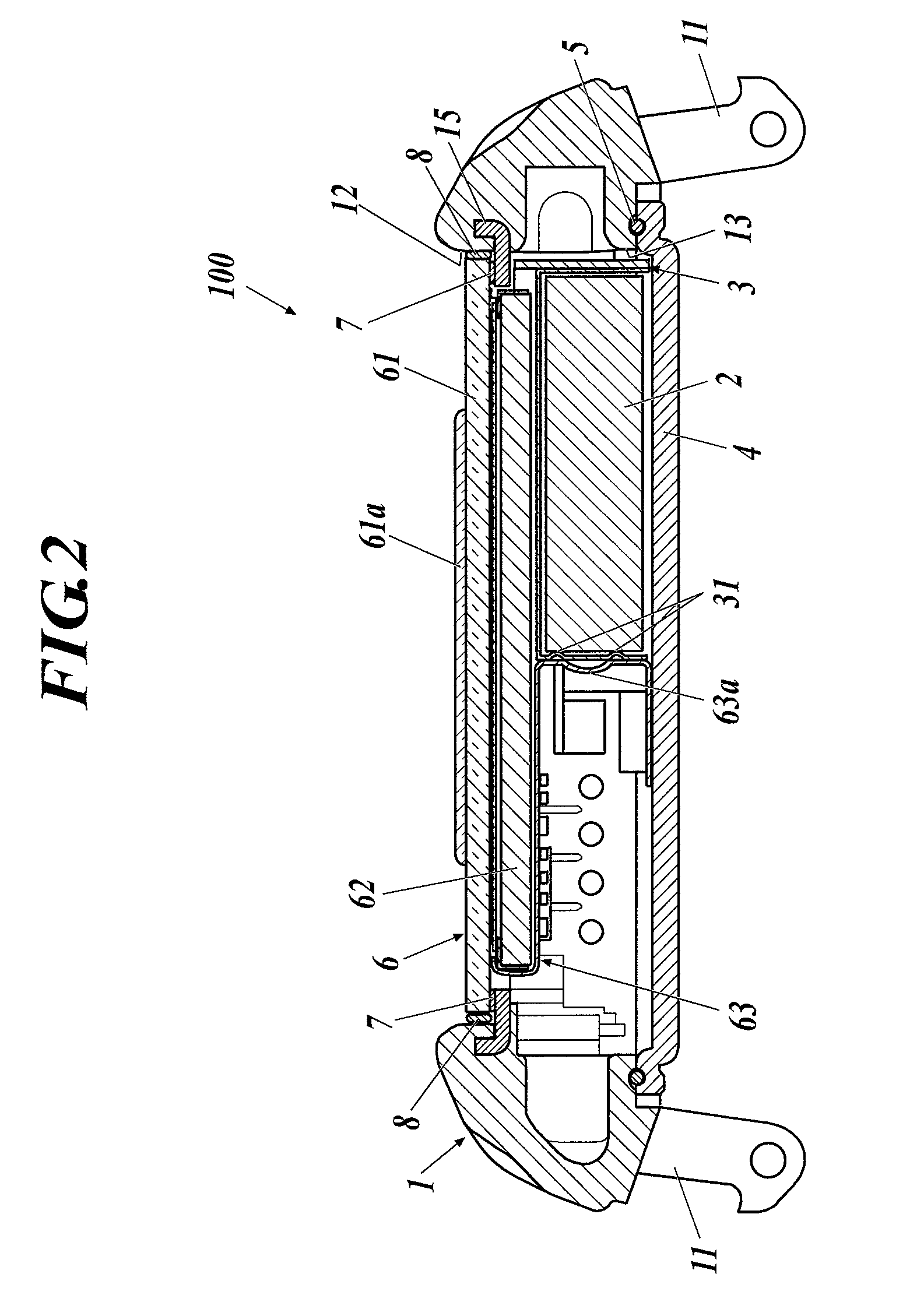

Electronic device

ActiveUS9391307B2Simple configurationKeep airtightElectronic time-piece structural detailsCasings/cabinets/drawers detailsInternal pressureEngineering

An electronic device includes a case body which includes an opening and a battery holder holding a battery, an inward flange which is disposed at least a part of a circumference of the opening, a display panel which is mounted on the inward flange so as to cover the opening of the case body, and an adhesive layer which is provided between the display panel and the inward flange. The adhesive layer gradually peels off to leak gas in a space sealed by the case body and the display panel, so as to prevent the display panel from swiftly popping out of the opening when an inner pressure of the space increases.

Owner:CASIO COMPUTER CO LTD

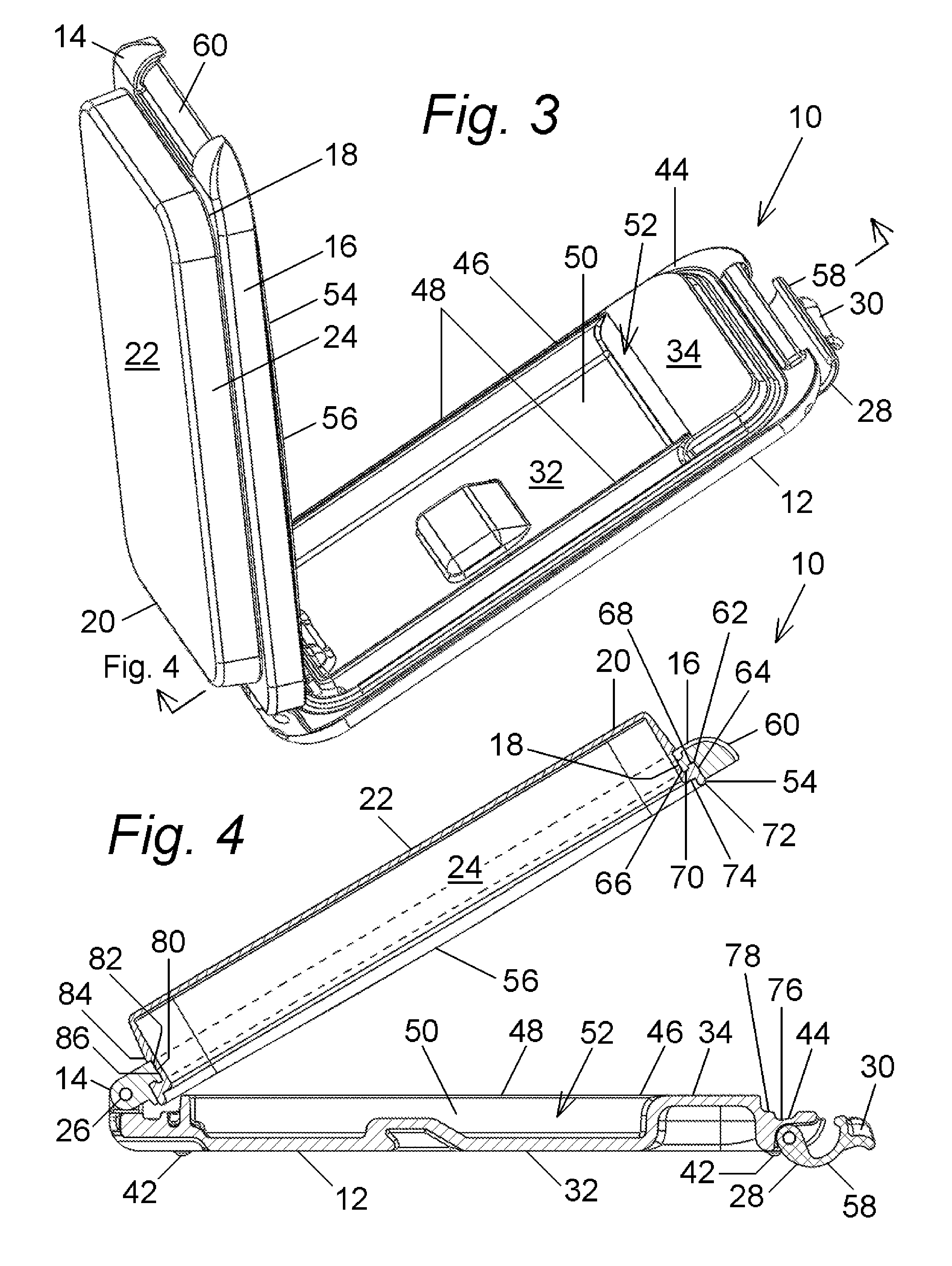

Compact ejectable component assemblies in electronic devices

ActiveUS8564965B2Devices with card reading facilityConveying record carriersElectricityComputer module

Owner:APPLE INC

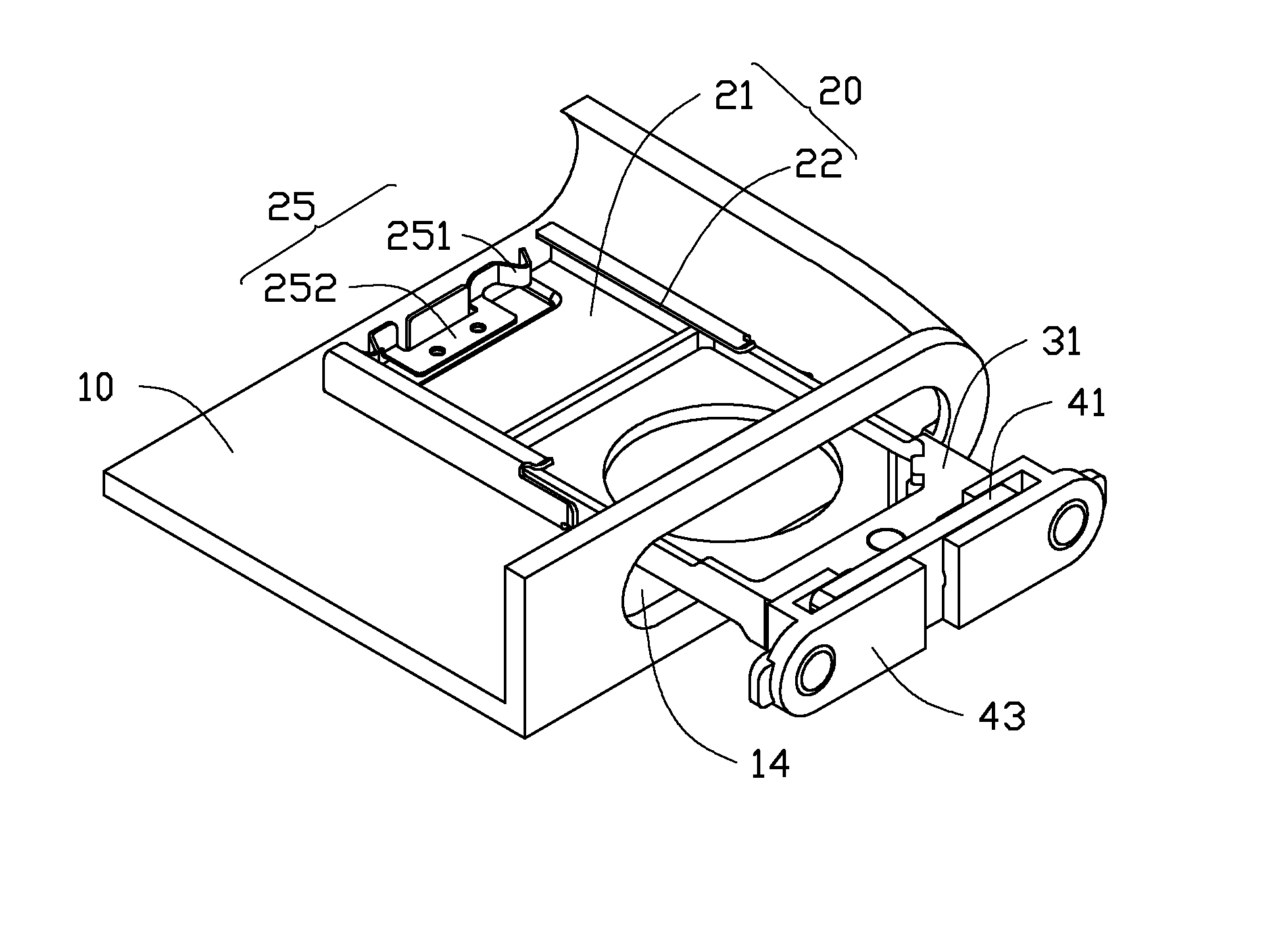

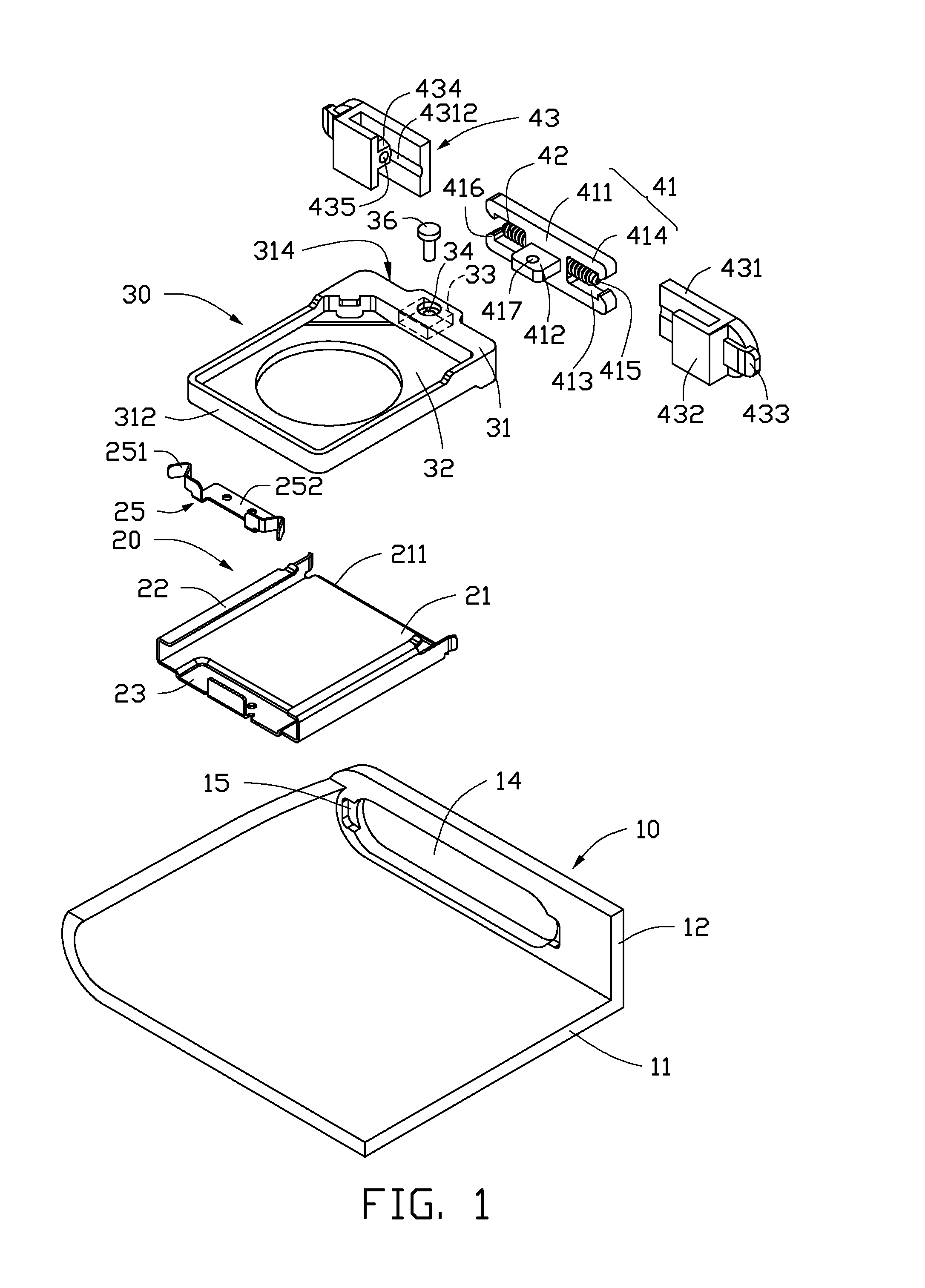

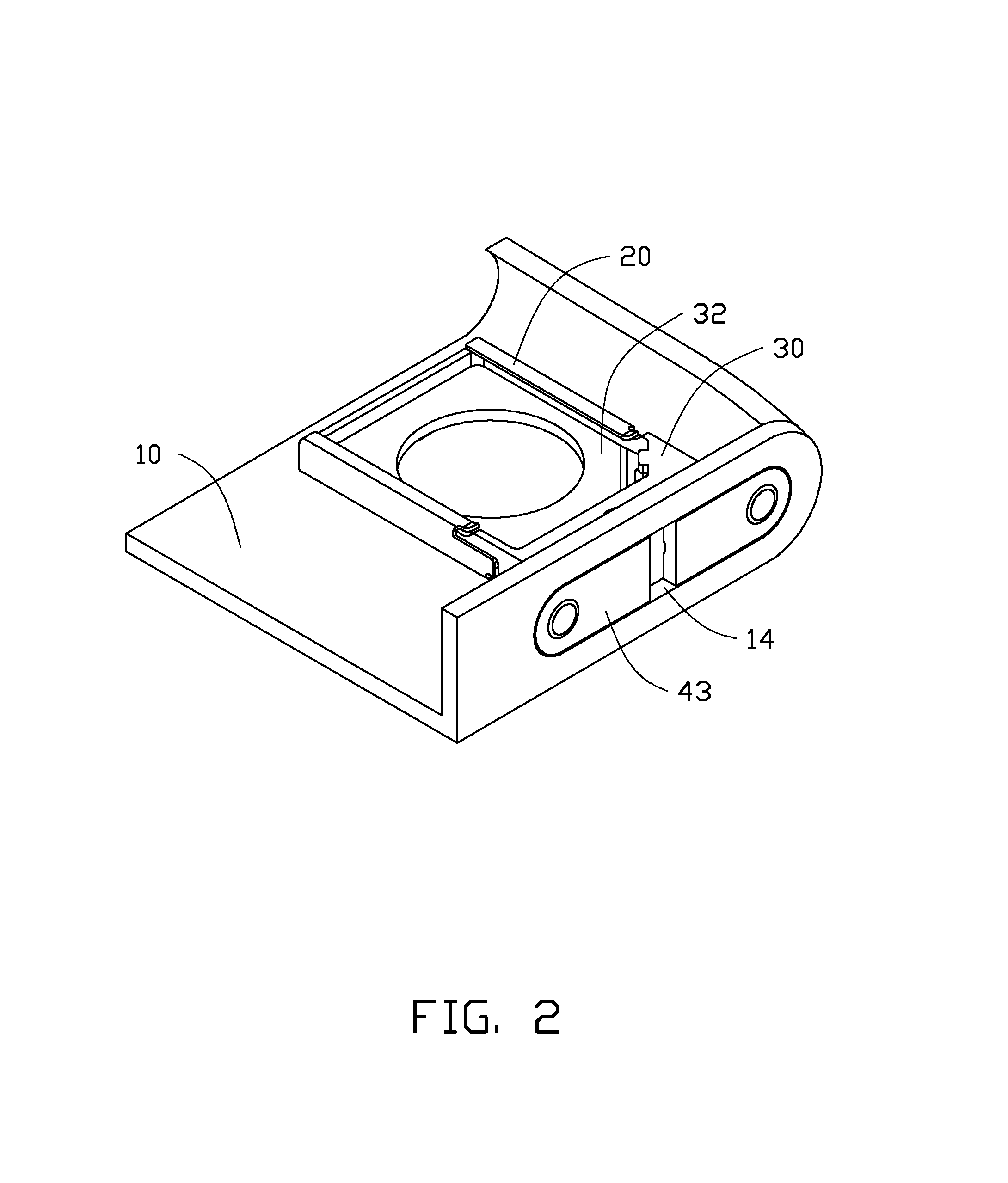

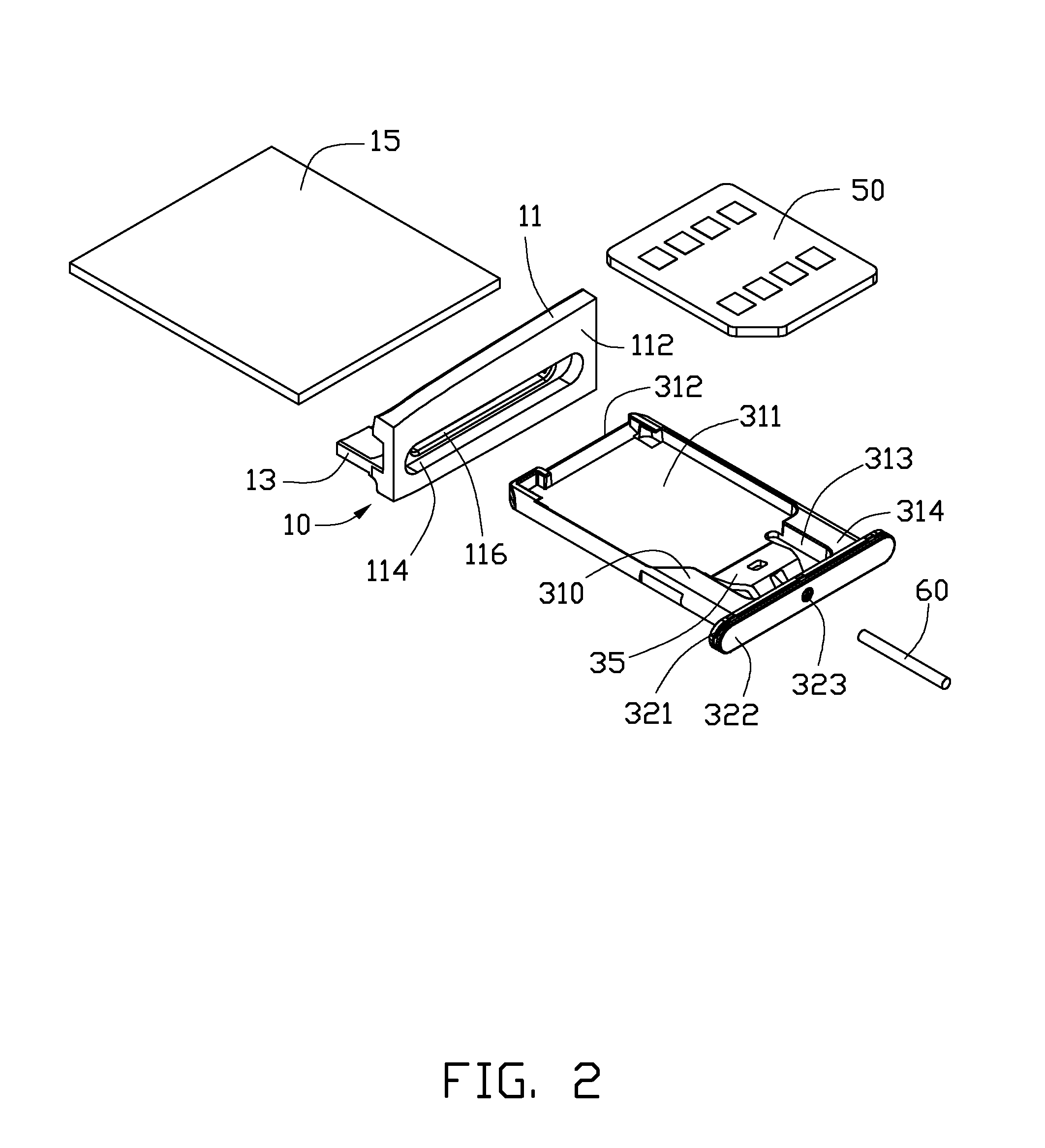

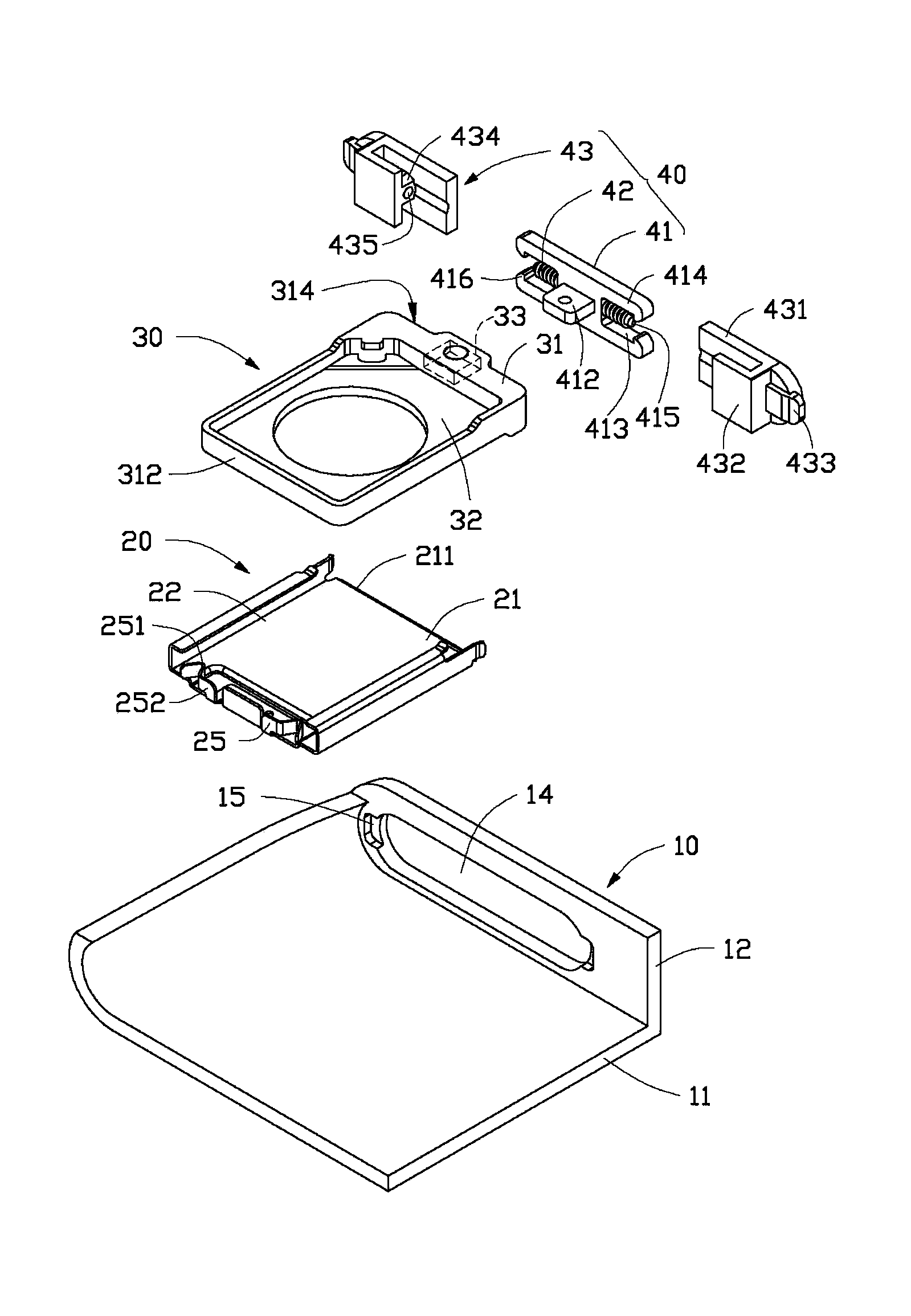

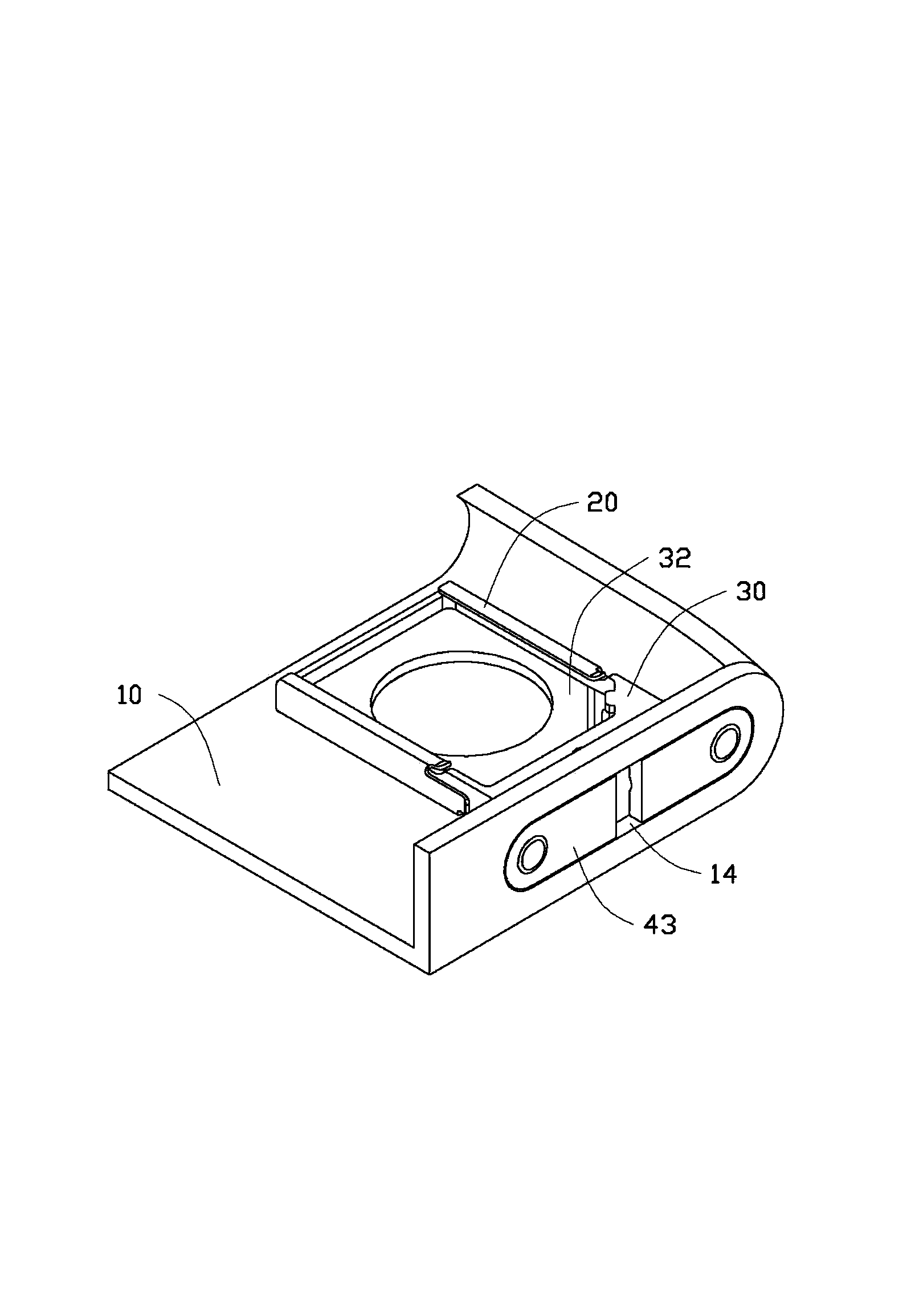

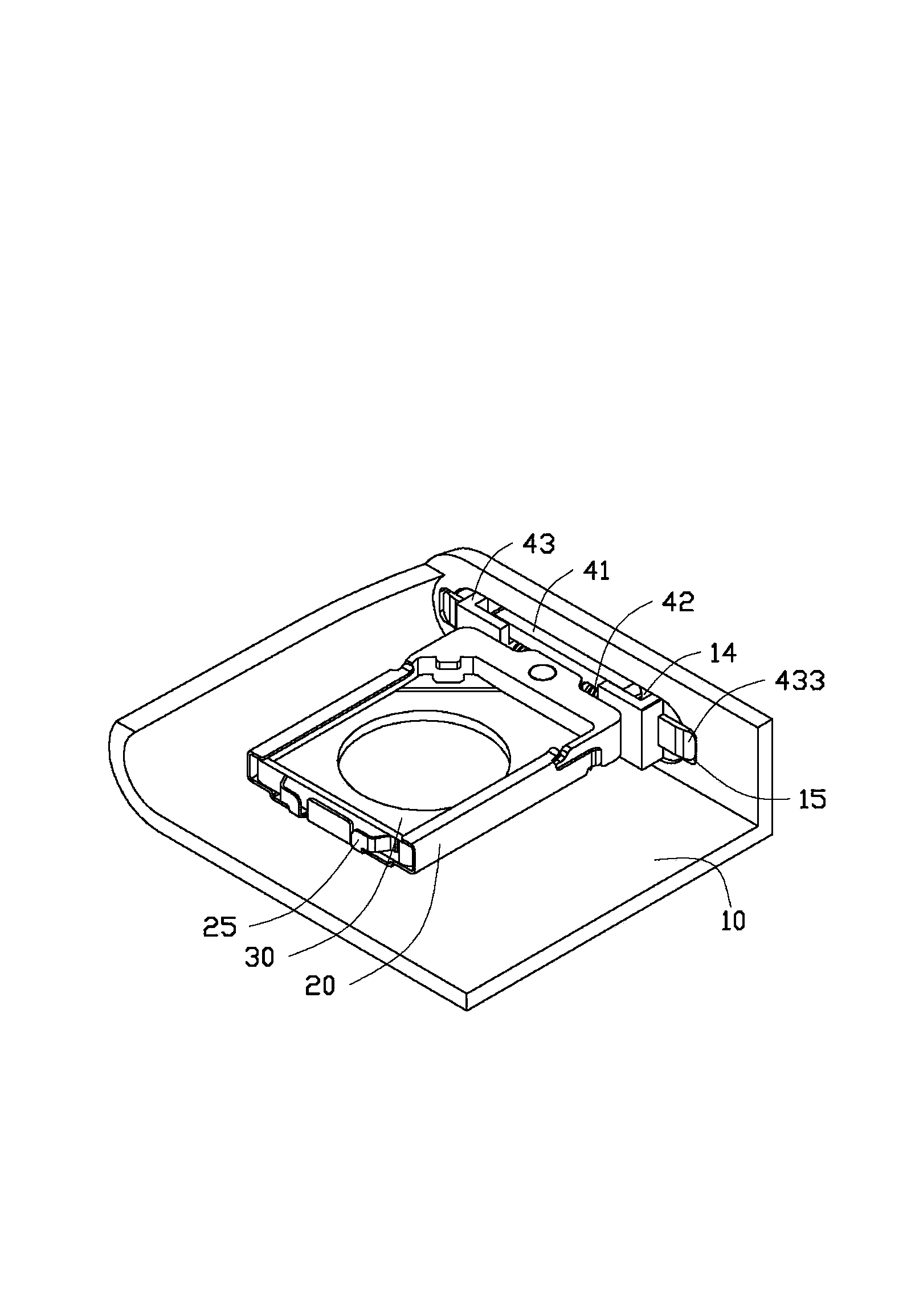

Chip card holder with protective cover for portable electronic devices

A chip card holder includes a housing, a receiving frame, an ejecting member, a tray, a protective cover, and two sliders. The housing defines a through hole and two latching grooves. The receiving frame is mounted on the housing. The ejecting member is positioned at one end of the receiving frame. The tray is slidably received in the receiving frame and abutted by the ejecting member. The protective cover is mounted to the tray and received in the through hole. The two sliders are slidably positioned on the protective cover and releasbly received in the latching grooves. When the two sliders slide relative to the protective cover and are unlocked from the housing, the ejecting member ejects the tray from the housing.

Owner:SHENZHEN FUTAIHONG PRECISION IND CO LTD +1

Manufacturing method of a packaging structure of electronic components

InactiveUS20100285636A1Increased complexityLow costMagnetic/electric field screeningSemiconductor/solid-state device detailsShell moldingEngineering

A manufacturing method of a packaging structure of electronic components includes the steps of: providing a substrate including a plurality of electronic components; covering the electronic components disposed on the substrate with a molding body; forming a plurality of pre-cut grooves on the molding body so as to define a plurality of molding units on the molding body; forming an electromagnet barrier layer covering the molding units on the molding units and the pre-cut grooves; and cutting along at least one of the pre-cut grooves deeply down to break the substrate so as to form separately a plurality of packaging structures of the electronic components.

Owner:ACSIP TECH

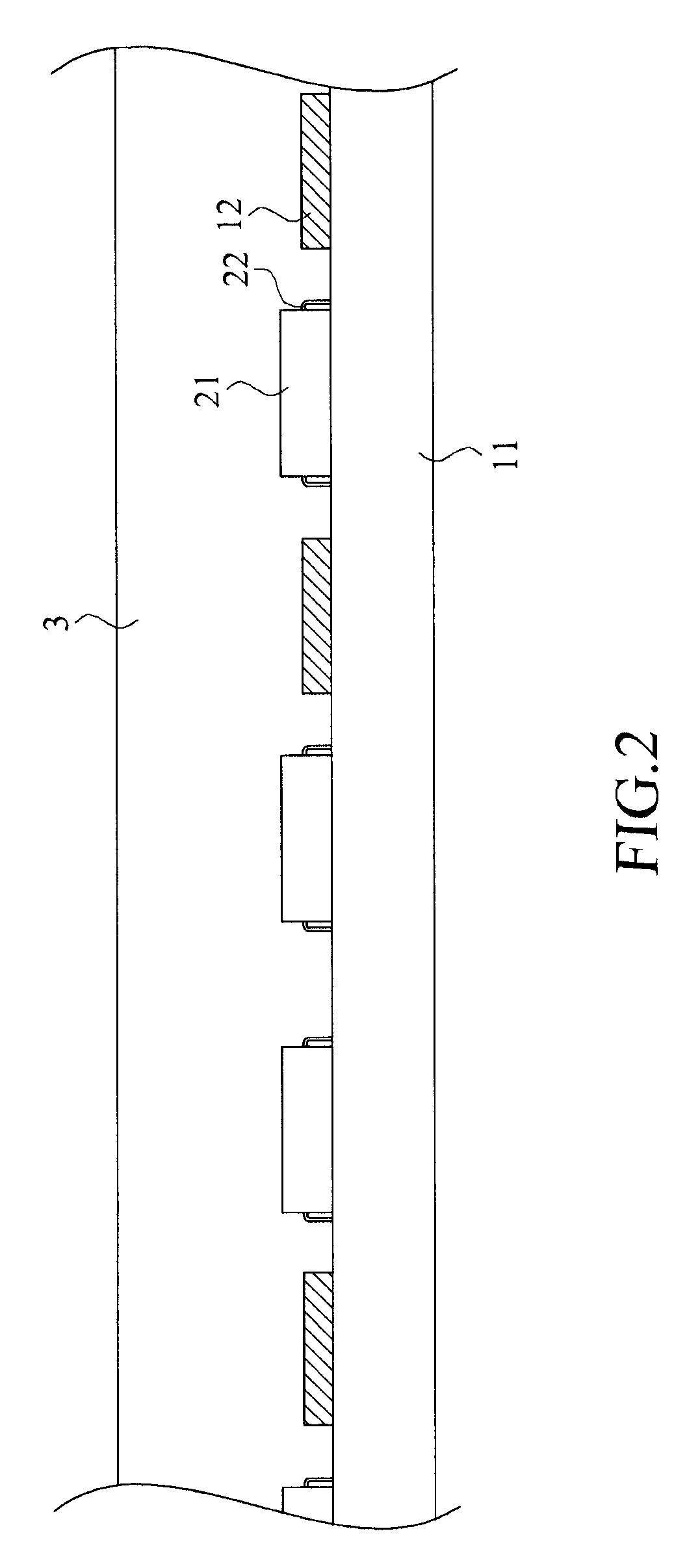

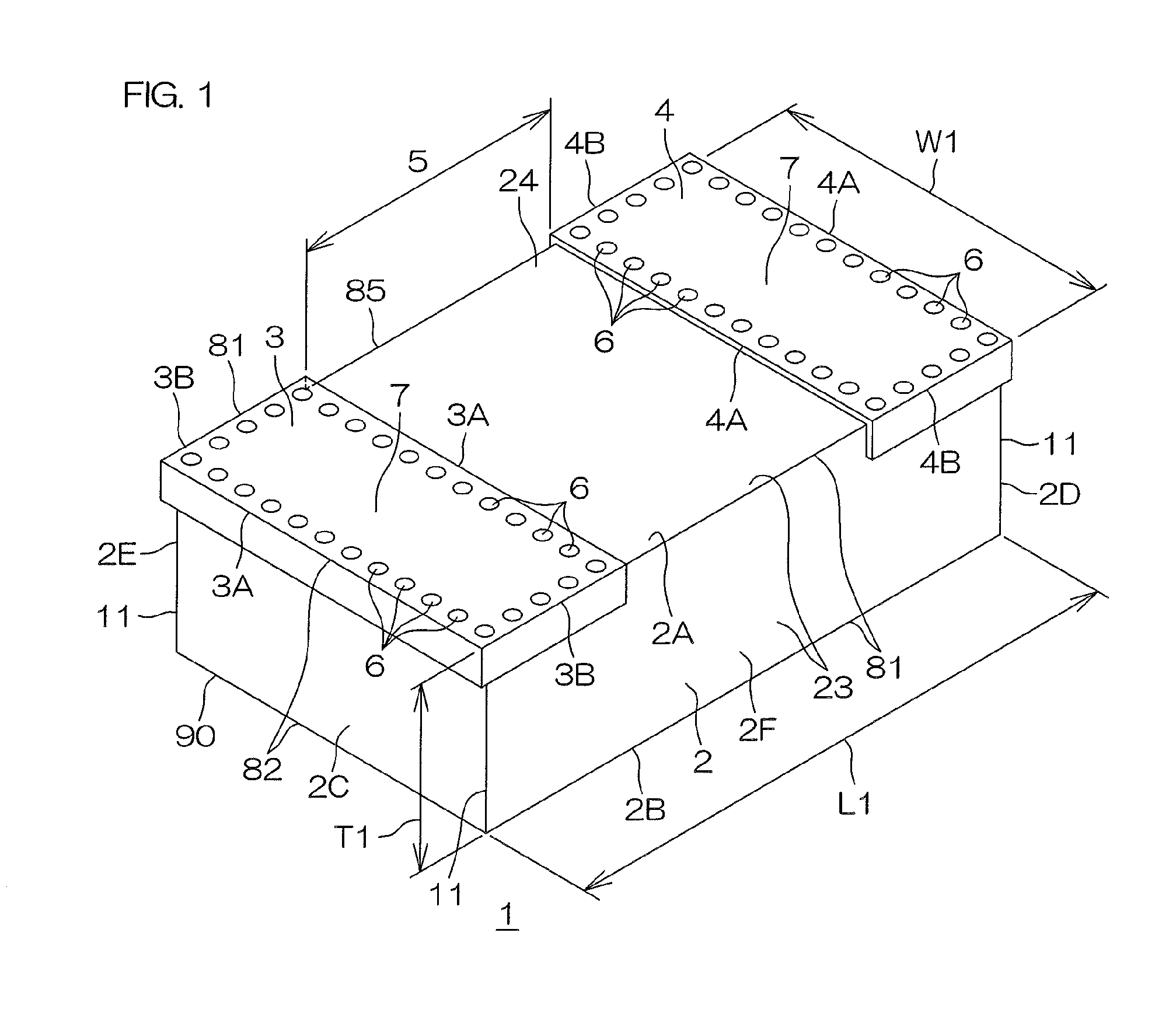

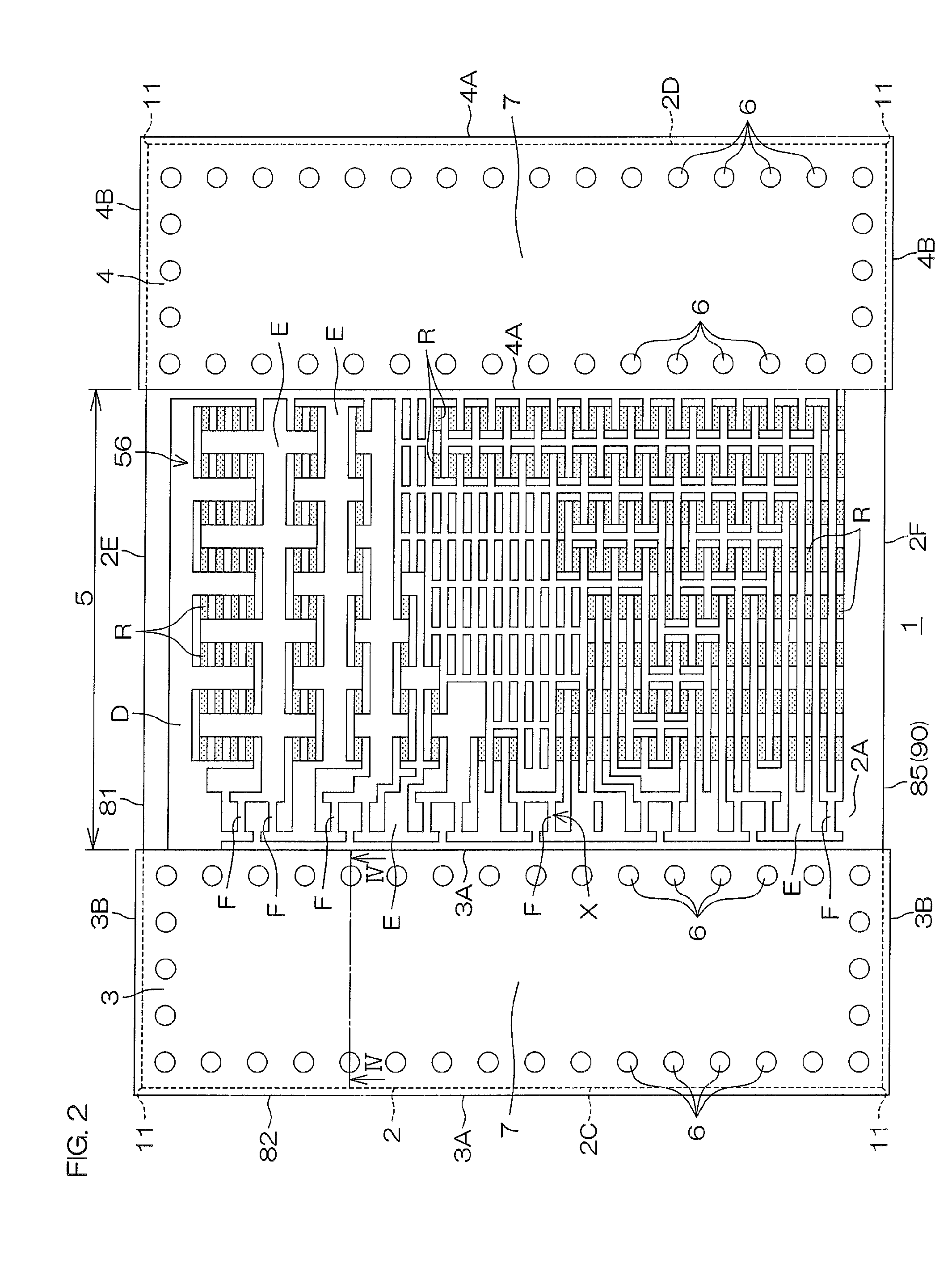

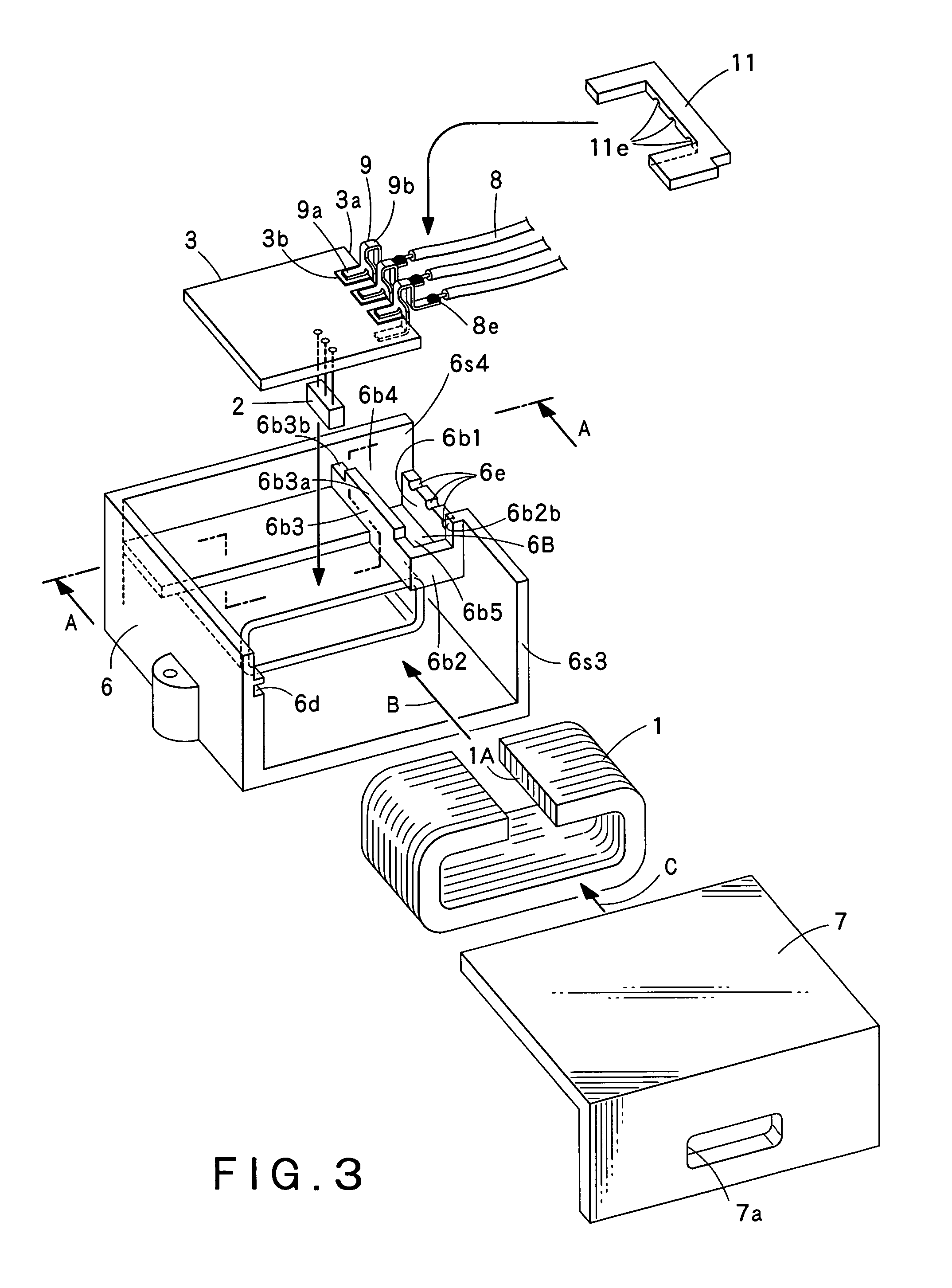

Circuit module and method of manufacturing the same

InactiveUS20130271928A1Permit thickness reductionStable functionPrinted circuit assemblingMagnetic/electric field screeningEngineeringConductive materials

Owner:TAIYO YUDEN KK

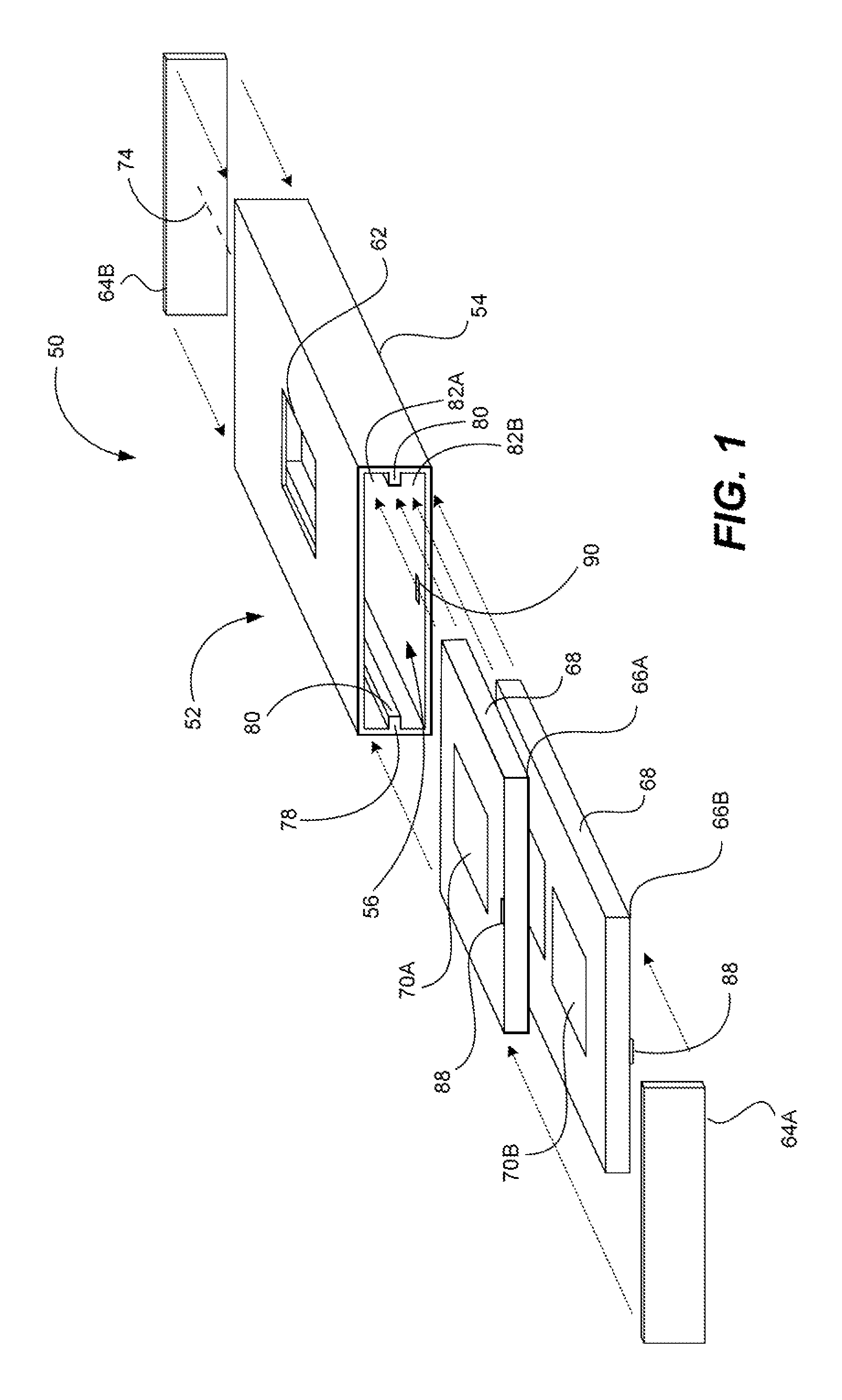

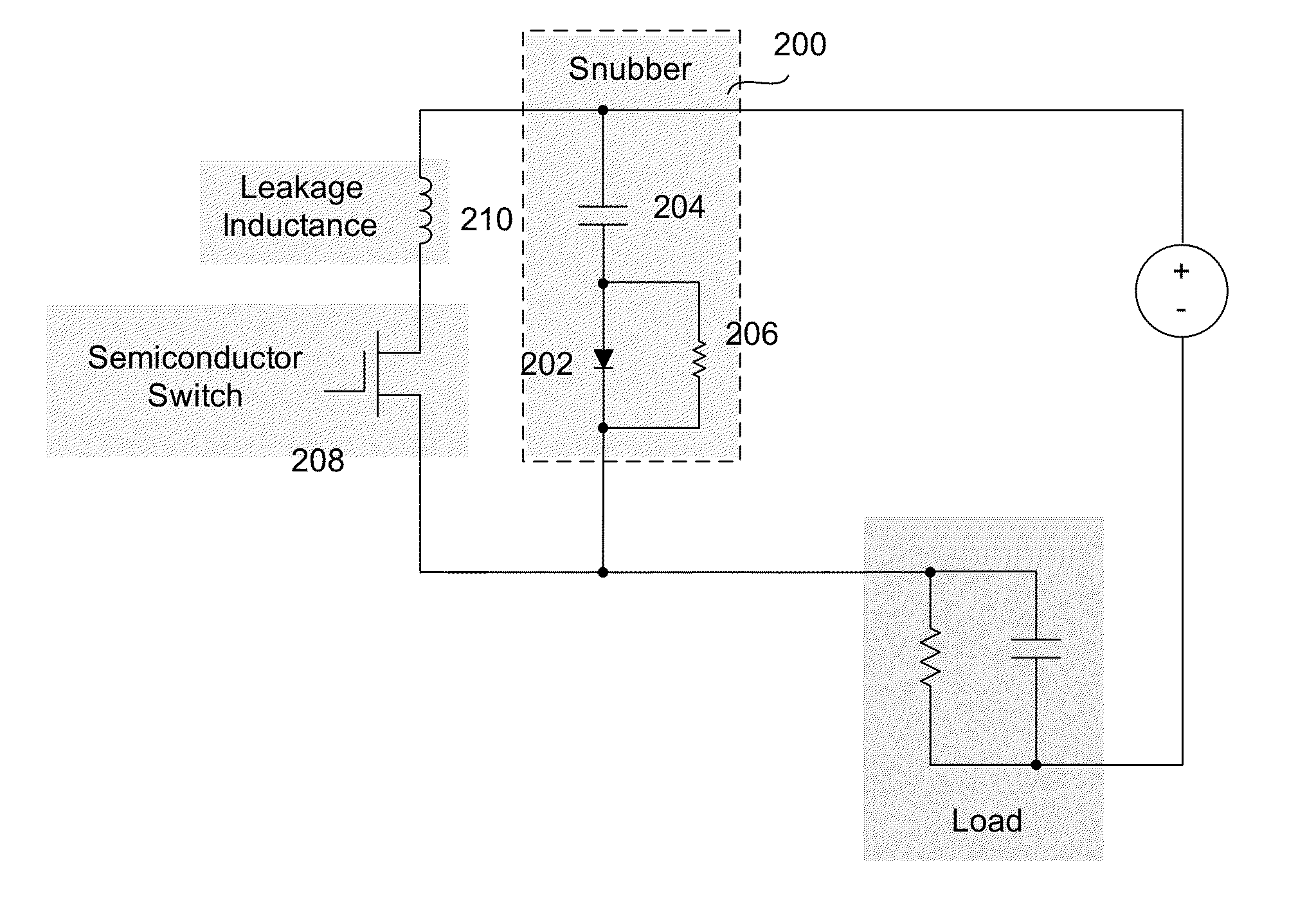

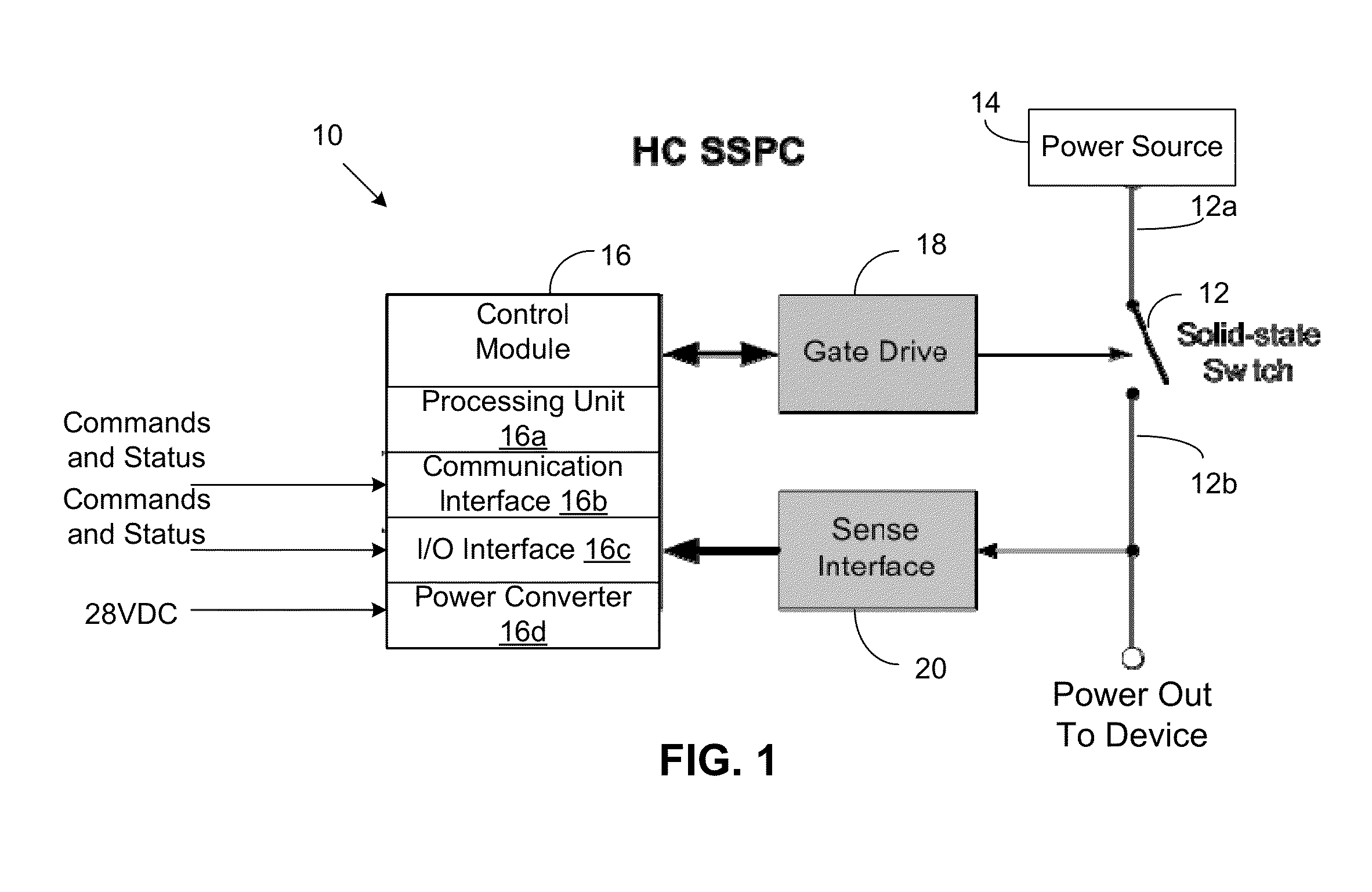

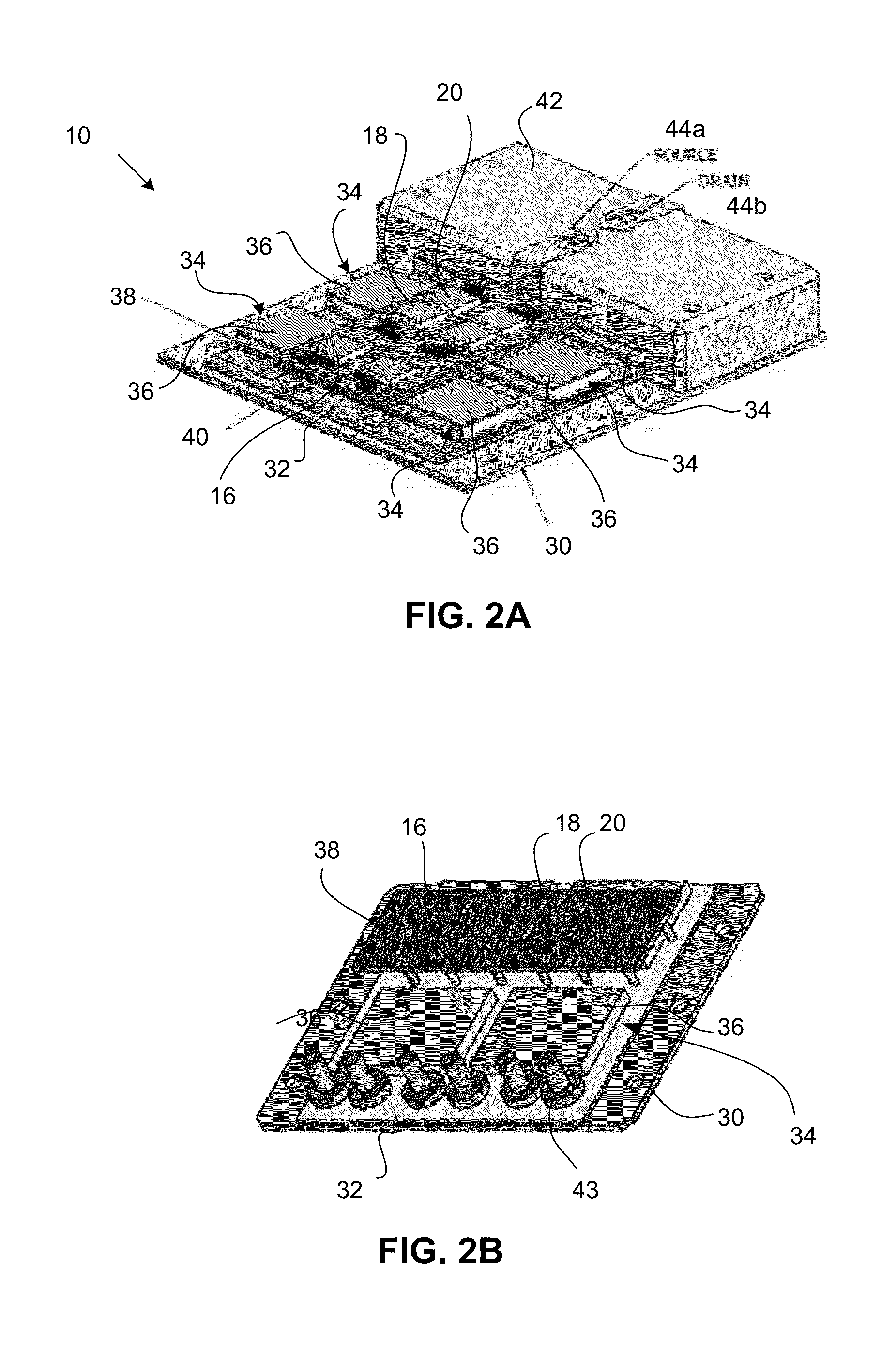

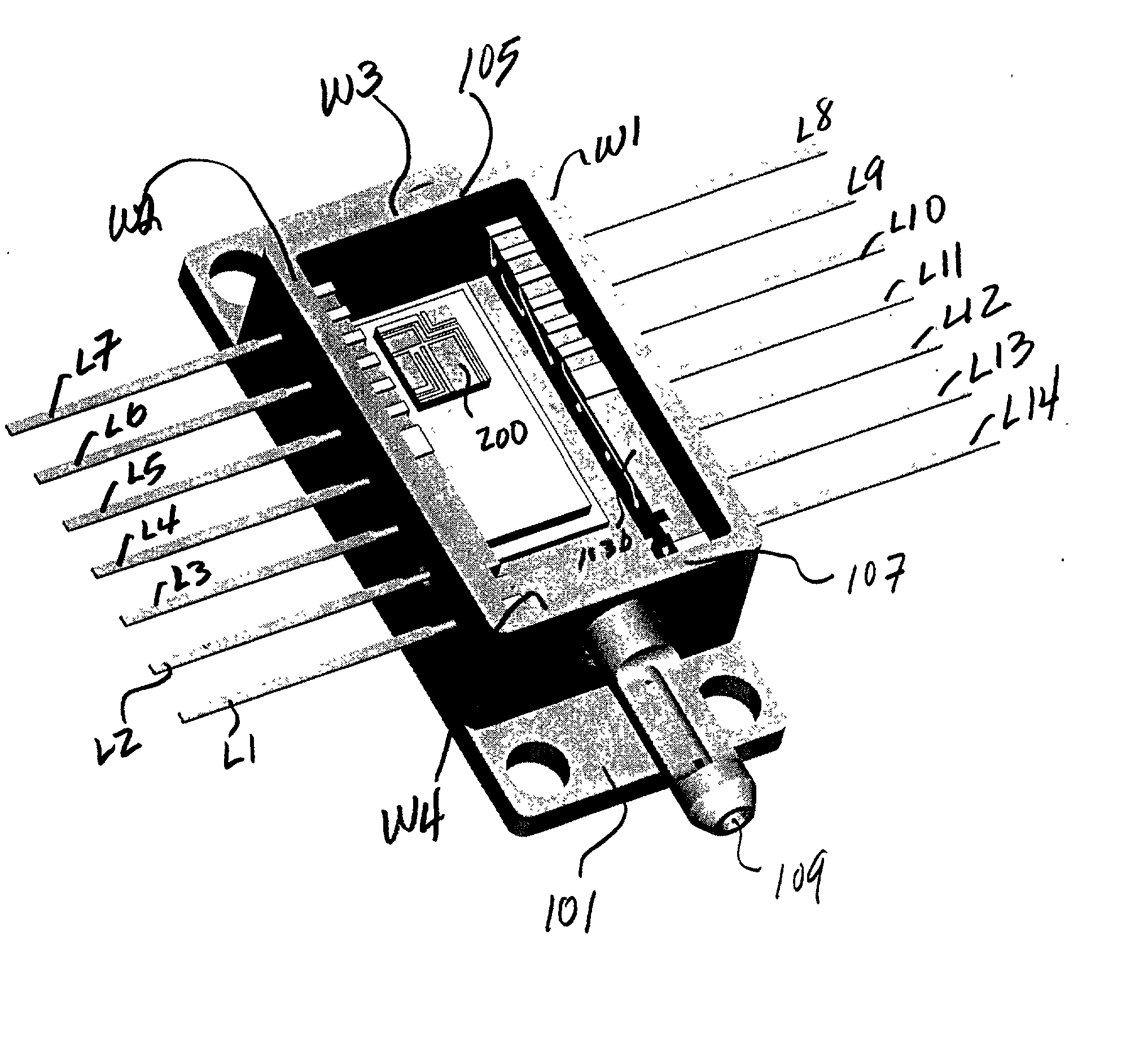

Hermetic high current solid state power controller

InactiveUS20150311815A1Less spaceIncrease rated powerConversion with intermediate conversion to dcConversion constructional detailsElectricityPower controller

A solid state power controller (SSPC) includes a support structure, and a first solid state power switch die arranged relative to the support structure, the solid state power switch die including a solid state power switch having an input terminal for connecting to a power source and an output terminal for providing power to an electrical component. A first gate driver is electrically coupled to the first solid state power switch die, and a control module is operatively coupled to the first gate driver. A hermetic enclosure surrounds at least the first solid state power switch die.

Owner:PARKER HANNIFIN CORP

Chip card holder for electronic device

InactiveUS20140362548A1Conveying record carriersDigital data processing detailsEngineeringCard holder

A chip card holder includes a housing, a receiving frame, a tray, and a pin. The housing defines a latching groove. The receiving frame is mounted to the housing, and the receiving frame includes at least one ejecting arm. The tray is slidably received in the receiving frame and defines a receiving groove configured for receiving a chip card. The tray includes a latching tongue. When the tray is received in the receiving frame, the latching tongue is latched in the latching groove, and the ejecting arm abuts against one end of the tray. The pin deforms the latching tongue to unlock the tray from the housing.

Owner:SHENZHEN FUTAIHONG PRECISION IND CO LTD +1

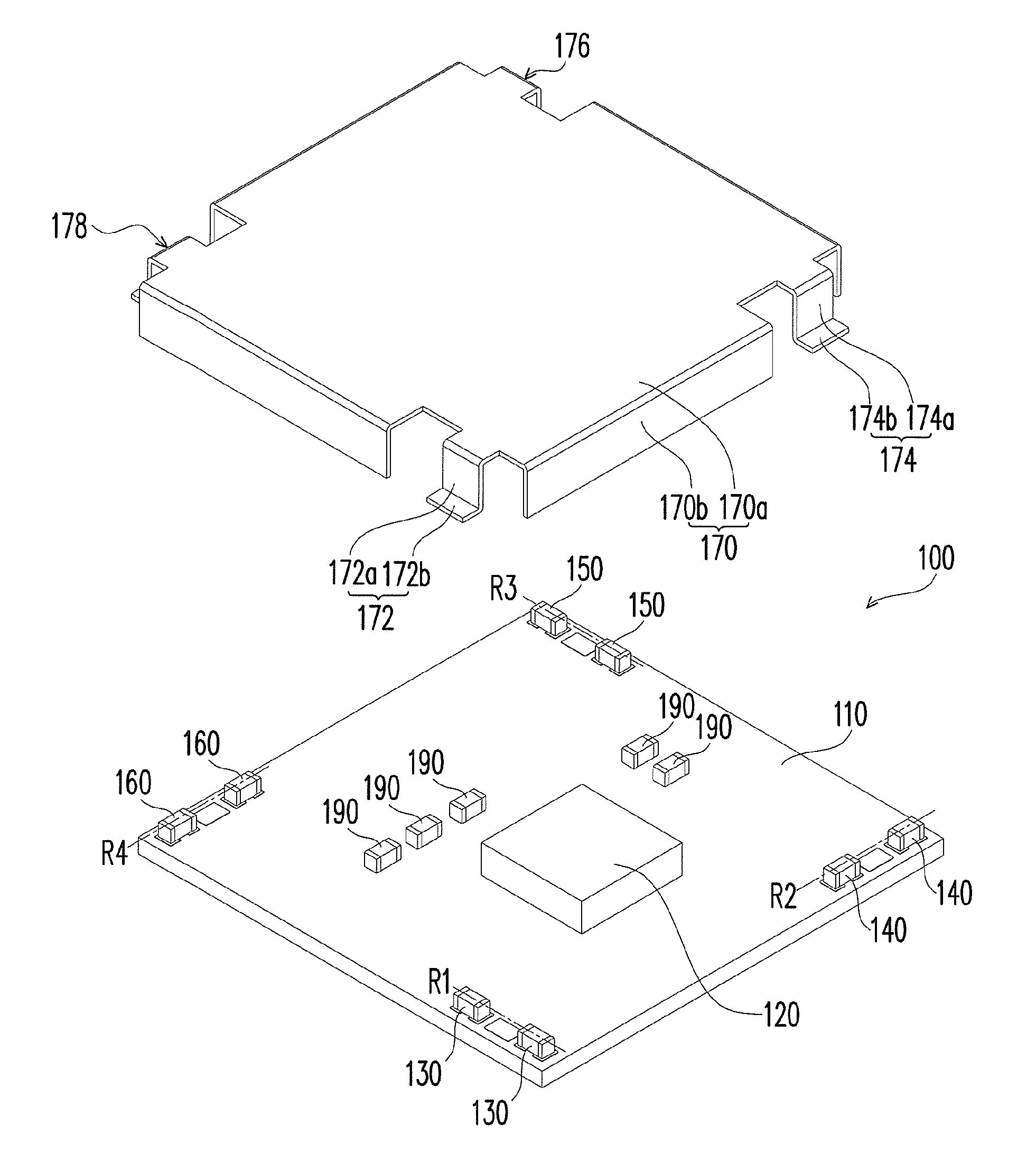

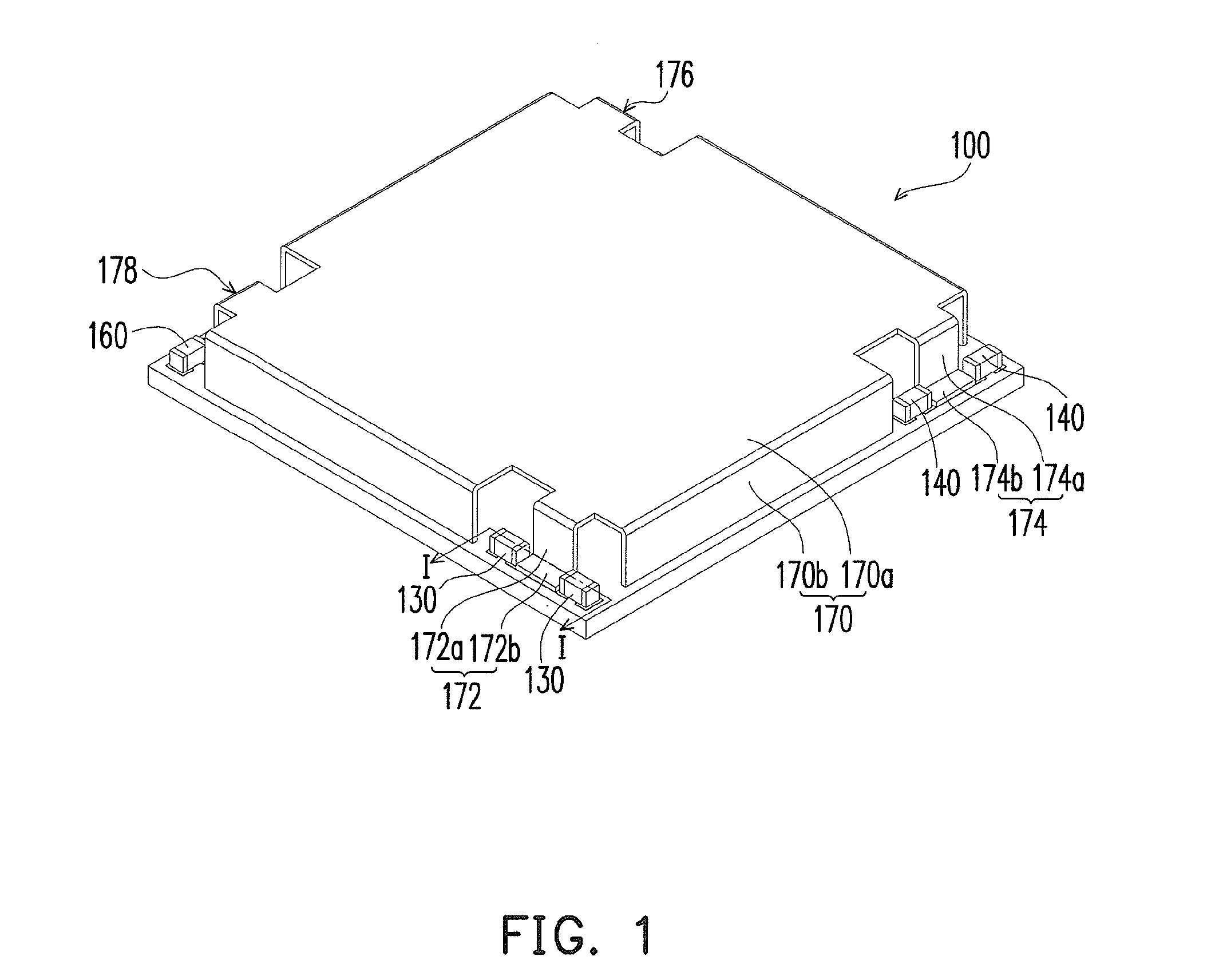

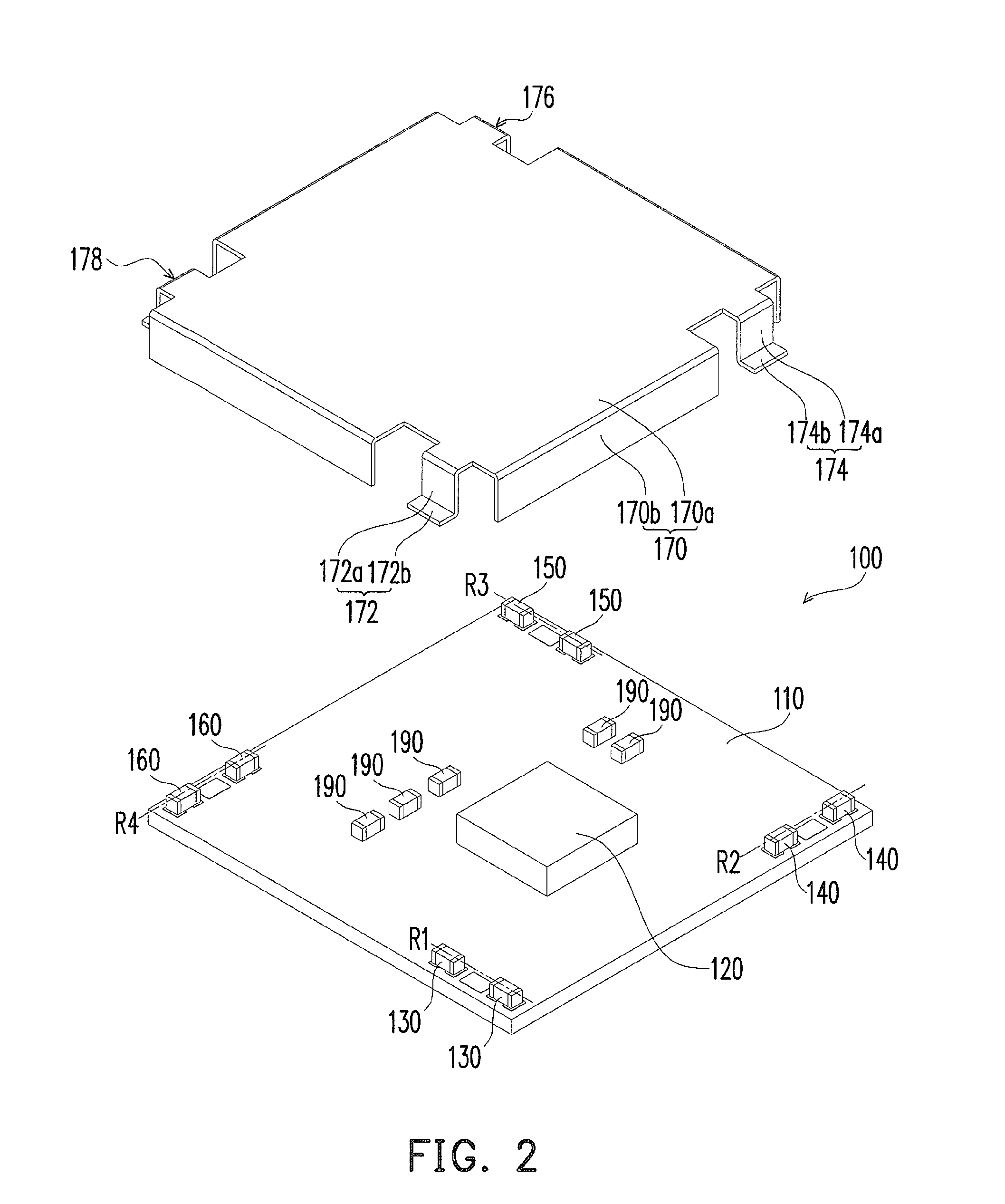

Chip package structure with shielding cover

ActiveUS20100085719A1Improve assembly yieldIncrease productionMagnetic/electric field screeningSemiconductor/solid-state device detailsElectrical and Electronics engineering

A chip package structure with a shielding cover includes a substrate, a chip, a pair of first passive components, a pair of second passive components, and a shielding cover. The chip, the pair of first passive components, the pair of second passive components, and the shielding cover are disposed on the substrate. The chip is electrically connected to the substrate. The shielding cover covers the chip and has leads connected to the substrate. The leads include a first lead and a second lead. The first lead connected to a portion of the substrate is located between the pair of first passive components and arranged along a first axis with the pair of first passive components. The second lead connected to a portion of the substrate is located between the pair of second passive components and arranged along a second axis with the pair of second passive components.

Owner:ADVANCED SEMICON ENG INC

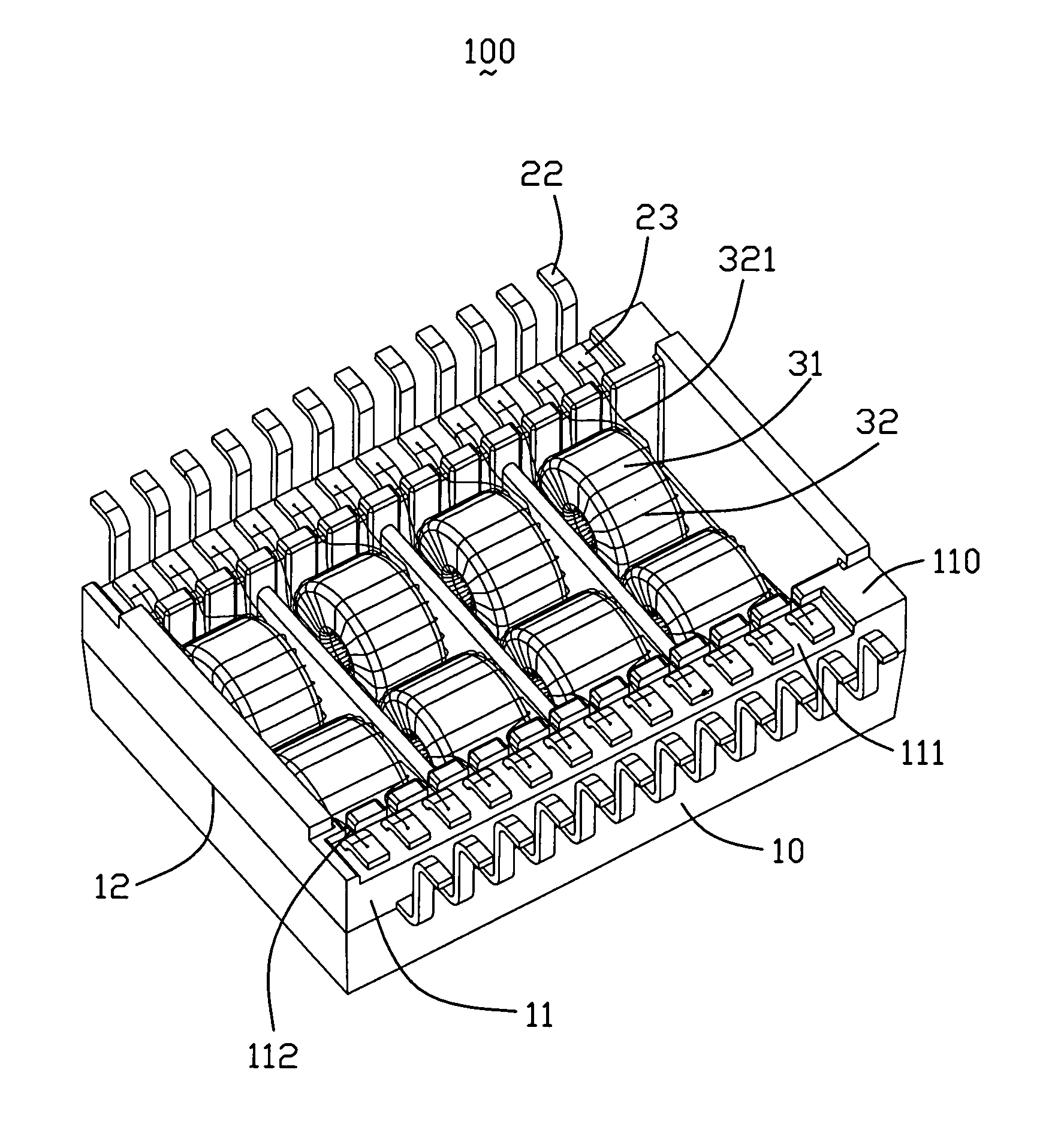

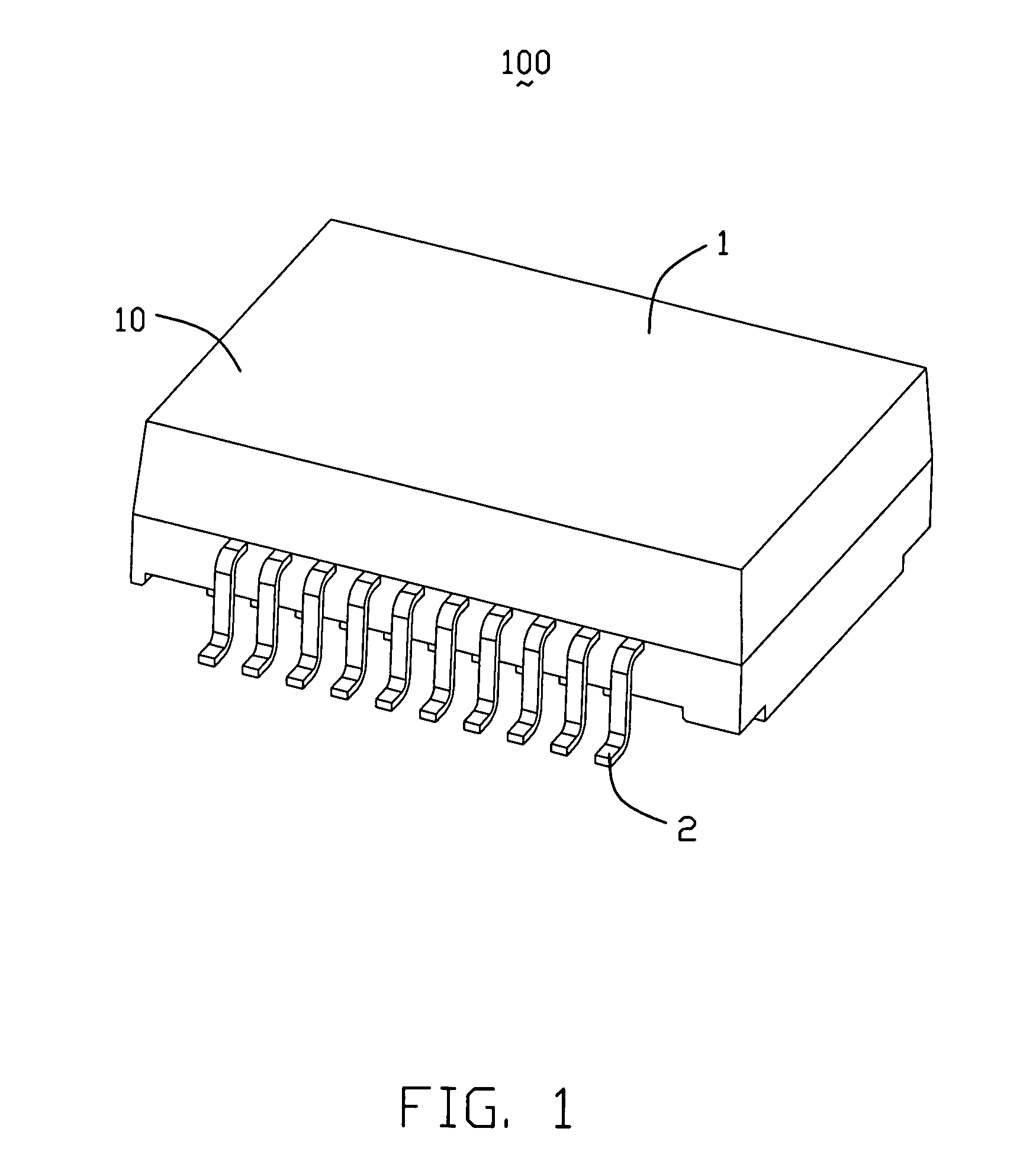

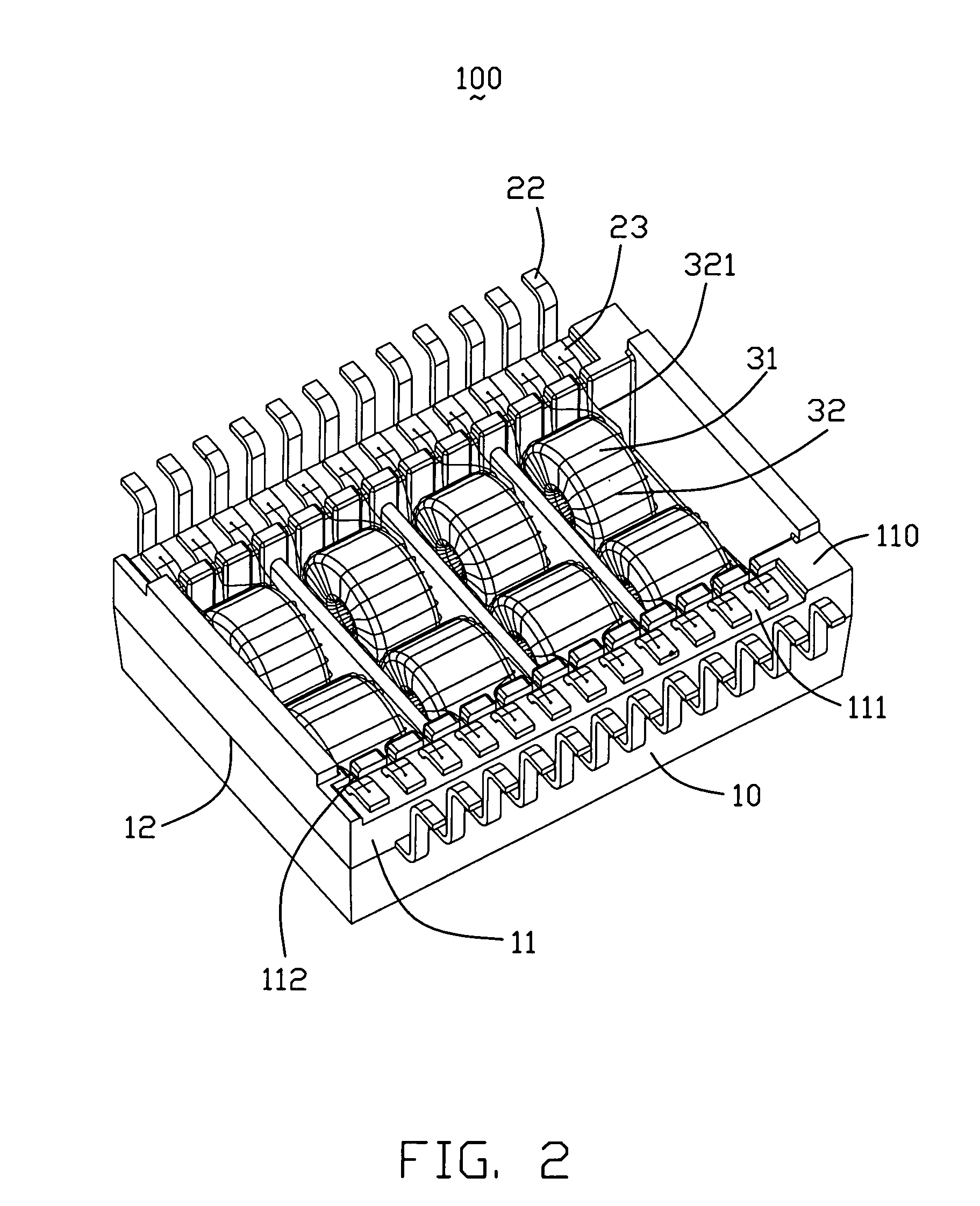

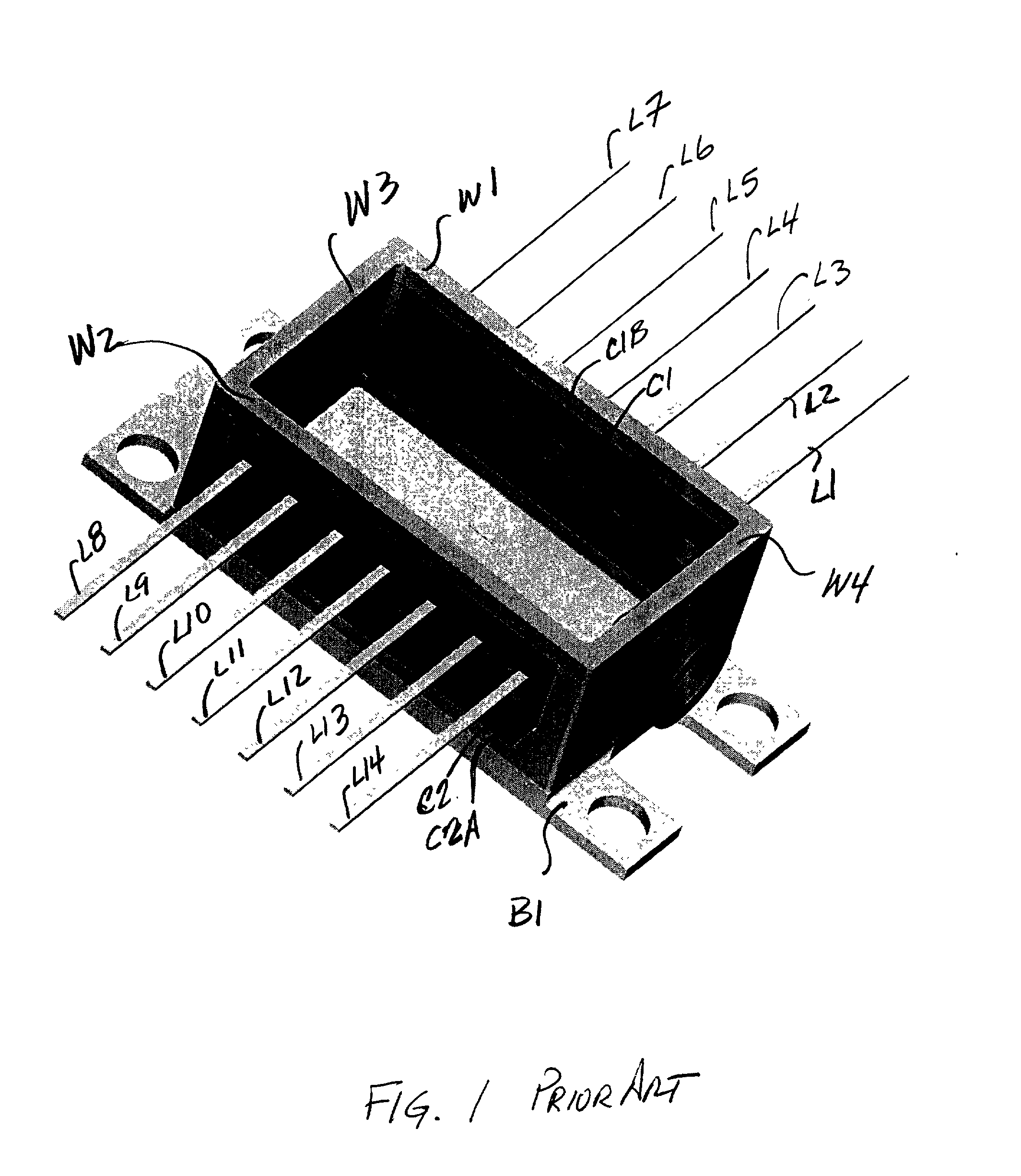

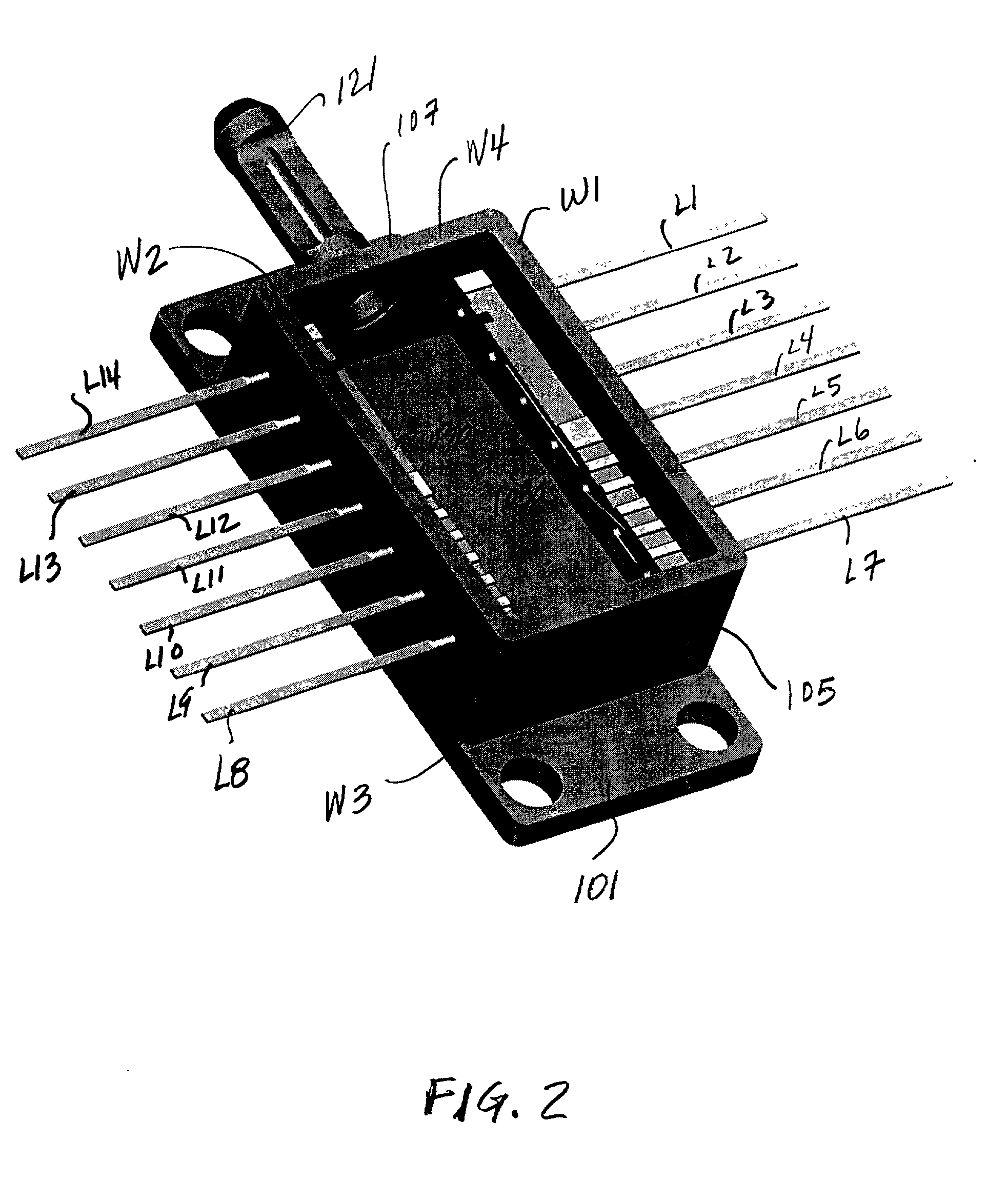

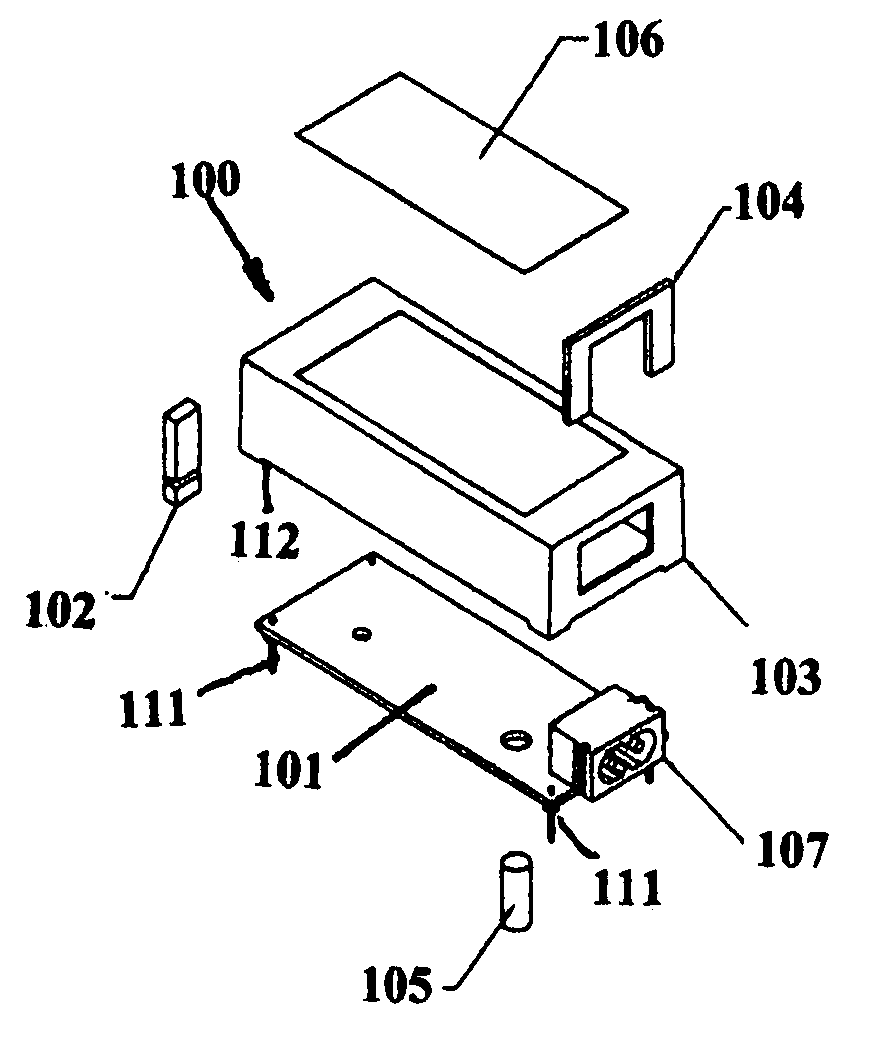

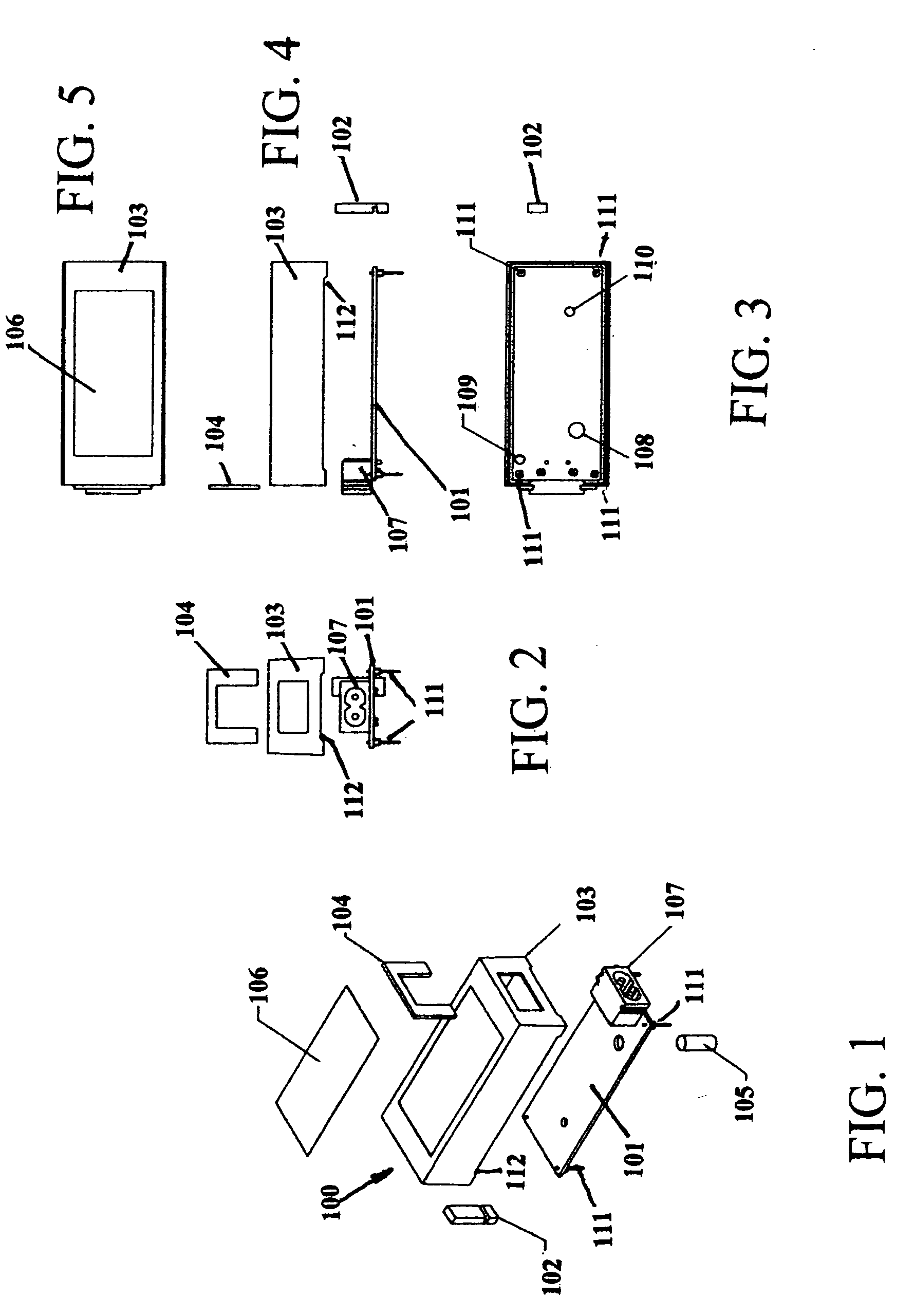

Electrical component and method for making the same

InactiveUS7948771B2Easy to assembleEasy to weldWave amplification devicesTransformers/inductances detailsEngineeringElectrical element

An electrical component (100) includes a housing (1), a number of terminals (2) molded within housing and at least one electrical element (3). The housing has at least a side wall (11) having a number of recesses (112) and an internal cavity (15). Each terminal has a first end (23) extending to a bottom of the side wall and formed with a platform portion (231) located onto the bottom of the side wall and aligned with the corresponding recess. The electrical element has a number of wires (321) wrapped thereon. One end of the wire extends outward the cavity through the recess and is soldered onto the corresponding platform portion.

Owner:HON HAI PRECISION IND CO LTD

Mobile phone case

ActiveCN104780241AImprove corrosion resistanceAppearance has no effectAnodisationSynthetic resin layered productsNanometreNanopore

A shell, a method of preparing the shell and an electronic product comprising the shell are provided. The shell may comprise: a metal shell body, a plastic part made of a resin, and an oxide layer formed between the metal body and the plastic part, joining the plastic part to the metal shell body, wherein the oxide layer contains corrosion pores having an average diameter of about 200 nm to about 2000 nm in the surface contacting the plastic part, and nanopores having a diameter of about 10 to 100 nm in the surface contacting the metal shell body, and a part of the resin is filled in the corrosion pore and corrosion pore.

Owner:BYD CO LTD

Hermetically sealed package

InactiveUS20030068907A1Secure positioningSemiconductor/solid-state device detailsSolid-state devicesDirect touchHermetic seal

A package embodying the invention includes a base plate for receiving an electronic device having input / output points to be connected to an external system. Side walls mounted on the base plate enclose the electronic device. Selected side walls have a plurality of hermetically sealed openings through which are passed conductive leads which extend from within the package to outside the package for connecting the electronic device to the external system. A ceramic insert is mounted on the inside of at least one of the side walls. The ceramic insert has a first set of holes (terminals) for the direct contacting and connection thereto of selected conductive leads. The ceramic insert also has a second set of terminals whose layout is customized for optimally connecting selected ones of the second set of terminals to selected input / output points of the electronic device. The ceramic insert also includes a custom designed conductive pattern interconnecting selected ones of the first and second set of terminals.

Owner:CIT GRP BUSINESS CREDIT

Chip card fixture structure and electronic device with same

A chip card holder includes a housing, a receiving frame, an ejecting member, a tray, a protective cover, and two sliders. The housing defines a through hole and two latching grooves. The receiving frame is mounted on the housing. The ejecting member is positioned at one end of the receiving frame. The tray is slidably received in the receiving frame and abutted by the ejecting member. The protective cover is mounted to the tray and received in the through hole. The two sliders are slidably positioned on the protective cover and releasbly received in the latching grooves. When the two sliders slide relative to the protective cover and are unlocked from the housing, the ejecting member ejects the tray from the housing.

Owner:SHENZHEN FUTAIHONG PRECISION IND CO LTD

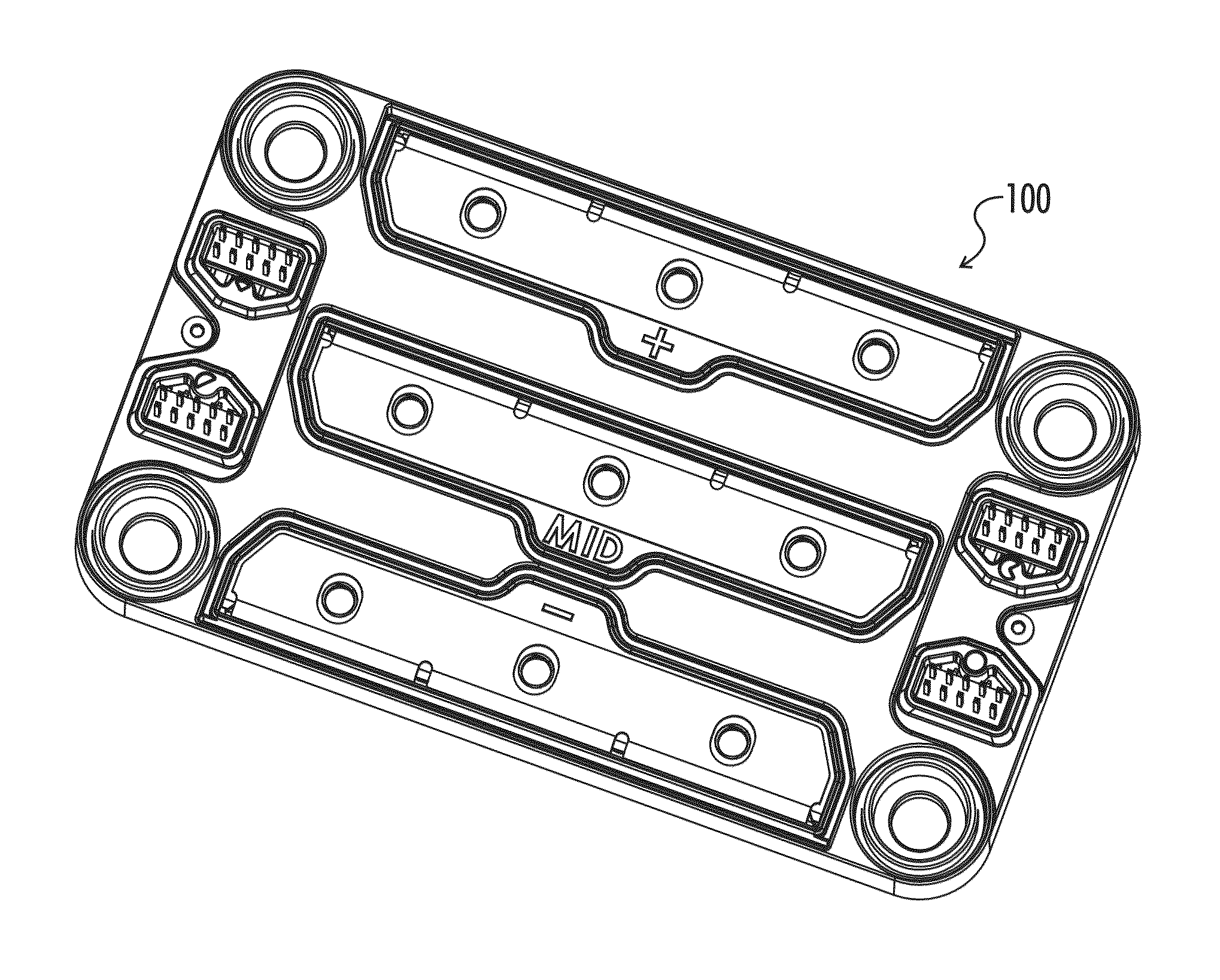

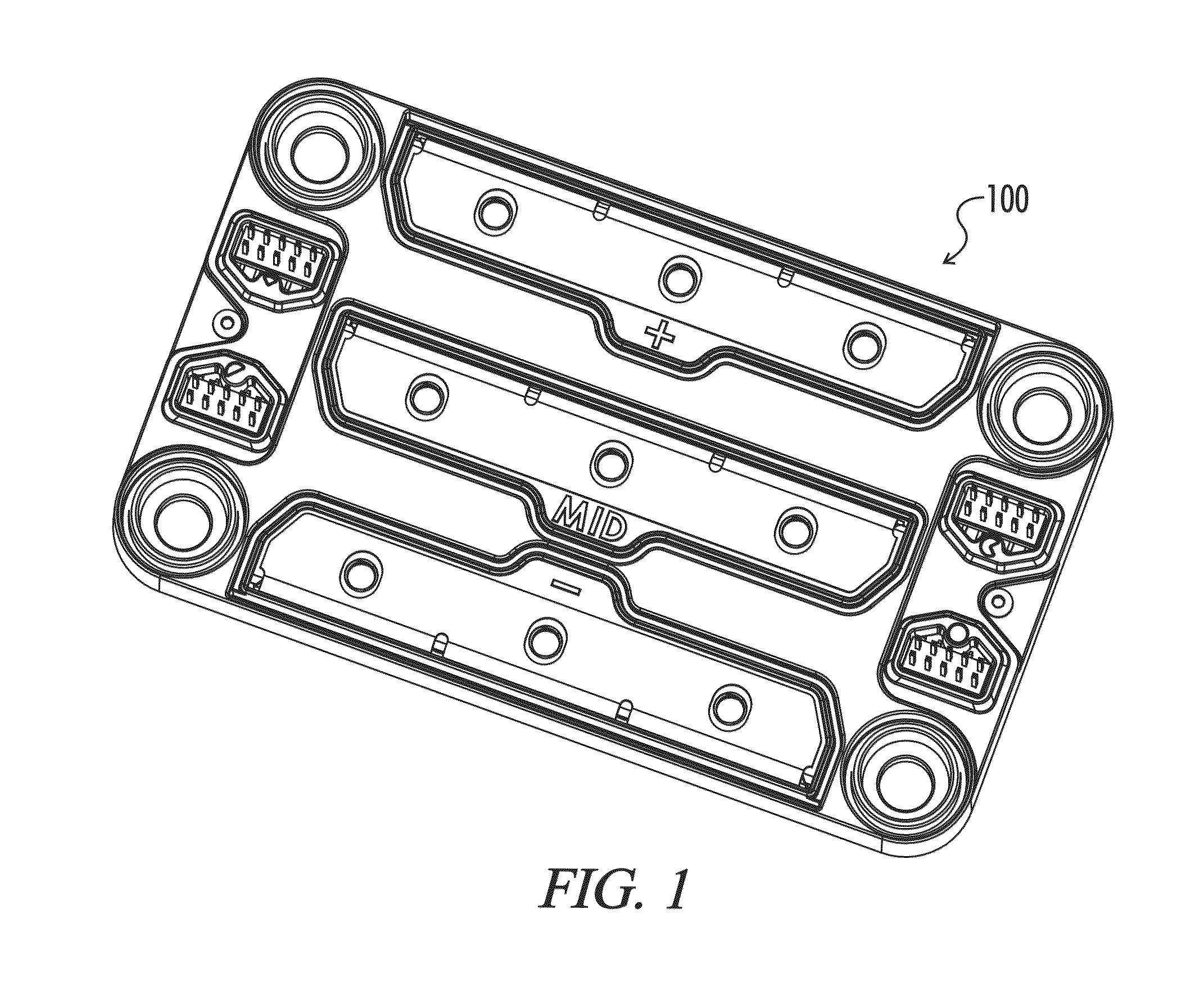

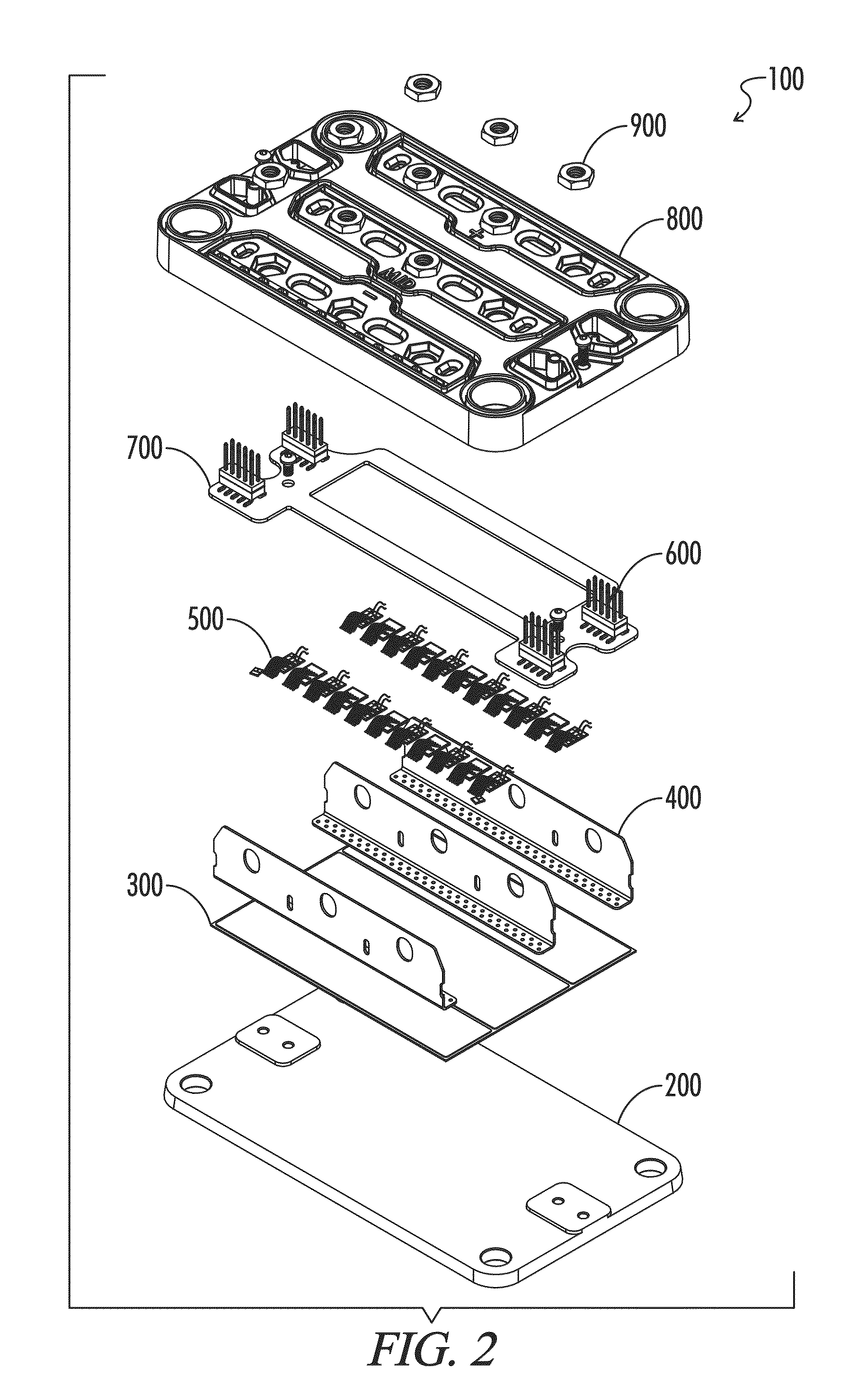

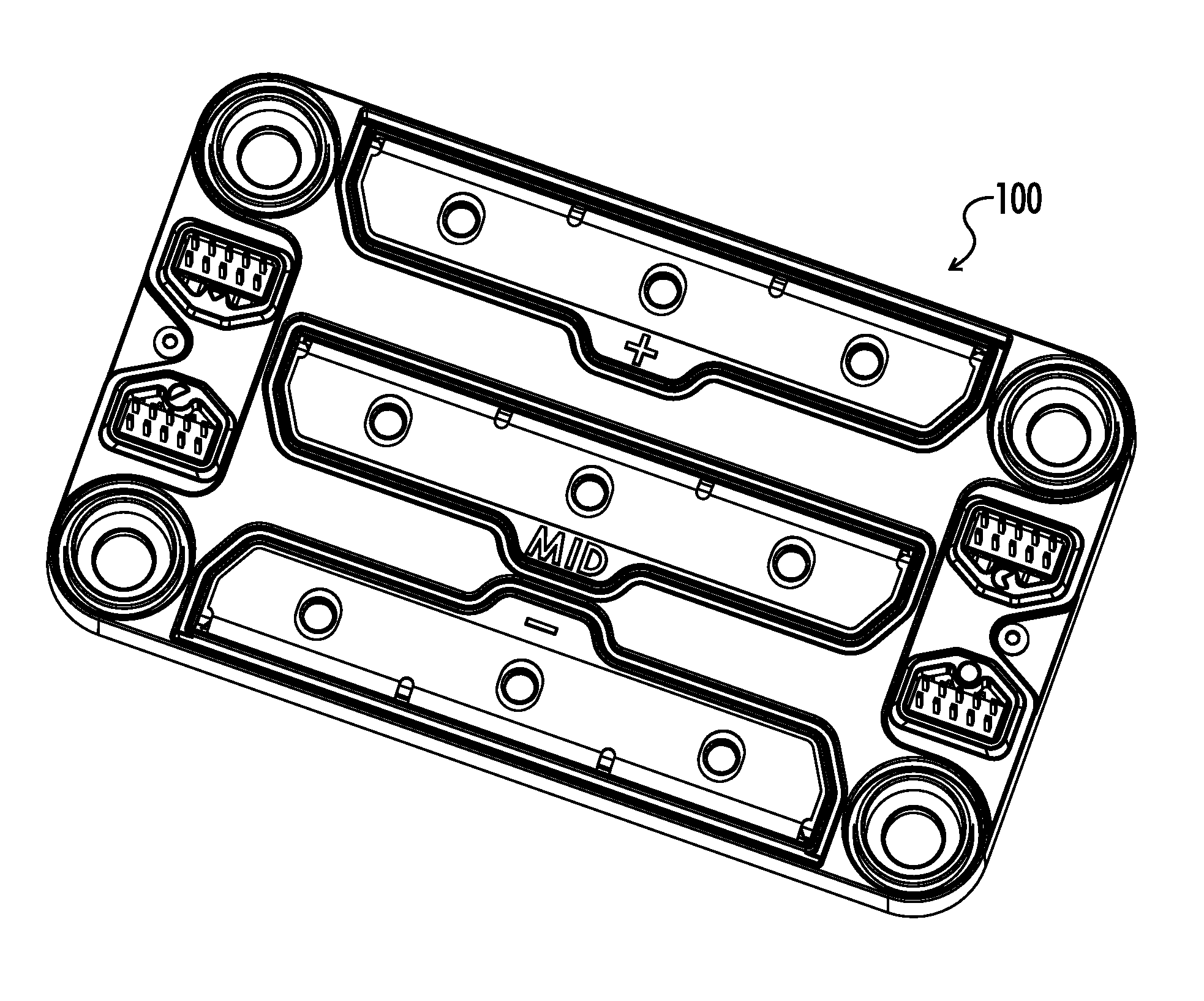

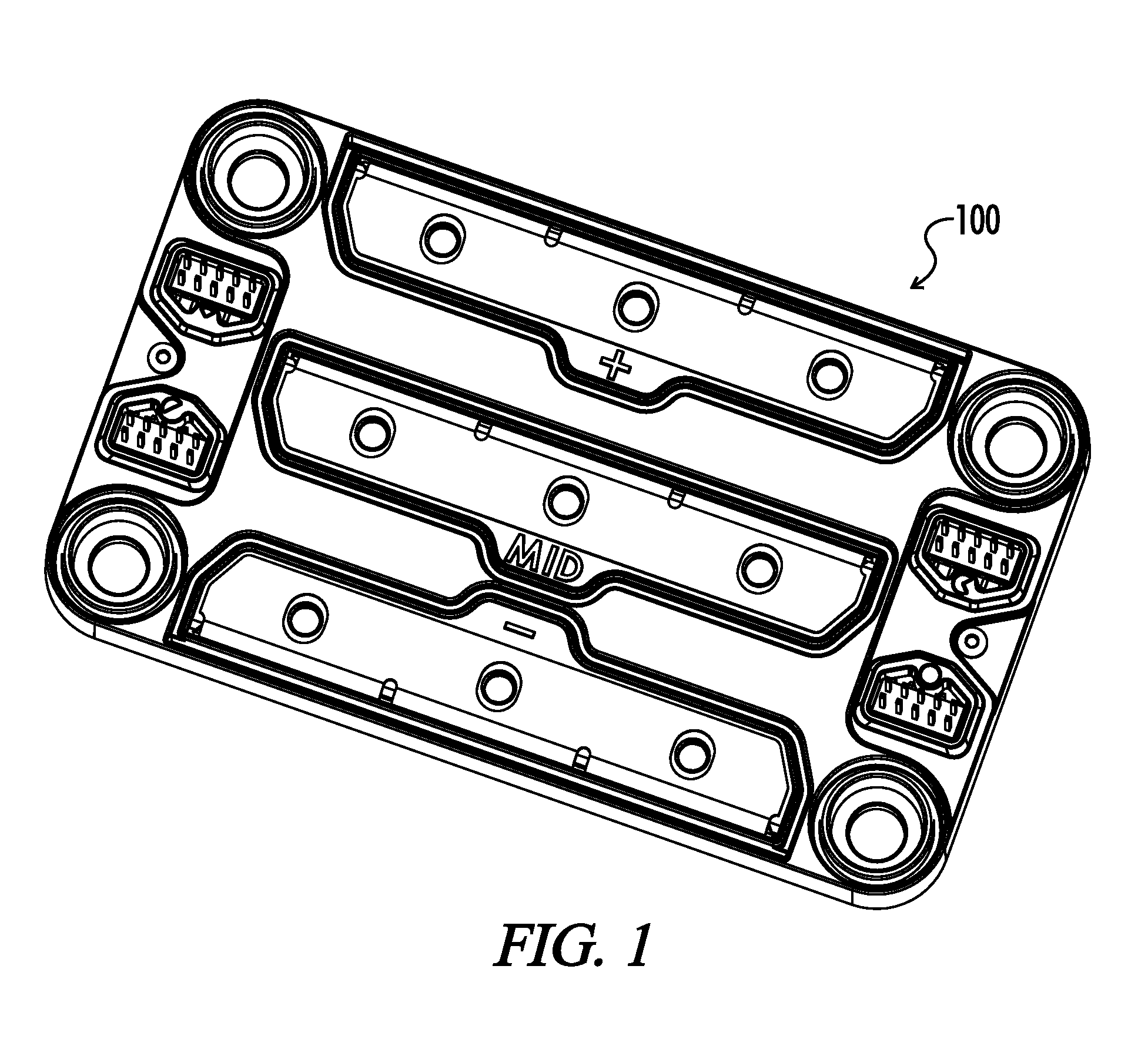

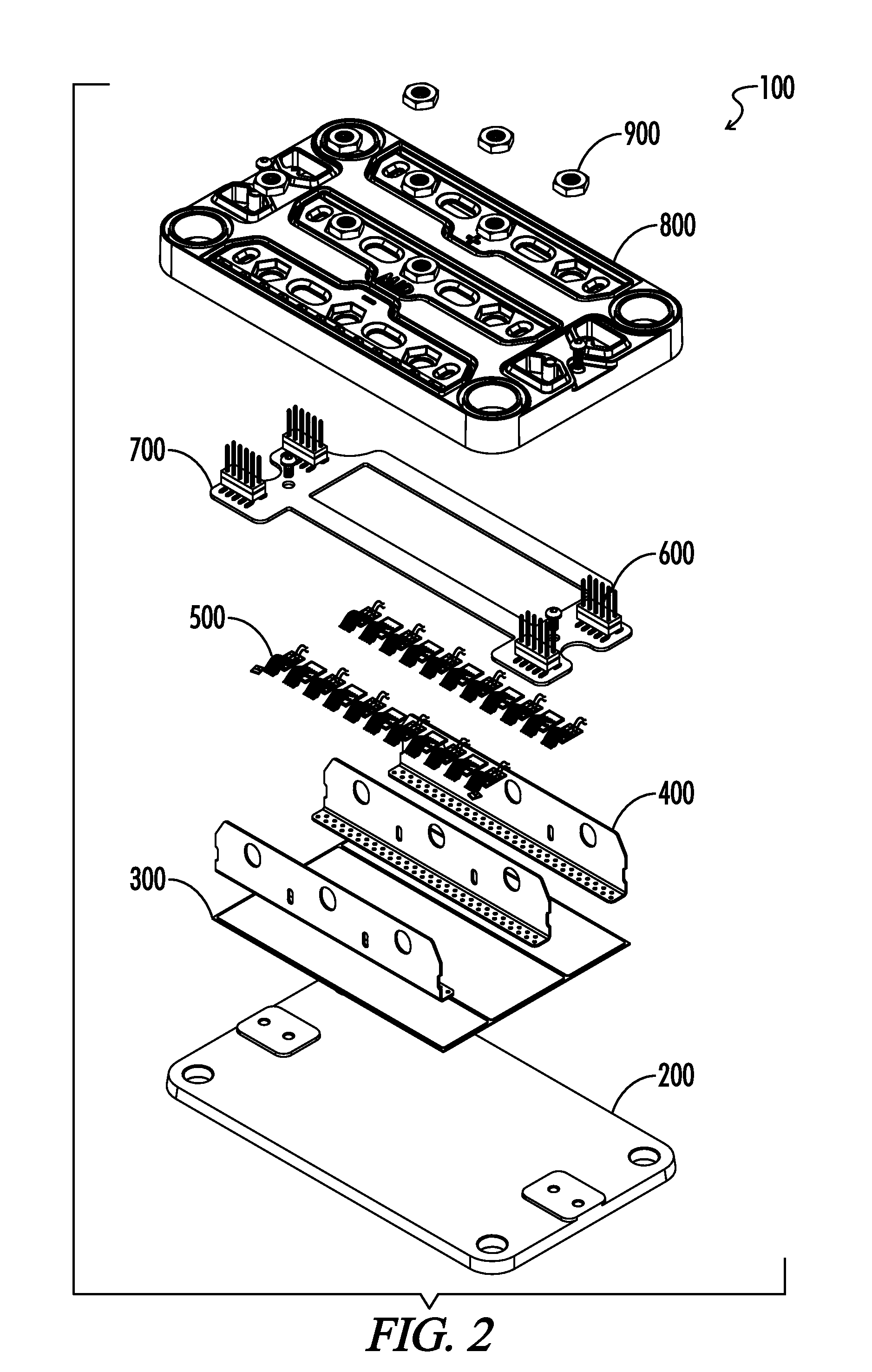

Low profile, highly configurable, current sharing paralleled wide band gap power device power module

ActiveUS9426883B2Closed casingsSemiconductor/solid-state device detailsElectrical conductorFull bridge

Owner:WOLFSPEED INC

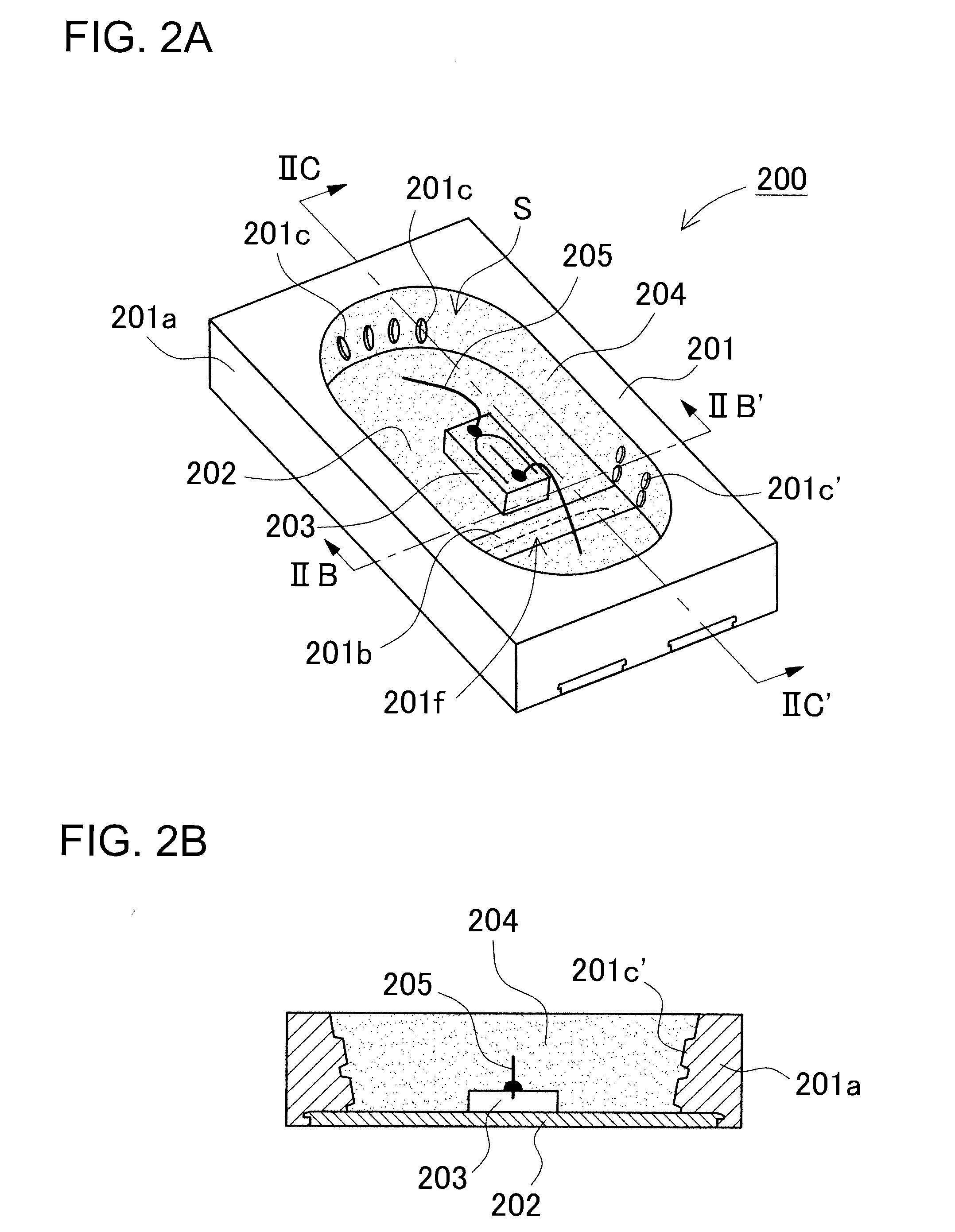

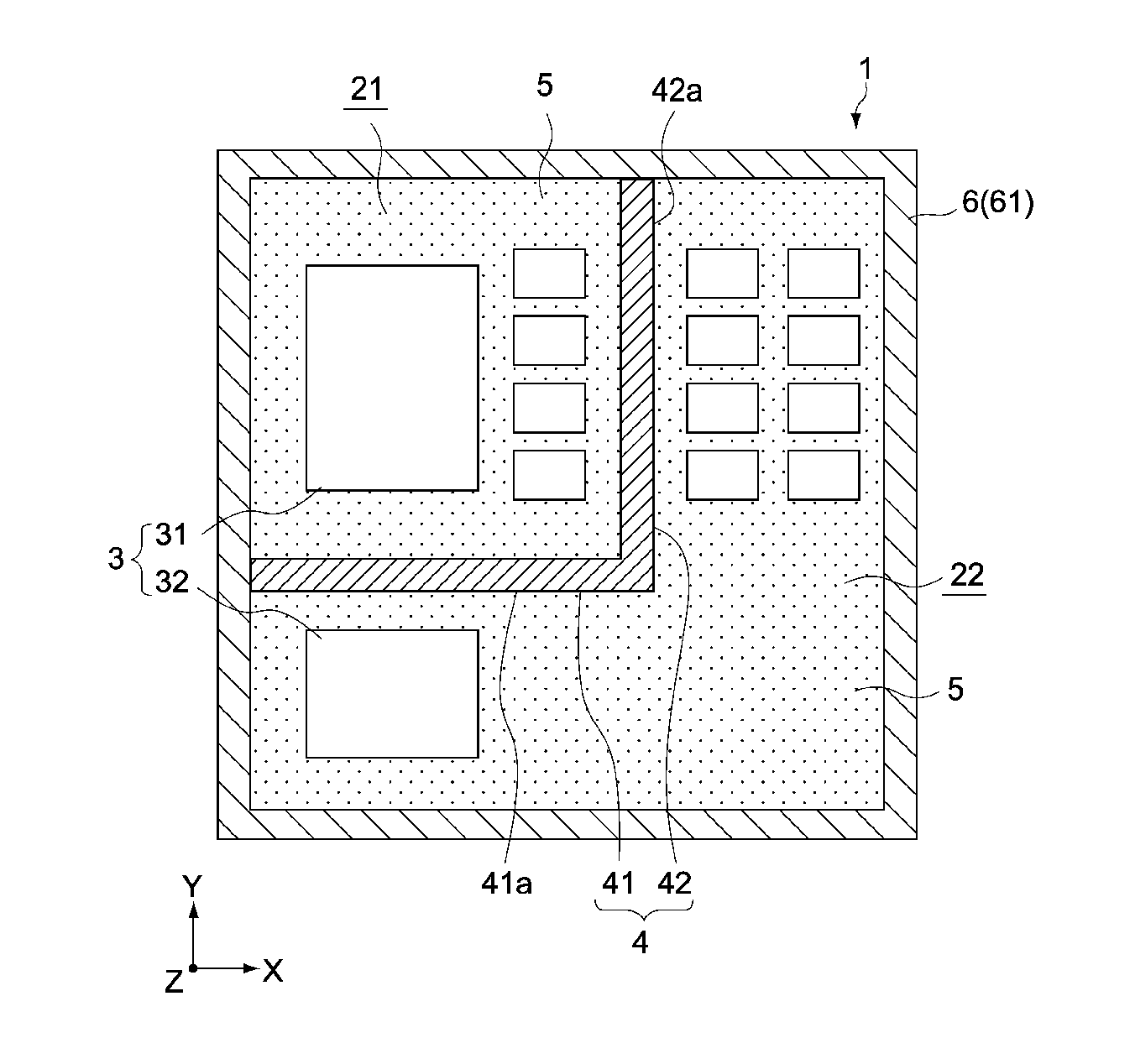

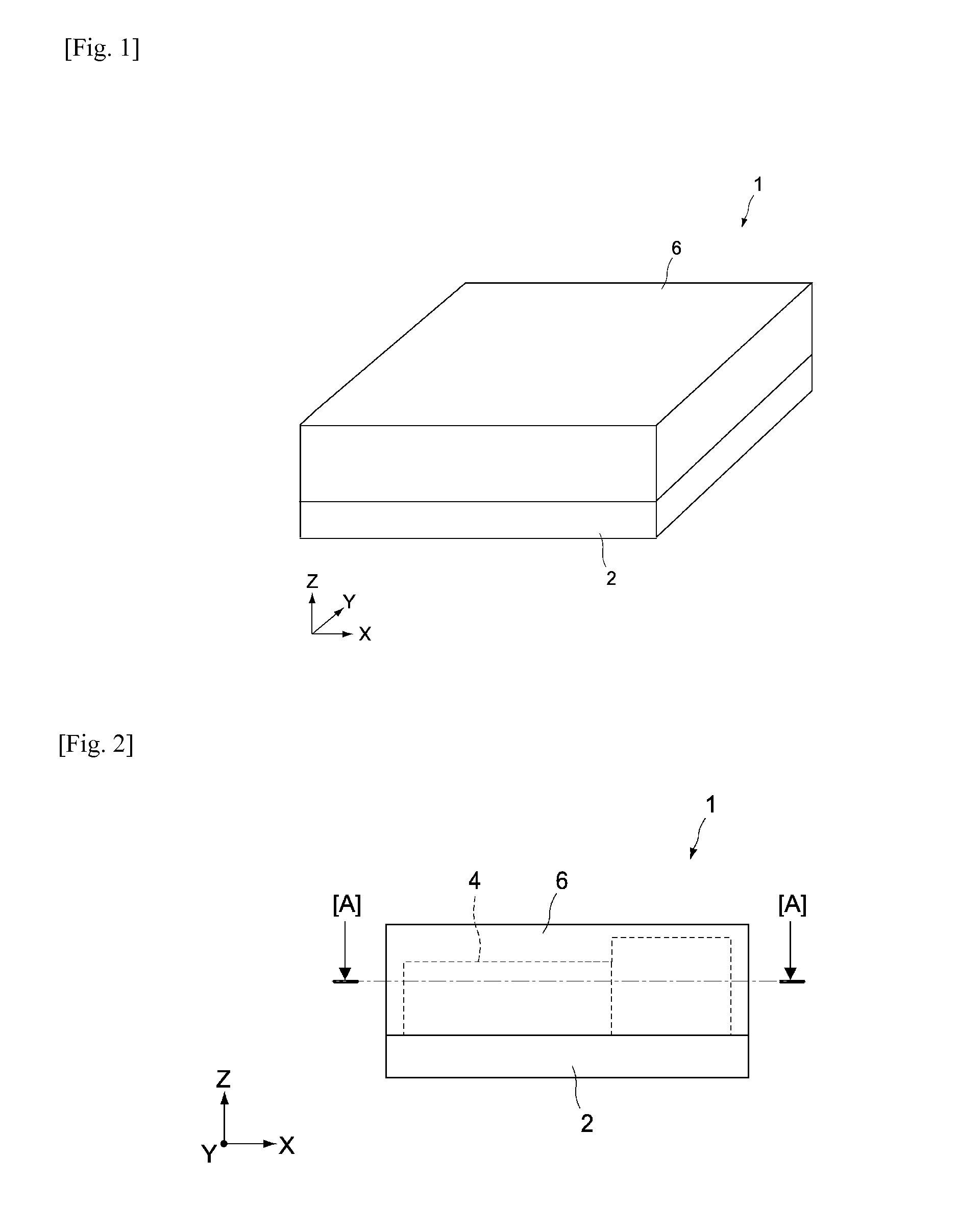

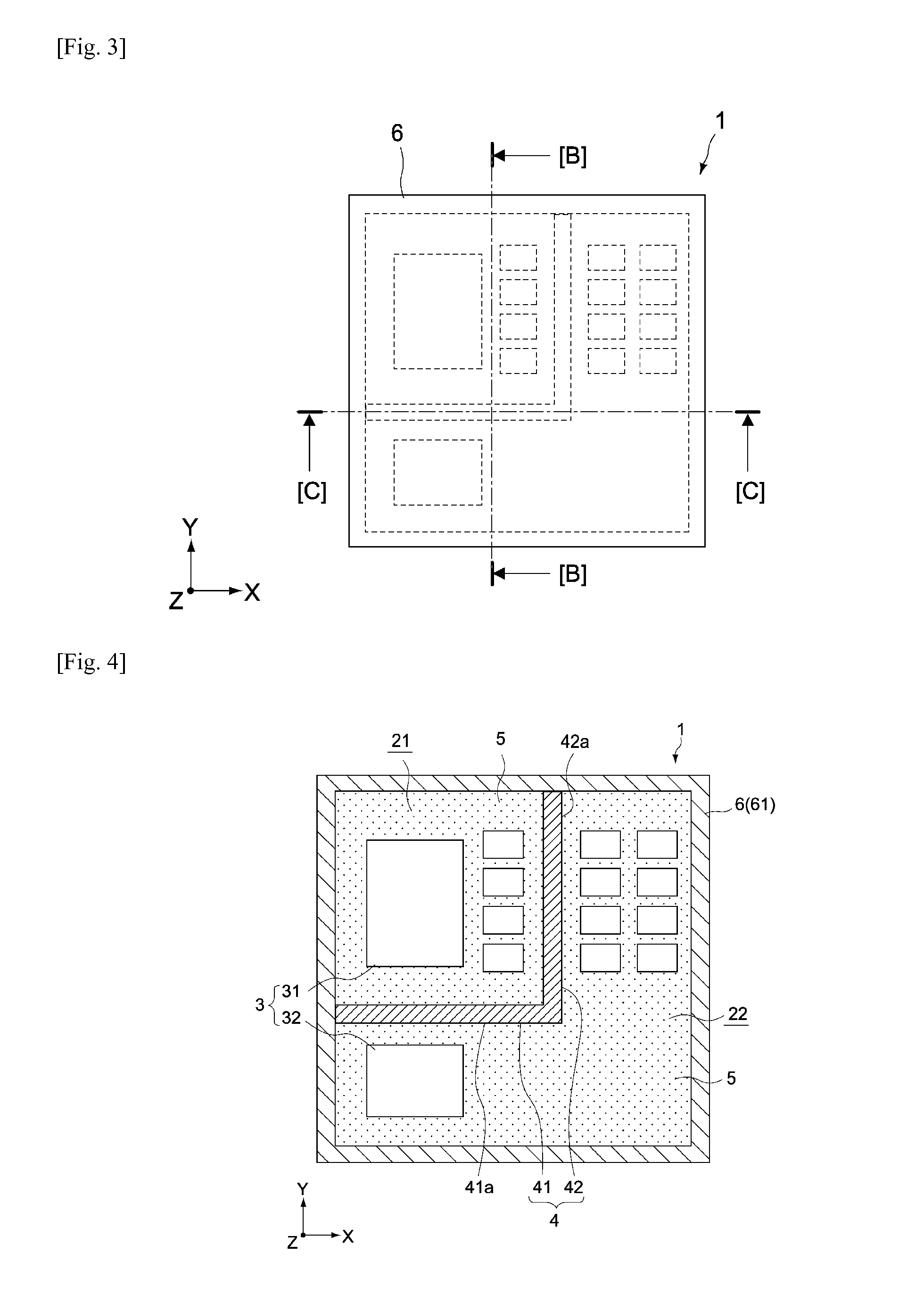

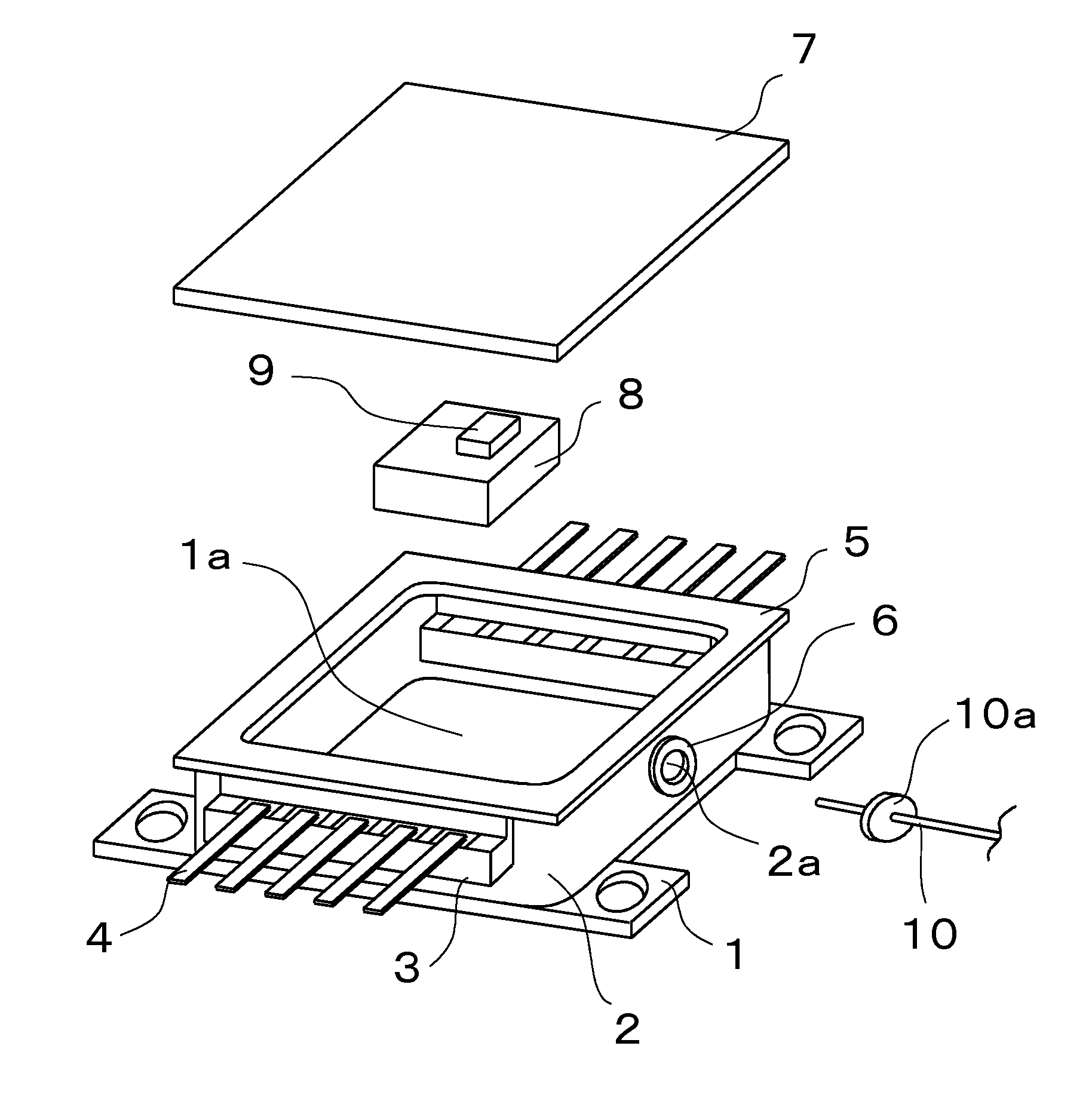

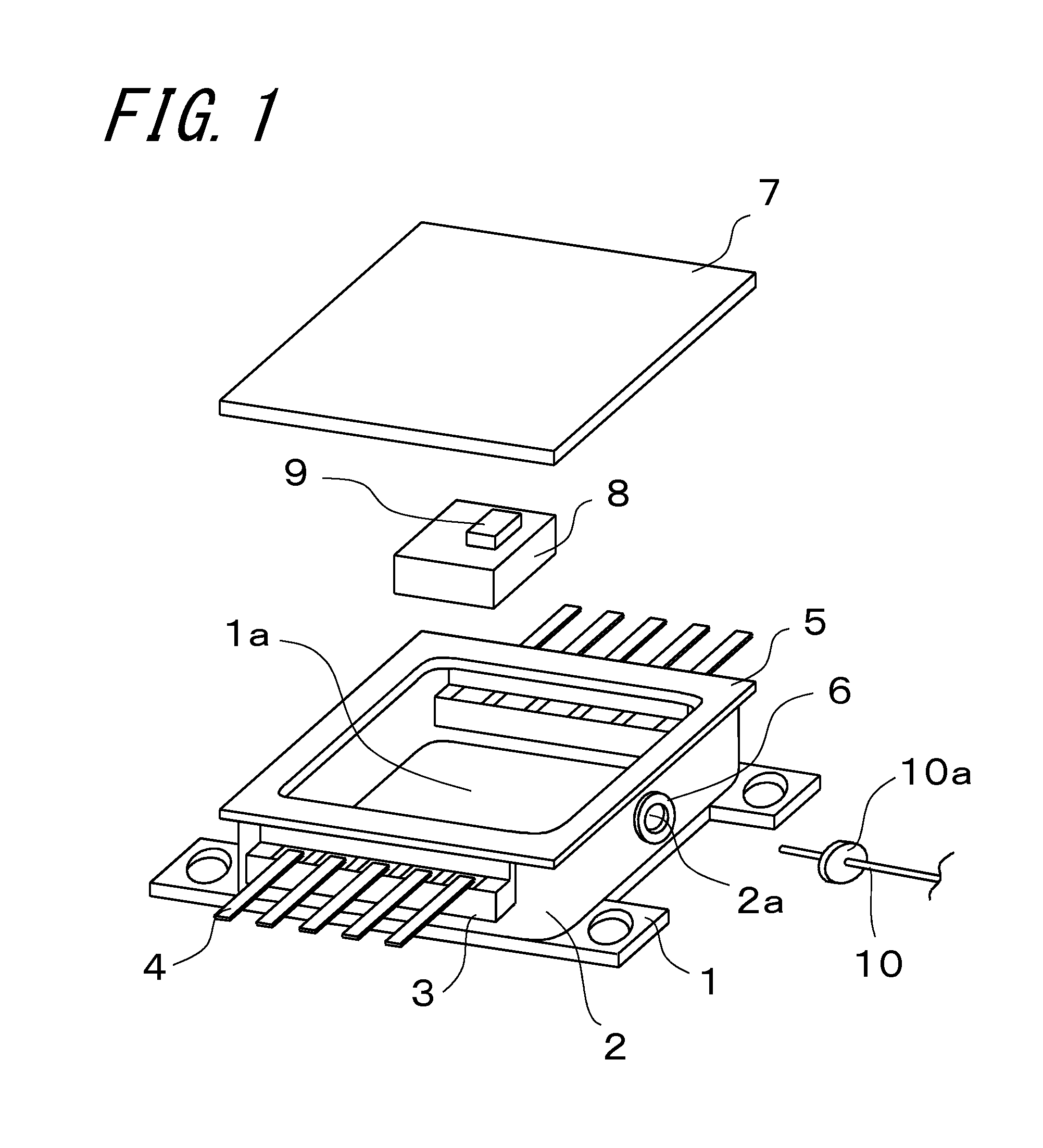

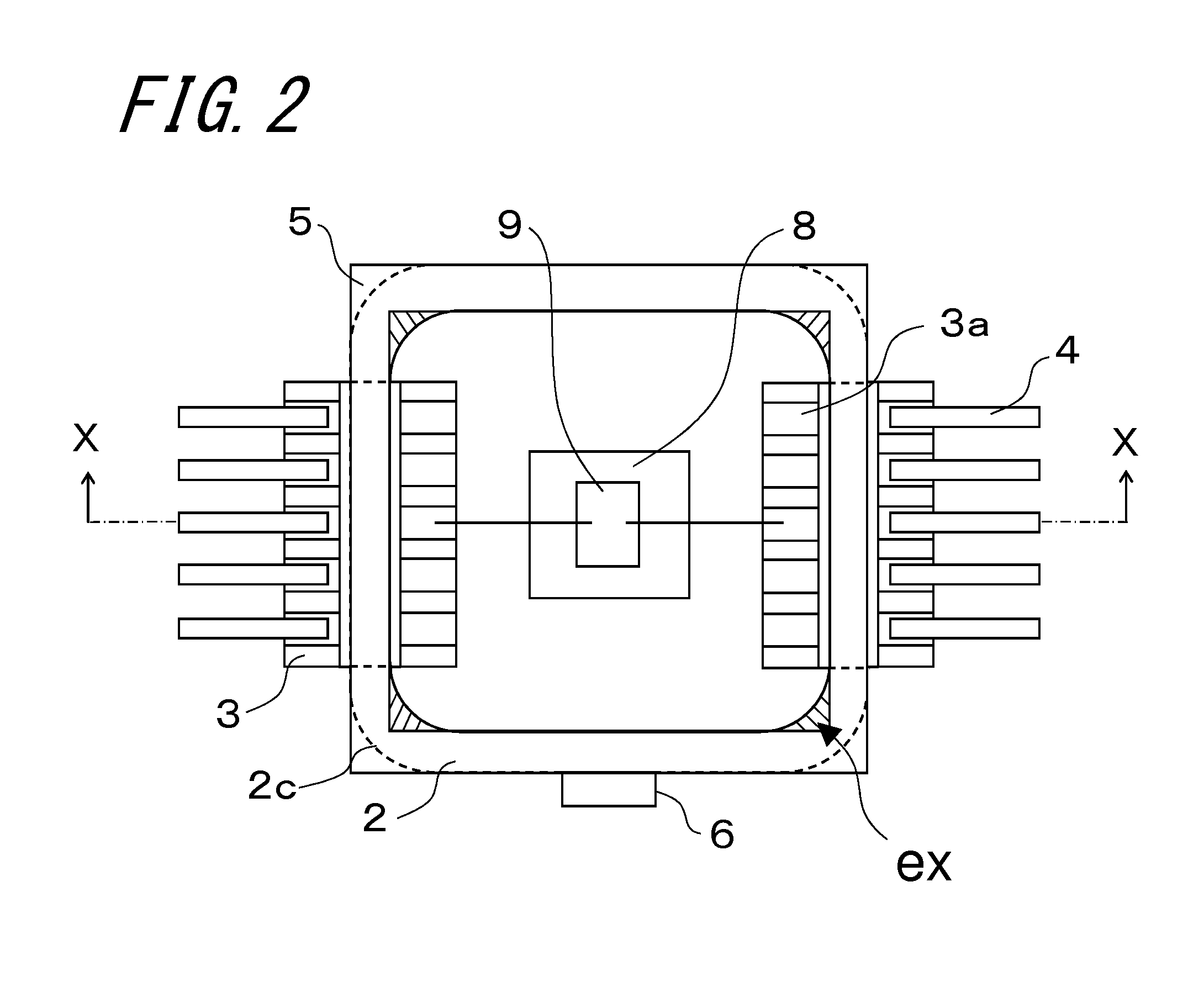

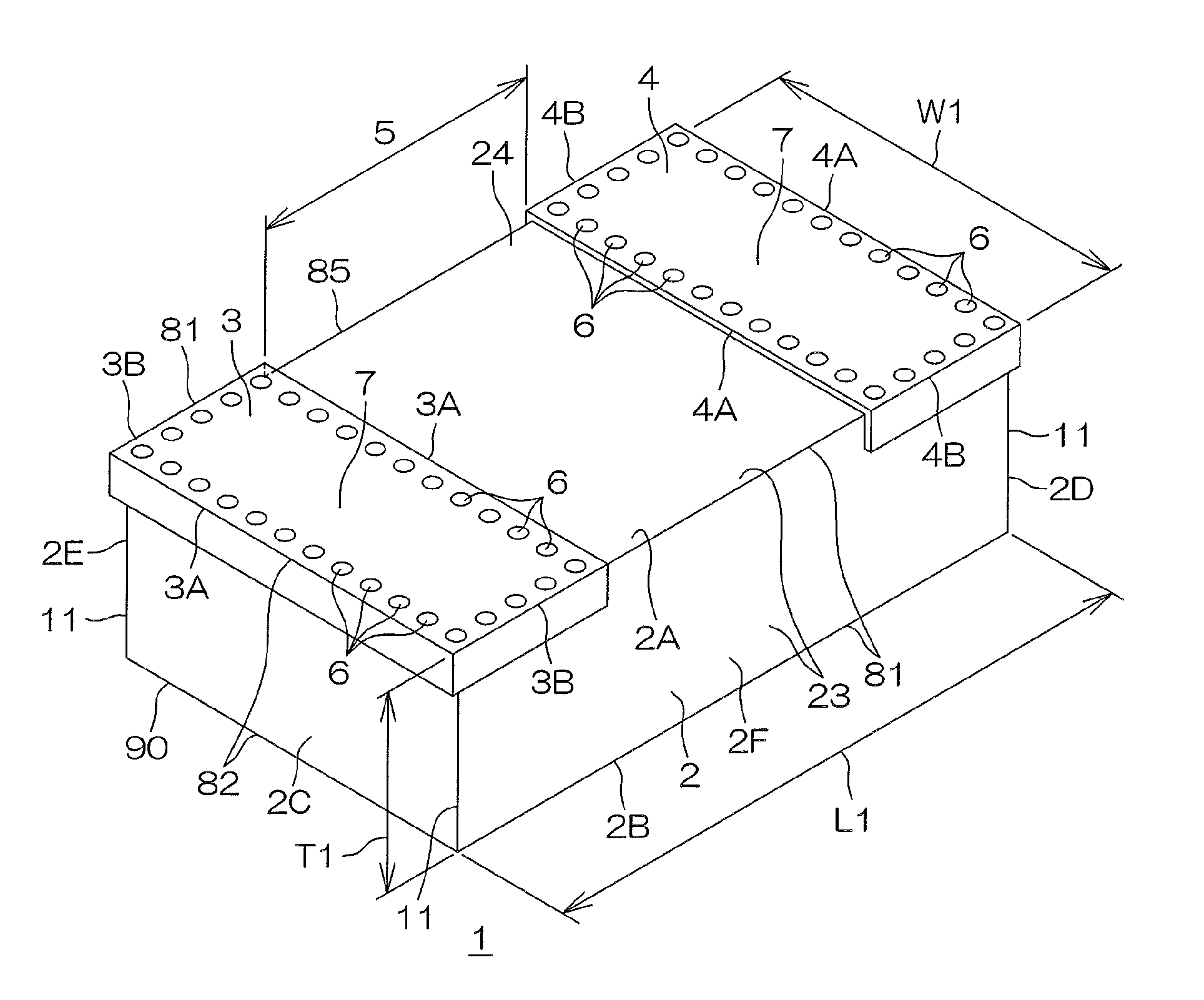

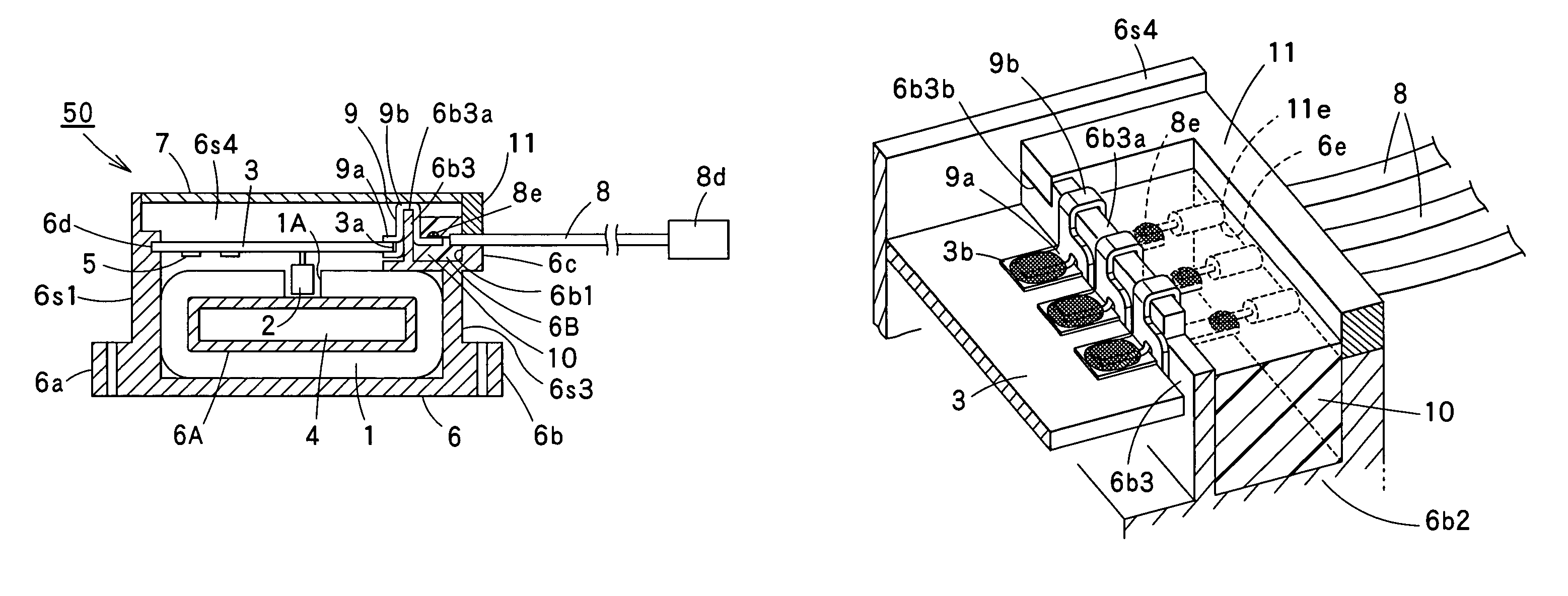

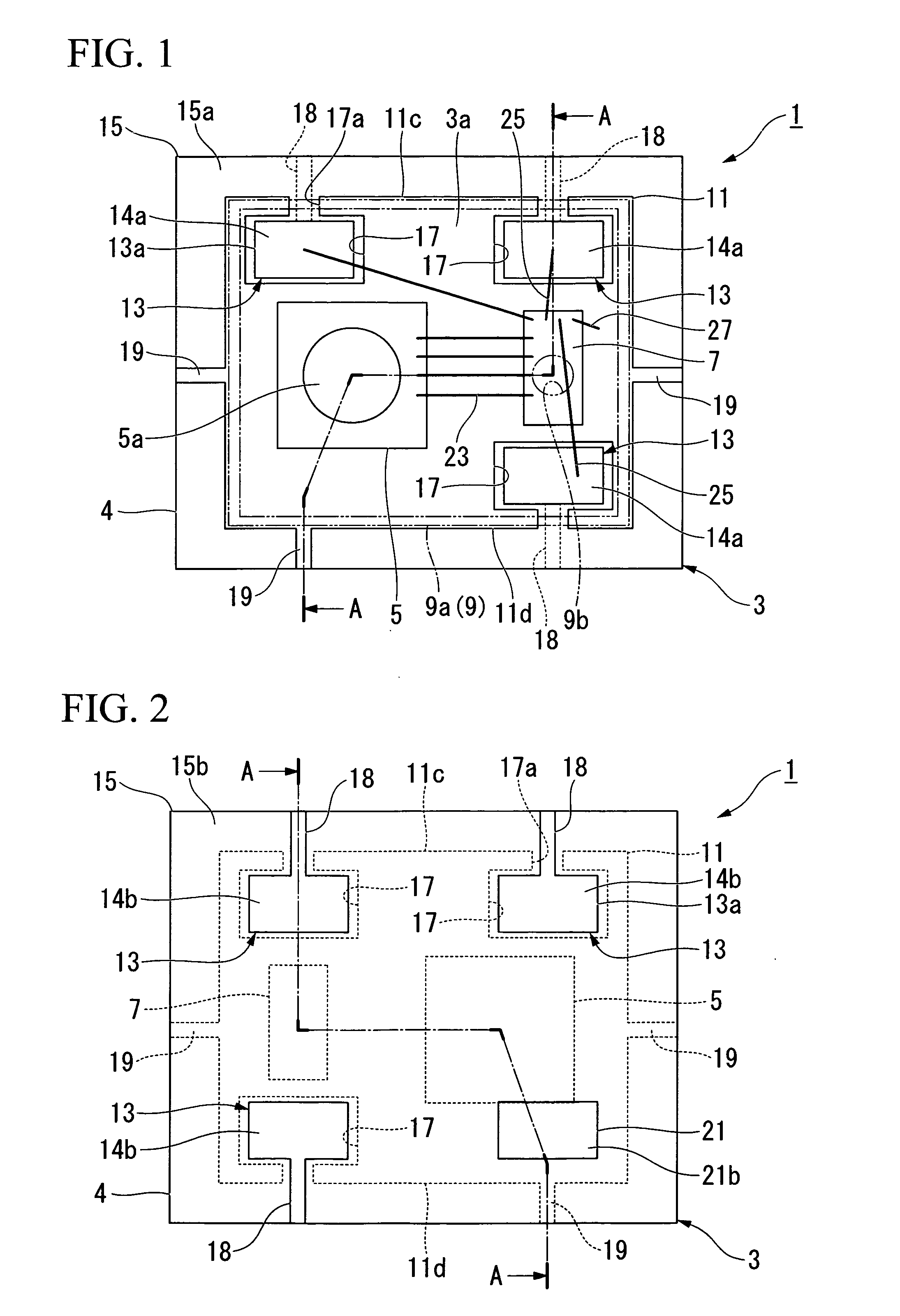

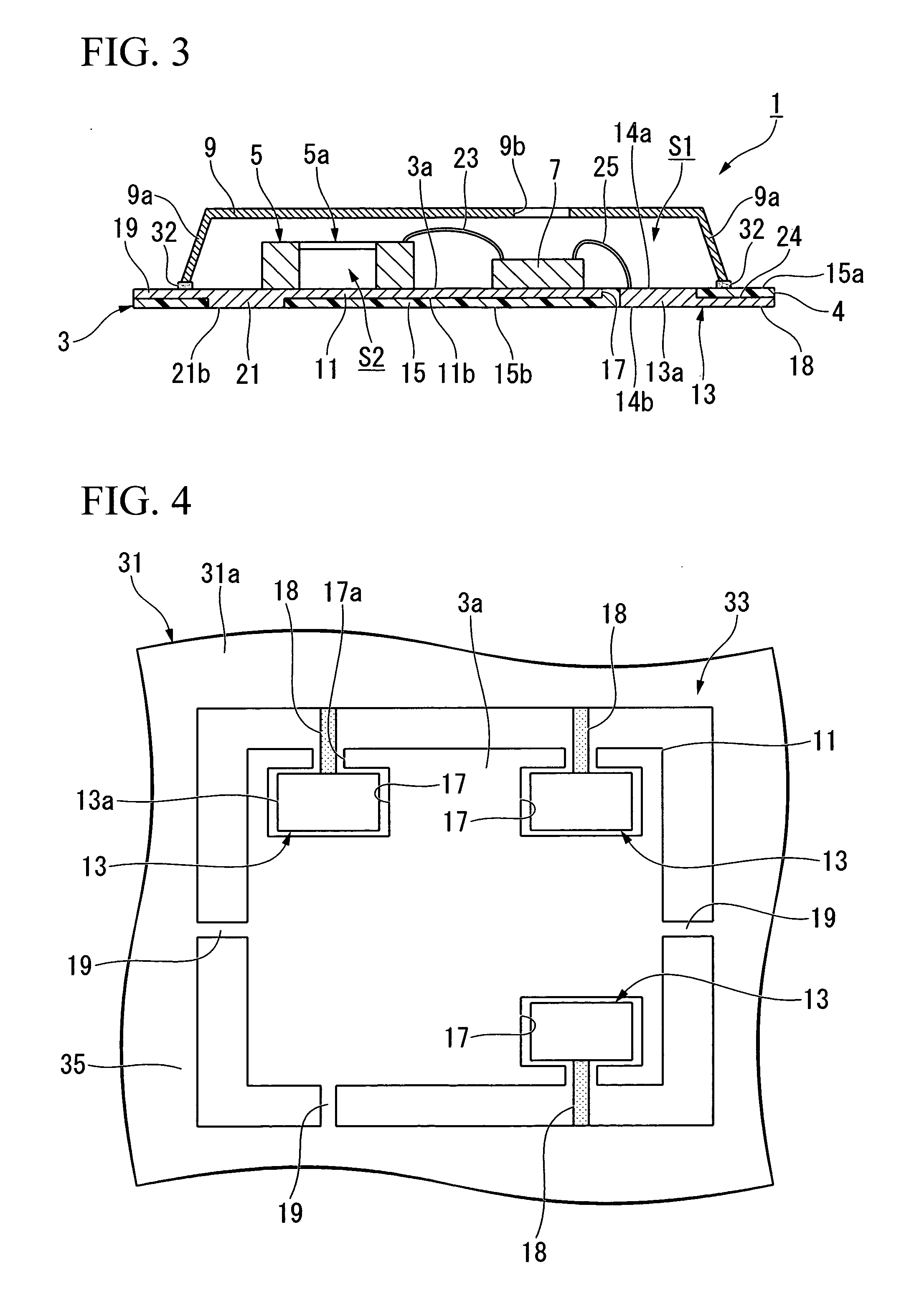

Device housing package and electronic apparatus employing the same

ActiveUS20130128489A1Semiconductor/solid-state device detailsCircuit arrangements on support structuresElectrical conductorDevice material

A device housing package includes a base body (1) including, at its upper surface, a placement portion (1a) of a semiconductor device (9); a frame body (2) disposed on the base body (1) surrounding the placement portion (1a), including a notch (2b) formed by cutting a side wall thereof; an input-output terminal (3) attached to the notch (2b), including a wiring conductor layer (3a) electrically connected to the semiconductor device (9); and a sealing ring (5) disposed on an upper portion of the frame body (2). Moreover, side walls of the frame body (2) have, when seen in a plan view, an outer corner (2c) of adjacent side walls having a curved surface, the outer corner (2c) lying within a region overlapping the sealing ring (5) as seen in a plan view.

Owner:KYOCERA CORP

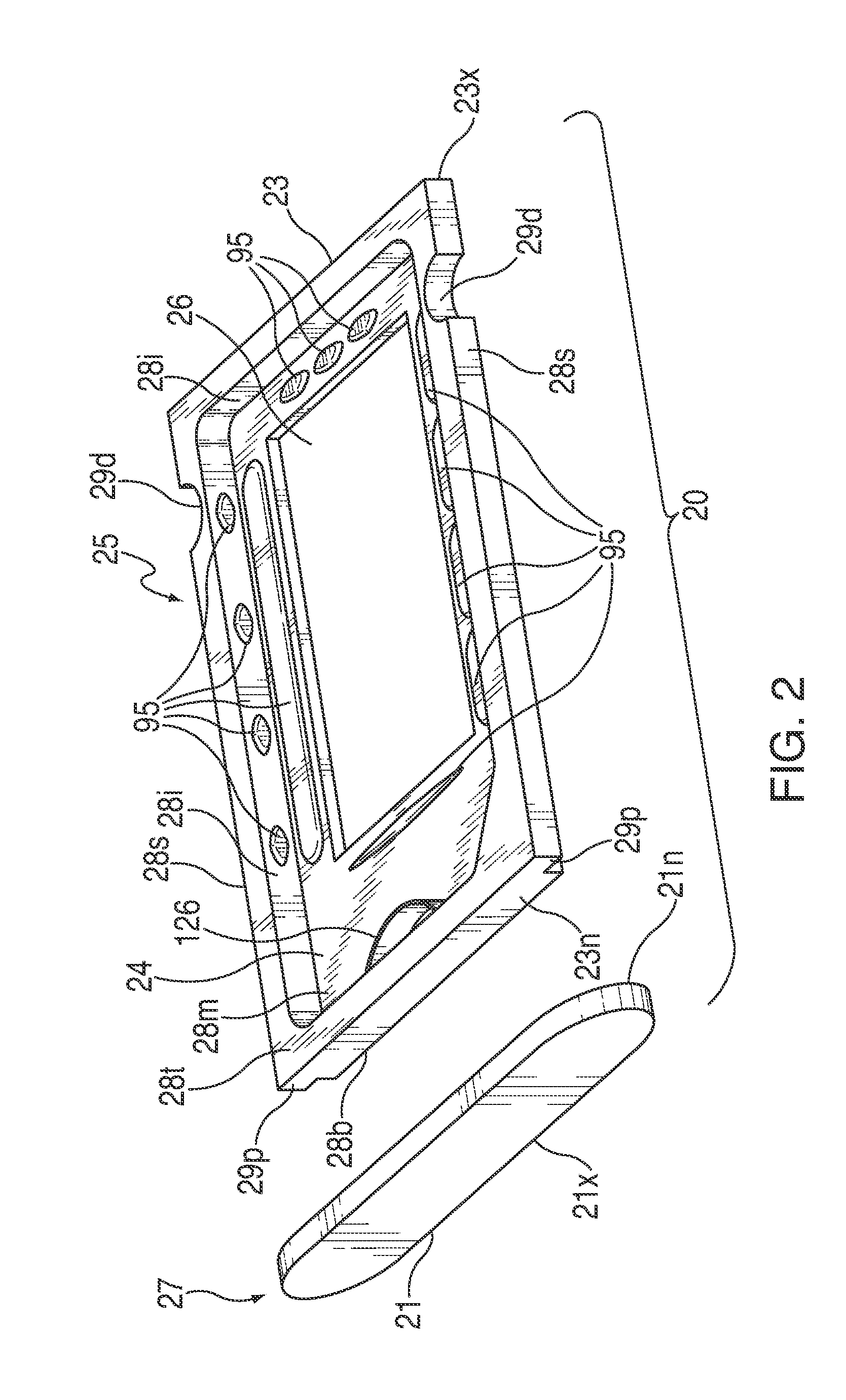

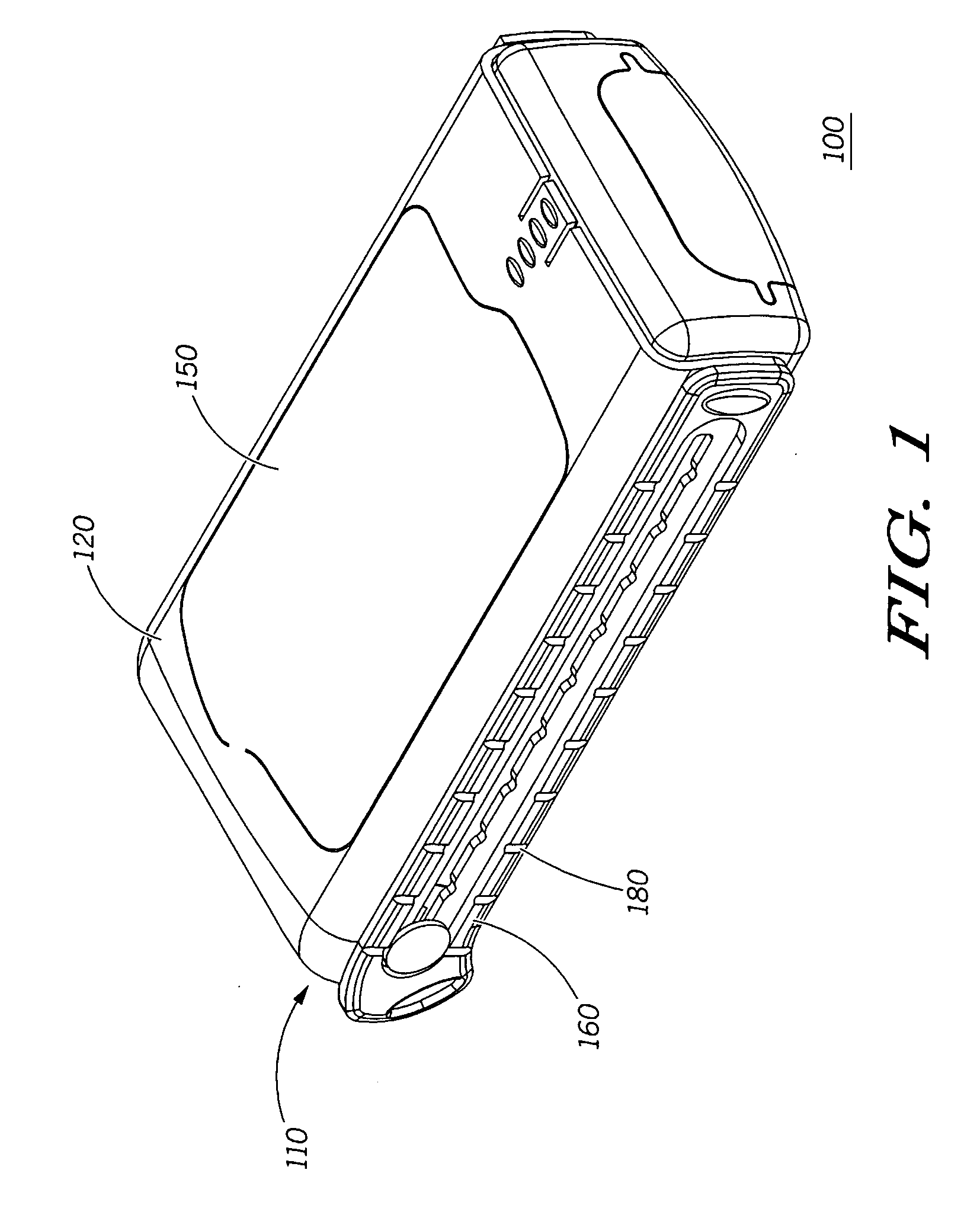

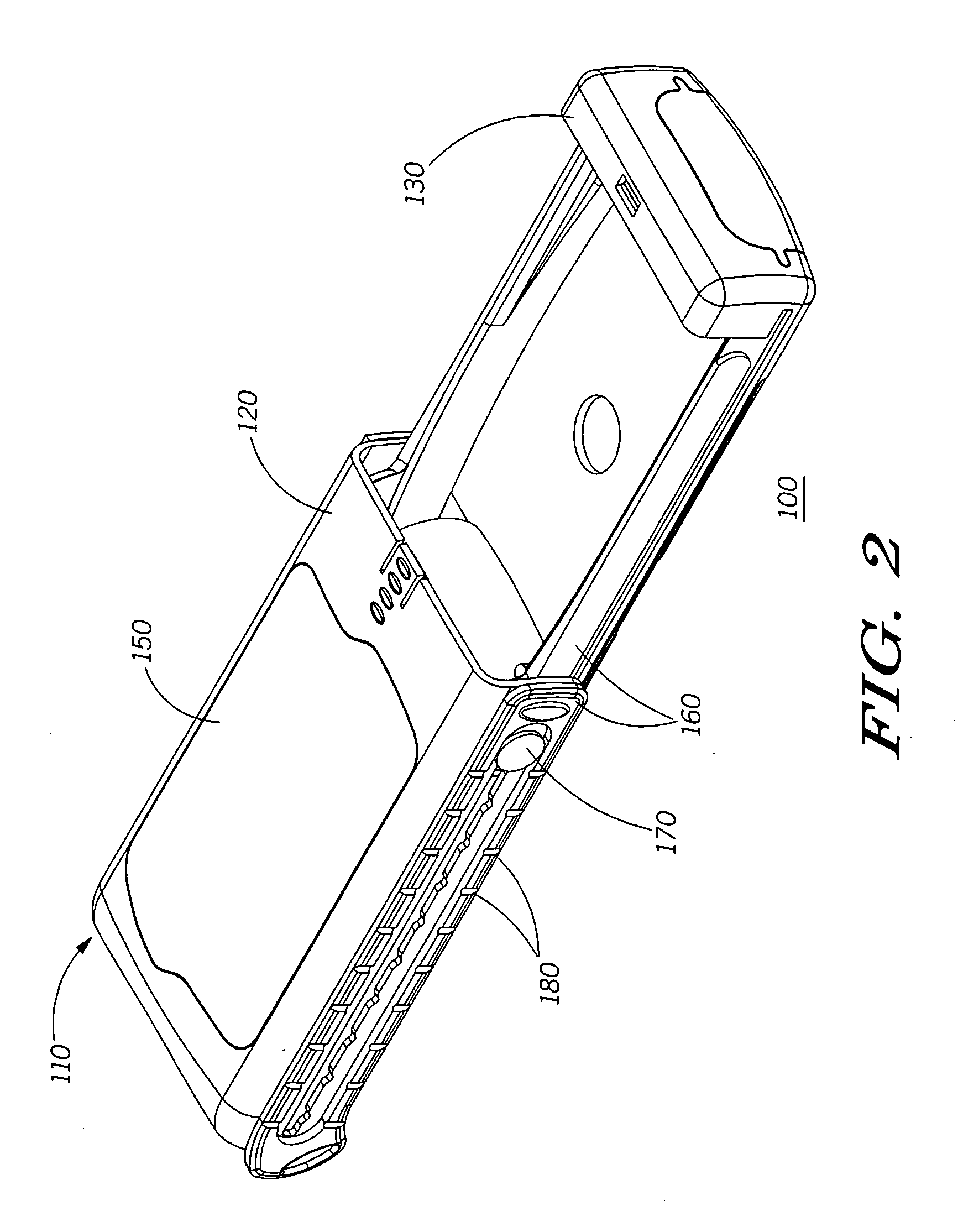

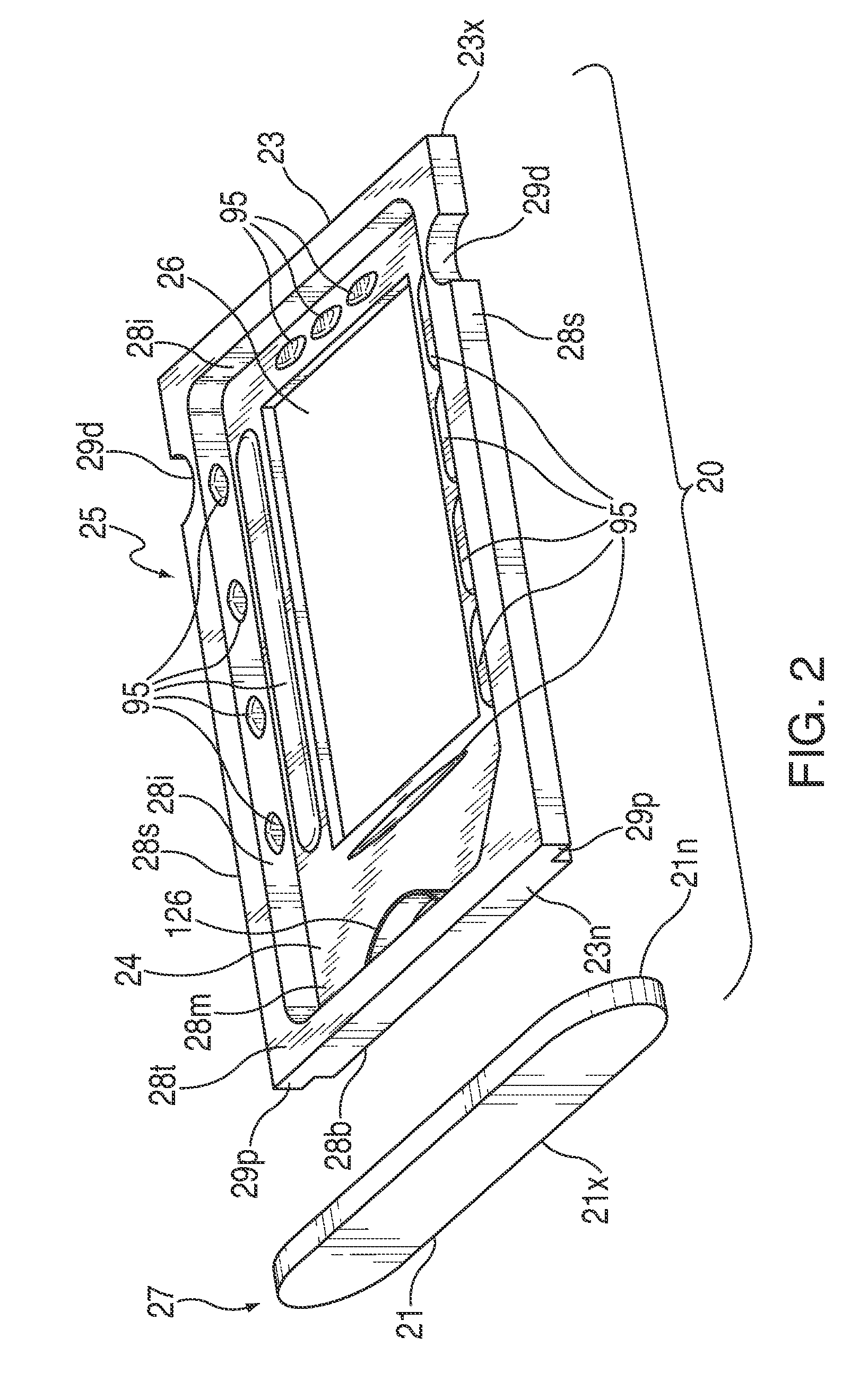

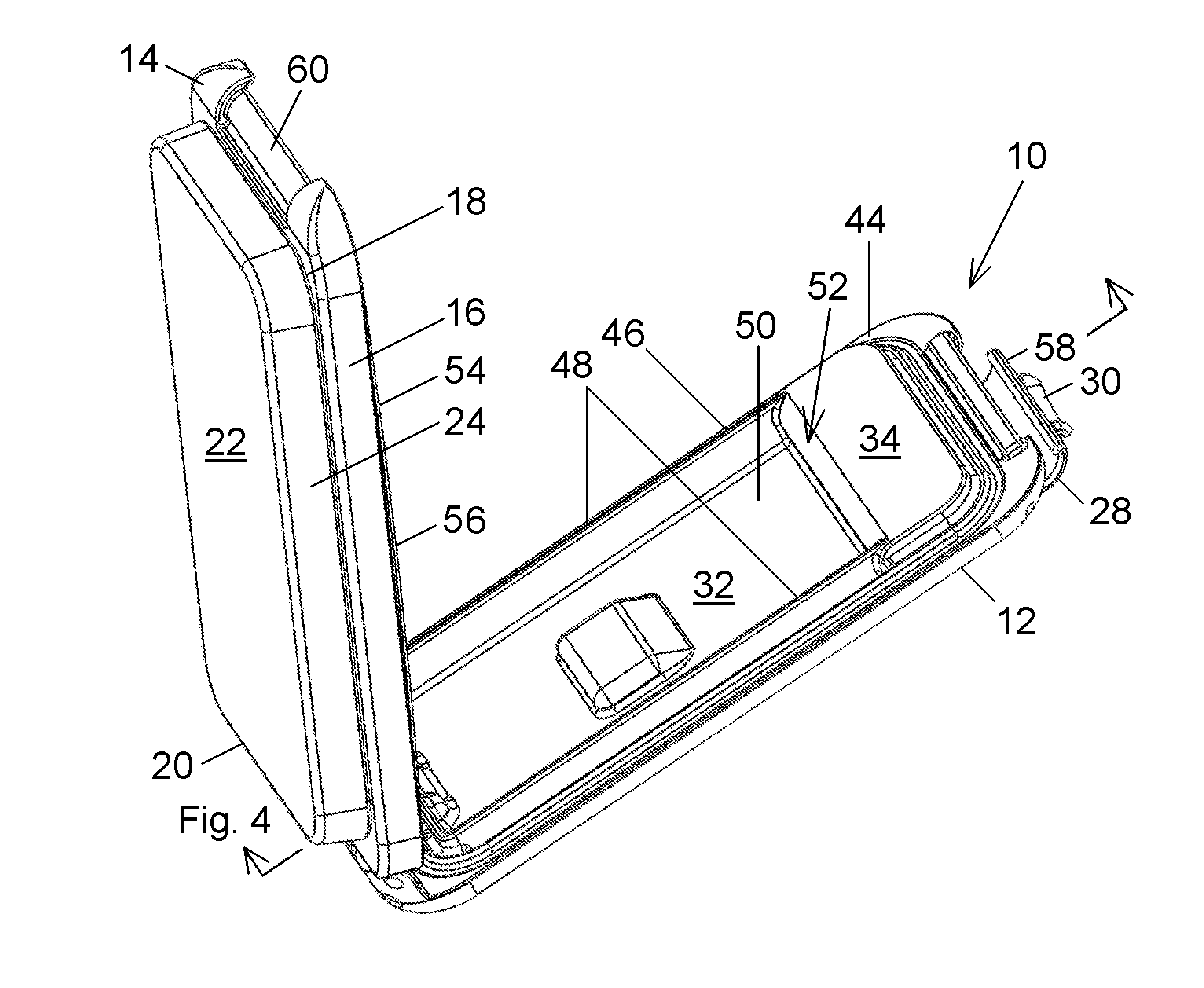

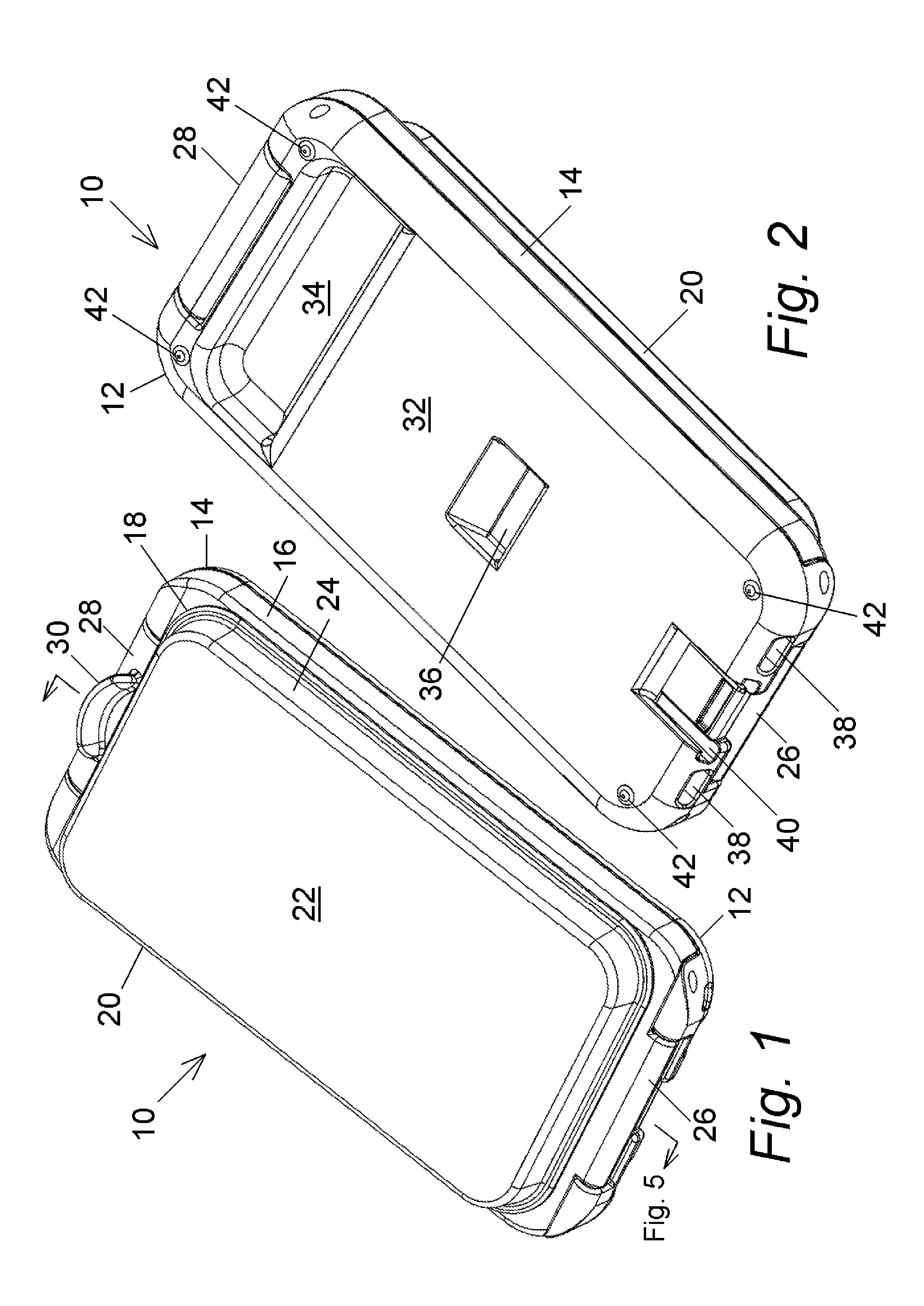

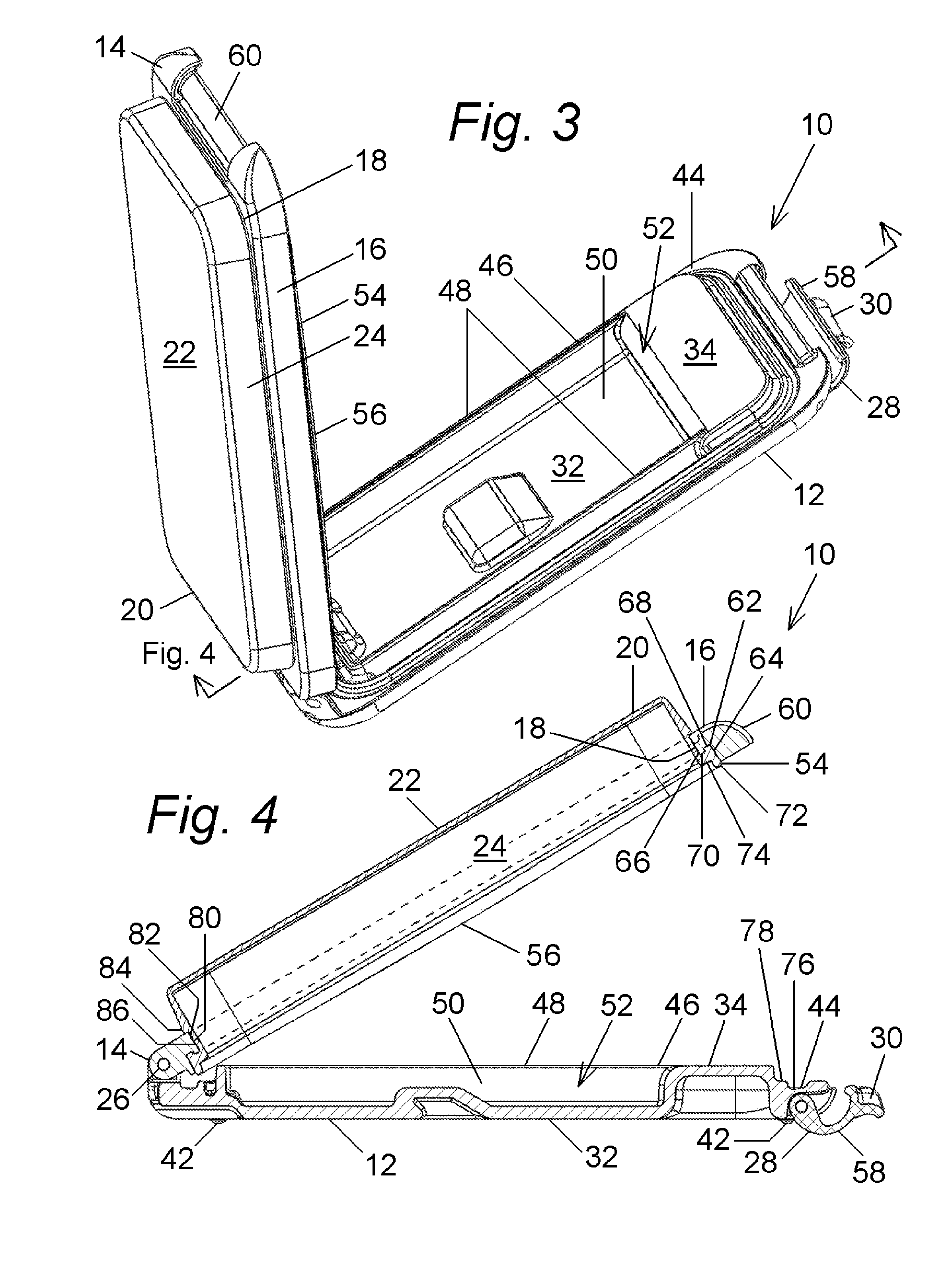

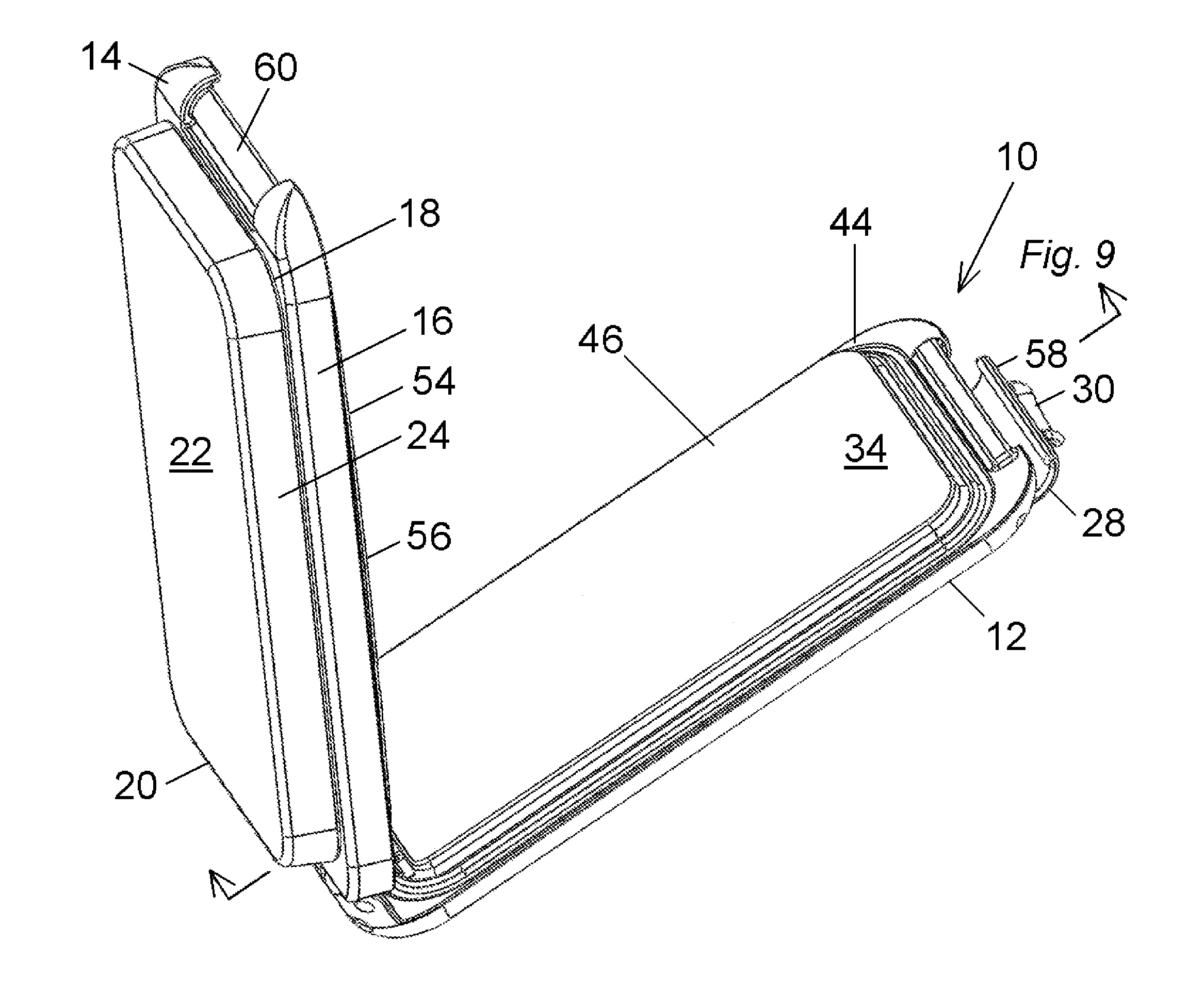

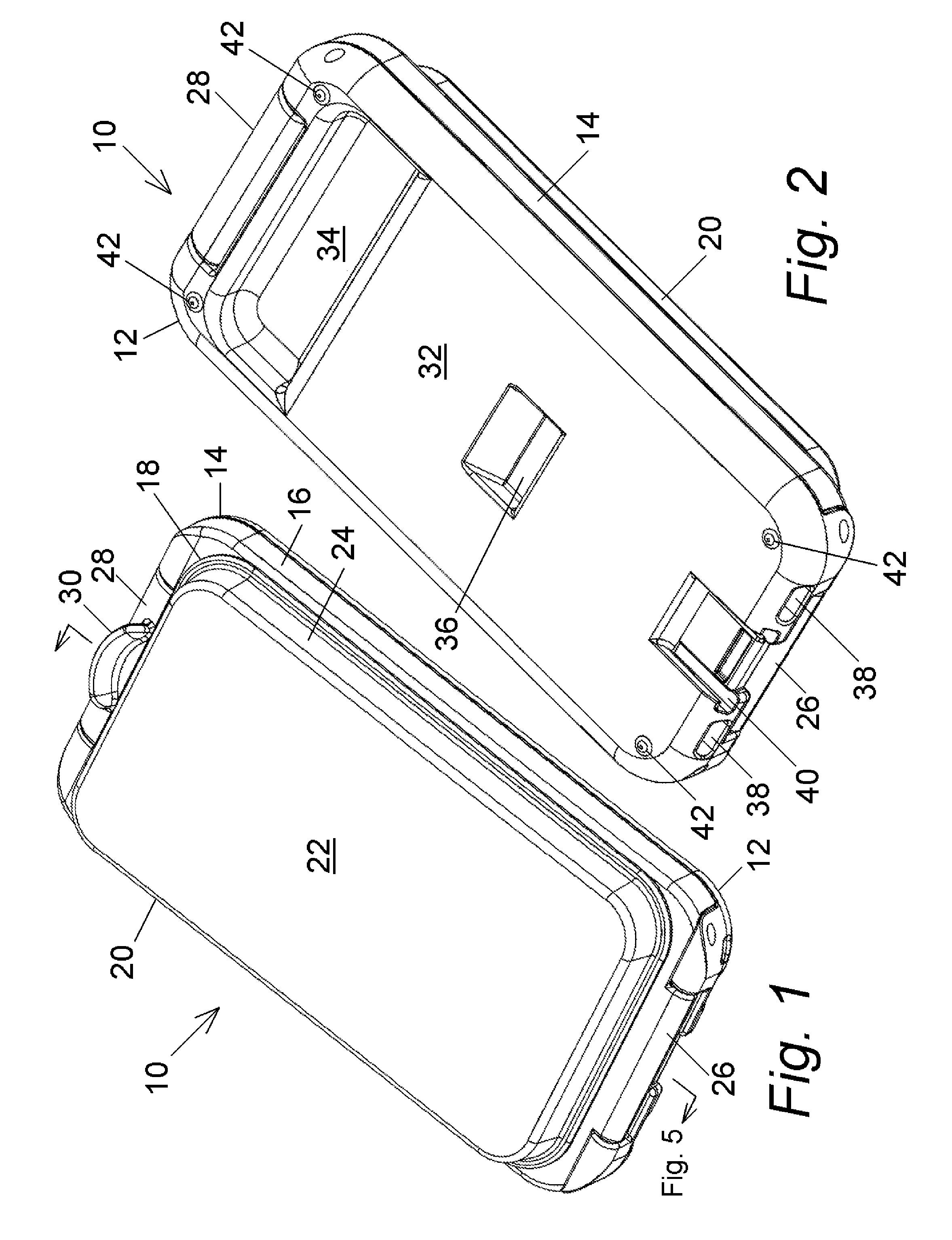

Protective enclosure for touch screen device

A protective enclosure adapted to hold a touch screen device and allow operation of both the touch screen and actuators on a side of the device, the enclosure formed of a tray having a rim surrounding an interior device seating surface; a lid having a rim corresponding to the rim of the tray and surrounding a window aperture; a protective membrane having a transparent membrane forming an interior window portion positioned in the viewing aperture of the lid, and a continuous pliable seal adapted to be compressible between the corresponding rims of the lid and the tray; and a mechanism for clamping the rim of the lid and the rim of the tray with the pliable seal forming a continuous seal therebetween.

Owner:CARNEVALI JEFFREY D

Protective enclosure for touch screen device

A protective enclosure adapted to hold a touch screen device and allow operation of both the touch screen and actuators on a side of the device, the enclosure formed of a tray having a rim surrounding an interior device seating surface; a lid having a rim corresponding to the rim of the tray and surrounding a window aperture; a protective membrane having a transparent membrane forming an interior window portion positioned in the viewing aperture of the lid, and a resiliently pliable skirt about the interior window portion, the skirt projecting the interior window portion outwardly of the rim around the aperture of the lid; a continuous pliable seal adapted to be compressible between the corresponding rims of the lid and the tray; and a mechanism for clamping the rim of the lid and the rim of the tray with the pliable seal forming a continuous seal therebetween.

Owner:CARNEVALI JEFFREY D

Encapsulation using microcellular foamed materials

InactiveUS20020009584A1Layered productsSemiconductor/solid-state device detailsMaterials scienceSupercritical fluid

Injection molding encapsulation processes for packaging an object or objects in microcellular foamed material, comprising the steps of providing a mold having a mold cavity, positioning at least one object in the mold cavity, providing a packaging material, introducing a fluid into the packaging material under conditions sufficient to produce a supercritical fluid-packaging material solution, introducing the solution into the mold cavity, and converting the solution into a microcellular foamed material. Such processes are advantageously employed in encapsulation of electronic or electrical components. Packaged objects produced therefrom may be completely or partially encapsulated.

Owner:EI DU PONT DE NEMOURS & CO

Low profile, highly configurable, current sharing paralleled wide band gap power device power module

ActiveUS20150216067A1Shorten the counting processReduce system costSemiconductor/solid-state device detailsSolid-state devicesElectrical conductorFull bridge

A power module with multiple equalized parallel power paths supporting multiple parallel bare die power devices constructed with low inductance equalized current paths for even current sharing and clean switching events. Wide low profile power contacts provide low inductance, short current paths, and large conductor cross section area provides for massive current carrying. An internal gate & source kelvin interconnection substrate is provided with individual ballast resistors and simple bolted construction. Gate drive connectors are provided on either left or right size of the module. The module is configurable as half bridge, full bridge, common source, and common drain topologies.

Owner:WOLFSPEED INC

Chip parts and method for manufacturing the same, circuit assembly having the chip parts and electronic device

ActiveUS20150216044A1Evenly partitionedEasy to installResistor chip manufactureResistor terminals/electrodesEngineeringElectron

The chip part of the present invention includes a substrate, an electrode on the substrate and having a front surface in which a plurality of recessed portions are formed toward the thickness direction thereof, and an element region having a circuit element that is electrically connected to the electrode.

Owner:ROHM CO LTD

Electronic component

ActiveUS7002807B2Improve reliabilitySufficient amountPrinted circuit assemblingContact member assembly/disassemblyEngineeringElectronic component

An electronic component has a casing having a resin injecting section having at least one wall. At least one circuit board is housed in the casing, next to the resin injecting section via the wall. At least one lead terminal is provided in the casing. The lead terminal has a first end and a second end, and a middle section connected between the first and second ends. The first end of the lead terminal is connected to the circuit board in a way that the middle section of the lead terminal is provided as straddling the wall of the resin injecting section. Also provided is at least one lead wire having a third end and a fourth end. The third end of the lead wire is connected to the second end of the lead terminal in the resin injecting section. The fourth end of the lead wire is pulled out from the casing. The third end of the lead wire and the second end of the lead terminal connected to each other are embedded in resin injected in the resin injecting section whereas the middle section of the lead terminal straddling the wall of the resin injecting section is not embedded in the resin. Instead of straddling the wall of the resin injecting section, the middle section of the lead terminal may be inserted into an opening provided on the wall and connected to the circuit board.

Owner:JVC KENWOOD CORP A CORP OF JAPAN

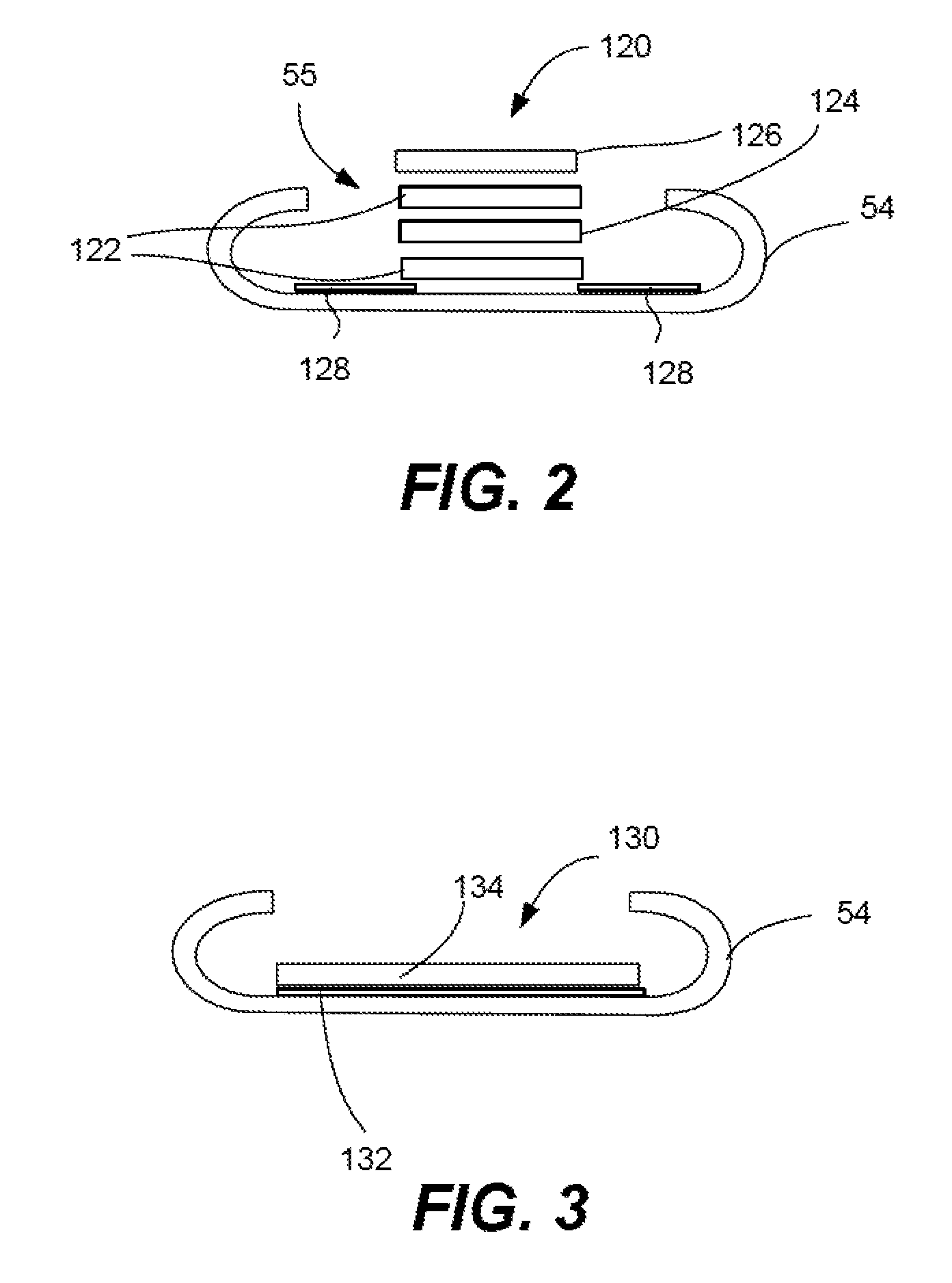

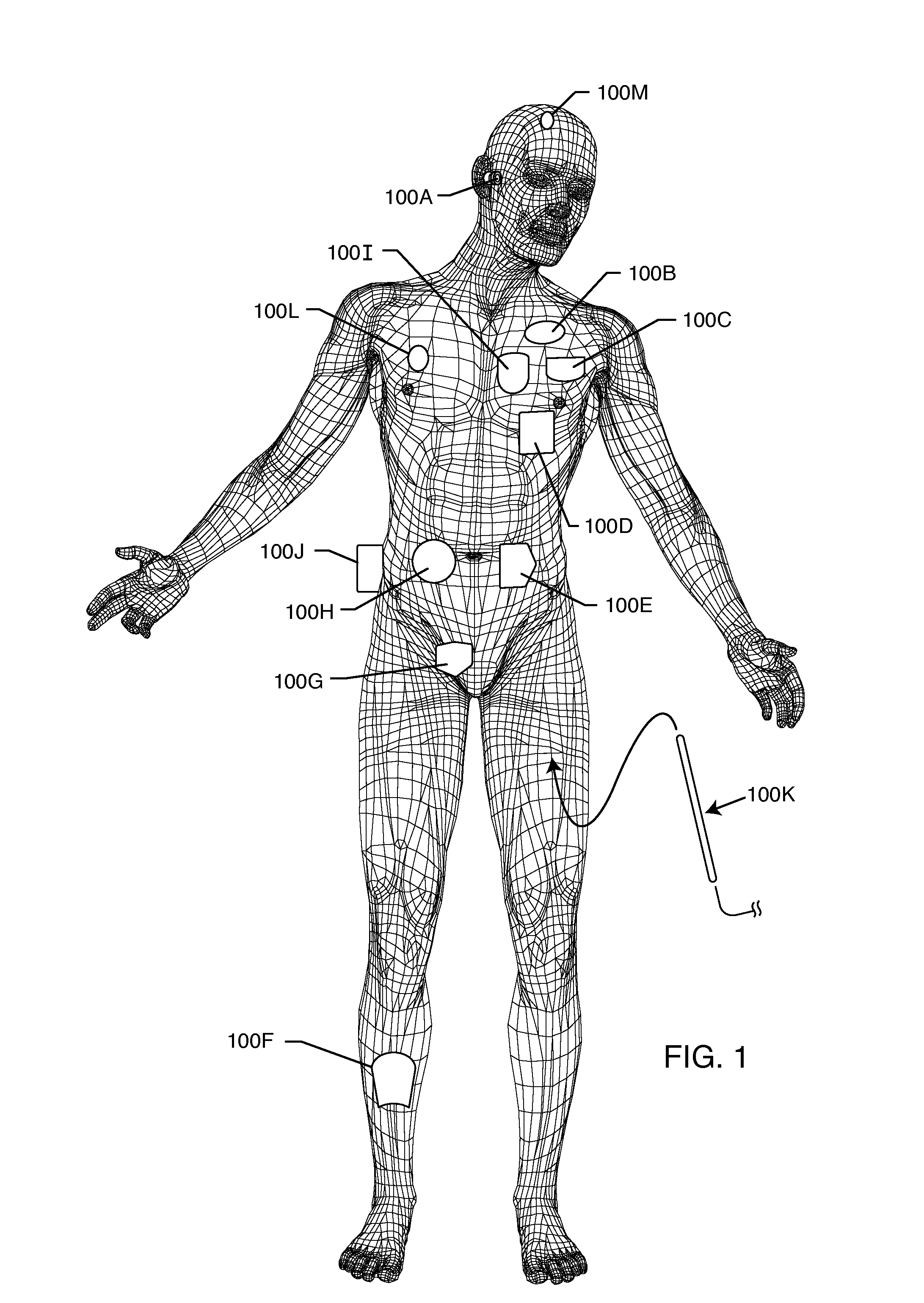

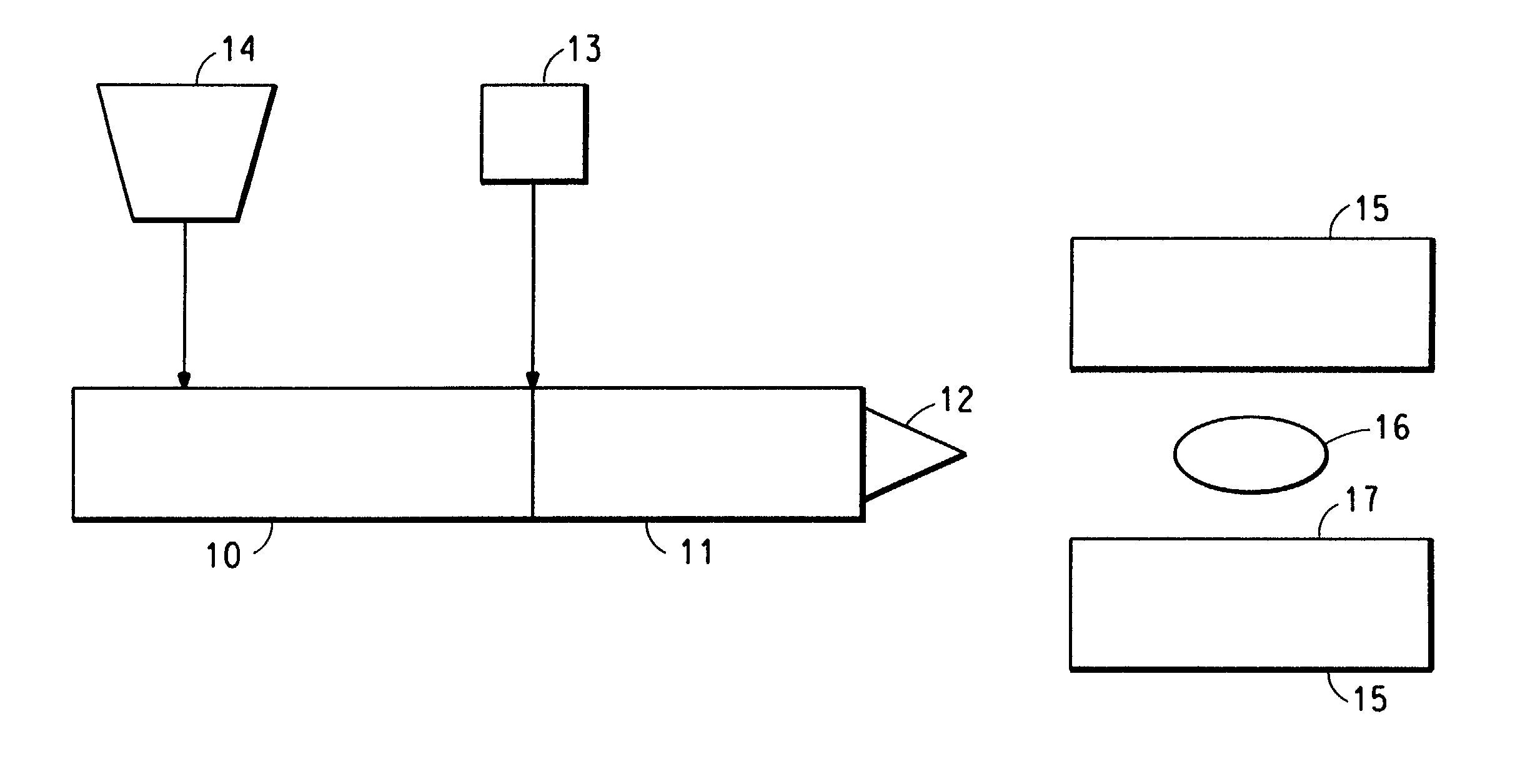

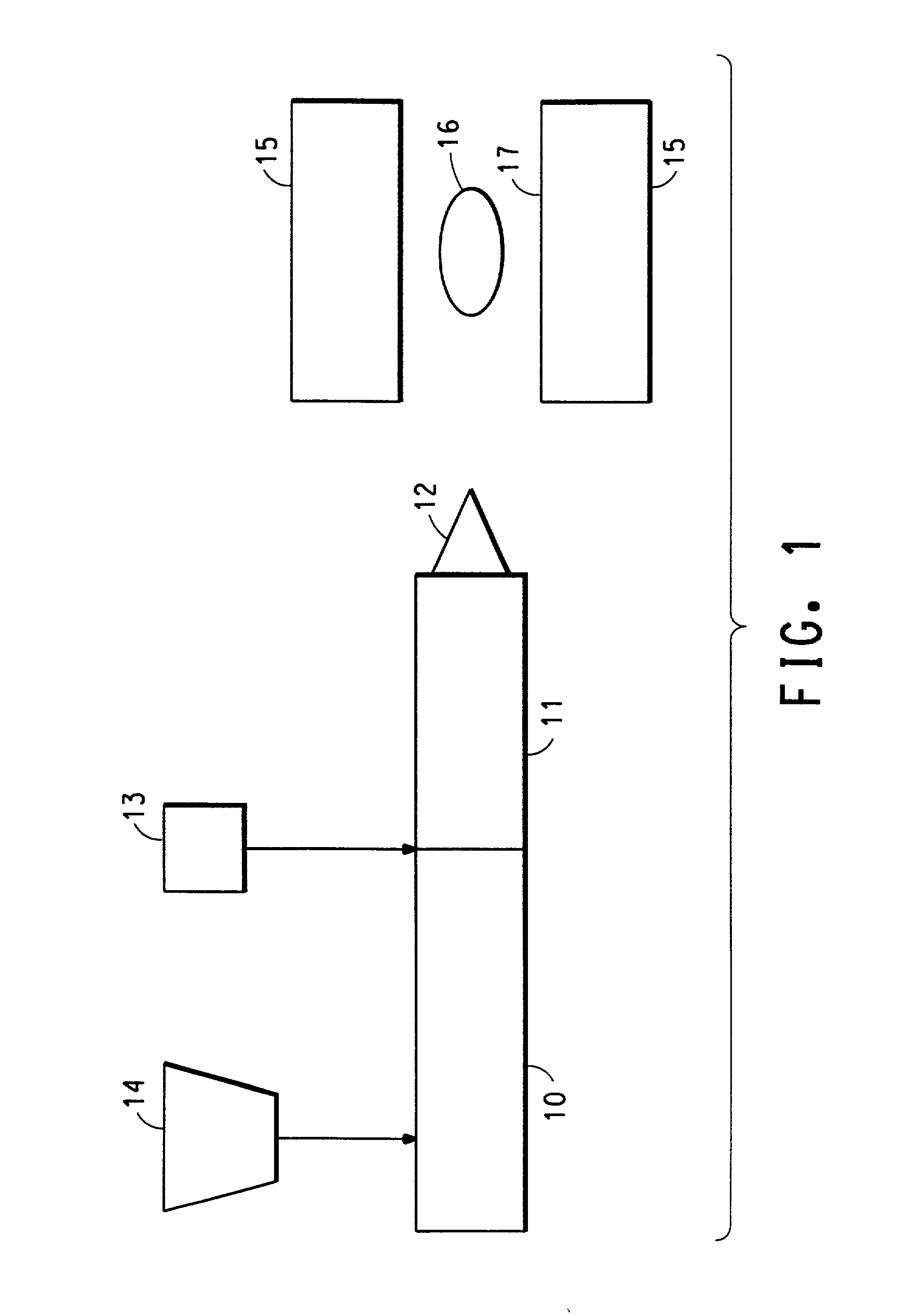

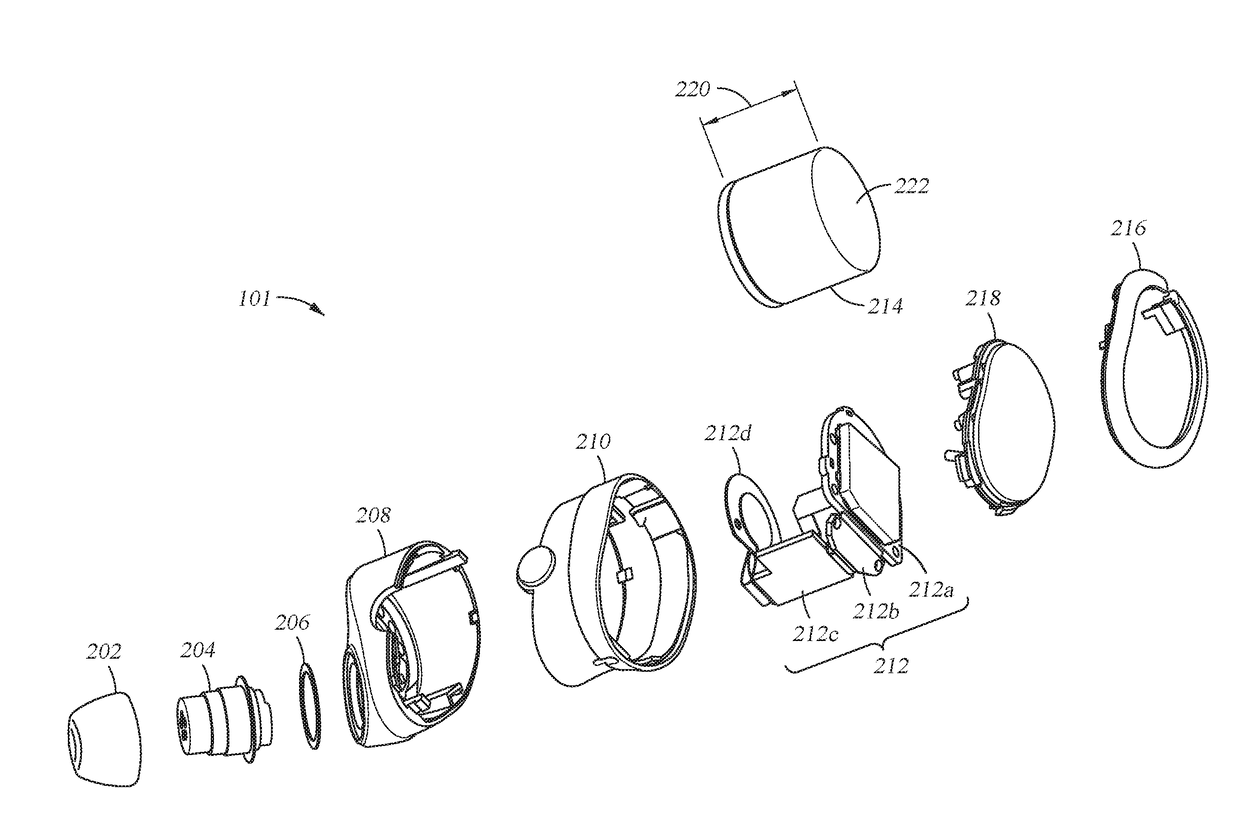

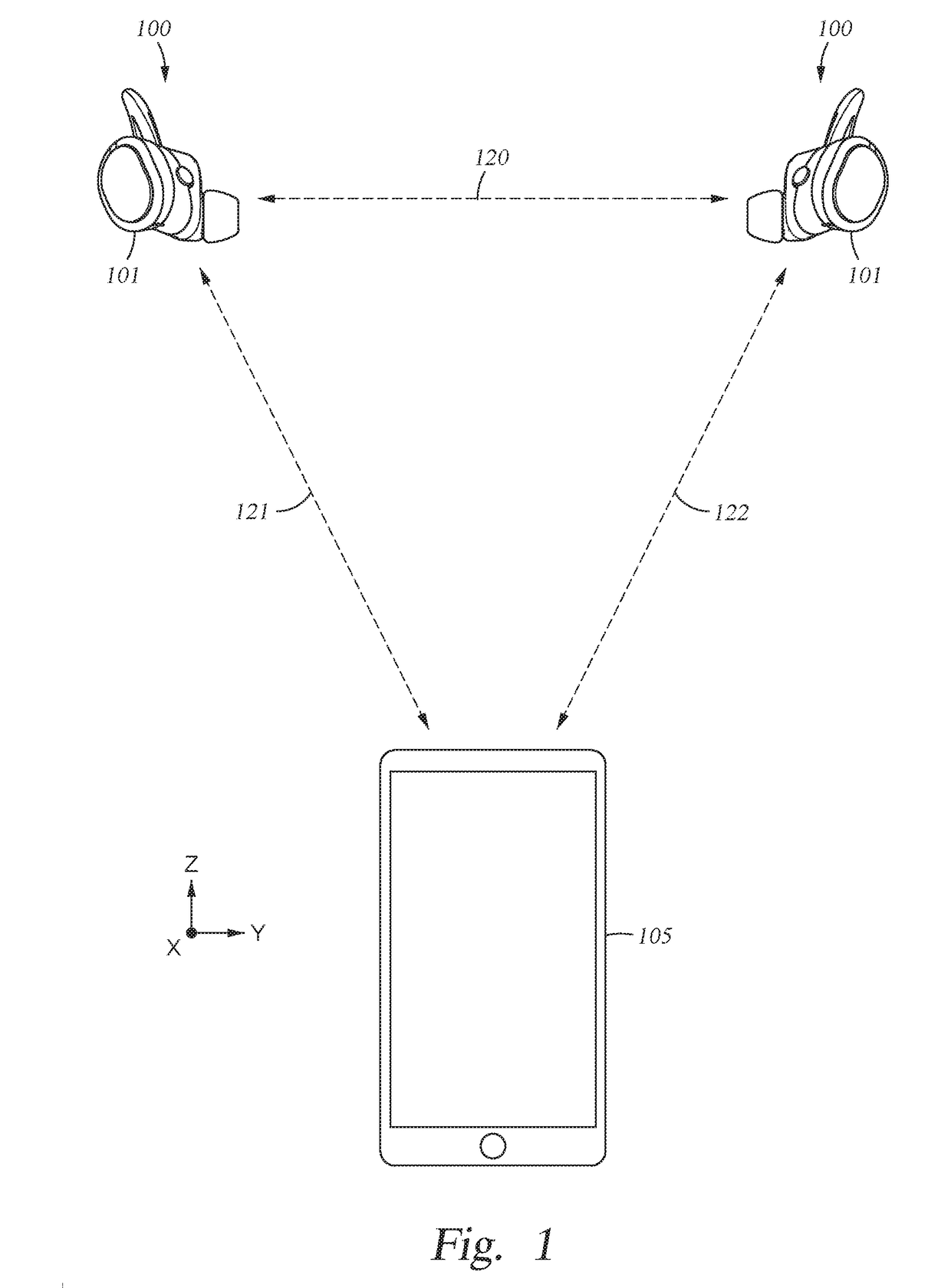

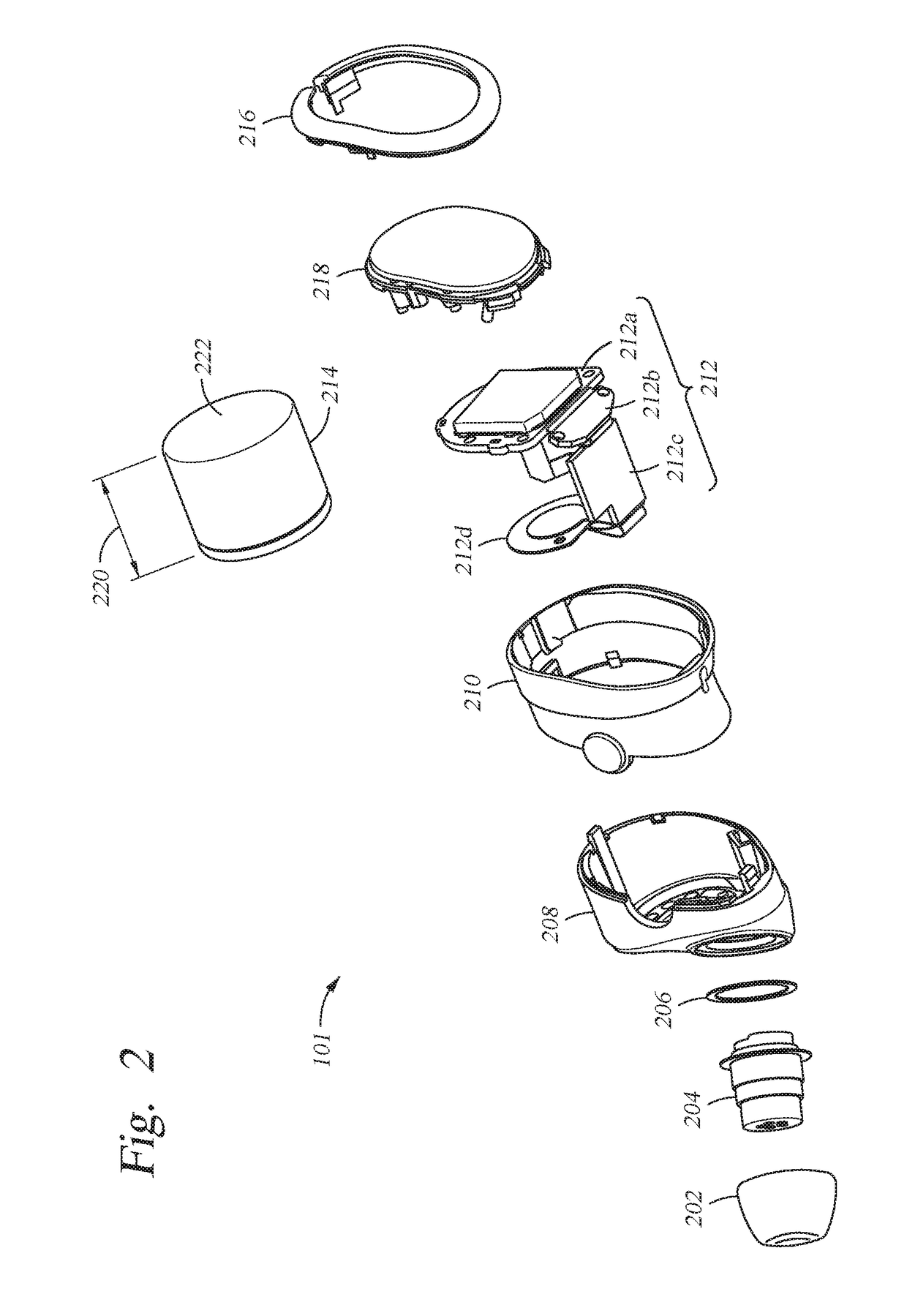

Wireless wearable electronic device communicatively coupled to a remote device

ActiveUS20180254546A1Facilitate communicationPrinted circuit aspectsAntenna adaptation in movable bodiesGround planeOmni directional

Disclosed is a wireless wearable electronic device having an antenna that communicatively couples the wearable electronic device to another wearable electronic device and to a remote, portable device. The antenna is generally shaped like a loop or ring, has a bow with respect to the plane of the loop or ring and operates in conjunction with the ground planes of the printed circuit boards in proximity to the antenna to form a principal omni-directional lobe about the ear of the user and a secondary lobe downwardly directed from the head of the user to communicate with the remote device.

Owner:LOGITECH EURO SA

Integrated internal power supply

InactiveUS20050213305A1Improve abilitiesImprove power supply capacityEmergency protective arrangement detailsSmall component housingsEngineeringElectrolytic capacitor

Owner:PATTON ELECTRONICS

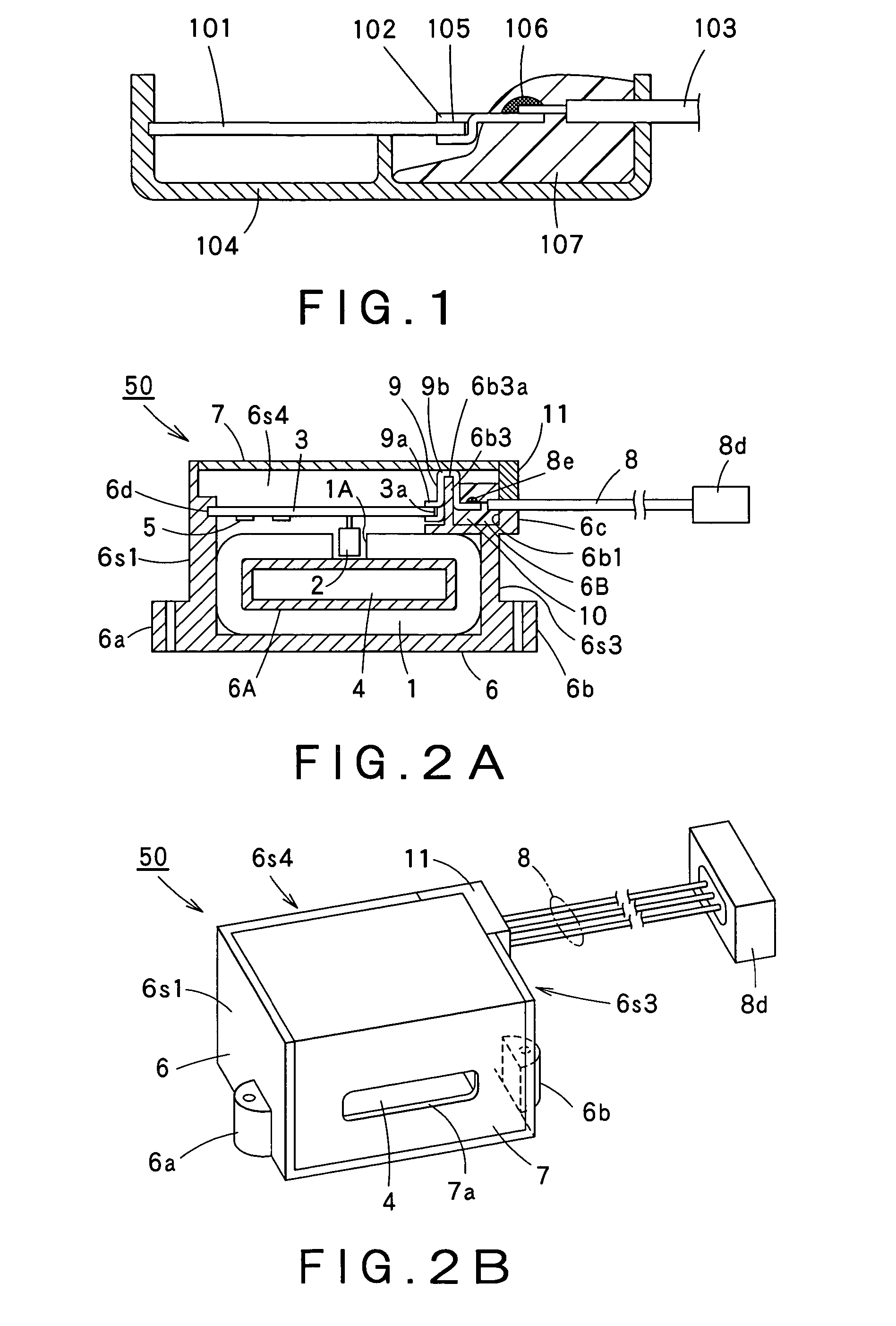

Semiconductor device, lead frame, and microphone package therefor

InactiveUS20090065882A1Reduce gapSemiconductor/solid-state device detailsSemiconductor electrostatic transducersEngineeringLead frame

A semiconductor device is constituted of a mold sheet for mounting a sensor chip and a cover having a box-like shape, both of which are combined together so as to form a cavity therebetween. The mold sheet includes a stage having a rectangular shape in a plan view, a plurality of cutouts formed in the periphery of the stage, and a plurality of lead terminals arranged inside of the cutouts. The lead terminals include a plurality of connection portions electrically connected to the sensor chip and a plurality of support leads which are externally extended from the periphery of the stage. The stage and the lead terminals are sealed with a mold resin, by which they are electrically insulated from each other. The recesses of the support leads are sealed with the insulating resin mold relative to the surface of the mold sheet so as to mount the opening end of the cover.

Owner:YAMAHA CORP

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com