Patents

Literature

413results about How to "Light extraction efficiency can be improved" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Bendable high flux LED array

ActiveUS6936855B1Easily variableWell formedSolid-state devicesSemiconductor devices for light sourcesLed arrayHigh flux

A bendable light emitting diode (LED) array in accordance with the present invention includes heat spreaders, dielectric material disposed above each heat spreader, and a bendable electrical interconnection layer disposed above these heat spreaders and electrically insulated from these heat spreaders by the dielectric material. At least one via passes through the dielectric material above each heat spreader, and at least one LED die is disposed above each via. The bendable electrical interconnection layer may be a lead frame comprising metal pathways that electrically interconnect some or all LED dice in series, in parallel, in anti-parallel, or in some combination of these configurations. Each via contains a thermally conductive material in thermal contact with the corresponding heat spreader below it and in thermal contact with the corresponding LED die above it. The LED dice may be thermally and electrically coupled to submounts disposed above corresponding heat spreaders in some embodiments.

Owner:EPISTAR CORP

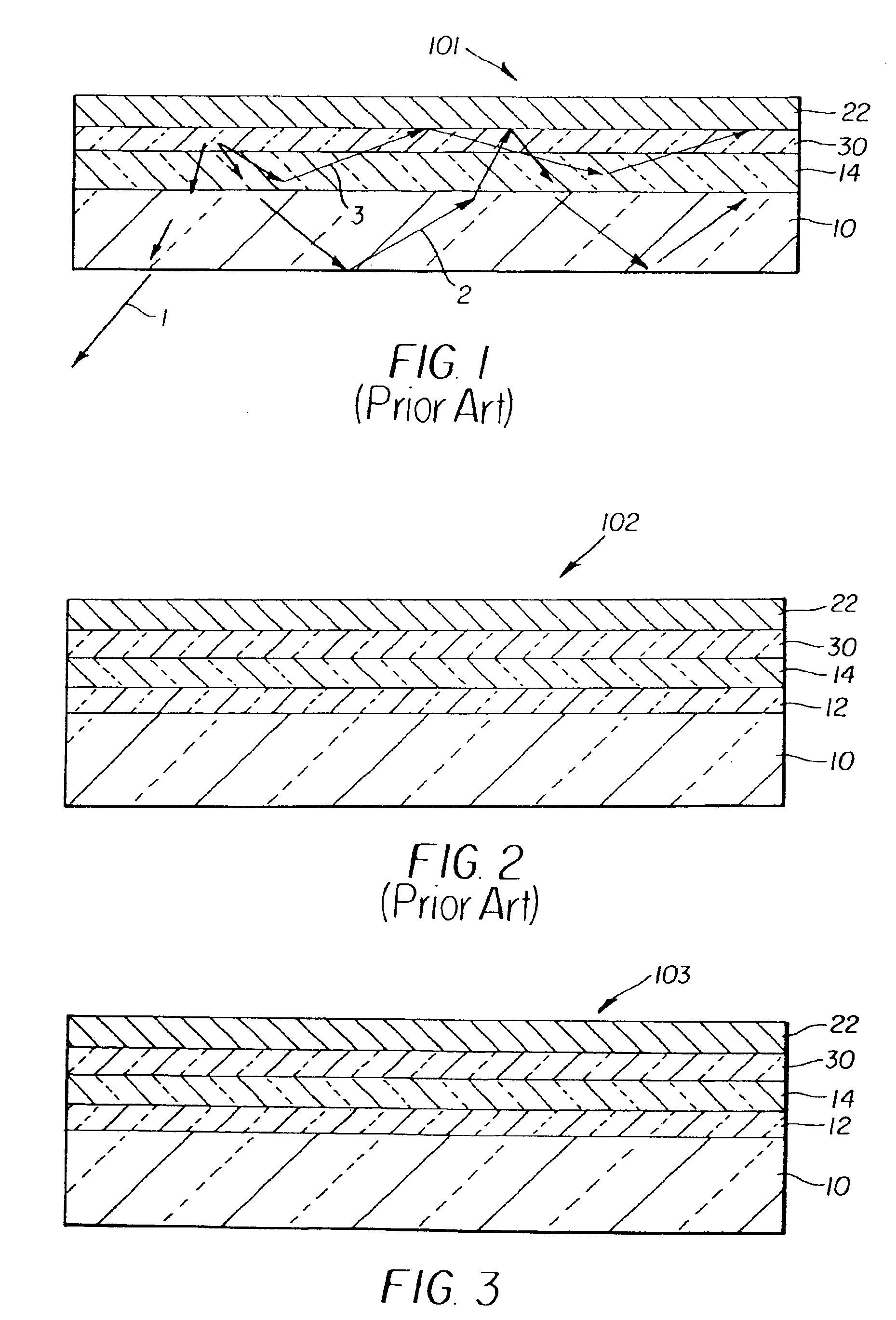

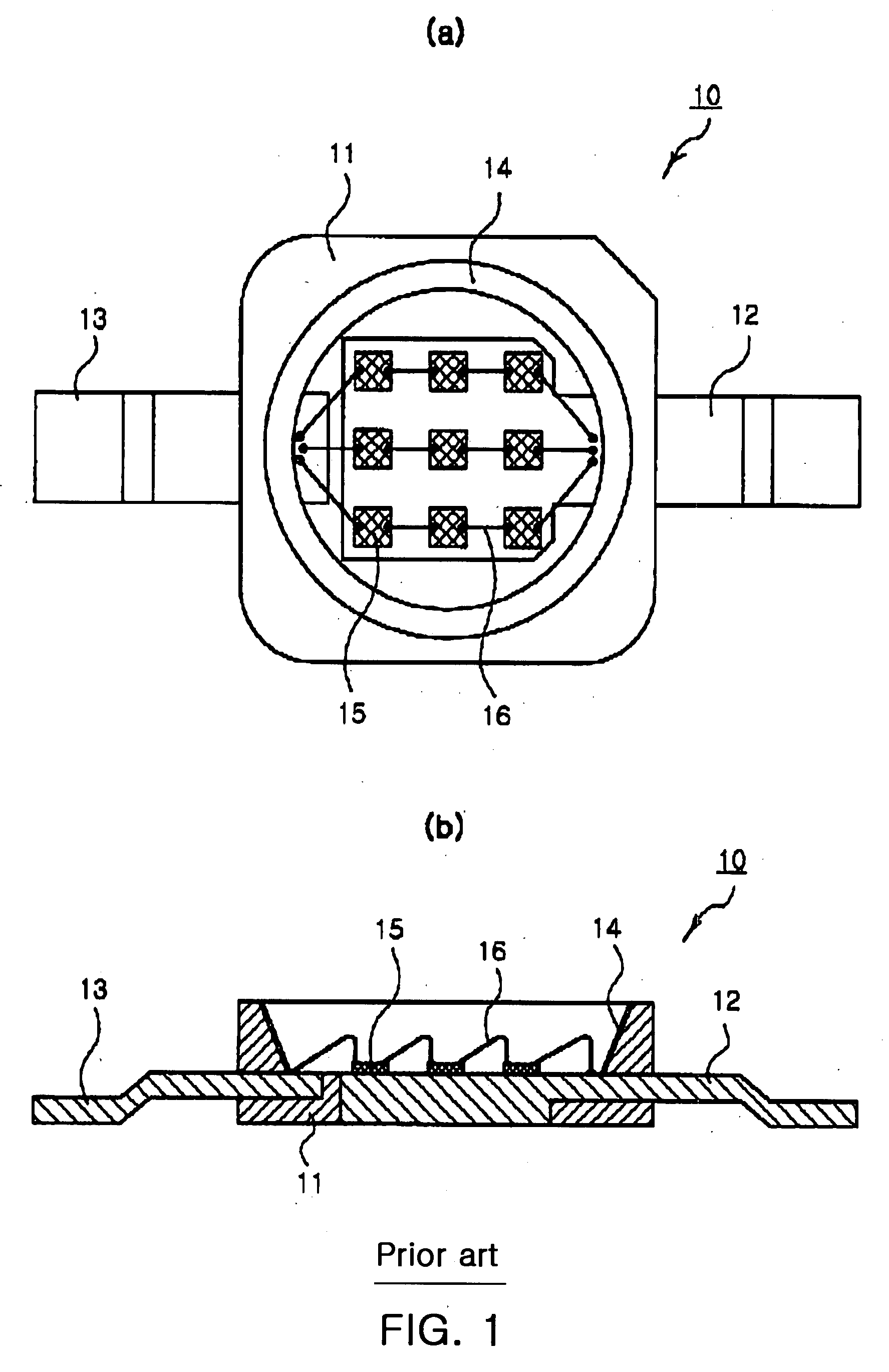

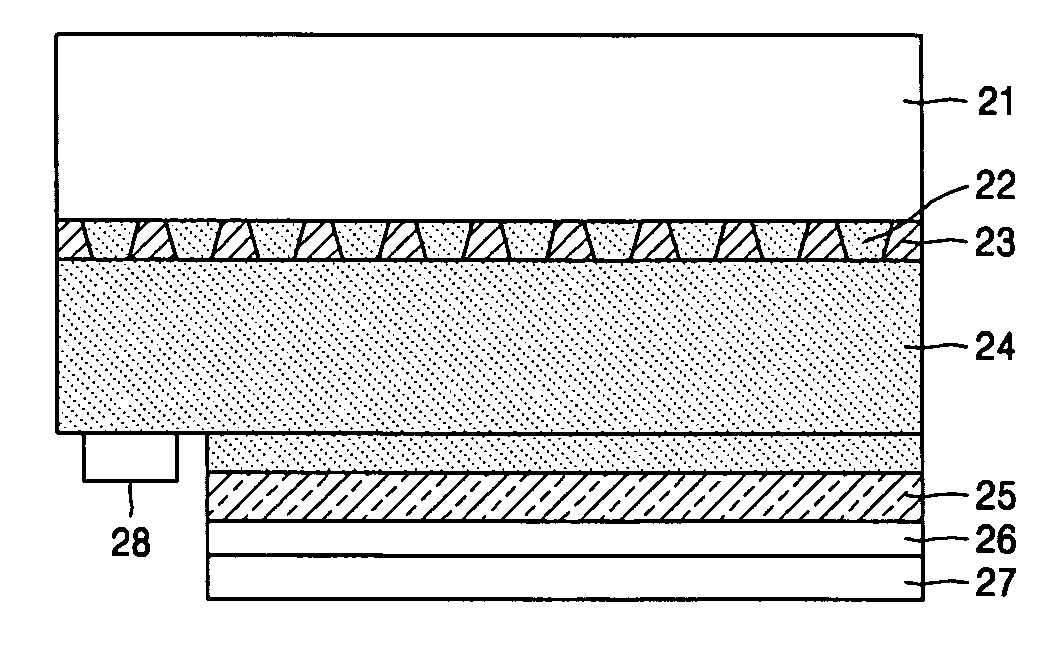

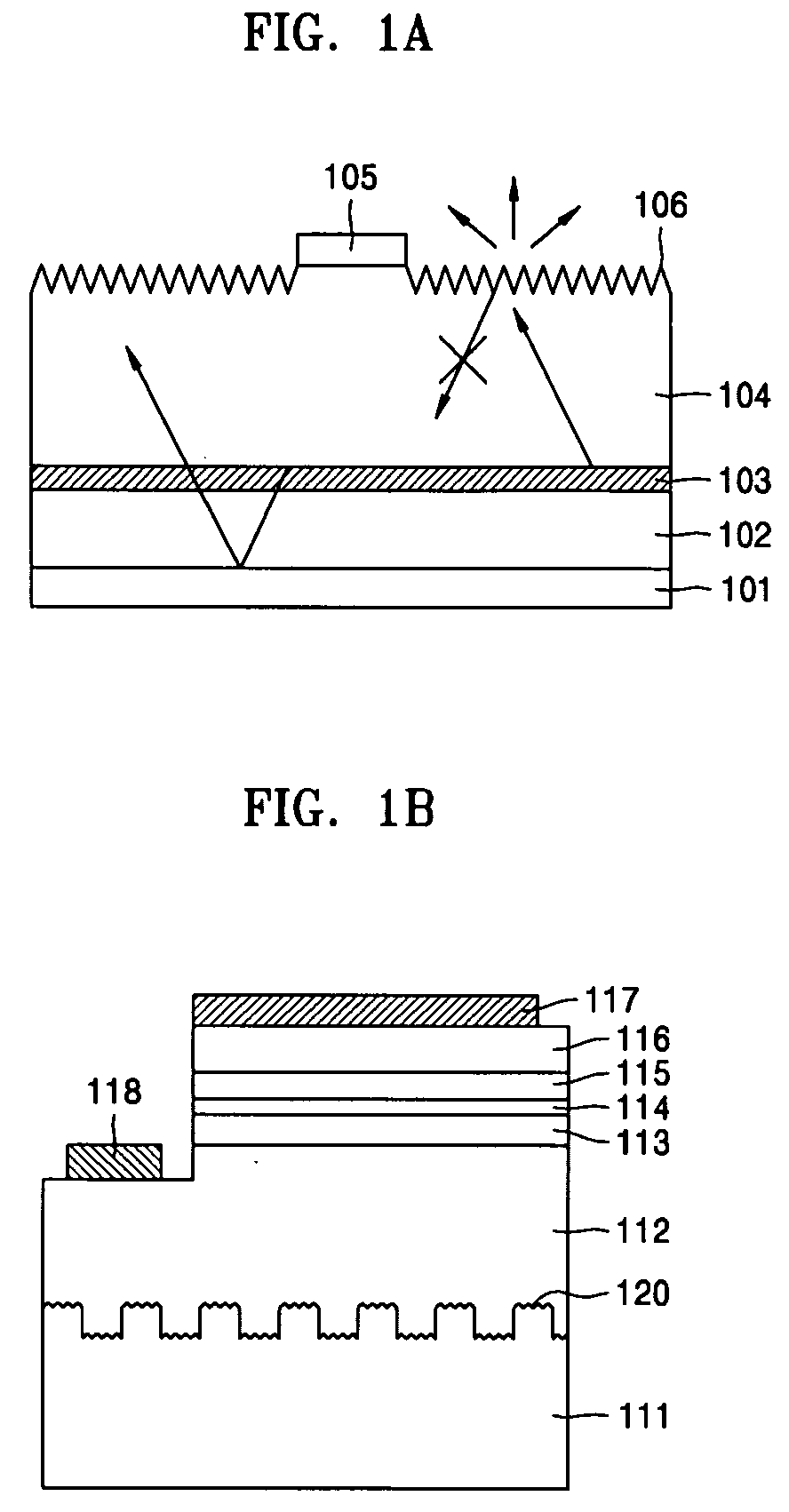

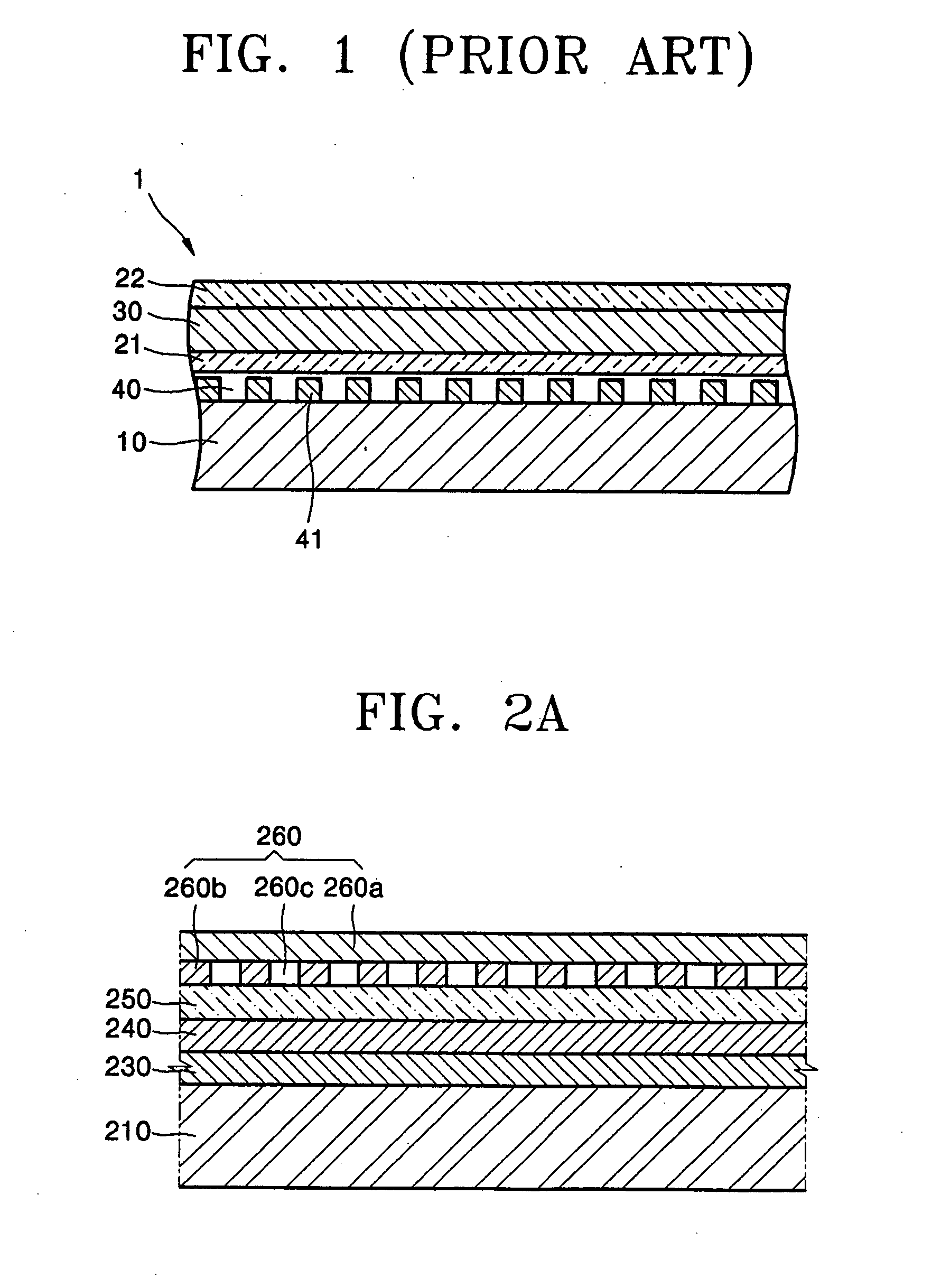

Organic light-emitting device having enhanced light extraction efficiency

InactiveUS6965197B2Light extraction efficiency can be improvedPlanar light sourcesDischarge tube luminescnet screensOrganic light emitting deviceOrganic layer

An enhanced light extraction OLED device including a transparent substrate; light scattering layer disposed over a first surface of the transparent substrate; a transparent first electrode layer disposed over the light scattering layer; an organic EL element disposed over the transparent first electrode layer and including one or more organic layers but at least one light emitting layer in which light is produced; and a transparent second electrode layer disposed over the organic EL element.

Owner:GLOBAL OLED TECH

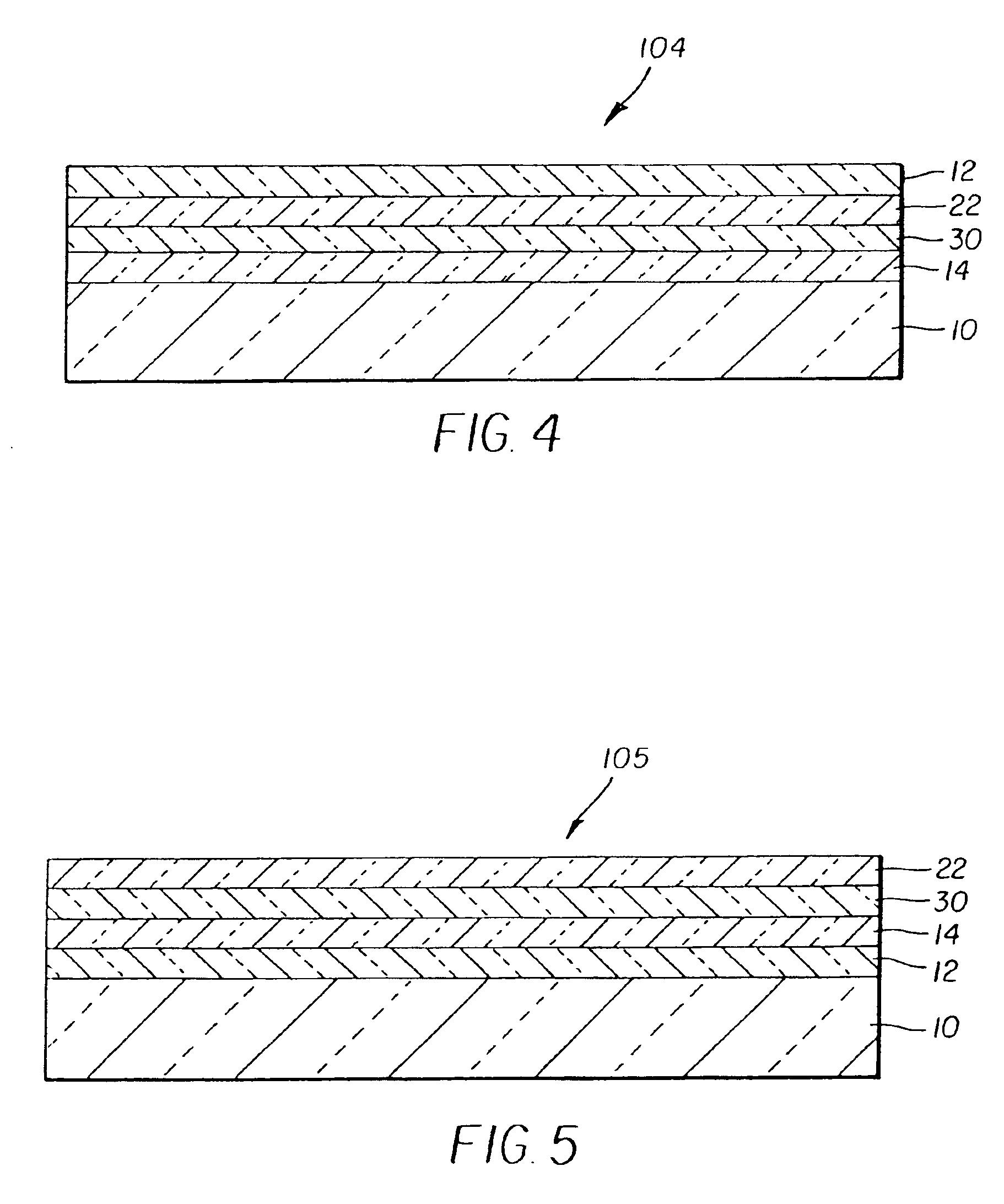

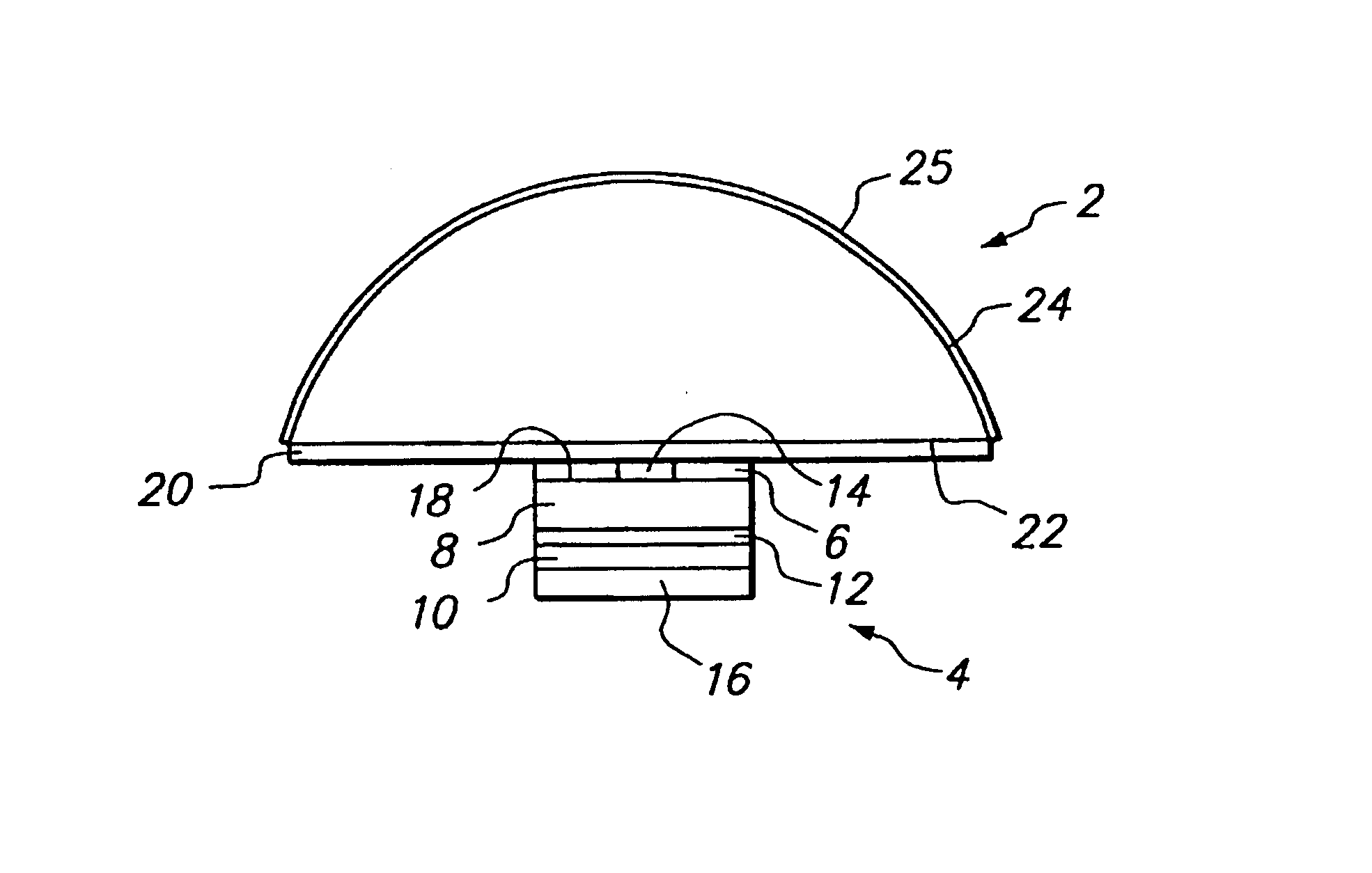

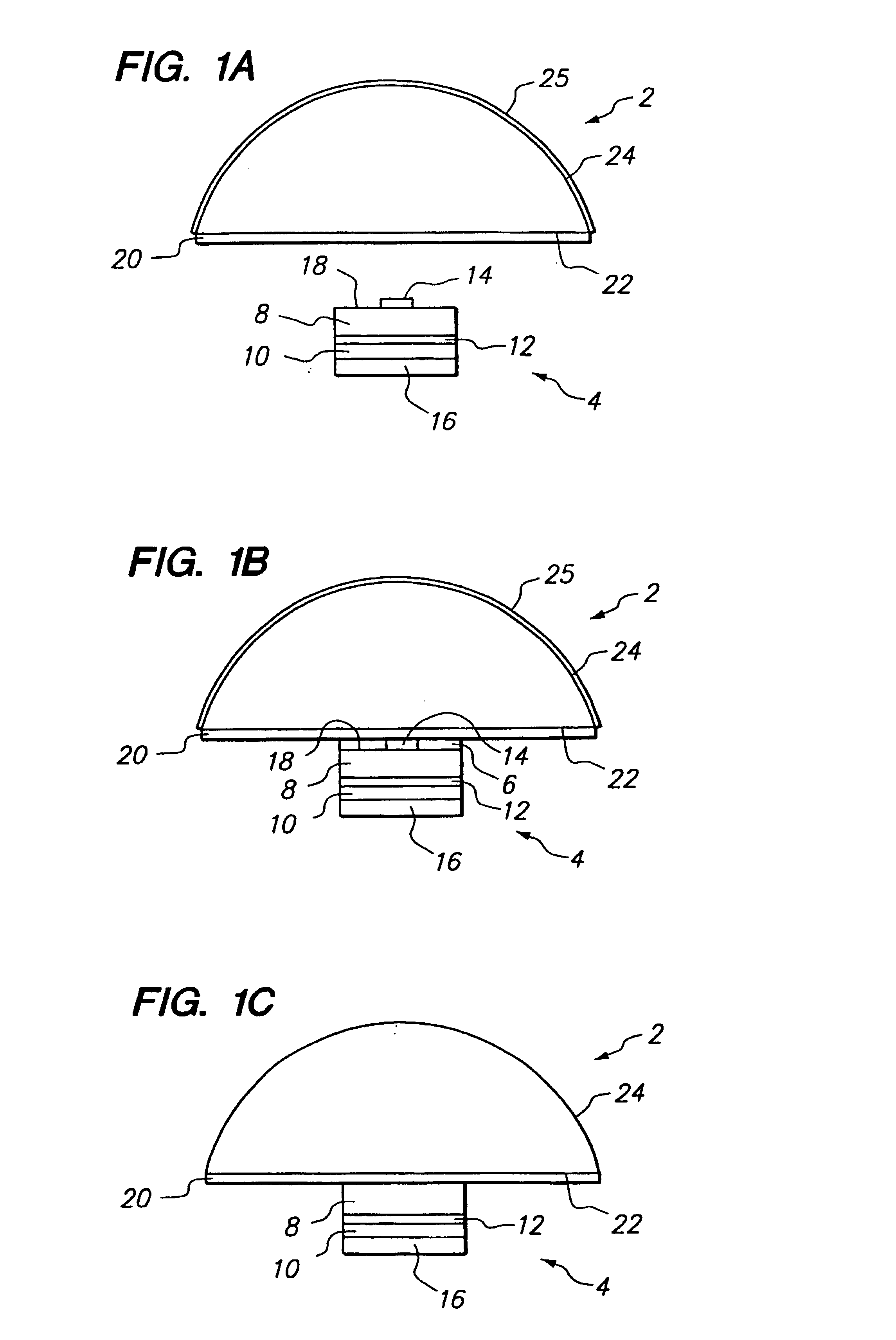

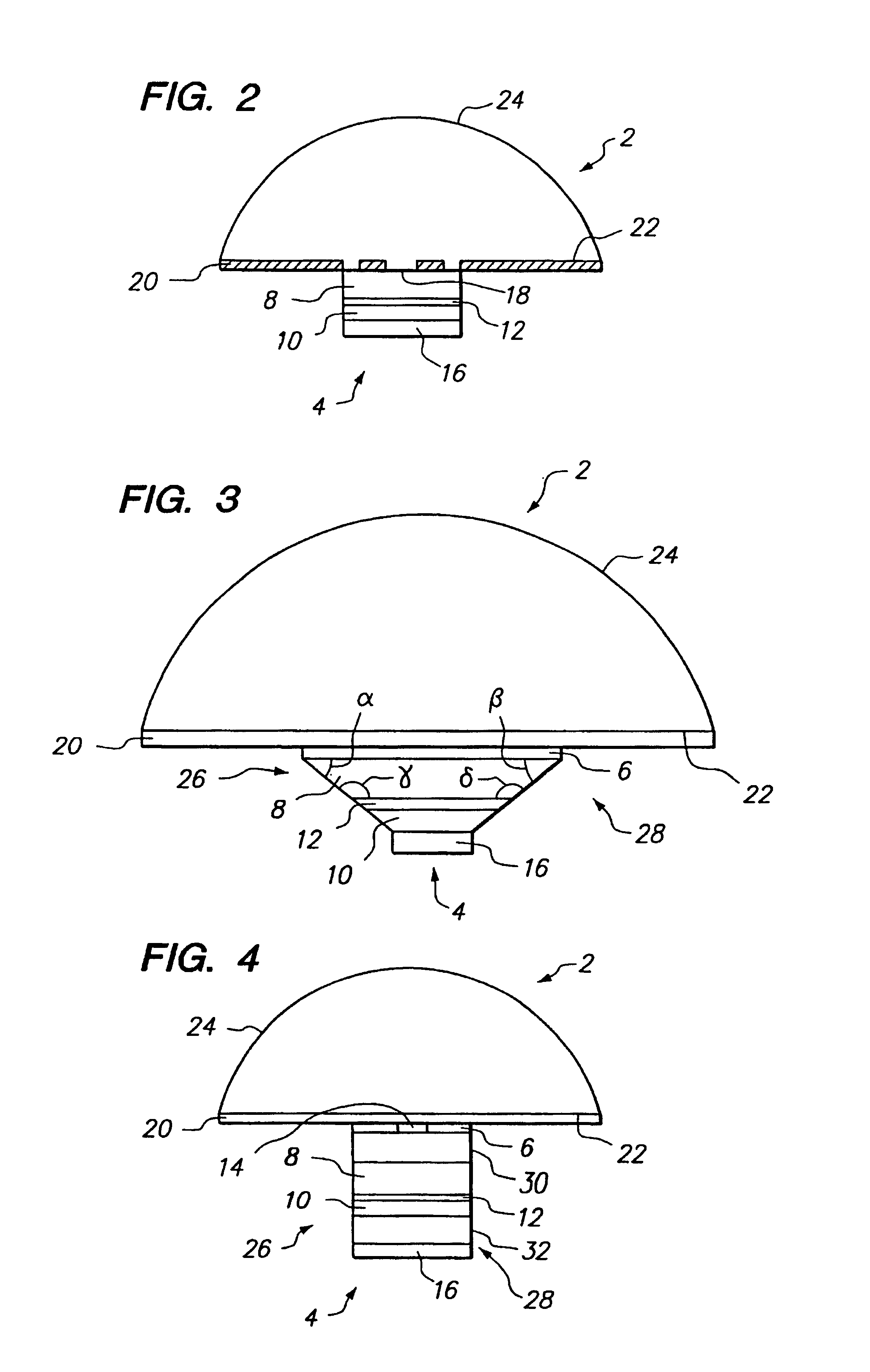

Light emitting diodes with improved light extraction efficiency

InactiveUS7053419B1Light extraction efficiency can be improvedReduce lossesLensSemiconductor devicesTotal internal reflectionRefractive index

Light emitting devices with improved light extraction efficiency are provided. The light emitting devices have a stack of layers including semiconductor layers comprising an active region. The stack is bonded to a transparent lens having a refractive index for light emitted by the active region preferably greater than about 1.5, more preferably greater than about 1.8. A method of bonding a transparent lens to a light emitting device having a stack of layers including semiconductor layers comprising an active region includes elevating a temperature of the lens and the stack and applying a pressure to press the lens and the stack together. Bonding a high refractive index lens to a light emitting device improves the light extraction efficiency of the light emitting device by reducing loss due to total internal reflection. Advantageously, this improvement can be achieved without the use of an encapsulant.

Owner:LUMILEDS

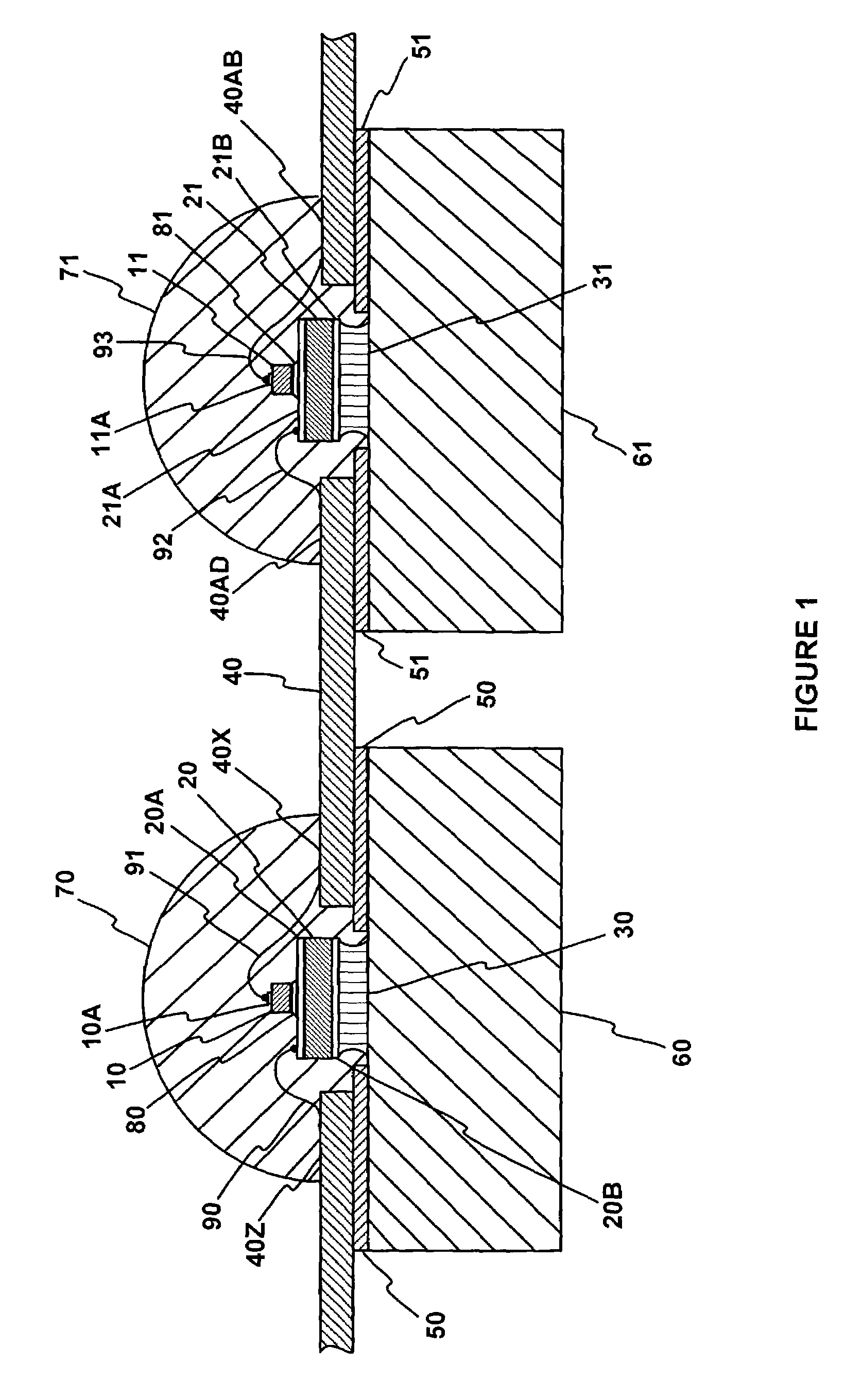

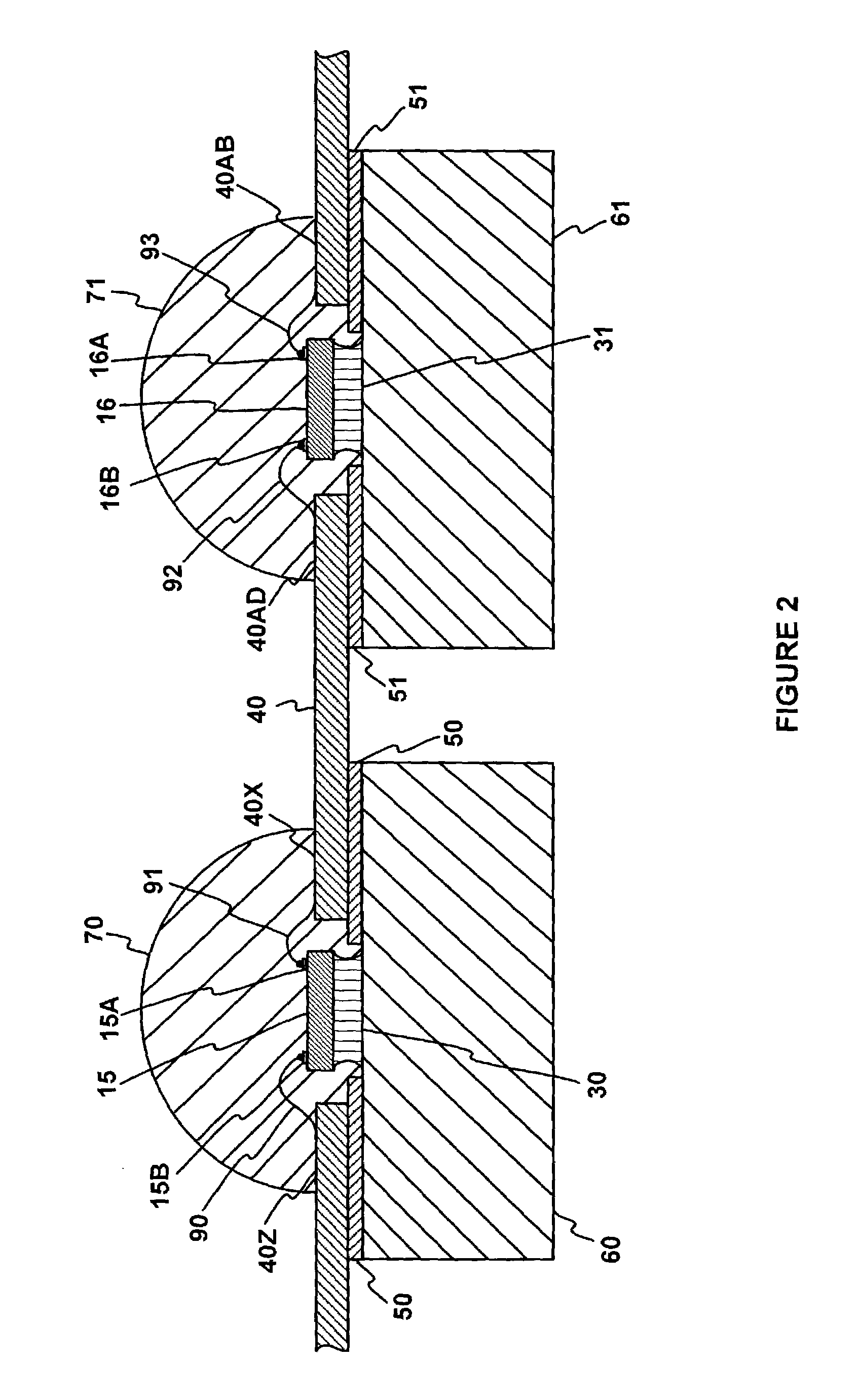

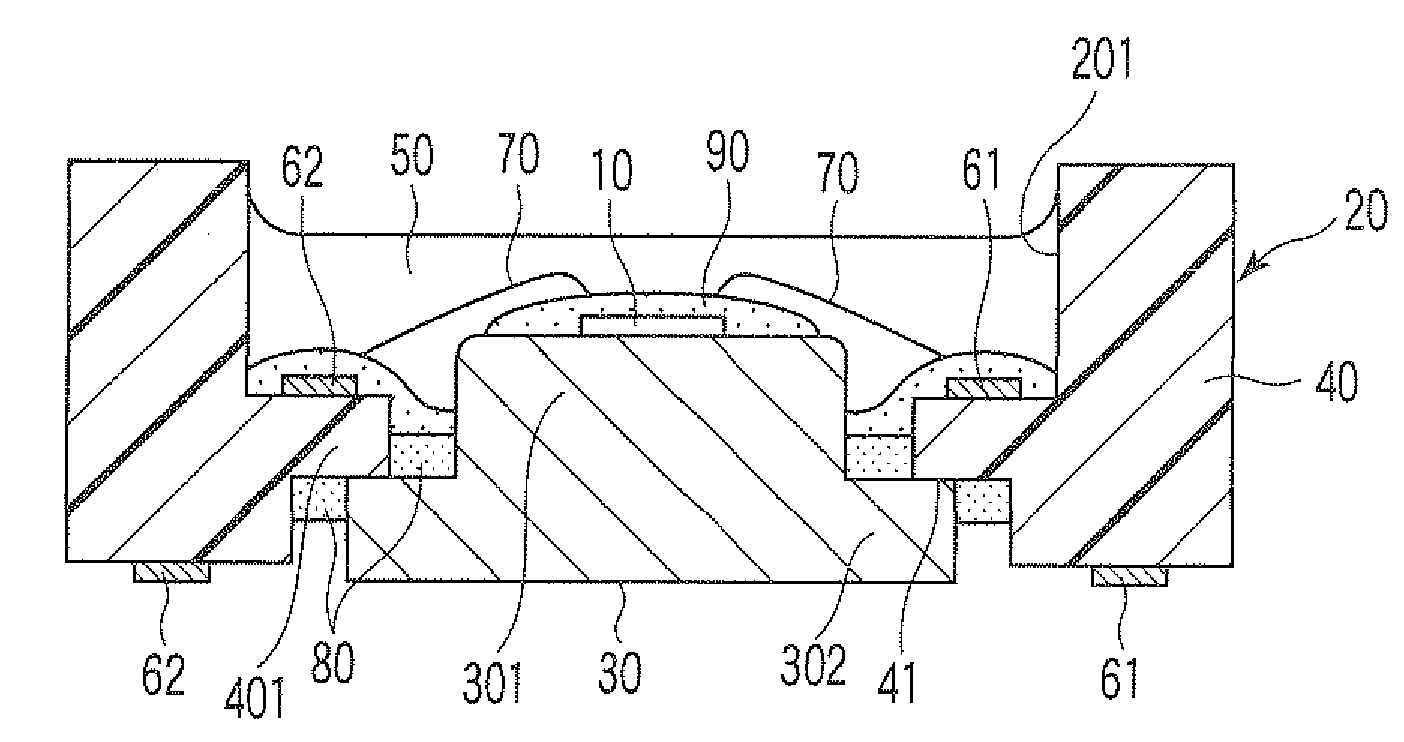

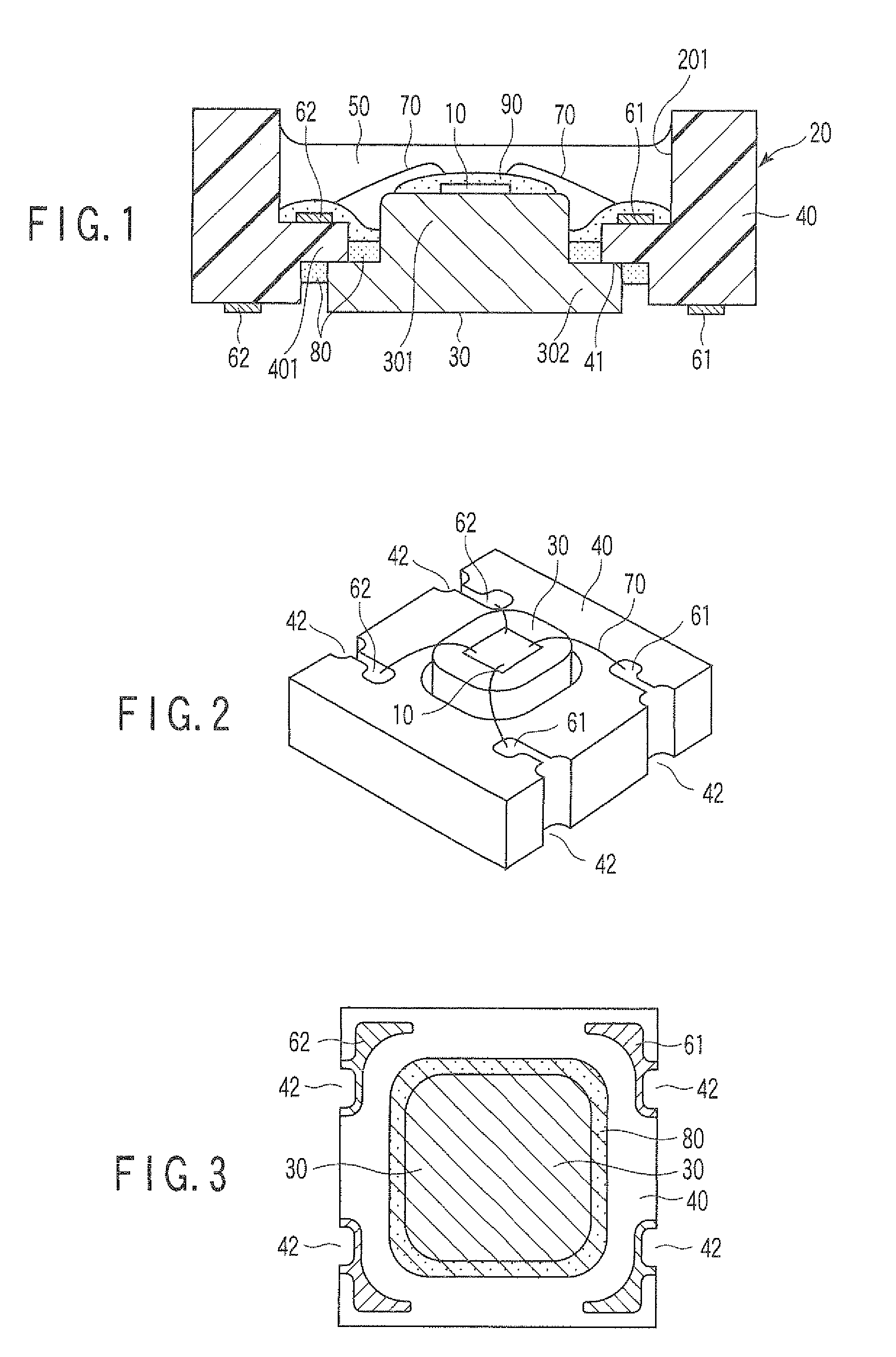

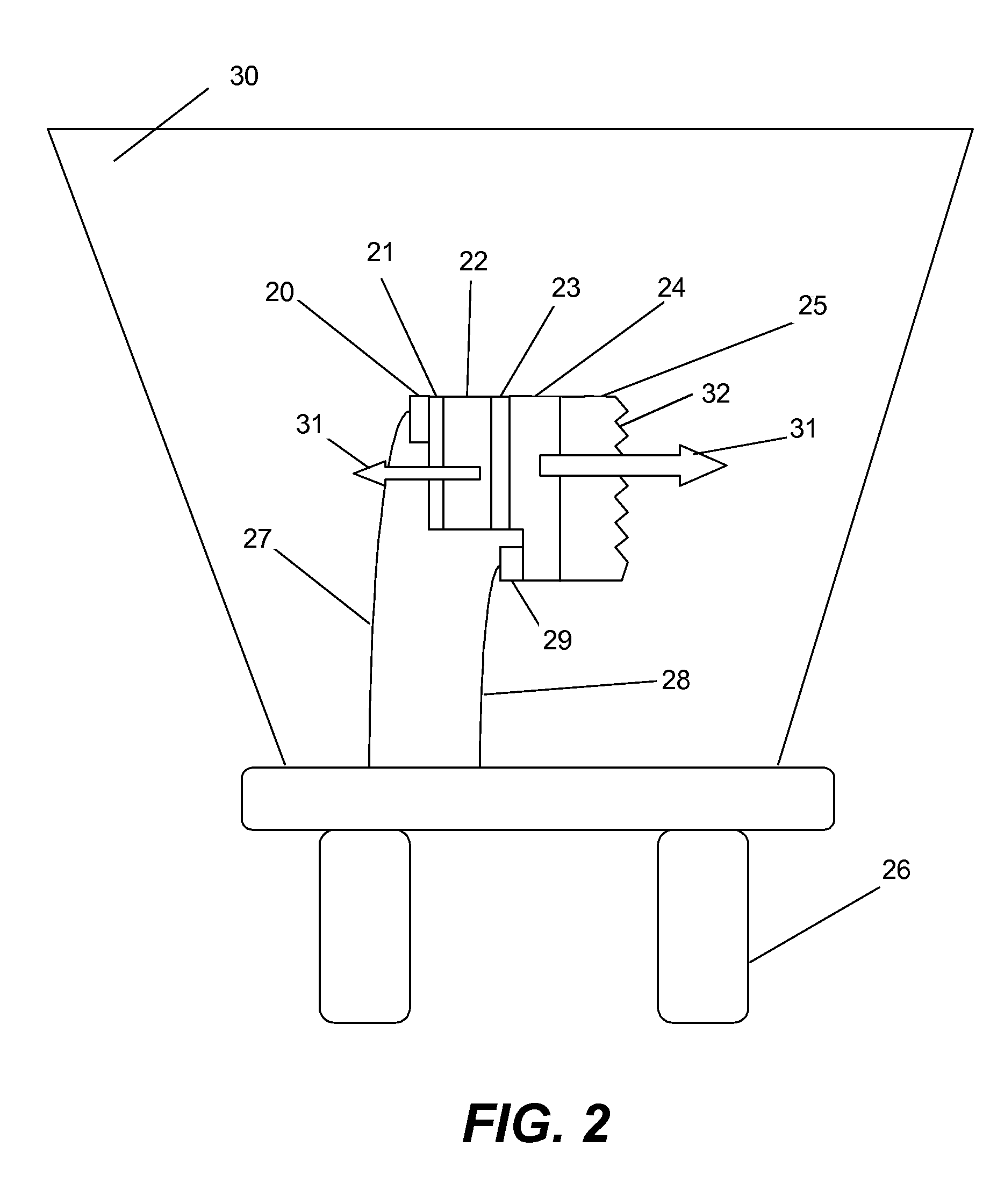

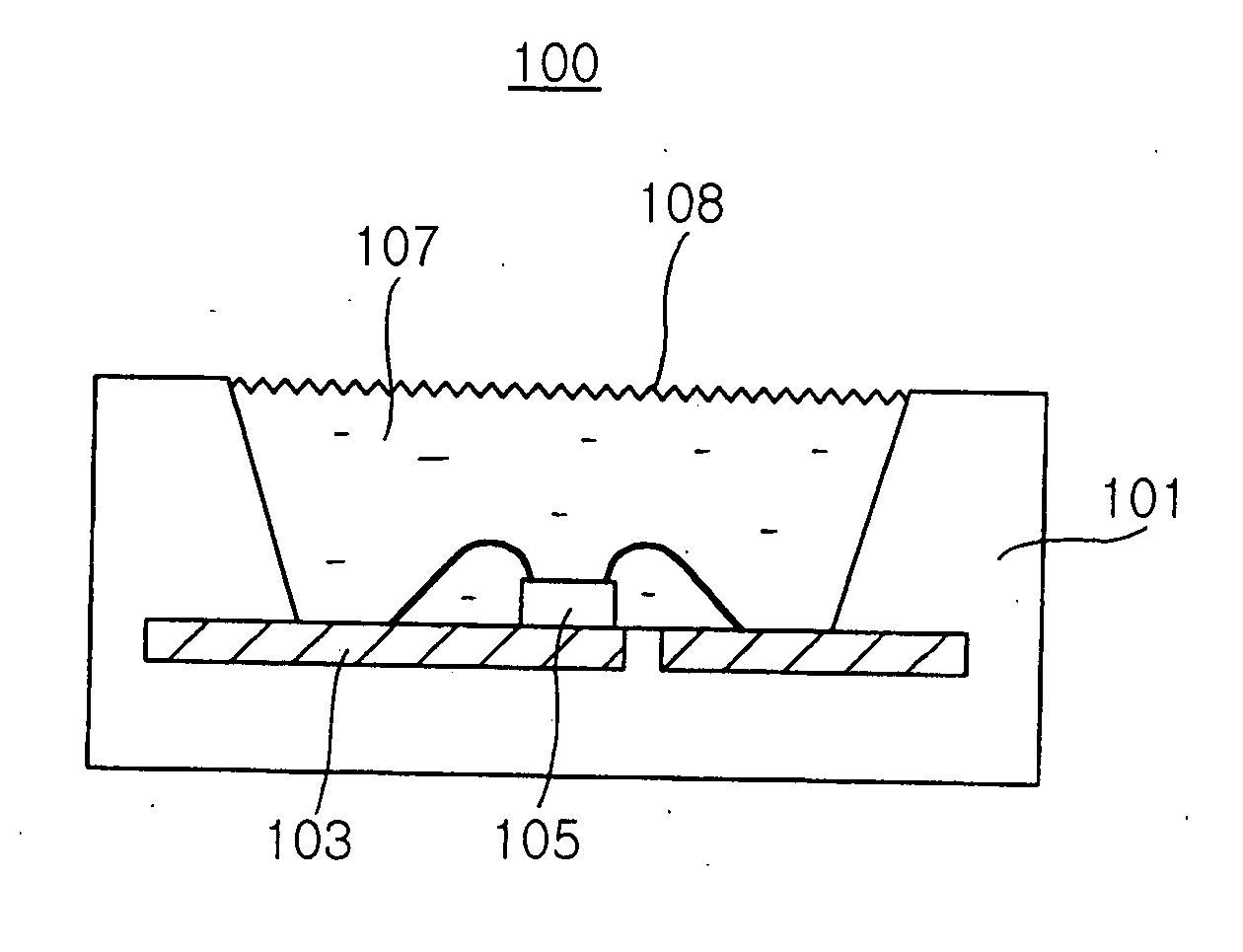

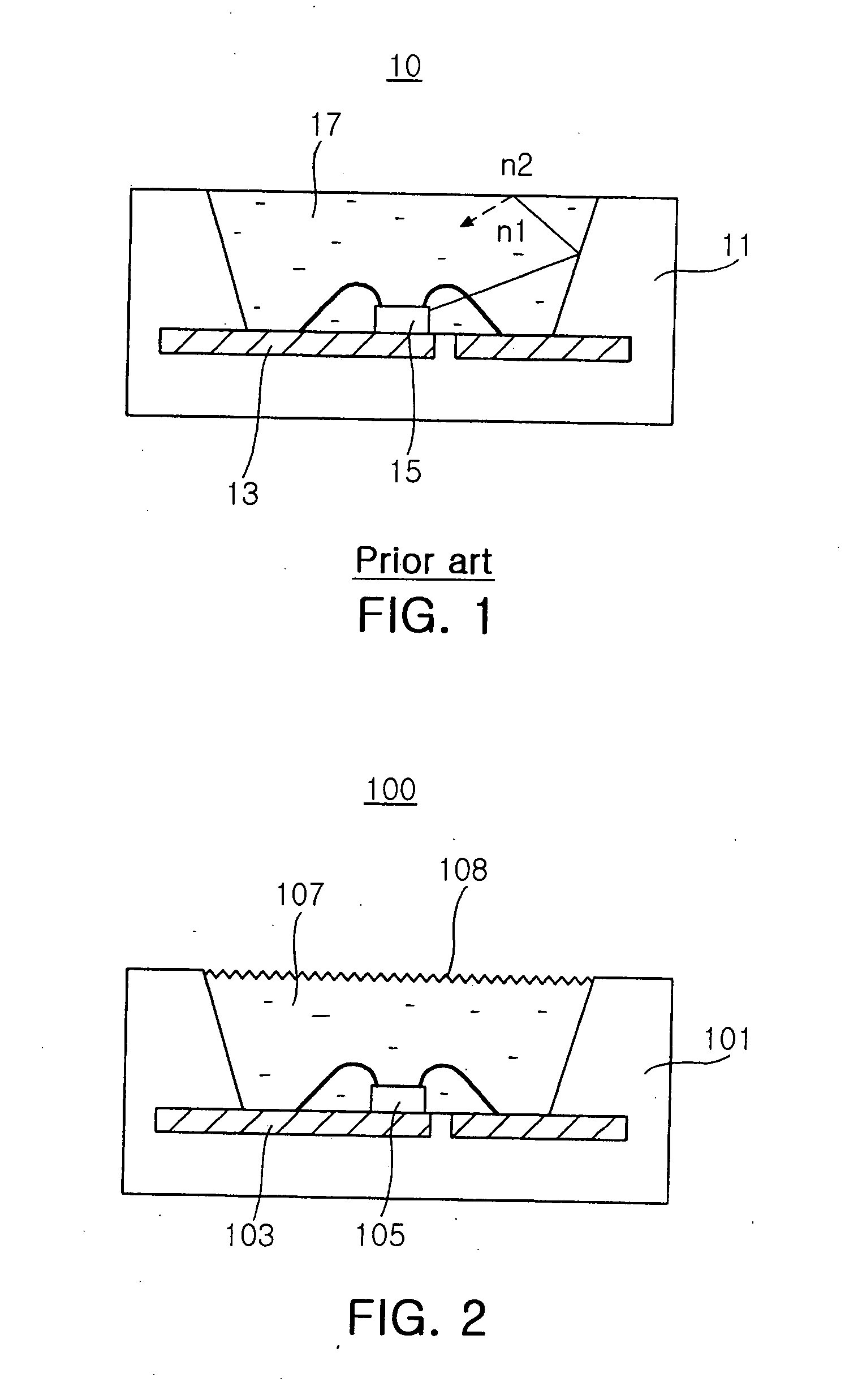

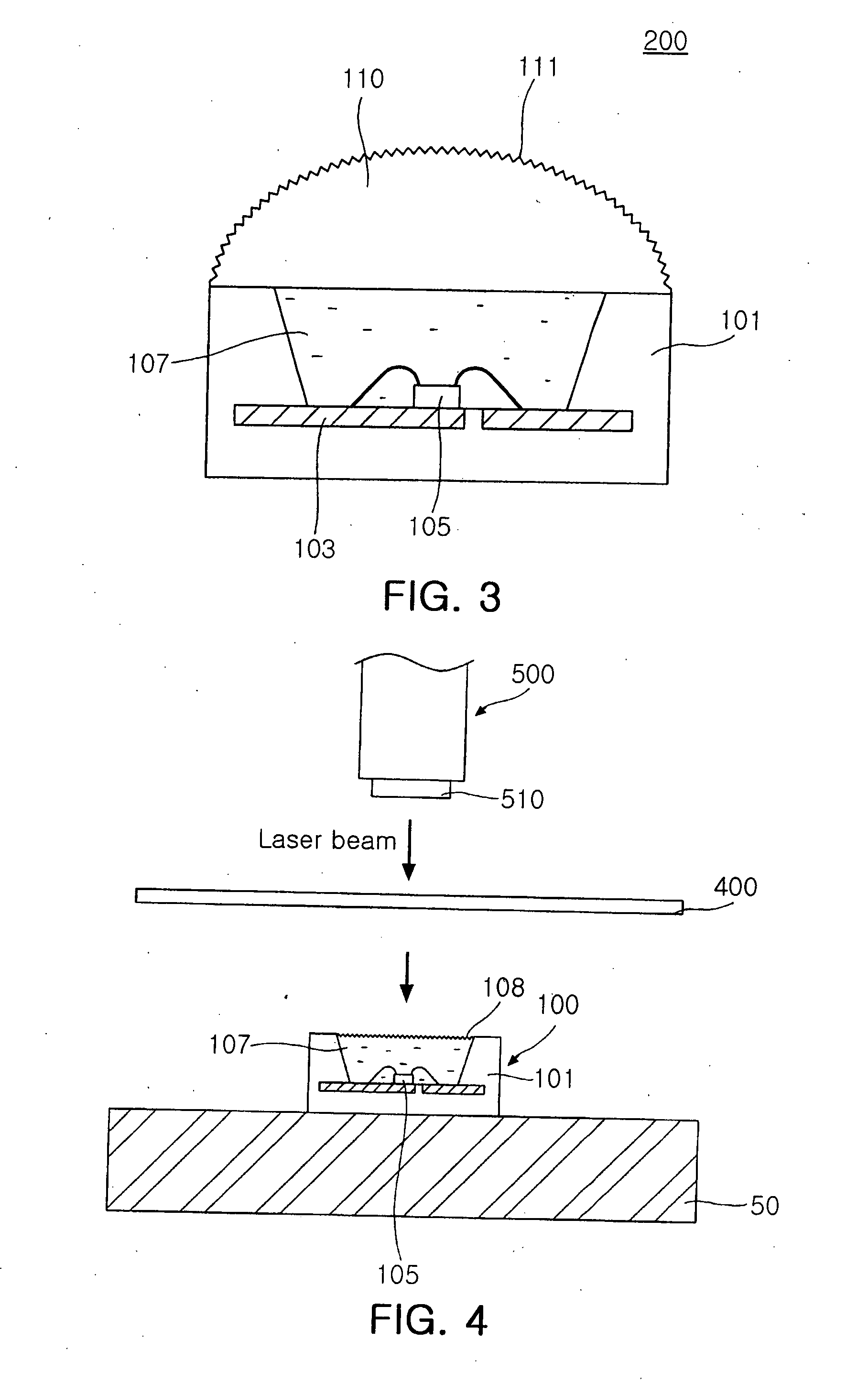

Light-emitting apparatus and method of producing the same

ActiveUS20080149960A1Light extraction efficiency can be improvedSmall color irregularitySolid-state devicesSemiconductor/solid-state device manufacturingLight emitting deviceElectrical and Electronics engineering

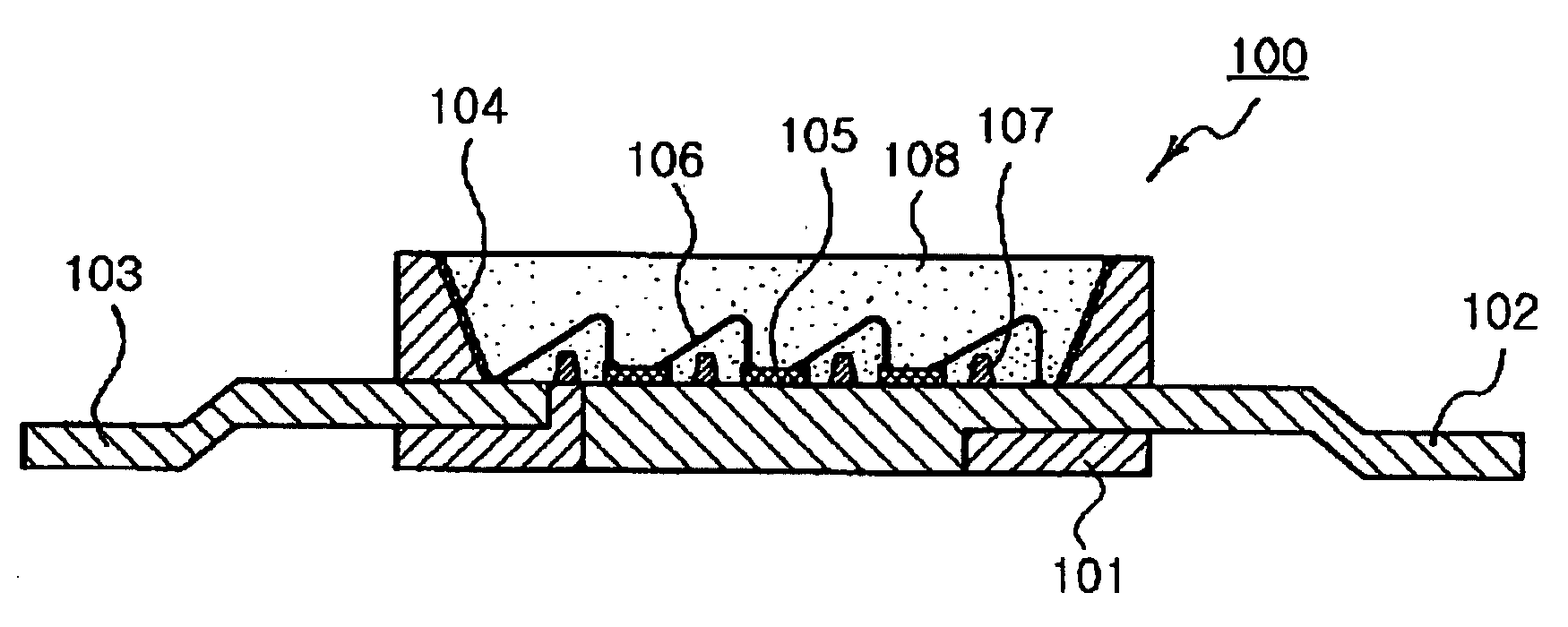

A light-emitting apparatus includes a package including a support having a central section and a peripheral section around the central section. The central section is raised upwardly from the peripheral section, providing a pedestal for supporting a light-emitting device. A light-emitting device secured on an upper surface of the pedestal and has electrodes. Electrically conductive members are provided on a peripheral region of the package and electrically connected to the electrodes of the light-emitting device. A color conversion layer covers the light-emitting device. A light-transmitting member is formed in the package, sealing at least the light-emitting device together with the color conversion layer. The pedestal has its side surface at least partially exposed from the color conversion layer.

Owner:NICHIA CORP

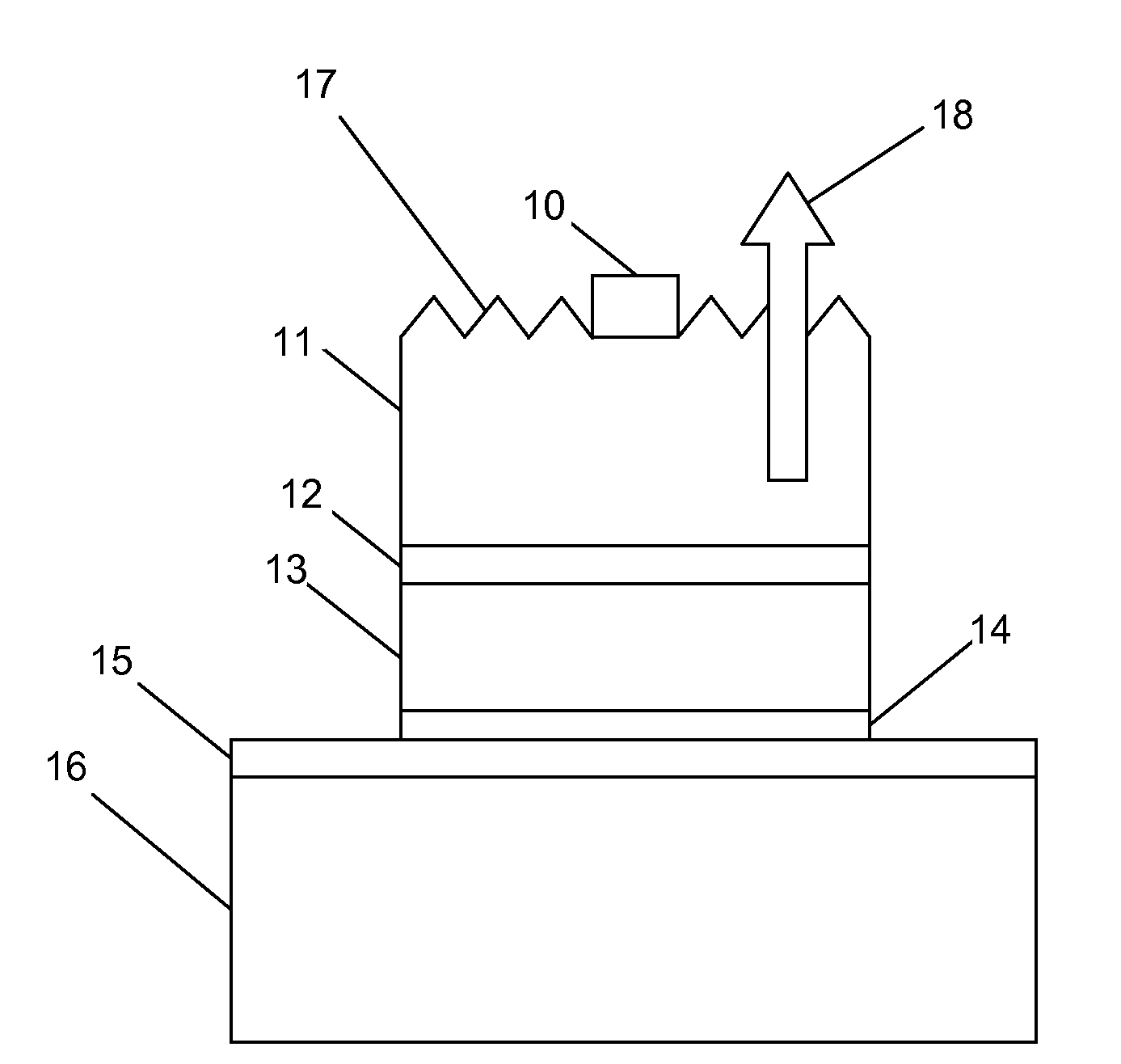

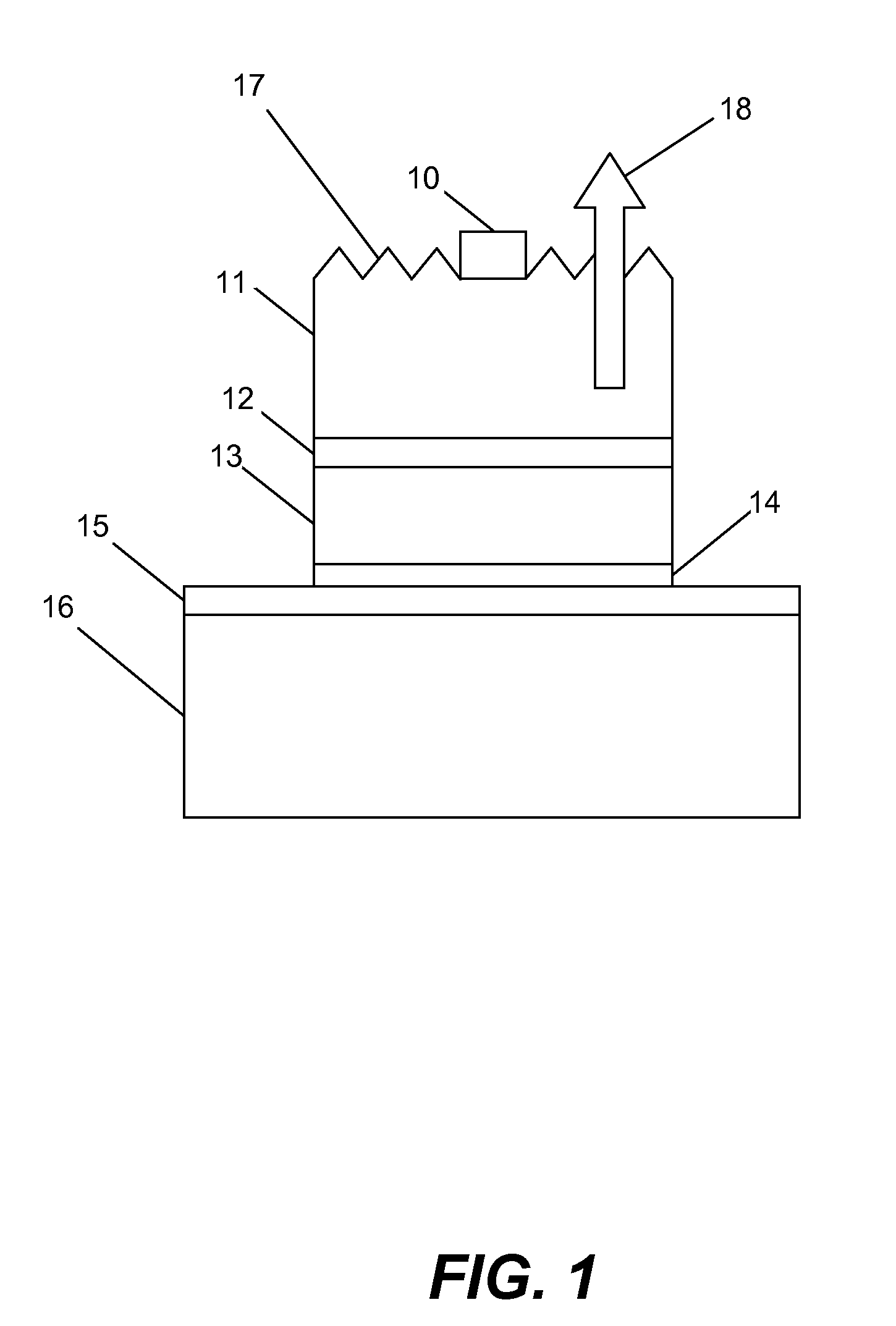

High light extraction efficiency nitride based light emitting diode by surface roughening

ActiveUS20090146170A1Reduce the angle of incidenceIncrease the angle of incidenceSemiconductor/solid-state device manufacturingSemiconductor devicesEtchingNitride

A III-nitride light emitting diode (LED) and method of fabricating the same, wherein at least one surface of a semipolar or nonpolar plane of a III-nitride layer of the LED is textured, thereby forming a textured surface in order to increase light extraction. The texturing may be performed by plasma assisted chemical etching, photolithography followed by etching, or nano-imprinting followed by etching.

Owner:RGT UNIV OF CALIFORNIA

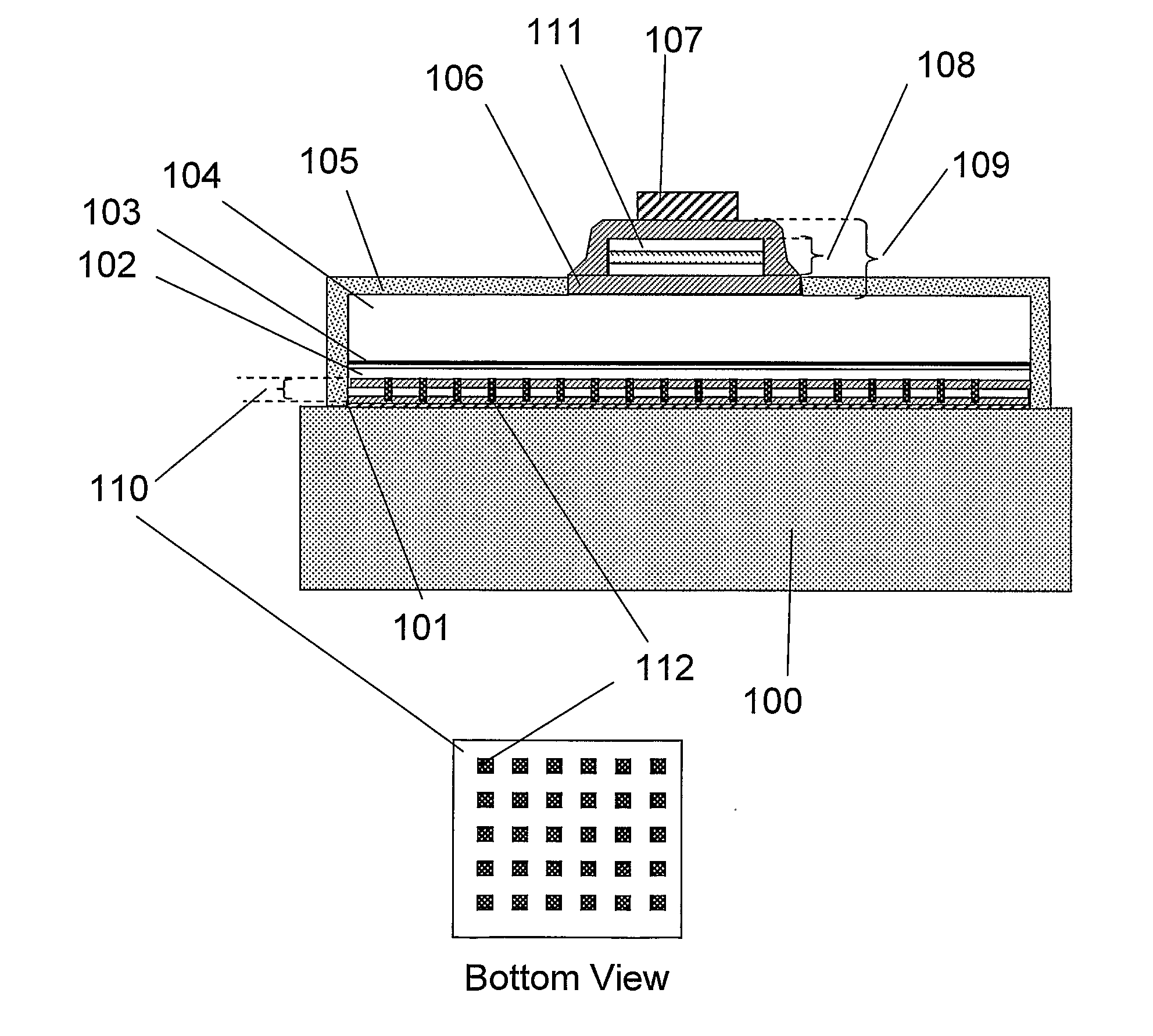

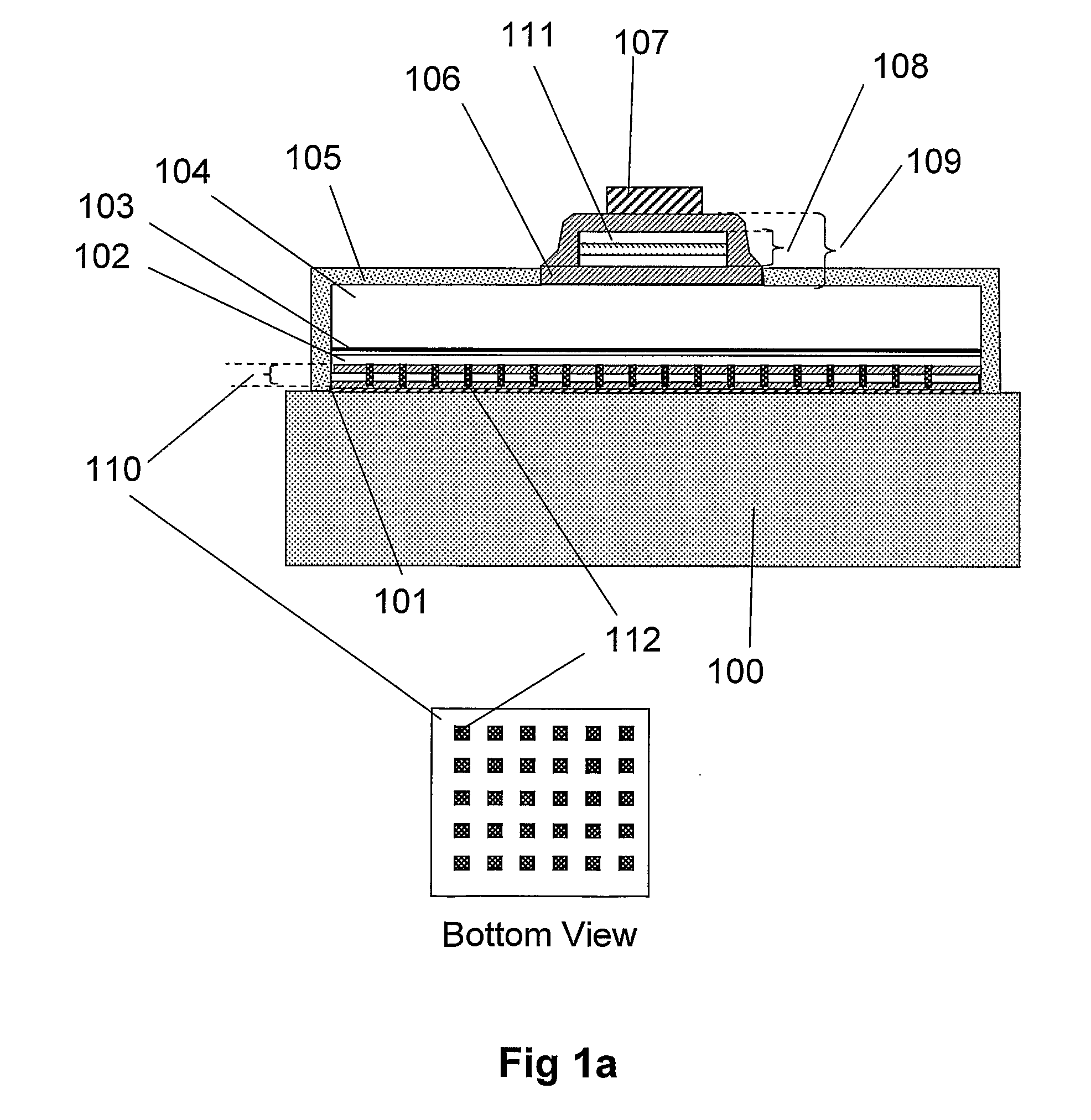

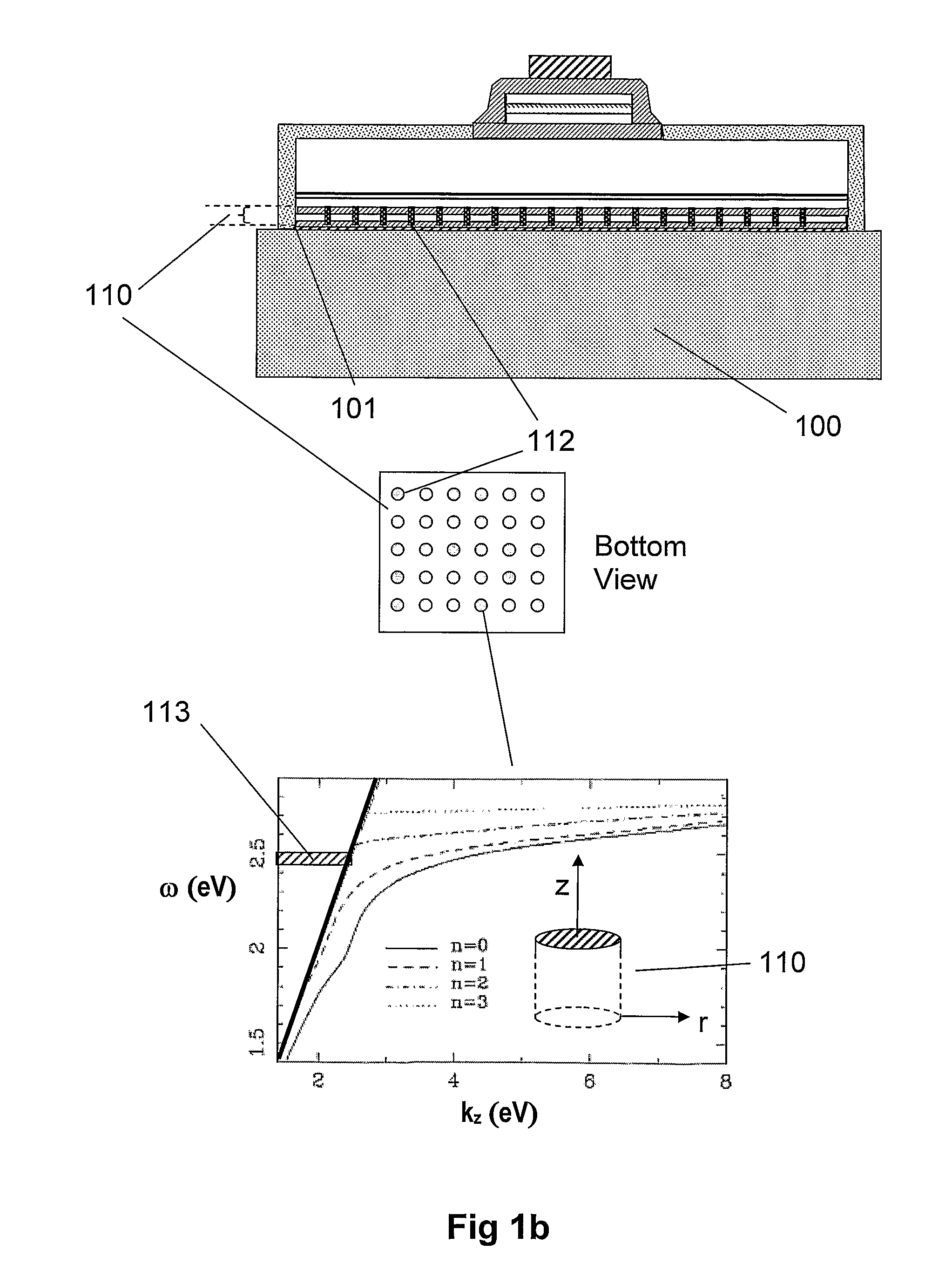

Vertical LED with conductive vias

ActiveUS20100213485A1Maximizing light extractionLight extraction efficiency can be improvedSolid-state devicesSemiconductor/solid-state device manufacturingSurface plasmonHigh reflectivity

A light emitting device comprises a novel low-loss array of conductive vias embedded in a dielectric multilayer stack, to act as an electrically-conductive, low-loss, high-reflectivity reflector layer (CVMR). In one example the CVMR stack is employed between a reflective metal bottom contact and a p-GaN semiconductor flip chip layer. The CVMR stack comprises at least (3) layers with at least (2) differing dielectric constants. The conductive vias are arranged such that localised and propagating surface plasmons associated with the structure reside within the electromagnetic stopband of the CVMR stack, which in turn inhibits trapped LED modes coupling into these plasmonic modes, thereby increasing the overall reflectivity of the CVM R. This technique improves optical light extraction and provides a vertical conduction path for optimal current spreading in a semiconductor light emitting device. A light emitting module and method of manufacture are also described.

Owner:LUMILEDS HLDG BV

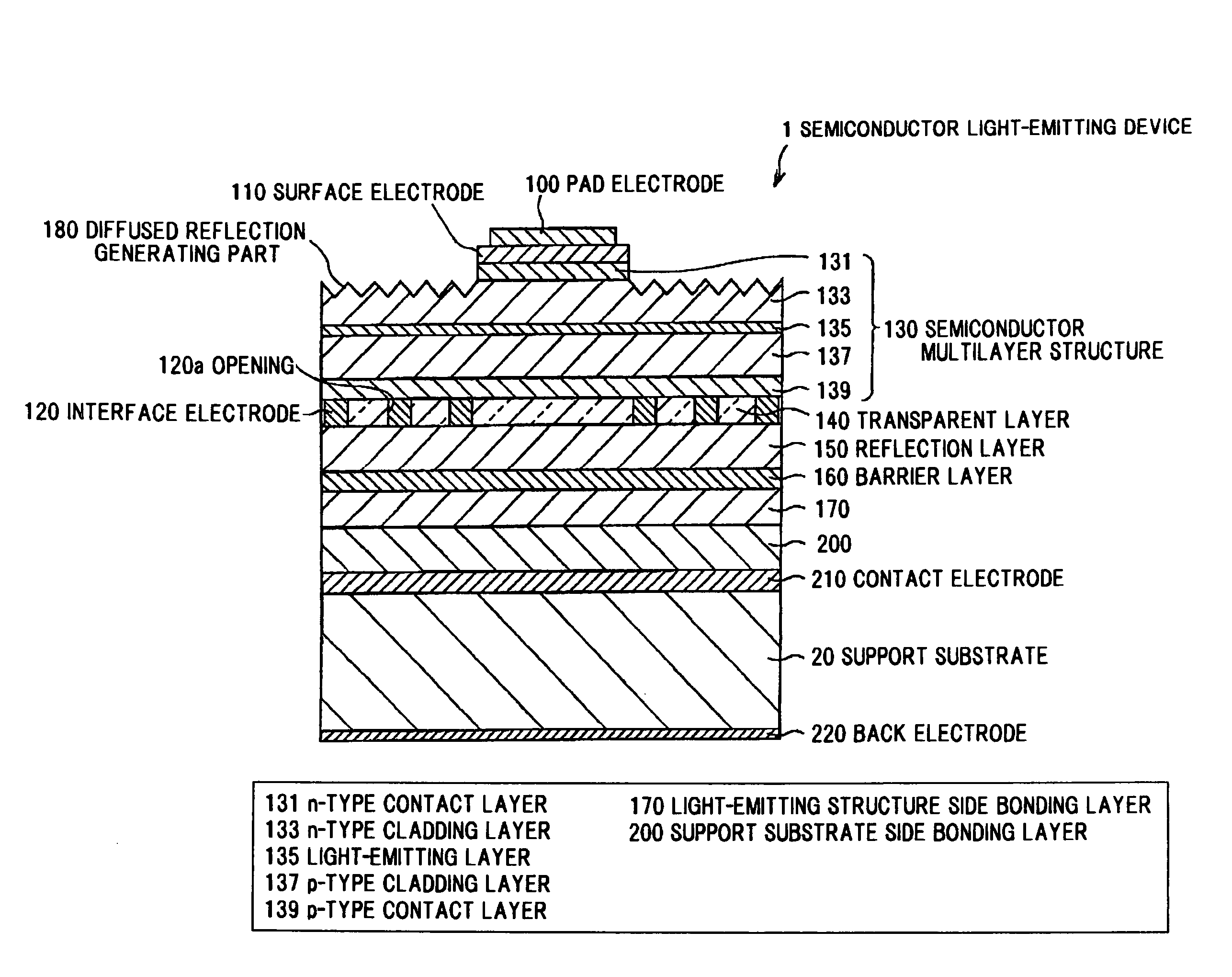

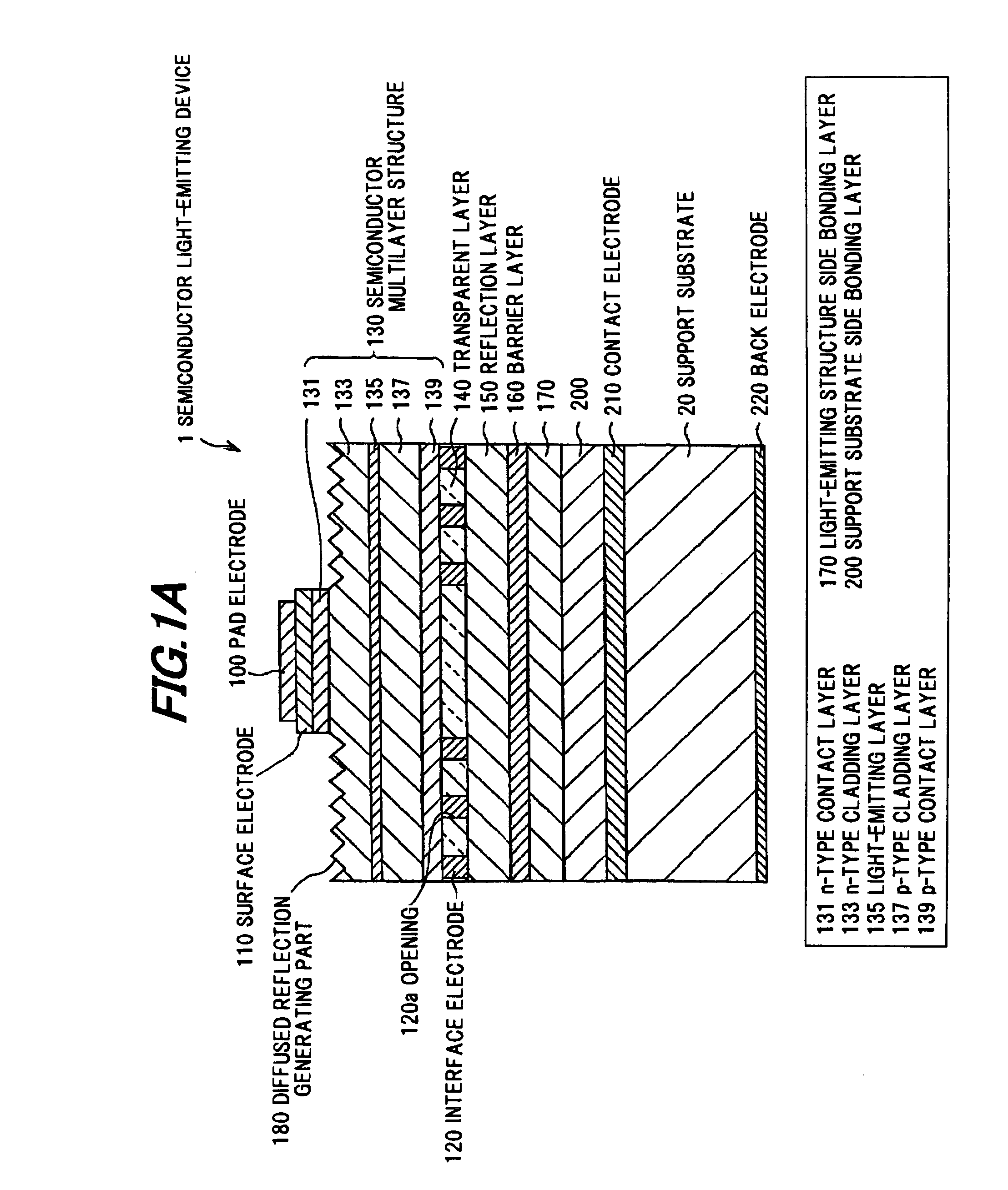

Semiconductor light-emitting device

InactiveUS20090206354A1Light extraction efficiency be improveImprove provabilitySolid-state devicesSemiconductor devicesEngineeringMetallic materials

A semiconductor light-emitting device includes a support structure, and a light-emitting structure. The support structure includes a support substrate, and a support substrate side bonding layer disposed on one surface of the support substrate. The light-emitting structure includes a light-emitting structure side bonding layer bonded to the support substrate side bonding layer, a reflection region disposed on the support substrate side bonding layer opposite the support substrate, and a semiconductor multilayer structure including a light-emitting layer disposed on the reflection region opposite the light-emitting structure side bonding layer for emitting a light with a predetermined wavelength, and a light-extraction surface disposed on the light-emitting layer opposite the reflection region for reflecting diffusely the light. The reflection region includes a transparent layer of a material with a lower refractive index than that of the semiconductor multilayer structure, and a reflection layer of a metallic material. The transparent layer has such a thickness that interference caused by multiple reflection of light inputted to the transparent layer can be suppressed.

Owner:SUMITOMO CHEM CO LTD

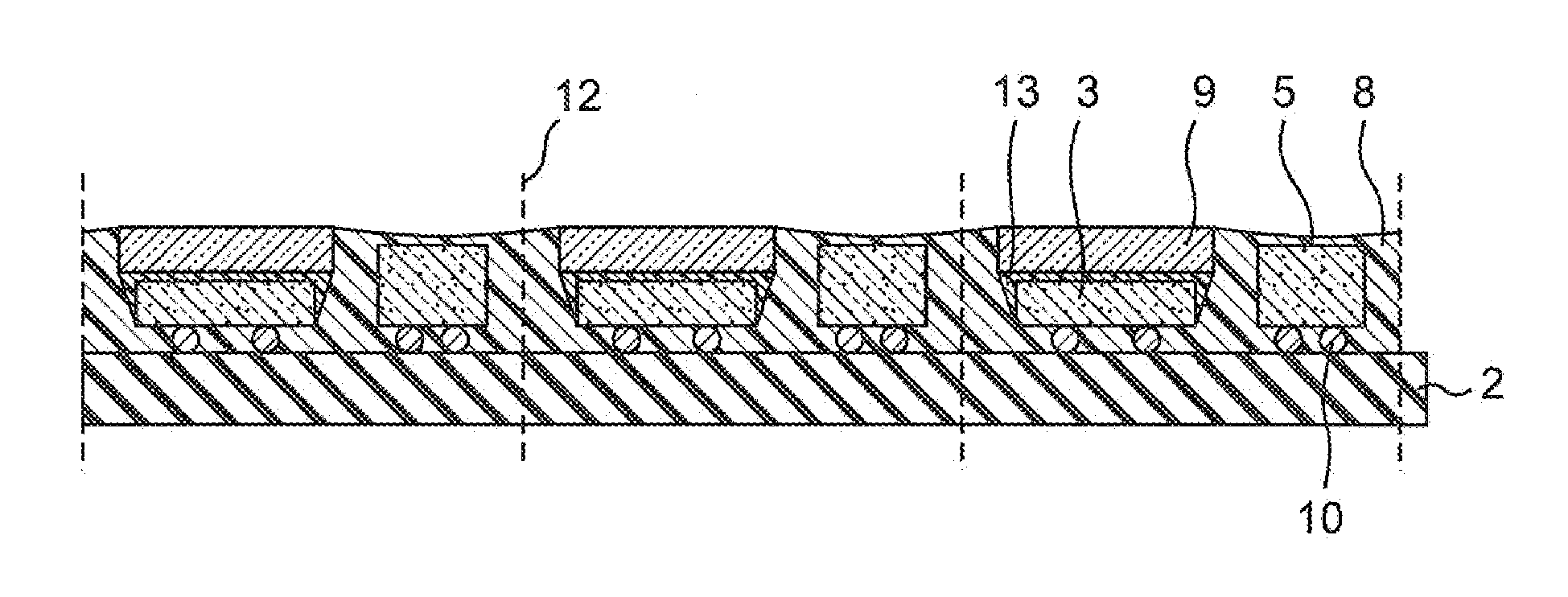

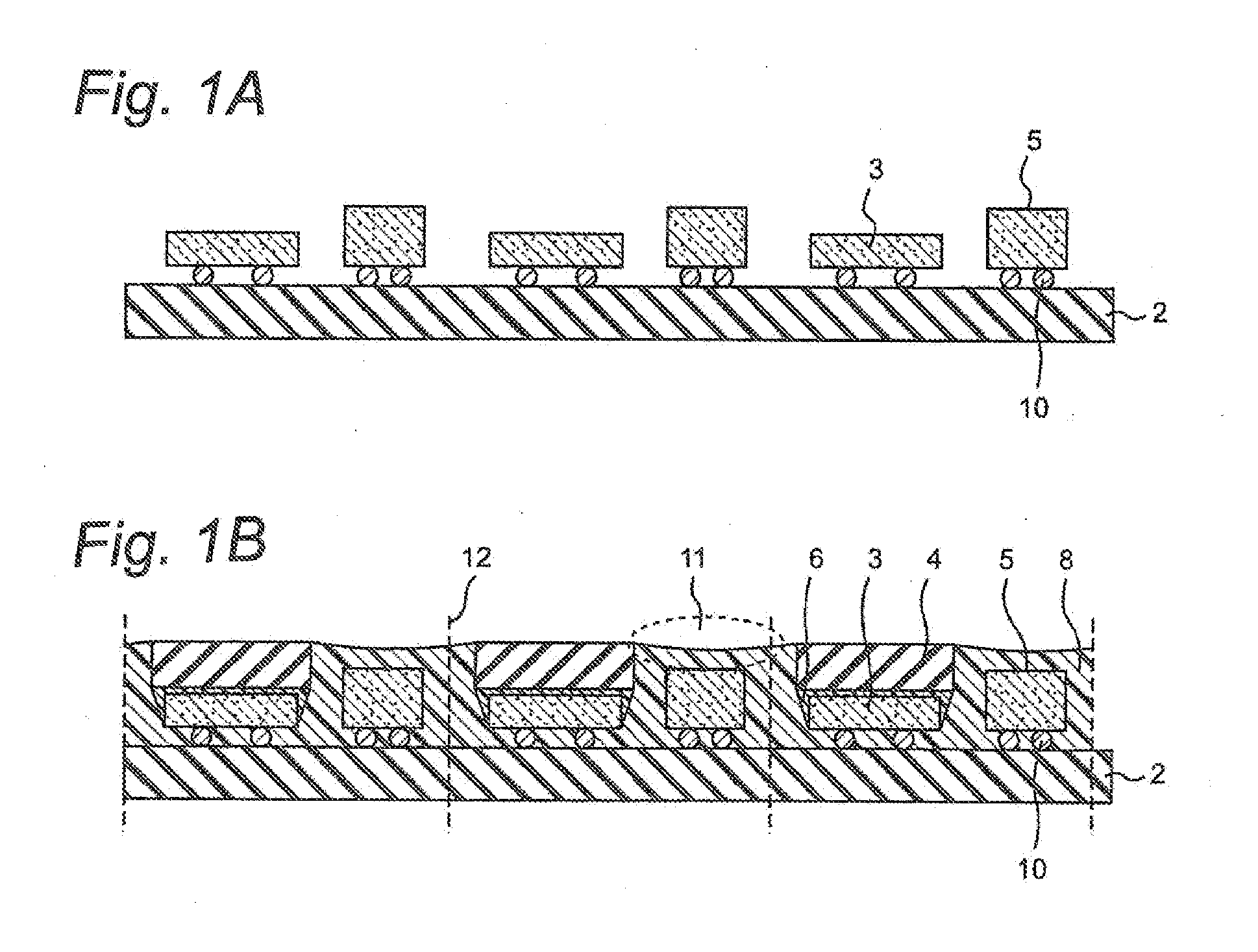

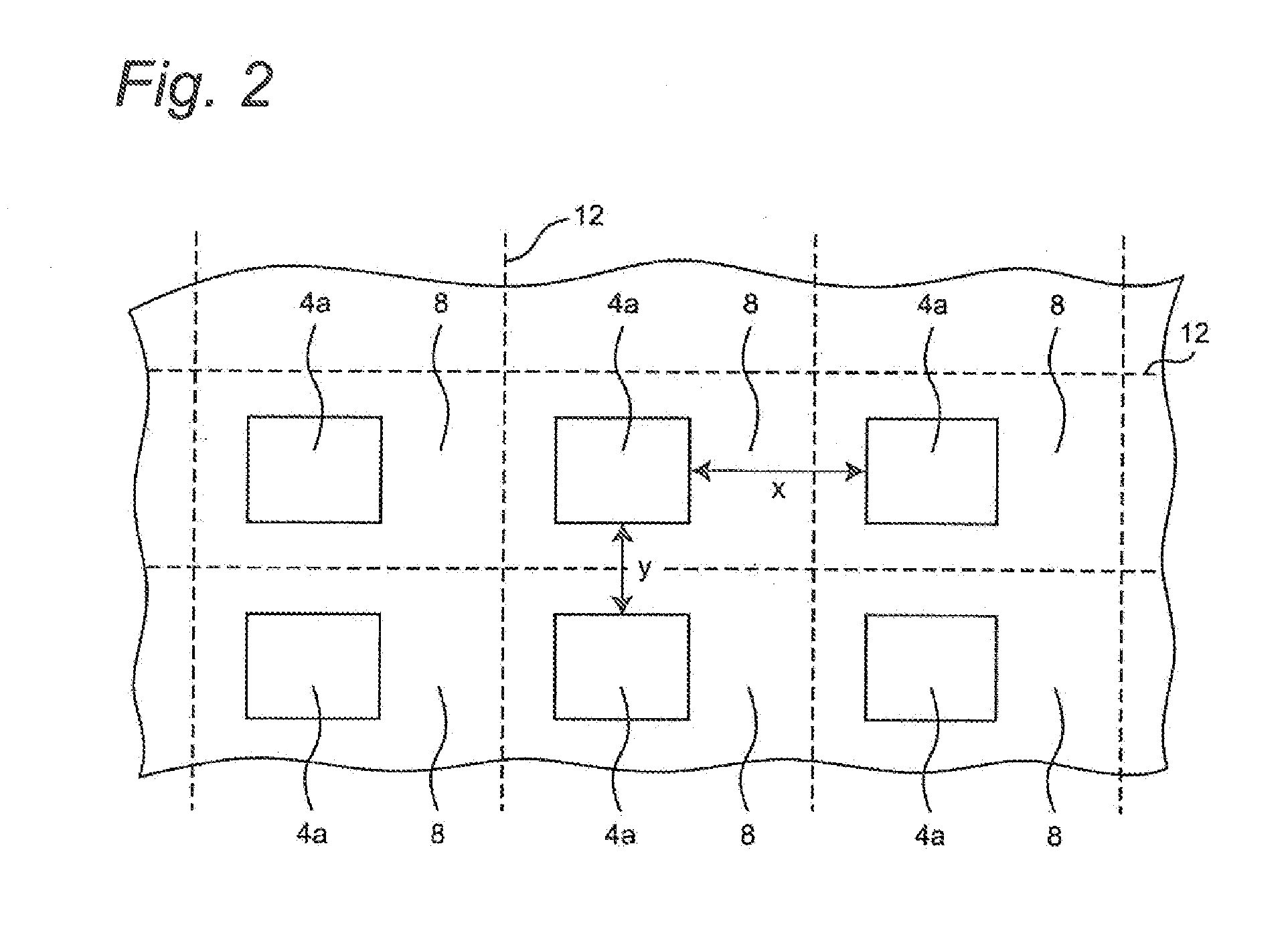

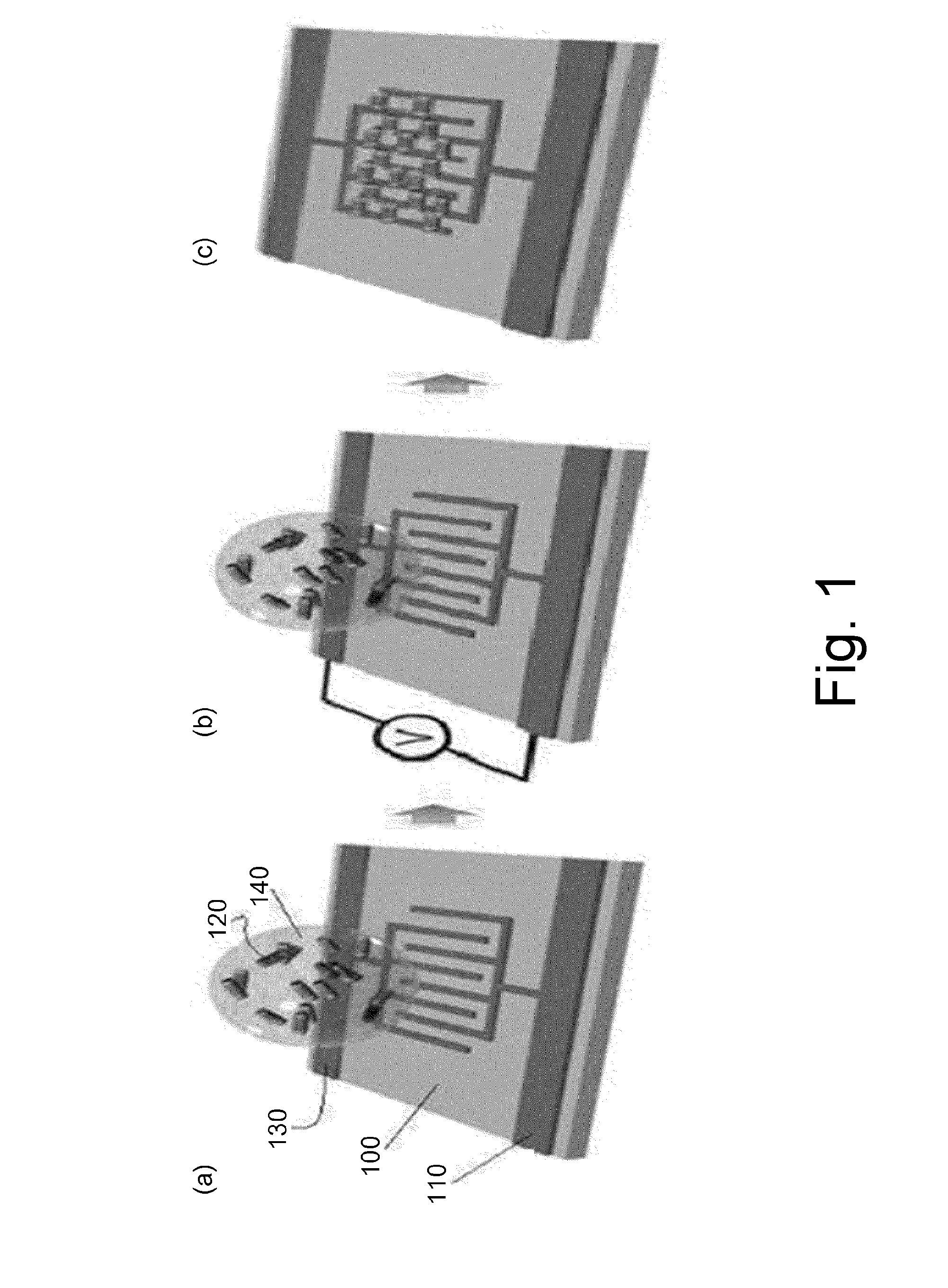

Method for manufacturing light emitting device and light emitting device

ActiveUS20140131753A1Increasing the thicknessImprove efficiencySemiconductor/solid-state device detailsSolid-state devicesPhosphorFluorescence

A manufacturing method of a light emitting device includes a light emitting element disposed over a substrate and a reflective resin disposed along the side surface of the light emitting element. The method includes disposing light emitting elements in a matrix over an aggregate substrate, and disposing a semiconductor element between the adjacent light emitting elements in one direction of column and row directions of the light emitting elements in the matrix. A reflective resin is disposed to cover the semiconductor elements along the side surfaces of the light emitting elements and the side surfaces of the phosphor layers. The reflective resin and the substrate disposed in between the adjacent light emitting elements is cut in the column or row direction and between the light emitting element and the adjacent semiconductor element in the other direction, to include a light emitting element or a semiconductor element.

Owner:NICHIA CORP

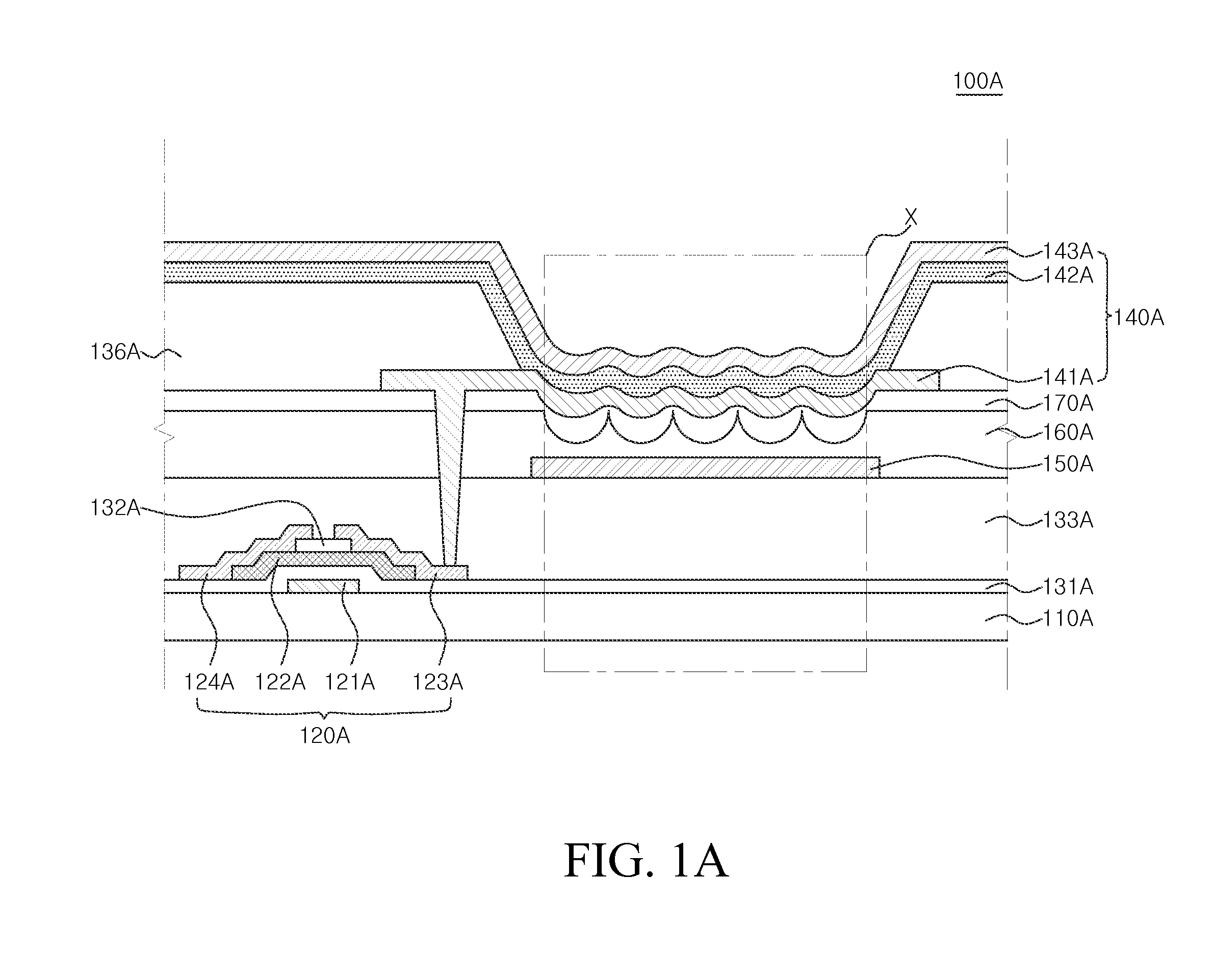

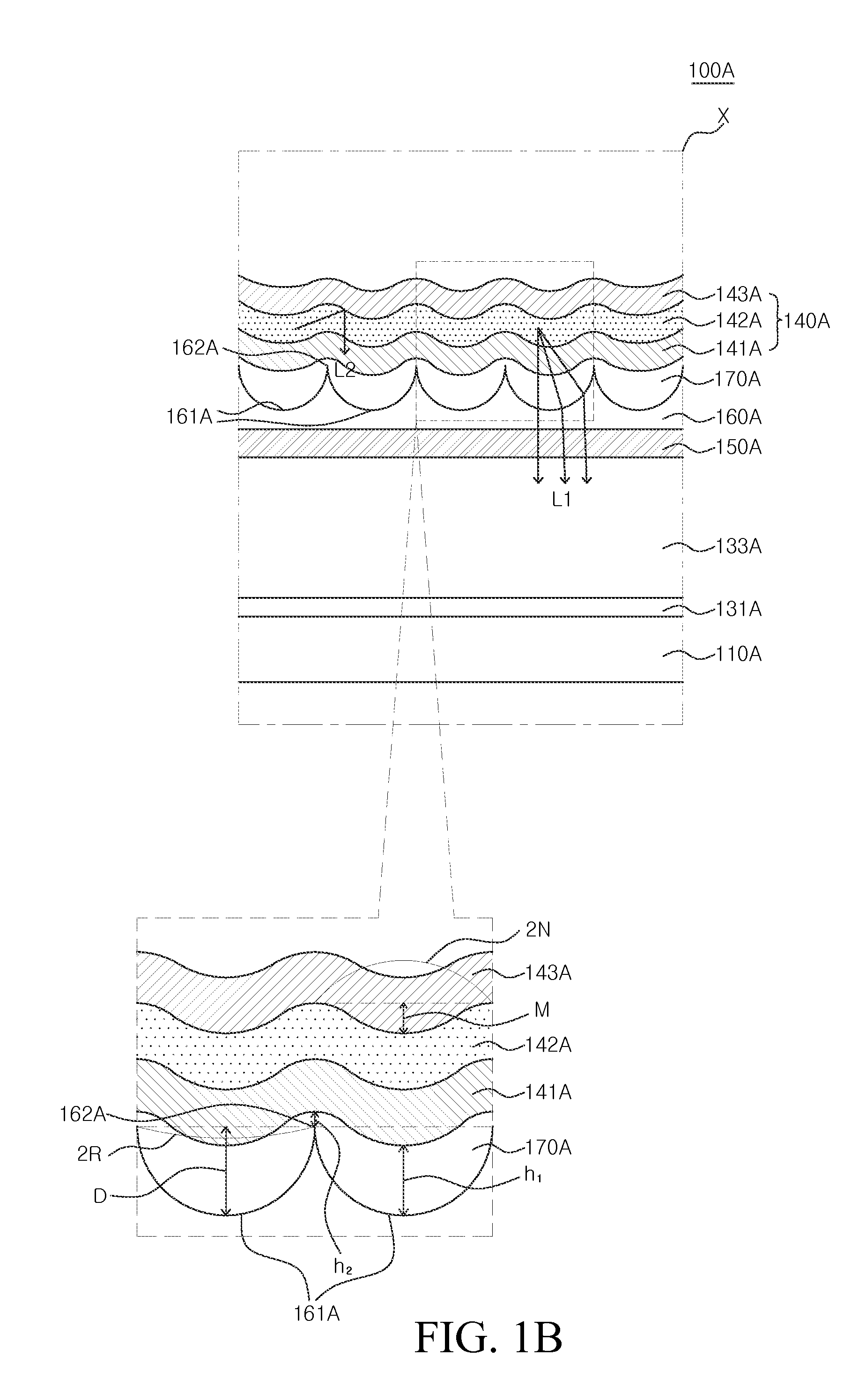

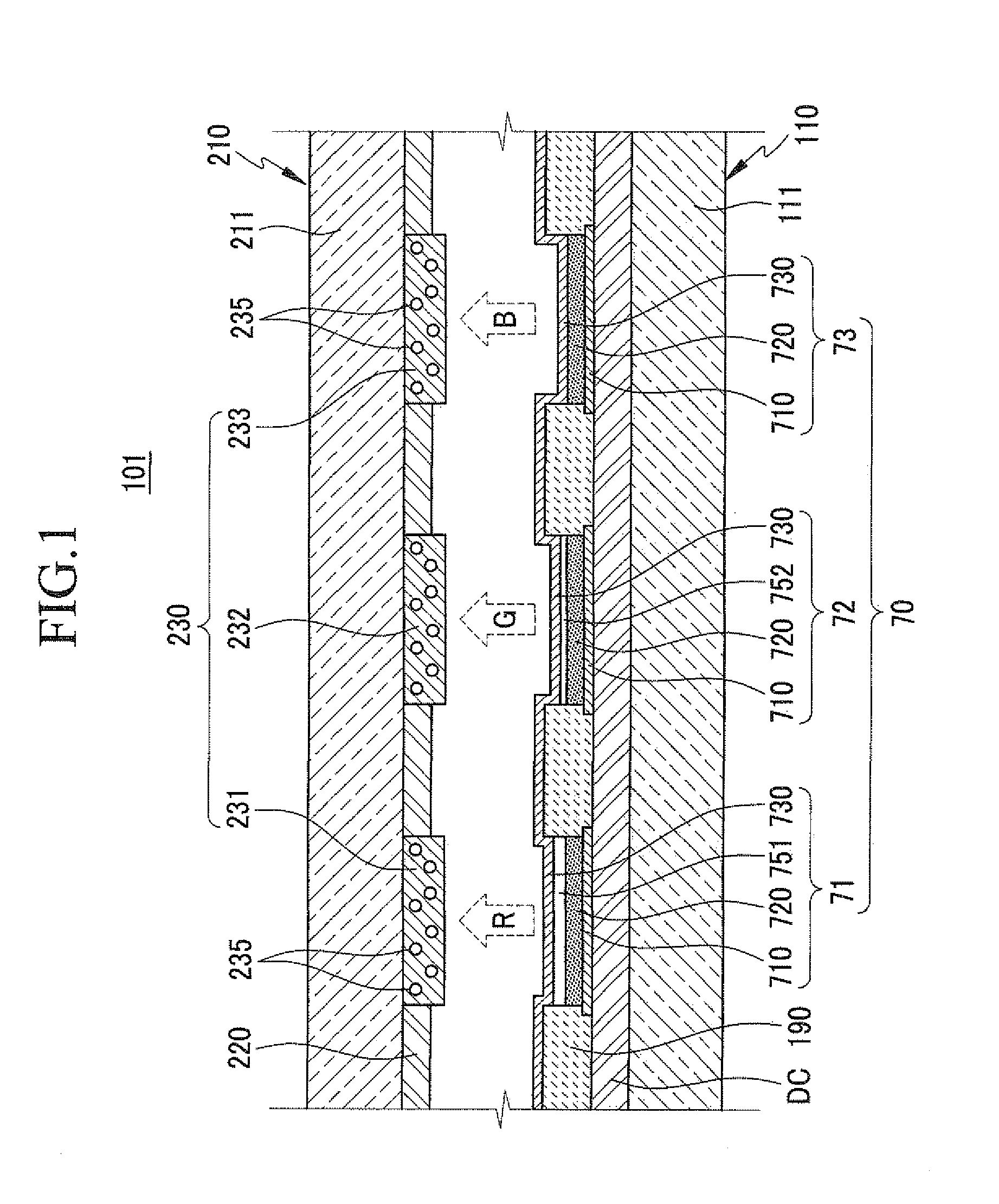

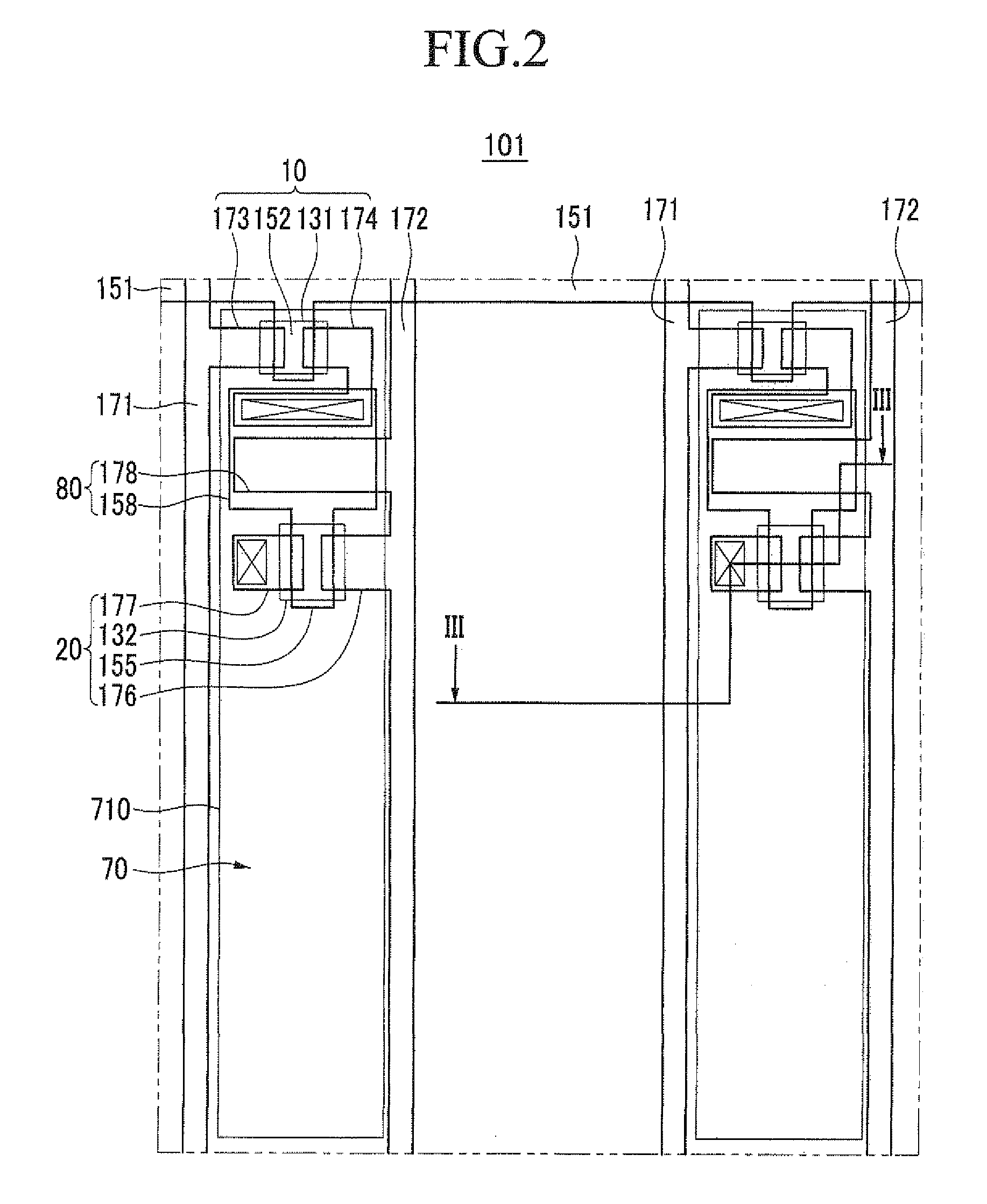

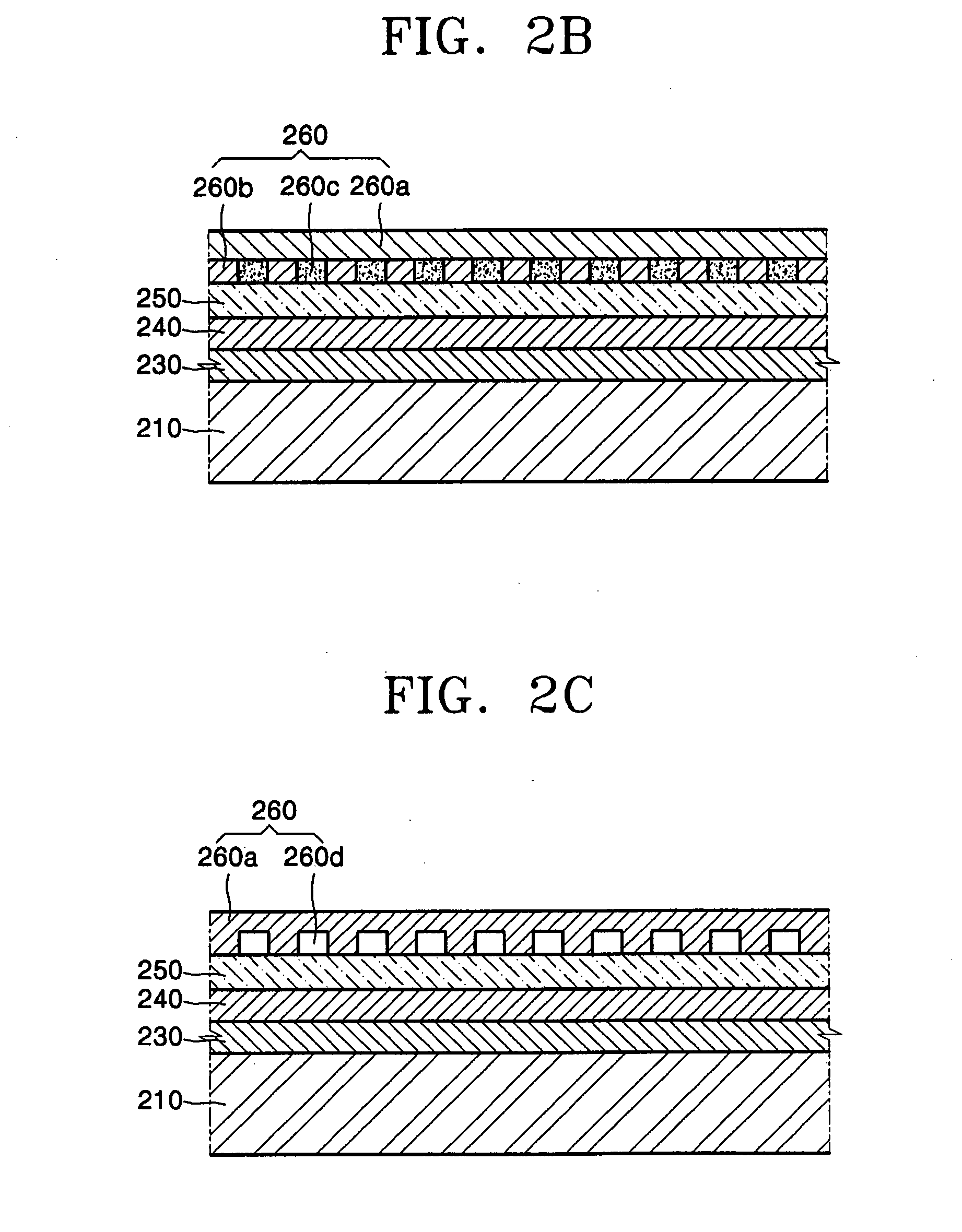

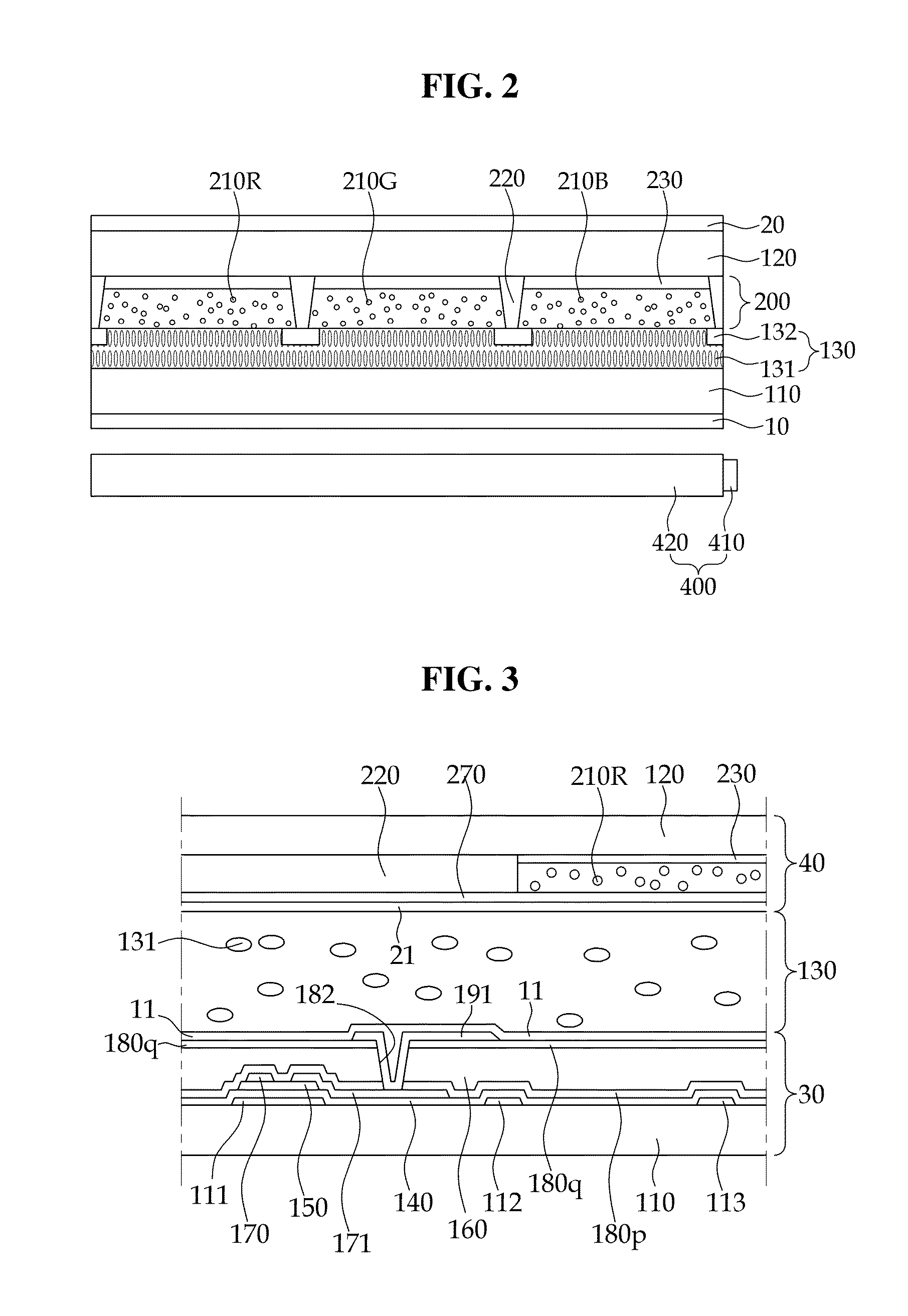

Organic light emitting display device and method for manufacturing the same

ActiveUS20150380466A1Reduce step differenceHigh refractive indexSolid-state devicesSemiconductor/solid-state device manufacturingRefractive indexDisplay device

Provided are an organic light emitting display device and a method for manufacturing the same. A color filter is disposed on a substrate. An overcoating layer is disposed on the color filter and includes a plurality of protrusions or a plurality of recesses. The plurality of protrusions and the plurality of recesses are disposed on the color filter to be overlapped with the color filter. A buffer layer for reducing step difference is disposed on the overcoating layer. The buffer layer has a higher refractive index than the overcoating layer and reduces a step difference caused by the plurality of protrusions and the plurality of recesses. An organic light emitting element including an anode, an organic light emitting layer, and a cathode is disposed on the buffer layer. Since the buffer layer has a higher refractive index than the overcoating layer, light extraction efficiency can be increased.

Owner:LG DISPLAY CO LTD

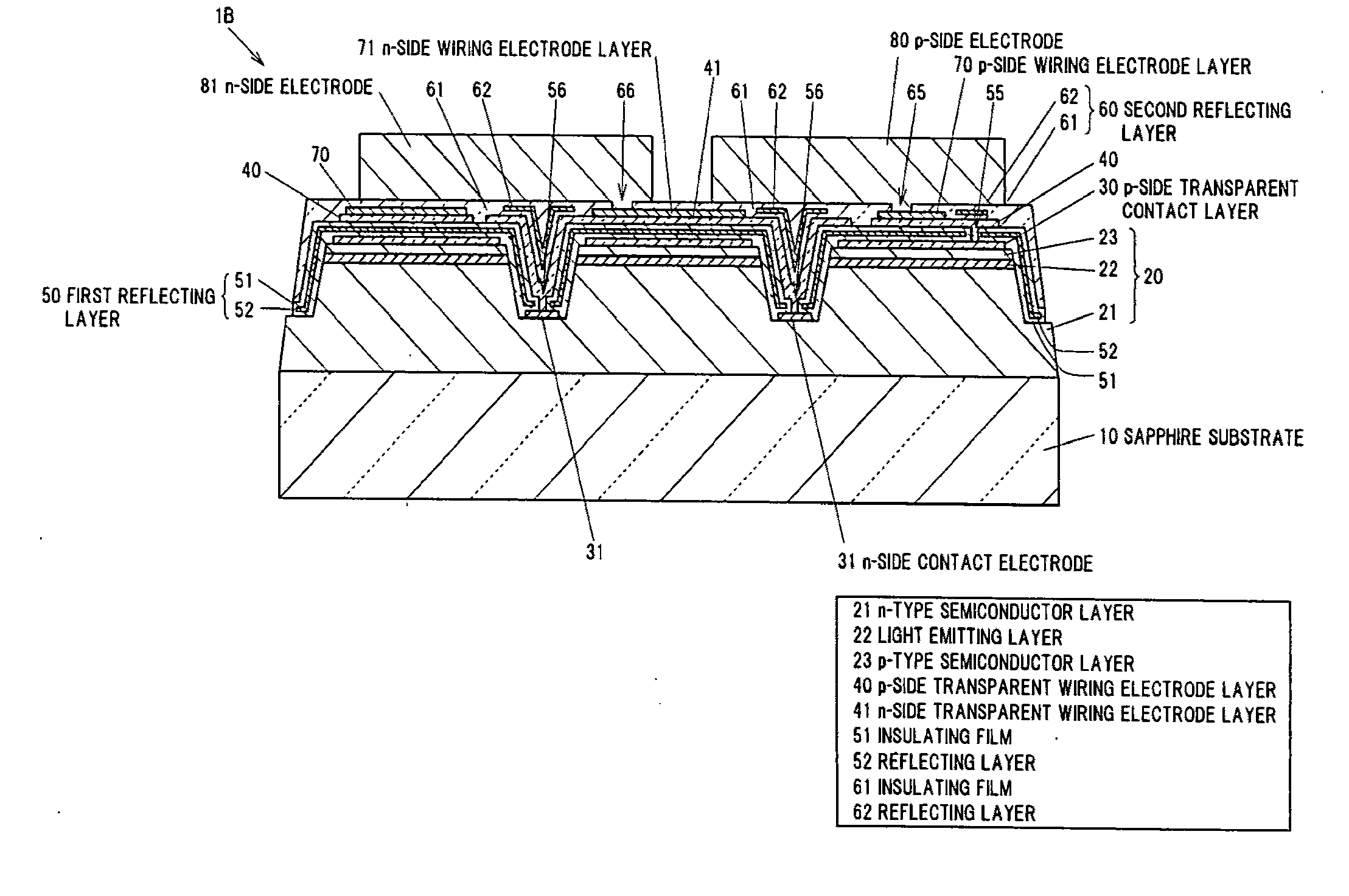

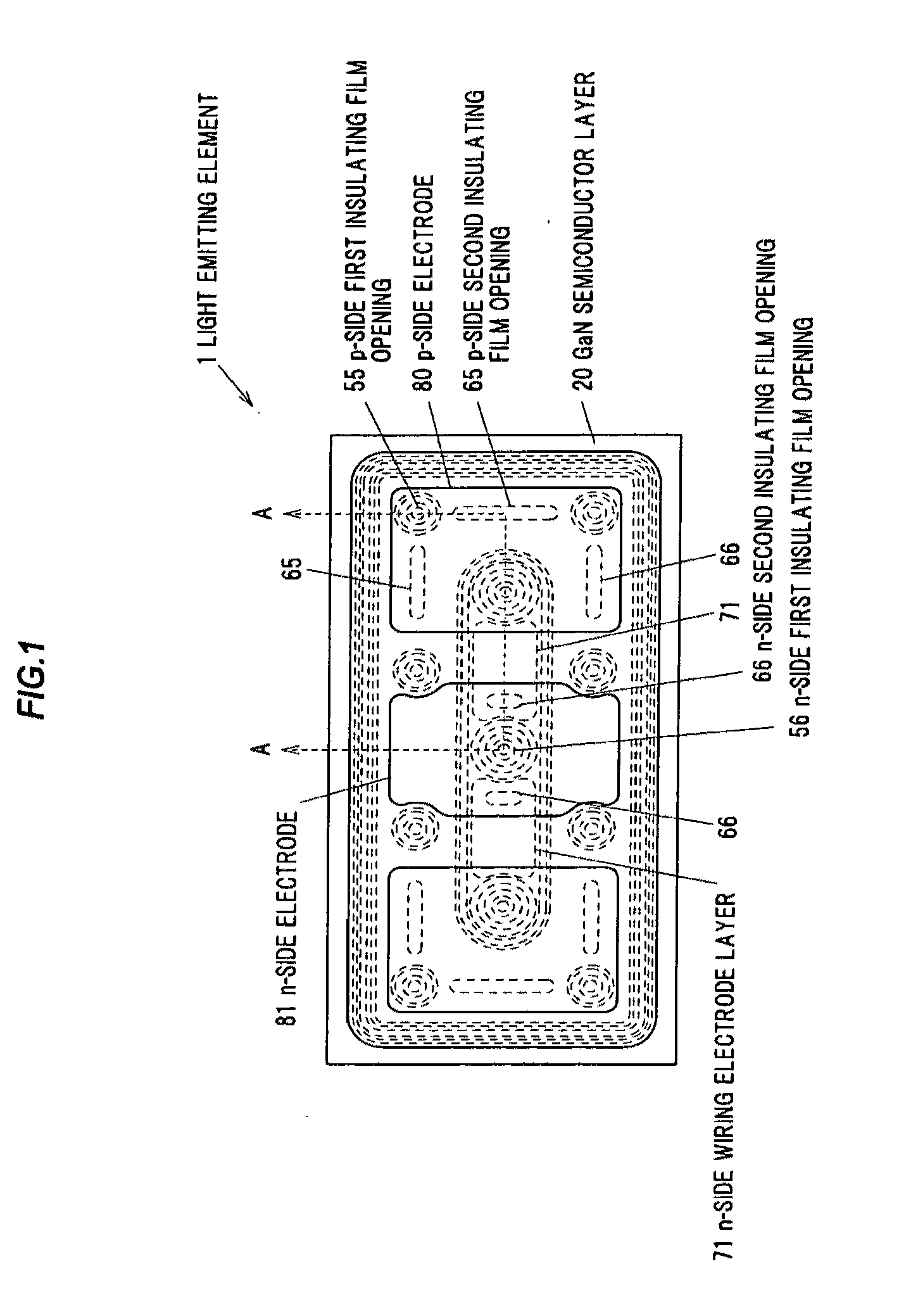

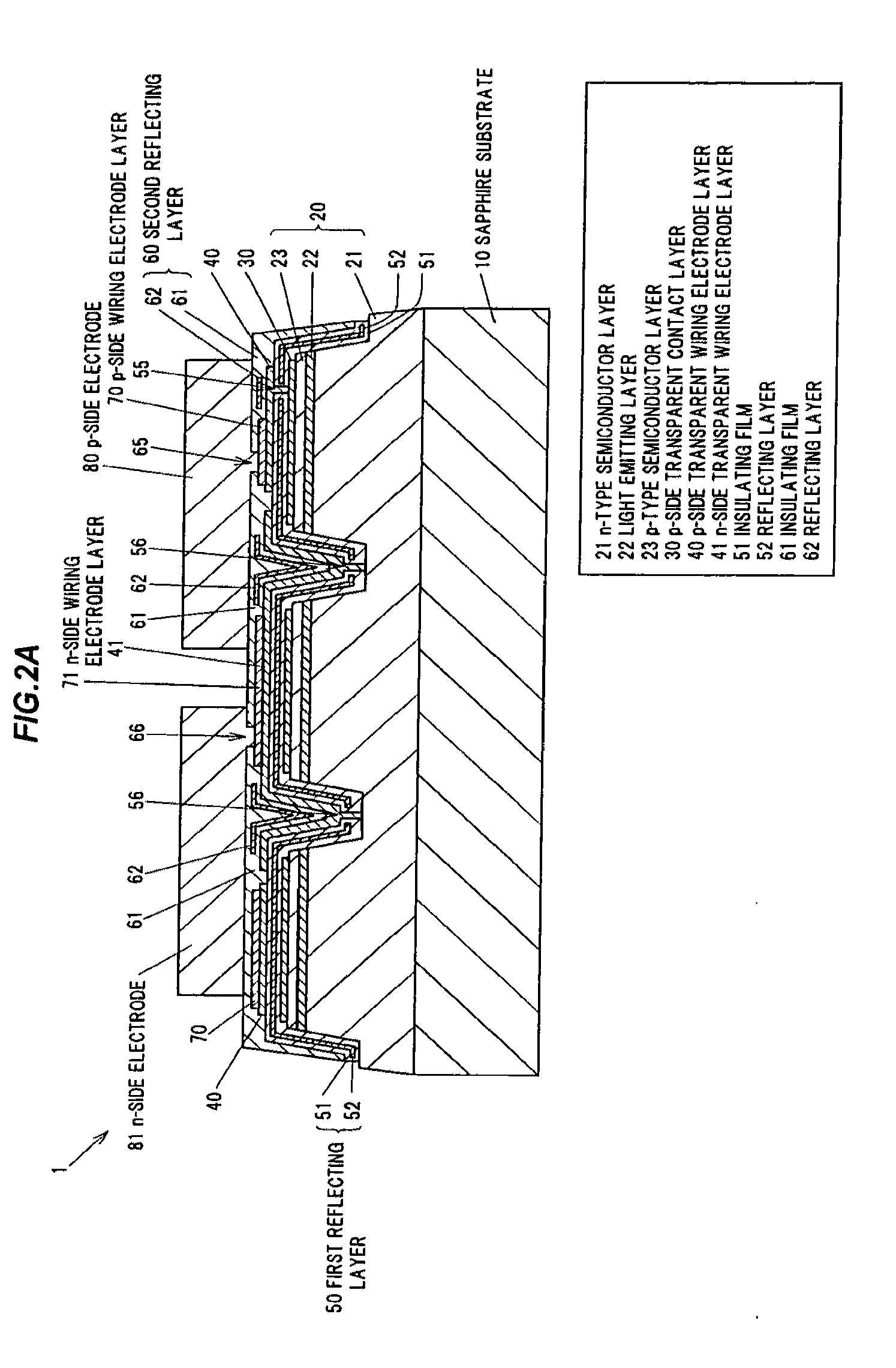

Light emitting element

ActiveUS20120049219A1Improve lighting efficiencyLight extraction efficiency can be improvedSolid-state devicesSemiconductor devicesElectrical conductorLight-emitting diode

A light emitting element includes a semiconductor laminate structure including a first semiconductor layer of a first conductivity type, a light emitting layer, and a second semiconductor layer of a second conductivity type different from the first conductivity type, a part of the second semiconductor layer and the light emitting layer being removed to expose a part of the first semiconductor layer: a first reflecting layer on the semiconductor laminate structure and including an opening, the opening being formed in the exposed part of the first semiconductor layer, a transparent wiring electrode for carrier injection into the first semiconductor layer or the second semiconductor layer through the opening, a second reflecting layer formed on the transparent wiring electrode and covering a part of the opening so as to reflect light emitted from the light emitting layer and passing through the opening back to the first semiconductor layer.

Owner:TOYODA GOSEI CO LTD

Light-emitting device and method of manufacturing the same

ActiveUS20050199885A1Light extraction efficiency can be improvedSolid-state devicesSemiconductor/solid-state device manufacturingLight emissionLight emitting device

A light-emitting device capable of improving light extraction efficiency is provided. This light-emitting device comprises a support substrate set on a side opposite to a light emission surface and a semiconductor element layer, bonded to the support substrate, having a side surface inclined by a prescribed angle with respect to at least the normal of the light emission surface.

Owner:BYRD CHAD +1

Organic Light Emitting Diode Display

ActiveUS20110042697A1Suppress reflection of external lightImprove light extraction rateOptical filtersSolid-state devicesDisplay deviceLight-emitting diode

An organic light emitting diode display includes a display substrate including a plurality of organic light emitting diodes, a plurality of color filters on the plurality of organic light emitting diodes respectively corresponding thereto, and a plurality of light scattering particles dispersed in the plurality of color filters.

Owner:SAMSUNG DISPLAY CO LTD

Method of fabricating algainp light-emitting diode and structure thereof

ActiveUS20050287687A1Increased light output intensityReduce reflectionSolid-state devicesSemiconductor/solid-state device manufacturingReflective layerLight-emitting diode

A soft transparent adhesive layer is utilized to bond a transparent substrate material onto an AlGaInP light-emitting diode epitaxy on a GaAs substrate, and the GaAs substrate is next removed entirely. Then, a mesa etching process is performed to form a first top surface and a second top surface on the AlGaInP light-emitting diode epitaxy for respectively exposing an n-type layer and a p-type layer in the AlGaInP light-emitting diode epitaxy. Next, a metal reflective layer and a barrier layer are formed on the AlGaInP light-emitting diode epitaxy in turn, and electrodes are finally fabricated on the barrier layer.

Owner:EPISTAR CORP

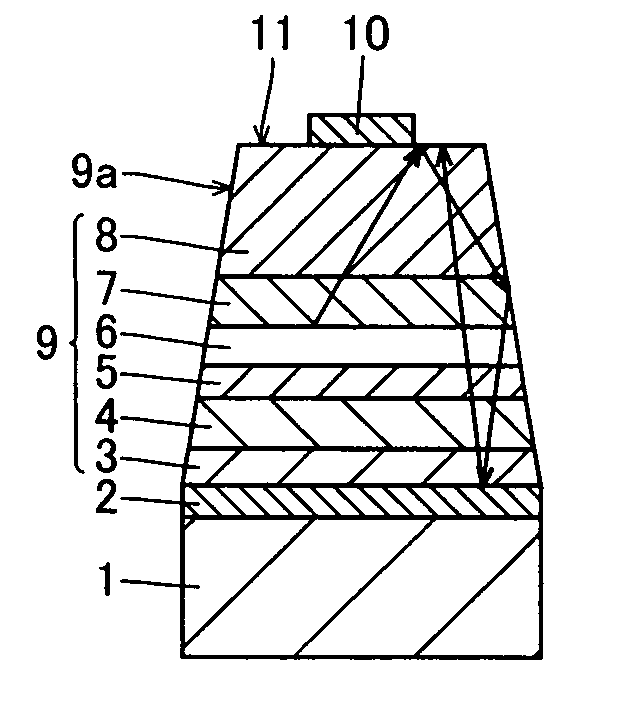

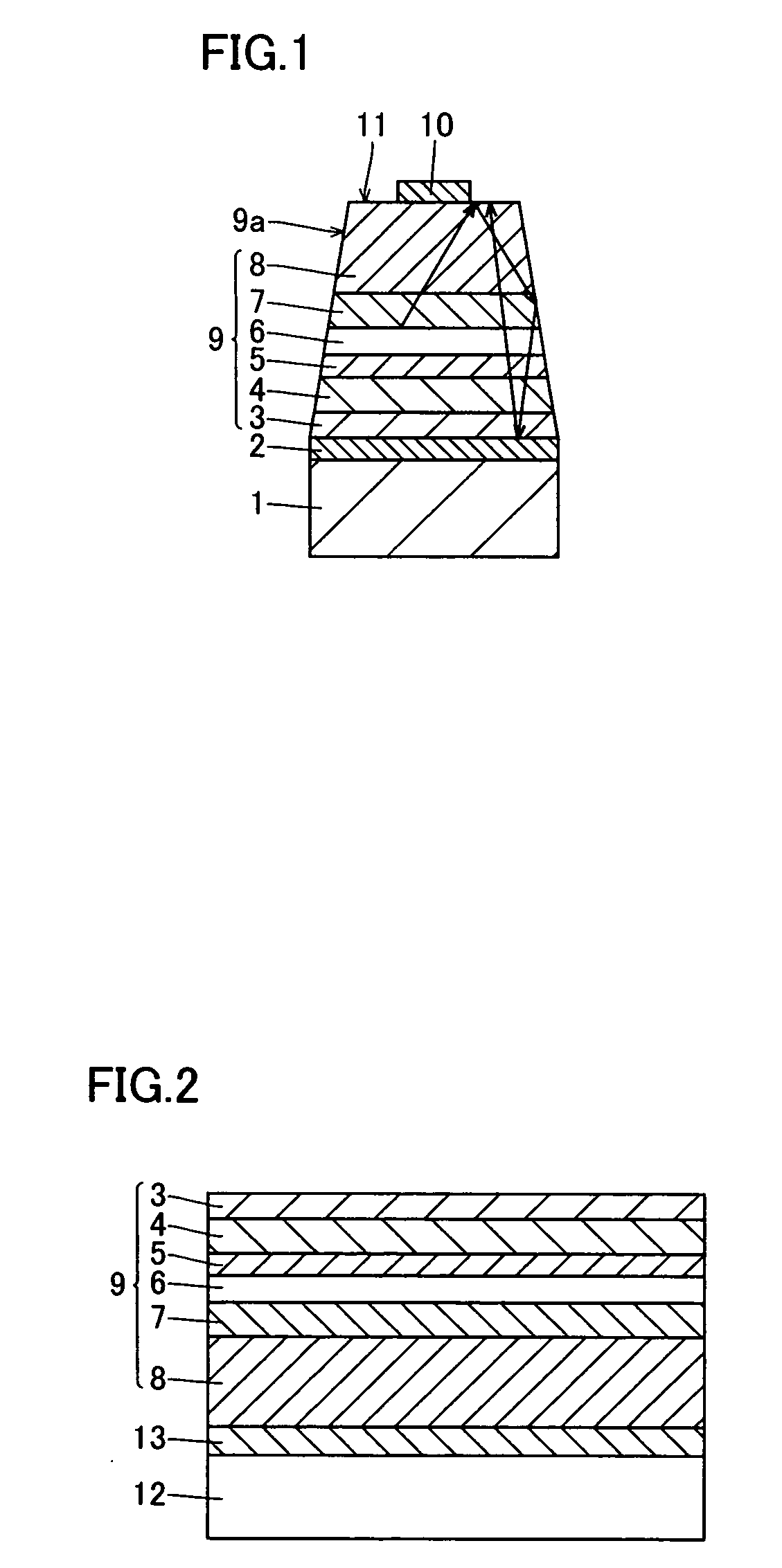

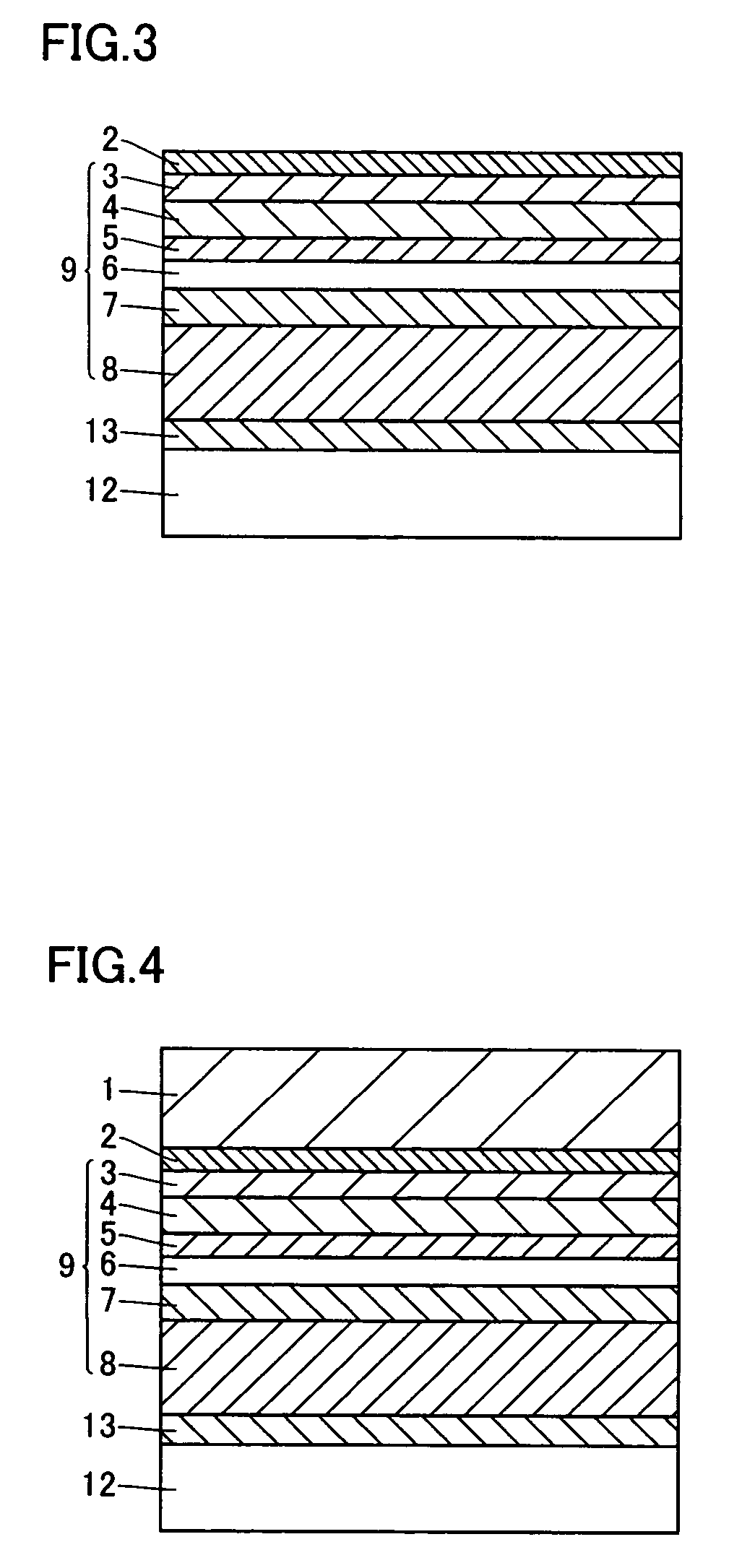

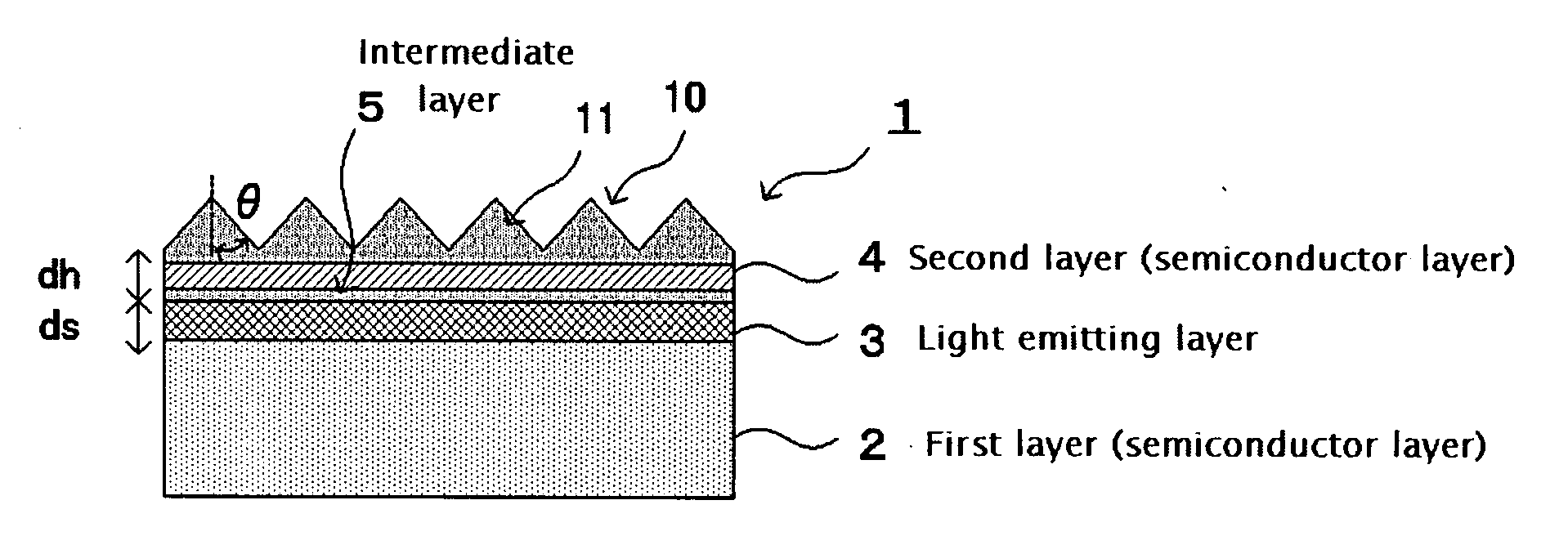

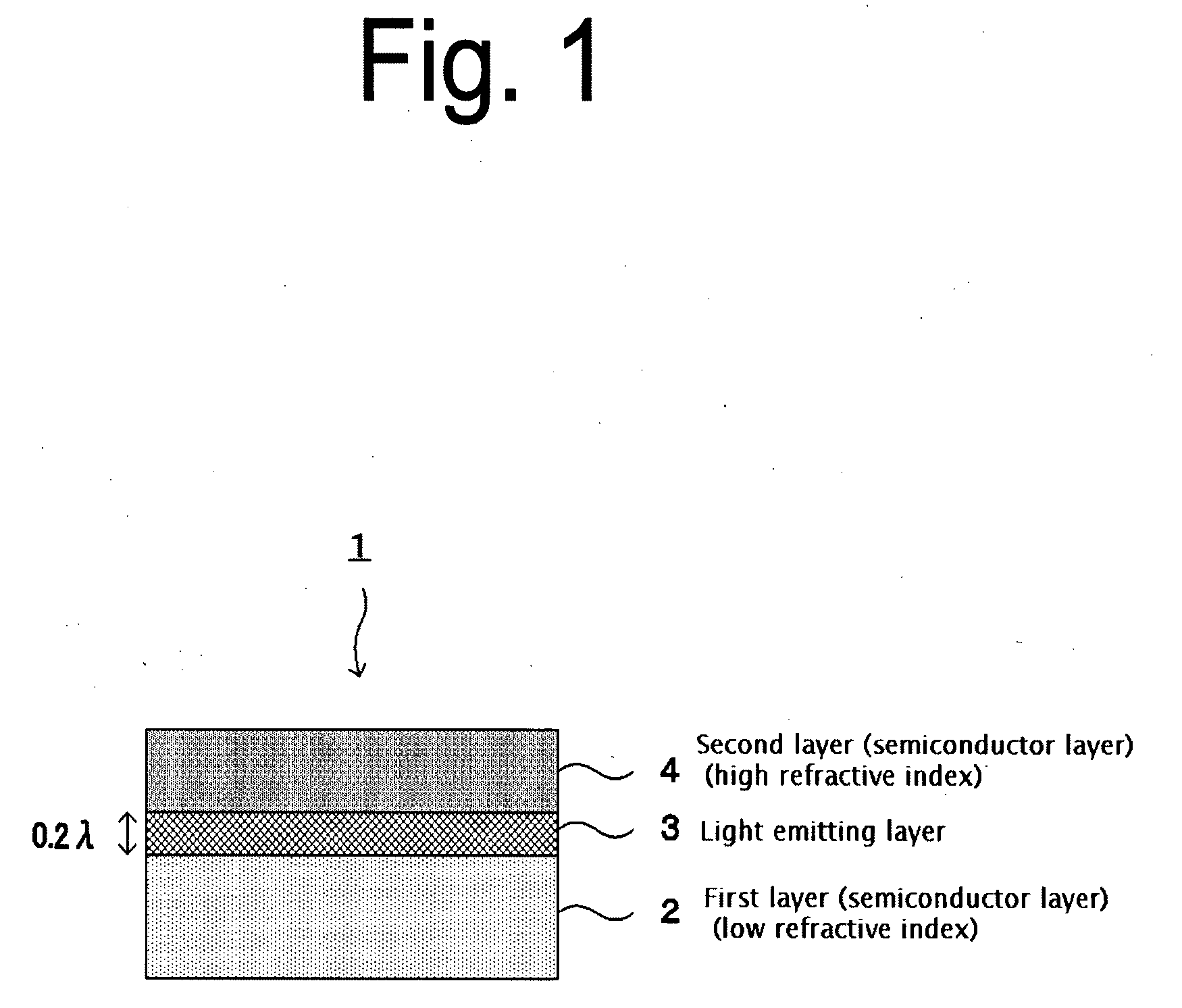

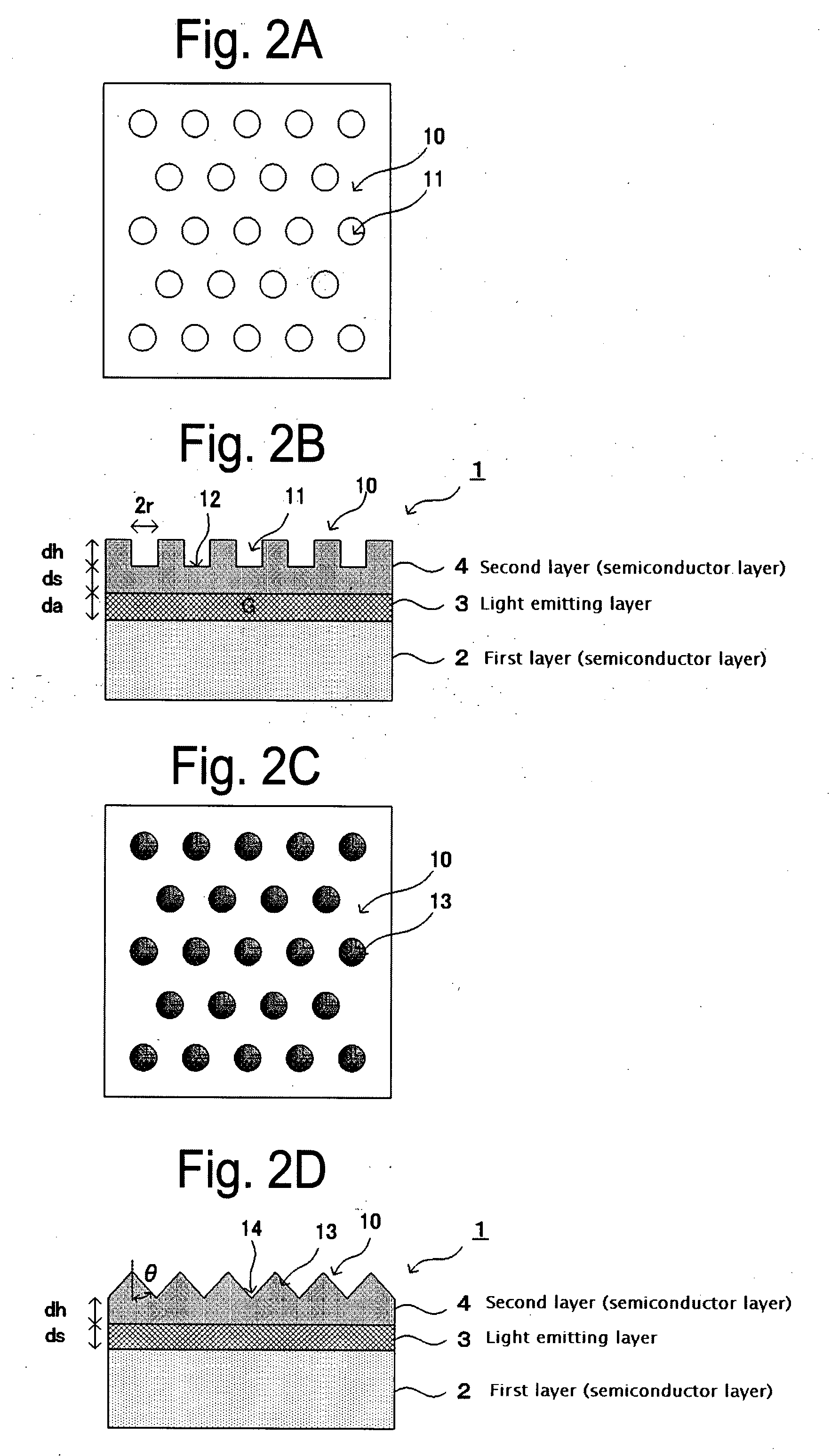

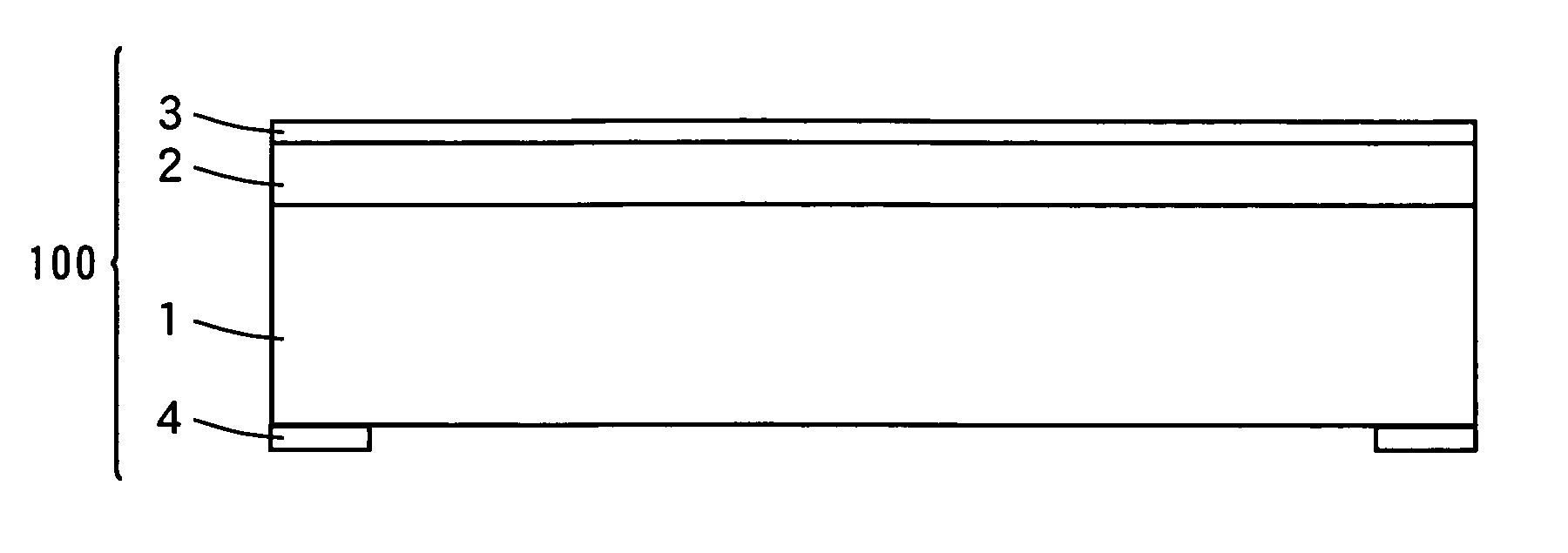

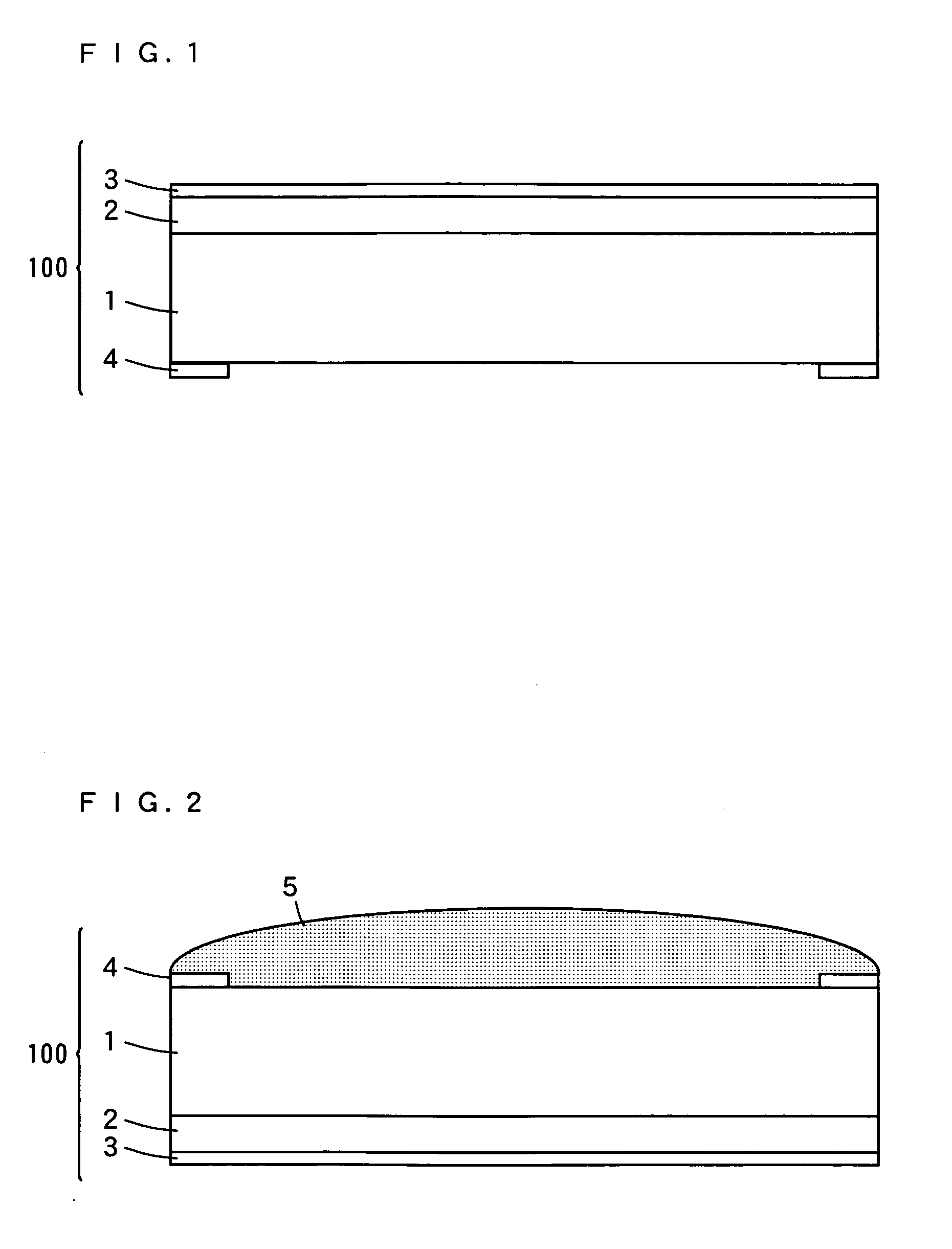

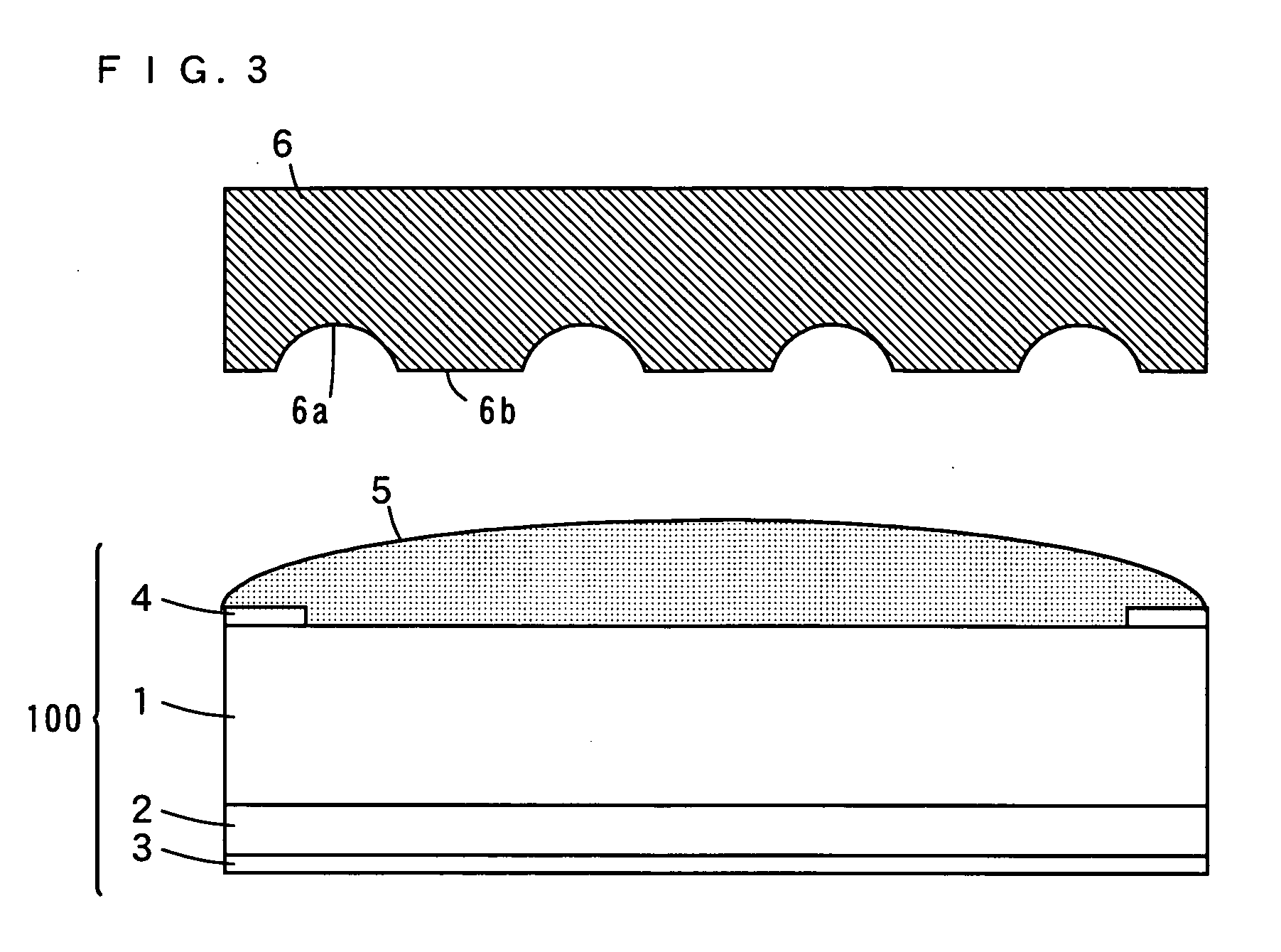

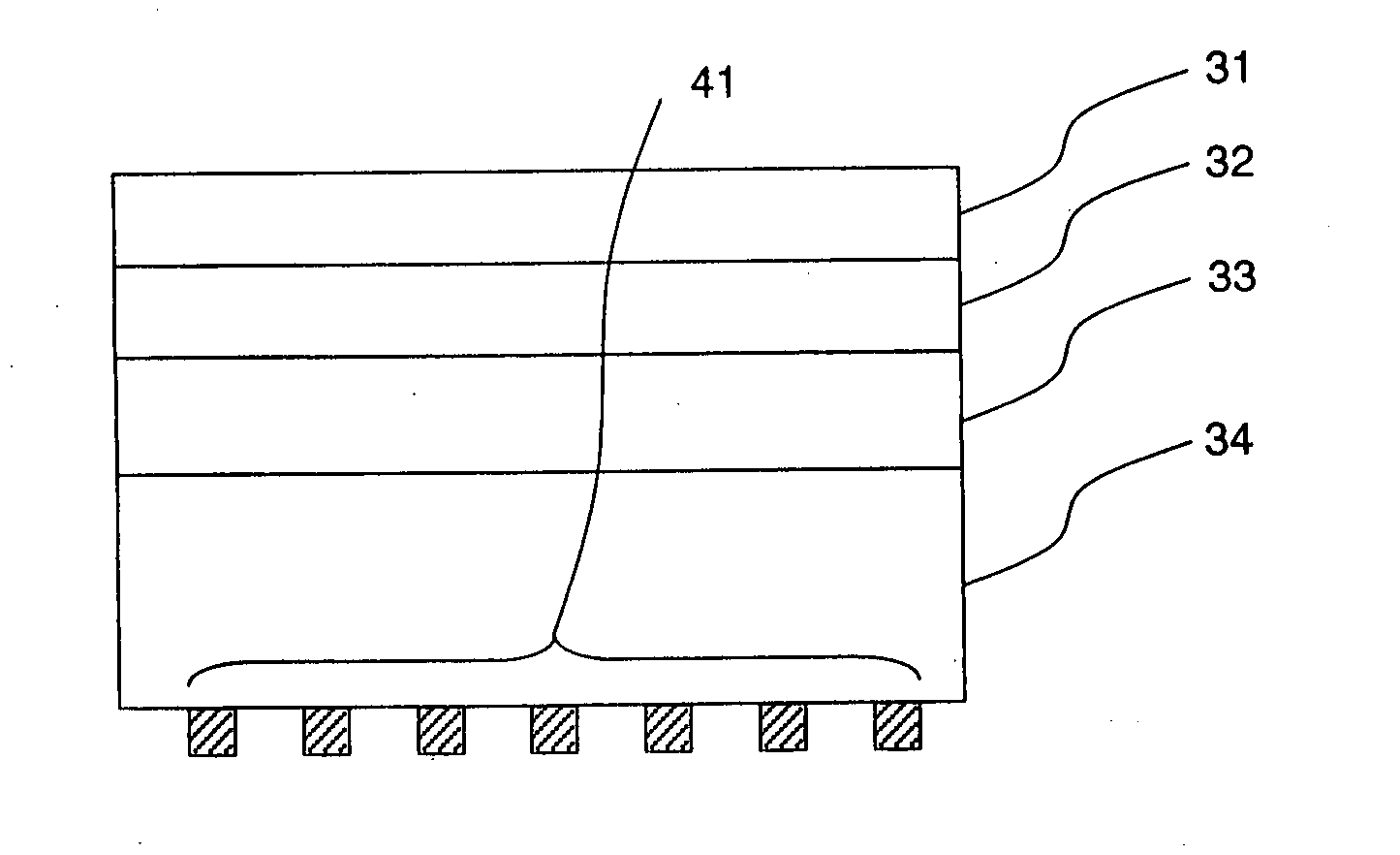

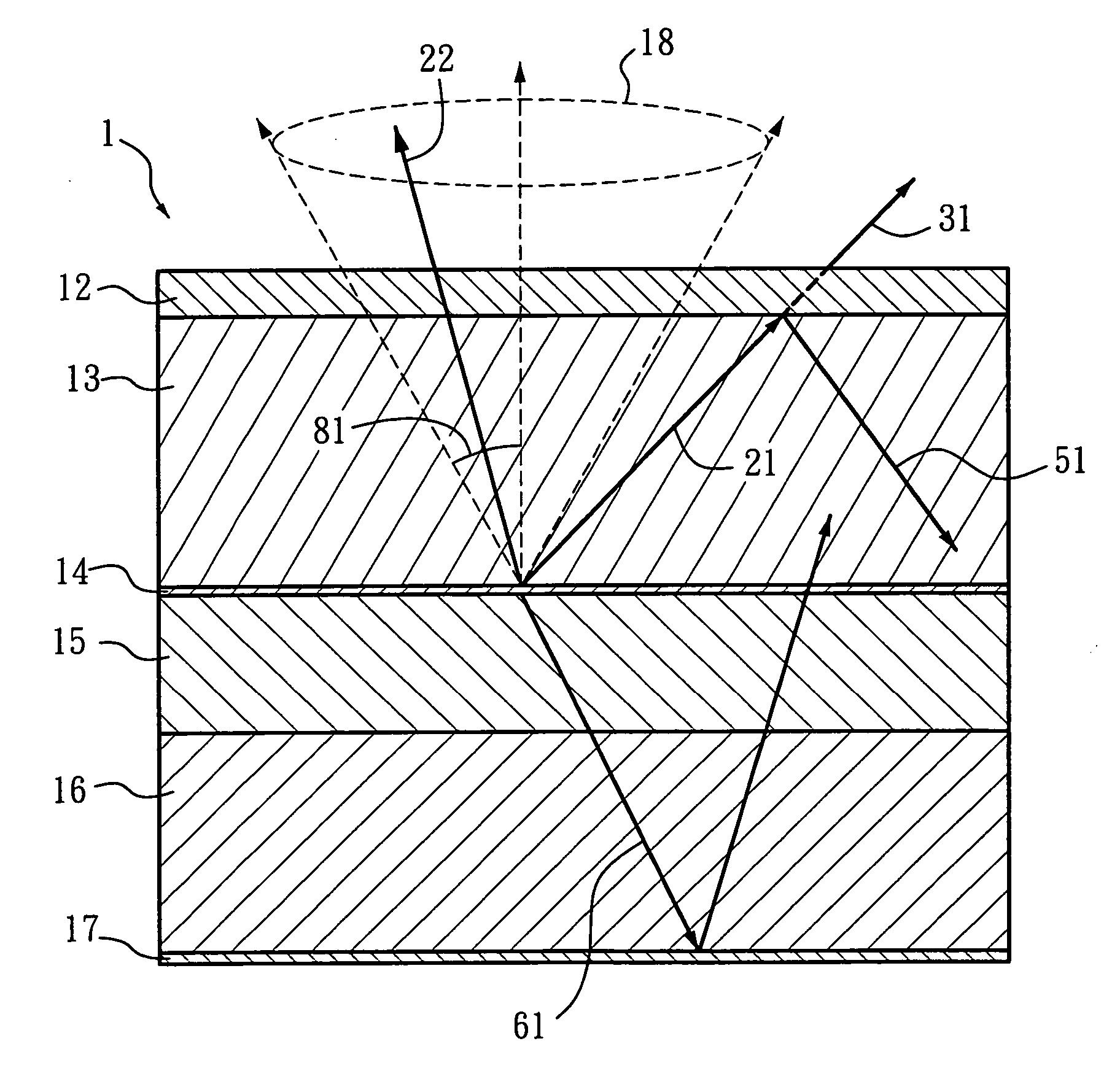

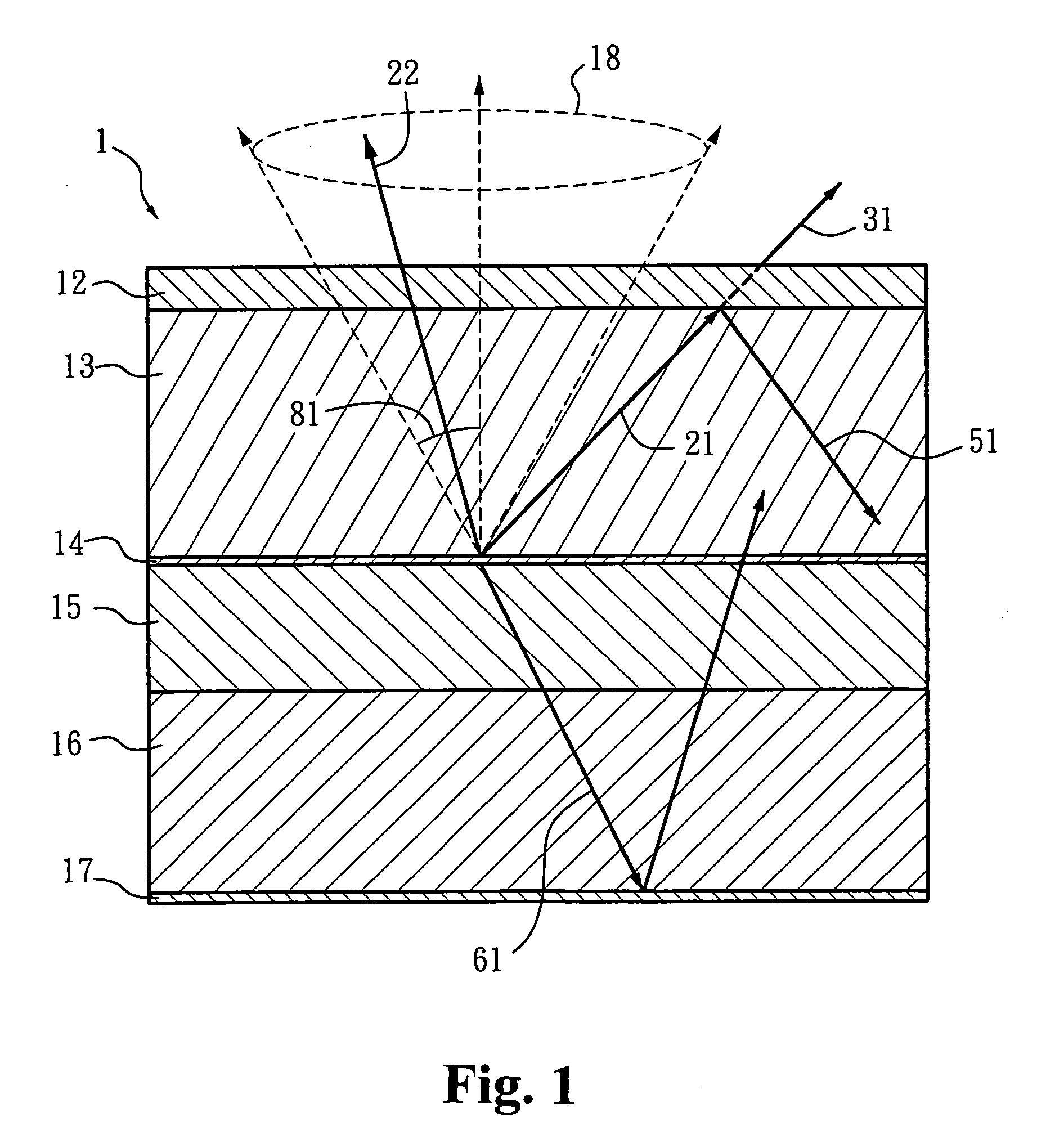

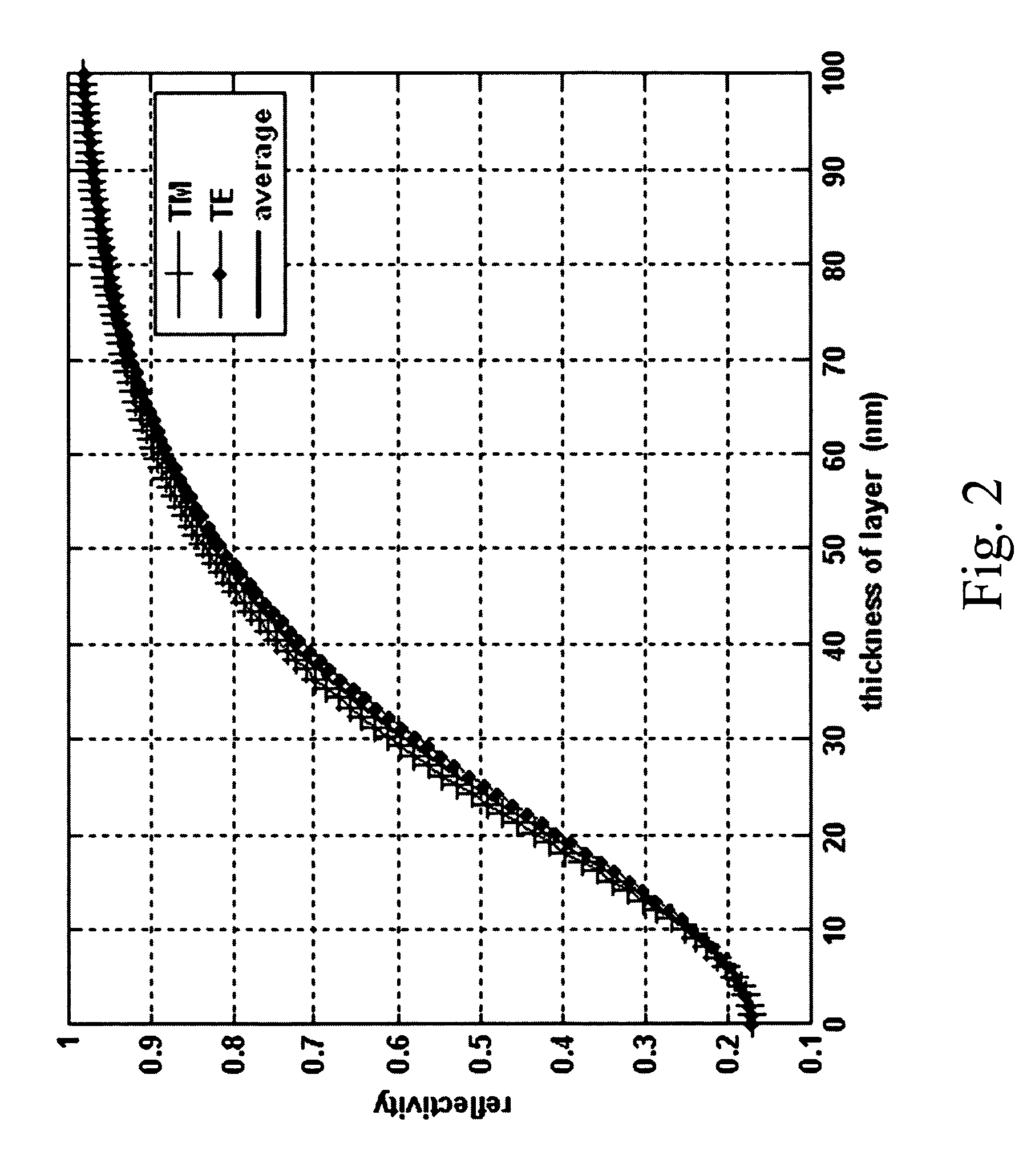

Self-luminous device

InactiveUS20080173887A1Improve light extractionHigh light extractionSemiconductor devicesComputational physicsSecondary layer

A self-luminous device 1 is one embodiment which has an increased light extraction efficiency by optimizing the distribution of refractive index in semiconductor layers. The self-luminous device 1 includes a first layer (semiconductor layer 2), a light emitting layer 3 overlaying the first layer (semiconductor layer 2), and a second layer (semiconductor layer 4) overlaying the light emitting layer 3. The first layer (semiconductor layer 2) and the second layer (semiconductor layer 4) have different refractive indices so that the refractive indices of the two layers (semiconductor layers 2 and 4) are asymmetric with respect to the light emitting layer interposed therebetween. In the refractive index distribution of asymmetric layers (semiconductor layers), the refractive index of the second layer (semiconductor layer 4) is higher than that of the first layer (semiconductor layer 2).

Owner:STANLEY ELECTRIC CO LTD

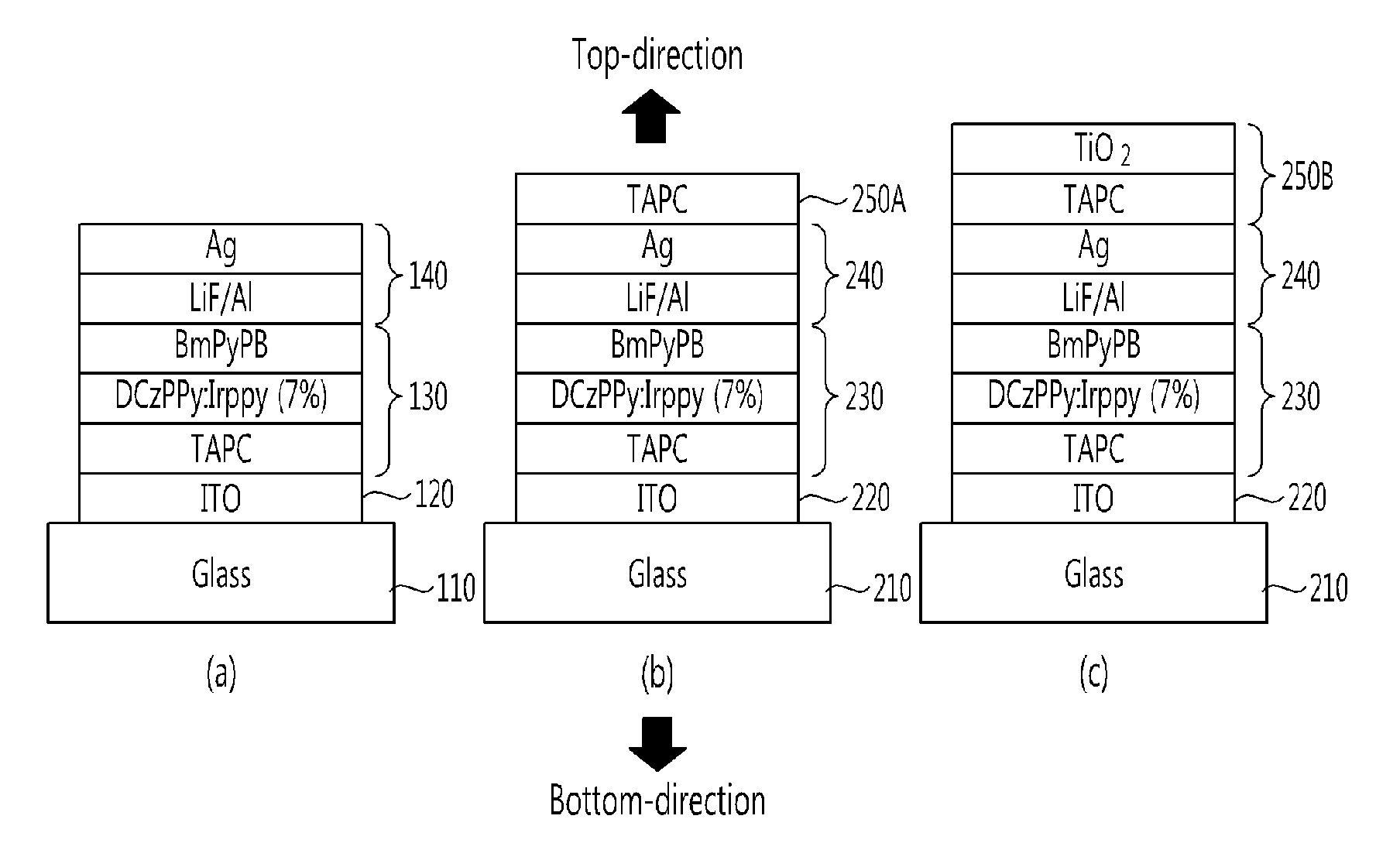

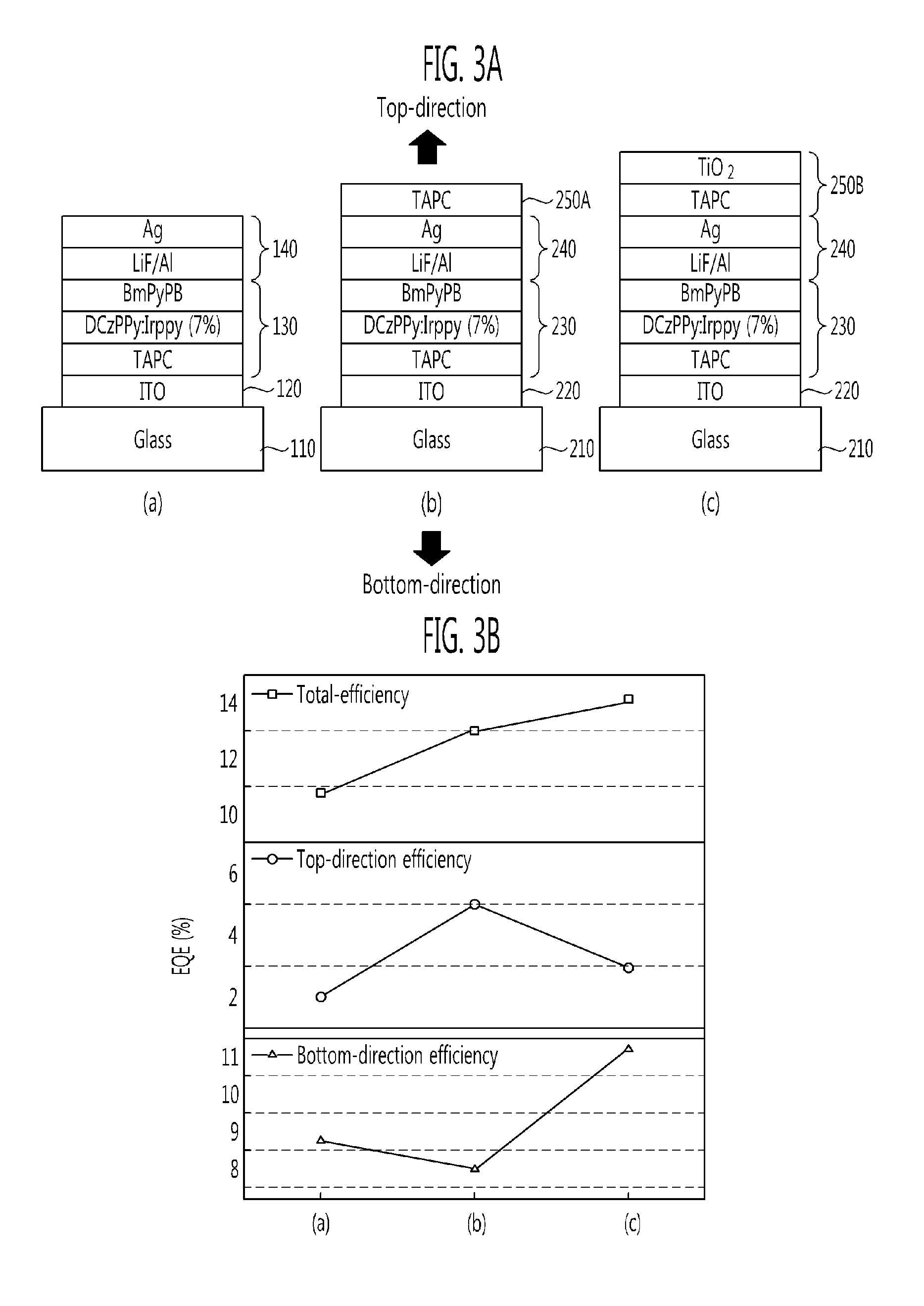

Transmissive organic light emitting diode and transmissive lighting device using the same

InactiveUS20110260148A1Light extraction efficiency can be improvedSolid-state devicesSemiconductor/solid-state device manufacturingPhysicsAnode

A transmissive organic light emitting diode (OLED) with improved external light efficiency and a transmissive lighting device including the same are provided. The OLED includes a transparent anode formed on a substrate, an organic emission layer formed on the transparent anode, a cathode formed on the organic emission layer, and a light extraction enhancing layer formed on the transparent cathode, and configured to change a path of light generated from the organic emission layer to enhance light extraction efficiency of the OLED. The external light extraction efficiency is enhanced in both-sided or single-sided emission of the OLED and the external light extraction efficiencies of bottom and top surfaces of the OLED are selectively or simultaneously enhanced. An external light extraction ratio between the bottom and top surfaces in both-sided emission is controlled.

Owner:ELECTRONICS & TELECOMM RES INST

Light emitting device and fabrication method thereof

InactiveUS20050141240A1Light extraction efficiency can be improvedSufficient lightingLaser detailsSolid-state devicesInorganic materialsLight emitting device

A pre-curing viscous solution (precursor solution) is applied to the back surface of a substrate for forming an optically transparent layer principally composed of an inorganic material. The substrate is heated or irradiated with UV light while being pressed with unevenness of a mold. By removing the substrate from the mold, the optically transparent, inorganic material layer principally composed of the inorganic material is formed on the substrate. In this manner, the inorganic material layer with the unevenness is formed on the back surface of the substrate (a light extraction surface) by embossing.

Owner:SANYO ELECTRIC CO LTD

Light emitting device and method of making the same

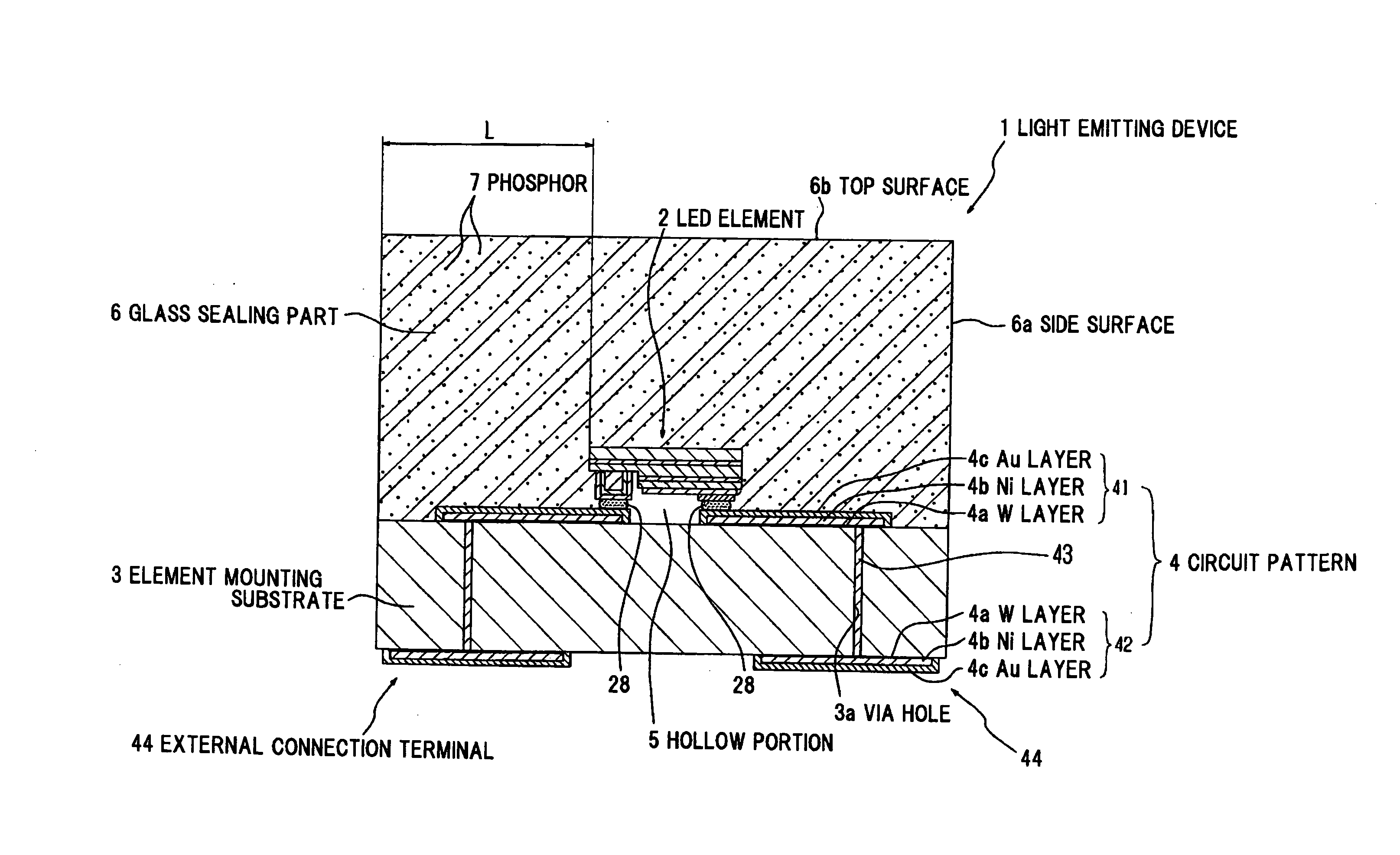

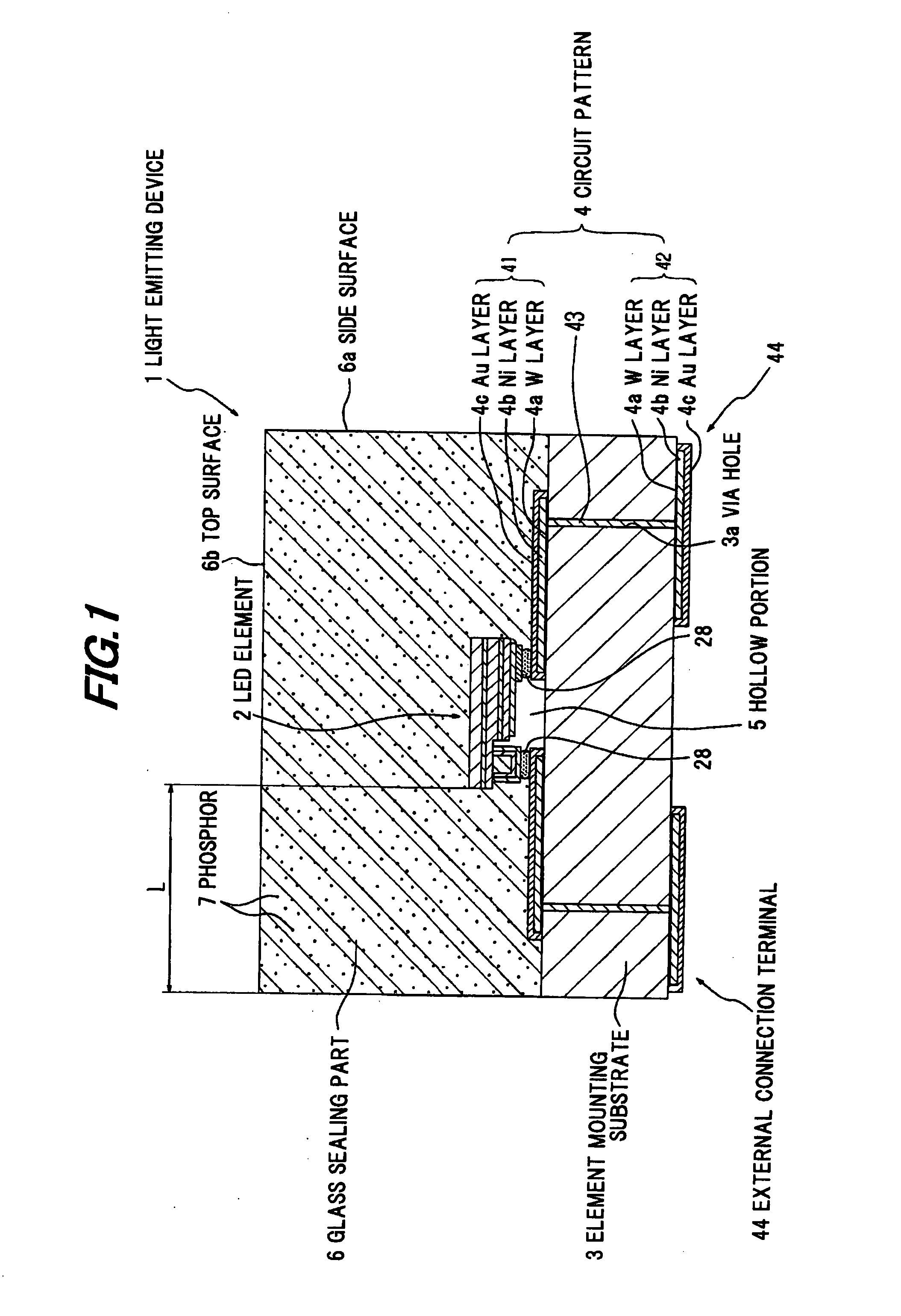

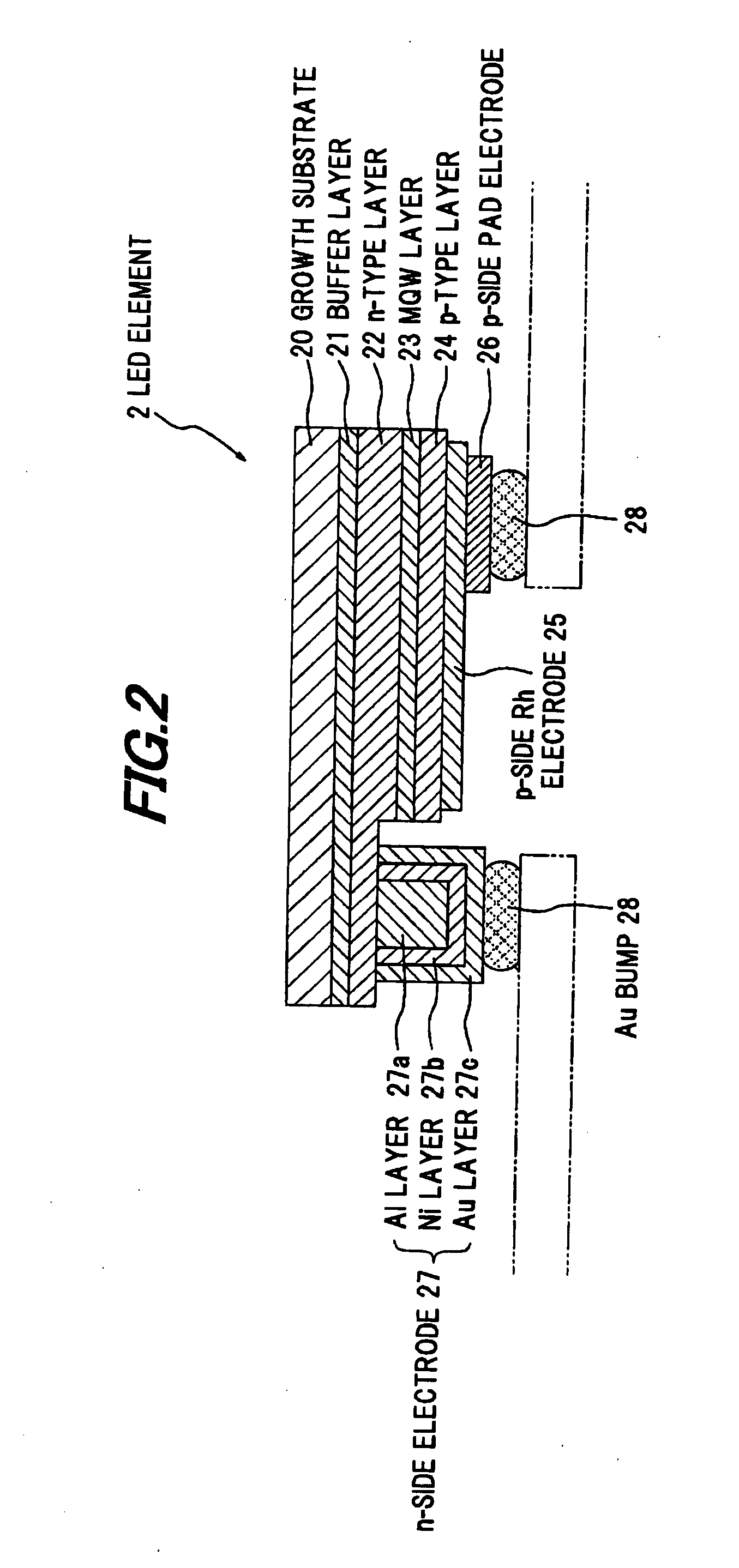

ActiveUS20080074029A1Evenly dispersedInhibit deteriorationDischarge tube luminescnet screensLamp detailsPhosphorLength wave

A light emitting device has a light emitting element, a mounting portion and a sealing part. On the mounting portion, the light emitting element is mounted and a circuit pattern is formed to supply power to the light emitting element. The sealing part is formed on the mounting portion, sealing the light emitting element, and formed of a glass and a phosphor uniformly dispersed in the glass. The phosphor is adapted to emit a wavelength-converted light by being excited by a light emitted from the light emitting element.

Owner:TOYODA GOSEI CO LTD

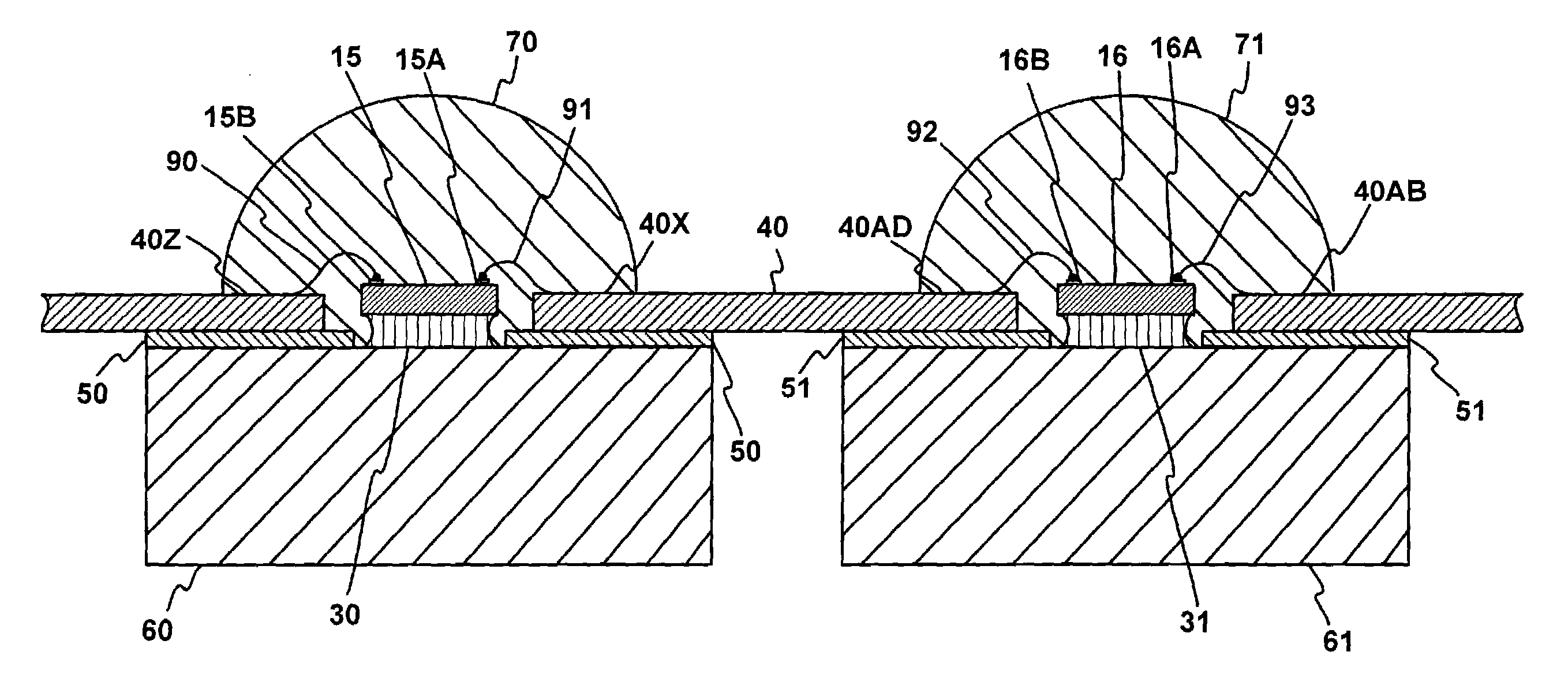

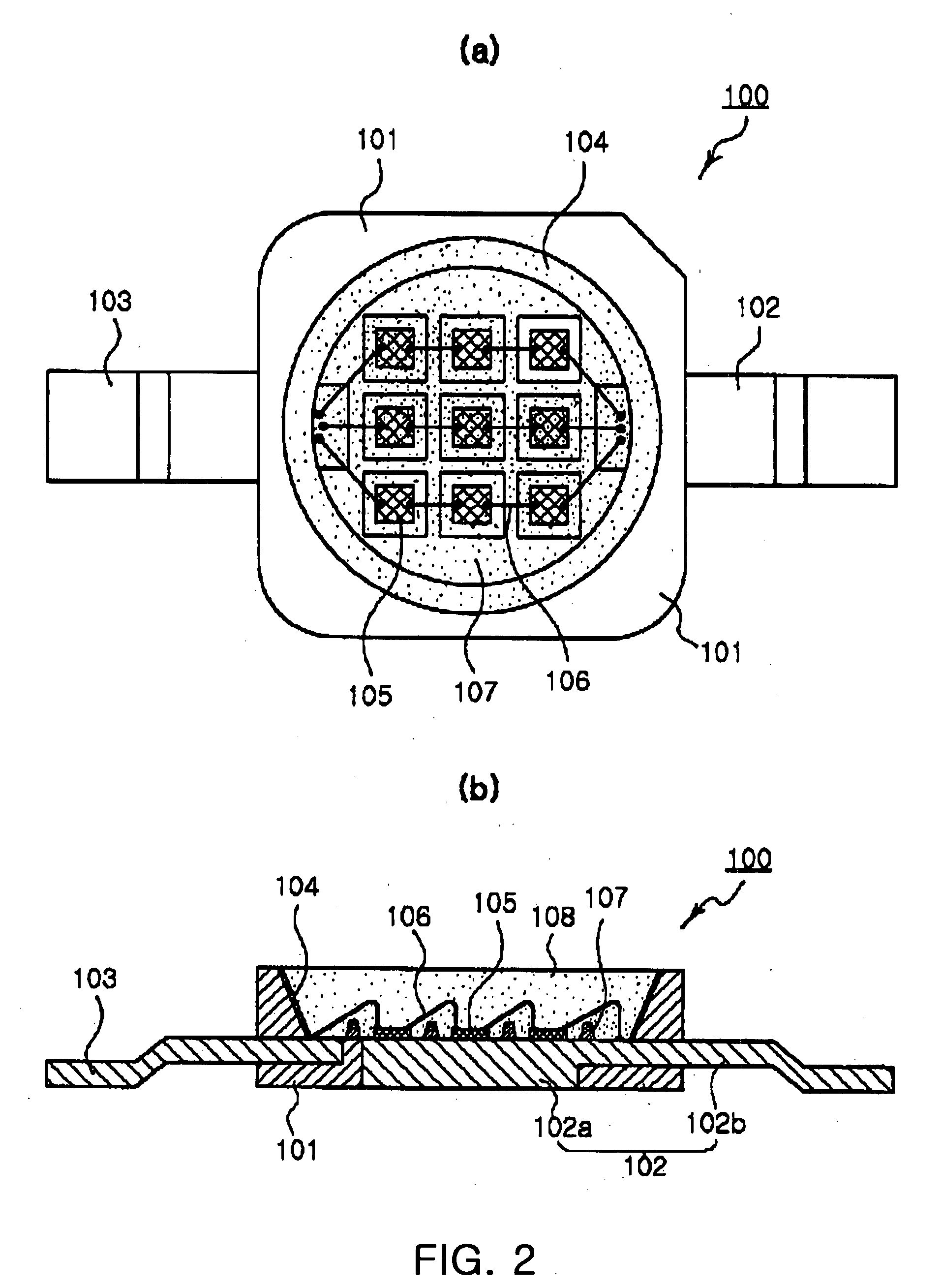

High power light emitting diode package and method of producing the same

ActiveUS20080042151A1Light extraction efficiency can be improvedIncrease powerSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringLead frame

A high power Light Emitting Diode (LED) package and a method of producing the same. The high power LED package according to the present invention includes a plurality of light emitting diode chips, a first lead frame with the light emitting diode chips mounted thereon, and a second lead frame disposed at a predetermined interval from the first lead frame. The LED package also includes a package body fixing the first and second lead frames and bonding wires for electrically connecting the plurality of LED chips. The package body includes at least one first reflecting part separately surrounding each of the plurality of LED chips with upward-inclined inner side walls thereof and a second reflecting part surrounding the entire plurality of LED chips with an upward-inclined inner side wall thereof.

Owner:SAMSUNG ELECTRONICS CO LTD

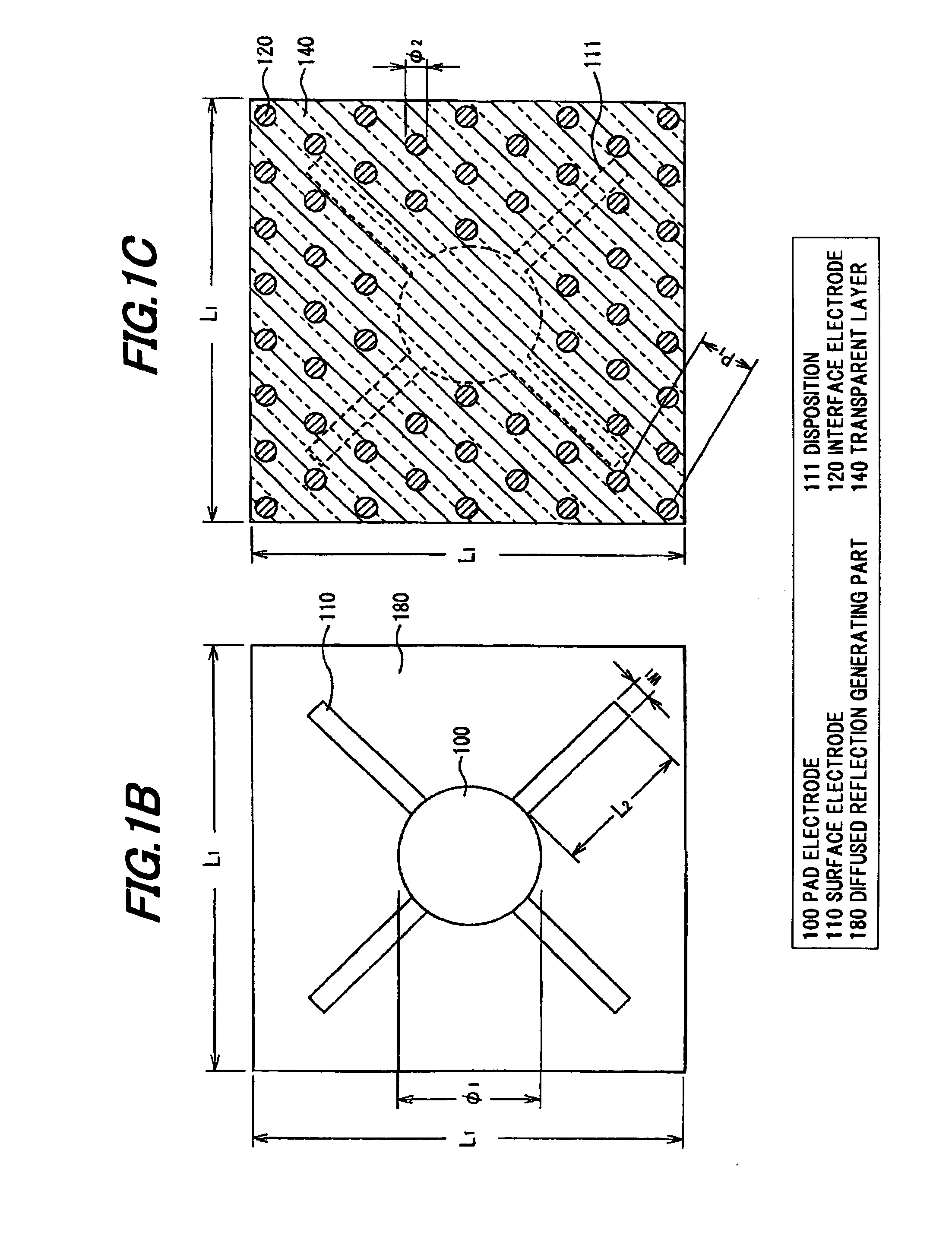

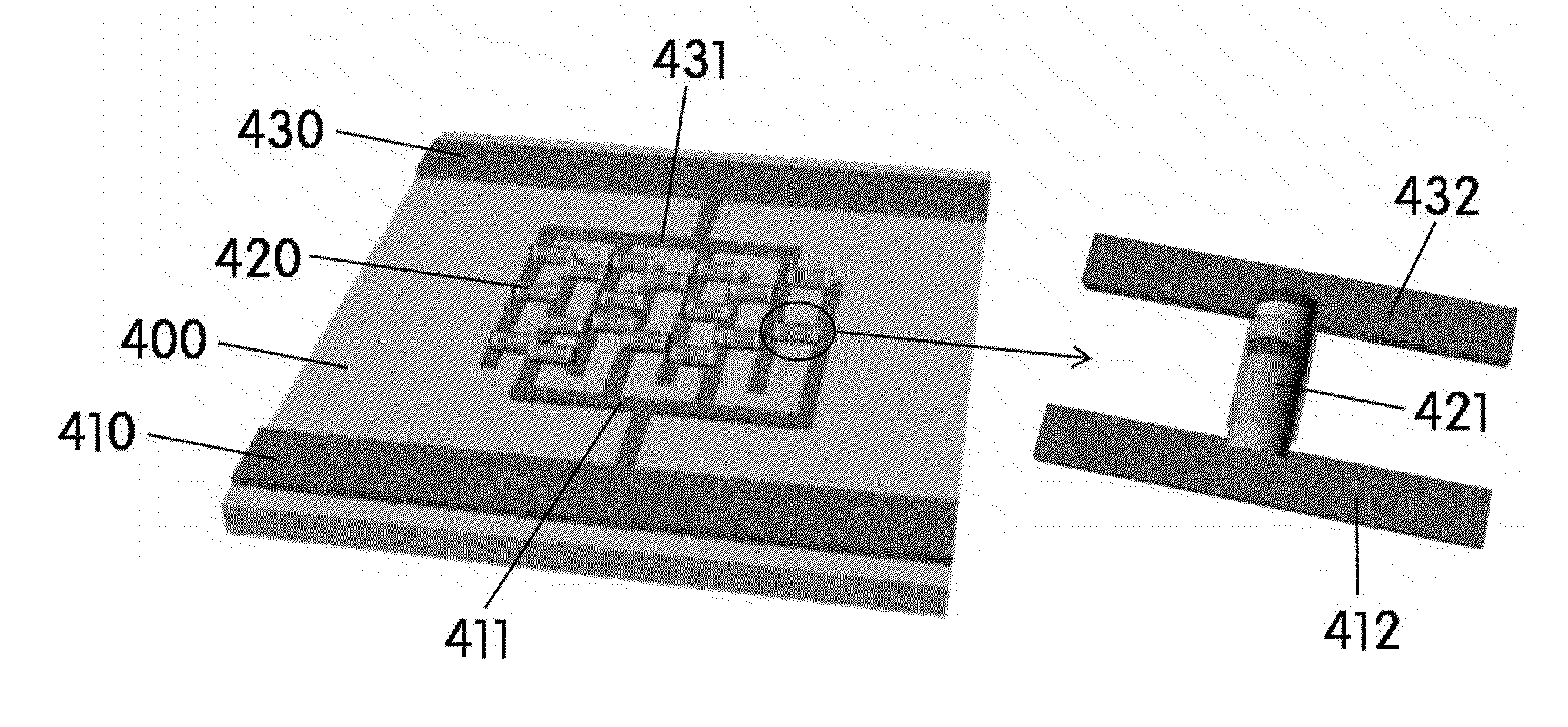

Ultra-small LED electrode assembly and method for manufacturing same

ActiveUS20160148911A1Light extraction efficiency can be improvedImprove extraction efficiencyFinal product manufacturePrinted circuit aspectsEngineeringLead electrode

Provided are a nano-scale LED assembly and a method for manufacturing the same. First, a nano-scale LED device that is independently manufactured may be aligned and connected to two electrodes different from each other to solve a limitation in which a nano-scale LED device having a nano unit is coupled to two electrodes different from each other in a stand-up state. Also, since the LED device and the electrodes are disposed on the same plane, light extraction efficiency of the LED device may be improved. Furthermore, the number of nano-scale LED devices may be adjusted. Second, since the nano-scale LED device does not stand up to be three-dimensionally coupled to upper and lower electrodes, but lies to be coupled to two electrodes different from each other on the same plane, the light extraction efficiency may be very improved. Also, since a separate layer is formed on a surface of the LED device to prevent the LED device and the electrode from being electrically short-circuited, defects of the LED electrode assembly may be minimized. Also, in preparation for the occurrence of the very rare defects of the LED device, the plurality of LED devices may be connected to the electrode to maintain the original function of the nano-scale LED electrode assembly.

Owner:SAMSUNG DISPLAY CO LTD

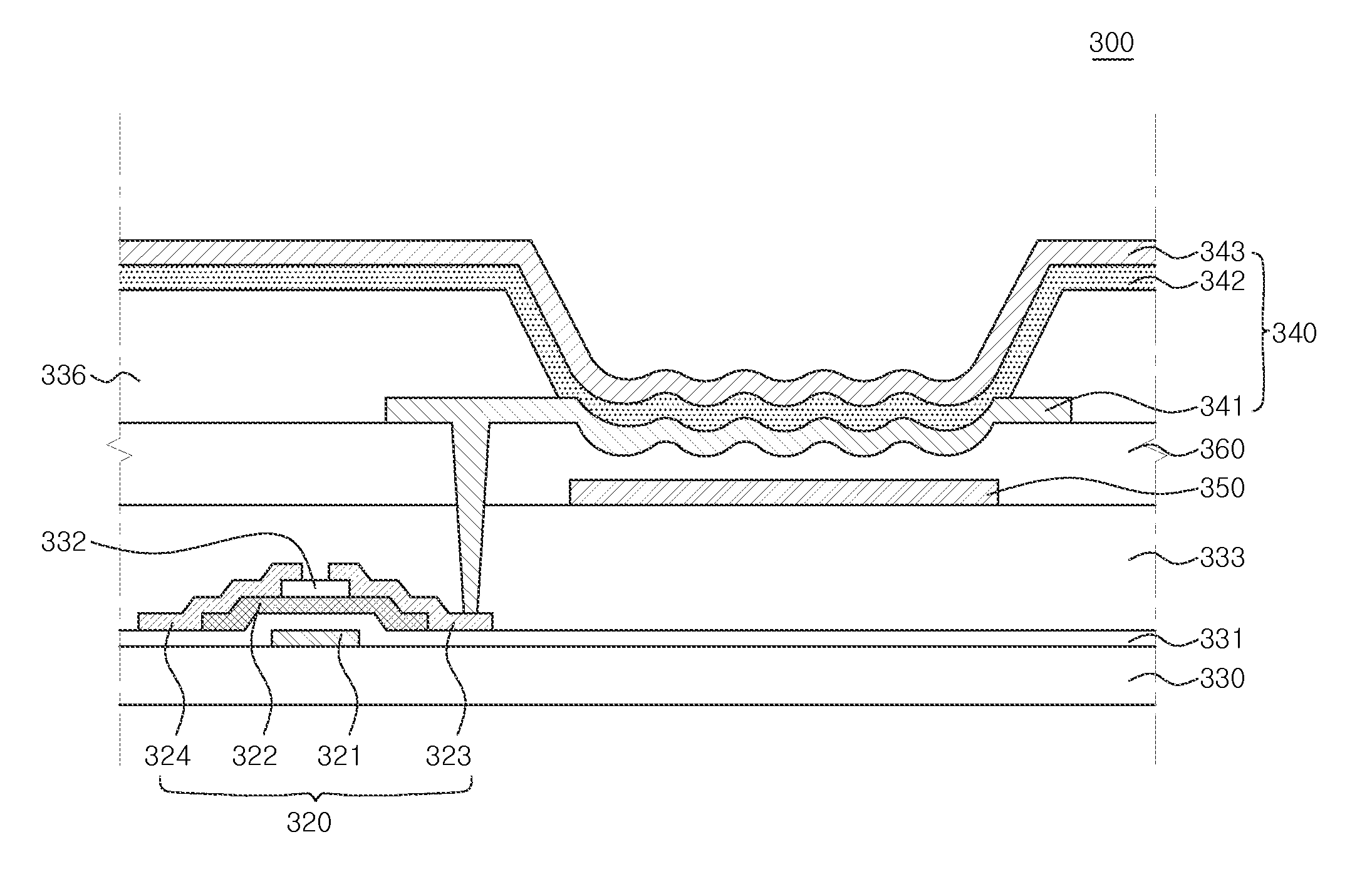

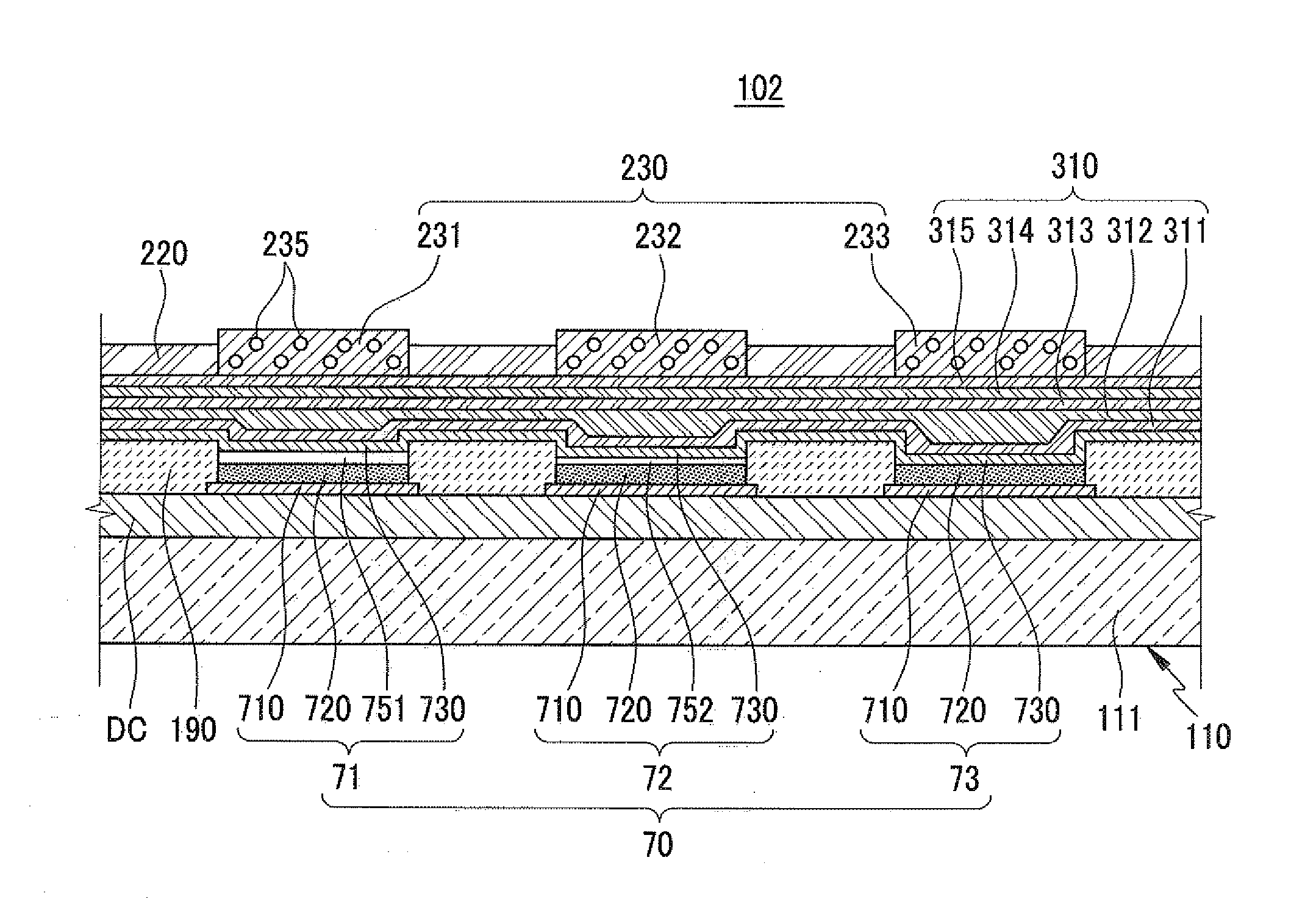

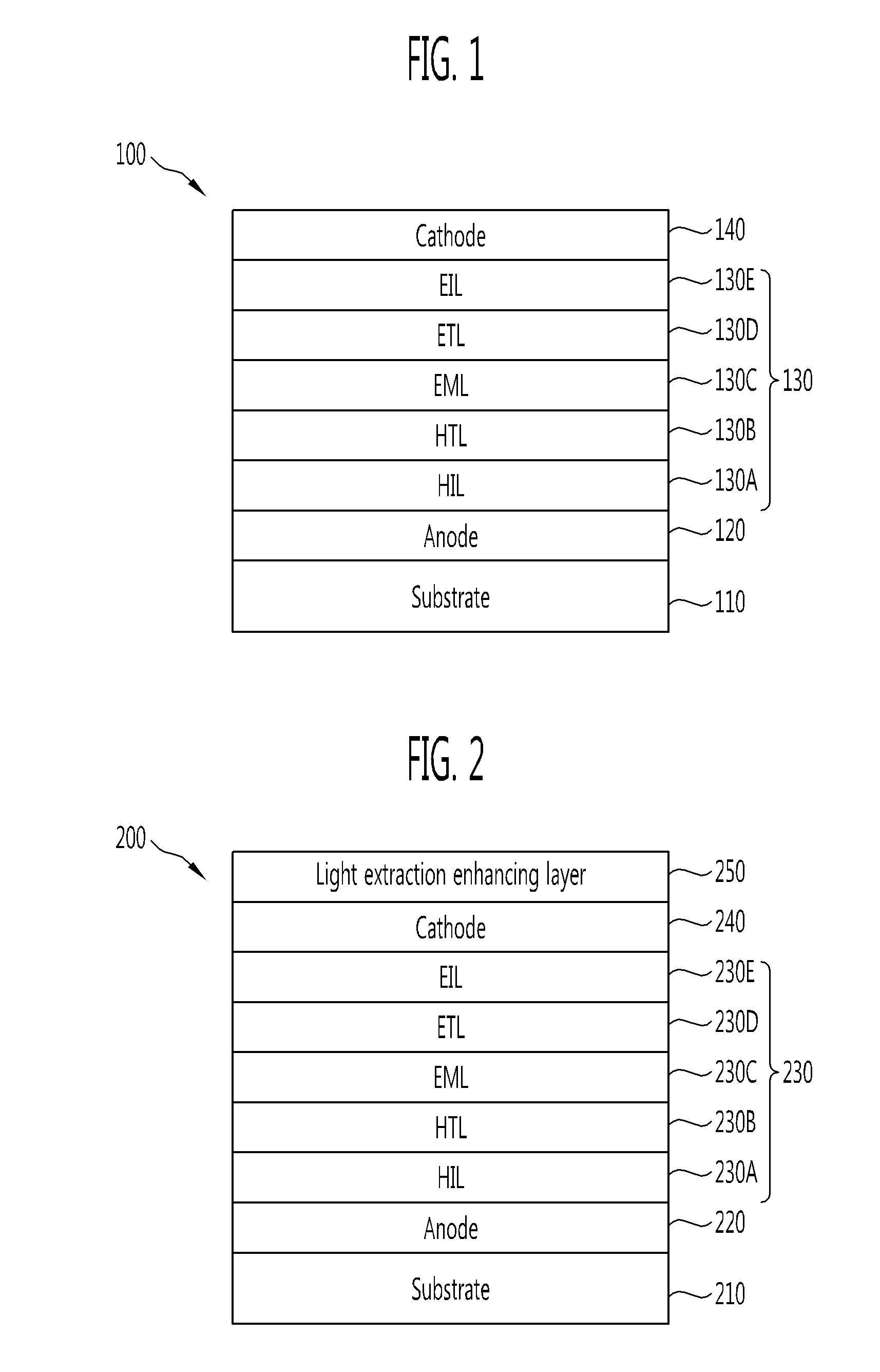

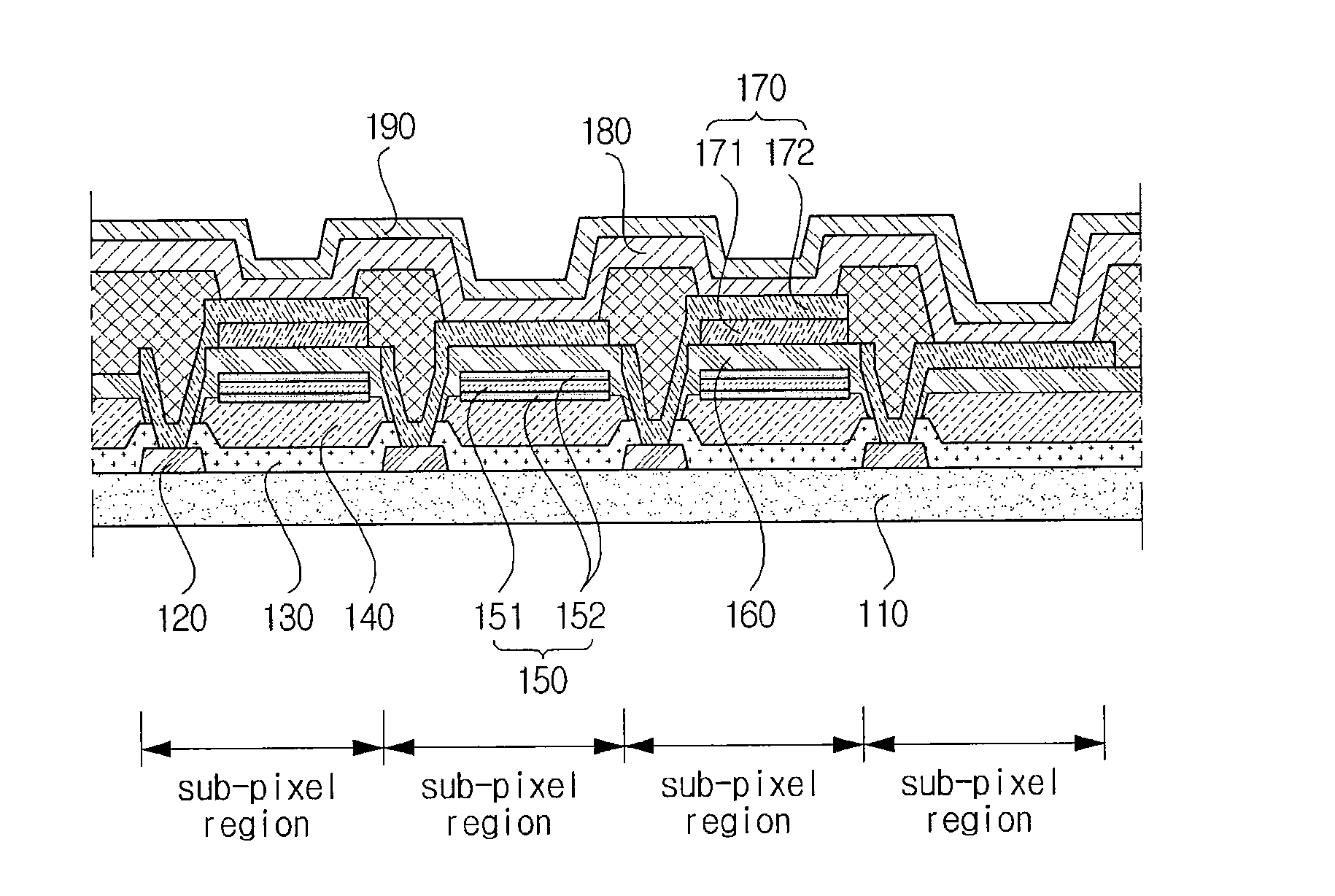

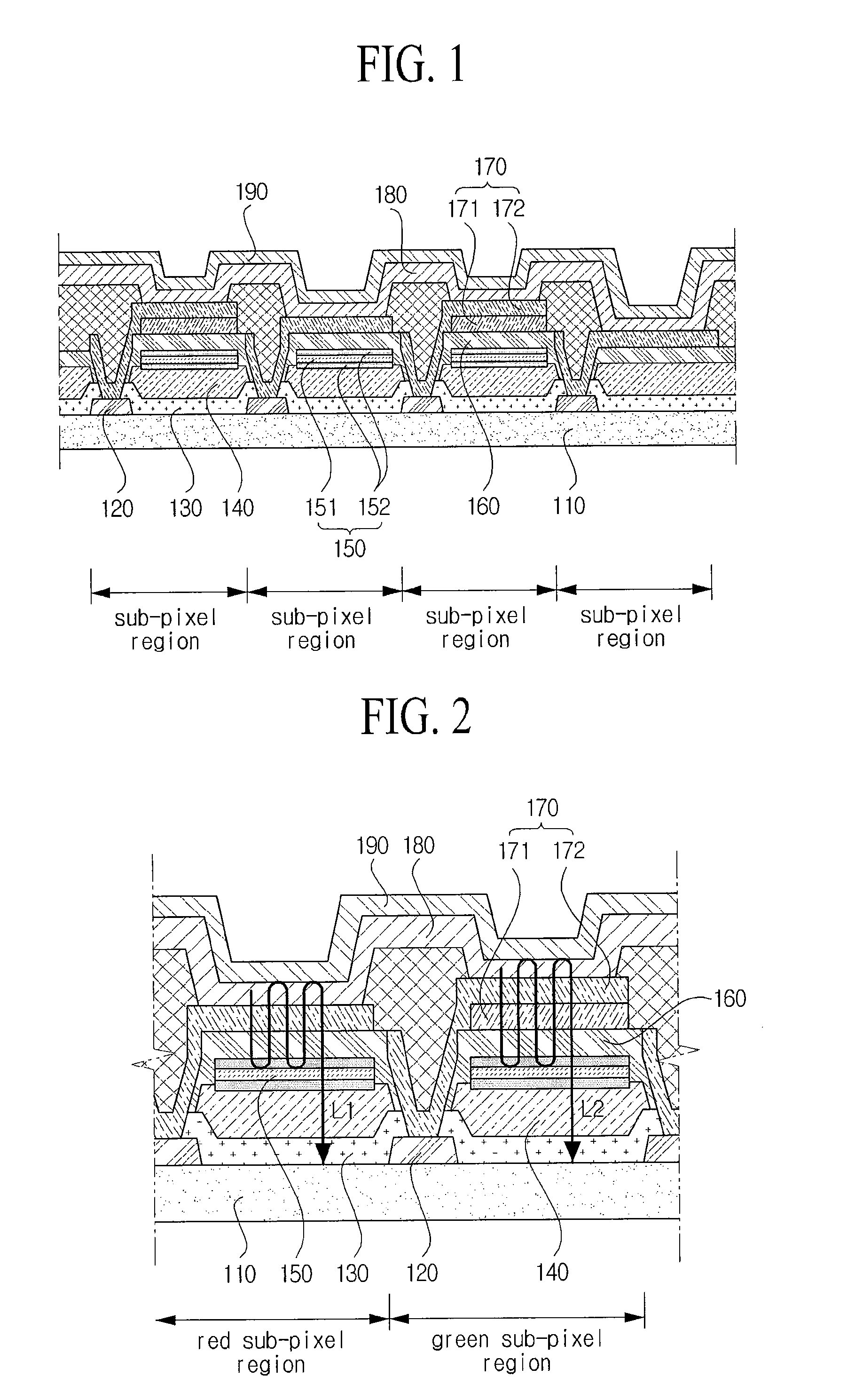

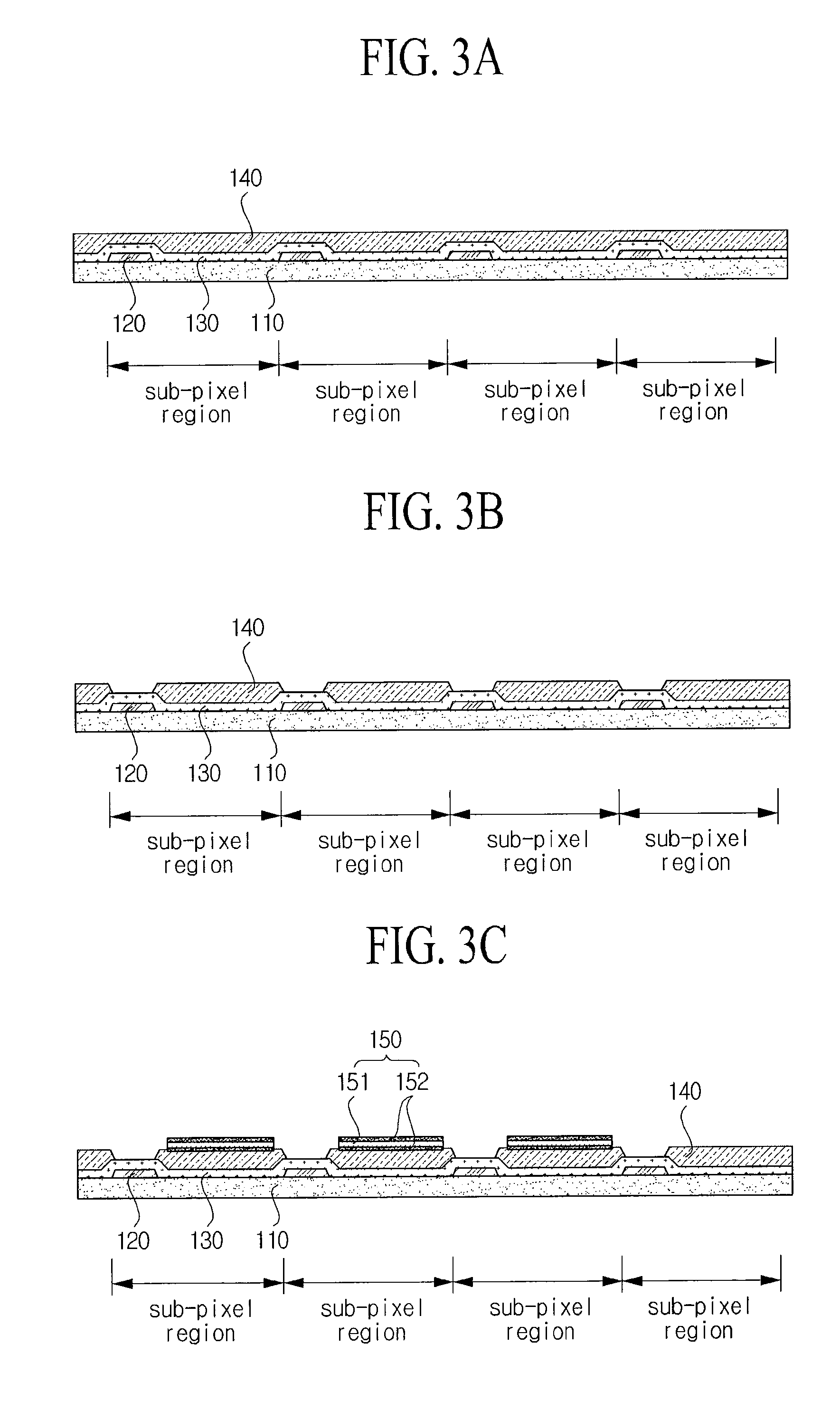

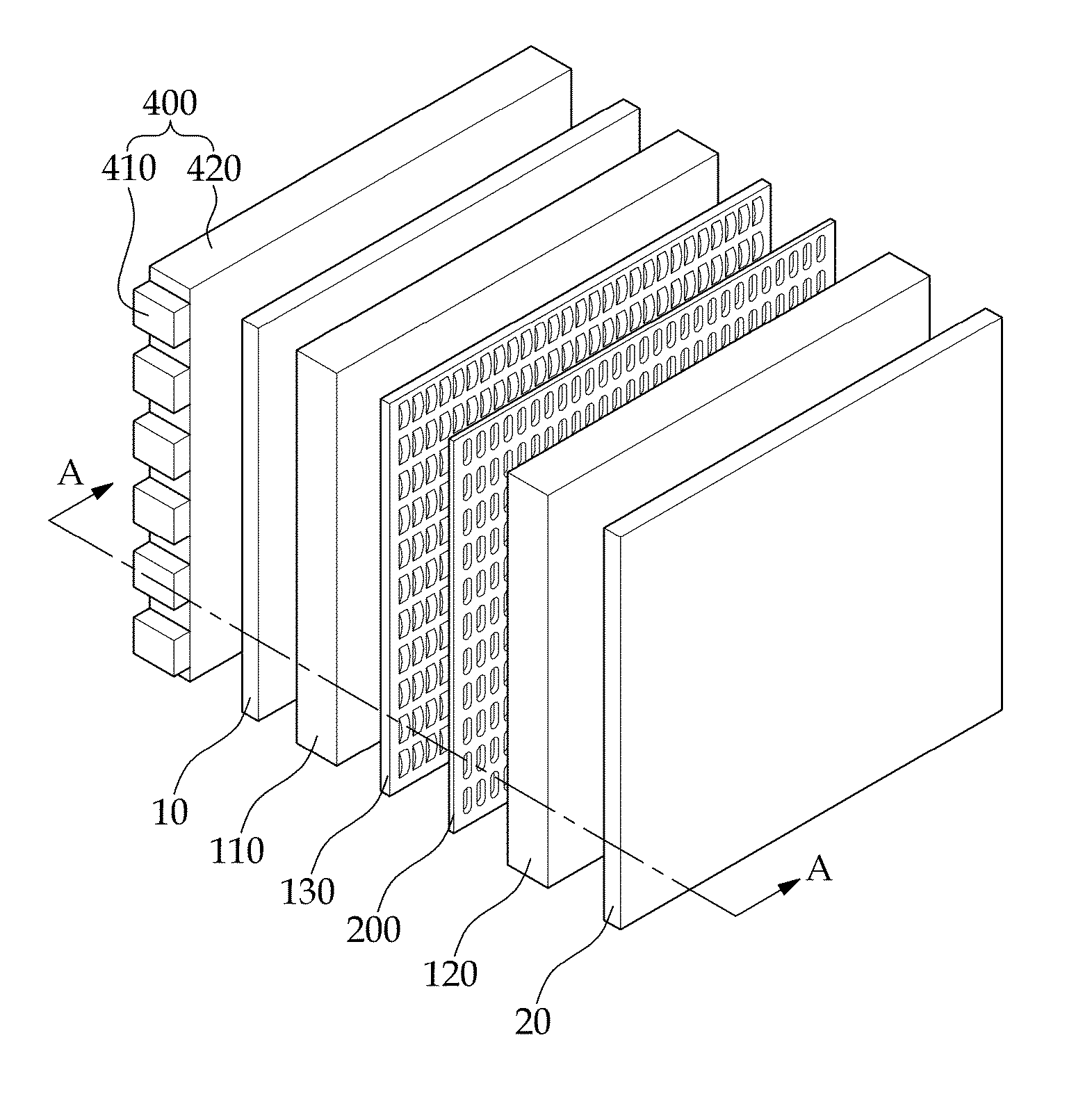

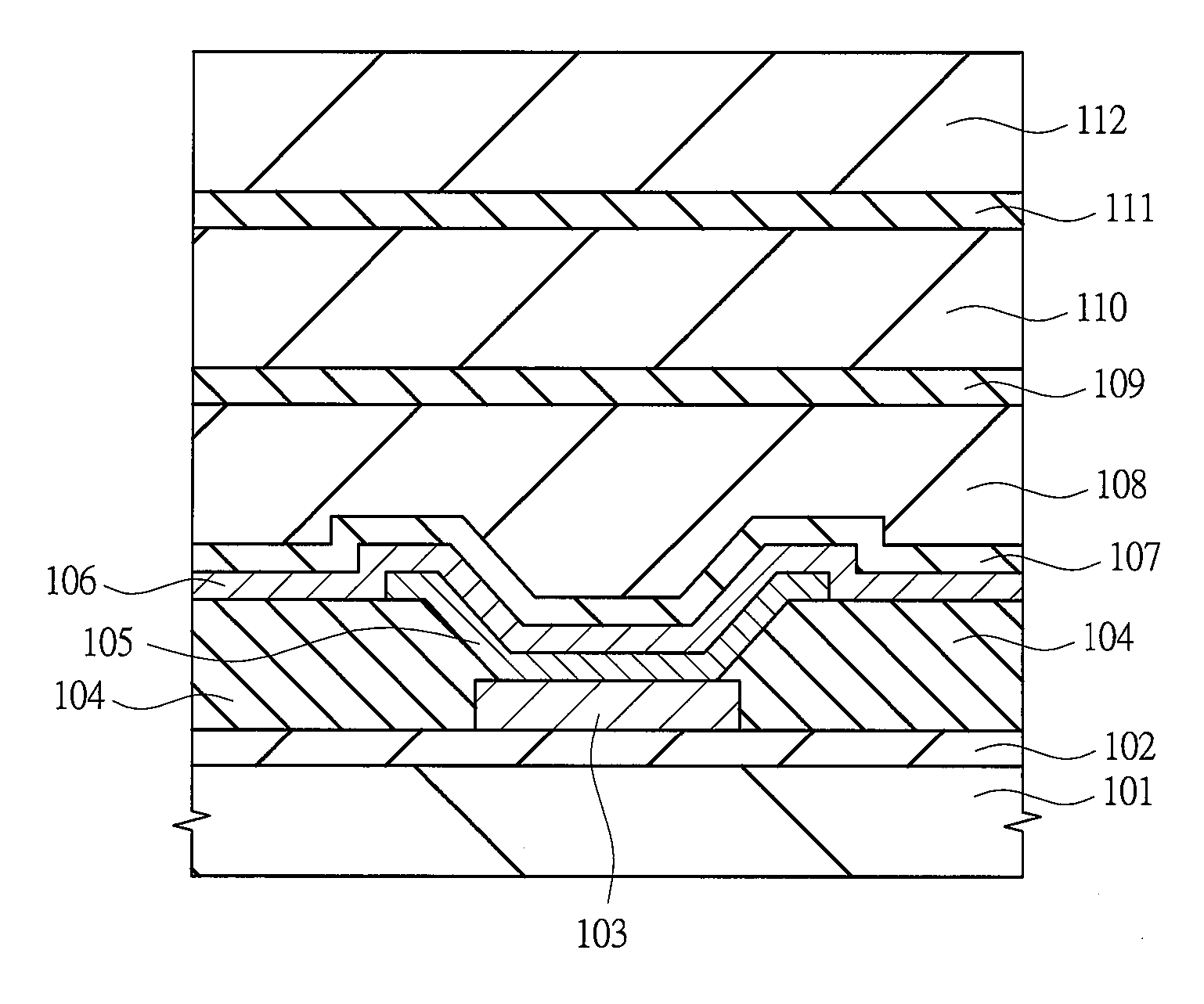

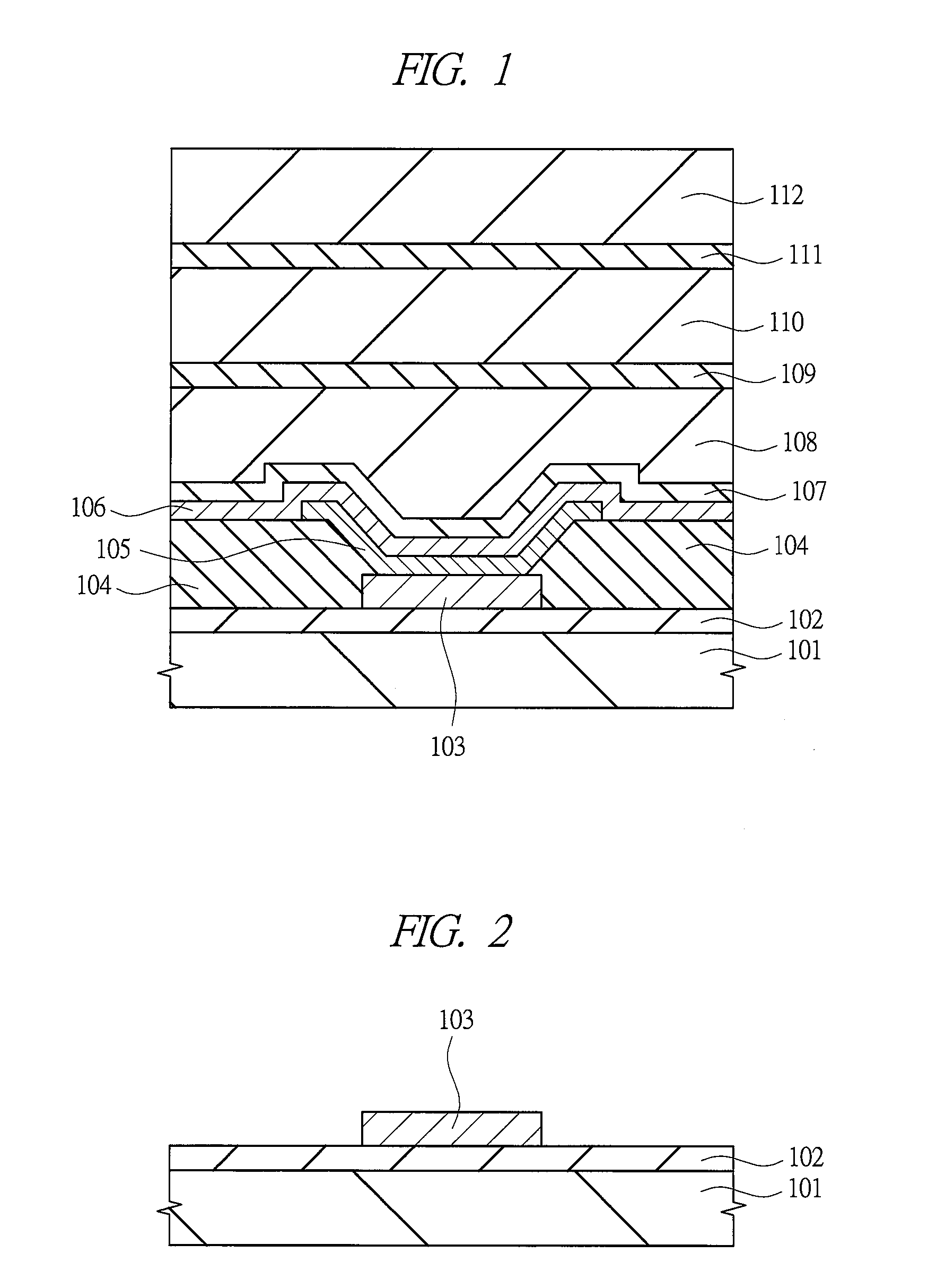

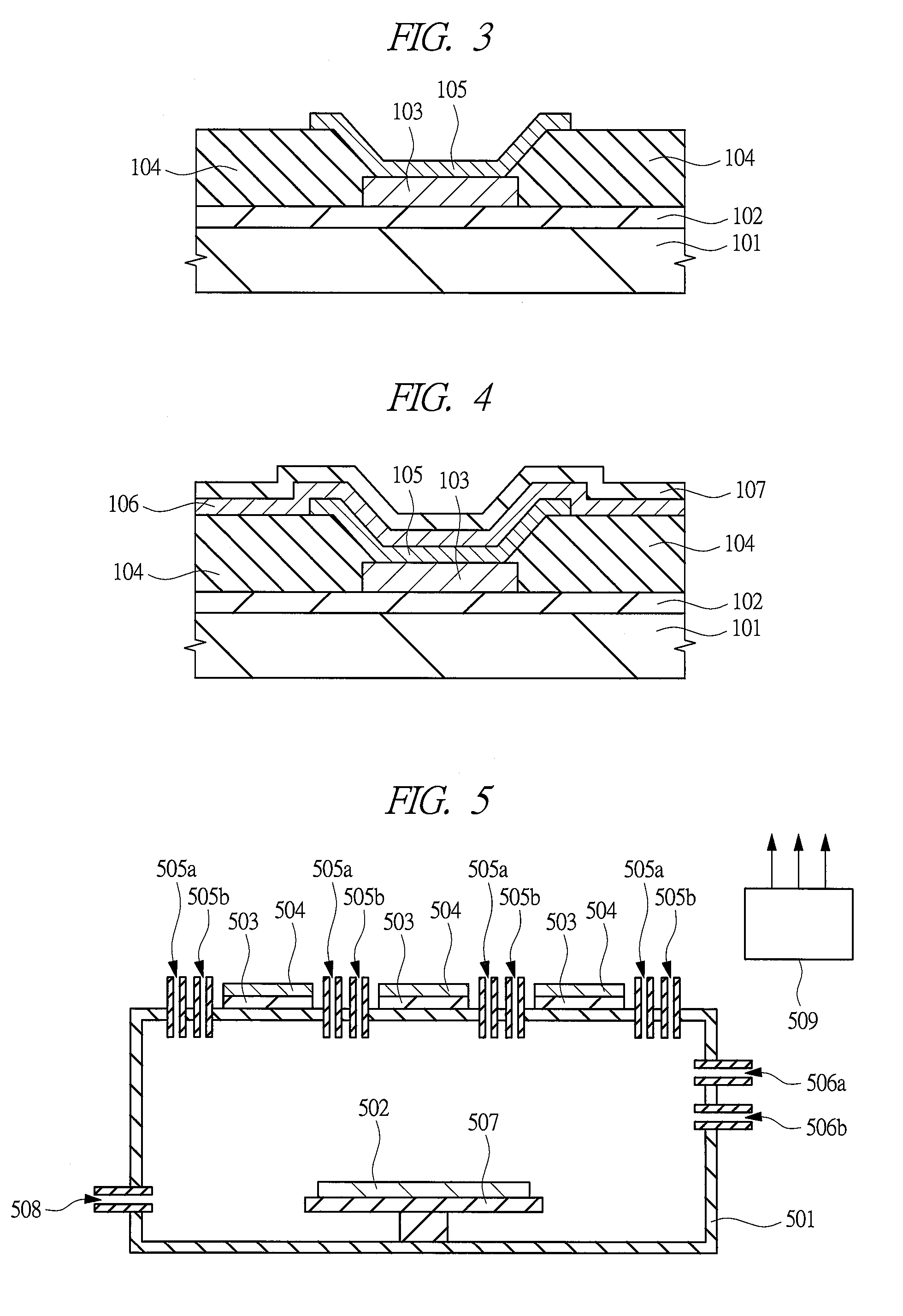

Organic light emitting diode display device and method of manufacturing the same

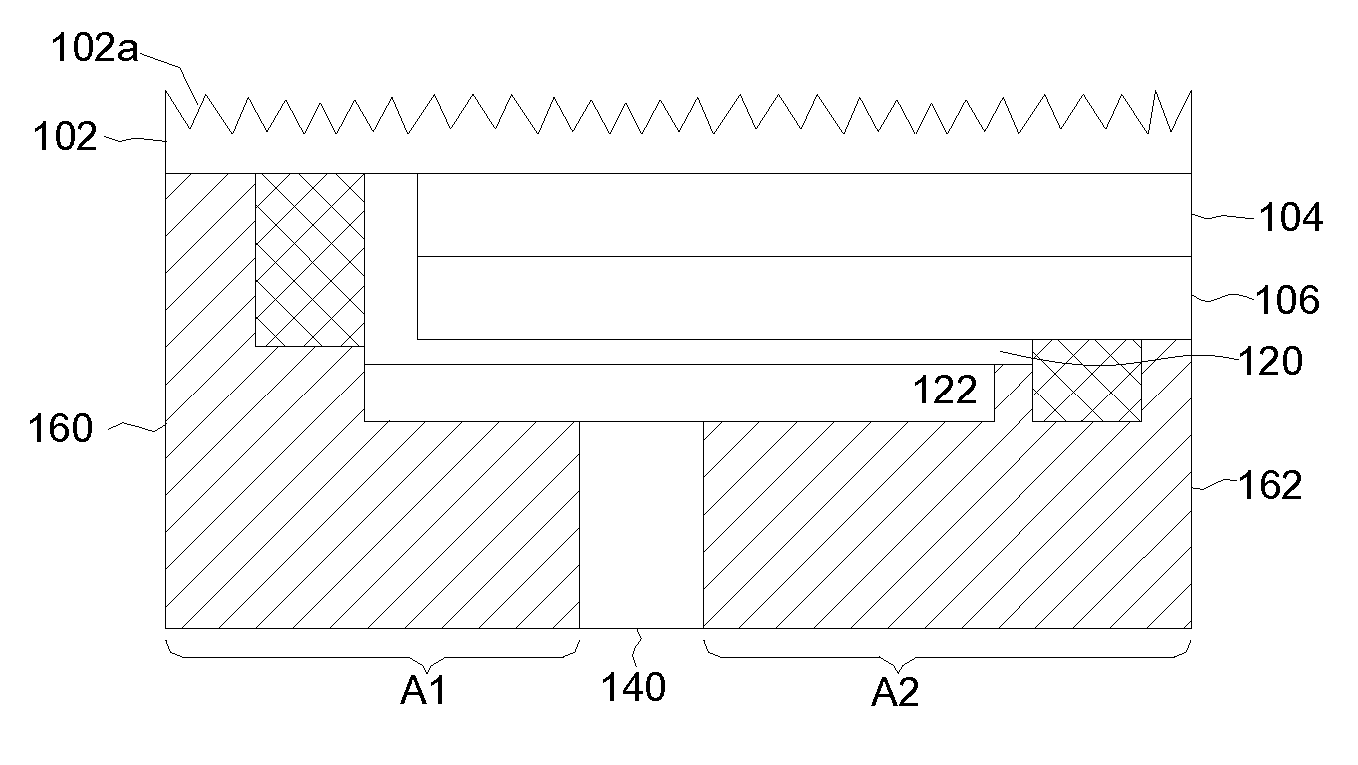

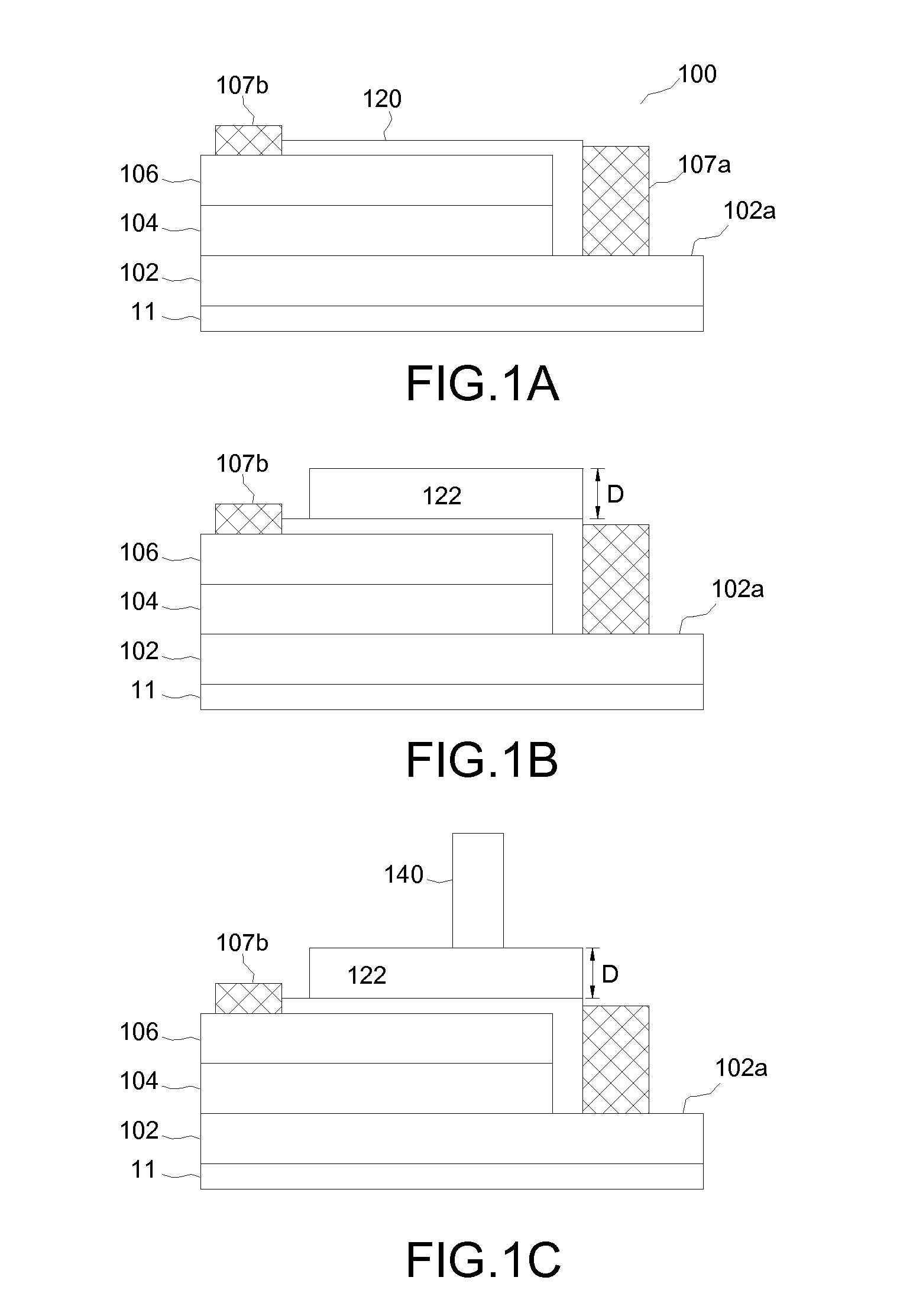

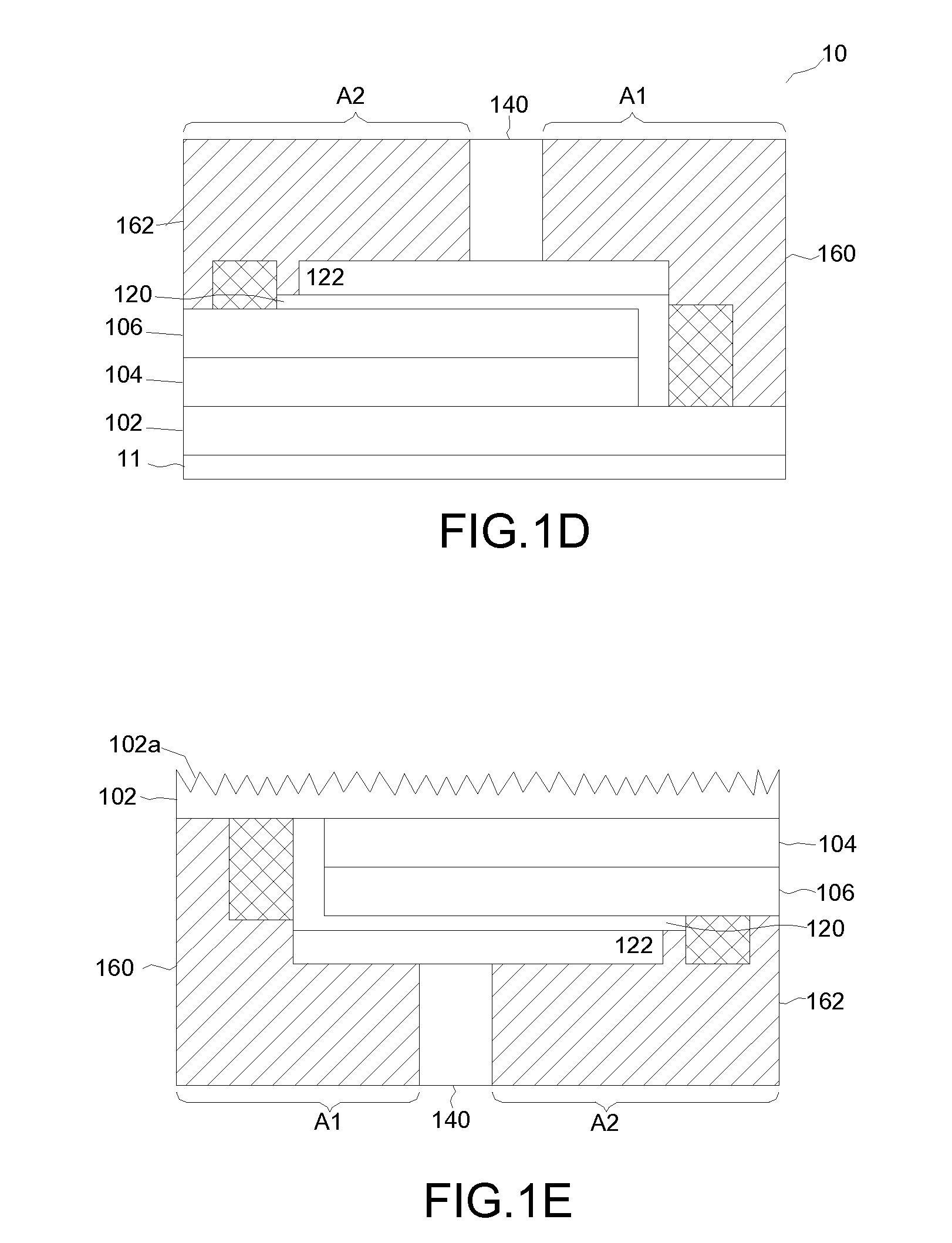

ActiveUS20140061595A1Light extraction efficiency can be improvedSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceReflective layer

An OLED display device is provided. The OLED display device includes a substrate segmented into a plurality sub-pixel regions, a thin film transistor formed in each of the sub-pixel regions, an insulating layer and a planarizion layer formed on the thin film transistor, a semitransparent reflective layer selectively formed in each sub-pixel region on the planarizion layer, a protective layer formed on the semitransparent reflective layer, an anode electrode formed in a region corresponding to the semitransparent reflective layer on the protective layer and connected to the thin film transistor, an organic light emitting layer connected to the anode electrode, and emitting light, and a cathode electrode formed on the organic light emitting layer.

Owner:LG DISPLAY CO LTD

Semiconductor light emitting device having textured structure and method of manufacturing the same

ActiveUS20060118802A1Light extraction efficiency can be improvedReduce internal crystal defectSolid-state devicesSemiconductor/solid-state device manufacturingElectrical conductorActive layer

A semiconductor light emitting diode having a textured structure and a method of manufacturing the same are provided. The semiconductor light emitting diode includes a first semiconductor layer formed into a textured structure, an intermediate layer formed between the textured structures of the patterned first semiconductor layer, and a second semiconductor layer, an active layer, and a third semiconductor layer sequentially formed on the first semiconductor layer and the intermediate layer.

Owner:SAMSUNG ELECTRONICS CO LTD

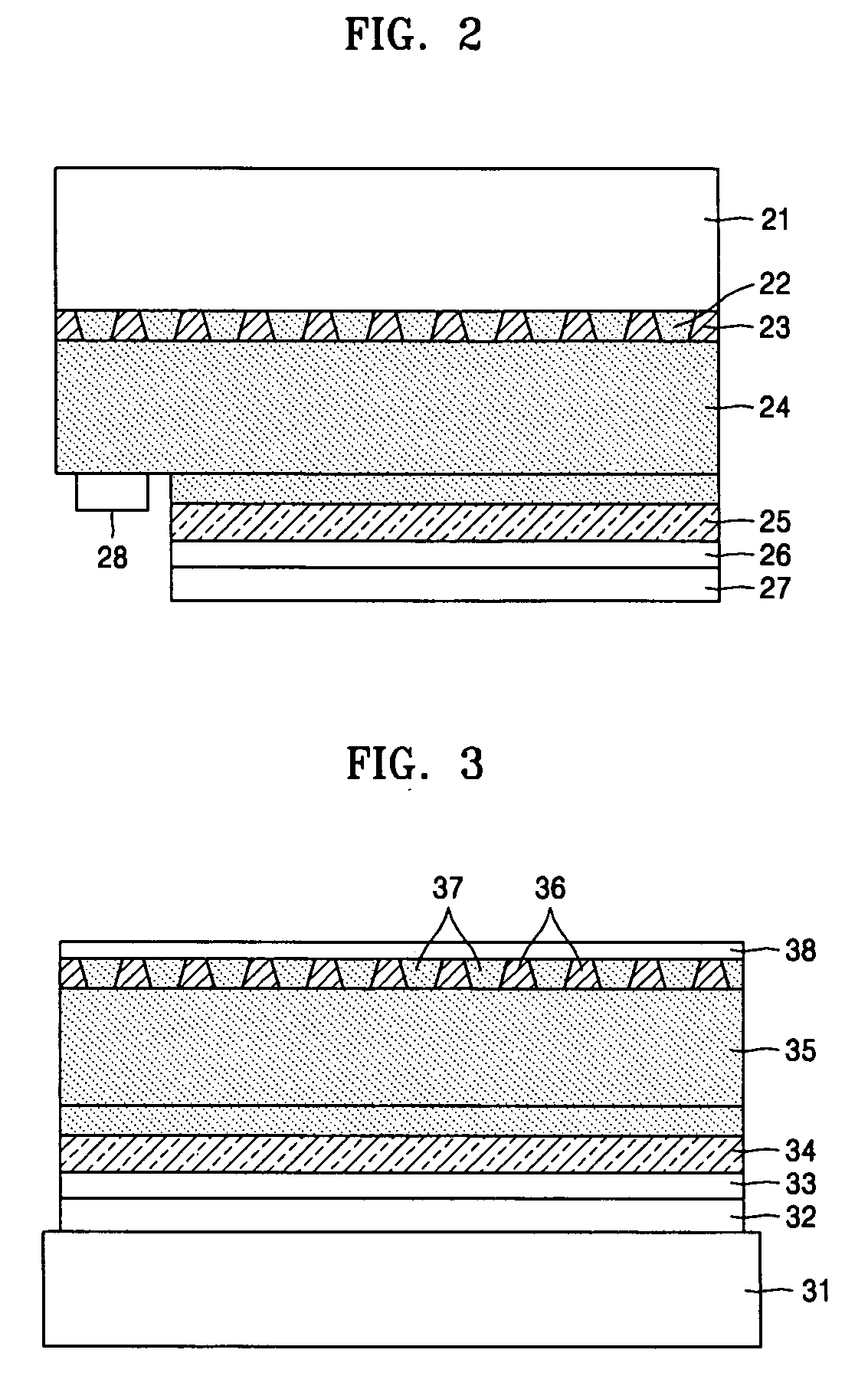

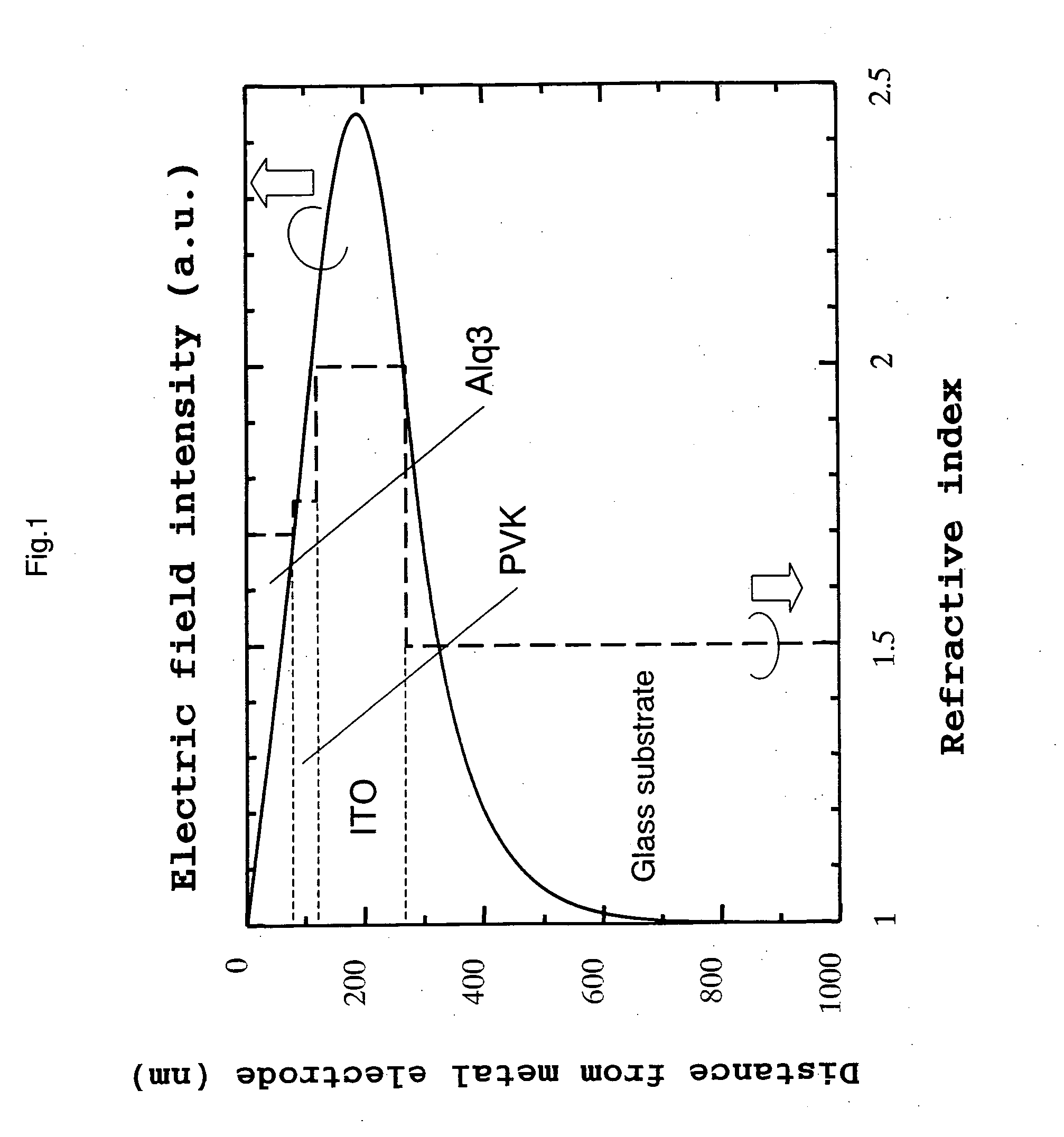

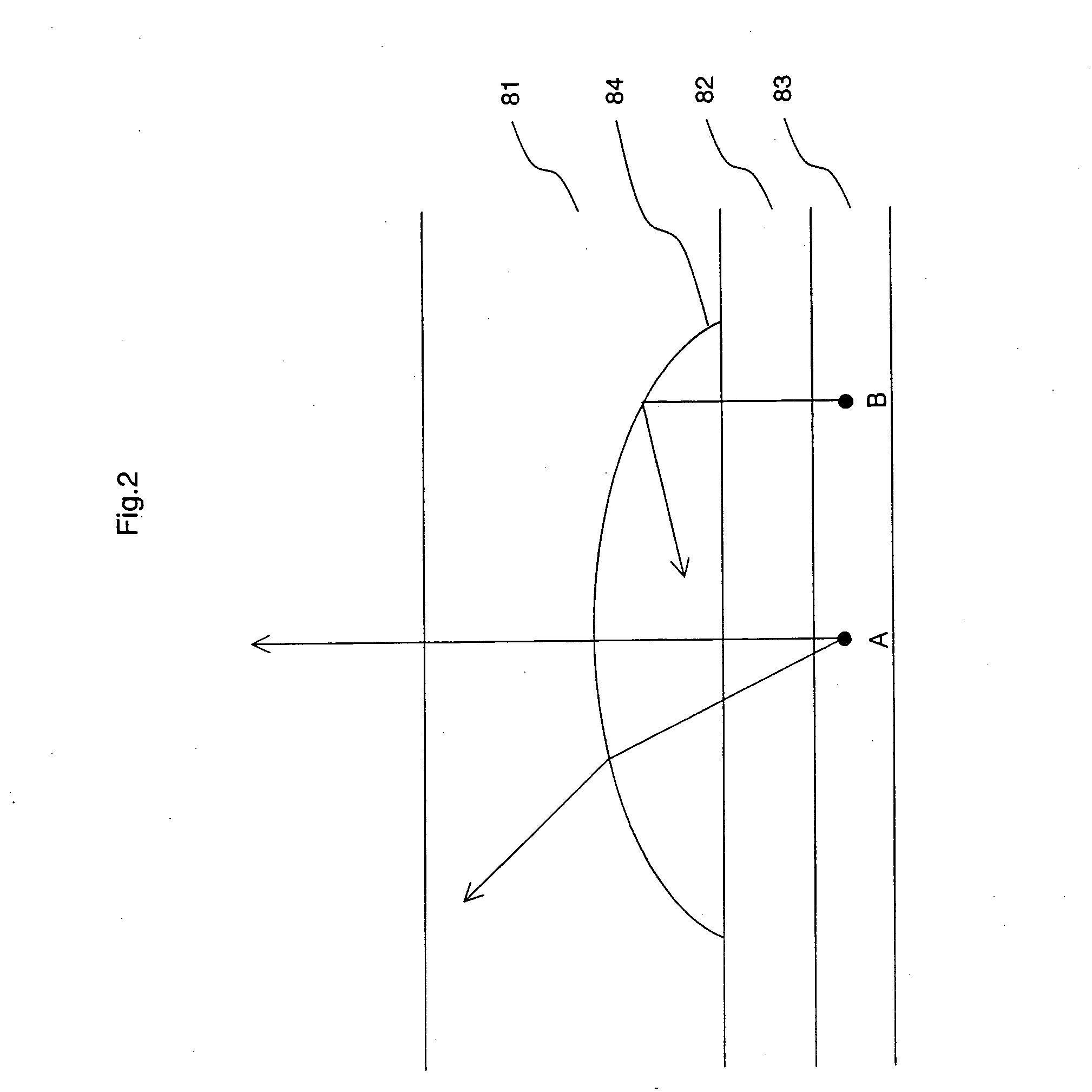

Light-emitting device and organic electroluminescence light-emitting device

InactiveUS20070120136A1Light extraction efficiency can be improvedElectroluminescent light sourcesSolid-state devicesOrganic light emitting deviceRefractive index

In conventional organic EL light-emitting devices, the ITO used for a transparent electrode has a refractive index of about 2.0 larger than the refractive index of 1.5 of a transparent glass substrate. As a result, the mode of most of light traveling from the transparent electrode toward the glass substrate is the transparent electrode guided mode, and no light is emitted from the transparent electrode toward the glass substrate. According to the invention, the light extraction efficiency of conventional light-emitting devices such as organic EL light-emitting devices is improved by using mode conversion means so as to solve the problem that conventional light-emitting devices such as organic EL light-emitting devices have low light extraction efficiencies. A light-emitting device of the invention comprises a light-emitting layer on a substrate and mode conversion means for converting the mode from the guided mode into an emission mode. The mode conversion means is provided in the substrate, in the light-emitting layer, or at the interface between the substrate and the light-emitting layer.

Owner:ROHM CO LTD

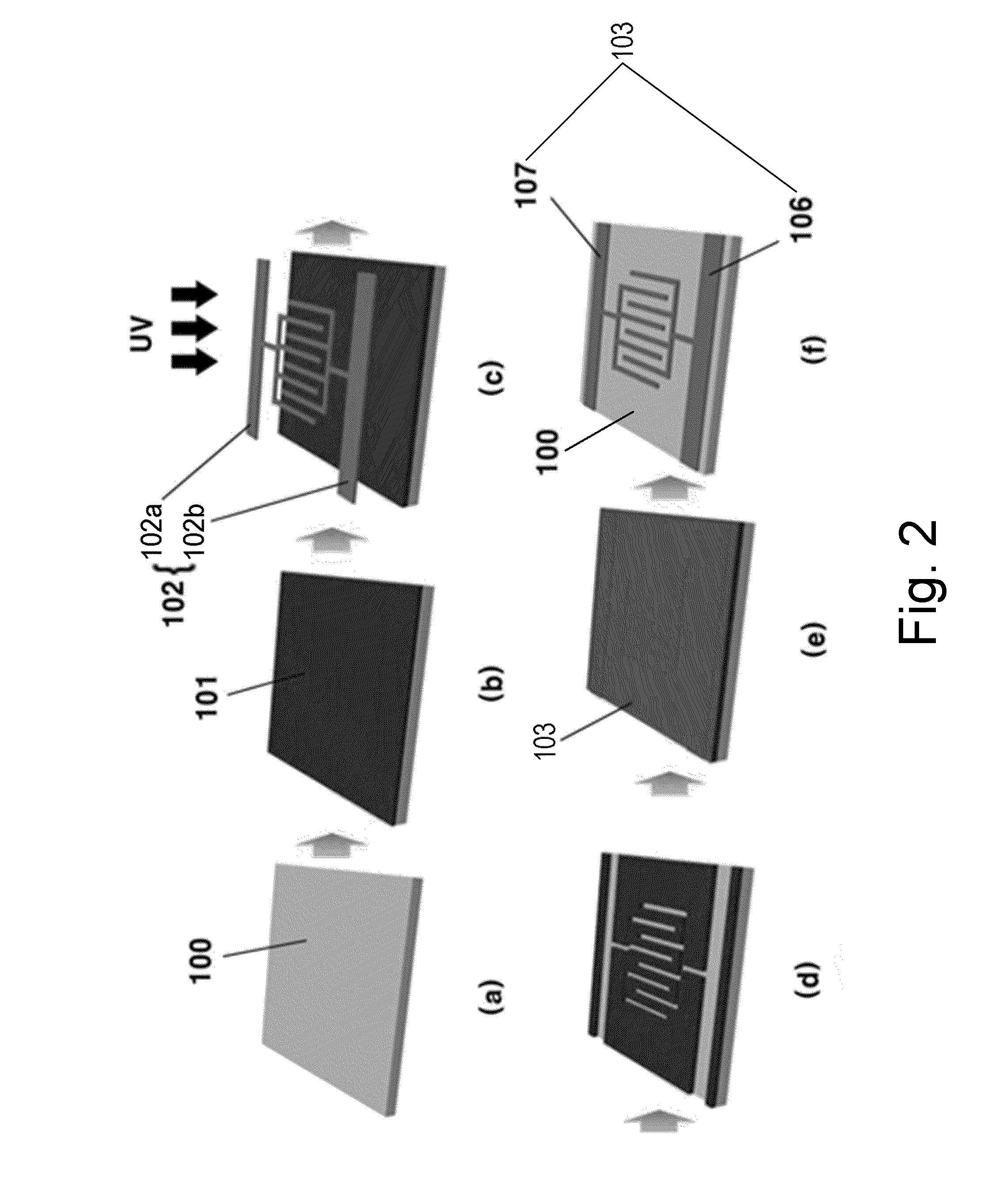

Method for manufacturing light emitting diode package

InactiveUS20070212802A1Light extraction efficiency can be improvedImprove extraction efficiencySolid-state devicesMedical devicesLight beamEngineering

Owner:SAMSUNG ELECTRONICS CO LTD

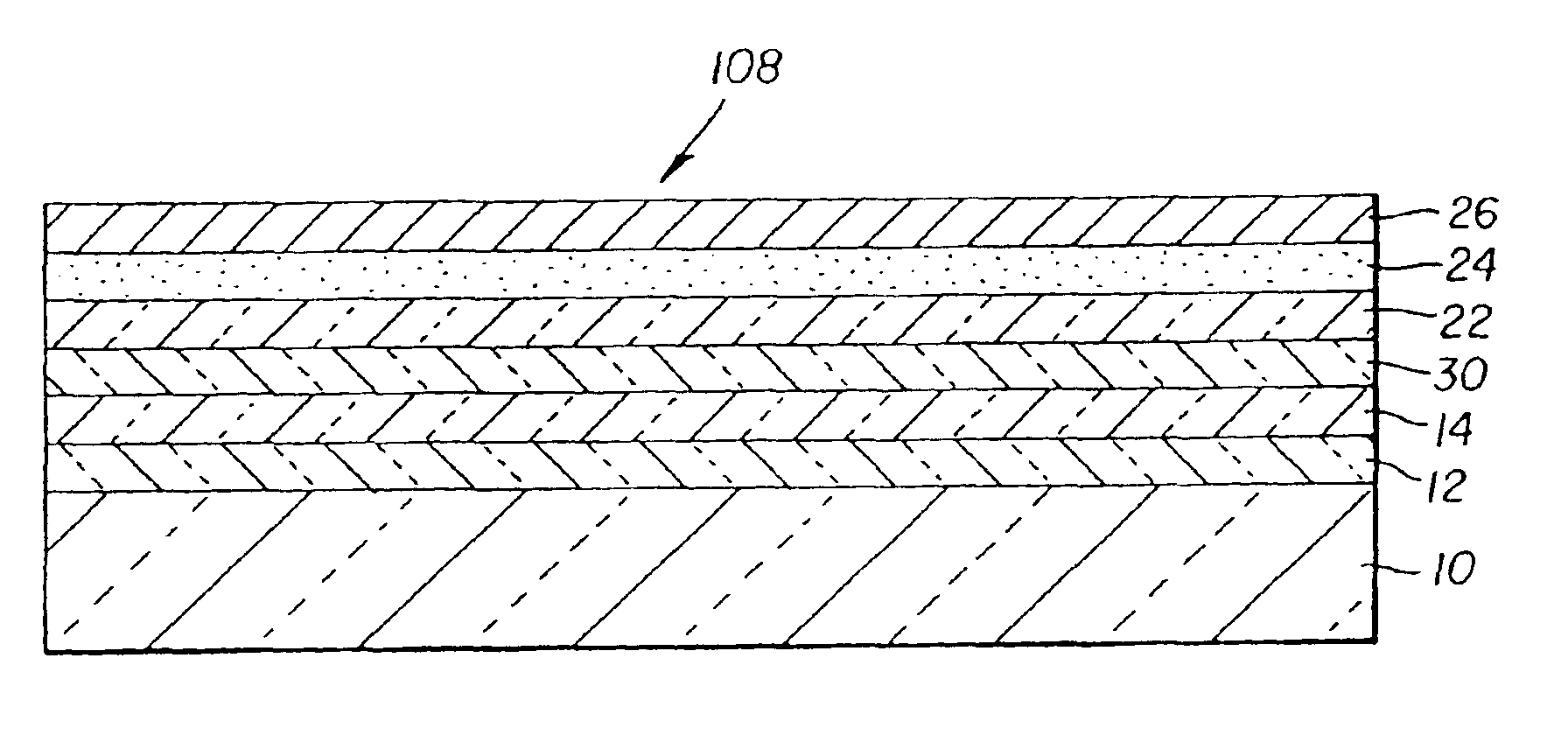

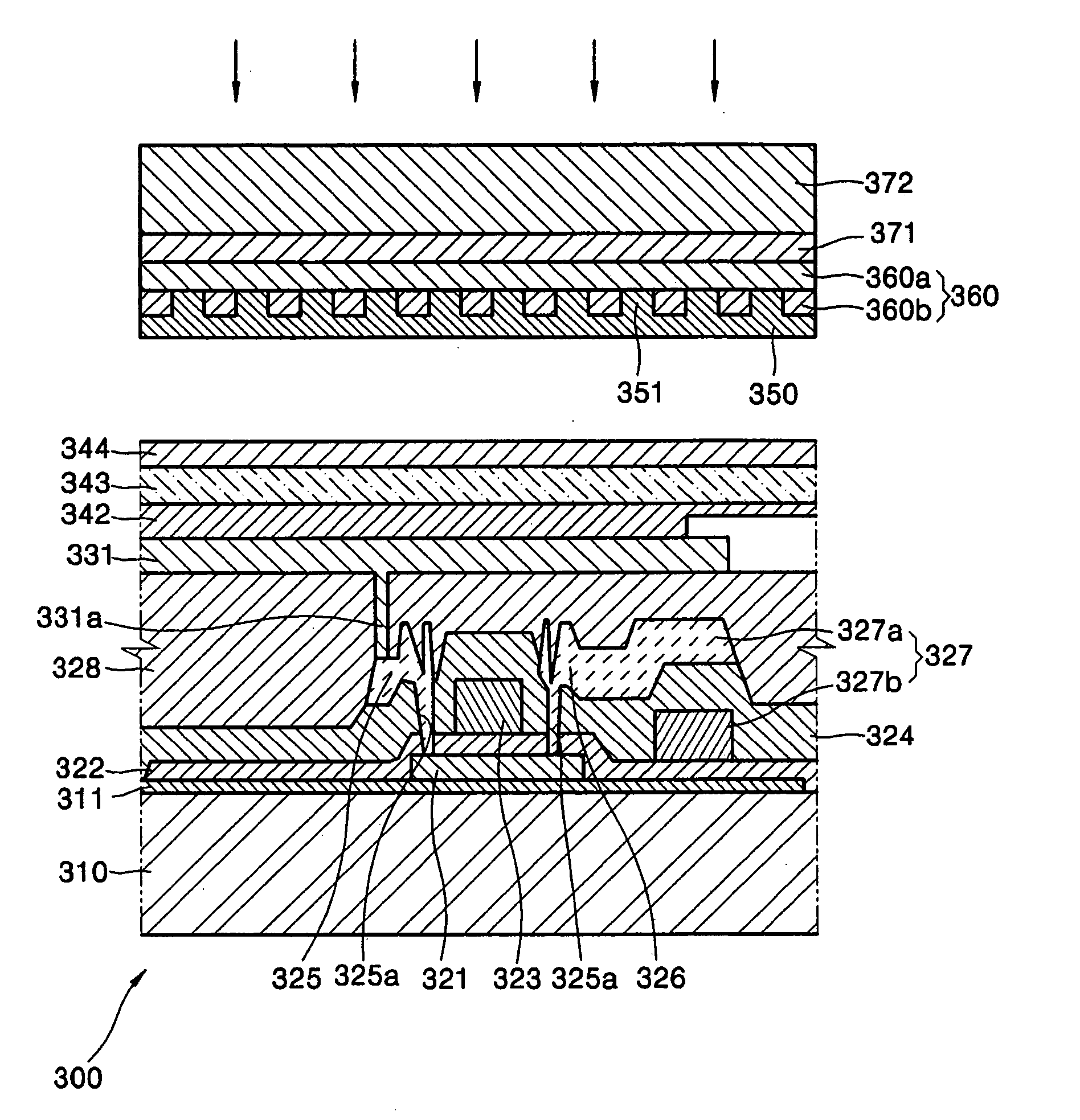

Electroluminescent display device and thermal transfer donor film for the electroluminescent display device

ActiveUS20050116625A1Light extraction efficiencyImprove light extractionDischarge tube luminescnet screensElectroluminescent light sourcesPhotonic crystalLength wave

The invention is directed to an organic electroluminescent (EL) display device having an improved light extracting efficiency due to a photonic crystal layer formed proximate one side of a stack. Among other elements, the stack may include a first electrode formed on a substrate, an organic light emitting layer formed above the first electrode, and a second electrode formed above the organic light emitting layer. Additionally, the photonic crystal layer may be configured to correspond to a wavelength of colored light. An organic EL display device having an improved light extracting efficiency may be manufactured using a thermal transfer donor film to adhere the photonic crystal layer to the stack.

Owner:SAMSUNG DISPLAY CO LTD

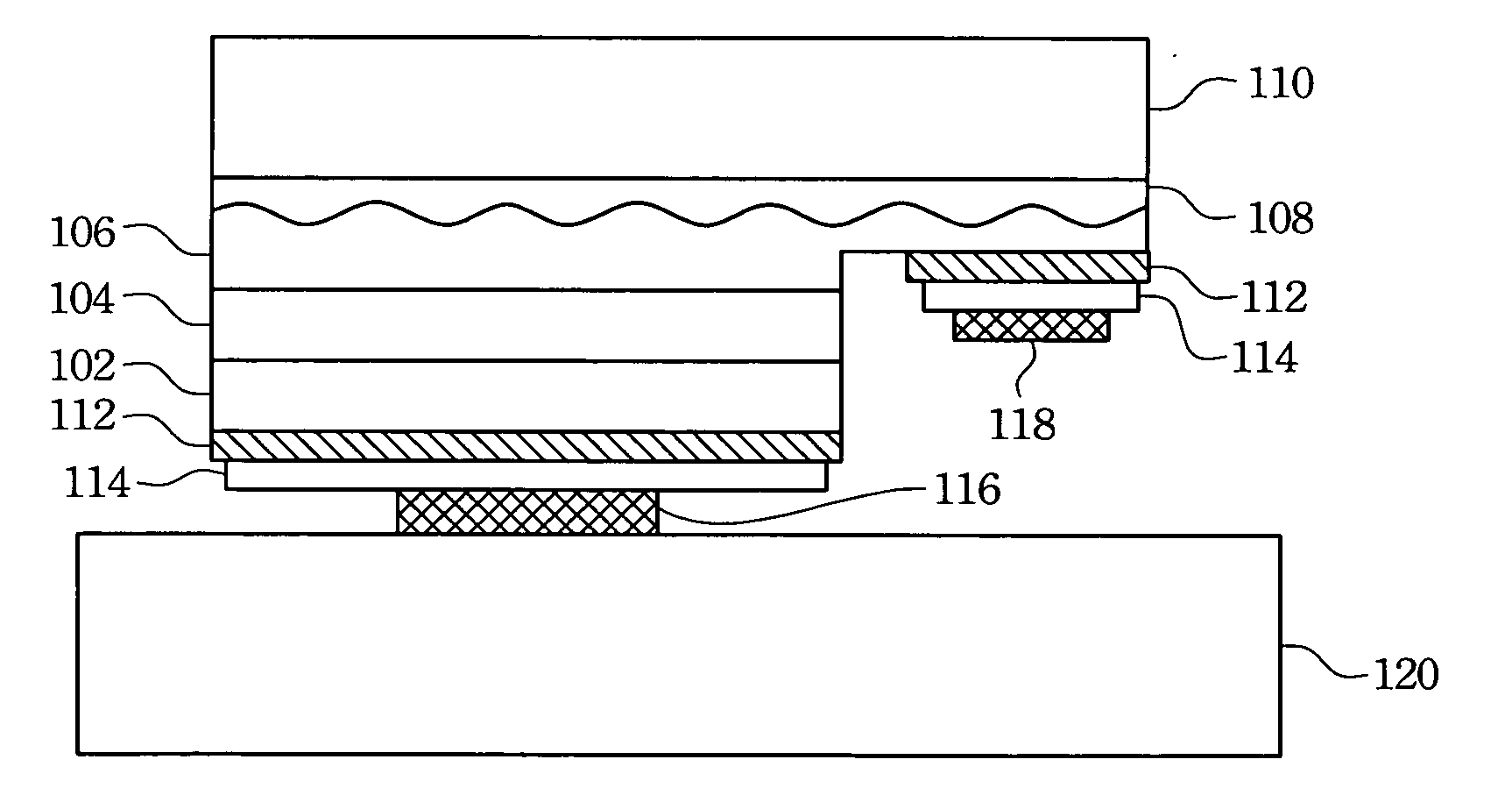

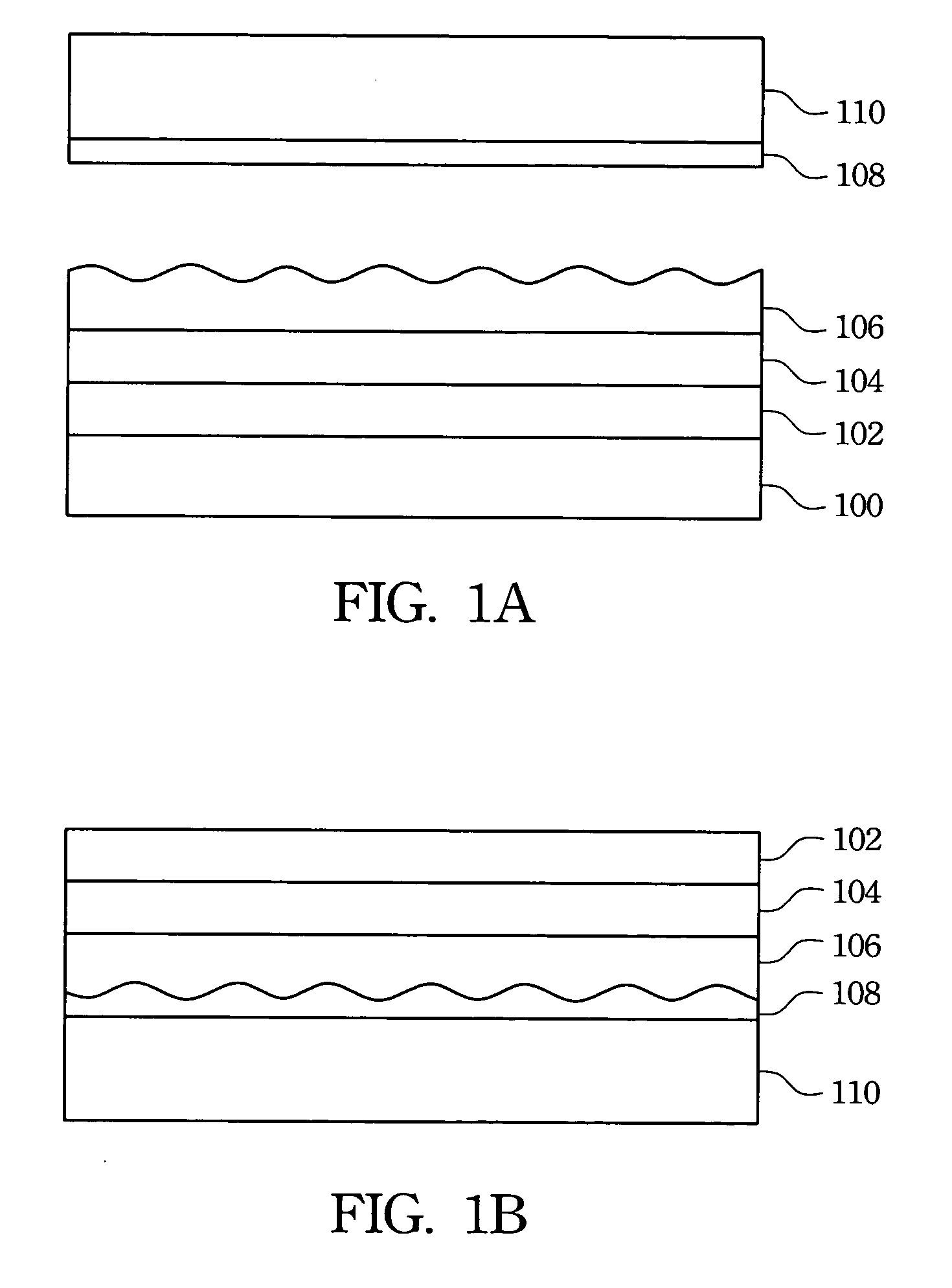

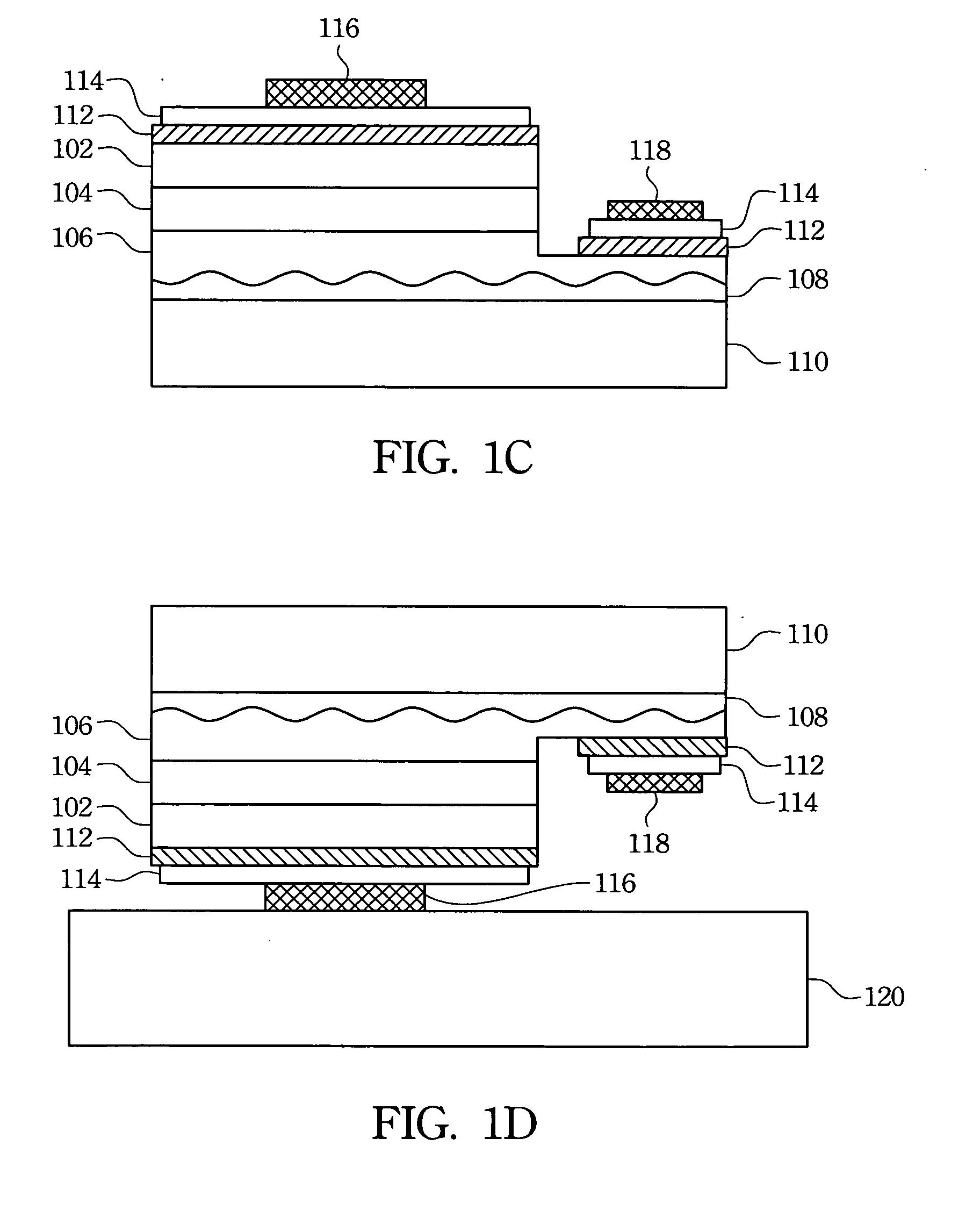

Light emitting device and manufacture method thereof

InactiveUS20070126016A1Light extraction efficiency can be improvedImprove luminous efficiencySolid-state devicesSemiconductor devicesRough surfaceActive layer

A flip-chip LED including a light emitting structure, a first dielectric layer, a first metal layer, a second metal layer, and a second dielectric layer is provided. The light emitting structure includes a first conductive layer, an active layer, and a second conductive layer. The active layer is disposed on the first conductive layer, and the second conductive layer is disposed on the active layer. The first metal layer is disposed on the light emitting structure and is contact with the first conductive layer, and part of the first metal layer is disposed on the first dielectric layer. The second metal layer is disposed on the light emitting structure and is in contact with the second conductive layer, and part of the second metal layer is disposed on the first dielectric layer. The second dielectric layer is disposed on the first dielectric layer. The first conductive layer includes a rough surface so as to improve a light extraction efficiency.

Owner:EPISTAR CORP

Light-emitting devices with high extraction efficiency

InactiveUS20070029560A1Light extraction efficiencyLight extraction efficiency can be improvedSolid-state devicesSemiconductor devicesRefractive indexLength wave

The present invention relates to a light-emitting device having a substrate and a light-emitting layer comprising an electroluminescent material, wherein the light-emitting layer (p-n junction) is sandwiched between a p-type cladding layer with a p-electrode layer and an n-type cladding layer with an n-electrode layer. The light-emitting device is characterized in that a light control portion is deposited on a light-exiting surface of the light-emitting device. Said light control portion comprises at least one light-tunneling layer. Said light-tunneling layer has a refractive index with respect to the wavelength of the main emitting-light from the light-emitting layer lower than the refractive indices of the substrate, the cladding layers and the electrode layers. The light extraction efficiency is increased by the light tunneling effect when the emitting-light emitted by the light-emitting layer enters the interface between the epitaxial layer and the surrounding material with an incident angle larger than the critical angle. The tunneling light from the light control portion can be polarized, such that a polarized light-emitting device can be realized in practice.

Owner:SU JUNG CHIEH

Display device

ActiveUS20160041430A1Widen perspectiveHigh color reproductionNon-linear opticsPhosphorDisplay device

A display device includes: a first substrate; a second substrate facing the first substrate; a light-amount adjusting layer interposed between the first substrate and the second substrate; and a backlight unit disposed under the first substrate, wherein the second substrate includes a plurality of color conversion layers respectively disposed on a plurality of pixel regions, the color conversion layer includes a partition wall; and a phosphor disposed on areas defined by the partition wall, and the color conversion layer includes an air layer between the second substrate and the phosphor.

Owner:SAMSUNG DISPLAY CO LTD

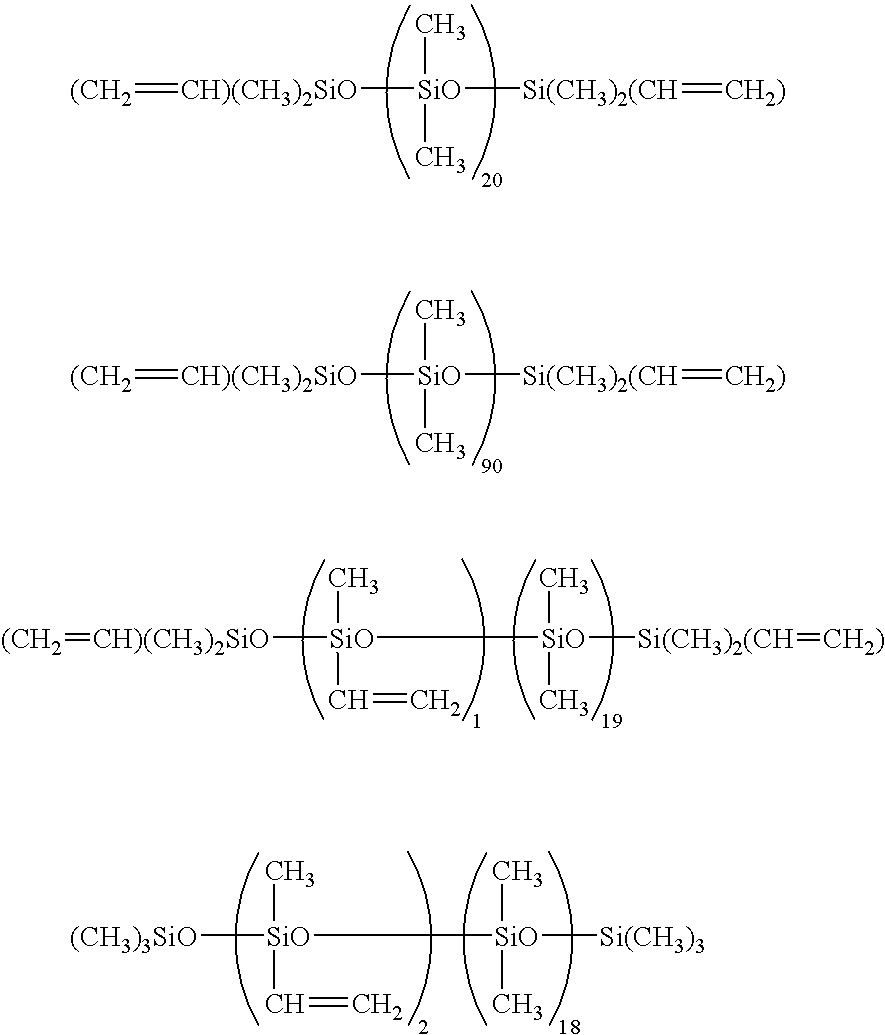

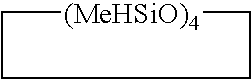

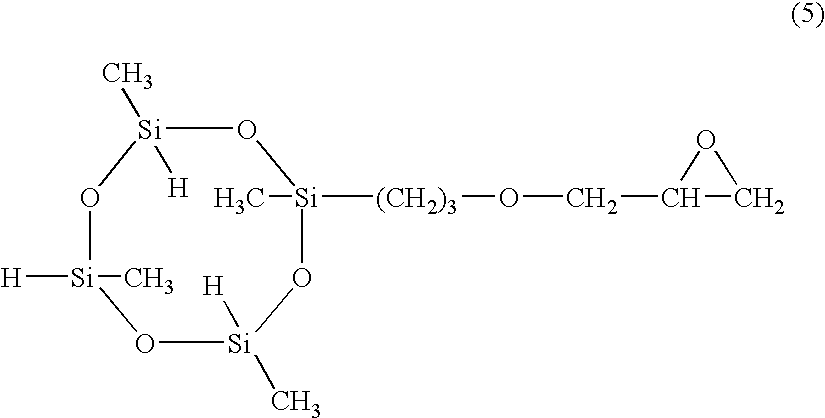

Silicone adhesive for semiconductor element

InactiveUS20090258216A1Improve concealmentEffective reflectionNon-macromolecular adhesive additivesLayered productsPolymer scienceColored white

A silicone adhesive for a semiconductor element that is suitable as a die bonding material for fixing a light emitting diode chip to a substrate. The adhesive includes (a) an addition reaction-curable silicone resin composition having a viscosity at 25° C. of not more than 100 Pa·s, and yielding a cured product upon heating at 150° C. for 3 hours that has a type D hardness prescribed in JIS K6253 of at least 30, (b) a white pigment powder having an average particle size of less than 1 μm, and (c) a white or colorless and transparent powder having an average particle size of at least 1 μm but less than 10 μm. The adhesive exhibits high levels of concealment, effectively reflects light emitted from the LED chip, and also exhibits favorable chip positioning properties, superior adhesive strength, and excellent durability.

Owner:SHIN ETSU CHEM IND CO LTD

Optical semiconductor device and manufacturing method thereof

InactiveUS20120248422A1Reduce reflectivityLight extraction efficiency can be improvedElectroluminescent light sourcesSolid-state devicesRemote plasmaDevice material

In a device having an anode electrode, an organic EL layer, and a cathode electrode formed on a substrate in this order from a main surface side of the substrate, and an encapsulating film provided on the substrate so as to cover the emission layer, the encapsulating film includes a laminated film obtained by alternately laminating buffer films serving as flattening films and barrier films having high moisture barrier property, and the flattening film and the barrier film include a silicon oxynitride film. In the manufacturing process of the device, the buffer film including silicon oxynitride is formed by an optical CVD method using vacuum ultraviolet light, and in this process, radical irradiation by remote plasma is performed during the irradiation of the vacuum ultraviolet light.

Owner:HITACHI HIGH-TECH CORP +1

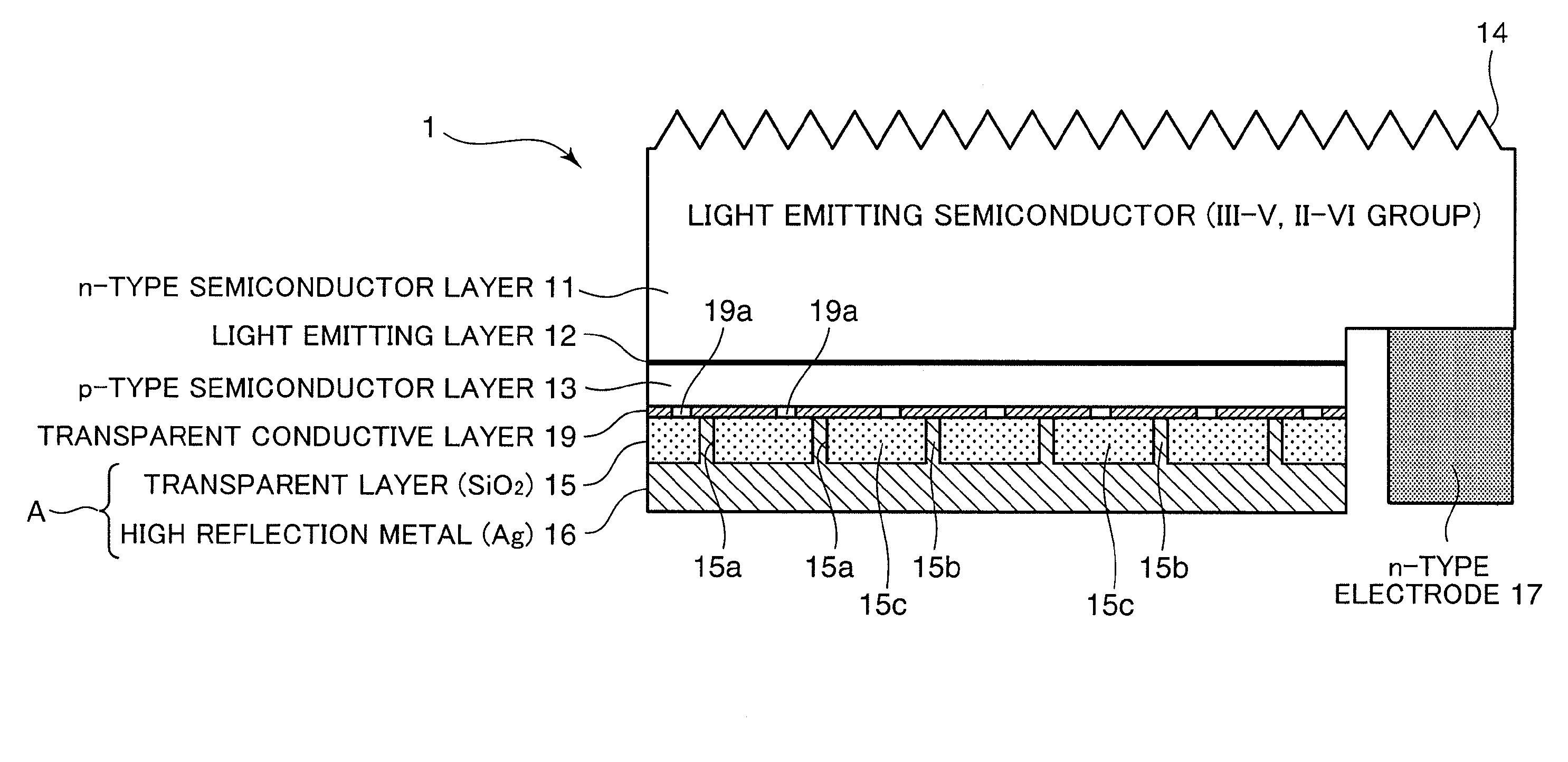

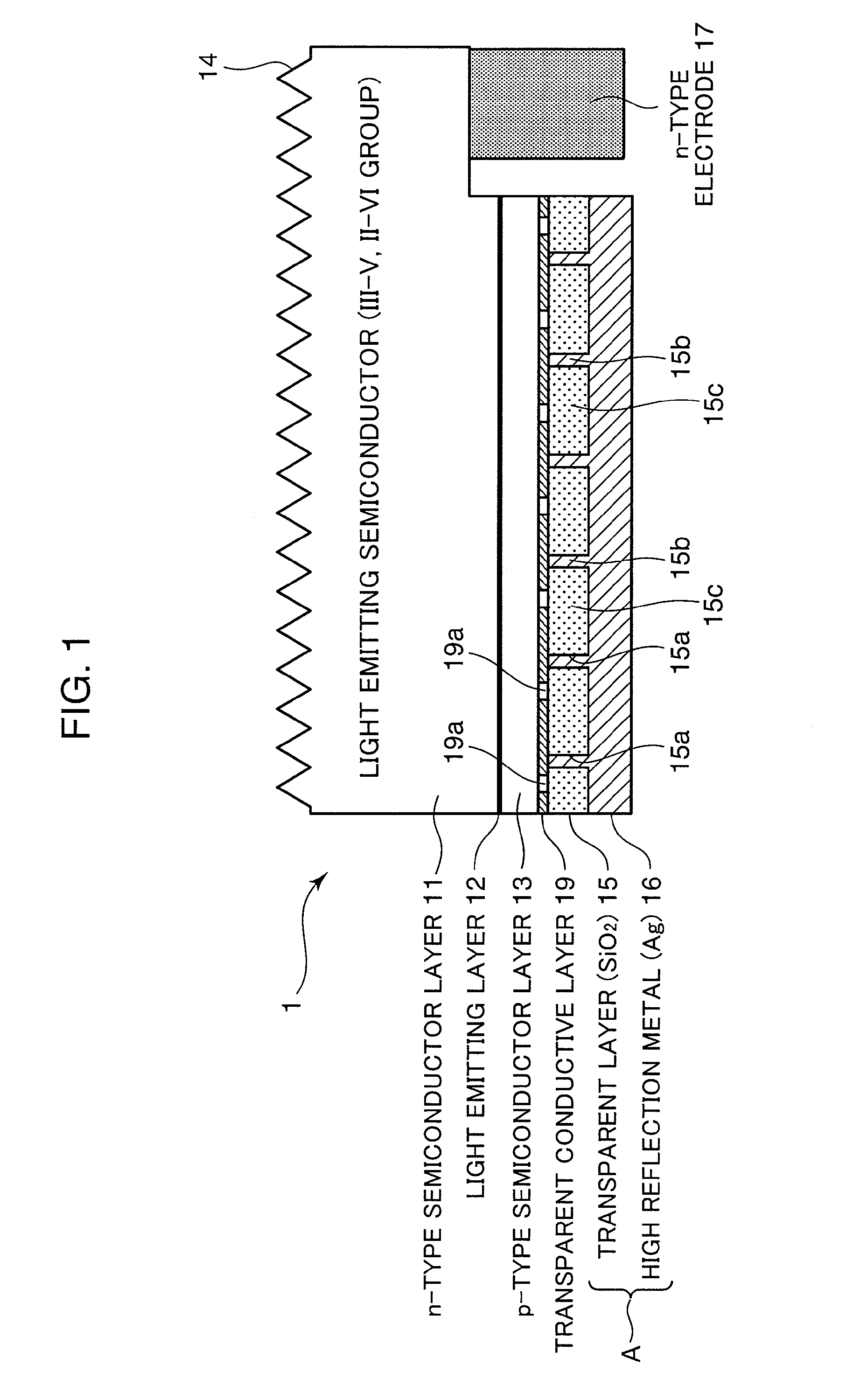

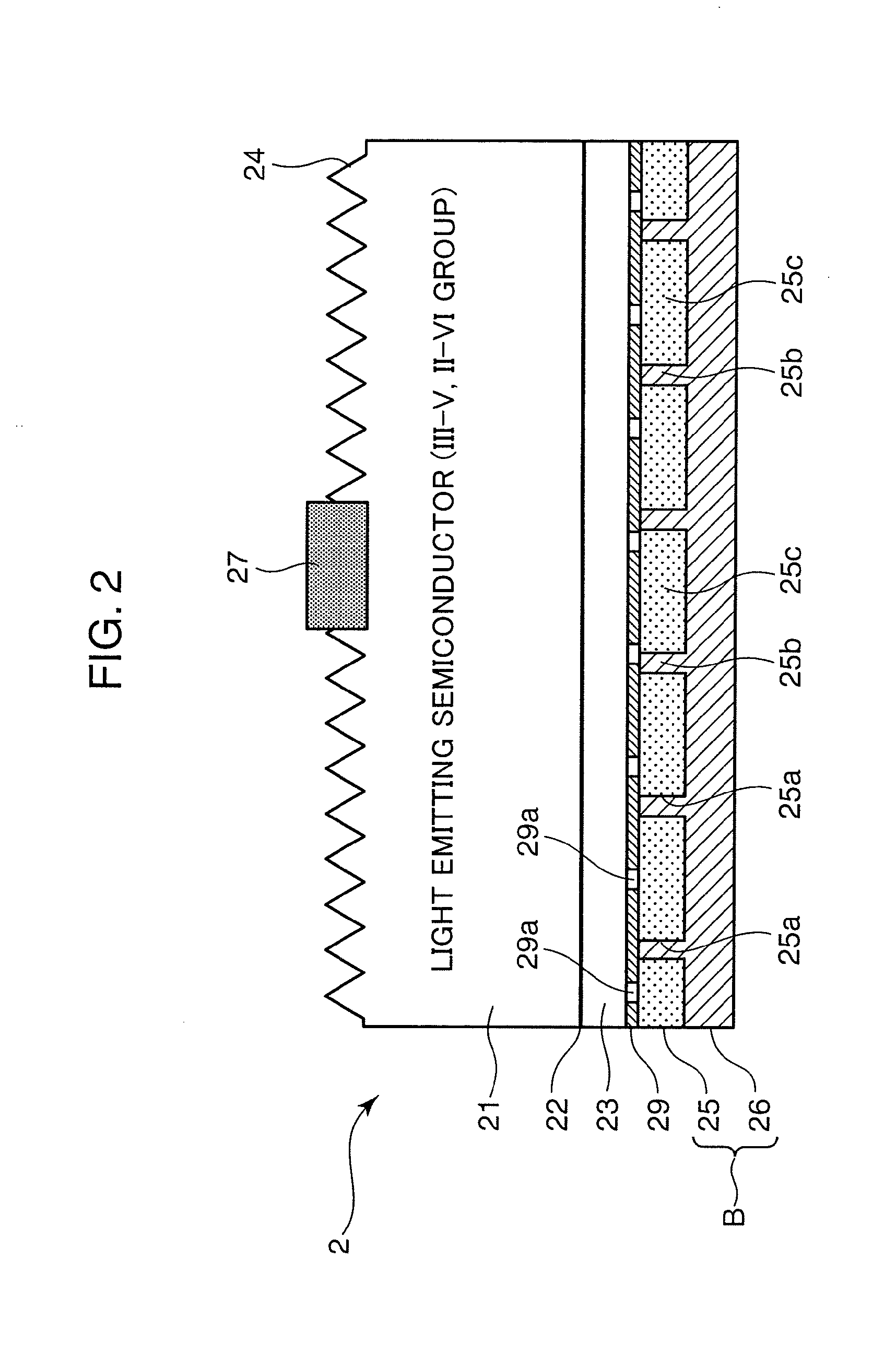

Semiconductor light emitting element and illuminating apparatus using the same

ActiveUS20110018024A1Light extraction efficiency can be improvedEfficient extractionSemiconductor/solid-state device manufacturingSemiconductor devicesOptical transparencyMetallic materials

A semiconductor light emitting element, including: an n-type semiconductor layer having optical transparency with an emission wavelength of a light emitting layer, the light emitting layer and a p-type semiconductor layer, which are laminated; and a reflection film which is disposed on a side opposite to a surface from which light emitted from the light emitting layer is extracted, wherein the reflection film comprises: a transparent layer having optical transparency with the emission wavelength of the light emitting layer, and a metal layer, which is laminated on the transparent layer on a side opposite to the light emitting layer and is constituted by a metal material having a high reflectance, the transparent layer has a refractive index lower than a refractive index of a layer disposed on a side of the light emitting layer when viewed from the transparent layer, with the emission wavelength, and a thickness of the transparent layer is equal to or more than a value obtained by dividing a value of ¾ of the emission wavelength by the refractive index of the transparent layer.

Owner:PANASONIC CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com