Patents

Literature

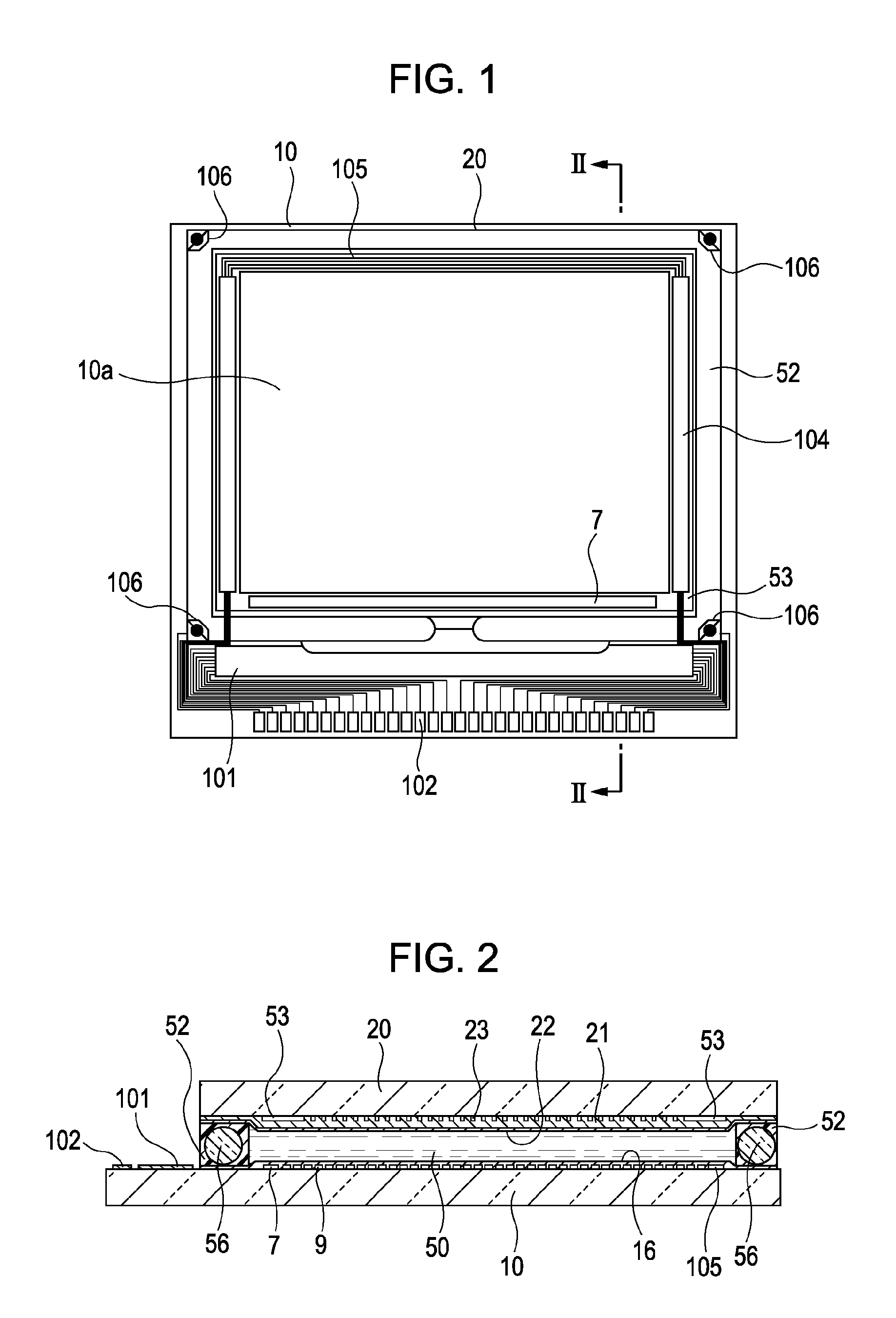

73results about How to "Reduce step difference" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

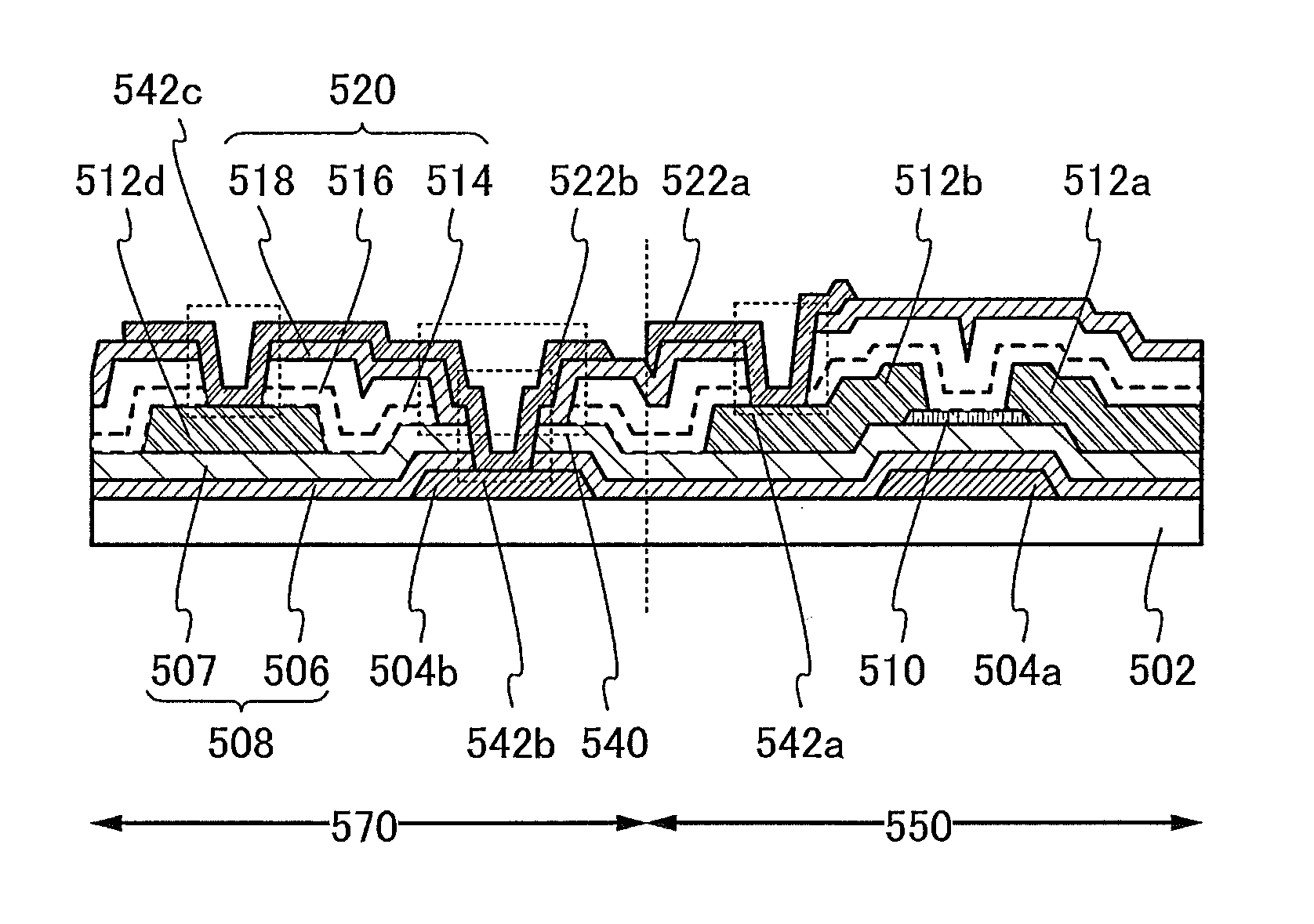

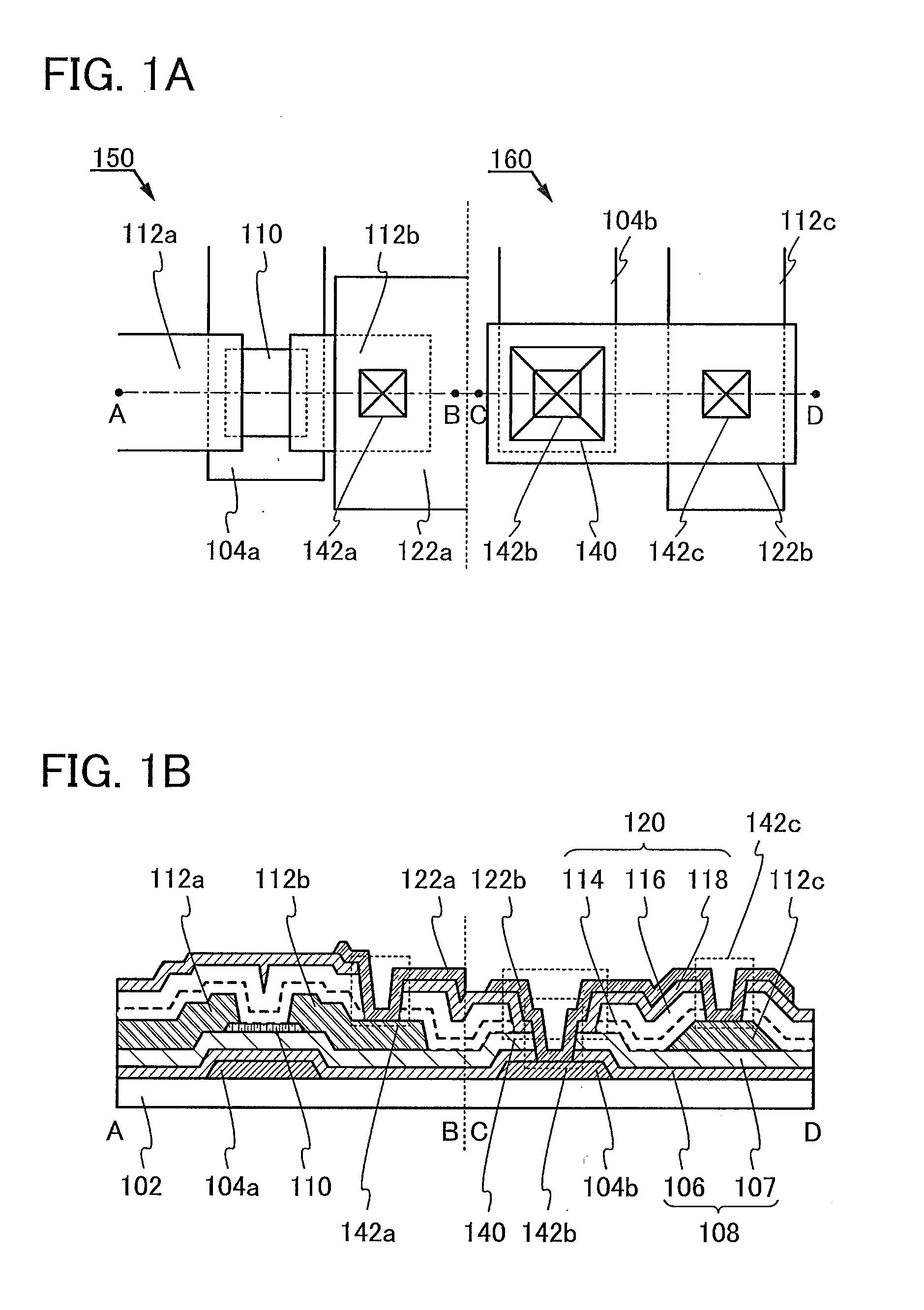

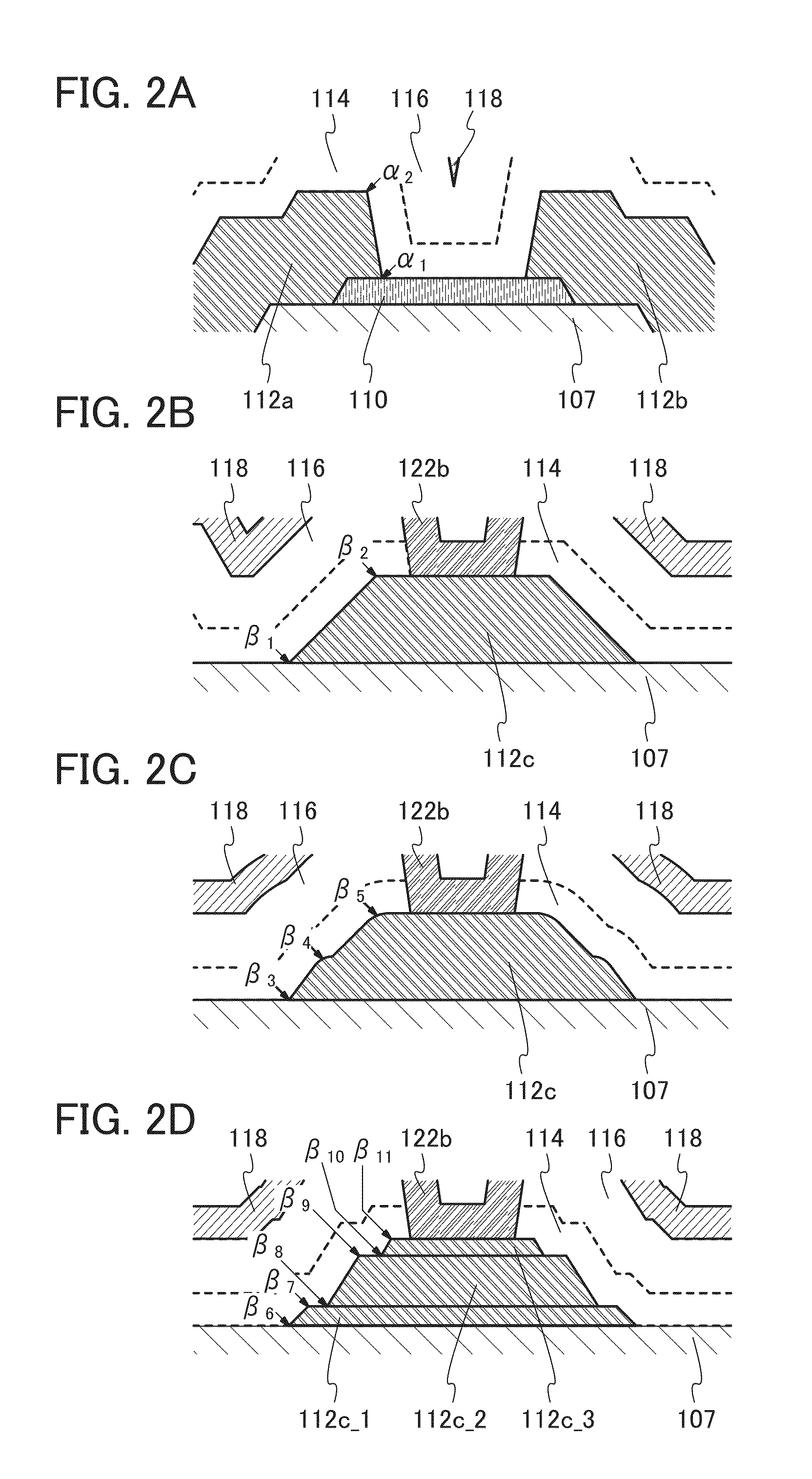

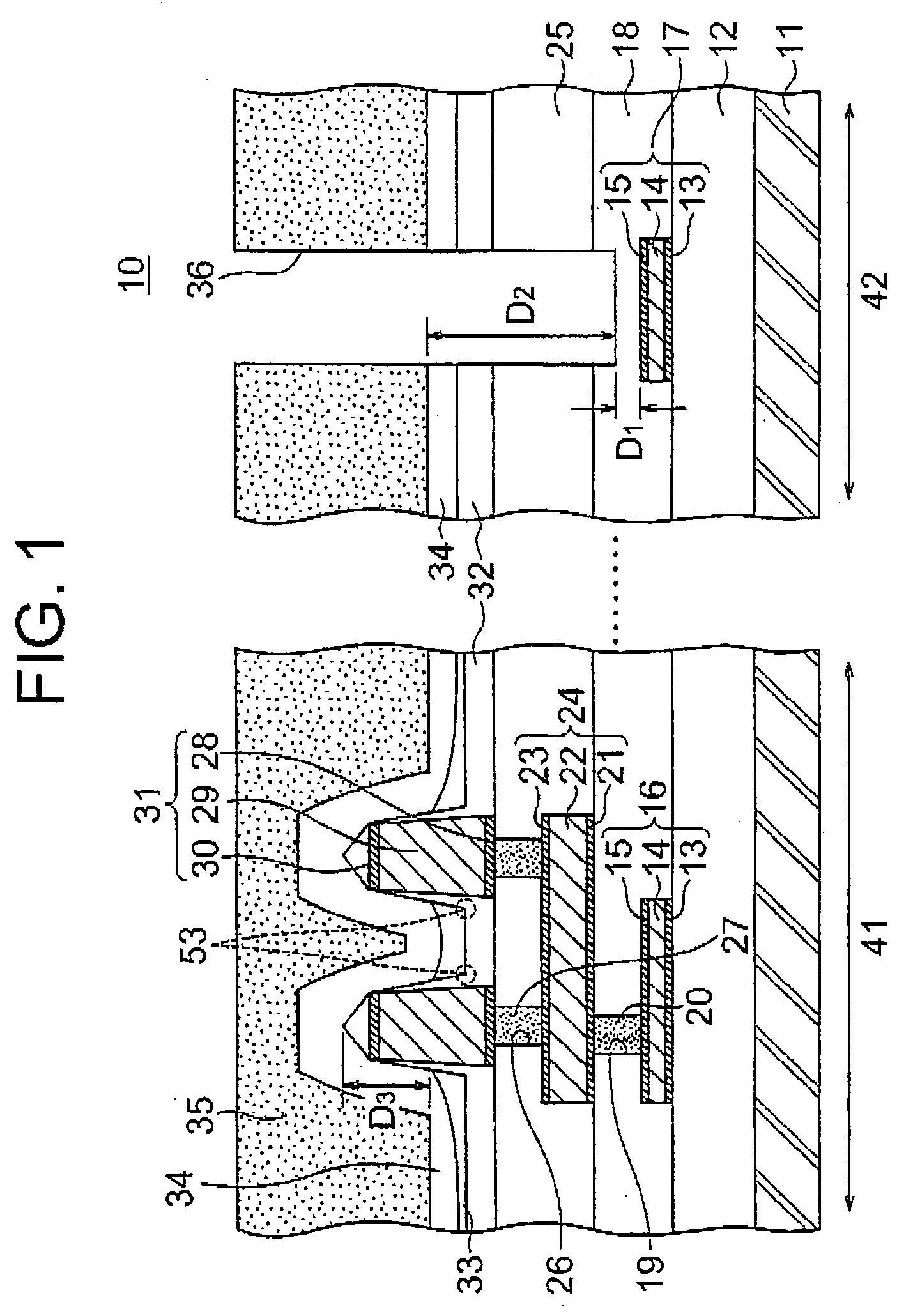

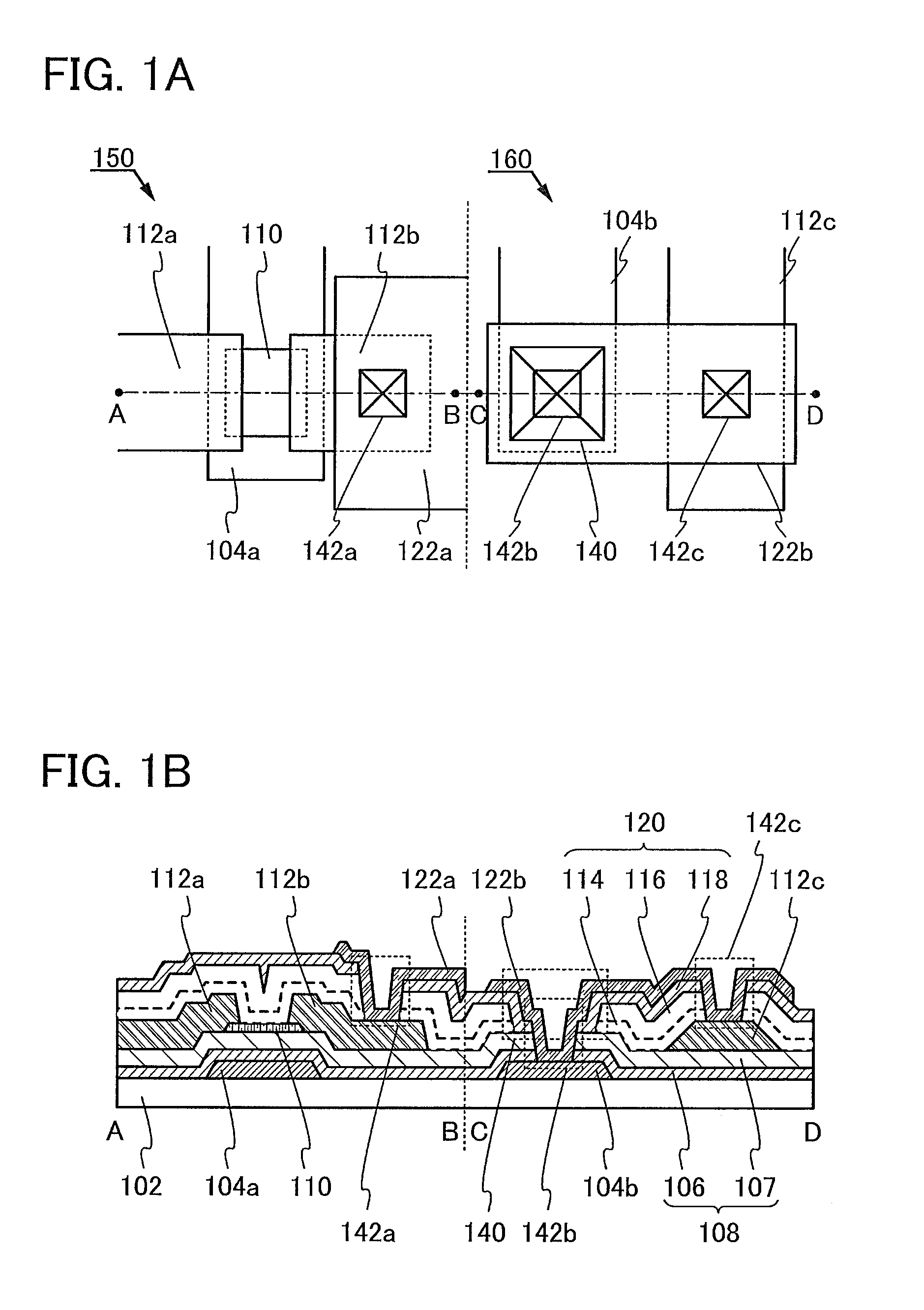

Semiconductor device and display device including the semiconductor device

ActiveUS20150014680A1Excellent electrical propertiesImprove featuresSolid-state devicesNon-linear opticsPower semiconductor deviceDisplay device

A semiconductor device including a transistor and a connection portion is provided. The transistor includes a gate electrode, a first insulating film over the gate electrode, an oxide semiconductor film over the first insulating film and at a position overlapping with the gate electrode, and source and drain electrodes electrically connected to the oxide semiconductor film; and the connection portion includes a first wiring on the same surface as a surface on which the gate electrode is formed, a second wiring on the same surface as a surface on which the source and drain electrodes are formed, and a third wiring connecting the first wiring and the second wiring. The distance between an upper end portion and a lower end portion of the second wiring is longer than the distance between an upper end portion and a lower end portion of each of the source and drain electrodes.

Owner:SEMICON ENERGY LAB CO LTD

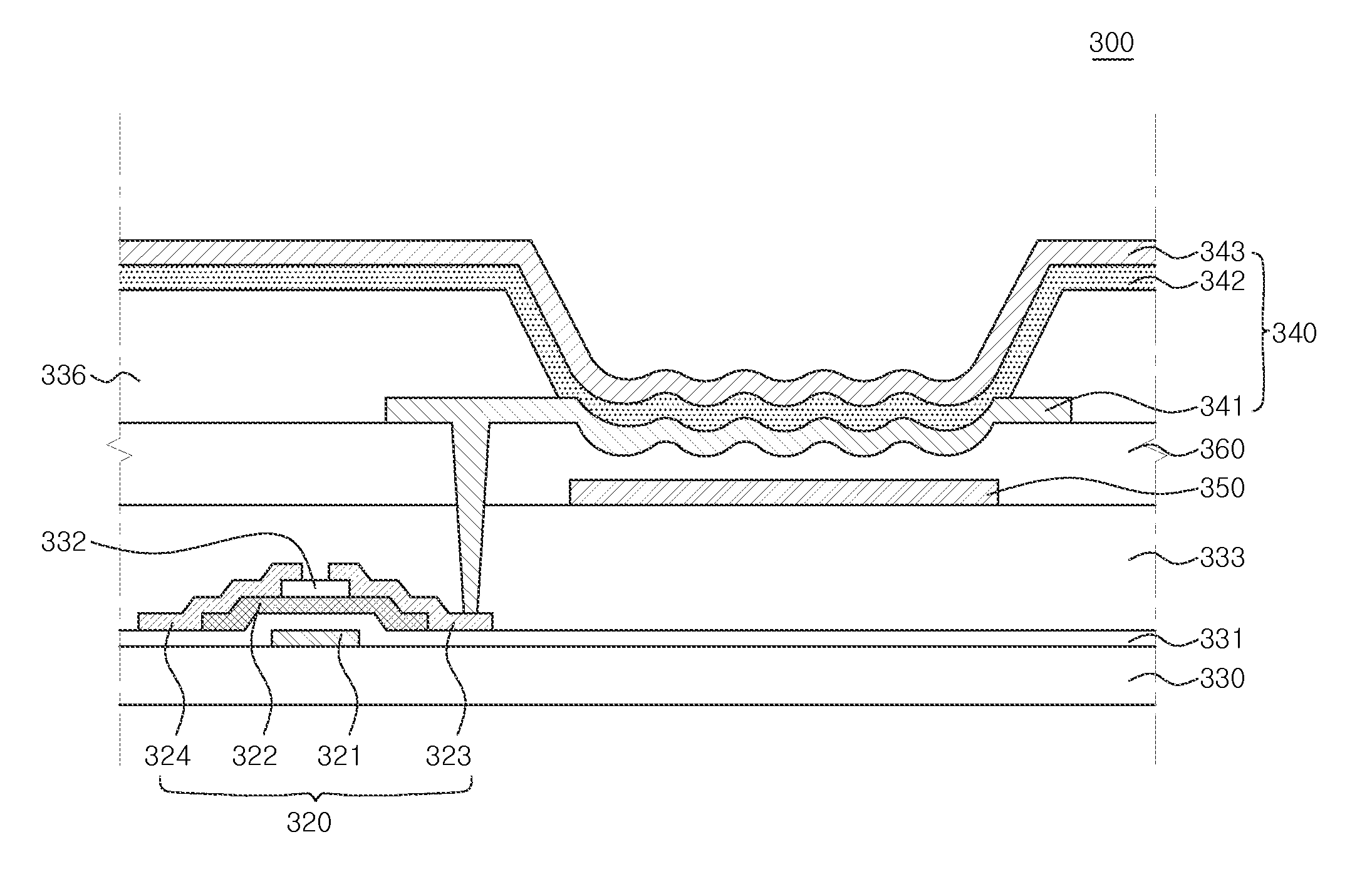

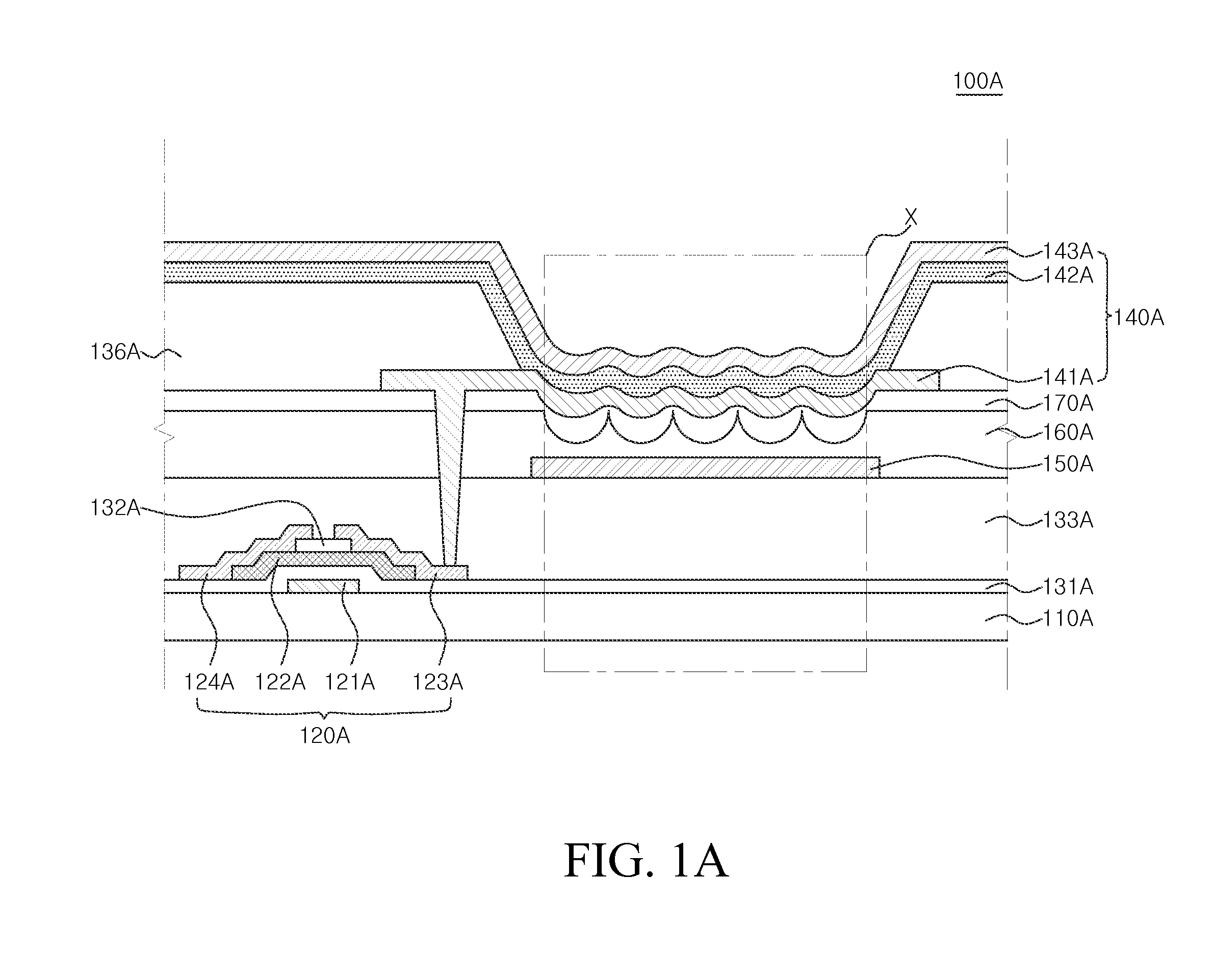

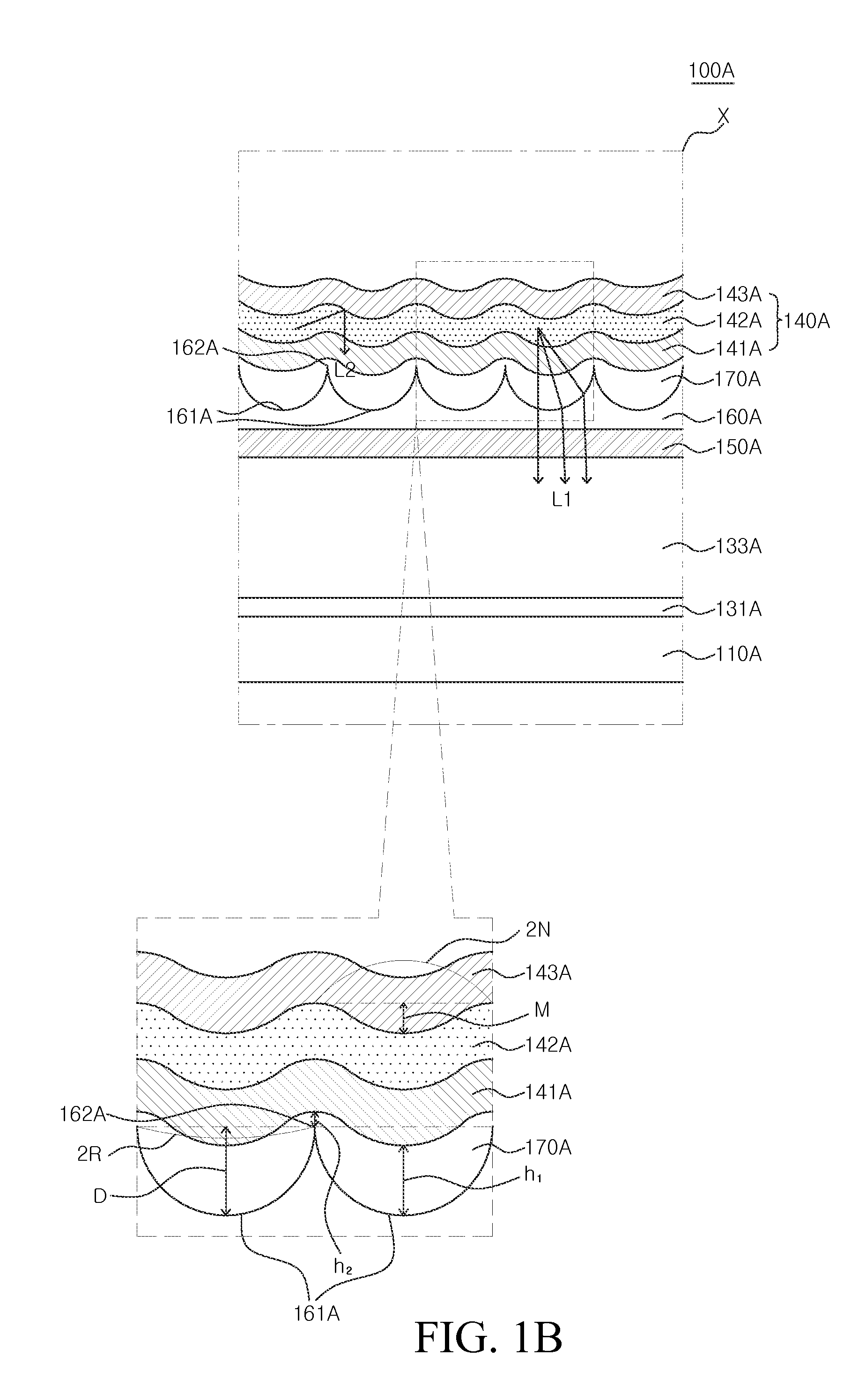

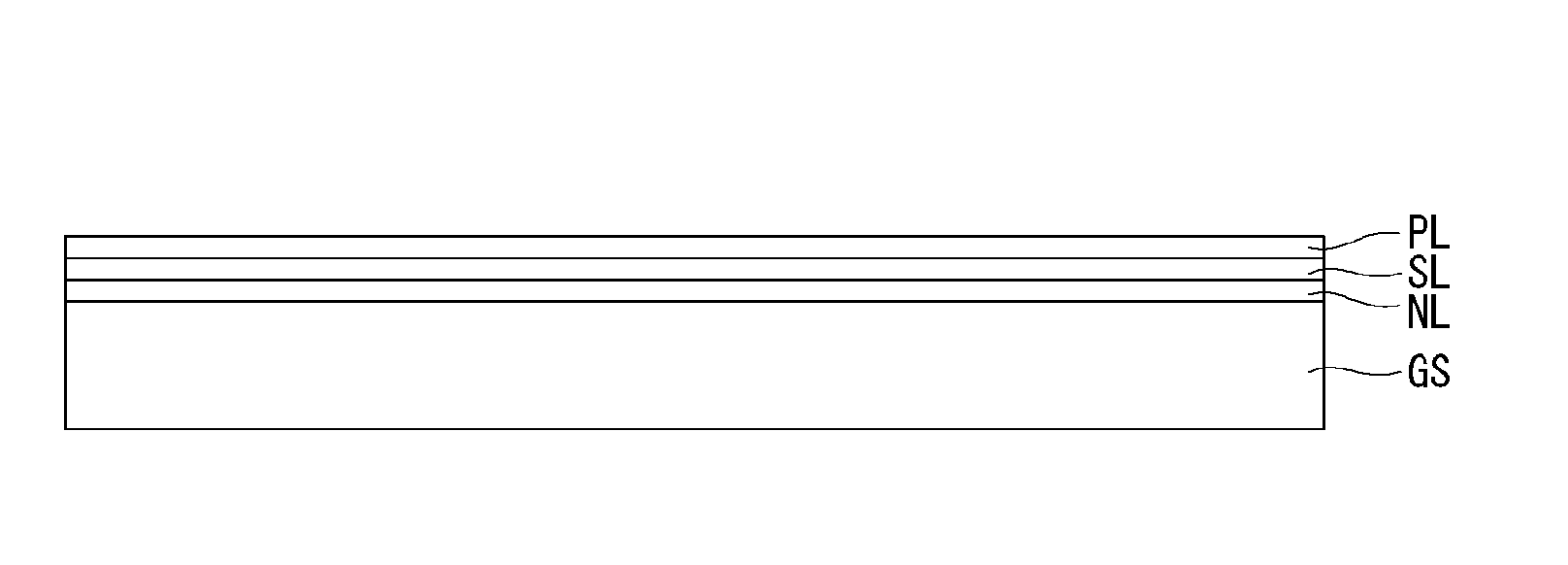

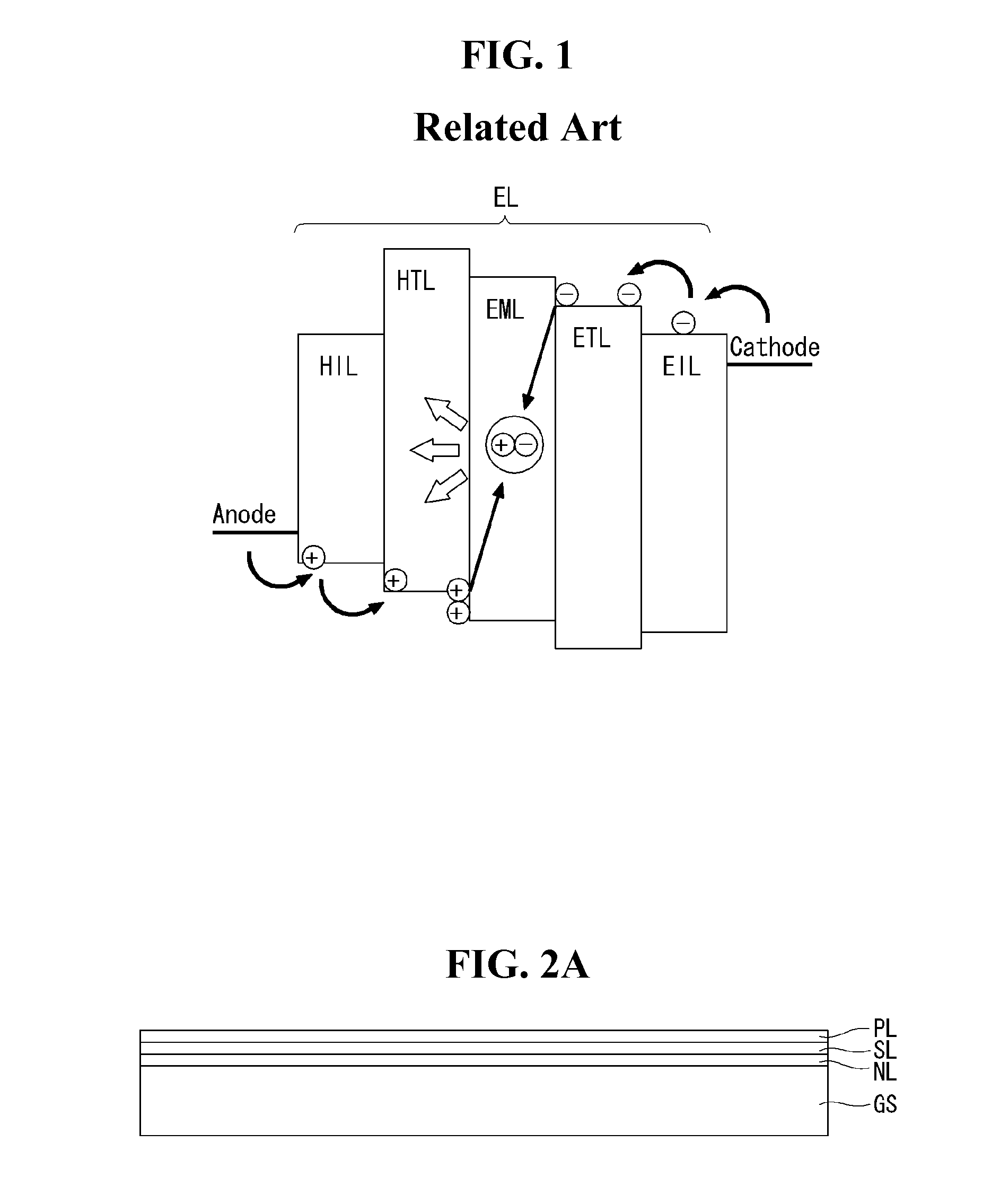

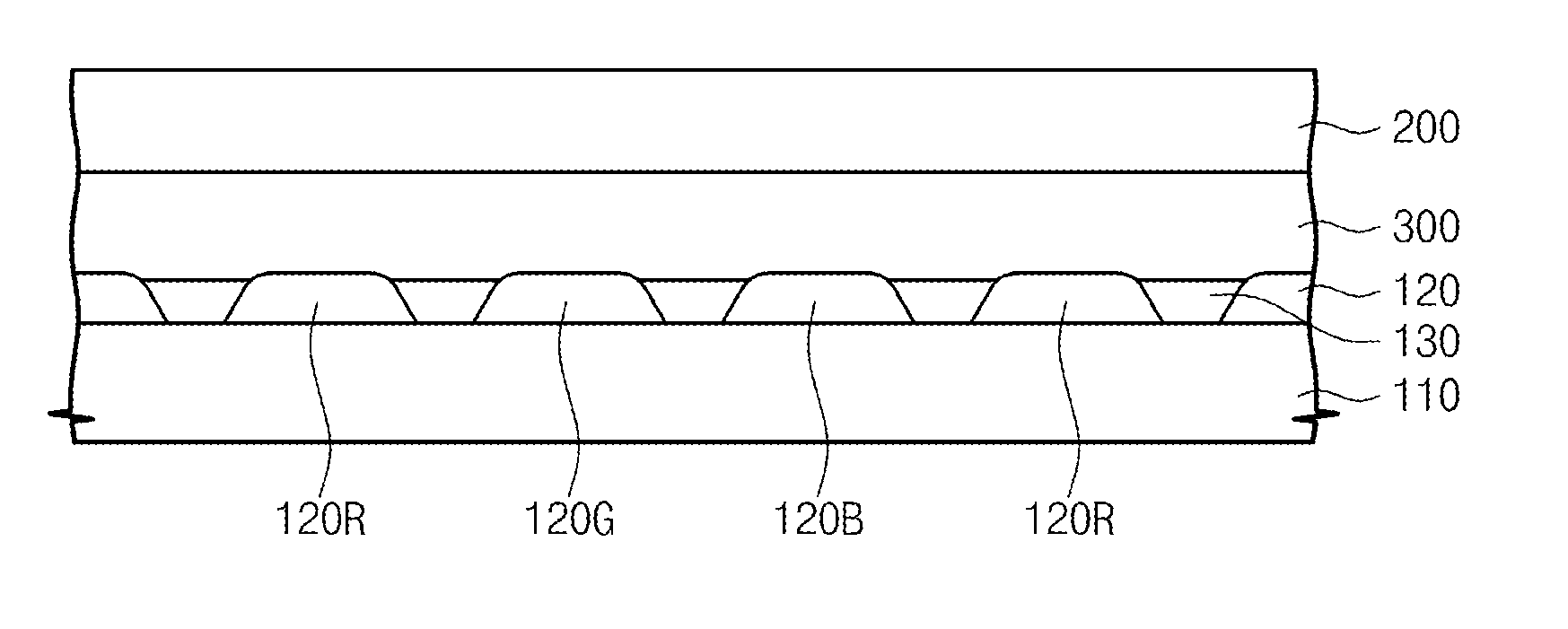

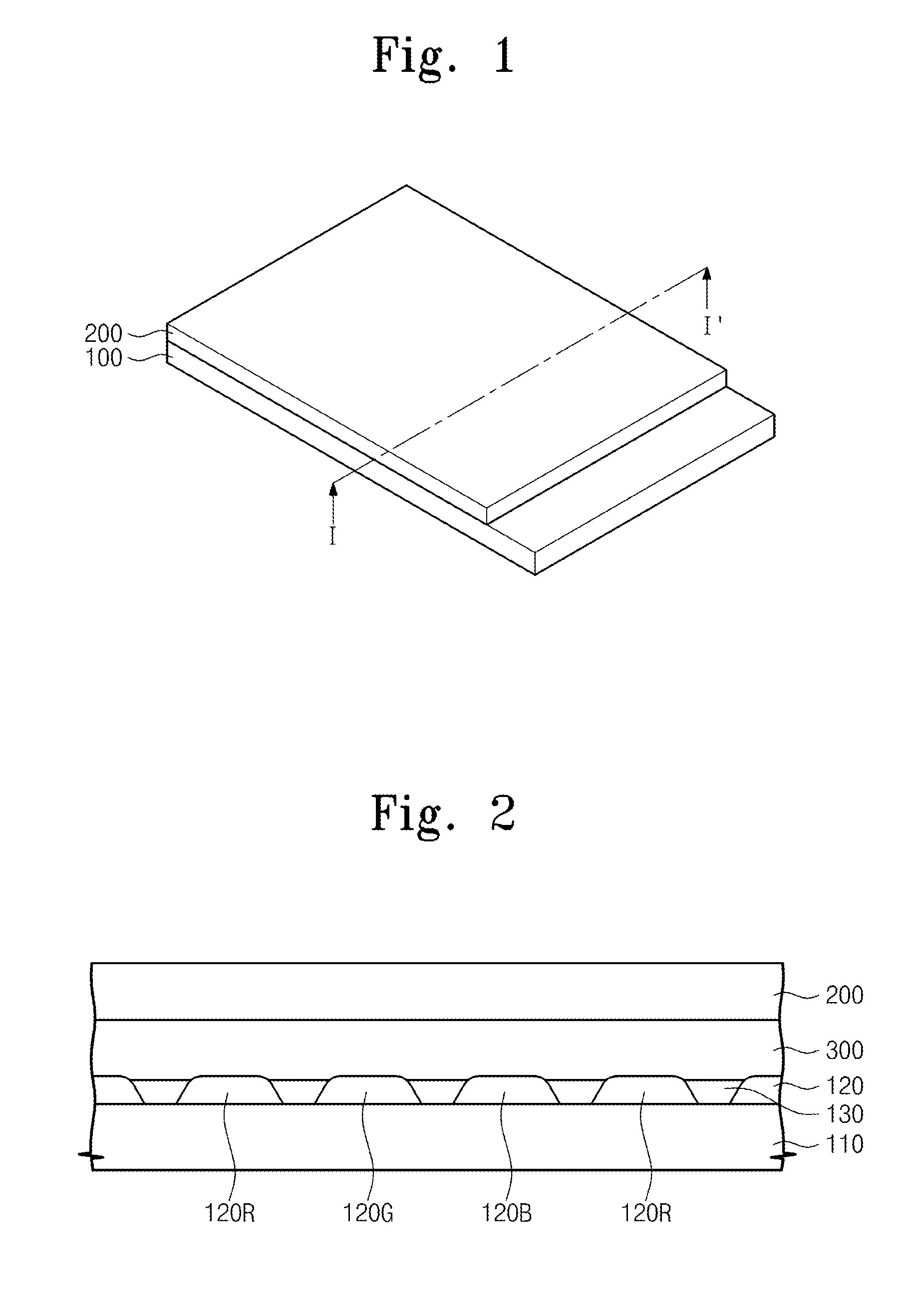

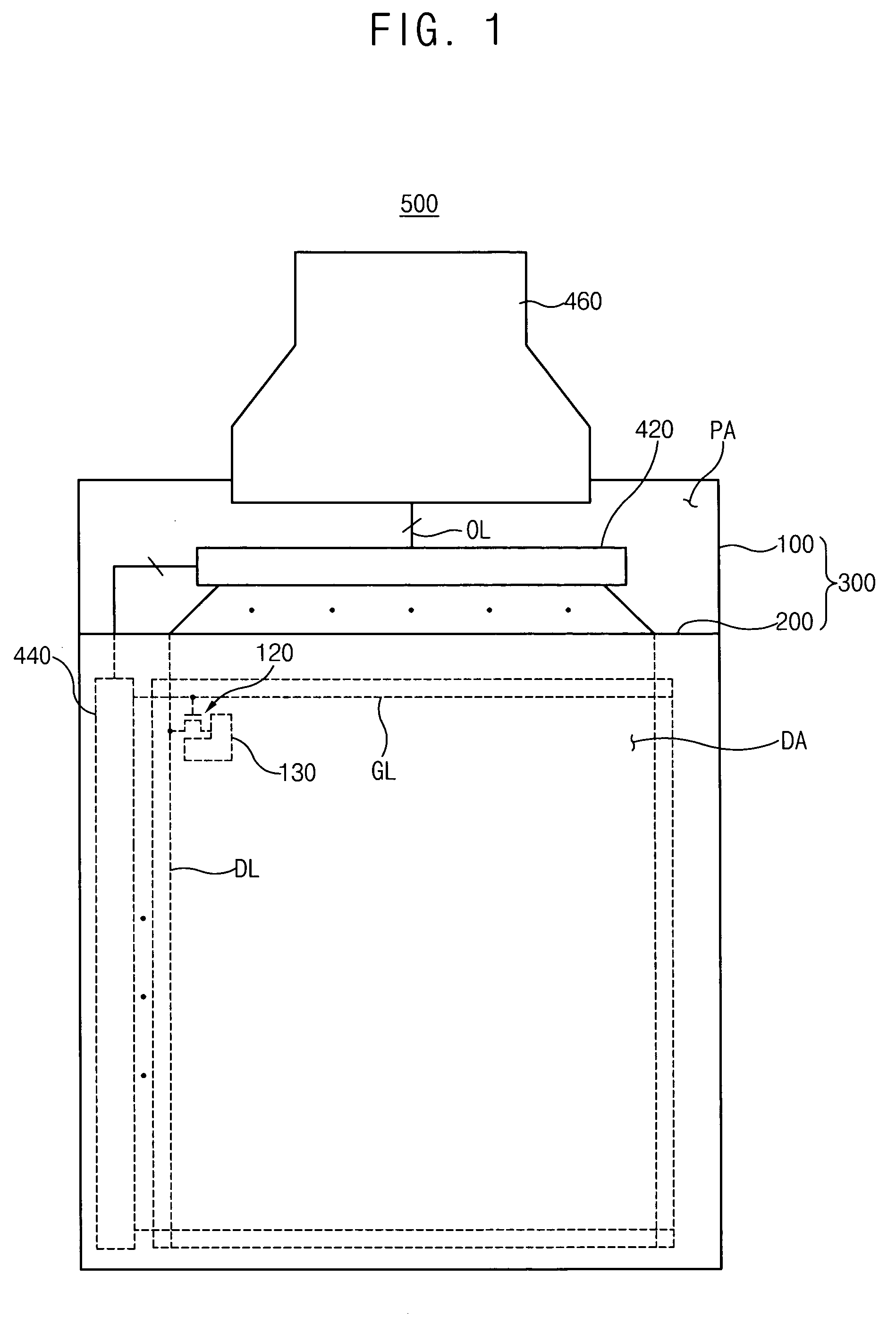

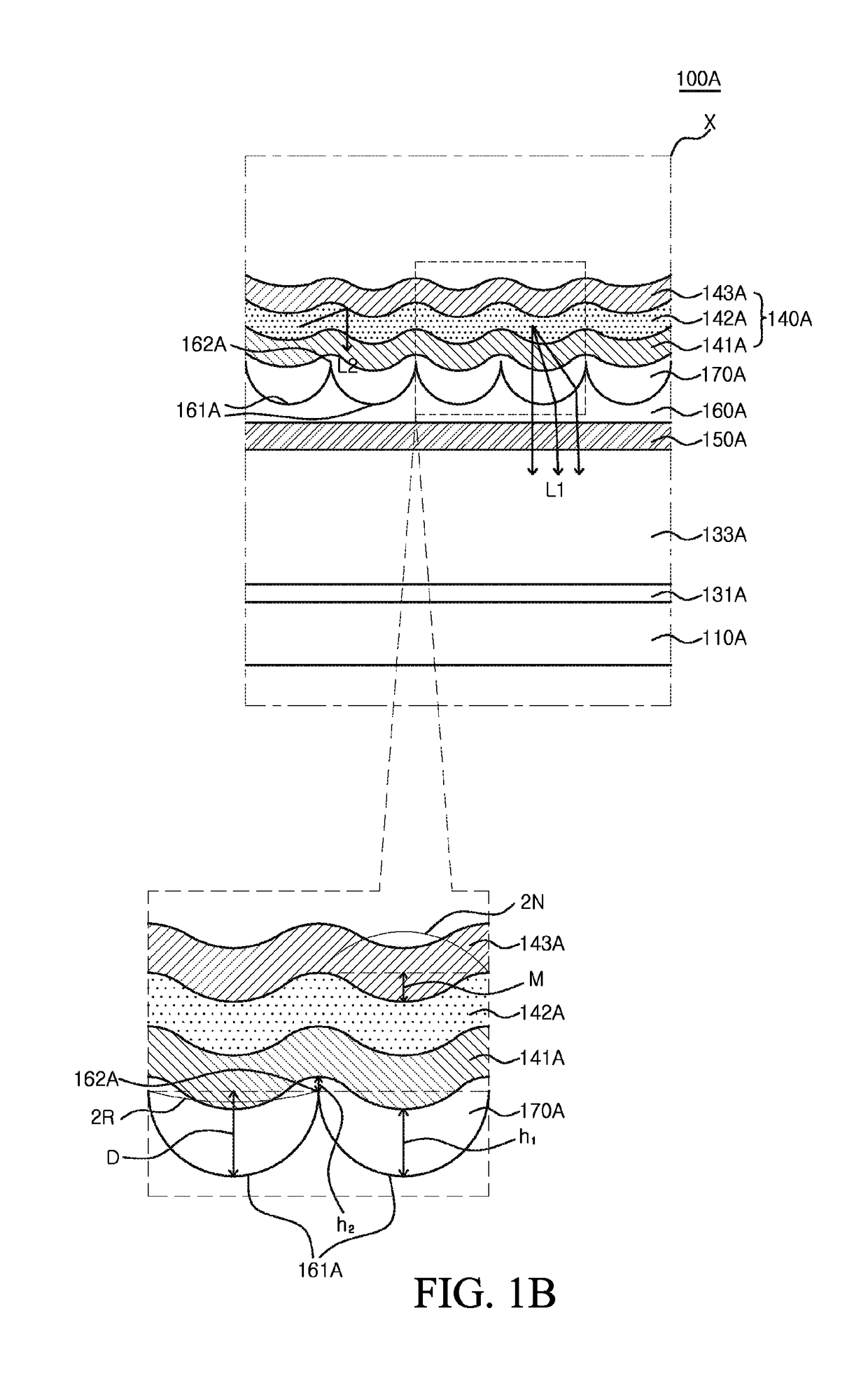

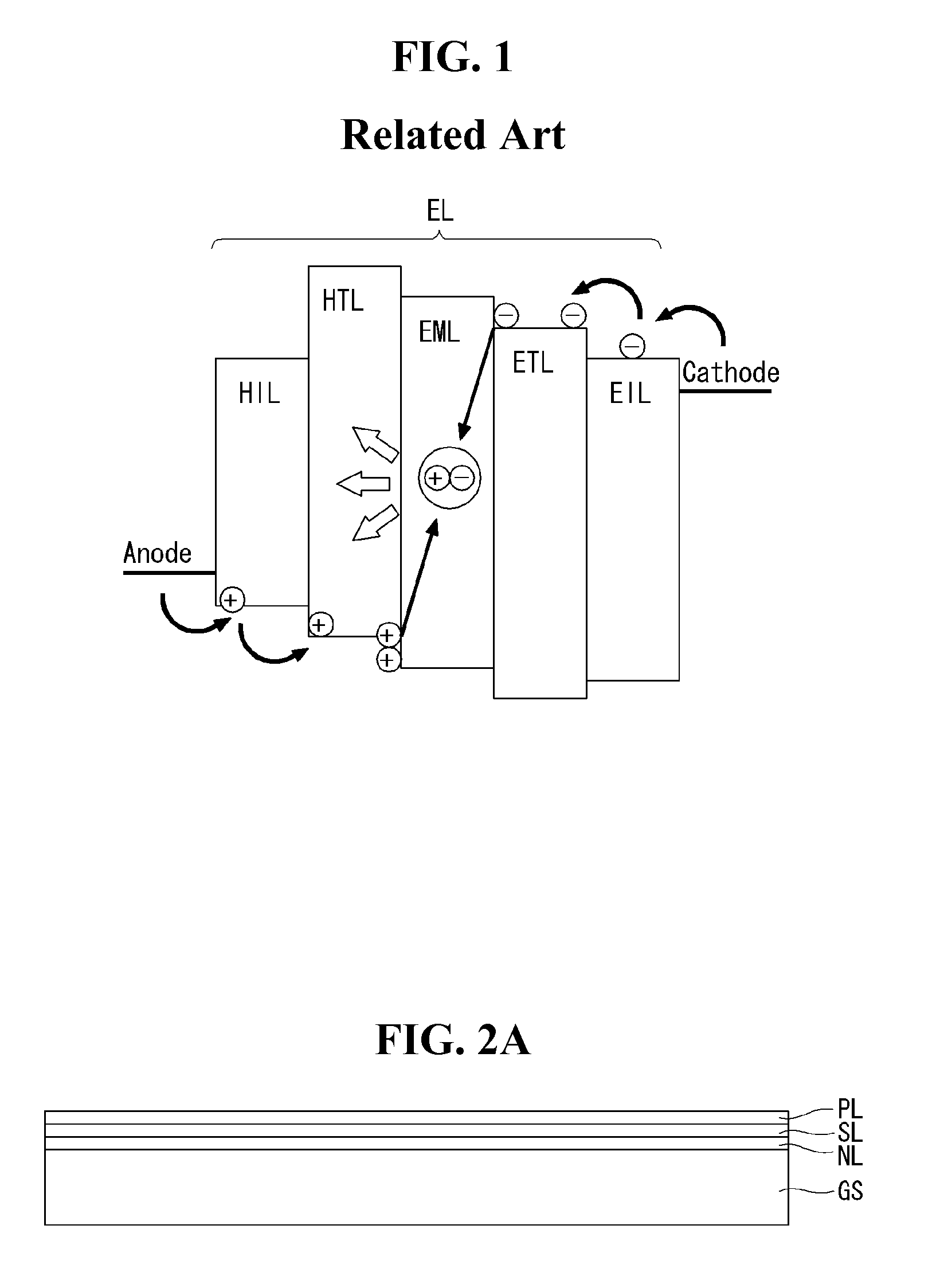

Organic light emitting display device and method for manufacturing the same

ActiveUS20150380466A1Reduce step differenceHigh refractive indexSolid-state devicesSemiconductor/solid-state device manufacturingRefractive indexDisplay device

Provided are an organic light emitting display device and a method for manufacturing the same. A color filter is disposed on a substrate. An overcoating layer is disposed on the color filter and includes a plurality of protrusions or a plurality of recesses. The plurality of protrusions and the plurality of recesses are disposed on the color filter to be overlapped with the color filter. A buffer layer for reducing step difference is disposed on the overcoating layer. The buffer layer has a higher refractive index than the overcoating layer and reduces a step difference caused by the plurality of protrusions and the plurality of recesses. An organic light emitting element including an anode, an organic light emitting layer, and a cathode is disposed on the buffer layer. Since the buffer layer has a higher refractive index than the overcoating layer, light extraction efficiency can be increased.

Owner:LG DISPLAY CO LTD

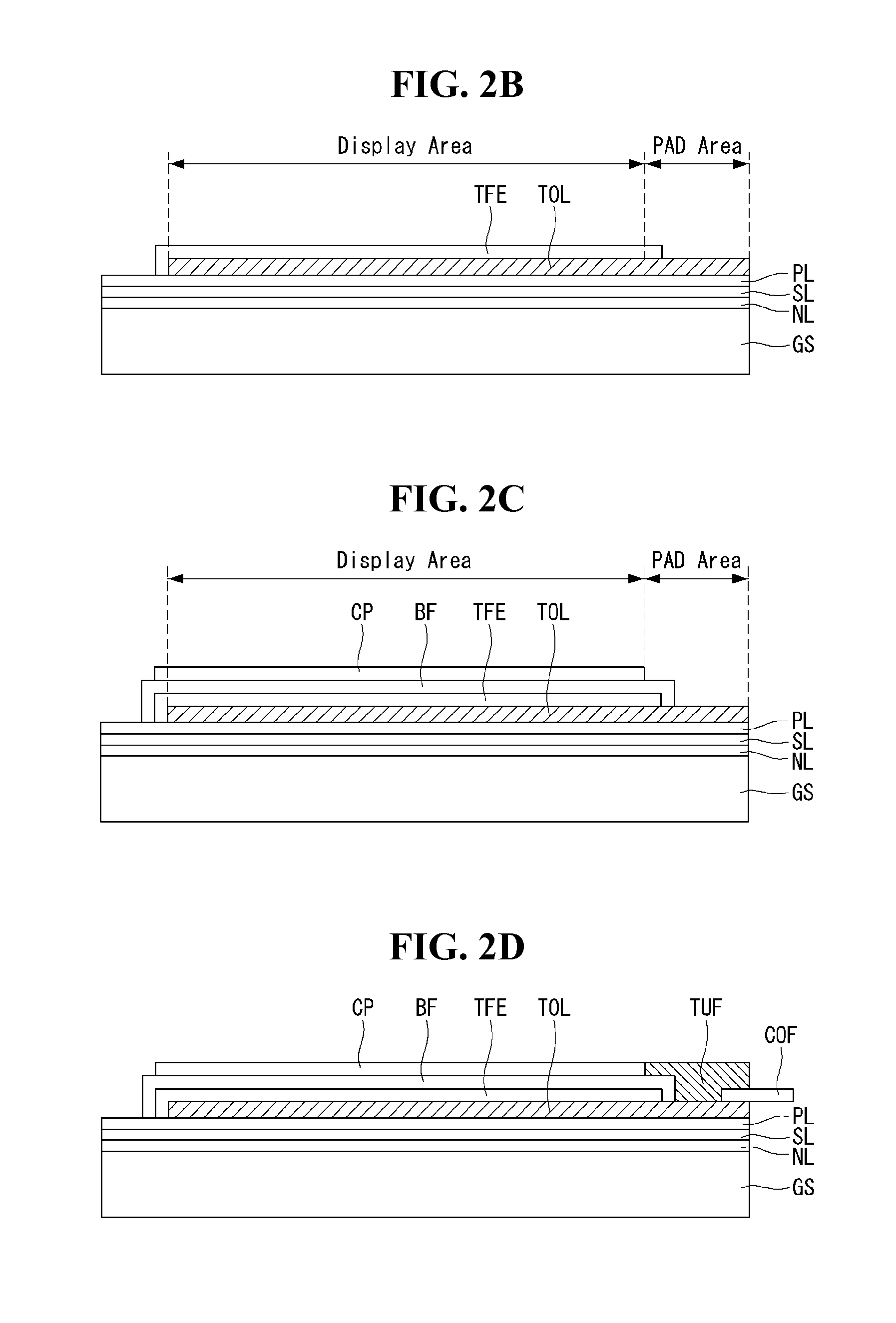

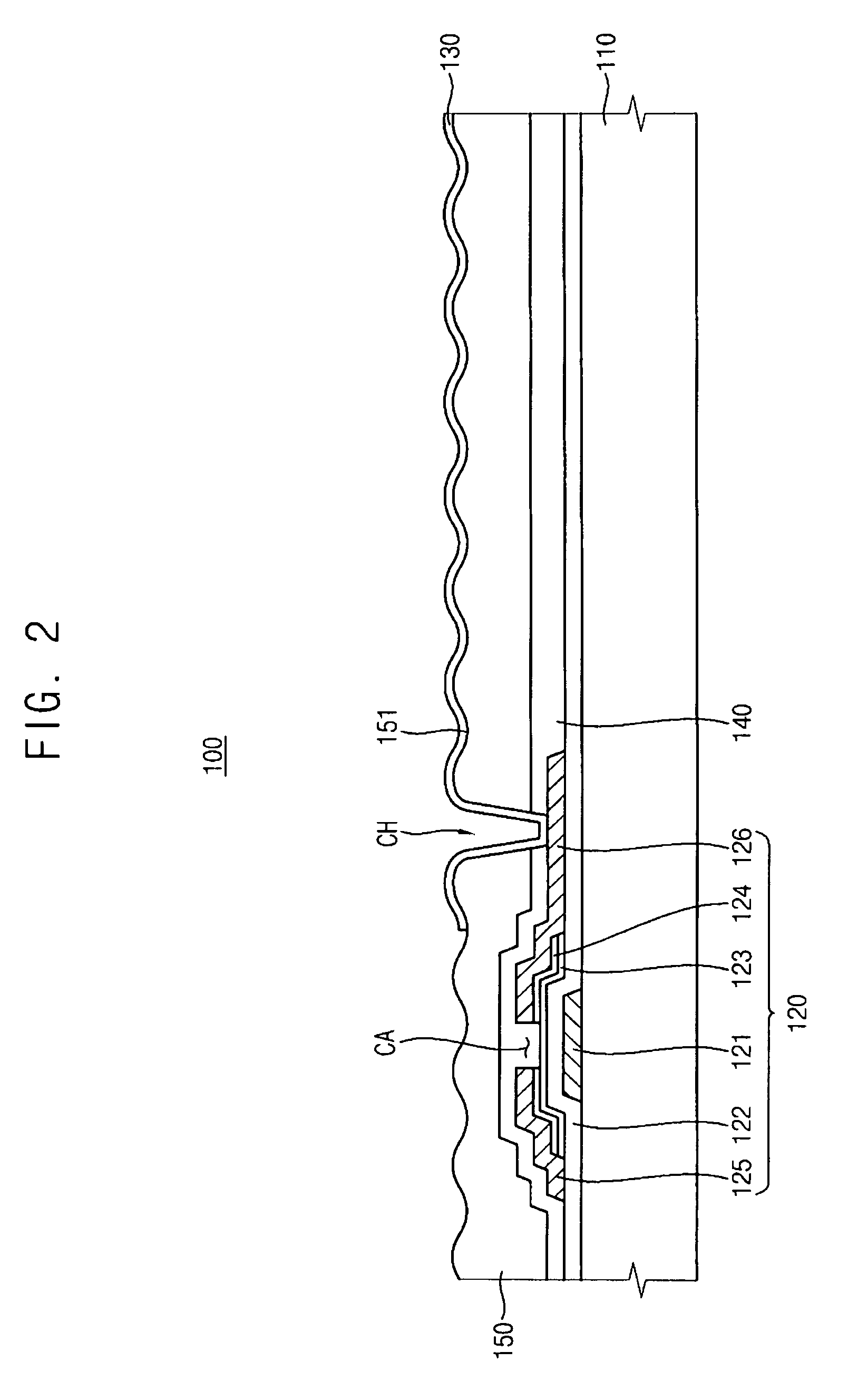

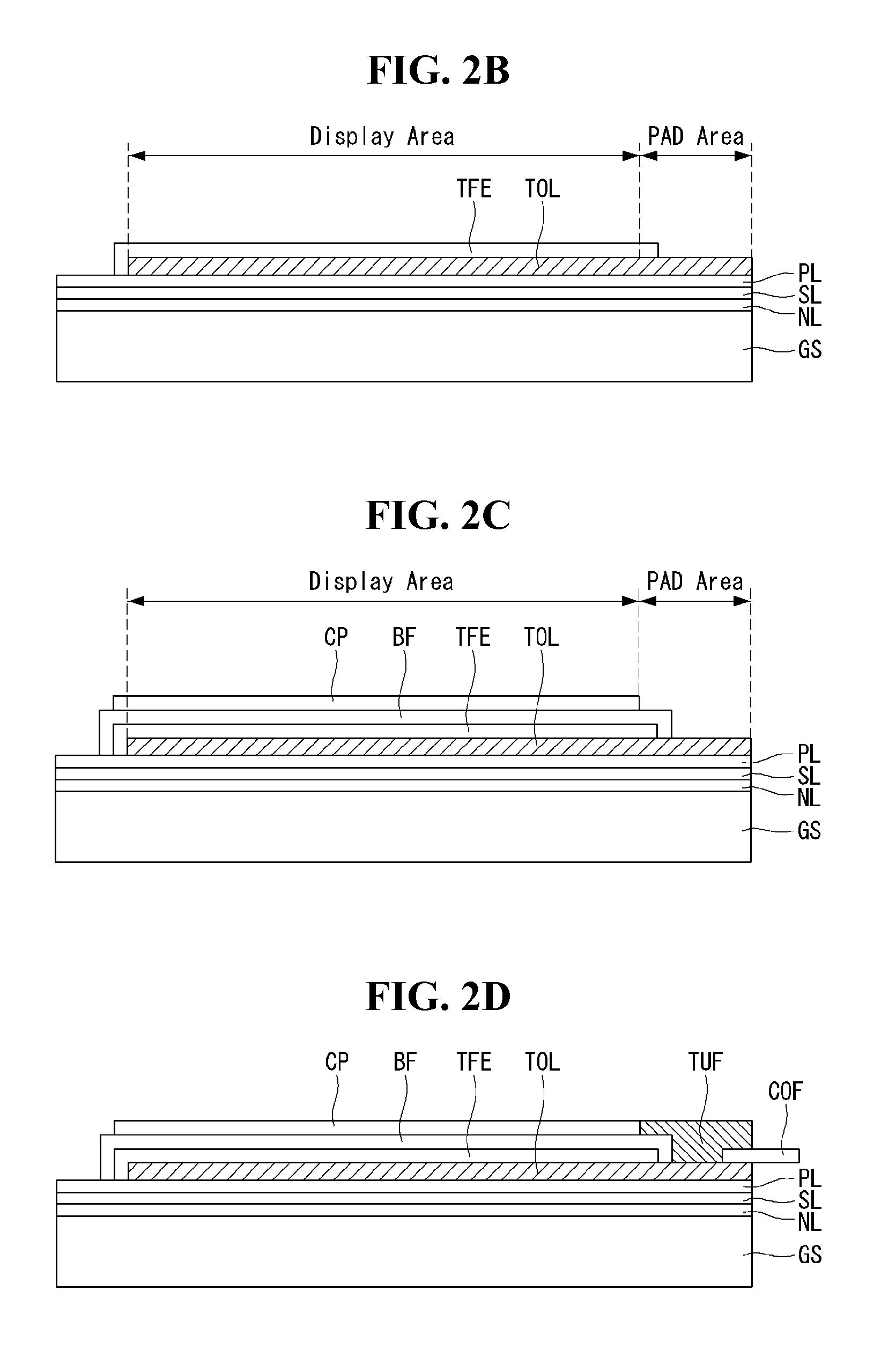

Organic Light Emitting Display Device and Method for Manufacturing the Same

ActiveUS20120139821A1Reduce step differenceImprove contact reliabilityStatic indicating devicesElectroluminescent light sourcesAdhesiveOrganic layer

The present disclosure relates to an organic light emitting display device and a method for manufacturing the same. The present disclosure suggests an organic light emitting display device including an organic layer; a display element layer including a display area representing video data and a pad area extended from the display area, on the organic layer; film elements formed on the display element layer; a film type printed circuit board connected to the pad area; and a reinforcing adhesive filling a space between the film type printed circuit board and the film elements

Owner:LG DISPLAY CO LTD

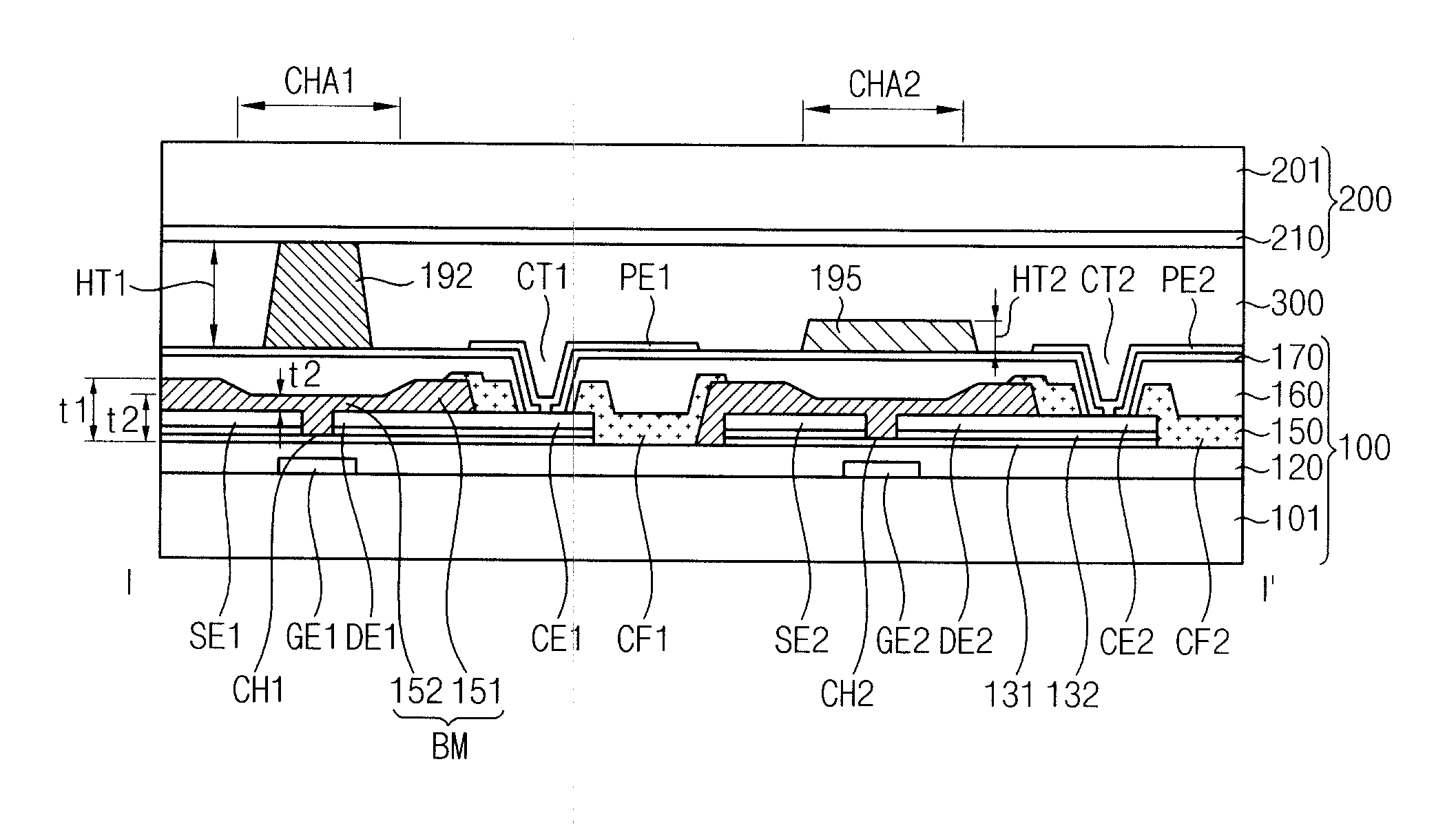

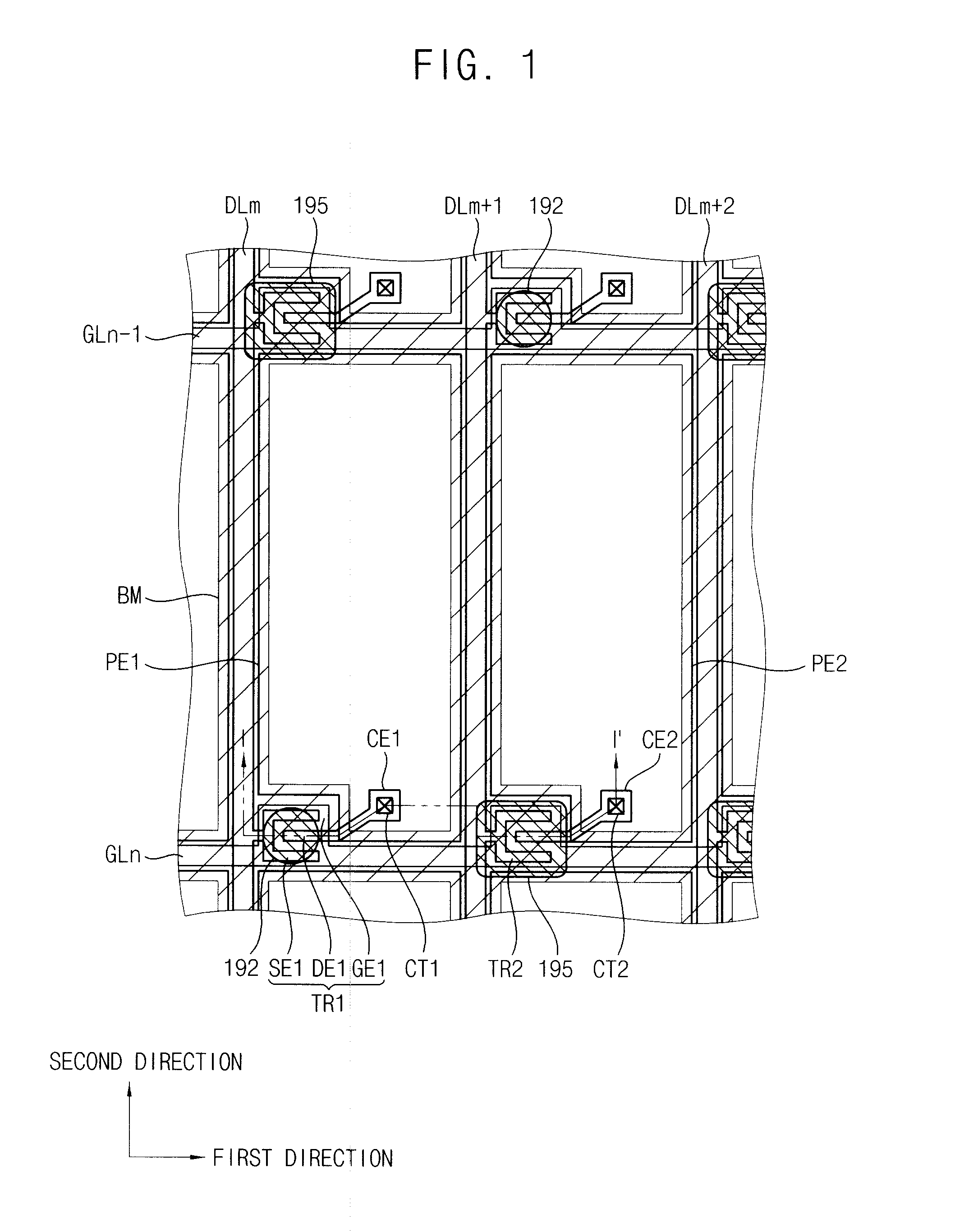

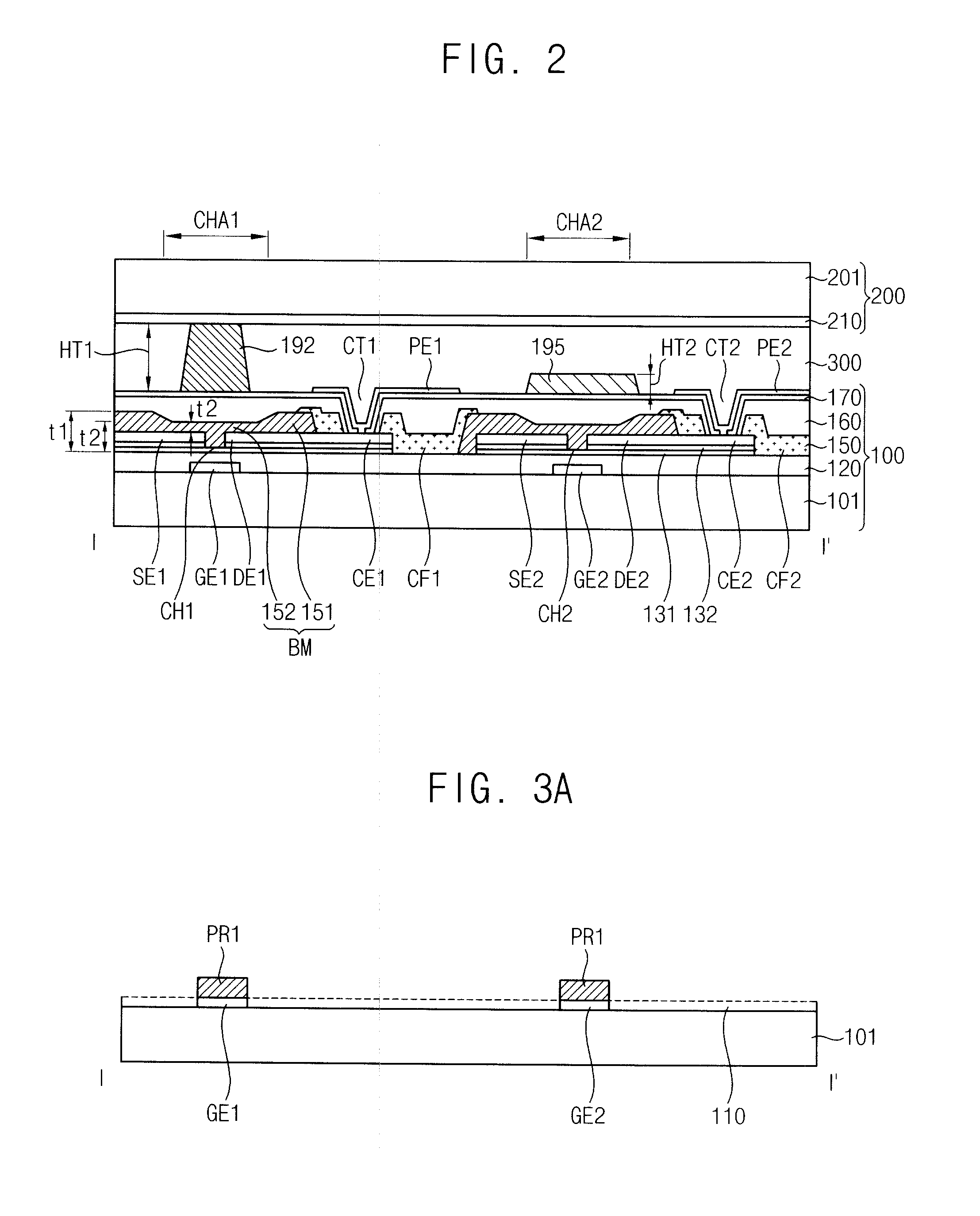

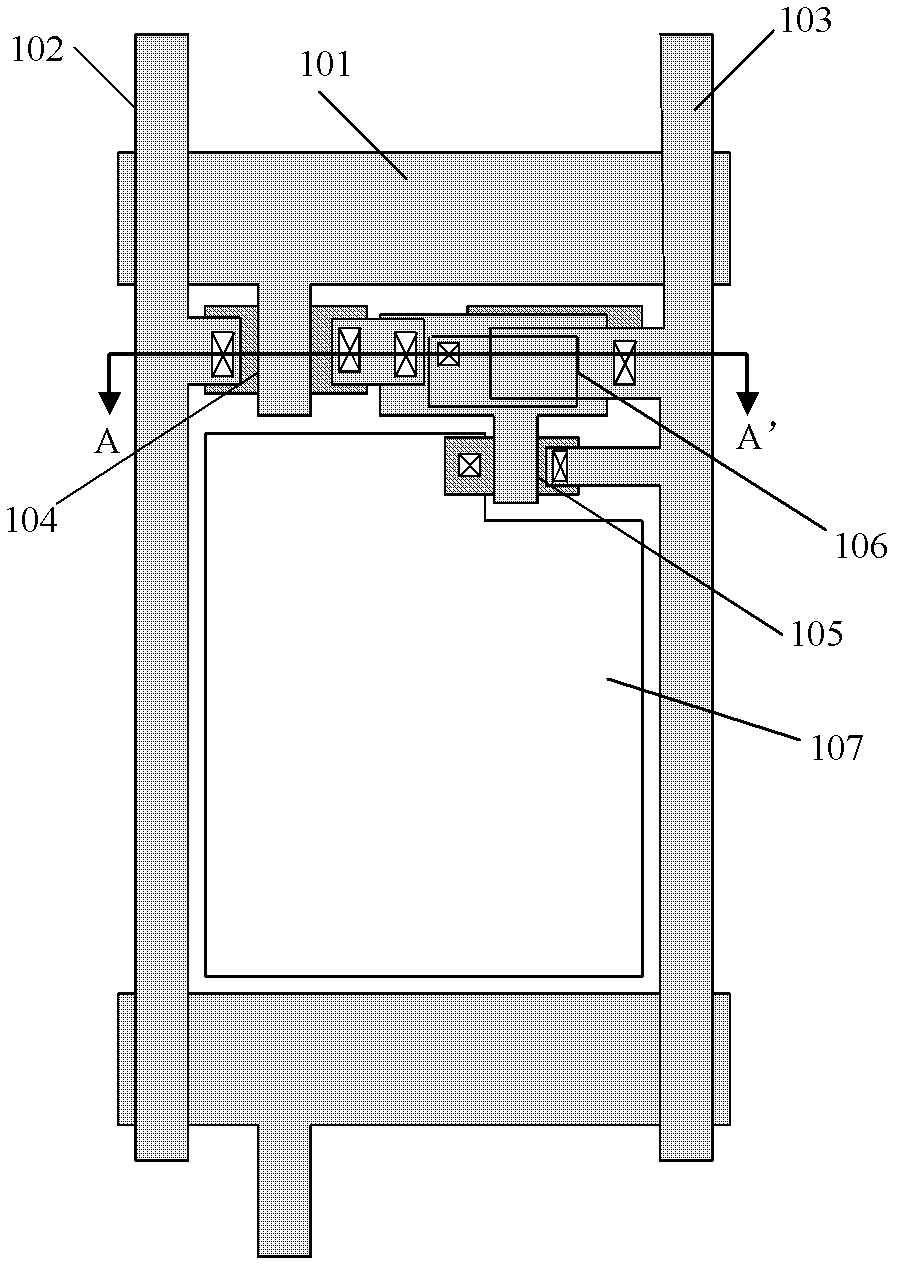

Display substrate and method of manufacturing the same

ActiveUS20110180798A1Enhancing structure characteristicIncrease process marginSemiconductor/solid-state device testing/measurementCarpet cleanersEngineeringBlack matrix

A display substrate includes a transistor, a black matrix and a color spacer. The transistor is connected to a gate line, and a data line crossing the gate line. The black matrix includes a first light-blocking portion covering the gate line and the data line, and a second light-blocking portion covering a channel of the transistor. The second light-blocking portion has a thickness which is smaller than a thickness of the first light-blocking portion. The color spacer is disposed on the second light-blocking portion.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS TECH CO LTD

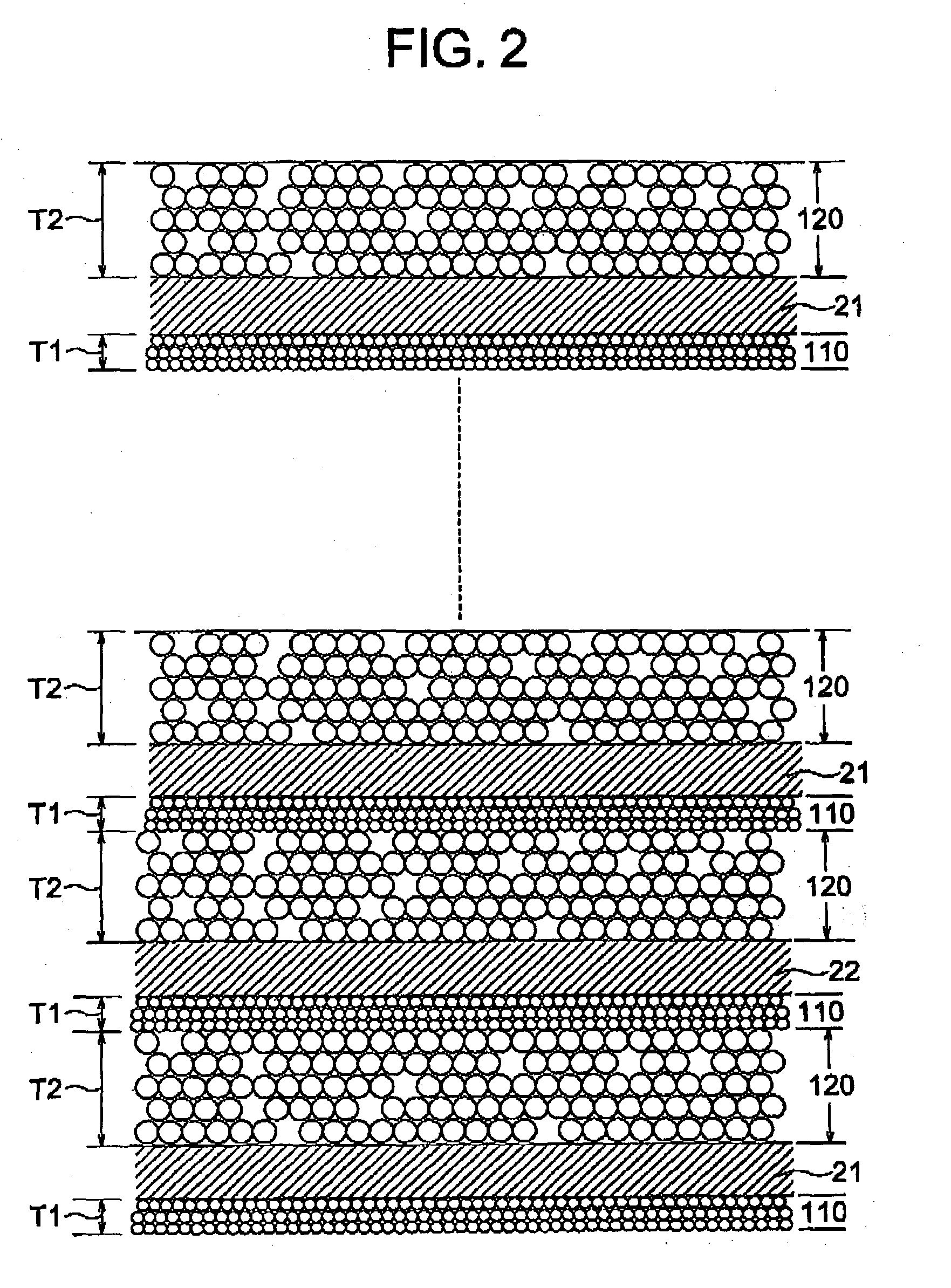

Ceramic electronic device and method of production of same

InactiveUS20030170432A1Reduce difficulty in peeling and probability of occurrence of defectImprove accuracyDead plant preservationArtificial flowers and garlandsCeramic coatingMetallurgy

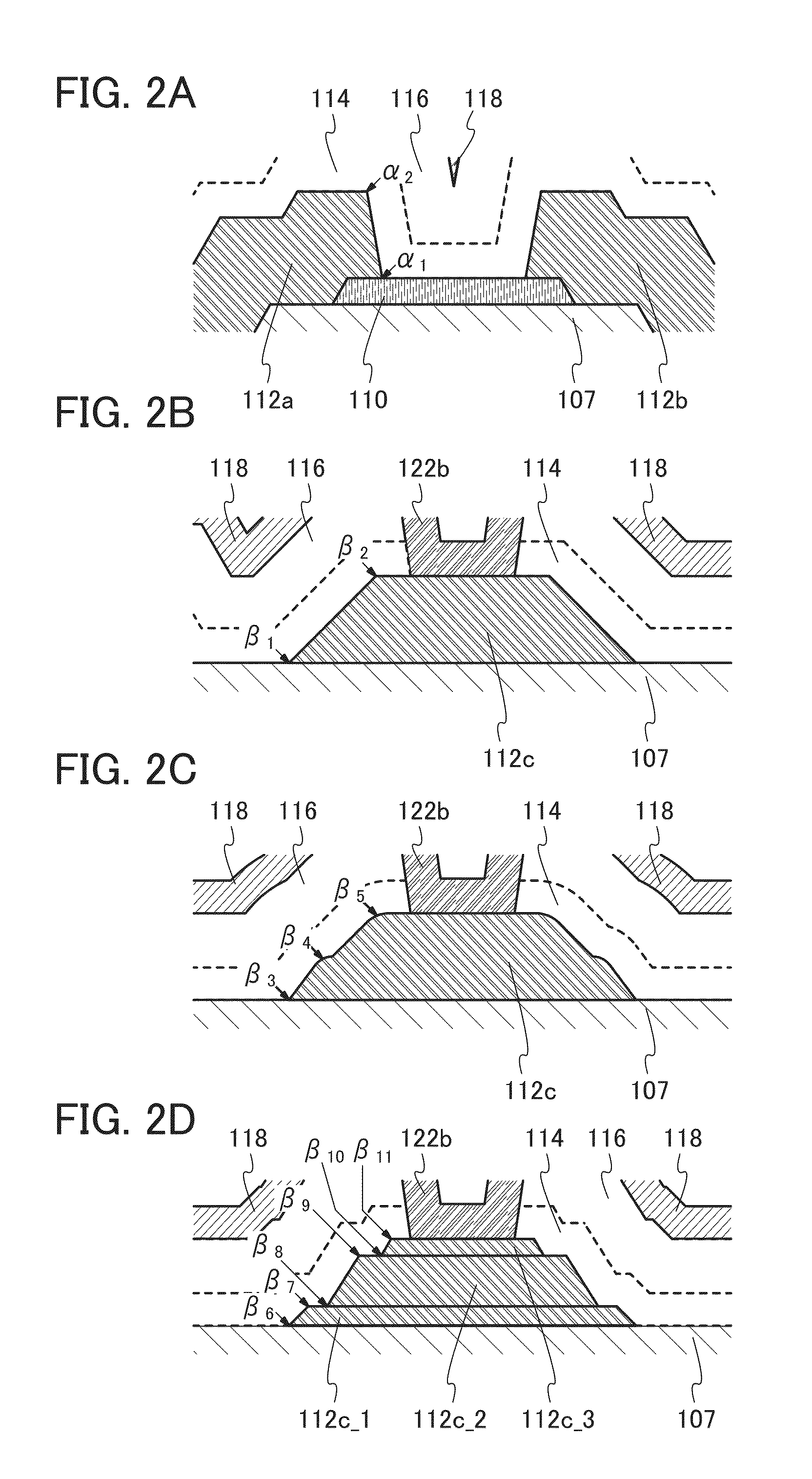

A method of production of a ceramic electronic device such as a multilayer ceramic capacitor, comprising forming a first ceramic coating layer on the surface of a substrate, forming an internal electrode on the surface of the first ceramic coating layer, then forming a second ceramic coating layer on the surface of the first ceramic coating layer so as to cover the internal electrode. In this case, when a mean particle size of ceramic particles of the first ceramic coating layer is alpha1, a thickness of the first ceramic coating layer is T1, a mean particle size of ceramic particles of the second ceramic coating layer is alpha2, and a thickness of the second ceramic coating layer is T2, the conditions of alpha1<=alpha2, 0.05<alpha1<=0.35 mum, T1<T2, and 0<T1<1.5 mum are satisfied. As a result, it is possible to provide a ceramic electronic device, in particular a multilayer ceramic capacitor, resistant to short-circuit defects, withstand voltage defects, and other structural defects.

Owner:TDK CORPARATION

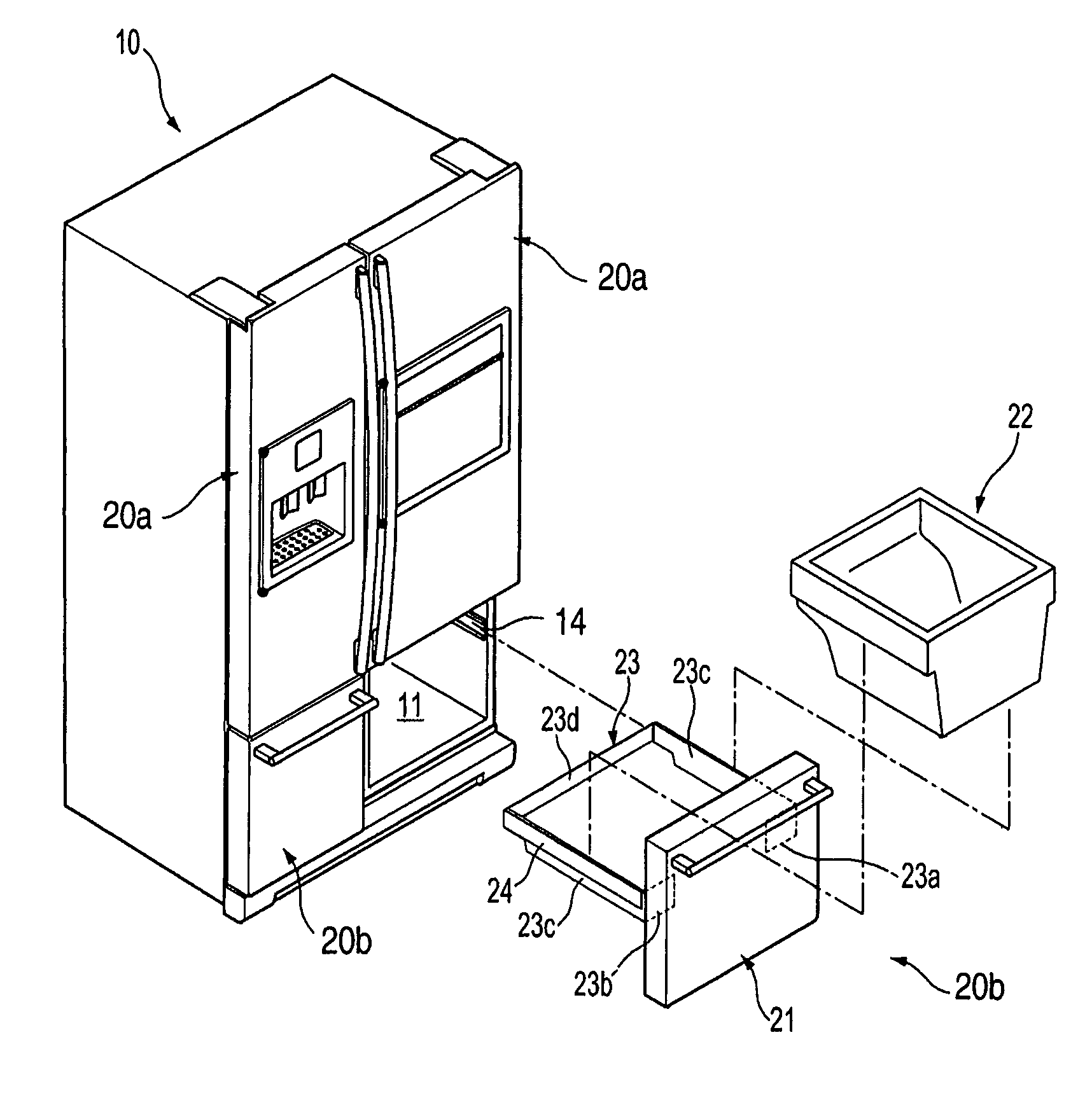

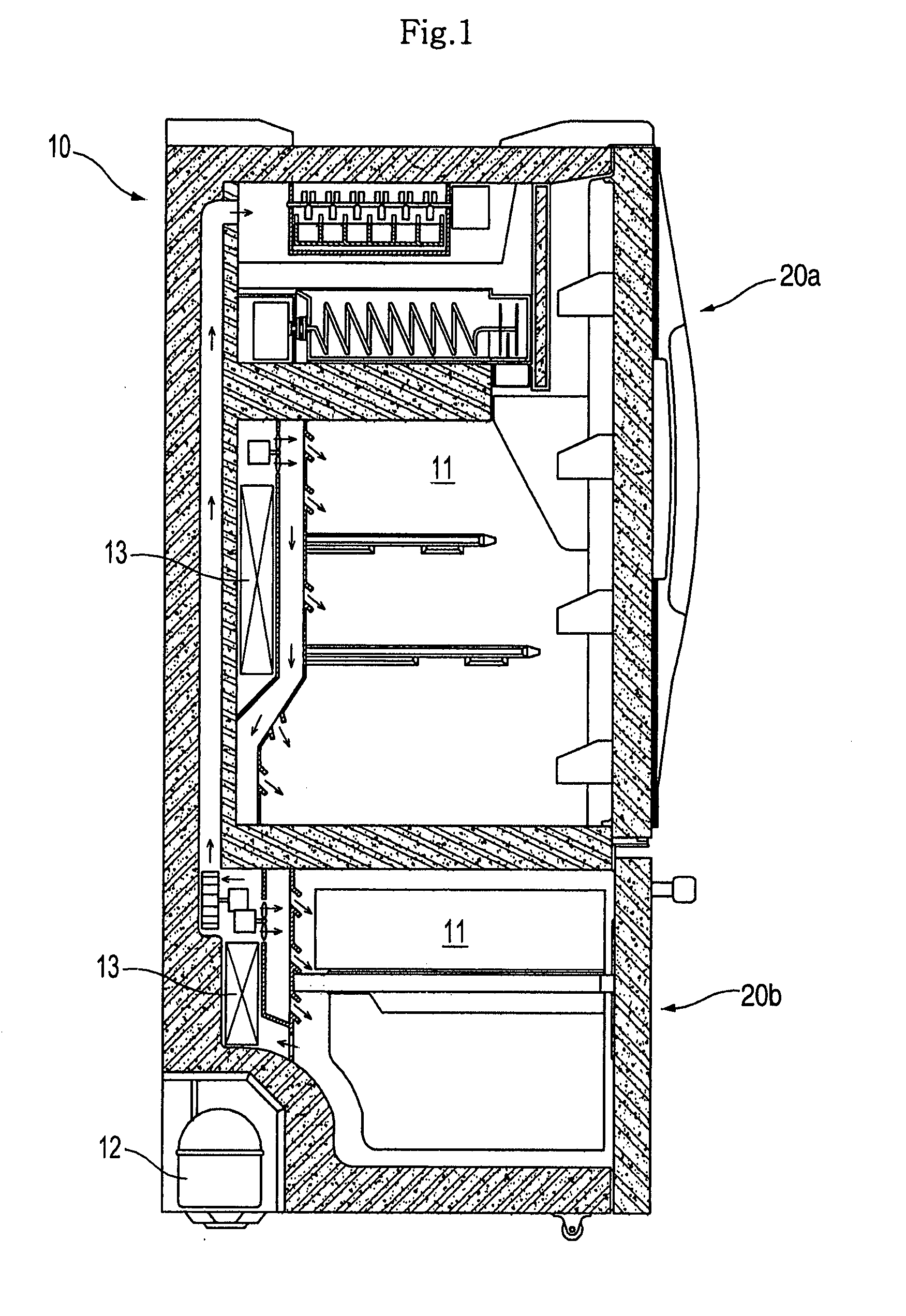

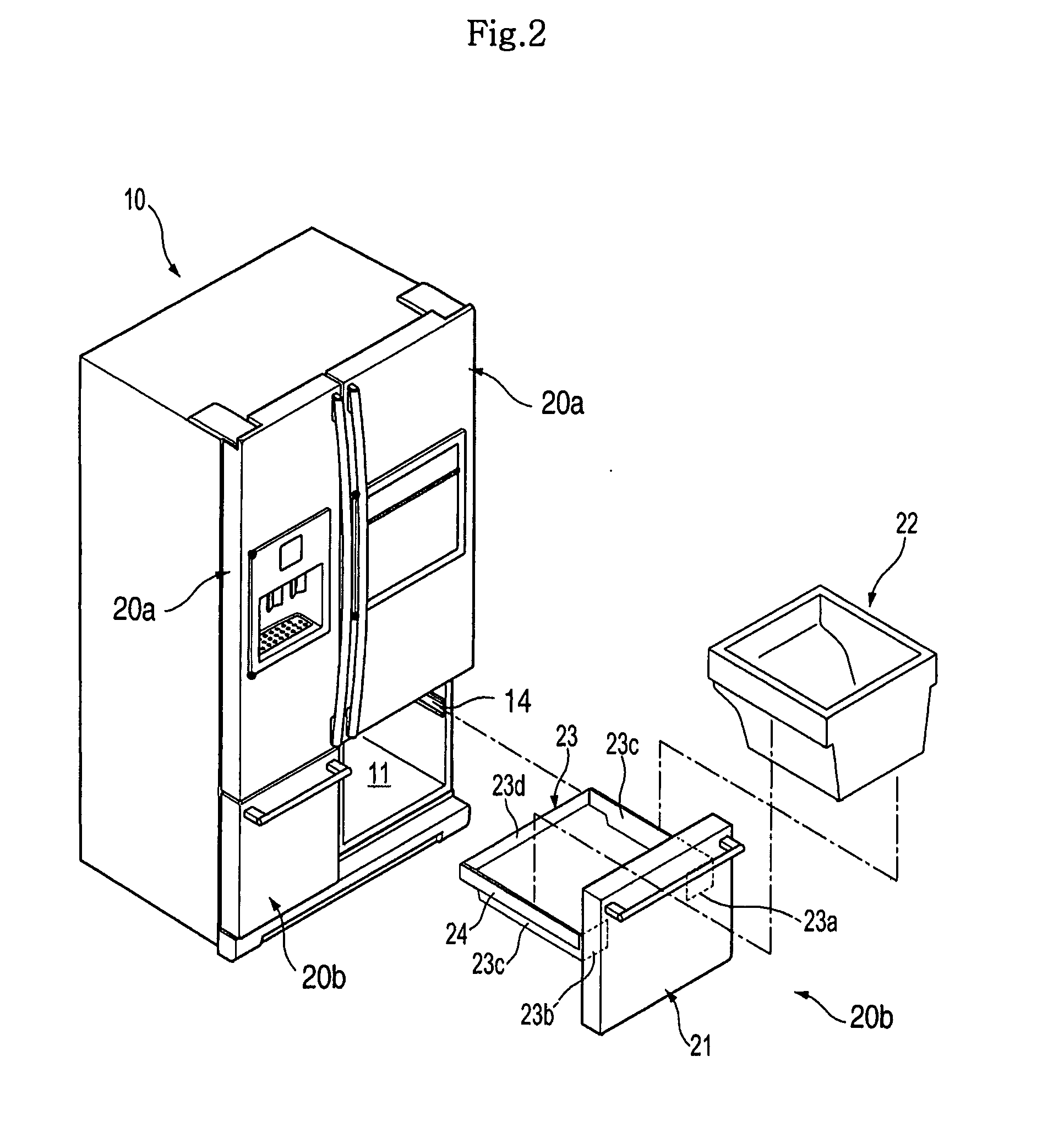

Drawer type door and refrigerator having the same

InactiveUS20080074019A1Reduce step differenceShow cabinetsLighting and heating apparatusRefrigerated temperatureHolding room

Disclosed is a refrigerator having a plurality of drawer-type doors installed in a transverse direction in parallel to each other. The refrigerator includes a body provided at left and right portions thereof with a plurality of storage chambers which are aligned in parallel to each other to store materials therein, and a plurality of drawer-type doors installed in the storage chambers and capable of being moved forward or backward. A step difference adjusting device is provided to adjust installation positions of the drawer-type doors to reduce a step difference between adjacent drawer-type doors.

Owner:SAMSUNG ELECTRONICS CO LTD

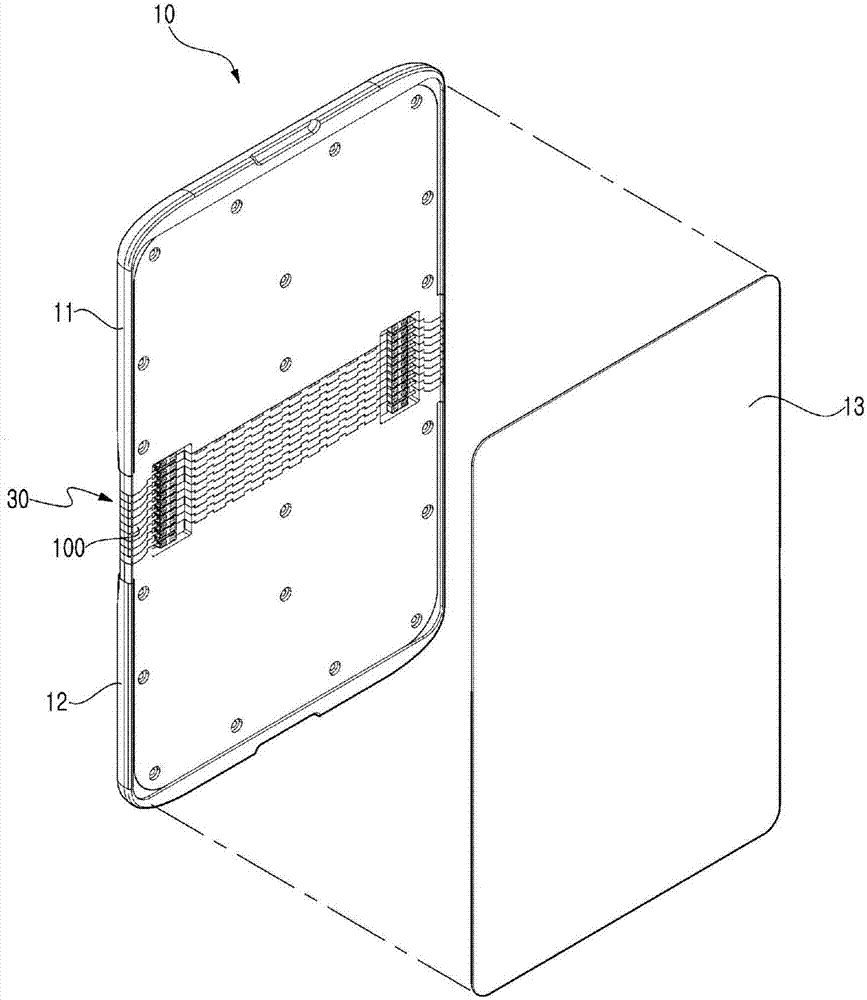

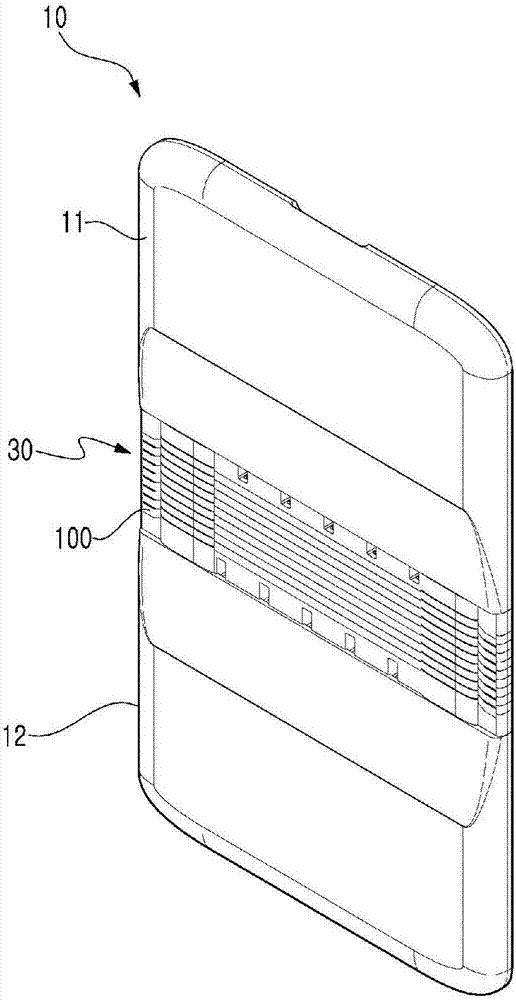

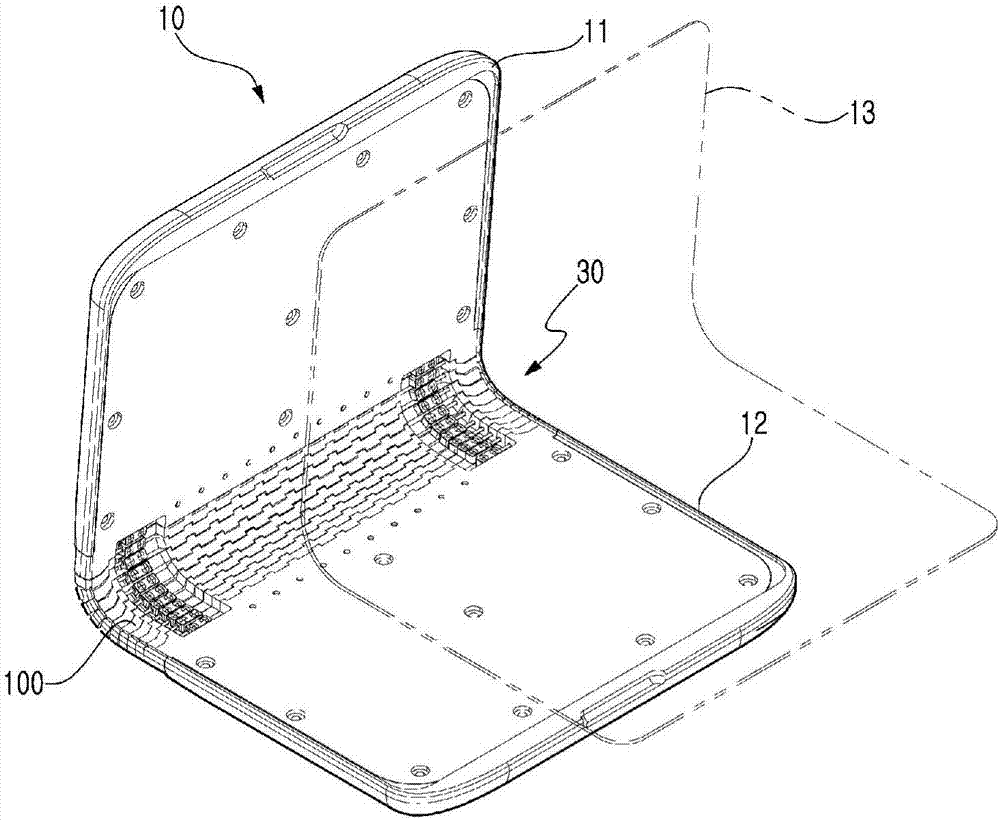

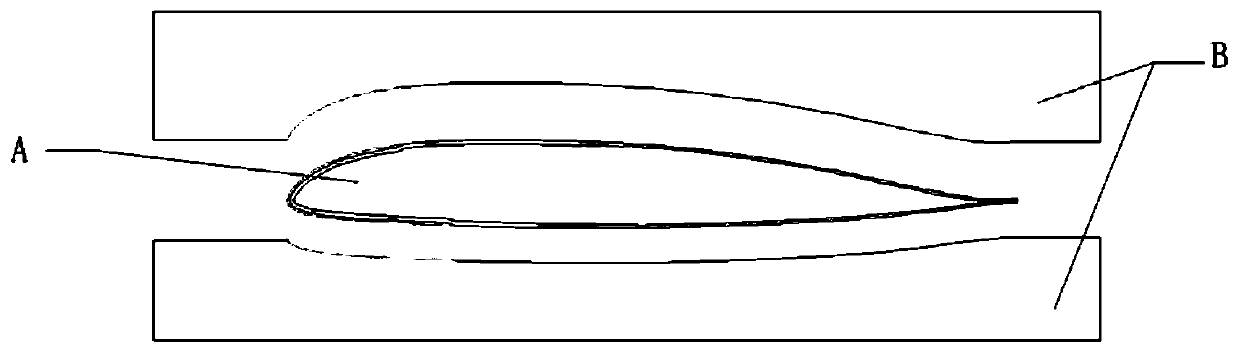

Flexible hinge device having cam structure

InactiveCN107077172AReduce step differenceSame bendDigital data processing detailsSubstation equipmentDisplay deviceEngineering

A flexible hinge device, according to the present invention, comprises: a first plate and a second plate to the top surfaces of which a flexible display screen having a bend is attached; and a hinge portion connecting the first plate and the second plate, and performing hinge operation by being folded or spread open. The hinge portion comprises: a cam portion in which a plurality of segment members are connected so that the hinge portion can be folded or spread open, wherein the first plate and the second plate are respectively connected to segment members positioned at two end portions, from among the plurality of segment members, and wherein the segment members are extended in the lengthwise direction; a fixed portion extendedly formed on the inside of and apart from two ends of the cam portion; a fixing member formed by having a head portion and a pin portion extending in the lengthwise direction from one end of the head portion; and a rotating portion extendedly formed on the outside of and apart from two ends of the fixed portion. .

Owner:PREXCO

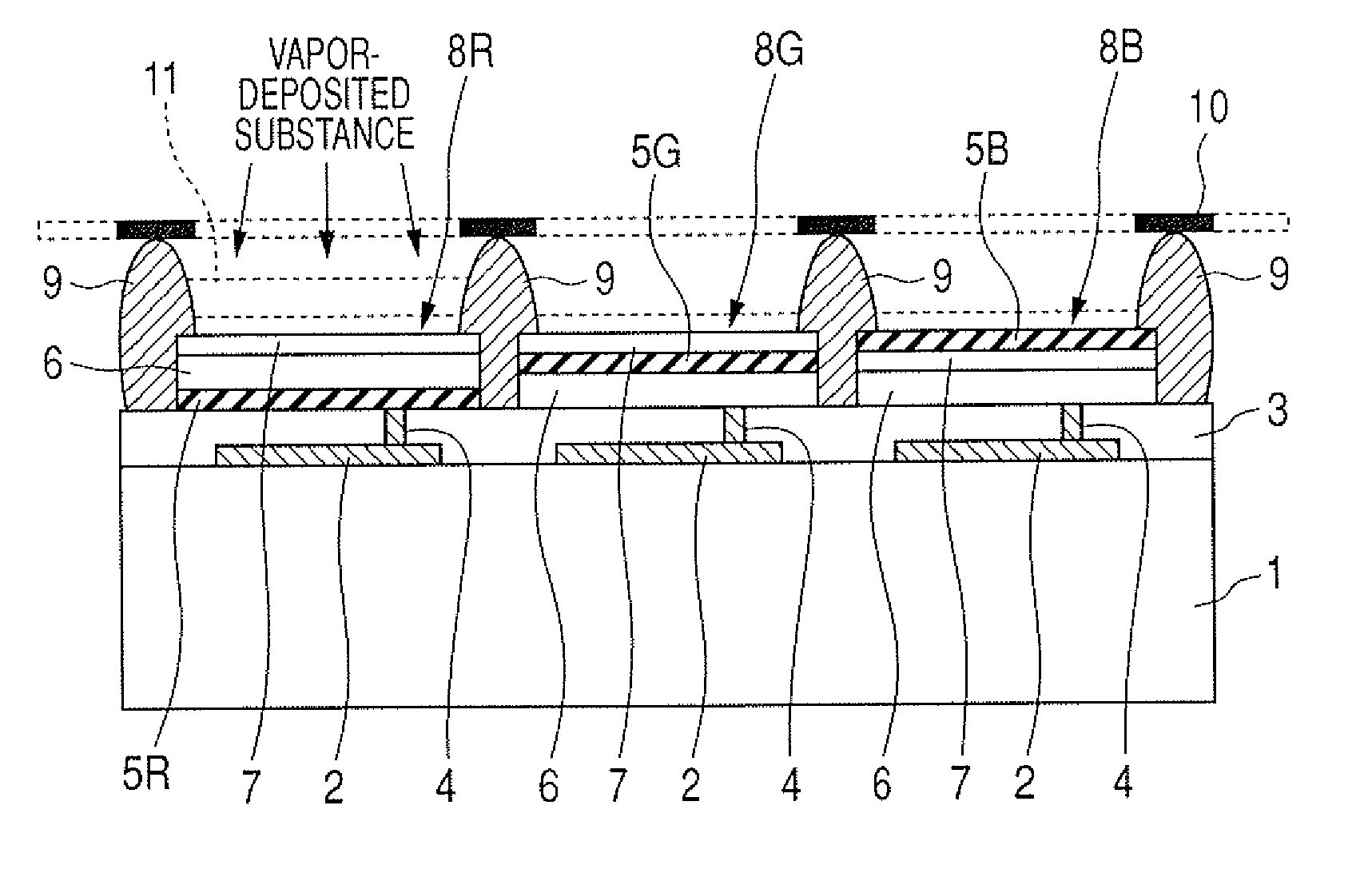

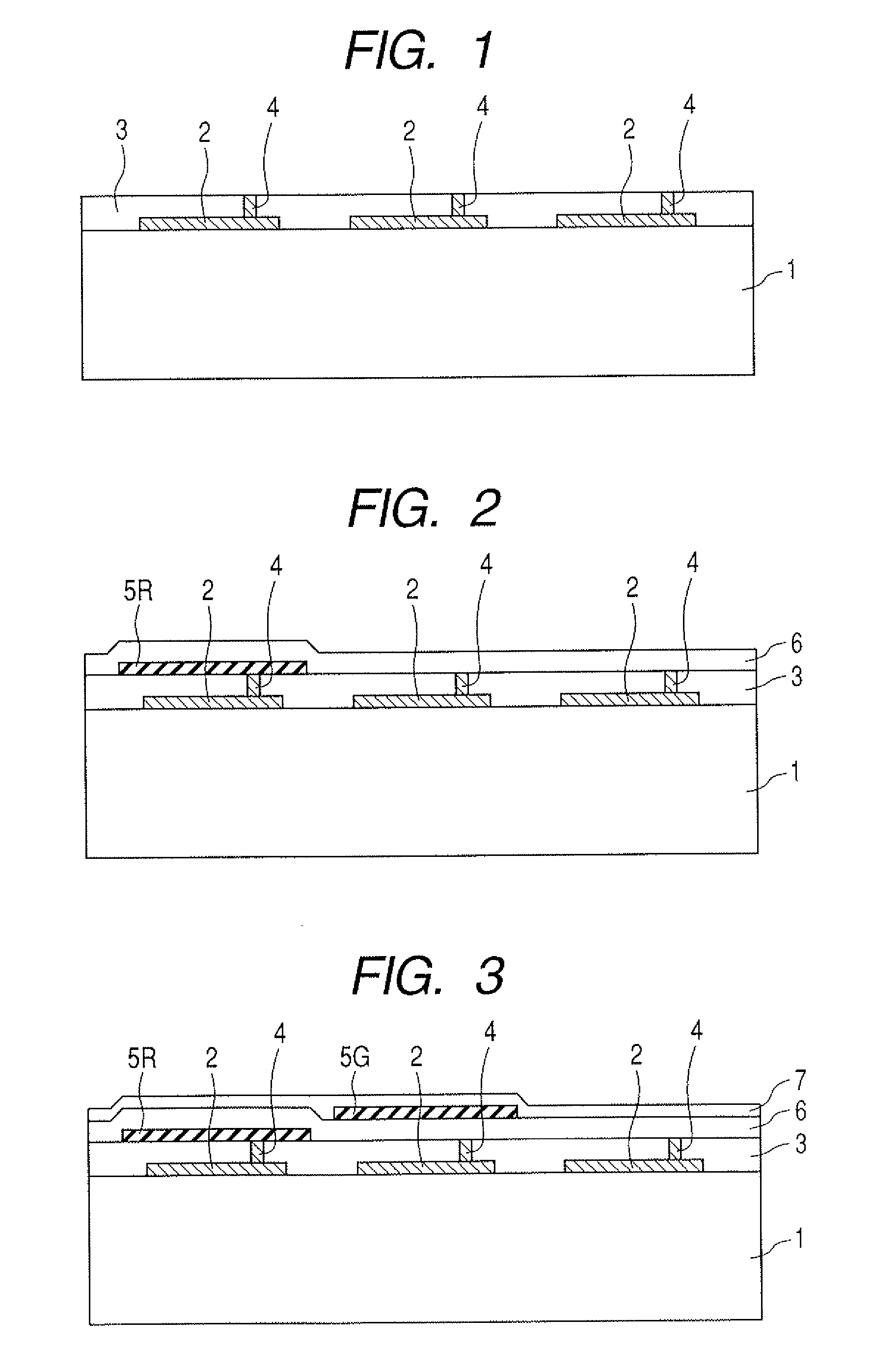

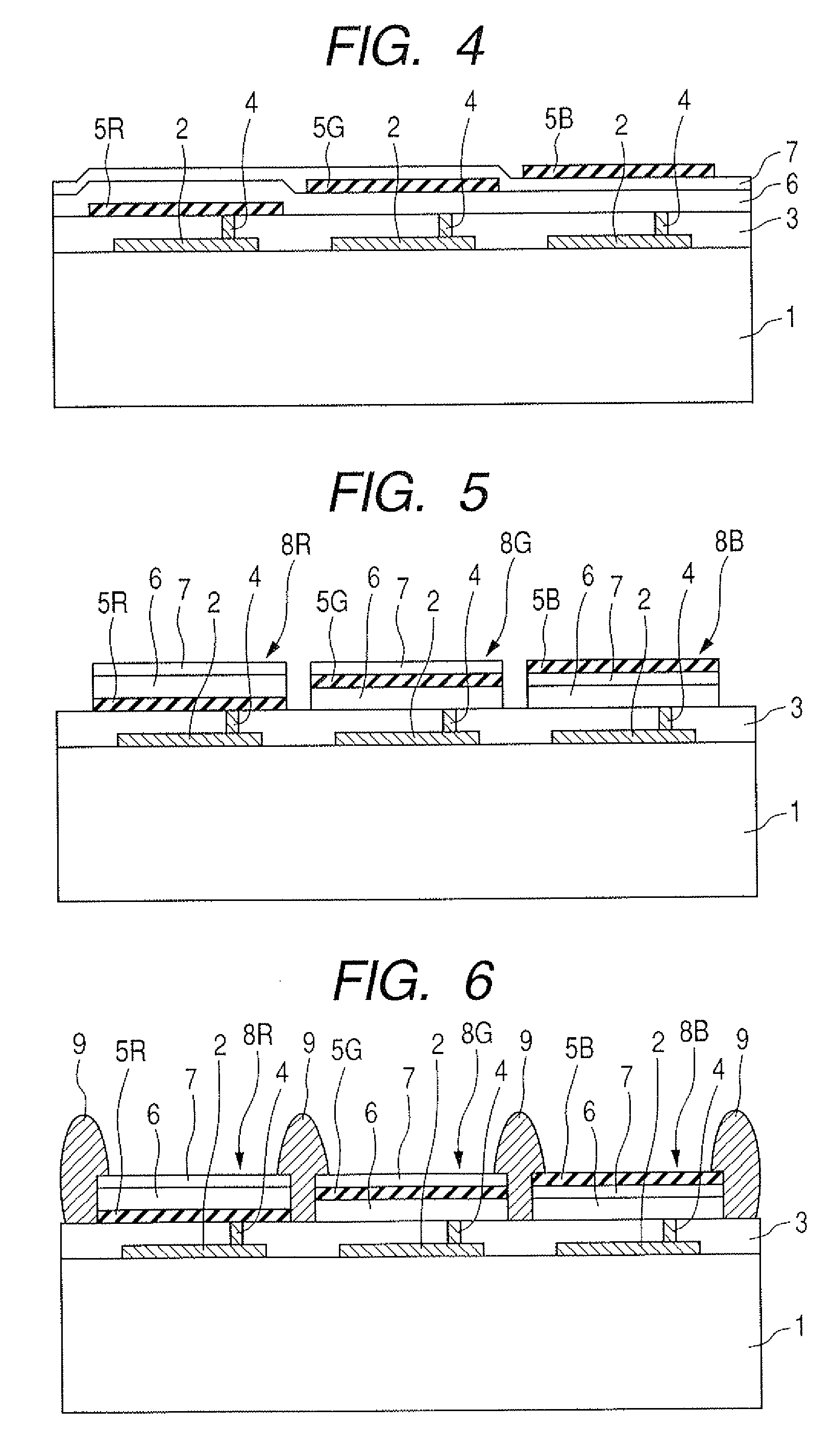

Organic light-emitting elements of LED with light reflection layers in each spaced on opposite sides of transparent conductive layer

ActiveUS7923920B2Light extraction efficiency can be improvedSimple processDischarge tube luminescnet screensElectroluminescent light sourcesOrganic light emitting deviceLight reflection

An organic light-emitting device has a substrate and a plurality of organic light-emitting elements formed on the substrate. The plurality of the organic light-emitting elements include a first light-emitting element emitting light of a first emission color, and a second light-emitting element emitting light of a different emission color. Each light-emitting element has, in sequence, a first electrode having a light reflection layer and a transparent conductive layer, an organic compound layer containing a light-emitting layer, and a second electrode on the substrate. The light reflection layer of the first element is between the substrate and the transparent conductive layer and the light reflection layer of the second element is between the transparent conductive layer and the organic compound layer. A thickness of the transparent conductive layer of the first and second organic light-emitting elements is the same.

Owner:CANON KK

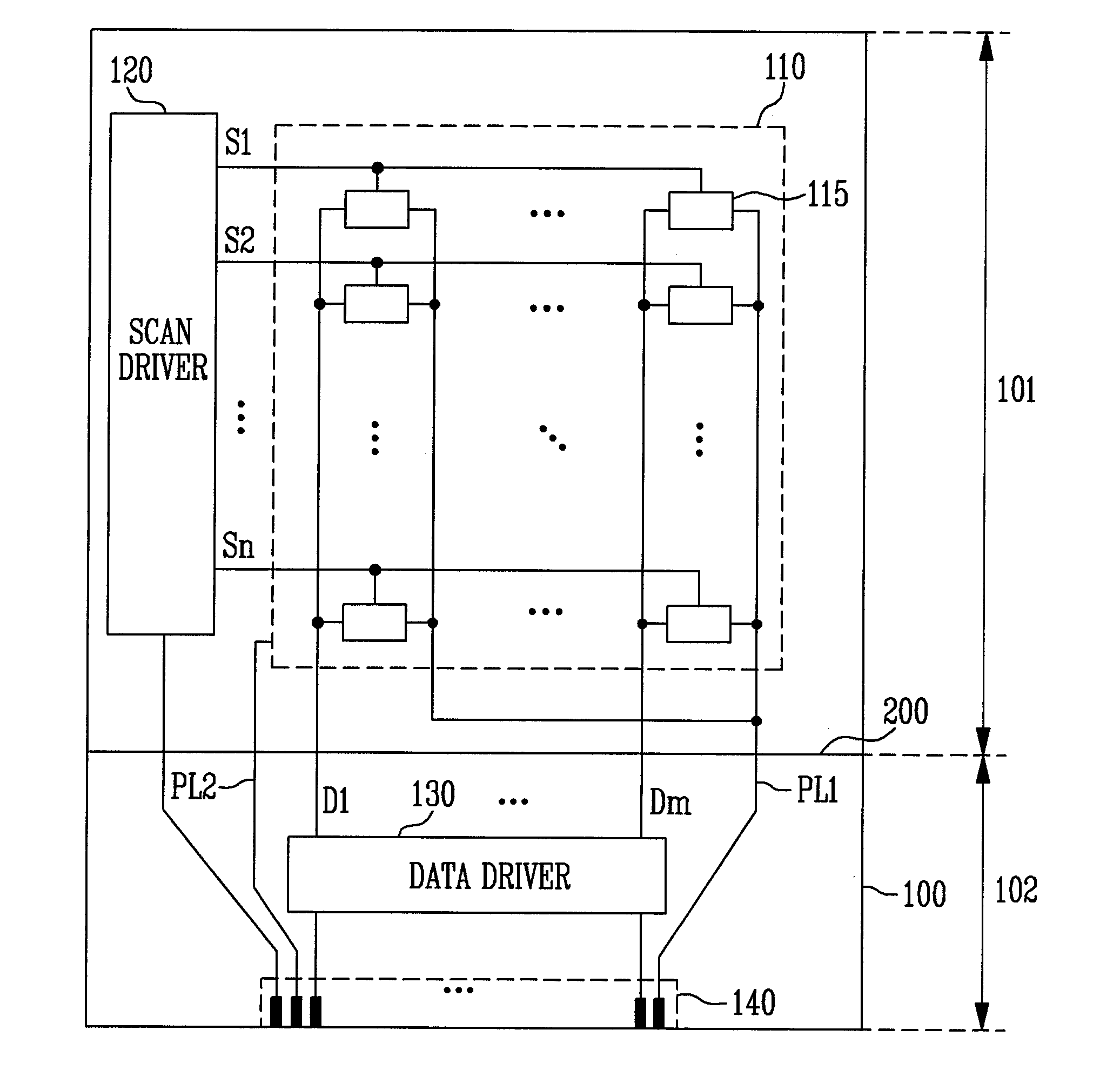

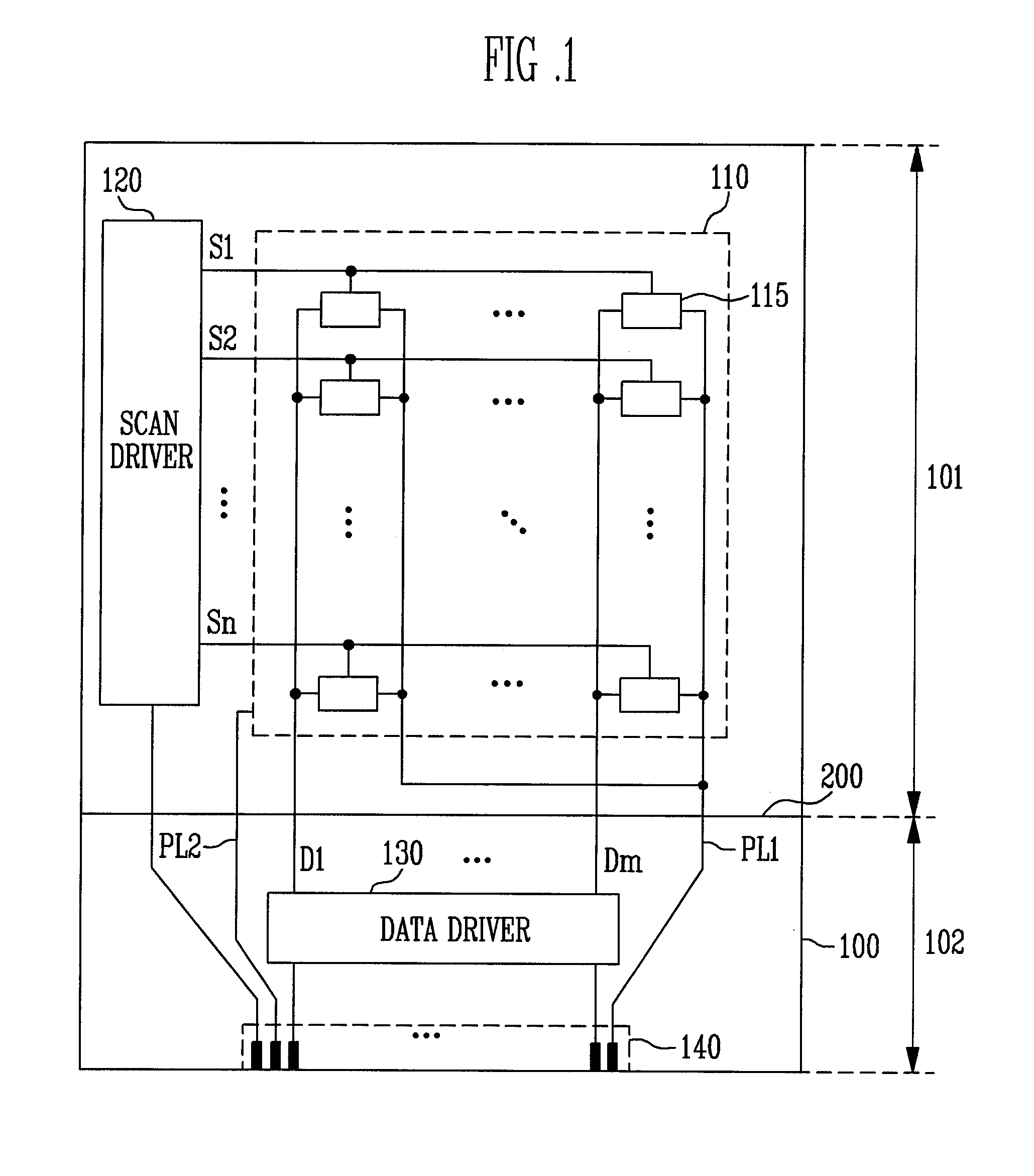

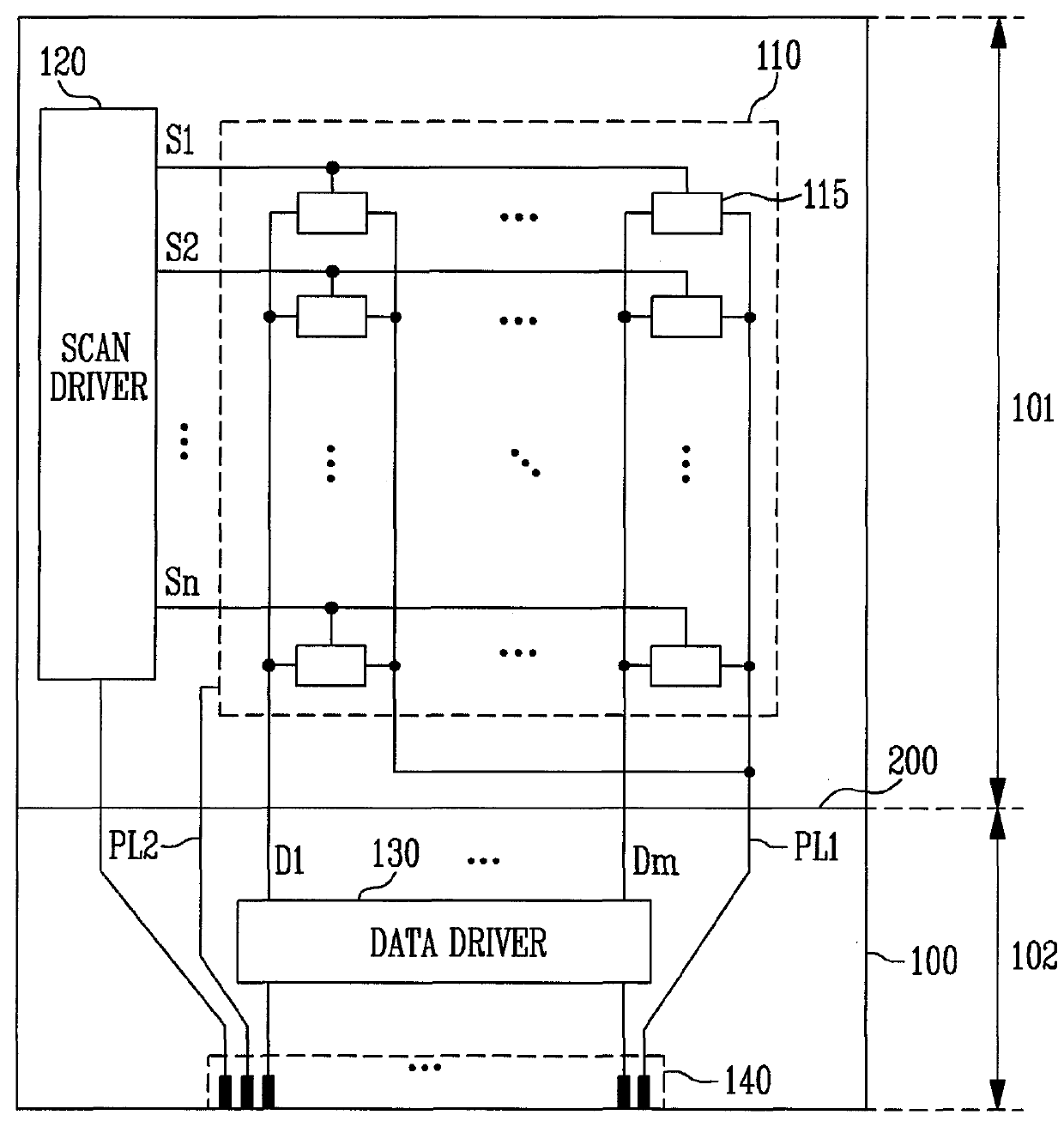

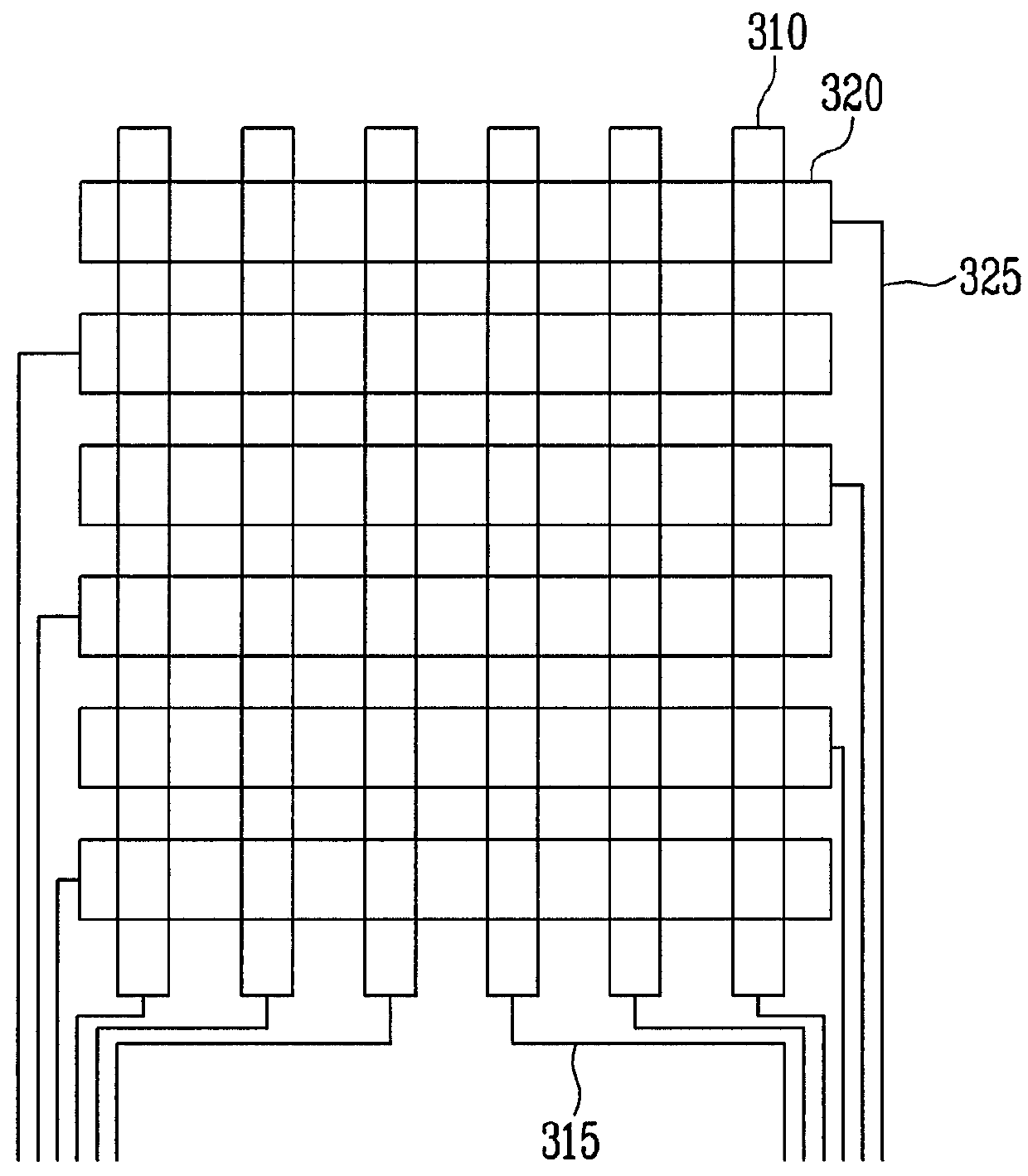

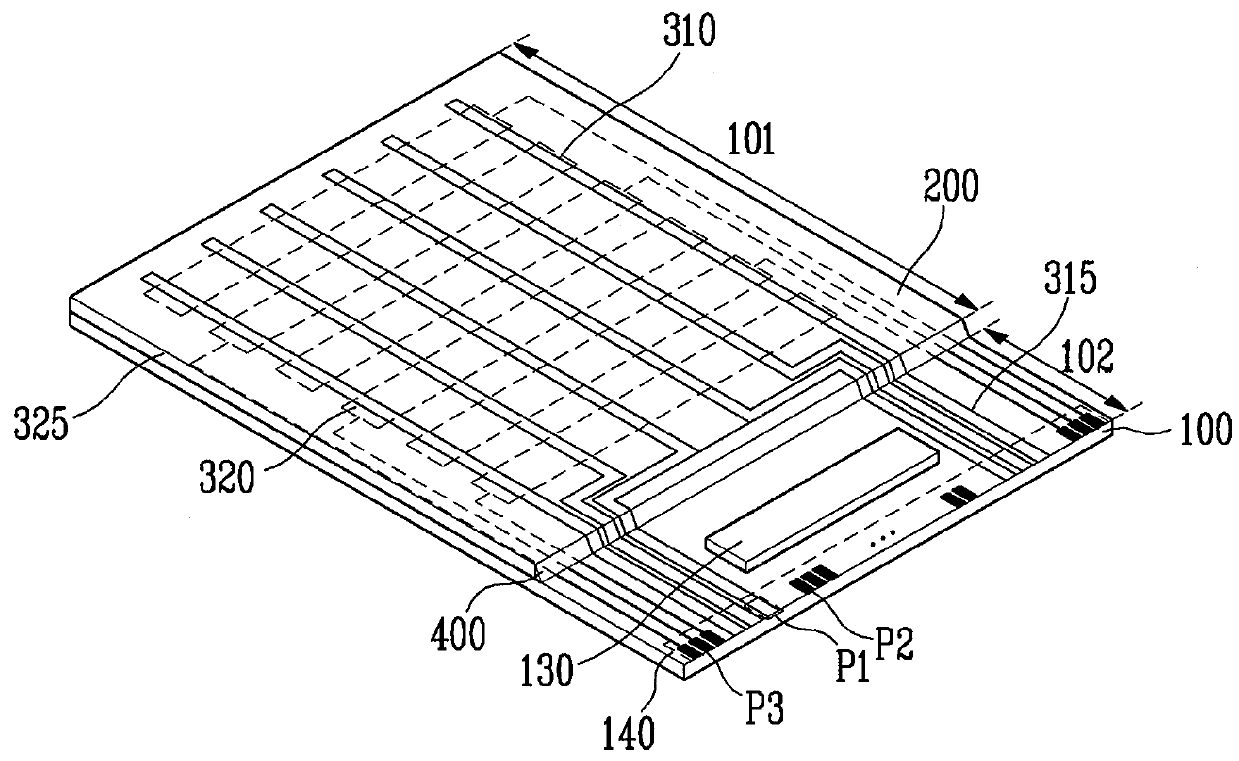

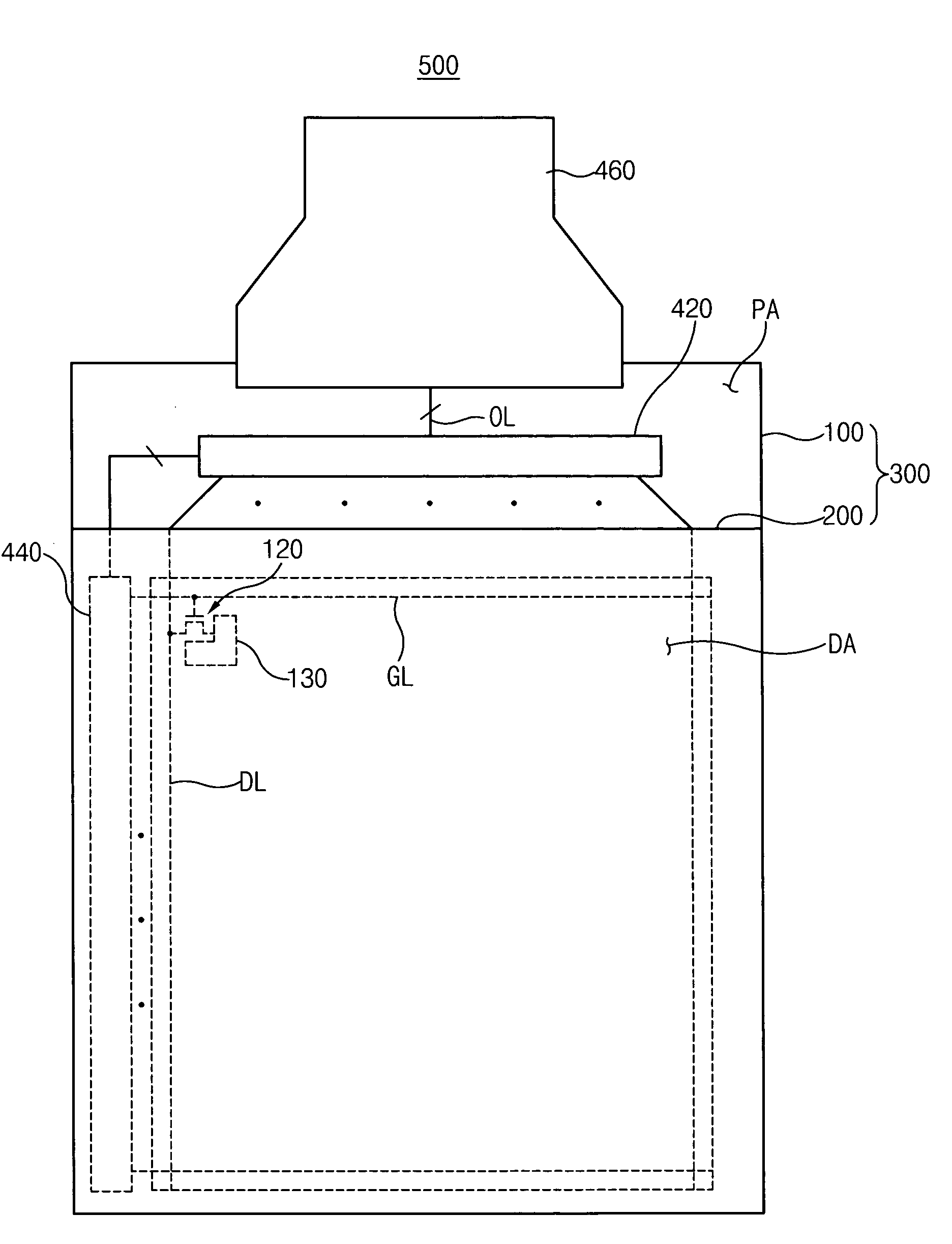

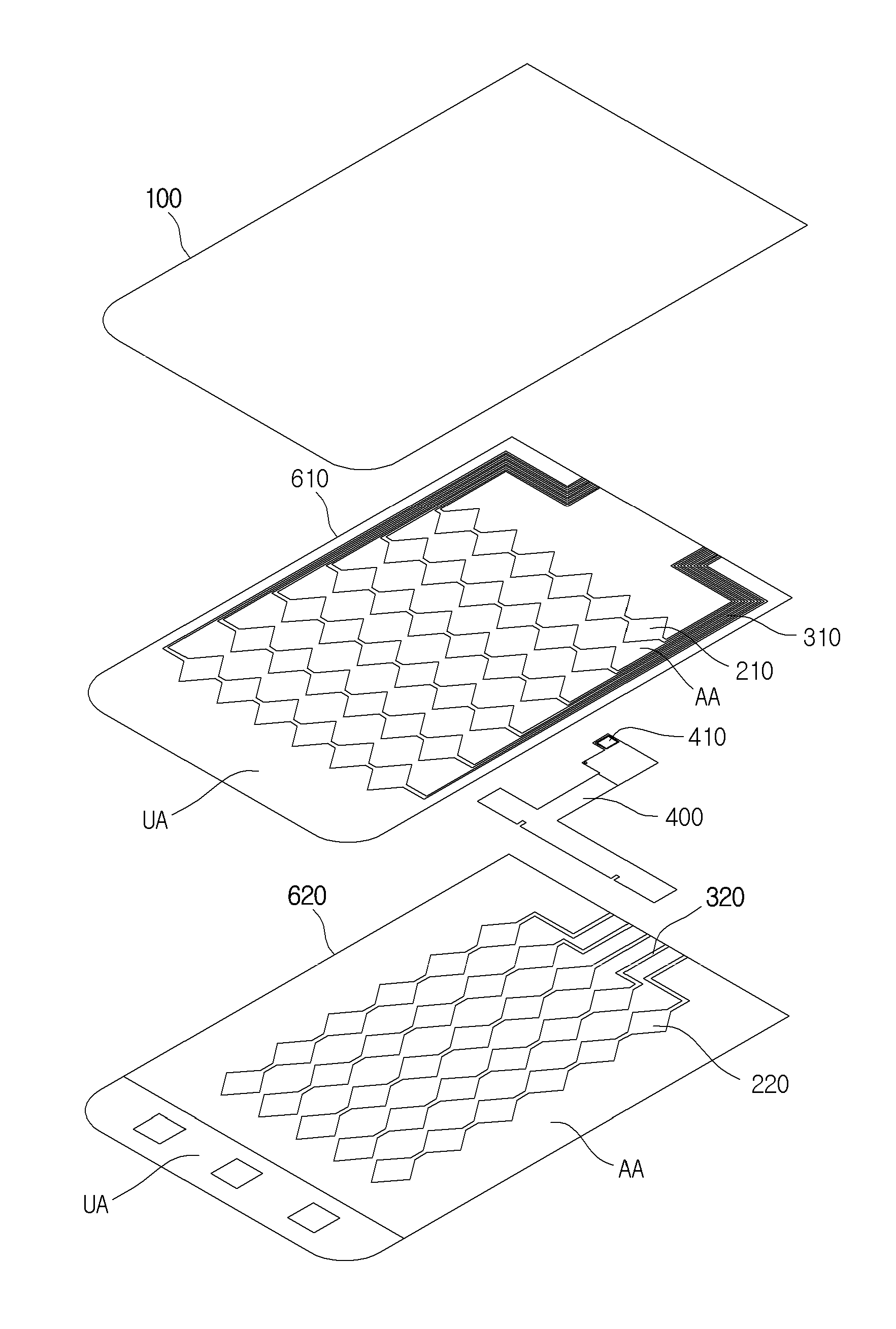

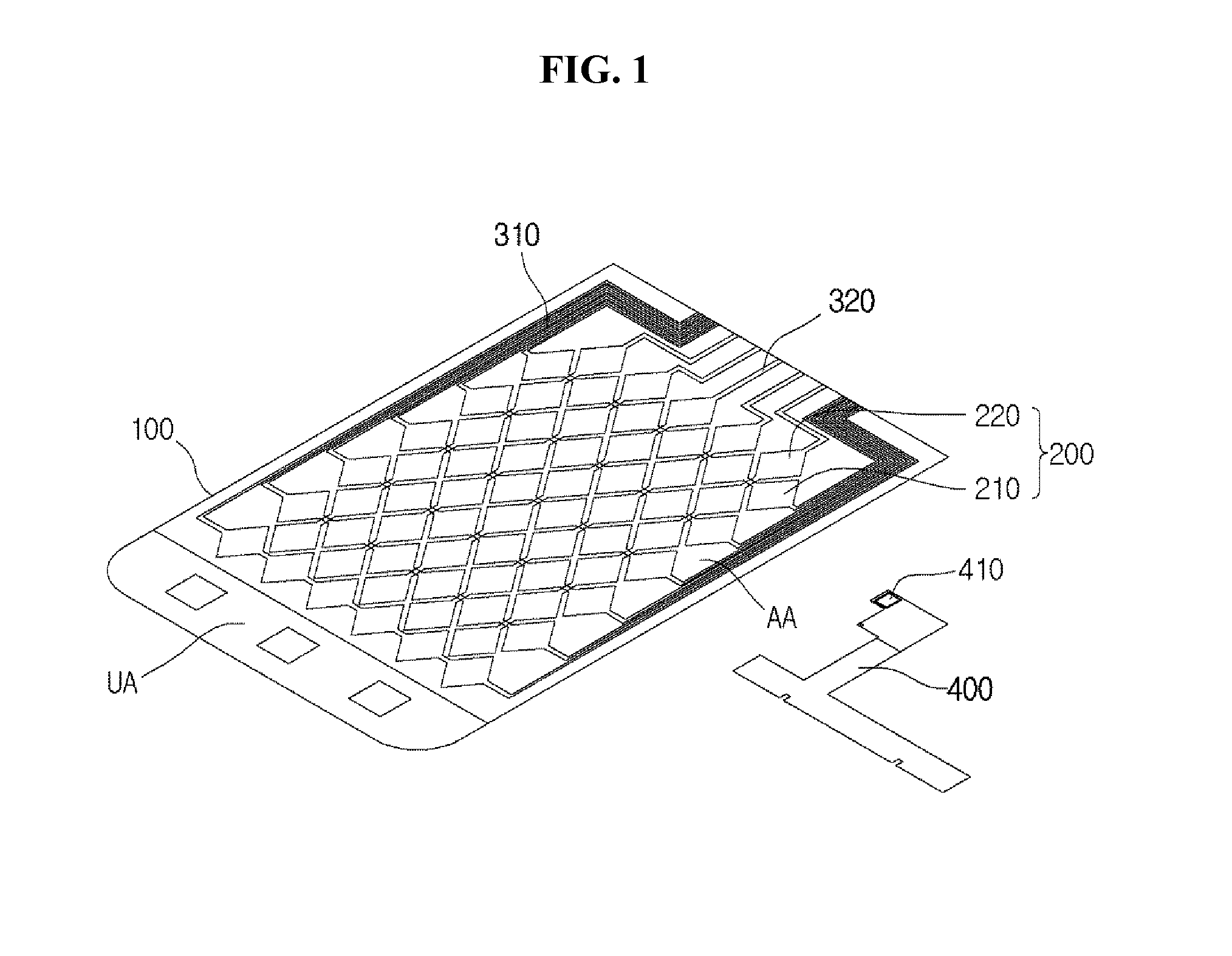

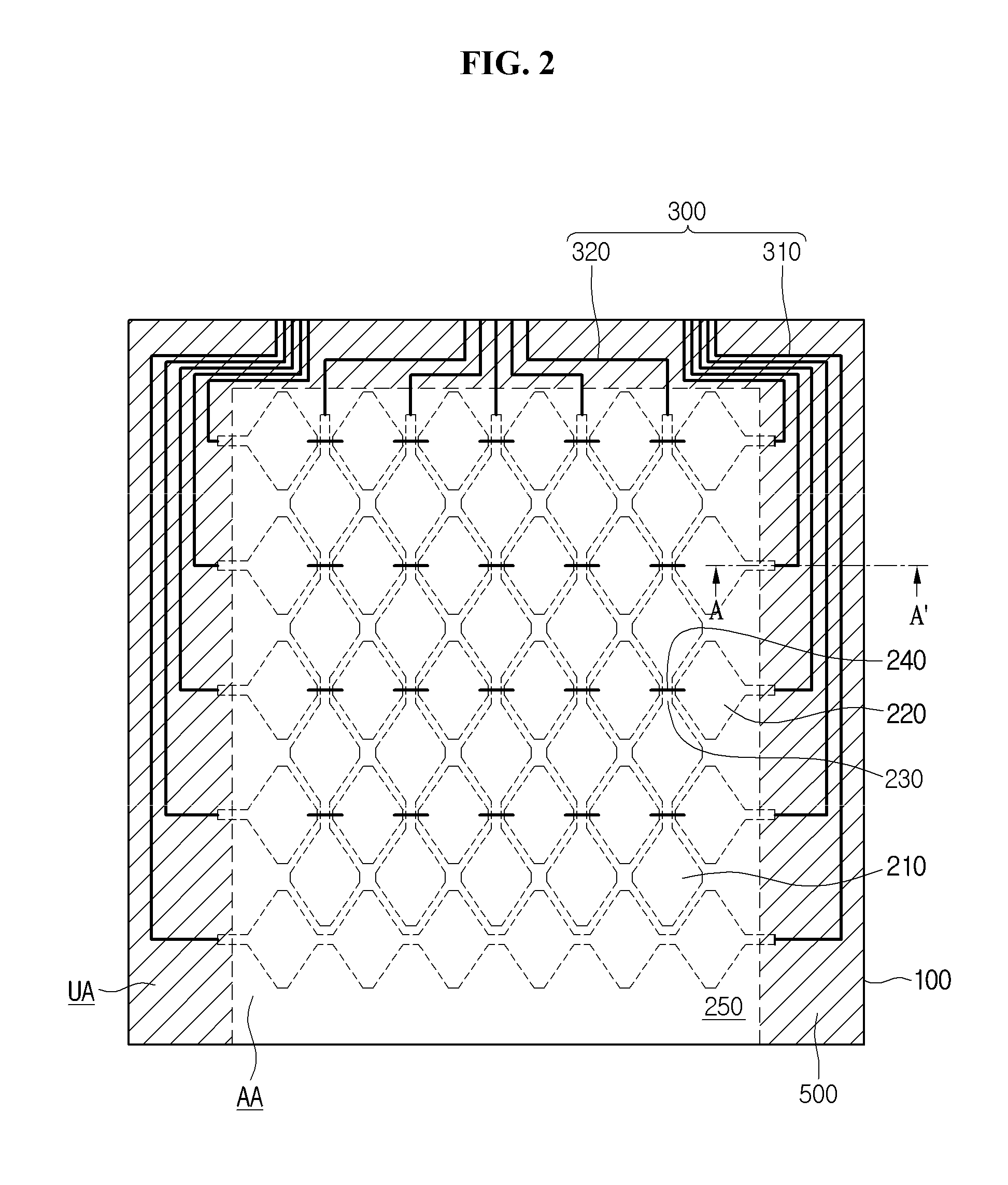

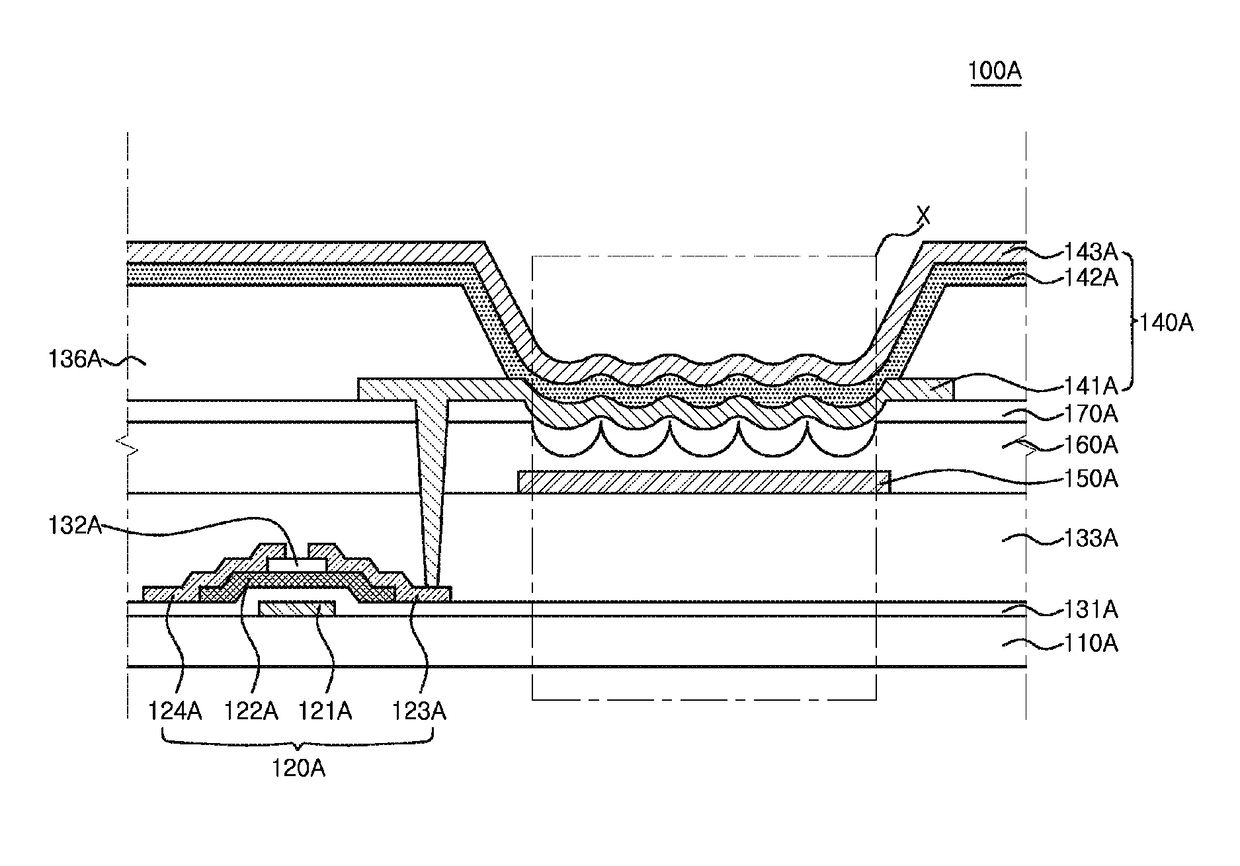

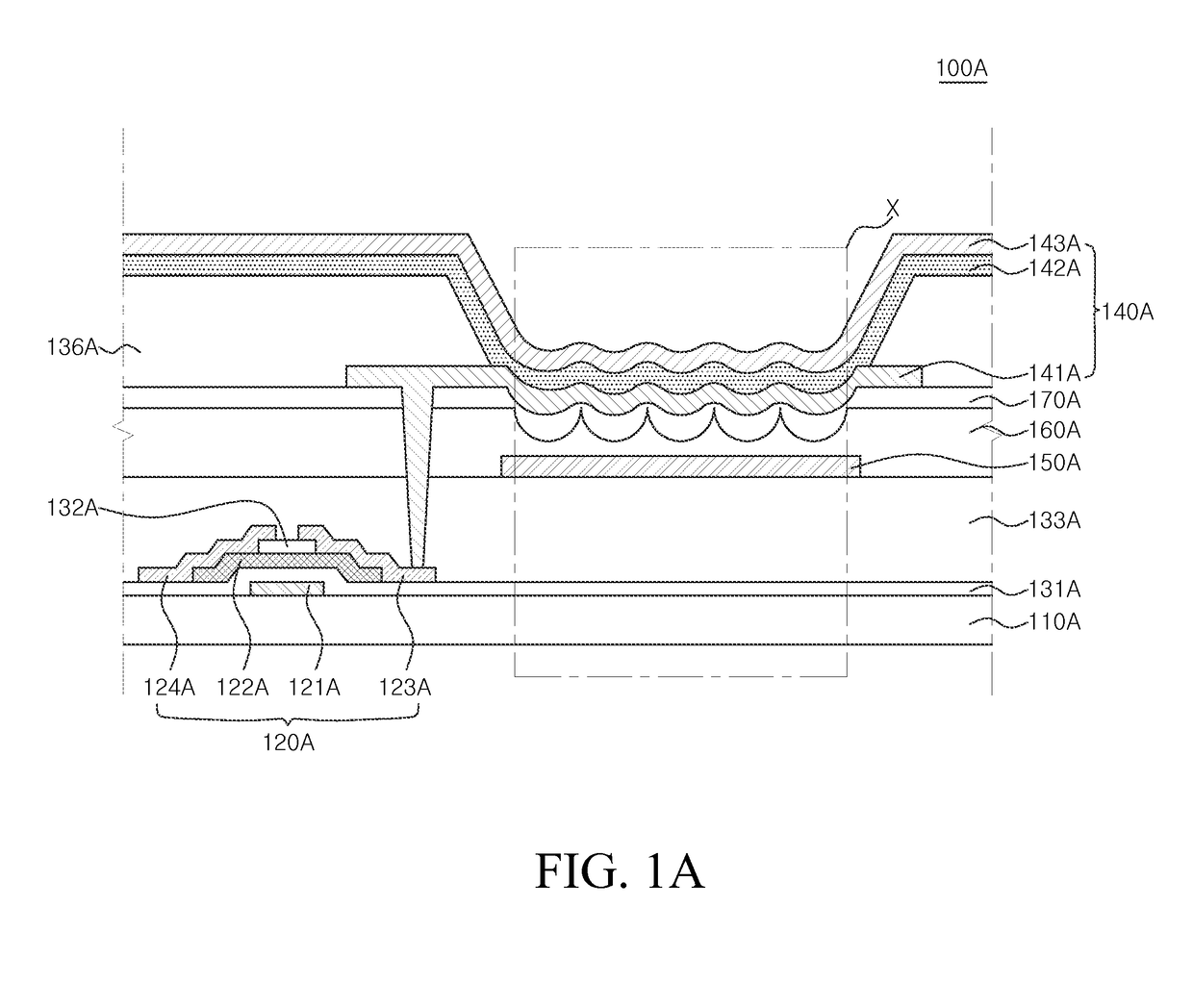

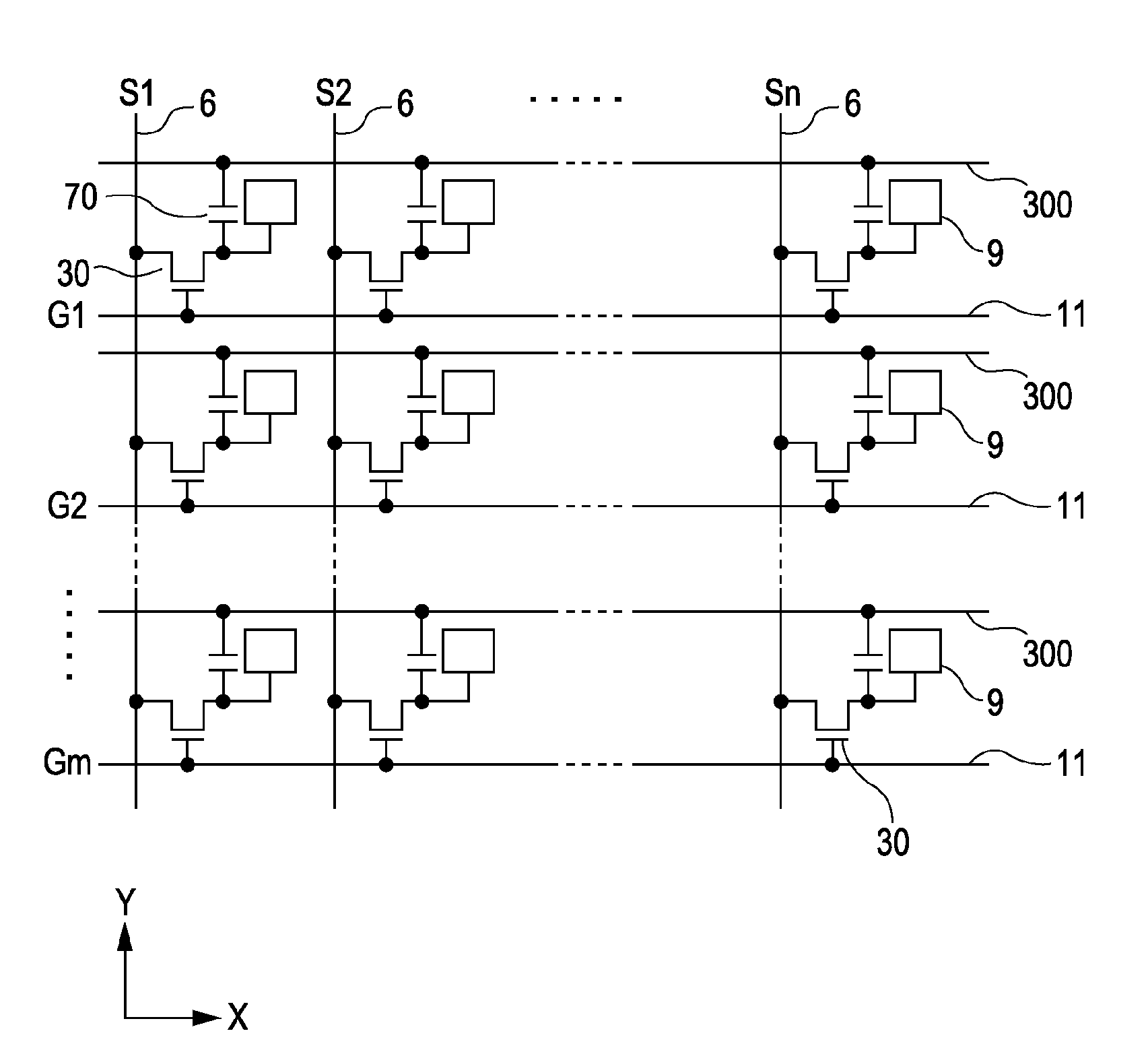

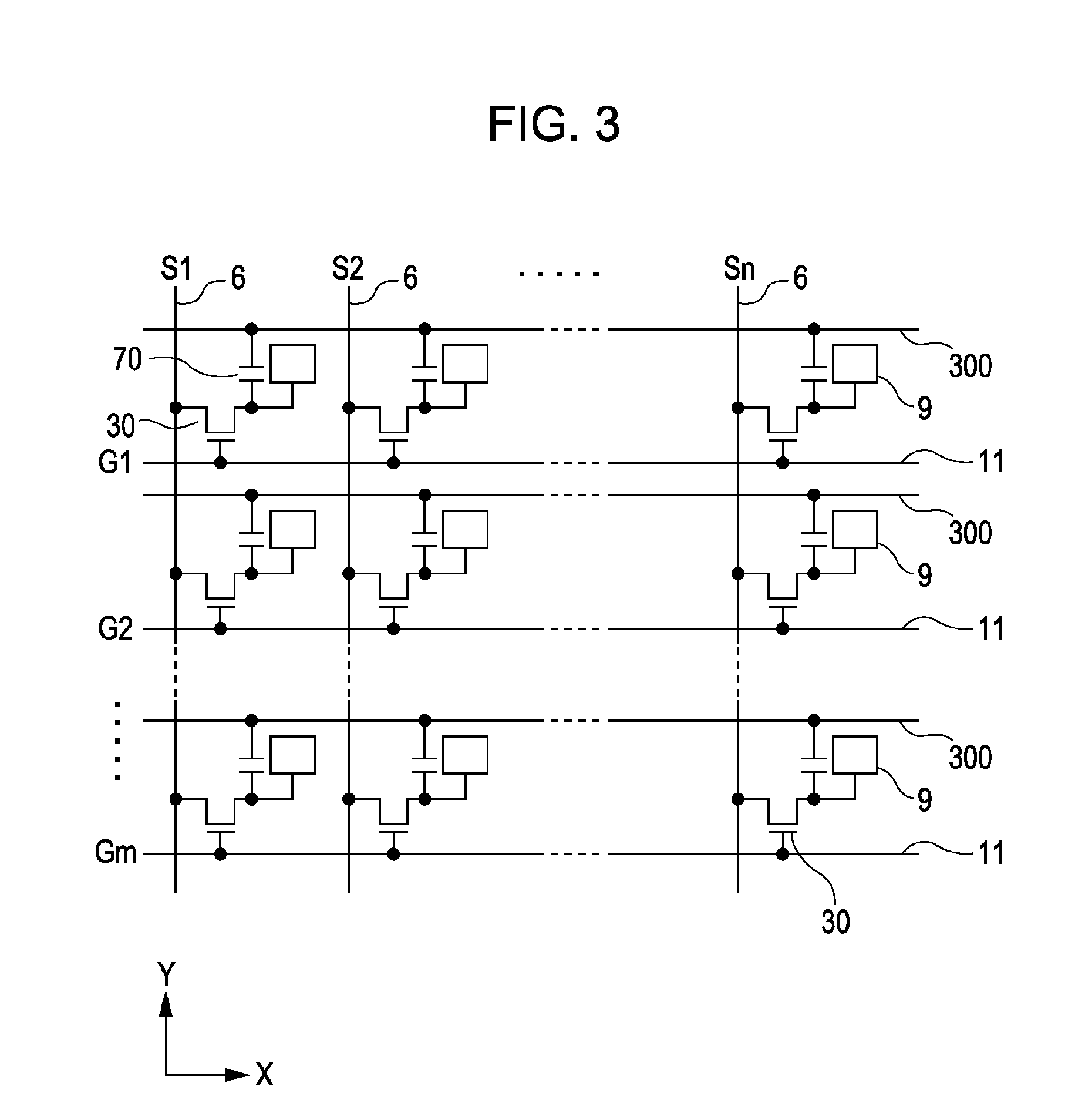

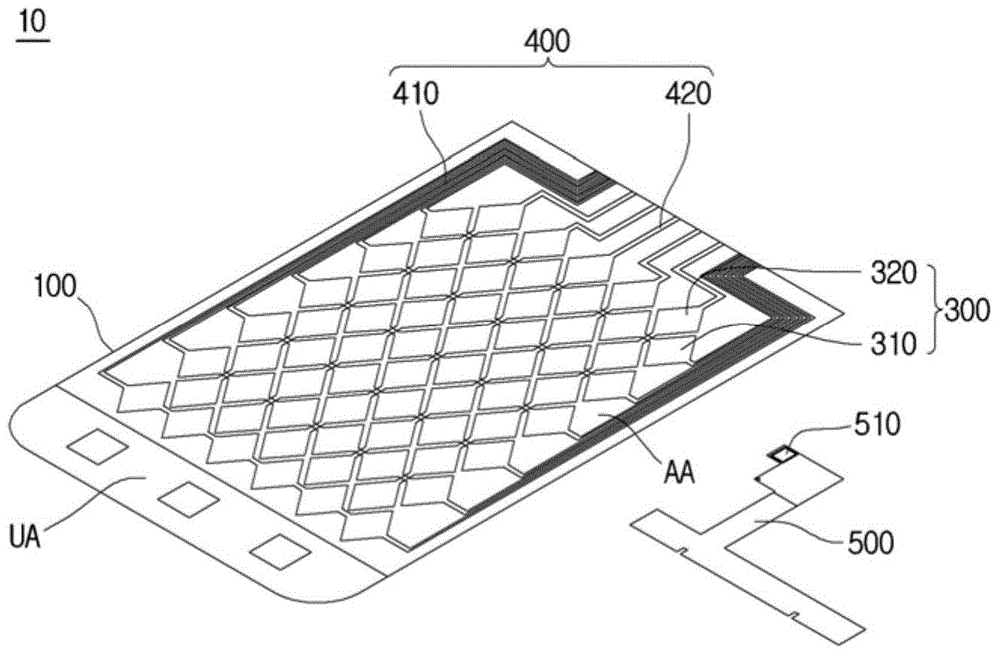

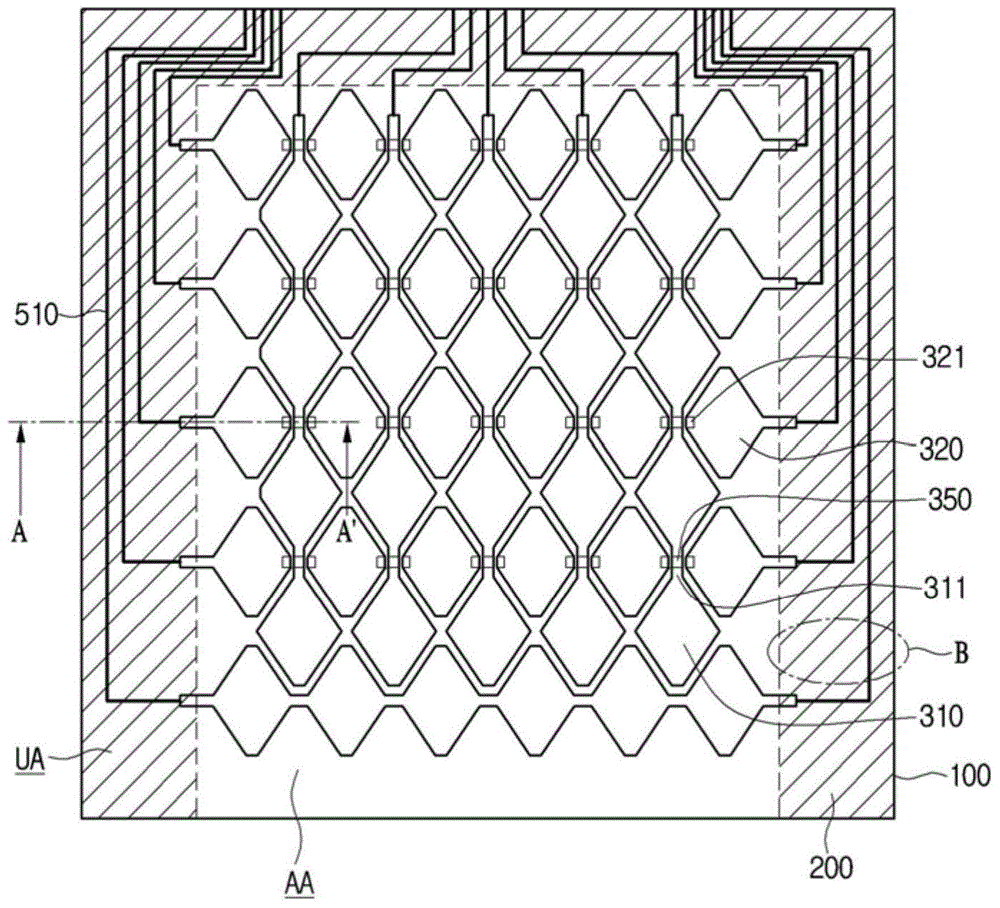

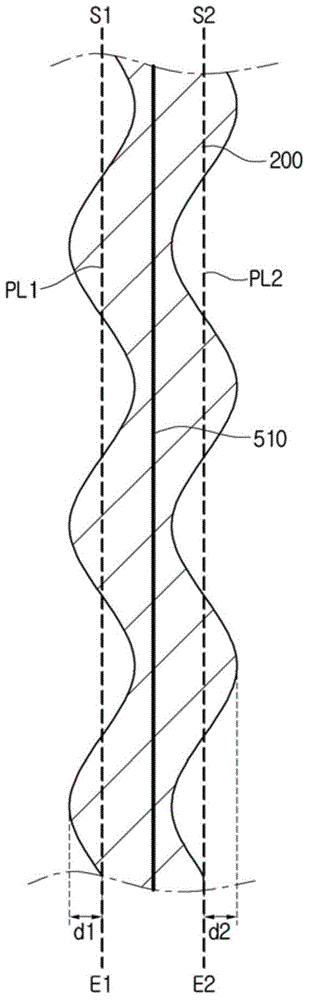

Display device integrated with touch screen panel

ActiveUS20140210738A1Simplify the display processReduce step differenceNon-linear opticsInput/output processes for data processingDisplay deviceEngineering

Provided is a display device integrated with a touch screen panel including a display unit including a plurality of pixels at a sealed region between a lower substrate and an upper substrate; first touch electrodes extending in a first direction on the upper substrate in the sealed region, wherein one ends of the first touch electrodes extend to a non-sealed region on the lower substrate; and a sloped portion beneath the first touch electrodes at a boundary between the sealed region and the non-sealed region.

Owner:SAMSUNG DISPLAY CO LTD

Display device integrated with touch screen panel

ActiveUS9383849B2Avoid failureSimplify the display processNon-linear opticsInput/output processes for data processingDisplay deviceEngineering

Provided is a display device integrated with a touch screen panel including a display unit including a plurality of pixels at a sealed region between a lower substrate and an upper substrate; first touch electrodes extending in a first direction on the upper substrate over the sealed region, wherein ends of the first touch electrodes extend to a non-sealed region on the lower substrate; and a sloped portion beneath the first touch electrodes at a boundary between the sealed region and the non-sealed region.

Owner:SAMSUNG DISPLAY CO LTD

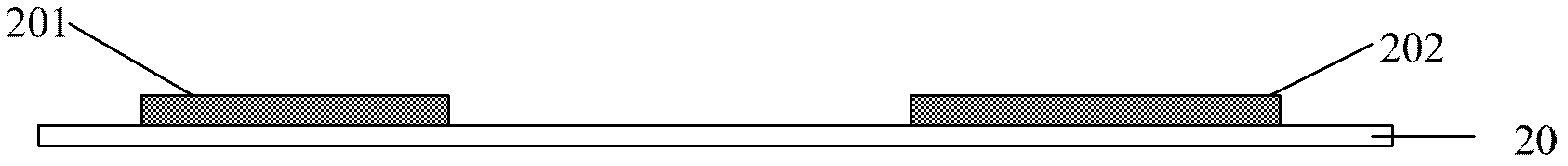

Display substrate, method of manufacturing the same, and display panel having the same

ActiveUS20120154722A1Difference in heightFlat surfaceVessels or leading-in conductors manufactureNon-linear opticsEngineeringBlocking layer

A display panel includes a base substrate having a plurality of pixel areas, in which each pixel area includes a plurality of sub-pixel areas, a light blocking layer pattern generally defining the sub-pixel areas, and a plurality of color filter patterns. Upper surfaces of the light blocking layer pattern and the plurality of color filter patterns collectively form a generally flat surface.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS TECH CO LTD

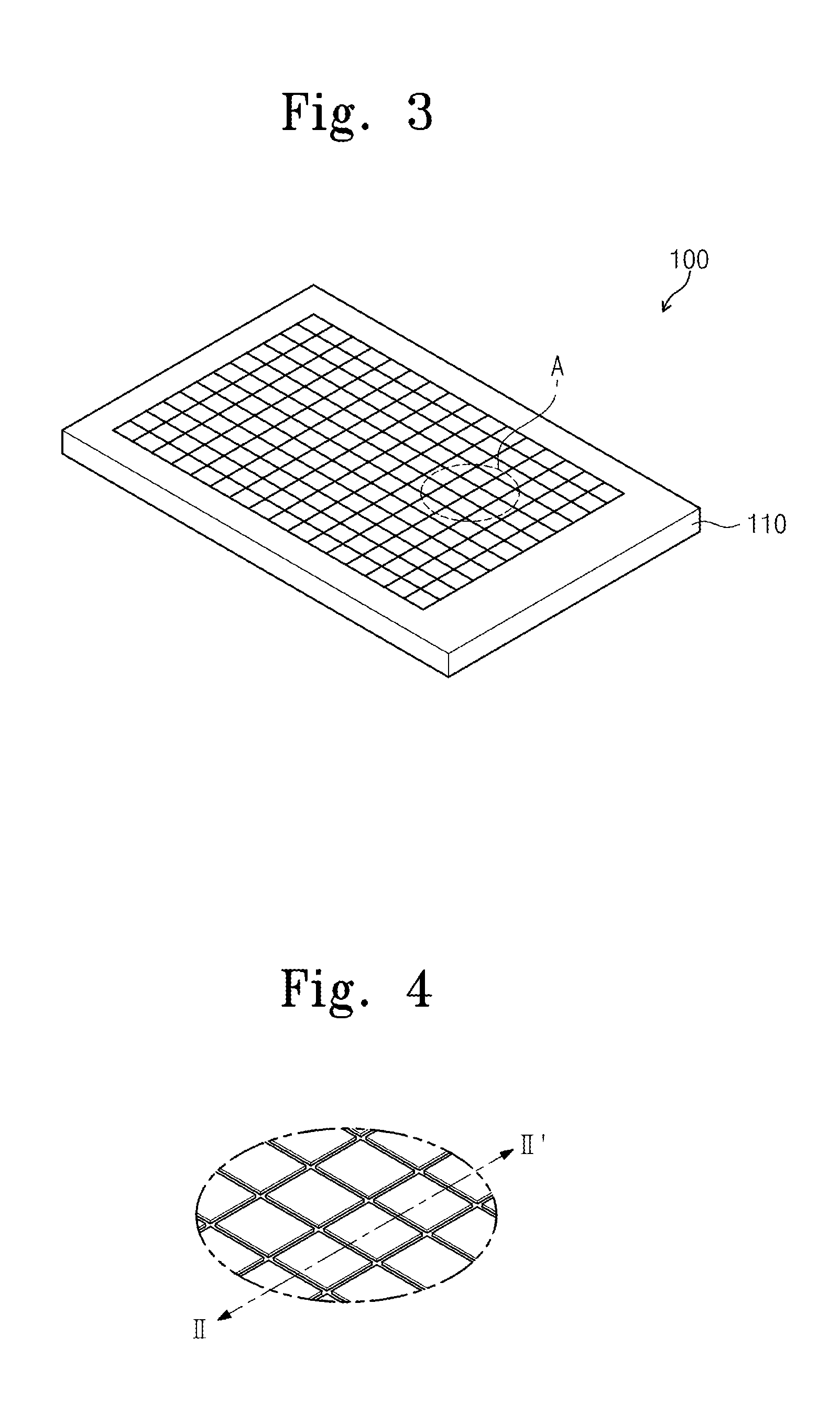

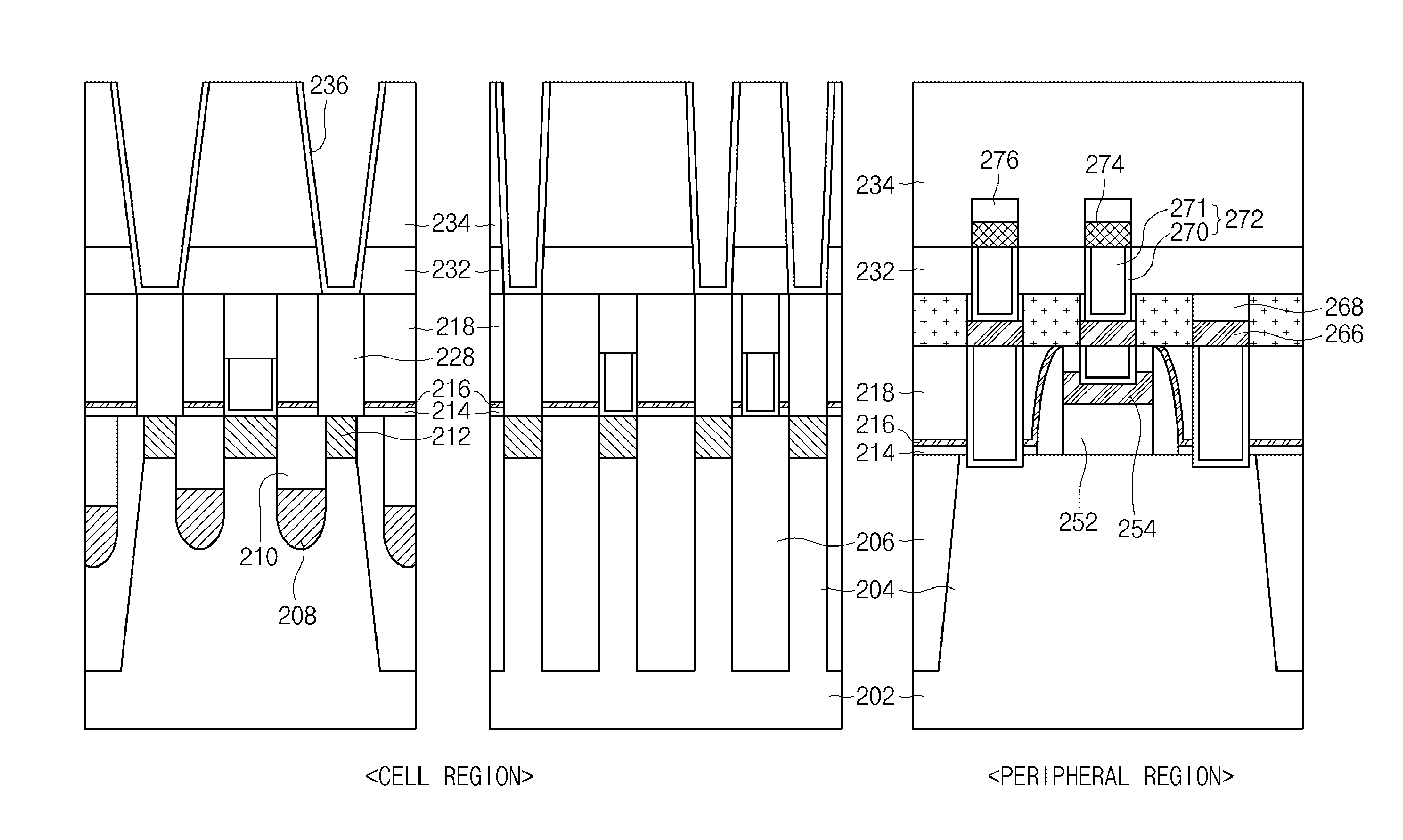

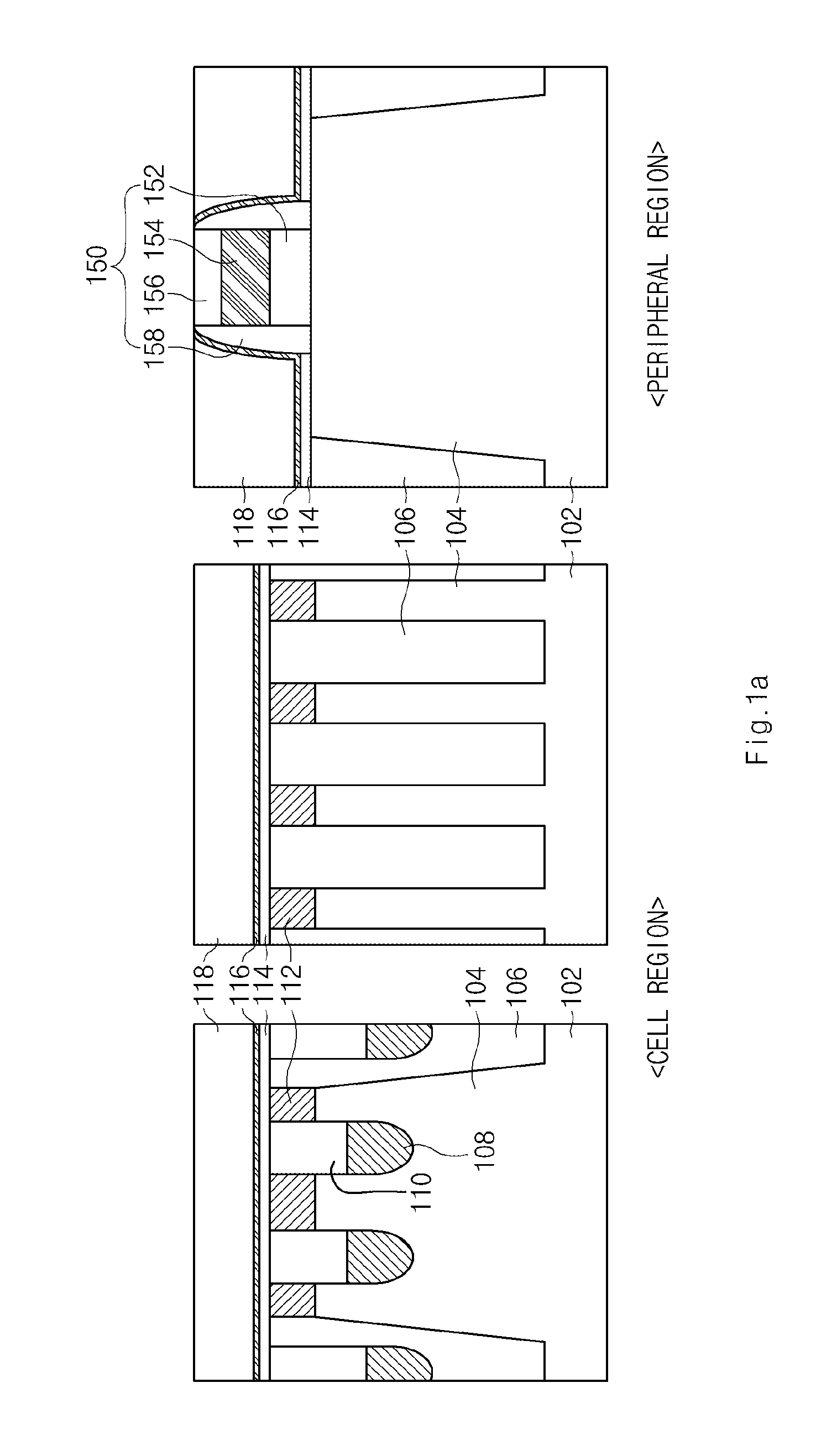

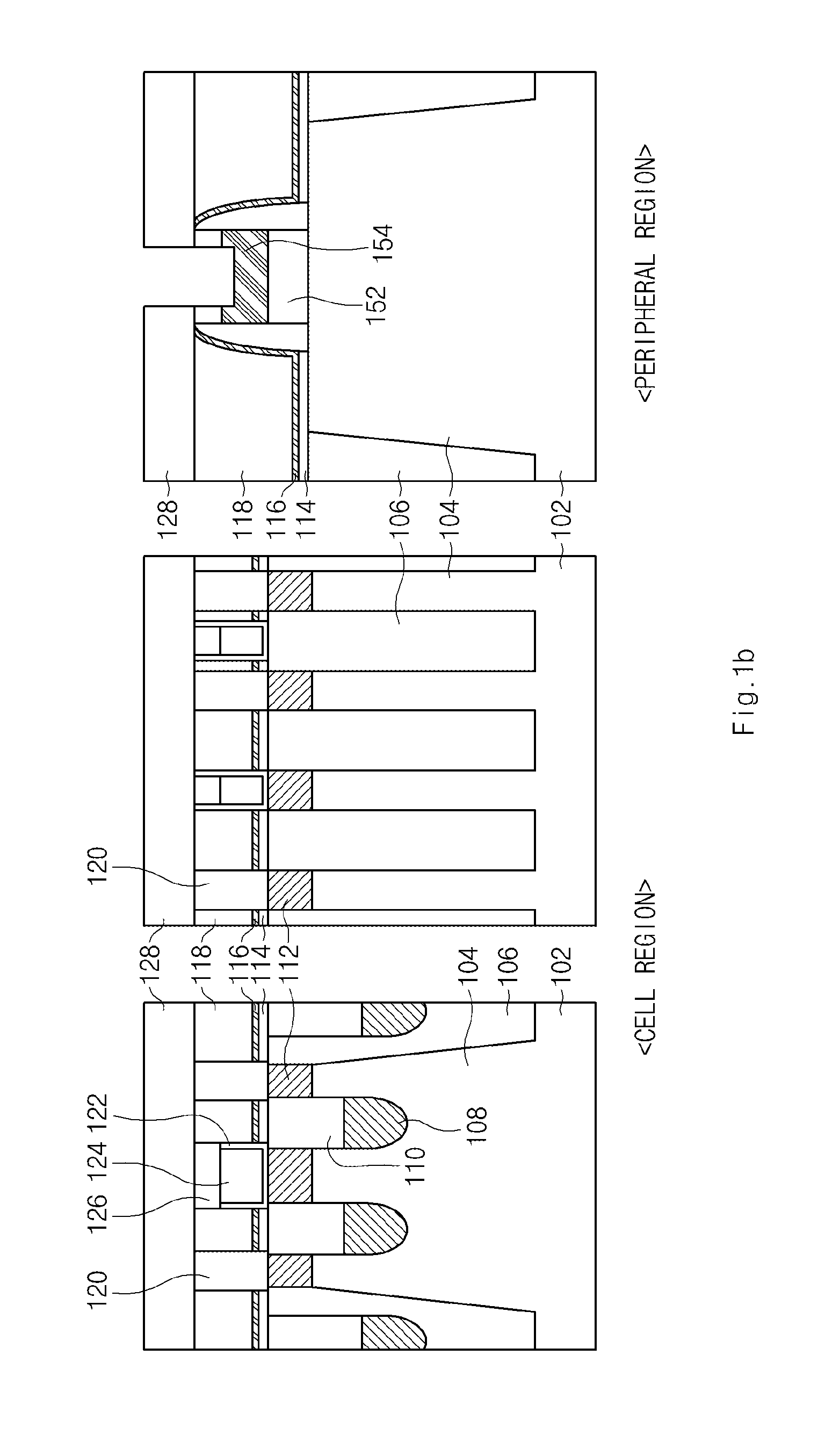

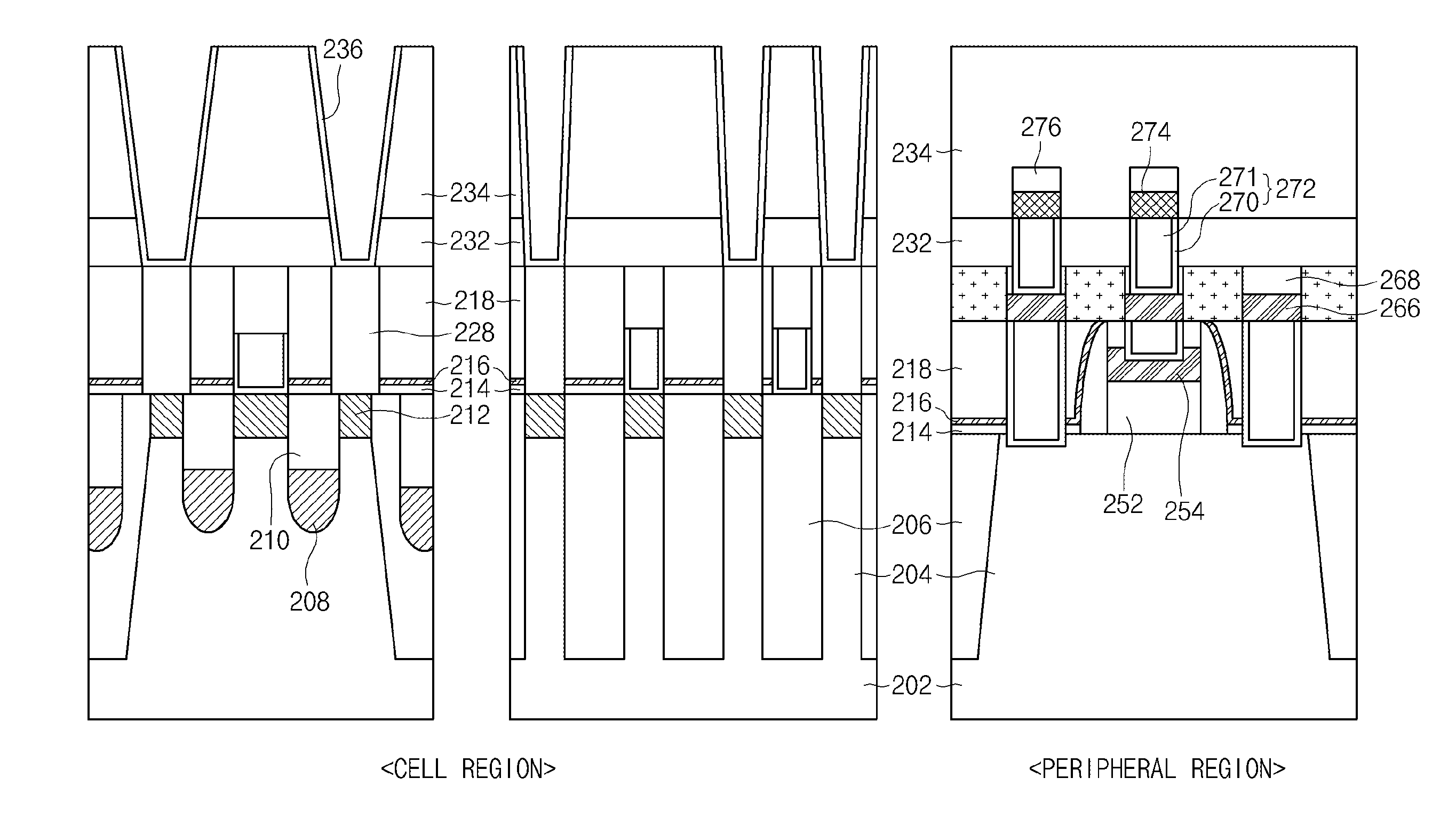

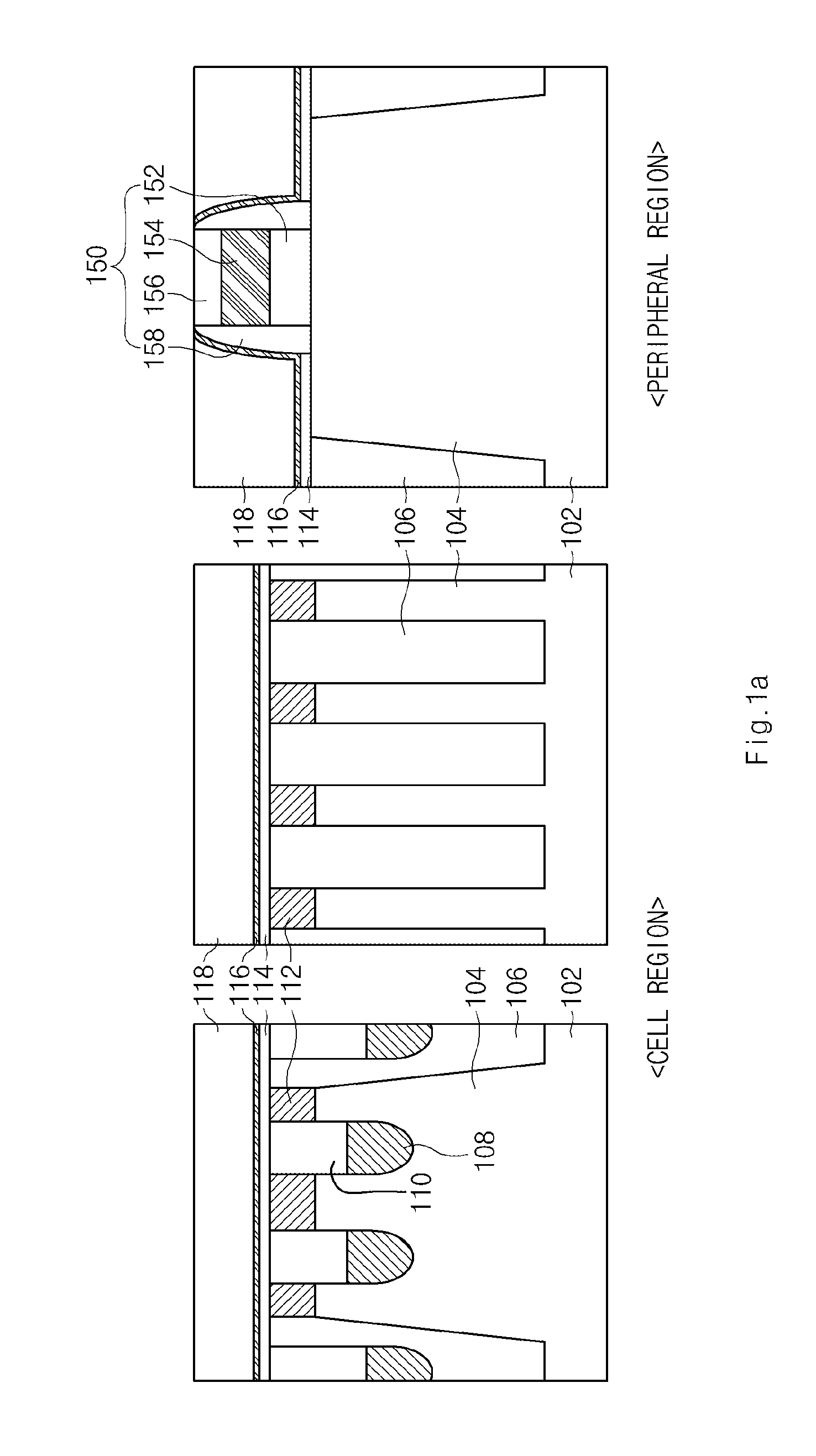

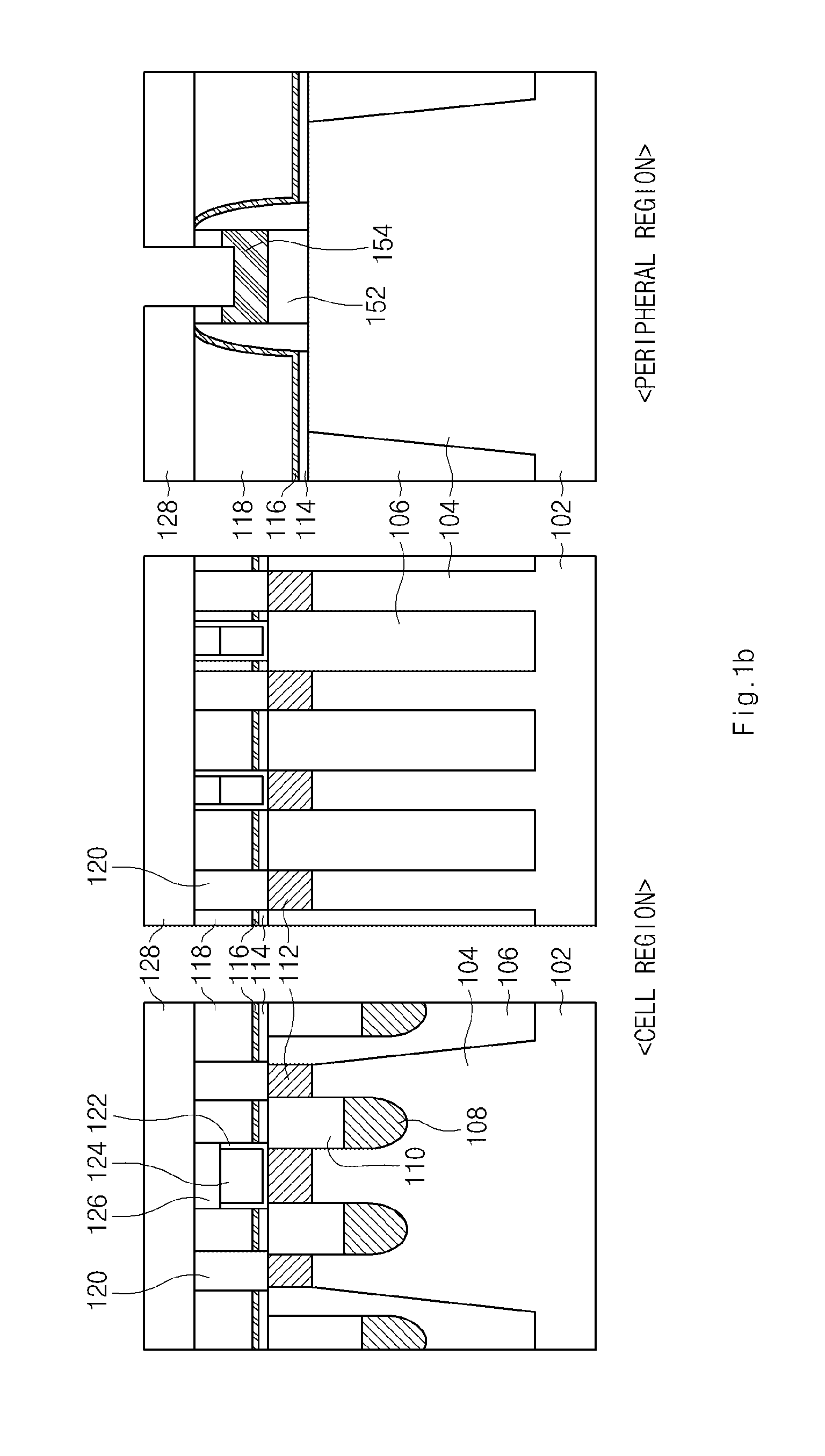

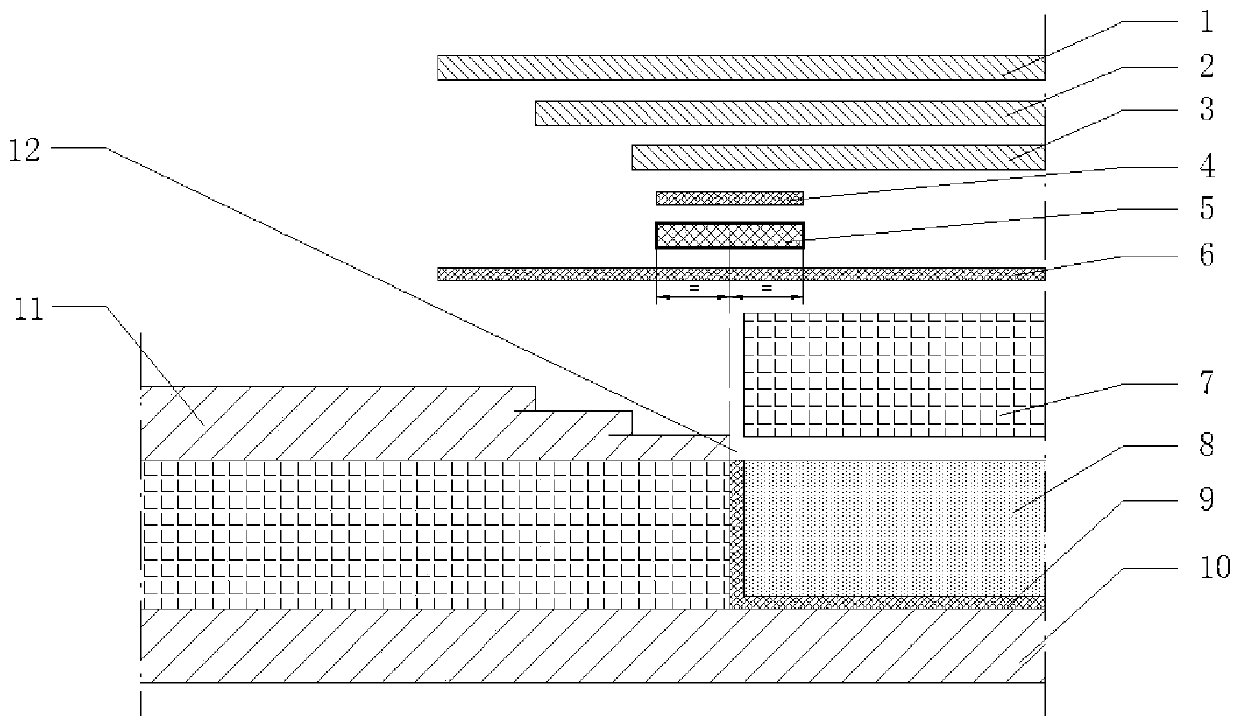

Method for manufacturing semiconductor device

ActiveUS20120135592A1Parasitic capacitanceReduce step differenceSolid-state devicesSemiconductor/solid-state device manufacturingBit lineCell region

A method for manufacturing a semiconductor device is disclosed, which reduces a step difference between a peripheral region and a cell region. In the semiconductor device, a metal contact of the peripheral region is configured in a multi-layered structure. Prior to forming a bit line and a storage node contact in the cell region, a contact and a line are formed in the peripheral region, such that a step difference between the cell region and the peripheral region is reduced, resulting in a reduction in parasitic capacitance between lines.

Owner:SK HYNIX INC

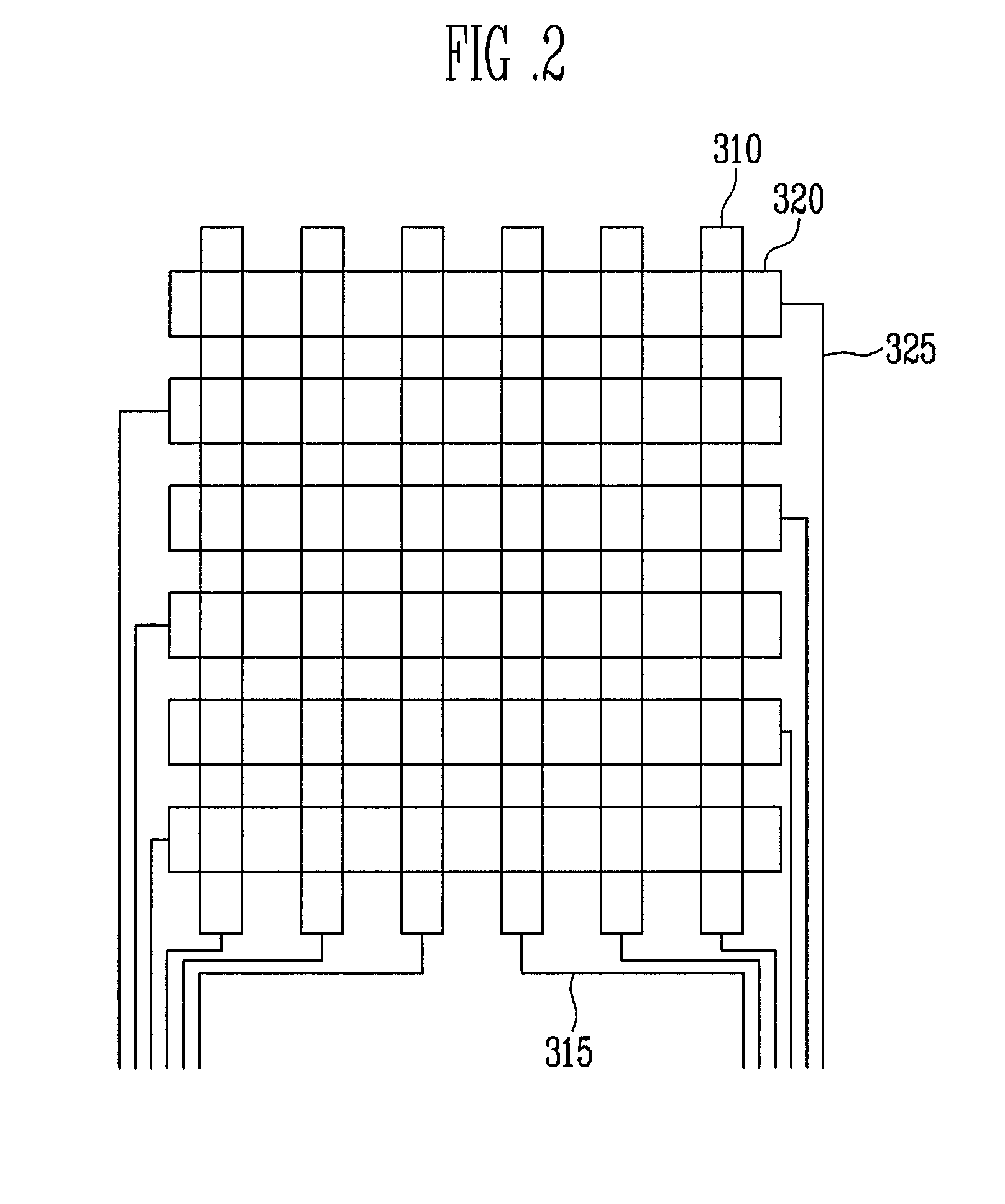

Display apparatus and method of manufacturing the same

ActiveUS7636145B2Enhanced couplingImprove production yieldPrinted circuit aspectsPrinted circuit manufactureElectricitySignal generator

In a display apparatus and a manufacturing method of the display apparatus, the display apparatus includes a display panel having signal lines and an insulating layer, and a signal generator electrically connected to the signal lines and adhering to the display panel. The signal lines include pads formed at ends thereof, respectively. The organic insulating layer is partially removed such that the via holes are formed between the pads of the signal lines to reduce a step-difference between an area in which the pads are formed and an area in which the pads are not formed. Thus, the display apparatus may enhance the coupling force between the signal generator and the display panel.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

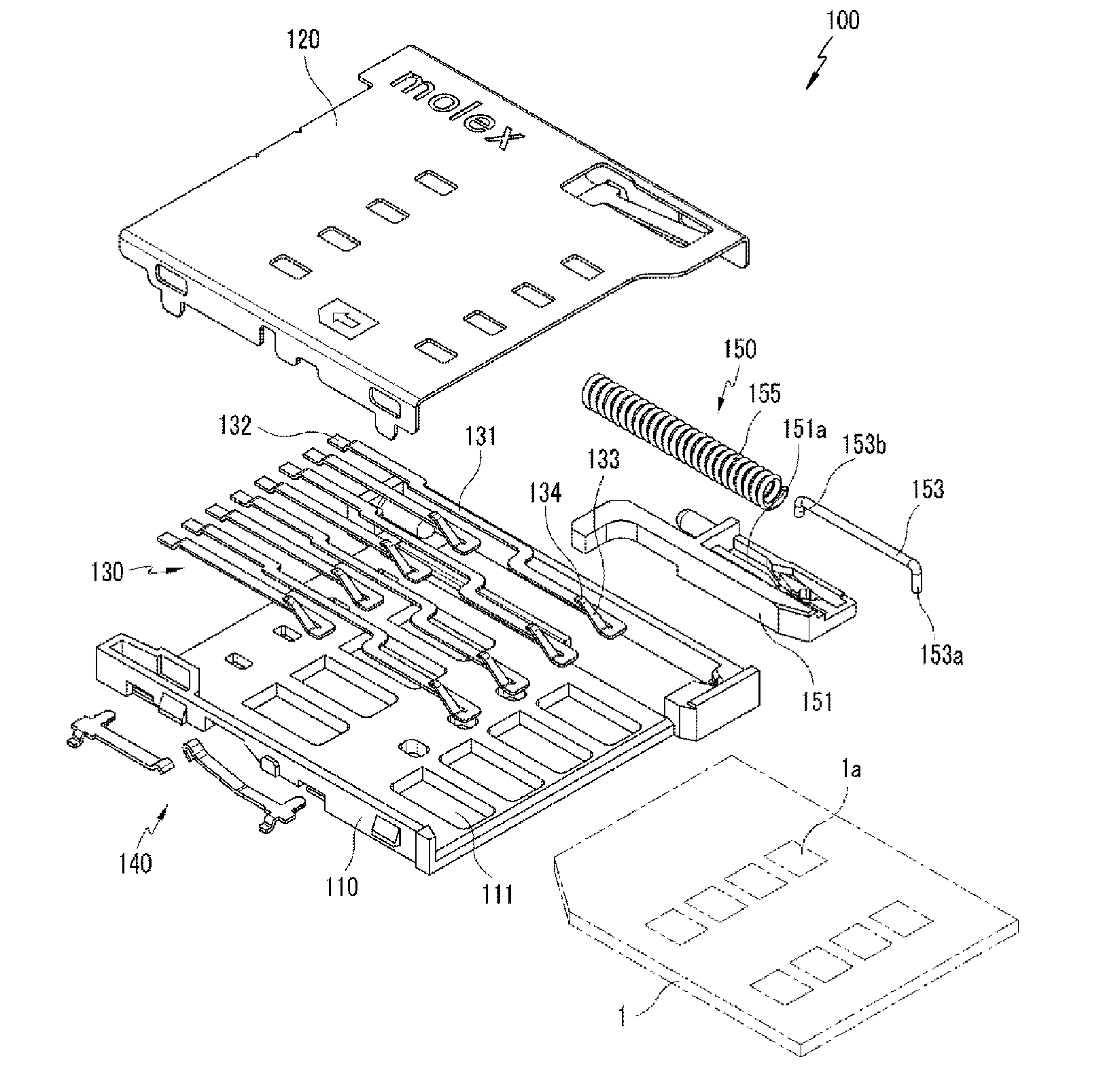

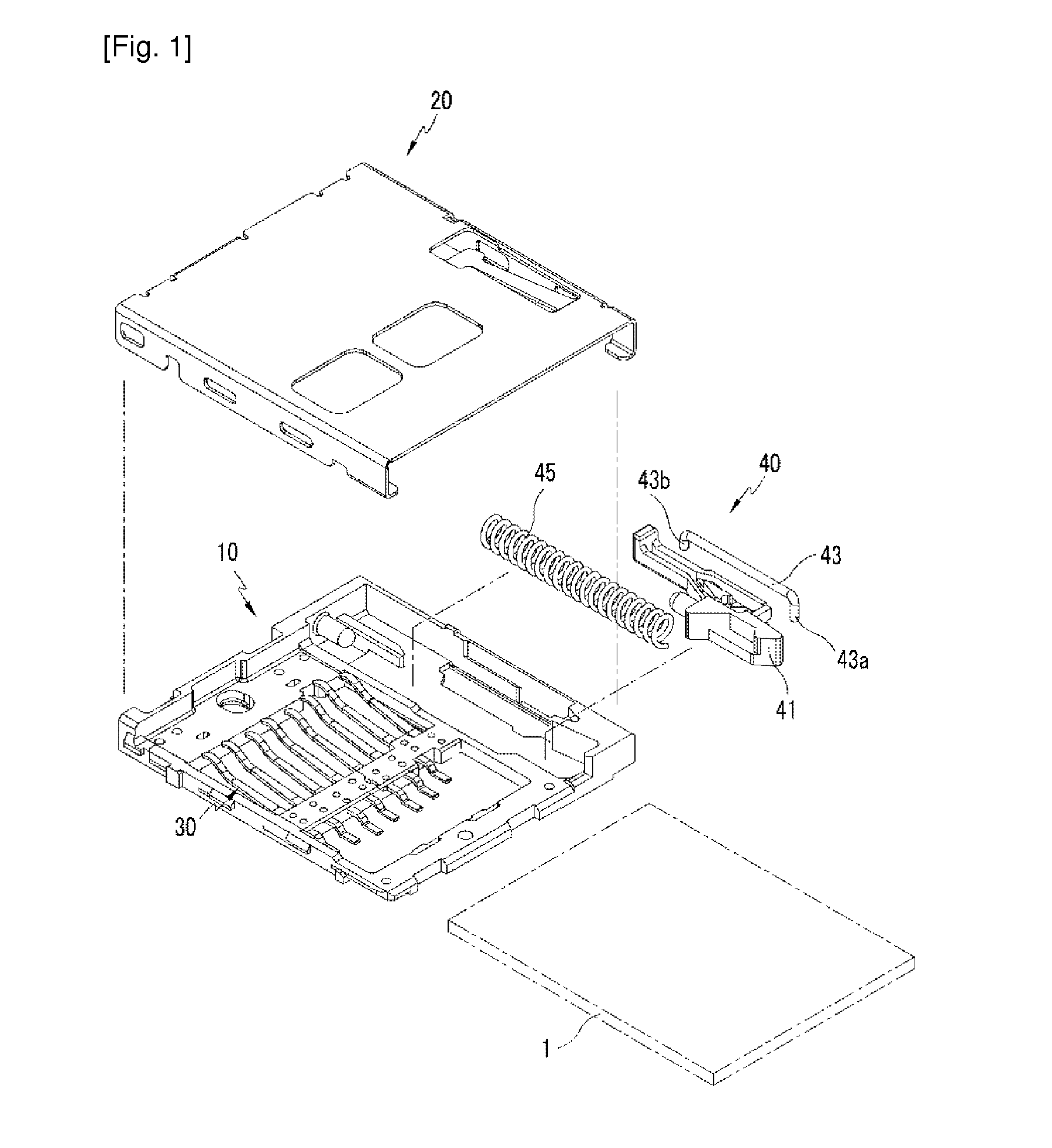

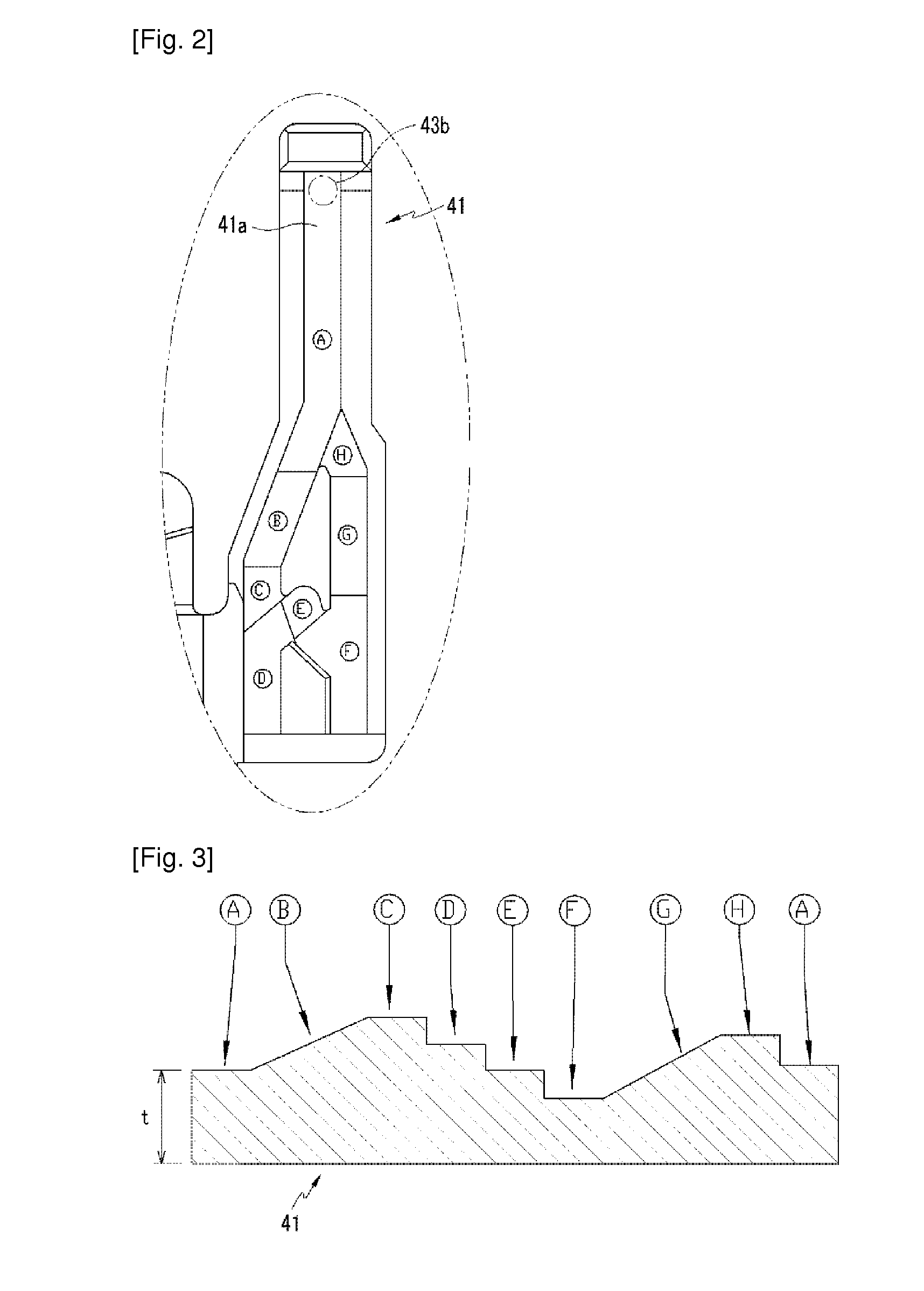

Memory card socket and hard cam for same

InactiveUS20130231001A1Reduce thicknessEliminate step differenceConveying record carriersCoupling device detailsSoftware engineeringMechanical engineering

The memory card socket of the Present Disclosure can achieve a microminiaturized and ultraslim configuration of a memory card / micro SIM card socket, in regard to the formation of the movement zones having step differences in the guide groove in order to ensure movement of the end of the pin rod along the guide groove, wherein a heart-shaped guide groove is formed within the heart cam and the end of the pin rod is inserted into the guide groove, by reducing the total thickness of the heart cam, through a reduction in the number of step differences of the zones from at least three to one, and replacement of the eliminated step differences with sloped protrusions.

Owner:MOLEX INC

Production method for array substrate of active-matrix organic light-emitting display (OLED)

ActiveCN102623399AReduce step differenceImprove display qualitySemiconductor/solid-state device manufacturingEtchingActive matrix

The invention discloses a production method for an array substrate of an active-matrix organic light-emitting display (OLED). The production method comprises the following steps of: providing a substrate; forming a first semiconductor graph and a second semiconductor graph on the substrate; continuing to form a grid insulating layer and a first metal layer, and forming a grid by photo-etching; depositing an interlayer insulating layer, and forming four contact holes by means of etching; continuing to form a second metal layer, a source, a drain and a storage capacitor electrode; then continuing to form a passivation insulating layer and a transparent electrode layer; and finally forming a protecting film layer and an evaporation material layer on the whole surface, and exposing by a multi-grey-scale mask plate to form a stepped protecting film layer. In the production method for the array substrate of the OLED provided by the invention, the multi-grey-scale mask plate is used for exposing to form the stepped protecting film layer, thus effectively reducing the step difference of the protecting film layer and decreasing the occurrence probability of the poor display of the point defects of an AMOLED (active-matrix / organic light-emitting diode), and then improving the display quality of the AMOLED.

Owner:KUNSHAN NEW FLAT PANEL DISPLAY TECH CENT

Method for manufacturing semiconductor device having multi-layered contact

ActiveUS8298893B2Parasitic capacitanceReduce step differenceSolid-state devicesSemiconductor/solid-state device manufacturingBit lineCell region

A method for manufacturing a semiconductor device is disclosed, which reduces a step difference between a peripheral region and a cell region. In the semiconductor device, a metal contact of the peripheral region is configured in a multi-layered structure. Prior to forming a bit line and a storage node contact in the cell region, a contact and a line are formed in the peripheral region, such that a step difference between the cell region and the peripheral region is reduced, resulting in a reduction in parasitic capacitance between lines.

Owner:SK HYNIX INC

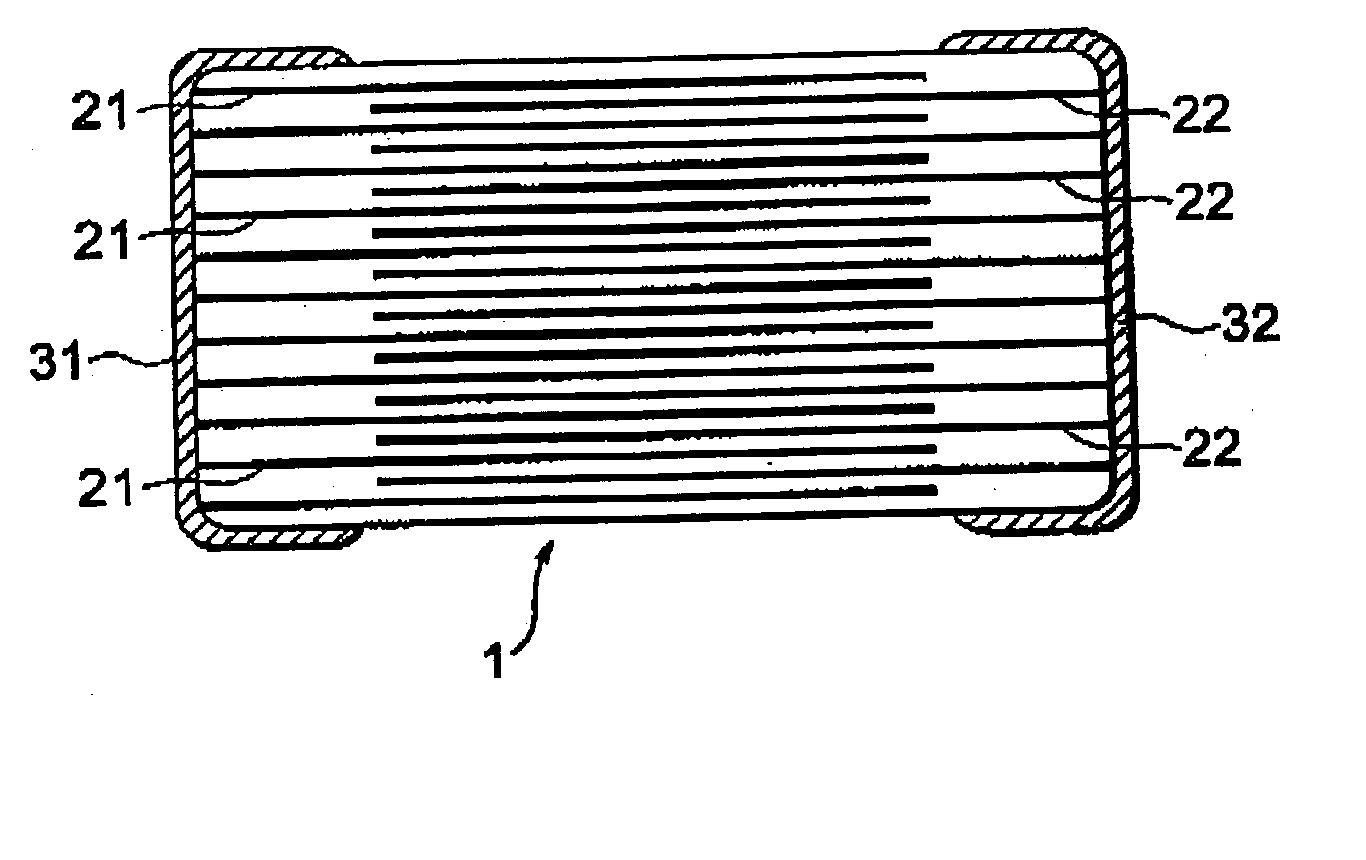

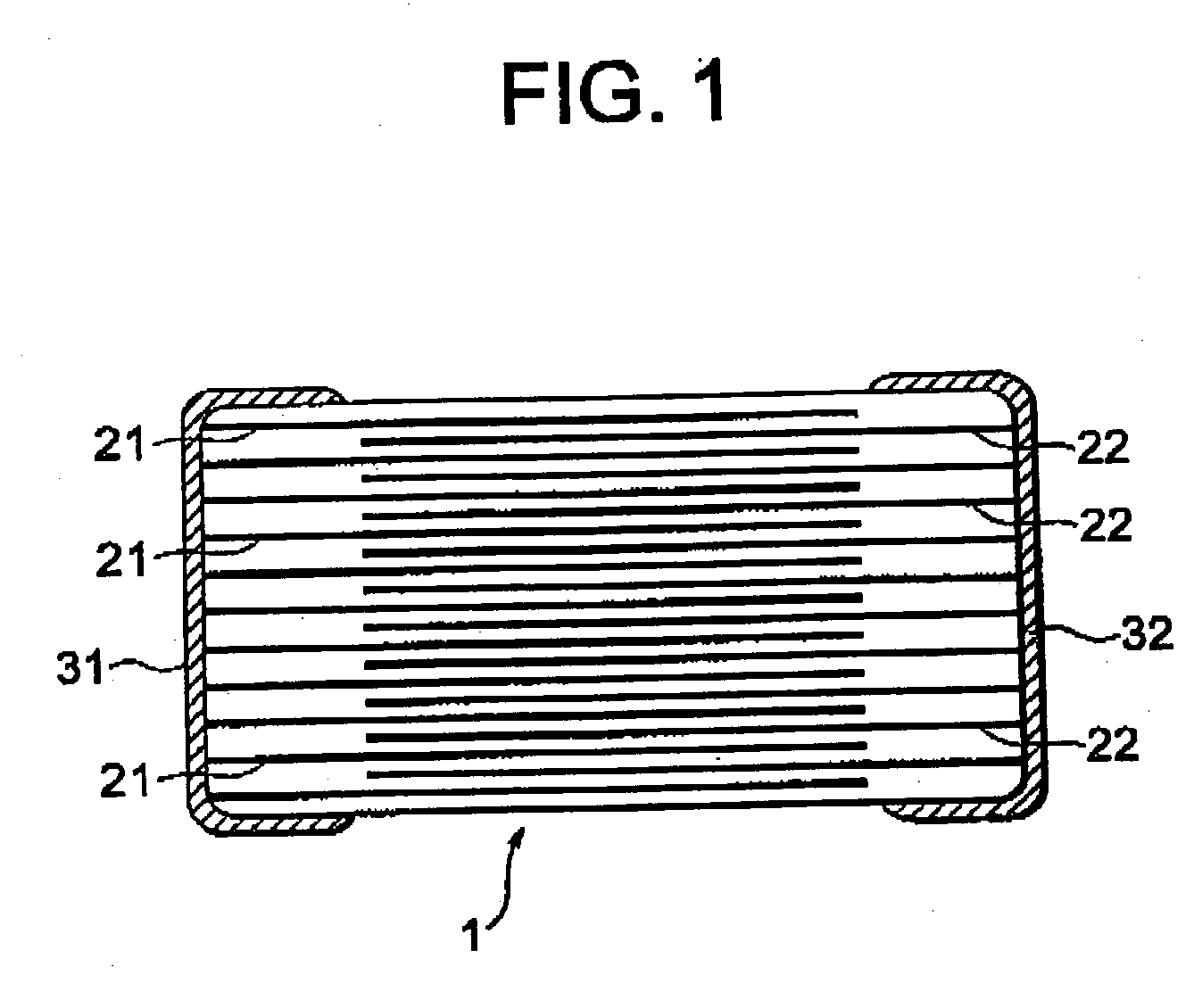

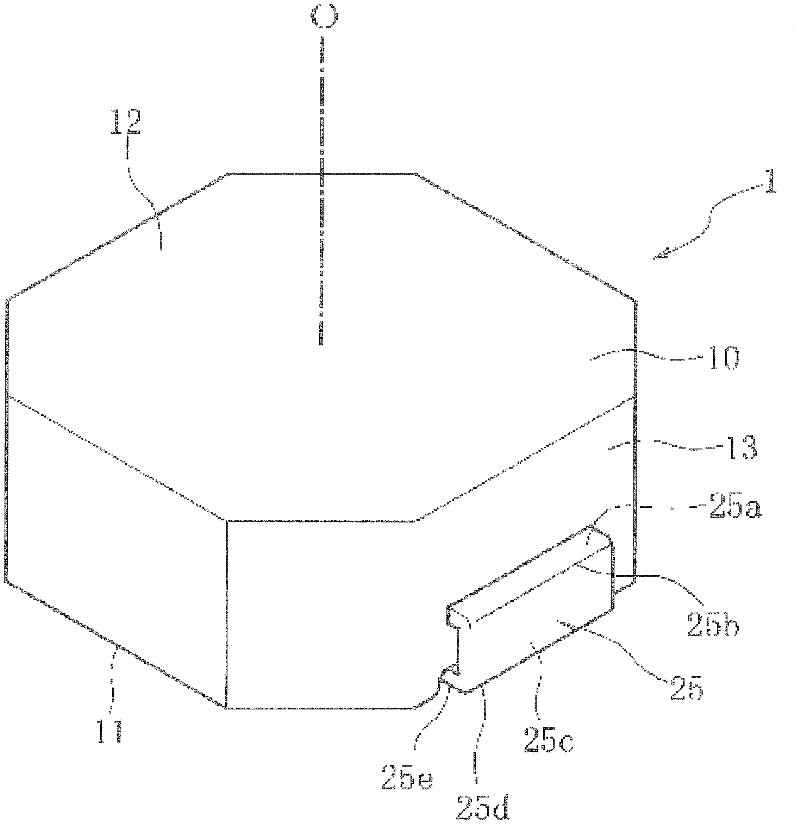

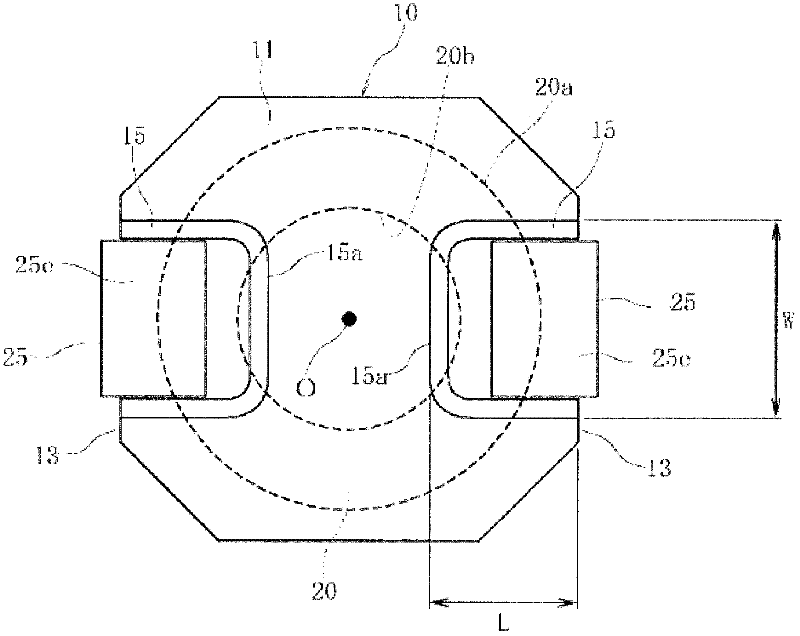

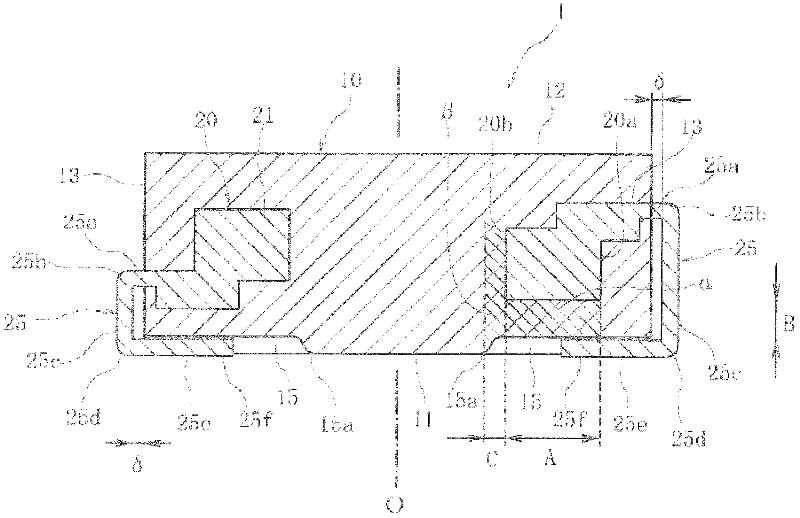

Inductance element

ActiveCN102568779AReduce step differenceImprove soldering strengthTransformers/inductances coils/windings/connectionsInductance with magnetic coreInductorInductance

The invention provides an inductance element, wherein a bottom part of a magnetic core is configured with a concave part of a terminal plate. In the inductance element, the decrease of the inductance of the concave part can be suppressed. A coil body (20) is embedded in the magnetic core (10), namely a collection body of the magnetic powder. A bottom surface of the magnetic core (10) is provided with a concave part (15,15) of the terminal plate (25,25) extending from the coil body (20), and the step difference between the surface of the terminal plate (25,25) and the bottom surface of the magnetic core (10). The density of the magnetic powder of the magnetic core (10) in an area between the concave part (15) and the coil body (20), thereby the magnetic flow of the area can be improved. Therefore the inductance decrease aused by the concave part (15) can be suppressed.

Owner:ALPS ALPINE CO LTD

Touch panel

InactiveUS20150085204A1Reduce step differenceReduce thicknessNon-linear opticsInput/output processes for data processingEngineeringTouch panel

Disclosed is a touch panel including a cover substrate including an active area and an inactive area, and a printing layer only on the inactive area. The printing layer includes a first printing layer, and a second printing layer to surround the first printing layer. The second printing layer includes a top surface making contact with the top surface of the first printing layer and a lateral side making contact with a lateral side of the first printing layer. The lateral side of the second printing layer has an average inclination angle in a range of about 1.5° to about 2.7° with respect to one surface of the cover substrate.

Owner:LG INNOTEK CO LTD

Organic light emitting display device and method for manufacturing the same

ActiveUS9620570B2Light extraction efficiency can be improvedImproving light extraction efficiency without deteriorating image or image qualitySolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceRefractive index

Provided are an organic light emitting display device and a method for manufacturing the same. A color filter is disposed on a substrate. An overcoating layer is disposed on the color filter and includes a plurality of protrusions or a plurality of recesses. The plurality of protrusions and the plurality of recesses are disposed on the color filter to be overlapped with the color filter. A buffer layer for reducing step difference is disposed on the overcoating layer. The buffer layer has a higher refractive index than the overcoating layer and reduces a step difference caused by the plurality of protrusions and the plurality of recesses. An organic light emitting element including an anode, an organic light emitting layer, and a cathode is disposed on the buffer layer. Since the buffer layer has a higher refractive index than the overcoating layer, light extraction efficiency can be increased.

Owner:LG DISPLAY CO LTD

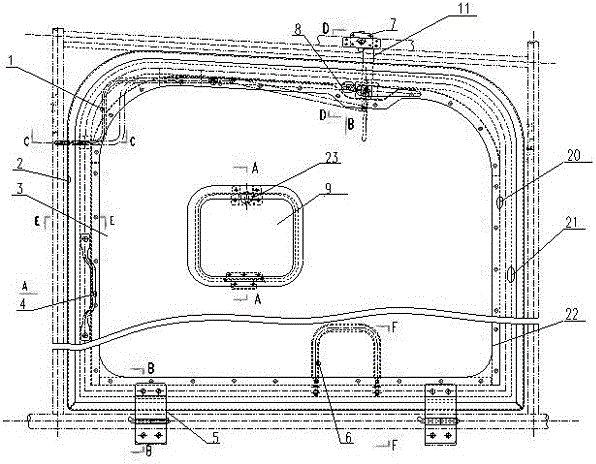

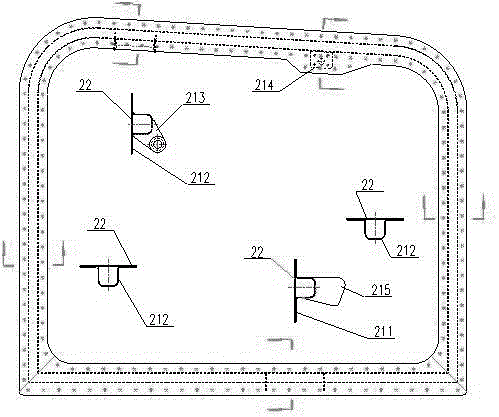

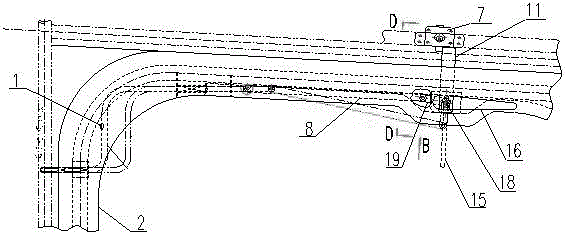

Glass compartment door structure of agriculture and forestry plane

The invention provides a glass compartment door structure of an agriculture and forestry plane. The glass compartment door structure comprises a door frame and compartment door glass arranged in the door frame, and is characterized in that the door frame is a welded piece formed by welding an aluminum panel and a cap type profile frame; a compartment door frame is formed by welding a cap profile straight section and a cap profile U-shaped section; the compartment door glass and the door frame are screwed with each other through battens after being overlapped; rubber plates 0.5 mm in thickness are respectively adhered to two sides, which are in contact with the door frame, of the compartment door glass; screw connection holes are formed in the compartment door glass; rubber linings are mounted on screws during connection; the surrounding of the door frame is covered with tubular rubber sealing profiles; an antitheft lock is arranged at the upper side of the door frame; an antitheft lock seat is mounted on a steel structure of a plane body. The glass compartment door structure is high in buffering property, high in durability, convenient to turn over and favorable for boarding.

Owner:JIANGXI HONGDU AVIATION IND GRP

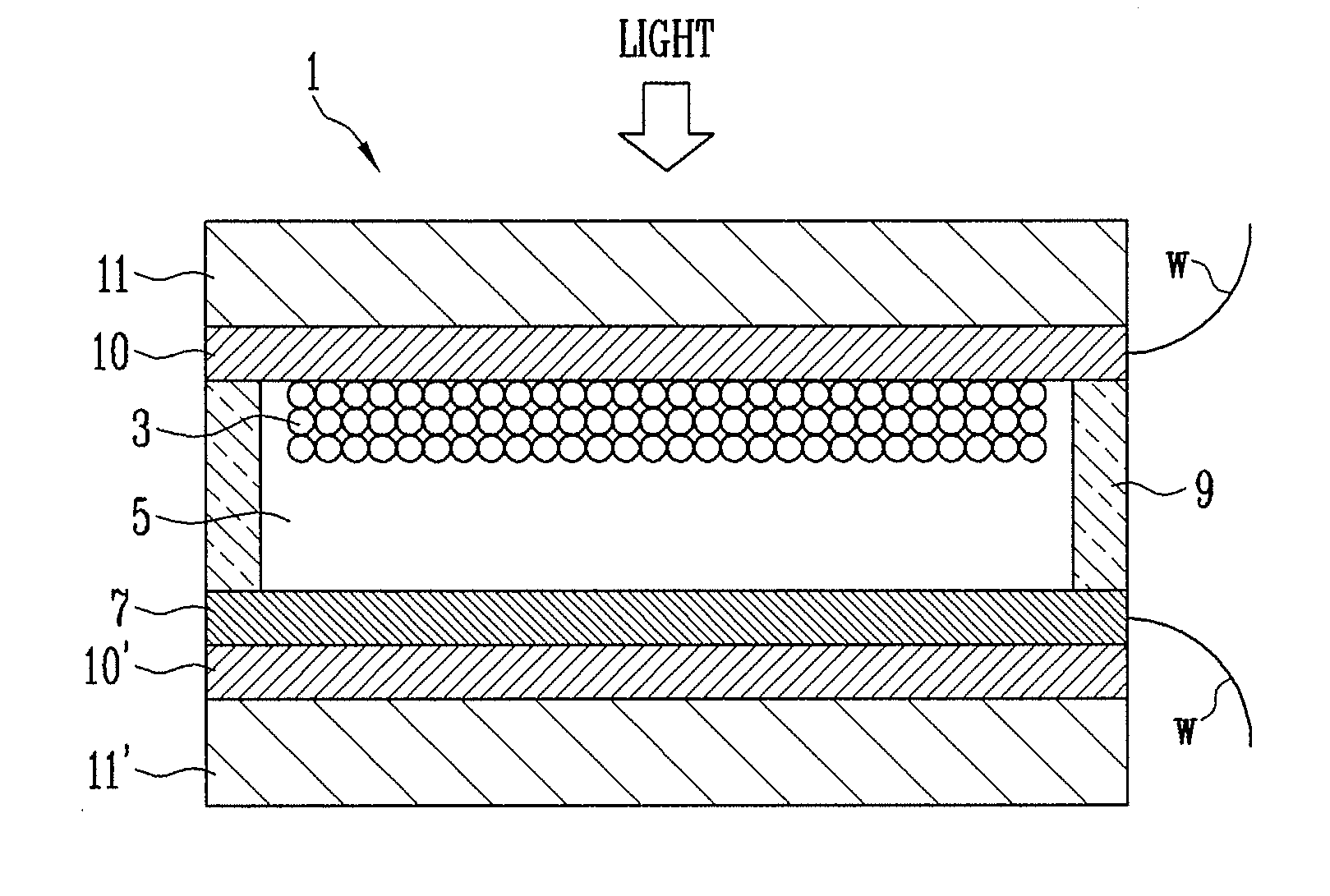

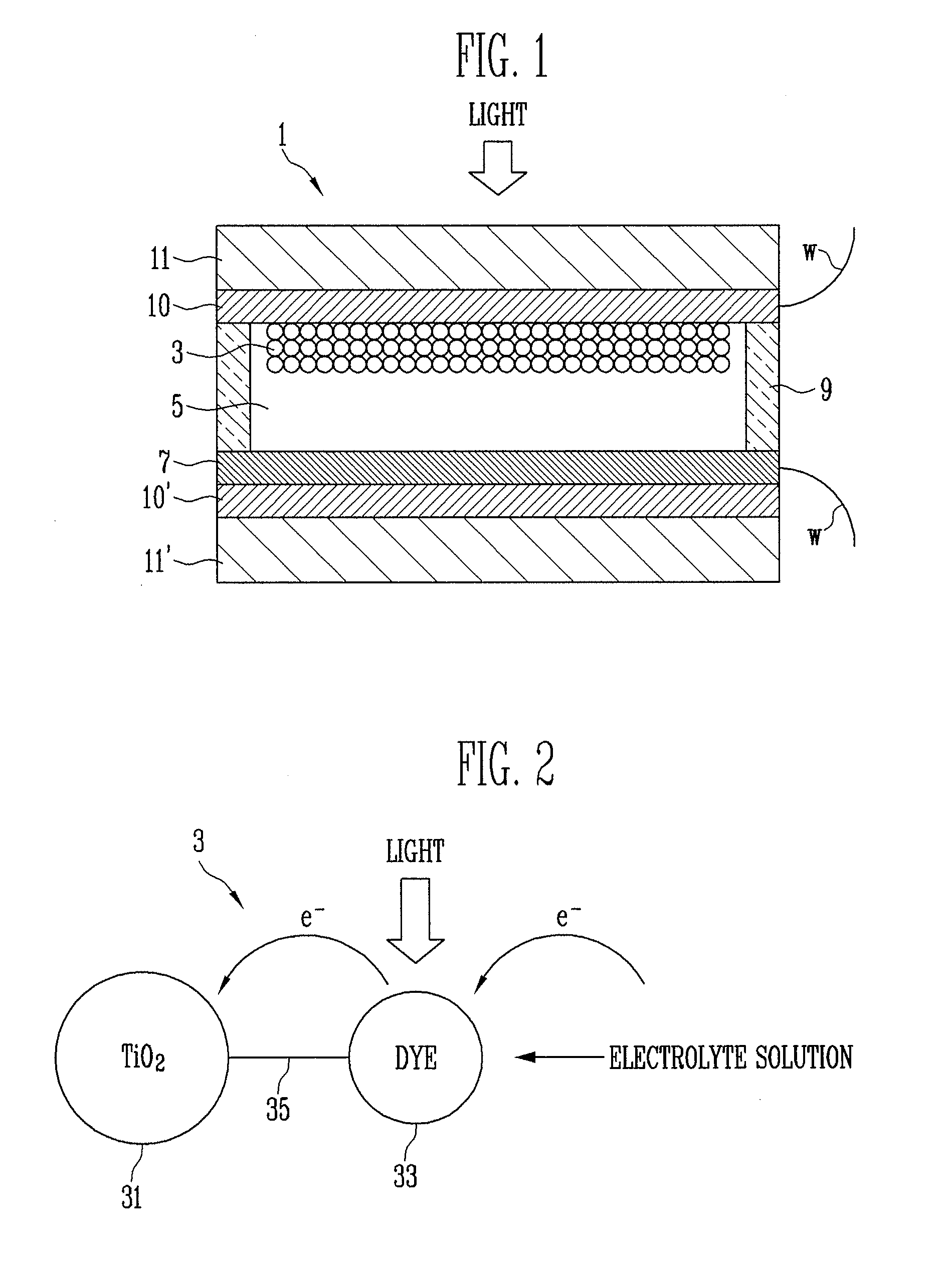

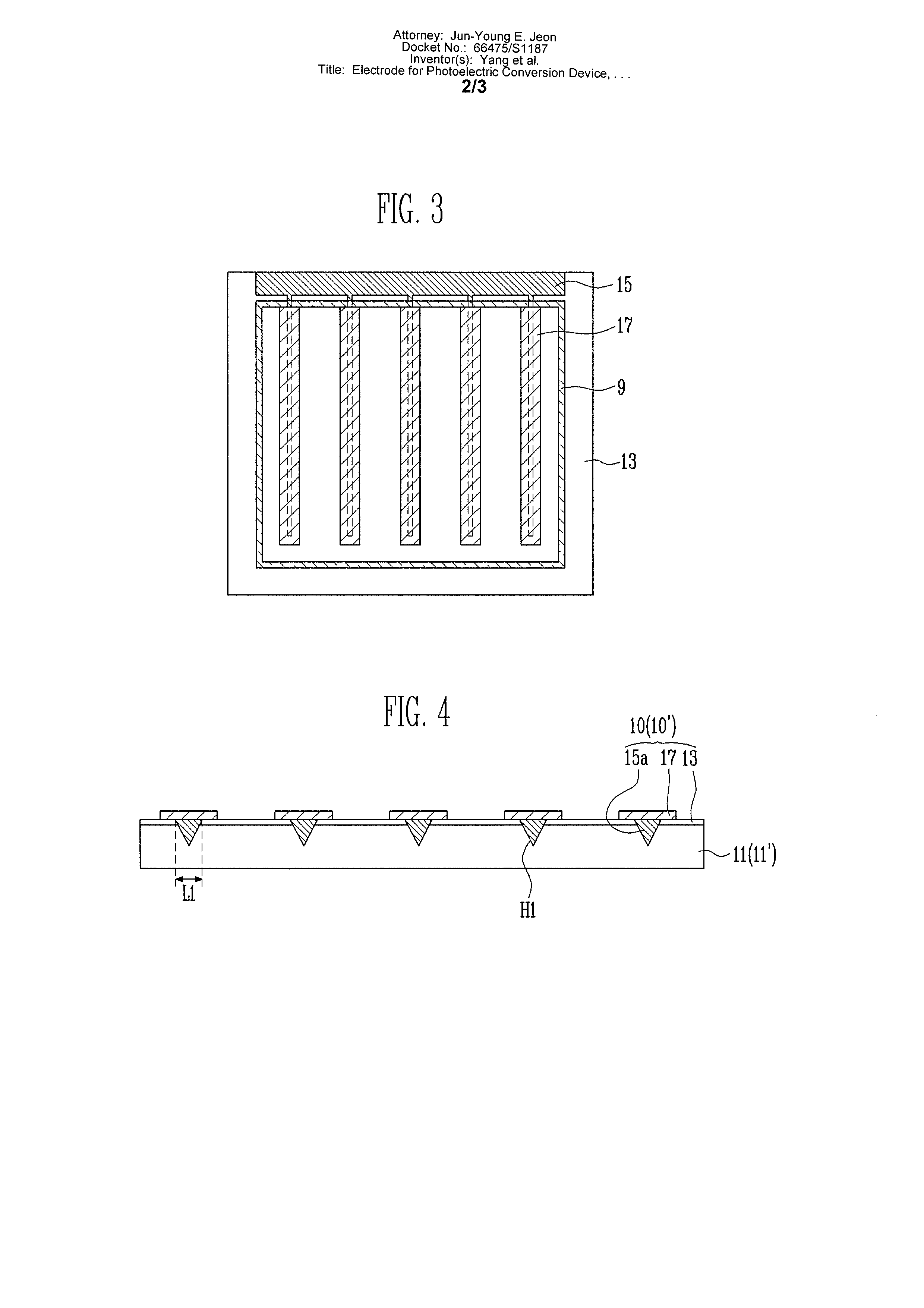

Electrode for photoelectric conversion device, method of preparing the same and photoelectric conversion device comprising the same

InactiveUS20120024367A1Improve product reliabilityImproving and enhancing shapeElectrolytic capacitorsSemiconductor/solid-state device manufacturingPhotoelectric conversionProtection layer

An electrode for a photoelectric conversion device, a method of preparing the same and a photoelectric conversion device comprising the same. In one embodiment, an electrode for a photoelectric conversion device includes a transparent conductive layer, a metal electrode layer and a protection layer. The transparent conductive layer is formed on a substrate to have spacing regions formed at a set interval. The metal electrode layer is formed in a corresponding one of the spacing regions. The protection layer is formed on the transparent conductive layer and the metal electrode layer to coat the metal electrode layer. Accordingly, the shape of a protruded electrode is improved, thereby enhancing the reliability of products through a simple process.

Owner:SAMSUNG SDI CO LTD

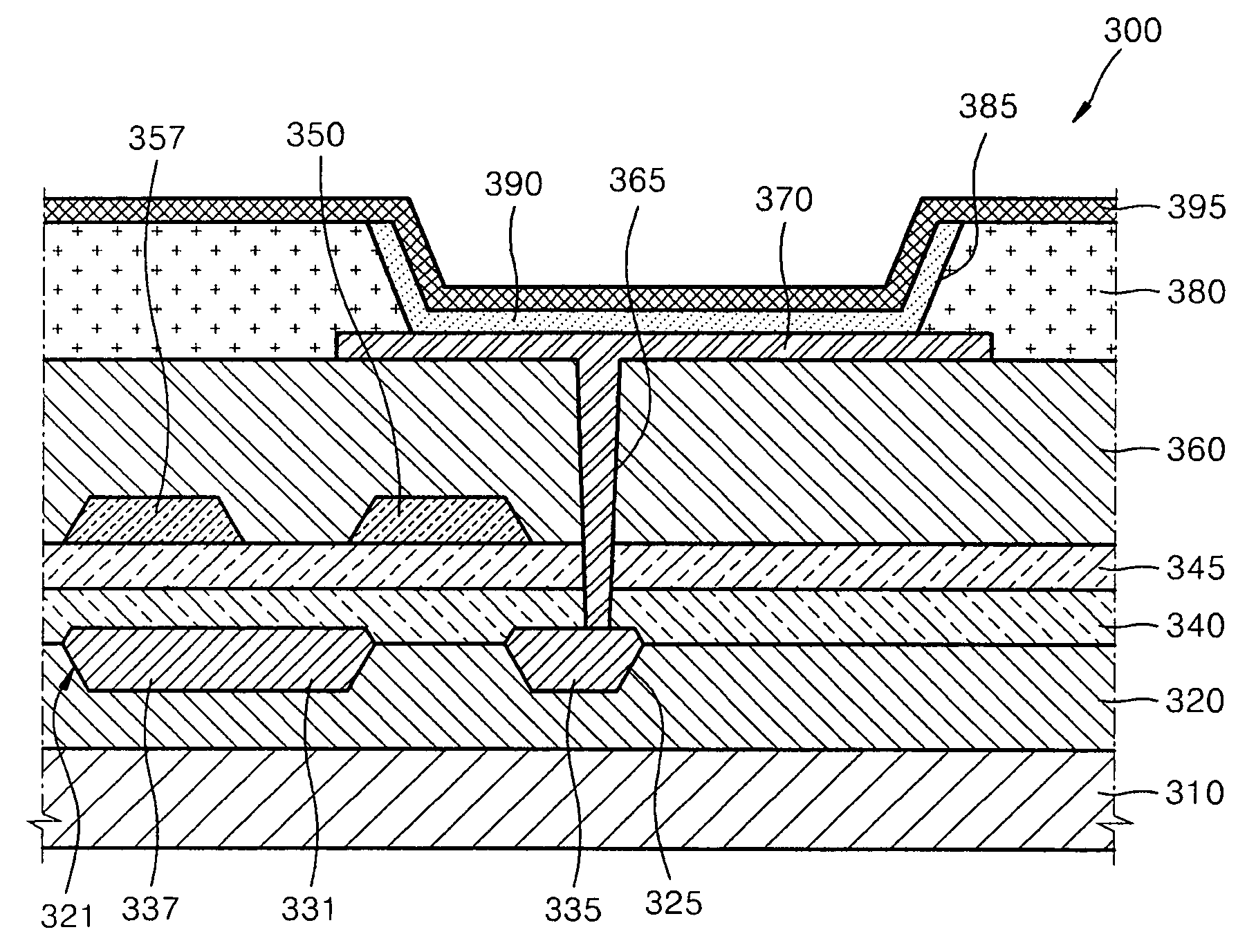

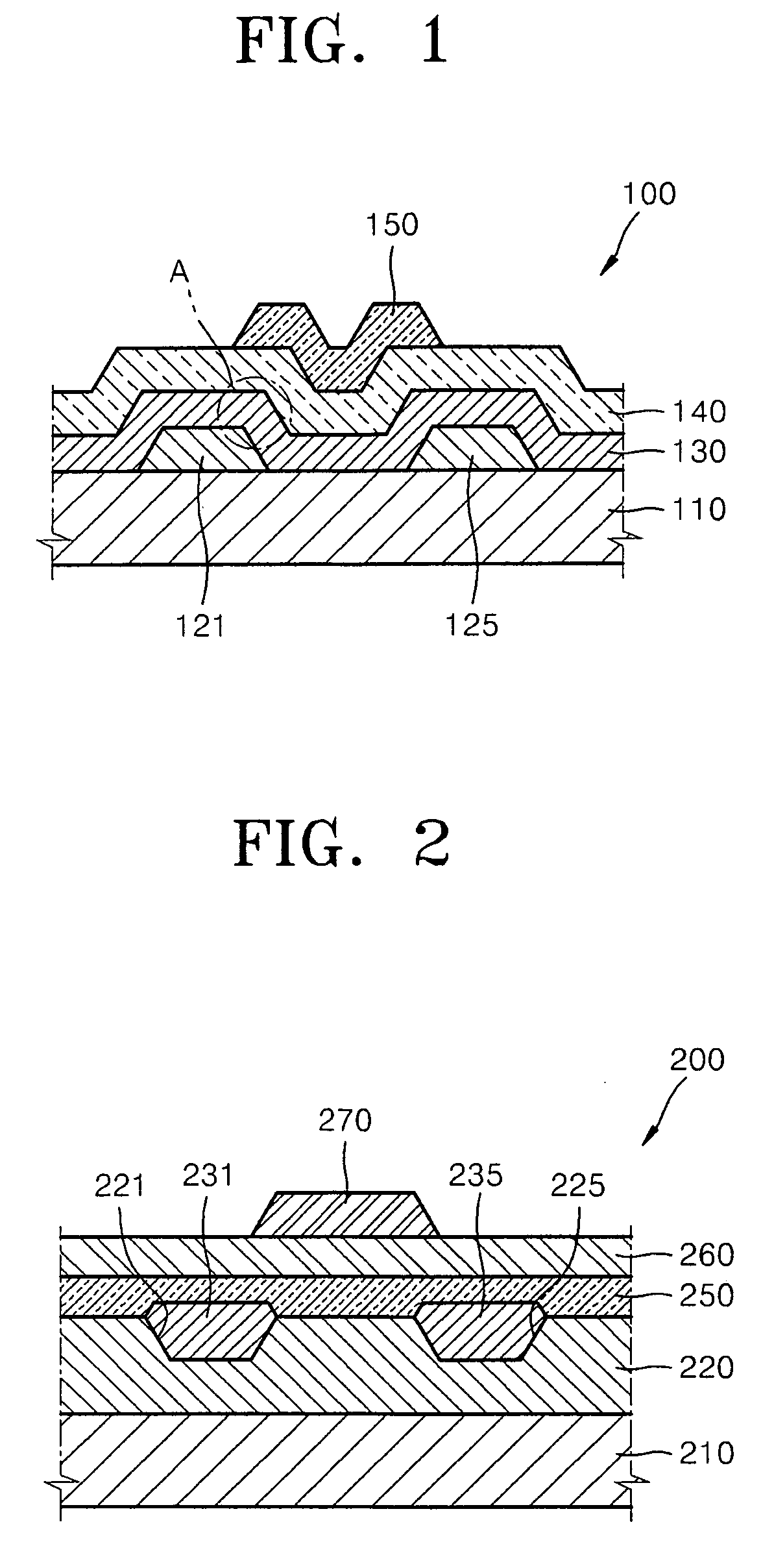

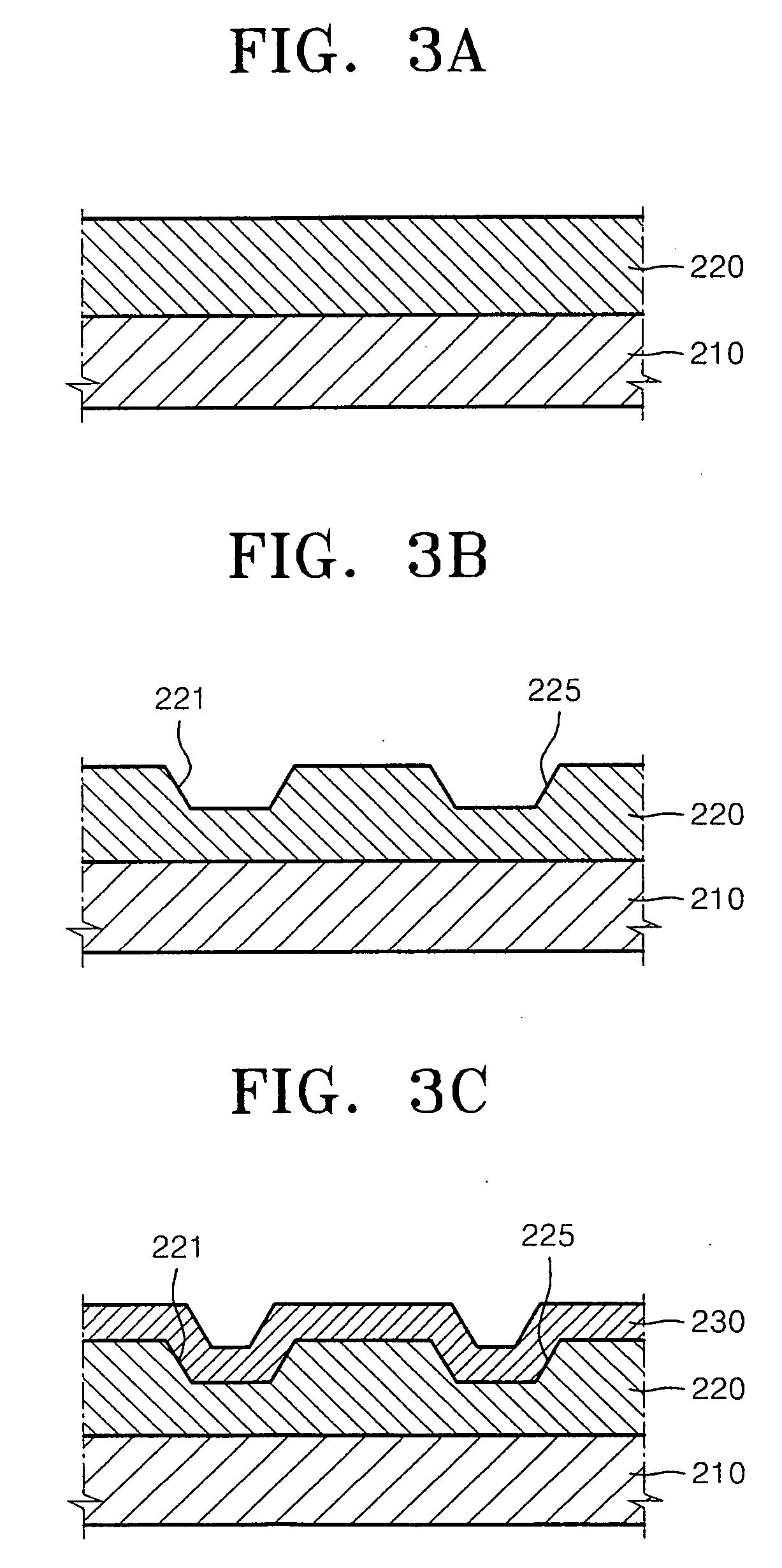

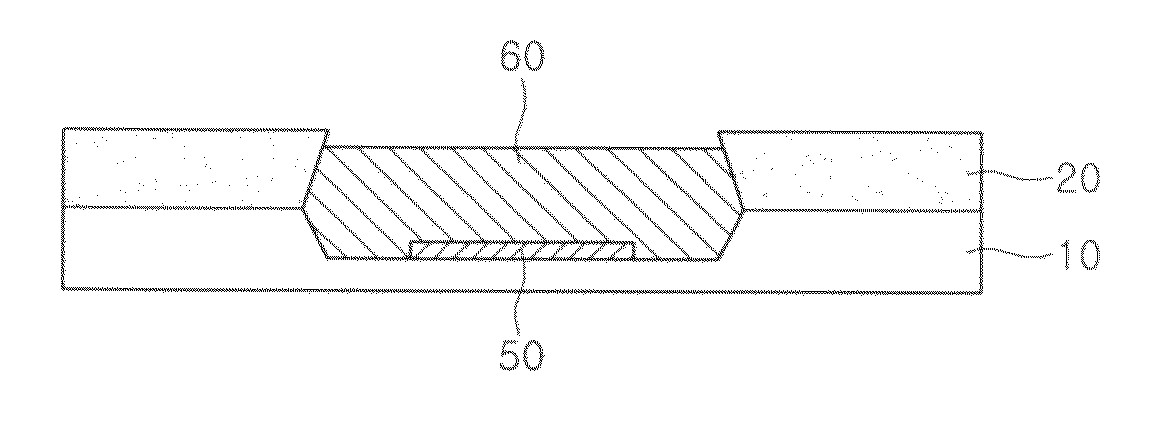

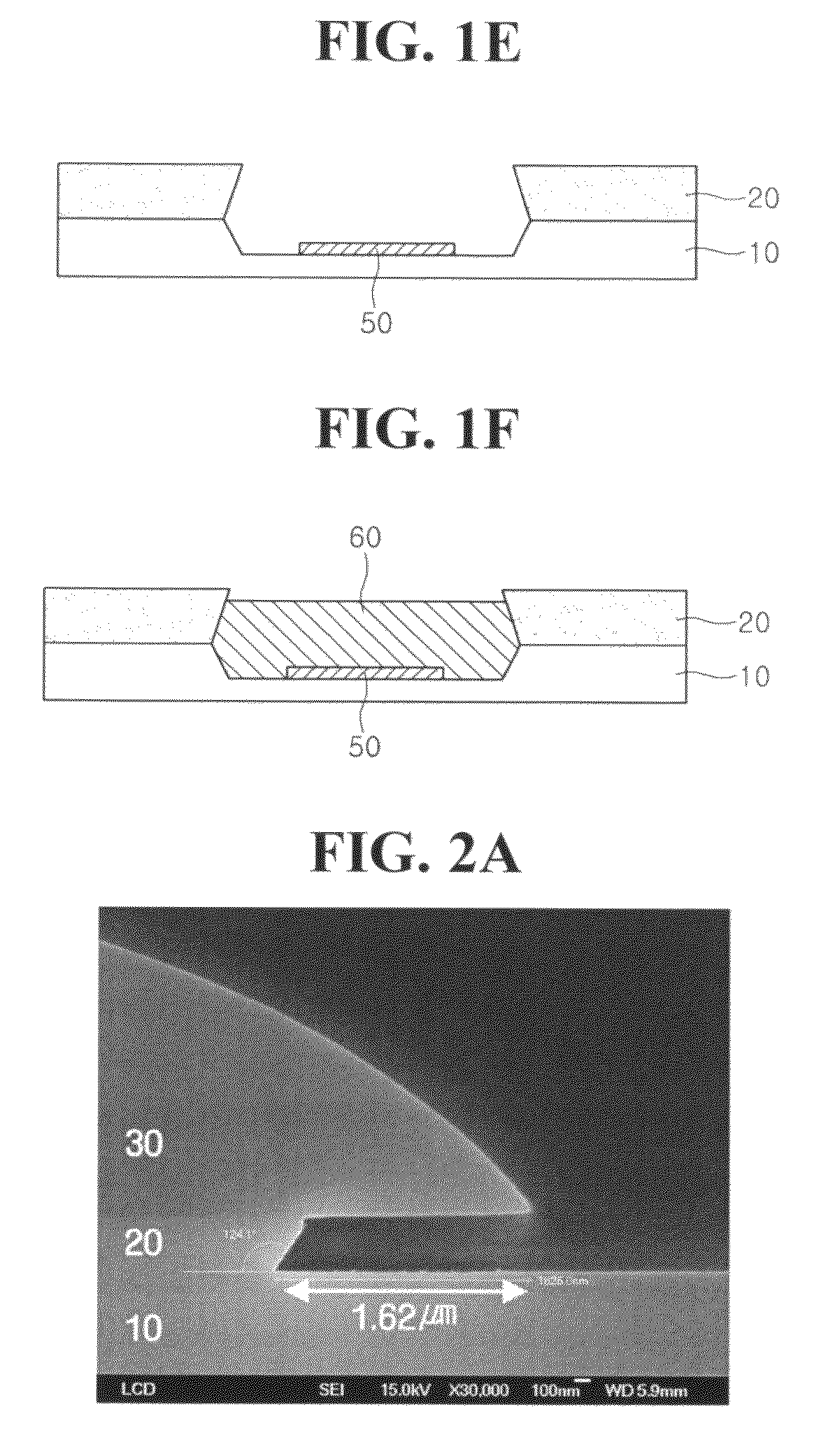

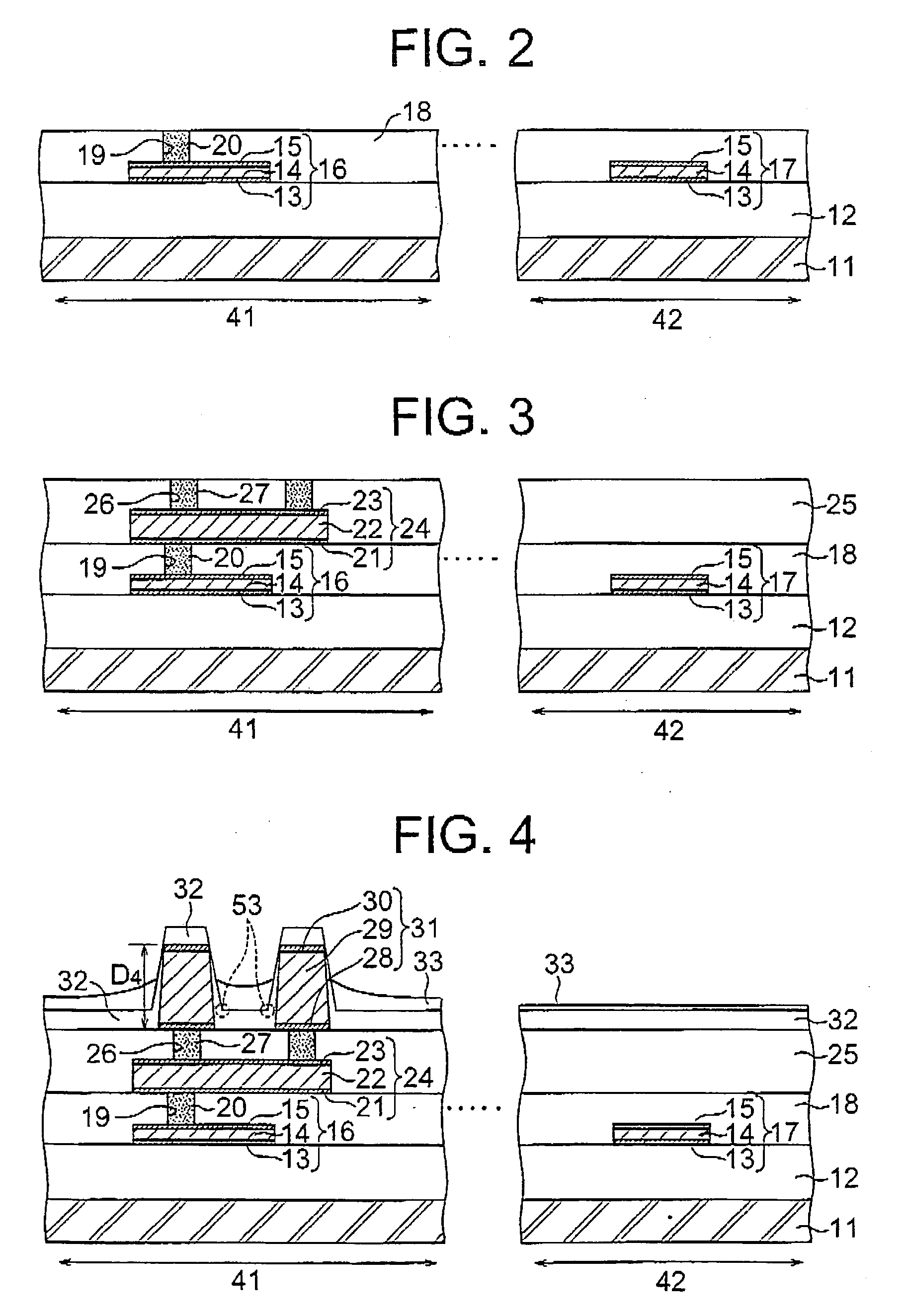

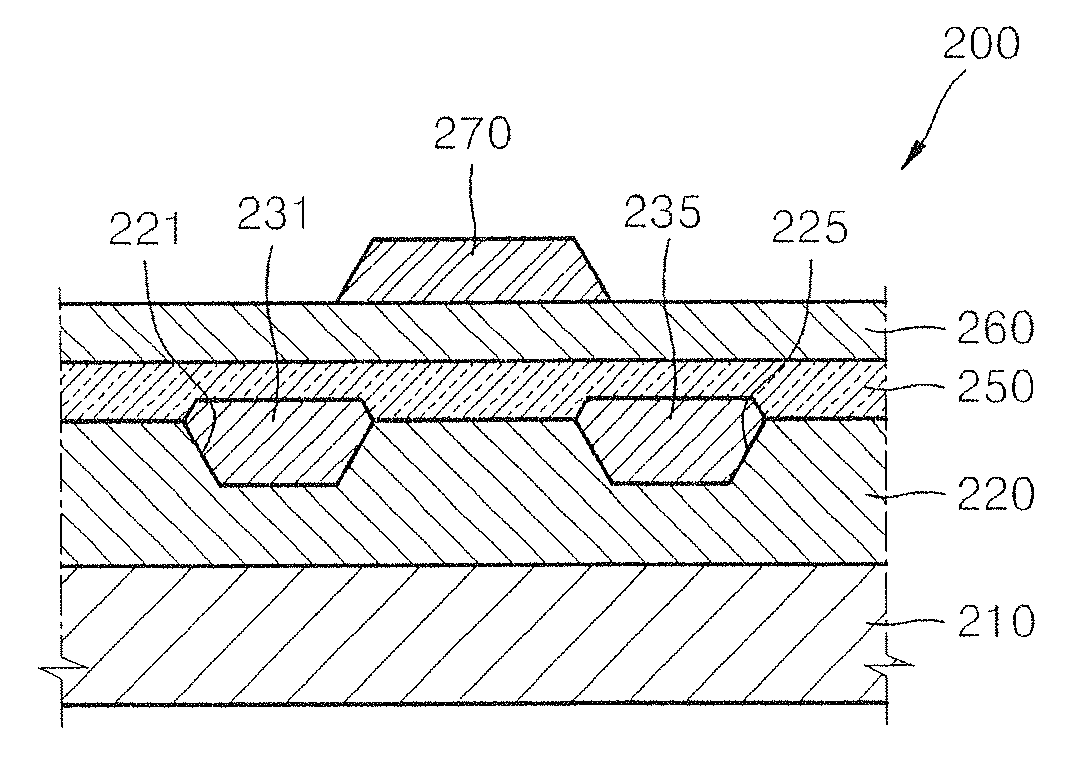

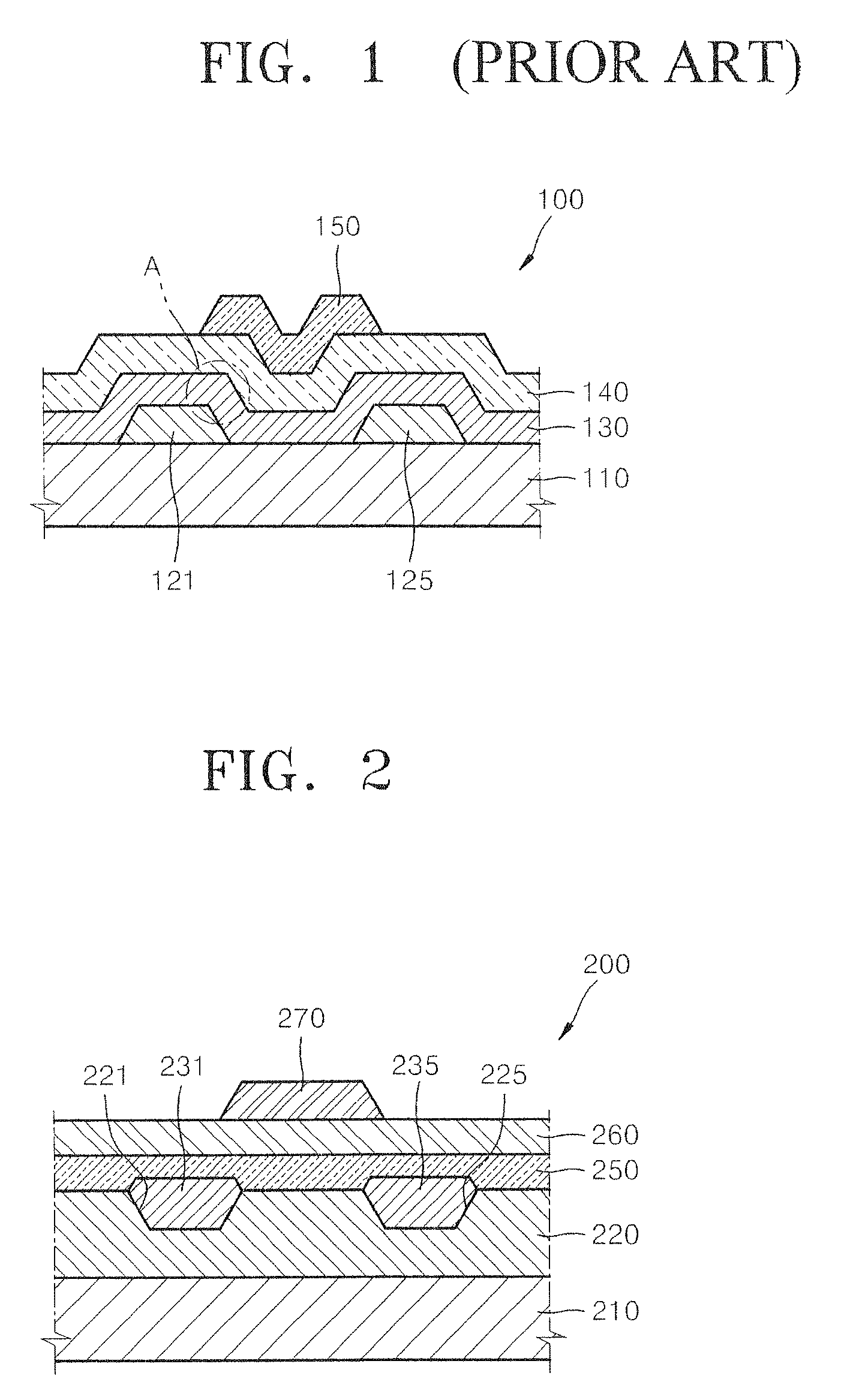

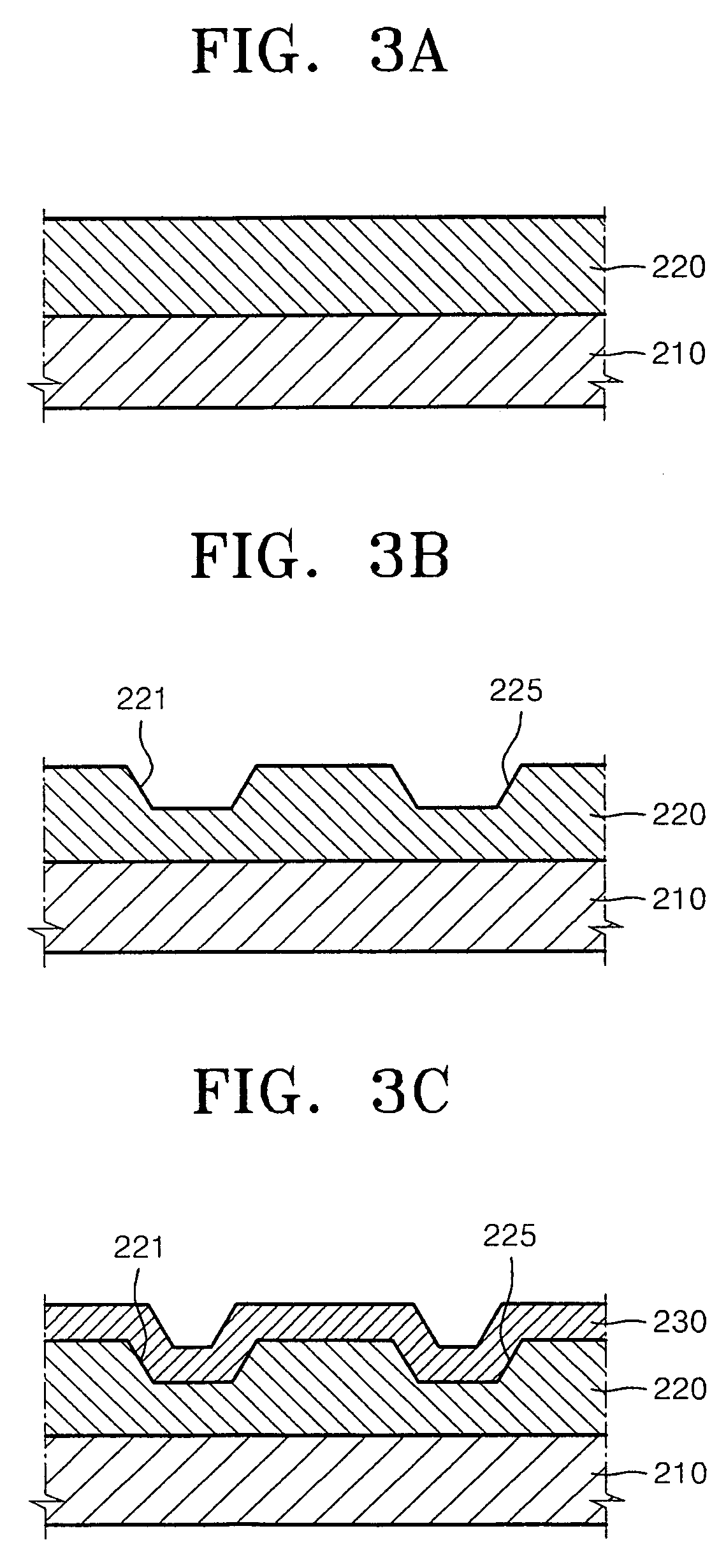

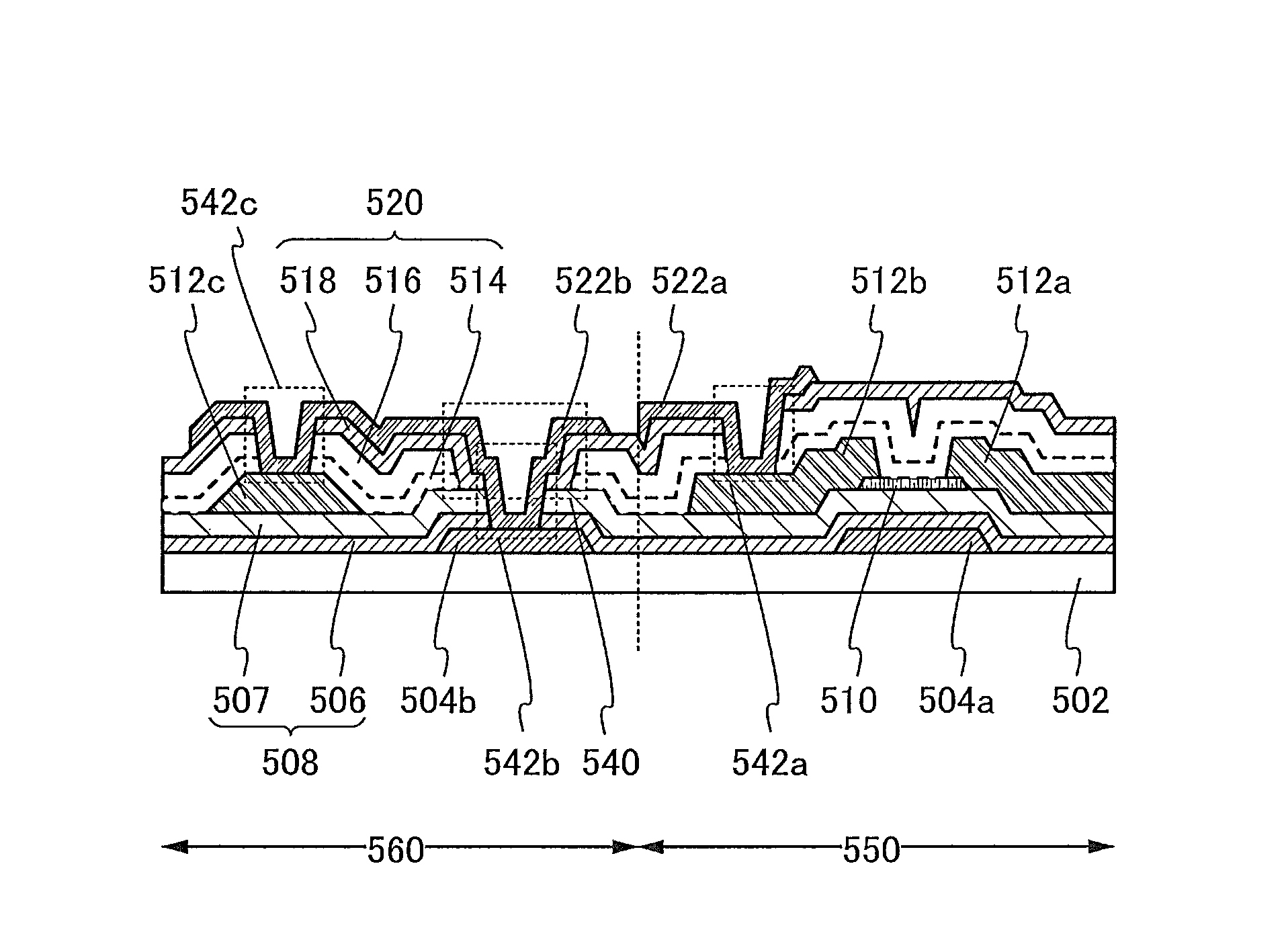

Organic TFT, method of manufacturing the same and flat panel display device having the same

ActiveUS20060270122A1Pattern failure be avoidReduce step differenceTransistorSolid-state devicesFlat panel displayPhotolithography

An organic thin film transistor (TFT), a method of making and a display including the organic TFT. In the TFT, the disconnection of a channel region does not occur because a step difference between a substrate and source and drain electrodes is lessened or eliminated by forming the source and drain electrodes in grooves in a buffer film. The method of manufacturing the organic TFT includes forming a buffer film on a substrate, forming concave units separated by a distance from each other in the buffer film by etching the buffer film, forming an electrode layer on the buffer film, forming source and drain electrodes within the concave units by etching the electrode layer using a photolithography process, forming a semiconductor layer on the source and drain electrodes and on the buffer film, forming a gate insulating film on the semiconductor layer and forming a gate electrode on the gate insulating film.

Owner:SAMSUNG DISPLAY CO LTD

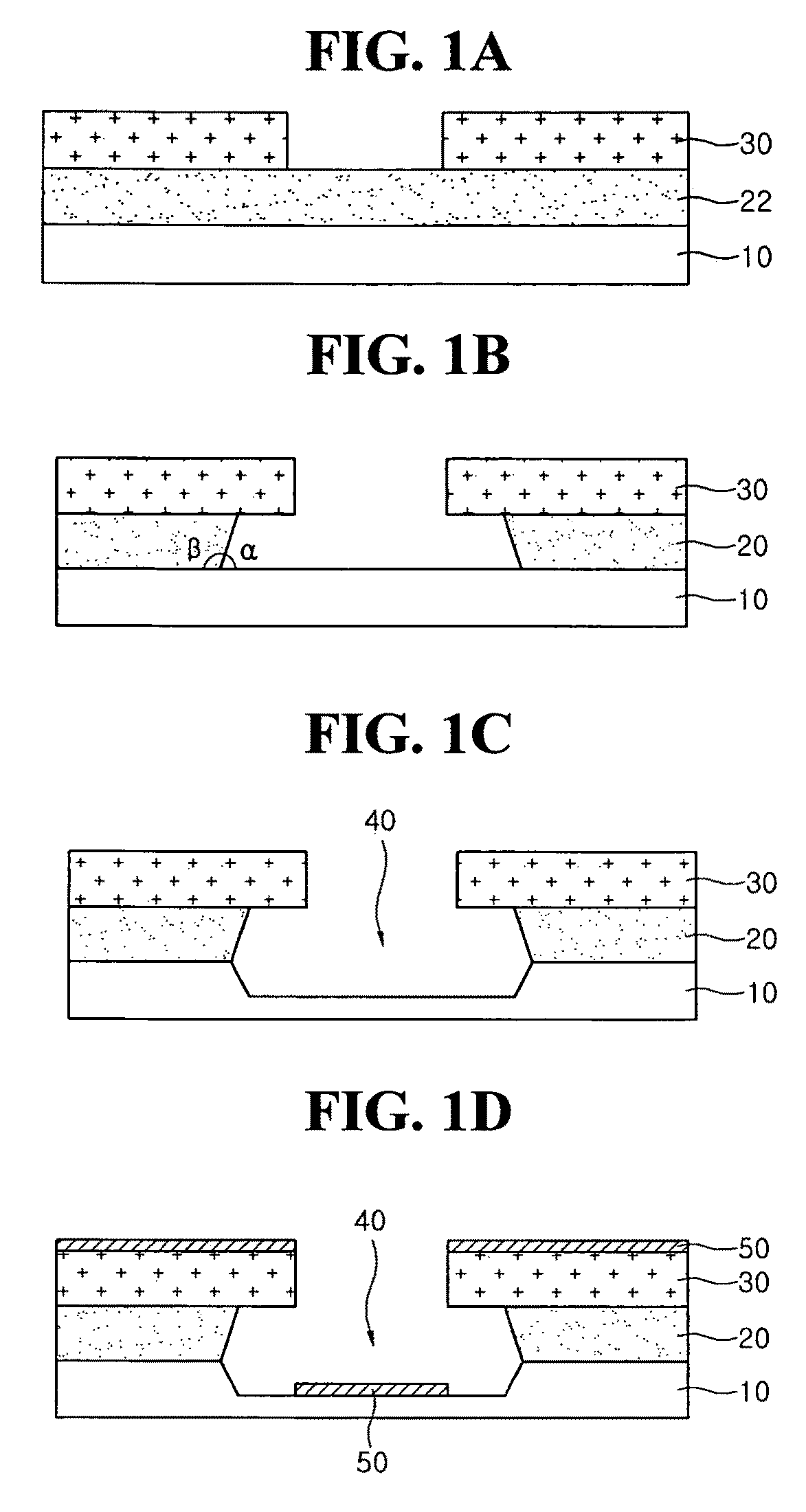

Metal wiring layer and method of fabricating the same

ActiveUS8211797B2Reduce step differenceAvoid it happening againSemiconductor/solid-state device detailsSolid-state devicesTransmittanceDielectric layer

A metal wiring layer and a method of fabricating the metal wiring layer are provided. The method includes forming a dielectric layer on a substrate, forming a plurality of dielectric layer patterns and holes therein on the substrate by etching part of the dielectric layer, with a cross sectional area of the holes in the dielectric layer patterns decreasing with increasing distance away from the substrate and the holes exposing the substrate, forming a trench by etching a portion of the substrate exposed through the holes in the dielectric layer patterns, and forming a metal layer which fills the trench and the holes in the dielectric layer patterns. Thus, it is possible to prevent the occurrence of an edge build-up phenomenon by forming a metal layer in a plurality of holes in the dielectric layer patterns having a cross sectional area decreasing with increasing distance away from the substrate. Therefore, it is possible to prevent the transmittance of a liquid crystal layer from decreasing due to a failure to properly fill liquid crystal molecules in the liquid crystal layer, and thus to increase the quality of display.

Owner:SAMSUNG DISPLAY CO LTD

Enhanced repair method after damage of composite material blade skin

The invention belongs to repair technology of a composite material blade of a rotor system, and relates to an enhanced method after damage of a composite material blade skin and internal filling. Theenhanced method comprises the following steps that after damaged areas are cleaned, a filling area is formed; adhesive films are laid in the filling area, the bottom surface and the side surfaces of acore material filling area are coated with the adhesive films; the core material filling area is filled with core materials, adhesive film materials are laid on an entire repair area on the upper part of the filling core materials, and the all skin damaged areas are covered with the adhesive film materials; and the upper part of a docking area of the filling core materials and a blade structure is covered with a prepreg. The enhanced method is used for smoothing the small jump between the filling core materials and the blade structure.

Owner:哈尔滨哈飞航空工业有限责任公司

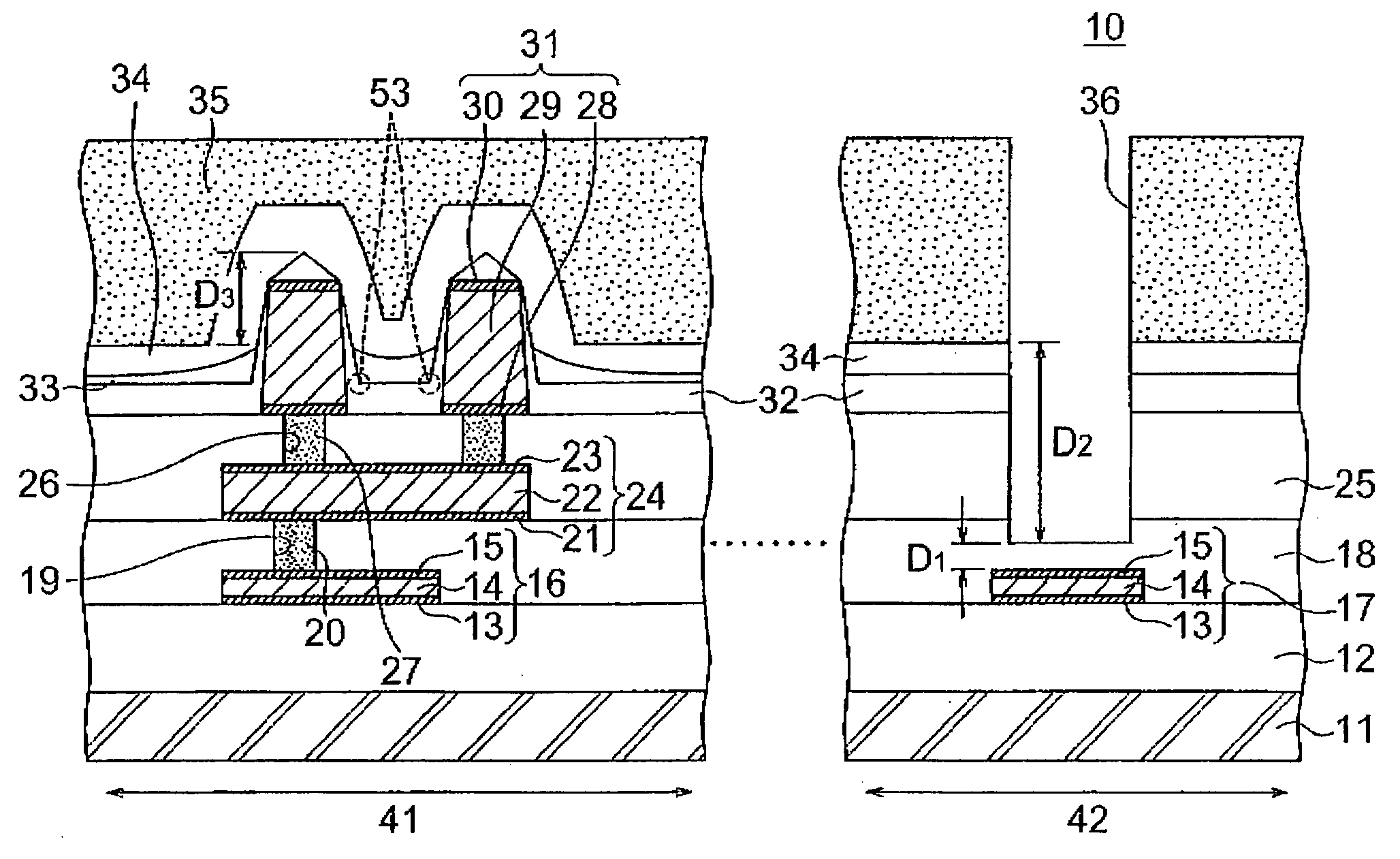

Semiconductor device having a modified dielectric film

ActiveUS20070181883A1Relieve pressureInhibition of thickness increaseTransistorSemiconductor/solid-state device detailsHigh densitySilicon oxide

A semiconductor device has a plurality of interconnect layers each including a plurality of interconnect lines. The semiconductor device includes a dielectric film (HDP film) formed by means of high density plasma-enhanced CVD and including an edge formed on the side surface of the topmost-layer interconnect lines, a silicon oxide film formed by modifying a SOG film on the HDP film between adjacent two of the topmost-layer interconnect lines in the element forming region, and a passivation film formed to cover the HDP film and the topmost-layer interconnect lines.

Owner:MICRON TECH INC

Electro-optical device and electronic apparatus

InactiveUS20100188591A1High-quality image displaySuppressing alignment failureNon-linear opticsElectronElectronic equipment

Provided is an electro-optical device including: a plurality of pixel electrodes arranged in a pixel region; a lower electrode disposed at a lower layer side of the plurality of pixel electrodes with a dielectric film interposed therebetween so as to at least partially overlap the plurality of pixel electrodes in plan view; and a step difference reduction film disposed on an underlying surface of the lower electrode and formed in at least a portion of a lower electrode non-forming region of the pixel region so as to reduce a step difference between the upper surfaces of the lower electrode and the underlying surface in the lower electrode non-forming region.

Owner:SEIKO EPSON CORP

Organic TFT, method of manufacturing the same and flat panel display device having the same

An organic thin film transistor (TFT), a method of making and a display including the organic TFT. In the TFT, the disconnection of a channel region does not occur because a step difference between a substrate and source and drain electrodes is lessened or eliminated by forming the source and drain electrodes in grooves in a buffer film. The method of manufacturing the organic TFT includes forming a buffer film on a substrate, forming concave units separated by a distance from each other in the buffer film by etching the buffer film, forming an electrode layer on the buffer film, forming source and drain electrodes within the concave units by etching the electrode layer using a photolithography process, forming a semiconductor layer on the source and drain electrodes and on the buffer film, forming a gate insulating film on the semiconductor layer and forming a gate electrode on the gate insulating film.

Owner:SAMSUNG DISPLAY CO LTD

Organic light emitting display device and method for manufacturing the same

ActiveUS9147859B2Improve contact reliabilityReliable contactElectroluminescent light sourcesSolid-state devicesAdhesiveOrganic layer

Owner:LG DISPLAY CO LTD

Touch panel

InactiveCN105278737AAvoid breakingImprove straightnessCircuit optical detailsPrinted circuit aspectsSurface roughnessEngineering

Provided is a touch panel including a cover substrate including an active area and an unactive area, and a printing layer on the unactive area. The printing layer has surface roughness in a range of 0.4 [mu] m to 0. 6 [mu] m. The printing layer has straightness in a range of +-0.1 [mu] m to +-10 [mu] m.

Owner:LG INNOTEK CO LTD

Semiconductor device and display device including the semiconductor device

ActiveUS9293480B2Excellent electrical propertiesImprove productivityTransistorSolid-state devicesDisplay deviceSemiconductor

A semiconductor device including a transistor and a connection portion is provided. The transistor includes a gate electrode, a first insulating film over the gate electrode, an oxide semiconductor film over the first insulating film and at a position overlapping with the gate electrode, and source and drain electrodes electrically connected to the oxide semiconductor film; and the connection portion includes a first wiring on the same surface as a surface on which the gate electrode is formed, a second wiring on the same surface as a surface on which the source and drain electrodes are formed, and a third wiring connecting the first wiring and the second wiring. The distance between an upper end portion and a lower end portion of the second wiring is longer than the distance between an upper end portion and a lower end portion of each of the source and drain electrodes.

Owner:SEMICON ENERGY LAB CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com