Patents

Literature

504results about How to "Improve contact reliability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

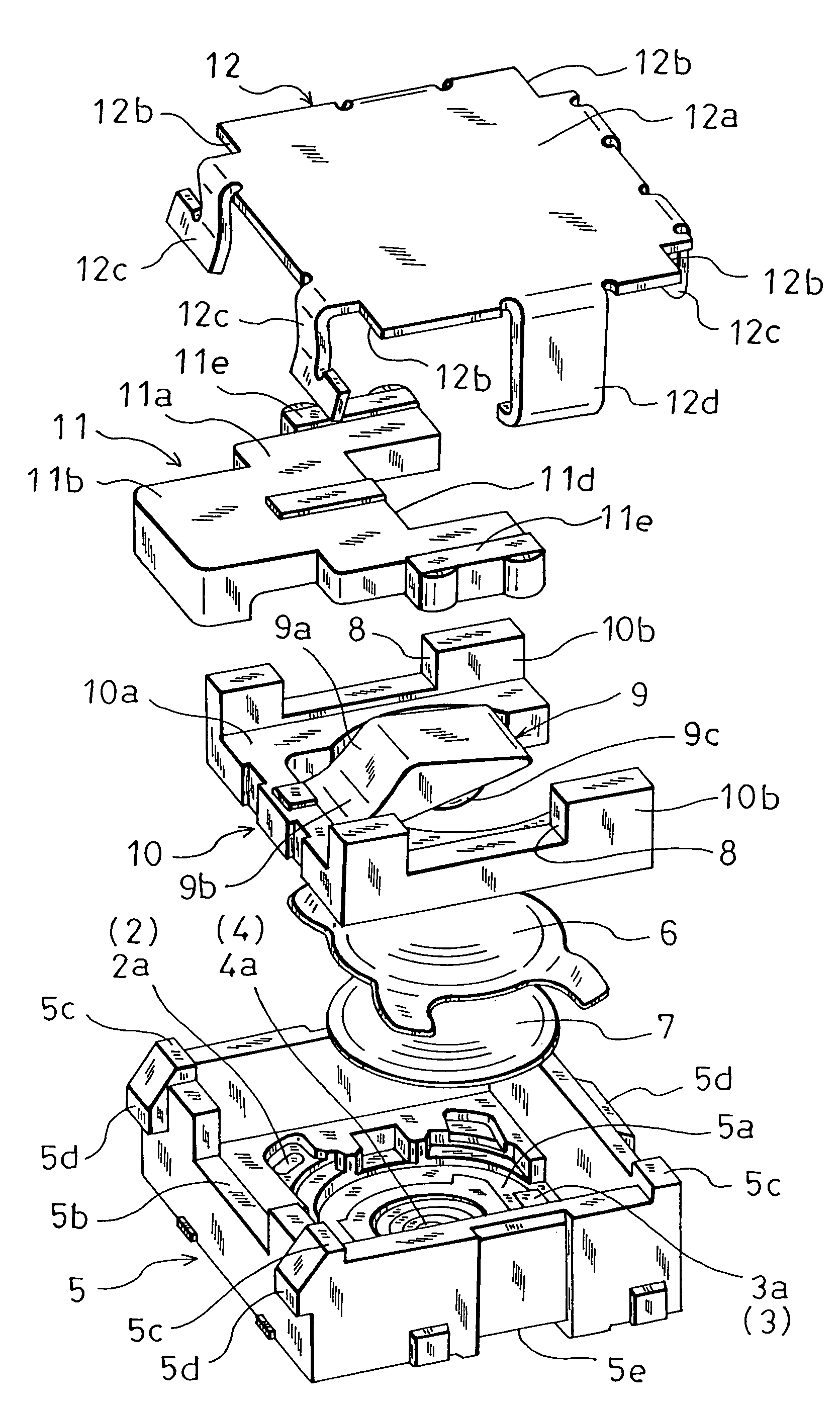

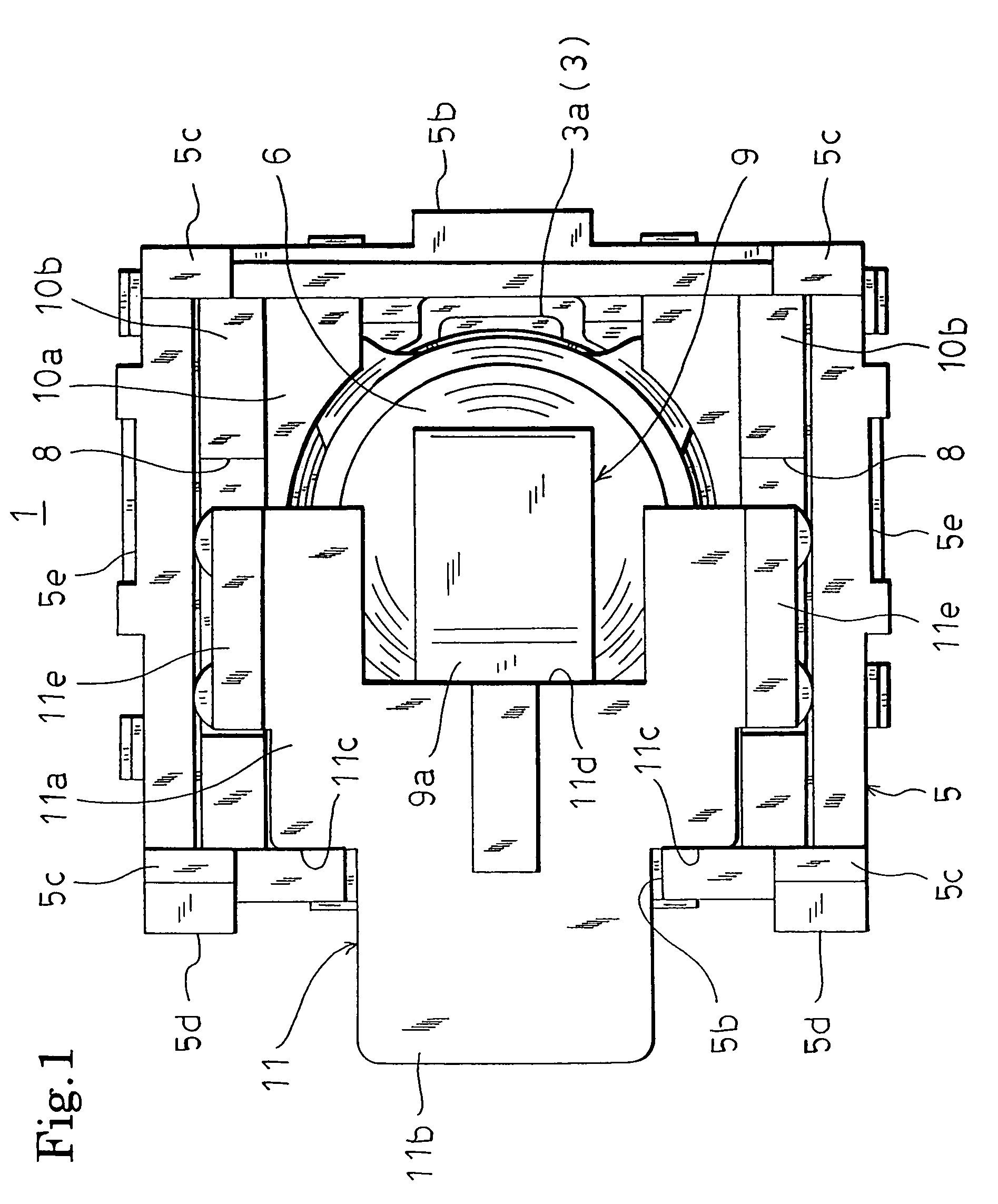

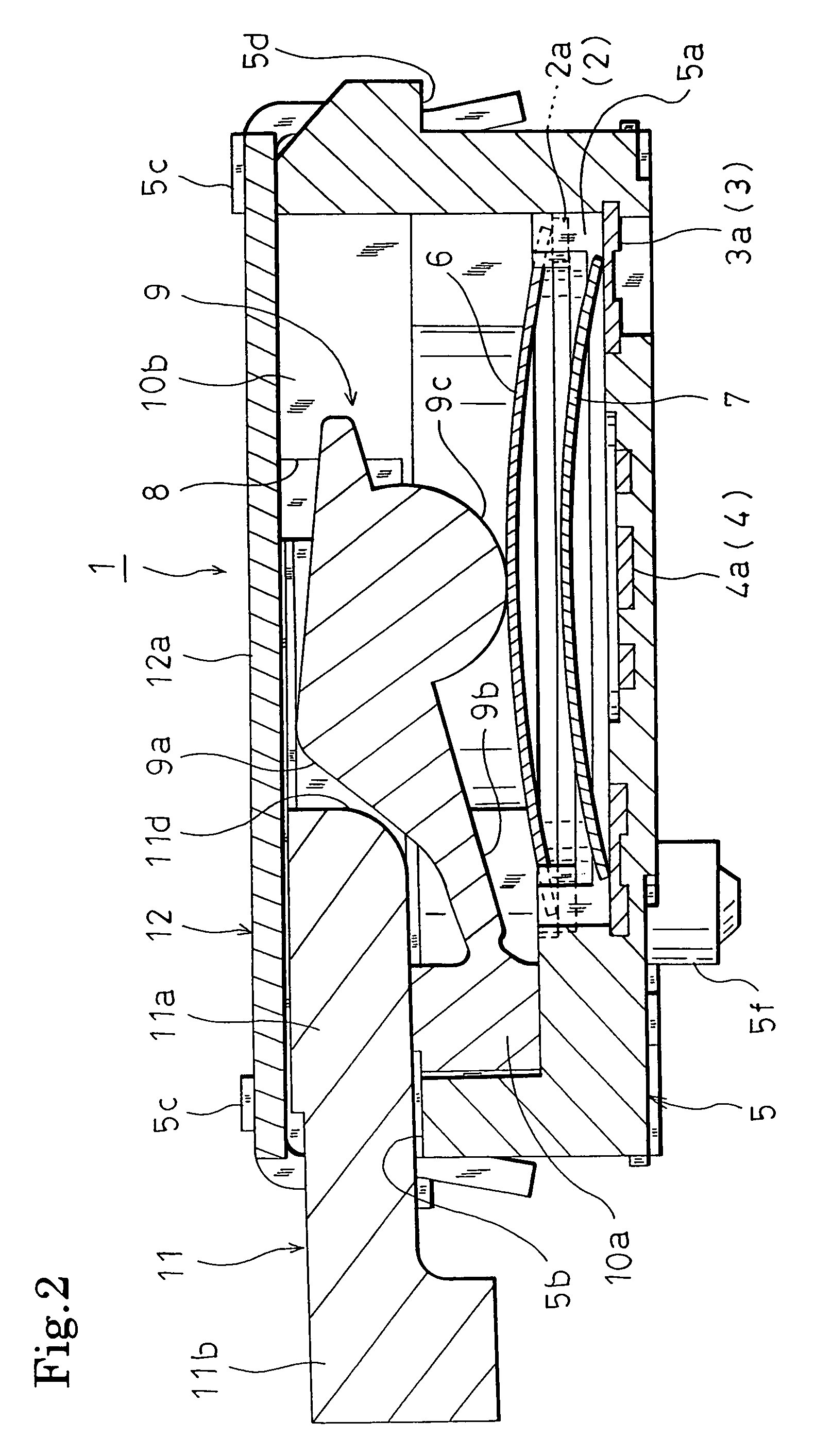

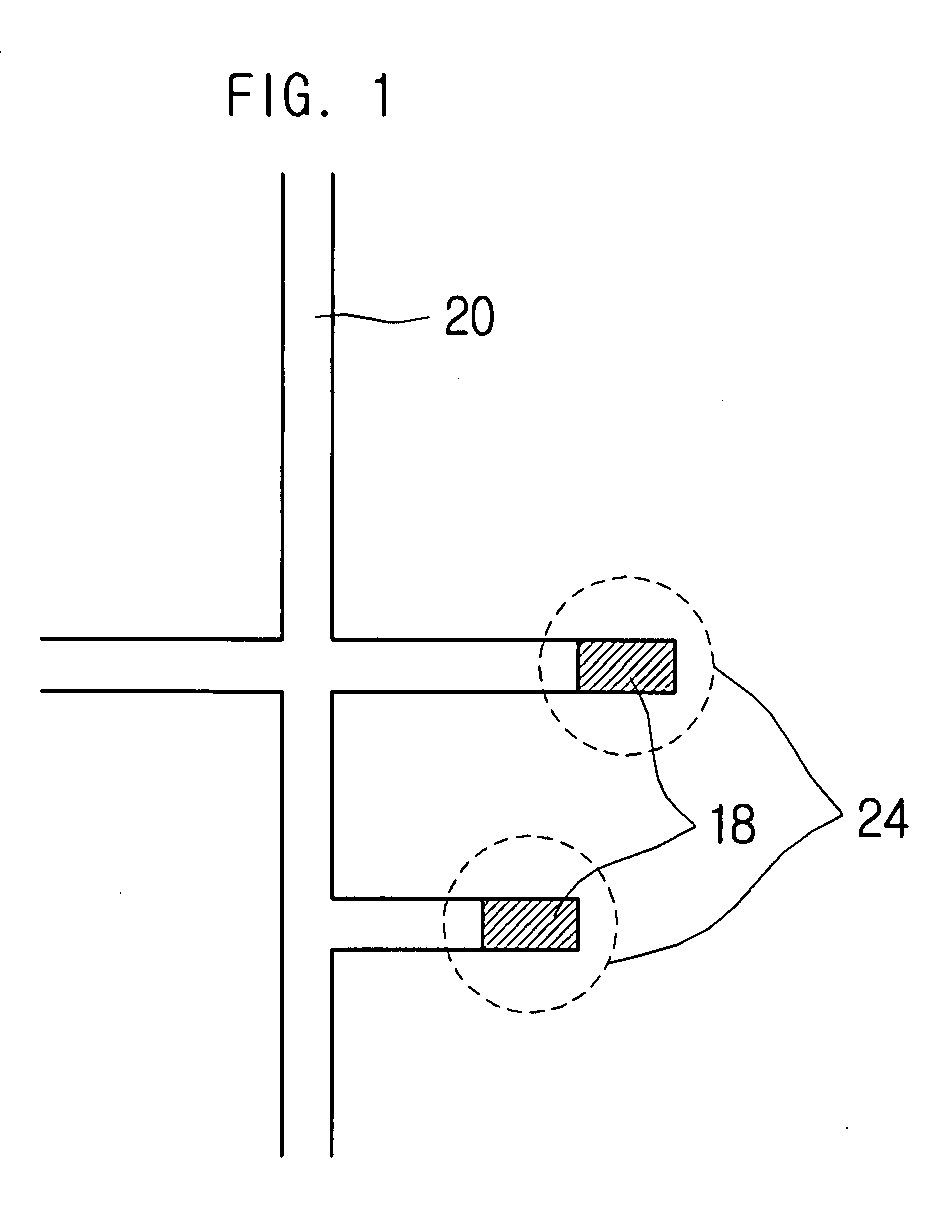

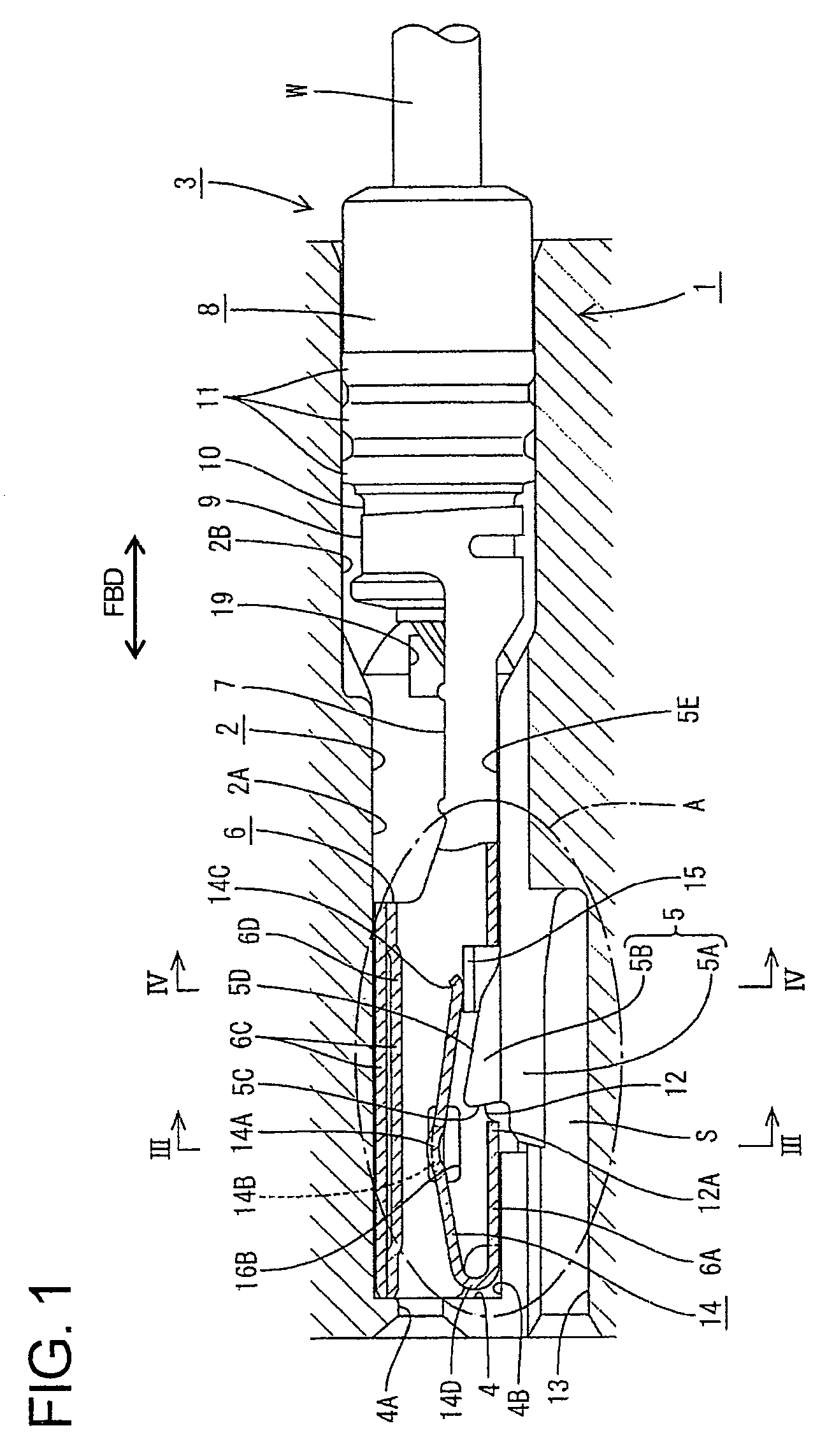

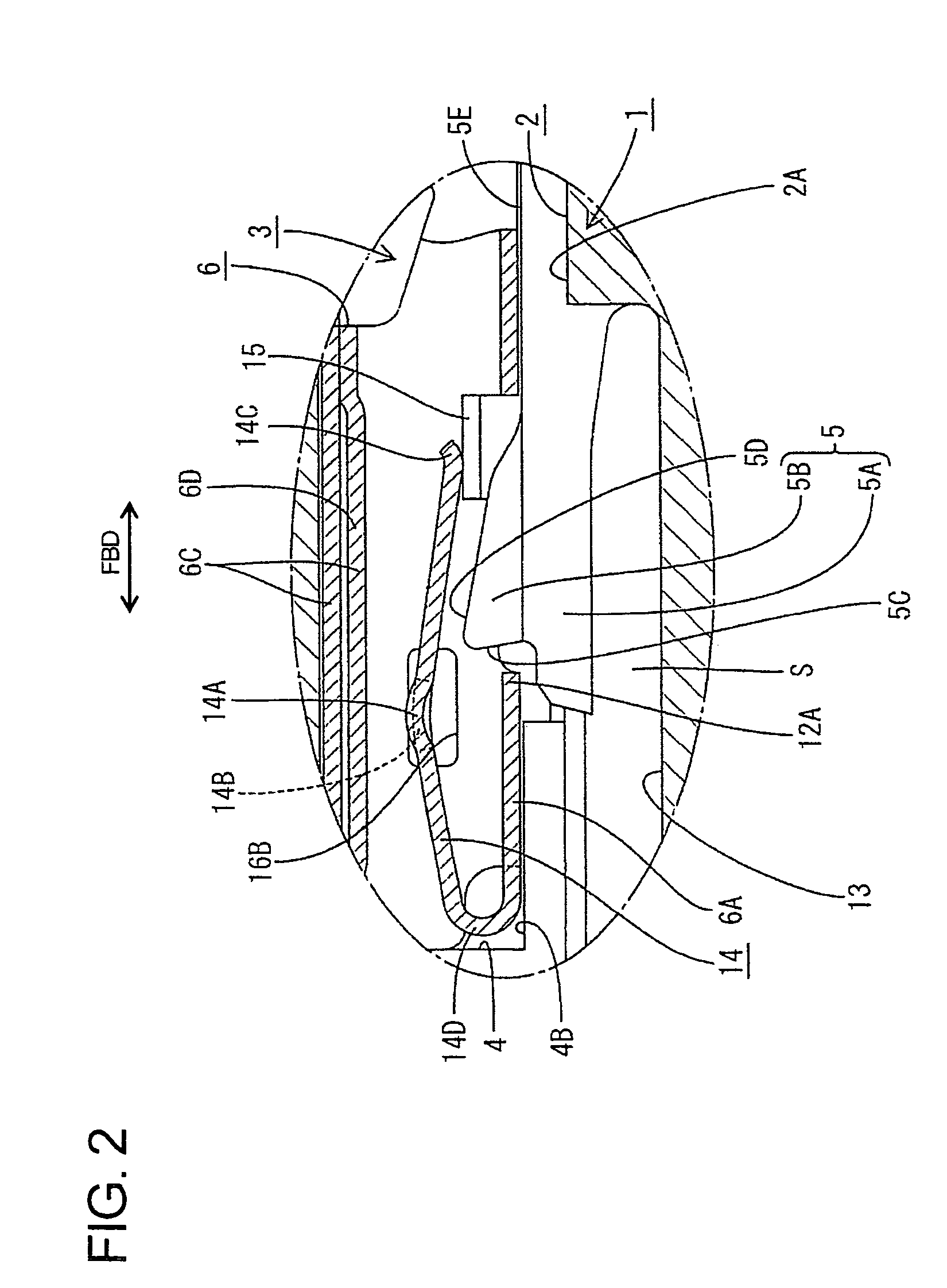

Lateral pushing type push switch

InactiveUS7449654B2Easy to operateImprove contact reliabilityContact driving mechanismsSnap-action arrangementsEngineeringPush switch

Owner:HOSIDEN CORP

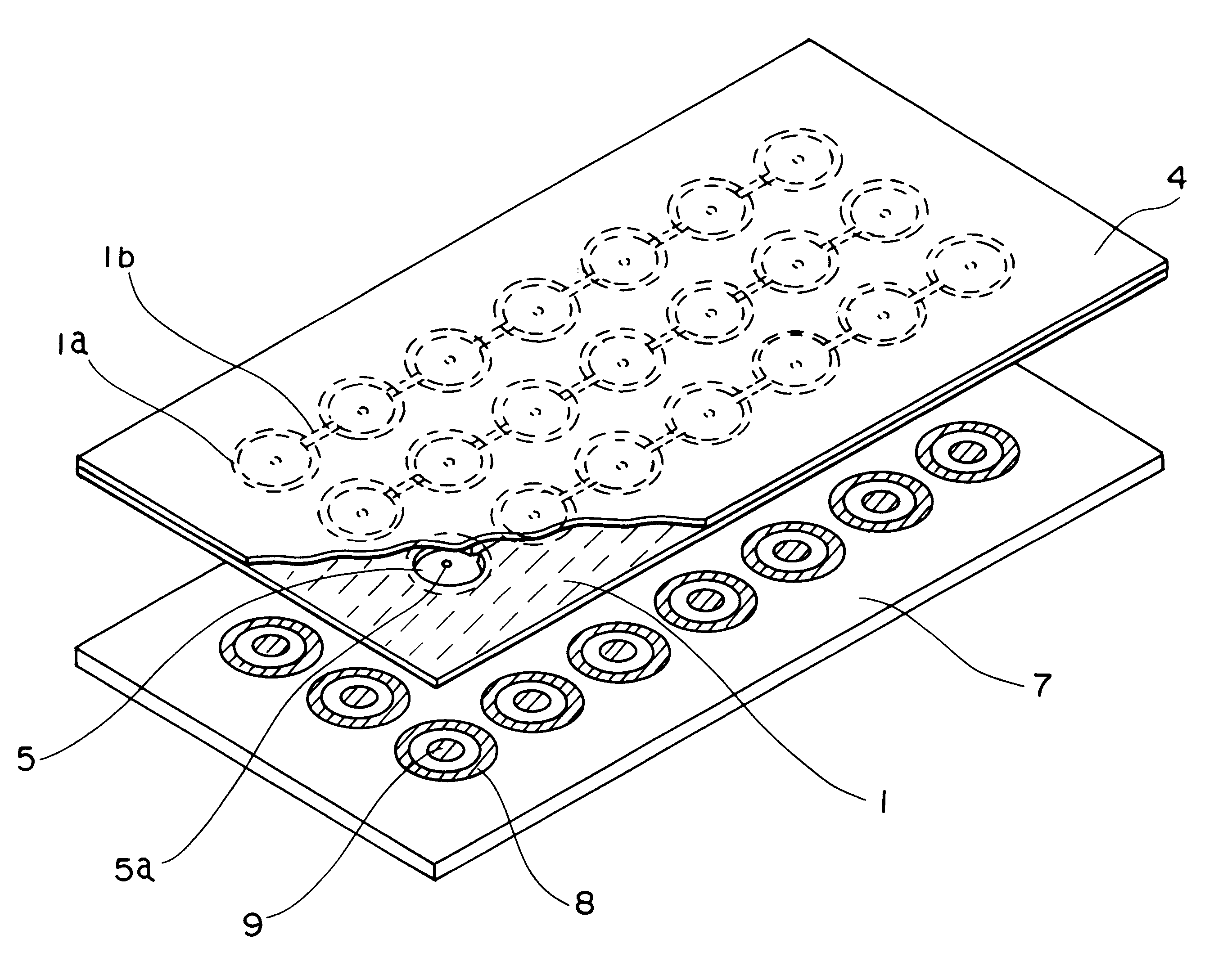

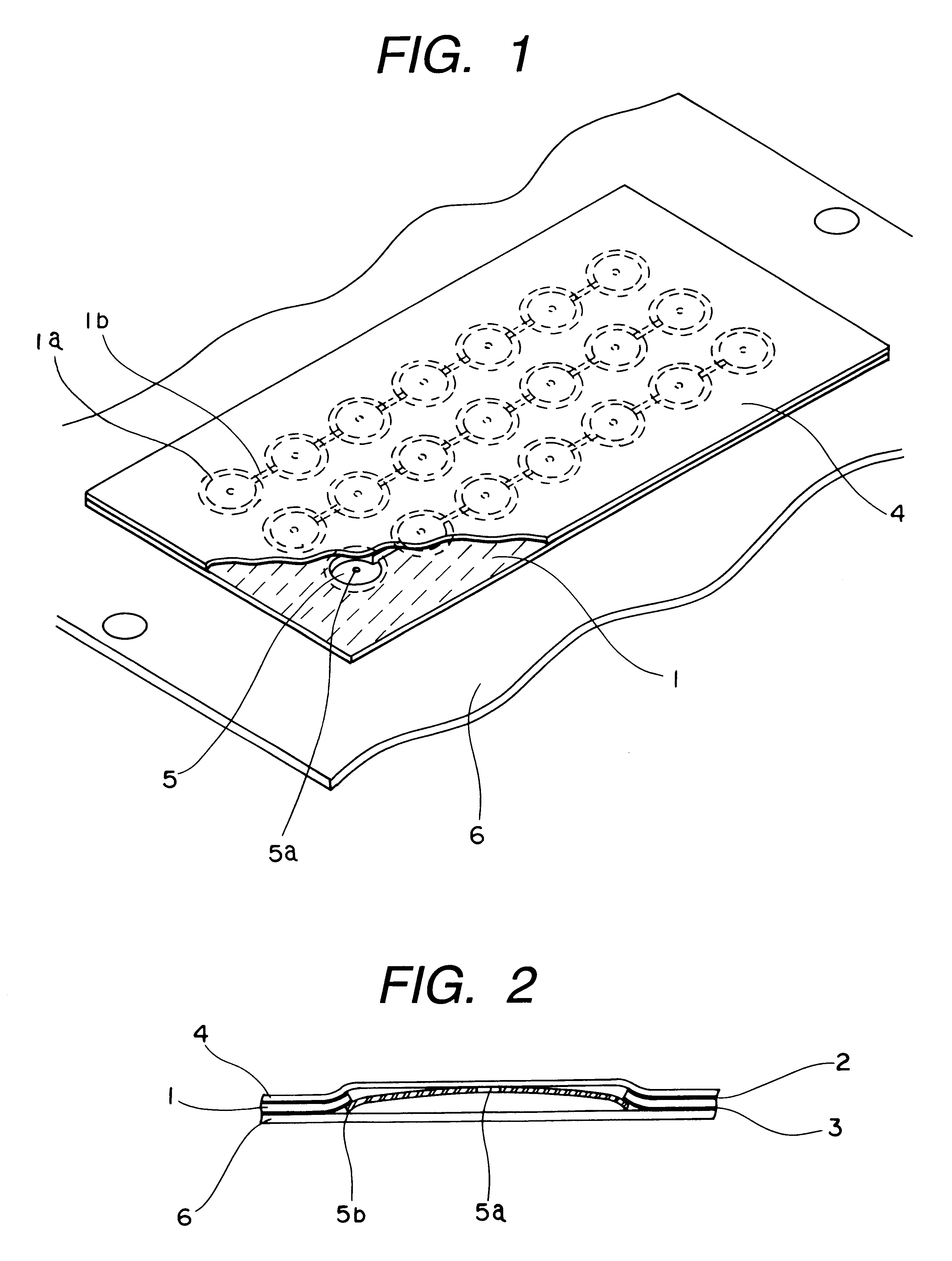

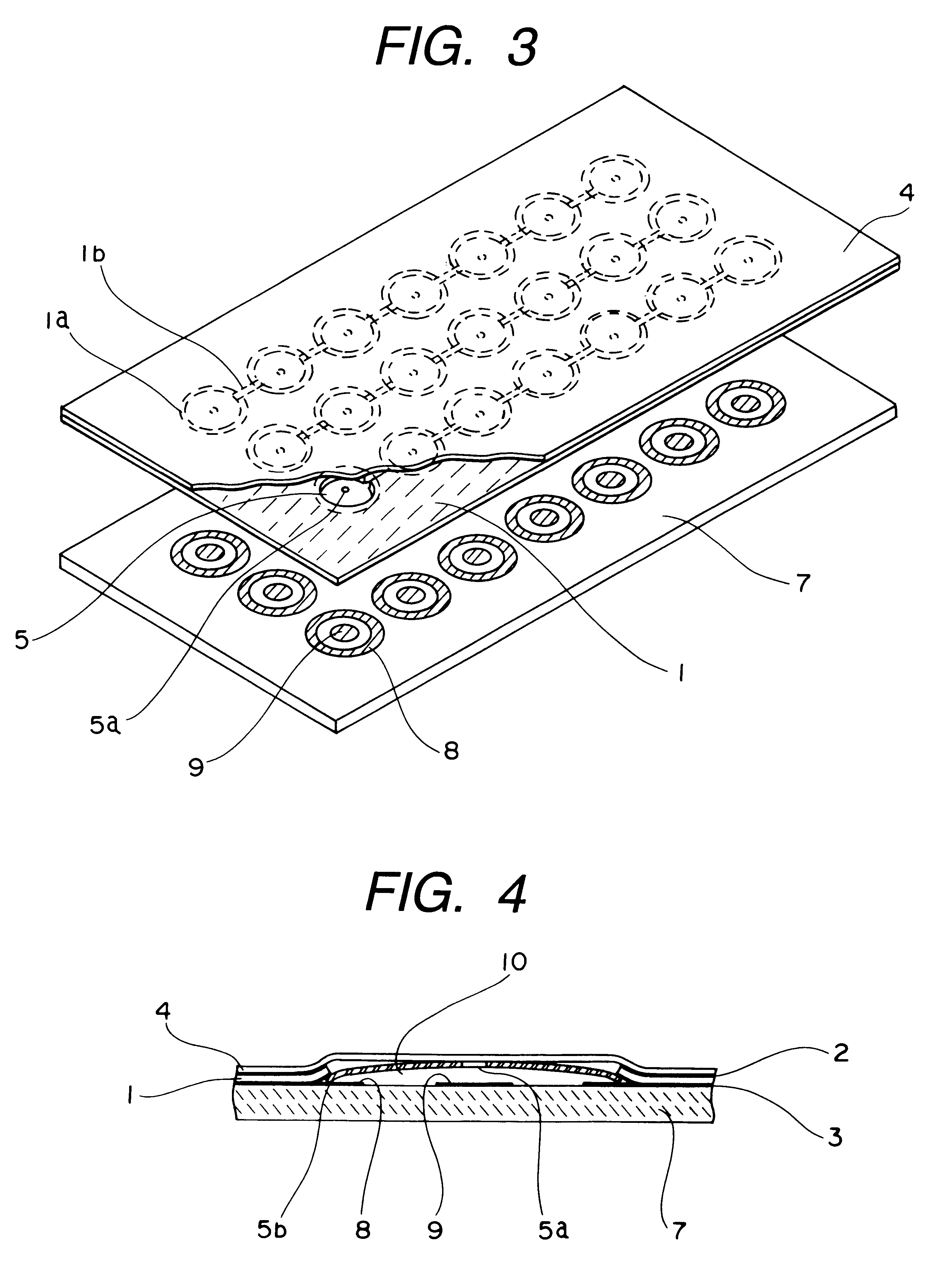

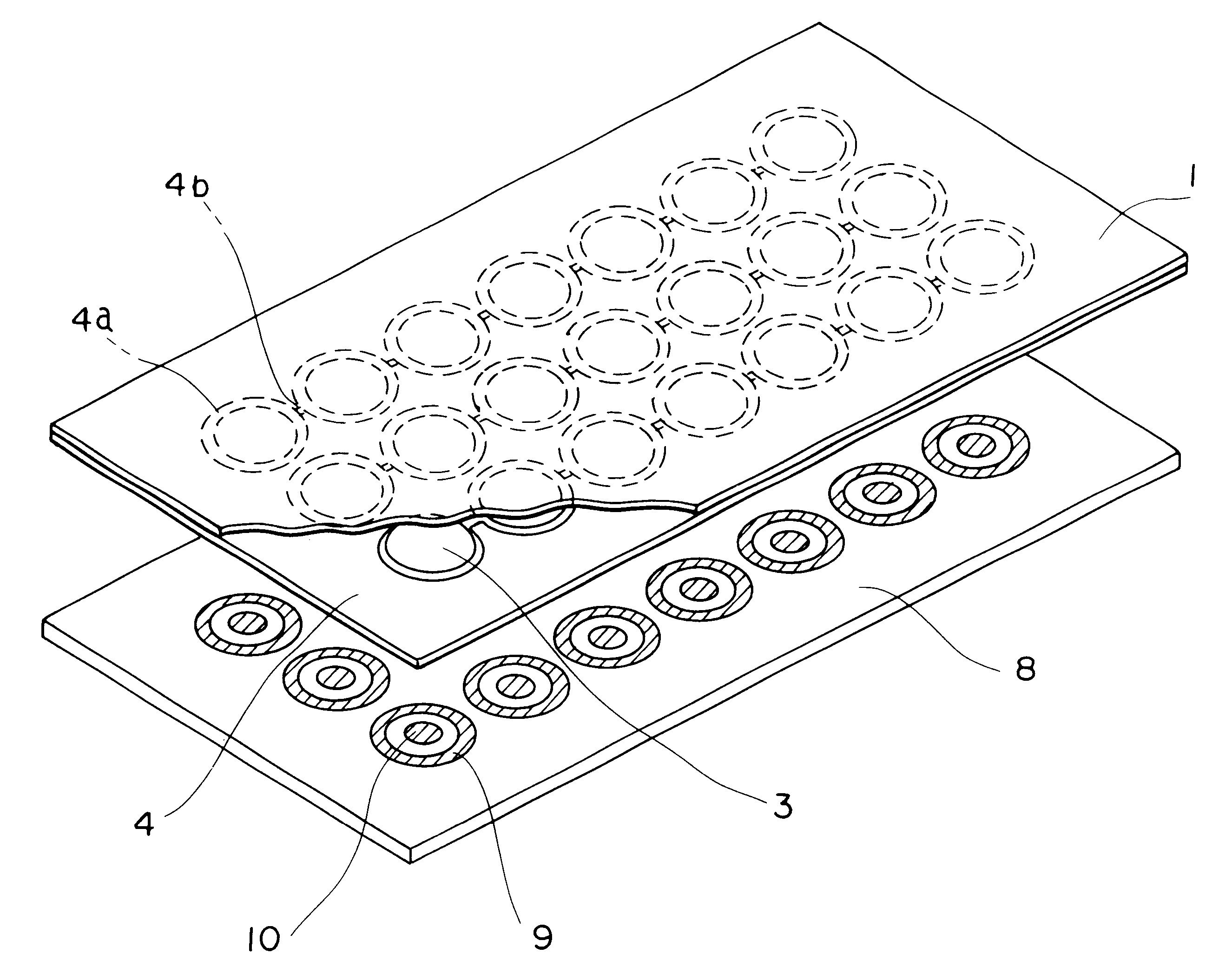

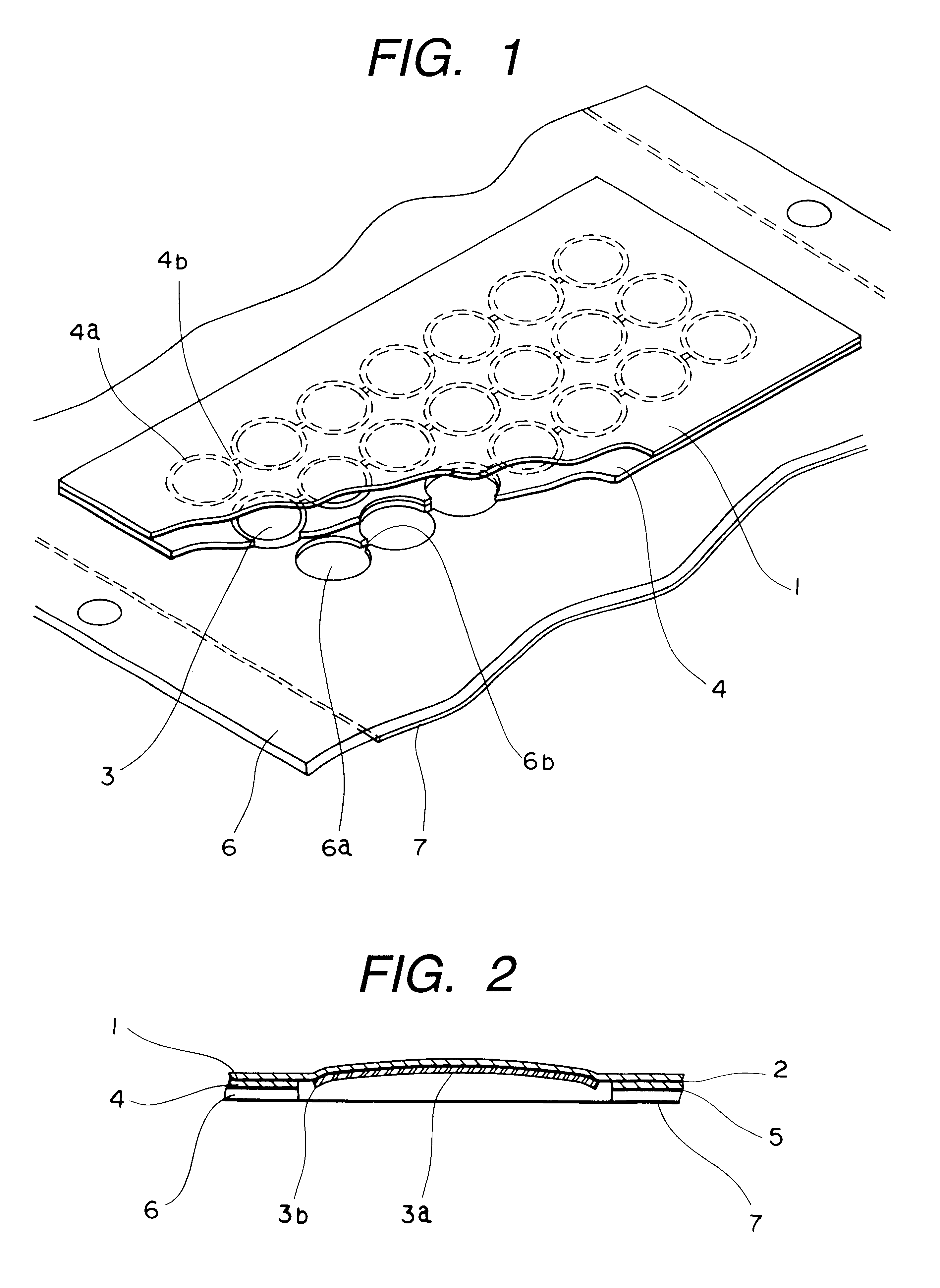

Sheet with movable contacts and sheet switch

InactiveUS6259046B1Improve contact reliabilityEasy to operateContact surface shape/structureMovable contactsAdhesiveEngineering

Owner:ALPS ALPINE CO LTD

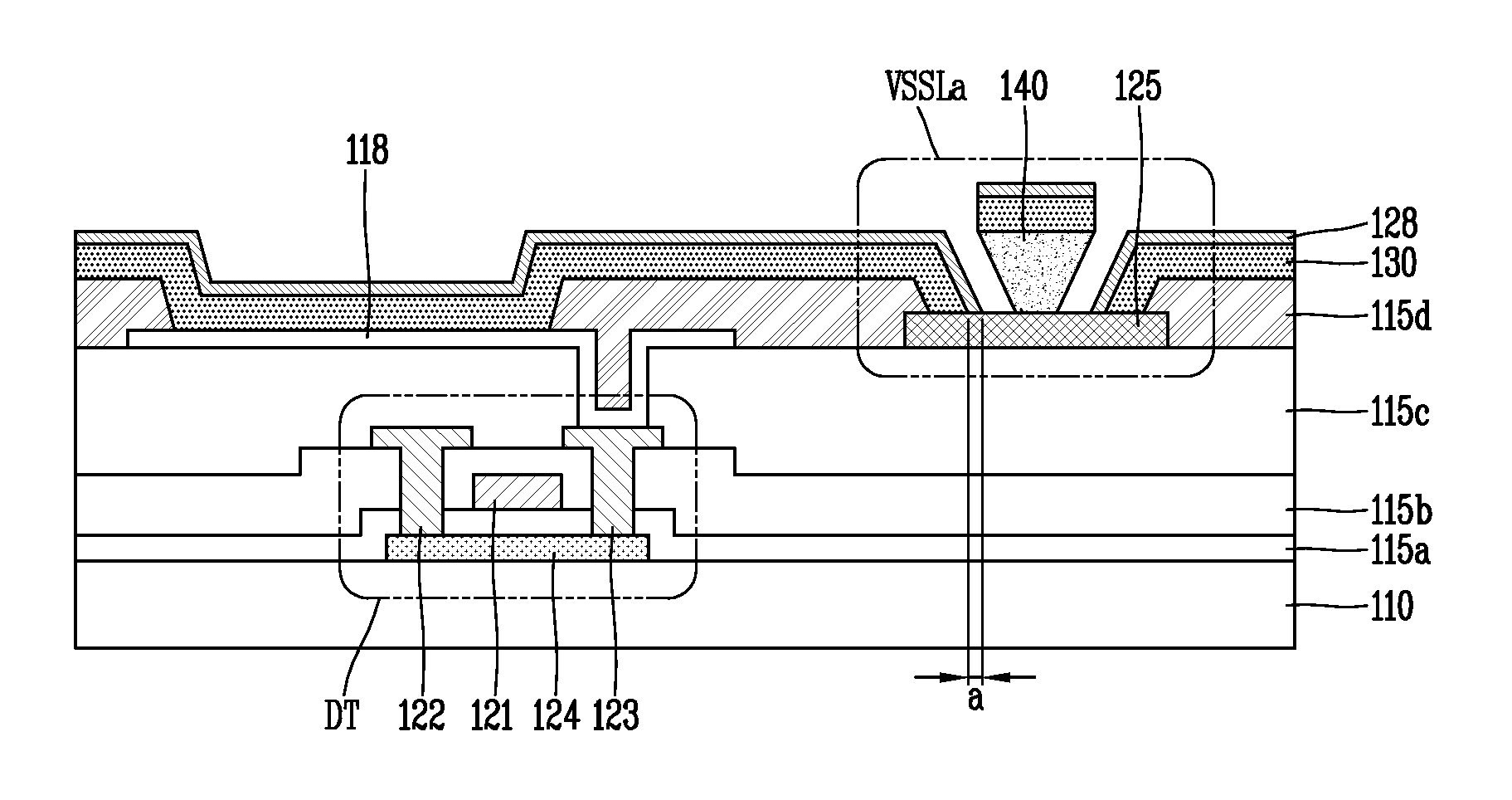

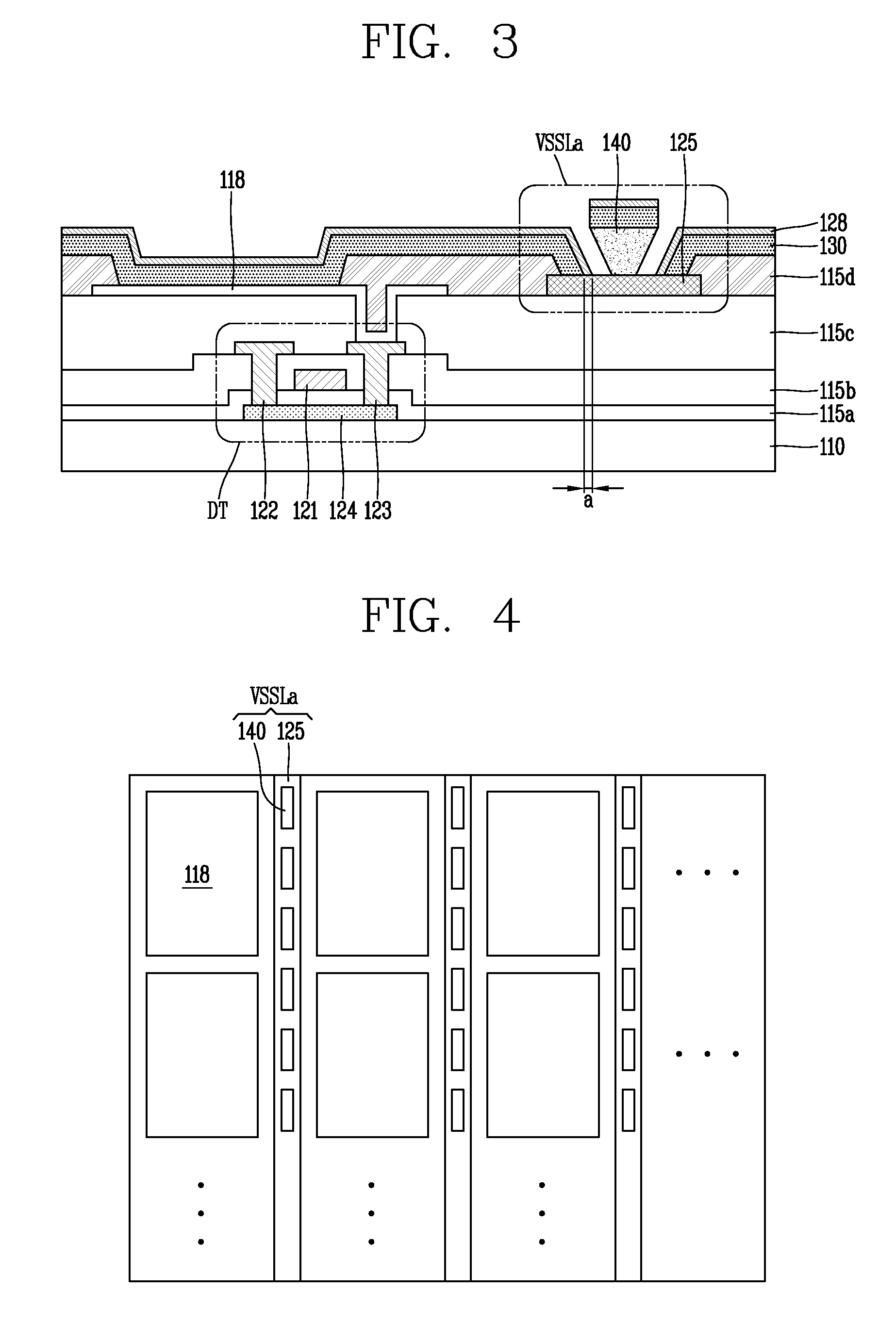

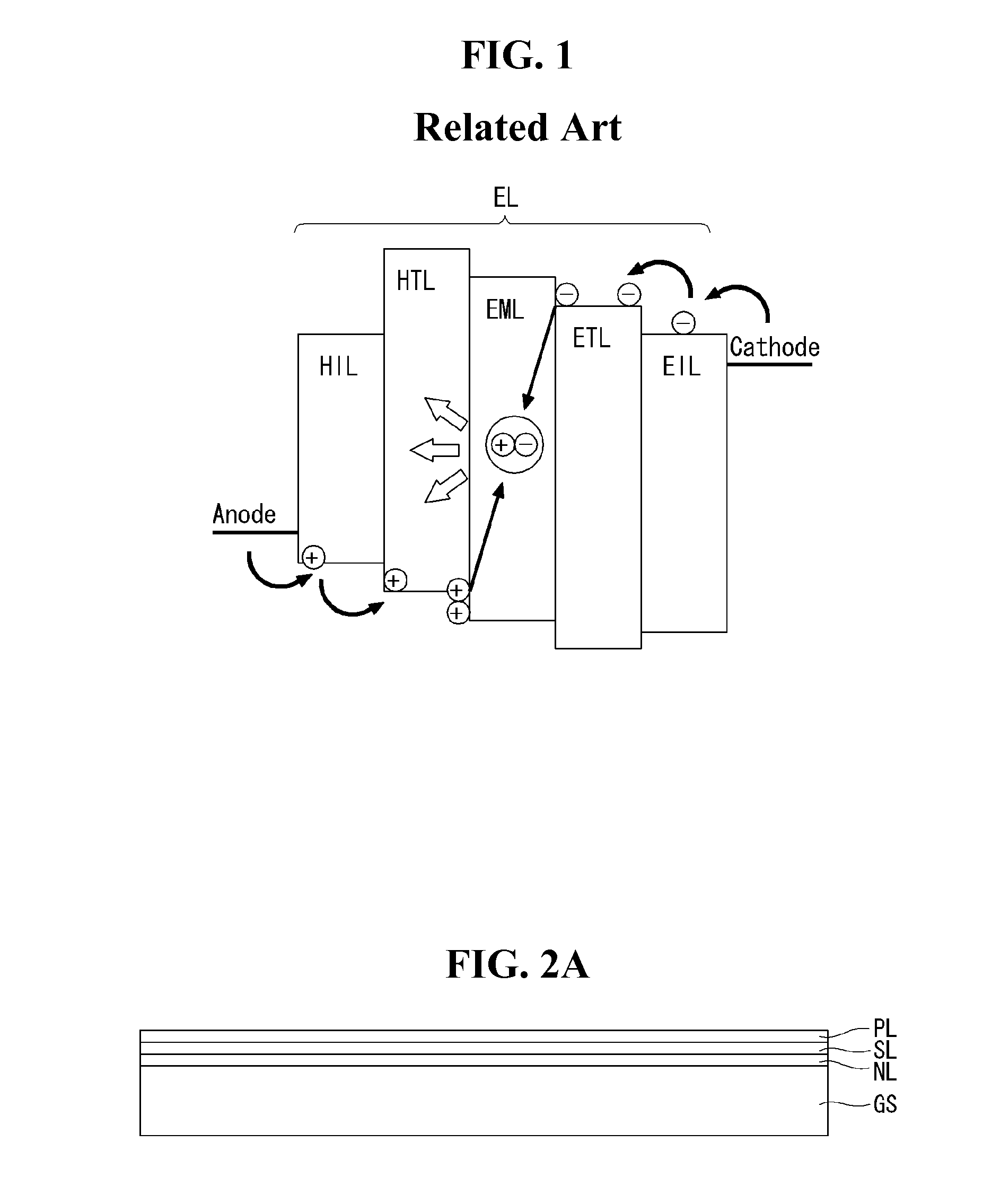

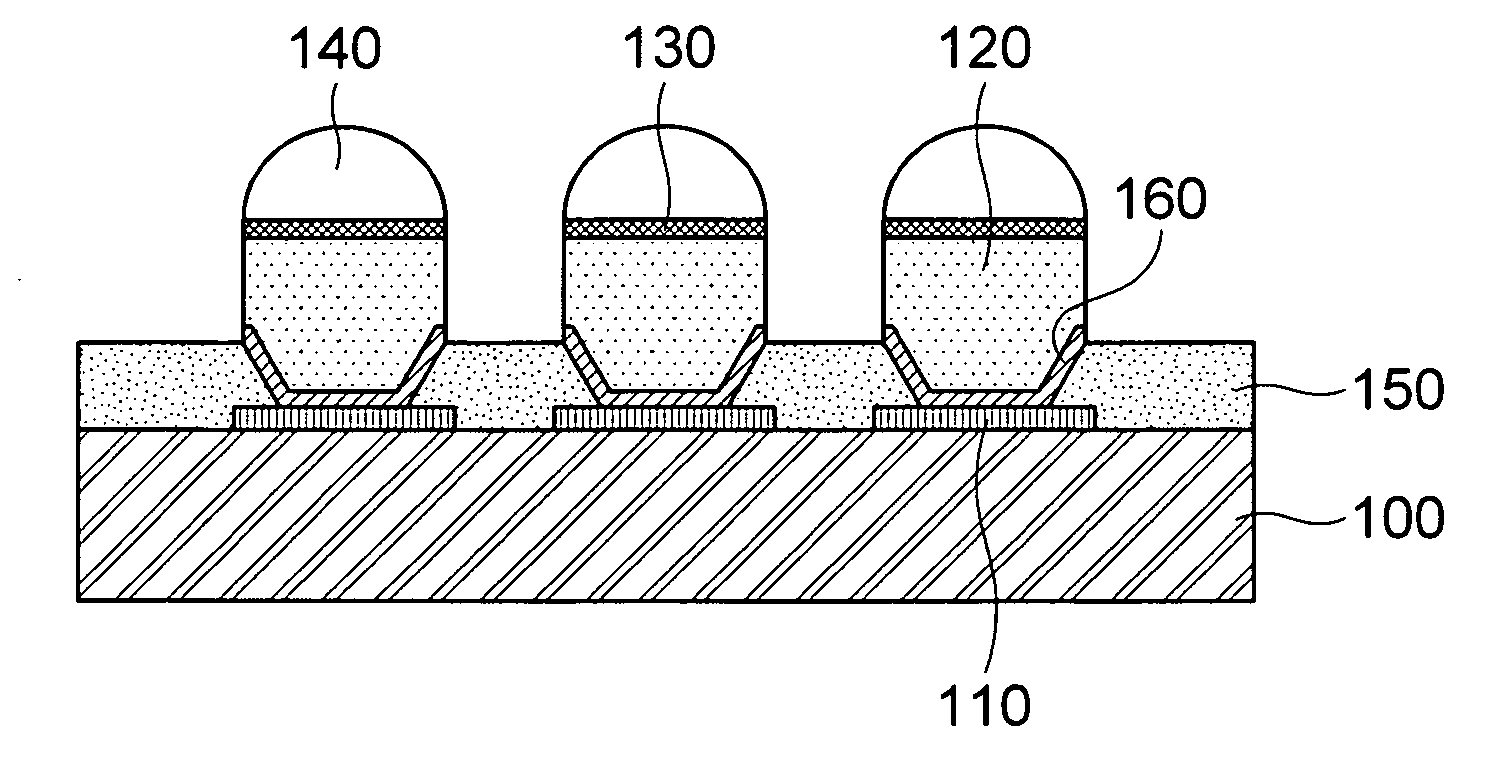

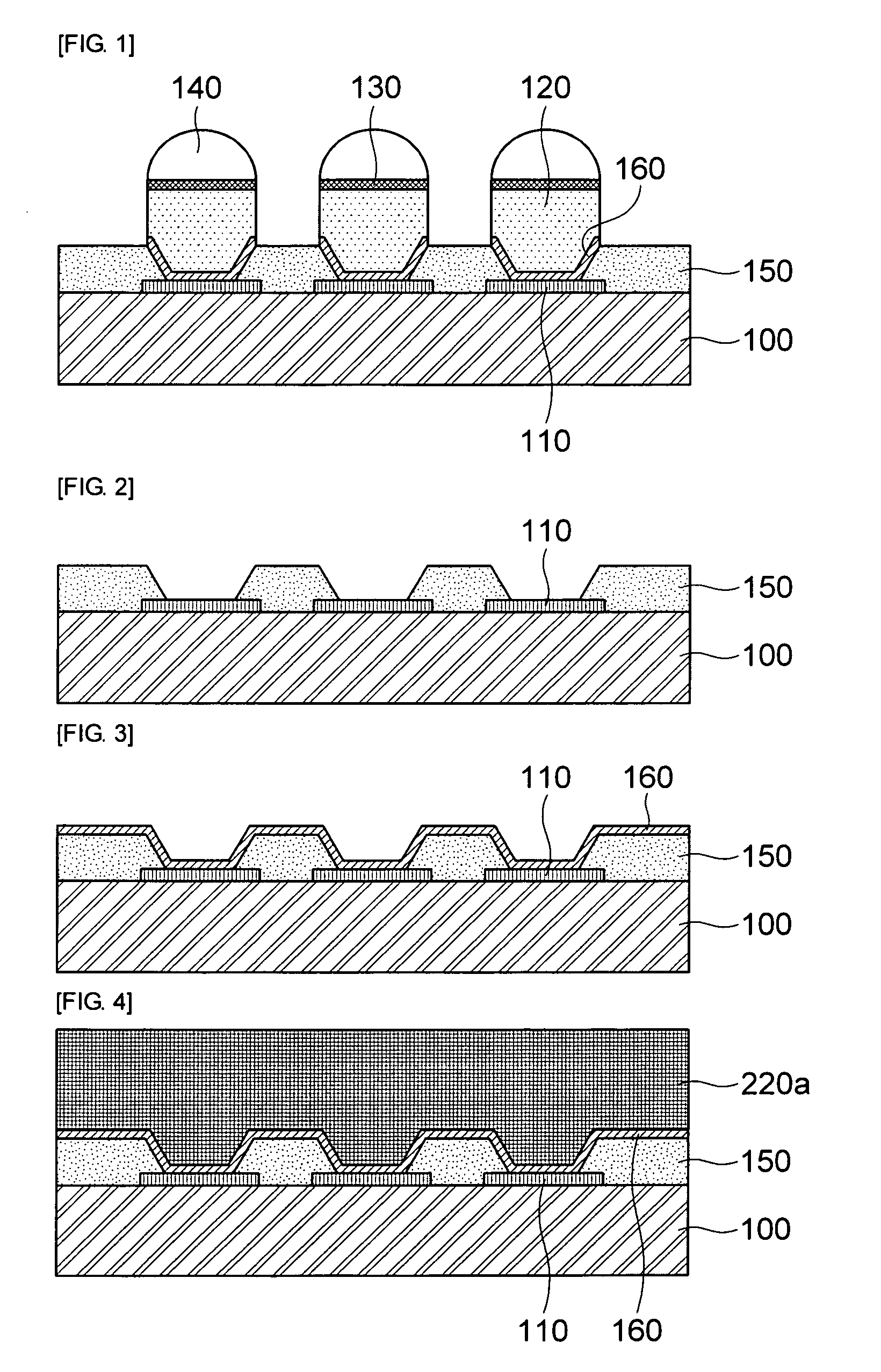

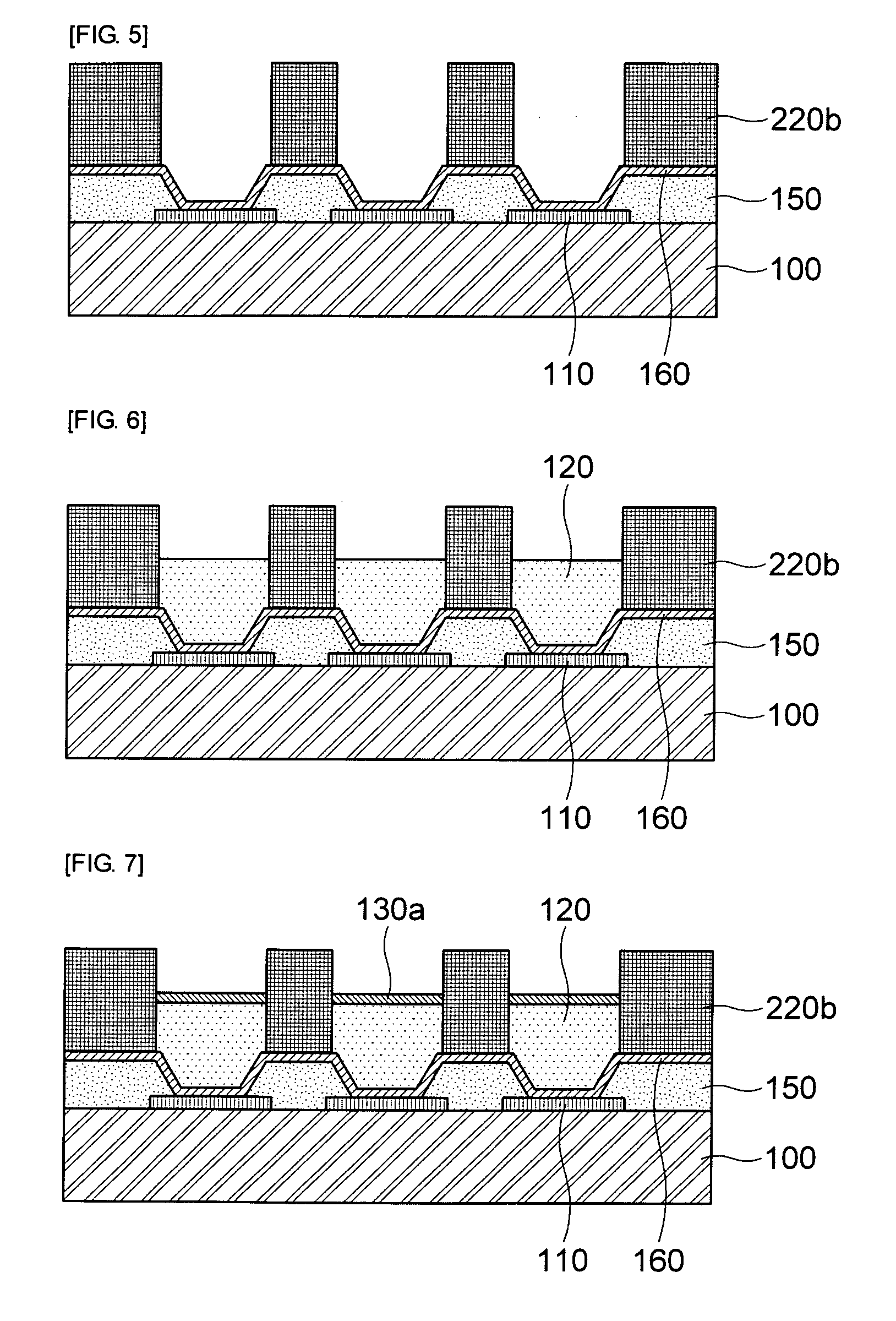

Organic light emitting display device and manufacturing method thereof

ActiveUS20160013438A1Simple processAvoid voltage dropSemiconductor/solid-state device detailsSolid-state devicesDisplay deviceAuxiliary electrode

Provided are an organic light emitting display device and a manufacturing method thereof. In the organic light emitting display device, after an auxiliary electrode having a multilayer structure including different kinds of metals different in etching speed is formed, a void is formed within the auxiliary electrode upon formation of an anode. The resulting structure is created by a simplified process, with contact reliability between a cathode and the auxiliary electrode being enhanced, while resistance of the cathode is reduced.

Owner:LG DISPLAY CO LTD

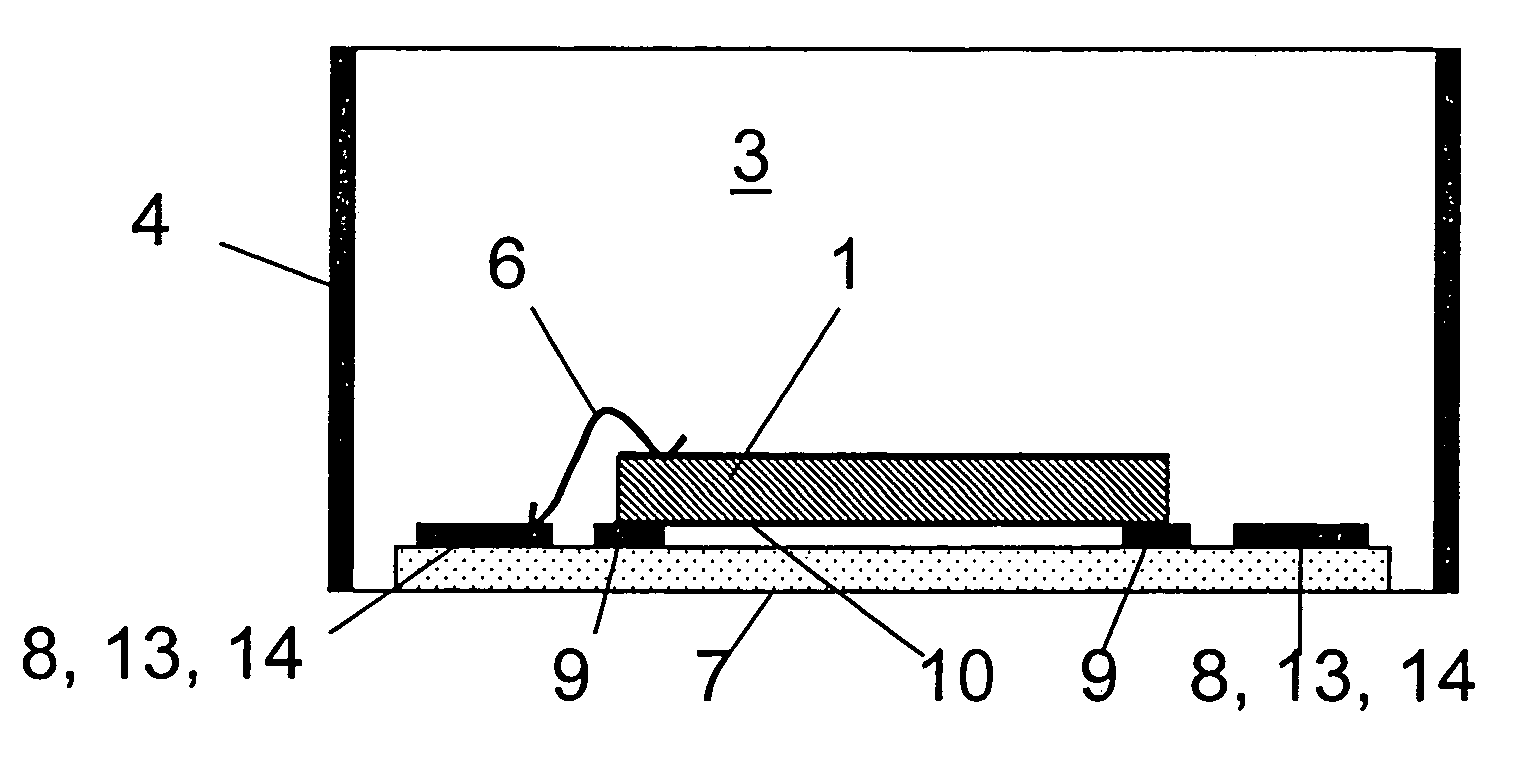

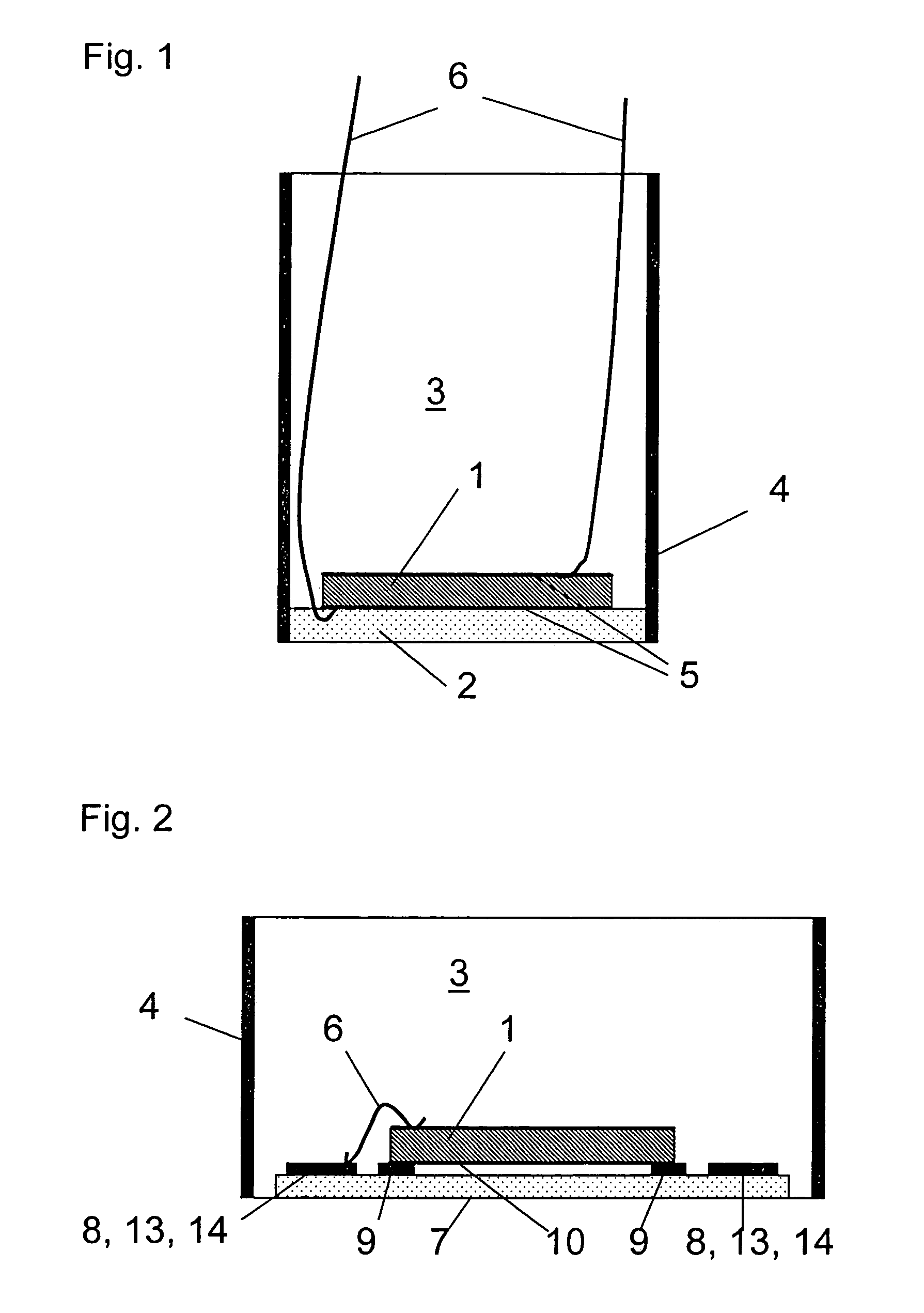

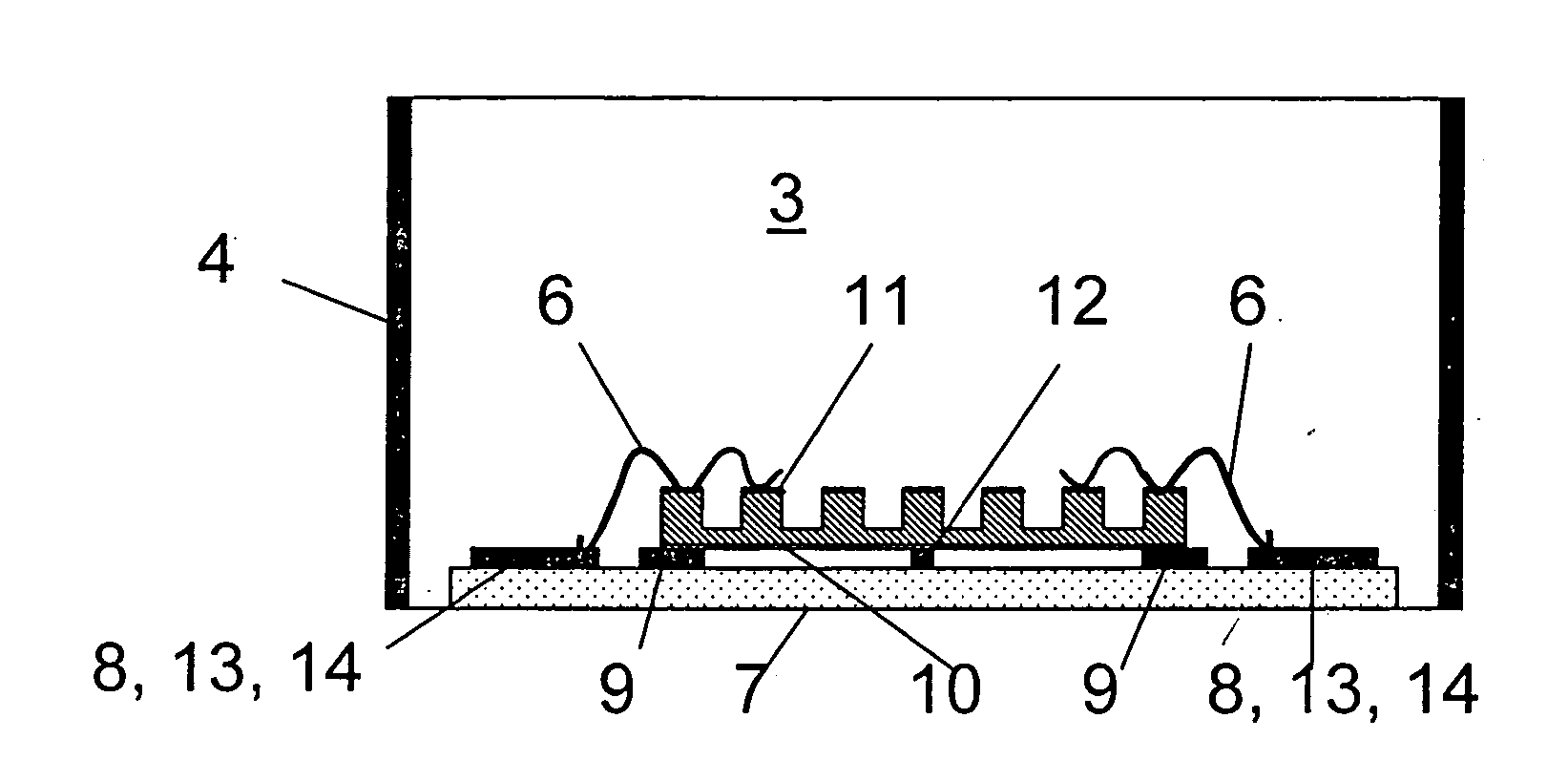

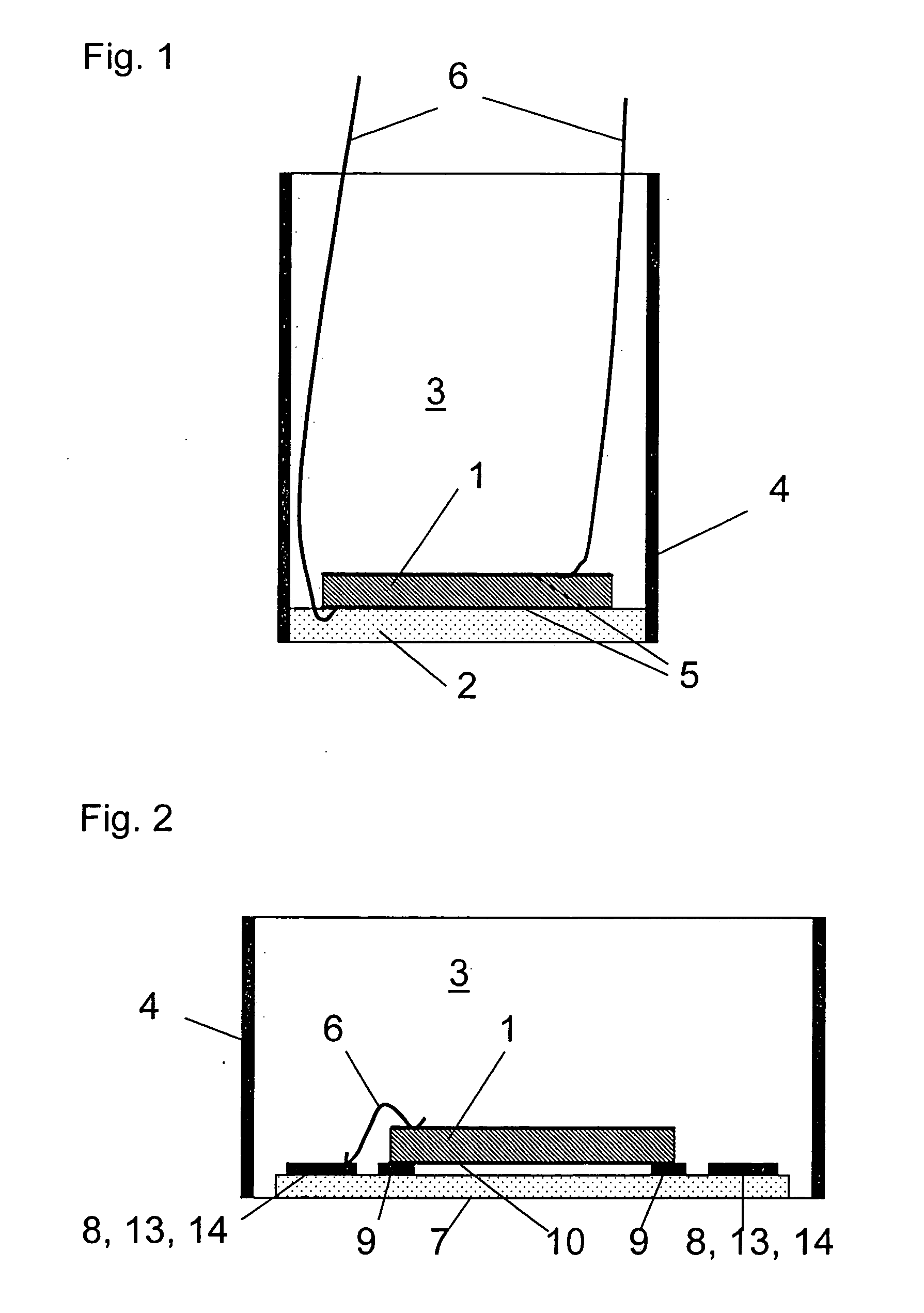

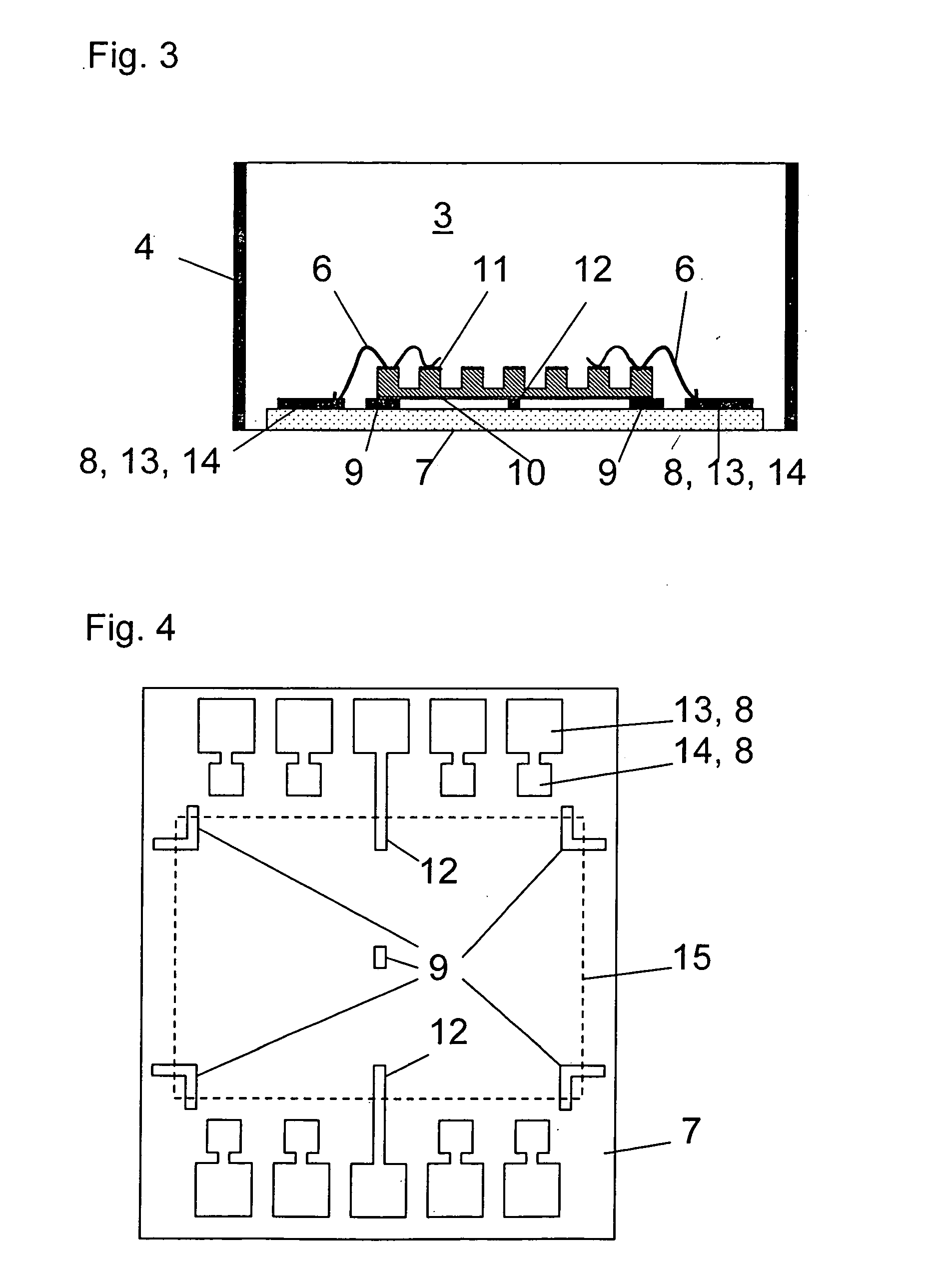

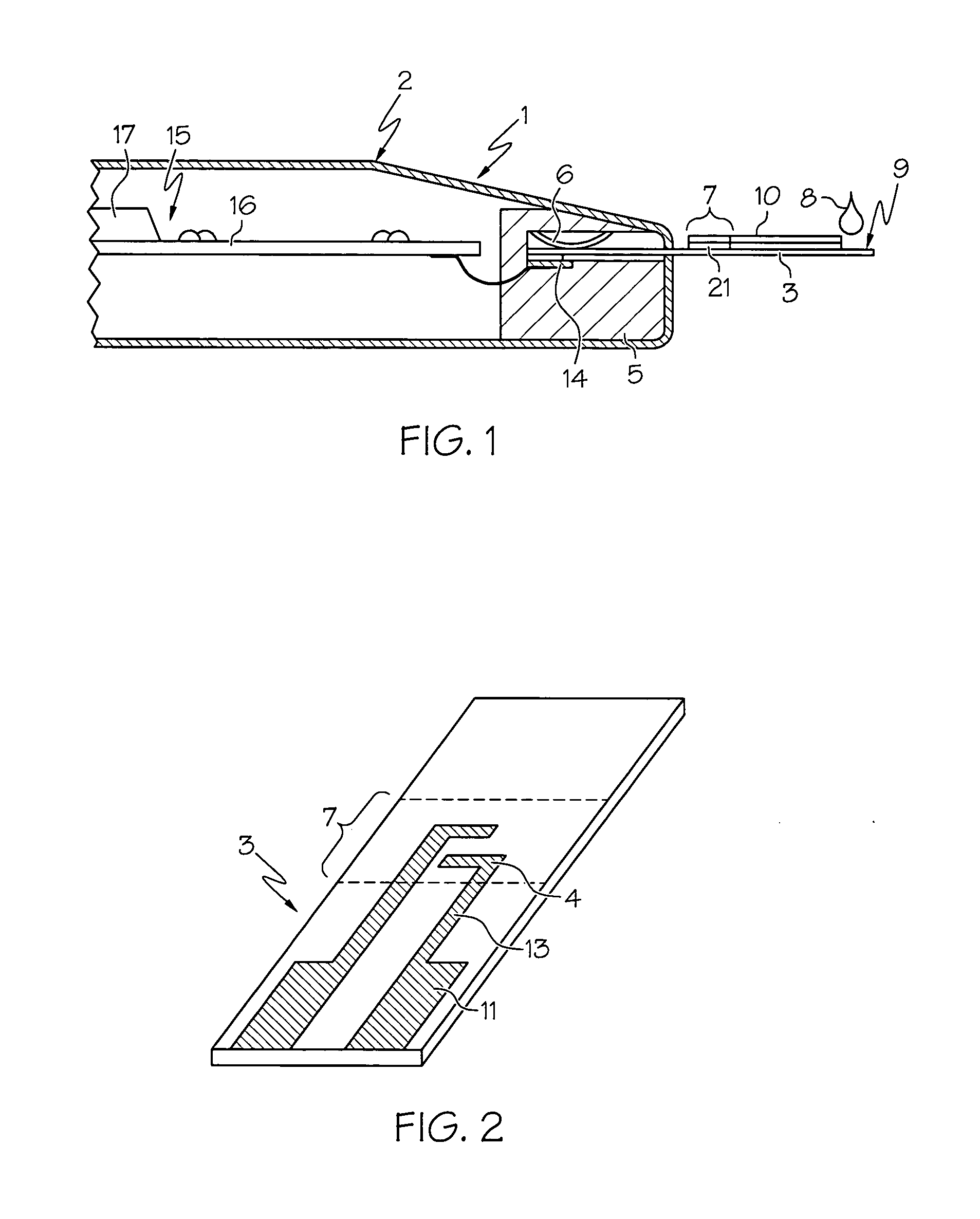

Ultrasound transducer and method of producing the same

InactiveUS7471034B2InhibitionImprove contact reliabilityUltrasonic/sonic/infrasonic diagnosticsPiezoelectric/electrostriction/magnetostriction machinesElectrical conductorUltrasonic sensor

In an ultrasound transducer arrangement comprising at least one piezoelectric body with a lower and an upper electrode and a coupling layer including a wafer on which the ultrasound transducers are disposed and are connected to the lower electrode, a conductor structure of uniform height is disposed on the wafer and is in contact with the lower electrode and any space between the piezoelectric body and the wafer is completely filled with a cement material.

Owner:KERNFORSCHUNGSZENTRUM KARLSRUHE GMBH

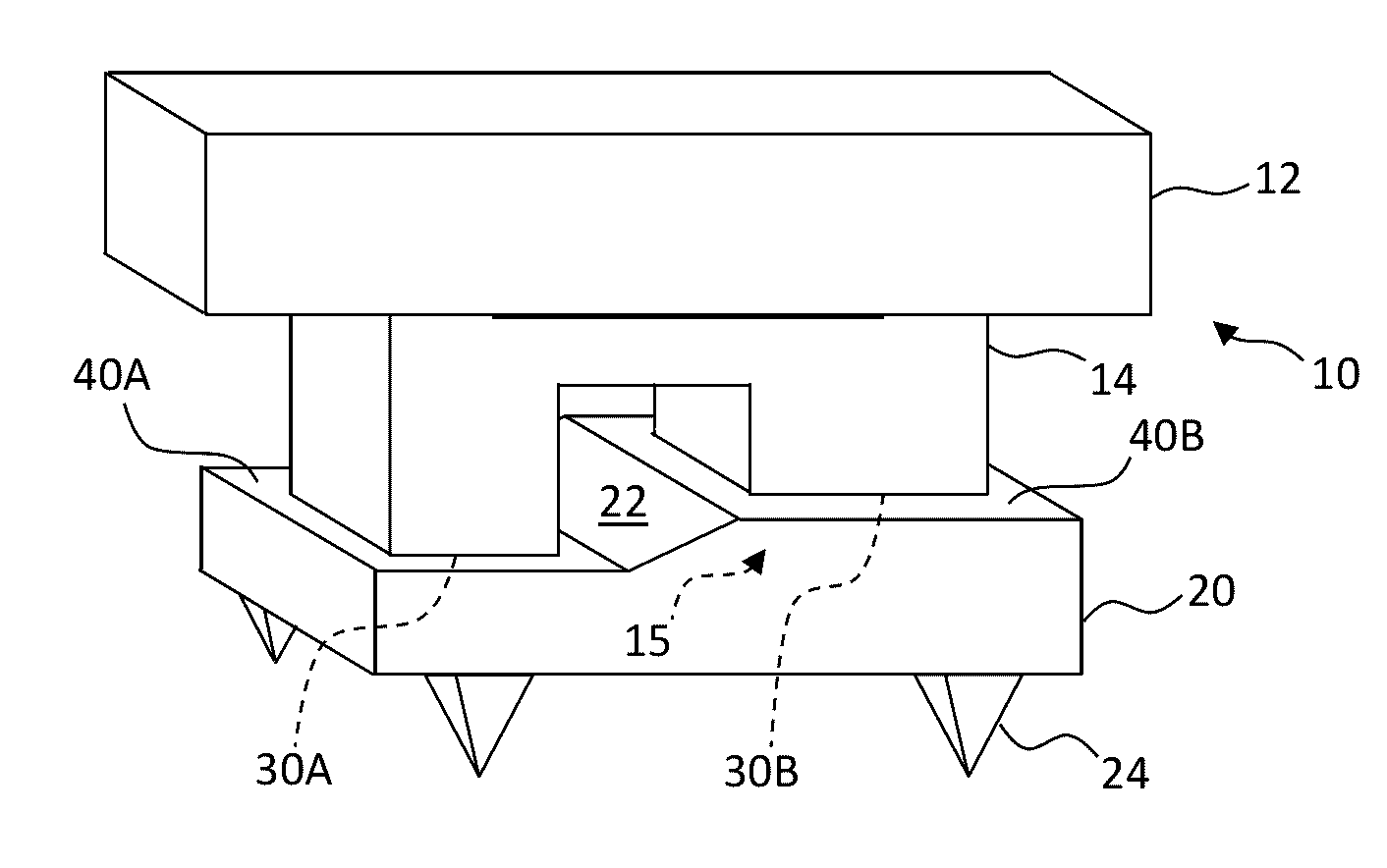

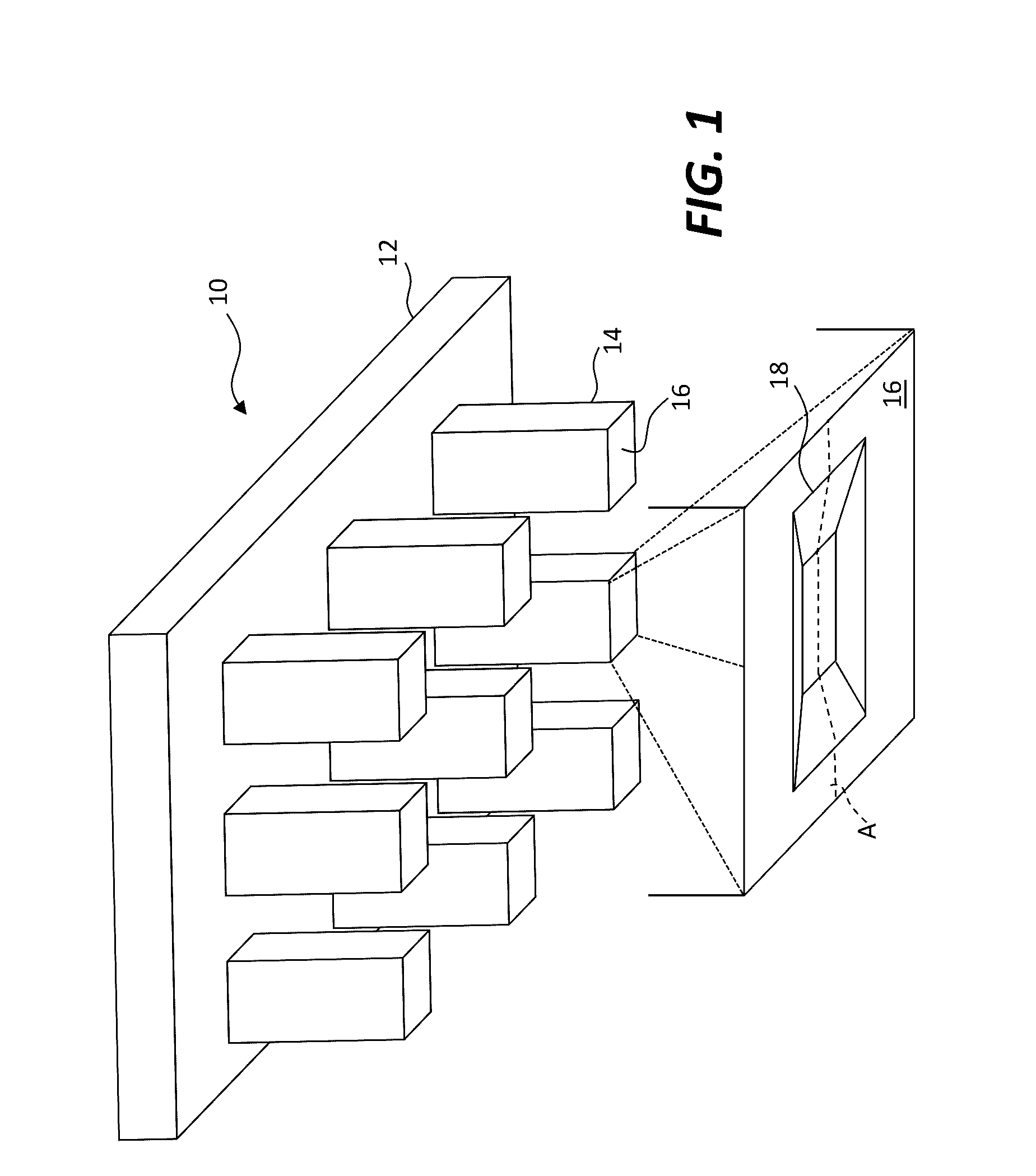

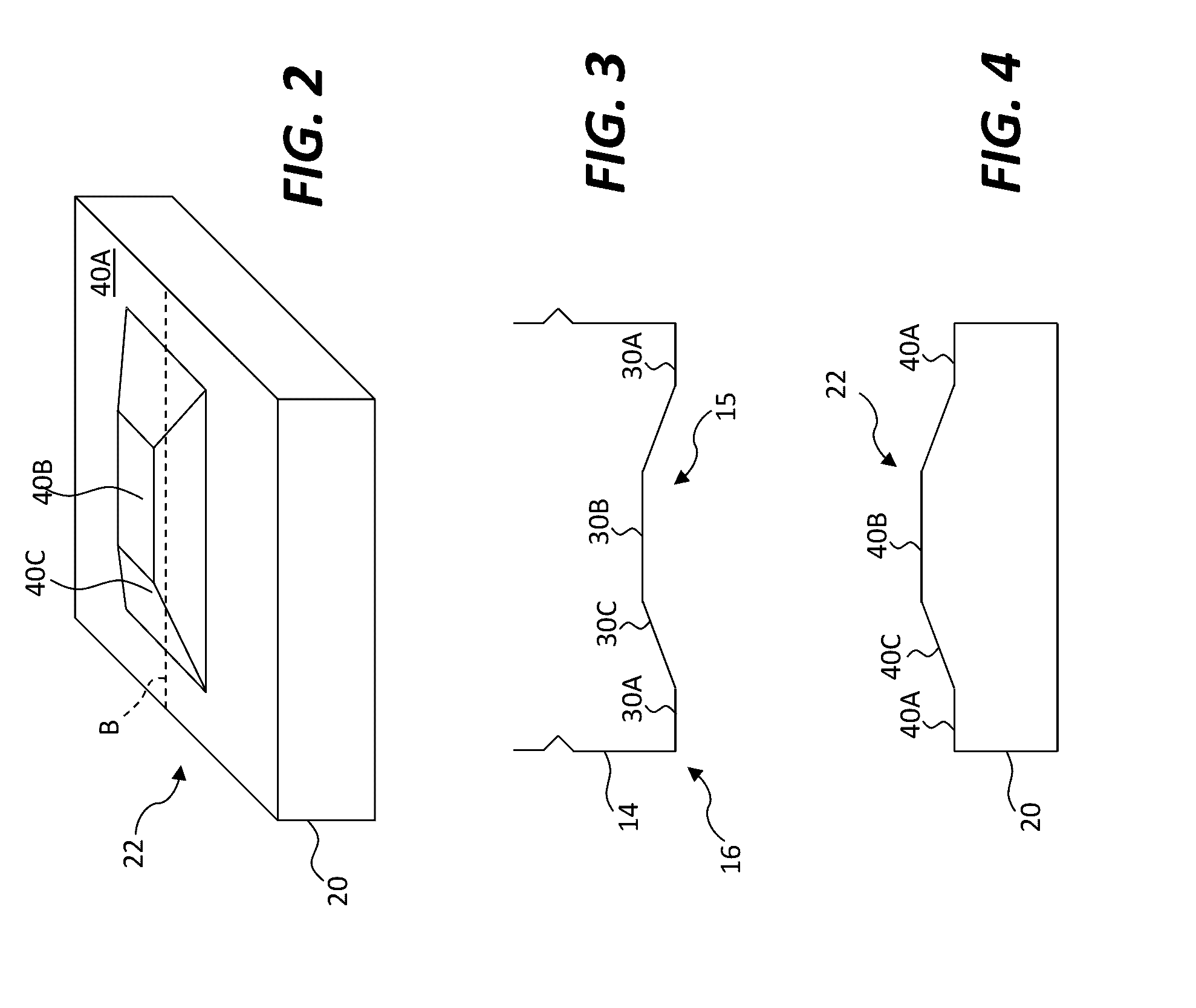

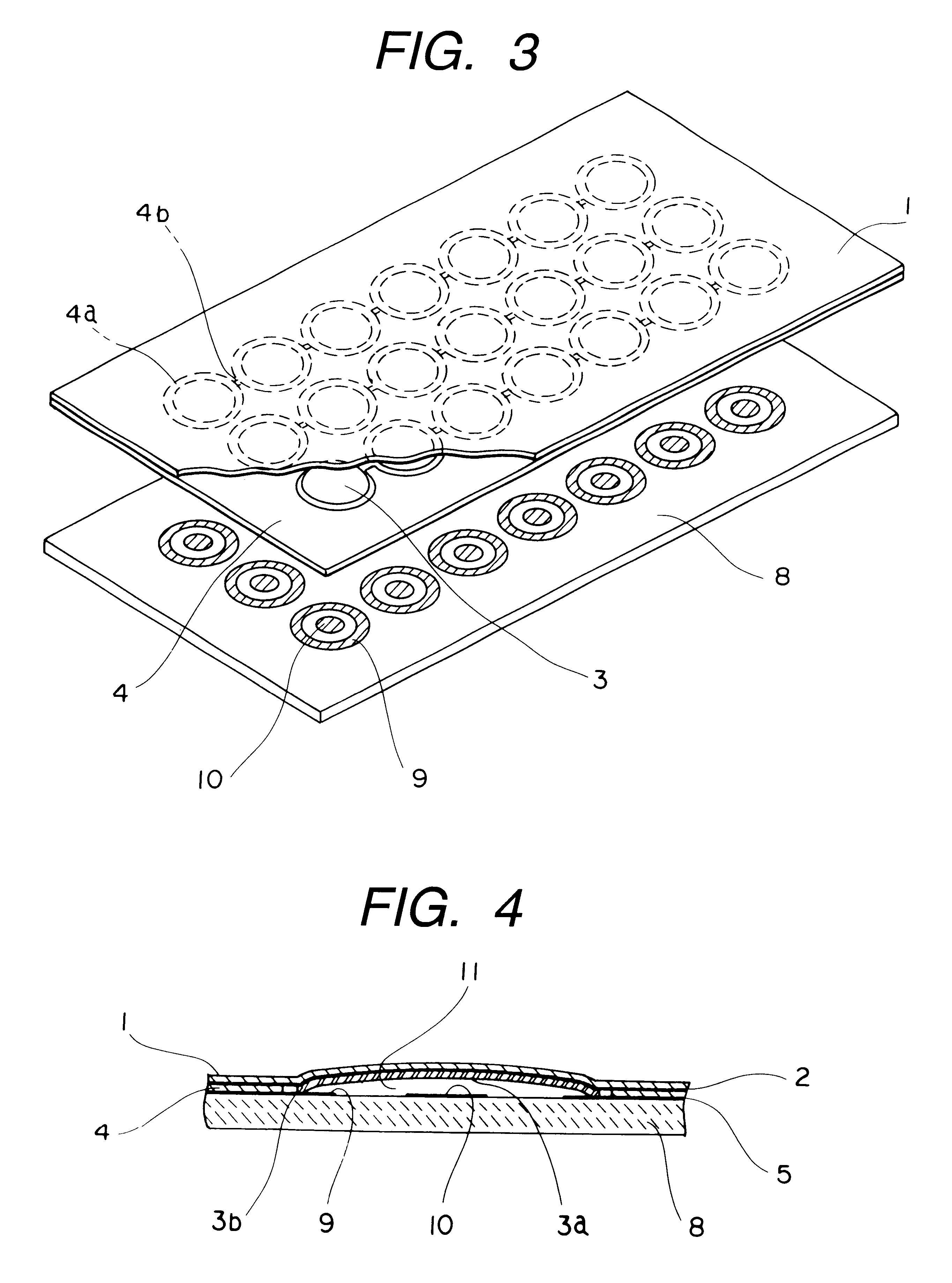

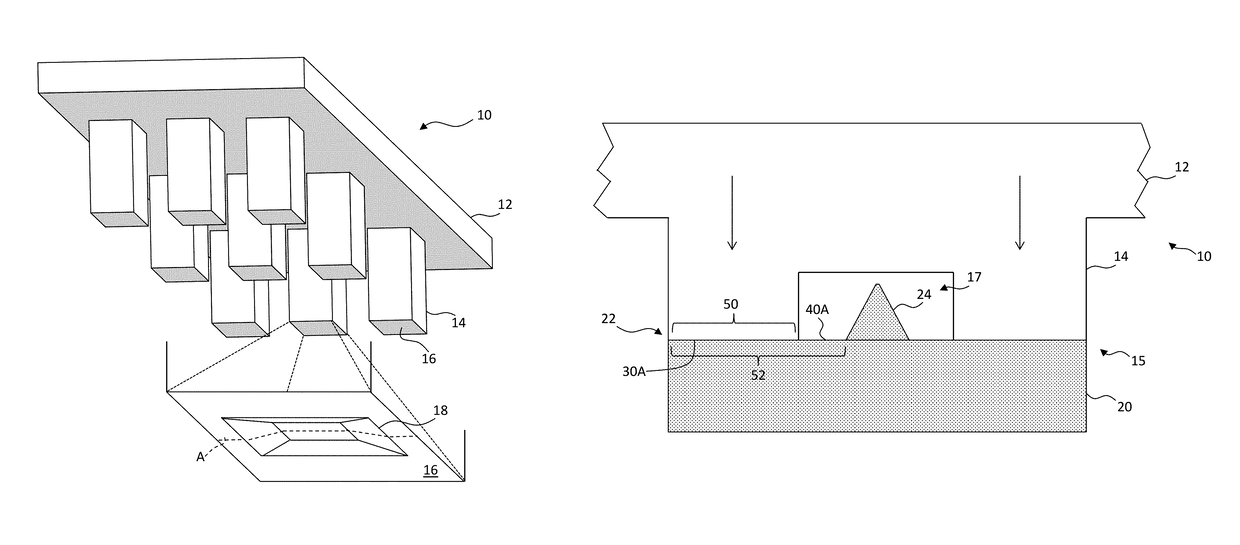

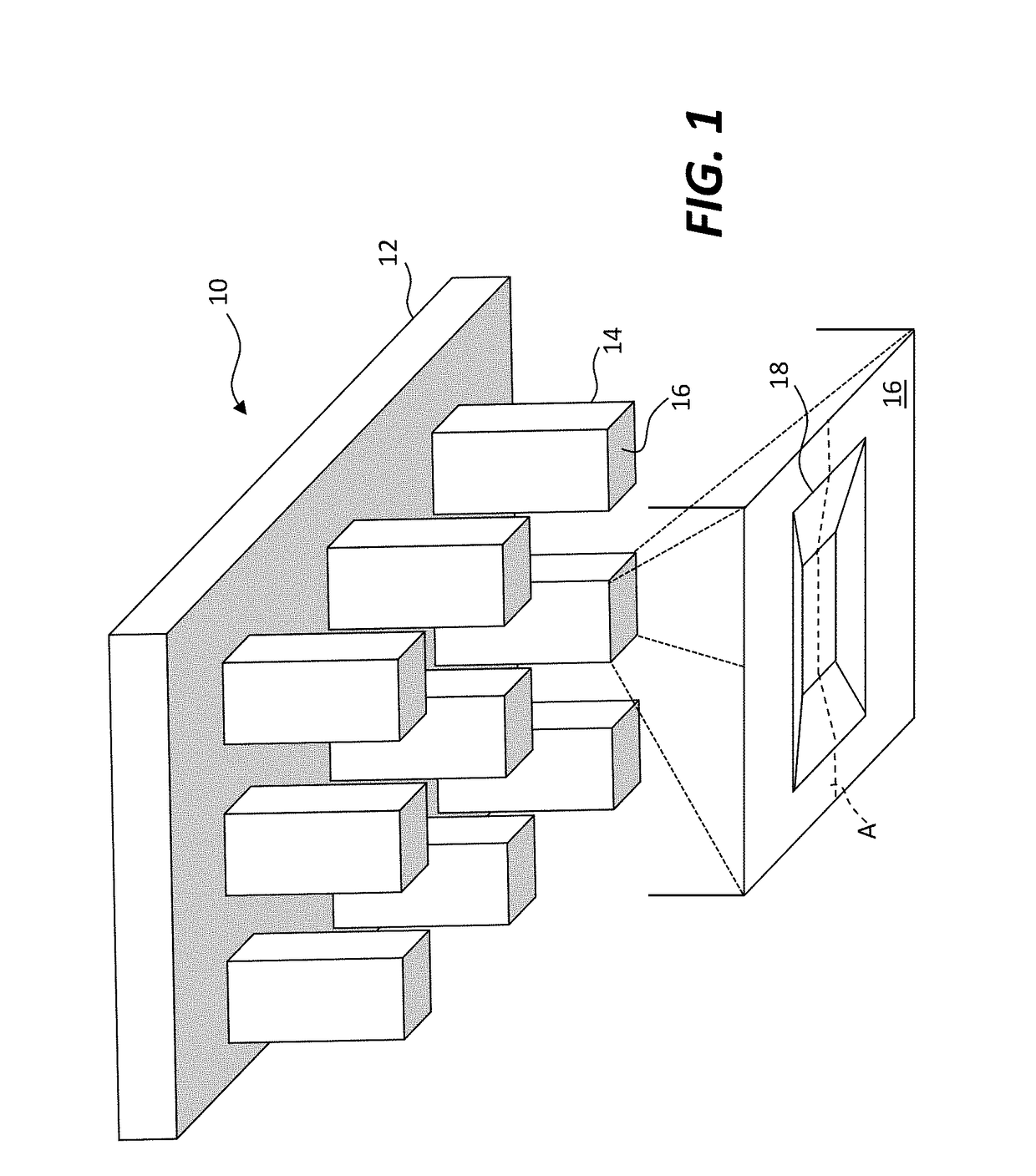

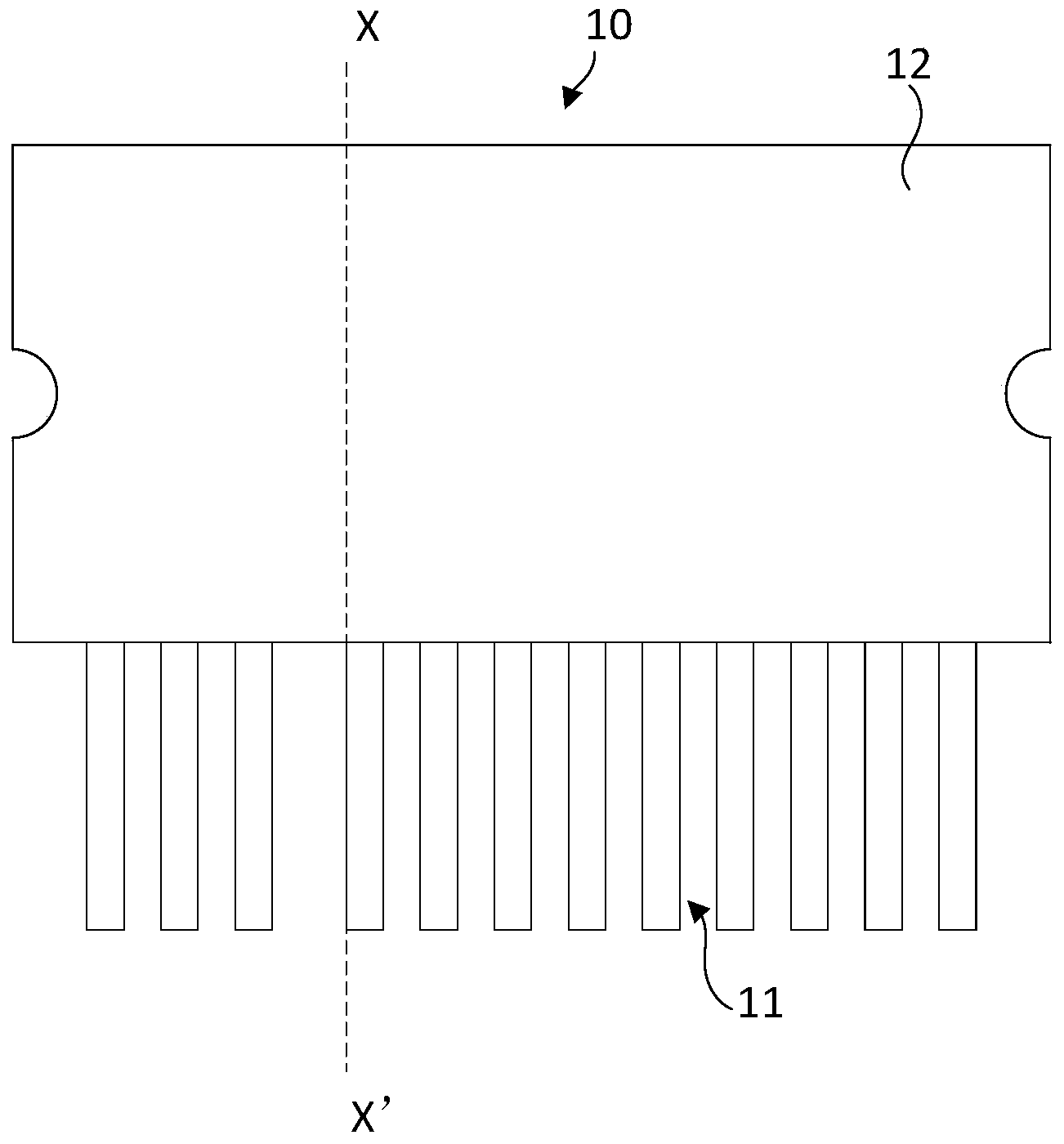

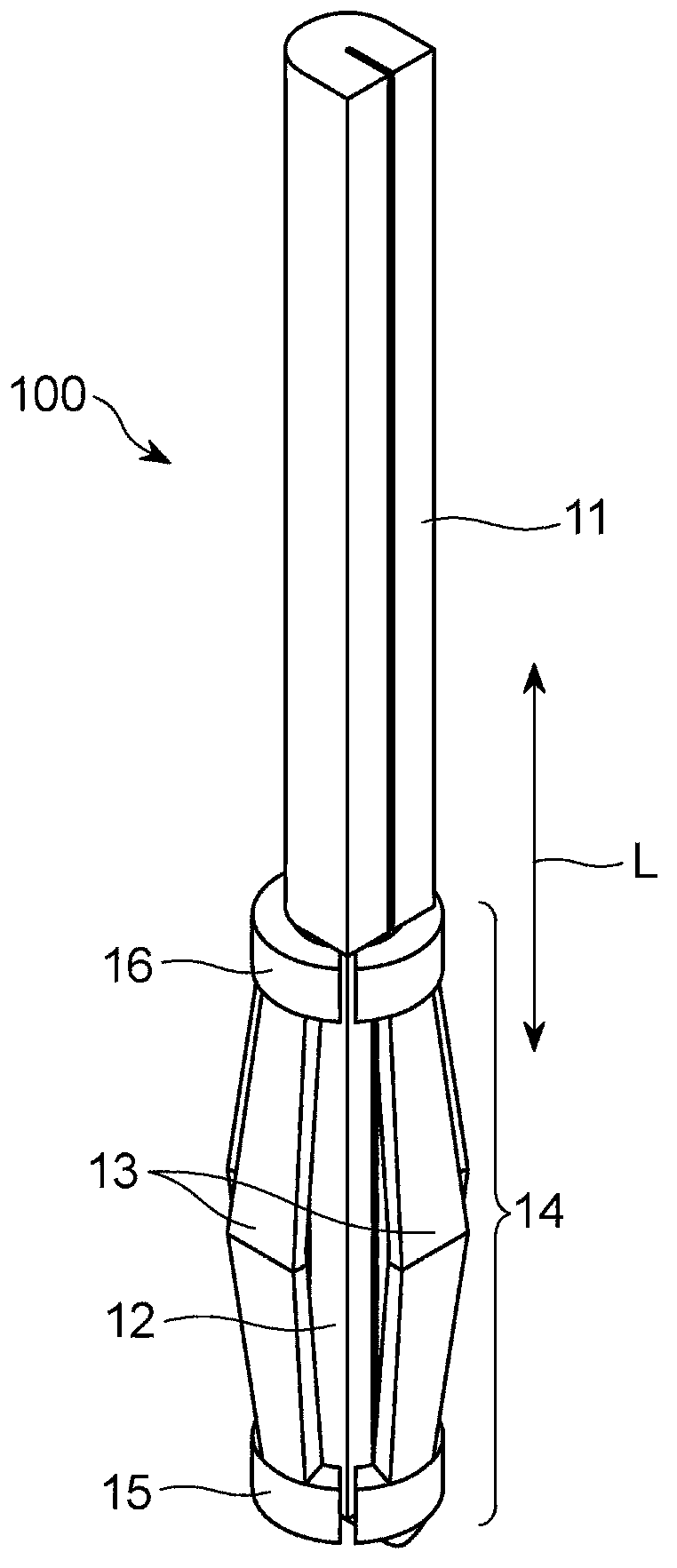

Stamp with structured posts

ActiveUS20170047306A1Great contact surface height variationLittle strengthTransfer printingSemiconductor/solid-state device detailsEngineeringSurface contour

A stamp for micro-transfer printing includes a body and one or more posts extending from the body. At least one of the posts has a non-planar surface contour on the distal end of the post having a size, shape, or size and shape that accommodates a non-planar contact surface of a micro-transfer printable device.

Owner:X DISPLAY CO TECH LTD

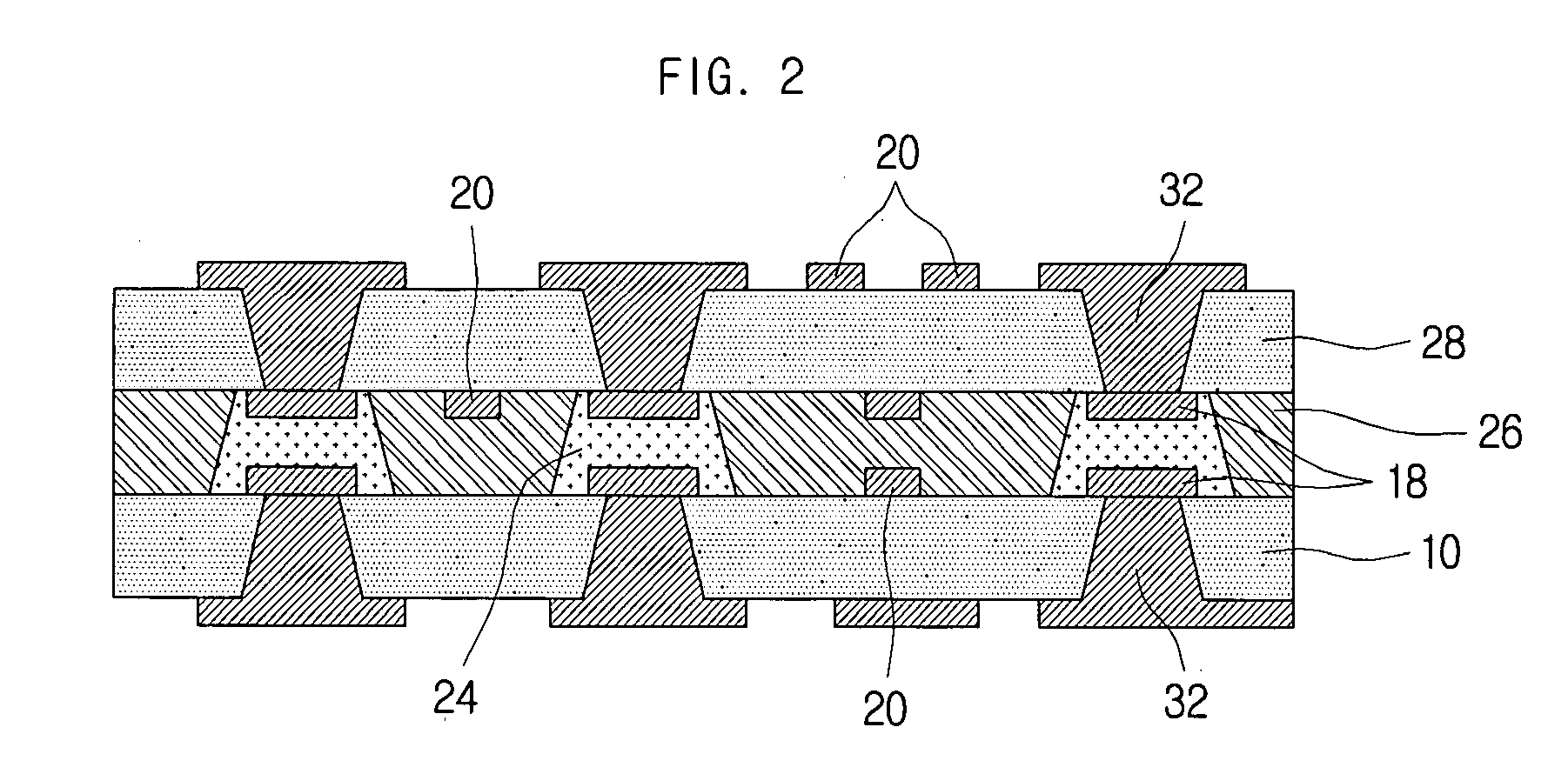

Printed circuit board and manufacturing method thereof

InactiveUS20080115961A1High densityImprove contact reliabilityPrinted circuit aspectsConductive pattern formationHigh densityEngineering

A printed circuit board and a manufacturing method thereof are disclosed. Using a method of manufacturing a printed circuit board which includes forming a circuit pattern, which includes lands, on a first board; forming a paste bump on the land of the first board; and stacking an insulation on a surface of the first board such that the paste bump penetrates the insulation, where the paste bump is formed to cover the land of the first board, the areas of the lands can be reduced to manufacture a printed circuit board of high density, and the contact reliability can be increased due to the increase in contact area between the lands and paste bumps to improve the performance of the high-density printed circuit-board.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

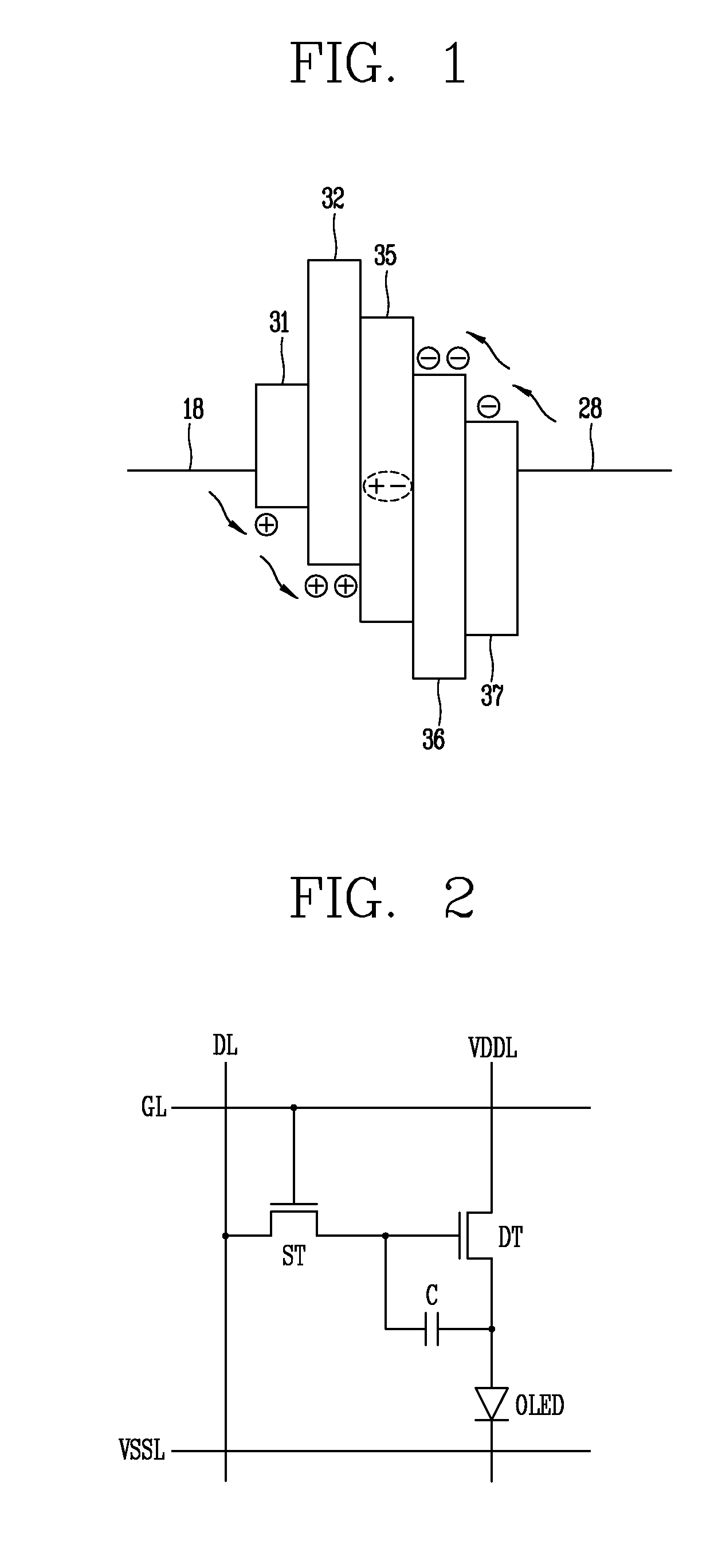

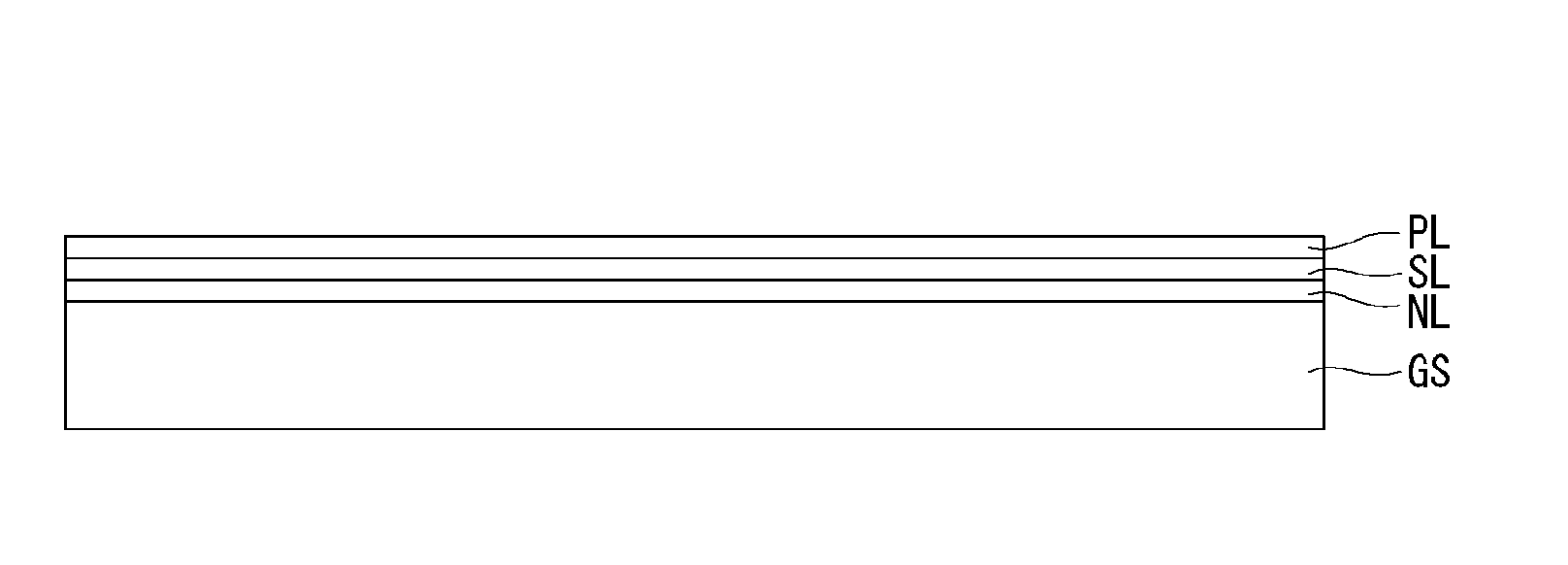

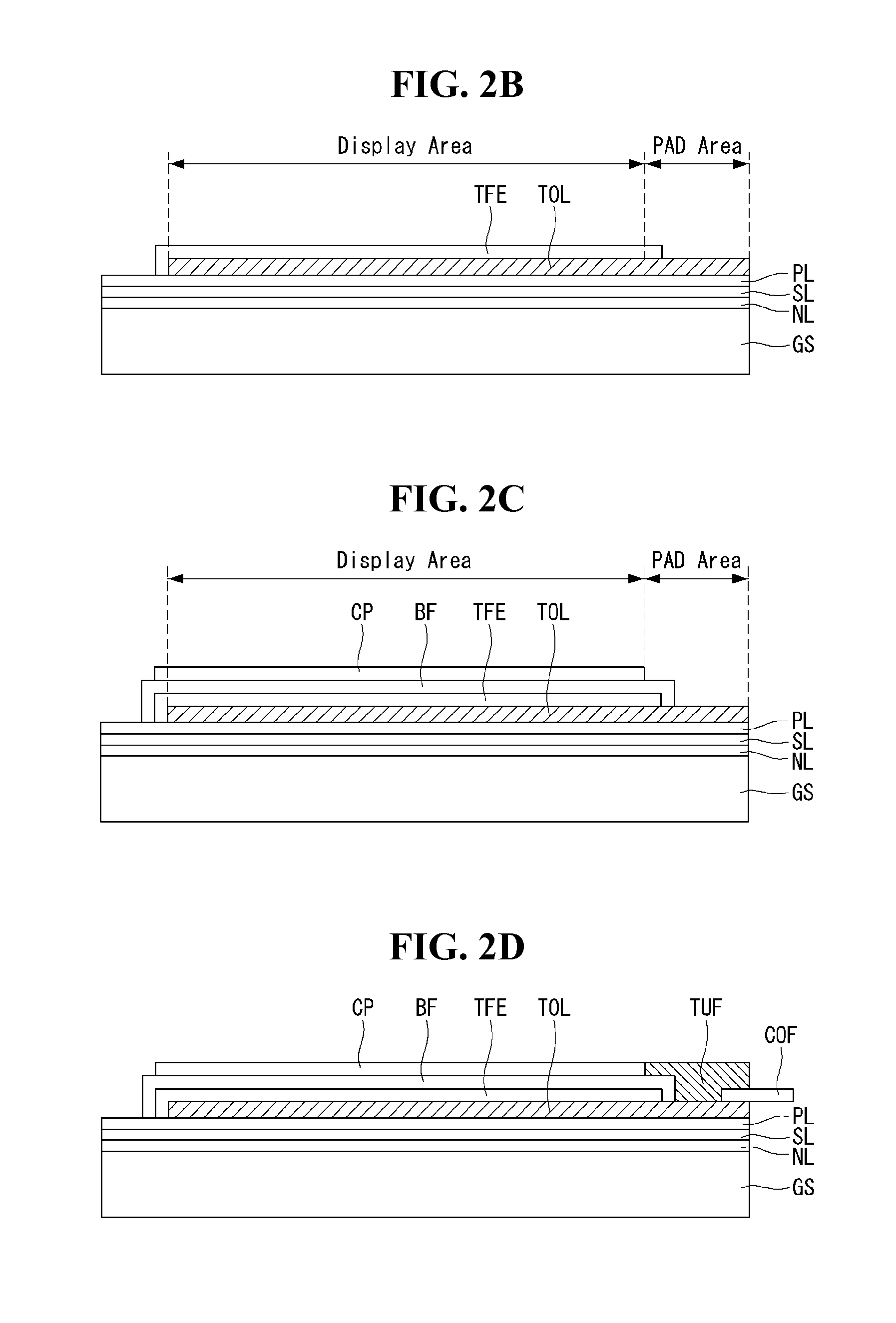

Organic Light Emitting Display Device and Method for Manufacturing the Same

ActiveUS20120139821A1Reduce step differenceImprove contact reliabilityStatic indicating devicesElectroluminescent light sourcesAdhesiveOrganic layer

The present disclosure relates to an organic light emitting display device and a method for manufacturing the same. The present disclosure suggests an organic light emitting display device including an organic layer; a display element layer including a display area representing video data and a pad area extended from the display area, on the organic layer; film elements formed on the display element layer; a film type printed circuit board connected to the pad area; and a reinforcing adhesive filling a space between the film type printed circuit board and the film elements

Owner:LG DISPLAY CO LTD

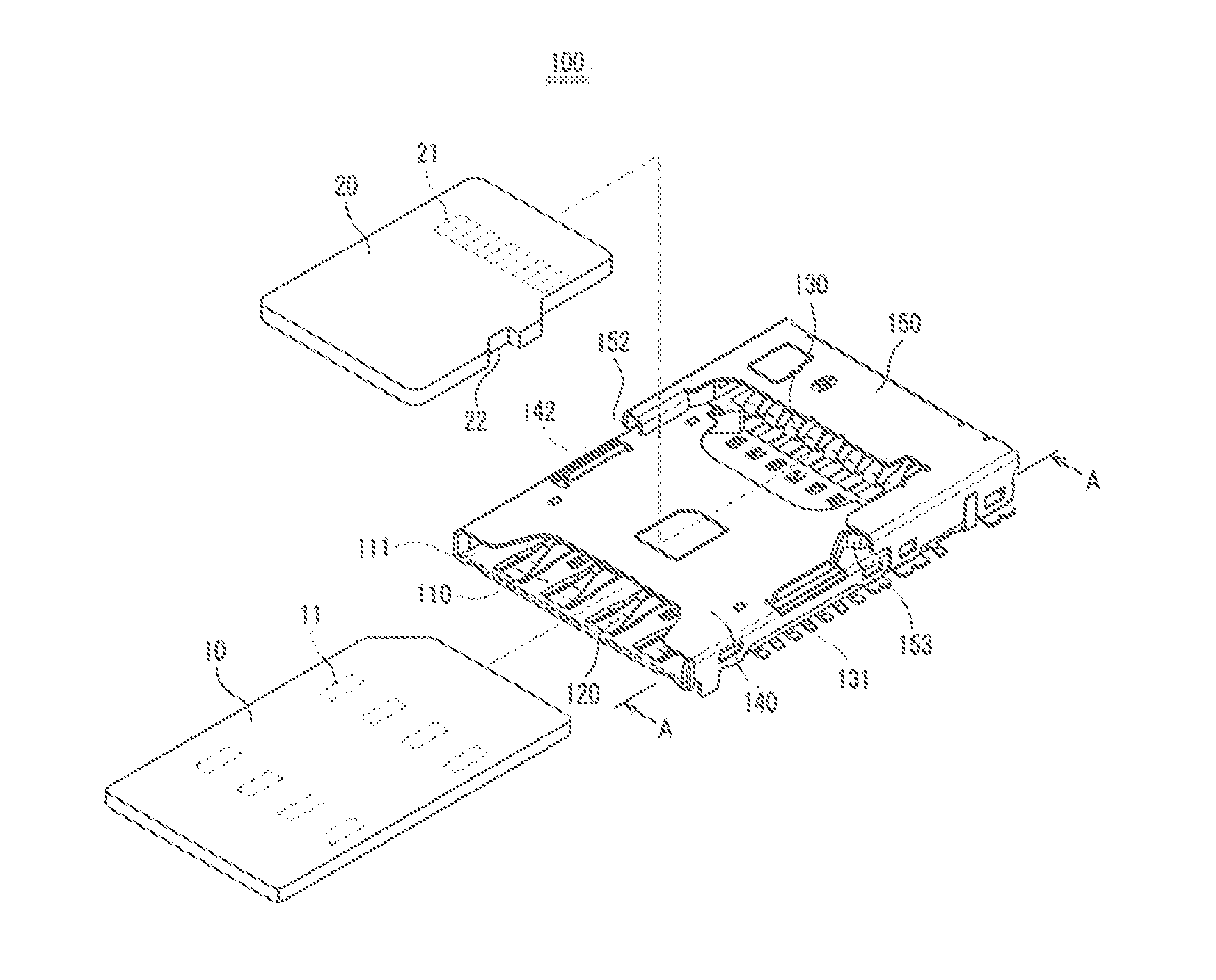

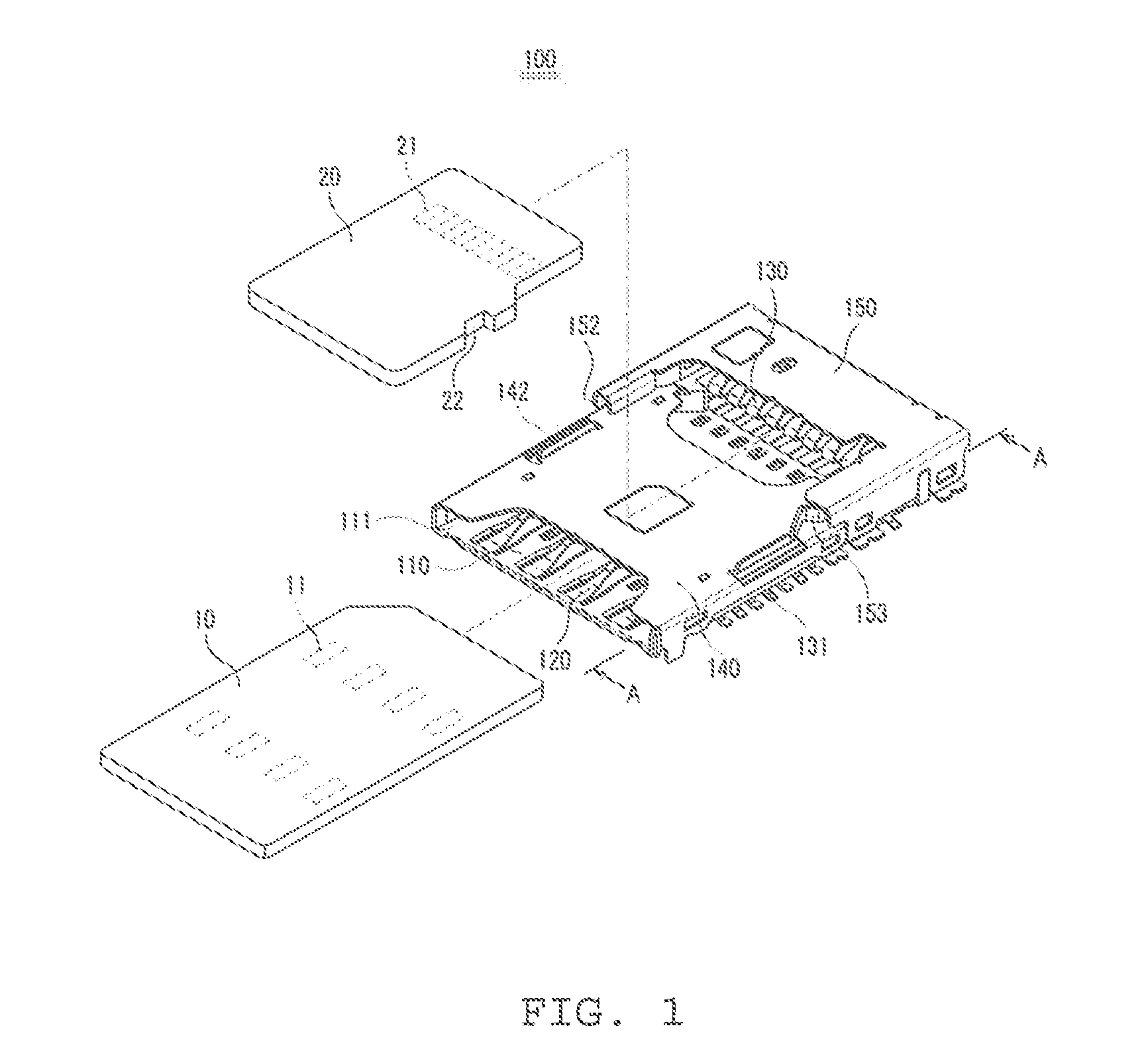

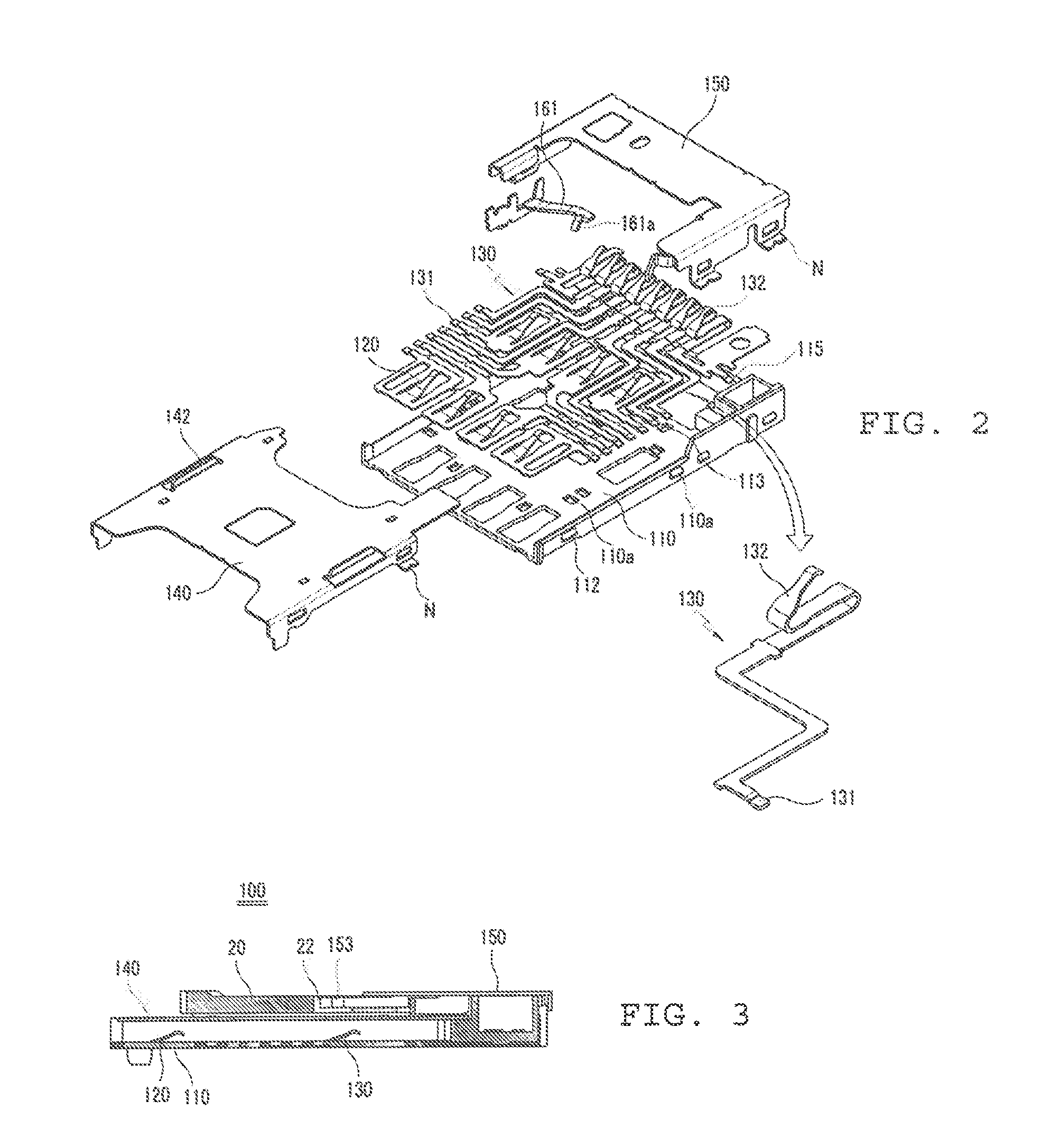

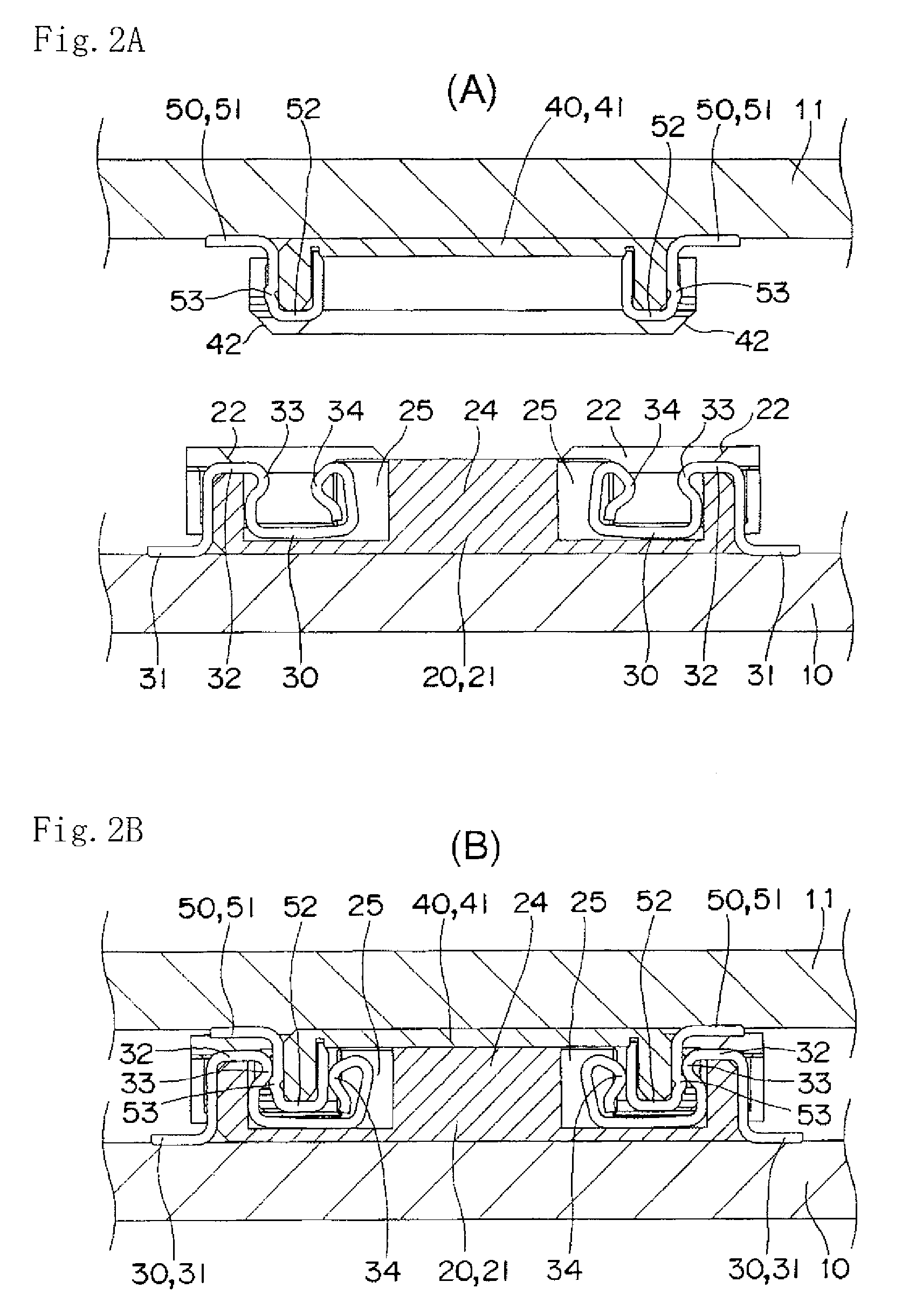

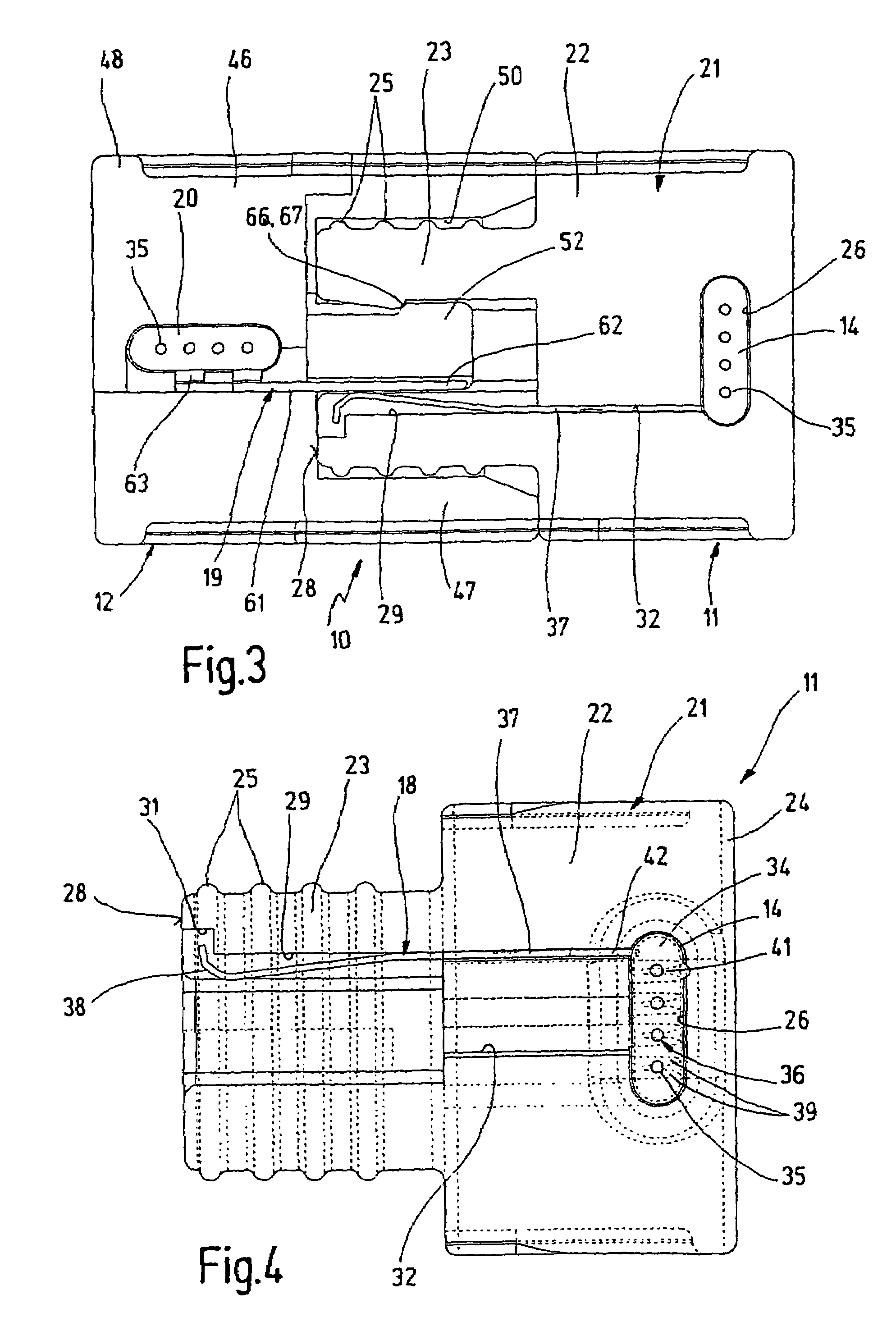

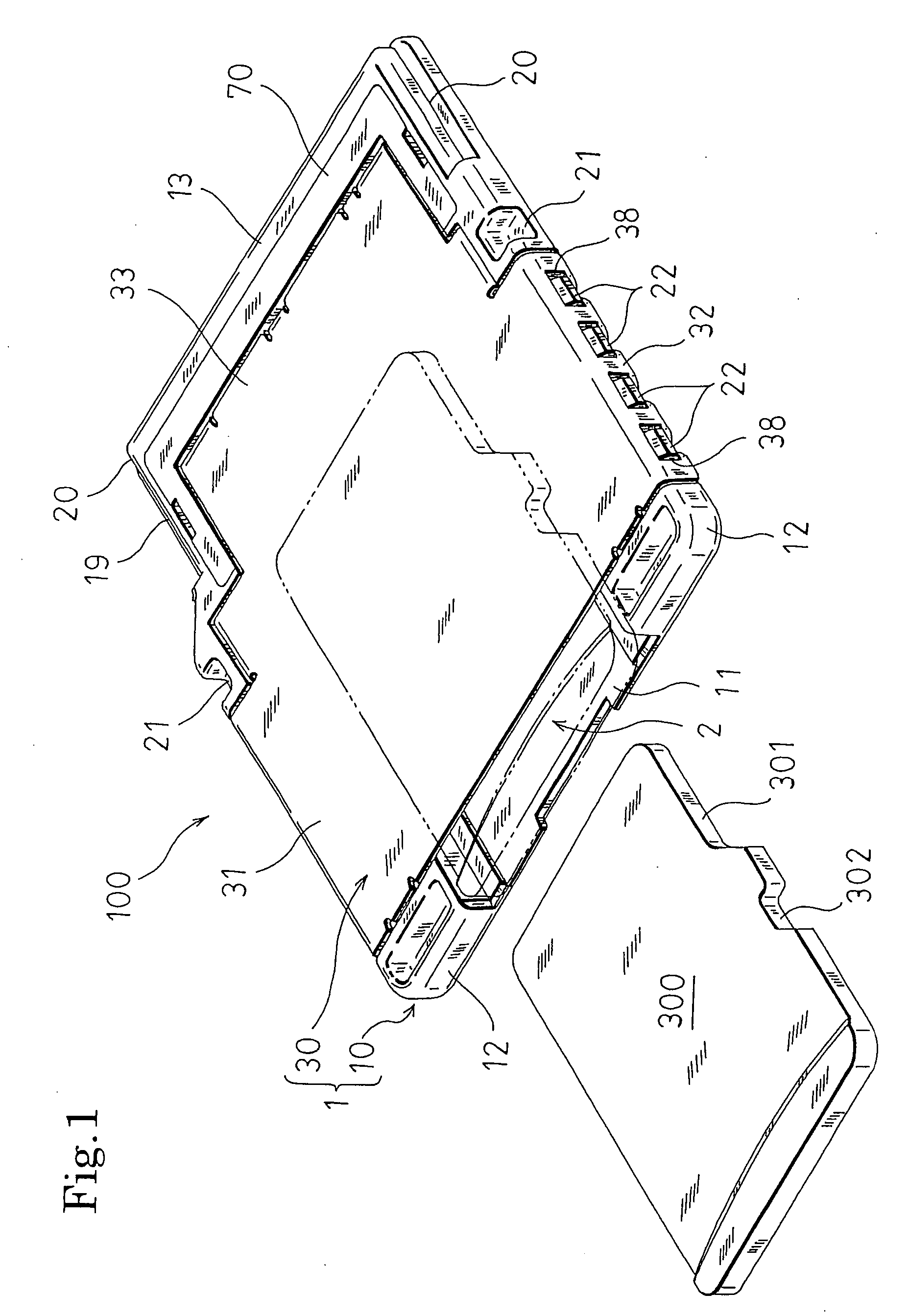

Dual memory card socket

ActiveUS20130288535A1Prevent saggingReduce manufacturing costCoupling device detailsTwo-part coupling devicesEngineeringMemory cards

The Present Disclosure relates to mold a micro SIM card connecting terminal and a micro SD card connecting terminal by means of an integrated terminal mold, so as to significantly reduce the whole length of the dual memory card socket and manufacturing method thereof. The Present Disclosure is formed by a structure manufactured by molding the micro SIM card connecting terminal and the micro SD card connecting terminal by means of an integrated terminal mold, and then separating them by a cutting process.

Owner:MOLEX INC

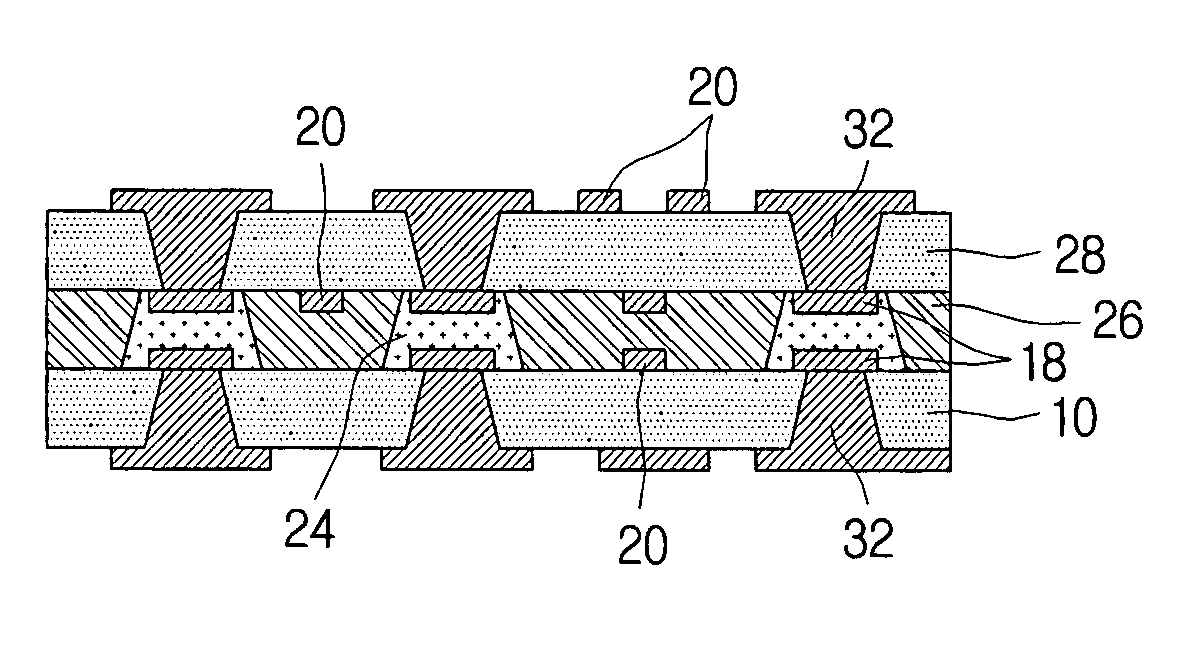

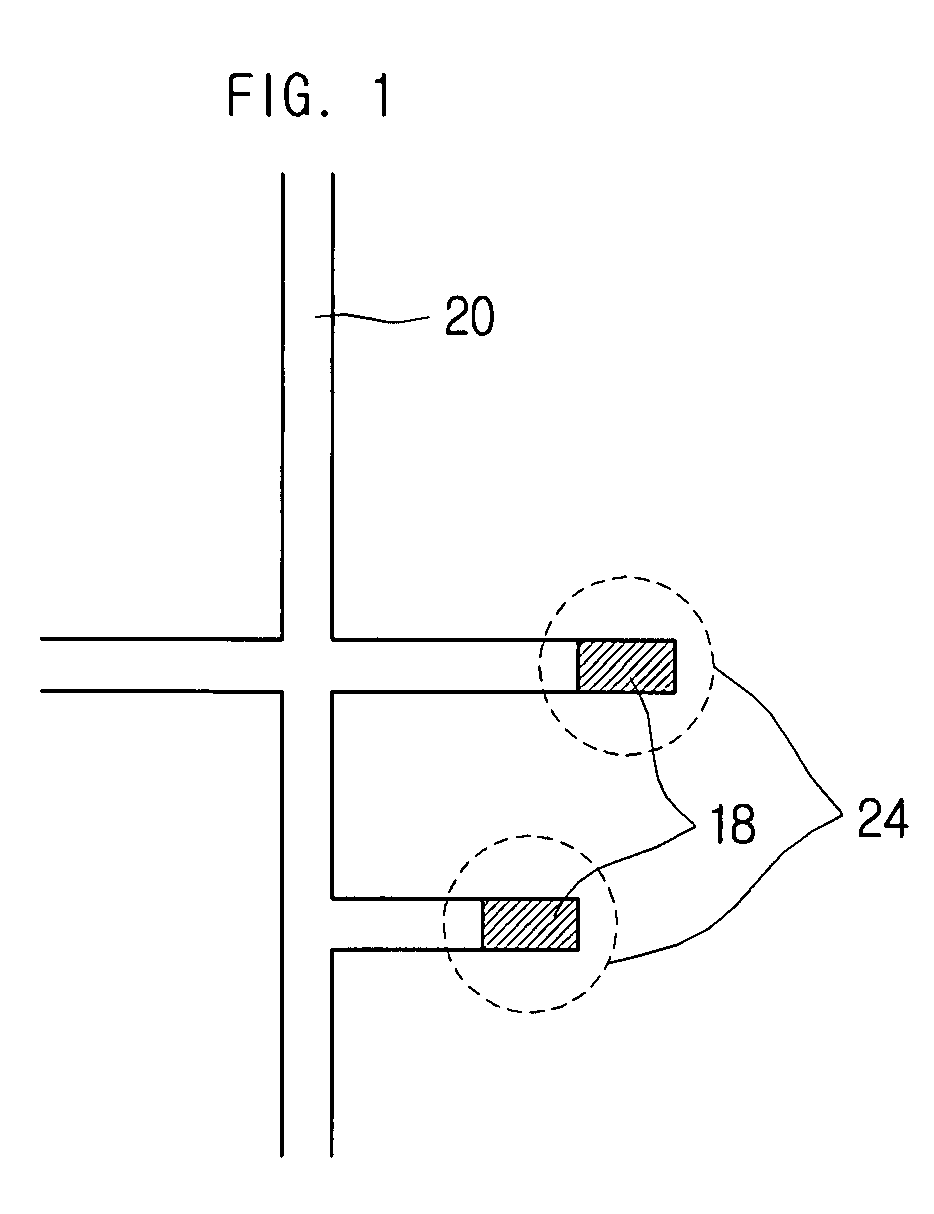

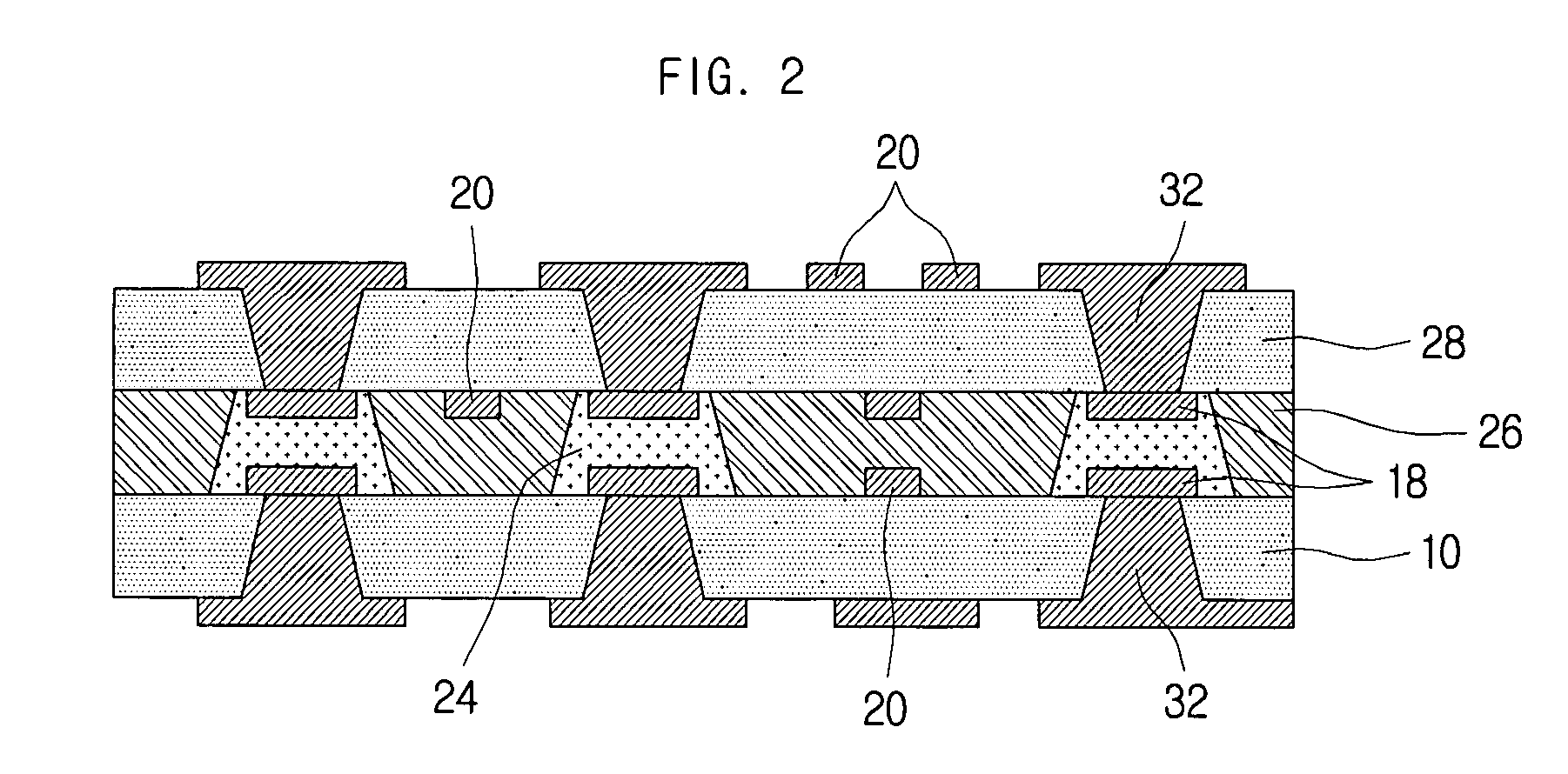

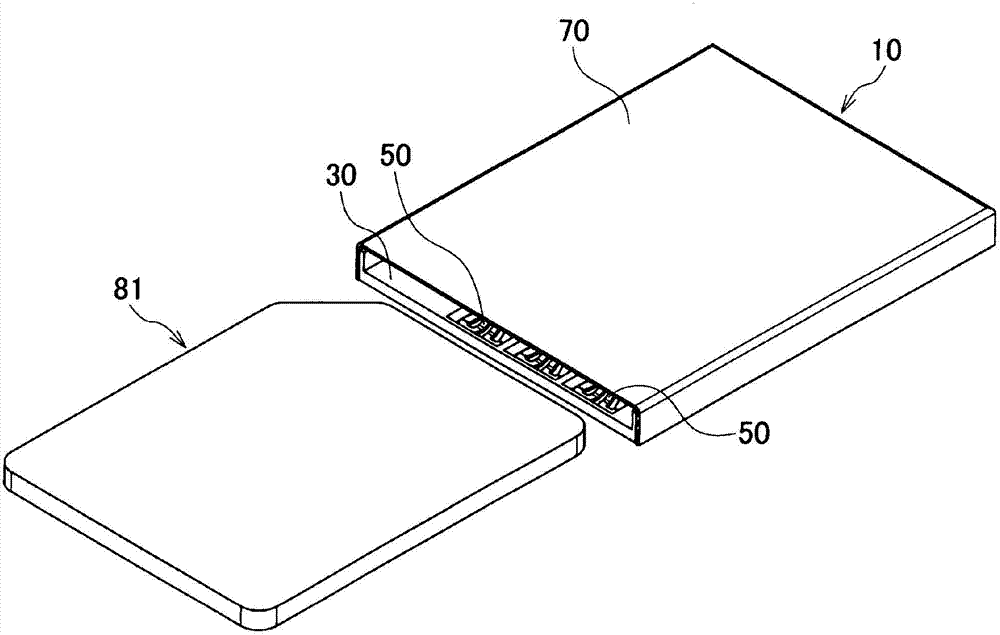

Printed circuit board and manufacturing method thereof

InactiveUS8058558B2High densityImprove contact reliabilityPrinted circuit aspectsConductive pattern formationHigh densitySolder paste

A printed circuit board and a manufacturing method thereof are disclosed. Using a method of manufacturing a printed circuit board which includes forming a circuit pattern, which includes lands, on a first board; forming a paste bump on the land of the first board; and stacking an insulation on a surface of the first board such that the paste bump penetrates the insulation, where the paste bump is formed to cover the land of the first board, the areas of the lands can be reduced to manufacture a printed circuit board of high density, and the contact reliability can be increased due to the increase in contact area between the lands and paste bumps to improve the performance of the high-density printed circuit-board.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

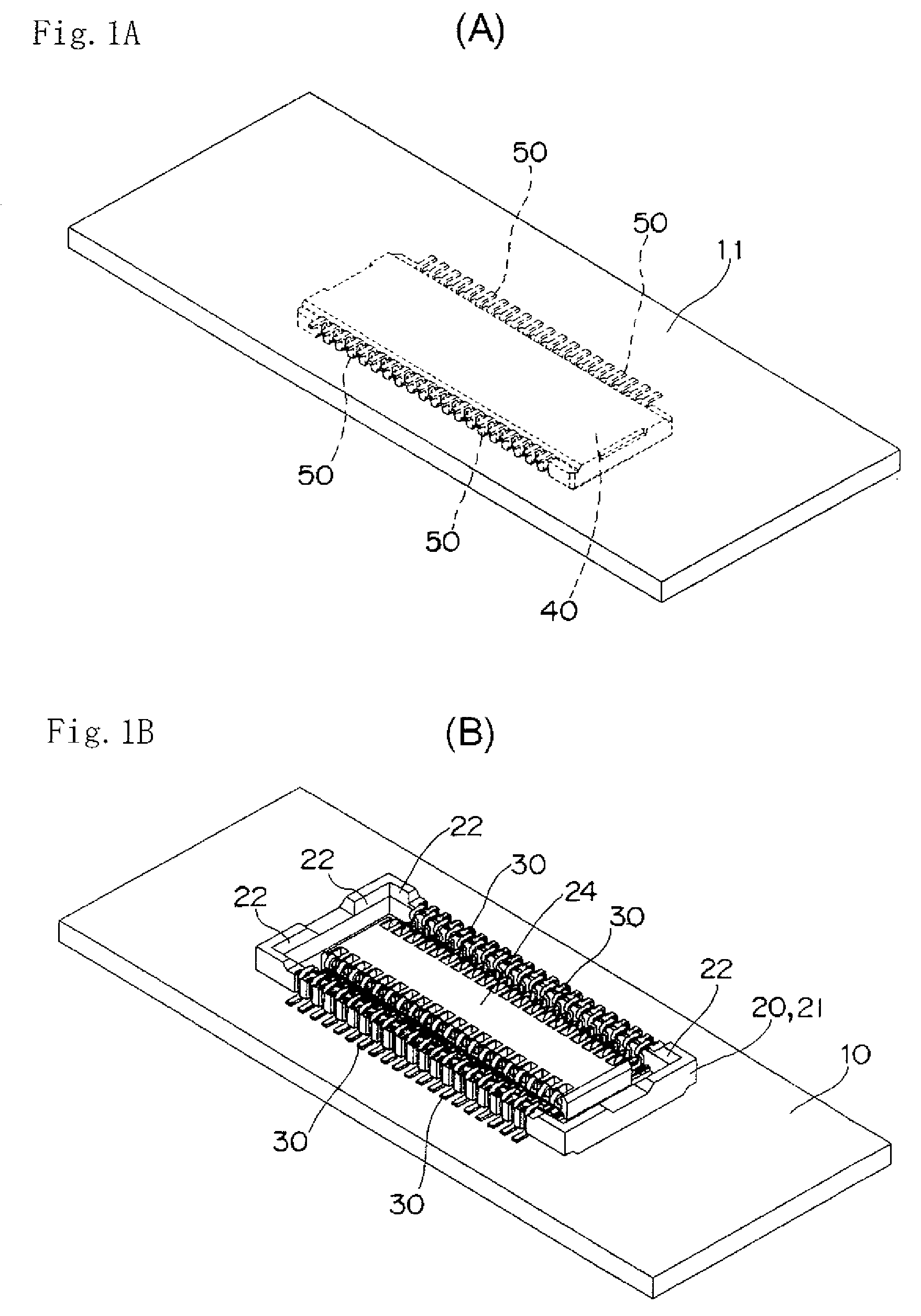

Connector

ActiveCN103050806AIncreased durabilityImprove contact reliabilitySecuring/insulating coupling contact membersCoupling contact membersElectronic componentEngineering

A connector capable of improving the durability and the contact reliability of a contact. In the contact, a pair of spring portions for pressing a contact portion against a card-type electronic component are formed continuous with the contact portion that is brought into contact with the card-type electronic component. A holding portion held by a housing is formed continuous with the spring portions A connection portion connected to a printed board is formed continuous with the holding portion. The spring portions are made elastically deformable independently of each other, and are bent such that part and the other part of each spring portion do not interfere with each other in a direction of height of the housing when the spring portion is elastically deformed.

Owner:JAPAN AVIATION ELECTRONICS IND LTD

Ultrasound transducer and method of producing the same

InactiveUS20060230605A1Improve the preparation effectSuitable mounting arrangementUltrasonic/sonic/infrasonic diagnosticsElectrical transducersElectrical conductorUltrasound

In an ultrasound transducer arrangement comprising at least one piezoelectric body with a lower and an upper electrode and a coupling layer including a wafer on which the ultrasound transducers are disposed and are connected to the lower electrode, a conductor structure of uniform height is disposed on the wafer and is in contact with the lower electrode and any space between the piezoelectric body and the wafer is completely filled with a cement material.

Owner:KERNFORSCHUNGSZENTRUM KARLSRUHE GMBH

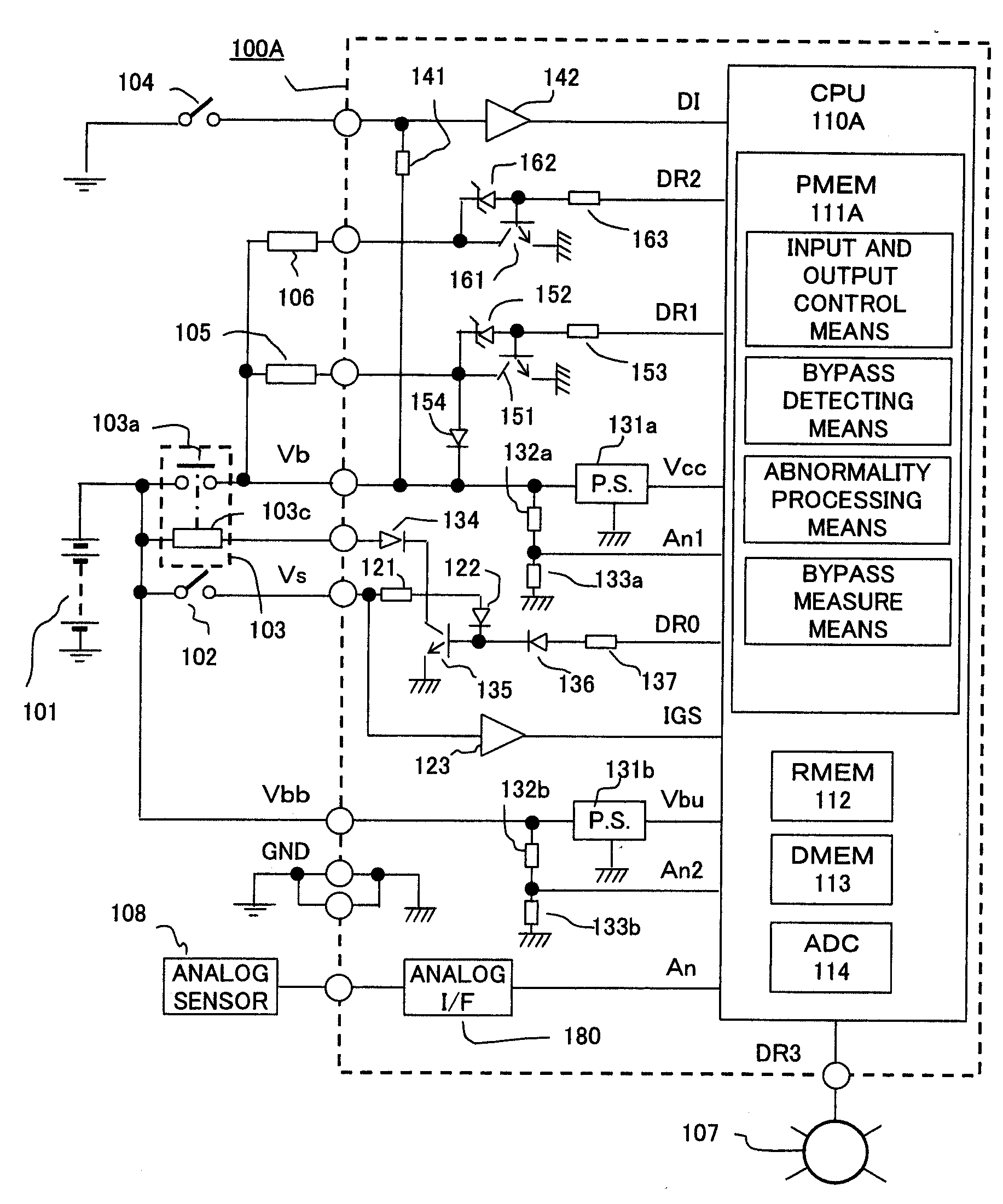

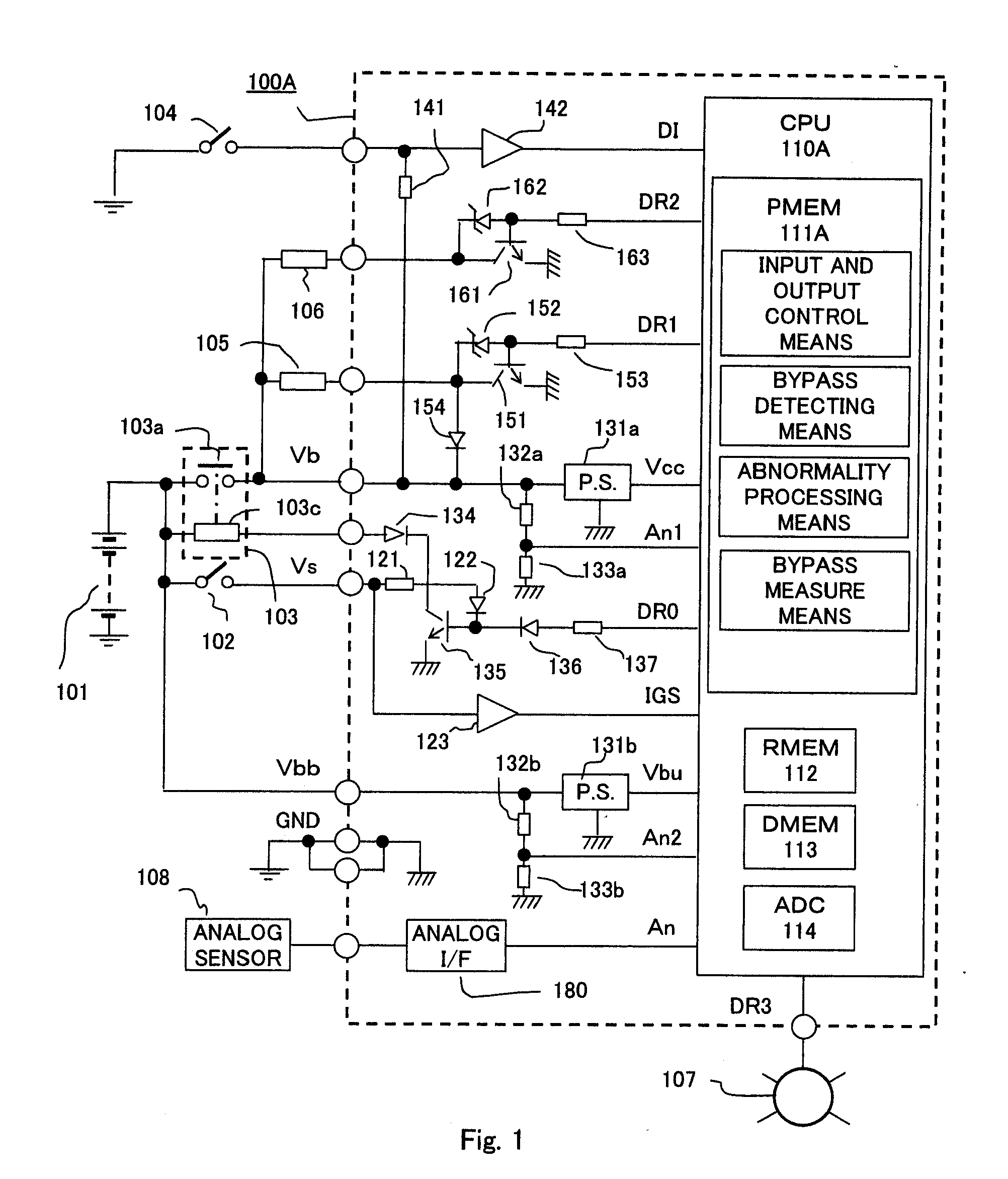

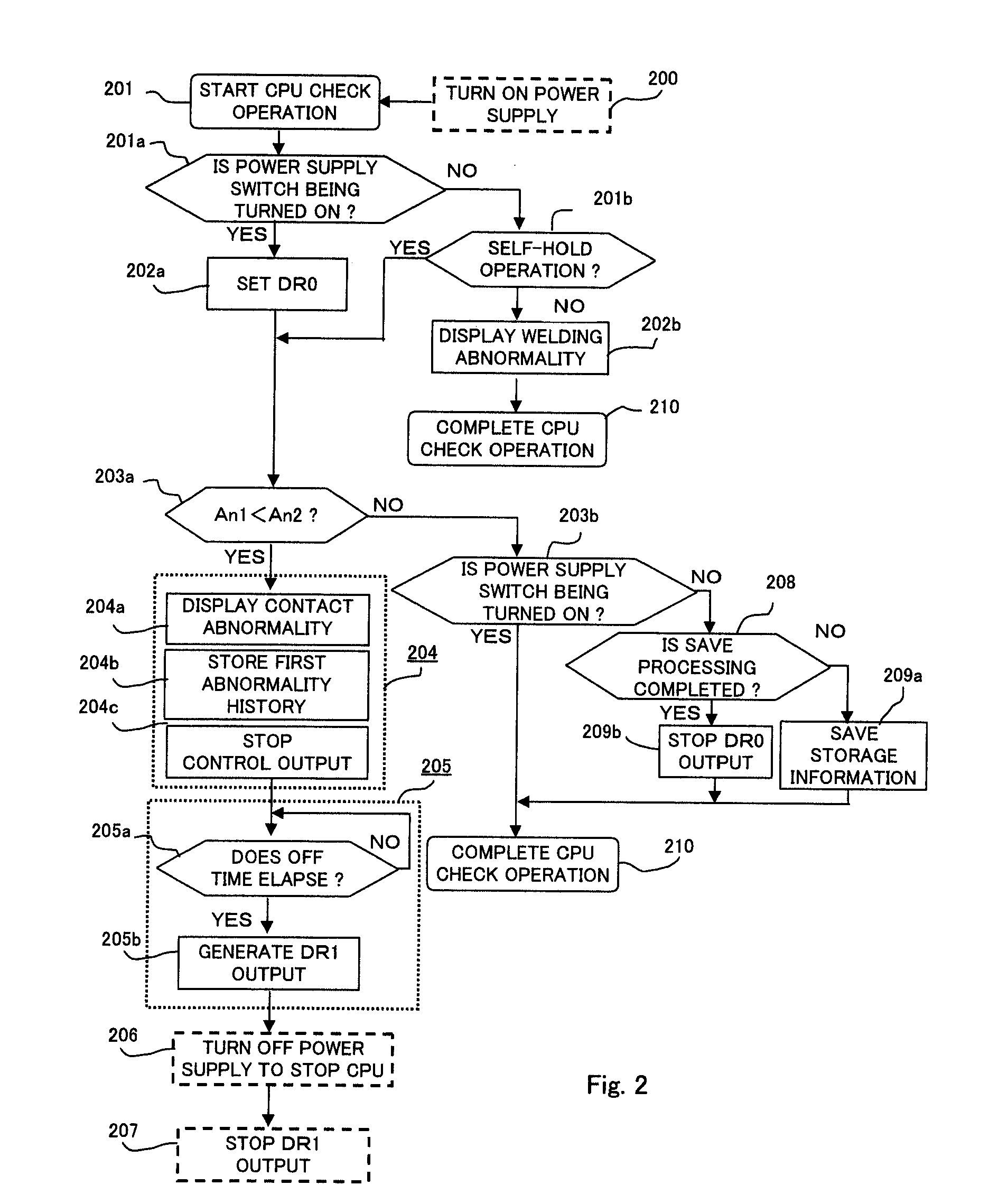

Power supply abnormality detection circuit for on-vehicle electronic control device

ActiveUS20090316320A1Improve maintainabilityImprove contact reliabilityTesting electric installations on transportEmergency protection for supplying operative powerContact failureEngineering

The on-vehicle electronic control device includes a main power supply circuit fed with power from an on-vehicle battery through an output contact of a power supply relay and a main power supply terminal of a connector to supply a stabilized control voltage to a microprocessor. When contact failure occurs in the main power supply terminal, the main power supply circuit is fed with bypass power from the output contact through a first electrical load and a commutation diode to perform the one of the report of the abnormality and the storage of the abnormality occurrence history information. A bypass power fed state is detected when an input voltage to the main power supply circuit is lower than a power supply voltage of the on-vehicle battery.

Owner:MITSUBISHI ELECTRIC CORP

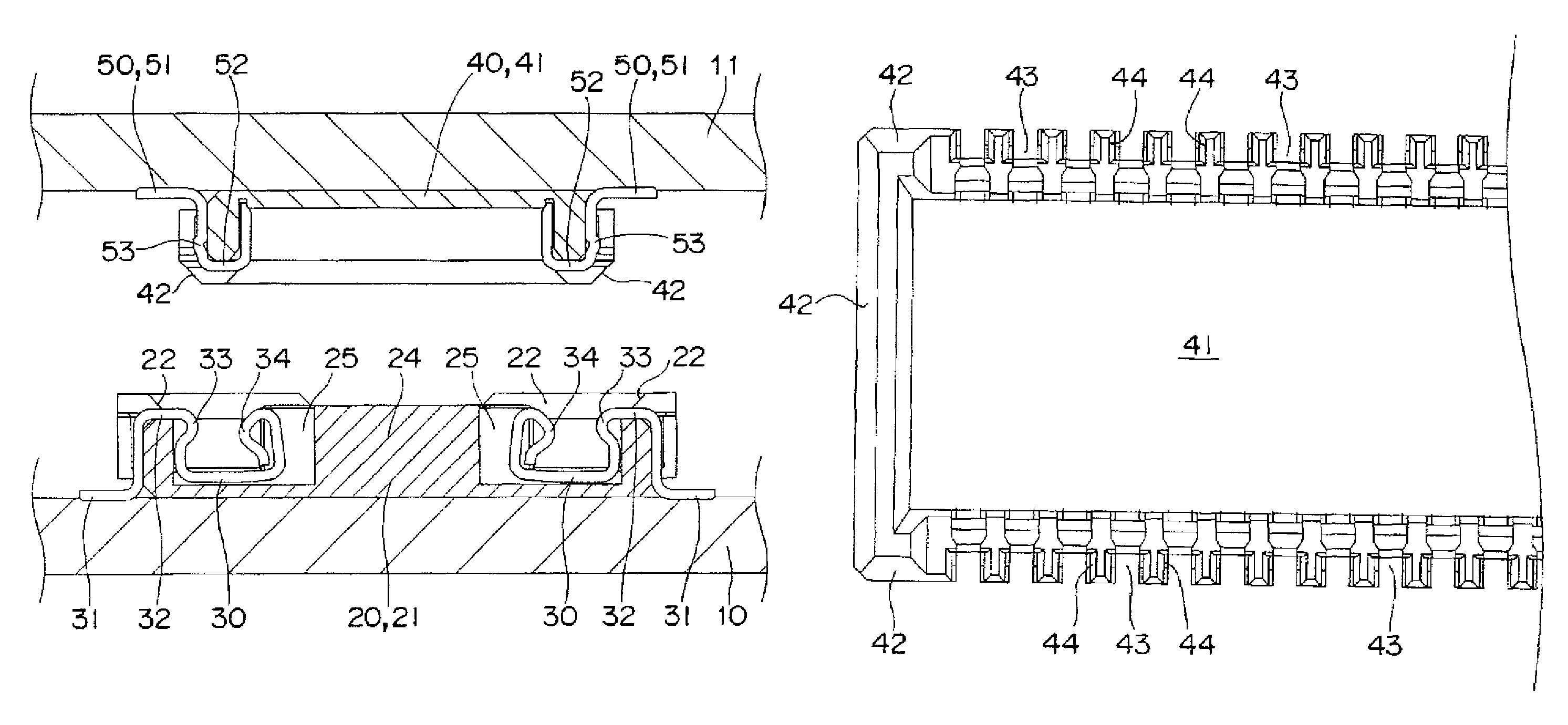

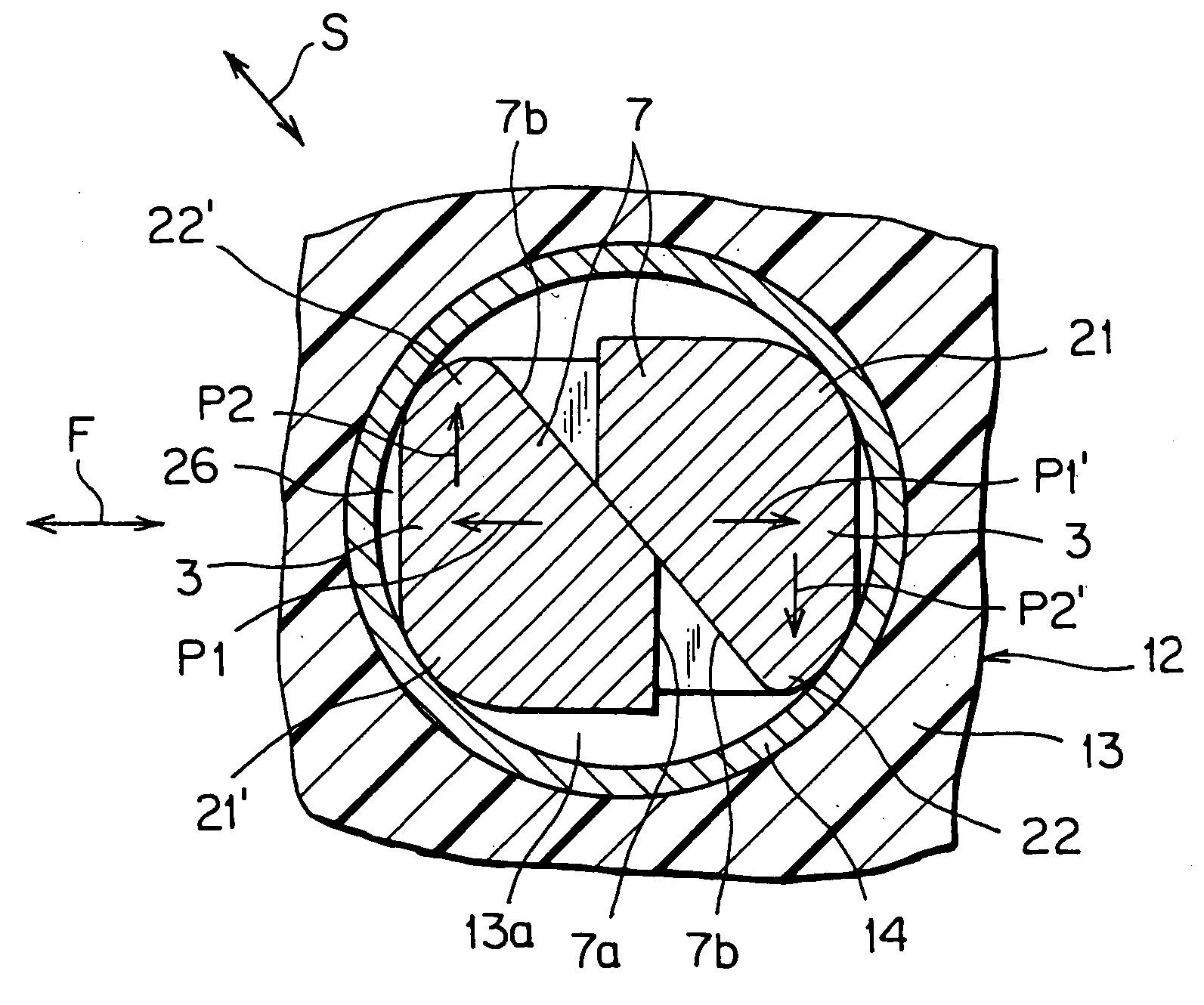

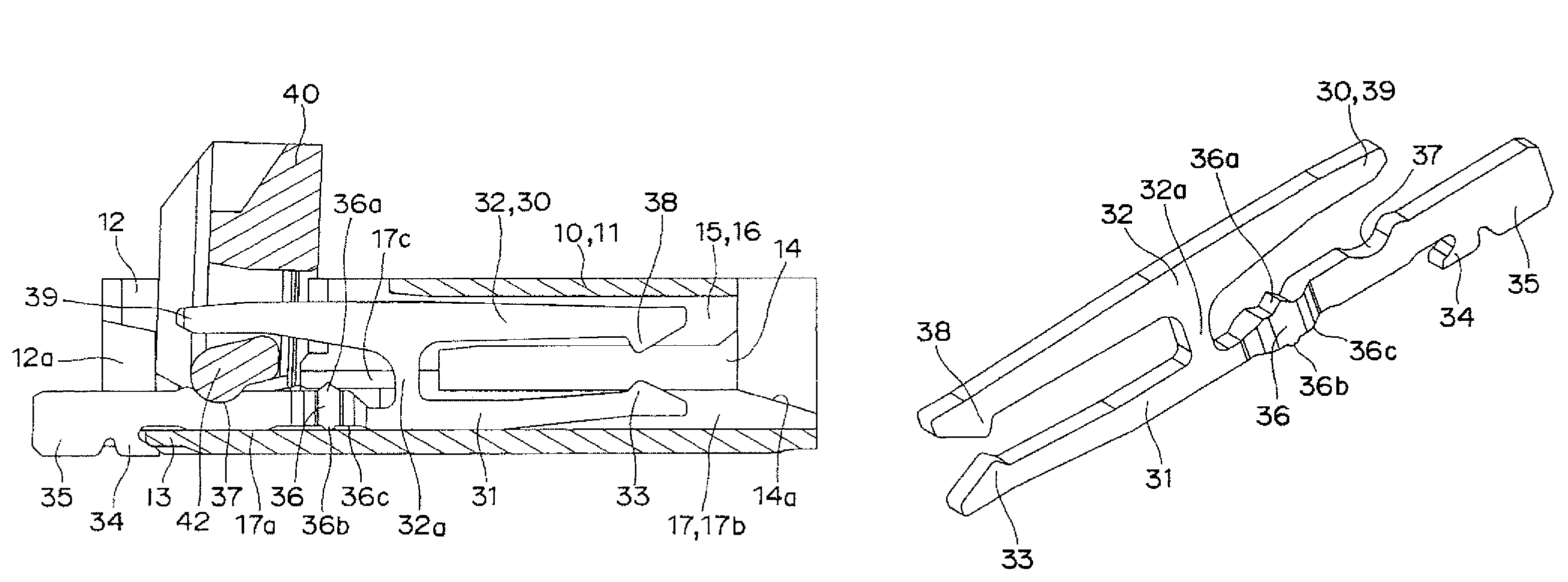

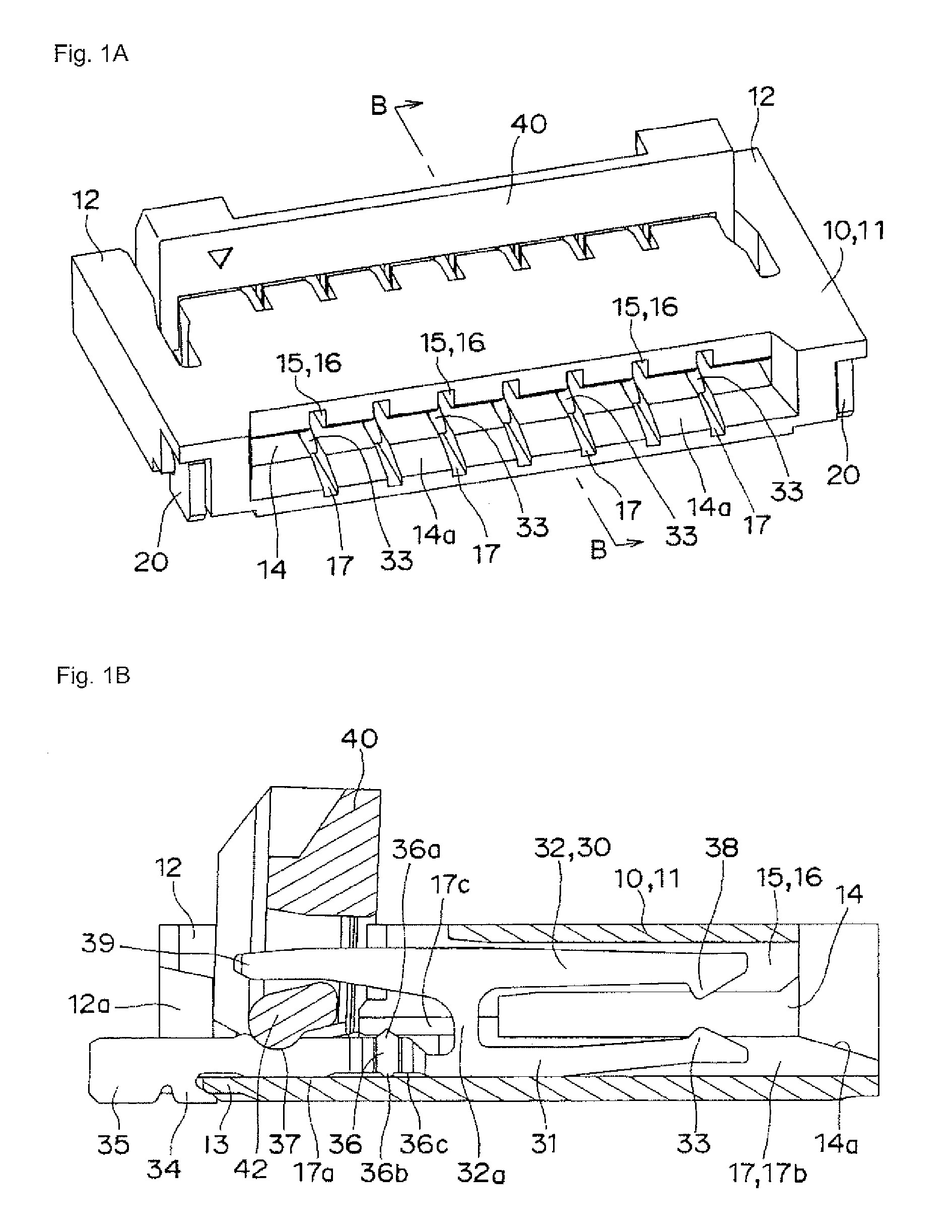

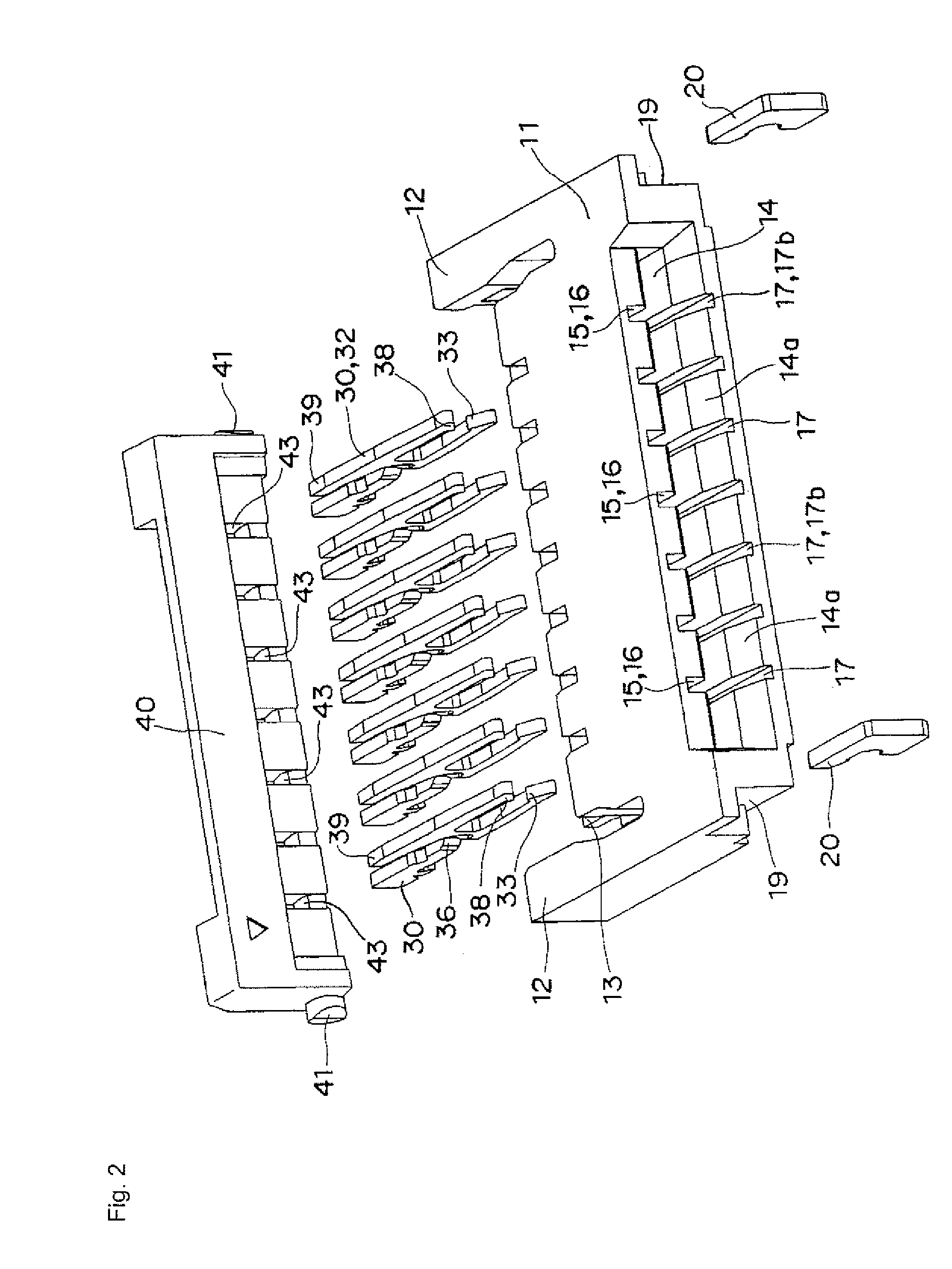

Connector for connecting printed boards having a plug having press-in grooves fitted into a socket

InactiveUS7568919B2Improve contact reliabilityAccurate contactCoupling contact membersPrinted circuitsElectrical connectionEngineering

A connector includes a socket in which a plurality of first splices are provided in parallel in an opening edge portion and a plug which has a flat shape. The plug is capable of being fitted in the opening edge portion of the socket. The plug includes a plurality of second splices press-fitted in press-in grooves provided in parallel at positions corresponding to the first splices in the plug. Each of the first splices is fitted and abuts on an inside surface of one of the press-in grooves. Each of the first splices is brought into elastic contact wit one of the second splices to establish electrical connection.

Owner:ORMON CORP

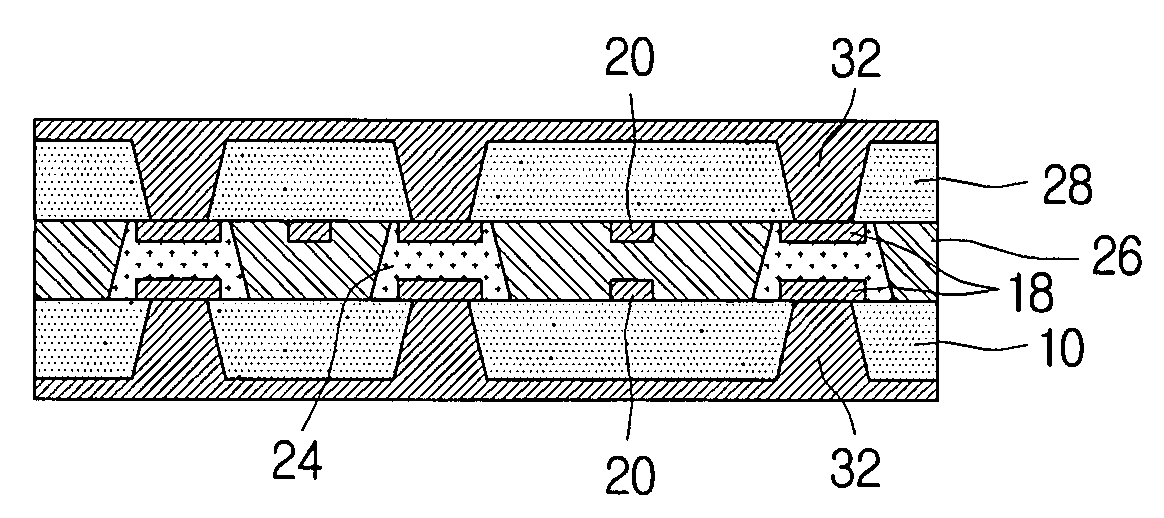

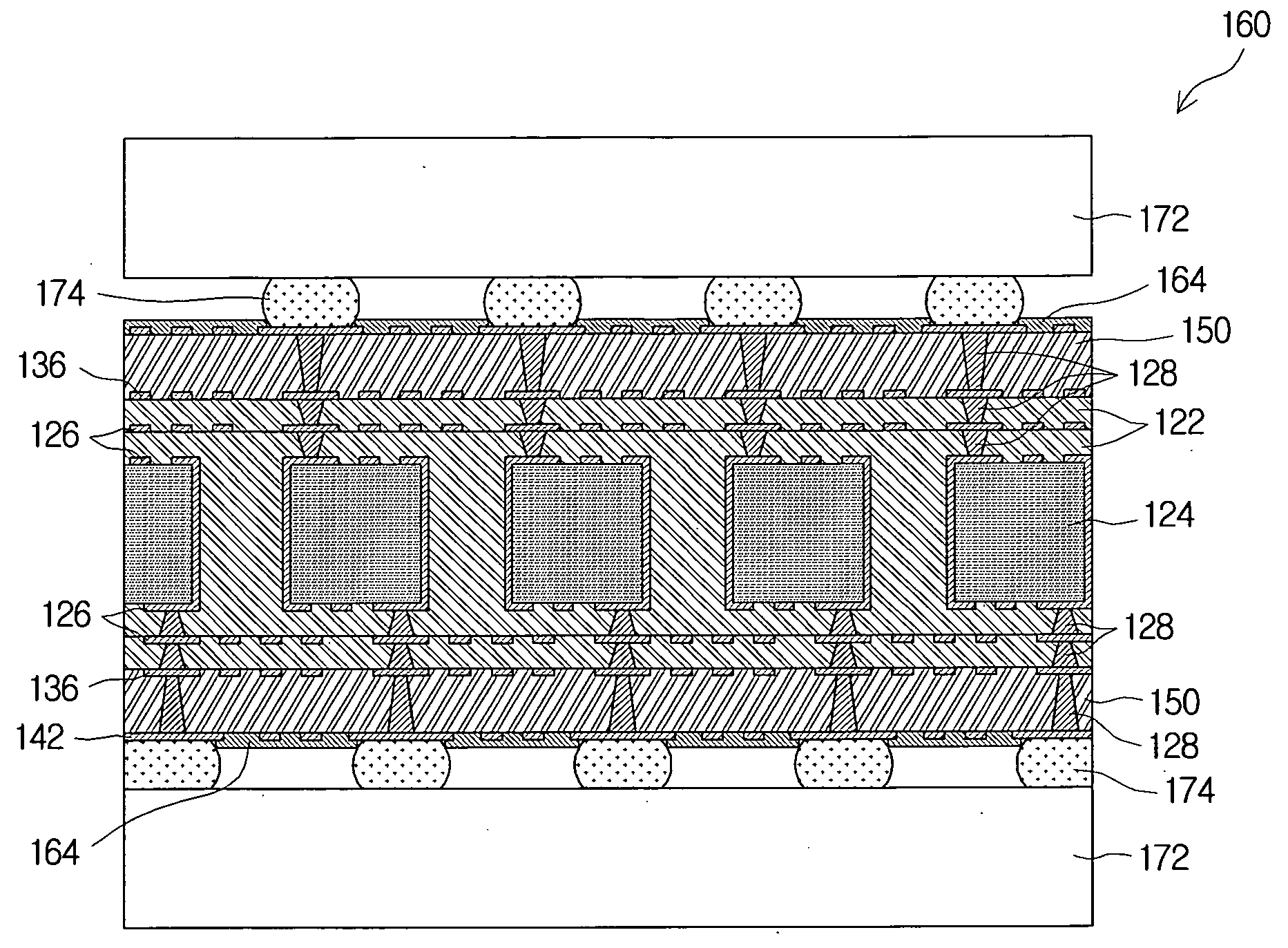

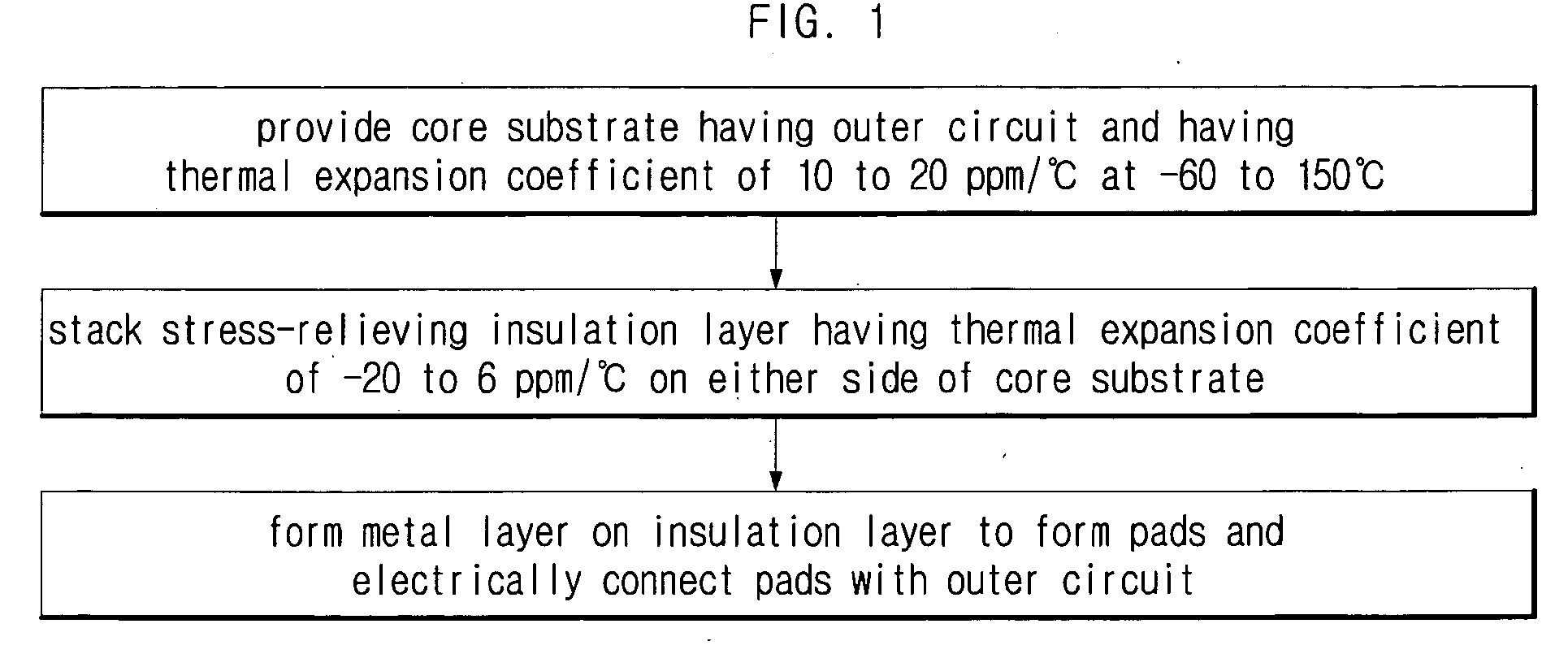

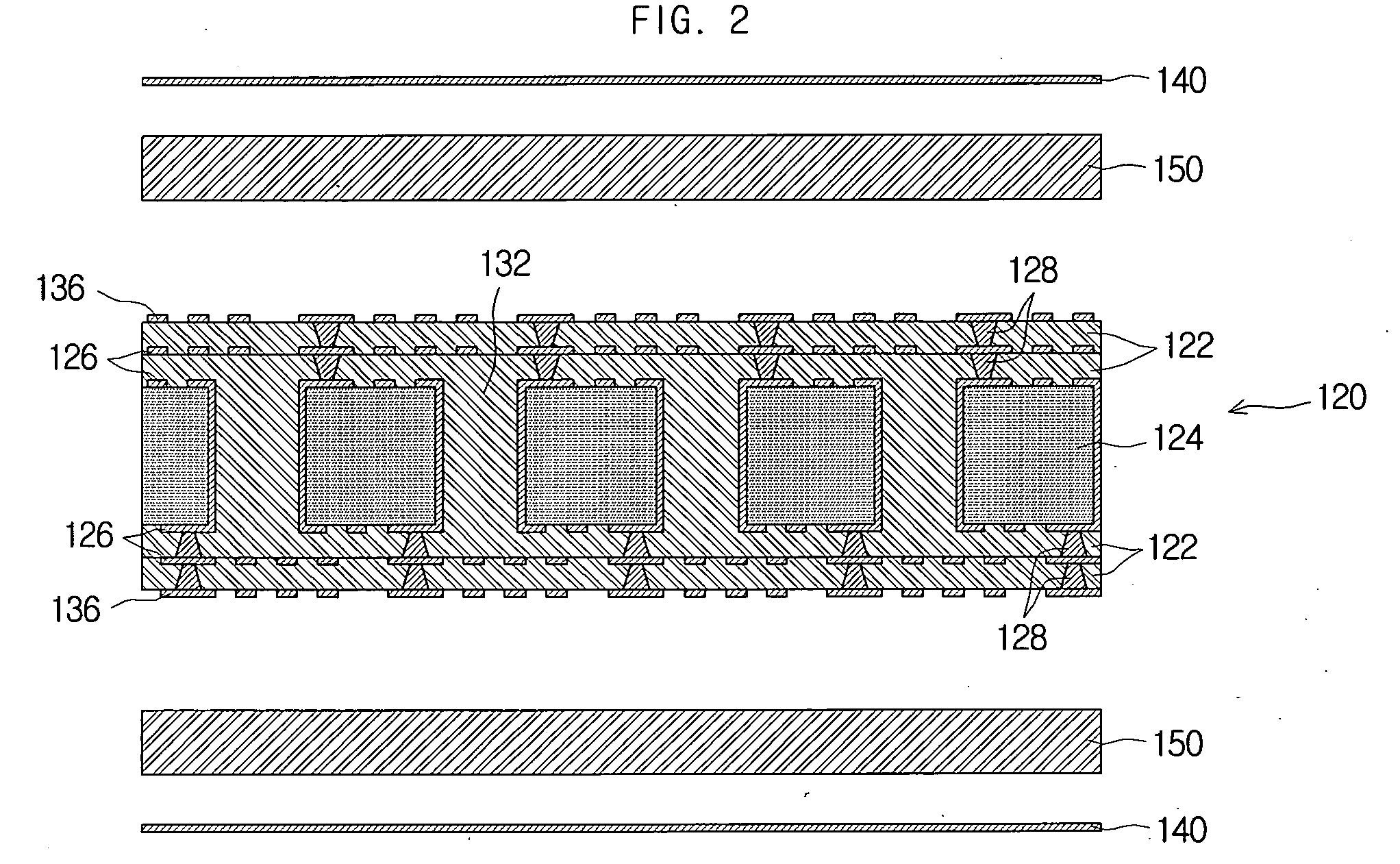

Multilayered printed circuit board and fabricating method thereof

InactiveUS20090008136A1Improve contact reliabilityElectrically conductive connectionsSemiconductor/solid-state device detailsInsulation layerStress relieving

A multilayered printed circuit board and a method of fabricating the printed circuit board are disclosed. The method of fabricating the multilayered printed circuit board can include: providing a core substrate, which has an outer circuit, and which has a thermal expansion coefficient of 10 to 20 ppm / ° C. at −60 to 150° C.; stacking a stress-relieving insulation layer, which has a thermal expansion coefficient of −20 to 6 ppm / ° C., on either side of the core substrate; and forming a metal layer on the insulation layer and forming at least one pad and electrically connecting the pad with the outer circuit. This method can provide high reliability, as the stress-relieving insulation layers can prevent bending and warpage, etc., in the board overall.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

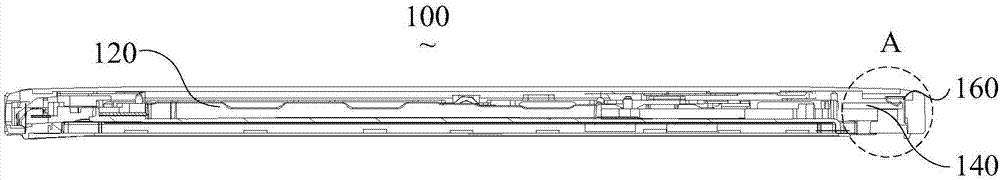

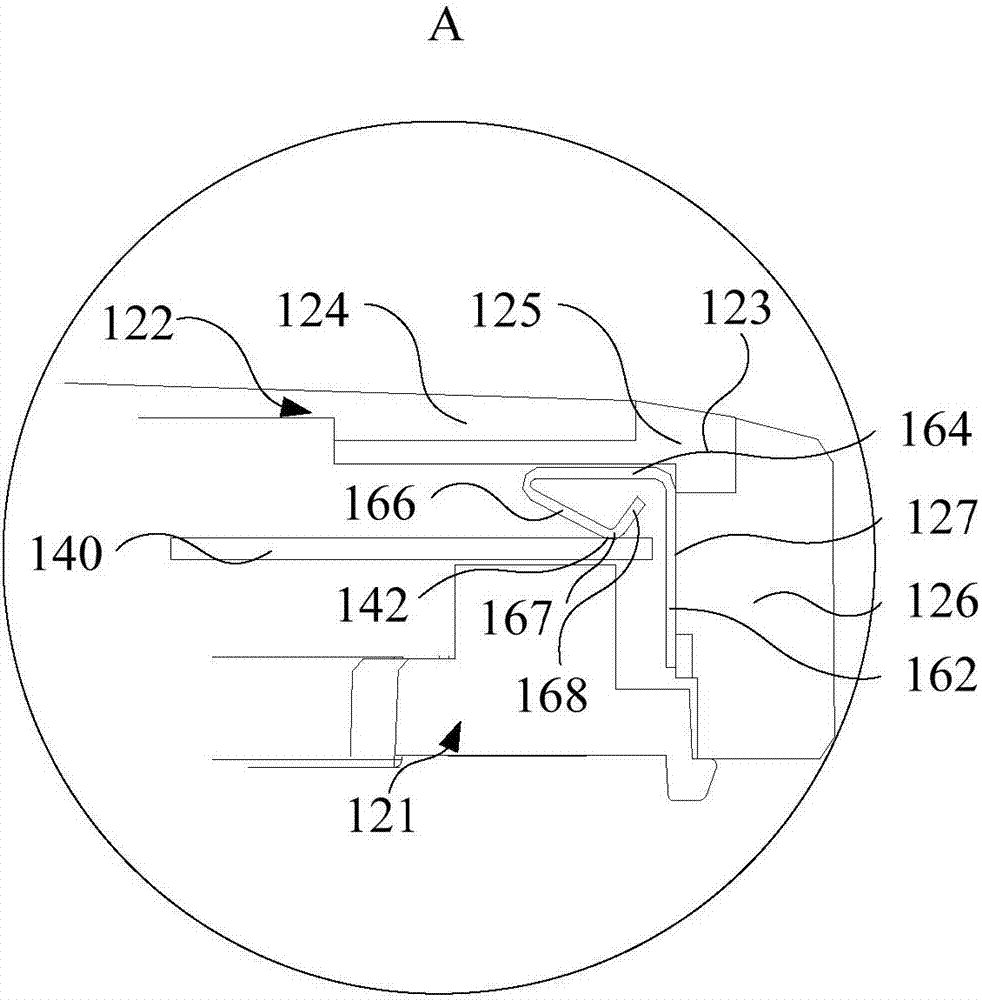

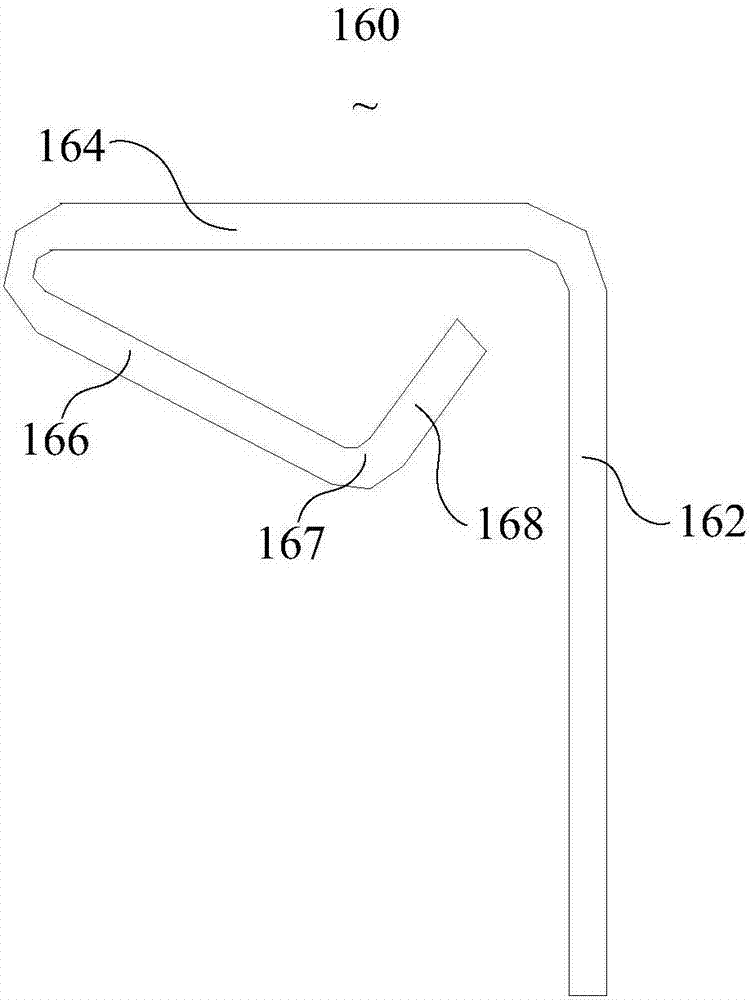

Mobile terminal

InactiveCN106887695AImprove contact reliabilityReduce the difficulty of assemblyAntenna supports/mountingsSoldered/welded conductive connectionsElectrical connectionAntenna feed

The invention provides a mobile terminal, including a shell, a PCB and antenna adaptive sheets. The shell comprises a main wall and a side wall, an antenna gap is arranged between the main wall and the side wall, a filler is arranged in the antenna gap, and an antenna connection point is arranged on the side wall. The PCB is provided with an antenna feed point which is opposite to the filler. The antenna adaptive sheets are used to connect the antenna connection point and the antenna feed point. The first antenna adaptive sheet is welded with the antenna connection point. The second antenna adaptive sheet is pressed against the surface of the filler. A connection part of the third antenna adaptive sheet and the fourth adaptive sheet is elastically crimped with the antenna feed point, so that electrical connection between the antenna feed point and the antenna connection point is formed. By the abovementioned mode, the antenna adaptive sheets are integrally formed and in bending connection, so that side-surface contact between the antenna feed point on the PCB and the antenna connection point on the side wall is changed to front-surface contact, the contact reliability is improved, and the assembly difficulty is reduced.

Owner:JRD COMM

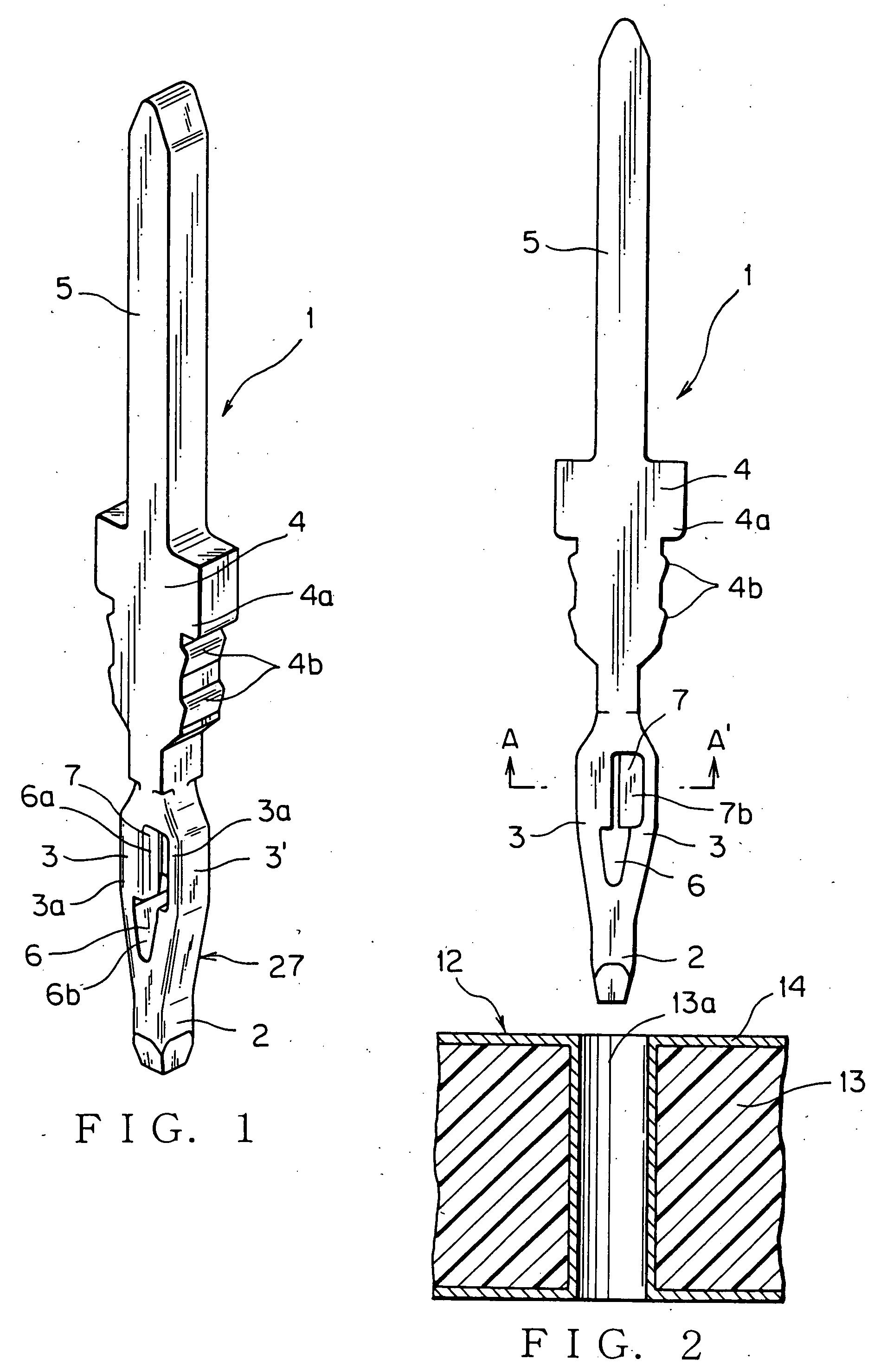

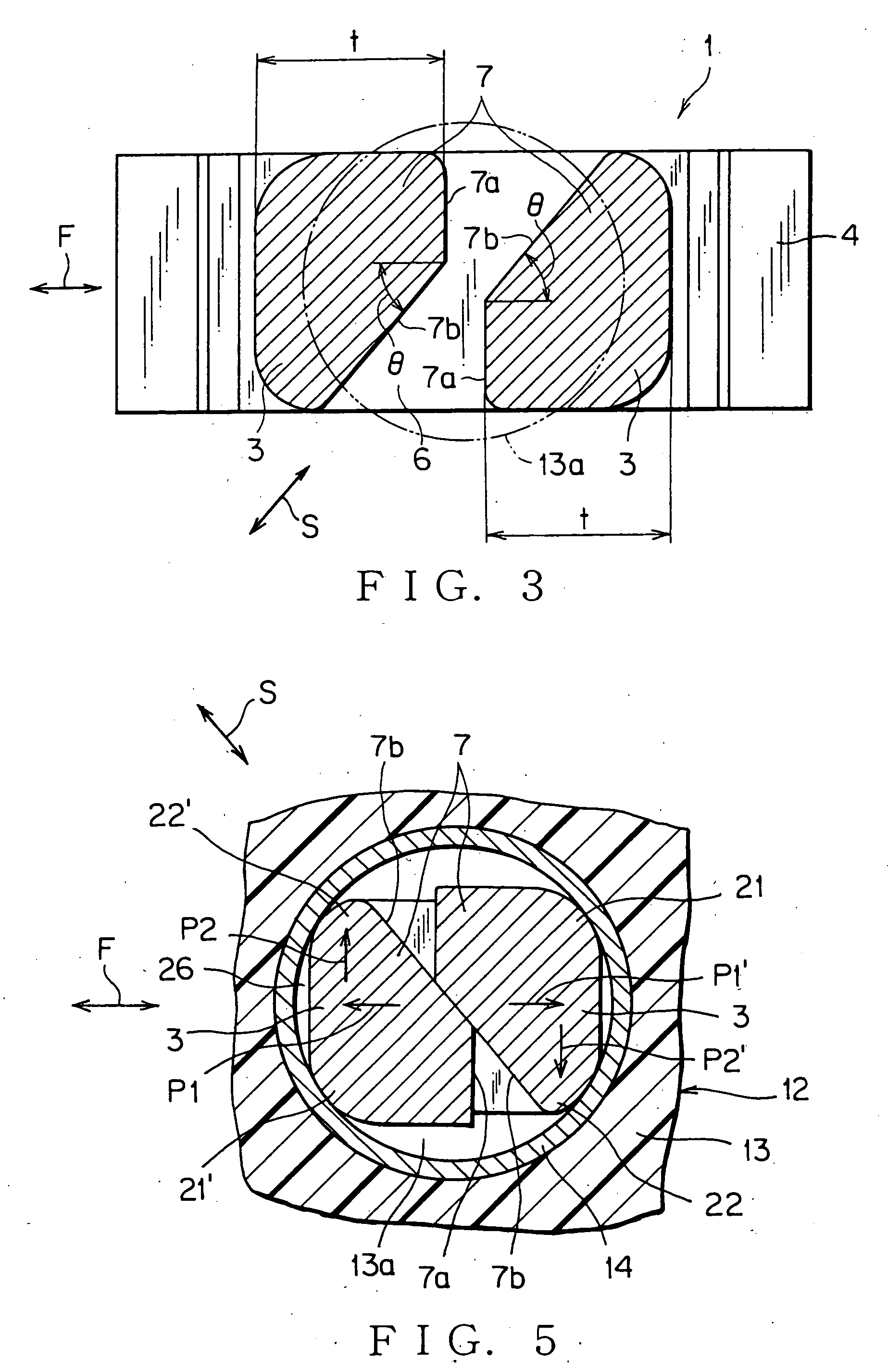

Press-fit terminal and circuit board module using the same

InactiveUS20050250356A1Improve connection workabilityIncrease forceElectrically conductive connectionsSecuring/insulating coupling contact membersEngineeringElectrical and Electronics engineering

Owner:YAZAKI CORP

Connector

InactiveUS7452227B2Improve contact reliabilitySmall footprintEngagement/disengagement of coupling partsCoupling contact membersCouplingH shaped

A connector has a base having insertion holes in parallel at a predetermined pitch, A connector has a base having insertion holes in parallel at a predetermined pitch, H-shape connecting terminals laterally inserted into the insertion holes, each connecting terminal having a support contact piece on a lower side of the connecting terminal, a manipulation contact piece on an upper side of the connecting terminal, and a coupling portion which couples the support contact piece and the manipulation piece, and a manipulation lever rotatably attached to a bearing portion of the support contact piece disposed on a first side of the base. A latching pawl, formed on a first end of the support contact piece, is latched on an edge portion of the base. A flexible board is inserted from an opening on a second side of the base. The manipulation lever manipulates the manipulation contact piece to bring an end portion of the manipulation contact piece into pressure-contact with the flexible board.

Owner:DAIICHI SEIKO CO LTD

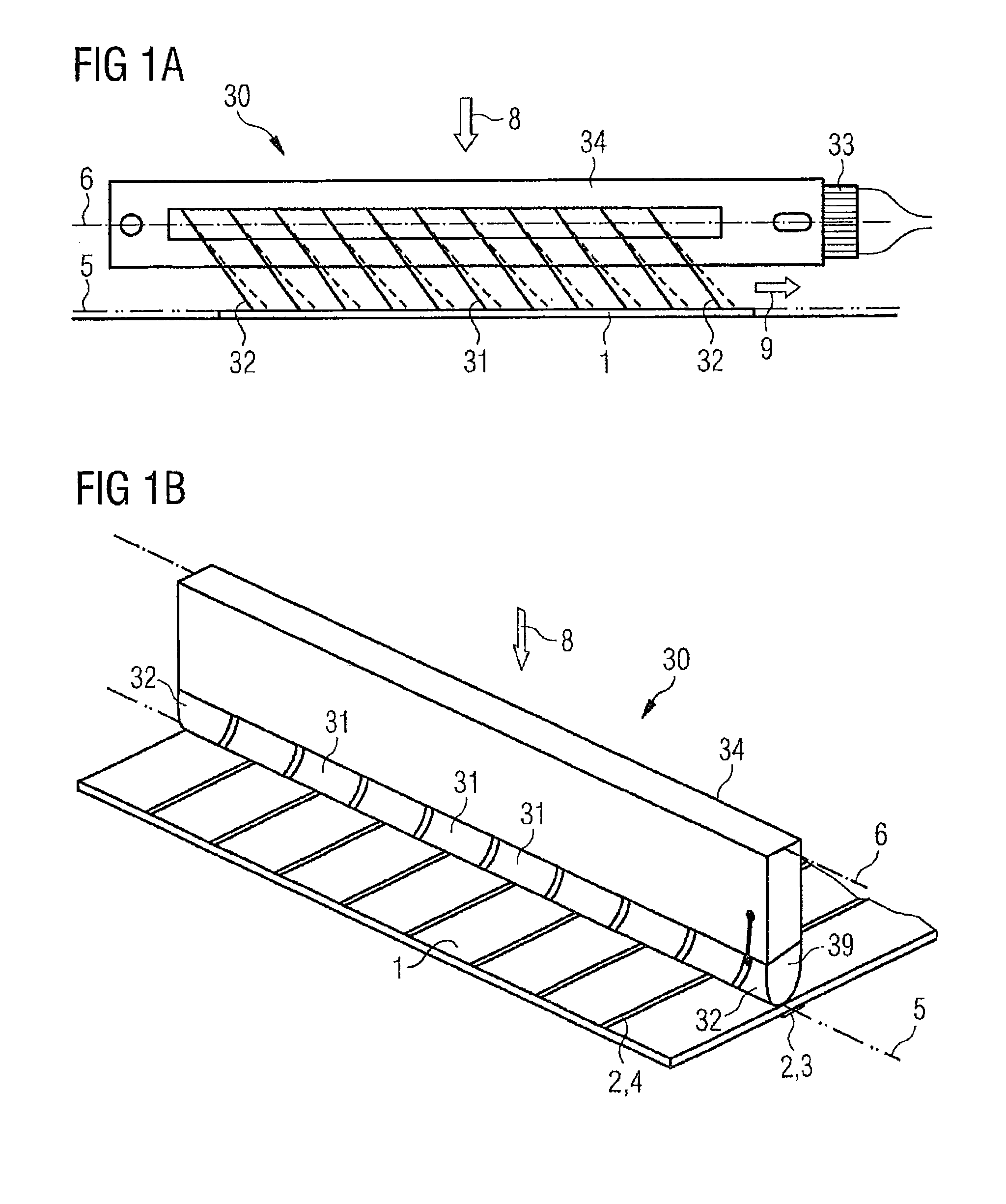

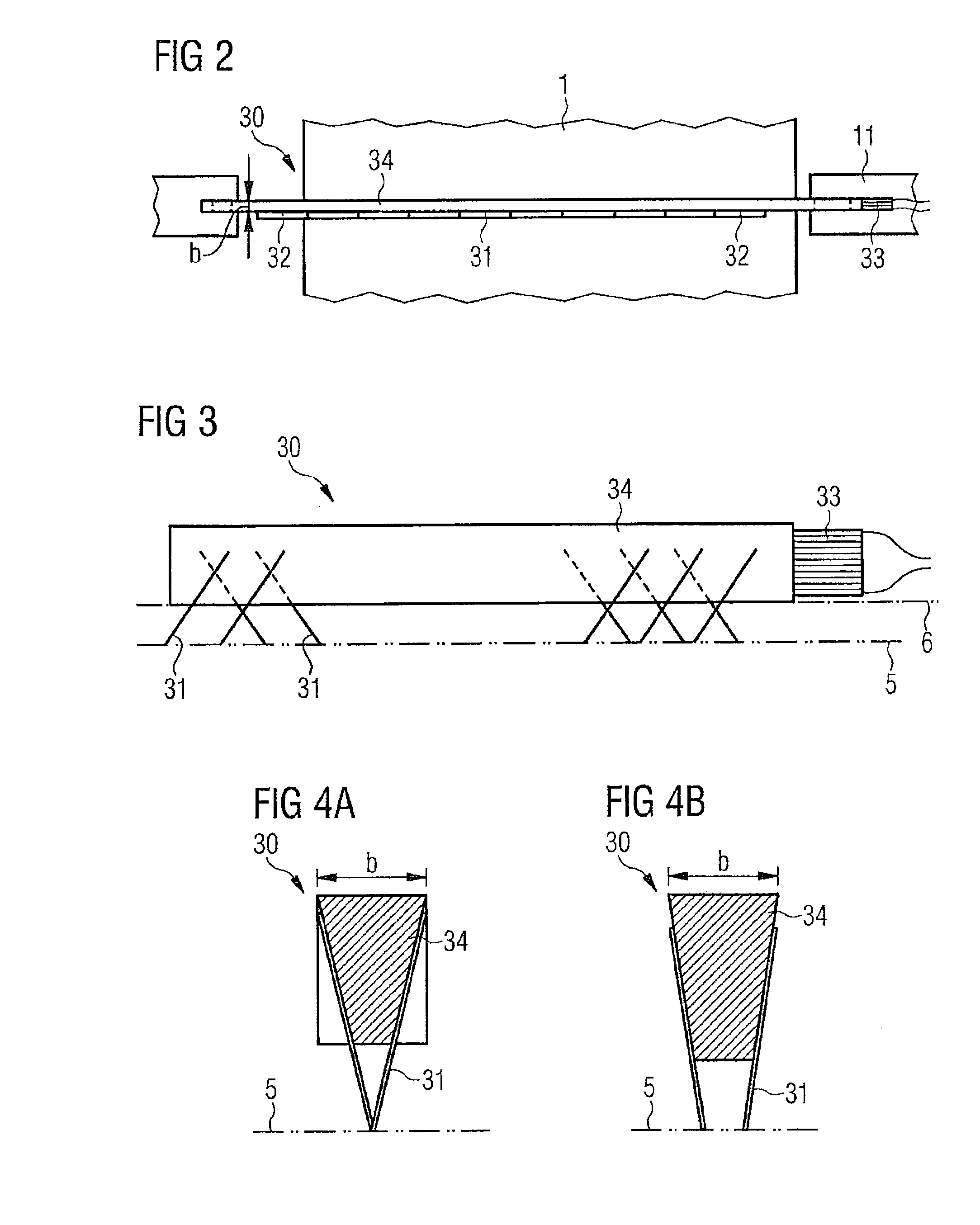

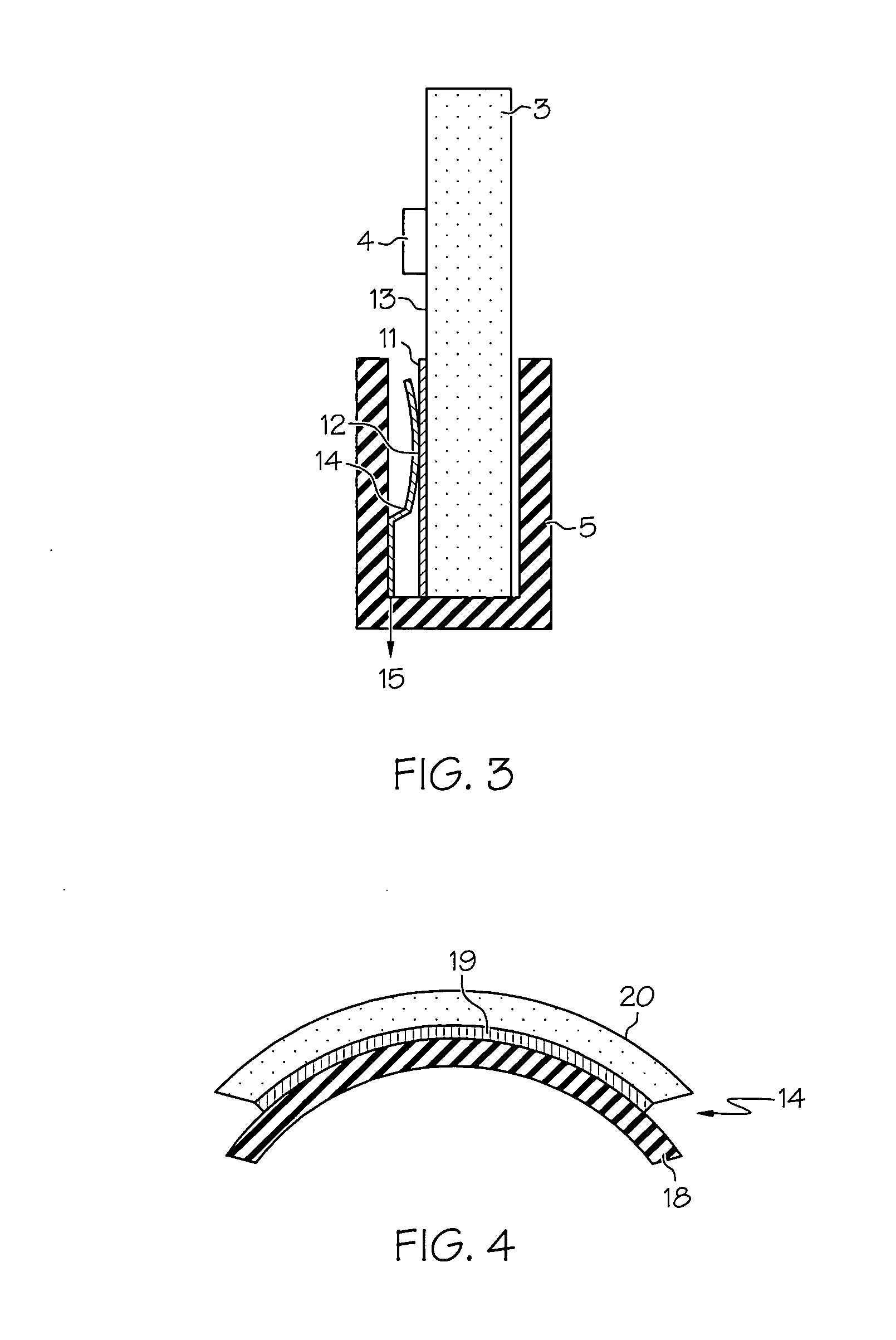

Probe for temporarily electrically contacting a solar cell

InactiveUS20100045264A1Blocking may occurImprove contact reliabilityPhotovoltaic monitoringElectrical testingElectricityElectrical battery

A probe for temporarily electrically contacting a solar cell for testing purposes, has at least one elastic, electrically conductive contact element for producing the electrical contact, at least one reference sensor for indicating a distance of the contact element to an external reference surface using an electrical signal of the reference sensor, and a mounting plane to which the tip of the contact element is oriented. The probe ensures a secure electrical contact of the solar cell in a testing station with minimal mechanical stress, and is also suitable for use in an industrial continuous production method.

Owner:CASCADE MICROTECH

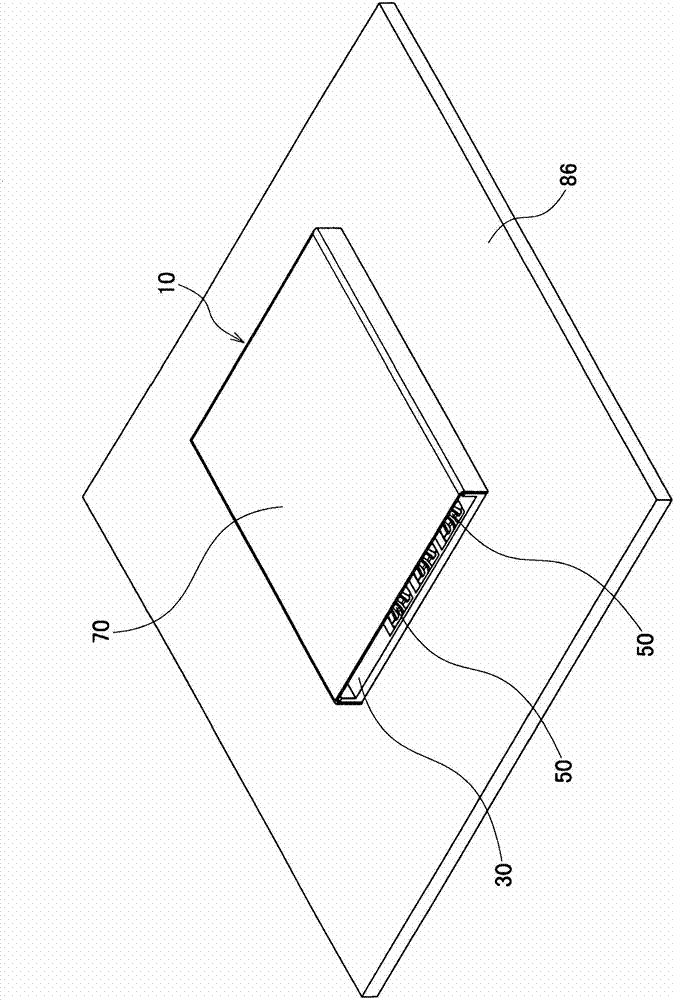

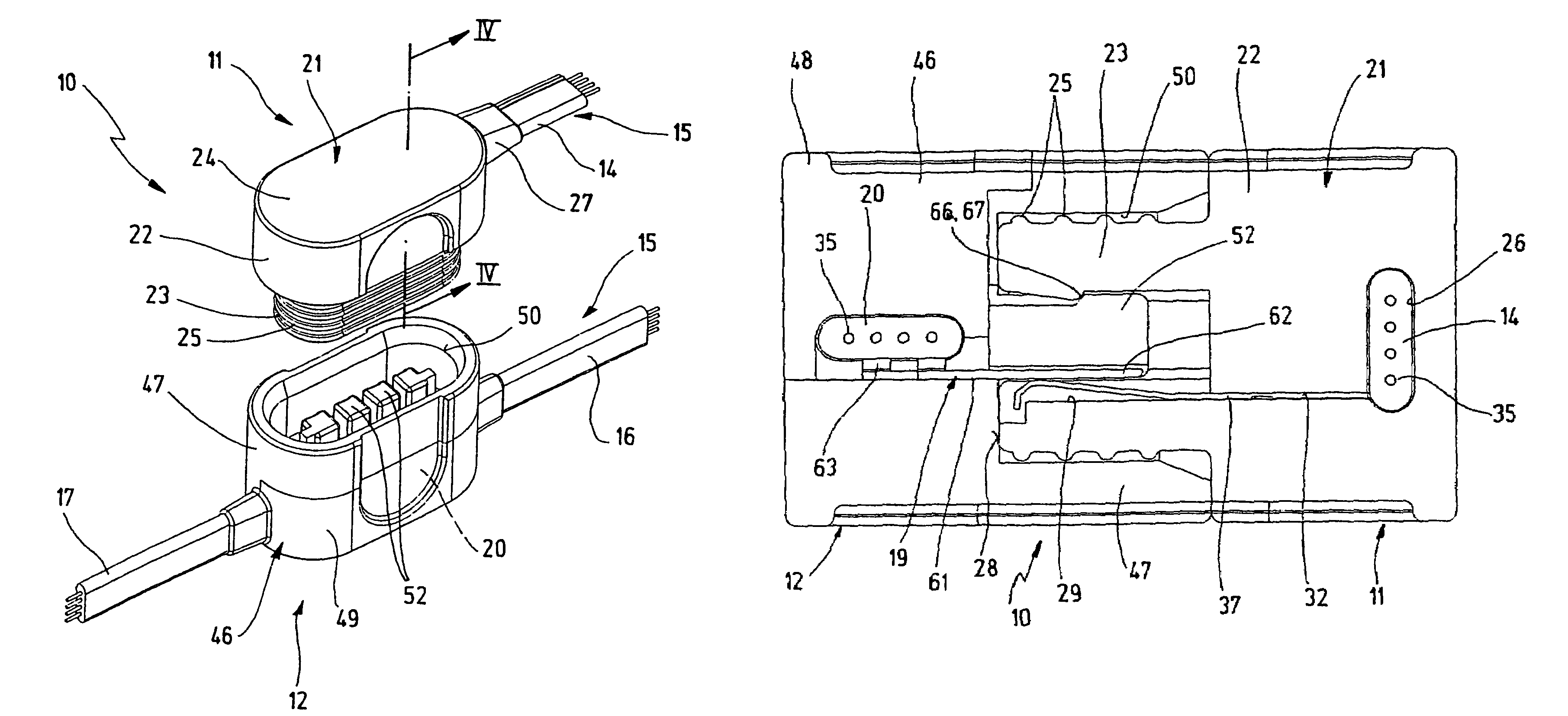

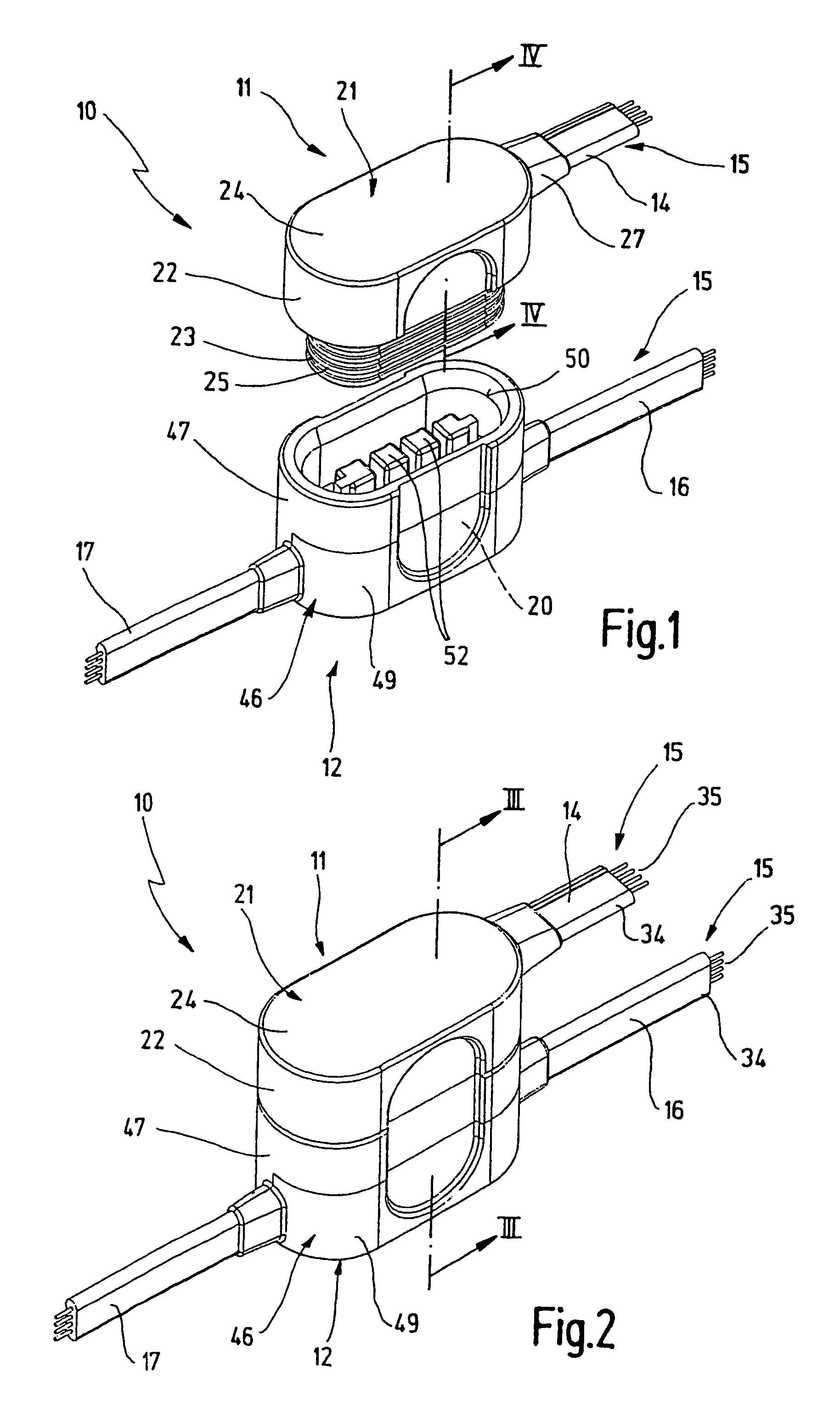

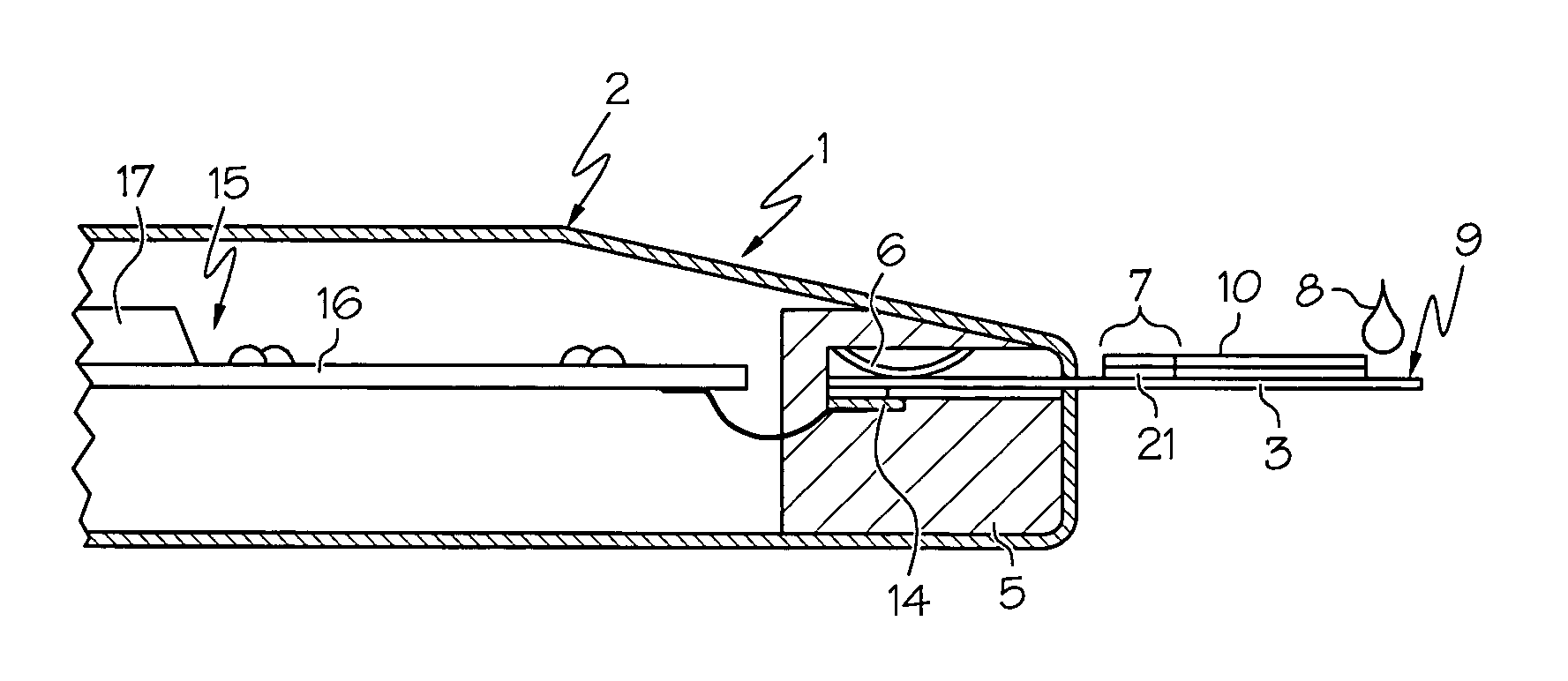

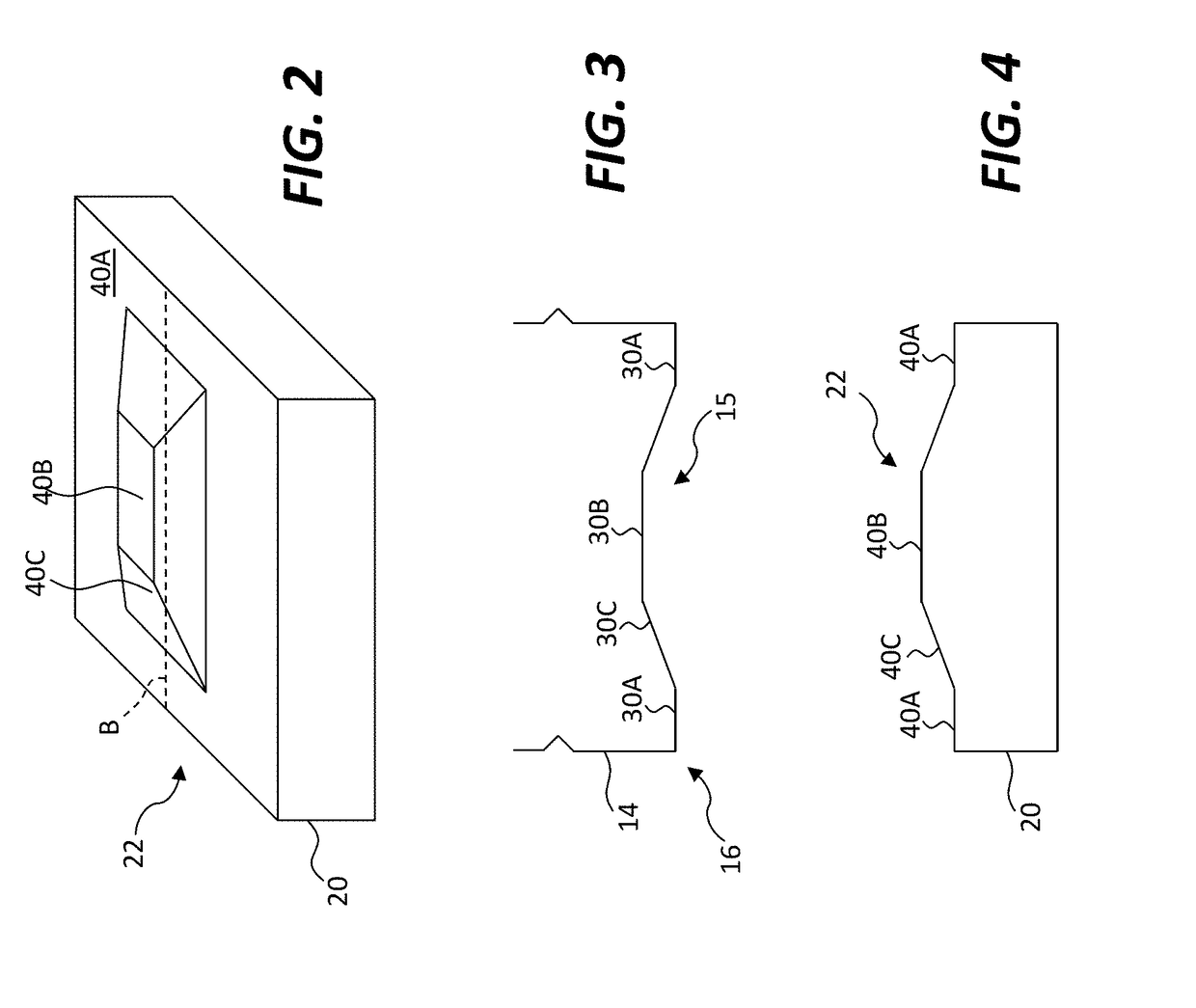

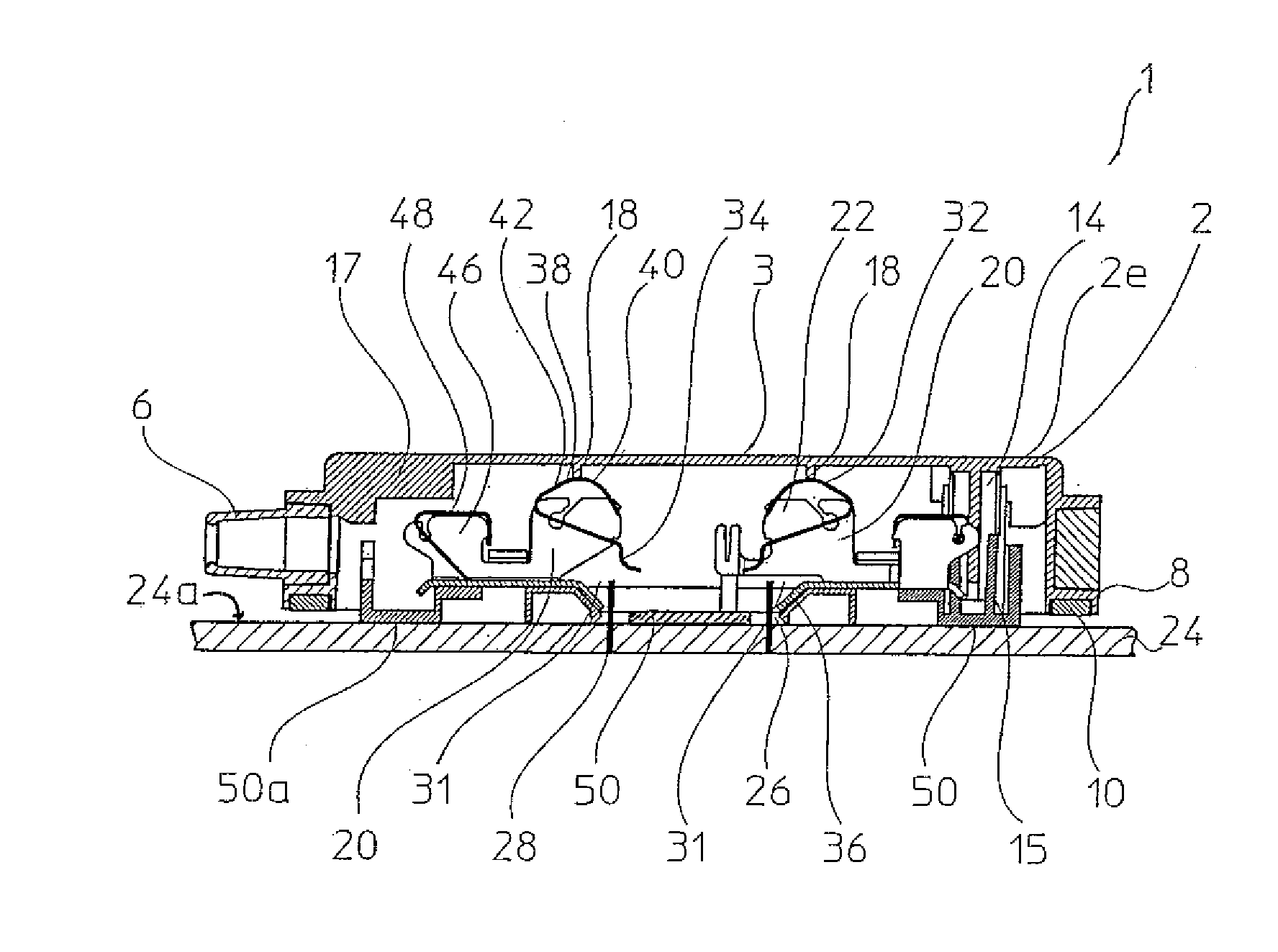

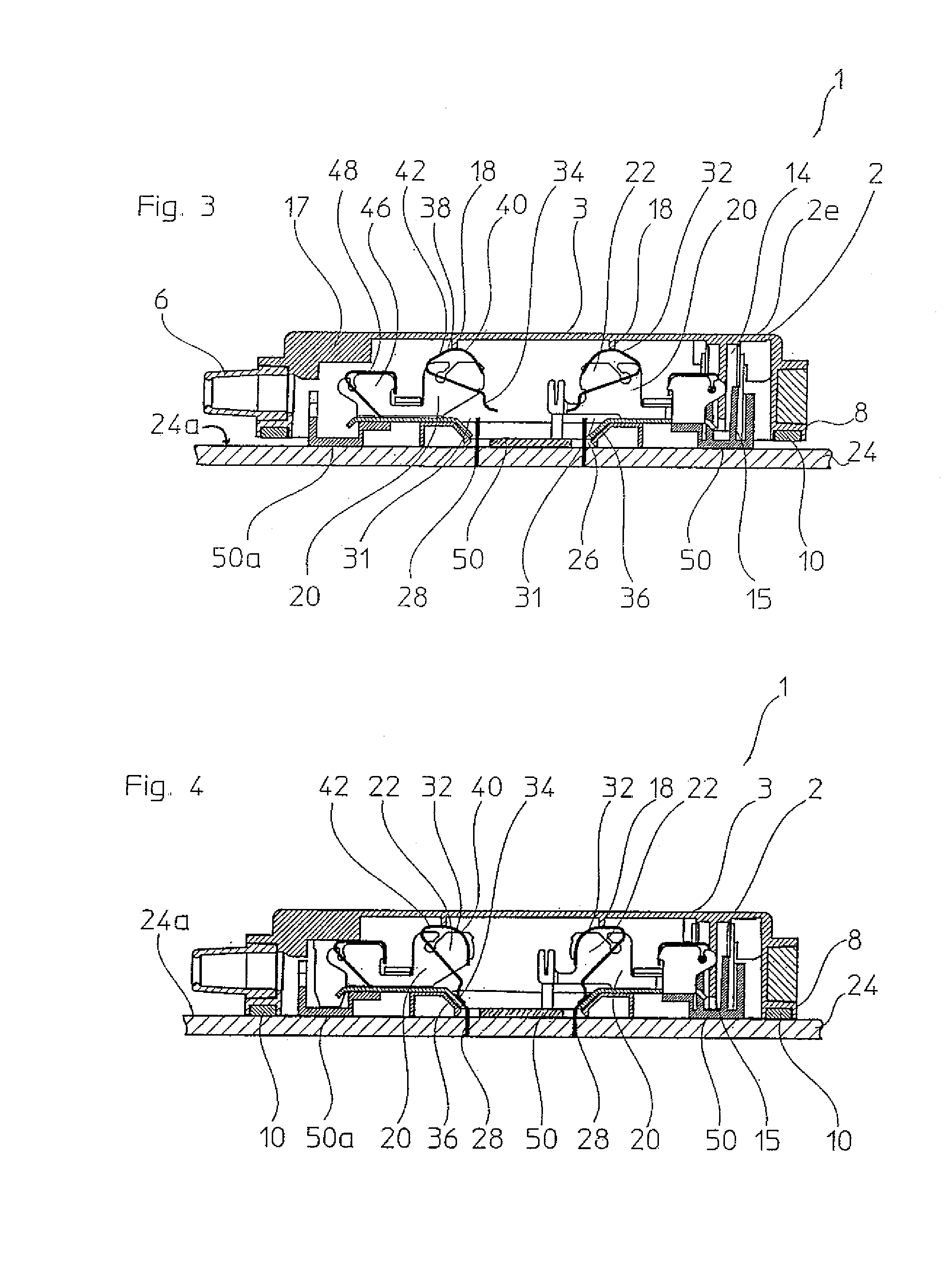

Plug connector device for multicore flat cables

InactiveUS7255590B2Improve contact reliabilityReliable contactCouplings bases/casesContact members penetrating/cutting insulation/cable strandsElectrical connectionContact element

A plug connector device (10) for multicore flat cables (15), has a plug (11) which can be fixedly joined to one end of a flat cable in a mechanical fashion, and a plug socket (12) which can be run through by the flat cable (15) such that, with their first contact ends (62), contact elements of the plug socket (12) engaging in the plug (11) can be electronically connected to the flat cable at their other contact ends (63) using IDC technology. To assure that the plug connector device is robust and has high contacting reliability, provision is made that plug (11) is provided with contact elements (18), whose first contact ends (38) are configured for the electrical connection to the first contact ends (62) of the contact elements (19) of the plug socket (12), and whose other contact ends (36) are configured for the connection to the flat cable (15) using IDC technology.

Owner:ITT MFG ENTERPRISES LLC

Test element analysis system with contact surfaces coated with hard material

ActiveUS20070202007A1Good effectImprove resistance to transition resistanceAnalysis using chemical indicatorsResistance/reactance/impedenceElectrical conductorMeasurement device

The invention concerns a test element analytical system for the analytical examination of a sample, especially a body fluid, comprising at least one test element with one or more measuring zones and contact areas located on the test element, in particular electrodes or conductor paths, the sample to be examined being brought into the measuring zone to carry out an analysis in order to determine a characteristic measured quantity for the analysis, and an evaluation instrument with a test element holder for positioning the test element in a measuring position and a measuring device for measuring the characteristic change, the test element holder containing contact elements with contact areas which enable an electrical contact between the contact areas of the test element and the contact areas of the test element holder, characterized in that one of these contact areas is provided with an electrically conductive hard material surface.

Owner:ROCHE DIAGNOSTICS OPERATIONS INC

Sheet with movable contacts and sheet switch

InactiveUS6417467B1Improve adhesionImprove contact reliabilityContact surface shape/structureMovable contactsAdhesiveThin sheet

The sheet with movable contacts comprises a first sheet formed by an insulating film, the first sheet having an adhesive surface formed by applying an adhesive to a lower surface of the first sheet, a plurality of domed, metallic, movable contacts whose upper surfaces are covered with and affixed to the adhesive surface of the first sheet, and a second sheet formed by an insulating film, the second sheet being affixed to the lower surface of the first sheet and having a plurality of receptacle holes for receiving the movable contacts therein, with an adhesive being applied to a lower surface of the second sheet, wherein the second sheet has connecting slots formed therein for connecting adjacent such receptacle holes with each other.

Owner:ALPS ALPINE CO LTD

Stamp with structured posts

ActiveUS9704821B2Improve performanceImprove contact reliabilityTransfer printingSemiconductor/solid-state device detailsEngineeringSurface contour

A stamp for micro-transfer printing includes a body and one or more posts extending from the body. At least one of the posts has a non-planar surface contour on the distal end of the post having a size, shape, or size and shape that accommodates a non-planar contact surface of a micro-transfer printable device.

Owner:X DISPLAY CO TECH LTD

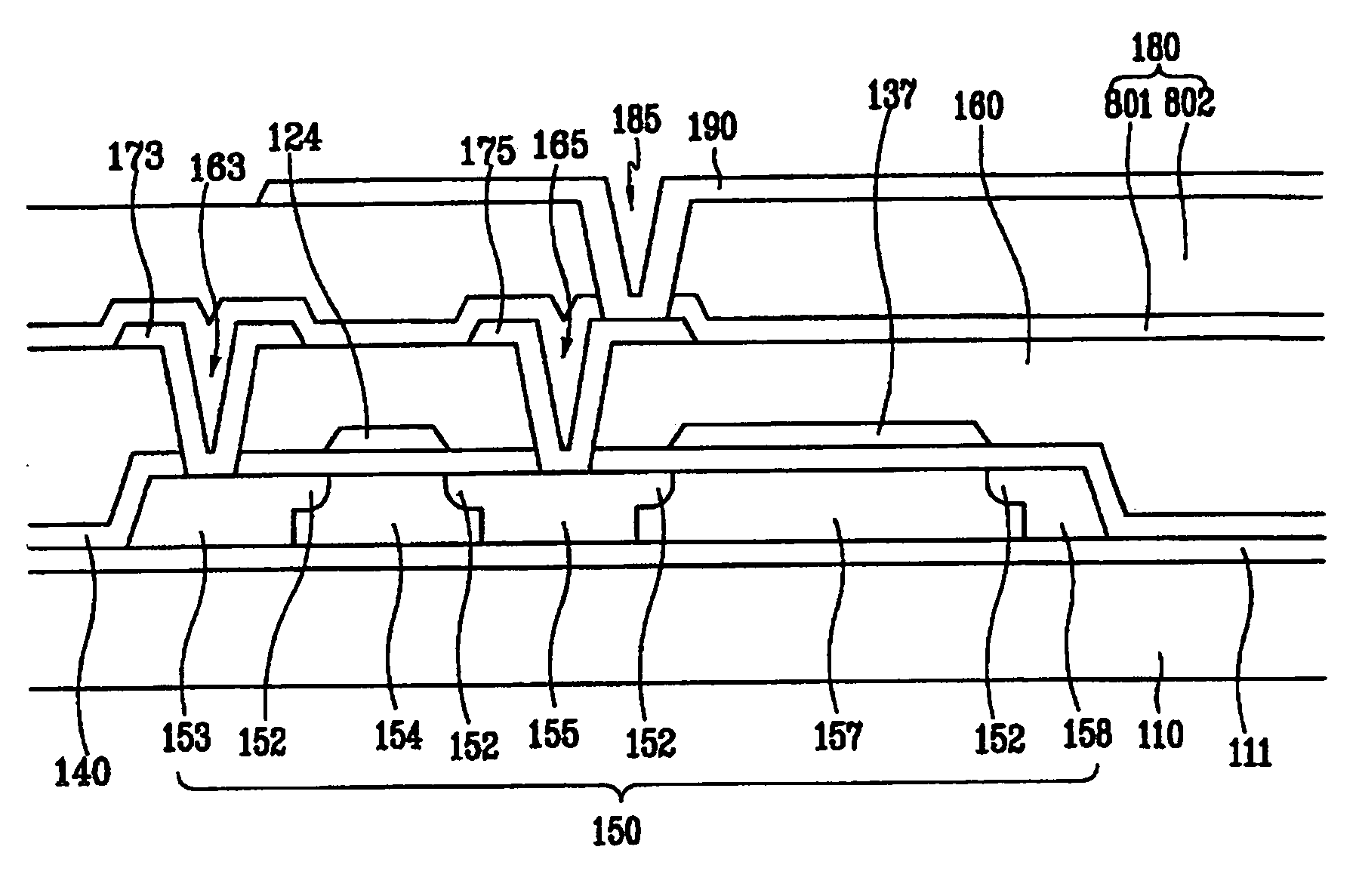

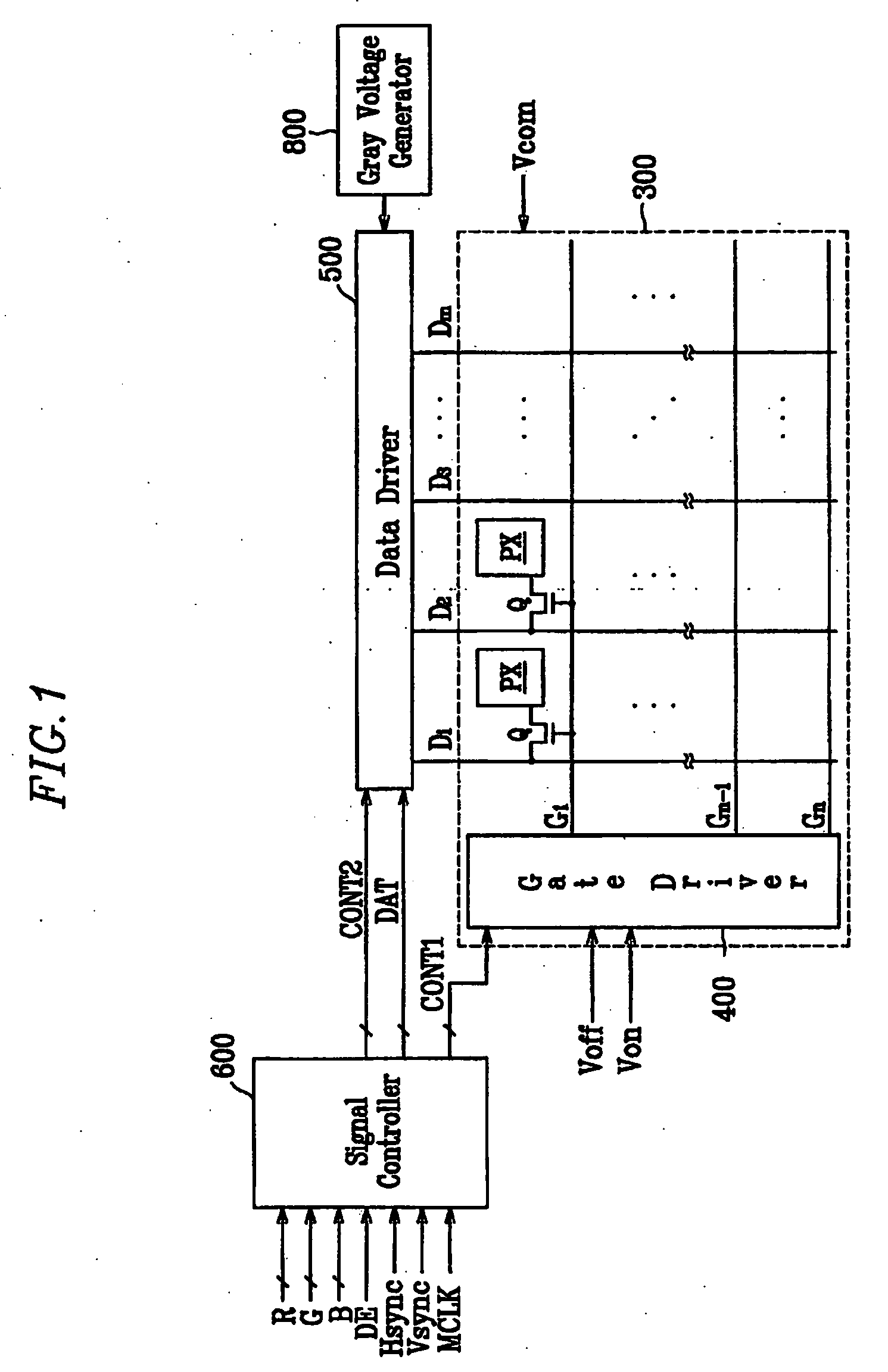

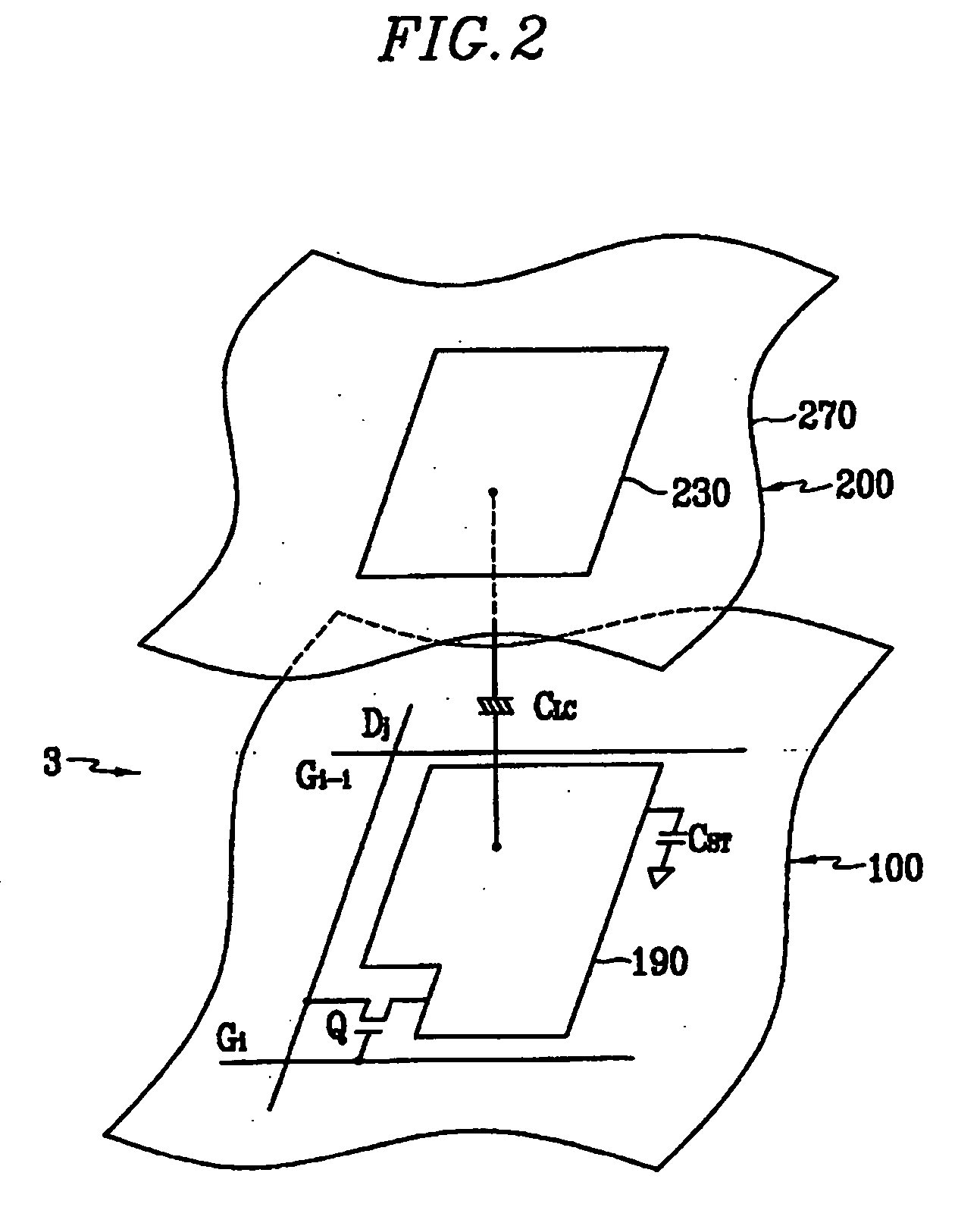

Thin film transistor array panel

ActiveUS20060049407A1Low resistivityAvoid signal delaySolid-state devicesNon-linear opticsTransistorElectrical and Electronics engineering

Improved thin film transistor array panels are provided. In one embodiment, a panel includes a plurality of gate lines, data lines, and a plurality of switching elements connected to the gate lines and the data lines. An interlayer insulating layer is formed between the gate lines and the data lines. A passivation layer covering the gate lines, the data lines, and the switching elements is also provided having a plurality of first contact holes exposing portions of the data lines, wherein the switching elements and the pixel electrodes are connected through the first contact holes. A plurality of contact assistants are formed on the passivation layer and are connected to the data lines through a plurality of second contact holes in the passivation layer. A plurality of auxiliary lines are connected to the data lines through a plurality of third contact holes in the interlayer insulating layer.

Owner:SAMSUNG DISPLAY CO LTD

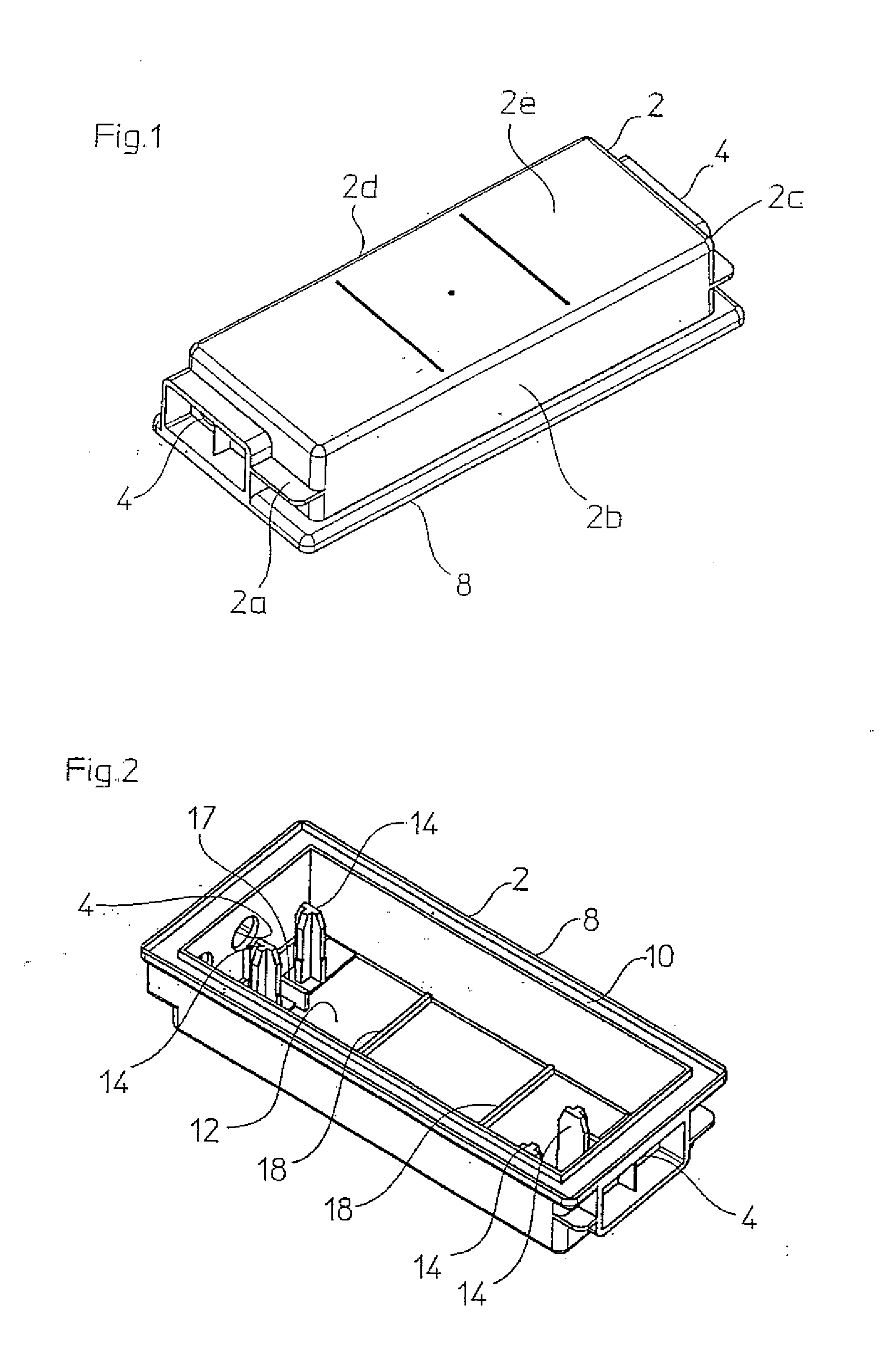

Connection and Junction Box for a Solar Module

InactiveUS20100139760A1Easily and fast and efficientlyImprove contact reliabilityCoupling device detailsPhotovoltaicsPhotovoltaic solar energyElectrical conductor

The invention relates to a connection and junction box (1) for a photovoltaic solar module (24), which box in a mounting state, is put on the solar module (24) with open contact clamp(s) (22), and the contact clamps are actively closed for contacting the flexible flat conductor band(s) (28). Preferably, the actuating the contact clamp(s) (22) is automatically carried out by means of a device between two housing parts (2, 50), when putting on.

Owner:PHOENIX CONTACT GMBH & CO KG

Printed circuit board and method of manufacturing the same

InactiveUS20100044084A1Improve contact reliabilityElectrically conductive connectionsSemiconductor/solid-state device detailsResistPrinted circuit board

Provided is a printed circuit board (PCB) including a substrate that has a pad formed thereon; solder resist that is disposed on the substrate so as to expose the pad; a post that is disposed on the post; a surface-treatment layer that is disposed on the post; and a bump that is disposed on the surface-treatment layer.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

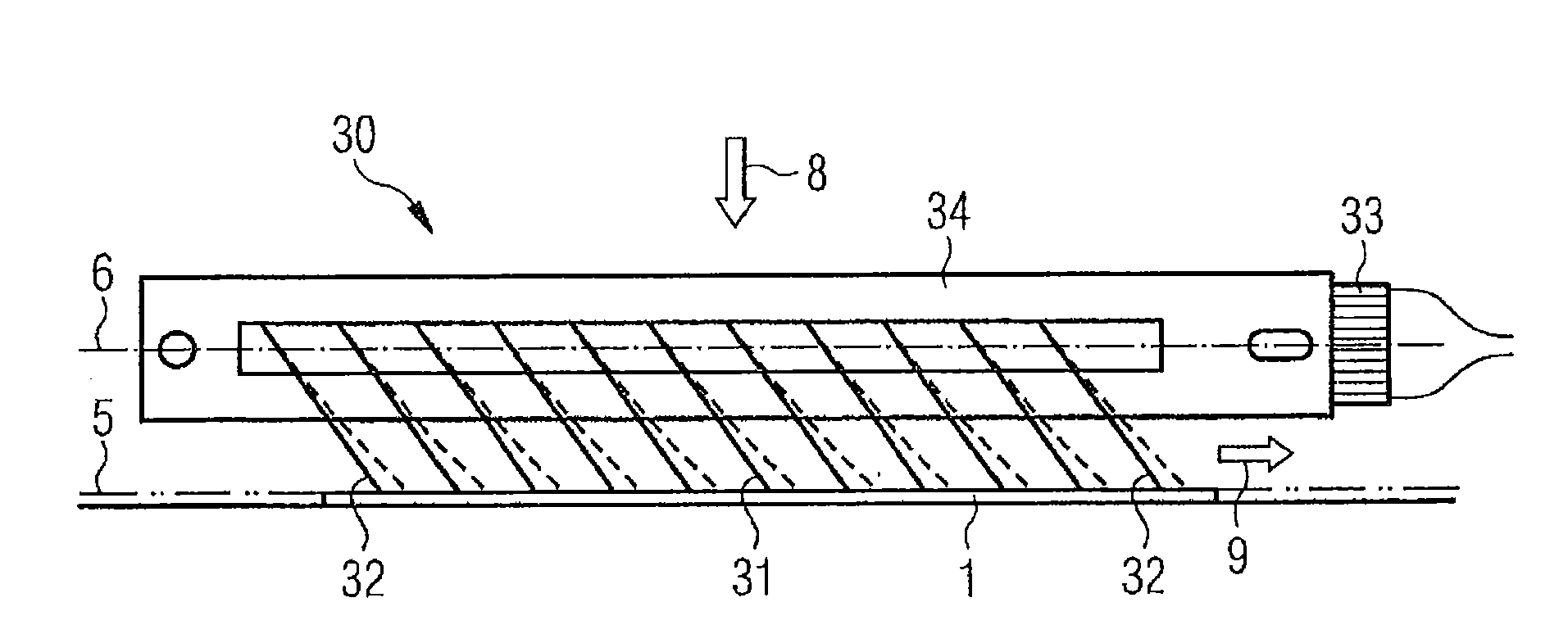

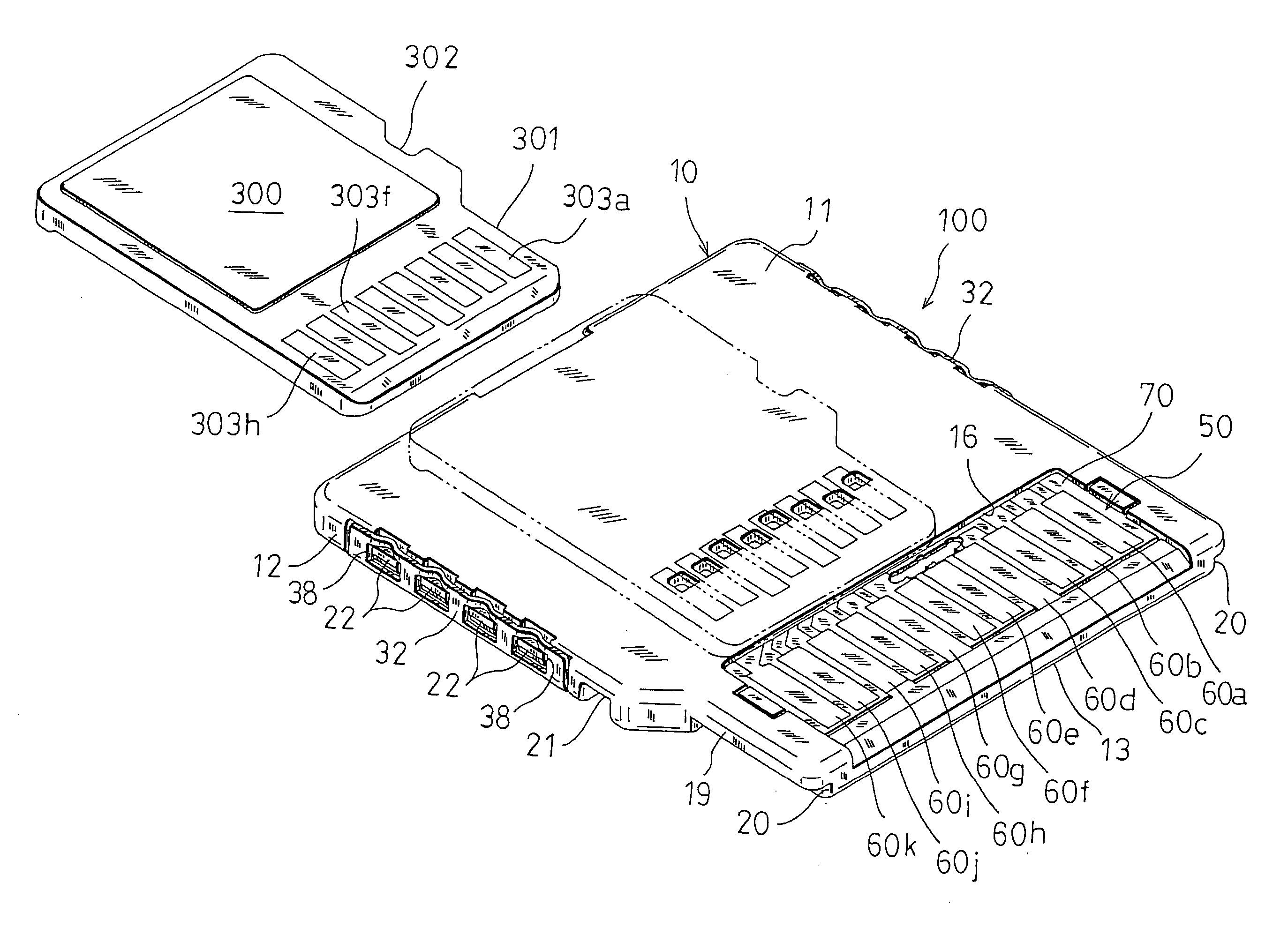

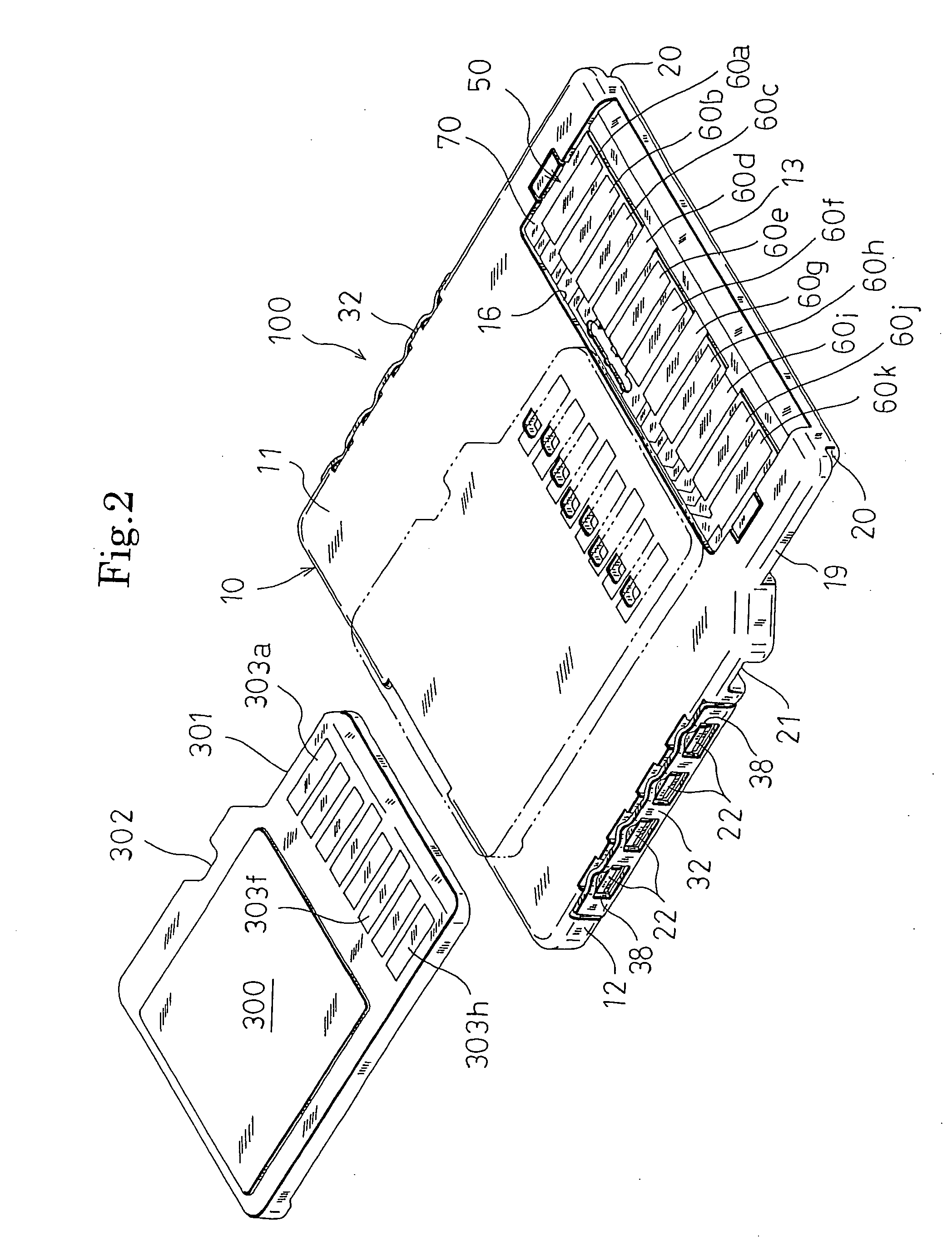

Memory card adaptor

InactiveUS20070032135A1Improve contact reliabilityPreventing function is maintainedTwo-part coupling devicesRecord carriers used with machinesGround contactElectrical connection

The invention relates to a memory card adaptor which enables a small memory card to be used in a card connector for a large memory card that is larger than the small memory card. A connecting terminal 37 which is elastically displaceable is formed integrally on a conductive (metal-made) cover 30 that is one of components of the adaptor body 1. The connecting terminal 37 is contacted with plural grounding contacts 60d, 60i, and electrical connection is established between the grounding contacts 60d, 60i, and between the grounding contacts 60d, 60i and the cover 30. High contact reliability is ensured, and an electrostatic breakdown preventing function is surely maintained.

Owner:HOSIDEN CORP

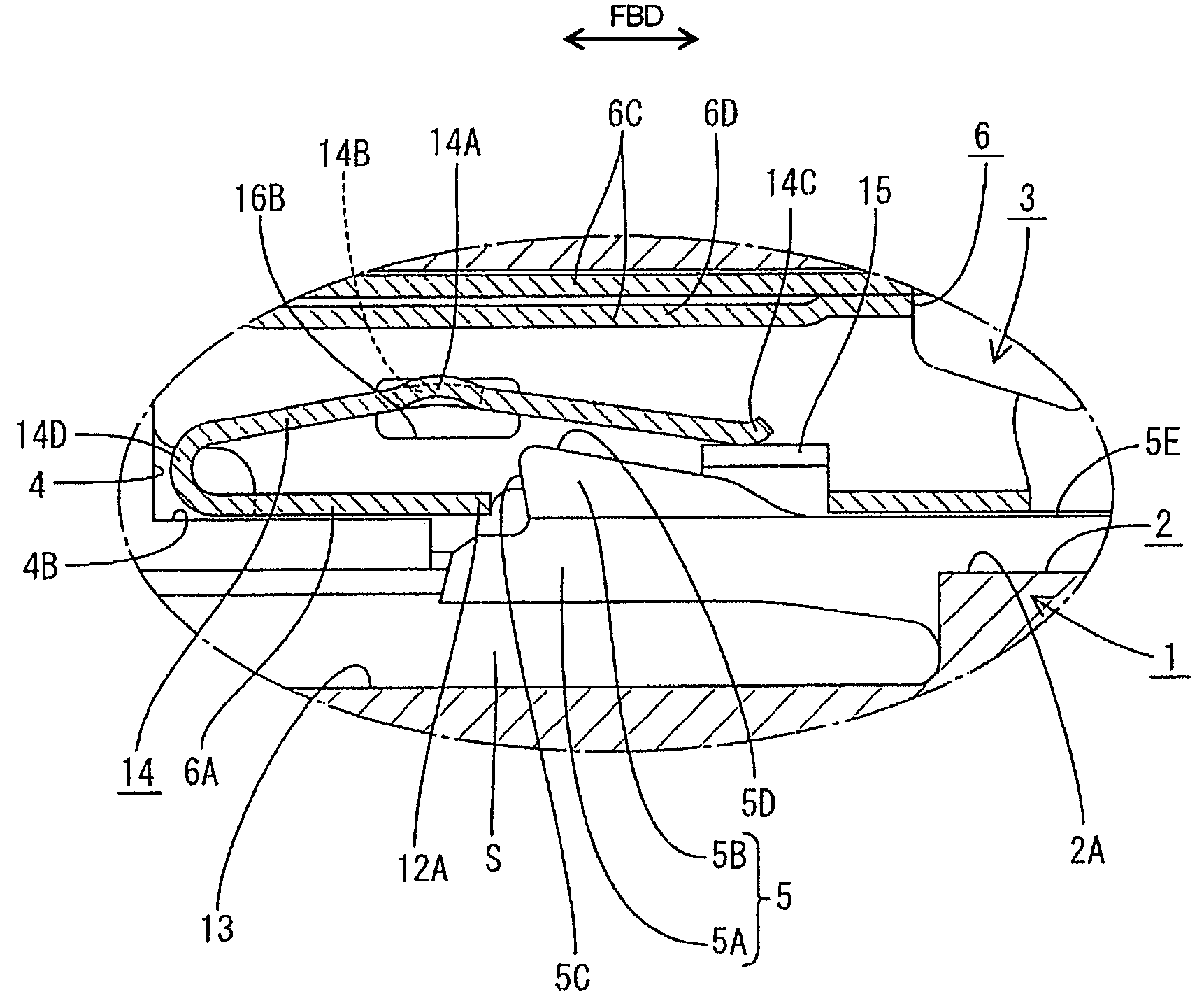

Connector

InactiveUS7374465B2Avoid interferenceIncrease contact pressureSecuring/insulating coupling contact membersCoupling contact membersEngineeringFront edge

A connector has a housing (1) with a cavity (2) for receiving a terminal fitting (3). The terminal fitting (3) has a tubular main portion (6) and a locking hole (12) is formed in the main portion (6) for receiving locking projection (5B) of a lock (5). A tongue (14) extends from the front end of the main portion (6) and is folded back into the main portion (6). The front end of the locking projection (5B) is located before an extending end (14C) of the tongue (14) and the rear end thereof is located behind the extending end (14C) of the tongue (14). Accordingly, the locking projection (5B) is long at a position where a front end surface (5C) of the locking projection (5B) receives a shear force from a front edge (12A) of the locking hole (12), thereby enlarging a sectional area against the shear force.

Owner:SUMITOMO WIRING SYST LTD +1

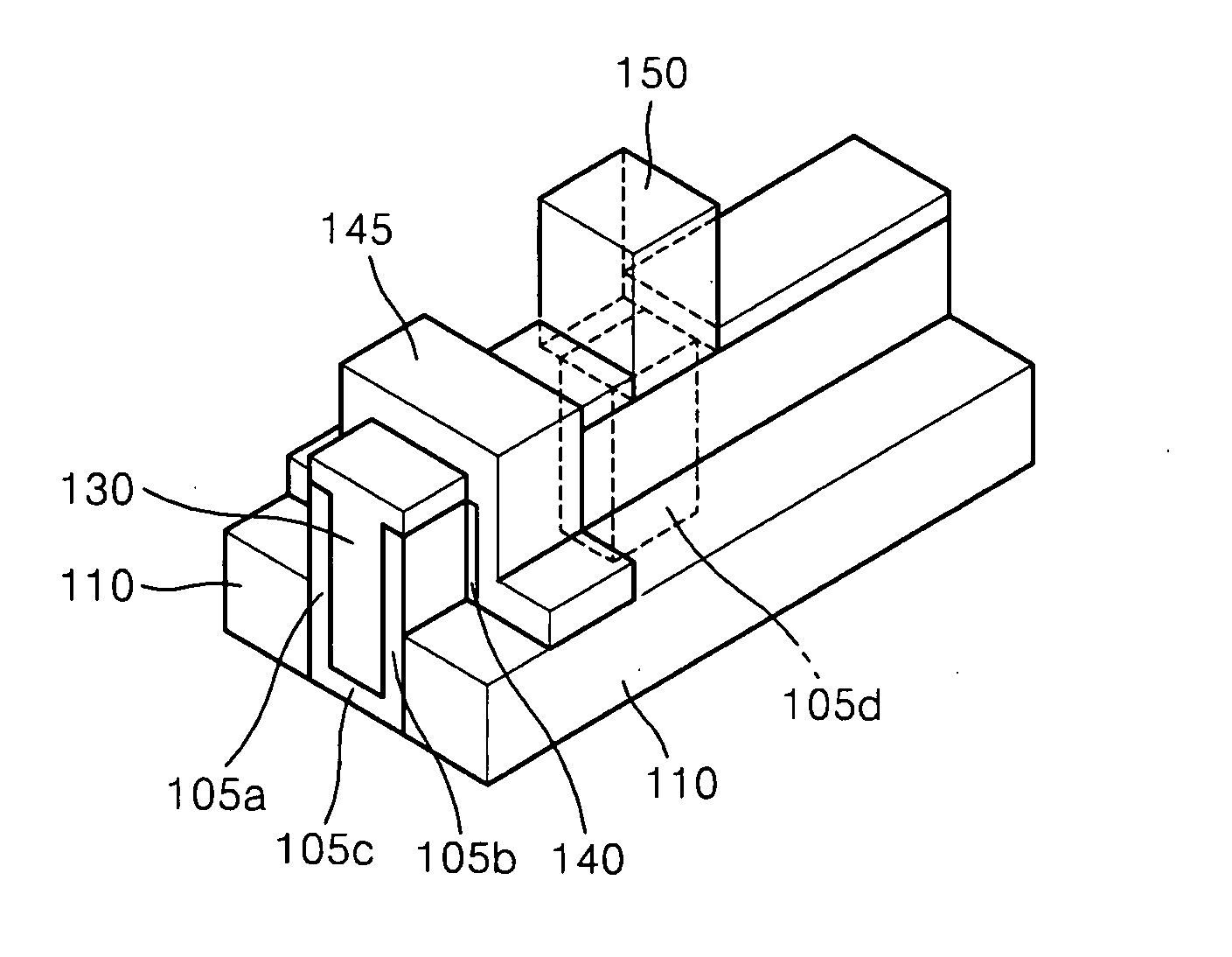

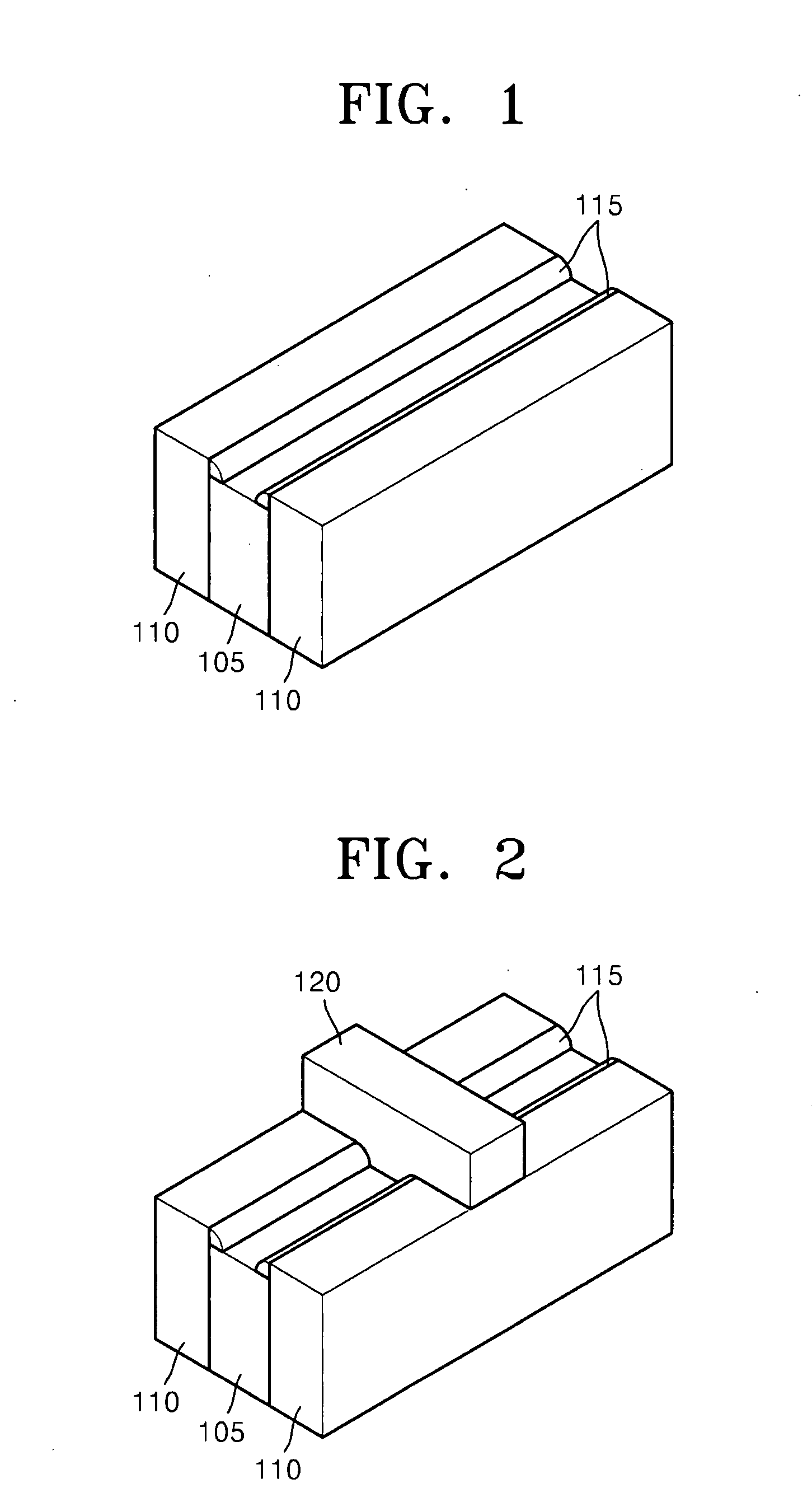

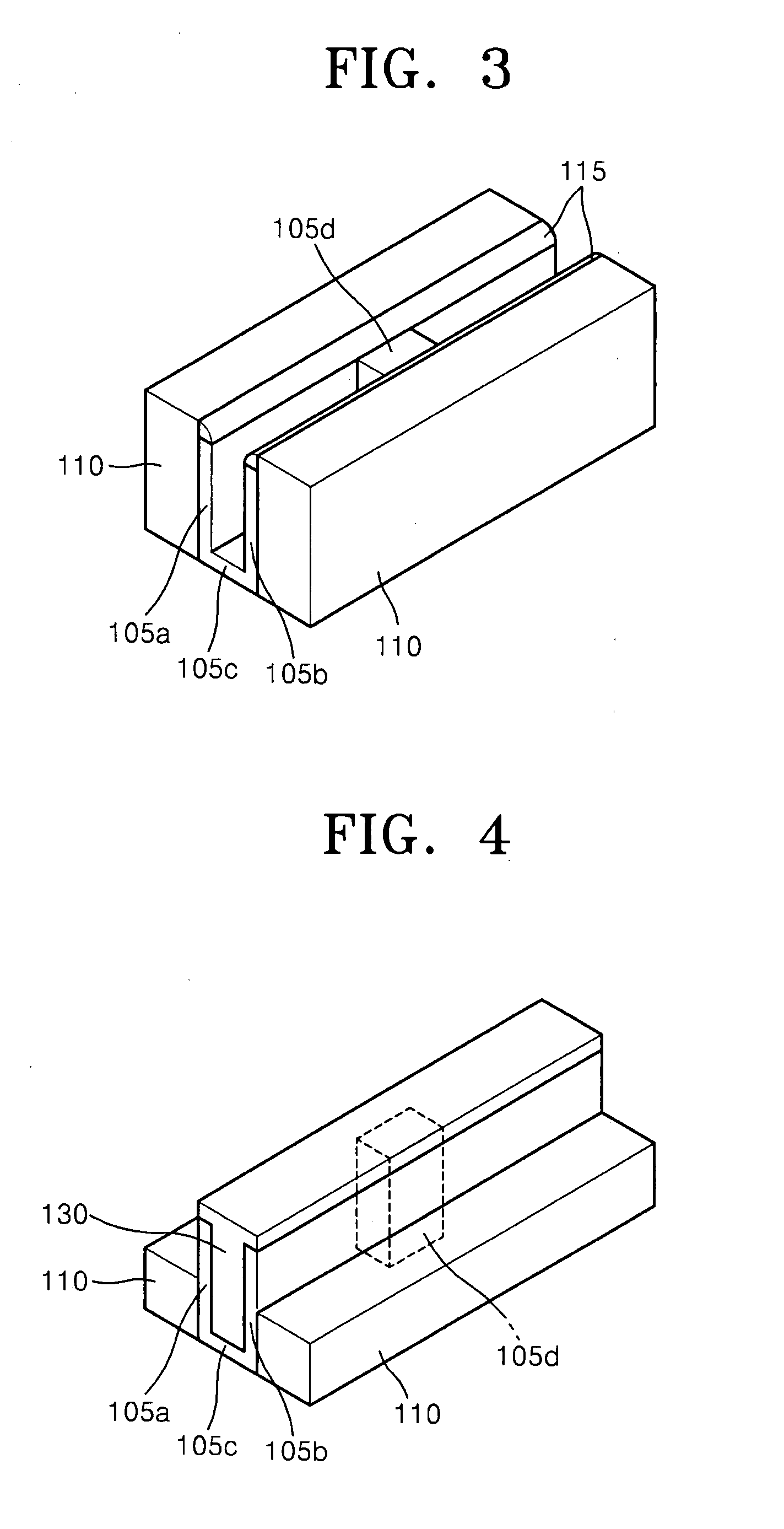

Semiconductor device and method of fabricating the same

ActiveUS20080157182A1Improve contact reliabilityImprove stabilityTransistorSemiconductor/solid-state device manufacturingDevice materialSemiconductor

Example embodiments relate to a semiconductor device including a fin-type channel region and a method of fabricating the same. The semiconductor device includes a semiconductor substrate, a semiconductor pillar and a contact plug. The semiconductor substrate includes at least one pair of fins used (or functioning) as an active region. The semiconductor pillar may be interposed between portions of the fins to connect the fins. The contact plug may be disposed (or formed) on the semiconductor pillar and electrically connected to top surfaces of the fins.

Owner:SAMSUNG ELECTRONICS CO LTD

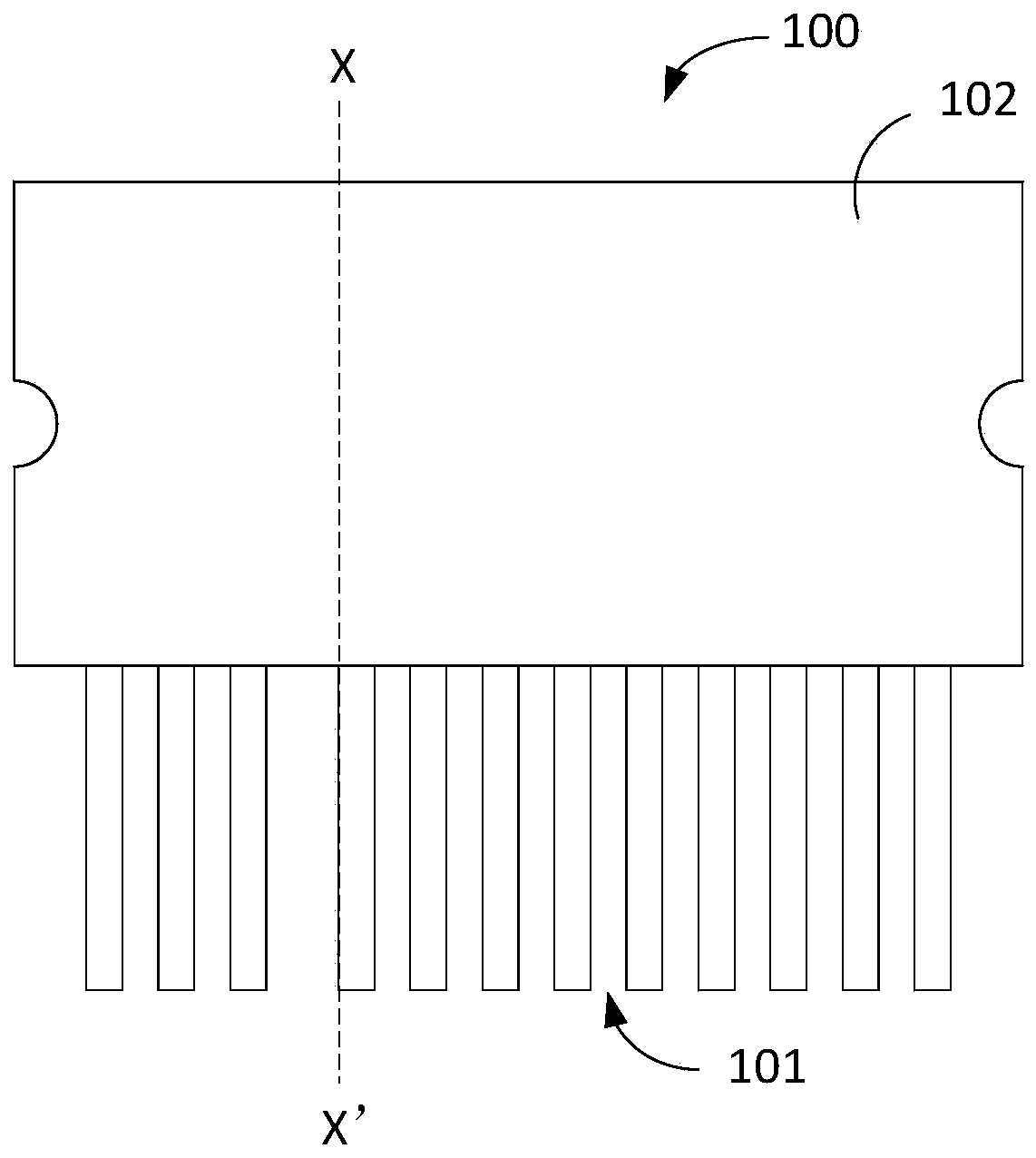

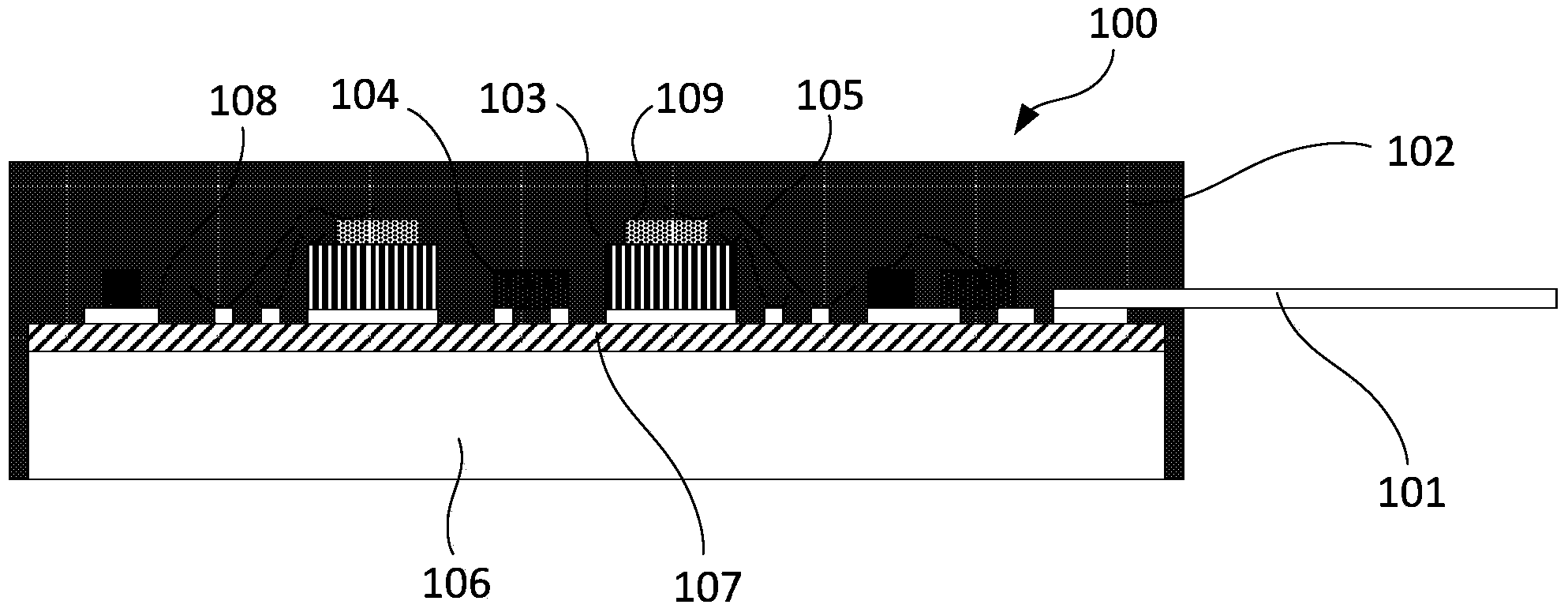

Hybrid integrated circuit module and manufacturing method thereof

ActiveCN104112719AReduce areaLow raw material costSemiconductor/solid-state device detailsSolid-state devicesGlass fiberPunching

Provided is a hybrid integrated circuit module and a manufacturing method thereof. The manufacturing method comprises the steps that a substrate, a heat radiator and a glass fiber plate with through holes arranged at preset positions are manufactured, and an insulating layer is covered on one of the surfaces of the substrate; the glass fiber plate and the heat radiator are arranged on the surface of the insulating layer; a circuit wiring layer is arranged on the surface of the glass fiber plate; power elements and non-power elements are respectively distributed on the heat radiator and the corresponding positions of the circuit wiring layer; and metal wires are connected between the circuit wiring layer, the heat radiator, the power elements and the non-power elements. Contact reliability of bonding points is enhanced, length of bonding wires is reduced and height difference of the bonding wires is reduced so that wire punching rate in molding can be effectively reduced, and thus qualified rate of manufacturing and long-term reliability of an intelligent power module are enhanced.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD

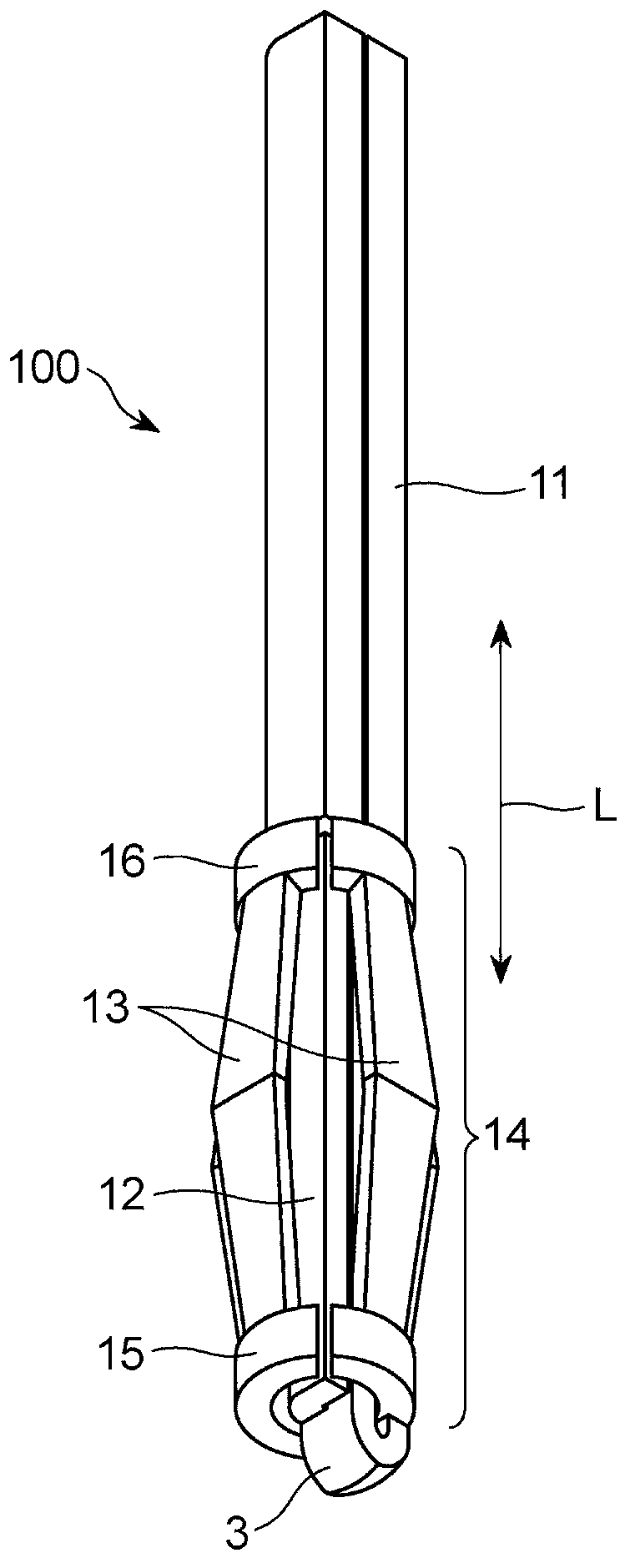

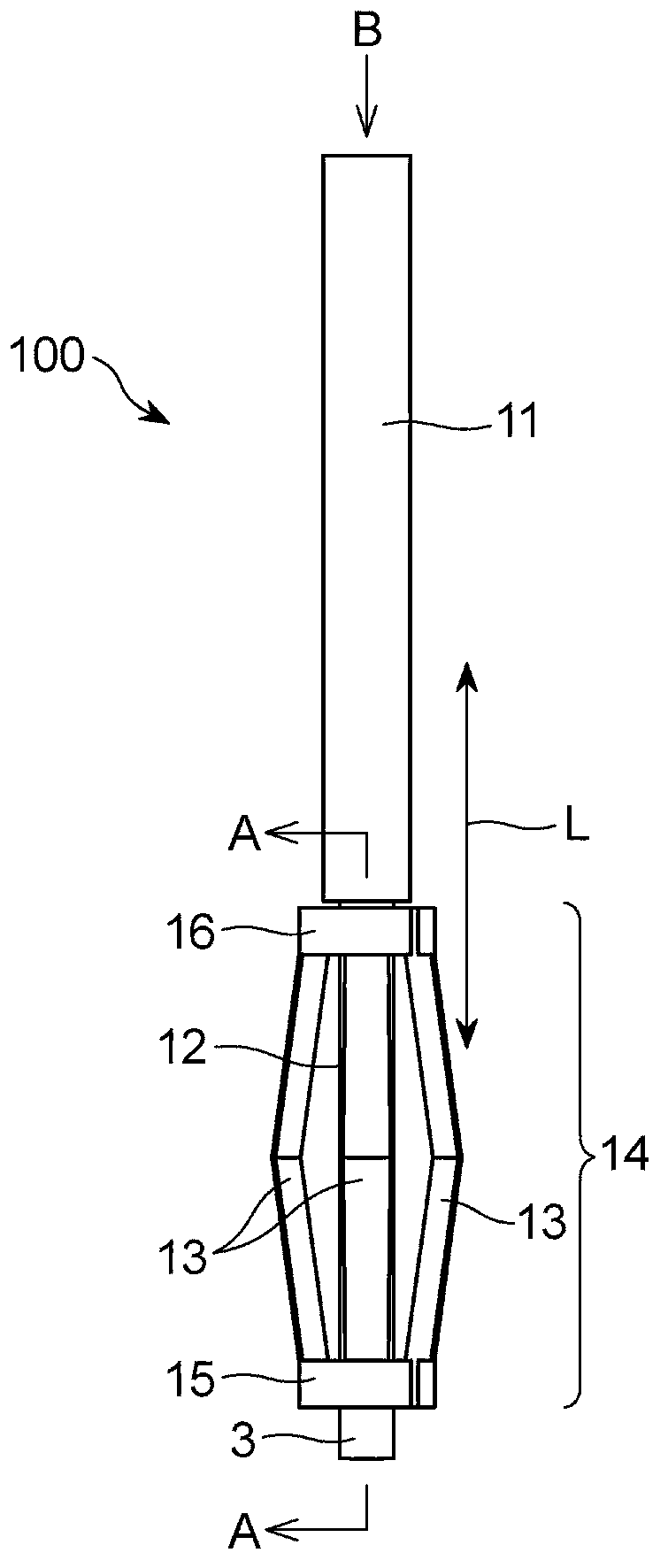

Press-fit type connector terminal

ActiveCN103311708AHigh yield strengthGood repeatabilityContact member manufacturingCoupling contact membersMechanical engineering

The press-fit type connector terminal includes a pin section having a U-shaped or quadrangular cross-section, and a contact section situated at a front end of the pin section. The contact section includes a contact piece surrounding an imaginary center line parallel to a longitudinal axis of the pin section, and a slit formed at a part of the contact piece and extending substantially parallel to the imaginary center line. The connector terminal is comprised of a single bent metal plate having elasticity.

Owner:DAIICHI SEIKO CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com