Connector

A connector and electrical connection technology, which is applied in the direction of connection, fixed connection, and parts of the connection device, etc., can solve the problems of displacement of the arrangement direction, inability to ensure contact stability, inability to follow the tilting action of the connector 901, etc. The effect of improving durability and contact reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] Hereinafter, embodiments of the present invention will be described based on the drawings.

[0049] First, based on Figure 1 to Figure 23 The first embodiment of the present invention will be described.

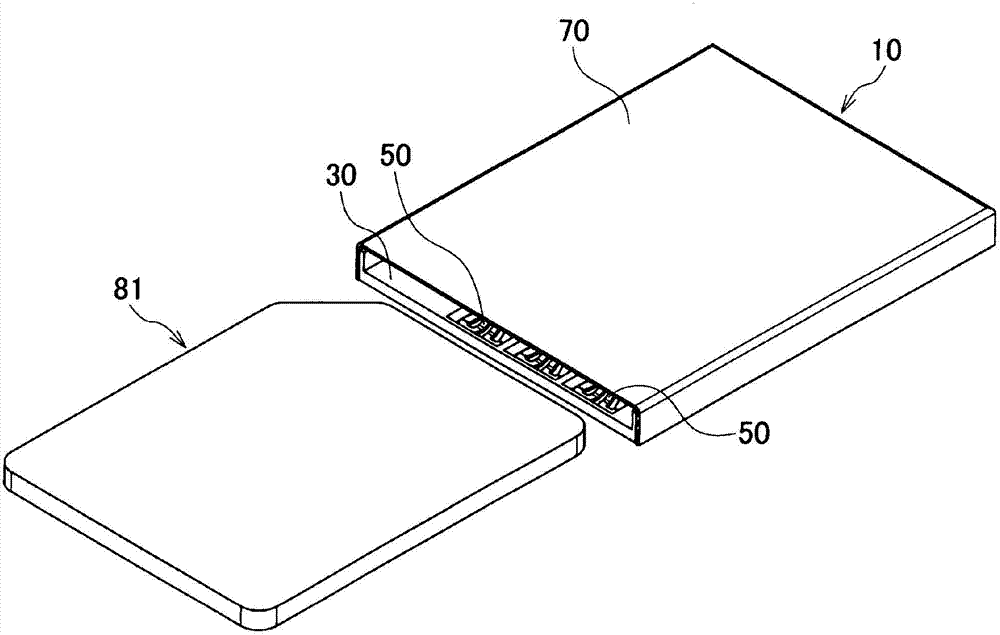

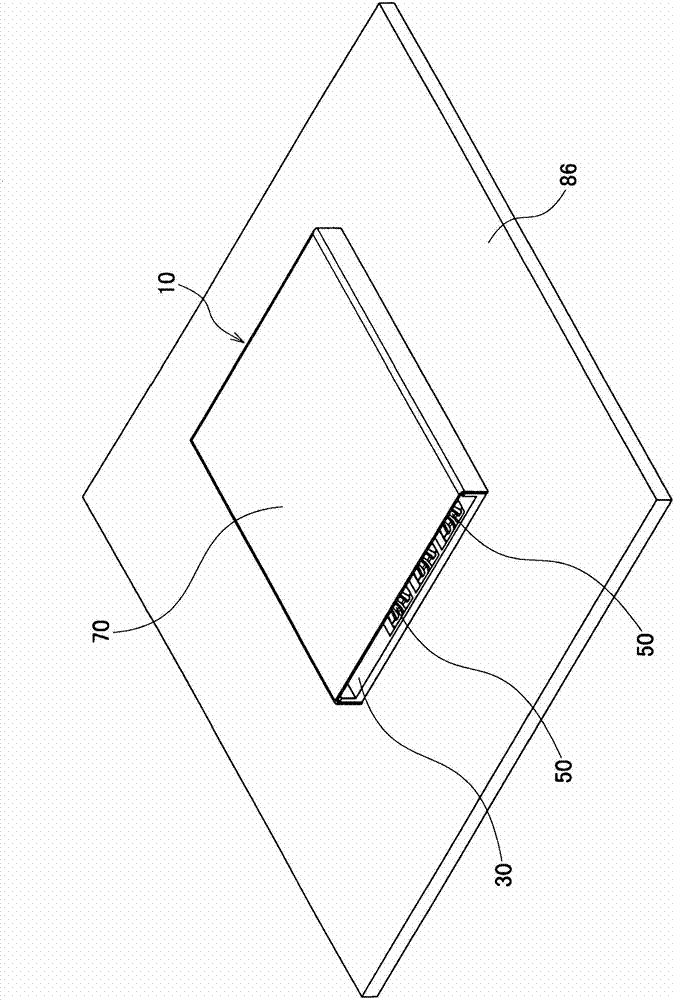

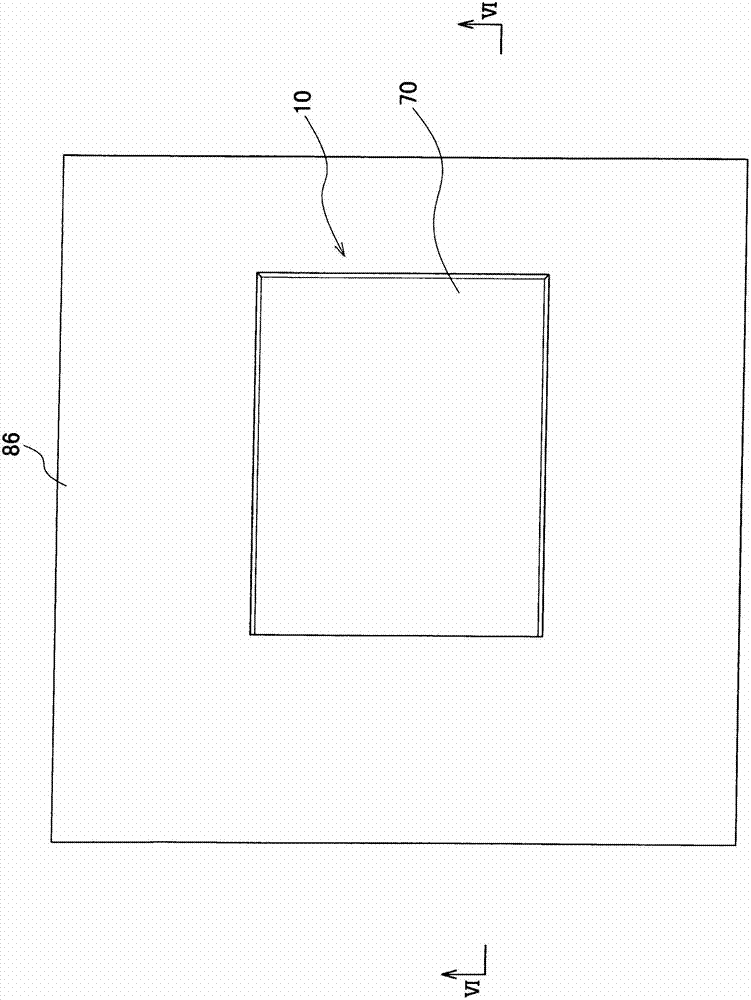

[0050] Such as figure 1 , figure 2 , image 3 As shown, the connector 10 electrically connects a card-type electronic component (first connection object) 81 and a printed circuit board (second connection object) 86 .

[0051] The connector 10 includes a housing 30 , six contacts 50 , and a cover 70 .

[0052] Such as Figure 4 As shown, the housing 30 is in the shape of a shell whose front and upper portions are open, and has a bottom portion 31 , two side wall portions 32 , and a rear wall portion 33 . The bottom portion 31 has a flat plate shape, and the card-type electronic component 81 is disposed on the bottom portion 31 . The arrangement surface 82 of the bottom portion 31 and the card-type electronic component 81 (refer to Figure 19 )relatively. Six...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com