Patents

Literature

928 results about "Stress relieving" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Stress relieving is a heat treatment process in which a metal is subjected to a constant temperature that is below the metal's critical temperature, followed by controlled cooling. Drawing, forming and machining induce stresses in materials.

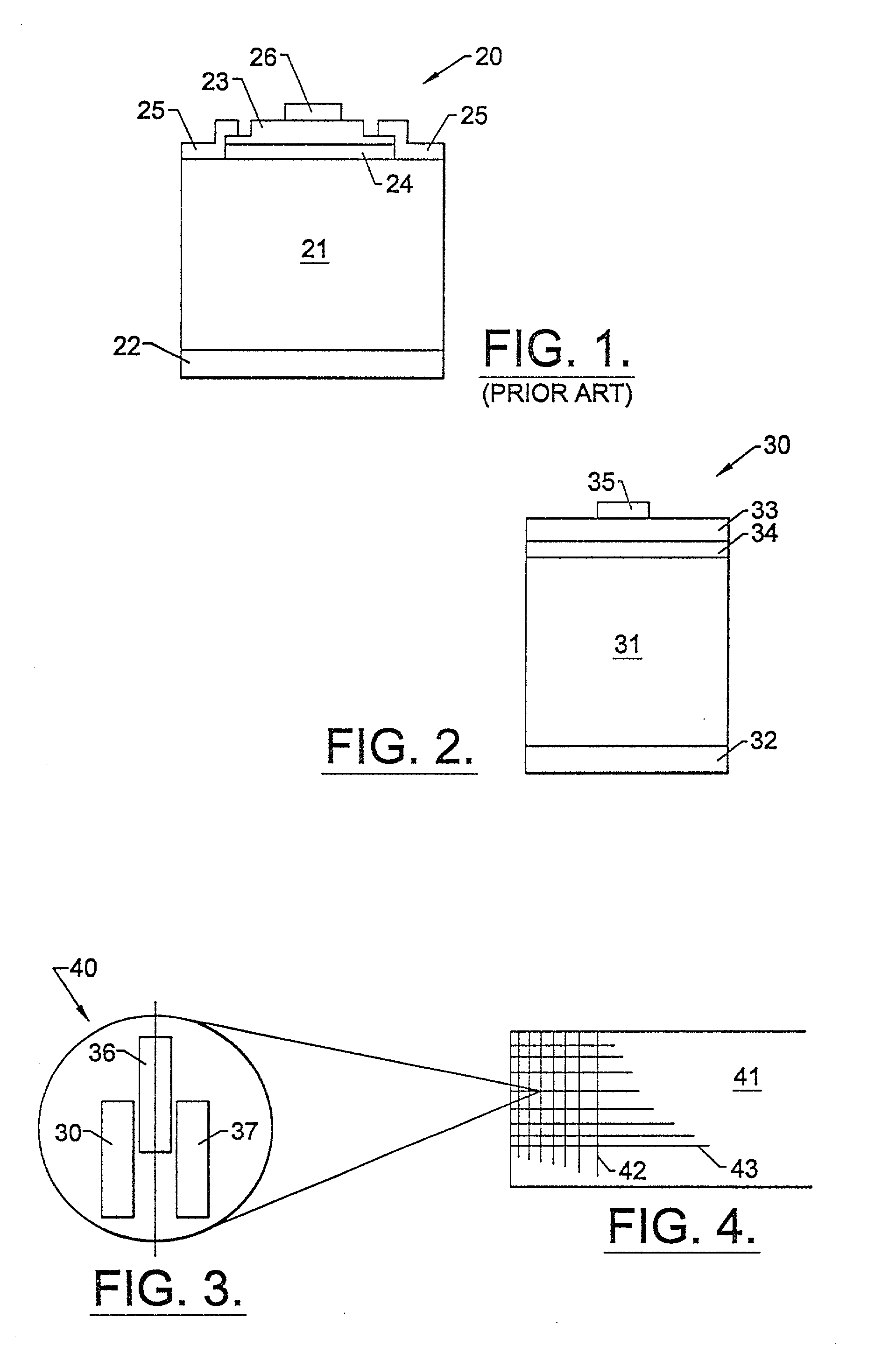

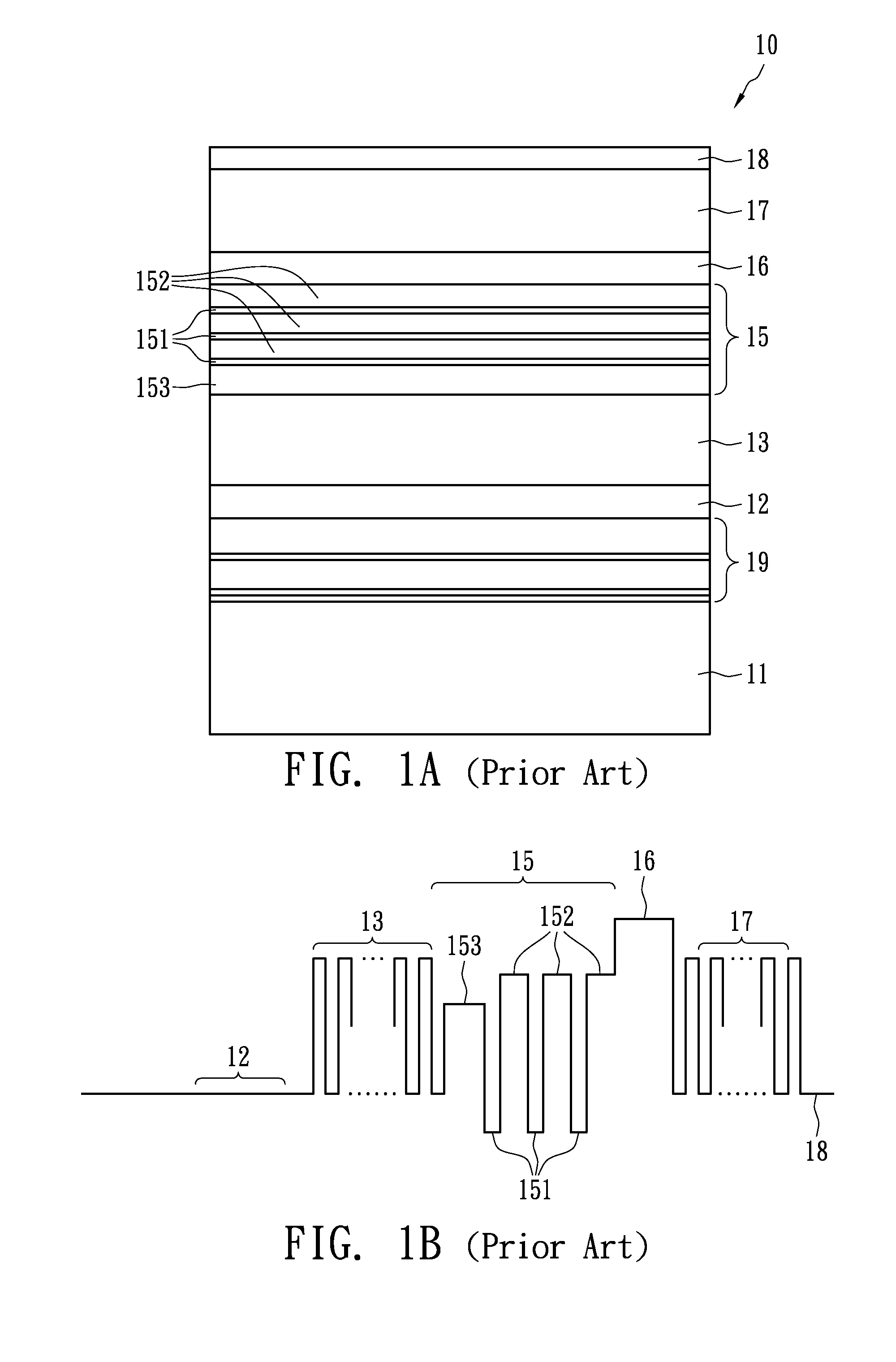

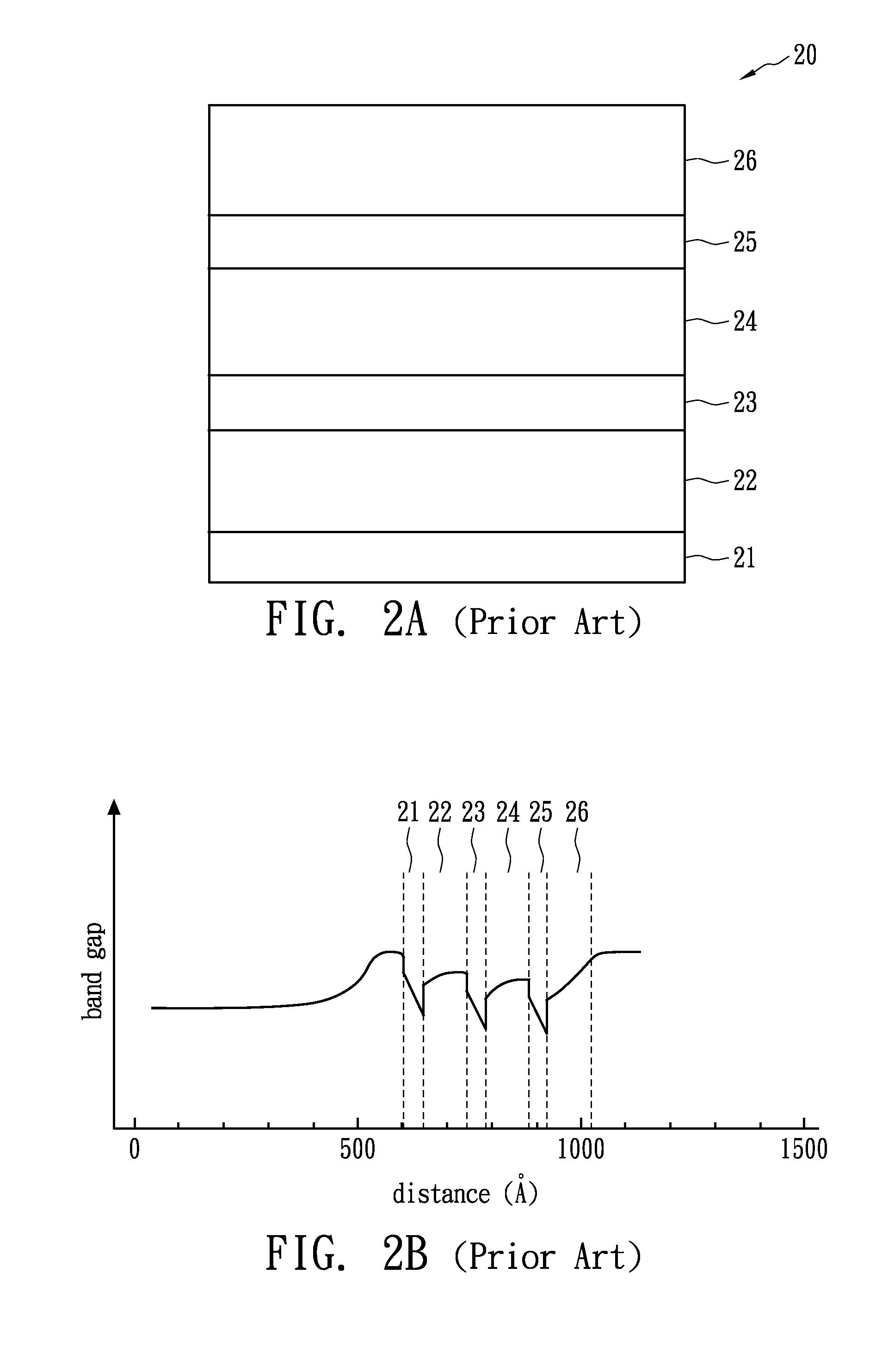

Group III nitride photonic devices on silicon carbide substrates with conductive buffer interlay structure

InactiveUS6201262B1Avoid crackingEasy to manufactureSemiconductor/solid-state device manufacturingSemiconductor devicesStress inducedStress relieving

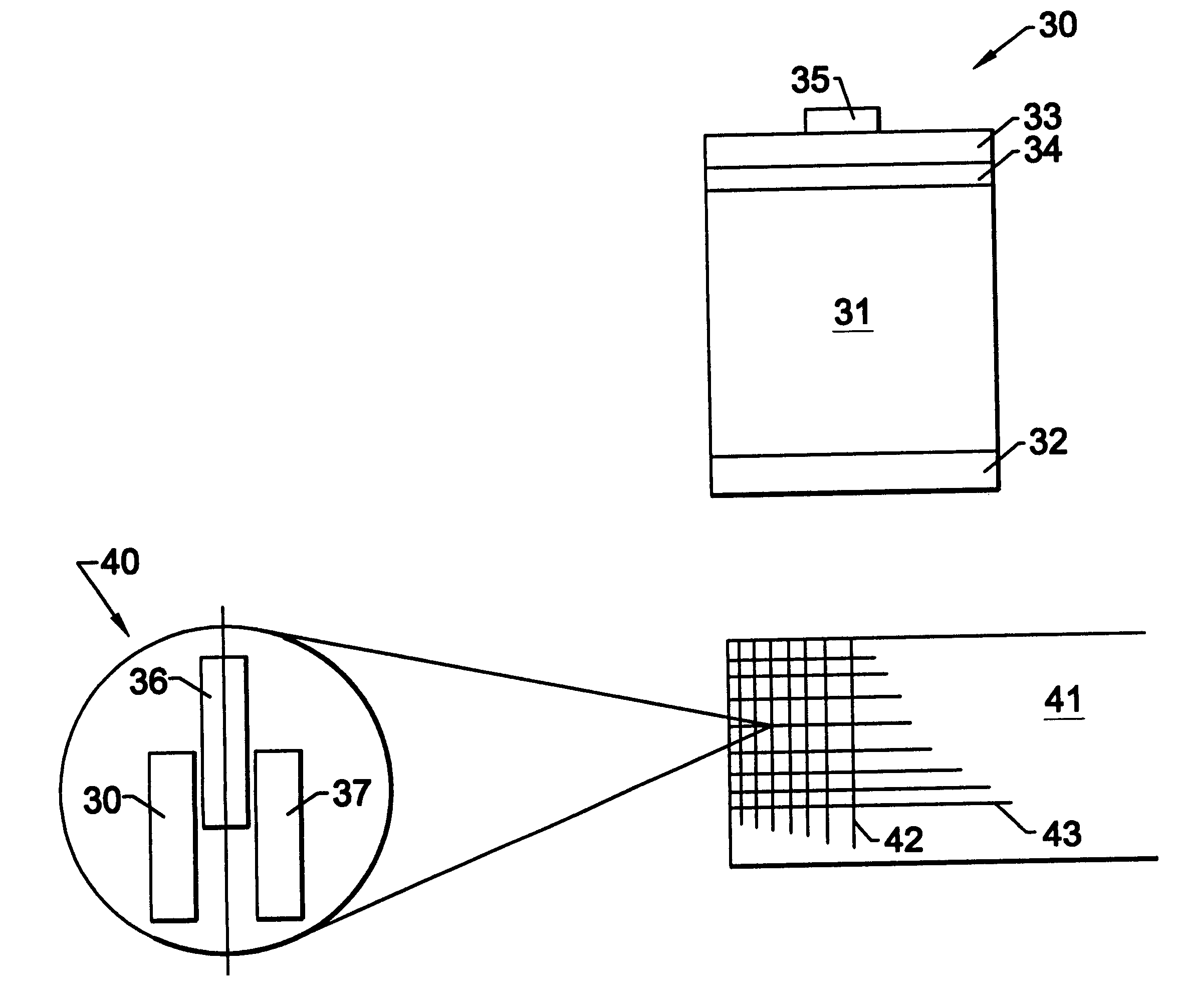

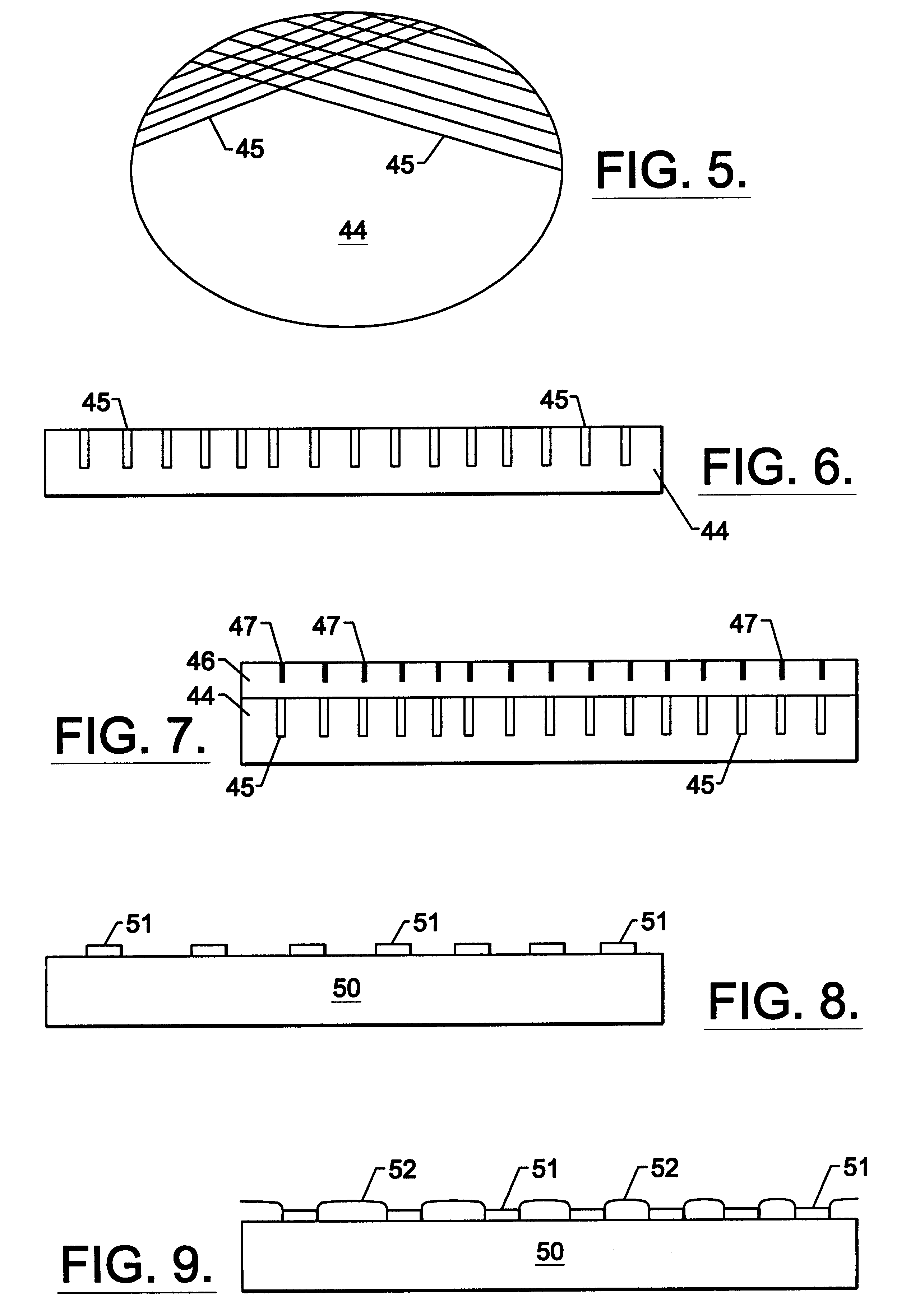

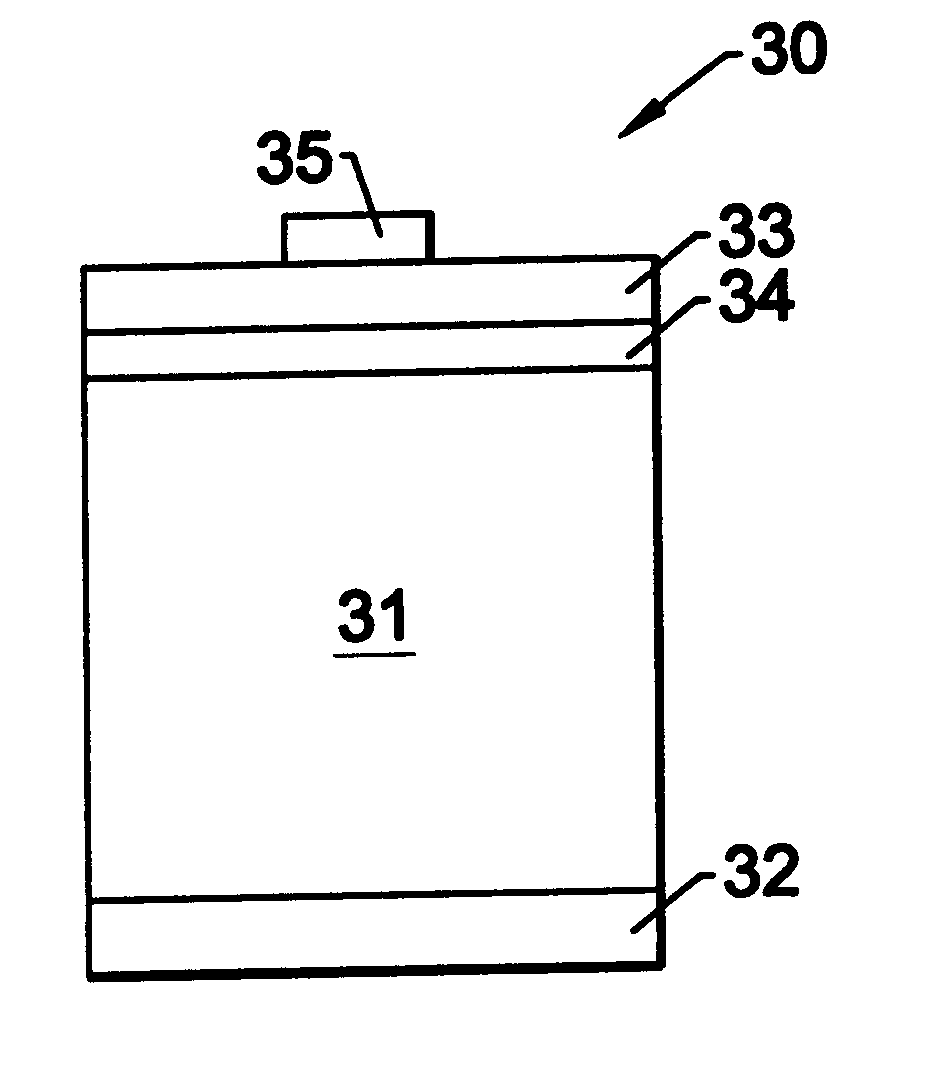

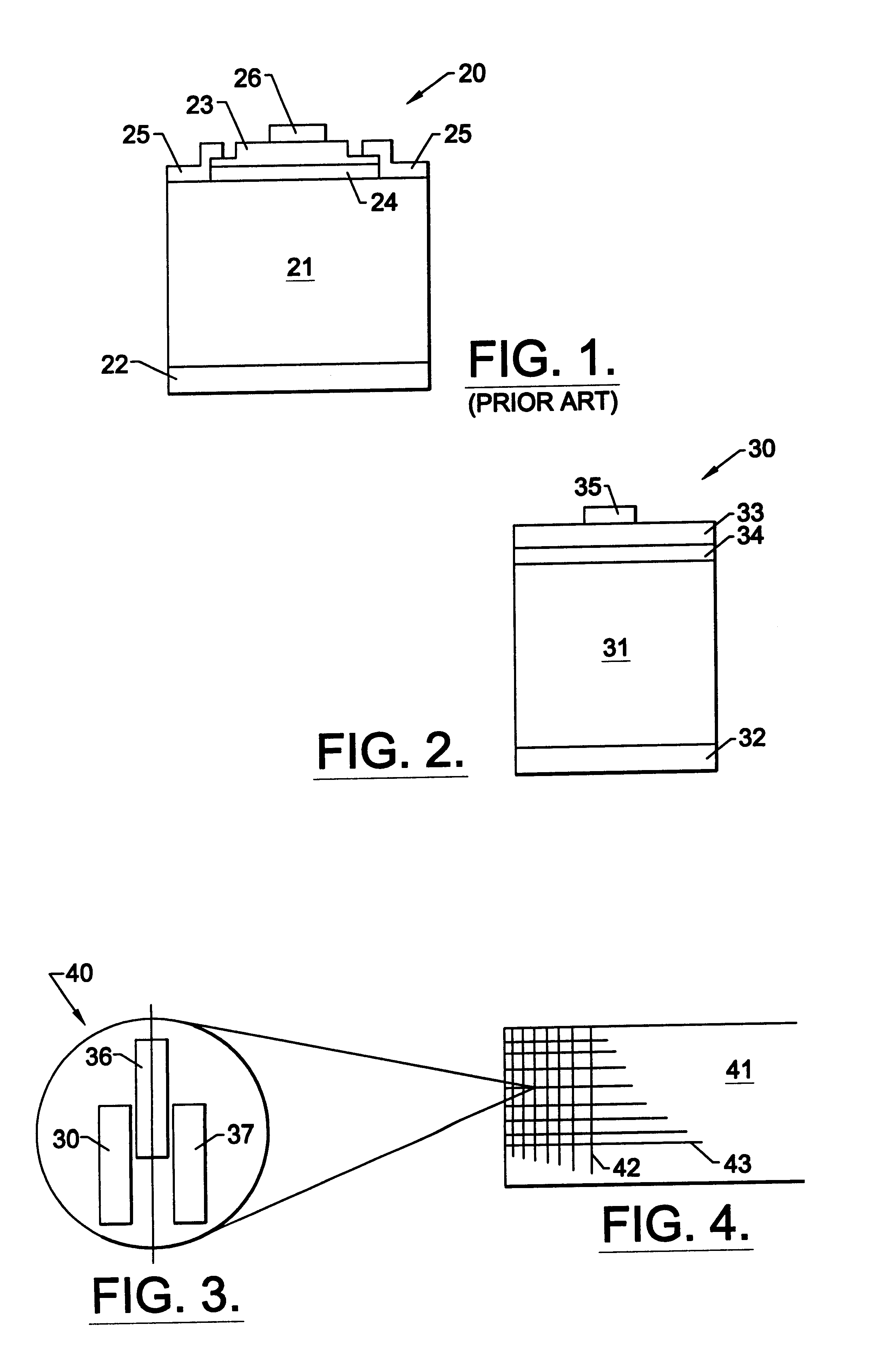

An optoelectronic device with a Group III Nitride active layer is disclosed that comprises a silicon carbide substrate; an optoelectronic diode with a Group III nitride active layer; a buffer structure selected from the group consisting of gallium nitride and indium gallium nitride between the silicon carbide substrate and the optoelectronic diode; and a stress-absorbing structure comprising a plurality of predetermined stress-relieving areas within the crystal structure of the buffer structure, so that stress-induced cracking that occurs in the buffer structure occurs at predetermined areas rather than elsewhere in the buffer structure.

Owner:CREE INC

Group III nitride photonic devices on silicon carbide substrates with conductive buffer interlayer structure

InactiveUS6187606B1Avoid crackingMinimize and eliminate heterobarrierSemiconductor/solid-state device manufacturingSemiconductor devicesStress inducedStress relieving

An optoelectronic device with a Group III Nitride active layer is disclosed that comprises a silicon carbide substrate; an optoelectronic diode with a Group III nitride active layer; a buffer structure selected from the group consisting of gallium nitride and indium gallium nitride between the silicon carbide substrate and the optoelectronic diode; and a stress-absorbing structure comprising a plurality of predetermined stress-relieving areas within the crystal structure of the buffer structure, so that stress-induced cracking that occurs in the buffer structure occurs at predetermined areas rather than elsewhere in the buffer structure.

Owner:CREE INC

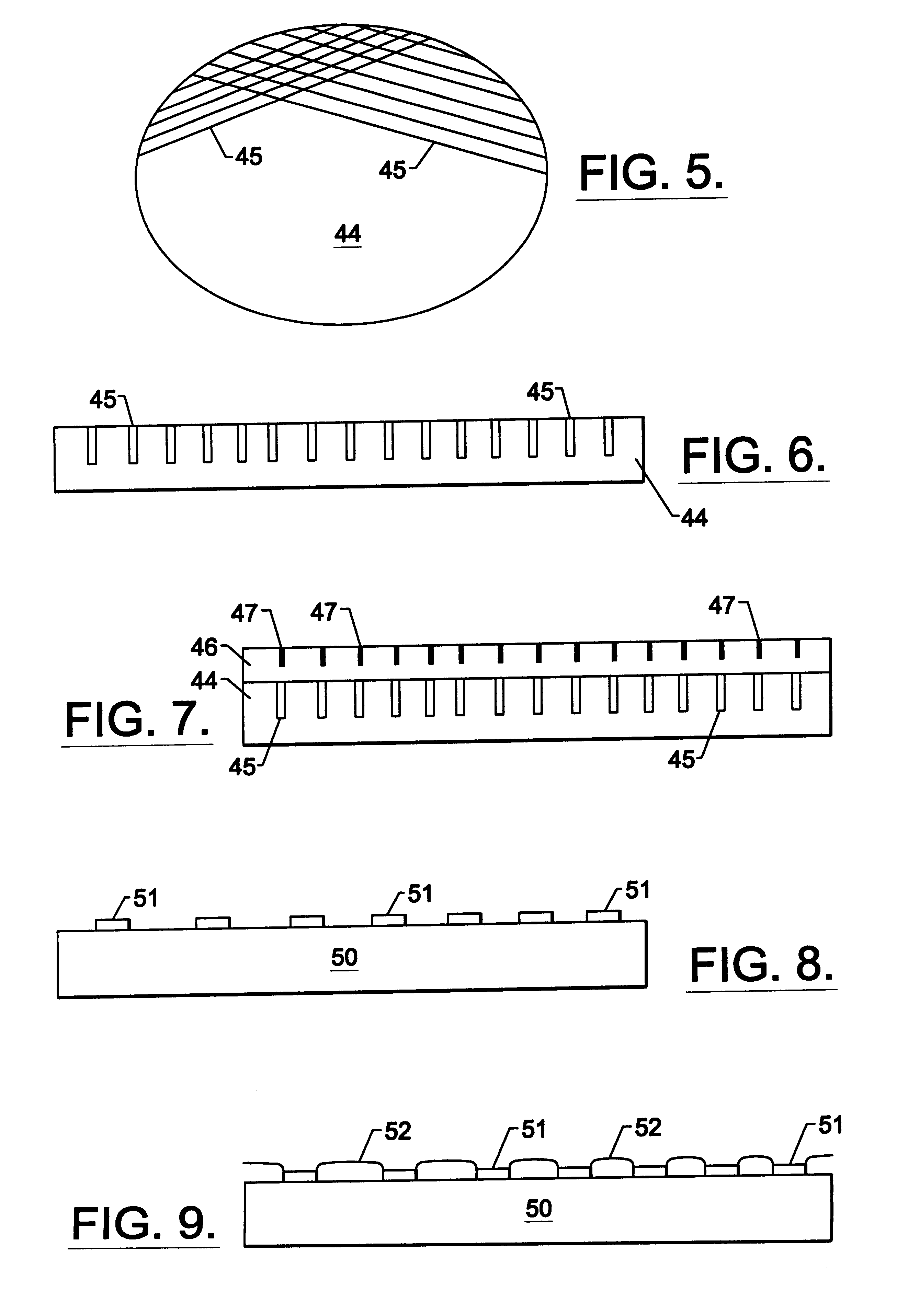

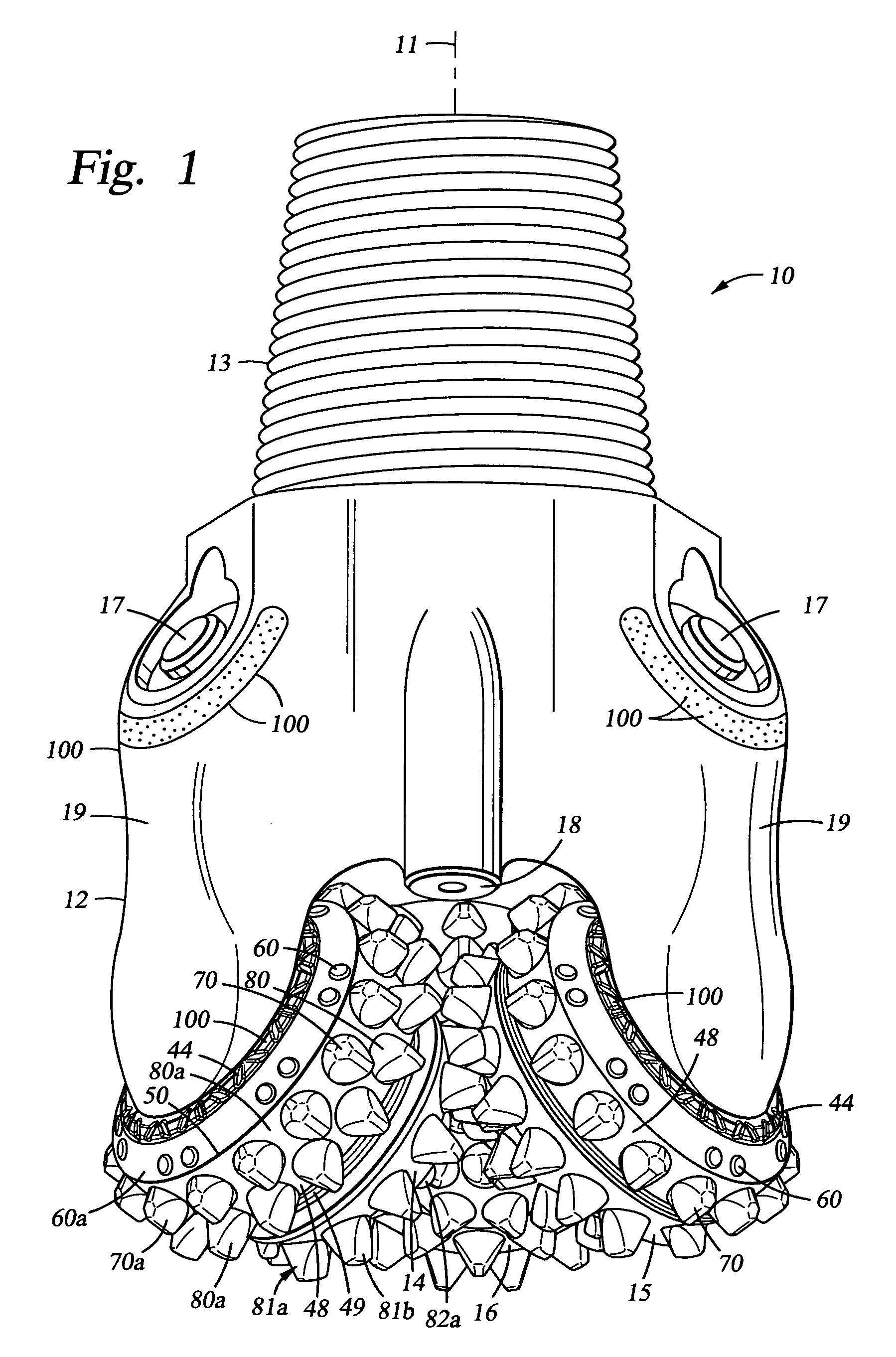

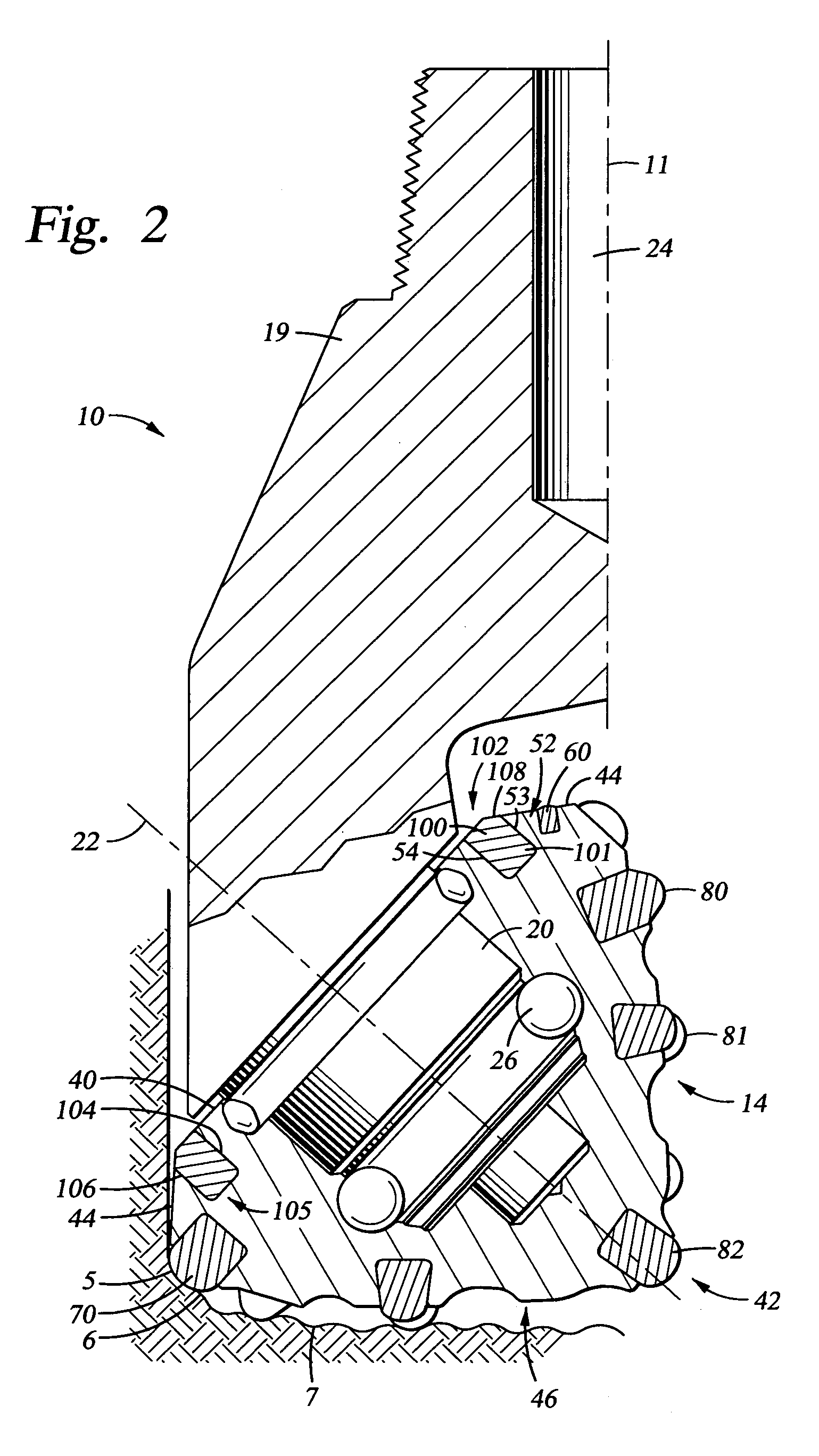

Drill bit arcuate-shaped inserts with cutting edges and method of manufacture

InactiveUS7331410B2Extended bit lifeImprove abilitiesDrill bitsMetal-working drilling toolsStress relievingEngineering

Disclosed are a variety of arcuate-shaped inserts for drill bits, and in particular, for placement in rolling cone cutters of drill bits. The arcuate inserts include 360° or ring-shaped inserts, as well as inserts of smaller arcuate length. The arcuate inserts are suitable for use in all surfaces of the rolling cone cutter, and in other locations in drill bits, and may have specialized cutting surfaces and material enhancements to enhance their cutting duty performance. Certain arcuate inserts may include stress relieving discontinuities such that, upon assembly into the cone or during drilling, the arcuate inserts may fragment in a controlled and predicted manner into shorter arcuate lengths.

Owner:SMITH INT INC

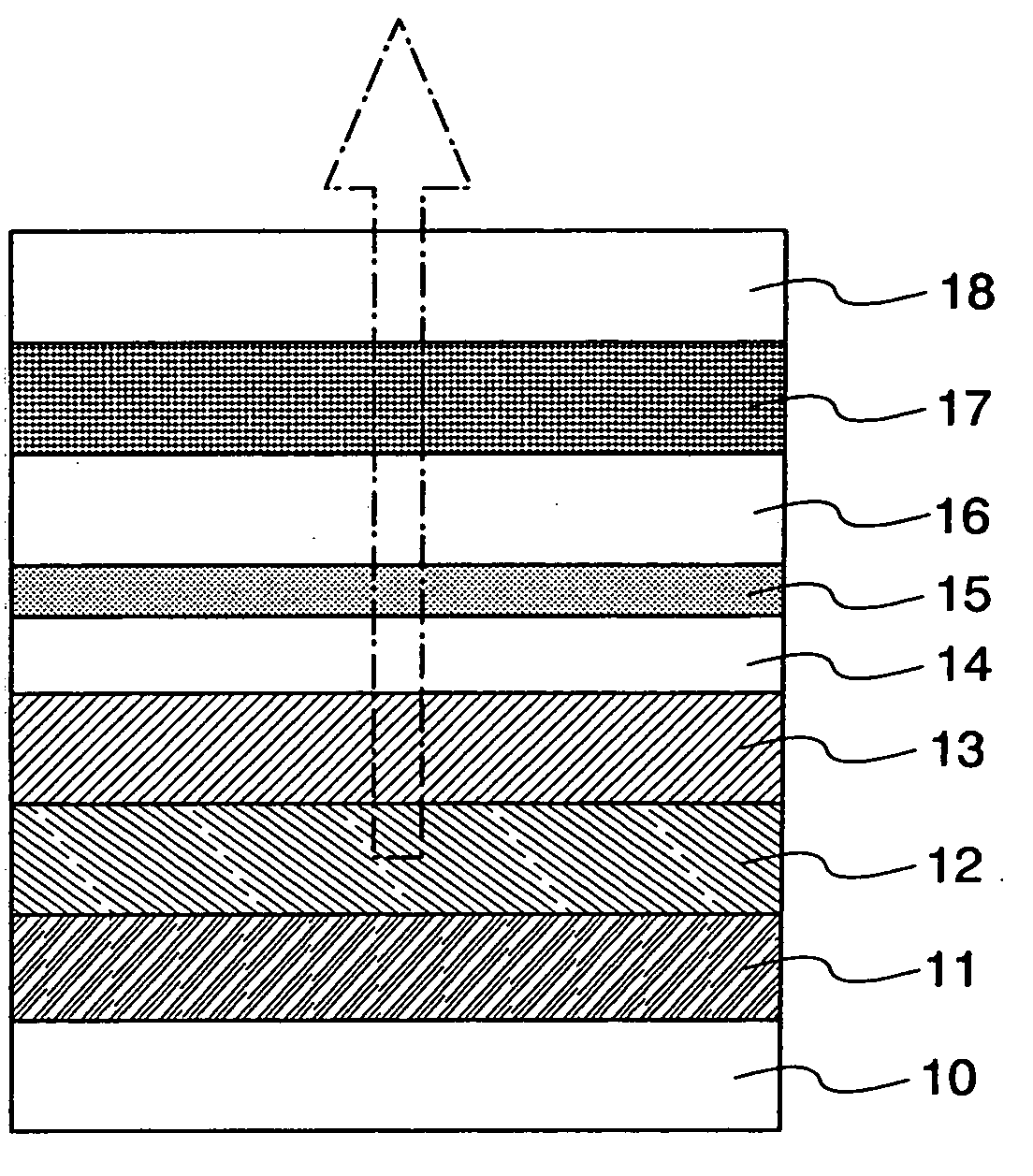

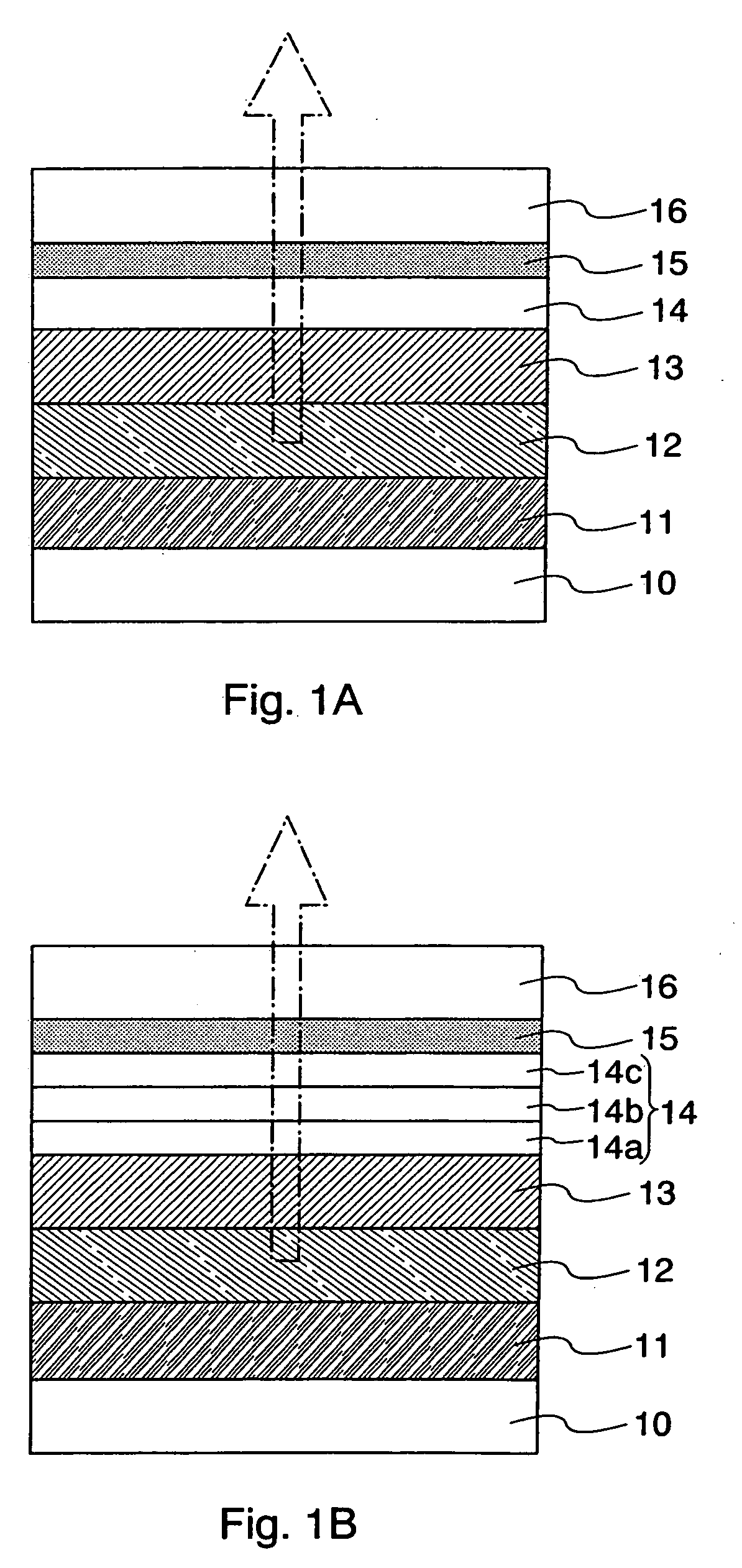

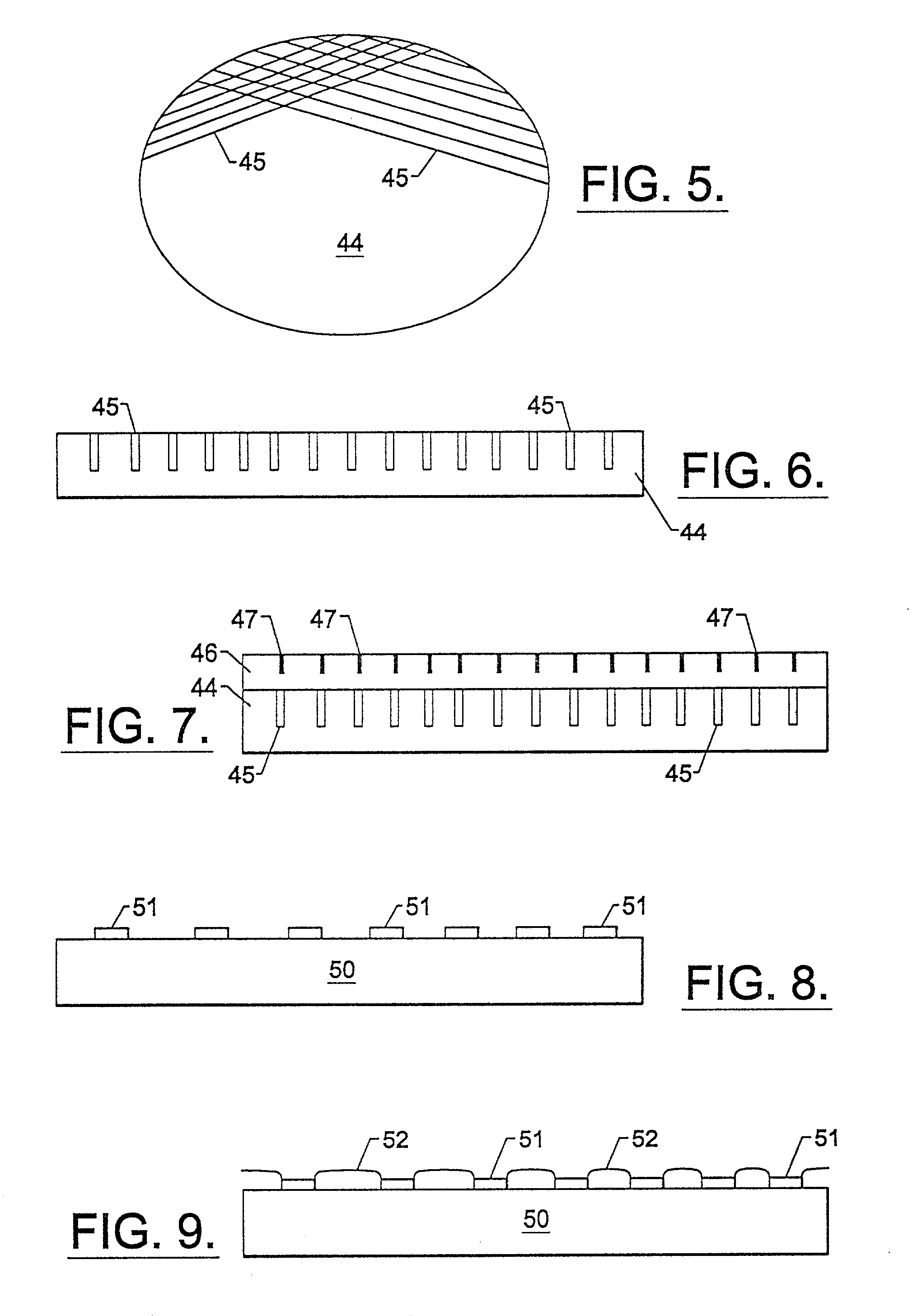

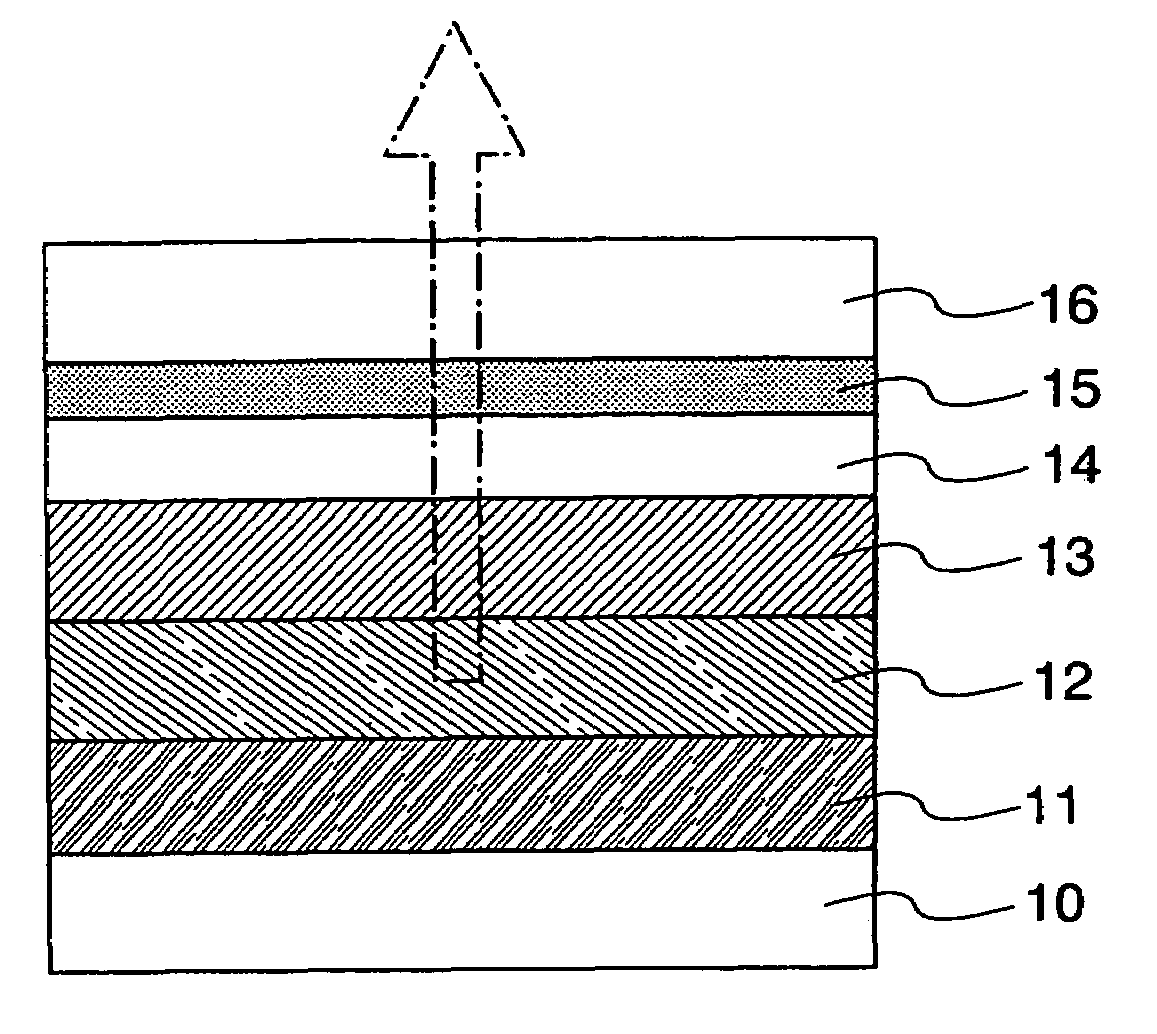

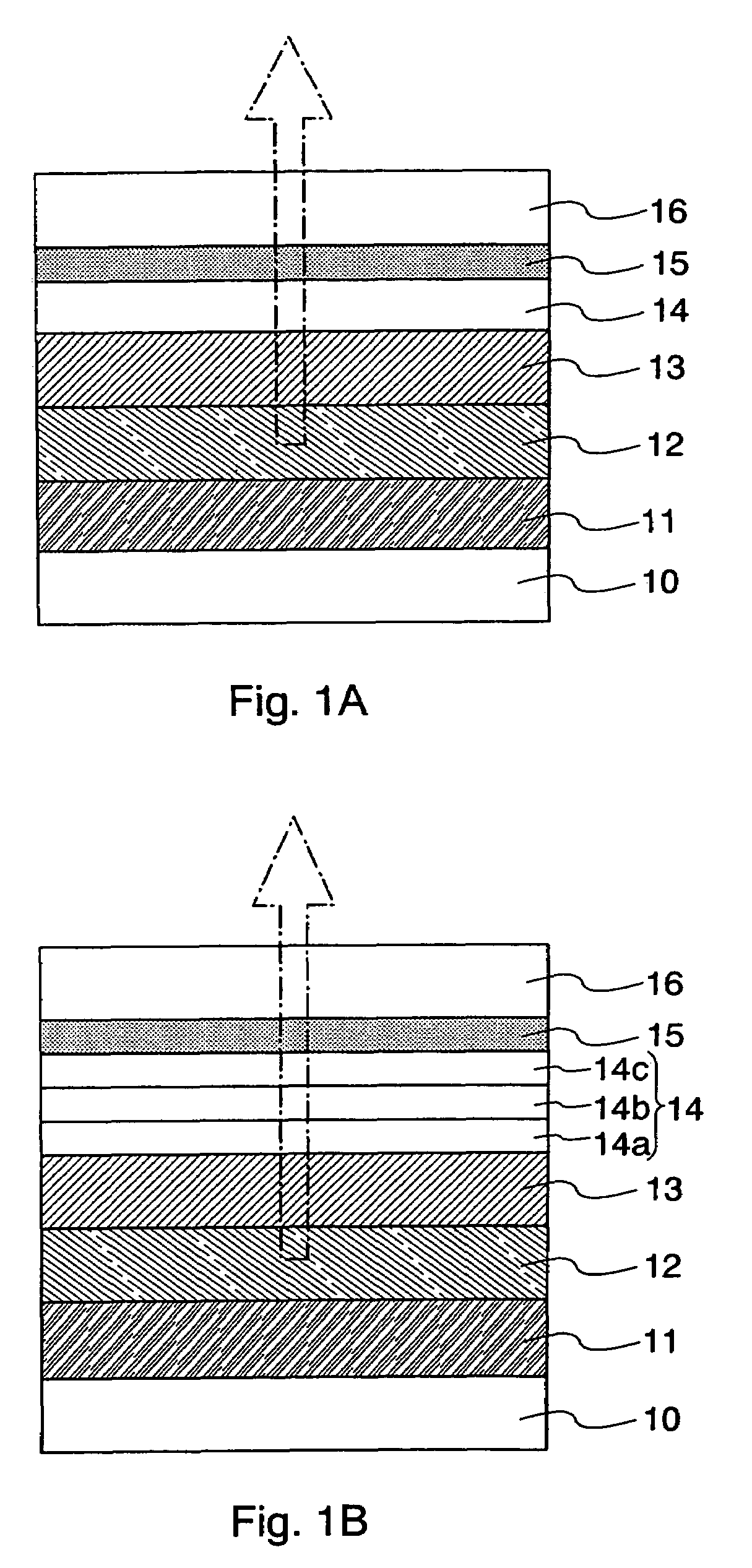

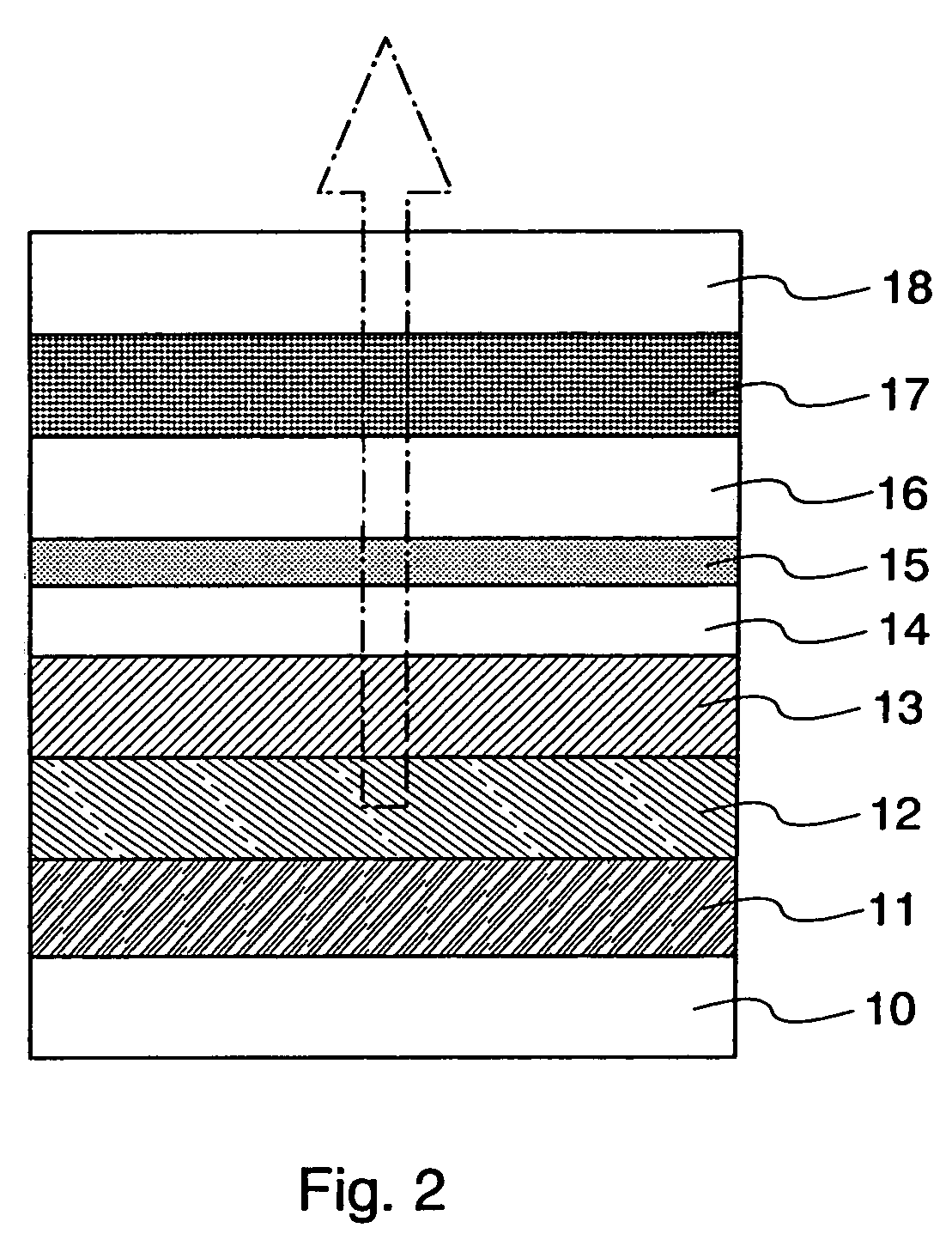

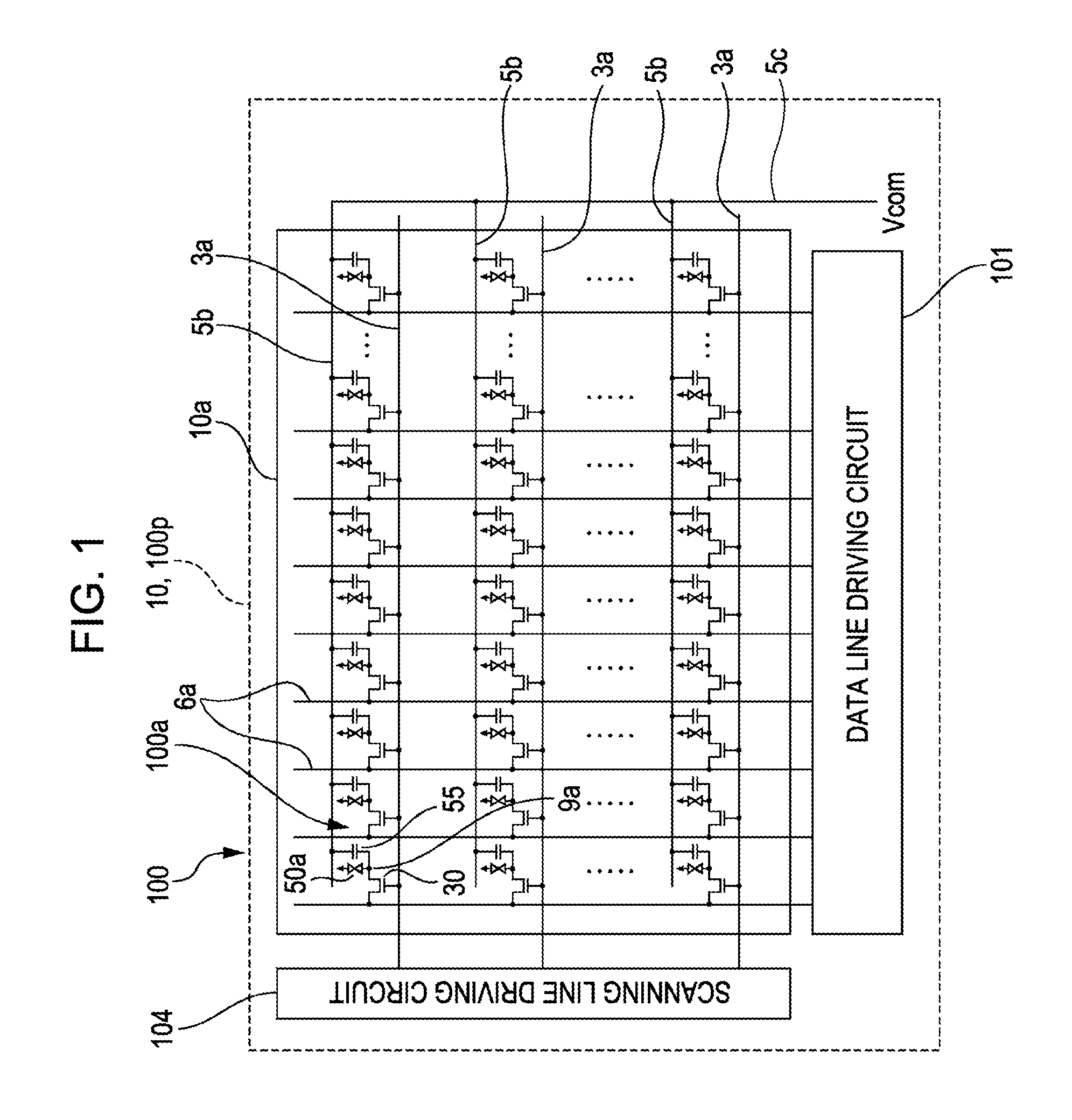

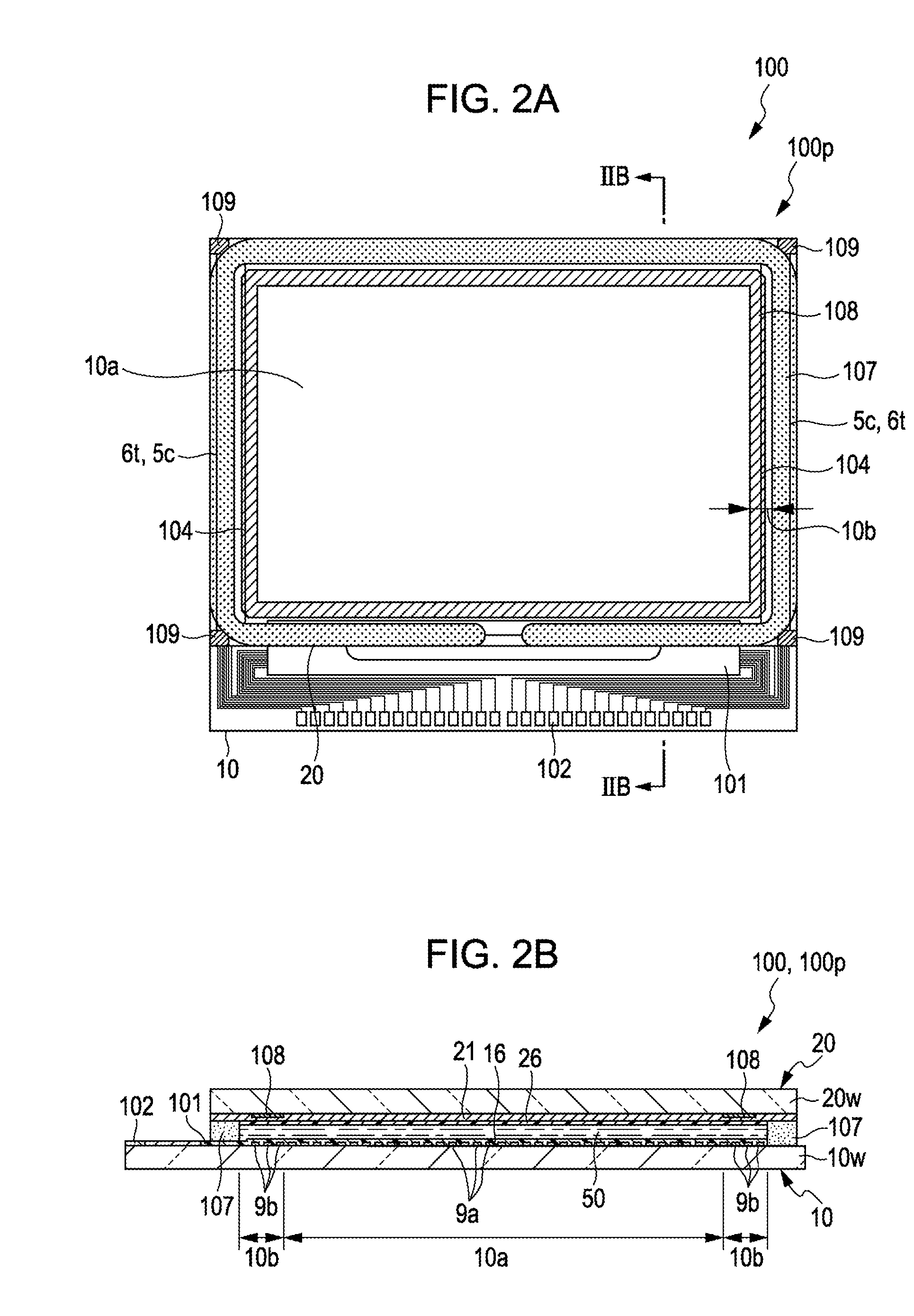

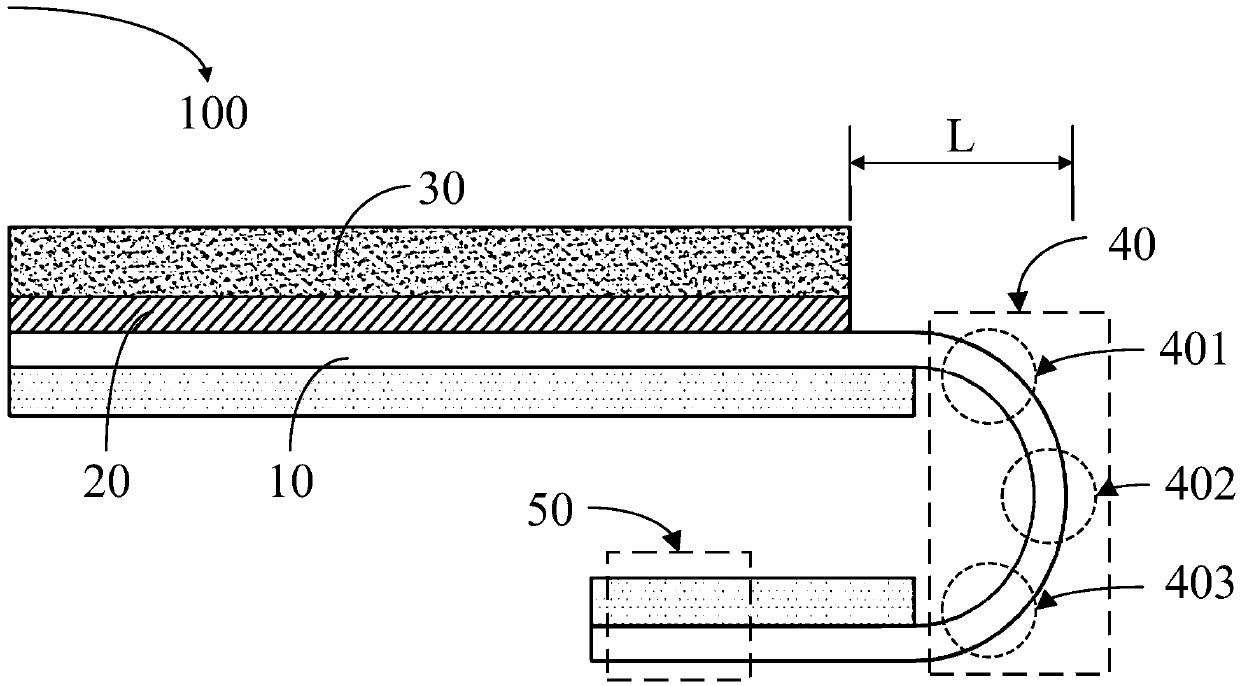

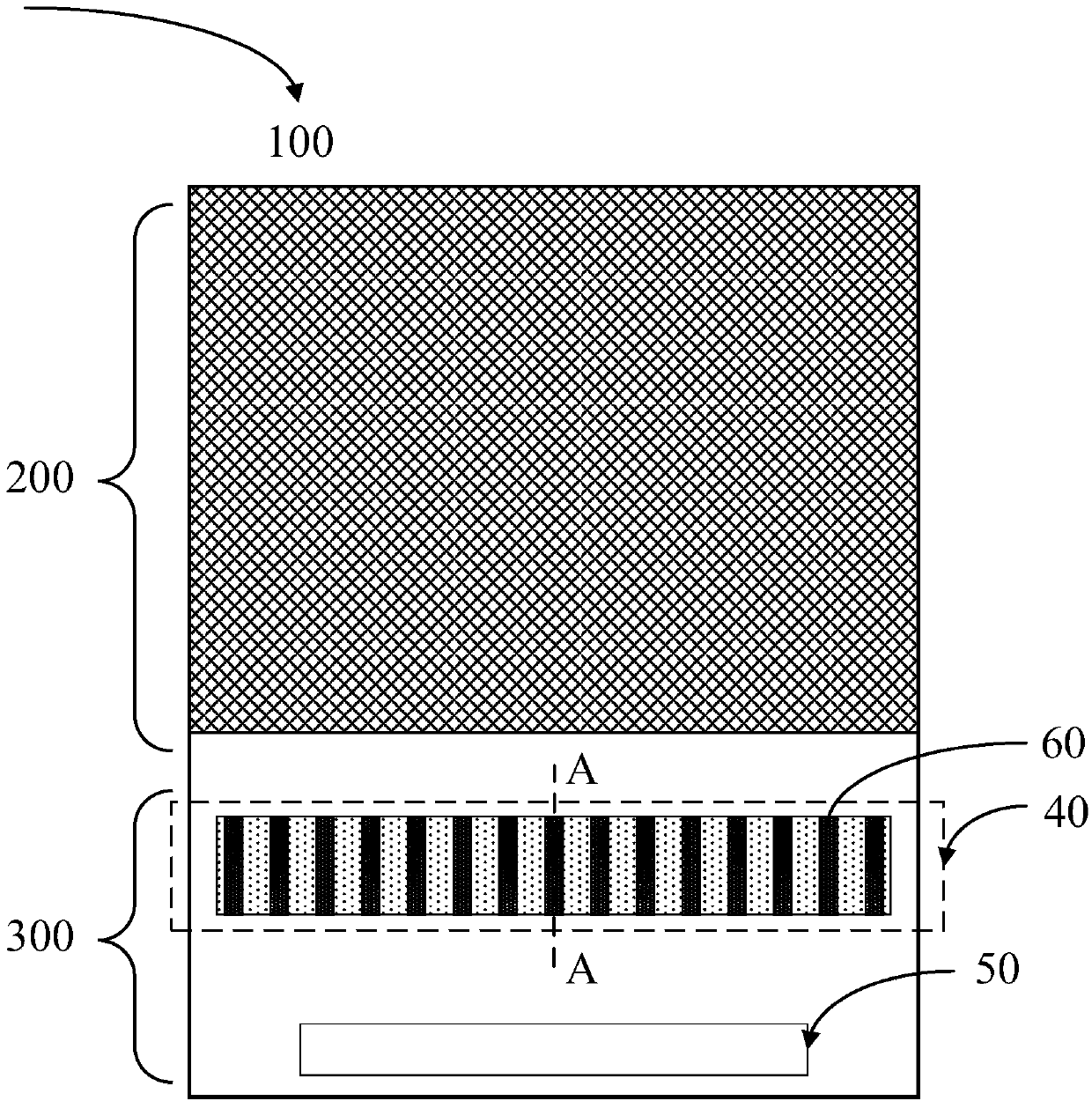

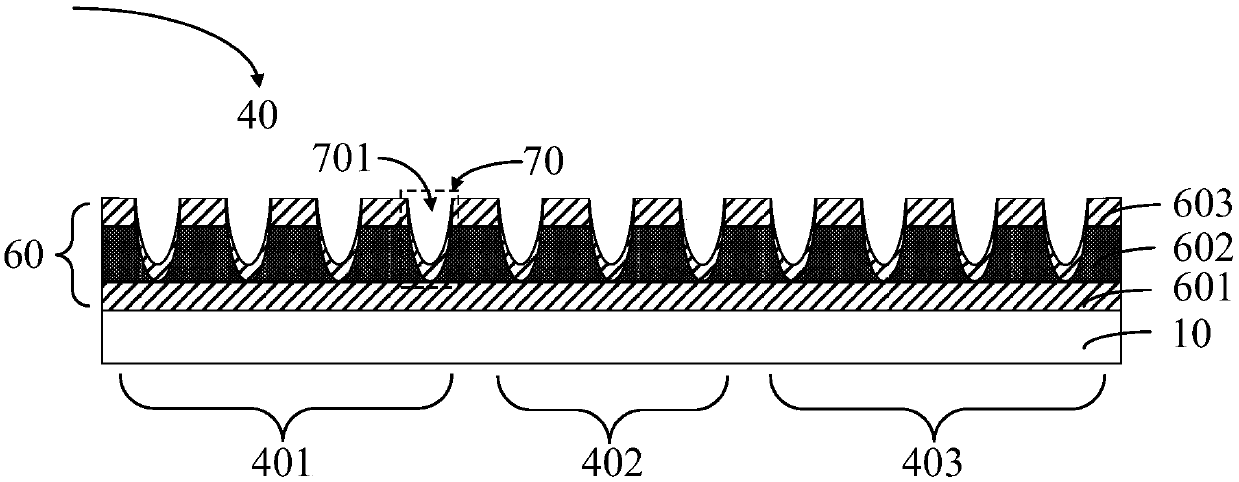

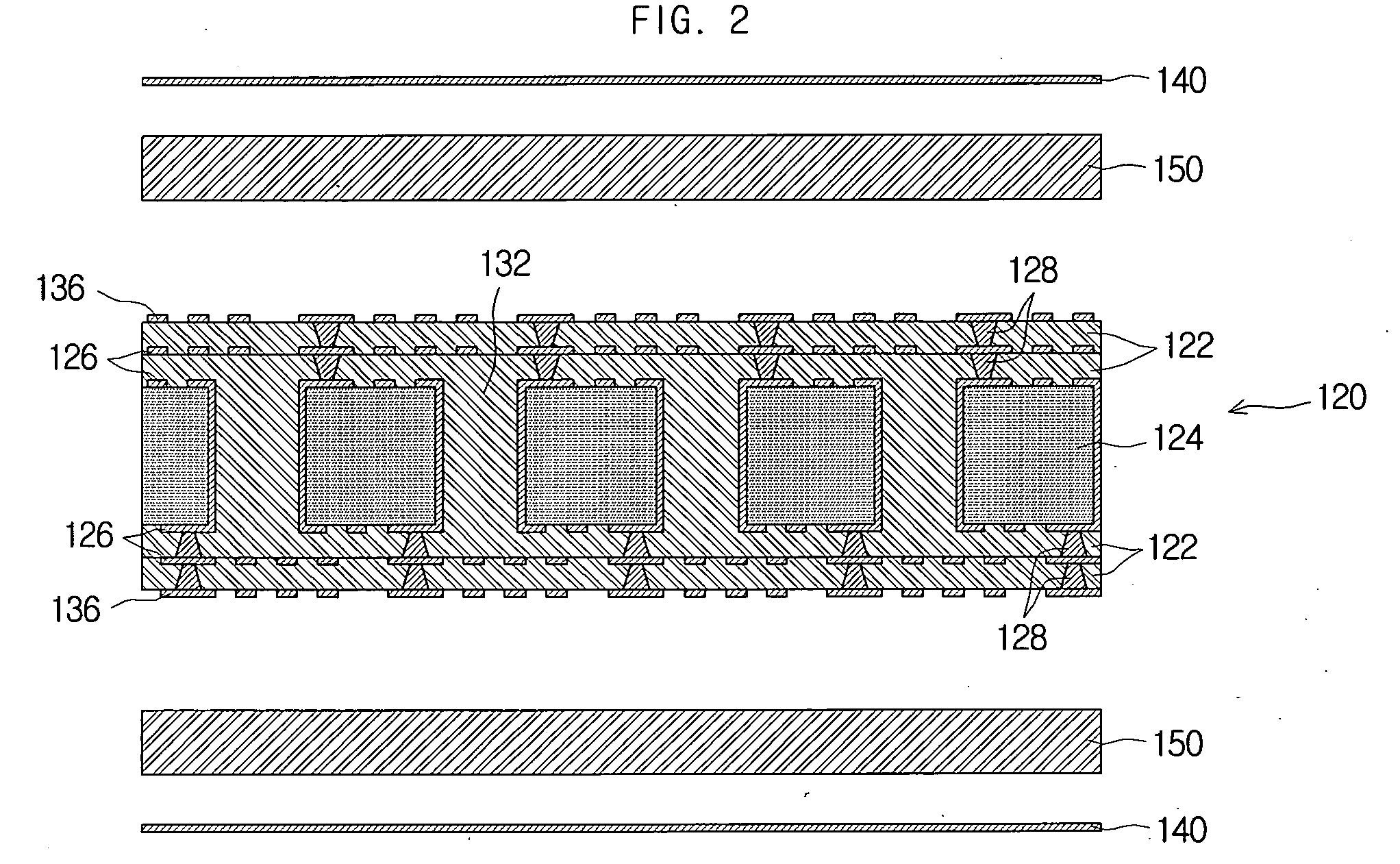

Light-emitting element and display device

InactiveUS20050263775A1Improve reliabilityImprove light extraction efficiencyStatic indicating devicesElectroluminescent light sourcesStress relievingRefractive index

There has been a problem that difference in refractive index between an opposite substrate or a moisture barrier layer (passivation film) such as SiN provided thereover, and air is maintained large, and light extraction efficiency is low. Further, there has been a problem that peeling or cracking due to the moisture barrier layer is easily generated, which leads to deteriorate the reliability and lifetime of a light-emitting element. According to the present invention, a light-emitting element comprises a pixel electrode, an electroluminescent layer, a transparent electrode, a passivation film, a stress relieving layer, and a low refractive index layer, all of which are stacked sequentially. The stress relieving layer serves to prevent peeling of the passivation film. The low refractive index layer serves to reduce reflectivity of light generated in the electroluminescent layer in emitting to air. Therefore, a light-emitting element with high reliability and long lifetime and a display device using the light-emitting element can be provided.

Owner:SEMICON ENERGY LAB CO LTD

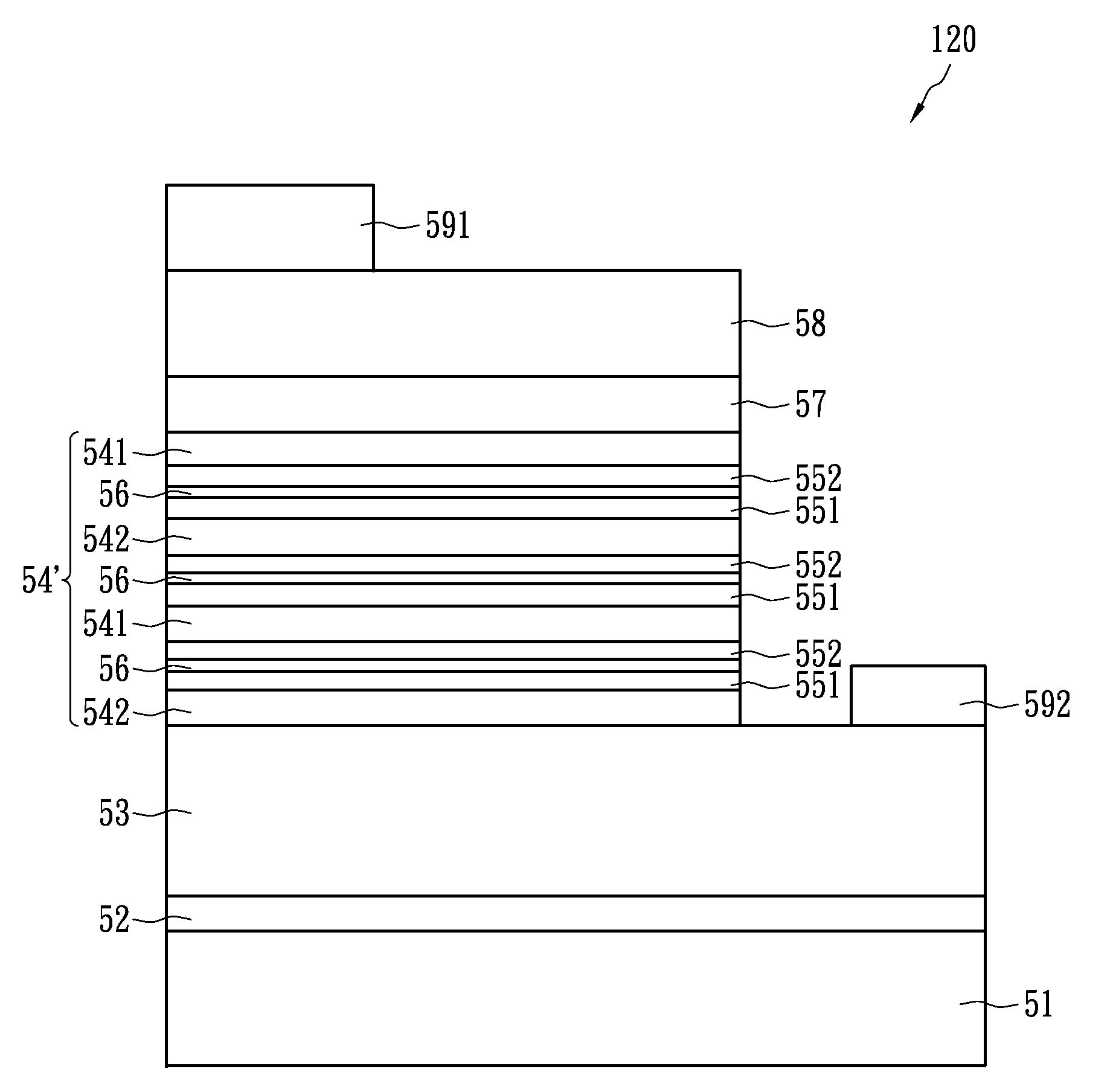

Group III nitride photonic devices on silicon carbide substrates with conductive buffer interlayer structure

InactiveUS20020008241A1Avoid crackingEasy to manufactureTransistorSolid-state devicesStress inducedStress relieving

An optoelectronic device with a Group III Nitride active layer is disclosed that comprises a silicon carbide substrate; an optoelectronic diode with a Group III nitride active layer; a buffer structure selected from the group consisting of gallium nitride and indium gallium nitride between the silicon carbide substrate and the optoelectronic diode; and a stress-absorbing structure comprising a plurality of predetermined stress-relieving areas within the crystal structure of the buffer structure, so that stress-induced cracking that occurs in the buffer structure occurs at predetermined areas rather than elsewhere in the buffer structure.

Owner:CREE INC

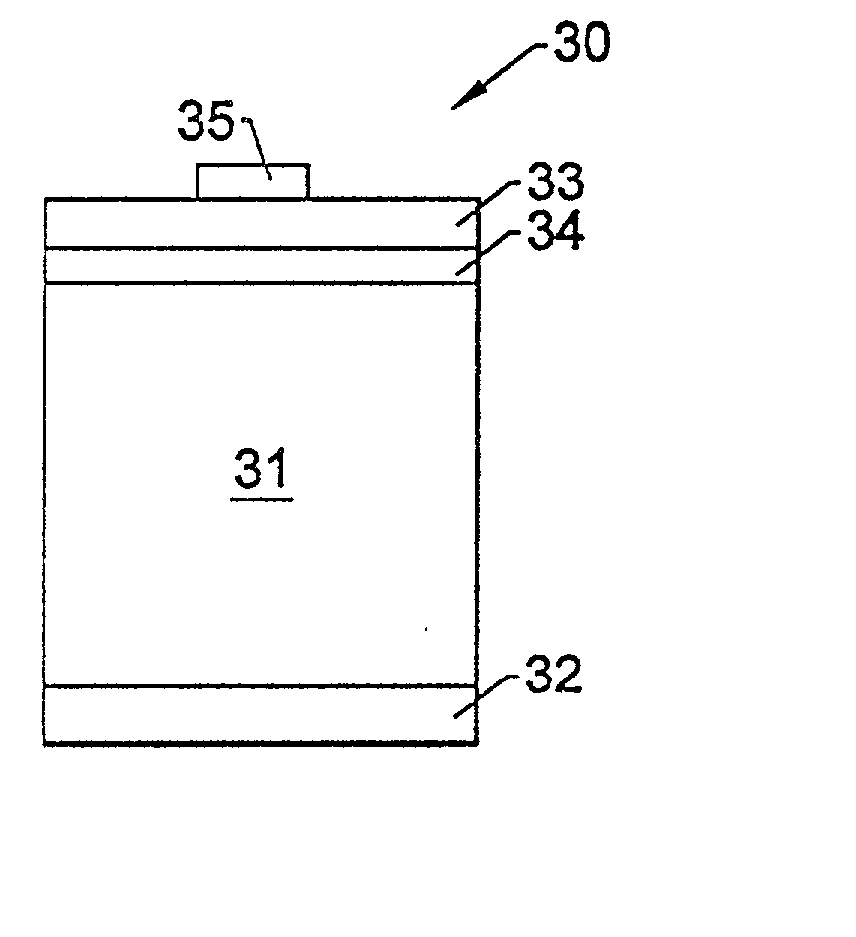

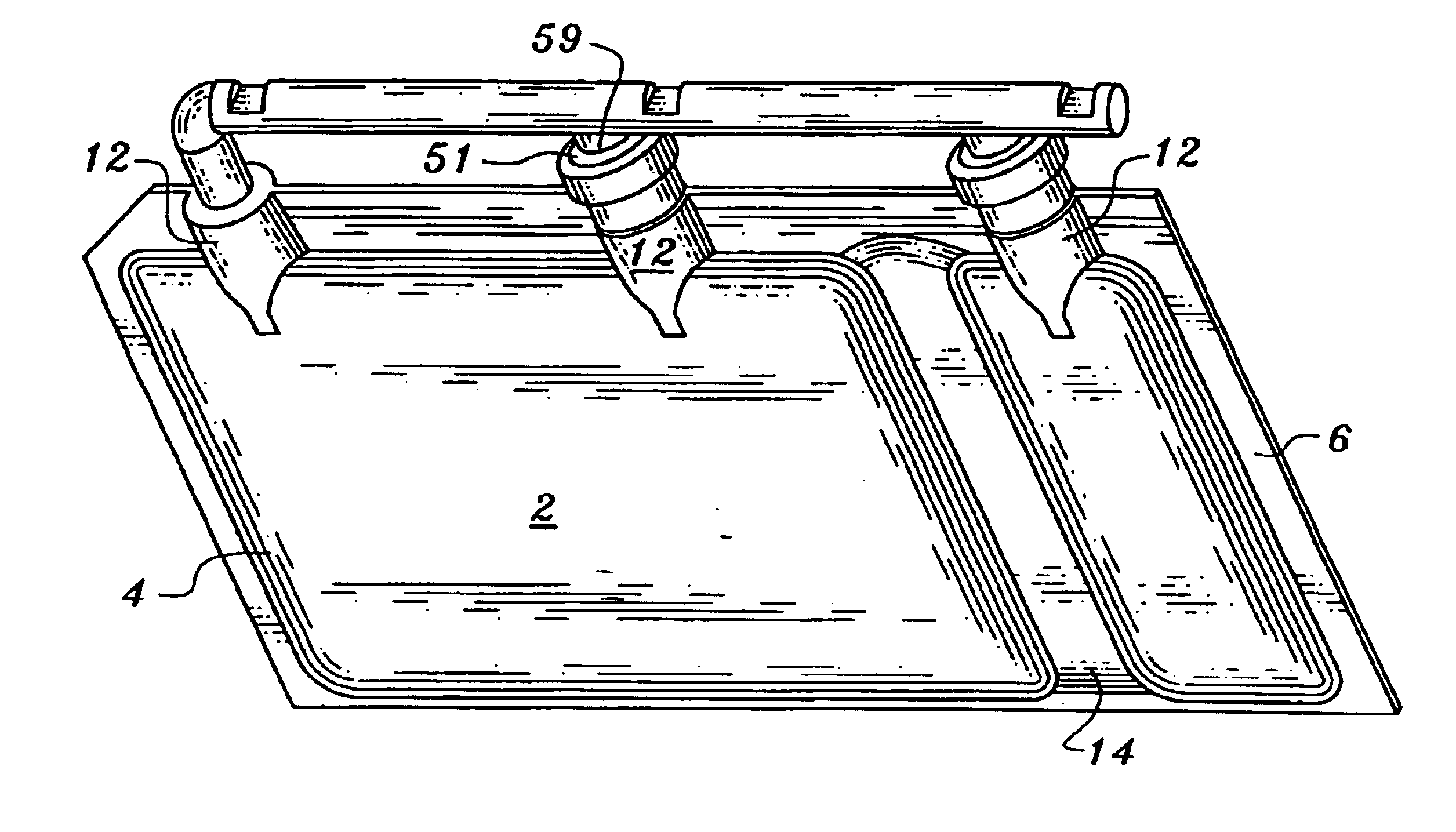

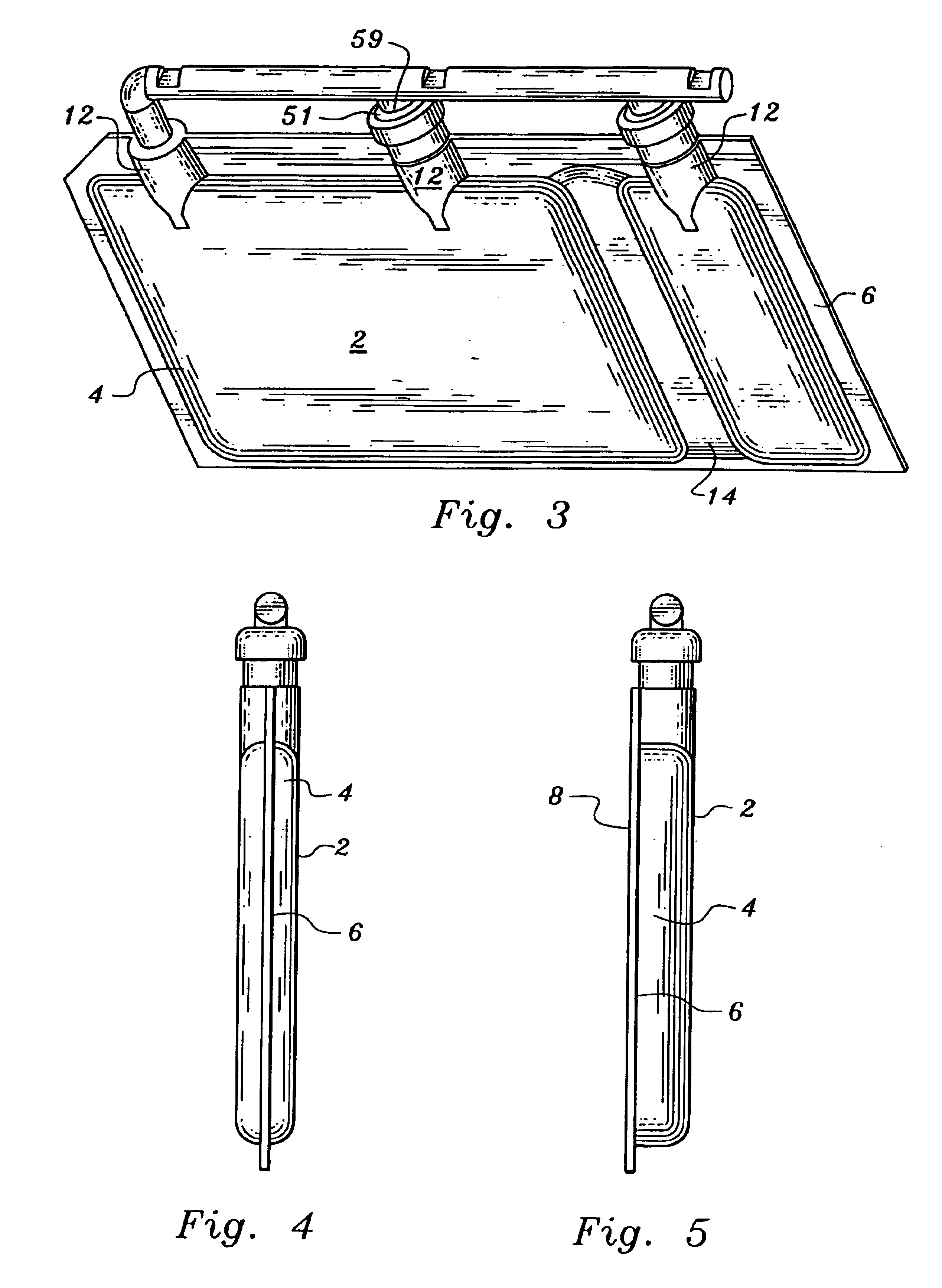

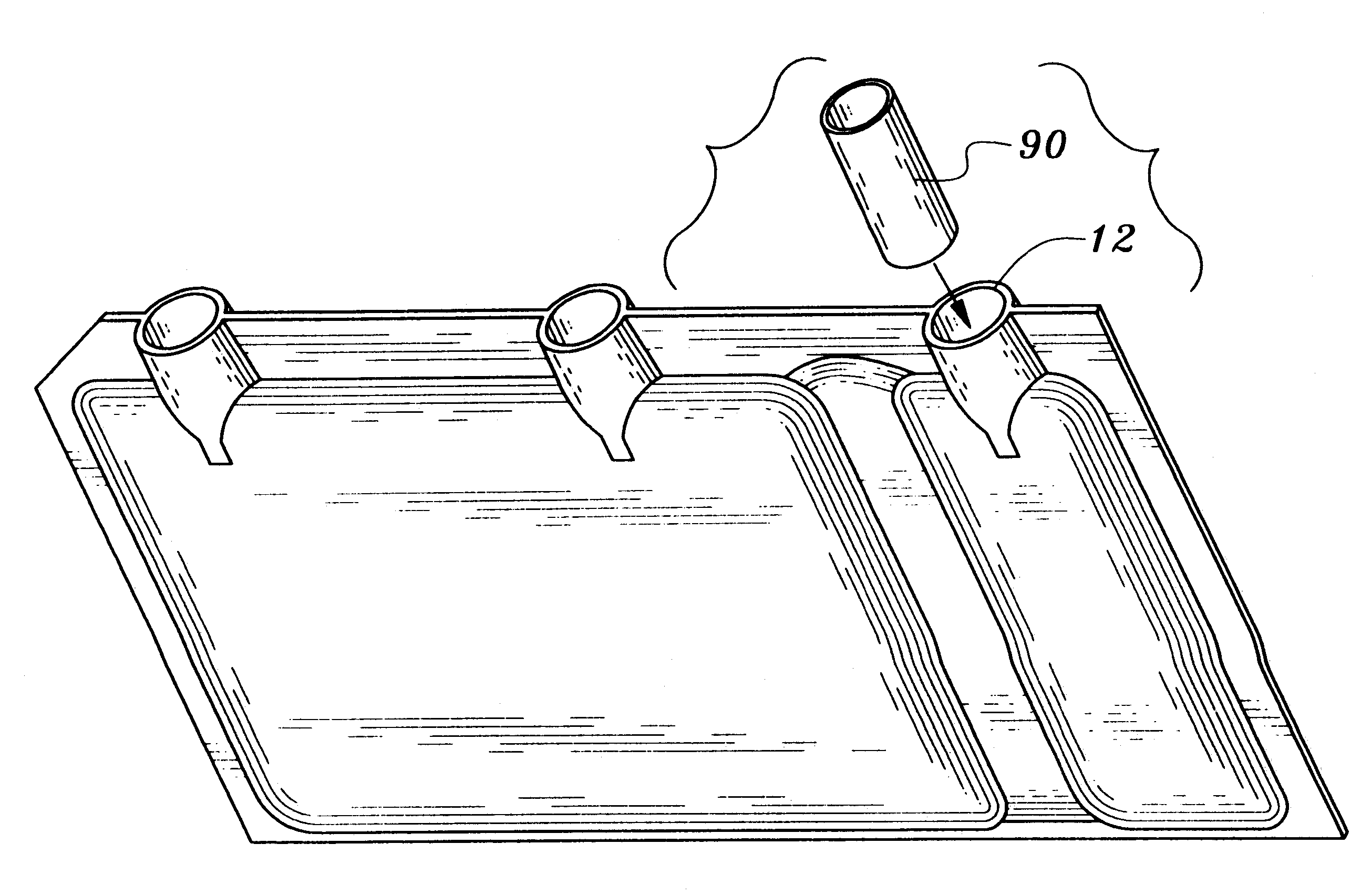

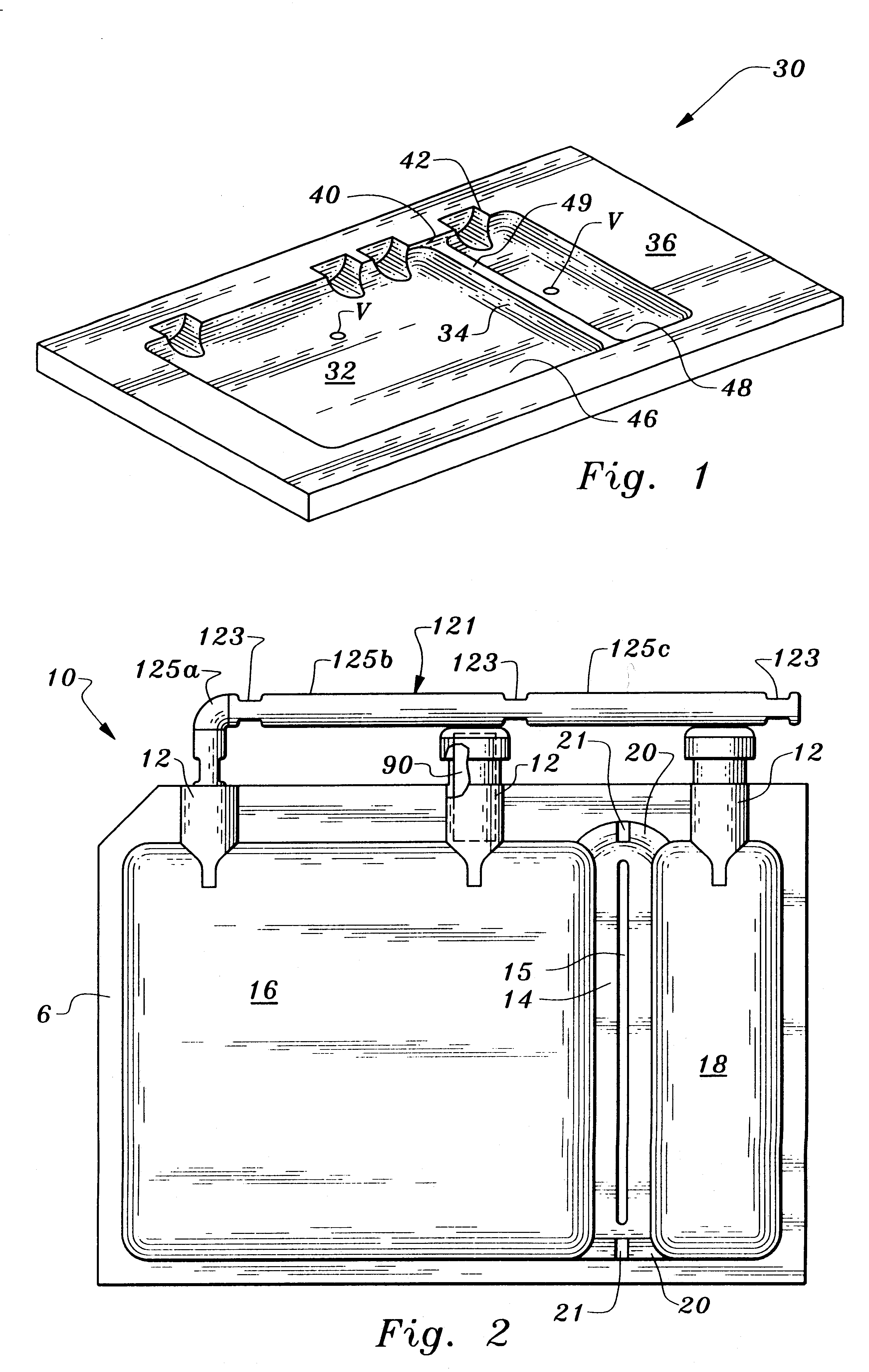

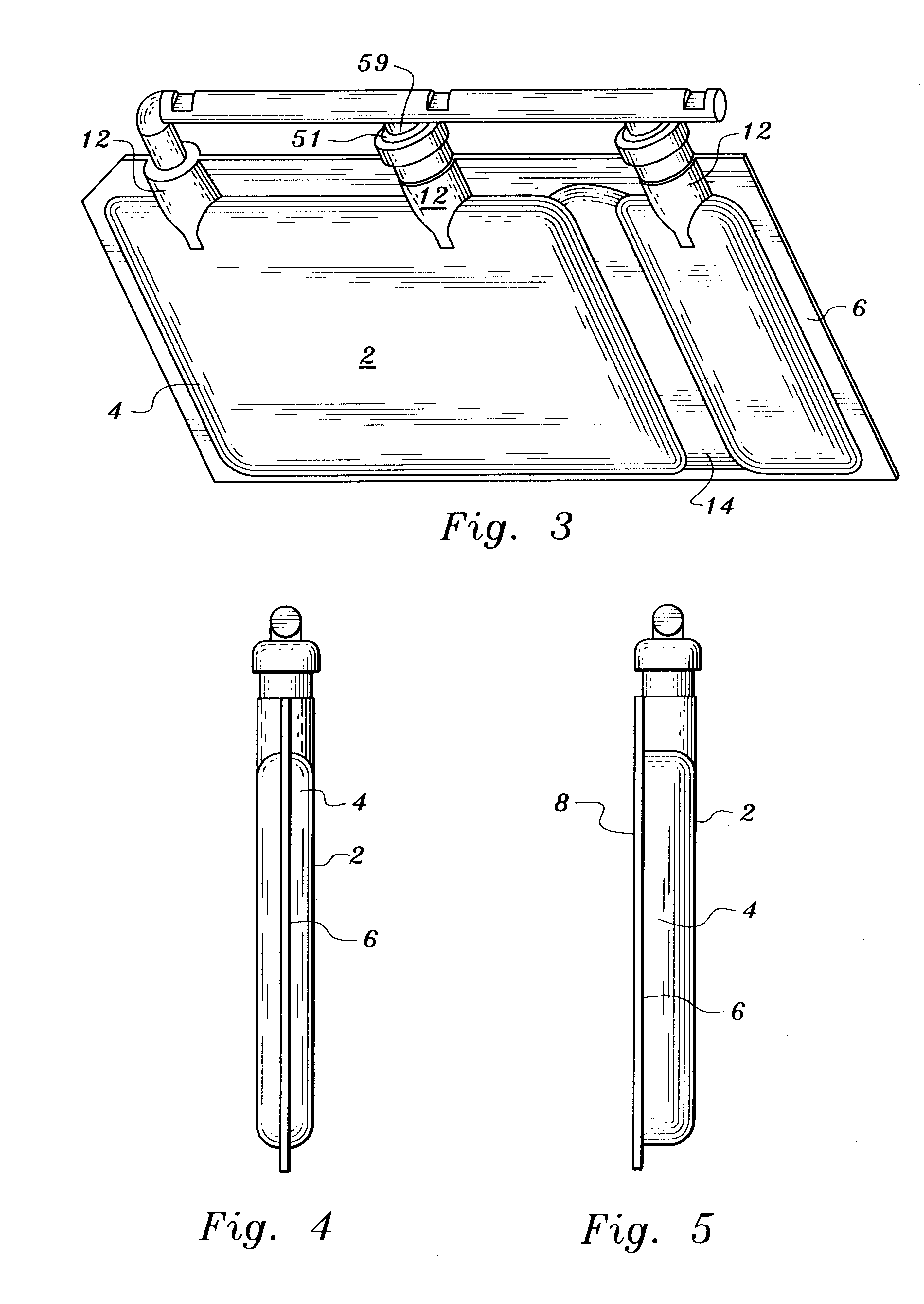

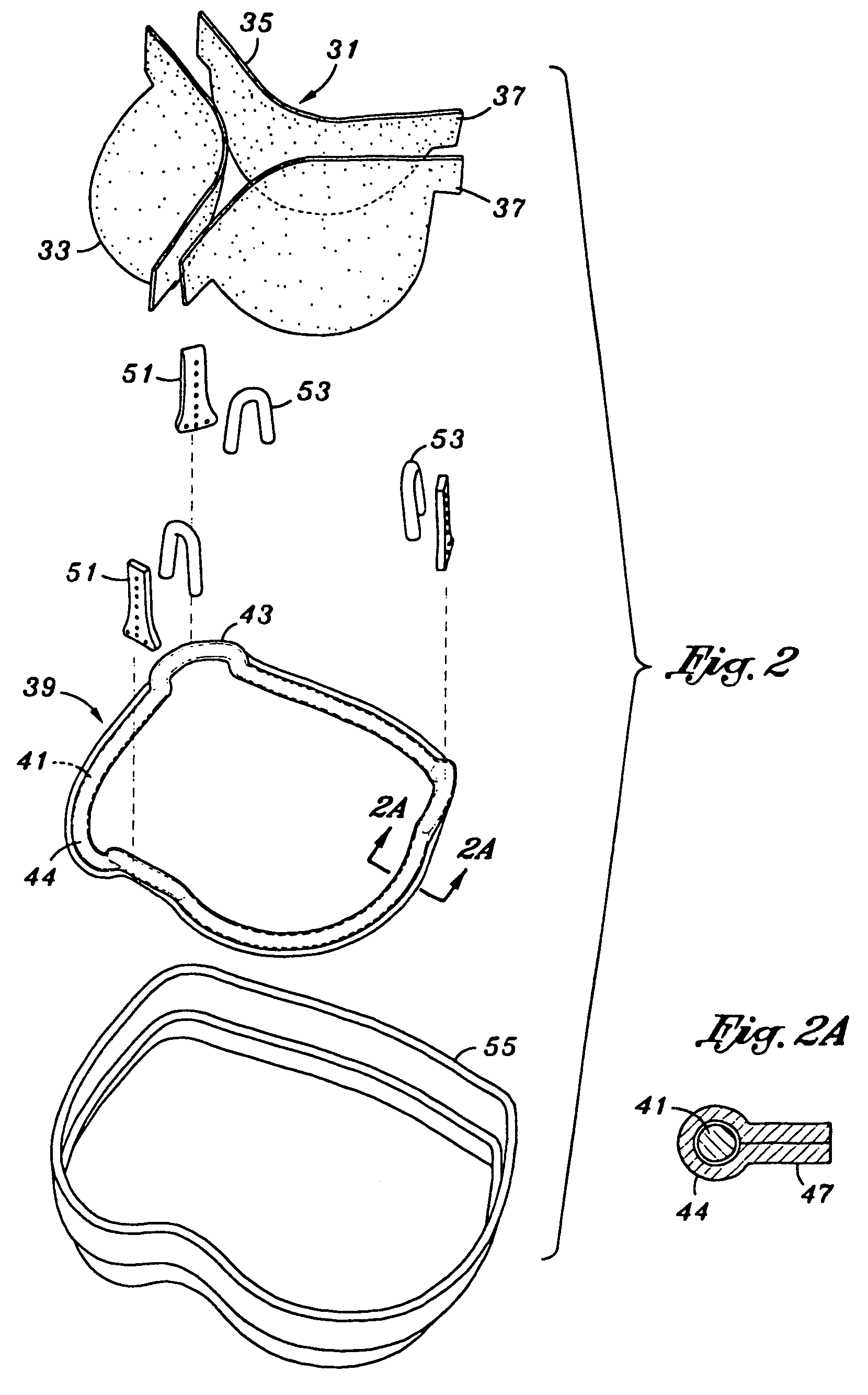

Freezing and thawing bag, mold, apparatus and method

InactiveUS6808675B1High strengthImprove integrityBioreactor/fermenter combinationsBiological substance pretreatmentsStress relievingFreeze and thaw

A bag, method of manufacture and process are disclosed for the cryopreservation of thermolabile substances. The bag is characterized as having substantially uniform thickness throughout its length and height. The bag features a radiused peripheral edge wall for stress relief and to provide the constant cross-section. A peripheral flashing circumscribes the radiused edge wall and provides a suitable purchase area for sealing so that the thus formed bag is less susceptible to fracture particularly when exposed to cryogenic temperatures. The uniform thickness of the bag promulgates uniform heat transfer to and from the contents of the bag in relation to any surrounding medium at a different temperature. The bag affords more space for efficient storage and reduces heat invasion into the contents of the bag when a plurality of bags are placed with their larger planar surfaces in contact with each other.

Owner:CESCA THERAPEUTICS

Freezing and thawing bag, mold, apparatus and method

InactiveUS6232115B1High strengthImprove integrityBioreactor/fermenter combinationsBiological substance pretreatmentsStress relievingFreeze and thaw

A bag, method of manufacture and process are disclosed for the cryopreservation of thermolabile substances. The bag is characterized as having substantially uniform thickness throughout its length and height. The bag features a radiused peripheral edge wall for stress relief and to provide the constant cross-section. A peripheral flashing circumscribes the radiused edge wall and provides a suitable purchase area for sealing so that the thus formed bag is less susceptible to fracture particularly when exposed to cryogenic temperatures. The uniform thickness of the bag promulgates uniform heat transfer to and from the contents of the bag in relation to any surrounding medium at a different temperature. The bag affords more space for efficient storage and reduces heat invasion into the contents of the bag when a plurality of bags are placed, with their larger planar surfaces, in contact with each other.

Owner:NEW YORK BLOOD CENT

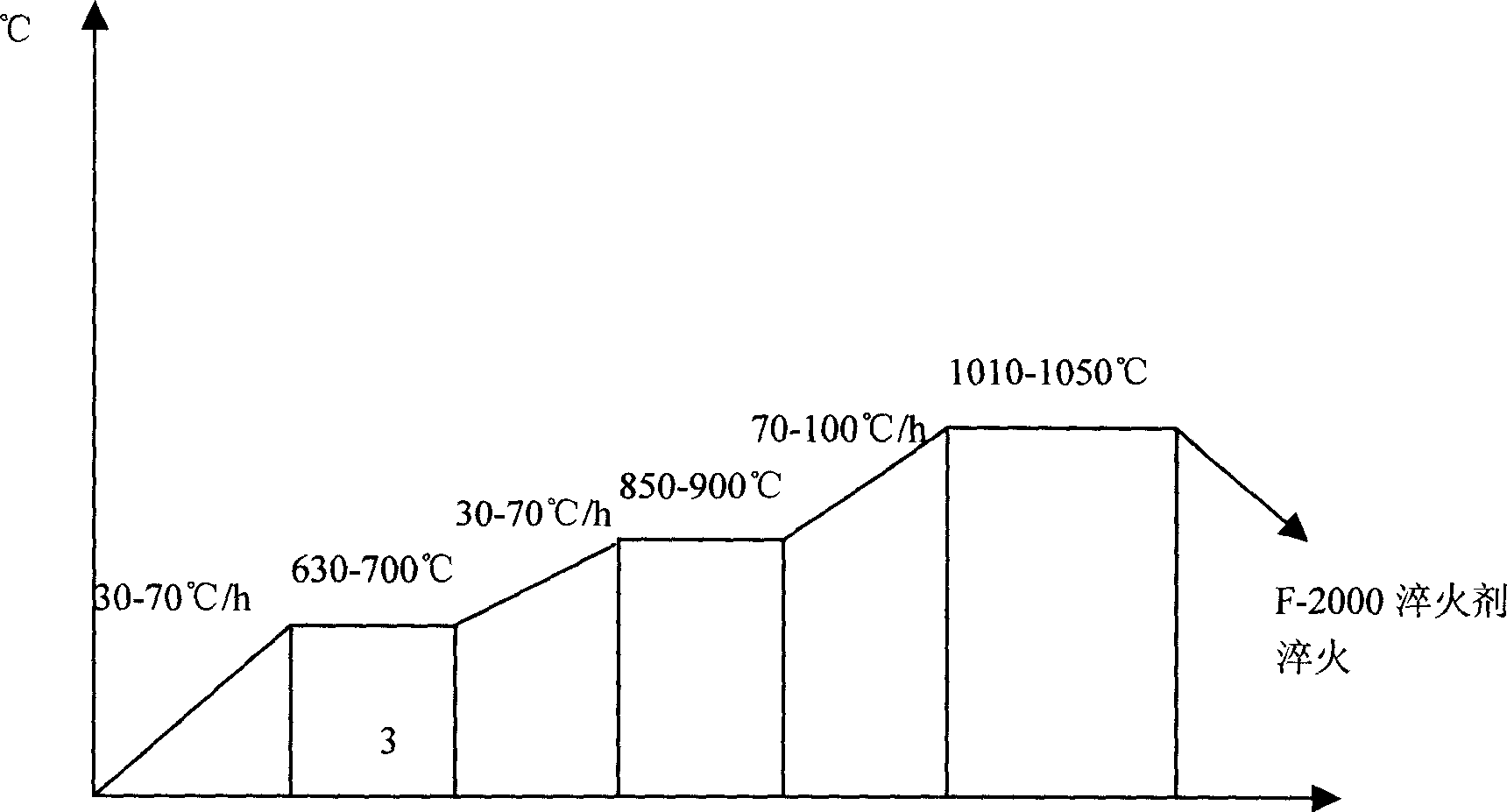

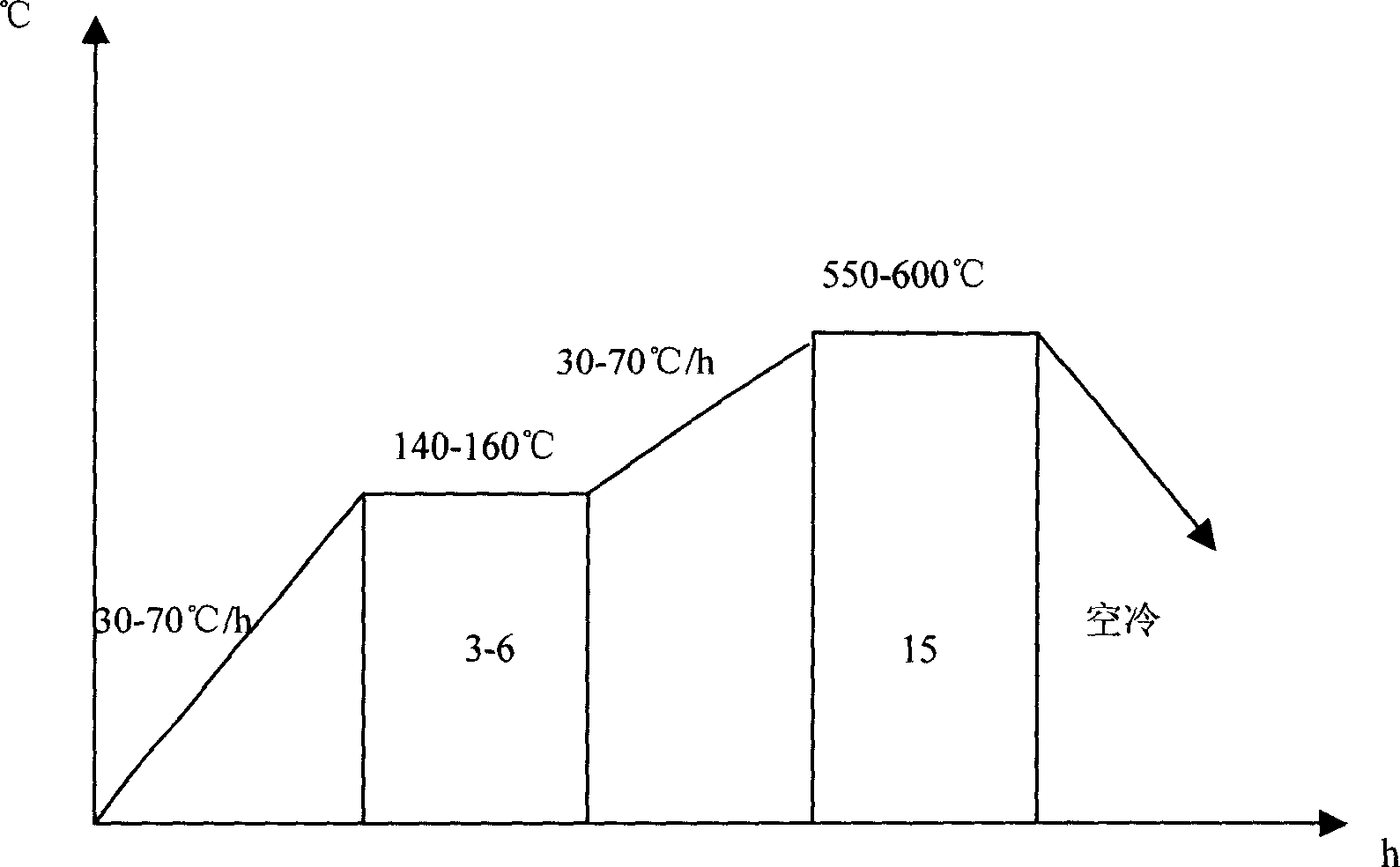

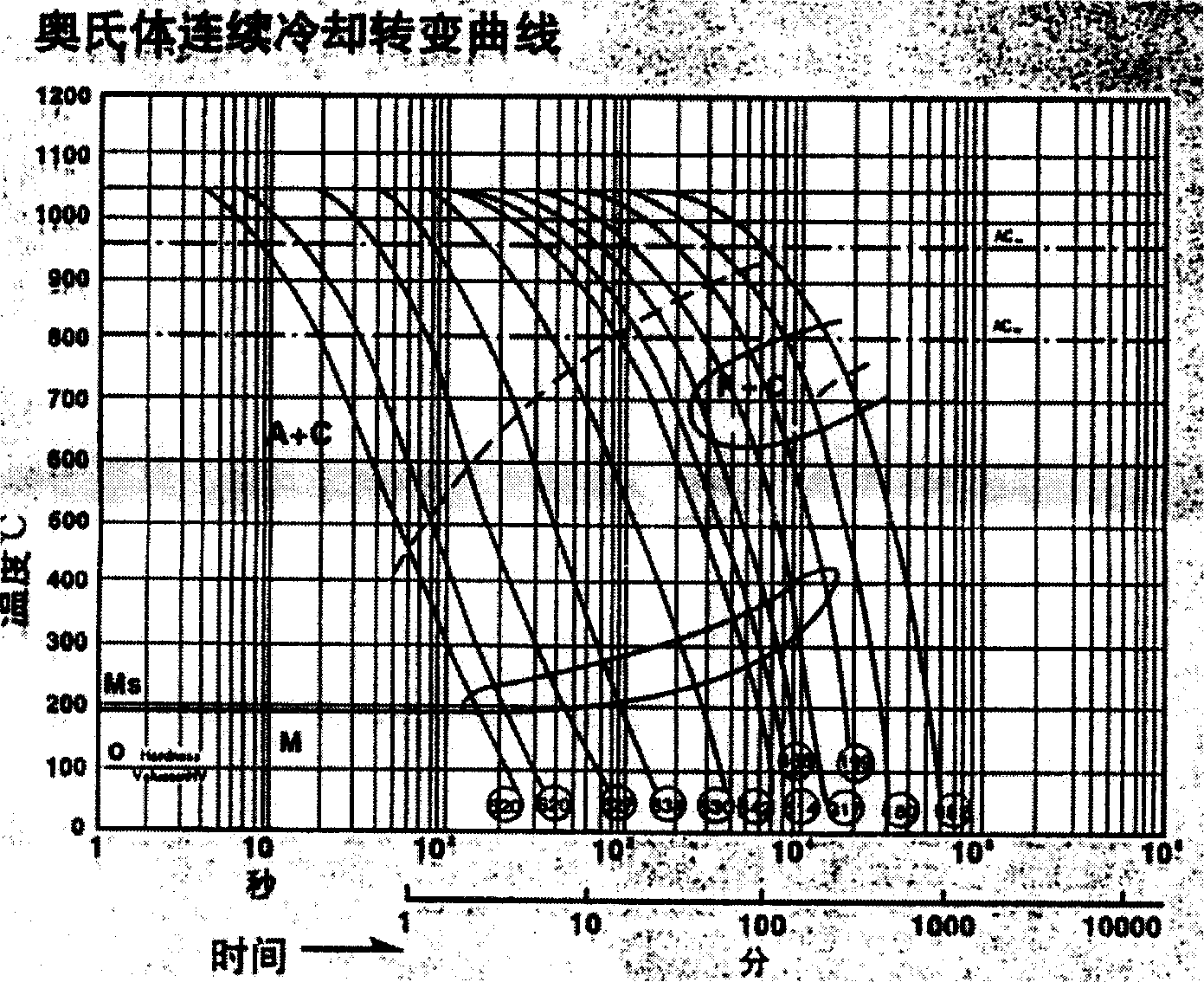

Anticorrosion, wear-resistant plastic die steel 4Cr16Mo and its mirror large-die-block preparing and producing method

ActiveCN1676653AImprove lateral performanceMeet mirror polishing requirementsHeat treatment process controlProcess efficiency improvementChemical compositionWear resistant

It is a new preparation and production method of corrosion-resistant and anti-abrasive plastic die steel 4Cr16Mo and its big mirror module. The characteristic is about its chemical composition. There are 0.33-0.43%C, 0.30-1.00%Mn, 0.30-1.00%Si, less than 0.045%S, less than 0.045%P, 14-18%Cr, 0.10-1.00%Ni, 0.80-1.50%Mo besides Fe. The method includes double refinement consisting of the primer smelting in electric furnace and vacuum handling outside the furnace and electroslag remelting, and necessary stress relieving annealing static ingot and electroslag ingot to refine electroslag ingot of component-uniform. After that, it uses hot machining forging technology and necessary stress relieving annealing of module to make the electroslag ingot into big module (thickness: 500mm, width:1200mm, length: 2500mm). At last, special heat-treat module modified treatment technology is used to bring out big highly corrosion-resistant and highly anti-abrasive plastic die steel module. This kind of module has stable quality and the nature reaching the standard(dirty component A<=2.0, B<=2.0, C thinness<=2.0, C thickness<=1.5, D<=2.0). To sum up, it has significant economic and social efficiency.

Owner:宝武特种冶金有限公司

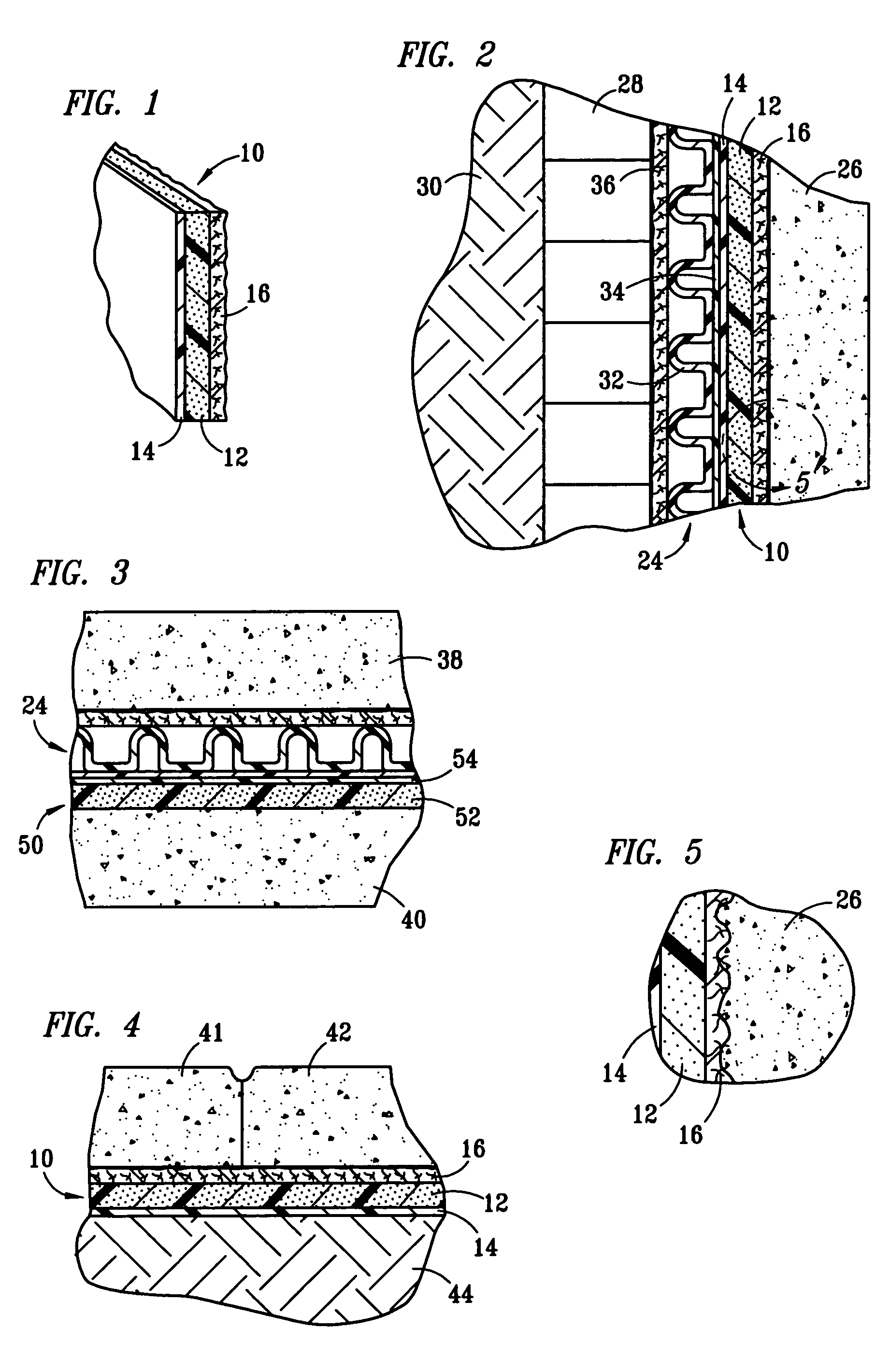

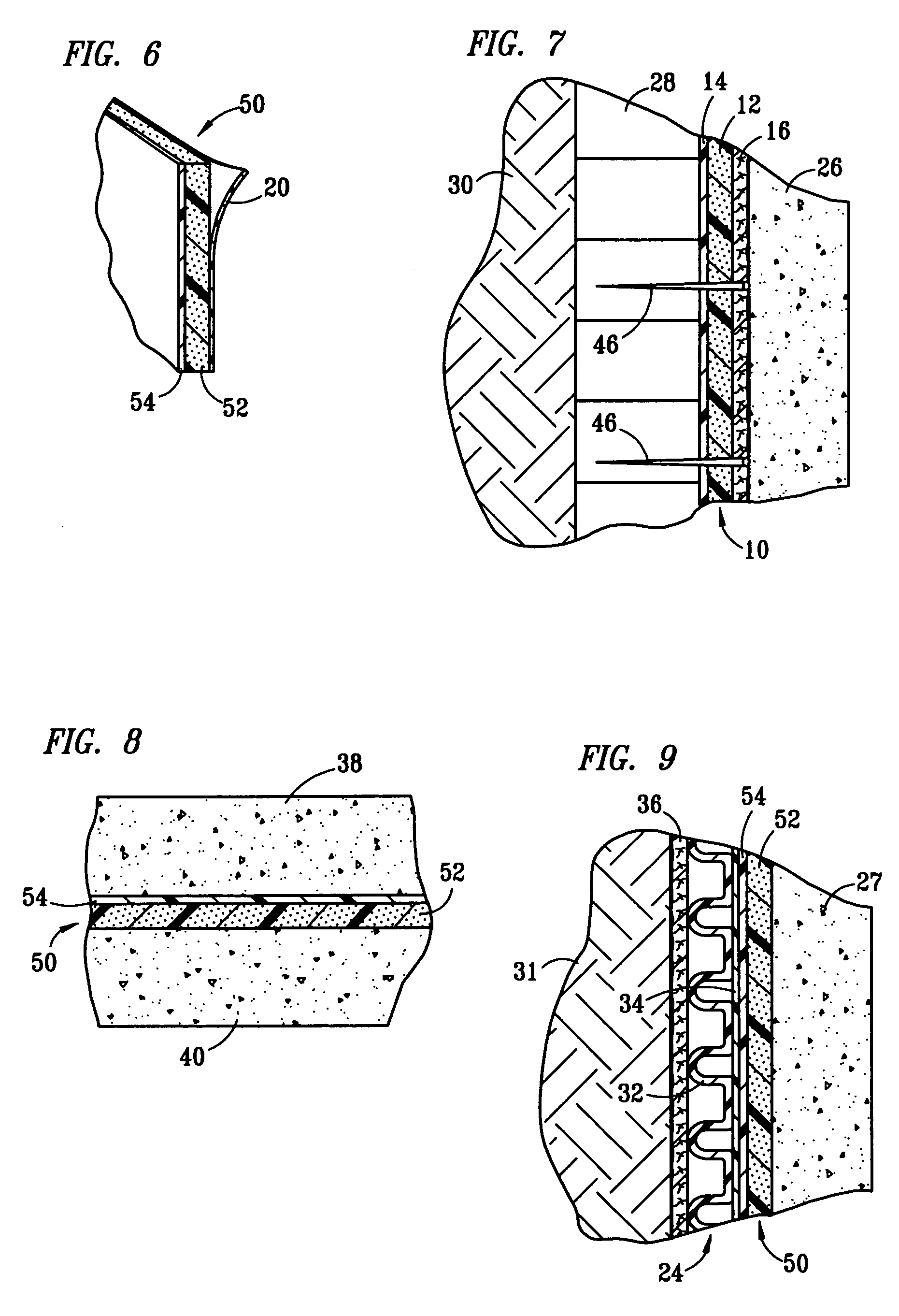

Stress-relieving barrier membrane for concrete slabs and foundation walls

ActiveUS7488523B1Relieve pressureReduce crack formationPaving reinforcementsIn situ pavingsStress relievingToxic material

A composite membrane comprising a layer of rubberized asphalt having a heavy duty plastic film layer continuously bonded to one side and, optionally, a layer of nonwoven geotextile continuously bonded to the other side. The membrane can be used in vertical or horizontal applications, and is particularly useful for its stress-relief properties that resist crack formation and propagation in concrete walls and slabs in addition to serving as a barrier to moisture, toxic substances and insects. An appropriate composite membrane of the invention can be advantageously utilized in positive side, blindside, underslab or split slab applications. The thickness of the composite membrane preferably ranges from about 30 mils to about 150 mils.

Owner:POLYGUARD PRODS

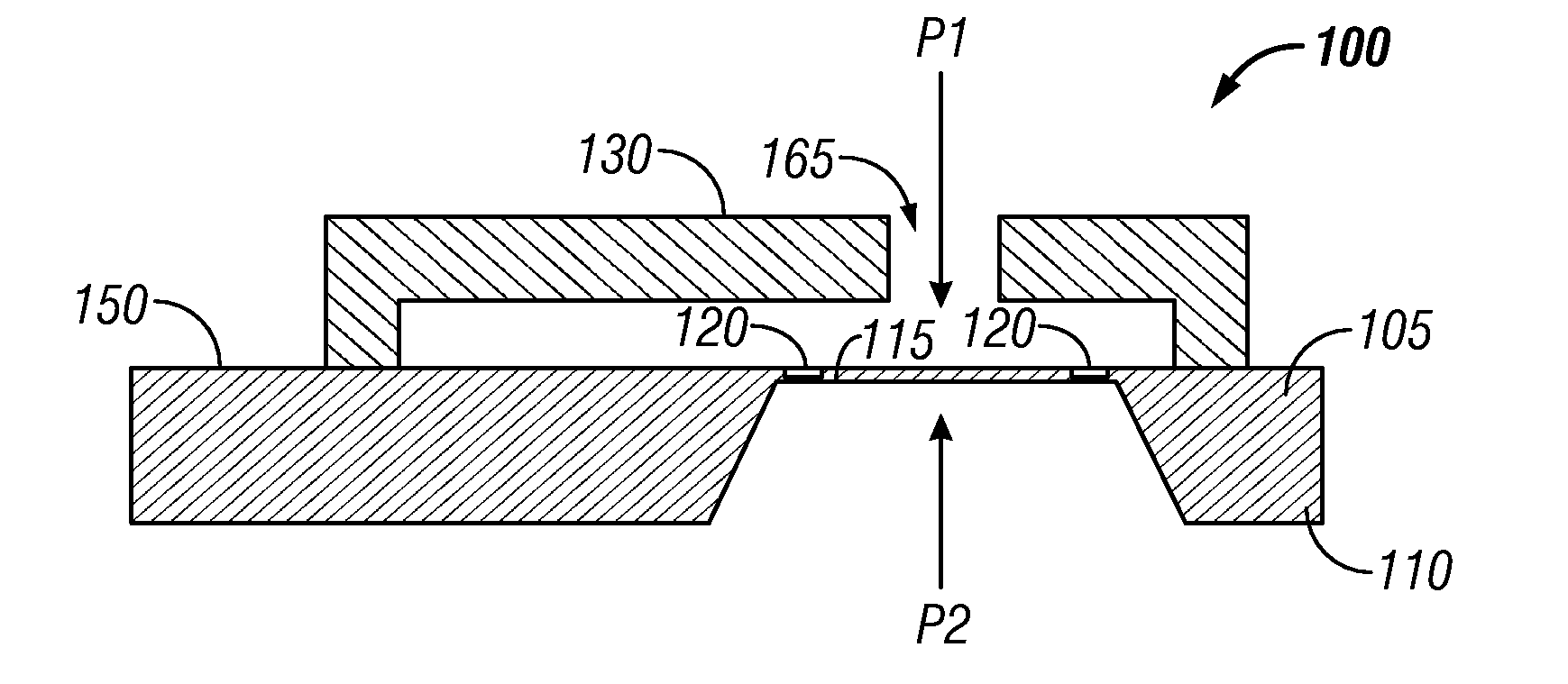

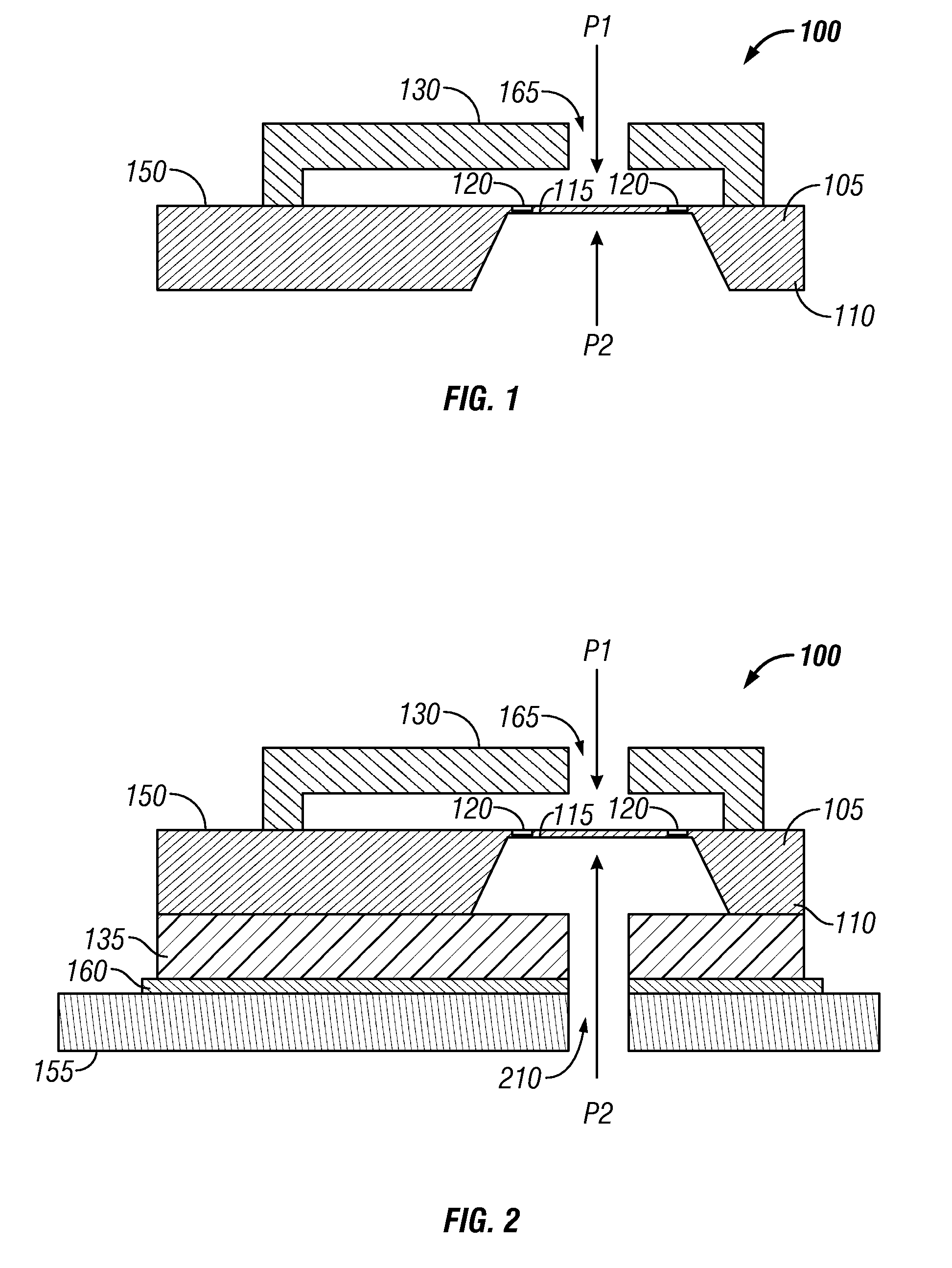

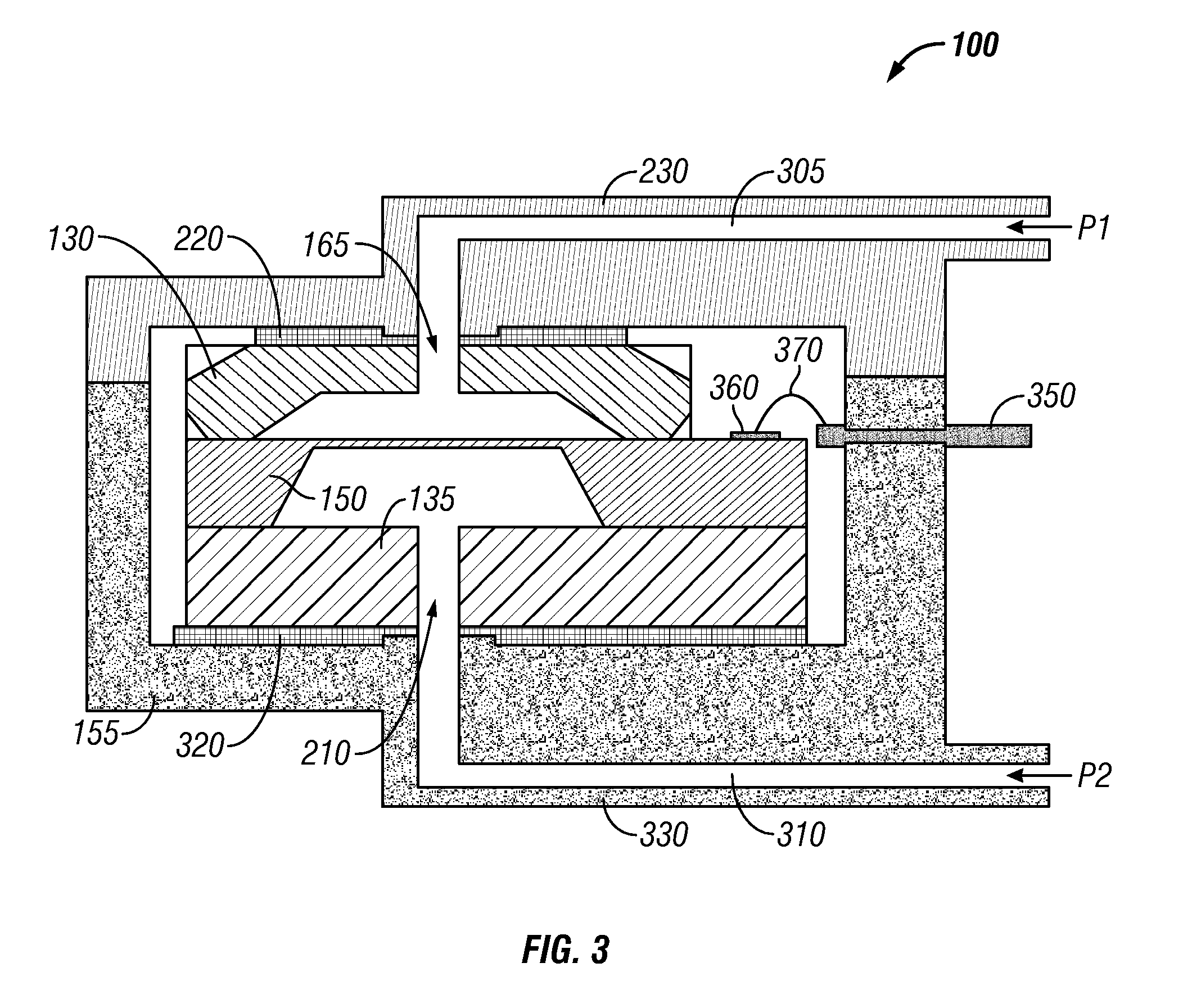

Design of wet/wet differential pressure sensor based on microelectronic packaging process

ActiveUS20100122583A1Fluid pressure measurement using ohmic-resistance variationFluid pressure measurement using elastically-deformable gaugesEffective solutionStress relieving

Method and system for a wet / wet differential pressure sensor based on microelectronic packaging process. A top cap with a hole can be attached to a topside of a MEMS-configured pressure sense die with a pressure sensing diaphragm in order to allow sensed media to come in contact with the topside of the pressure sensing diaphragm. An optional constraint with a hole for stress relief can be attached to a backside of the pressure sense die. Adhesive and / or elastomeric seals and / or solder can be utilized to seal the pressure sense die allowing sensed media to come in contact with both sides of the pressure sensing diaphragm without coming into contact with wirebonds and other metallized surfaces. The MEMS-configured pressure sense die can also be bonded to a substrate with standard die attach materials. Such microelectronic packaging processes yield a high performance and cost effective solution thereby providing wet-wet pressure sensing capability.

Owner:HONEYWELL INT INC

High boron wear-resisting casting steel and preparation process thereof

InactiveCN100999803ASufficient sourceReduce manufacturing costFurnace typesHeat treatment process controlFerromanganeseAluminium

The present invention discloses one kind of antiwear high-boron cast steel and its preparation process. The antiwear high-boron cast steel has the chemical components including C 0.10-0.50 wt%, B 0.8-5.0 wt%, Cu 0.3-0.6 wt%, Mn 0.8-2.0 wt%, Cr 1.0-2.5 wt%, Si less than 1.5 wt%, Ti 0.08-0.20 wt%, Ce 0.04-0.12 wt%, Mg 0.02-0.18 wt%, N 0.06-0.18 wt%, S less than 0.05 wt%, P less than 0.05 wt%, and Fe and inevitable impurity for the rest. Its preparation process includes smelting in an electric furnace while adding ferromanganese, frrroboron and Al to deoxidize, composite modification of molten steel, fast cooling, and low temperature tempering to eliminate stress. The present invention has simple production process, low production cost and other advantages.

Owner:XI AN JIAOTONG UNIV

Production process of precise stainless steel band for vehicle sealing pad

InactiveCN101716594AImprove quality requirementsThickness tolerance fluctuations are smallBell type furnacesTension/compression control deviceSolution treatmentStress relieving

The invention relates to a production process of a precise stainless steel band for a vehicle sealing pad. The production process comprises the following working procedures of: first cold rolling, solid solution, second cold rolling, spraying and degreasing, hot water spraying, hot wind drying, pre-bending straightening, stress relieving annealing, final bending straightening, finished product cutting, and the like. The production process adopts a 20-roller sendzimir mill and a unique rolling process to carry out cold rolling. Through the processes of degreasing, solid solution treatment, bending straightening, stress relieving annealing, and the like, the thickness tolerance undulation of a product is small, mechanical properties are stable, the plate flatness is good, the product is not easy to generate cracks and secondary deformation during stamping, and the quality of the product is obviously improved, thus the production process is suitable for industrial production and can meet the requirement for high quality of the vehicle part industry.

Owner:YONGXIN PRECISION MATERIAL WUXI

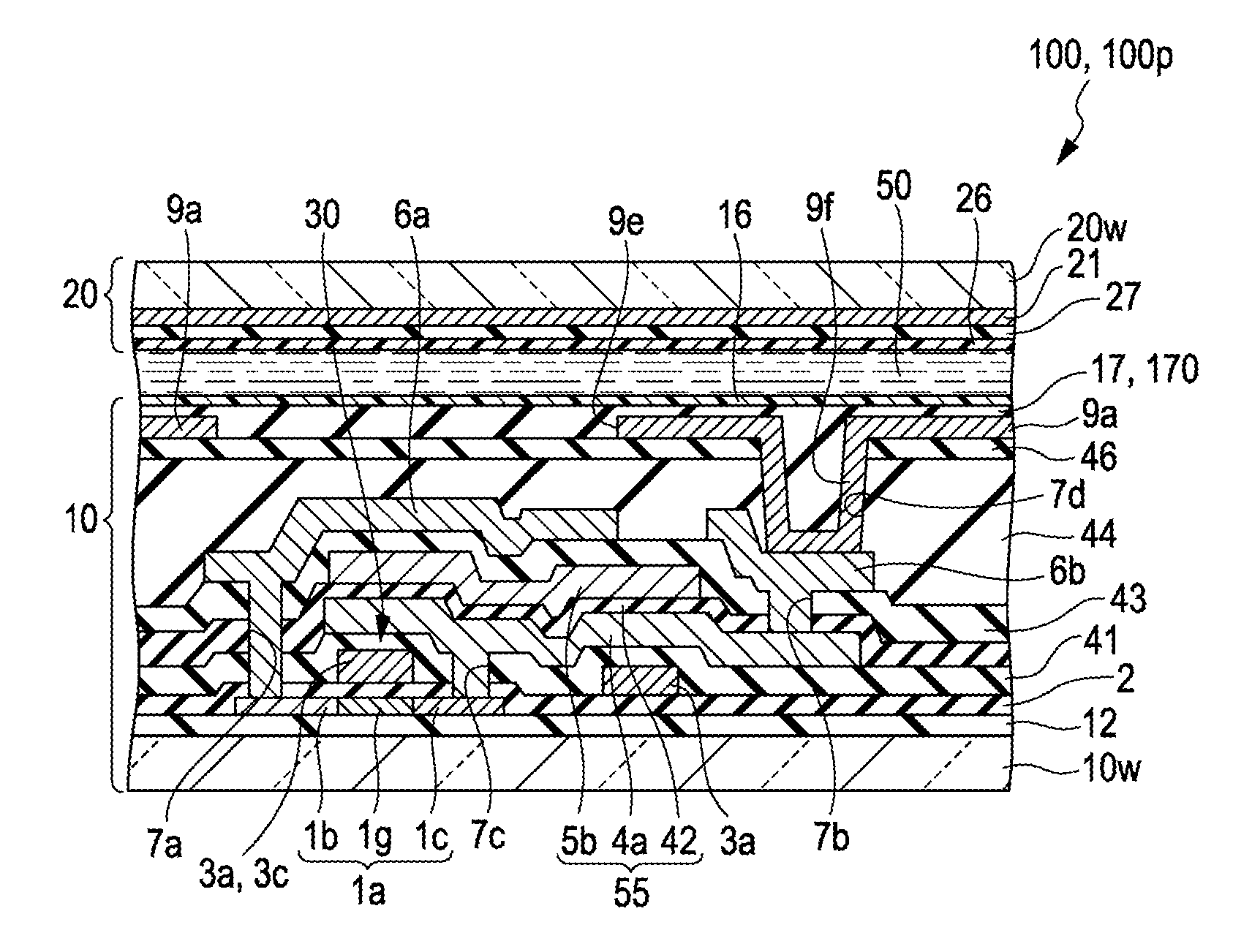

Light-emitting element and display device

InactiveUS7202504B2Improve reliabilityImprove light extraction efficiencyStatic indicating devicesElectroluminescent light sourcesStress relievingDisplay device

There has been a problem that difference in refractive index between an opposite substrate or a moisture barrier layer (passivation film) such as SiN provided thereover, and air is maintained large, and light extraction efficiency is low. Further, there has been a problem that peeling or cracking due to the moisture barrier layer is easily generated, which leads to deteriorate the reliability and lifetime of a light-emitting element. According to the present invention, a light-emitting element comprises a pixel electrode, an electroluminescent layer, a transparent electrode, a passivation film, a stress relieving layer, and a low refractive index layer, all of which are stacked sequentially. The stress relieving layer serves to prevent peeling of the passivation film. The low refractive index layer serves to reduce reflectivity of light generated in the electroluminescent layer in emitting to air. Therefore, a light-emitting element with high reliability and long lifetime and a display device using the light-emitting element can be provided.

Owner:SEMICON ENERGY LAB CO LTD

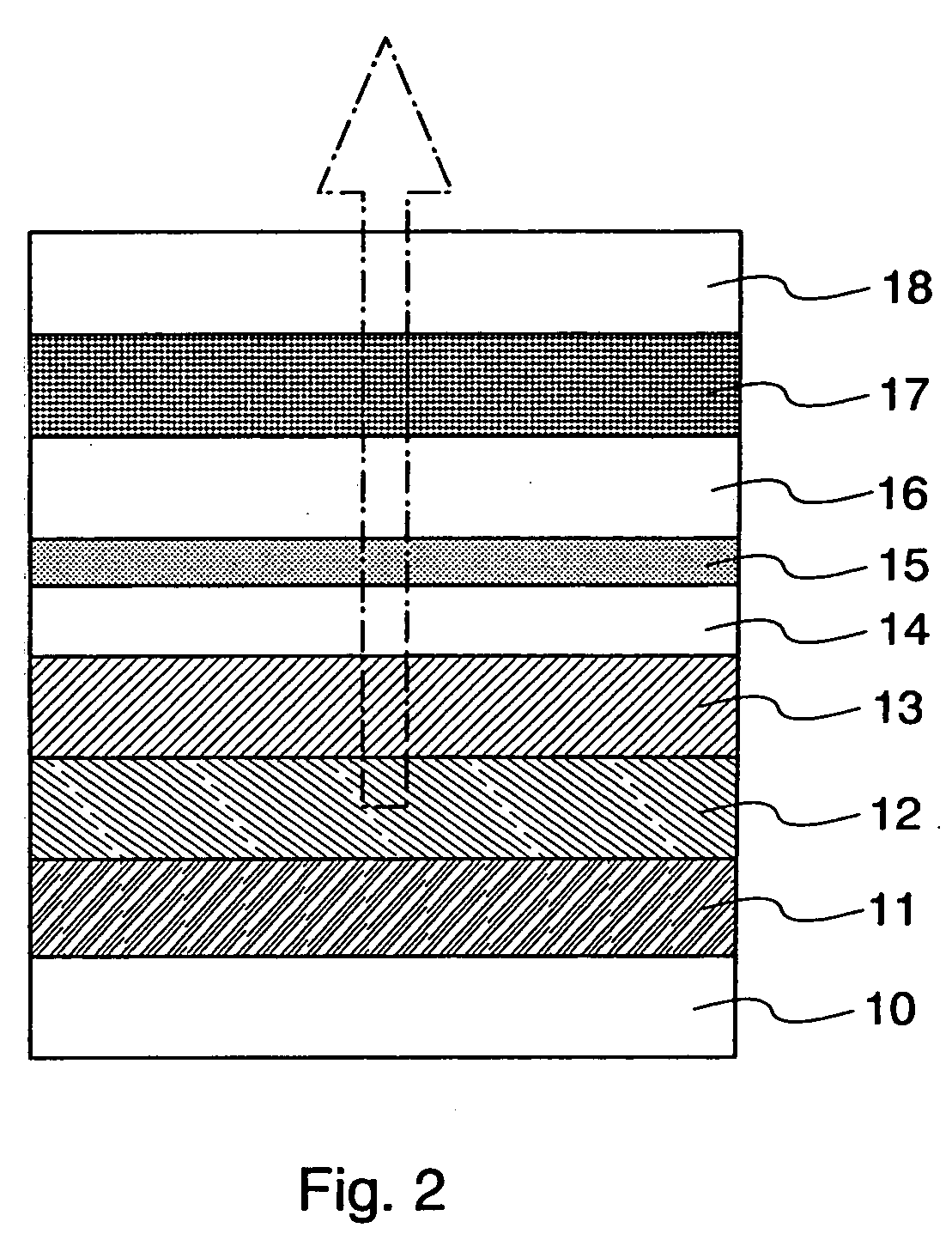

Light emitting device of group iii nitride based semiconductor

A light emitting device of Group III nitride based semiconductor comprises a substrate, an N-type semiconductor layer formed on the substrate, an active layer formed on the N-type semiconductor layer, and a P-type semiconductor layer formed on the quantum well layer. The active layer comprises at least one quantum well layer, at least two barrier layers formed to sandwich the quantum well layer therebetween and at least one stress relieving layer, wherein the stress relieving layer is interposed between the quantum well layer and one of the at least two barrier layers, and the composition of the stress relieving layer, made of Group III nitride based material, is graded along the direction from the quantum well layer to the barrier layers adjacent thereto.

Owner:ADVANCED OPTOELECTRONICS TECH

Method and tooling for controlling deformation of nickel-based ageing-strengthening high-temperature alloy casing welding assembly

ActiveCN103551770AAvoid fatigue crackingMeet reliabilityWelding/cutting auxillary devicesAuxillary welding devicesWelding residual stressElectron

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

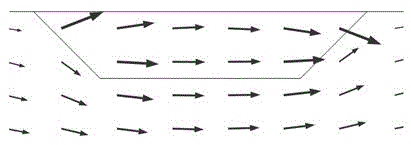

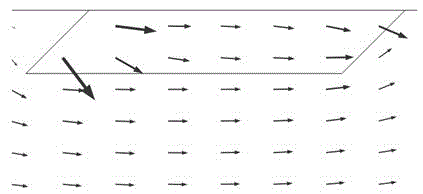

Manufacturing method of oriented silicon steel sheets for low-noise transformer

ActiveCN106282512AReduce noise levelReduce iron lossTransformers/inductances detailsInductances/transformers/magnets manufactureLow noiseTransformer

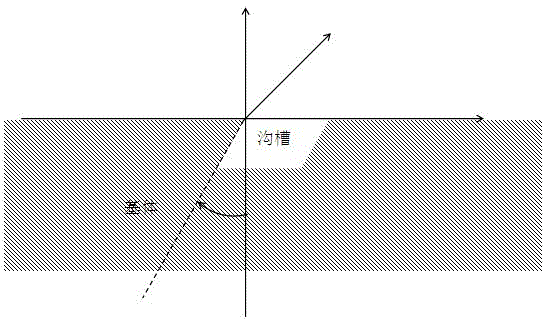

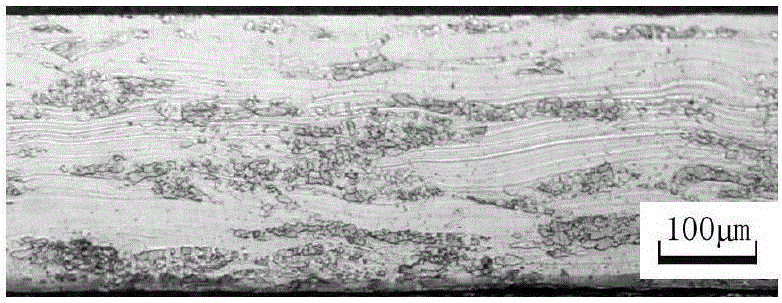

The invention discloses a manufacturing method of oriented silicon steel sheets for a low-noise transformer. Grooves in special shaped are formed in a single side or double sides of silicon steel sheets in a mark carving method; the bottom surfaces of the grooves are parallel to approximately parallel to the surfaces of the silicon steel sheets; the angle with the maximum absolute value in included angles between the single side or multiple sides of the inner walls of the groove and the normal plane is defined to be the included angle theta; the include angle theta is in a range of being greater than or equal to -60 degrees but smaller than 0 degree; the included angle theta of each side edge is identical or different; the normal plane refers to a plane vertical to the rolling direction of the silicon steel sheets. The mark carving processing mode is set before or after the decarburizing annealing, or is after the high-temperature annealing, or is after the insulation coating flattening annealing. Pulse laser beams with the single-pulse instantaneous peak value power density not lower than 2.0*10<6>W / mm<2> are used for processing on the surface of the silicon sheets; the laser injection total energy is between 0.002J / mm to 1.3J / mm. The oriented silicon steel sheets manufactured by the method have the advantages that the iron loss is low; after the stress relief annealing, the performance is not reduced; in addition, under the same manufacturing and test conditions, the noise level of the transformer is lowered.

Owner:BAOSHAN IRON & STEEL CO LTD

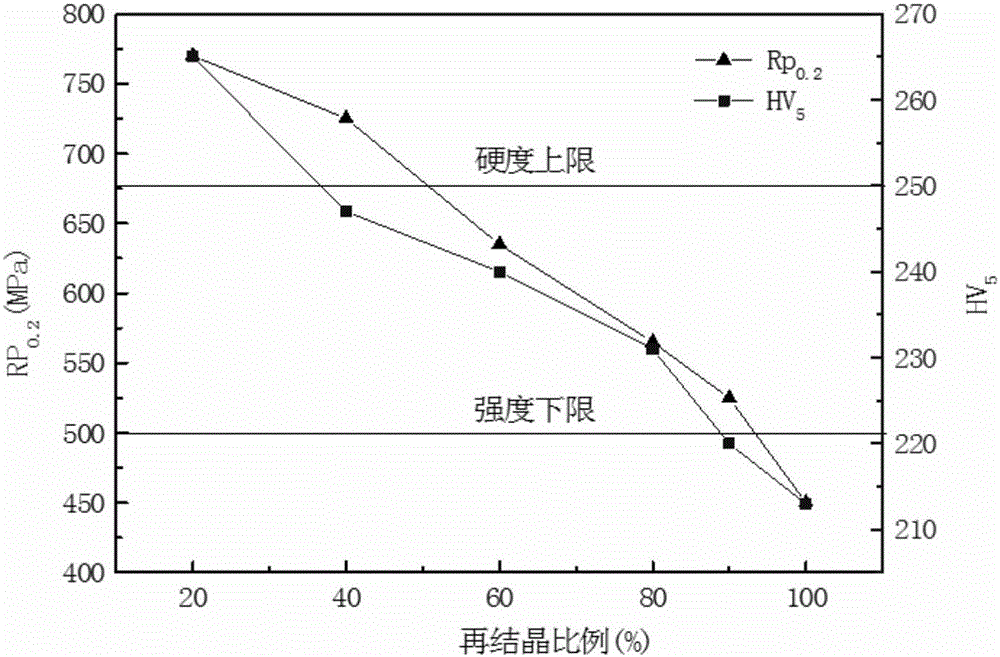

Non-oriented silicon steel for drive motor of electric automobile and preparation method thereof

The invention discloses non-oriented silicon steel for a drive motor of an electric automobile and a preparation method thereof. The performance of a silicon steel strip is controlled by optimizing chemical compositions and controlling the soaking time and soaking temperature of incomplete recrystallization annealing to regulate the recrystallization proportion. According to a rotor core made of the non-oriented silicon steel strip obtained after incomplete recrystallization annealing, the yield strength can reach 500 MPa or above, the Vickers hardness is 250 or below, and abrasion to a die is fully considered on the premise of guaranteeing the rotor strength. In addition, after stress annealing of the non-oriented silicon steel strip obtained after incomplete recrystallization annealing, a stator core manufactured from the steel strip is quite excellent in magnetic performance, i.e., the magnetic level of the stator core product after stress annealing is equivalent or even superior to that of a traditional full-process product.

Owner:武汉钢铁有限公司

Electro-optic device and projection-type display apparatus

ActiveUS20120120357A1Preventing a defect such as hillockReduce generationNon-linear opticsStress relievingSilicon oxide

An electro-optic device is provided with an substrate, in which a stress relieving film formed of a doped silicon oxide film is formed between a third interlayer insulating film formed of a non-doped silicon oxide film and a pixel electrode formed of an aluminum film or the like. The stress relieving film is formed of the doped silicon oxide film, has a thermal expansion coefficient different from that of the third interlayer insulating film, comes in contact with the third interlayer insulating film, has a thermal expansion coefficient different from that of the pixel electrode, and comes in contact with the pixel electrode. The thermal expansion coefficients are in the following relation of Third Interlayer Insulating Film<Stress relieving Film<Pixel Electrode.

Owner:SEIKO EPSON CORP

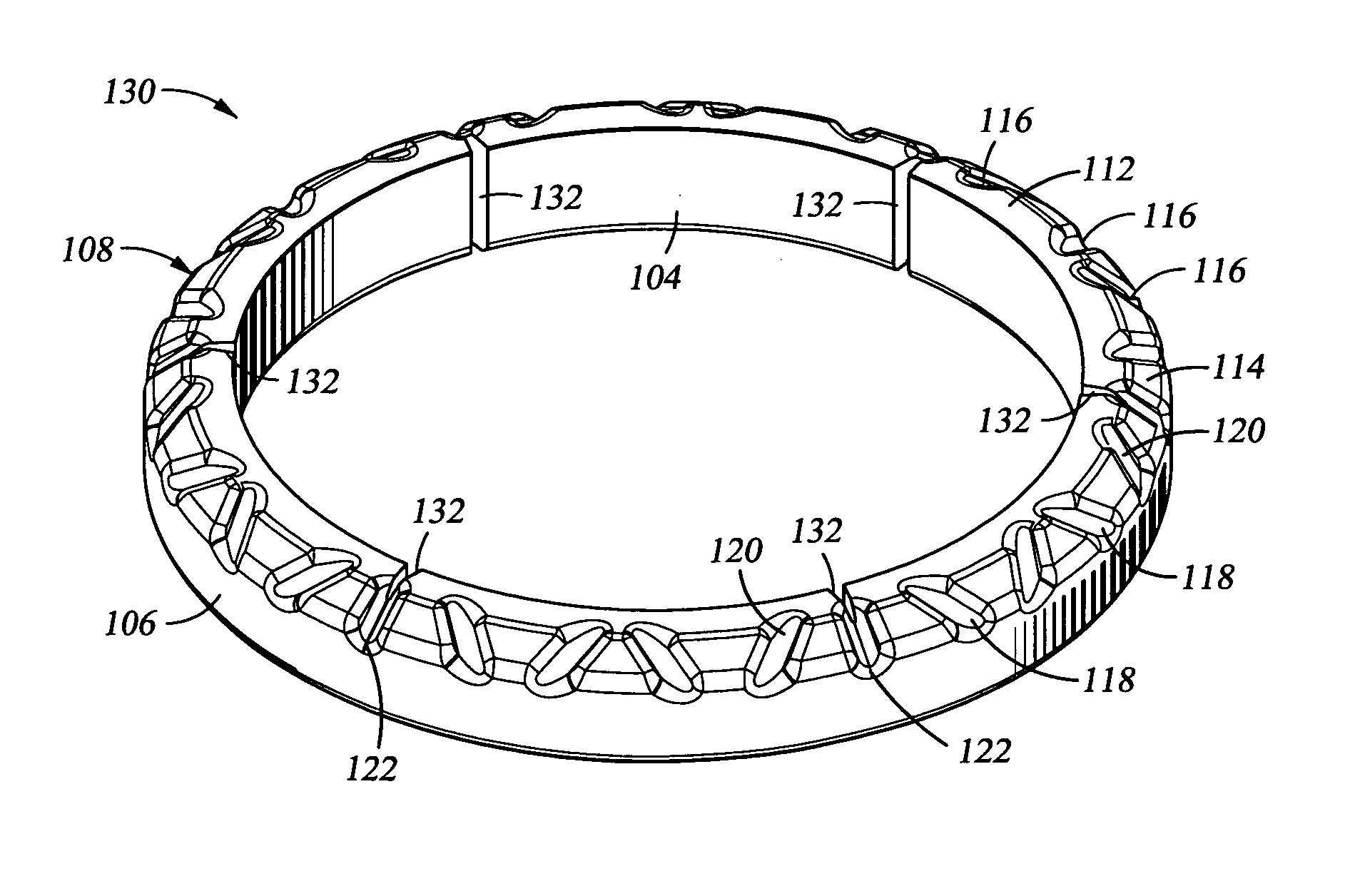

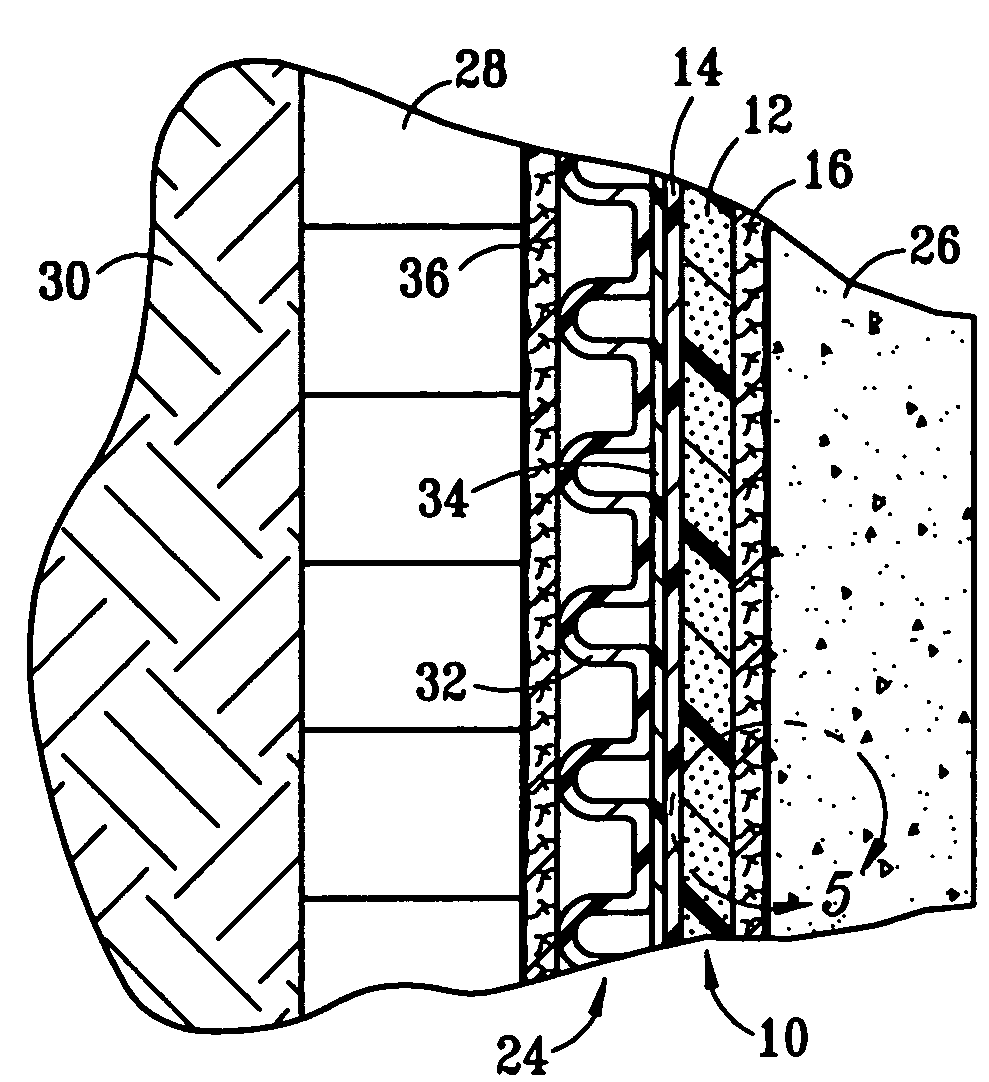

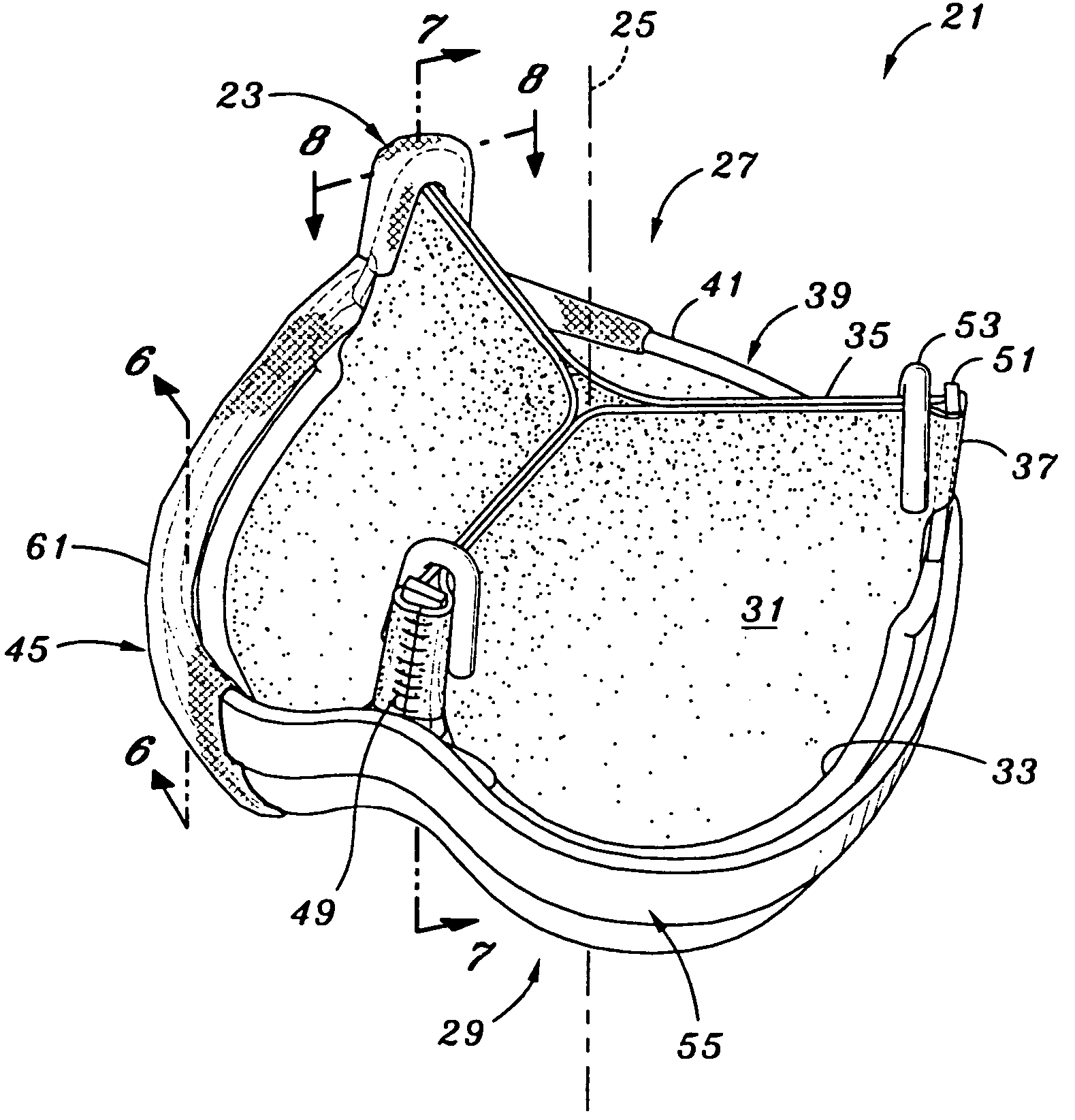

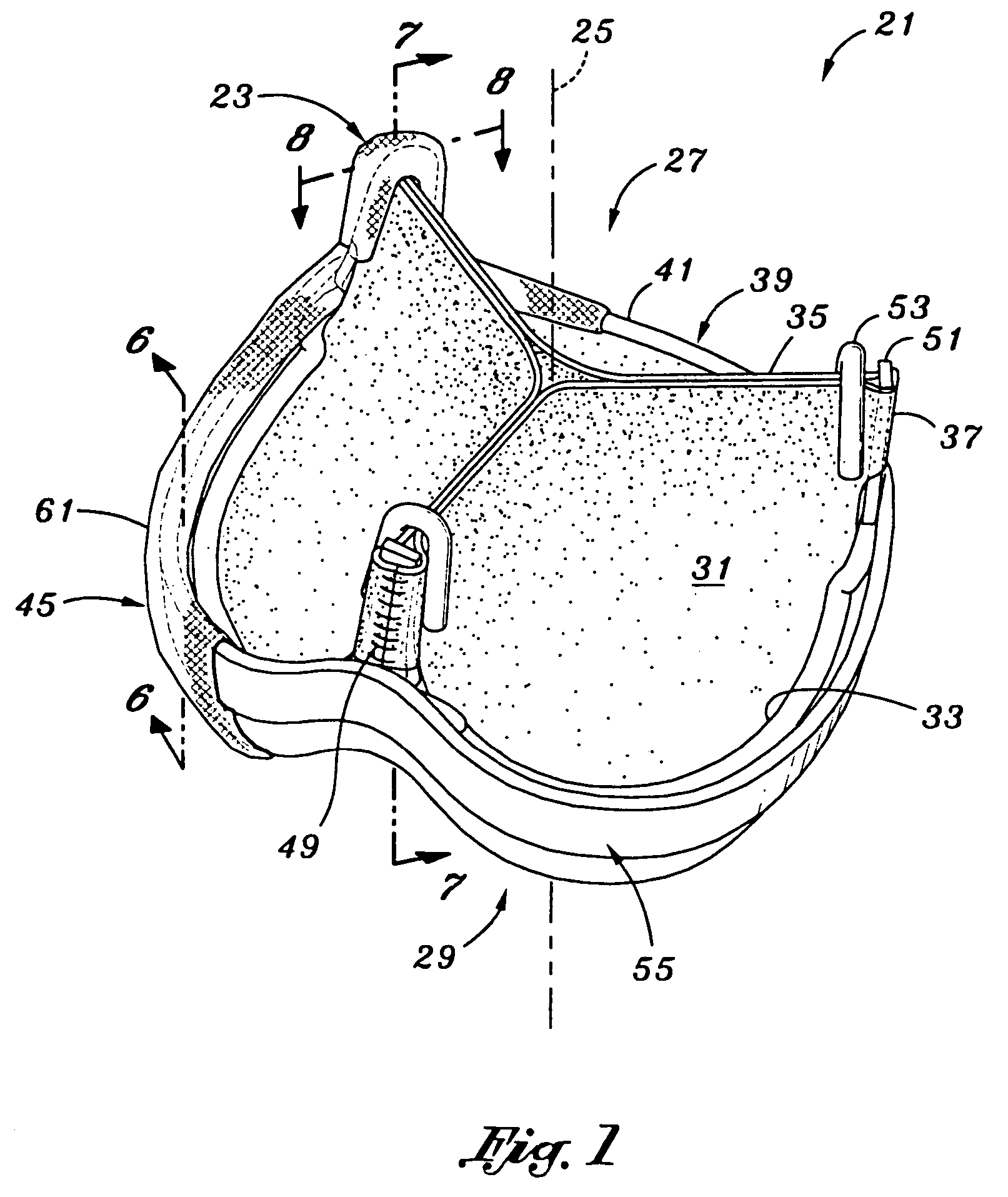

Flexible heart valve

A flexible prosthetic tissue-type heart valve having commissures that are substantially decoupled from a cusp support structure. The valve includes three leaflets having arcuate cusp edges and opposed concave shaped free edges, with outwardly-directed attachment tabs therebetween. A cusp support structure in either one or more pieces attaches to the leaflet cusp edges. Three commissures are each formed partly with an axially-extending insert member to which two adjacent leaflet tabs attach. An inverted V-shaped clip maintains close contact between the adjacent leaflet tabs and provides a stress-relieving clamping action in conjunction with the insert member. The insert member attaches about its lower end to base sections of the cusp support structure, or to an intermediate sewing ring, so that the commissures may pivot about the cusp support structure.

Owner:EDWARDS LIFESCIENCES CORP

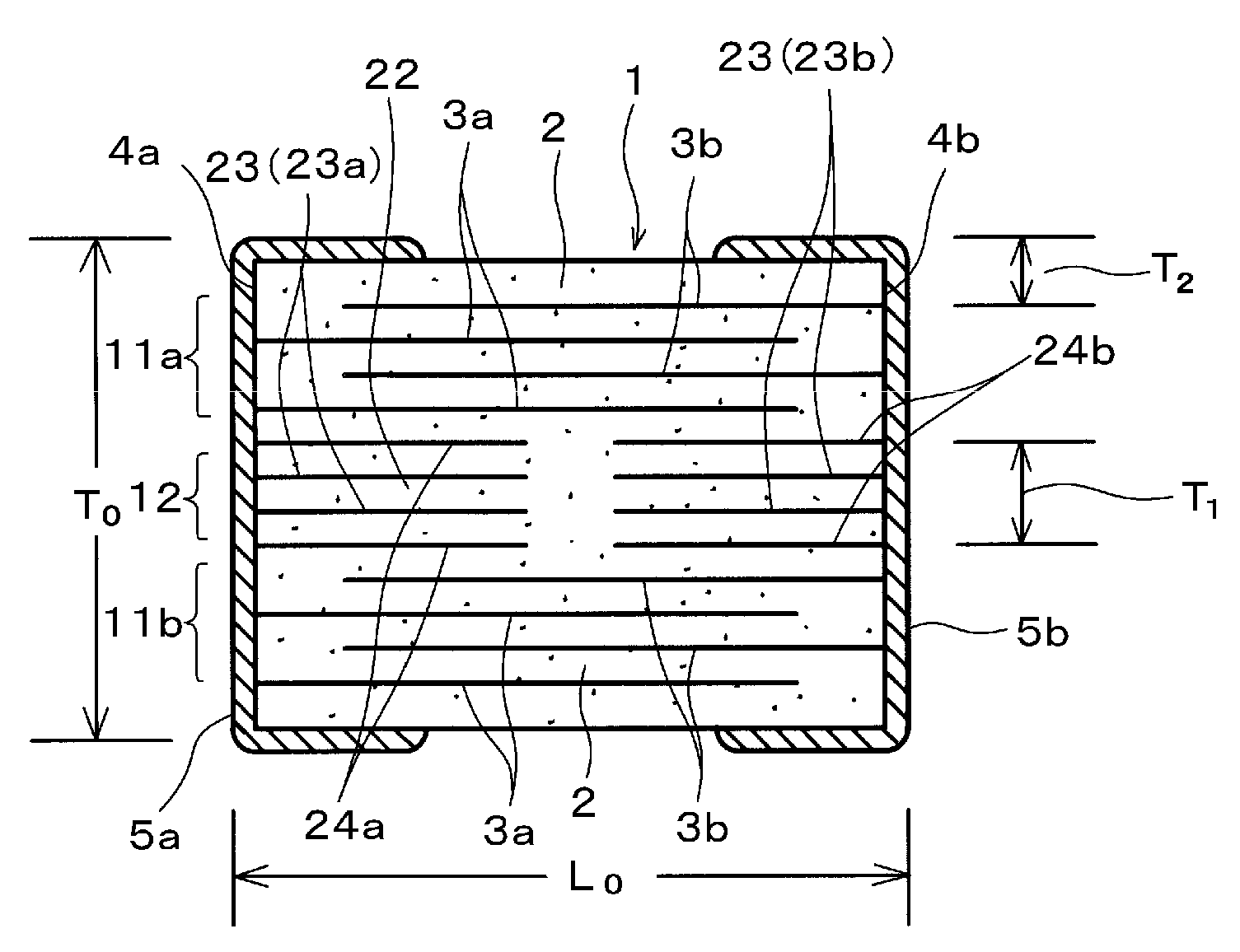

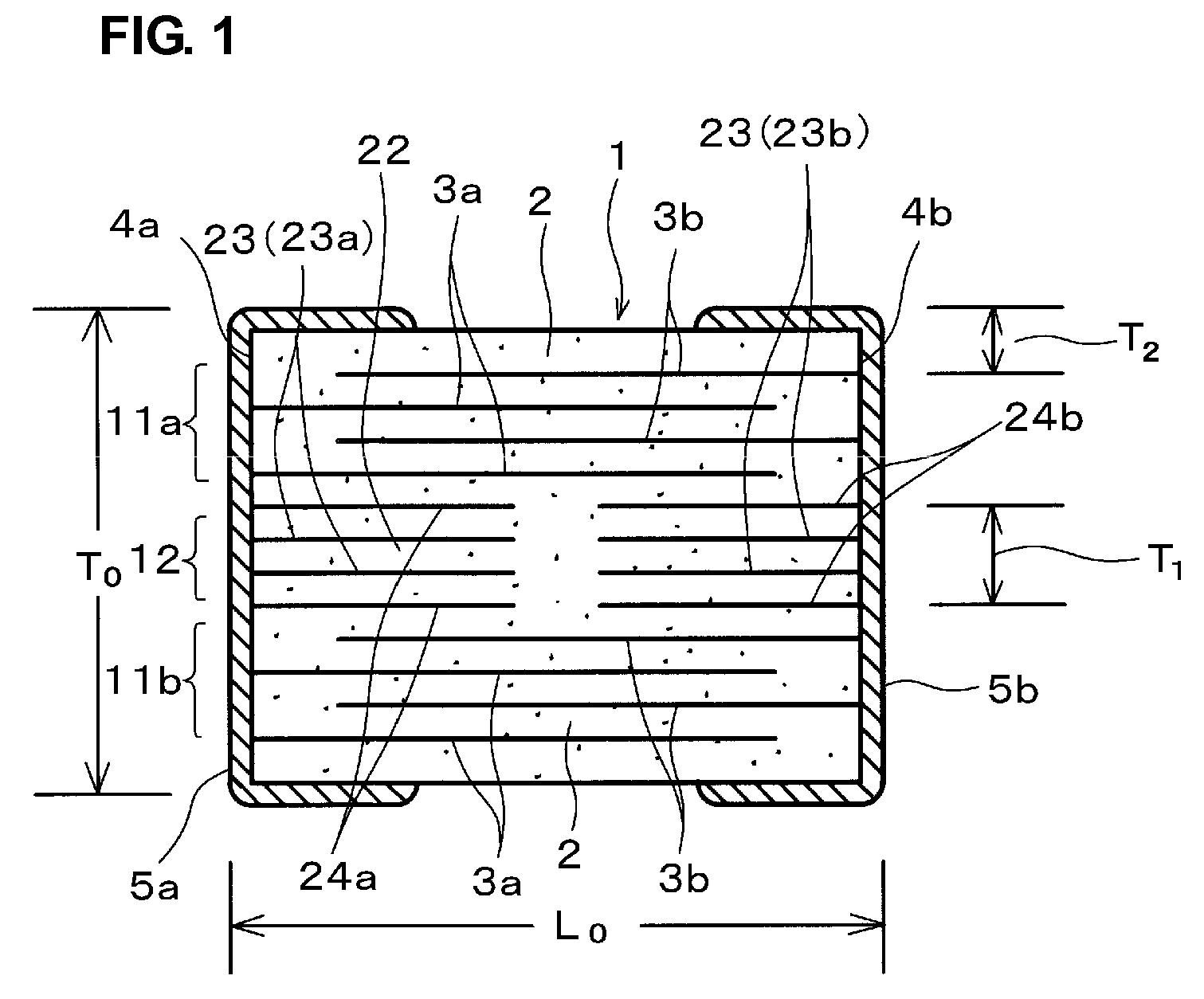

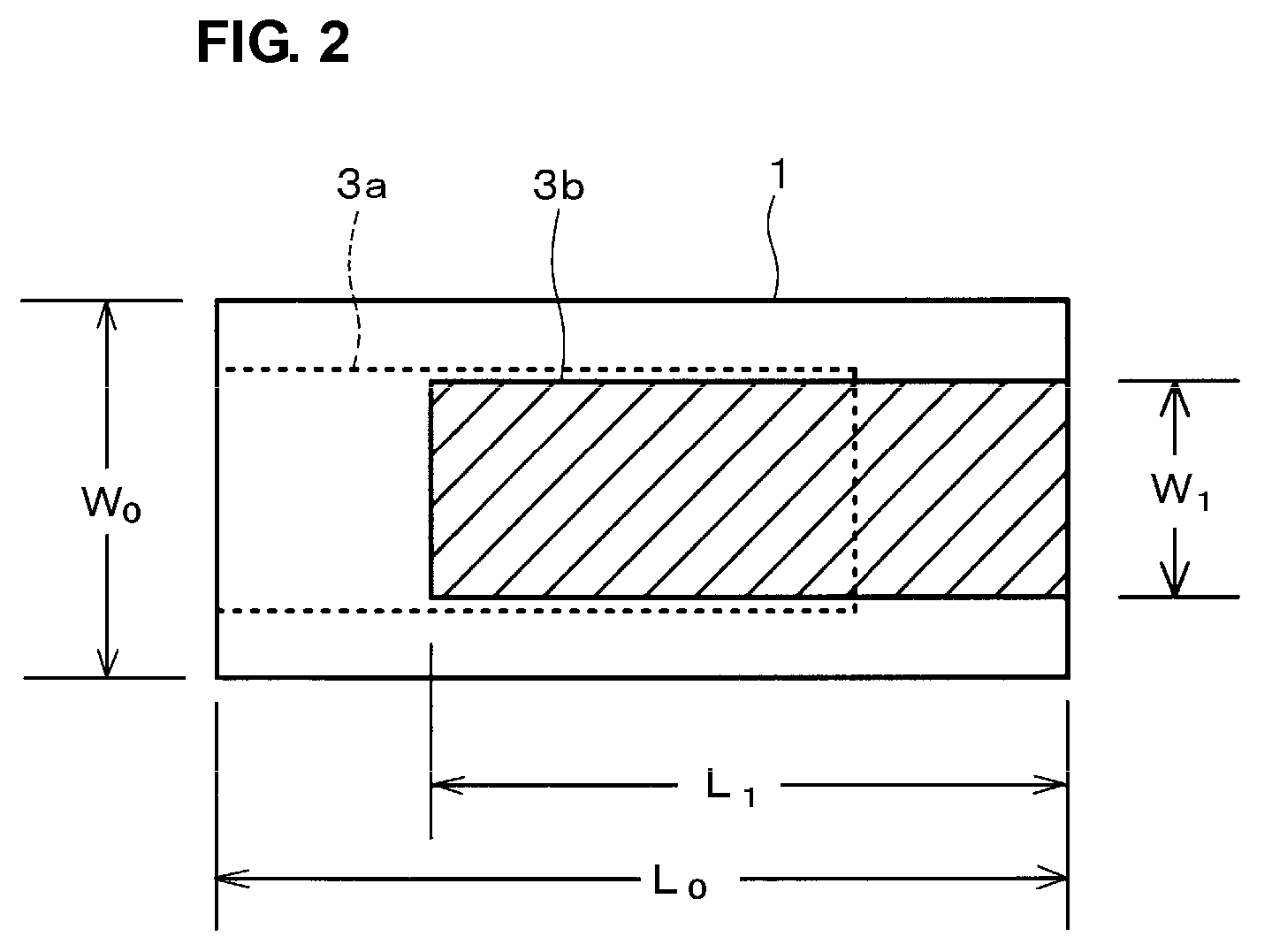

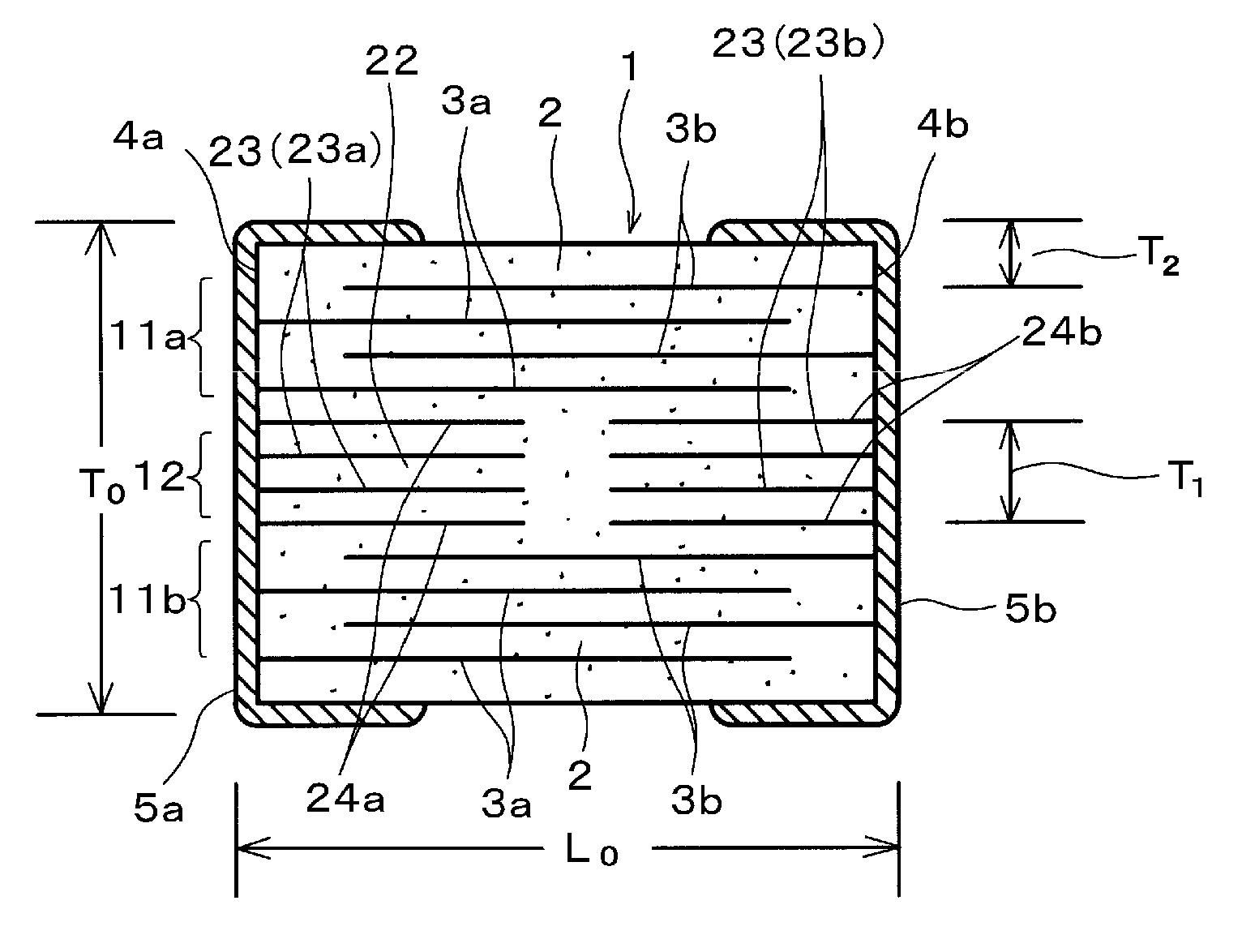

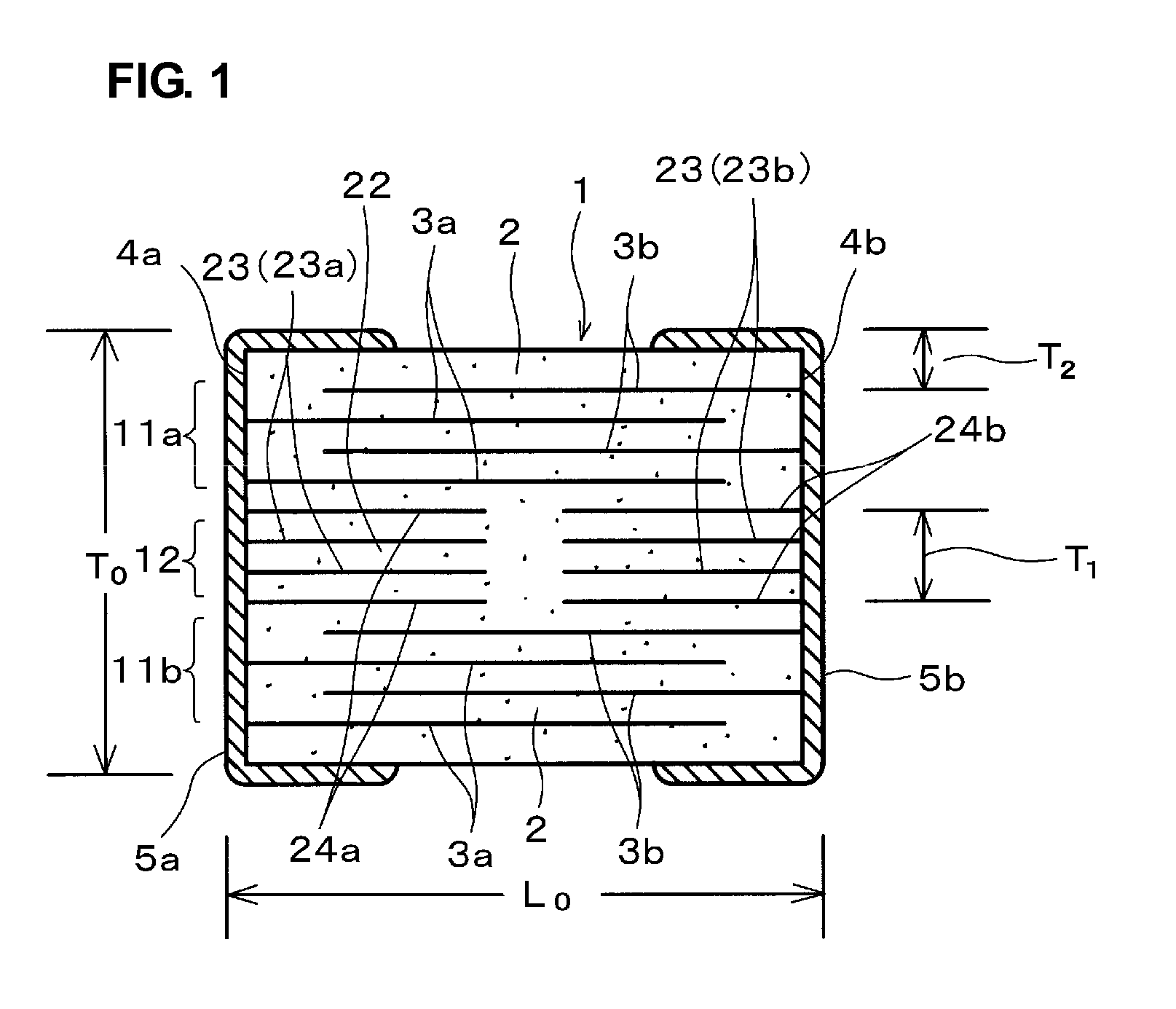

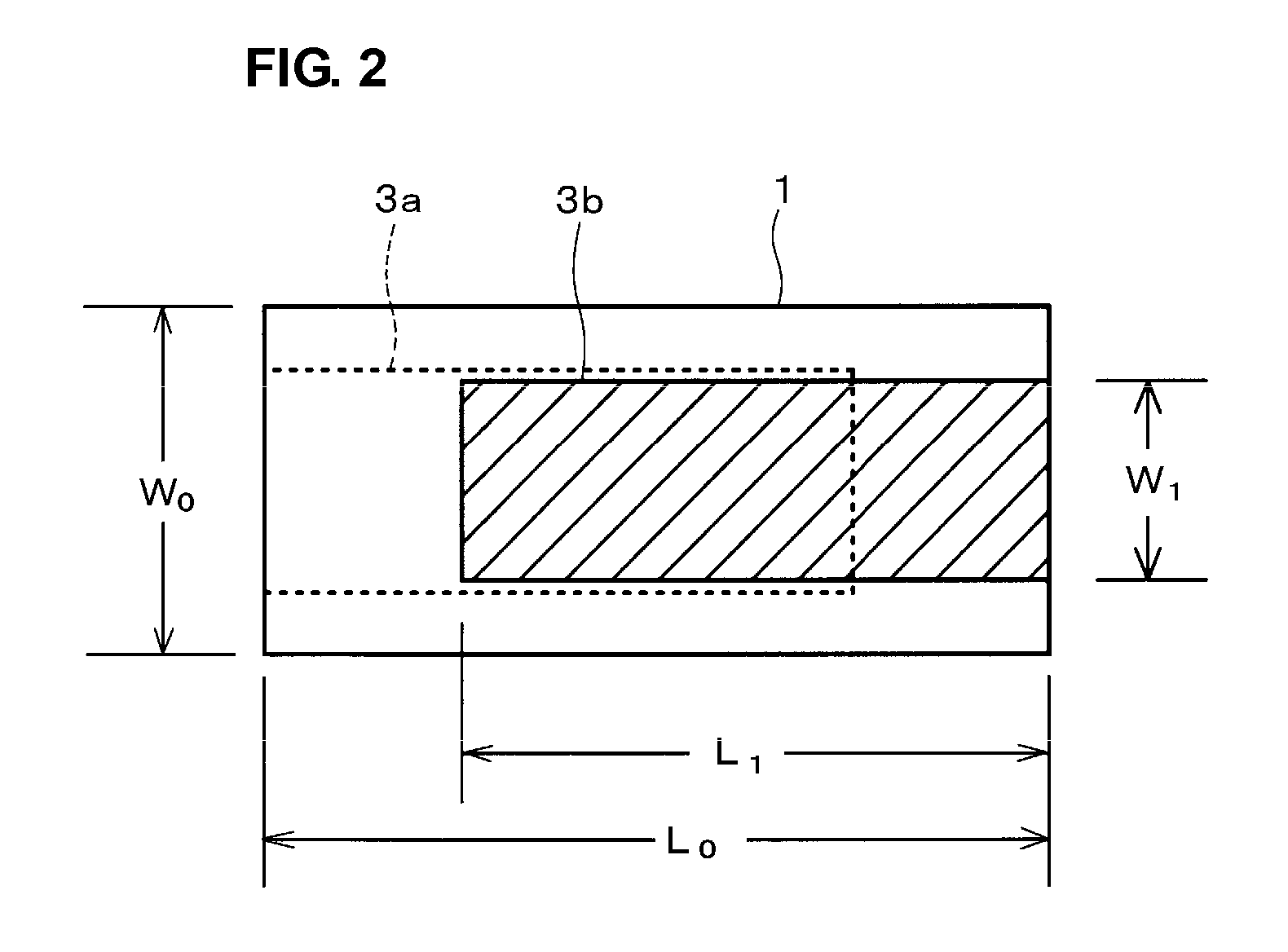

Laminated ceramic capacitor

ActiveUS7436650B2Improve breakdown voltageImprove pressure resistanceFixed capacitor electrodesFixed capacitor dielectricCapacitanceStress relieving

A laminated ceramic capacitor has a high breakdown voltage and excellent withstand-voltage performance, and prevents cracks generated during firing even when the number of lamination layers constituted by ceramic layers and inner electrode layers is increased. The laminated ceramic capacitor includes capacitance forming layers in which ceramic dielectric layers and capacitance-forming inner electrode layers are laminated, and a stress relieving layer. The stress relieving layer is disposed between the capacitance forming layers. In the stress relieving layer, ceramic dielectric layers, dummy inner electrode layers (split electrodes) that do not contribute to the formation of electrostatic capacitance, and capacitance-formation-preventing inner electrode layers that prevent capacitance from being formed between the capacitance-forming inner electrode layers and the dummy inner electrode layers are laminated. The thickness of the stress relieving layer is in the range of about 100 μm to about 300 μm inclusive. The plane area of the dummy inner electrode layers is about 60% or more of that of the capacitance-forming inner electrode layers. The dummy inner electrode layers are undivided or are divided into two or three parts in a single layer. With this structure, stress caused by electrostriction is relieved.

Owner:MURATA MFG CO LTD

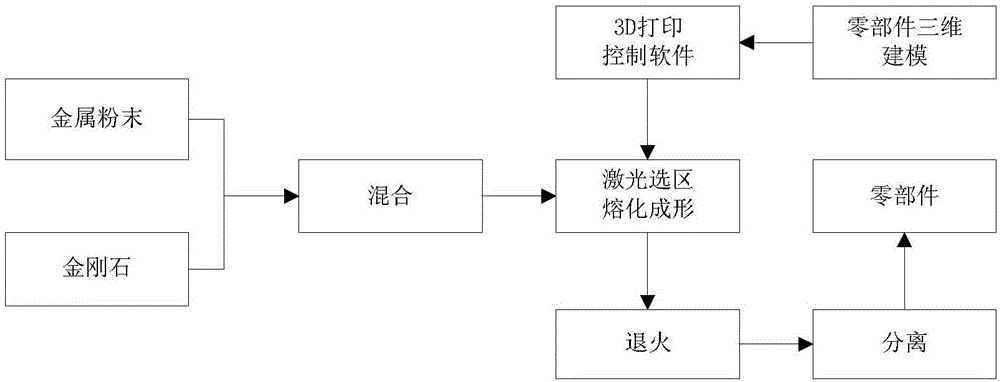

Metal-matrix diamond composite material and 3D (three dimensional) printing manufacturing method of parts of metal based diamond composite material

InactiveCN106825568AHigh hardnessImprove wear resistanceAdditive manufacturing apparatusIncreasing energy efficiencyStress relievingHardness

The invention discloses a metal-matrix diamond composite material and a 3D (three dimensional) printing manufacturing method of parts of the metal-matrix diamond composite material. The composite material is made from, by weight, 2%-3% of diamond and the balance of metal powder; the metal powder is 15umm-65umm in grain size; the grade of the diamond is above SMD 30, and the diamond is 35-18 meshes in particle size; the diamond is evenly mixed with metal matrix powder prior to being put in a feeding device of a melting unit in a selective laser region to perform three-dimensional printing to form the parts on a substrate; the parts are subjected to stress-relieving annealing treatment after formation is completed, microcrack healing is promoted, structure defect is removed, and the performance is controlled. By the arrangement, metal matrix alloying can be realized, the diamond is effectively embedded, the metal-matrix diamond composite material with ideal hardness and abrasion performance is obtained, and the metal-matrix diamond composite material parts with the complex structure are manufactured.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

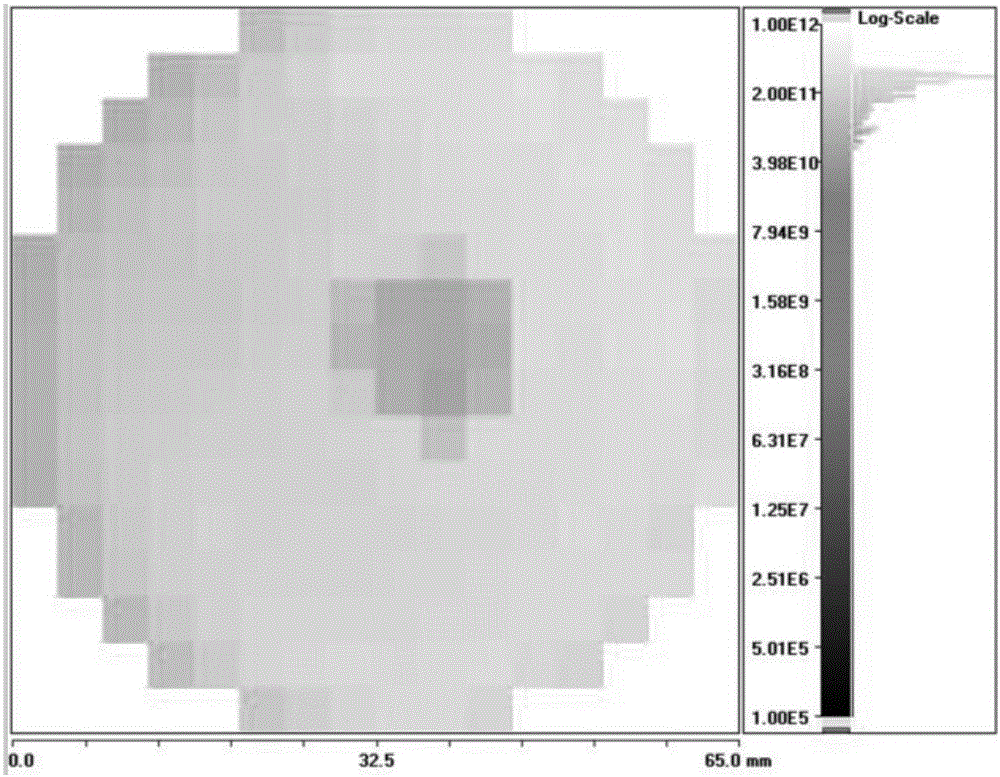

Preparation method of low-stress and high-purity semi-insulating SiC single crystal

ActiveCN105821471AReduce stressQuality improvementPolycrystalline material growthFrom condensed vaporsGas phaseSeed crystal

The invention relates to a preparation method of a low-stress and high-purity semi-insulating SiC single crystal. The method includes the steps that synthesis of high-purity SiC powder is carried out, crystal growth is carried out with a physical vapor transport method, the concentration of shallow energy level impurities is reduced in the synthesis and crystal growth processes, a heat insulation material is subjected to high-temperature pretreatment, and boron impurities are prevented from being blended in; a silicon powder raw material and a carbon powder raw material are put into a graphite crucible with a coating for SiC synthesis; the obtained high-purity SiC powder is pretreated, seed crystals are fed, vacuumizing is carried out, high-purity argon or mixed gas of argon and hydrogen is introduced in to carry out crystal growth, then the temperature is rapidly lowered to enlarge point defects, and then the temperature is slowly lowered to the room temperature to eliminate stress. SiC crystal growth is carried out in an equilibrium state, so that the obtained crystal is small in stress, low in microtubule density and good in quality, and the resistivity on the area of the whole crystal is 108 ohm.cm or above. The method is small in preparation investment, high in safety and free of pollution.

Owner:SHANDONG UNIV

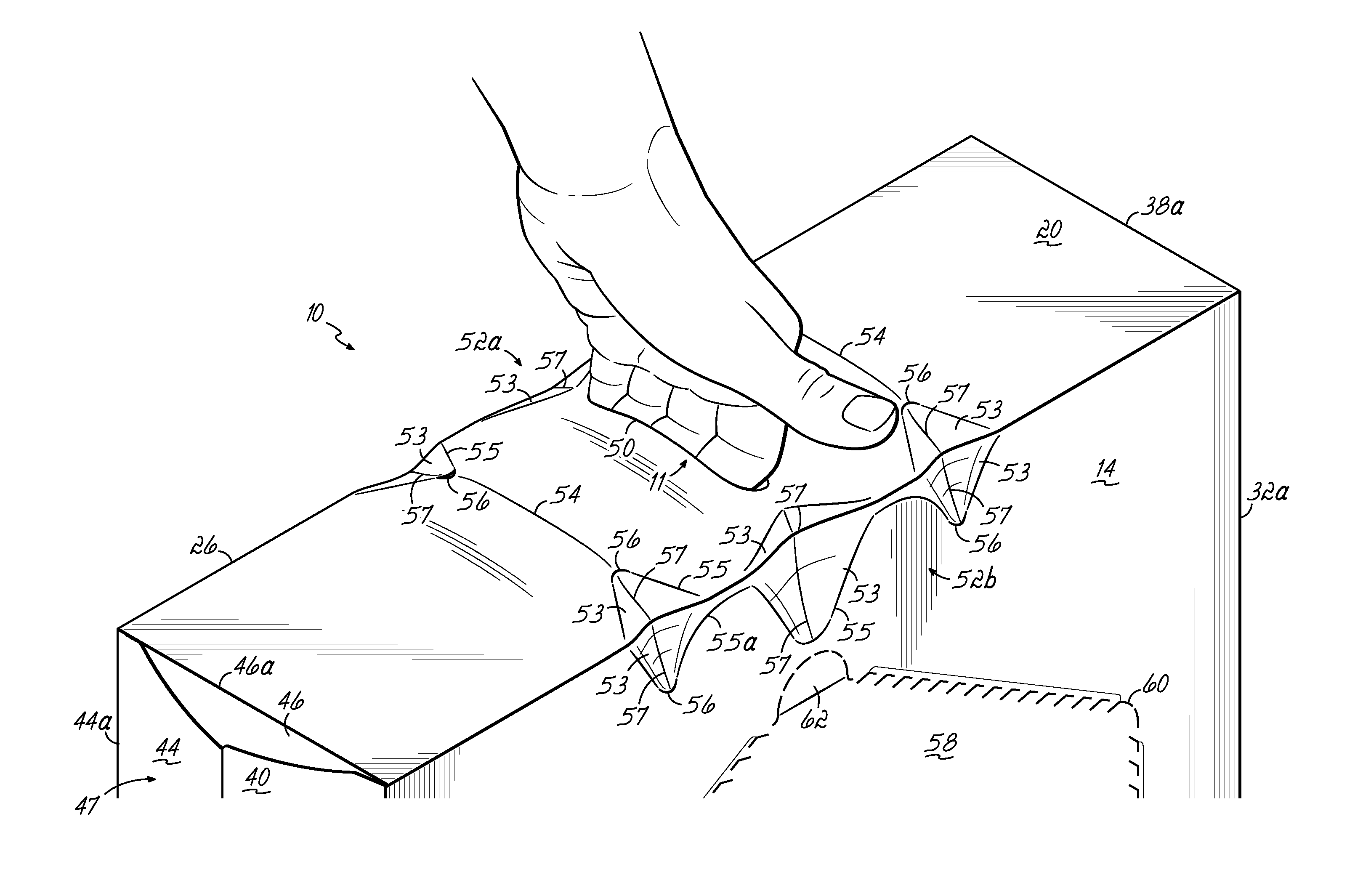

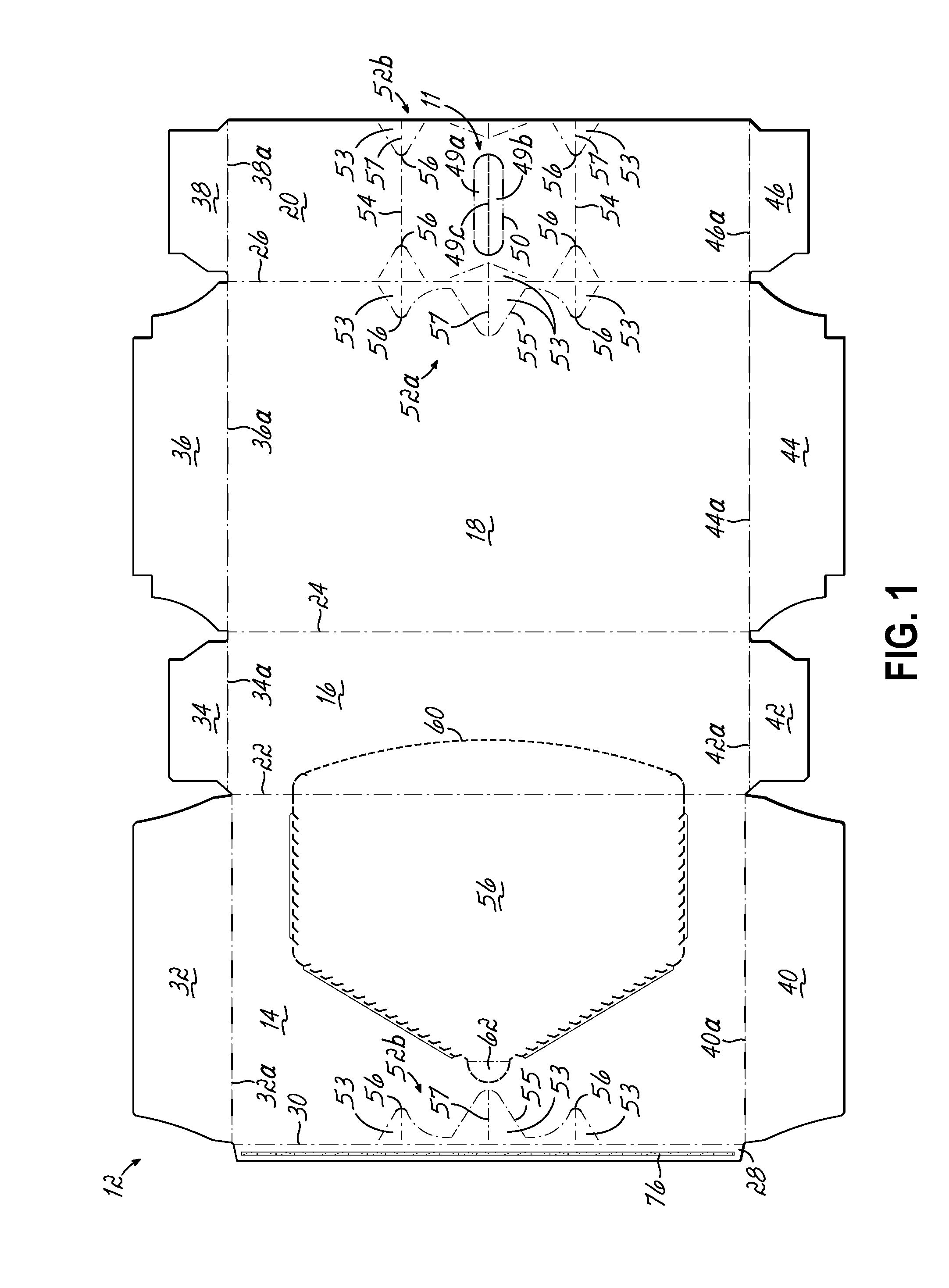

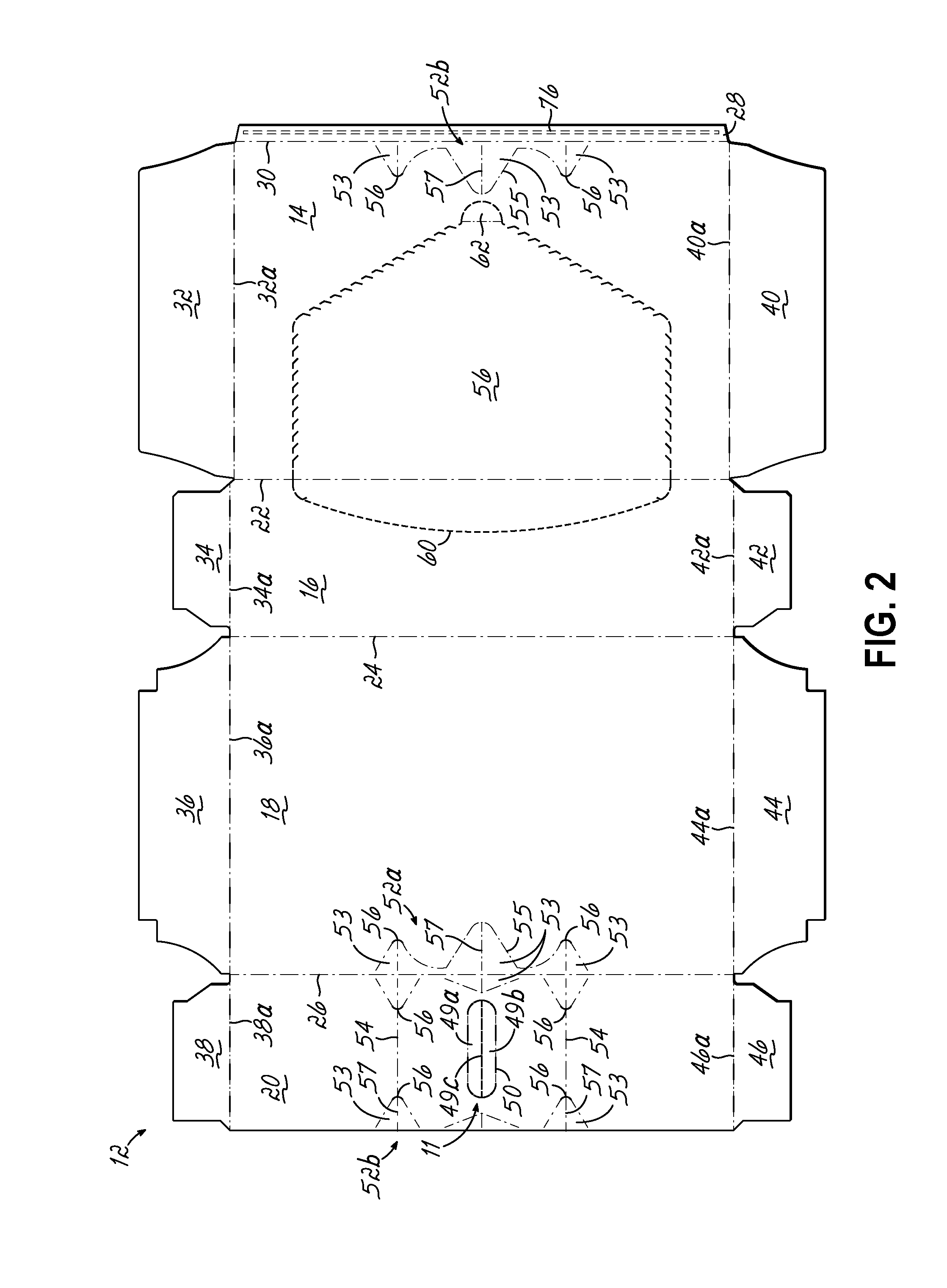

Carton and stress relieving pattern for handle

InactiveUS20160009442A1Increase ratingsHigh strengthContainer/bottle contructionRigid containersStress relievingCarton

A carton blank is assembled into a carton for beverage containers, the blank having a number of panels including a top panel, a bottom panel and a pair of side panels each joined by a fold line to an adjacent one of the panels. A number of end flaps are each joined by an end flap fold line to one of the panels and the end flaps are adapted to be folded upon selected other end flaps to form composite end panels of the carton. A carrying handle is formed in a selected one of the panels and adapted to be grasped by a user to carry the erected carton filled with the beverage containers. A pattern of stress-relieving lines are formed in the carton blank to produce a desired buckling of the carton when erected, filled and lifted to avoid tearing of the carton material.

Owner:C W ZUMBIEL

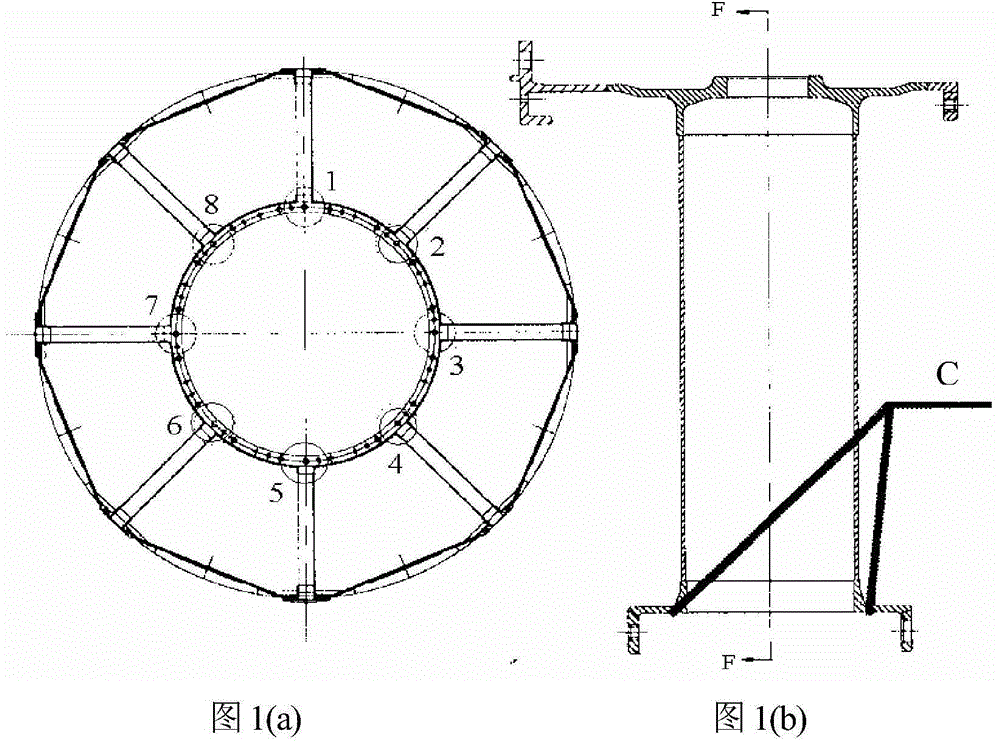

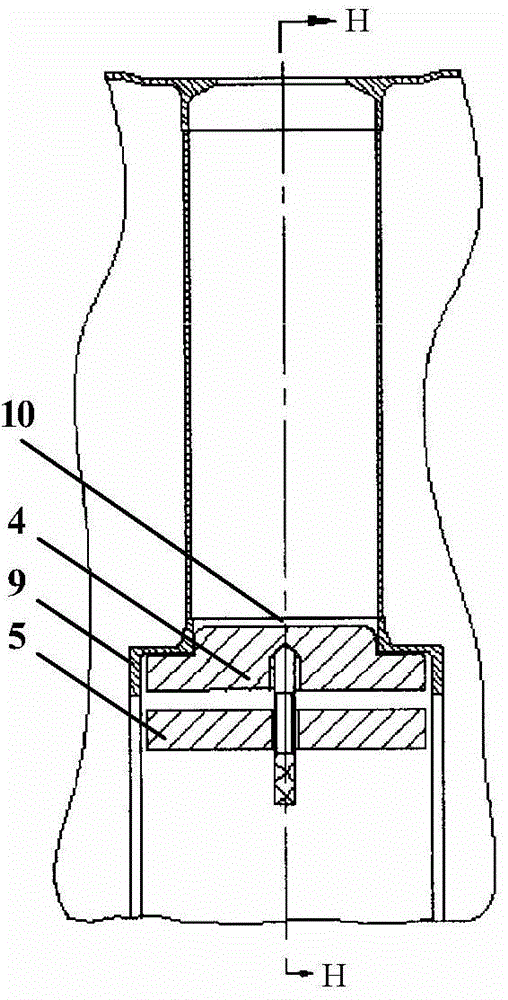

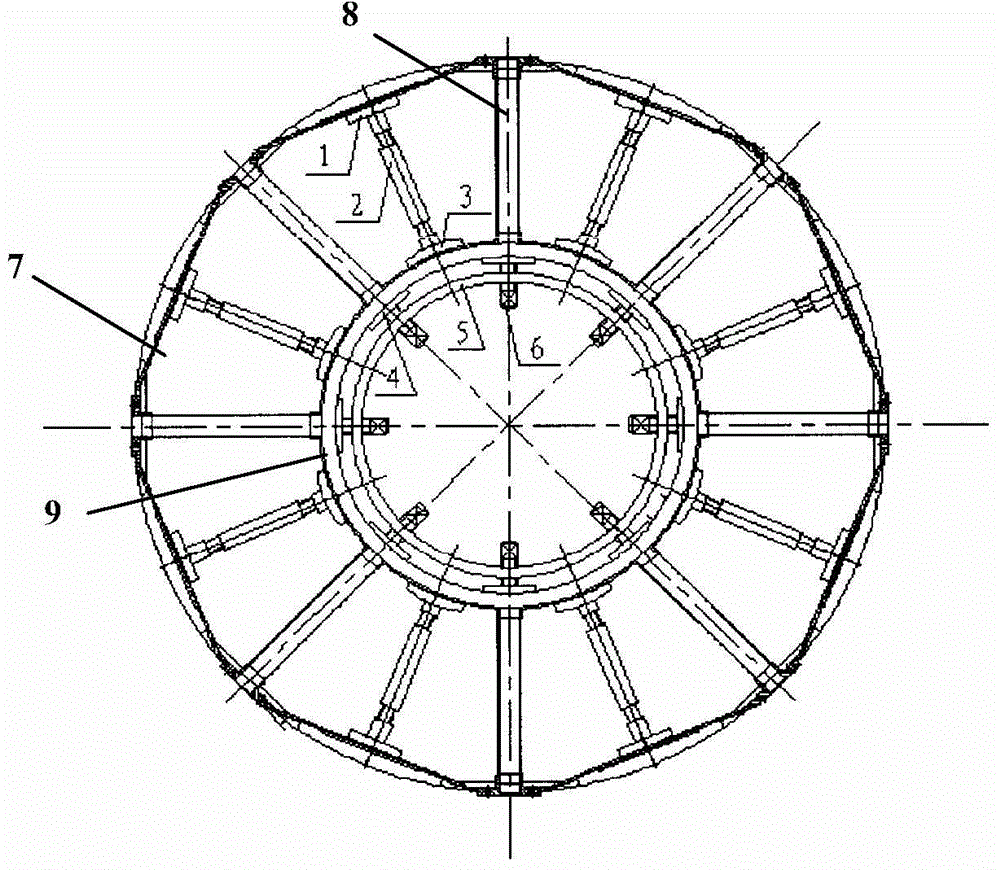

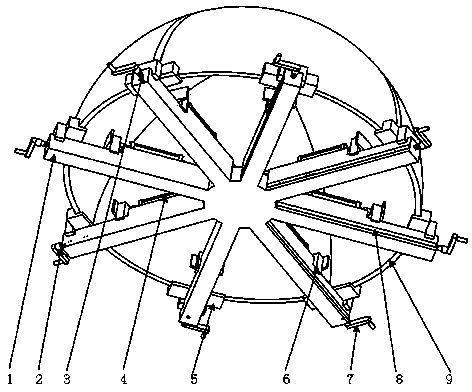

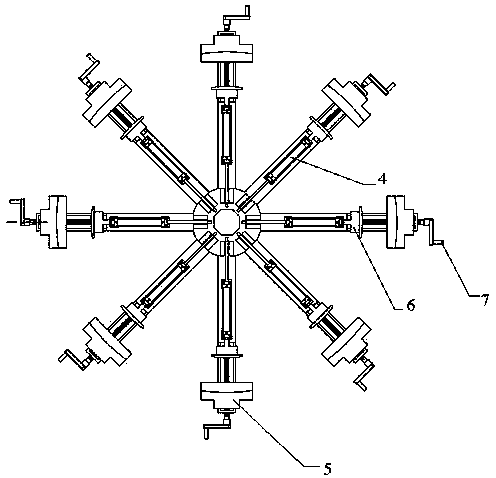

Assembly welding tool device and method commonly used for large curved surface end sockets of pressure containers

ActiveCN103862215AGuaranteed sizeGuaranteed reliabilityWelding/cutting auxillary devicesFurnace typesStress relievingBall screw

The invention relates to an assembly welding tool device and method commonly used for large curved surface end sockets of pressure containers. The assembly welding tool device comprises a supporting base plate, a ball screw, grouped rolling bearings, a movement air cylinder, external locating blocks, internal locating blocks, a manual rocker and a graduated scale, wherein the ball screw and an executive component drive most of the external locating blocks and most of the internal locating blocks to move along guide rails of the supporting base plate so as to carry out integrated locating clamping fixation on the curved surface end sockets. According to the assembly welding tool device and method commonly used for the large curved surface end sockets of the pressure containers, in the manufacturing process of the pressure containers, tool locating of the large end sockets can be achieved, welding deformation is prevented, the curved surface end sockets are placed on the assembly welding tool device to be clamped in an assembly locating mode, spot fixation is carried out on weld joints, and then welding operation is carried out on the internal weld joints and the external weld joints; after welding is accomplished, the curved surface end sockets are naturally cooled to have the normal temperature, postwelding is carried out on the curved surface end sockets, stress relieving is carried out on the curved surface end sockets, labor intensity of workers is reduced, the production and manufacturing cycle of products is shortened, and the production cost is reduced.

Owner:哈尔滨市黎明锅炉容器封头有限公司

Flexible display panel and manufacturing method thereof

ActiveCN109671718AReduce bending stressLower impedanceSolid-state devicesIdentification meansStress relievingData signal

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

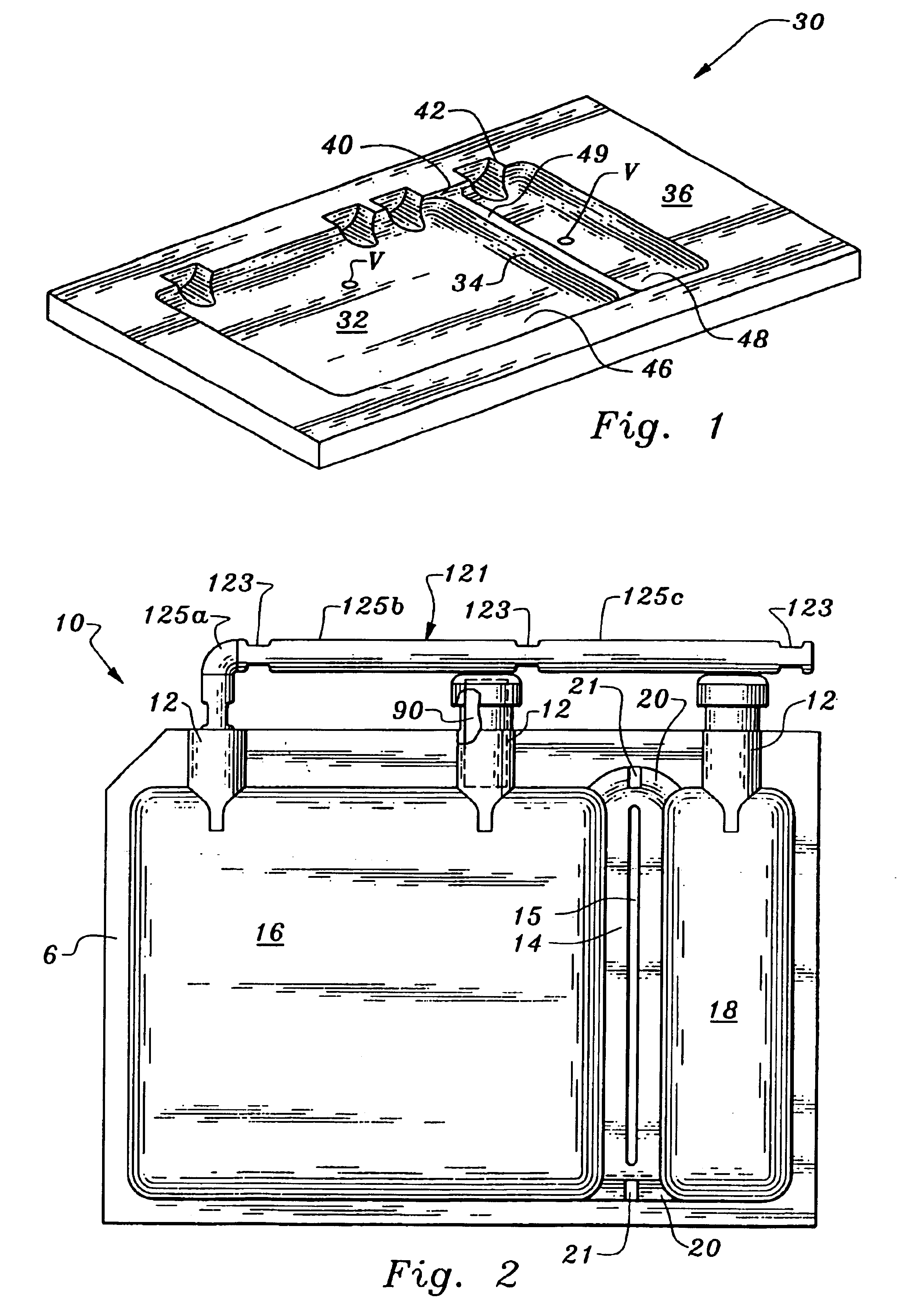

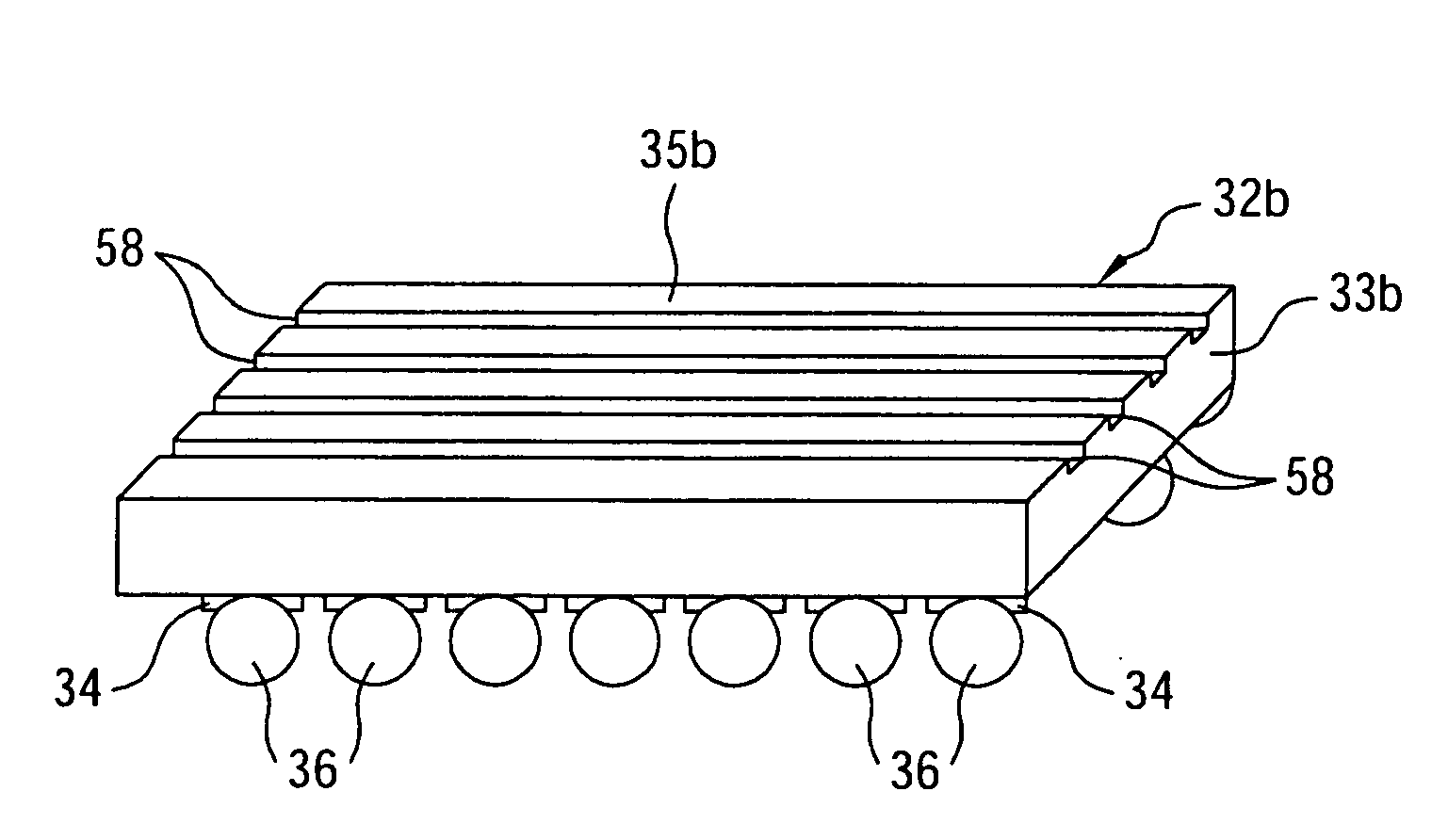

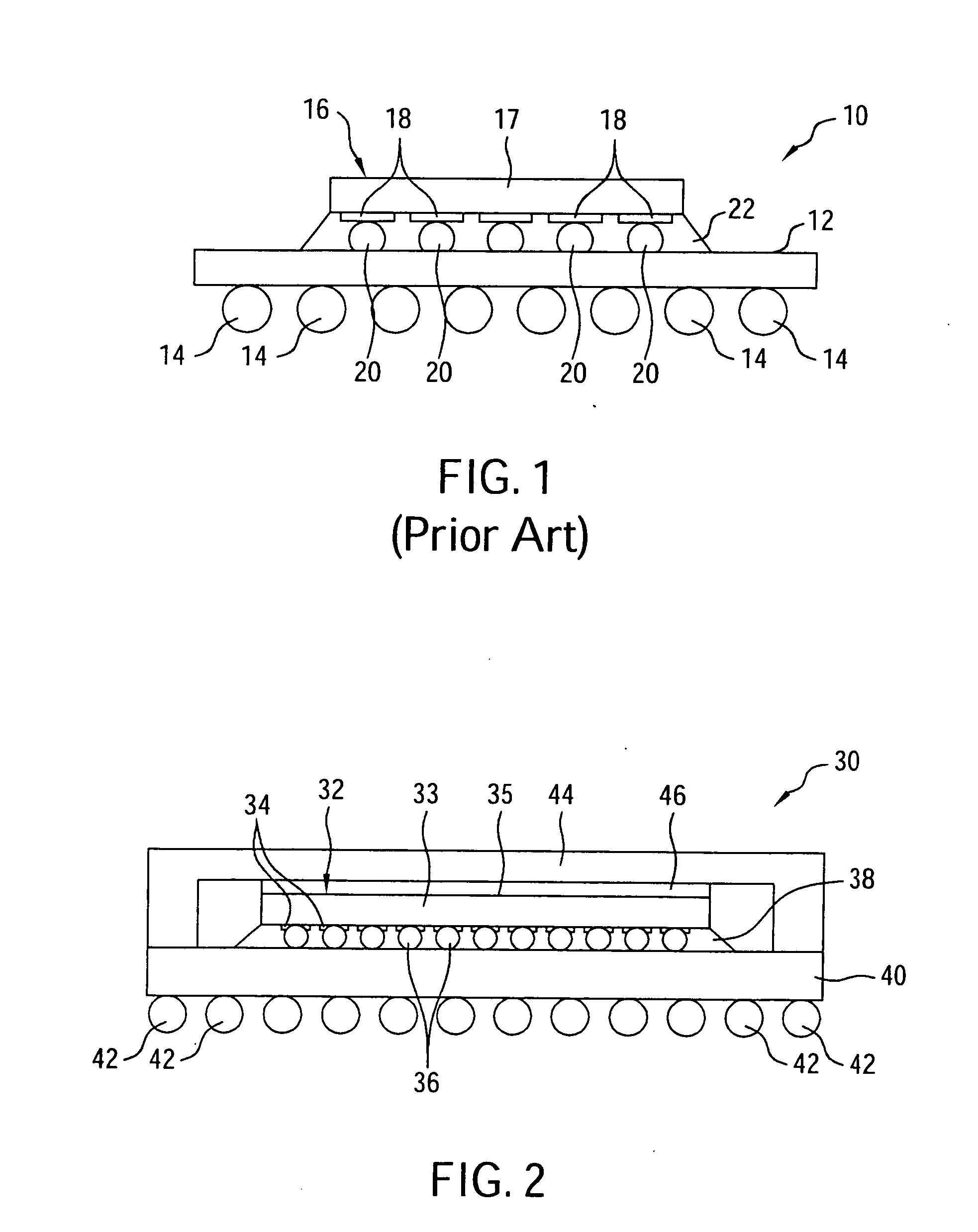

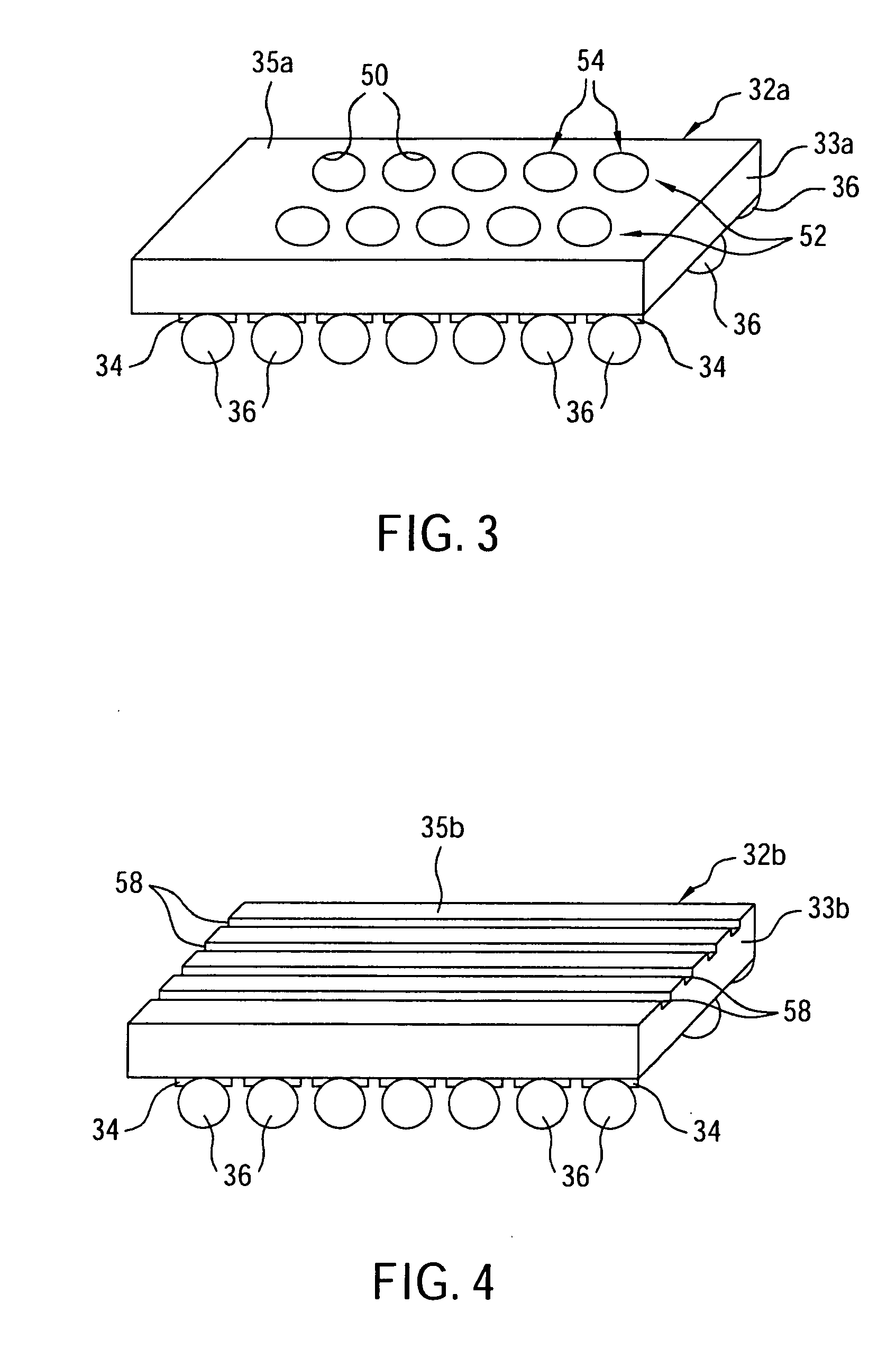

Novel chip packaging structure for improving reliability

ActiveUS20070215985A1Relieve pressureImprove reliabilitySemiconductor/solid-state device detailsSolid-state devicesStress relievingAdhesive materials

A novel chip packaging structure is disclosed. The chip packaging structure includes a flip chip having a chip backside, at least one concave stress-relieving structure provided in the chip backside, a carrier substrate bonded to the flip chip and an adhesive material interposed between the flip chip and the carrier substrate. During thermal testing and / or functioning of the flip chip, the stress-relieving structure reduces stresses between the flip chip and the carrier substrate and dissipates heat from the flip chip to reduce thermally-induced delamination stresses applied to the adhesive material and thereby enhances reliability of the flip chip.

Owner:TAIWAN SEMICON MFG CO LTD

Laminated ceramic capacitor

ActiveUS20080084651A1Improve breakdown voltageImprove pressure resistanceFixed capacitor electrodesFixed capacitor dielectricCapacitanceCrazing

A laminated ceramic capacitor has a high breakdown voltage and excellent withstand-voltage performance, and prevents cracks generated during firing even when the number of lamination layers constituted by ceramic layers and inner electrode layers is increased. The laminated ceramic capacitor includes capacitance forming layers in which ceramic dielectric layers and capacitance-forming inner electrode layers are laminated, and a stress relieving layer. The stress relieving layer is disposed between the capacitance forming layers. In the stress relieving layer, ceramic dielectric layers, dummy inner electrode layers (split electrodes) that do not contribute to the formation of electrostatic capacitance, and capacitance-formation-preventing inner electrode layers that prevent capacitance from being formed between the capacitance-forming inner electrode layers and the dummy inner electrode layers are laminated. The thickness of the stress relieving layer is in the range of about 100 μm to about 300 μm inclusive. The plane area of the dummy inner electrode layers is about 60% or more of that of the capacitance-forming inner electrode layers. The dummy inner electrode layers are undivided or are divided into two or three parts in a single layer. With this structure, stress caused by electrostriction is relieved.

Owner:MURATA MFG CO LTD

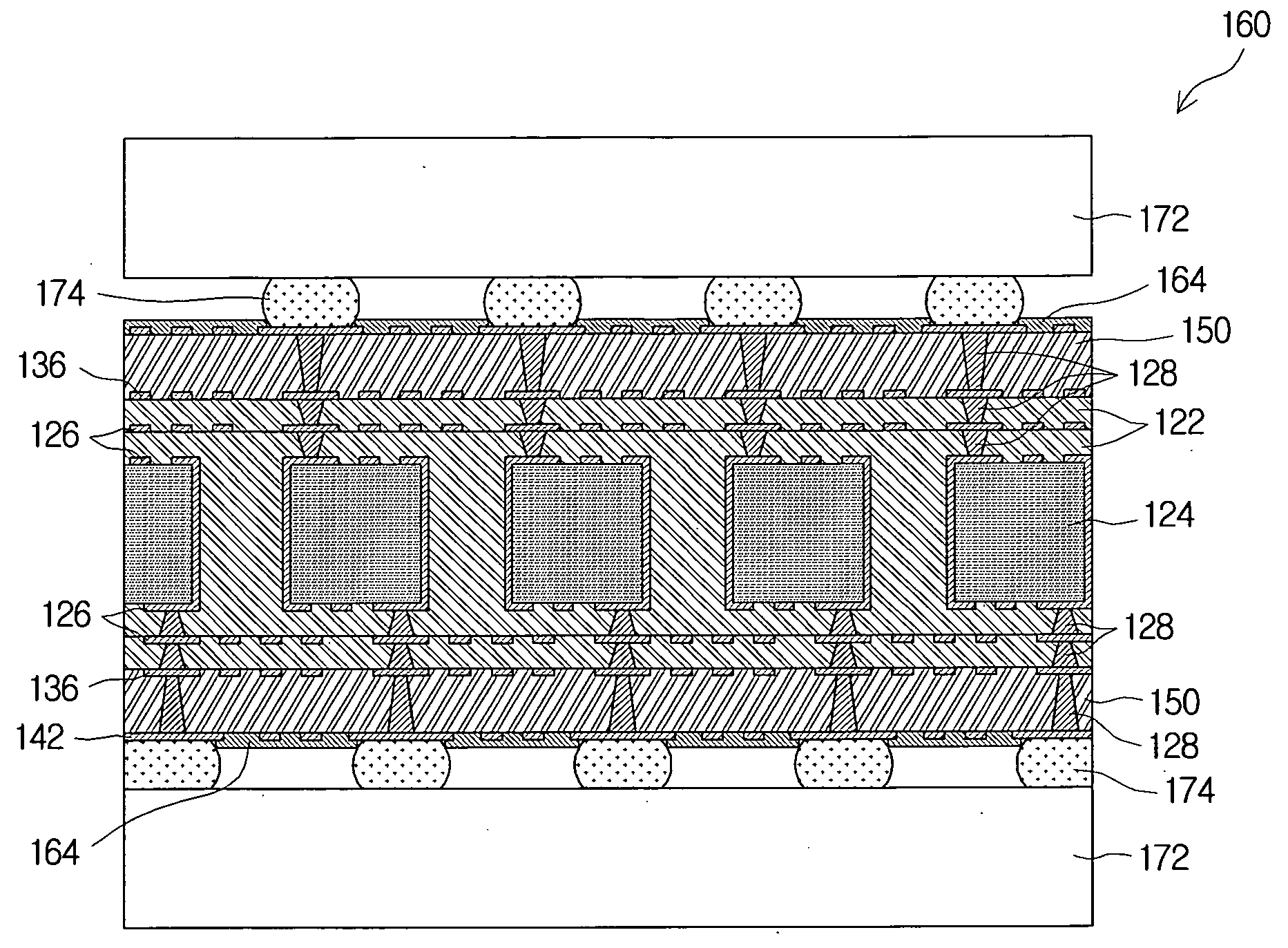

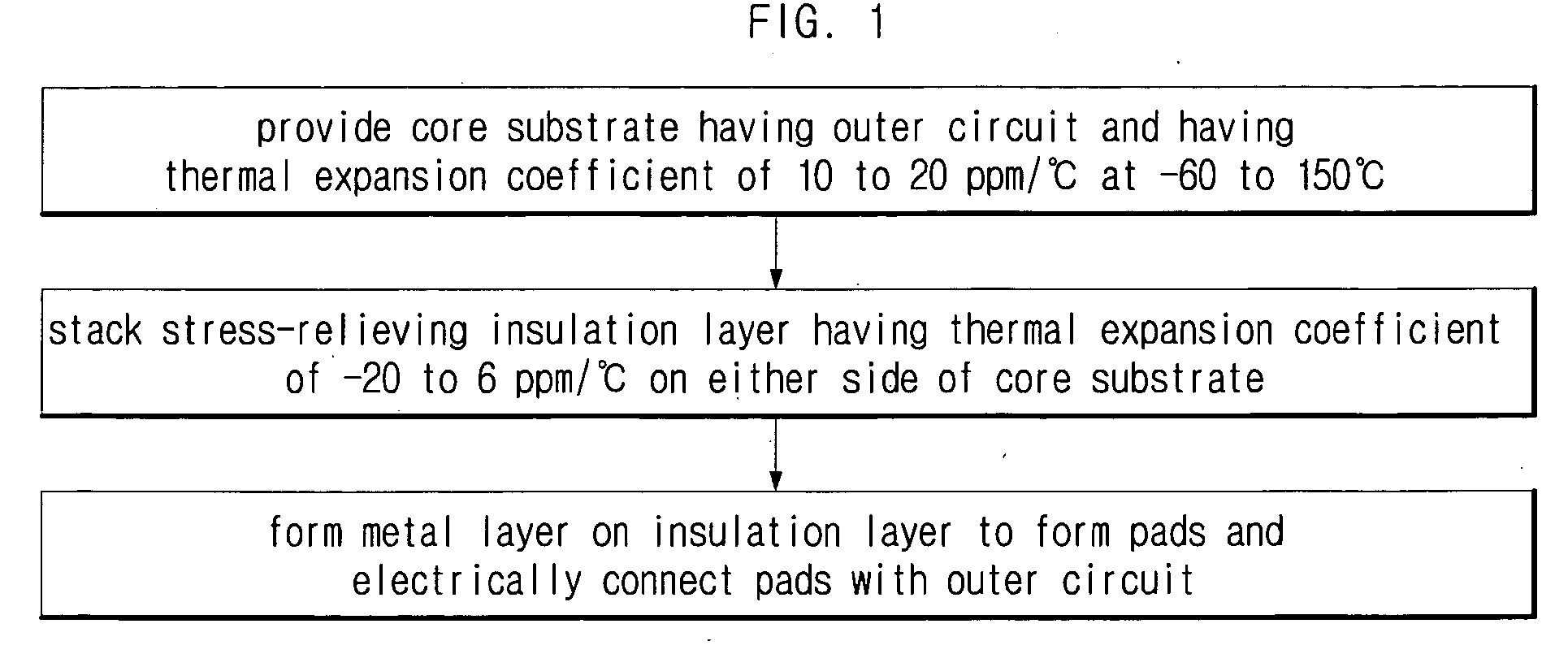

Multilayered printed circuit board and fabricating method thereof

InactiveUS20090008136A1Improve contact reliabilityElectrically conductive connectionsSemiconductor/solid-state device detailsInsulation layerStress relieving

A multilayered printed circuit board and a method of fabricating the printed circuit board are disclosed. The method of fabricating the multilayered printed circuit board can include: providing a core substrate, which has an outer circuit, and which has a thermal expansion coefficient of 10 to 20 ppm / ° C. at −60 to 150° C.; stacking a stress-relieving insulation layer, which has a thermal expansion coefficient of −20 to 6 ppm / ° C., on either side of the core substrate; and forming a metal layer on the insulation layer and forming at least one pad and electrically connecting the pad with the outer circuit. This method can provide high reliability, as the stress-relieving insulation layers can prevent bending and warpage, etc., in the board overall.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

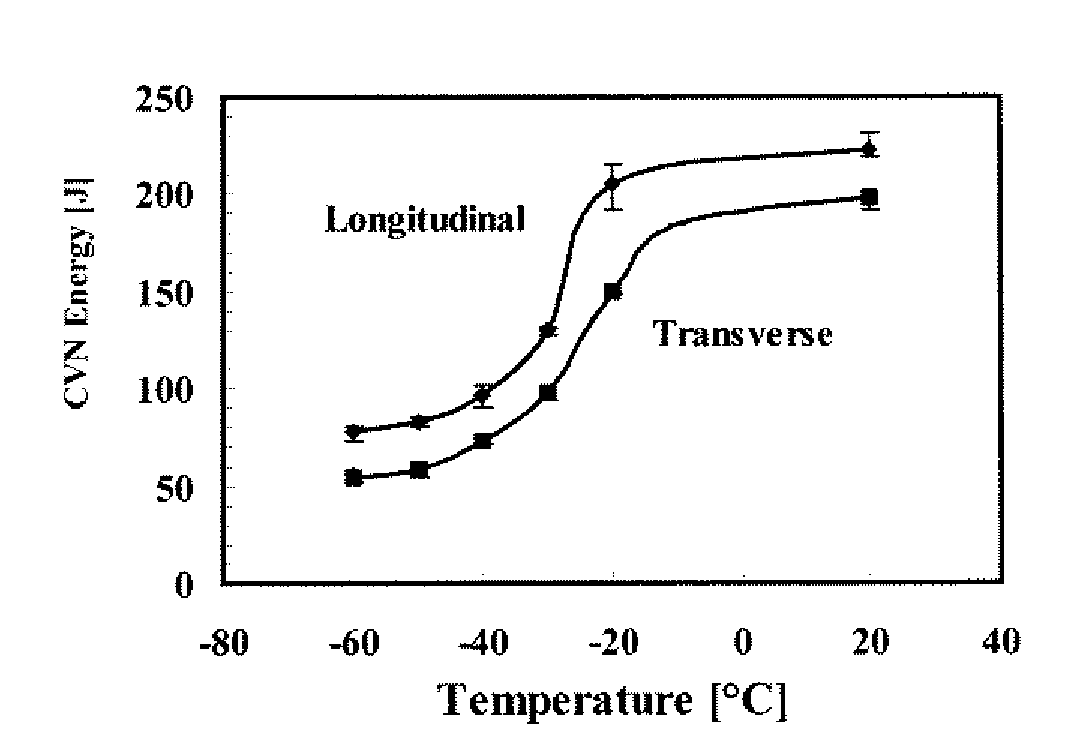

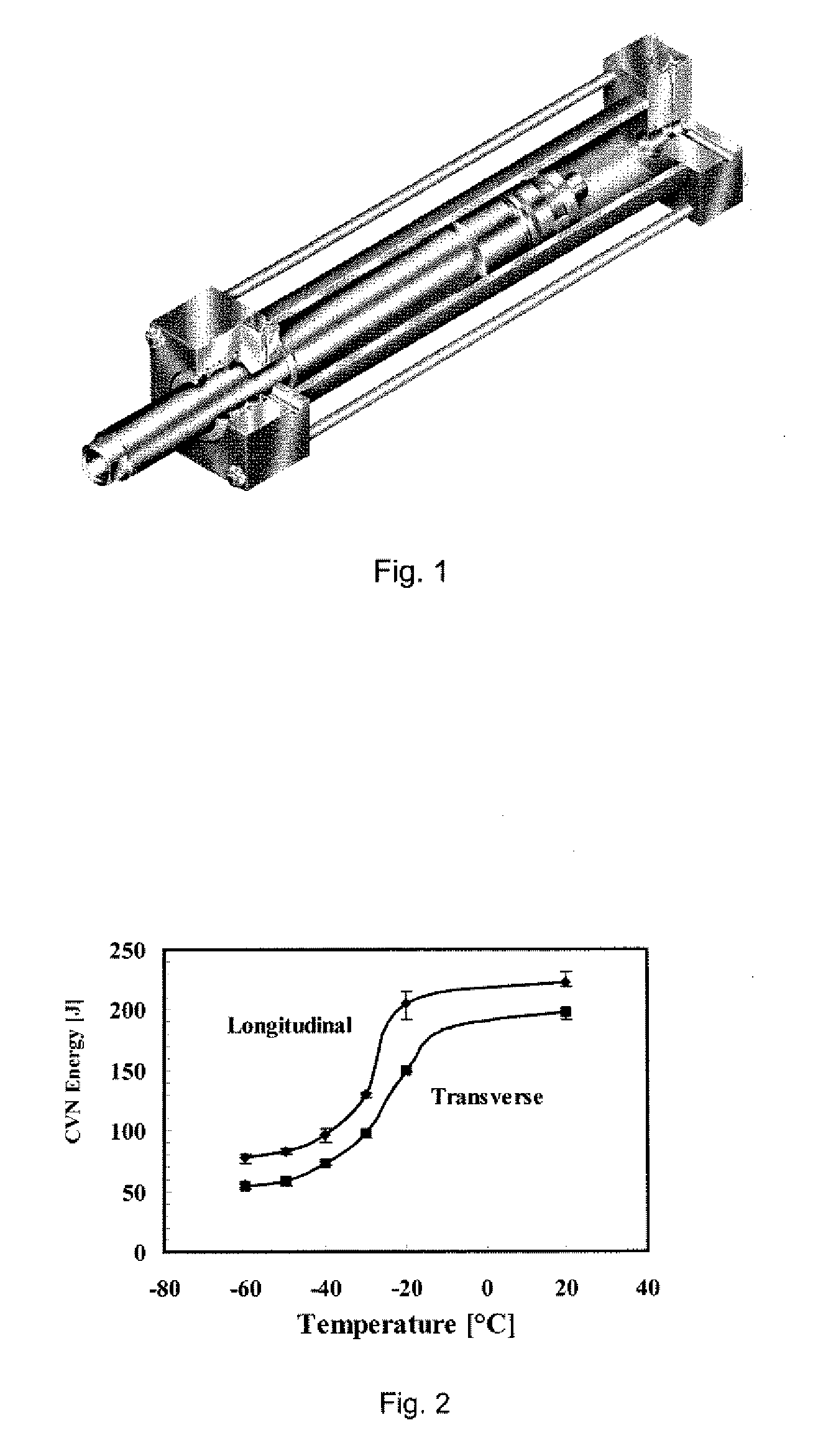

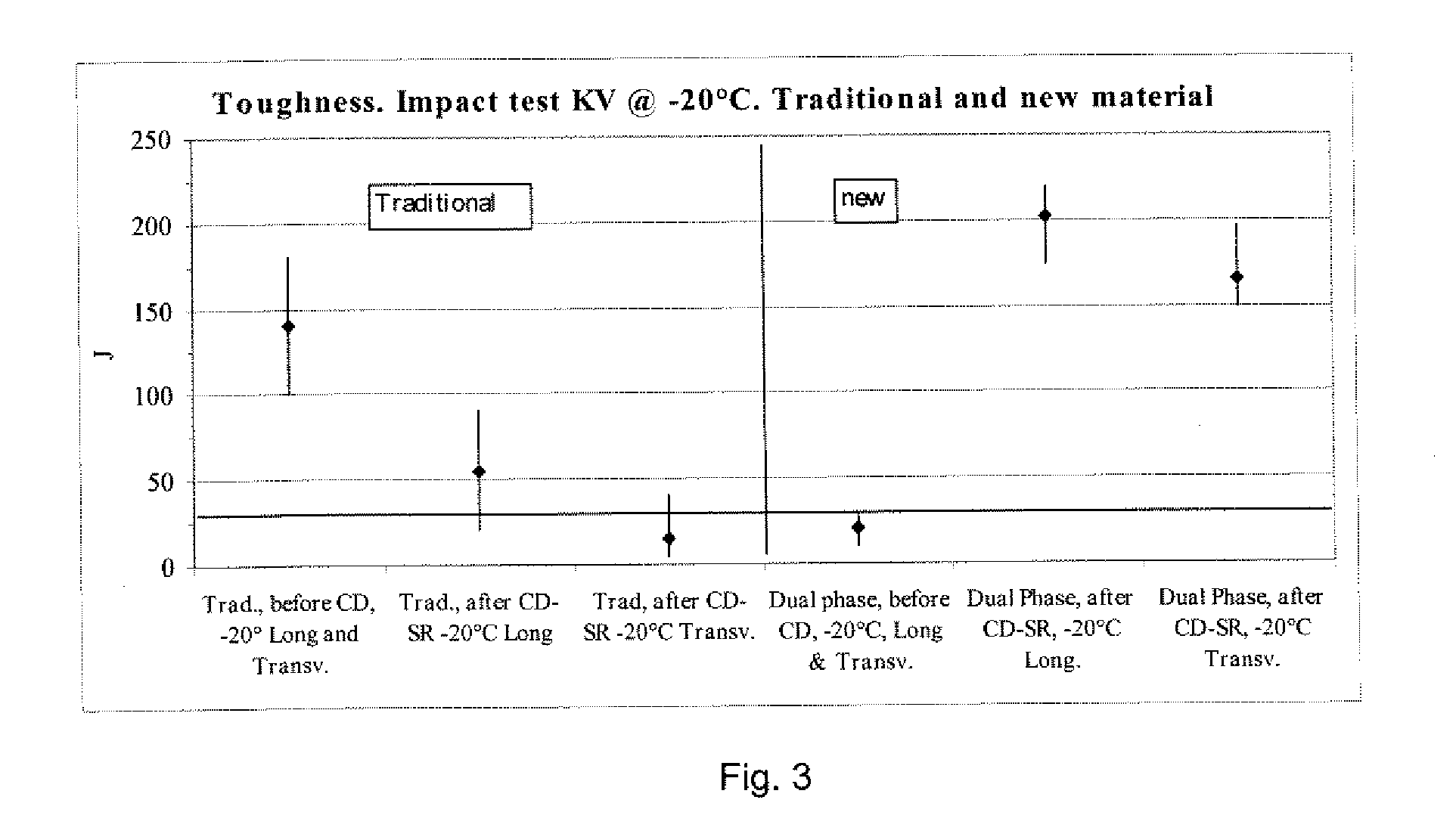

Seamless precision steel tubes with improved isotropic toughness at low temperature for hydraulic cylinders and process for obtaining the same

InactiveUS20100068549A1Improved isotropic toughnessLayered productsBlade accessoriesHydraulic cylinderStress relieving

Process for manufacturing seamless precision steel tubes with improved isotropic toughness at low temperature for hydraulic cylinders comprising the following steps; —(i) providing a steel having a composition comprising 0.06-0.15% by weight of carbon, 0.30-2.5% by weight of Mn, and 0.10-0.60% by weight of Si, —(ii) hot-rolling the said steel at a temperature higher than Ac3 such as to obtain a seamless steel tube, —(iii) heating the said seamless steel tube at a temperature in the range between Ac1 and Ac3, —(iv) quenching the said heated seamless steel tube, such as to establish a dual (or multi-) phase microstructure in the steel employed, composed of ferrite and martensite and optionally bainite and / or retained austenite, —(v) cold drawing the quenched seamless steel tube such as to provide a seamless precision steel tube of the desired dimensions, —(vi) subjecting the so-obtained seamless precision steel tube to stress relieving treatment to improve its isotropic toughness, and optionally —(vii) straightening the so-obtained seamless precision steel tube with improved toughness.

Owner:TENARIS CONNECTIONS

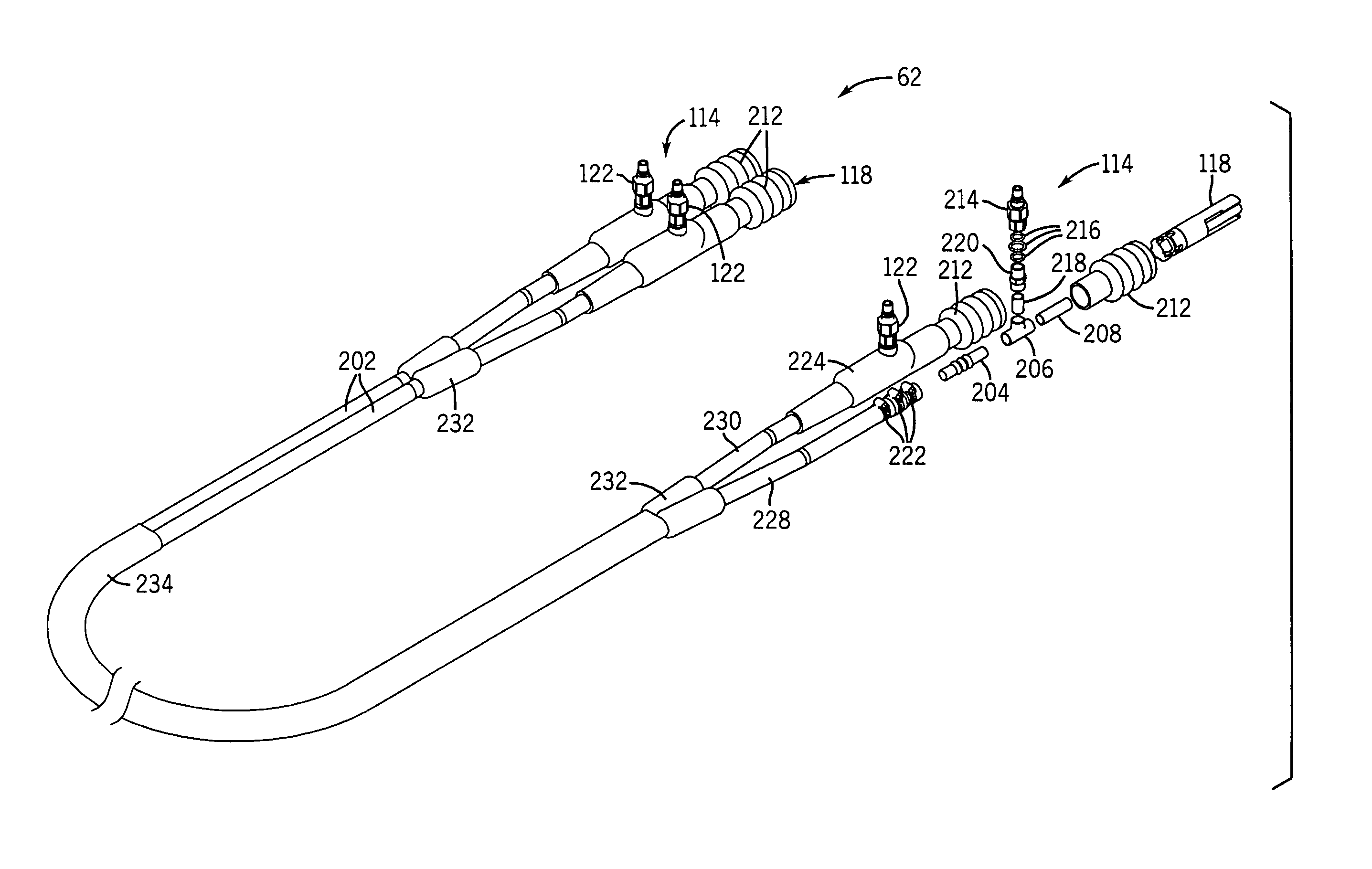

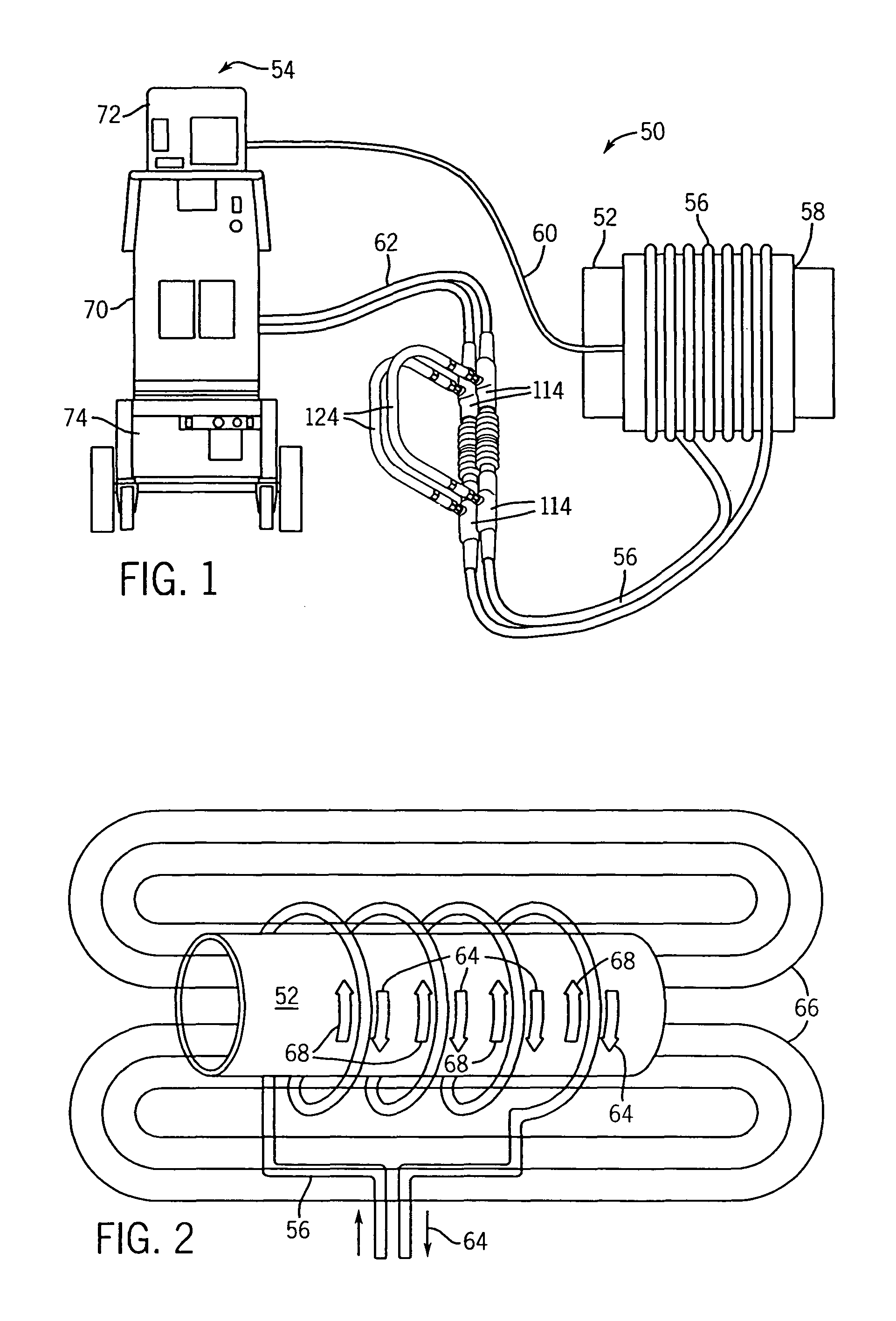

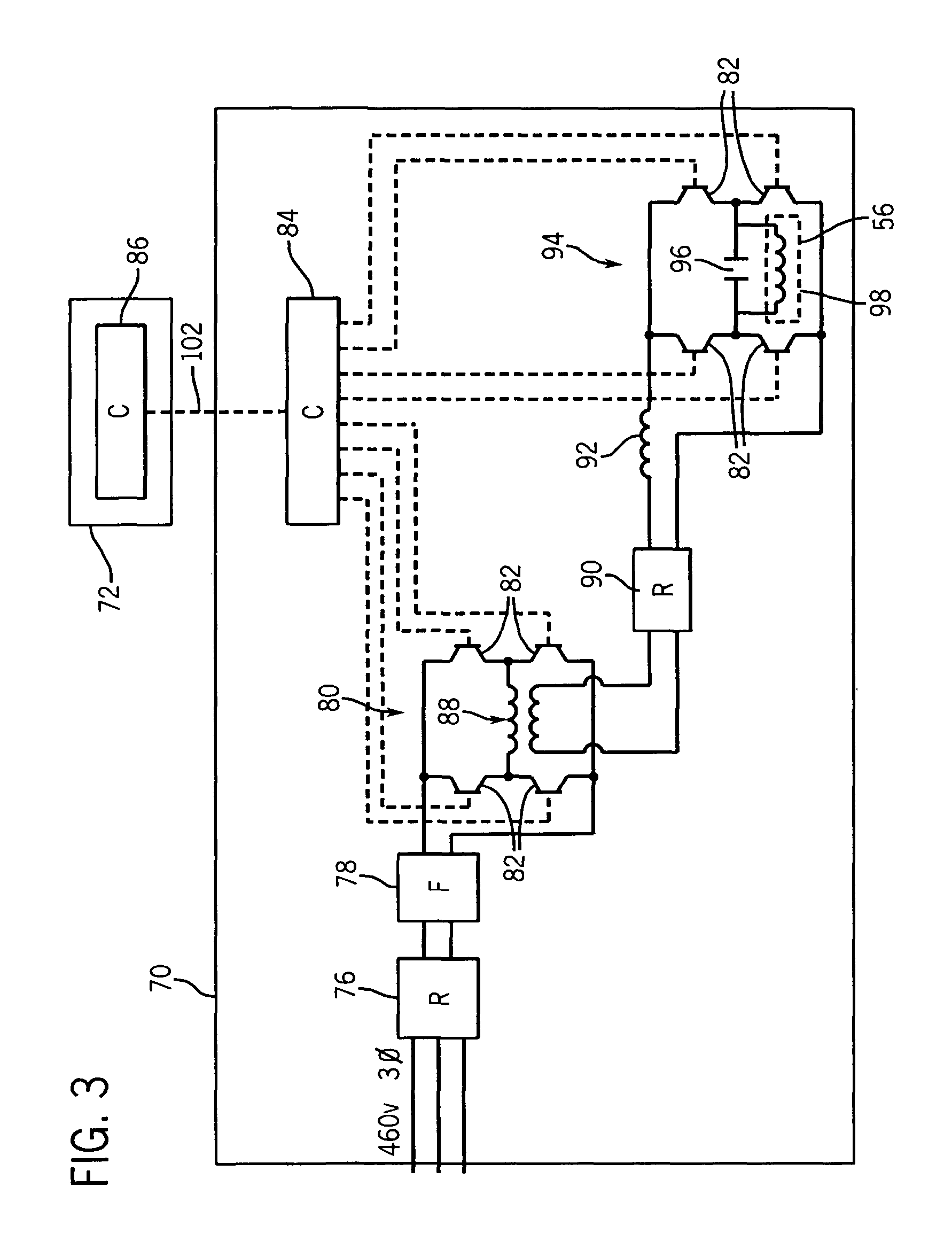

On-site induction heating apparatus

A method and apparatus for heating a workpiece. An induction heating system is used to induce magnetic fields in a workpiece to inductively heat the workpiece. The induction heating system may comprise a portable power source, a portable power source controller, a fluid-cooled induction heating cable, and a portable cooling unit. The induction heating system may be used to perform a variety of induction heating operations, including: annealing, surface hardening, heat treating, stress-relieving, curing, shrink-fitting, etc.

Owner:ILLINOIS TOOL WORKS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com