Patents

Literature

2122results about "Fluid pressure measurement using ohmic-resistance variation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

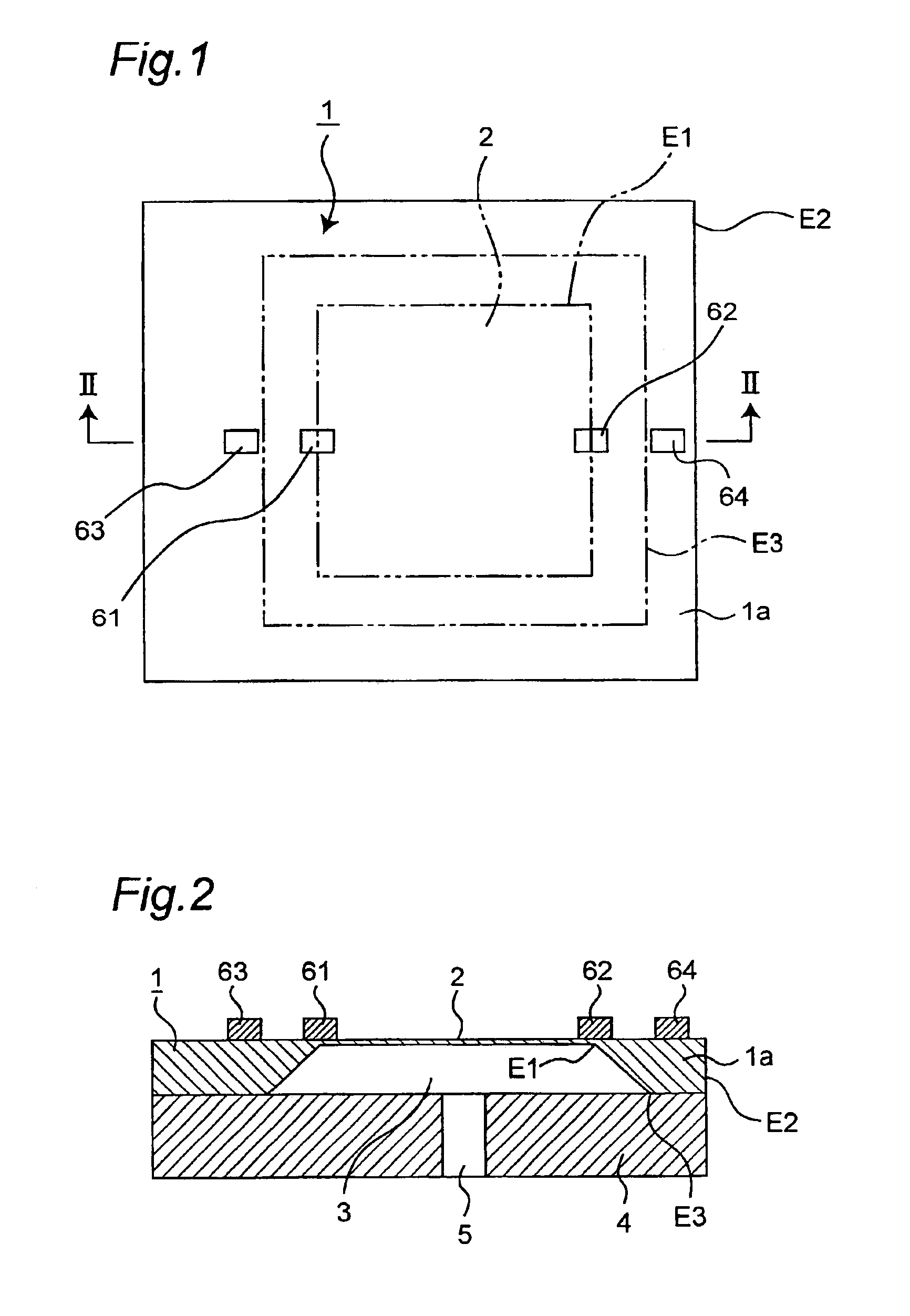

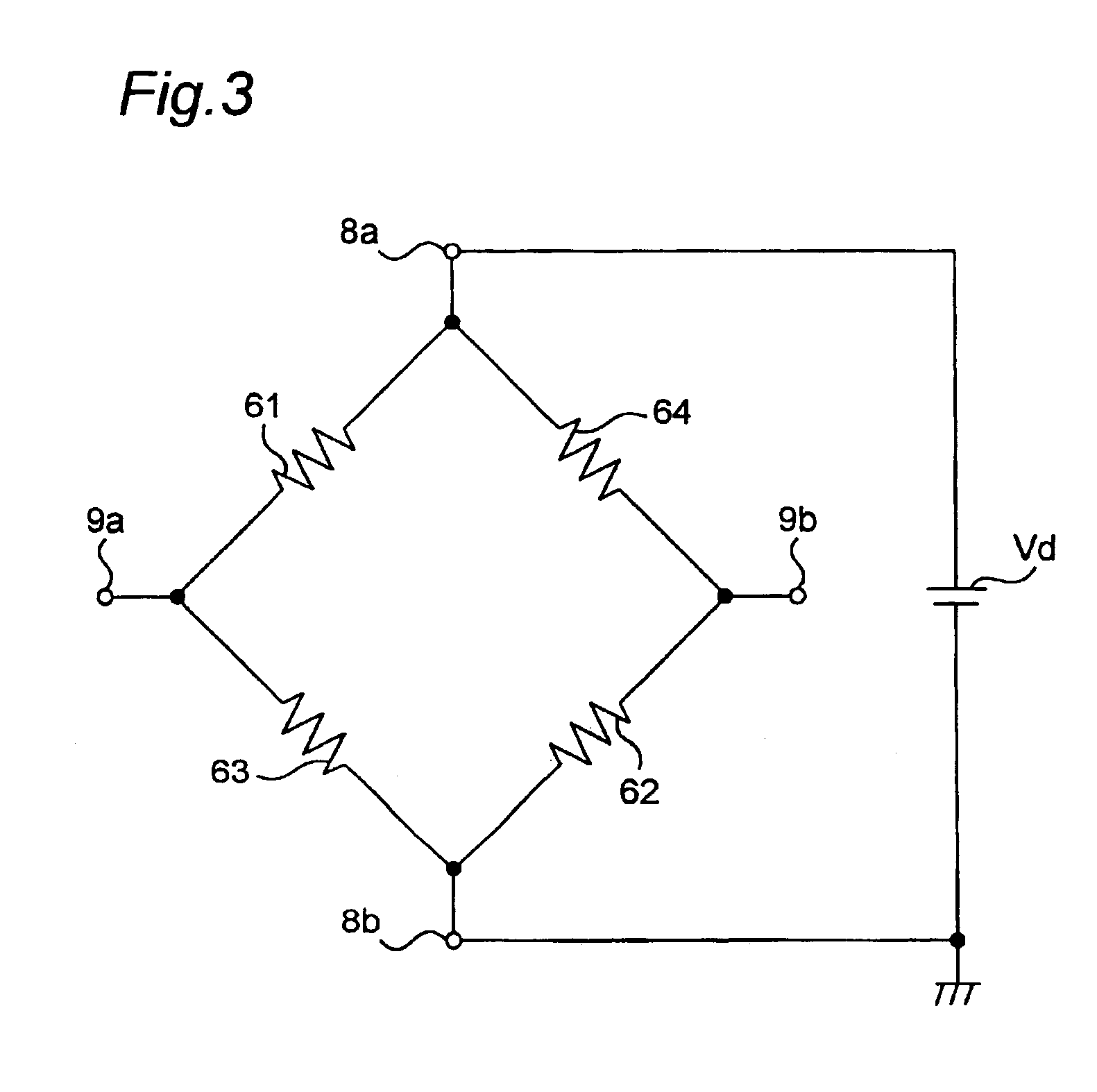

Sensor failure or abnormality detecting system incorporated in a physical or dynamic quantity detecting apparatus

InactiveUS6422088B1Detect failureFluid pressure measurement using ohmic-resistance variationForce measurementElectrical resistance and conductanceAnomaly detection

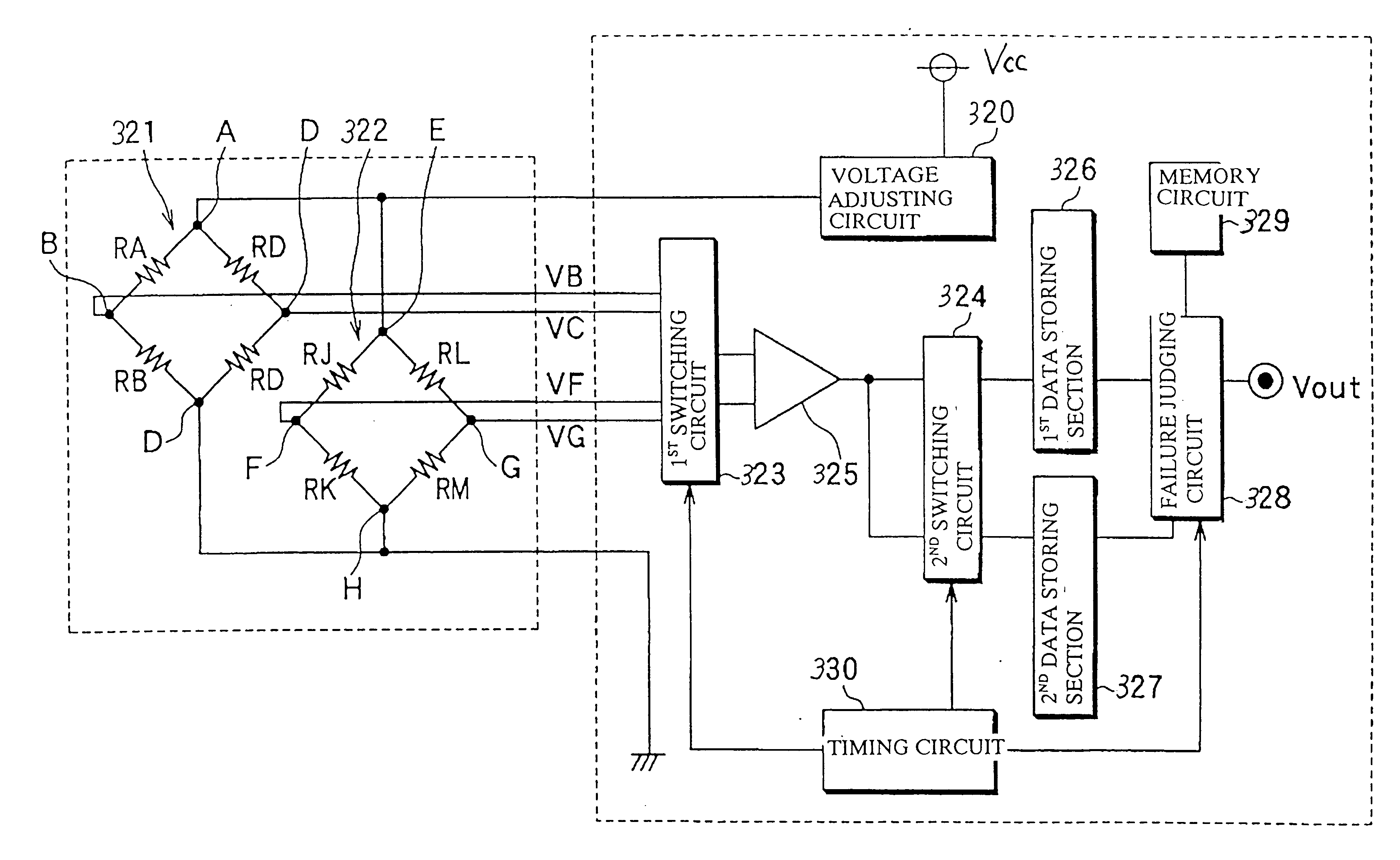

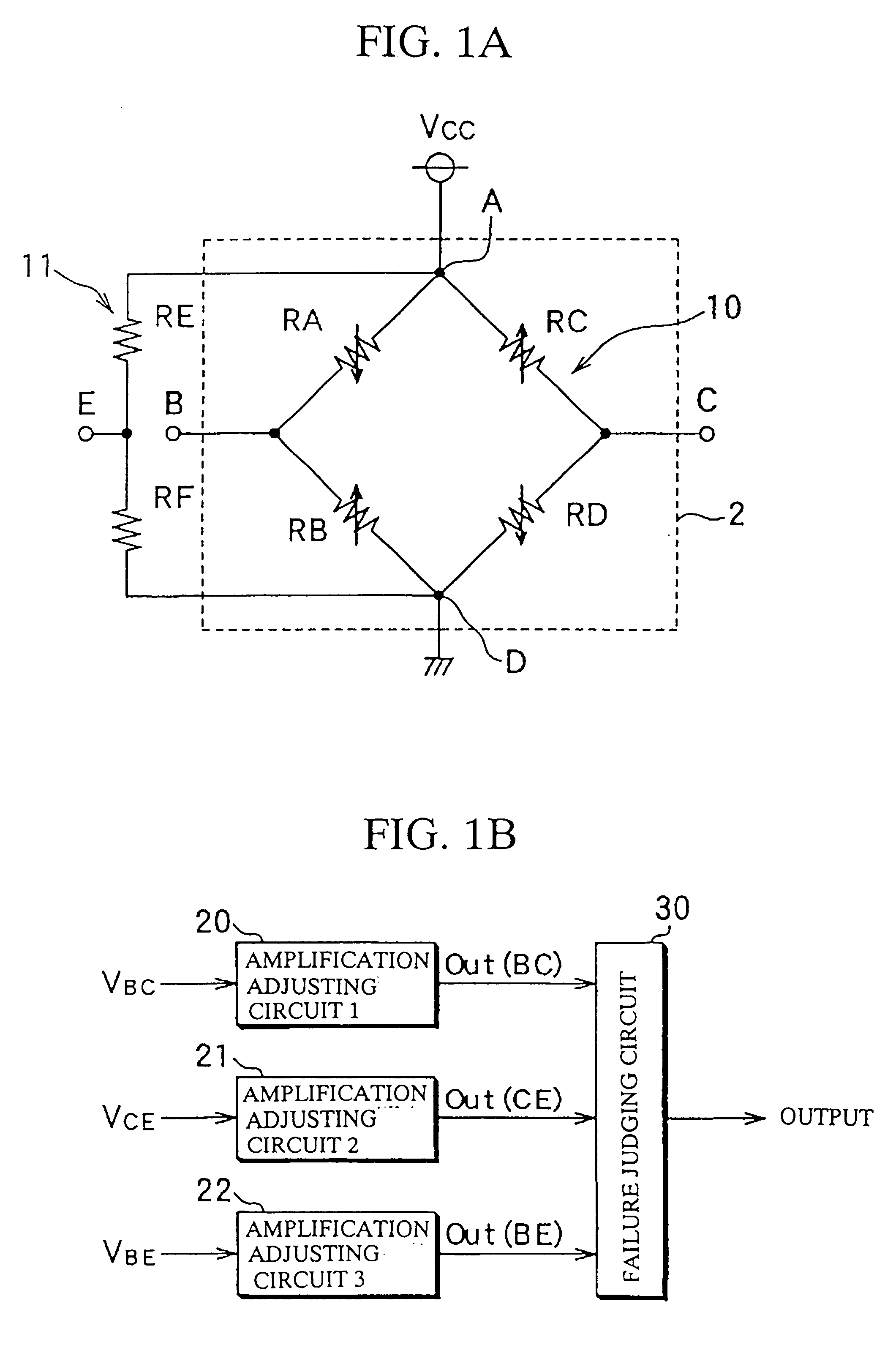

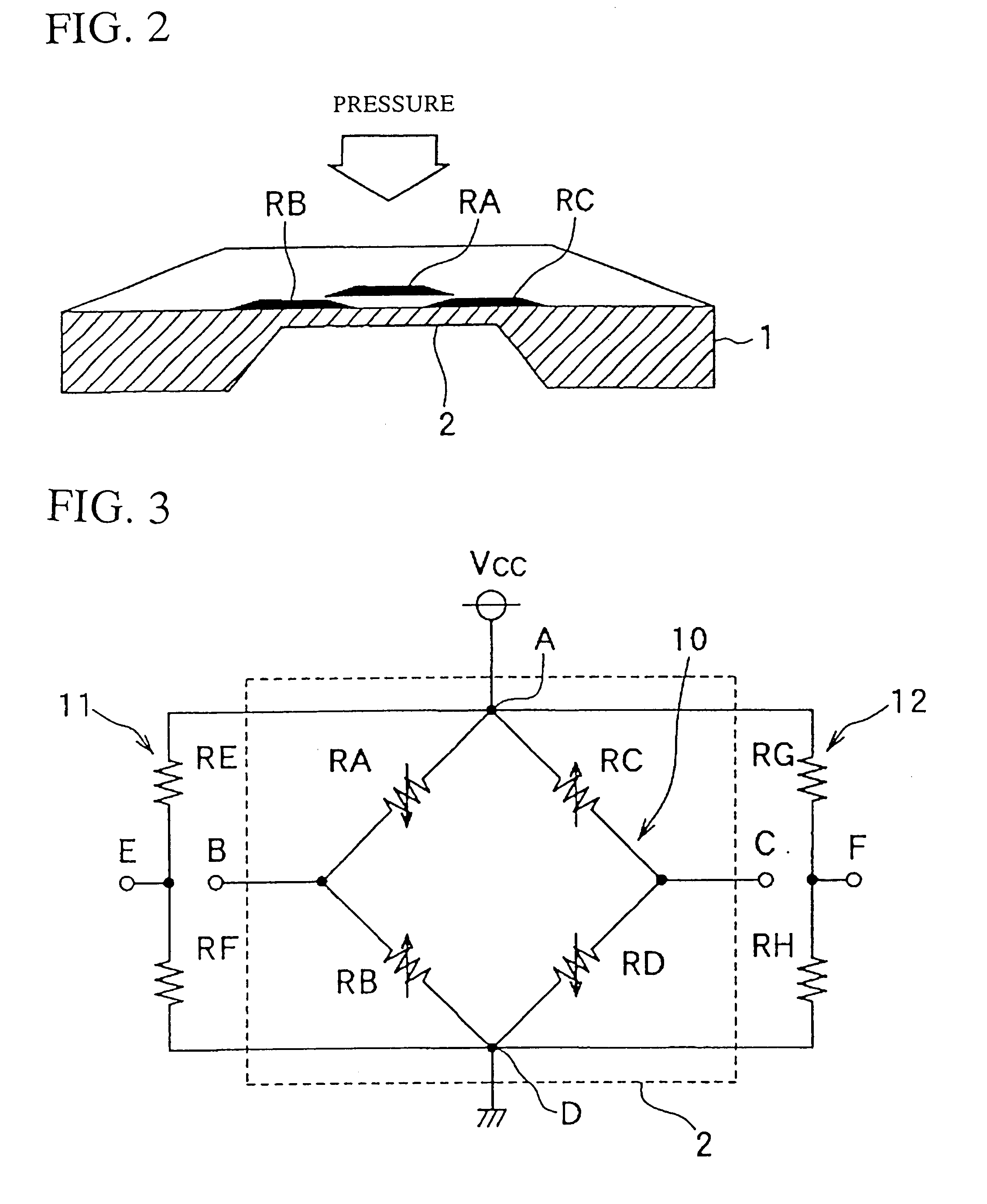

A reference voltage generating circuit is constituted by resistors RE and RF each having a resistance not influenced by an application of pressure. The reference voltage generating circuit is connected between one and the other ends of a bridge circuit. A failure judgement of the bridge circuit is performed based on a comparison of a voltage difference VBC between two midpoints B and C of the bridge circuit and voltage differences VCE and VBE between a reference voltage level of the reference voltage generating circuit and the voltage levels of two midpoints B and C.

Owner:DENSO CORP

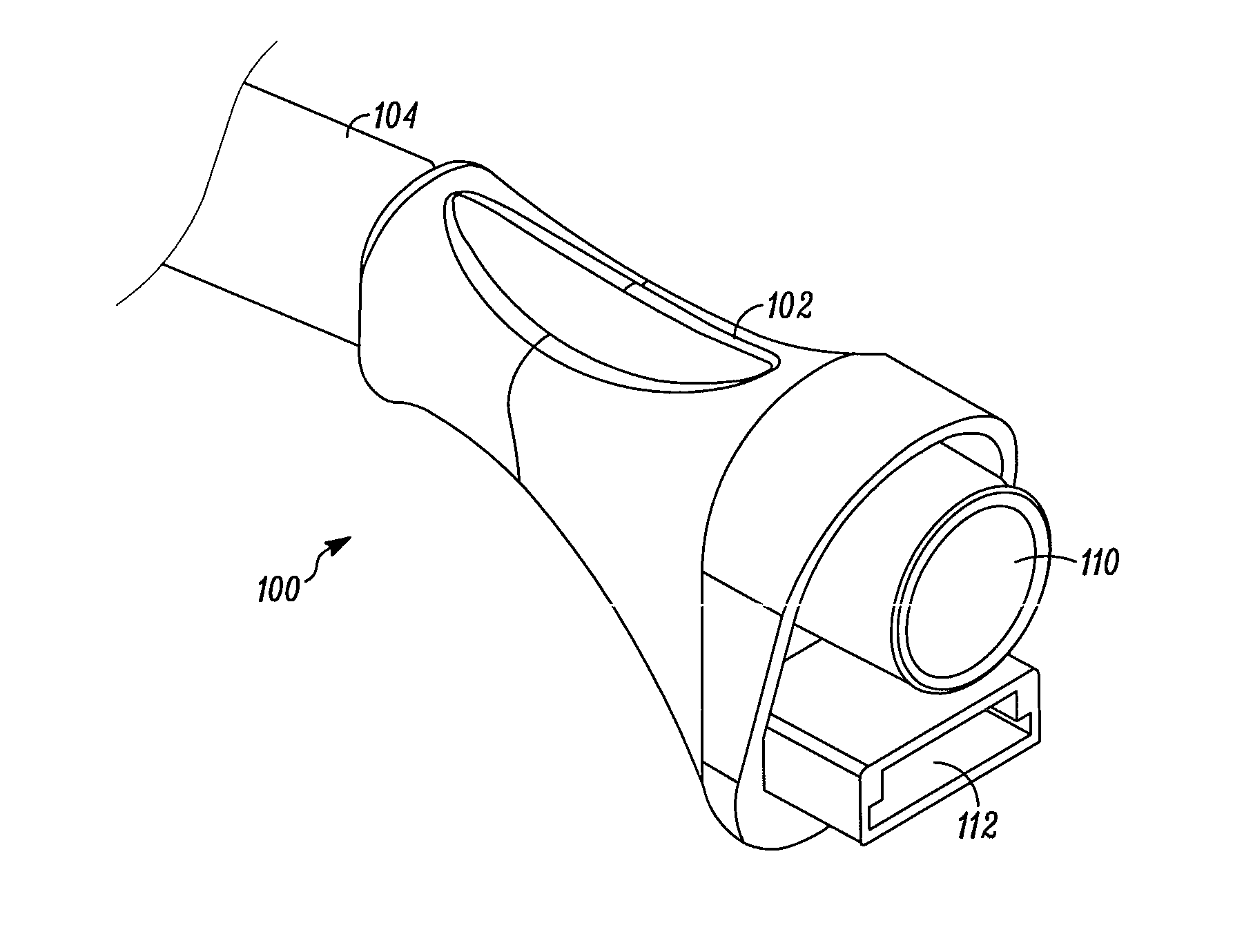

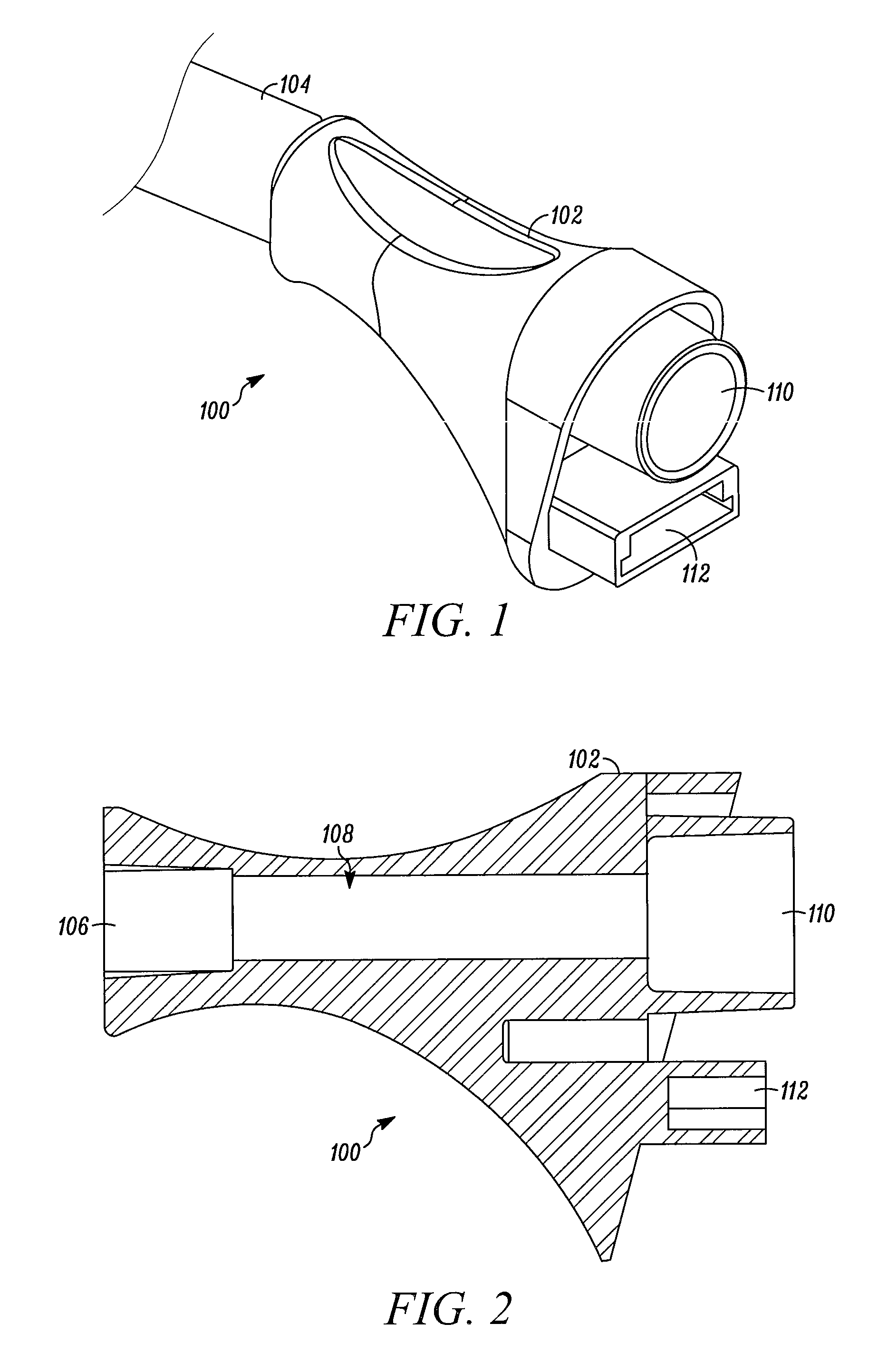

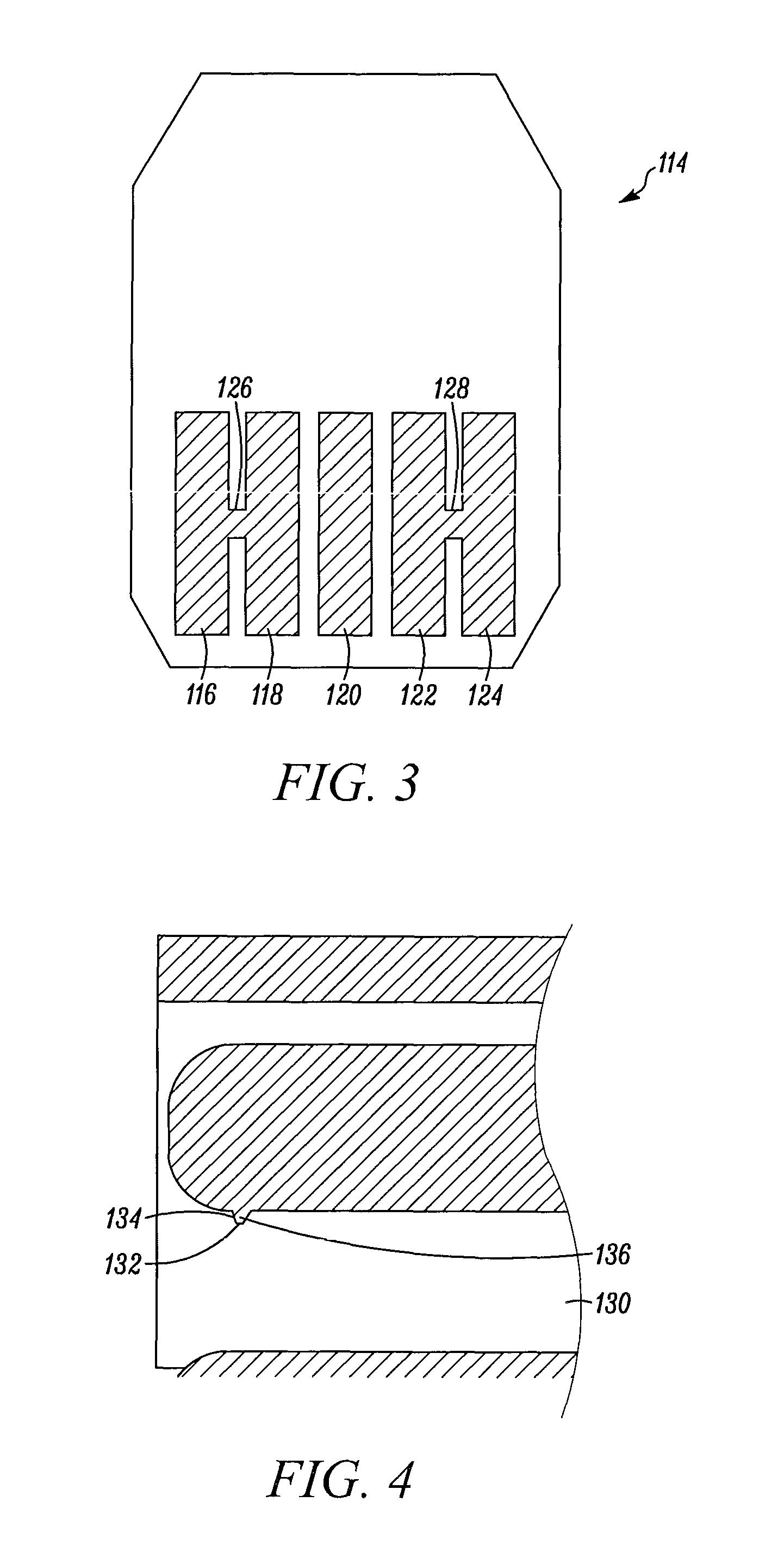

System for identifying the presence and correctness of a medical device accessory

ActiveUS9283334B2Fluid pressure measurement using ohmic-resistance variationDiagnosticsElectricityElectrical conductor

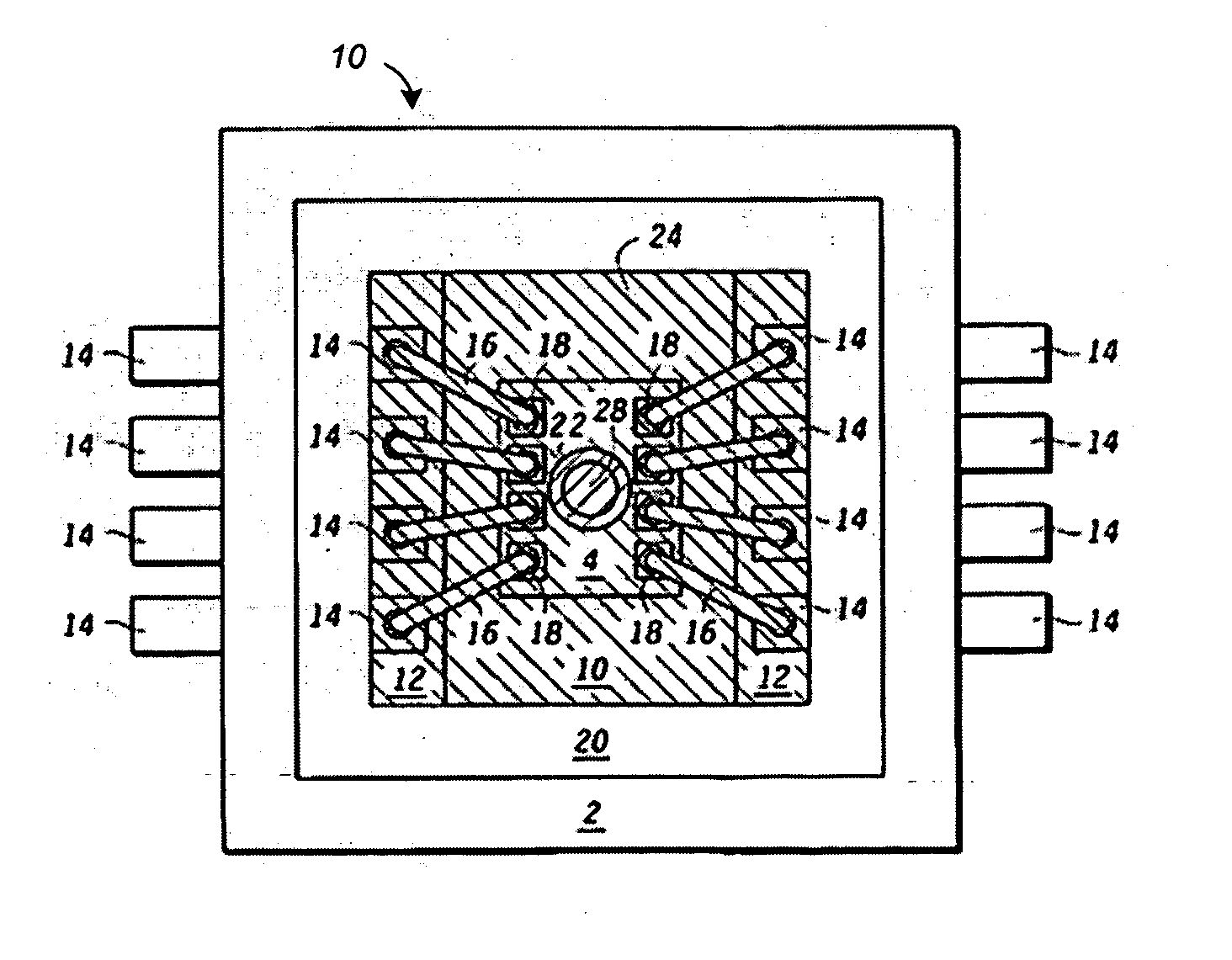

A medical device accessory comprising an interface configured to connect the medical device accessory with a medical device for administration of a medical treatment using the medical device and the medical device accessory, a plurality of electrical contacts proximate the interface, the electrical contacts comprising a lead electrical contact adapted to receive an voltage from a power source associated with the medical device and one or more identifying electrical contacts, and at least one conductor providing an electrical connection between the lead electrical contact and the one or more identifying electrical contacts. An arrangement of the one or more identifying electrical contacts connected to the lead electrical contact identifies a characteristic of the medical device accessory.

Owner:NORTHGATE TECH

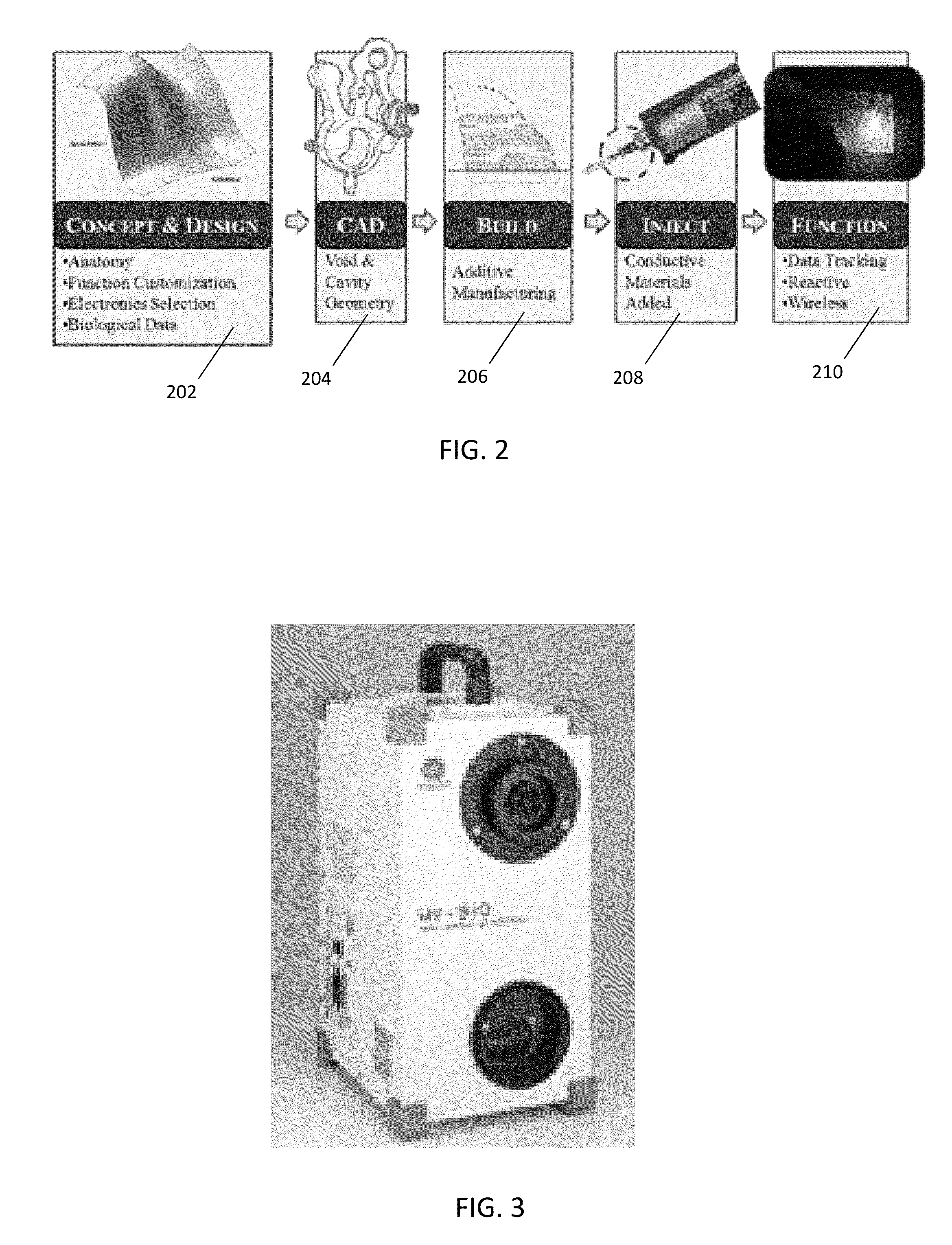

Customizable Embedded Sensors

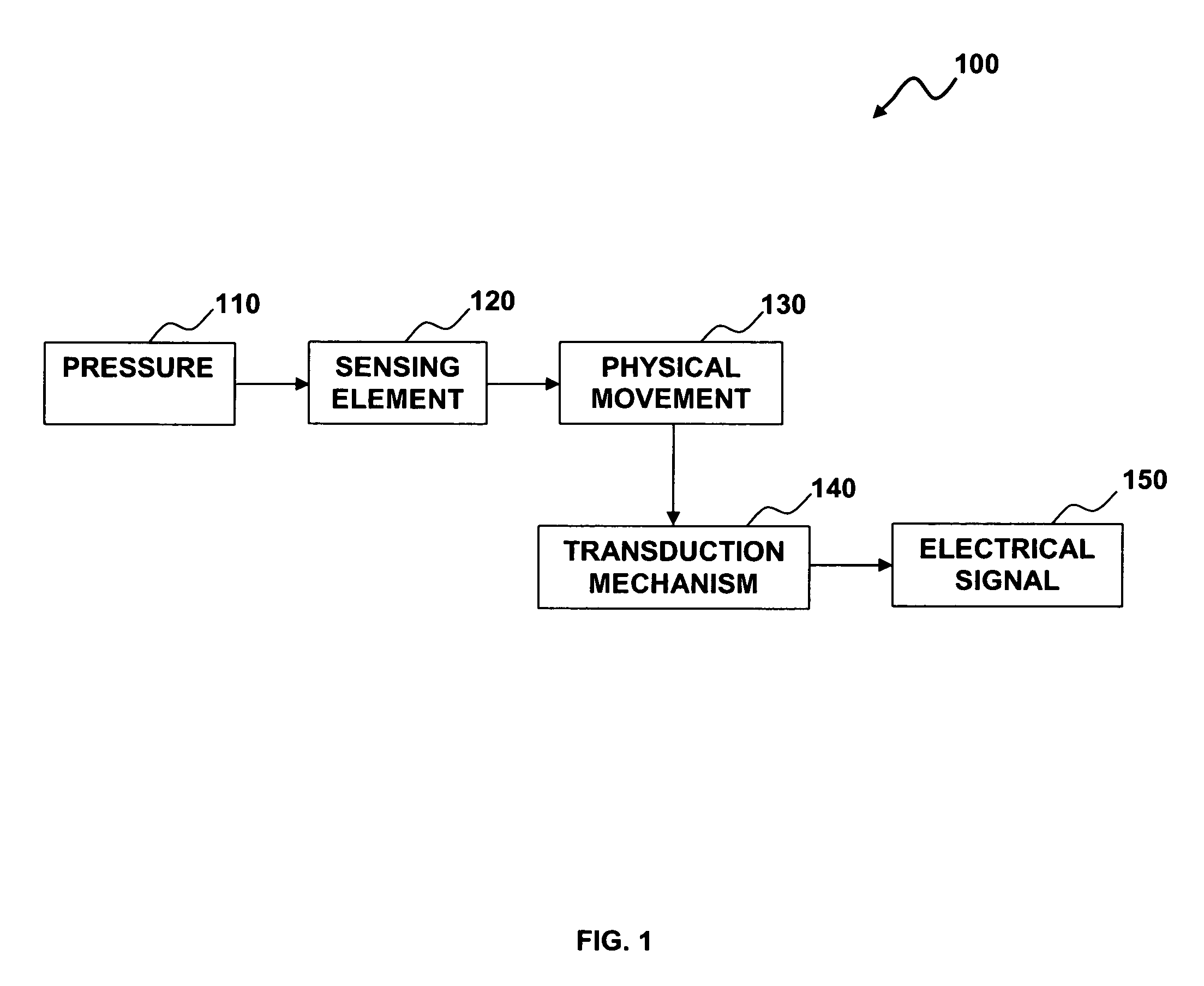

InactiveUS20130079693A1Force measurement by permanent gauge deformationMeasurement apparatus componentsEngineeringEngineering physics

Owner:NORTHEASTERN UNIV

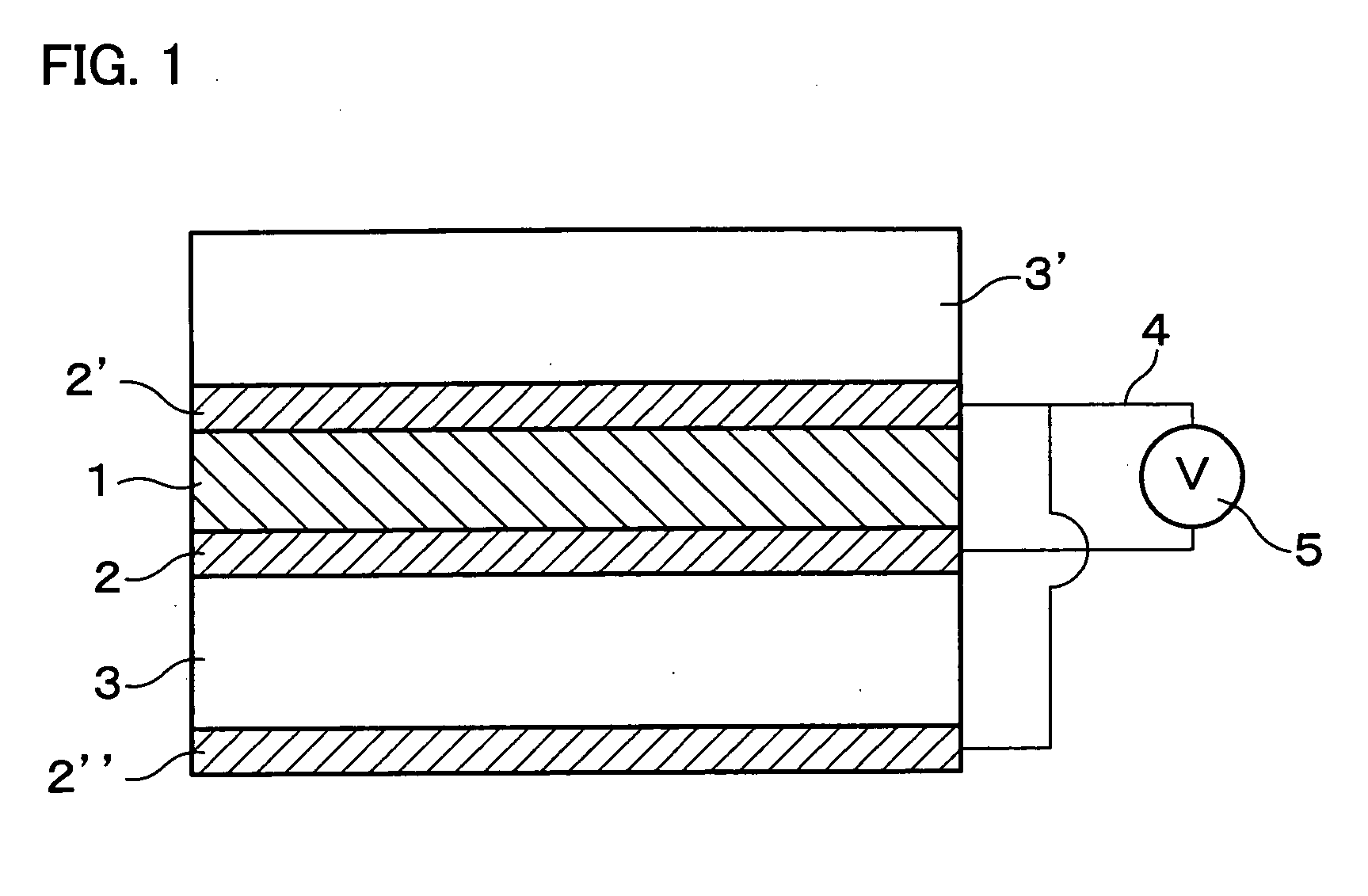

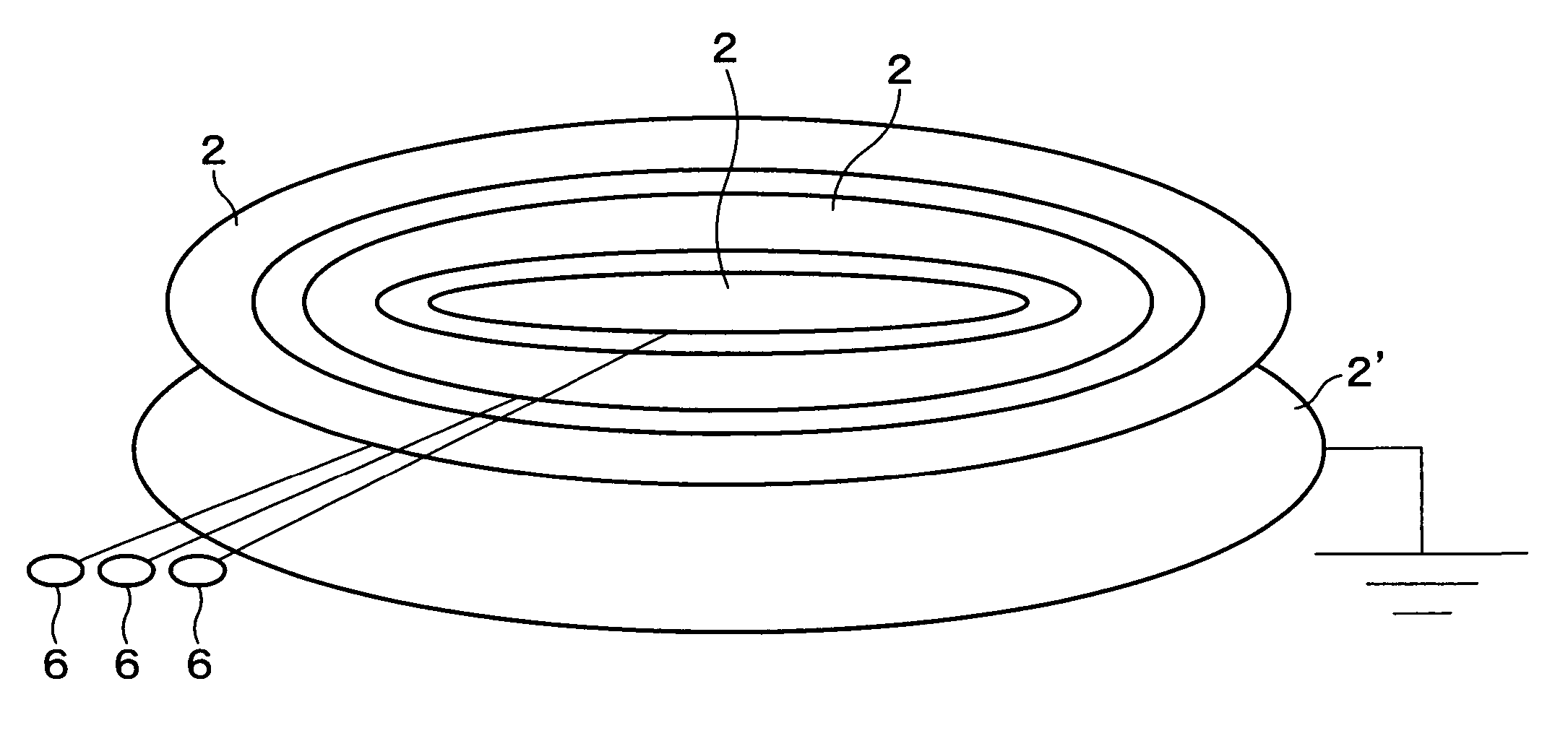

Piezoelectric sensor and input device comprising same

InactiveUS20060144154A1Increased durabilityFlaw can be preventedFluid pressure measurement using ohmic-resistance variationFluid pressure measurement using elastically-deformable gaugesElectrical conductorPressure transmission

A piezoelectric sensor arranged so as to includes: a transparent piezoelectric element having a piezoelectric property; and a pair of transparent conductor film layers opposed to each other with the piezoelectric element therebetween, the transparent piezoelectric element and the transparent conductor film layers are formed between a pair of transparent substrates, opposed to each other, which serve as pressure transmission means. Consequently, the transparent piezoelectric sensor has an excellent durability. A piezoelectric sensor comprises a piezoelectric element with a piezoelectric property which is made of a piezoelectric material having no Curie point and has a dipole orientation degree of not less than 75%. Consequently, the piezoelectric sensor having an excellent durability and a simple structure is provided at low cost.

Owner:NAT INST OF ADVANCED IND SCI & TECH

Combined flow, pressure and temperature sensor

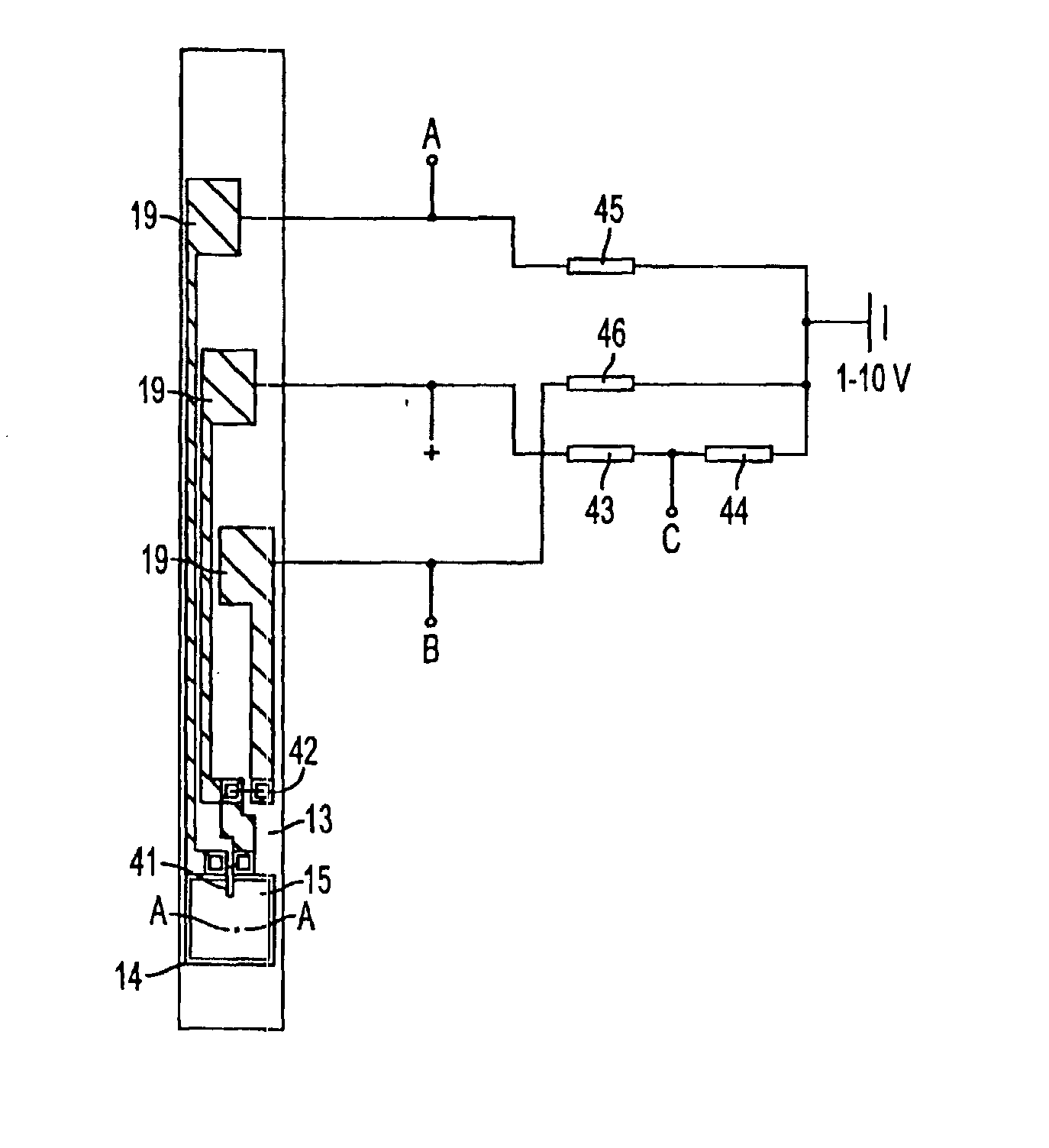

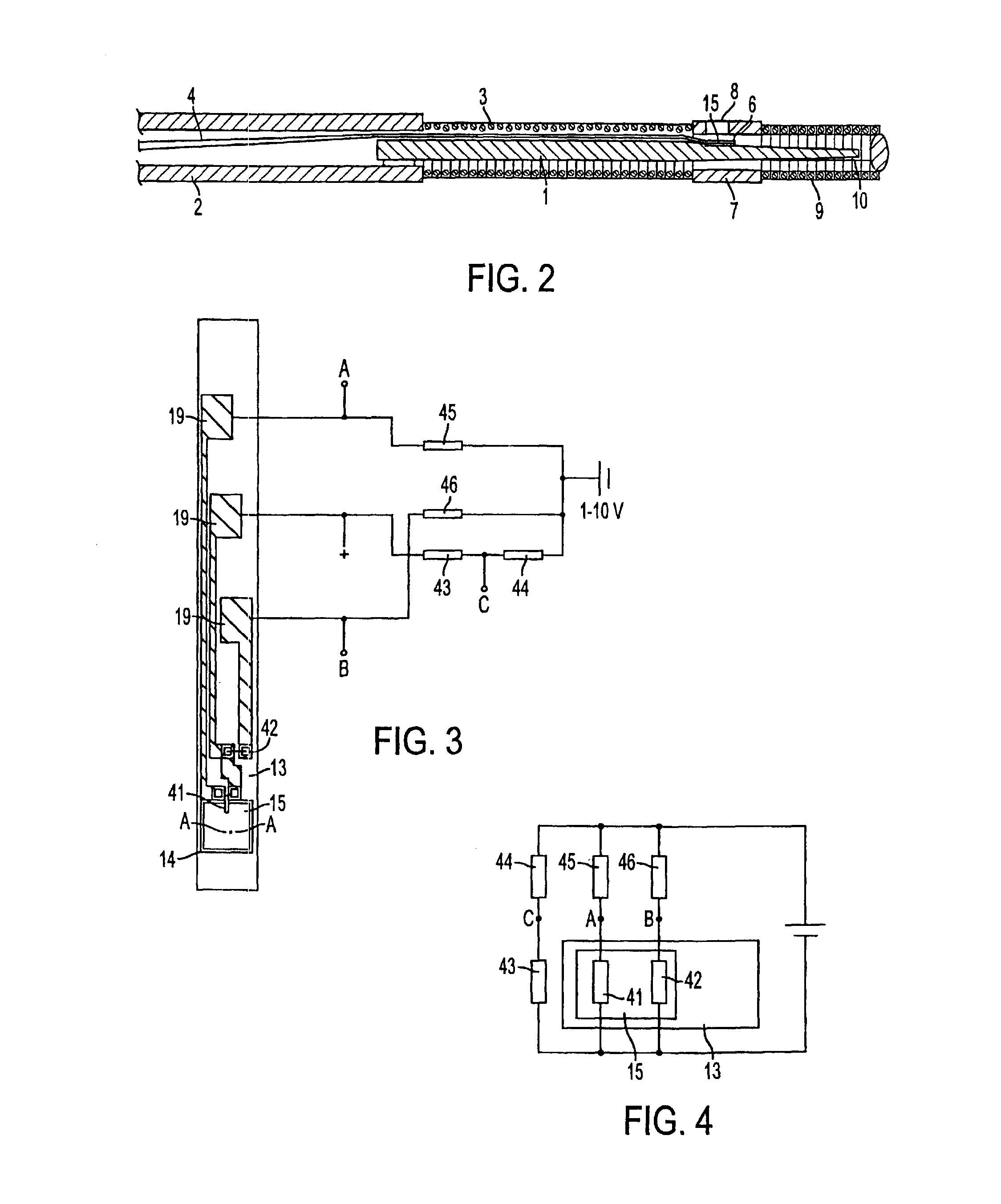

InactiveUSRE39863E1Reliable diagnosisConvenient investigationThermometer detailsFluid pressure measurement using ohmic-resistance variationTemperature sensitiveResistor

The invention relates to a device for measuring pressure, temperature and / or flow velocity. It includes a sensor (6) with a sensor support body (13) provided with a diaphragm (15) covering a cavity (14) formed in the support body (13). A pressure sensitive element (41) is mounted on the diaphragm, for recording pressure. Furthermore, a temperature sensitive resistor (42) is mounted in the vicinity of the pressure sensitive resistor and has a known temperature dependence, for recording temperature. It also includes an electrical circuit (43, 44, 45, 46) selectively outputting signals from either of the pressure sensitive element and the temperature sensitive resistor.

Owner:ST JUDE MEDICAL COORDINATION CENT

Dual span absolute pressure sense die

InactiveUS7503221B2Accurate measurementSmall voltageFluid pressure measurement using ohmic-resistance variationMultiple fluid pressure valves simultaneous measurementPressure senseHigh pressure

An absolute pressure sensor includes a sense die with a reference chamber on a top side thereof. The reference chamber comprises a precisely fabricated beam that limits the travel of a diaphragm. The beam can be positioned in a cap or cover member of the sense die, thereby allowing the sense die diaphragm to move freely for a particular distance. Over this distance, the sense die will have one sensitivity. When the sense die is pressurized to a certain point, the diaphragm moves until it contacts the beam member in the cap or cover. When the diaphragm hits the beam, the sensitivity of the sense die changes, thereby allowing a smaller voltage out for the greater pressure in. Such an arrangement permits the sensor to provide a function that accurately measures low pressure and measures a higher pressure without utilizing a linear scale.

Owner:HONEYWELL INT INC

Media isolated pressure transducer having boss comprising single metal diaphragm

ActiveUS20100180688A1Fluid pressure measurement using ohmic-resistance variationFluid pressure measurement using elastically-deformable gaugesElectrical conductorTransducer

A pressure sensor for sensing a pressure of a fluid includes a monolithic metal including substrate having a substantially planar top side, wherein the metallic comprising substrate includes s a relatively thick boss near a center of the substrate and a thinned sensing portion that is elastically deformable and pressure-sensitive positioned radially outward from the boss. At least one dielectric layer is on the top side of the substrate. A plurality of piezoresistors are on the dielectric layer, wherein the piezoresistors are positioned over the thinned diaphragm portion. At least one overglaze layer is over the conductor layer that provides apertures for electrically contacting the plurality of piezoresistors. A sensing system includes a housing including at least a first port for coupling to a fluid for measurement of a pressure of the fluid and at least one sensor in the housing including a pressure sensor according to an embodiment of the invention.

Owner:HONEYWELL INT INC

Mechanical deformation amount sensor

InactiveUS6848320B2High sensitivityIncrease changeMaterial nanotechnologyAcceleration measurement using interia forcesElectrical resistance and conductanceCarbon nanotube

A mechanical deformation amount sensor includes a sensor structure which is formed by a semiconductor substrate or an insulating substrate and integrally includes a deformation portion deformable, when a physical quantity to be detected is applied to the sensor structure, due to the physical quantity and a support portion for supporting the deformation portion, a carbon nanotube resistance element which is provided on the deformation portion so as to be mechanically deformed in response to deformation of the deformation portion and a wiring pattern which is formed in a pattern on the sensor structure so as to be connected to the carbon nanotube resistance element. By applying a voltage to the carbon nanotube resistance element via the wiring pattern, a change of electrical conductivity of the carbon nanotube resistance element upon mechanical deformation of the carbon nanotube resistance element is fetched as an electrical signal.

Owner:MATSUSHITA ELECTRIC WORKS LTD

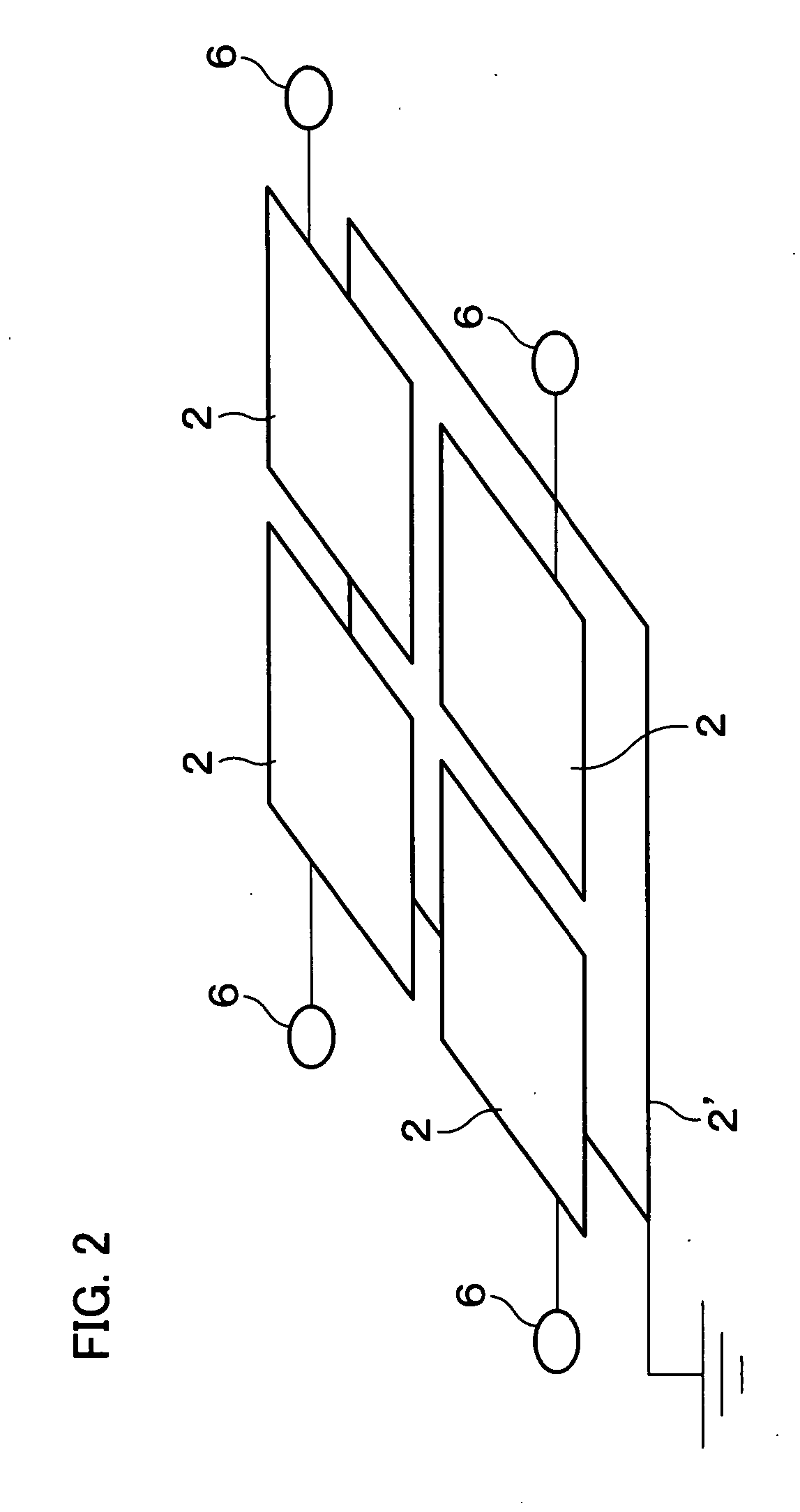

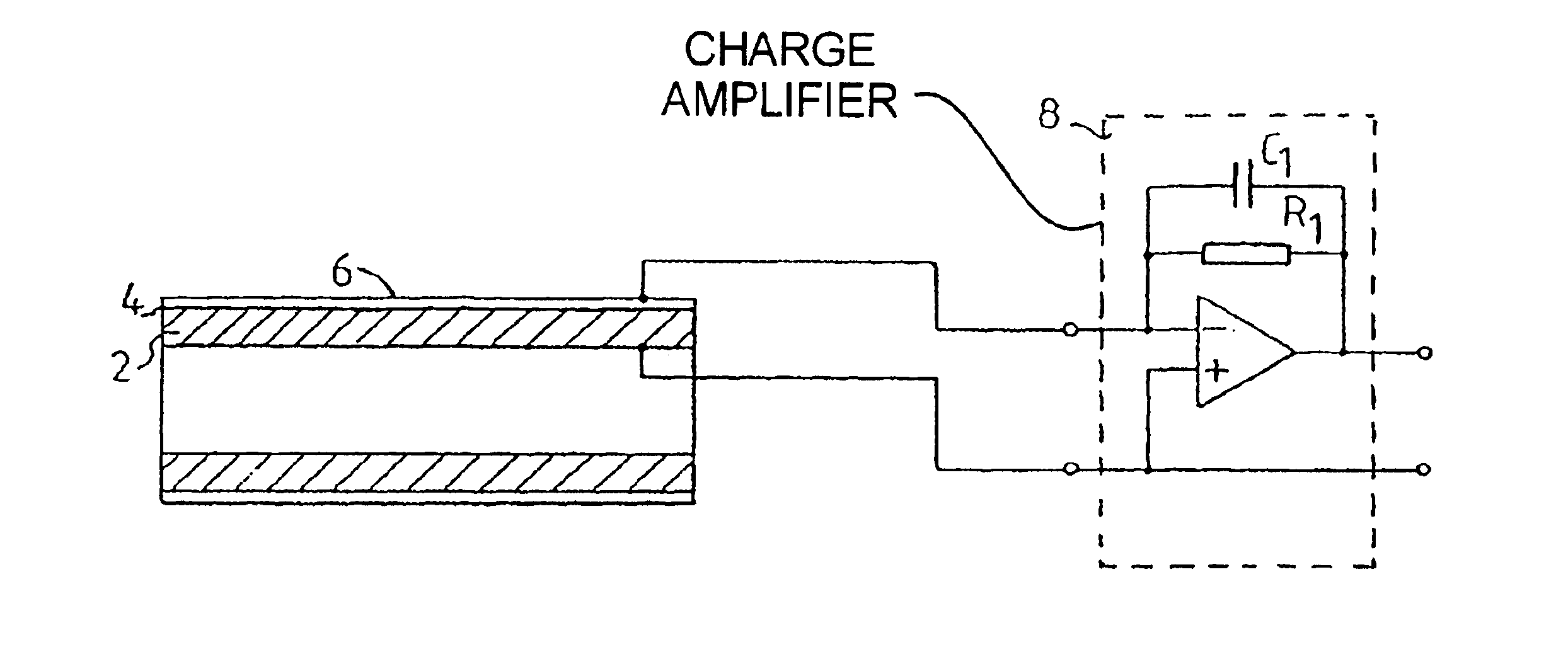

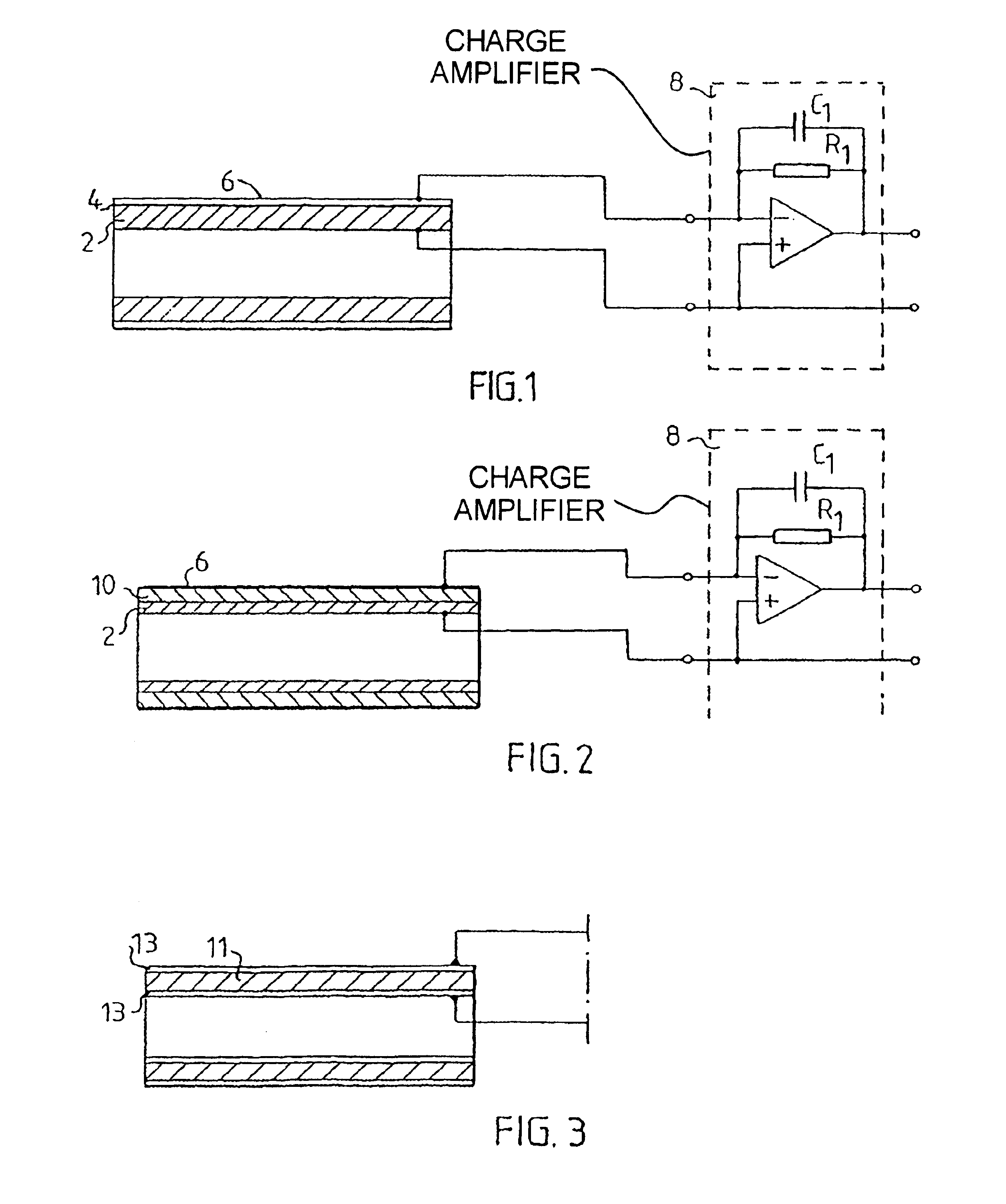

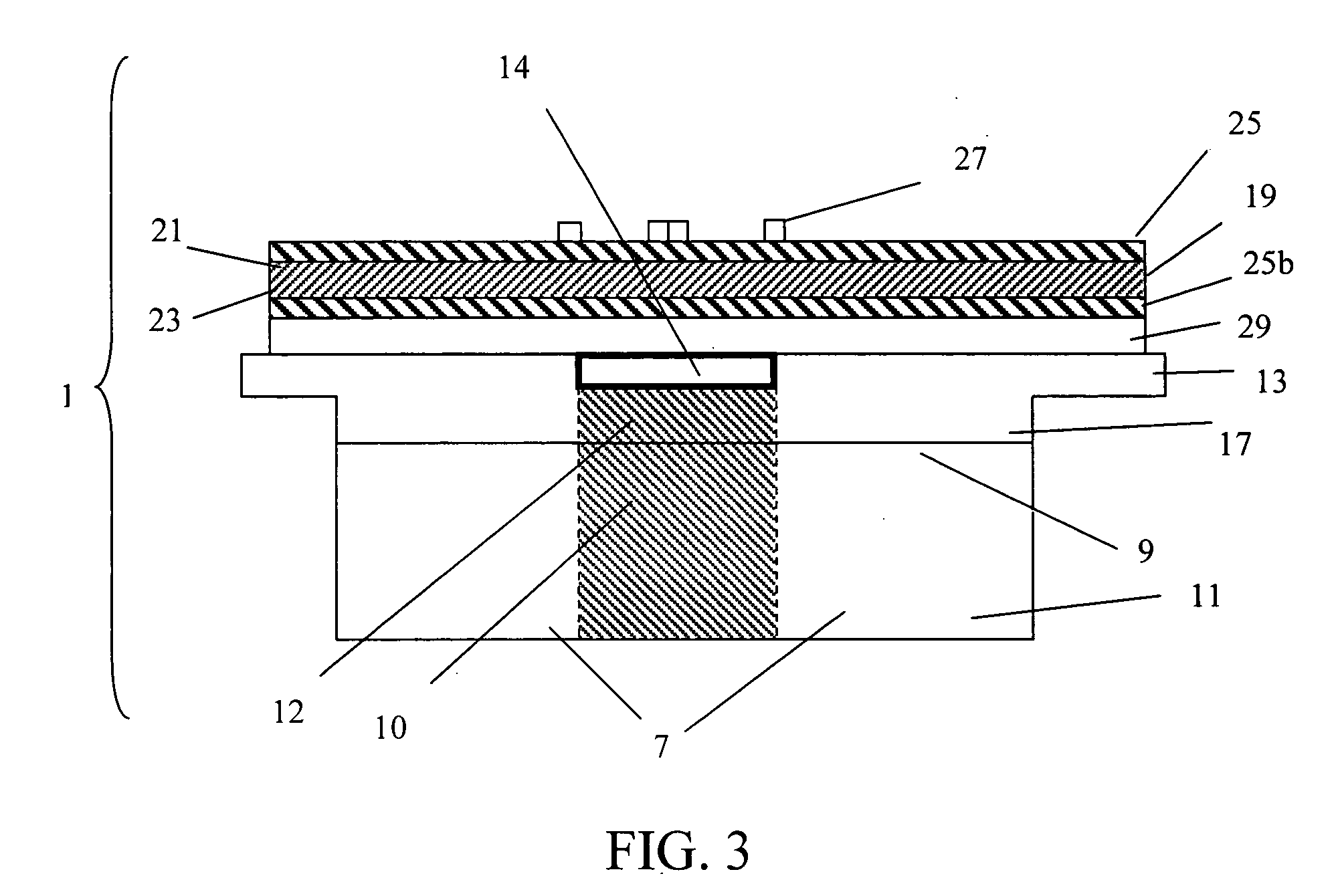

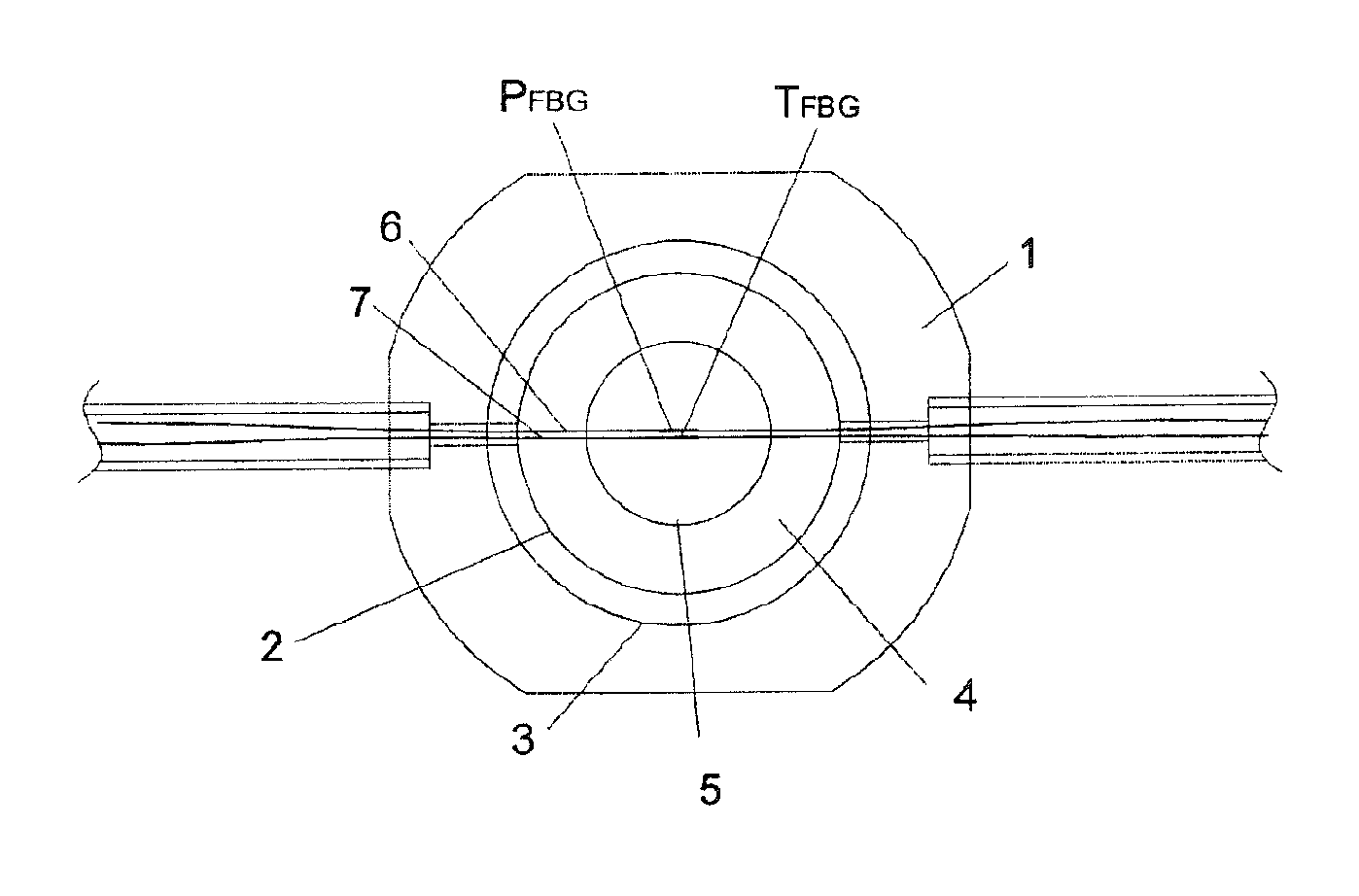

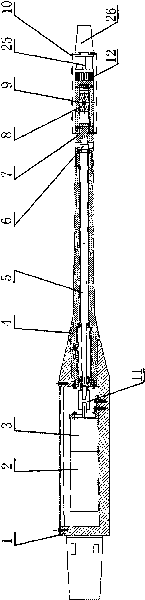

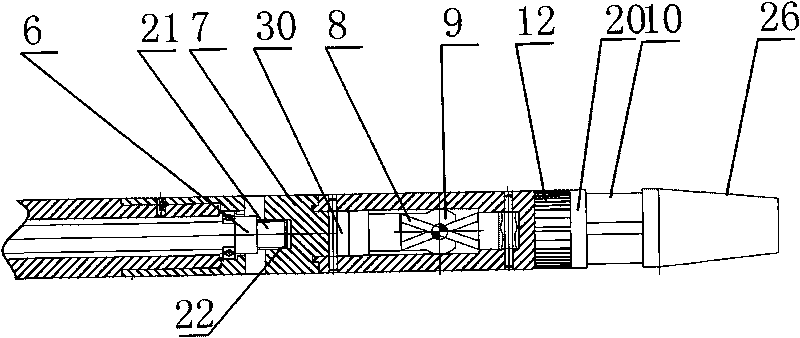

Piezoelectric sensor in a living organism for fluid pressure measurement

InactiveUS6886411B2Sensitive to pressure variationReliable measurement signalFluid pressure measurement using piezo-electric devicesFluid pressure measurement using ohmic-resistance variationBiological bodyElectricity

A fluid pressure sensor for a lead or catheter intended for placement in a living organism, such as a human heart, includes a rigid annular or tubular supporting structure and a piezoelectric element disposed on at least a portion of the outer surface thereof. The piezoelectric element delivers an electrical signal when subjected to a pressure variation, and exhibits circumferential sensitivity. The rigidity of the sensor is defined to satisfy predetermined criteria to ensure that the sensor, when sensing pressure transferred to the sensor through an on-growth of tissue on the sensor, which is at least 90% of the signal which the sensor would emit without the on-growth.

Owner:ST JUDE MEDICAL

Low cost high-pressure sensor

InactiveUS20070095144A1Low costLess materialFluid pressure measurement using ohmic-resistance variationFluid pressure measurement using elastically-deformable gaugesPressure senseHigh pressure

A pressure sensing apparatus including a thin disc of a metal having a ceramic material layer and piezoresistive elements formed thereon. A surface of the disc is bonded to a diaphragm assembly on a pressure port base constructed of a low cost metal. The bonding process is performed at low temperatures, (<700° C.), so that the diaphragm assembly and pressure port do not require high temperature corrosion resistance, and can thus be formed of less expensive materials. The inventive apparatus provides a lower cost alternative to conventional high pressure sensors since less material is used, less expensive materials are used, and fabrication is less complex. The inventive apparatus is also more reliable and exhibits greater thermal stability than conventional high pressure sensors.

Owner:HONEYWELL INT INC

Piezoelectric sensor and input device including same

InactiveUS7152482B2Increased durabilityFlaw can be preventedFluid pressure measurement using ohmic-resistance variationFluid pressure measurement using elastically-deformable gaugesElectrical conductorPressure transmission

A piezoelectric sensor arranged so as to includes: a transparent piezoelectric element having a piezoelectric property; and a pair of transparent conductor film layers opposed to each other with the piezoelectric element therebetween, the transparent piezoelectric element and the transparent conductor film layers are formed between a pair of transparent substrates, opposed to each other, which serve as pressure transmission means. Consequently, the transparent piezoelectric sensor has an excellent durability. A piezoelectric sensor comprises a piezoelectric element with a piezoelectric property which is made of a piezoelectric material having no Curie point and has a dipole orientation degree of not less than 75%. Consequently, the piezoelectric sensor having an excellent durability and a simple structure is provided at low cost.

Owner:NAT INST OF ADVANCED IND SCI & TECH

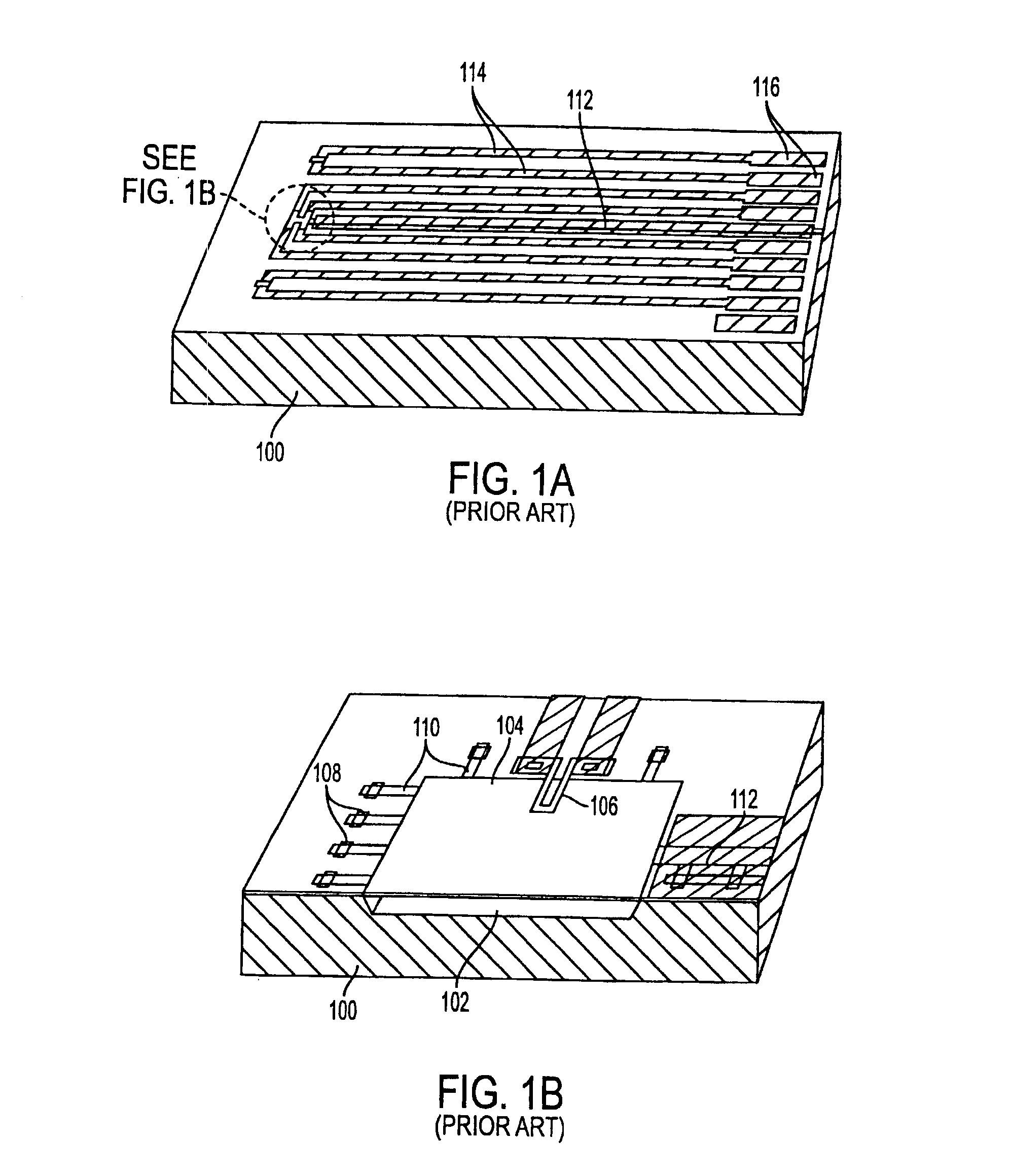

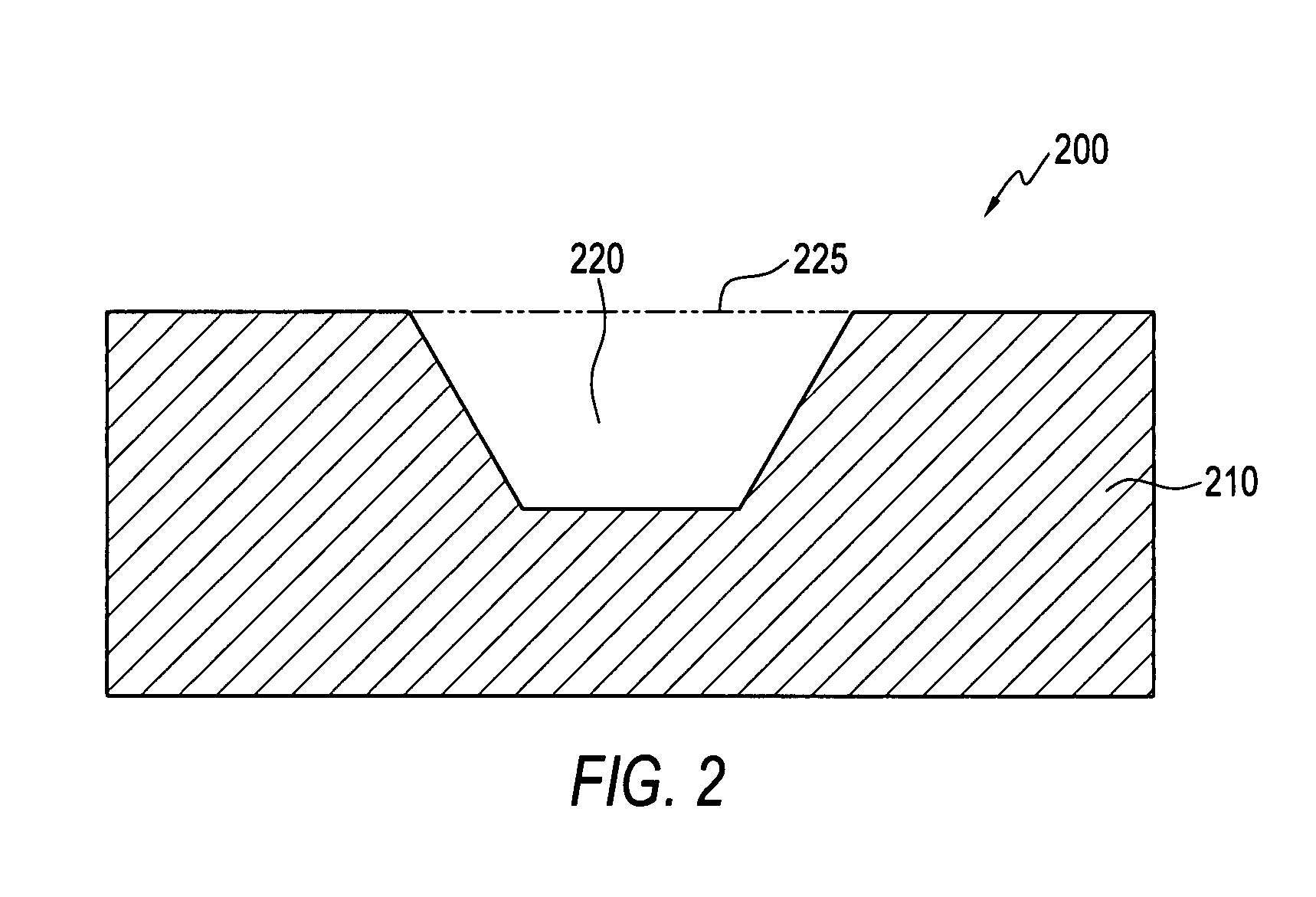

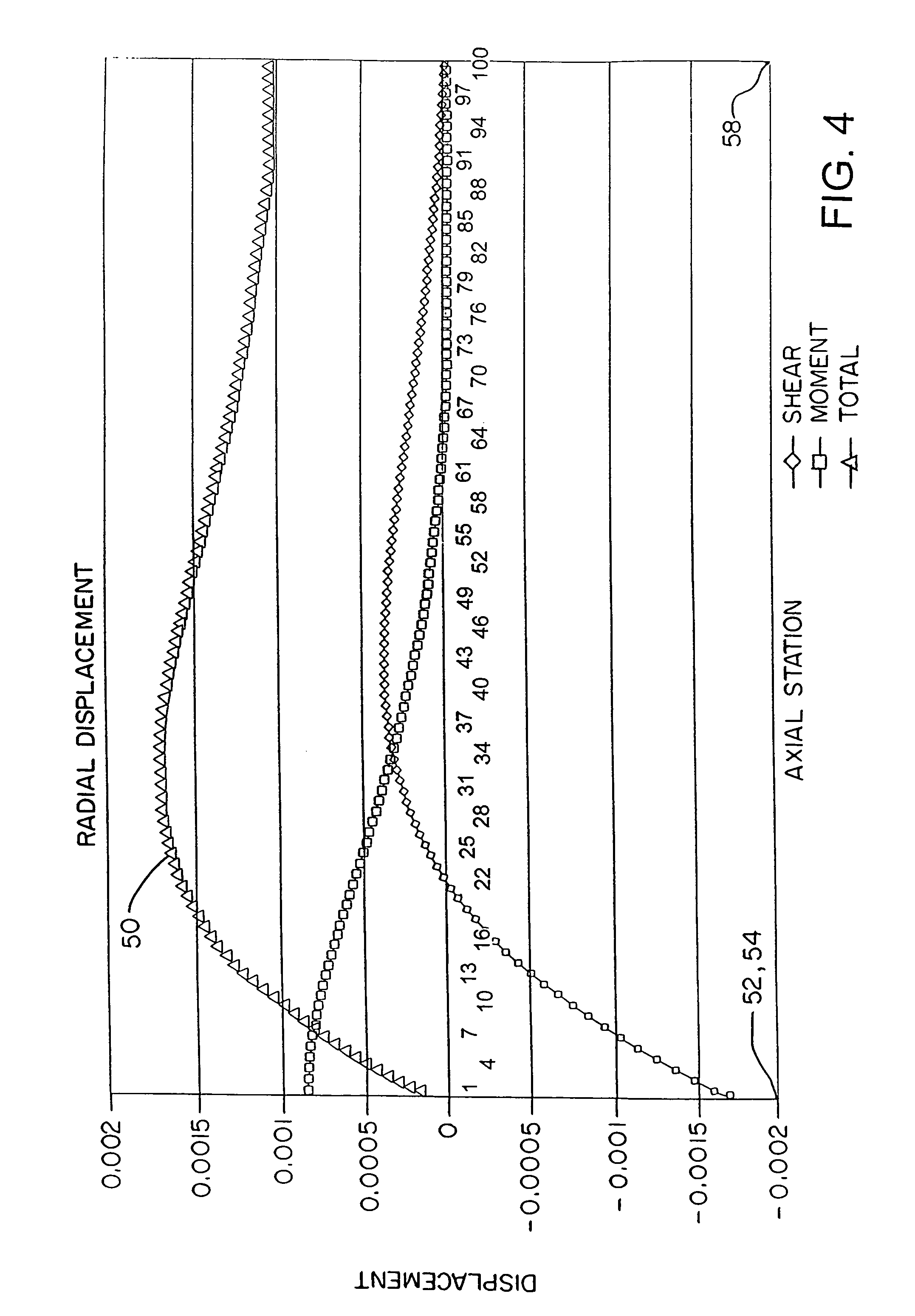

Small gauge pressure sensor using wafer bonding and electrochemical etch stopping

ActiveUS7493822B2Small sizeFluid pressure measurement using ohmic-resistance variationSemiconductor/solid-state device manufacturingEngineeringWafer bonding

A gauge pressure sensor apparatus and a method of forming the same. A constraint wafer can be partially etched to set the diaphragm size, followed by bonding to a top wafer. The thickness of the top wafer is either the desired diaphragm thickness or is thinned to the desired thickness after bonding. The bonding of top wafer and constraint wafer enables electrochemical etch stopping. This allows the media conduit to be etched through the back of the constraint wafer and an electrical signal produced when the etching reaches the diaphragm. The process prevents the diaphragm from being over-etched. The invention allows the die size to be smaller than die where the diaphragm size is set by etching from the back side.

Owner:HONEYWELL INT INC

Pressure sensor

InactiveUS7331236B2Fluid pressure measurement using ohmic-resistance variationFluid pressure measurement by mechanical elementsAcoustic waveEngineering

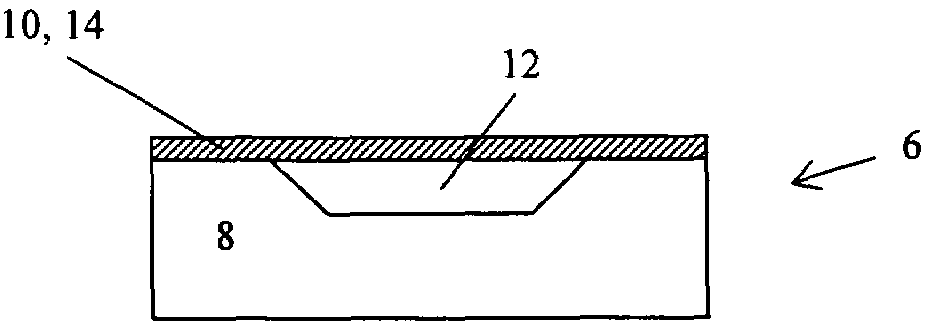

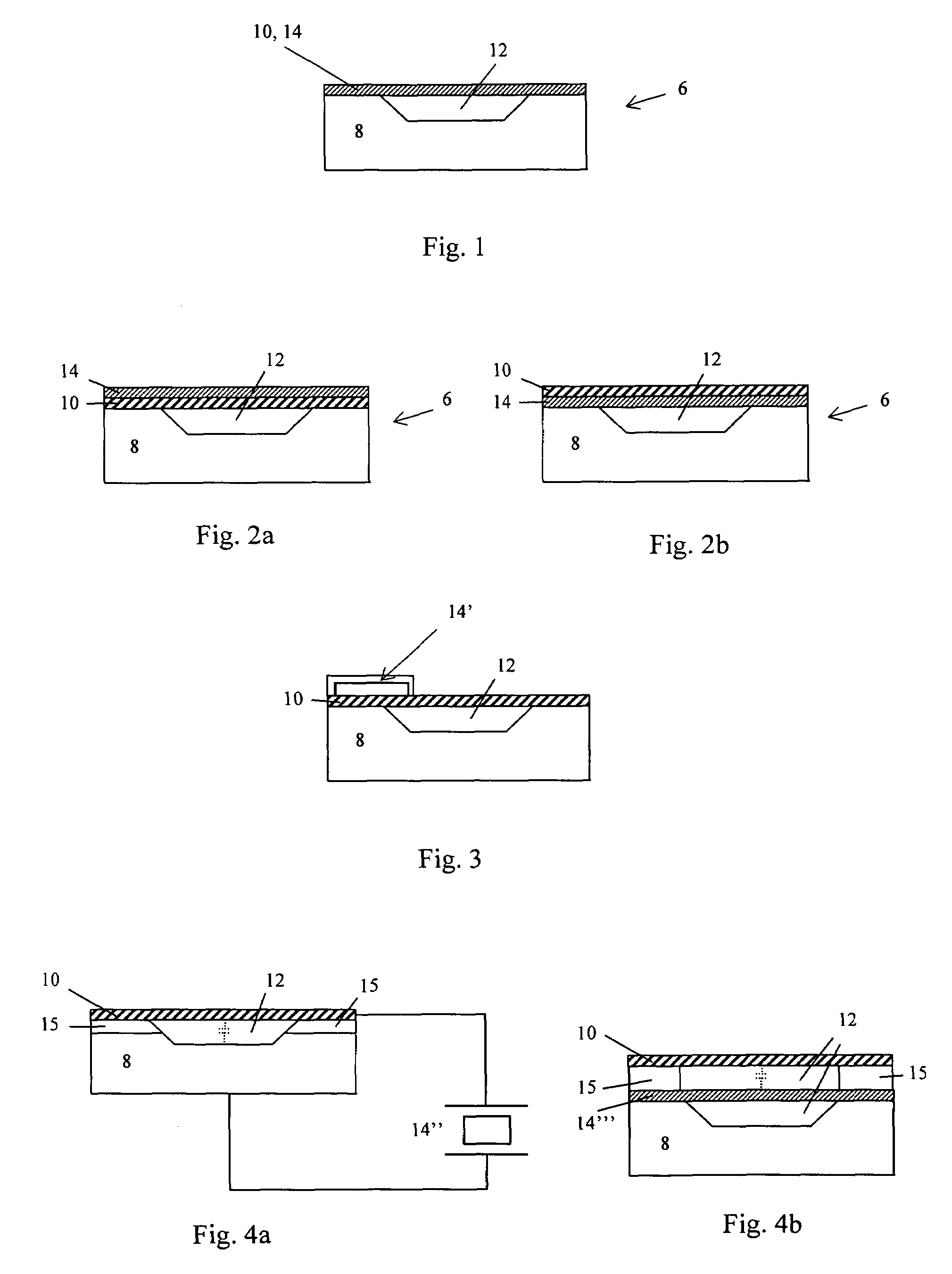

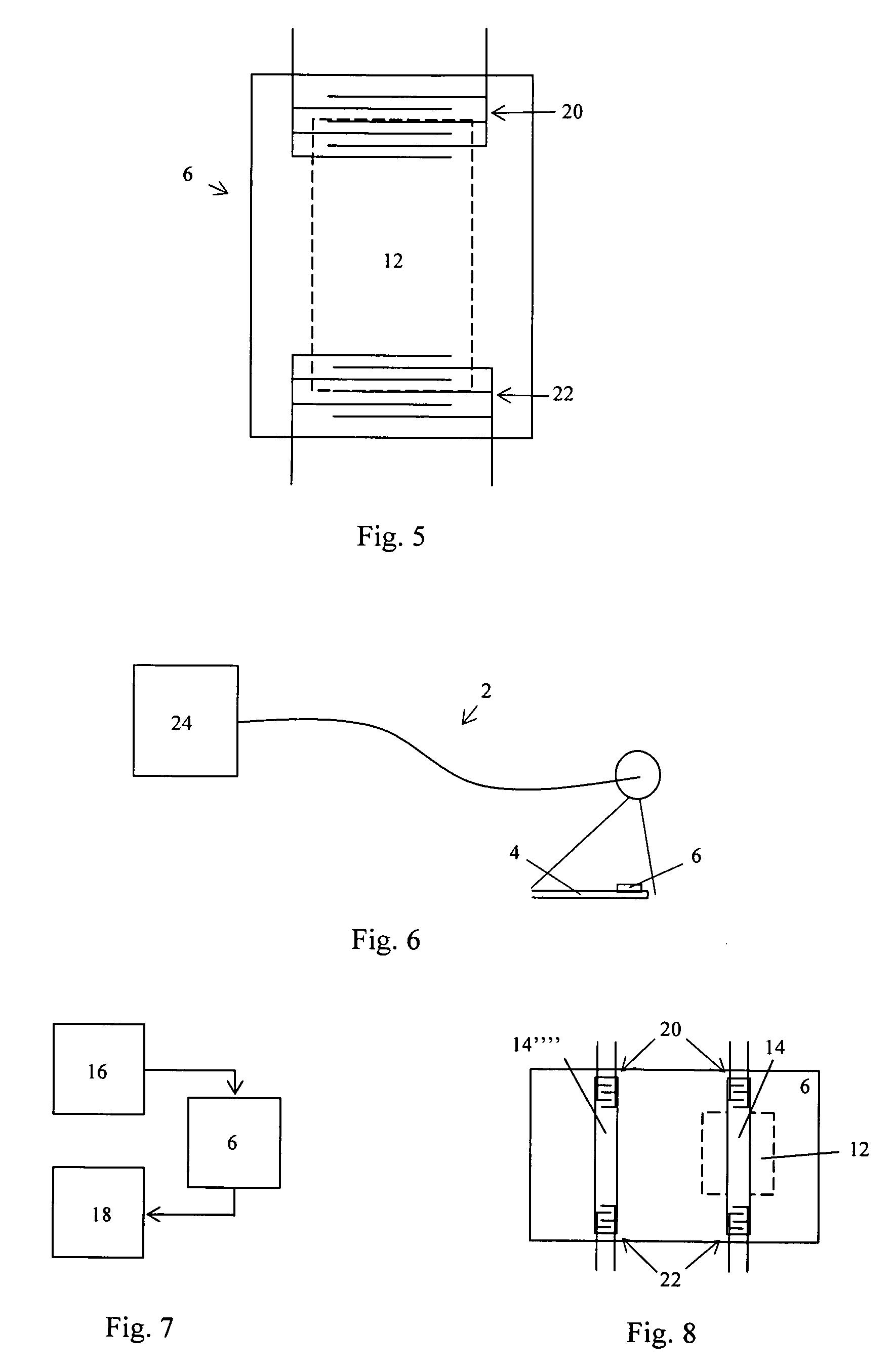

A sensor and insertion assembly 2 is used for intravascular measurement of pressure in a living body. The assembly includes, a sensor chip 6 having a substrate body 8 with a recess covered by a pressure sensitive film 10 thereby forming a cavity 12. A piezoelectric element, preferably in the form of a piezoelectric film 14, is arranged in connection with the pressure sensitive film, and energy is applied to the piezoelectric element such that acoustic waves are generated in the element. The piezoelectric element is arranged to generate an output signal, representing the pressure at the film, in dependence on the measured properties of the acoustic waves related to the deflection of the pressure sensitive film.

Owner:ST JUDE MEDICAL COORDINATION CENT

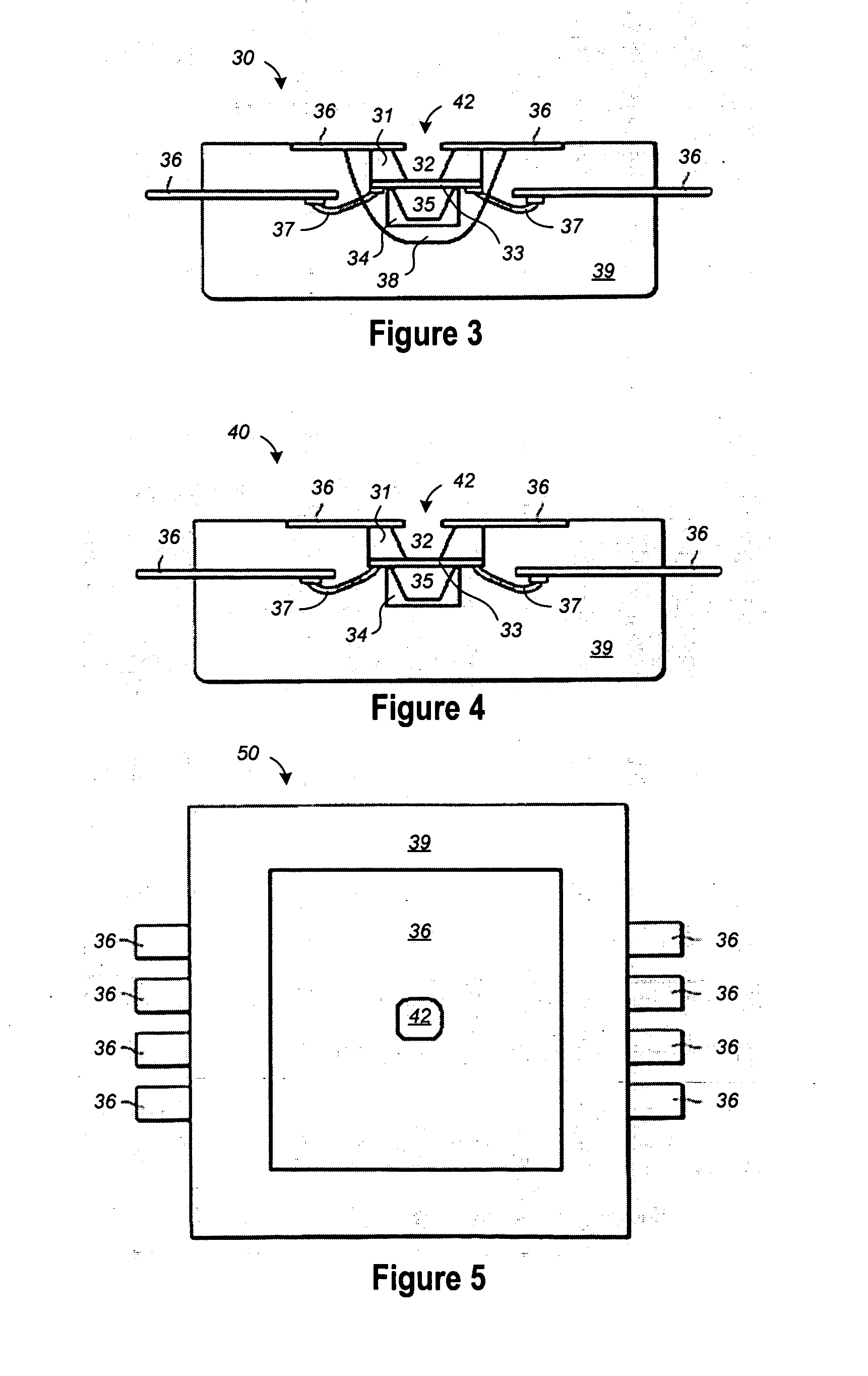

Exposed Pad Backside Pressure Sensor Package

InactiveUS20100199777A1Fluid pressure measurement using piezo-electric devicesInflated body pressure measurementTransducerEngineering

A method and apparatus are described for fabricating an exposed backside pressure sensor (30) which protects interior electrical components (37) formed on a topside surface of a pressure sensor transducer die (31) from corrosive particles using a protective gel layer (38) and molding compound (39), but which vents a piezoresistive transducer sensor diaphragm (33) formed on a backside of the pressure sensor transducer die (31) through a vent hole (42) formed in an exposed die flag (36), enabling the sensor diaphragm (33) to directly sense pressure variations without the influence of a protective gel.

Owner:NORTH STAR INNOVATIONS

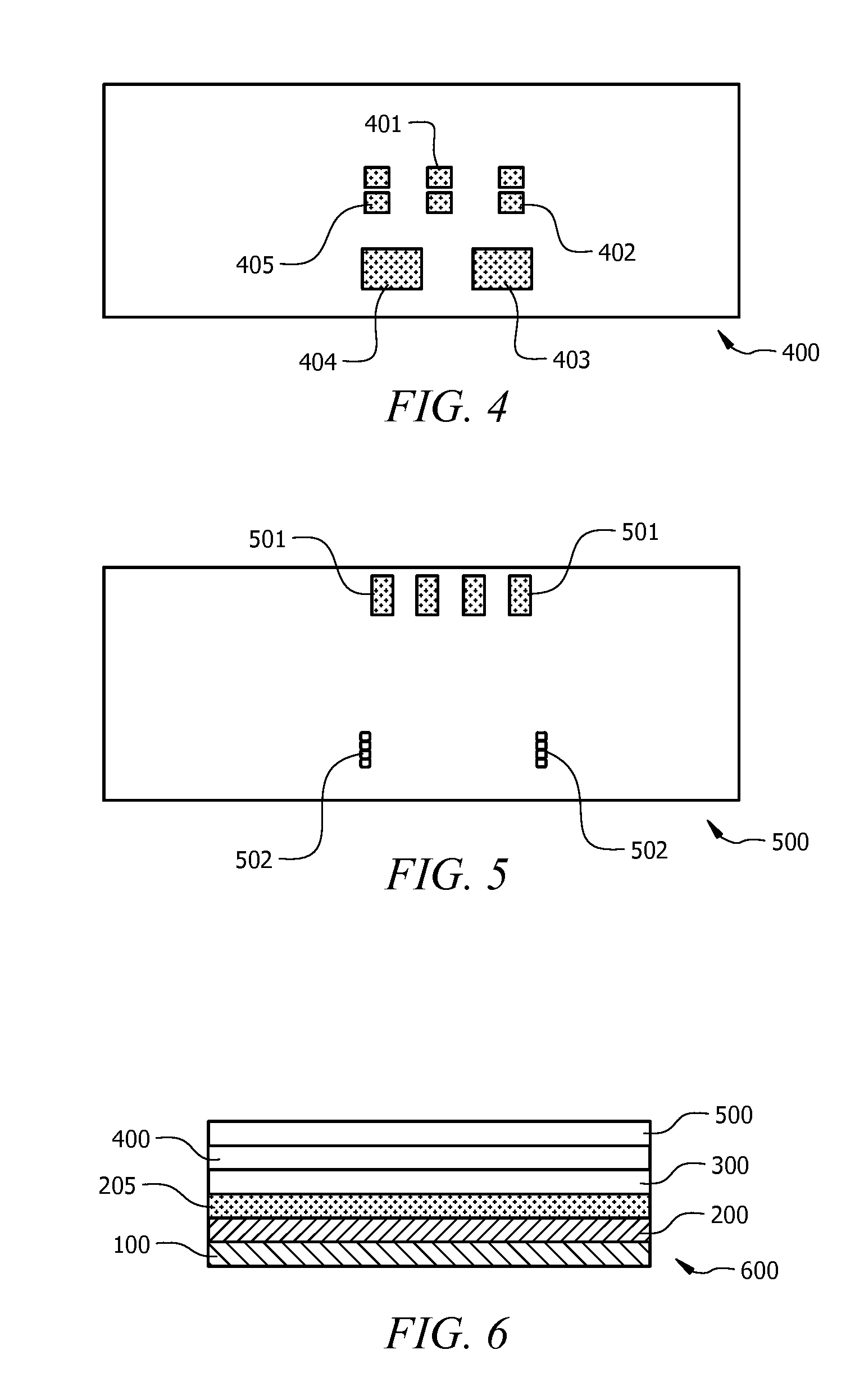

Composite MEMS pressure sensor configuration

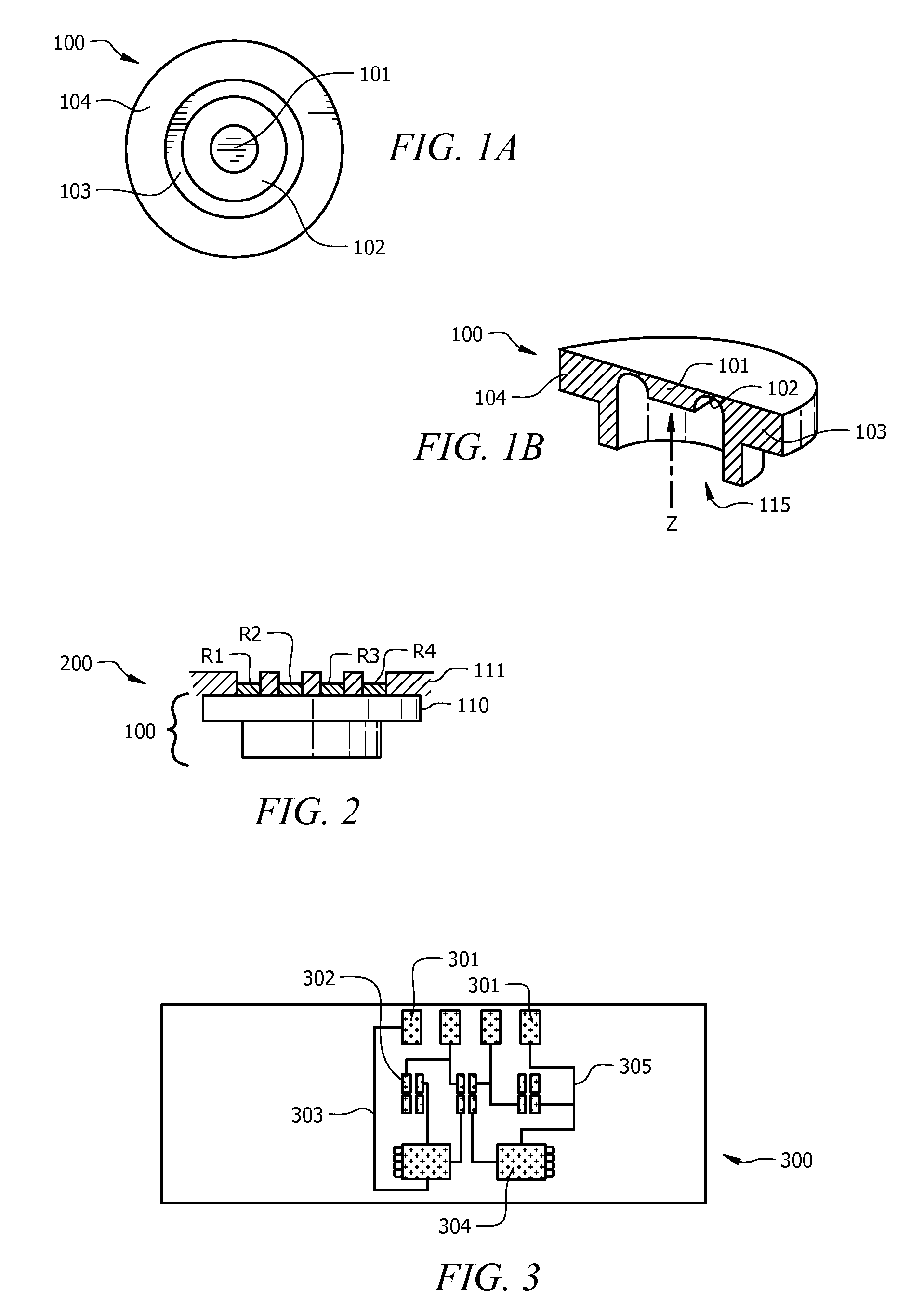

ActiveUS20060144153A1Control deflectionReduce gravity errorFluid pressure measurement using ohmic-resistance variationFluid pressure measurement using elastically-deformable gaugesCantilevered beamMems pressure sensor

A pressure sensor assembly comprised of a single and dual layer diaphragm with integrated force sensing flexure, such as a cantilever beam. Strain gages are positioned on the force sensing beam. The pressure forces the diaphragm to deflect. The deflection is constrained by the beam, which is compelled to bend. The bending induces strains in strain gages located on the beam. The strain gages are connected in a Wheatstone bridge configuration. When a voltage is applied to the bridge, the strain gages provide an electrical output signal proportional to the pressure. Composite diaphragm—beam pressure sensors convert pressure more efficiently and improve sensor performance.

Owner:BROSH AMNON

Flexible piezocapacitive and piezoresistive force and pressure sensors

InactiveUS8904876B2Facilitate measuring and mapping forcesFluid pressure measurement using ohmic-resistance variationFluid pressure measurement by mechanical elementsCapacitanceDielectric

Owner:PATIENTECH LLC

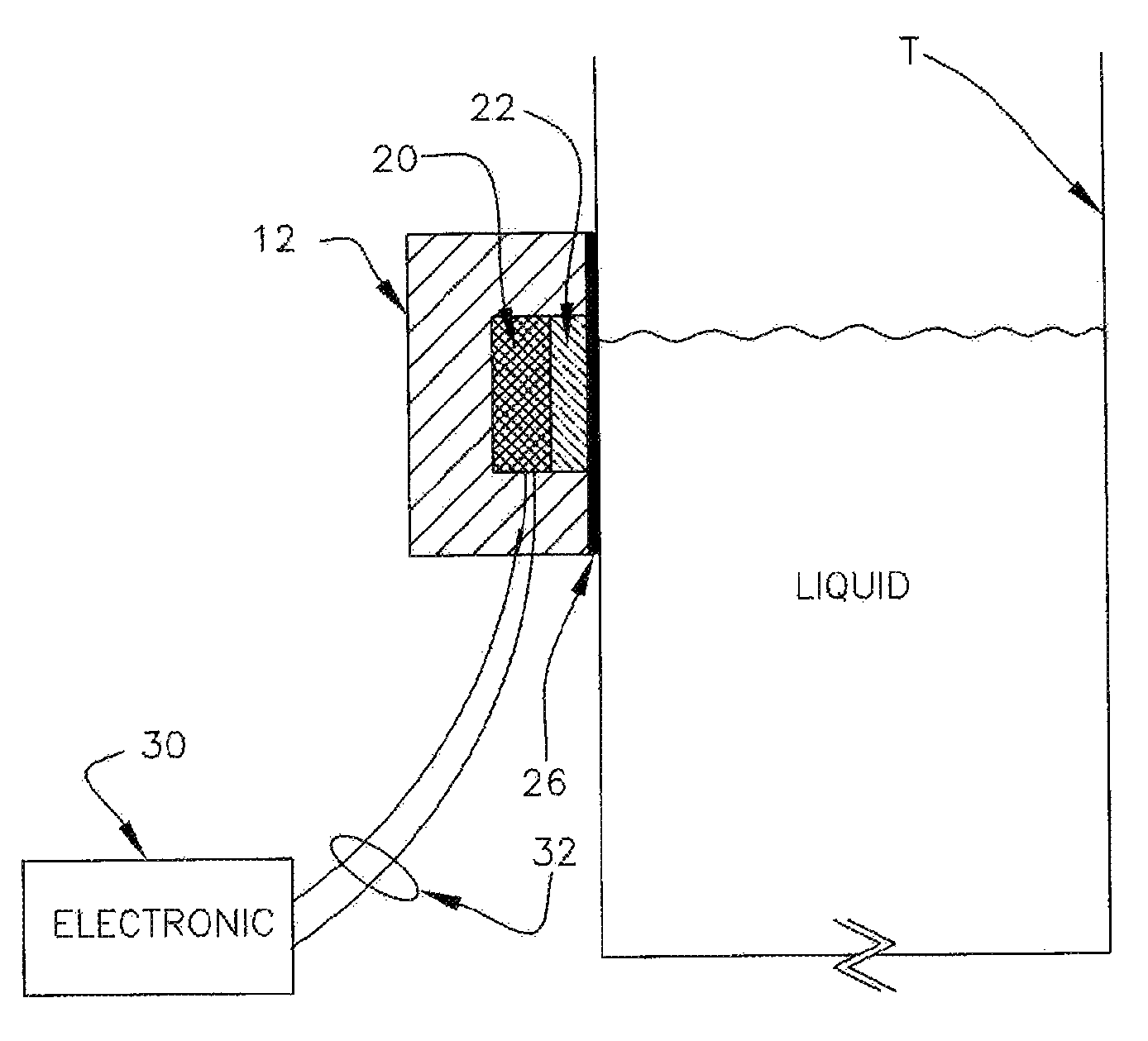

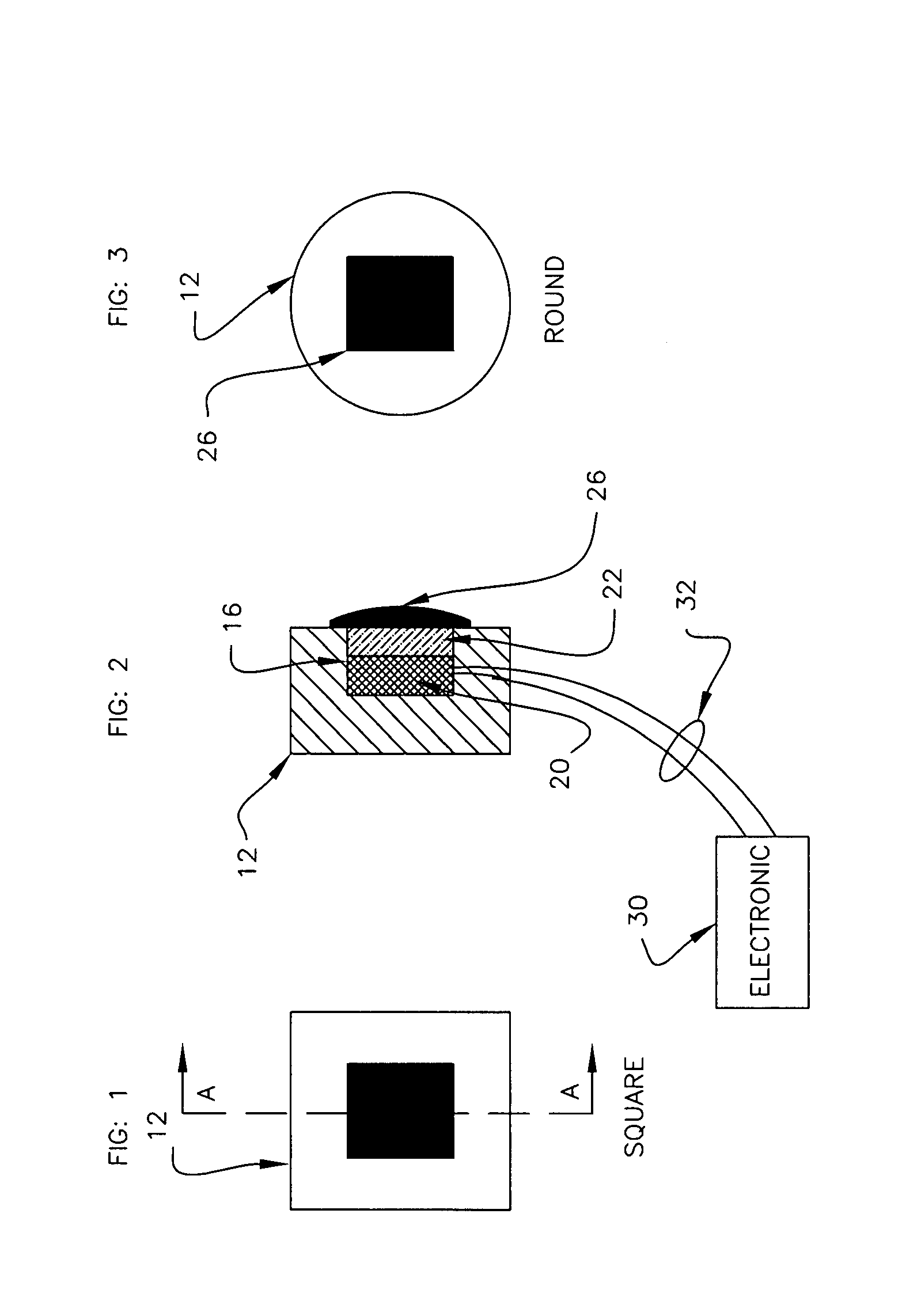

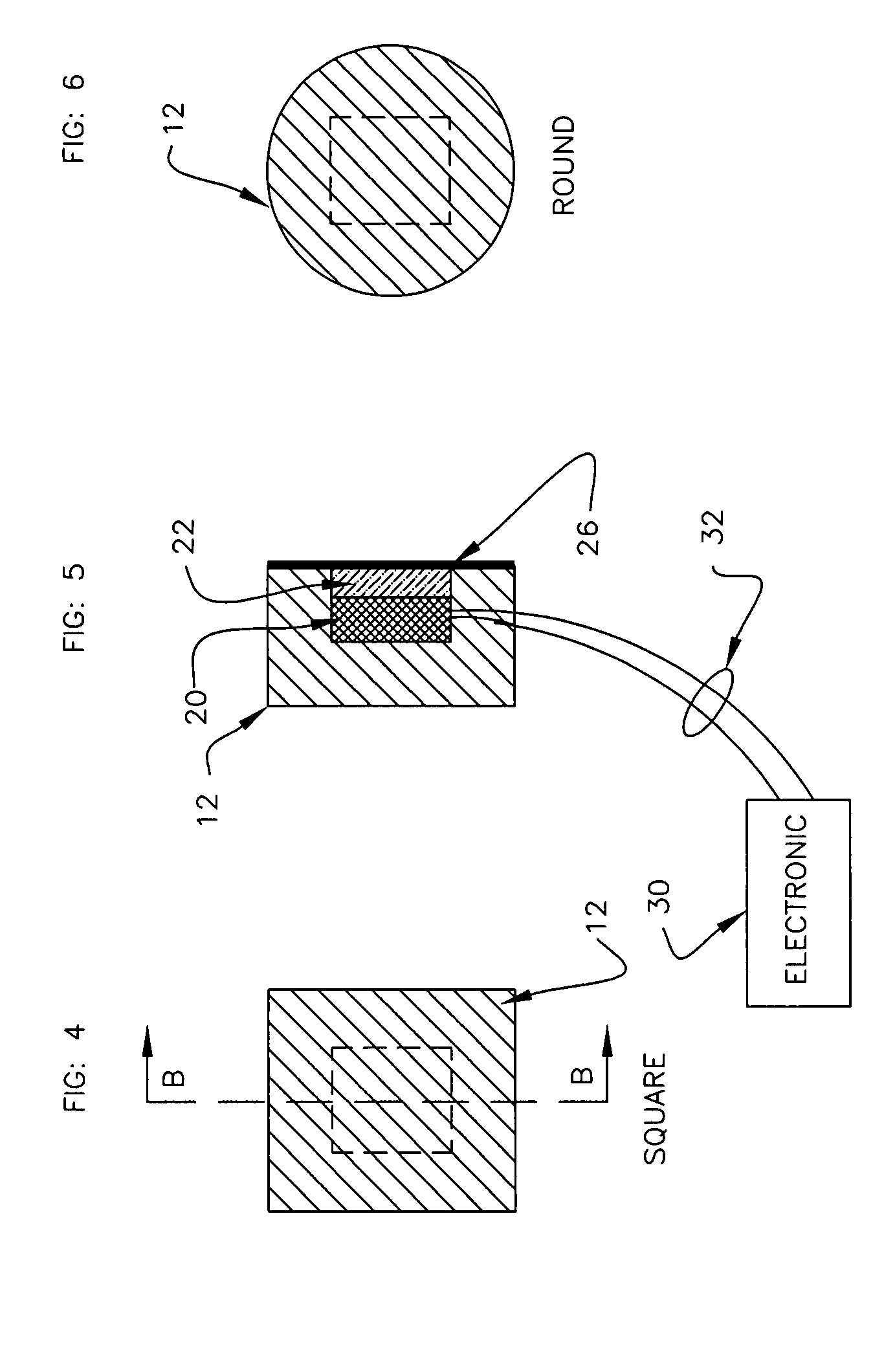

Non-invasive dry coupled disposable/reusable ultrasonic sensor

ActiveUS7694570B1Analysing fluids using sonic/ultrasonic/infrasonic wavesAnalysing solids using sonic/ultrasonic/infrasonic wavesUltrasonic sensorEngineering

A non-invasive dry coupled disposable / reusable ultrasonic sensor has a housing and a piezoelectric element at one end of the housing to which connected signal leads are connected that extend out from the housing. A piece of double-sided adhesive tape has one adhesive side secured directly to the face at the one end of the housing with the other adhesive side to be secured directly to the outer surface of a pipe or vessel. The tape can cover the entire face of the one end of the housing or only that part that the piezoelectric element faces.

Owner:MEASUREMENT SPEC

Integrated silicon chip for testing acceleration, pressure and temperature, and manufacturing method thereof

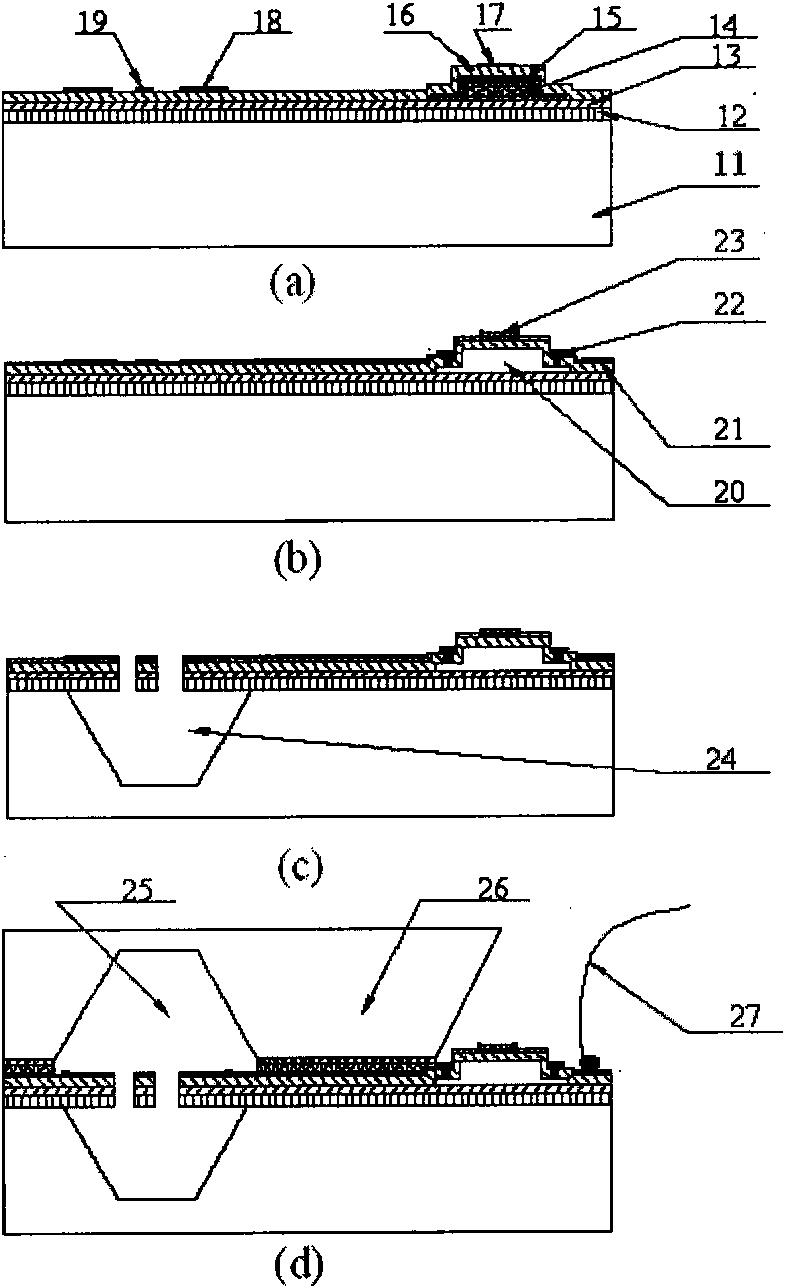

ActiveCN101551403AHigh sensitivityImprove stabilityFluid pressure measurement using ohmic-resistance variationDecorative surface effectsAccelerometerThermopile

The invention relates to an integrated silicon chip for testing acceleration, pressure and temperature, and the manufacturing method thereof. The invention is characterized in manufacturing the pressure sensor, temperature sensor and accelerometers of thermoelectric pile on to one chip by the same micro processing technology. The acceleration is detected by adopting thermal convection type accelerometers, using polysilicon resistor as heater, using a thermoelectric pile composed of two pairs of metals (such as aluminium and tungsten-titanium) and P type or N type polysilicon to detect the temperature difference in the sealed cavity caused by acceleration. The high accurate absolute pressure sensor is manufactured by using silicon nitride film with low stress as the core structure layer of the pressure sensor chip, and forming force sensitive resistor track by polysilicon film, forming vacuum reference cavity by TEOS bolt in LPCVD furnace. At the same time, the temperature sensor is composed by using polysilicon thermistor to detect temperature change. The integrated chip achieves the advantages of microminiaturization, low cost, high precision, high reliability and high stability.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

Pressure sensor

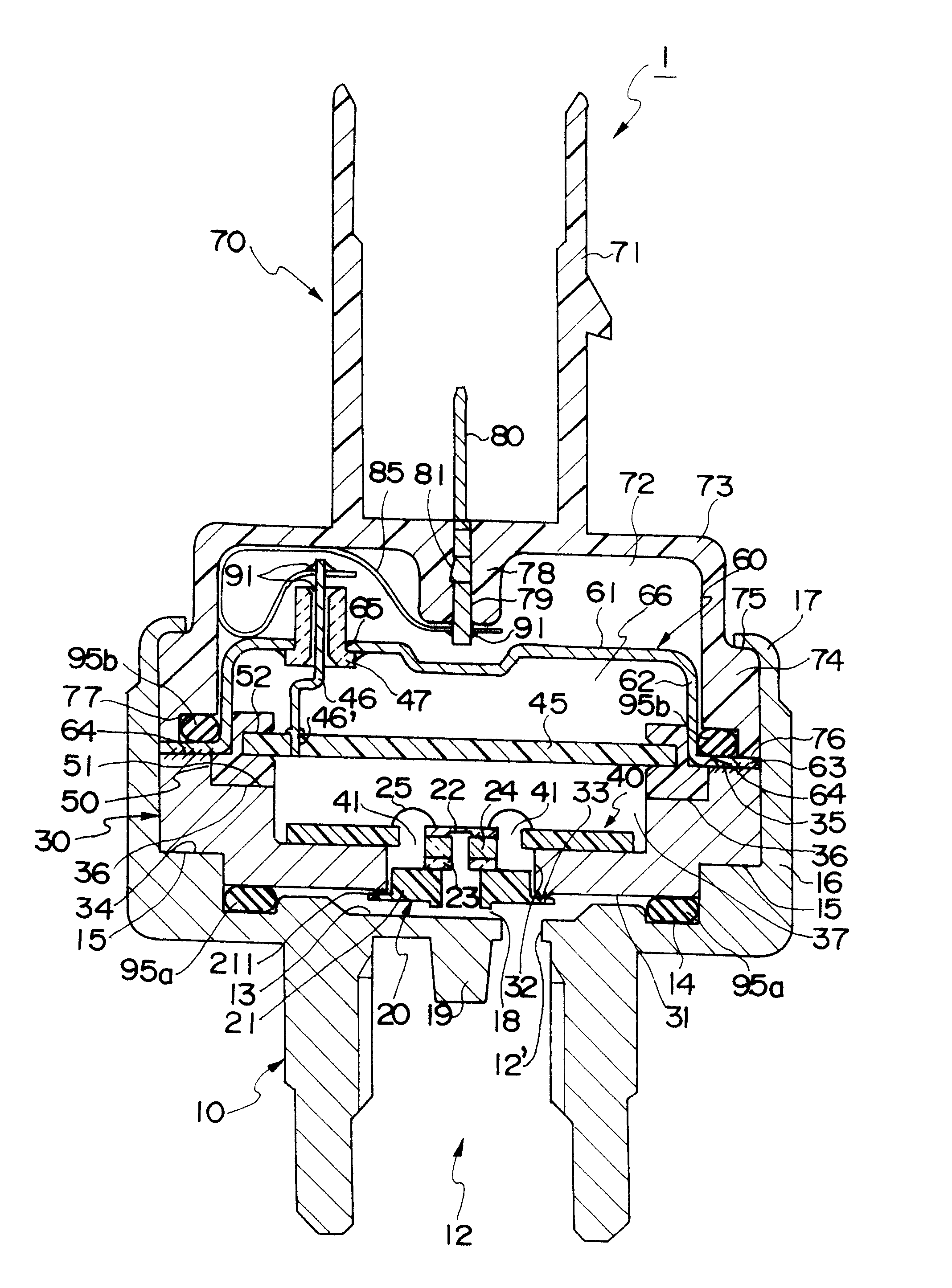

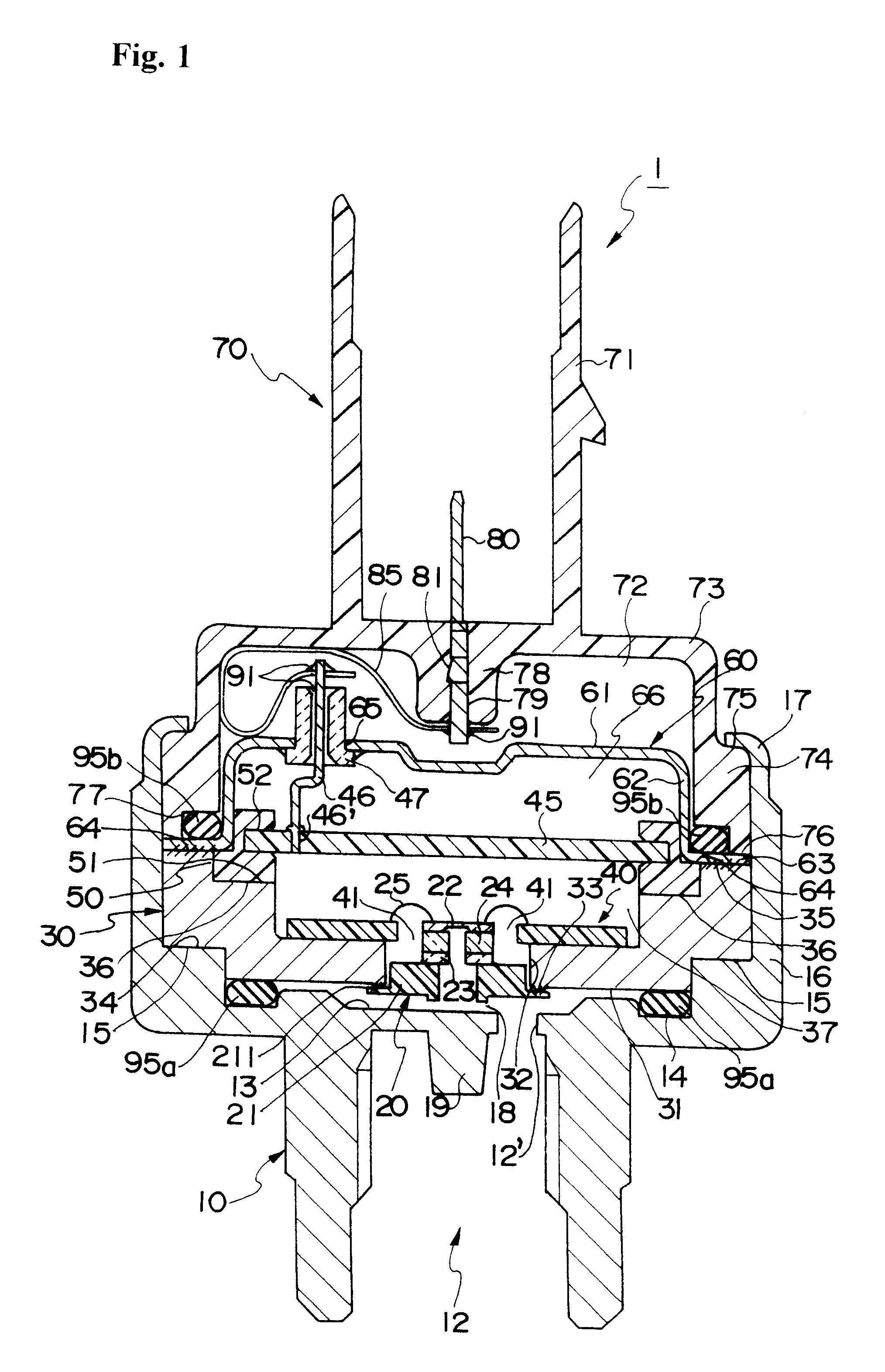

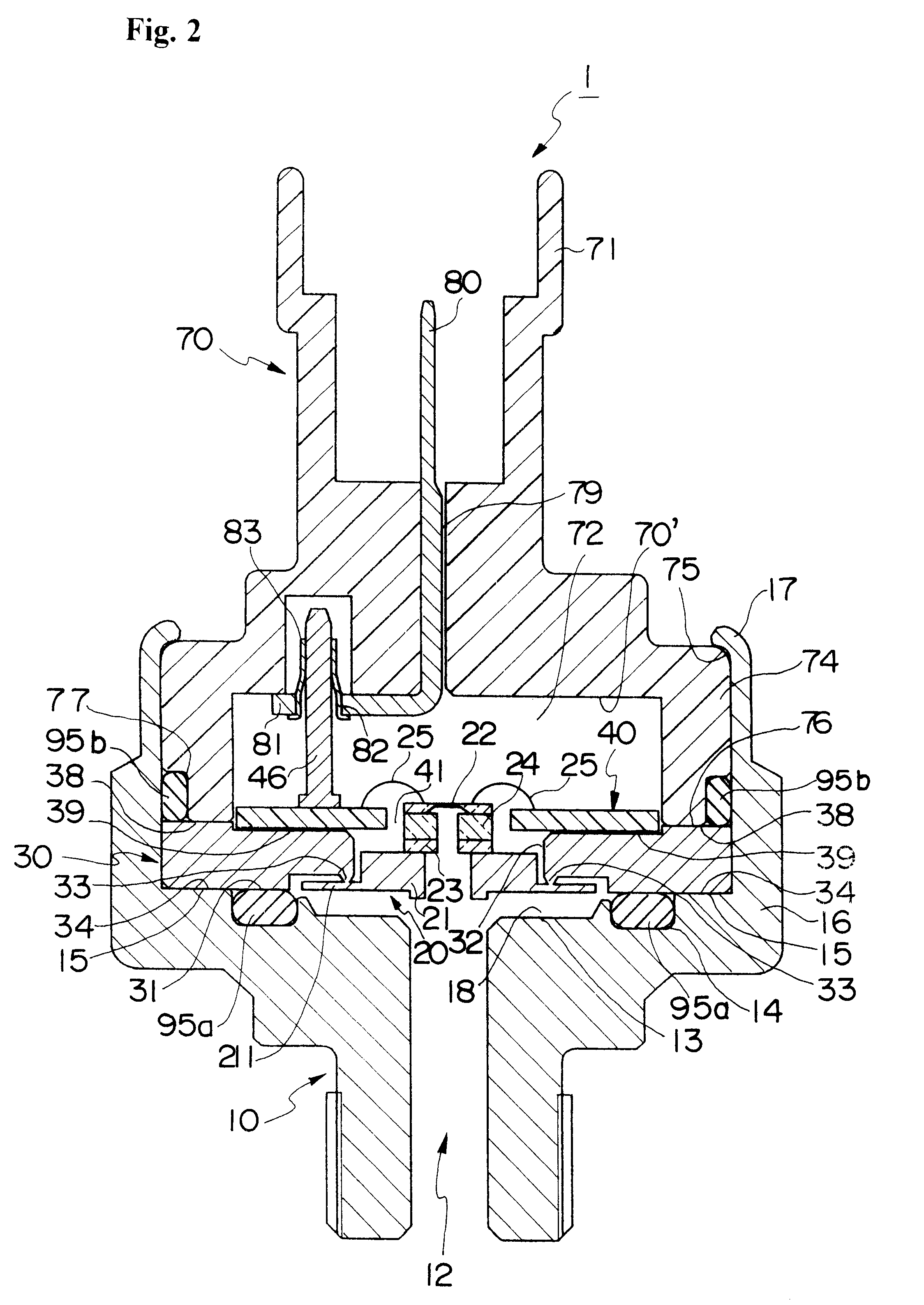

InactiveUS6176137B1Fluid pressure measurement using ohmic-resistance variationSolid-state devicesInterior spacePressure sense

A pressure sensor 1 comprises a metallic housing 10 having a space 18 communicated to a pressure detection space and a thin rising portion 17 formed on the upper end of the peripheral area, a sensor element 20, a sensor element holder 30, a metallic pressure case 60 having a ceiling portion 61, and a connector case 70 formed of an insulating material, wherein a collar portion 211 of a base plate 21 of the sensor element 20 including a pressure sensing element 22 is contacted to an annular protrusion 33 positioned around the opening 32 of the sensor element holder 30, and the collar portion 211 is airtightly welded to the annular protrusion 33 by projection welding. Further, the collar portion 63 on the pressure case 60 and the peak surface 35 of the holder 30 is airtightly welded by an electron beam welding. The airtight interior space defined by the sensor element 20, the sensor element holder 30 and the pressure case 60 is utilized as the reference pressure space.

Owner:FUJIKOKI CORP

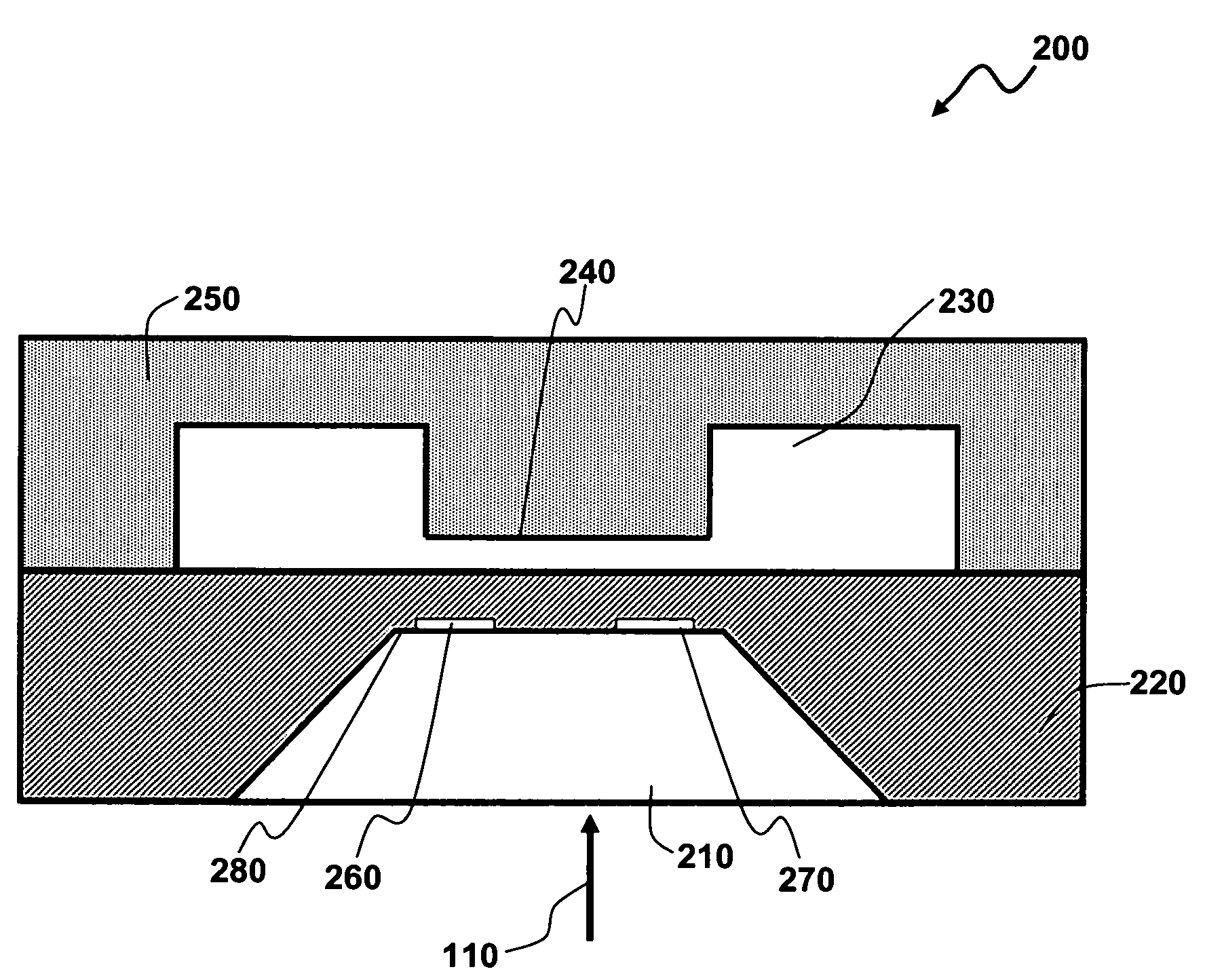

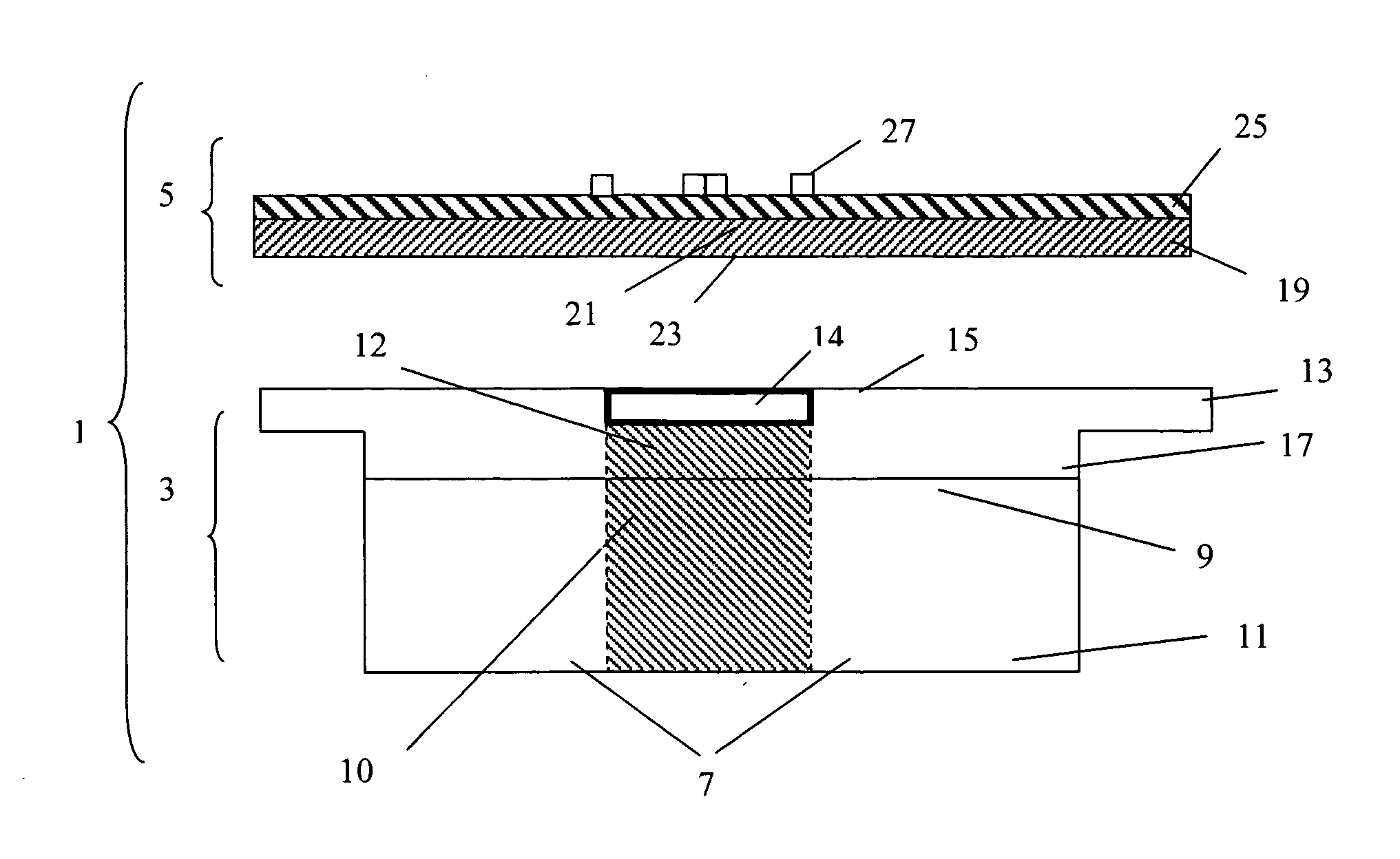

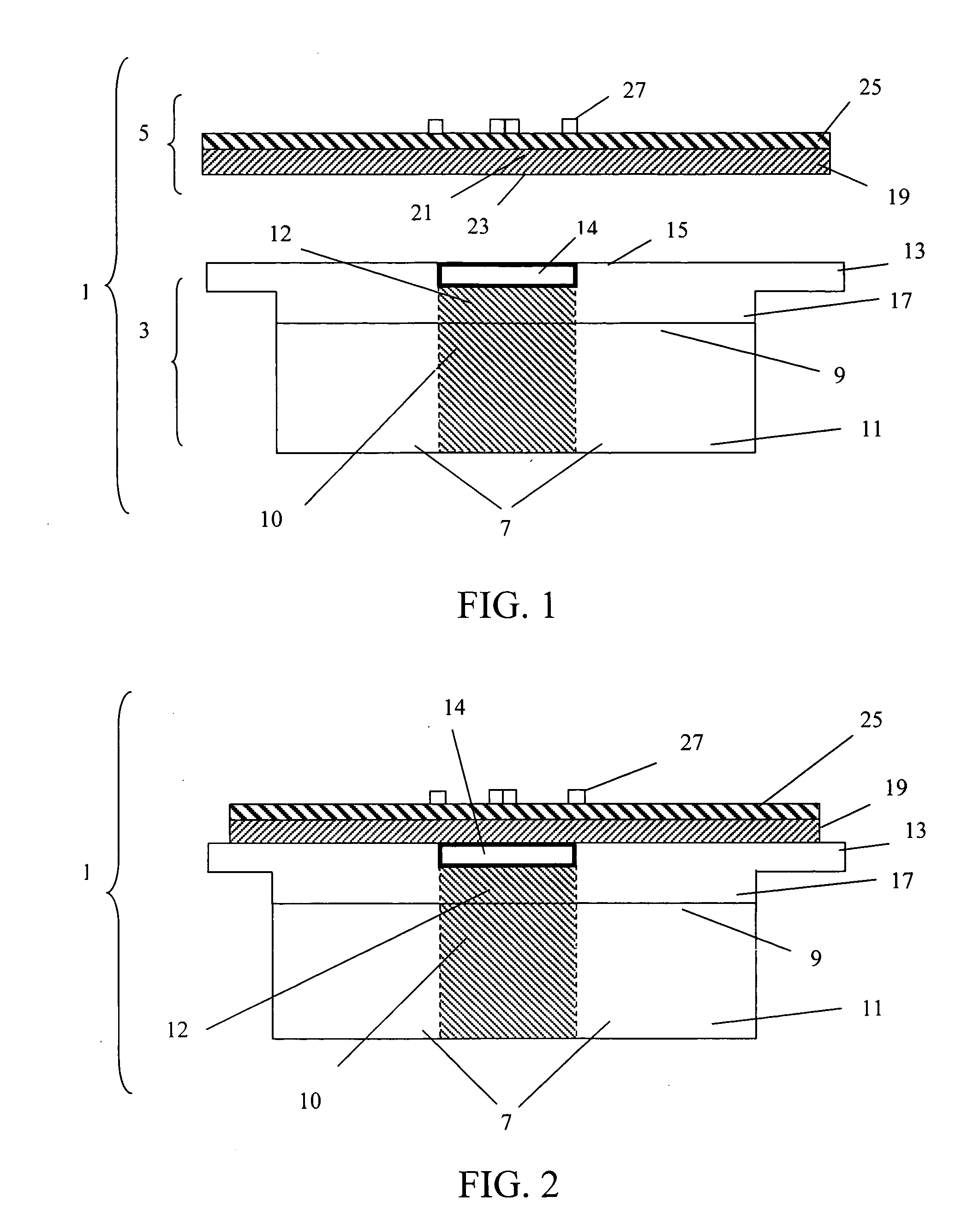

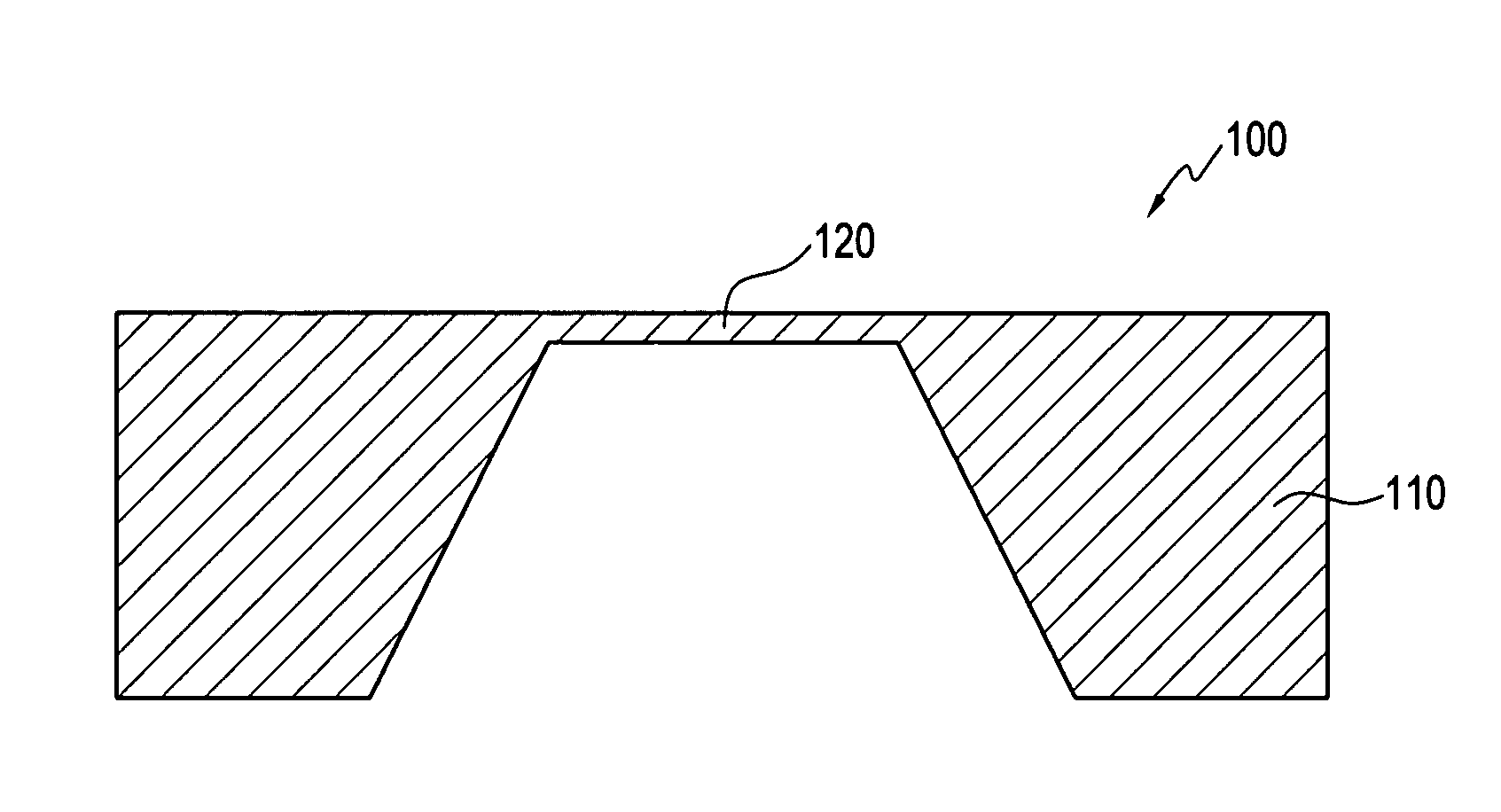

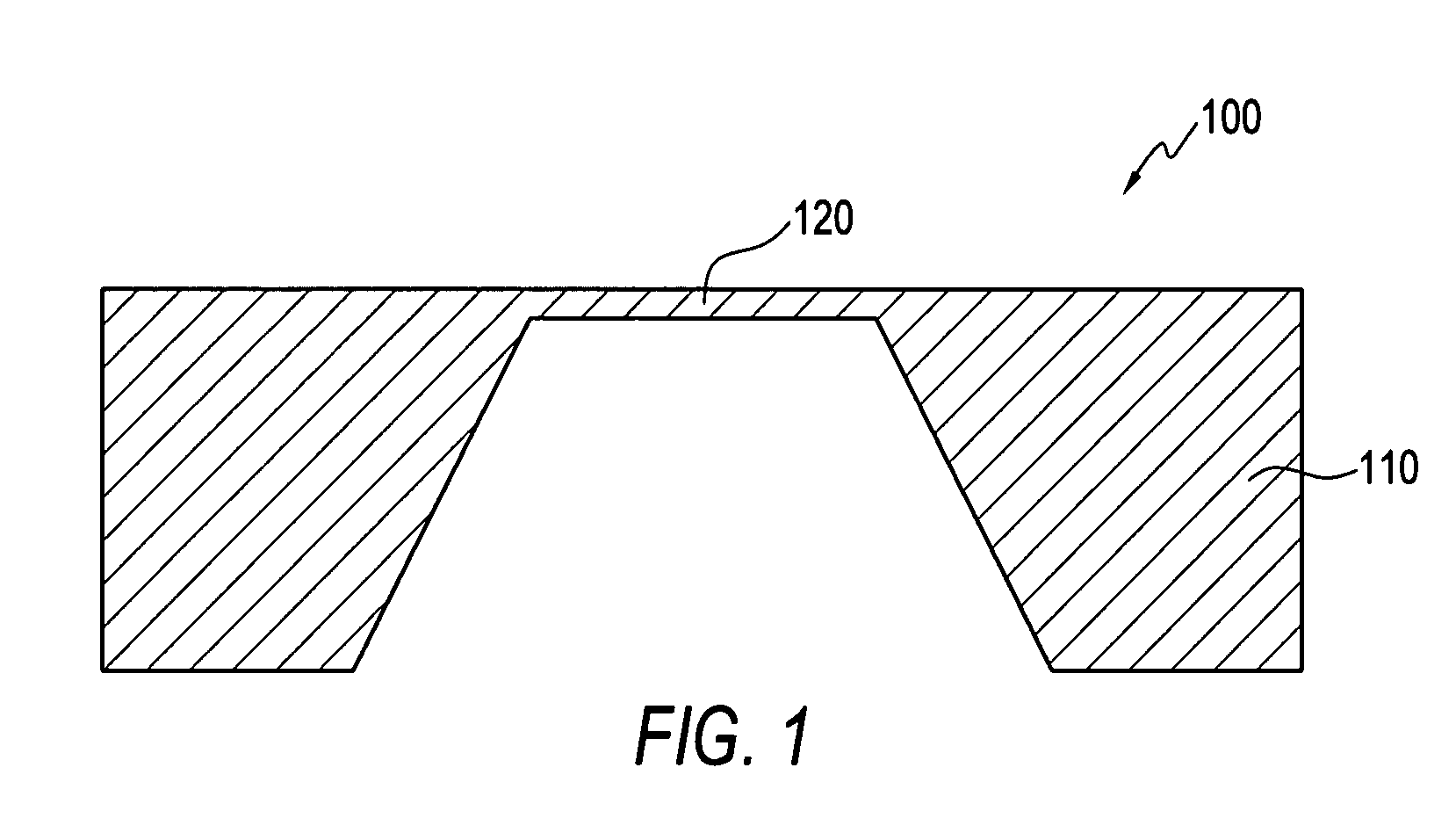

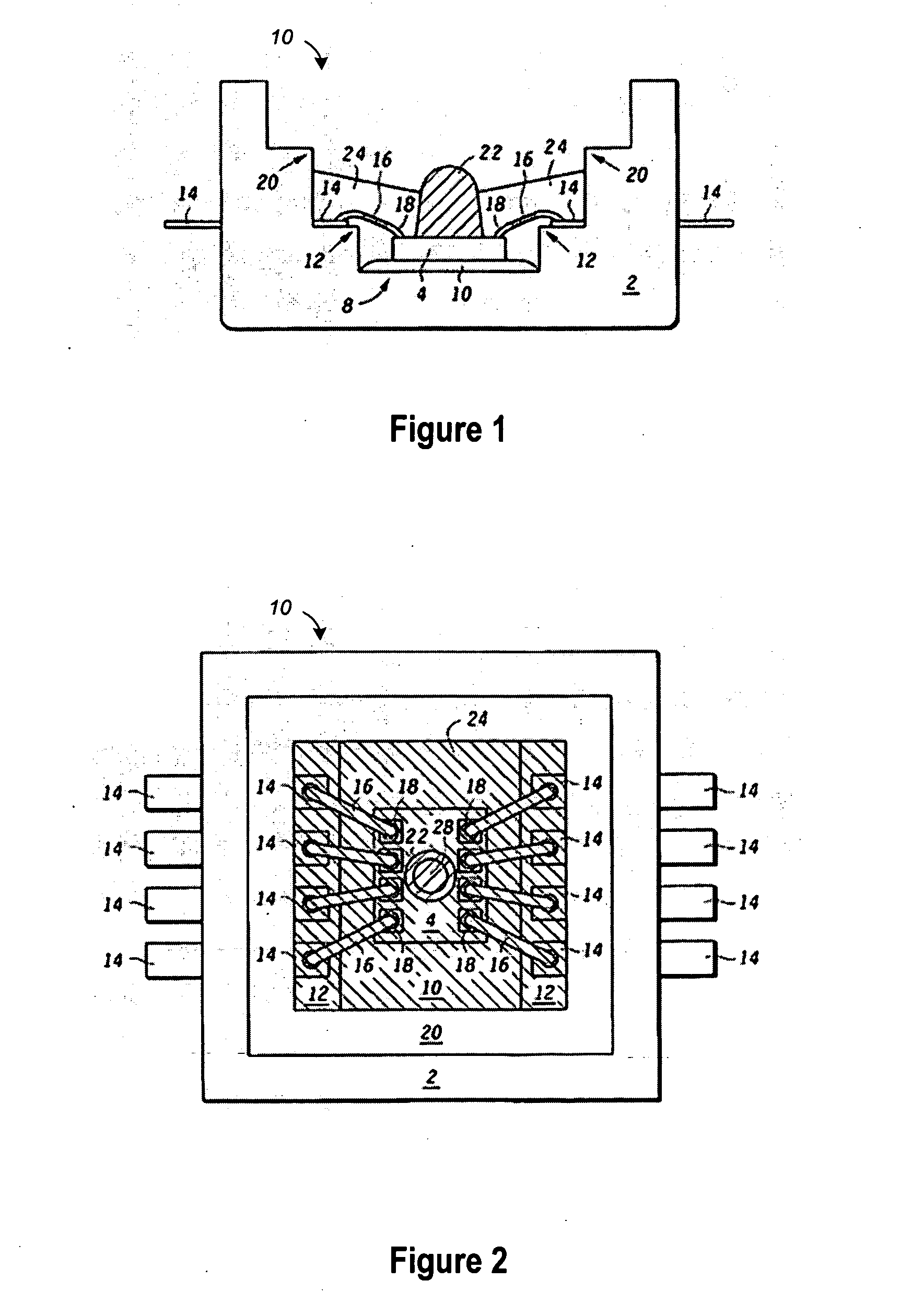

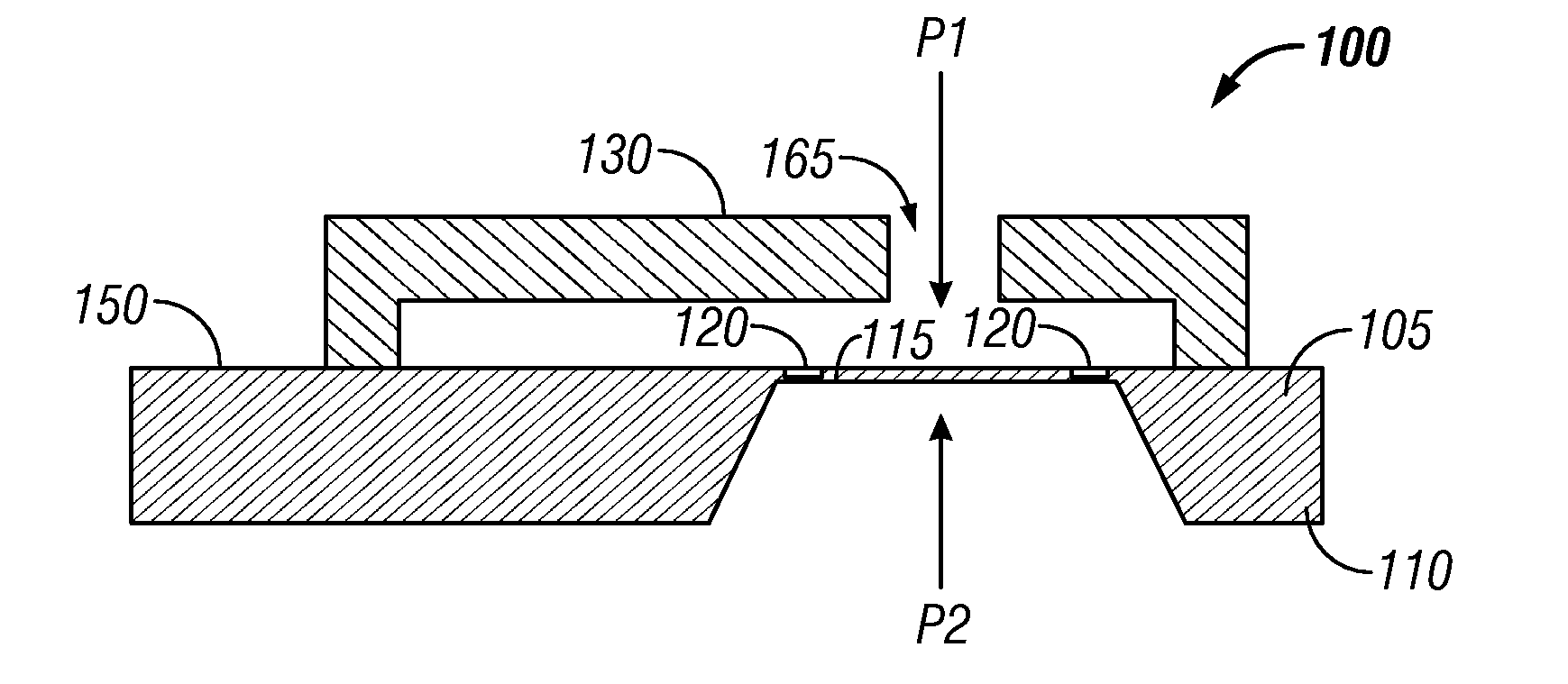

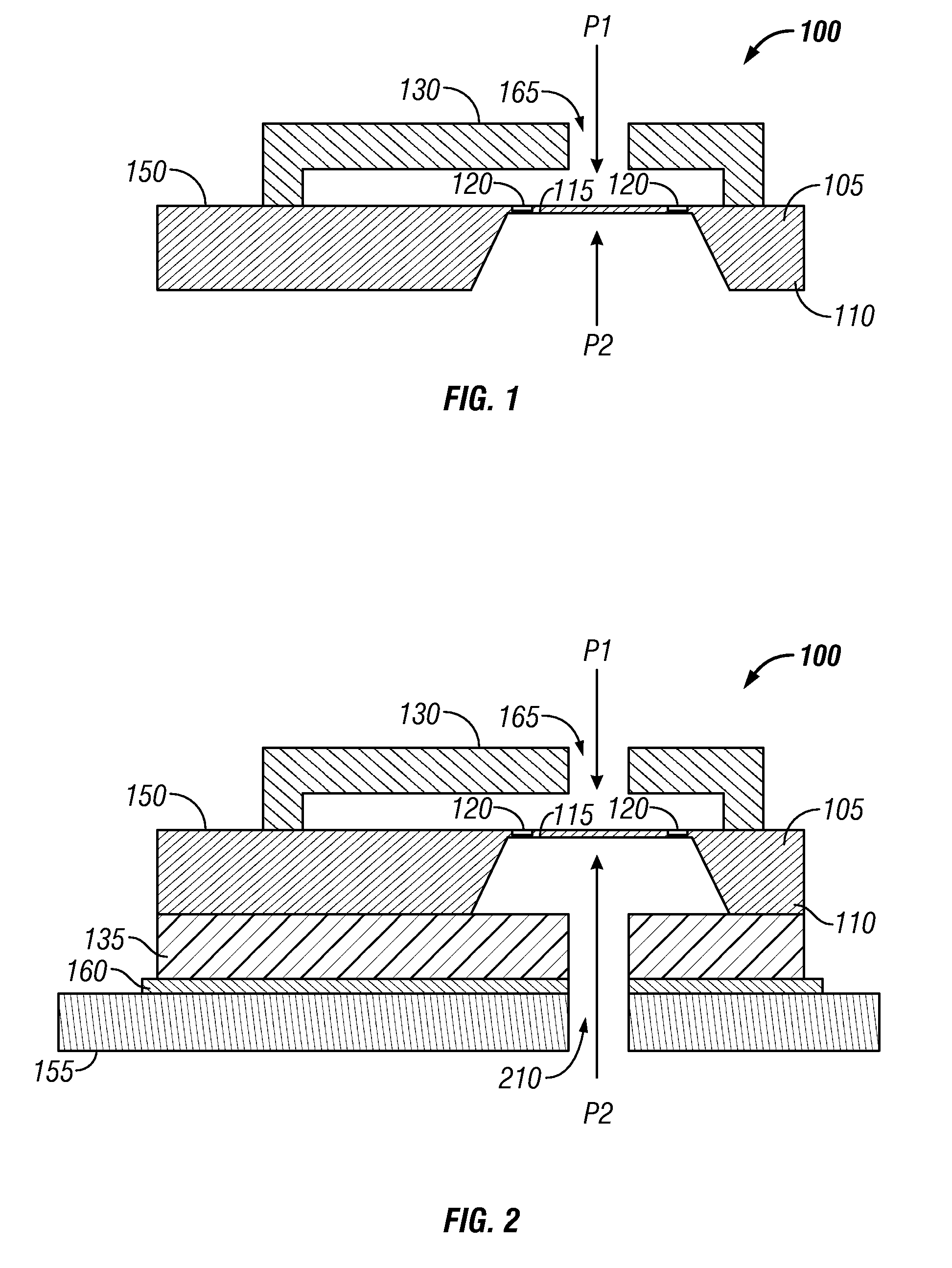

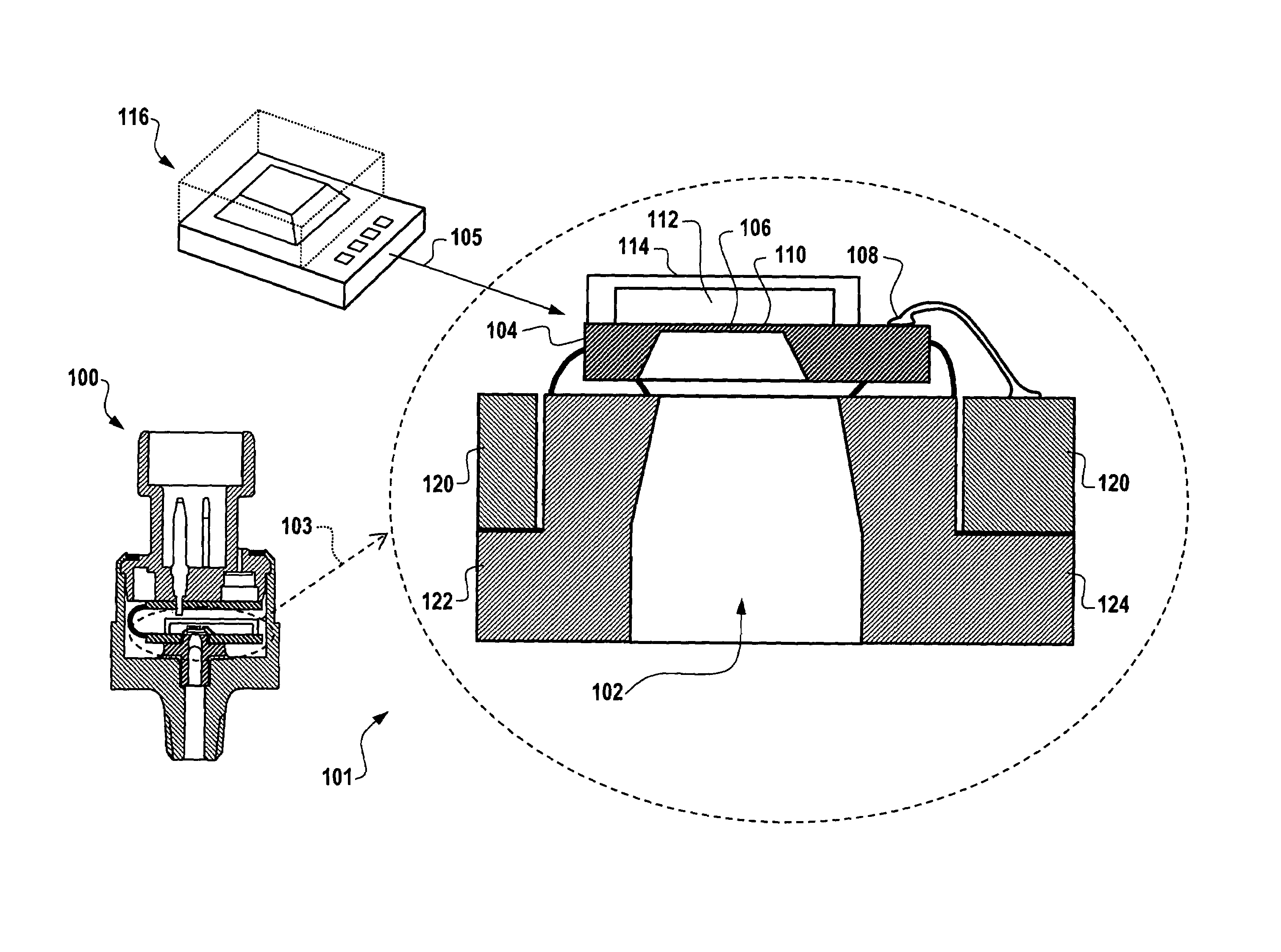

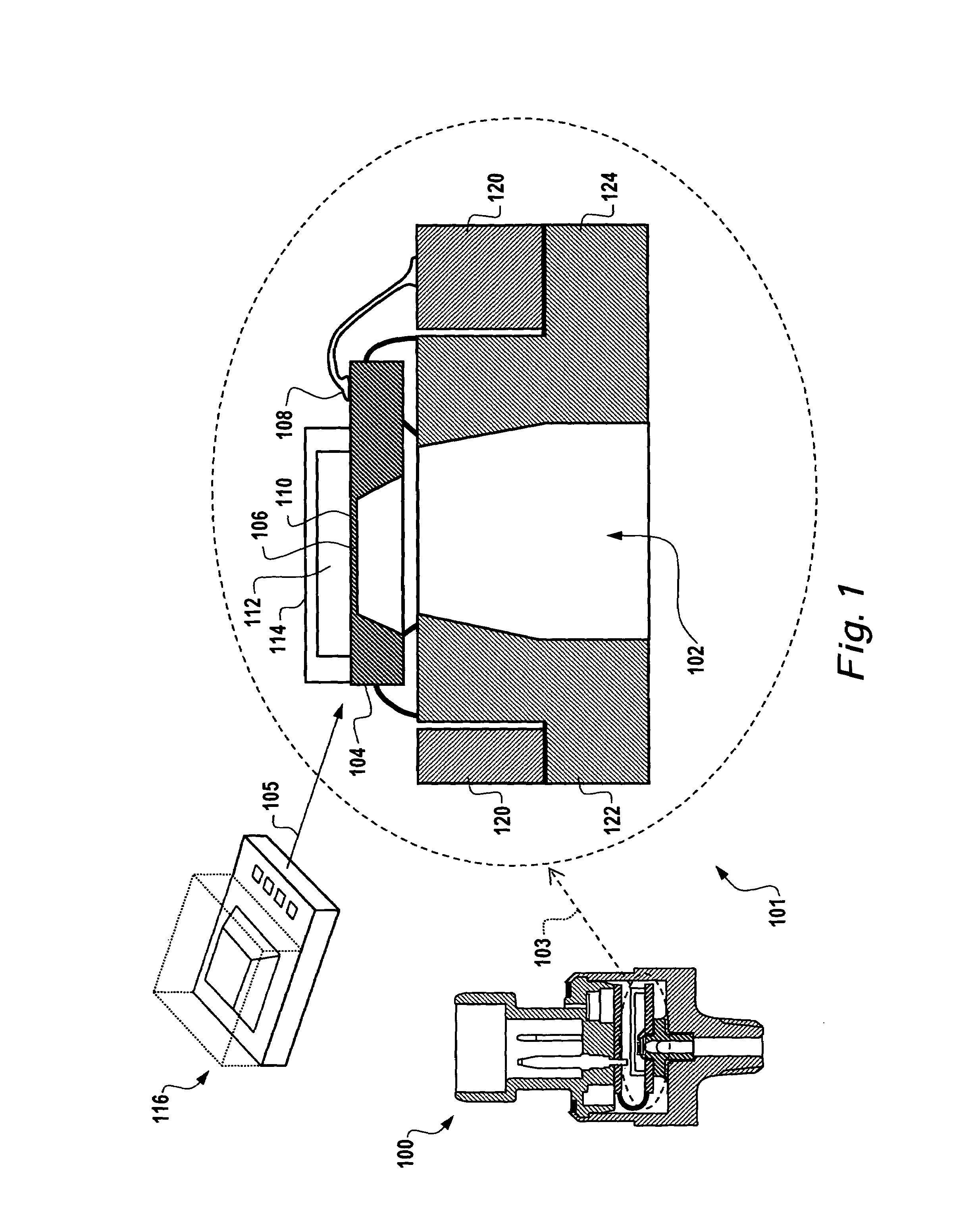

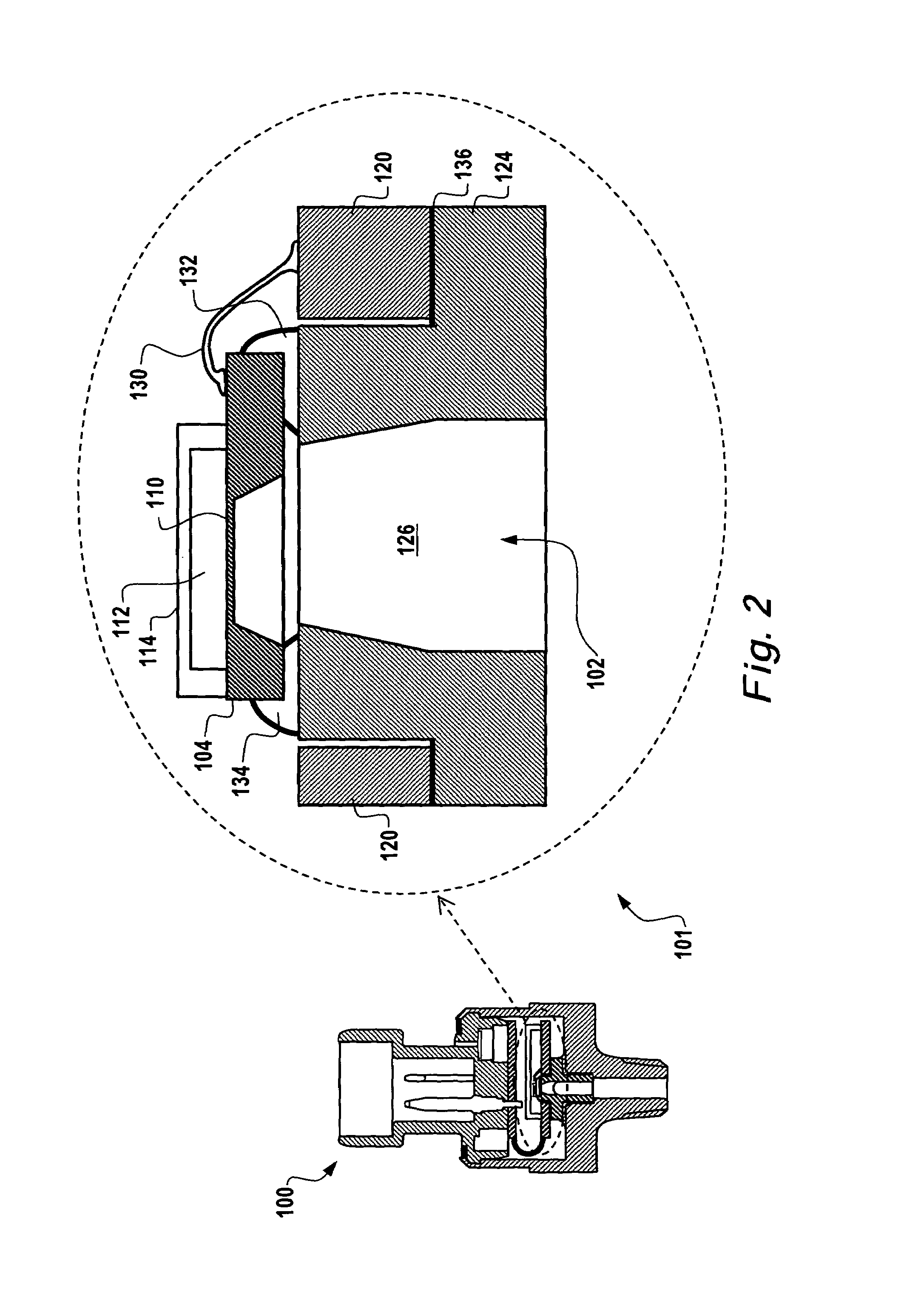

Design of wet/wet differential pressure sensor based on microelectronic packaging process

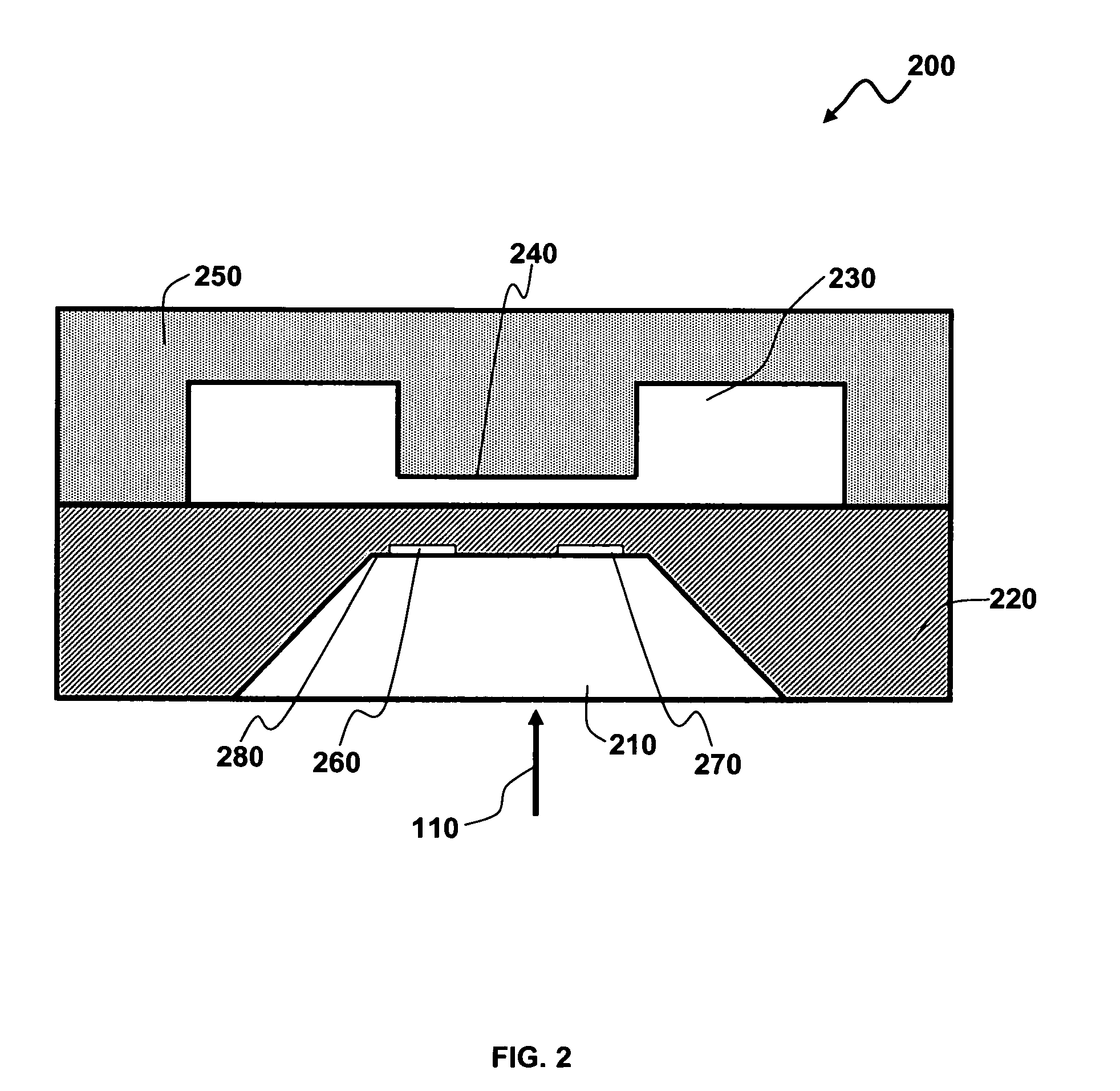

ActiveUS20100122583A1Fluid pressure measurement using ohmic-resistance variationFluid pressure measurement using elastically-deformable gaugesEffective solutionStress relieving

Method and system for a wet / wet differential pressure sensor based on microelectronic packaging process. A top cap with a hole can be attached to a topside of a MEMS-configured pressure sense die with a pressure sensing diaphragm in order to allow sensed media to come in contact with the topside of the pressure sensing diaphragm. An optional constraint with a hole for stress relief can be attached to a backside of the pressure sense die. Adhesive and / or elastomeric seals and / or solder can be utilized to seal the pressure sense die allowing sensed media to come in contact with both sides of the pressure sensing diaphragm without coming into contact with wirebonds and other metallized surfaces. The MEMS-configured pressure sense die can also be bonded to a substrate with standard die attach materials. Such microelectronic packaging processes yield a high performance and cost effective solution thereby providing wet-wet pressure sensing capability.

Owner:HONEYWELL INT INC

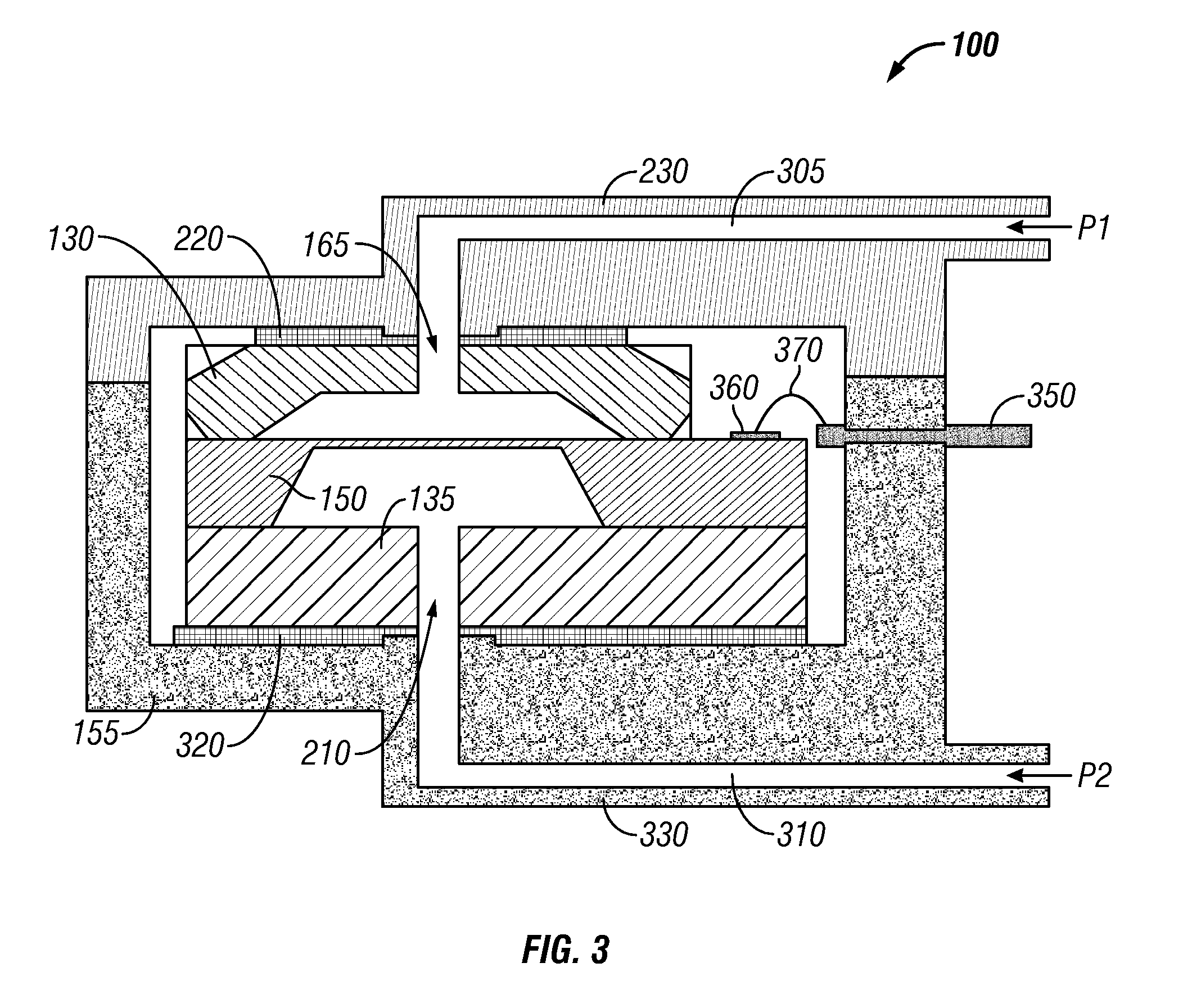

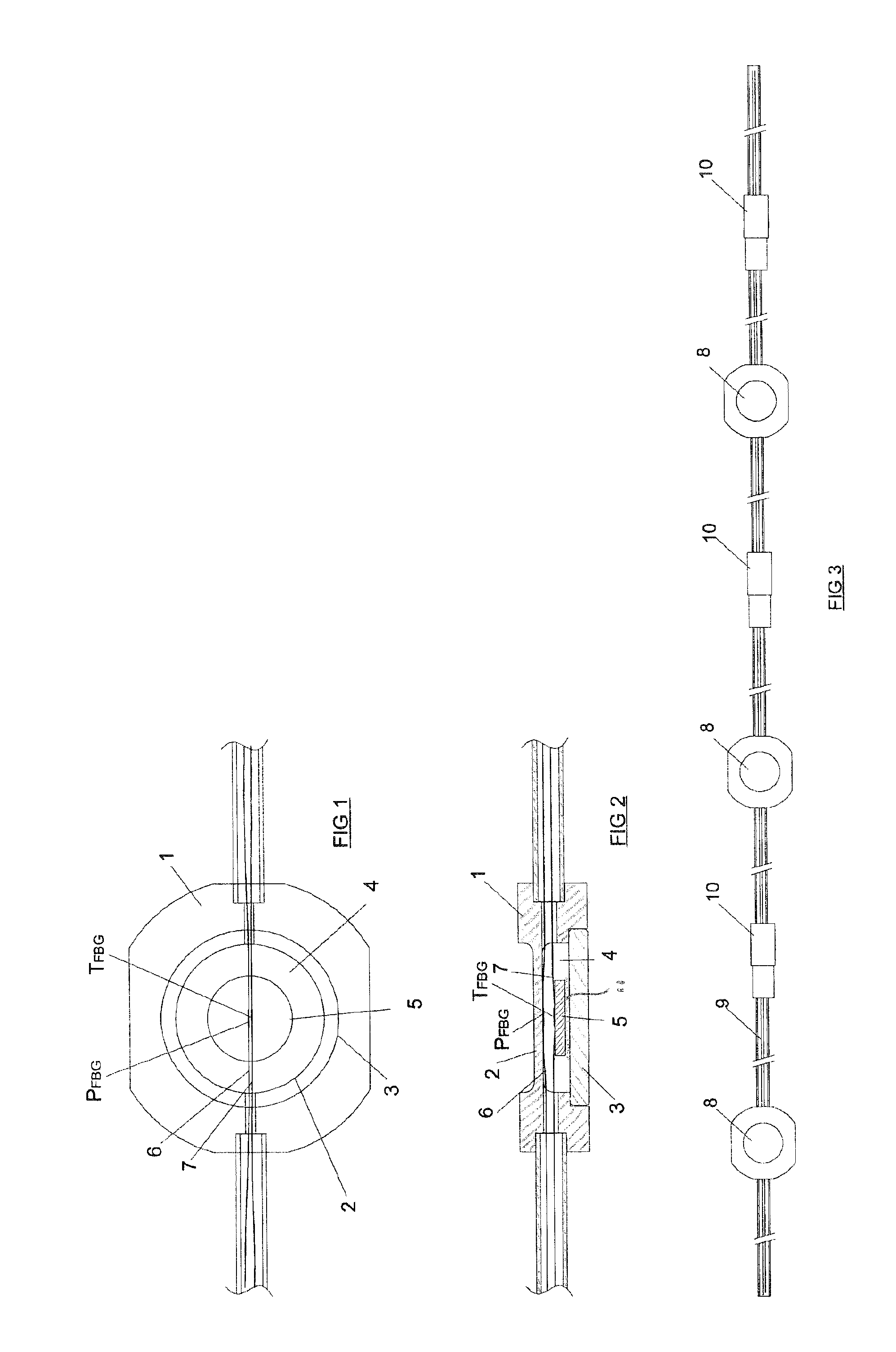

Pressure sensor assembly and method of using the assembly

A pressure sensor assembly comprises a sensor housing having a flexible wall that is configured to deform in response to a pressure difference between the interior and exterior of the sensor housing; —a first fiber optical cable section that is bonded to the flexible wall of the sensor housing such that the length of the first fiber optical cable section changes in response to deformation of the wall in response to the said pressure difference; a second fiber optical cable section which is bonded to a thermal reference body, which body is connected to the sensor housing by a strain decoupled connection mechanism, such as a tack weld or flexible glue, and is configured to deform substantially solely in response to thermal deformation, such that the length of the second fiber optical cable section solely changes in response to thermal deformation of the thermal reference body.

Owner:SHELL USA INC

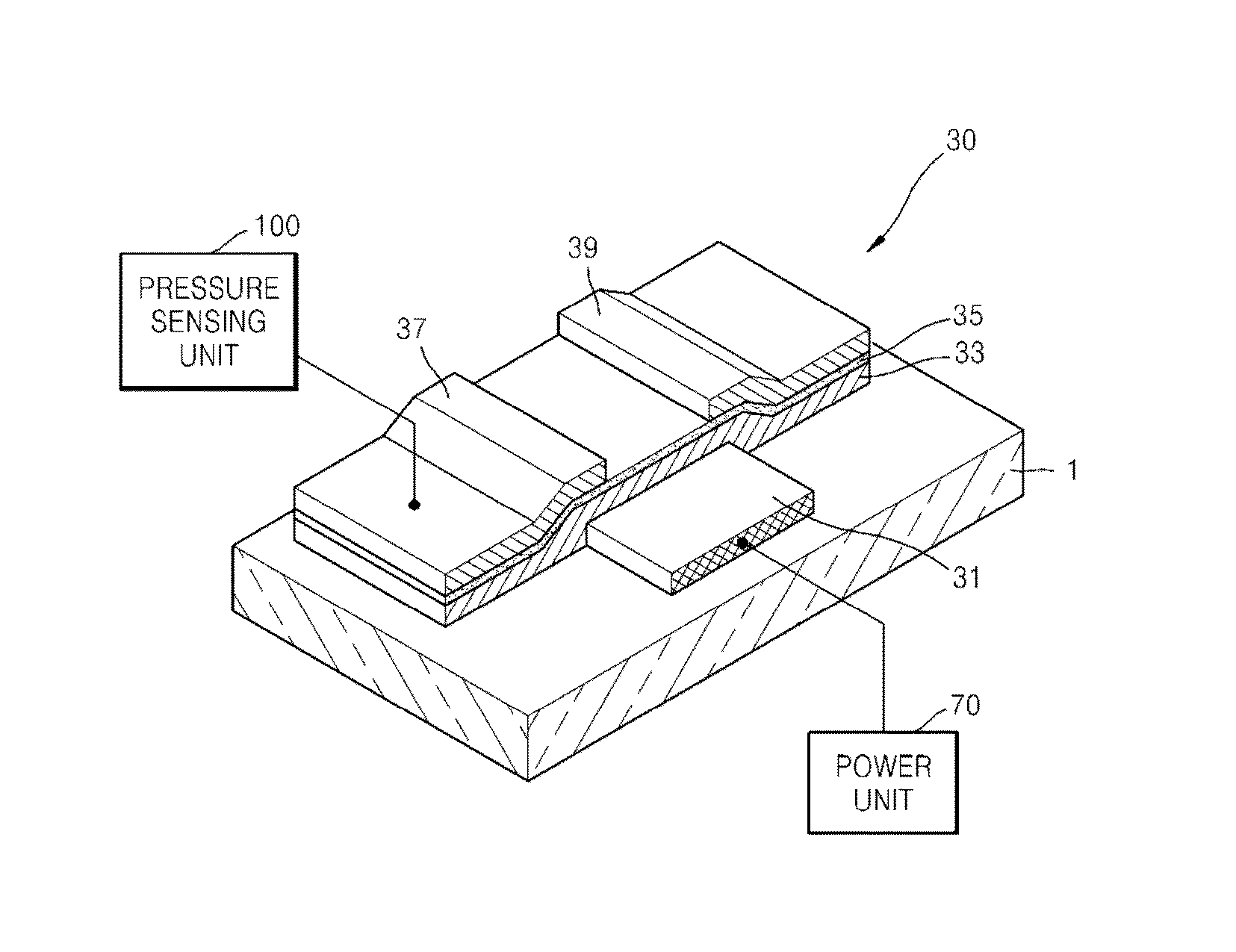

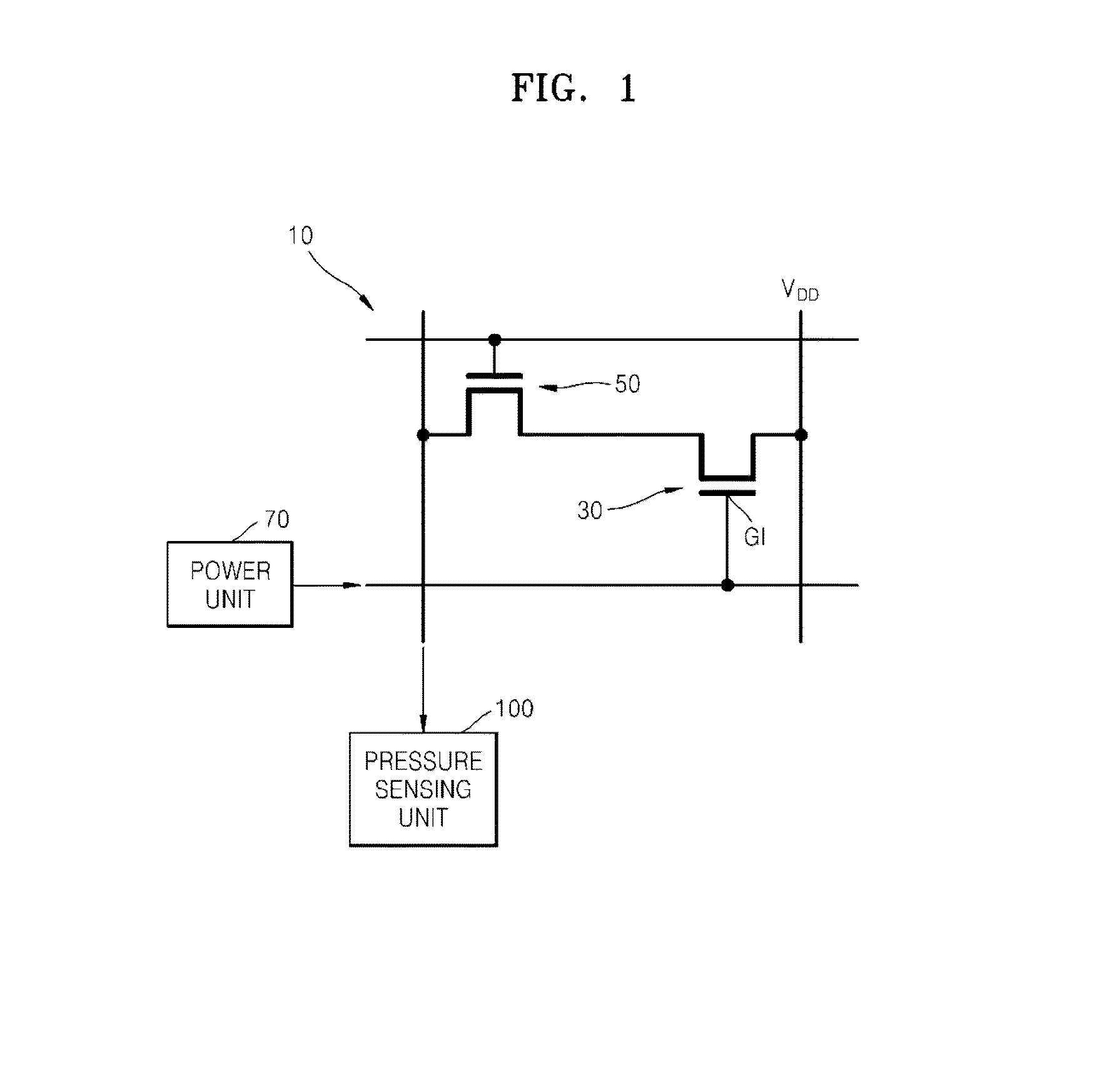

Pressure sensor and pressure sensing method

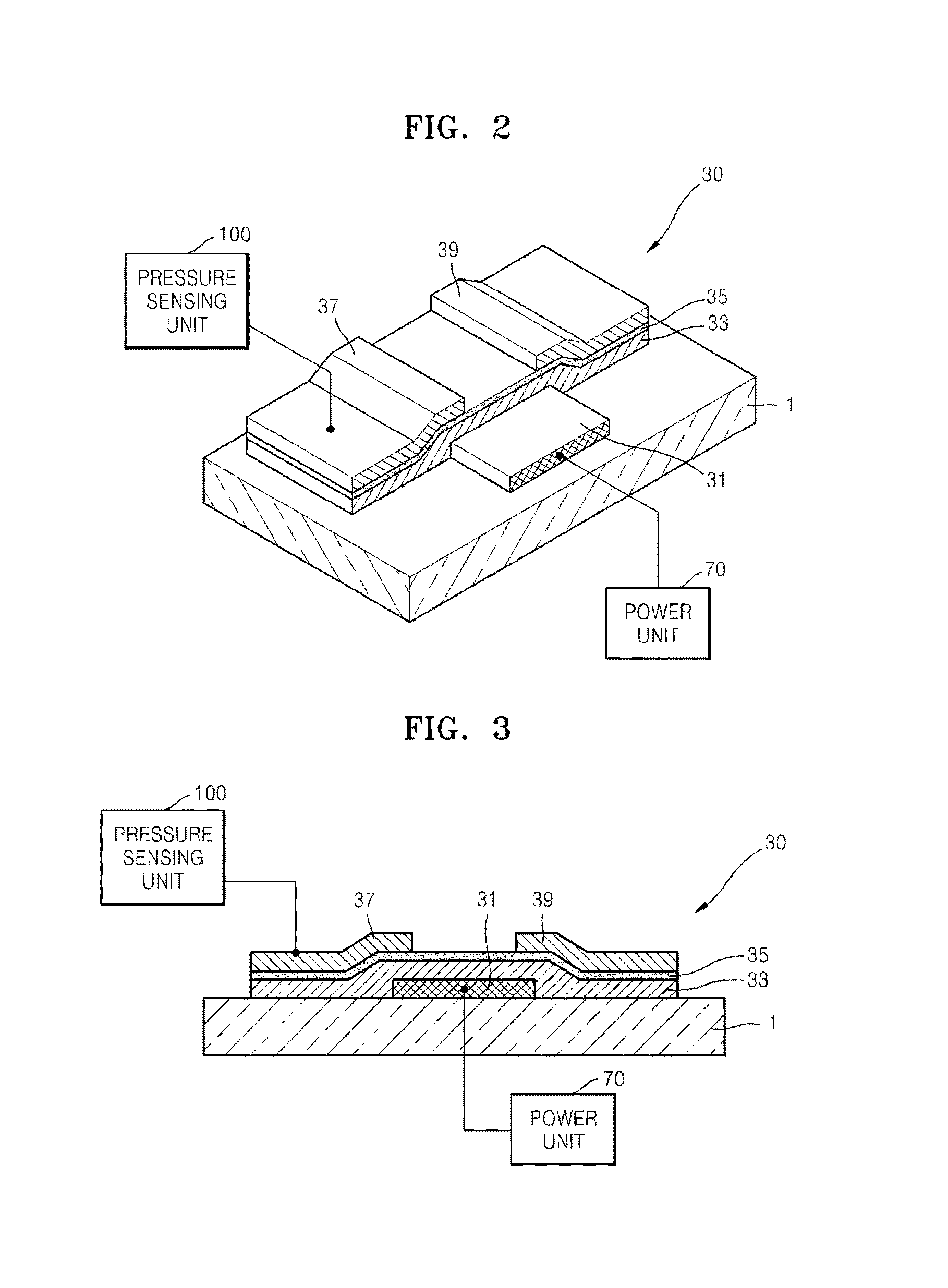

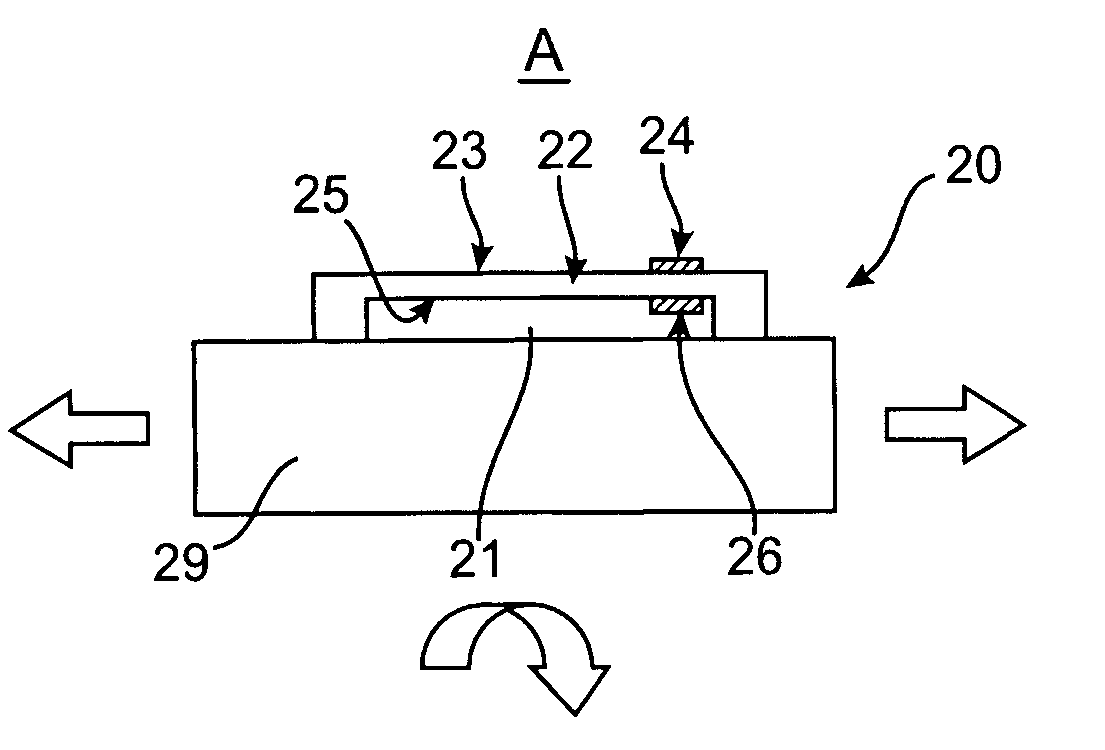

ActiveUS20140060210A1Fluid pressure measurement using ohmic-resistance variationForce measurement using piezo-electric devicesPressure senseEngineering

A pressure sensor and a pressure sensing method are provided. The pressure sensor includes a substrate; a sensor thin film transistor (TFT) disposed on the substrate and including a gate insulating layer, wherein the gate insulating layer includes an organic matrix in which piezoelectric inorganic nano-particles are dispersed; a power unit configured to apply an alternating current (AC) signal to a gate of the sensor TFT; and a pressure sensing unit configured to obtain a remnant polarization value based on a drain current which is generated in response to the AC signal and detected by the sensor TFT, and to sense a pressure based on the remnant polarization value.

Owner:SAMSUNG ELECTRONICS CO LTD +1

Pressure sensors having transducers positioned to provide for low drift

ActiveUS20050160827A1Fluid pressure measurement using ohmic-resistance variationFluid pressure measurement using elastically-deformable gaugesTransducerSubject matter

Owner:PROTEUS DIGITAL HEALTH INC

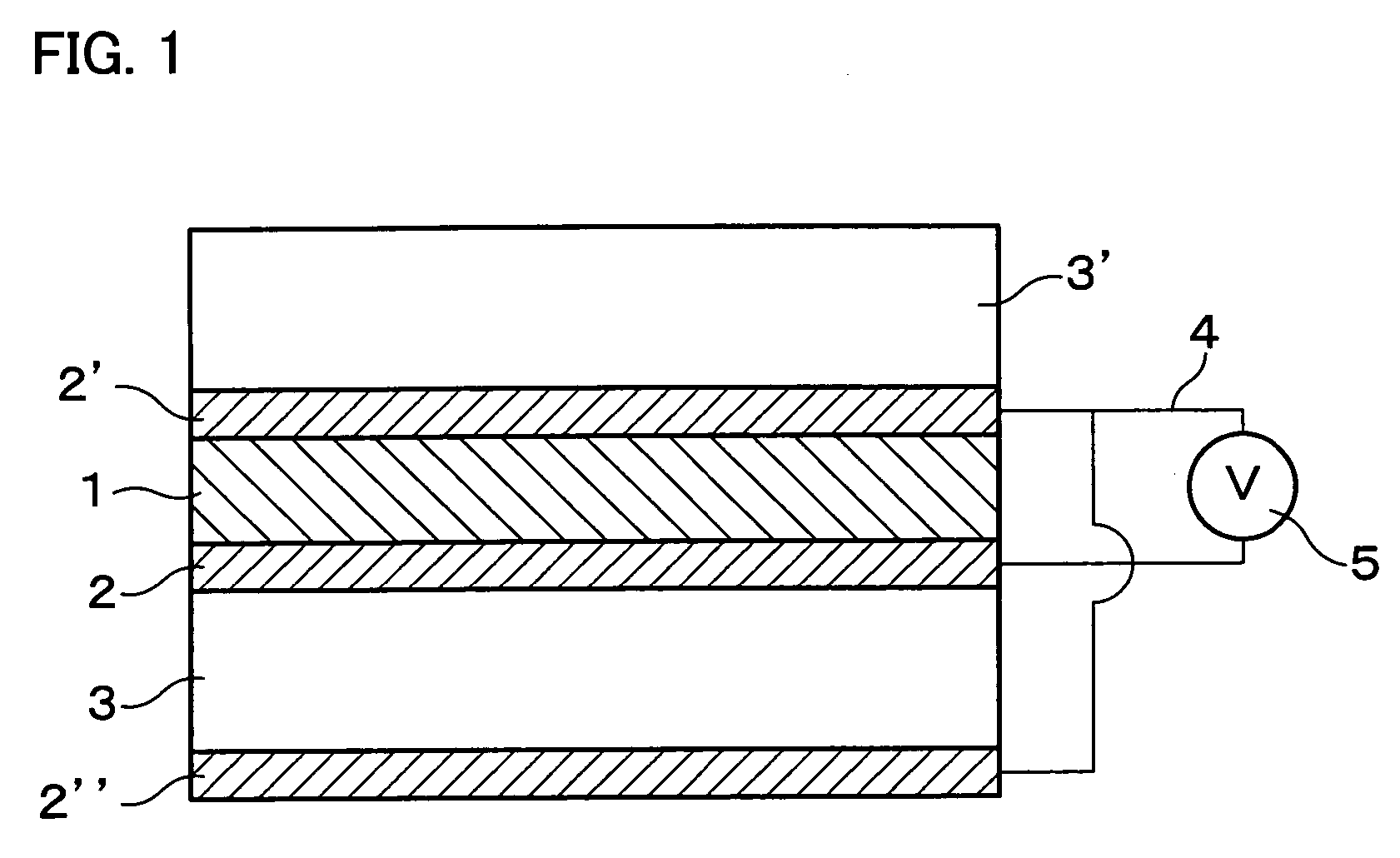

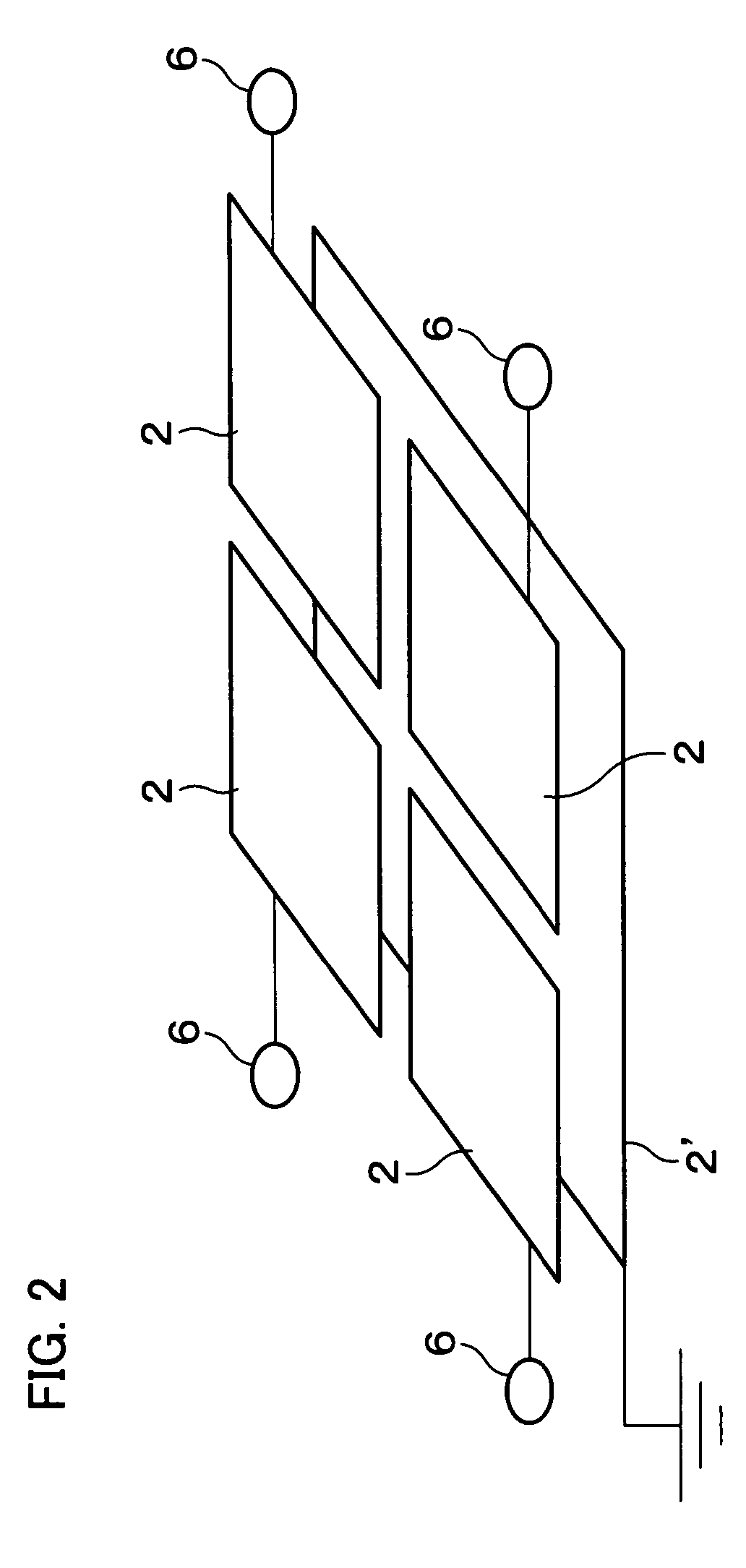

Exhaust gas recirculation system using absolute micromachined pressure sense die

ActiveUS6945120B1Fluid pressure measurement using ohmic-resistance variationFluid pressure measurement by mechanical elementsElectricityAutomatic control

An absolute pressure sensor is disclosed that includes a plurality of pressure sense die and a hermetically sealed cover located above the plurality of pressure sense die. A carrier can be provided to which the pressure sense die are mounted by a cured adhesive. The carrier and the pressure sense die can be attached to a circuit board populated with a plurality of surface mounted components for electrical connection to the absolute pressure sensor. An ASIC can also be provided for digitally calibrating the pressure sense die with temperature compensation, wherein the ASIC automatically controls a plurality of output modes thereof during calibration.

Owner:HONEYWELL INT INC

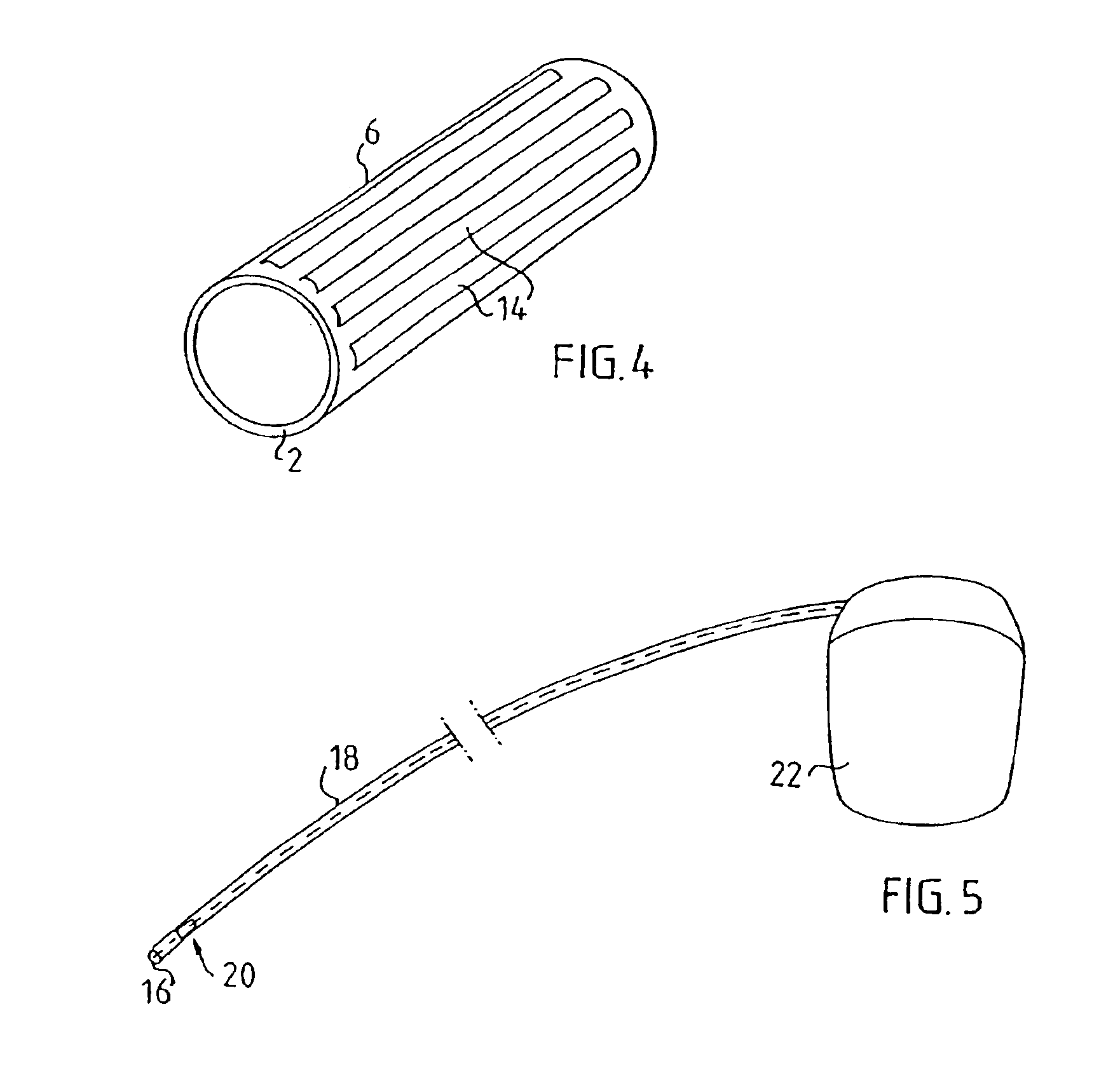

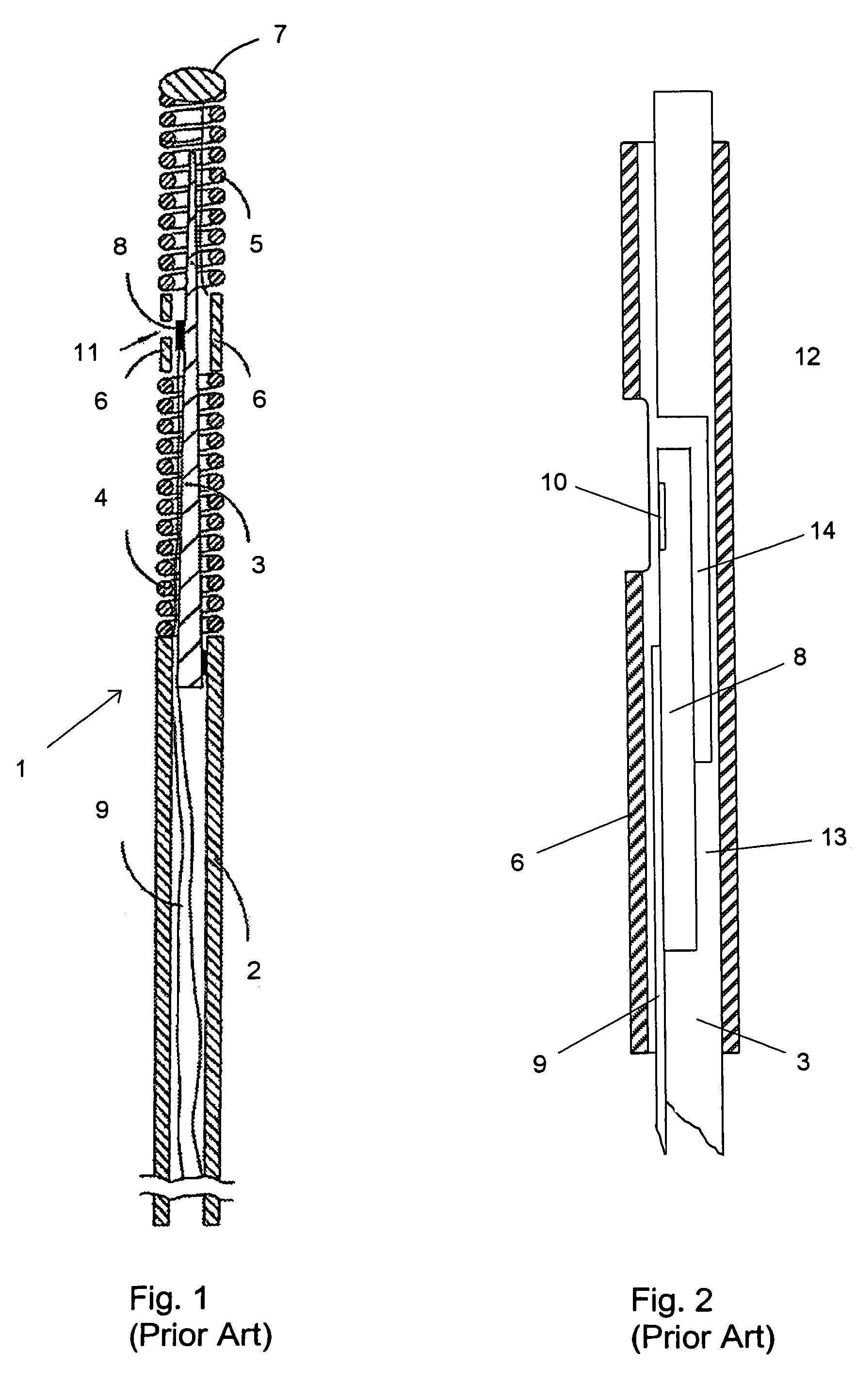

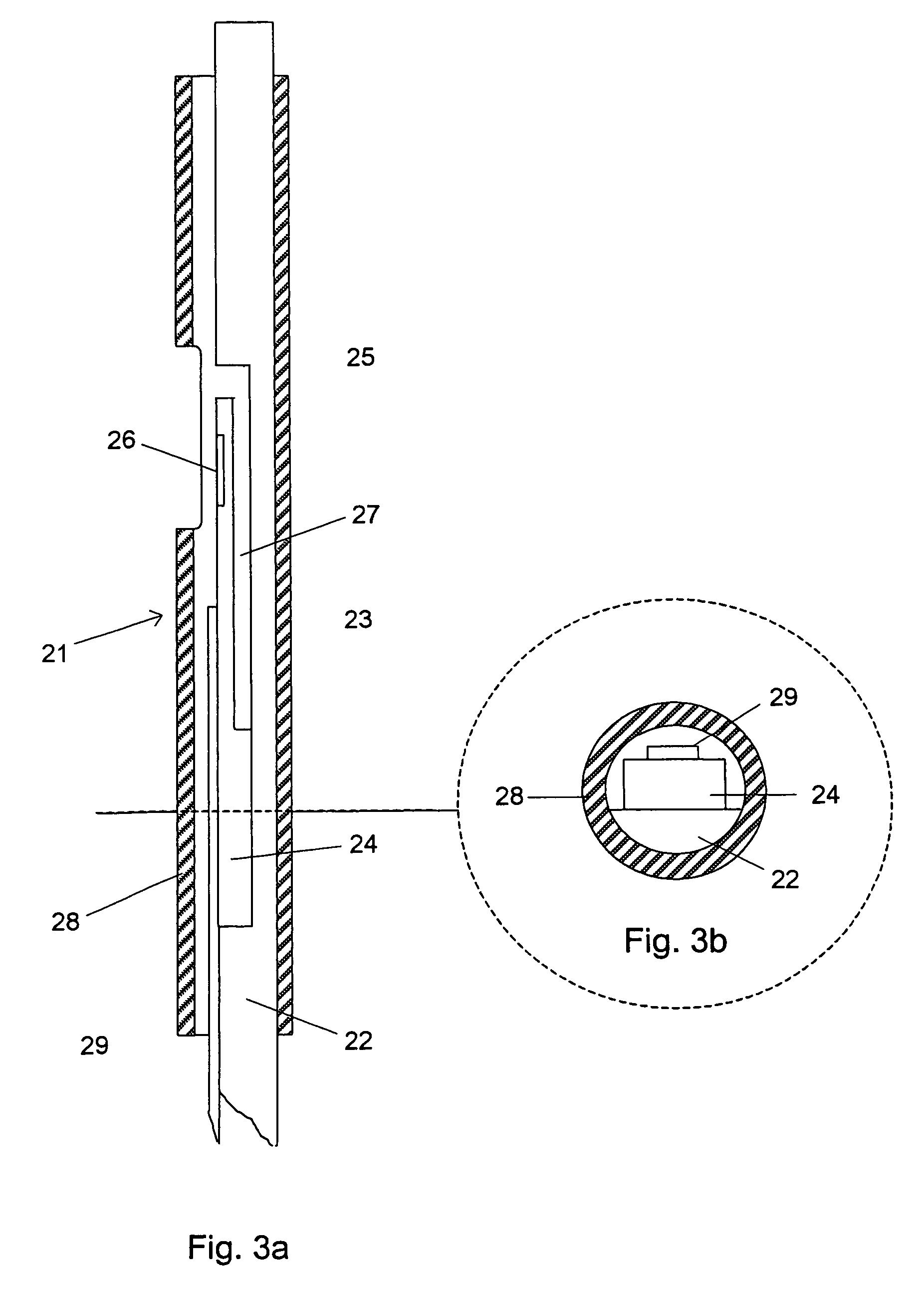

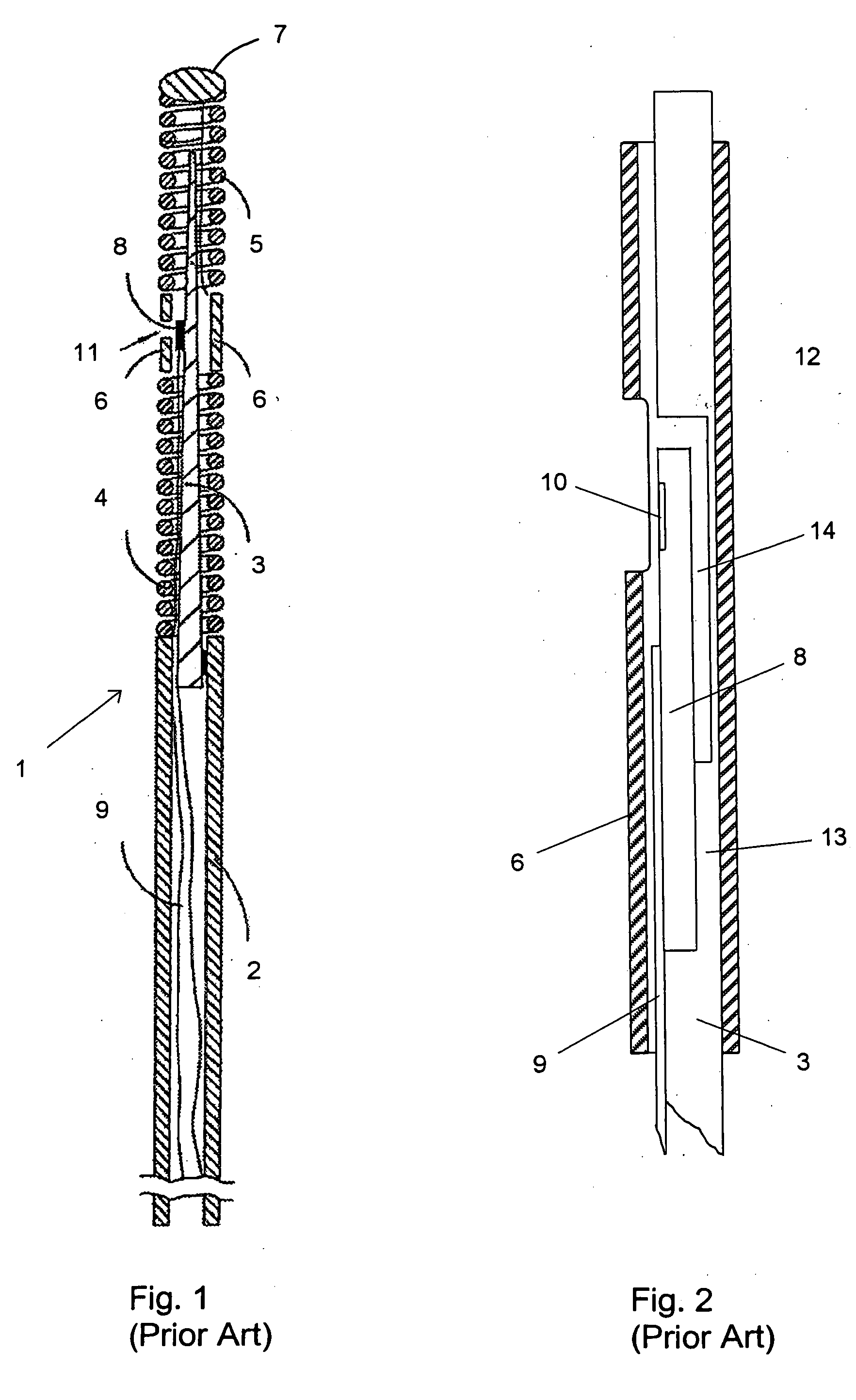

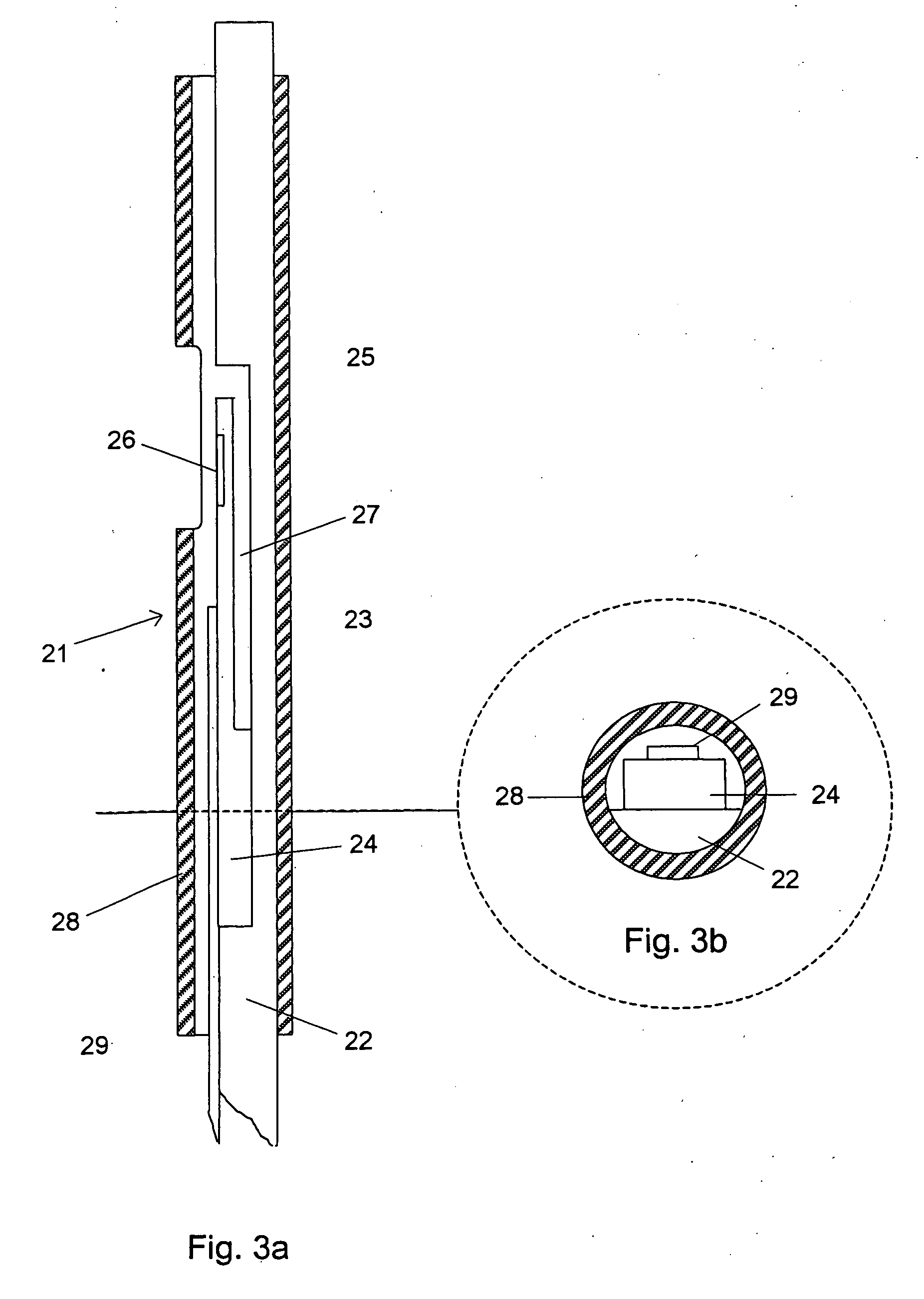

Sensor and guide wire assembly

InactiveUS6993974B2Same or better characteristics regarding resistance against bending artefactsReduce manufacturing costFluid pressure measurement using ohmic-resistance variationGuide wiresBiological bodyLiving body

Owner:ST JUDE MEDICAL COORDINATION CENT

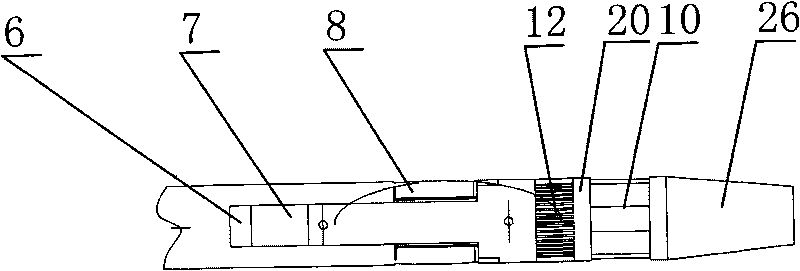

Scale measuring device for pitching dynamic derivative experiment

InactiveCN101726401AAccurate detectionDesign scienceSubsonic/sonic/ultrasonic wave measurementAerodynamic testingMeasurement deviceDrive shaft

The invention provides a scale measuring device for a pitching dynamic derivative experiment. An electric motor is arranged in a motor support rod; a motor output shaft is connected with a transmission shaft via a speed reducer and a shaft coupling; the transmission shaft is rotationally connected with a scale support rod; the rear end of the scale support rod is fixedly connected with the front end of the motor support rod; the front end of the transmission shaft is provided with an eccentric wheel which is provided with a lug; the lug is inserted into a sliding chute of a slide block; upper and lower cross springs of a cross spring scale have a crisscross structure respectively, and the front and rear ends thereof are fixedly connected with a scale frame via a front seat; and central positions of the upper and lower cross springs are provided with supporting cylinders. The scale measuring device for the pitching dynamic derivative experiment is a novel pitching dynamic derivative scale device. A pitching direct derivative of an aerial craft and a rolling crossover derivative induced by yaw oscillation can be measured under a big attack angle by designing a special vibrating mechanism, the cross spring scale and a pitching five-component scale structure. The scale measuring device for the pitching dynamic derivative experiment can meet the requirement of a wind tunnel trial.

Owner:SHENGYANG AERODYNAMIC INST AVIATION IND CORP OF CHINA

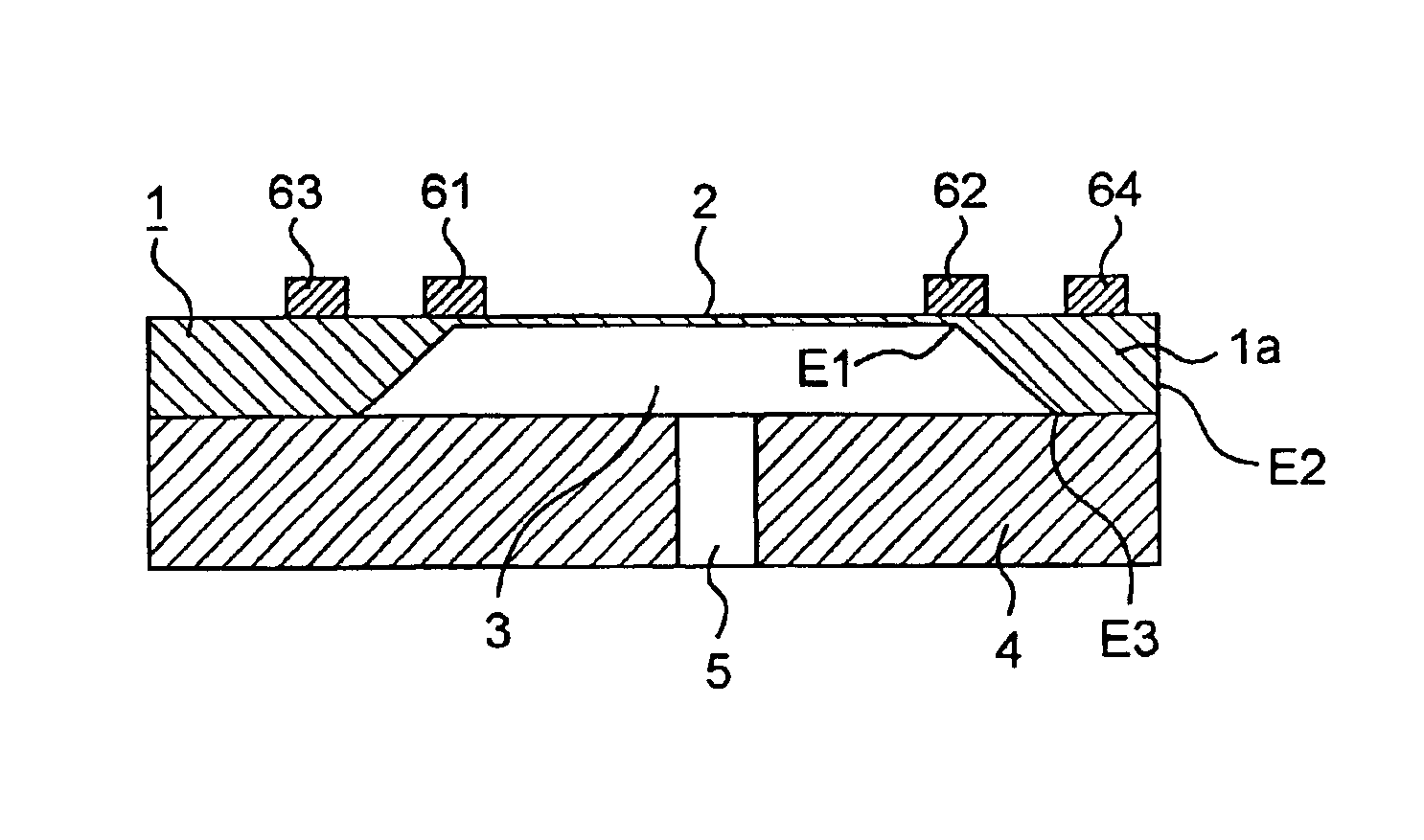

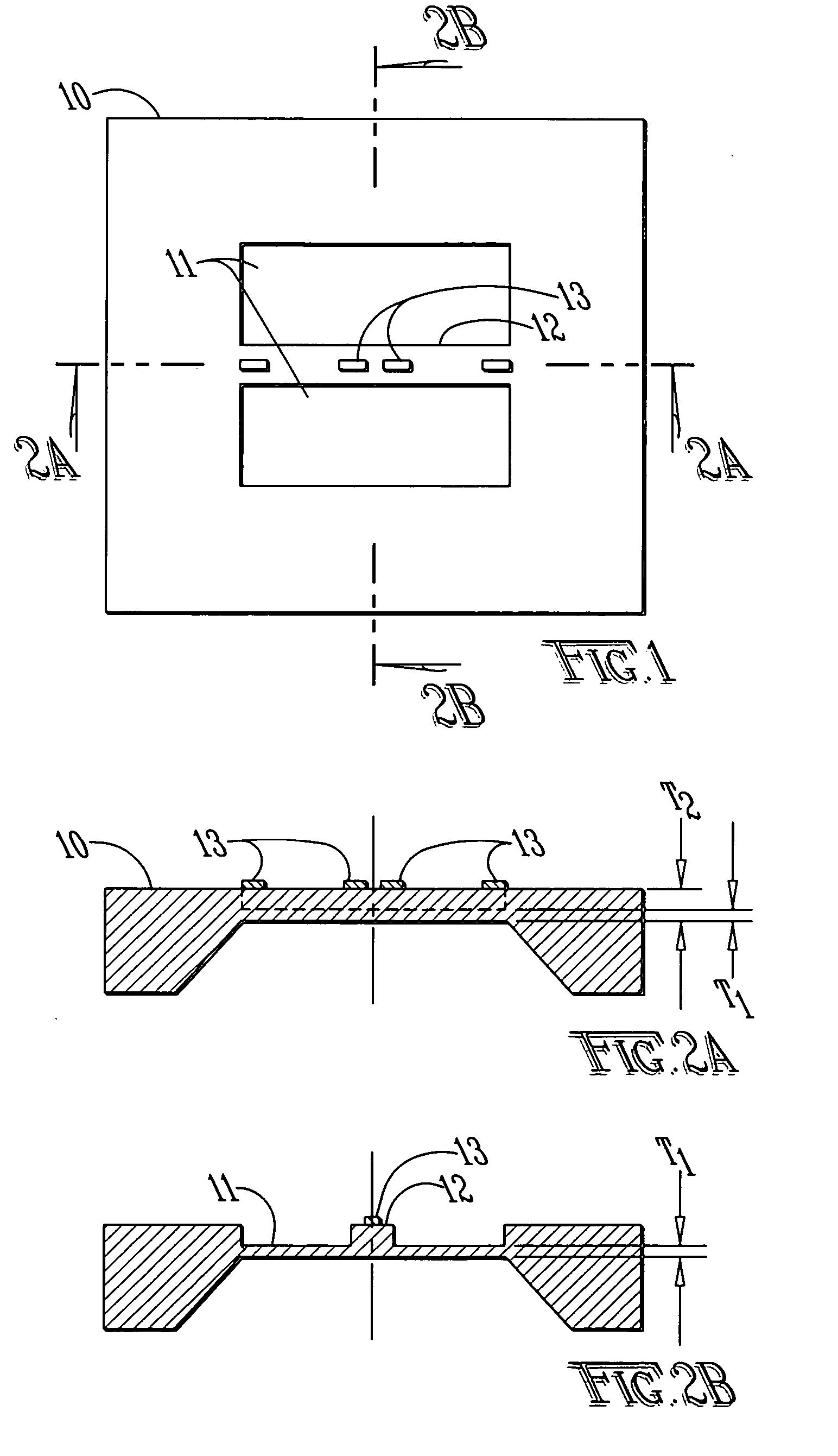

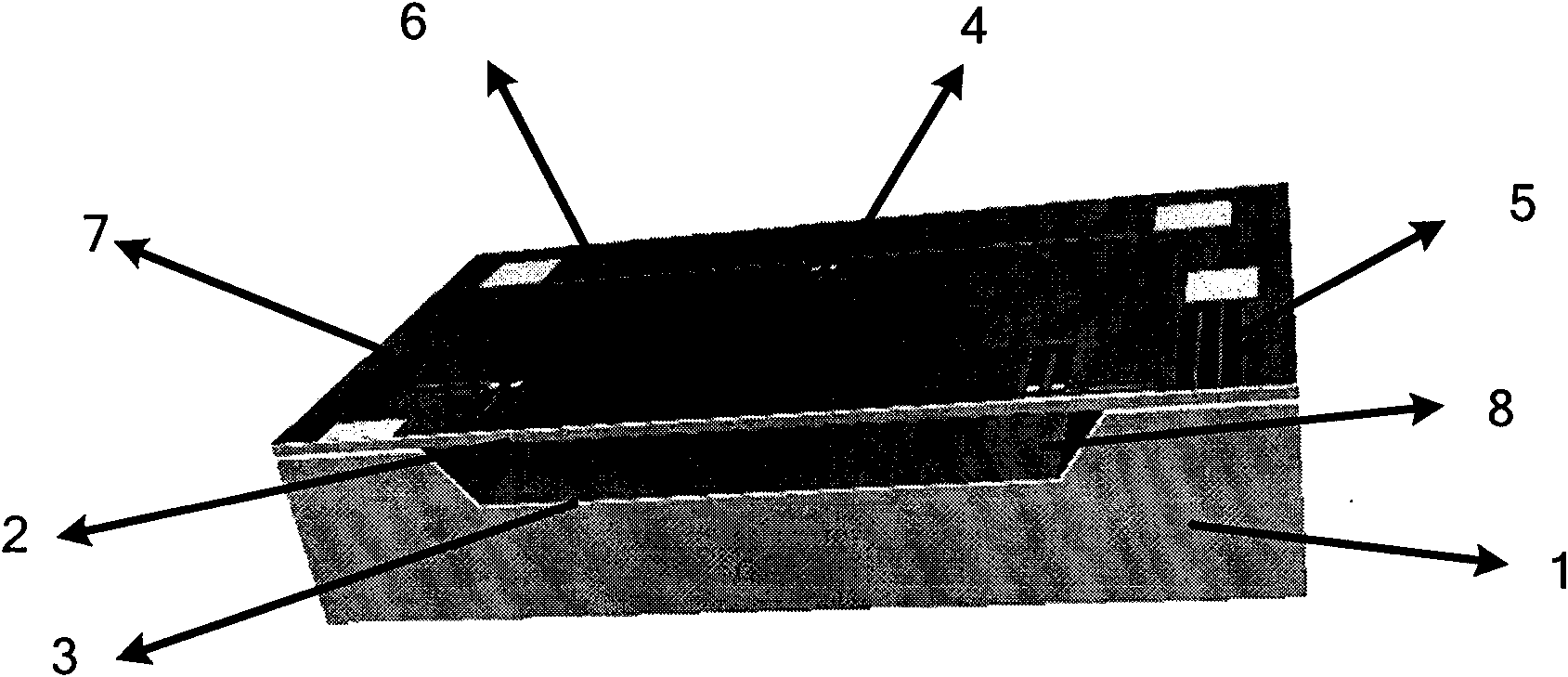

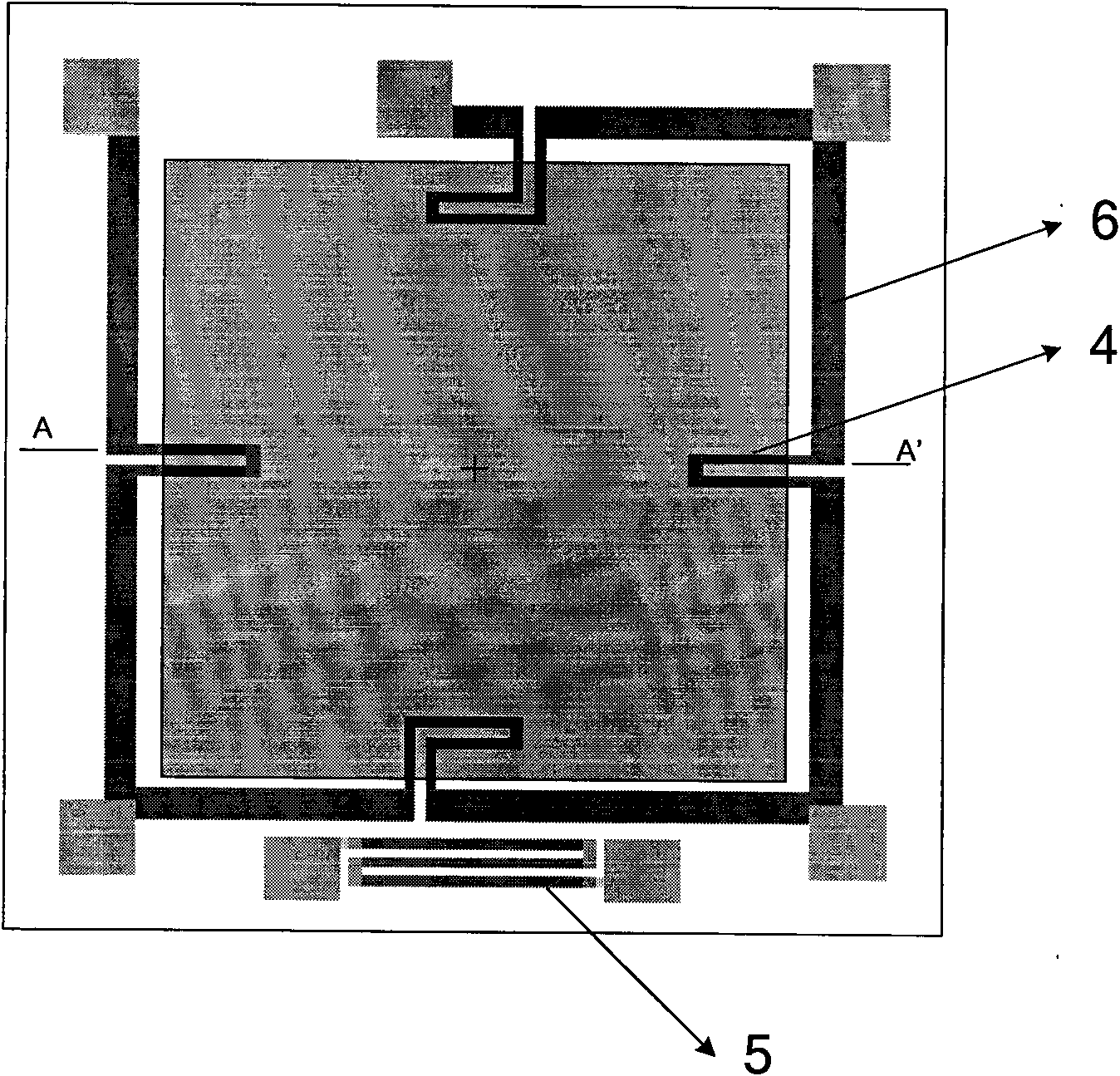

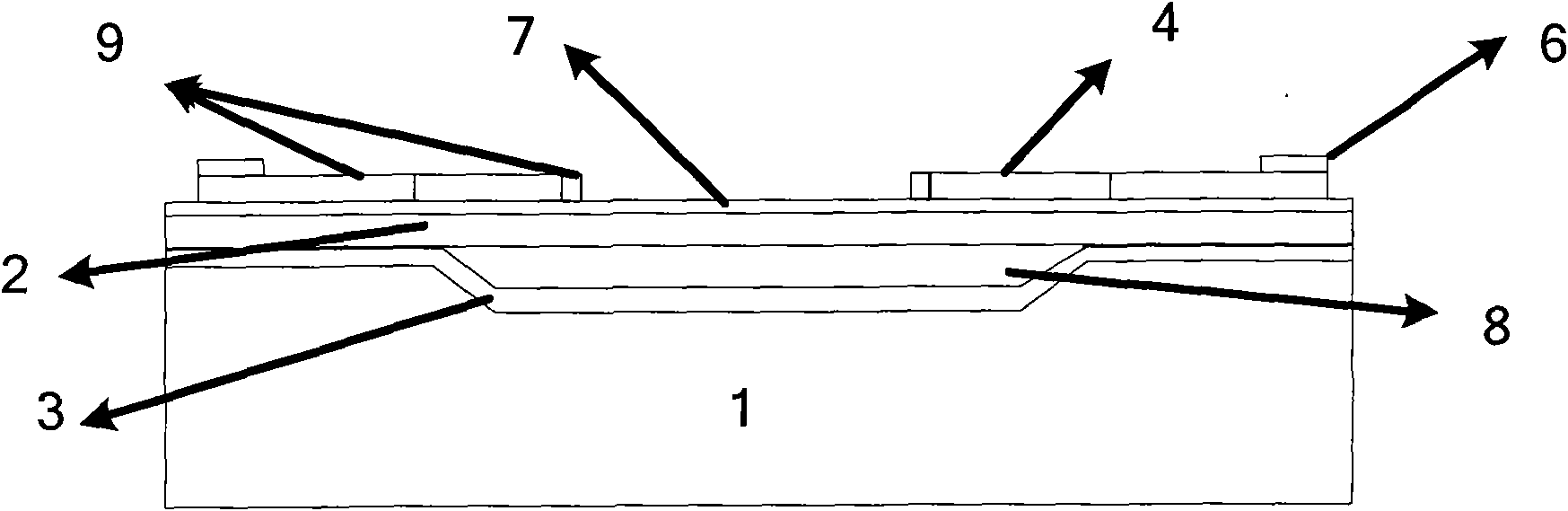

Pressure sensor based on Si-Si direct bonding and manufacturing method thereof

InactiveCN101551284APrecise size controlOvercome performance degradation flawsTelevision system detailsSemi-permeable membranesWorking temperatureBoron

The invention discloses a pressure sensor based on Si-Si direct bonding, comprising a silicon substrate (1) with a shallow groove (8); the silicon substrate (1) is provided with a single crystal silicon stress membrane (2); a silicon dioxide layer (3) is arranged between the silicon substrate (1) and the stress membrane (2); four P-type single crystal silicon piezoresistors (4) are arranged on the stress membrane (2); an insulating medium silicon dioxide layer (7) is arranged among the stress membrane (2) and the piezoresistors (4); and a Wheatstone bridge is formed among the piezoresistors (4) by utilizing concentrated boron doped silicon (9) and a golden lead (6). The pressure sensor adopts Si-Si direct bonding technology to form the stress membrane and the sealing cavity; the piezoresistors thereof adopt silicon dioxide as an insulating layer and the working temperature can be up to 300 DEG C; and the pressure sensor has firm structure and excellent performance and can meet the requirements on high-temperature pressure sensors in the fields of automobile, aerospace and the like. The invention also relates to a manufacturing method of the pressure sensor.

Owner:江苏英特神斯科技有限公司

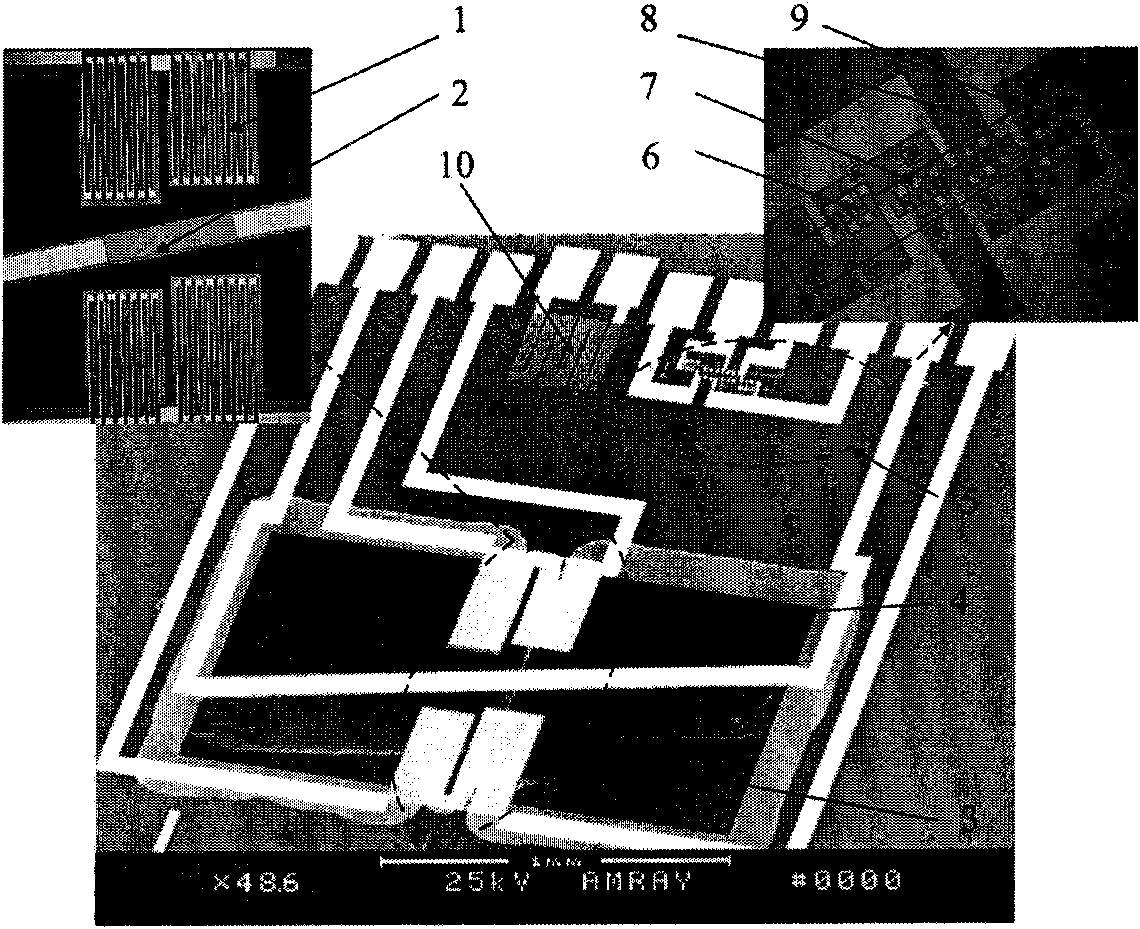

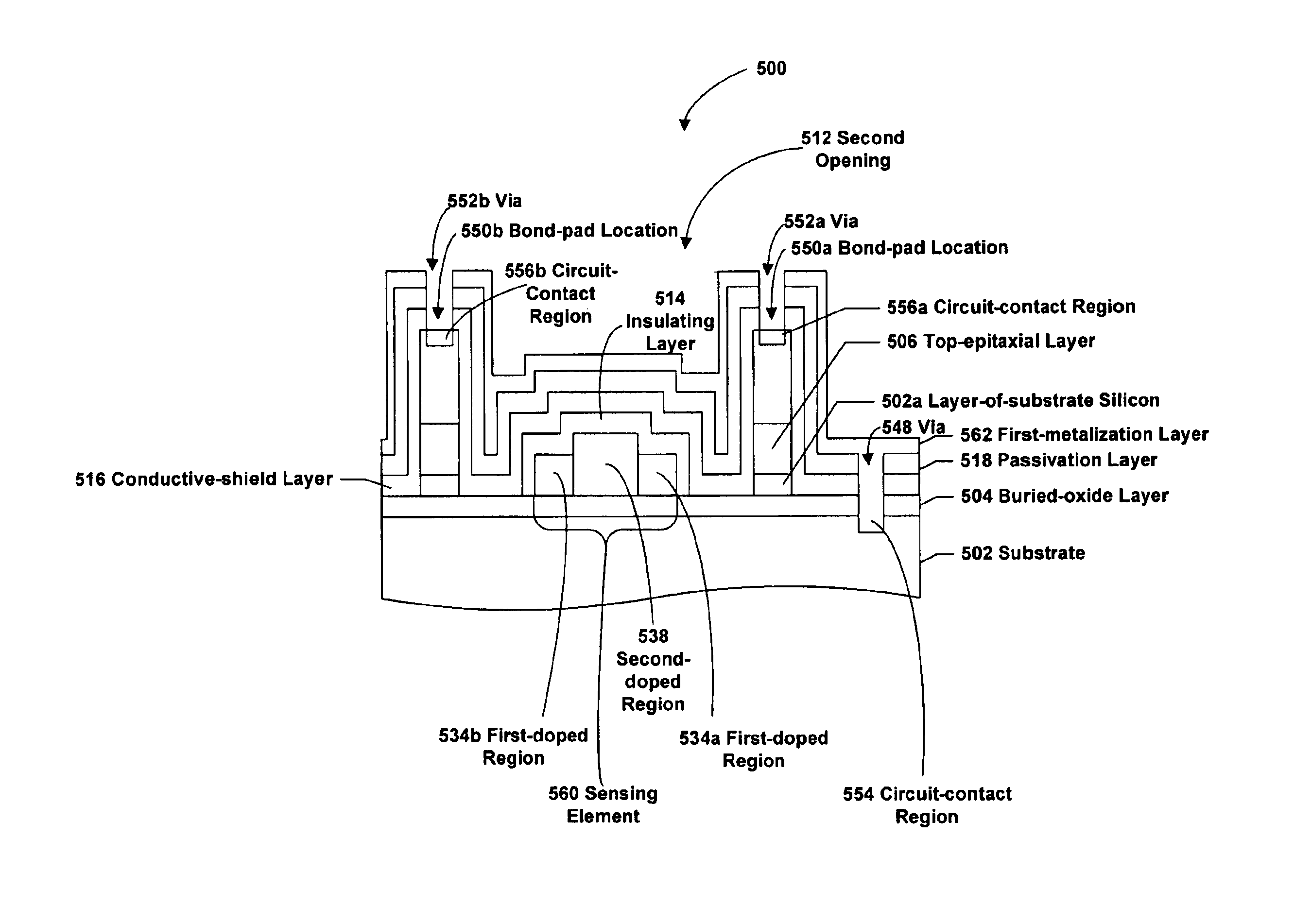

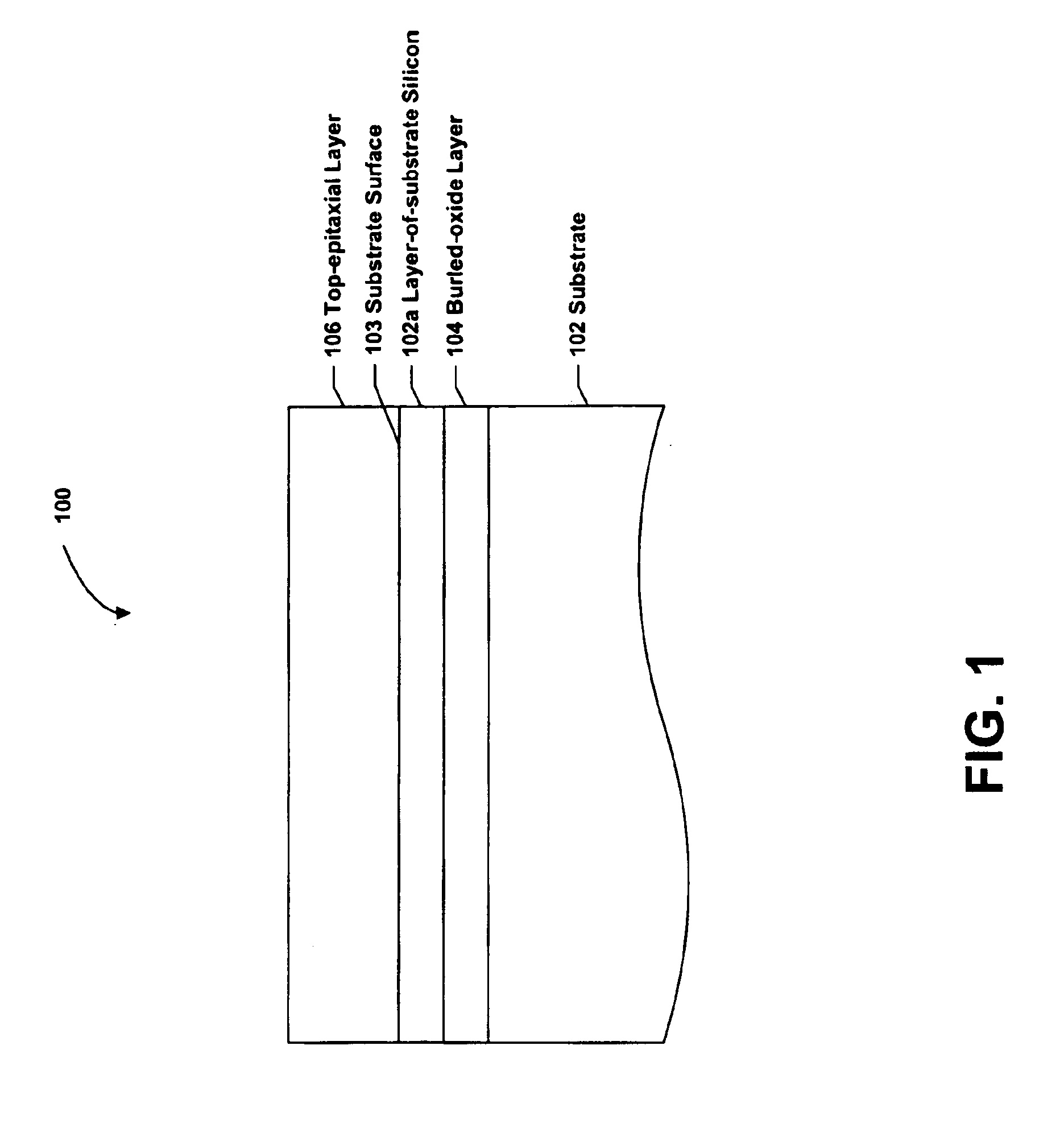

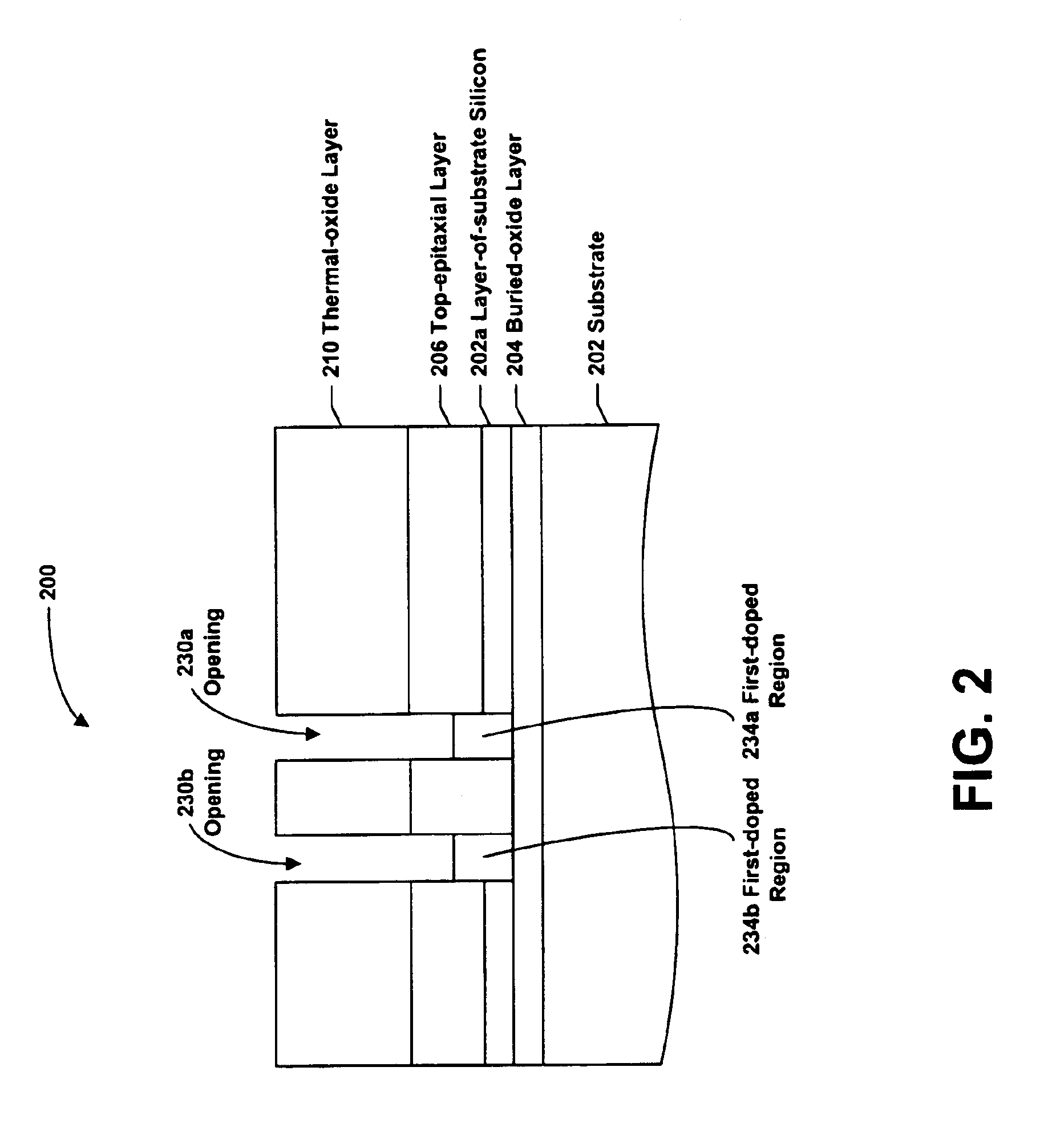

Microelectromechanical device with integrated conductive shield

InactiveUS6952042B2Television system detailsAcceleration measurement using interia forcesMicroelectromechanical systemsEngineering

A microelectromechanical device and method of fabricating the same, including a layer of patterned and deposited metal or mechanical-quality, doped polysilicon inserted between the appropriate device element layers, which provides a conductive layer to prevent the microelectromechanical device's output from drifting. The conductive layer may encapsulate of the device's sensing or active elements, or may selectively cover only certain of the device's elements. Further, coupling the metal or mechanical-quality, doped polysilicon to the same voltage source as the device's substrate contact may place the conductive layer at the voltage of the substrate, which may function as a Faraday shield, attracting undesired, migrating ions from interfering with the output of the device.

Owner:HONEYWELL INT INC

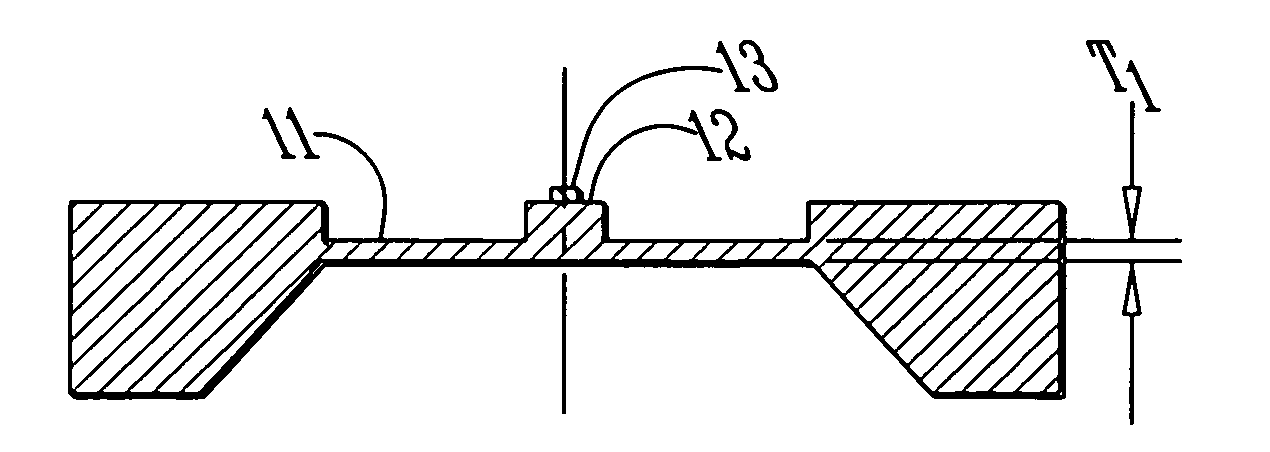

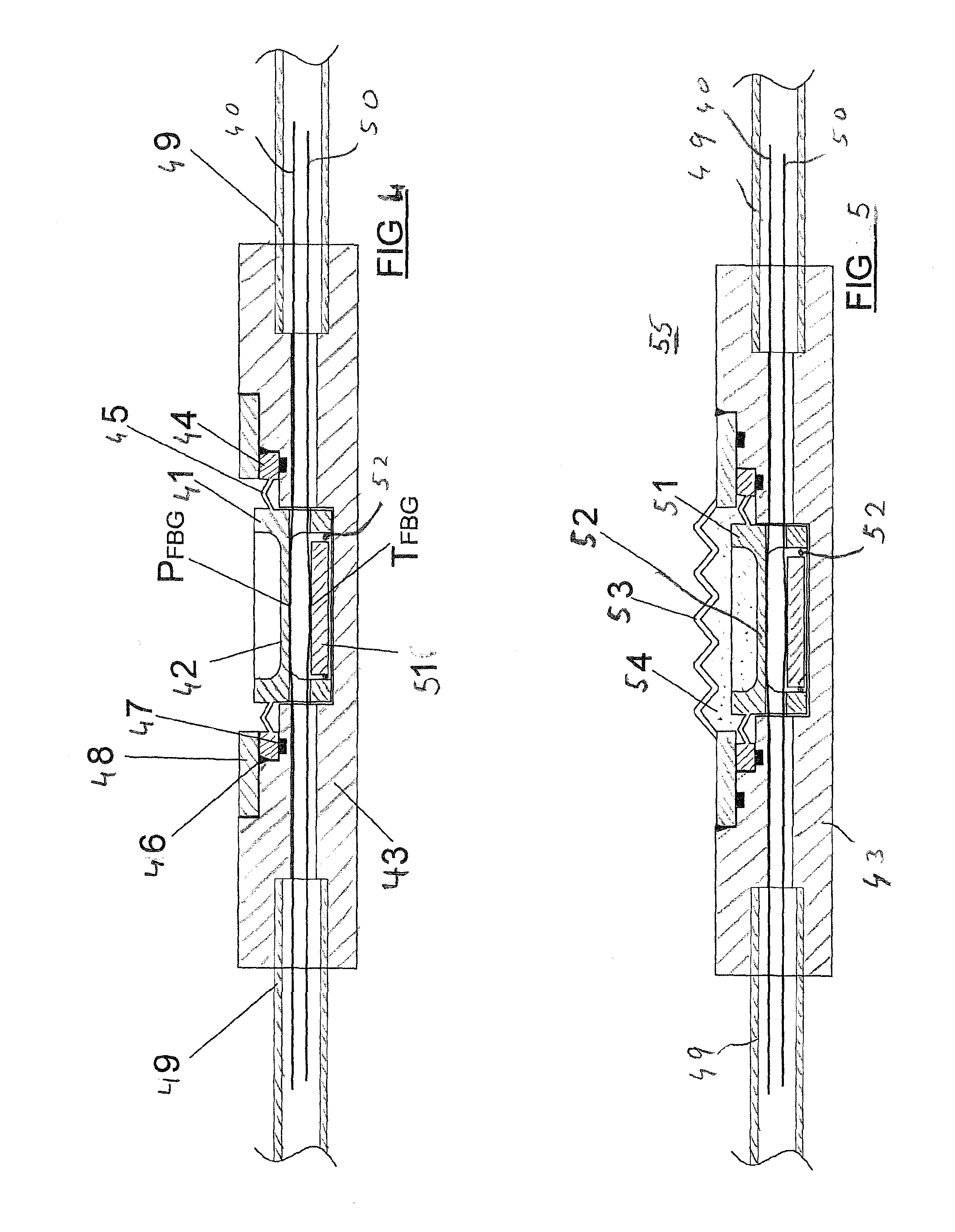

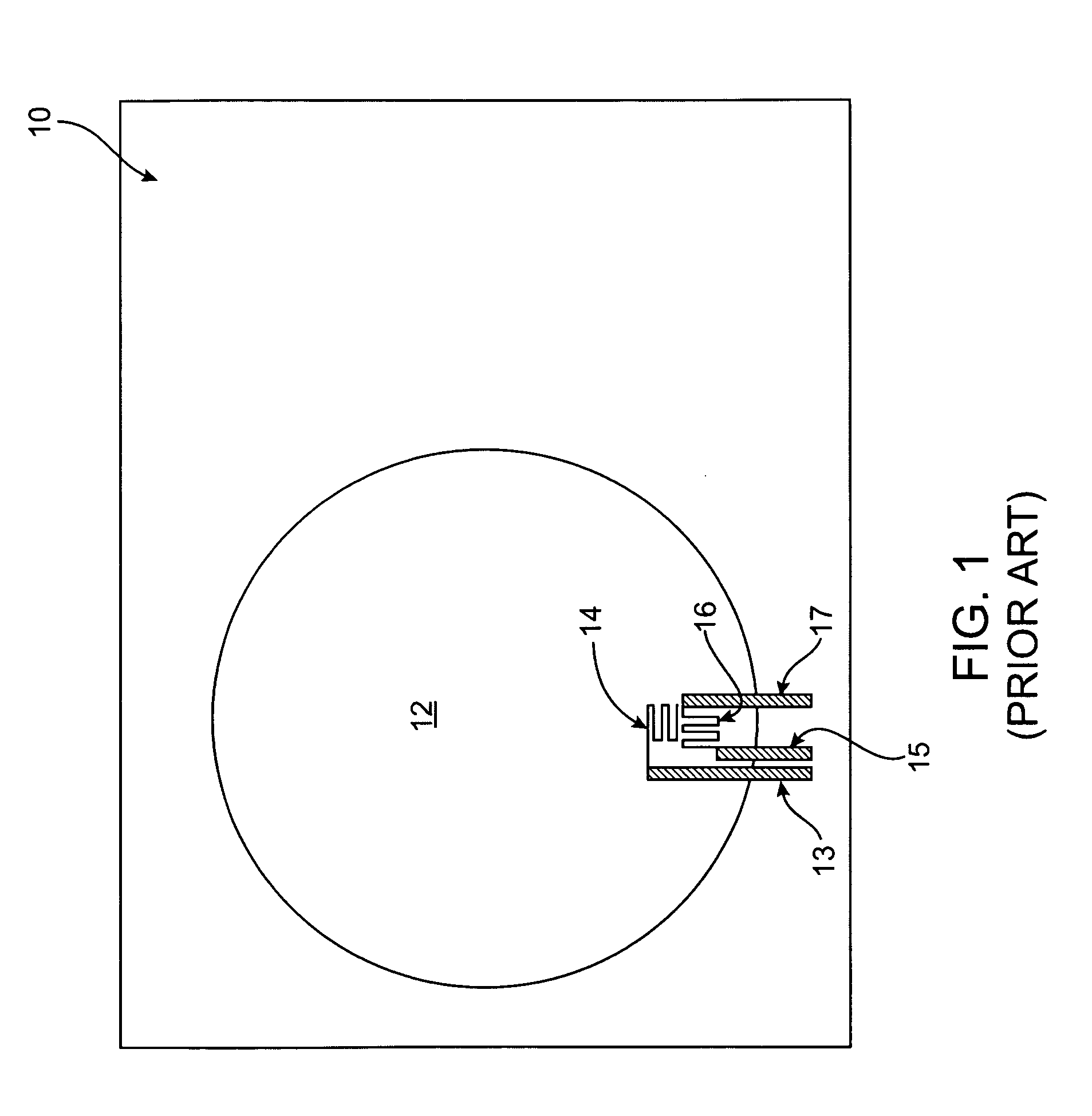

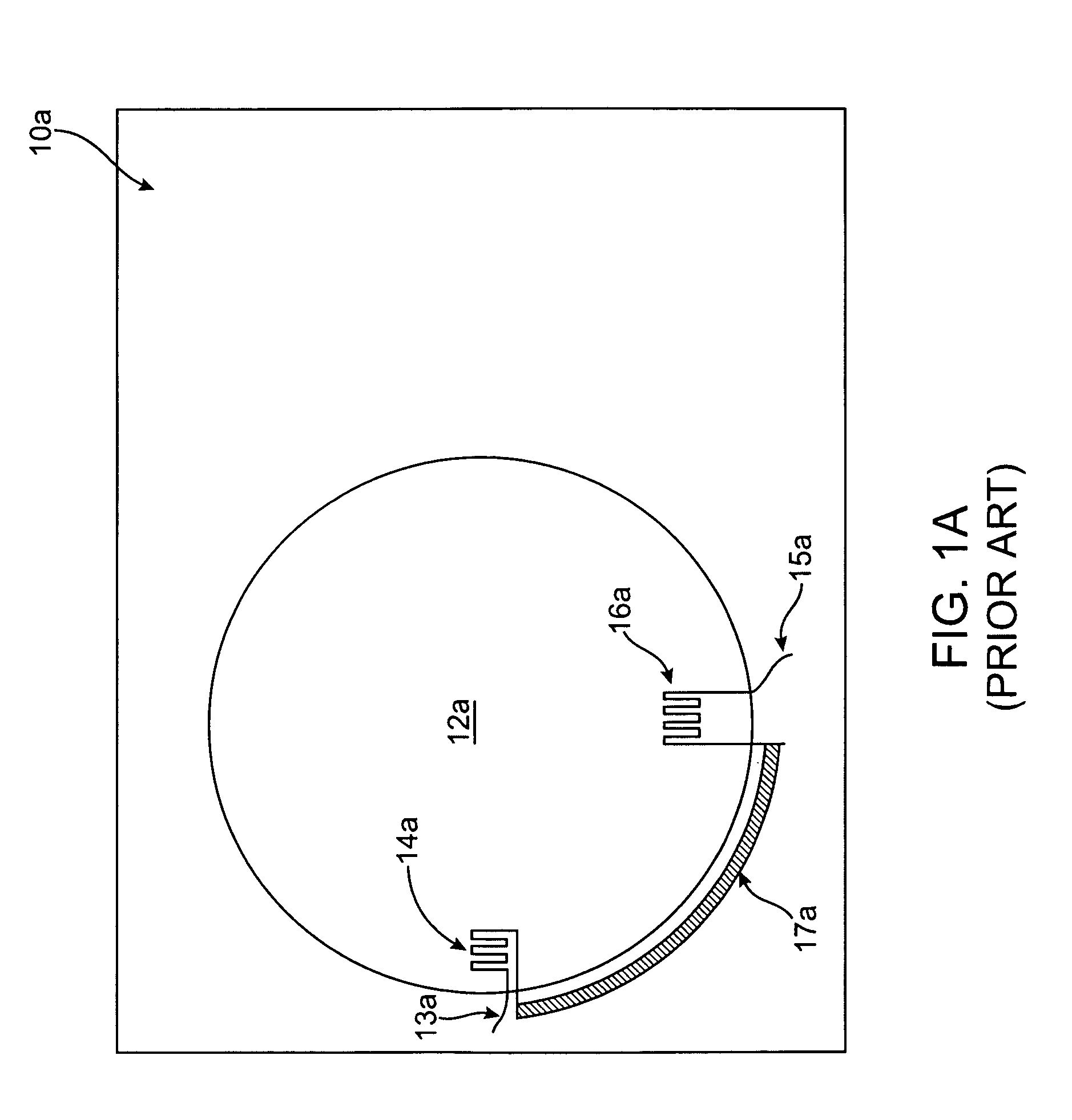

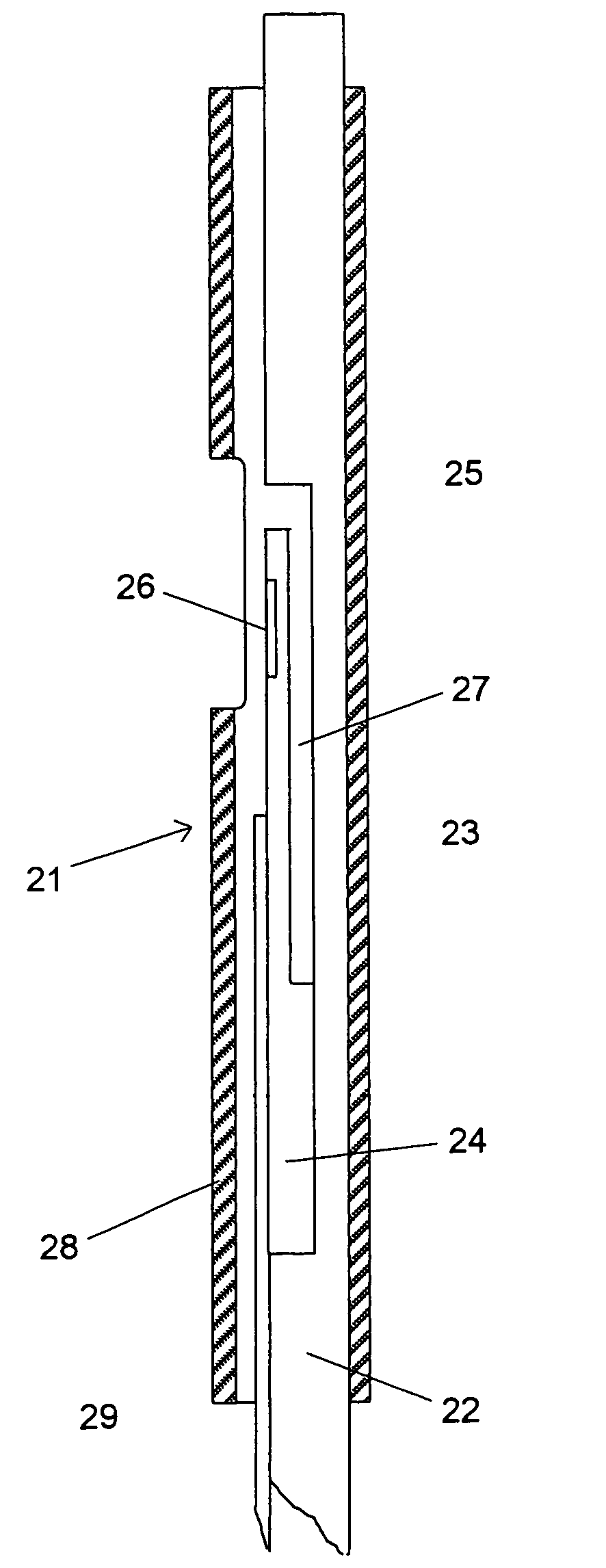

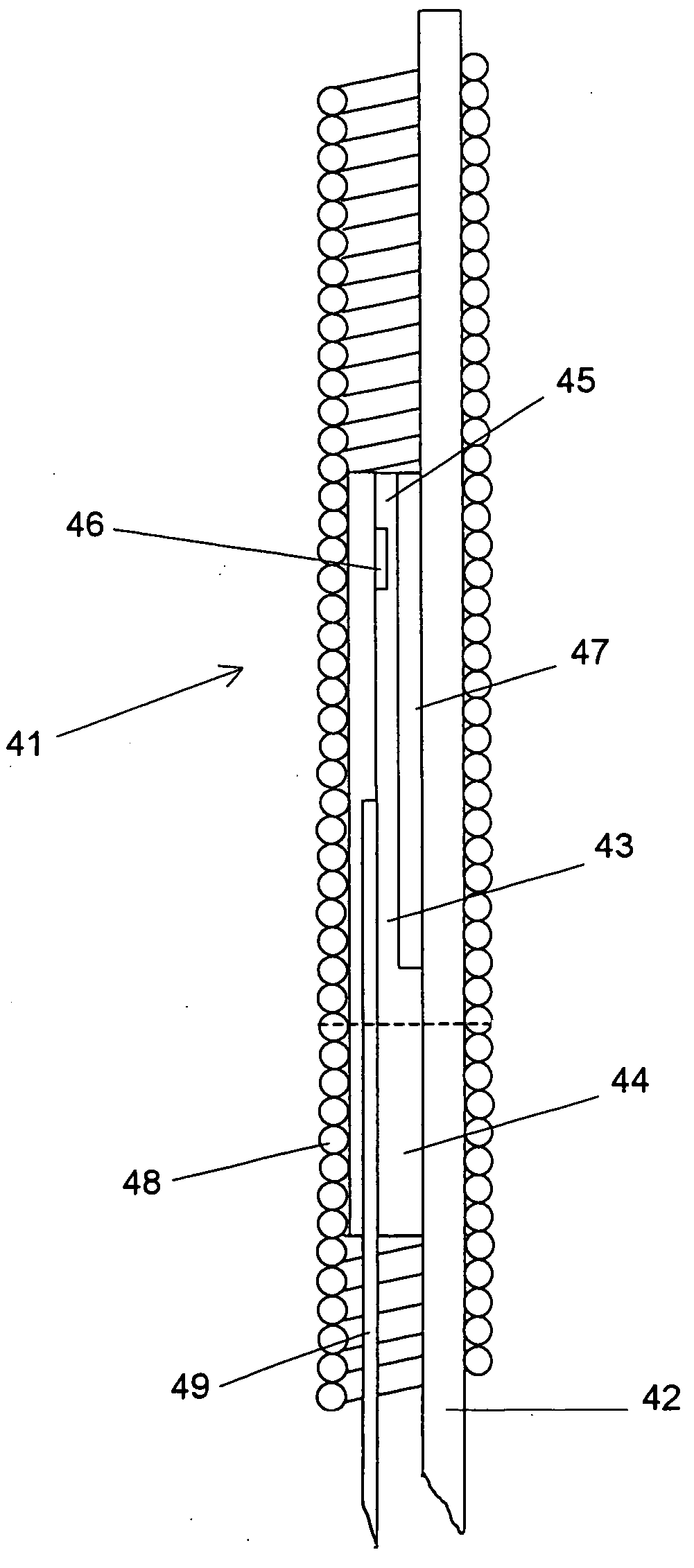

Sensor and guide wire assembly

InactiveUS20050000294A1Reduce manufacturing costSame or better characteristics regarding resistance against bending artefactsFluid pressure measurement using ohmic-resistance variationGuide wiresLiving bodyGuide wires

The invention relates to a sensor and guide wire assembly (21; 31; 41) for intravascular measurements of physiological variables in a living body, comprising a core wire (22; 32; 42) and sensor element (23; 33; 43). The sensor element (23; 33; 43) according to the invention comprises basically a mounting base (24; 34; 44) and a pressure sensitive end portion (25; 35; 45) whose upper side is provided with a pressure sensitive device, such as a membrane (26; 36; 46). The mounting base (24; 34; 44) extends downwards from the end opposite to the pressure sensitive end (25; 35; 45), such that, when the sensor element (23; 33; 43) is mounted on the core wire (22; 32; 42), a clearance (27; 37; 47) is formed below the pressure sensitive end (25; 35; 45).

Owner:ST JUDE MEDICAL COORDINATION CENT

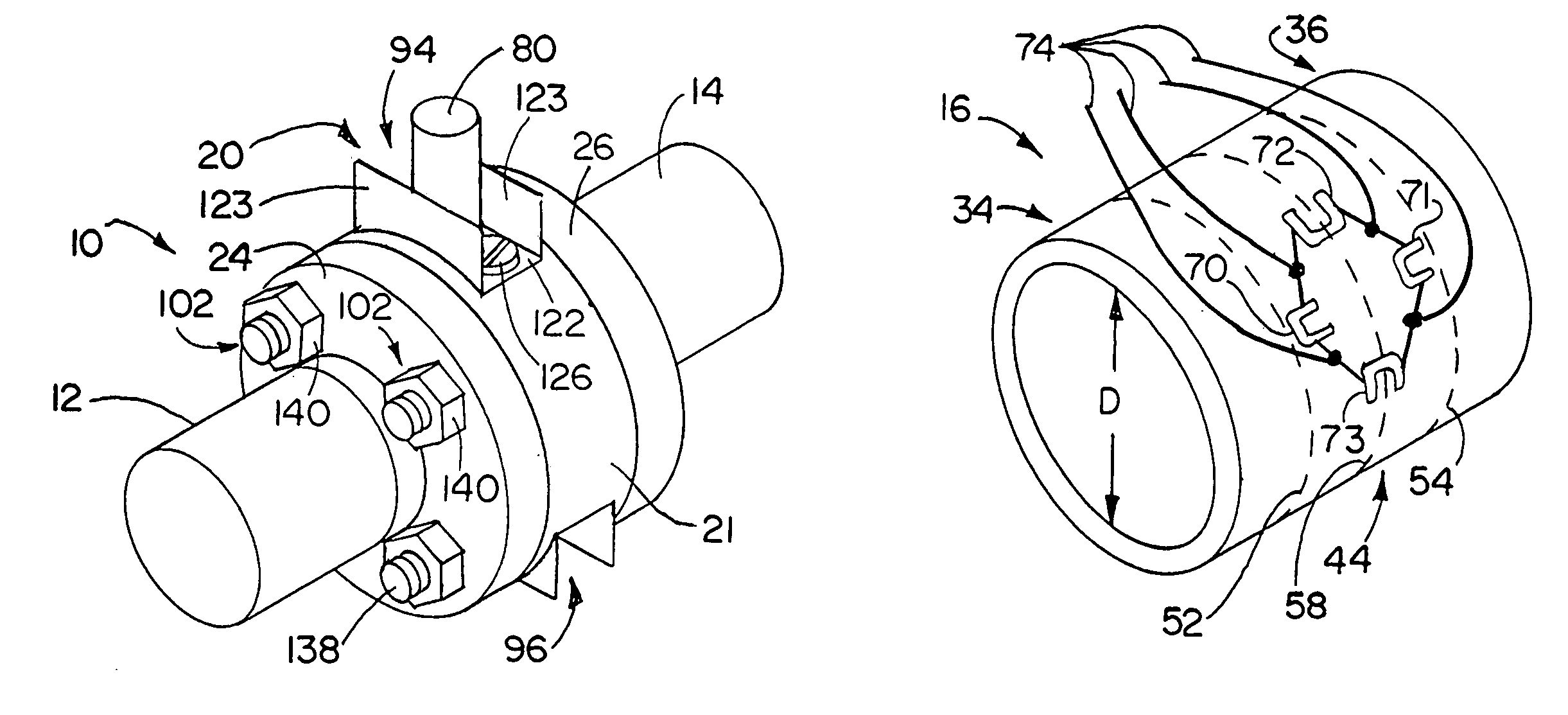

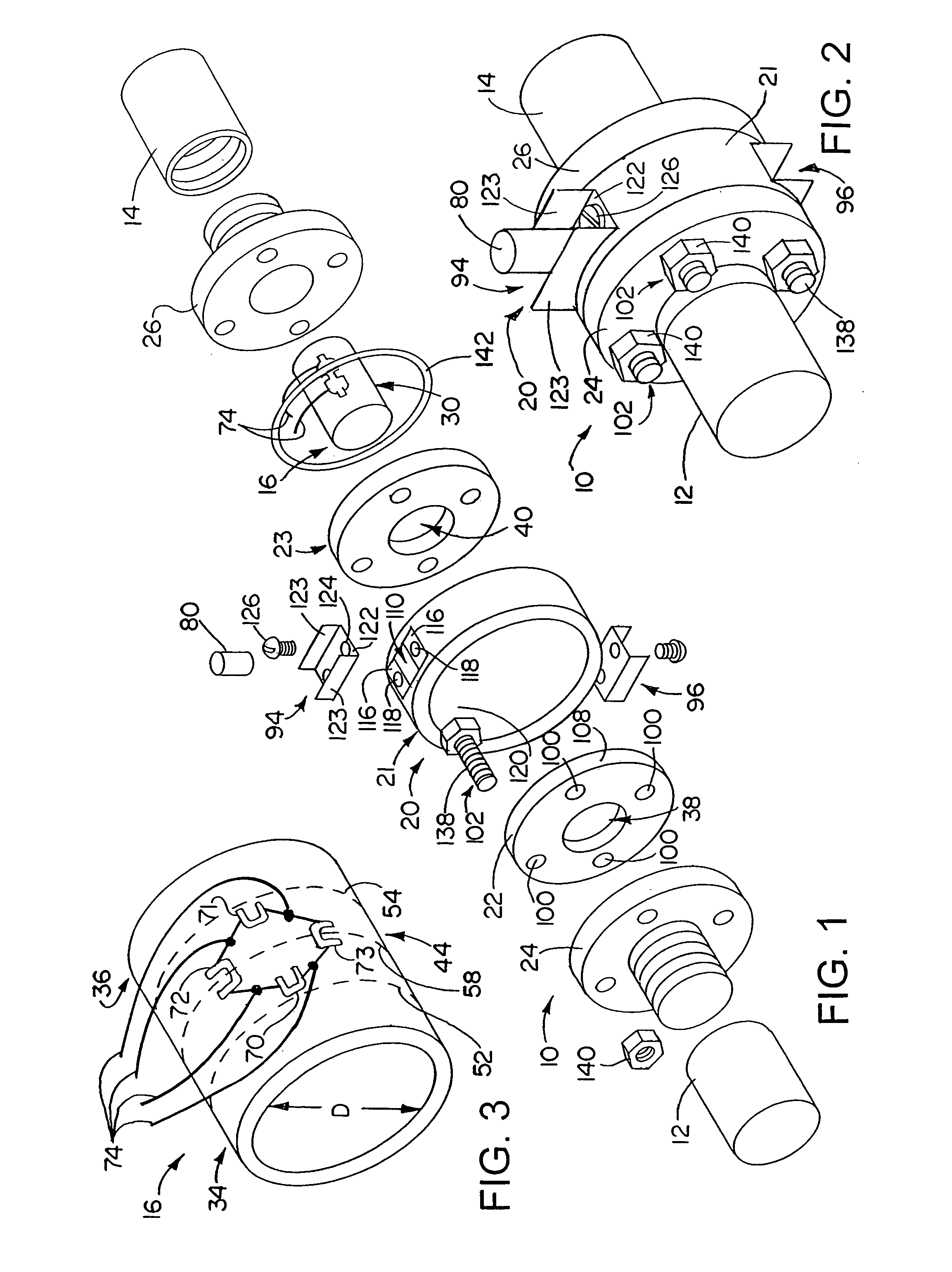

Fluid measuring device and method

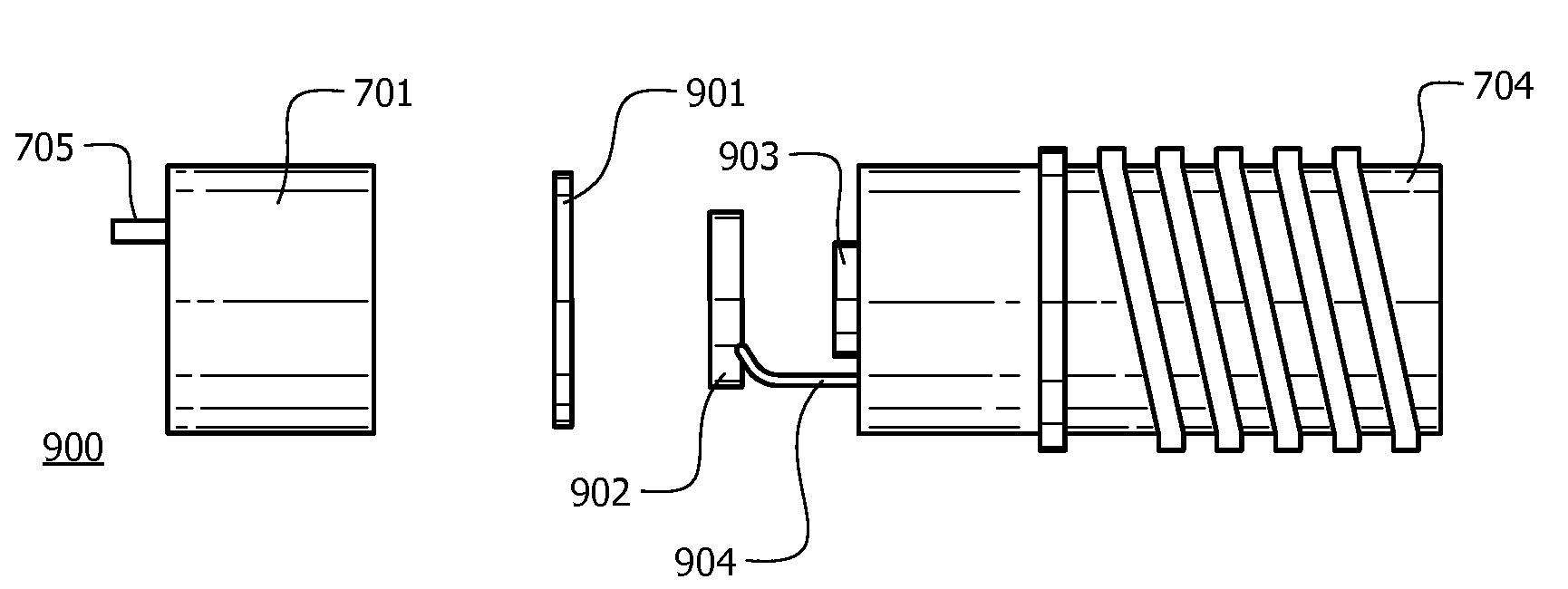

InactiveUS6957588B1Relieve extraneous stressAvoid damageFluid pressure measurement using ohmic-resistance variationVolume/mass flow by differential pressureMomentumTransducer

A pressure transducer and method for measuring pressure of a fluid flow in a tube include use of a sensing tube through which the pressurized flow passes. The sensing tube deforms outward in response to the pressurized flow within. Deformation measuring devices, such as strain gages, measure the outward deformation and allow computation of the pressure of the flowing fluid. A housing surrounds the sensing tube to relieve stresses on the sensing tube, to prevent damage to the sensing tube, and to contain any rupture of the sensing tube. The sensing tube may have a round, rectangular, or other shape cross-section. The pressure transducer allows continuous and non-invasive measurement of pressure inside a tube. In addition, a flow restriction such as an orifice may be provided in the sensing tube to enable a flow rate to be determined from the pressure drop across the flow restriction. Further, measuring device for measuring flow rate may utilize a sensing tube that bent (strained) because of forces causes by a change of momentum of flowing fluid due to a direction change of the fluid.

Owner:THOMAS P KICHER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com