Patents

Literature

146 results about "Reference cavity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

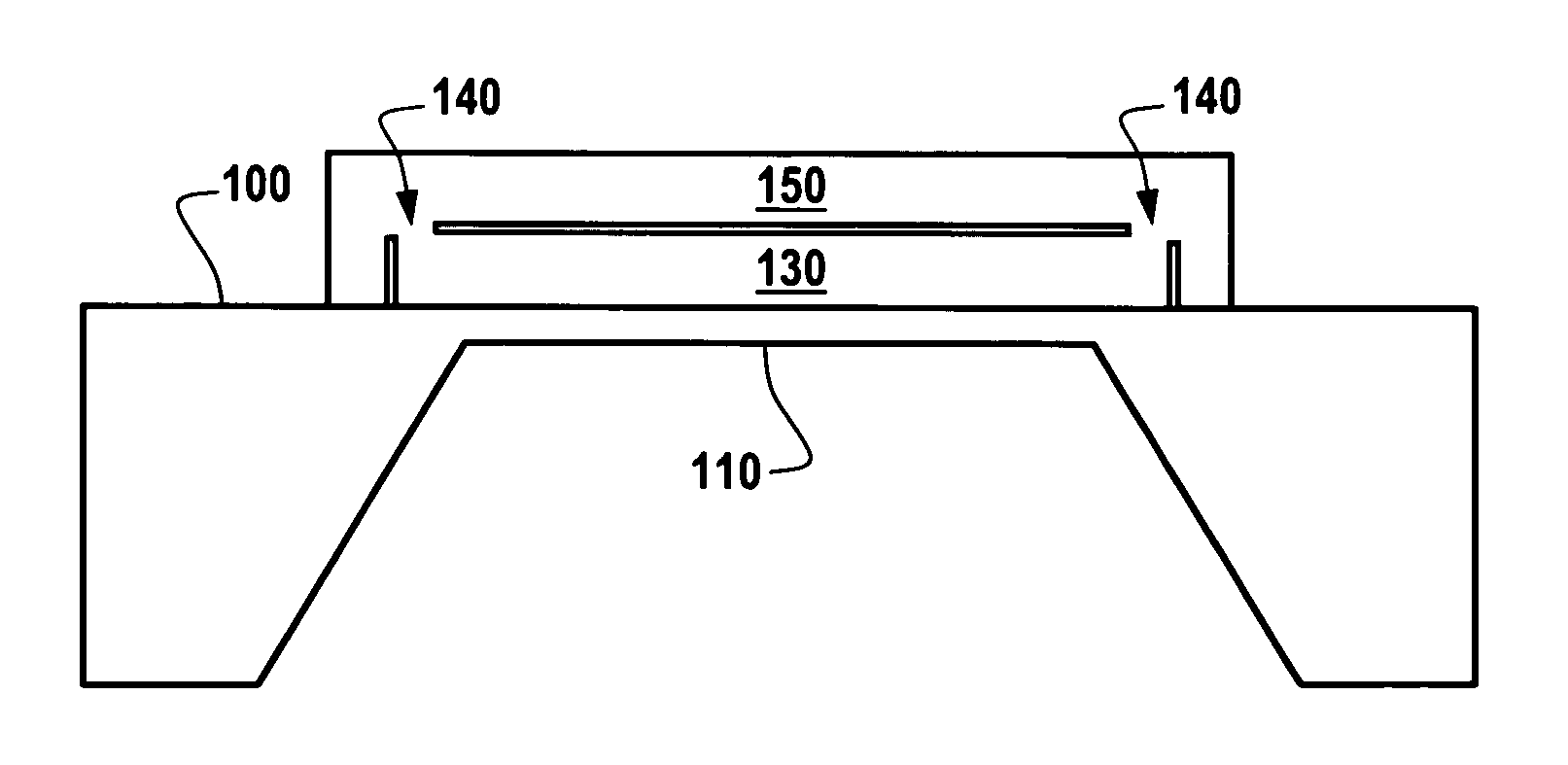

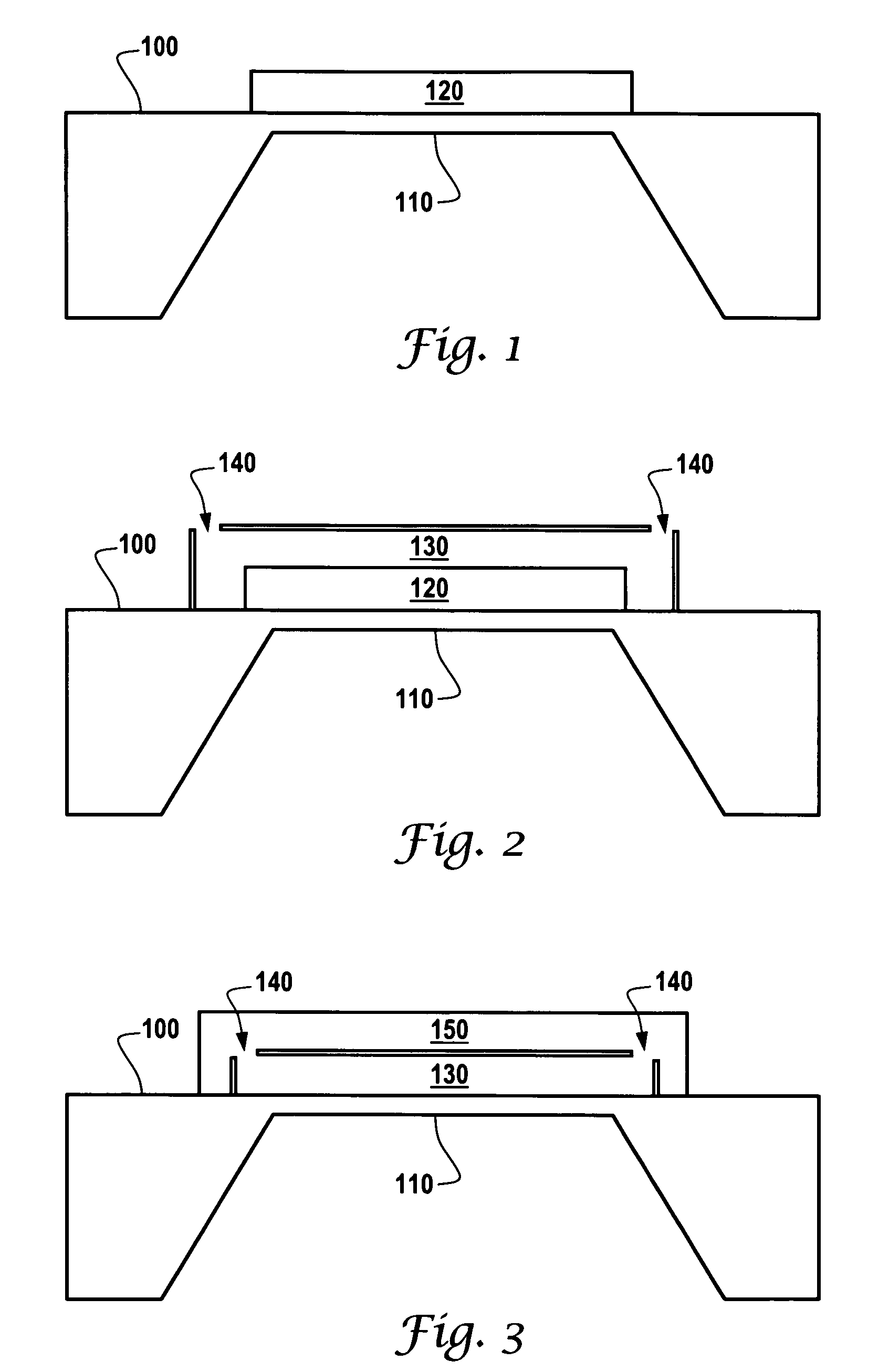

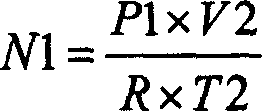

Top side reference cavity for absolute pressure sensor

A pressure sensor includes a silicon diaphragm having bottom and topside surfaces. The bottom surface has been formed using methods known to those skilled in the art. A first layer is formed and patterned on the topside surface of the diaphragm having an area larger than the diaphragm. A second layer is formed and patterned over the first layer, the second layer being larger in area than the first layer. Holes formed in the second layer are used to remove the first layer using methods known to those skilled in the art. A third layer is formed and patterned over the second layer. The third layer seals the holes in the second layer creating a sealed cavity with a reference pressure on the topside surface of the diaphragm. During operation, media is applied to the bottom surface of the diaphragm wherein the media pressure can be sensed by the pressure sensor in relation to the reference pressure sealed on the topside of the diaphragm.

Owner:HONEYWELL INT INC

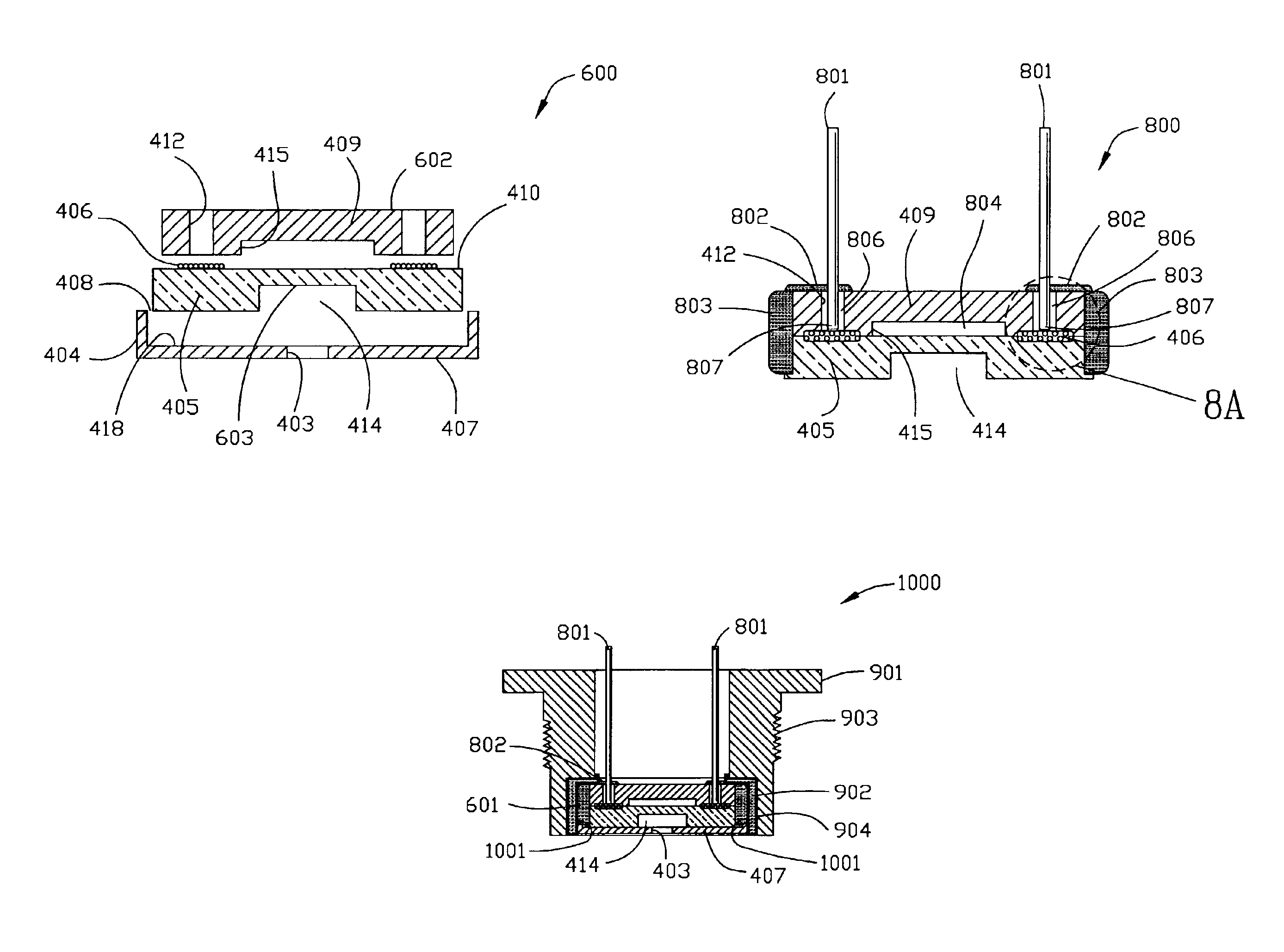

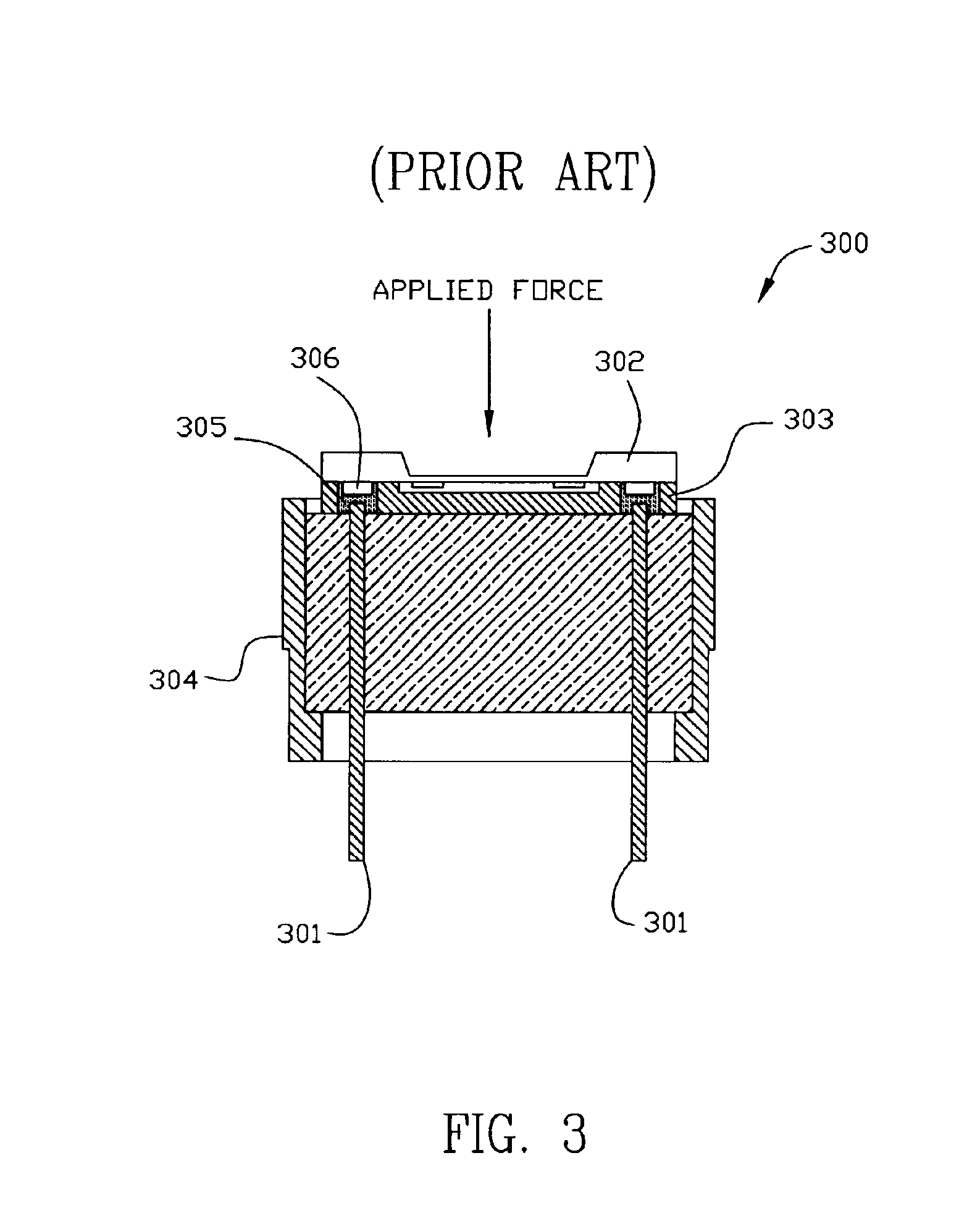

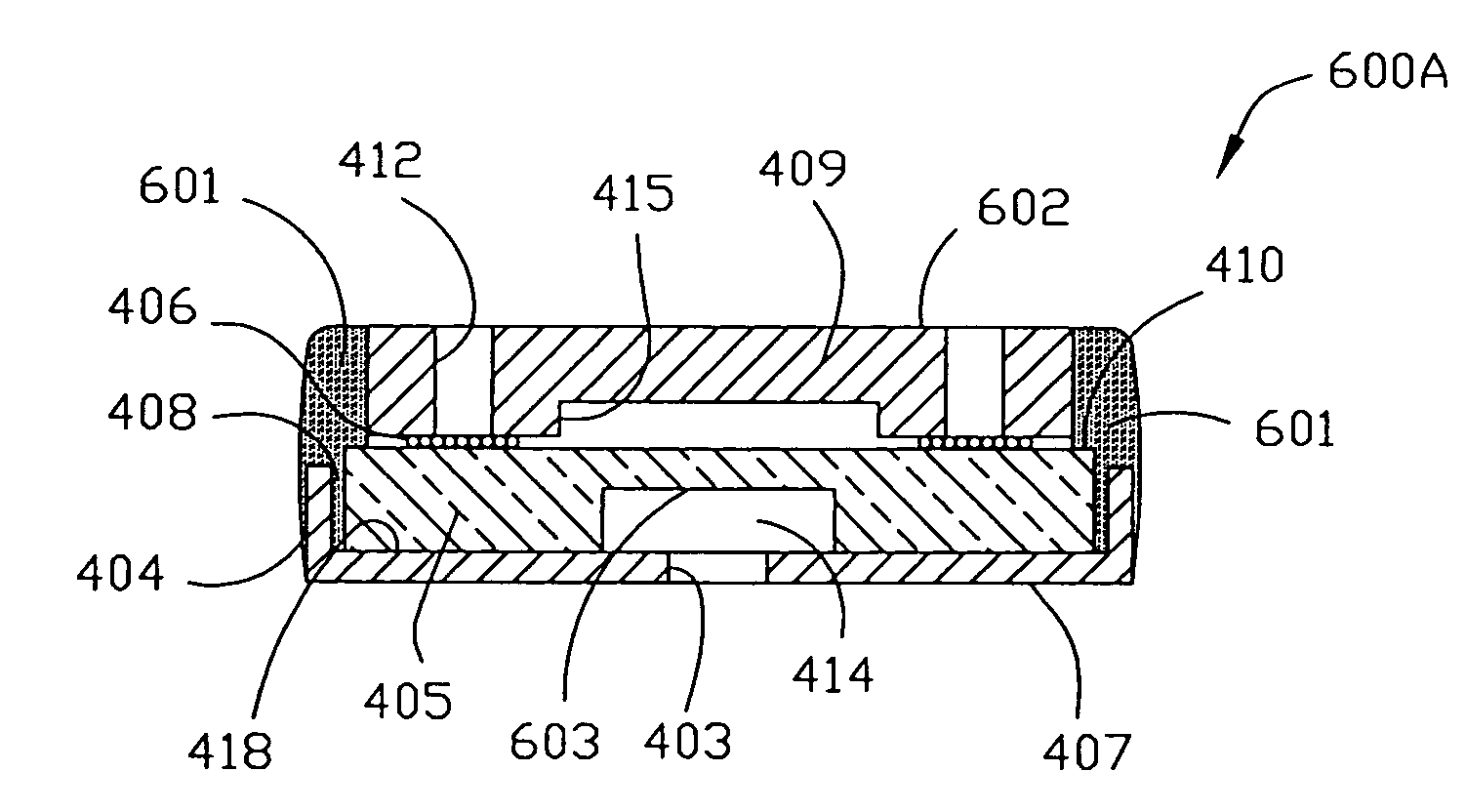

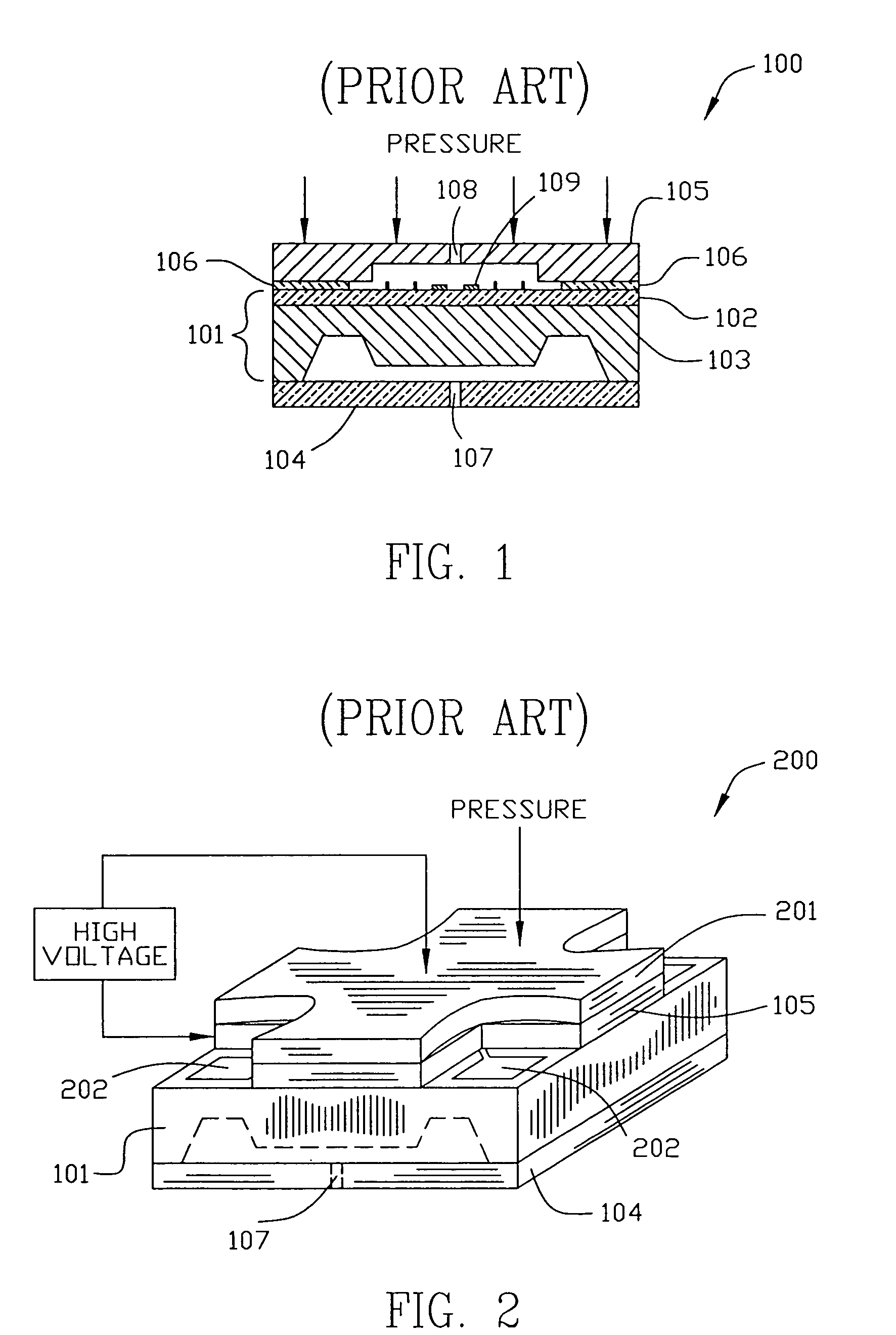

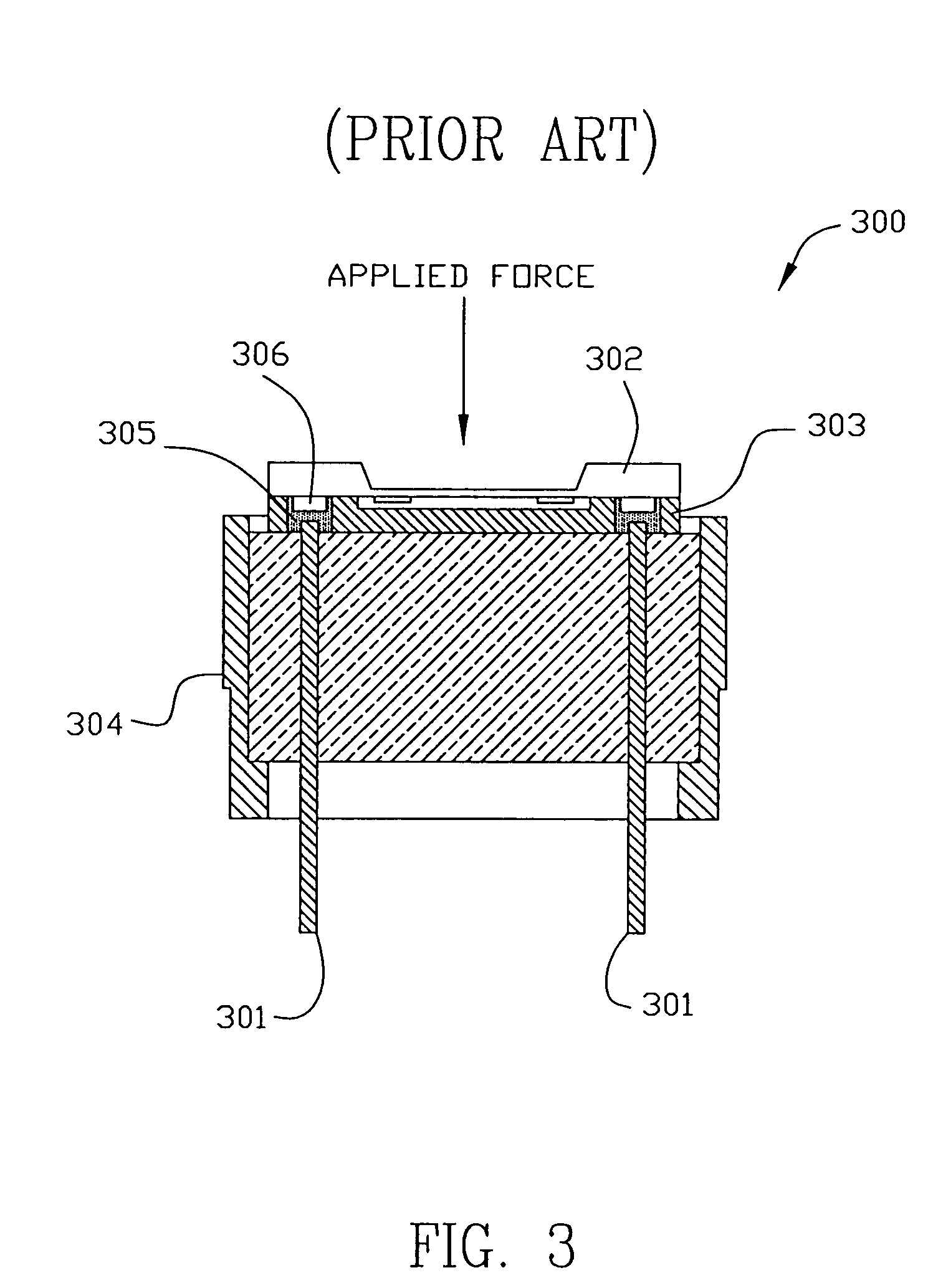

MEMS direct chip attach packaging methodologies and apparatuses for harsh environments

InactiveUS6845664B1Thermal expansion mismatchEffectively thermally decoupleSemiconductor/solid-state device detailsSolid-state devicesAccelerometerContact pad

Methods of bulk manufacturing high temperature sensor sub-assembly packages are disclosed and claimed. Sensors are sandwiched between a top cover and a bottom cover so as to enable the peripheries of the top covers, sensors and bottom covers to be sealed and bound securely together are disclosed and claimed. Sensors are placed on the bottom covers leaving the periphery of the bottom cover exposed. Likewise, top covers are placed on the sensors leaving the periphery of the sensor exposed. Individual sensor sub-assemblies are inserted into final packaging elements which are also disclosed and claimed. Methods of directly attaching wires or pins to contact pads on the sensors are disclosed and claimed. Sensors, such as pressure sensors and accelerometers, and headers made out of silicon carbide and aluminum nitride are disclosed and claimed. Reference cavities are formed in some embodiments disclosed and claimed herein where top covers are not employed.

Owner:NAT AERONAUTICS & SPACE ADMINISTATION UNITED STATES OF AMERICA AS REPRESENTED BY THE ADMINSTRATOR OF THE

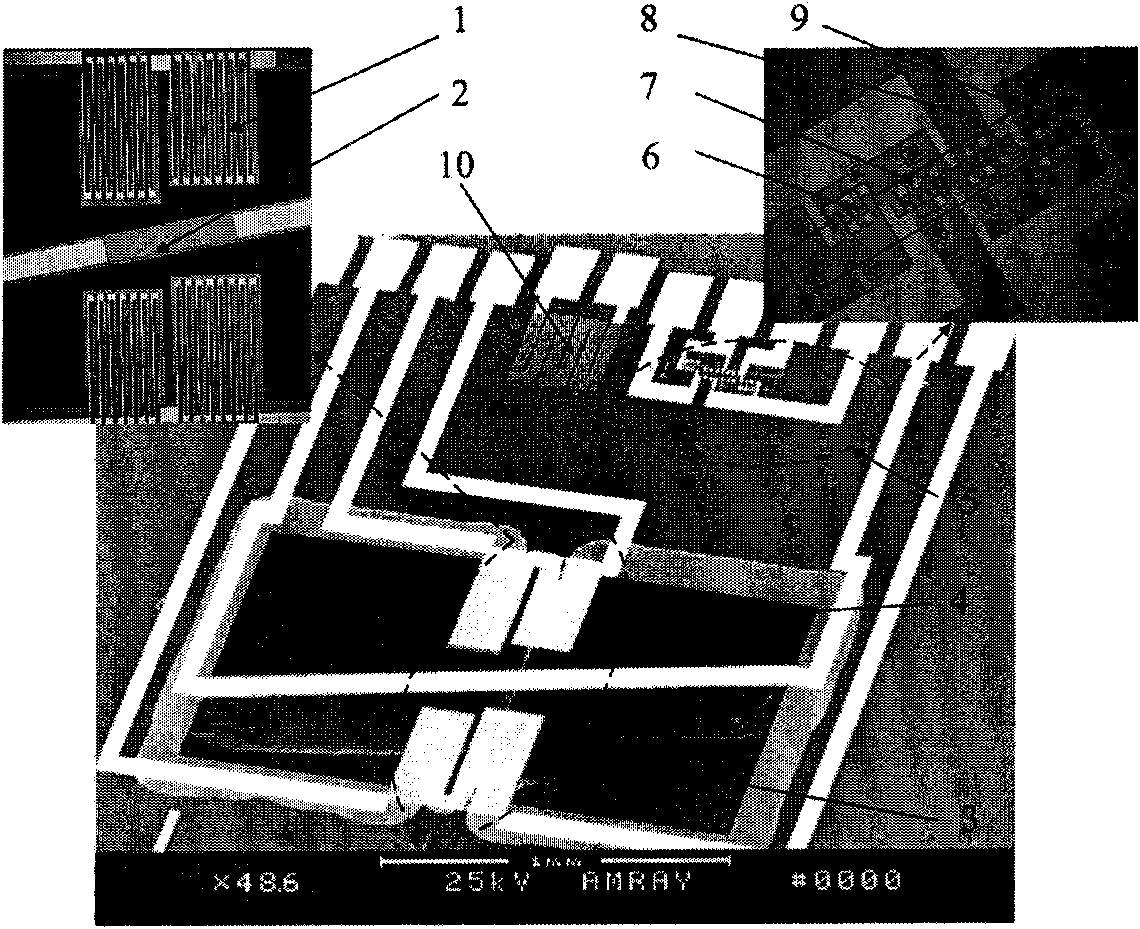

Integrated silicon chip for testing acceleration, pressure and temperature, and manufacturing method thereof

ActiveCN101551403AHigh sensitivityImprove stabilityFluid pressure measurement using ohmic-resistance variationDecorative surface effectsAccelerometerThermopile

The invention relates to an integrated silicon chip for testing acceleration, pressure and temperature, and the manufacturing method thereof. The invention is characterized in manufacturing the pressure sensor, temperature sensor and accelerometers of thermoelectric pile on to one chip by the same micro processing technology. The acceleration is detected by adopting thermal convection type accelerometers, using polysilicon resistor as heater, using a thermoelectric pile composed of two pairs of metals (such as aluminium and tungsten-titanium) and P type or N type polysilicon to detect the temperature difference in the sealed cavity caused by acceleration. The high accurate absolute pressure sensor is manufactured by using silicon nitride film with low stress as the core structure layer of the pressure sensor chip, and forming force sensitive resistor track by polysilicon film, forming vacuum reference cavity by TEOS bolt in LPCVD furnace. At the same time, the temperature sensor is composed by using polysilicon thermistor to detect temperature change. The integrated chip achieves the advantages of microminiaturization, low cost, high precision, high reliability and high stability.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

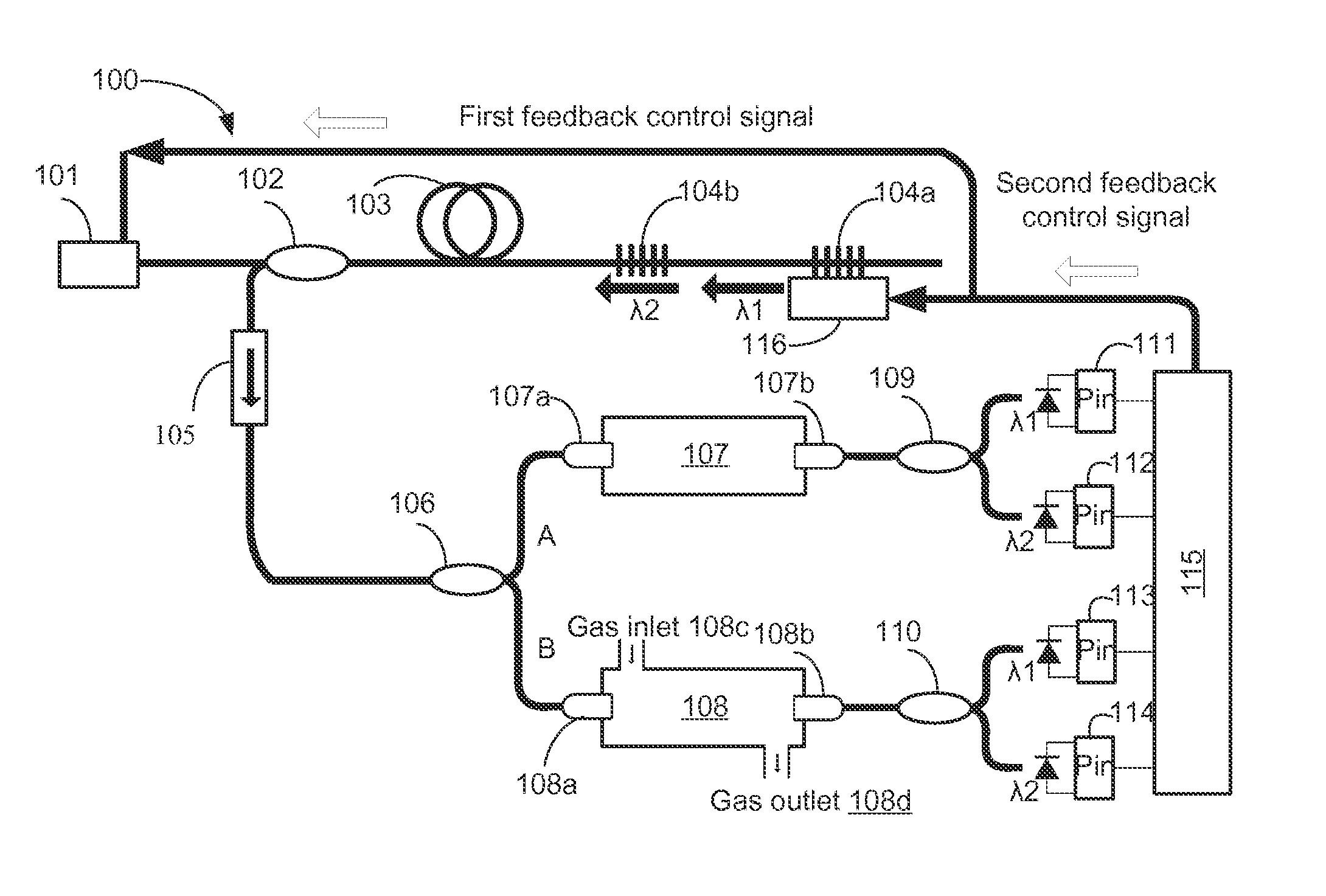

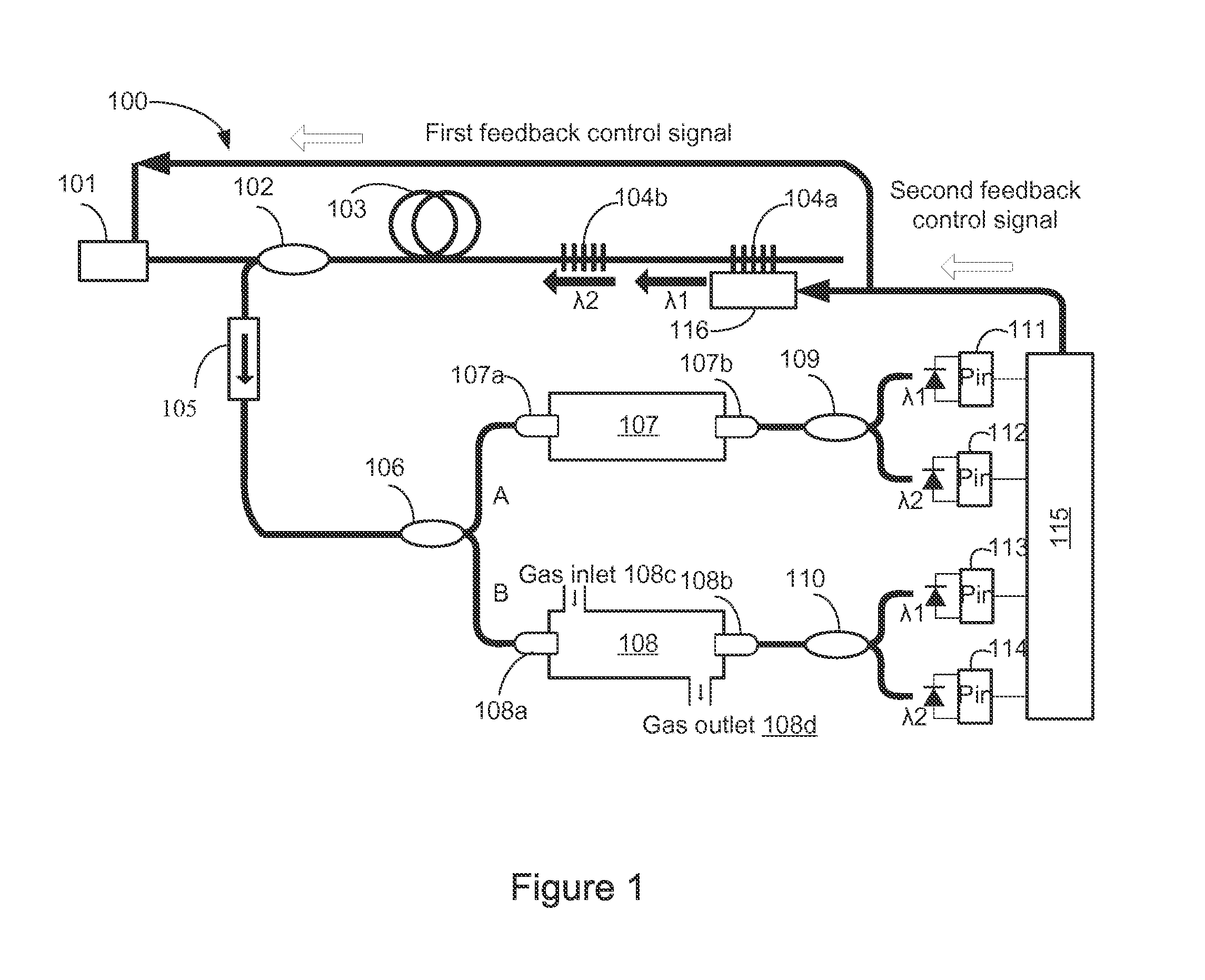

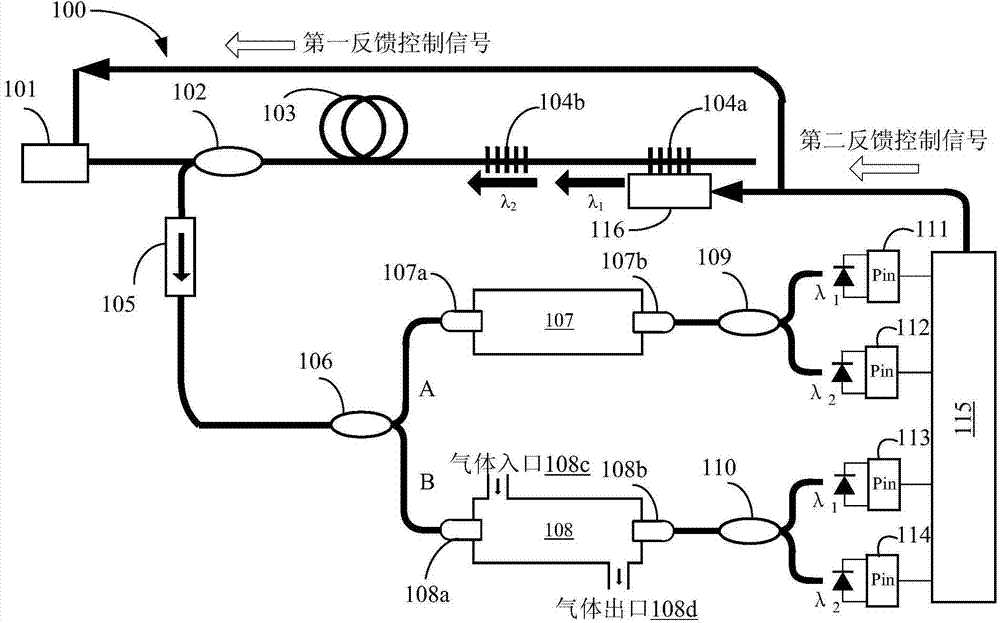

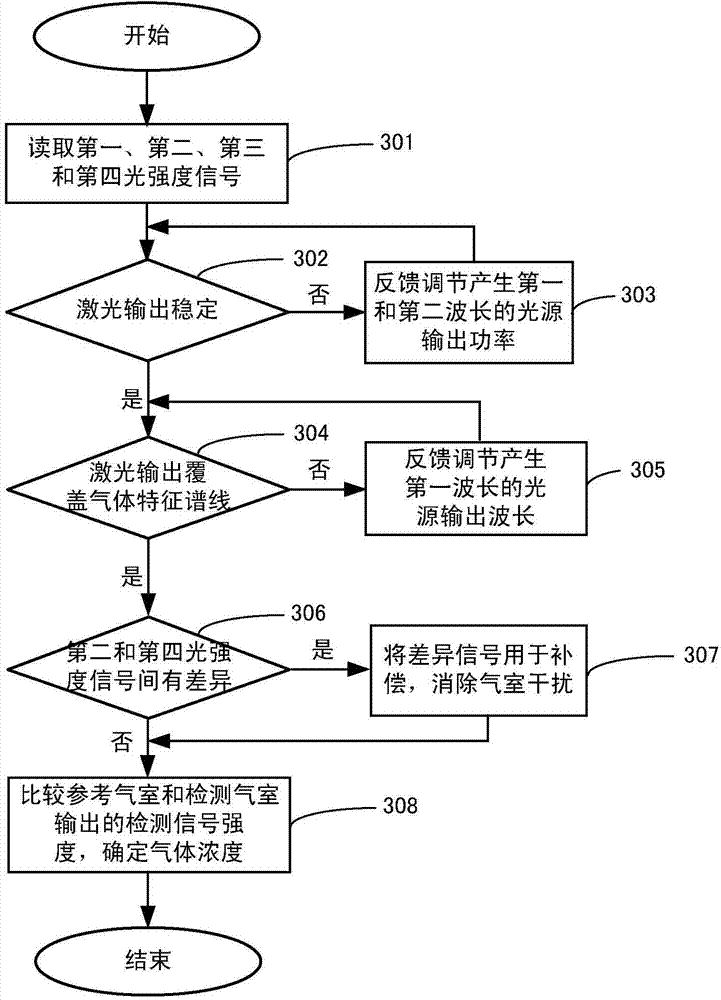

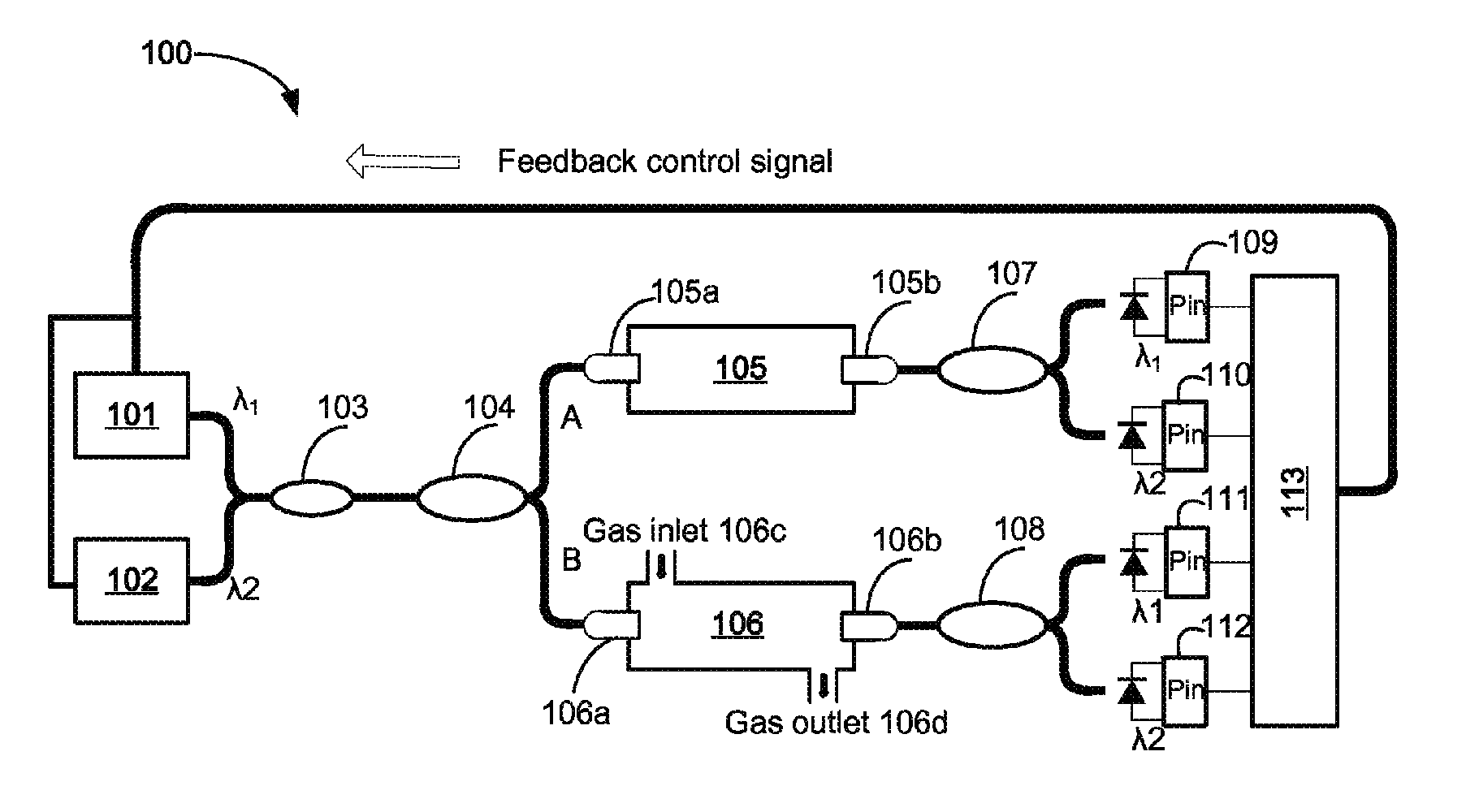

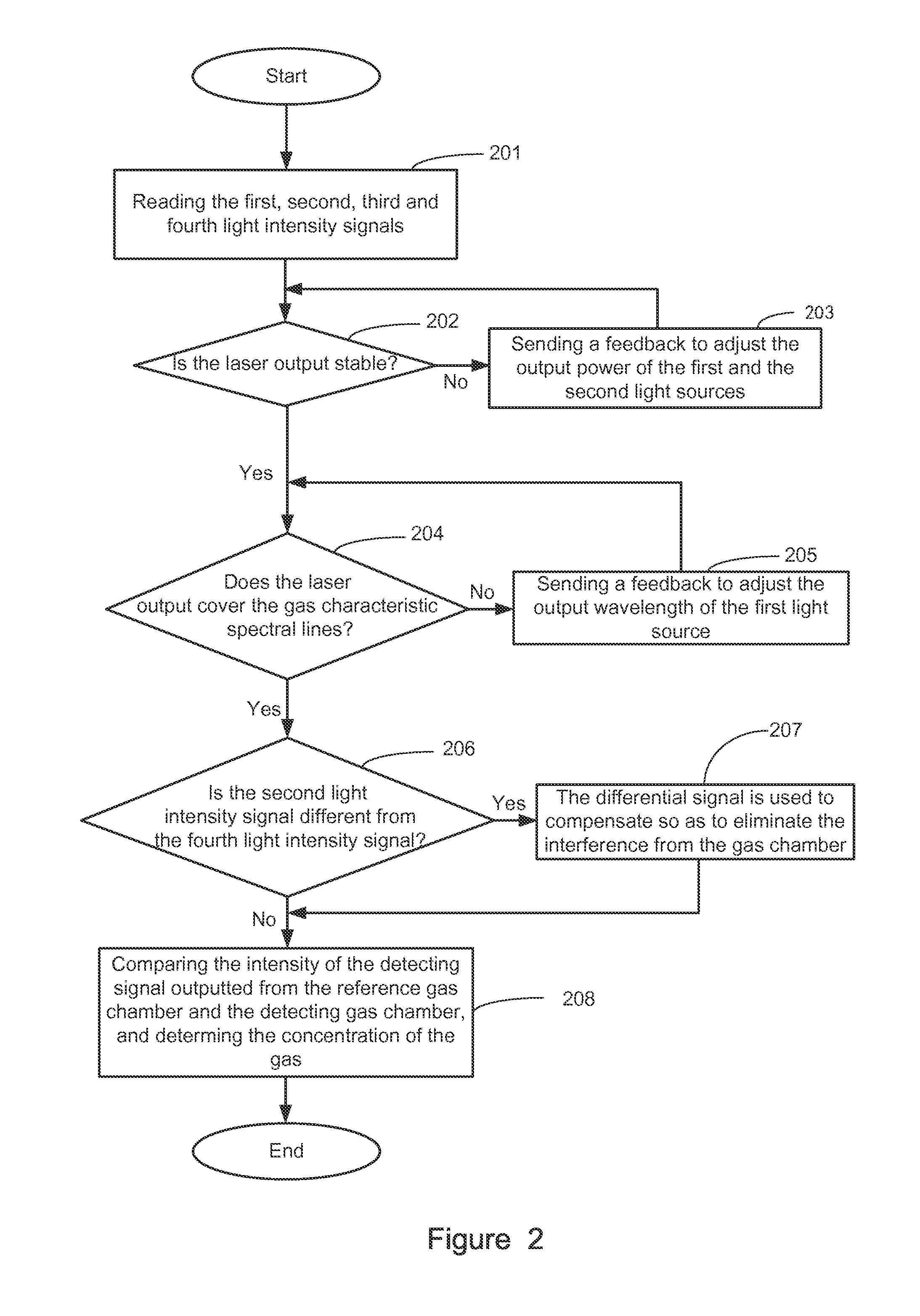

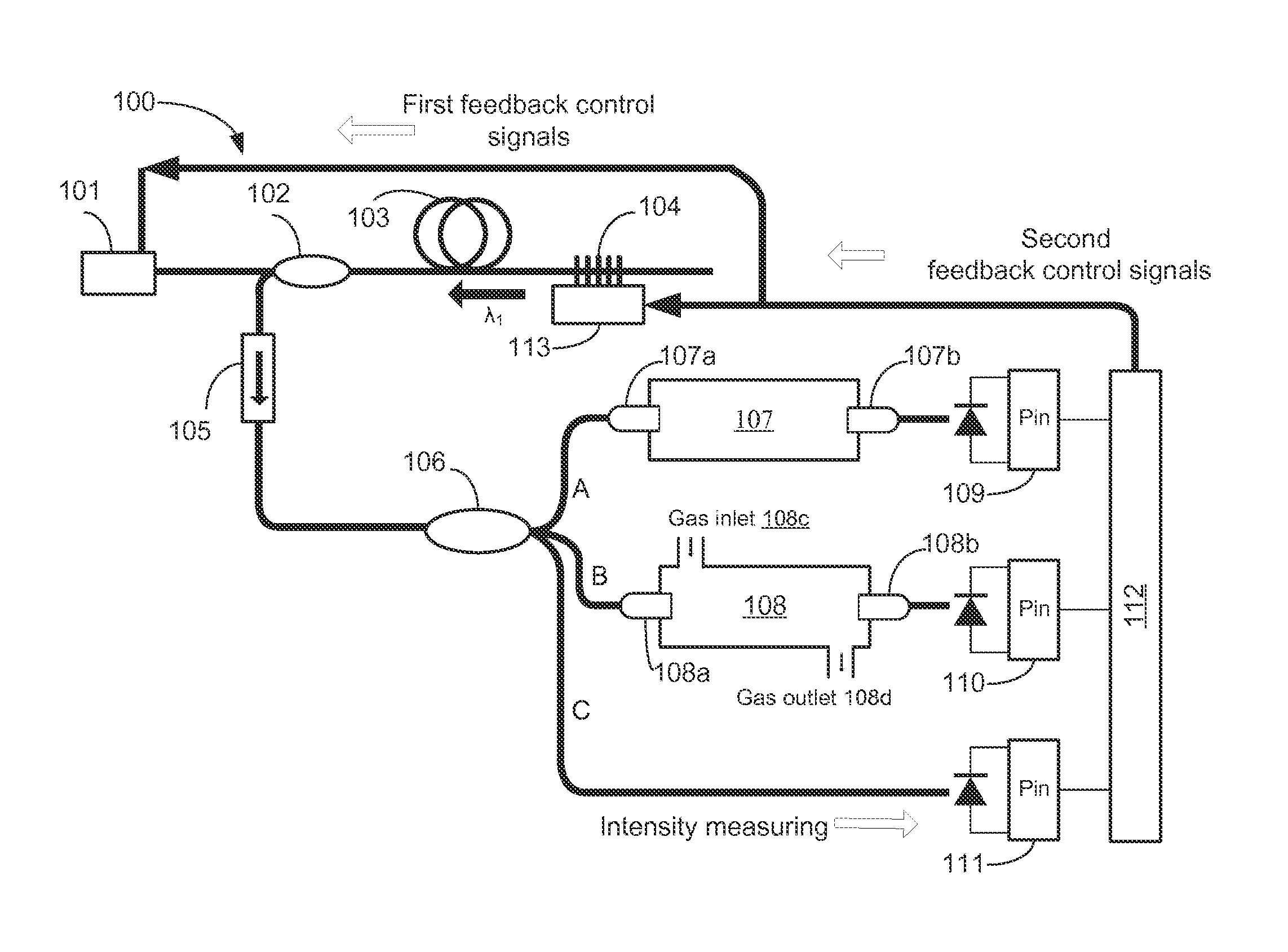

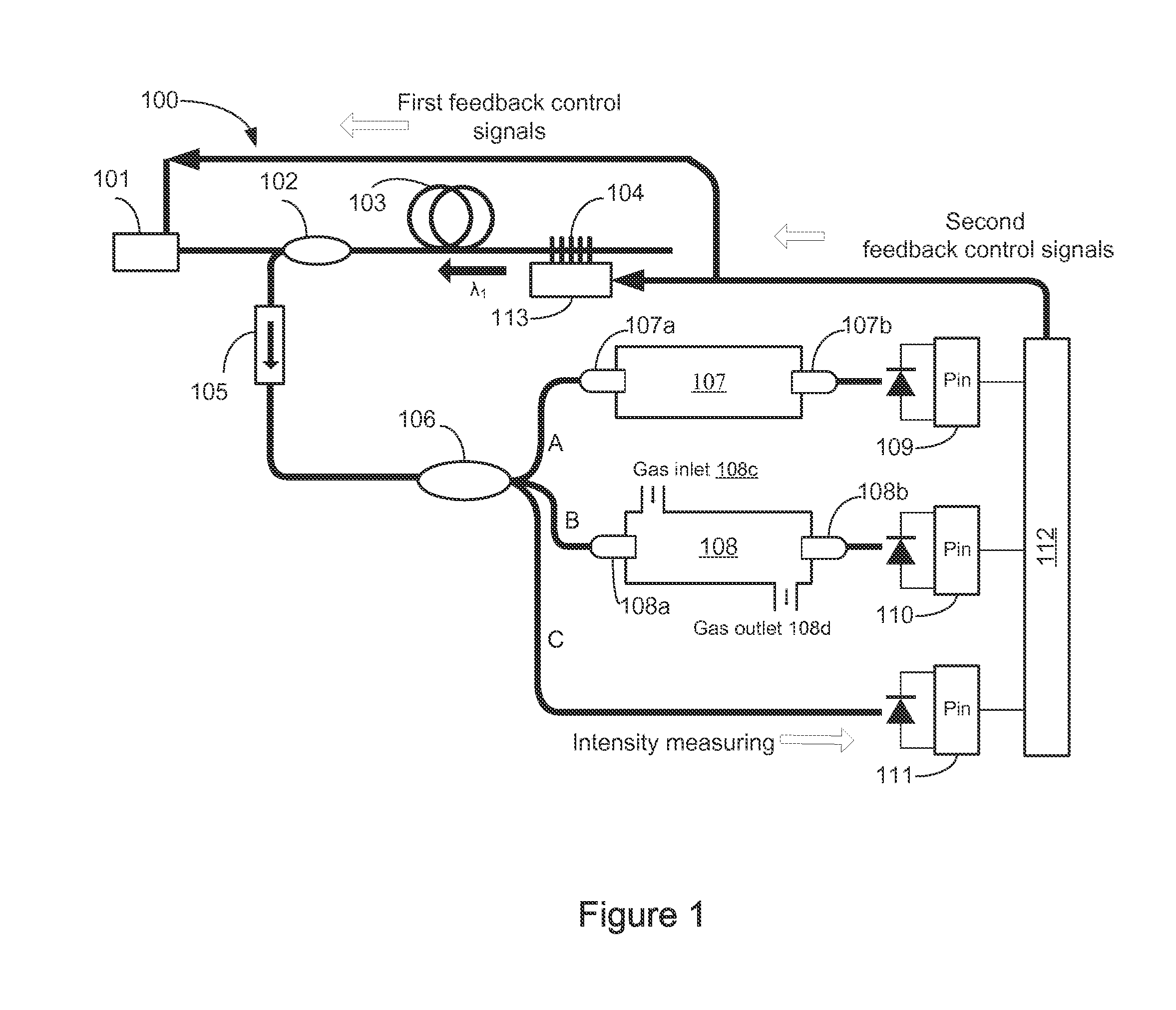

Gas detection system using a fiber laser with double-wavelength combination having reference-cavity compensation function

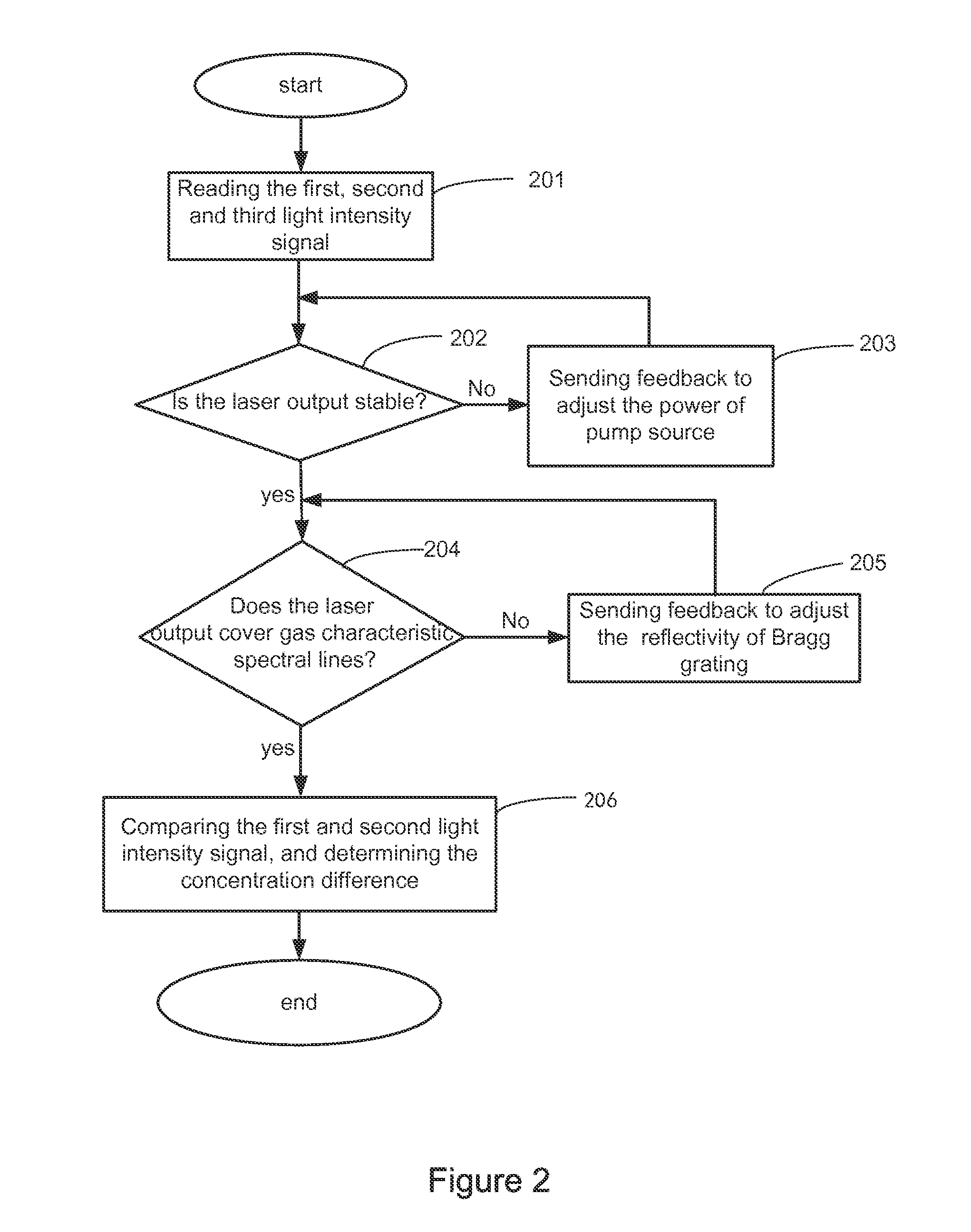

InactiveUS8964185B1Eliminate detection errorsCompact structureTransmissivity measurementsColor/spectral properties measurementsGratingFeedback control

A fiber laser gas detection system with a double wavelength combination using reference cavity compensation is provided. The system comprises an optical fiber laser respectively emitting beams having a first and second wavelengths, which consists of a laser diode pump source, a first wavelength division multiplexer, an active optical fiber, a first fiber bragg grating and a second fiber bragg grating connected successively; an optical isolator; a coupler for dividing the beams according to power ratio, the divided beams is introduced into a reference gas chamber and a detecting gas chamber respectively; a second wavelength division multiplexer connecting the reference room and a third wavelength division multiplexer connecting the detecting gas chamber; a first, a second, a third and a fourth photoelectric detector; a feedback control unit, receiving the first to fourth light intensity signals and adjusting the fiber laser using the comparison results as a feedback signal.

Owner:LUO FEI

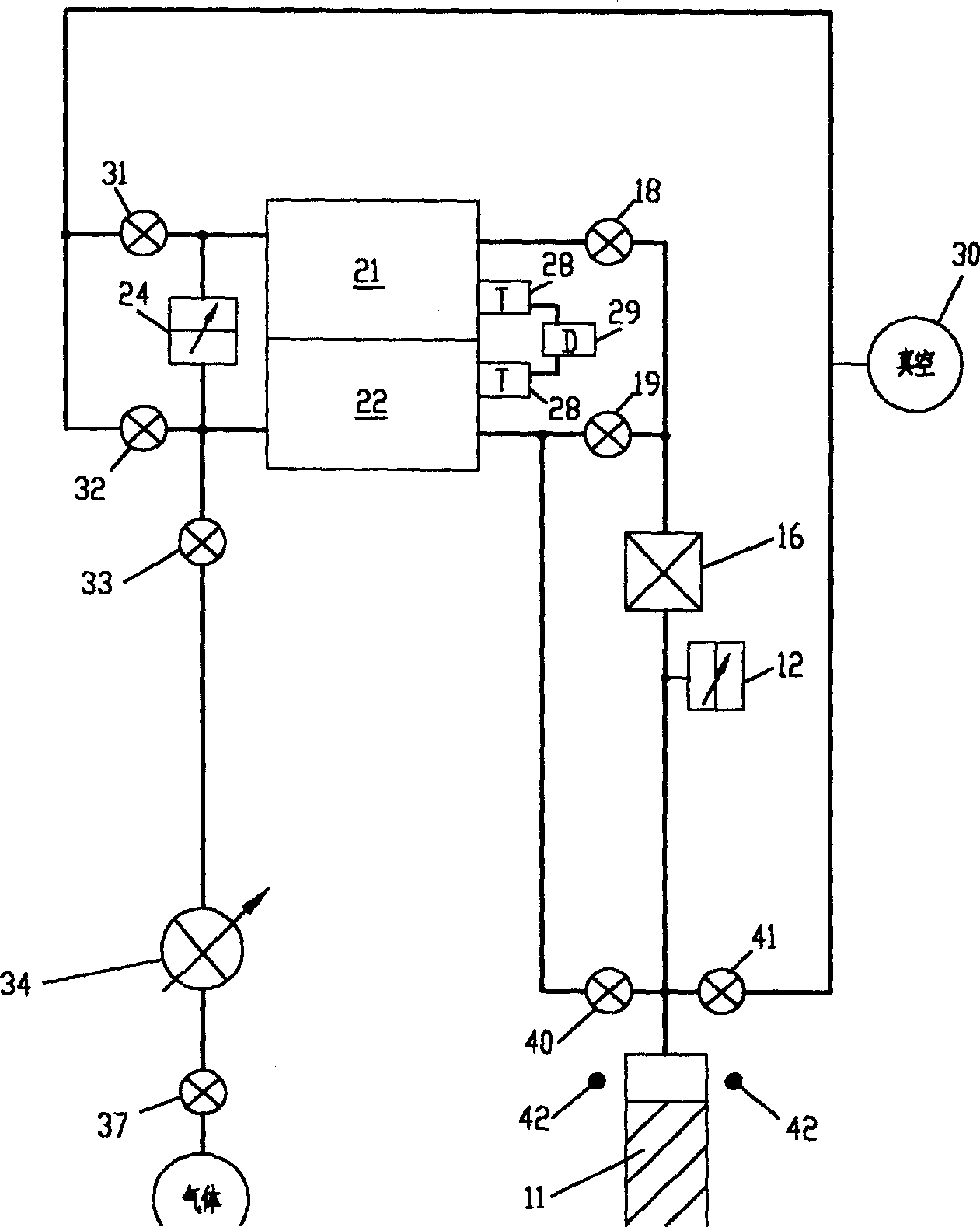

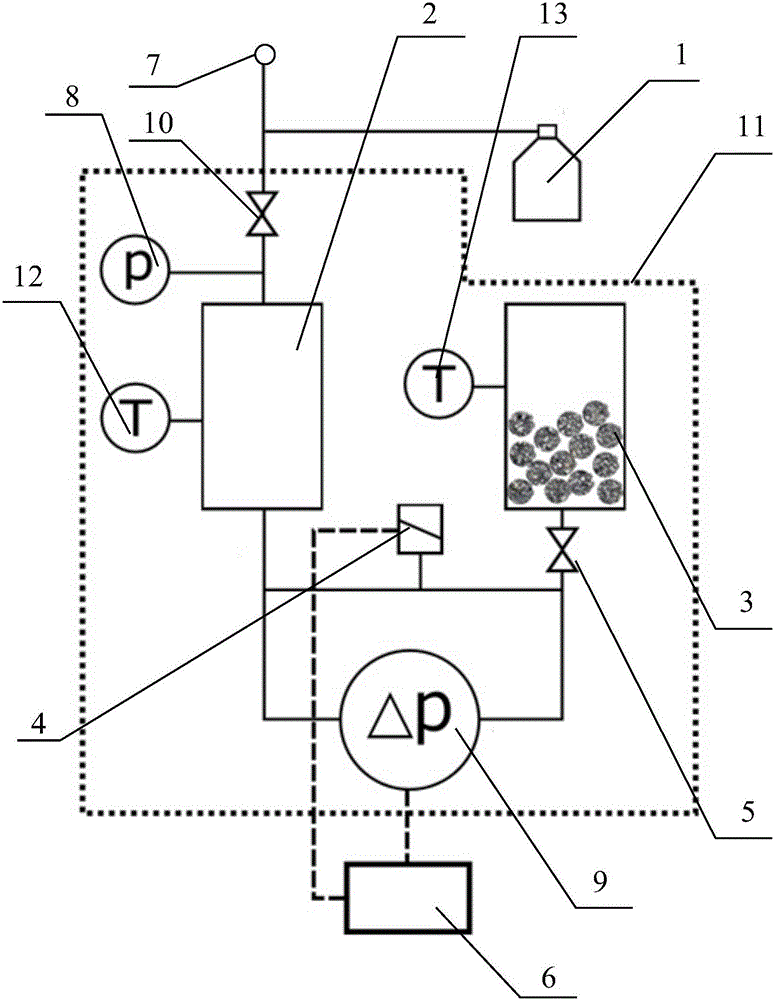

Method and equipment for measuring amount of gas adsorbed by powder

InactiveCN1517695AAccurate measurementHigh resolutionPermeability/surface area analysisImage resolutionPhysical chemistry

A method and device for measuring the amount of gas adsorbed by powder features that a prssure difference sensor is used to directly measure the pressure difference between gas supplying cavity and reference cavity whose gas amount is constant, and the algorithm for calculating the adsorbed amount is based on the pressure variations of specimen pool and gas supplying cavity or reference cavity. Its advantage is high correctness, precision and resolution.

Owner:TSINGHUA UNIV

MEMS direct chip attach packaging methodologies and apparatuses for harsh environments

ActiveUS7518234B1Semiconductor/solid-state device detailsSolid-state devicesContact padAccelerometer

Methods of bulk manufacturing high temperature sensor sub-assembly packages are disclosed and claimed. Sensors are sandwiched between a top cover and a bottom cover so as to enable the peripheries of the top covers, sensors and bottom covers to be sealed and bound securely together are disclosed and claimed. Sensors are placed on the bottom covers leaving the periphery of the bottom cover exposed. Likewise, top covers are placed on the sensors leaving the periphery of the sensor exposed. Individual sensor sub-assemblies are inserted into final packaging elements which are also disclosed and claimed. Methods of directly attaching wires or pins to contact pads on the sensors are disclosed and claimed. Sensors, such as pressure sensors and accelerometers, and headers made out of silicon carbide and aluminum nitride are disclosed and claimed. Reference cavities are formed in some embodiments disclosed and claimed herein where top covers are not employed.

Owner:NASA

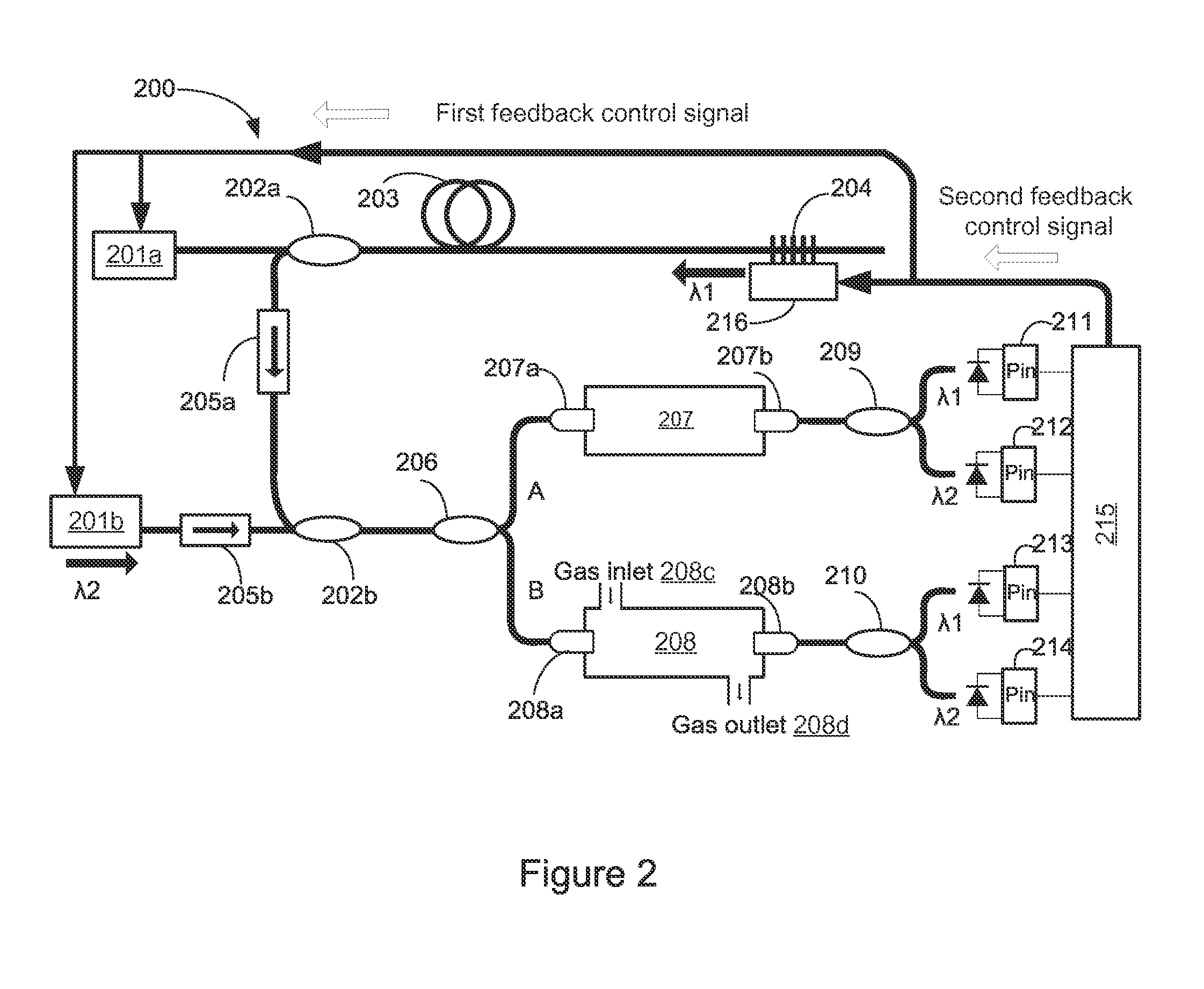

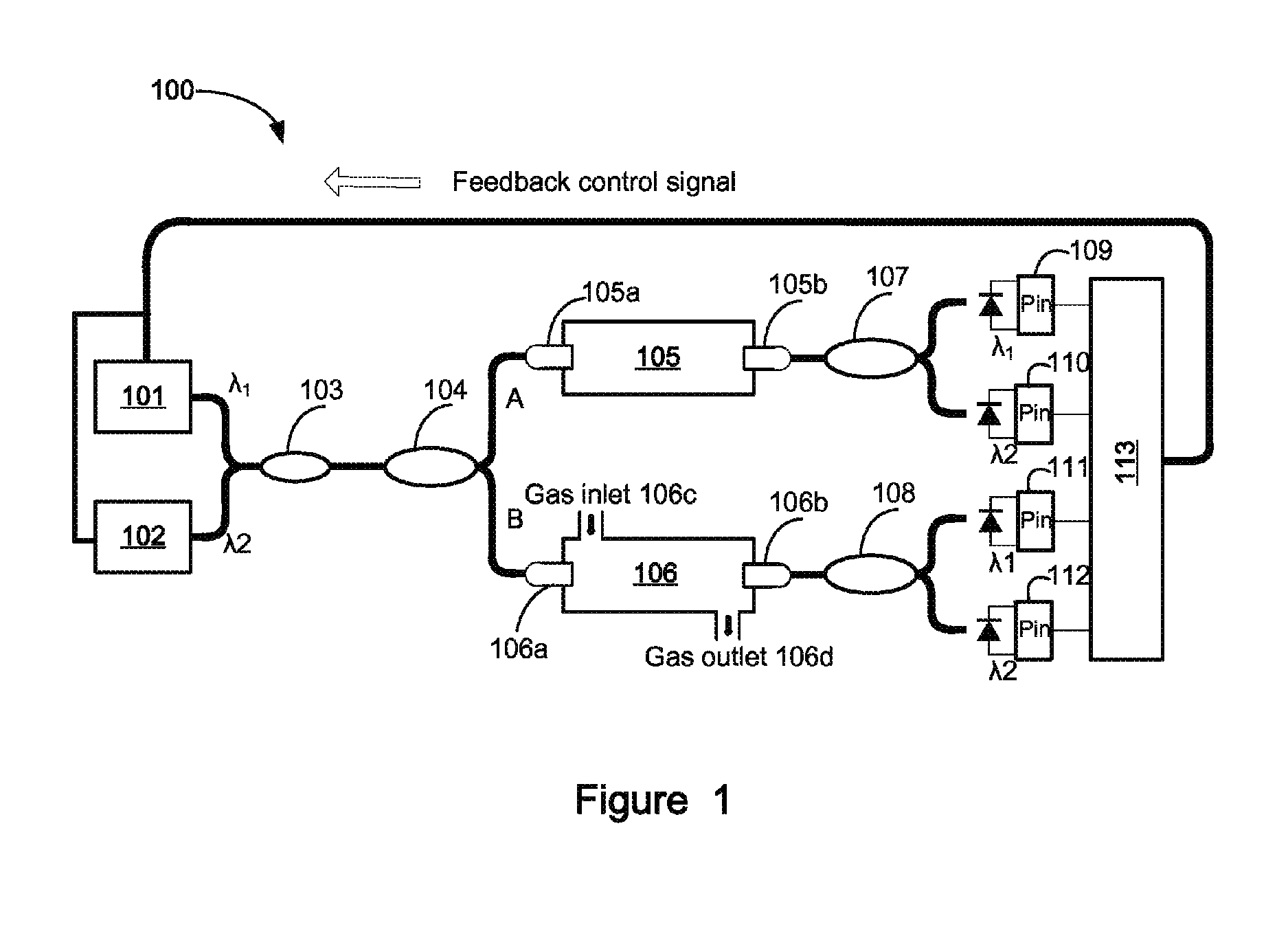

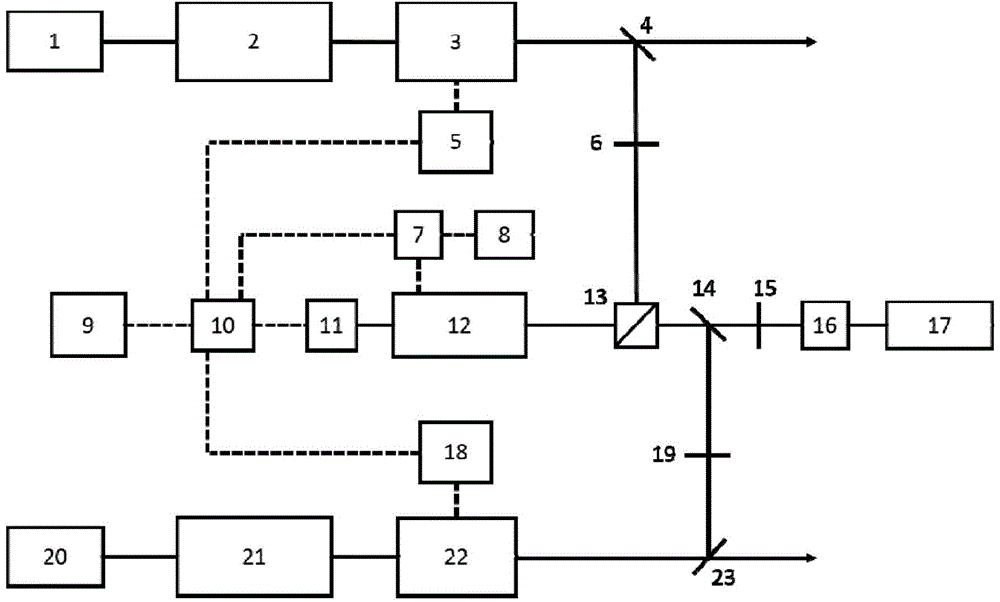

Fiber bragg grating combined optical fiber laser gas detection system with reference cavity compensation

ActiveCN103487403ACompact structureEliminate measurement errorsColor/spectral properties measurementsGratingBeam splitting

The invention provides a fiber bragg grating combined optical fiber laser gas detection system with reference cavity compensation. The fiber bragg grating combined optical fiber laser gas detection system comprises an optical fiber laser, an optical isolator, a coupler, a second wavelength division multiplexer, a third wavelength division multiplexer, a first photoelectric detector, a second photoelectric detector, a third photoelectric detector, a fourth photoelectric detector, and a feedback control unit which are sequentially connected, wherein the optical fiber laser comprises a laser diode pumping source, a first wavelength division multiplexer, an active optical fiber, a first fiber bragg grating and a second fiber bragg grating and respectively emits a first wavelength laser beam and a second wavelength laser beam, the coupler is used for carrying out power beam splitting on light beams, the light beams subjected to the beam splitting are respectively introduced into a reference air chamber and a detection air chamber, the second wavelength division multiplexer is connected with the reference air chamber, the third wavelength division multiplexer is connected with the detection air chamber, the first photoelectric detector and the second photoelectric detector are connected to the second wavelength division multiplexer, the third photoelectric detector and the fourth photoelectric detector are connected to the third wavelength multiplexer to generate a first optical intensity signal, a second optical intensity signal, a third optical intensity signal and a fourth optical intensity signal; the feedback control unit receives the first optical intensity signal, the second optical intensity signal, the third optical intensity signal and the fourth optical intensity signal and uses a comparing result as a feedback signal for regulating the optical fiber laser.

Owner:BEIJING INFORMATION SCI & TECH UNIV

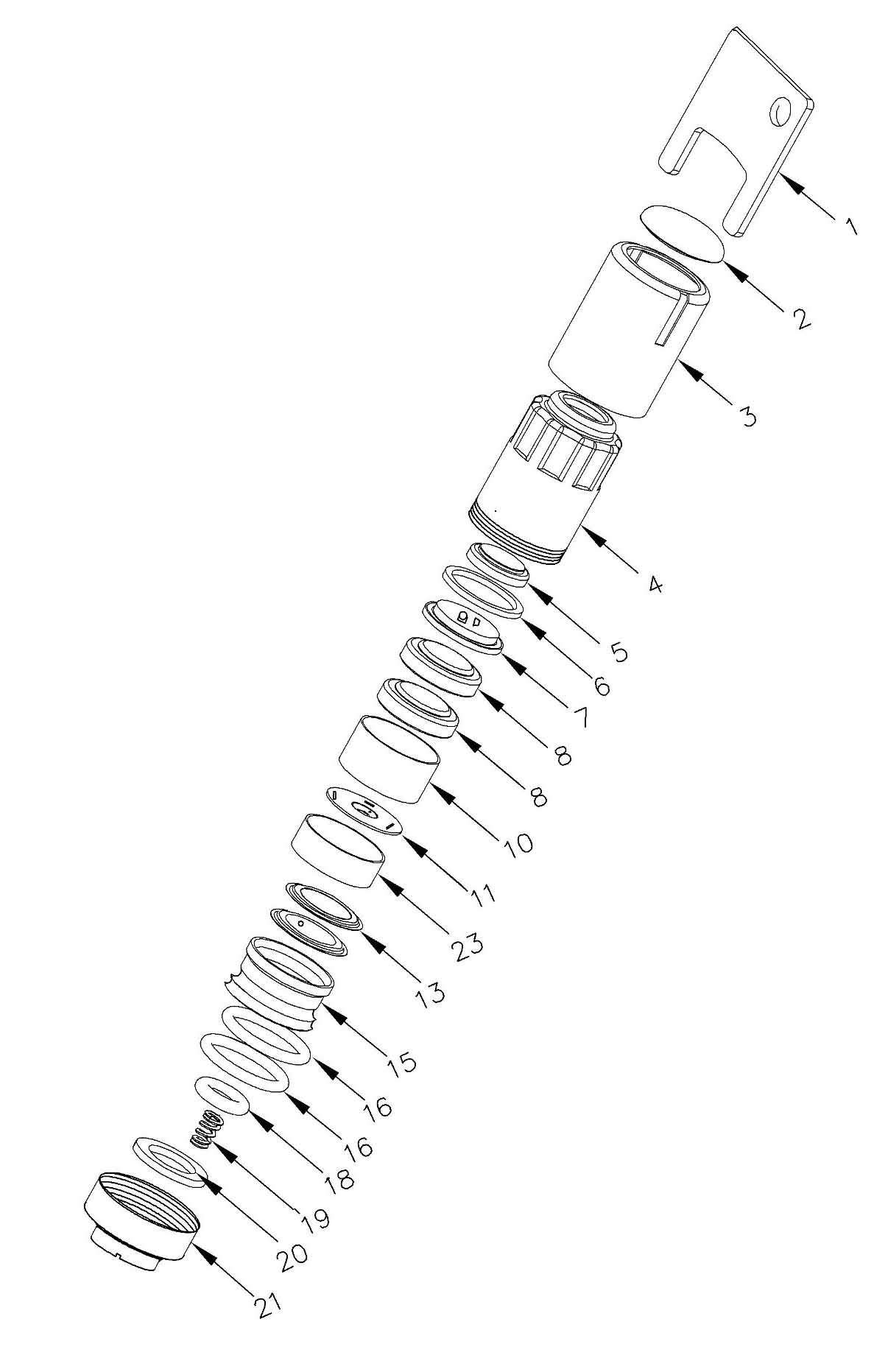

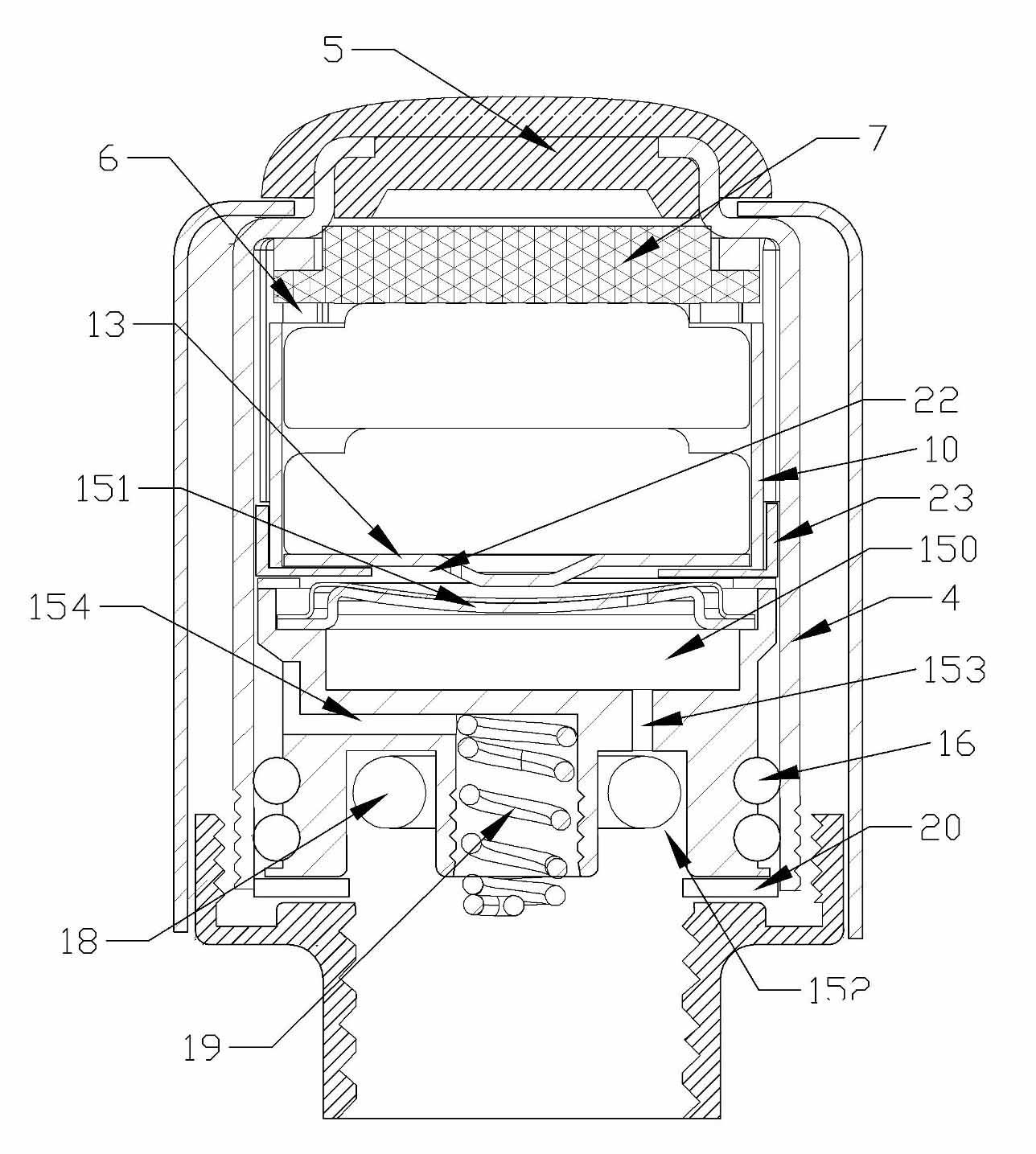

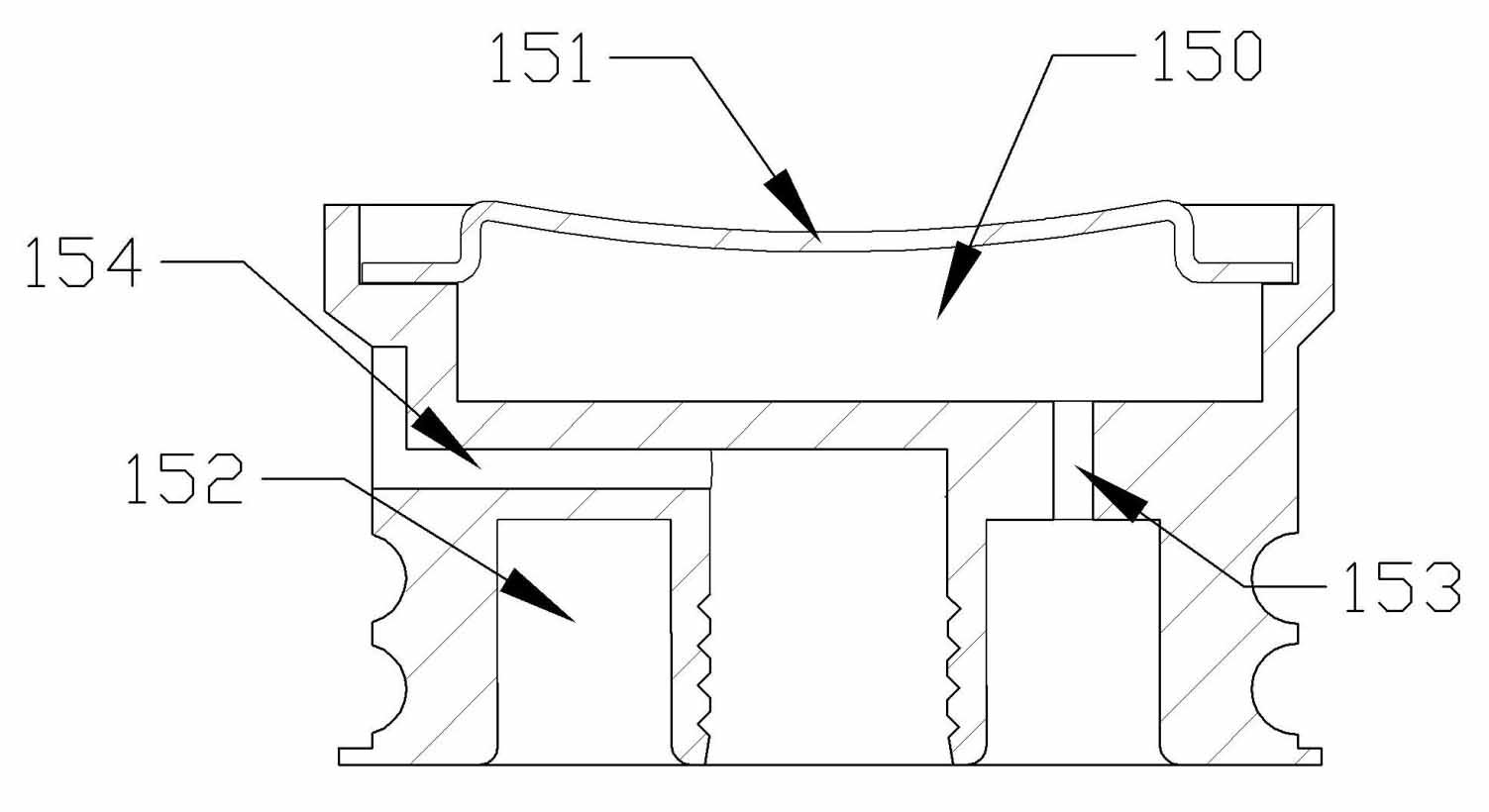

Tire pressure monitoring alarm device

ActiveCN101830152AUnderstand the stress situation in real timeTimely supplement pressureTyre measurementsReference cavityAlarm device

The invention discloses a tire pressure monitoring alarm device, which comprises a bottom nut which is screwed at a valve core and a shell which is screwed on the nut, the top of the shell is sealed by a lens, and the shell is internally provided with an alarm circuit board, a battery, an elastic metal sheet, a reference cavity component and an inflating valve spring sequentially from top to bottom; the anode of the alarm circuit board is connected with the anode of the battery, and the cathode of the alarm circuit board is connected with the elastic metal sheet below the cathode of the battery; and the elastic metal sheet attaches to another elastic metal sheet on the top surface of a reference cavity at the top of the reference cavity component, and the space above the reference cavity inside the shell is sealed as a monitoring cavity. The pressure of the reference cavity and the initial pressure of the tire are the same, the pressure in the monitoring cavity and the real-time pressure of the tire are the same, and when the pressure difference of the reference cavity and the monitoring cavity reaches a certain value, the elastic metal sheets are deformed to contact with the cathode of the battery, thus conducting the alarm circuit board. By adopting the monitoring device, the tire pressure can be known in real time, and pressure can be timely supplemented to the tire with low pressure, thus keeping good manipulability and safety performance of an automobile.

Owner:DONGGUAN NANNAR ELECTRONICS TECH

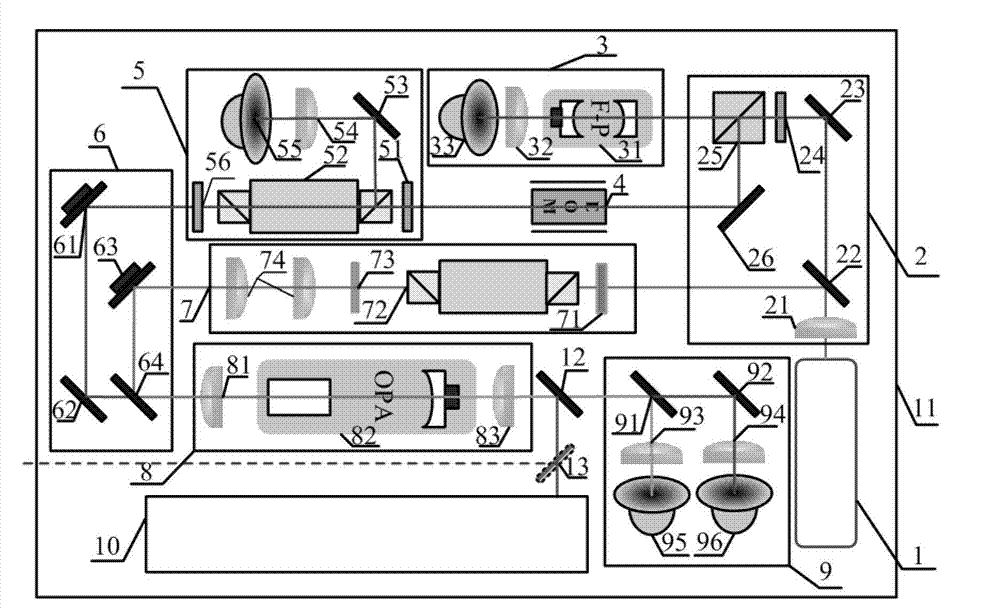

Continuous variable quantum entanglement source generating device

ActiveCN103176329ASolve temperature problemsSolve the influence of dust, etc.Non-linear opticsBell stateOptical parametric amplifier

The invention provides a continuous variable quantum entanglement source generating device. The device comprises a laser module, a beam split coupling module, a laser reference cavity module, a phase modulator, an optical parametric amplifier locking module, an anti-phase regulating and locking module, an isolator and beam shaping module, an optical parametric amplifier module, a detection system module and a Bell state direct detection system module, wherein the modules are all fixed on each base plate, and after being subjected to sealing treatment, the modules are sequentially fixed at corresponding positions of an entanglement source total base plate, and a polysulfone cover covers nonlinear crystals in the optical parametric amplifier module for heat preservation. The entanglement source generating device is beneficial to improvement of stability, reliability, operability and exchangeability and is easy for productization, mass production, and the like.

Owner:SHANXI UNIV

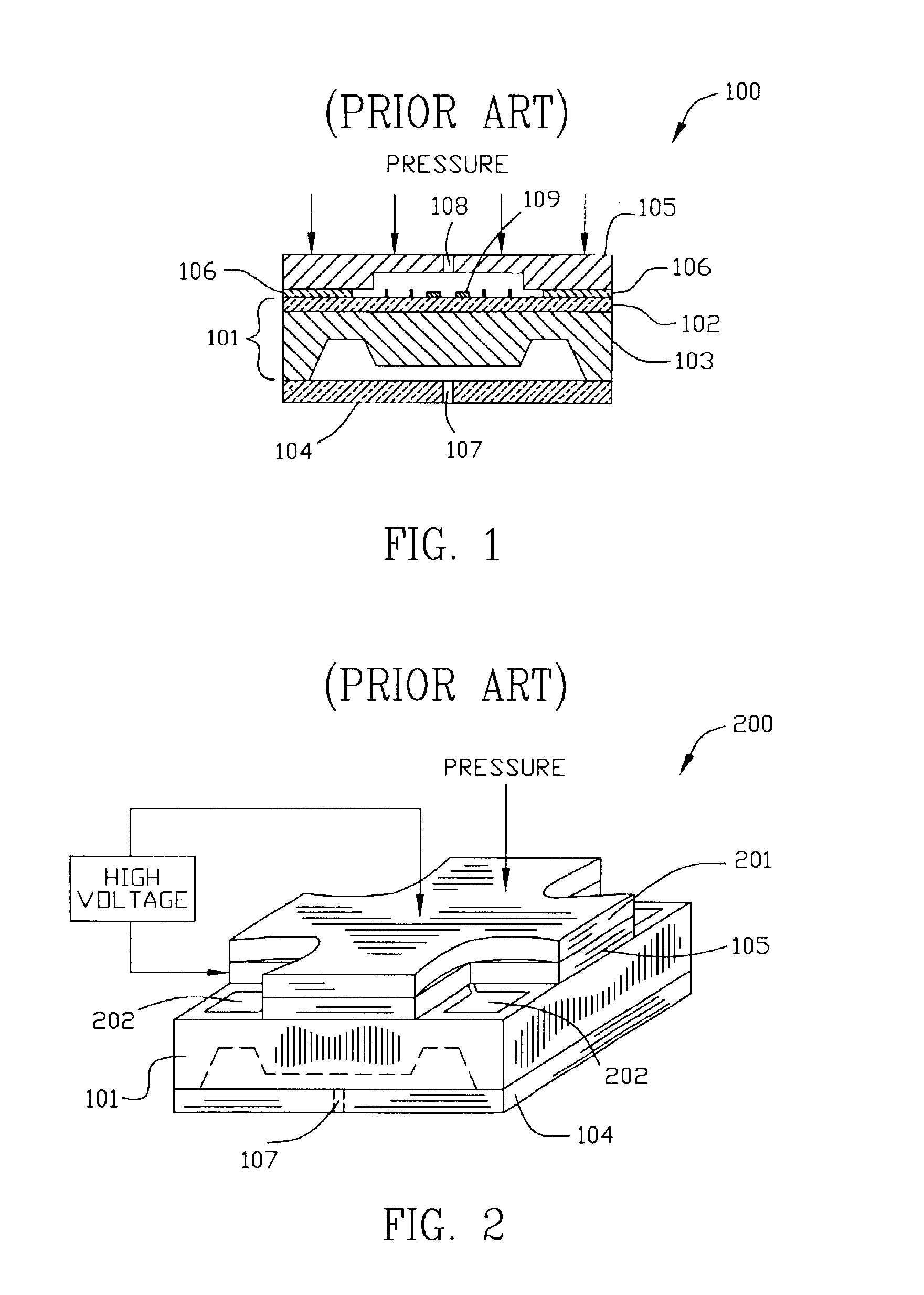

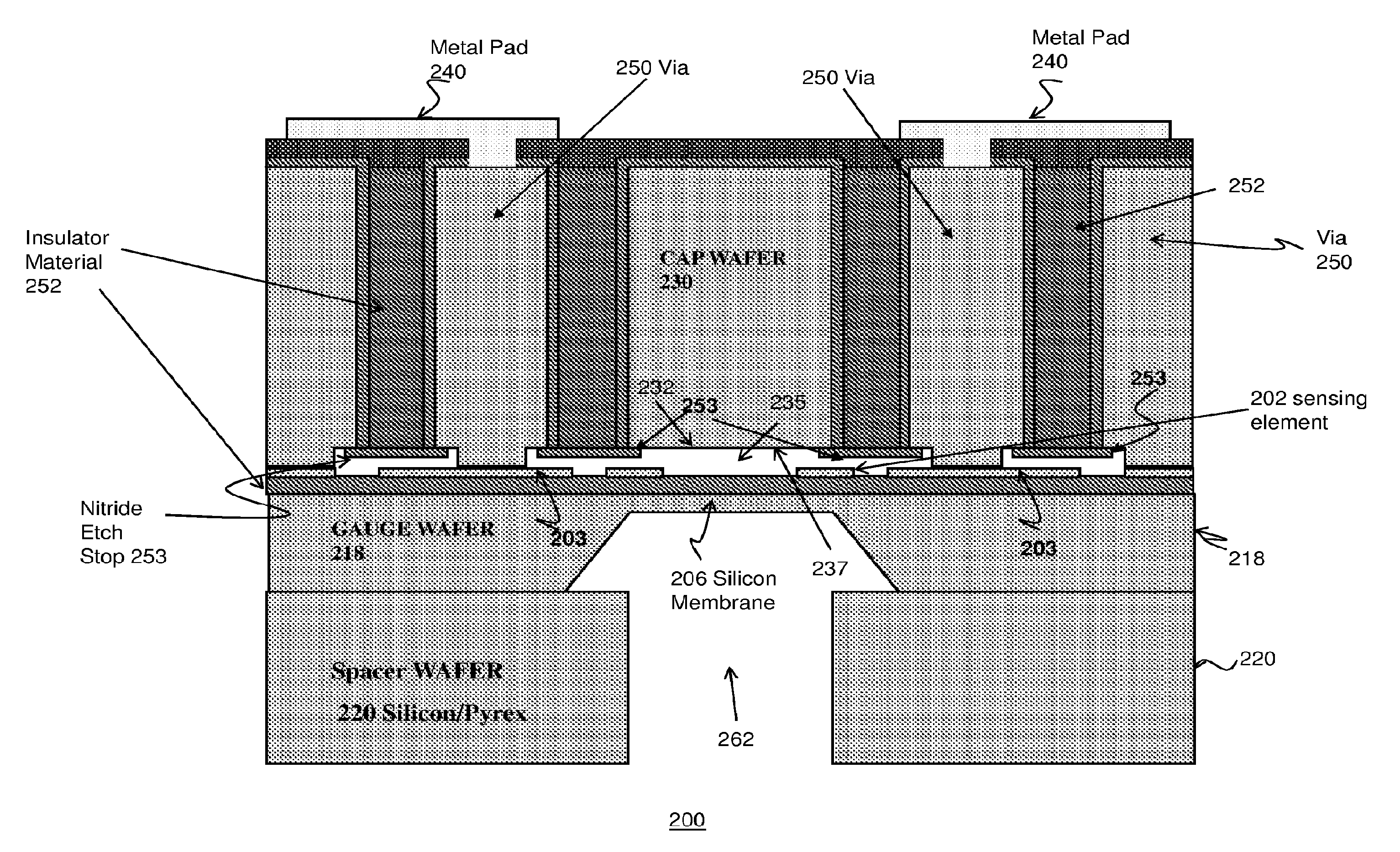

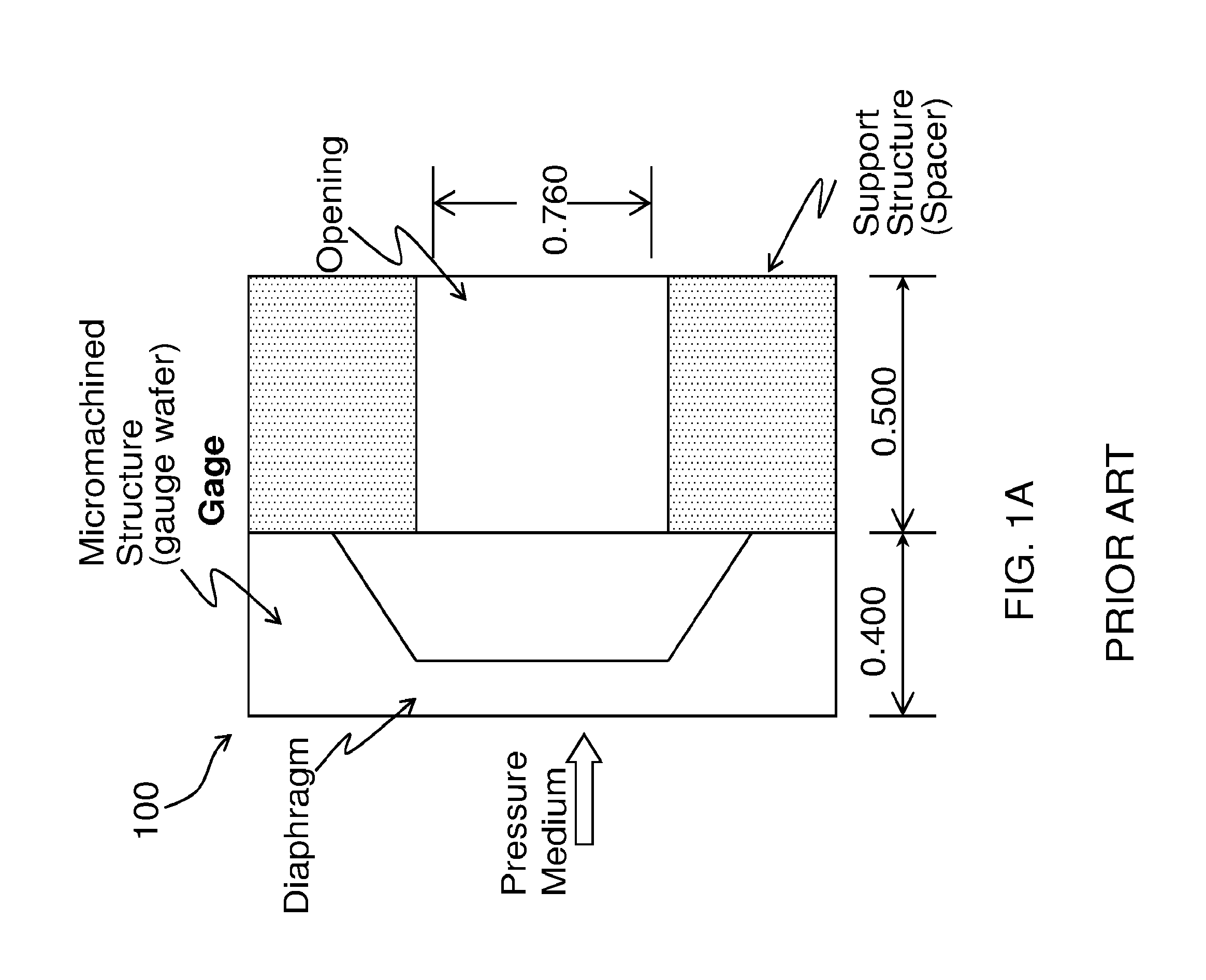

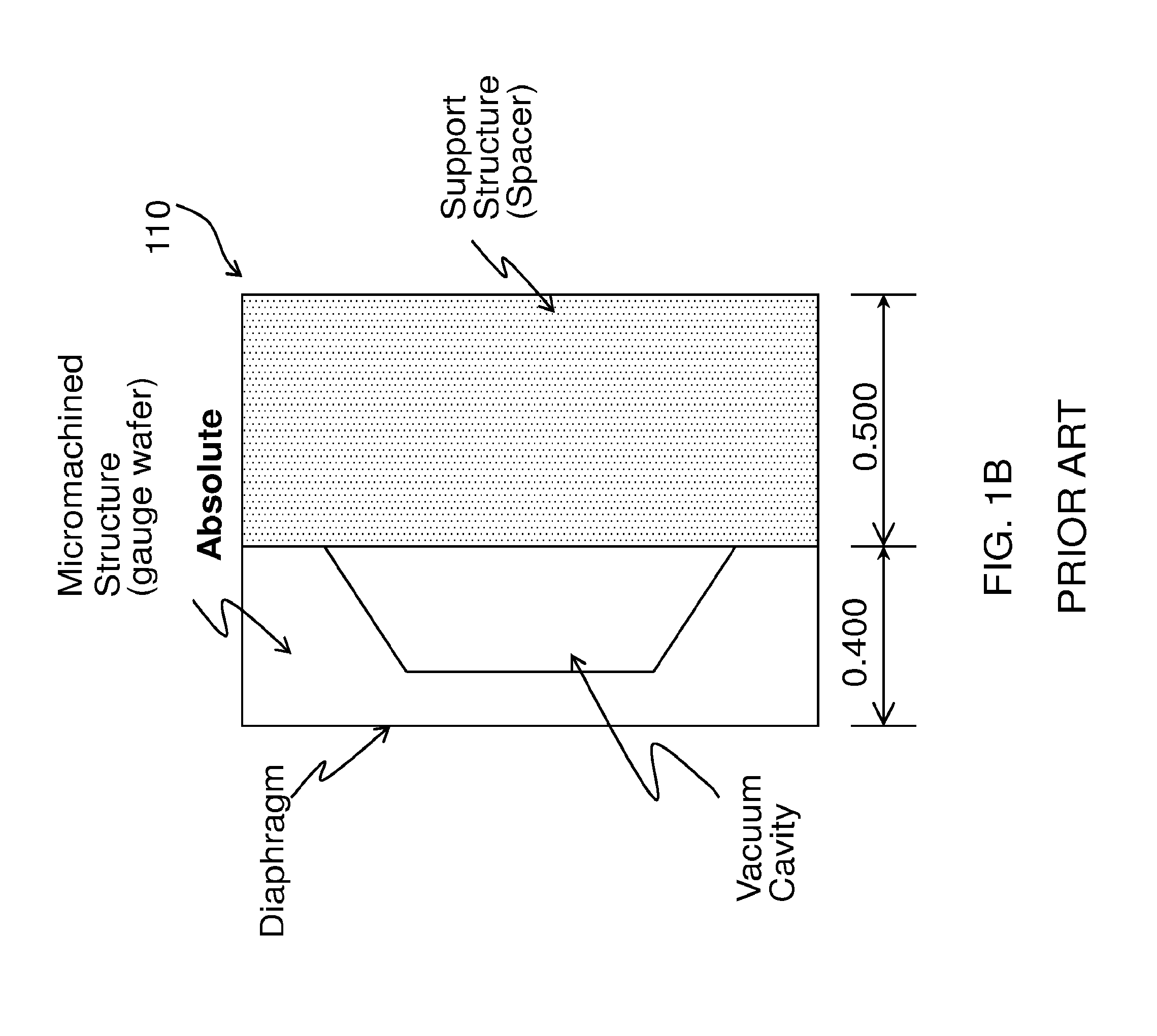

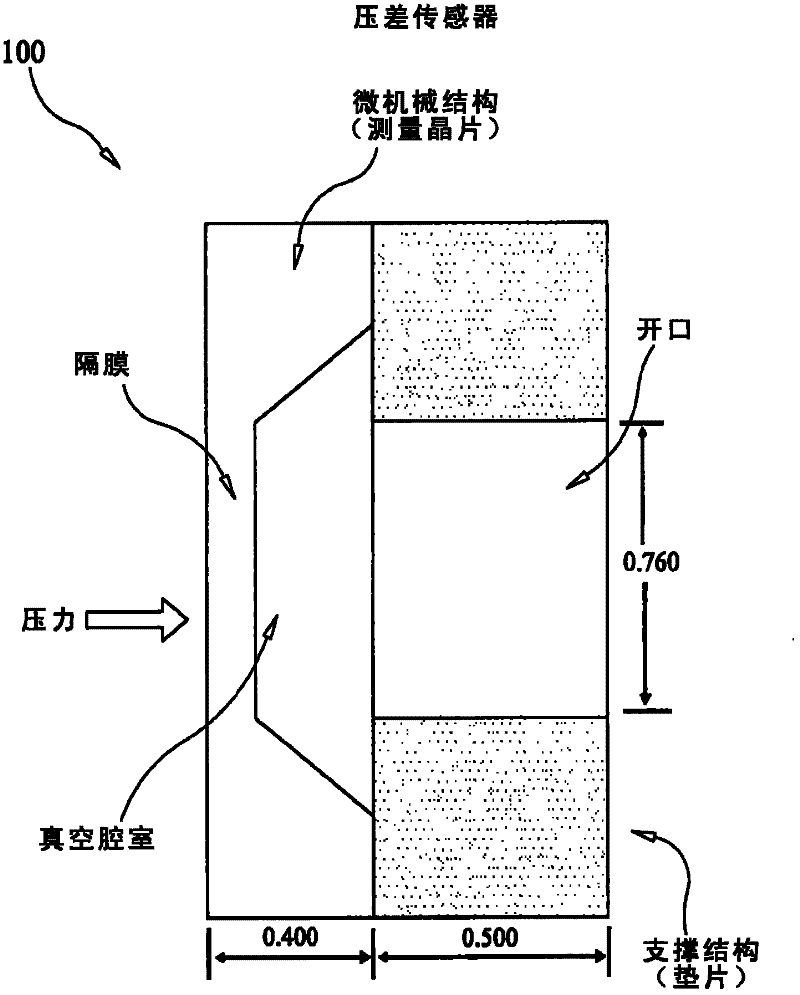

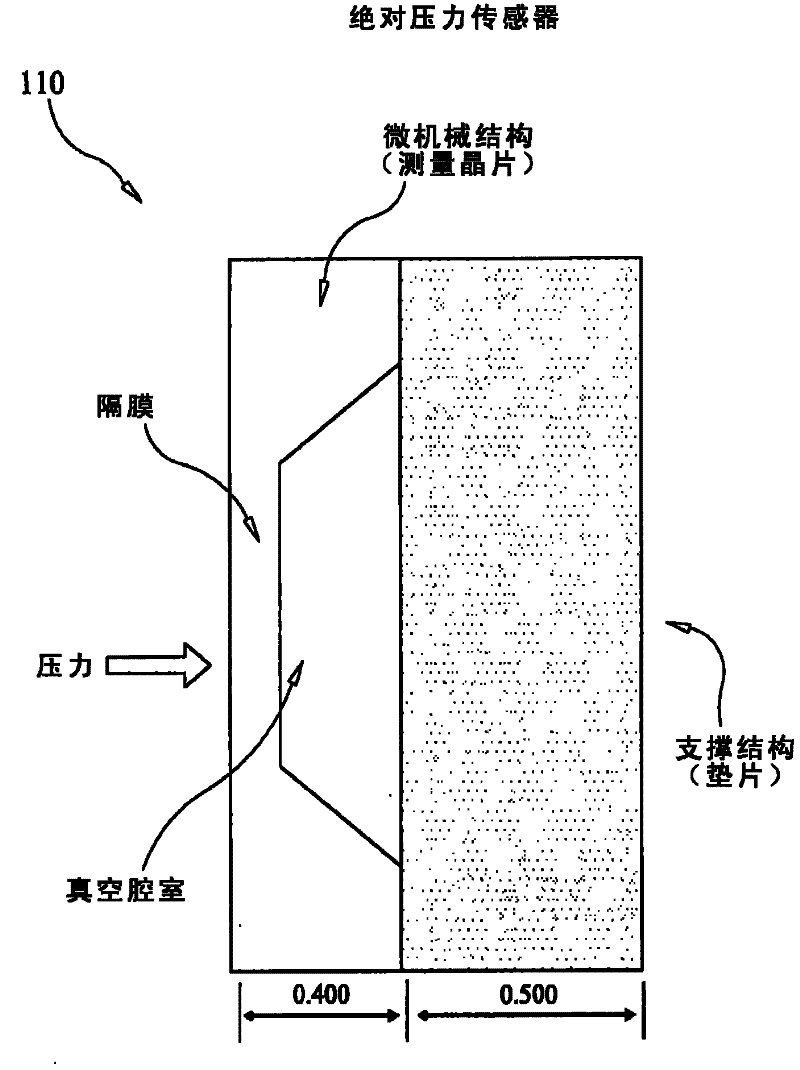

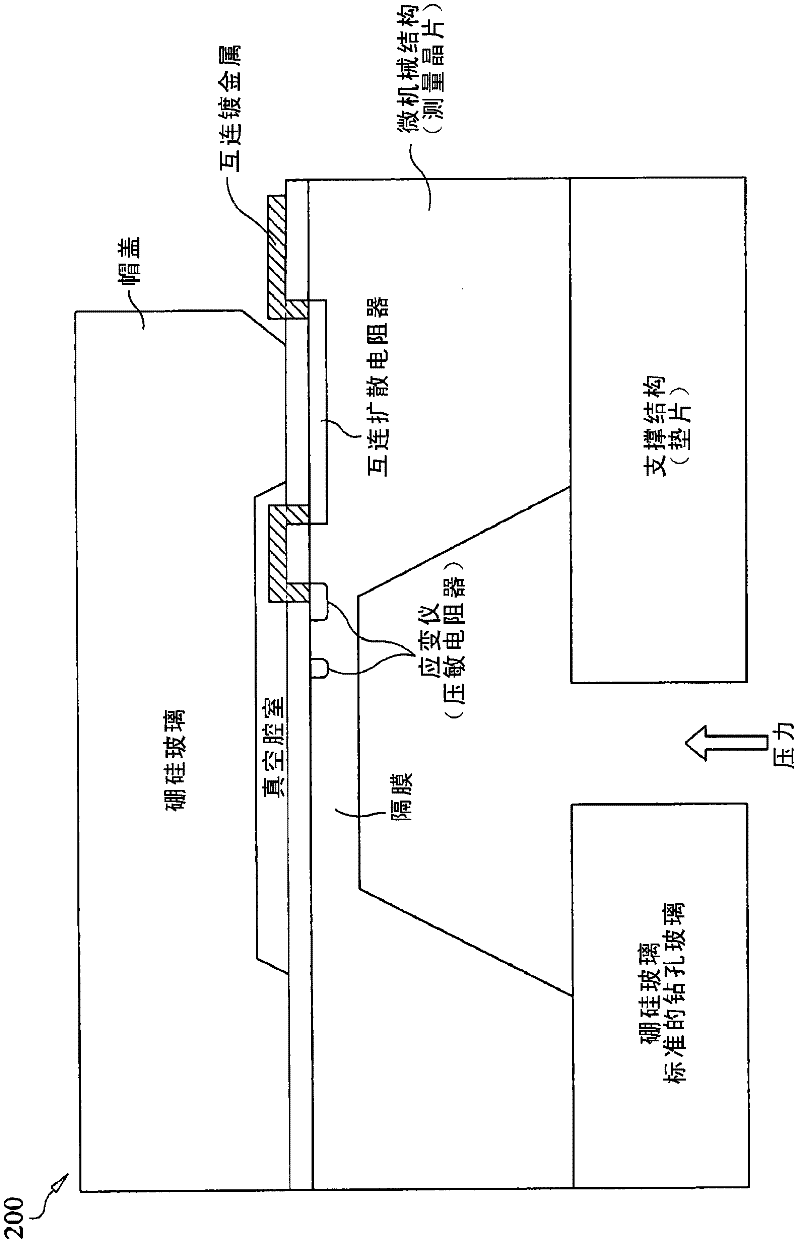

System and method for minimizing deflection of a membrance of an absolute pressure sensor

InactiveUS20130214370A1Avoid contactAvoid skewFluid pressure measurement by electric/magnetic elementsSolid-state devicesInsulation layerThermal expansion

A Micro-Electro-Mechanical System (MEMS) pressure sensor is disclosed, comprising a gauge wafer, comprising a micromachined structure comprising a membrane region and a pedestal region, wherein a first surface of the micromachined structure is configured to be exposed to a pressure medium that exerts a pressure resulting in a deflection of the membrane region. The gauge wafer also comprises a plurality of sensing elements patterned on the electrical insulation layer on a second surface in the membrane region, wherein a thermal expansion coefficient of the material of the sensing elements substantially matches with a thermal expansion coefficient of the material of the gauge wafer. The pressure sensor comprises a cap wafer coupled to the gauge wafer, which includes a recess on an inner surface of the cap wafer facing the gauge wafer that defines a sealed reference cavity that encloses and prevents exposure of the sensing elements to an external environment.

Owner:S3C

Media-compatible electrically isolated pressure sensor for high temperature applications

InactiveCN102341685AFluid pressure measurement using ohmic-resistance variationMicrostructural device manufactureElectricityElectrical connection

A pressure sensor is described with sensing elements electrically and physically isolated from a pressurized medium. An absolute pressure sensor has a reference cavity, which can be at a vacuum or zero pressure, enclosing the sensing elements. The reference cavity is formed by bonding a recessed cap wafer with a gauge wafer having a micromachined diaphragm. Sensing elements are disposed on a first side of the diaphragm. The pressurized medium accesses a second side of the diaphragm opposite to the first side where the sensing elements are disposed. A spacer'wafer may be used for structural support and stress relief of the gauge wafer. In one embodiment, vertical through-wafer conductive vias are used to bring out electrical connections from the sensing elements to outside the reference cavity. In an alternative embodiment, peripheral bond pads on the gauge wafer are used to bring out electrical connections from the sensing elements to outside the reference cavity. In various embodiments, a regular silicon-on-insulator wafer or a double silicon-on-insulator wafer may be used as the gauge wafer, and appropriate micromachining steps are adopted to define the diaphragm. A layer of corrosion resistant material is deposited on the surface of the diaphragm that is accessed by the pressurized medium.

Owner:NAGANO KEIKI

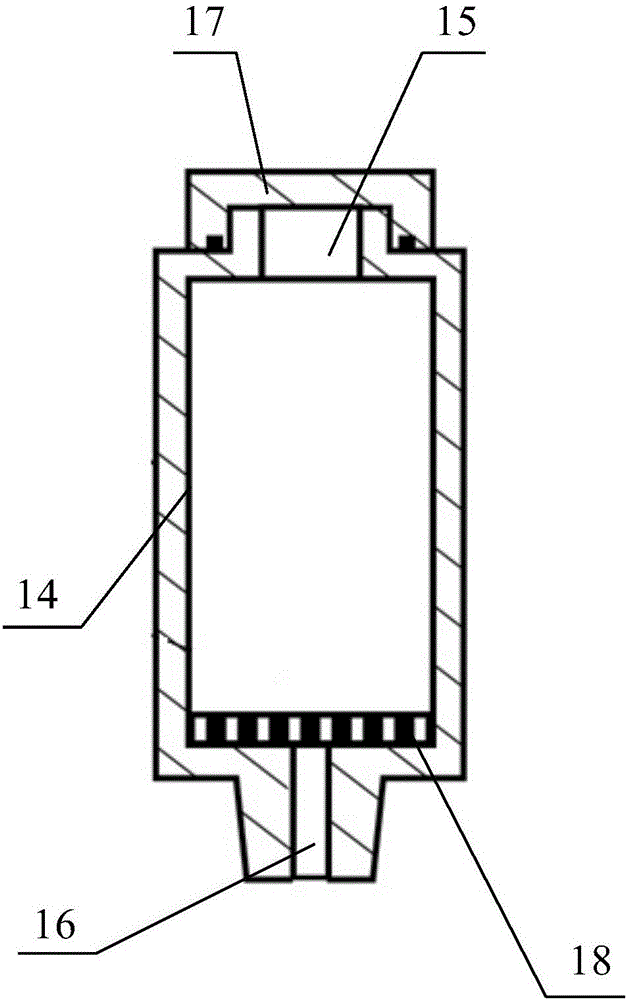

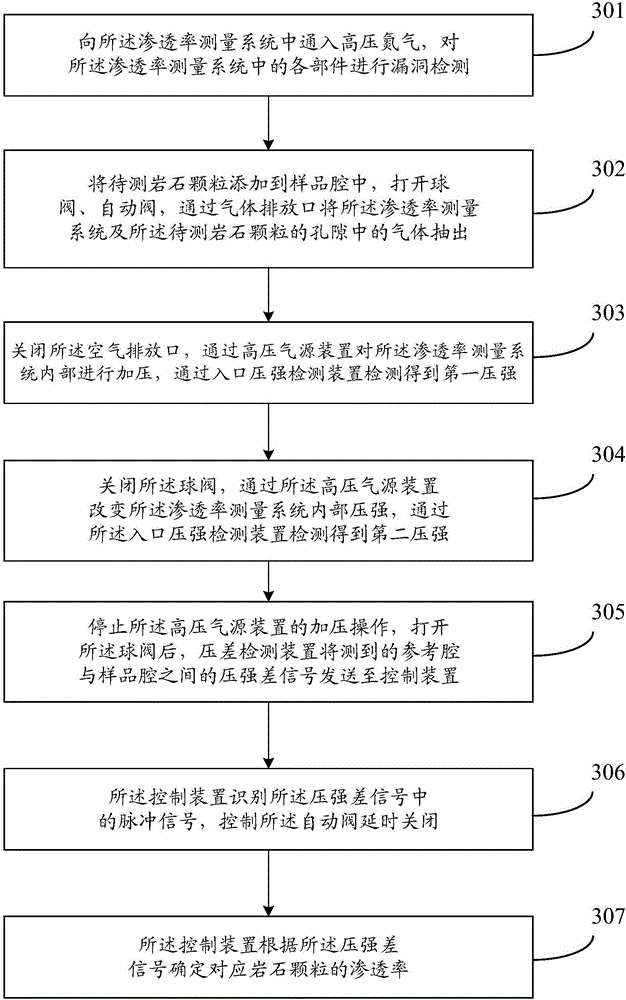

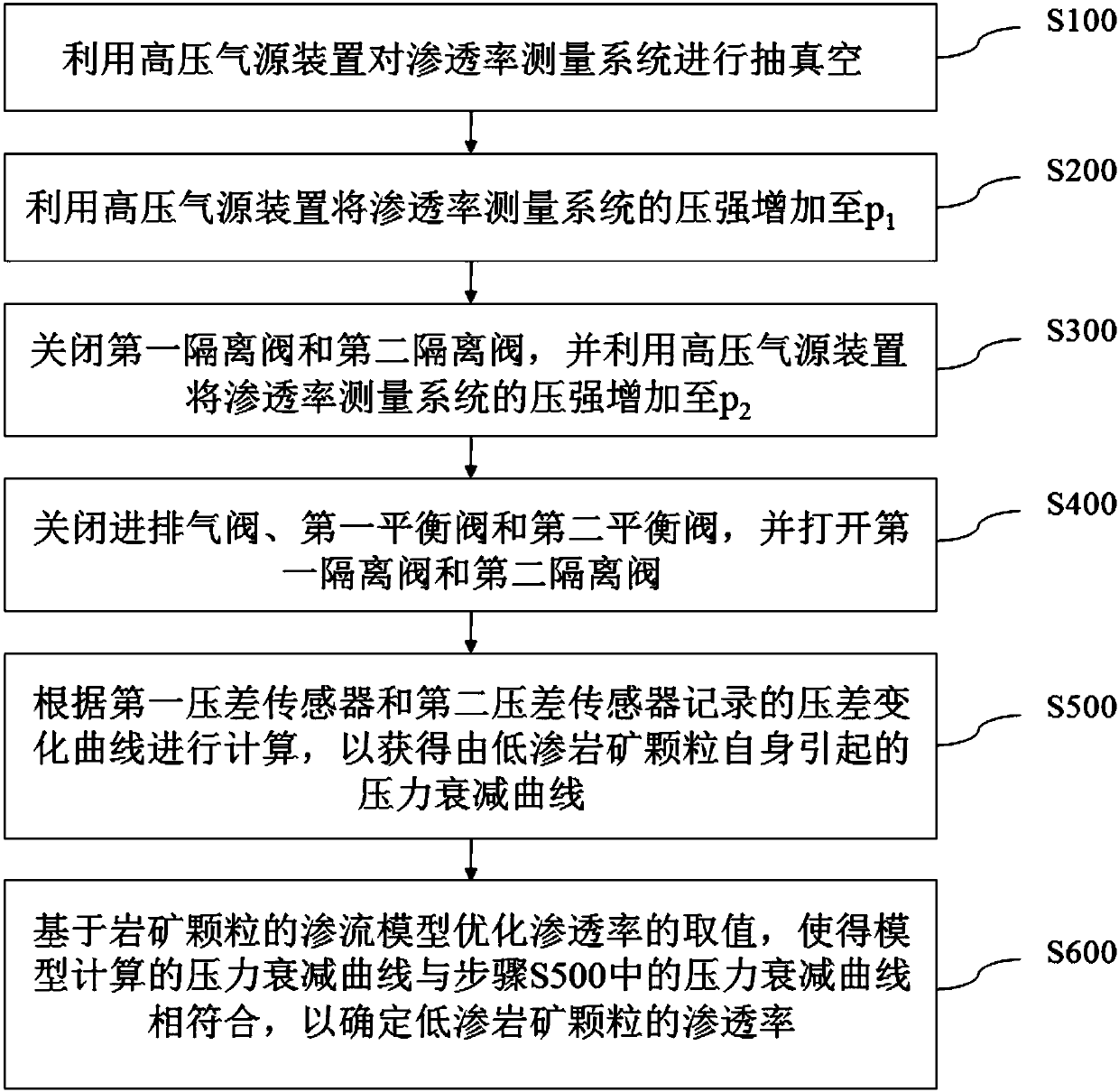

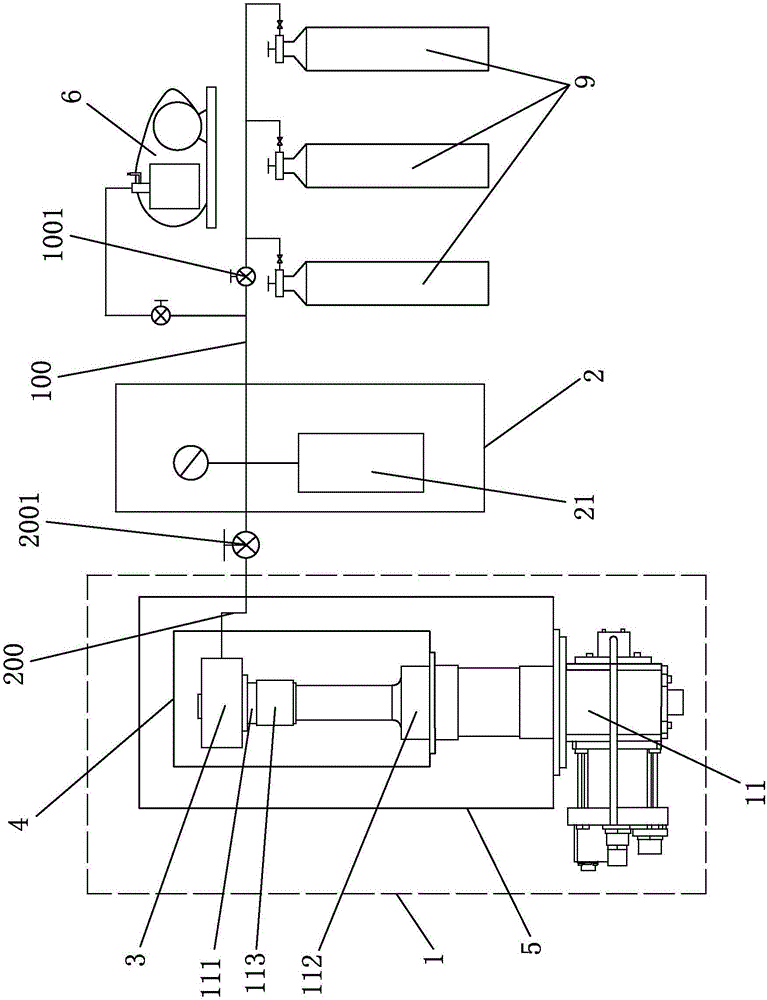

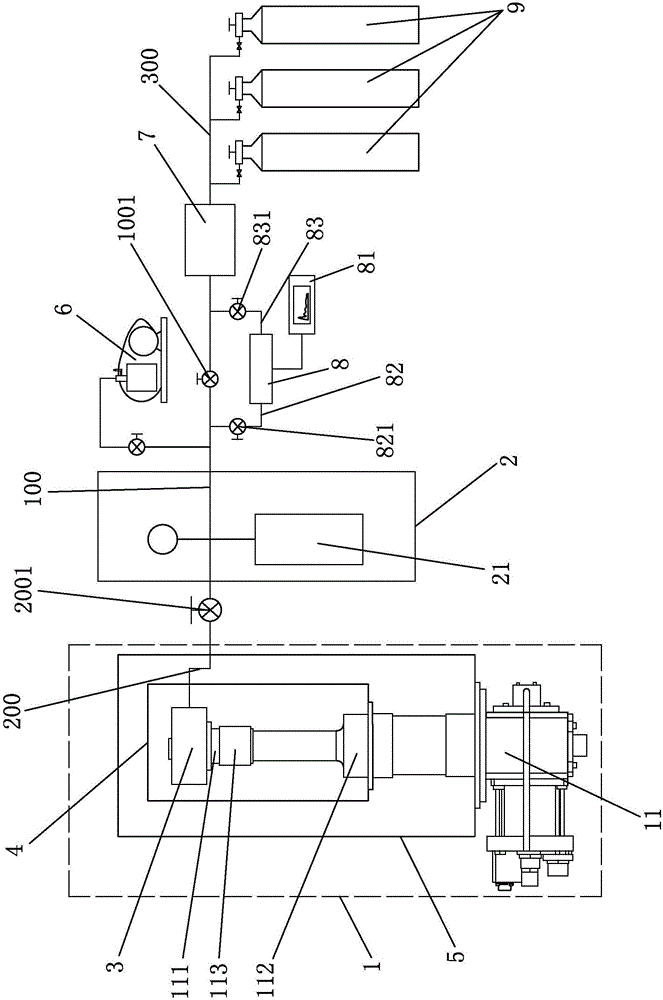

Low-permeability rock particle penetration rate measuring system and measuring method

ActiveCN106769778AAchieve high-precision inversionImproving Permeability Measurement AccuracyPermeability/surface area analysisParticle penetrationRate of penetration

The invention discloses a low-permeability rock particle penetration rate measuring system and measuring method. The penetration rate measuring system comprises a high-pressure air source device, a reference cavity, a sample cavity, an inlet pressure intensity detecting device, an automatic valve, a ball valve, a pressure difference detecting device and a control device, wherein the automatic valve and the ball valve are sequentially arranged on a pipeline communicating the reference cavity and the sample cavity; the pressure difference detecting device and the automatic valve are connected in parallel; the control device is respectively connected with the automatic valve and the pressure difference detecting device; an output pipeline of the high-pressure air source device communicates with the reference cavity or the sample cavity; the inlet pressure intensity detecting device is arranged on the output pipeline of the high-pressure air source device; an air exhaust opening is formed in a pipeline of the inlet pressure intensity detecting device and the high-pressure air source device. The high-pressure air source device is connected with the reference cavity or the sample cavity; the change of the pressure intensity inside the reference cavity and the sample cavity can be controlled; the pressure intensity difference is detected through the pressure difference detecting device, so that the control device can accurately obtain a pressure intensity change curve and the particle penetration rate of rock to be measured.

Owner:TSINGHUA UNIV

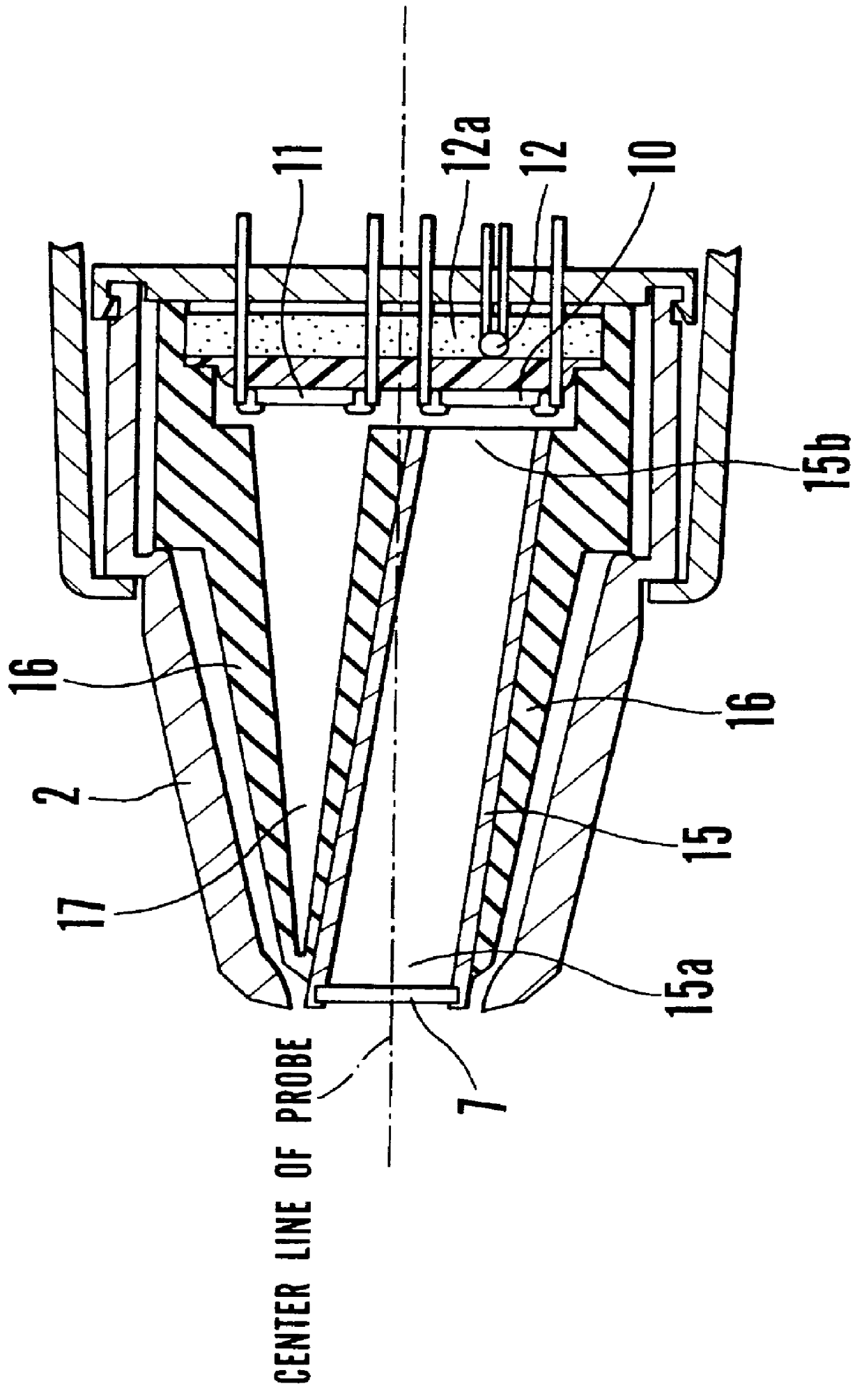

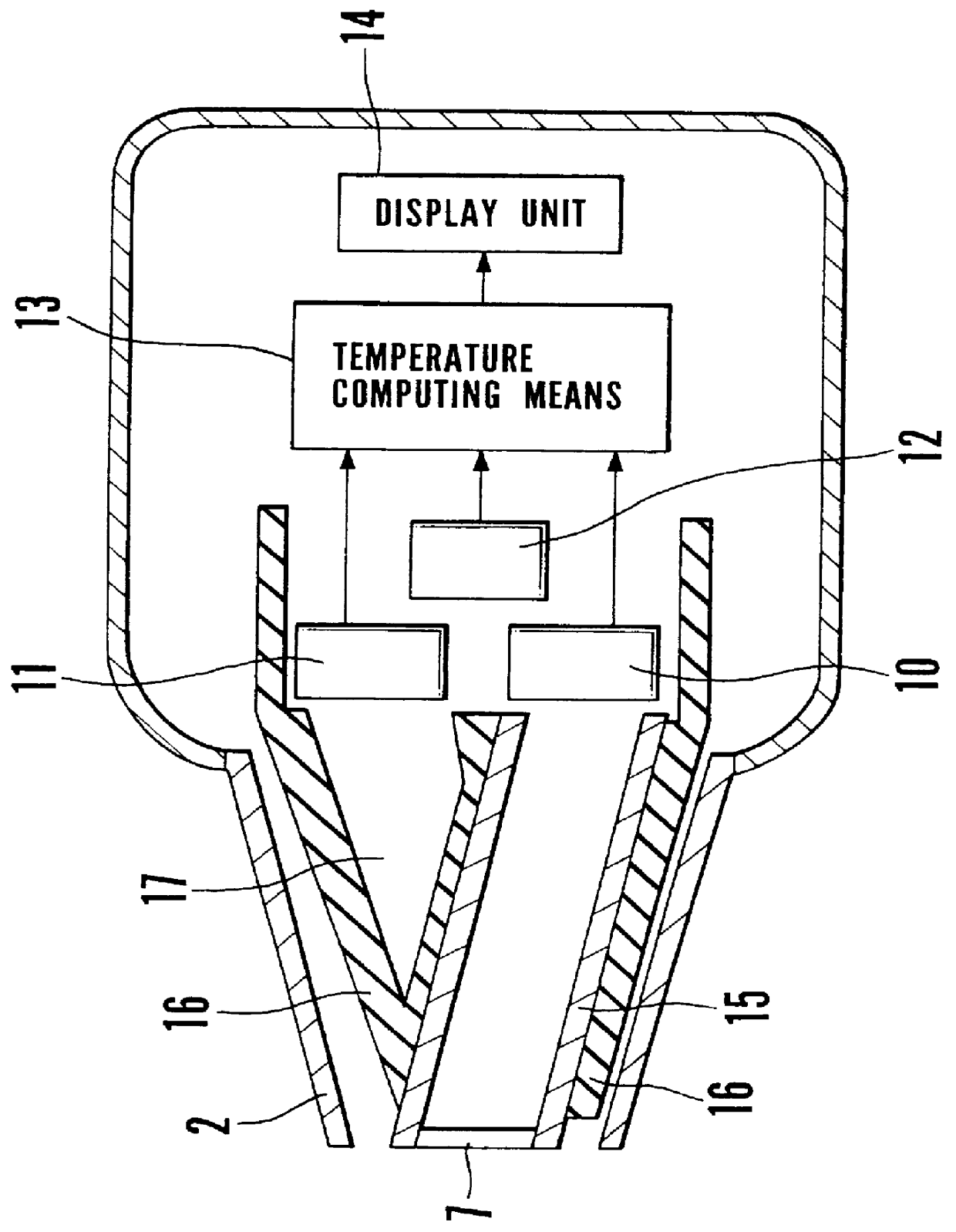

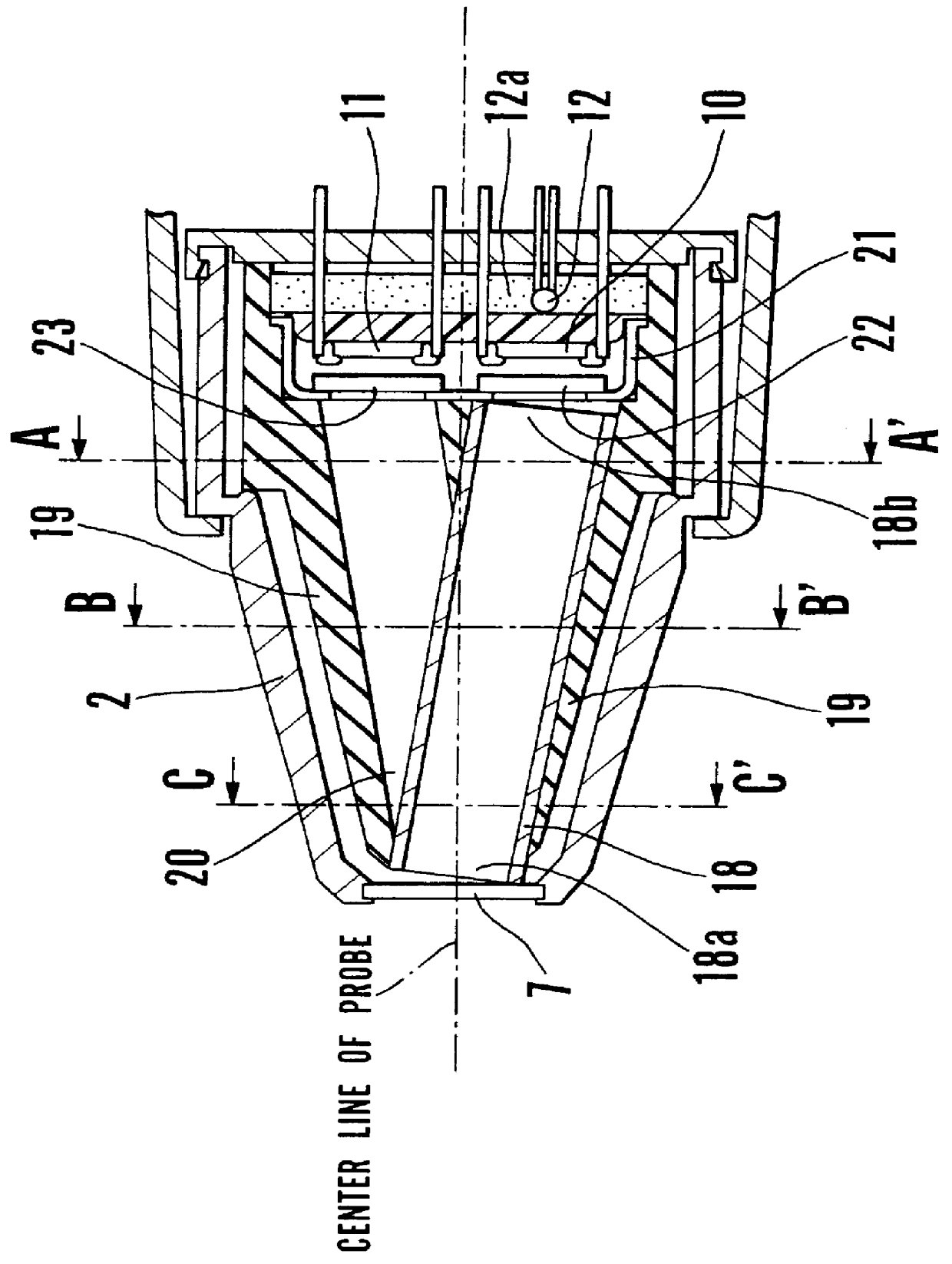

Radiation thermometer

PCT No. PCT / JP97 / 03977 Sec. 371 Date Jul. 10, 1998 Sec. 102(e) Date Jul. 10, 1998 PCT Filed Oct. 31, 1997 PCT Pub. No. WO98 / 20790 PCT Pub. Date May 22, 1998The radiation clinical thermometer of the present invention is provided with a light guide tube 15 to guide the infrared radiation from the temperature-measured object, a first infrared sensor 10 for detecting the infrared radiation from the light guide tube 15, a temperature sensitive sensor 12 which generates a reference temperature signal, a reference cavity 17 which has approximately the same temperature condition as the light guide tube 15 and is sealed so as to shut out infrared radiation from outside, a second infrared sensor 11 for detecting the infrared radiation from the reference cavity 17, a temperature computing means 13 for calculating temperature in accordance with the signals from the first infrared sensor 10 and the second infrared sensor 11, a temperature sensitive sensor 12, and a display unit 14 for displaying temperature in accordance with the signal from the temperature computing means 13; and at least either the light guide tube 15 or the reference cavity 17 is tapered off toward the emission inlet of the light guide tube 15 from the first or second infrared sensor 10 or 11 side.

Owner:CITIZEN WATCH CO LTD

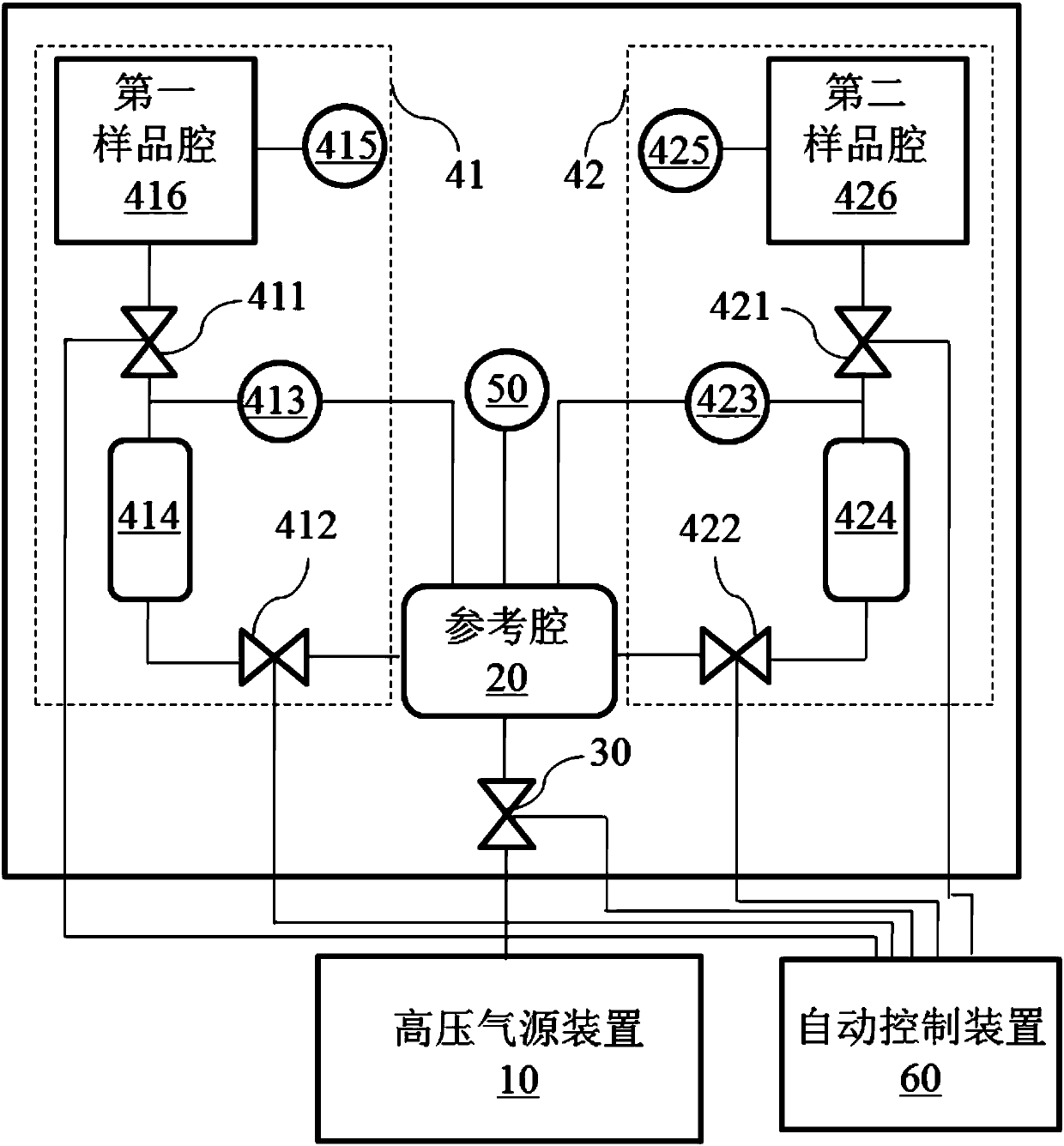

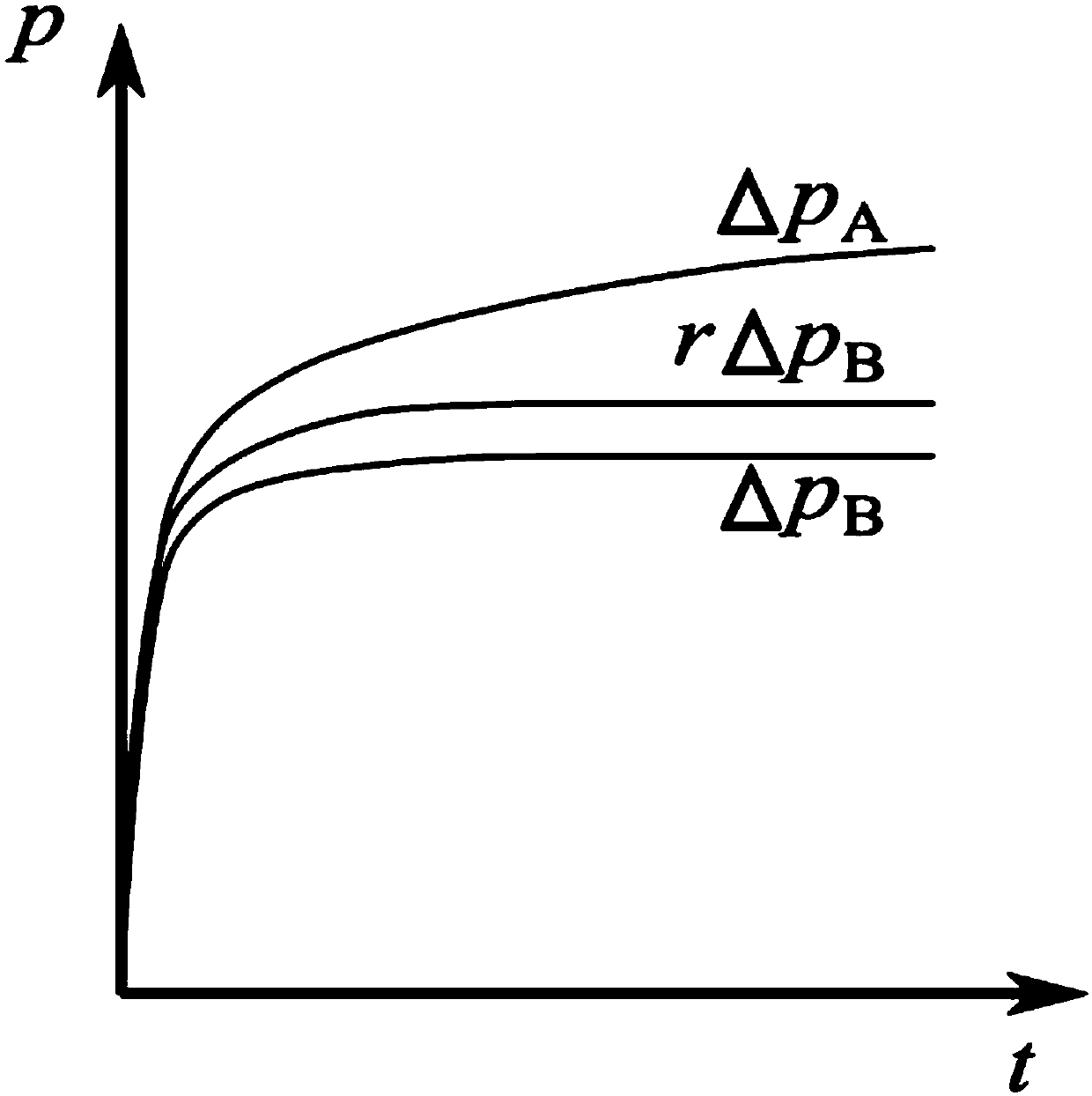

Permeability measurement system and method for low-permeability rock ore particles

ActiveCN107655805AEnables Permeability MeasurementsEasy maintenancePermeability/surface area analysisIsolation valveExhaust valve

The invention provides a permeability measurement system and method for low-permeability rock ore particles. The permeability measurement system comprises a high-pressure air source device, a reference cavity, a suction and exhaust valve and two symmetrically-arranged sample side devices; each sample side device comprises a sample cavity, an isolation valve and a balance valve, the sample cavity is communicated with the reference cavity through a circulation pipeline to receive high pressure air transmitted from the reference cavity; the isolation valve is arranged at the position of the circulation pipeline and close to the sample cavity; the balance valve is arranged at the position of the circulation pipeline and close to the reference cavity; the two sample cavities are respectively used for accommodating to-be-detected low-permeability rock ore particles and impermeable solids, the impermeable solids and the to-be-detected low-permeability rock ore particles are identical in particle size and volume, and the sample side devices are arranged at the same height. The permeability measurement system is simple and easy to maintain, small in dimension and high in safety; the permeability measurement system and method has the advantages that credibility and measurement precision of permeability of low-permeability rock ores are remarkably increased.

Owner:苏州开洛泰克科学仪器科技有限公司

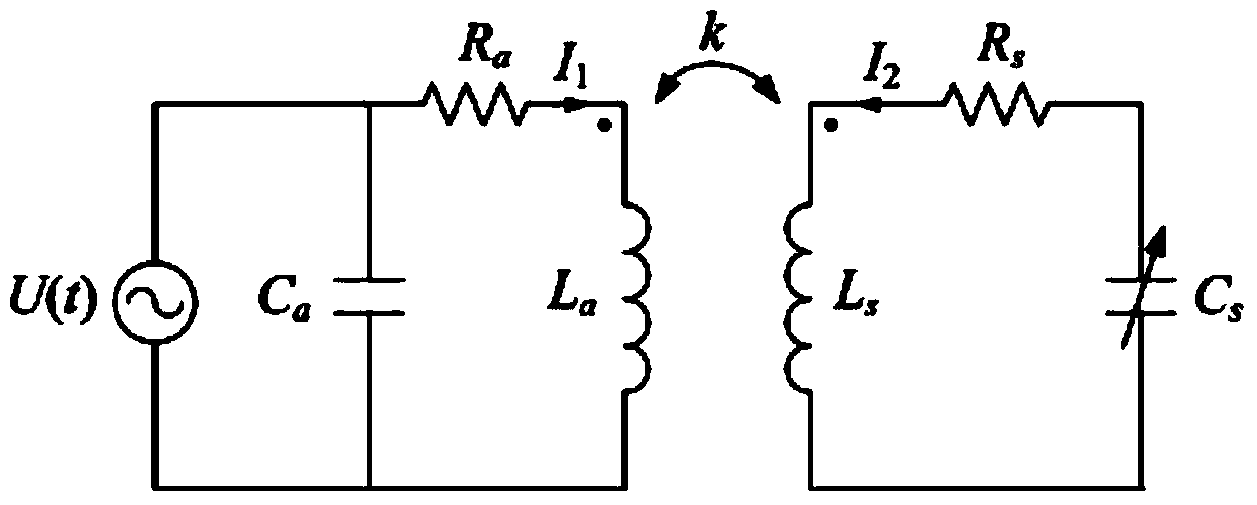

Built-in high-temperature wireless pressure sensor

InactiveCN103926026AIncreasing the thicknessLower the resistance valueForce measurement by measuring frquency variationsFluid pressure measurement using capacitance variationCapacitanceChinese characters

The invention relates to a pressure sensor, in particular to a built-in high-temperature wireless pressure sensor. The built-in high-temperature wireless pressure sensor is provided with a pressure sensitive film, a sensor upper covering plate, a capacitor upper counter electrode, a capacitor lower counter electrode, an inductance coil, a sensor base and a pressure reference cavity, wherein a square groove is formed in the sensor upper covering plate to form the pressure sensitive film, the capacitor upper counter electrode is manufactured on the back surface of the sensor upper covering plate, a groove shaped like a Chinese character 'hui' is formed in the sensor base, the capacitor lower counter electrode and the inductance coil are manufactured on the sensor base, the upper surface of the capacitor lower counter electrode is flush with the upper surface of the inductance coil, and the inductance coil is manufactured in the groove shaped like the Chinese character 'hui'. The capacitor upper counter electrode, the capacitor lower counter electrode and the inductance coil are all made of silicon doped with metal, the capacitor upper counter electrode and the capacitor lower counter electrode form a parallel plate capacitor, the capacitor upper counter electrode and the inductance coil lead out wires at the upper layer and wires at the lower layer respectively, the sensor upper covering plate and the sensor base are bonded, the wires at the upper layer make tight contact with the wires at the lower layer, the capacitor upper counter electrode, the inductance coil and the capacitor lower counter electrode are connected in series to form a standard RLC loop, and the pressure reference cavity is formed.

Owner:XIAMEN UNIV

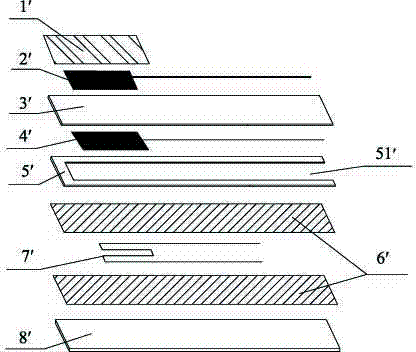

Planar oxygen sensor and method for producing same

ActiveCN102478538AAvoid deformationIncrease binding areaMaterial analysis by electric/magnetic meansOxygen sensorOptoelectronics

The invention provides a planar oxygen sensor, which comprises a heating layer, a reference gas layer and a sensing layer sequentially from bottom to top. The planar oxygen sensor is characterized in that the reference gas layer is provided with through holes, and closed reference cavities are formed at the through holes of the heating layer, the reference gas layer and the sensing layer. The reference gas layer is provided with the through holes, so that the combination area of the reference gas layer with the upper layer and the lower layer is enlarged, and product yield can be increased effectively. In addition, the sensing layer, the reference gas layer and the heating layer are stacked to form the closed reference cavities, so that voltage signals outputted by the planar oxygen sensor are stable.

Owner:BYD CO LTD

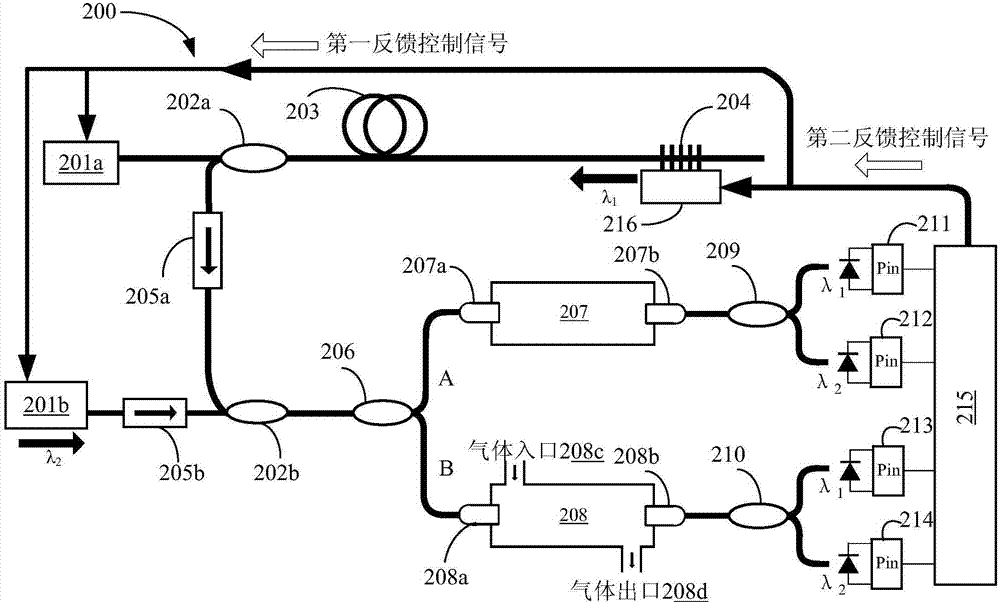

Gas detection system using semiconductor laser with feedback compensation by gas reference cavity

InactiveUS8928885B1Sensitive highImprove accuracyTransmissivity measurementsColor/spectral properties measurementsMultiplexerLight beam

A gas detection system using a semiconductor laser with a reference gas cavity compensation is provided, said system comprising a first light source emitting a first beam of a first wavelength as a detection beam; a second light source emitting a second beam of a second wavelength, which is different from the first wavelength, as a reference beam; a first wavelength division multiplexer connected with said first light source and said second light source; a broadband coupler connected with said first wavelength division multiplexer; a reference gas chamber, which is introduced with reference gas of the same composition as that of the gas to be detected and of a known concentration; a detection gas chamber, which is introduced with the gas to be detected.

Owner:LUO FEI

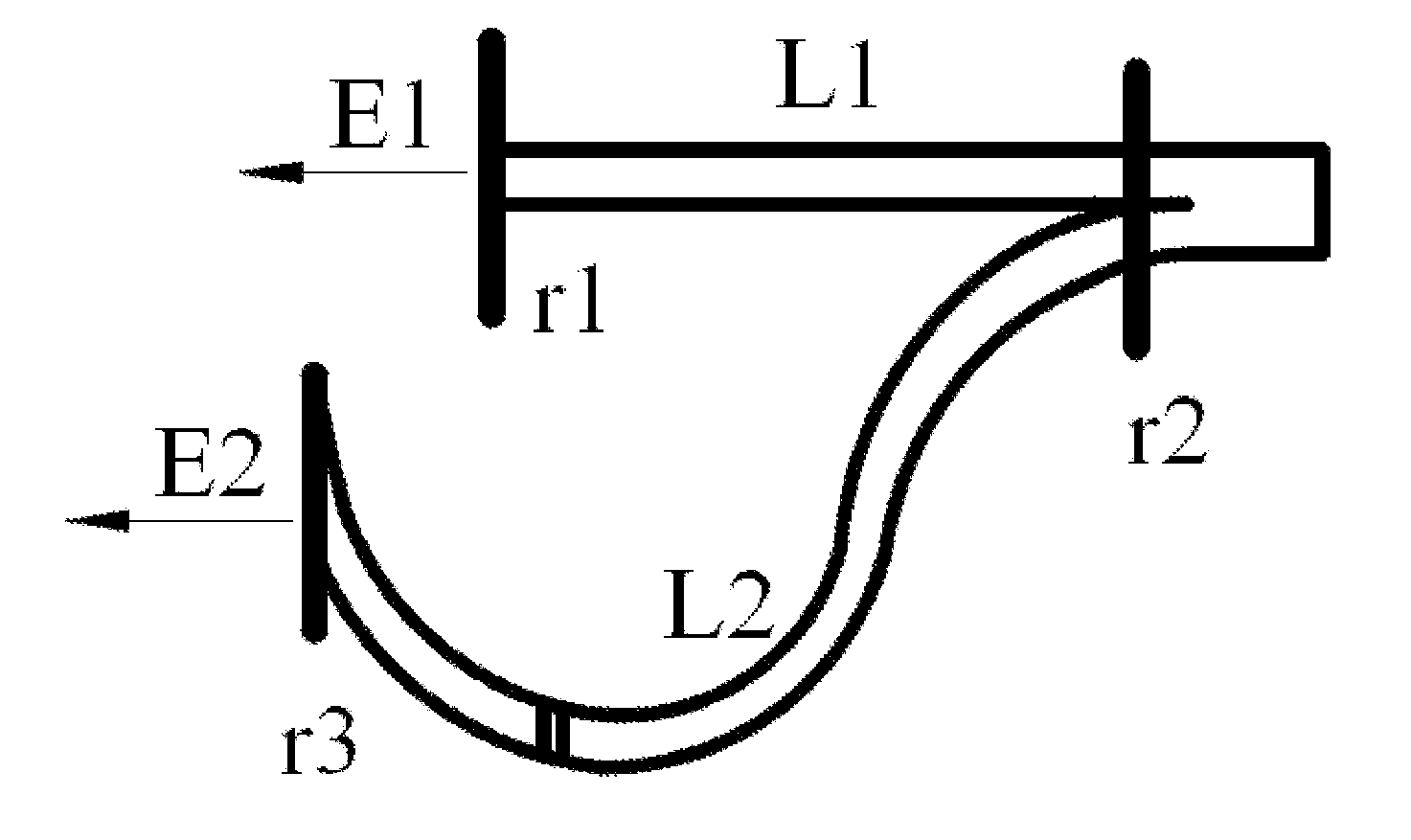

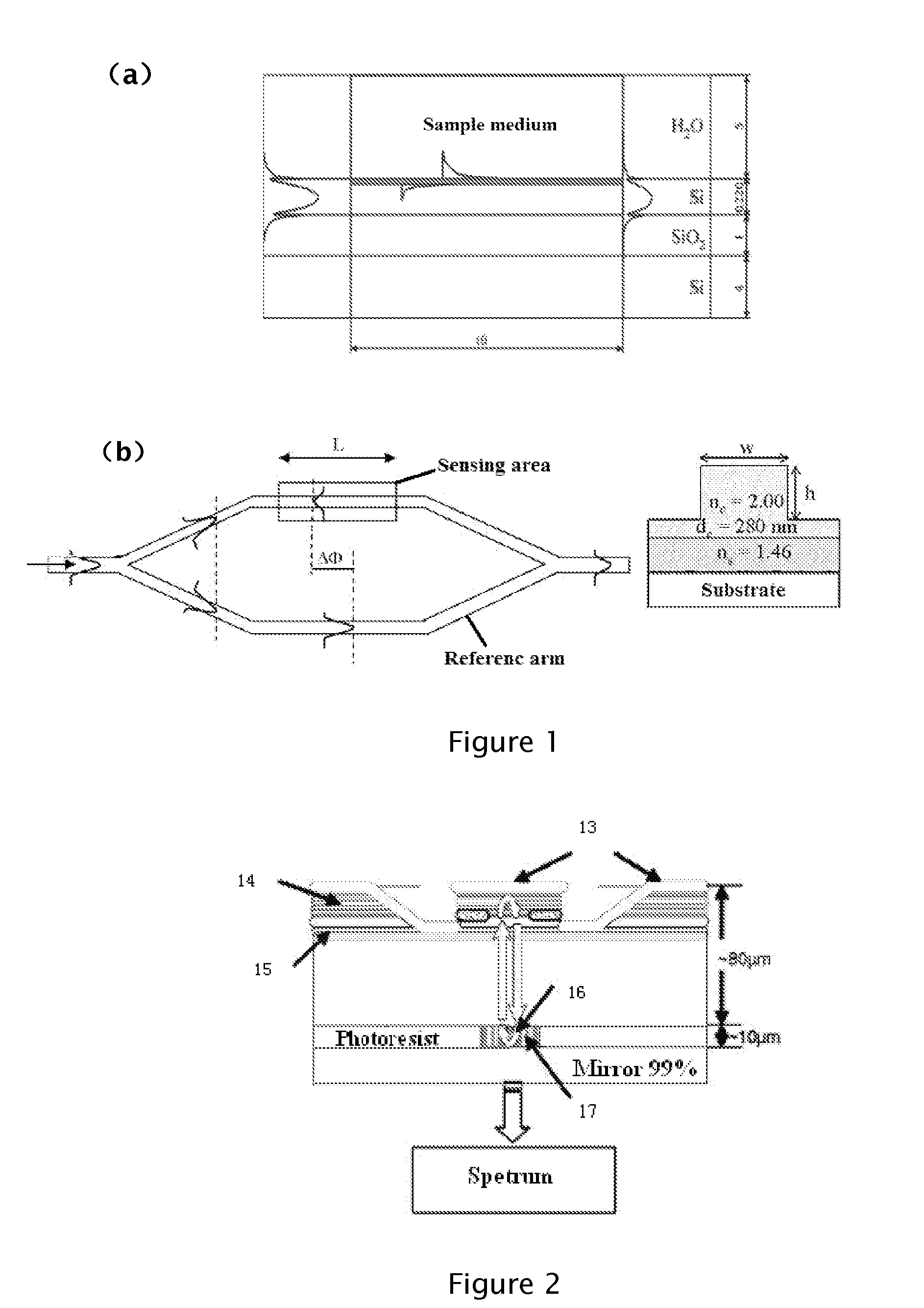

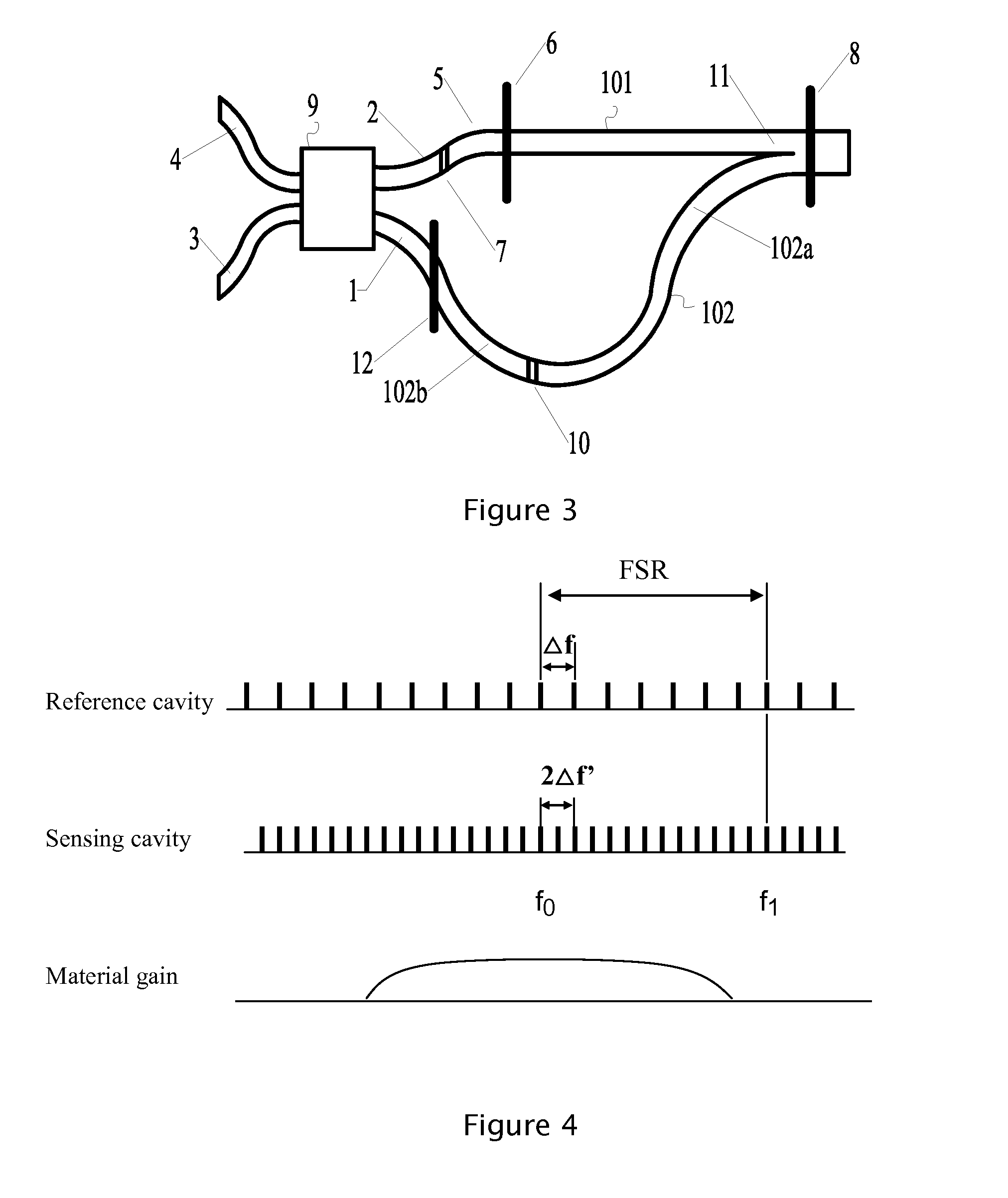

Semiconductor laser based intra-cavity optical micro-fluidic biosensor

InactiveUS20120194804A1Improve performanceComprehensive functionsPhase-affecting property measurementsComing outPhase difference

A semiconductor laser based intra-cavity optical micro-fluidic biosensor comprises a coupled-cavity semiconductor laser, a 2×2 coupler and a phase adjustment section on one input port of the coupler. The dominant mode of the coupled-cavity laser appears in one output port of the coupler, while the adjacent mode comes out from the other output port of the coupler. The resonant frequency interval of the sensing cavity is slightly larger or smaller than one half of that of the reference cavity. Part of the sensing cavity is the sensing section which is covered by an analyte. The refractive index change of the analyte will cause the lasing mode of the coupled cavity to switch to an adjacent mode, resulting in a π-phase change in the phase difference between the two output ports of the two resonance cavities. By applying the Vernier effect, the power ratio of the two output ports of the coupler will change and the refractive index change of the analyte can be derived. A detection limit of 10−8 RIU or smaller can be achieved.

Owner:ZHEJIANG UNIV

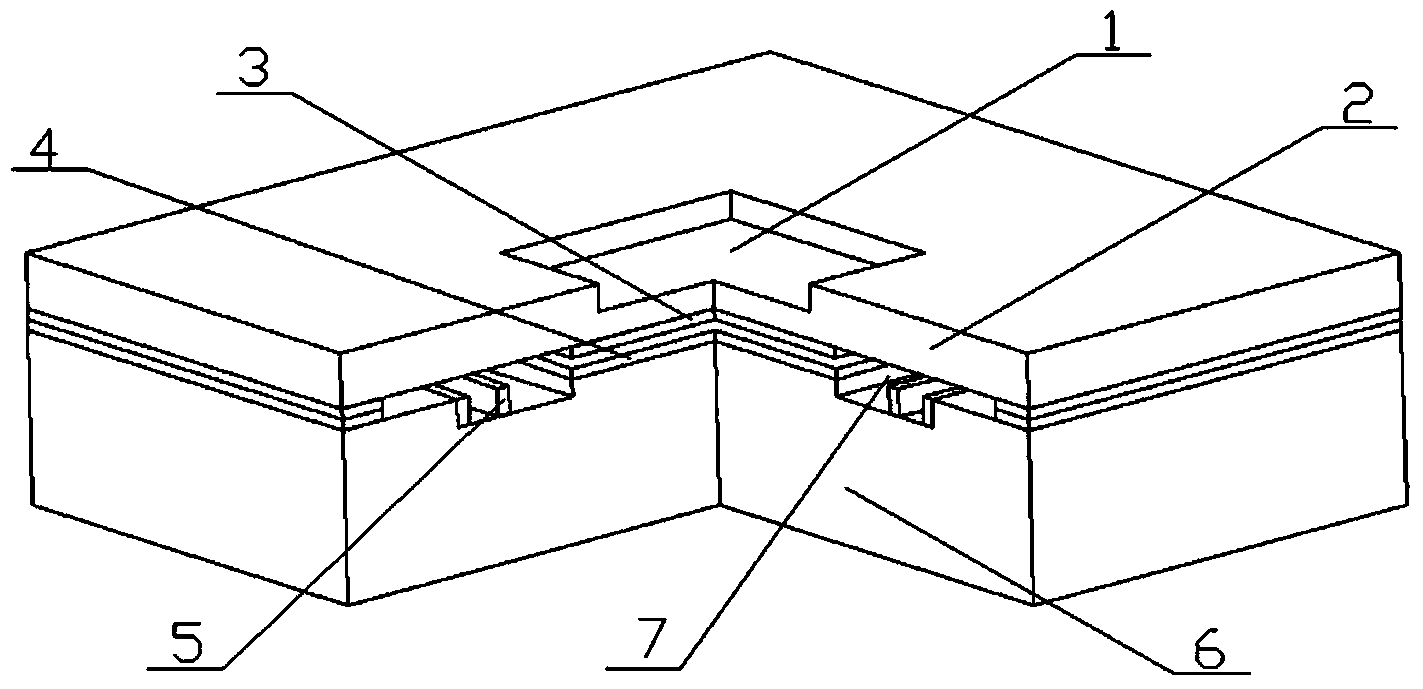

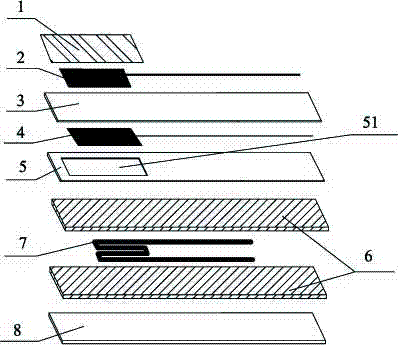

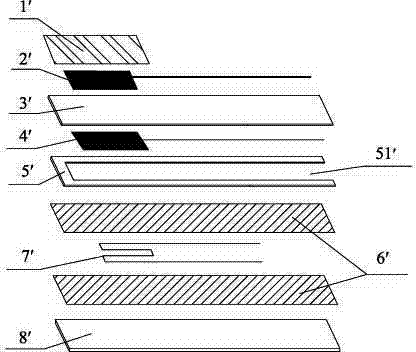

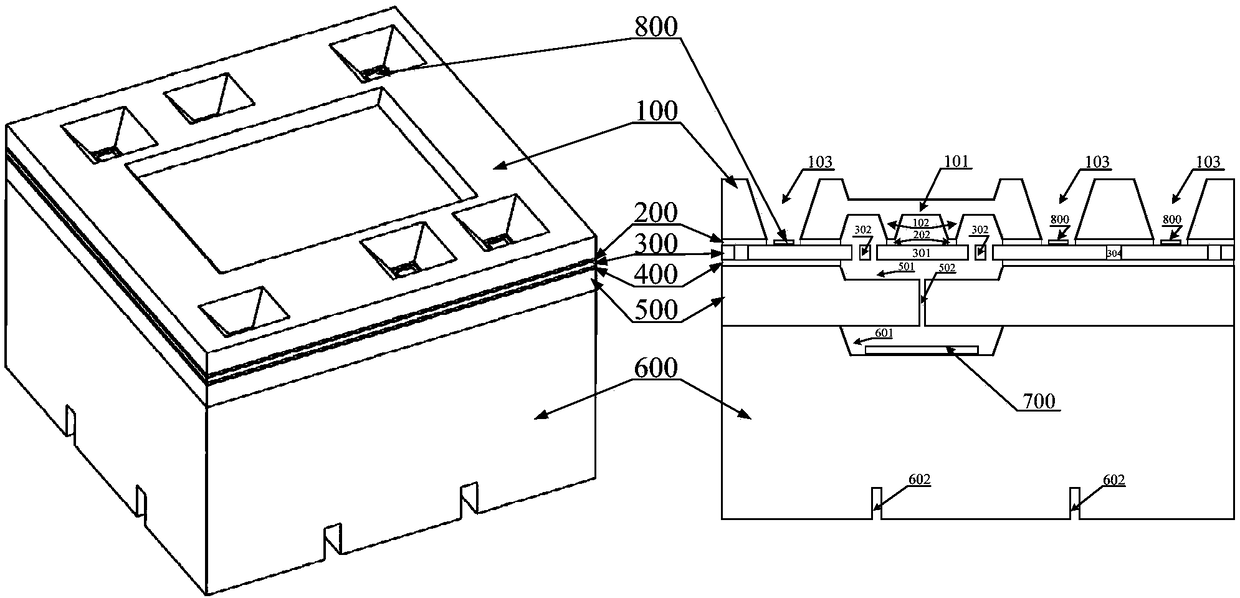

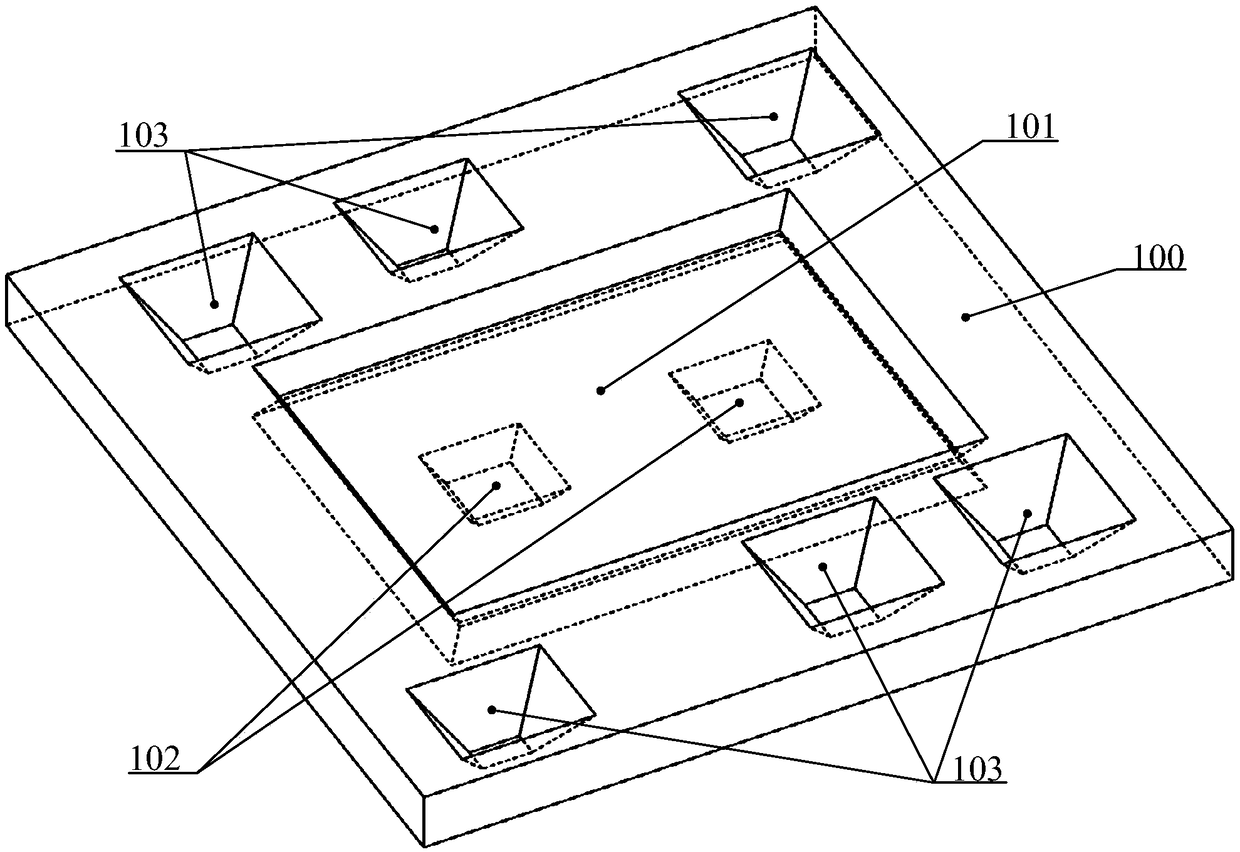

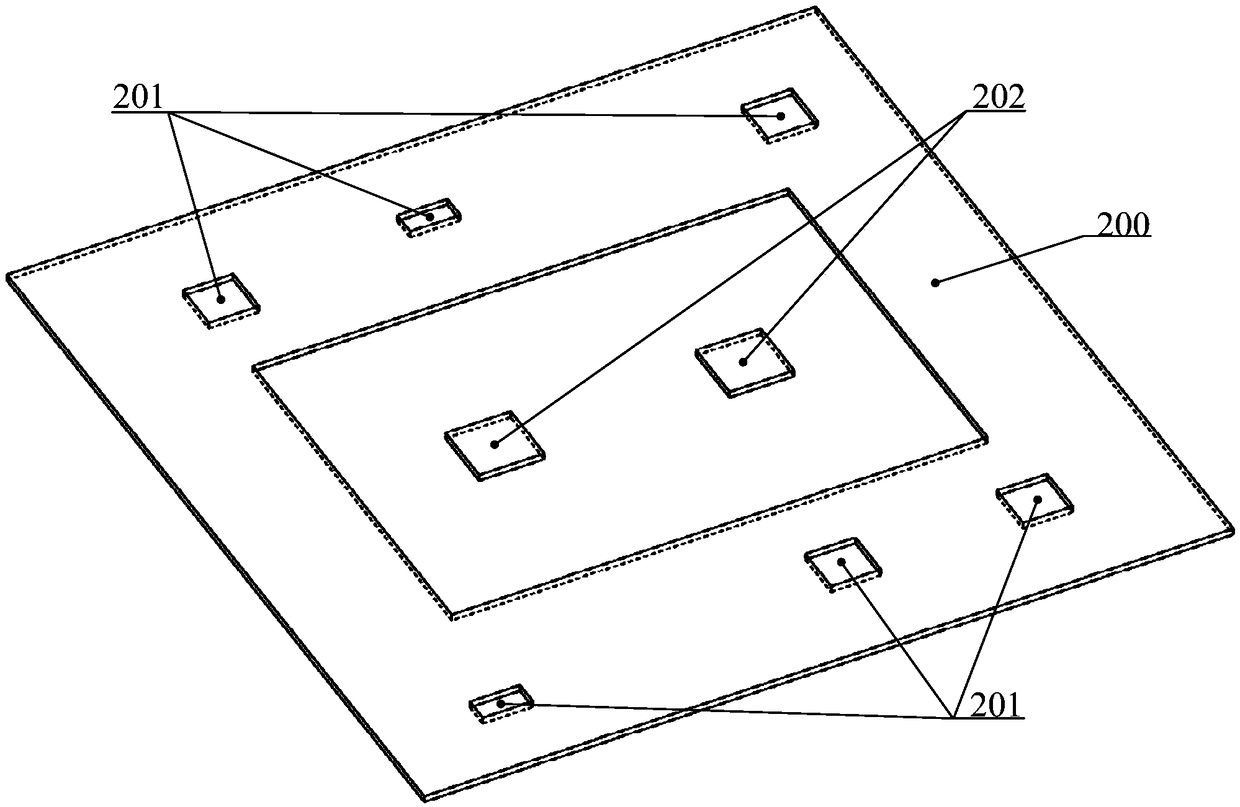

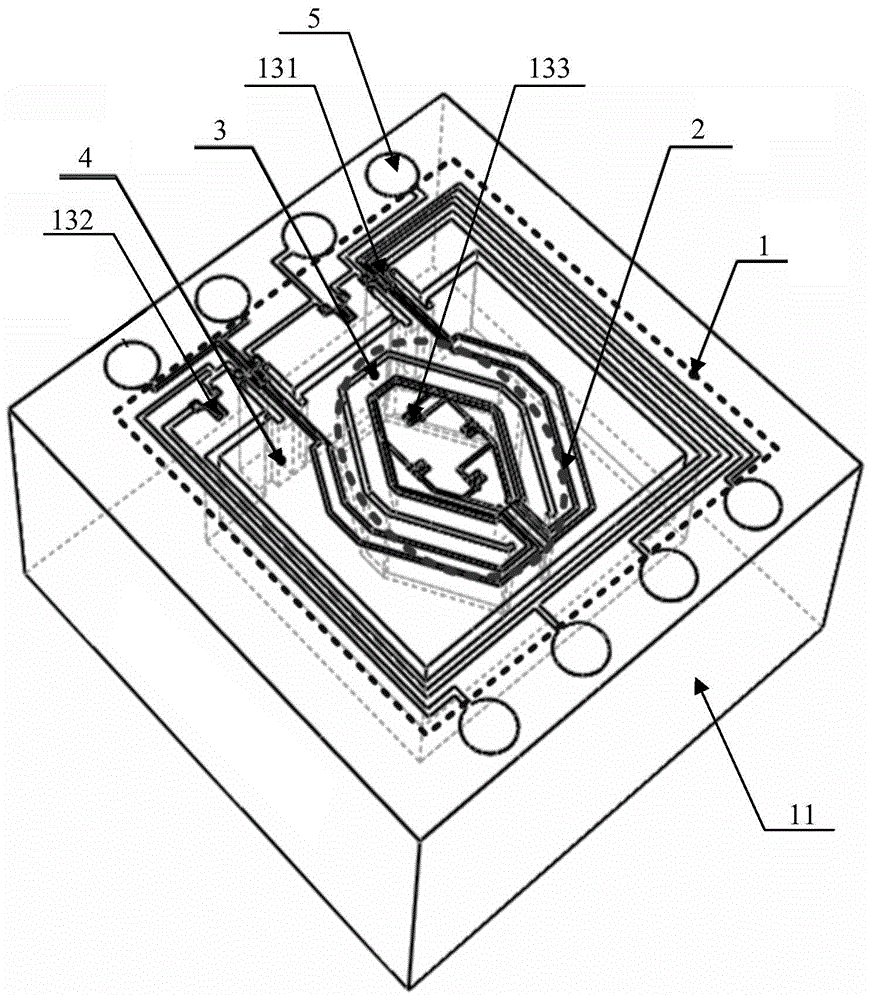

MEMS resonant pressure sensor based on Si-Si-Si-glass wafer bonding technology and manufacturing process thereof

ActiveCN109485011AIncreased full temperature rangeHigh precisionTelevision system detailsPiezoelectric/electrostriction/magnetostriction machinesMicro nanoBonding process

The invention discloses a MEMS resonant pressure sensor based on Si-Si-Si-glass wafer bonding technology and a manufacturing process thereof. The order of the MEMS resonant pressure sensor from top tobottom is a Si pressure sensitive layer, a Si resonator layer, a Si pit substrate layer, a glass pit substrate layer, a Si pressure sensitive layer and a Si resonator layer. The Si resonator layer and the Si pit substrate layer are bonded by a Si-Si bonding process. The Si pit substrate layer and the glass pit substrate layer are bonded by a Si-glass anodic bonding process. A first SiO2 layer isarranged between the Si pressure sensitive layer and the Si resonator layer, and a second SiO2 layer is arranged between the Si resonator layer and the Si pit substrate layer. According to the MEMS resonant pressure sensor of the invention, the process difficulty of MEMS micro-nano processing and high vacuum packaging is reduced; residual stress and thermal stress are effectively reduced; reliability and vacuum and long-term maintenance of the vacuum reference cavity are improved; temperature compensation accuracy is improved; the overall accuracy and stability of the pressure sensor is improved.

Owner:BEIJING RES INST OF TELEMETRY +1

Testing device for testing low-temperature adsorption performance of gas

ActiveCN106442895ASolve wastePrecise and controllable temperatureMaterial analysisProcess engineeringEngineering

The invention discloses a testing device for testing a low-temperature adsorption performance of gas. The testing device comprises a low-temperature device, a gas adsorption device and a gas inlet pipeline, wherein the low-temperature device comprises a refrigerating machine, a sample cavity which is arranged on a secondary cold head of the refrigerating machine and is used for storing a sample for testing, a shielding cover which covers the secondary cold head of the refrigerating machine and the sample cavity, and a vacuum cover which covers the shielding cover and enables a primary cold head of the refrigerating machine, the secondary cold head of the refrigerating machine and the sample cavity to be in a vacuum environment; the sample cavity is connected with an adsorption device reference cavity in the gas adsorption device through a gas conveying pipeline. According to the testing device provided by the invention, the refrigerating machine is used as a cold source, and problems that a low-temperature adsorption performance testing device excessively depends on low-temperature liquid so that experimental operations are complicated and a lot of raw materials of the low-temperature liquid are wasted in the prior art are solved.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

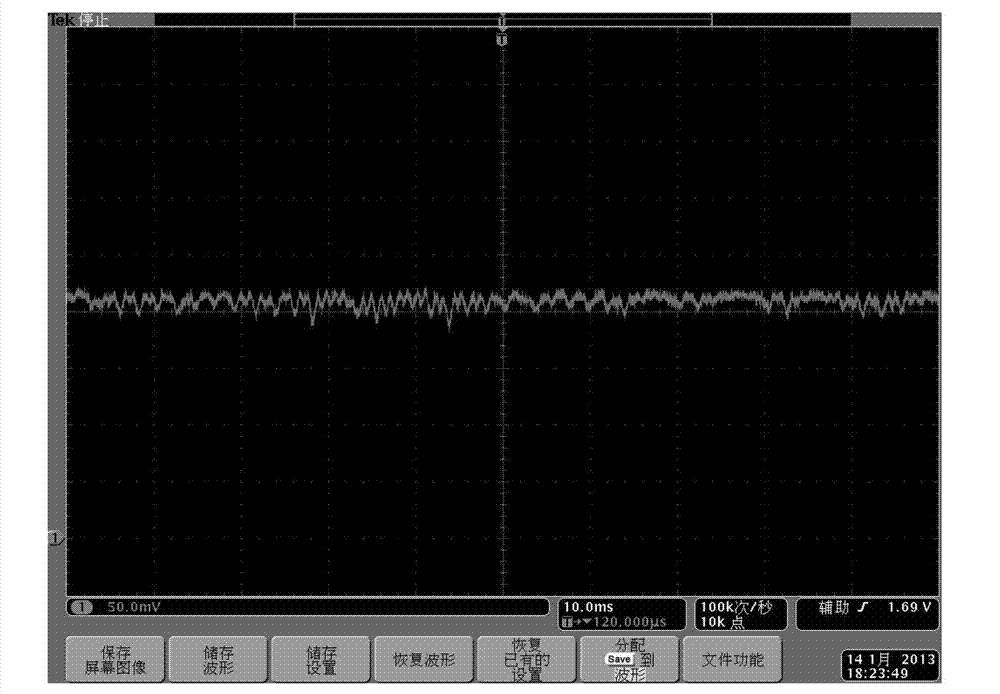

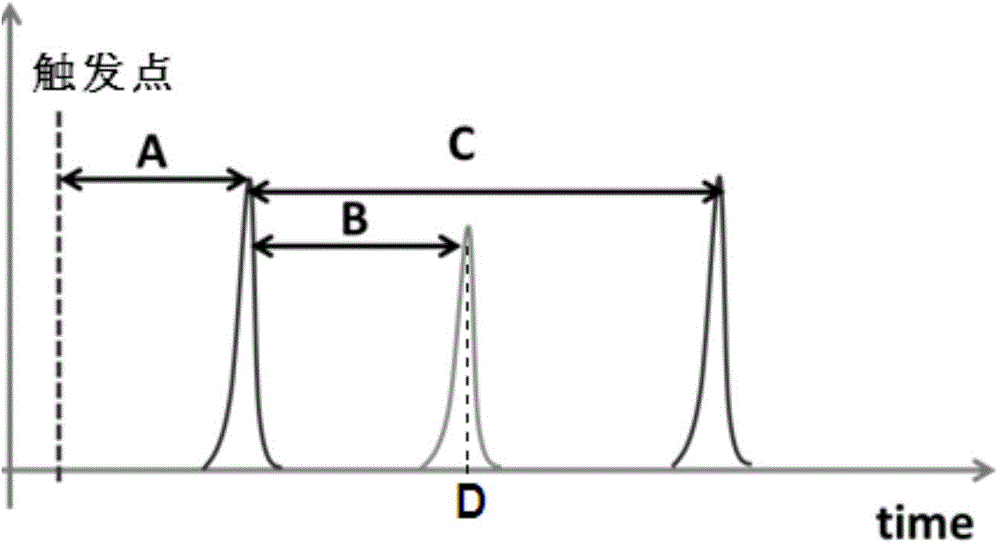

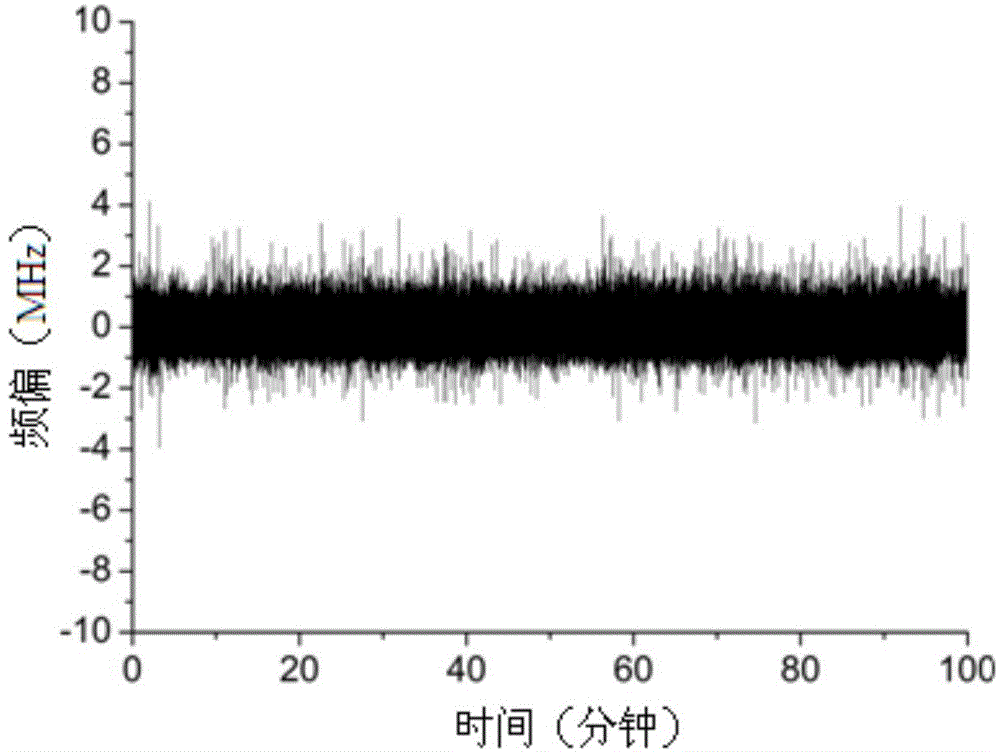

Narrow-linewidth and long-time-stable frequency dye laser and frequency stabilization method thereof

ActiveCN104409963AThe principle is simpleEasy to implementActive medium materialFrequency stabilizationLine width

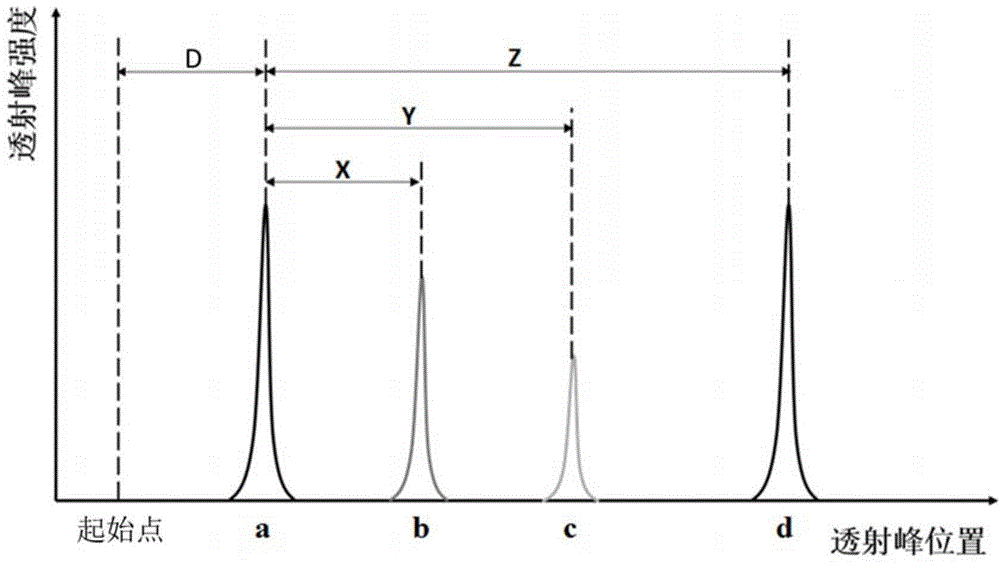

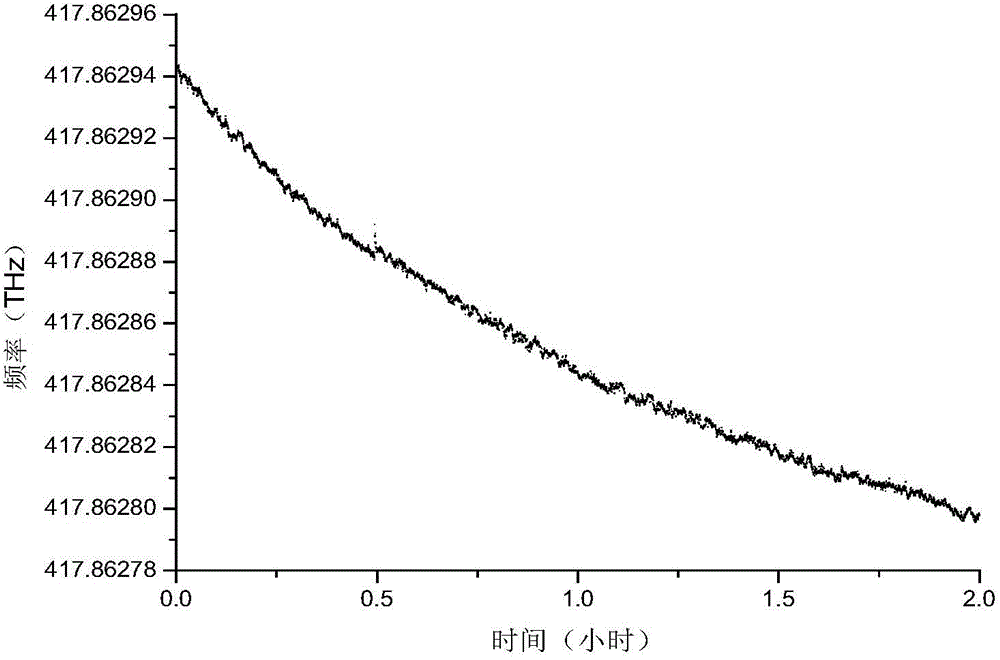

The invention discloses a narrow-linewidth and long-time-stable frequency dye laser. The narrow-linewidth and long-time-stable frequency dye laser includes a reference-used laser generator, a dye laser, a reference cavity, a polarization beam splitter, a transmission cavity, a light detector, a data acquisition card, a processor, a signal adder and a function generator. According to the narrow-linewidth and long-time-stable frequency dye laser of the invention, two kinds of frequency stabilization methods are combined together to generate a narrow-linewidth and long-time-stable frequency laser beam, and the linewidth of the laser beam is 200kHz, and the frequency long-time drift of the laser beam is smaller than 2MHz. The narrow-linewidth and long-time-stable frequency dye laser of the invention has the advantages of simple circuit design, convenient realization and high scalability. The invention also provides a frequency stabilization method of the dye laser and is suitable for improving the long-time stability of the frequency of any dye lasers.

Owner:EAST CHINA NORMAL UNIV

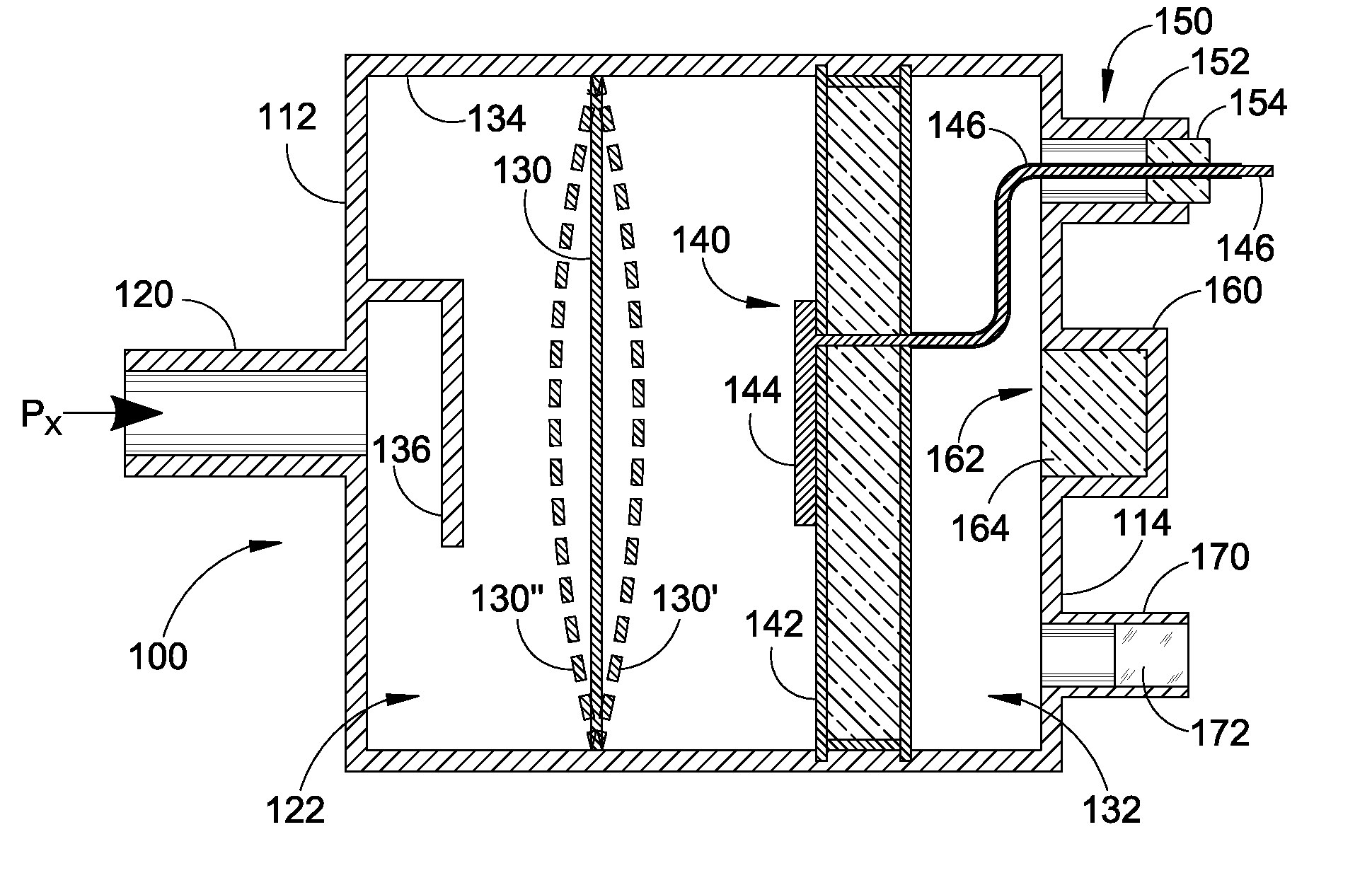

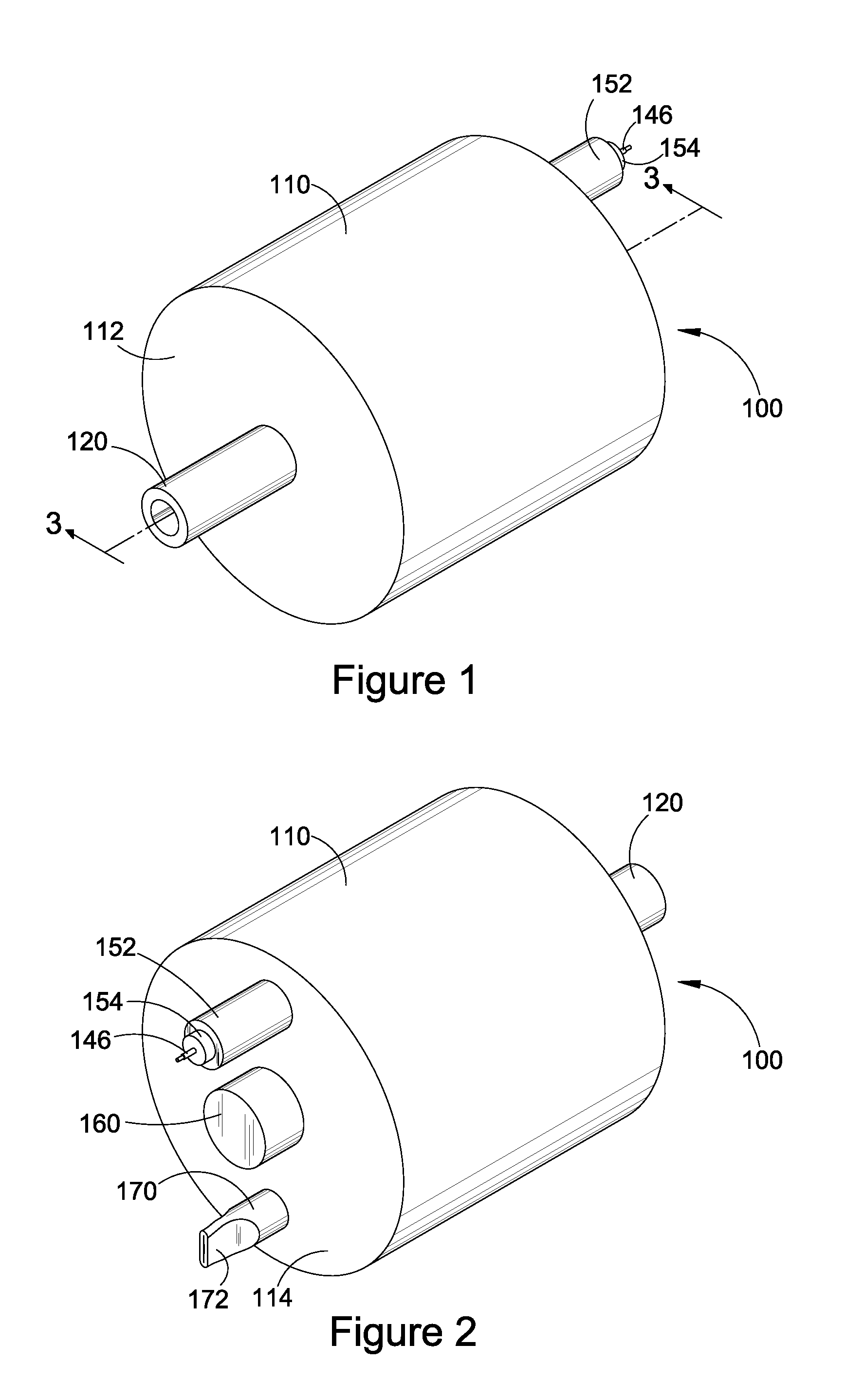

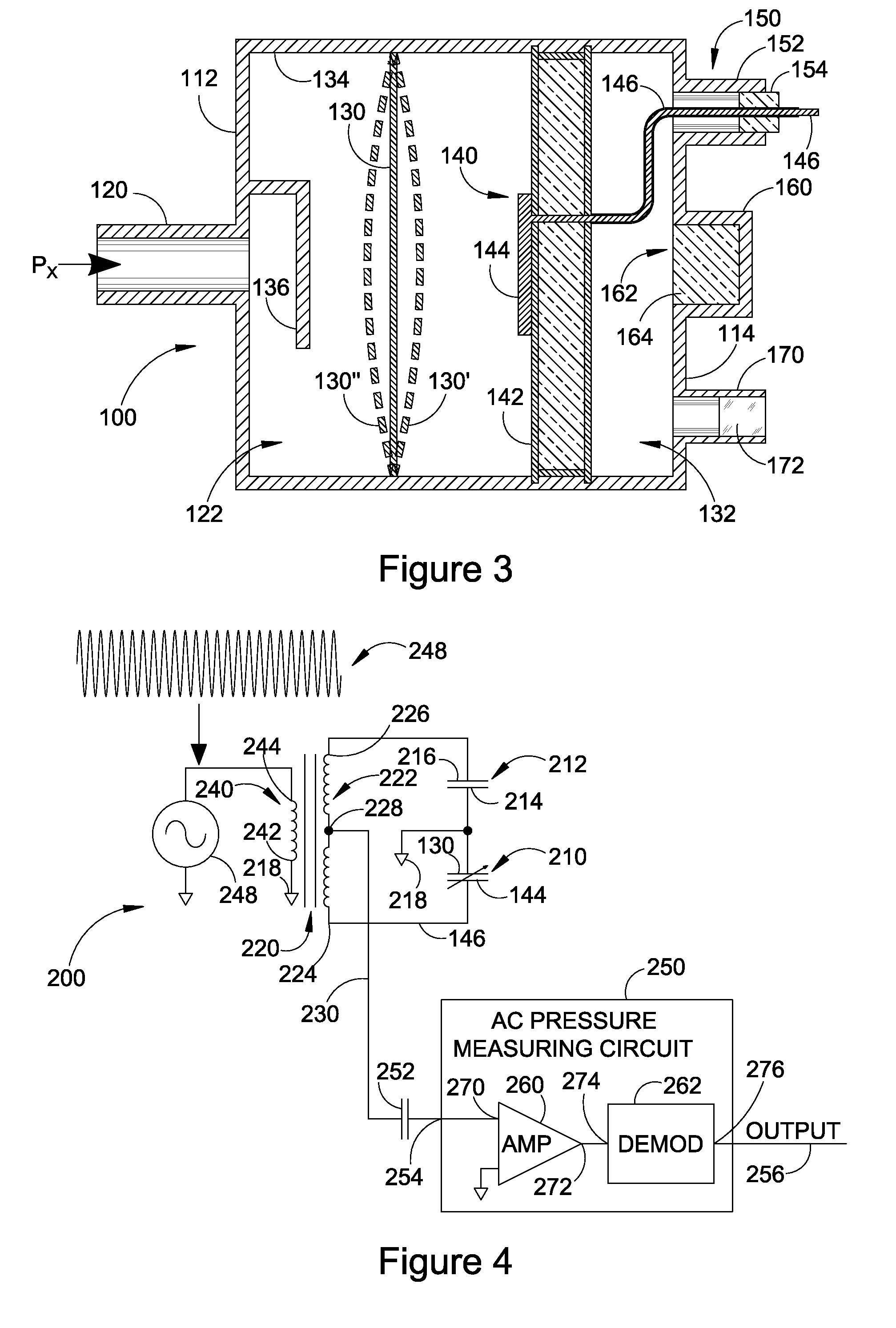

Integrity Monitor for Reference Cavity of Capacitance Diaphragm Gauge

ActiveUS20140202254A1Increase pressureVacuum gauge using ionisation effectsFluid pressure measurement using magnet displacementCapacitancePower flow

A system and method detect the presence of an unacceptable quantity of gas molecules in the reference vacuum cavity of a capacitance diaphragm gauge (CDG). An independent pressure transducer has an active portion exposed to the reference vacuum cavity. The transducer includes a ring anode, a cylindrical inner wall surface that forms at least one cathode, and a magnet positioned with respect to the ring anode such that the magnetic flux of the magnet is generally aligned with the central axis of the ring anode. A high voltage source applies a voltage between the ring anode and the cathode. A current sensor senses a magnitude of any current flowing between the ring anode and the cathode via ionized gas molecules. A monitoring unit monitors the magnitude of the current sensed by the current sensor and activates an alarm when the magnitude of the current exceeds an acceptable magnitude.

Owner:SUMITOMO SHI CRYOGENICS OF AMERICA

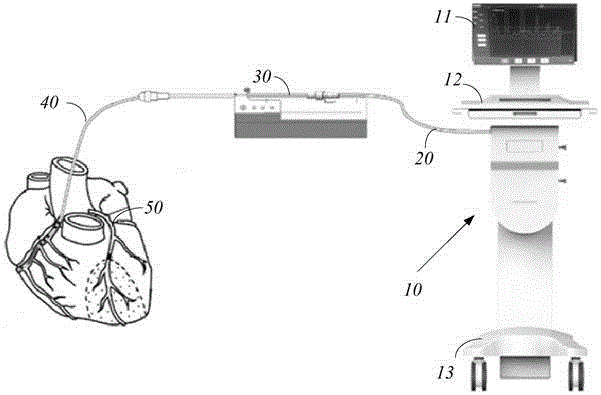

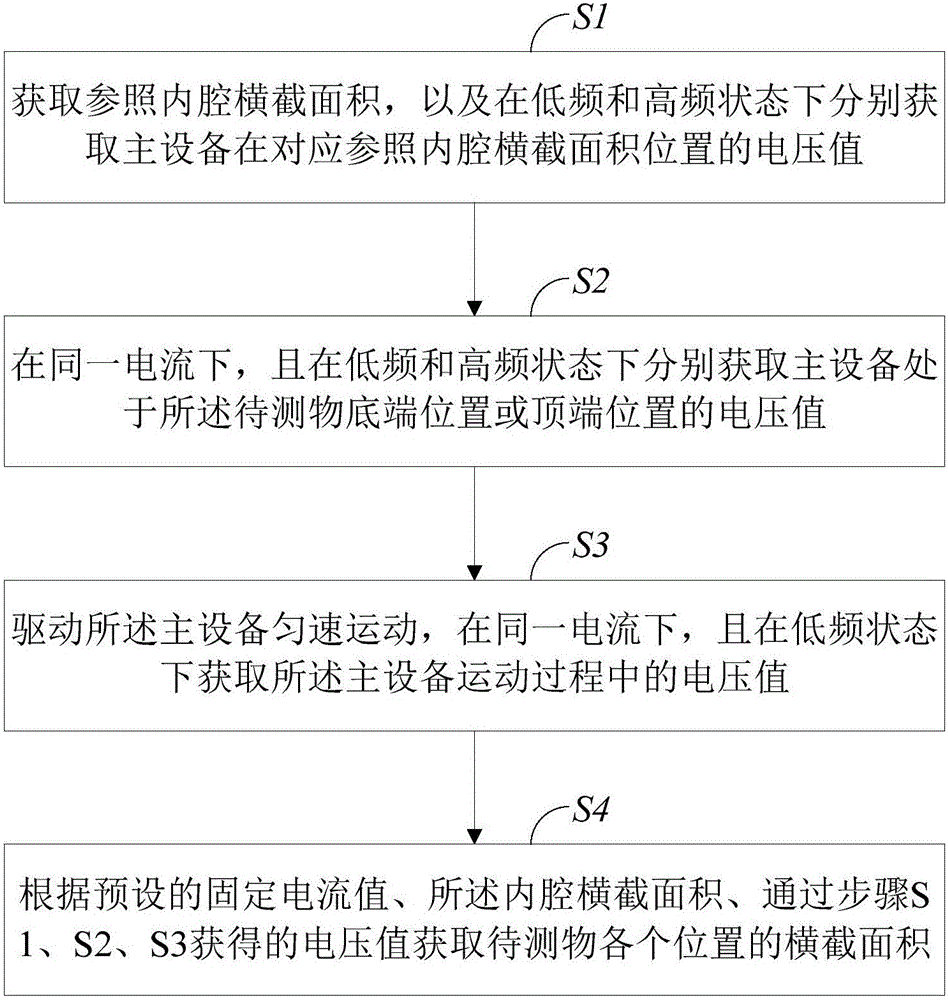

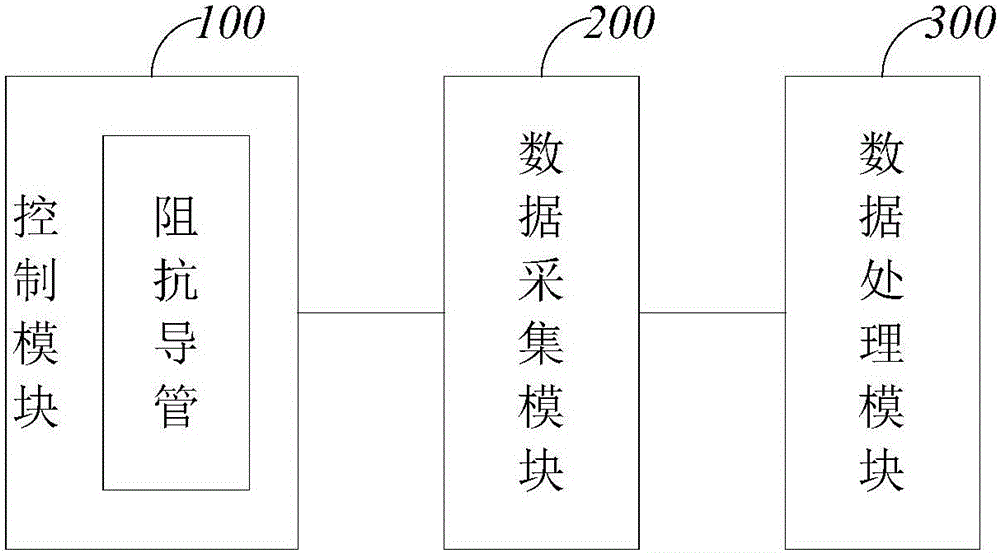

Coronary artery load detecting system and method

ActiveCN105078425AEliminate the effects ofReduce testing costsCatheterAngiographyCoronary arteriesPower flow

The invention provides a coronary artery load detecting system and a coronary artery load detecting method. The coronary artery load detecting method comprises the following steps: S1, acquiring the cross sectional area of a reference cavity, and acquiring voltage values of a main device at a position corresponding to the cross sectional area of the reference cavity under the lower frequency state and the high frequency state respectively; S2, acquiring the voltage values of the main device at positions of the bottom end or top end of a to-be-tested object under the lower frequency state and the high frequency state respectively under the same current; S3, driving the main device to move at uniform speed, and acquiring the voltage value of the main device in the movement process under the same current and under the lower frequency state; and S4, acquiring the cross sectional areas of all the positions of the to-be-tested object according to the preset fixed current value, the cross sectional area of the cavity, and the acquired voltage values. According to the system and the method, the voltage values of all the positions of the to-be-tested object are acquired through the frequency conversion manner, and further, the cross sectional areas of all the positions of the to-be-tested object are analyzed; and the parameters including the plaque parameters and the FFR of all the positions of the to-be-tested object are acquired according to the cross sectional areas, the operation and processing processes are greatly simplified, and the detection cost is reduced.

Owner:SUZHOU RAINMED MEDICAL TECH CO LTD

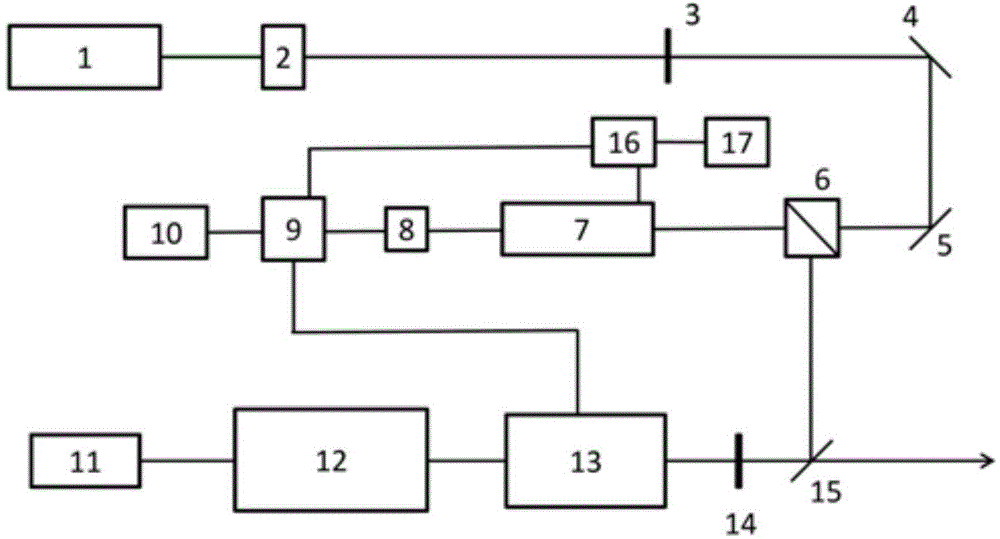

Gas detection system using fiber laser with active feedback compensation by reference cavity

The present invention provides a fiber laser gas detection system using active feedback compensation by a reference cavity, said system comprising: an optical fiber laser consists of a laser diode pump source, a wavelength division multiplexer, an active optical fiber and a fiber Bragg grating connected successively; an optical isolator coupled with said wavelength division multiplexer for blocking a reverse light transmission in said active fiber; a coupler connected with said optical isolator for dividing the laser light after being isolated by the optical isolator into a reference beam, a detecting beam and an intensity measuring beam according a certain ration power. The gas detection system according to the present invention can take advantages of the unique superiority of compact structure and narrow linewidth of the laser output of the fiber laser, and achieve a gas detection method with high sensitive and high precision by feedback controlling.

Owner:LUO FEI

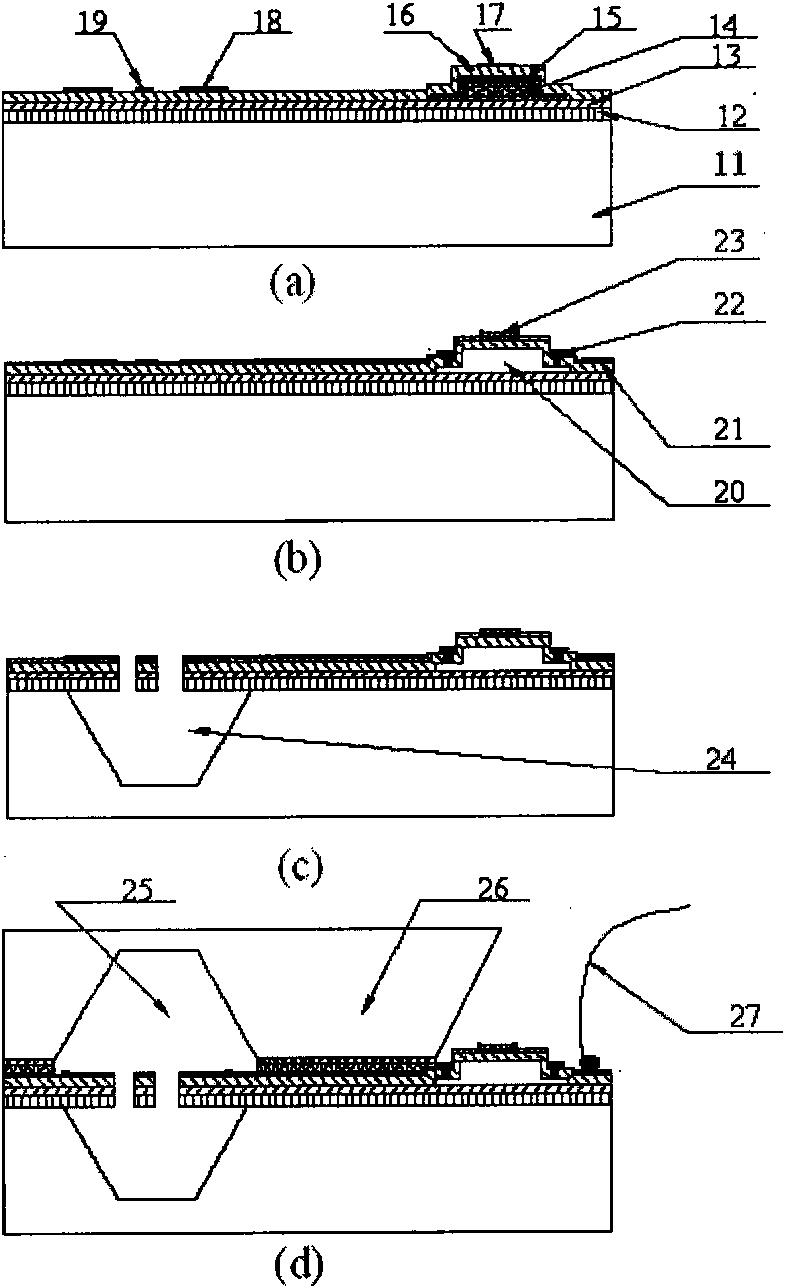

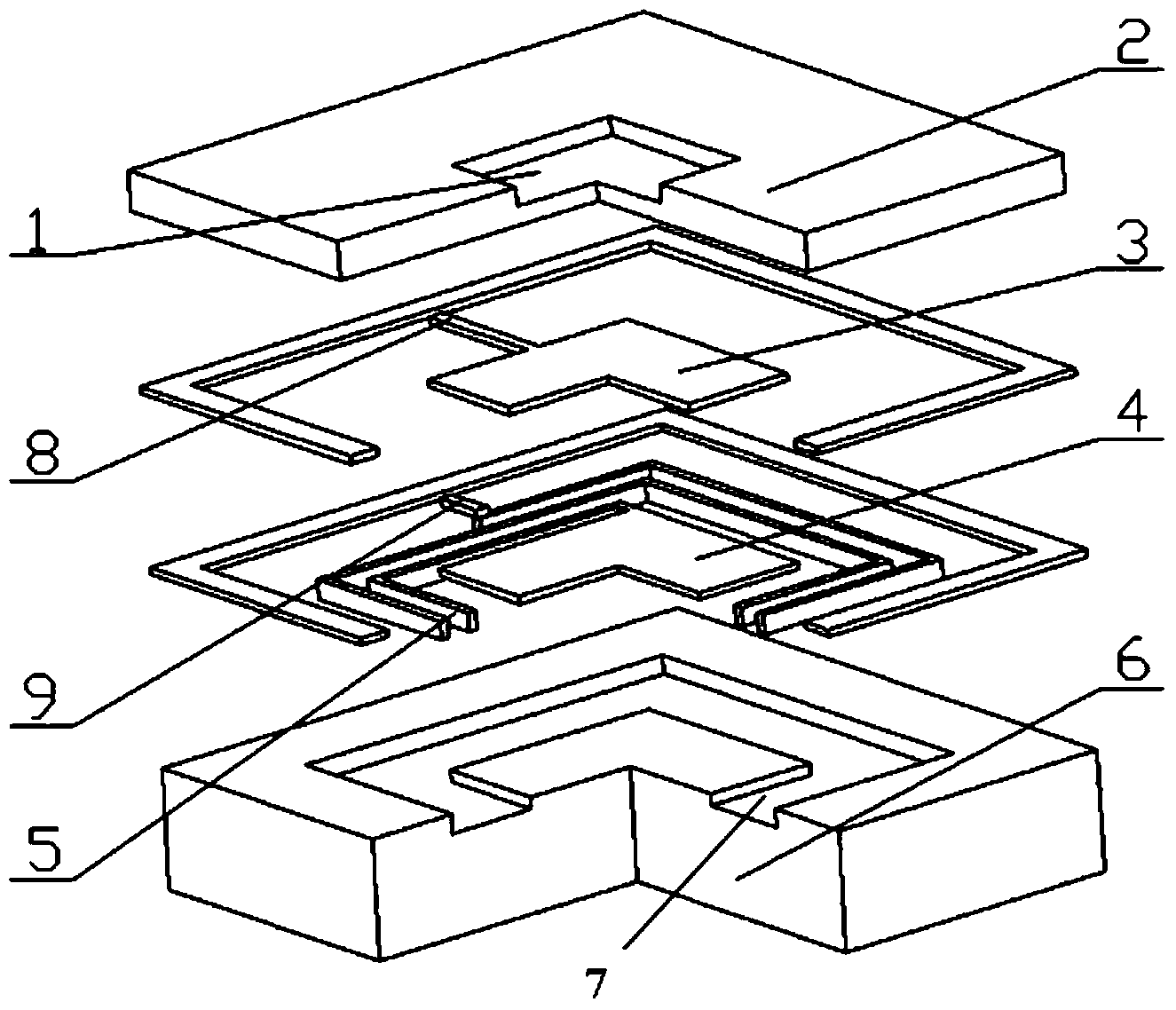

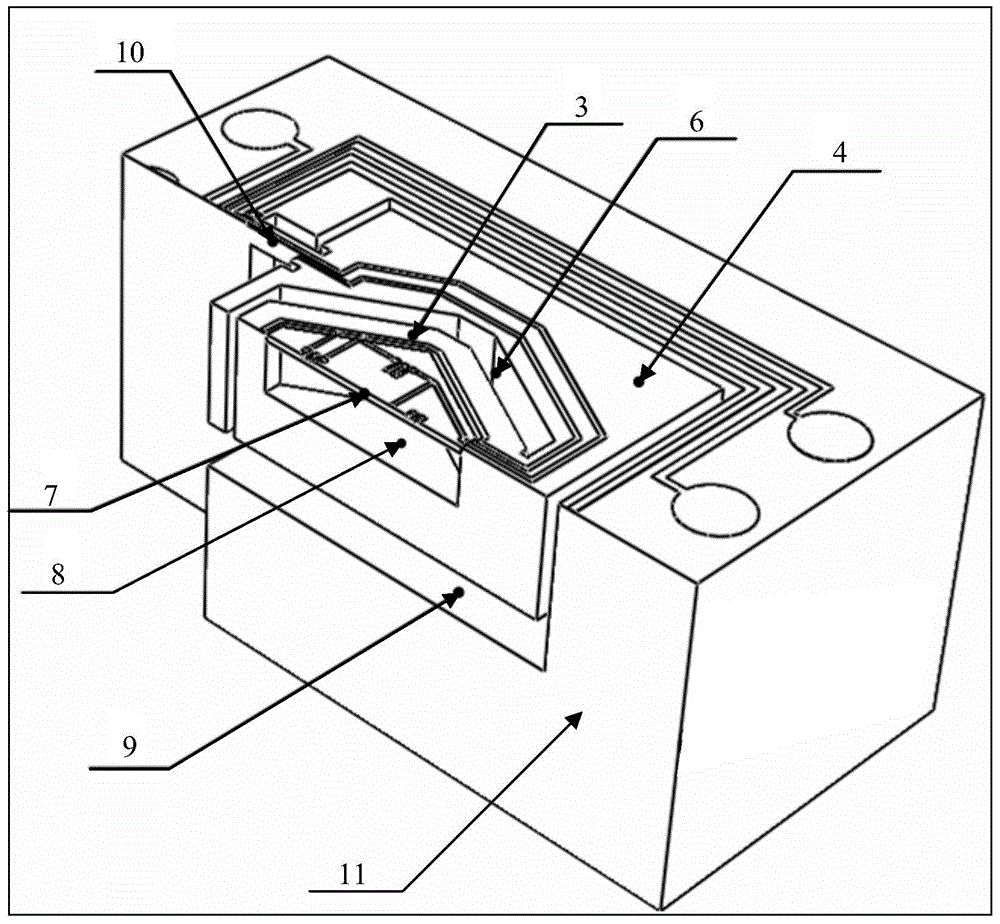

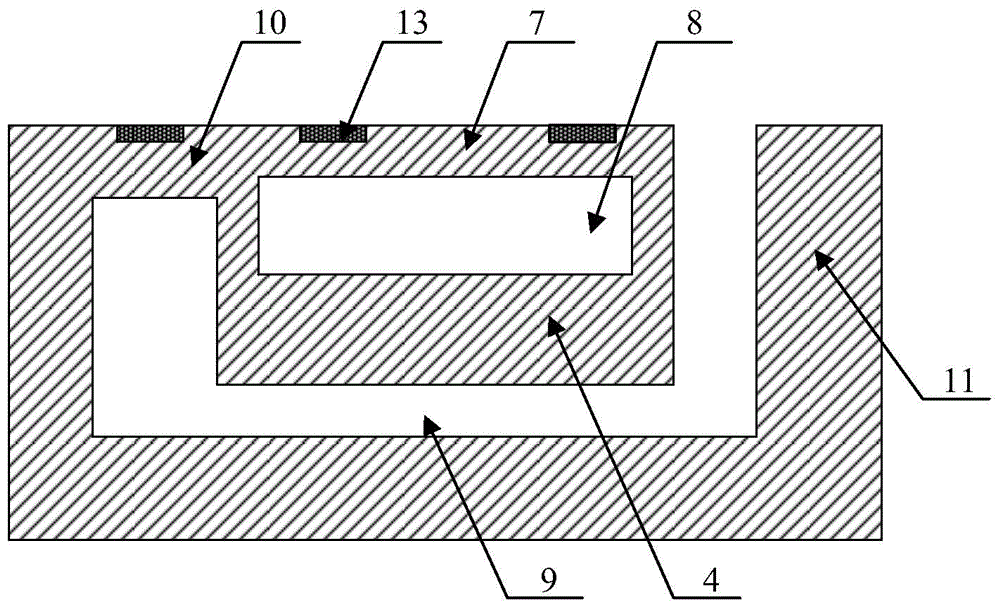

Single-silicon-wafer compound sensor structure with pressure sensor embedded in accelerometer and manufacturing method

ActiveCN104793015AImprove detection accuracyAvoid alignment problemsAcceleration measurement using interia forcesFluid pressure measurement using ohmic-resistance variationAccelerometerAcoustics

The invention relates to a single-silicon-wafer compound sensor structure with a pressure sensor embedded in an accelerometer and a manufacturing method. The compound sensor structure comprises a single silicon wafer, and an accelerated speed sensor and a pressure sensor which are integrated on the single silicon wafer, wherein the accelerated speed sensor and the pressure sensor are integrated on the surface of the single silicon wafer; the pressure sensor is suspended at the central position of a mass block of the accelerated speed sensor; a pressure reference cavity is directly buried into the mass block. According to the single-silicon-wafer compound sensor structure, the size of a chip is greatly reduced by the accelerated speed sensor and the pressure compound sensor, and the manufacturing cost is reduced; the structure is combined with an IC process so that large-batch manufacturing can be realized; meanwhile, the pressure sensor is directly suspended at the central position of the mass block, namely the size of the chip can be reduced to the greatest extent, and the mutual crosstalk of a detection signal between the accelerated speed sensor and the pressure sensor is also effectively eliminated, so that the detection precision of the compound sensor is greatly improved.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

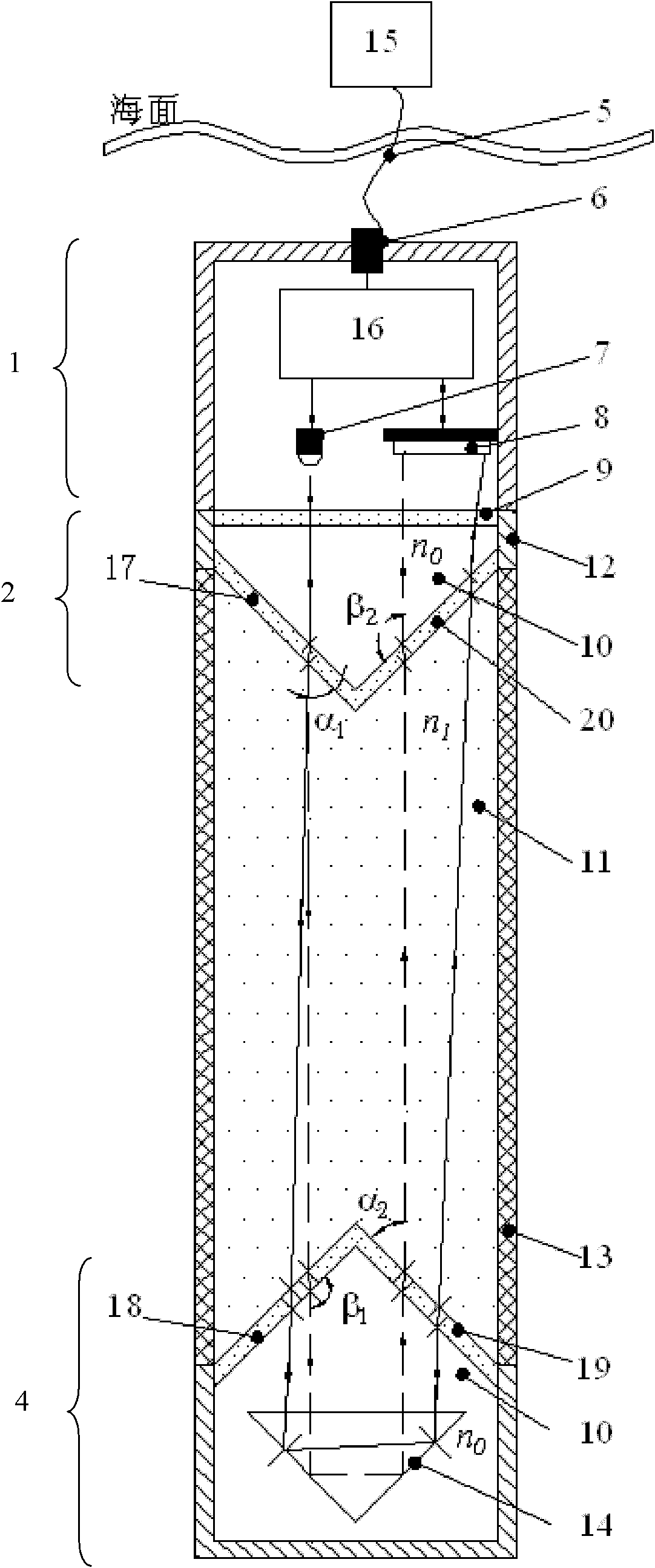

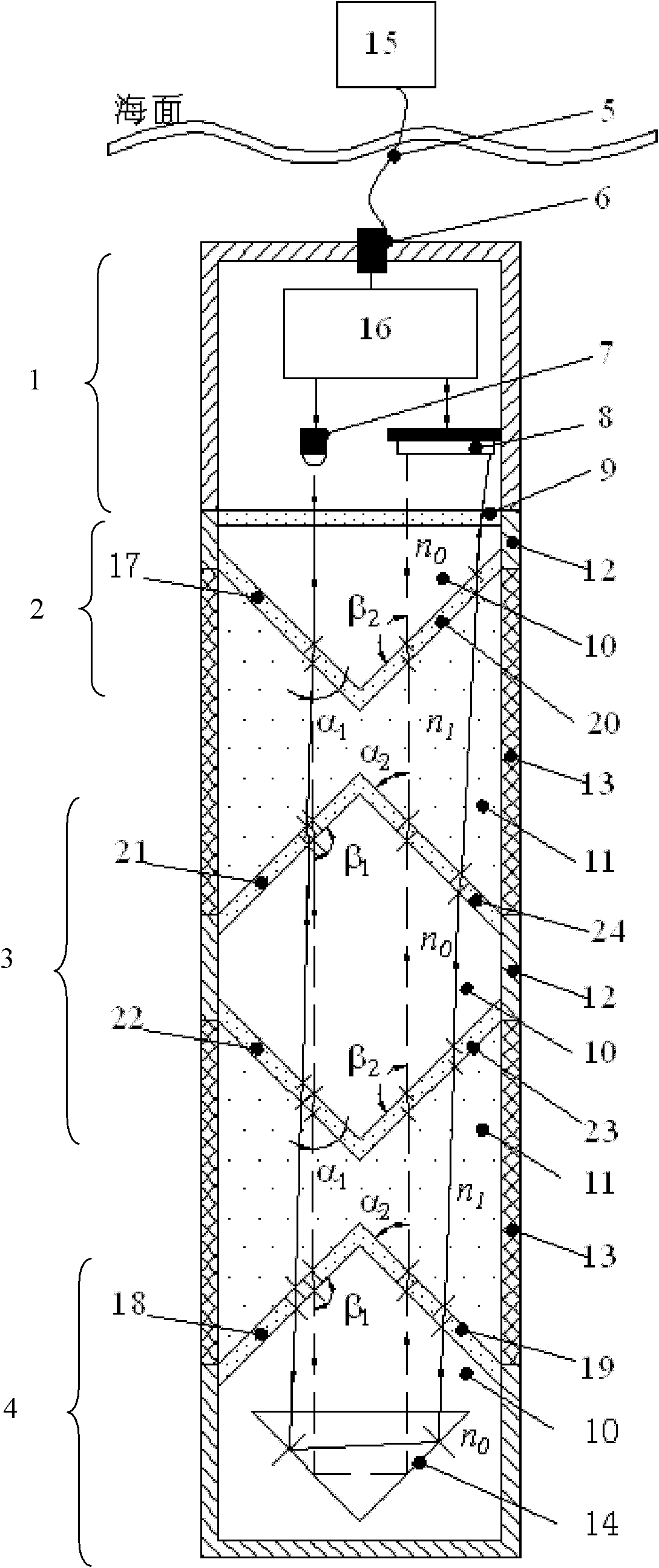

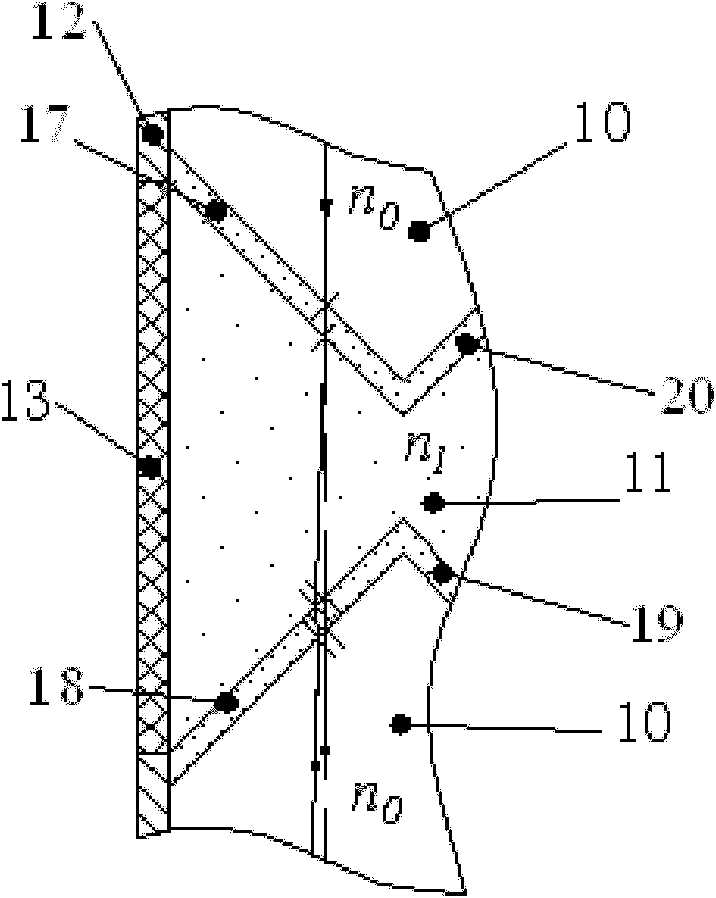

Seawater salinity detection device with prism model capable of refracting for multiple times

InactiveCN102128810AImprove offsetShorten the lengthPhase-affecting property measurementsAcute anglePrism

The invention relates to a seawater salinity detection device with a prism model capable of refracting for multiple times, which comprises an upper computer, a right-angle prism and a signal acquisition and processing module; optical glass which is perpendicular to an emitting light path of a laser and two pieces of optical glass which form a group of prism models in a mode of forming an acute angle alpha 1 and an obtuse angle beta 1 with the emitting light path of the laser are arranged below the laser and a position sensitive device, and two pieces of optical glass, which form a group of prism models and form an acute angle alpha 2 and an obtuse angle beta 2 with the opposite direction of the emitting light path of the laser respectively, are arranged above the right-angle prism sequentially; and the optical glass and a shell of the device enclose an upper closed reference cavity filled with reference liquid, and the optical glass and a shell at the bottom end of the device enclose a lower closed reference cavity which is provided with the right-angle prism and filled with the reference liquid. The seawater salinity detection device has a simple structure and is convenient to use, and due to the adoption of the prism models, the deflection angles of light rays are expanded, the resolution, accuracy and interference resistant capacity are improved, the length of the instrument is shortened, and the equipment cost and measuring cost are reduced.

Owner:OCEANOGRAPHIC INSTR RES INST SHANDONG ACAD OF SCI

Transmission cavity frequency stabilizing system and method for realizing long-term laser frequency stabilization

ActiveCN104953459AStable constrictionFrequency stabilityLaser detailsFrequency stabilizationTi doping

The invention discloses a transmission cavity frequency stabilizing system and method for realizing long-term laser frequency stabilization and belongs to the field of precise laser frequency stabilization. The frequency stabilizing system mainly comprises a plurality of Ti-doped sapphire lasers, reference cavities, control boxes, a reference laser (helium-noon laser) with stable frequency, a polarization beam splitter, a Fabry-Perot transmission cavity, a photoelectric detector, a function signal generator, an adder, a data acquisition card, a computer and the like. The frequency stabilizing method comprises steps as follows: firstly, two Ti-doped sapphire lasers are locked on the respective reference cavities, and then the reference cavities are locked on the reference laser with stable frequency, so that two Ti-doped sapphire lasers with laser line width smaller than 100 kHz and long-term frequency drift smaller than plus / minus 1 MHz are obtained. The system and the method have the advantages that only one reference laser is used for locking the plurality of Ti-doped sapphire lasers with frequency to be stabilized simultaneously and can lock the Ti-doped sapphire lasers at any frequency within the tunable range, and the extensibility and the frequency stability are very high.

Owner:EAST CHINA NORMAL UNIV

Automatic locking and relocking system of ultra-stable laser device and working method thereof

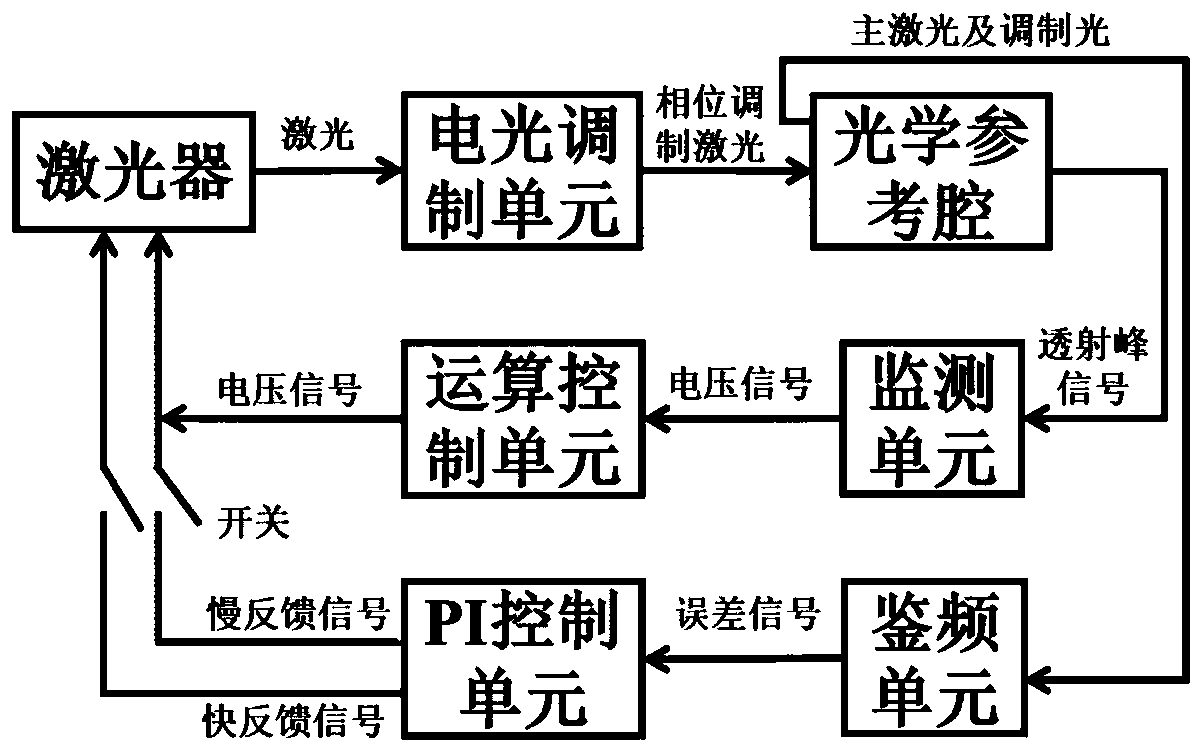

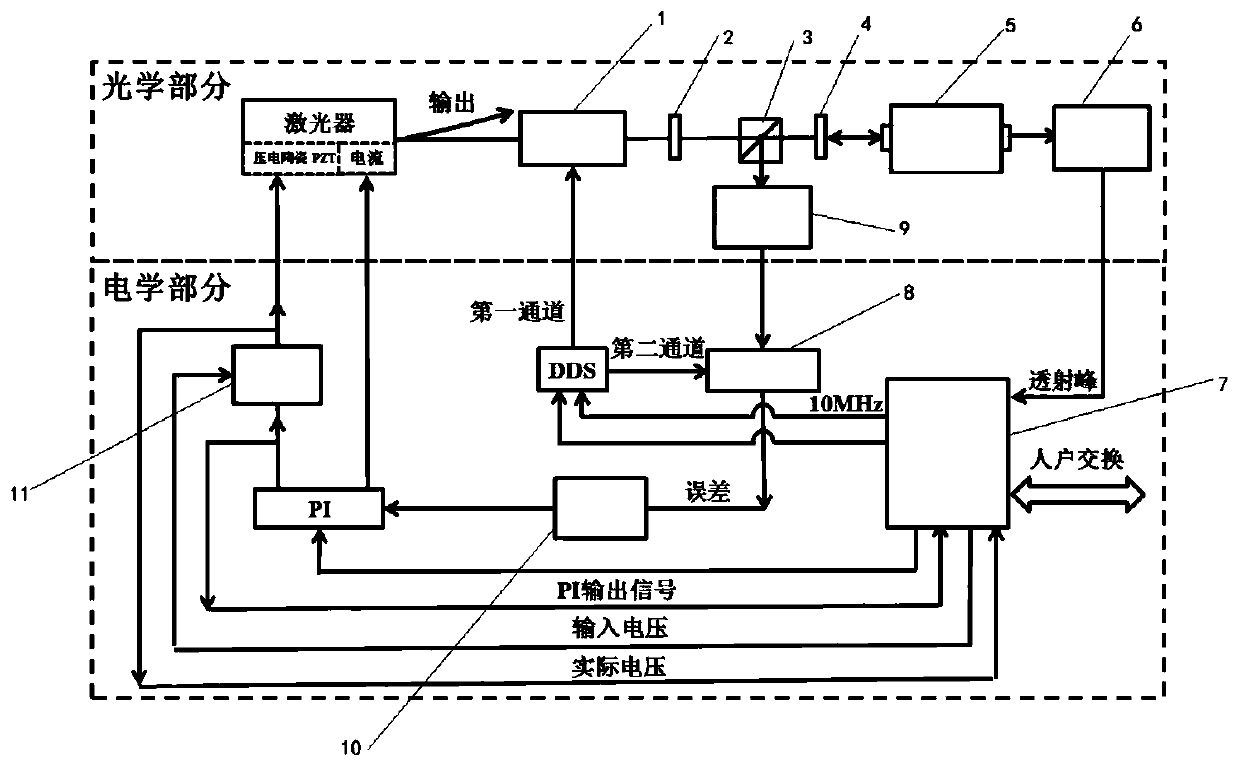

The invention discloses an automatic locking and relocking system of an ultra-stable laser device and a working method thereof. The system comprises an electro-optical modulator, a first wave plate, apolarization splitting prism, a second wave plate, an optical reference cavity, a monitoring unit, a photoelectric detector, an operation control unit, a frequency discrimination unit, a proportionalintegral control circuit (PI) and a voltage driver, wherein resonance is generated through the output frequency of the laser device and the optical reference cavity, parameters of the proportional-integral control circuit (PI) are adjusted through the operation control unit, so automatic locking of the ultra-stable laser device is realized, moreover, the monitoring unit is used for monitoring a locking state of the ultra-stable laser, so the unlocked laser device can be locked again. The system is advantaged in that the probability of successful locking of the laser device is improved, the time required by the locking process of the laser device is shortened, the locking quality of the laser device is guaranteed, and the commercialization and space application process of the ultra-stablelaser device is accelerated.

Owner:NAT TIME SERVICE CENT CHINESE ACAD OF SCI

Micromachined pressure sensor and method of making the same

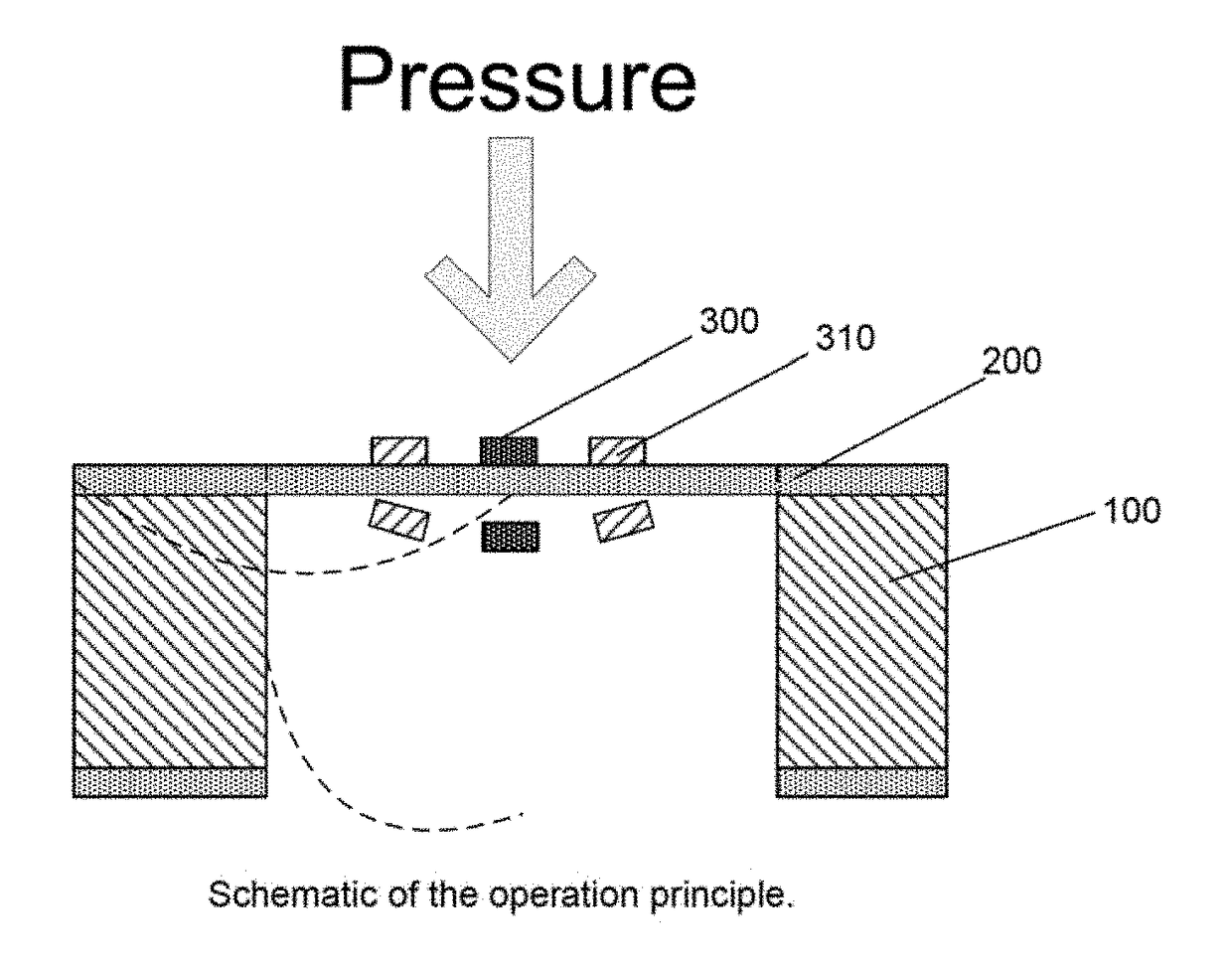

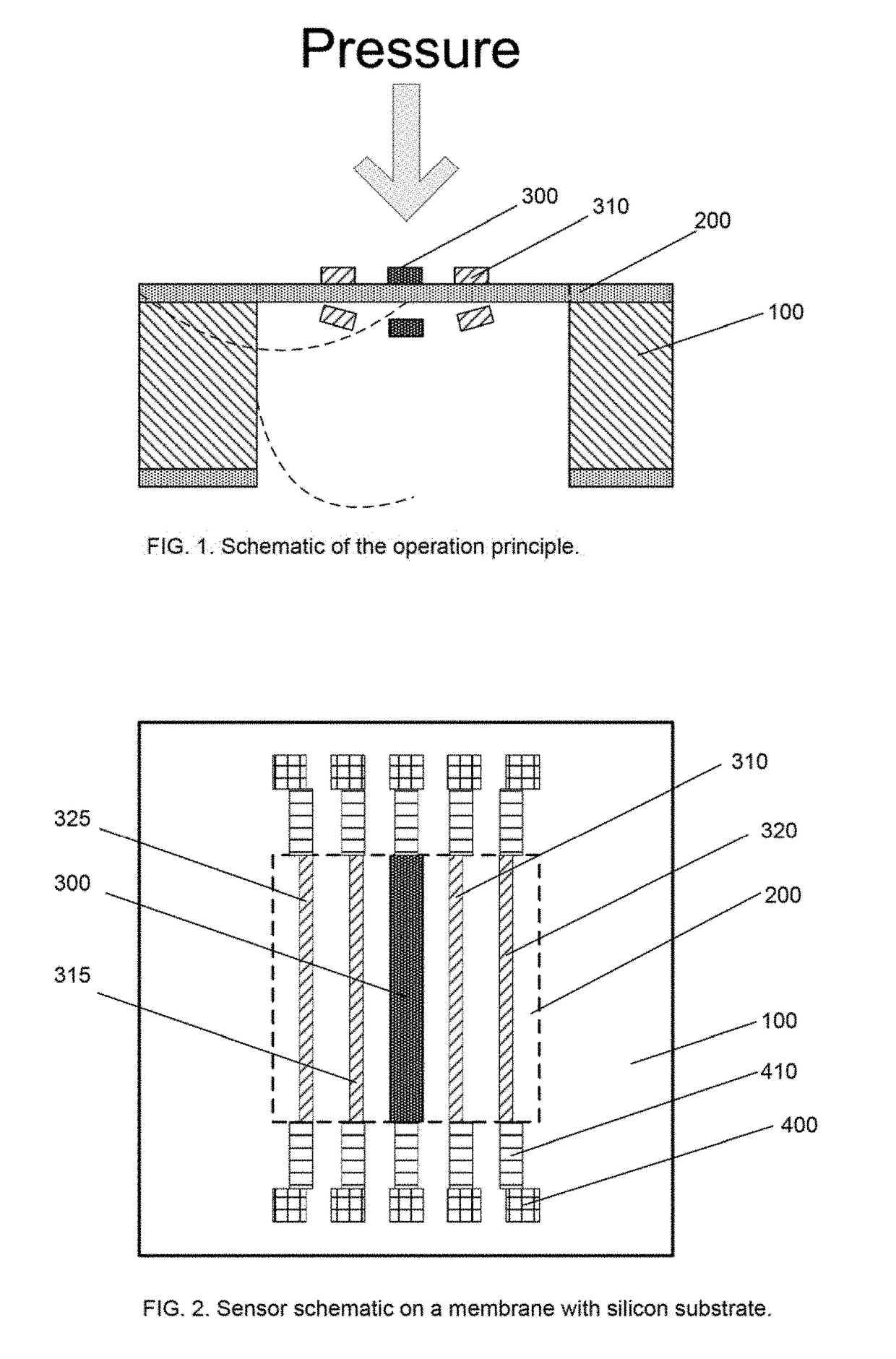

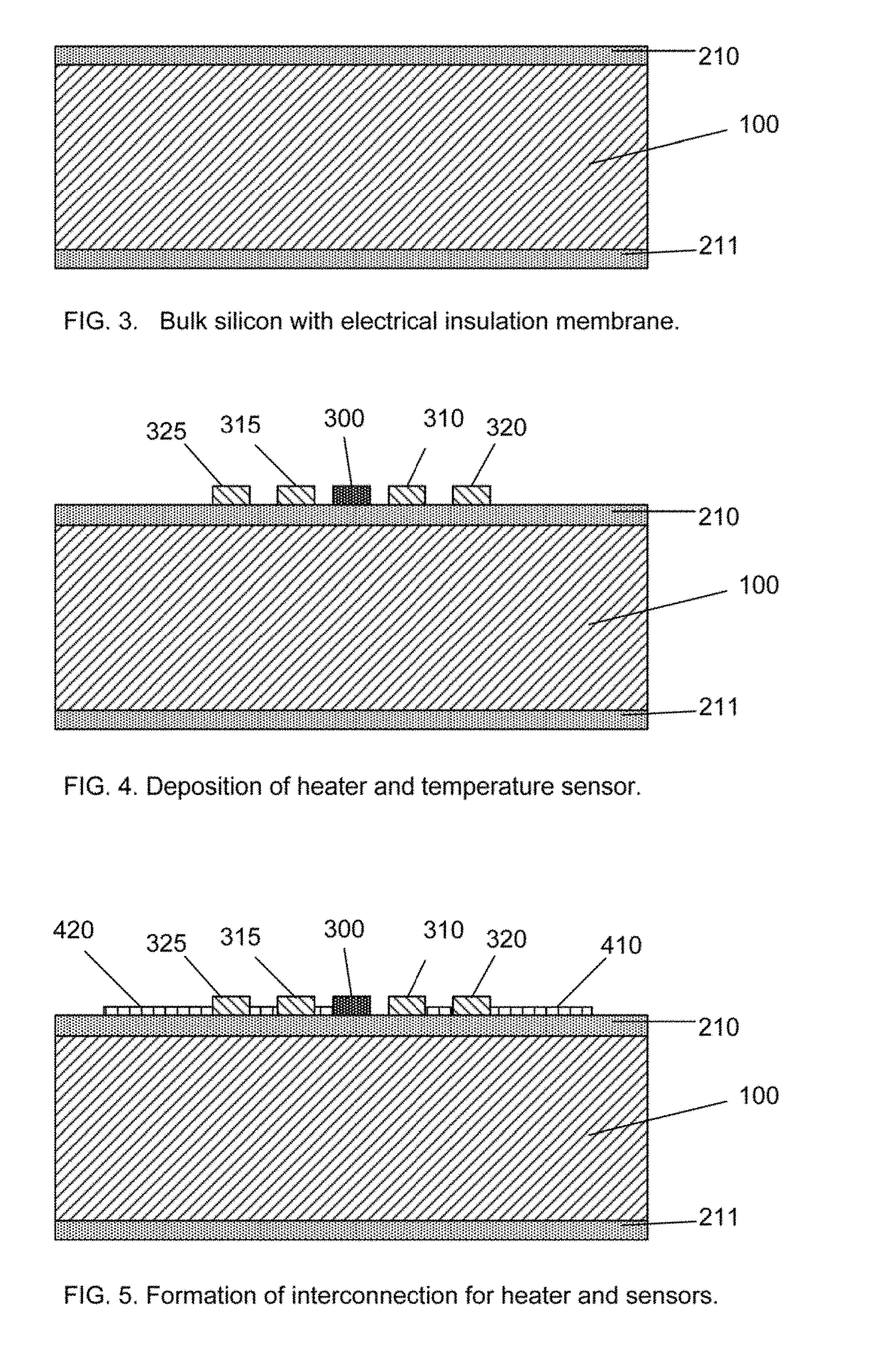

ActiveUS20180172532A1High accurate pressure dataLarge dynamic rangeFluid pressure measurement by electric/magnetic elementsFluid pressure measurement by thermal meansMetrologyDiaphragm structure

The design and manufacture method of a pressure sensor utilizing thermal field sensing with a thermal isolated membrane of a diaphragm structure is disclosed in the present invention. This device is made with silicon micromachining (a.k.a. MEMS, Micro Electro Mechanical Systems) process for applications of pressure measurement with large dynamic range, high accuracy and high stability during temperature variation. This device is applicable for all types of pressure metrology. The said thermal field pressure sensing device operates with thermistors on a membrane of the diaphragm structure made of silicon nitride with a heat isolation cavity underneath or a single side thermal isolated silicon nitride membrane with a reference cavity. This device can be seamlessly integrated with a thermal flow sensor with the same process.

Owner:WISENSTECH

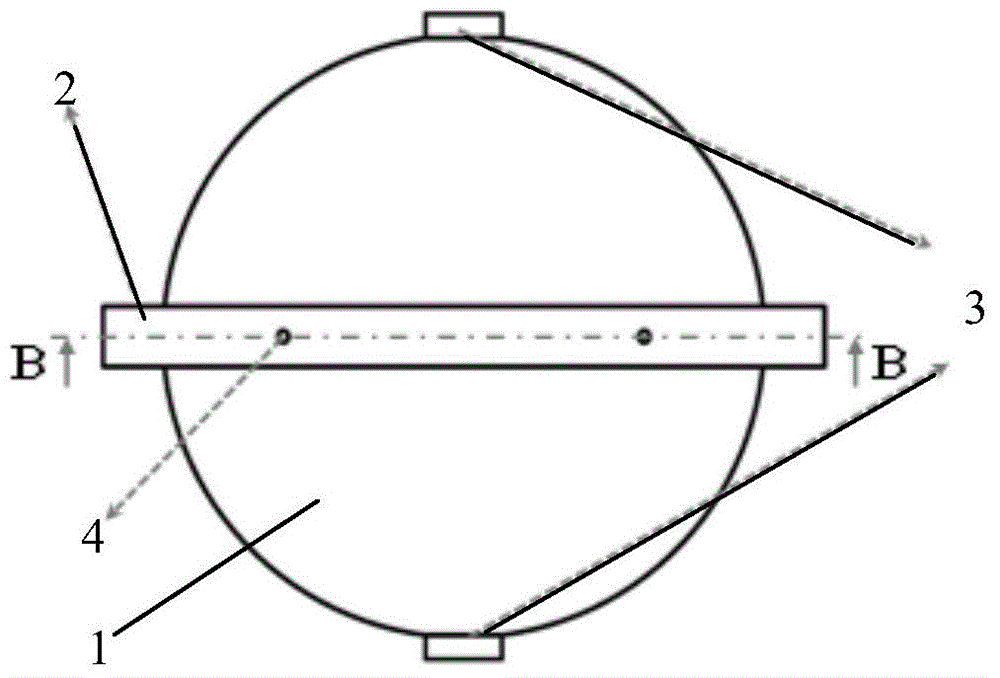

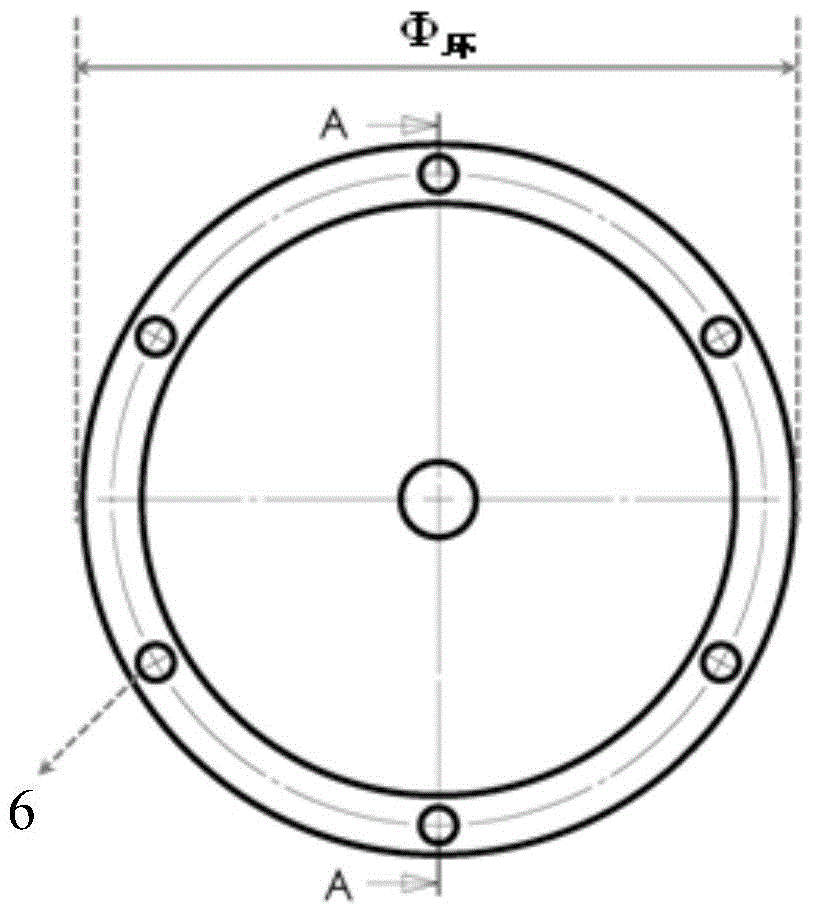

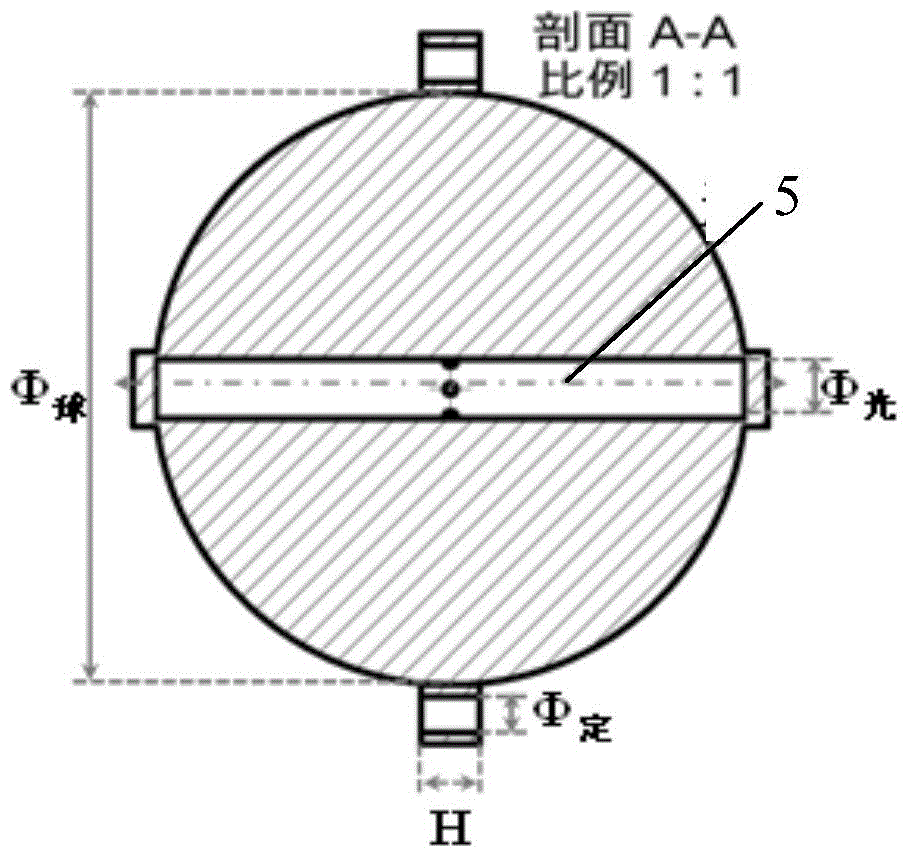

Conveyable super-stable optical reference cavity for space application

ActiveCN104898403AImprove integrityGood vibration sensitivityPulse automatic controlApparatus using atomic clocksSpatial structureDesign space

The invention discloses a conveyable super-stable optical reference cavity for space application. The conveyable super-stable optical reference cavity comprises a globoid and a ring for fixing the globoid. The globoid is provided with a light through hole passing the center of the globoid, optical lenses are arranged at the two ends of the light through hole and made by utilizing an ultralow expanding material as a substrate material, and the globoid is further provided with a vacuum vent hole and a fixing hole. The ultralow expanding material is ULE, single crystal silicon, ceramic, microcrystalline glass or fused quartz. The conveyable super-stable optical reference cavity for space application is designed in a mode of combining a sphere and the ring. As shown in the background technology, the conveyable super-stable optical reference cavity for space application can well protect sphere space structural mechanics integrity, not only can achieve good vibration sensitivity in the three-dimensional direction, but also can meet the harsh conditions of space vibration impact and is simple to assemble and adjust on the whole.

Owner:NAT TIME SERVICE CENT CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com