Patents

Literature

188 results about "Radiation thermometer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Radiation Thermometer. The purpose of the radiation thermometer is to put common radiation doses in perspective. This tool can help people assess their own risk in a radiation emergency.

Temperature measuring system, heating device using it and production method for semiconductor wafer, heat ray insulating translucent member, visible light reflection membner, exposure system-use reflection mirror and exposure system, and semiconductor device produced by using them and vetical heat treating device

InactiveUS20050063451A1Necessary numberGood choiceRadiation pyrometryDoor/window protective devicesDevice materialRadiation thermometer

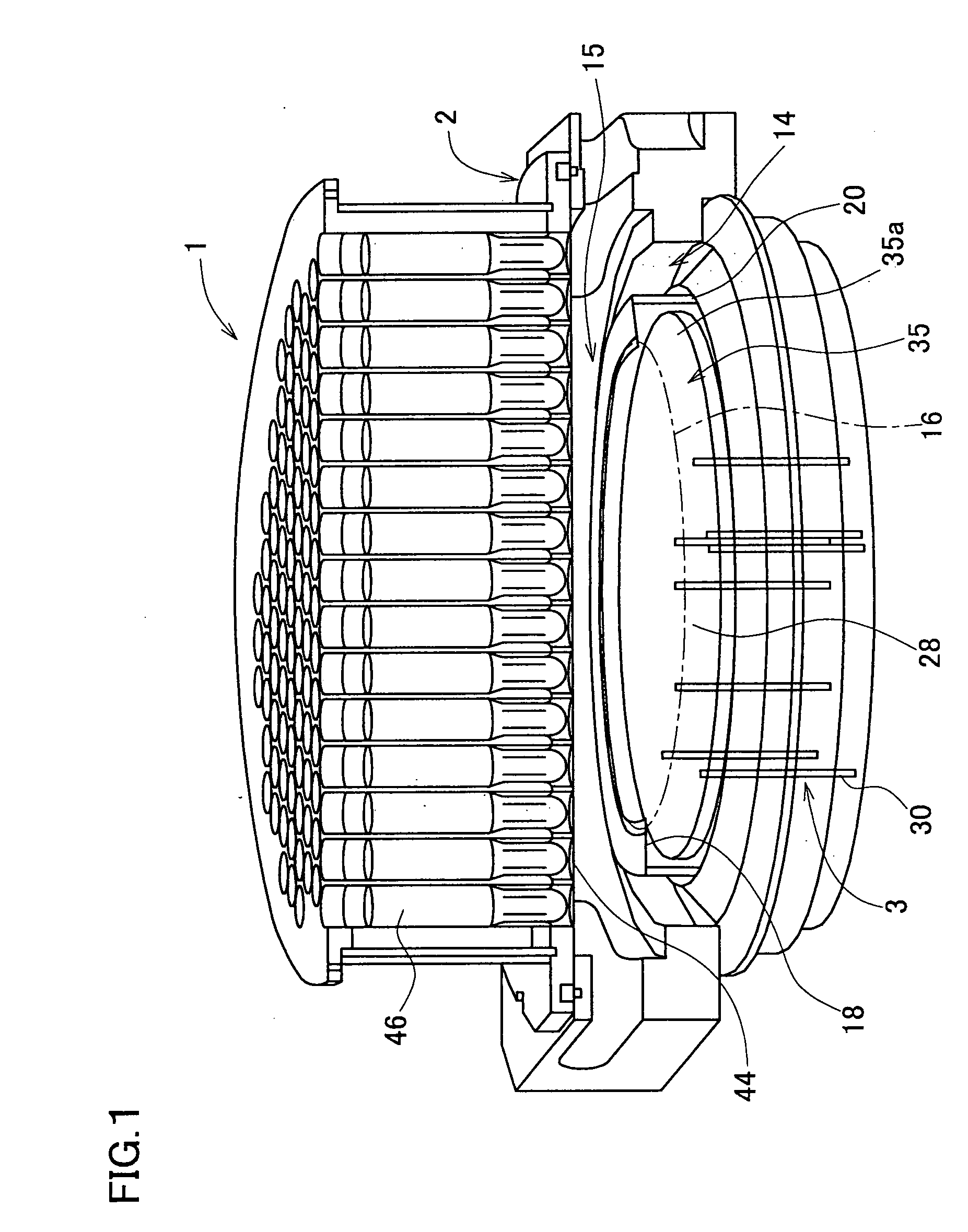

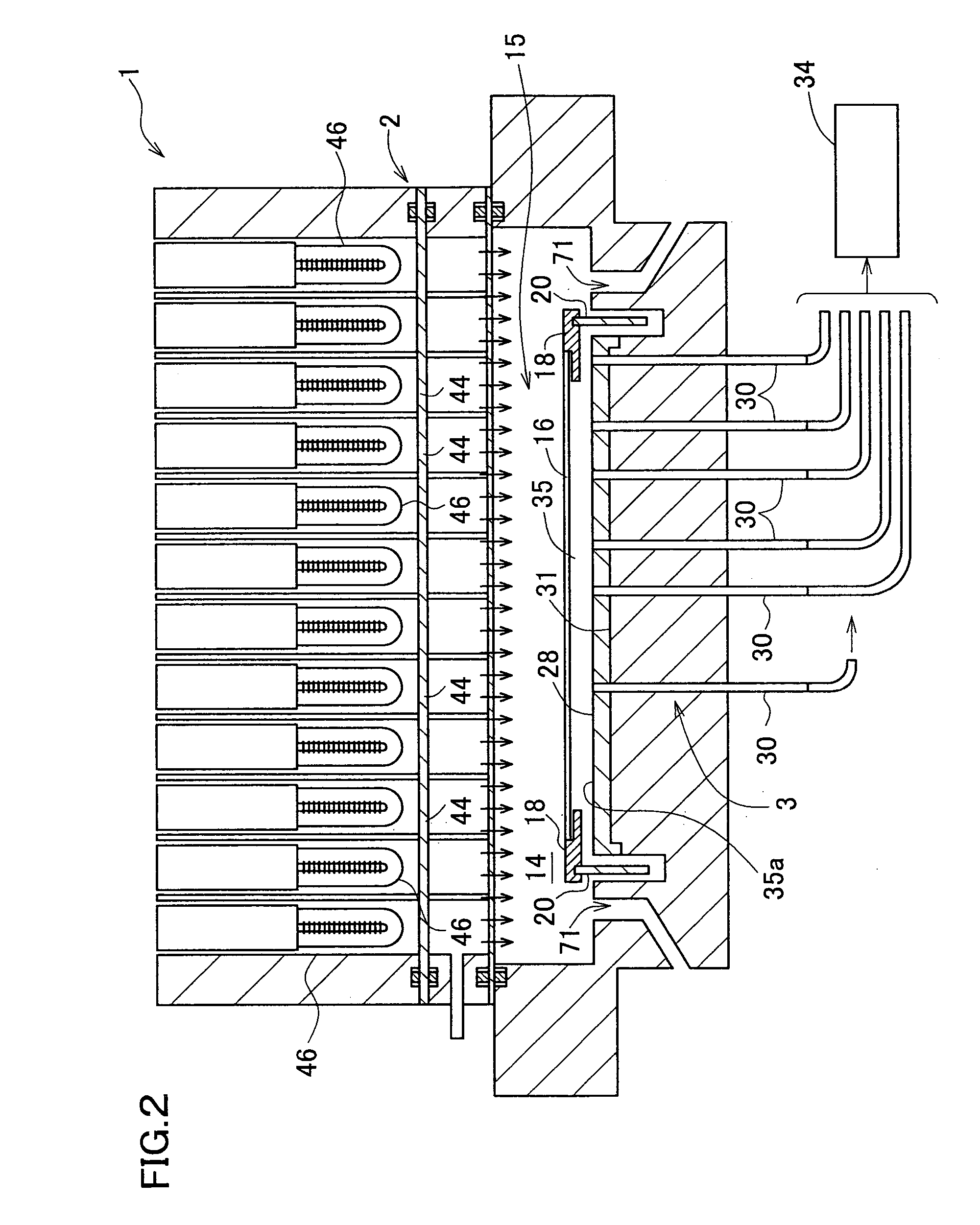

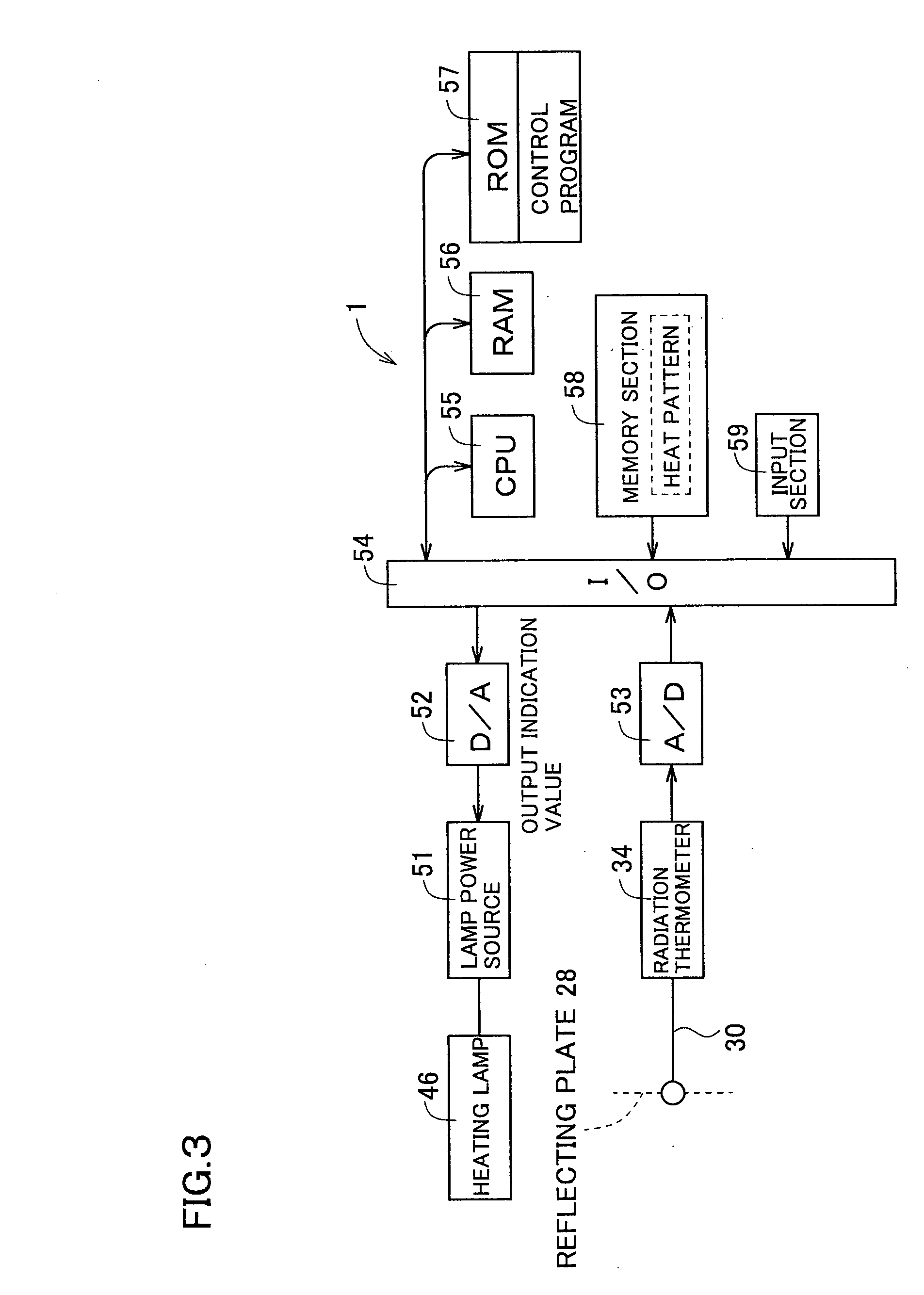

Oppositely of a temperature measuring surface of an object-to-be-measured 16, a reflecting member 28 is disposed while being spaced by a reflection gap 35 from the temperature measuring surface. The reflecting member 28 is composed of a heat ray reflecting material capable of reflecting heat ray in a specific wavelength band, in a portion including a reflection surface 35a. A heat ray extraction pathway section 30 is disposed through the reflecting member 28 so that one end thereof faces the temperature measuring surface. Heat ray extracted through the heat ray extraction pathway section from the reflection gap is detected by a temperature detection section 34. The heat ray reflecting material is configured in a form of a stack comprising a plurality of element reflecting layers composed of a material having transparent properties to the heat ray, in which every adjacent two element reflecting layers are composed of a combination of materials having refractive indices which differ from each other by 1.1 or more. This makes the measurement be hardly affected by radiation ratio of the object-to-be-measured when temperature of the object-to-be-measured is measured by a radiation thermometer, enables to measure its temperature more correctly irrespective of the surface state thereof, and can simplify configuration of a measurement system.

Owner:SHIN-ETSU HANDOTAI CO LTD

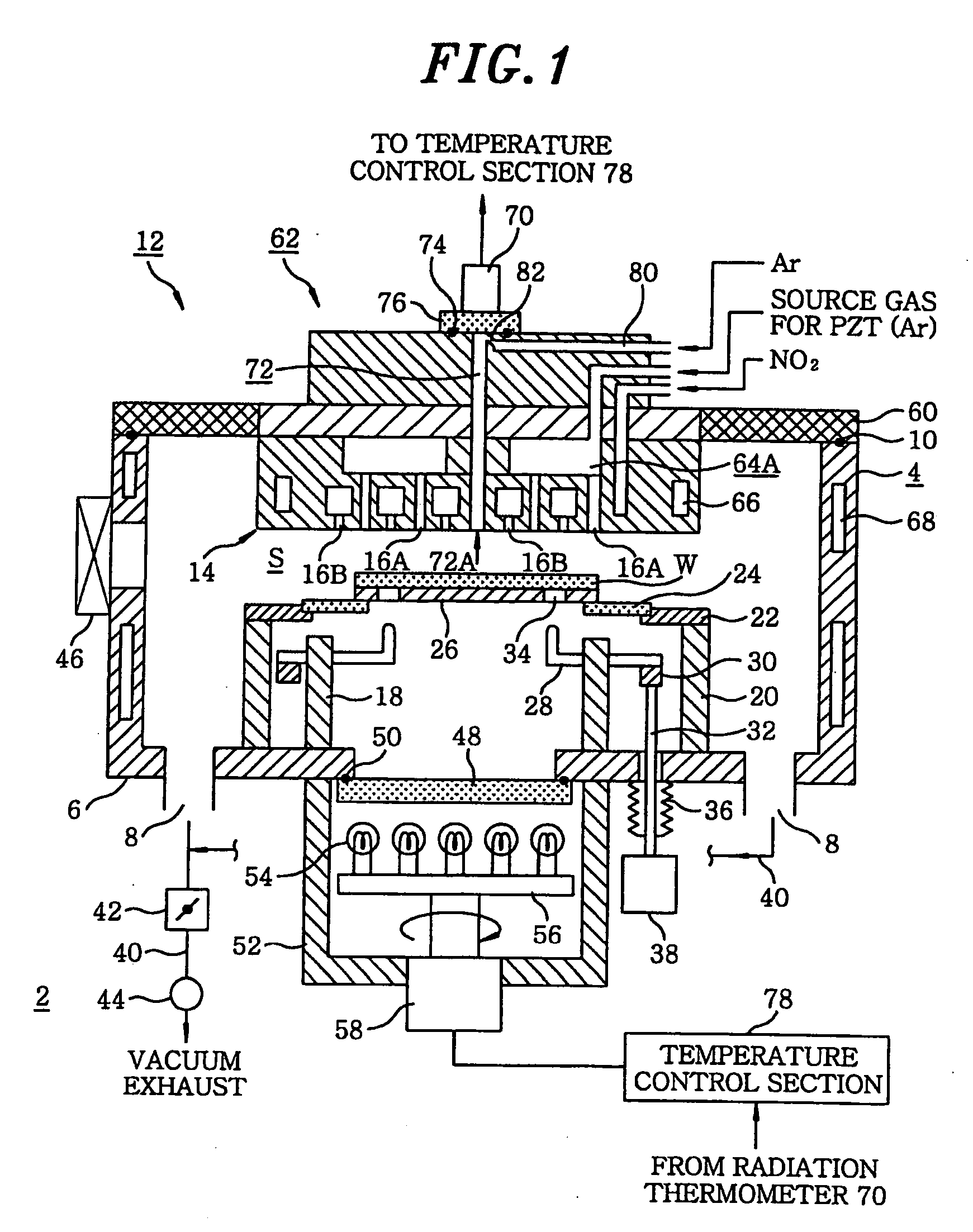

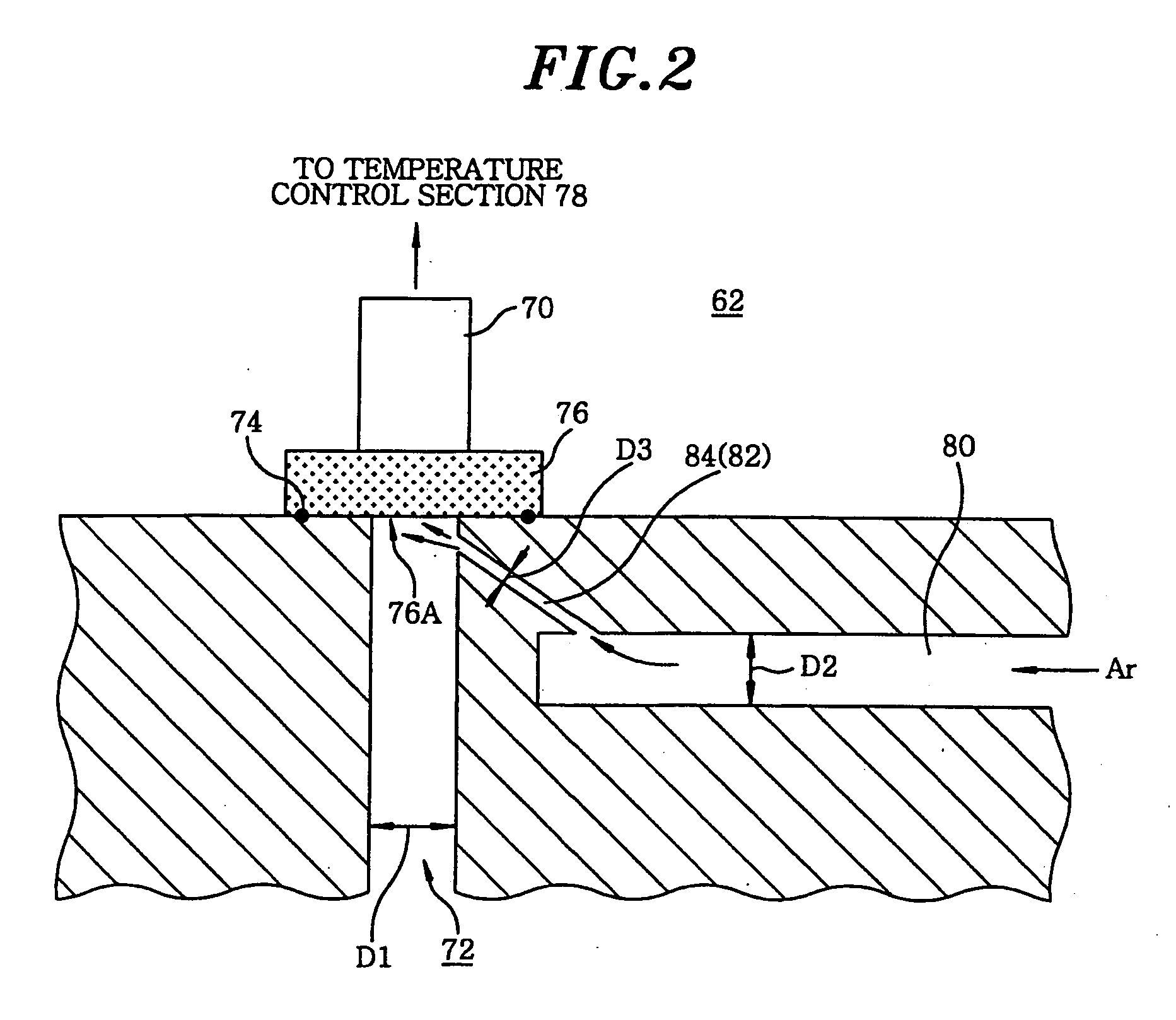

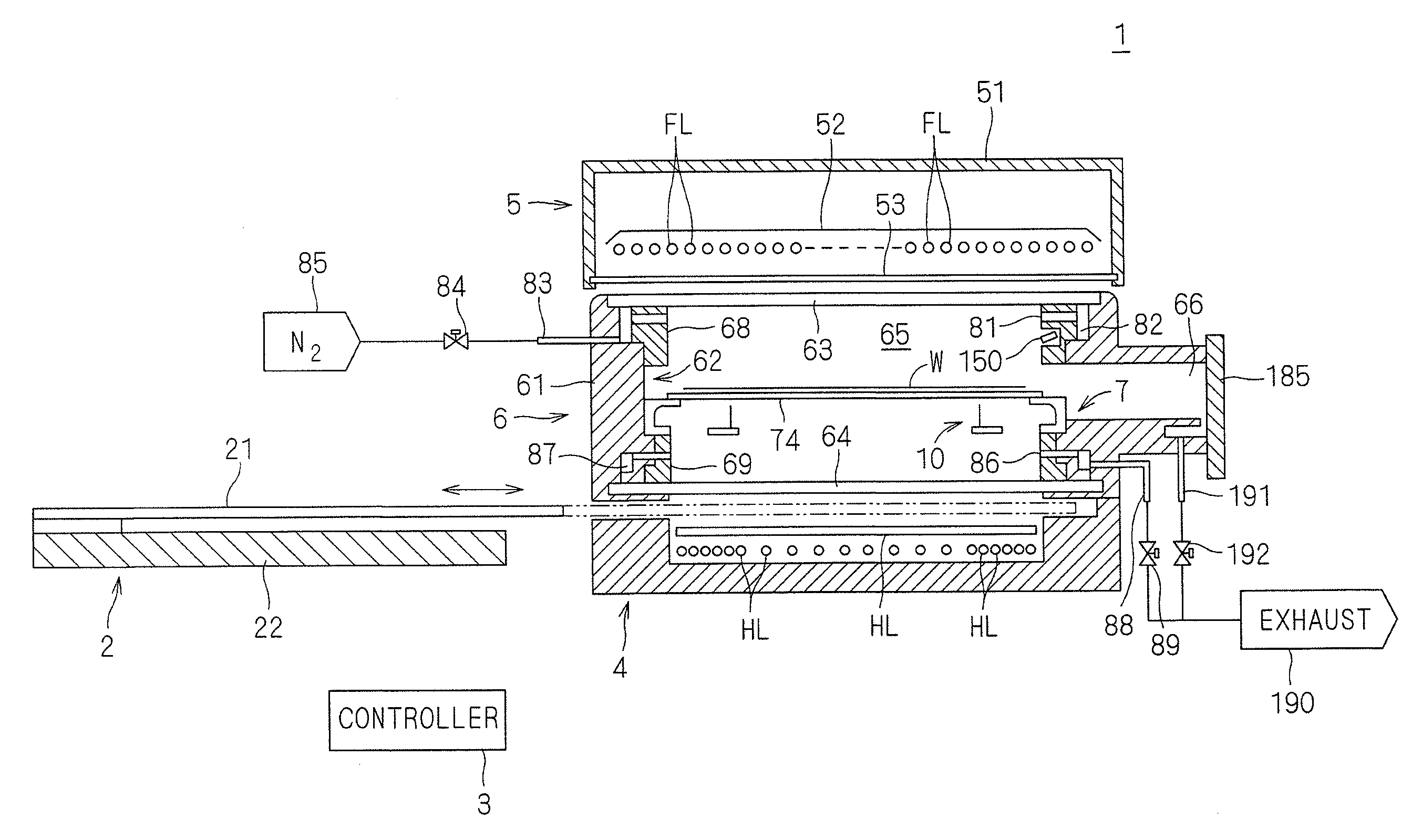

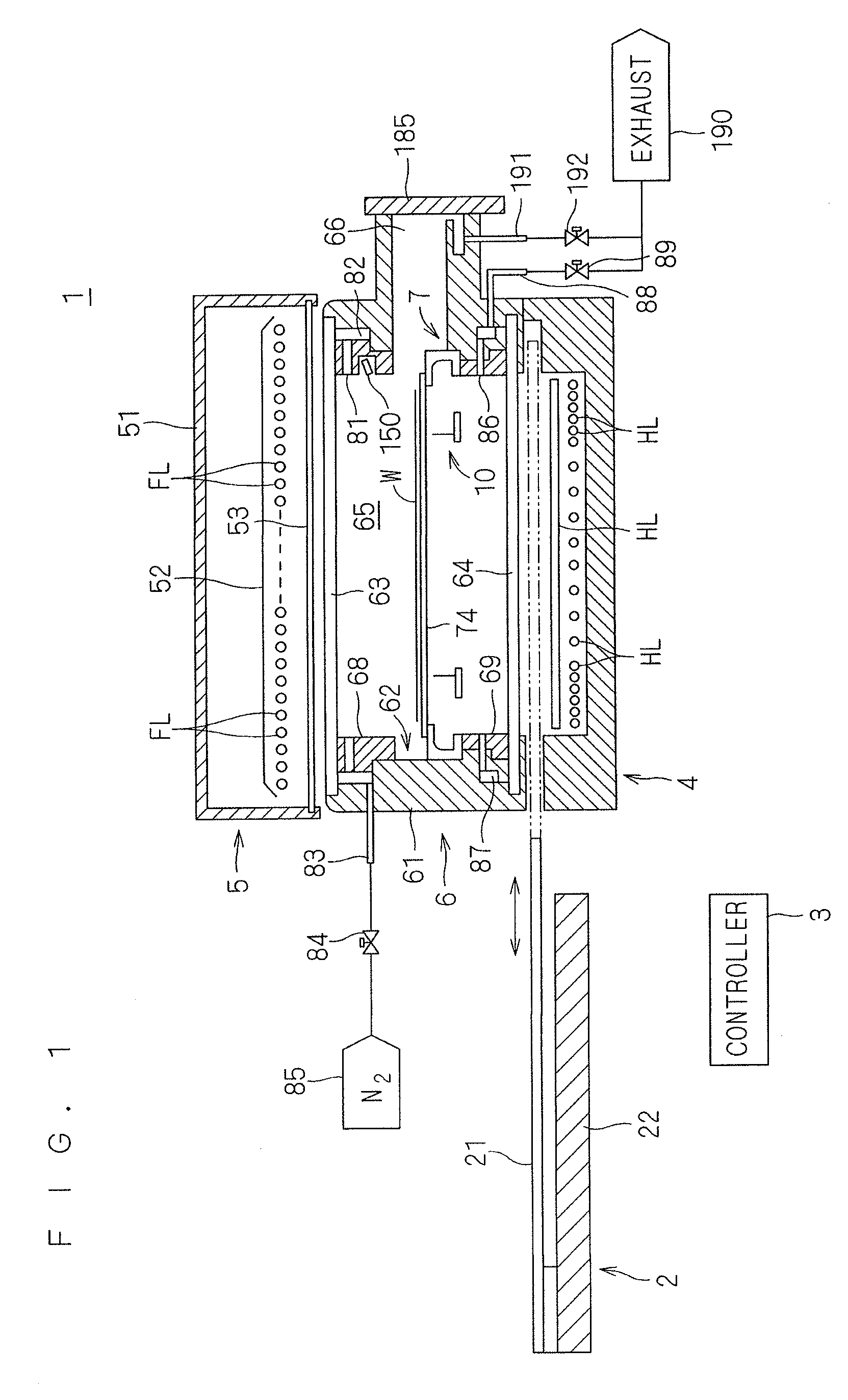

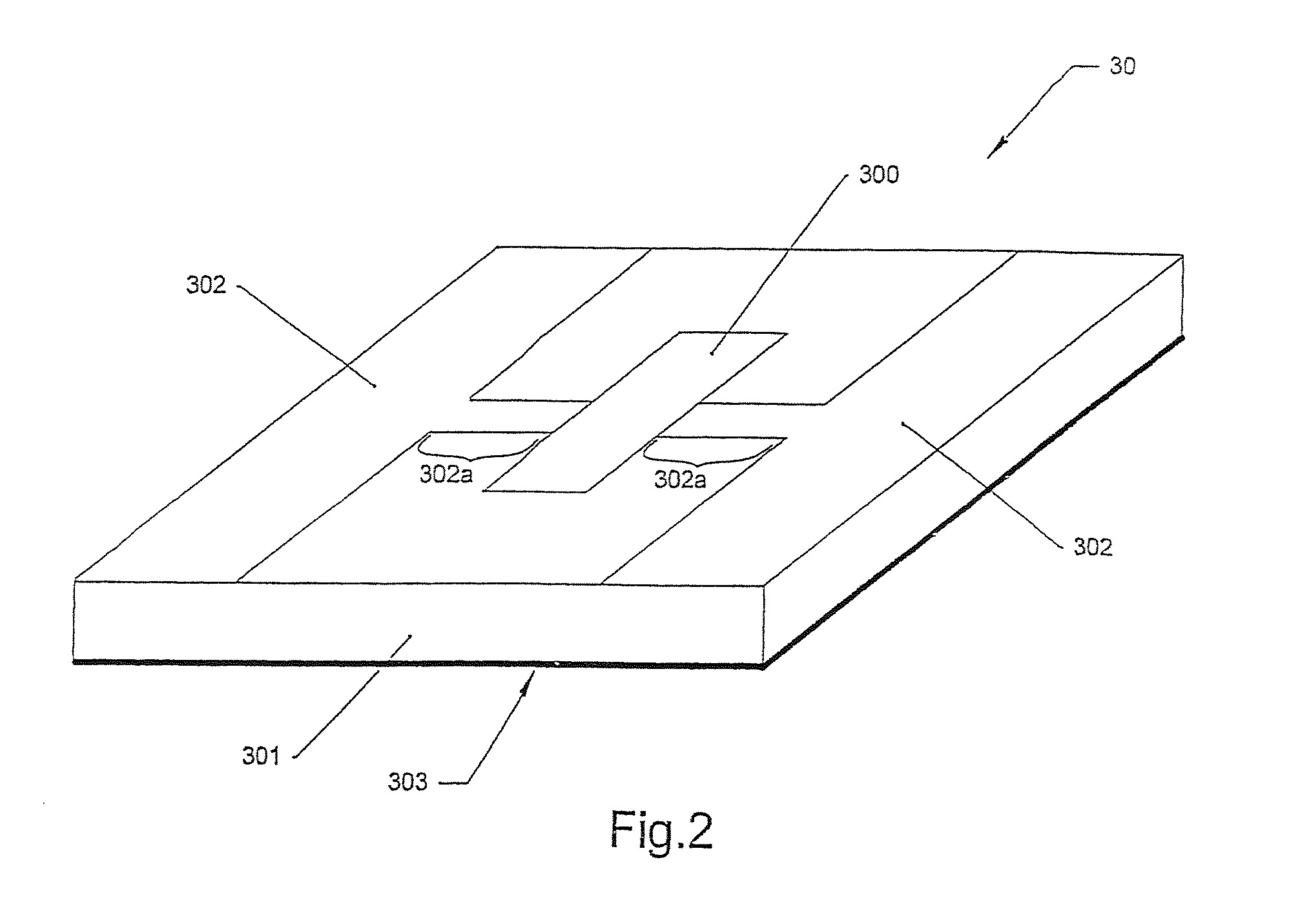

Shower head structure and treating device

InactiveUS20060021568A1Avoid depositionSuppression problemLiquid surface applicatorsSemiconductor/solid-state device manufacturingRadiation thermometerEngineering

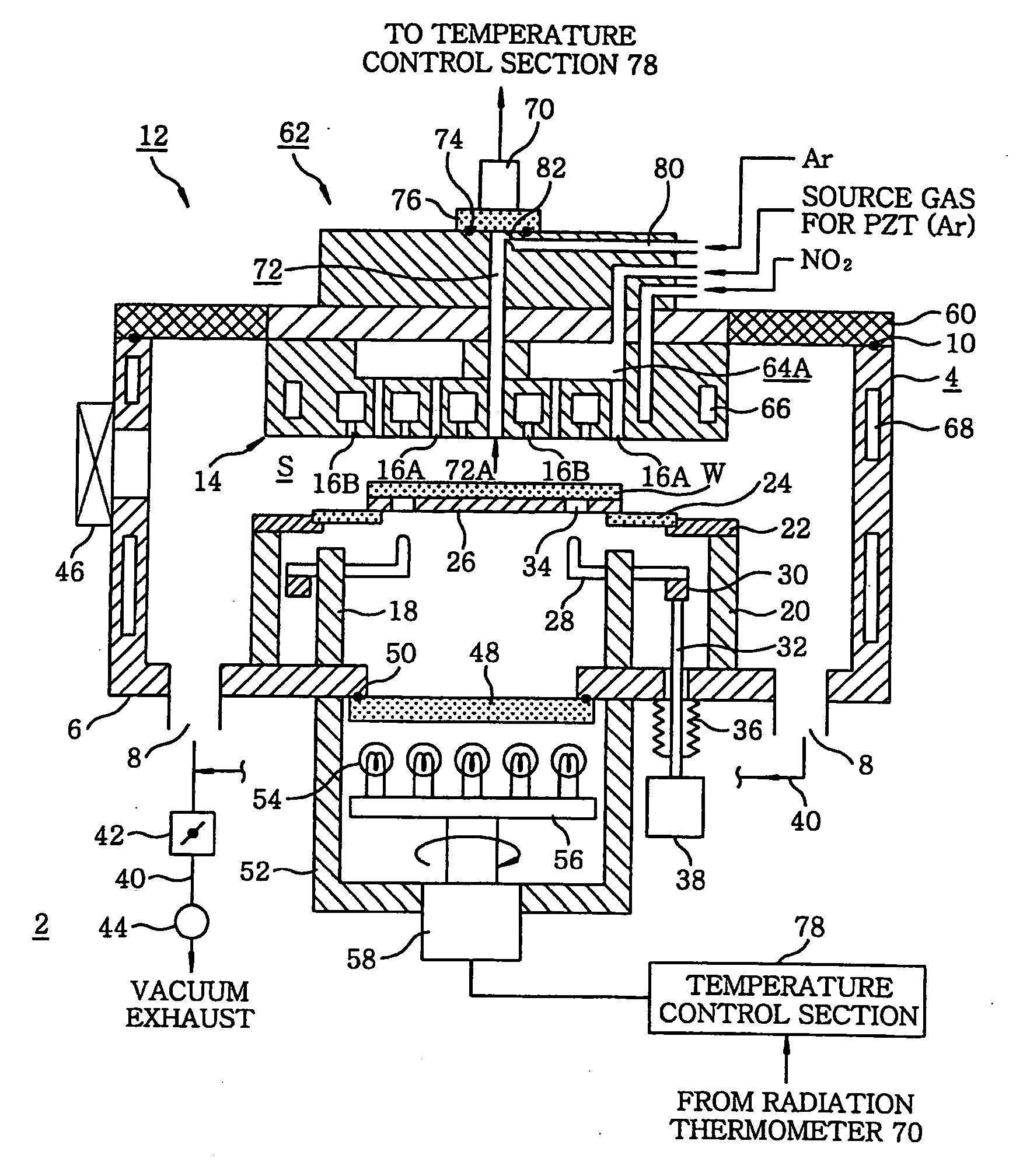

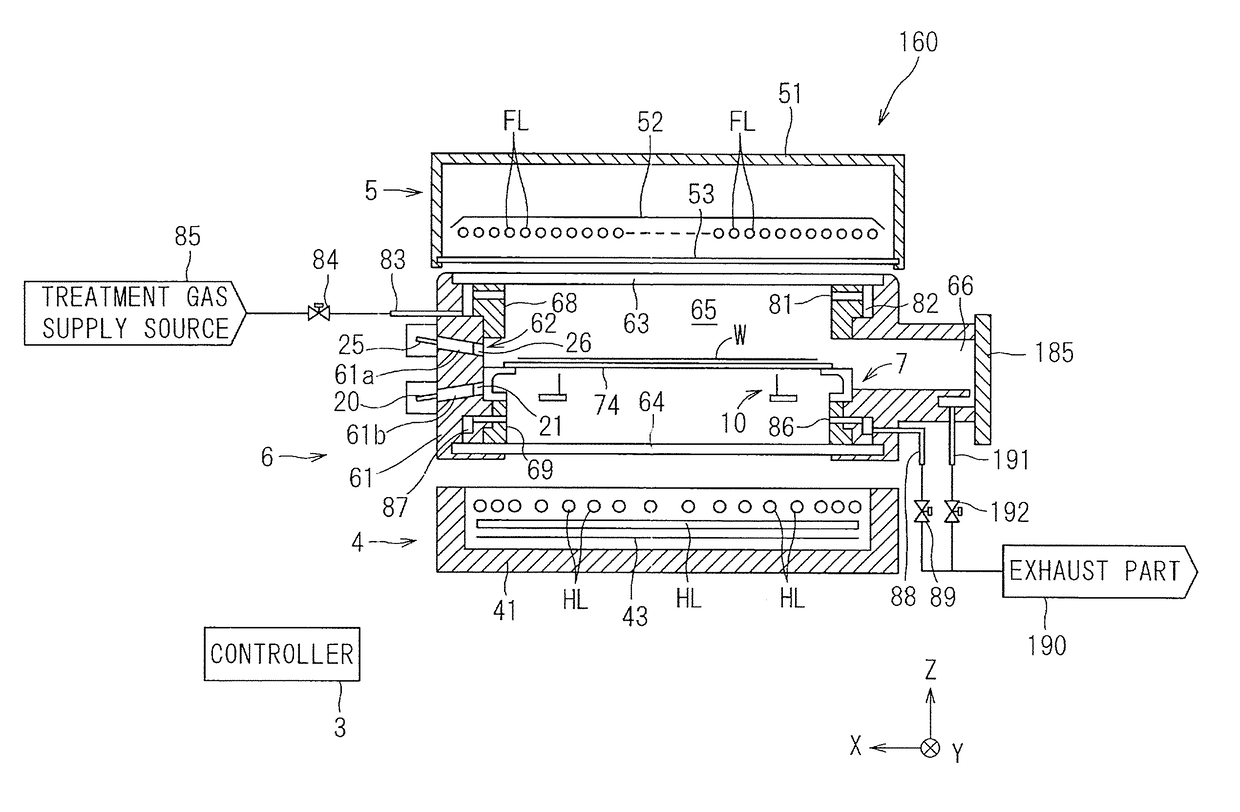

A shower head structure characterized by comprising a shower head section, opposed to the upper surface of a mounting table in an evacuable treating vessel, for injecting a processing gas into the treating vessel; a temperature observation through-hole which opens in the lower surface of the shower head so as to be opposed to the upper surface of the mounting table, a transparent observation window which hermetically seals the upper end of the temperature observation through-hole, a radiation thermometer disposed on the upper surface of the transparent observation window, an adhesion preventive gas supply path communicating with the temperature observation through-hole to prevent a film from adhering to the transparent observation window, wherein the adhesion preventive gas supply path communicates with the temperature observation through-hole through an injection nozzle for injecting the adhesion preventive gas to the transparent observation window.

Owner:TOKYO ELECTRON LTD

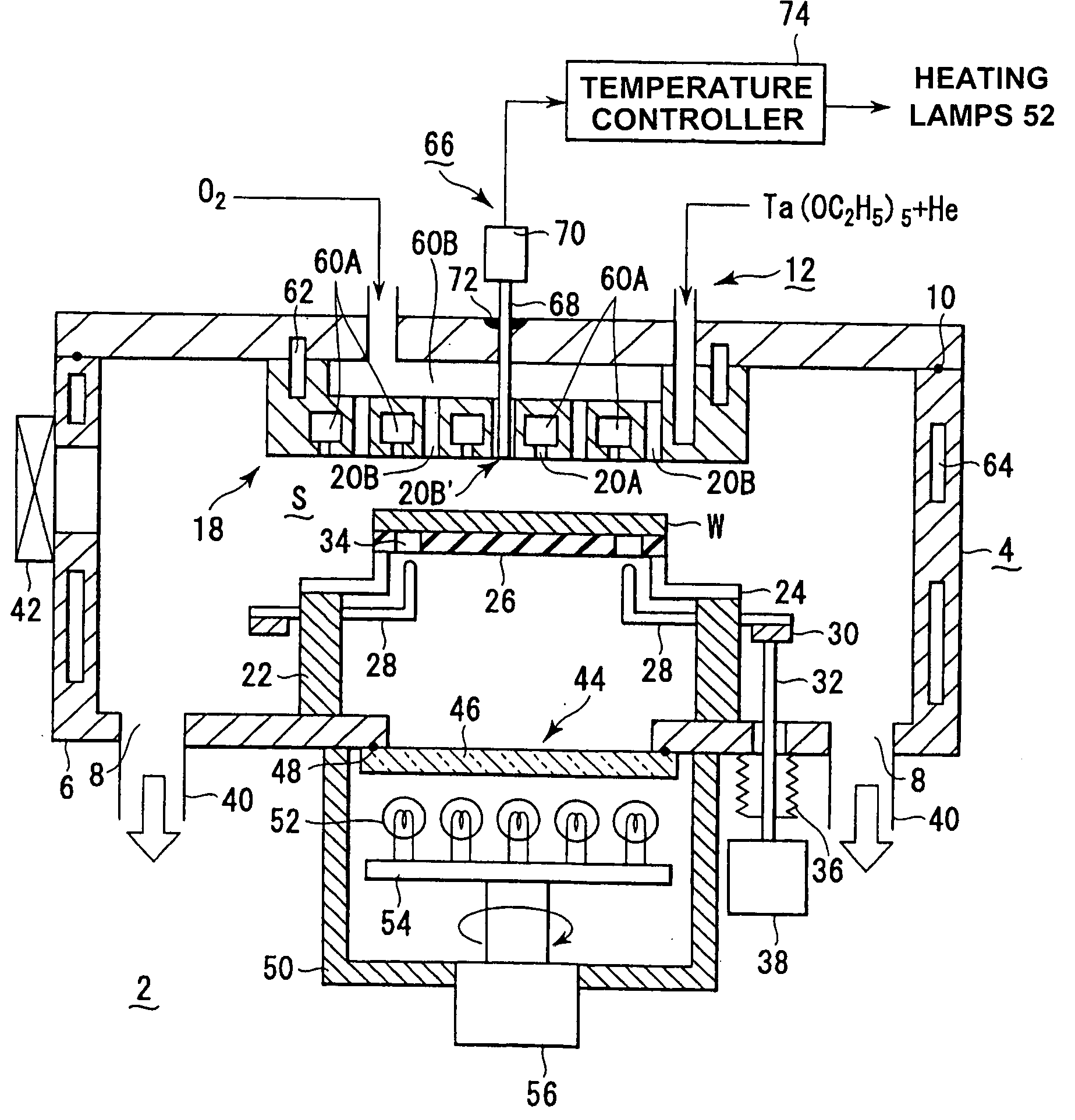

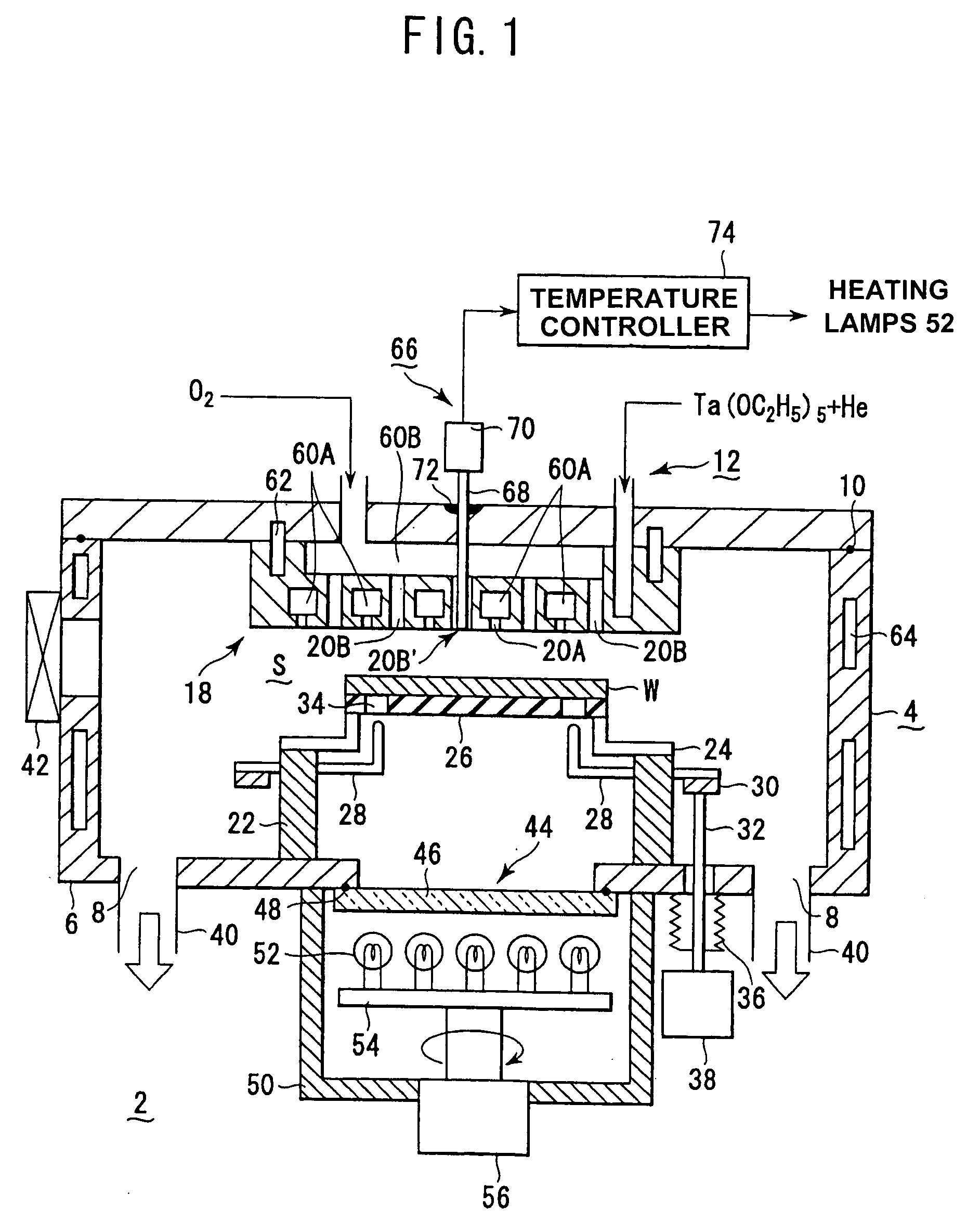

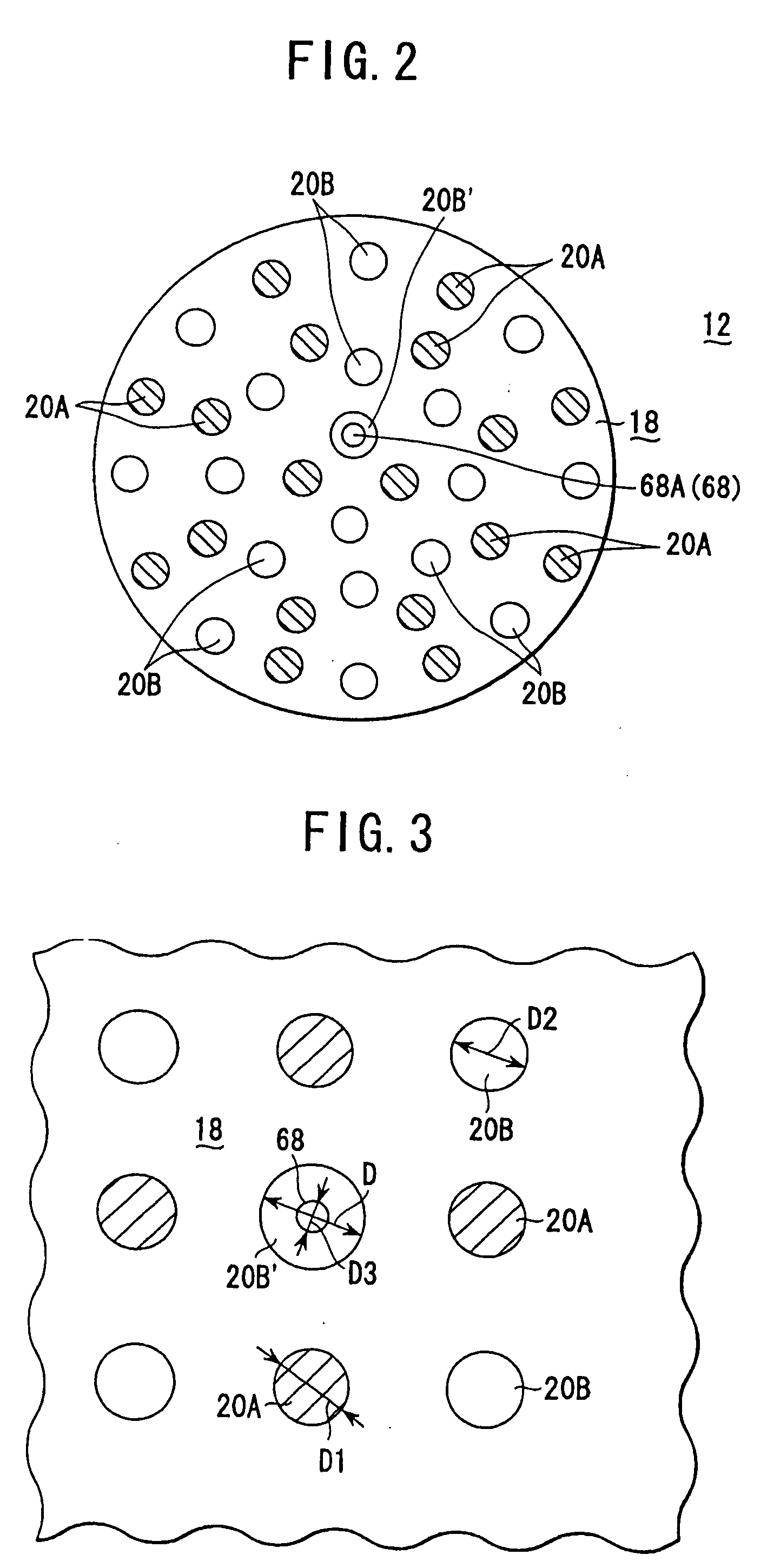

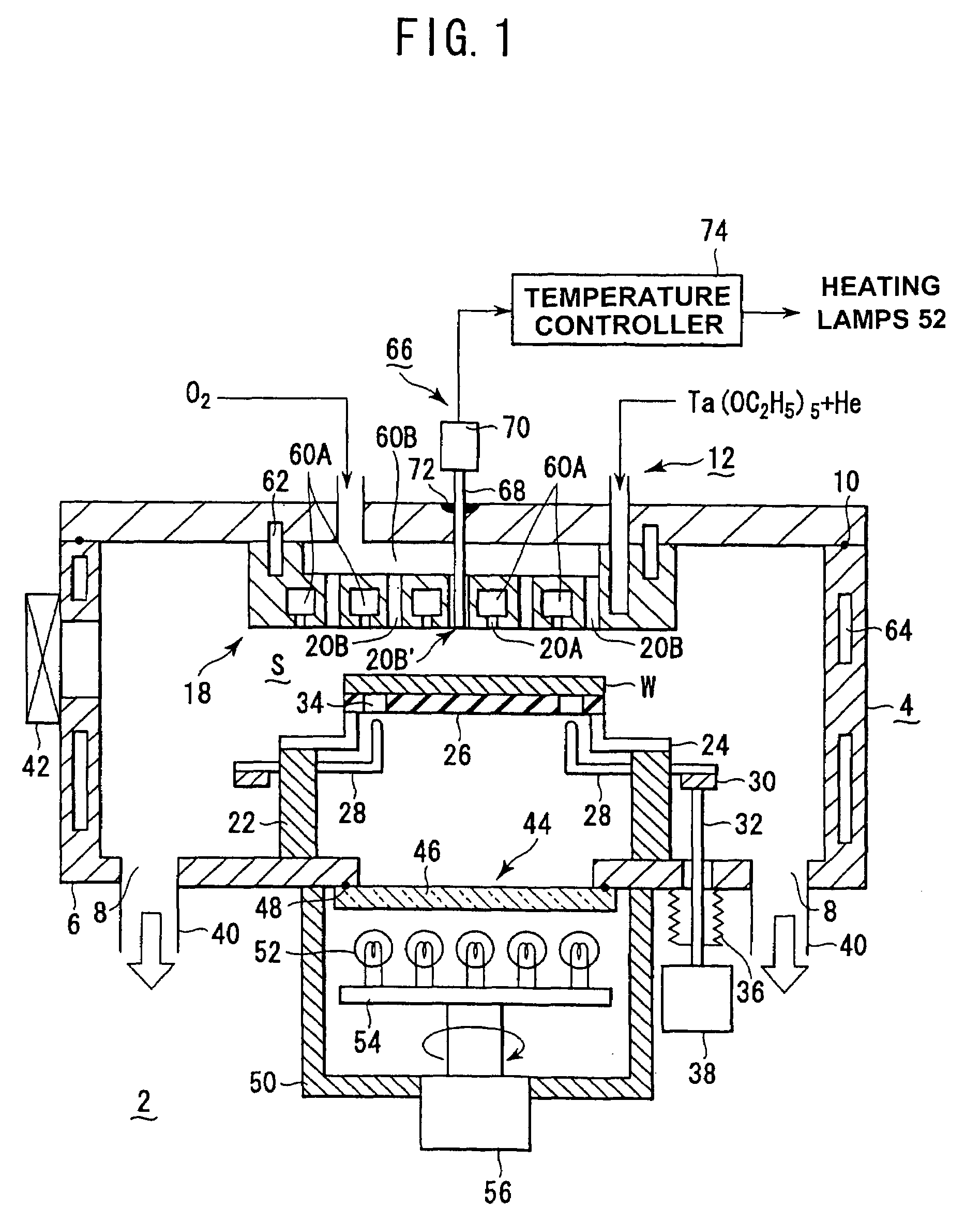

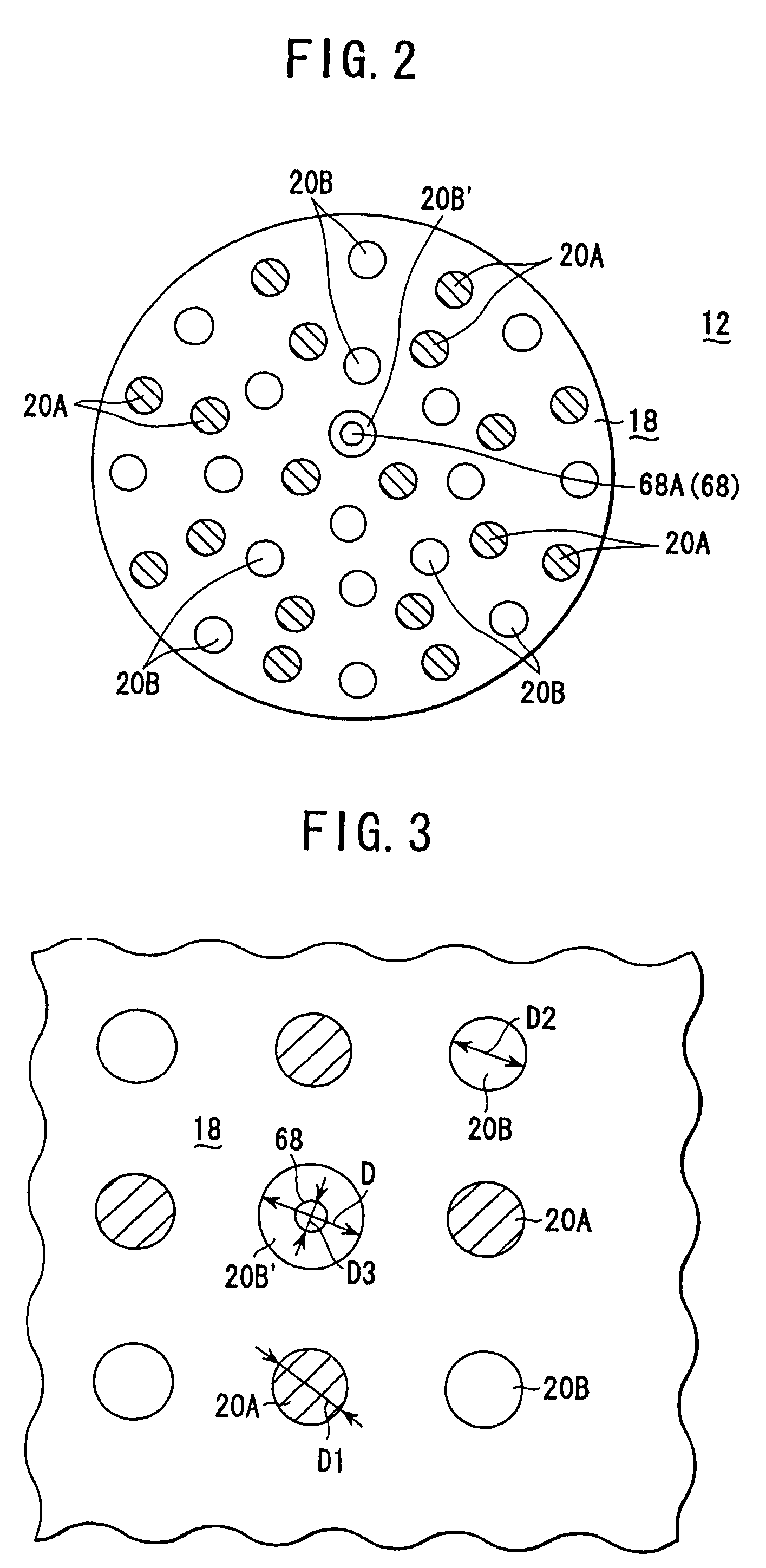

Shower head structure for processing semiconductor

InactiveUS20050118737A1Improve intra-surface uniformityImprove uniformitySemiconductor/solid-state device testing/measurementElectric discharge tubesRadiation thermometerEngineering

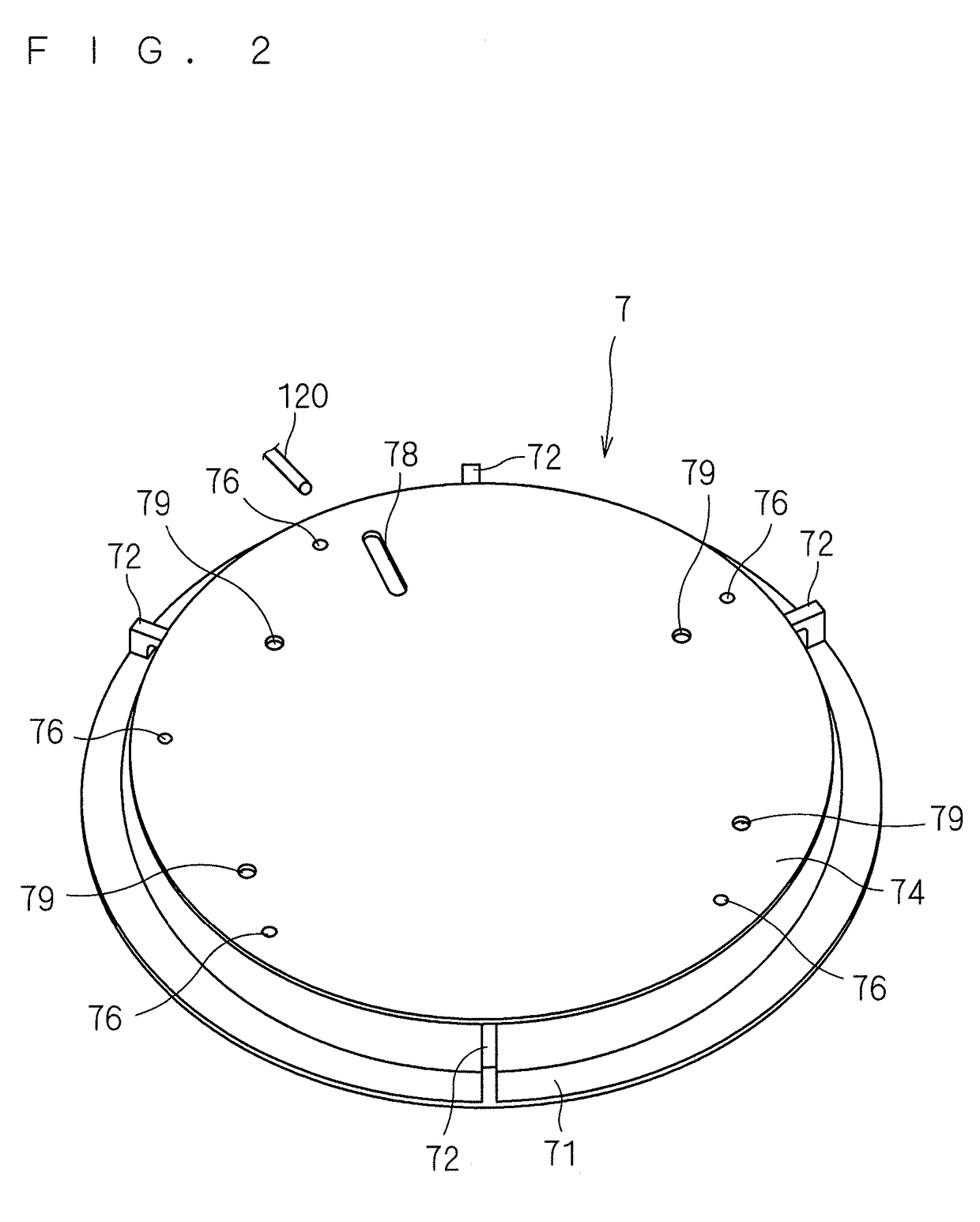

A shower head structure disposed in a device 2 for processing a semiconductor while supplying processing gas to a processing space S for storing a heated processed substrate W, comprising a shower head 12 having a plurality of gas injection holes 20B for supplying the processing gas and a light introducing rod 68 of a radiation thermometer 66 inserted into at least one of the gas injection holes 20B.

Owner:TOKYO ELECTRON LTD

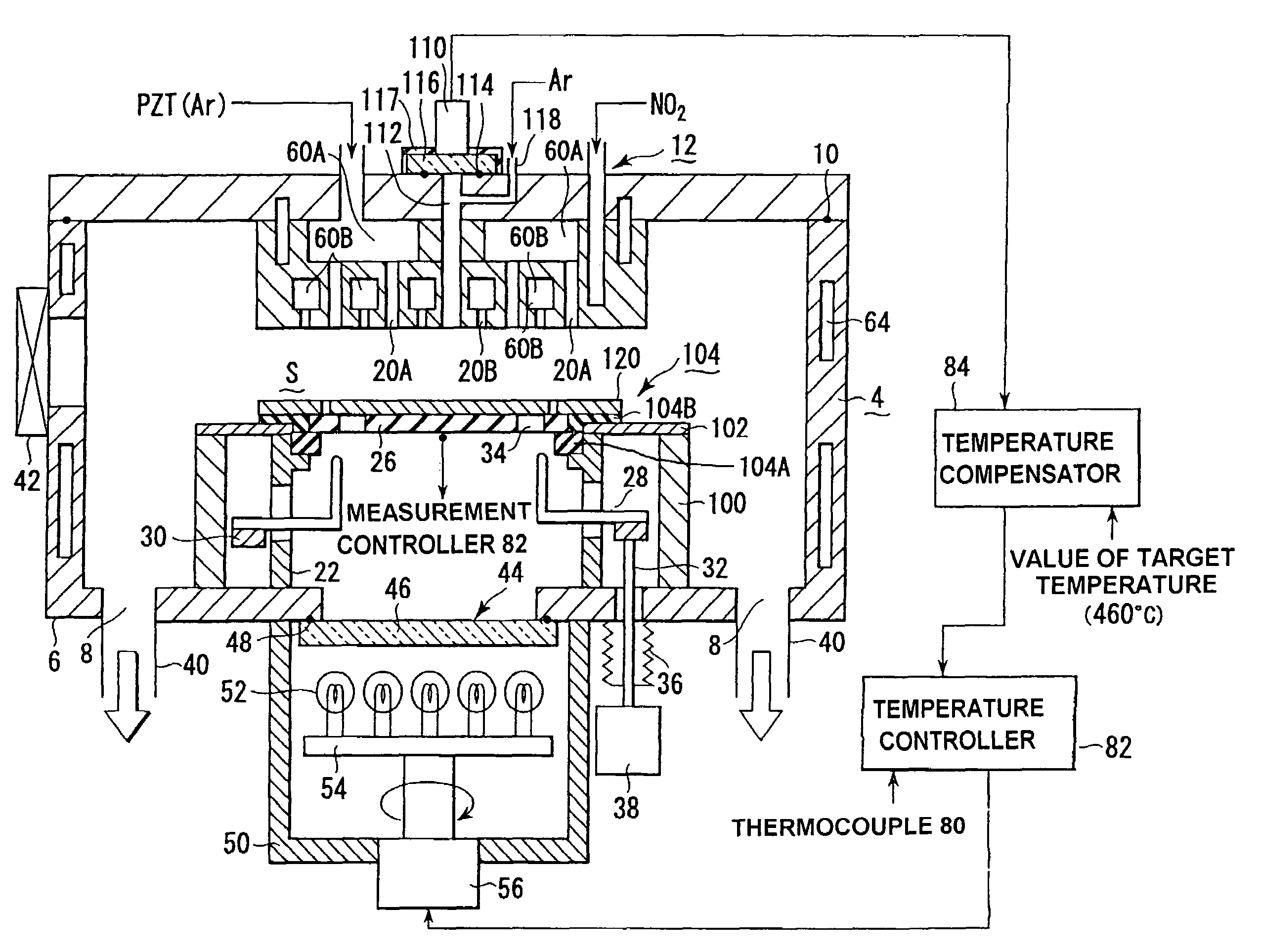

Heat treatment method and heat treatment apparatus for heating substrate by irradiating substrate with light

ActiveUS20120288970A1Radiation pyrometrySemiconductor/solid-state device testing/measurementEmissivityRadiation thermometer

After flash irradiation on a semiconductor wafer is started and then the temperatures of front and back surfaces of the semiconductor wafer become equal to each other, the temperature of the back surface of the semiconductor wafer, which has a known emissivity, is measured with a radiation thermometer. The emissivity of the front surface of the semiconductor wafer is calculated based on the intensity of radiated light from a black body having an equal temperature to the temperature of the back surface thereof, and the intensity of radiated light actually radiated from the front surface of the semiconductor wafer. Then, the temperature of the front surface of the semiconductor wafer heated by the flash irradiation is calculated based on the calculated emissivity and the intensity of the radiated light from the front surface of the semiconductor wafer that has been measured after the flash irradiation is started.

Owner:DAINIPPON SCREEN MTG CO LTD

Radiation clinical thermometer

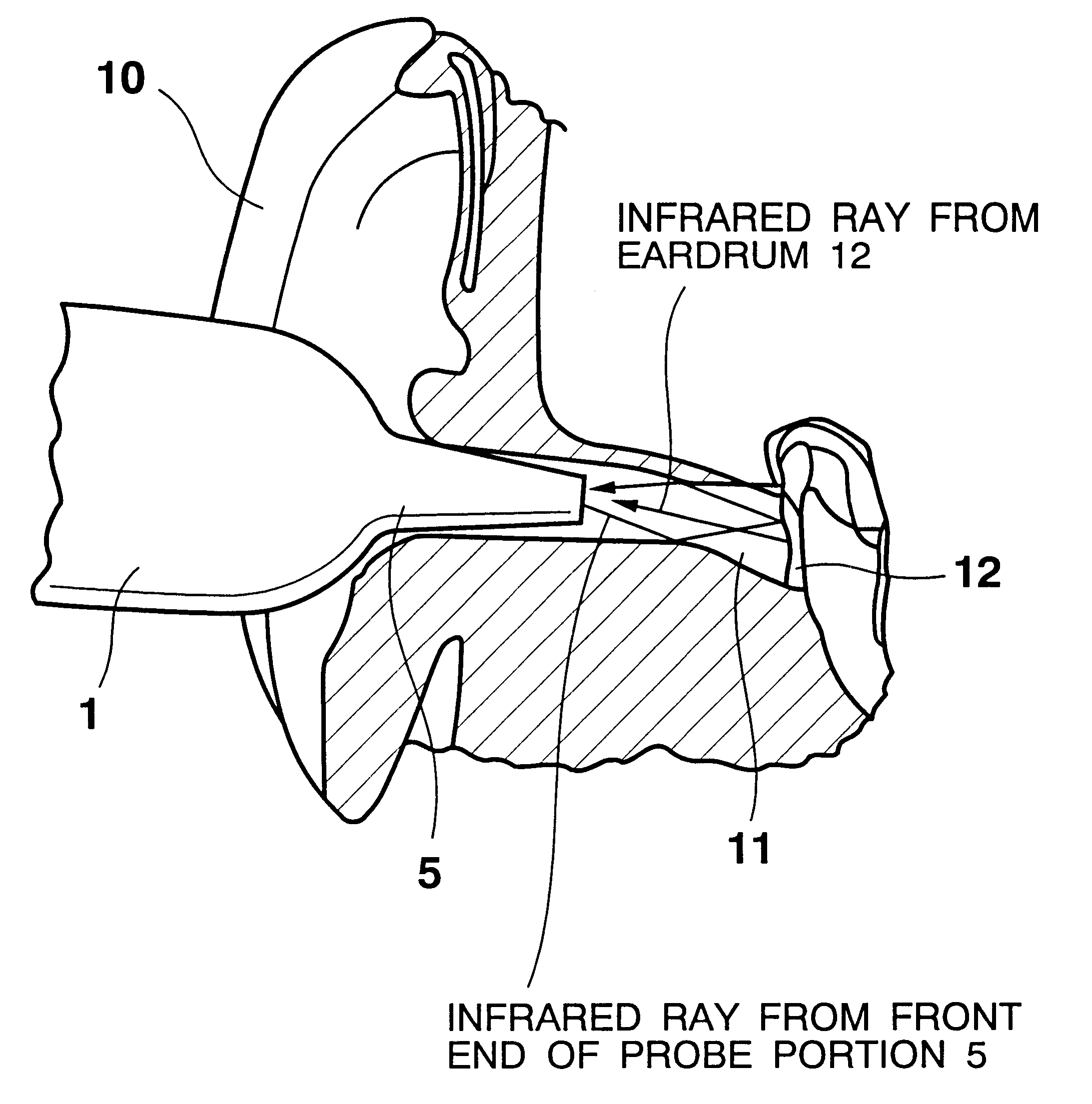

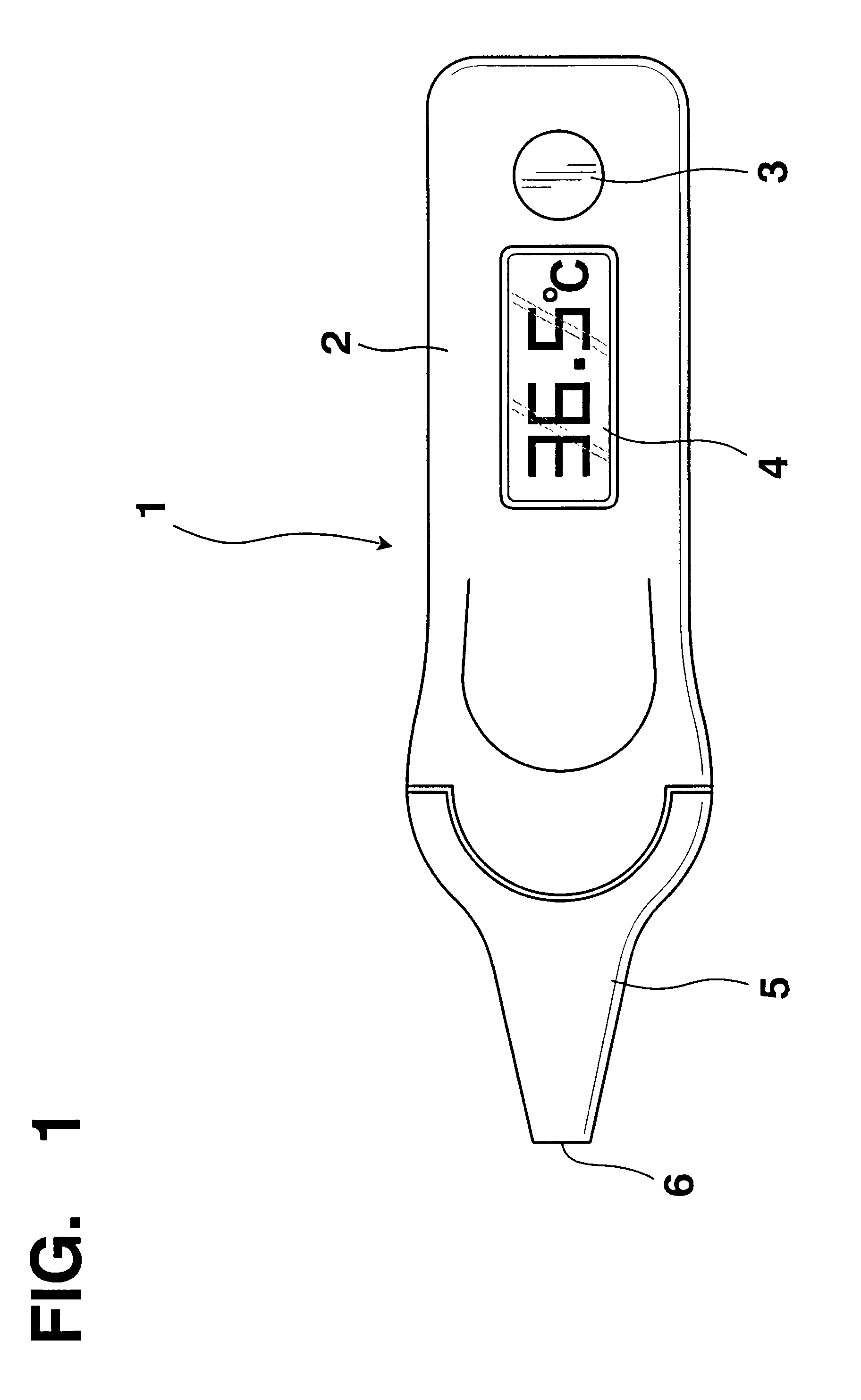

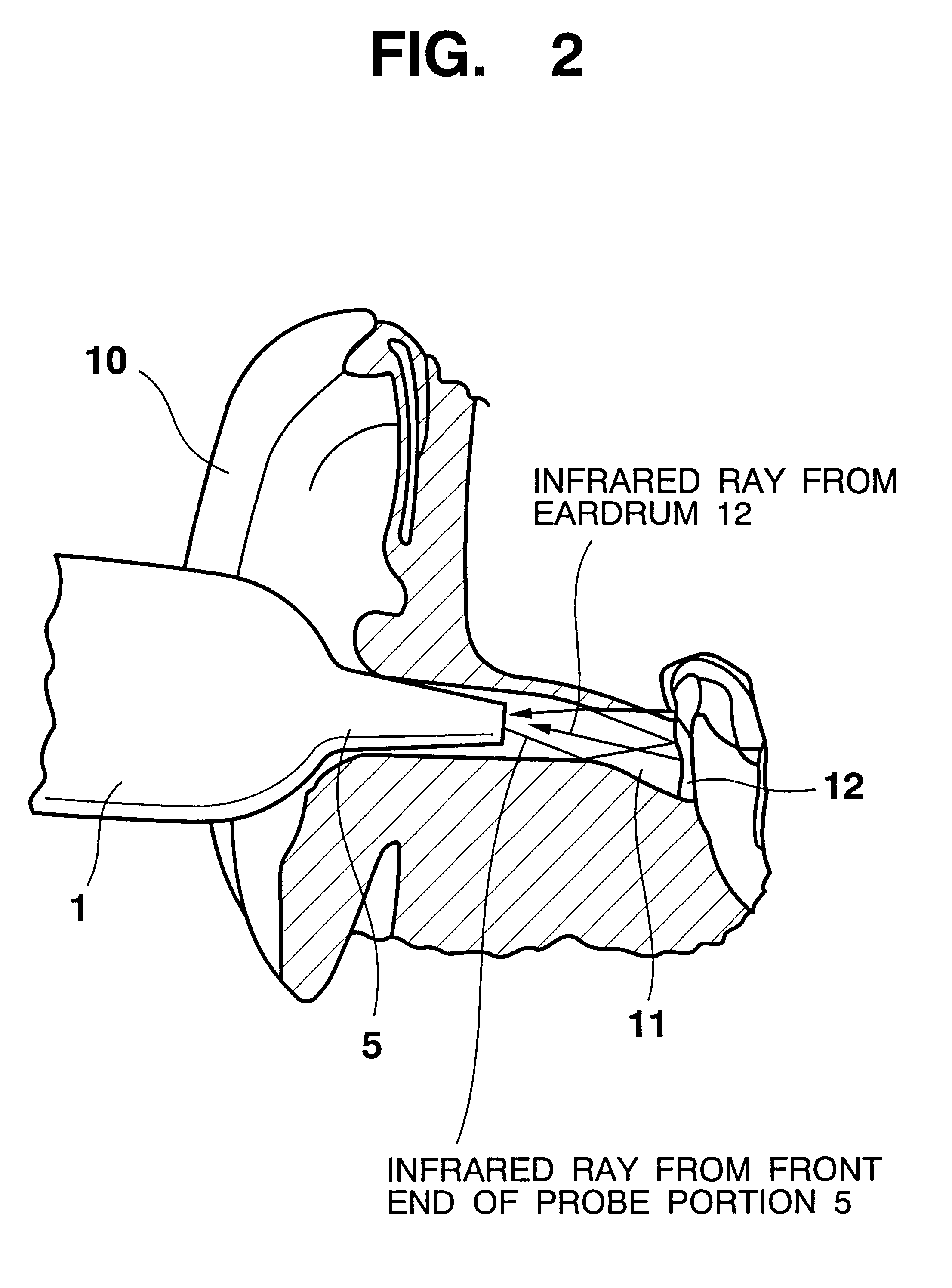

InactiveUS6572264B1Thermometer detailsThermometers using electric/magnetic elementsInfraredEmissivity

To provide a radiation thermometer capable of measuring a body temperature more accurately than it has been conventionally possible, by taking into account an infrared ray that is emitted from a front end of the probe portion and reflected from an eardrum or an external acoustic opening. The radiation thermometer has body temperature calculating means for calculating a body temperature according to a predetermined arithmetic expression based on an emissivity when the emissivity of the eardrum or the external acoustic opening is less than 1, an output of infrared-ray detecting means and an output of temperature-measuring means.

Owner:CITIZEN WATCH CO LTD

Method and device of measuring material thermal shock property

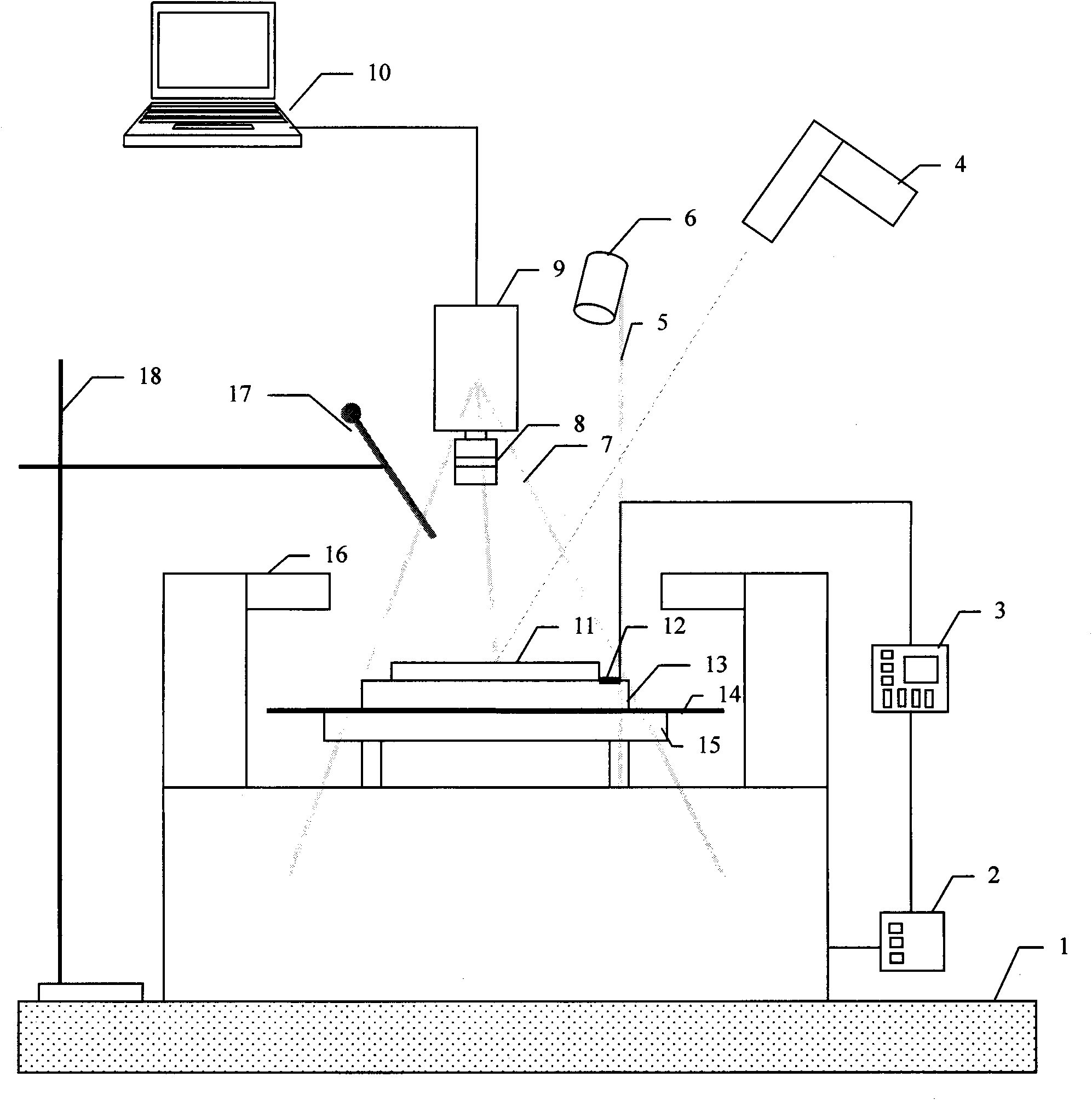

ActiveCN101666733AAccurate recordStable and reliable measurement environmentStrength propertiesStructural deformationWire gauze

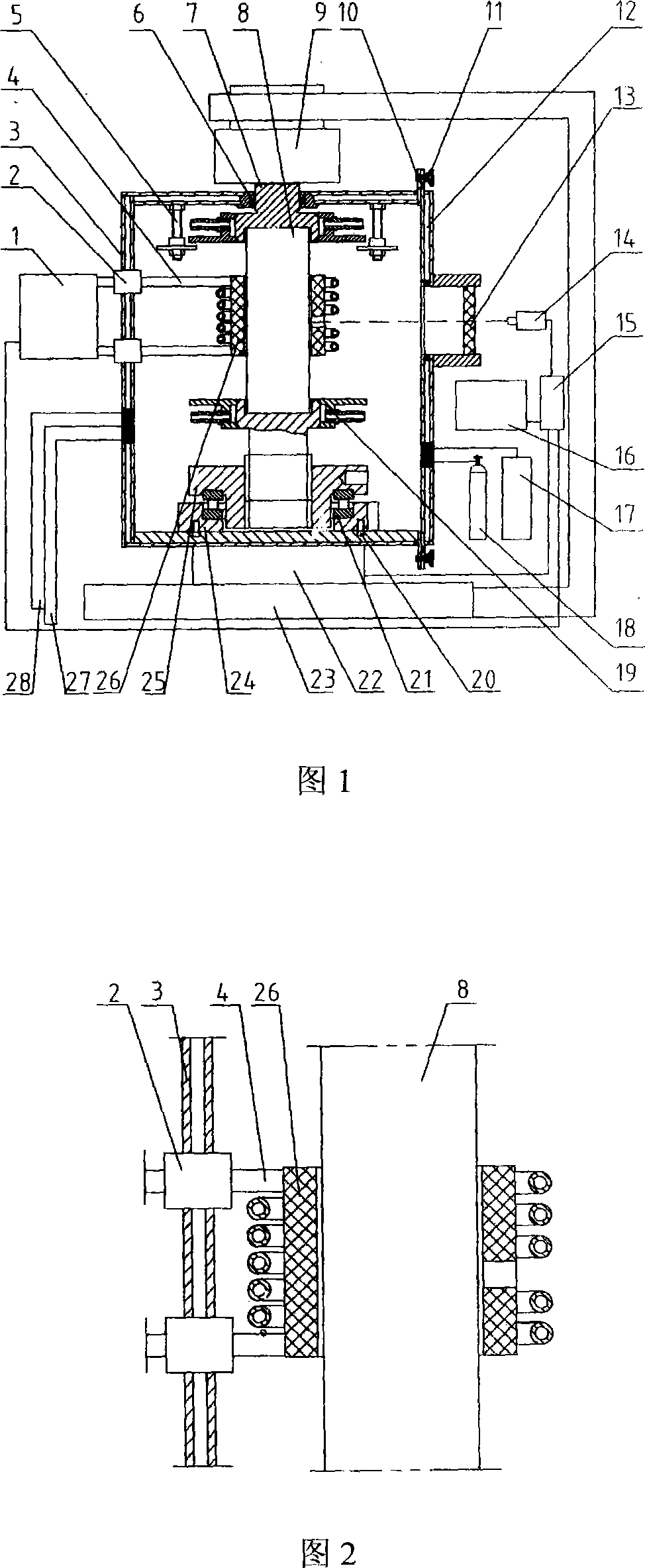

The invention relates to a method and a device of measuring material thermal shock property, which belongs to the technical field of engineering materials, structural deformation and mechanics experiment. The measuring device comprises an air cushion precision optical platform, a temperature controlled switch, a PID temperature controller, an infrared radiation thermometer, an LED lamp bracket, anLED lamp, an A-frame, a lens, a high speed camera, a computer, a test piece, a thermoelectric pair, alumina ceramics, asbestos wire gauze, a heating furnace, a thermal insulation shield, a burette and a stand. The invention combines heating equipment and an optical photographic apparatus, masterly utilizes a digital image cross-correlation method and provides the method and the device of measuring material thermal shock property. The invention has novel train of thought, compact structure and complete system, and can realize quantitative analysis and measurement on the material thermal shockproperty.

Owner:TSINGHUA UNIV

Radiometric thermometer

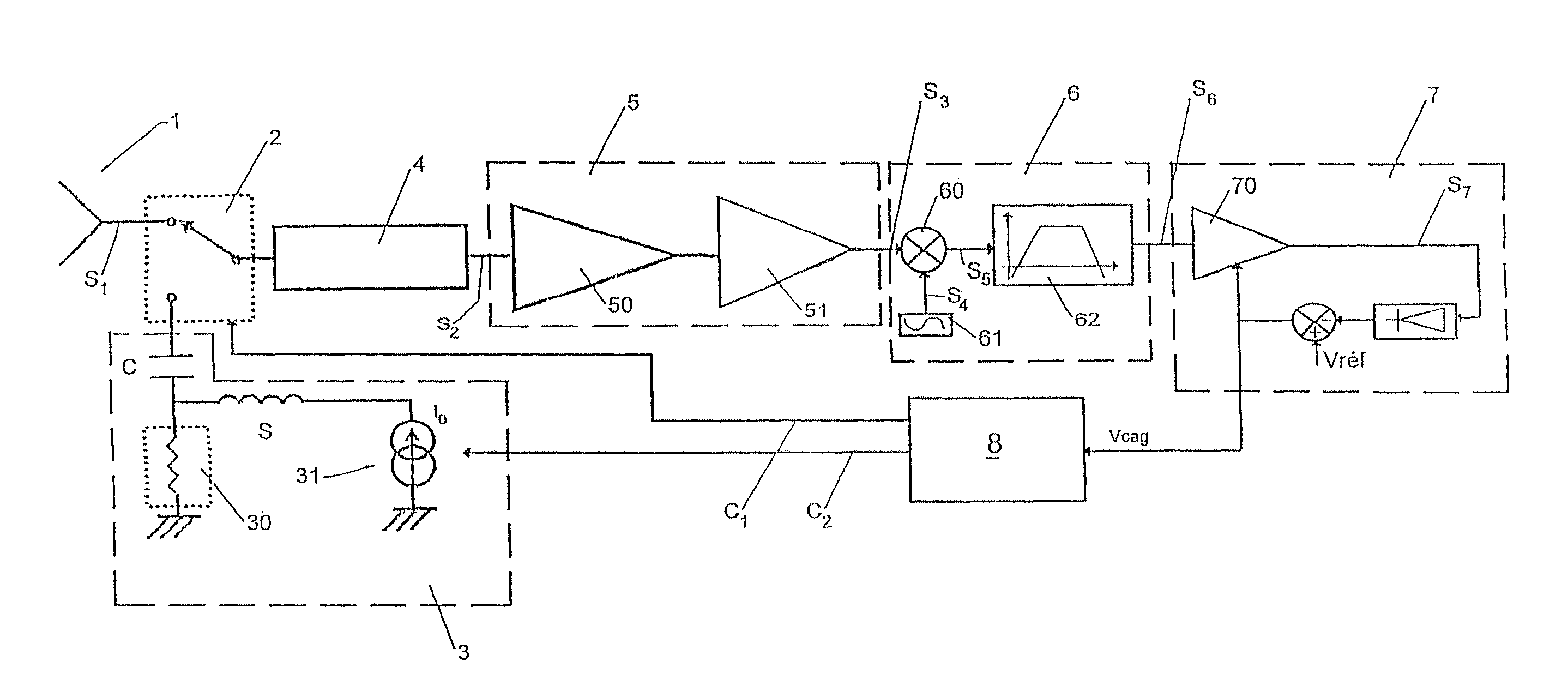

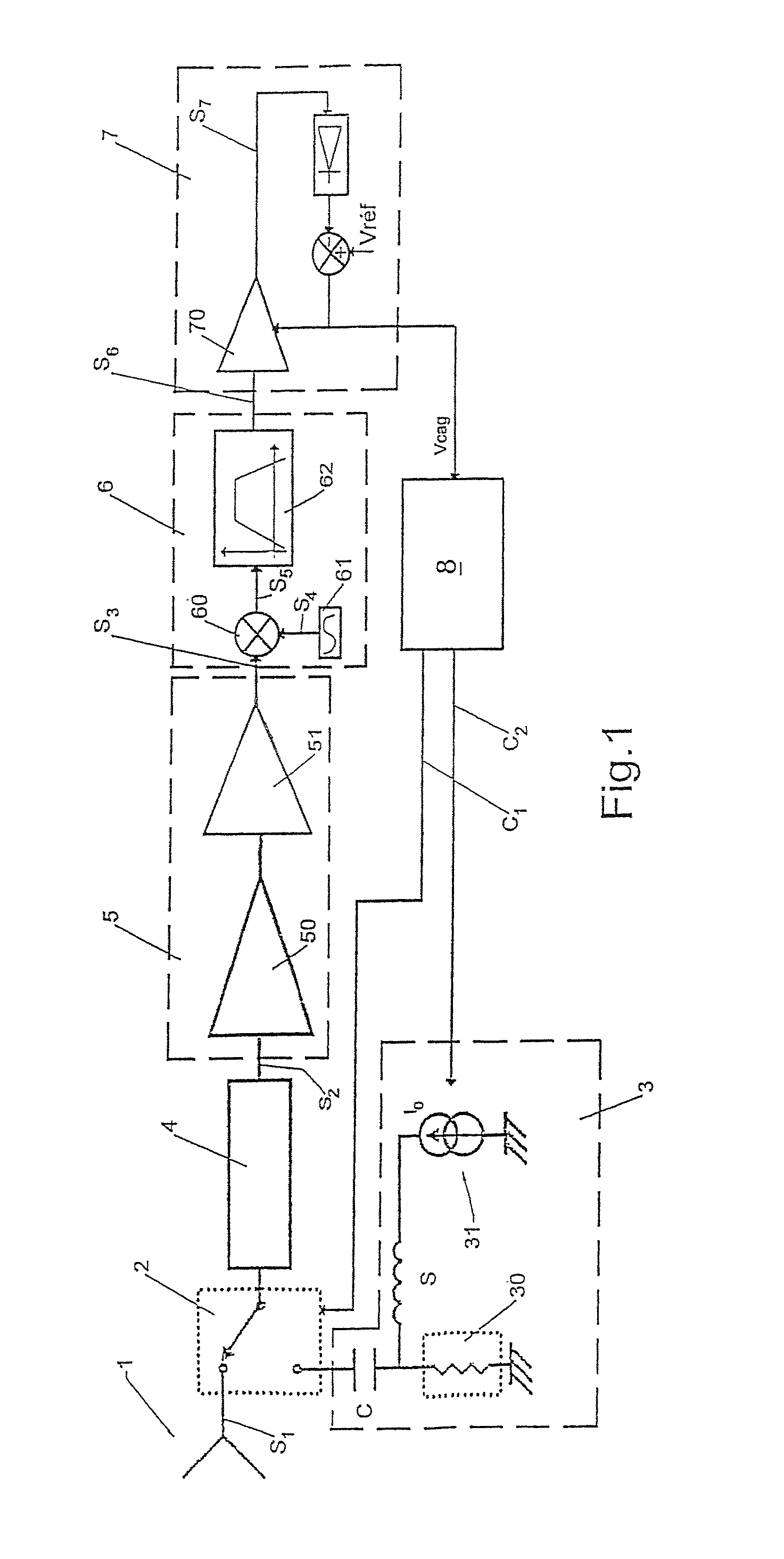

InactiveUS8157442B2Reduce manufacturing costEasy to useThermometers using electric/magnetic elementsThermometers using physical/chemical changesRadiation thermometerElectronic temperature

The radiometric thermometer includes a microwave sensor and electronic means for processing the electrical signal delivered by the sensor. The electronic means includes means for preamplifying the electrical signal delivered by the microwave sensor; variable-gain amplification means with automatic gain control, which means amplify the signal delivered by the preamplification means, the amplification means having an automatic gain control signal that allows the gain to be automatically adjusted on the basis of the signal output by the amplification means, and electronic temperature measurement means for measuring temperature on the basis of the automatic gain control signal.

Owner:UNIV DES SCI & TECH DE LILLE

Shower head structure for processing semiconductor

InactiveUS7540923B2Improve uniformitySatisfactory accuracyLiquid surface applicatorsElectric discharge tubesRadiation thermometerProduct gas

Owner:TOKYO ELECTRON LTD

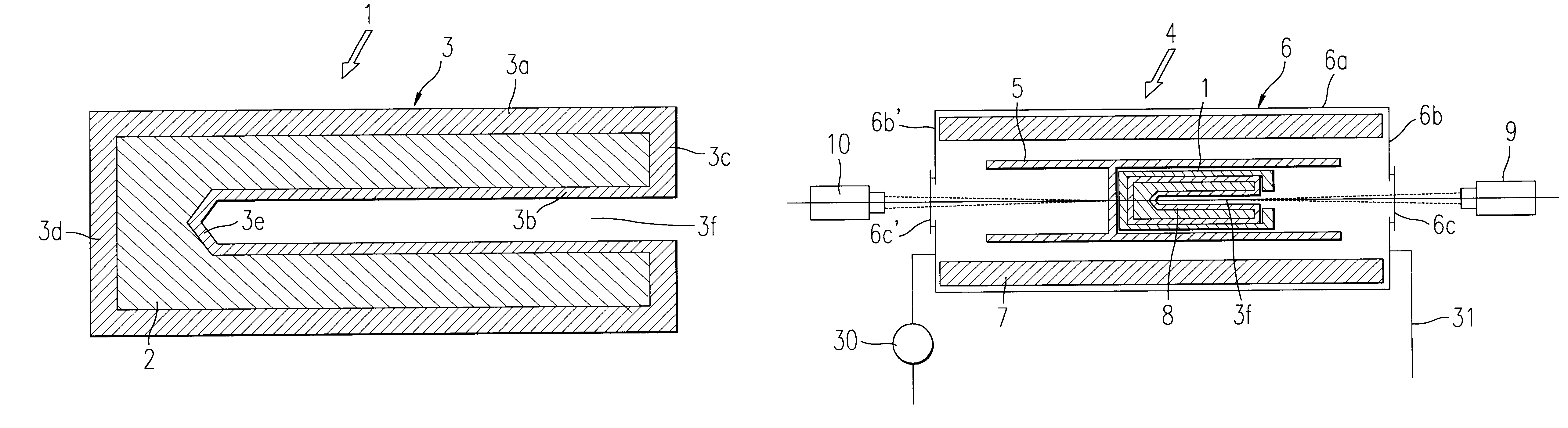

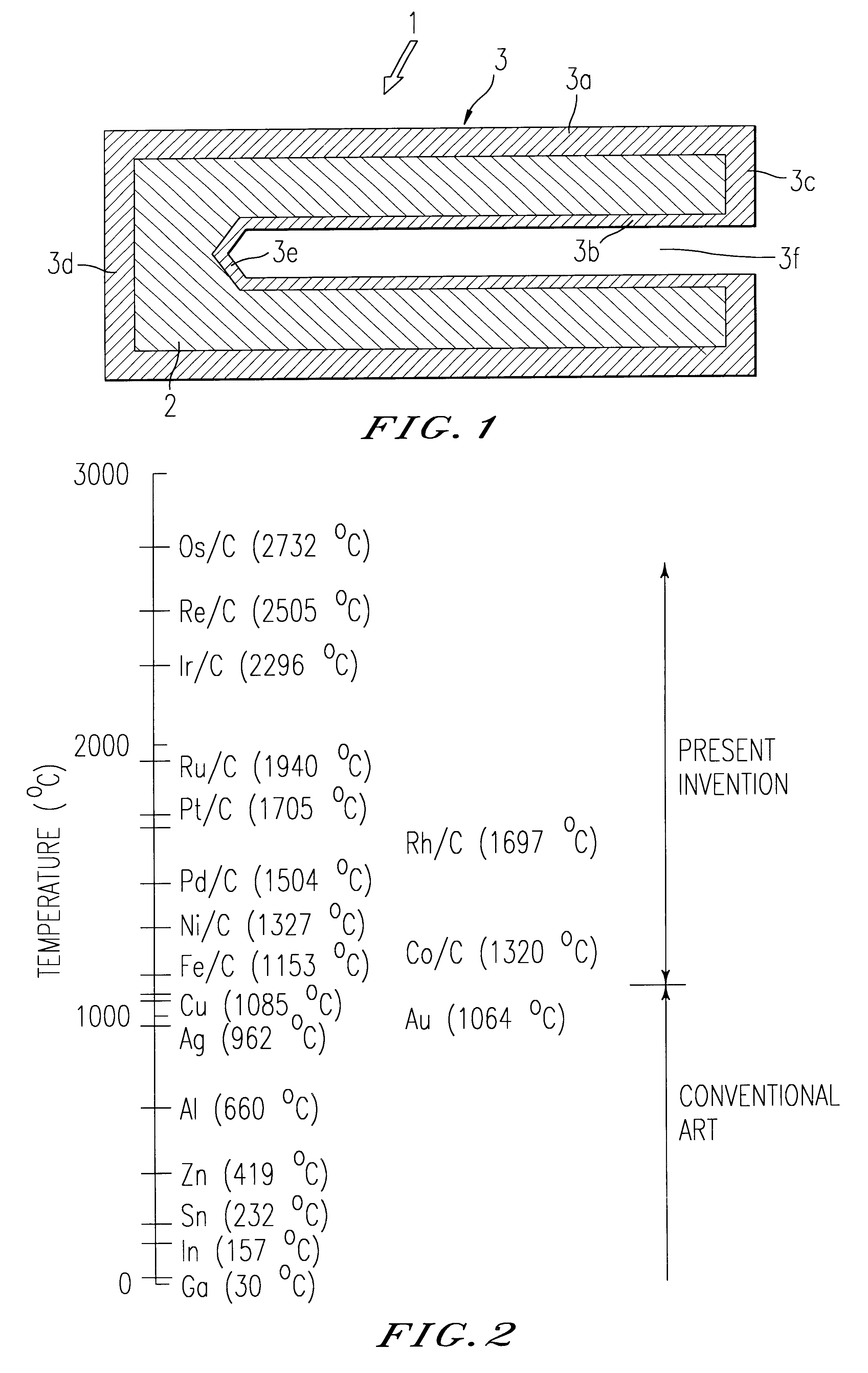

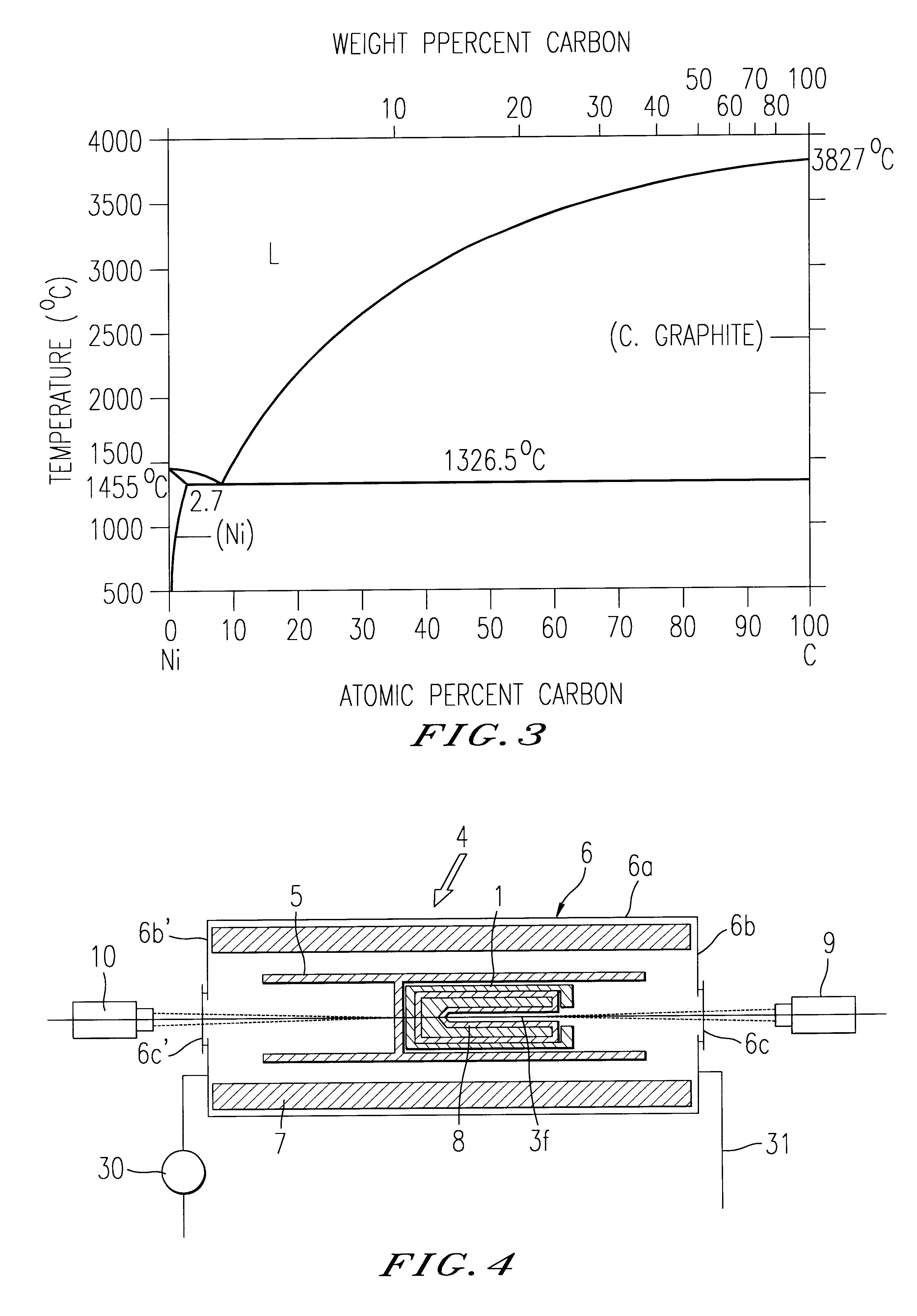

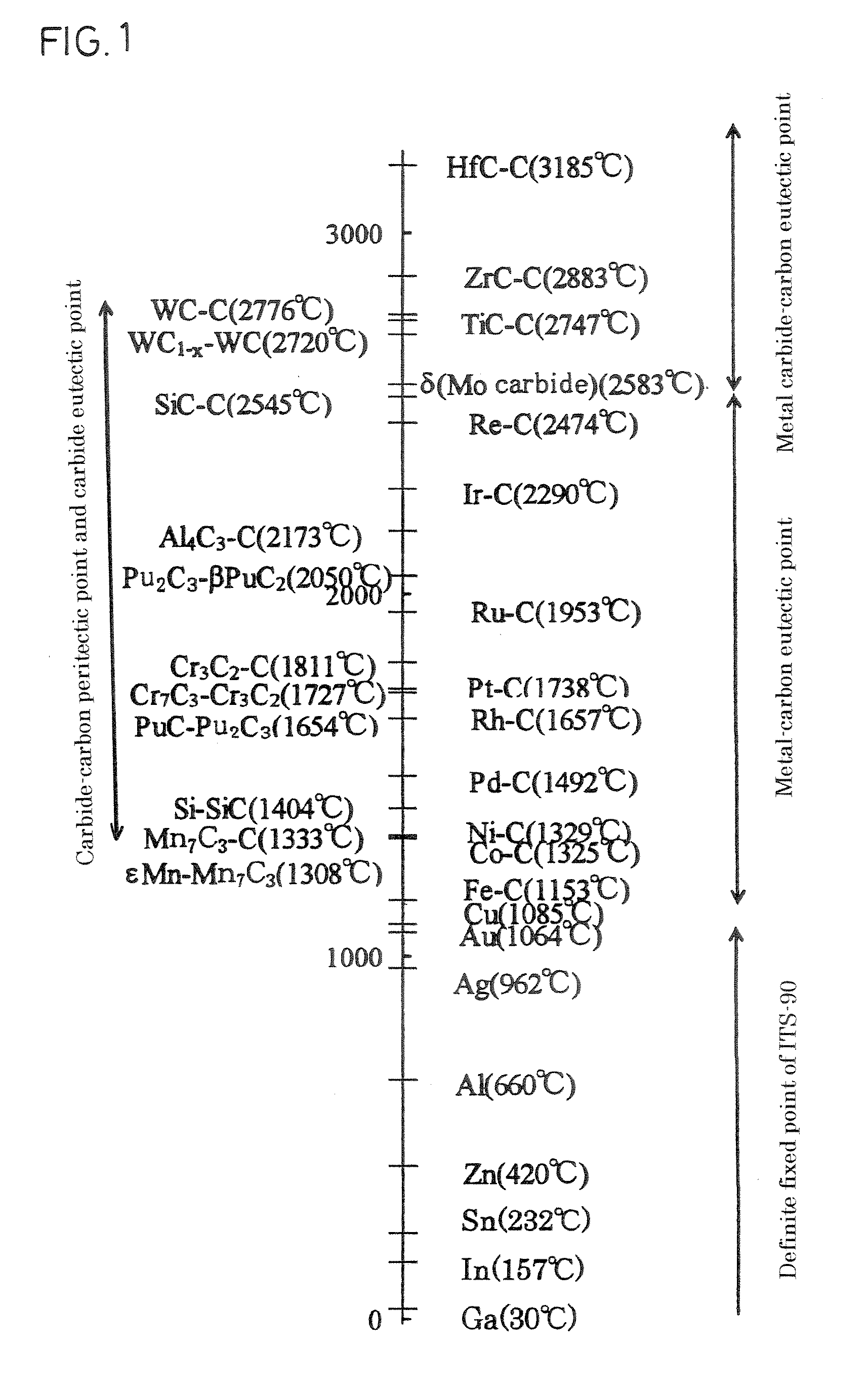

Fixed-point crucible, fixed-point temperature realizing apparatus using the crucible and temperature calibration method

InactiveUS6398405B1Improve accuracyEasy CalibrationThermometer testing/calibrationCalorimeterCrucibleRadiation thermometer

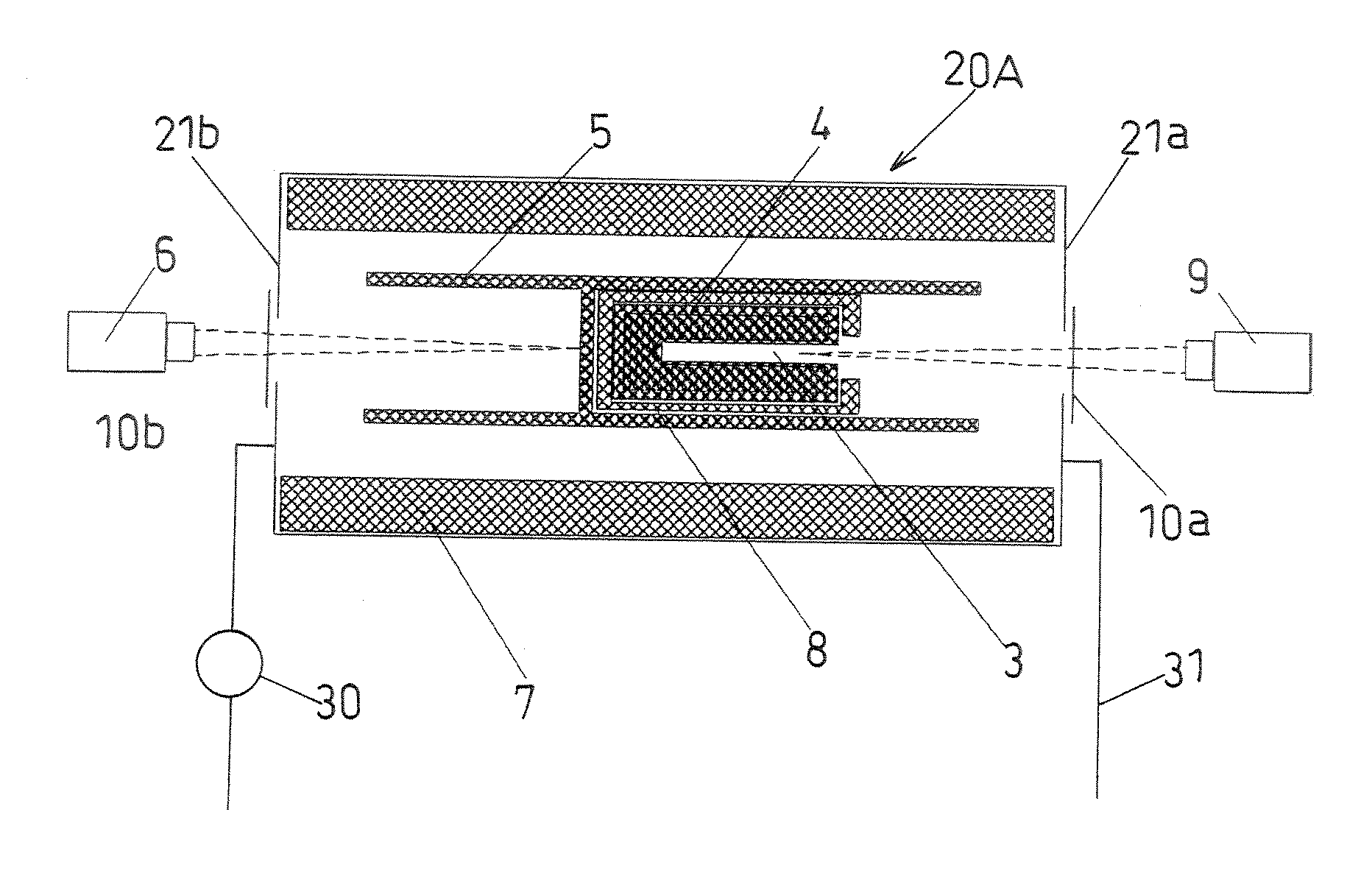

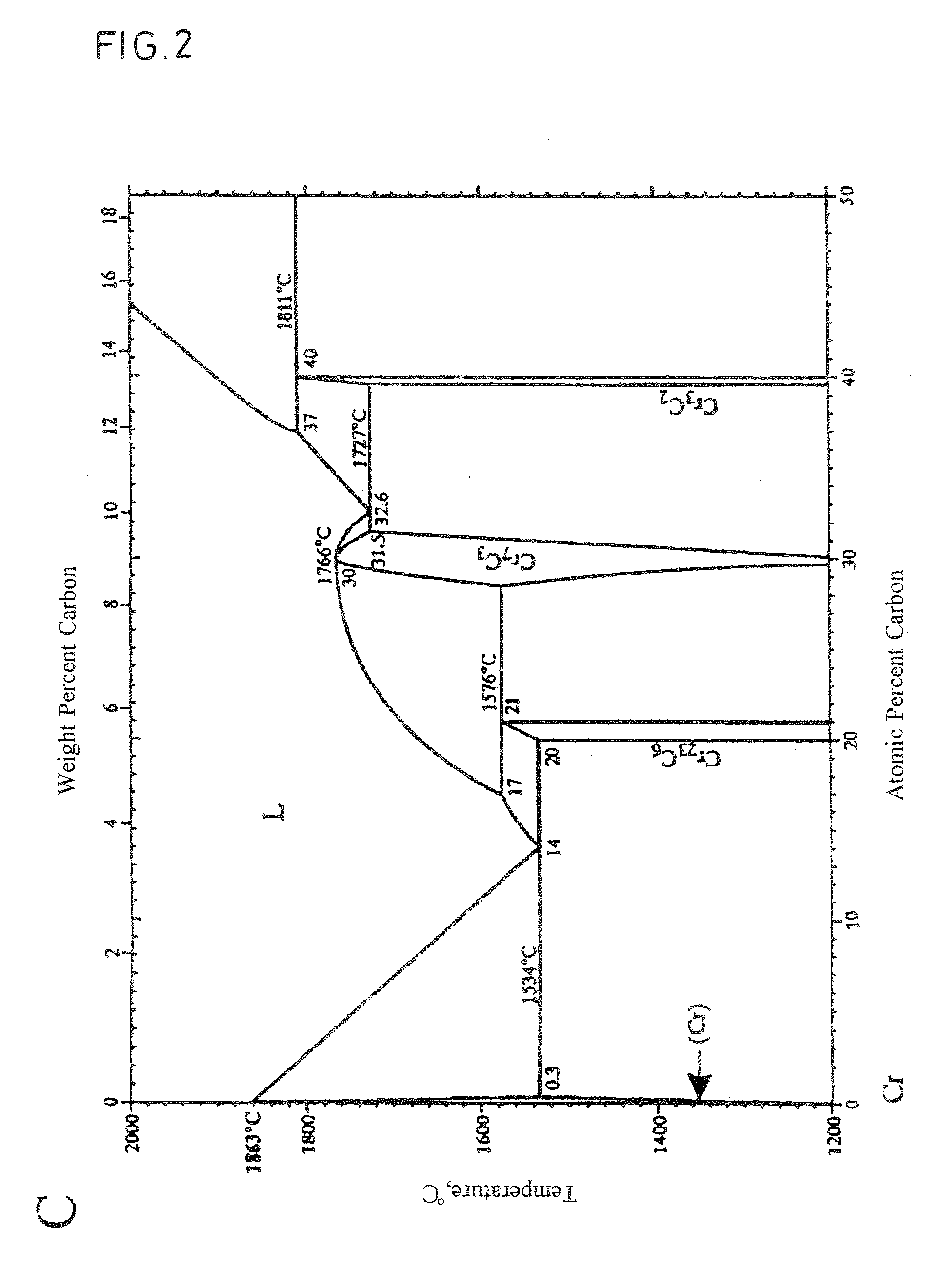

The present invention is to realize fixed points in a temperature region exceeding the melting point of copper, thereby highly accurately calibrating all the thermometers used in a high temperature region such as a radiation thermometer, a thermocouple, and the like. A fixed-point crucible 1 comprises a crucible composed of carbon and a fixed-point material of high melting point enclosed in the wall of the crucible. The fixed-point material is carbon-metal eutectic structure. The crucible 1 is disposed in a temperature-variable furnace 6, the environmental temperature of the crucible 1 is increased and decreased by the temperature-variable furnace 6, the temperature of the cavity in the crucible 1 at the time is measured with a thermometer 9 and the thermometer 9 is calibrated from the state of the temperature variation measured.

Owner:NAT INST OF ADVANCED IND SCI & TECH

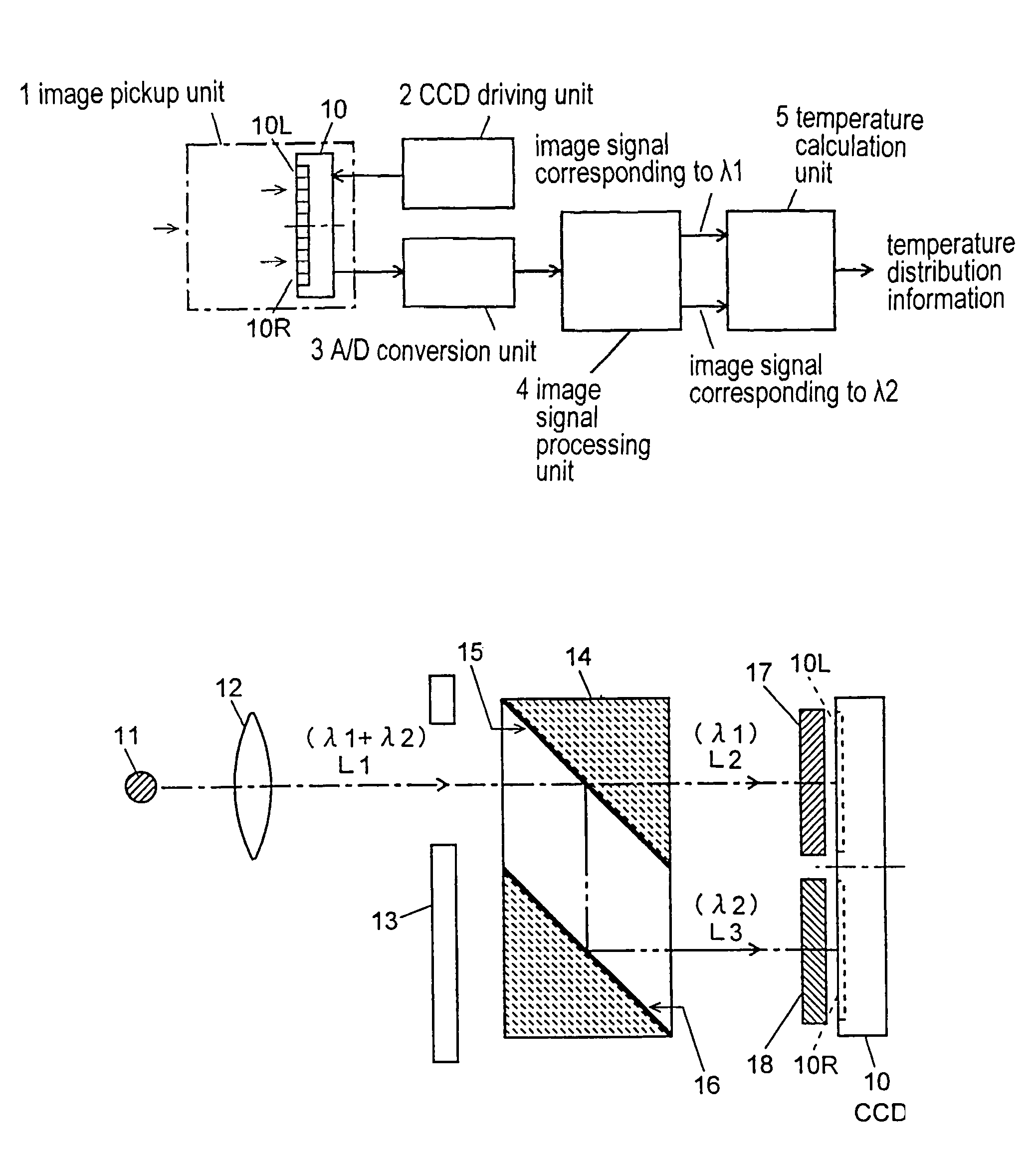

Two-color radiation thermometer

InactiveUS7114846B2Reducing size of costSmall device sizeThermometer detailsPhotometryObject basedRadiation thermometer

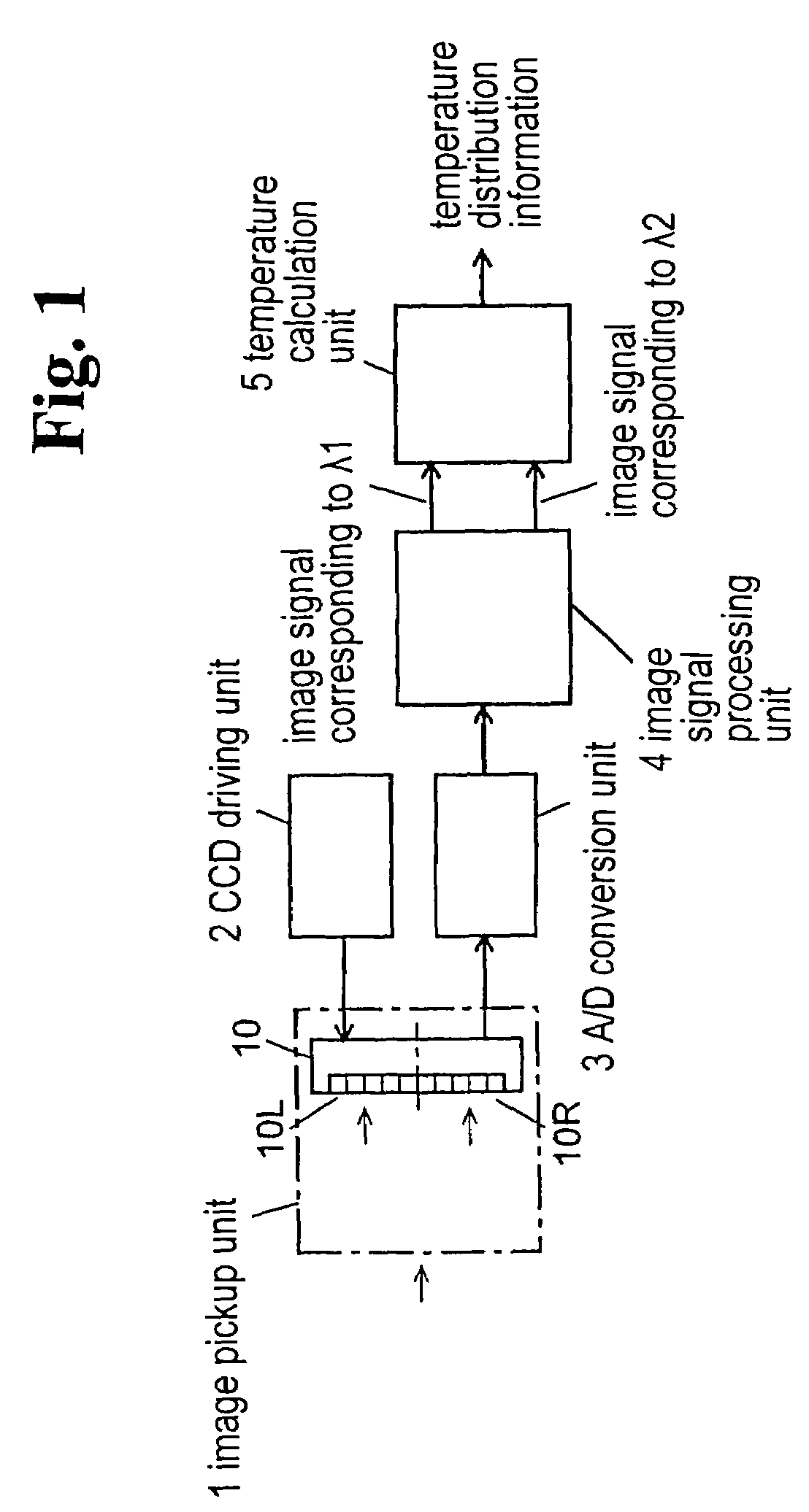

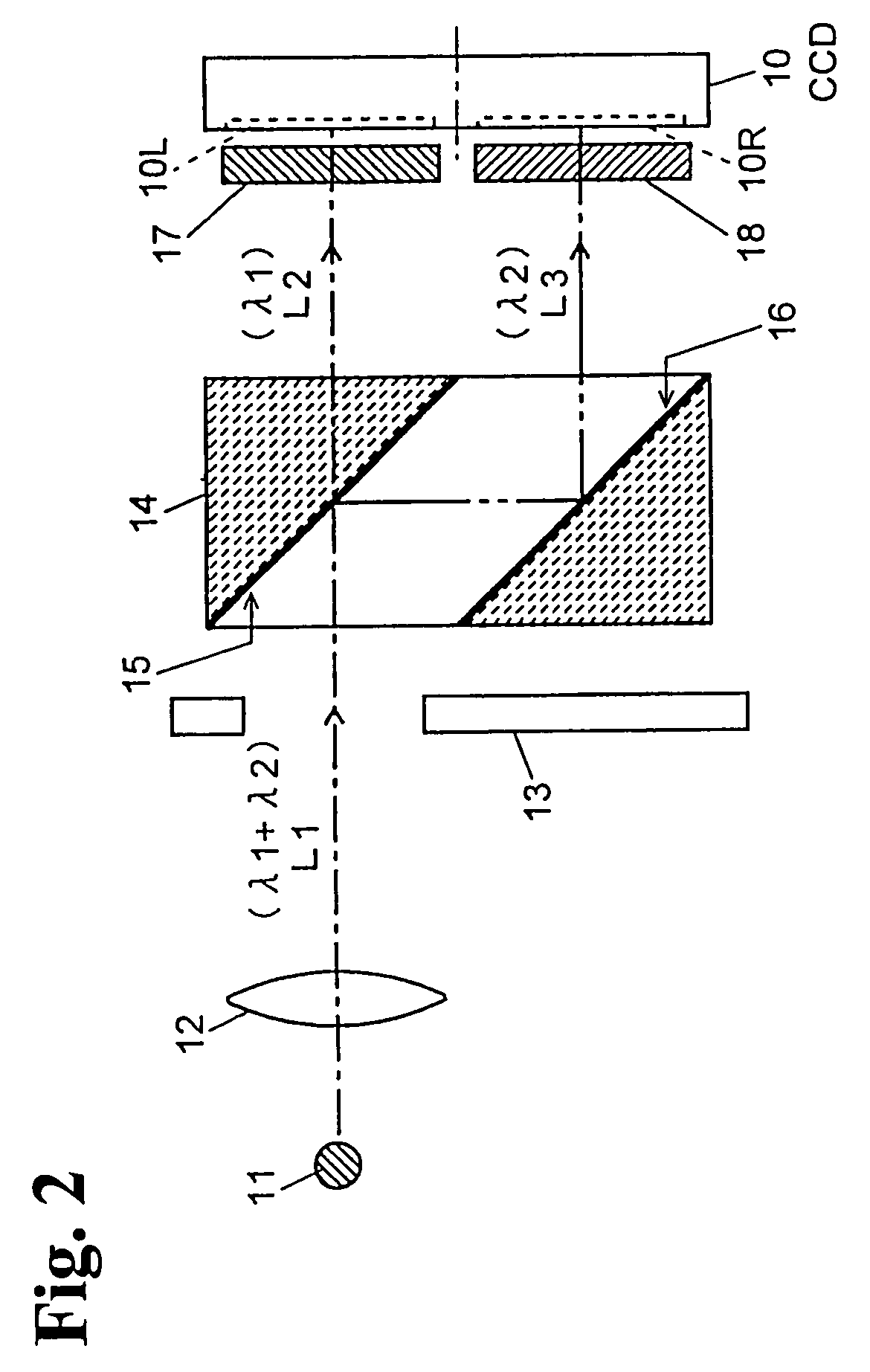

A two-color radiation thermometer includes an image pickup device having micro photo receiving units arranged two-dimensionally; a light diverging device for diverging incident light coming from a measuring object into two paths and irradiating the light on two different areas on a two-dimensional light receiving surface of the image pickup device; a wavelength limitation device for limiting wavelengths of the light irradiated on the two different areas to first and second wavelengths, respectively; and a temperature calculation device. The calculation device receives image signals corresponding to the first and second wavelengths respectively from the micro photo receiving units located at the two different areas, and calculates the temperature of the measuring object based on the two image signals.

Owner:SHIMADZU CORP

Method for measuring emissivity of infrared temperature measurement target body

ActiveCN102519606ALow costEasy to measurePyrometry using electric radation detectorsEmissivityRadiation thermometer

The invention relates to a method for measuring the emissivity of an infrared temperature measurement target body, which includes the following steps: (1), selecting an infrared radiation thermometer; (2) selecting a high-temperature tubular furnace; (3), selecting a temperature measurement standard equipment; (4), extracting and fabricating a sample of the object to be measured; (5), putting the sample of the object to be measured in the high-temperature tubular furnace; (6), keeping the infrared radiation thermometer coaxial with the sample of the object to be measured; (7), adjusting the distance for temperature measurement of the infrared radiation thermometer; (8), arranging a visor provided with an open pore between the sample of the object to be measured and the infrared radiation thermometer; (9), aiming a visual optical aiming system on the infrared radiation thermometer at the sample of the object to be measured; (10), heating the high-temperature tubular furnace and recording the standard temperature T; (12), adjusting the emissivity or gradient value of the infrared radiation thermometer and recording the emissivity or gradient value displayed after being adjusted; and (13), taking the data processing manner of 'equal precision and multiple measurements' to obtain a data set of the partial emissivities of the sample of the object to be measured within a certain temperature range. The method is simple, low in cost and easy to realize.

Owner:JIUQUAN IRON & STEEL GRP

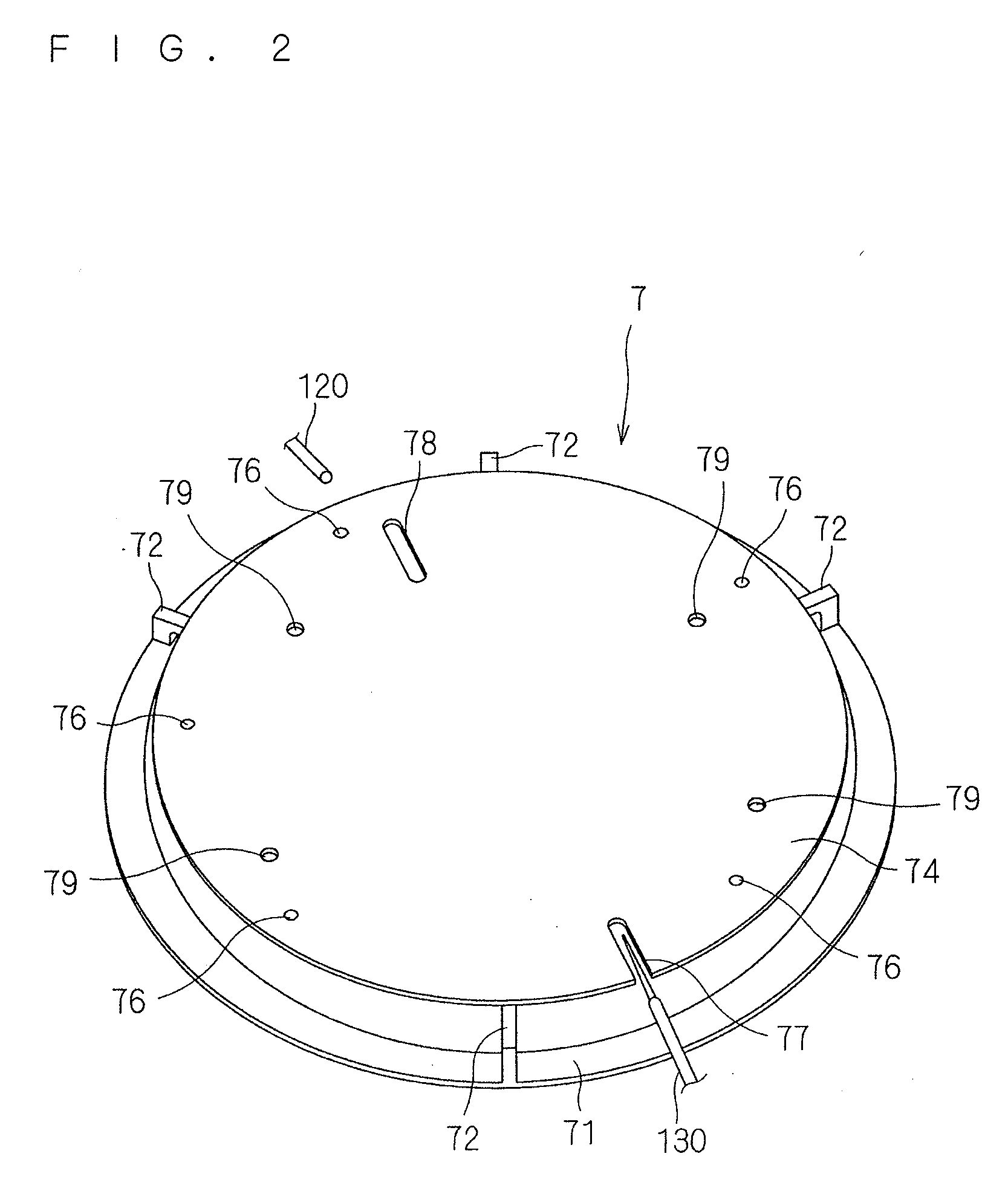

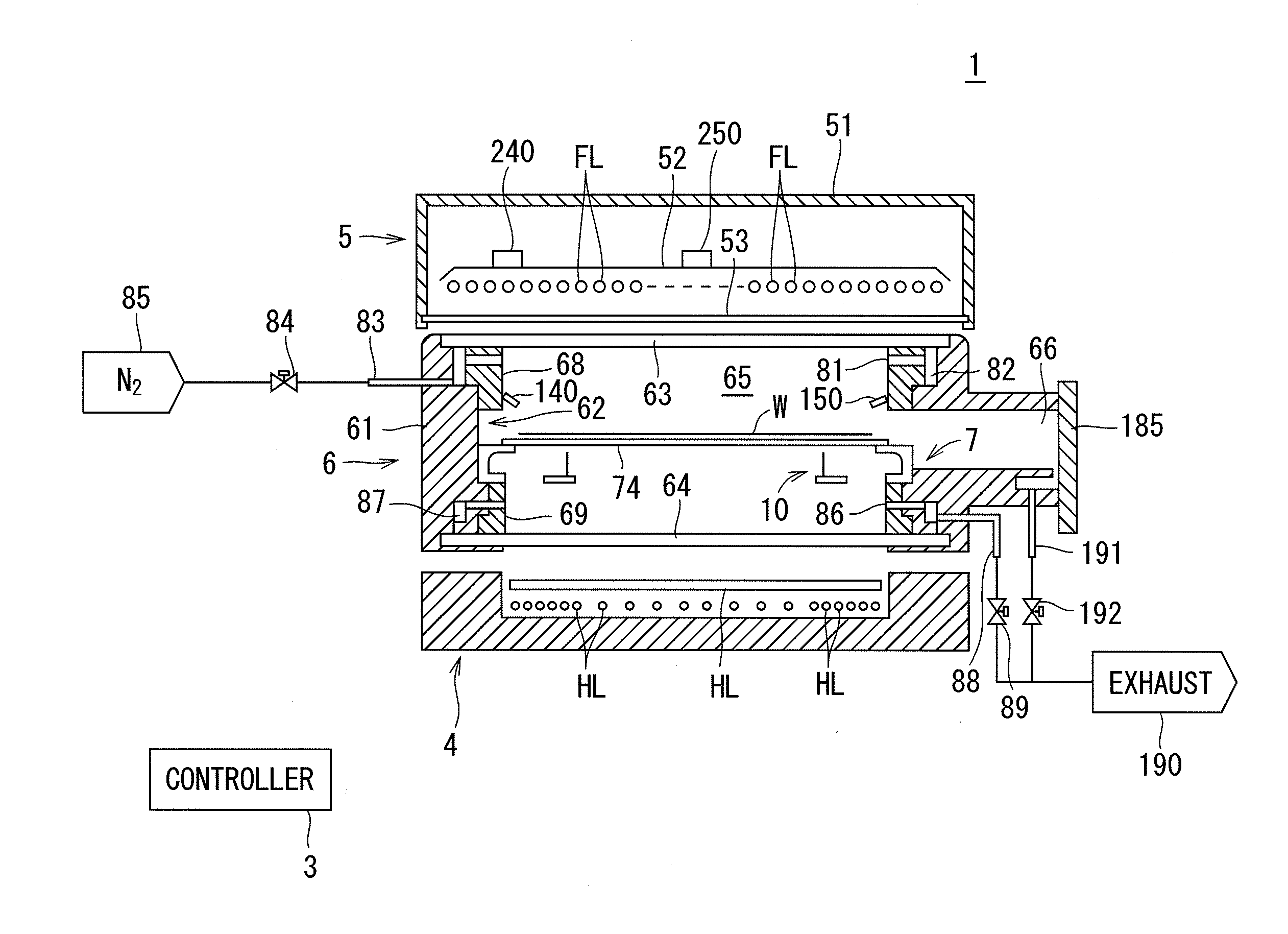

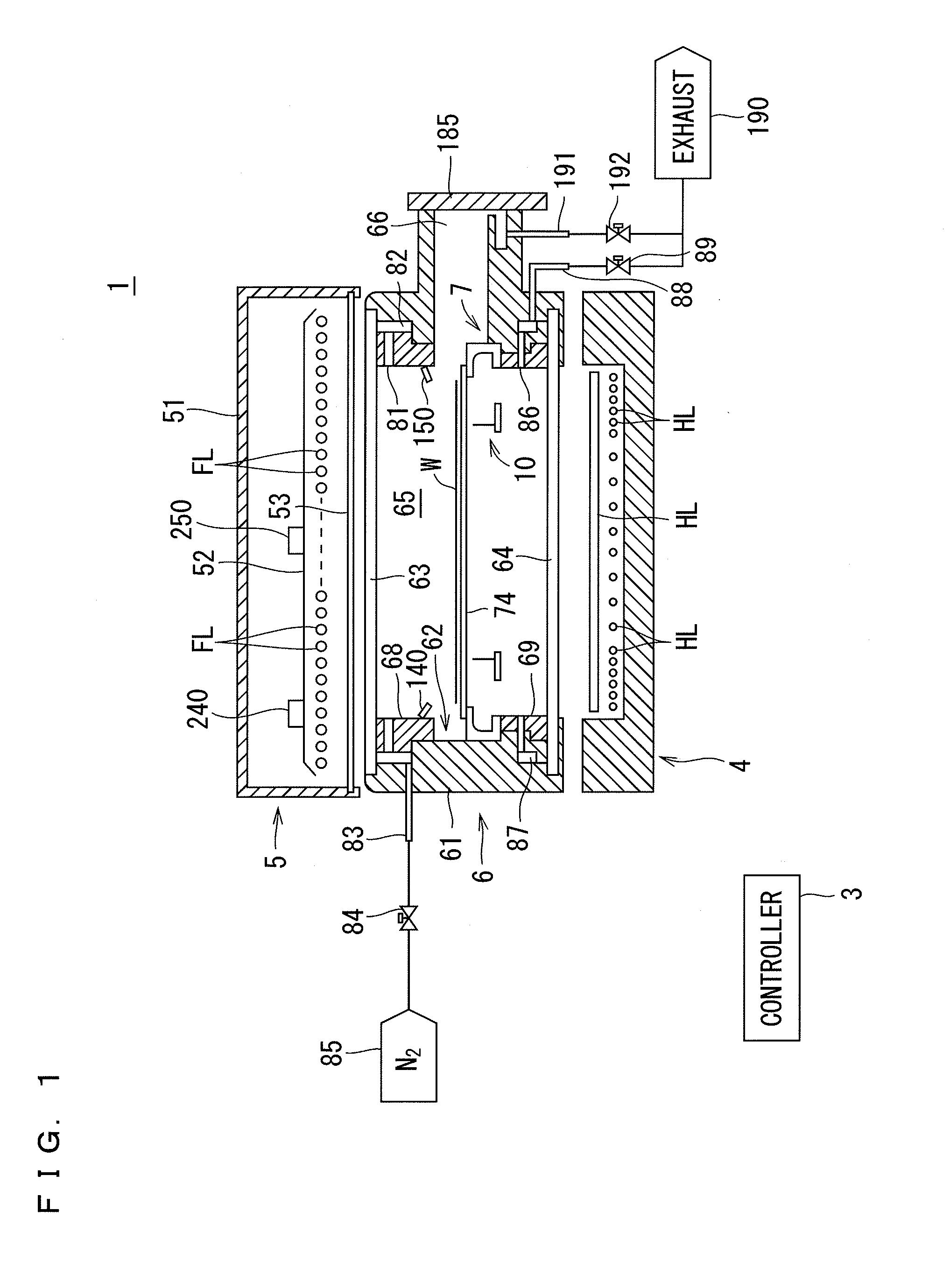

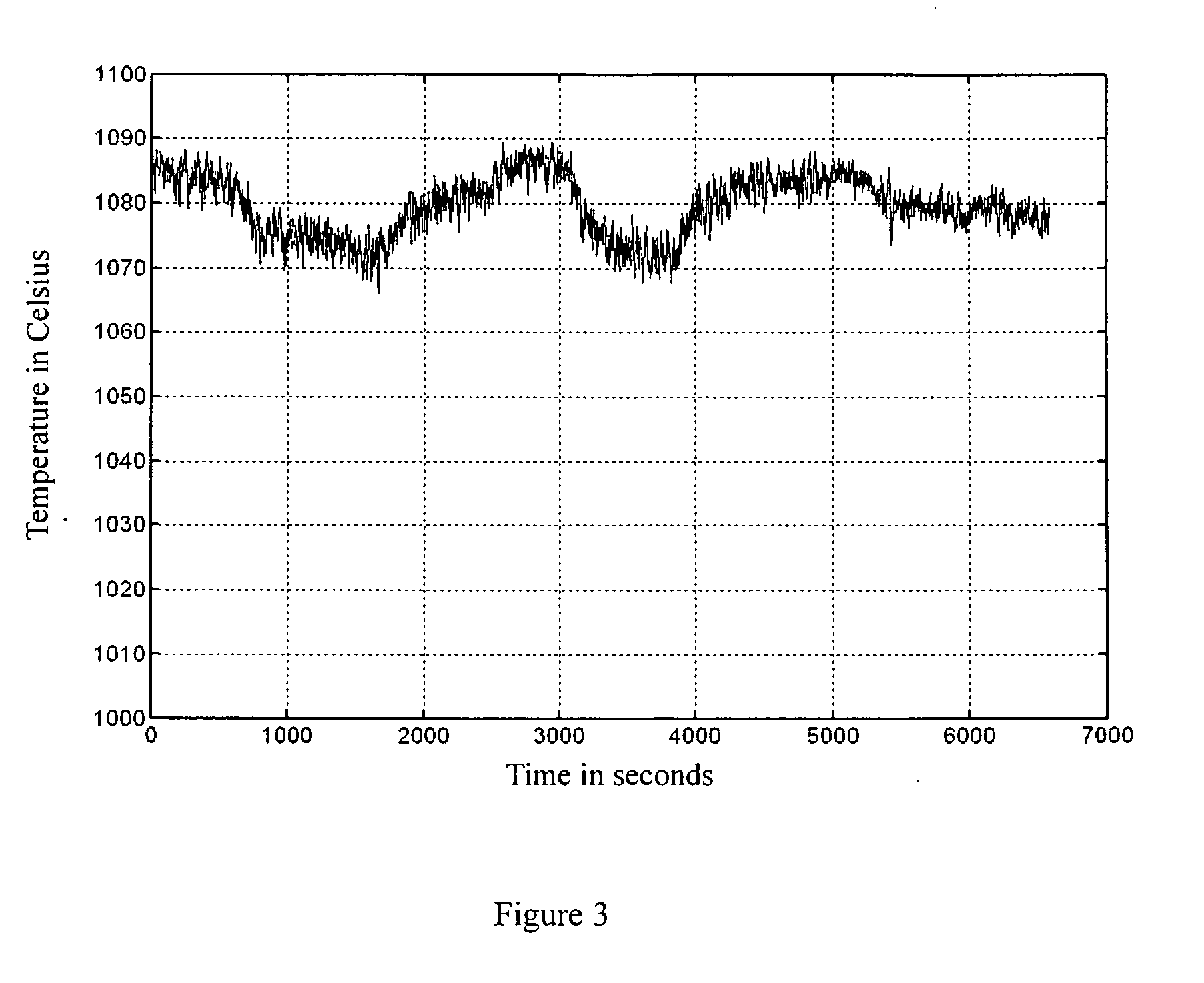

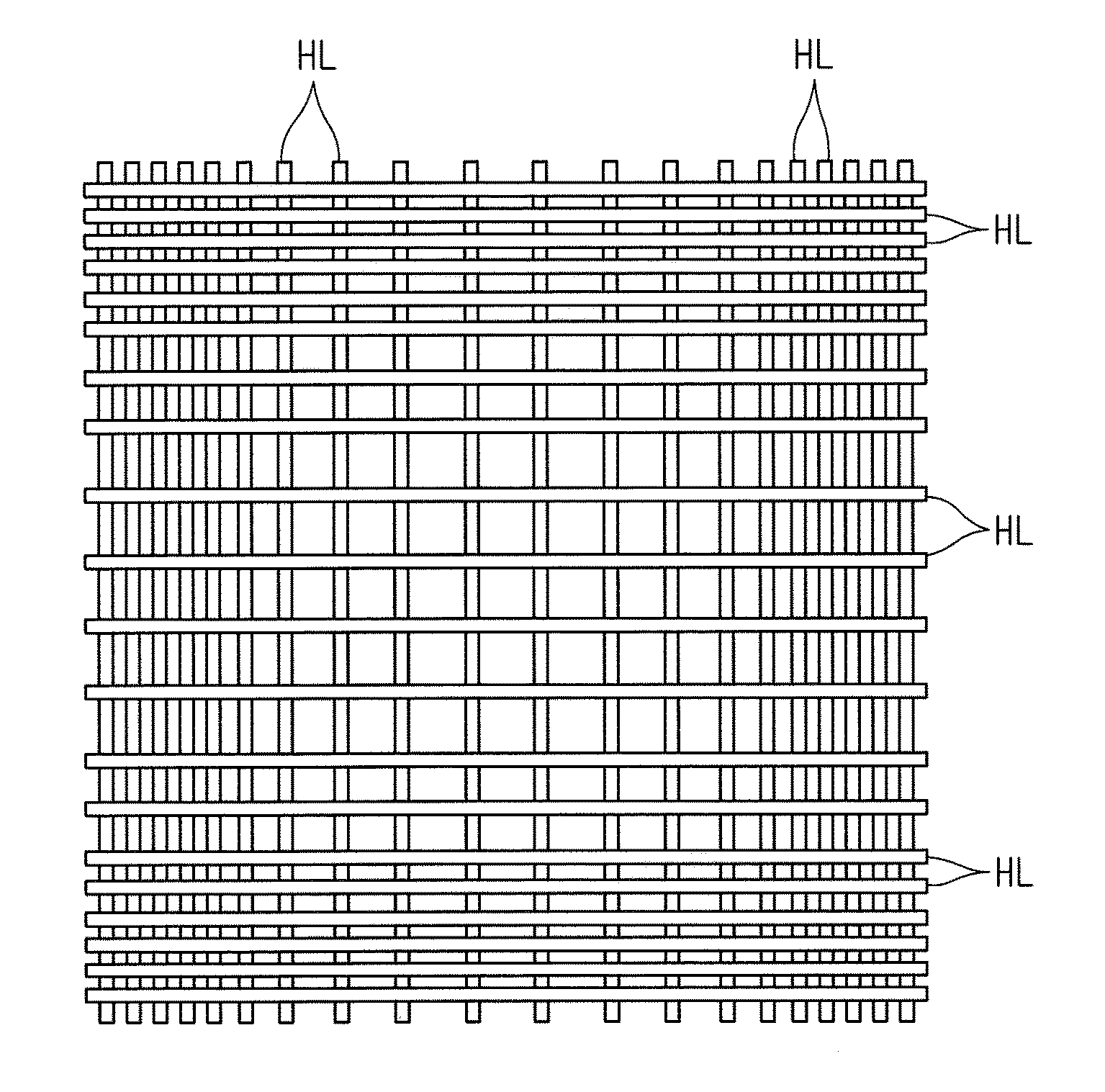

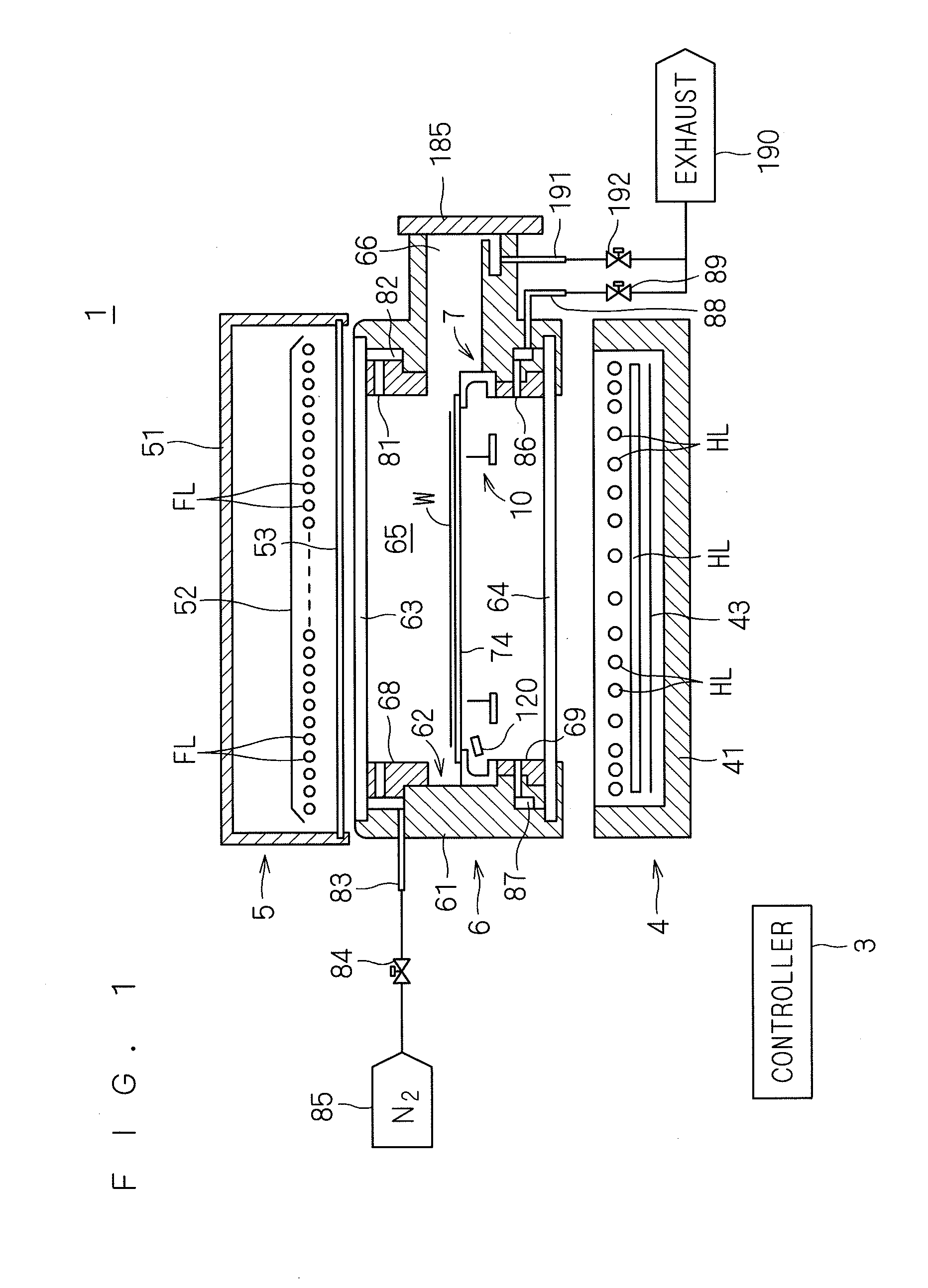

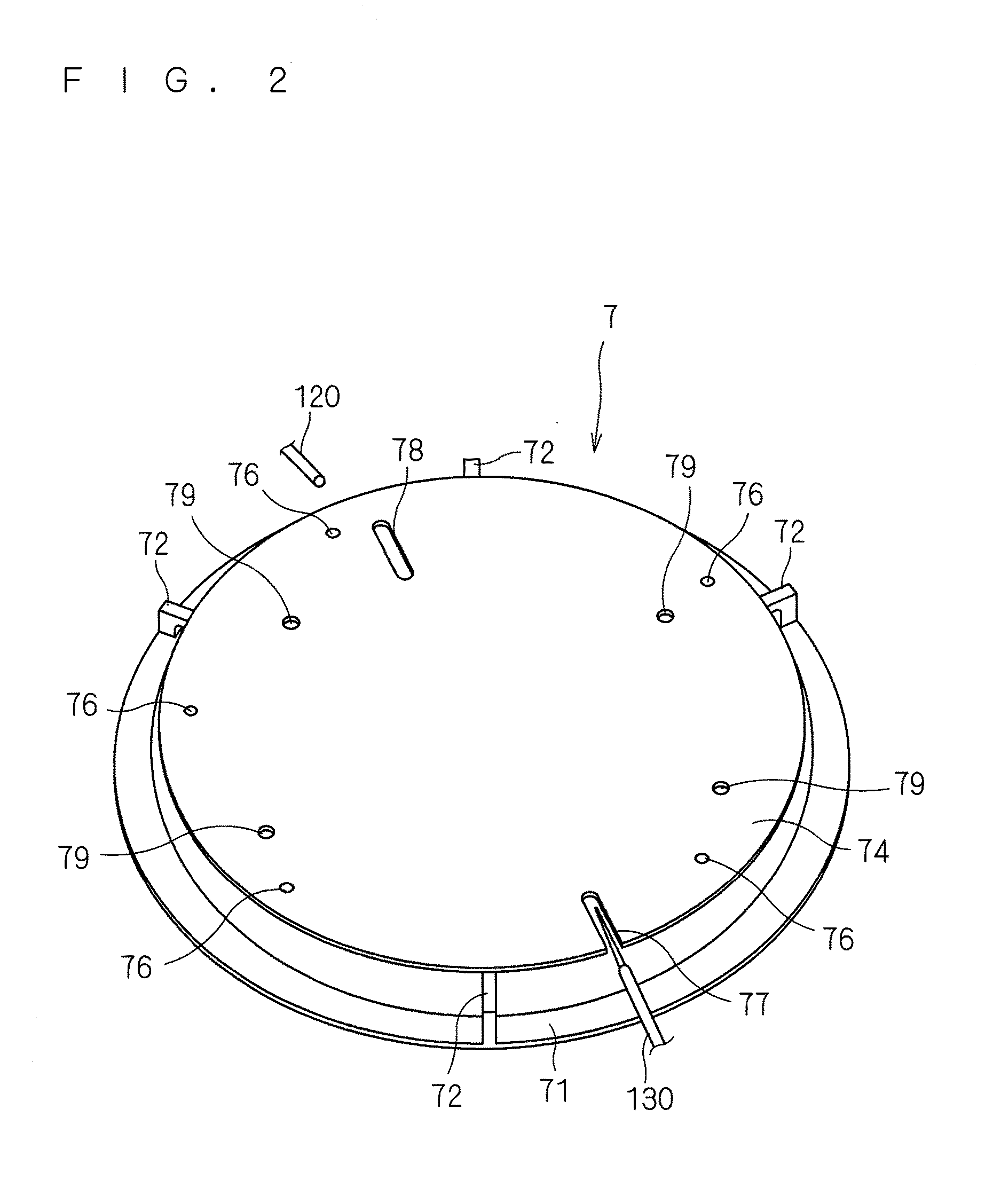

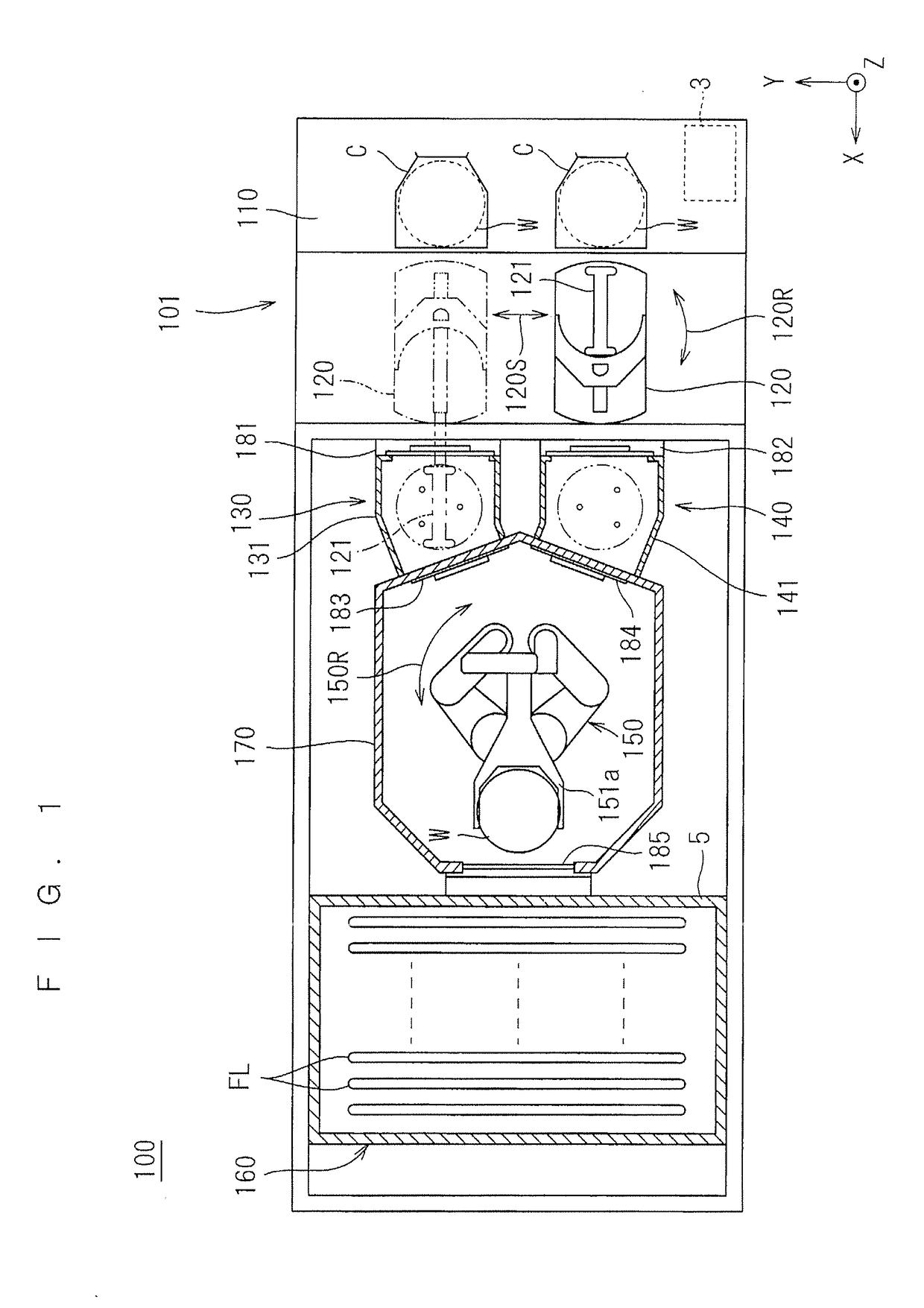

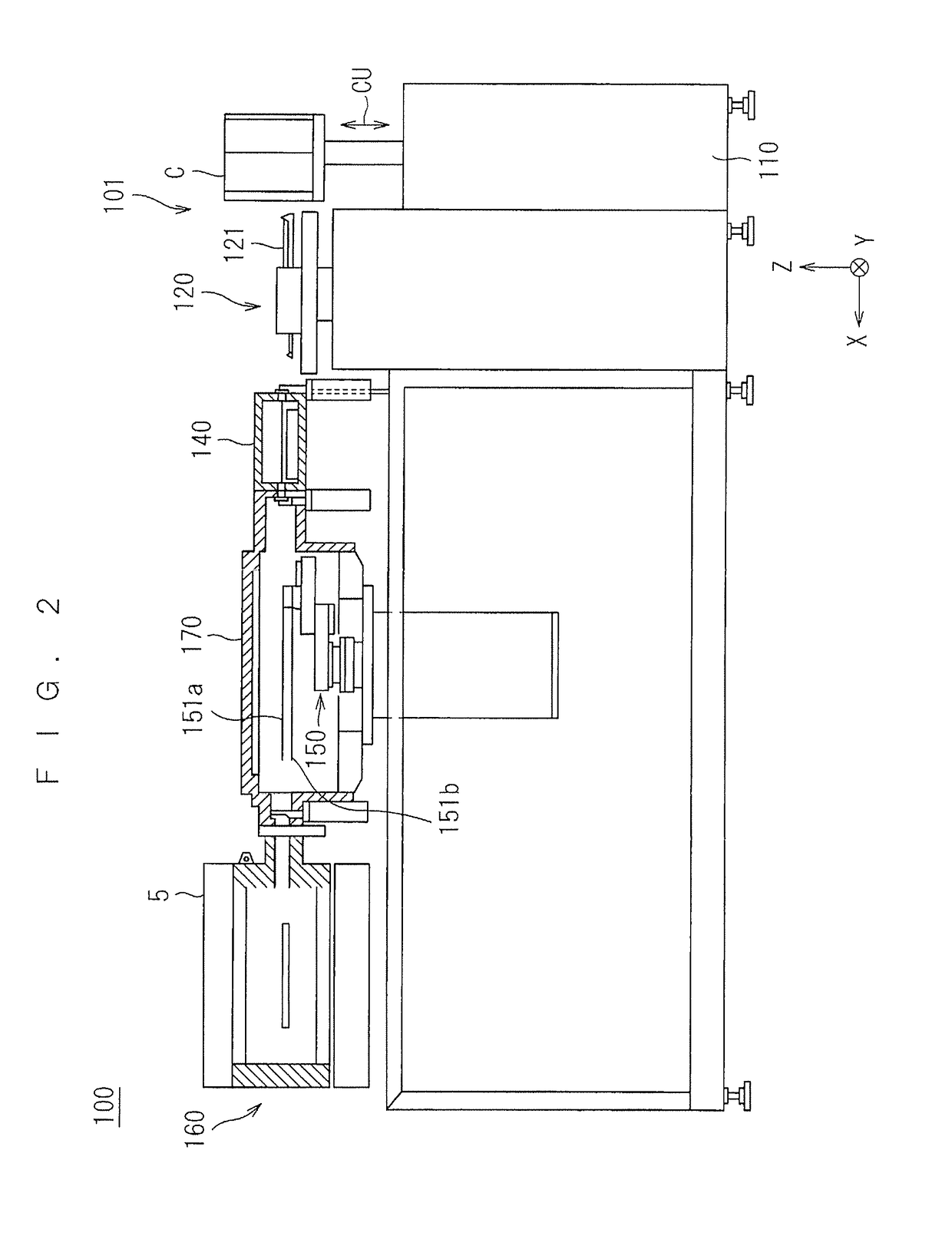

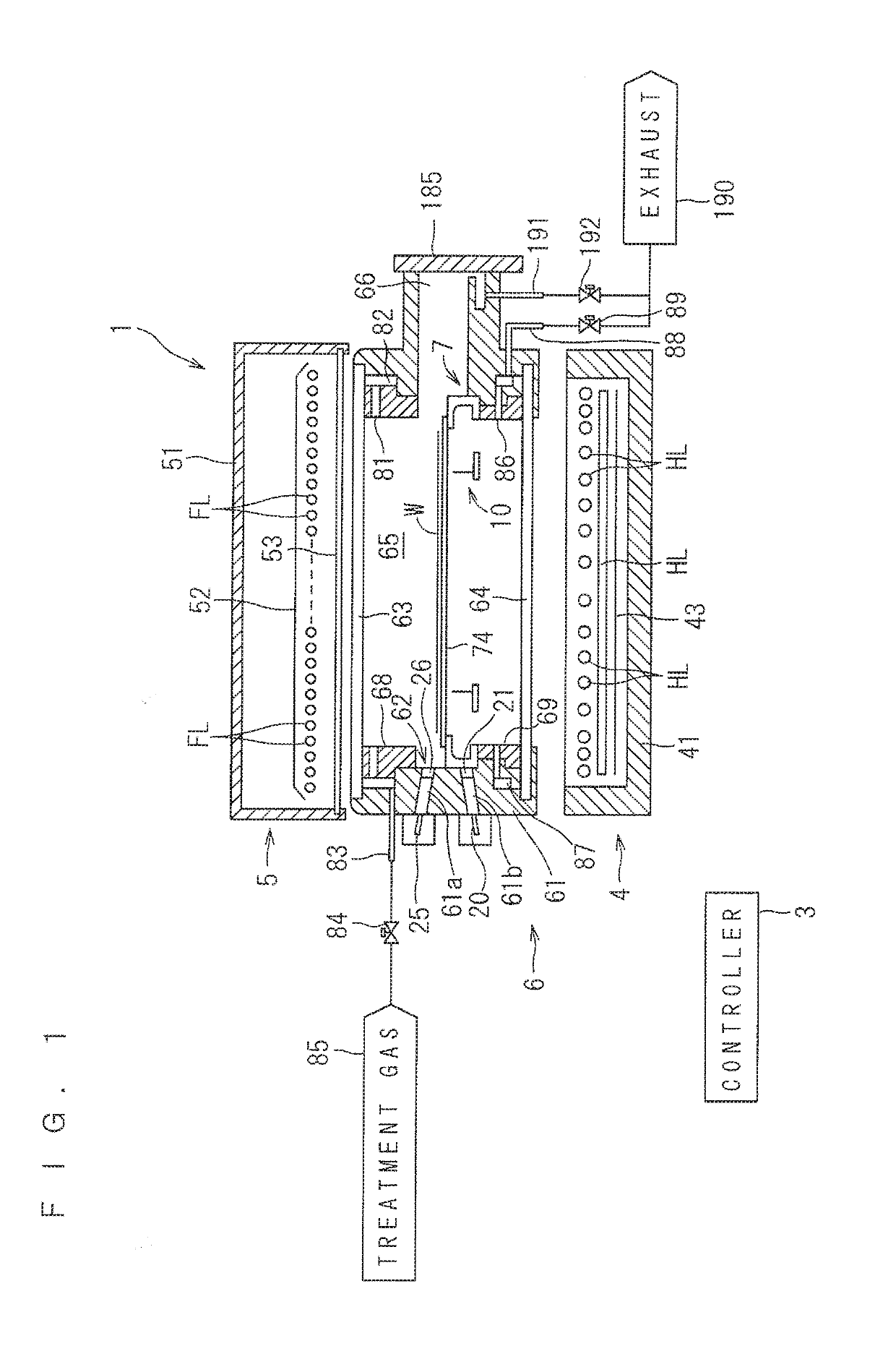

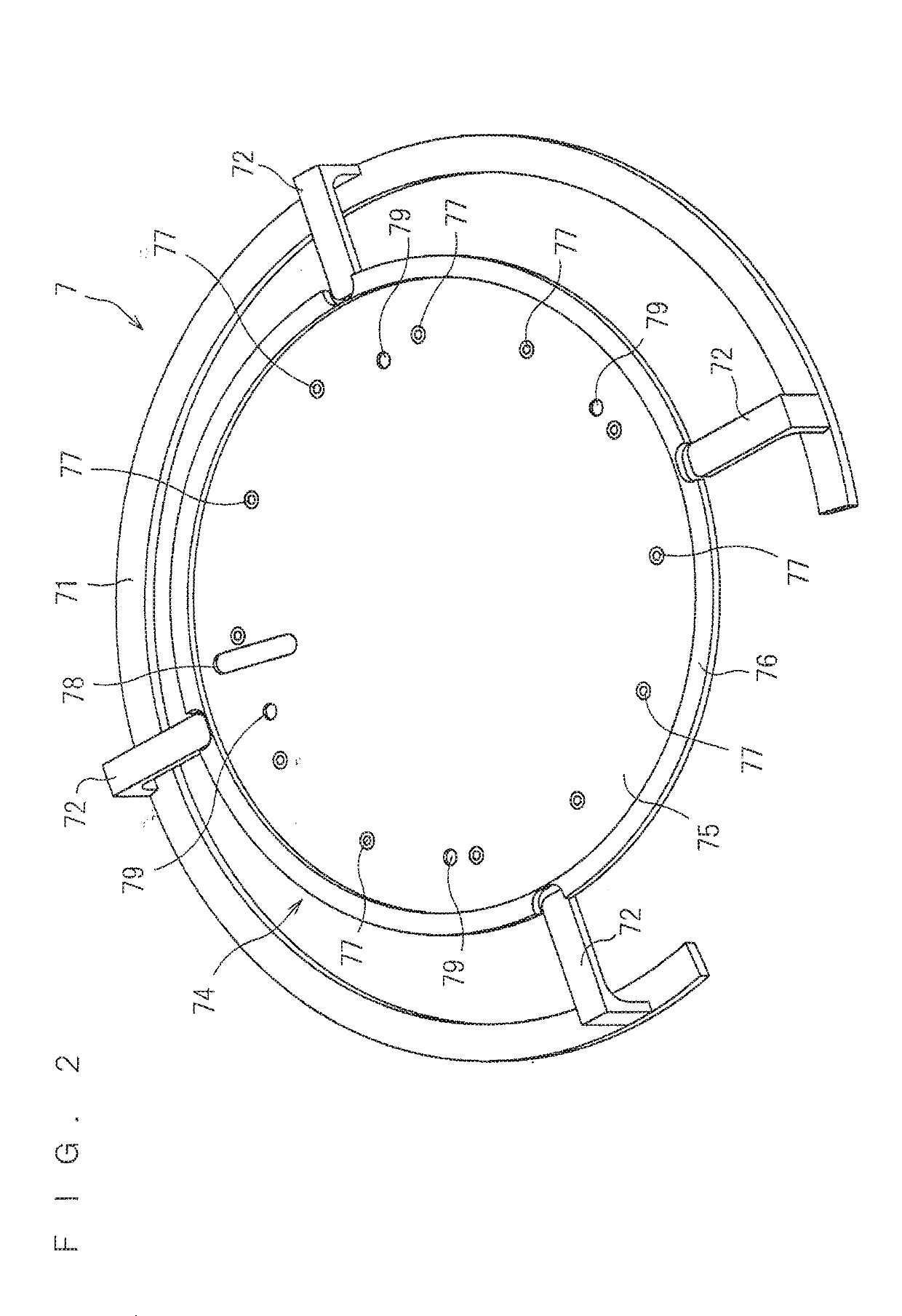

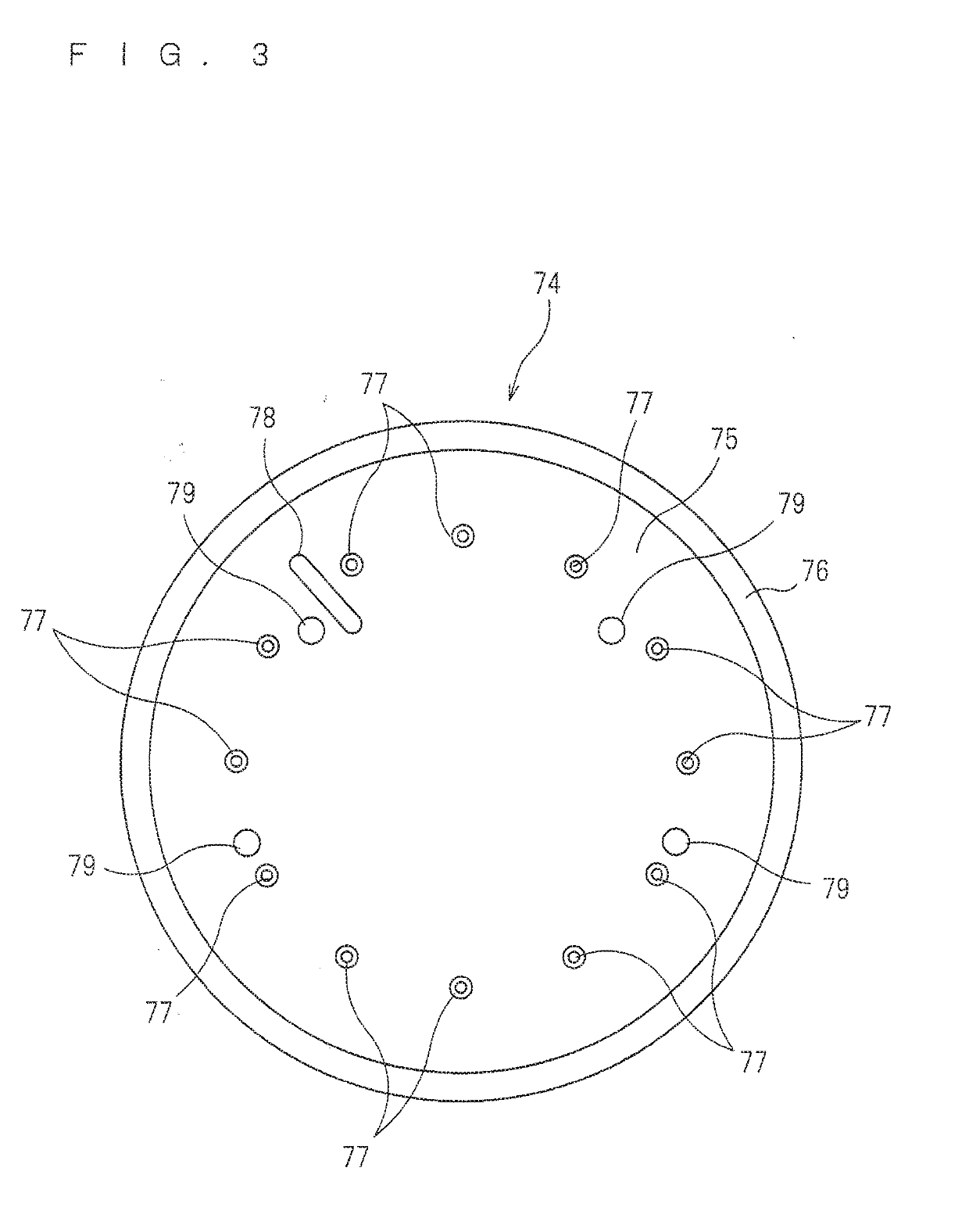

Heat treatment apparatus and heat treatment method for heating substrate by irradiating substrate with flash of light

ActiveUS20140206108A1Uniform temperature distributionDrying solid materials with heatSemiconductor/solid-state device testing/measurementIn planeRadiation thermometer

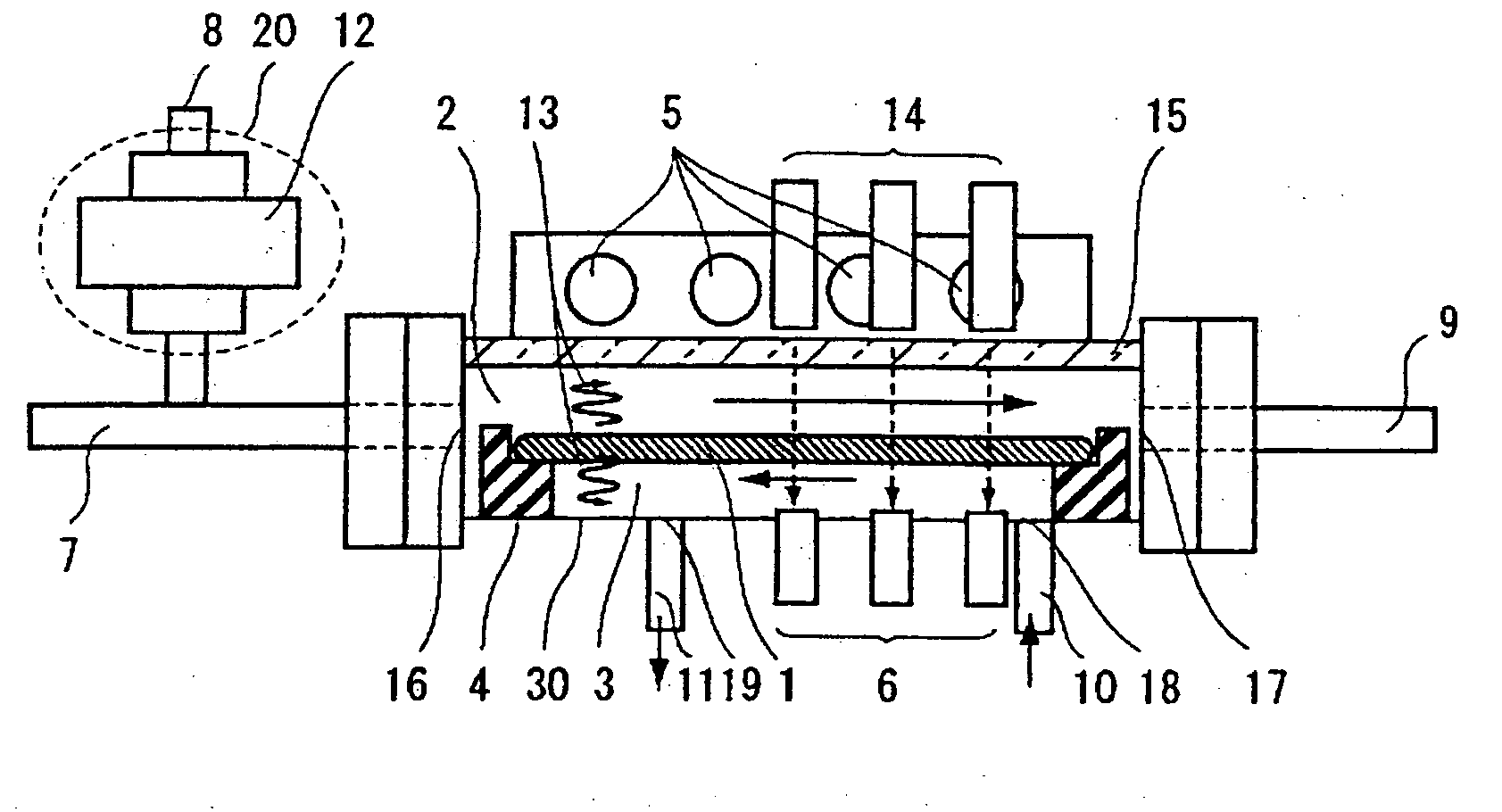

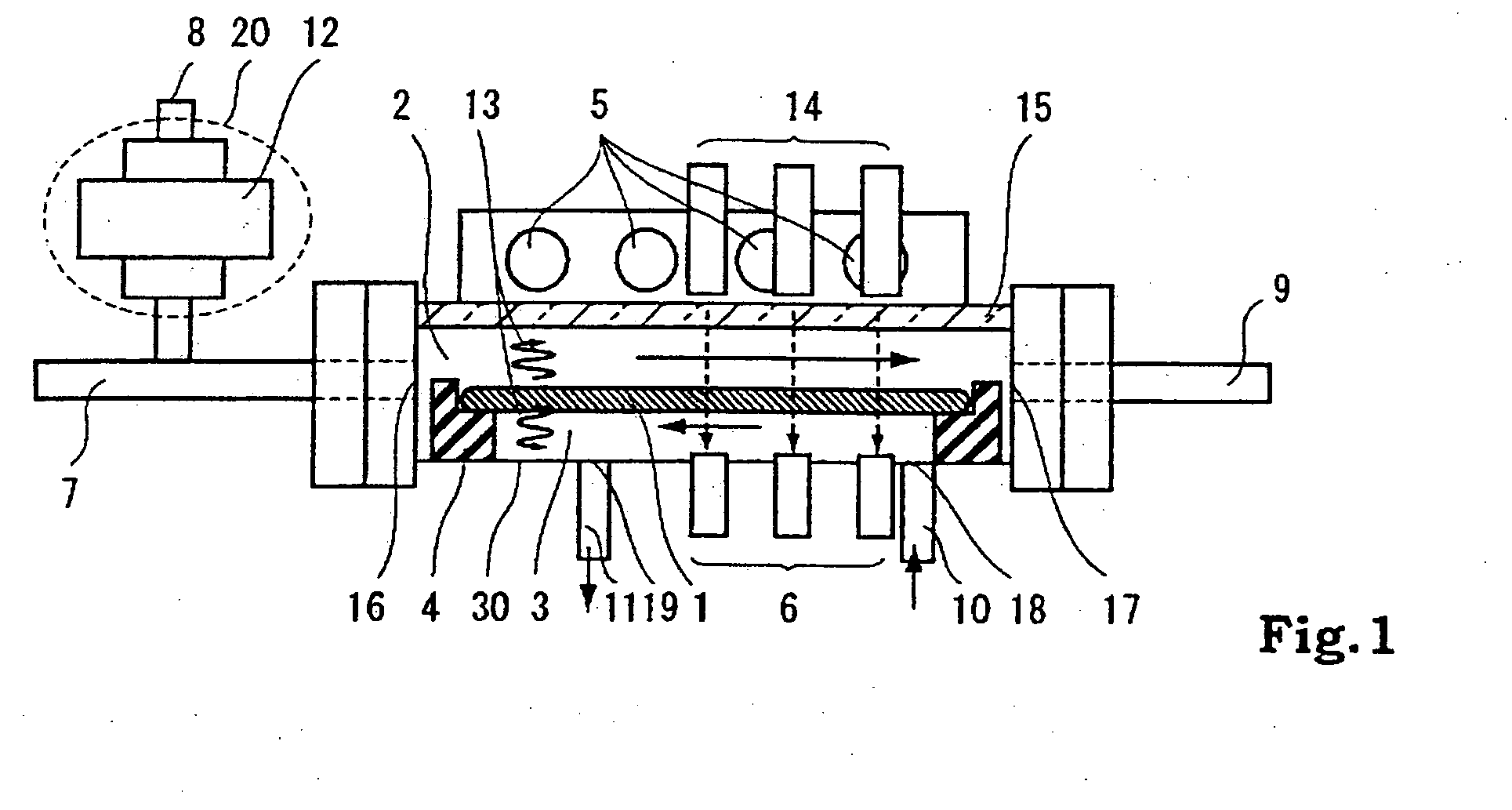

A flash heating part in a heat treatment apparatus includes 30 built-in flash lamps, and irradiates a semiconductor wafer held by a holder in a chamber with a flash of light. Thirty switching elements are provided in a one-to-one correspondence with the 30 flash lamps. Each of the switching elements defines the waveform of current flowing through a corresponding one of the flash lamps by intermittently supplying electrical charge thereto. Radiation thermometers measure an in-plane temperature distribution of the semiconductor wafer during flash irradiation. Based on the results of measurement with the radiation thermometers, a controller individually controls the operations of the 30 switching elements to individually define the light emission patterns of the 30 flash lamps.

Owner:DAINIPPON SCREEN MTG CO LTD

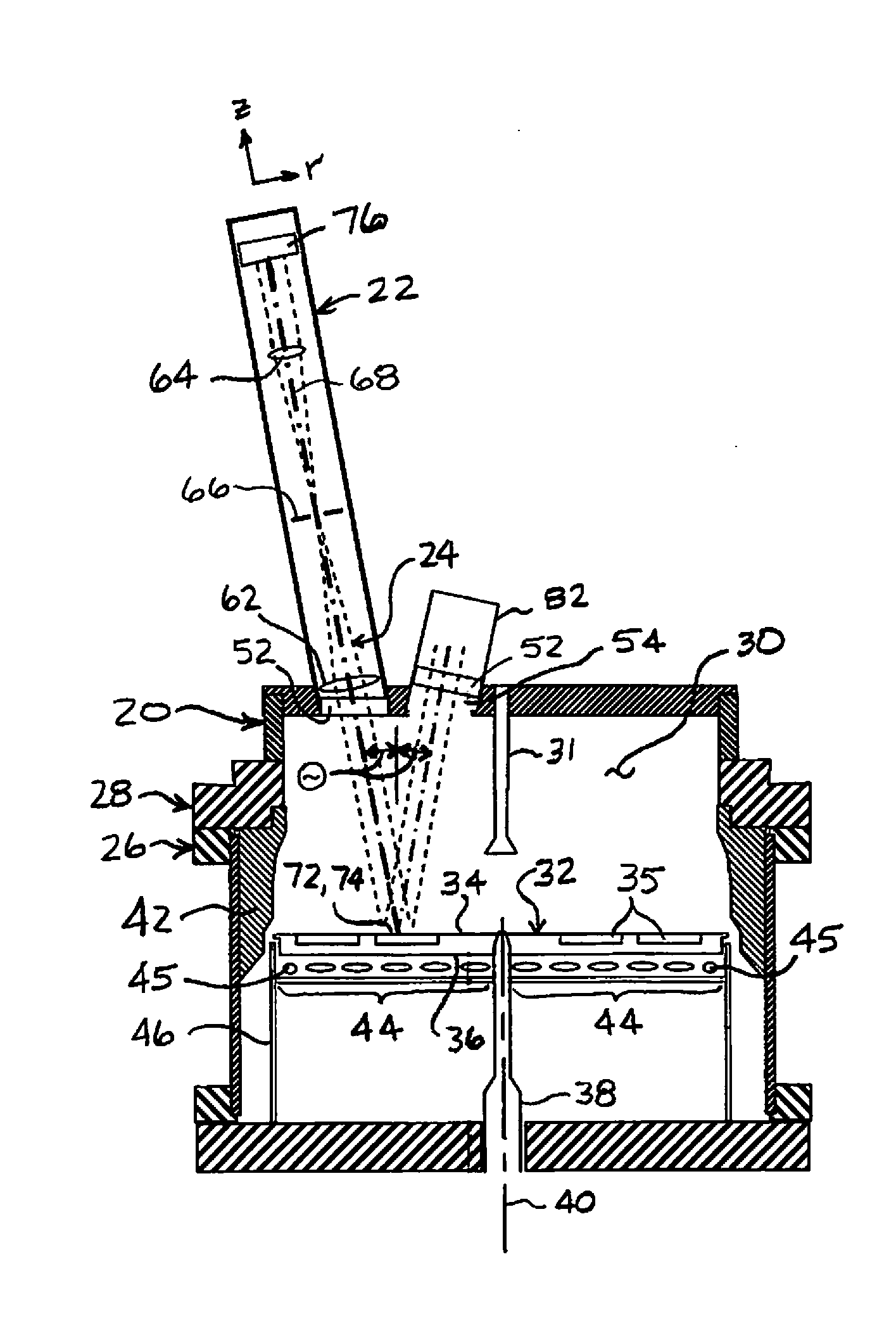

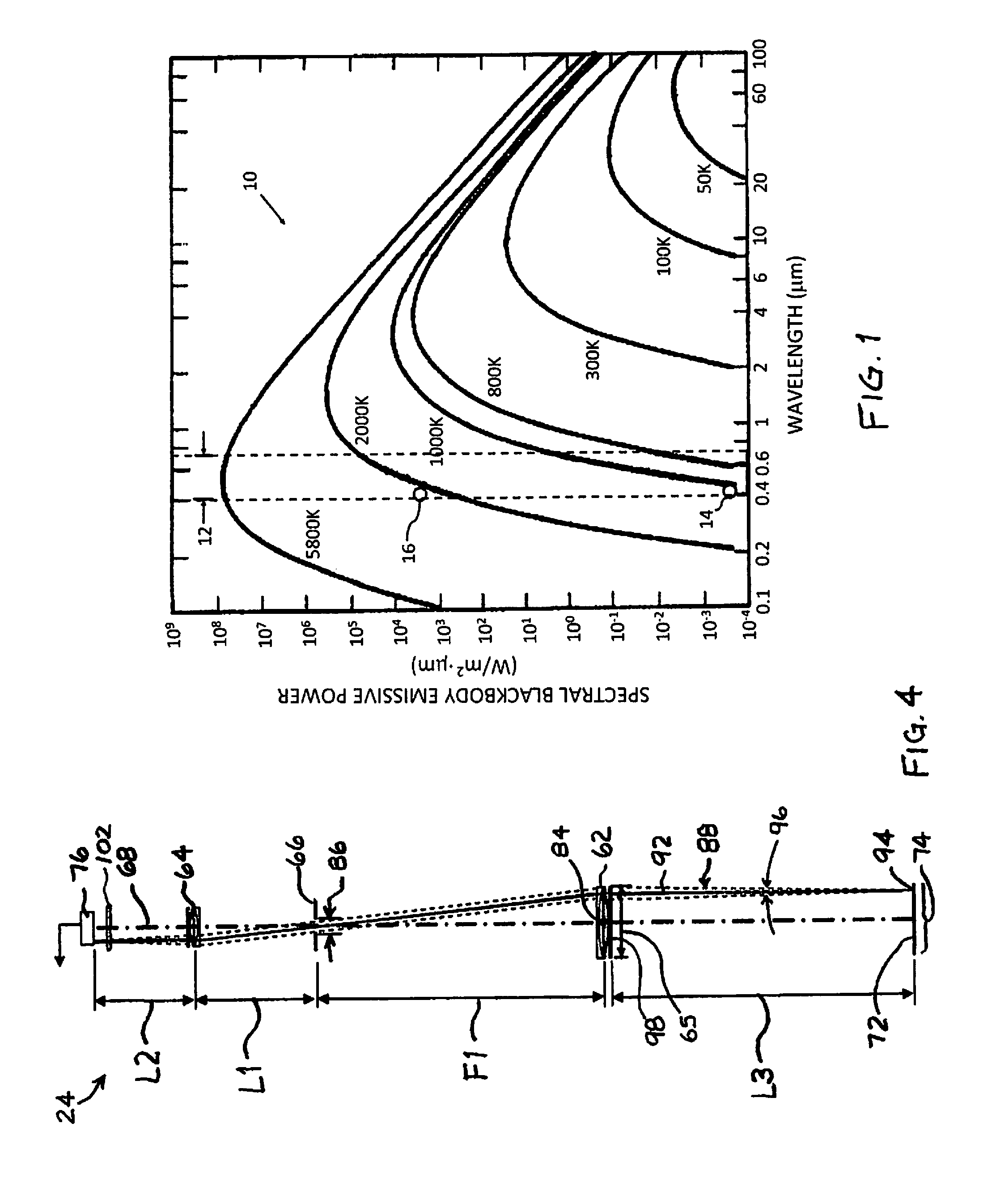

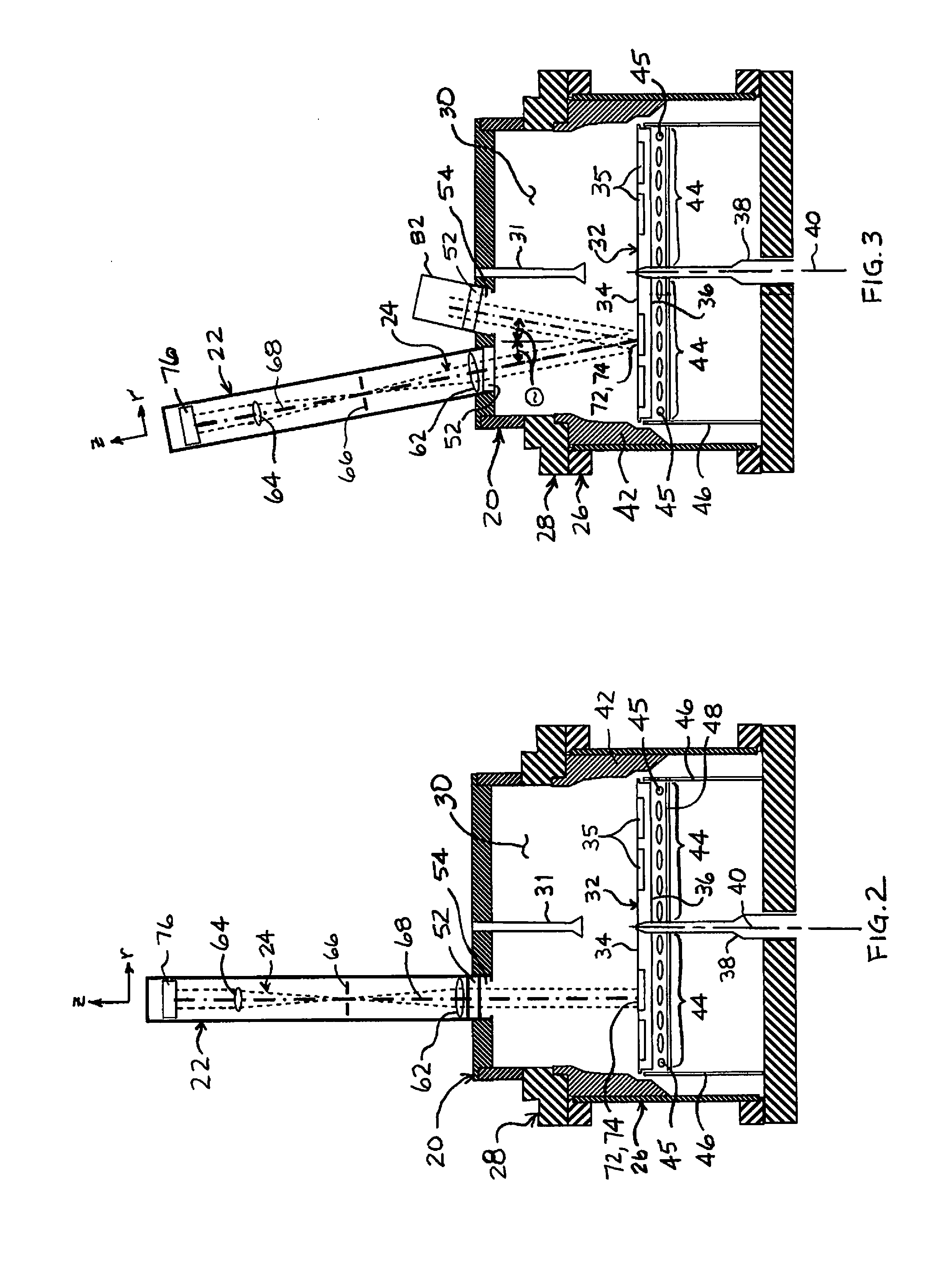

Radiation thermometer using off-focus telecentric optics

ActiveUS20130343425A1Increased rejectUniform magnificationRadiation pyrometryChemical vapor deposition coatingRadiation thermometerOptical axis

A radiation thermometer utilizing an off-focus telecentric lens arrangement in chemical vapor deposition reactors. An object assembly of one or more optical components is positioned at a distance equal to its focal length from an aperture stop. The aperture stop is dimensioned so that the chief rays are substantially parallel with the optical axis of the object assembly, and so that the rays that pass through the aperture stop define a narrow solid angle about the chief rays. The off-focus telecentric arrangement thus configured is focused at infinity, but is utilized to capture radiation from a relatively proximate target (e.g., within a couple meters) that is out of focus. The capture of collimated radiation from the target diminishes the contribution of stray radiation, particularly with targets having a highly specular surface.

Owner:VEECO INSTR

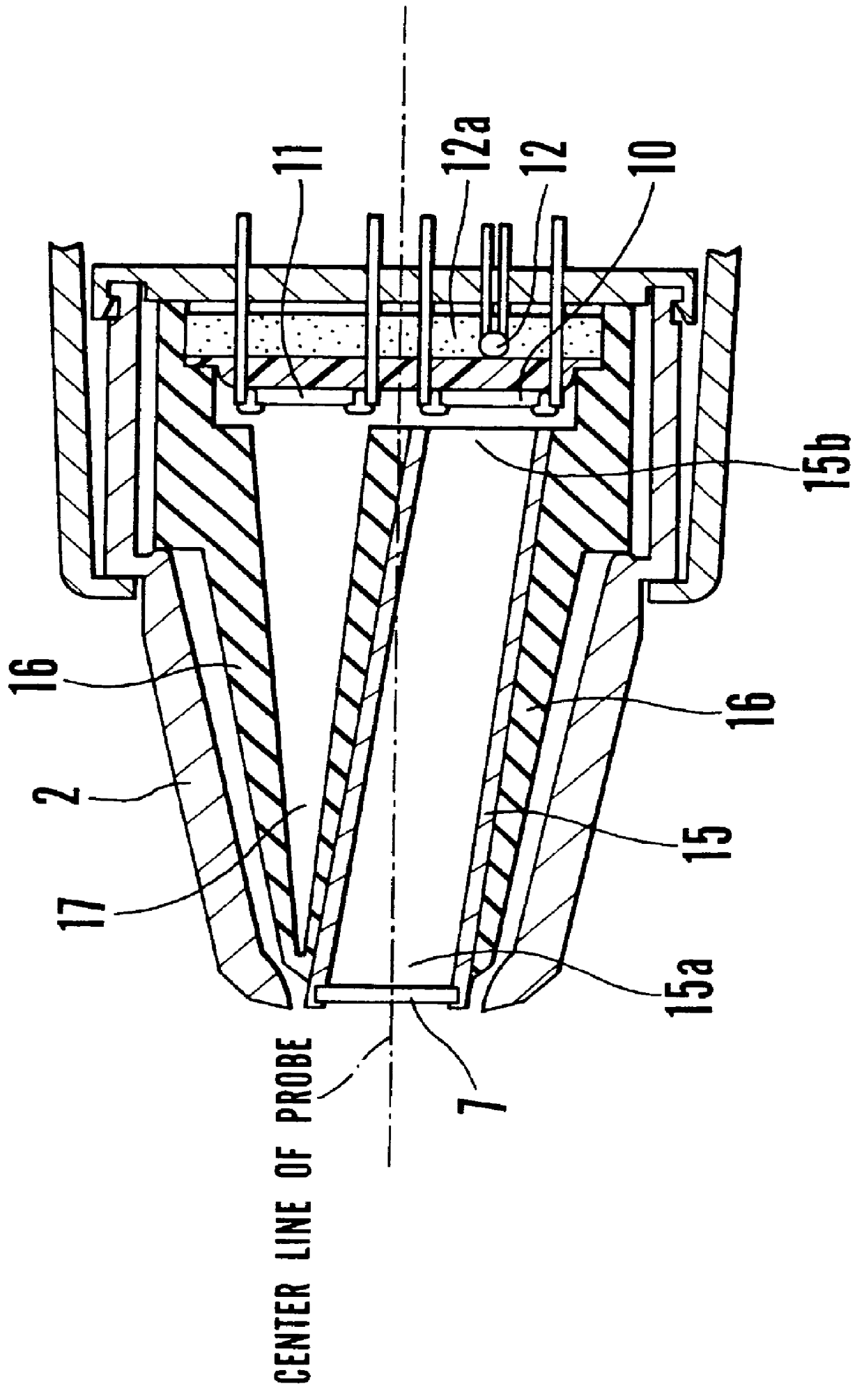

Radiation thermometer

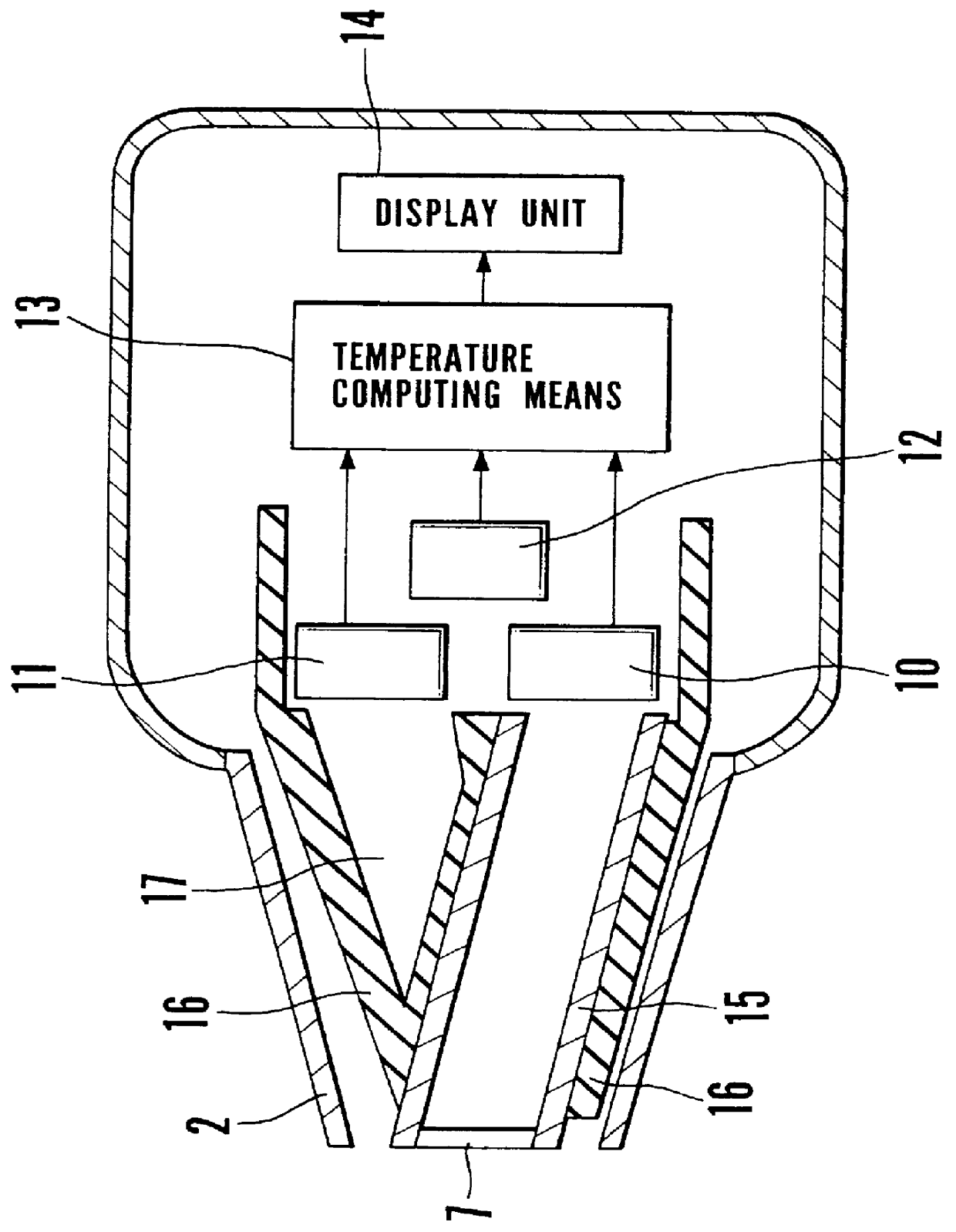

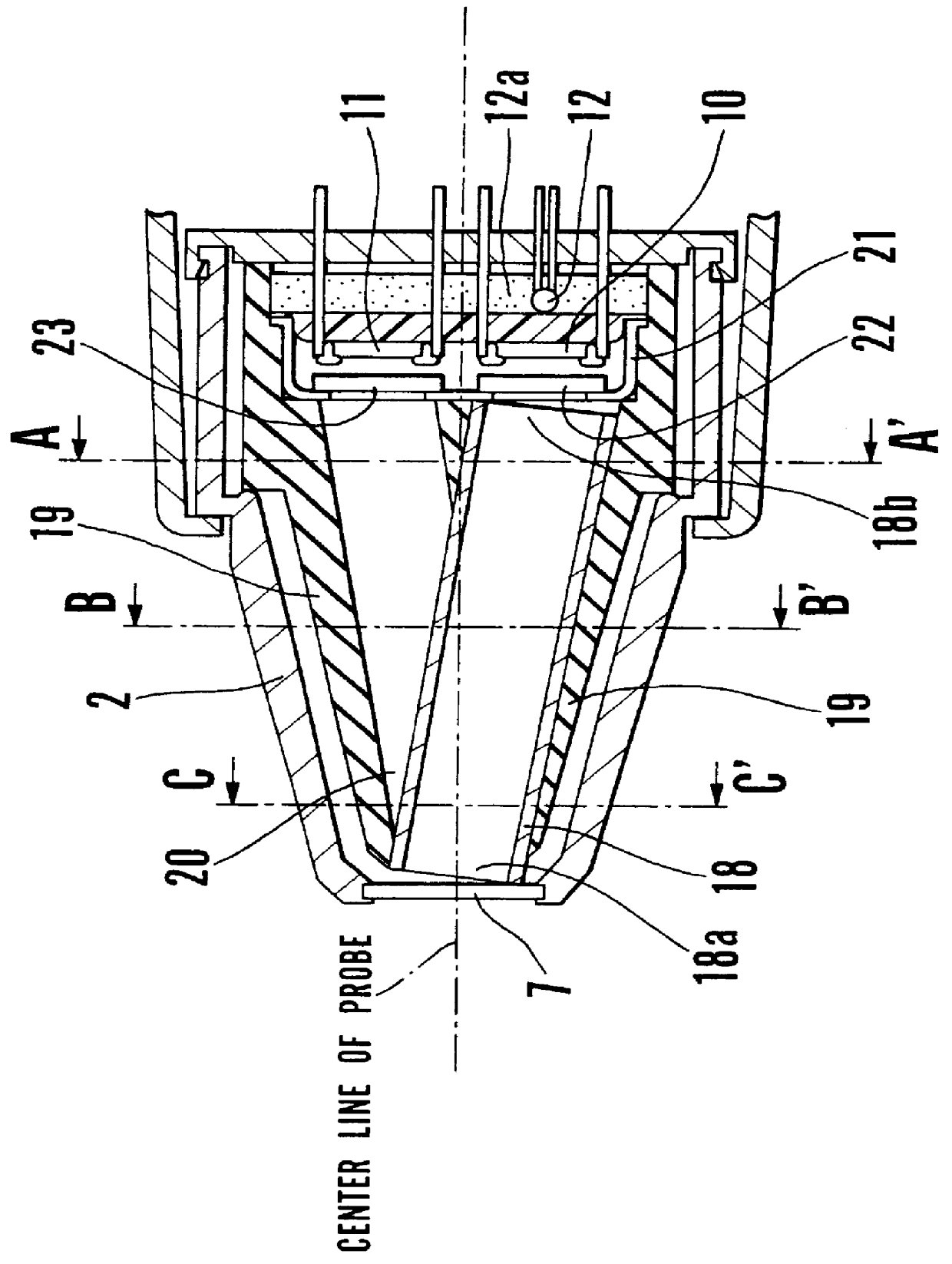

PCT No. PCT / JP97 / 03977 Sec. 371 Date Jul. 10, 1998 Sec. 102(e) Date Jul. 10, 1998 PCT Filed Oct. 31, 1997 PCT Pub. No. WO98 / 20790 PCT Pub. Date May 22, 1998The radiation clinical thermometer of the present invention is provided with a light guide tube 15 to guide the infrared radiation from the temperature-measured object, a first infrared sensor 10 for detecting the infrared radiation from the light guide tube 15, a temperature sensitive sensor 12 which generates a reference temperature signal, a reference cavity 17 which has approximately the same temperature condition as the light guide tube 15 and is sealed so as to shut out infrared radiation from outside, a second infrared sensor 11 for detecting the infrared radiation from the reference cavity 17, a temperature computing means 13 for calculating temperature in accordance with the signals from the first infrared sensor 10 and the second infrared sensor 11, a temperature sensitive sensor 12, and a display unit 14 for displaying temperature in accordance with the signal from the temperature computing means 13; and at least either the light guide tube 15 or the reference cavity 17 is tapered off toward the emission inlet of the light guide tube 15 from the first or second infrared sensor 10 or 11 side.

Owner:CITIZEN WATCH CO LTD

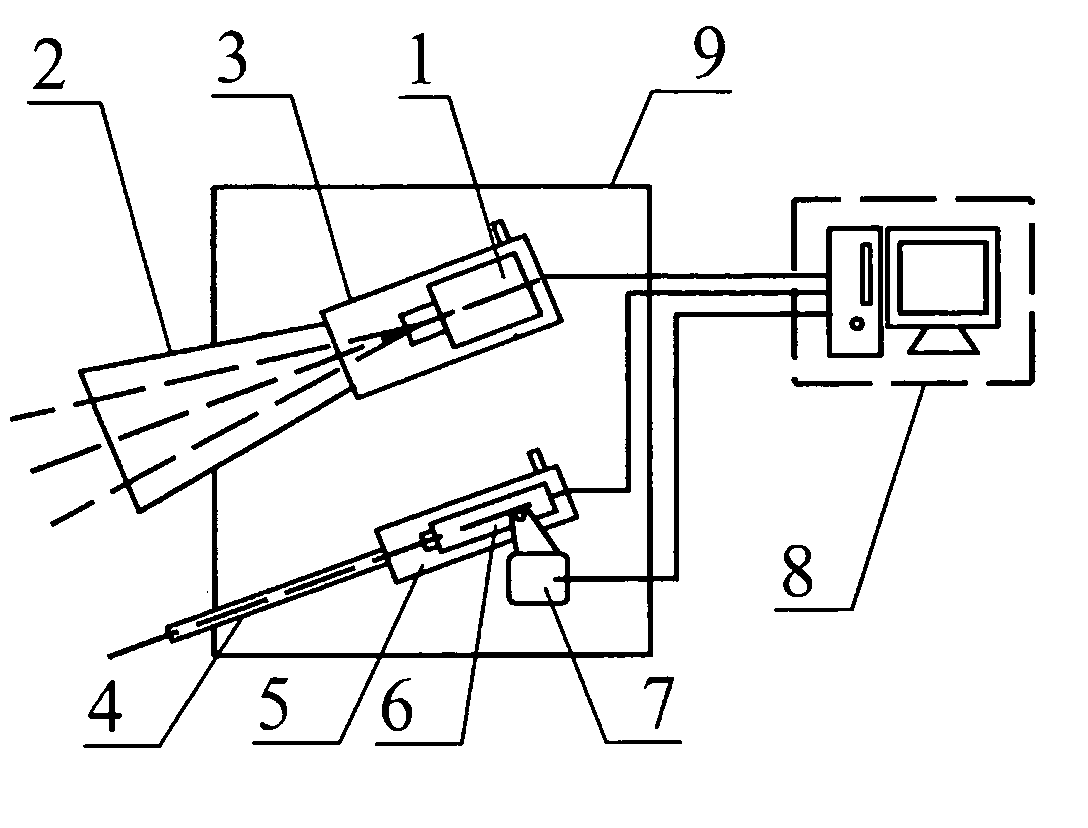

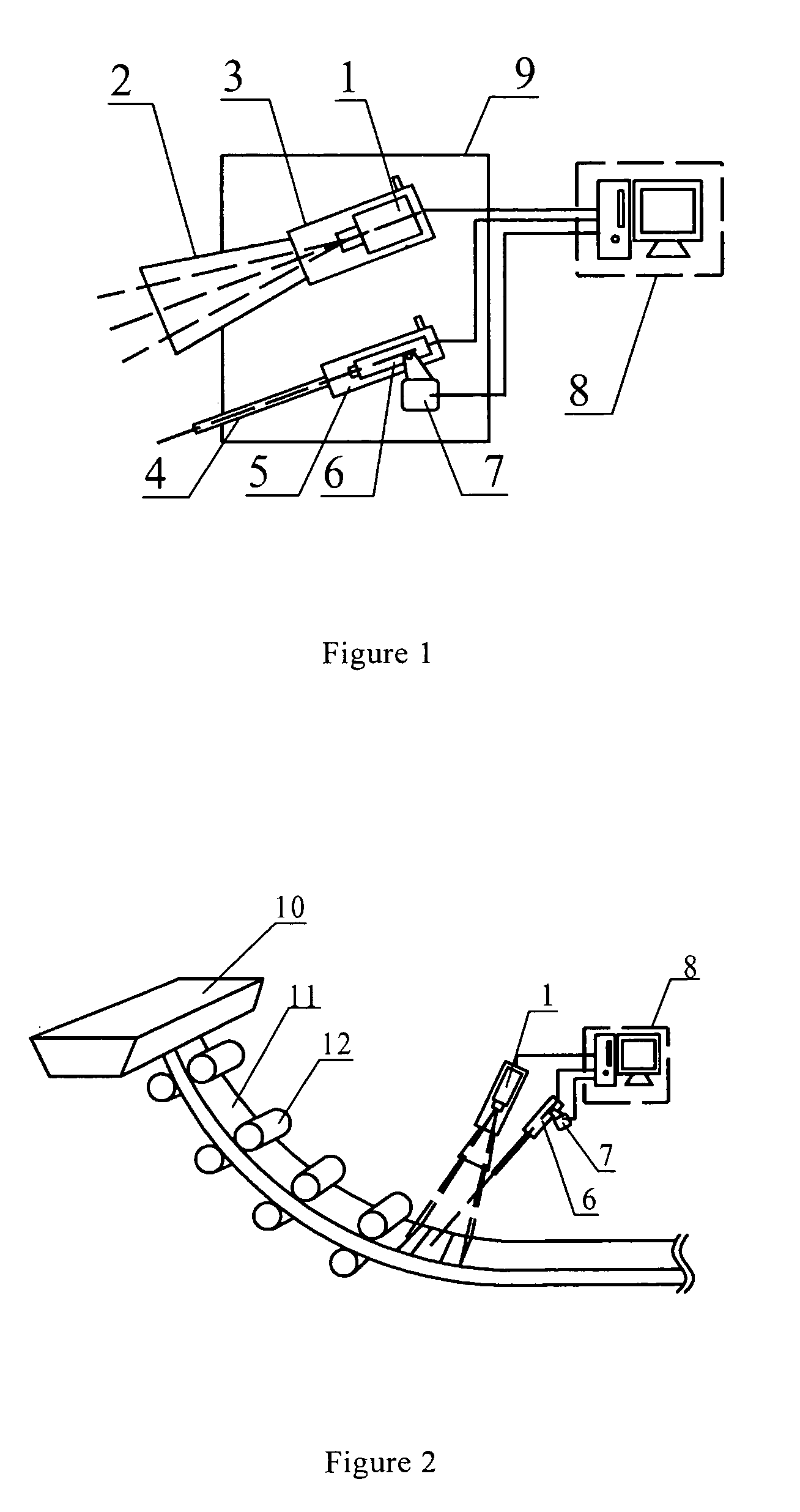

Apparatus and method for measuring the surface temperature of continuous casting billet/slab

ActiveUS20100236743A1Small geometryUneven thicknessThermometer detailsCasting safety devicesData processing systemRadiation thermometer

The present invention discloses a method and apparatus for measuring the temperature field on the surface of casting billet / slab, including: a thermal imager, an infrared radiation thermometer, a mechanical scanning unit, an image and data processing system; the thermal imager, the infrared radiation thermometer and the mechanical scanning unit are respectively connected to the image and data processing system; the infrared radiation thermometer is installed on the mechanical scanning unit and can measure the temperature of casting billet / slab surface by scanning; the thermal imager can measure the temperature of a certain area on the surface of casting billet / slab by thermal imaging. The present invention makes use of the combination of high-resolution thermal imager and scan-type infrared radiation thermometer, through the model-based filtering method, overcomes the influence of iron scales on the surface of casting billet / slab, and implements real-time stable measurement of surface temperature of casting billet / slab.

Owner:NORTHEASTERN UNIV +1

Light-irradiation type thermal processing method and thermal processing apparatus

ActiveUS20170053818A1Simple structureSemiconductor/solid-state device testing/measurementSolid-state devicesLight irradiationRadiation thermometer

From a stage of preheating by a halogen lamp to irradiation with a flash by a flash lamp, a radiation thermometer is used for measuring the temperature of a back surface of a semiconductor wafer. A increased temperature ΔT is determined by which the back surface of the semiconductor wafer is increased in temperature from the preheating temperature by irradiation with a flash. The specific heat of the semiconductor wafer has a known value. Further, the increased temperature ΔT is proportionate to the magnitude of energy applied to a front surface of the semiconductor wafer by irradiation with a flash. Thus, a front surface attained temperature of the semiconductor wafer can be determined using the increased temperature ΔT of the back surface of the semiconductor wafer during irradiation with a flash.

Owner:DAINIPPON SCREEN MTG CO LTD

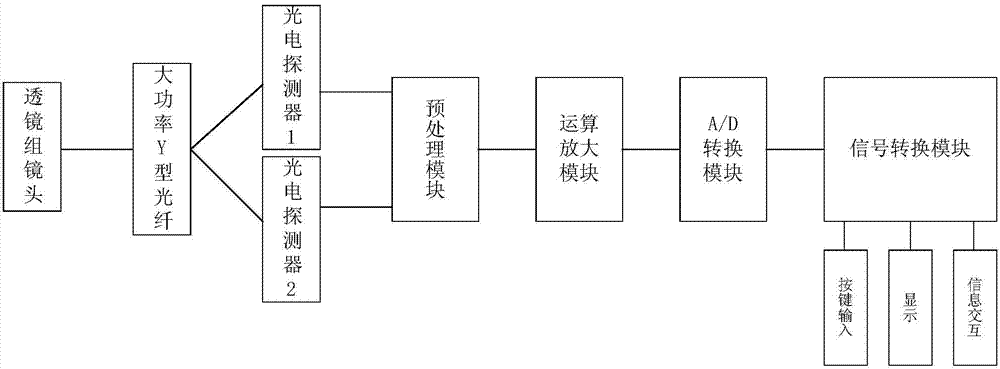

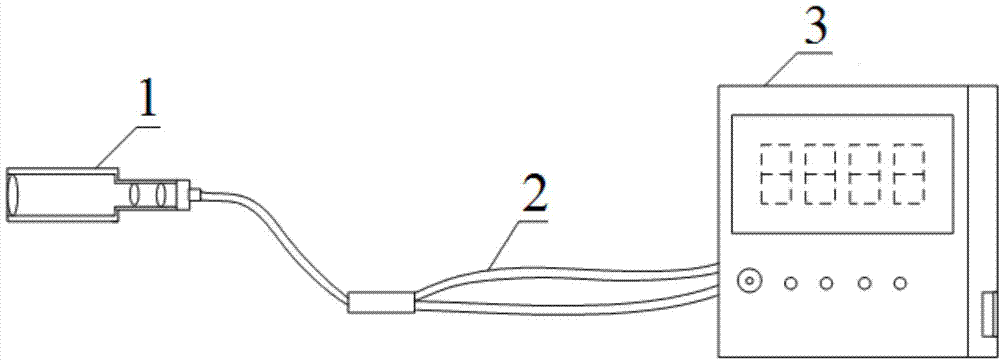

Optical fiber radiation thermometer based on colorimetric method

InactiveCN104330170AImprove the problem of easy foldingHigh precisionPyrometry using electric radation detectorsCamera lensRadiation thermometer

The invention discloses an optical fiber radiation thermometer based on a colorimetric method, and belongs to the field of high temperature measurement. The thermometer comprises an optical system and a circuit system, wherein lenses of a lens group are connected with a high-power Y-type power transmission optical fiber to form the optical system; the circuit system adopts signal dual-channel processing and comprises photoelectric detectors, a preprocessing module, a preamplifier, an AD sampling module, a signal processing module, a display module, a keyboard input module and an information interaction module. Signals are divided into two paths via the power transmission optical fiber and transmitted to the corresponding photoelectric detectors, optical signals are converted into current signals, the current signals are converted into voltage signals via the preprocessing module and the pre-amplification module, the signal processing module adopts a curve fitting algorithm for analysis, sampling signals are obtained, a corresponding temperature value is calculated through calibration, and difference setting is further improved through the interaction module. The optical fiber radiation thermometer structure based on the colorimetric method can be applied to measurement of a crystal furnace thermal field.

Owner:NANJING NORMAL UNIVERSITY

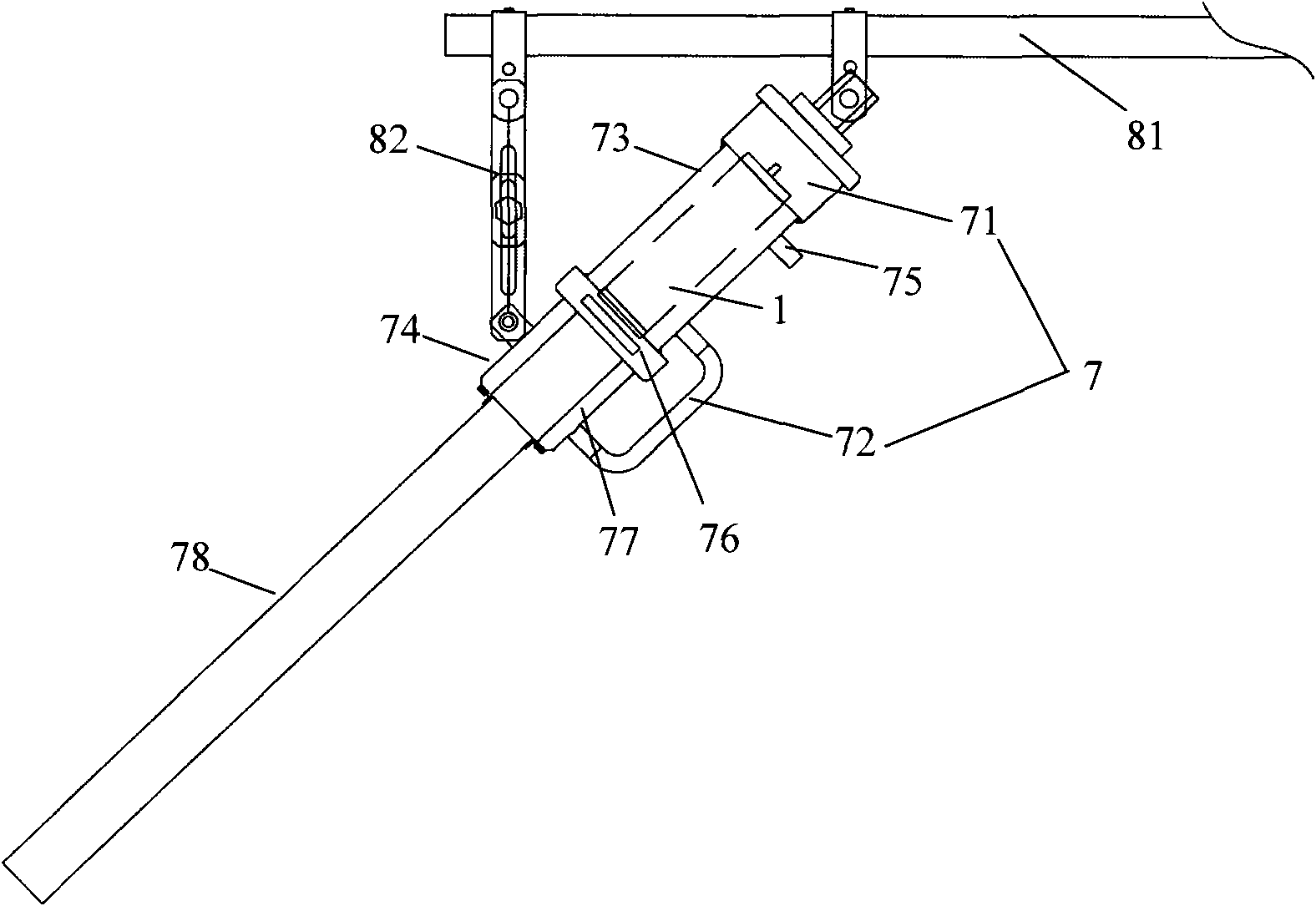

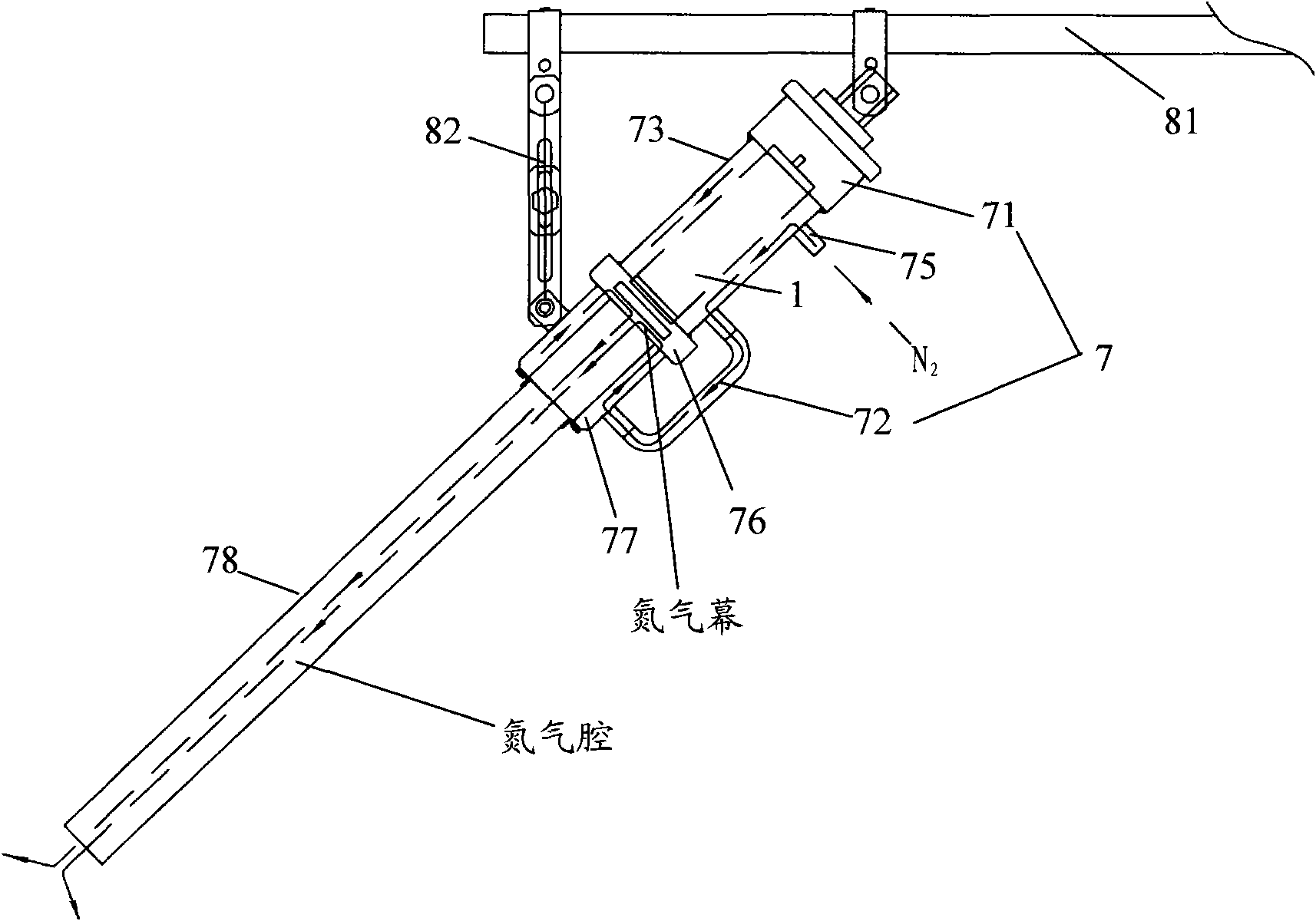

Special auxiliary device for continuous measurement of molten iron temperature and molten iron temperature continuous measurement system

ActiveCN101556188AAvoid errorsExtended service lifeRadiation pyrometryContinuous measurementRadiation thermometer

The invention relates to a special auxiliary device for continuous measurement of molten iron temperature. The device comprises an air-cooling jacket, wherein an auxiliary tube of the air-cooling jacket is communicated with a first end part and a second end part of a main tube; the first end part is provided with an air inlet; a mounting position for an infrared radiation thermometer positioned between the first end part and the second end part is arranged in the main tube; and preferably, an air path which is communicated with the auxiliary tube and oriented to the mounting position of the infrared radiation thermometer is arranged in the second end part. The device also comprises a light shading tube which is inserted and fixed in the second end part, an adjusting device and an air supply component, wherein the adjusting device comprises a fixed link and an adjusting part; the first end part is fixed on the fixed link; the adjusting part is fixed with the fixed link and the second end part respectively; and an air outlet pipeline of the air supply component is connected with the air inlet. The invention also relates to a molten iron temperature continuous measurement system with the special auxiliary device. The special auxiliary device has smart design, and can accurately and continuously measure the molten iron temperature, thereby realizing real application of the infrared radiation thermometer in molten iron temperature measurement.

Owner:SHANGHAI ADVANTECH AUTOMATION ENG

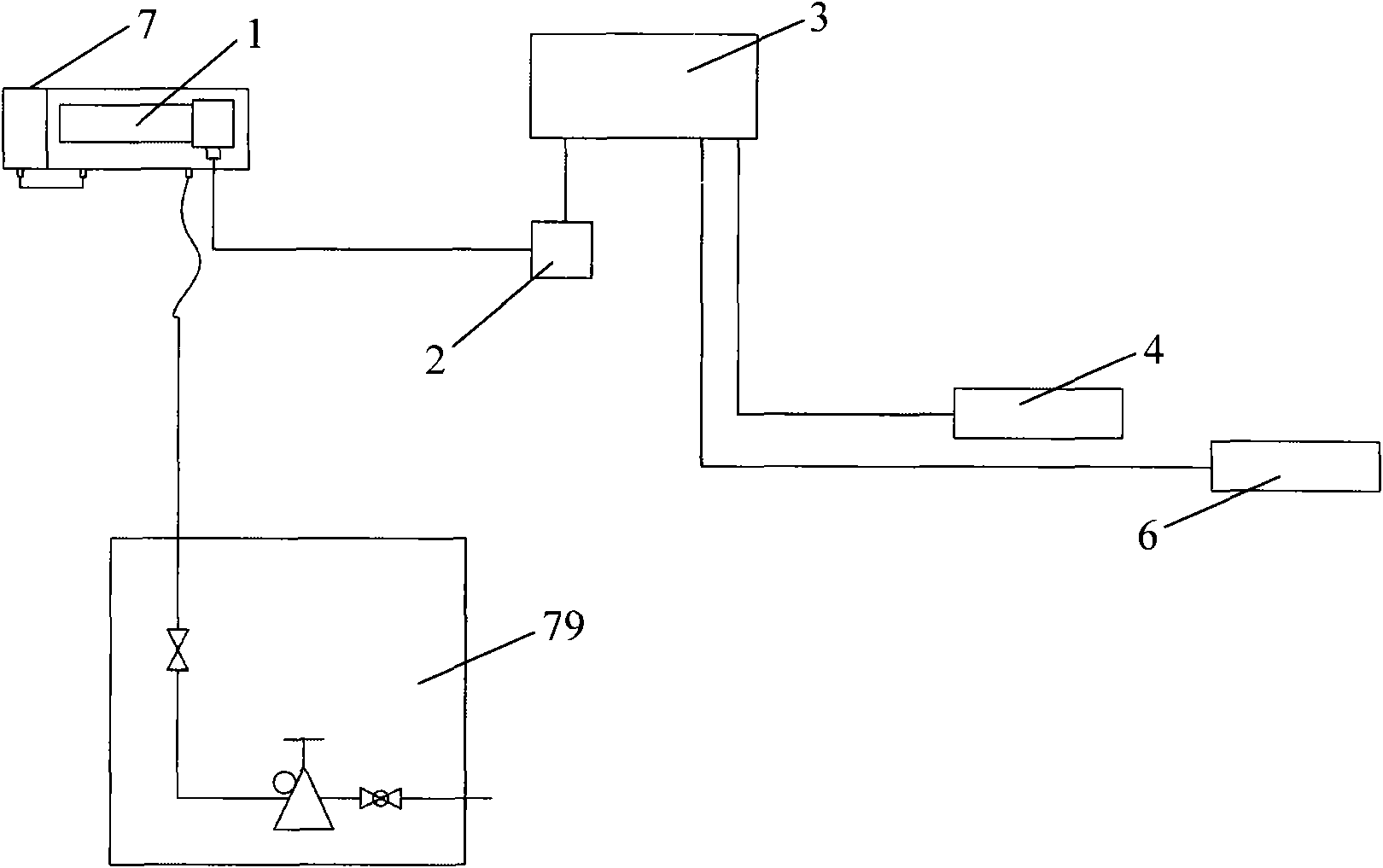

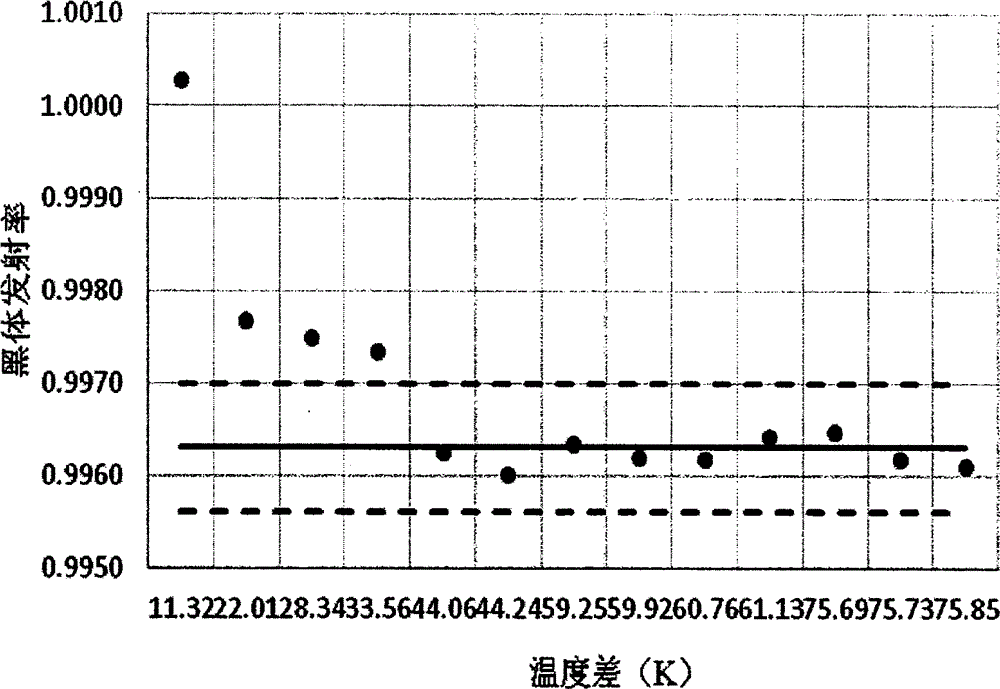

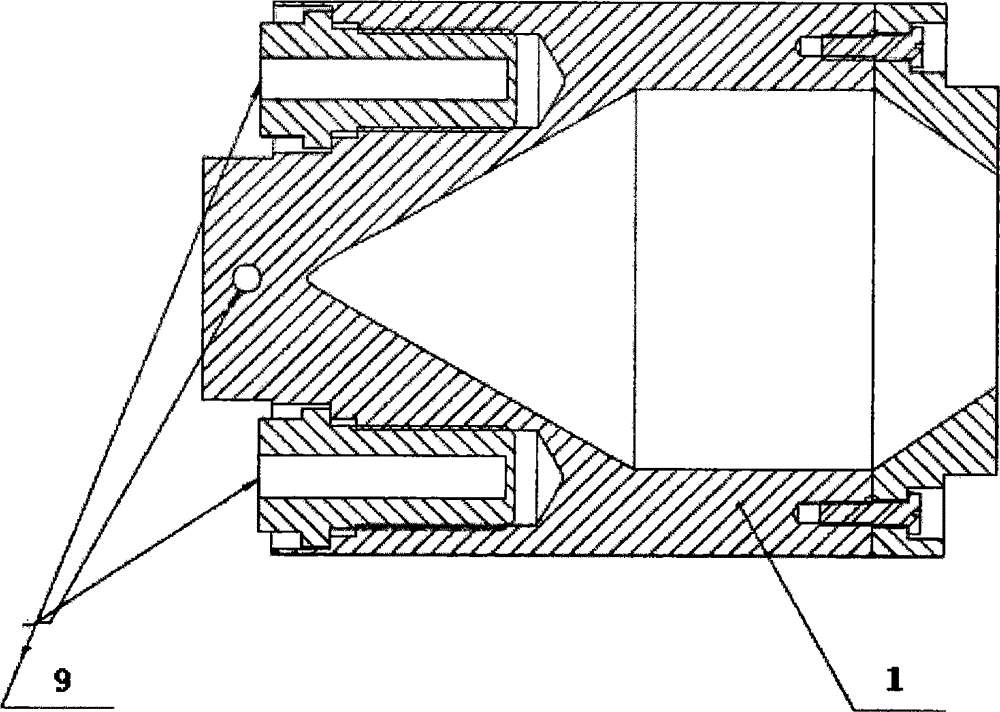

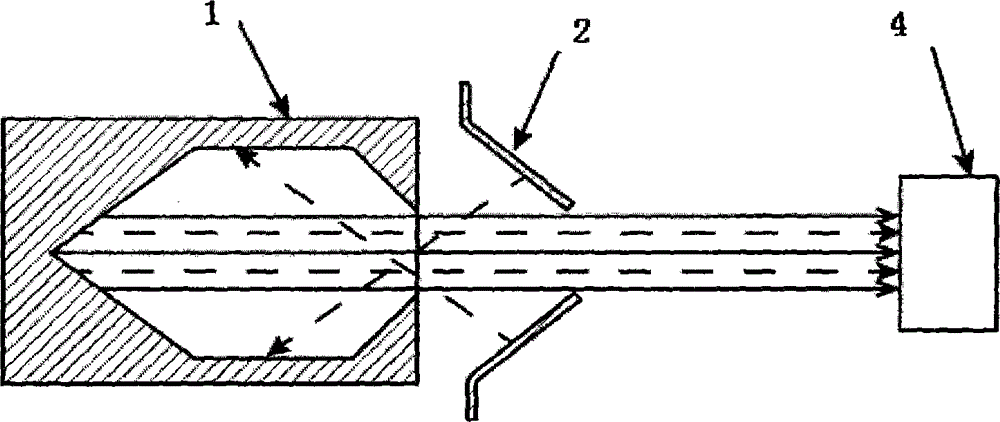

Black body emissivity measuring device based on control background radiation, and black body emissivity measuring method based on control background radiation

The present invention discloses a black body emissivity measuring device based on control background radiation, and a black body emissivity measuring method based on control background radiation. The measuring device comprises a to-be-measured black body; a heat radiation ring located at one side of an opening of the to-be-measured black body; and an infrared radiation thermometer for measuring an acquired radiation signal. A water cooling diaphragm is arranged between the heat radiation ring and the infrared radiation thermometer, and is used to reduce the stray radiation. The black body emissivity measuring device based on the control background radiation analyzes the influence of the temperature change of the heat radiation ring and the black body on a measurement result, and verifies the feasibility of the method applied to the spaceborne calibration black body emissivity on-orbit calibration.

Owner:NAT INST OF METROLOGY CHINA

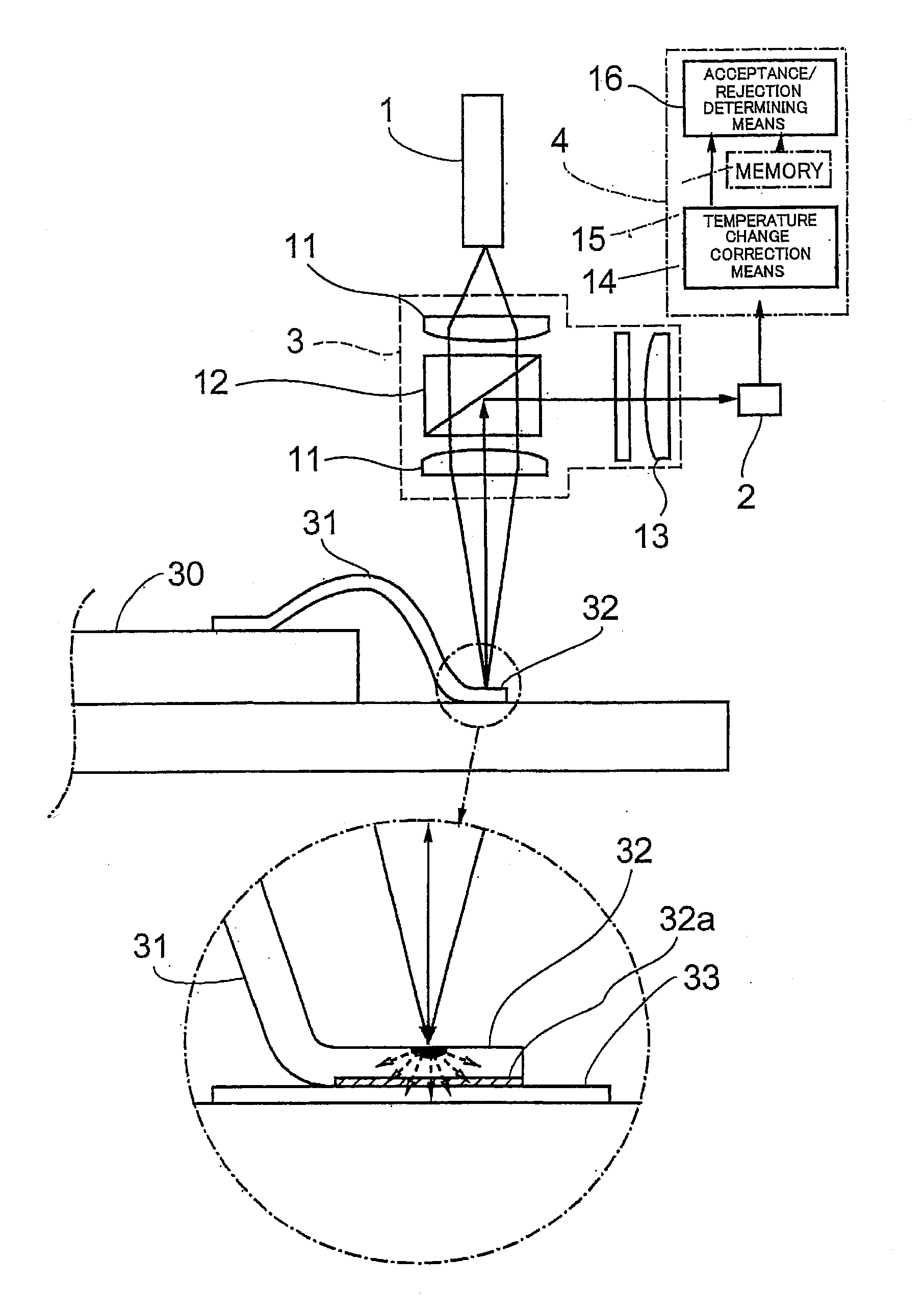

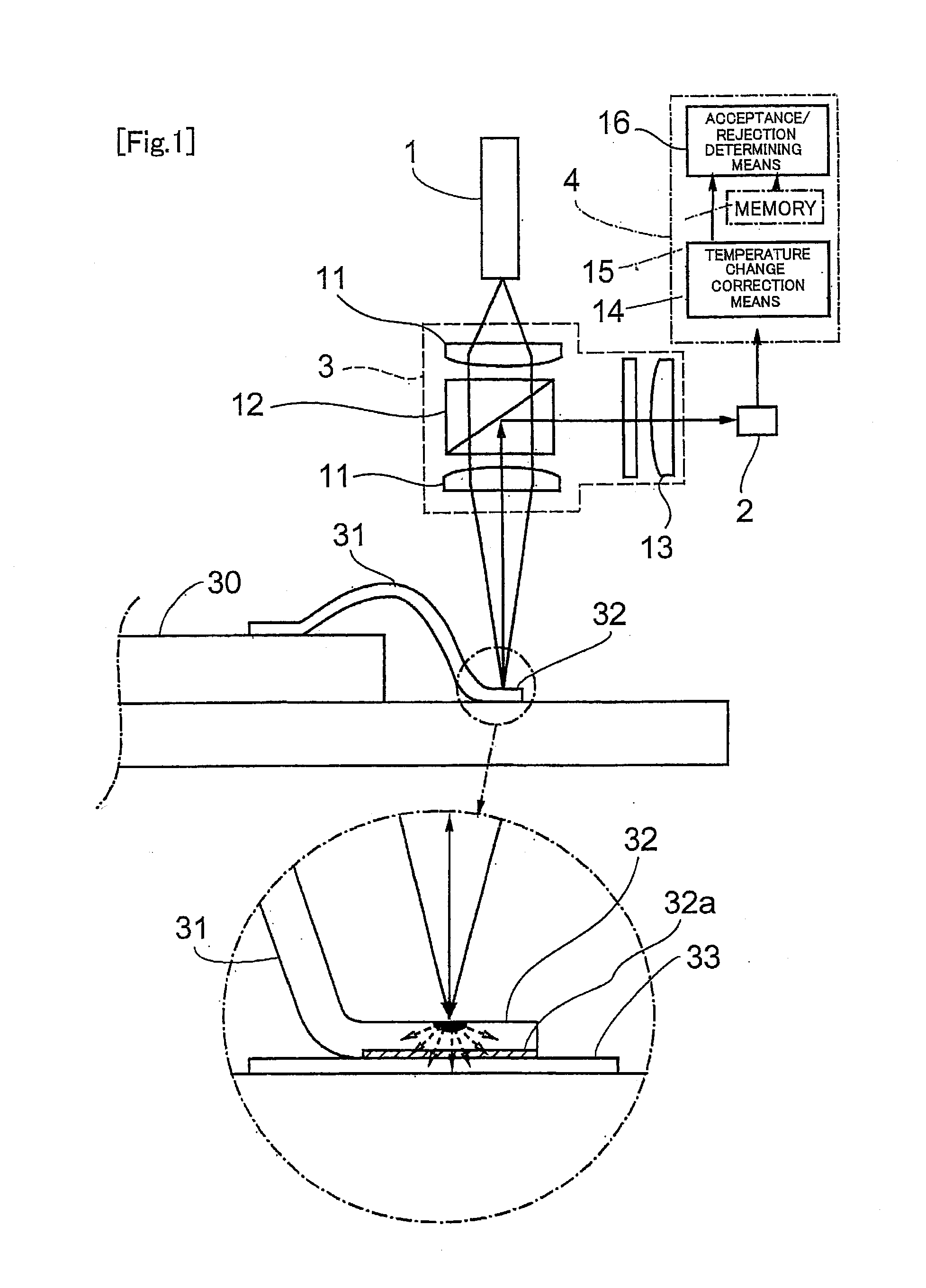

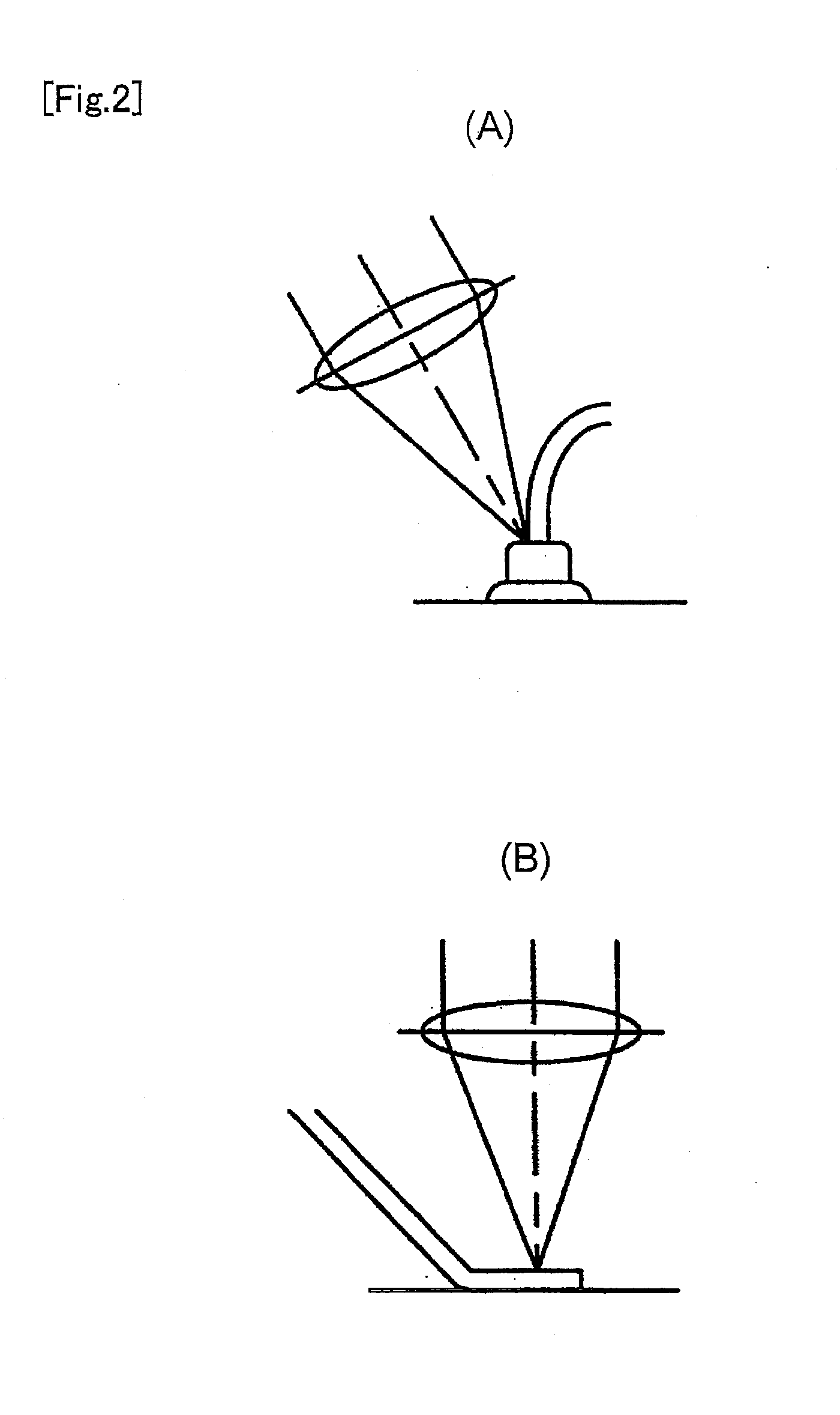

Method and apparatus for determining acceptance/rejection of fine diameter wire bonding

ActiveUS20130006565A1Easy to handleConveniently configuredSemiconductor/solid-state device testing/measurementSolid-state devicesInfraredRadiation thermometer

Disclosed are a method and apparatus for determining acceptance / rejection of fine diameter wire bonding of semiconductor devices, LED devices, and the like, which has been impossible with conventional methods, such as the method by image processing, with high accuracy and with no contact. The apparatus includes a heating laser device 1 for spot-heating the bonding portion of a fine diameter wire; a two-wavelength infrared radiation thermometer 2 for measuring temperature at high speed on the basis of a minute amount of infrared rays radiated from the heated portion of the fine diameter wire with correction of the emissivity; and a correction computing and determining means 4 for correcting the result of measurement with the two-wavelength infrared radiation thermometer 2 to a temperature change with the reference heating power, and then determining acceptance / rejection of the bonding by comparing the corrected temperature change or a numerical value correlated to a bonding area obtained from that temperature change, with a temperature change indicated by an acceptable product as a comparison criterion that has been corrected to the reference heating power or a numerical value correlated to a bonding area obtained from that temperature change.

Owner:JTEKT CORP

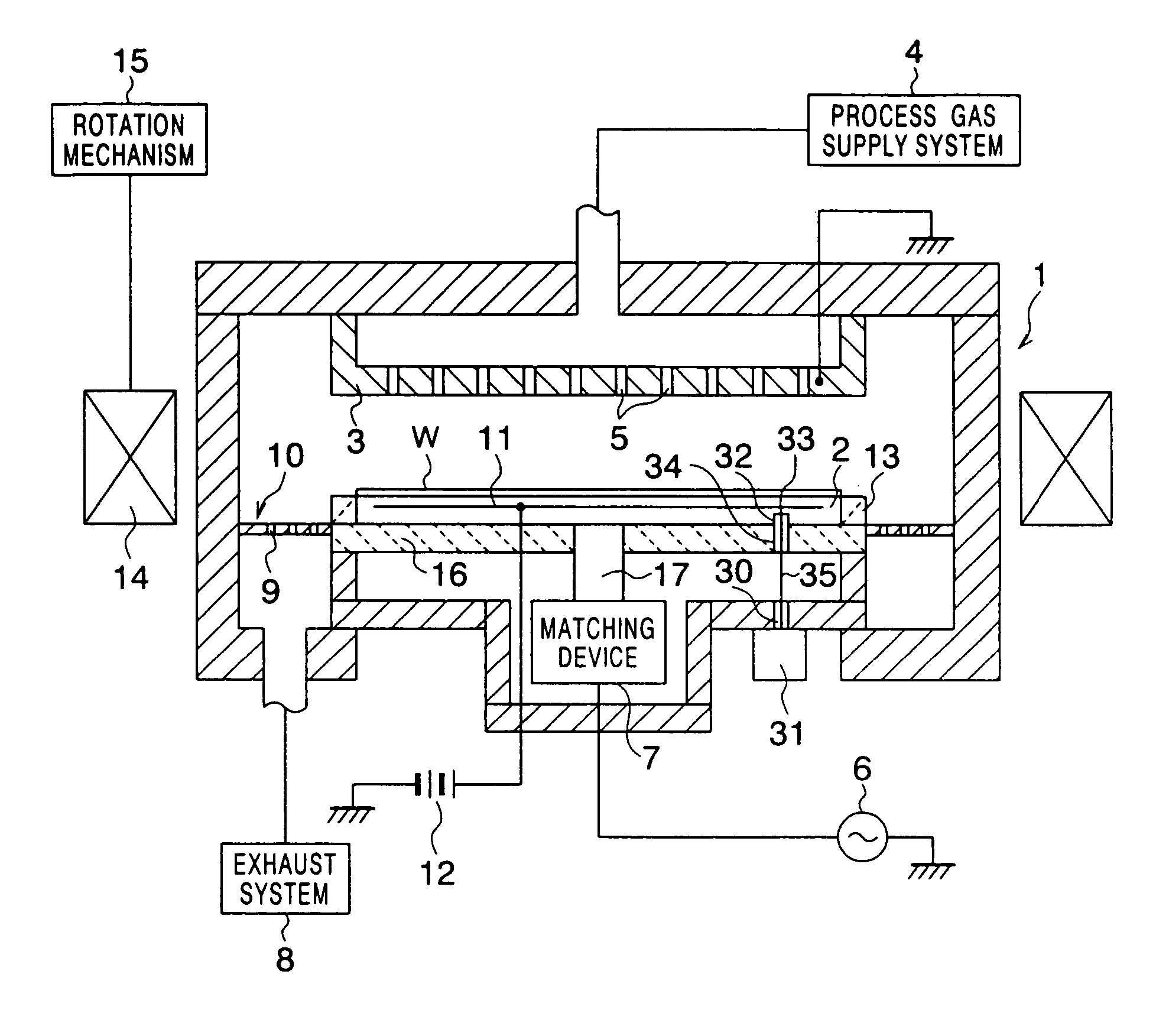

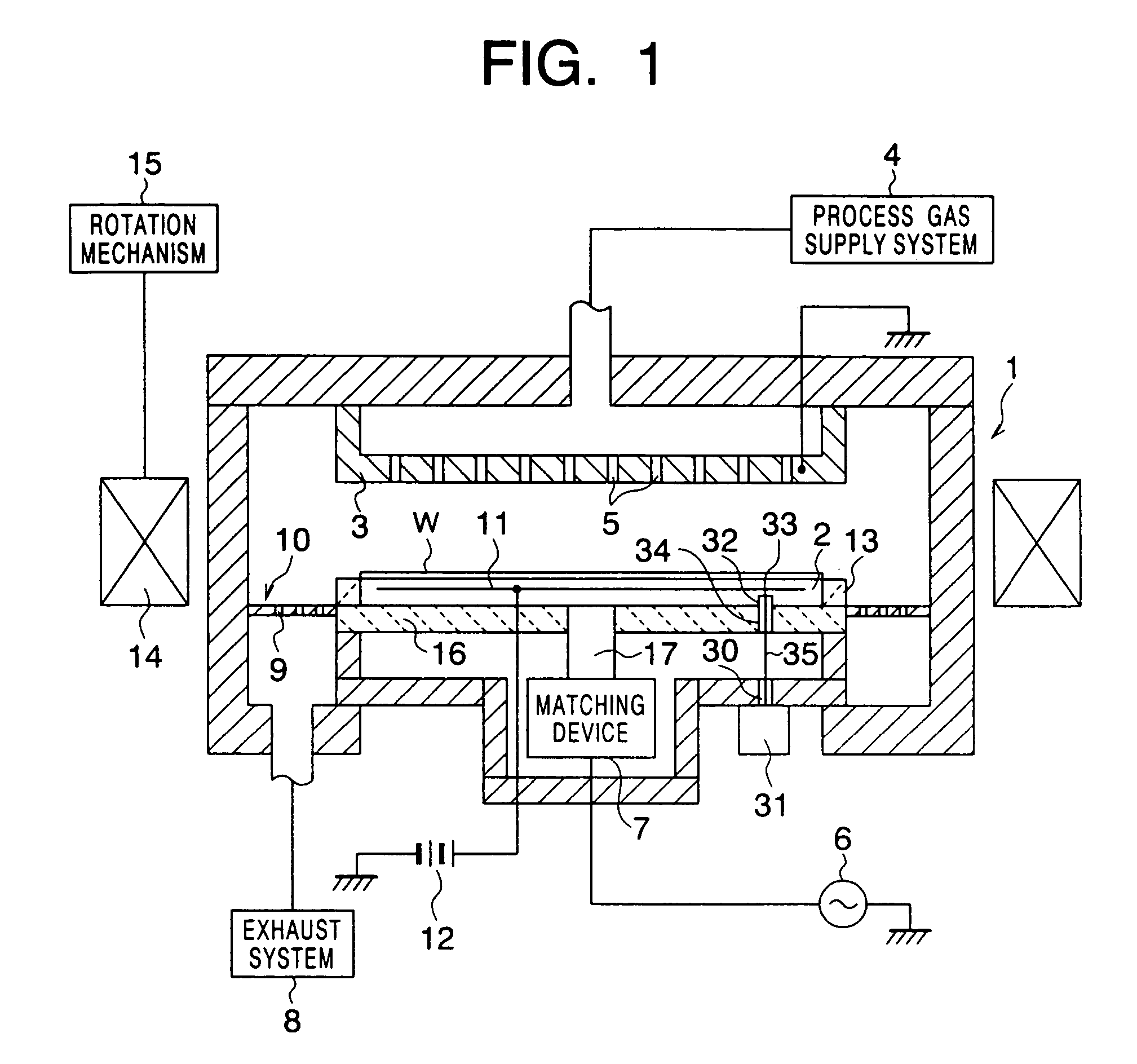

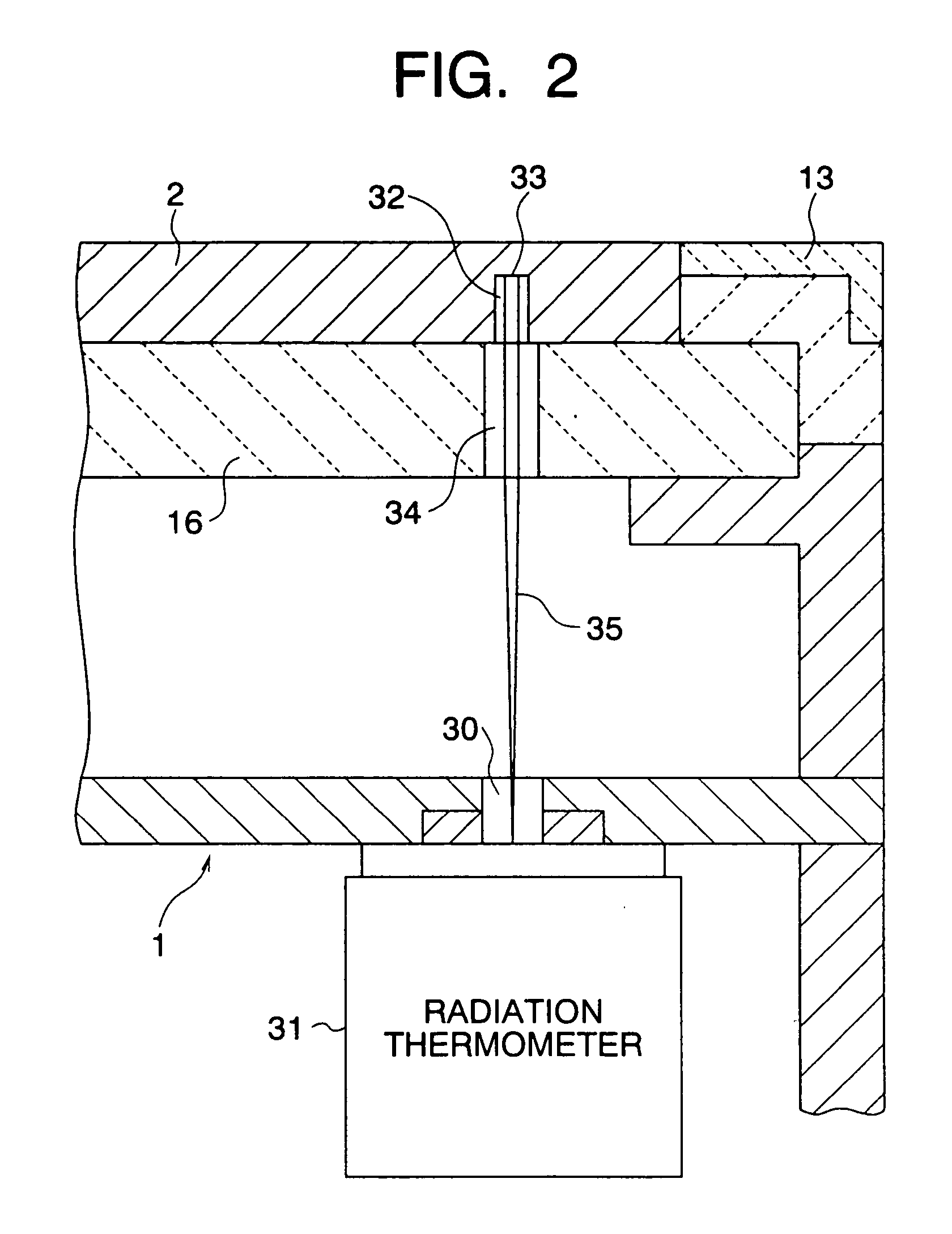

Temperature measuring method and plasma processing apparatus

A temperature measurement opening 30 is formed in a bottom portion of a process vessel 1 of a plasma etching apparatus, the temperature measurement opening 30 having a size not allowing a radio frequency power with a high frequency applied on a susceptor 2 to leak outside. To an external side of the temperature measurement opening 30, a radiation thermometer 31 is attached. The radiation thermometer 31 detects an infrared ray 35 emitted from the inside of a temperature measurement hole 32 formed on a rear face side of the susceptor 2 to measure the temperature of the susceptor 2.

Owner:TOKYO ELECTRON LTD

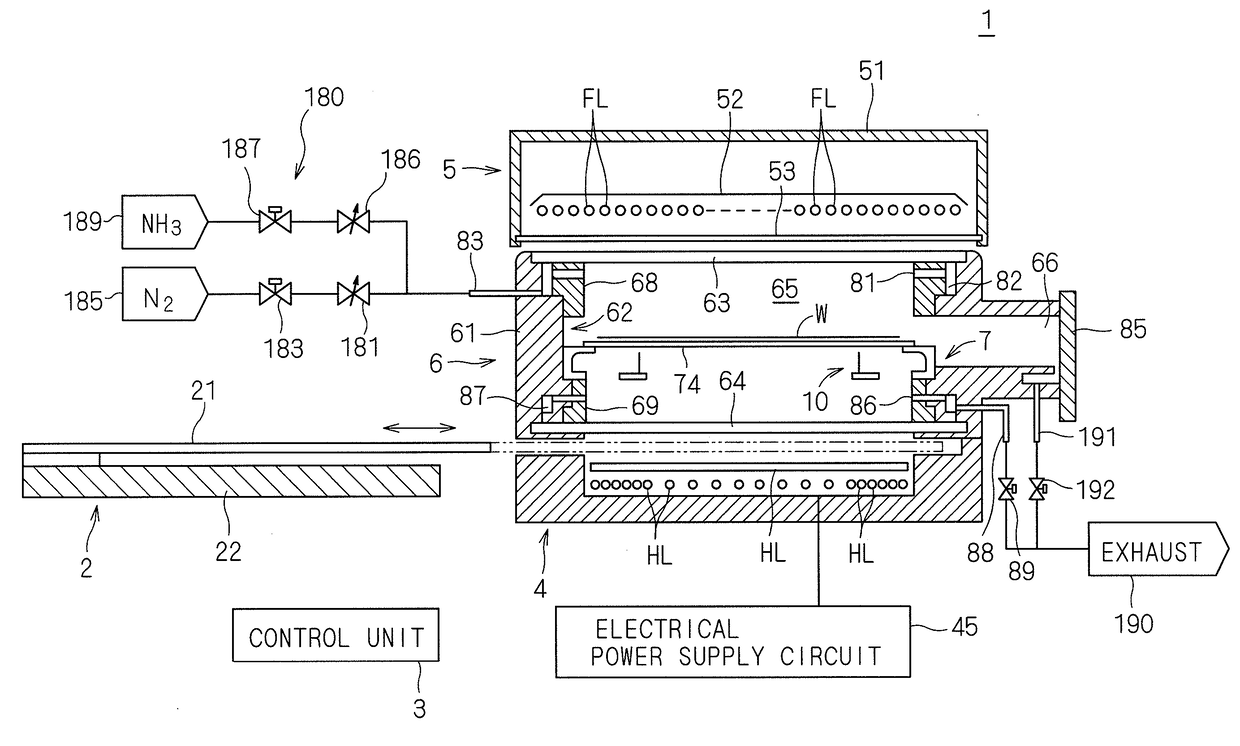

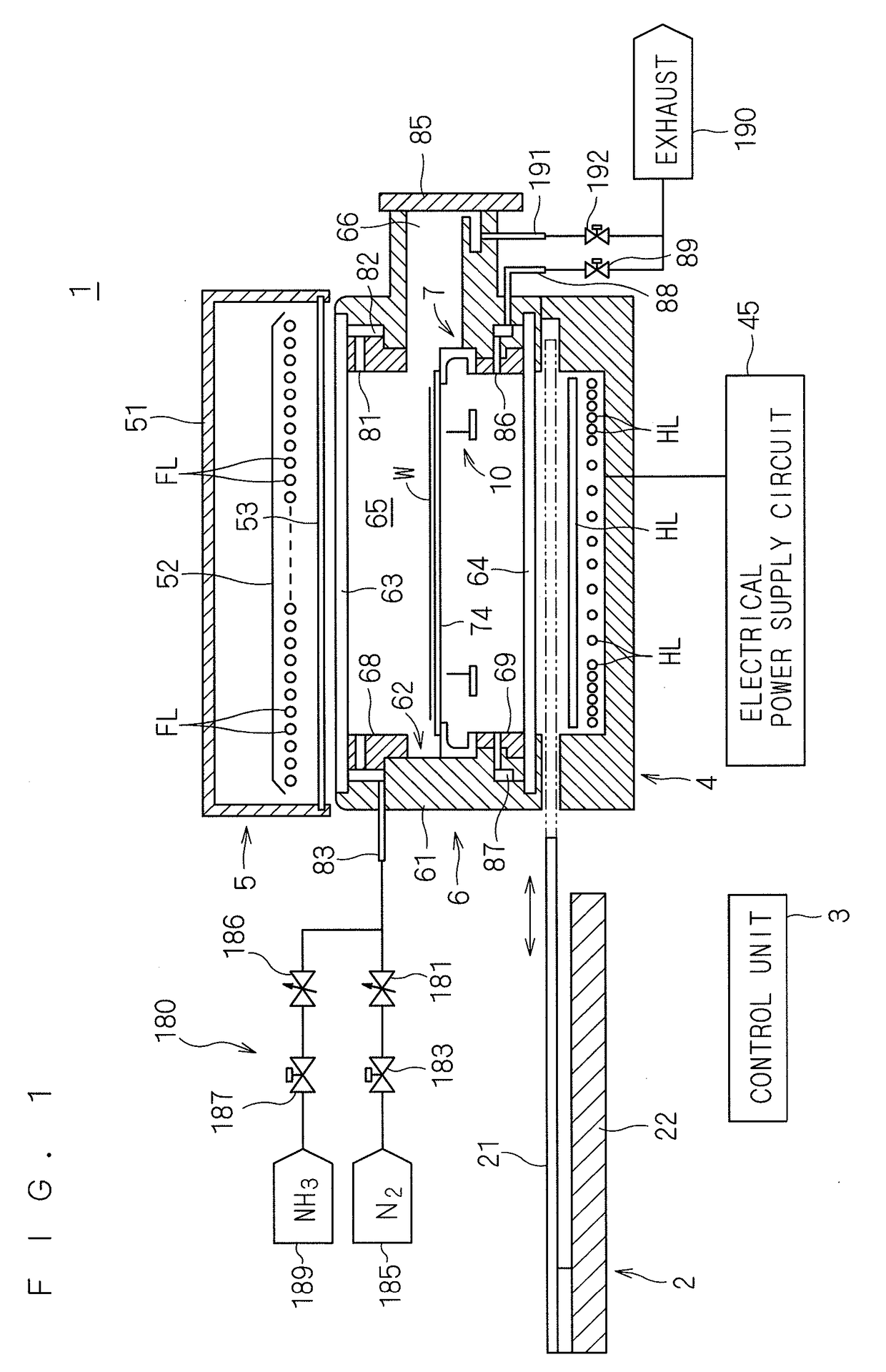

Thermal processing apparatus and thermal processing method through light irradiation

InactiveUS20170178979A1Accurate measurementRadiation pyrometrySemiconductor/solid-state device testing/measurementRadiation thermometerHeat treated

A substrate in a chamber is preheated through light irradiation by a halogen lamp and then heated through irradiation with flash light from a flash lamp. Ammonia is supplied to the chamber from an ammonia supply mechanism to form ammonia atmosphere. The temperature of the substrate at heating processing is measured by a radiation thermometer. When the measurement wavelength band of the radiation thermometer overlaps with the absorption wavelength band of ammonia, the set emissivity of the radiation thermometer is changed and set to be lower than the actual emissivity of the substrate. When radiation light emitted from the substrate is absorbed by the ammonia atmosphere, the radiation thermometer can accurately output the temperature of the substrate as a measured value by reducing the set emissivity of the radiation thermometer.

Owner:DAINIPPON SCREEN MTG CO LTD

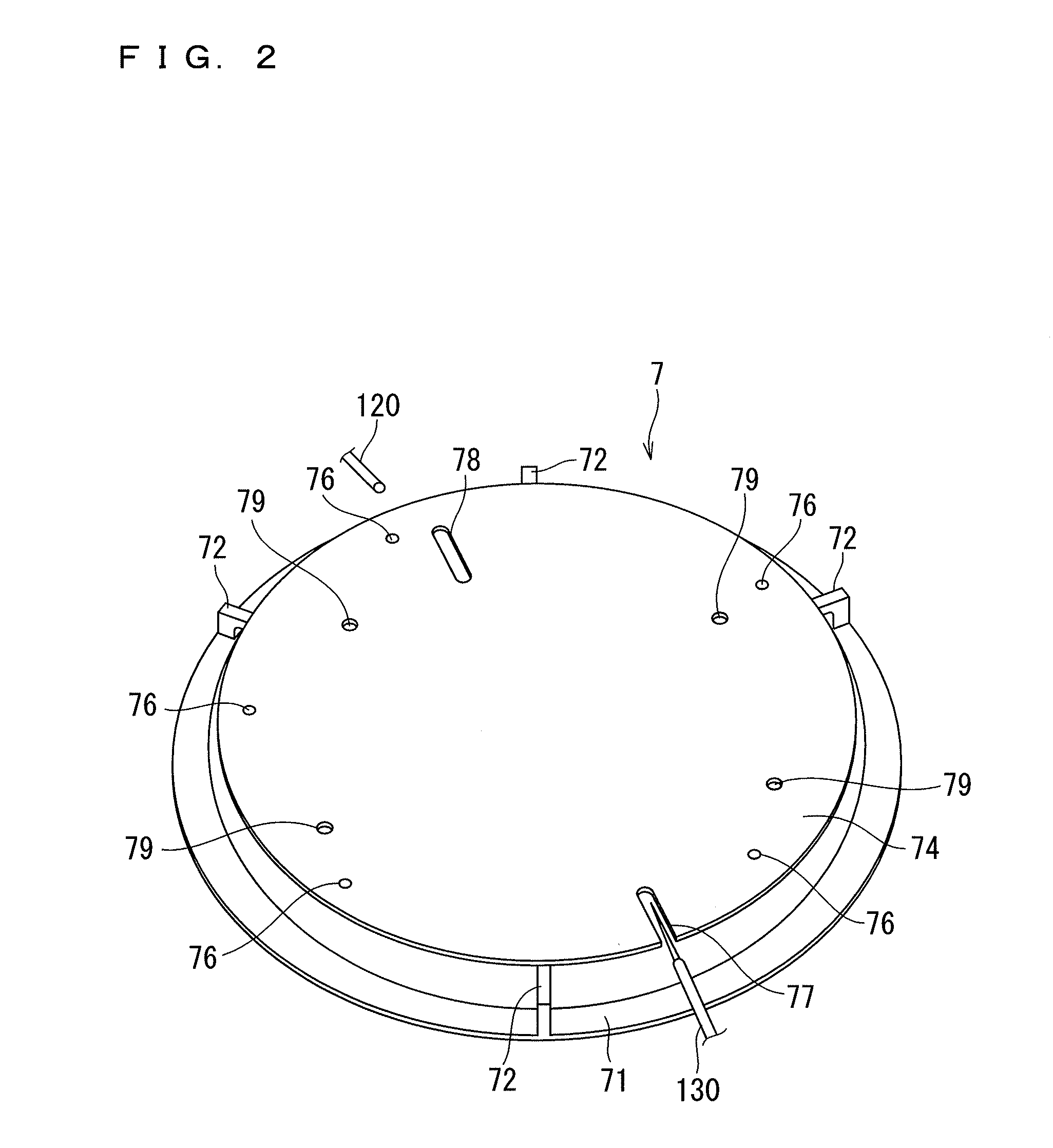

Light irradiation type heat treatment apparatus and heat treatment method

ActiveUS20180240689A1Accurate measurementDollsSemiconductor/solid-state device testing/measurementSusceptorLight irradiation

A semiconductor wafer that has a plane orientation of (100) and is made of monocrystalline silicon is warped along an axis, i.e., a diameter along a <100> direction of the semiconductor wafer when irradiated with a flash of light. The semiconductor wafer is placed on a susceptor while the direction of the semiconductor wafer is adjusted so that the diameter along the <100> direction coincides with an optical axis of an upper radiation thermometer. This adjustment makes a diameter along a direction in which a warp of the semiconductor wafer is smallest during irradiation with a flash of light coincide with the optical axis of the upper radiation thermometer. As a result, the semiconductor wafer is hardly warped along the optical axis direction of the upper radiation thermometer even during irradiation with a flash of light, thus hardly changing the emissivity of the semiconductor wafer, so that it is possible to accurately measure the temperature of an upper surface of the semiconductor wafer.

Owner:DAINIPPON SCREEN MTG CO LTD

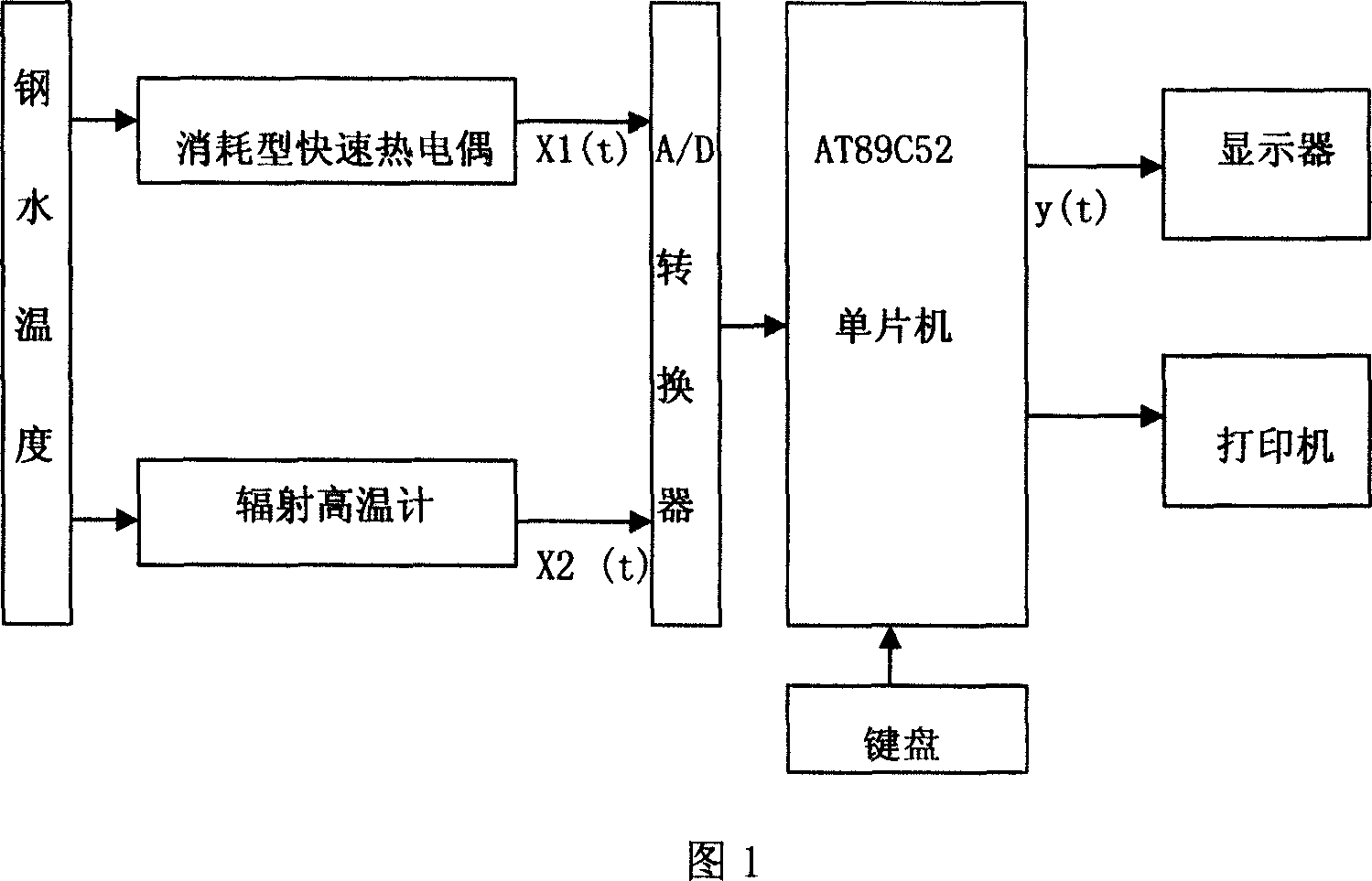

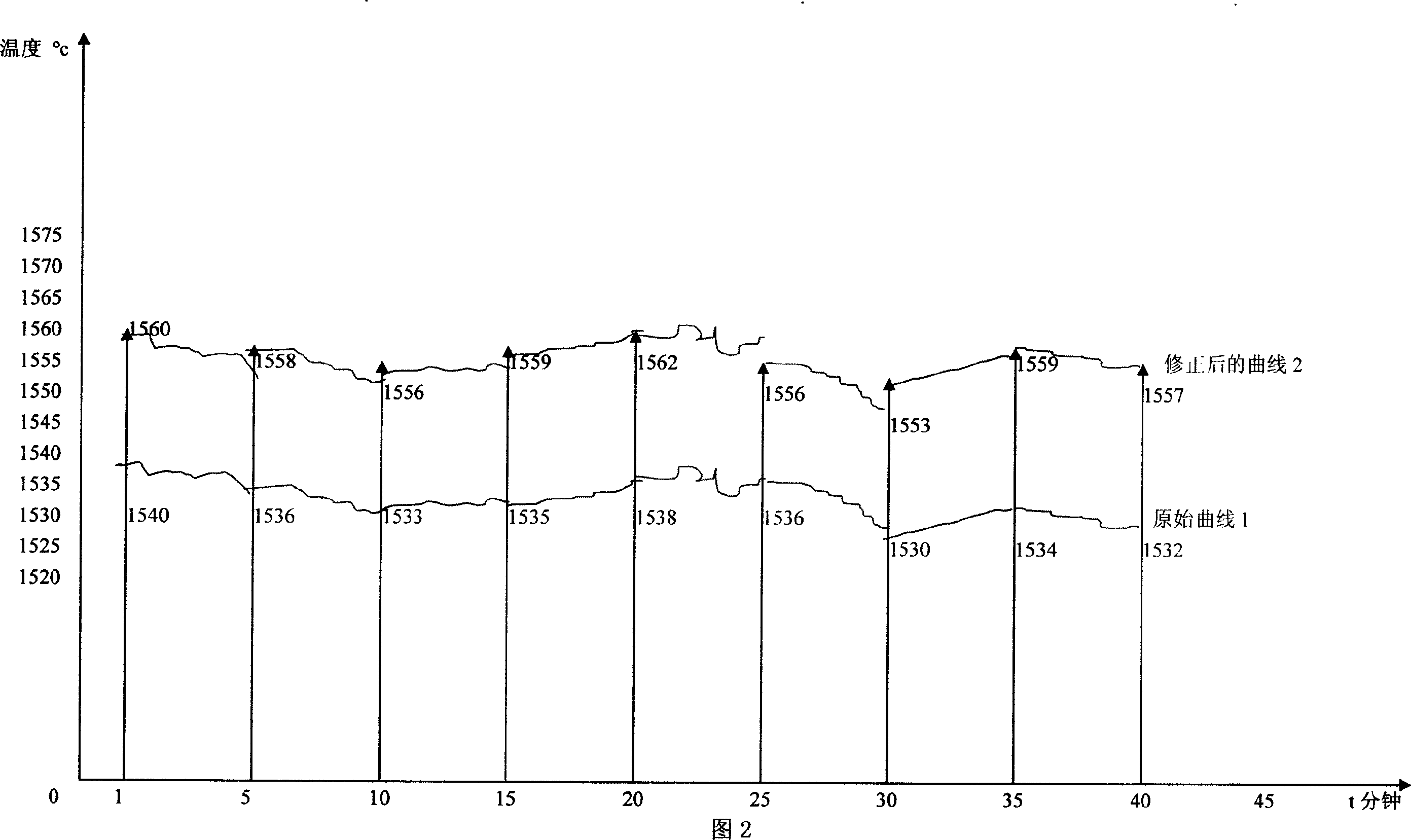

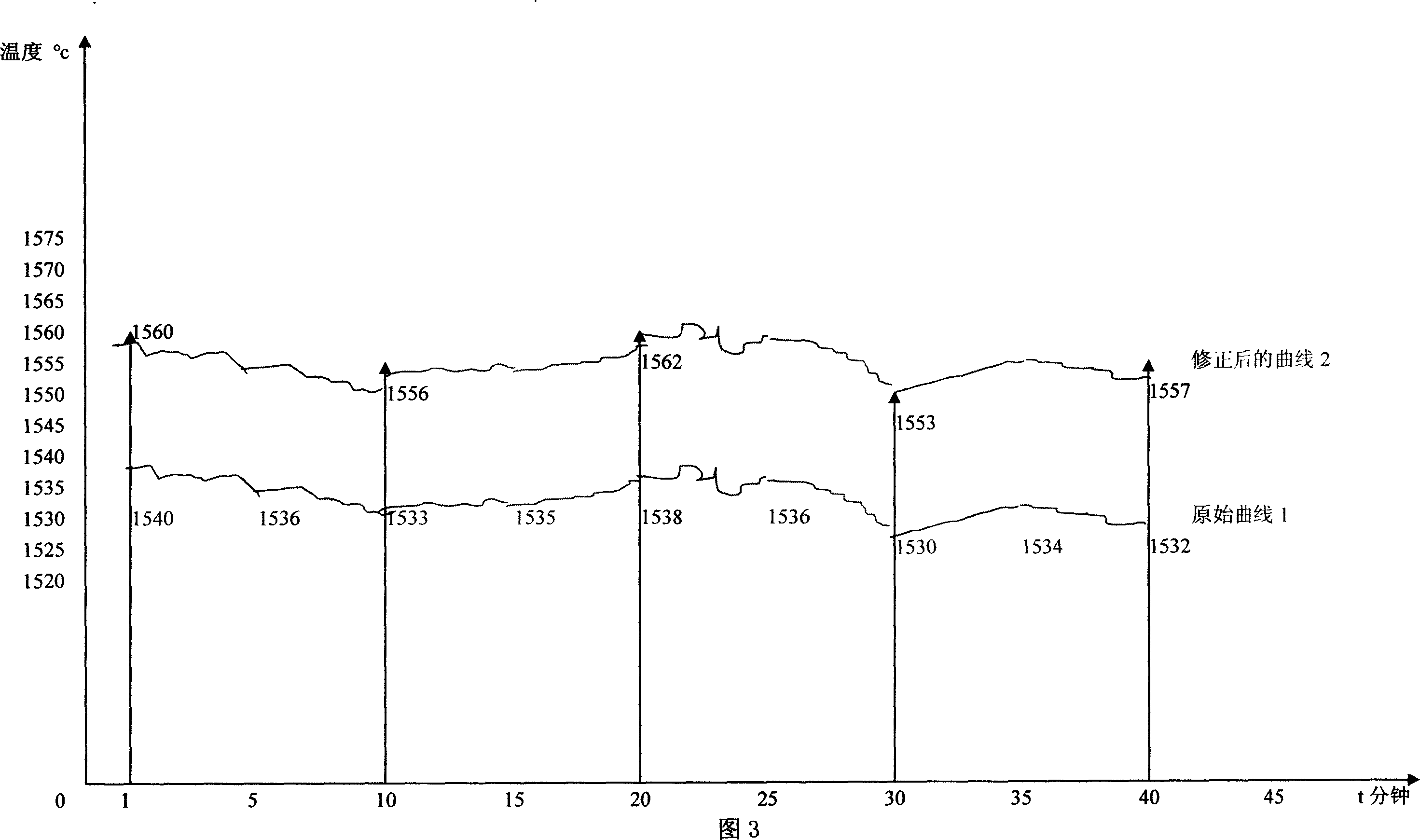

Contacting/non-contacting molten metal high temperature measuring apparatus and measuring method

InactiveCN101034010ARadiation pyrometryThermometers using electric/magnetic elementsMeasurement deviceRadiation thermometer

This invention relates to a high temperature measuring method of contact / non- contact molten metal. Specifically the invention is a measuring device and measuring means, which aim at temperature of iron and molten steel, to use discrete temperature signal X1 (T) of asynchronism expending electro heat to continual modify continually varying temperature signal x2 ( T) of high temperature radiation thermometer. The invention includes expend type fast thermocouple, high temperature radiation thermometer, A / D data converter, single chip and output equipment. The described expend type fast thermocouple and high temperature radiation thermometer respectively connect with A / D data converter's input end; A / D data converter's output port connect with single chip; single chip respectively connect with keyboards, display unit and printer.

Owner:武钢集团有限公司

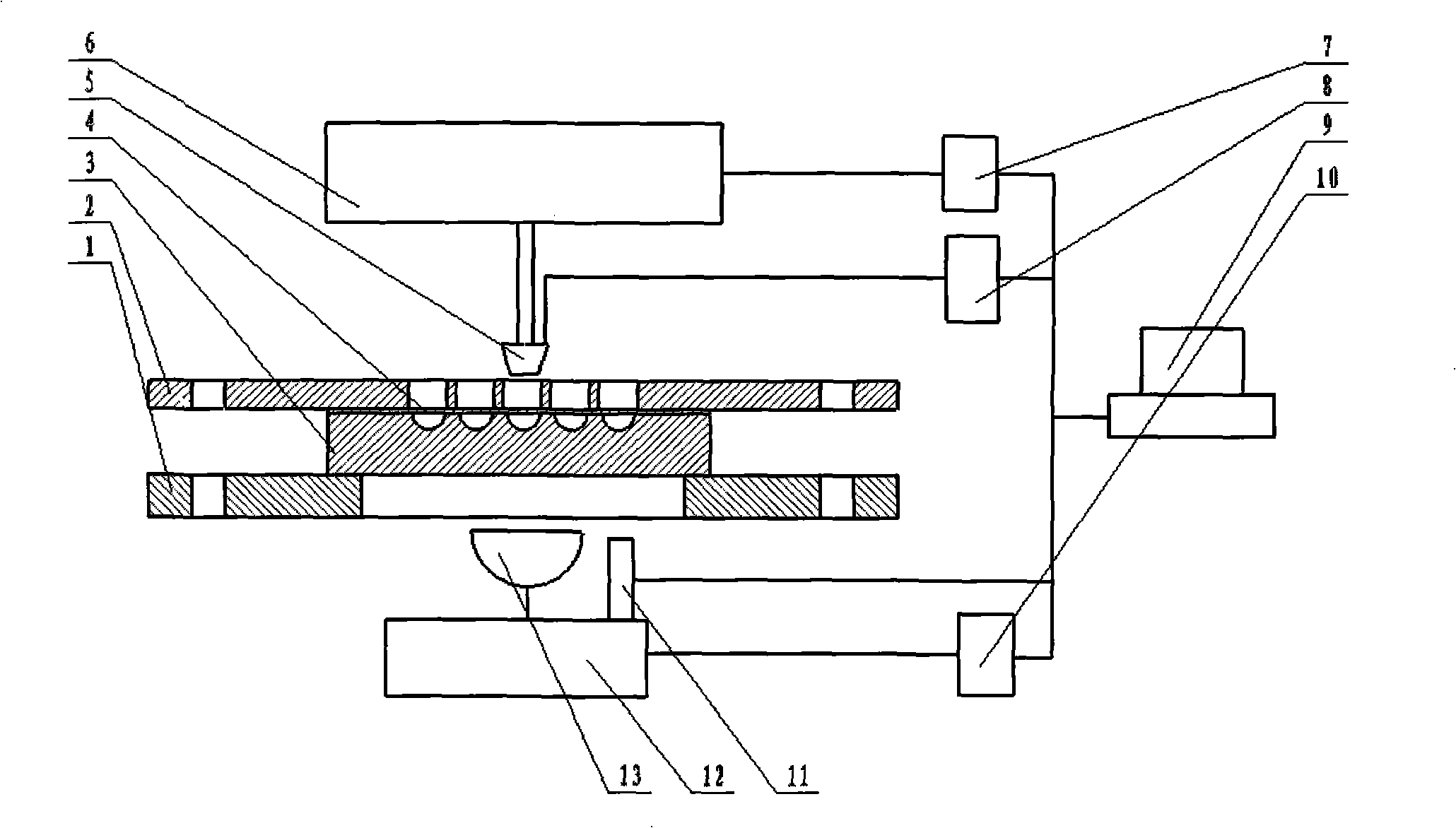

Infra-red heating tinsel plate pneumatic forming method and apparatus

InactiveCN101318204AUniform plastic deformationImprove yieldShaping toolsRadiation thermometerMetallurgy

The invention relates to an air pressure forming method of an infrared heating metal foil plate and a device; wherein, the method includes the steps of accurately heating a metal foil plate with an infrared heat source, applying pressure to the softened metal foil plate with high pressure gas and realizing the precise forming of the metal foil plate by matching a micro mold; the device consists of a bottom plate, an upper pressure plate, a micro mold, a gas pressure nozzle, a three-dimensional mobile platform, a three-dimensional mobile platform controller, an air compressor, a computer, a drive, an infrared radiation thermometer, a three-dimensional worktable and an infrared focusing heating device. The method and the device integrates the technologies of infrared heating, infrared temperature measurement and air pressure forming to a micro-forming process, thus improving the forming performance of the metal foil plate, ensuring the quality of the surfaces of work pieces; the high pressure gas is used for replacing a male mold, thus simplifying the technique, causing the loading pressure to be more even and strengthening the filling ability; the method and the device can realize the low cost and mass production of the metal foil plate by combining an array female mold.

Owner:JIANGSU UNIV

Temperature fixed-point cell, temperature fixed-point device and method of calibration of thermometer

ActiveUS20070201534A1Simplify workEasy maintenanceRadiation pyrometryThermometers using electric/magnetic elementsCrucibleRadiation thermometer

A temperature fixed-point cell is configured with a crucible composed of carbon and a fixed-point material enclosed in the crucible. The fixed-point material has a peritectic structure of carbon and a carbon compound. A thermometer is calibrated by installing the temperature fixed-point crucible in a furnace, increasing or decreasing the ambient temperature thereof, measuring the temperature of the temperature fixed-point cell with the thermometer, observing the state of temperature change, and using this state of temperature change as a basis for the calibration. This invention is aimed at realizing a fixed point in the temperature range exceeding the copper point and accomplishing great improvement in accuracy in the calibration of radiation thermometers, thermocouples and all thermometers used in high temperature ranges.

Owner:NAT INST OF ADVANCED IND SCI & TECH

Measuring equipment of non-metallic material high-temperature expansive power and method of use thereof

InactiveCN101183093AReduce volumeSimple structureMaterial thermal analysisTemperature controlRadiation thermometer

Owner:WUHAN UNIV OF SCI & TECH

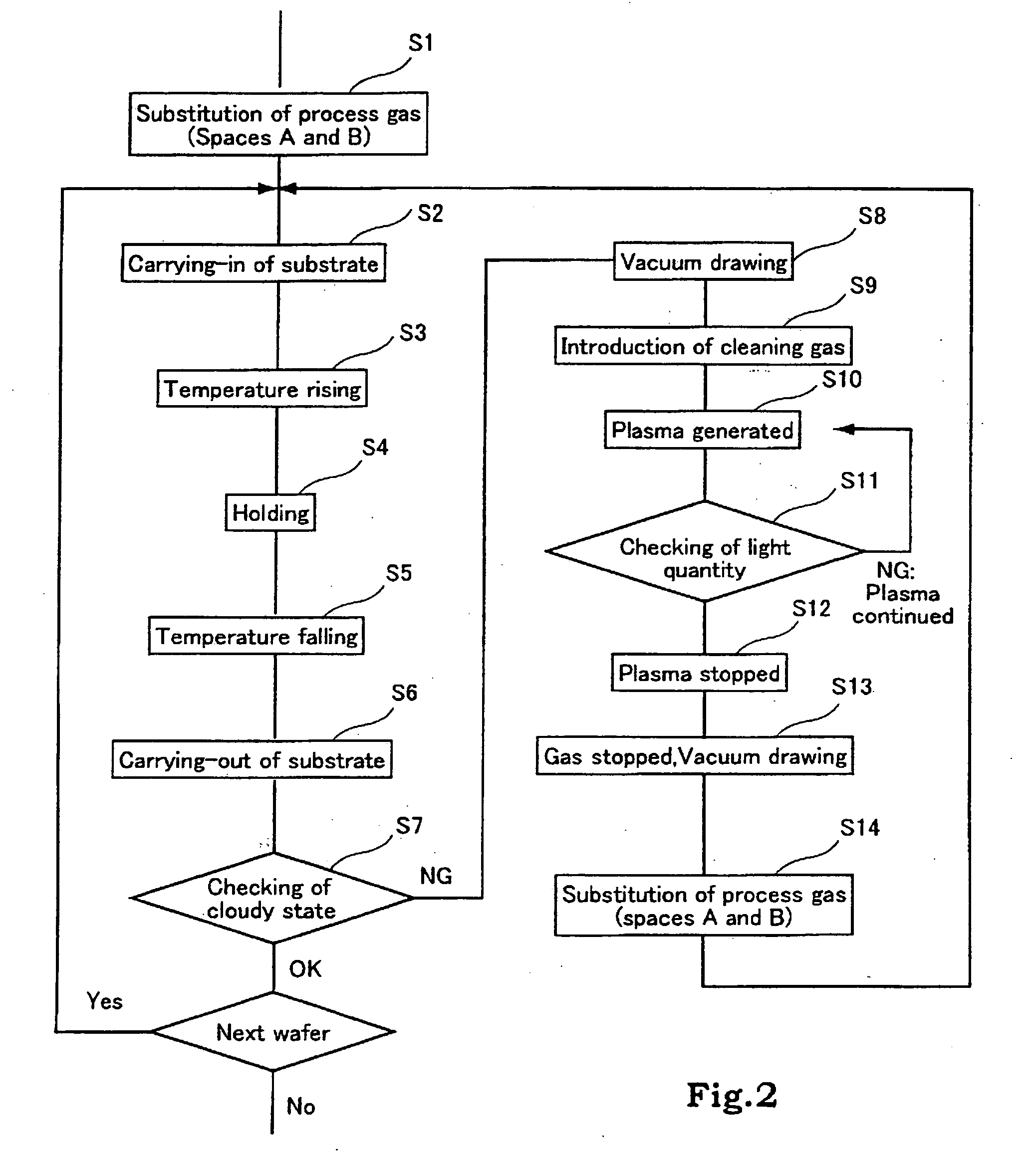

Lamp heating apparatus and method for producing semiconductor device

InactiveUS20080247739A1Improve uniformityImprove processing stabilitySemiconductor/solid-state device manufacturingHigh-frequency/infra-red heating bakingRadiation thermometerRadiant heat

A lamp heating apparatus has: a chamber having a transparent window and housing a substrate; a heating lamp for heating the substrate by radiant heat of a heating lamp through the transparent window; a radiation thermometer that optically detects the temperature of the substrate and has a sensing portion provided in the chamber; a radical generating portion for generating a radical outside the chamber and supplying the radical into the chamber; and a light quantity sensor for determining the time for cleaning the inside of the chamber from a cloudy state of the transparent window and the surface of the sensing portion. This lamp heating apparatus enables a series of operations including heat annealing of the substrate and cleaning of the inside of the chamber. According to this invention, a lamp heating apparatus that has good temperature uniformity and reproductivity of heat processing conditions is obtained.

Owner:SHARP KK

Light irradiation type heat treatment method and heat treatment apparatus

ActiveUS20190157168A1Simple configurationQuickly grasping the behavior of the substrateSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingLight irradiationSusceptor

A front surface of a semiconductor wafer is momentarily heated by irradiation with a flash of light from flash lamps. An upper radiation thermometer and a high-speed radiation thermometer unit measure a temperature of the front surface of the semiconductor wafer after the irradiation with the flash of light. The temperature data are sequentially accumulated, so that a temperature profile is acquired. An analyzer determines the highest measurement temperature of the semiconductor wafer subjected to the flash irradiation from the temperature profile to calculate a jump distance of the semiconductor wafer from a susceptor, based on the highest measurement temperature. If the calculated jump distance is greater than a predetermined threshold value, there is a high probability that the semiconductor wafer is significantly out of position, so that the transport of the semiconductor wafer to the outside is stopped.

Owner:DAINIPPON SCREEN MTG CO LTD

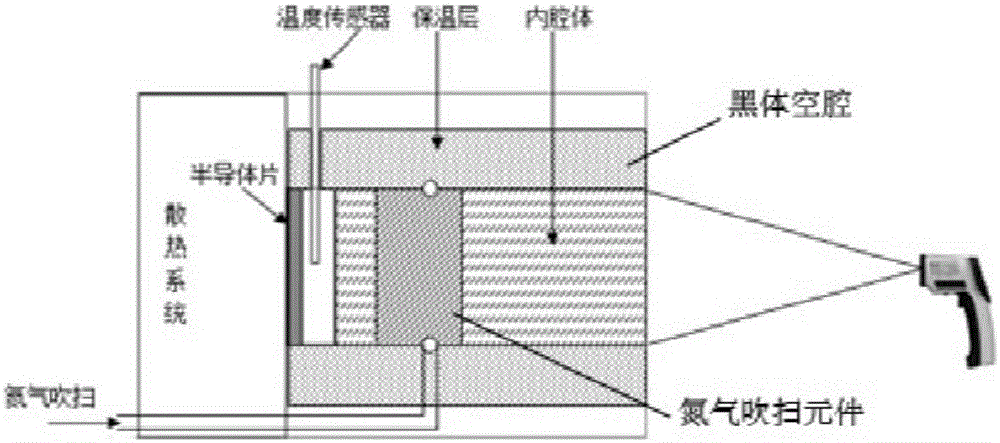

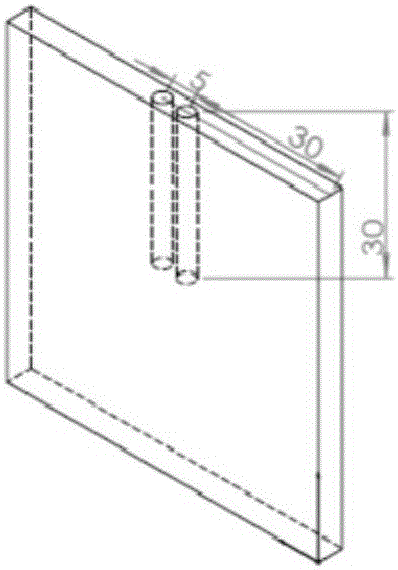

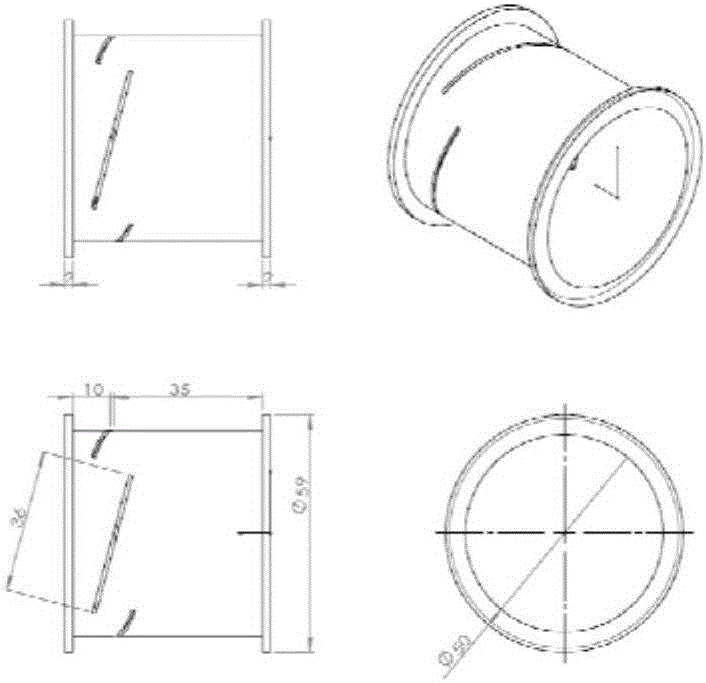

Portable blackbody metering furnace based on semiconductor and mini-sized water cooling and heat radiation technology

InactiveCN105865632AFast heating and coolingHigh emissivityRadiation pyrometryTemperature controlRough surface

The invention discloses a portable blackbody metering furnace based on a semiconductor and a mini-sized water cooling and heat radiation technology. The furnace includes a blackbody cavity of which one end is provided with a uniform temperature block. The uniform temperature block is provided with a temperature sensor at the center position inside the uniform temperature block. Outside the blackbody cavity, a surface of the uniform temperature block is closely adhered to a semiconductor sheet. A surface of the semiconductor sheet is closed adhered to a heat radiation system. Inside the blackbody cavity, a surface of the uniform temperature block is subject to rough treatment and assumes a rough surface, and is also subject to blackening treatment. The blackbody cavity is provided with a nitrogen purging element therein. An external circumference of the blackbody cavity is wrapped with a heat-insulation layer. The furnace also includes a PCB temperature control circuit which is intended for regulating heating or cooling of the semiconductor sheet based on an output of a temperature control instrument. The furnace provides a comparatively stable calibration source for a medium and low temperature infrared thermometric indicator on an industrial site to conduct accurate calibration. The furnace is easy to carry out and fast in temperature increasing and decreasing rate, and can greatly increase calibration efficiency of a radiation thermometer.

Owner:ZHEJIANG MEASUREMENT SCI RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com