Thermal processing apparatus and thermal processing method through light irradiation

a technology of thermal processing apparatus and thermal processing method, which is applied in the direction of optical radiation measurement, semiconductor/solid-state device testing/measurement, instruments, etc., can solve the problems of encumbrance of radiation thermometers and excessive output of lamps, and achieve the effect of accurately measuring the temperature of substrates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037]Preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

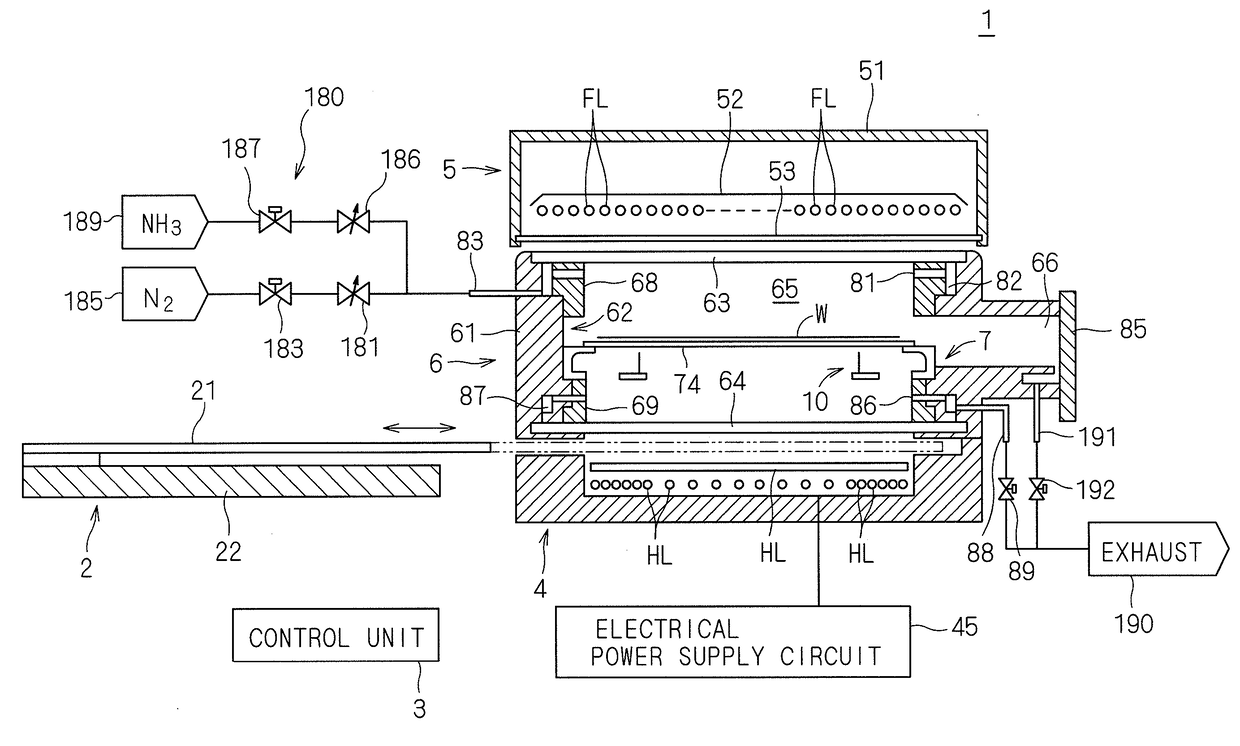

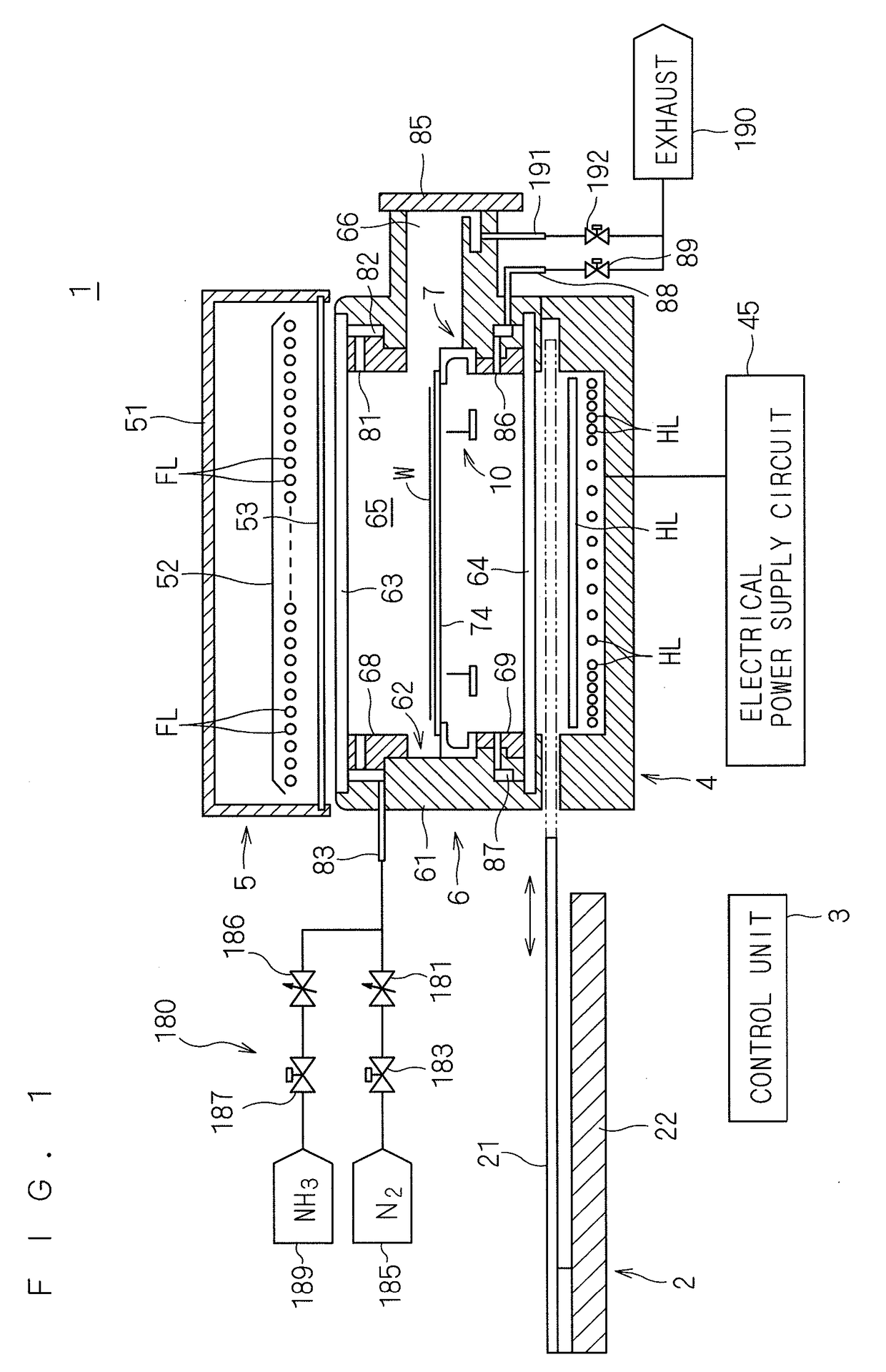

[0038]FIG. 1 is a vertical sectional view illustrating the configuration of a thermal processing apparatus 1 according to the present invention. The thermal processing apparatus 1 according to the present preferred embodiment is a flash lamp annealer configured to facilitate post deposition annealing (PDA) of a high-dielectric-constant gate insulating film (high-k film) by irradiating, with flash light in ammonia atmosphere, a semiconductor substrate W on which the high-dielectric-constant gate insulating film is deposited. In FIG. 1 and the following drawings, the dimension of each component and the number thereof are exaggerated or simplified as necessary to facilitate understanding.

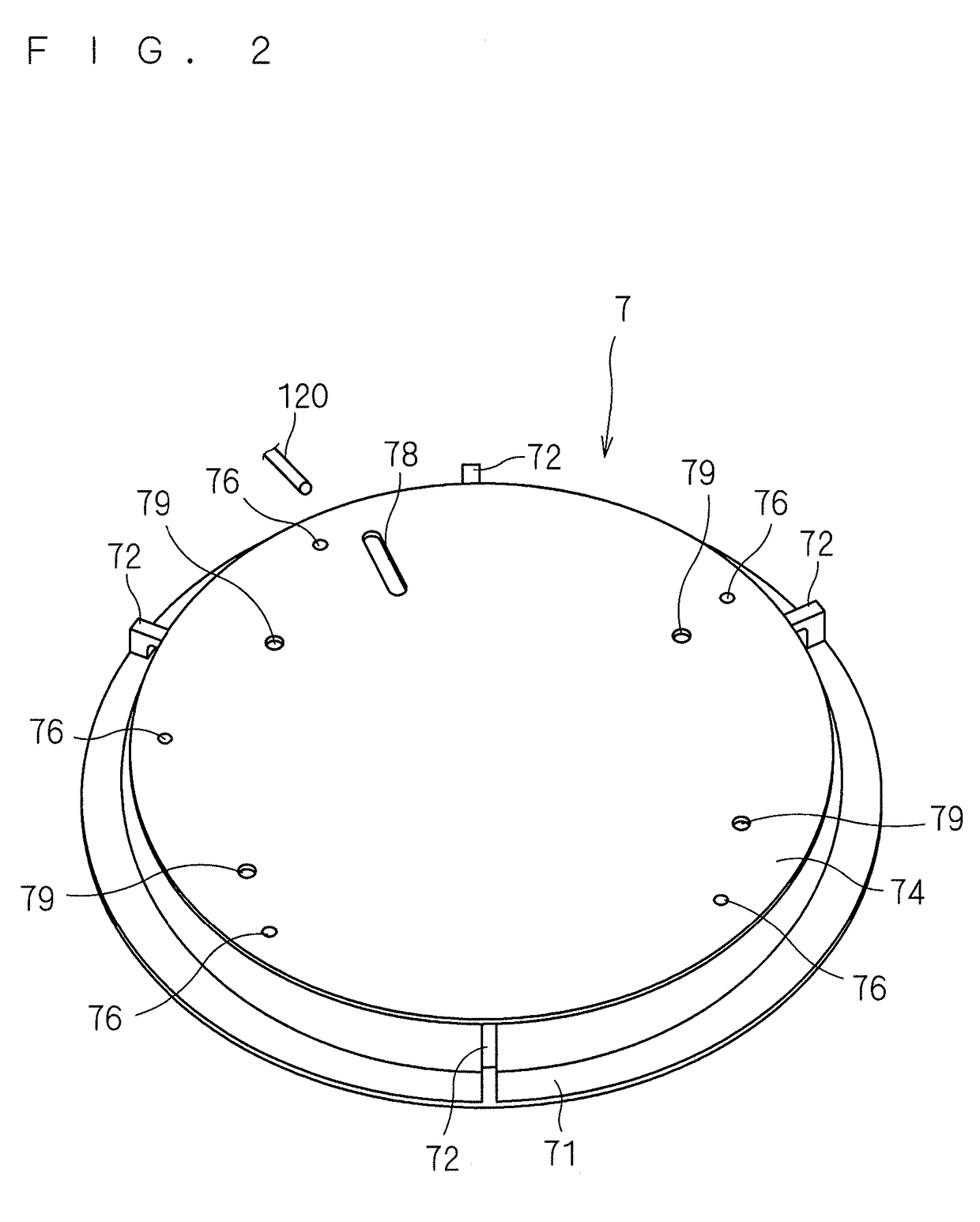

[0039]The thermal processing apparatus 1 includes a chamber 6 configured to house the substrate W, a flash heating unit 5 including a plurality of built-in flash lamps FL, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com