Patents

Literature

107results about How to "Uneven thickness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

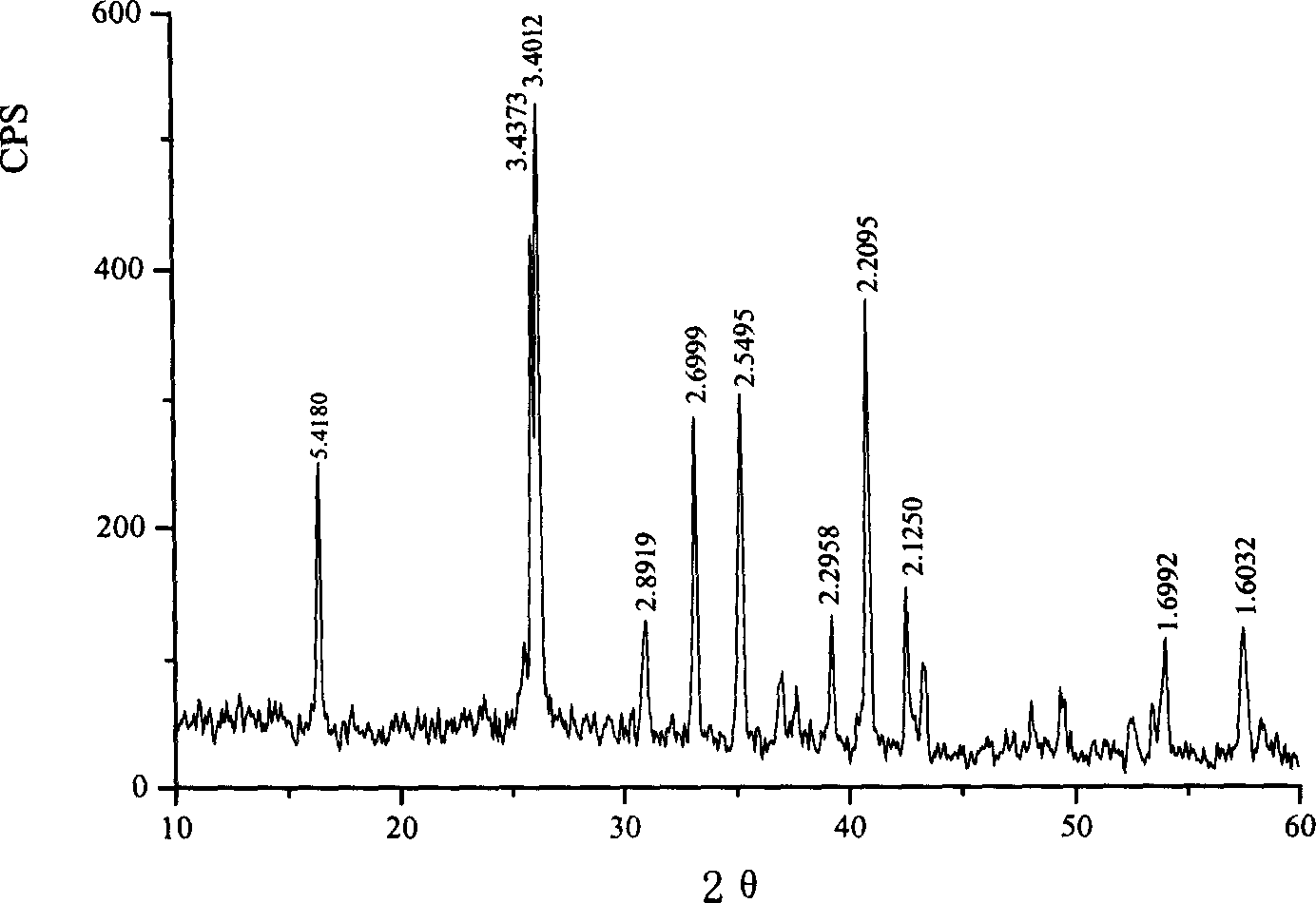

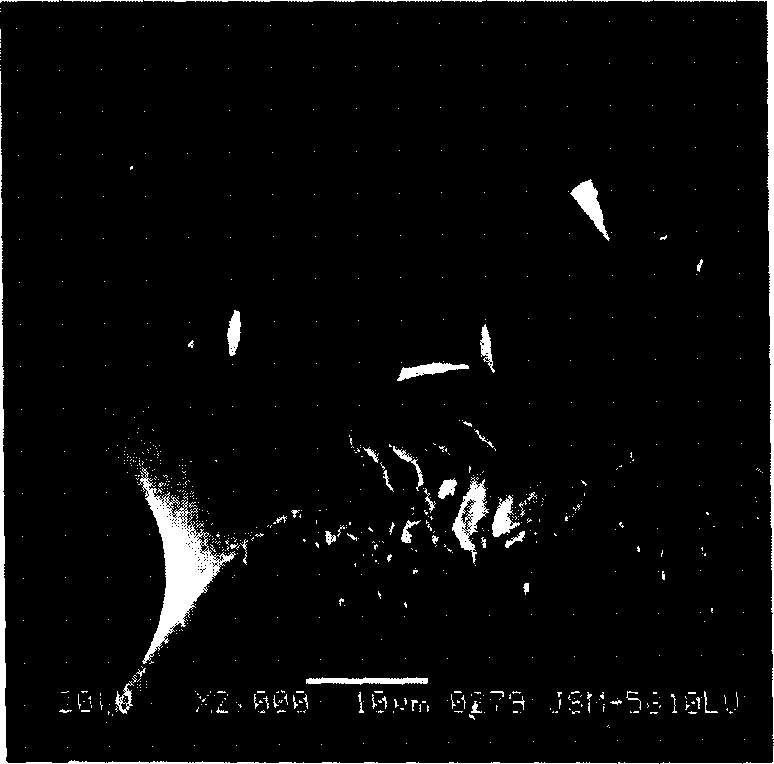

Mullite whisker-mullite composite coating and preparation process thereof

InactiveCN1793017AModerate thicknessOvercome the problem of being thin, dry and easy to crackMulliteOxidation resistant

The invention relates to mullite crystal whisker mullite compounding coating layer that the manufacture method includes the following steps: coating the mixture slime of silica sol, aluminum sol and mullite slime in vacuum of the basal material, or coating orderly, under the catalyzing effect of metal fluoride mineralizer, sintering by high temperature. The invention is simple structure, low cost of raw material, acid proof, alkali proof, etc. it could improve the intension of the material and prolong the use life.

Owner:WUHAN UNIV OF TECH

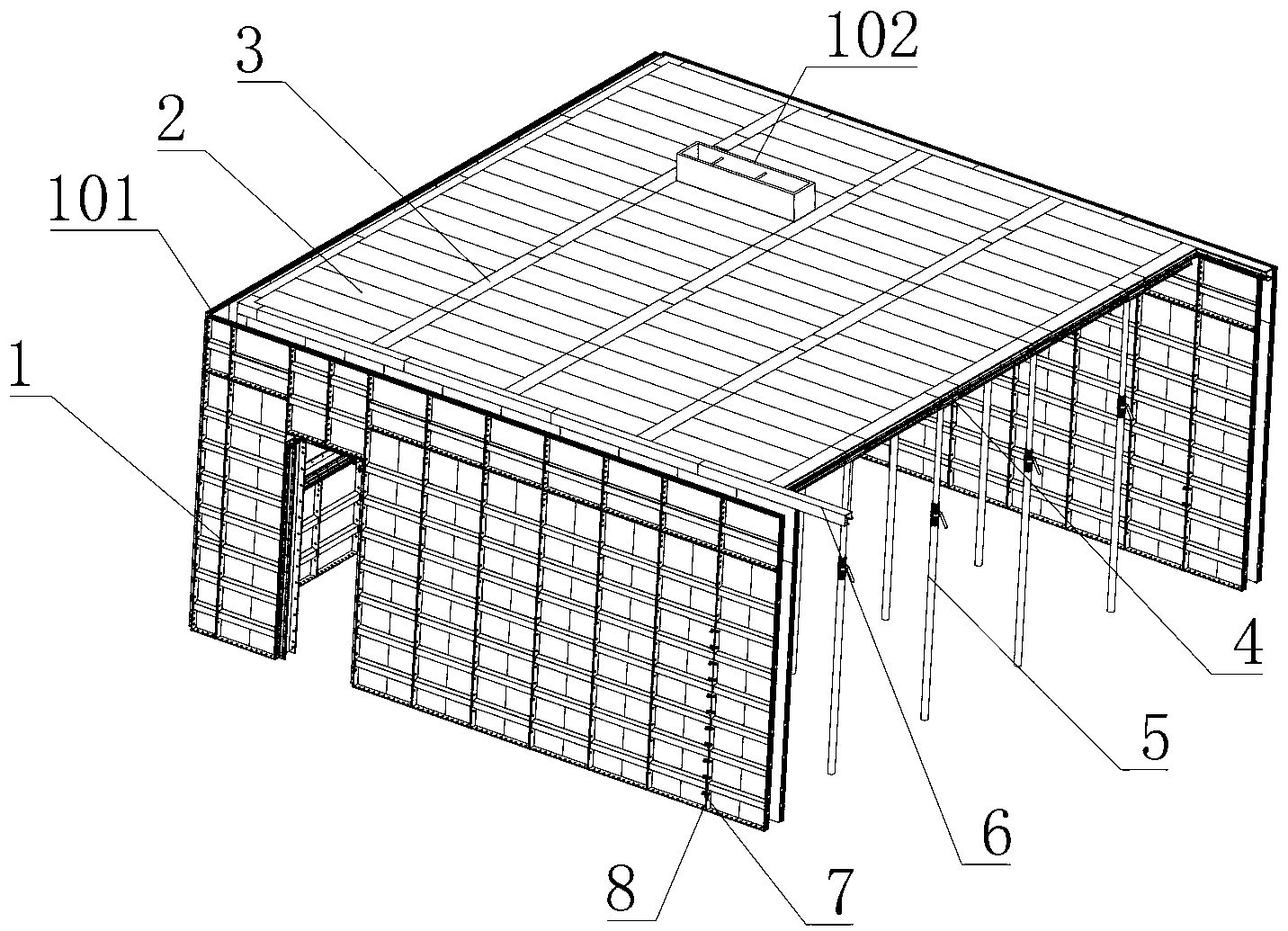

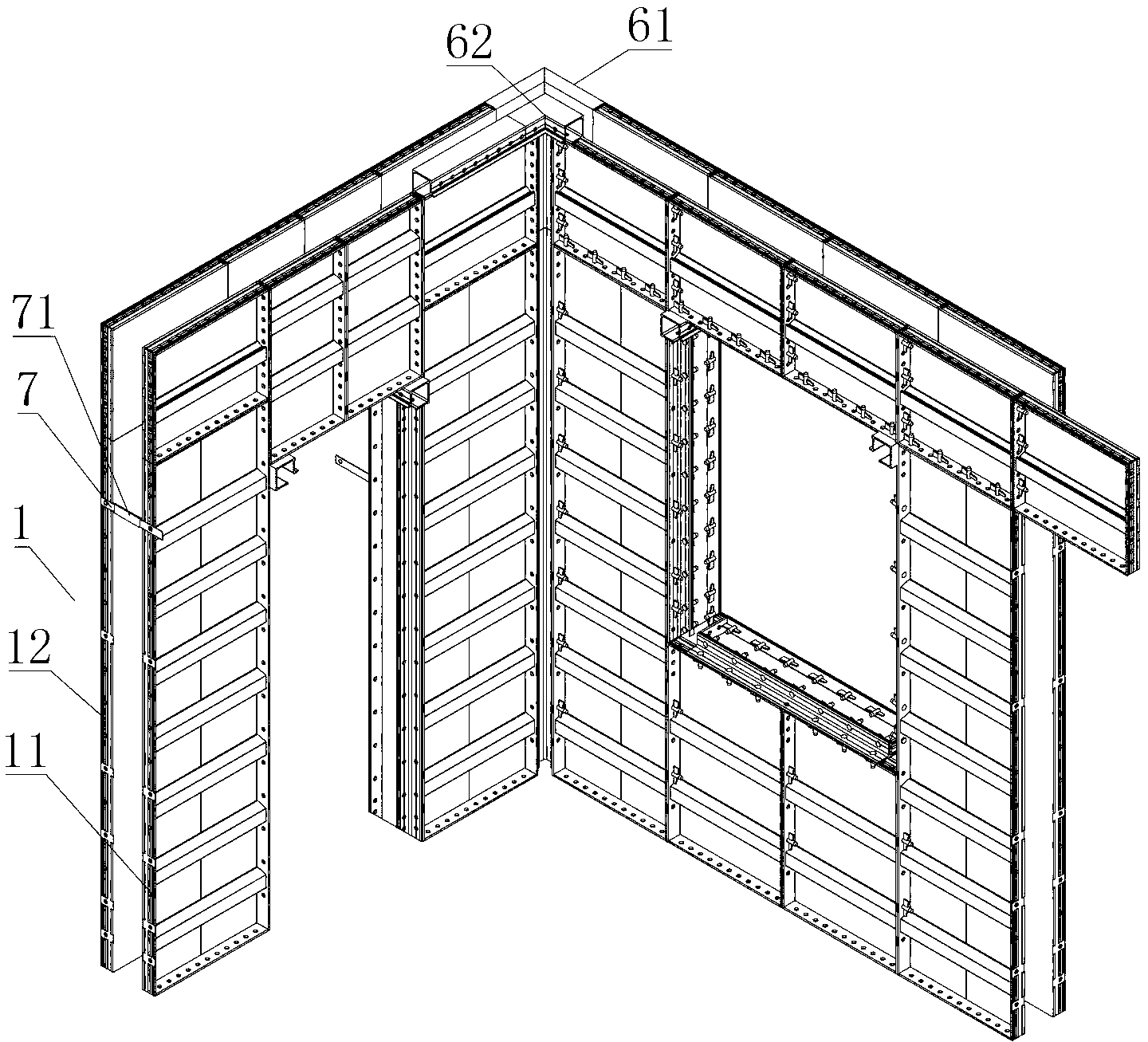

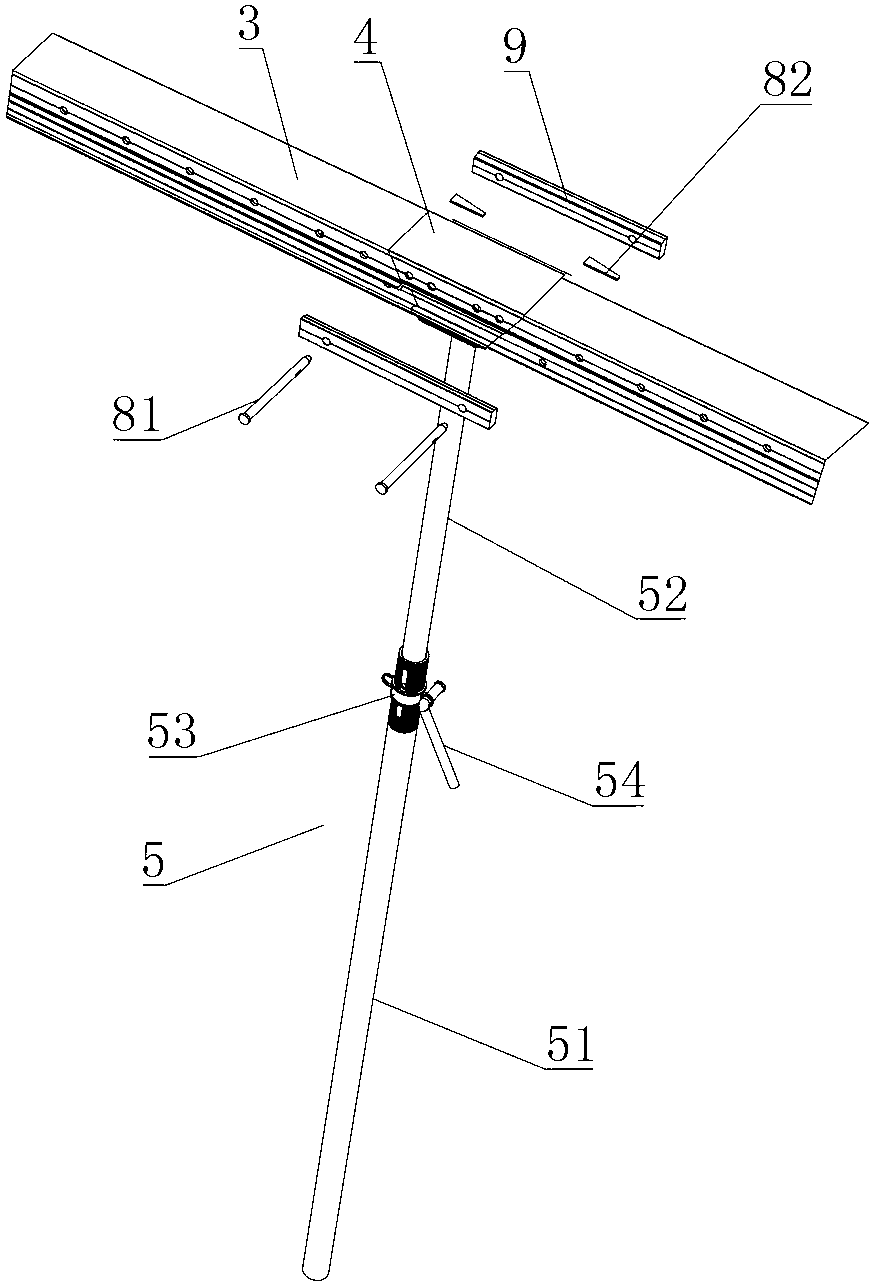

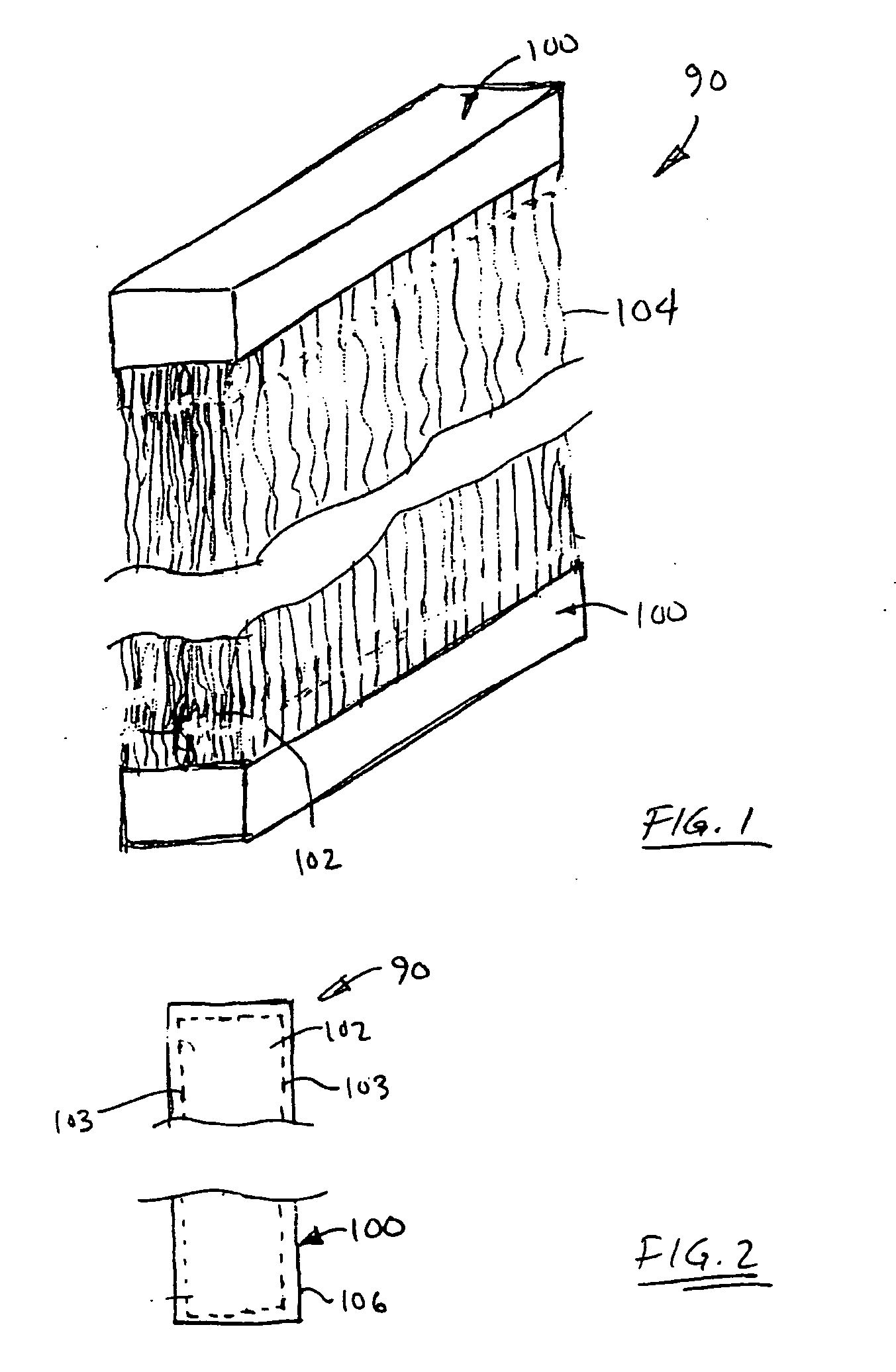

Aluminum template system for building

InactiveCN103276891AImprove turnover rateReduce construction costsForms/shuttering/falseworksAuxillary members of forms/shuttering/falseworksUtilization rateBuilding construction

The invention belongs to the technical field of building construction and particularly discloses an aluminum template system for building. The system comprises wall boards, floor boards and supporting structures used for supporting the floor boards. The wall boards comprise inner wall boards and outer wall boards. The supporting structures comprise support columns, end beams and top head sleeves rotating at the top ends of the support columns and connected with the end beams. Quick locking and connection of adjacent templates are achieved through a bolt locking structure. Corner templates are arranged at the corner positions among the boards. Matching splicing of standard templates and non-standard templates is adopted in the system to form a building floor, then concrete is poured conveniently and quickly, the supporting structures adopt the mode that the end beams are separated from the support columns, the wall boards can be disassembled 12 hours after the concrete is poured, the floor boards and the end beams can be disassembled after 35 hours, template utilization rate is improved, the standard degree is high, construction cost is reduced, construction efficiency is improved, and the requirement for modern construction can be met.

Owner:GUANGDONG TAIAO SPECIAL ALUMINUM

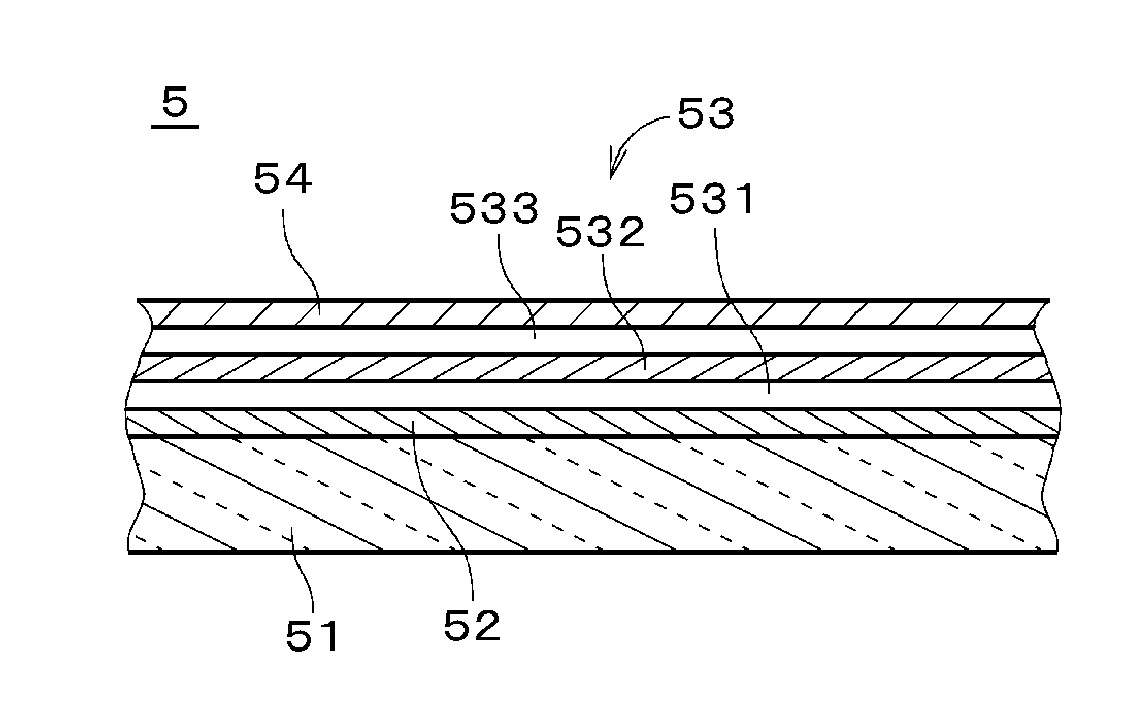

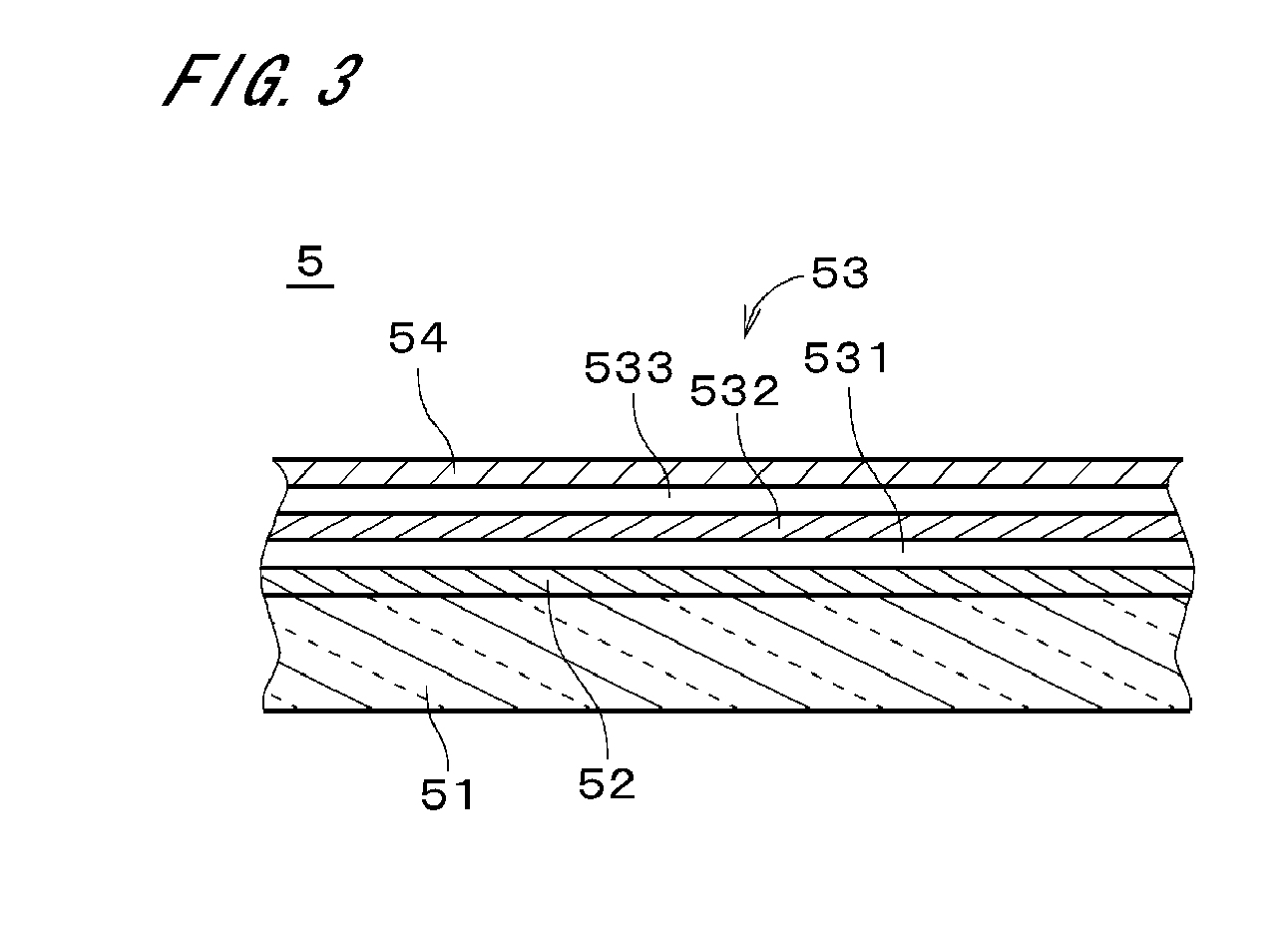

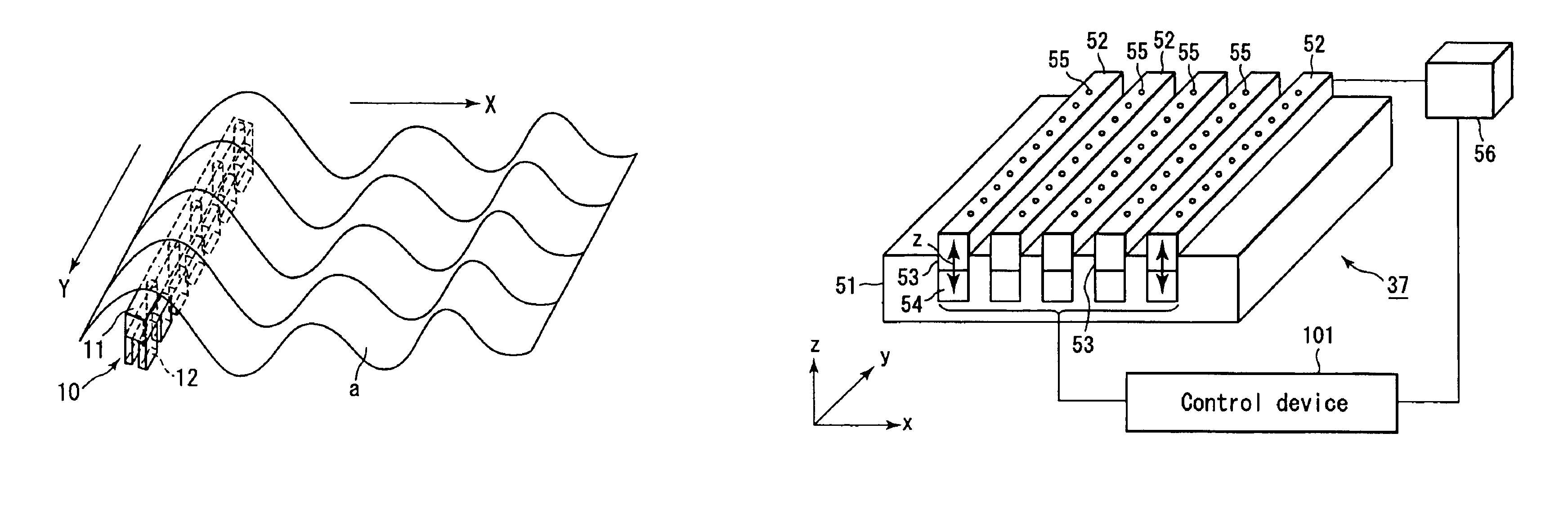

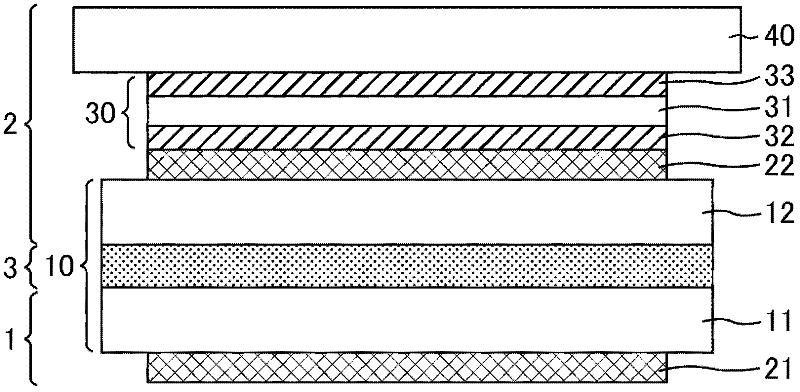

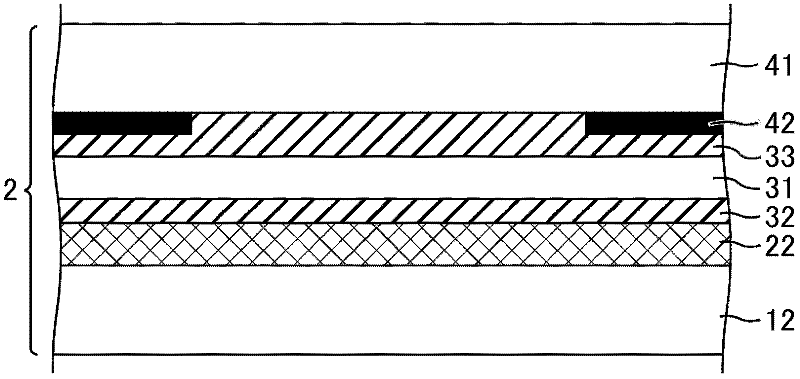

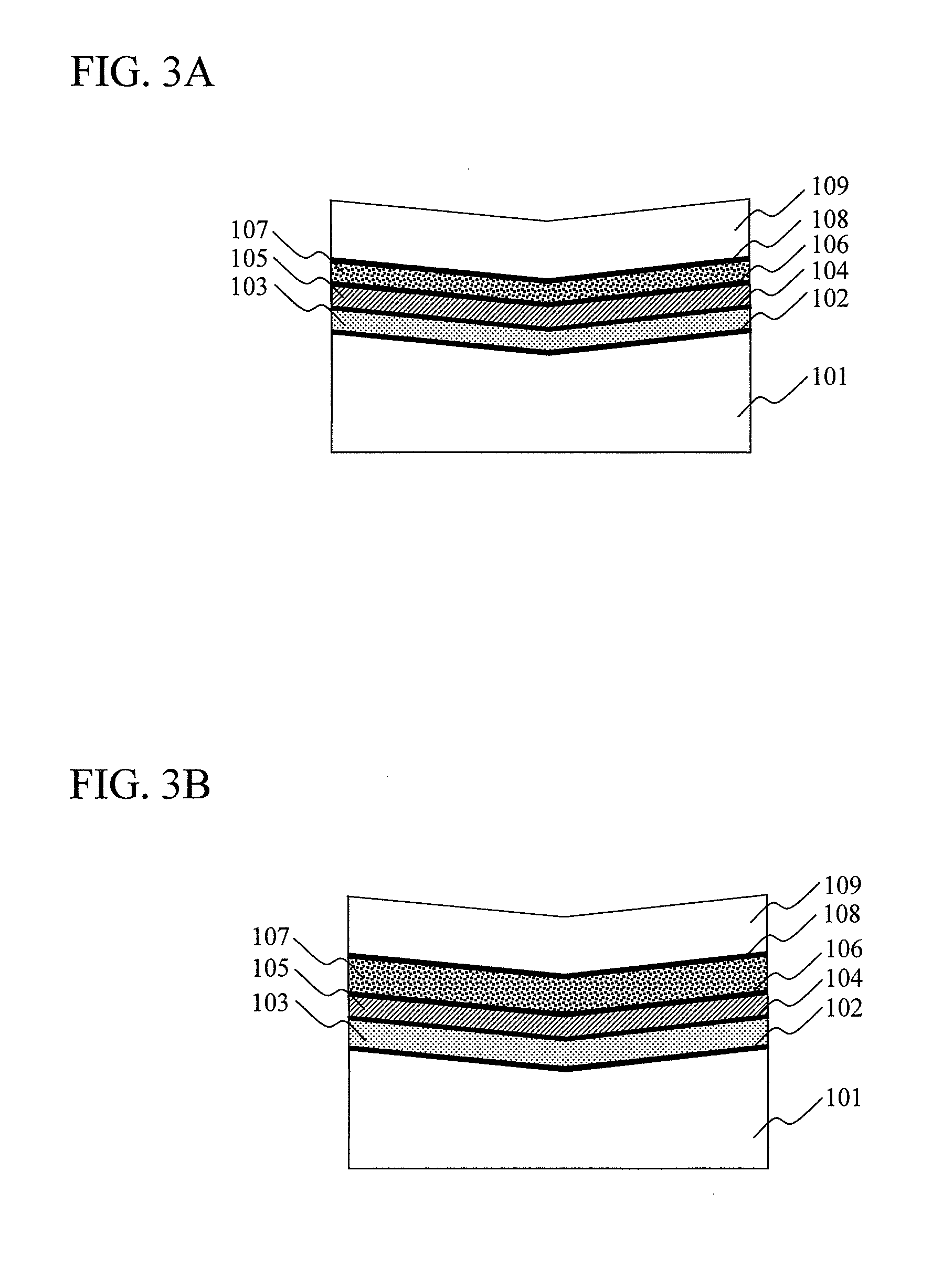

Printed material, method of producing printed material, and printer

ActiveUS20120076999A1Prevent and suppress undulationUneven thicknessLayered productsDuplicating/marking methodsPrinting pressComputer science

A printed material (5) has a transparent base member (51), a first image layer (52) formed on the base member, an intermediate layer (53) formed on the first image layer, and a second image layer (54) formed on the intermediate layer. The intermediate layer has a lower white background layer (531) positioned above the first image layer, a light blocking layer (532) positioned above the lower white background layer, and an upper white background layer (533) positioned above the light blocking layer. In the printed material, a thickness of the light blocking layer is uneven in conformity with undulation of the first image layer, and therefore a surface of the intermediate layer which is in contact with the second image layer is flat. With this structure, it is possible to prevent or suppress the undulation of the first image layer from appearing in the second image layer.

Owner:DAINIPPON SCREEN MTG CO LTD

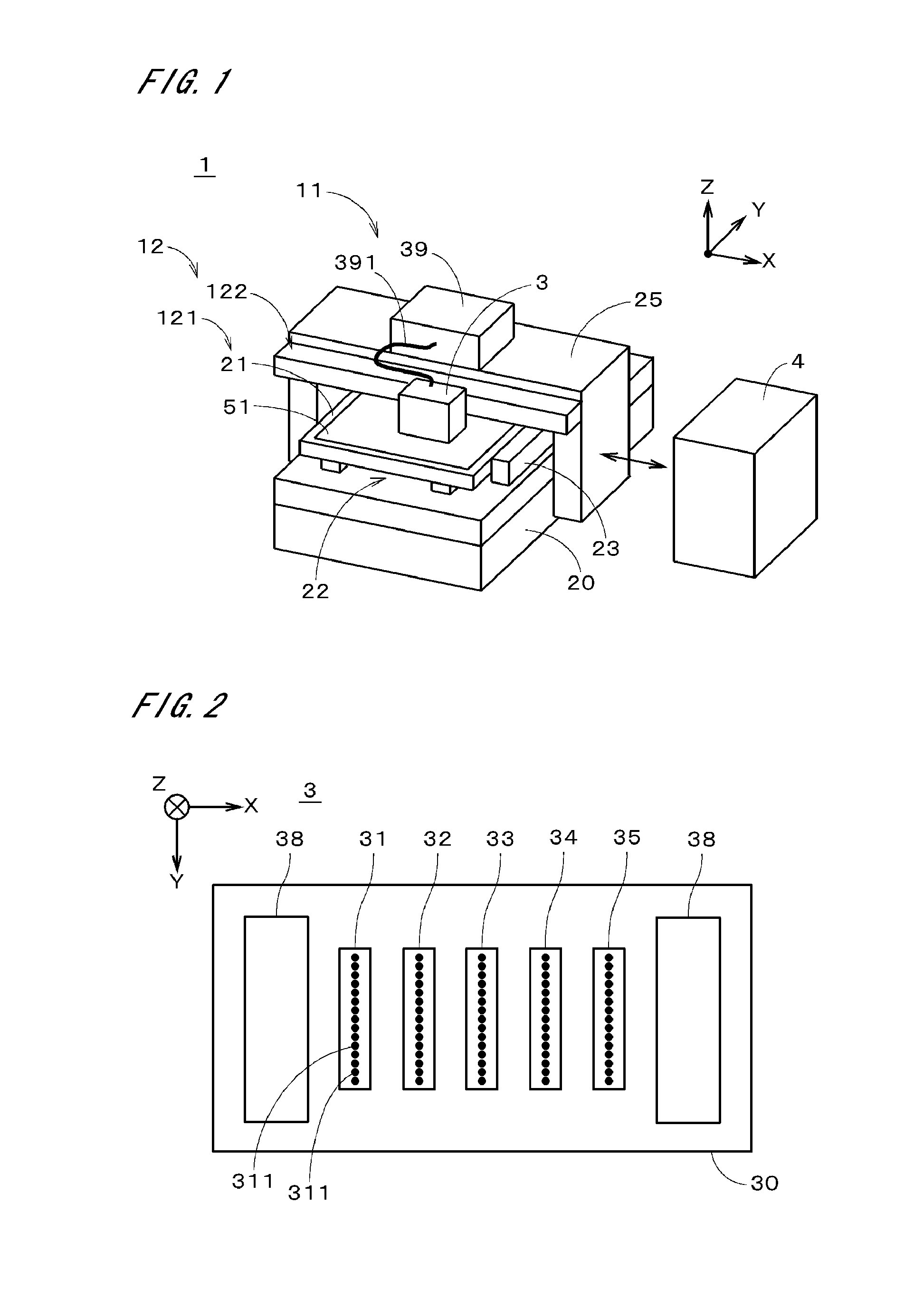

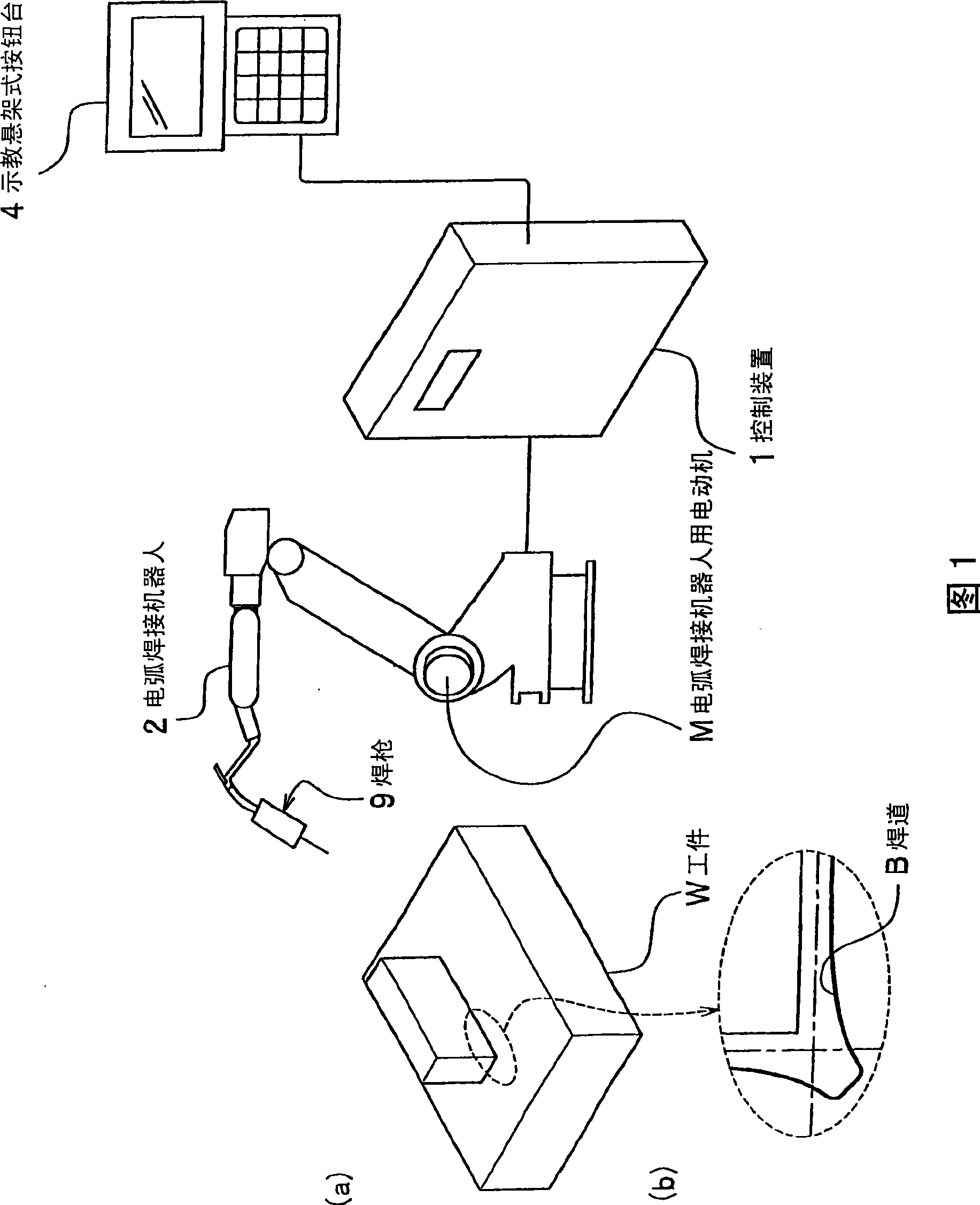

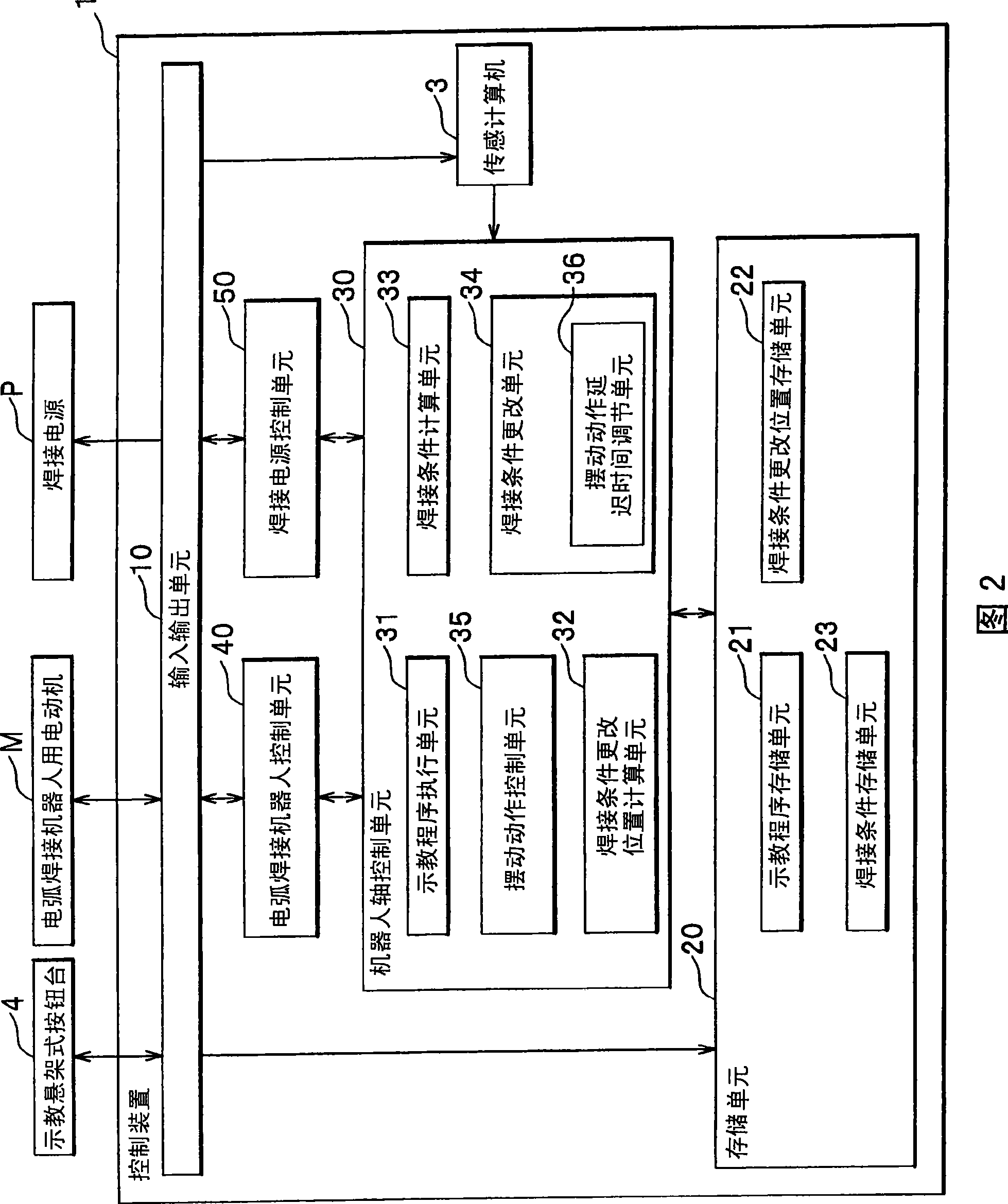

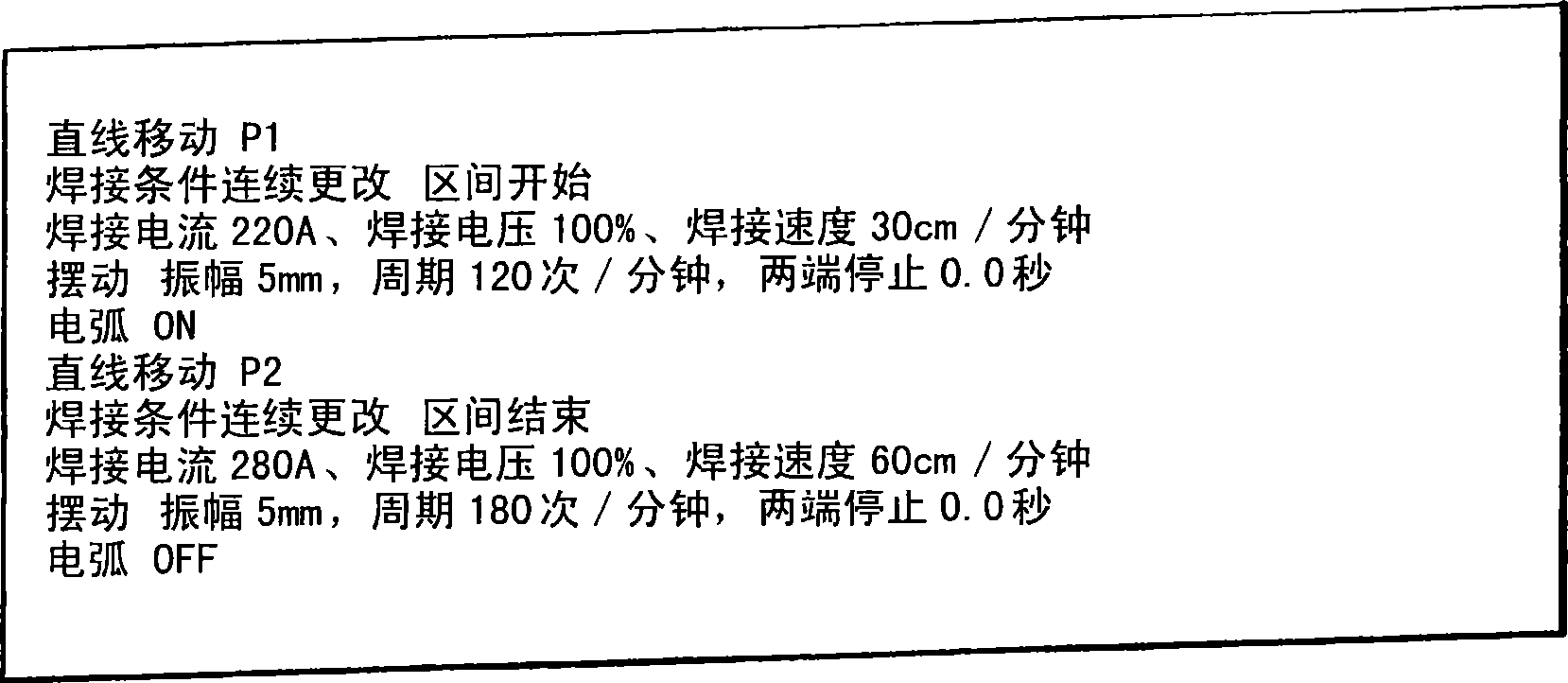

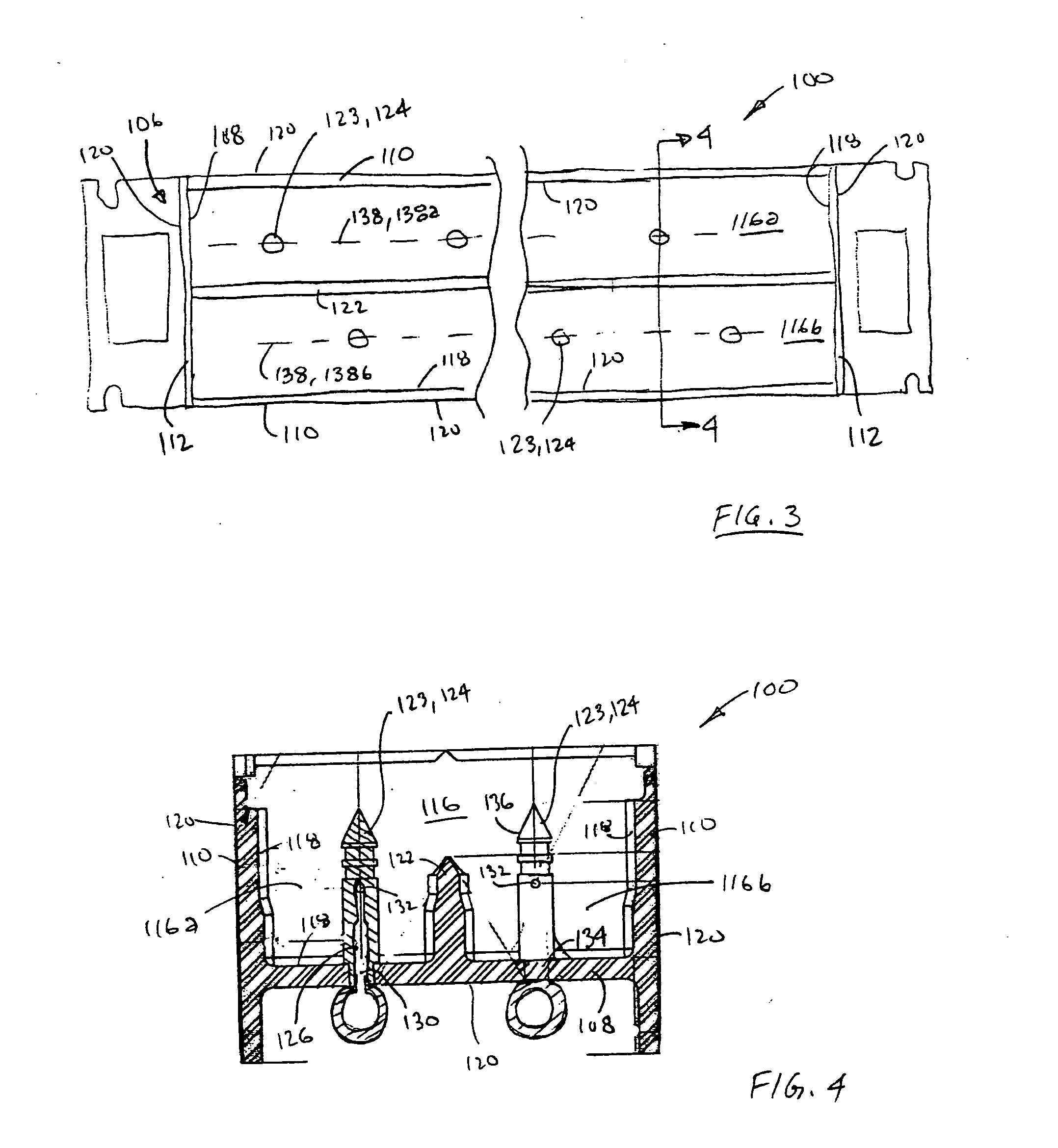

Arc welding robot control system and method thereof

ActiveCN101422837AUneven thicknessReduce latency impactProgramme controlComputer controlChange positionsRobot control system

An arc welding robot control system of the present invention includes memory devices, controlling devices, a welding condition changing position calculating device (32), a weaving operation controlling device (35) that outputs a signal of completion of one weaving cycle every time when a welding torch completes to perform one weaving cycle of a predetermined movement pattern, a welding condition calculating device (33) for calculating to-be-changed welding conditions, and a welding condition changing device (34) that changes welding conditions of an arc welding robot, based on to-be-changed welding conditions, every time when a signal of completion of one weaving cycle is input. With this configuration, it enables a continuous change of welding conditions and a copying arc welding with high accuracy even in the case in which the arc welding robot performs a weaving operation.

Owner:KOBE STEEL LTD

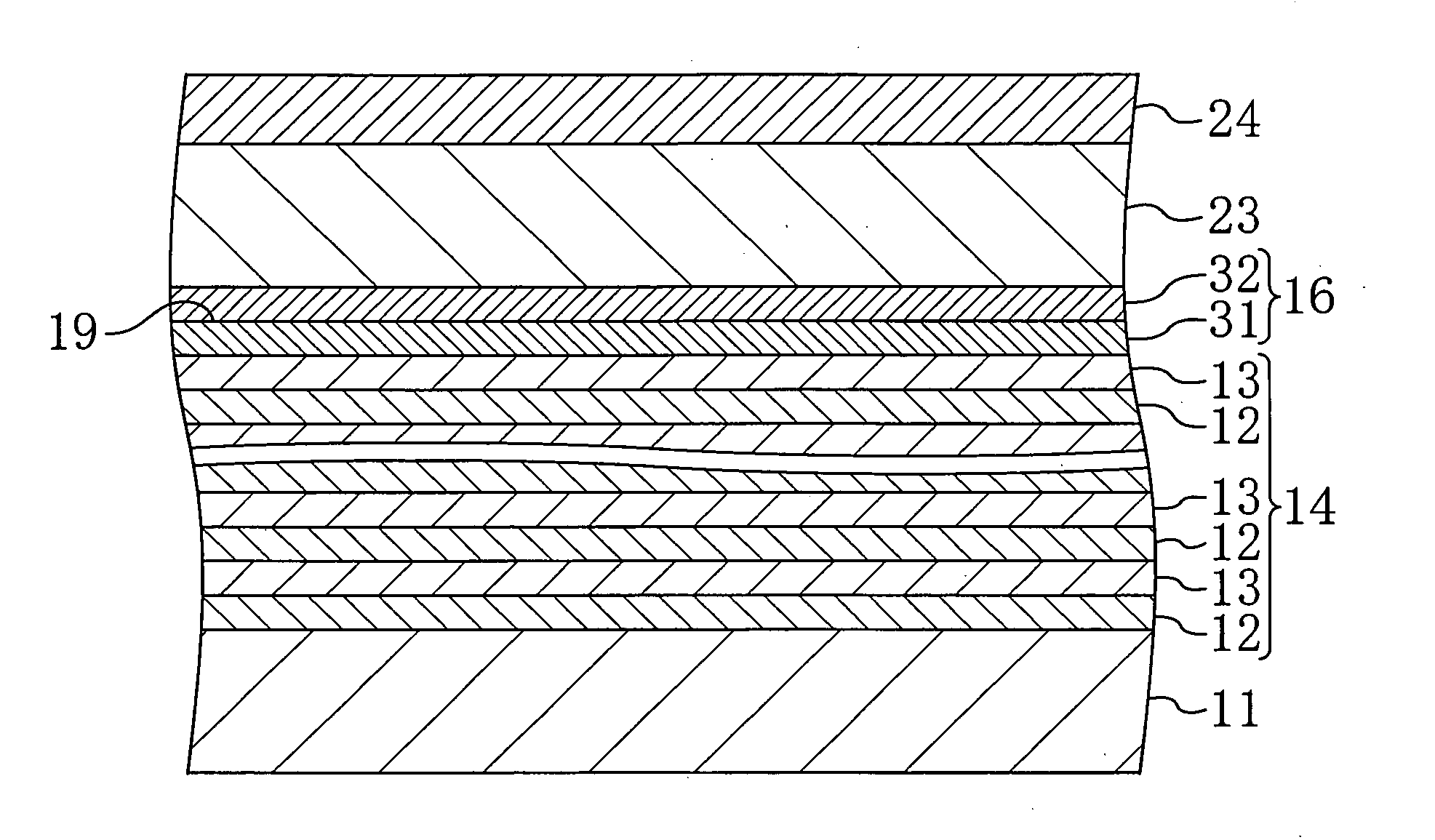

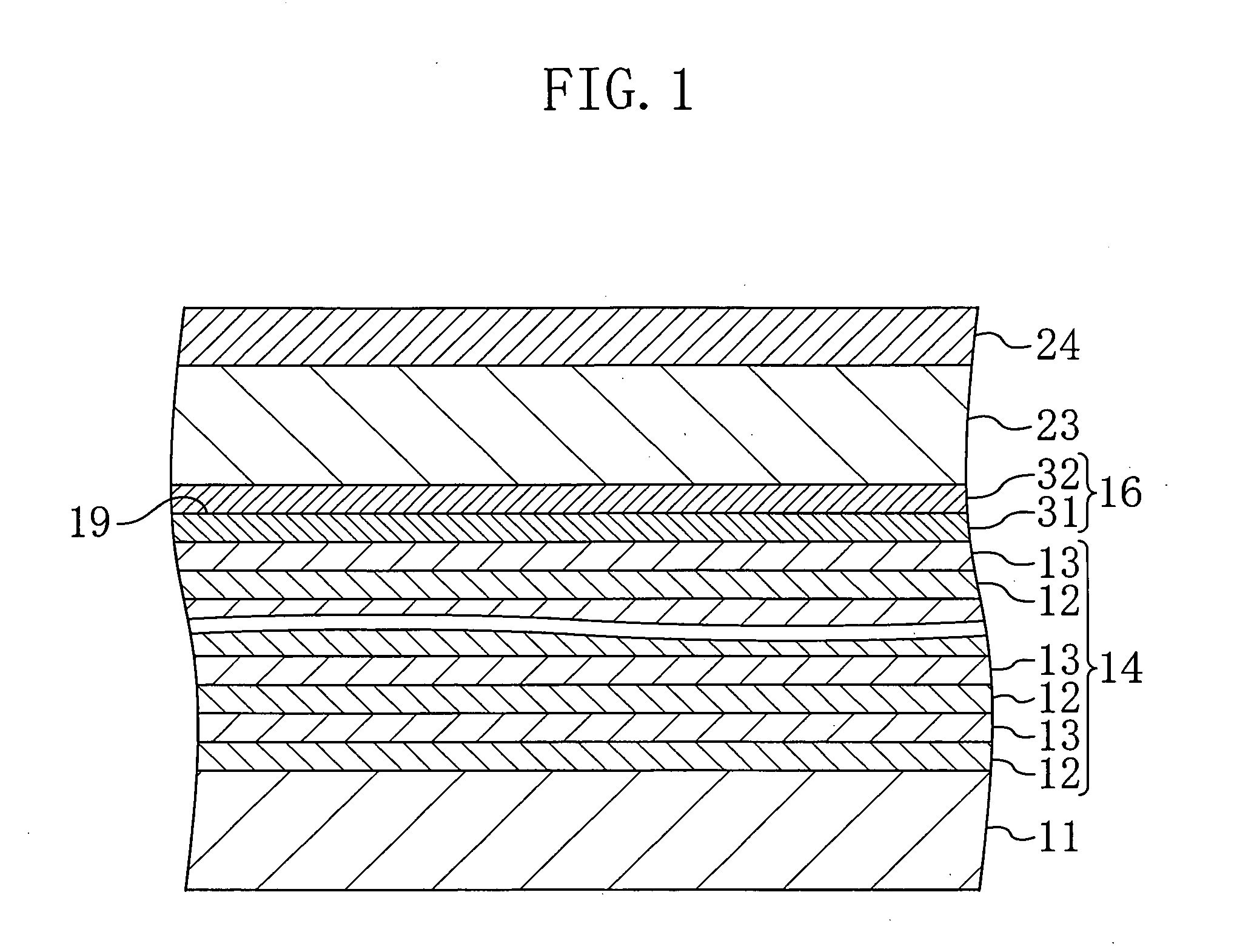

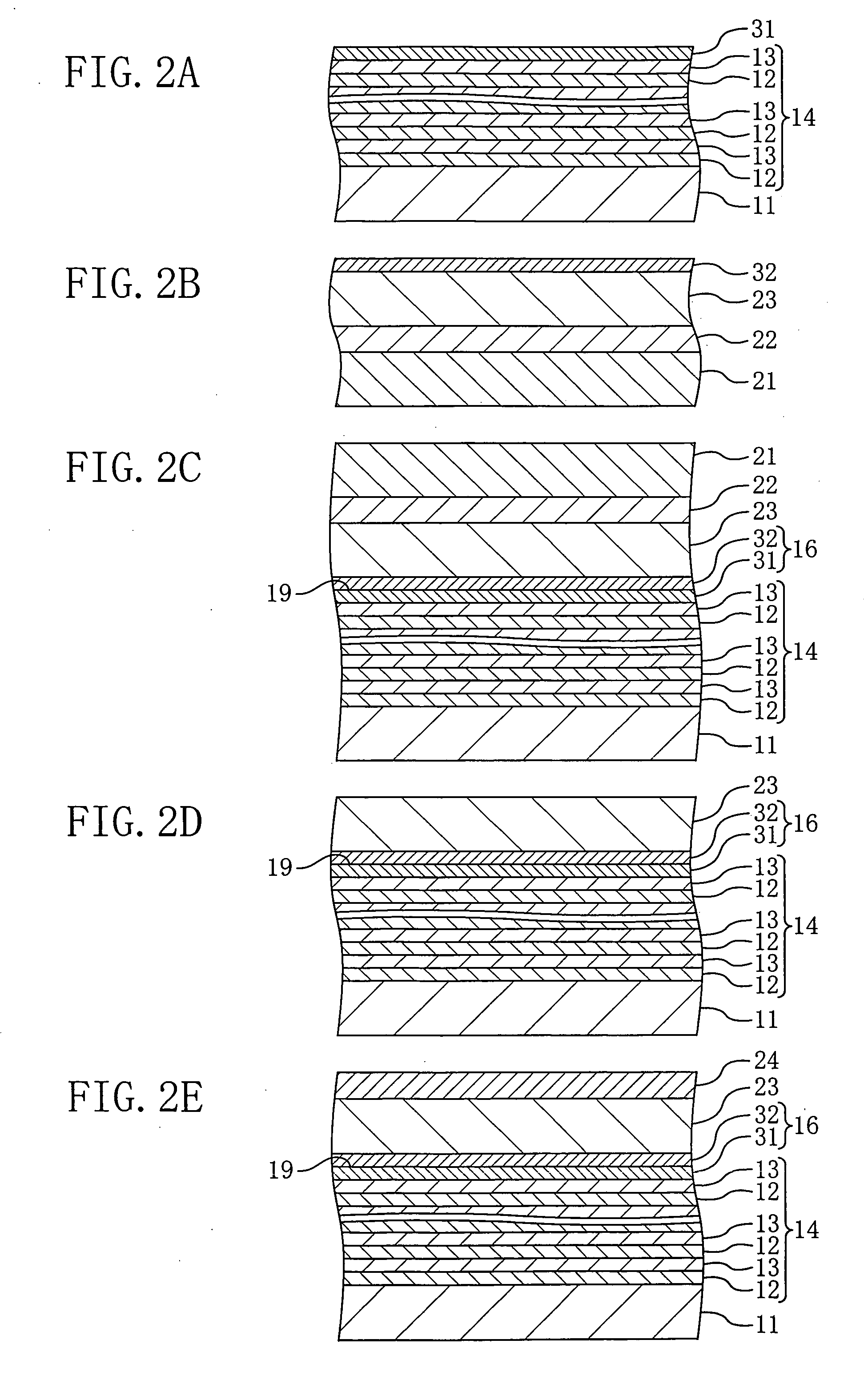

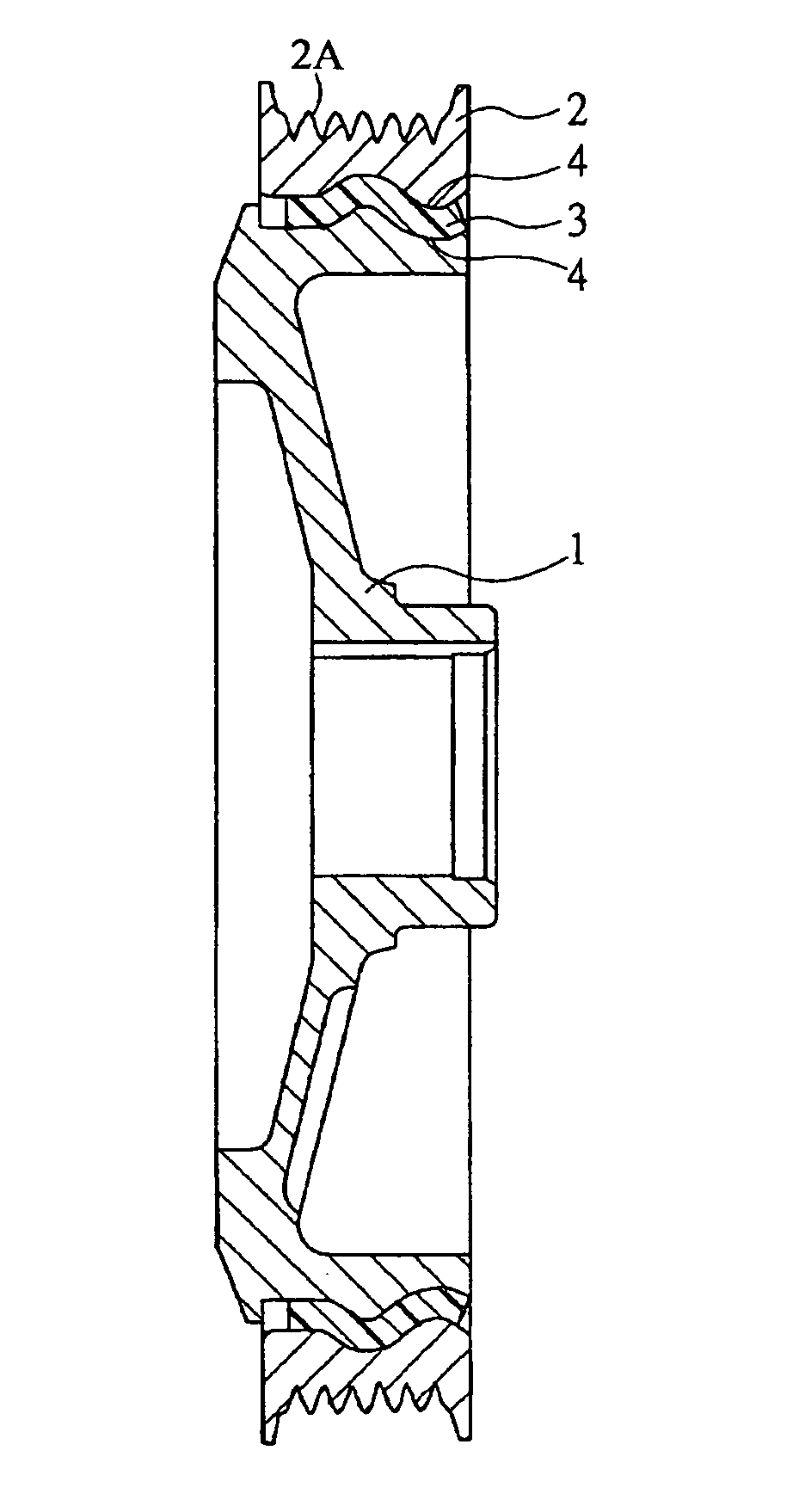

Piezoelectric resonator and method for manufacturing the same

InactiveUS20060145785A1Prevent interdiffusionEliminate needPiezoelectric/electrostrictive device manufacture/assemblyImpedence networksBond interfaceAcoustics

A piezoelectric resonator includes a substrate, an acoustic mirror formed on the substrate and includes alternately stacked first acoustic mirror material layers and second acoustic mirror material layers having higher acoustic impedance than that of the first acoustic mirror material layers, a piezoelectric film formed on the acoustic mirror, a top electrode formed on the piezoelectric film and a bottom electrode formed below the piezoelectric film. A bonding interface is provided between metal films bonded to each other between the substrate and the piezoelectric film.

Owner:PANASONIC CORP

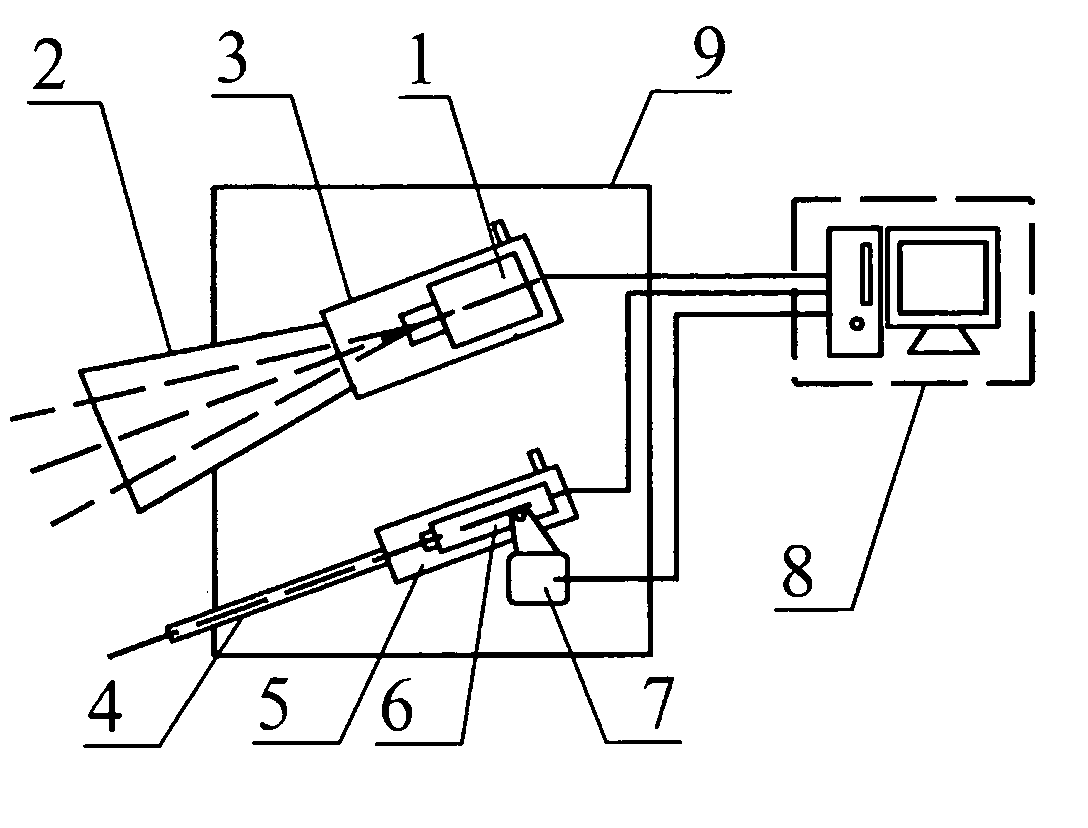

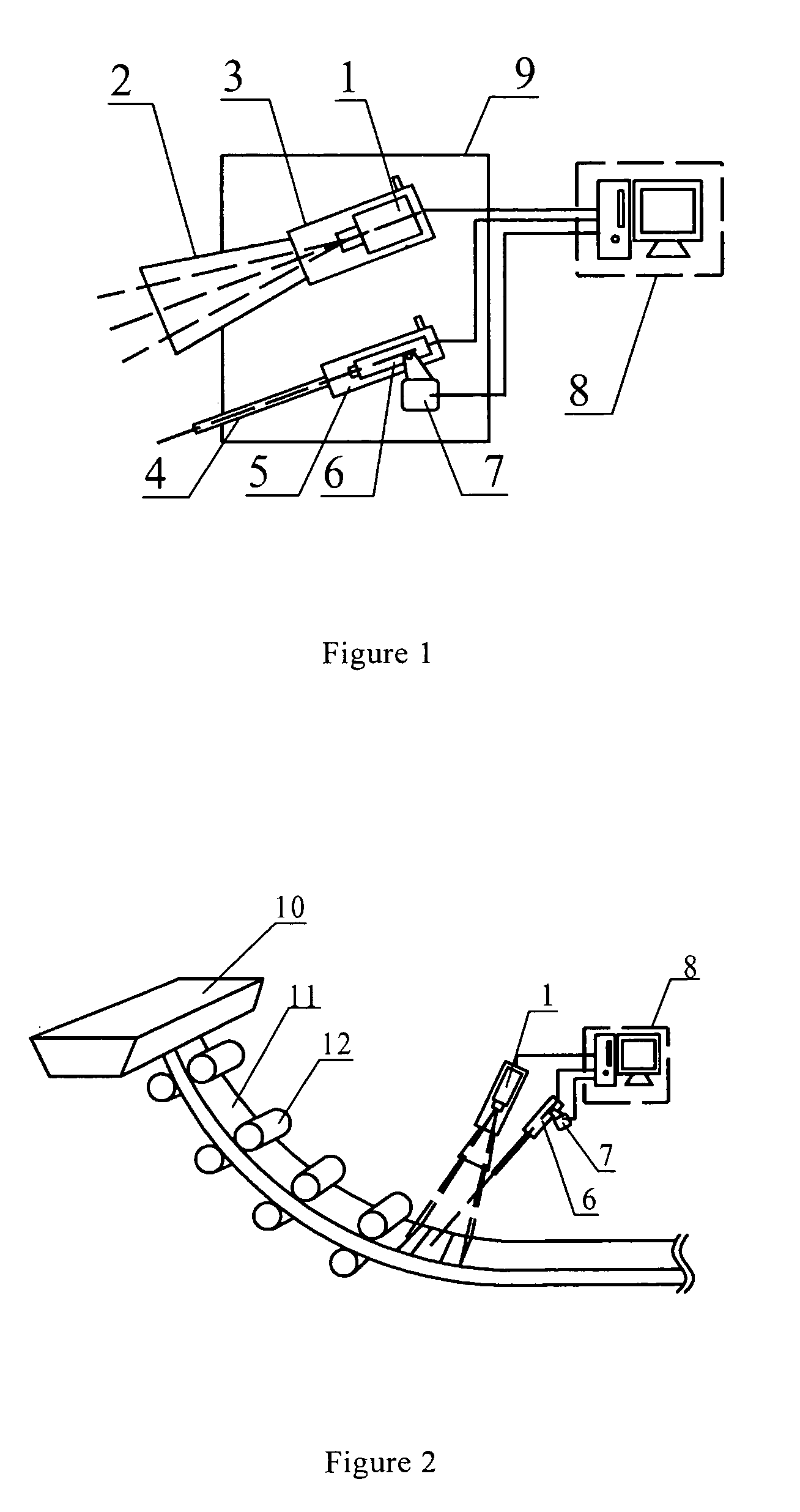

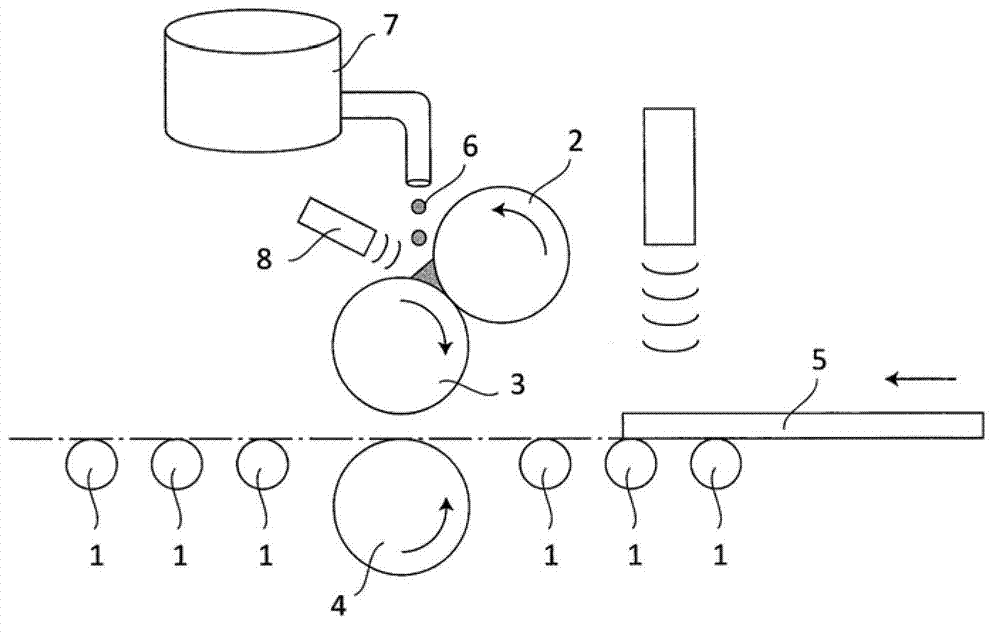

Apparatus and method for measuring the surface temperature of continuous casting billet/slab

ActiveUS20100236743A1Small geometryUneven thicknessThermometer detailsCasting safety devicesData processing systemRadiation thermometer

The present invention discloses a method and apparatus for measuring the temperature field on the surface of casting billet / slab, including: a thermal imager, an infrared radiation thermometer, a mechanical scanning unit, an image and data processing system; the thermal imager, the infrared radiation thermometer and the mechanical scanning unit are respectively connected to the image and data processing system; the infrared radiation thermometer is installed on the mechanical scanning unit and can measure the temperature of casting billet / slab surface by scanning; the thermal imager can measure the temperature of a certain area on the surface of casting billet / slab by thermal imaging. The present invention makes use of the combination of high-resolution thermal imager and scan-type infrared radiation thermometer, through the model-based filtering method, overcomes the influence of iron scales on the surface of casting billet / slab, and implements real-time stable measurement of surface temperature of casting billet / slab.

Owner:NORTHEASTERN UNIV +1

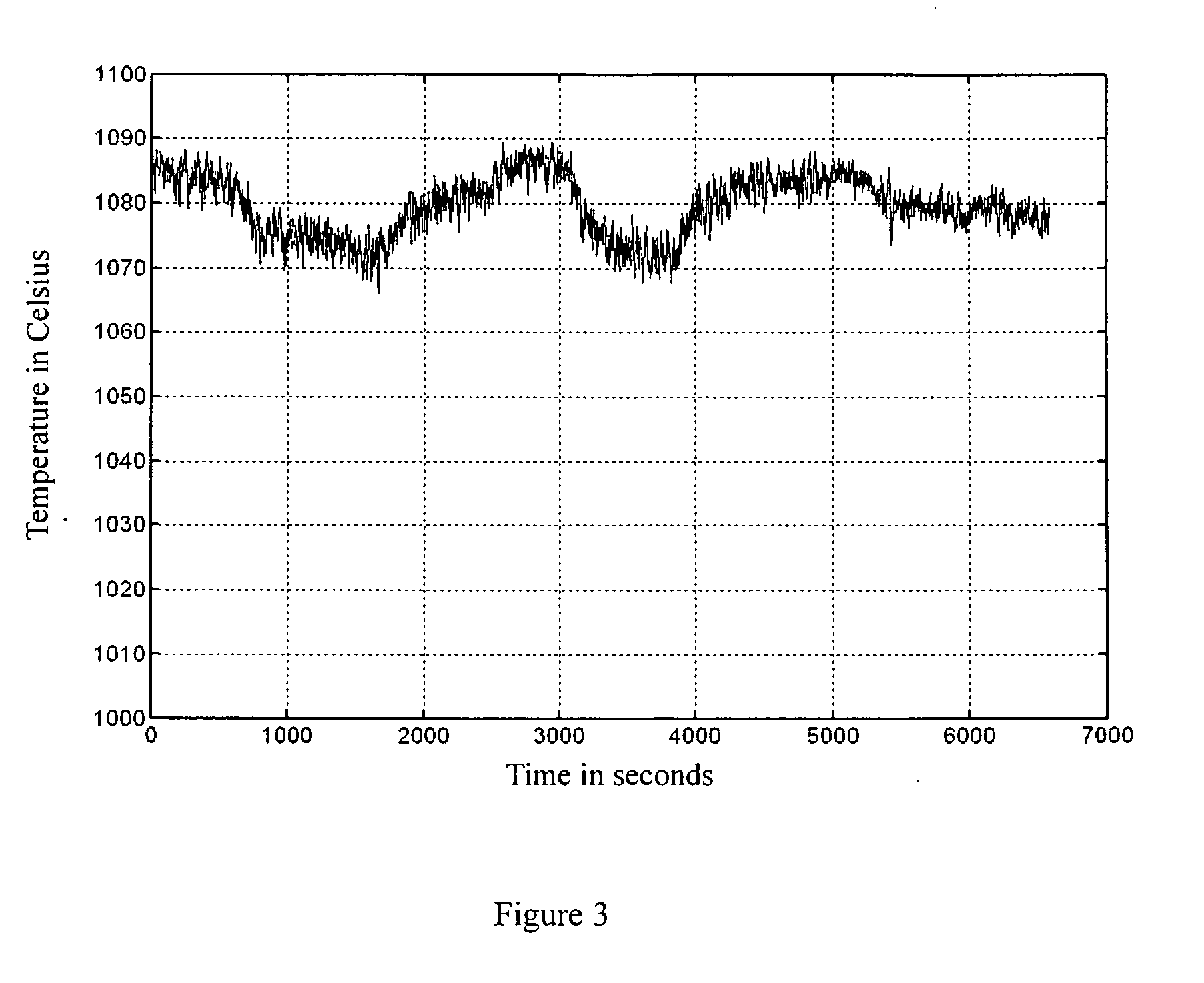

Method for coating material application to substrate and device for coating material application

ActiveCN103203304ACoating operation is easyImprove productivityLiquid surface applicatorsSuperimposed coating processMetallurgyCoating materials

The invention relates to a method for coating a material application to a substrate and a device for coating the material application. In order to thinly, uniformly and highly-efficiently coat the material application to surfaces of single or continuous glass or resin films, sheets and plates, the method and the device are provided. The method comprises providing the material application to a coating roll and then coating the material application to the surfaces of the conveying substrate through rotation of the coating roll, wherein the substrate is single or continuous. In a coating roll and a coating amount control roll in rotary contact with an outer surface of the coating roll, at least the coating amount control roll enables hydrophilic DLC film to form a film on surface of the roll. The coating amount control roll or a scraper is contacted with the coating roll, so as to coat the material application on the outer surface of the coating roll to be uniform and thin; and the outer surface is contacted with the conveying substrate through rotation of the coating roll, thereby coating the uniform and thin material application on the coating roll onto the substrate.

Owner:MIYAKO ROLLER IND

Potting method for membrane module

InactiveUS20050126978A1Improve the immunityResistance to penetrationSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisEngineeringMechanical engineering

Owner:ZENON TECH PARTNERSHIP

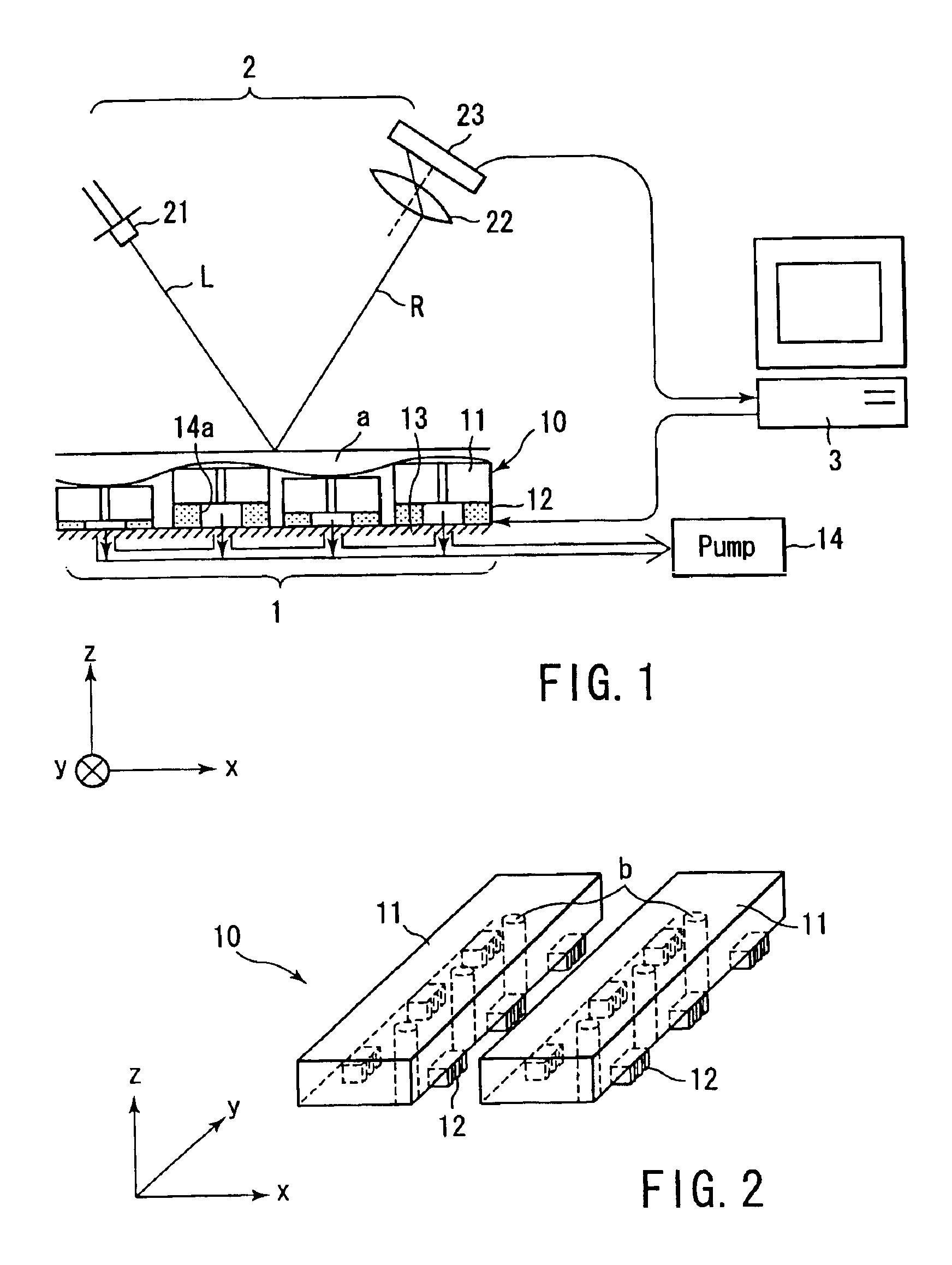

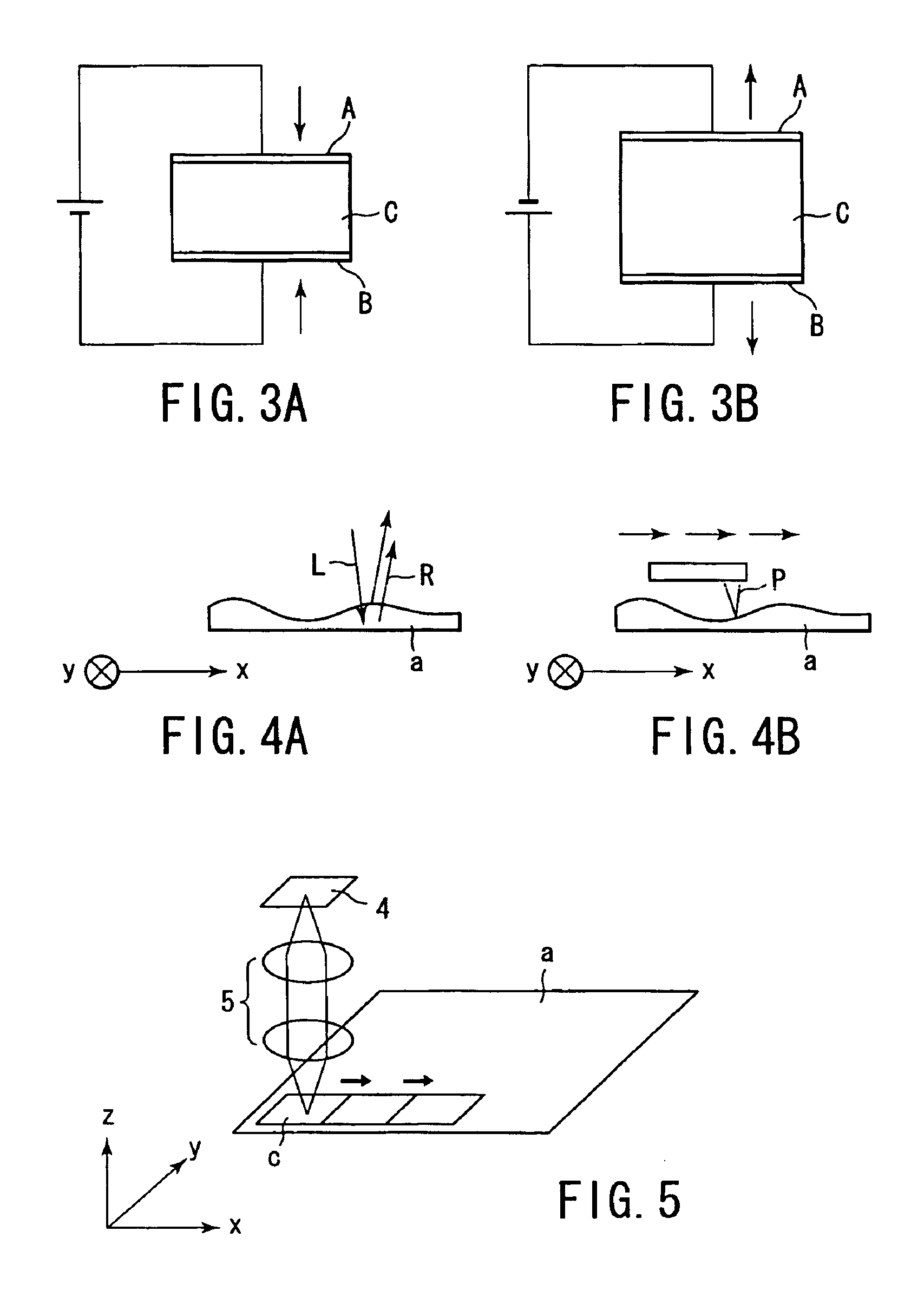

Method and apparatus for forming pattern on thin substrate or the like

InactiveUS6927839B2Uneven thicknessSemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusEngineering

A substrate processing apparatus of the present invention has a retaining base which retains a substrate, a device detecting undulation or thickness unevenness, and a control device which operates the detecting device. The substrate is deformed in a range of a field to be processed, by locally displacing the retaining base on the basis of the detected undulation or thickness unevenness of the substrate. Blurring of an image formed on the substrate can be thereby prevented.

Owner:DAI NIPPON PRINTING CO LTD

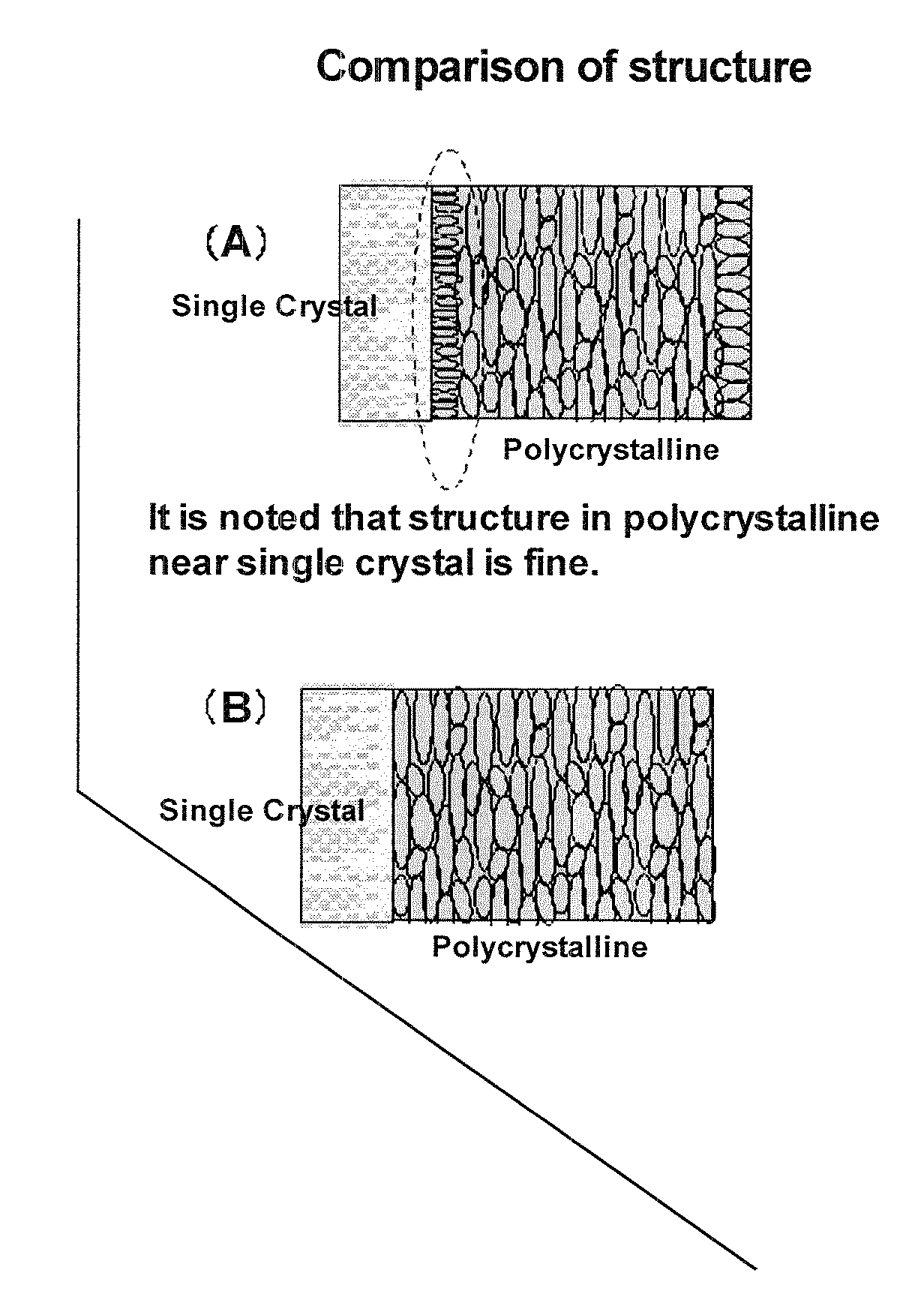

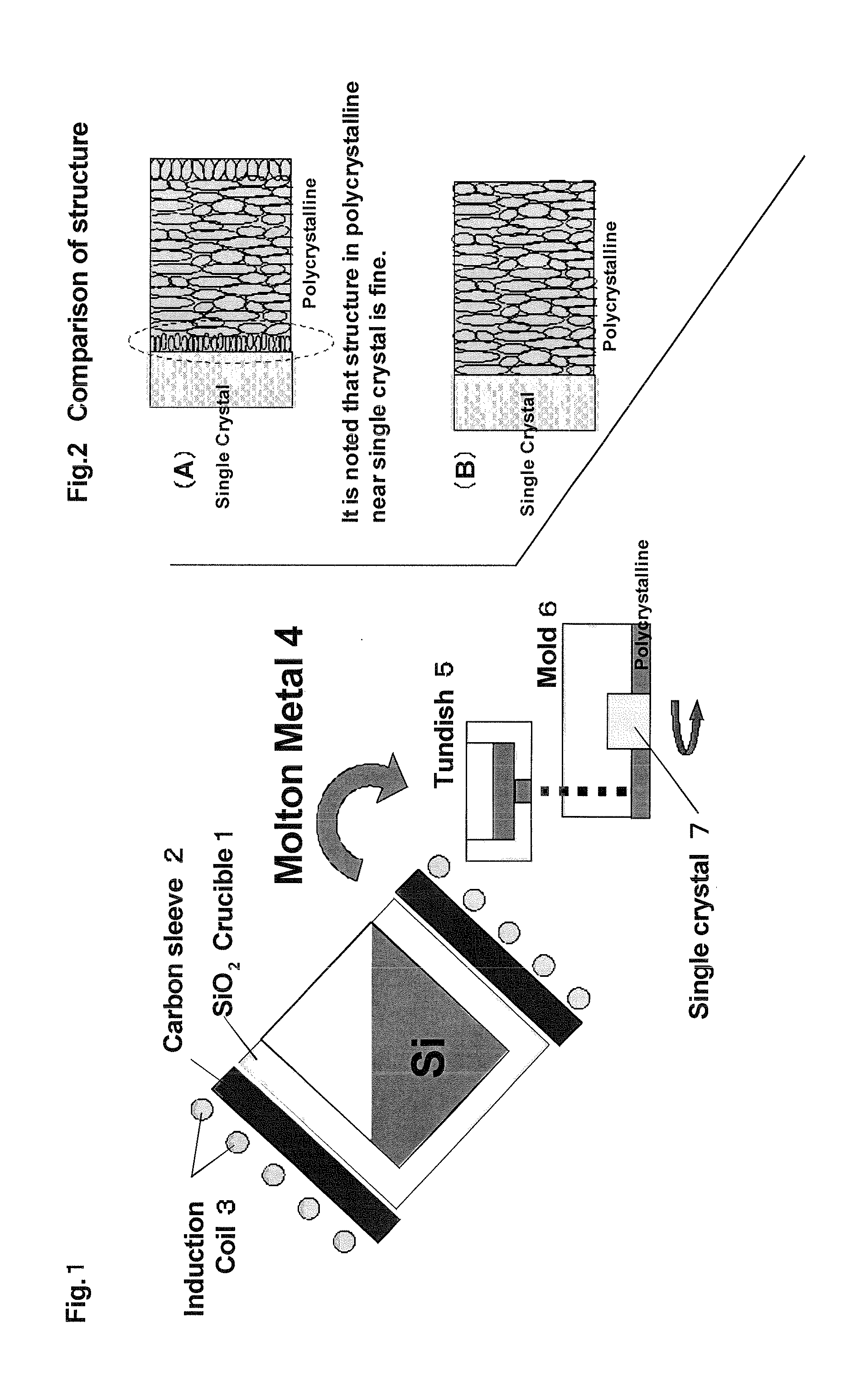

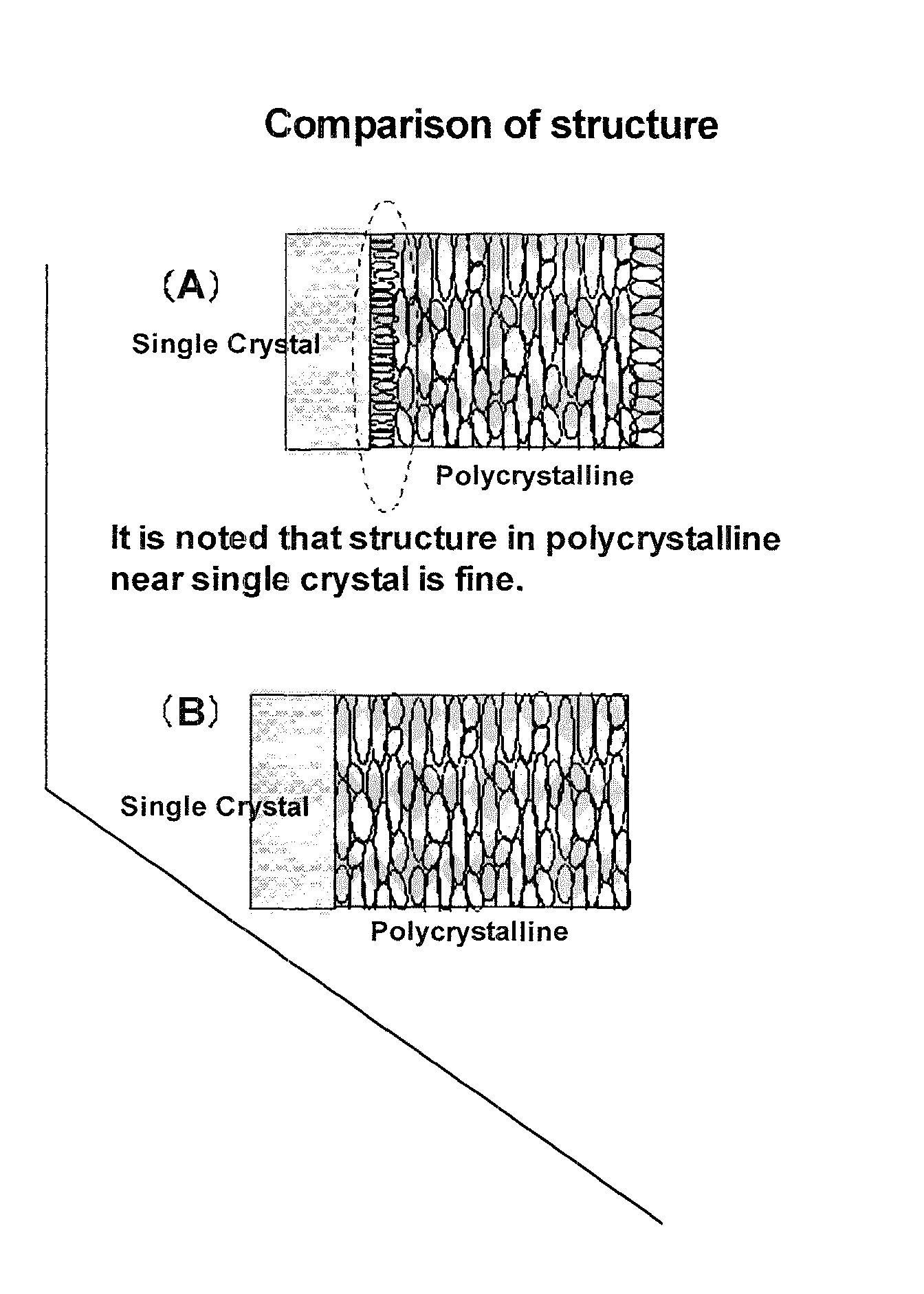

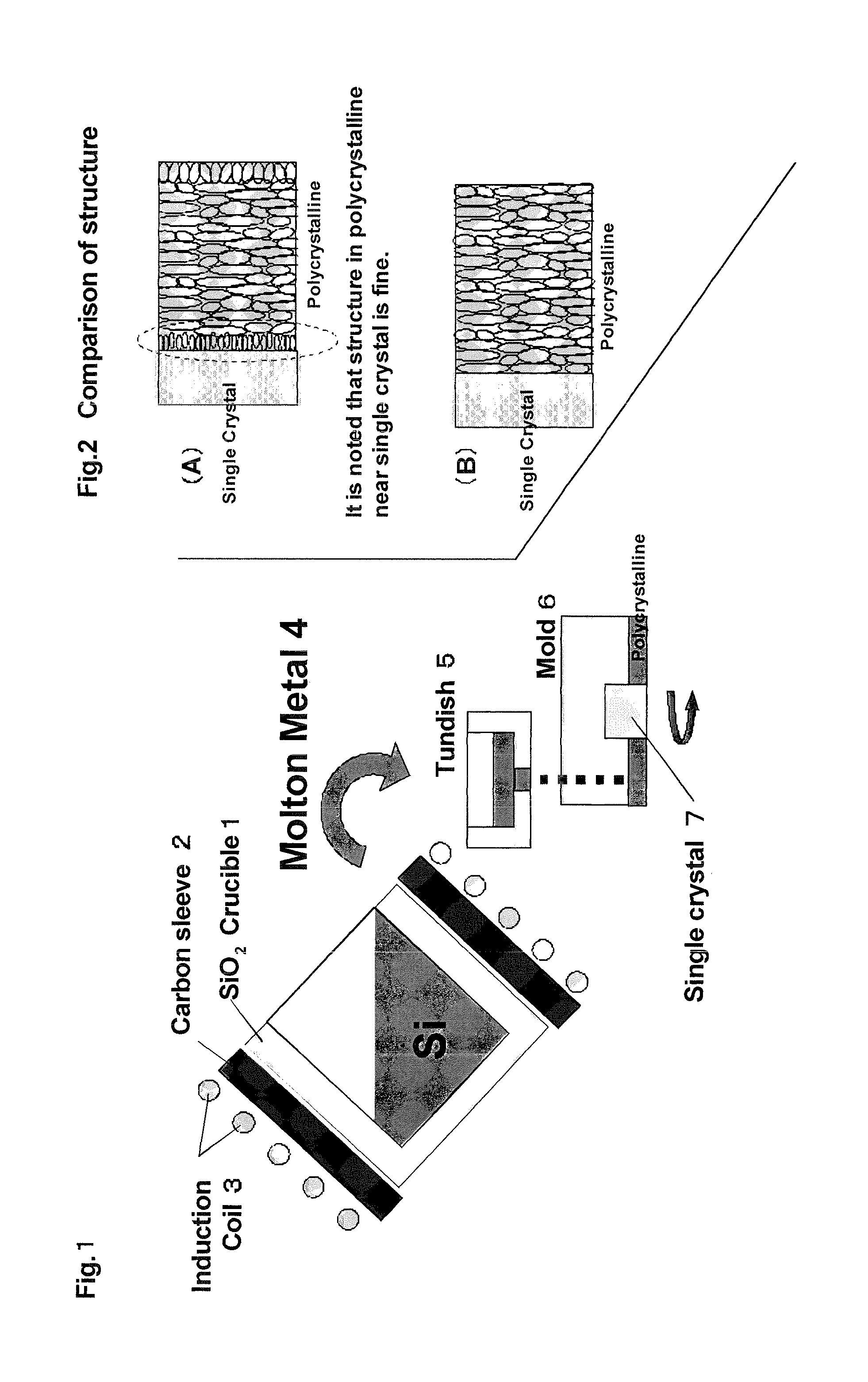

Hybrid Silicon Wafer and Method of Producing the Same

ActiveUS20120009374A1Easy to prepareImprove production yieldPolycrystalline material growthAfter-treatment detailsMolten stateWafering

Provided is a hybrid silicon wafer in which molten state polycrystalline silicon and solid state single-crystal silicon are mutually integrated, comprising fine crystals having an average crystal grain size of 8 mm or less at a polycrystalline portion within 10 mm from a boundary with a single-crystal portion. Additionally provided is a method of manufacturing a hybrid silicon wafer, wherein a columnar single-crystal silicon ingot is sent in a mold in advance, molten silicon is cast around and integrated with the single-crystal ingot to prepare an ingot complex of single-crystal silicon and polycrystalline silicon, and a wafer shape is cut out therefrom. The provided hybrid silicon wafer comprises the functions of both a polycrystalline silicon wafer and a single-crystal wafer.

Owner:JX NIPPON MINING& METALS CORP

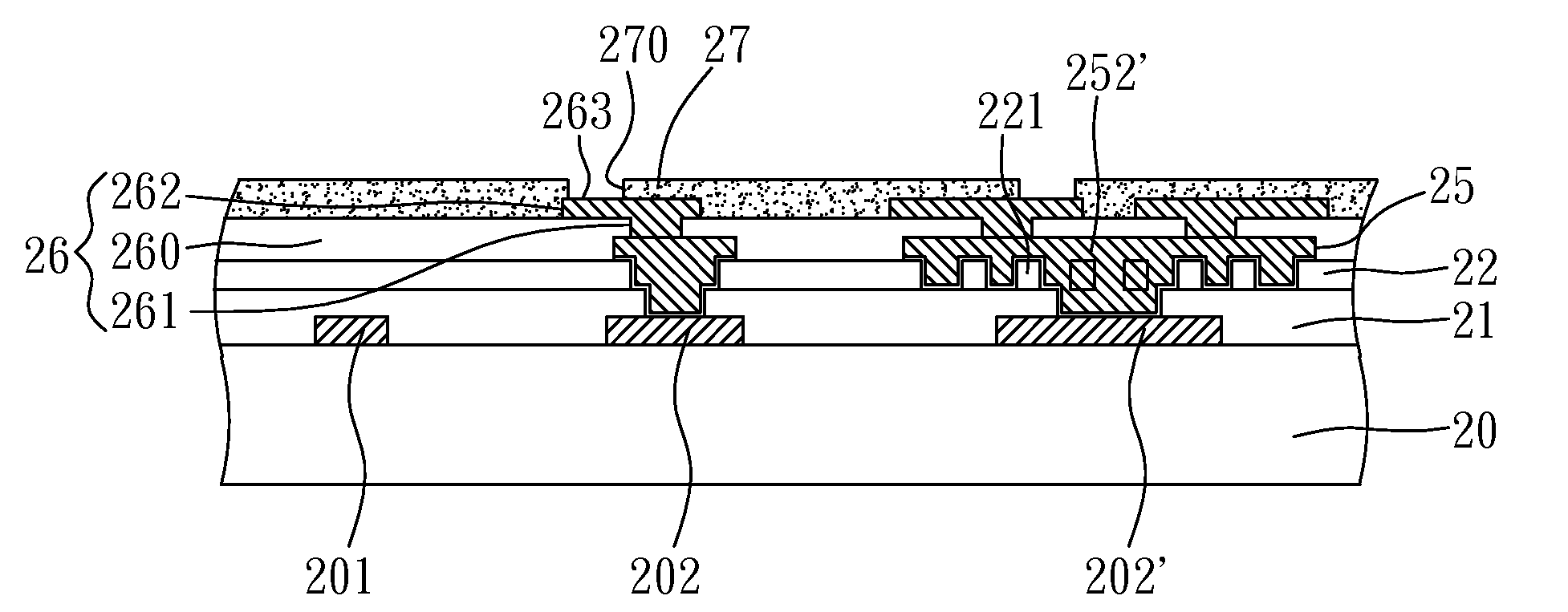

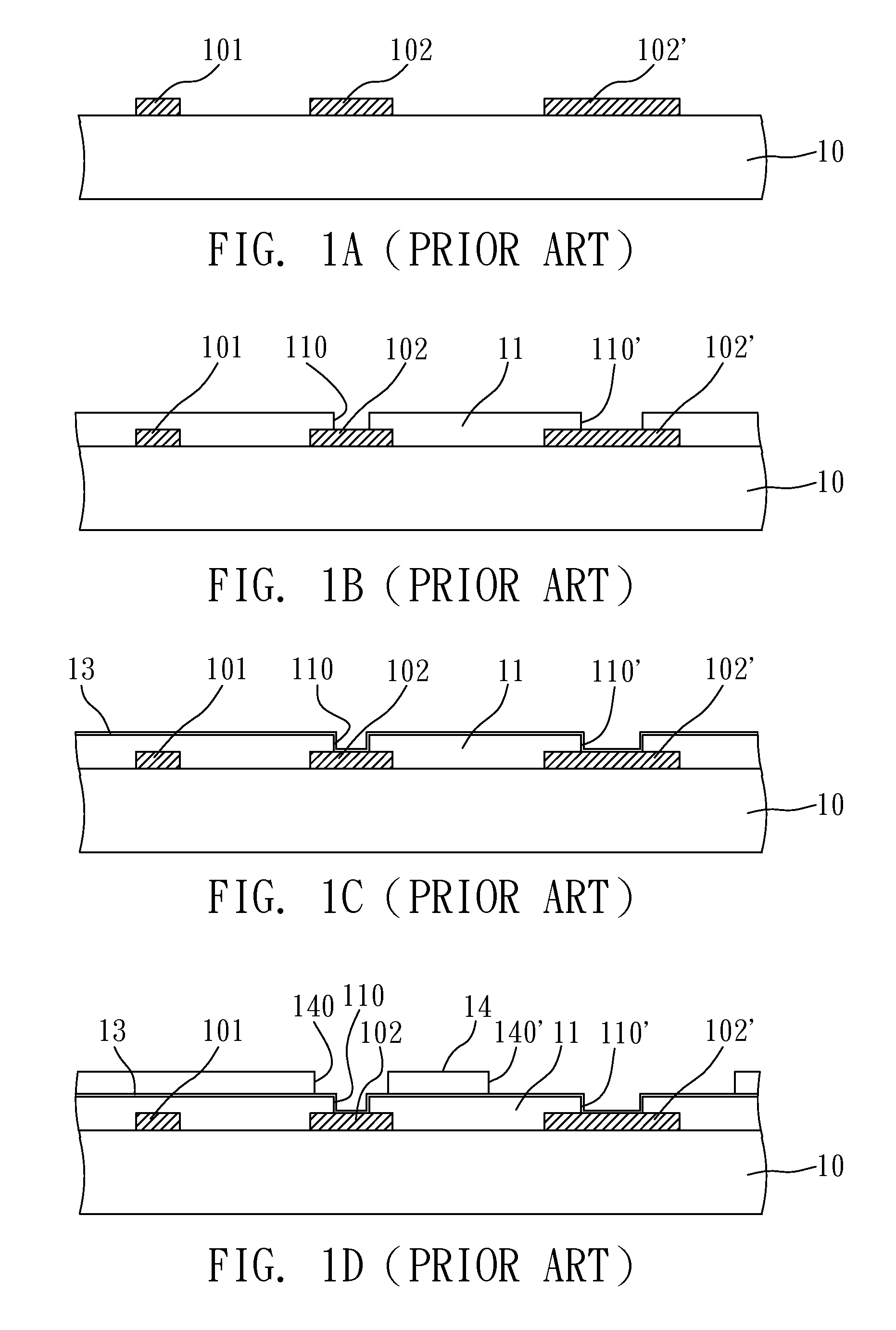

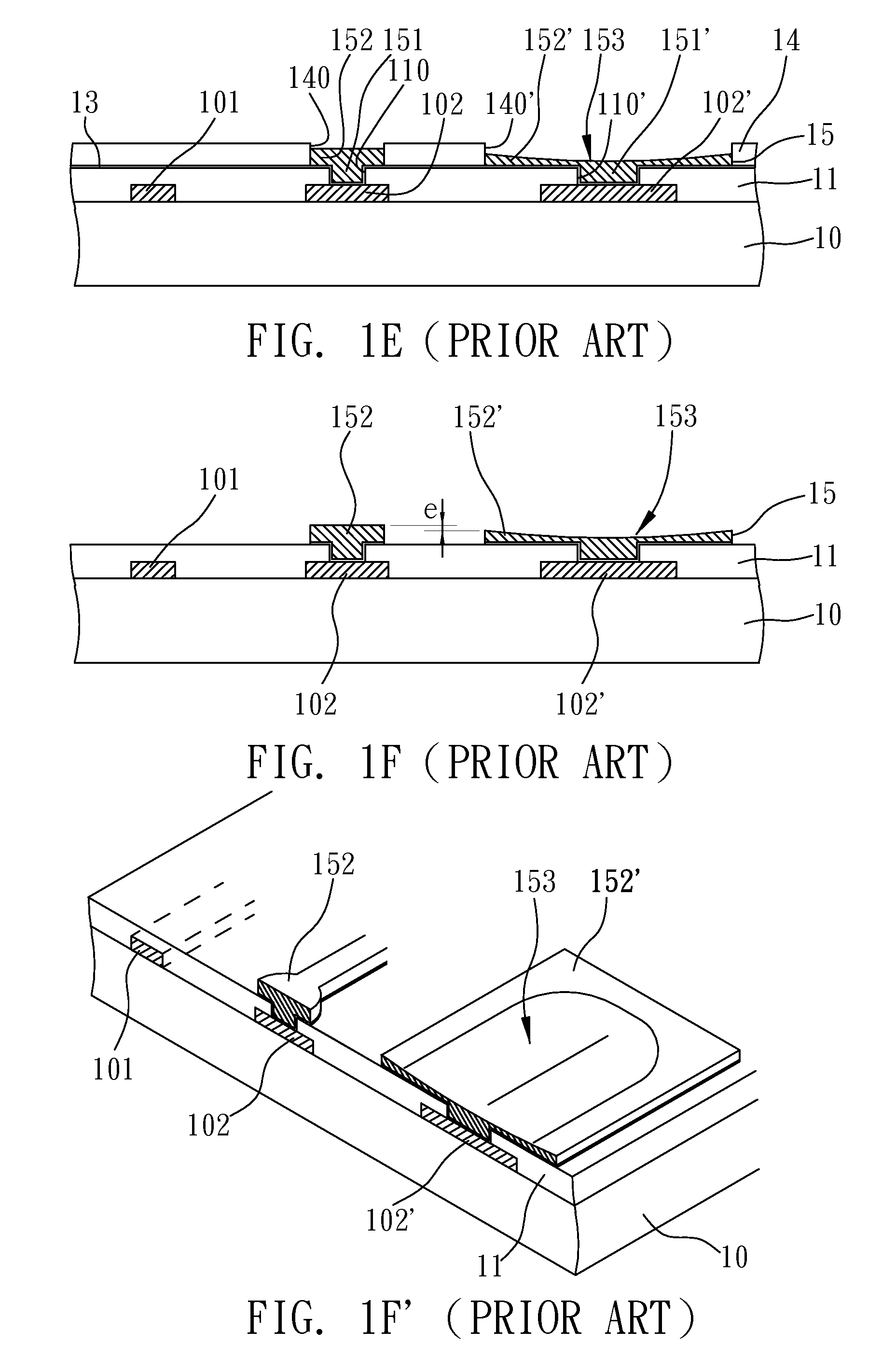

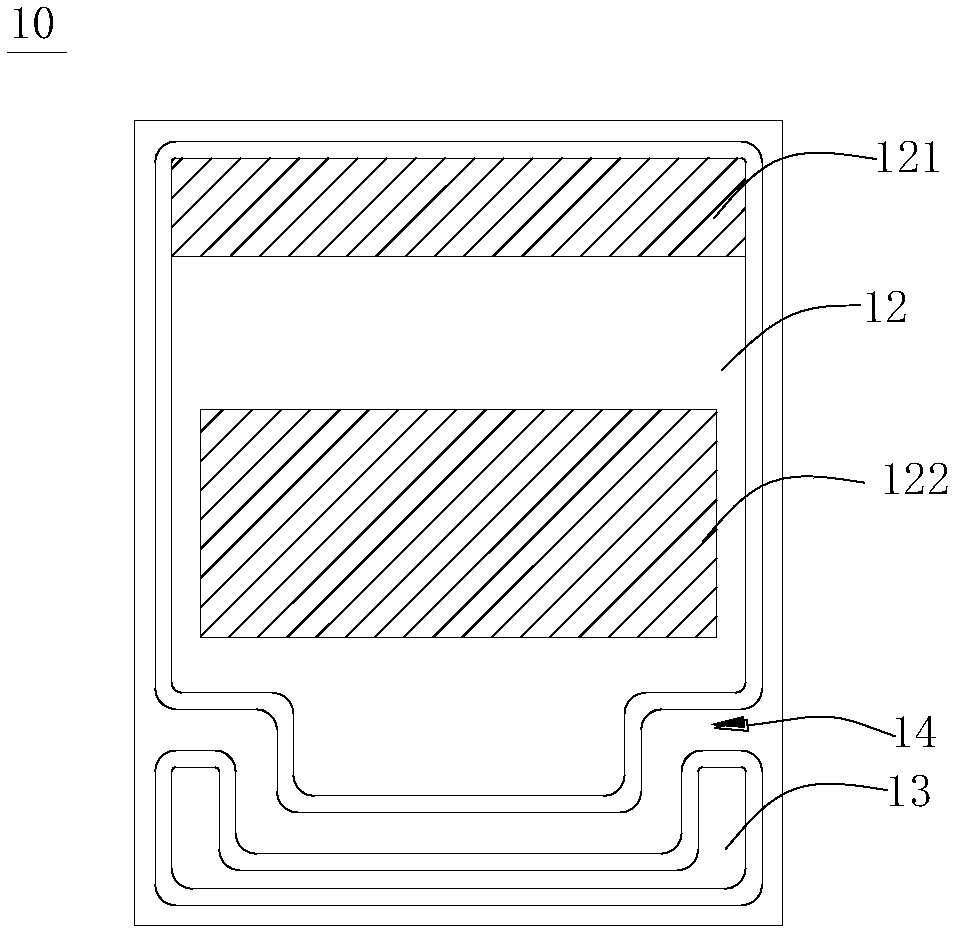

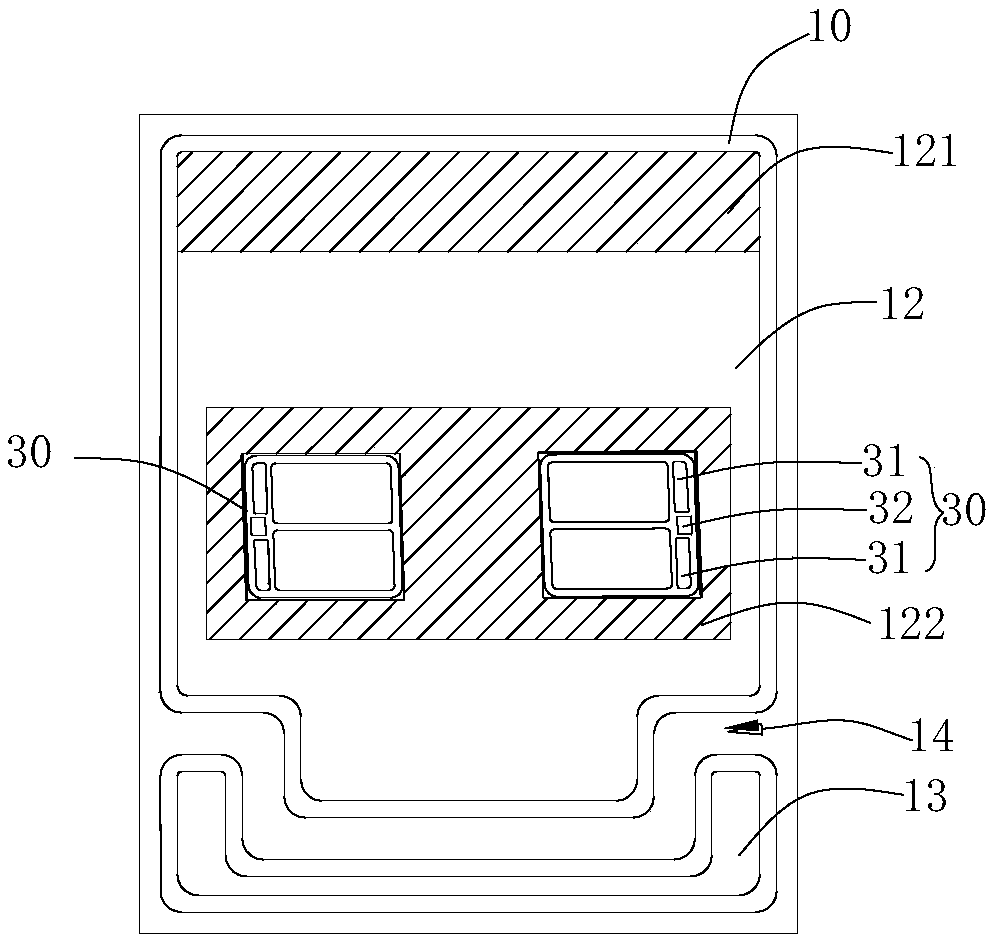

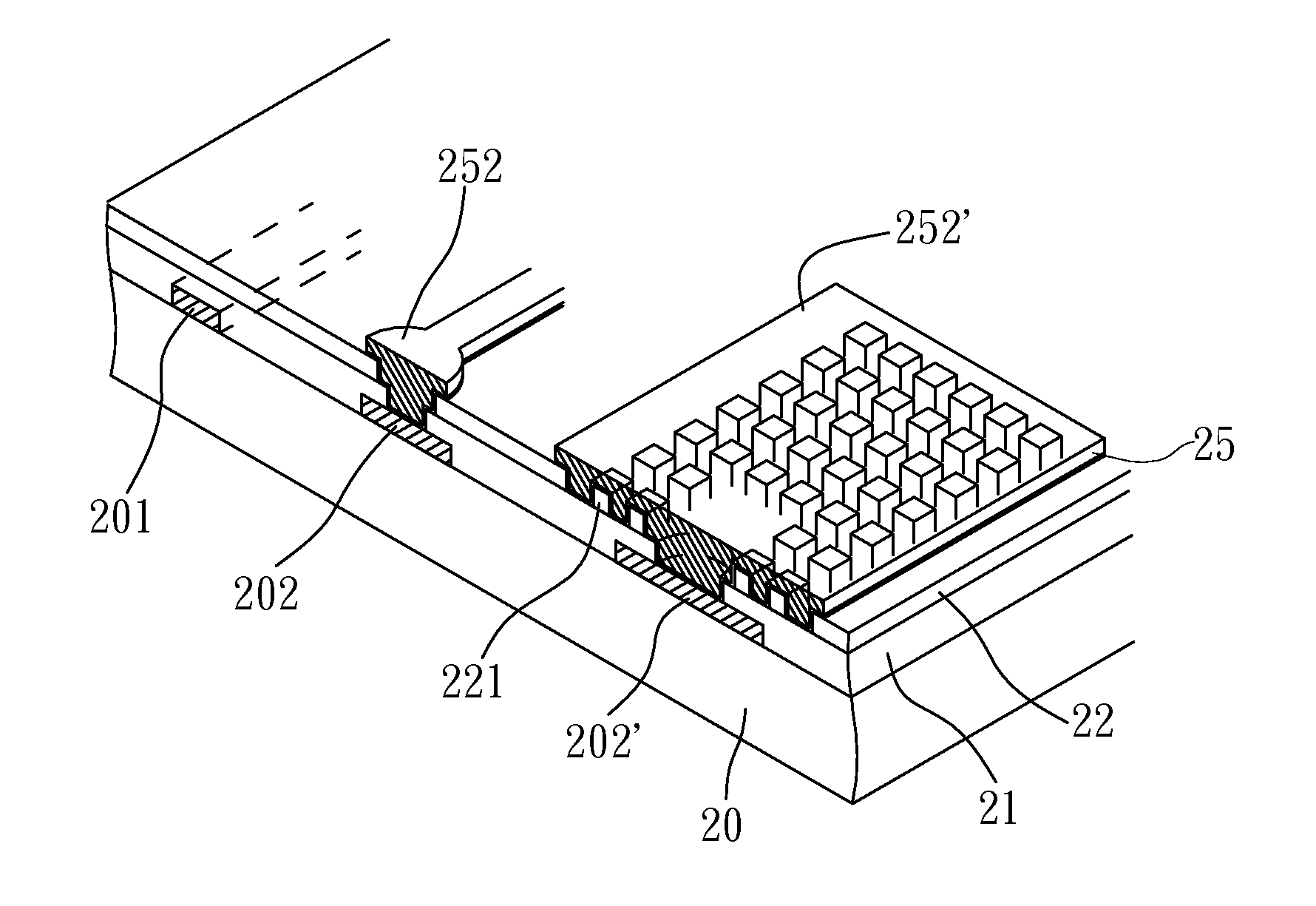

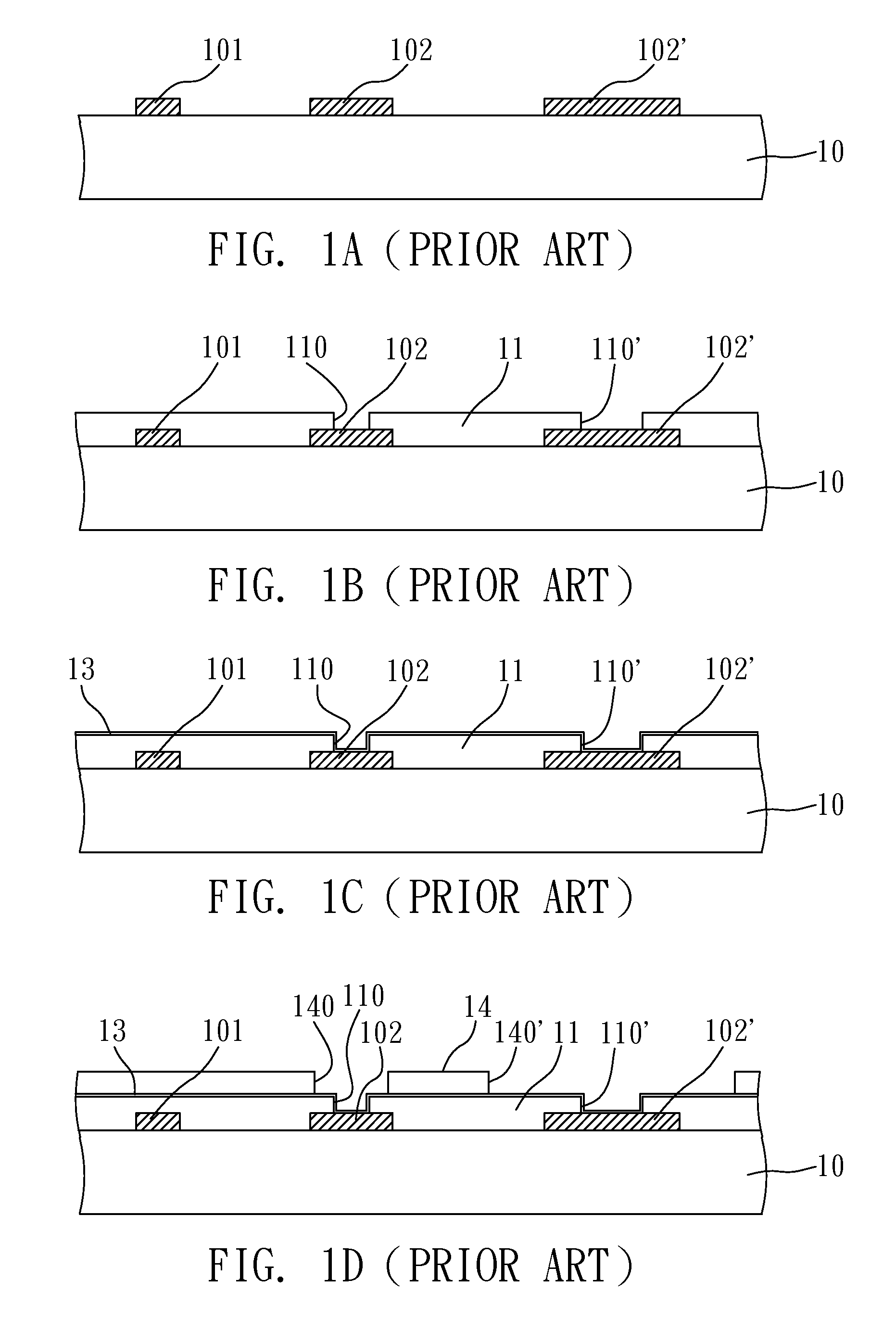

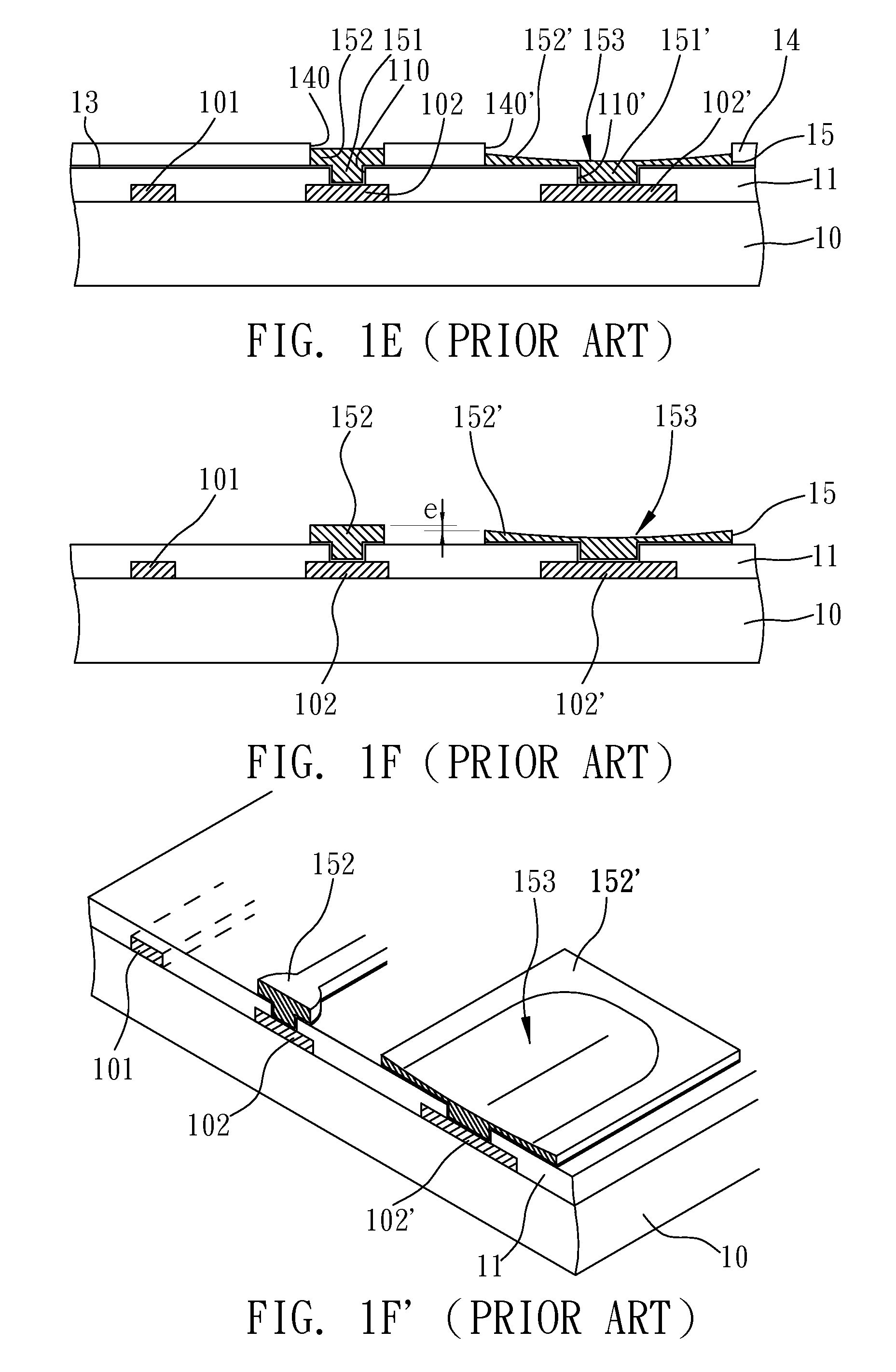

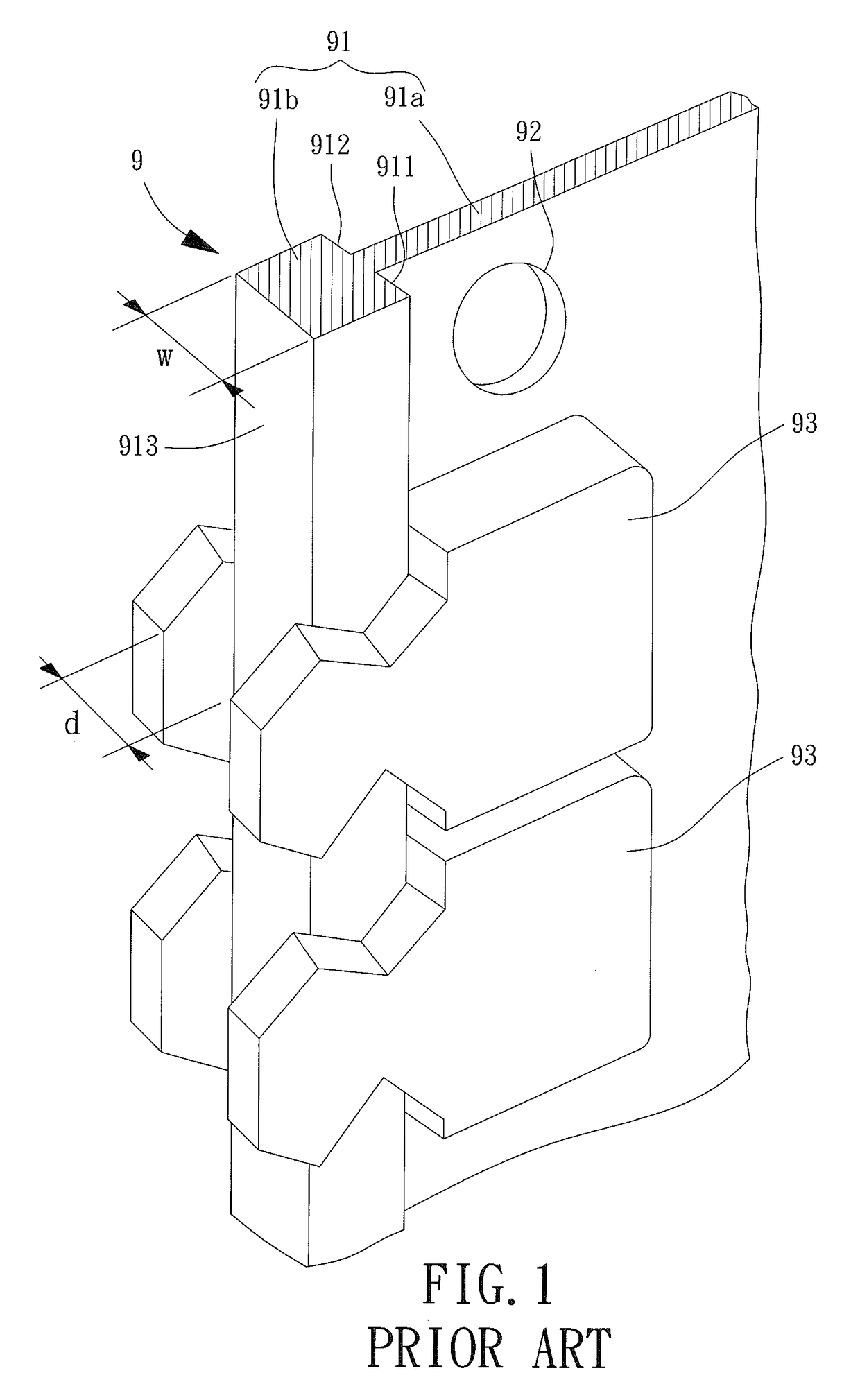

Packaging substrate structure and manufacturing method thereof

ActiveUS20090000813A1Reduce the differenceUneven thicknessPrinted circuit aspectsElectrical connection printed elementsDensity distributionDielectric layer

A packaging substrate structure includes a dielectric layer with a plurality of dielectric pillars disposed on a portion of a large-dimension opening area of the dielectric layer; and a first circuit layer with a plurality of first circuits disposed on a portion of the dielectric layer, and a conductive block disposed in the large-dimension opening area of the dielectric layer having the dielectric pillars. The dielectric pillars reduce the difference of the electrical current density distribution between the large-dimension opening area and small-dimension opening areas during electroplating, thereby overcoming the conventional drawback of insufficient thickness or a hollow center of the conductive block that results in an uneven thickness of the circuit layer. The invention further provides a method of manufacturing the packaging substrate structure.

Owner:UNIMICRON TECH CORP

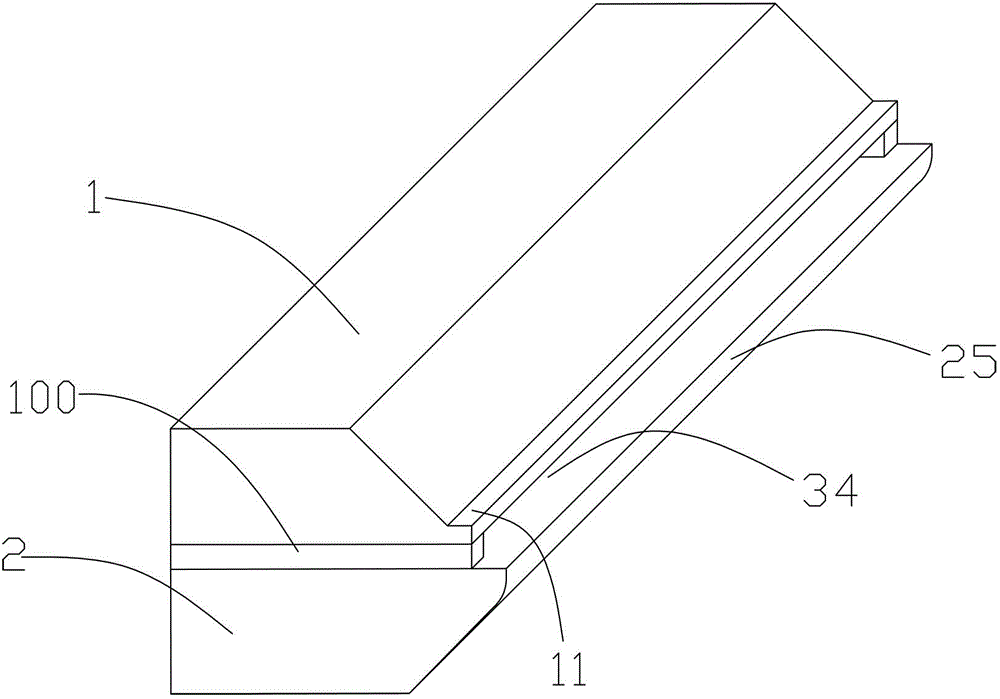

Extrusion coating head and coating machine thereof

ActiveCN104148238AUniform thicknessNo foilLiquid surface applicatorsCoatingsEngineeringMechanical engineering

The invention relates to an extrusion coating head and a coating machine thereof. The extrusion coating head comprises an upper lip of an extrusion head and a lower lip of the extrusion head, wherein an extrusion passage is arranged between the upper lip of the extrusion head and the lower lip of the extrusion head, the extrusion passage is communicated with a storage cavity which is arranged in the lower lip of the extrusion head, a feeding passage and a return passage are also arranged in the lower lip of the extrusion head, and the feeding passage and the return passage are respectively communicated with the storage cavity; when the extrusion coating head is in coating, the return passage is closed, an upper extrusion surface which is arranged on the upper lip of the extrusion head in the extrusion passage can be inclined upwards, and air in the extrusion passage is discharged from a discharging opening of the extrusion passage along the upper extrusion surface. The air in the extrusion passage is discharged from the discharging opening of the extrusion passage, and the area of the cross section of the storage cavity is gradually reduced from middle part to two ends, so that a sizing agent is prevented from being blocked in the storage cavity; the discharging end of the lower lip of the extrusion head is provided with a protrusion part, so that the sizing agent is facilitated to be adhered onto a base material. The extrusion coating head and the coating machine thereof have the advantages of uniformity in coating, no exposure of foil, good coating effect, high production efficiency, high product quality and the like.

Owner:SHENZHEN XINYUREN TECH

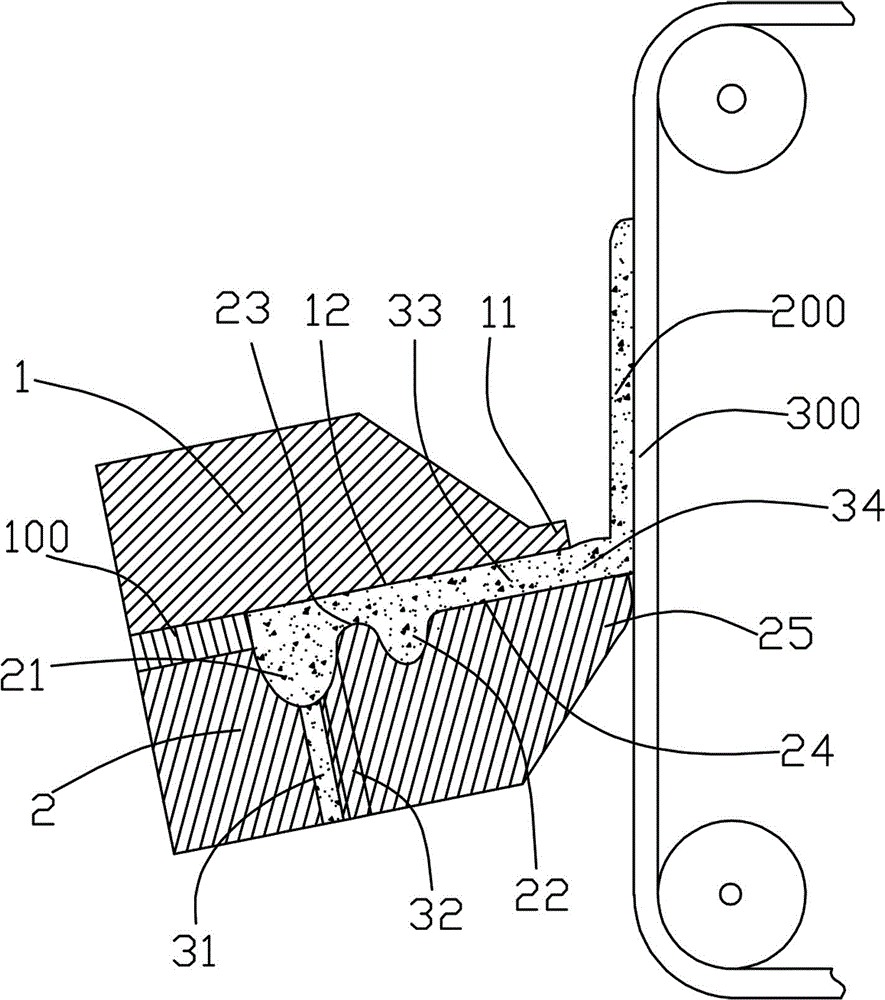

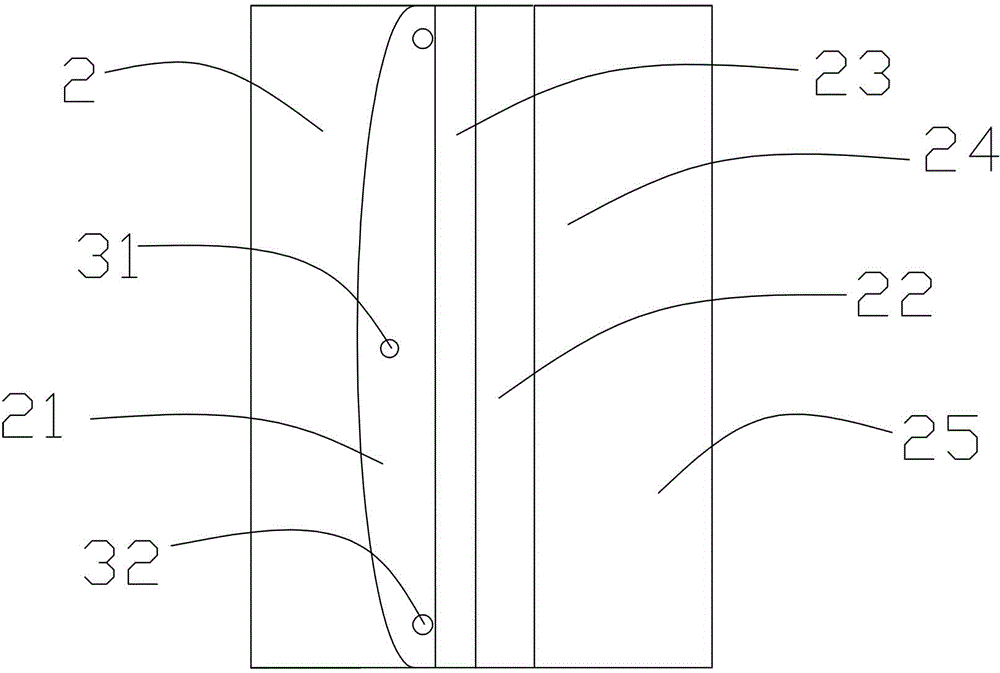

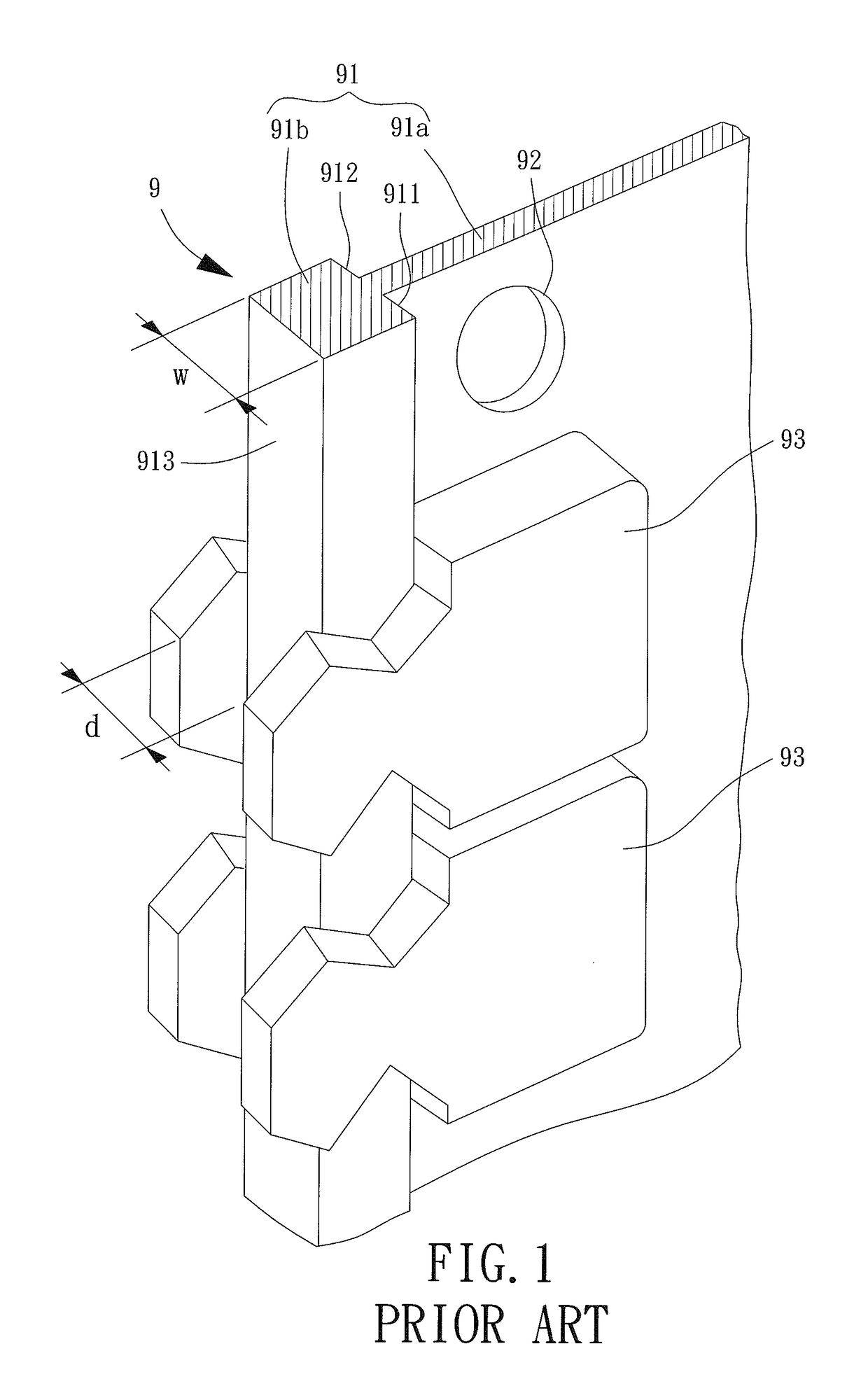

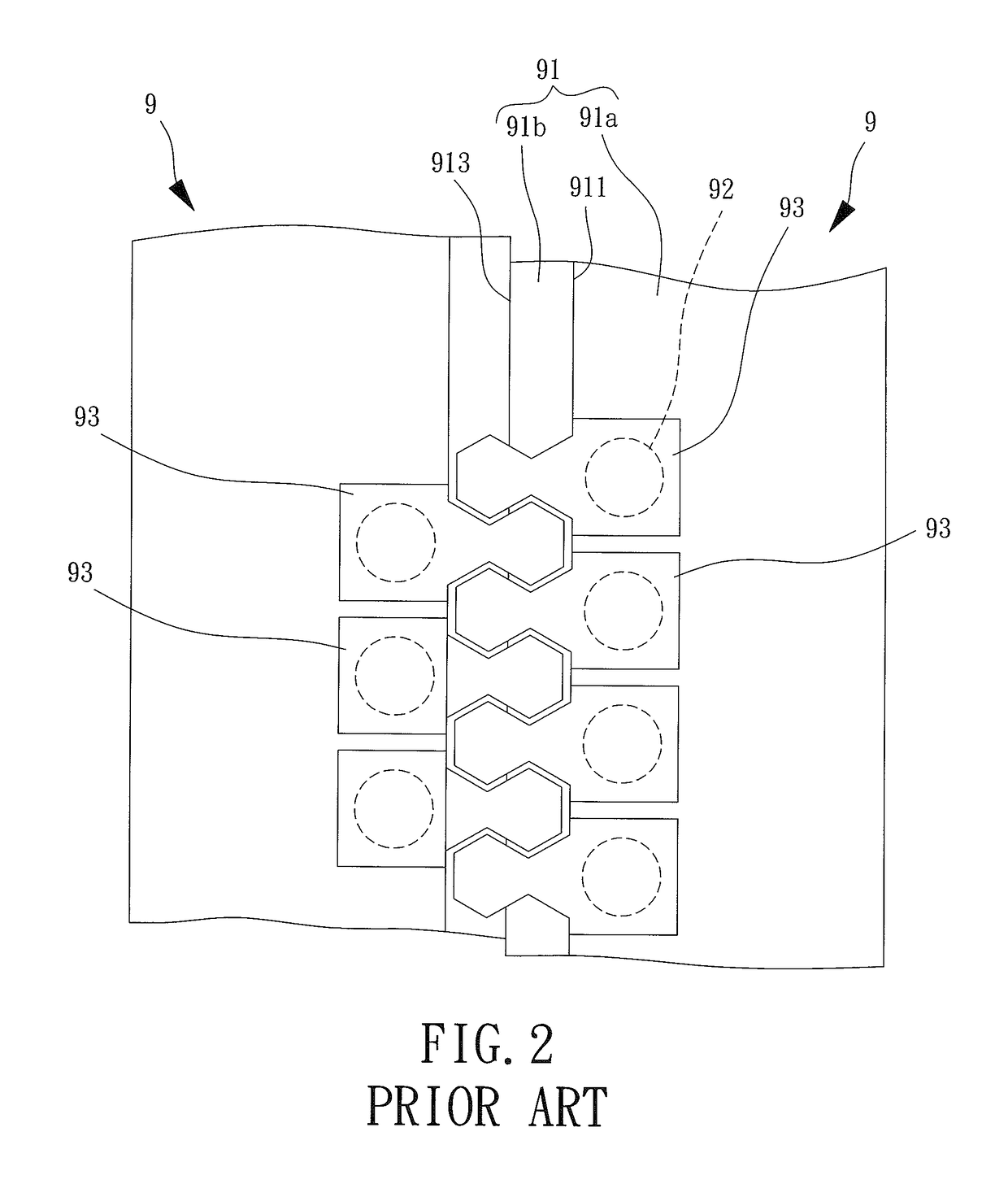

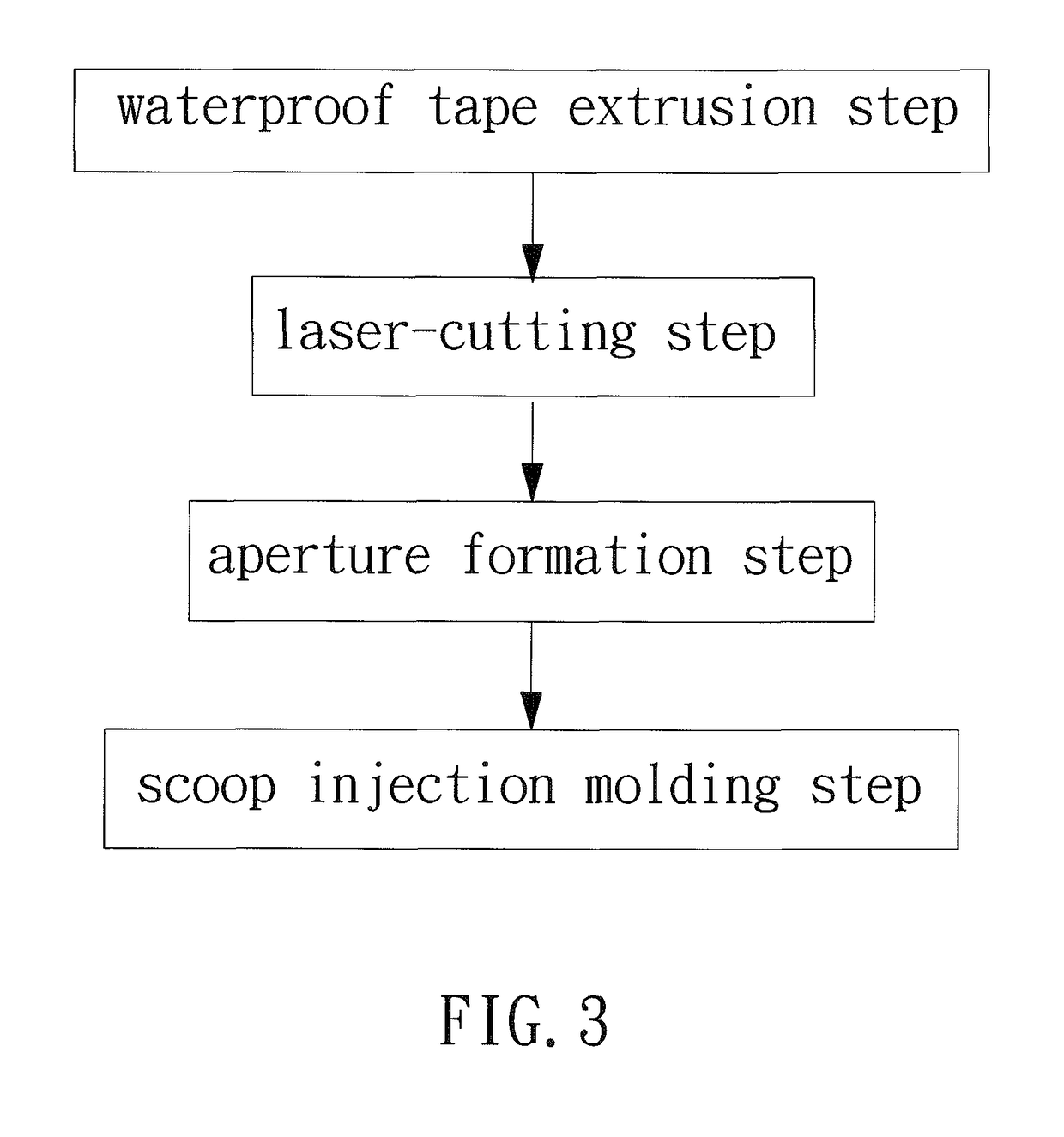

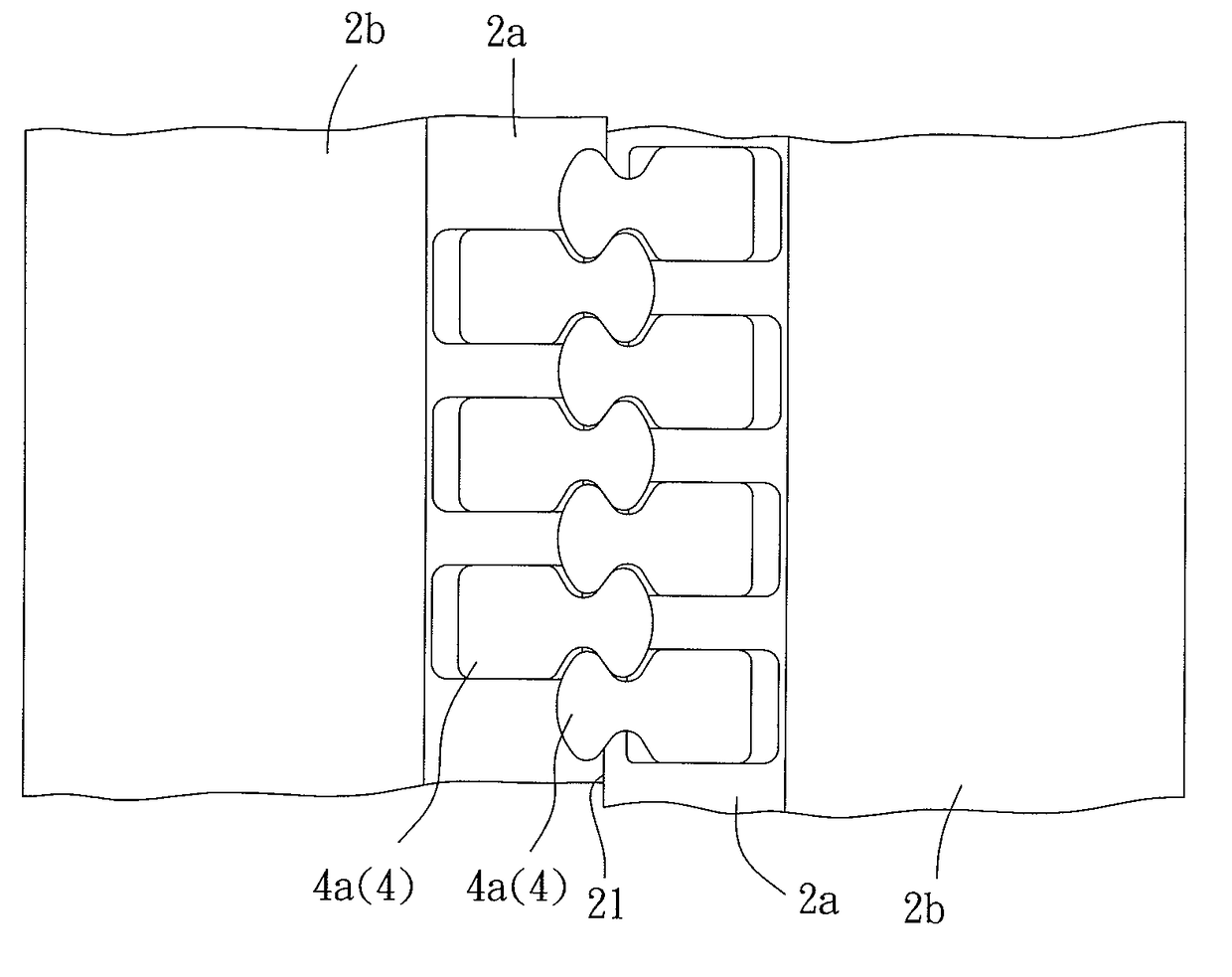

Method for manufacturing a watertight zipper

ActiveUS10144160B2Uneven thicknessImprove sealing functionSlide fastenersDomestic slide fastenersEngineeringMechanical engineering

A method for manufacturing a watertight zipper includes forming a waterproof tape by extruding a polymeric material in a melted state wrapping around a cloth tape, cutting a side of the waterproof tape that is covered by the thick waterproof layer to form a side surface of the thick waterproof layer as an abutting surface, forming a plurality of apertures in the waterproof tape that extends through the cloth tape and the thick waterproof layer, and forming a plurality of scoops spaced from the thin waterproof layer and corresponding to the apertures. The waterproof tape includes a thick waterproof layer and a thin waterproof layer both formed by the polymeric material. The thick waterproof layer covers an upper surface, a lower surface and an edge of the cloth tape. The thin waterproof layer connects with the thick waterproof layer. An end of each scoop extends beyond the abutting surface.

Owner:TAIWAN UNITED OUTDOOR GRP INC

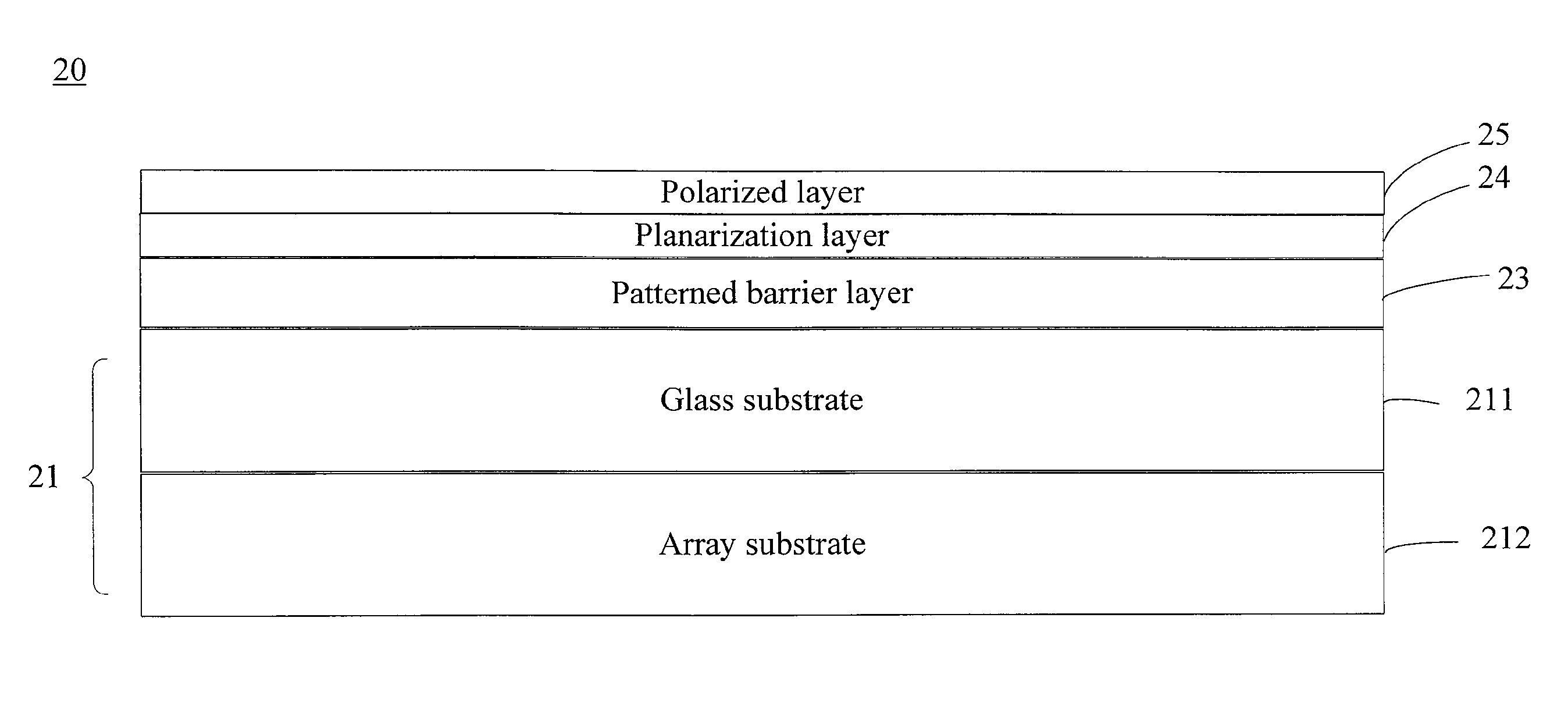

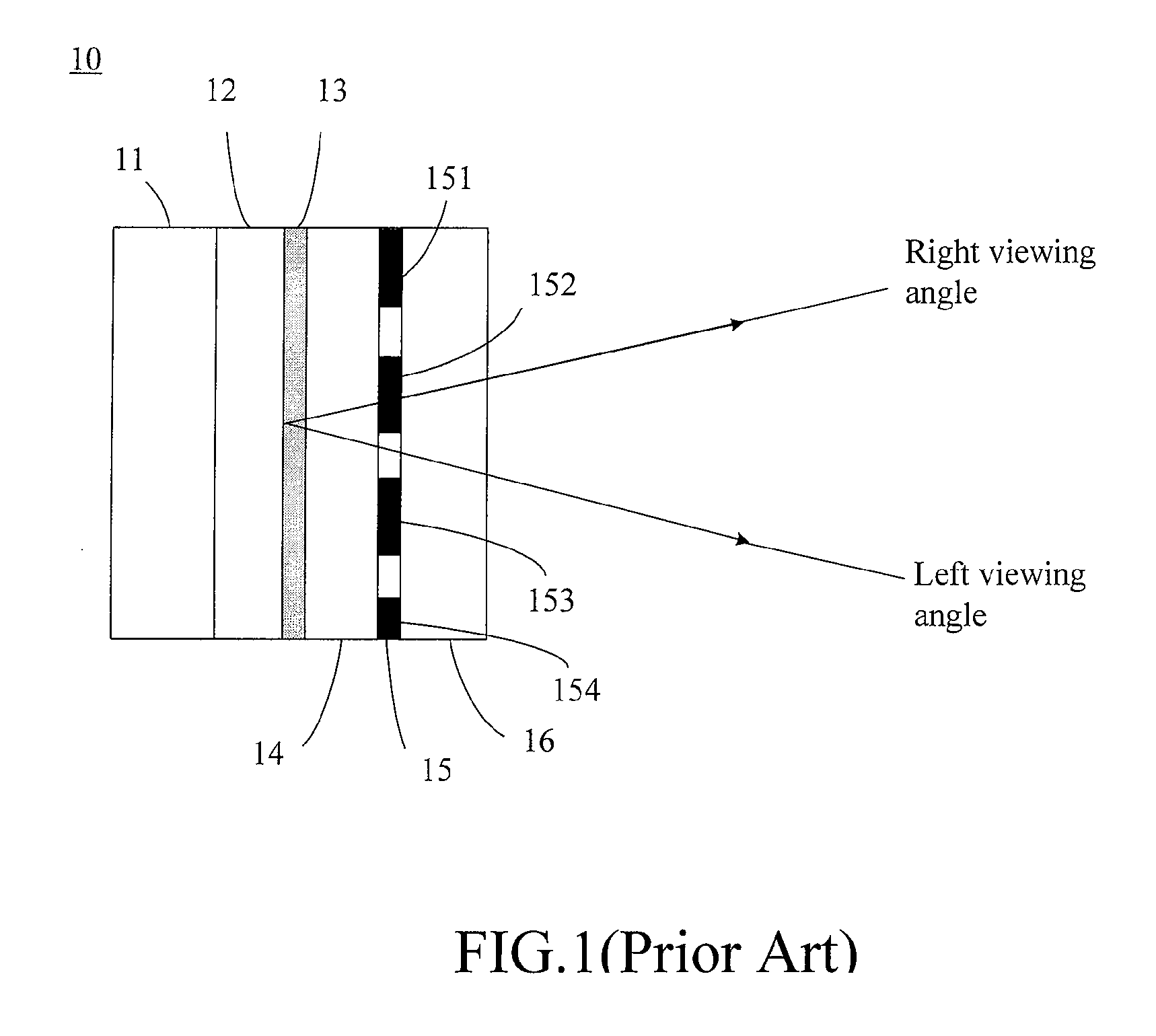

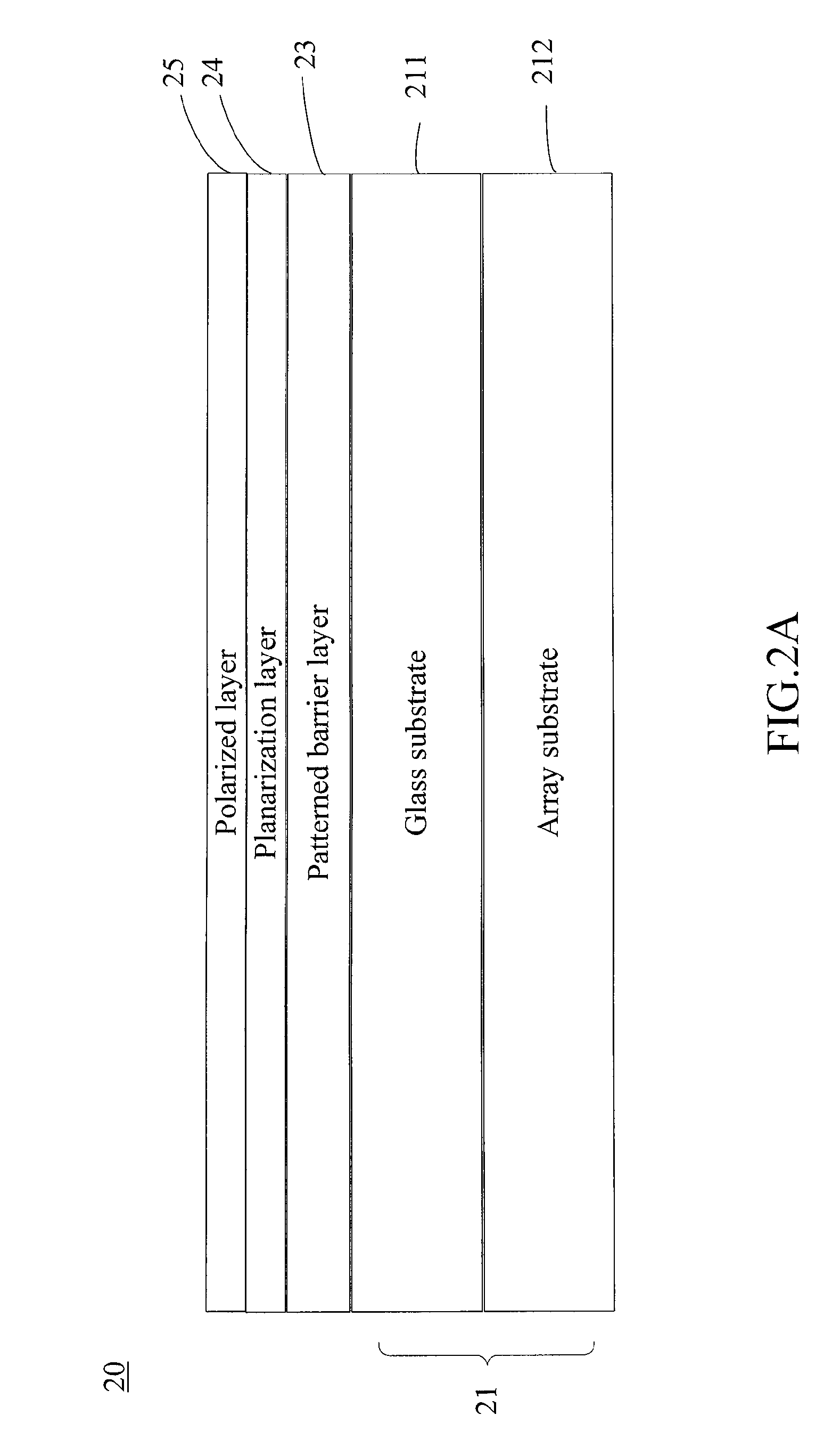

Dual-View Display Panel Structure and Method for Producing the Same

ActiveUS20090103024A1High light transmittanceGood viewing angleSemiconductor/solid-state device manufacturingPretreated surfacesDisplay deviceComputer science

A dual view display structure and a method for producing the same are provided. First, a display panel is provided. Then, a patterned barrier layer is formed on a transparent substrate. The transparent substrate with the patterned barrier layer is attached to the display panel. Because there is a gap between the display panel and the patterned barrier layer, a liquid transparent material is injected into the gap to form a transparent material layer to fill the gap. The invention can not only increase the viewing angles of the dual view display, but also increase the production yield.

Owner:AU OPTRONICS CORP

Vacuum coating method of protective film

ActiveCN103774143AImprove densification performancePlay protective abilityVacuum evaporation coatingSputtering coatingGratingMetal membrane

The invention relates to the technical field of coating metal films with protective films, and specifically relates to a vacuum coating method of a protective film. The vacuum coating method of the protective film comprises the following preparation steps of 1, vacuumizing, namely putting a product to be coated in a vacuum chamber, and then vacuumizing, and heating simultaneously so that water vapor is formed on the upper layer of a container; 2, plating a metal film, namely plating a metal film through an evaporative metal film coating process; 3, introducing air after finishing coating of the metal film, namely, turning off a diffusion pump, turning on a molecular grating, charging air into the vacuum chamber through a flowmeter and stabilizing the degree of vacuum and keeping for 0.2-1 minutes; 4, cleaning the surface of the metal film, namely starting an ion bombardment power source; and 5, plating the protective film, including charging liquid vapor of organic silicon, keeping the pressure unchanged, and starting the ion bombardment power source again so that the organic silicon grows on the metal film layer by layer to form the protective film. The vacuum coating method of the protective film has the characteristics of high production efficiency and low cost, and the protective film is good in compactness, strong in protection performance and wide in application range.

Owner:北京三重镜业(大厂)有限公司

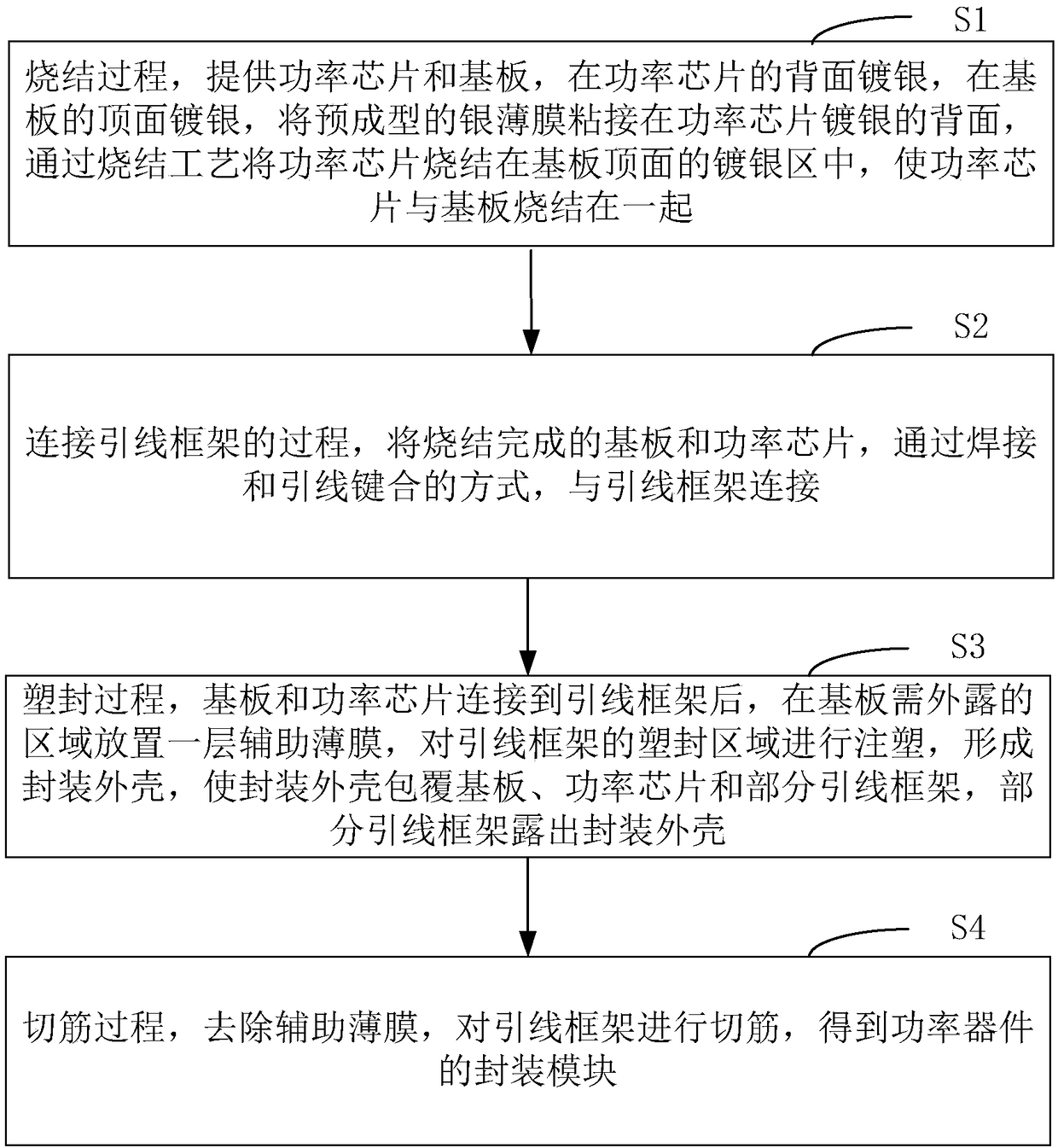

Power device packaging method as well as packaging module and lead frame thereof

PendingCN108321129AMeet the requirements of high thermal conductivityAvoid warpingSemiconductor/solid-state device detailsSolid-state devicesPlastic packagingSilver plate

The invention discloses a power device packaging method as well as a packaging module and a lead frame thereof. The packaging method comprises a sintering process, a lead frame connecting process, a plastic packaging process and a rib cutting process. The sintering process comprises the steps: adhering a silver film onto the silver-plated back of a power chip, and sintering the power chip in a silver plating area on the top of a substrate by using a sintering process. The substrate and the power chip subjected to sintering are connected with the lead frame in a manner of welding and lead bonding. During plastic packaging, an auxiliary film is arranged in a to-be-exposed area of the substrate, and the plastic packaging area of the lead frame is subjected to injection molding so as to form apackaging shell. The auxiliary film is removed, and the lead frame is subjected to rib cutting, thereby obtaining the power device packaging module. The power device packaging module is obtained by adopting the packaging method. According to the packaging method and the packaging module, the heat conduction performance between the power chip and the substrate is enhanced, and the product reliability is improved. A connecting line is formed between first source pins of the lead frame, and the connecting stability is improved.

Owner:SHENZHEN STS MICROELECTRONICS

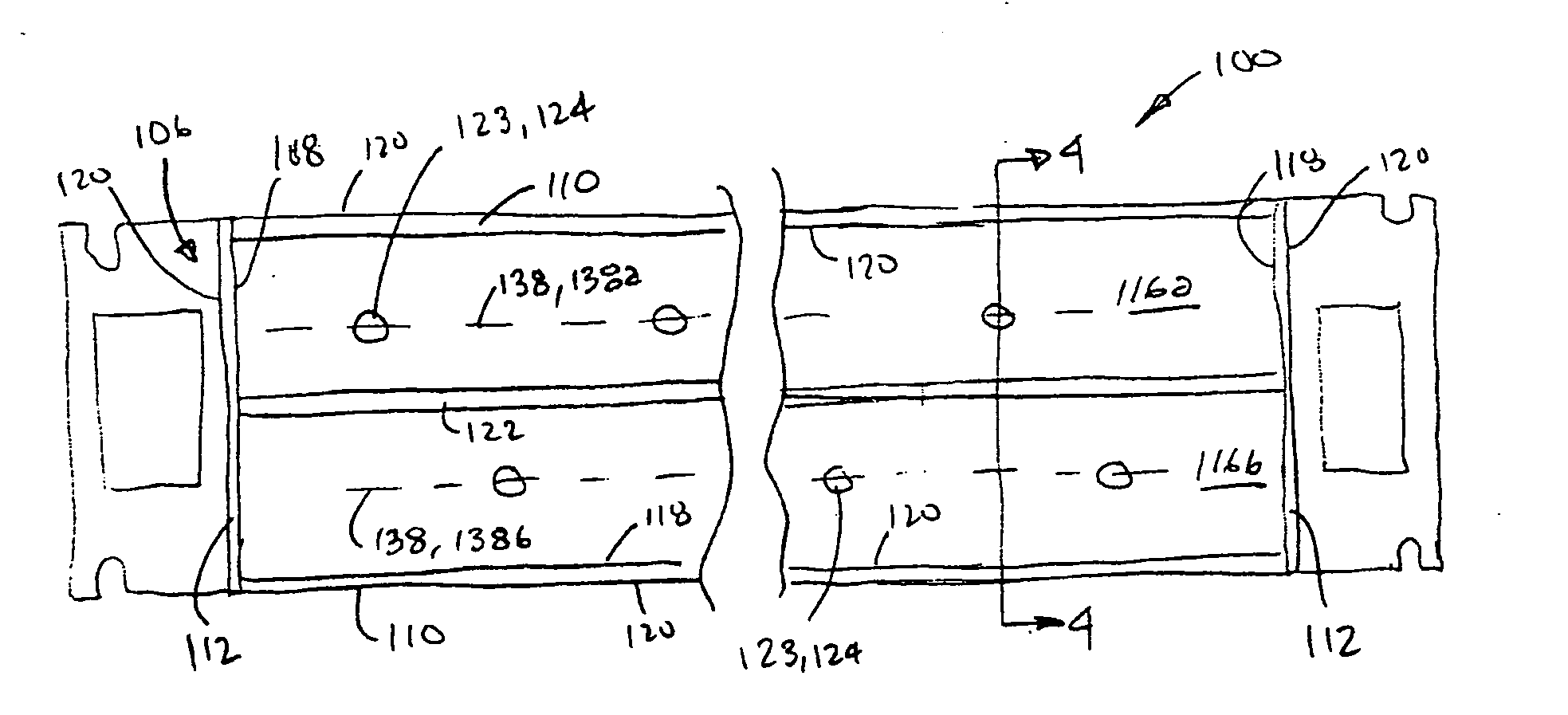

Packaging substrate structure and manufacturing method thereof

ActiveUS8058566B2Uneven thicknessEasy to processPrinted circuit aspectsElectrical connection printed elementsPower flowDensity distribution

A packaging substrate structure includes a dielectric layer with a plurality of dielectric pillars disposed on a portion of a large-dimension opening area of the dielectric layer; and a first circuit layer with a plurality of first circuits disposed on a portion of the dielectric layer, and a conductive block disposed in the large-dimension opening area of the dielectric layer having the dielectric pillars. The dielectric pillars reduce the difference of the electrical current density distribution between the large-dimension opening area and small-dimension opening areas during electroplating, thereby overcoming the conventional drawback of insufficient thickness or a hollow center of the conductive block that results in an uneven thickness of the circuit layer. The invention further provides a method of manufacturing the packaging substrate structure.

Owner:UNIMICRON TECH CORP

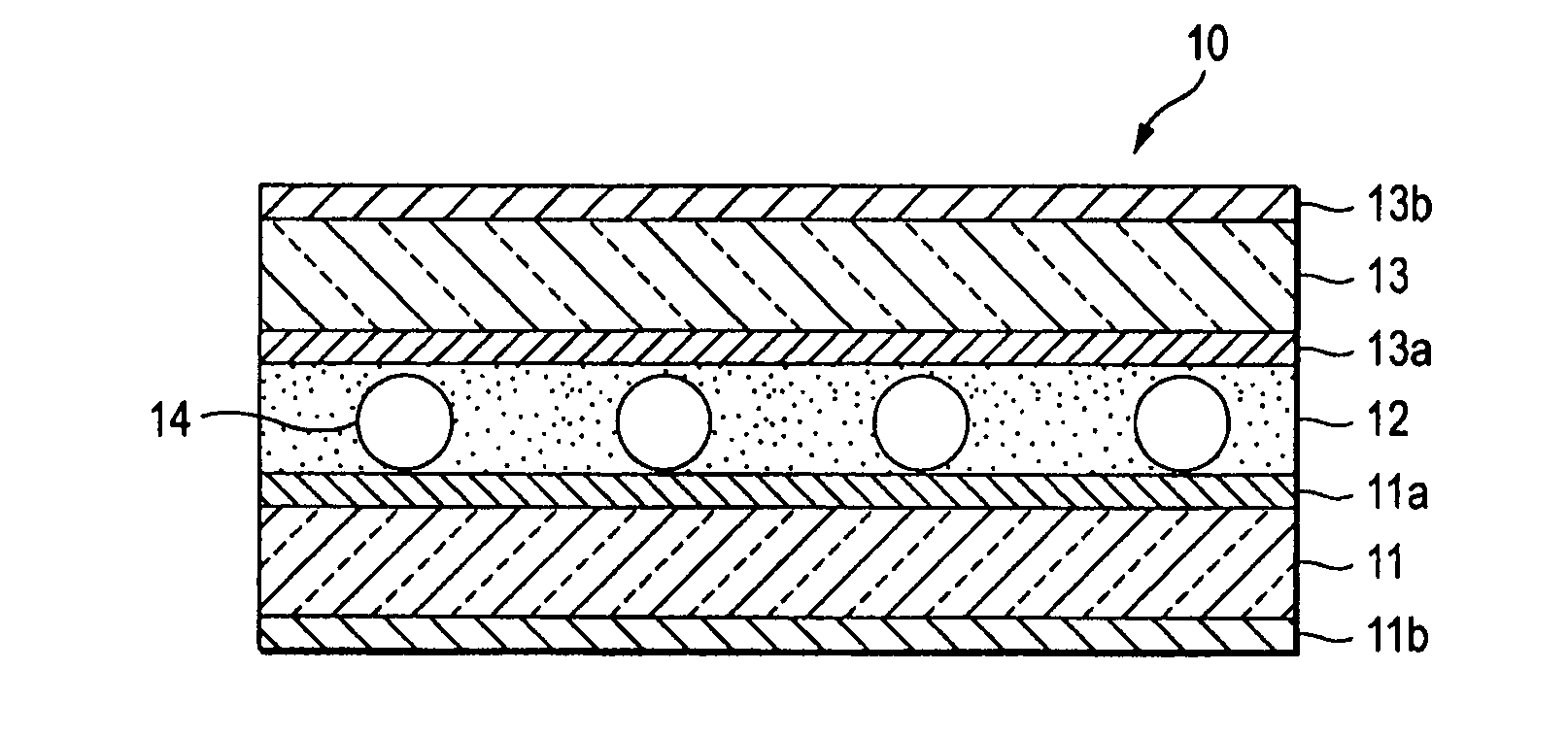

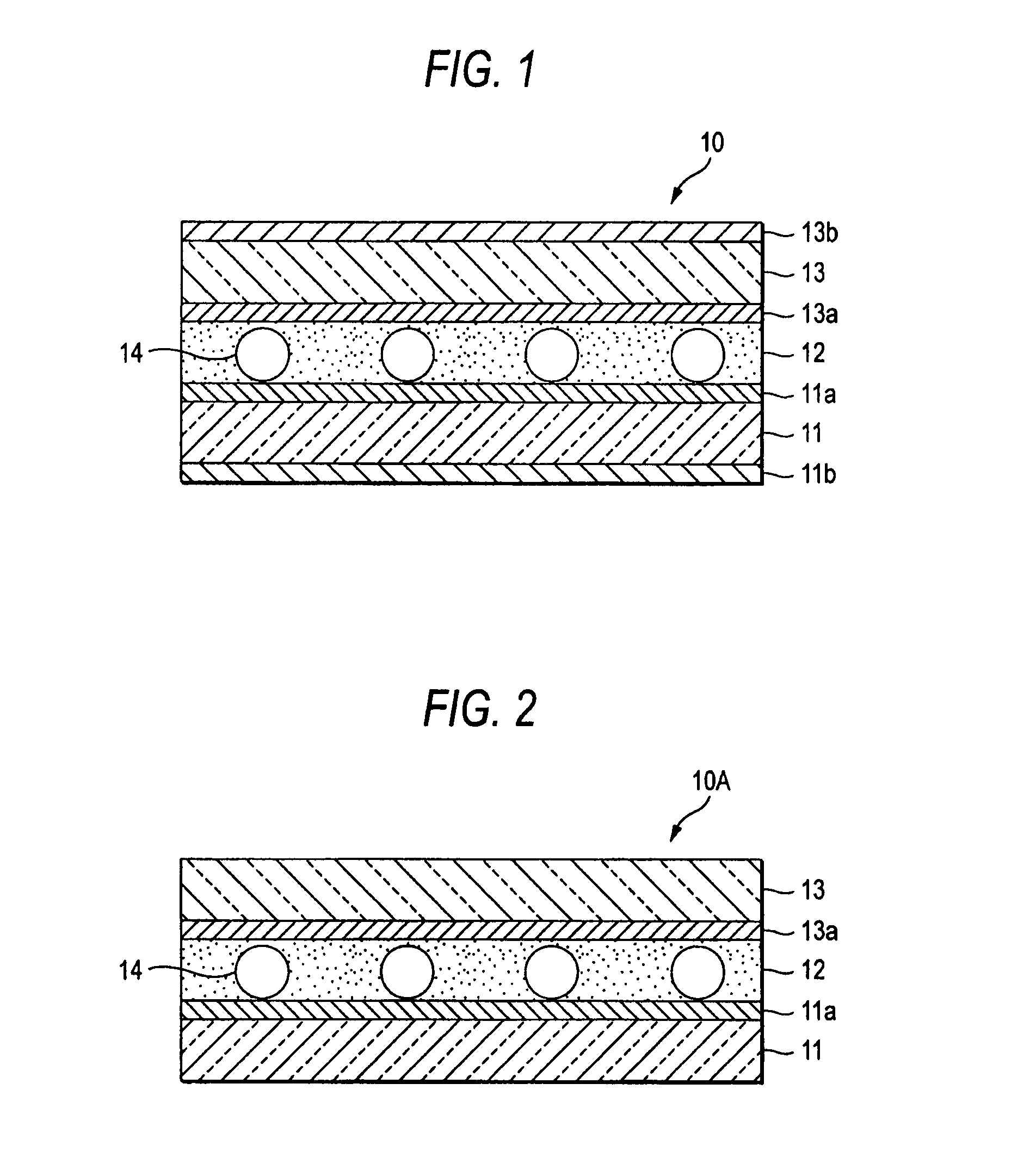

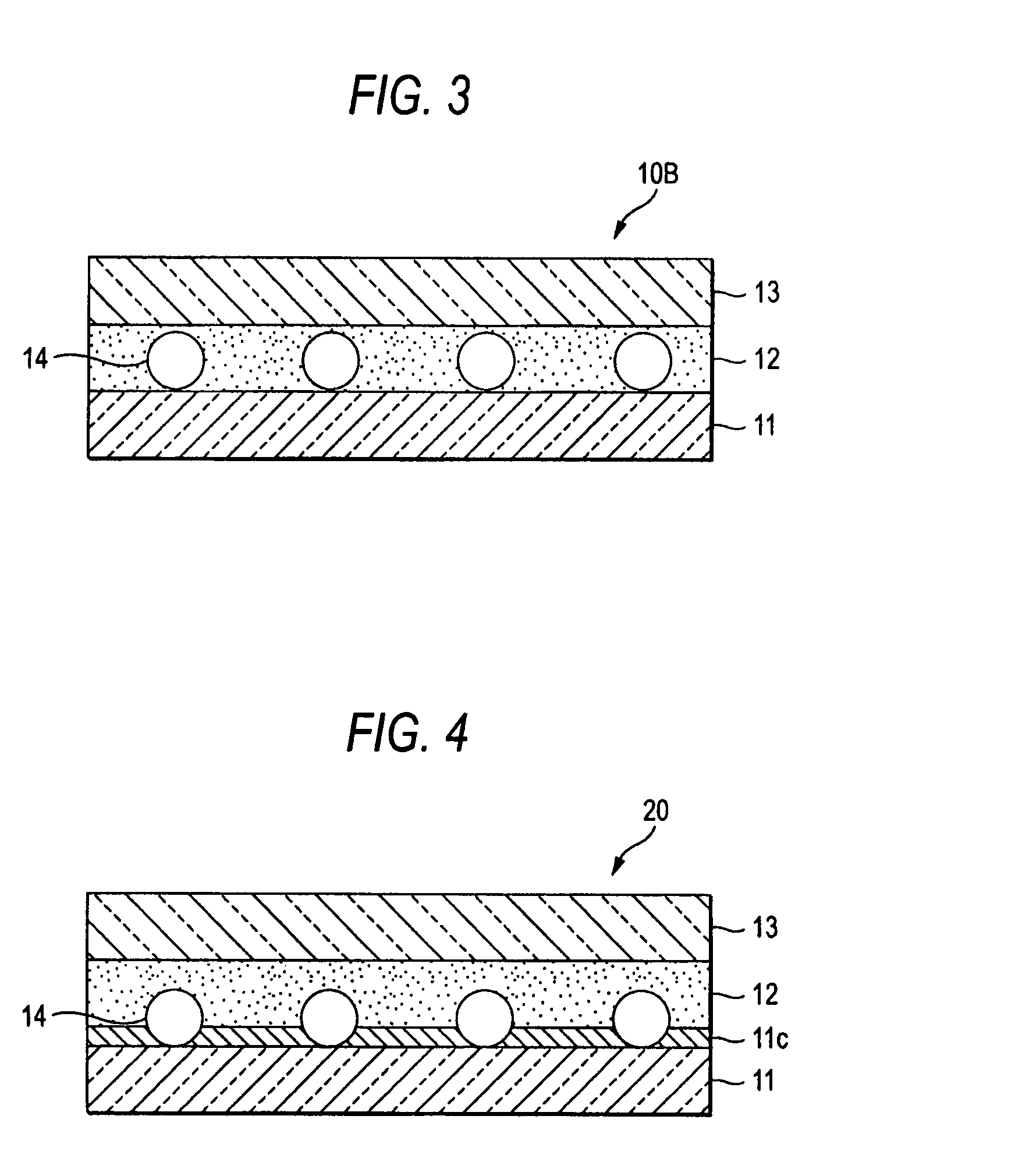

Hologram recording medium

InactiveUS7751104B2Reduce exposure timeAvoid uneven thicknessPhotomechanical apparatusHolographic optical componentsOptoelectronicsRecording layer

A hologram recording medium includes a stack of at least a lower transparent substrate, a recording layer made of a photocurable organic material, and an upper transparent substrate, wherein a spacer for keeping a thickness of the recording layer is dispersed and disposed in the inside of the recording layer in a direction of a principal plane of the hologram recording medium.

Owner:SONY CORP

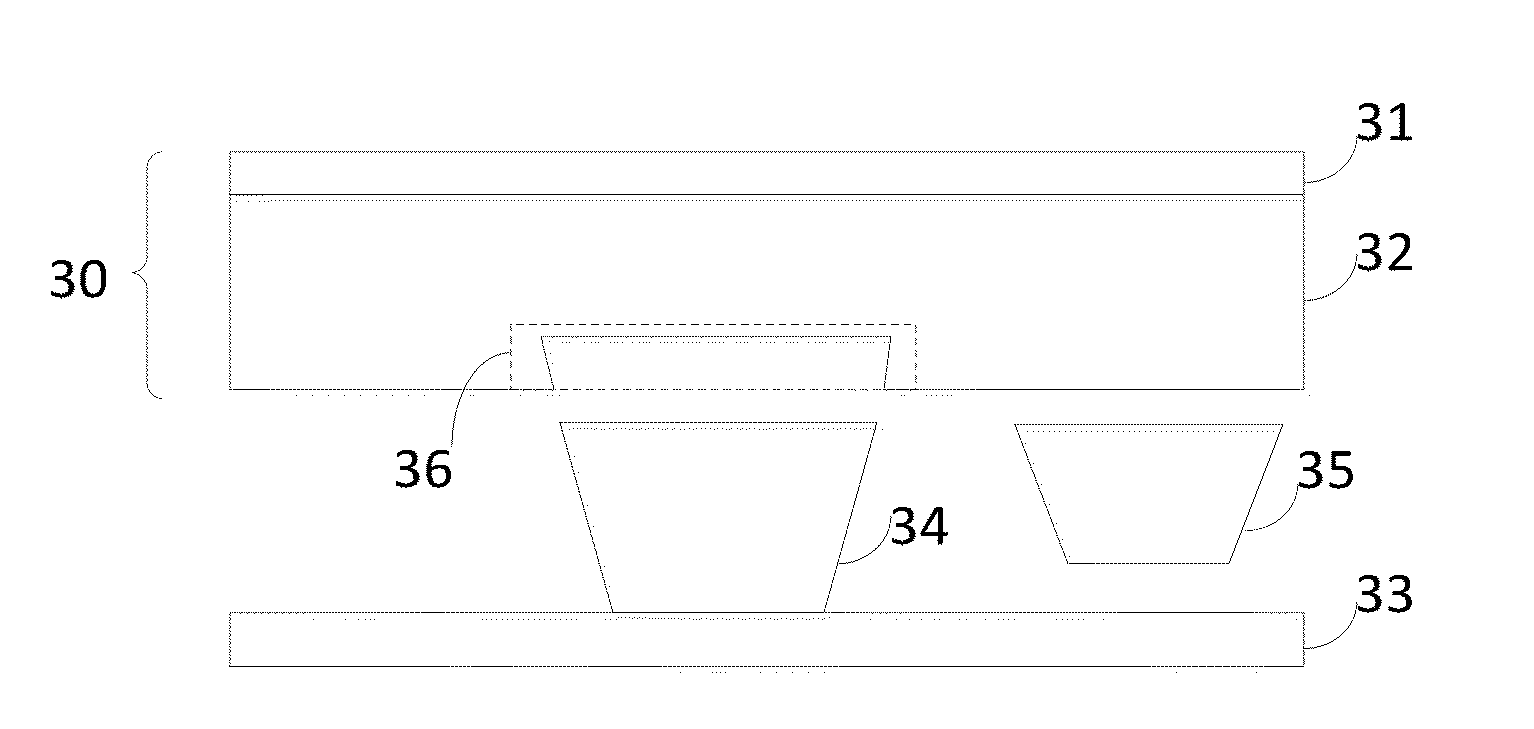

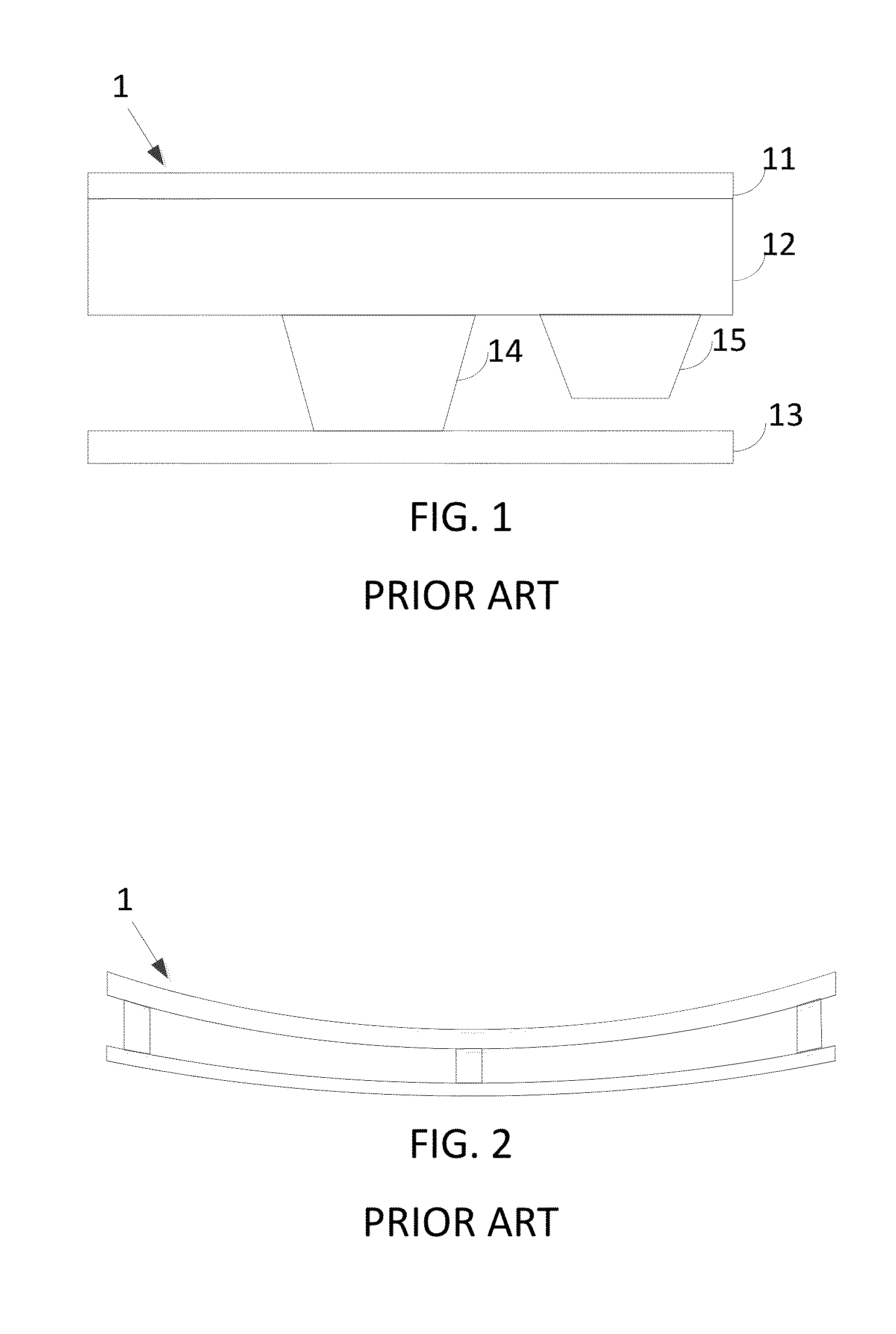

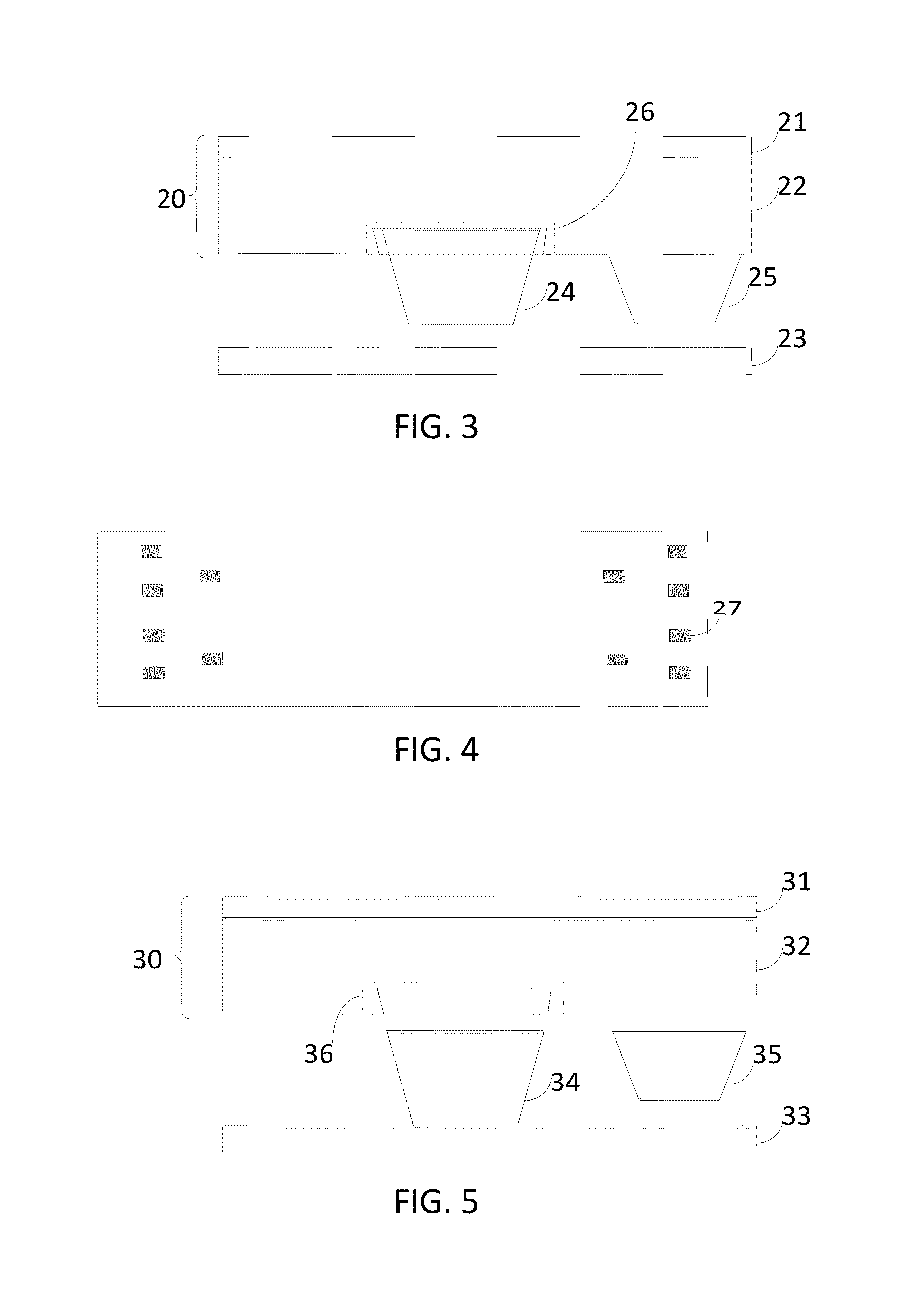

Curved liquid crystal display panel and manufacturing method thereof

ActiveUS20160170251A1Improve display effectUneven thicknessPhotomechanical apparatusVessels or leading-in conductors manufacturePhotoresistLiquid-crystal display

A curved liquid crystal display panel and a manufacturing method thereof are disclosed. The method includes a step of using a mask having a light-shielding portion to expose a color-filter photoresist layer, wherein the light-shielding portion is arranged in a position corresponding to an edge of the display panel; a step of developing the exposed color-filter photoresist layer, so that a concave portion corresponding to the position of the light-shielding portion is formed on the color-filter photoresist layer; and a step of forming photo spacers at a position corresponding to the concave portion of the color-filter photoresist layer on a substrate of the display panel.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

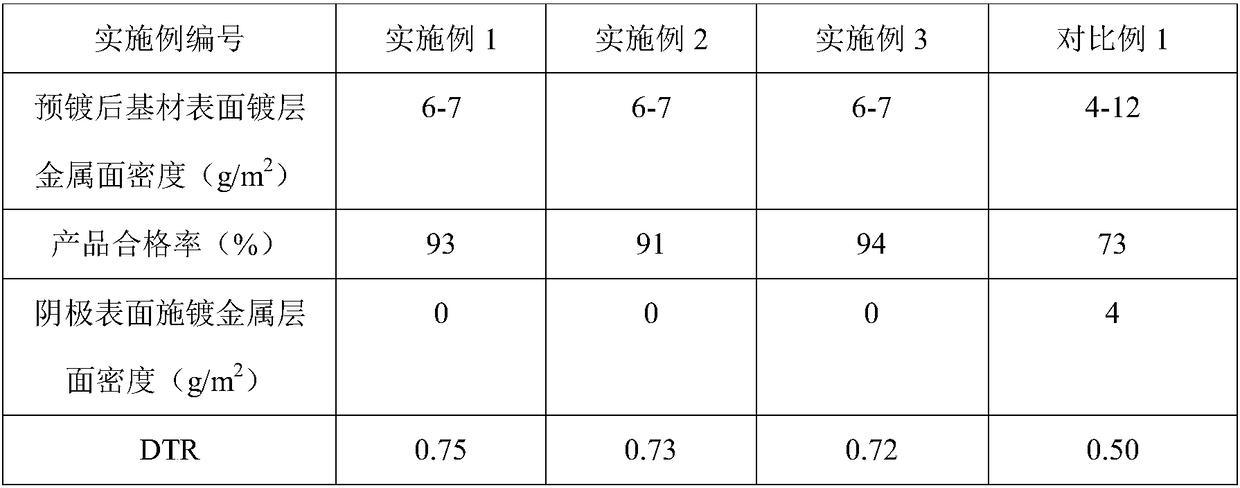

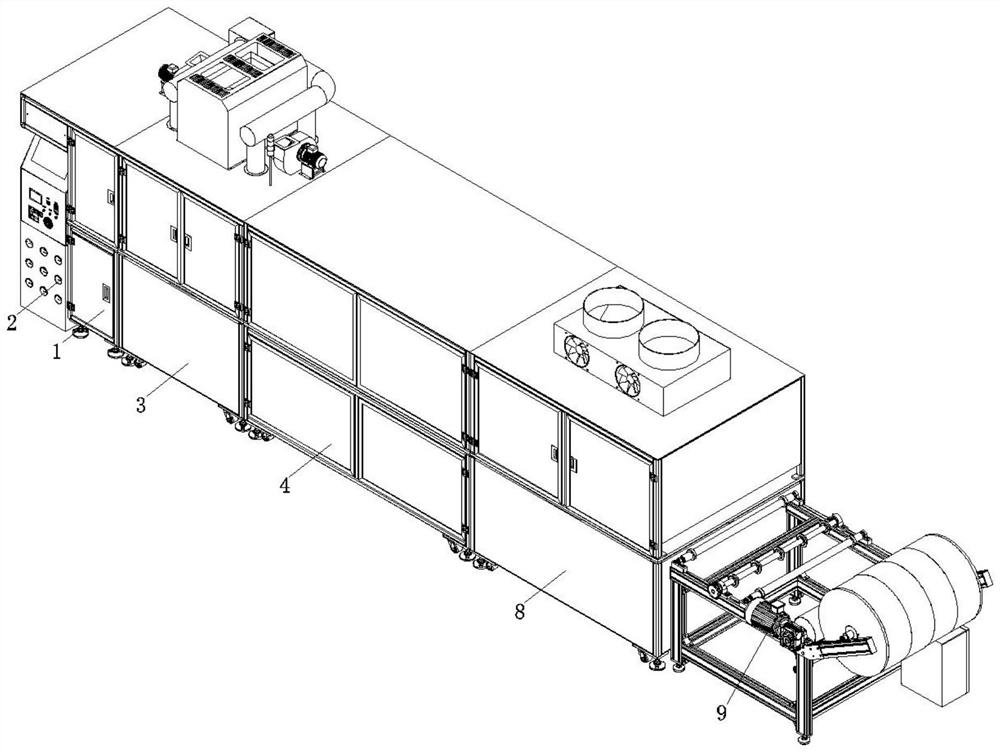

Electroplating equipment and electroplating method for foam metal material

The invention discloses electroplating equipment and electroplating method for a foam metal material. The electroplating equipment comprises an unrolling device, a pre-plating slot, an electroplatingslot and a rolling device, wherein the pre-plating slot comprises a pre-plating slot body, an anode I and an anode II which are distributed up and down in the pre-plating slot body, and a cathode plate I arranged above the pre-plating liquid level; the anode I and the anode II are in an arc shape; and arc length of the anode I is smaller than that of the anode II. The electroplating method comprises the following steps of extruding out air inside a foam base material subjected to conductive treatment before pre-plating through mutual action of a transmission roller and a hydraulic roller, providing electroplating positive ions by the anode I and the anode II, energizing a cathode, and performing primary plating and post-treatment to obtain the foam metal material. The upper and lower anodes are arranged in the pre-plating slot, and thickness of metal plated on front and back surfaces of the base material is more uniform. The cathode in the pre-plating slot body is not soaked into pre-plating liquid, and metal is not deposited or plated on the surface of the cathode, so that a product qualification rate is 90% or more, and a cathode utilization rate is increased.

Owner:CHANGDE LYRUN MATERIAL

Liquid crystal display device

InactiveCN102449540AUneven thicknessImprove reliabilityPolarising elementsNon-linear opticsInter layerLiquid-crystal display

Provided is a liquid crystal display device wherein the thickness of the liquid crystal layer does not easily change even if the liquid crystal display device has an air gapless structure. The liquid crystal display device is provided with a first substrate, a liquid crystal layer, and a second substrate in this order toward the display surface, and the second substrate is provided with a polarization plate, an intermediate layer including an adhesive layer, and a protection plate in this order toward the display surface. The polarization plate and the protection plate are adhered to each other with the intermediate layer therebetween, and the elasticity of the material constituting the adhesive layer is 1.0105Pa or less.

Owner:SHARP KK

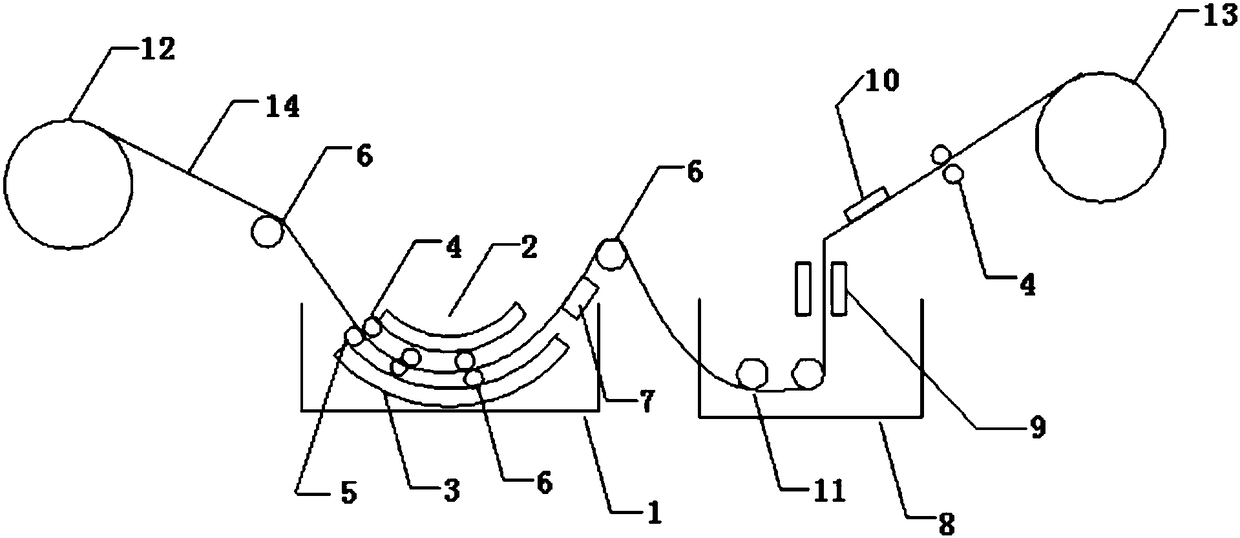

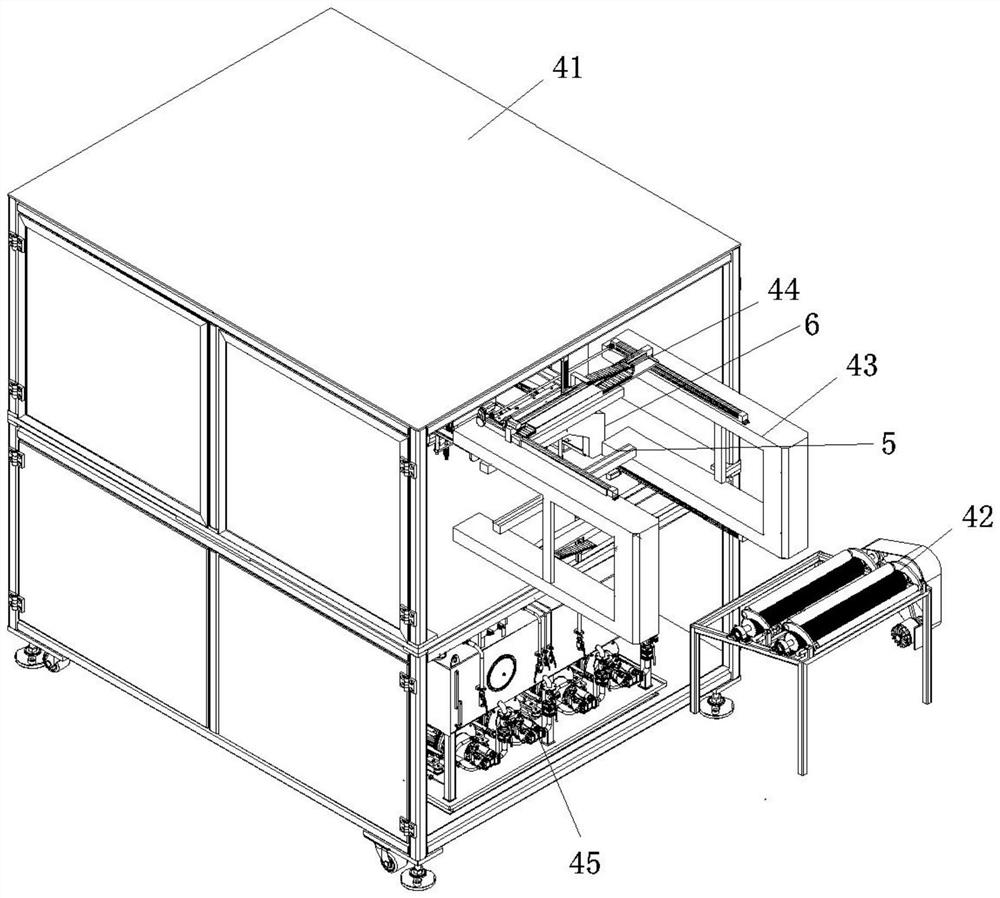

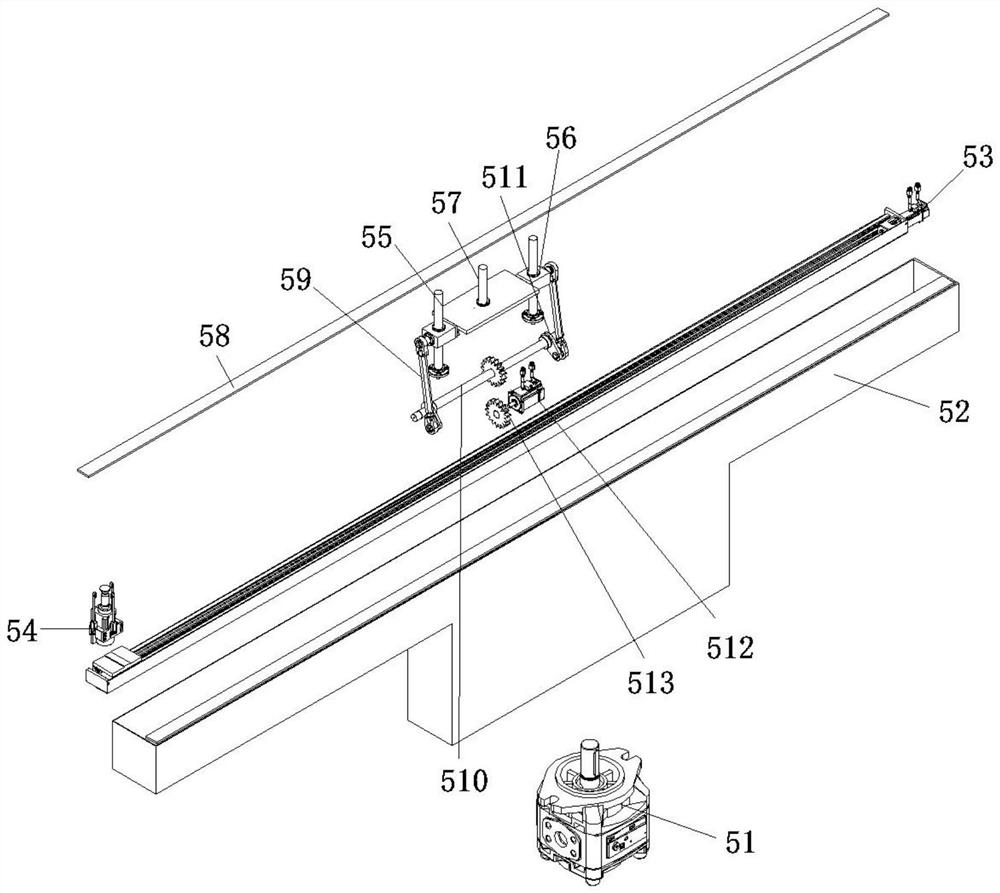

Coating equipment for preparing special coating glass fiber cloth

ActiveCN113909062ASolve the problem of coating dead angleUneven thicknessMechanical cleaningLiquid surface applicatorsGlass fiberWinding machine

The invention discloses coating equipment for preparing special coating glass fiber cloth. The coating equipment comprises a feeding machine, a controller, a dust remover, a coating mechanism, a light sensation drying machine and a winding machine. The controller is arranged on the front side of the feeding machine, and the controller is electrically connected with the feeding machine. The dust remover is arranged on the right side of the feeding machine, and the feeding machine is communicated with the dust remover. The coating mechanism is arranged on the right side of the dust remover, and the coating mechanism communicates with the dust remover. The light sensation drying machine is arranged on the right side of the coating mechanism. And the winding machine is arranged at the position corresponding to a discharging outlet, of the right side of the light sensation drying machine. According to the coating equipment for preparing the special coating glass fiber cloth, in the glass fiber cloth processing course, double-face synchronous coating can be conducted on the surface of the glass fiber cloth, the processing time is shortened, the processing efficiency is improved, and the problems that in the traditional glass fiber cloth coating process, coating dead corners exist, and the thickness of a coating on the surface of the glass fiber cloth is uneven are solved.

Owner:JIANGSU CHANGHAI COMPOSITE MATERIALS CO LTD

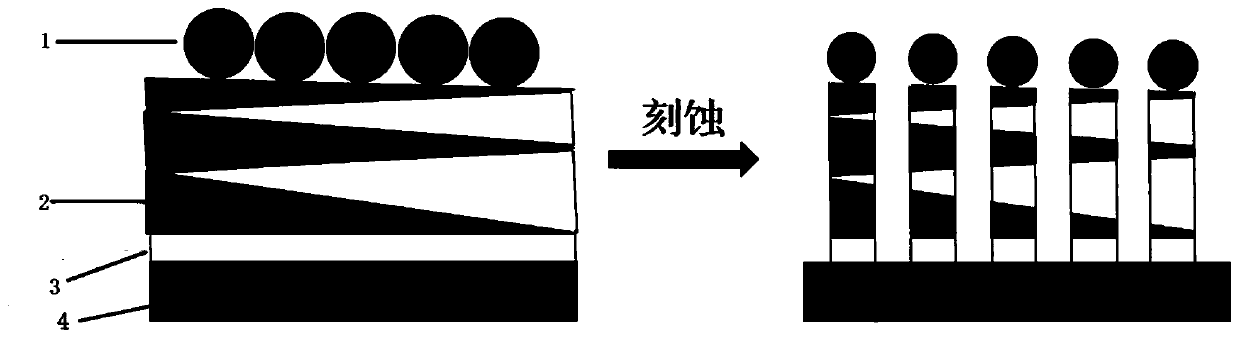

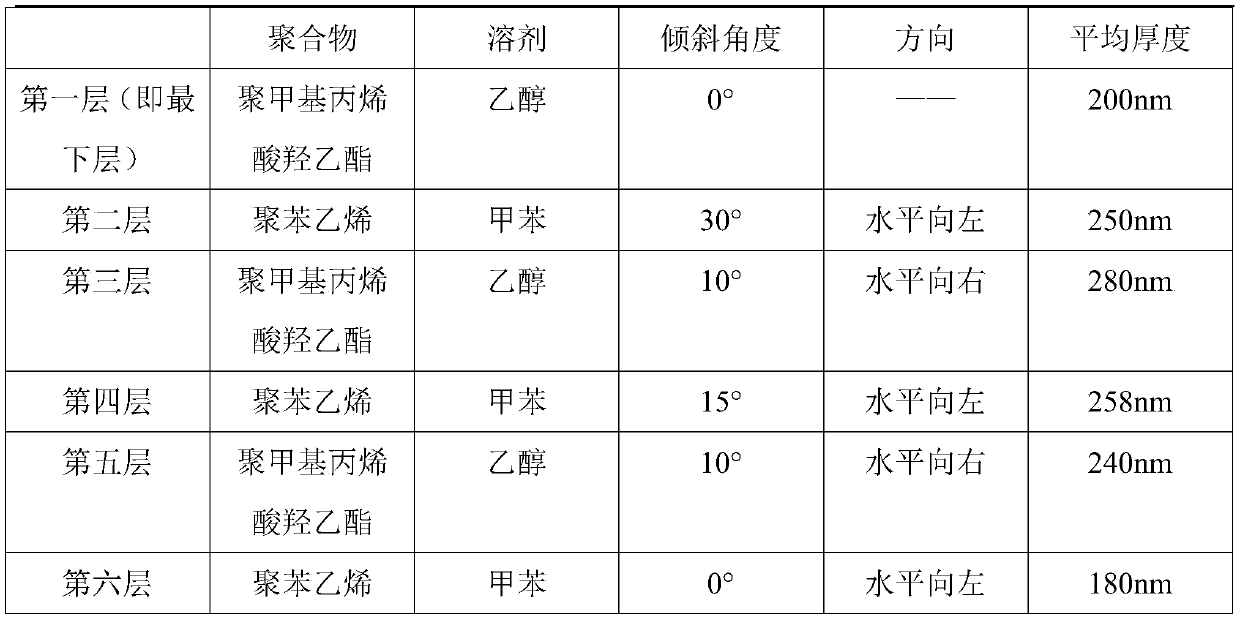

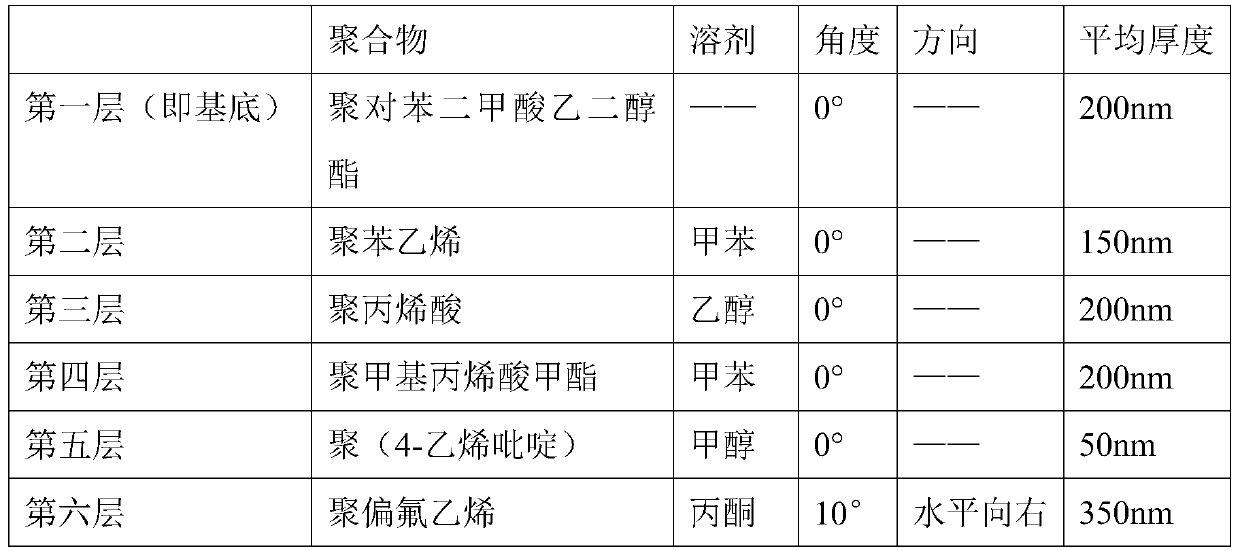

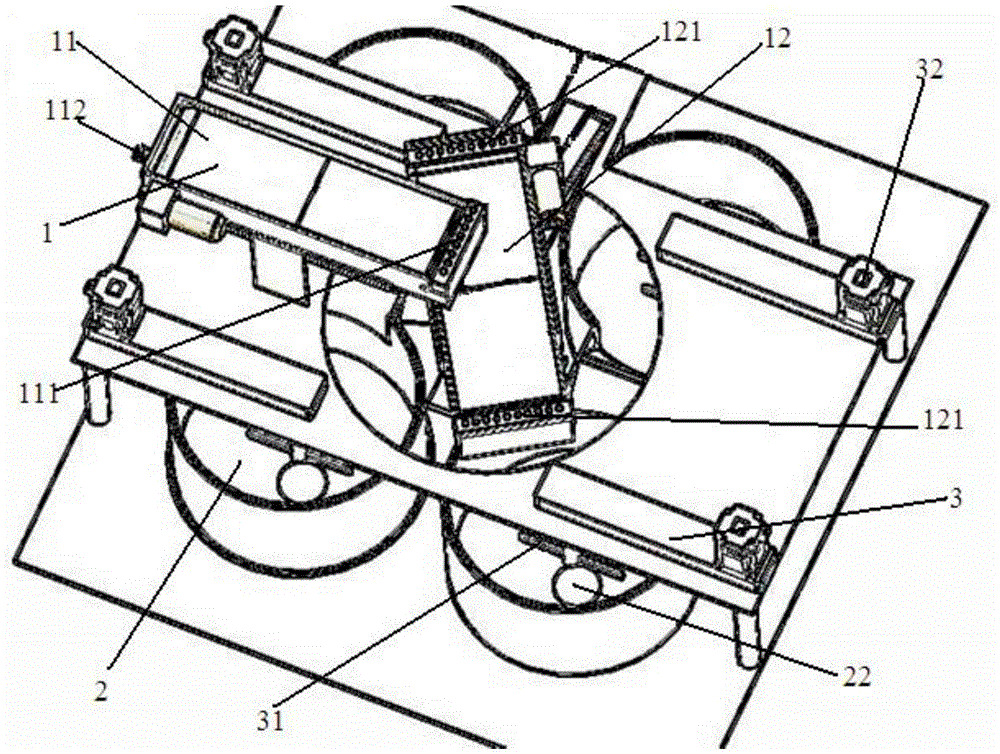

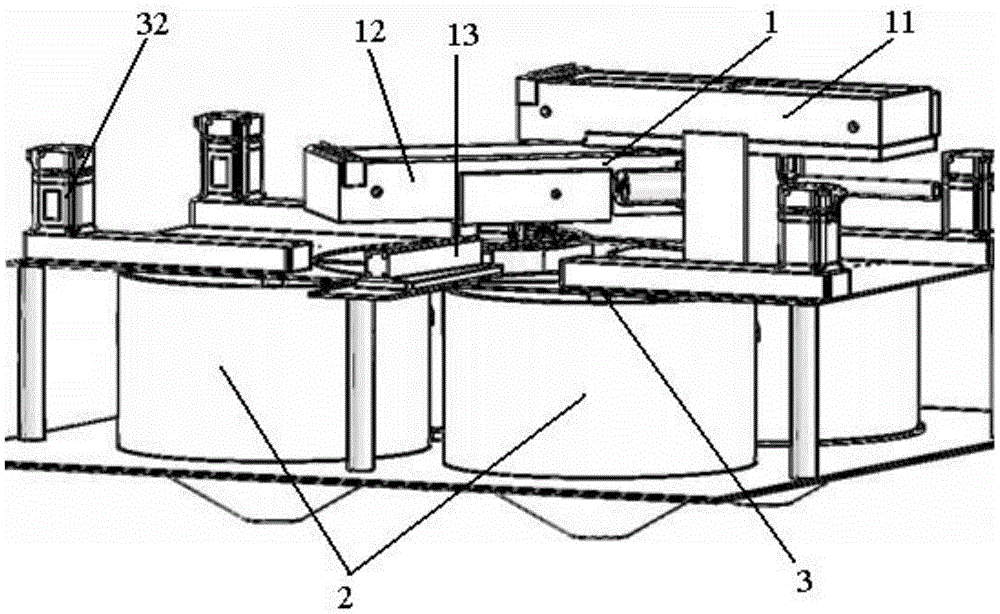

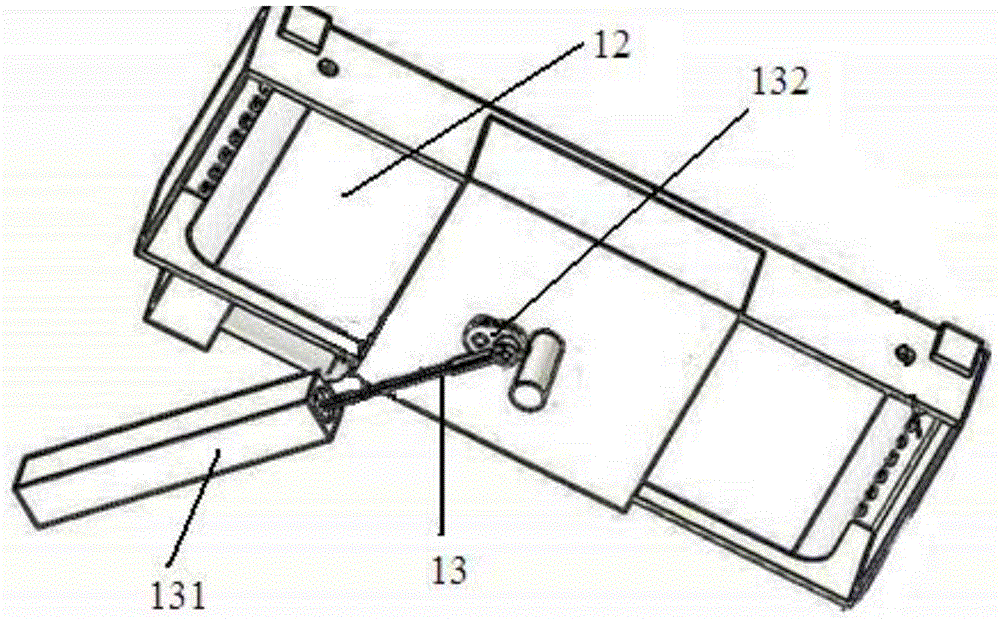

Segment thickness coded bar code nanorod and preparation method thereof

ActiveCN110964221ALow costLarge encoding capacityCoatingsRecord carriers used with machinesBarcodeEngineering

The invention relates to a segment thickness coded bar code nanorod and a preparation method thereof. The preparation method includes: in the process of constructing a multi-segment nanorod, when eachlayer of polymer film is deposited, controlling the inclination angle of a substrate relative to a horizontal plane to a certain degree and not 0 completely; the prepared segment thickness coded barcode nanorod is a multi-segment nanorod which comprises two or more segments and has at least one segment with non-uniform in thickness, and the non-uniformity means gradual change along the directionperpendicular to the length direction of the multi-segment nanorod. The preparation method of the segment thickness coded bar code nanorod is simple and practicable and low in cost, and can achieve batch preparation. According to the segment thickness coded bar code nanorod, at least one segment is uneven in thickness, and the encoding capacity of the bar code nanorod is greatly increased by introducing morphological factors into a nanorod array.

Owner:JIAXING UNIV

Solid-liquid separation device for capsule preparation

ActiveCN105536661AAvoid stickingImprove work efficiencyMicroballoon preparationMoving filtering element filtersBiochemical engineering

The invention relates to the technical field of cigarette manufacture, and particularly, relates to a solid-liquid separation device for capsule preparation. The solid-liquid separation device includes a filter transmission assembly and a plurality of reaction tanks; the filter transmission assembly is located above the reaction tanks and includes a filter conveying belt and a transmission component; the output end of the filter conveying belt is arranged above the transmission component and is used for conveying capsules separated from a solid and liquid mixture and located on the filter conveying belt to the transmission component; the output end of the transmission component is arranged above the reaction tanks and is used for conveying the capsules into the reaction tanks for fixed mold forming. The capsules can be quickly and effectively separated with a prepared solution during production through the filter conveying belt, the capsules are prevented from being bonded during fixed mold forming, the capsule outer wall thickness is prevented from being not uniform, and thus the product quality is improved; at the same time, the used time of preliminary forming of the capsules is less than the mold forming time, the filtered capsules can be transmitted into the plurality of reaction tanks through the transmission component, the mold forming working efficiency is increased, and the work continuity of the device is ensured.

Owner:CHINA TOBACCO GUIZHOU IND

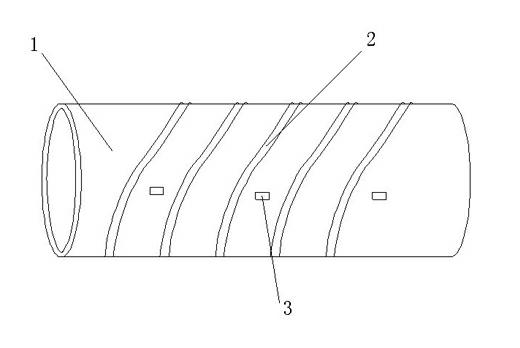

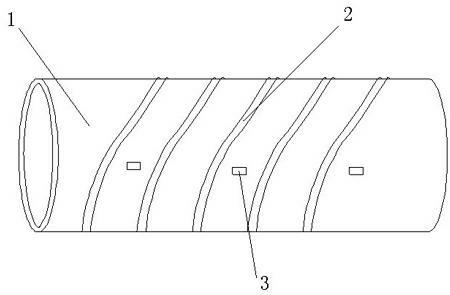

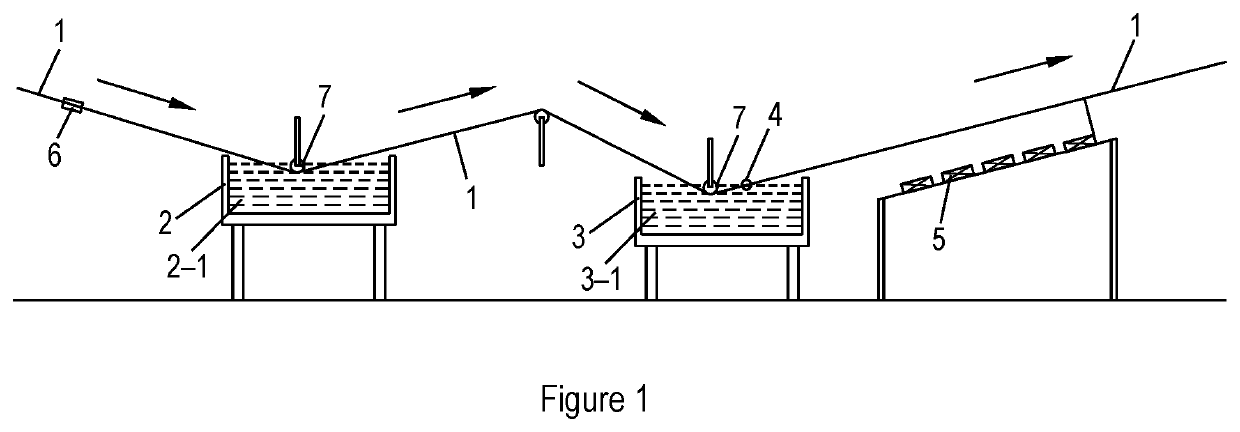

Roll-welded pipe spiral electroplating equipment and electroplating method thereof

The invention relates to roll-welded pipe spiral electroplating equipment and an electroplating method thereof. In the roll-welded pipe spiral electroplating equipment, a roller is arranged in an electroplating tank, so that blank roll-welded pipes can be wound on the roller spirally to perform rolling electroplating. The roll-welded pipes are wound on the roller spirally to fulfill the aim that more blank roll-welded pipes are put into the electroplating tank with the same volume and are electroplated continuously, and the floor space of the electroplating equipment is reduced, and the cost of the equipment is saved while the electroplating efficiency is improved.

Owner:FUJIAN JINGTAI PIPE IND

Process for Producing Tinned Copper Wires

PendingUS20210310111A1Good fluidityImprove wettabilityHot-dipping/immersion processesMolten spray coatingTinningMetallurgy

Provided is a process for producing a tinned copper wire. The process comprises subjecting a copper wire sequentially to activation treatment, a first hot tinning treatment, a first cooling, a second hot tinning treatment, and a second cooling to obtain a tinned copper wire. The first hot tinning treatment is carried out at a first temperature and the second hot tinning treatment is carried out at a second temperature. The first temperature is higher than the second temperature. The first temperature is at least 38° C. higher than the melting point of tin. The second temperature is at least 8° C. higher than the melting point of tin.

Owner:JIANGXI ADVANCED COPPER IND RES INST

Method for Manufacturing A Watertight Zipper

ActiveUS20170266856A1Uneven thicknessImprove sealing functionSlide fastenersDomestic slide fastenersEngineeringMechanical engineering

The present disclosure provides a method for manufacturing a watertight zipper for solving the problem of production difficulties. A method for manufacturing a watertight zipper according to the present disclosure includes: forming a waterproof tape by extruding a polymeric material in melted state wrapping around an outer surface of a cloth tape, cutting a side of the waterproof tape that is covered by the thick waterproof layer by laser to form a side surface of the thick waterproof layer in a plane form as an abutting surface, forming a plurality of apertures at the waterproof tape, wherein each of the plurality of apertures extends through the cloth tape and the thick waterproof layer, and forming a plurality of scoops corresponding to the plurality of apertures by injection molding. The waterproof tape includes a thick waterproof layer and a thin waterproof layer both formed by the polymeric material in solidified state. The thick waterproof layer covers a side surface, an upper surface and a lower surface of the cloth tape. The thin waterproof layer connects with the thick waterproof layer. Each of the plurality of scoops spaces from the thin waterproof layer. An end of each of the plurality of scoops extends beyond the abutting surface of the thick waterproof layer.

Owner:TAIWAN UNITED OUTDOOR GRP INC

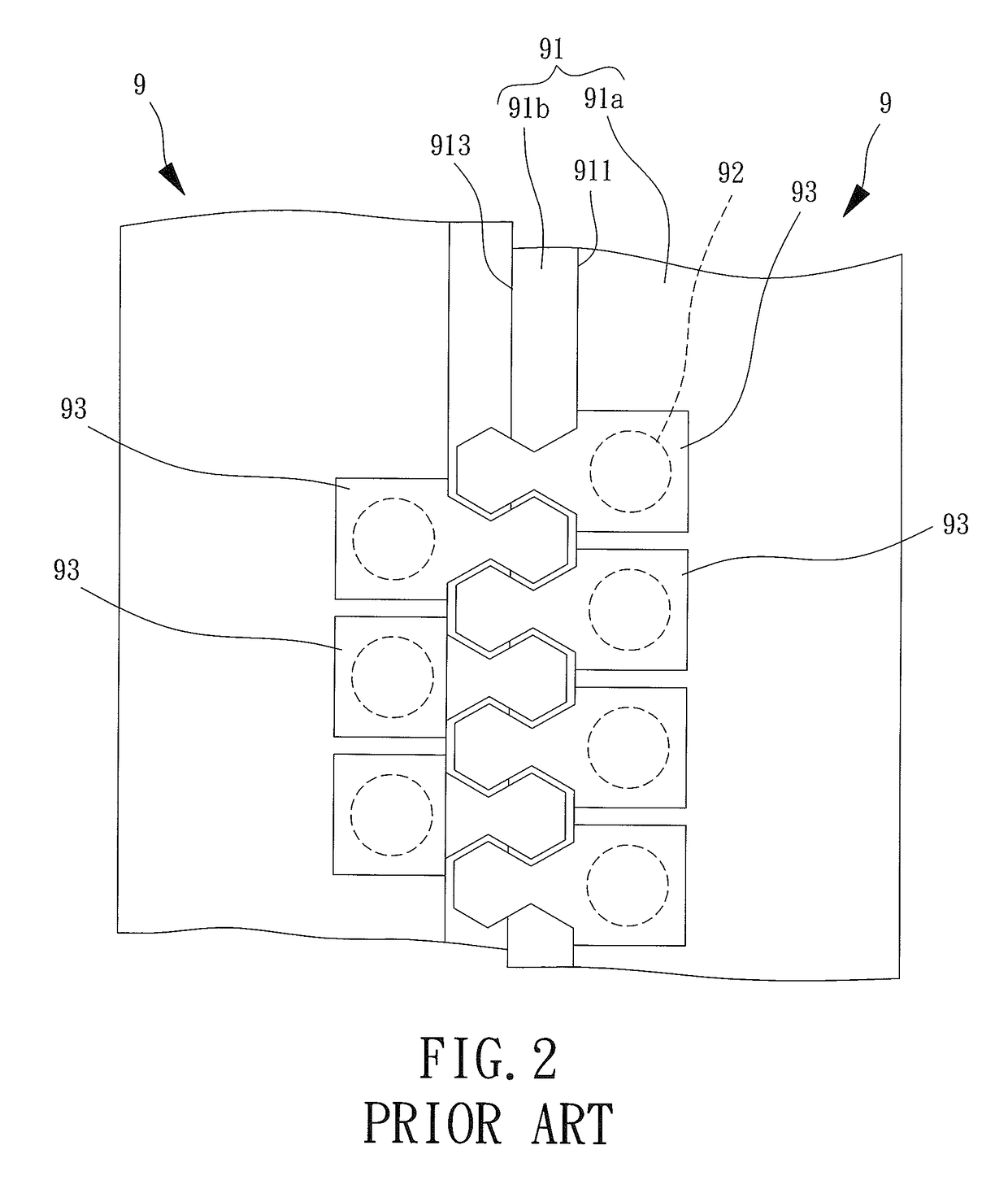

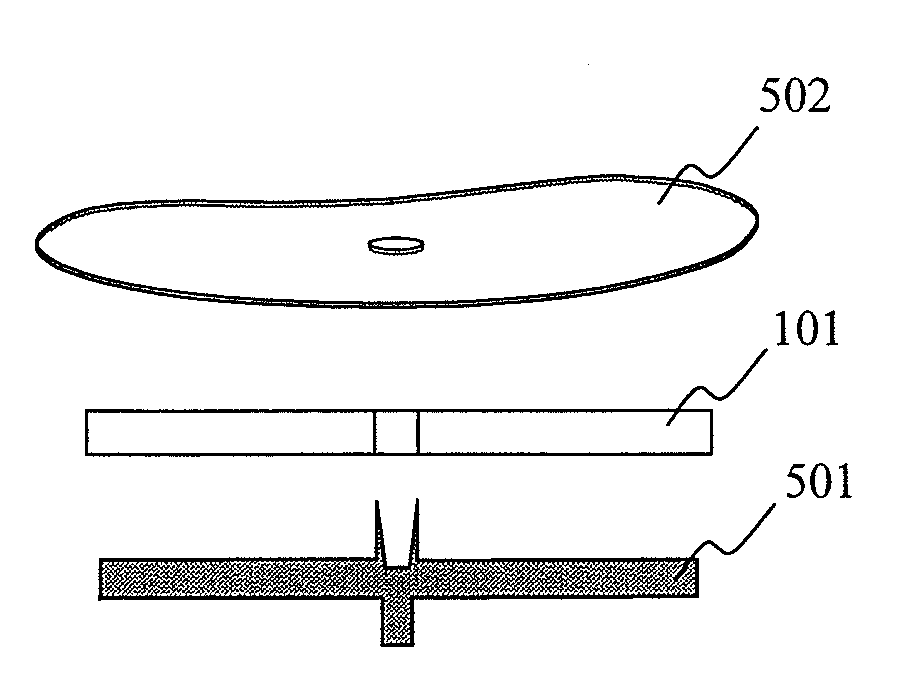

Multi-information-layer recording medium and manufacturing process

InactiveUS20090017251A1Improve adhesionLong lifetime characteristicLayered productsRecord information storageEngineeringRecording media

In forming a space layer of a multi-formation-layer recording medium, there are provided a medium having a high precision in a thickness of the space layer and its manufacturing process. In the multi-formation-layer recording medium wherein at least two pairs of an information recording layer and a translucency spacer are layered on a substrate having physical patterns composed of an optical spot groove and / or pits on the surface, an average thickness of the translucency spacers in an information zone is 15 μm or less, and a difference in spacer thickness between a minimum value and a maximum value is 2 μm or less.

Owner:HITACHI LTD

Hybrid silicon wafer and method of producing the same

ActiveUS8647747B2Improve production yieldHigh strengthPolycrystalline material growthAfter-treatment detailsMolten stateWafering

Provided is a hybrid silicon wafer in which molten state polycrystalline silicon and solid state single-crystal silicon are mutually integrated, comprising fine crystals having an average crystal grain size of 8 mm or less at a polycrystalline portion within 10 mm from a boundary with a single-crystal portion. Additionally provided is a method of manufacturing a hybrid silicon wafer, wherein a columnar single-crystal silicon ingot is sent in a mold in advance, molten silicon is cast around and integrated with the single-crystal ingot to prepare an ingot complex of single-crystal silicon and polycrystalline silicon, and a wafer shape is cut out therefrom. The provided hybrid silicon wafer comprises the functions of both a polycrystalline silicon wafer and a single-crystal wafer.

Owner:JX NIPPON MINING & METALS CORP

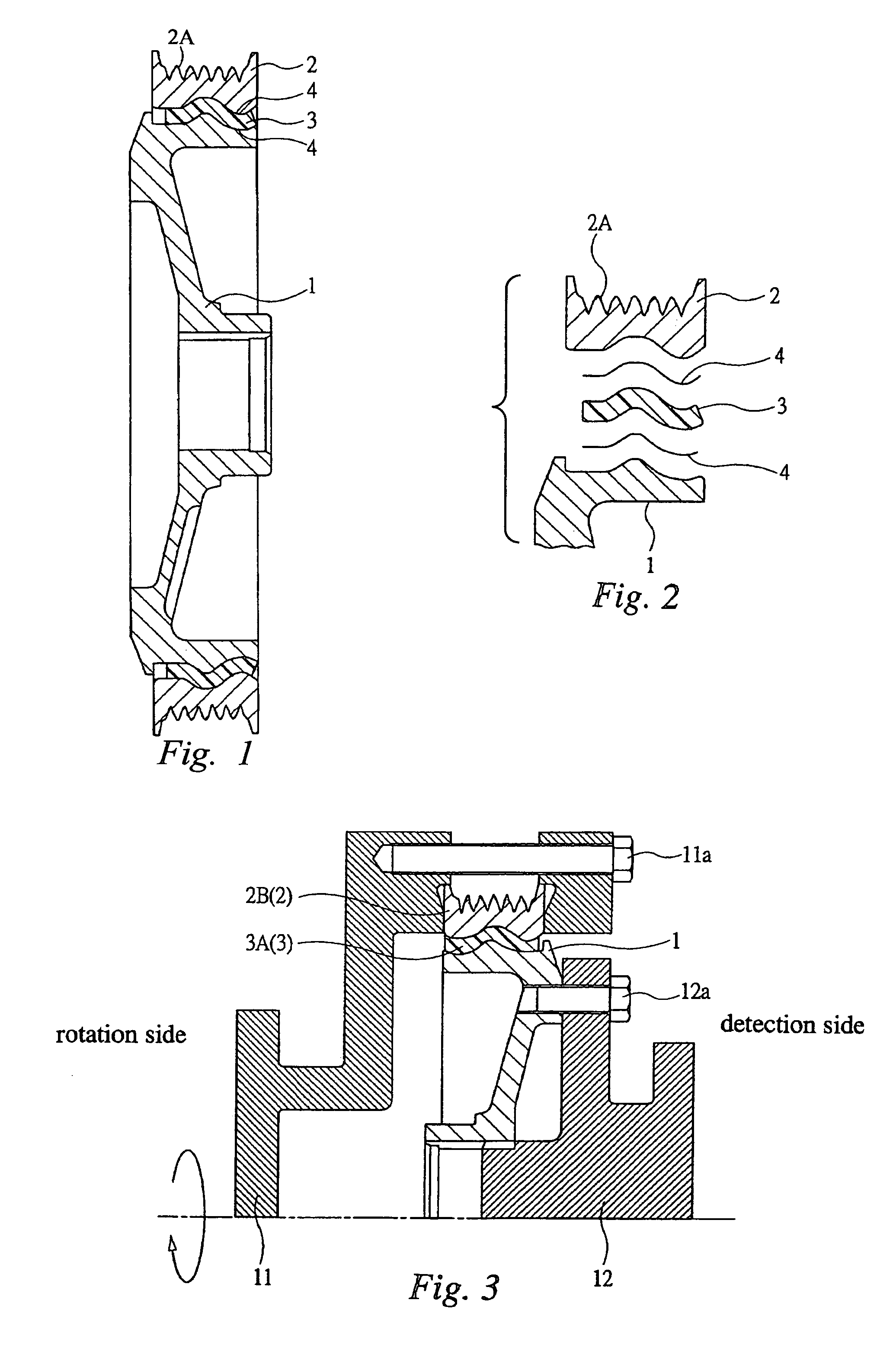

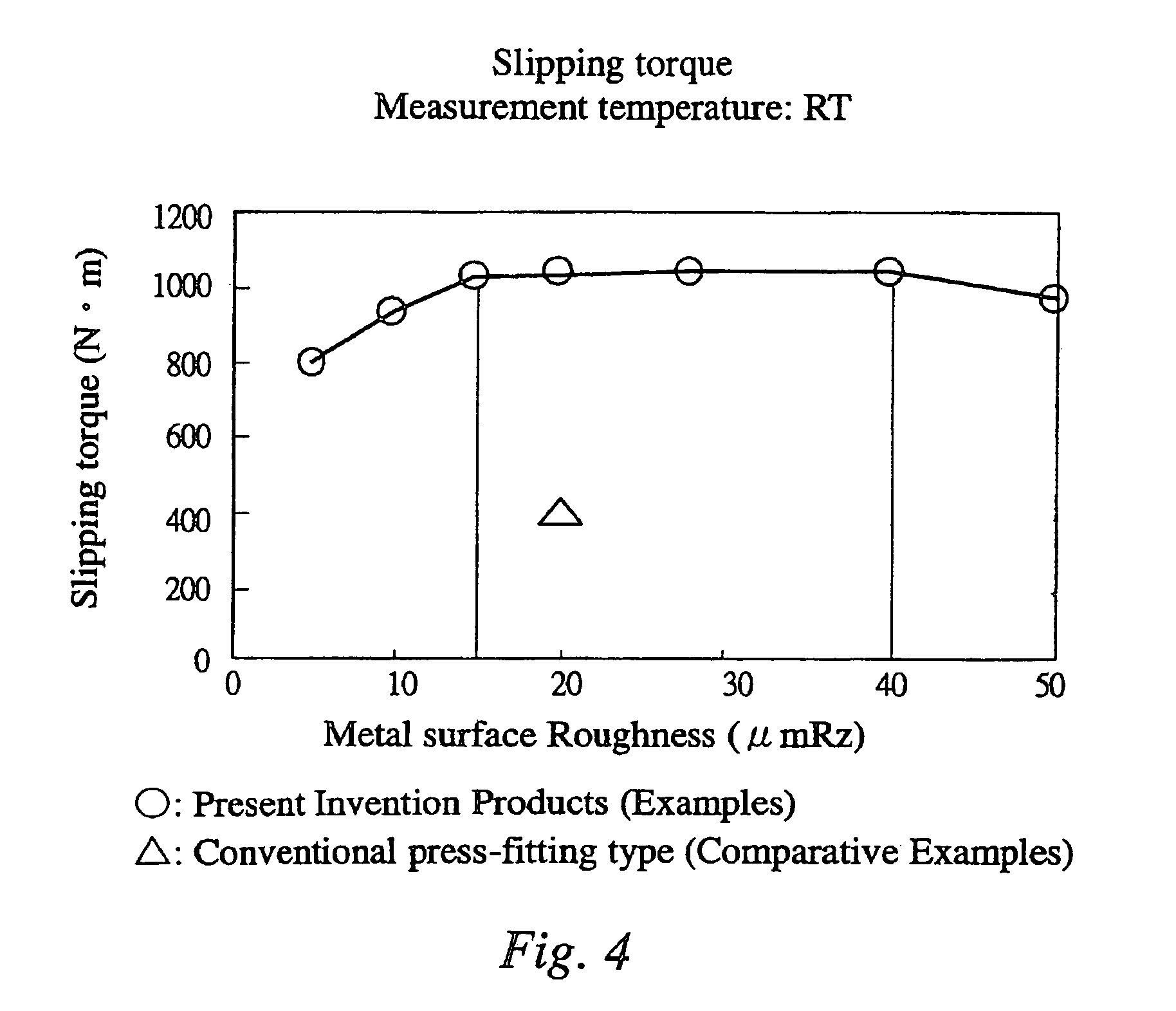

Damper and process thereof

InactiveUS7354637B2Treatment stableSufficient powerRotating vibration suppressionRecord information storageElastomerControl theory

Owner:FUKOKU CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com