Patents

Literature

430results about How to "Avoid uneven thickness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

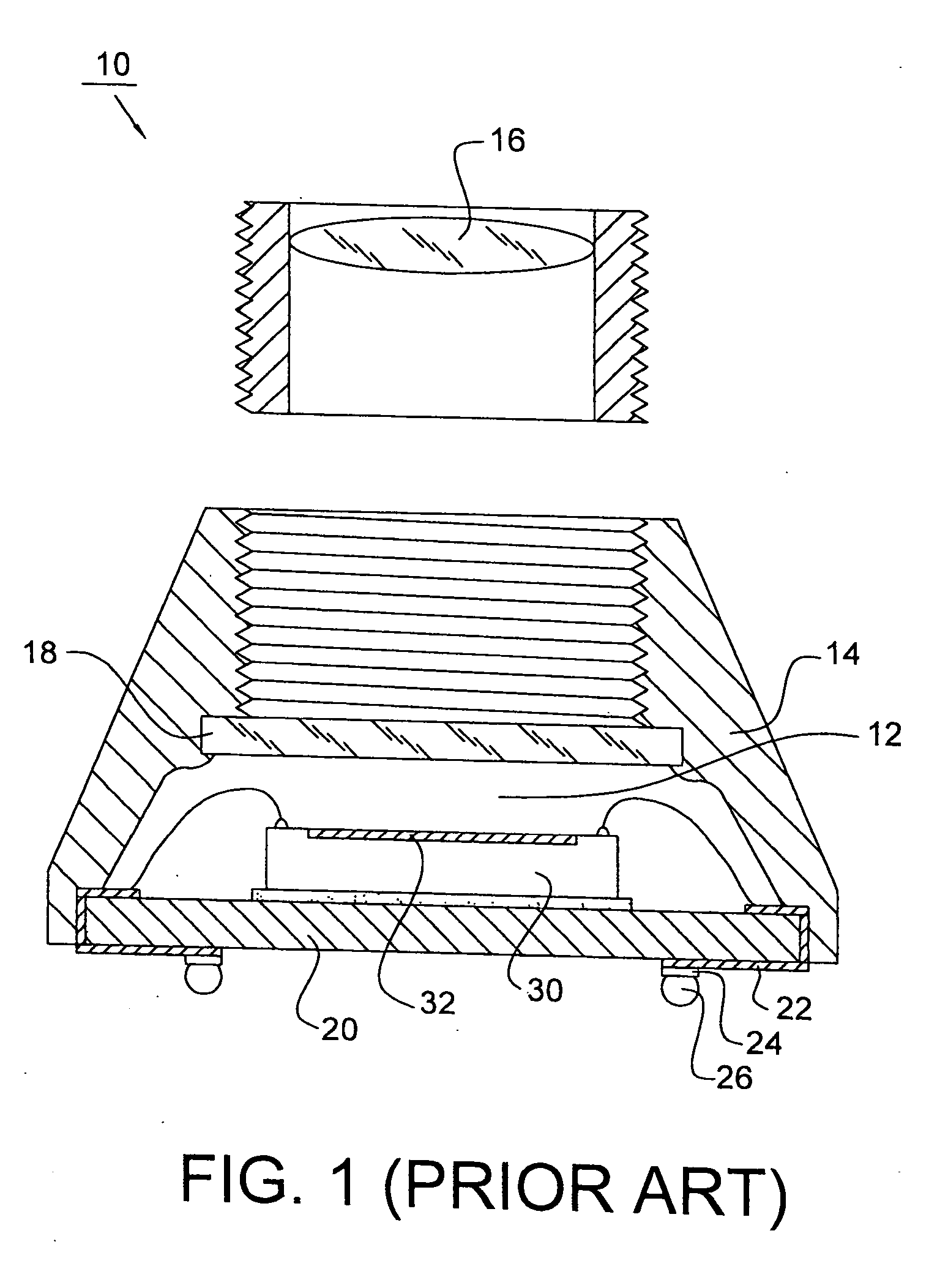

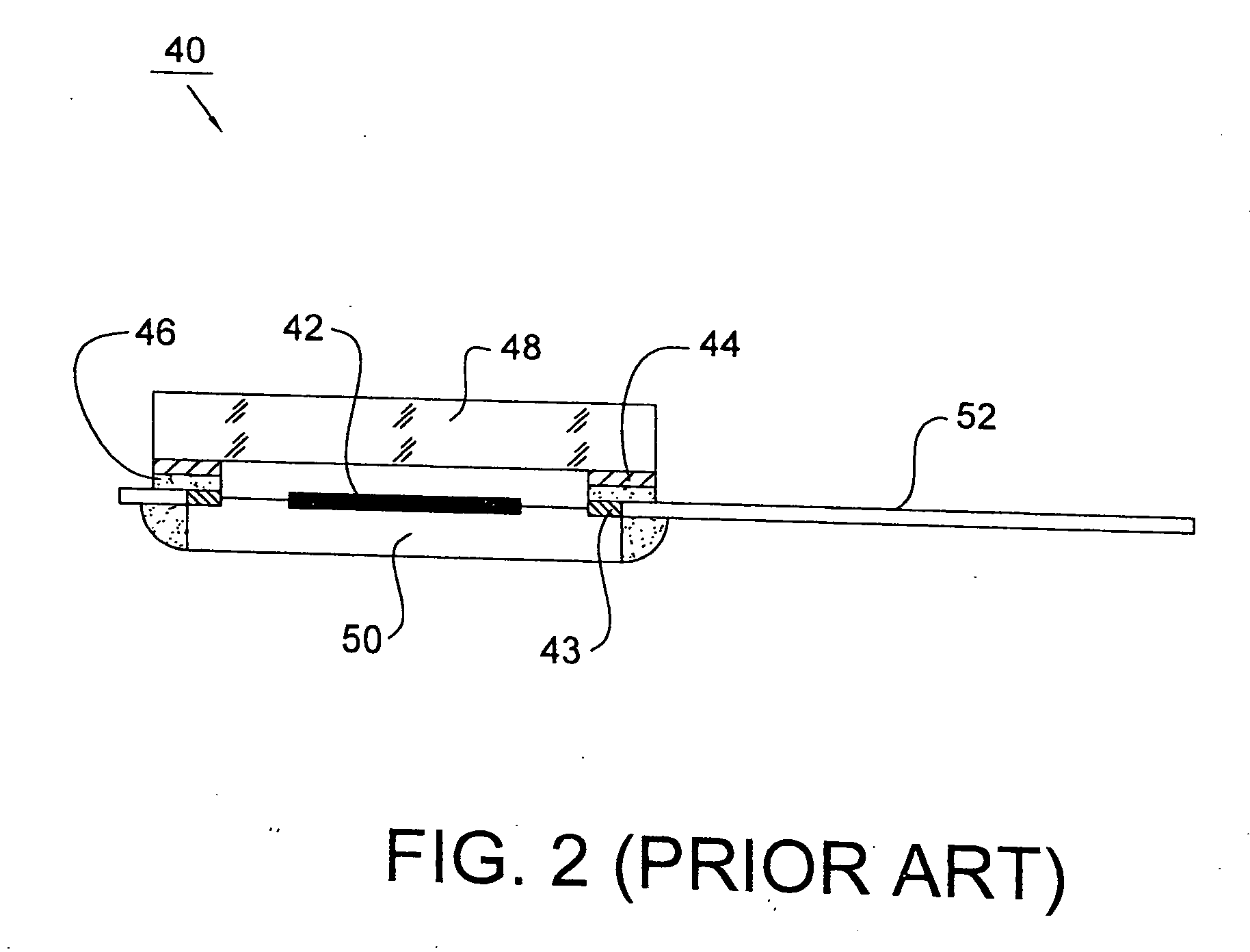

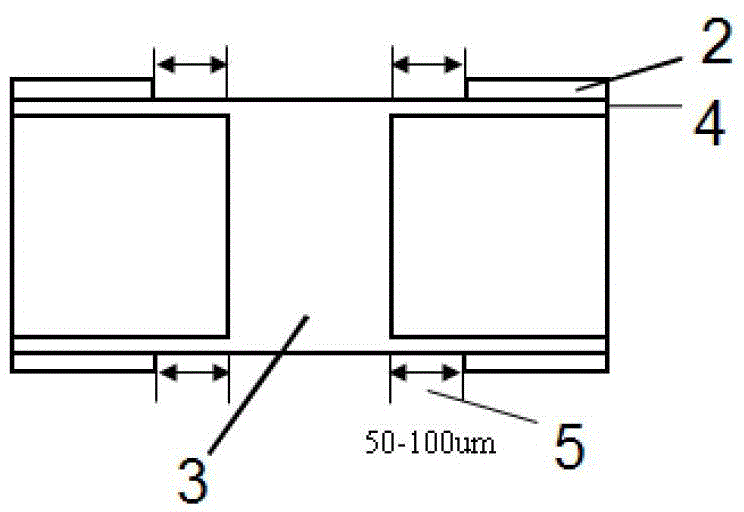

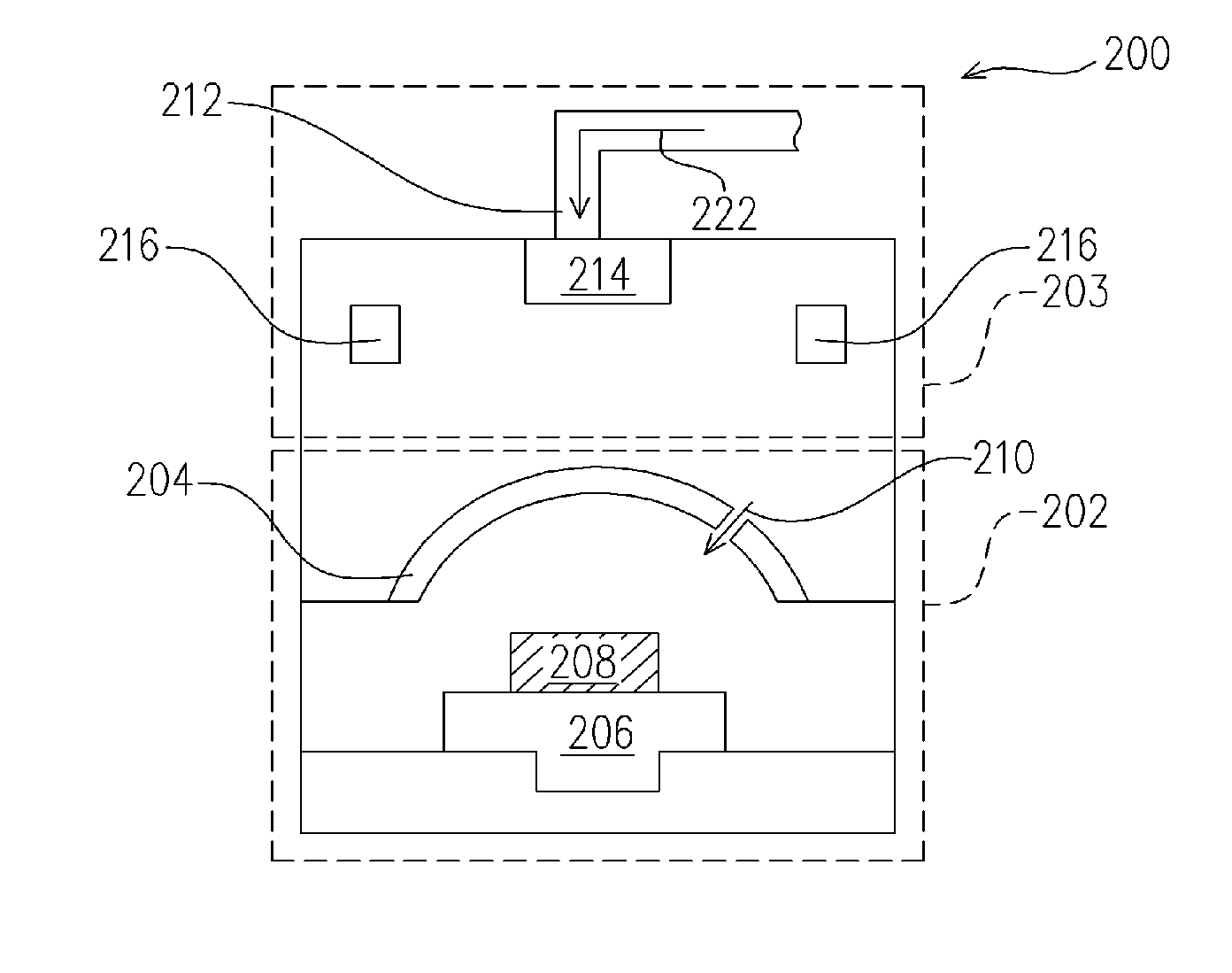

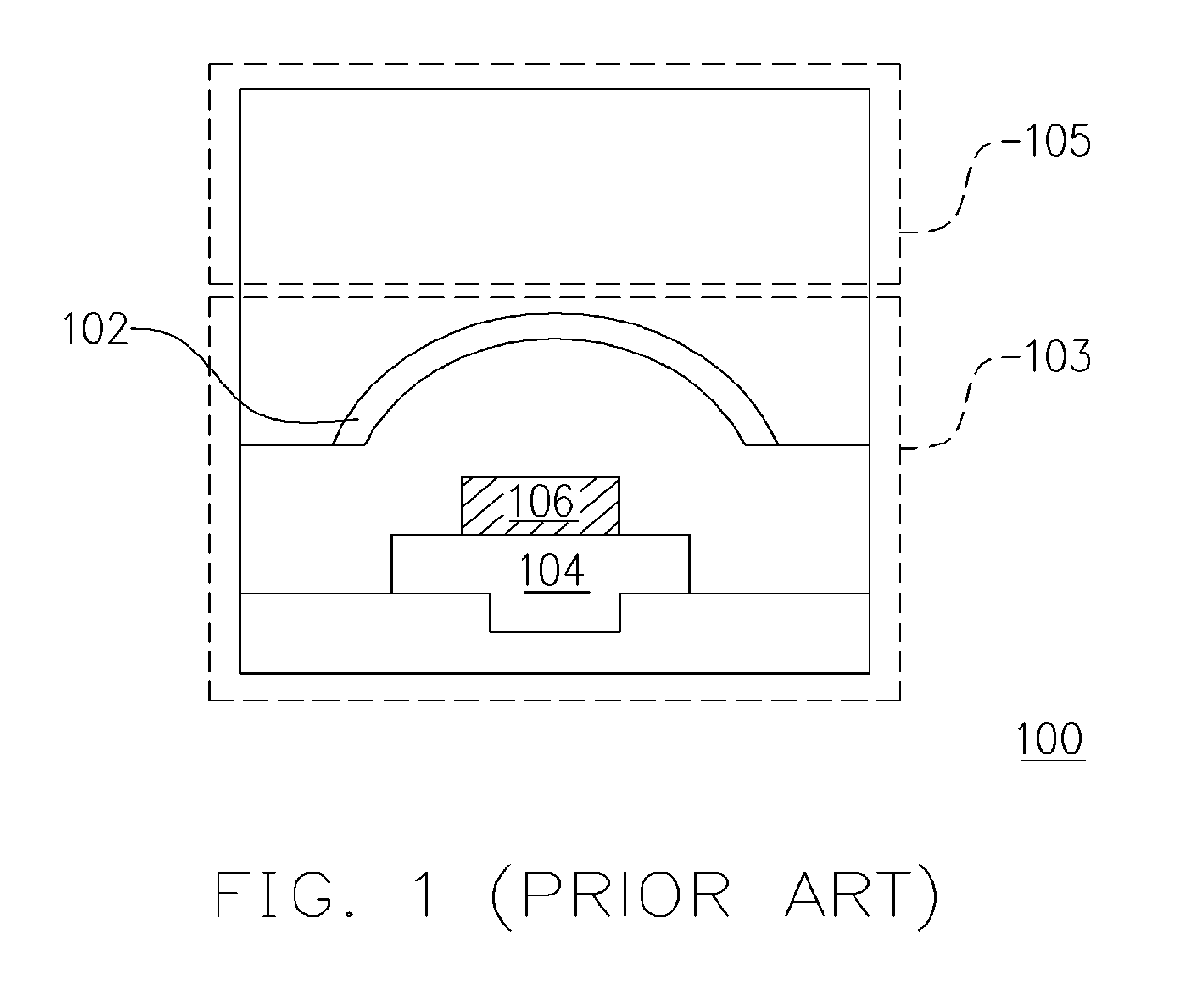

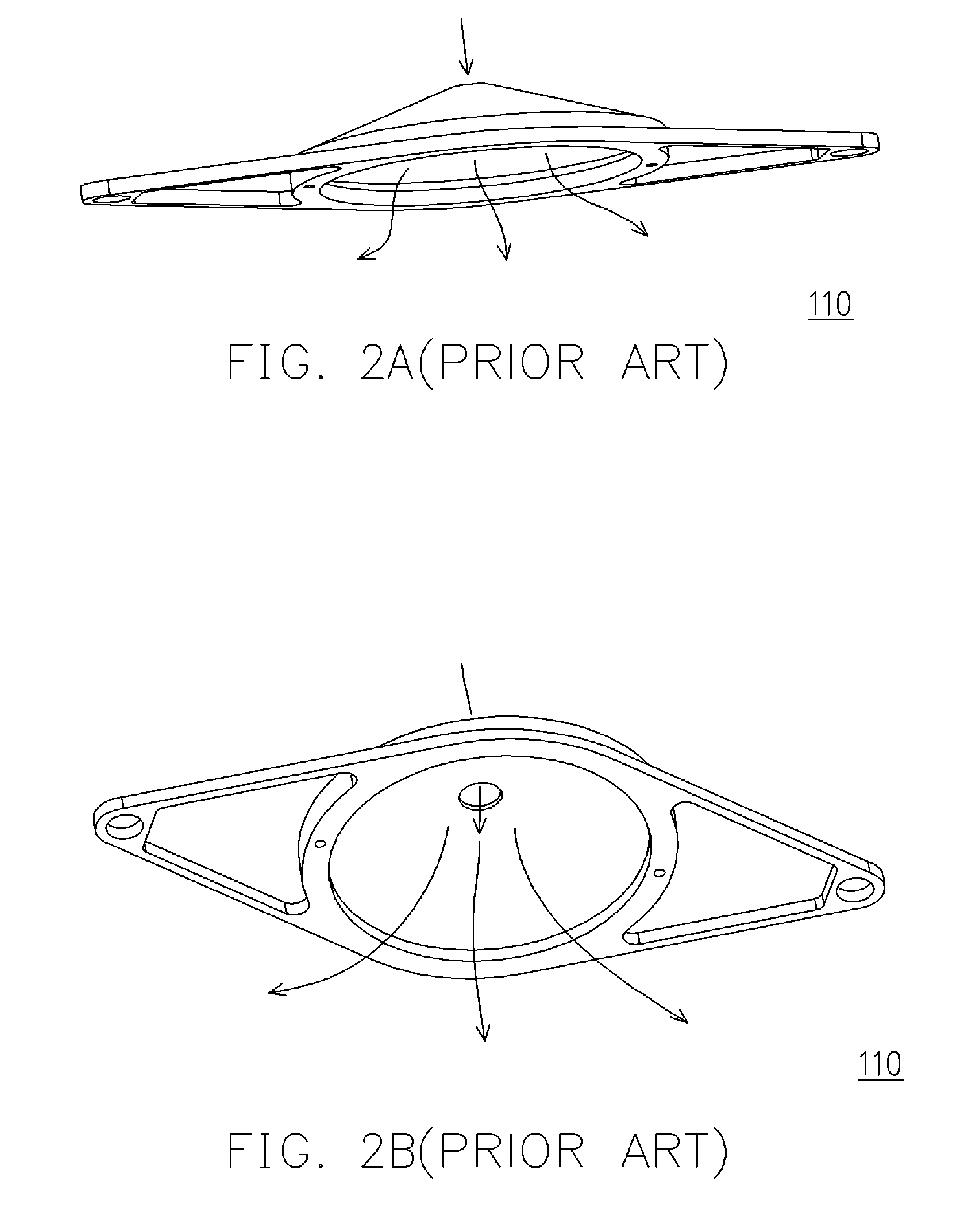

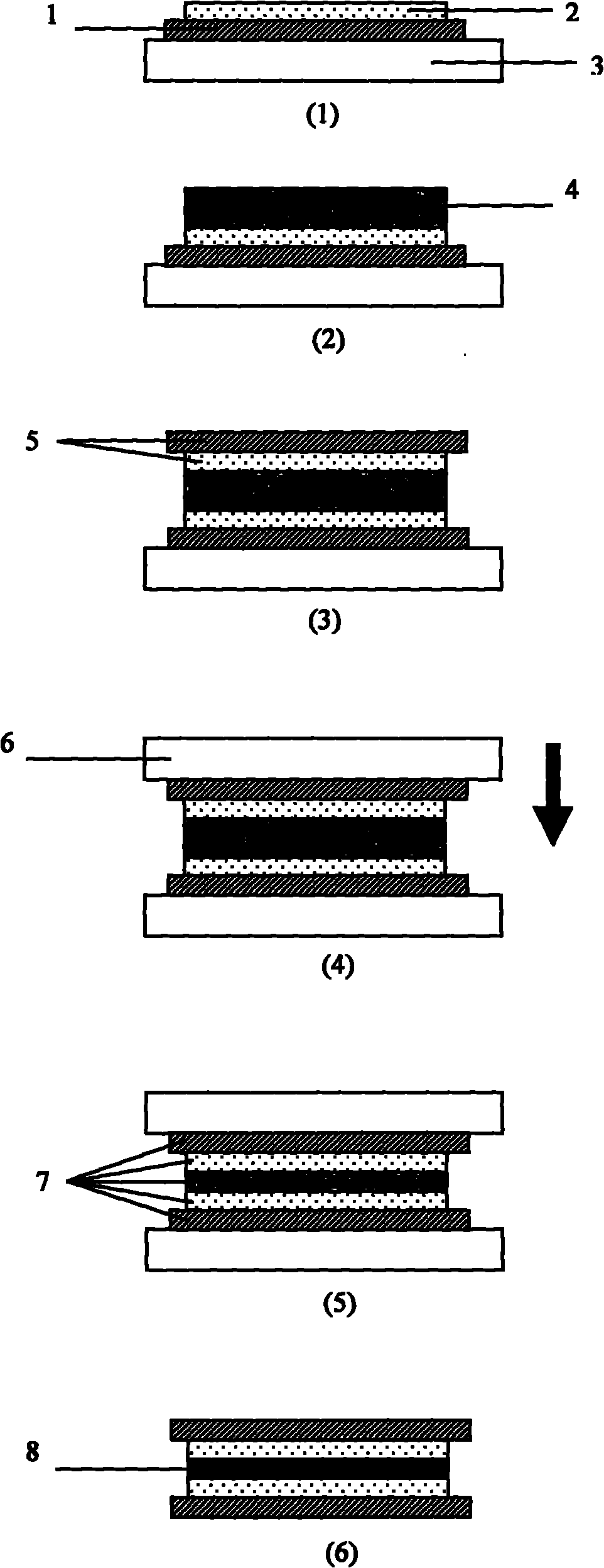

Sensor package

InactiveUS20060043555A1Maintaining gapInhibit swellingSemiconductor/solid-state device detailsSolid-state devicesAdhesiveEngineering

An image sensor package includes a bottom substrate, a transparent substrate, a plurality of spacers and adhesive. The bottom substrate includes a plurality of chips, which each includes an active surface and an image sensor disposed on the active surface. The transparent substrate includes a plurality of transparent substrate units which are respectively corresponding to the chips, wherein each transparent substrate unit is disposed above the active surface of the chip and covers the image sensor. The spacers are disposed between the transparent substrate unit and the chip for maintaining a predetermined gap between the transparent substrate unit and the image sensor. Each transparent substrate unit and chip are connected to each other by the adhesive.

Owner:HIMAX TECH LTD

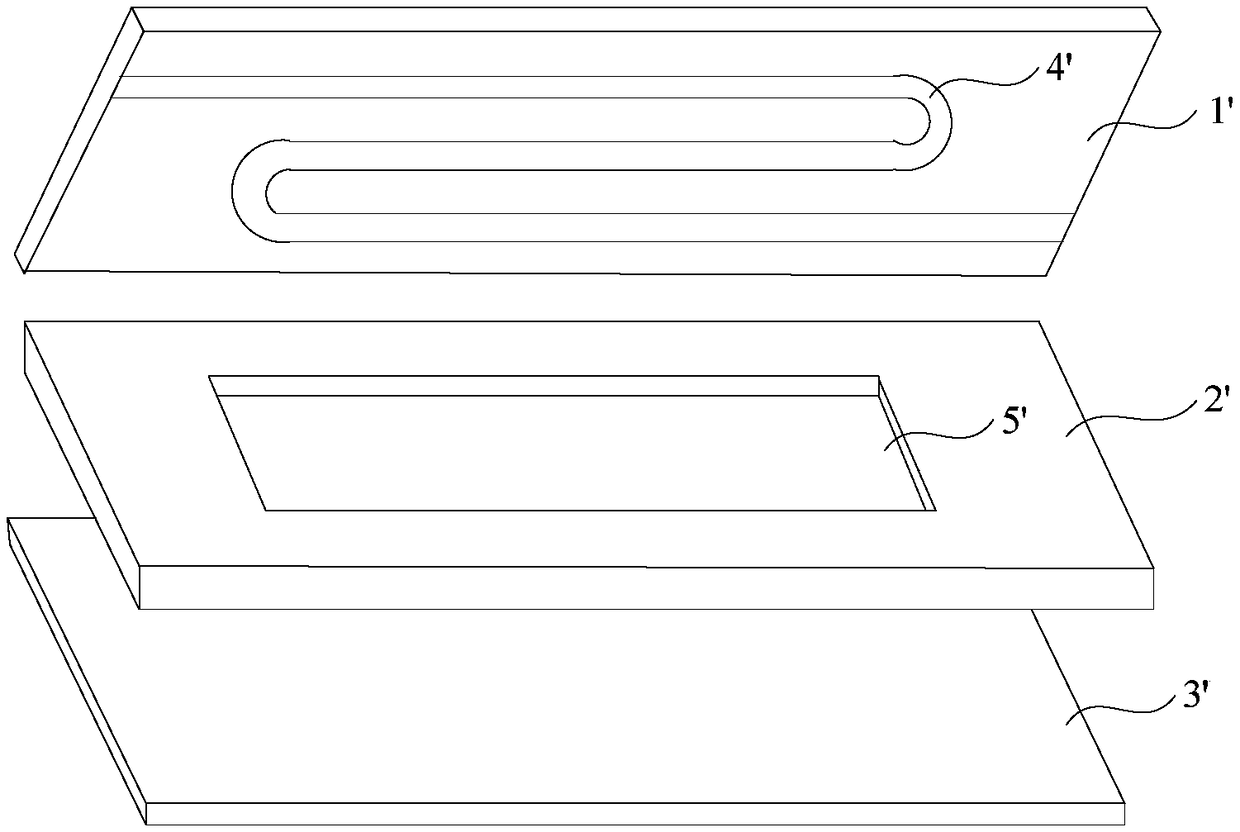

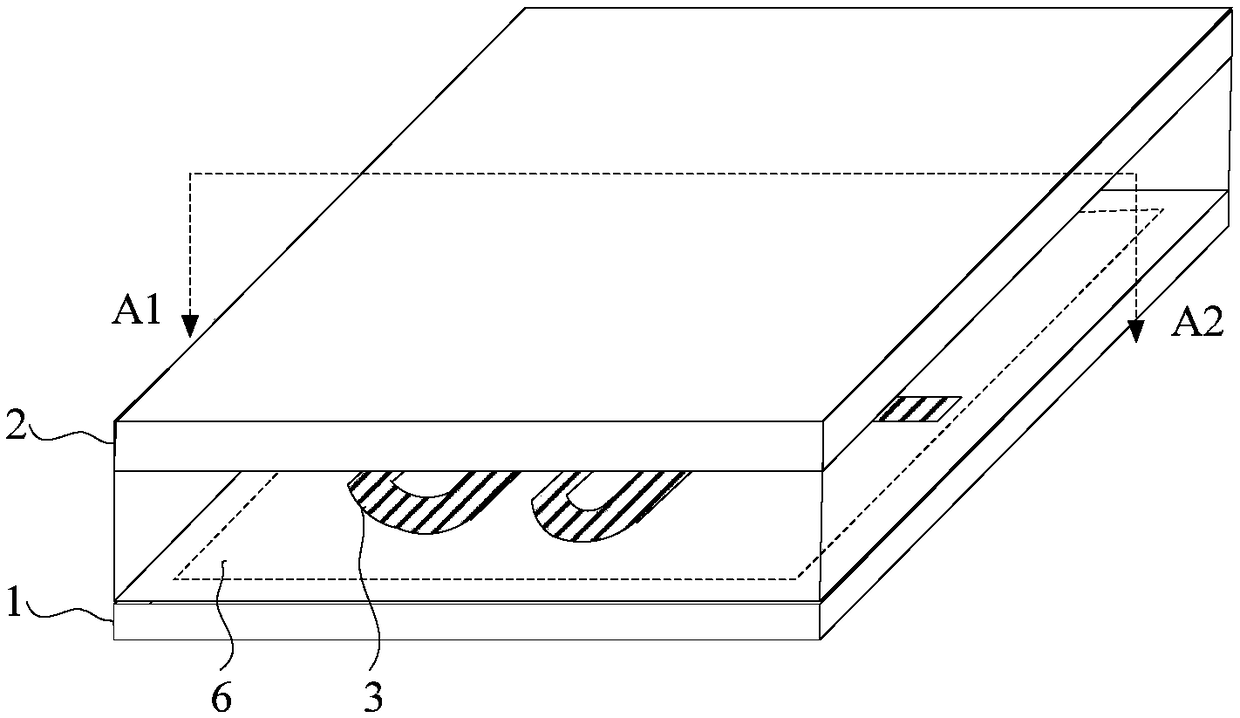

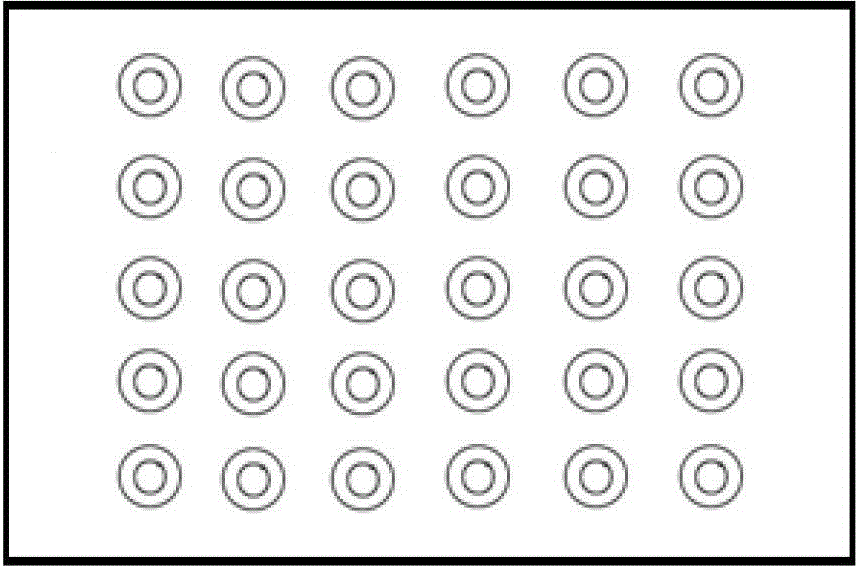

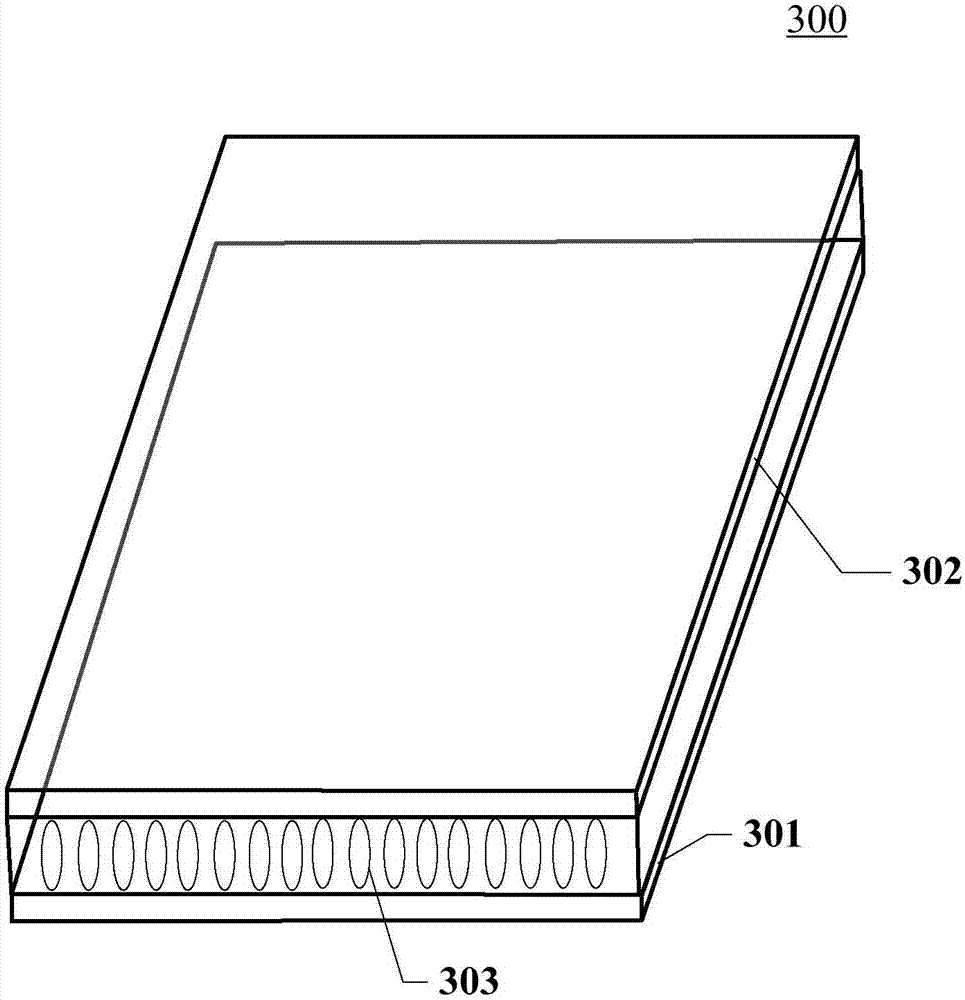

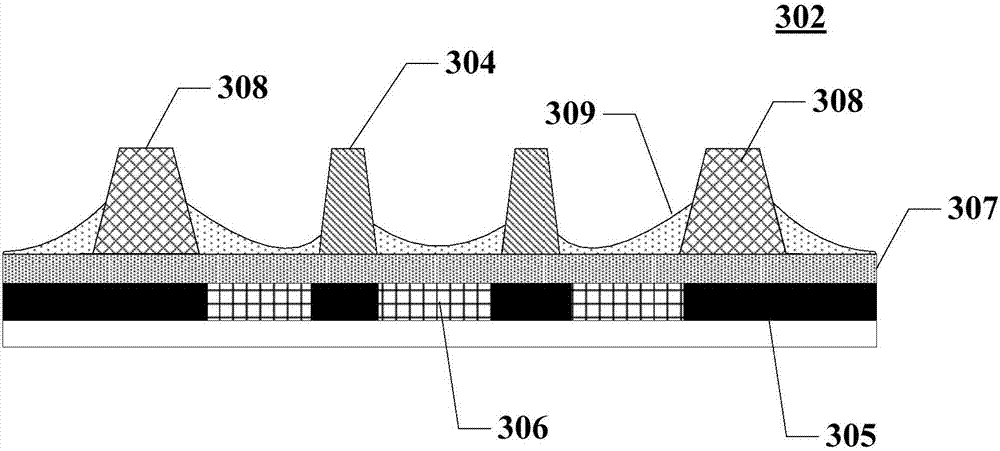

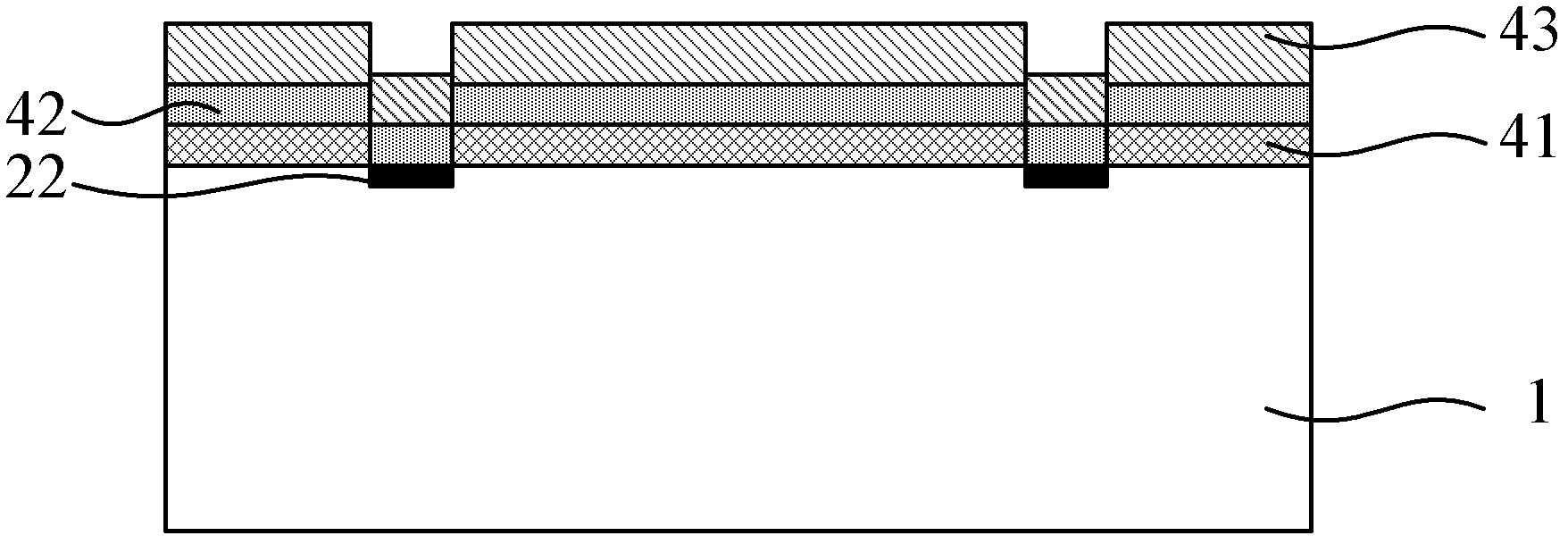

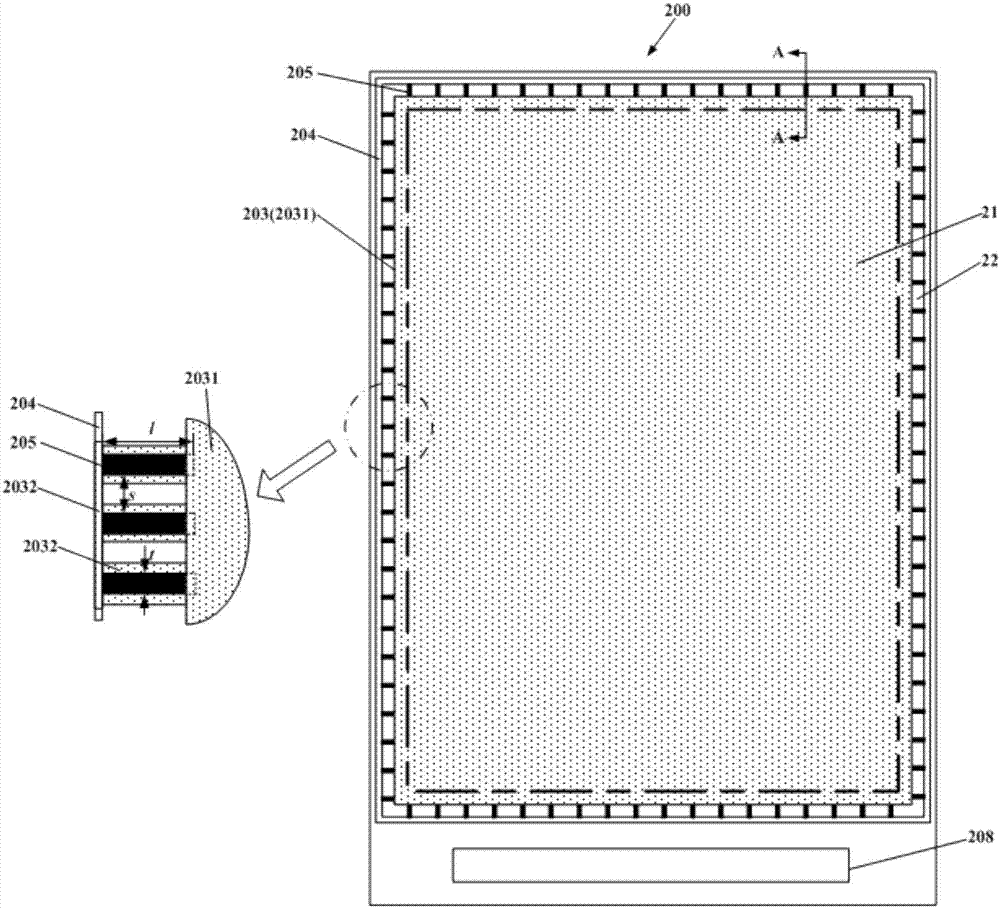

Liquid crystal phase shifting unit, a manufacturing method thereof, a liquid crystal phase shifting device and an antenna

ActiveCN108803096AReduce box thickness varianceImprove box thickness uniformityWaveguide type devicesNon-linear opticsEngineeringMicrowave signals

The embodiment of the invention provides a liquid crystal phase shifting unit, a manufacturing method thereof, a liquid crystal phase shifting device and an antenna and relates to the technical fieldof phase shifting. A liquid crystal filling area is stably supported through a supporting structure; the uniformity of box thickness is improved, and the transmission stability of microwave signals isimproved. The liquid crystal phase shifting unit includes a first substrate, a second substrate, microstrip lines, a supporting structure and liquid crystal molecules; the first substrate and the second substrate are arranged opposite to each other, and areas between the first substrate and the second substrate include the liquid crystal filling area; the microstrip lines are arranged on the surface, facing the second substrate, of the first substrate, and the orthographic projection of the microstrip lines on the first substrate is positioned in the liquid crystal filling area; the supporting structure is arranged between the first substrate and the second substrate and positioned in the liquid crystal filling area, and the orthographic projection of the supporting structure on the firstsubstrate is not overlapped with the microstrip lines; the liquid crystal filling area is filled with the liquid crystal molecules. The liquid crystal phase shifting unit is used for conducting phaseshifting on microwave signals.

Owner:CHENGDU TIANMA MICROELECTRONICS

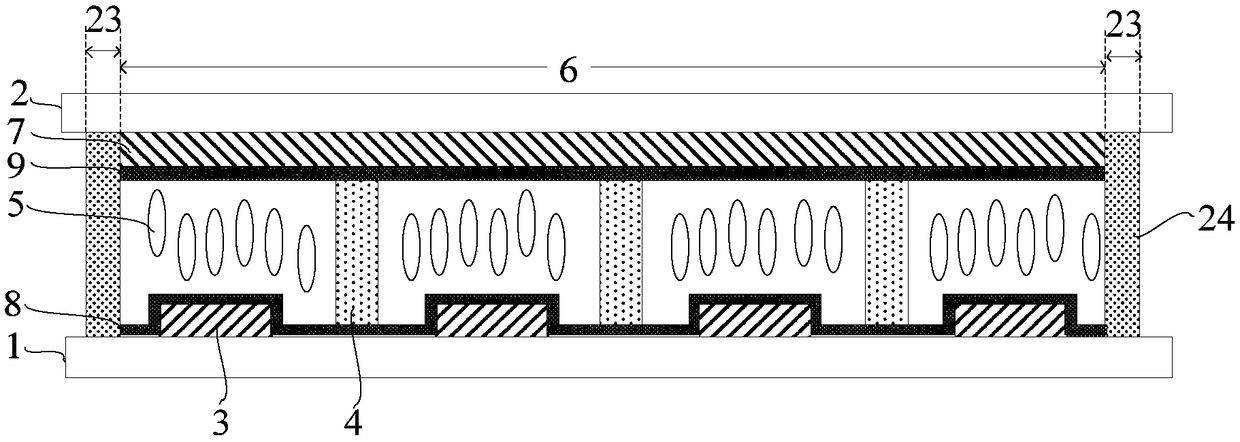

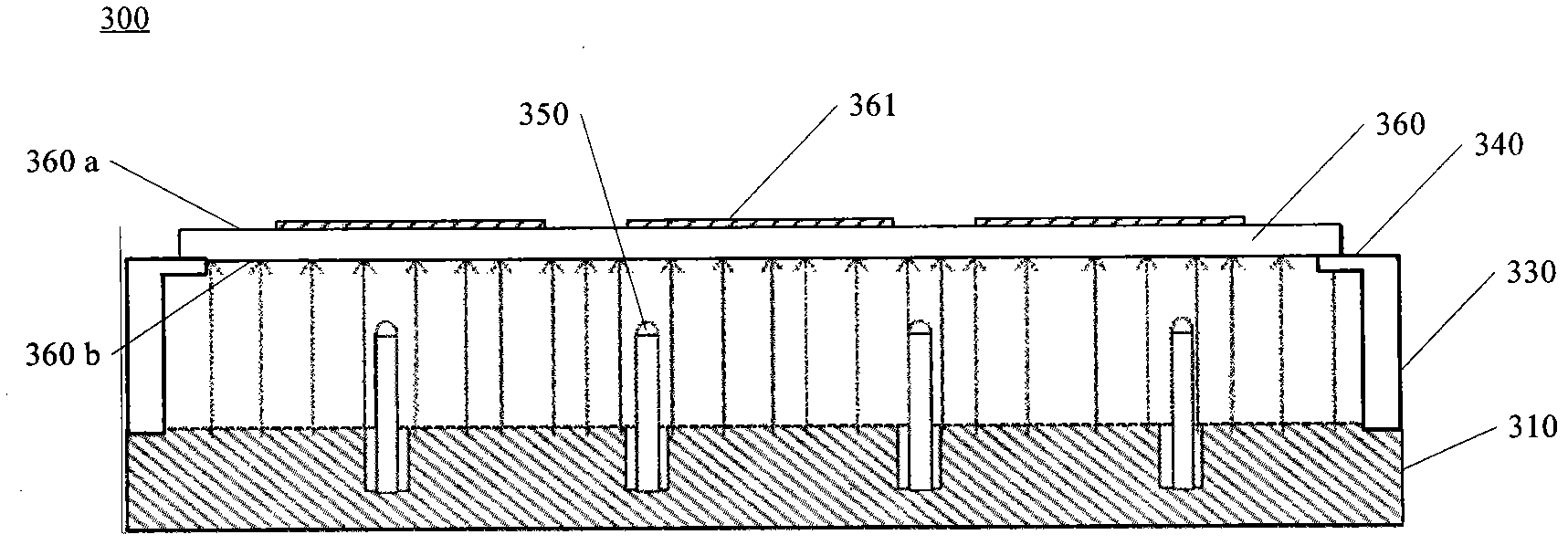

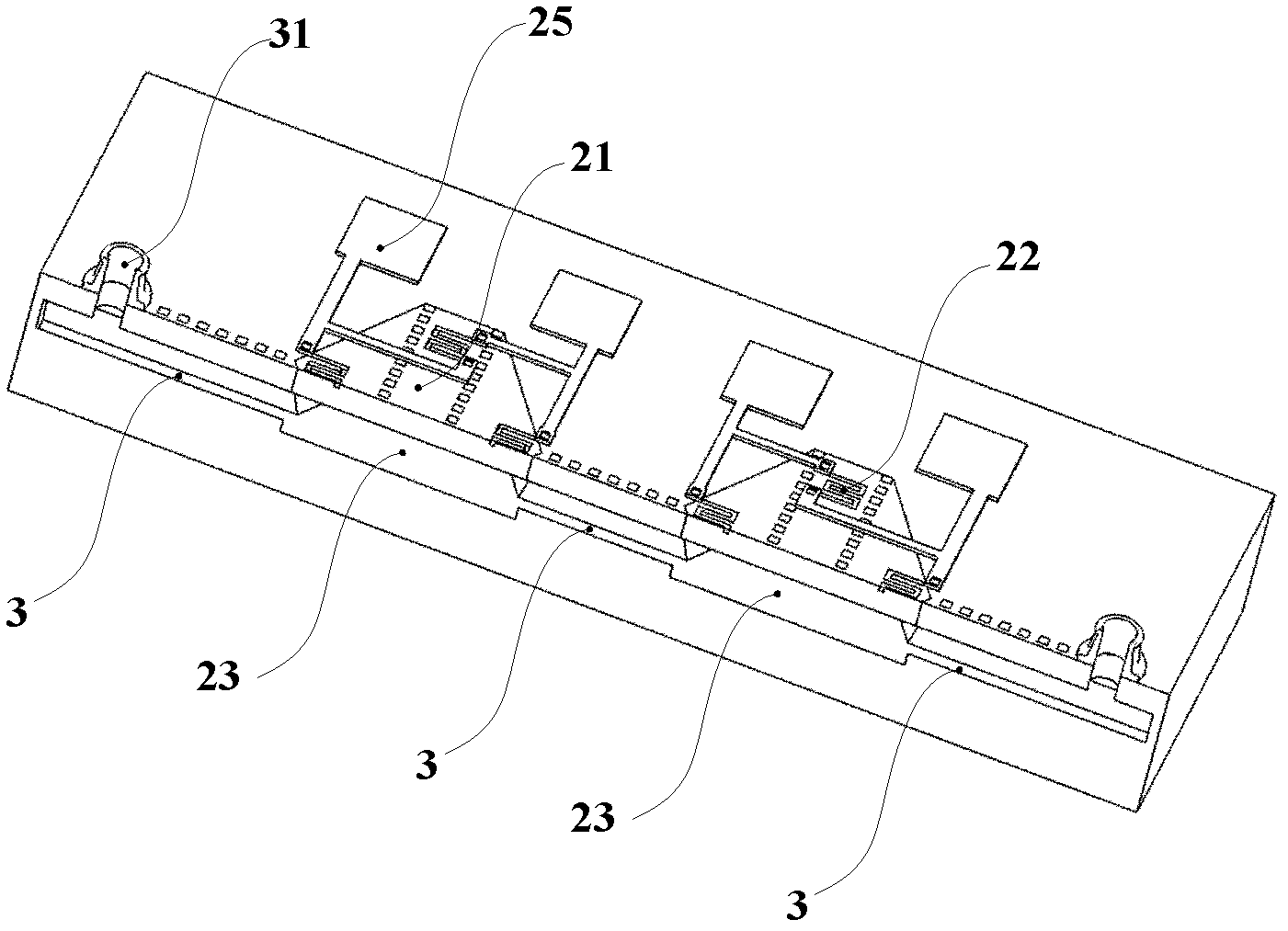

Alignment film drying device and method

InactiveCN102085511AEvenly heatedQuality improvementDrying solid materials with heatPretreated surfacesFilm materialLiquid crystal

The invention provides an alignment film drying device and method which are used for drying an alignment film material which is formed on a first surface of a substrate and diluted by a solvent. The device comprises a heating table, a peripheral support mechanism, multiple support pins and a lifting mechanism, wherein the heating table is used for heating a second surface of the substrate, and multiple air holes are uniformly distributed on the heating table; the peripheral support mechanism is arranged around the heating table and used for supporting the edge of the second surface of the substrate; the multiple support pins are uniformly distributed in the upper surface of the heating table; and the lifting mechanism controls the periphery support mechanism and the support pins to perform lifting. According to the invention, the phenomenon of drying non-uniformity in the drying process of the alignment film can be eliminated, the quality of the alignment film is optimized, the display characteristics of a liquid crystal panel are enhanced, and the quality and acceptability of the liquid crystal panel are improved.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

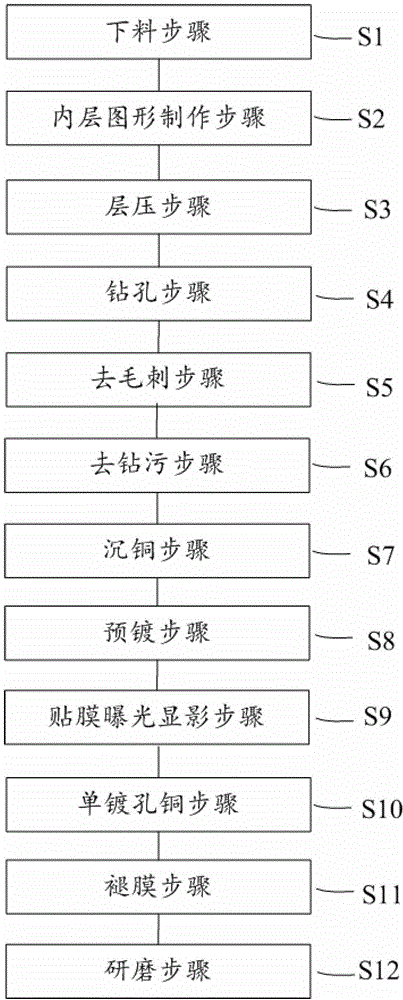

Manufacturing method of single plating hole copper

ActiveCN102883558AGuaranteed uniformityAvoid the problem of large copper thickness differencesPrinted element electric connection formationCopper foilEngineering

The invention provides a manufacturing method of single plating hole copper. The manufacturing method comprises the following steps: preparing a base plate as a printed circuit board, and cutting off the base plate; manufacturing each circuitous pattern of a multi-layer plate; laminating the inner layer circuitous pattern, an insulation material and an outer layer of copper foil together so as to form an integral printed circuit board structure; drilling holes with predetermined hole diameters on the surface of the printed circuit board; sinking a layer of copper on a hole wall, thus the original non-conductive hole wall is conductive; coating a layer of pre-plated copper on the surface and in the hole of the printed circuit board; pasting a layer of dry film on the surface of the printed circuit board, exposing the dry film by utilizing a base plate of an expected pattern which is manufactured in advance and is corresponding to the holes of the hole copper required to be electroplated, and manufacturing the expected pattern by a developing technology, thus the dry film is windowed at a plated-through hole part; plating copper on the developed holes, thus the copper of the hole wall is thickened to the required thickness; and then removing the dry film on the plate surface, exposing the copper surface at the surface; and rubbing down the copper surface protruding at the hole opening by a sand belt.

Owner:JIANGNAN INST OF COMPUTING TECH

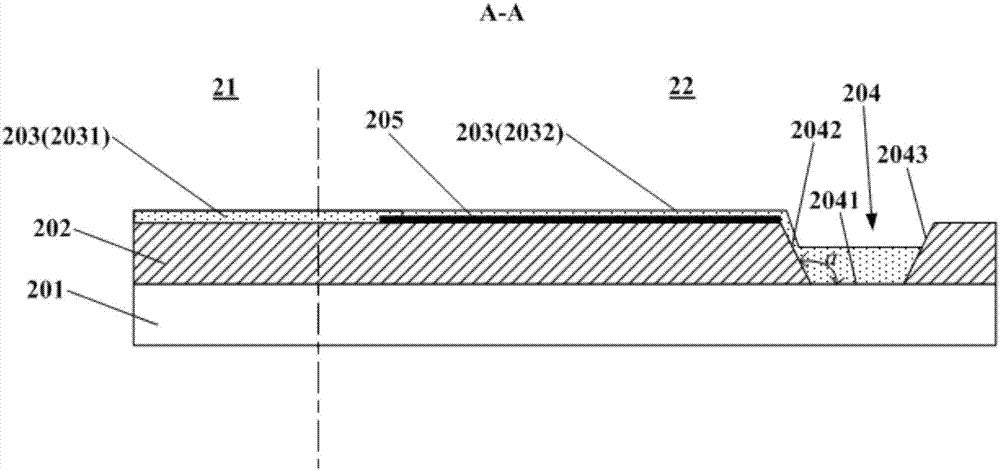

Heat-conduction EVA (ethylene-vinyl acetate) packaging adhesive film for photovoltaic module and method for preparing adhesive film

InactiveCN103045112AAvoid uneven thicknessUniform thicknessNon-macromolecular adhesive additivesFilm/foil adhesivesCarvacryl acetateLight reflectance

The invention relates heat-conduction EVA packaging adhesive film for a photovoltaic module and a method for preparing the adhesive film. The adhesive film comprises, by weight, 47wt% to 93.8wt% of EVA, 5wt% to 40wt% of a heat-conduction filler, 0.1wt% to 2wt% of an anti-aging auxiliary, 0.5wt% to 5wt% of a cross-linking agent, 0.1wt% to 1wt% of a tackifier and 0.5wt% to 5wt% of a plasticizer. According to the heat-conduction EVA packaging adhesive film for photovoltaic modules and the method for preparing the adhesive film, the high heat conduction modified inorganic filler is introduced in low heat conduction organic macromolecules, so that organic macromolecules in continuous phases and the inorganic filler in a dispersed phase in a whole system are mixed into a whole; and the adhesive film with a uniform thickness is molded through a rolling process, the heat conductivity and the light reflectance can be obviously enhanced, and further the efficiency and the output power of the photovoltaic module are improved.

Owner:CSI SOLAR POWER GROUP CO LTD +1

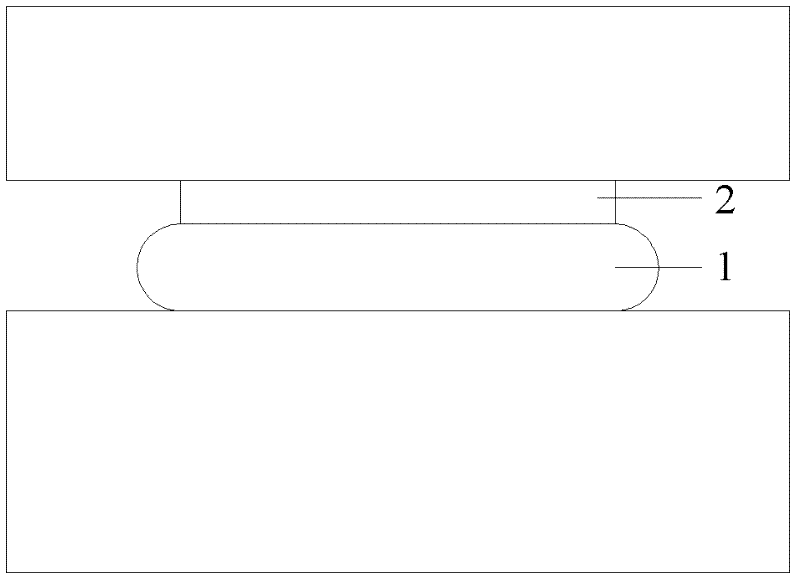

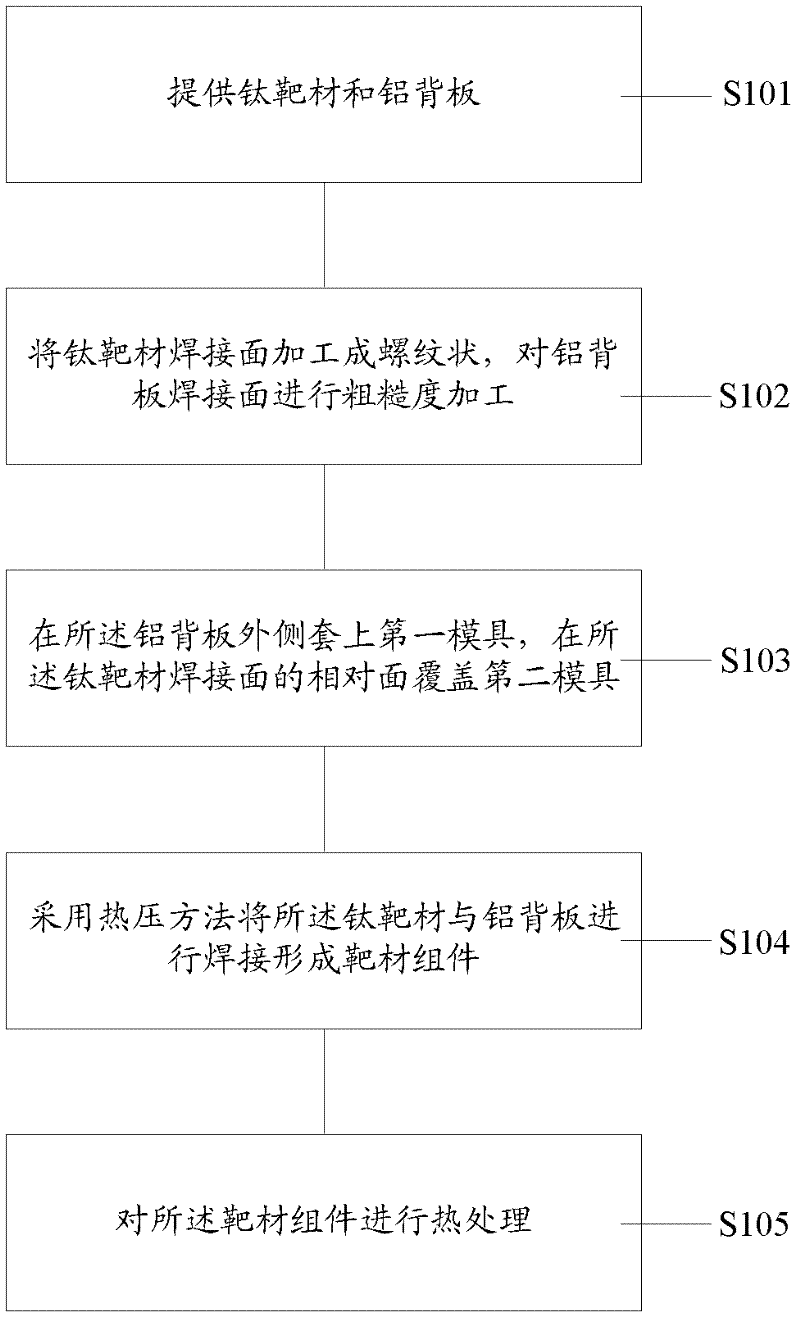

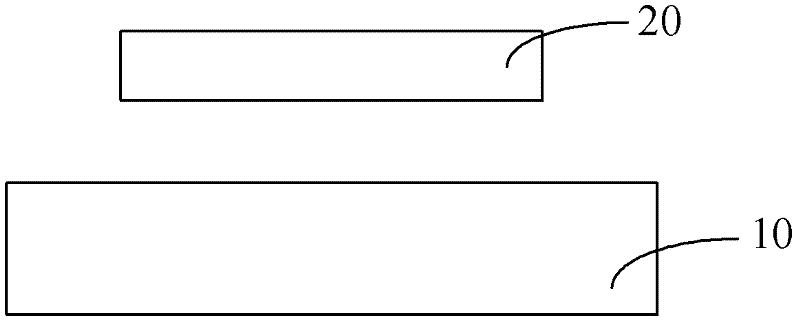

Welding method of target and back plate

InactiveCN102500909ALow input costEasy to operateNon-electric welding apparatusTitaniumBonding strength

The invention discloses a welding method of a target and a back plate. The welding method comprises the following steps of: providing a titanium target and an aluminium back plate; processing a welding surface of the titanium target into a thread shape, and carrying out roughness processing on the welding surface of the aluminium back plate; sheathing a first mold on the aluminium back plate and covering a second mold on the opposite surface of the welding surface of the titanium target; adopting a hot-pressing method to weld the titanium target and the aluminium back plate to form a target component; and carrying out heat treatment on the target component. According to the technical scheme of the welding method, the bonding strength between the titanium target and the aluminium back plate after welding is higher, the large-area welding of the titanium target and the aluminium back plate is realized, and the cost for producing the target component formed by the titanium target and the aluminium back plate is reduced.

Owner:余姚康富特电子材料有限公司

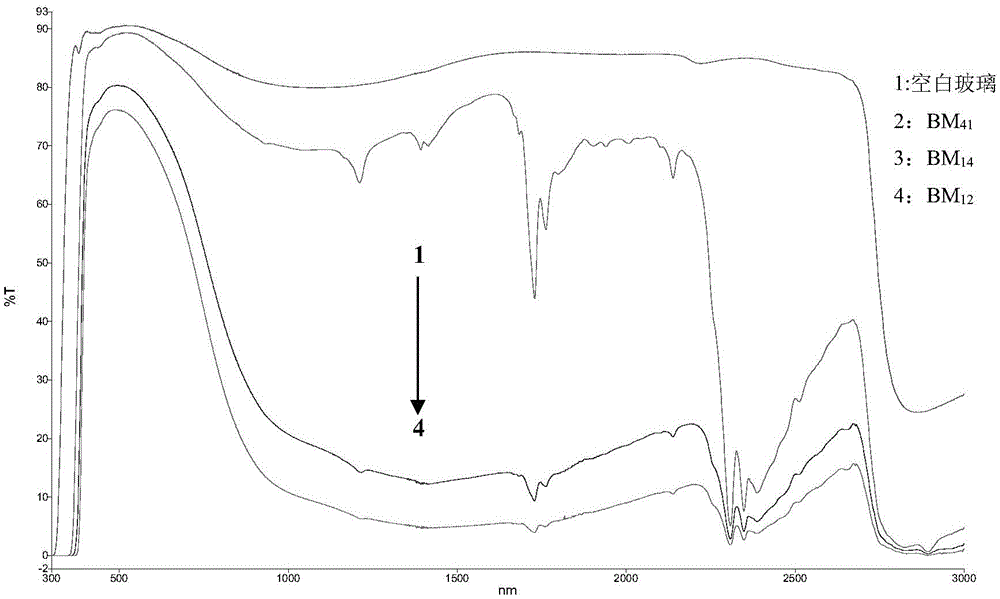

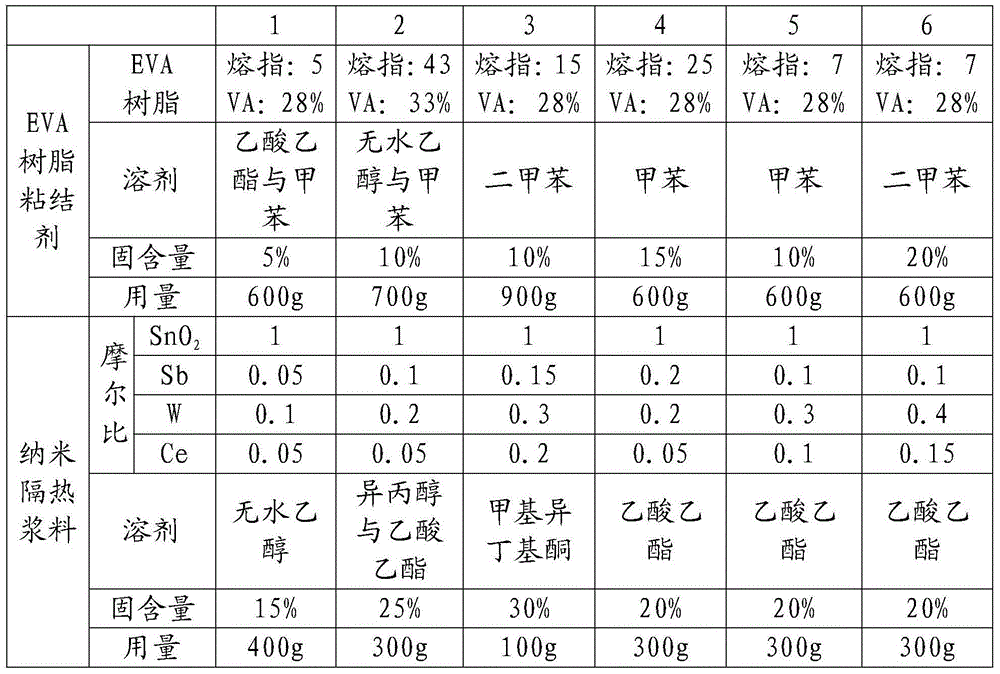

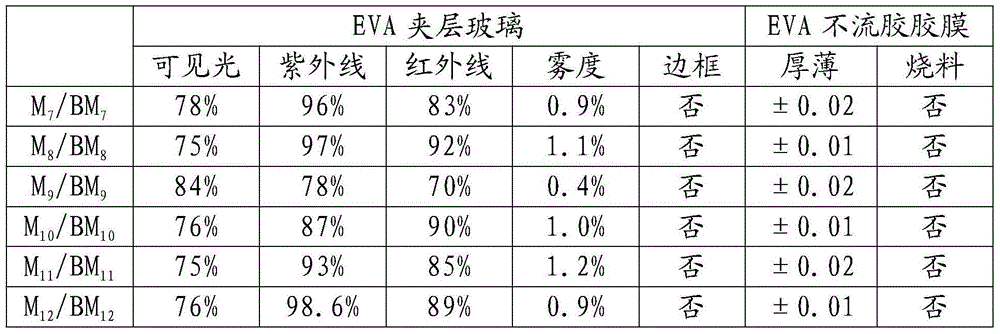

Core-shell anti-infrared auxiliary agent, heat-insulation EVA non-flowing glue film and preparation method

InactiveCN104130725AImprove thickness uniformityAvoid rotten edgesNon-macromolecular adhesive additivesFilm/foil adhesivesCross-linkInfrared

The invention relates to the technical field of heat-insulation materials, specifically to a core-shell anti-infrared auxiliary agent, a heat-insulation EVA non-flowing glue film and its preparation method. The core-shell anti-infrared auxiliary agent is prepared from W-Ce-Sb-doped stannic oxide, EVA resin and an organic solvent. The EVA non-flowing glue film is prepared from EVA resin, the core-shell anti-infrared auxiliary agent, a coupling agent, a cross-linking agent and an ultraviolet light absorber. Infrared ray and ultraviolet ray shielding performance of the EVA non-flowing glue film prepared with the addition of the core-shell anti-infrared auxiliary agent can be enhanced remarkably. By the use of the EVA non-flowing glue film, its infrared and ultraviolet rejection is remarkably raised under the circumstance of guaranteeing visible light transmittance. In addition, the EVA non-flowing glue film has characteristics of low haze and high thickness uniformity. As low temperature control treatment is carried out on a die-head of an extruder by oil bath during the production, broken selvage, burning burden or non-uniform thickness of the EVA non-flowing glue film in a highly cross-linked state is avoided, and thickness difference can be controlled within + / -0.02mm.

Owner:广州保均塑料科技有限公司 +1

A vertical roller mill

InactiveCN102284322AImprove adaptabilityInorganic adjustment of grinding forceGrain treatmentsHydraulic cylinderSlag

The invention relates to a vertical roller mill, which comprises a vertical main rotating shaft arranged on a machine body, wherein a speed reducer and a motor are connected to the lower end of the main rotating shaft sequentially; a grinding bowl is arranged at the upper end of the main rotating shaft; the upper part of the inner side of the grinding bowl contacts a plurality of grinding rollers; the grinding rollers arranged on the grinding roller shaft by a bearing; the grinding roller shaft is connected to one end of a rocker arm; the middle part of the rocker arm is hinged to the machinebody; the other end of the rocker arm is hinged with the upper end of a hydraulic cylinder; the lower end of the hydraulic cylinder is arranged on the machine body; a central feed pipe which aligns with the grinding bowl downwards is arranged on the top of the machine body; and a discharge hole is formed below the grinding bowl on the machine body. The vertical roller mill has the advantages of convenience for oil injection, high yield, low energy consumption, large processing capacity, high efficiency and sealing performance, adjustable grinding force and the like, is easy to maintain and overhaul, and the technical problems of enrichment of steel slag and iron granules, high abrasion of the mill, difficulty of overhauling of equipment and the like are solved radically.

Owner:TIANJIN SUMEIR ENVIRONMENTAL PROTECTION INVESTMENT

Additive for manufacturing ultrathin electrolytic copper foil

InactiveCN101481811AIncrease the volume-to-capacity ratioIncrease the number of charge and discharge cyclesElectroforming processesElectrolysisPolyethylene glycol

The invention relates to an additive for manufacturing ultrathin electrolytic copper coil, which is characterized in that the additive is prepared by 300-800 milligram of acid amide, 20-40 milligram of casein, 5-10 milligram of tetrahydro-thiazoles sulfur copper, 5-10 milligram of polyethyleneglycol, and 40-50 milligram of gelatin which are added into per 10000 liter deionized water and well blended. The electrolytic copper coil with high performance ,which is manufactured by the additive and used in lithium ion batteries with high capacity, has basically consistent double sided structure, namely, double sided light copper coil; the thickness of the copper coil is thin; the actually measured thickness & is less than equal to 12micron; the crystal structure of the rough surface is uniform, smooth and compact; the metal density is close to the theoretical density of pure copper; the profile tolerance of the rough surface Rz is less than 2 micron; and the elongation is larger than 5%; the tensile strength is larger than 400N / mm2; the thickness extreme difference of the copper coil with the same mass area ratio is less than equal to 0.5 micron.

Owner:GUANGDONG FINE YUAN SCI TECH CO LTD

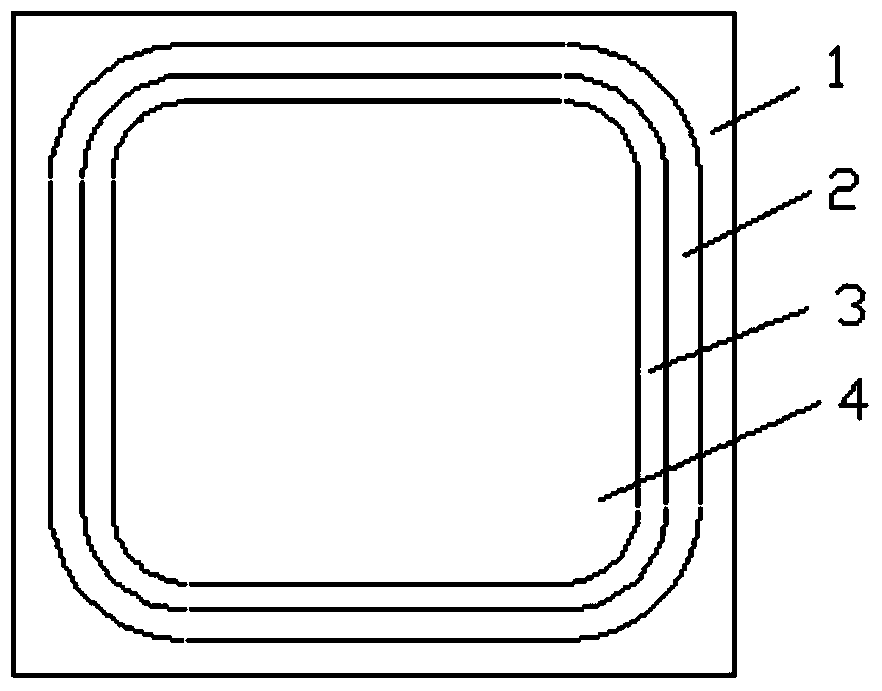

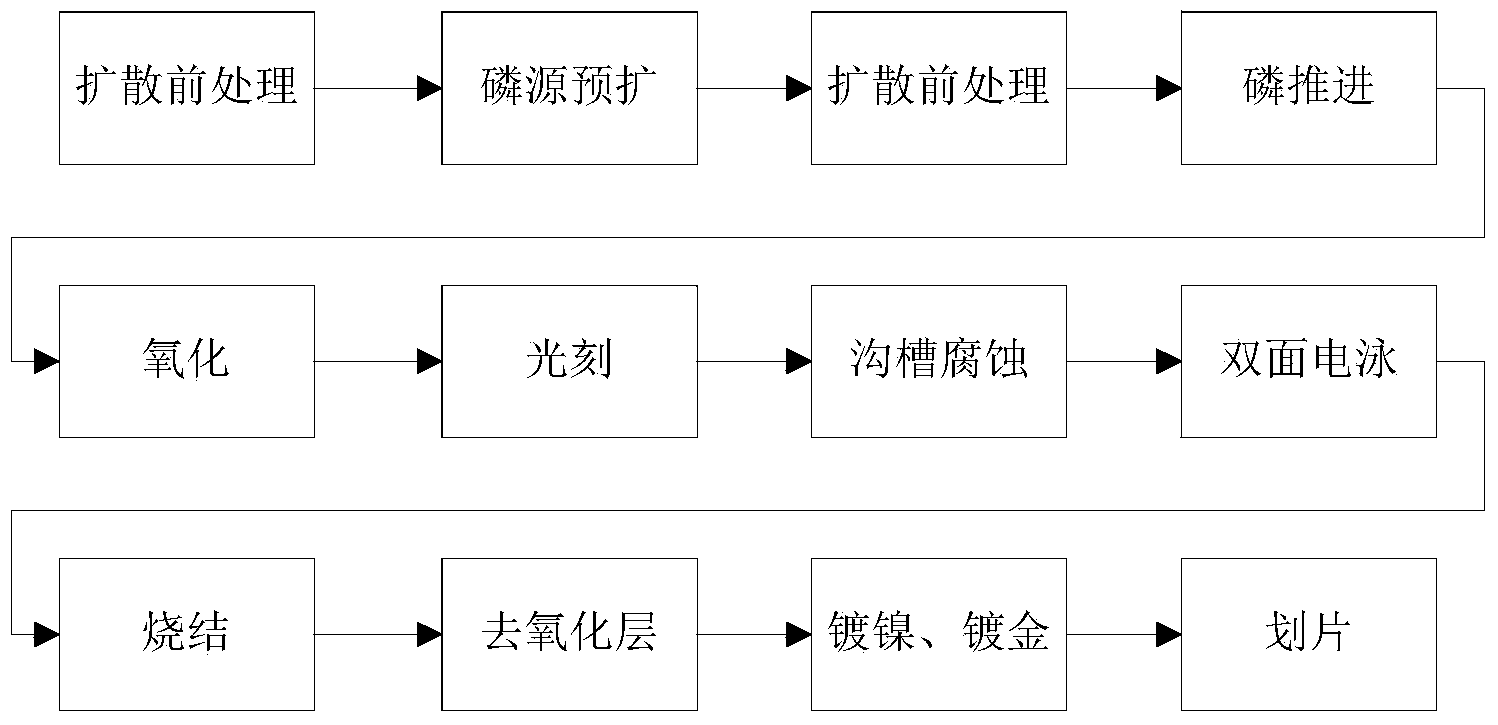

Production technology for transient voltage suppressor chip with channeling effect

InactiveCN103956324AAnti-suppression to surge capability improvementLow calorific valueSemiconductor/solid-state device manufacturingSemiconductor devicesElectrical resistance and conductanceElectrophoresis

The invention provides a production technology for a transient voltage suppressor chip with the channeling effect. By means of the steps of gaseous state source diffusion, channel corrosion and double-faced electrophoresis, in the reverse state, the width of depletion layers and the reverse voltage of the high-voltage transient voltage suppressor chip which is of the N+PN+ structure are increased along with the increase of a reverse current, when the reverse current is increased to be close to Ic, the depletion layers on the two faces make contact with each other, the channeling effect is produced, the equivalent resistance is reduced, the clamp voltage is reduced, the reverse surge capacity is improved, the reliability of a diode is improved, the service life of the diode is prolonged, and the transient voltage suppressor chip has the advantages of being good in electrical parameter uniformity, better in ohmic contact and high in reliability, the problem that the thicknesses of two glass layers are uneven due to two times of single-face electrophoresis is avoided, the glass is high in stress-resisting capability of protection and not prone to damage, and the reliability of the transient voltage suppressor chip is further improved.

Owner:TIANJIN ZHONGHUAN SEMICON CO LTD

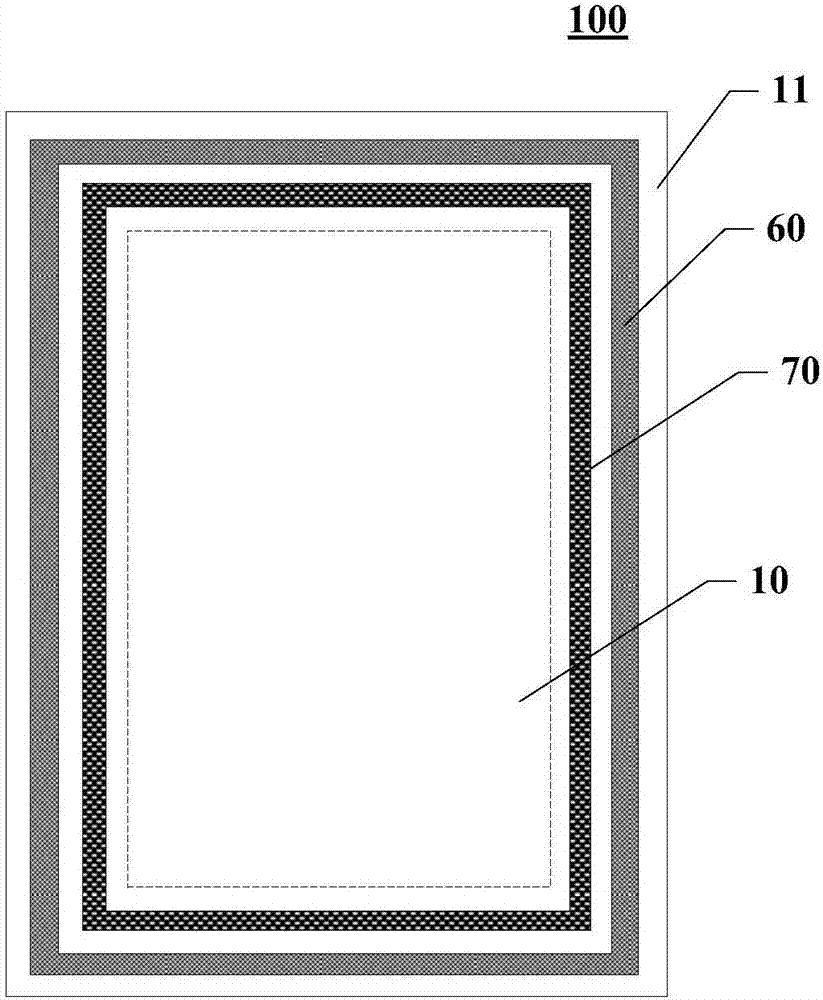

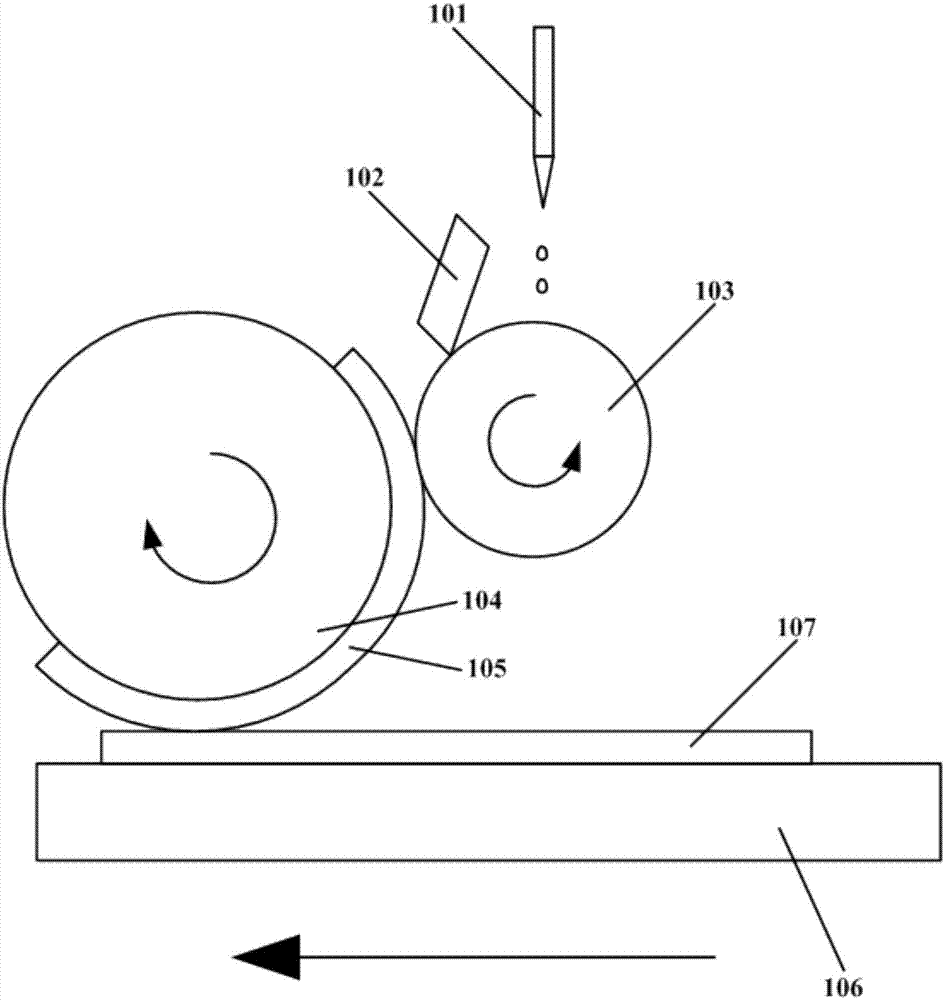

Color film substrate and display device

InactiveCN107219658AAvoid uneven thicknessAvoid misalignmentNon-linear opticsColor filmDisplay device

The invention discloses a color film substrate and a display device, and relates to the technical field of displaying. The color film substrate is provided with a displaying area and a non-displaying area around the displaying area, and is characterized by comprising a lining substrate, a black matrix area, a color resisting area, protection films, barrier walls, an alignment film barrier structure and alignment films. The black matrix area and the color resisting area are arranged on the lining substrate. Color resistors arranged in lines and columns are arranged in the color resisting area. The protection films are arranged on one sides, far away from the lining substrate, of the black matrix area and the color resisting area. The barrier walls are arranged on one sides, far away from the lining substrate, of the protection films and are arranged in the non-displaying area to surround the displaying area. The alignment film barrel structure is arranged on the lining substrate, is positioned in the non-displaying area, surrounds the displaying area, and is arranged on one sides, close to the displaying area, of the barrier walls. The alignment films are arranged on one sides, far away from the lining substrate, of the protection films. According to the scheme, the color film substrate and the display device have the advantages that unevenness in thickness of the alignment films, caused by alignment film extending, in the displaying area is avoided, and the problem of bad alignment during displaying can be further avoided.

Owner:XIAMEN TIANMA MICRO ELECTRONICS

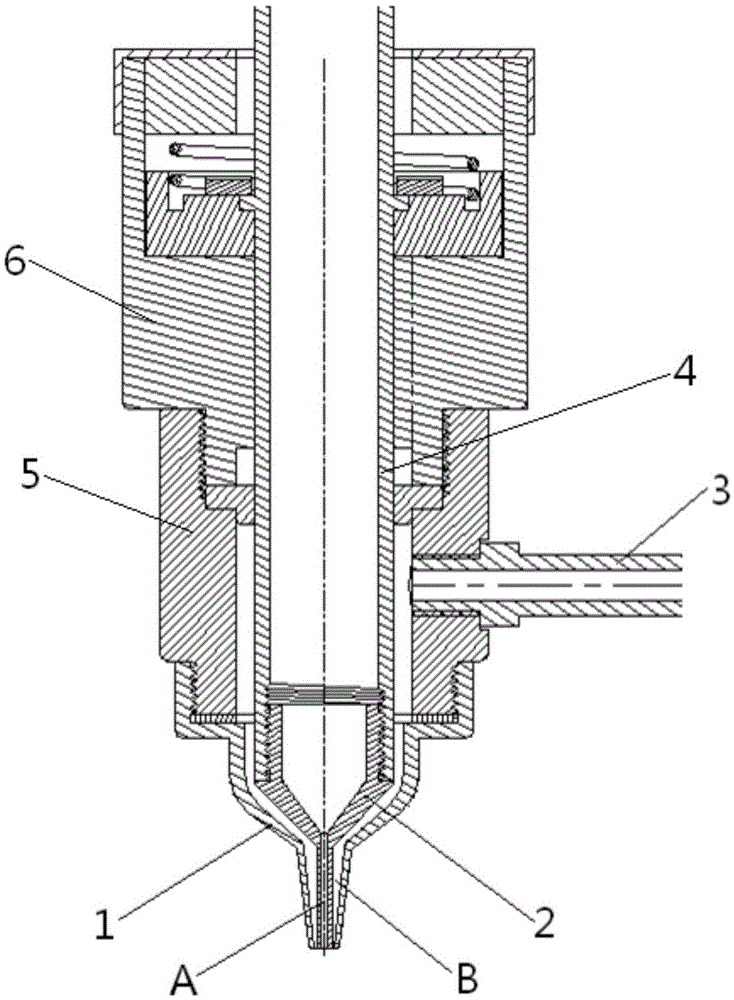

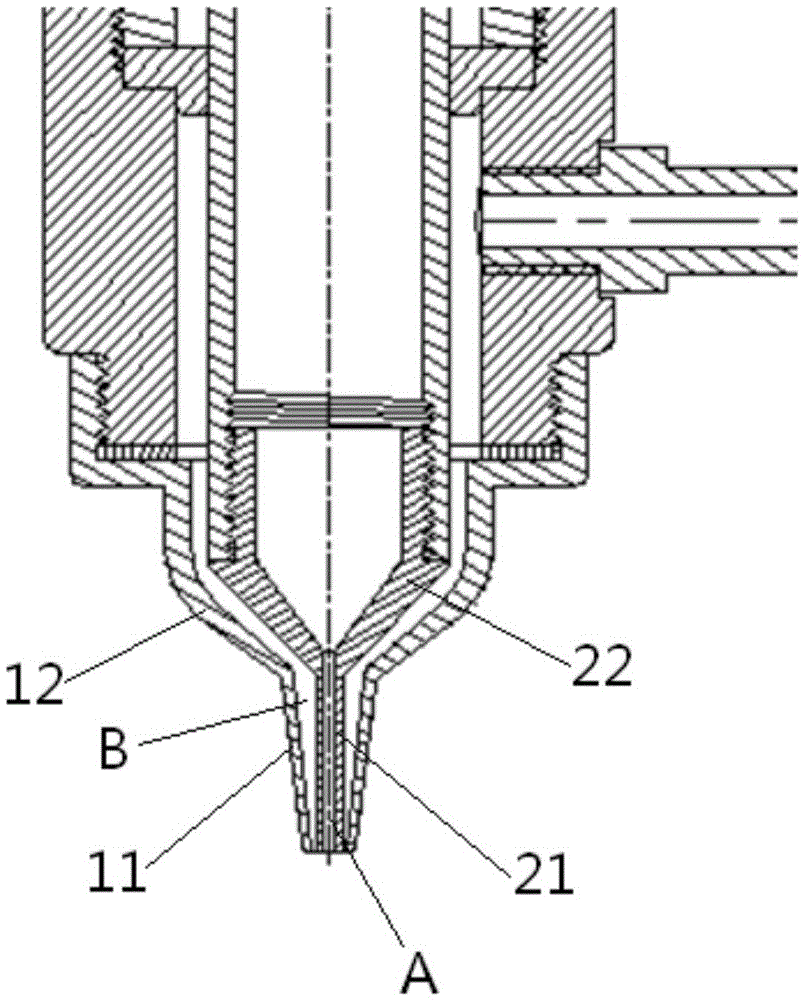

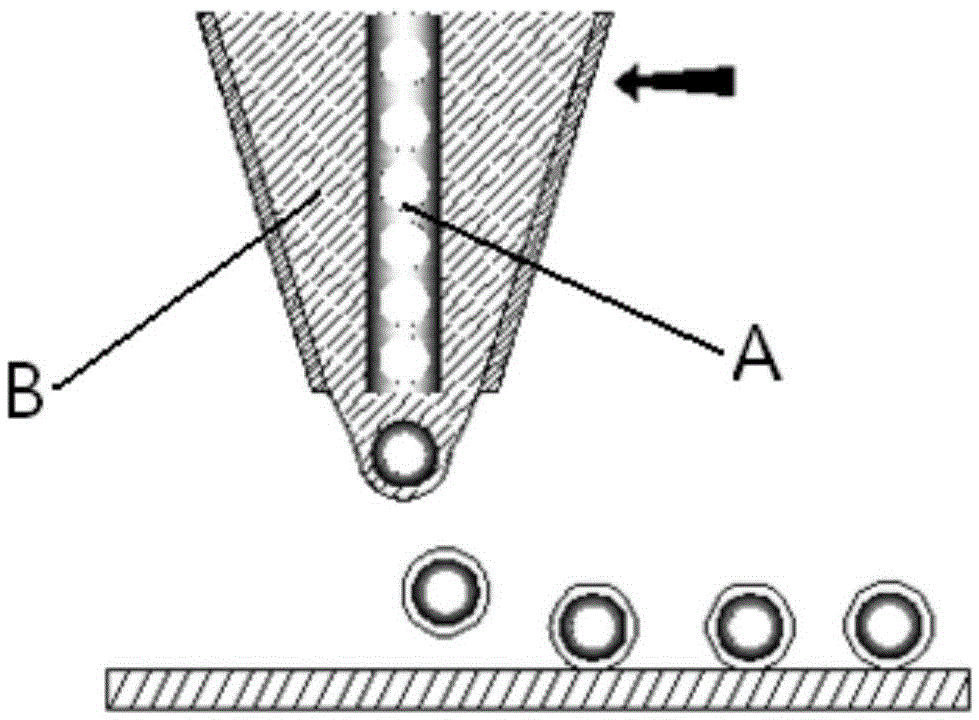

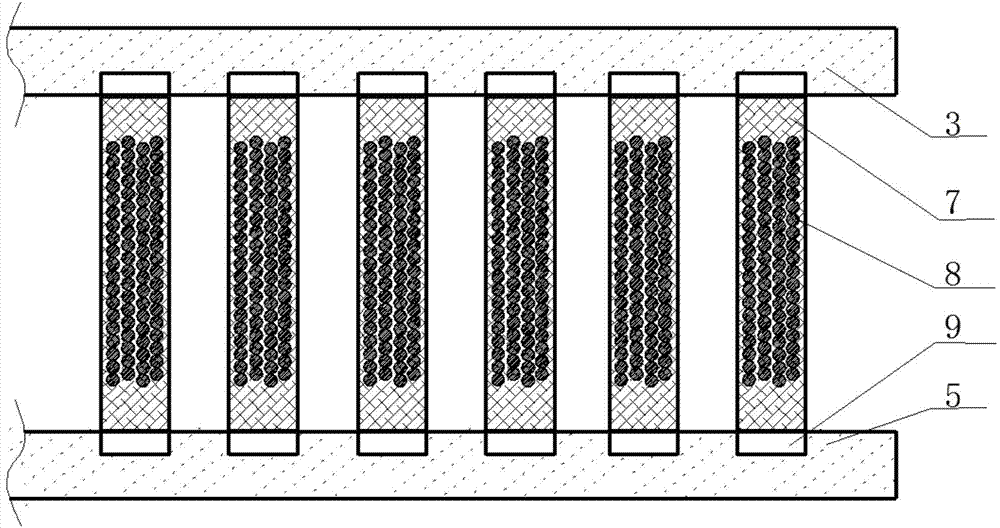

Inkjet head assembly of biological printer and biological printer

ActiveCN105647801AQuality improvementAvoid damageAdditive manufacturing apparatusTissue/virus culture apparatusEngineeringNozzle

The invention relates to an inkjet head assembly of a biological printer and the biological printer. The inkjet head assembly of the biological printer comprises an outer inkjet nozzle with a second channel and an inner inkjet nozzle with a first channel; the inner inkjet nozzle is coaxially arranged in the second channel; a first material channel is formed by the first channel; a second material channel is formed by an annular space between the outer inkjet nozzle and the inner inkjet nozzle; the second material channel surrounds the first material channel at an outlet of the first material channel and is used for enabling second materials ejected from an outlet of the second material channel to gather towards first materials ejected from the outlet of the first material channel so as to form a fluid printing unit. According to the inkjet head assembly, the second materials are uniformly coated with the first materials at the outlet of the inkjet head assembly, so that the fluid printing unit with higher quality is formed for protecting the cells, further cell damage caused by an extrusion pressure and a frictional force in the printing process is reduced, and the survival rate of the cells is improved.

Owner:SICHUAN REVOTEK CO LTD

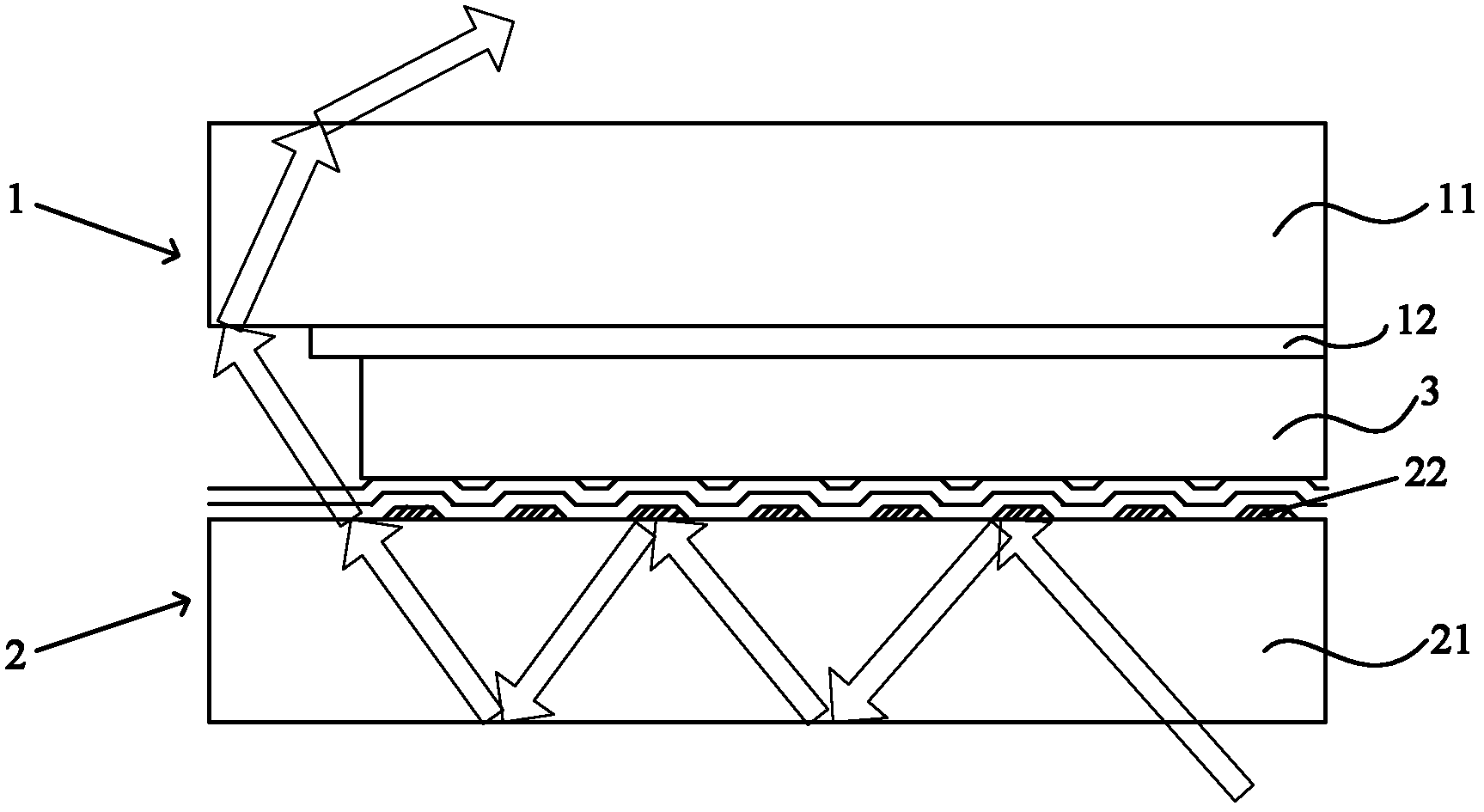

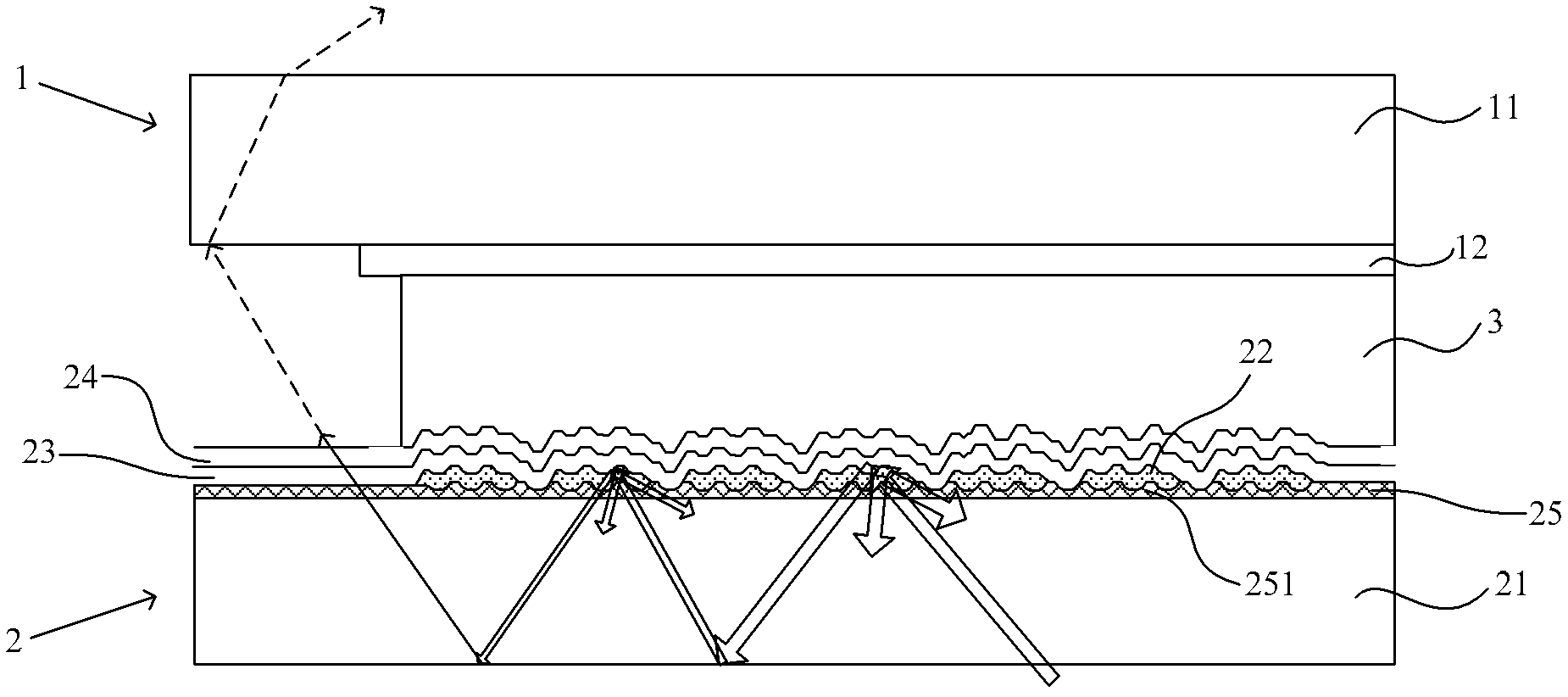

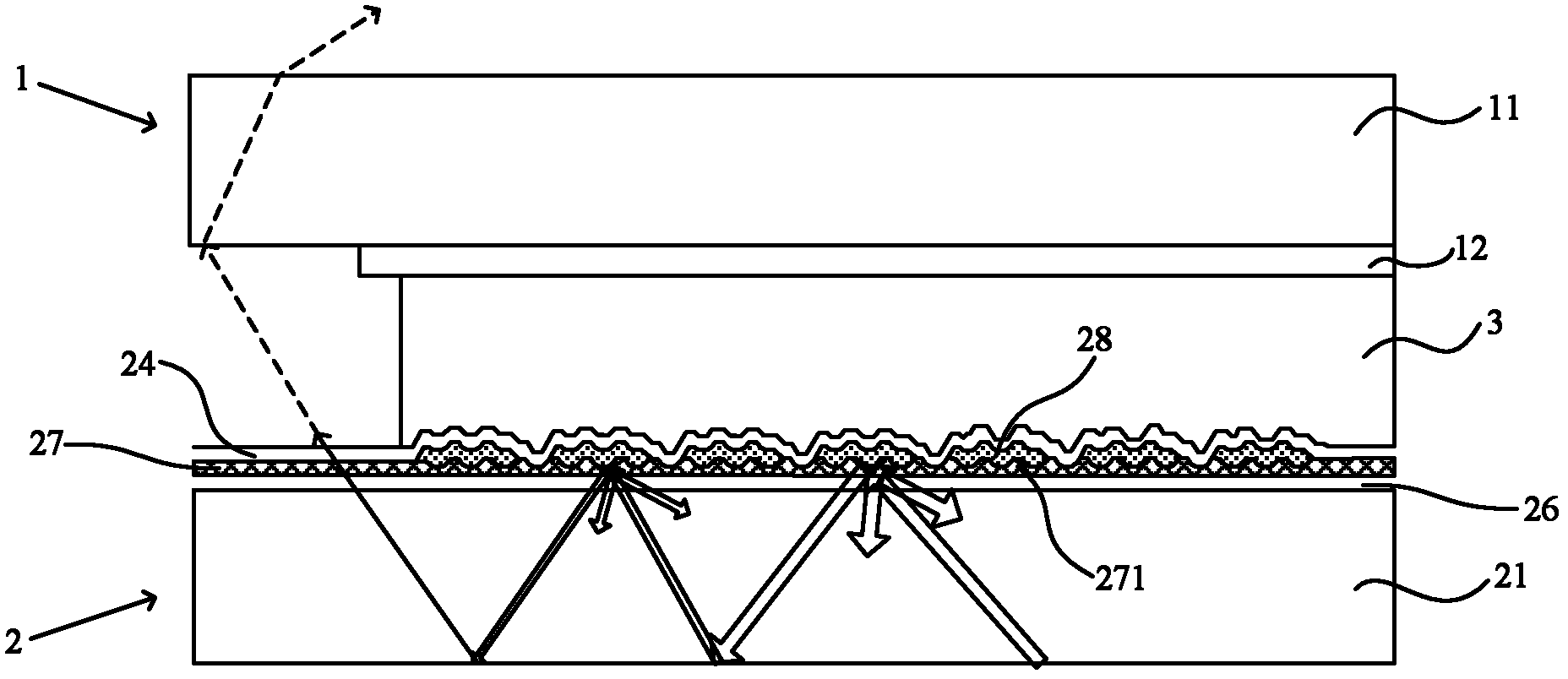

Liquid crystal panel and manufacturing method thereof

ActiveCN103185978AReduce light leakageAvoid uneven thicknessSemiconductor/solid-state device manufacturingNon-linear opticsLiquid-crystal displayDiffuse reflection

The invention discloses a liquid crystal panel and a manufacturing method thereof. The liquid crystal panel comprises an active element array substrate and a color filtering substrate which are connected with each other through frame sealing glue, wherein the active element array substrate comprises a substrate, a public electrode wire and a plurality of thin film transistors; the color filtering substrate comprises a black matrix; the liquid crystal panel is provided with a display area and a border area surrounding the display area; the active element array substrate further comprises a light absorbing layer having a light absorbing property; the light absorbing layer is positioned in the border area, and is positioned between the substrate and a metal structure which is closest to the substrate in the border area; the metal structure is provided with a first diffused reflection structure; and the first diffused reflection structure is used for making light coming from a backlight source enter the first diffused reflection structure to generate diffused reflection. Due to the adoption of the liquid crystal panel, the border light leakage of the liquid crystal panel can be reduced greatly on the premise of not elongating the black matrix till the edge of the black matrix is aligned with the edge of the substrate.

Owner:BEIHAI HKC OPTOELECTRONICS TECH CO LTD

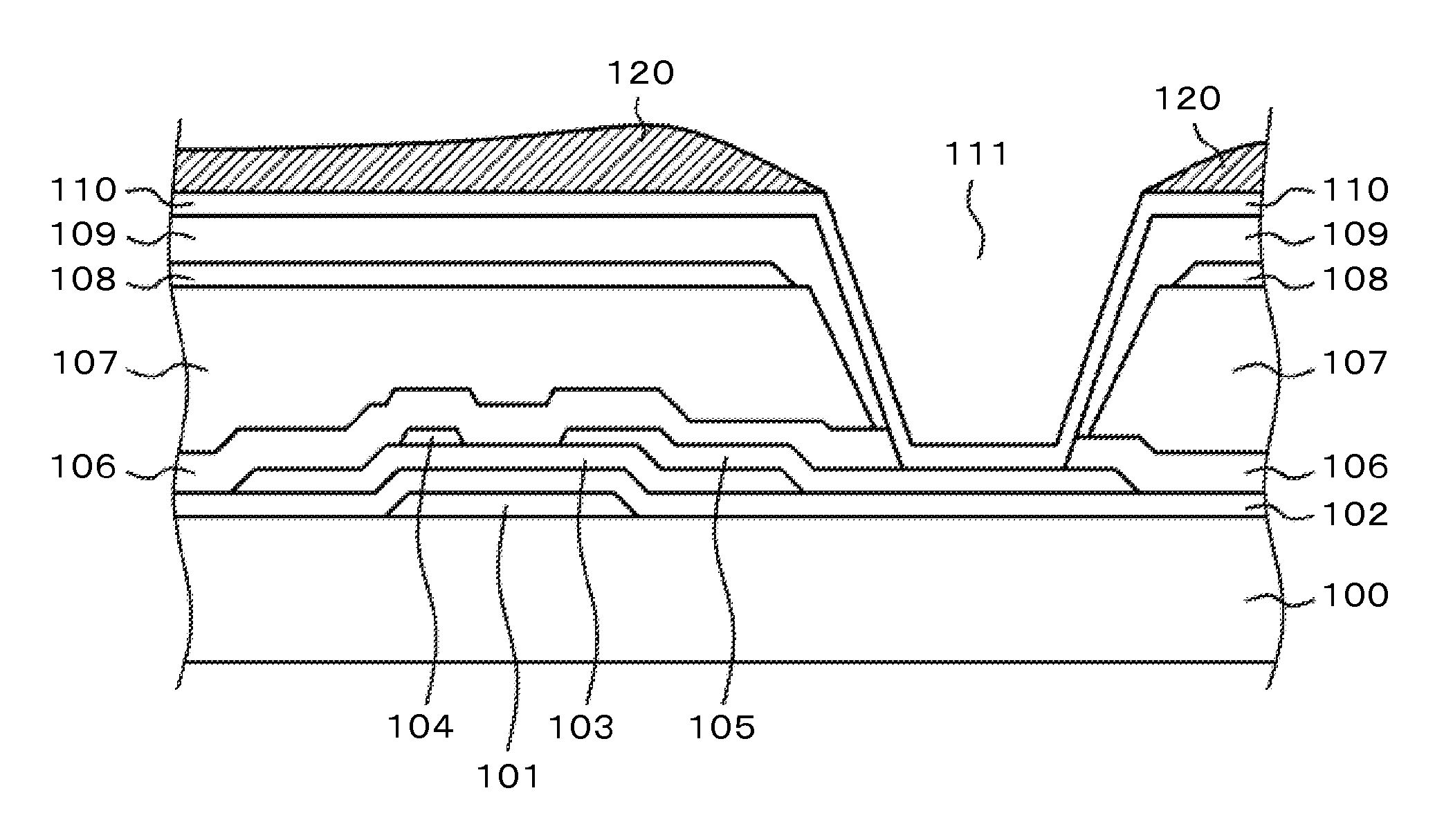

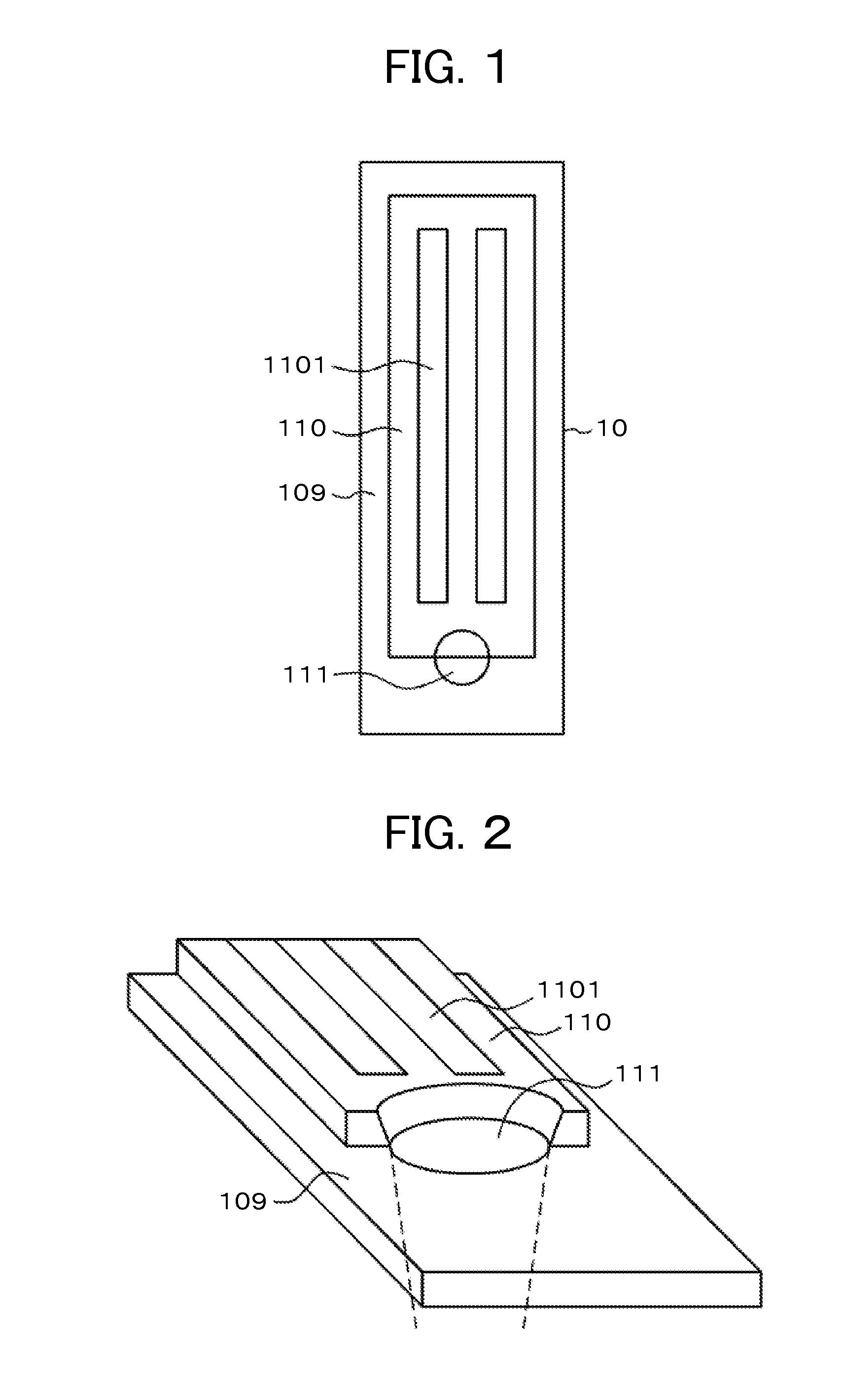

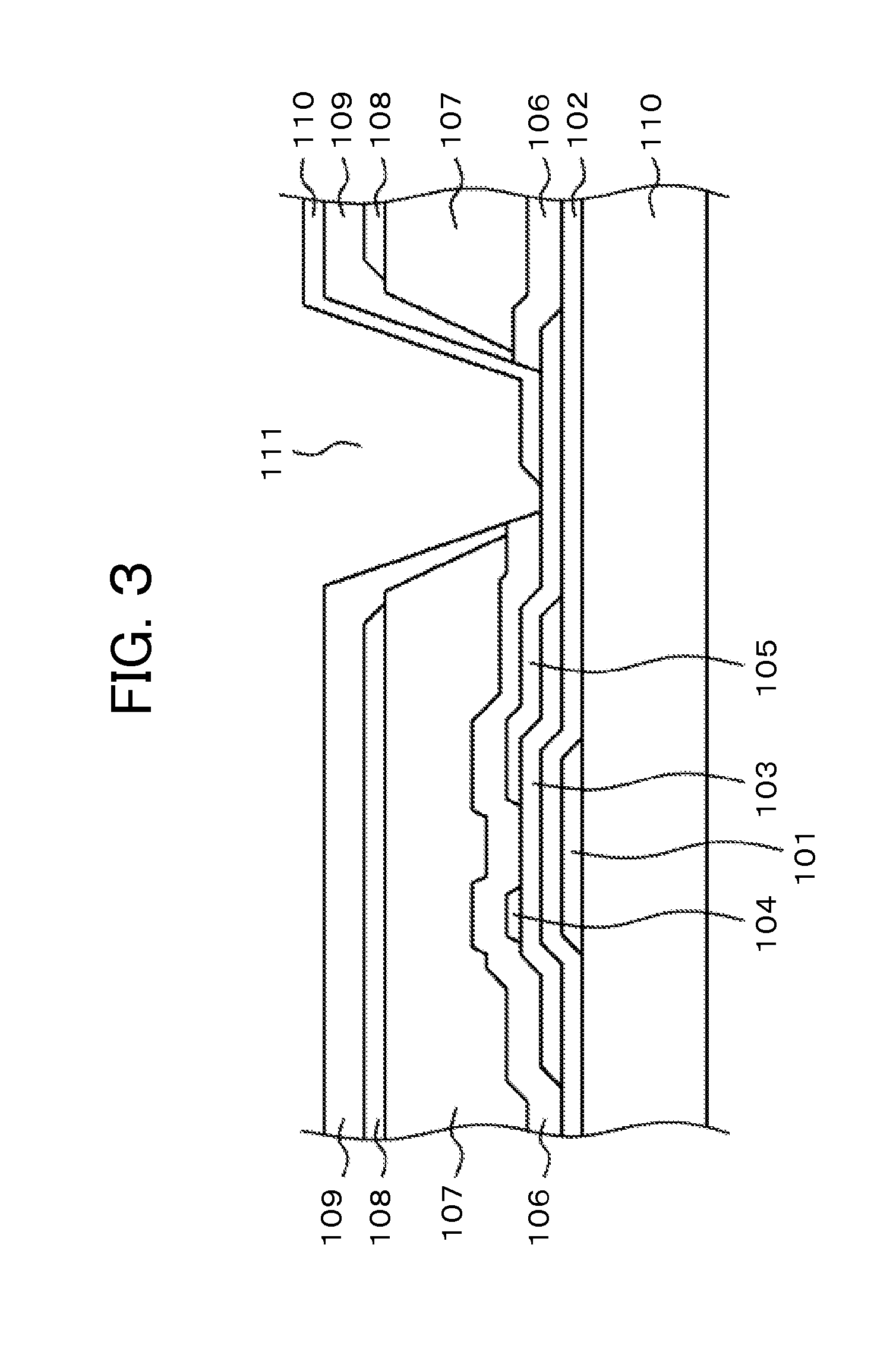

Liquid crystal display device

ActiveUS20150138476A1Reduce areaPrevent display irregularityNon-linear opticsLiquid-crystal displayInter layer

To take measures against the phenomenon of difficulty for the orientation film material to flow into the through-hole when the diameter of through-holes which connects the pixel electrode and the source electrode becomes small.An interlayer insulating film 109 made of SiN is formed on a counter electrode, and a pixel electrode 110 having a slit 1101 is formed on the interlayer insulating film 109. A through-hole 111 which connects the pixel electrode 110 and the source electrode of a TFT has a large opening on the upper side, a small opening on the lower side, and an inner wall extending between the large opening and the small opening. The pixel electrode 110 covers the through-hole 111 on an inner side of the pixel of the through-hole 111 but does not cover a periphery of the large opening of the through-hole on an outer side of the through-hole 111. Consequently, an orientation film material can easily flow from a starting point given by an end portion of the pixel electrode into the inside of the through-hole.

Owner:JAPAN DISPLAY INC

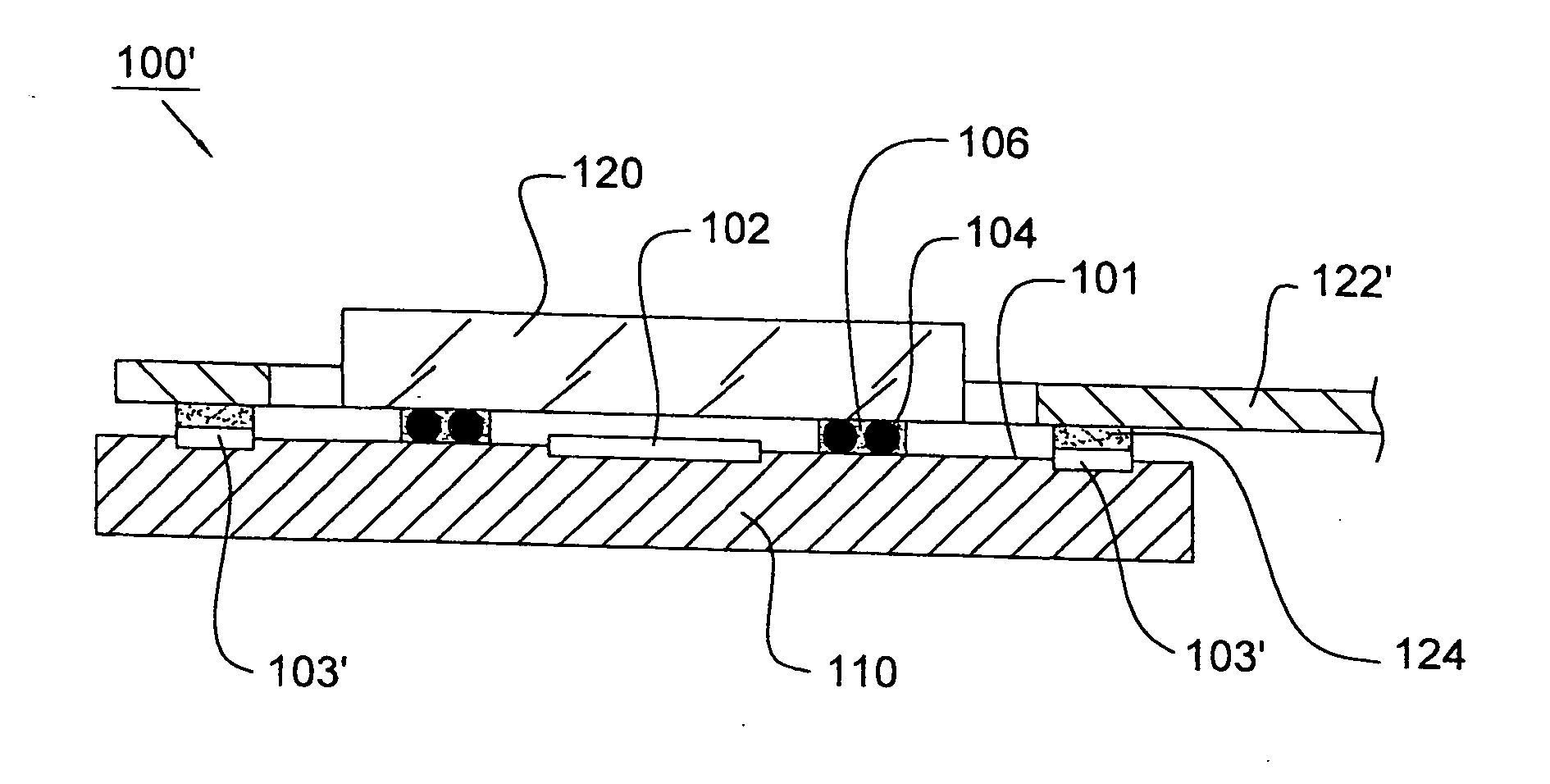

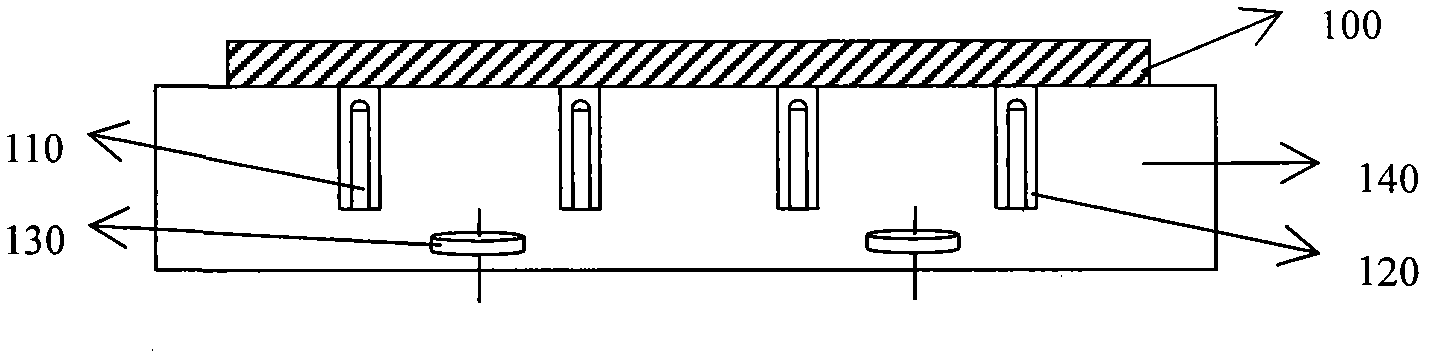

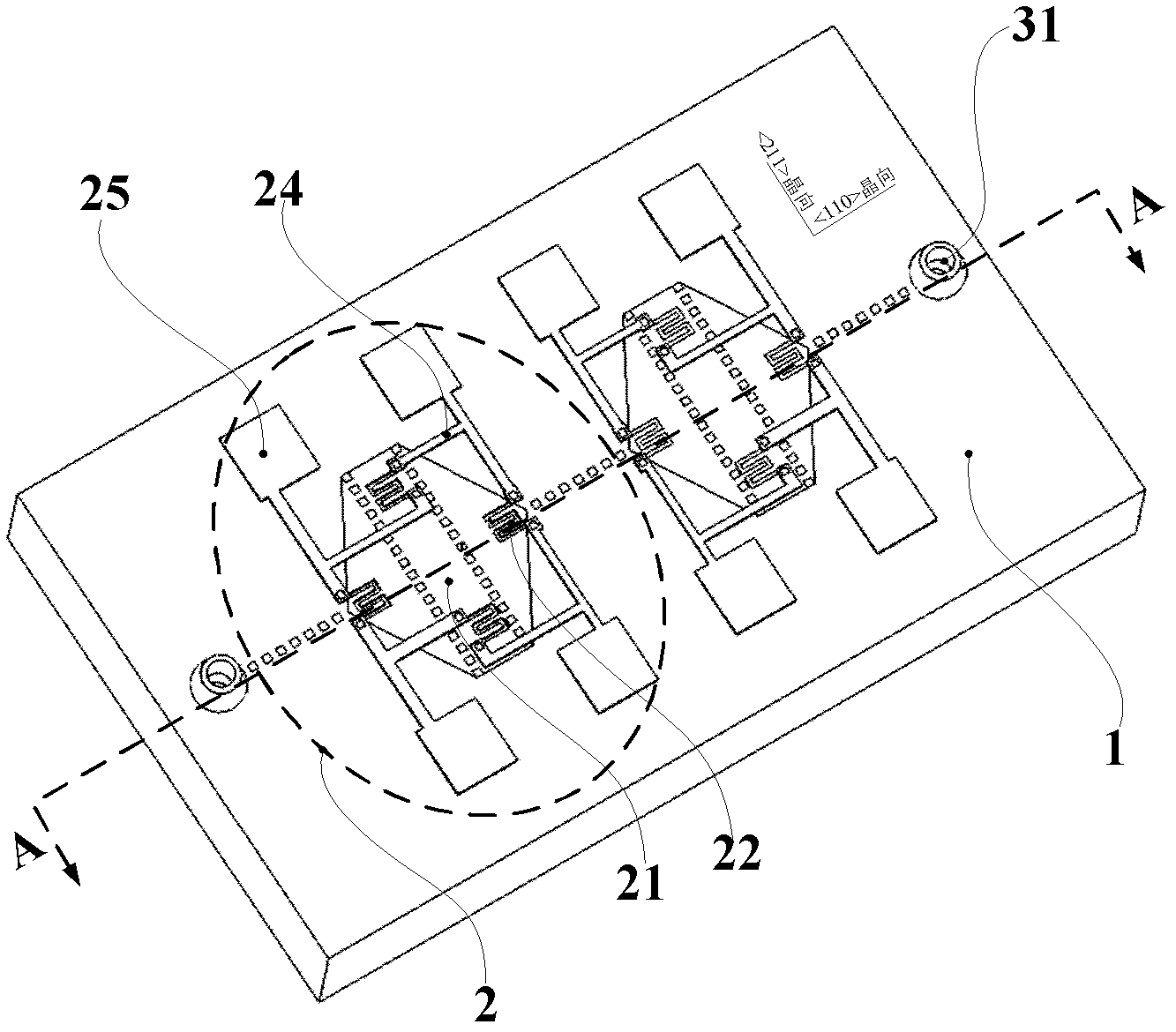

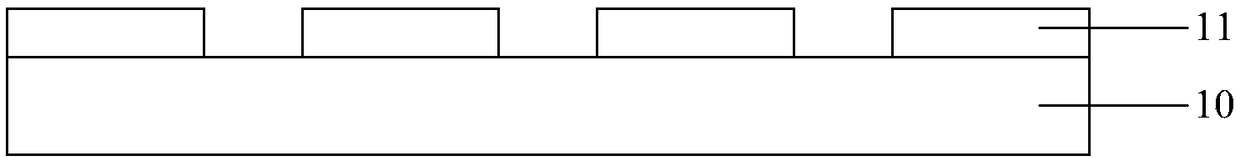

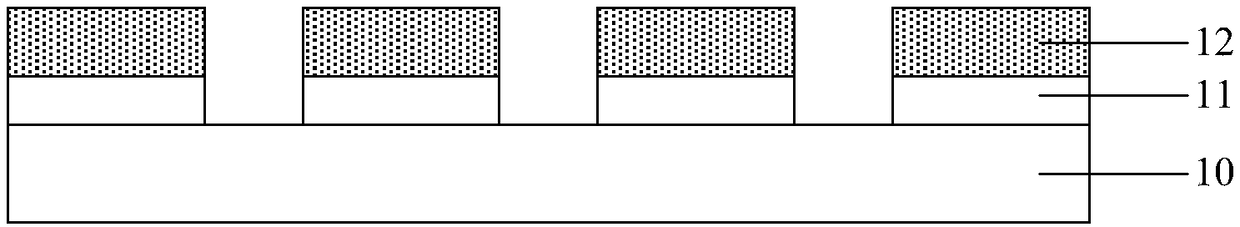

Single-silicon chip microflow sensor suitable to be packaged in surface mounting way and manufacturing method for single-silicon chip microflow sensor

ActiveCN103185613ASimple structureAvoid residual stressFluid pressure measurement using ohmic-resistance variationVolume/mass flow by differential pressureSilicon chipPressure sensitive

The invention provides a single-silicon chip microflow sensor suitable to be packaged in a surface mounting way and a manufacturing method for the single-silicon chip microflow sensor. The single-silicon chip microflow sensor comprises a monocrystalline silicon substrate, two pressure sensors and a microfluidic channel with an inlet / outlet. A single-silicon chip single-sided bulk silicon micromachining method is adopted, so that the microfluidic channel and reference pressure cavities of the pressure sensors are formed in the monocrystalline silicon substrate, and the two pressure sensors and the inlet / outlet of the microfluidic channel are ingeniously integrated on the same surface of the same monocrystalline silicon substrate, so that the single-silicon chip microflow sensor is simple in structure. The problems of residual stress caused by heat mismatch between different bonding materials and the thickness non-uniformity of pressure sensitive thin films of the pressure sensors are avoided, a surface mounting packaging technology is suitable for the integration of a bare chip of the single-silicon chip microflow sensor and a microfluidic system, the single-silicon chip microflow sensor and the manufacturing method have the characteristics of low production cost, convenience in packaging, high sensitivity, high stability and the like, and the single-silicon chip microflow sensor is suitable for mass production.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

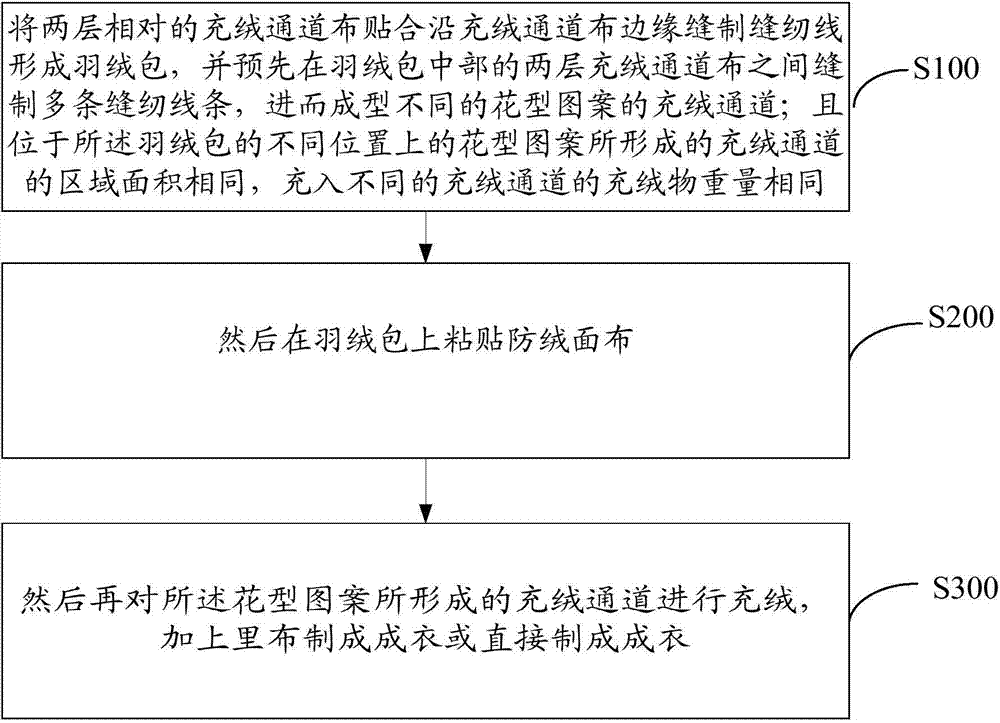

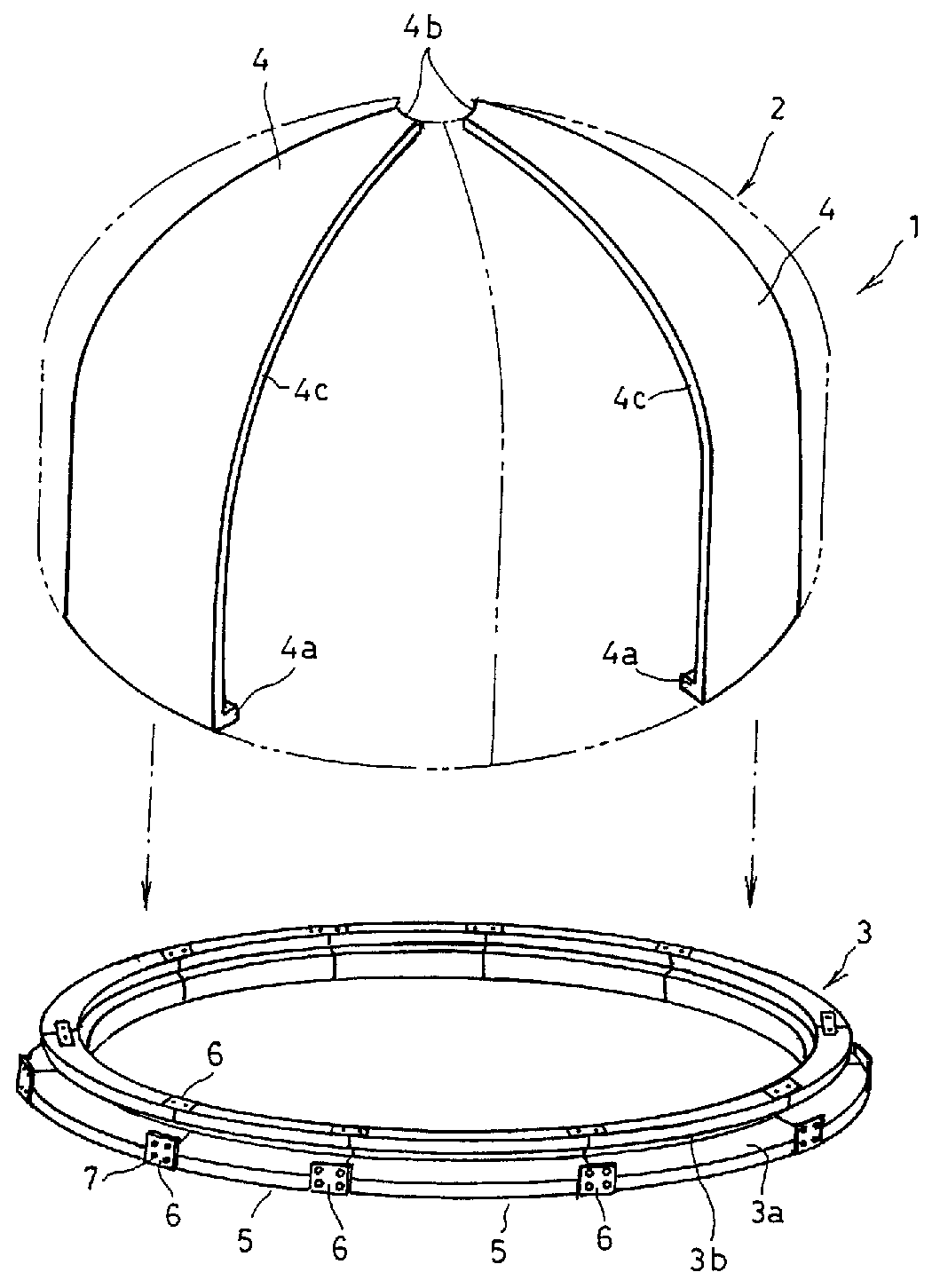

Manufacturing method of down feather escape-free down jacket and down feather escape-free down jacket

InactiveCN104705880AAvoid uneven thicknessWon't run outOvergarmentsProtective garmentEngineeringMechanical engineering

The invention discloses a manufacturing method of a down feather escape-free down jacket and the down feather escape-free down jacket. The manufacturing method comprises the following steps: pre-sewing a plurality of sewing threads between two pieces of down feather filling channel cloth in the middle of a down feather bag so as to mould down feather filling channels with different patterns; then adhering down feather resisting shell cloth on the down feather bag; and then filling down feather into the down feather filling channels formed by the patterns and adding liner cloth to prepare product clothes or directly preparing product clothes. The manufacturing method of the down feather escape-free down jacket and the down feather escape-free down jacket disclosed by the invention can be used for mainly solving the problems that down feather of a conventional down jacket in the market escapes, is pressed and split in a nonuniform manner and the like.

Owner:江志宏

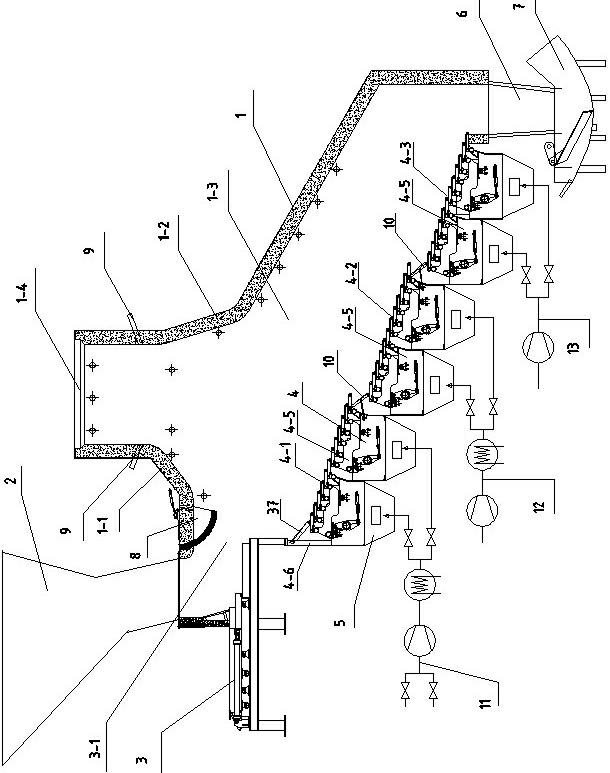

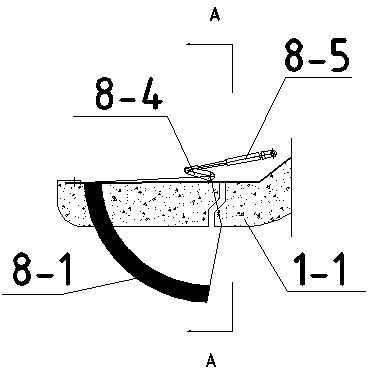

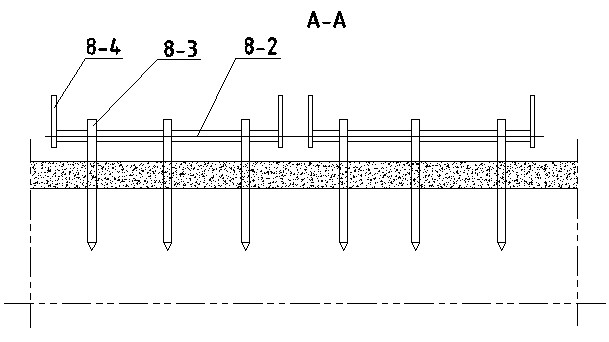

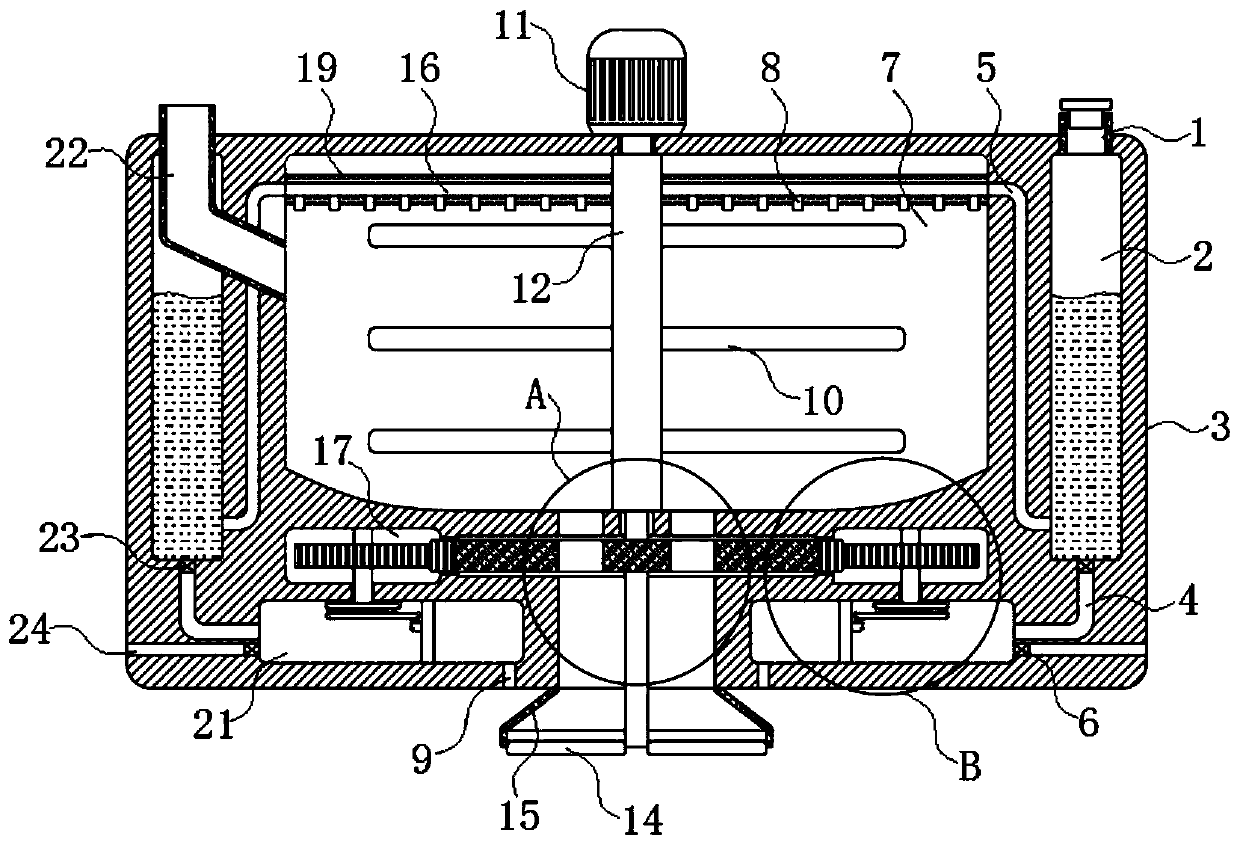

Unit modular large household refuse incineration furnace

The invention discloses a unit modular large household refuse incineration furnace and relates to household refuse incineration treatment equipment. The unit modular large household refuse incineration furnace comprises an incineration grate mechanism, air chambers and air supply systems, wherein the incineration grate mechanism comprises a drying section grate, a burning section grate, a burnout section grate and a rack; the drying section grate, the burning section grate and the burnout section grate respectively comprise two groups of grate units; each group of grate units comprises a spindle, a partition plate, a front wall plate, a rear wall plate and a grate with stepped drop; each grate comprises two groups of edge modules and at least one group of middle modules; each edge module and each middle module respectively consist of a plurality of grate sheets; each group of edge modules is fixed on the corresponding rack through a sidewall protection plate device; each air chamber is formed below each middle module and each edge module; an air inlet is formed at the lower end of each air chamber and connected with the corresponding air supply system; and each air supply system comprises a drying section air supply system, a burning section air supply system and a burnout section air supply system. The unit modular large household refuse incineration furnace is stable in operation, low in energy consumption and long in service life.

Owner:江苏楹能环保科技发展有限公司

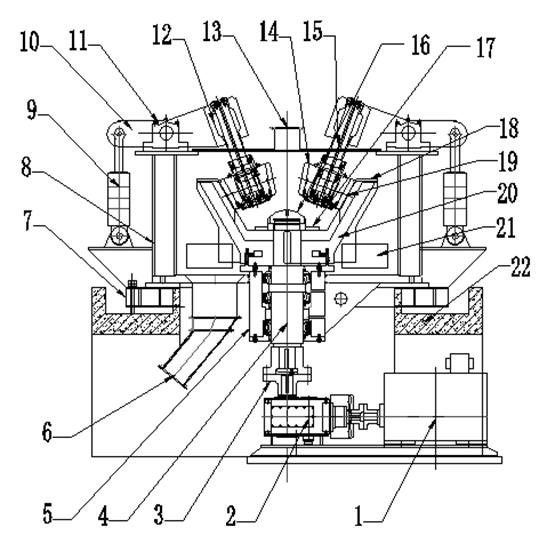

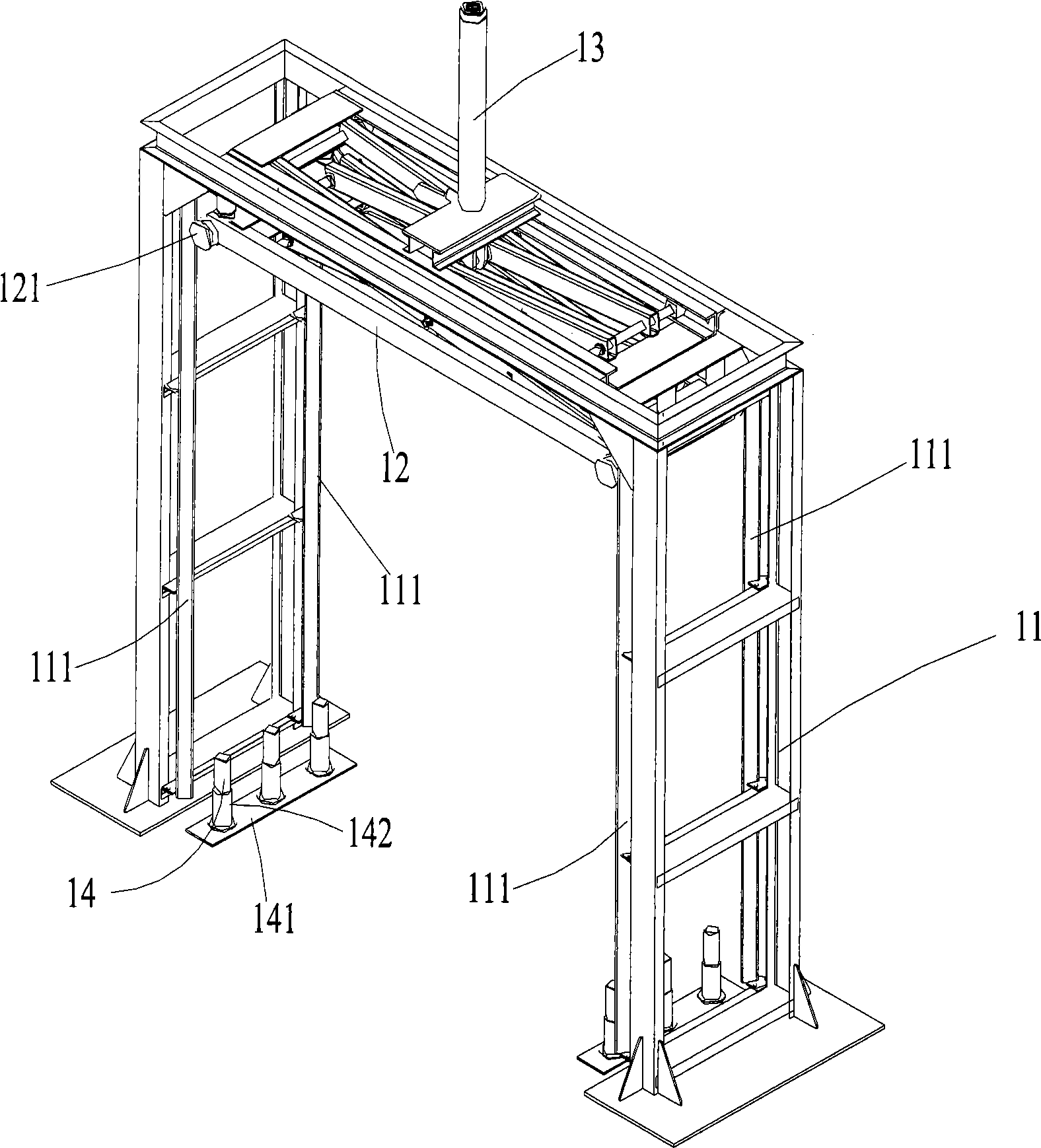

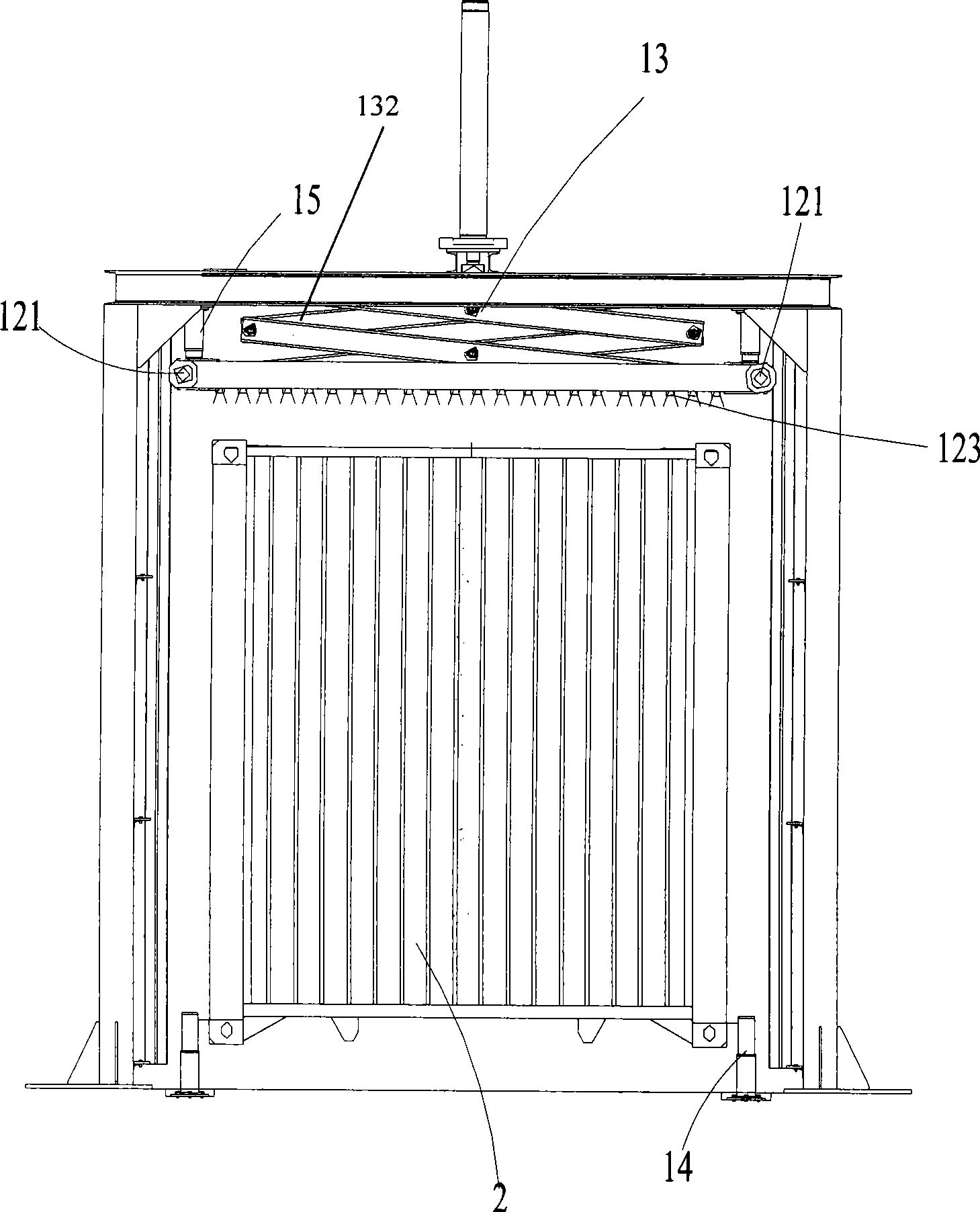

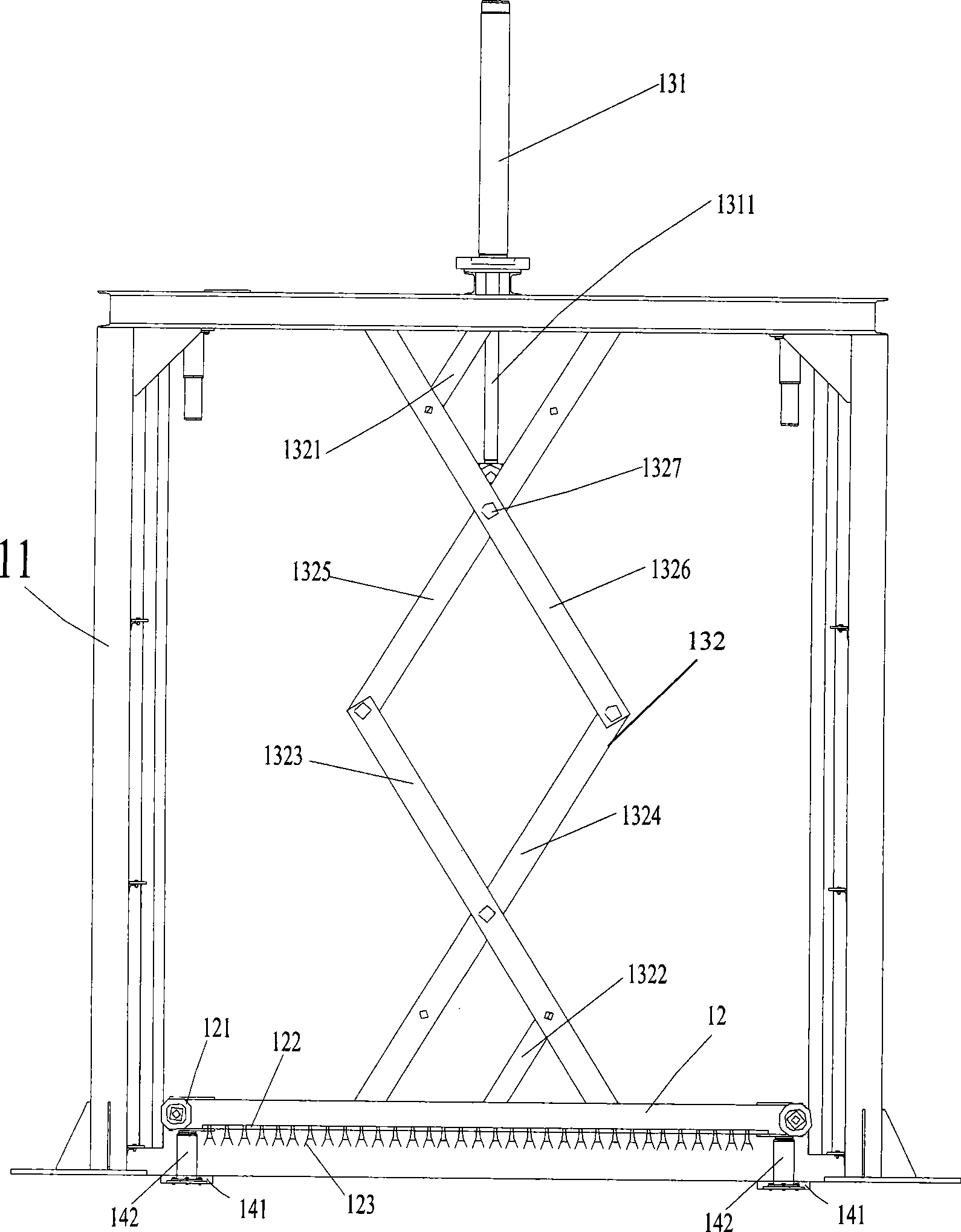

Device for automatically lacquering external case of frontend wall of shipping container

ActiveCN101480643AImprove spraying efficiencyImprove spray qualityLiquid surface applicatorsSpraying apparatusEngineeringPortal frame

The invention discloses a device for spraying paint on the outer surface of the front end wall of a container, which comprises a planer-type frame. The planer-type frame can contain the front end wall of the container and is matched with the front end wall of the container in shape. Furthermore, the inner side of the planer-type frame is provided with a spray gun support along a transverse horizontal direction, the top of the planer-type frame is provided with a drive set, the spray gun support is connected with the drive set and reciprocates up and down along the planer-type frame under the action of the drive set, and one side of the spray gun support, which corresponds to the frond end wall of the container is horizontally provided with a plurality of spray guns with adjustable angles. The device has the advantages of high production efficiency, high paint spraying quality, and the like.

Owner:TAICANG CIMC CONTAINER CO LTD

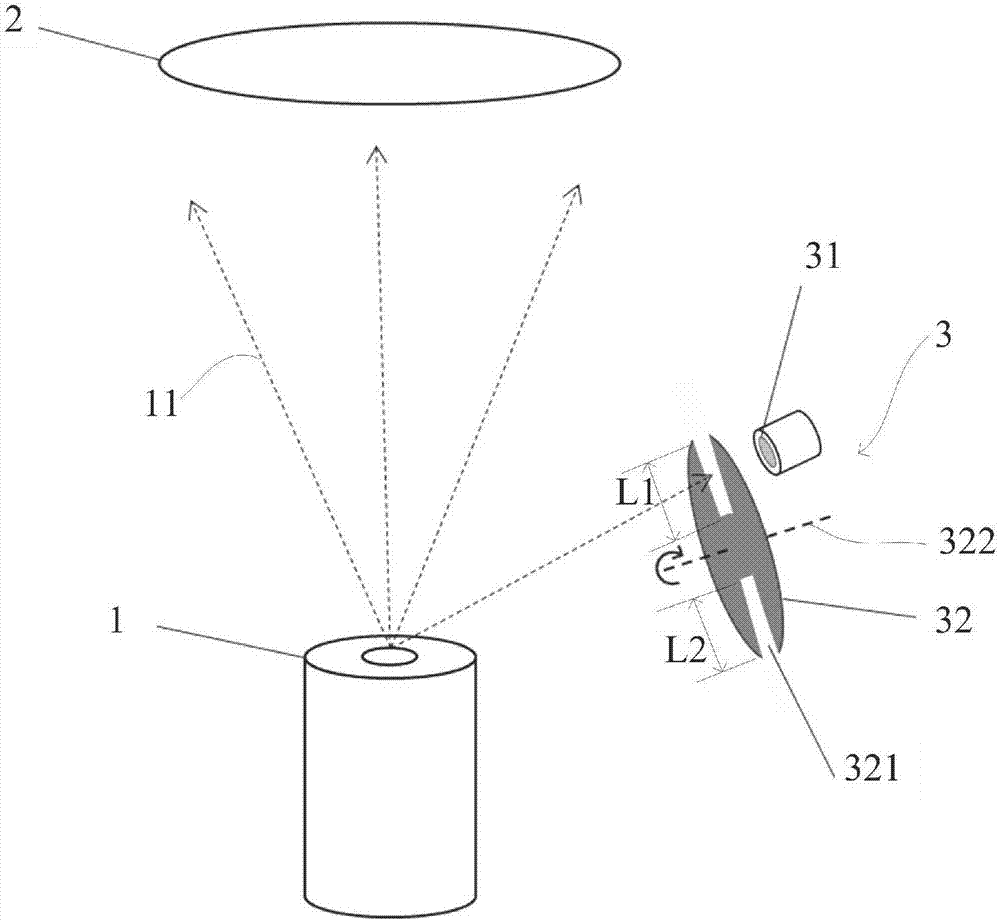

Film coating system and film thickness monitoring device thereof, and film coating method and film thickness monitoring method thereof

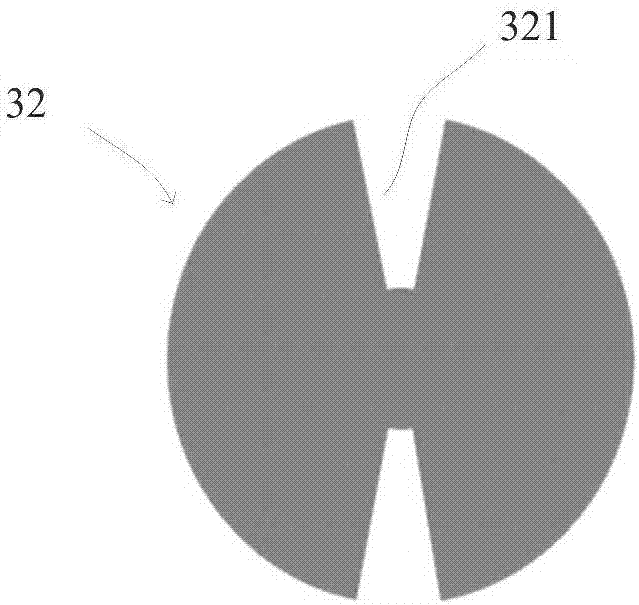

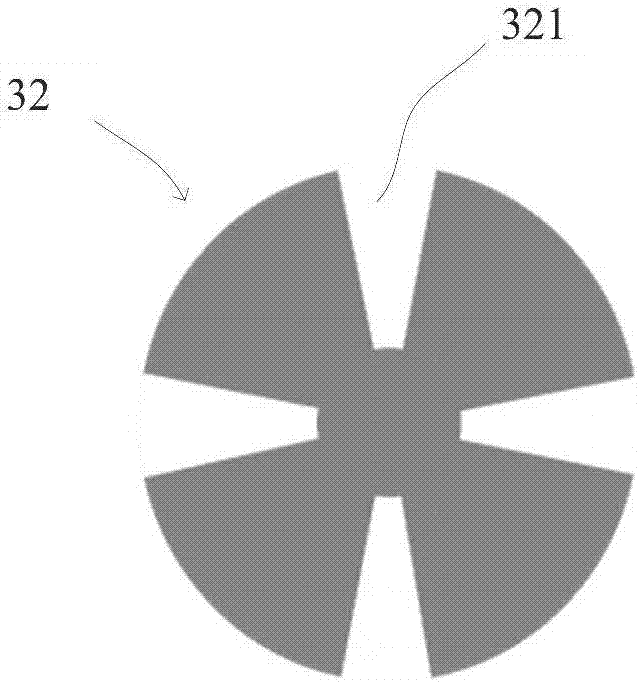

InactiveCN107385406AExtended use timeReduce deposition rateVacuum evaporation coatingSputtering coatingEngineeringRunning time

The invention relates to a film coating system and a film thickness monitoring device thereof, and a film coating method and a film thickness monitoring method thereof. The film thickness monitoring device comprises a shielding plate and a quartz crystal wafer, wherein the shielding plate and the quartz crystal wafer can rotate relative to each other, and the shielding plate is provided with an opening; and in the relative rotating process, the opening allows airflow of a film coating material to pass through to enable the airflow to reach the quartz crystal wafer, and other parts, except the opening, of the shielding plate block the airflow from reaching the quartz crystal wafer. The shielding plate is adopted for blocking the airflow, the deposition velocity of film on the quartz crystal wafer is slowed down, the service time of the quartz crystal wafer is prolonged, and therefore the continuous running time of the equipment is prolonged, and the cost is correspondingly reduced. In addition, the shielding plate and the quartz crystal wafer can rotate relative to each other, so that the airflow of the film coating material can pass through the opening in the rotating process and then is uniformly deposited on the quartz crystal wafer, the situation that the thickness of the film coating materials deposited on the quartz crystal wafer is not uniform due to the fact that the opening is arranged is avoided, and the monitoring accuracy is guaranteed and improved.

Owner:茆胜

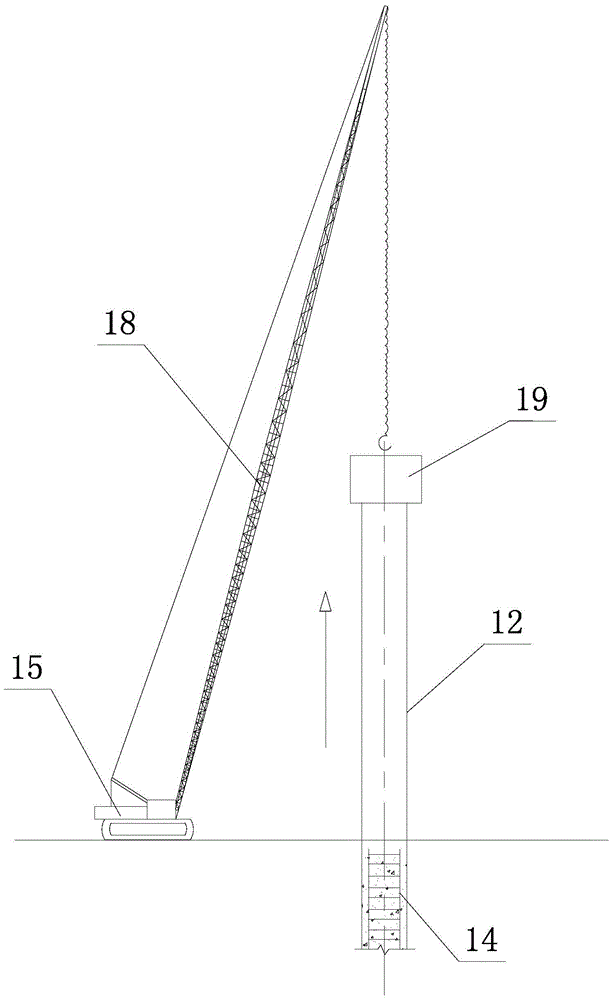

Full casing long-spiral bored pile machine and method of using same for construction

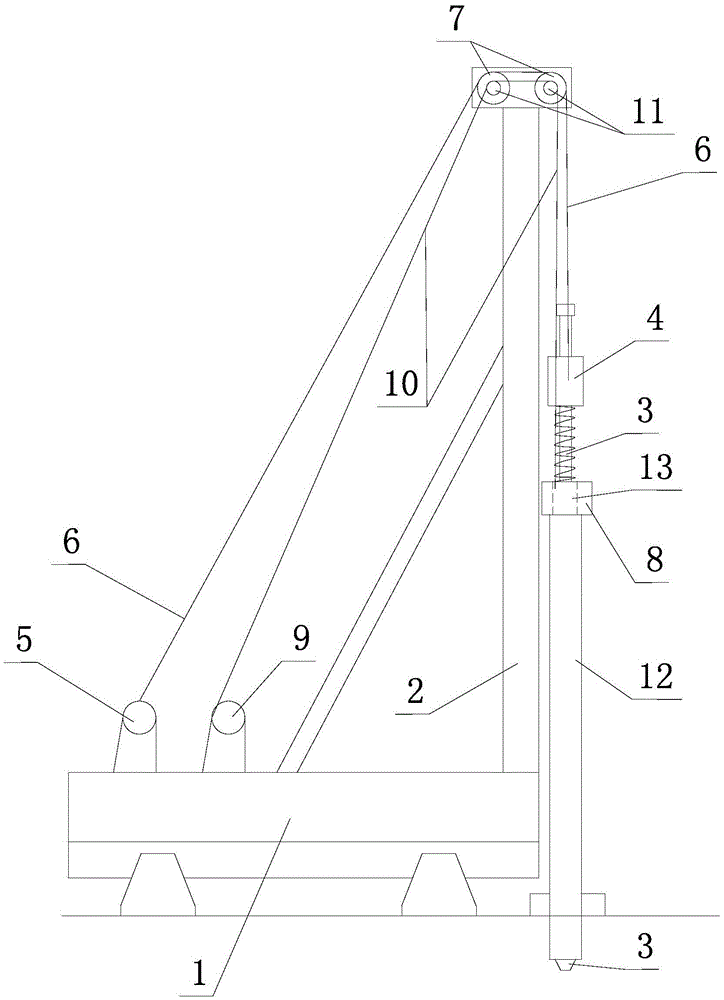

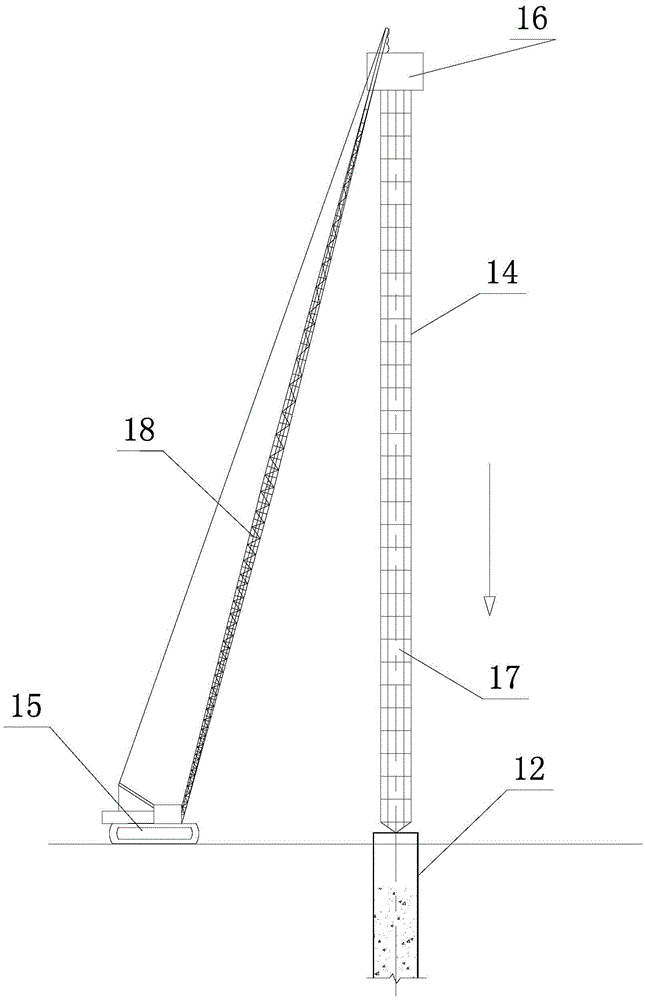

ActiveCN105569560APrevent penetrationAvoid churnDerricks/mastsRotary drillingEngineeringCement slurry

The invention discloses a full casing long-spiral bored pile machine and a construction method. The pile machine comprises an upper power head (4), a first winch (5), a first pulling rope (6), a lower power head (8), a second winch (9) and a second pulling rope (10); the upper power head (4) and the lower power head (8) are in slide fit with a main mast (2), the first winch (5) is connected with the upper power head (4) through the first pulling rope (6), and a long spiral drill stem (3) and the upper power head (4) are fixed; the second winch (9) is connected with the lower power head (8) through the second pulling rope (10), and the lower power head (8) is provided with a full casing (12). The key of the construction method is that the long spiral drill stem (3) and the full casing (12) synchronously rotate to enter a soil body under driving of the two power heads (4). According to the pile machine and the construction method, hole collapse and water gushing are prevented, and loss of cement slurry is avoided.

Owner:NINGBO HONGCHEN CONSTR

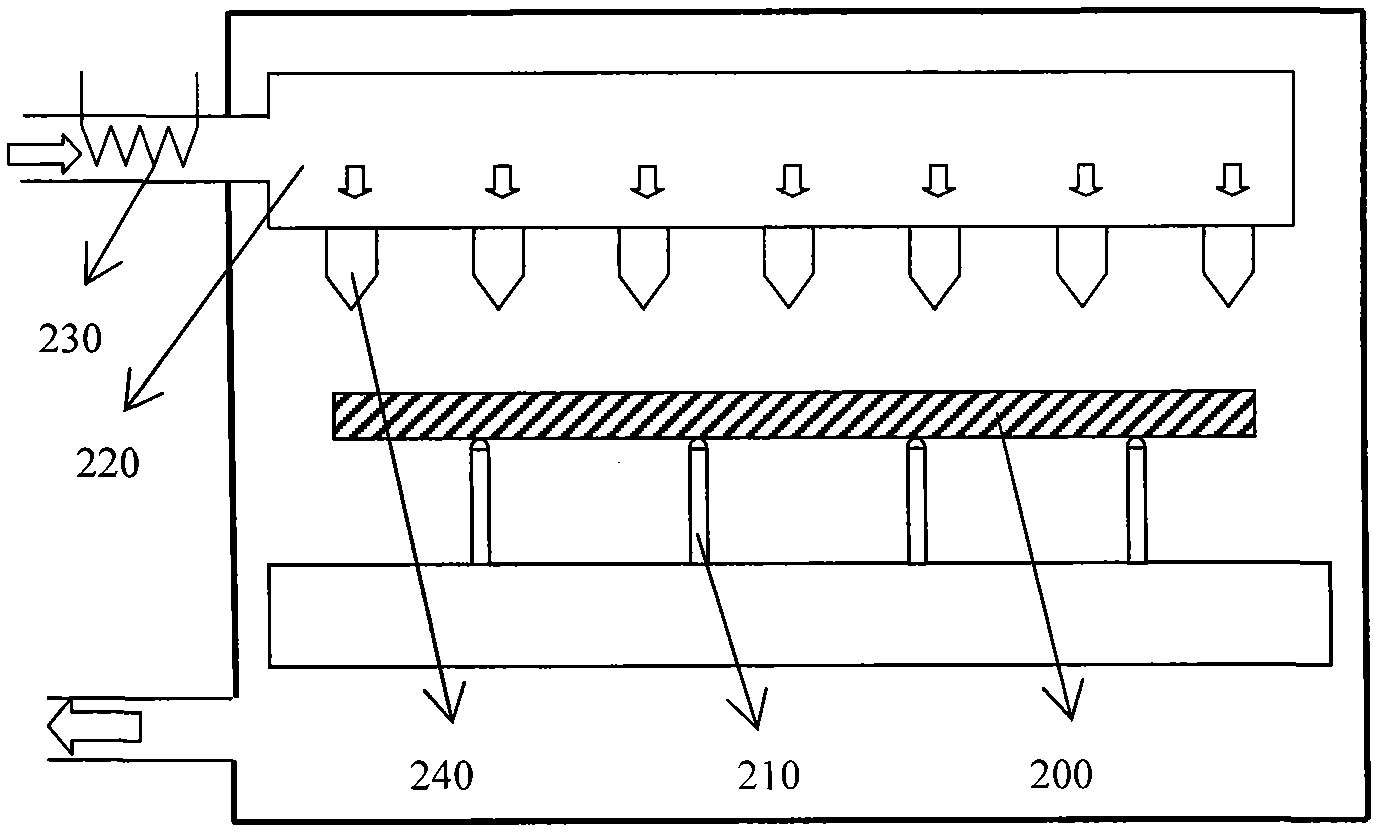

Etching apparatus and etching method

InactiveUS20070138134A1Increase temperatureAvoid uneven thicknessElectric discharge tubesDecorative surface effectsEngineering

An etching apparatus is described, including an etching chamber, a gas pipe, a gas distribution plate and a heater. The gas pipe is disposed above the etching chamber for delivering a gas to the exterior surface of the etching chamber. The gas distribution plate is disposed at the outlet of the gas pipe, including a plate body and an inner collar-shaped part thereon facing the outlet of the gas pipe. The inner collar-shaped part and the portion of the plate body around the inner collar-shaped part each has multiple through holes therein. The heater is disposed around the space between the gas pipe and the etching chamber for heating the gas flowing out of the gas distribution plate.

Owner:UNITED MICROELECTRONICS CORP

Display substrate, display panel and display device

ActiveCN107479235AAvoid uneven thicknessImprove picture brightness unevennessNon-linear opticsDisplay deviceComputer science

The invention discloses a display substrate, a display panel and a display device. The thickness uniformity of an alignment layer is improved, the image brightness nonuniformity phenomenon of the display device is improved, and the display quality of the display device is improved. The display substrate is divided into a display area and a nondisplay area surrounding the display area, the display substrate comprises an underlayer substrate and an insulating layer, a drainage wire layer and the alignment layer which are arranged in sequence in the direction far away from the underlayer substrate, the insulating layer and the alignment layer cover the display area and extend to the nondisplay area, and the drainage wire layer is located in the nondisplay area, wherein a groove is formed in the portion, in the nondisplay area, of the insulating layer; the drainage wire layer is located on the side, close to the display area, of the groove and comprises multiple drainage wires, and the first end of each drainage wire extends to the groove; the alignment layer comprises a body part and a drain extension part, the body part covers the second ends of the drainage wires, and the drain extension part extends to the groove along the drain wires.

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD

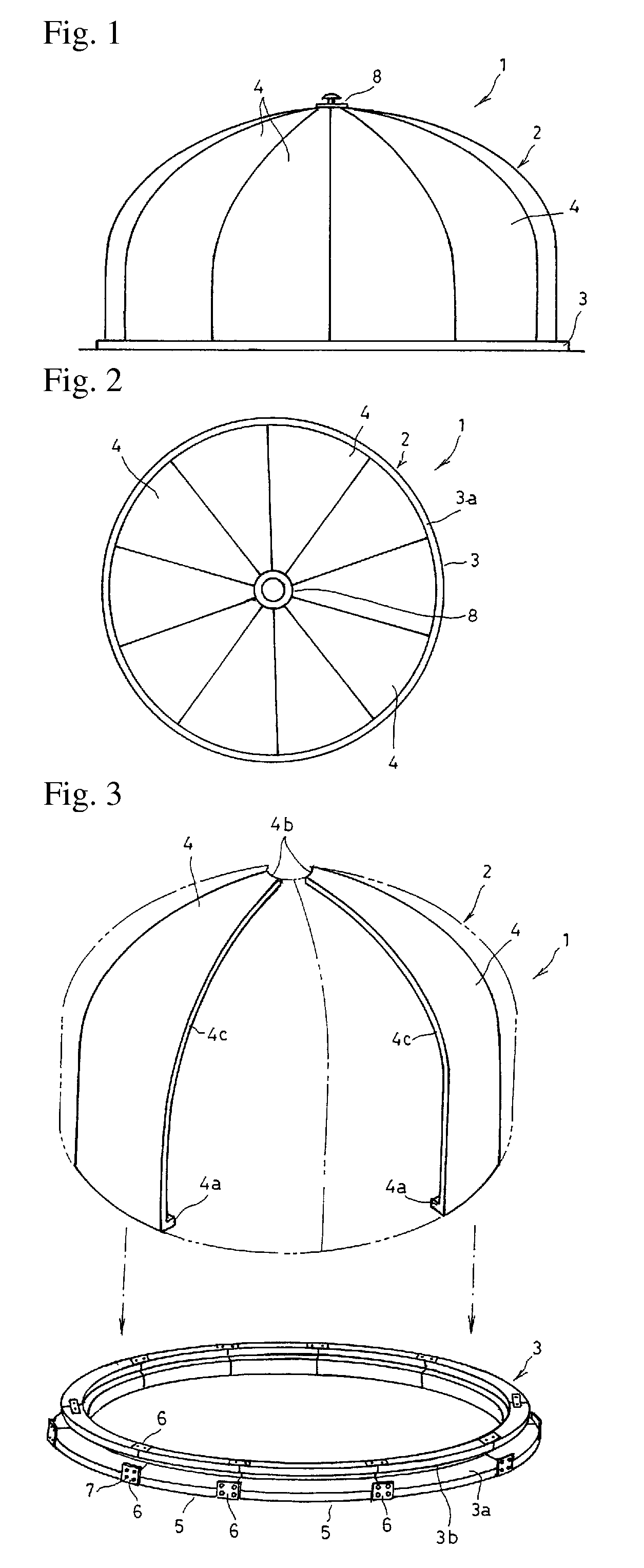

Knockdown structure and methods of assembling same

A knockdown structure and assembly method are provided so as to prevent cracking of the sealant, reinforce the junction between sections, and improve the livability of the structure. A structure's body is assembled by using a mortar-powder mixed adhesive to join together a plurality of sections that are made of foam polystyrene and that constitute the parts of a structure having a predetermined shape. The adhesive is applied to cover at least the places where the sections are joined together with a woven inorganic-fiber mesh sheet. A sealant is applied, made by dispersing inorganic fiber and mortar powder in a plastic-type paint, onto the exterior and interior faces of the structure in a predetermined thickness. Onto the sealant of the exterior of the structure is applied, on the exterior of the structure, a paint that is water repellant and can screen out ultraviolet light, and applying, over the sealant of the interior of the structure, a clayey paint made of natural substances.

Owner:YUGENKAISHA JAPAN TSUSYO

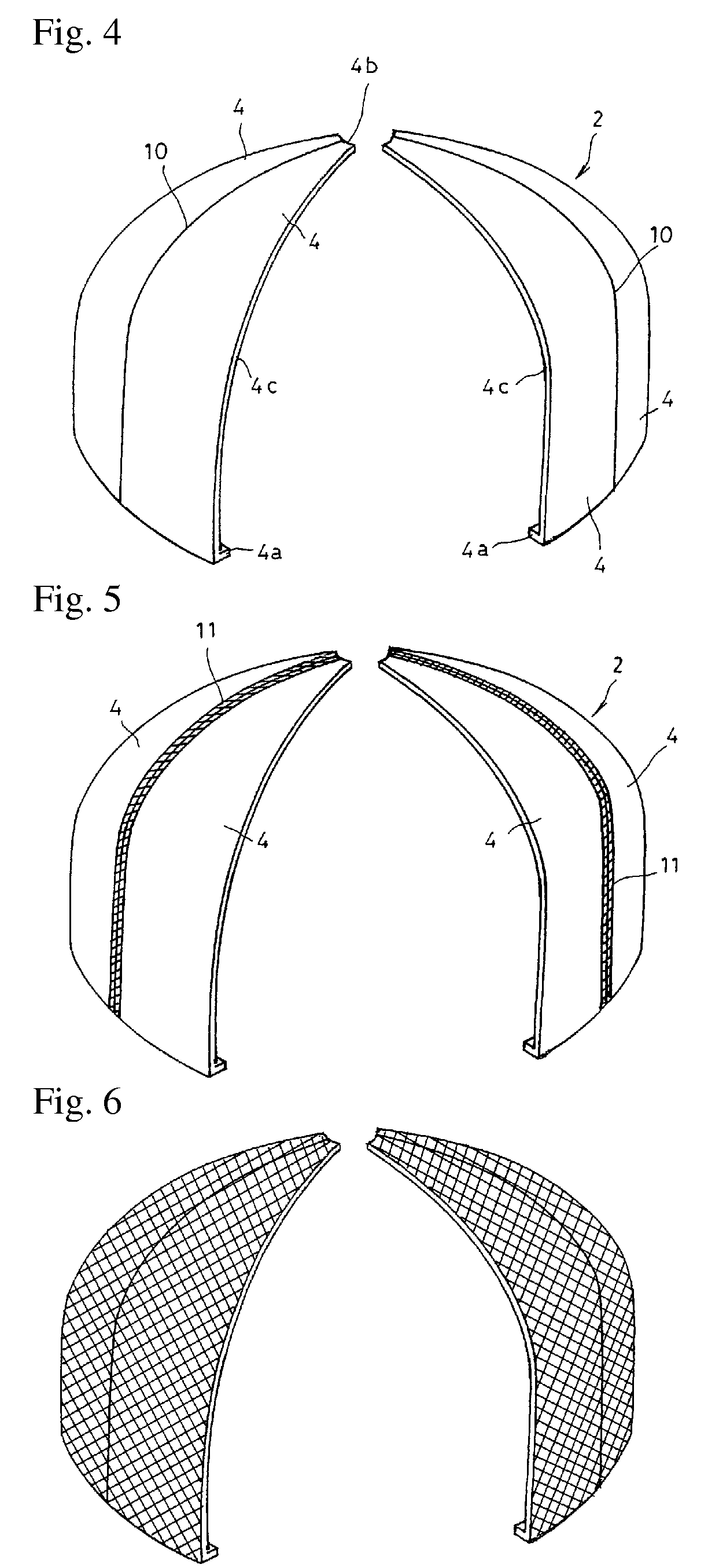

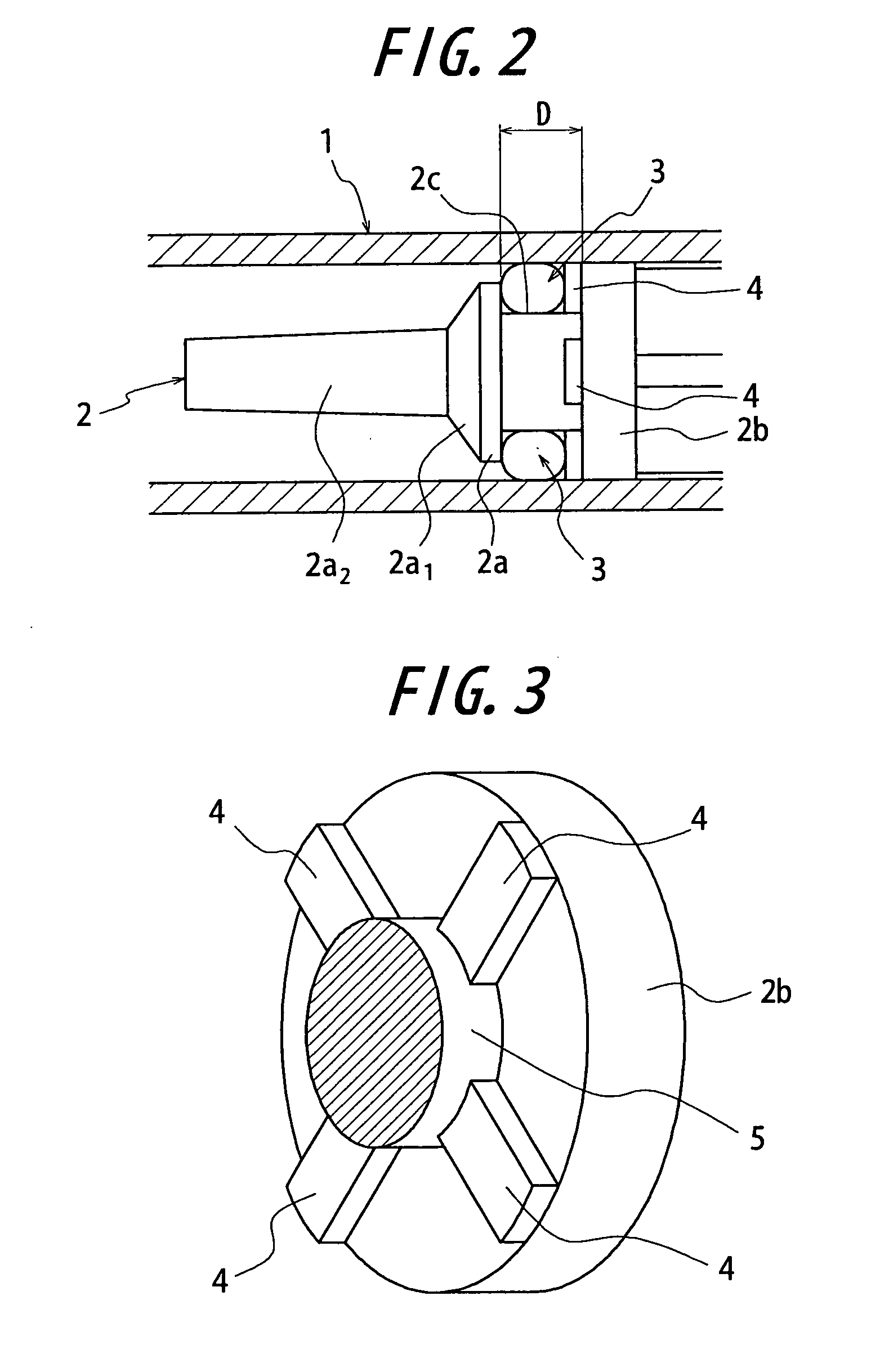

Viscous material extruding dispenser

ActiveUS20090289084A1Avoid drippingAvoid mixingLiquid surface applicatorsLarge containersEngineeringPlunger

There is provided a dispenser in which an operation load of a plunger is stable and contents of the dispenser do not leak out after pressing operation is interrupted. The invention provides a dispenser comprising a syringe body (1) having a space for filling contents equipped with a extruding nozzle at the front end thereof, a plunger (2) slid, by pressing force applied thereto, in the syringe body (1) to extrude the contents in the filling space (m) from the tip of the extruding nozzle, an O-ring (3) placed in an annular groove (2) formed in the front end section of the plunger and slidable on the inner wall surface of the syringe body (1), wherein the annular groove (2c) is formed as a defined recess having a flat bottom wall over its entirety; a plurality of projections or grooves (4) are formed on the sidewall of the annular groove (2c) with intervals therebetween so that restoring force of the O-rings (3) causes the plunger (2) to slide to the opposite direction of the press-in direction, thus inducing back suction of contents.

Owner:YOSHINO KOGYOSHO CO LTD +1

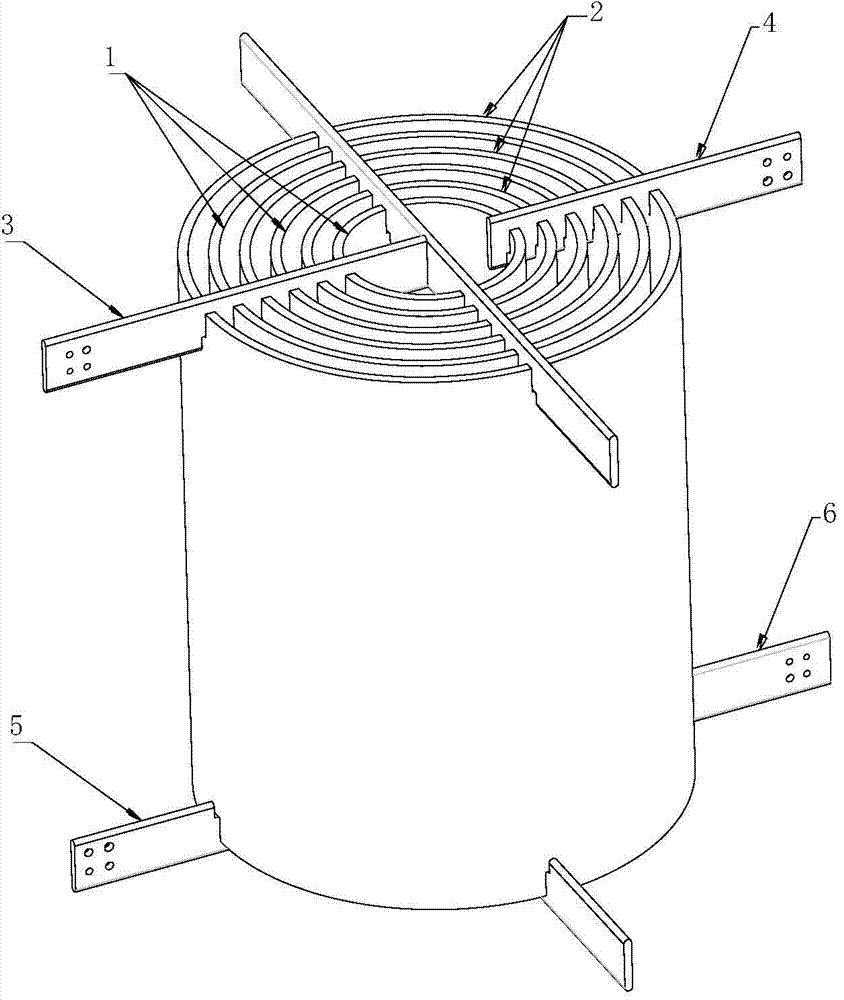

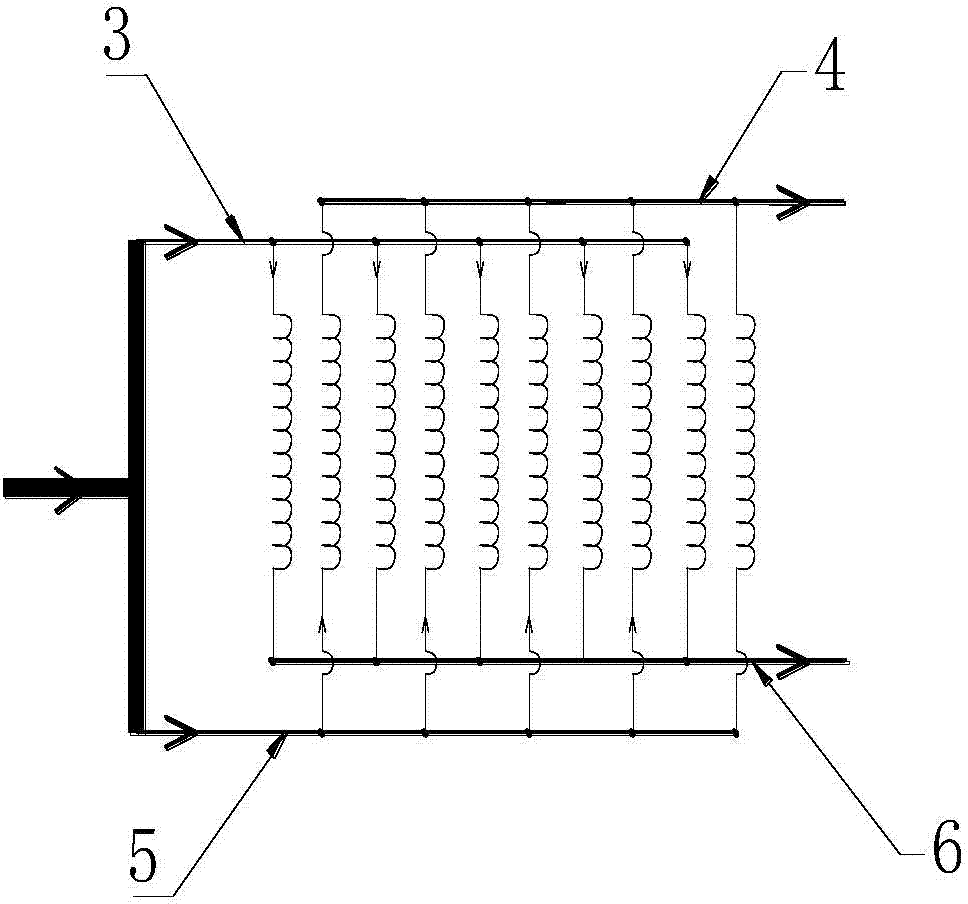

Casting type split reactor

InactiveCN104124043AEnsure consistencyAvoid uneven thicknessTransformers/inductances coils/windings/connectionsInsulation layerCasting types

The invention discloses a casting type split reactor. A coil of the casting type split reactor comprises a first winding and a second winding which are arranged coaxially, and encapsulation parts of the first winding and encapsulation parts of the second winding are arranged alternatively from inside to outside in sequence. A first wire inlet bar and a second wire outlet bar are arranged at an interval radially and fixed at the upper end of the coil, and the other first wire inlet bar and a first wire outlet bar are arranged at an interval radially, connected with a current introducing end of the second winding in a conductive mode and fixed at the lower end of the coil. Each encapsulation part comprises a conductive part formed by winding a plurality of multi-layer round leads, and an insulation part formed by casting epoxy resin in a vacuum mode is arranged outside the conductive part. According to the casting type split reactor, the encapsulation parts are formed by casting epoxy resin in the vacuum mode through a casting mould, consistency of sizes of the insulation layers can be ensured, and uneven thicknesses of the insulation layers are avoided. In addition, no bubbles exist in the windings, partial discharge is reduced, occurrence of air gaps can be avoided effectively, and therefore, insulation performance of the insulation layers can be improved.

Owner:STATE GRID CORP OF CHINA +2

Extrusion-type interelectrode sulfuration forming and encapsulating method for researching flexible sensor sensitive element

InactiveCN102023064AFully dispersedUniform thicknessForce measurementUsing electrical meansElectrical resistance and conductanceOrganic solvent

The invention relates to an extrusion-type interelectrode sulfonation forming and encapsulating method for researching a flexible sensor sensitive element, belonging to the technical field of sensors. The method comprises the following steps of: dispersing nano conductive powder into a polymeric substrate by utilizing a solution blending method, fully dispersing the nano conductive powder in the polymeric substrate by using a method of repeatedly adding and volatilizing an organic solvent to form nano conductive powder / polymeric material jelly; and coating the jelly between two layers of insulation films covered with electrodes to obtain a film with needed thickness by adopting a microcomputer control extrusion method. The jelly takes favorable adhesion action to the two layers of insulation films in the sulfonation process and is directly sulfonated and formed between the two layers of electrodes. The flexible sensor sensitive element researched by utilizing the forming encapsulating method provided by the invention has the advantages of uniform thickness, little contact resistance, simple process, and the like and is suitable for researching flexible sensor sensitive elements based on a composite conductive polymeric material at low cost.

Owner:NORTHEASTERN UNIV

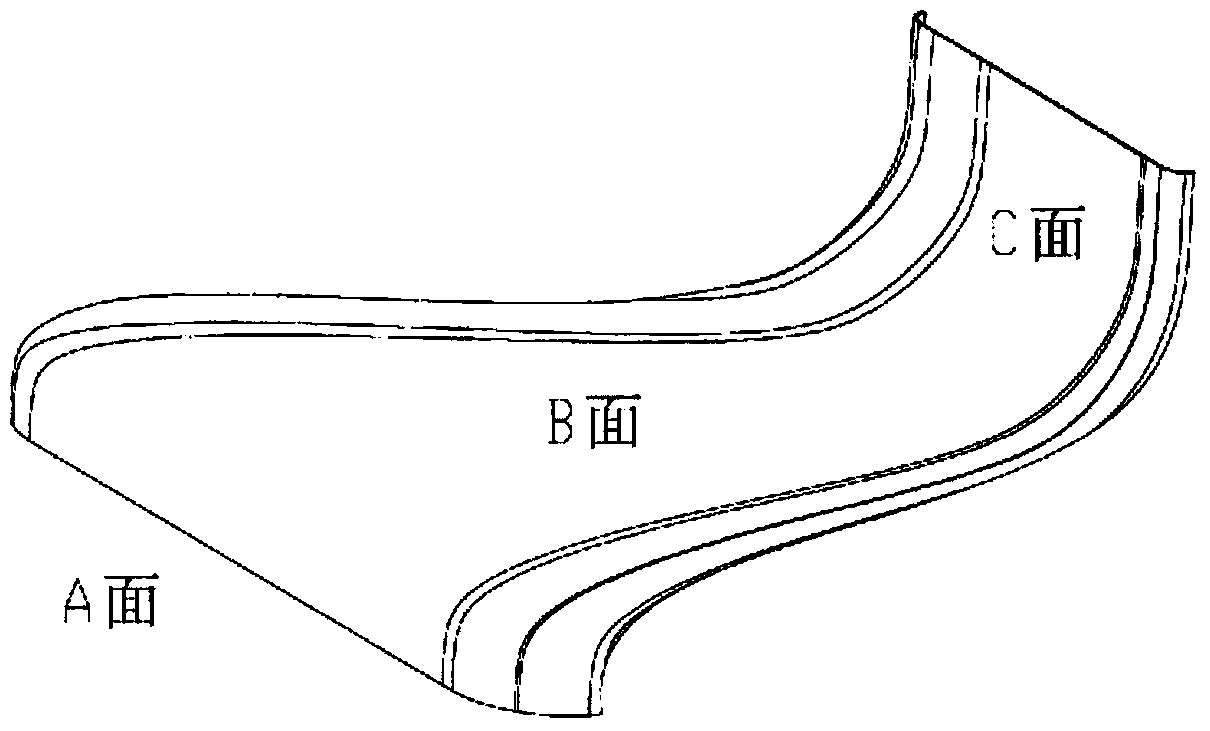

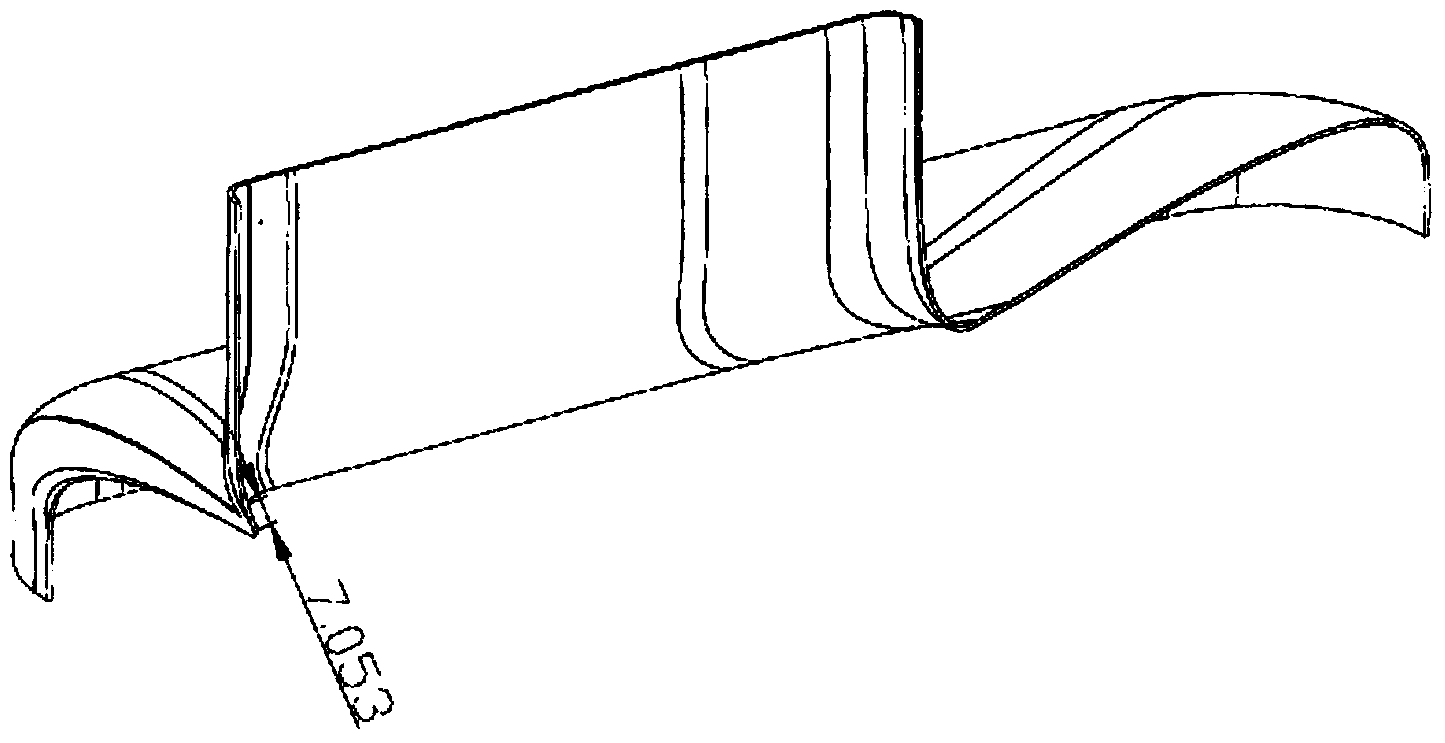

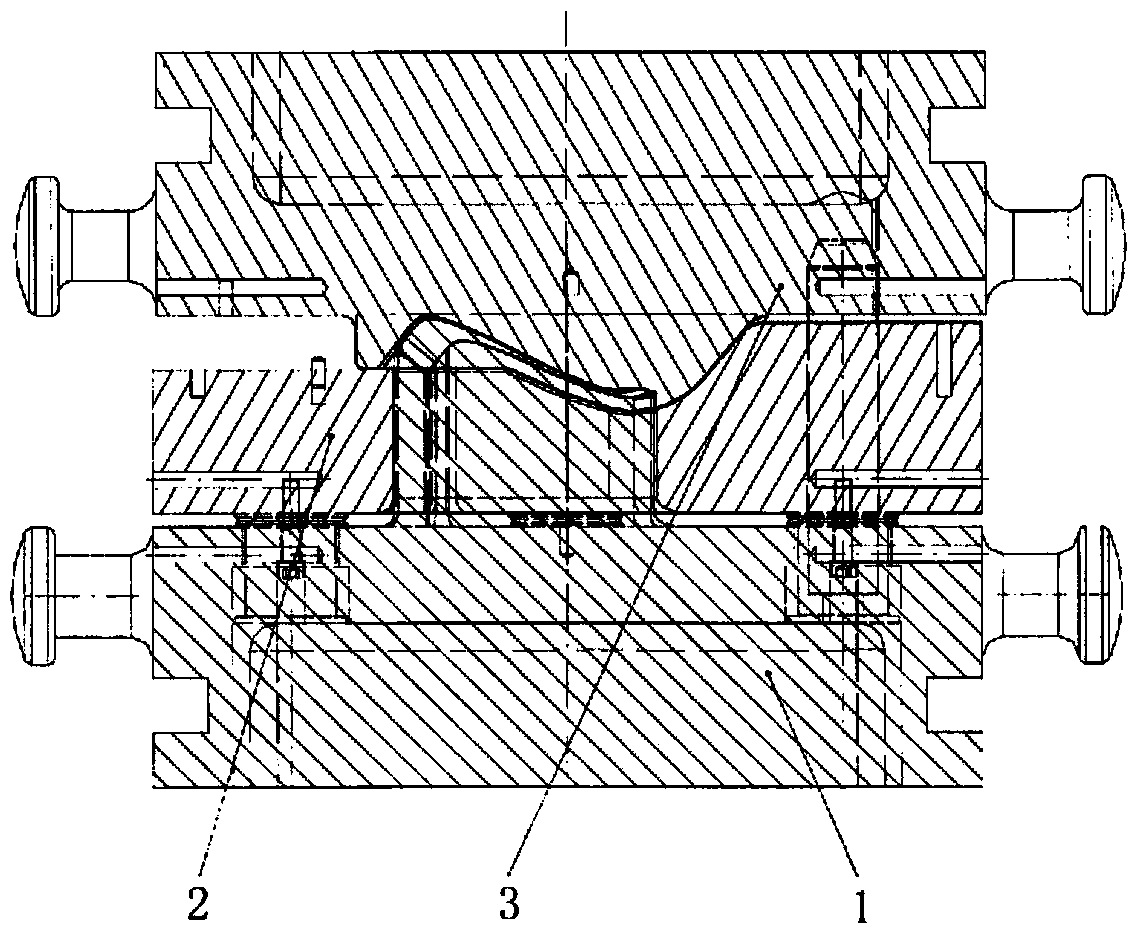

Multi-hook-face titanium alloy part forming device and method

The invention relates to a multi-hook-face titanium alloy part forming device and method. According to the technical scheme, a male die is pressed to coarsely manufacture a workblank into a multi-hook-face titanium alloy part with the unfolded appearance; deburring, washing, lubricant coating are carried out; the device is arranged on a heat engine to be pre-heated into 550 DEG C to 600 DEG C, and meanwhile the workblank is pre-heated into 550 DEG C to 600 DEG C; the pre-heated workblank is arranged between a blank holder and a female die, and after the blank holder and the female die are combined tightly, the temperature ranging from 550 DEG C to 600 DEG C is kept, the clamping pressure is 40 t, the female die slowly descends at the descending speed ranging from 5 mm / min to 6 mm / min, the female die stays for three minutes to five minutes after descending for three to five minutes every time, the process is executed three times till the female die and the male die are closed, and the pressure is kept for four minutes to five minutes; the appearance is manufactured, and checking is carried out. The workblank in the non-working area is clamped tightly through the blank holder force of the blank holder, and wrinkles and cracks produced by tremendous changes of the plate face of the workblank when the dies are closed are avoided.

Owner:SHENYANG AIRCRAFT CORP

Automatic concrete pouring device for building construction

InactiveCN110905211AAvoid cloggingThere will be no localized coagulation and agglomerationDischarging apparatusBuilding material handlingElectric machineArchitectural engineering

The invention discloses an automatic concrete pouring device for building construction. The automatic concrete pouring device for building construction comprises two guide rails fixed to the ground through two electric telescopic rods respectively, a cross beam sliding along the two guide rails, and a concrete pouring unit slidingly connected to the cross beam. The concrete pouring unit comprisesa pouring box, a motor, a stirring shaft and a plurality of stirring blades, and the motor is fixedly connected to the upper end of the pouring box. According to the automatic concrete pouring devicefor building construction, by arranging a dilution mechanism, a quantification mechanism, a water pumping mechanism, a spreading mechanism and trowels, concrete in the concrete pouring unit can be stirred and diluted, the situation that the viscosity of the concrete is excessively increased due to water evaporation is avoided, and blockage of the concrete pouring unit and high-load operation of the motor are prevented; quantitative pouring of the concrete can be achieved, and it is guaranteed that the concrete is uniformly poured; and besides, the concrete can be automatically spread and troweled after being poured, and thus the problem that automatic concrete pouring is fast and it is difficult for workers to perform troweling synchronously is solved.

Owner:菏泽城建工程发展集团有限公司

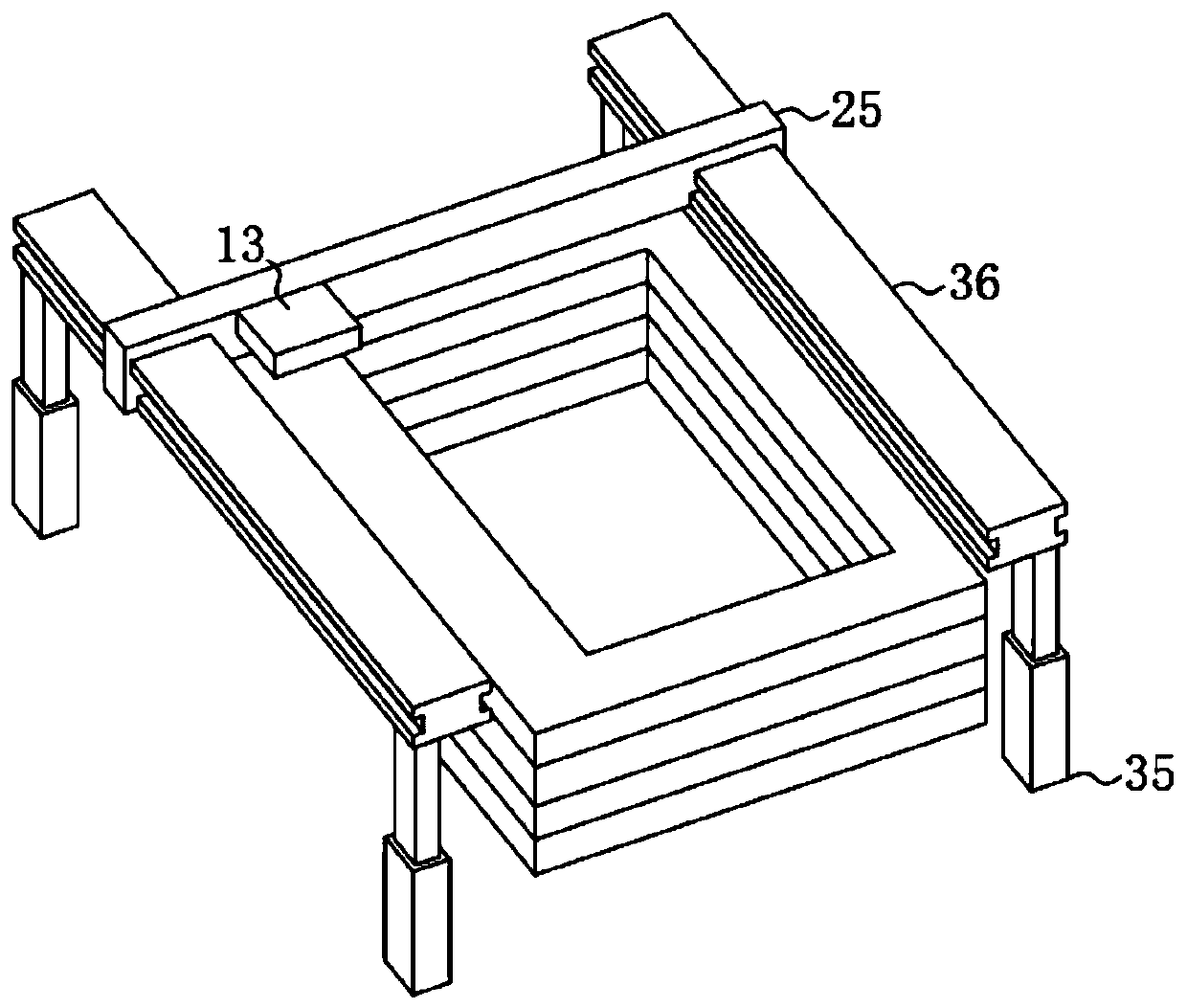

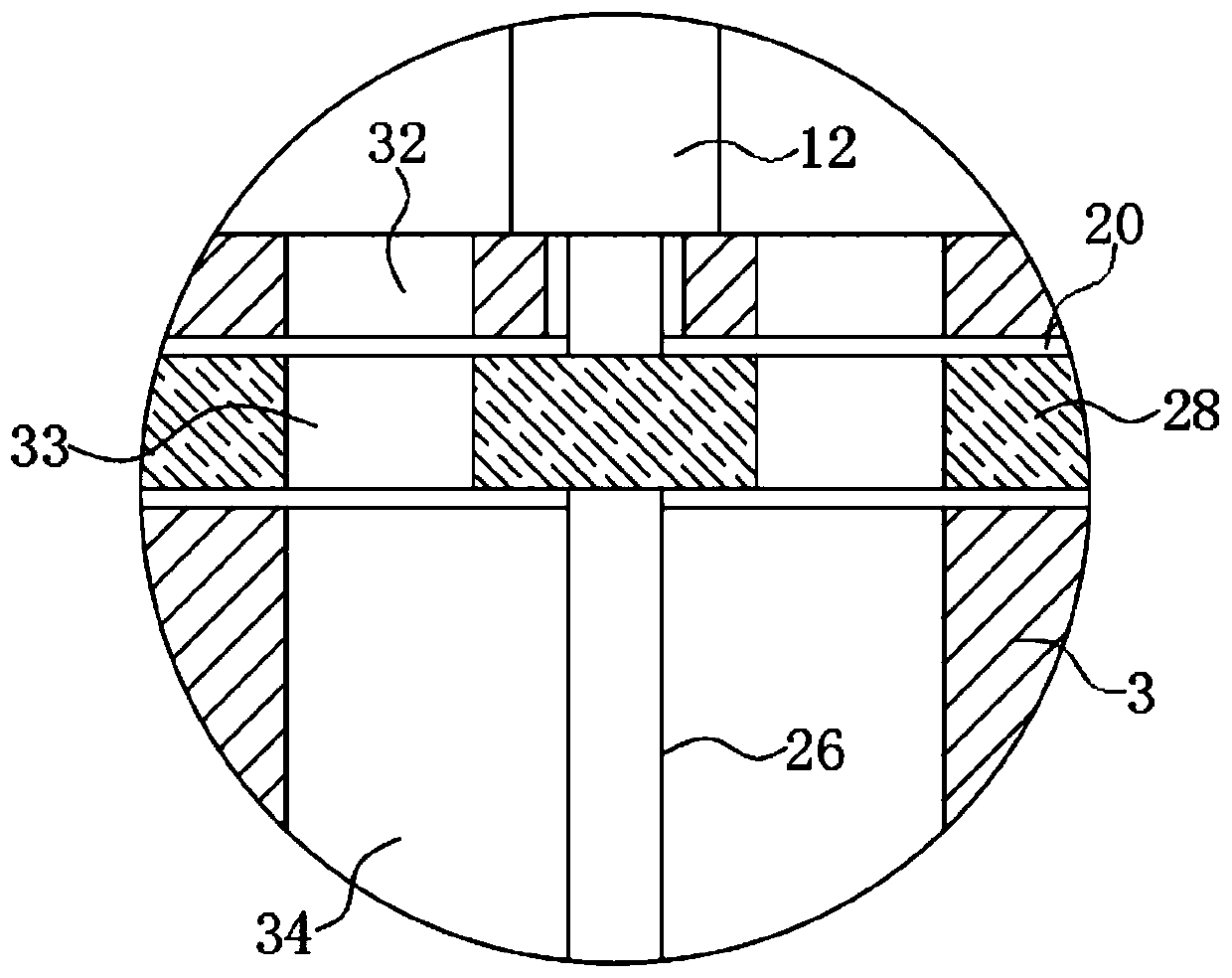

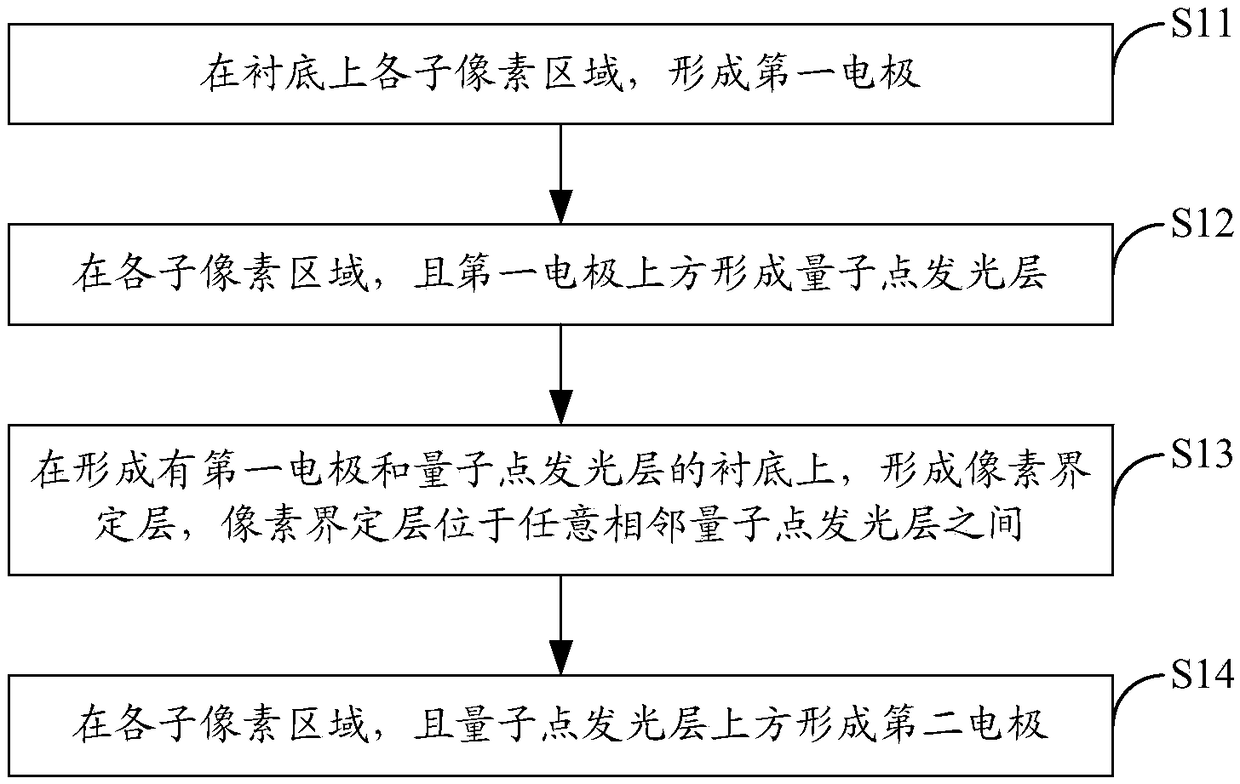

Array substrate, preparation method of array substrate, and display panel

InactiveCN109346506AAvoid climbingAvoid uneven thicknessSolid-state devicesSemiconductor/solid-state device manufacturingQuantum dotQuantum

Embodiments of the invention provide an array substrate, a preparation method of the array substrate and a display panel, relate to the technical field of display, and a quantum dot light-emitting layer can be prevented from climbing on a pixel definition layer, so that the thickness uniformity of the quantum dot light-emitting layer is avoided. The preparation method of the array substrate comprises the steps that a first electrode is formed in each sub-pixel area on a substrate; a quantum dot light-emitting layer is formed in each sub-pixel area and above the first electrode; a pixel definition layer is formed on a substrate where the first electrode and the quantum dot light-emitting layer are formed, wherein the pixel definition layer is located between any adjacent quantum dot light-emitting layers; and in each sub-pixel area, a second electrode is formed above the quantum dot light-emitting layer.

Owner:BOE TECH GRP CO LTD +1

Rolling method of titanium alloy plate-shaped forgings

The invention discloses a rolling method of titanium alloy plate-shaped forgings. The rolling method comprises the following steps of: substituting forging a titanium alloy billet by adopting three upsetting and three drawing firstly; then carrying out upsetting, punching, frame reaming and rolling on the titanium alloy billet after substituting forging to prepare a high-cylinder and thin-walled ring, wherein the inner diameter of the ring is 85-90 percent of the outer diameter; cutting the high-cylinder and thin-walled ring into two hemi-toroidal parts by using wire cutting; and then straightening by a forging hammer to acquire two plate-shaped forgings. The rolling method effectively avoids the defects about uneven thickness, poor organization homogeneity, multiple forging times and the like of the forgings, improves the quality and the production efficiency of the forging and is used for producing the titanium alloy plate-shaped forgings.

Owner:GUIZHOU ANDA AVIATION FORGING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com