Production technology for transient voltage suppressor chip with channeling effect

A technology of transient voltage suppression and channel effect, which is applied in semiconductor/solid-state device manufacturing, circuits, electrical components, etc., can solve problems such as poor uniformity of diffusion process, inaccurate control of junction depth, and influence on product reliability. Achieve the effect of good uniformity of resistivity, good consistency of electrophoresis, and easy control of junction depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

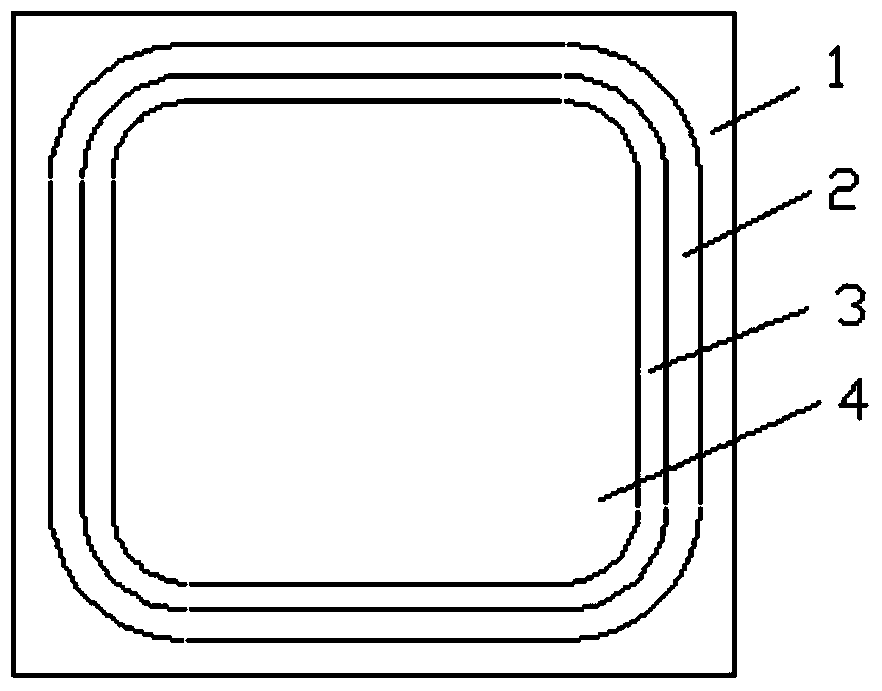

[0046] Such as figure 1 As shown, the chip structure of the transient voltage suppressor TVS is N + PN + Bi-directional high voltage transient voltage suppressor. The front section of the chip is as follows: 1TVS chip, 2 mesa grooves, 3 glass layers, 4 metal surfaces.

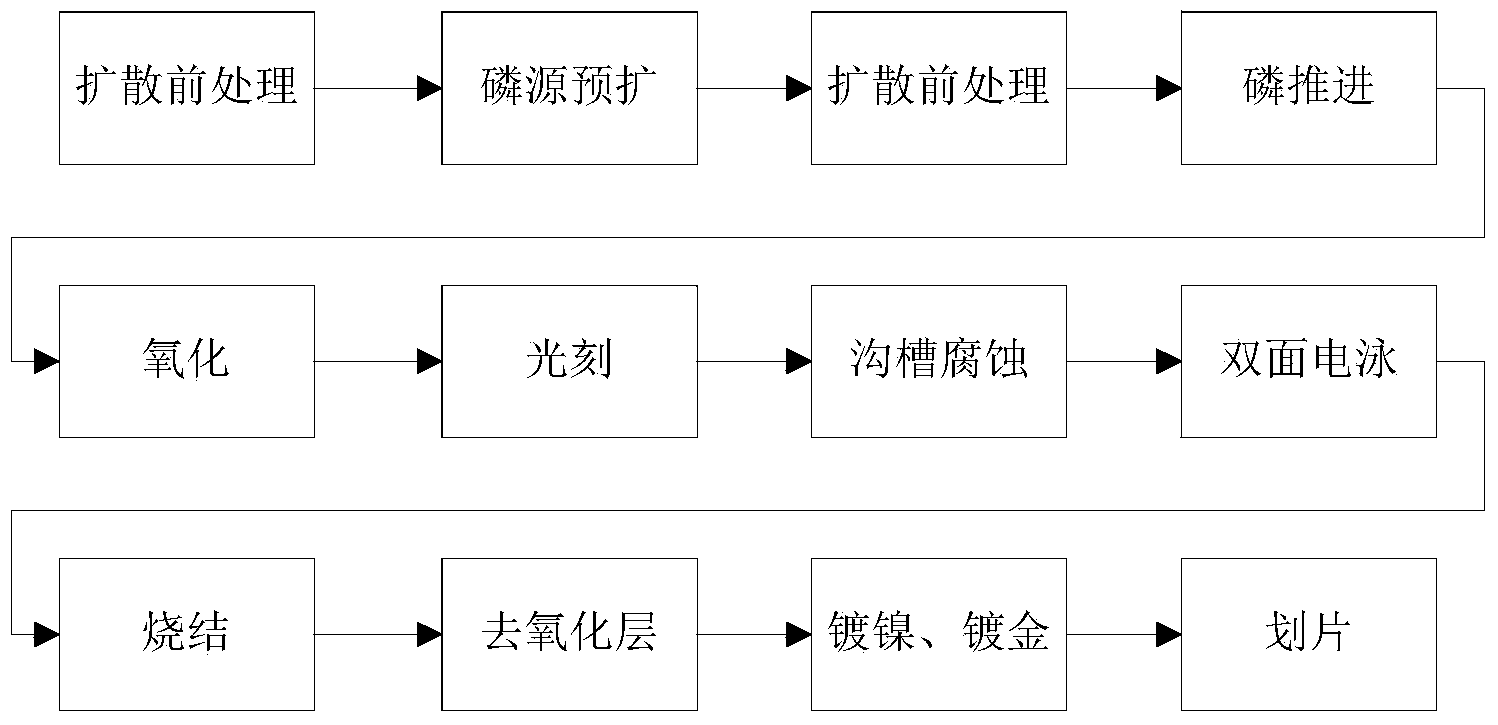

[0047] Such as figure 2 As shown, the chip process flow of the transient voltage suppressor TVS is as follows:

[0048] (1) Pre-diffusion treatment: Clean the surface of the silicon wafer through the ultrasonic cleaning process of acid, alkali and deionized water;

[0049] (2) Phosphorus source pre-expansion: Put the cleaned silicon wafer into a pre-diffusion furnace using a gaseous phosphorus source for diffusion to form a pre-expansion N + , the diffusion temperature of phosphorus source pre-expansion is 1100~1200℃, and the pre-expansion of N + Phosphorus diffusion junction sheet resistance is 0.2~0.6Ω / □, junction depth is 7~12um;

[0050] (3) Pre-diffusion treatment: acid immersion and deionized wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com