Patents

Literature

608results about How to "Not easy to penetrate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

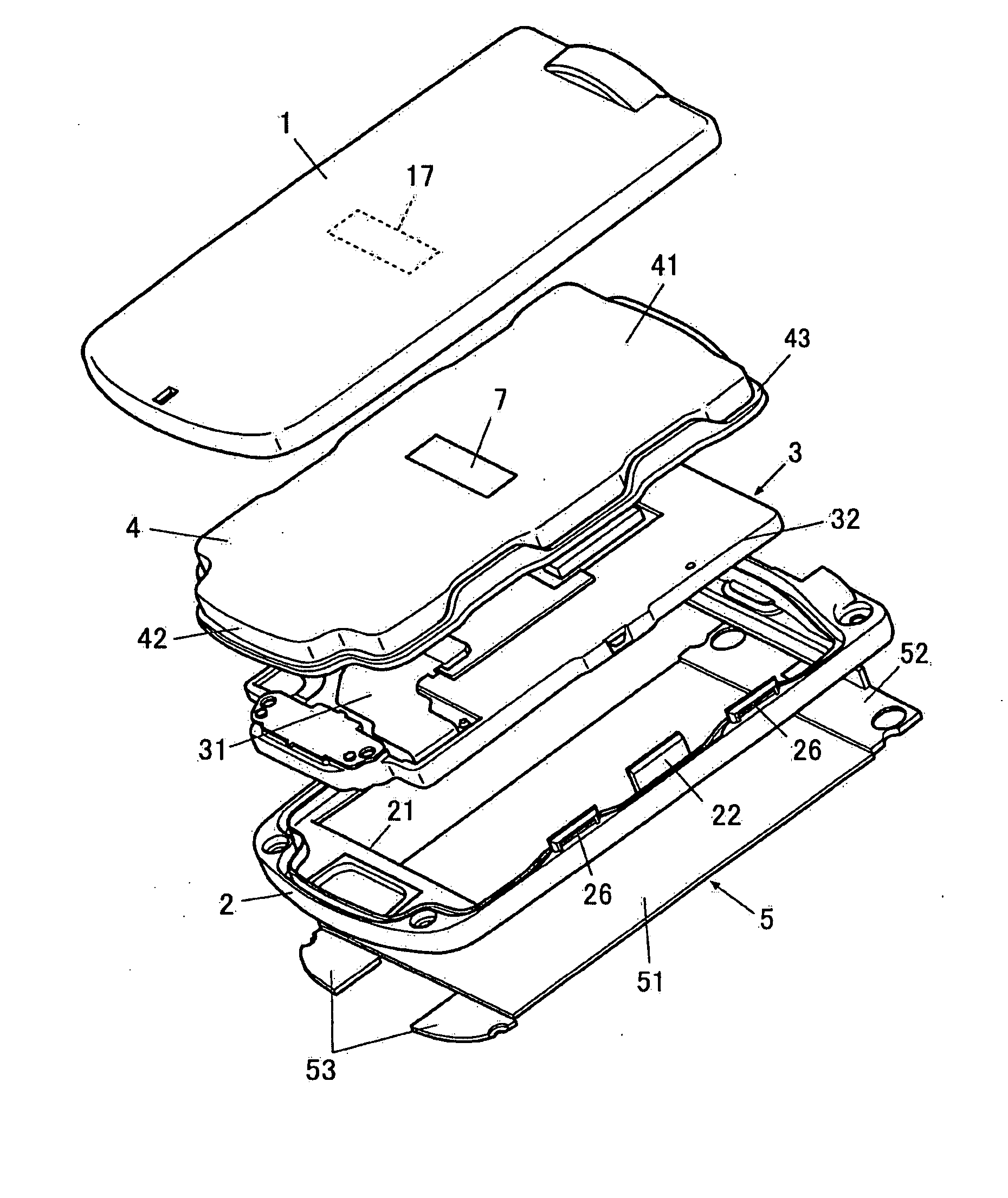

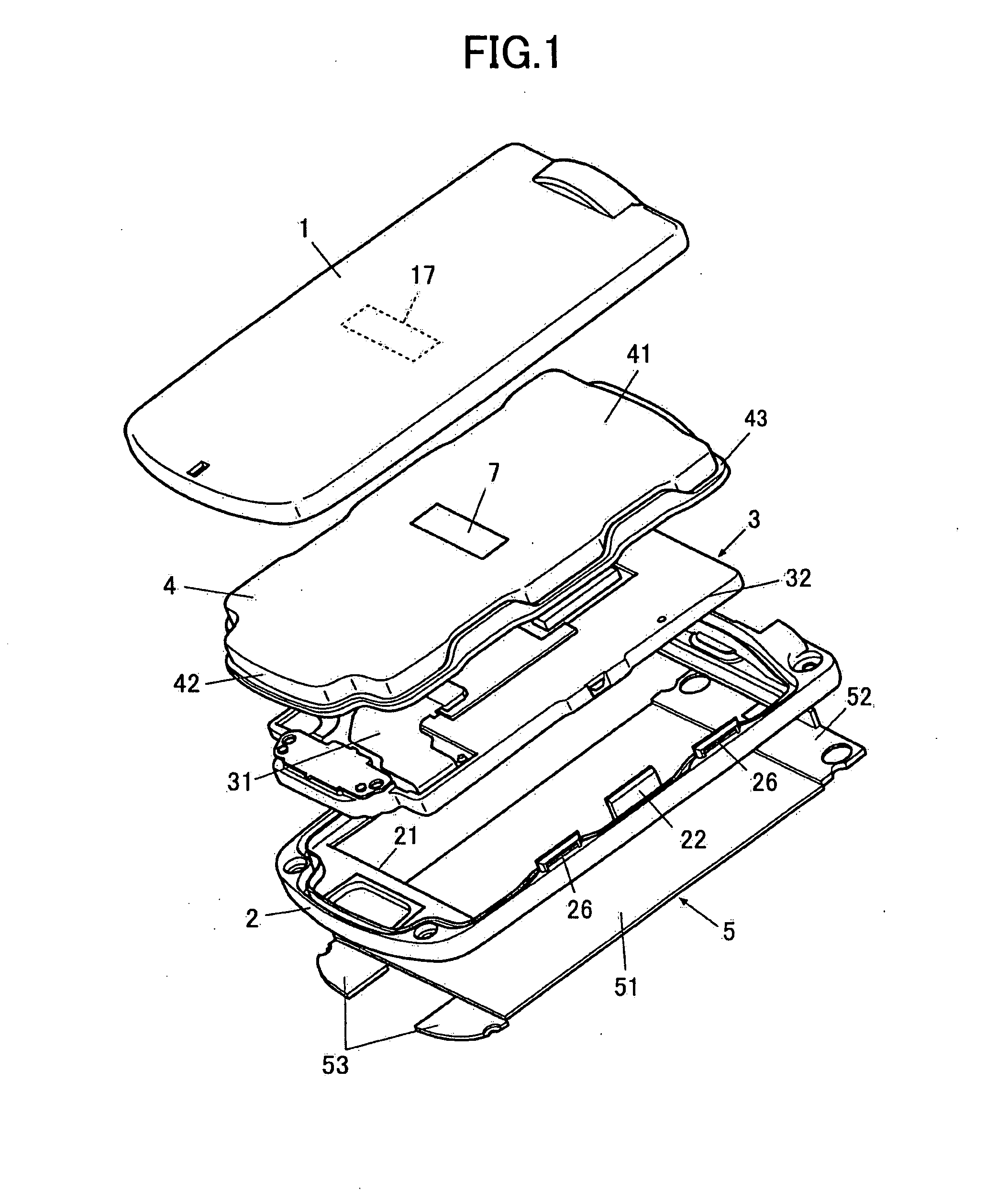

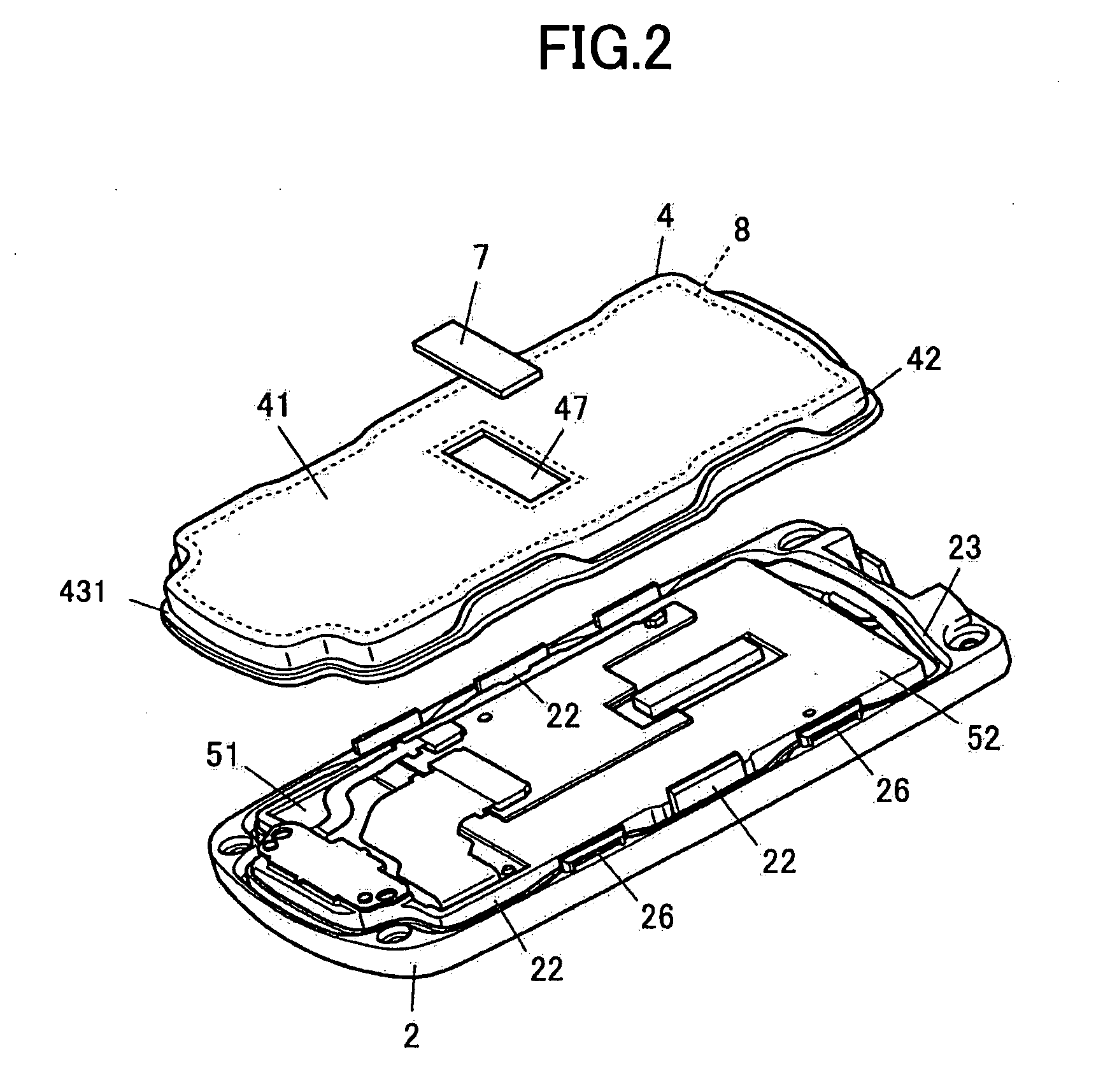

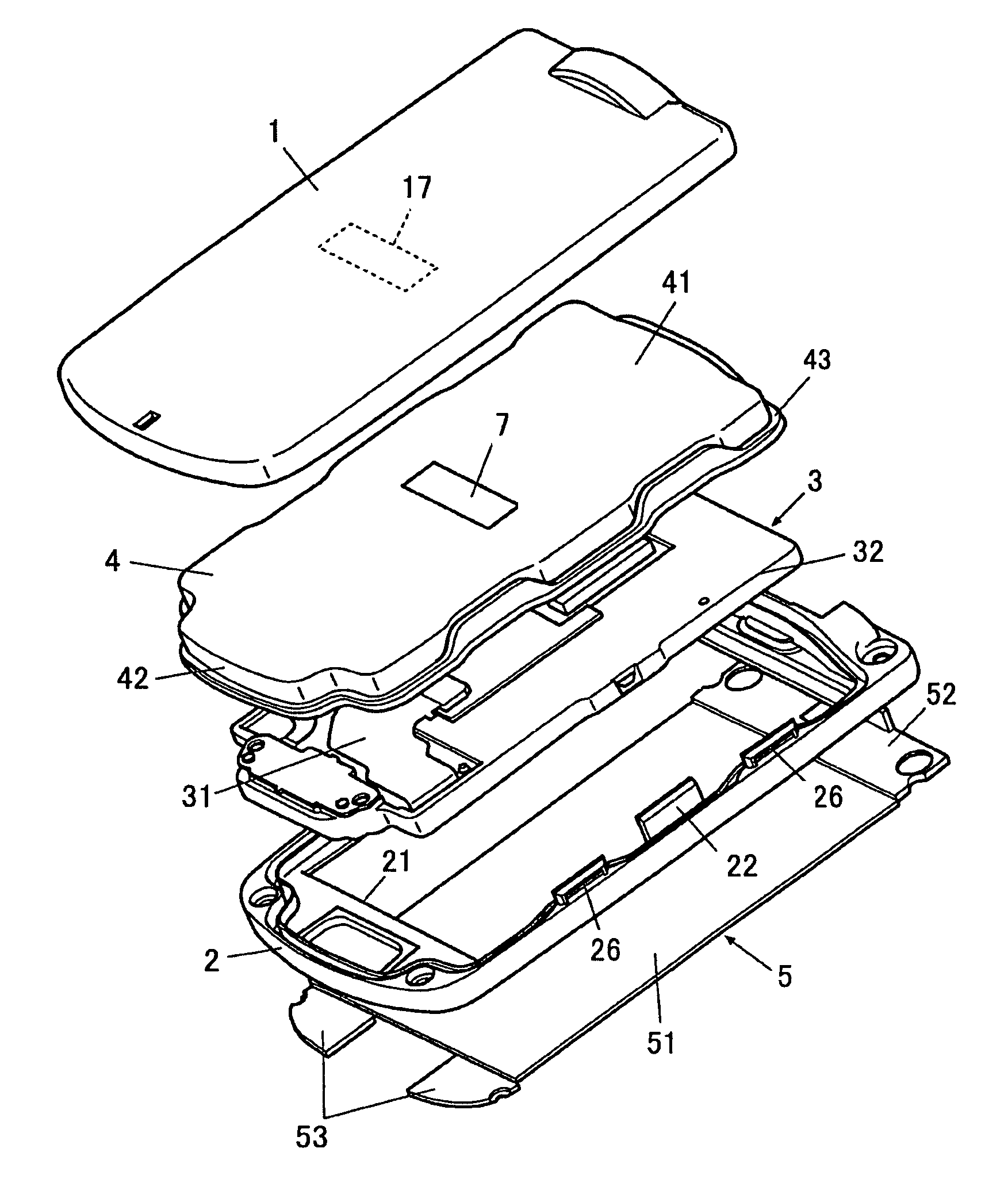

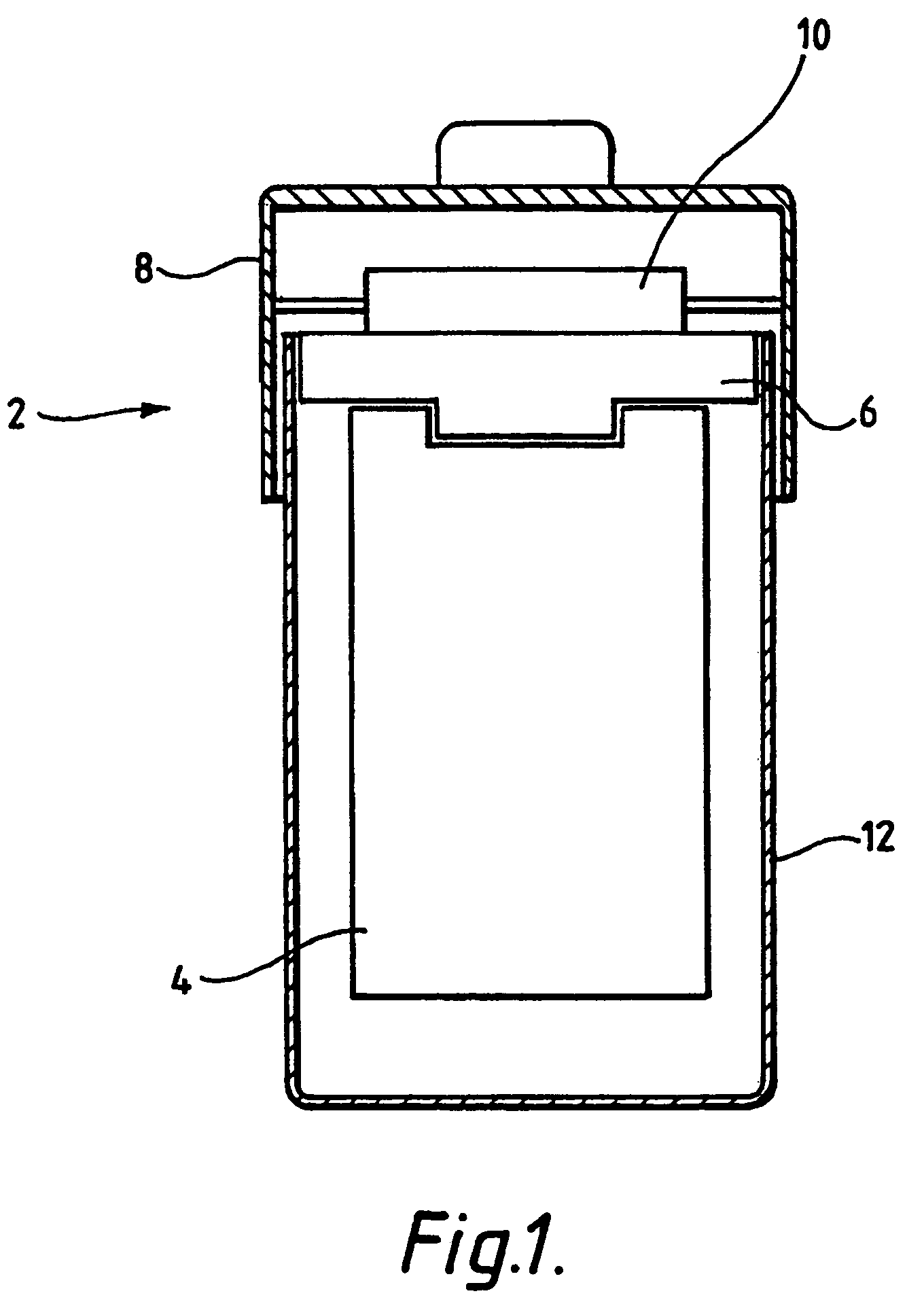

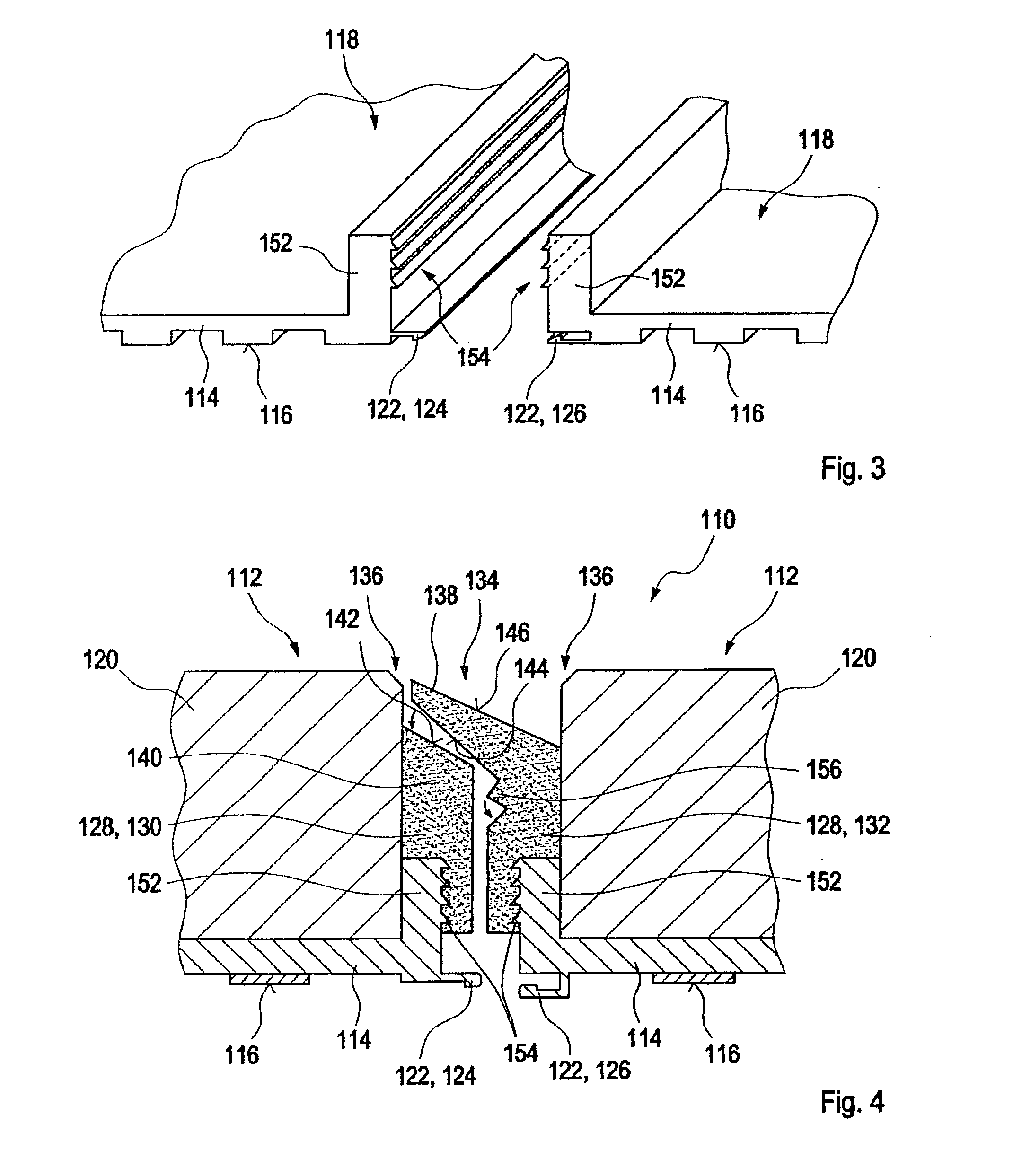

Waterproof structure

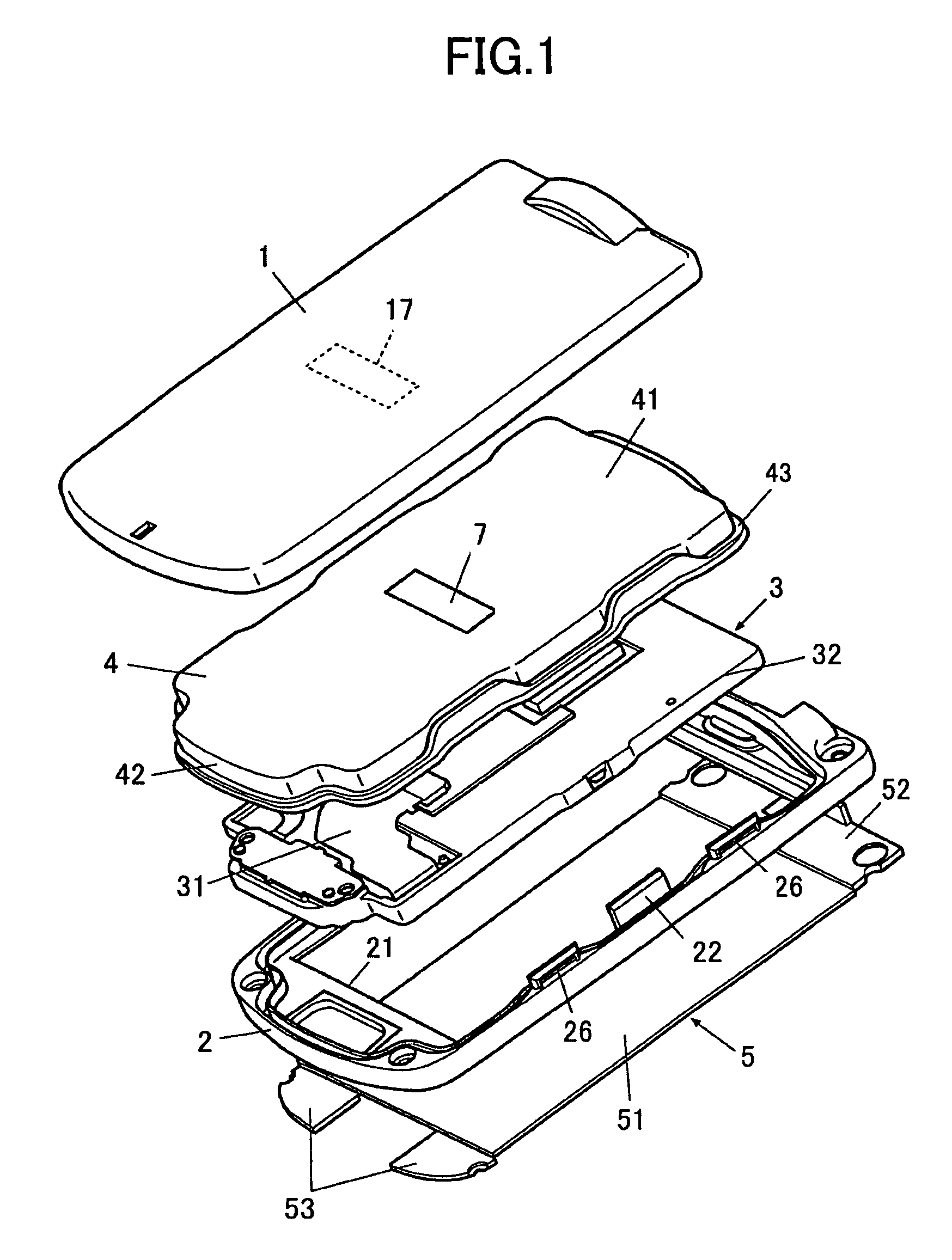

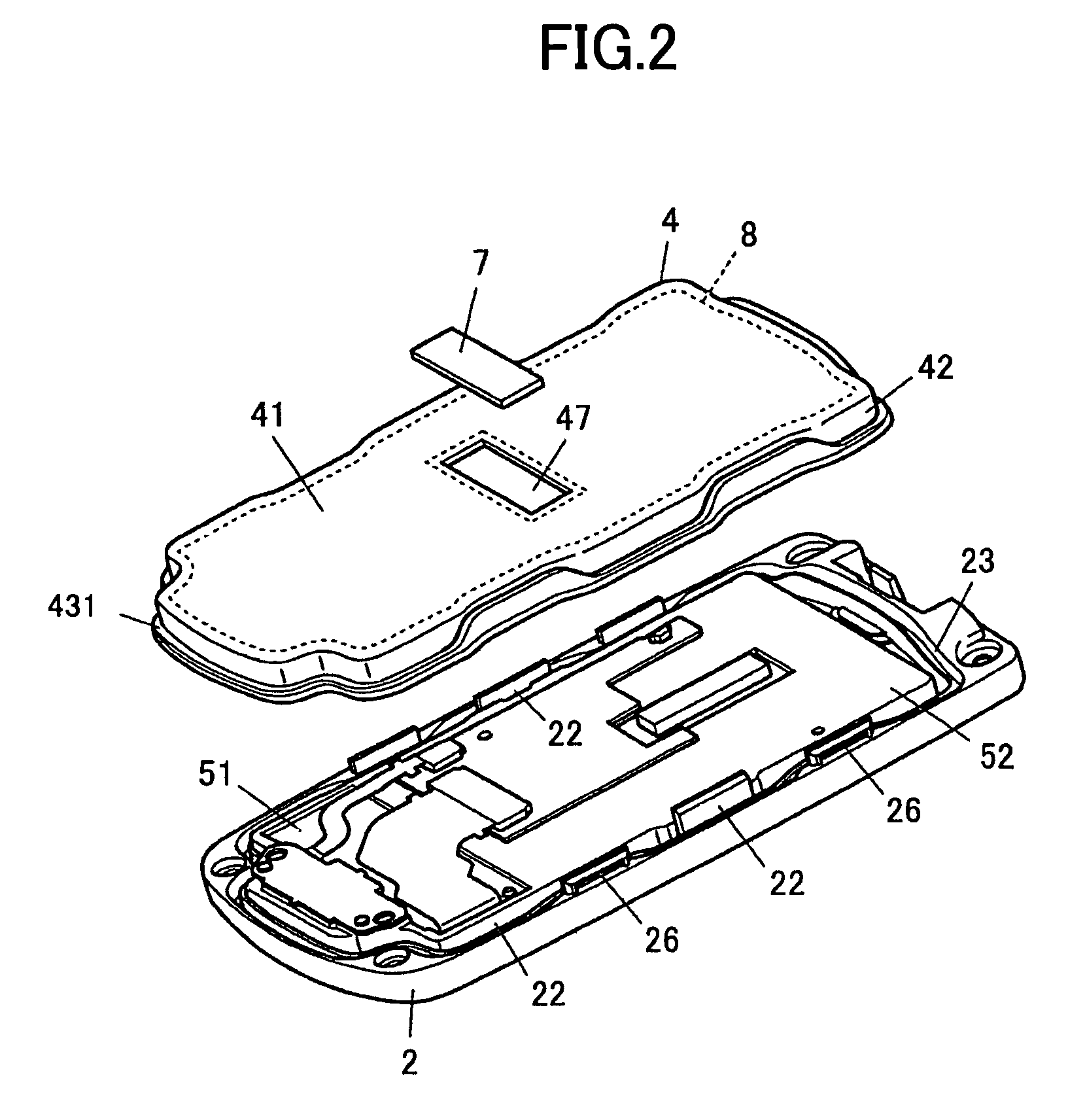

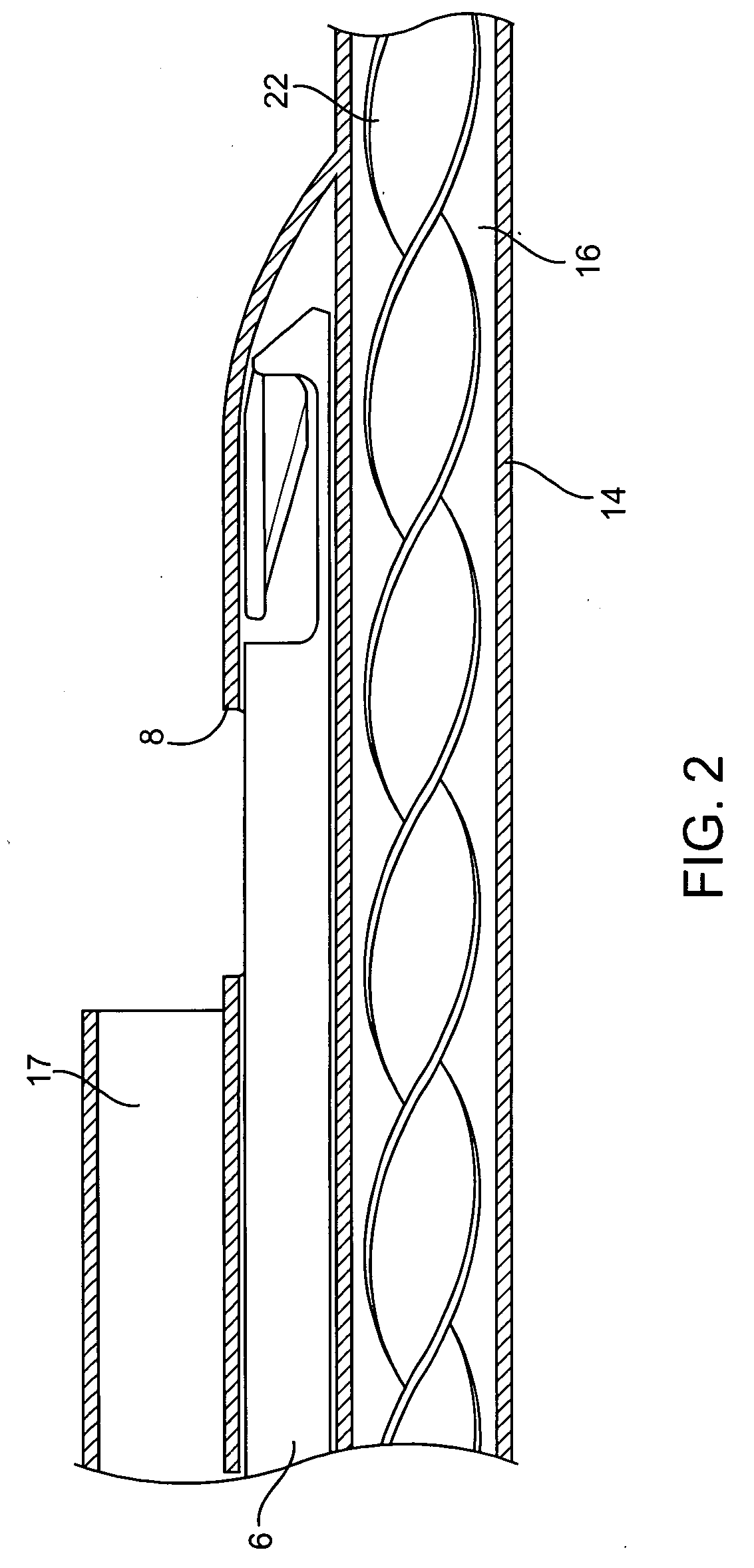

InactiveUS20080081679A1Prevent penetrationPromote repairInterconnection arrangementsTransmissionComing outMechanical engineering

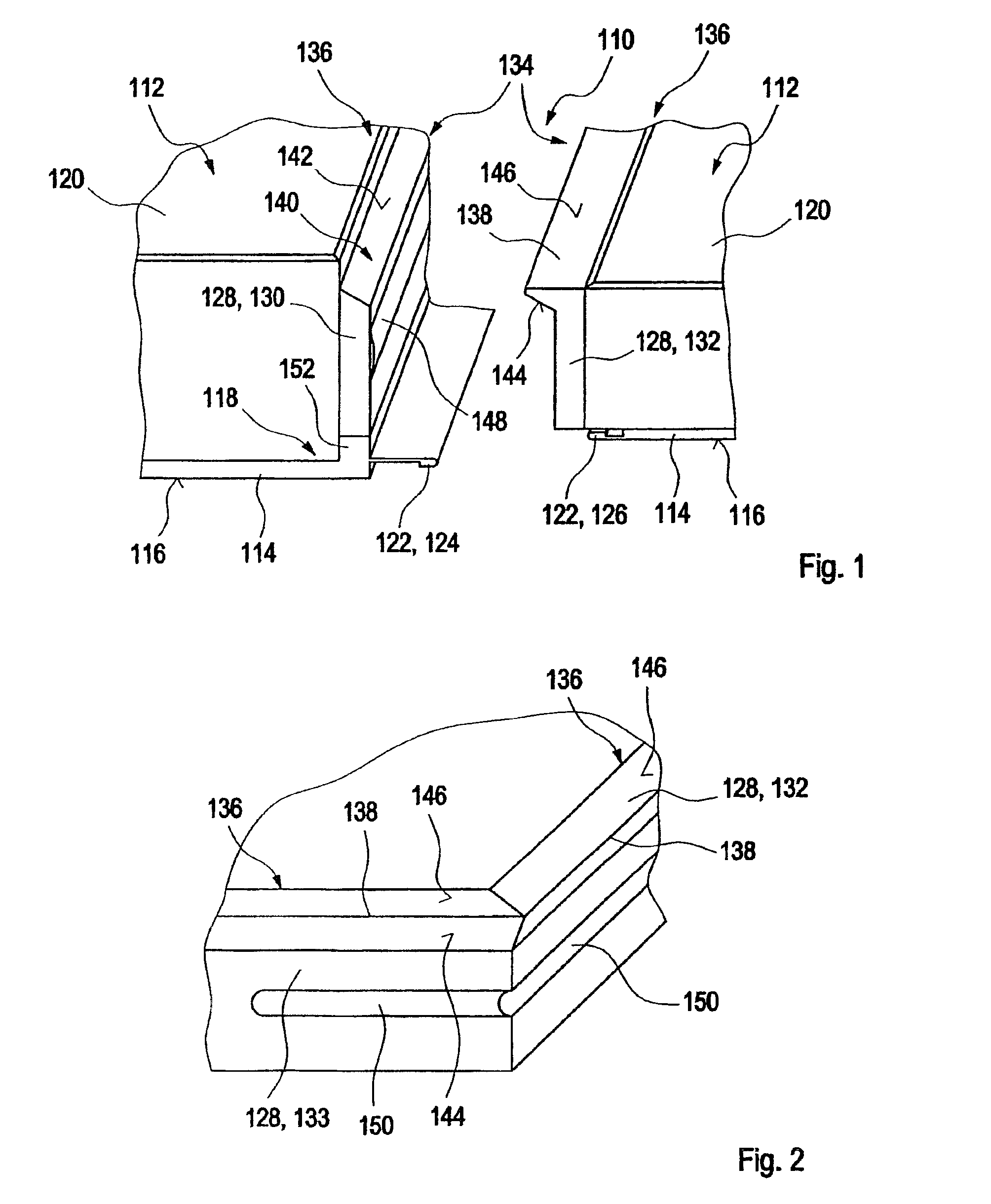

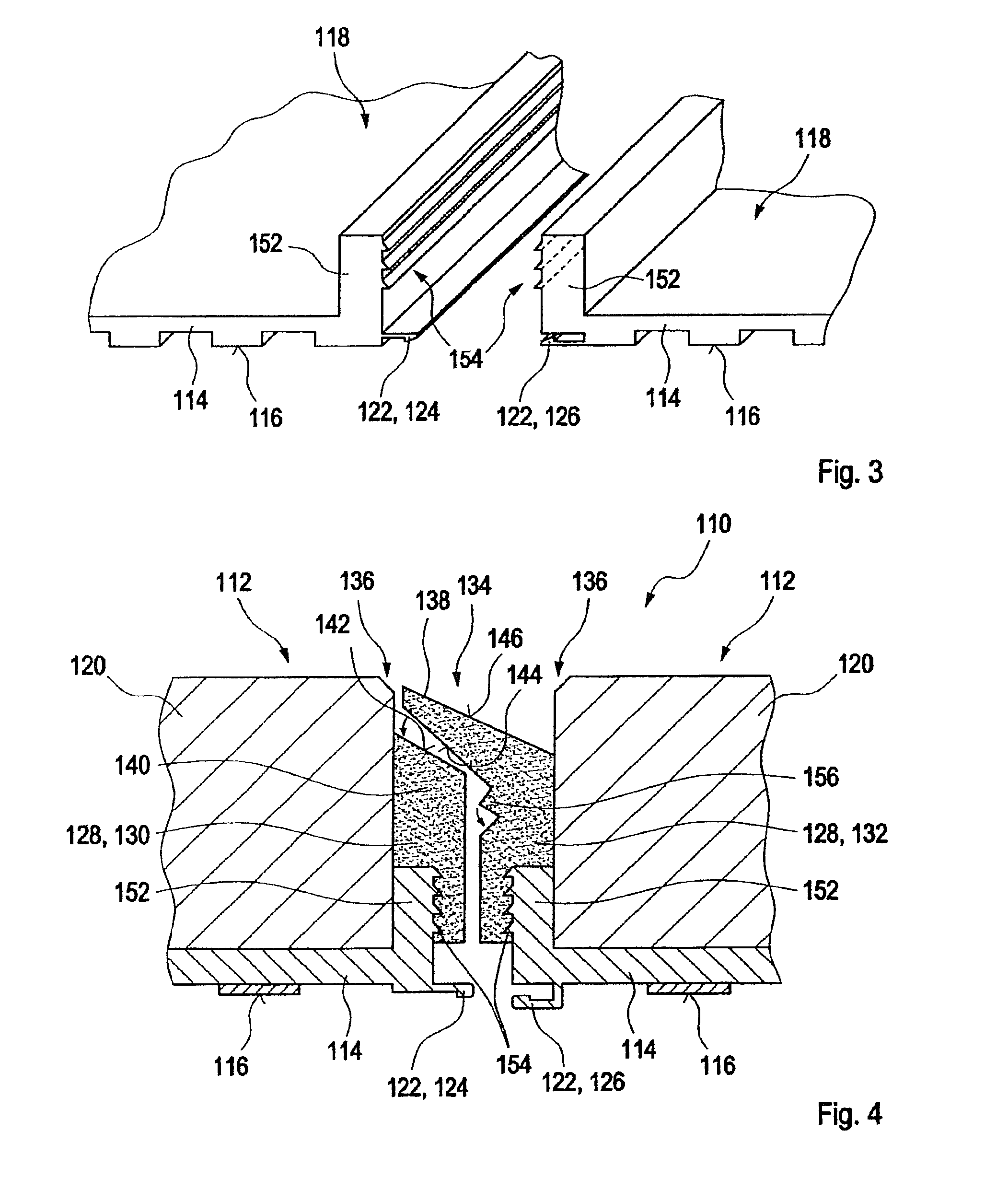

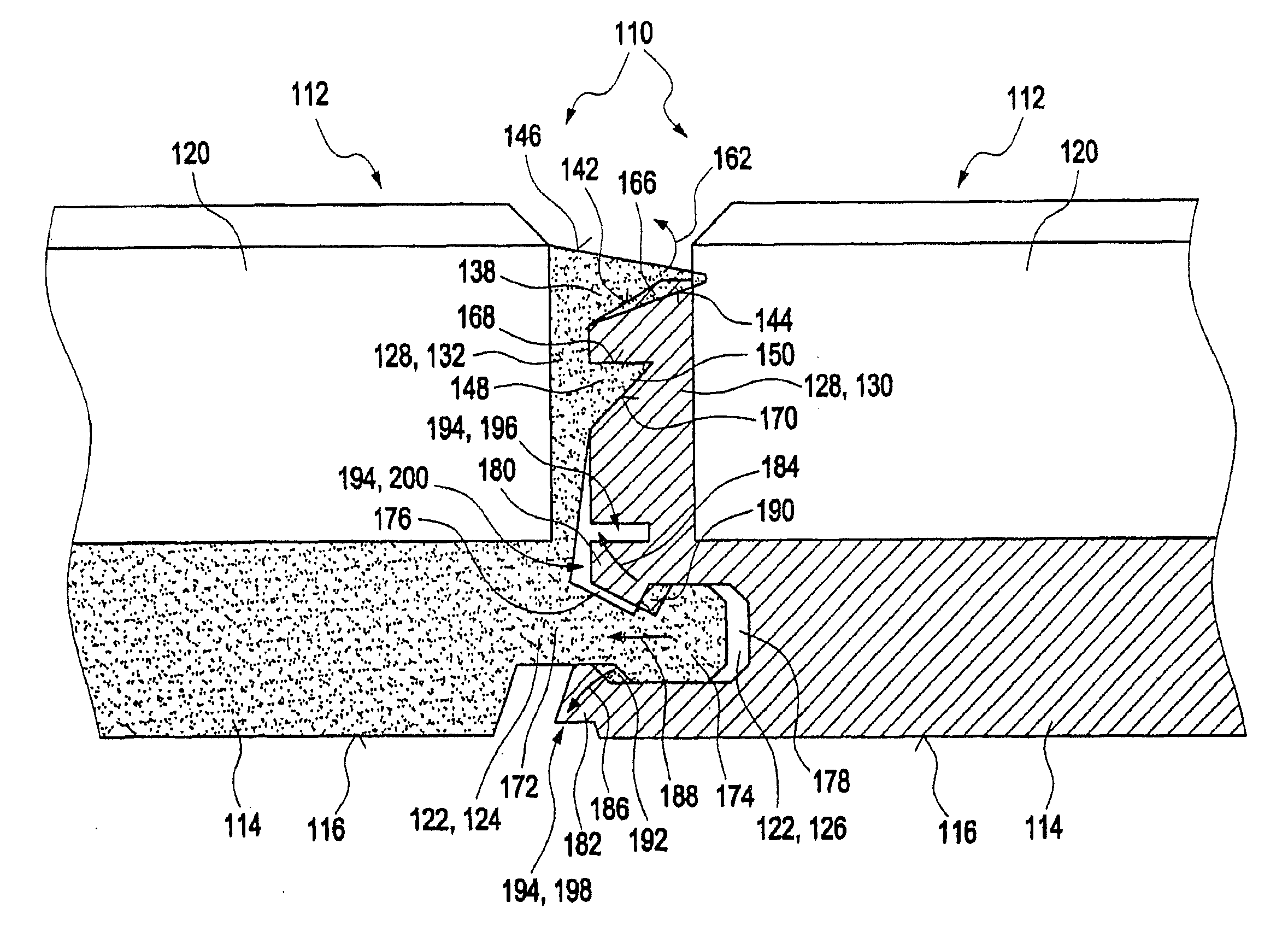

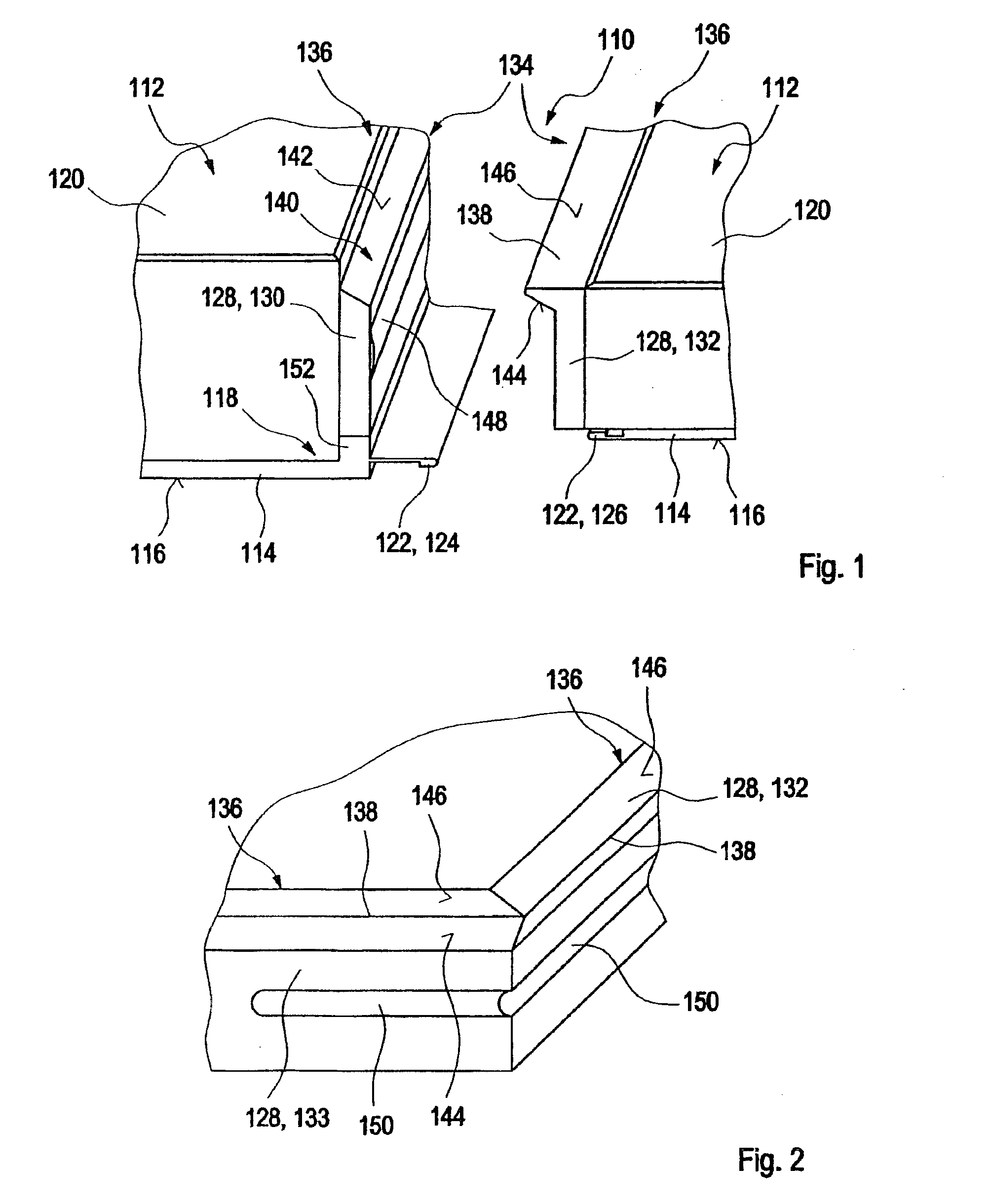

A waterproof structure for a casing has a first casing, a second casing to be put together with the first casing, and a waterproof member formed of an elastic material to prevent water from penetrating between the first casing and the second casing. The second casing has a recess. The waterproof member has a peripheral part which, when fitted into the recess, prevents penetration of water. The peripheral part is provided at the periphery of the waterproof member, which is laid out all around space between the first casing and the second casing. A projection engages with a dent. A restriction part of the first casing, provided at a position facing the peripheral part and protruding toward the second casing, prevents the peripheral part from coming out.

Owner:LENOVO INNOVATIONS LTD HONG KONG

Waterproof structure

InactiveUS7941196B2Promote repairNot easy to penetrateInterconnection arrangementsTransmissionStructural engineeringMechanical engineering

A waterproof structure for a casing has a first casing, a second casing to be put together with the first casing, and a waterproof member formed of an elastic material to prevent water from penetrating between the first casing and the second casing. The second casing has a recess. The waterproof member has a peripheral part which, when fitted into the recess, prevents penetration of water. The peripheral part is provided at the periphery of the waterproof member, which is laid out all around space between the first casing and the second casing. A projection engages with a dent. A restriction part of the first casing, provided at a position facing the peripheral part and protruding toward the second casing, prevents the peripheral part from coming out.

Owner:LENOVO INNOVATIONS LTD HONG KONG

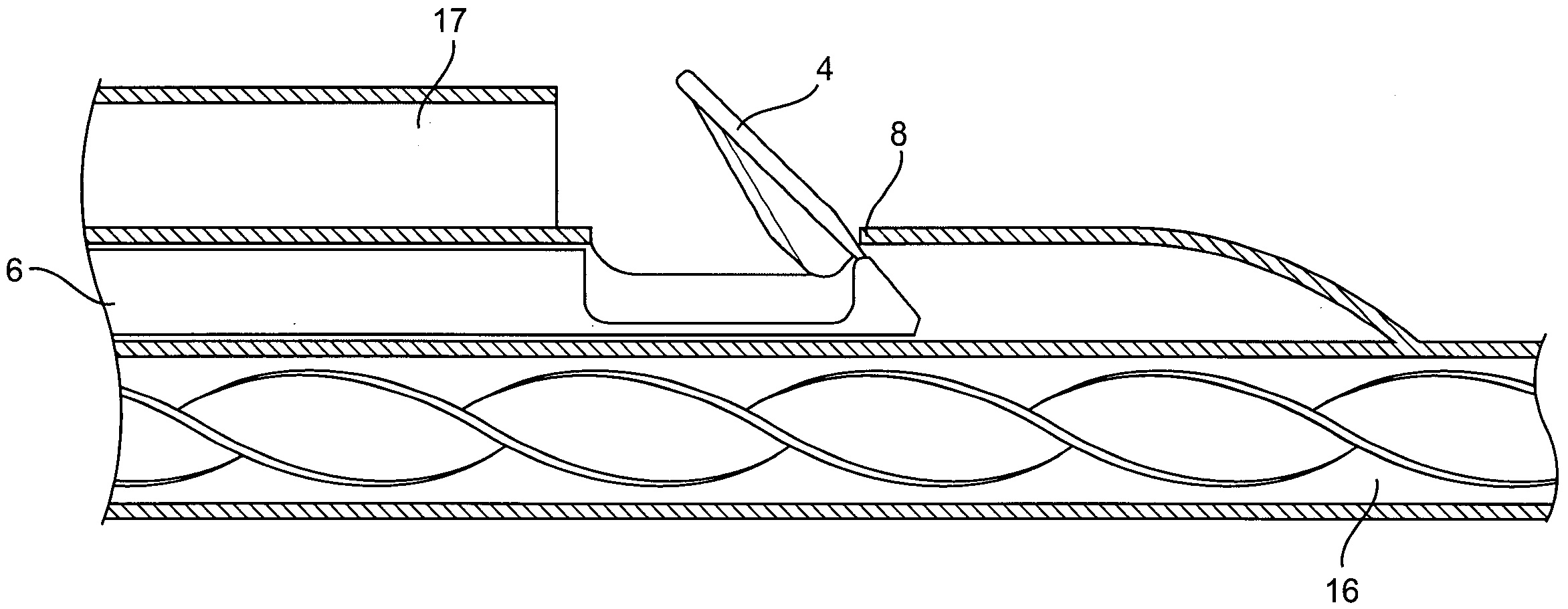

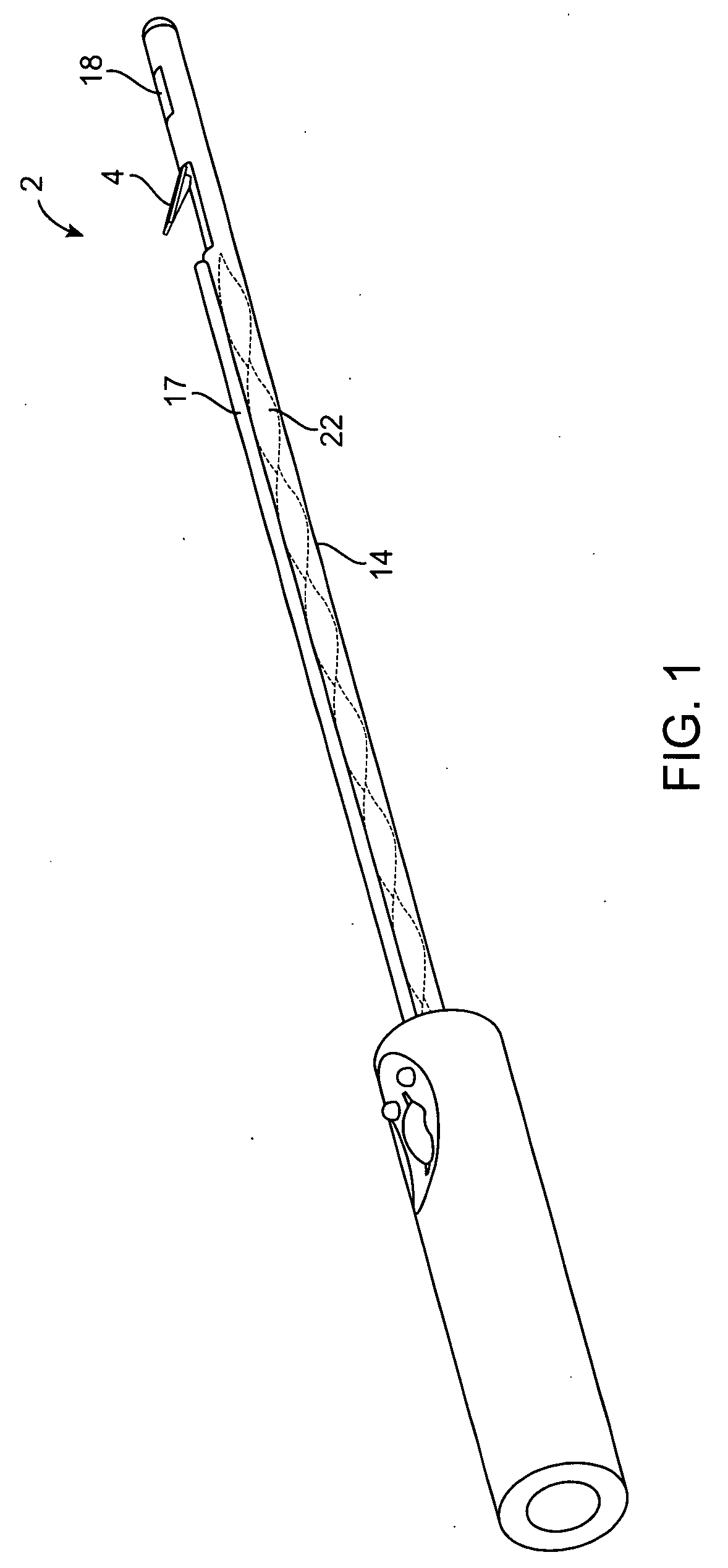

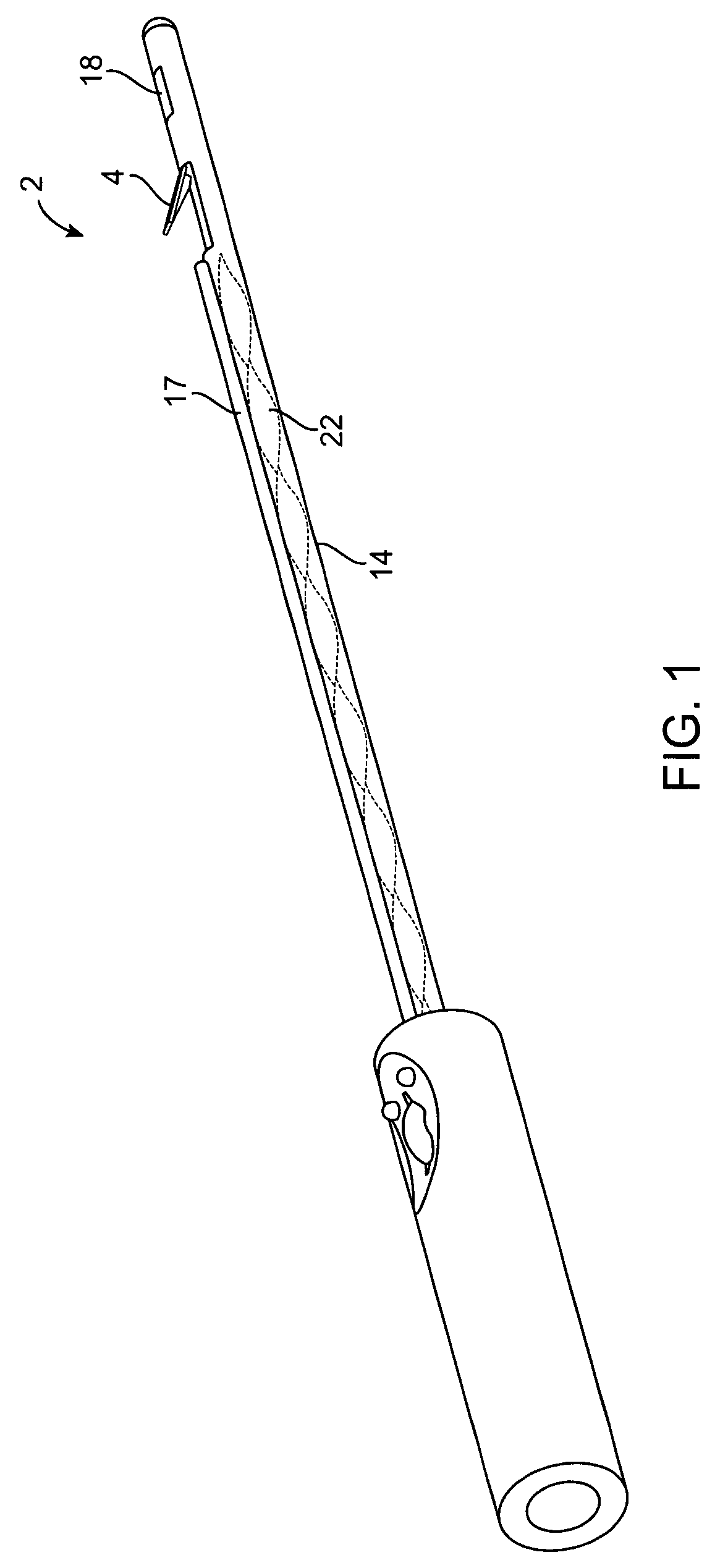

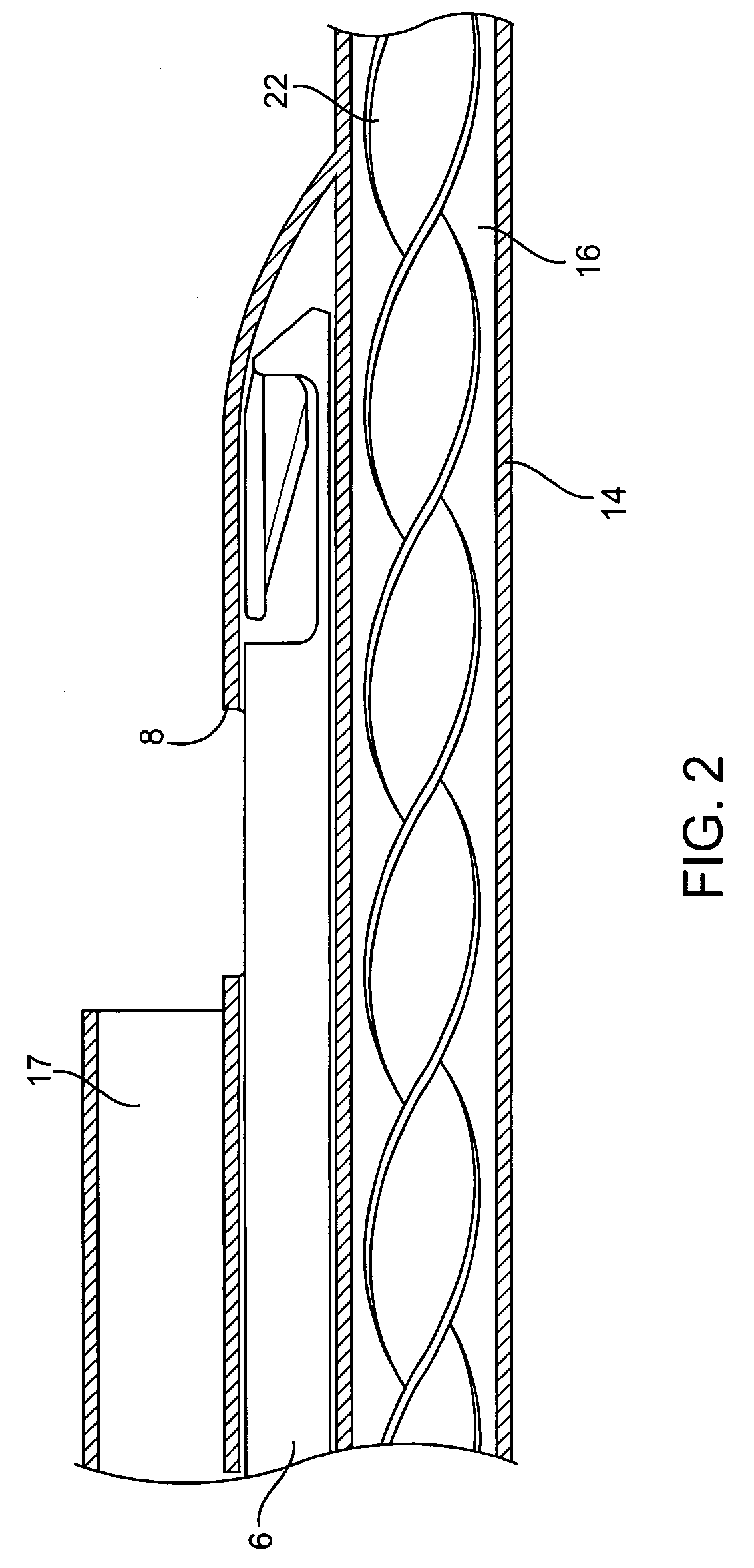

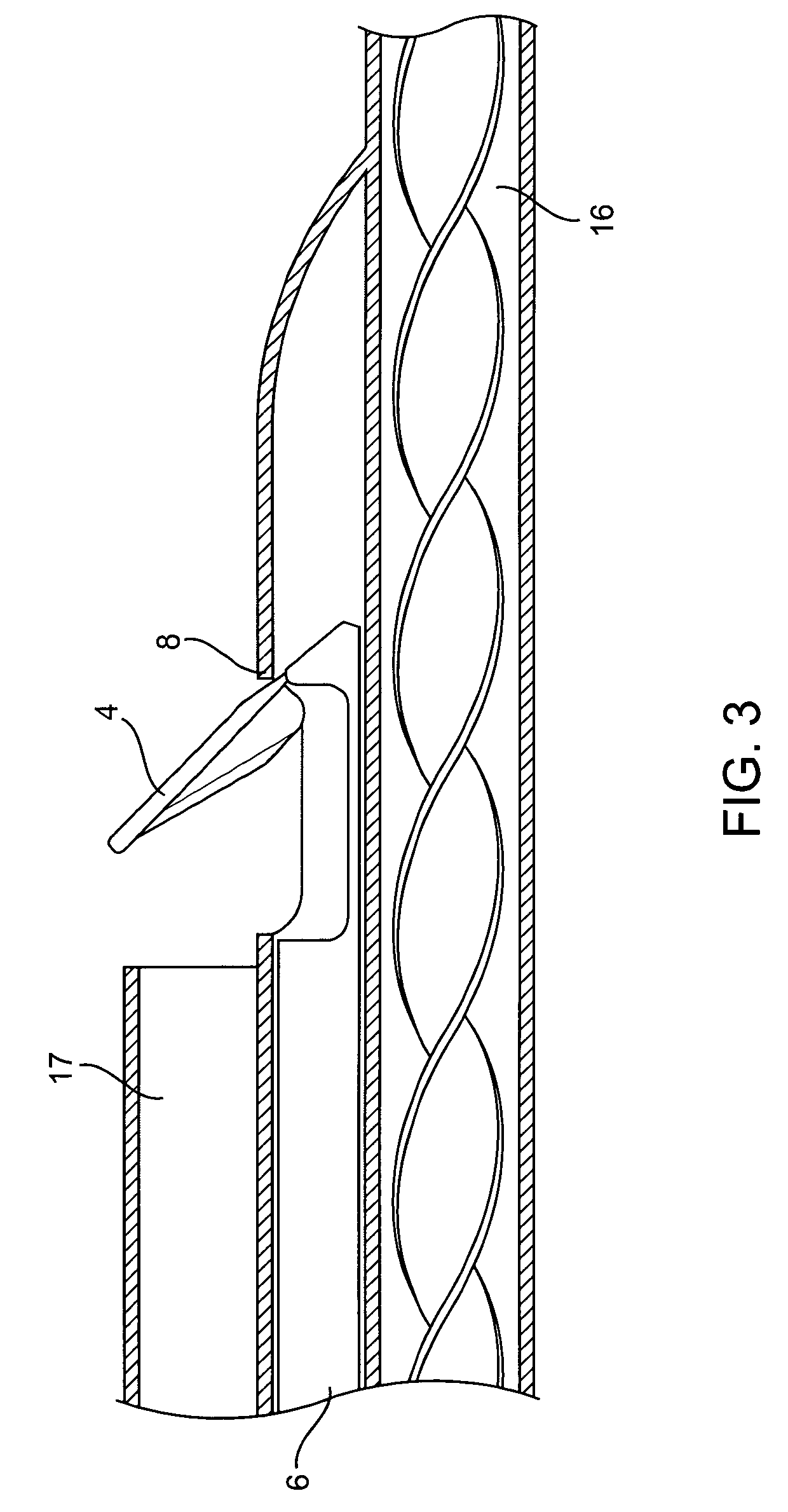

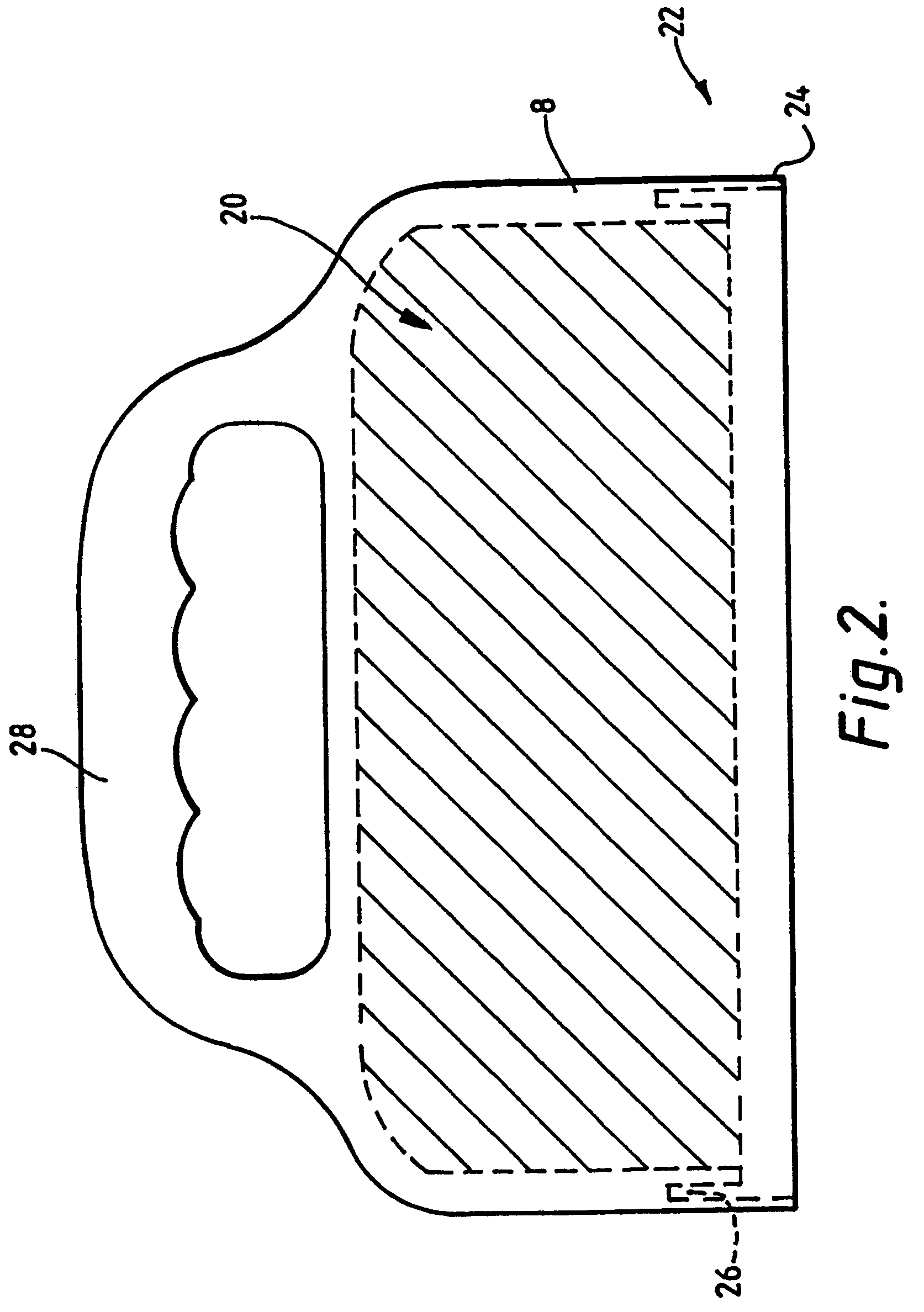

Methods and devices for improving the appearance of tissue

ActiveUS20100057056A1Easy to navigateNot easy to cutChiropractic devicesEye exercisersRadiologyCellulite

Cellulite is treated by severing septae, which interconnects the skin with the underlying muscle. The septae may be severed in connection with a liposuction procedure or independent of a liposuction procedure.

Owner:TAUTONA GRP IP HLDG CO L L C

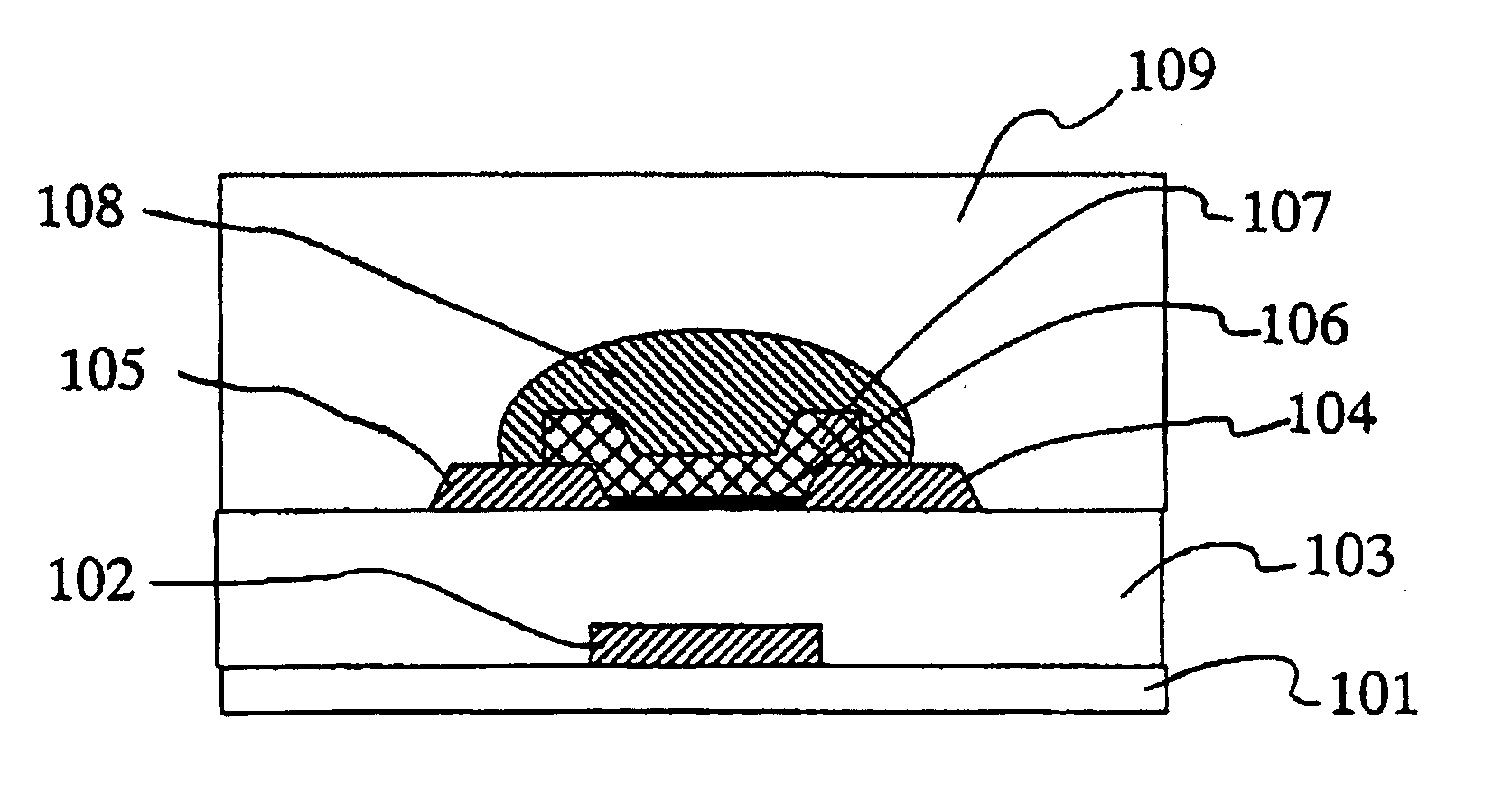

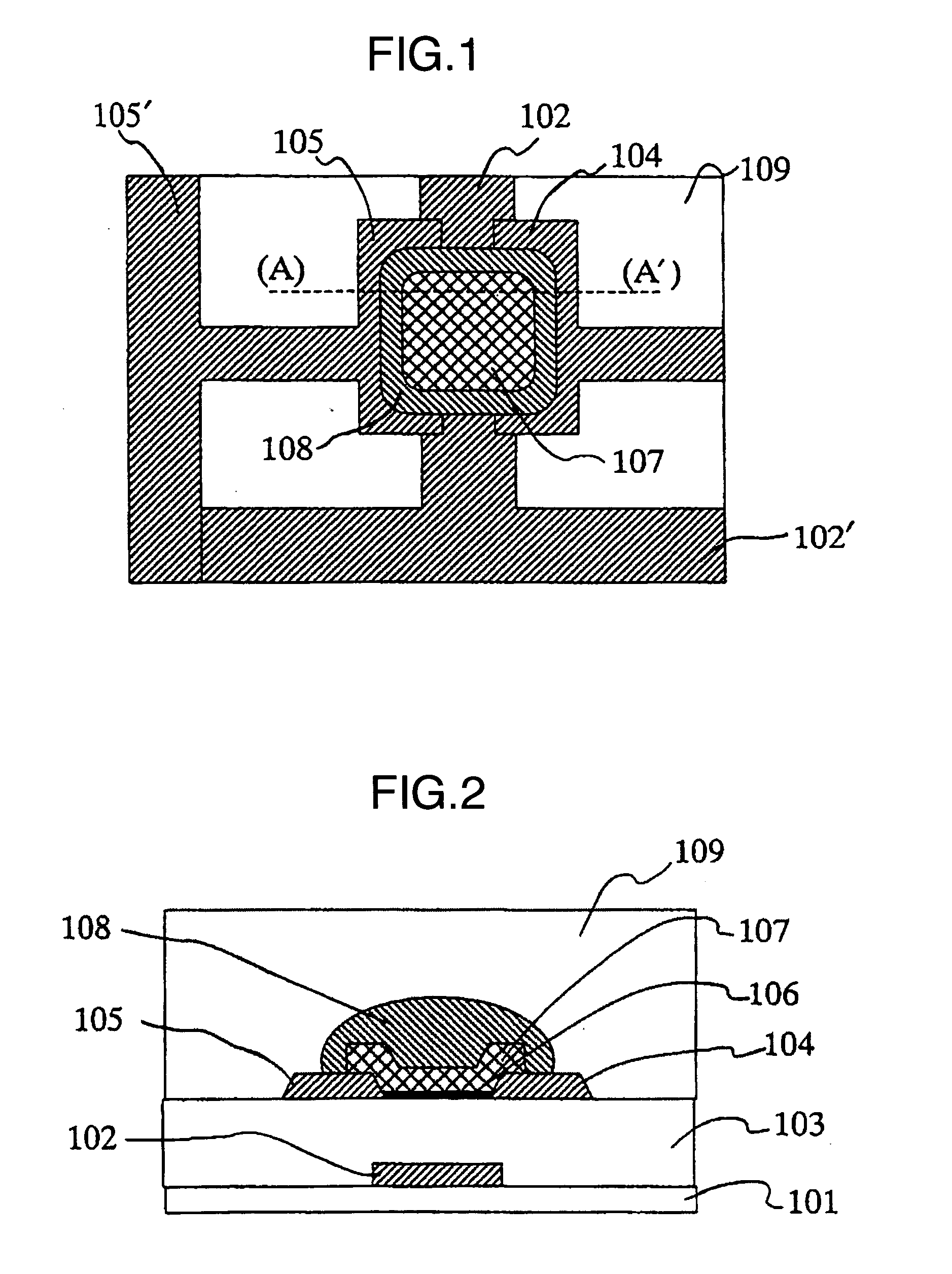

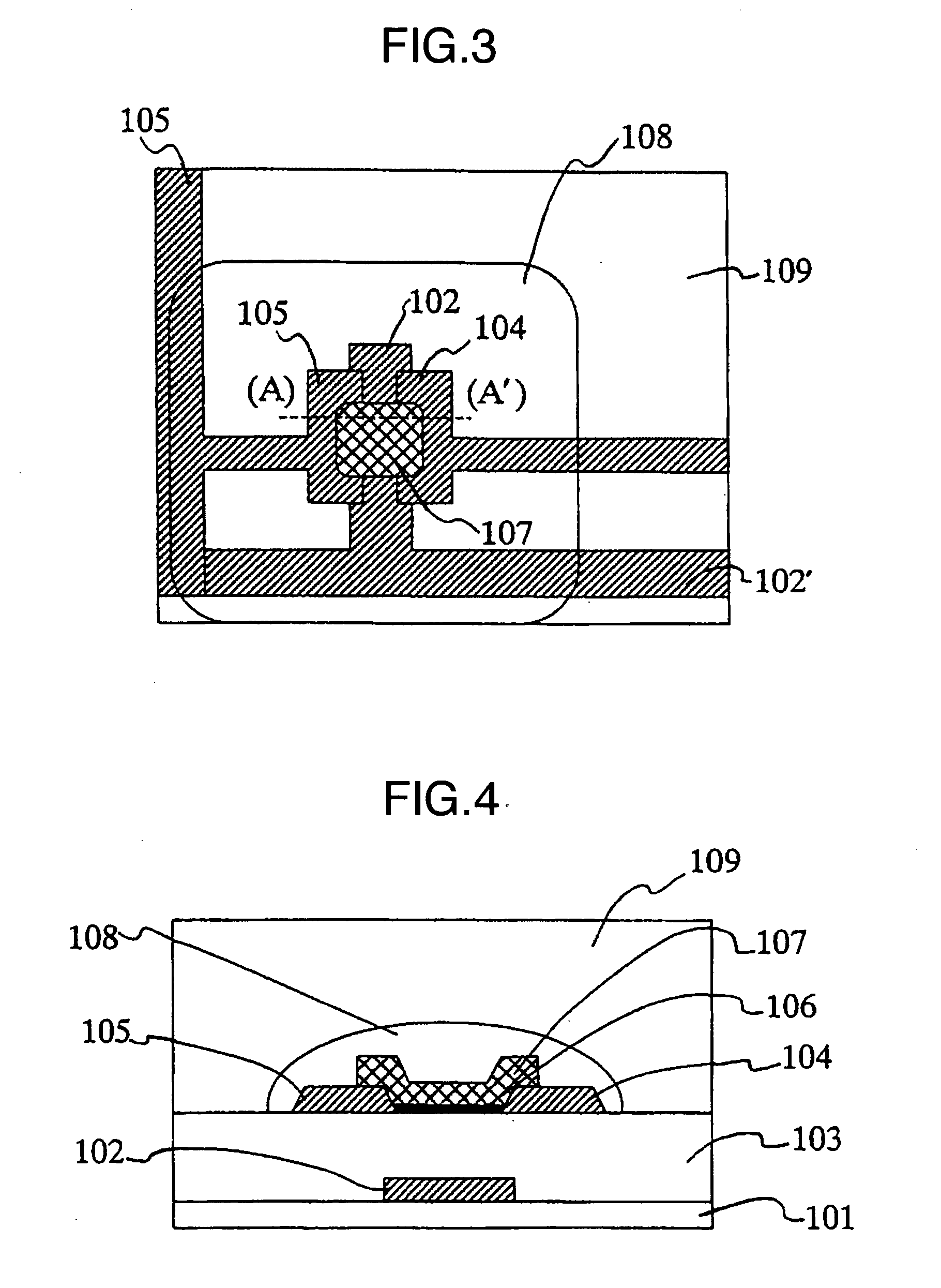

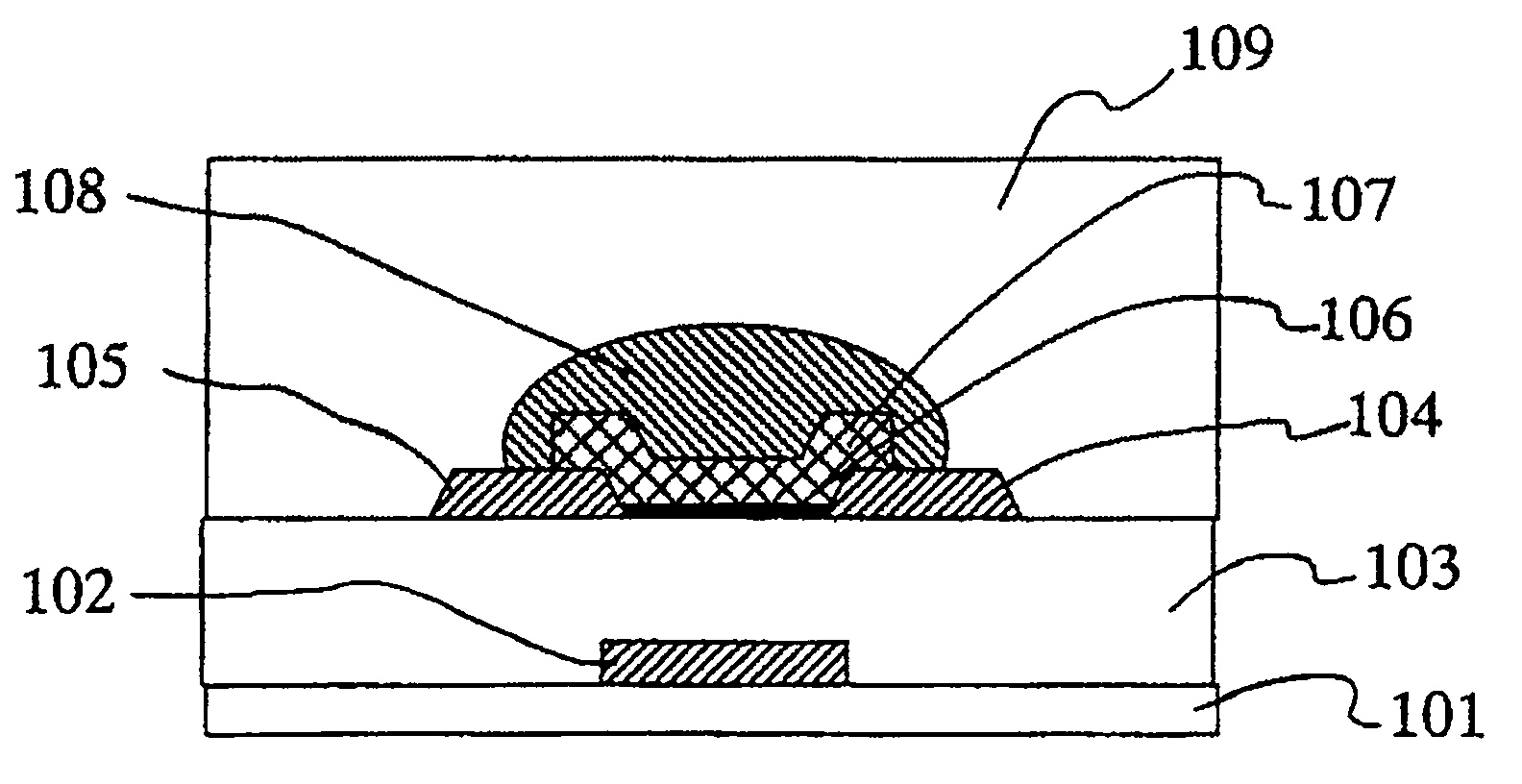

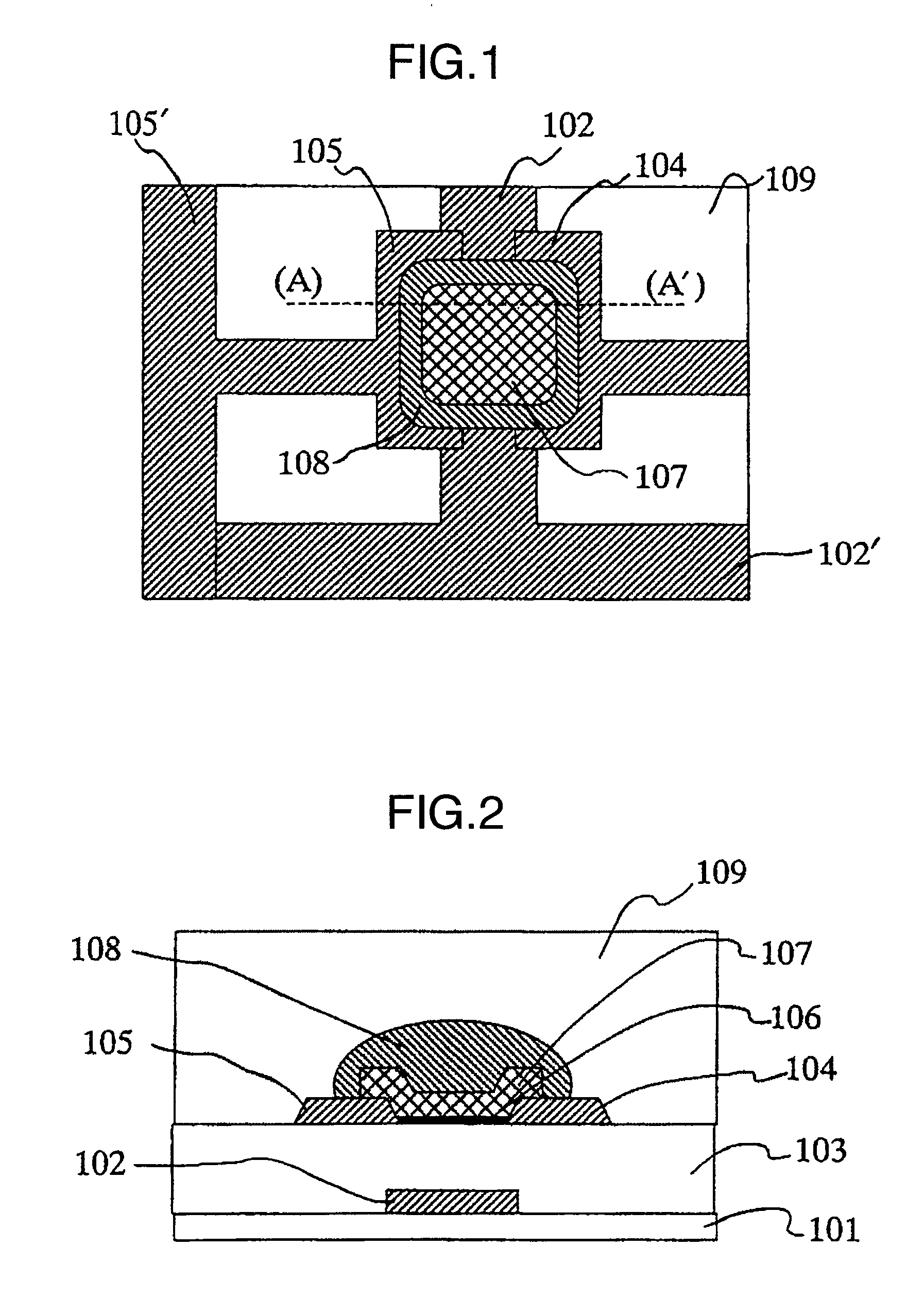

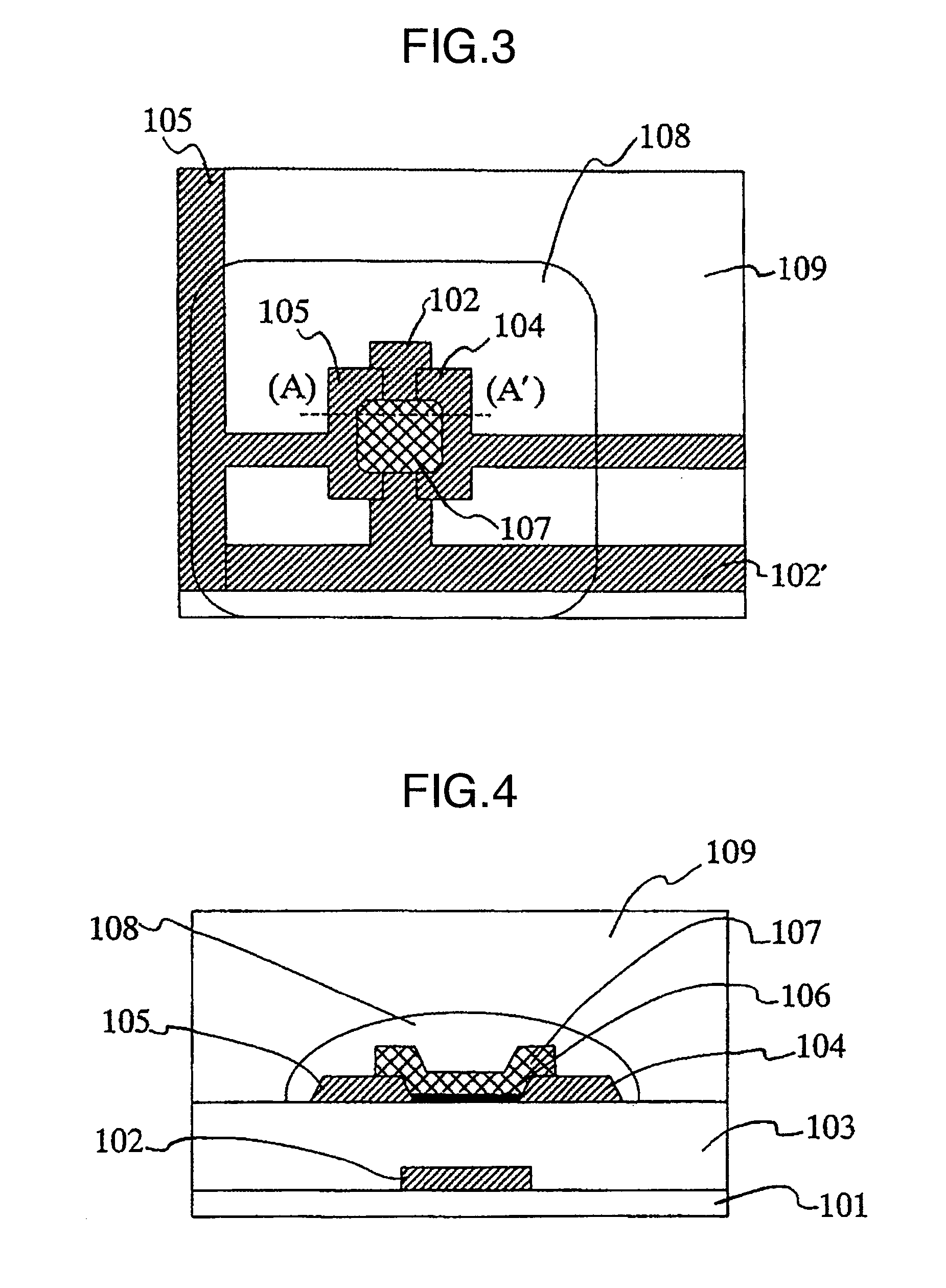

Thin film transistor and semiconductor device using the same

InactiveUS20050211975A1Preventing deterioration/peelingPrevent penetrationTransistorElectroluminescent light sourcesDevice materialDisplay device

The present invention aims at providing a high-performance semiconductor device such as display, IC tag, sensor or the like at a low cost by using an organic thin film transistor most members of which can be formed by printing, as a switching element. The present invention relates to a thin film transistor composed of members on a dielectric substrate, which are a gate electrode, a dielectric film, source / drain electrodes, and a semiconductor layer, wherein on said semiconductor layer there are formed at least two passivation films of a first passivation film capping said semiconductor layer to protect it and a second passivation film covering larger area than that of said first passivation film to protect all of said members.

Owner:HITACHI LTD

Methods and devices for improving the appearance of tissue

ActiveUS8652123B2Easy to navigateNot easy to cutChiropractic devicesEye exercisersRadiologyLiposuction procedure

Cellulite is treated by severing septae, which interconnects the skin with the underlying muscle. The septae may be severed in connection with a liposuction procedure or independent of a liposuction procedure.

Owner:TAUTONA GRP IP HLDG CO L L C

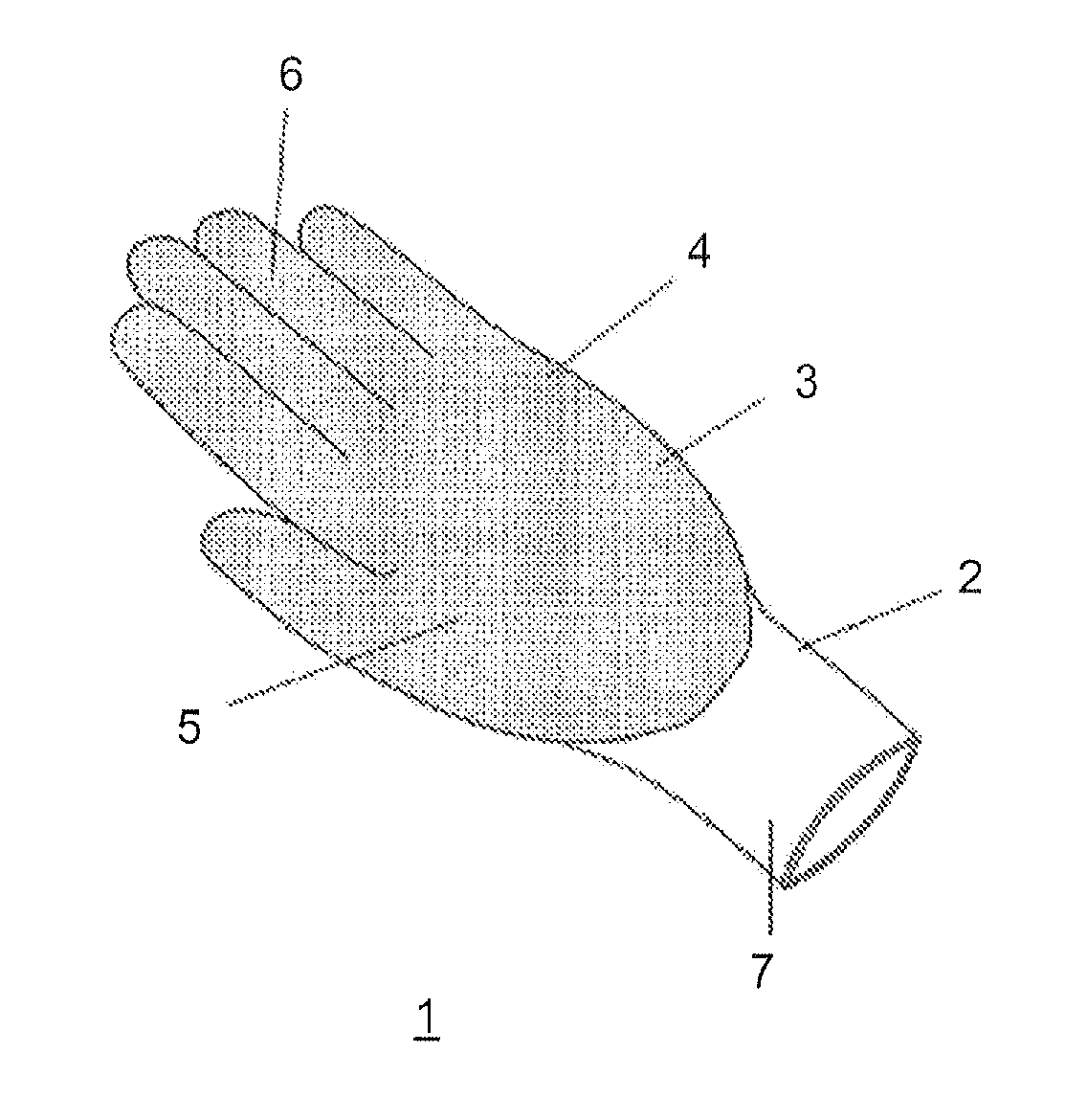

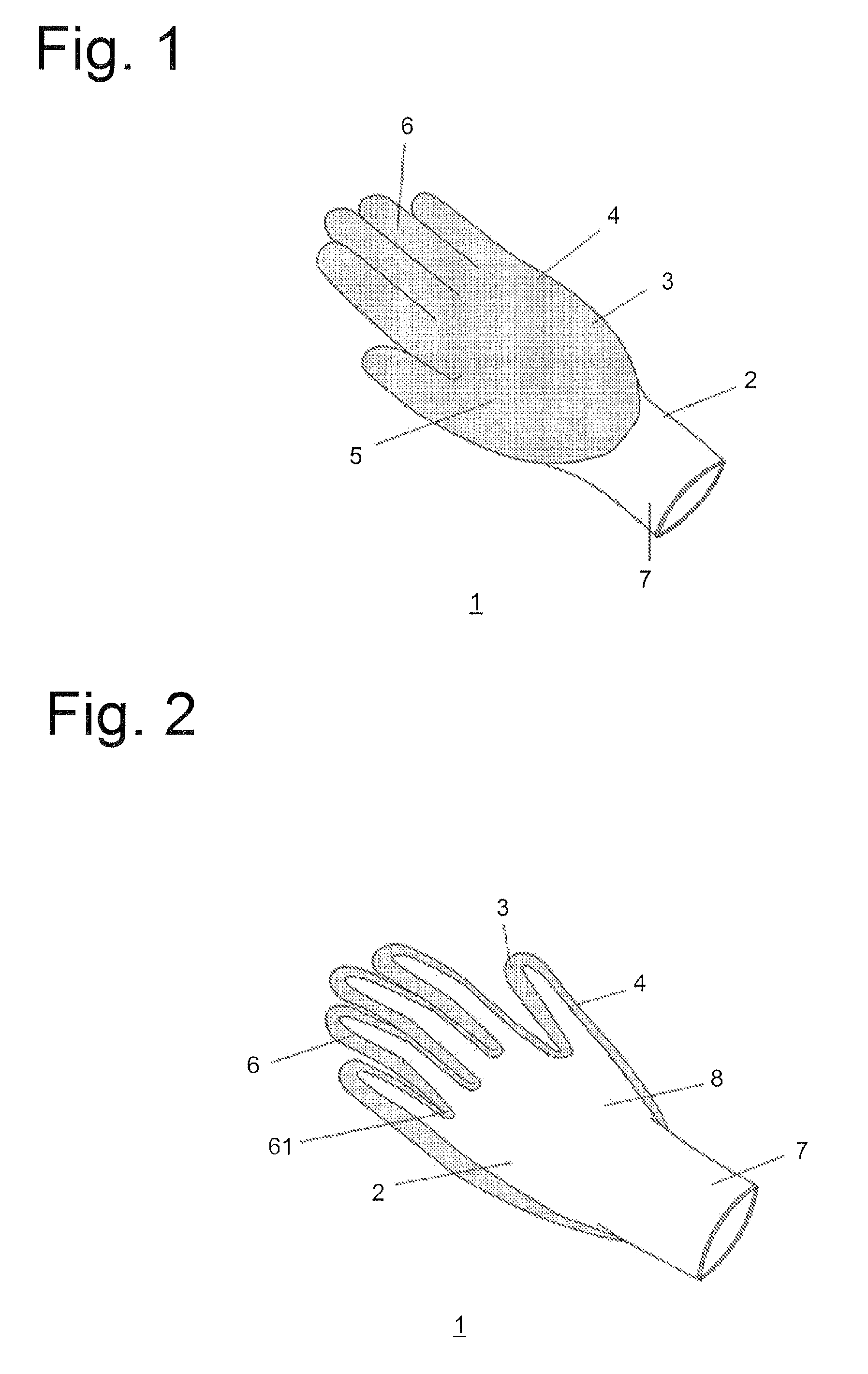

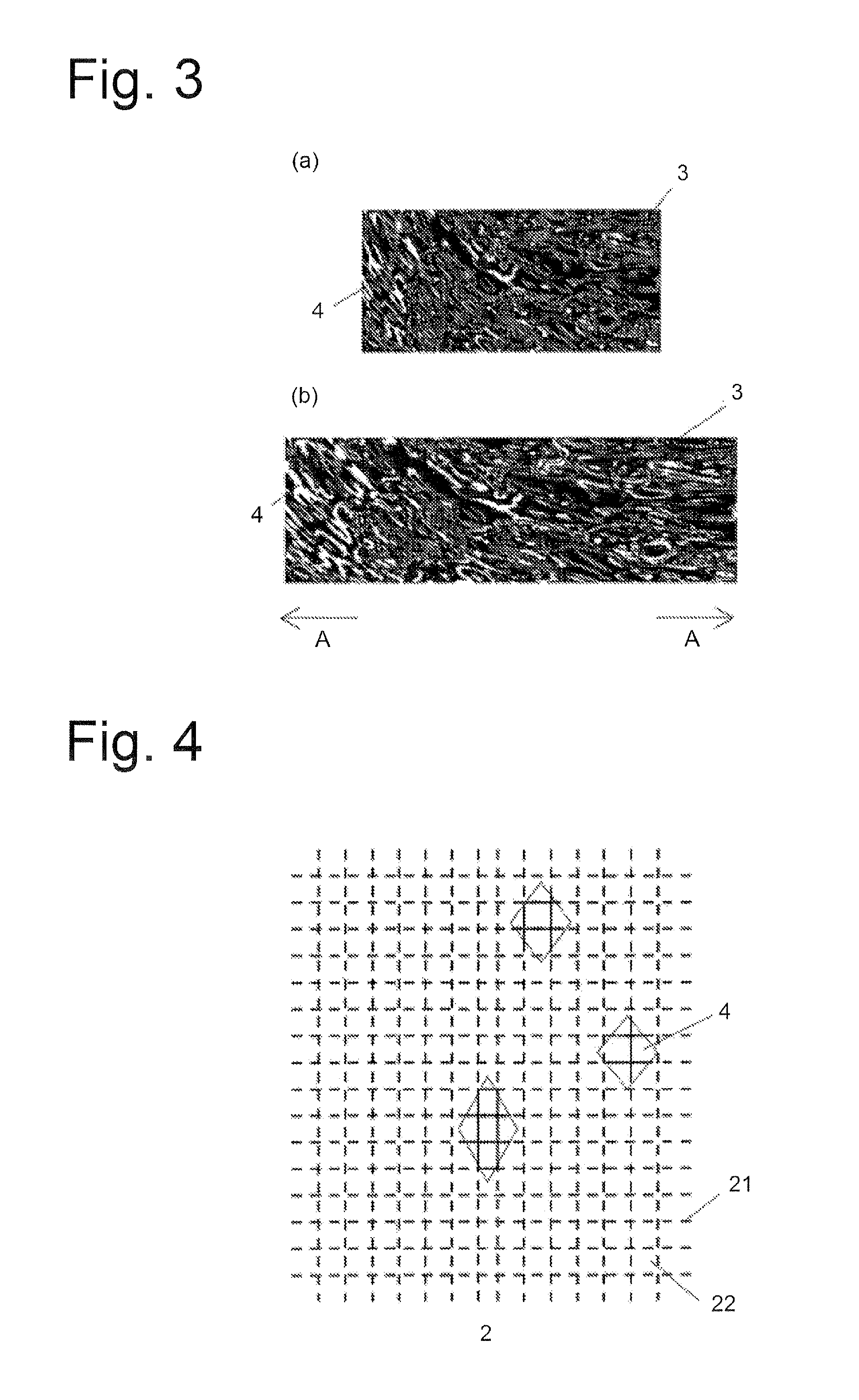

Glove

InactiveUS20130091618A1Improved object grip forceBreathability can be securedGarment special featuresGlovesBiomedical engineeringFiber

The present invention provides a glove that can reduce a humid feeling during usage while realizing a grip force, usability, workability, and breathability. The glove of the present invention includes a hand-shaped base layer (2a, 2b) made of fibers having a stretching property, a coating (3a, 3b) formed on the surface of the base layer (2a, 2b), at least on the surface of a palm of the base layer, and a plurality of breathing pores (4a, 4b) formed in the coating (3a, 3b), wherein the opening areas of the breathing pores (4b) when the glove is worn are larger than the opening areas of the breathing pores (4a) when the glove is not worn.

Owner:TOWA

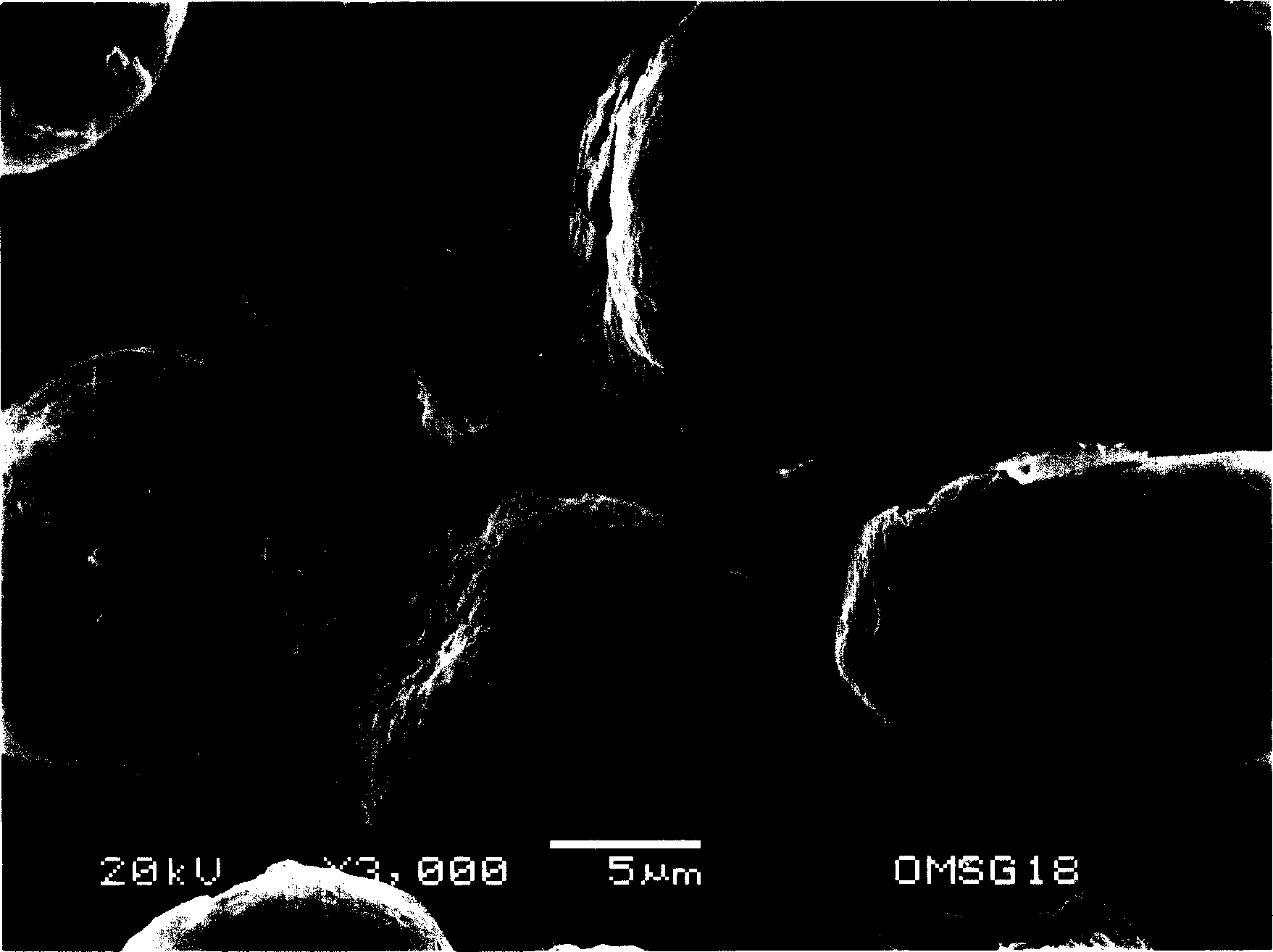

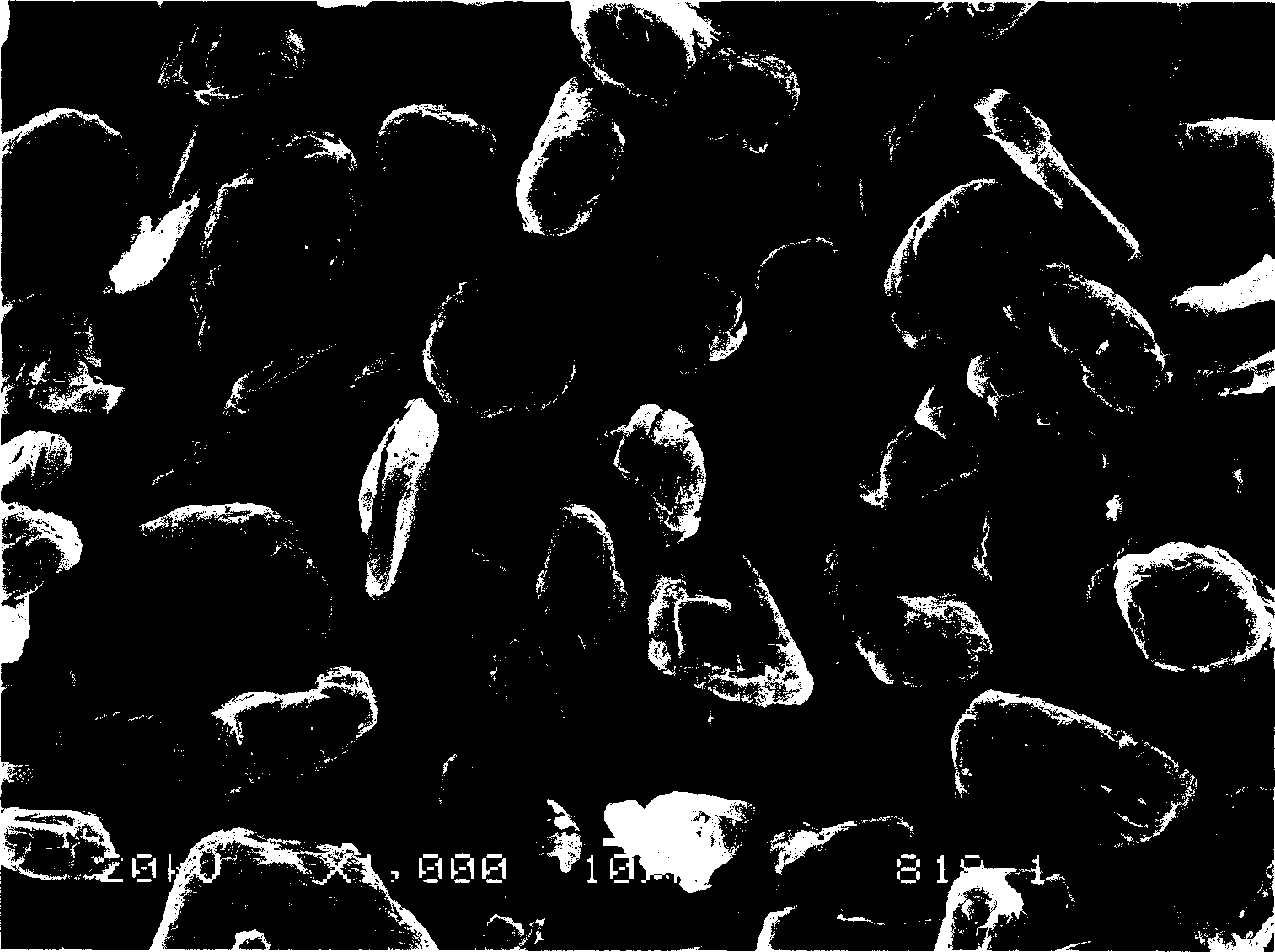

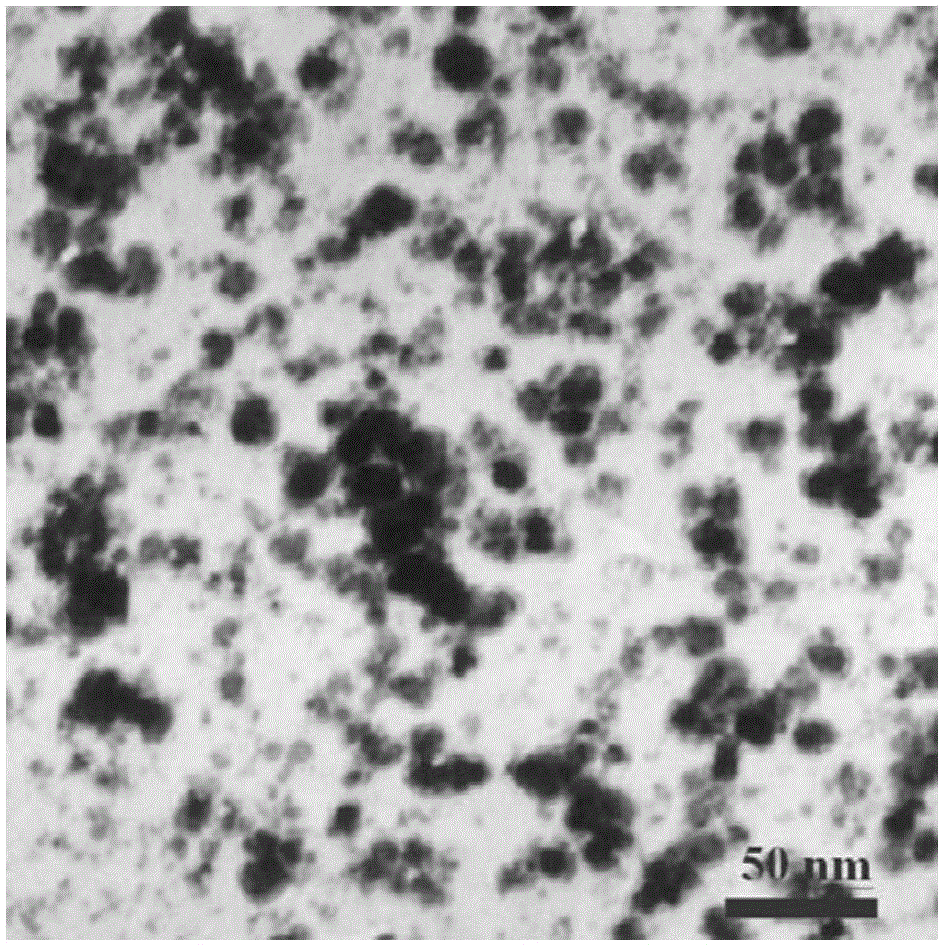

Cathode material of Li-ion battery and preparation method, battery cathode, battery thereof

ActiveCN1702893AImproved charge and discharge coulombic efficiencyImprove electrochemical performanceElectrode manufacturing processesSecondary cellsMaterials processingCrystallinity

This invention discloses one lithium battery negative electrode materials and its process method, wherein, the battery negative electrode, battery, lithium battery negative material comprise sphere natural graphite and the irregular shape carbon with low crystal degree; the natural graphite core has the radius proportion of one to three micro characteristics. The process method comprises the following steps: grinding the natural graphite and shaping and purification processing; surface decoration and mixture with the carbon materials; mixture materials processing.

Owner:BTR NEW MATERIAL GRP CO LTD

Hole sealing moisture-proof anticorrosive composite coating material and its prepn process

The pore sealing moisture-proof anticorrosive composite coating material includes pore sealing material and moisture-proof anticorrosive material. The pore sealing material includes gel with high solid phase content as the basic phase and filler(s) in the amount of 10-100 % of the solid phase component. The moisture-proof anticorrosive material is sol, hydrophobic organic matter or their mixture. The pore sealing moisture-proof anticorrosive composite coating material is prepared through the four steps of preparing pore sealing material, preparing moisture-proof anticorrosive material, preparing pore sealing coating and preparing moisture-proof anticorrosive coating. The pore sealing moisture-proof anticorrosive composite coating material has excellent water permeation arresting performance, high hydrophobicity and high corrosion resistance.

Owner:WUHAN UNIV OF TECH

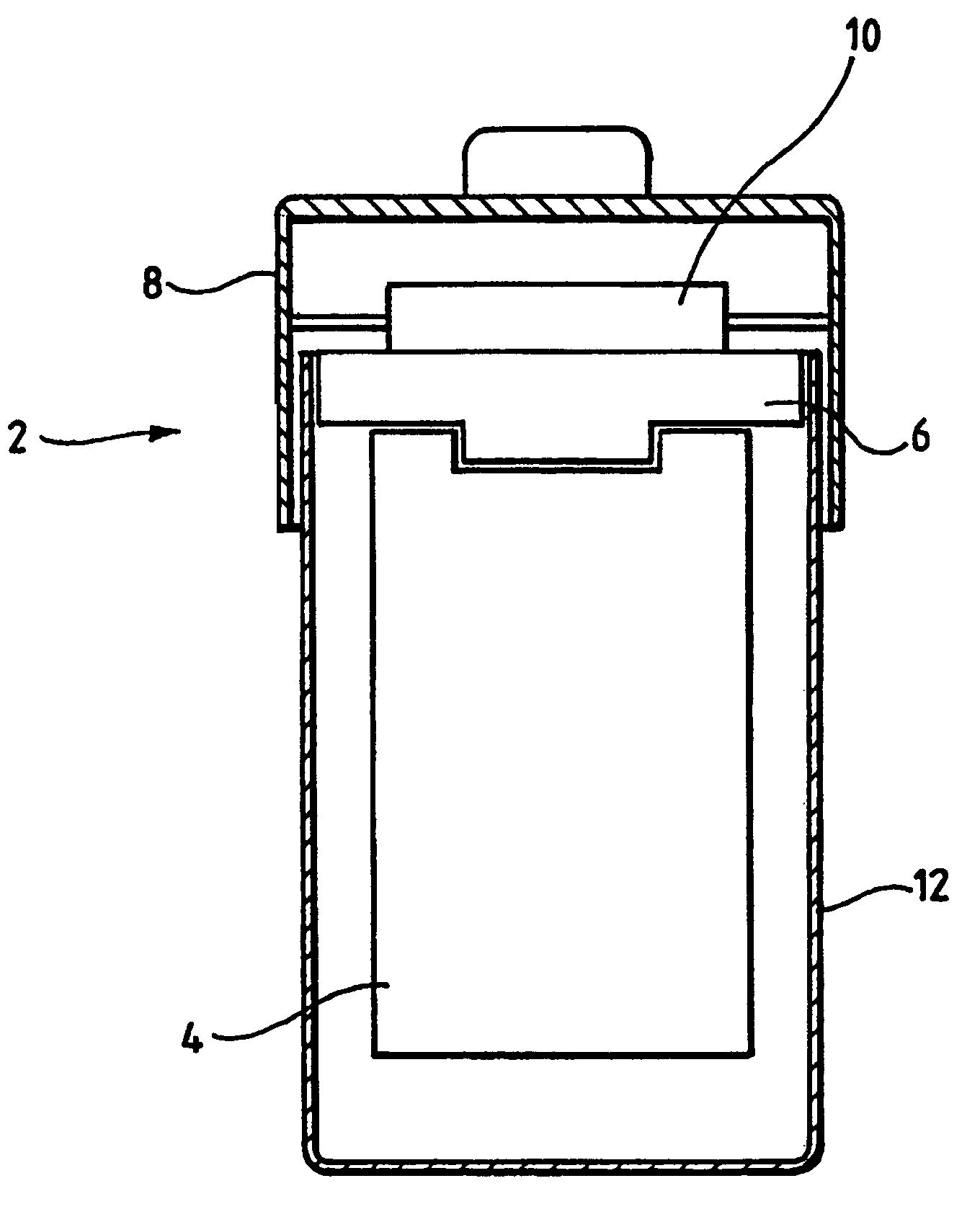

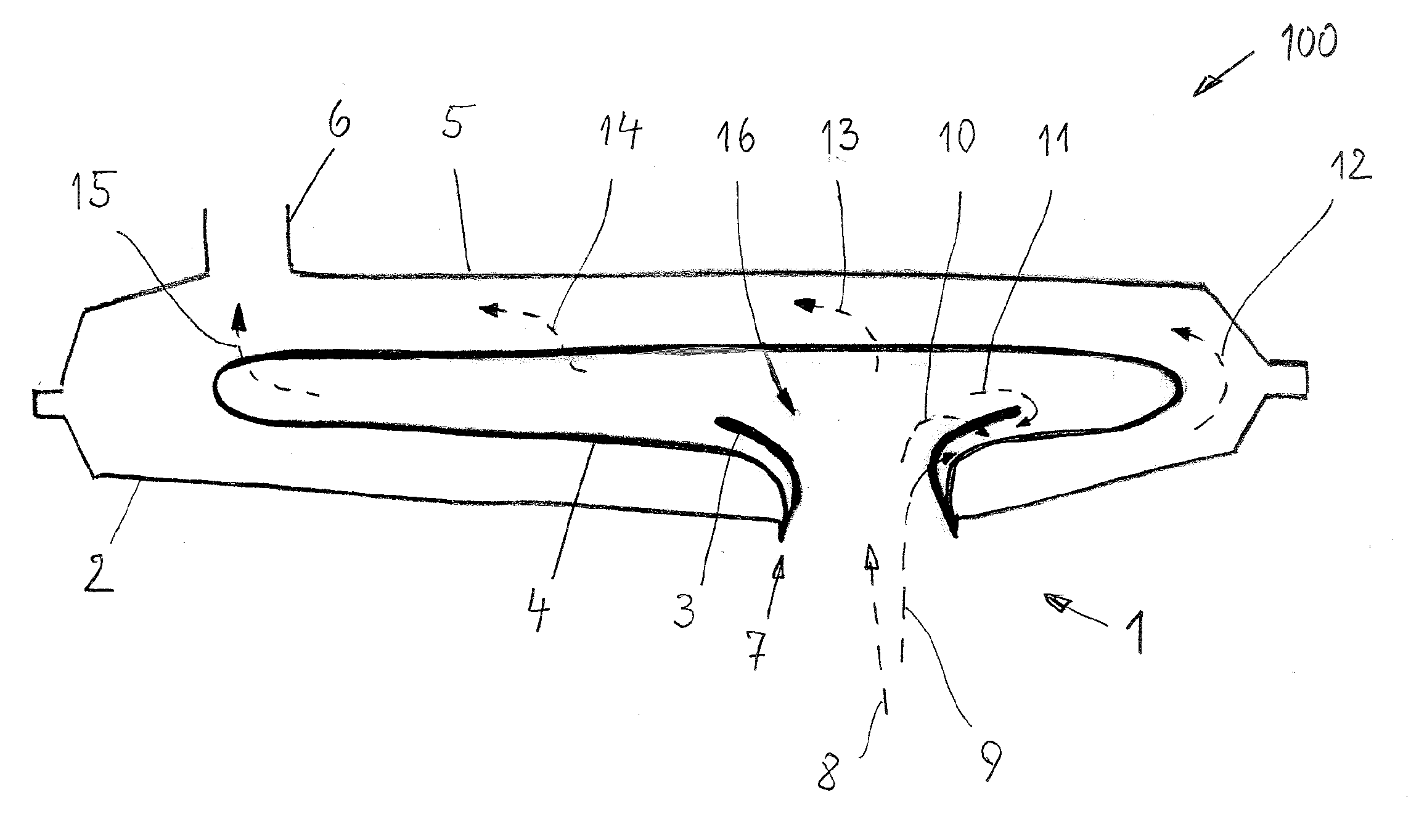

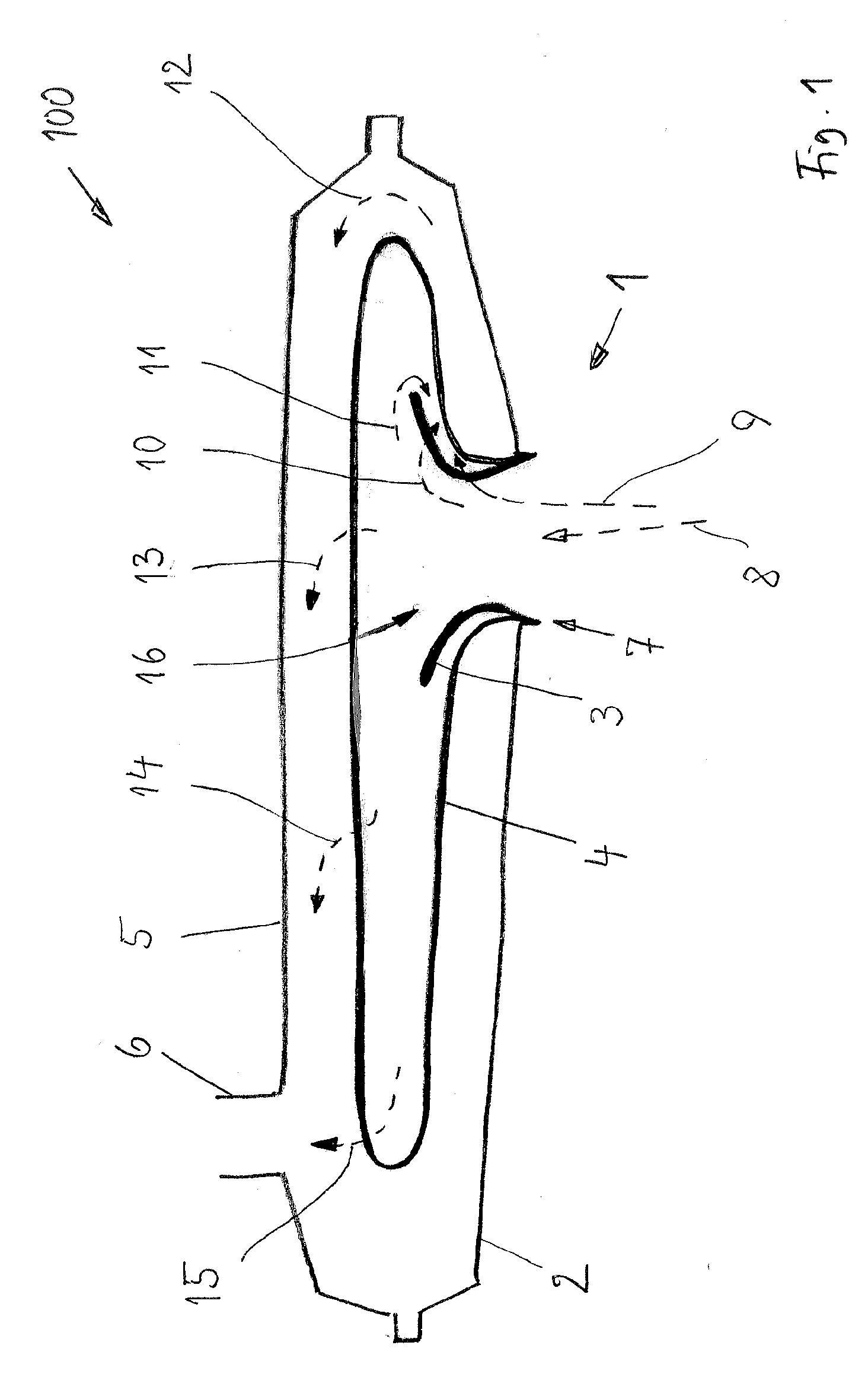

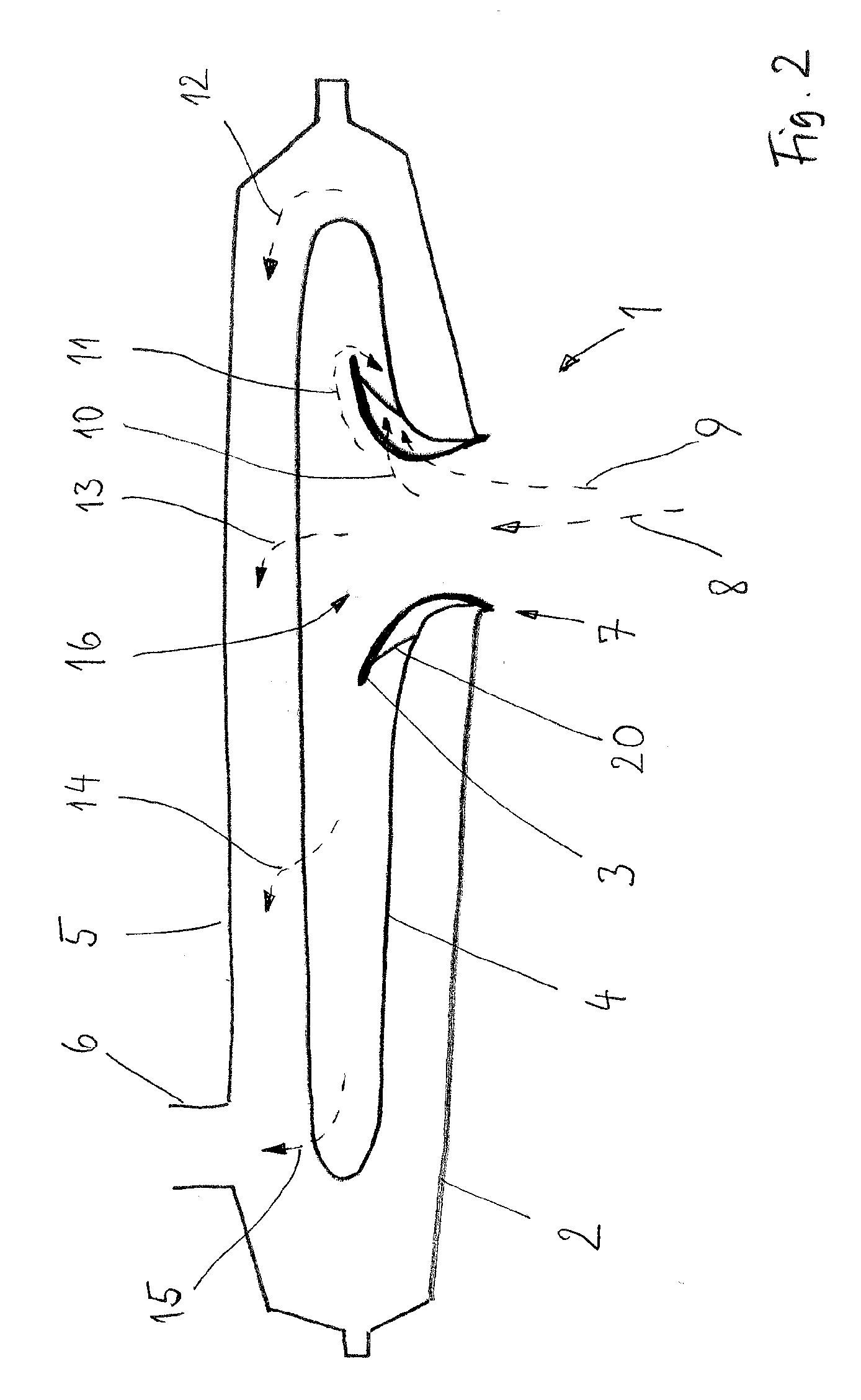

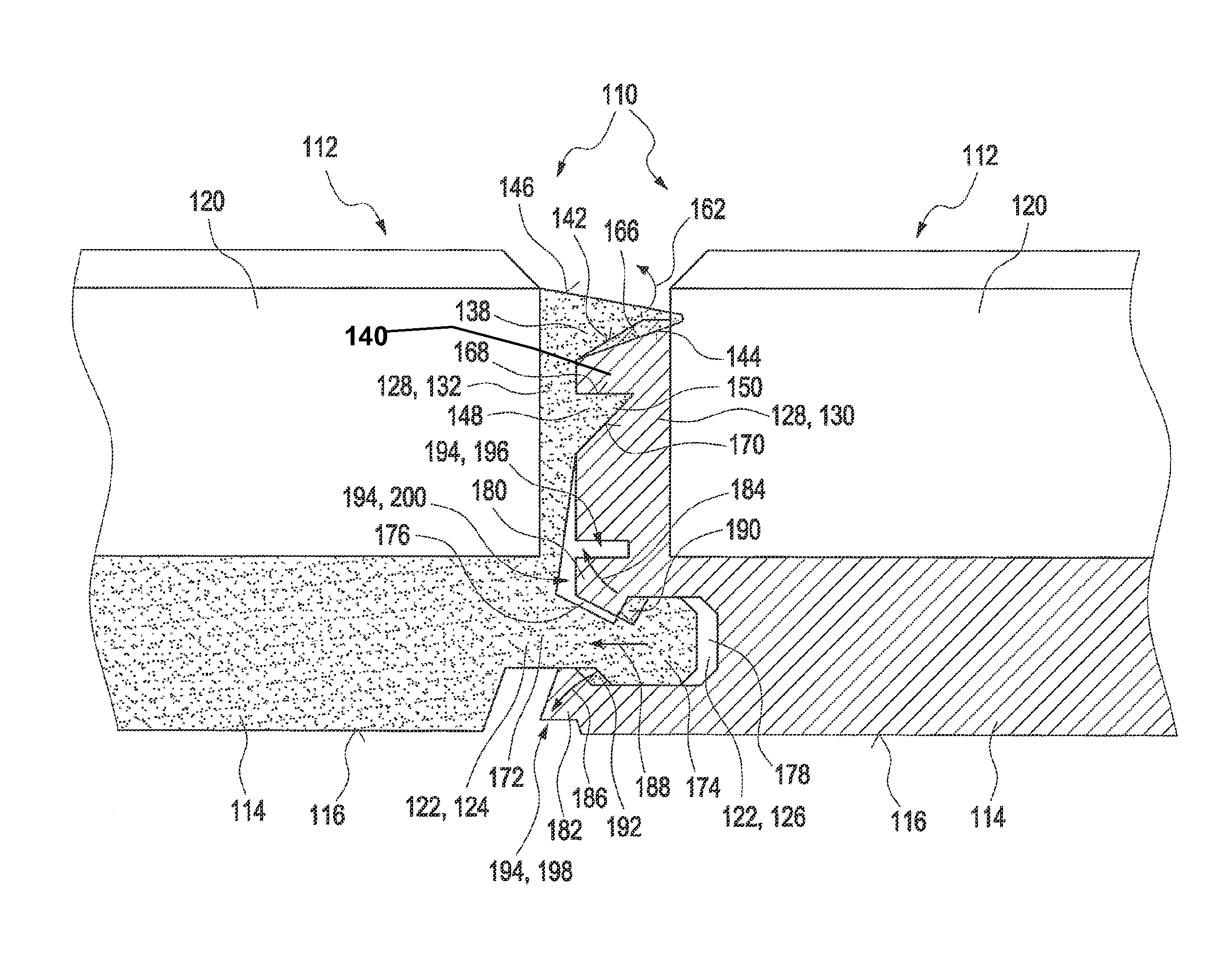

Security system

InactiveUS7428873B1Reconciliation of the amount of cash returned with the “empty” cash cassettes is simplifiedMinimize damageFrequency-division multiplex detailsDigital data processing detailsCouplingControl signal

A security apparatus is provided for use in an automatic teller machine. The security apparatus (100) has a coupling arrangement (110, 150) for engaging the unit with a cash cassette used to hold money within an automatic teller machine and a spoiling system (130, 132) for delivering a spoiling agent for spoiling the contents of the cassette in response to a control signal issued by a controller.

Owner:OBERTHUR CASH PROTECTION

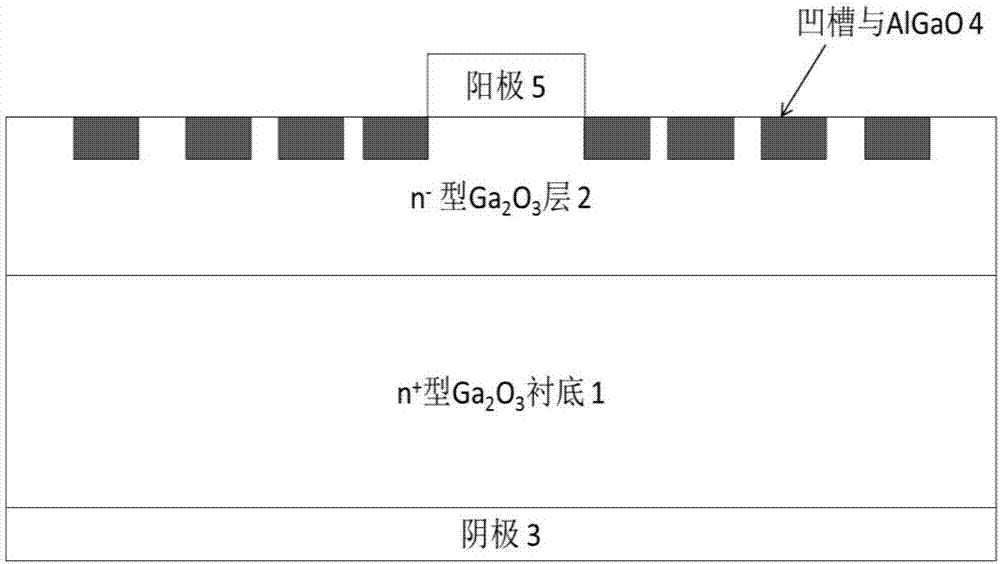

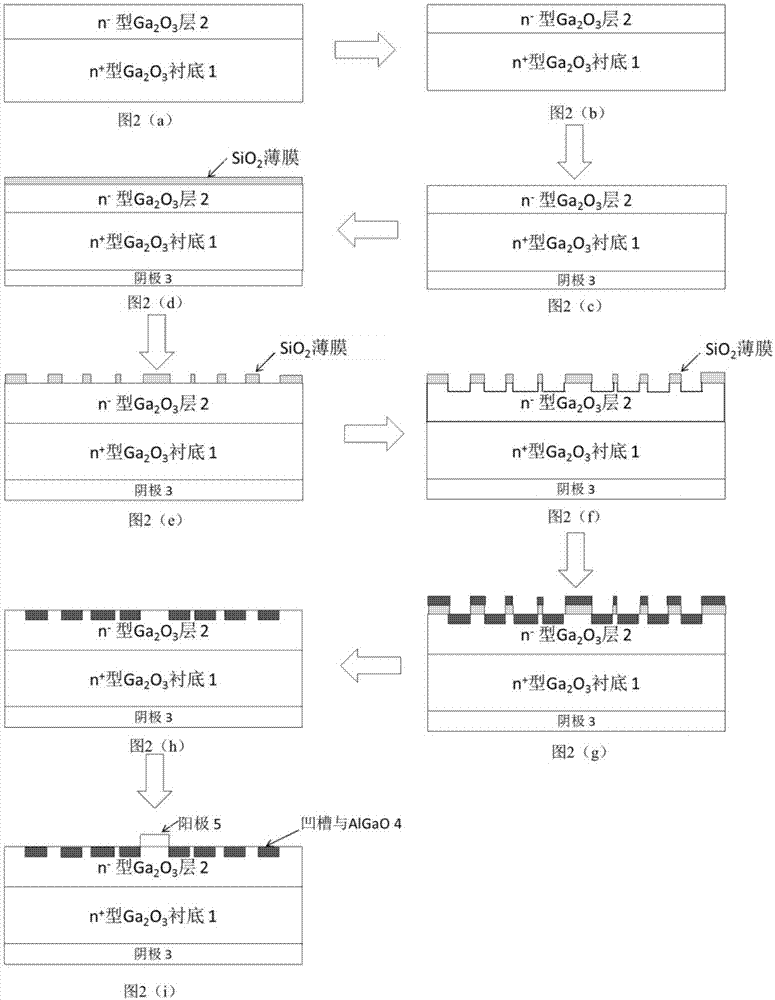

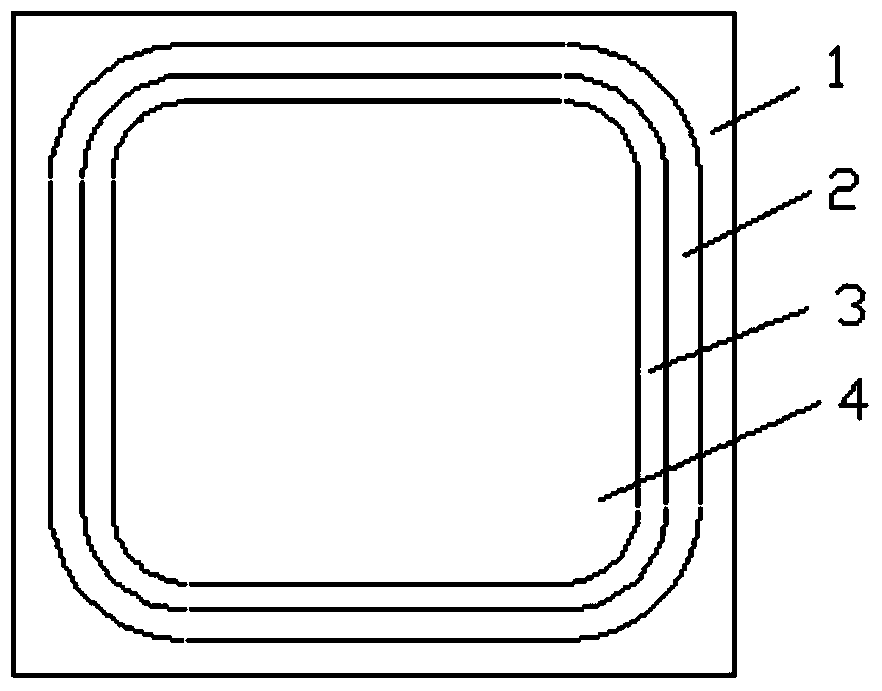

Ga2O3 Schottky diode device structure and manufacturing method thereof

ActiveCN106887470AMaintain positive characteristicsImprove breakdown voltageSemiconductor/solid-state device manufacturingSemiconductor devicesOhmic contactParasitic capacitance

The invention discloses a Ga2O3 Schottky diode device structure and a manufacturing method thereof, and mainly aims at solving the problems that a present Schottky diode device is low in reverse breakdown voltage and the parasitic capacitance in a field plate structure is high. The Ga2O3 Schottky diode device structure comprises a cathode electrode, a heavily-doped n type Ga2O3 substrate, a low-doped n type Ga2O3 epitaxial layer and an anode electrode from bottom to top; Schottky contact is formed in the part where the anode makes contact with the epitaxial layer, the cathode and the substrate make ohmic contact, grooves are distributed separately in the low-doped n type Ga2O3 epitaxial layer, intervals of grooves are increased progressively within the range of 0.3 to 0.5 micron, the first groove is positioned below the edge of the anode, the distance between the last groove and the first groove ranges from 10 to 15 micron, and AlGaO layers in which the Al component is greater than 20% are grown in an epitaxial manner in the grooves respectively. Thus, the reverse breakdown voltage is improved, the parasitic capacitance is reduced, positive characteristic is kept unchanged, and the structure and manufacturing method thereof can be used for high-speed integration circuits and microwave technologies.

Owner:XIDIAN UNIV

Oil filter device

ActiveUS20090230049A1Work lessImprove filtering effectMembrane filtersMachines/enginesFilter mediaOil filter

The present invention provides a suction oil filter device for an engine or a transmission that has an oil inlet and an oil outlet on the filter housing, a suction oil pump connectable to the oil outlet, using which a partial vacuum may be generated between oil inlet and oil outlet, a fine filter medium and an ultrafine filter medium, which are situated between the oil inlet and the oil outlet. The fine filter medium is attached to the oil inlet or to the oil outlet, and the ultrafine filter medium is situated before the fine filter medium in the flow direction and in a secondary flow area of the filter housing. A high filtration performance may thus be achieved at low production outlay.

Owner:IBS FILTRAN KUNST METALLERZEUGNISSE

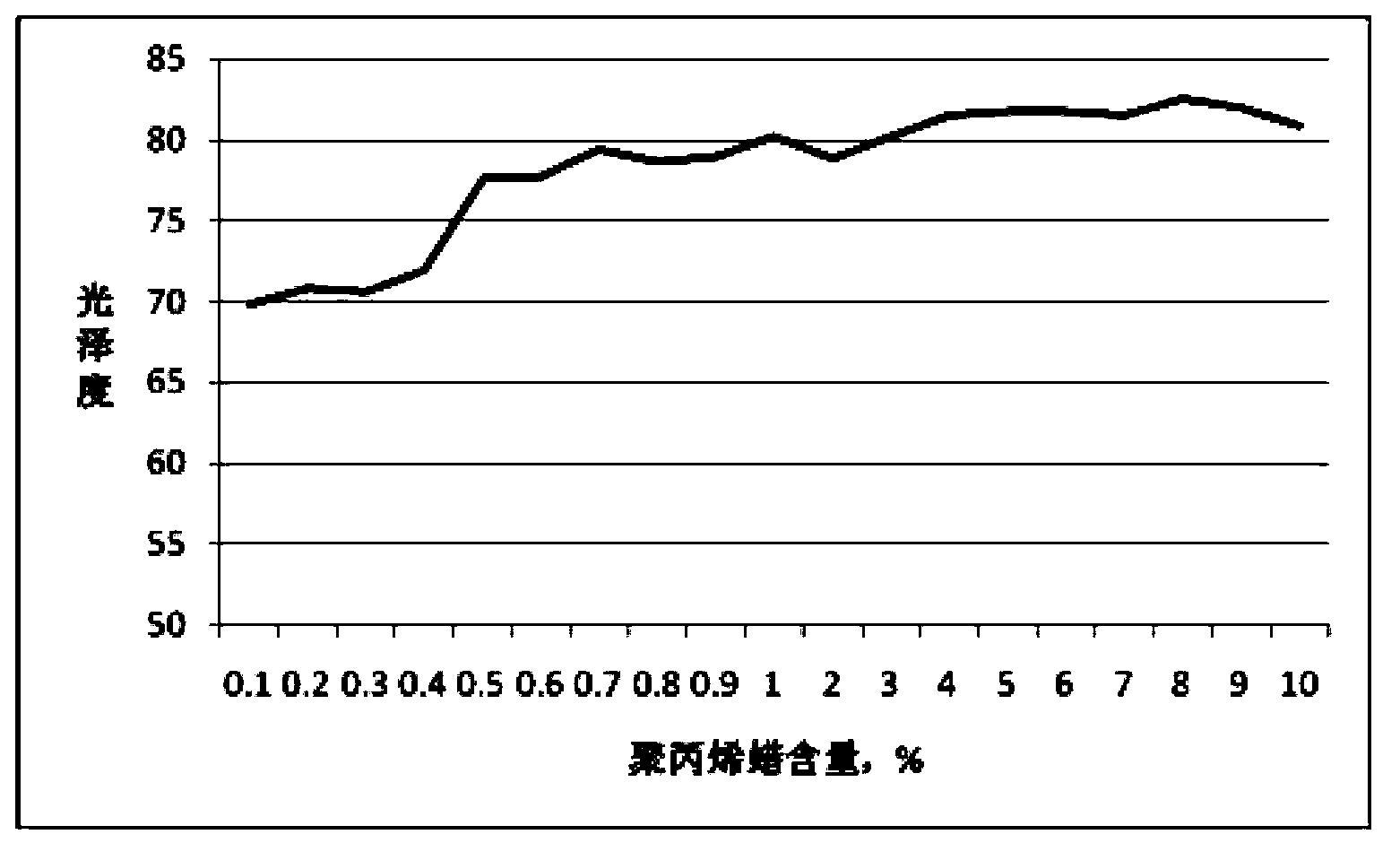

Stone crystal surface treatment composition and manufacturing method thereof

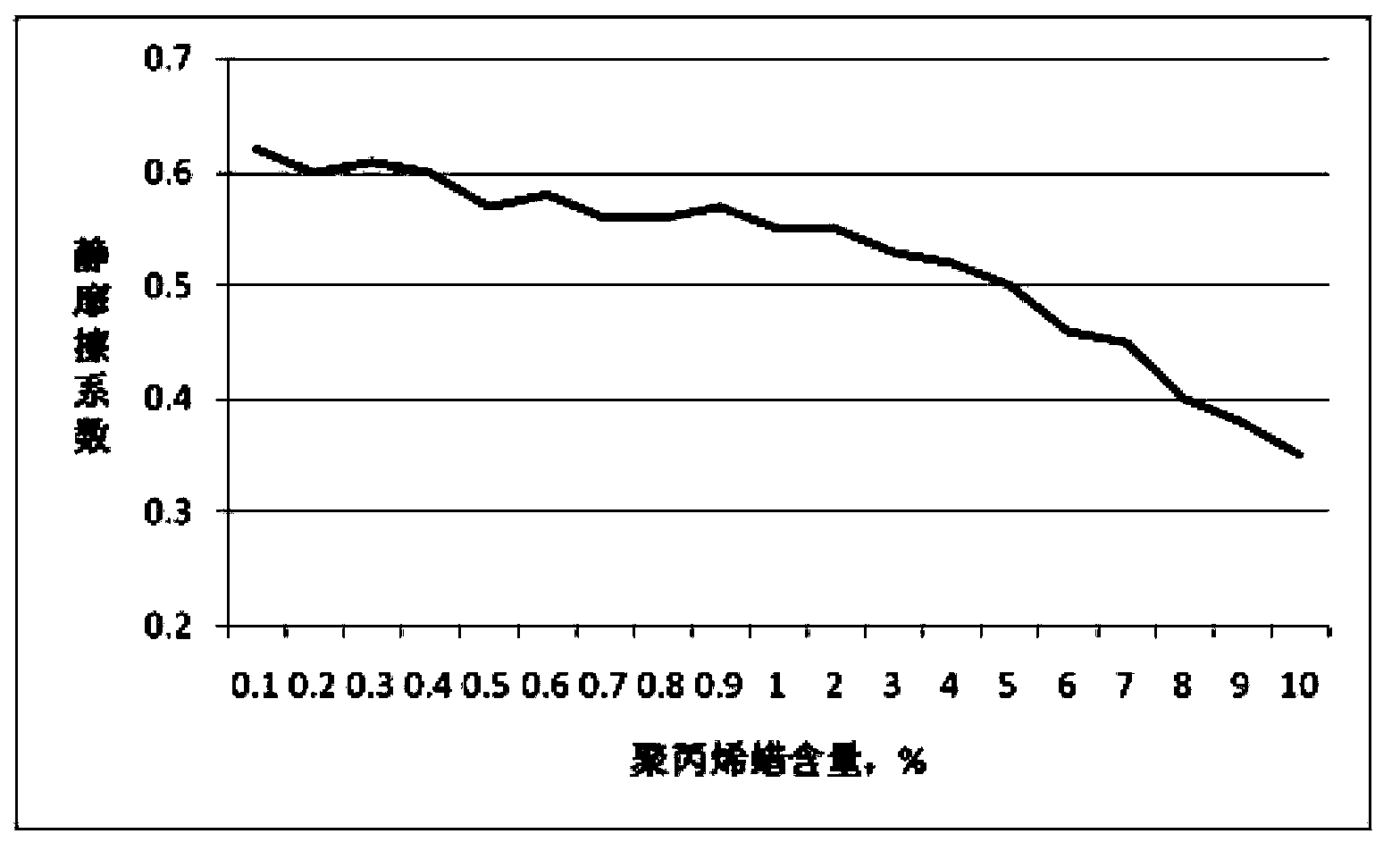

InactiveCN104119803AImprove mechanical propertiesNot easy to penetratePolishing compositionsHigh resistancePolyolefin

The invention discloses a stone surface treatment crystallizing agent comprising the following components in percentage by weight: 0.5-5% of polyolefin wax, 10-30% of fluorosilicic acid or fluorosilicate, 1-6% of acidity regulator, 0.5-5% of quick drying agent and the balance of water, wherein the polyolefin wax is added in an emulsion form, and the solid content of the polyolefin wax emulsion is kept within the range of 20-60%. The crystallizing agent disclosed by the invention can be used for crystallizing stones such as marble, waterstone or special granite and simultaneously hardening and brightening the surface of a stone floor so as to provide high glossiness and improved slip resistance for the crystal surface of the floor while protect the floor. Meanwhile, the treated stone surface has enhanced mechanical performance as well as higher wear resistance and chemical corrosion resistance, and water-soluble stains are not easy to permeate into the stone. The stone surface treated by using the crystallizing agent disclosed by the invention can be cleaned and treated by using water and is convenient and rapid in later-period maintenance and reduced in the maintaining cost as comparison with the stone surface treated by using a conventional waxing treatment method.

Owner:ECOLAB USA INC

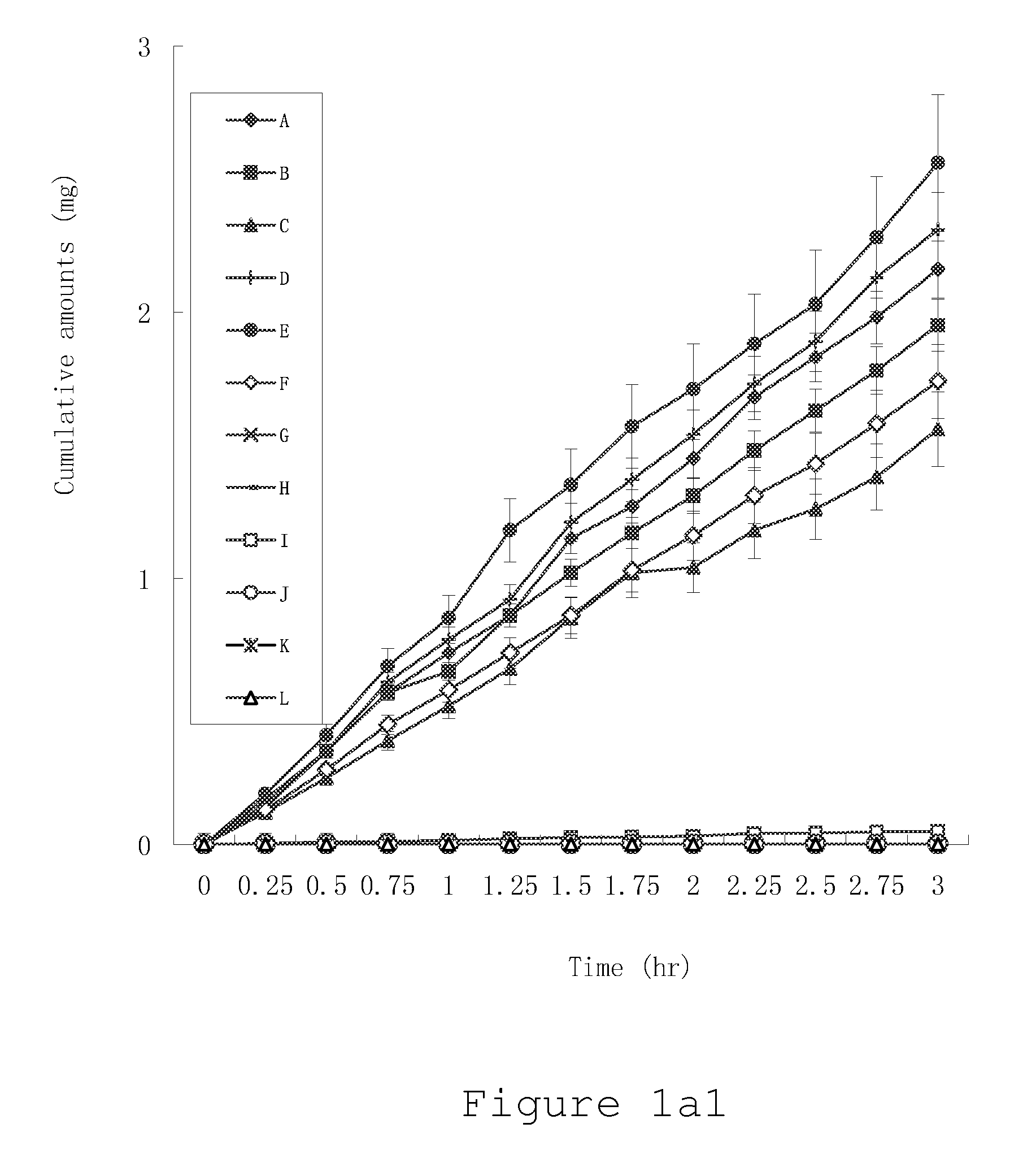

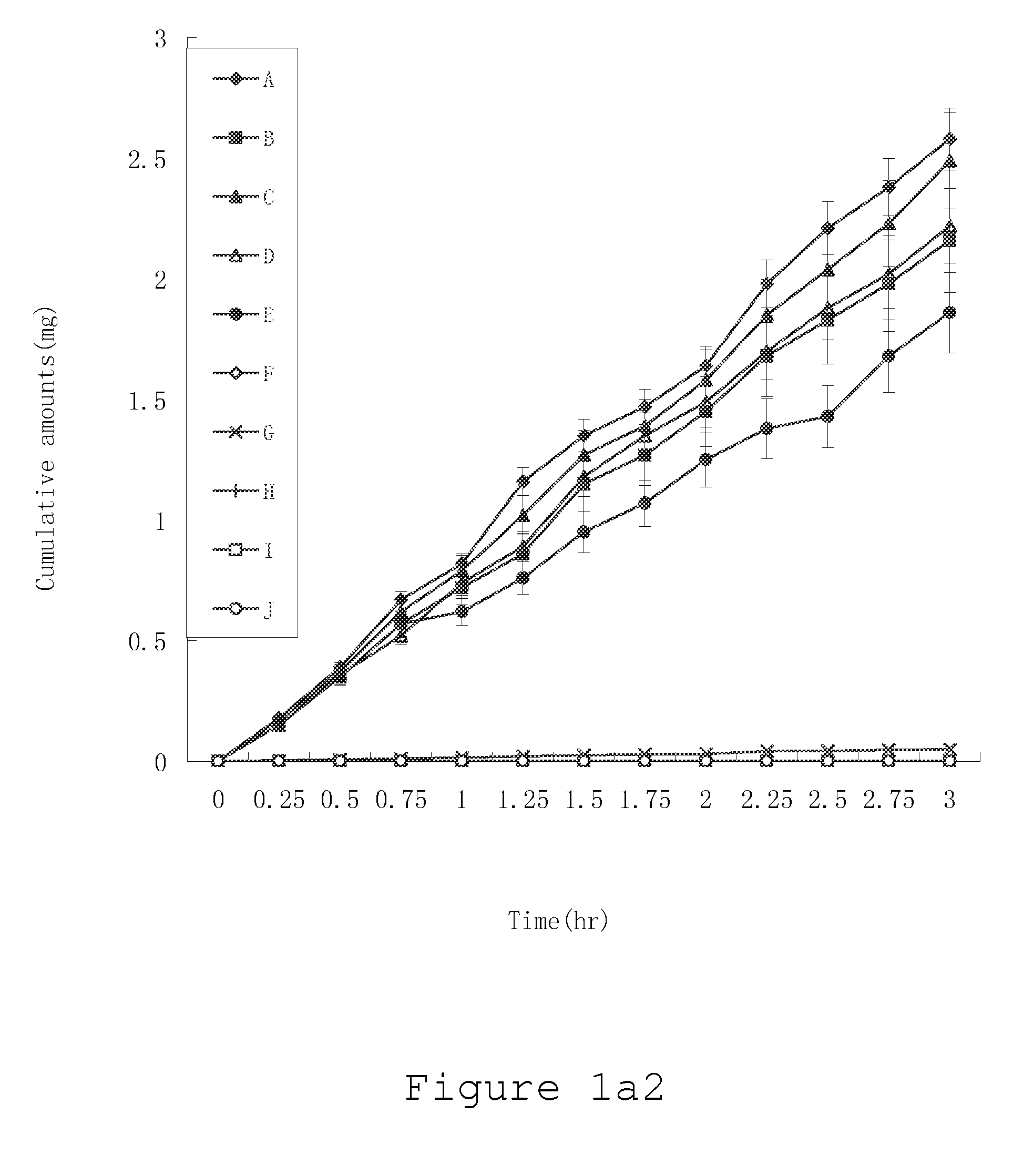

High penetration prodrug compositions of antimicrobials and antimicrobial-related compounds

InactiveUS20100040548A1Not easy to penetrateReduce potential sufferingAntibacterial agentsBiocideHigh concentrationMetabolite

The invention provides compositions of novel high penetration compositions (HPC) or high penetration prodrugs (HPP) of antimicrobials and antimicrobial-related compounds, which are capable of crossing biological barriers with high penetration efficiency. The HPPs are capable of being converted to parent active drugs or drug metabolites after crossing the biological barrier and thus can render treatments for the conditions that the parent drugs or metabolites can. Additionally, the HPPs are capable of reaching areas that parent drugs may not be able to access or to render a sufficient concentration at the target areas and therefore render novel treatments. The HPPs can be administered to a subject through various administration routes, e.g., locally delivered to an action site of a condition with a high concentration or systematically administered to a biological subject and enter the general circulation with a faster rate.

Owner:TECHFIELDS BIOCHEM CO LTD

Cathode material of lithium ion cell and preparation method thereof

ActiveCN1702894AImproved charge and discharge coulombic efficiencyImprove electrochemical performanceElectrode manufacturing processesSecondary cellsState of artCrystal structure

This invention discloses one lithium ion battery negative electrode materials and its process method, wherein the materials comprise sphere natural graphite and artificial graphite or sphere natural graphite and cross carbon, wherein, the sphere graphite is covered with graphite or cross carbon of different crystal degree. The graphite core has the radius proportion of one to three micro characteristics. The process method comprises the following steps: making the purification process on the graphite; mixing the carbon materials front drive; processing the low temperature carbon; finally making the thermal process.

Owner:BTR NEW MATERIAL GRP CO LTD

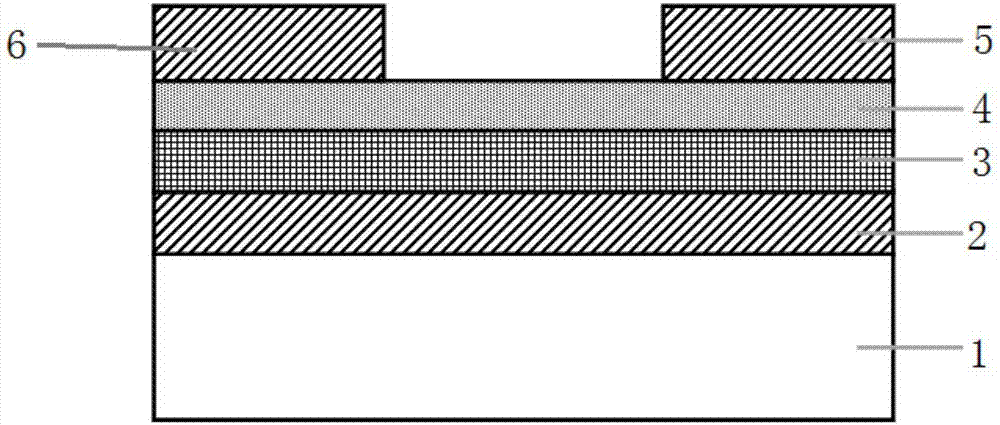

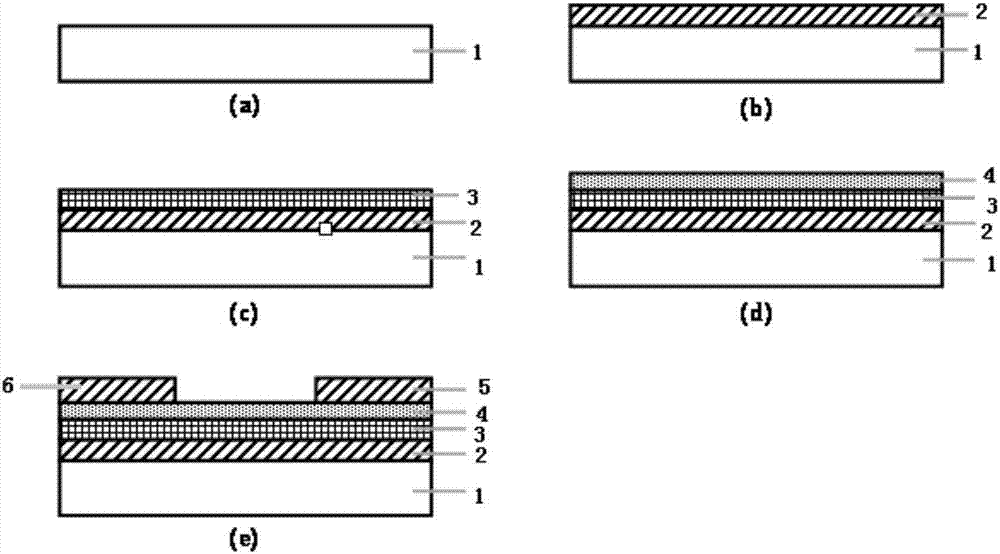

Ferroelectric thin-film transistor and preparation method thereof

ActiveCN107170812AReduce power consumptionImprove ferroelectric propertiesTransistorSemiconductor/solid-state device manufacturingFerroelectric thin filmsBottom gate

The invention discloses a ferroelectric thin-film transistor, which comprises a substrate; a bottom gate electrode formed on the substrate; a ferroelectric film layer formed on the bottom gate electrode; a channel layer formed on the ferroelectric film layer; a source electrode formed on the channel layer; and a drain electrode formed on the channel layer and separated from the source electrode. The invention also discloses a preparation method of the ferroelectric thin-film transistor. By introducing a hafnium-oxide-based material and SnO to the transistor to serve as a gate medium material and a channel material of the transistor respectively, the transistor is allowed to be compatible with existing silicon process in the preparation process, and can realize low power consumption; and the ferroelectric thin-film transistor can be widely applied to high-performance and low-power-consumption large-scale storage integrated circuits.

Owner:XIANGTAN UNIV

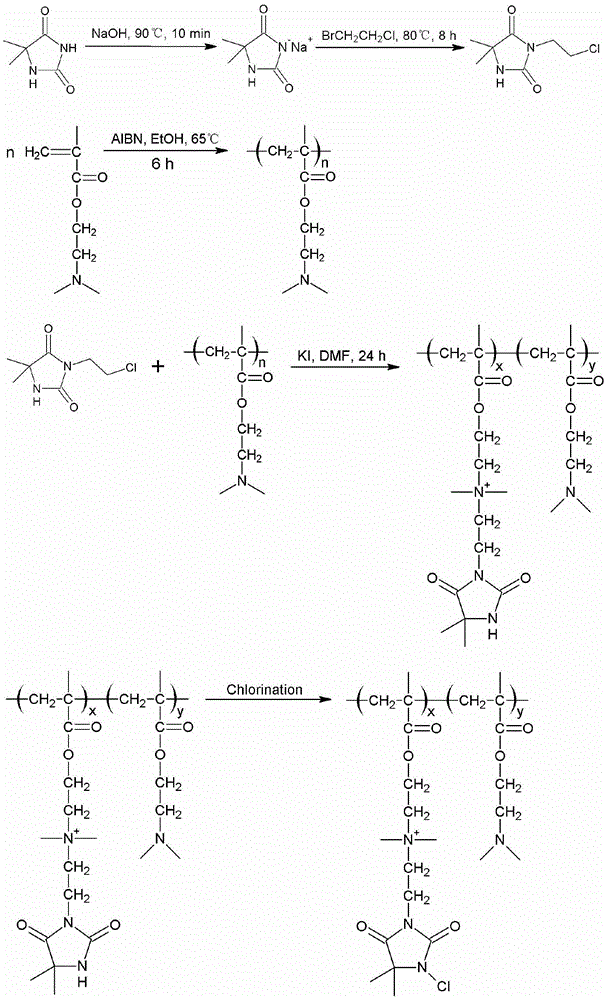

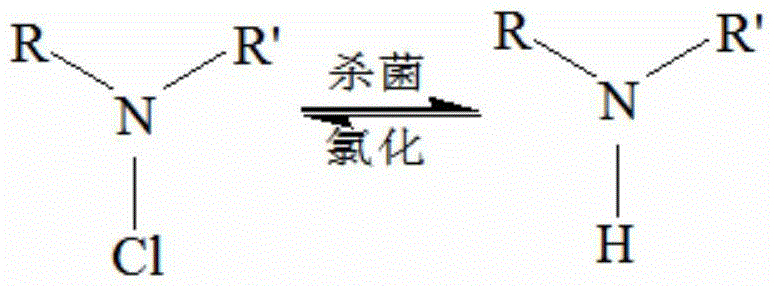

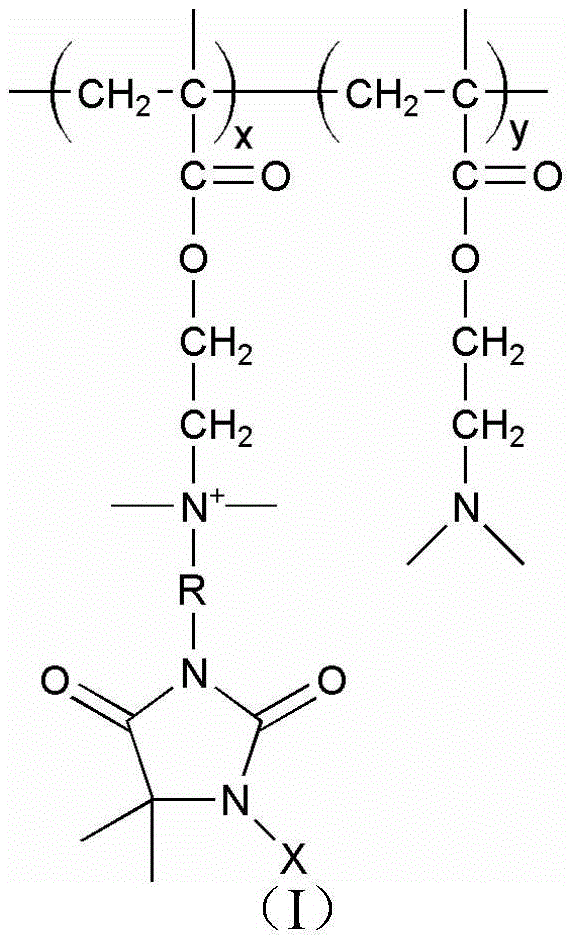

Annular halamine type polymeric antibacterial agent containing quaternary ammonium group and preparation method and application of polymeric antibacterial agent

ActiveCN105601778AFast sterilizationImprove antibacterial propertiesBiocideFungicidesHalogenConventional casting

The invention provides an annular halamine type polymeric antibacterial agent containing quaternary ammonium group and preparation method and application of the polymeric antibacterial agent. The preparation method includes: synthesizing an annular micromolecular halamine type polymeric antibacterial agent precursor and a polymeric autopolymer; enabling the precursor and the polymeric autopolymer to be in substitution reaction to obtain a polymeric antibacterial agent precursor; halogenating to obtain the annular halamine type polymeric antibacterial agent. The application includes: dissolving the polymeric antibacterial agent precursor in N, N-dimethyl formamide, and mixing with a base material; adopting electrostatic spinning technology or conventional casting dissolving process to obtain a membrane containing the antibacterial agent precursor; soaking the membrane in a solution containing active halogen for halogenating reaction; taking the membrane out for water washing, and drying to obtain an antibacterial material. The preparation method is mild in reaction condition, raw materials are low in cost and easy to get, production cost is low, equipment is simple and convenient, and process operation is simple; the antibacterial agent prepared by the method has excellent antibacterial performance and is stable, safe and nontoxic.

Owner:JIANGNAN UNIV

Permeable fireproof materials for aluminium refining and process for preparing same

The invention discloses a poromeric fire-proof material and preparing method of refined aluminum, which comprises the following parts: 60-92 percent sintered compact calcium hexaluminate, 8-30 percent auxiliary material and 2.5-5.5 percent binder, wherein the auxiliary material is some or all of board-shaped corundum, electric melting white corundum, mild-clay, quartz, kyanite, chromium hemitrioxide green and zircon. The preparing method comprises the following steps: blending poromeric fire-proof material and binder completely; loading the material in the mould; placing the mould on the vibrating platform; pressurizing on the material at 10-20 ton; vibrating at 3-5 mm amplitude at 5-15 s; sintering at 1400-1700 deg.c.

Owner:SINOSTEEL LUOYANG INST OF REFRACTORIES RES

Surface covering system

InactiveUS8640418B2Improve sealingImprove mechanical stabilityCovering/liningsWallsCovering systemBiomedical engineering

A surface covering system for covering surfaces with a covering material, particularly for covering wall surfaces or floor surfaces with tile material. The surface covering system includes at least two covering modules, which can be placed on the surface so as to adjoin each other. A first covering module has at least one first sealing profile, and a second covering profile has at least one second sealing profile. The sealing profiles are designed to engage each other in a positioned state of the covering modules and form a common seal.

Owner:GIANOLI GABRIELLA

Surface covering system

InactiveUS20110179735A1Avoid disadvantagesAesthetically pleasingConstruction materialCovering/liningsCovering systemBiomedical engineering

A surface covering system for covering surfaces with a covering material, particularly for covering wall surfaces or floor surfaces with tile material. The surface covering system includes at least two covering modules, which can be placed on the surface so as to adjoin each other. A first covering module has at least one first sealing profile, and a second covering profile has at least one second sealing profile. The sealing profiles are designed to engage each other in a positioned state of the covering modules and form a common seal.

Owner:GIANOLI GABRIELLA

Organic polyurethane foam dressing and preparation method thereof

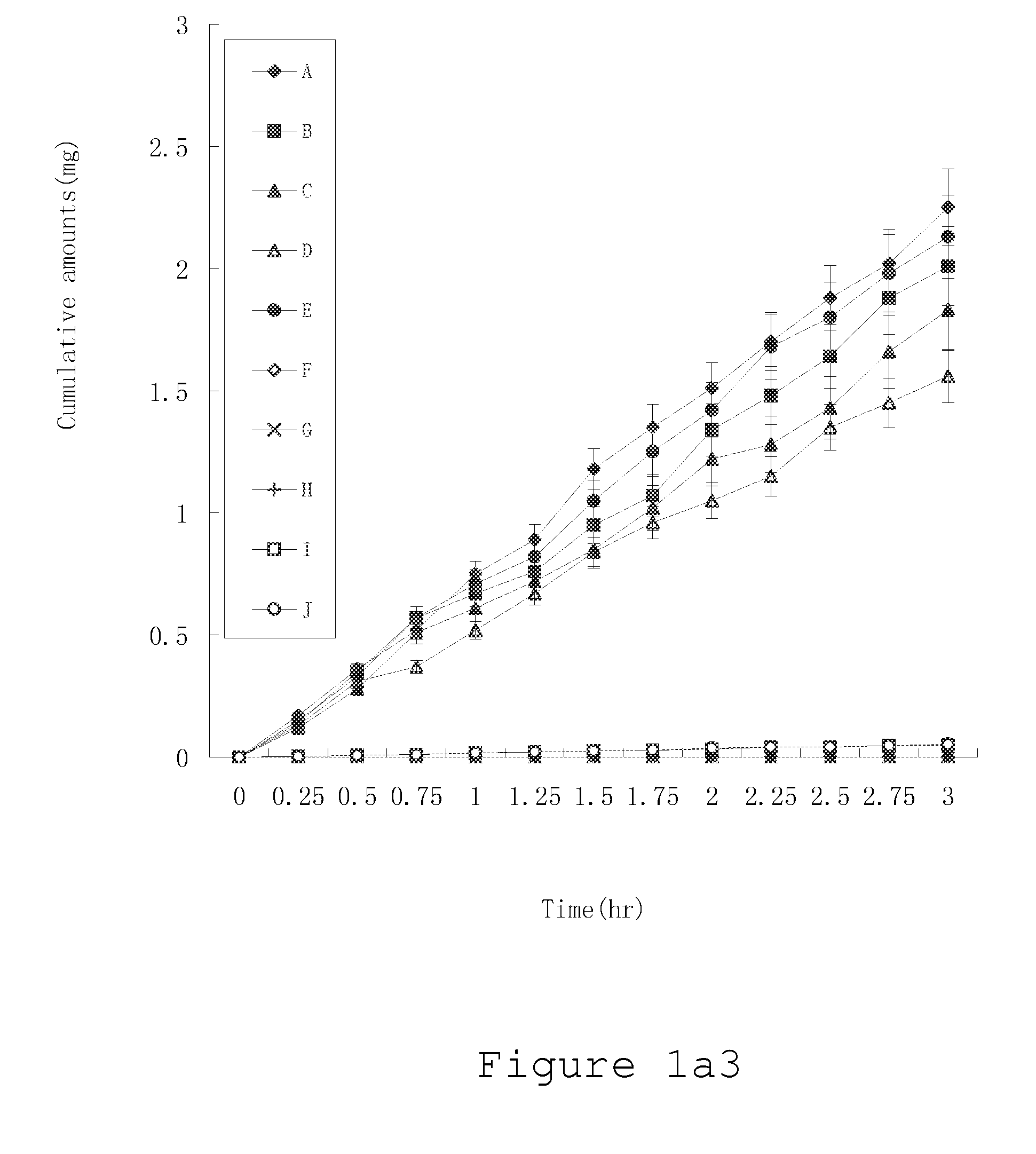

ActiveCN104225665AControlled release rateReduced release rateAbsorbent padsBandagesTherapeutic effectLow temperature plasma

The invention provides an organic polyurethane foam dressing and a preparation method thereof. An antibacterial component is added into a polyurethane foam synthesis formula to prepare polyurethane foam with an antibacterial function; the obtained polyurethane foam is subjected to low-temperature plasma surface modification treatment; a plasma membrane layer is added on the surface of the antibacterial polyurethane foam material to form a speed limiting barrier. The polyurethane foam dressing prepared by the preparation method disclosed by the invention is high in compliance to a wound and is soft and comfortable; the preparation technology is simple, is convenient to operate and good in treatment effect, has the characteristic of long-time bacteriostat and is suitable for industrial production.

Owner:HENAN HUIBO MEDICAL CO LTD

Insulated impregnating process for high-frequency transformers

ActiveCN101699586ANot easy to penetrateSufficient heat resistancePlastic/resin/waxes insulatorsTransformers/inductances coils/windings/connectionsEpoxyLacquer

The invention discloses an insulated impregnating process for high-frequency transformers. The method can significantly improve the surface quality of high-frequency transformers and ensure that the surface of a transformer is completely covered; gaps between iron cores and windings are completely filled; and paint layers are glossy and free from paint protrusions, wrinkled skin and large-area flowing paint. The process is implemented through a technical scheme comprising the following: a) a step of impregnating with paint, which is to impregnate an iron core component with high-temperature epoxy glue, put the iron core component into a sealed container and bake for 2 hours; b) a step of winding, which is to wrap the iron core component in a glass cloth belt for insulation, wind primary and secondary windings and tie the glass cloth belt for insulation; c) a step of impregnating with paint, which is to bake the obtained product at 70+ / -10 DEG C for 0.5 hour; d) a step of baking, whichis to put the obtained product into a vacuum tank, vacuumize the vacuum tank, maintain pressure for 10 minutes, raise pressure to normal pressure, pressurize to between 0.3 and 0.4 MPa, maintain pressure for 20 minutes and bake for 2 hours; and e) a step of packaging, which is to pour high-temperature epoxy glue and put the obtained product into the same sealed container for baking. The high-frequency transformers manufactured by the process have the advantages of good thermal stability, excellent insulation performance and capability of completing the boost output of high-energy pulses.

Owner:四川泛华航空仪表电器有限公司

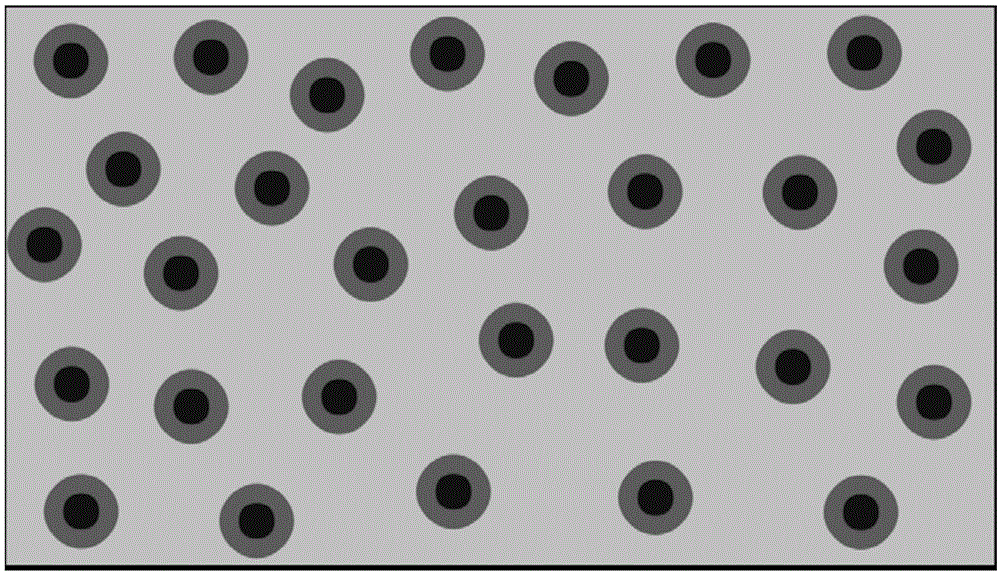

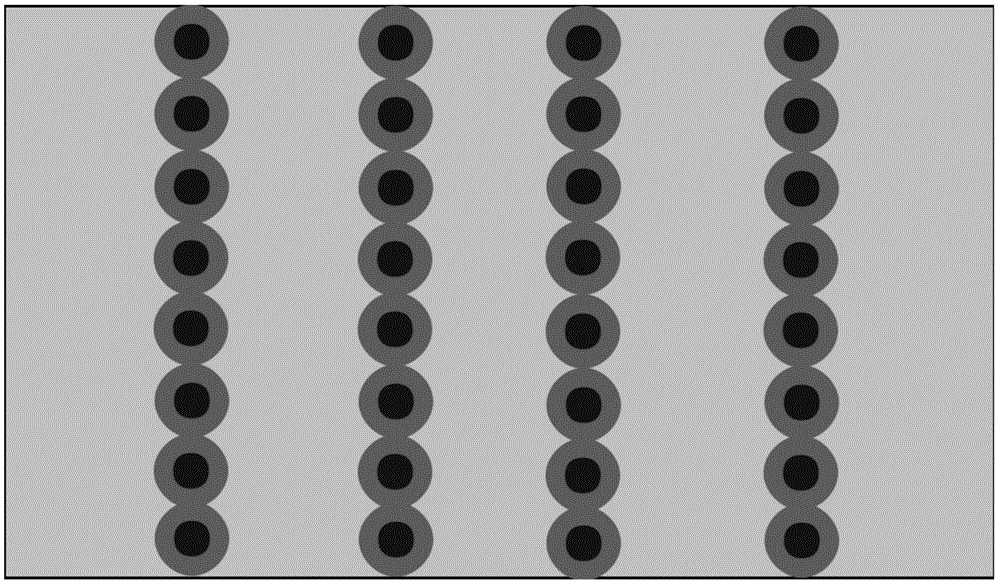

Multiferroic liquid and preparation method thereof

ActiveCN105006329AChange lengthChange the length and thicknessMagnetic liquidsMagnetoAcoustic property

The invention discloses a multiferroic liquid and a preparation method thereof, for solving the defects that a solid-state multiferroic material is large in coercive force, cannot be structurally changed once being formed, is low in magneto-electric coupling effect and is easily broken down by voltages. The multiferroic liquid is internally provided with a magnetic material, the outer surface of the magnetic material is wrapped by a ferroelectric material, nanometer particles with magneto-electric core shell structures are uniformly dispersed in a mixed liquid of a base solution and a surfactant, and a stable suspending liquid is formed in such a way. The multiferroic liquid has ferroelectricity and magnetism, also has fluidity and is quite small in coercive force. The length and the thickness of a nanometer chain composed of the nanometer particles in the multiferroic liquid can be adjsuted by applying different electric fields or magnetic fields to the multiferroic liquid according to needs, and accordingly, the electrical property, the magnetic property, the hydrodynamic property, the optical property and the acoustic property of the multiferroic liquid are adjusted. The invention brings forward the concept of the multiferroic liquid for the first time ever, and also provides the preparation method, expanding a new research direction for research on a multiferroic material.

Owner:嘉兴鼎尚信息科技有限公司

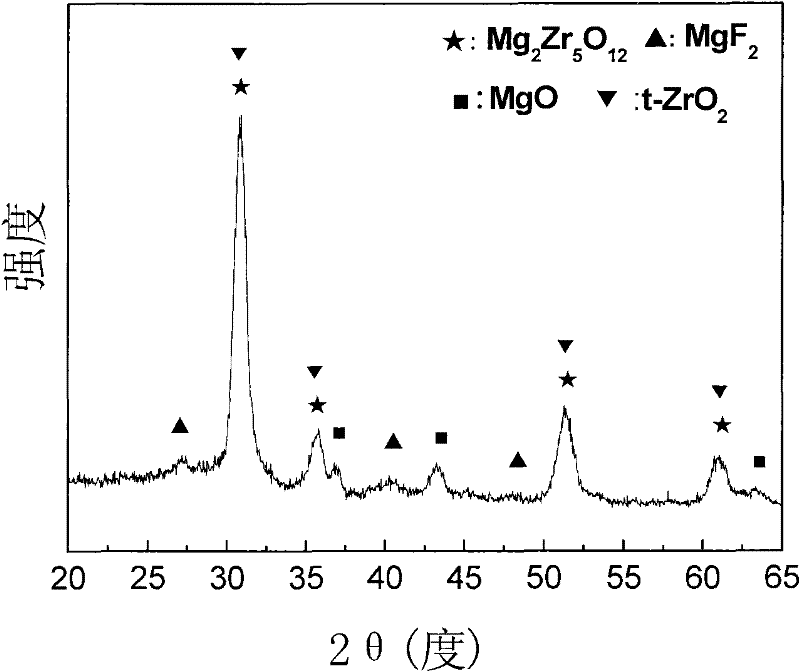

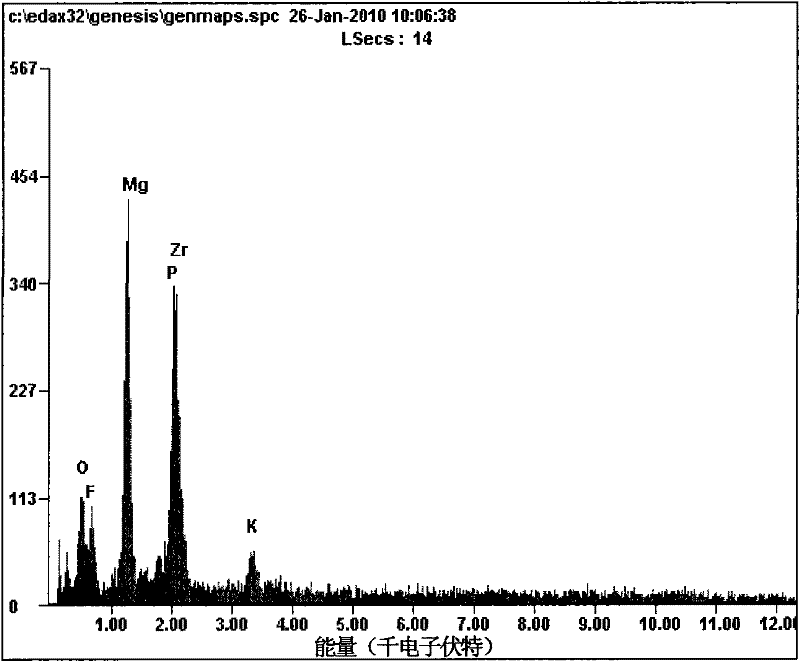

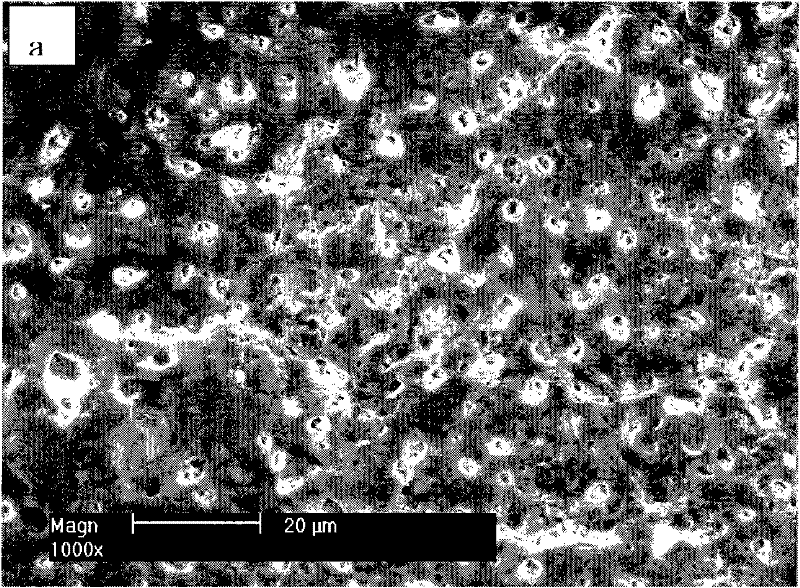

Solution for preparing high corrosion resistance self-sealing ceramic coating on magnesium alloy surface and its application

ActiveCN102268710ASimple ingredientsEasy to controlAnodisationMicro arc oxidationPlasma electrolytic oxidation

The invention relates to the technology for treating a magnesium alloy surface, in particular to a solution for preparing a self-hole-sealing ceramic coating with high corrosion resistance on the magnesium alloy surface and application thereof. The solution consists of the following components: 8-10g / L of fluozirconate, 8-14 g / L of dihydric phosphate, 15-20 g / L of fluoride, 3-8 g / L of citrate, 70-90 g / L of hexamethylene tetramine and the balance of water. In a constant-current constant-voltage working manner, the self-hole-sealing ceramic coating with high corrosion resistance is prepared on the magnesium alloy surface by adopting a microarc oxidation technology. The invention can overcome the disadvantages that the peak current density is too high when magnesium alloy workpieces in a fluozirconate-containing solution are subjected to the microarc oxidation treatment by adopting the constant-voltage working manner, and the film cannot be formed when the constant-current working manneris adopted in the prior art. The ceramic coating has better corrosion resistance, and the coating has uniform thickness, compactness and low surface roughness and does not need after-treatments such as hole sealing and the like; and the solution provided by the invention has simple components and readily available raw materials and is applicable to industrialization production.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

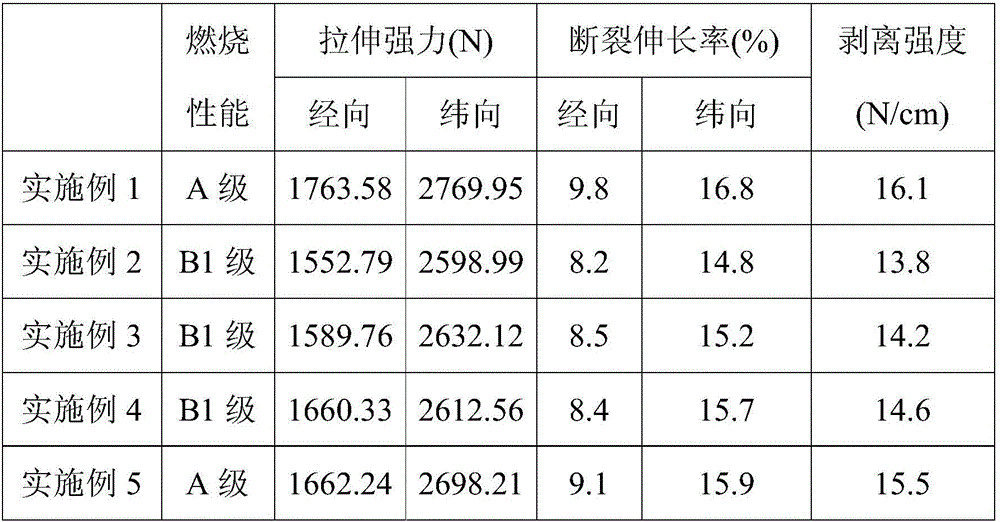

Long-lasting anti-fouling membranous-structure composite canopy material

ActiveCN106003931AIncreased static contact angleNot easy to penetrateSynthetic resin layered productsCoatingsPolyesterFiber

The invention relates to a long-lasting anti-fouling membranous-structure composite canopy material comprising a base membrane, base cloth and a surface membrane which are arranged sequentially from bottom to top, wherein a polyvinylidene fluoride coating is arranged on the surface membrane and is subjected to mirror face embossing treatment; the surface membrane as well as the base membrane is prepared from the following raw materials in parts by weight: 100 parts of polyvinyl chloride (PVC) resin powder, 50 to 70 parts of a dioctyl terephthalate plasticizer, 5 to 25 parts of calcium carbonate powder, 1 to 5 parts of a flame retardant, 1 to 4 parts of a smoke suppressant, 1 to 6 parts of a barium-zinc stabilizer and 1 to 5 parts of a titanium pigment; the base cloth is 1000D*1000D polyester fiber woven cloth. Raw materials such as PVC resin powder, the plasticizer, calcium carbonate, the stabilizer and the flame retardant are mixed, plasticizing and calendaring are carried out to obtain soft membranes, then the soft membranes are compounded with the 1000D*1000D polyester fiber woven cloth, and embossing is carried out after surface treatment of polyvinylidene fluoride, so that the long-lasting anti-fouling membranous-structure composite canopy material is a membranous-structure composite canopy material being long-lasting in fouling resistance, efficient in fire retardancy, and high in strength.

Owner:浙江明士达股份有限公司

Thin film transistor and semiconductor device using the same

InactiveUS20100090220A1Preventing deterioration/peelingPrevent penetrationTransistorElectroluminescent light sourcesDevice materialDisplay device

The present invention aims at providing a high-performance semiconductor device such as display, IC tag, sensor or the like at a low cost by using an organic thin film transistor most members of which can be formed by printing, as a switching element. The present invention relates to a thin film transistor composed of members on a dielectric substrate, which are a gate electrode, a dielectric film, source / drain electrodes, and a semiconductor layer, wherein on said semiconductor layer there are formed at least two passivation films of a first passivation film capping said semiconductor layer to protect it and a second passivation film covering larger area than that of said first passivation film to protect all of said members.

Owner:HITACHI LTD

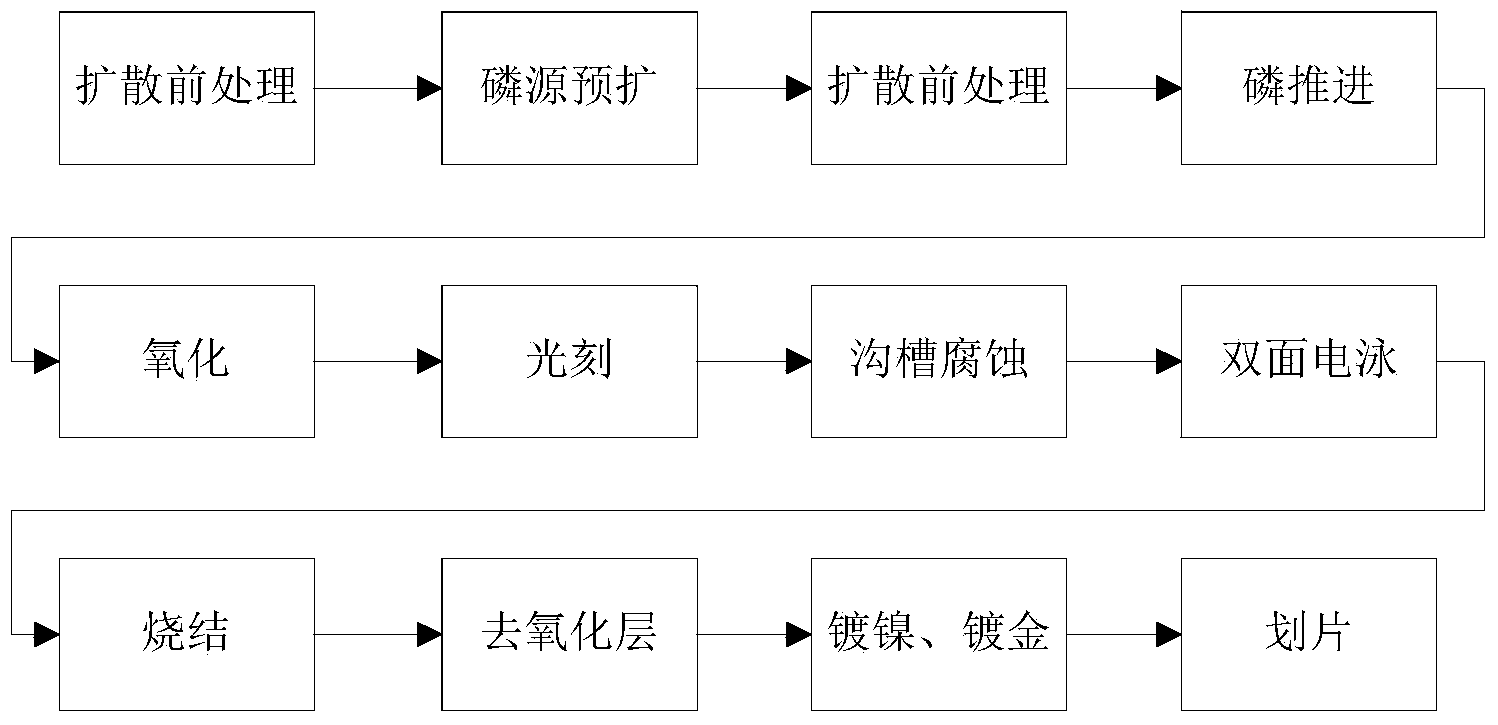

Production technology for transient voltage suppressor chip with channeling effect

InactiveCN103956324AAnti-suppression to surge capability improvementLow calorific valueSemiconductor/solid-state device manufacturingSemiconductor devicesElectrical resistance and conductanceElectrophoresis

The invention provides a production technology for a transient voltage suppressor chip with the channeling effect. By means of the steps of gaseous state source diffusion, channel corrosion and double-faced electrophoresis, in the reverse state, the width of depletion layers and the reverse voltage of the high-voltage transient voltage suppressor chip which is of the N+PN+ structure are increased along with the increase of a reverse current, when the reverse current is increased to be close to Ic, the depletion layers on the two faces make contact with each other, the channeling effect is produced, the equivalent resistance is reduced, the clamp voltage is reduced, the reverse surge capacity is improved, the reliability of a diode is improved, the service life of the diode is prolonged, and the transient voltage suppressor chip has the advantages of being good in electrical parameter uniformity, better in ohmic contact and high in reliability, the problem that the thicknesses of two glass layers are uneven due to two times of single-face electrophoresis is avoided, the glass is high in stress-resisting capability of protection and not prone to damage, and the reliability of the transient voltage suppressor chip is further improved.

Owner:TIANJIN ZHONGHUAN SEMICON CO LTD

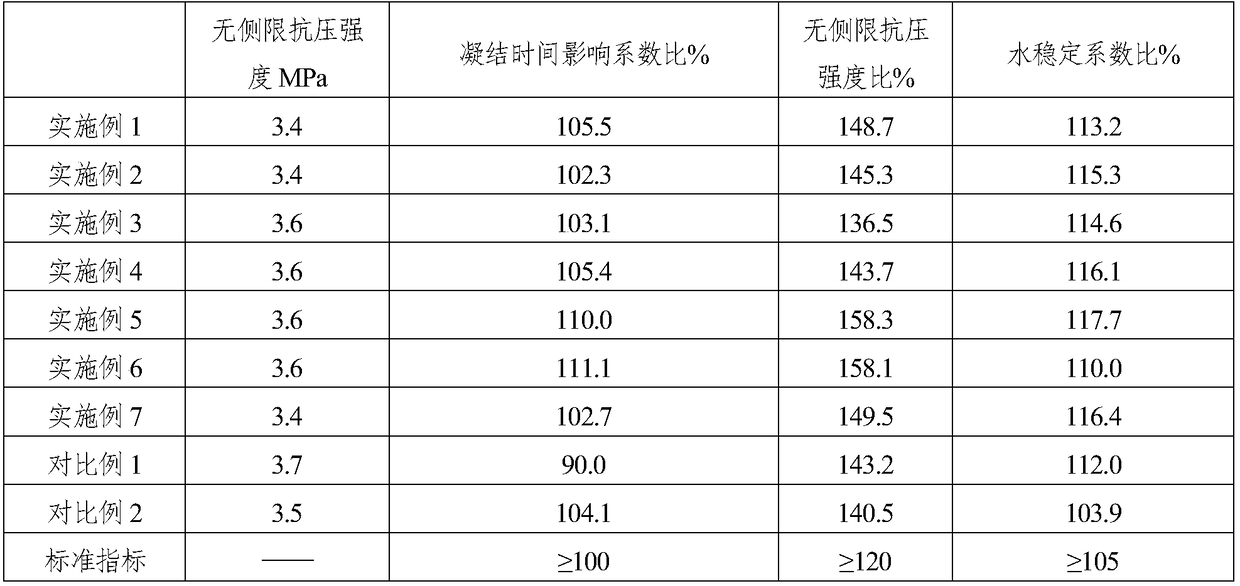

Soil curing agent and preparation method thereof

ActiveCN108707460AReduce spacingGravitational increaseBuilding constructionsOrganic fertilisersCellulosePolyol

The invention relates to a soil curing agent. The soil curing agent is prepared from the following components in parts by mass: 30 to 100 parts of sulfonated oil, 10 to 40 parts of alkylol amine, 10 to 80 parts of polyol, 0.1 to 0.5 part of polyanionic cellulose and 50 to 100 parts of water. A stabilized soil reagent prepared from the soil curing agent can obtain very good perform indexes including unconfined compression strength, high water stability and the like. Meanwhile, a soil curing agent solution is weakly alkaline so that the soil curing agent is safer to use and the environment protection is facilitated better. The invention further relates to a preparation method of the soil curing agent.

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI

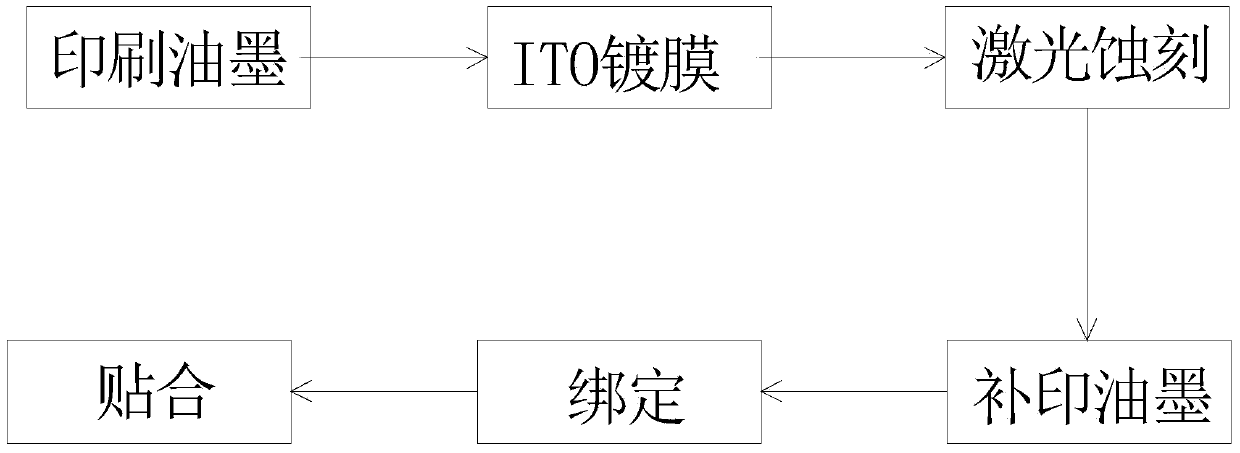

Printing ink printing method and capacitive type touch screen laser etching technology

ActiveCN103991299AInhibit sheddingNot easy to penetrateOther printing apparatusInput/output processes for data processingLaser etchingEngineering

The invention relates to the technical field of touch screens, and provides a printing ink printing method. The method comprises the following steps that firstly, a cover plate is printed with white printing ink, at least the binding area of the cover plate is printed with a white printing ink layer, and the thickness of the white printing ink layer printed on the binding layer ranges from 8 microns to 16 microns; secondly, the white printing ink layer on the cover plate is baked and solidified. The invention further provides a capacitive type touch screen laser etching technology. The technology comprises the printing ink printing procedure in the printing ink printing method, the ITO coating procedure, the laser etching procedure, the frame printing ink supplement printing procedure, the binding procedure and the pasting procedure. Compared with the prior art, the printing ink printing method has the advantage that the printing ink on the binding area can be prevented from disengaging. According to the capacitive type touch screen laser etching technology, the printing ink is prevented from being subjected to the laser in the laser etching procedure, and the yield of a capacitive touch screen is improved.

Owner:SHENZHEN YUSHUN IND INTELLIGENT TECH CO LTD +1

Method for preparing LaB6/Si-Mo gradient high-temperature anti-oxidation coating

The invention relates to a method for preparing a LaB6 / Si-Mo gradient high-temperature anti-oxidation coating. According to the method, a SiC internal coating is prepared on the surface of a C / C composite material to relieve the problem of concentrated thermal stress caused by thermal expansion coefficient difference between a matrix and the coating; the intermediate layer is a SiC-MoSi2 transition coating and serves as a transition layer of internal and external coatings, cracks, pores and other defects of the external coating generated under a high-temperature condition can be effectively reduced, the excellent high-temperature oxidation resistance of the coating can be achieved, and the resistance adaptability of the C / C composite material under high-temperature aerobic relieving condition is further improved; the LaB6 / Si-Mo coating is prepared by utilizing a plasma spraying method, so that the thickness of the coating can be accurately controlled, and the problem of uneven thickness of the coating is solved. Gradient is sequentially formed among the coatings, so that generation of thermal stress is reduced, and the binding force among the coatings is improved. Advantages of the plasma spraying method and an embedding method are combined, so that the high-temperature oxidation resistance of the coating can be greatly improved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Efficient electret filtration material and preparation method thereof

ActiveCN103657257AHigh temperature resistanceWith performanceDispersed particle filtrationFiltration separationPolymer scienceFiltration

The invention discloses an efficient electret filtration material and a preparation method thereof. The efficient electret filtration material comprises a non-woven fabric layer and a charged coating being subjected to an electret treatment, wherein the coating is positioned on the outer surface of the non-woven fabric layer. The preparation method comprises: (1) forming a non-woven fabric layer; (2) molding a coating on the outer surface of the non-woven fabric layer in a foaming manner; and (3) carrying out an electret treatment on the coating to make the coating be the electret. The efficient electret filtration material has effects of high filtration precision, low filtration resistance, high filtration efficiency, easy ash cleaning and improved filtration material service life.

Owner:中科瑞阳膜技术(北京)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com