Patents

Literature

32results about How to "Increased static contact angle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Process method for preparing ultra-hydrophobic surface by electrochemical method

ActiveCN101665968AEndows the superior performance of "self-cleaning"Apparent nanostructureAnodisationSpecial surfacesPhysical chemistryElectrochemistry

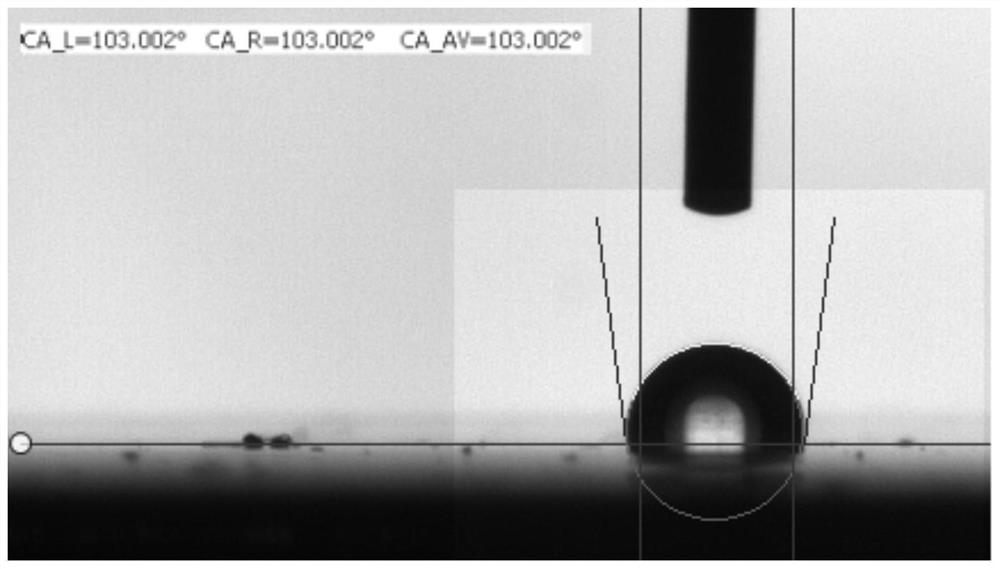

The invention discloses a process method for preparing an ultra-hydrophobic surface by the electrochemical method. The process adopts two processing steps: forming the micro nanometer double-structurerough surface by first electrochemical etching and then oxalic acid anodic oxidation; and preparing the ultra-hydrophobic surface by modifying the surface with fluorosilane. The method is simple andpractical, uses mature electrochemical etching and anodic oxidation technology, allows for easy mass production and avoids environmental pollution.

Owner:甘肃中安瑞科科技有限公司

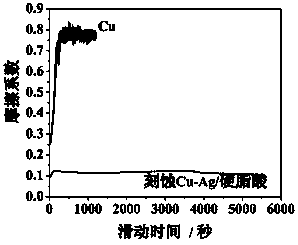

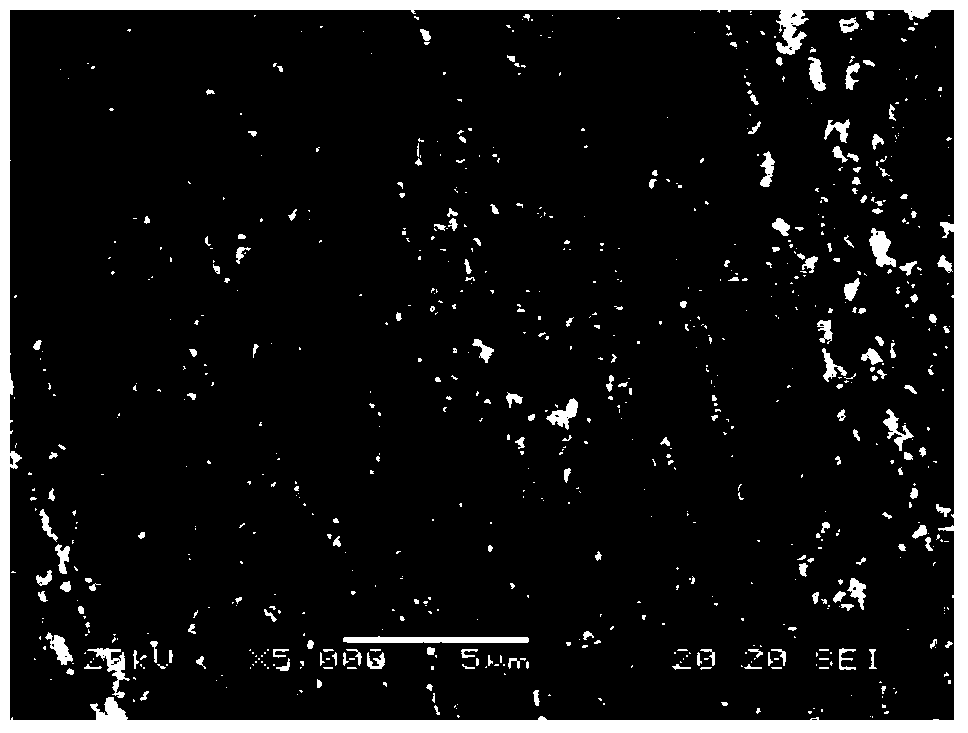

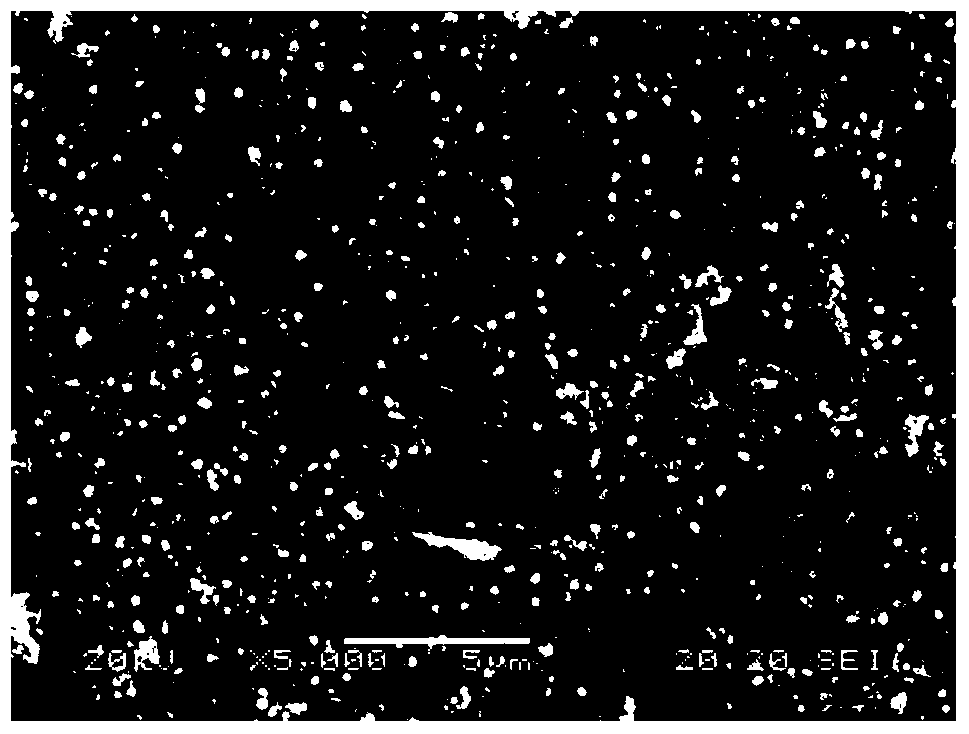

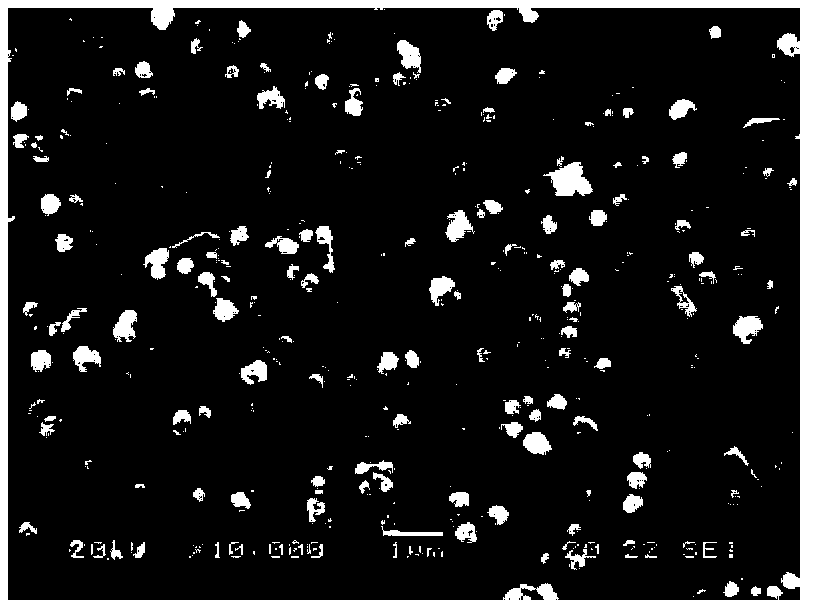

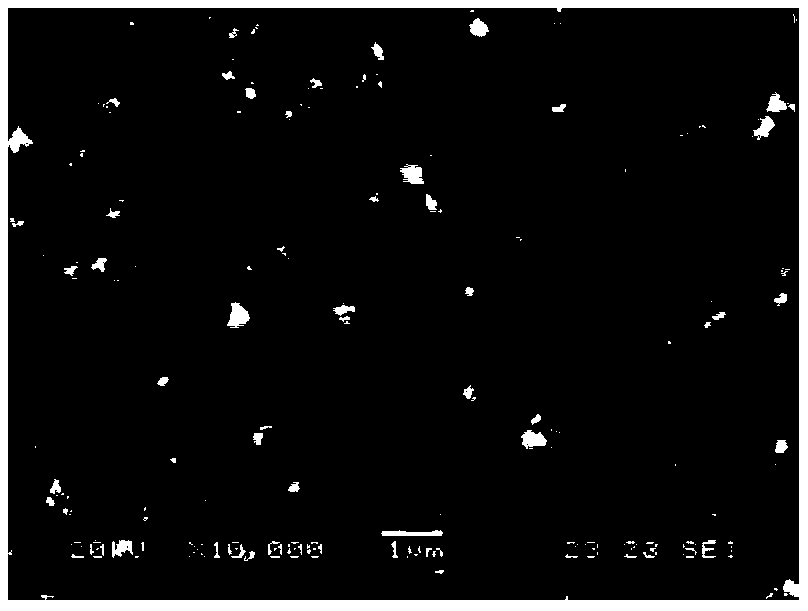

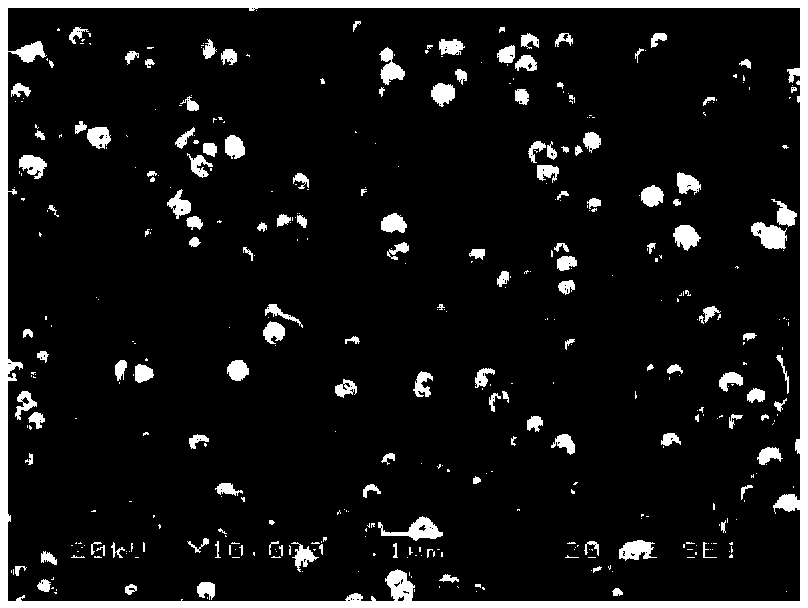

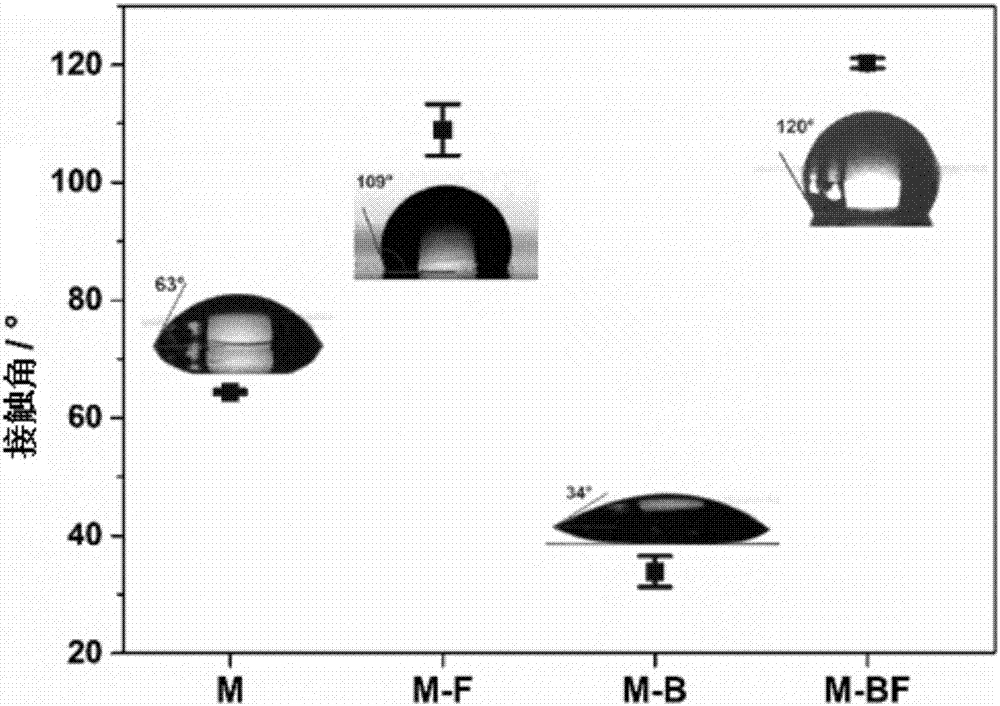

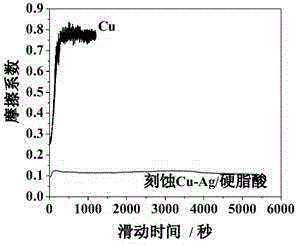

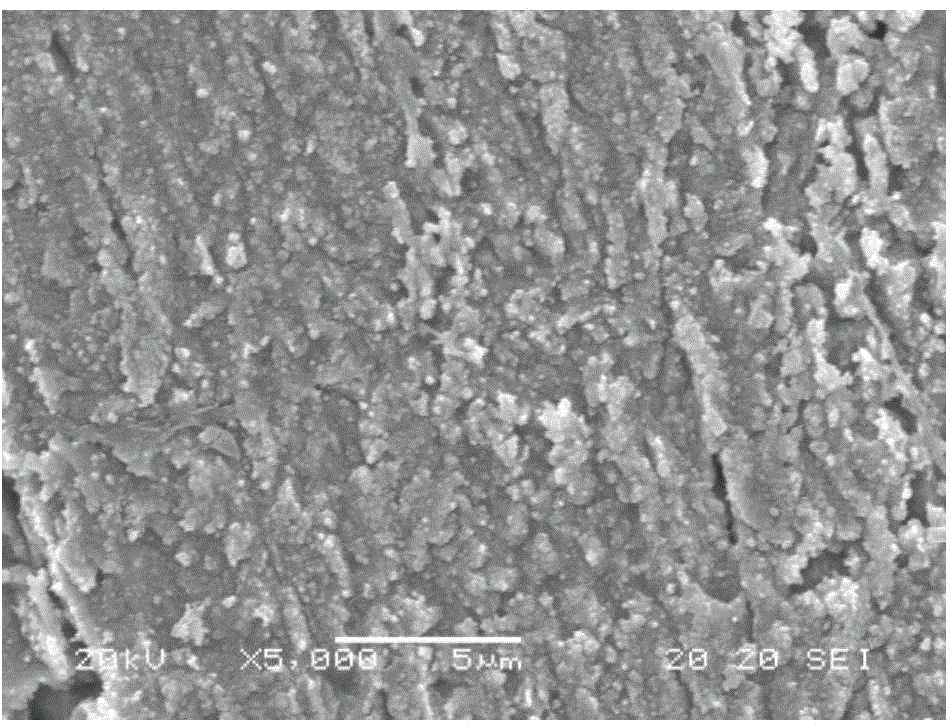

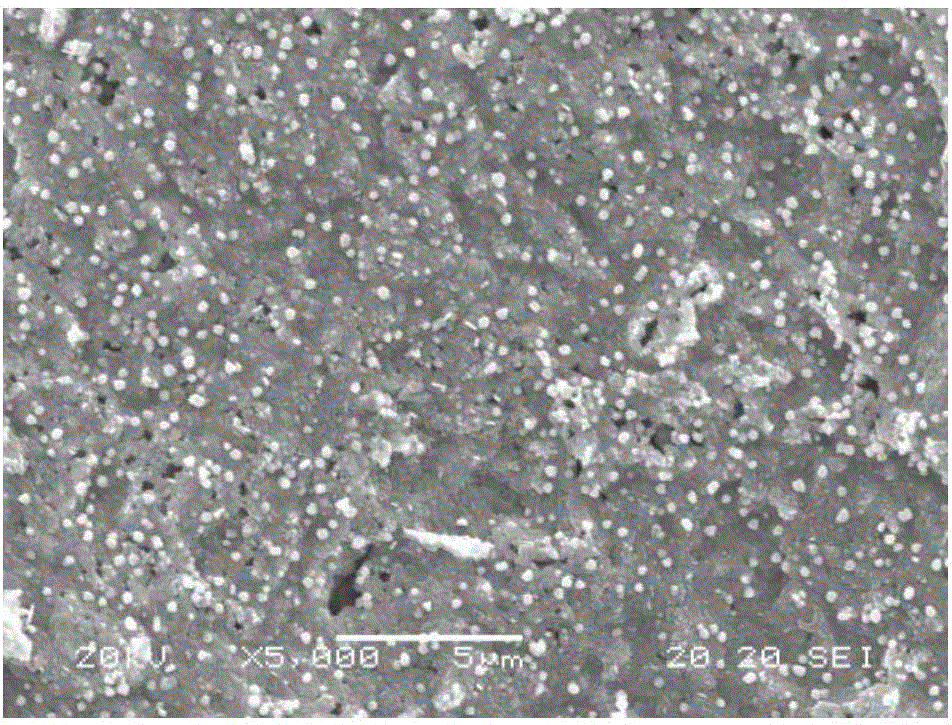

Copper based super-hydrophobic surface with low friction coefficient and preparation method thereof

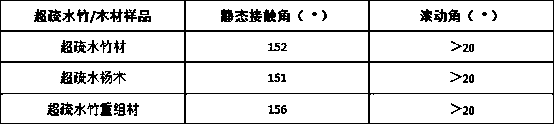

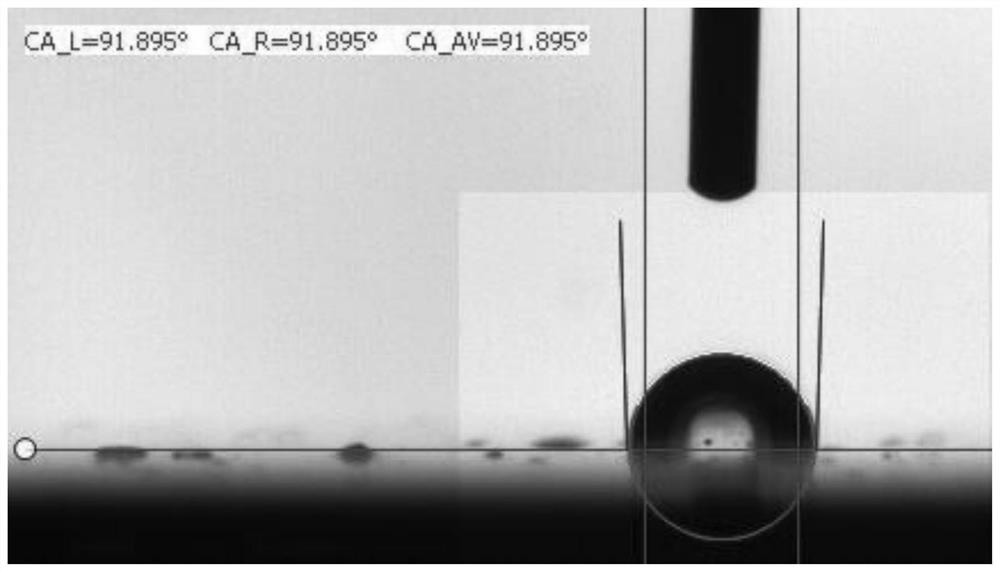

ActiveCN103469215AIncreased static contact angleReduce coefficient of frictionLiquid/solution decomposition chemical coatingMicron scaleEtching

The invention relates to a copper based super-hydrophobic surface with a low friction coefficient and a preparation method thereof. The copper based super-hydrophobic surface with a low friction coefficient is characterized in that chemical etching is performed on the surface of a copper based material to form a coarse structure with a micron-scale pit structure and submicron / nano-scale metal silver particles, and then a product is obtained through surface chemical modification. The copper based super-hydrophobic surface with low friction coefficient has a contact angle of more than 150 degrees to water, is low in friction coefficient, can be stably maintained, and has good super-hydrophobic properties and low friction coefficient.

Owner:XUCHANG UNIV

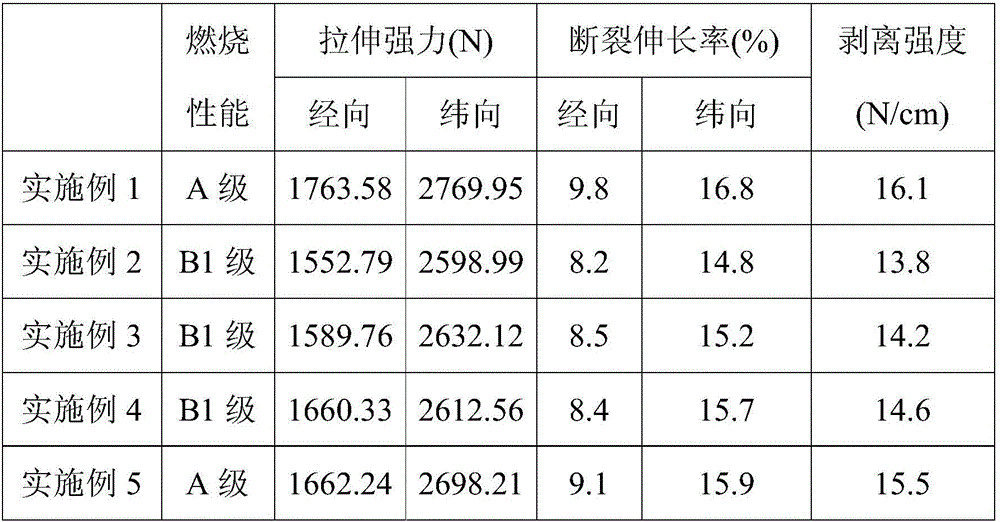

Long-lasting anti-fouling membranous-structure composite canopy material

ActiveCN106003931AIncreased static contact angleNot easy to penetrateSynthetic resin layered productsCoatingsPolyesterFiber

The invention relates to a long-lasting anti-fouling membranous-structure composite canopy material comprising a base membrane, base cloth and a surface membrane which are arranged sequentially from bottom to top, wherein a polyvinylidene fluoride coating is arranged on the surface membrane and is subjected to mirror face embossing treatment; the surface membrane as well as the base membrane is prepared from the following raw materials in parts by weight: 100 parts of polyvinyl chloride (PVC) resin powder, 50 to 70 parts of a dioctyl terephthalate plasticizer, 5 to 25 parts of calcium carbonate powder, 1 to 5 parts of a flame retardant, 1 to 4 parts of a smoke suppressant, 1 to 6 parts of a barium-zinc stabilizer and 1 to 5 parts of a titanium pigment; the base cloth is 1000D*1000D polyester fiber woven cloth. Raw materials such as PVC resin powder, the plasticizer, calcium carbonate, the stabilizer and the flame retardant are mixed, plasticizing and calendaring are carried out to obtain soft membranes, then the soft membranes are compounded with the 1000D*1000D polyester fiber woven cloth, and embossing is carried out after surface treatment of polyvinylidene fluoride, so that the long-lasting anti-fouling membranous-structure composite canopy material is a membranous-structure composite canopy material being long-lasting in fouling resistance, efficient in fire retardancy, and high in strength.

Owner:浙江明士达股份有限公司

Copper-based super-hydrophobic composite film with low friction coefficient and preparation method thereof

ActiveCN103448316AReduce coefficient of frictionLower contact angleLiquid/solution decomposition chemical coatingSuperimposed coating processComposite filmNano structuring

The invention belongs to the field of preparation of micro or / and nano-structures on surfaces of solids and specifically relates to a copper-based super-hydrophobic composite film with a low friction coefficient and a preparation method thereof. The copper-based super-hydrophobic composite film with the low friction coefficient is characterized in that a composite structure with a micro-scale cuprous oxide crystal structure and submicro-scale metal silver particles is firstly formed on the surface of a copper-based material, and then surface chemical modification is performed to obtain a product. Each contact angle between the copper-based super-hydrophobic composite film with the low friction coefficient and water exceeds 150 degrees, the friction coefficient is low (can be as low as about 0.1) and can be stably kept, and the copper-based super-hydrophobic composite film has good super-hydrophobic performance and relatively low friction coefficient.

Owner:XUCHANG UNIV

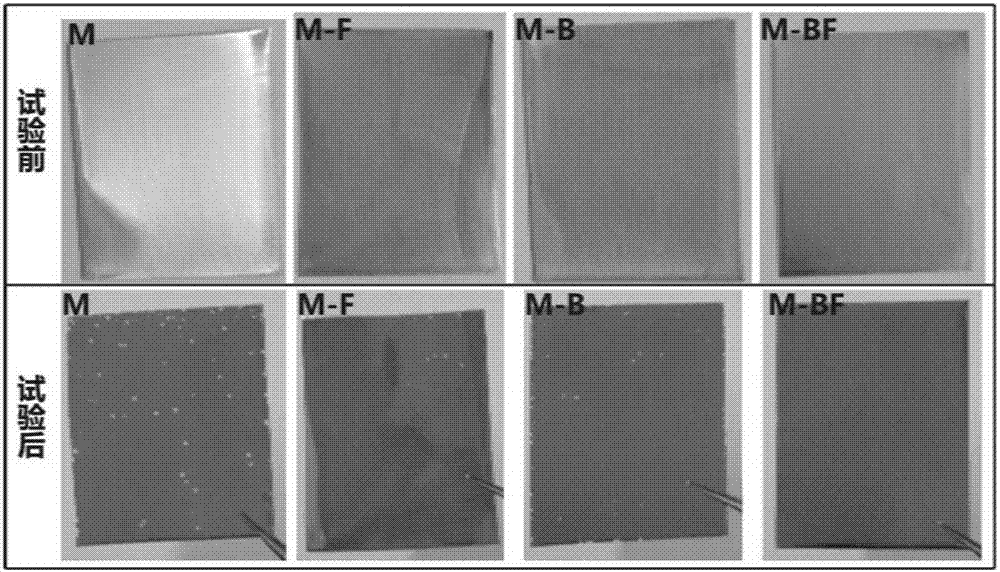

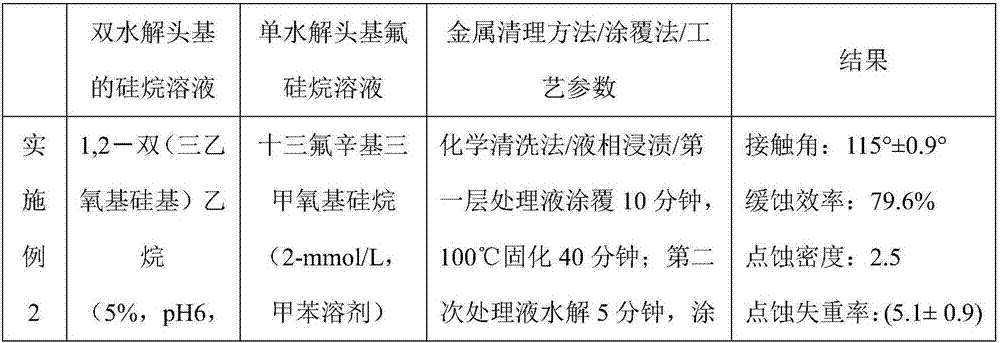

Composite silane film for metal surface and preparation method

InactiveCN107099247AImprove compactnessImprove anti-corrosion performanceAnti-corrosive paintsSilanesSewage

The invention discloses a composite silane film for metal surface. The composite silane film comprises a bihydrolysis head based silane layer and a monohydrolysis head based fluorine-containing silane layer. The composite silane film can be used for preventing corrosion and scaling, solves the problem that existing metal is prone to local corrosion and scaling in bad working conditions like seawater, sewage and chemical media and is high in compactness and superior in corrosion-resistant effect.

Owner:NANJING UNIV OF TECH

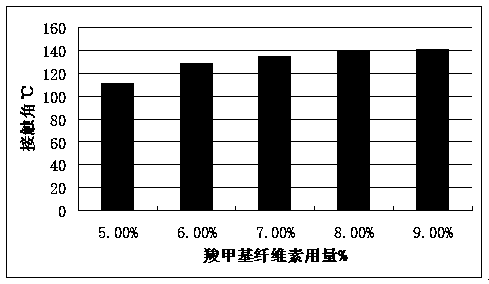

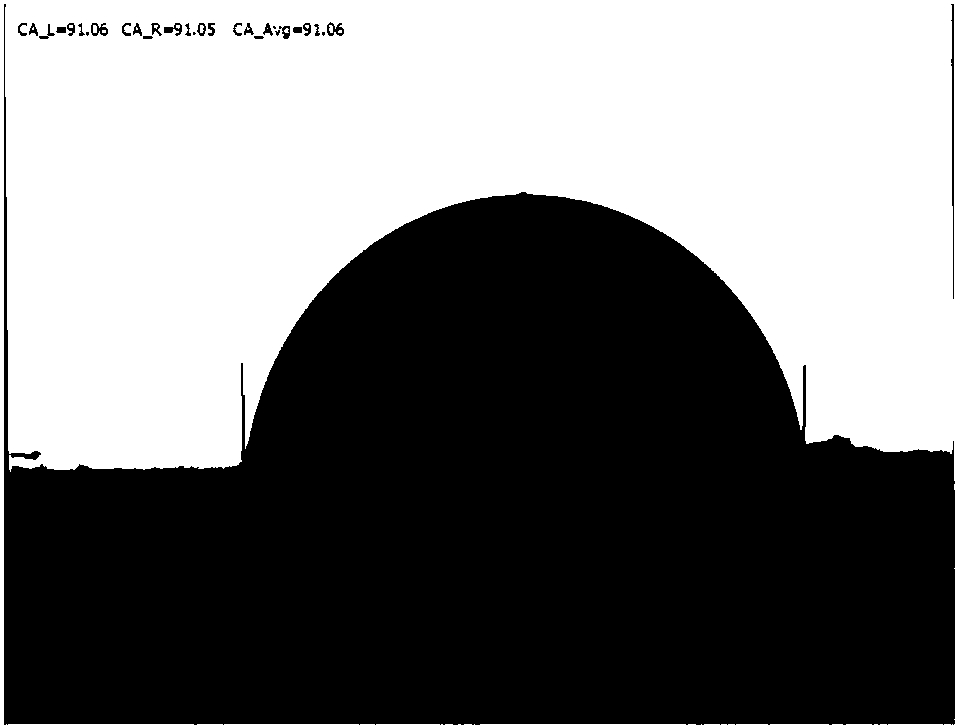

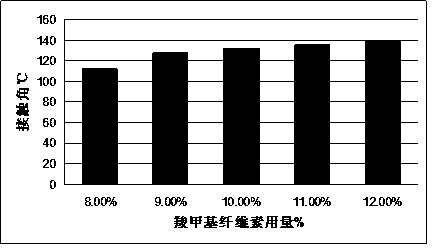

Carboxymethyl cellulose modified nanosilica-made paper

ActiveCN104358182AReduce negative impactDamage reliefPaper/cardboardInorganic compound additionCarboxymethyl celluloseAluminum sulphate

The invention relates to carboxymethyl cellulose modified nanosilica-made paper which is prepared according to the following steps: (1) aluminum sulfate is firstly made into an aqueous solution with the mass concentration of 5-20%, filter paper is impregnated with the aqueous solution of aluminum sulfate for 1-3 min, and the filter paper is dried at 100-105 DEG C and then numbered; and (2) carboxymethyl cellulose with the concentration of 6-10% is added into ethanol, nanosilica is added and dispersed in the carboxymethyl cellulose-ethanol solution according to the nanosilica-to-carboxymethyl cellulose ratio of 1:1-1:4 so as to obtain a carboxymethyl cellulose-ethanol solution containing nanosilica, and the filter paper impregnated with aluminum sulfate from the step (1) undergoes dipping-coating in the ethanol solution of carboxymethyl cellulose-nanosilica for several times; and finally air-drying is carried out for 24-48h so as to obtain the carboxymethyl cellulose modified nanosilica-made paper.

Owner:广东冠豪新材料研发有限公司

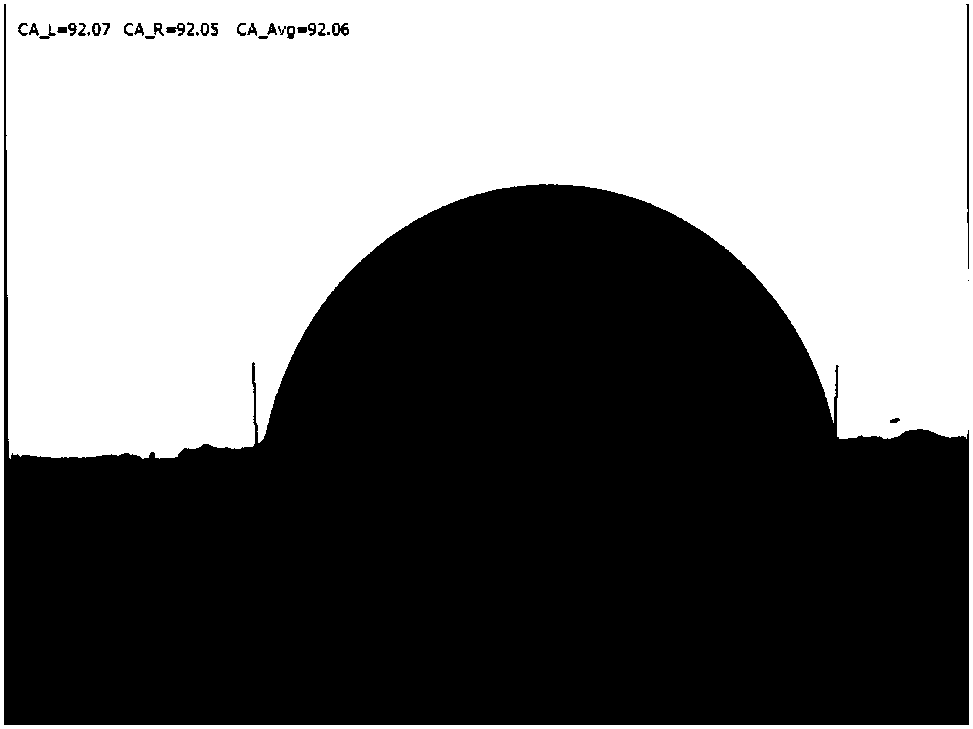

Paper manufactured with pulp by carboxymethylcellulose modified nanometer titania and preparation method thereof

ActiveCN104213463AReduce negative impactDamage reliefWater-repelling agents additionInorganic compound additionCelluloseNano titania

The invention relates to paper manufactured with pulp by carboxymethylcellulose modified nanometer titania. The paper is prepared by the following steps that (1) aluminum sulfate is prepared to form an aqueous solution with mass concentration of 5%-20%, filter paper is impregnated for one to three minutes, and the filter paper is dried at the temperature of 100 DEG C to 105 DEG C and numbered; (2) carboxymethylcellulose with concentration of 5%-9% is added into ethyl alcohol, nanometer titania is added and dispersed in a carboxymethylcellulose-ethyl alcohol solution in a ratio of nanometer titania to carboxymethylcellulose being (1:1)-(1:4) to obtain the carboxymethylcellulose-ethyl alcohol solution with the nanometer titania, and the filter paper impregnated in aluminum sulfate in the step (1) is subjected to dip-coating in the carboxymethylcellulose-nanometer titania ethanol solution for many times; then air drying is performed for 24 hours to 48 hours to obtain the paper.

Owner:度测(上海)科技服务中心

Communication base station with self-cleaning and anti-corrosion effect

ActiveCN106917085BImprove hydrophobicityIncreased static contact angleMetallic material coating processesHydrophobic effectCorrosion resistant

The application relates to a telecommunication base station with self-cleaning and corrosion-resistant effects. The telecommunication base station comprises a base station body, wherein the base station body comprises a base and a hydrophobic anti-corrosion layer arranged on the surface of the base; the hydrophobic anti-corrosion layer is formed in the way that mixed particles are sprayed onto the surface of the base through the cold spraying technology; and the base station body has a favorable hydrophobic effect, manifested as favorable self-cleaning and corrosion-resistant performance.

Owner:JIANGSU ETERN +1

Greenhouse thin film water-based hydrophobic coating as well as preparation method and application thereof

The invention discloses a water-based hydrophobic coating as well as a preparation method and application thereof. The coating comprises the following components in mass fraction: 57-80% of modified fluorocarbon resin, 2.4-4.8% of coalescing agent, 0.5-0.8% of base material wetting agent, 0.3-0.8% of leveling agent, 0-0.2% of antifoaming agent, 0-1% of thickener, 1-2% of hydrophobic agent, 3.8-7.7% of curing agent, and the balance liquid paraffin. The prepared fluorocarbon resin water-based hydrophobic coating has excellent film forming property and hydrophobicity, has high coating adhesion, is safe and environment-friendly, has simple process, and is easy for industrial production and large-scale popularization and application.

Owner:JIANGSU ACADEMY OF AGRICULTURAL SCIENCES

Paper prepared through carboxymethylcellulose modified sodium silicate pulp and preparation method thereof

InactiveCN104233904AReduce negative impactDamage reliefWater-repelling agents additionInorganic compound additionCelluloseCarboxymethyl cellulose

The invention provides paper prepared through carboxymethylcellulose modified sodium silicate pulp. The paper is prepared through the following steps: firstly, preparing water solution of aluminum sulfate with the mass concentration percent of 5-20%, dipping filter paper for 1-3 min, then drying and numbering the filter paper at 100-105 DEG C, secondly, adding sodium silicate into carboxymethylcellulose ethyl alcohol with carboxymethylcellulose concentration of 8-12% according to the ratio of sodium silicate to carboxymethylcellulose being 1:1 to 1:4, so as to ensure that the sodium silicate is dispersed in carboxymethylcellulose-ethyl alcohol solution, obtaining carboxymethylcellulose-ethyl alcohol solution containing sodium silicate, lifting and dipping the filter paper dipped by aluminum sulfate and obtained in step one into the carboxymethylcellulose-sodium silicate ethyl alcohol solution for multiple times, and then performing air drying on the filter paper for 24-48 h, so as to obtain the paper.

Owner:济南科纳信息科技有限公司

Preparation method for super-hydrophobic bamboo/wood

InactiveCN108972777AImprove hydrophobicityImprove waterproof performanceWood treatment detailsReed/straw treatmentAlcoholSurface layer

The invention discloses a preparation method for super-hydrophobic bamboo / wood. The preparation method comprises the following steps: drying bamboo and wood, soaking the dried bamboo and wood into a methylbenzene-alcohol mixed solution and vacuumizing, soaking, drying, ultrasonically cleaning and drying in vacuum for later use; preparing spherical ZnO nano-particles, and dispersing the spherical ZnO nano-particles into absolute ethyl alcohol, dropwise adding to the surfaces of bamboo and wood to form a spherical ZnO nano particle thin layer; continuously reacting to form spindle shaped ZnO nano-particles, taking out to cool, clean and dry, and vacuum drying to obtain a bamboo and wood product with a super-hydrophobic function. The preparation method has the advantages that: firstly, metaloxides are easier to deposit to form a surface layer by removing extracted components on the surface, so that waterproof properties of bamboo and wood are greatly improved; and secondly, a two-step process is adopted to construct ZnO nano-particles of different shapes on the surfaces of bamboo and wood; and the ZnO nano-particles are tightly arranged, are high in surface roughness, and are excellent in waterproof effect.

Owner:NANJING FORESTRY UNIV

A copper-based superhydrophobic surface with low coefficient of friction and preparation method thereof

ActiveCN103469215BIncreased static contact angleReduce coefficient of frictionLiquid/solution decomposition chemical coatingMicron scaleEtching

The invention relates to a copper based super-hydrophobic surface with a low friction coefficient and a preparation method thereof. The copper based super-hydrophobic surface with a low friction coefficient is characterized in that chemical etching is performed on the surface of a copper based material to form a coarse structure with a micron-scale pit structure and submicron / nano-scale metal silver particles, and then a product is obtained through surface chemical modification. The copper based super-hydrophobic surface with low friction coefficient has a contact angle of more than 150 degrees to water, is low in friction coefficient, can be stably maintained, and has good super-hydrophobic properties and low friction coefficient.

Owner:XUCHANG UNIV

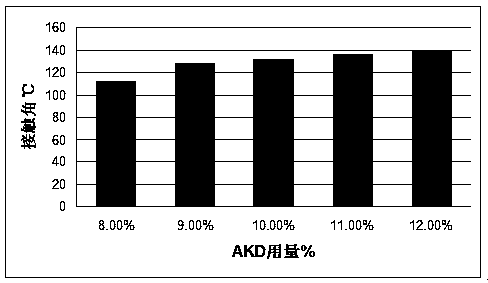

Paper made through AKD modified sodium silicate, and preparation method thereof

InactiveCN105507064AReduce negative impactDamage reliefInorganic compound additionAluminum sulphateAlcohol ethyl

The present invention relates to paper made through AKD modified sodium silicate. The preparation method comprises: (1) preparing an aluminum sulfate aqueous solution with a concentration of 5-20%, dipping filtration paper in the solution for 1-3 min, drying the filtration paper at a temperature of 100-105 DEG C, and numbering; and (2) adding AKD with a concentration of 8-12% to ethanol, adding sodium silicate according to a ratio of the sodium silicate to the AKD of 1:1-1:4, dispersing into the AKD-ethanol solution to obtain the AKD-ethanol solution containing the sodium silicate, carrying out pulling dipping on the filtration paper obtained in the step (1) in the AKD-sodium silicate ethanol solution a plurality of times, and carrying out air drying for 24-48 h so as to obtain the product.

Owner:刘瑾

Paper made through stearic acid modified nanometer silica, and preparation method thereof

InactiveCN105507072AReduce negative impactDamage reliefPaper coatingFiltration separationAluminum sulphateStearic acid

The present invention relates to paper made through stearic acid modified nanometer silica. The preparation method comprises: (1) preparing an aluminum sulfate aqueous solution with a concentration of 5-20%, dipping filtration paper in the solution for 1-3 min, drying the filtration paper at a temperature of 100-105 DEG C, and numbering; and (2) adding stearic acid with a concentration of 6-10% to ethanol, adding nanometer silica according to a ratio of the nanometer silica to the stearic acid of 1:1-1:4, dispersing into the stearic acid-ethanol solution to obtain the stearic acid-ethanol solution containing the nanometer silica, carrying out pulling dipping on the filtration paper obtained in the step (1) in the stearic acid-nanometer silica ethanol solution a plurality of times, and carrying out air drying for 24-48 h so as to obtain the product.

Owner:扈晓楠

Super-hydrophobic coating and preparation method and application thereof

InactiveCN110591007AFully dispersedEvenly dispersedPretreated surfacesLiquid repellent fibresCross-linkWater baths

The present invention discloses a super-hydrophobic coating and a preparation method and application thereof. By cross-linking and solidifying raw materials of a hydrophobic resin, a good solvent of the hydrophobic resin, organosilane, polystyrene, a photo initiator, a cross-linking agent, a curing agent and the like, through high-speed dispersion, water-bath reaction and other steps, the super-hydrophobic coating is obtained. The preparation process of the invention is simple, the reaction condition is mild, the super-hydrophobic coating prepared by the method has good adhesion and wear resistance, and has a wide application prospect in production and life.

Owner:深圳市心晴网络科技有限责任公司

Anti-condensation coating and preparation method thereof

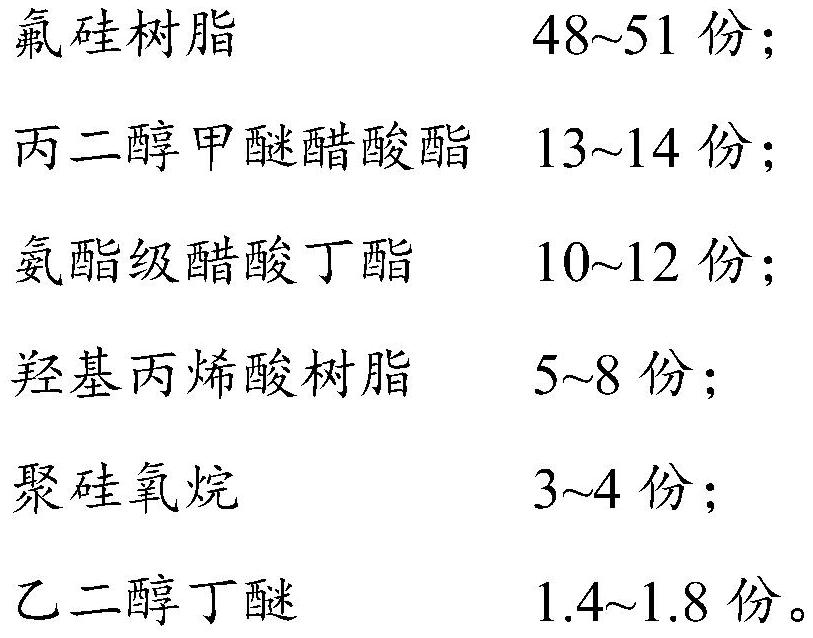

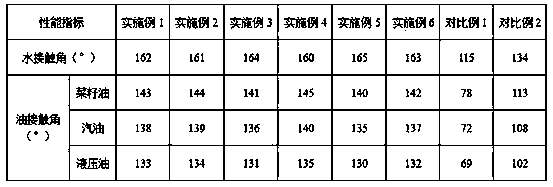

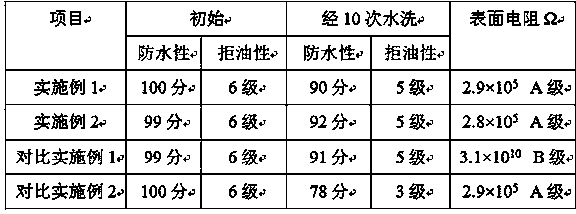

InactiveCN112920708AGood solvent resistanceGood weather resistanceCoatingsPolymer scienceWeather resistance

The invention discloses an anti-condensation coating and a preparation method thereof, and relates to the technical field of coatings. According to the anti-condensation coating provided by the invention, fluorosilicon resin is taken as a main body, and the fluorosilicon resin low-surface-energy coating has both organic silicon resin and organic fluororesin, so that the content of low-surface-energy components in the coating is increased, on the basis, other resin systems, cross-linking agents and auxiliaries are matched, so that the coating can be endowed with excellent weather resistance, hydrophobic property and the like, and therefore, the long-acting and lasting anti-condensation effect and excellent low surface energy performance are achieved. When the anti-condensation coating is sprayed on the surface of power distribution equipment, the surface performance of an insulating part and a cabinet body can be improved for a long time, condensation is prevented, and the construction, operation and maintenance cost of the anti-condensation device of the power distribution equipment can be greatly reduced.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID

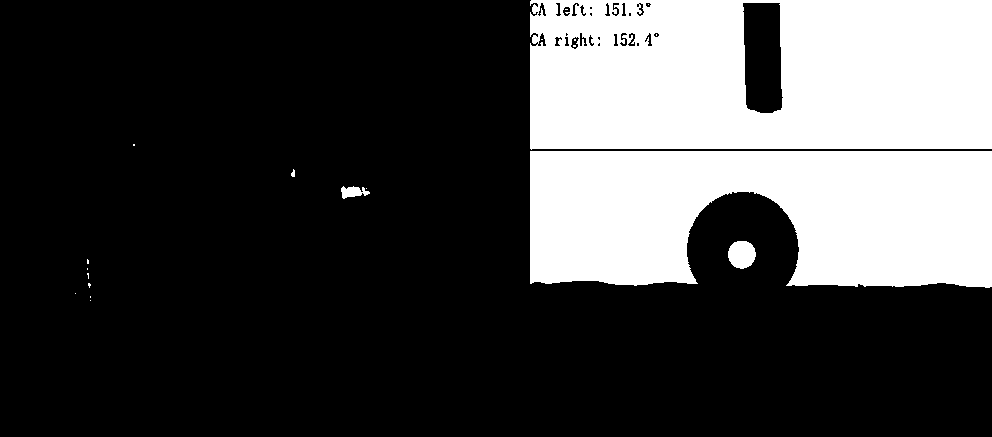

Self cleaning heat insulation paint for building outer wall and roof and preparation method thereof

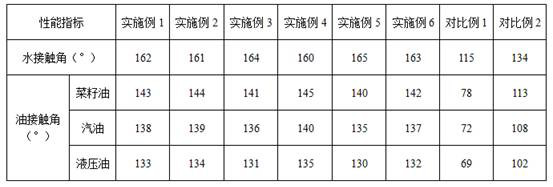

ActiveCN109880475AIncreased static contact angleImprove self-cleaning effectCoatingsSilanesPolyvinyl alcohol

The invention provides self cleaning heat insulation paint for a building outer wall and a roof and a preparation method thereof. According to the method, firstly, vinyl-vinyl acetate copolymer emulsion is used as polymerization seeds; the grafting polymerization is performed with perfluoroalkylethyl acrylate and acrylic acid; a composite emulsion is prepared; then, heptadecyl trimethoxy silane isused for performing surface modification on the micrometer and nanometer heat insulation filling materials; finally, the composite emulsion, the fluorine modified micrometer filling materials, pigments, wet dispersing agents, polyvinyl formal glue, ammonium hydroxide, crosslinking agents, antifoaming agents, UV absorbing agents and a proper amount of water are uniformly mixed to prepare the selfcleaning heat insulation paint for the building outer wall and the roof. Compared with a conventional method, the coating prepared by the heat insulation paint has high contact angle on water and oil;water drips or oil drips cannot be automatically spread on the surface of the coating and can maintain the sphere shape; the rolling falling on the surface can easily occur; other adhered contaminants can be brought away, so that good self cleaning effects are shown.

Owner:中山多涂乐建材有限公司

Method for making waterproof, oil-proof and antistatic polyester needled felt by magnetron sputtering-plasma

InactiveCN109023920AIncreased flexural lengthIncreased Static Drape CoefficientUltrasonic/sonic fibre treatmentLiquid repellent fibresPolyesterWater baths

The invention discloses a method for making a waterproof, oil-proof and antistatic polyester needled felt by magnetron sputtering-plasma. The method comprises the following steps: adding an adhesive polyacrylate to a nanometer antimony tin oxide dispersion to prepare a finishing solution, carrying out water bath heating on the finishing solution, placing a pretreated polyester needled felt in theheated finishing solution, oscillating the solution with the felt, and carrying out two-dip-two-padding, pre-drying and curing to obtain an antistatic finished polyester needled felt; and vacuumizinga vacuum chamber, introducing argon, carrying out pre-sputtering, fixing the antistatic finished polyester needled felt on a sample holder, rotating the sample holder, and carrying out magnetron sputtering on the polyester needled felt with polytetrafluoroethylene through a radiofrequency source magnetron sputtering technology by using a high-vacuum multifunctional magnetron sputtering device to obtain the waterproof, oil-proof and antistatic polyester needled felt. The obtained waterproof, oil-proof and antistatic polyester needled felt is placed in a normal-pressure plasma processing device,a vehicle speed and a treatment voltage are set, and the above polyester fabric goes through a plasma treatment area in a nitrogen atmosphere.

Owner:ANHUI LISIDA NET IND

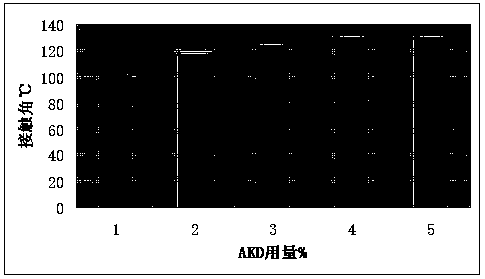

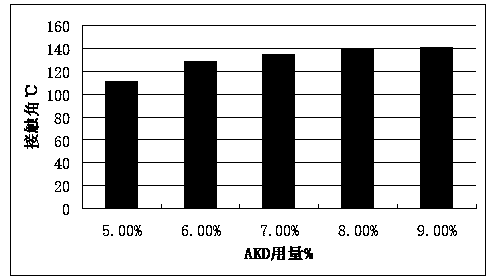

Paper made through AKD modified nanometer silica, and preparation method thereof

InactiveCN105507065AReduce negative impactDamage reliefInorganic compound additionAluminum sulphateEngineering

The present invention relates to paper made through AKD modified nanometer silica. The preparation method comprises: (1) preparing an aluminum sulfate aqueous solution with a concentration of 5-20%, dipping filtration paper in the solution for 1-3 min, drying the filtration paper at a temperature of 100-105 DEG C, and numbering; and (2) adding AKD with a concentration of 6-10% to ethanol, adding nanometer silica according to a ratio of the nanometer silica to the AKD of 1:1-1:4, dispersing into the AKD-ethanol solution to obtain the AKD-ethanol solution containing the nanometer silica, carrying out pulling dipping on the filtration paper obtained in the step (1) in the AKD-nanometer silica ethanol solution a plurality of times, and carrying out air drying for 24-48 h so as to obtain the product.

Owner:刘瑾

Paper made through AKD modified nanometer titanium dioxide, and preparation method thereof

InactiveCN105507063AReduce negative impactDamage reliefInorganic compound additionAluminum sulphateFilter paper

The present invention relates to paper made through AKD modified nanometer titanium dioxide. The preparation method comprises: (1) preparing an aluminum sulfate aqueous solution with a concentration of 5-20%, dipping filtration paper in the solution for 1-3 min, drying the filtration paper at a temperature of 100-105 DEG C, and numbering; and (2) adding AKD with a concentration of 5-9% to ethanol, adding nanometer titanium dioxide according to a ratio of the nanometer titanium dioxide to the AKD of 1:1-1:4, dispersing into the AKD-ethanol solution to obtain the AKD-ethanol solution containing the nanometer titanium dioxide, carrying out pulling dipping on the filtration paper obtained in the step (1) in the AKD-nanometer titanium dioxide ethanol solution a plurality of times, and carrying out air drying for 24-48 h so as to obtain the product.

Owner:刘瑾

Paper made through stearic acid modified nanometer titanium dioxide, and preparation method thereof

InactiveCN105507071AReduce negative impactDamage reliefCoatings with pigmentsPaper/cardboardAluminum sulphateStearic acid

The present invention relates to paper made through stearic acid modified nanometer titanium dioxide. The preparation method comprises: (1) preparing an aluminum sulfate aqueous solution with a concentration of 5-20%, dipping filtration paper in the solution for 1-3 min, drying the filtration paper at a temperature of 100-105 DEG C, and numbering; and (2) adding stearic acid with a concentration of 5-9% to ethanol, adding nanometer titanium dioxide according to a ratio of the nanometer titanium dioxide to the stearic acid of 1:1-1:4, dispersing into the stearic acid-ethanol solution to obtain the stearic acid-ethanol solution containing the nanometer titanium dioxide, carrying out pulling dipping on the filtration paper obtained in the step (1) in the stearic acid-nanometer titanium dioxide ethanol solution a plurality of times, and carrying out air drying for 24-48 h so as to obtain the product.

Owner:扈晓楠

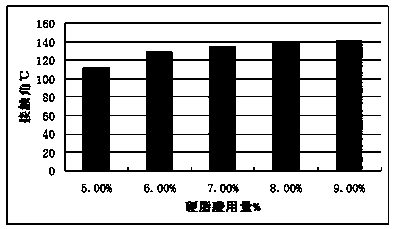

Hydrophobic modification method of mulberry twig AQ-sodium hydroxide method chemical pulp papermaking paper

InactiveCN105507066AReduce negative impactDamage reliefInorganic compound additionTriethoxysilaneAluminum sulphate

The present invention relates to a paper made through isobutyl triethoxy silane-modified wollastonite. The preparation method comprises: (1) preparing an (1) preparing an aluminum sulfate aqueous solution with a concentration of 5-20%, dipping filtration paper in the solution for 1-3 min, drying the filtration paper at a temperature of 100-105 DEG C, and numbering; and (2) adding isobutyl triethoxy silane with a concentration of 8-12% to ethanol, adding wollastonite according to a ratio of the wollastonite to the isobutyl triethoxy silane of 1:1-1:4, dispersing into the isobutyl triethoxy silane-ethanol solution to obtain the isobutyl triethoxy silane-ethanol solution containing the wollastonite, carrying out pulling dipping on the filtration paper obtained in the step (1) in the isobutyl triethoxy silane-wollastonite ethanol solution a plurality of times, and carrying out air drying for 24-48 h so as to obtain the product.

Owner:张琳

Paper made through ASA modified nanometer silica, and preparation method thereof

InactiveCN105507068AReduce negative impactDamage reliefPaper/cardboardInorganic compound additionAluminum sulphateFilter paper

The present invention relates to paper made through ASA modified nanometer silica. The preparation method comprises: (1) preparing an aluminum sulfate aqueous solution with a concentration of 5-20%, dipping filtration paper in the solution for 1-3 min, drying the filtration paper at a temperature of 100-105 DEG C, and numbering; and (2) adding ASA with a concentration of 6-10% to ethanol, adding nanometer silica according to a ratio of the nanometer silica to the ASA of 1:1-1:4, dispersing into the ASA-ethanol solution to obtain the ASA-ethanol solution containing the nanometer silica, carrying out pulling dipping on the filtration paper obtained in the step (1) in the ASA-nanometer silica ethanol solution a plurality of times, and carrying out air drying for 24-48 h so as to obtain the product.

Owner:唐雯

Paper made through solid paraffin modified nanometer silica, and preparation method thereof

InactiveCN105507069AReduce negative impactDamage reliefWax additionInorganic compound additionParaffin waxAluminum sulphate

The present invention relates to paper made through solid paraffin modified nanometer silica. The preparation method comprises: (1) preparing an aluminum sulfate aqueous solution with a concentration of 5-20%, dipping filtration paper in the solution for 1-3 min, drying the filtration paper at a temperature of 100-105 DEG C, and numbering; and (2) adding solid paraffin with a concentration of 6-10% to ethanol, adding nanometer silica according to a ratio of the nanometer silica to the solid paraffin of 1:1-1:4, dispersing into the solid paraffin-ethanol solution to obtain the solid paraffin-ethanol solution containing the nanometer silica, carrying out pulling dipping on the filtration paper obtained in the step (1) in the solid paraffin-nanometer silica ethanol solution a plurality of times, and carrying out air drying for 24-48 h so as to obtain the product.

Owner:扈嘉正

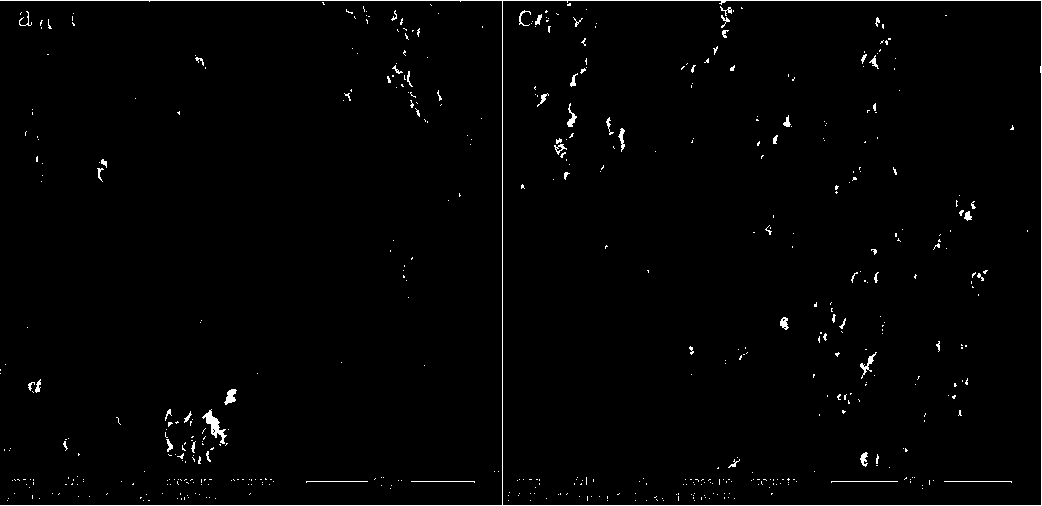

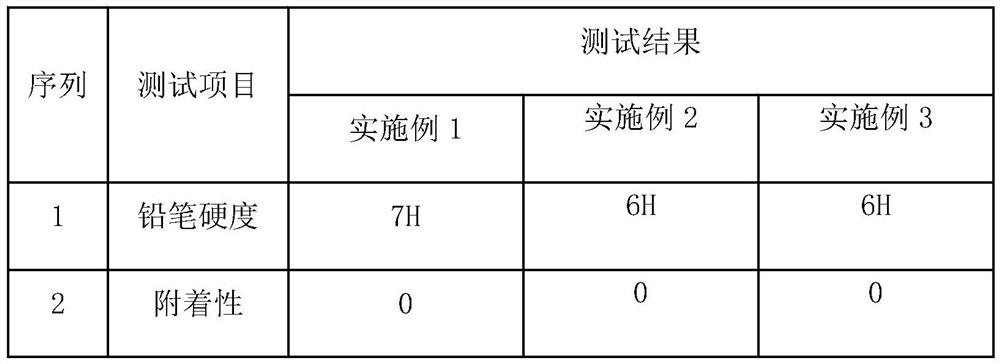

A kind of high wear-resistant rose petal effect titanium alloy surface preparation method

ActiveCN113463159BIncreased static contact angleExcellent Adhesive PropertiesAnodisationPretreated surfacesTitanium alloyLubrication

The invention discloses a method for preparing a surface of a titanium alloy with a high wear-resistant rose petal effect, which is specifically implemented according to the following steps: step 1, surface pretreatment of the titanium alloy; step 2, construction of a microstructure on the surface of the titanium alloy; step 3, electrophoretic deposition treatment; Step 4, fluorination treatment, and finally a high adhesion surface is obtained. The present invention solves the problem of lubricant creep loss during mechanical lubrication existing in the prior art.

Owner:XIAN UNIV OF TECH

Preparation method of high-abrasion-resistant titanium alloy surface with rose petal effect

ActiveCN113463159AIncreased static contact angleExcellent Adhesive PropertiesAnodisationPretreated surfacesElectrophoresesTitanium alloy

The invention discloses a preparation method of a high-abrasion-resistant titanium alloy surface with a rose petal effect. The preparation method is implemented specifically according to the following steps: step 1, pretreating the titanium alloy surface; step 2, constructing a titanium alloy surface microstructure; step 3, carrying out electrophoretic deposition treatment; and step 4, carrying out fluoridation treatment, so as to obtain the high-adhesion surface finally. Through the preparation method, the problem about the creeping loss of a lubricant during mechanical lubrication in the prior art can be solved.

Owner:XIAN UNIV OF TECH

A kind of self-cleaning heat-insulation paint for building exterior wall, roof and preparation method

ActiveCN109880475BIncreased static contact angleImprove self-cleaning effectCoatingsPolymer sciencePolyvinyl alcohol

The invention provides a self-cleaning heat-insulating coating for building exterior walls and roofs and a preparation method. In this method, ethylene-vinyl acetate copolymer emulsion is used as the polymerization seed, and perfluoroalkyl ethyl acrylate and acrylic acid are grafted and copolymerized to obtain a composite emulsion, and then micronized with heptadecafluorodecyltrimethoxysilane and nano thermal insulation fillers for surface modification, and finally composite emulsion, fluorine-modified micro-fillers, fluorine-modified nano-fillers, pigments, wetting and dispersing agents, polyvinyl formal glue, ammonia water, cross-linking agents, defoamers, ultraviolet absorbers The self-cleaning heat-insulating coating for exterior walls and roofs of buildings can be obtained by mixing uniformly with the agent and appropriate amount of water. Compared with the traditional method, the coating made of the heat-insulating coating of the present invention has a higher contact angle to water and oil, and the water drop or oil drop cannot automatically expand on the coating surface and maintain a spherical shape, and it is easy to roll off the surface And take away other adhered pollutants, thus showing a good self-cleaning effect.

Owner:中山多涂乐建材有限公司

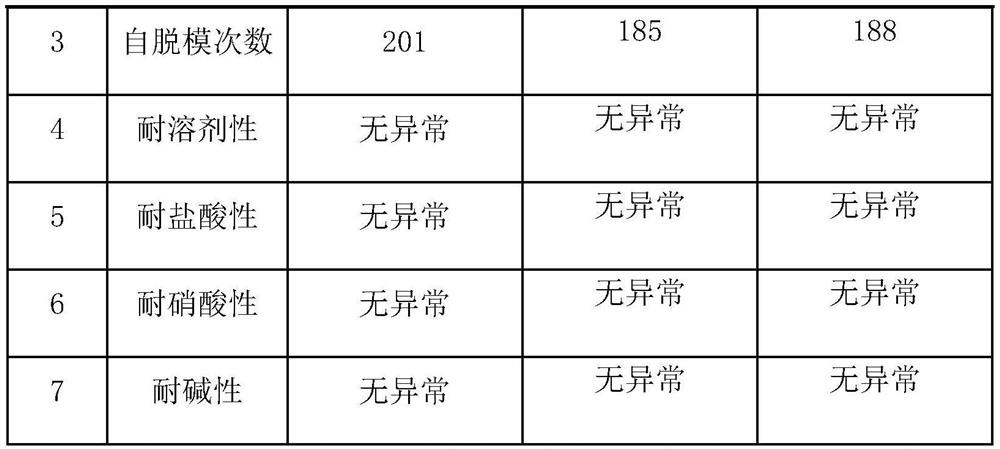

Self-demoulding mold and preparation method thereof

The invention discloses a self-demolding mold, which comprises a mold base material, the use surface of the mold base material is coated with a self-demolding layer, and the self-demolding layer is an inorganic coating; wherein the inorganic coating is prepared from the following components by mass: 25-45 parts of nano silicon dioxide sol, 25-45 parts of organosilane, 5-10 parts of functional filler, 5-15 parts of water, 10-20 parts of inorganic pigment, 2-5 parts of a functional additive and 0.1-2 parts of a thickening agent. The mold disclosed by the invention has the characteristics of self-demolding property, high environmental friendliness, reduction of production flow and saving of production time and production cost.

Owner:舾蒙新材料科技(上海)有限公司

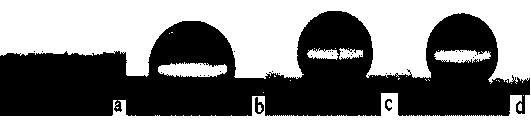

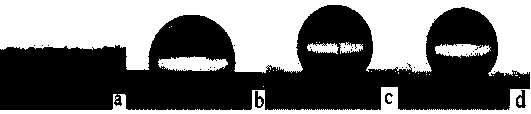

PVC film with self-cleaning function

The invention provides a PVC film with a self-cleaning function, and belongs to the technical field of chemical materials. The invention discloses a PVC (polyvinyl chloride) composite material which comprises the following raw materials in parts by weight: 80-120 parts of PVC resin powder, 20-25 parts of a plasticizer, 20-25 parts of a stabilizer, 15-25 parts of polyethersulfone and 1-5 parts of fluorine-containing polysiloxane. The fluorine-containing polysiloxane forms relatively loose ion pairs, a micro-nano coarse structure simulating the lotus leaf surface is formed, the super-hydrophobic state is achieved, the static contact angle of water drops on the surface of the PVC film can be remarkably increased, more gas is intercepted, at the moment, the liquid drops are not prone to permeating into the coarse structure, and the PVC film has the excellent self-cleaning performance.

Owner:浙江宏仕达科技股份有限公司

A composite canopy material with long-lasting antifouling film structure

ActiveCN106003931BIncreased static contact angleNot easy to penetrateSynthetic resin layered productsCoatingsFiberPolyester

The invention relates to a long-lasting anti-fouling membranous-structure composite canopy material comprising a base membrane, base cloth and a surface membrane which are arranged sequentially from bottom to top, wherein a polyvinylidene fluoride coating is arranged on the surface membrane and is subjected to mirror face embossing treatment; the surface membrane as well as the base membrane is prepared from the following raw materials in parts by weight: 100 parts of polyvinyl chloride (PVC) resin powder, 50 to 70 parts of a dioctyl terephthalate plasticizer, 5 to 25 parts of calcium carbonate powder, 1 to 5 parts of a flame retardant, 1 to 4 parts of a smoke suppressant, 1 to 6 parts of a barium-zinc stabilizer and 1 to 5 parts of a titanium pigment; the base cloth is 1000D*1000D polyester fiber woven cloth. Raw materials such as PVC resin powder, the plasticizer, calcium carbonate, the stabilizer and the flame retardant are mixed, plasticizing and calendaring are carried out to obtain soft membranes, then the soft membranes are compounded with the 1000D*1000D polyester fiber woven cloth, and embossing is carried out after surface treatment of polyvinylidene fluoride, so that the long-lasting anti-fouling membranous-structure composite canopy material is a membranous-structure composite canopy material being long-lasting in fouling resistance, efficient in fire retardancy, and high in strength.

Owner:浙江明士达股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com