Patents

Literature

293results about "Wax addition" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Absorbent sheet exhibiting resistance to moisture penetration

ActiveUS20040250969A1Reduce feelingsReduce wetted areaNatural cellulose pulp/paperMechanical working/deformationWaxFiber

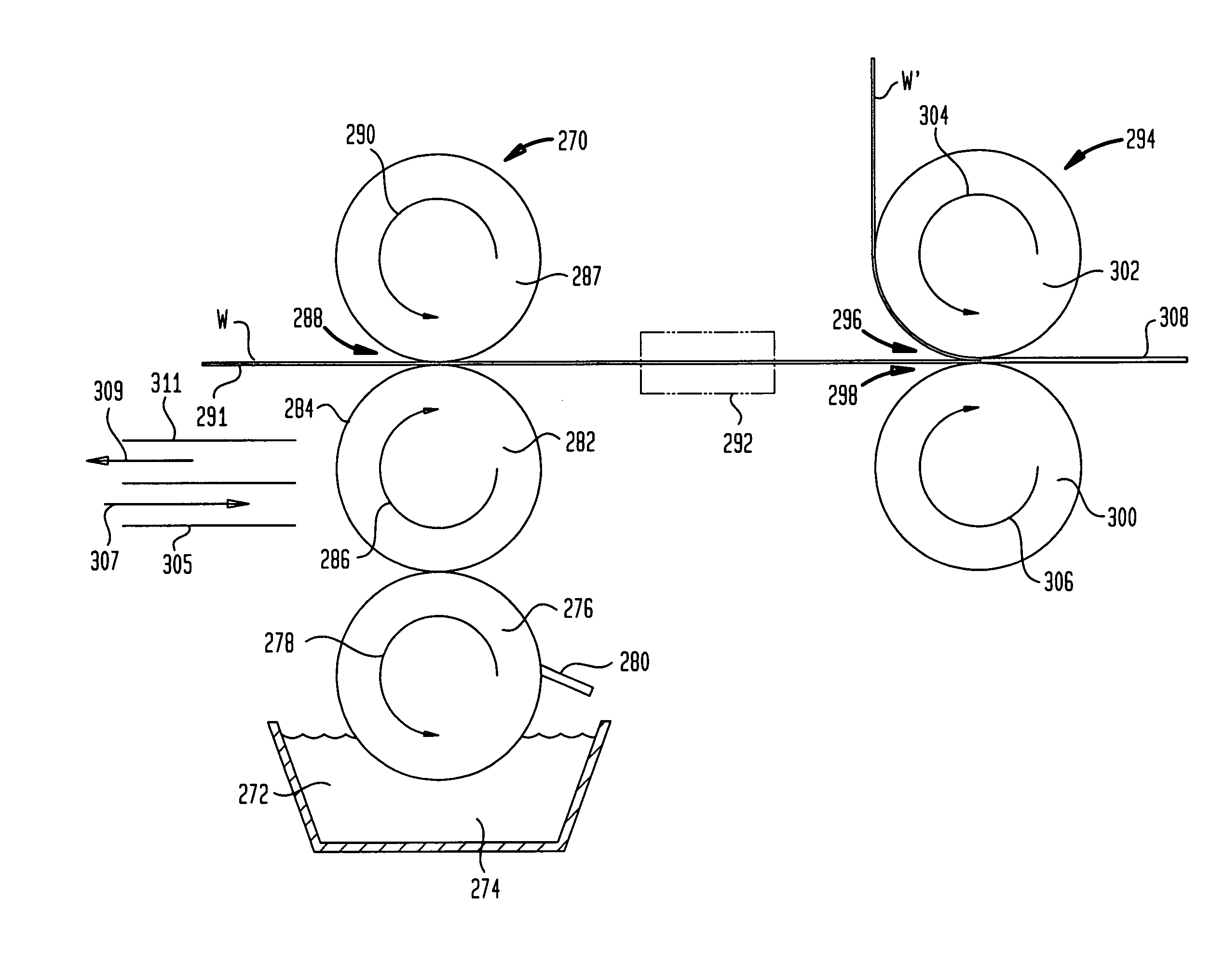

An absorbent paper sheet is treated with an aqueous wax dispersion such that the sheet includes a fused wax and emulsifier residue in an amount of from about 1 to about 20 weight percent of the sheet based on the combined weight of the fiber, wax residue and an emulsifier residue in the sheet. The fused wax emulsion operates to make at least one surface of the sheet laterally hydrophobic, exhibiting a moisture penetration delay of at least about 2 seconds and less than about 40 seconds as well as a typical contact angle with water at one minute of at least about 50 degrees. There is thus provided absorbent products which exhibit both absorbency and resistance to moisture penetration. The treated sheet further exhibits microbial barrier properties, impeding transfer of bacteria, for example, through the sheet. There are produced tissue products which resist moisture penetration from propelled liquids as well as sequester sorbed liquids in the interior of the tissue.

Owner:GPCP IP HLDG LLC

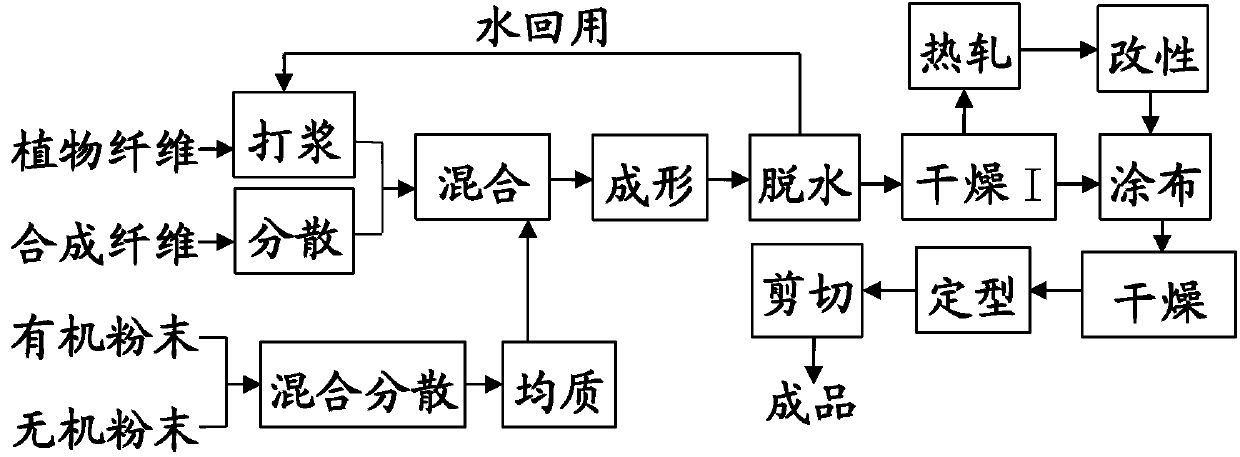

Battery and capacitor diaphragm filter material formed by wet nonwoven fabrics and preparation method of filter material

InactiveCN103100264AImprove uniformityHigh strengthCoatings with pigmentsElectrolytic capacitorsSocial benefitsHigh diaphragm

The invention discloses a battery and capacitor diaphragm filter material formed by wet nonwoven fabrics and a preparation method of the filter material. The fiber materials are as follows in percentage by weight: 0.1%-2.5% of plant fibers and 80%-99.9% of synthetic fibers, inorganic powder being 45%-1000% of the weight of the fiber, organic powder being 0-50% of the weight of the fibers, and strengthening binder being 0.5%-15% of the weight of the fibers. The preparation method of the filter material comprises the following steps of: pulping the plant fiber and the synthetic fibers, respectively; homogenizing and mixing the inorganic powder with the organic powder under high pressure, and forming the mixture into a single layer or a plurality of layers by a mixer; coating, thermally rolling and modifying the mixture, so that various physical and chemical indexes of the diagram are improved, the pore diameter size can be effectively controlled and the uniformity of the pore diameter is improved; moreover, treelike crystals can be prevented from being generated by maze type bent holes; the filtering precision and the efficiency are high; the inner resistance of the diagram is high; the liquid retaining rate and the high temperature resistance of the diagram are improved; the over-temperature closed-cell protection is improved; the dimension deformation is small; the service life is long; and the economic benefits and the social benefits are better.

Owner:吕凯

Wax emulsion preservative compositions and method of manufacture

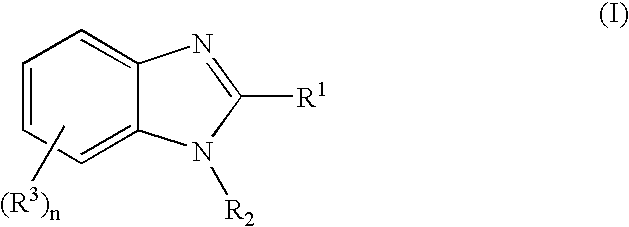

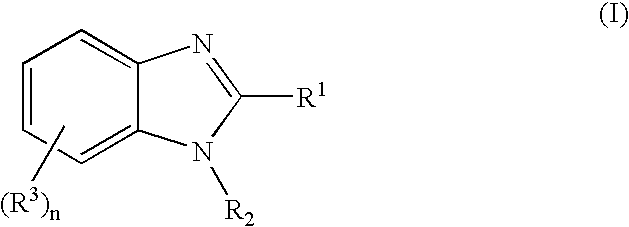

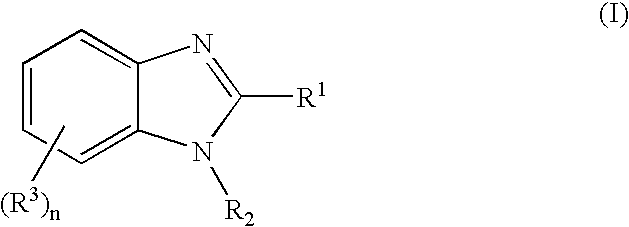

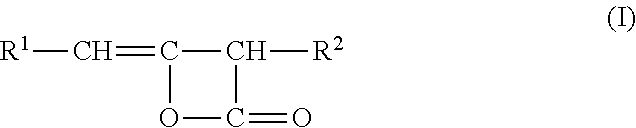

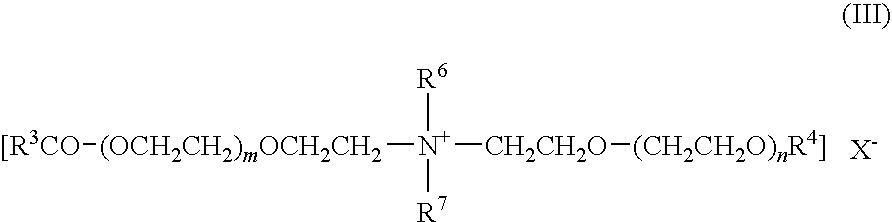

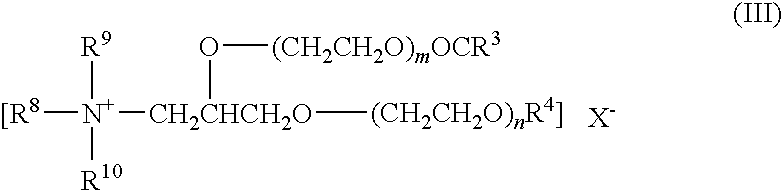

An emulsion comprising water as the continuous phase, a wax as the discontinuous phase, an emulsifier and a preservative having the general structure:wherein R1 can be a heterocycle containing nitrogen and sulfur, such as thiazolyl, isothiazolyl, or thiadiazolyl, which can optionally be substituted with C1–C6 alkyl; R2 can be hydrogen or C1–C6 alkyl, specifically hydrogen; n is 0, 1, 2, or 3; each instance of R3 can independently be hydrogen, C1–C6 alkyl, phenoxy, C1–C6 alkoxy, halo, amino, C1–C6 alkylamino, di C1–C6 alkyl amino, imidazolyl, thiazolyl, isothiazolyl, thiadiazolyl, thienyl, furyl, pyrryl, naphthyl, phenyl, halophenyl, C1–C6 alkyl phenyl, or C1–C6 alkoxyphenyl. The preservative may be added to the emulsion after the emulsion is formed. The emulsion can be incorporated into a gypsum product such as gypsum board or gypsum wood fiber board. The gypsum product may be made by forming a slurry containing gypsum, water, and the emulsion into a solid product. A method for improving the water resistance of a lignocellulosic composite product prepared by mixing lignocellulosic material with a binder to form a mixture and solidifying the mixture in a selected configuration to form the composite product may include adding to the mixture an emulsion as described above.

Owner:MOMENTIVE SPECIALTY CHEMICALS

Absorbent sheet exhibiting resistance to moisture penetration

ActiveUS7300547B2Reduce feelingsReduce wetted areaNatural cellulose pulp/paperMechanical working/deformationWaxFiber

An absorbent paper sheet is treated with an aqueous wax dispersion such that the sheet includes a fused wax and emulsifier residue in an amount of from about 1 to about 20 weight percent of the sheet based on the combined weight of the fiber, wax residue and an emulsifier residue in the sheet. The fused wax emulsion operates to make at least one surface of the sheet laterally hydrophobic, exhibiting a moisture penetration delay of at least about 2 seconds and less than about 40 seconds as well as a typical contact angle with water at one minute of at least about 50 degrees. There is thus provided absorbent products which exhibit both absorbency and resistance to moisture penetration. The treated sheet further exhibits microbial barrier properties, impeding transfer of bacteria, for example, through the sheet. There are produced tissue products which resist moisture penetration from propelled liquids as well as sequester sorbed liquids in the interior of the tissue.

Owner:GPCP IP HLDG LLC

Softening lotion composition, use thereof in paper making, and resulting paper product

InactiveUS6207014B1Soft and slippery feelGreat pliancyCosmetic preparationsNatural cellulose pulp/paperFiberLotion

The invention concerns in particular a composition for a softening lotion used in fiber treatment. In the invention, the lotion composition is aqueous and liquid at a temperature of at least 5° C. and comprises, as active substances: (a) one or more saturated linear fatty alcohols having at least 16 carbon atoms, and (b) one or more waxy esters having a total of at least 24 carbon atoms. The application of the invention is to the manufacture of fibrous products such as disposable absorbent paper products.

Owner:COGNIS FRANCE SA +1

Wax emulsion coating applications

Owner:MARCUS OIL & CHEM

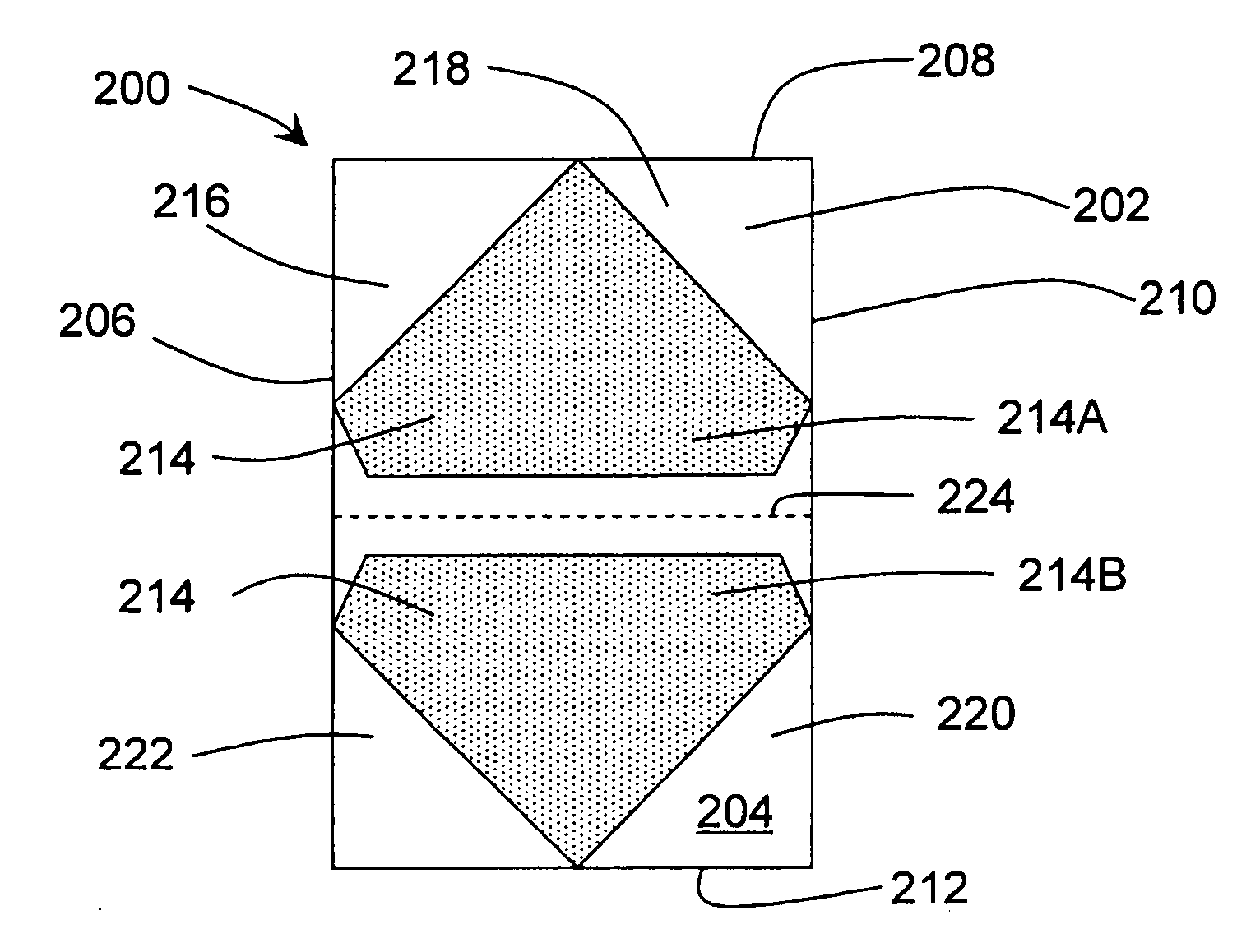

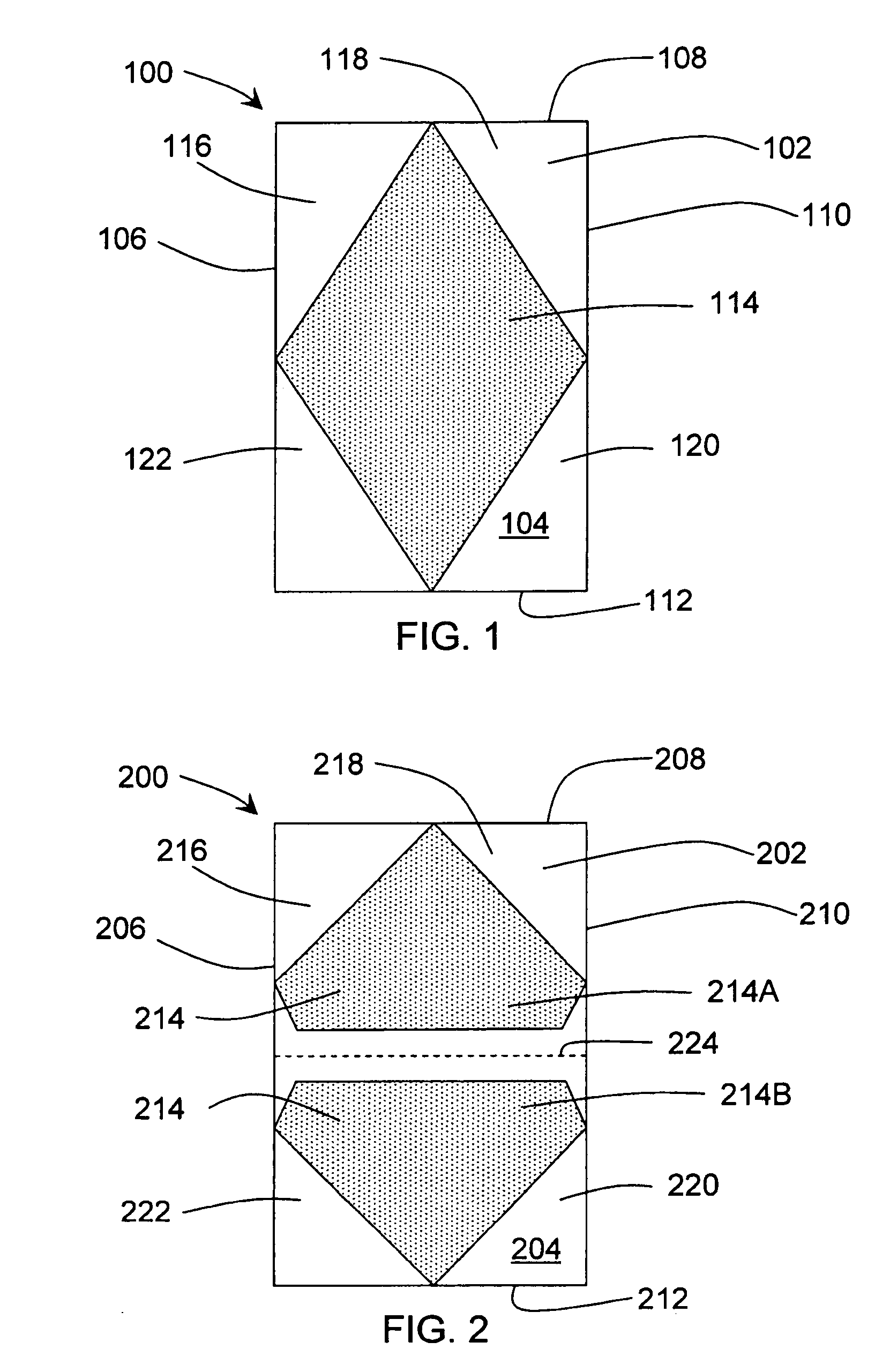

Surface treated paper product

InactiveUS20050241789A1Natural cellulose pulp/paperPaper after-treatmentProduct PartBiomedical engineering

A soft tissue product includes a surface treatment composition disposed on a treated portion that extends to the edges of the product, but which leaves the corners of the product untreated. The shape of the treated portion effectively ensures consumer benefit while reducing the total amount of additive composition on the product by placing the treatment composition in the portion of the product that is most likely to come into contact with the skin of a user.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Crepe facilitating composition

InactiveUS20070000630A1Improve stress distributionGood flexibilityMechanical working/deformationSpecial paperFiberWater insoluble

The invention relates to a crepe facilitating aqueous composition comprising at least one water-insoluble, non-surface active thermoplastic material having a softening or melting point within the range of from 40° C. to 100° C., and at least one water-soluble polymer, preferably a cationic water-soluble polymer. As the composition is comprised in a wet fibre web during creping thereof, a more uniform creping is obtained while the integrity of the web is preserved and dust formation is reduced, and a tissue product having improved properties is provided.

Owner:BIM KEMI

Tissue paper penetrated with softening lotion

InactiveUS6860967B2Excellent penetration behaviourGood flexibilityBiocideNatural cellulose pulp/paperWaxEmulsion

A tissue paper penetrated with a lotion composition being a liquid, viscous W / O emulsion includes(A) 20 to 75 weight % of at least one oil,(B) 3 to 40 weight % of at least one non-ionic W / O emulsifier,(C) optionally 0.5 to 10 weight % of at least one wax,(D) 1 to 15 weight % of at least one humectant,(E) 6 to 25 weight % of water. The lotioned tissue paper of the invention shows an excellent surface softness and in particular bulk softness. Simultaneously it is capable of efficiently transferring lotion to the skin of the user.

Owner:ESSITY OPERATIONS MANNHEIM GMBH

Method for producing metallic high temperature transfer base paper

ActiveCN101255662AImprove high temperature resistanceHigh strengthNatural cellulose pulp/paperWax additionFiberExtremely good

The invention discloses the production method of a metal high temperature transfer printing base paper, including to use 50-70% blanching needle wood-pulp and 30-50% blanching broad-leaf wood-pulp to be the raw material, which is pulped by a pulper, then is added by beating with chemical auxiliary materials: 1-4% a wet strength agent, 1-3% a high temperature resistance agent, 1- 4% starch, 2-4% aluminum sulfate, 1.0-2.5% a rosin milk, 0.1-1.5% a remover, and 0.03 -0.1% a retention agent to make into a slurry; after making, the slurry is rewound to be the base paper when passing through a rewinder. The transfer printing base paper produced by the method has the advantages of extremely good high temperature resistance, being able to satisfy the request of the metal high temperature transfer printing, fine superficial smoothness, and full patterns, bright color and good transfer printing effect after printed. The intensity of the paper is very high, which can satisfy the need of the transfer printing, and the paper is crispness, is not coking and has good stripping paper effect after transfer printed on metal; the waste paper can be recycled to be used as secondary fiber, which saves resources and protects environment.

Owner:HUANGSHAN XINLONG SPECIALITY PAPER

Formulation for achievement of oil and grease resistance and release paper properties

A formulation, and a process for making same, is disclosed which is useful as a coating or treatment for imparting oil and grease resistance to an underlying substrate. The formulation does not contain any fluorochemicals. At the same time, however, the formulation provides oil and grease resistance properties that are equivalent to known coatings and treatments which contain fluorochemicals, particularly those coatings which are permitted to come into direct contact with food products. Therefore, the formulation of the present invention is ideal for use as a coating for paper and paperboard, including paper packaging such as that utilized in food wrappers, food containers, food receptacles and the like, and for other shaped articles. The formulation is also useful as a coating or treatment for providing release properties to an underlying substrate without the use of silicone. In addition, the present invention relates to the process for making the underlying substrate ideal for holdout of the release coating without excessive fiber refining, as in glassine papers. The formulation is a low solids coating that can be applied on the size press of a paper machine, eliminating the need for a post-machine coating process. The formulation does not include silicone, thereby allowing the release paper to be re-pulped. The wet end additive that provides sheet holdout combines with the release formulation to provide a release paper for pressure sensitive adhesives.

Owner:GLATFELTER CORP

Method for preparing stainless steel lining paper

InactiveCN1936182AImprove performanceSolve the problem of only producing high-weight paperNatural cellulose pulp/paperFlexible coversFiberParaffin wax

The invention discloses a manufacturing method for a stainless steel lining paper that includes the following steps: adopting white wood pulp as raw material, and white sulfate softwood pulp: white hardwood pulp =70-80wt%: 30-20wt%; adopting short fiber shiny beating method, and 330 disc mill basalt stone lapping to take jordaning; using chemical auxiliary agent that adding 5-20wt% olefin emulsion, 0.5-1.0wt% positive ion starch, 0.5-1.0wt% AKD, 1.0-2.0wt% silicone emulsion, 0.3-0.5wt% CPAM, and 0.25-0.75wt% PAE. It has the advantages of high intension, laceration endurable, super smooth, clean and high temperature endurable. It could fit different manufacture technology requests of stainless steel.

Owner:樊运民

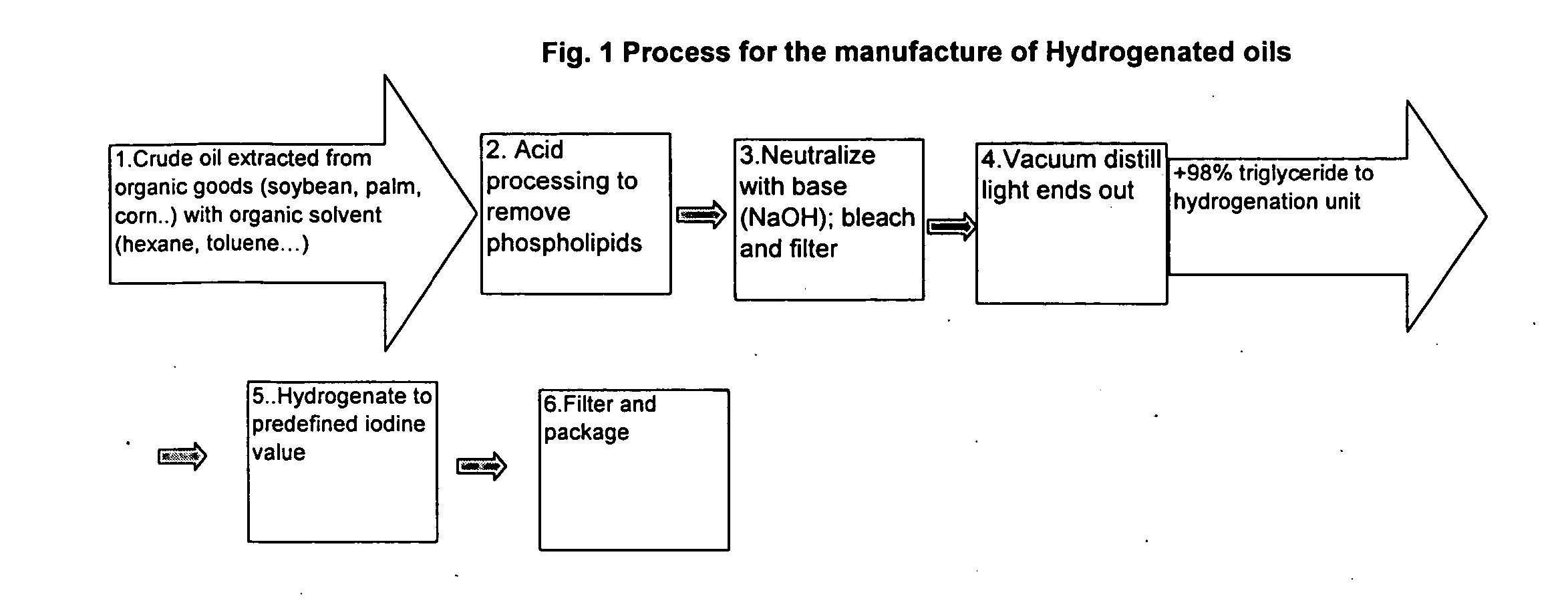

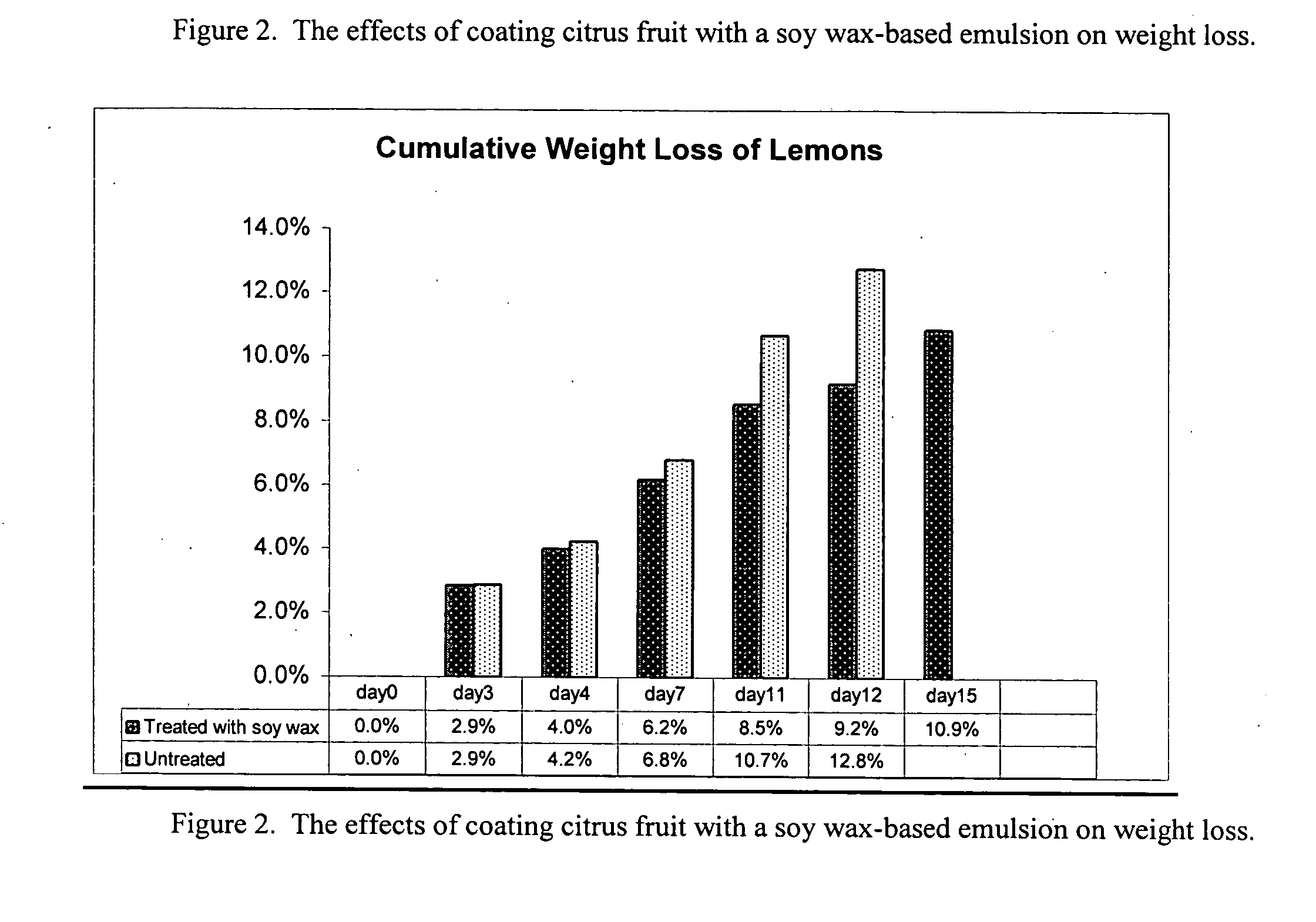

Novel wax emulsion coating applications

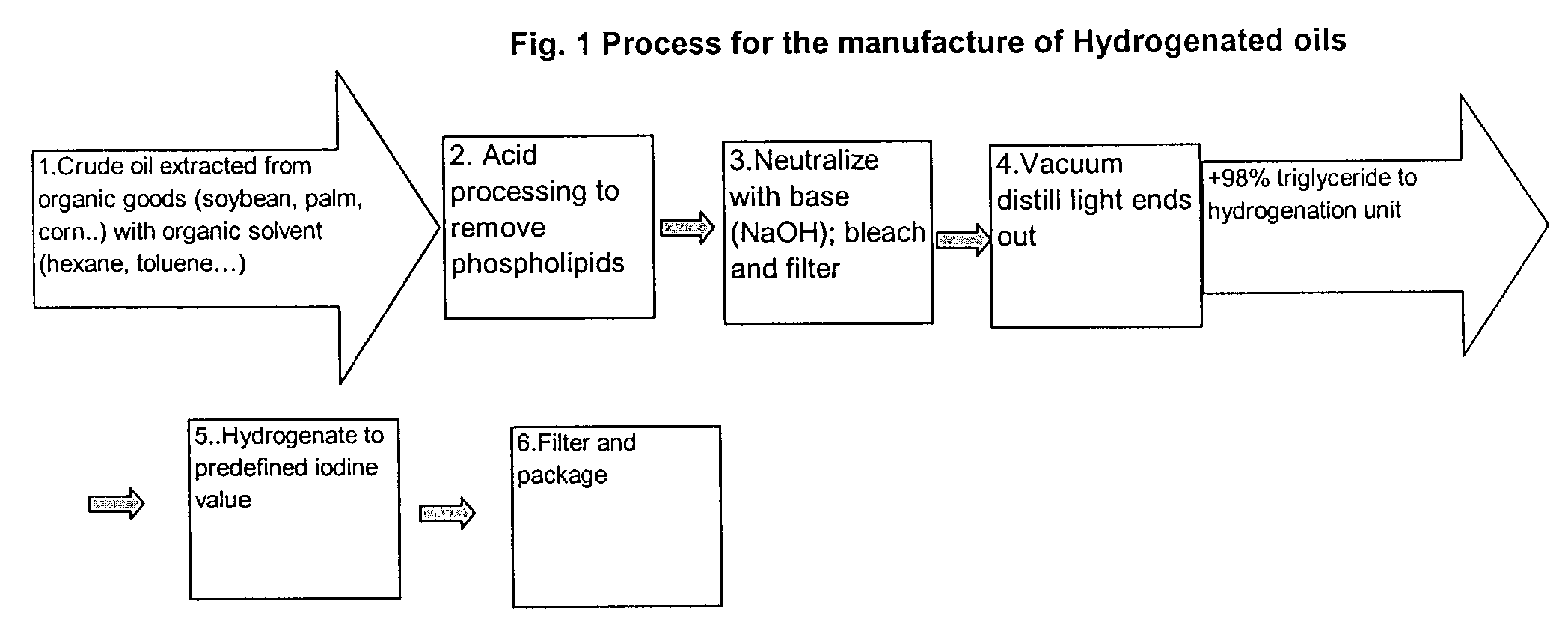

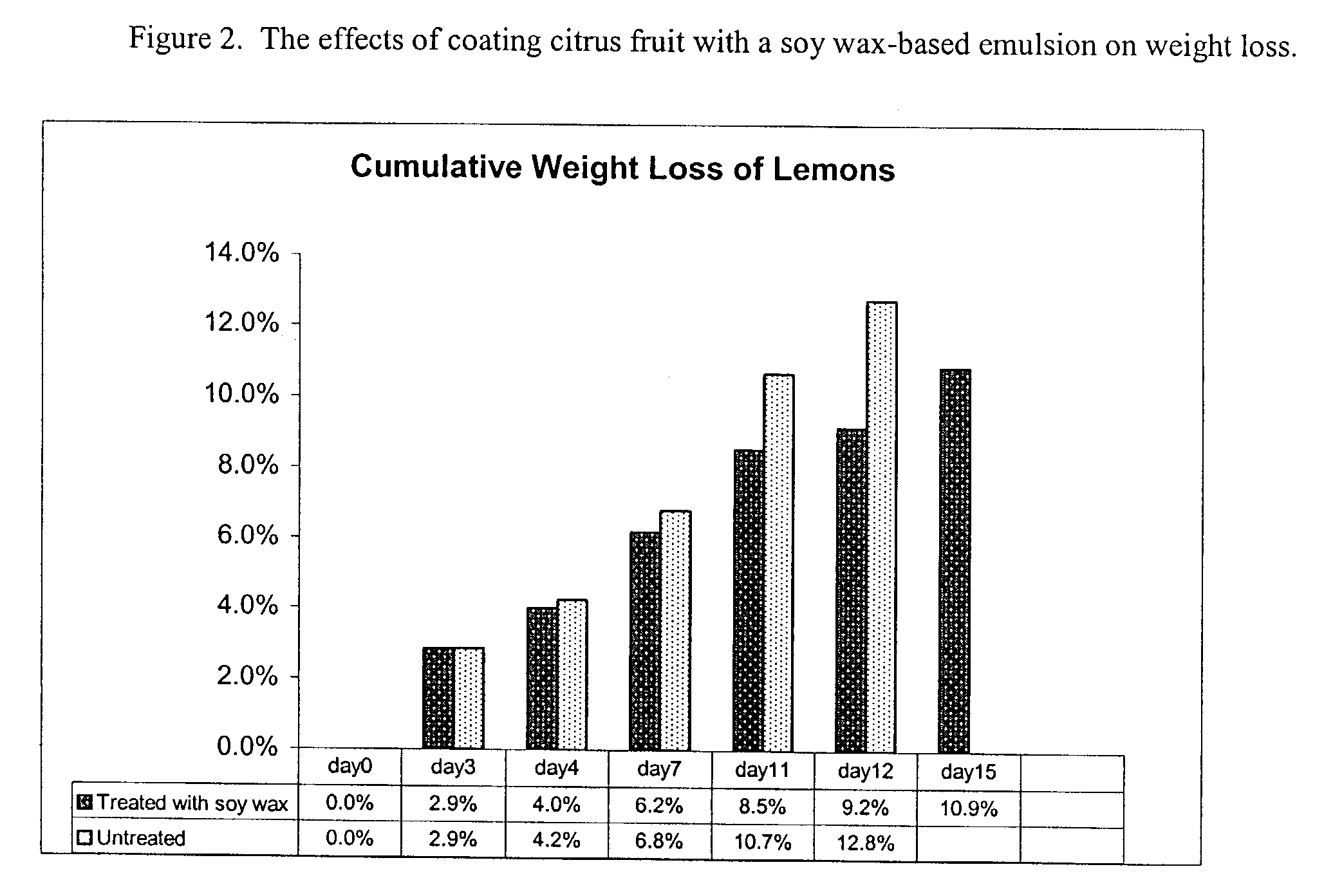

Waxes prepared from hydrogenated plant oils, such as castor, palm, and soybean, are used to prepare water based emulsions. The inventive waxes, obtained from naturally derived, renewable resources, were emulsified under anionic, cationic and nonionic conditions, producing emulsions having a solids content up to about 45% solids. The emulsions are stable, and are characterized by having an average particle size less than 1000 nanometers. When used to coat fibrous cellulosic articles, such as paperboard, the emulsions' performance was similar to emulsions containing petroleum-derived waxes. The inventive waxes have a low iodine value (between 2-5), and melting points between approximately 120-200 degrees F (49-94 degrees C) (Mettler Drop Point). The inventive waxes are used as an alternative to petroleum-derived, or expensive naturally-occurring waxes in the manufacture of emulsions used in coatings, polishes, adhesives, paper products, paperboard and other manufacturing operations.

Owner:HRD CORP

Wetting solution for wet wipes for cosmetic, personal hygiene, dermatological and/or cleaning purposes

The present invention relates to a wetting solution for manufacturing wet wipes or other wet flexible materials, and to such wet wipes for cosmetic, body care, dermatological and / or cleaning purposes, such as cleaning wipes, facial cleaning wipes, make-up remover wipes, refreshment wipes, baby wipes, wet toilet paper or eyeglass cleaning wipes, wherein the preferably aqueous wetting solution contains at least one amino acid ester, preferably from the group of pyrrolidone carboxylic acid esters, as an emulsifier. The invention further relates to the use of such amino acid esters as emulsifiers in wetting solutions for manufacturing said wet tissues.

Owner:ZSCHIMMER & SCEWARZ GMBH & CO KG

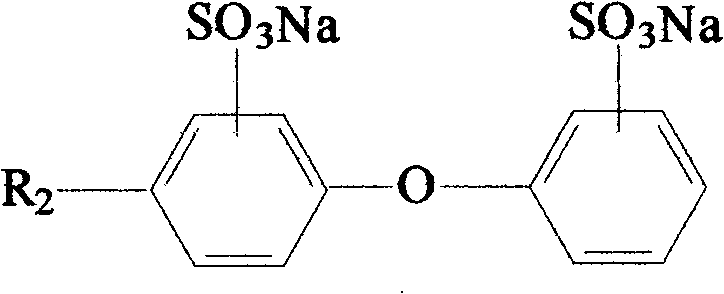

Additives for water-resistant gypsum products

ActiveUS7473713B2Provides water resistanceFireproof paintsStarch dervative coatingsWater resistantPhenol

Emulsions are provided which are useful in imparting water-resistance to gypsum products. In one embodiment, the emulsions comprise at least one wax, an alkyl phenol, a salt of polynaphthalenesulfonic acid, and a complexed starch. Emulsions of this embodiment may be added to hot, even boiling, water without the emulsion separating or curdling. The emulsions of the present invention are stable for extended periods of time when stored at room temperature and do not require the addition of a bactericide. The emulsions of the present invention are pourable liquids at room temperature.

Owner:HEXION INC

Wax emulsion coating applications

Waxes prepared from hydrogenated plant oils, such as castor, palm, and soybean, are used to prepare water based emulsions. The inventive waxes, obtained from naturally derived, renewable resources, were emulsified under anionic, cationic and nonionic conditions, producing emulsions having a solids content up to about 45% solids. The emulsions are stable, and are characterized by having an average particle size less than 1000 nanometers. When used to coat fibrous cellulosic articles, such as paperboard, the emulsions' performance was similar to emulsions containing petroleum-derived waxes. The inventive waxes have a low iodine value (between 2-5), and melting points between approximately 120-200 degrees F. (49-94 degrees C.) (Mettler Drop Point). The inventive waxes are used as an alternative to petroleum-derived, or expensive naturally-occurring waxes in the manufacture of emulsions used in coatings, polishes, adhesives, paper products, paperboard and other manufacturing operations.

Owner:HRD CORP

Emulsions for composite materials

Emulsions are provided which are useful in imparting water-resistance to lignocellulosic composite products. In one embodiment, the emulsions comprise at least one wax, an alkyl phenol, a salt of polynaphthalenesulfonic acid, and a complexed starch. Emulsions of this embodiment may be added to hot, even boiling, water without the emulsion separating or curdling. The emulsions of the present invention are stable for extended periods of time when stored at room temperature, do not require the addition of a bactericide, and are pourable liquids at room temperature.

Owner:HEXION INC

Production process of greaseproof paper

The invention discloses a production process of greaseproof paper. The production process includes: taking a needle pulp board and a nonfluorescent bamboo pulp board, pulping, preparing pulp, slushing, applying glue, papermaking on a screen, pressing, pre-drying, surface-gluing, post-drying, press-polishing, controlling quality, coiling, and packing to obtain the finished paper, wherein weight percent of the needle pulp board and the nonfluorescent bamboo pulp board is 30+ / -5% and 70+ / -5%, preferred ratio of the needle pulp board to the nonfluorescent bamboo pulp board is 30%:70%, speed of papermaking on the screen is 90m / min, mass concentration of the screen is 0.45-0.55%, preferred pulping grinding teeth are 2.2mm in width, 1.9mm in teeth channel width, and 3.6mm in teeth depth, preferred press polishing machine is a four-roller soft press polishing machine with double pressing areas, preferred raw material is food grade, and preferred pipeline is made of 304L type stainless steel. By the production process, potential safety hazard due to larger amount of oil-proofing agent used in the greaseproof paper in traditional production process is avoided, and amount of the oil-proofing agent used in the greaseproof paper is reduced greatly. The greaseproof paper produced by the process has fine gloss, tightness, and oil resistance, and reaches food grade.

Owner:福建省建宁县联丰造纸有限公司

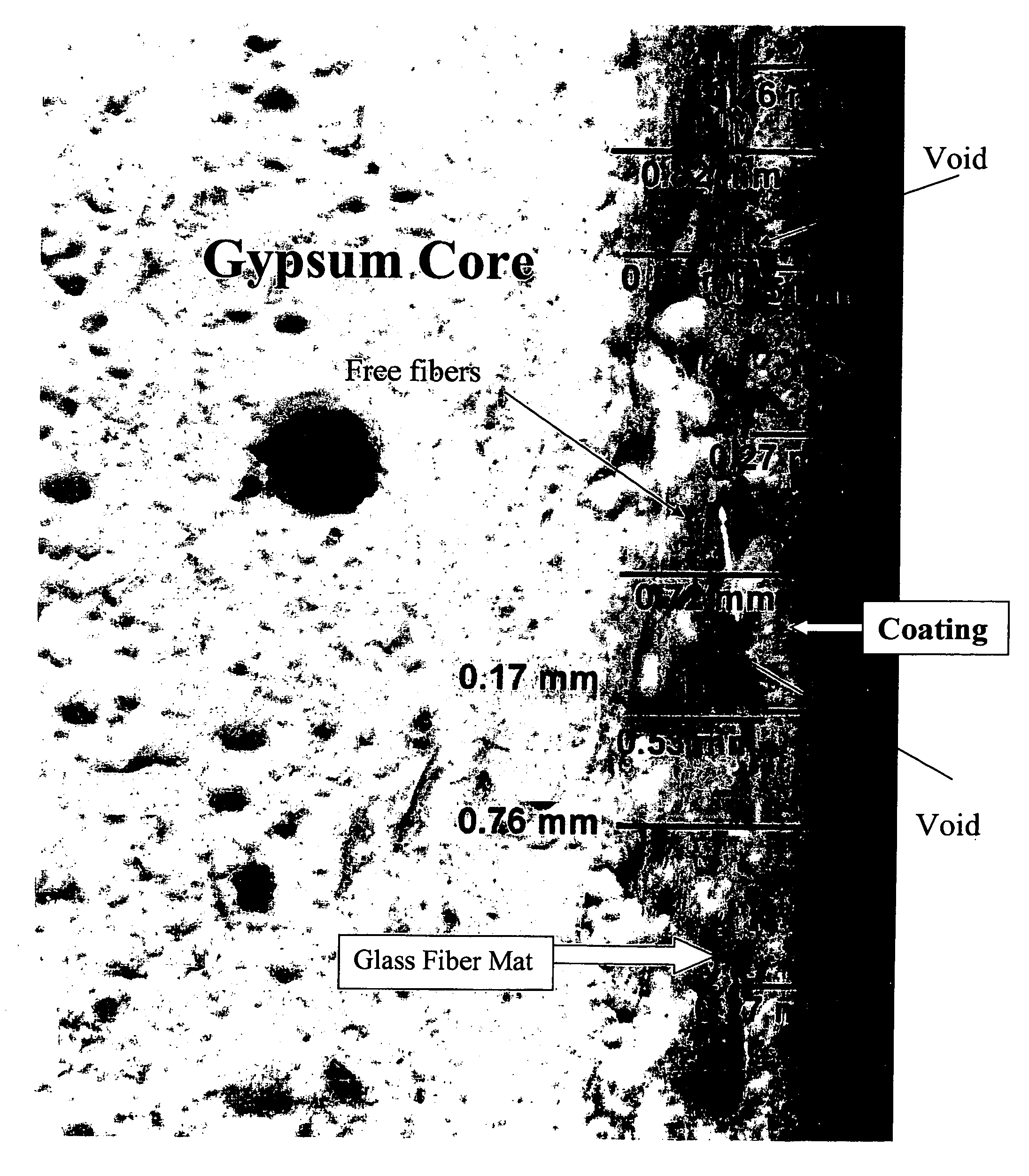

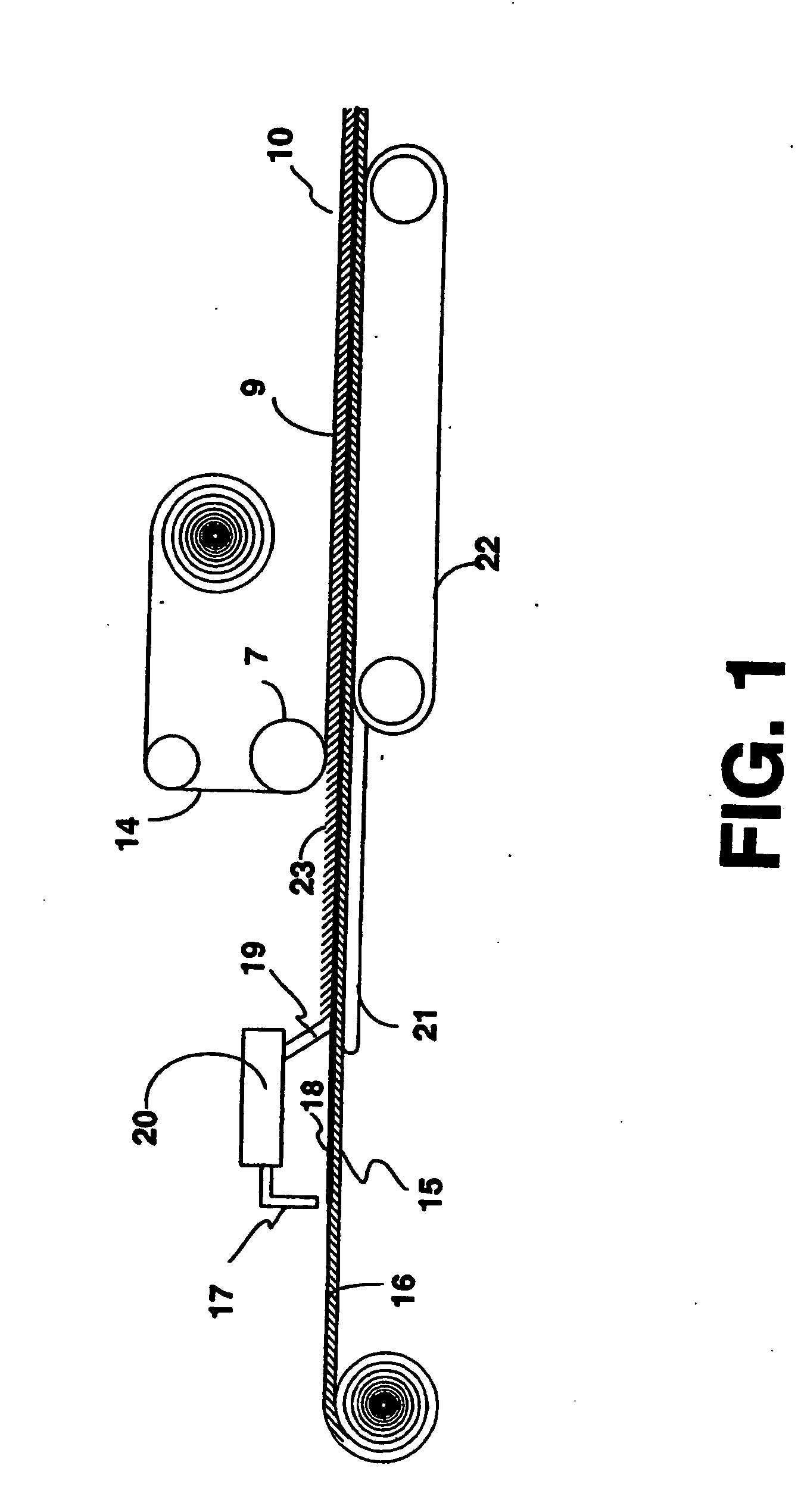

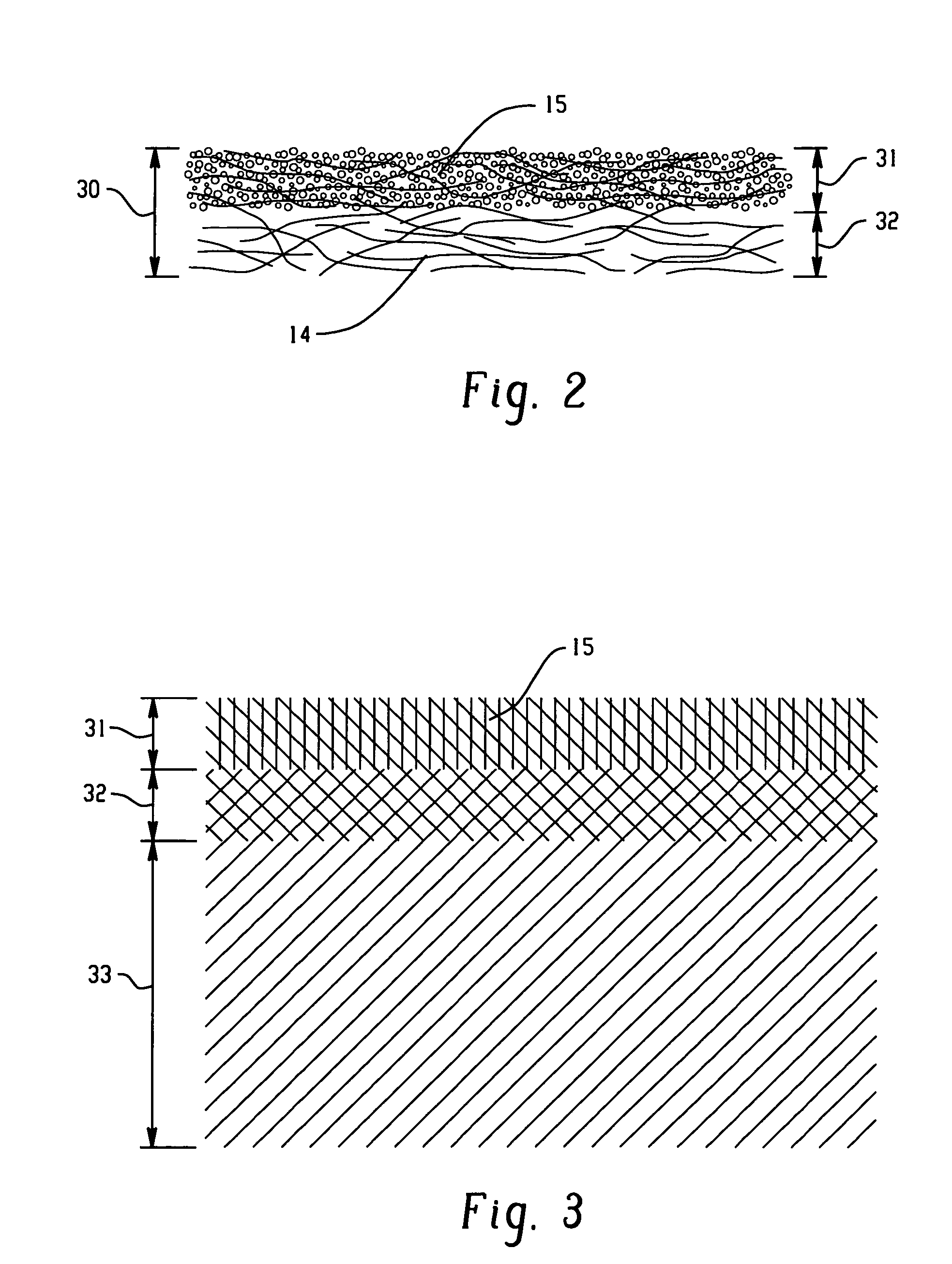

Use of pre-coated mat for preparing gypsum board

A gypsum board which comprises a set gypsum core sandwiched between and faced with fibrous mats, wherein a free surface of one of said mats is pre-coated with a combination of a mineral pigment, optionally an inorganic adhesive binder and an organic binder, preferably a hydrophobic, UV resistant polymer latex adhesive binder applied to said surface as an aqueous coating composition, said aqueous coating composition upon drying and setting providing a pre-coated mat satisfying certain morphology requirements.

Owner:SMITH RUSSELL +1

Waterproof flame-retardant paper cone, speaker and preparation method of paper cone

ActiveCN110219206AGuaranteed acoustic performanceGuaranteed soundInorganic fibres/flakesElectrical transducersPulp and paper industryFire retardant

The invention provides a waterproof flame-retardant paper cone, a speaker and a preparation method of the paper cone. The waterproof flame-retardant paper cone is composed of pulp, the front surface of the waterproof flame-retardant paper cone contains a waterproof agent, and the back surface of the paper cone contains a flame retardant. According to the waterproof flame-retardant paper cone provided by the invention, the suitable pulp is selected, so that acoustic performance and tone of the paper cone are ensured; at the same time, the paper cone is subjected to waterproof treatment and flame-retardant treatment, the front surface of the paper cone is coated with the waterproof agent, the back surface is coated with the flame retardant, so that the usage amount of the flame retardant andthe waterproof agent can be reduced, the weight increment of the paper cone can be effectively controlled within 5% without affecting the paper pulp composition of the paper cone, the problem that effects are affected because a mutual reaction exists when the flame retardant and the waterproof agent are mixed for use is avoided, the flame retardant grade can reach V-0, the waterproof grade can reach IPX-7, and the flame-retardant waterproof effects are excellent; and the paper cone has good effects when used in the speaker, and has wide market prospects.

Owner:GUOGUANG ELECTRIC

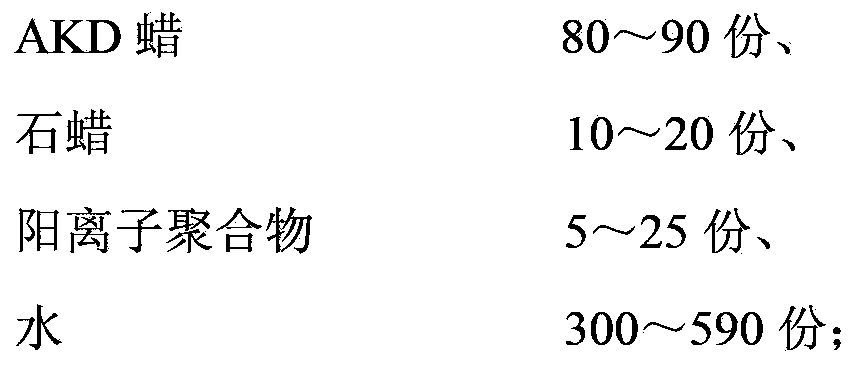

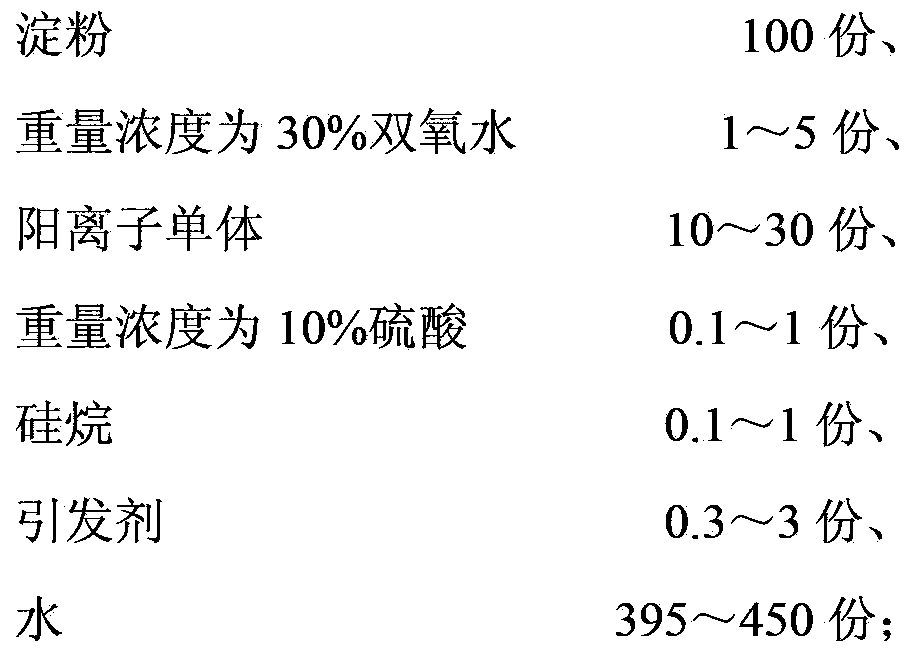

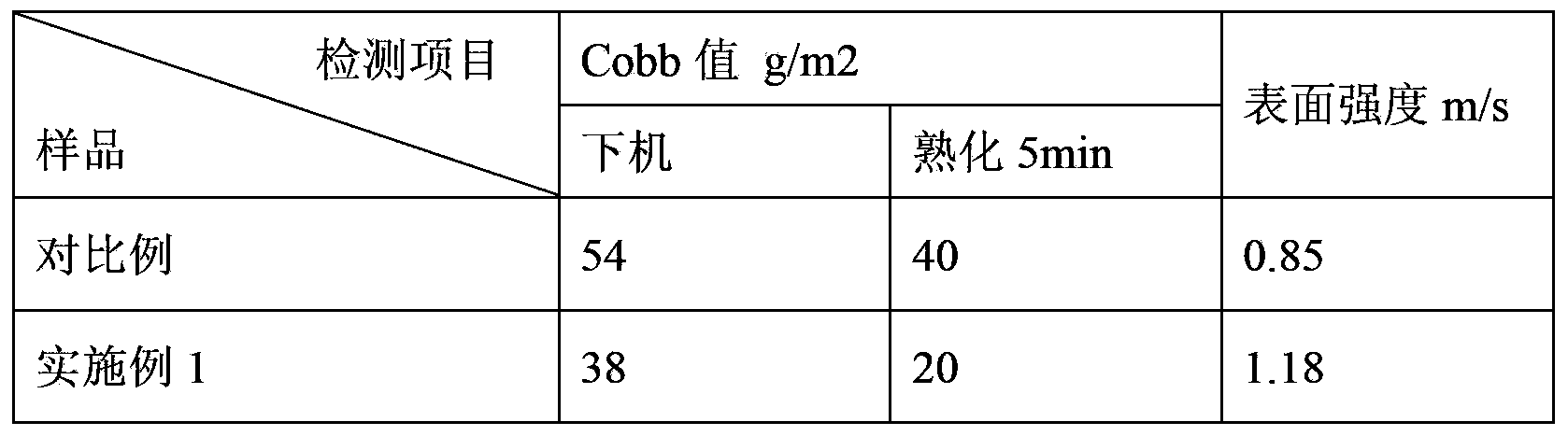

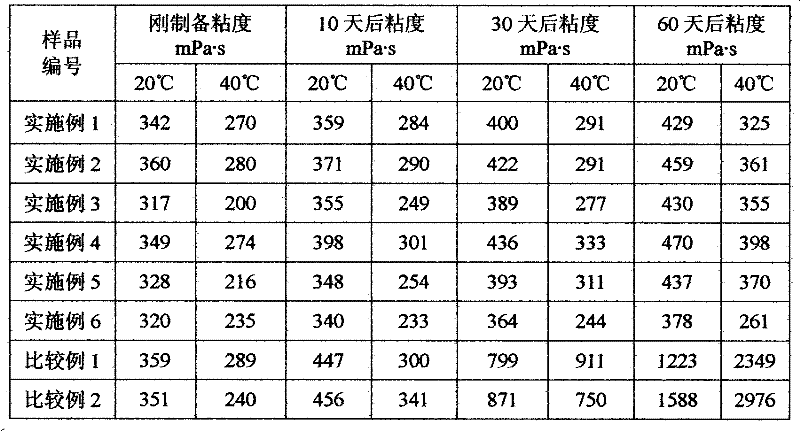

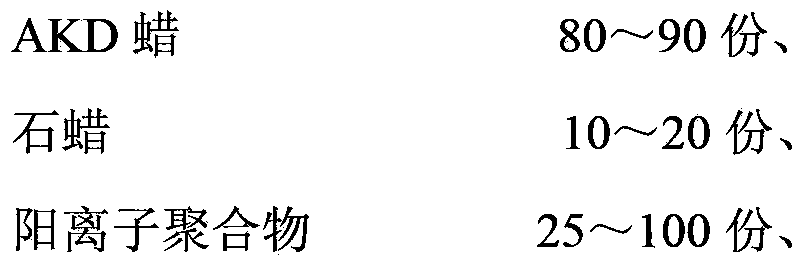

Preparation method for surface sizing agent emulsion

InactiveCN103410052AImprove hydrophobicityImprove surface strengthWater-repelling agents additionWax additionParaffin waxSilanes

The invention provides a preparation method for a surface sizing agent emulsion. The preparation method comprises the following steps: mixing a cationic polymer with water; adding molten AKD (alkyl ketene dimer) wax and paraffin wax at 70-75 DEG C; and then homogenizing in a condition of 10-15 Mpa, so as to obtain the surface sizing agent emulsion, wherein the cationic polymer is prepared by reacting a cationic monomer, starch, hydrogen peroxide, silane and sulphuric acid under the action of an initiator; the surface sizing agent emulsion comprises the following components in parts by weight: 80-90 parts of the AKD wax, 10-20 parts of the paraffin wax, 5-25 parts of the cationic polymer, and 300-590 parts of water, wherein the total of the AKD wax and the paraffin wax is 100 parts by weight. The high-performance sizing agent emulsion provided by the invention is a high-performance and environment-friendly product capable of meeting application for a papermaking coatings; the product is capable of obviously improving the hydrophobicity of paper, reducing the Cobb value, and improving the surface strength of the paper in case of being applied to surface sizing for the paper.

Owner:SHANGHAI DONGSHENG NEW MATERIALS

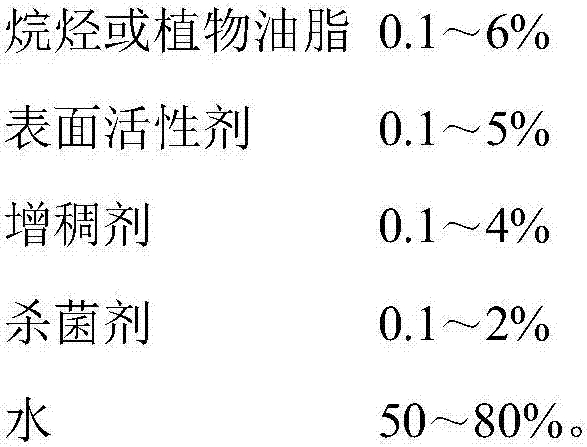

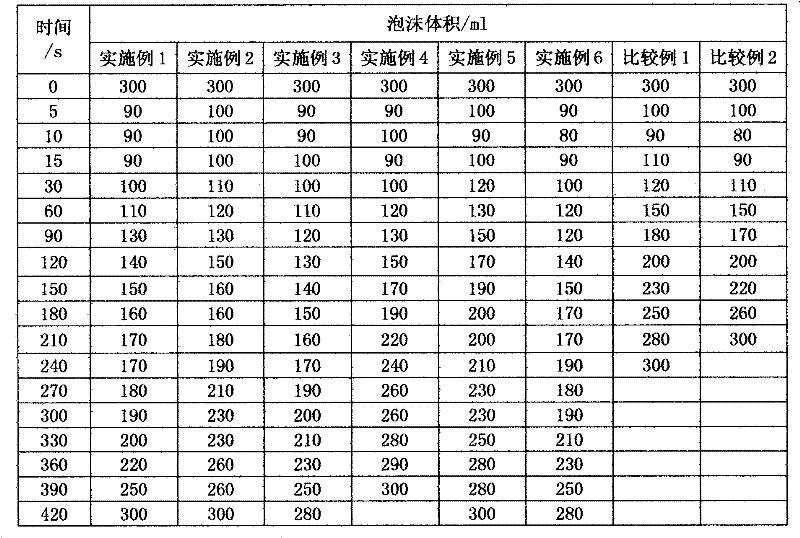

Higher aliphatic alcohol emulsion antifoaming agent

ActiveCN107059474ASuitable for defoamingSuitable for degassingDefoamers additionNon-macromolecular organic additionEmulsionActive component

The invention provides a higher aliphatic alcohol emulsion antifoaming agent. The antifoaming agent is prepared from rice bran wax, ax, alkane or vegetable fat, a surfactant, a thickening gent, a bactericide and water, and the rice bran wax is the active component of the emulsion antifoaming agent. The rice bran wax takes higher aliphatic acid, higher aliphatic alcohol and higher aliphatic alcohol ester as main components and contains abundant hexacosanol, octacosanol, triacosanol and corresponding alcohol ester. The higher aliphatic alcohol emulsion prepared from the rice bran wax is applicable to foam control in each section of pulping and papermaking, particularly a papermaking system and foam control of papermaking wet-ends.

Owner:济宁南天农科化工有限公司

Antifoaming agent for low-temperature paper making system

The invention provides a high-alcohol emulsion type antifoaming agent for a low-temperature paper making system. The antifoaming agent comprises the components of high alcohol, a nonionic surfactant, an anionic surfactant, high alcohol polyether ester, a wax-shaped substance, a thickening agent and water. In the invention, after the high alcohol polyether ester is introduced, the problem that theantifoaming effect of the high alcohol emulsion is poor under a low temperature condition is solved, thus the high alcohol emulsion can keep outstanding antifoaming performance under the low temperature paper making system, and the storage stability of the high alcohol emulsion can also be enhanced.

Owner:JIANGSU SIXIN SCI-TECH APPL RES INST CO LTD

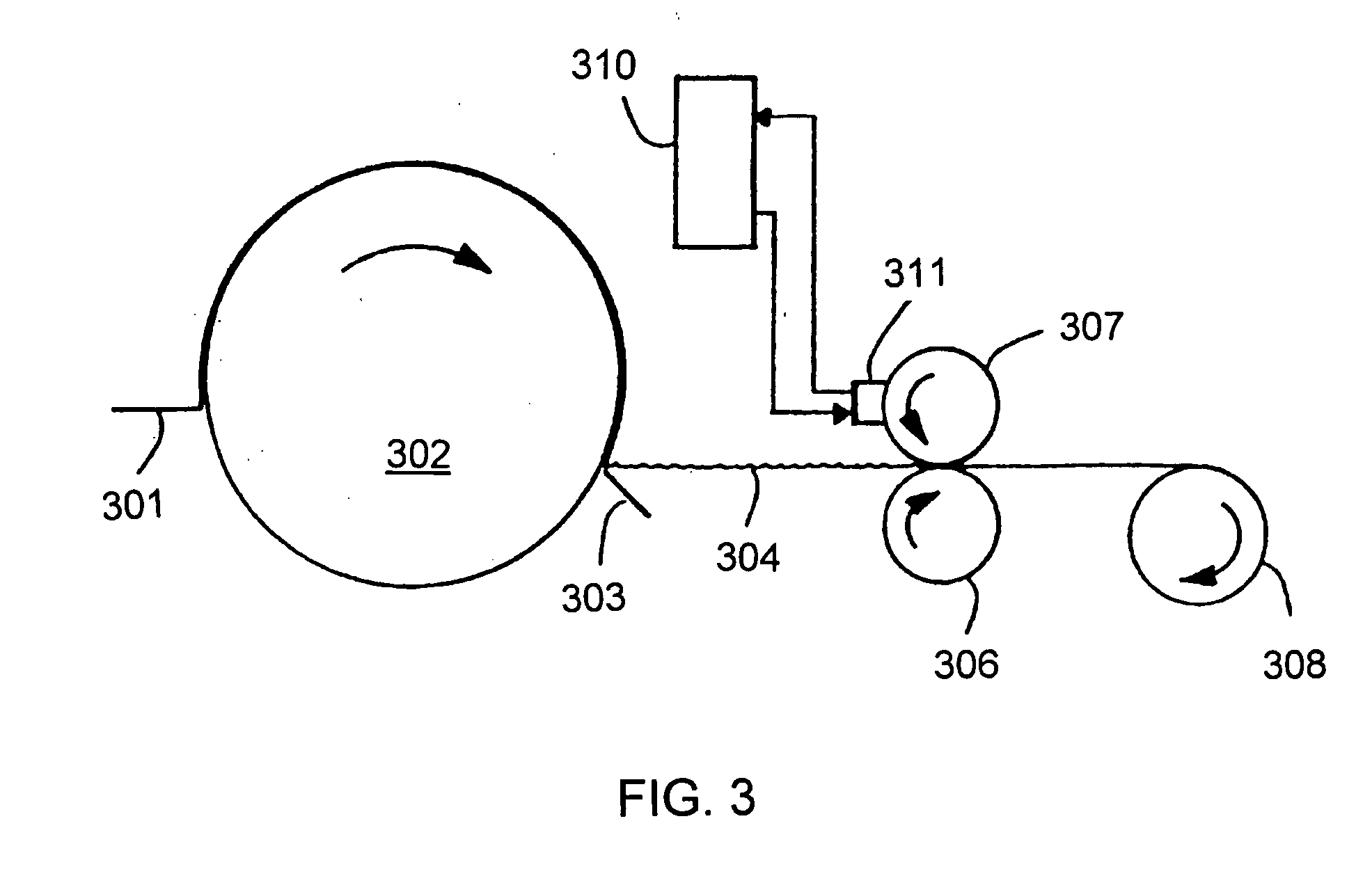

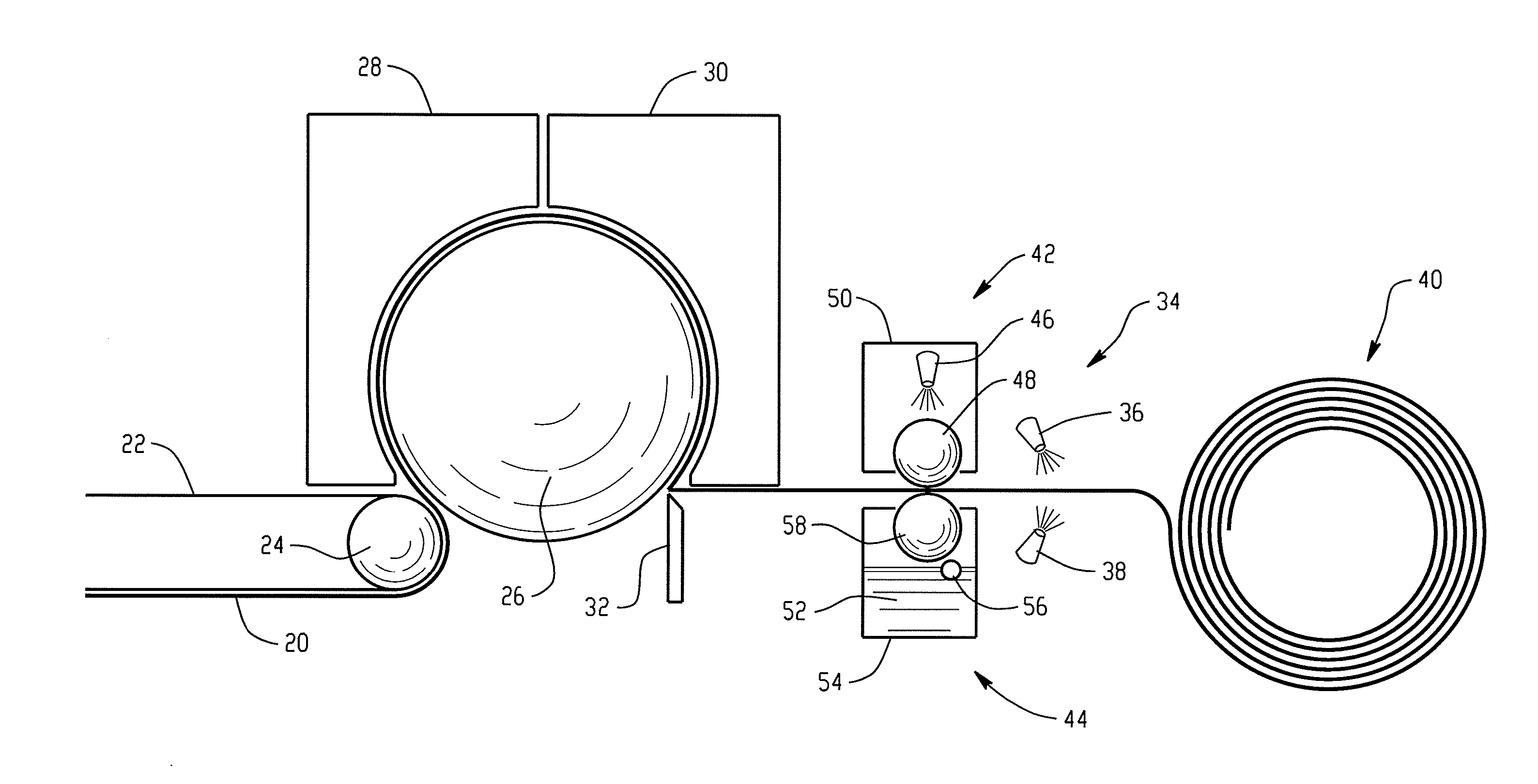

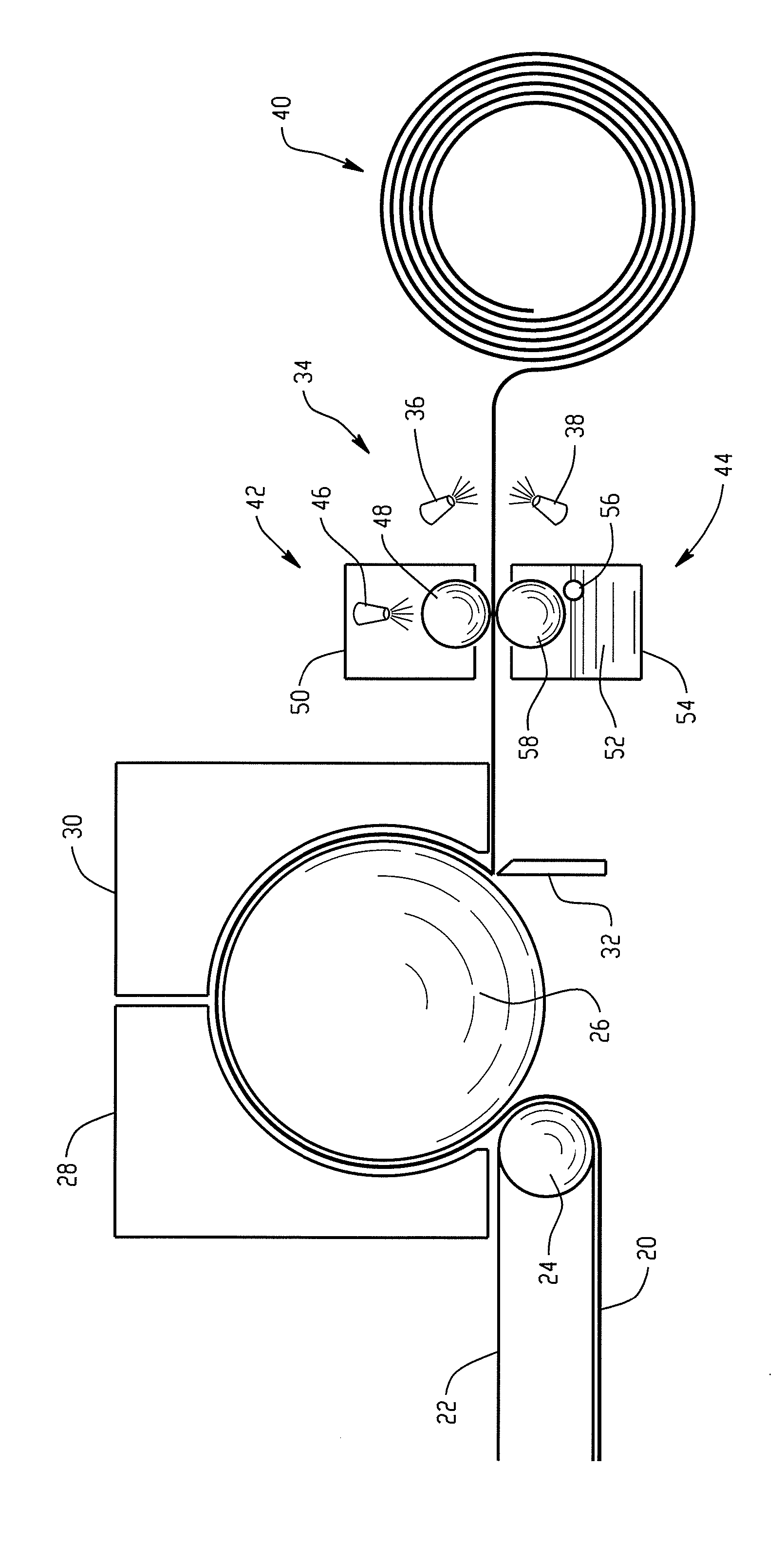

Method Of Applying Fugitive Hydrophobic Treatment To Tissue Product

InactiveUS20120107511A1Effective mergerNatural cellulose pulp/paperWater-repelling agents additionCelluloseMoisture barrier

Cellulosic tissue sheets having temporary moisture barrier properties are prepared by applying a solution of reactive size in emollient at an elevated temperature to a previously formed tissue sheet.

Owner:GEORGIA PACIFIC CONSUMER PRODS LP

Lacquer wax sizing agent and preparation method thereof

InactiveCN103835185AImprove smoothnessHigh strengthWater-repelling agents additionWax additionPolymer scienceEthylic acid

The invention discloses a lacquer wax sizing agent and a preparation method of the lacquer wax sizing agent. The lacquer wax sizing agent belongs to the field of sizing agents in papermaking. The lacquer wax sizing agent is produced by taking lacquer wax extracted from lacquer tree seeds, starch / modified starch, an enhancer, chitosan, acetic acid, citric acid or hydrochloric acid as raw materials and taking an emulsifying tank, a rosin cooking tank and a mixing and stirring tank as production equipment; the production method is simple in process, nontoxic, free of chemical pollution and mild in reaction condition, and the lacquer wax sizing agent is high in quality, good in service effect and purely natural in raw materials and can be used as an internal sizing agent or a surface sizing agent; by using the lacquer wax sizing agent, performances such as the water resistance, oil resistance, printing ink resistance and the like of a paper product can be effectively improved, and meanwhile, the smoothness, stiffness, barrier property, antibacterial property and printability of paper can be improved.

Owner:云南省轻工业科学研究院有限公司 +1

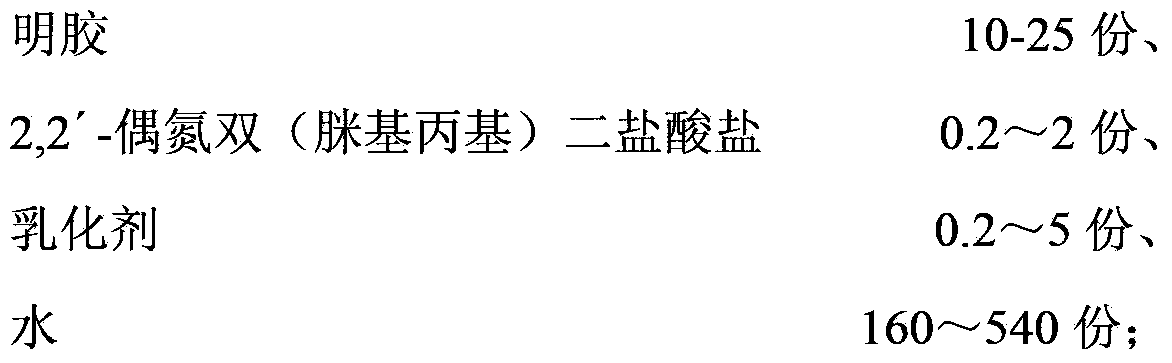

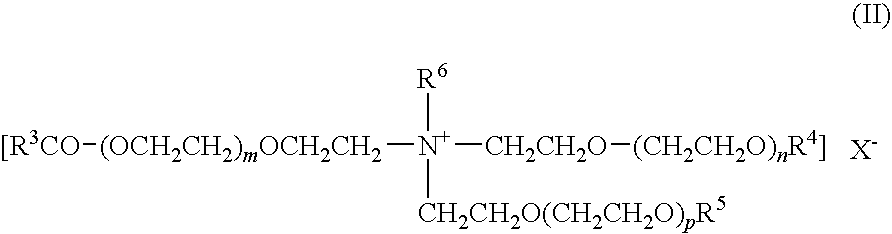

Surface sizing agent emulsion as well as preparation method and application thereof

ActiveCN103410050AImprove hydrophobicityImprove surface strengthWater-repelling agents additionNon-macromolecular organic additionParaffin waxSurface strength

The invention provides a preparation method for a surface sizing agent emulsion. The preparation method comprises the following steps: mixing a cationic polymer with water; adding molten AKD (alkyl ketene dimer) wax and paraffin wax at 70-75 DEG C; and then homogenizing in a condition of 10-25 Mpa, cooling, and then adding glyoxal, so as to obtain the surface sizing agent emulsion, wherein the cationic polymer is an aqueous dispersoid copolymerized from a cationic monomer, a (methyl) acrylate monomer and (methyl) styrene, and prepared by taking gelatine as a dispersing agent, taking a cationic and non-ionic compound surfactant as an emulsifying agent, taking 2,2'-azo-bis (amidino-propyl) dihydrochloride as an initiator, and performing free radical emulsion polymerization on the mixed monomers; the surface sizing agent emulsion comprises the following components in parts by weight: 80-90 parts of the AKD wax, 10-20 parts of the paraffin wax, 25-100 parts of the cationic polymer, 1-5 parts of glyoxal, and 270-610 parts of water, wherein the total of the AKD wax and the paraffin wax is100 parts by weight. The surface sizing agent emulsion provided by the invention is capable of obviously improving the hydrophobicity of paper and improving the surface strength of the paper.

Owner:SHANGHAI DONGSHENG NEW MATERIALS

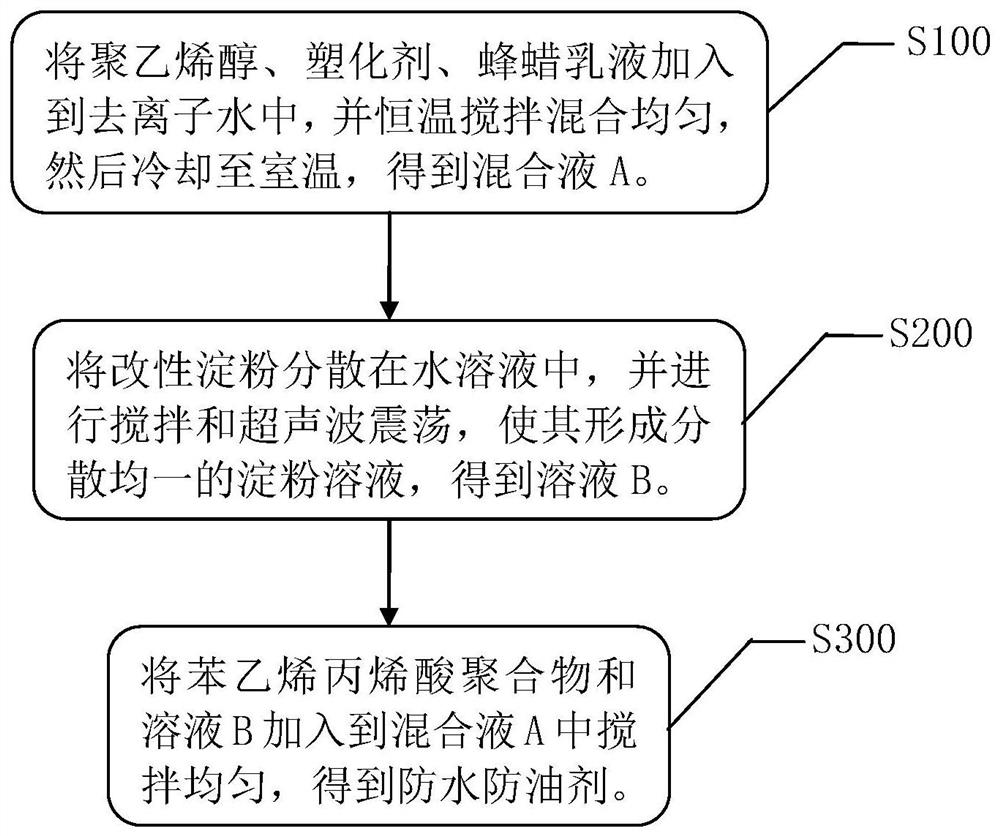

Waterproof and oilproof agent as well as preparation method and application thereof

InactiveCN111749042AGood film formingImproved water and oil repellencyNon-macromolecular organic additionPaper coatingPolymer sciencePolyvinyl alcohol

The invention relates to a waterproof and oilproof agent as well as a preparation method and application thereof. The waterproof and oilproof agent is prepared from the following components in percentage by weight: 30%-50% of styrene acrylic polymer, 5%-10% of beeswax emulsion, 2.5%-4.5% of polyvinyl alcohol, 2%-5.5% of modified starch, 0.5%-2% of plasticizer and 28%-60% of deionized water. The waterproof and oilproof agent is good in film-forming property; beeswax emulsion in a formed coating and the styrene-acrylic acid polymer are combined to form a hydrophobic and oleophobic surface layer;meanwhile, the hydrophobic and oleophobic surface layer is compounded with the modified starch, so that the waterproof and oilproof effects of the waterproof and oilproof coating on food-grade raw paper are obviously improved; the waterproof and oilproof properties of the waterproof and oilproof agent are extremely good; the waterproof and oilproof agent can completely replace traditional waxing,silicon coating and laminating processes; and the paper can directly enter a papermaking pulping system to be recycled when being recycled, the pollution of the laminated paper to the environment isreduced; and therefore, the waterproof and oilproof agent is an environment-friendly material.

Owner:ZHONGSHAN TIAN JIA PAPER PROD

Active carbon filtering paper

InactiveCN104674606AExcellent wet tensile indexImprove filtering effectWax additionPaper/cardboardPolyvinyl alcoholAcrylic resin

The invention discloses active carbon filtering paper which is prepared from the following raw materials in parts by mass: 50-100 parts of wood pulp fibers, 80-100 parts of Lyocell fibers, 50-100 parts of viscose fibers, 250-400 parts of active carbon, 50-100 parts of anthracite filter media, 1-10 pars of polyurethane acrylic resin, 2-10 parts of polyurethane resin, 2-8 parts of chloride vinyl resin, 3-5 parts of polyvinyl alcohol, 1-2 parts of a sodium carboxymethylcellulose emulsifier, 2-3 parts of a stabilizer, 1-3 parts of a solidifier and 2-3 parts of an initiator. The active carbon filtering paper is high in wet anti-tension index and excellent in filtering effect and has the advantages of long service life, simple production technology, convenience in control, low cost and the like.

Owner:黄文武

Process for paper substrates using an emulsion and products produced thereby

Owner:COGNIS DEUT GMBH & CO KG

Method for manufacturing outer bag paper of fruit raising bags by using adherography

InactiveCN102660890ASimple production processFastReinforcing agents additionWax additionPaper productionPrinting ink

A method for manufacturing outer bag paper of fruit raising bags by using adherography comprises repulping, slurry matching, net portion shaping, dehydrating by squeezing, stoving, rolling and separately cutting body paper products obtained by rewinding. Offset printing comprises mixing black printing ink and printing on a machine. The outer bag paper of the fruit raising bags produced by the method can be separated into body paper and an ink layer, shading performance is achieved by printing the black ink layer on the body paper, and the method has the advantages of being simple in body paper production process, capable of producing by using a long net paper machine, rapid in speed, low in cost, less in pollution and the like, and simultaneously solves the problem that carbon black in a lamination method and used in the liquid for dying causes pollution, use ratio is low, a circular net paper machine is slow in speed and the like. The black printing ink is used for printing, anti-liquid-permeation performance of the paper can be improved, simultaneously the paper has good opaqueness, is not prone to fade, keeps high compliance and air permeability.

Owner:SHAANXI UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com