Antifoaming agent for low-temperature paper making system

A defoaming agent and system technology, applied in the field of fine chemical preparations, can solve the problems of poor defoaming and suppressing ability, affecting the use of defoaming agents, and inability to adapt to foaming systems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

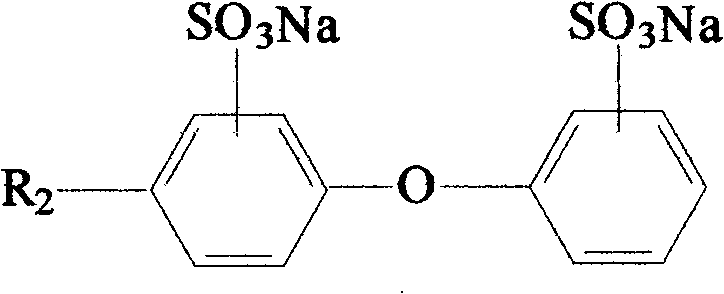

[0023] With 16 parts of stearyl alcohol, 6 parts of carnauba wax, 6 parts of high carbon alcohol polyether ester (C 12 h 26 O(EO) 1 (PO) 30 COC 9 h 19 ), 1 part of nonionic surfactant (C 12 h 26 O(EO) 40 H), 1 part of anionic emulsifier (sodium dodecyl diphenyl ether disulfonate), add to the reaction kettle, mix and heat up to 70°C, after stirring evenly, add 70 parts of water at 75°C, and obtain by high-speed shearing equipment Emulsion, adding acrylate thickener to adjust viscosity to obtain defoamer.

Embodiment 2

[0025] With 20 parts of eicosanol, 4 parts of microcrystalline wax, 4 parts of high carbon alcohol polyether ester (C 16 h 34 O(EO) 5 (PO) 20 COC 13 h 27 ), 1 part of nonionic surfactant (C 16 h 34 O(EO) 20 H), 1 part of anionic emulsifier (sodium octyl diphenyl ether disulfonate), added to the reactor, mixed and heated to 85 ° C, after stirring evenly, 70 parts of water at 75 ° C were added, and the emulsion was obtained by high-speed shearing equipment. Acrylate thickener is added to adjust viscosity to obtain defoamer.

Embodiment 3

[0027] 18 parts of tetracosanol, 6 parts of polyethylene wax, 4 parts of high carbon alcohol polyether ester (C 22 h 46 O(EO) 9 (PO) 8 COC 15 h 31 ), 1 part of nonionic surfactant (C 20 h 42 O(EO) 60 H), 1 part of anionic emulsifier (sodium hexadecyl diphenyl ether disulfonate), add to the reaction kettle, mix and heat up to 90 ° C, after stirring evenly, add 70 parts of water at 75 ° C, and obtain by high-speed shearing equipment Emulsion, adding acrylate thickener to adjust viscosity to obtain defoamer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com