Defoaming kettle used in synthetic process of polyamic acid resin

A polyamic acid resin, synthesis process technology, applied in the direction of foam dispersion/prevention, can solve problems such as high viscosity, abnormal production continuity, and defects in manufactured products, achieve uniform color, good temperature uniformity, and reduce discoloration Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

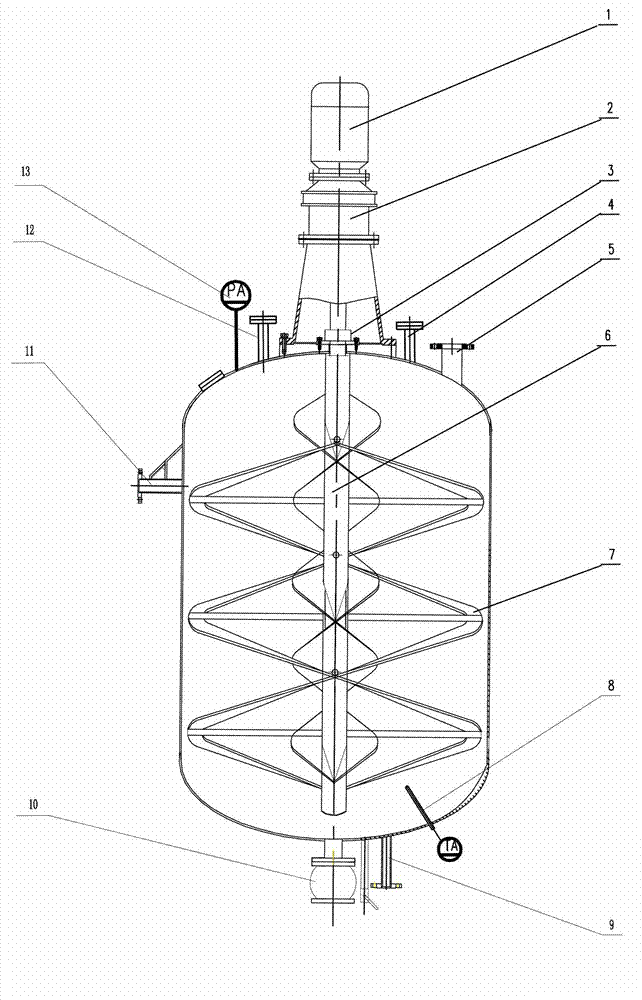

[0018] Example of defoaming device in polyamic acid resin synthesis process figure 1 As shown, it includes a defoaming kettle to accommodate the polyamic acid resin solution. The tank body of the defoaming kettle has a feed nozzle 5 above and a discharge nozzle 10 below. A jacket is installed on the tank of the defoaming kettle in this example. There is a jacket medium inlet 9 below the jacket, and a jacket medium outlet 11 above. The pipes connect the jacket medium inlet, the jacket medium outlet and the heat-conducting medium heating device.

[0019] The stirring shaft 6 is a hollow shaft, located in the middle of the tank body, and its top end is fixedly installed in the tank body through the rotary joint 3, and is connected with the stirring motor 1 and the reducer 2 installed on the top of the tank body. The stirring shaft 6 has a multi-layer spiral stirring blade 7, and the stirring blade 7 is a hollow blade with a heat-conducting medium delivery pipeline designed therei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com