Patents

Literature

391results about How to "Good defoaming" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Epoxy resin embedding glue and method for producing the same

The invention relates to an epoxy resin potting adhesive which consists of component A and component B. By weight portion, the component A consists of 90-130 portions of bisphenol A type epoxy resin, 240-320 portions of filling, 15-25 portions of thinner, 10-25 portions of toughener, 1-2.5 portions of defoamer and 0.8-2 portions of black pigment, and the component B consists of 60-130 portions of estolide and 1-3 portions of imidazole accelerator. The mixing proportion of the component A and the component B is (3-5):1. The invention also provides a preparation method of the epoxy resin potting adhesive. The epoxy resin potting adhesive provided by the invention has low cost and long resting period; after being mixed, the component A and the component B have low viscidity, good wetting quality, good heat resistance, good defoaming performance, good fluidity and long operating time and are solidified between 70 DEG C and 160 DEG C; a product after solidifying has bright surface, good mechanical performance and insulating performance and high glass transition temperature; and the quality of a potting component is stable.

Owner:NICHE TECH KAISER SHANTOU

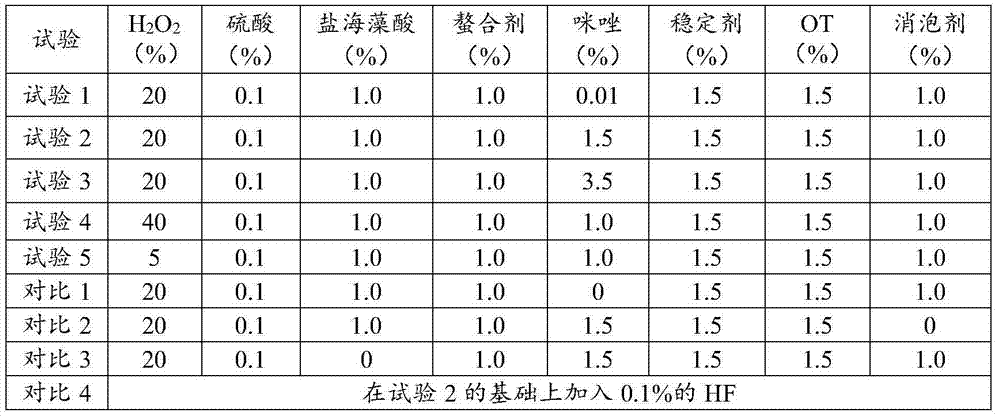

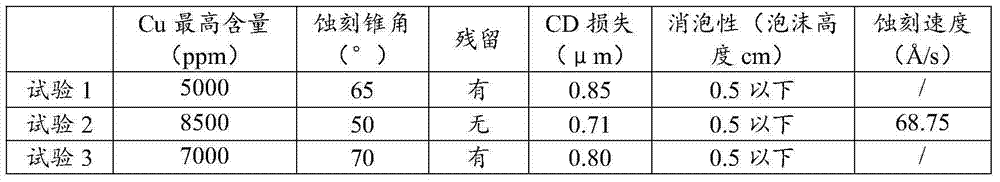

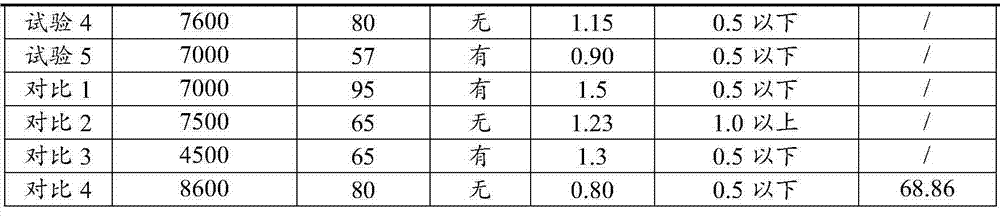

Oxydol etching solution for copper-molybdenum alloy films

The invention discloses an oxydol etching solution for copper-molybdenum alloy films. The etching solution is free of fluorides, and comprises the following main components in percentage by weight: 1-35% of hydrogen peroxide, 0.05-5% of inorganic acid, 0.1-5% of hydrogen peroxide stabilizer, 0.1-5% of metal chelator, 0.1-5% of etching additive, 0.1-5% of surfactant, 0.1-5% of defoaming agent and the balance of deionized water. The etching solution has the advantages of no environment pollution, mild and controllable reaction, proper cone angle after etching, small CD loss, favorable defoaming property and higher overall performance, and lays foundation for high-precision processing.

Owner:SHENZHEN CAPCHEM TECH

Preparation for general defoaming agent and its application

InactiveCN101053706AGood defoamingGood anti-foam performanceTransportation and packagingMixingDefoaming AgentsMetal

The invention discloses a general anorganosilicon antifoaming agent compound and preparation thereof, comprising 20-90% by weight of organic hydrocarbons material, 0.5-10% by weight of main antifoaming material, 1-15% by weight of antifoaming synergist and 1-10% by weight of emulsifying agent. The preparation method is: (1) mixing half of organic hydrocarbons material with main antifoaming material, rising the temperature to 80-120 degree C and keeping for 0.5-3h to make sure the main antifoaming material to be dispersed completely; (2) adding the rest of the organic hydrocarbons material and the antifoaming synergist to said mixture in turns, and keeping the temperature at 60-90 degree C for 0.5-2.0h to make sure to be mixed thoroughly; (3) dropping the temperature below 50 degree C, adding the emulsifying agent and mixing blend even. The anorganosilicon antifoaming agent compound substantially improves the defoaming properties of the antifoaming agent based on adding high molecular antifoaming synergist, has the advantage of good stability, little recruitment and good security, and is used in the process of papermaking and coating, circuit board developing and metal cleaning of the paper industry.

Owner:JIANGSU SIXIN SCI-TECH APPL RES INST CO LTD

Preparation method of scratch-resistant polyurethane matt black finish for woodware

ActiveCN103013325AEliminate Bubble ProblemsNo surface foggingPolyurea/polyurethane coatingsLacquerSolvent

The invention relates to a preparation method of a scratch-resistant polyurethane matt black finish for woodware. The scratch-resistant polyurethane matt black finish comprises a resin paint component A and a curing agent component B in the weight ratio of 1: 0.5, wherein the resin paint component A comprises alkyd resin, extinction powder, a dispersing agent, carbon black paste, a modifying flatting agent, an antifoaming agent, an anti-settling agent and a solvent; and the curing agent component B comprises a TDI-HDI (Toluene Diisocynate-Hexamethylene Diisocyanate) mixed tripolymer or a TDI / TMP (Trimethylolpropane) affixture, an HDI tripolymer and a solvent. The scratch-resistant double-component polyurethane matt black finish for woodware, prepared by the preparation method provided by the invention, brings no precipitate during being stored, is high in solidity, low in viscosity and excellent in leveling property; and the filming can be realized at one time, and the film is thick, free from sagging, and soft, full, fine, smooth, slippery in hand feel, shows alternate kindness with severity, is given the effect of full decoration like a mirror plane, brings a graceful and comfortable feel, and is adapted to modern aesthetic view and widely popular with the market and customers. The scratch-resistant polyurethane matt black finish is widely applied to protective decoration of surfaces of products such as the woodware, metals and plastics.

Owner:UNION FOSHAN CHEM +1

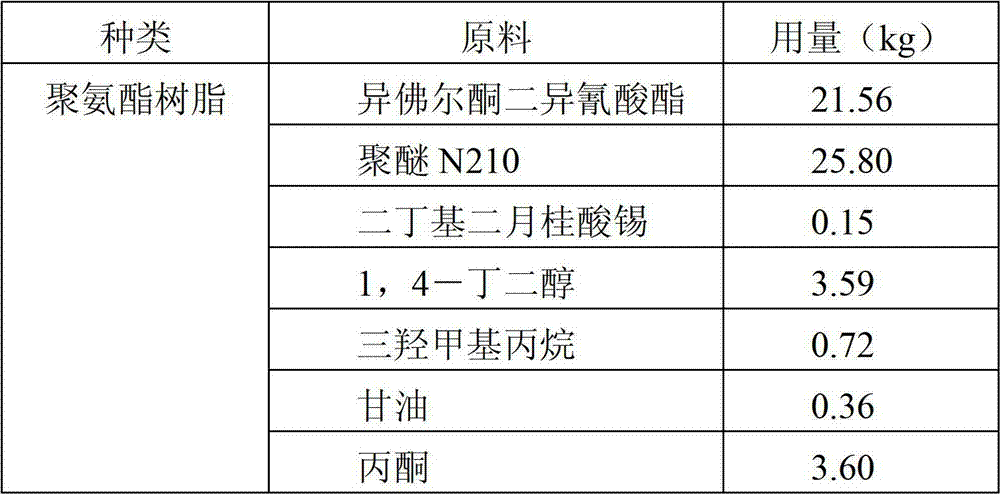

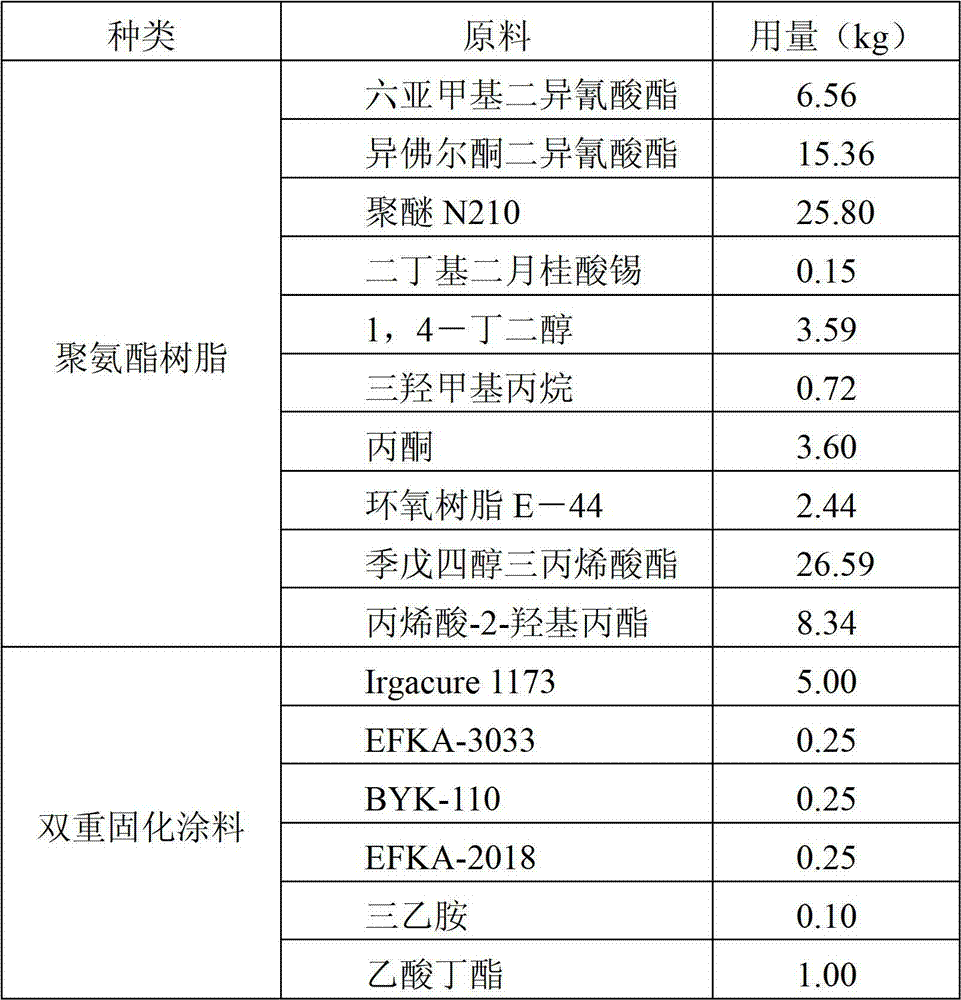

Humidity and ultraviolet dual-cured polyurethane woodware coating and preparation method thereof

The invention discloses humidity and ultraviolet dual-cured polyurethane woodware coating and a preparation method thereof. A synthesis method includes synthesizing initial polyurethane polymer I, polyurethane pre-polymer II, polyurethane pre-polymer III, polyurethane acrylate oligomer and ultraviolet cured woodware coating. The humidity and ultraviolet dual-cured polyurethane woodware coating is mainly prepared by aliphatic diisocyanate, dihydric alcohol pre-polymer, polyhydroxy acid, epoxy resin and hydroxy acrylic ester and the like, and by adding auxiliaries such as photoinitiators, flatting agents, defoamers, substrate wetting agents and catalysts, the ultraviolet cured woodware coating is prepared. The ultraviolet cured woodware coating can form films and be cured under irradiation of ultraviolet, also can be cured by humidity in the air within 5 hours at the room temperature, and has the advantages of high solid, NCO (isocyanate) group content and adhesion force, fine resistance to chemical corrosion, high film coating hardness and fine storage stability and the like, can be used for irregular coating surfaces, hone finished UV (ultraviolet) paint and UV colored paint and the like where cannot be irradiated by the ultraviolet.

Owner:广州常圣新材料科技有限公司

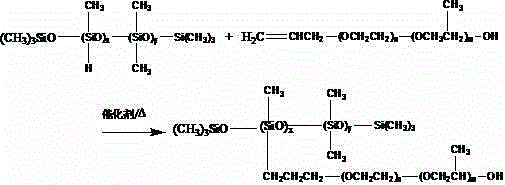

Solvent-free method for preparing polyether modified polysiloxane antifoaming agent

ActiveCN102977377AAvoid crosslinkingIncrease reaction rateInksFoam dispersion/preventionSolventMolecular sieve

Owner:KUSN ZHANGPU COLOR PRINTING FACTORY

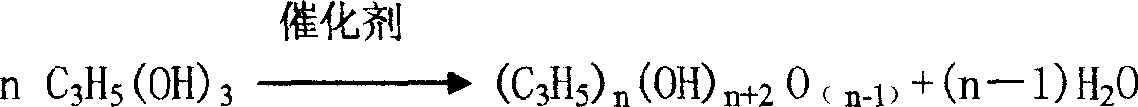

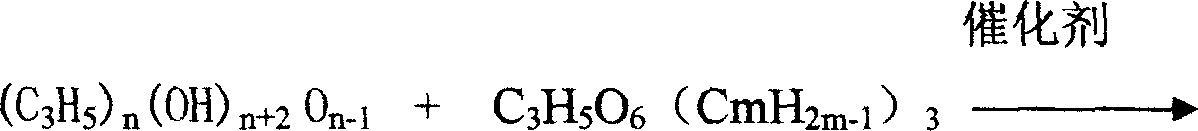

Preparation method of industrial defoaming agent

InactiveCN1721031AGood defoamingGood anti-foam performanceFoam dispersion/preventionGlycerolSugar refining

The preparation method for industrial defoaming agent belongs to organic chemical industry field. First polymerize the glycerin to polyglycerol with polymerization degree of 2-10 under activator, add glycerin fatty acid ester or fatty acid for determined mass rate to process ester interchange and obtain the product. It is simple in technique, has good defoaming and foam inhibiting effect, gets raw material easily and fits to many techniques, such as paper making, sugar refining and fermentation.

Owner:温木盛

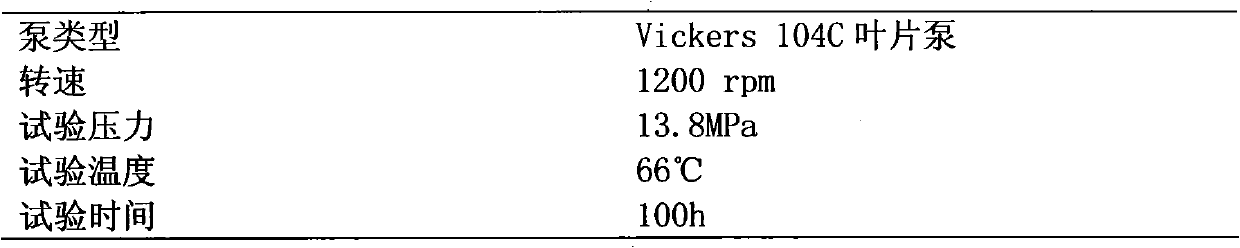

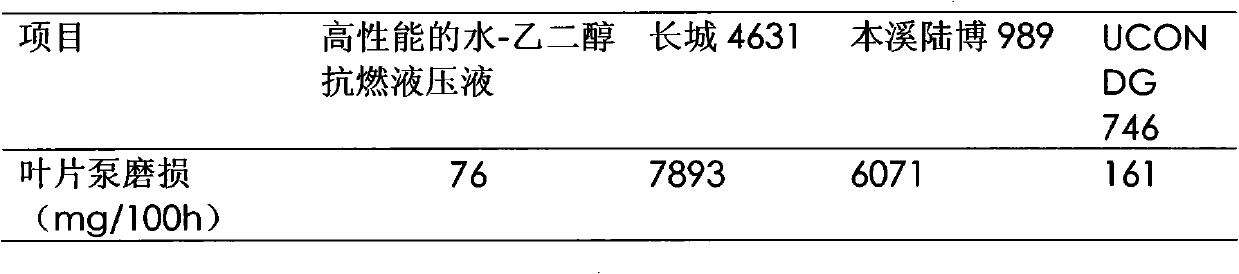

Water-glycol fire-resistant hydraulic fluid

InactiveCN102086422AEnhanced high-pressure anti-wear propertiesImprove the lubrication effectLubricant compositionBenzoic acidCapric Acid

The invention relates to a water-glycol fire-resistant hydraulic fluid. The water-glycol fire-resistant hydraulic fluid comprises the following components in percentage by weight: 37 to 42 percent of water, 12 to 15 percent of the balance of glycol or diethylene glycol and water-soluble polyether tackifier, 0.1 to 0.2 percent of sulfur-containing extreme pressure antiwear additive, 1.0 to 3.0 percent of antiwear additive formed by capric acid or the compounding of the capric acid and caprylic acid, 1.5 to 3.0 percent of at least one amine type antirust agent, 0.1 to 0.3 percent of metal passivator, 0.01 to 0.02 percent of ethylenediaminetetraacetic acid disodium, 0.005 to 0.02 percent of benzoic acid, and 0.002 to 0.005 percent of defoaming agent. The water-glycol fire-resistant hydraulic fluid has the characteristics that: the product has strong high-pressure abrasion resistance, and still has good lubricating property under high-pressure working conditions; and a Vickers 104C vane pump bench test (ASTM D7043) with test pressure of 14MPa prove that the abrasion of a vane pump is less than 100mg.

Owner:PETROCHINA CO LTD

Organosilicone composition, preparation method and application thereof

ActiveCN104274998AGood defoamingGood anti-foam performanceFoam dispersion/preventionPolymer scienceUnsaturated hydrocarbon

The present invention relates to a crosslinked network polymer obtained on the basis of an addition reaction of a hydrogen-containing polyorganosiloxane, an organic silicon resin and an unsaturated hydrocarbon, followed by the process of adding a crosslinking agent containing an active group and silicon dioxide; the polymer has an improved defoaming performance, good anti-foaming effect, and is easy to handle and process, and the addition of an emulsifier does not reduce the anti-foaming effect. The polymer has a good anti-foaming performance with no decay, and the polymer formed therefrom can easily be processed.

Owner:JIANGSU SIXIN SCI-TECH APPL RES INST CO LTD

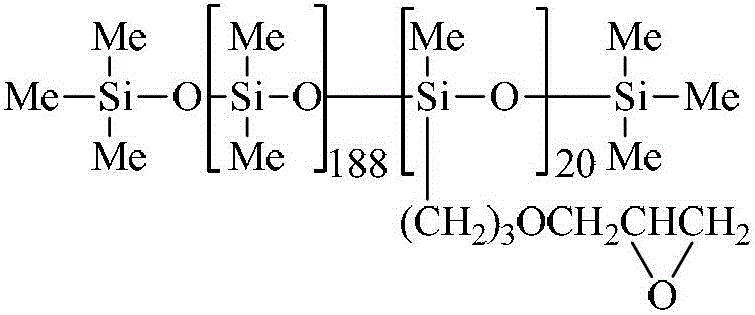

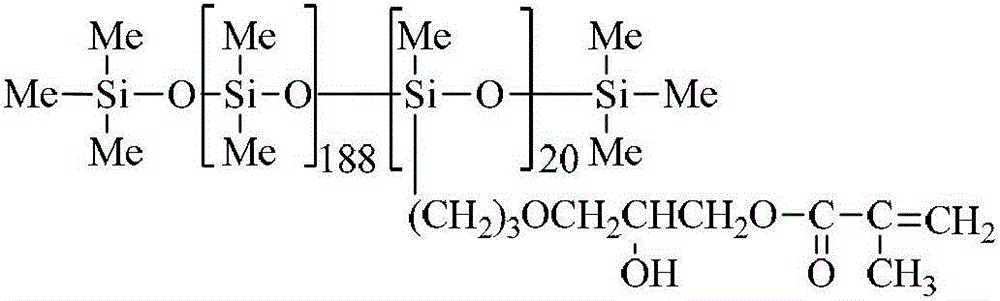

Preparation method for organosilicone acrylate

The invention discloses a preparation method for organosilicone acrylate, and belongs to the preparation field of coating defoamer. The method comprises two steps of preparing an epoxy organosilicone intermediate by reacting low hydrogen-containing silicone oil and an unsaturated epoxy compound; and then preparing organosilicone acrylate by reacting the obtained epoxy organosilicone intermediate and unsaturated carboxylic acid. Compared with a conventional synthetic method for organosilicone acrylate, the method provided by the invention prevents phenomena of self-polymerization and copolymerization of bi-functional monomers, obtains a series of organosilicone acrylate containing different side chain acrylic ester groups by selecting different raw materials and reaction conditions, overcomes the disadvantage that side chain acrylic ester groups are constant, meets the requirements for good defoaming property and good levelling property of the organosilicone acrylate defoamer in an ultraviolet-curable coating system.

Owner:SHANGHAI PHICHEM MATERIAL CO LTD

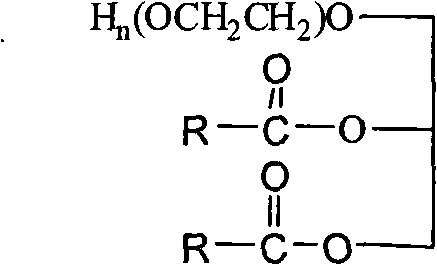

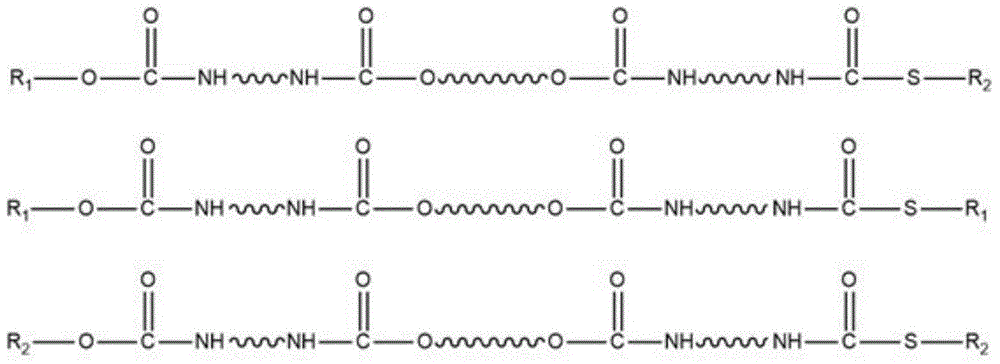

UV curing liquid optical cement and preparation method and application thereof

ActiveCN105985749AThere will be no glue overflow problemModerate bond strengthPolyureas/polyurethane adhesivesEster polymer adhesivesUV curingOligomer

The invention discloses UV curing liquid optical cement. The UV curing liquid optical cement is prepared from, by weight, 20-70 parts of active oligomer, 10-50 parts of tackifying resin, 10-40 parts of reactive diluent, 0.3-5 parts of photoinitiator and 1-5 parts of additive. The tackifying resin has a unique molecular structural formula. A preparation method of the UV curing liquid optical cement comprises the steps that the active oligomer, the tackifying resin, the reactive diluent, the photoinitiator and the additive are placed in a planetary vacuum mixer and are stirred and mixed to be uniform, and a finished product is obtained through filtering and defoaming. The problem of cement overflow that common liquid optical cement cannot overcome and the problem that the common liquid optical cement is not suitable for the special lamination process of UV precuring, lamination and UV curing for cement overflow prevention are solved, a cement film formed by the UV curing liquid optical cement has moderate bonding strength and a good locating effect, the bonding strength is greatly improved after UV curing is carried out again, the surface of the cement film is very smooth, a certain edge shape is kept, and no edge collapse phenomenon occurs; the UV curing liquid optical cement is suitable for automatic equipment coating and especially suitable for full lamination of modules.

Owner:DONGGUAN POWERBOND NEW MATERIALS TECH DEV

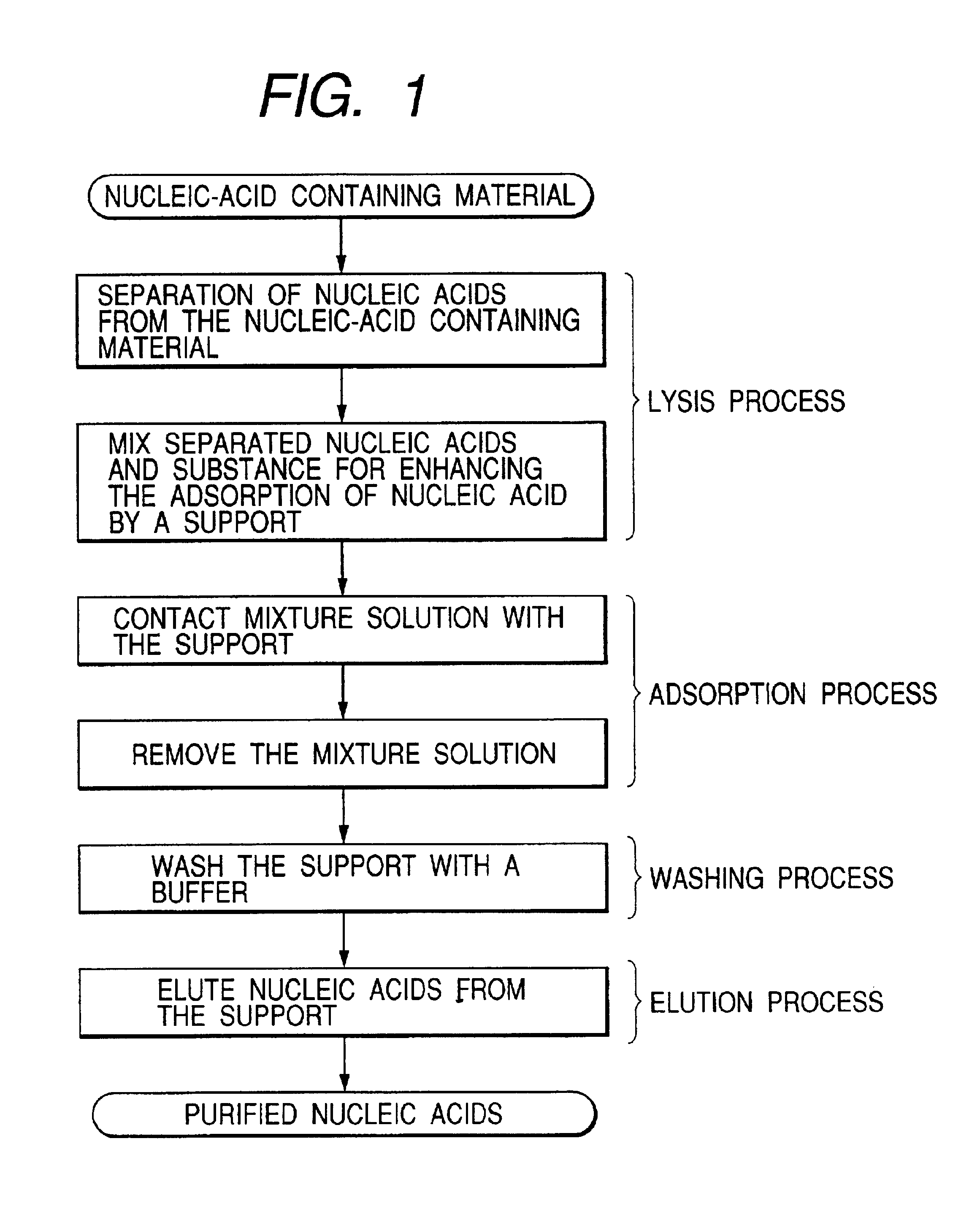

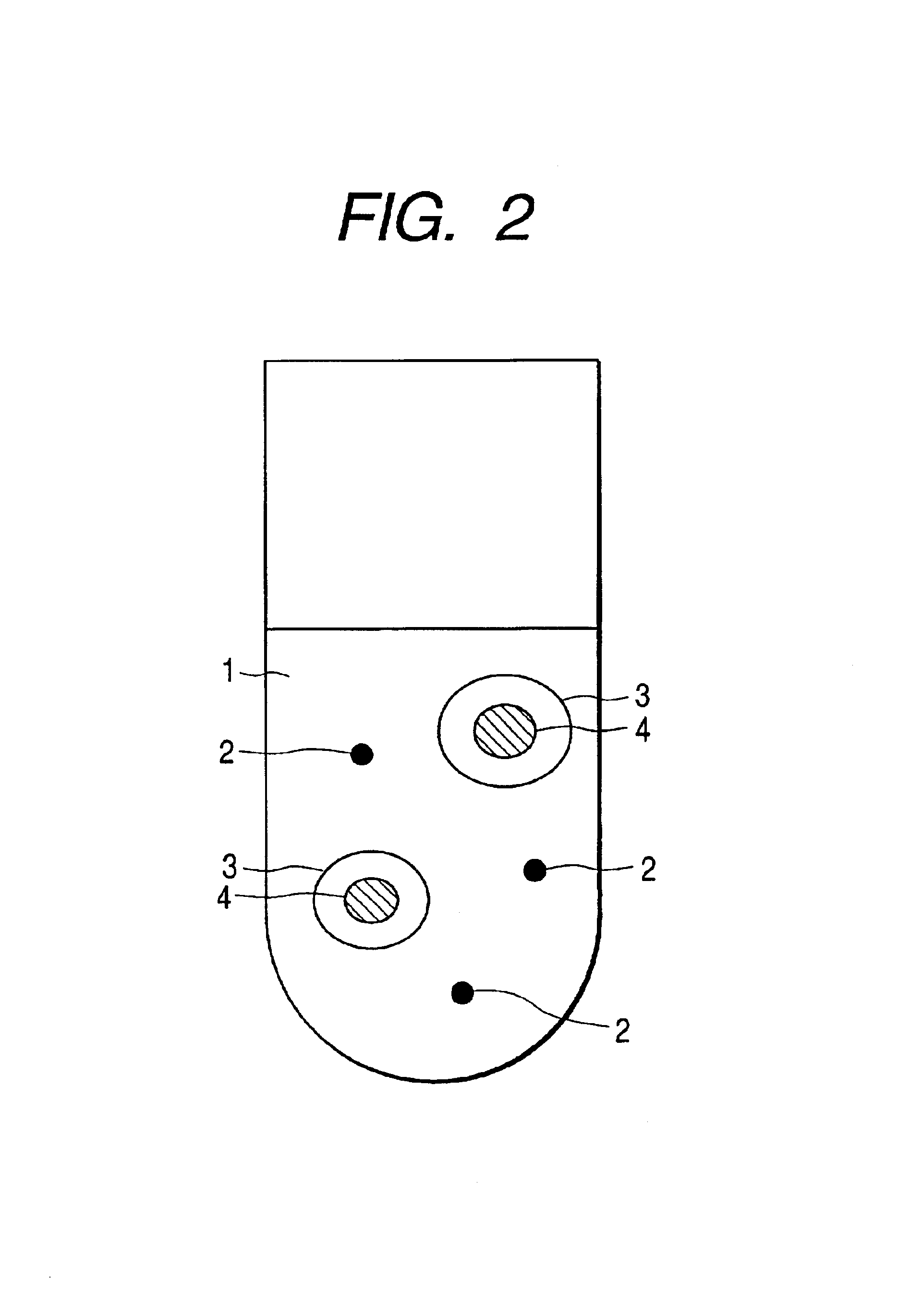

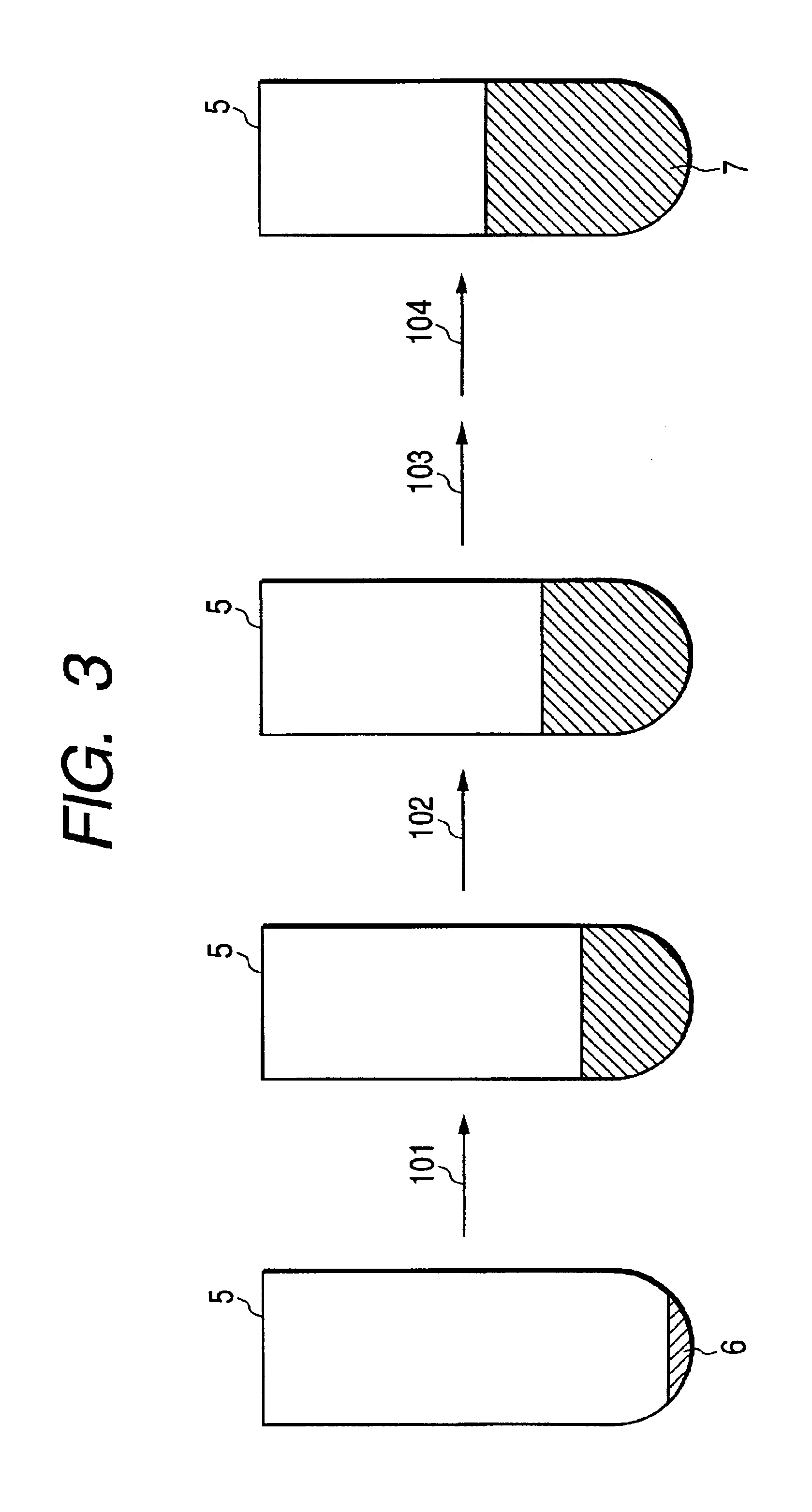

Method for isolating and purifying nucleic acids

InactiveUS6905825B2Easy to operateLess susceptible to pollutionImmobilised enzymesBacteriaOrganic solventEther

A method for isolating and purifying nucleic acids with an improved recovery yield is provided. A mixed solution containing the nucleic acids, salts, and an organic solvent is contacted with an adsorption support to cause the nucleic acids to be adsorbed on the support. Then, the nucleic acids are desorbed from the support using an elution buffer. At least one compound containing 2 to 10 carbon atoms as selected from the group consisting of aliphatic ether, aliphatic ester, and aliphatic ketone is used as the organic solvent. The method improves the yield of nucleic acids collection, is easy to implement and less susceptible to contamination.

Owner:HITACHI LTD

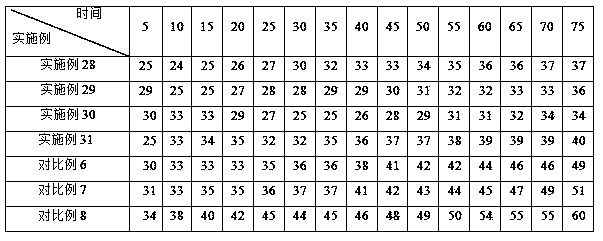

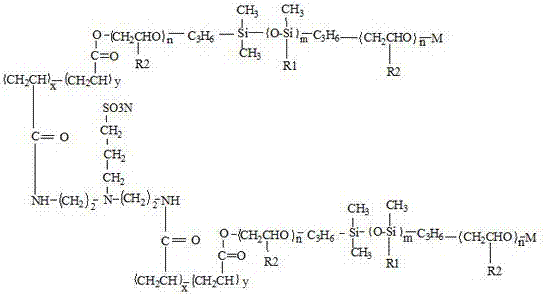

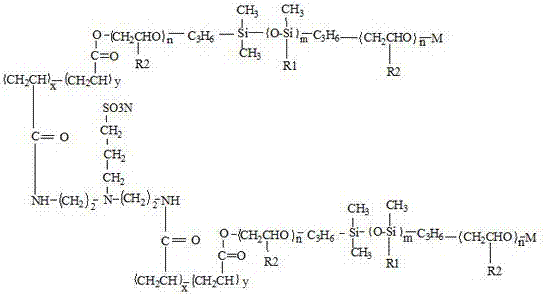

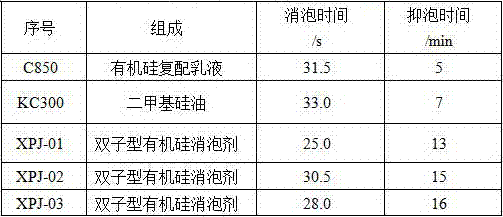

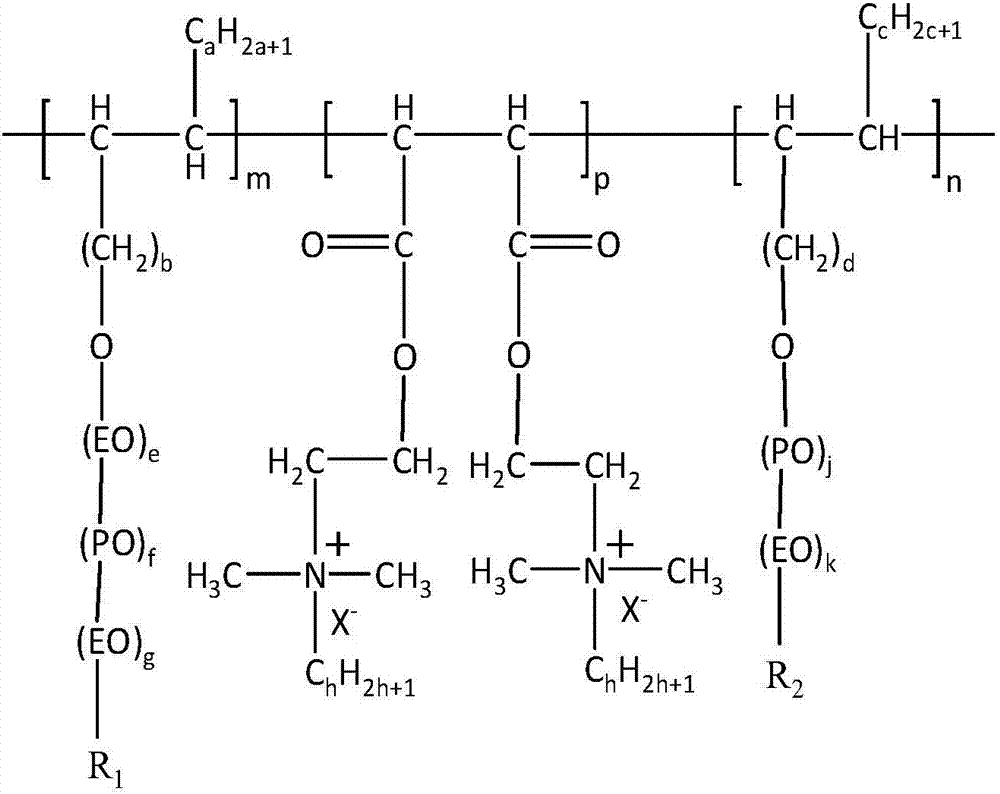

Gemini organic silicon defoamer

ActiveCN106977632AGood defoaming effectGood defoamingFoam dispersion/preventionDissolutionSilicone oil

The invention relates to a gemini organic silicon defoamer. The gemini organic silicon defoamer is of an improved polyether organosilicon diamide sulfonate structure; hydrophilic groups are ethylene oxide, an amido bond and sulfonate; hydrophobic groups are polysiloxane and epoxypropane; through a plurality of hydrophilic groups, the low-temperature defoaming affect is good; through a comb structure, polyether-modified silicone oil can quickly spread on a gas-liquid interface of a foaming system, and locally intrudes to break foam, and the gemini organic silicon defoamer has better defoaming activity; through a macromolecular comb structure, the dissolution rate in a system is reduced and a continuous foam inhibition effect is generated. The gemini organic silicon defoamer is a silicone-modified defoamer which is good in defoaming and foam inhibiting properties, especially good in low-temperature defoaming and foam inhibiting effects.

Owner:福建昆冈化学助剂科技有限公司

Method for preparing nonionic surfactant with alkamine modified swill-cooked dirty oil

InactiveCN101766974AGood value for moneyGood emulsificationTransportation and packagingMixingChemical productsAdditional values

The invention relates to a method for preparing nonionic surfactant with alkamine modified swill-cooked dirty oil. The method comprises the following steps: firstly refining the reclaimed swill-cooked dirty oil, secondly using alkamine to perform amidation modification, and then performing ethylene oxide or propylene oxide addition of the modified mixture product to prepare the environmentally friendly nonionic surfactant with high cost performance. The product is pale yellow-reddish brown viscous fluid, and the HLB value is 6-15 which is determined by the structure of the product and the adduct number of ethylene oxide or propylene oxide. The nonionic surfactant has good emulsifiability and functions of softening and defoaming, is suitable to be used in fields of leather, textile dyeing and finishing, industrial cleaning, pesticide and daily chemical engineering and has wide application range and good comprehensive performance. The design of the technical route of the invention is novel and unique and has innovativeness. On one side, the additional value of discarded edible oils and fats can be greatly increased, which has great significance in removing the pollution of discarded edible oils and fats; and on the other side, new chemical products can be produced.

Owner:SHAANXI UNIV OF SCI & TECH

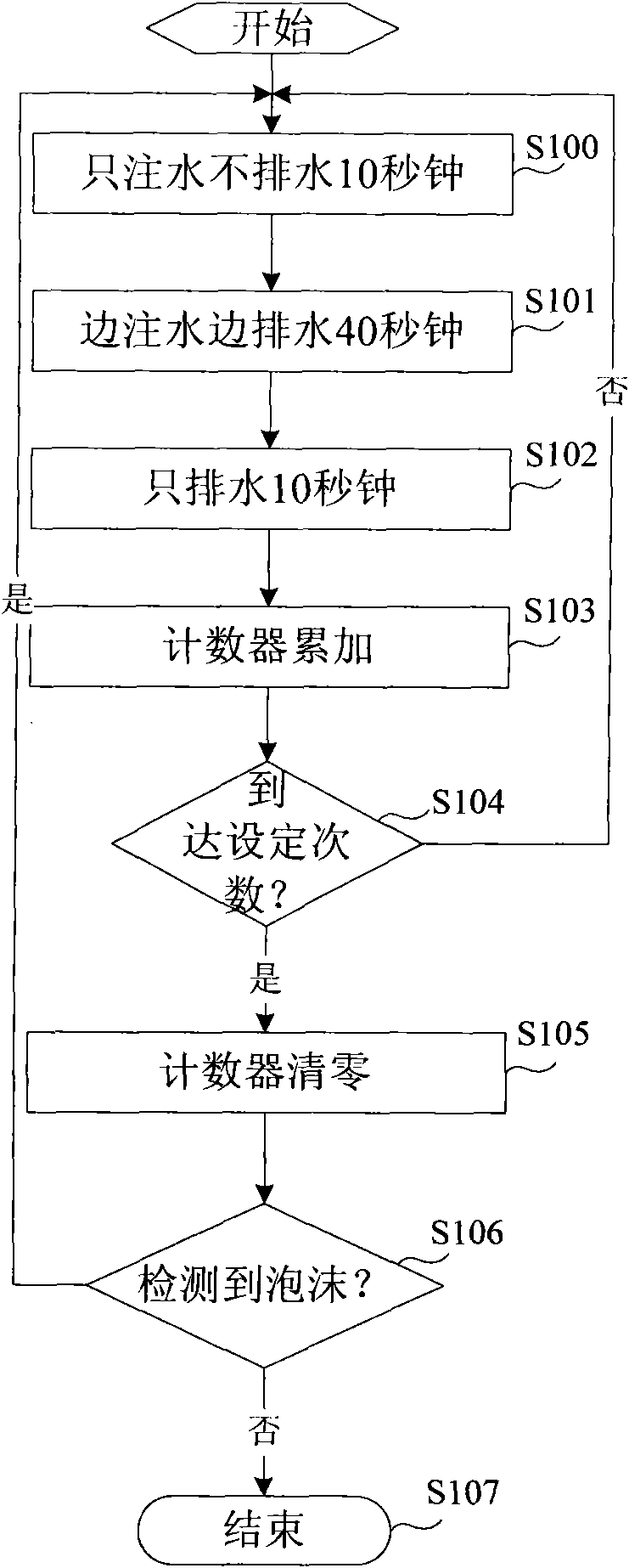

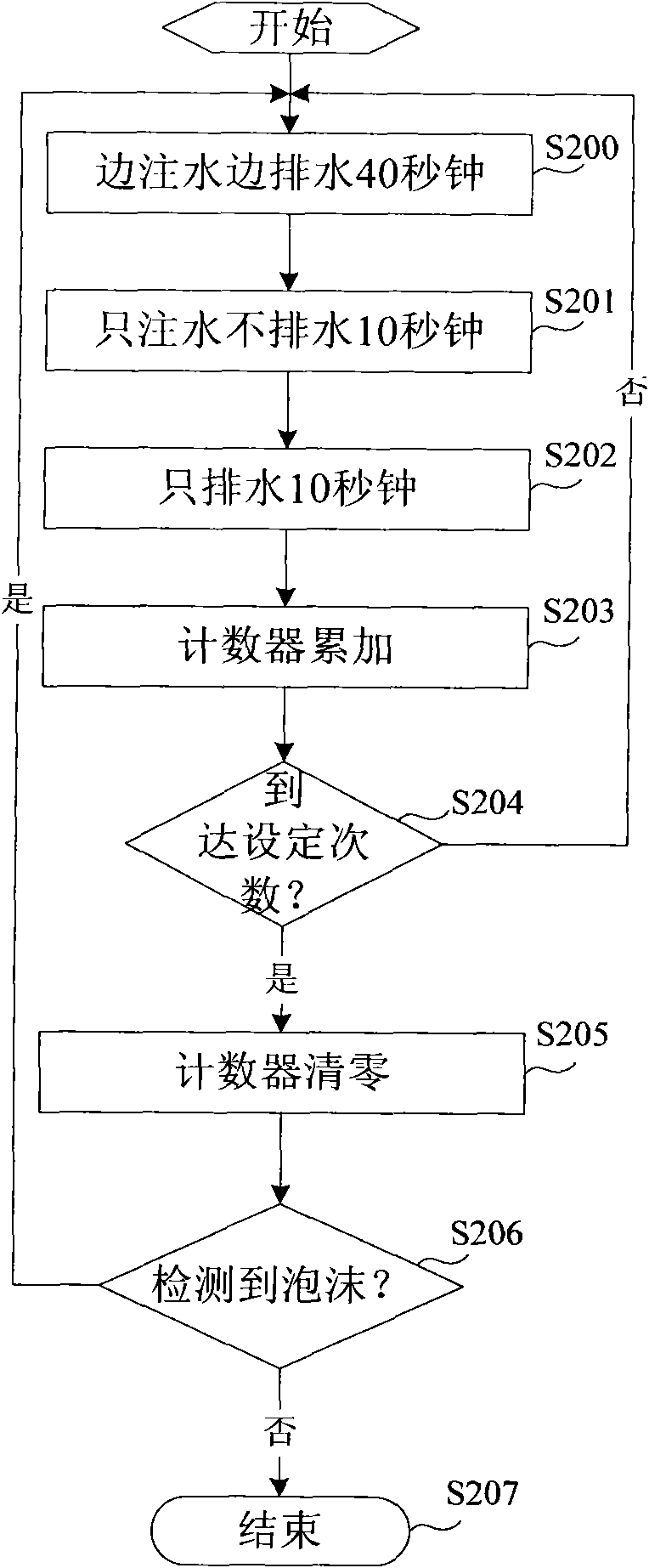

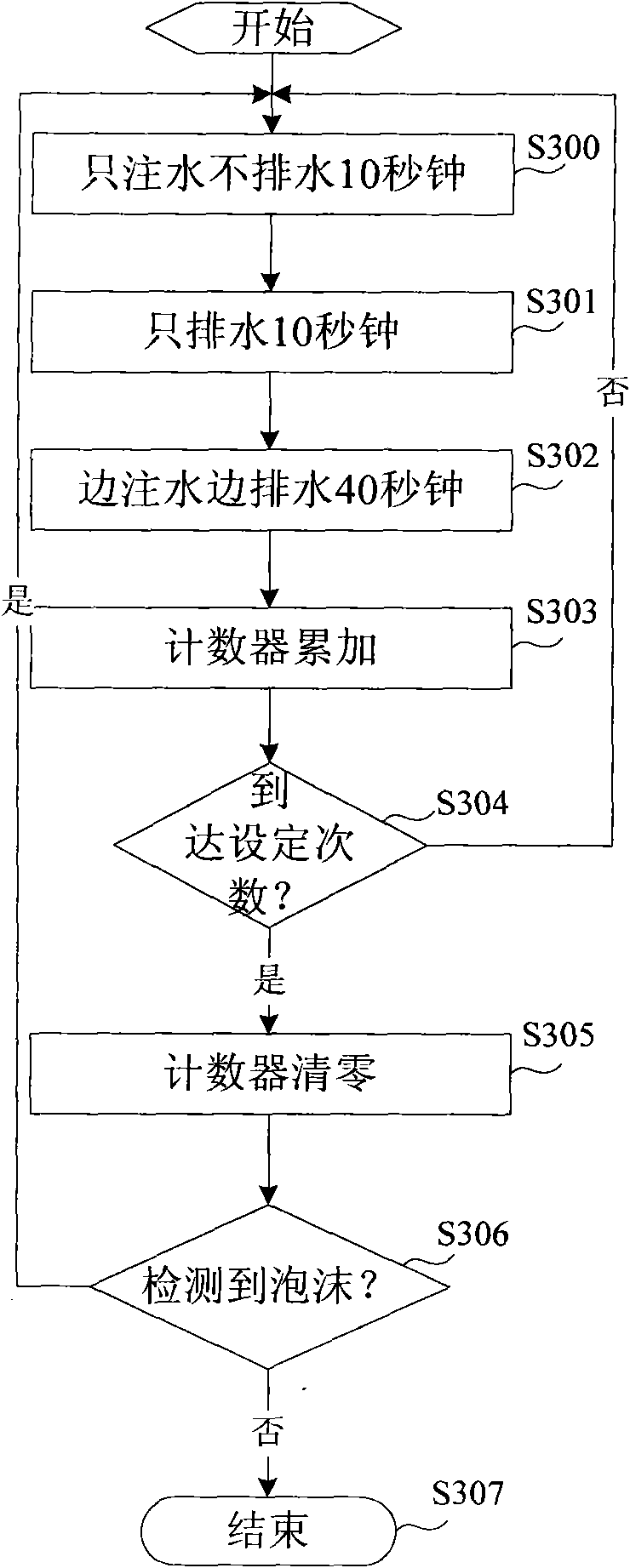

Washing machine defoaming method

InactiveCN101851842AEliminate pollutionEliminate potential safety hazardsOther washing machinesControl devices for washing apparatusEngineering

The invention discloses a washing machine defoaming method, which comprises the following steps of: independently injecting water; performing water injection and drainage simultaneously; and independently draining. In the method, because the steps of independently injecting water, performing water injection and drainage simultaneously, and independently draining are added, the combination effectively removes foams.

Owner:HAIER GRP CORP +1

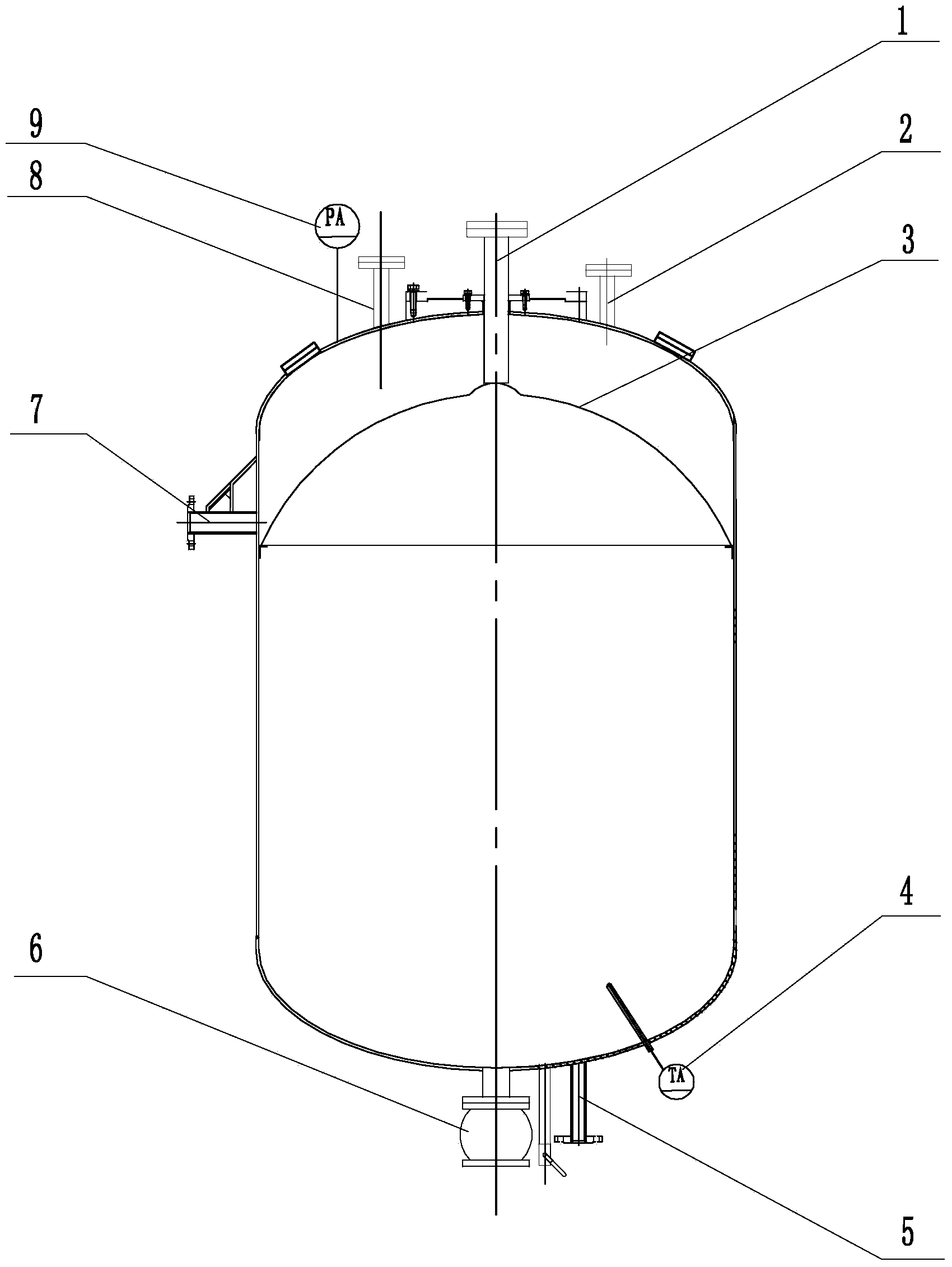

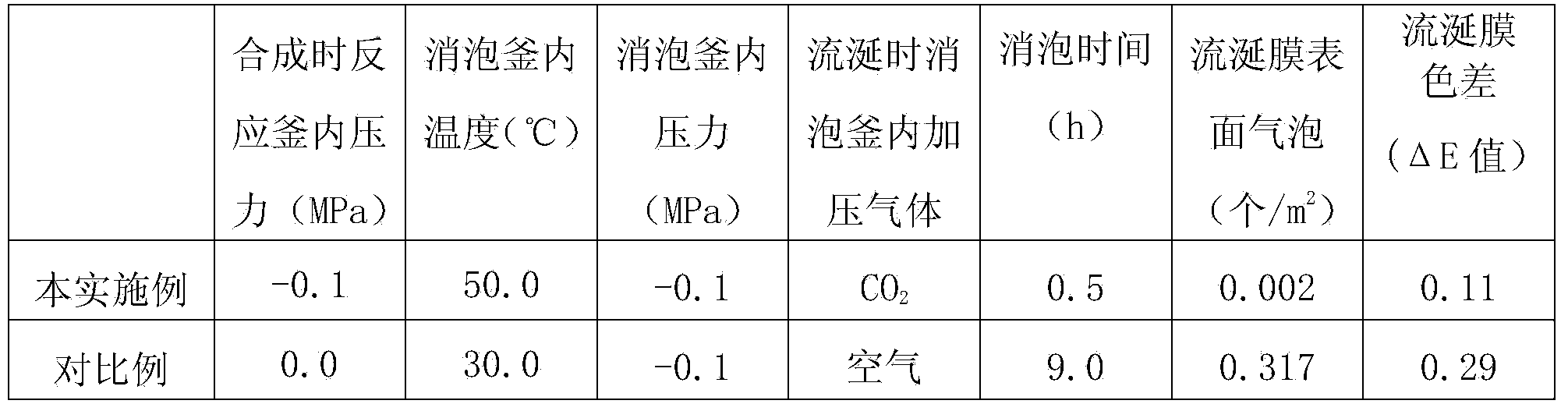

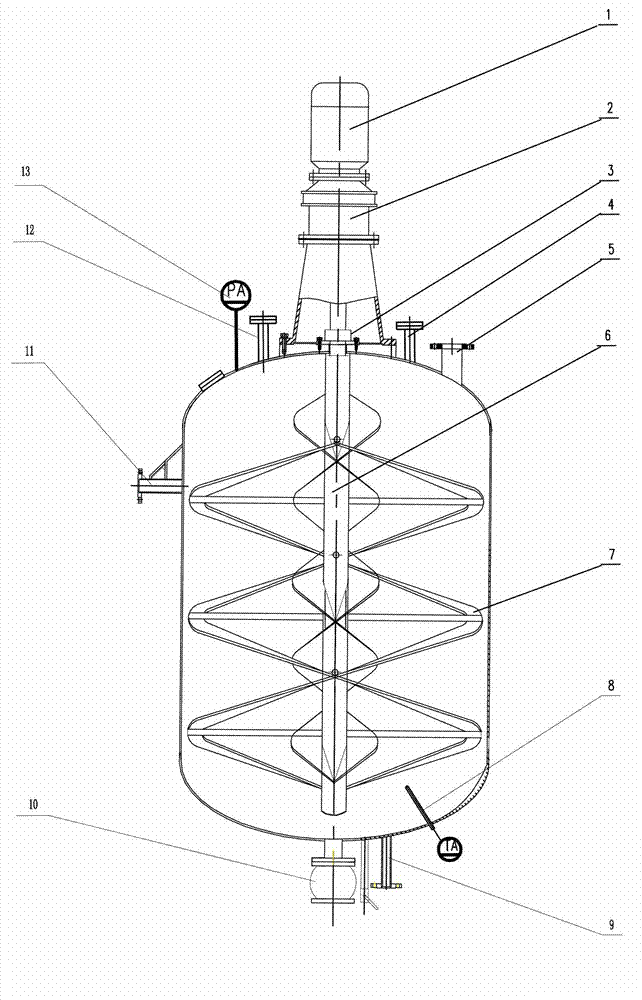

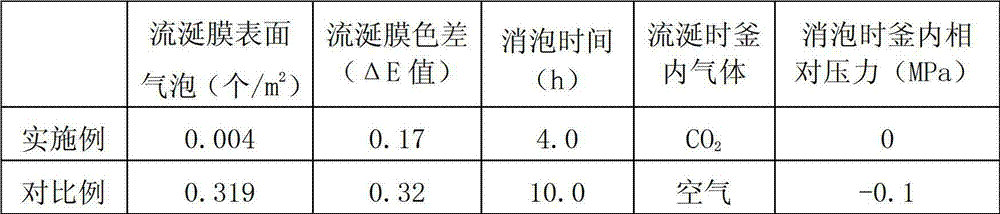

Defoaming kettle and defoaming method for preparing polyamide acid resin

ActiveCN104107565APrevent oxidationPrevent moisture absorptionFoam dispersion/preventionThin layerEngineering

The invention discloses a defoaming kettle and a defoaming method for preparing polyamide acid resin. A thin layer distributor with an arch rotary curve surface is fixedly installed in a defoaming kettle tank body; the distance from the curve surface arch top of the thin layer distributor to the lower end opening of a feeding pipe ranges from 0.01mm to 1 / 3 of the height of the tank body; the clearance between the lower edge of the curve surface of the thin layer distributor and the inner wall of the tank body is 0.01mm-10mm; the rotary curve surface of the thin layer distributor is a spherical surface; a resin conveying pipeline between a reaction kettle and the defoaming kettle is provided with a metering pump; the tank body is provided with a sandwiched sleeve, and an heat conduction medium inlet and outlet are formed at the top and bottom of the tank body. The defoaming method comprises the step that resin entering the defoaming kettle falls on the arch top of the curve surface of the thin layer distributor, and disperses and flows downward along the curve surface of the thin layer distributor to form a thin layer which results in bubble breakage. The metering pump is used for adjusting the flow rate of resin so as to keep that the thickness of the resin solution layer on the thin layer distributor is less than 5mm. Defoaming is completed immediately when resin is conveyed completely, and then pressurization is carried out for discharging. During defoaming, a heat conduction medium is introduced for warming, and negative pressure is kept in the tank body. According to the invention, defoaming is complete, and the defoaming time is shortened greatly so as to guarantee subsequent continuous film preparation. The defoaming kettle is simple in structure and convenient to operate.

Owner:GUILIN ELECTRICAL EQUIP SCI RES INST

Environment-friendly steel wire drawing lubricating agent and production method thereof

The invention relates to the field of lubricating grease, in particular to an environment-friendly steel wire drawing lubricating agent and a production method thereof. The lubricating agent is prepared by blending the following components in percentage by weight: 5.0 to 10 percent of base oil, 15 to 24 percent of emulsifier, 5.0 to 8.0 percent of alkaline reserve agent, 9.4 to 18.8 percent of extreme pressure antiwear agent, 5.3 to 8.3 percent of water soluble antirust agent, 0.01 to 0.03 percent of coupling agent, 0.01 to 0.03 percent of defoaming agent, 0.01 to 0.03 percent of bacteriacideand 30.81 to 60.27 percent of distilled water. The total percentage of the components is 100 percent. Compared with the prior art, the components do not react with the steel wire substrates; the antirust performance, defoaming performance and biostability are high; the deterioration in storage and use is slow, and the service life is long; and environment pollution is avoided and waste liquid canbe treated easily.

Owner:辽宁海华科技股份有限公司

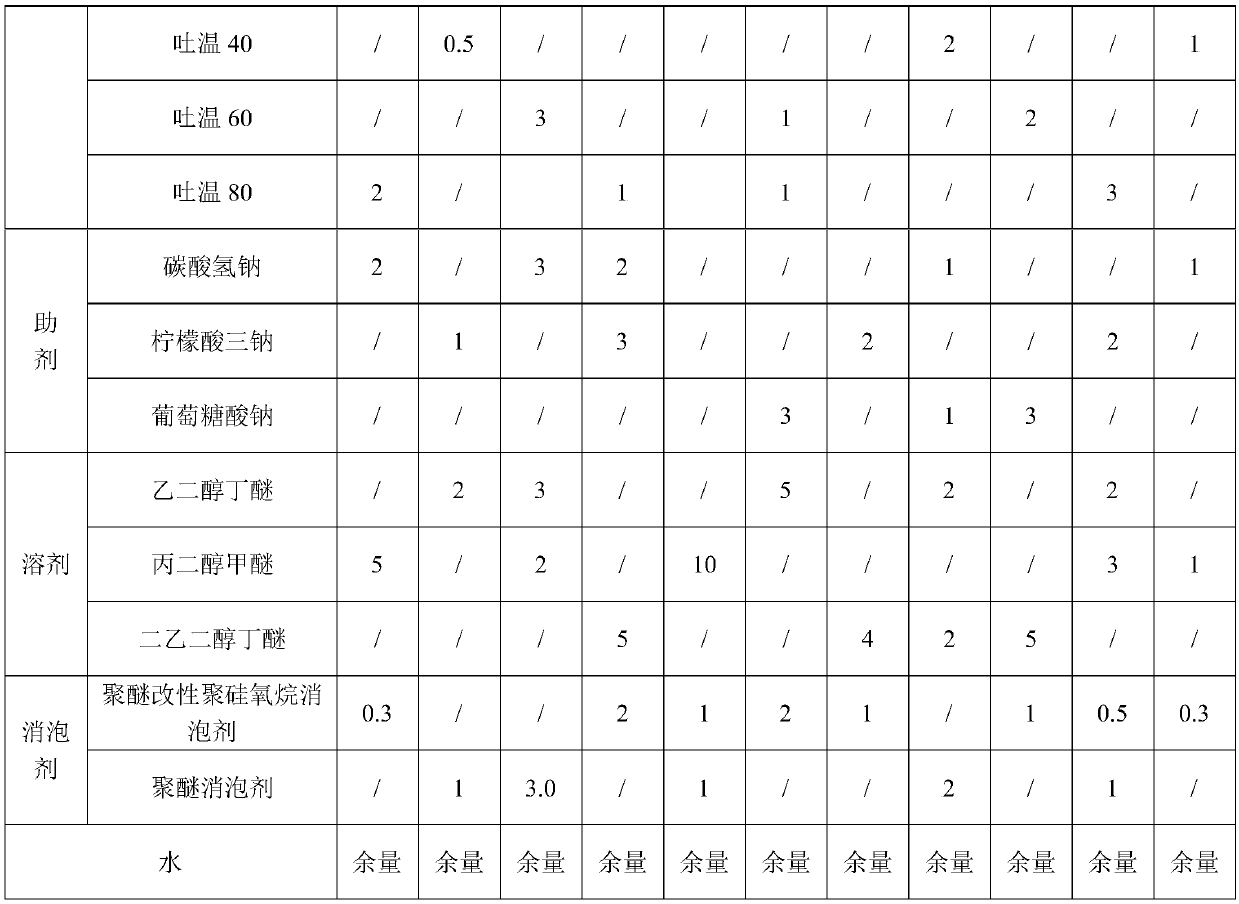

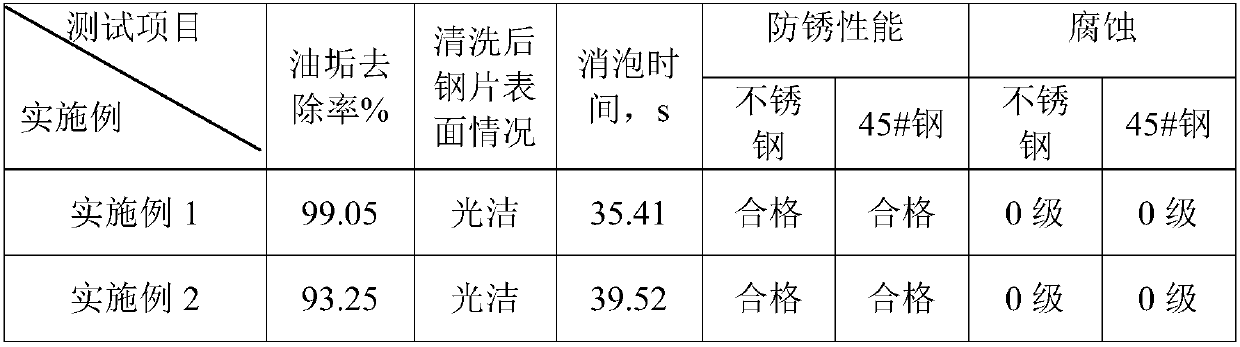

Environment-friendly neutral cleaning agent and preparation method and application thereof

The invention discloses an environment-friendly neutral cleaning agent. The environment-friendly neutral cleaning agent comprises, by mass percent, 2%-20% of a surface active agent, 1%-5% of an emulgator, 1%-5% of an auxiliary, 1%-10% of an organic solvent, 0.3%-4.0% of a defoaming agent and the balance deionized water. The surface active agent comprises at least one kind in fatty acid methyl ester ethoxylate and modified grease ethoxylate, at least one kind in alcohol alkoxylate and normal fatty alcohol polyoxyethylene ether, at least one kind in coconutt diethanol amide and laurel based amphiprotic sodium acetate and at least one kind in fatty alcohol glucoside and alkyl glycoside. Raw materials related to in the formula of the cleaning agent contain no phosphorus and are green and environment-friendly, the components are coordinated and cooperate with one another, the excellent properties of wetting, permeation, emulsification and dispersion are achieved, and grease and other dirt on the surfaces of stainless steel workpieces can be removed fast.

Owner:SHANGHAI FINE CHEM CO LTD

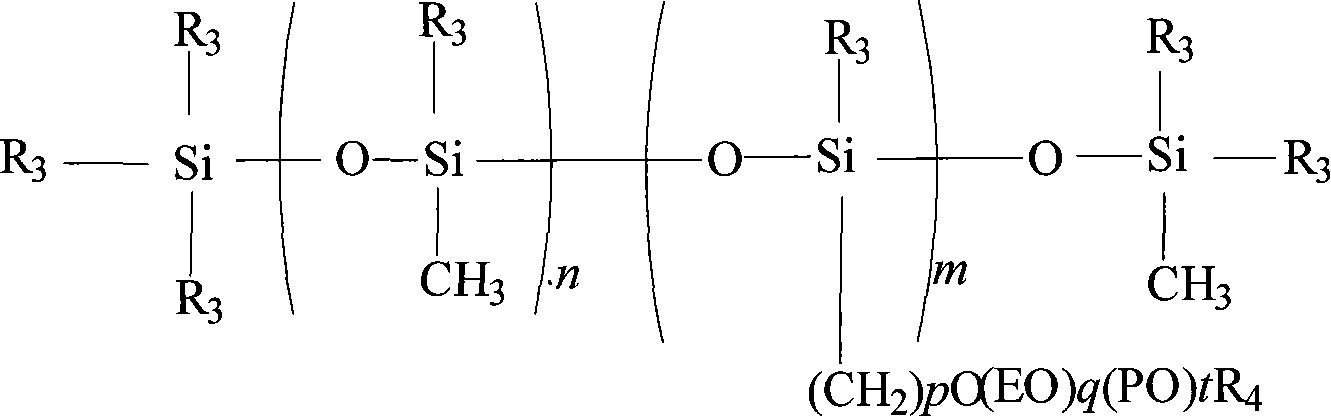

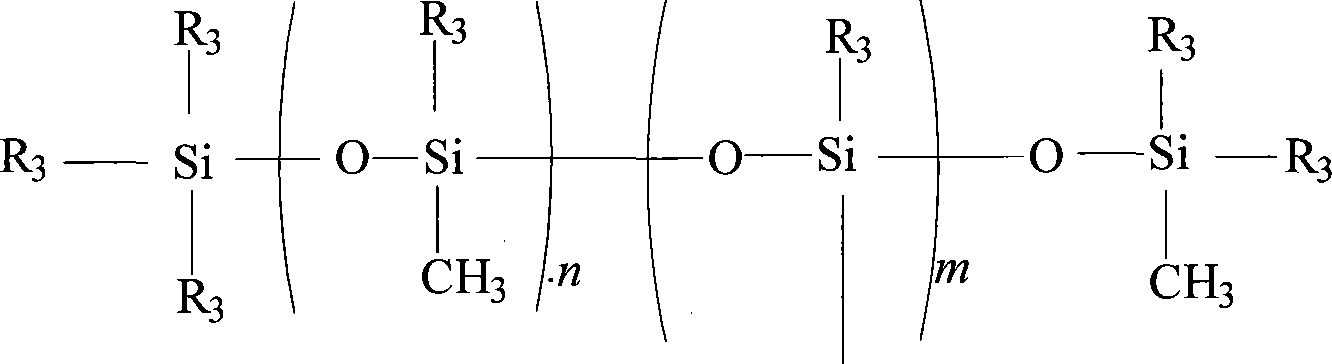

Polyoxyalkylene aminosilicone-based antifoam agent and its process of manufacture

ActiveUS8481476B2Negative effectWell mixedInorganic/elemental detergent compounding agentsSilicon organic compoundsPolymer scienceAminosilochrome

Modified aminoalkyl- and polyoxyalkylene-functional organopolysiloxanes exhibit delayed antifoaming activity in washing operations, minimizing foaming of rinse water. When applied to a pulverulent carrier, they may also be used in powder detergent formulations.

Owner:WACKER CHEM GMBH

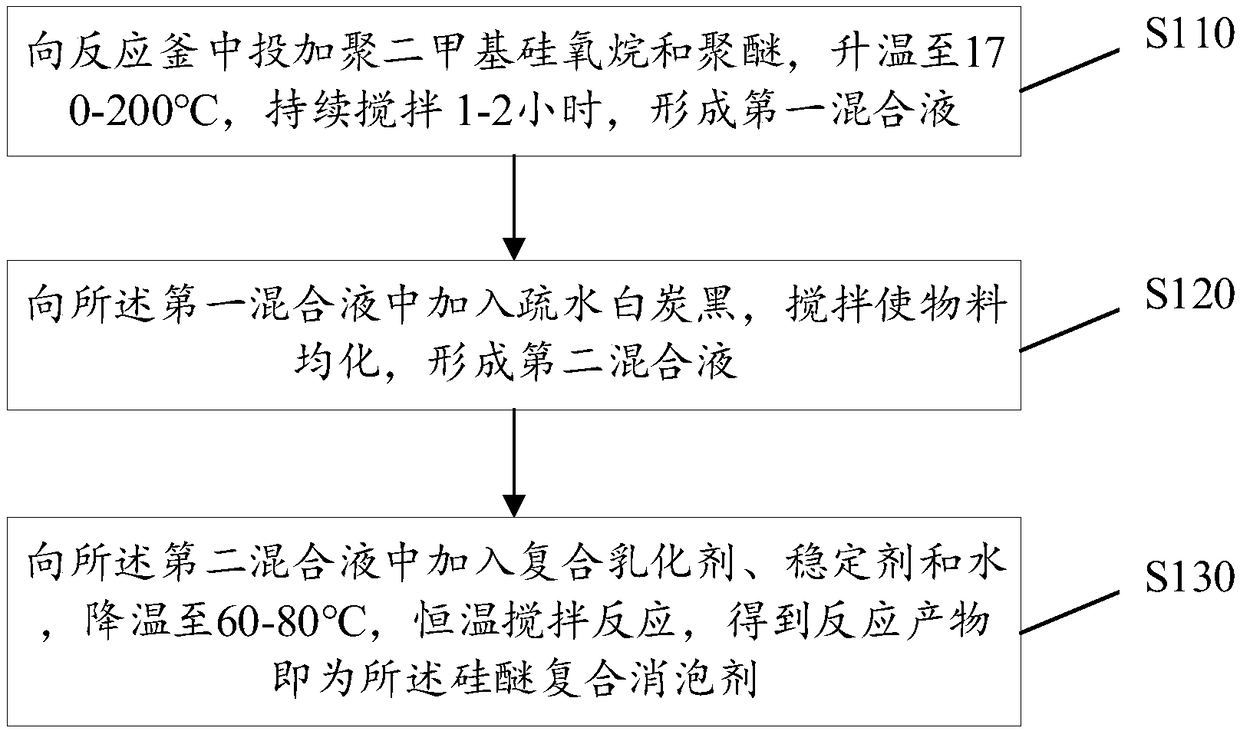

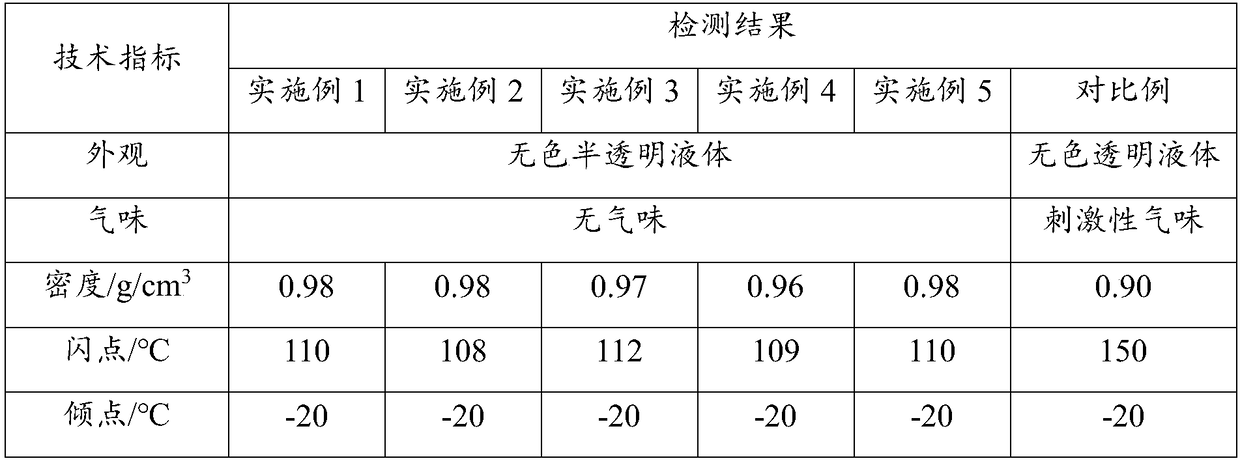

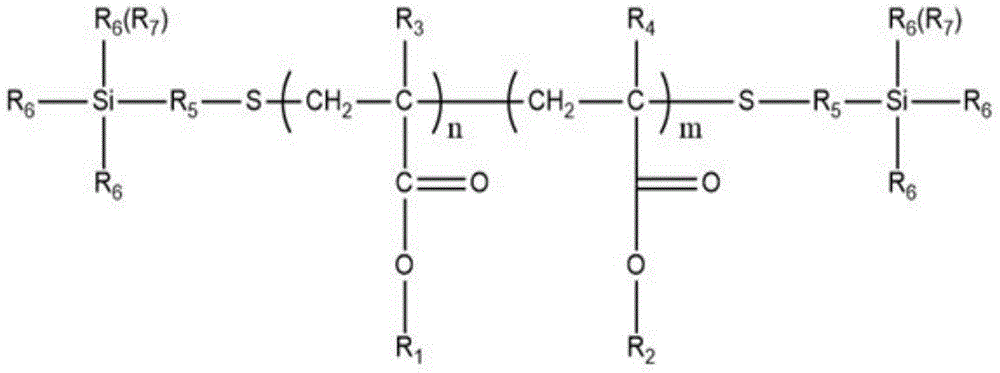

Silyl ether composite defoaming agent as well as preparation method and application thereof

ActiveCN108726913AGood defoamingImprove cementing qualityDrilling compositionChemical industryDefoaming Agents

The invention discloses a silyl ether composite defoaming agent as well as a preparation method and an application thereof, and belongs to the technical field of oilfield chemical industry. The composite defoaming agent is prepared from components in percentage by mass as follows: 15%-25% of polysiloxane, 15%-25% of polyether, 2%-5% of hydrophobic white carbon black, 2%-5% of a compound emulsifier, 1%-2% of a stabilizer and the balance of water. The preparation method comprises steps as follows: polydimethylsiloxane and polyether are added to a reaction kettle, the temperature is increased to170-200 DEG C, and the materials are continuously stirred for 1-2 h; hydrophobic white carbon black is added and stirred to be homogenized; the compound emulsifier, the stabilizer and water are added,the temperature is reduced to 60-80 DEG C, a stirring reaction is performed at constant temperature, and the silyl ether composite defoaming agent is obtained. The composite defoaming agent is used for defoaming and foam inhibition in a stirring process of well cementing slurry containing an admixture. The composite defoaming agent is high in defoaming and foam inhibition capacity, can be appliedto various cement slurry systems, and is good in compatibility with common admixtures, safe and environmentally friendly.

Owner:TIANJIN BO XING ENG SCI & TECH LIMITED COMPANY OF CNPC +1

Aqueous emulsion non-silicon defoamer and preparation method thereof

ActiveCN101780383BImprove surface activityEnhanced defoamingTransportation and packagingMixingWater basedEmulsion

The invention discloses an aqueous emulsion non-silicon defoamer and a preparation method thereof. The defoamer consists of a material with defoaming activity, an emulsifying material and a dispersion medium, wherein the material with defoaming activity consist of alkynol, higher aliphatic alcohol and glyceryl polyether; the emulsifying material consists of anionic emulsifier and non-ionic emulsifier; and the dispersion medium consists of water and glycol. The defoamer of the invention has excellent defoaming and anti-foaming functions and high wettability and stability and is particular suitable for water-based paint, oil ink and other systems.

Owner:JIANGSU SAIOUXINYUE DEFOAMER

UV-moisture dual-curing liquid optical cement and preparation method and application thereof

ActiveCN105985750ARealize the function of dual curingReduce consumptionPolyureas/polyurethane adhesivesEster polymer adhesivesUV curingReactive diluent

The invention discloses UV-moisture dual-curing liquid optical cement. The UV-moisture dual-curing liquid optical cement is prepared from, by weight, 45-80 parts of UV moisture curing matrix resin, 10-50 parts of tackifying resin, 10-35 parts of reactive diluents, 0.3-5 parts of photoinitiator and 1-5 parts of additive. The matrix resin and the tackifying resin have unique molecular structures. The invention further provides a preparation method of the UV-moisture dual-curing liquid optical cement. The preparation method comprises the following steps that the matrix resin and the tackfying resin are prepared; then all the materials are placed in a planetary vacuum mixer and are stirred and mixed to be uniform, and the finished product is obtained through filtering and defoaming. The problem of cement overflow that common liquid optical cement cannot overcome and the problem that the common liquid optical cement is not suitable for the special lamination process of UV precuring, lamination and moisture curing for cement overflow prevention are solved, a cement film formed by the UV-moisture dual-curing liquid optical cement after primary UV curing has moderate bonding strength and a good locating effect, the bonding strength is greatly improved after moisture curing, the surface of the cement film is very smooth, a certain edge shape is kept, no edge collapse phenomenon occurs, and the UV-moisture dual-curing liquid optical cement is suitable for automatic equipment coating.

Owner:DONGGUAN POWERBOND NEW MATERIALS TECH DEV

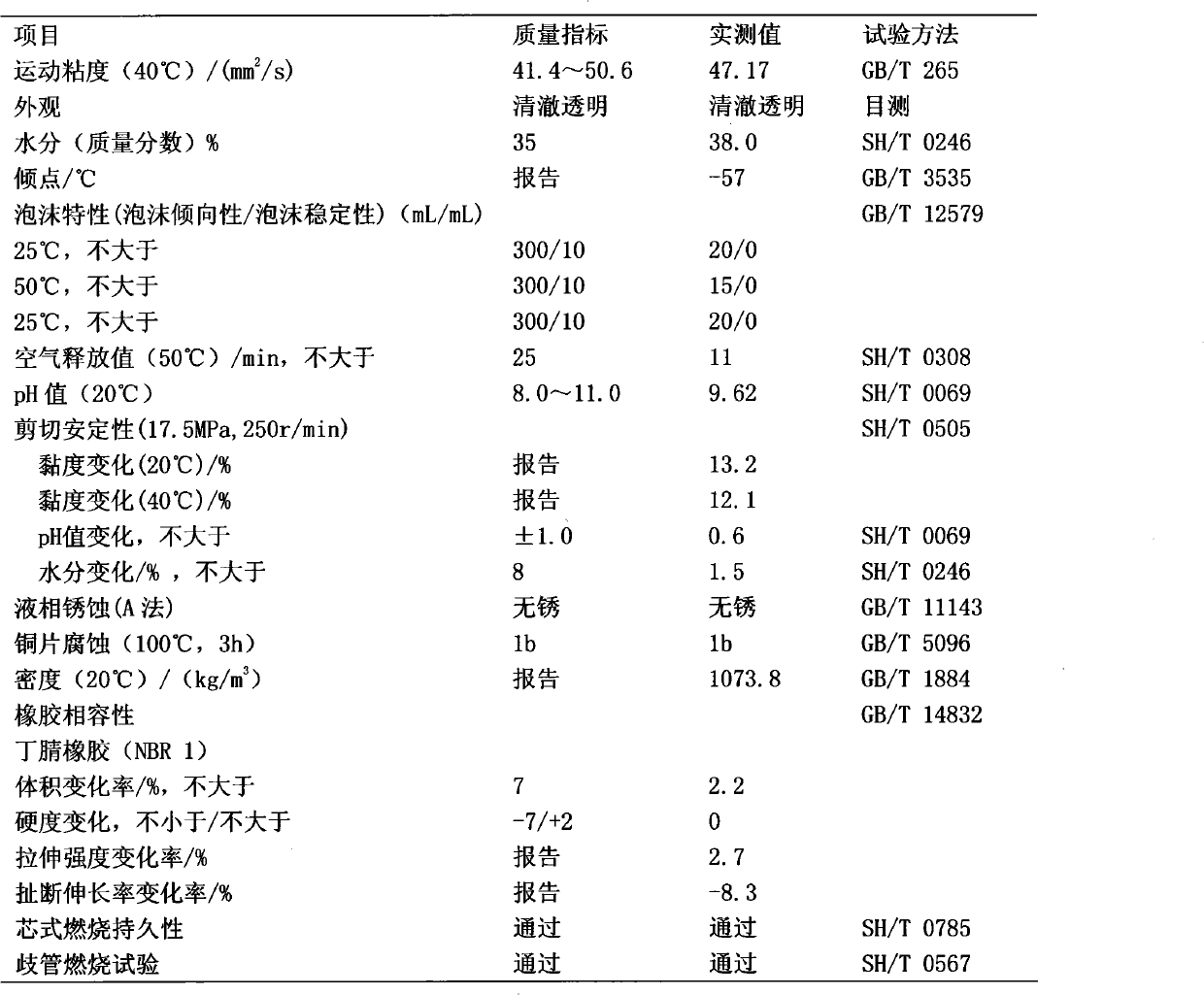

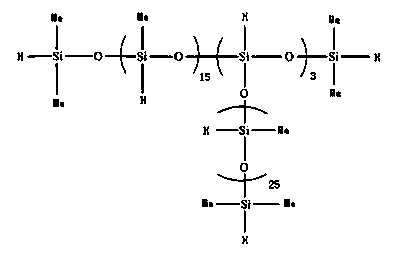

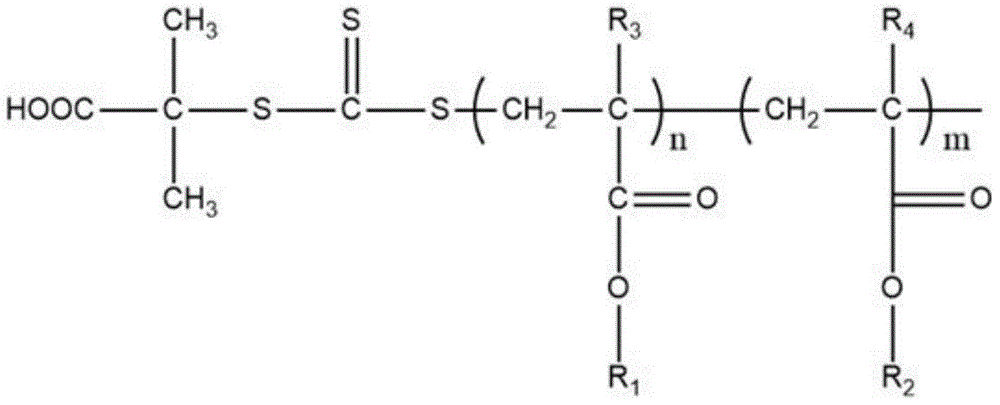

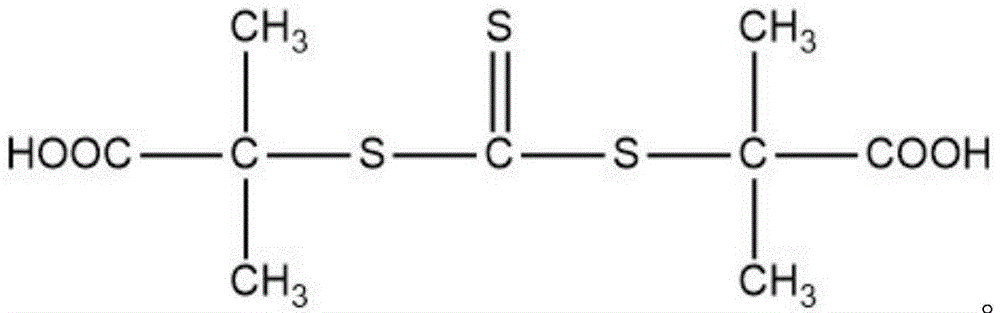

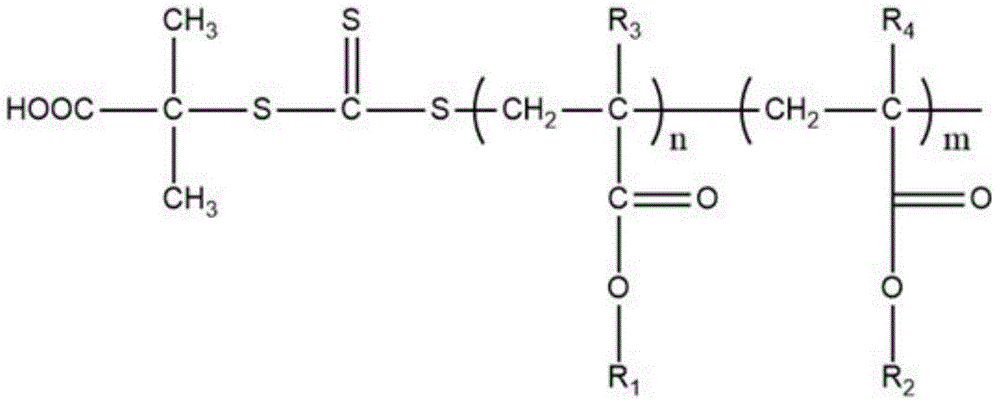

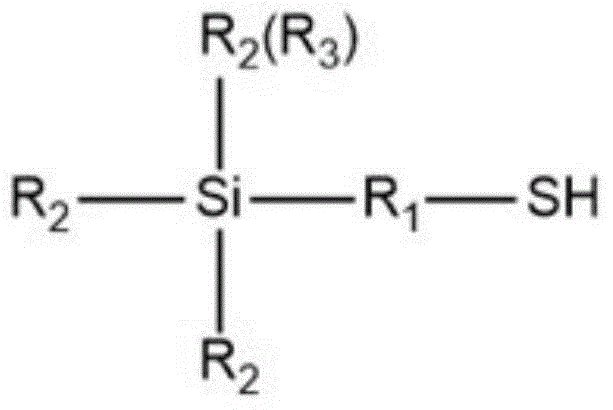

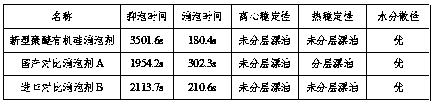

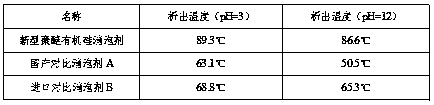

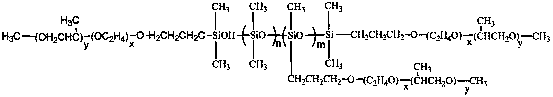

Preparation method of novel polyether modified organic silicon defoamer

InactiveCN111151033AGood defoaming and anti-foaming propertiesGood dispersionFoam dispersion/preventionSide chainDisiloxane

The invention discloses a preparation method of a novel polyether modified organic silicon defoamer, wherein the method comprises the following steps: S1, preparing double-end and side-chain hydrogen-containing silicone oil by using tetramethyldihydrodisiloxane, octamethylcyclotetrasiloxane and tetramethylcyclotetrasiloxane as raw materials and concentrated sulfuric acid as a catalyst; S2, taking5 parts of the double-end and side-chain hydrogen-containing silicone oil and 1 part of allyl polyether as raw materials, and taking 0.15 part of chloroplatinic acid as a catalyst for grafting to obtain double-end and side-chain polyether modified silicone oil; and S3, mixing the double-end and side-chain polyether modified silicone oil, silicon paste and a compound emulsifier, emulsifying, homogenizing, then adding a thickener, stirring and diluting to obtain the novel polyether modified organic silicon defoamer which is high in foam breaking rate, strong in defoaming capacity, short in defoaming time, resistant to acid and alkali at high temperature, strong in stability and simple in process condition.

Owner:GUANGDONG IND TECHN COLLEGE

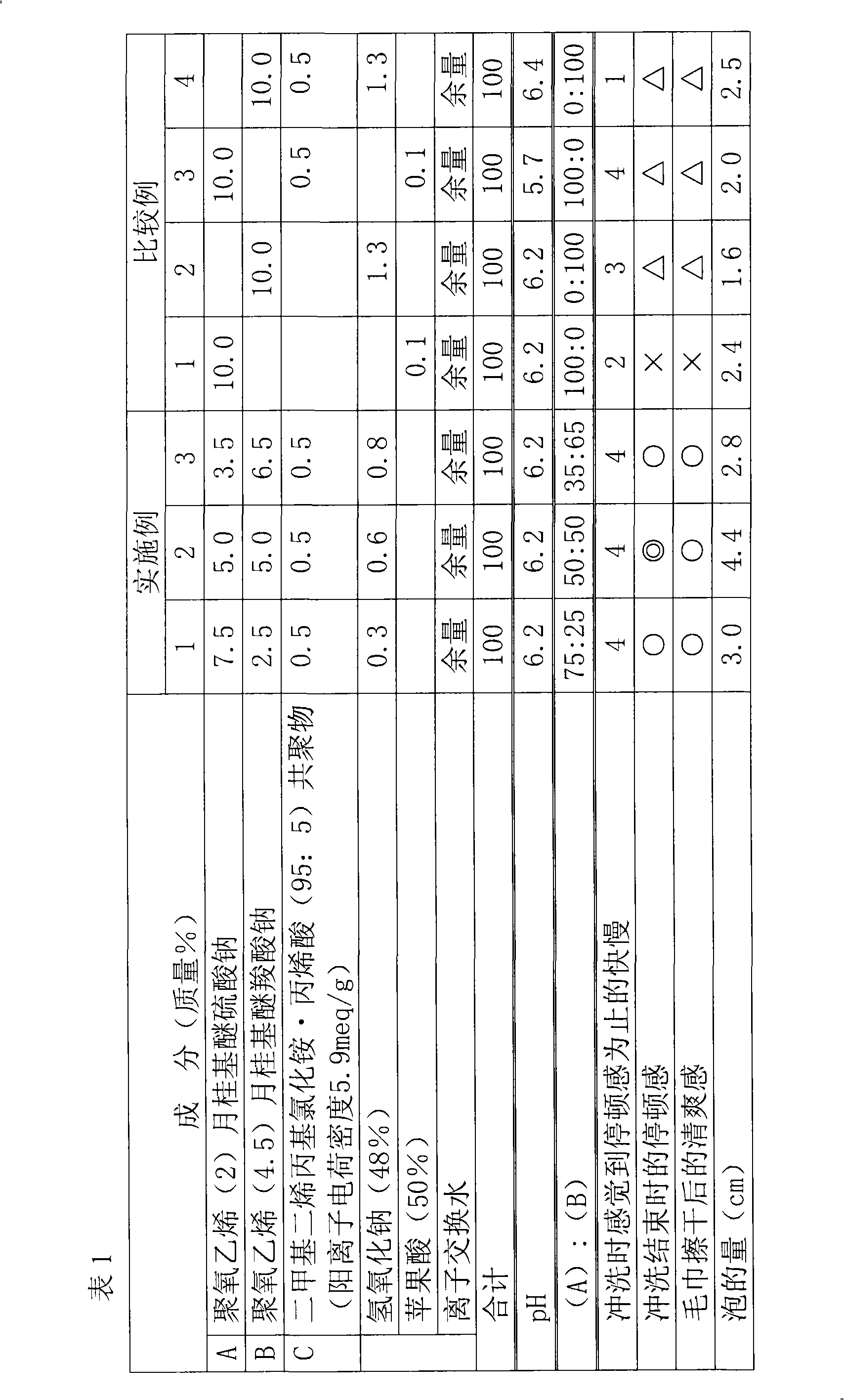

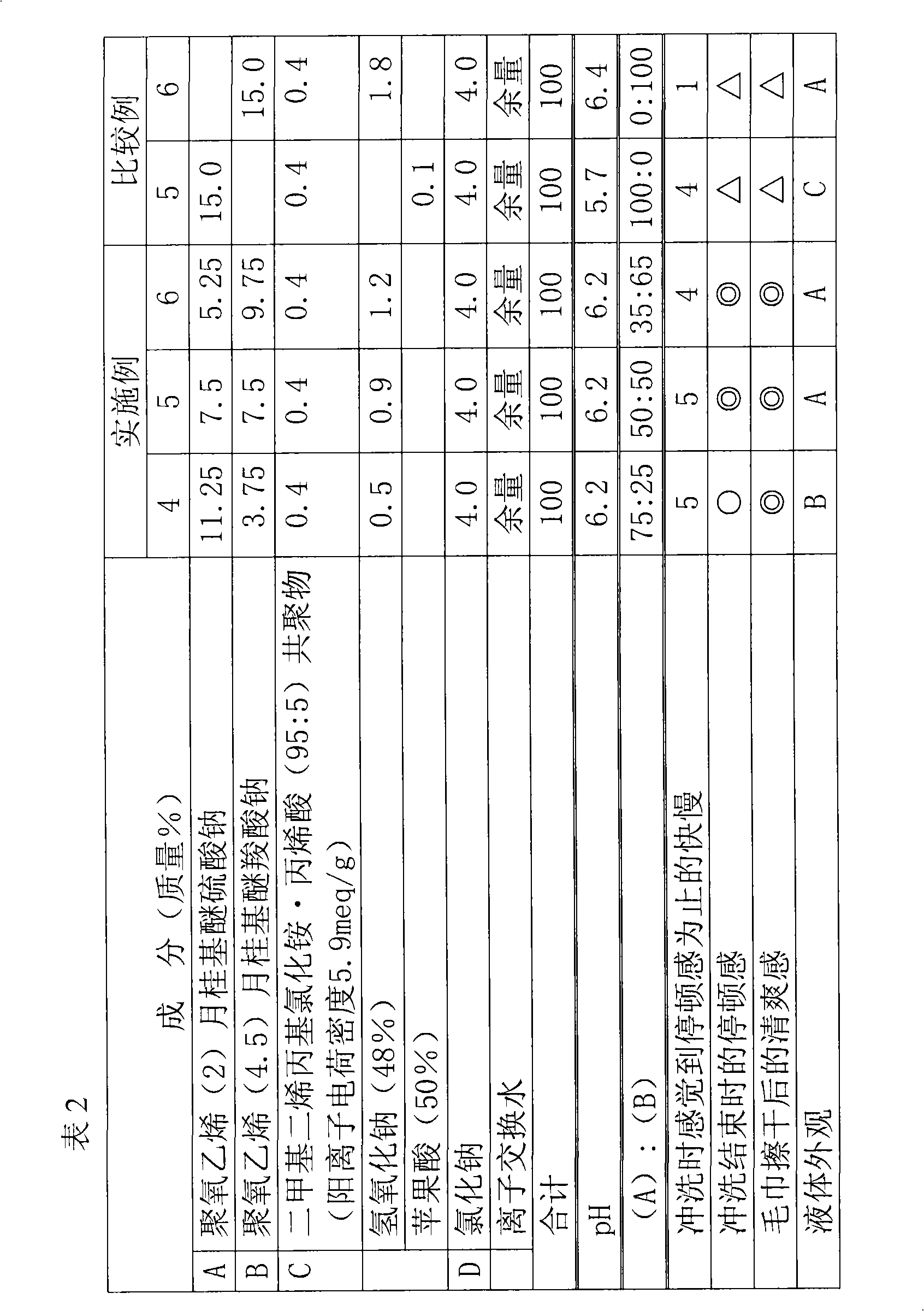

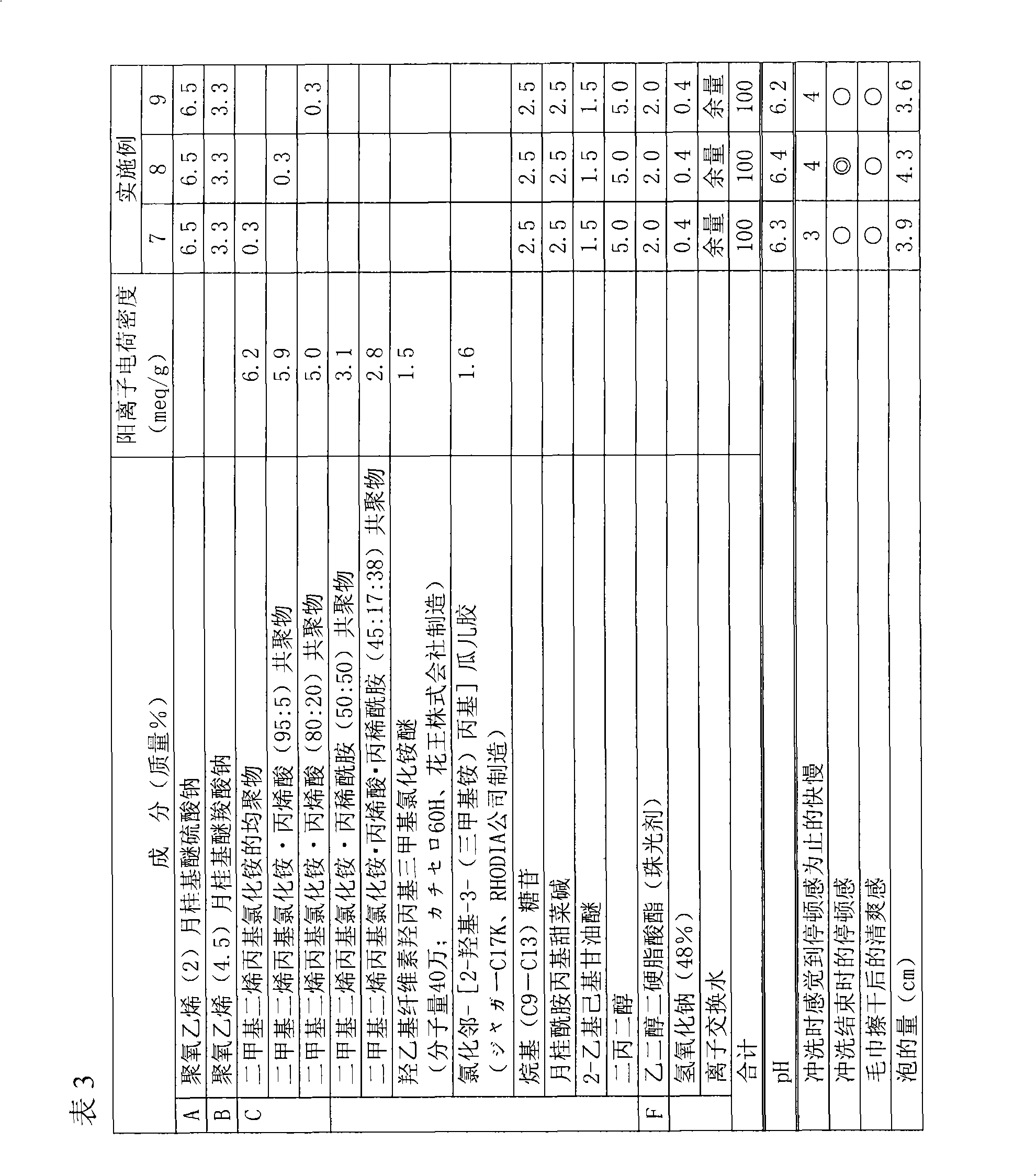

Skin cleaning agent composite

ActiveCN101288631AFoaming fastExcellent foam volumeCosmetic preparationsToilet preparationsSulfateAdditive ingredient

A skin cleansing composition contains the following ingredients (A), (B) and (C): (A) a polyoxyethylene alkylether sulfate, (B) a polyoxyethylene alkylether carboxylate, and (C) a cationic group-containing polymer having a cationic charge density of not less than 4.5 meq / g, and / or polyvinylpyrrolidone. A weight ratio (A):(B) of the ingredient (A) to the ingredient (B) is from 85:15 to 25:75. A total content of the ingredients (A) and (B) based on the whole composition ranges from 5 to 25 wt %. A content of the ingredient (C) ranges from 0.05 to 1 wt %. The skin cleansing composition is excellent in foamability and foam quality, and provides a good stop feeling during rinsing and a refreshed touch feeling after towel blotting.

Owner:KAO CORP

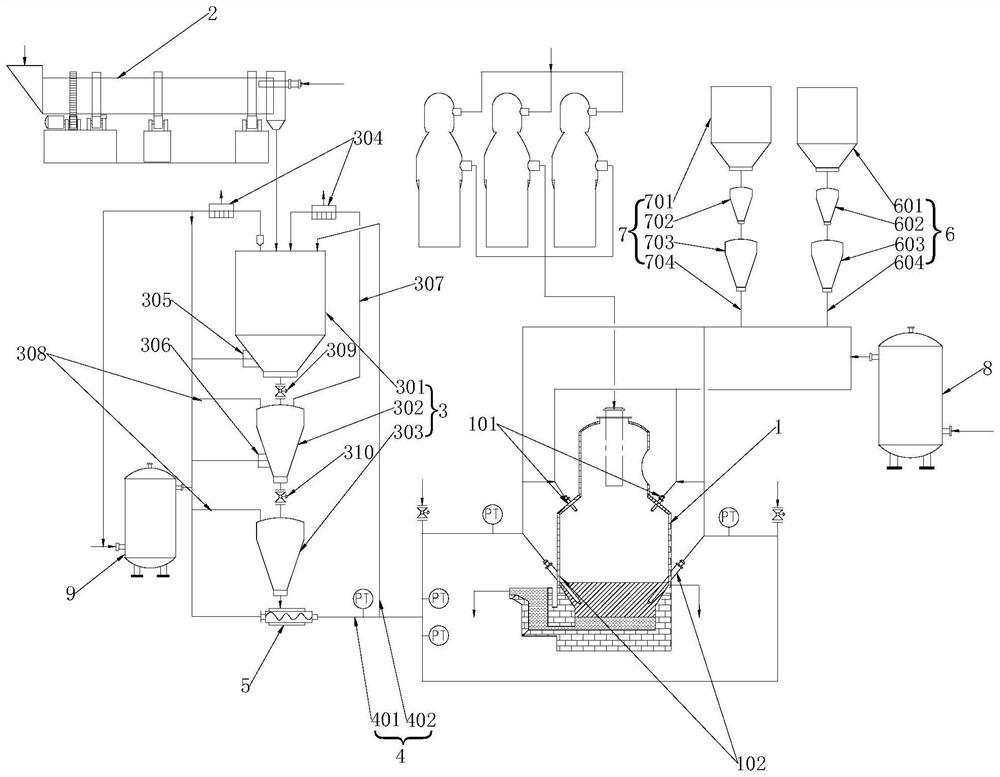

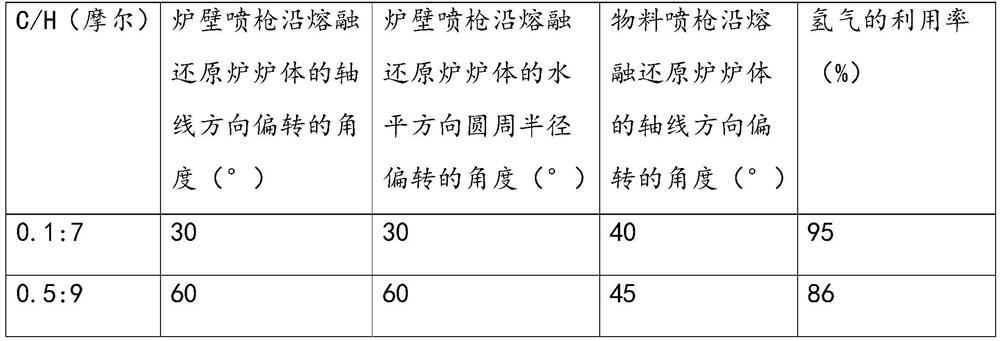

Smelting reduction hydrogen metallurgy process and device

The invention discloses a smelting reduction hydrogen metallurgy process and device. The smelting reduction hydrogen metallurgy process includes the steps that hydrogen is injected into a combustion area of a smelting reduction furnace to form high-pressure rotational flow in the combustion area; and a mixture of an iron-containing material and a magnesium-containing flux, a first carburant and first lime are blown into an iron bath area of the smelting reduction furnace by taking the hydrogen as a carrier gas. According to the smelting reduction hydrogen metallurgy process, the high-pressurerotational flow is formed in the combustion area, so that the retention time of the hydrogen in the smelting reduction furnace and the contact time of the hydrogen and iron-containing materials are prolonged, the amount of the hydrogen entering the combustion area discharged out of the smelting reduction furnace along with flue gas is reduced, the reduction reaction of the iron bath area is enhanced, the content of FeO in slag is reduced, the refractory material erosion speed is reduced, and the hydrogen utilization rate is increased; and the hydrogen is used as the carrier gas, so that the injection depth of a reducing agent can be effectively increased, the fountain effect in the smelting reduction furnace is enhanced, the reduction efficiency in the smelting reduction furnace is improved, and carbon emission in the metallurgical process is reduced.

Owner:SHANDONG MOLONG PETROLEUM MACHINERY

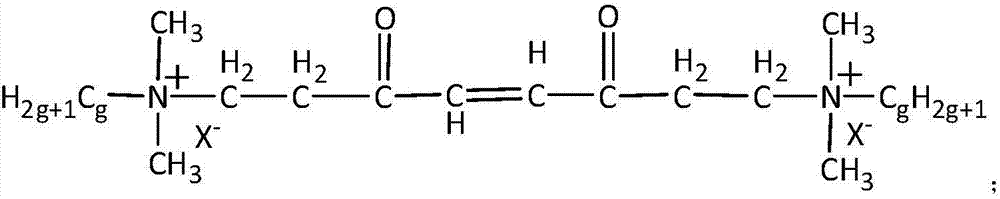

Defoaming agent and synthesis method thereof

ActiveCN107034727AGood defoamingWide adaptabilityDefoamers additionPaper/cardboardSynthesis methodsHydrophile

The invention provides a defoaming agent and a synthesis method thereof. The defoaming agent comprises special polyether which comprises first unsaturated enol polyether, second unsaturated enol polyether and unsaturated gemini quaternary ammonium salt. By different combination of EO and PO in gemini polyether and change of the ratio of the unsaturated polyether and unsaturated gemini quaternary ammonium salt, the special polyether which is the main ingredient of the defoaming agent can rapidly permeate into coating, the ratio of EO to PO of block polyether is adjusted to adjust the hydrophile-lyophile ratio of the special polyether, and the defoaming agent is synthesized by a positive and negative charge attracting principle. The defoaming agent has the characteristics that the defoaming effect is good, compatibility of the defoaming agent and the coating is good, and the applicability is wide. Compared with a compound defoaming agent which is compounded by other defoaming agents in markets, the provided defoaming agent is simple in components; the structure is clear and controllable; and the quality and the property are stable.

Owner:威尔(福建)生物有限公司

Amino silicone based antifoam agent and its process of manufacture

ActiveUS20120329701A1Low costNegative effectInorganic/elemental detergent compounding agentsSilicon organic compoundsRinse waterAntifoam agent

Modified aminoalkyl- and polyoxyalkylene-functional organopolysiloxanes exhibit delayed antifoaming activity in washing operations, minimizing foaming of rinse water. When applied to a pulverulent carrier, they may also be used in powder detergent formulations.

Owner:WACKER CHEM GMBH

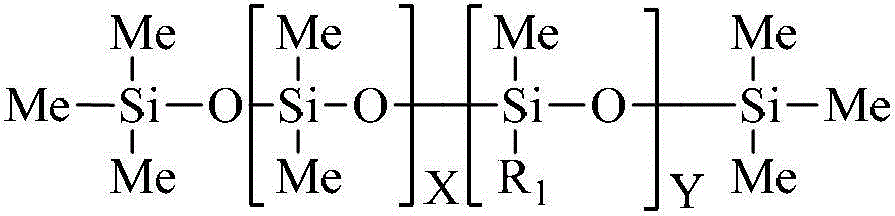

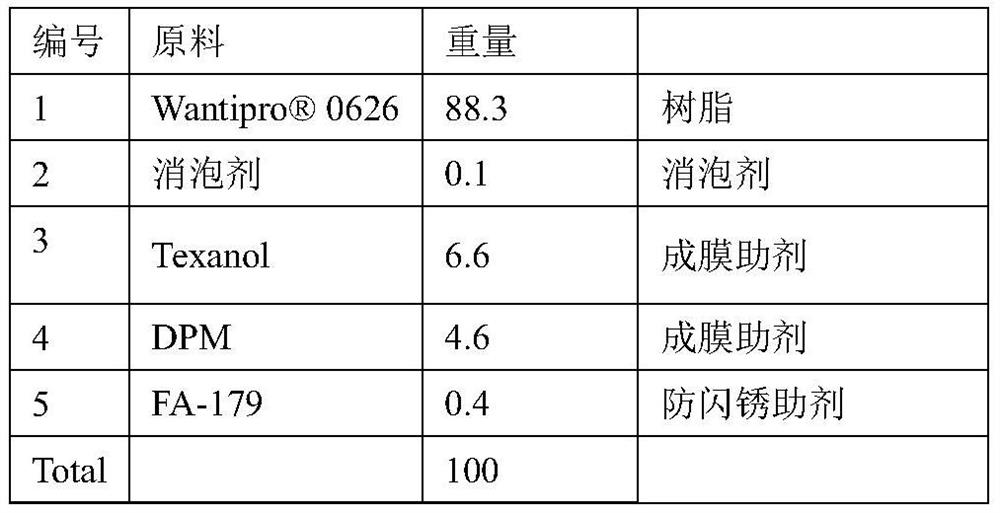

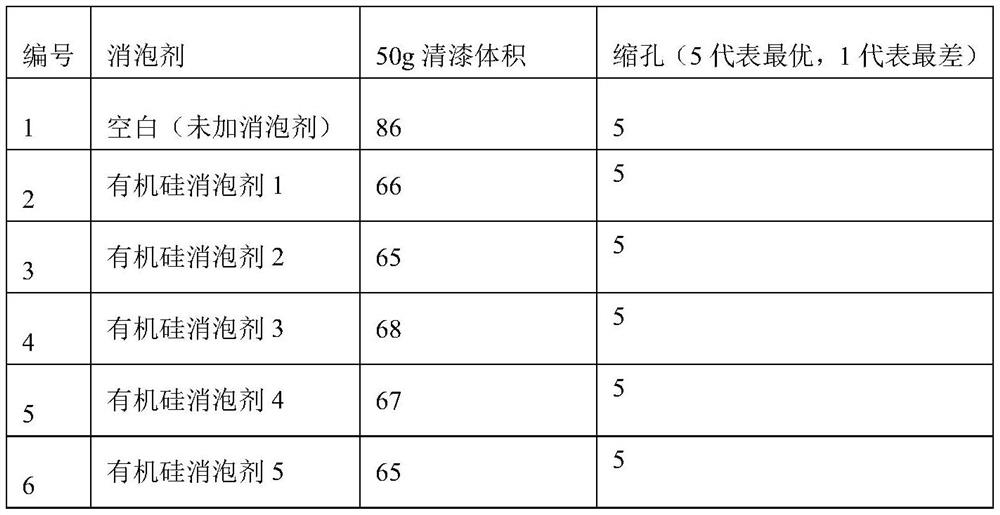

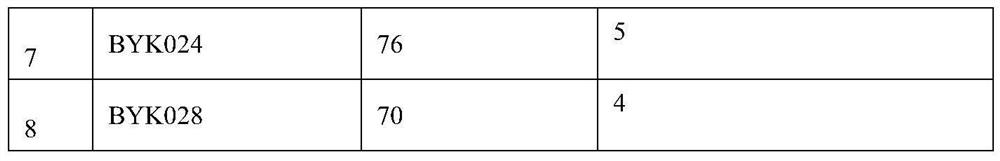

Organic silicon defoaming agent capable of being used for water-based coating material and preparation method thereof

ActiveCN113069796ARaw materials are easy to getSimple processFoam dispersion/preventionEnd-groupEngineering

The invention relates to an organic silicon defoaming agent for a water-based coating material and a preparation method thereof. The preparation method comprises the following steps: (1) synthesizing isomeric alcohol ether terminated allyl polyether; (2) synthesizing end group isomeric alcohol ether terminated polyether modified silicone oil; (3) preparing silicon paste; and (4) preparing the defoaming agent. According to the invention, end group isomeric alcohol ether terminated polyether modified polysiloxane with a symmetrical structure is used, a hydrophilic eo chain segment, a hydrophobic po chain segment and an isomeric macromolecular alkyl alcohol ether group are simultaneously introduced to the end group of a polysiloxane chain, and the hydrophilic and hydrophobic properties of the polymer can be effectively adjusted by controlling the ratio of eo to po, so that better defoaming performance is realized; and the organic silicon defoaming agent disclosed by the invention has the advantages of easily available raw materials, simple process, good stability, capability of effectively eliminating foams of a water-based coating material system, excellent defoaming and foam inhibition performance, difficulty in causing the defects of shrinkage cavities and the like, good wetting performance and capability of saving the use amount of a wetting agent in the water-based coating material.

Owner:WANHUA CHEM GRP CO LTD

Alkali-free glass and alkali-free glass substrate

ActiveUS8455378B2Excellent devitrification resistanceImprove meltabilityNon-linear opticsAlkali freeAlkali metal oxide

An alkali-free glass characterized by having a glass composition being substantially free of an alkali metal oxide, As2O3 and Sb2O3 and including, in terms of mol %, 55 to 75% of SiO2, 7 to 15% of Al2O3, 7 to 12% of B2O3, 0 to 3% of MgO, 7 to 12% of CaO, 0 to 5% of SrO, 0 to 2% of BaO, 0 to 5% of ZnO and 0.01 to 1% of SnO2 and has a liquidus viscosity of 105.2 dPa·s or higher and a temperature corresponding to a viscosity of 102.5 dPa·s of 1,550° C. or lower.

Owner:NIPPON ELECTRIC GLASS CO LTD

Defoaming kettle used in synthetic process of polyamic acid resin

InactiveCN103041620AUniform colorConvenient temperature and pressureFoam dispersion/preventionHeat conductingProduct gas

The invention discloses a defoaming kettle used in the synthetic process of polyamic acid resin. A pot body of the defoaming kettle is provided with a jacket; a stirring shaft of a multilayer spiral mixing blade is located in the defoaming kettle, and the top end of the stirring shaft is connected with a stirring electric motor and a reductor, which are located at the top of the pot body; the stirring shaft is a hollow shaft, and the mixing blade is a hollow blade, wherein a heat-conducting medium transmission pipeline is arranged in the mixing blade; a heat-conducting medium inlet on a rotary joint is connected with the upper end of the heat-conducting medium transmission pipeline of the mixing blade, and heat-conducting medium passes through the hollow shaft to a heat-conducting medium outlet at the upper end of the hollow shaft; a jacket medium inlet, a jacket medium outlet, the heat-conducting medium inlet and the heat-conducting medium outlet are connected with a heat-conducting medium heating device; and a gas inlet and a discharge pipe are arranged on the pot body in a sealed manner.

Owner:GUILIN ELECTRICAL EQUIP SCI RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com