Solvent-free method for preparing polyether modified polysiloxane antifoaming agent

A polysiloxane defoamer and polyether modification technology, which is applied in the direction of foam dispersion/prevention, ink, household appliances, etc., can solve the problems of unfriendly organic solvents, turbid products, low purity, etc., and achieve transparent products. Increased reaction rate and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

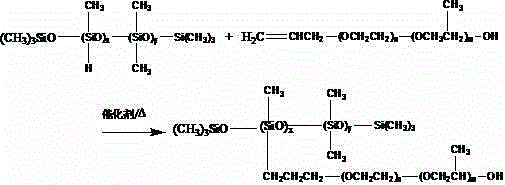

Image

Examples

Example

[0028] Example 1 to Example 5: A method for preparing polyether modified polysiloxane defoamer without solvent

[0029] In the reactor, add the allyl-terminated polyether after the water has been removed by rotary evaporation, then add nitrogen gas, and then add 0.0302 grams of antioxidant 264; add 900μg of platinum catalyst to the reactor, while heating the reactor and stirring , The heating temperature provided is between 50~60℃; then add low-hydrogen silicone oil and 4A molecular sieve accounting for 5%~10% of the total mass of the reactants into the reactor, the bulk density of the 4A molecular sieve is 0.69~ 0.75 g / ml, and the effective pass rate is greater than or equal to 97%. At this time, the hydrosilylation reaction begins. Because the reaction is an exothermic reaction, the temperature in the reactor rises sharply. After the temperature stabilizes, control the temperature in the reactor Stir at 80°C and constant temperature for 1.5 hours; add hydrochloric acid or sulfu...

Example

[0032] Example 6~Example 10: A method for preparing polyether modified polysiloxane defoamer without solvent

[0033] In the reactor, add the allyl-terminated polyether after the water has been removed by rotary evaporation, then add nitrogen gas, and then add 0.0302 grams of antioxidant 264; add 900μg of platinum catalyst to the reactor, while heating the reactor and stirring , The heating temperature provided is at 50°C; then add low-hydrogen silicone oil and 4A molecular sieves accounting for 5% to 10% of the total mass of the reactants into the reactor, the bulk density of the 4A molecular sieve is 0.69 to 0.75 g / ml , The effective pass rate is greater than or equal to 97%, and the hydrosilylation reaction begins at this time. Because the reaction is an exothermic reaction, the temperature in the reactor rises sharply. After the temperature stabilizes, the temperature in the reactor is controlled at 70°C. , 80 ℃, 90 ℃, 100 ℃, 110 ℃, and constant temperature stirring for 1.5 h...

Example

[0035] Example 11~Example 15: A method for preparing polyether modified polysiloxane defoamer without solvent

[0036] In the reactor, add the allyl-terminated polyether after the water has been removed by rotary evaporation, and then add nitrogen gas, and then add 0.0302 grams of antioxidant 264; add 600μg, 900μg, 1200μg, 1500μg, 1800μg platinum to the reactor The catalyst is heated and stirred at the same time in the reactor, and the heating temperature provided is 60°C; then low-hydrogen silicone oil and 4A molecular sieve accounting for 5% to 10% of the total mass of the reactants are added to the reactor. The accumulation of the 4A molecular sieve The density is 0.69~0.75 g / ml, and the effective pass rate is greater than or equal to 97%. At this time, the hydrosilylation reaction begins. Because the reaction is an exothermic reaction, the temperature in the reactor rises sharply. After the temperature stabilizes, control The temperature in the reactor is at 80℃, and stirring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com