Patents

Literature

5144 results about "Solvent free" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Solvent-free refers to a substance that contains little or no solvent. Paint, adhesives, hash oil and epoxy are substances that normally contain very little solvent. When adhesive contains less than 5% solvent, it is considered a solvent-free adhesive. Solvent-free epoxy resin is solid and contains no water or solvent as diluents.

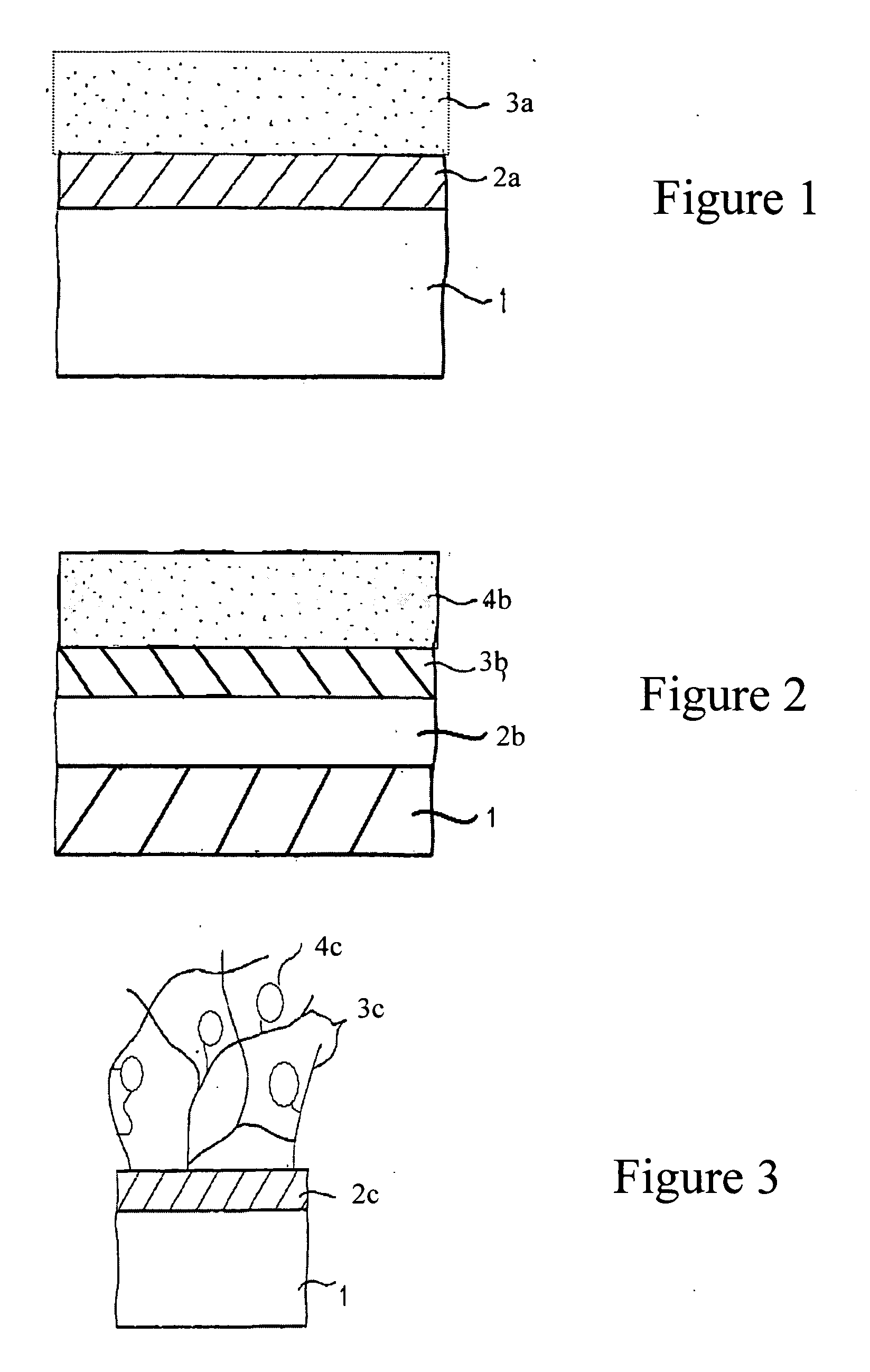

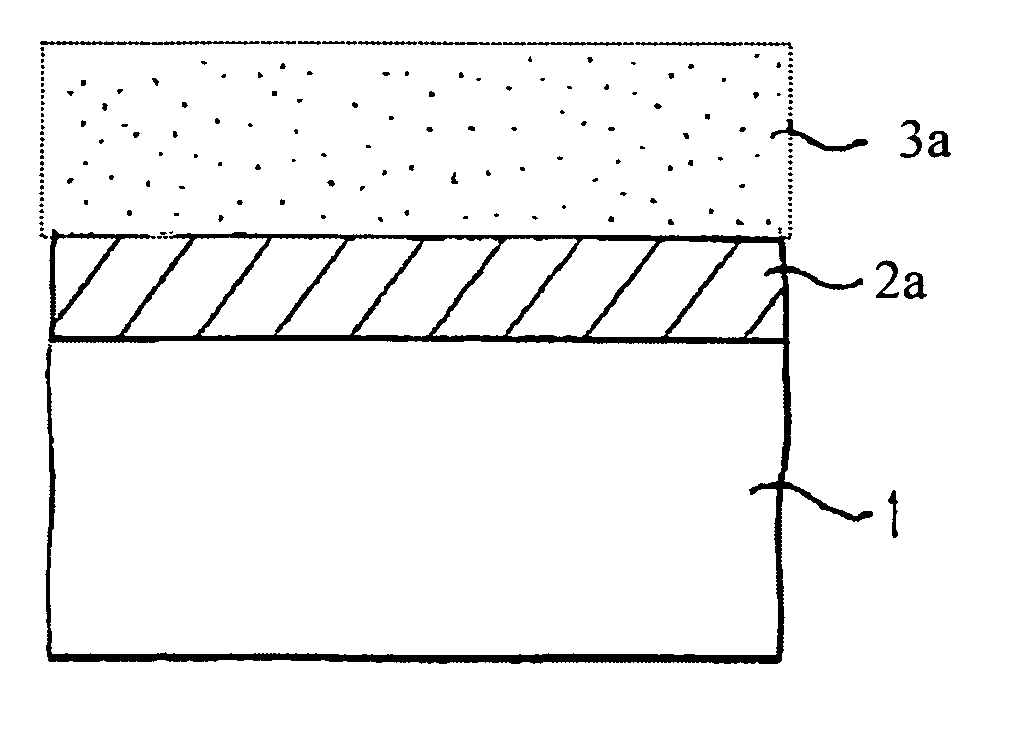

Articles having bioactive surfaces and solvent-free methods of preparation thereof

Methods for preparing articles having a bioactive surface comprising treating a substrate to form free reactive groups, depositing a monomer onto the treated substrate, and covalently immobilizing a biologically functional molecule onto the deposited monomer. Additional embodiments include methods for the deposition of the monomer onto the treated substrate in a solvent-free environment. Further embodiments include articles having surfaces prepared using the methods described herein. Additional embodiments include articles prepared using the methods described herein.

Owner:BECTON DICKINSON & CO

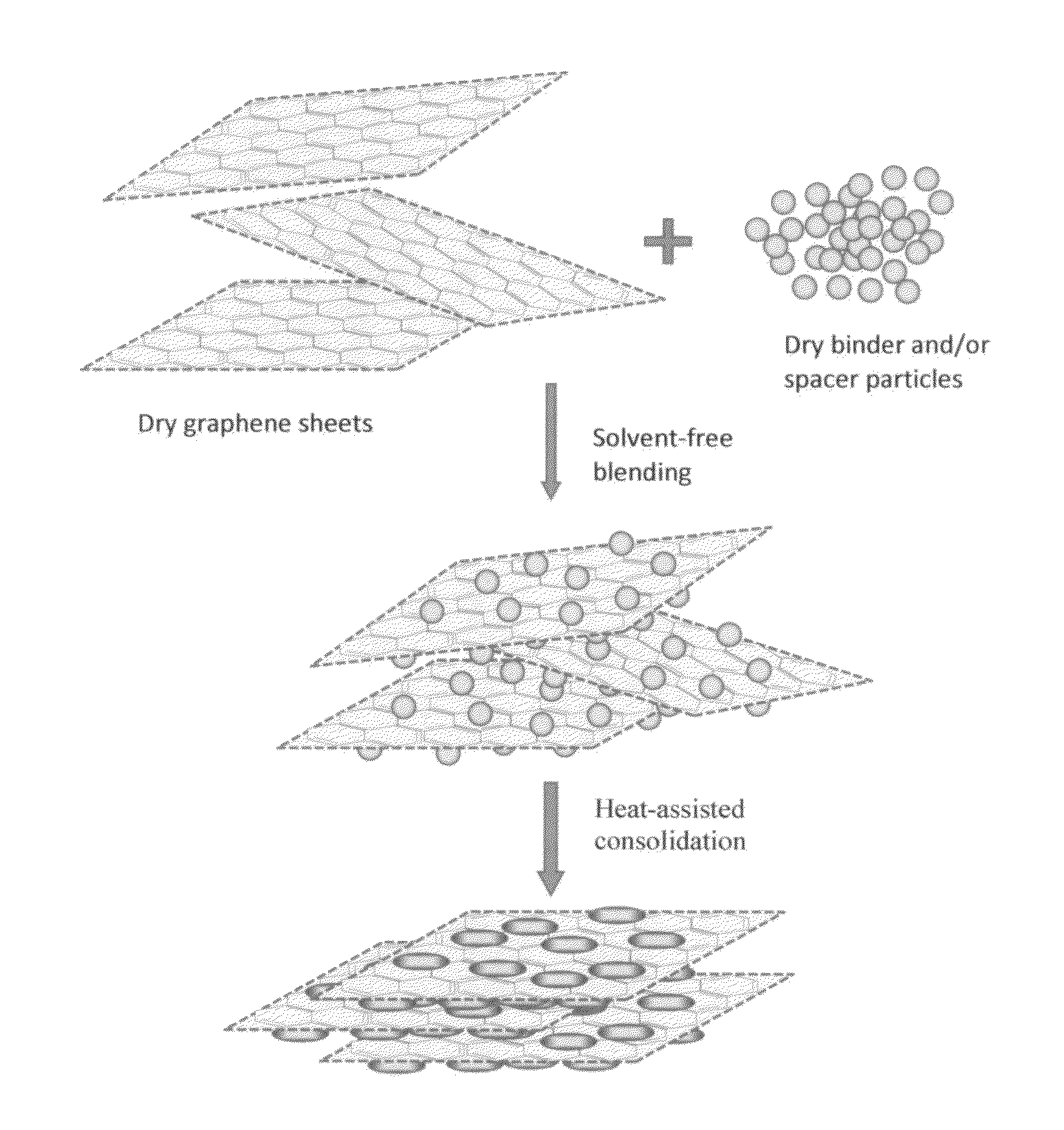

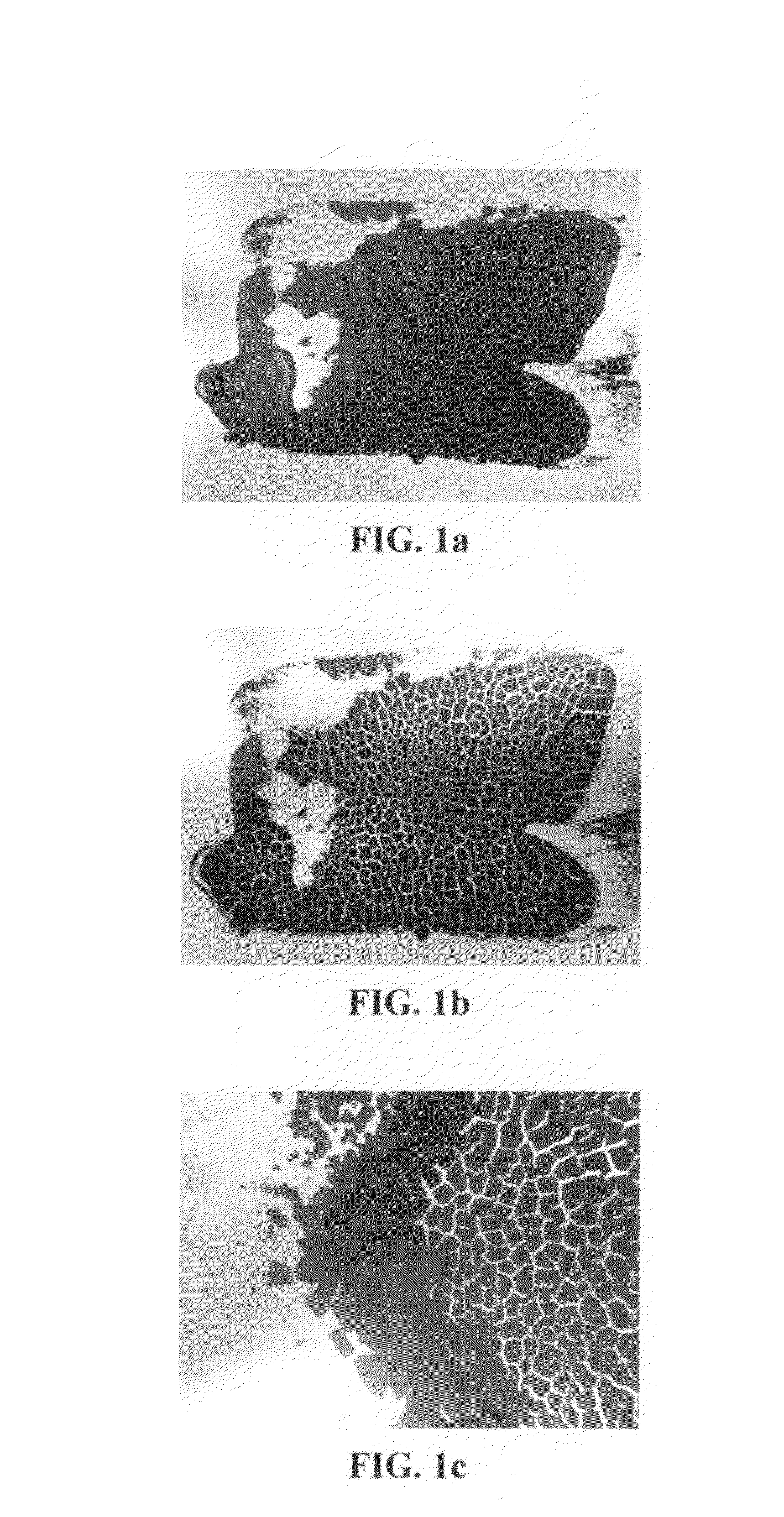

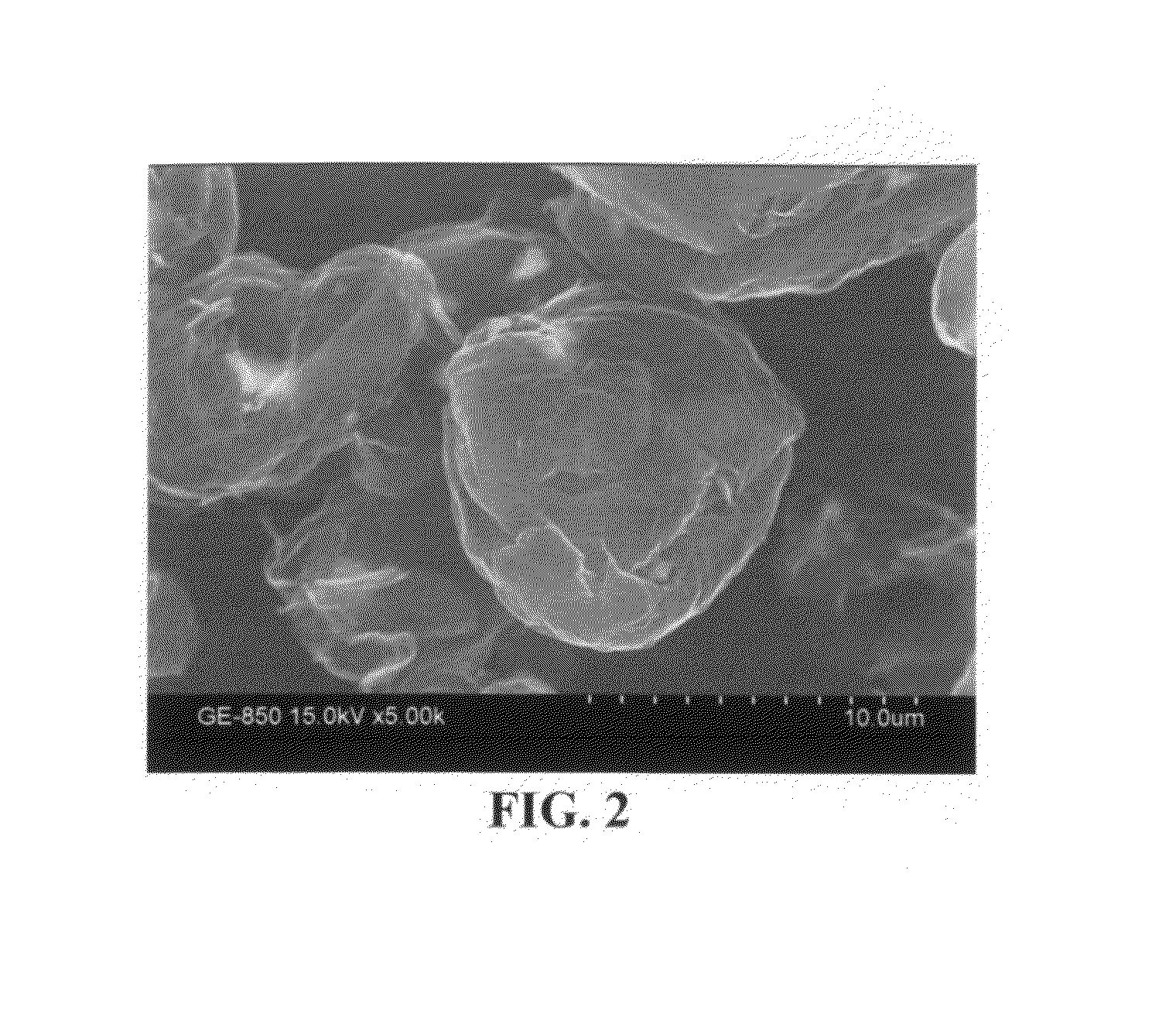

Solvent-free process based graphene electrode for energy storage devices

PendingUS20140030590A1Inexpensive and durable and highly reliableHigh capacitanceMaterial nanotechnologyHybrid capacitor electrodesGraphene flakeSolvent free

Disclosed is an electrode for an electrochemical energy storage device, the electrode comprising a self-supporting layer of a mixture of graphene sheets and spacer particles and / or binder particles, wherein the electrode is prepared without using water, solvent, or liquid chemical. The graphene electrode prepared by the solvent-free process exhibits many desirable features and advantages as compared to the corresponding electrode prepared by a known wet process. These advantages include a higher electrode specific surface area, higher energy storage capacity, improved or higher packing density or tap density, lower amount of binder required, lower internal electrode resistance, more consistent and uniform dispersion of graphene sheets and binder, reduction or elimination of undesirable effect of electrolyte oxidation or decomposition due to the presence of water, solvent, or chemical, etc.

Owner:GLOBAL GRAPHENE GRP INC

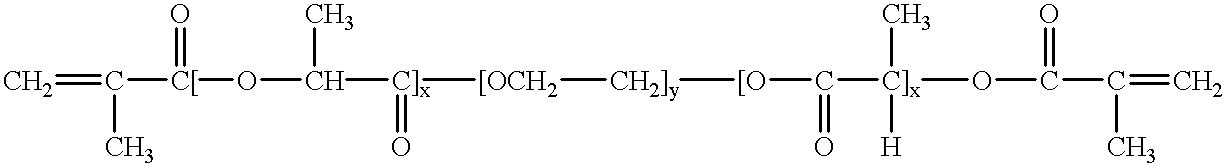

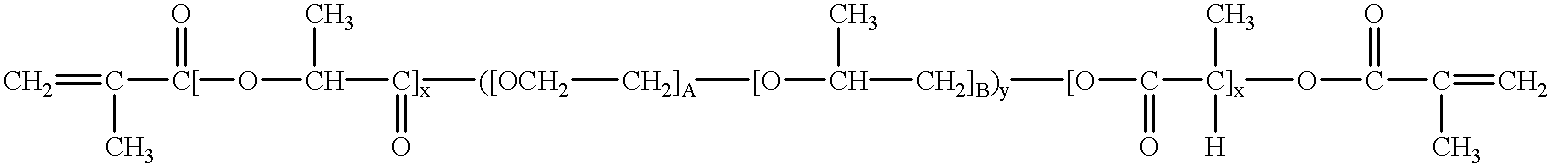

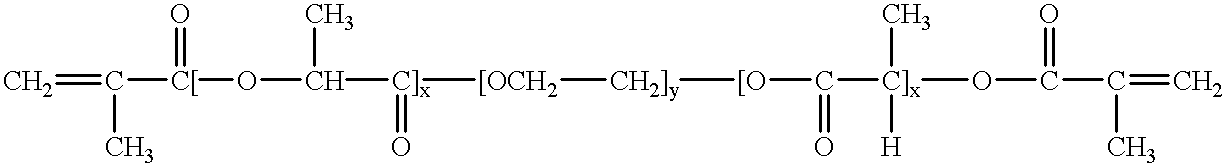

Bioresorbable hydrogel compositions for implantable prostheses

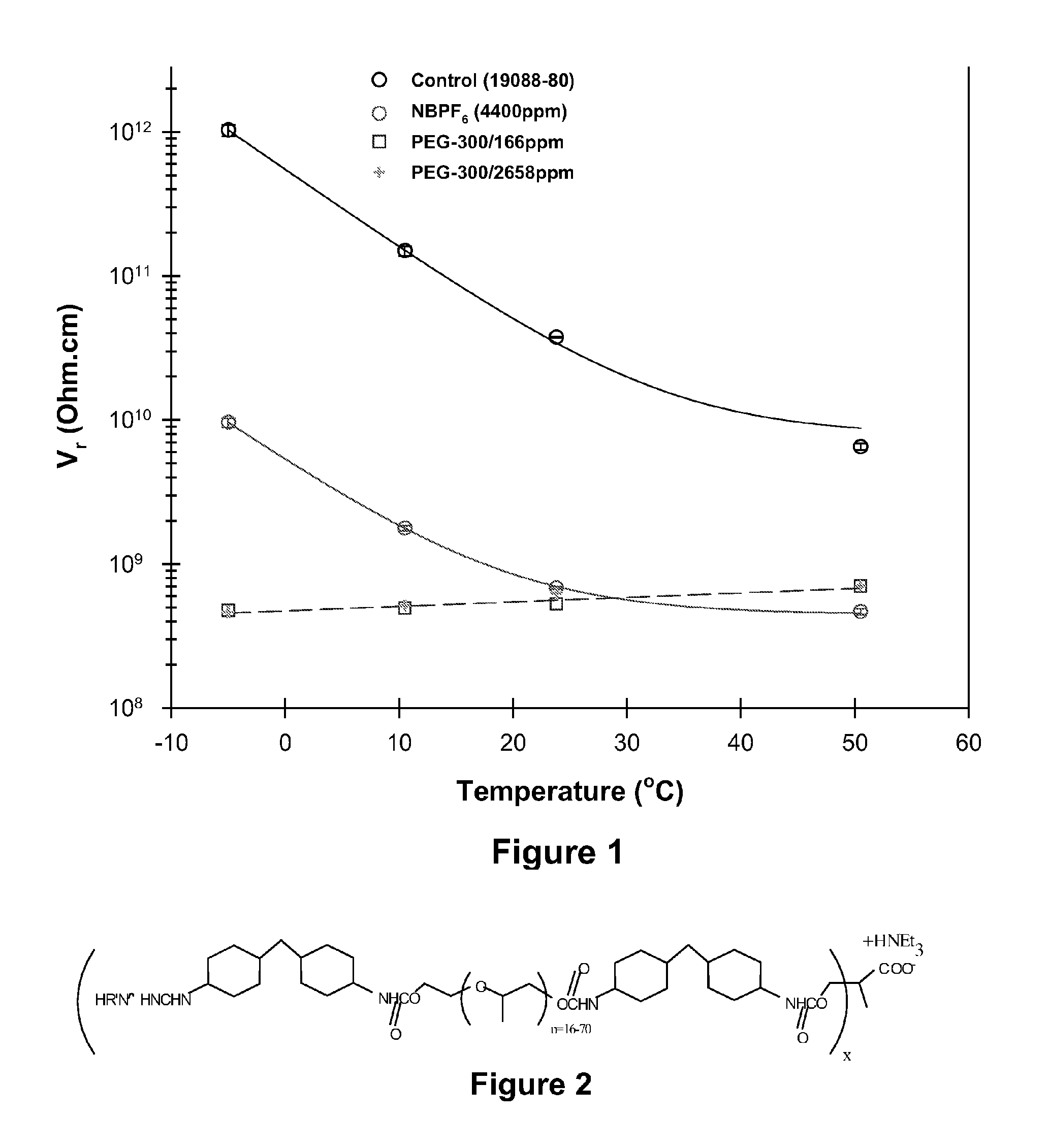

Crosslinked compositions formed from water-insoluble copolymers are disclosed. These compositions are copolymers having a bioresorbable region, a hydrophilic region and at least two cross-linkable functional groups per polymer chain. Crosslinking of these polymers can be effected in solution in organic solvents or in solvent-free systems. If crosslinking occurs in a humid environment, a hydrogel will form. If crosslinking occurs in a non-humid environment, a xerogel will form which will form a hydrogel when exposed to a humid environment and the resulting crosslinked materials form hydrogels when exposed to humid environments. These hydrogels are useful as components in medical devices such as implantable prostheses. In addition, such hydrogels are useful as delivery vehicles for therapeutic agents and as scaffolding for tissue engineering applications.

Owner:LIFESHIELD SCI

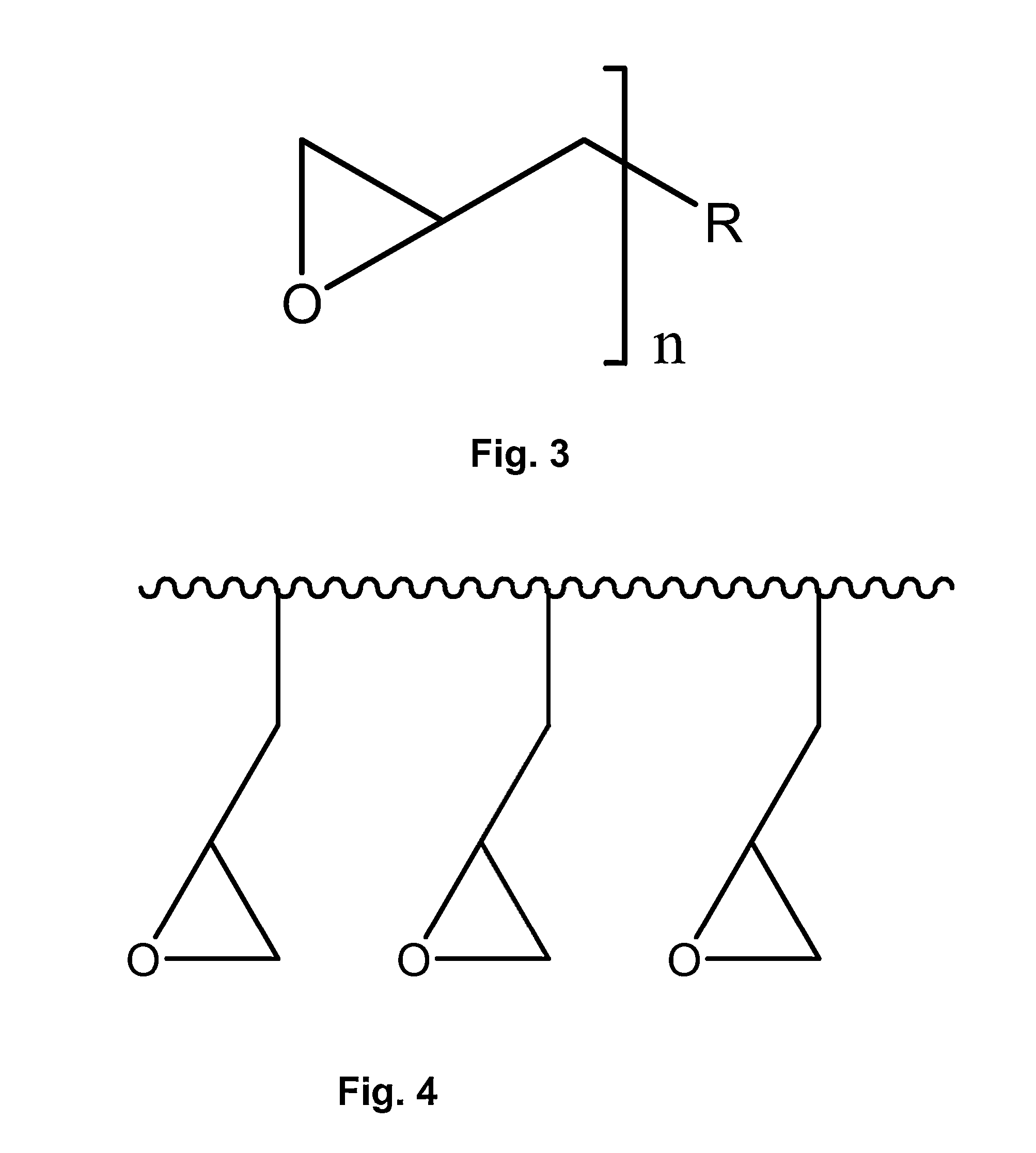

Modified epoxy resin composition, production process for the same and solvent-free coating comprising the same

InactiveUS6677426B2Satisfactory curabilityImprove mechanical propertiesEpoxy resin coatingsAcetoacetatesEpoxy

There is provided a modified epoxy resin composition including a reaction product of an epoxy resin and an alkyl-substituted acetoacetate and a reaction product of an alcohol having at least one hydroxyl group in one molecule and an alkyl-substituted acetoacetate; a production process for the same; and a solvent-free coating using the same. The composition provides a solvent-free epoxy resin composition which has a low viscosity and excellent low-temperature curability.

Owner:WESTLAKE EPOXY INC

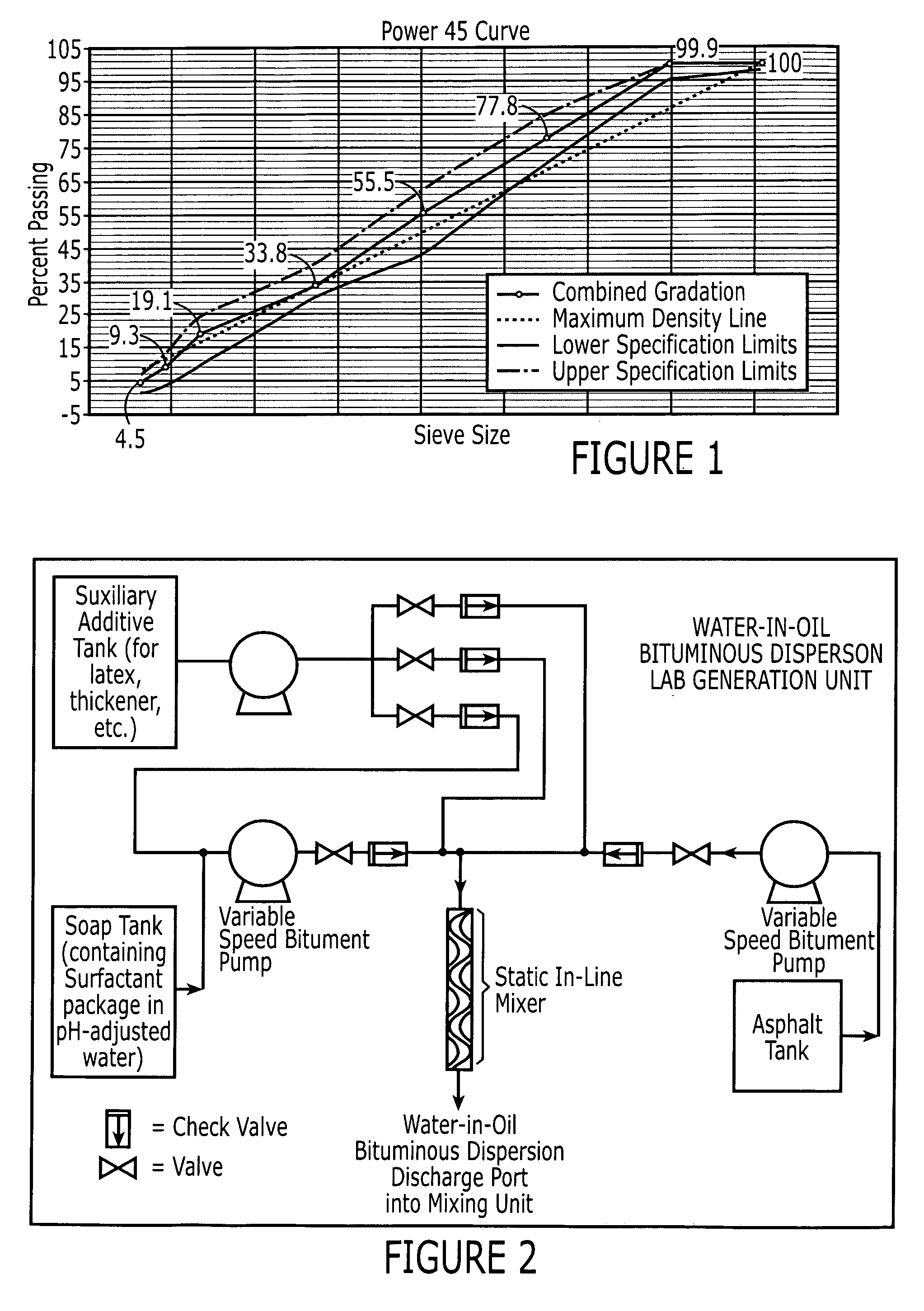

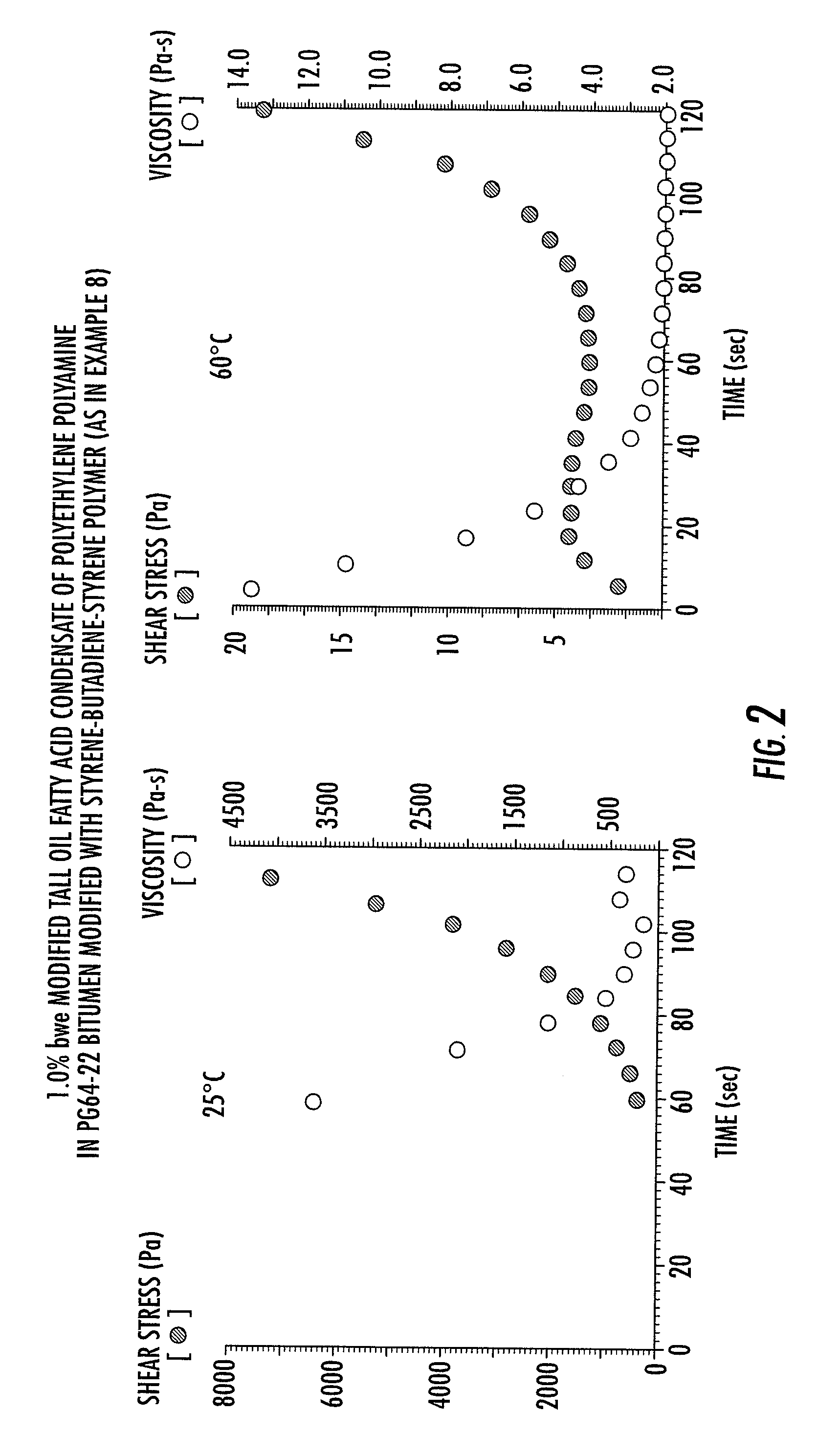

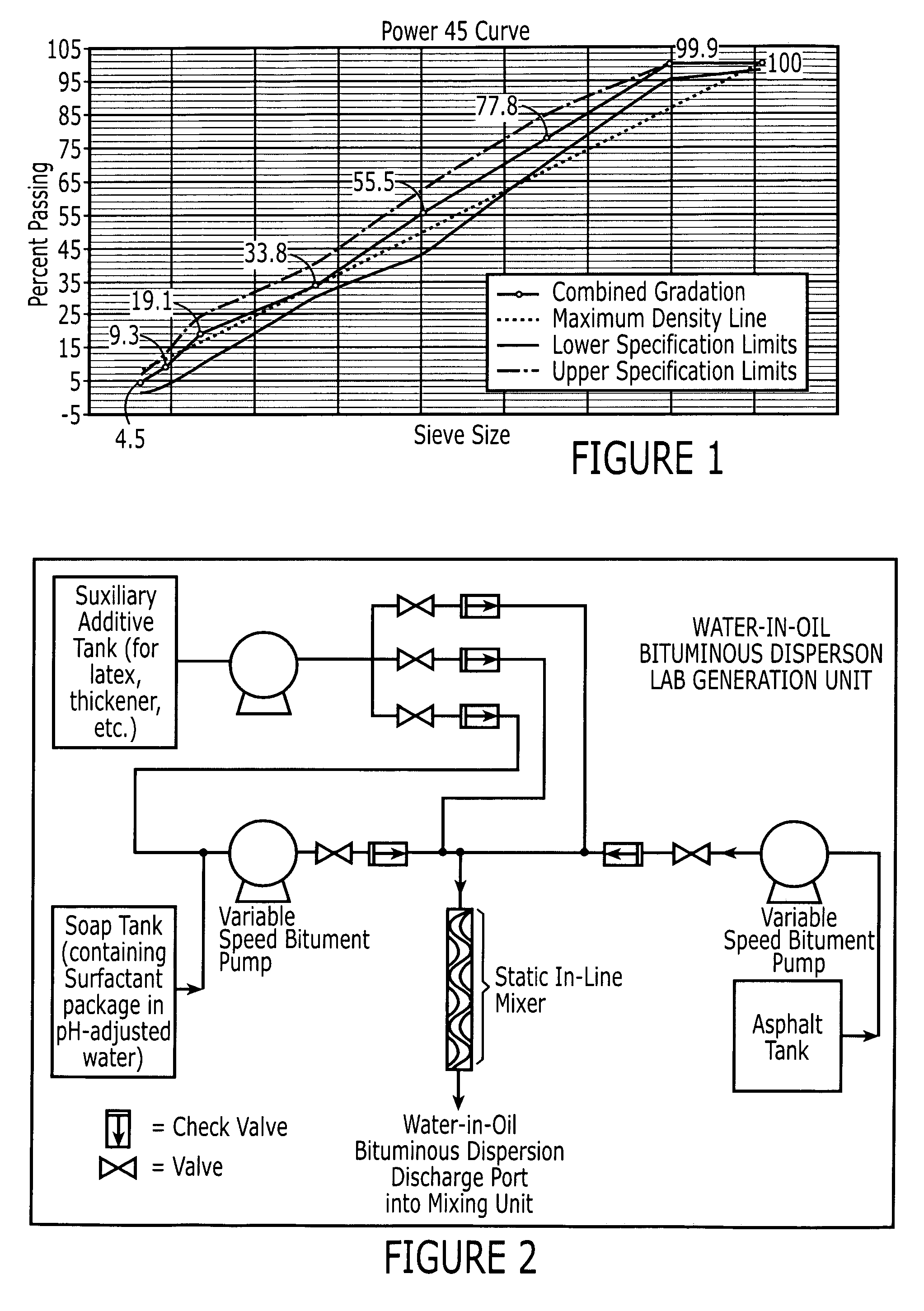

Water-in-oil bituminous dispersions and methods for producing paving compositions from the same

ActiveUS20070082983A1Low viscosityAccelerated strength developmentProductsIn situ pavingsSolvent freeSURFACTANT BLEND

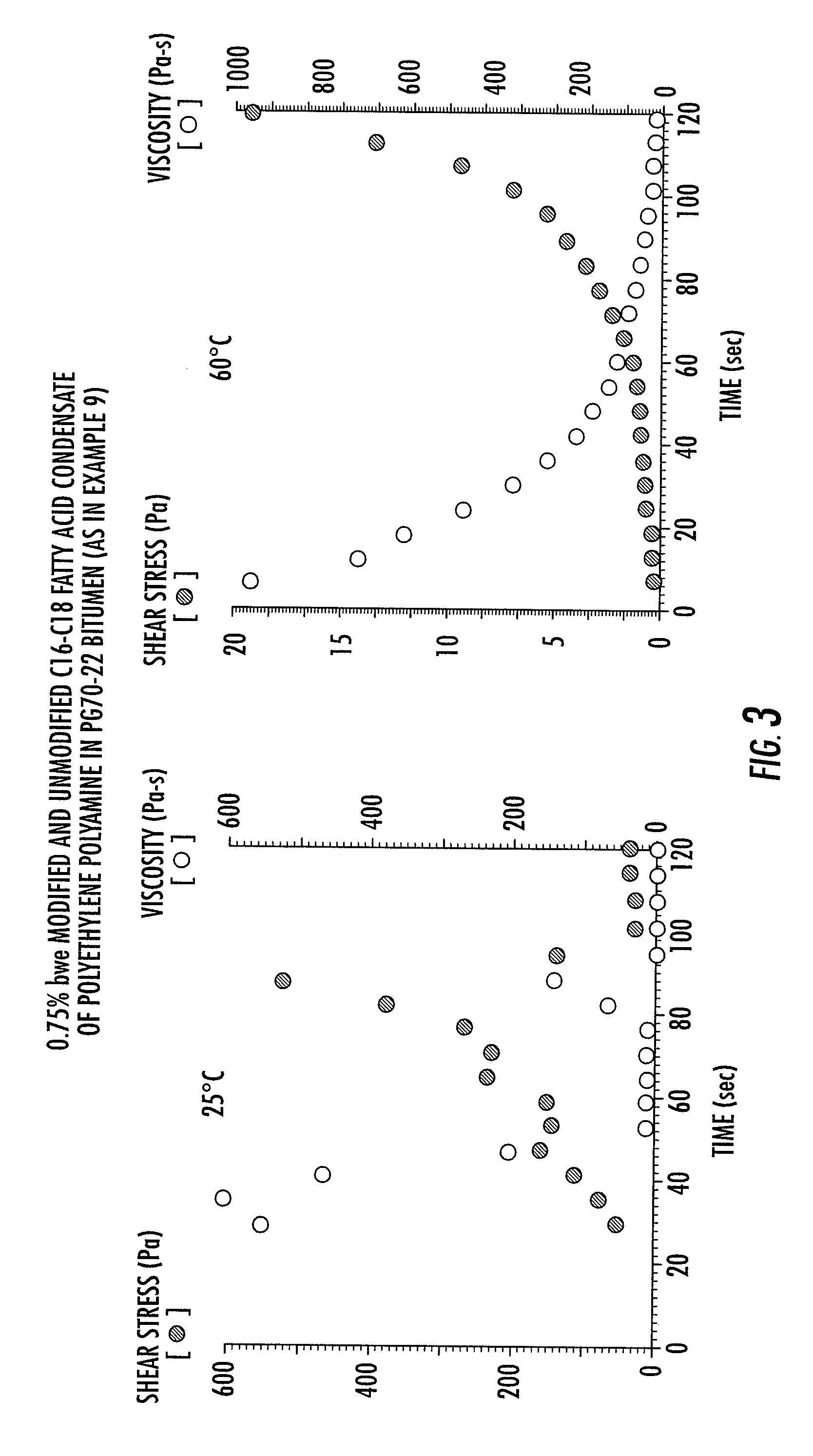

There is provided a method for making bituminous compositions comprising water-in-oil bituminous dispersion and aggregate by the steps of: preparing a solvent-free, water-in-oil bituminous dispersion comprising: (1) bitumen, in an amount from about 75.0% to about 95.0% by total weight of the bitumen dispersion; (2) a surfactant in an amount from about 0.05% to about 2.0% by total weight of the bitumen dispersion; and (3) water in an amount to complete the water-in-oil bituminous dispersion, and producing the bituminous composition having a temperature from about 50° C. to about 120° C. by mixing: (1) the water-in-oil bituminous dispersion of step (A), having a temperature from about 75° C. to about 95° C., in an amount from about 2.0% to about 10.0% by total weight of the bituminous composition, and (2) aggregate, having a temperature from about 60° C. to about 140° C., in an amount from about 90.0% to about 98.0% by total weight of the bituminous composition.

Owner:INGEVITY SOUTH CAROLINA

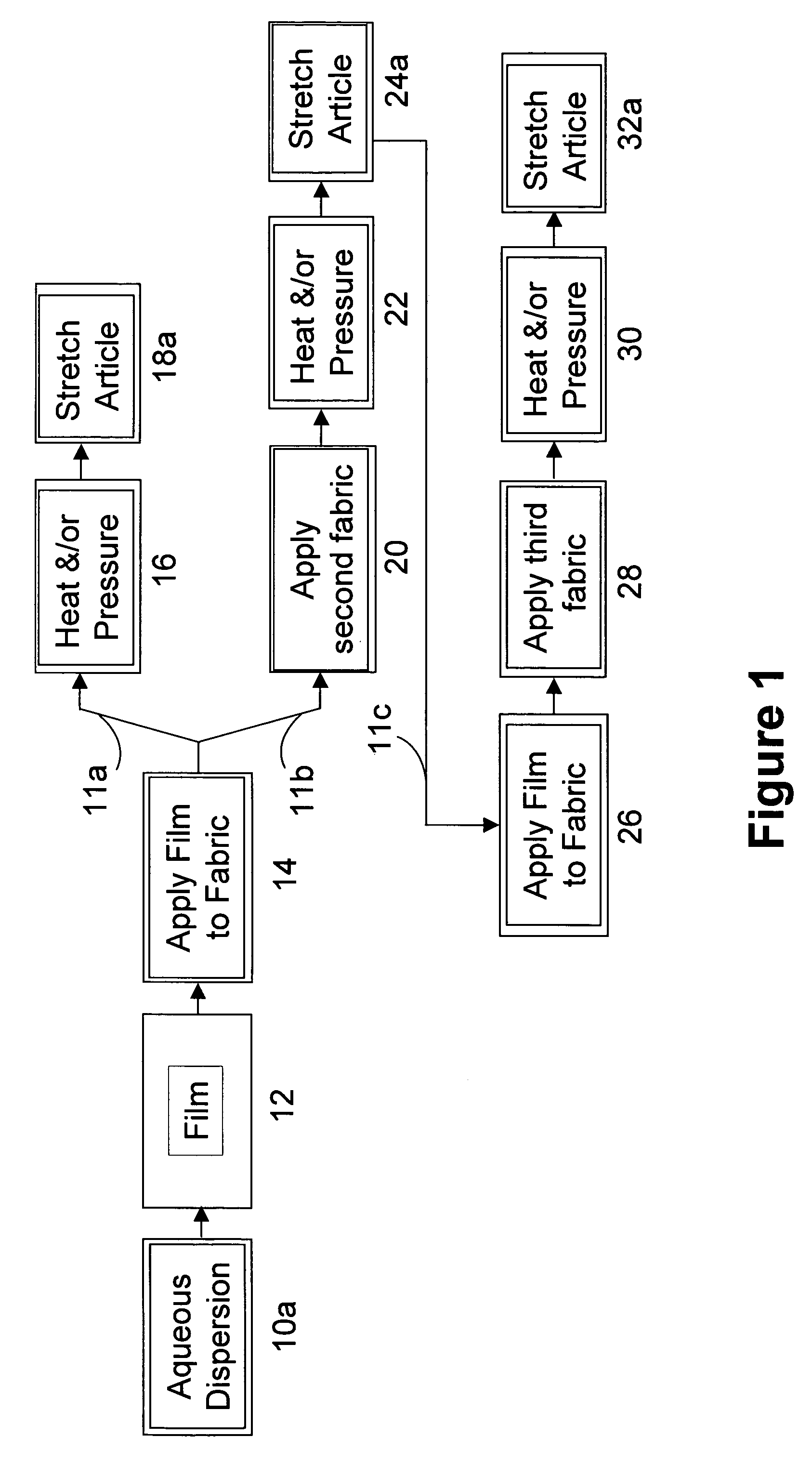

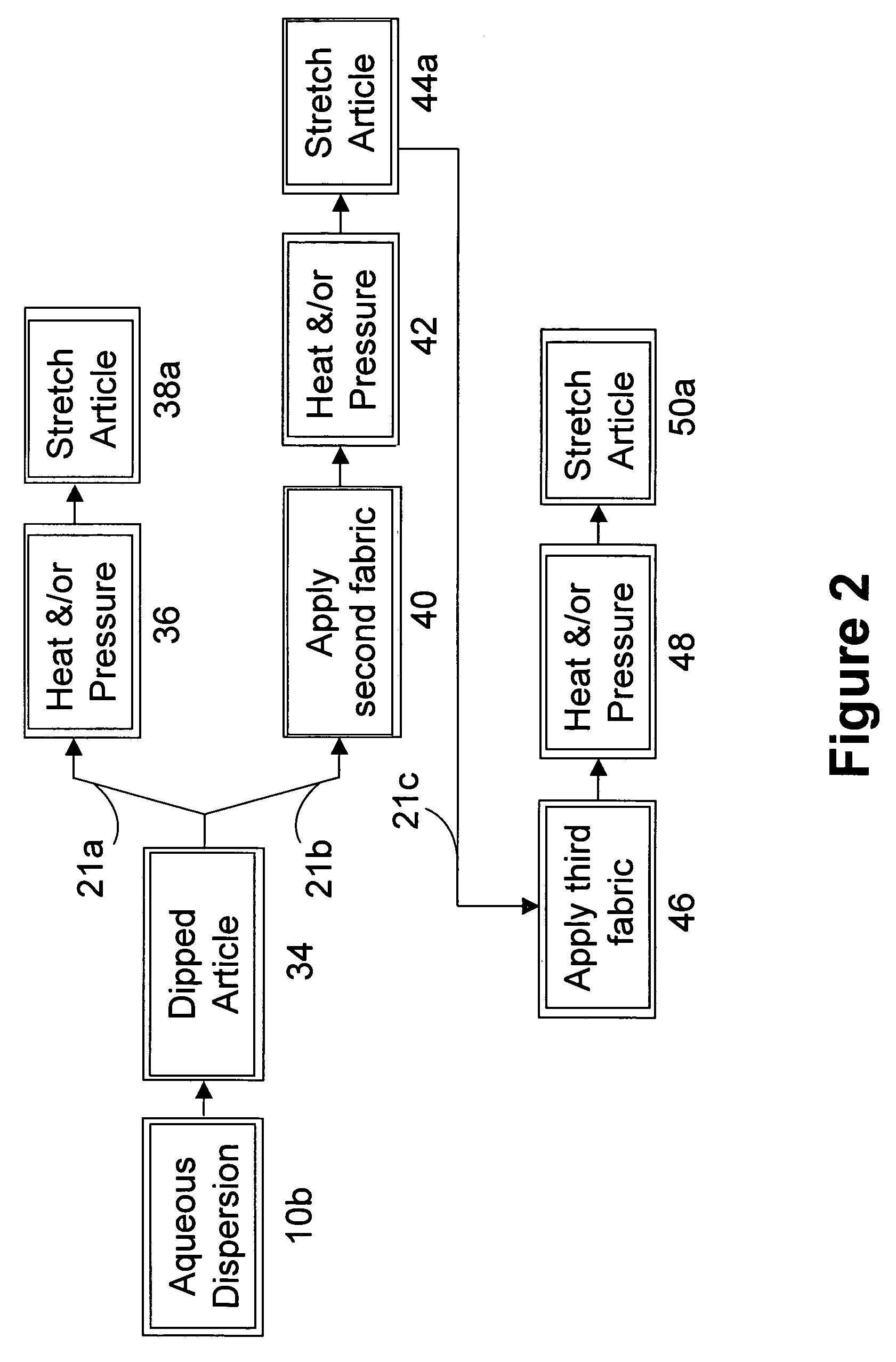

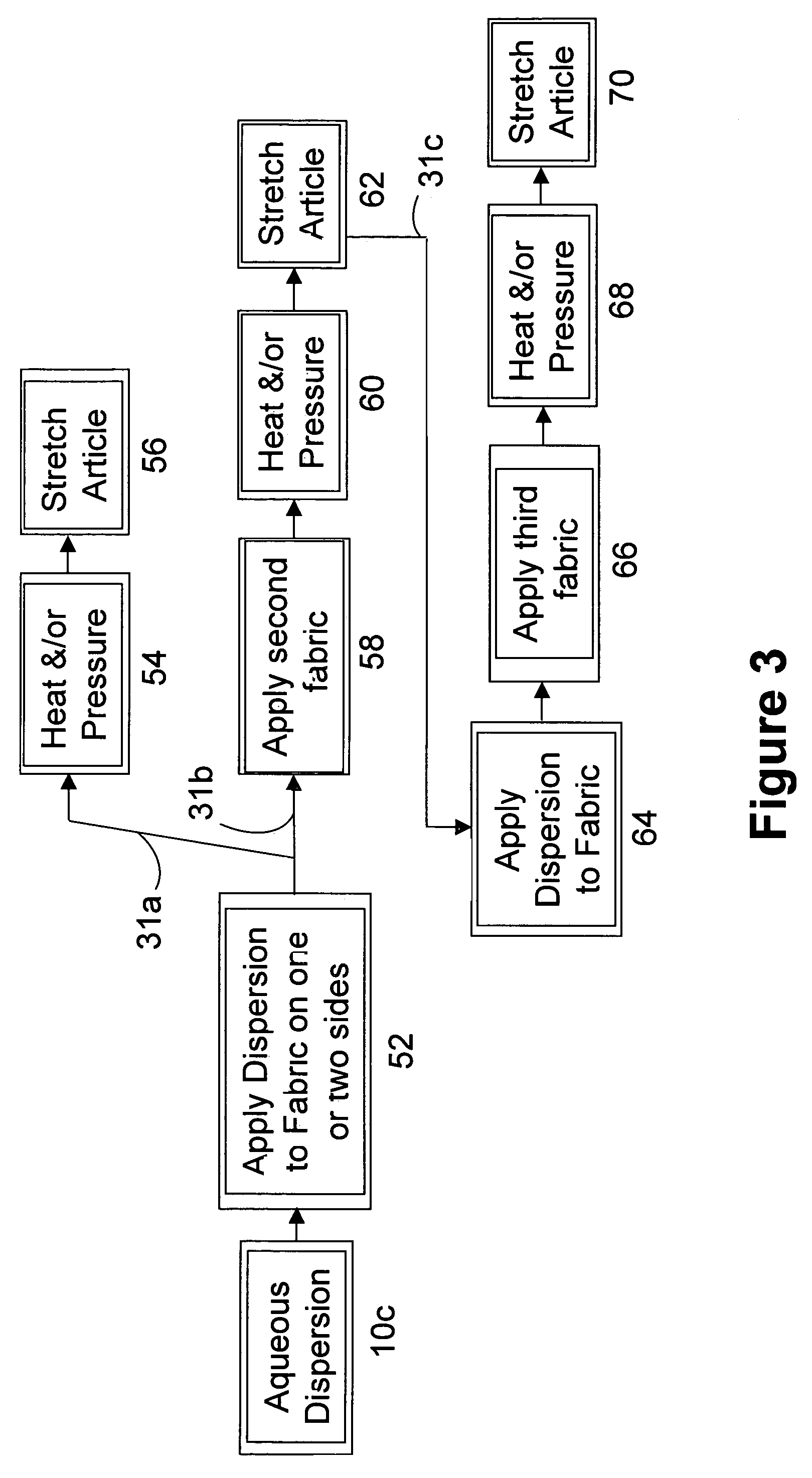

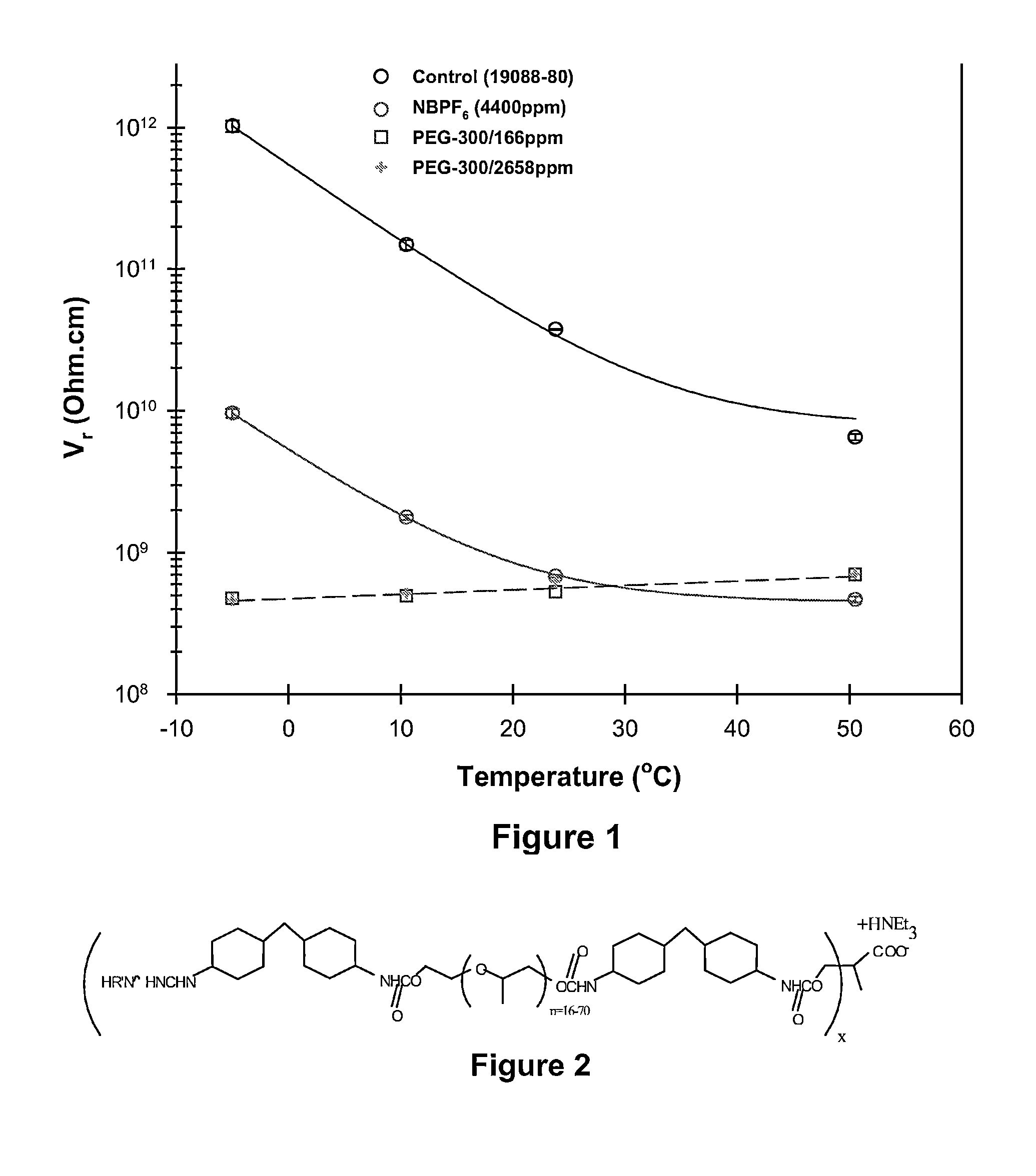

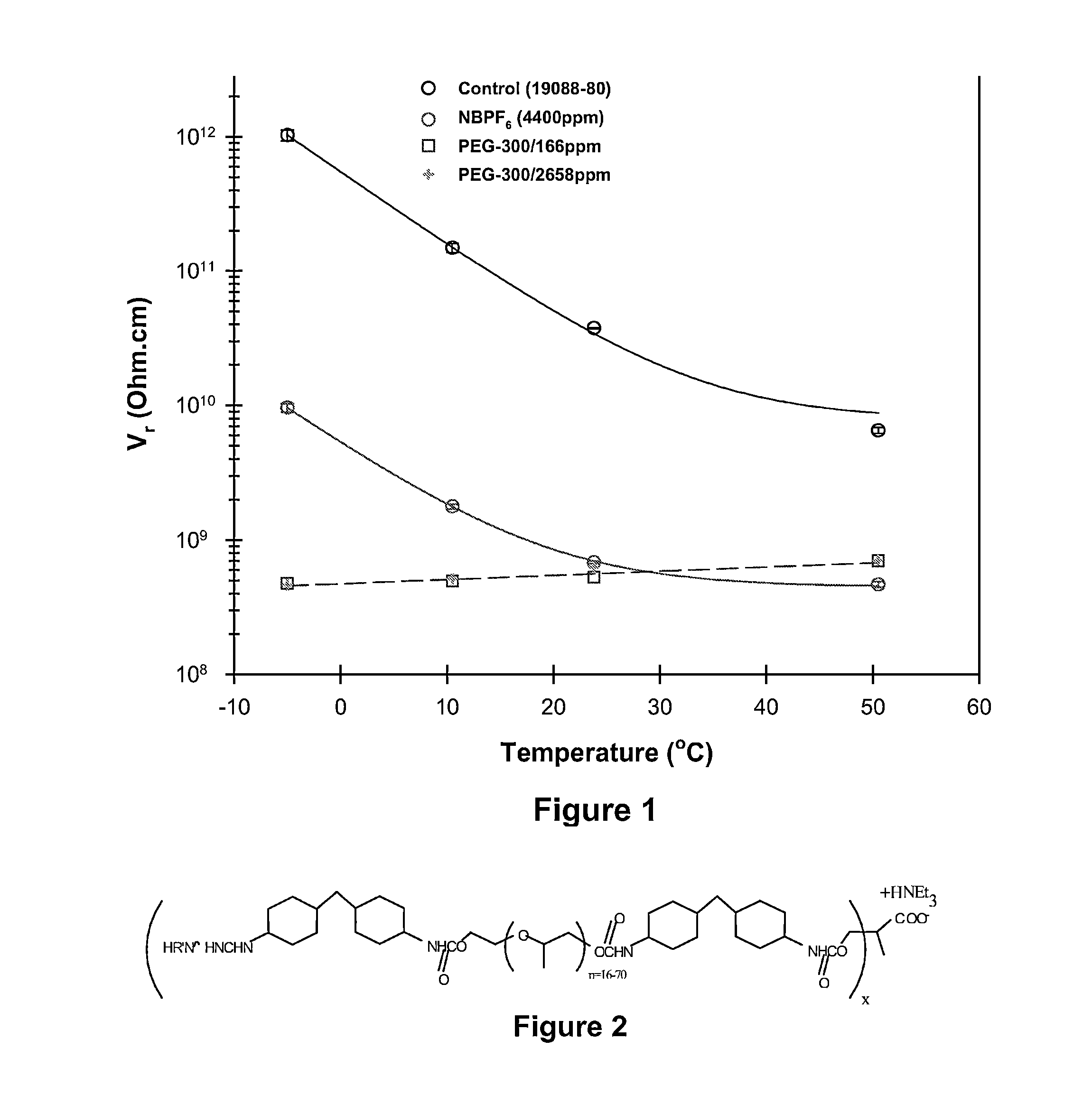

Solvent free aqueous polyurethane dispersions and adhesive films therefrom for stretch fabrics

Novel aqueous polyurethane dispersions and adhesive films formed therefrom are provided. The aqueous polyurethane dispersions are provided in solvent-free systems of a prepolymer comprising at least one polyether or polyester polyol, a mixture of MDI isomers, and a diol. The adhesive films from such dispersions can be heat-activated for bonding, lamination, and adhesion of textile fabrics, including stretch fabrics.

Owner:THE LYCRA CO LLC

Porous sintered metal-containing materials

InactiveUS20060211802A1Adversely affecting the physical and/or chemical stabilityInhibit aggregationAdditive manufacturingTransportation and packagingSolvent freeMetallic materials

A process for manufacturing a porous metal-containing material is provided. For example, a composition is provided comprising particles dispersed in at least one solvent, the particles comprising at least one polymer material and at least one metal-based compound. The solvent can be substantially removed from the composition, and the polymer material can be substantially decomposed, thereby converting the solvent-free particles into a porous metal-containing material. In addition, metal-containing materials produced in accordance with the above process and their use in implantable medical devices can be provided.

Owner:CINVENTION AG

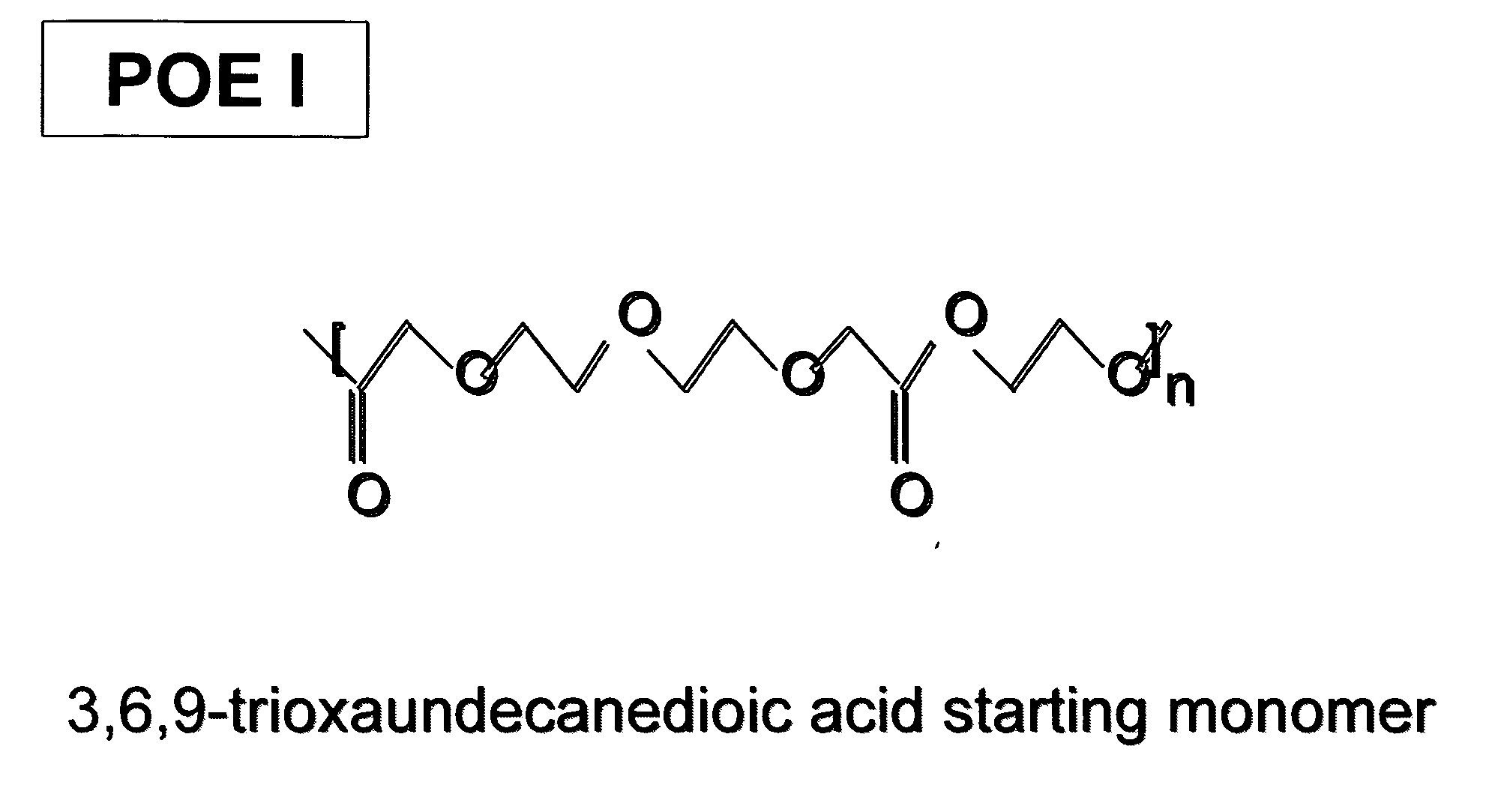

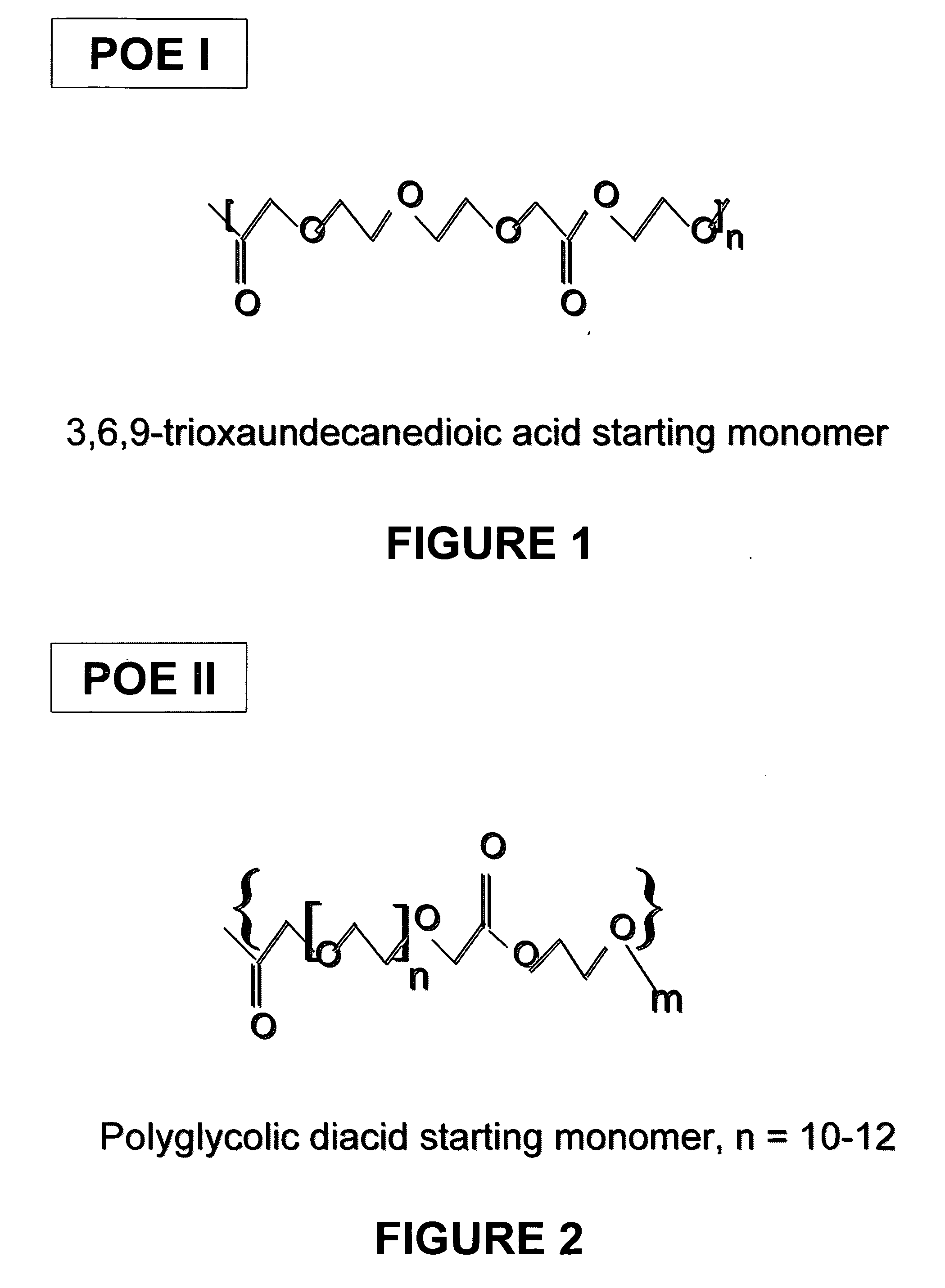

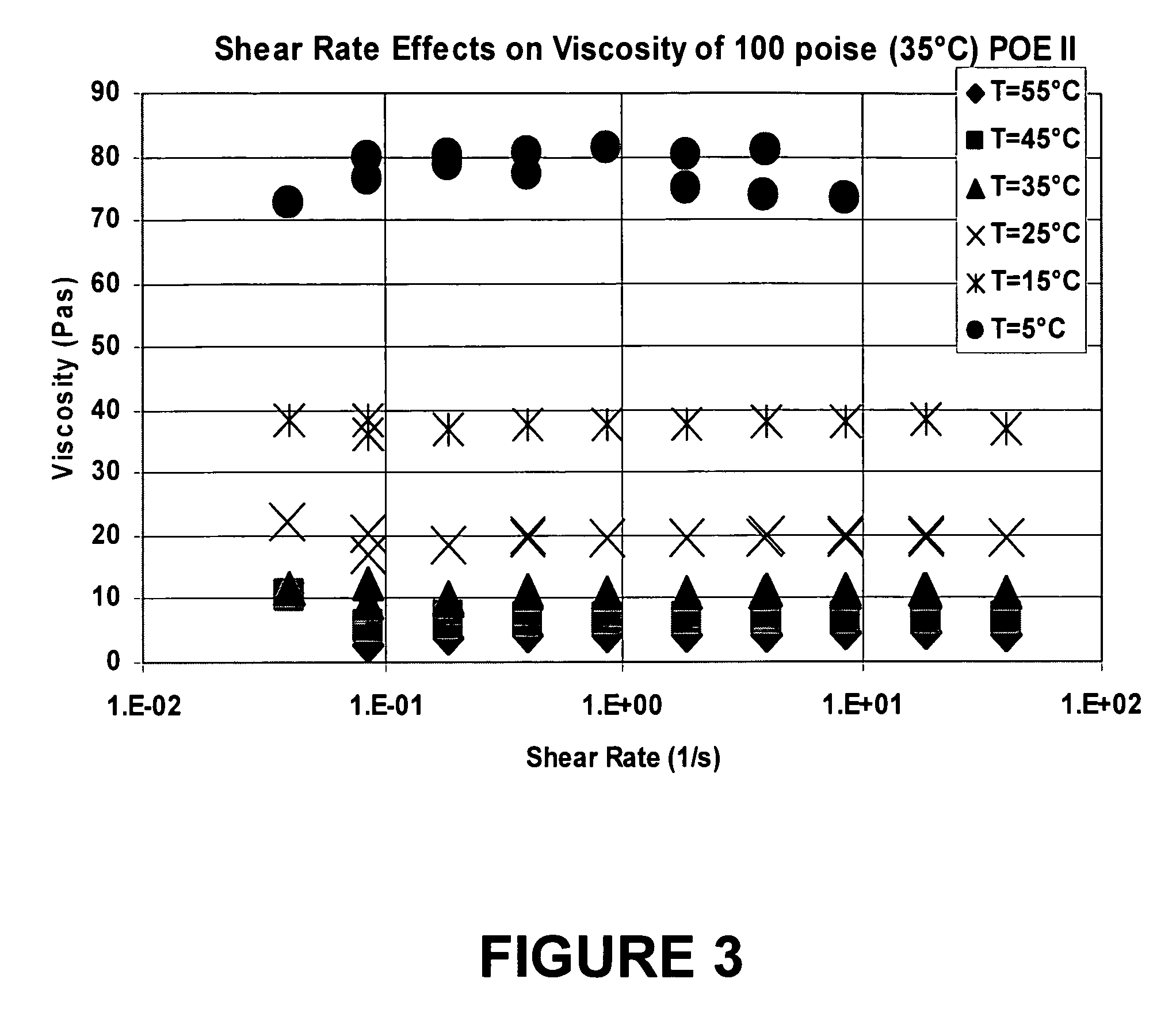

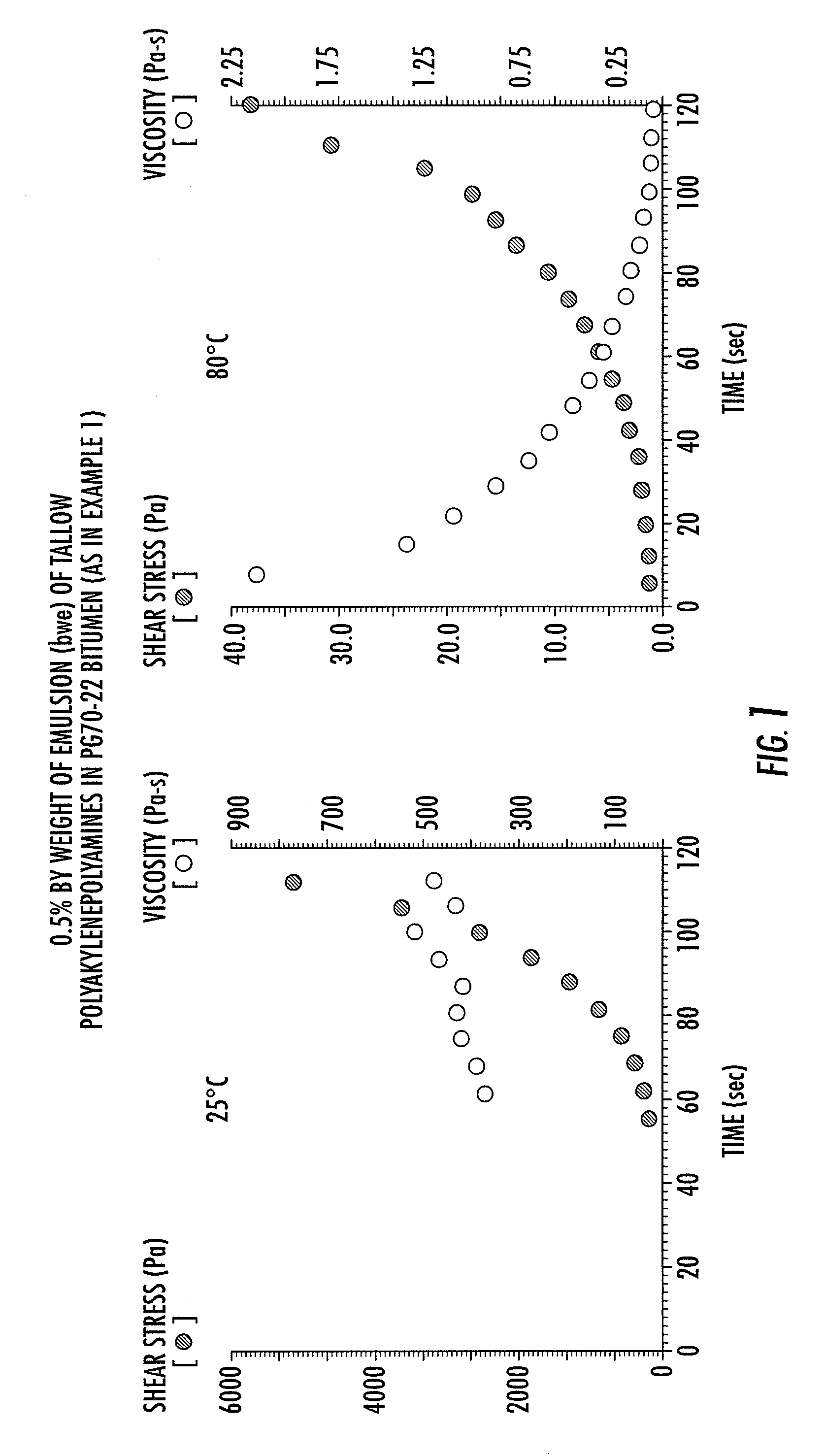

Polyoxaester suspending vehicles for use with implantable delivery systems

ActiveUS20060246138A1LimitMaintain stabilityPowder deliveryOrganic active ingredientsSUSPENDING VEHICLEActive agent

Liquid polyoxaester polymer materials are provided as suspending vehicles suitable for dispensing of pharmaceutically active agents, such as proteins, from delivery devices, for example, pump-driven dosage forms. Polyoxaesters are made from at least one diacid and at least one diol. Through the use of polyoxaesters virtually solvent-free pharmaceutical suspensions can be created.

Owner:INTARCIA THERAPEUTICS INC

Method for producing bituminous compositions

InactiveUS20070039520A1Low viscosityHighly preventive effectOrganic chemistrySingle unit pavingsEmulsionSolvent free

This invention relates to bituminous compositions and methods of producing the same. More particularly, the invention relates to the production of bituminous compositions formulated with performance-graded bitumen-containing solvent-free bitumen emulsions which exhibit controllable, temperature-dependent interfacial rheology. When employed in paving applications, these bituminous compositions develop adhesive strength and load-bearing strength properties at rates comparable to traditional hot mix paving compositions and at rates faster than traditional cold mix paving compositions.

Owner:MEADWESTVACO CORP

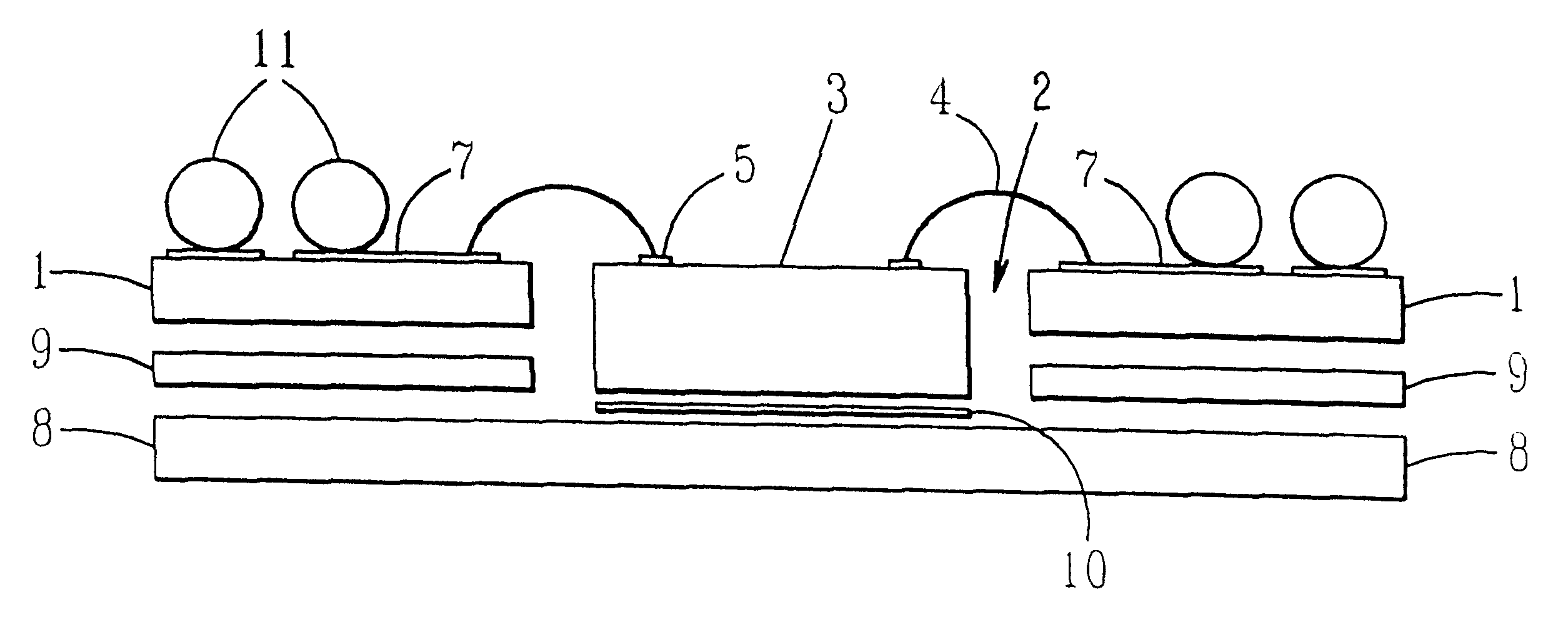

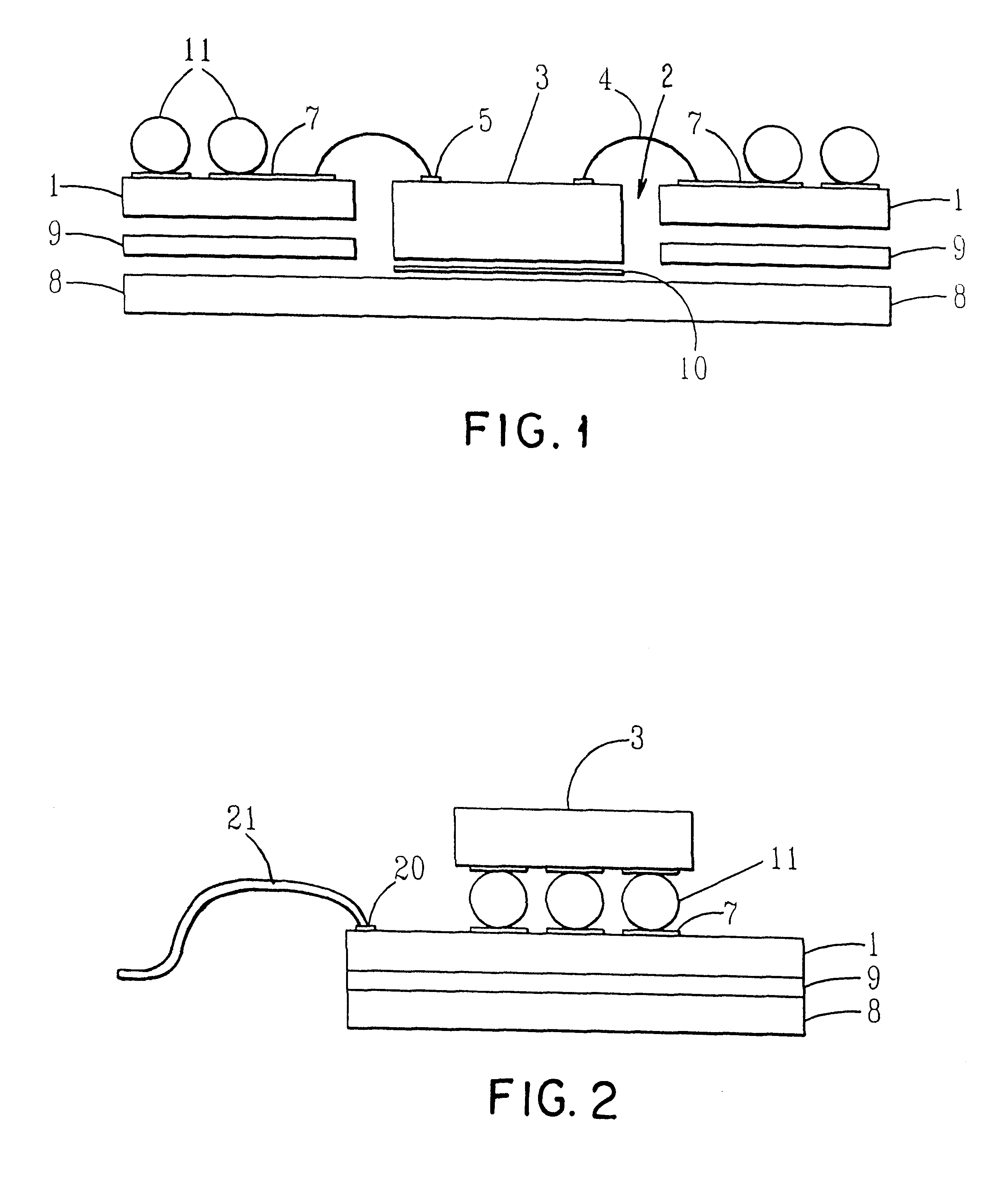

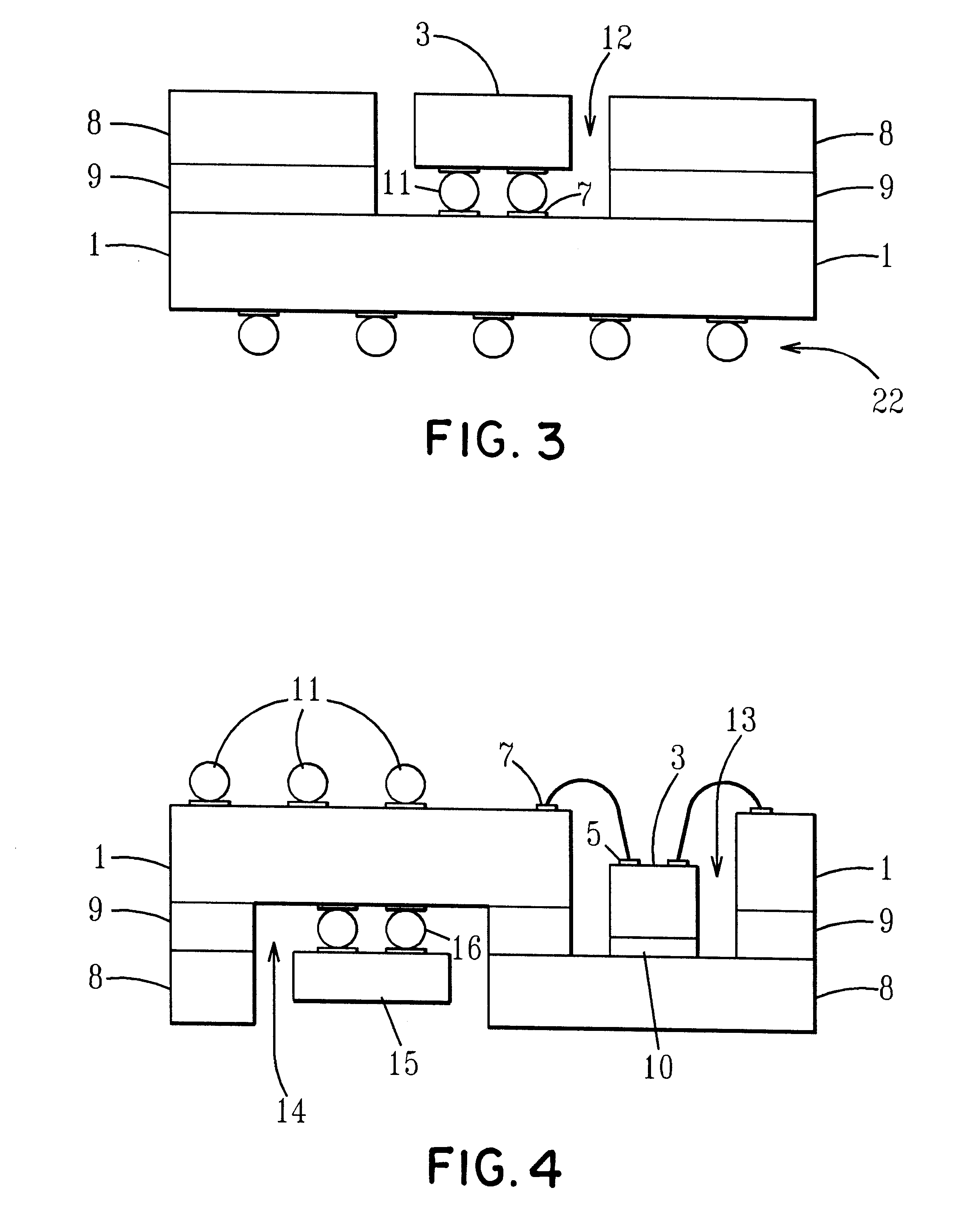

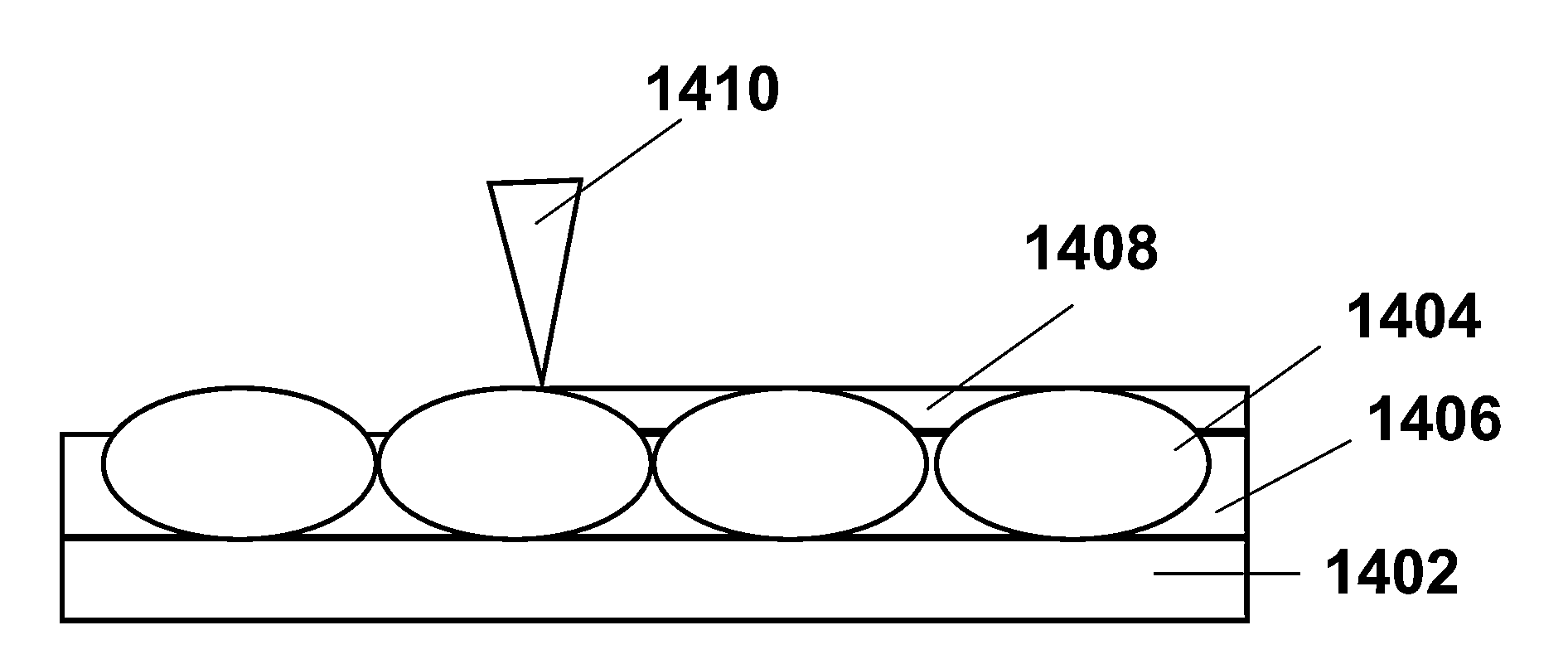

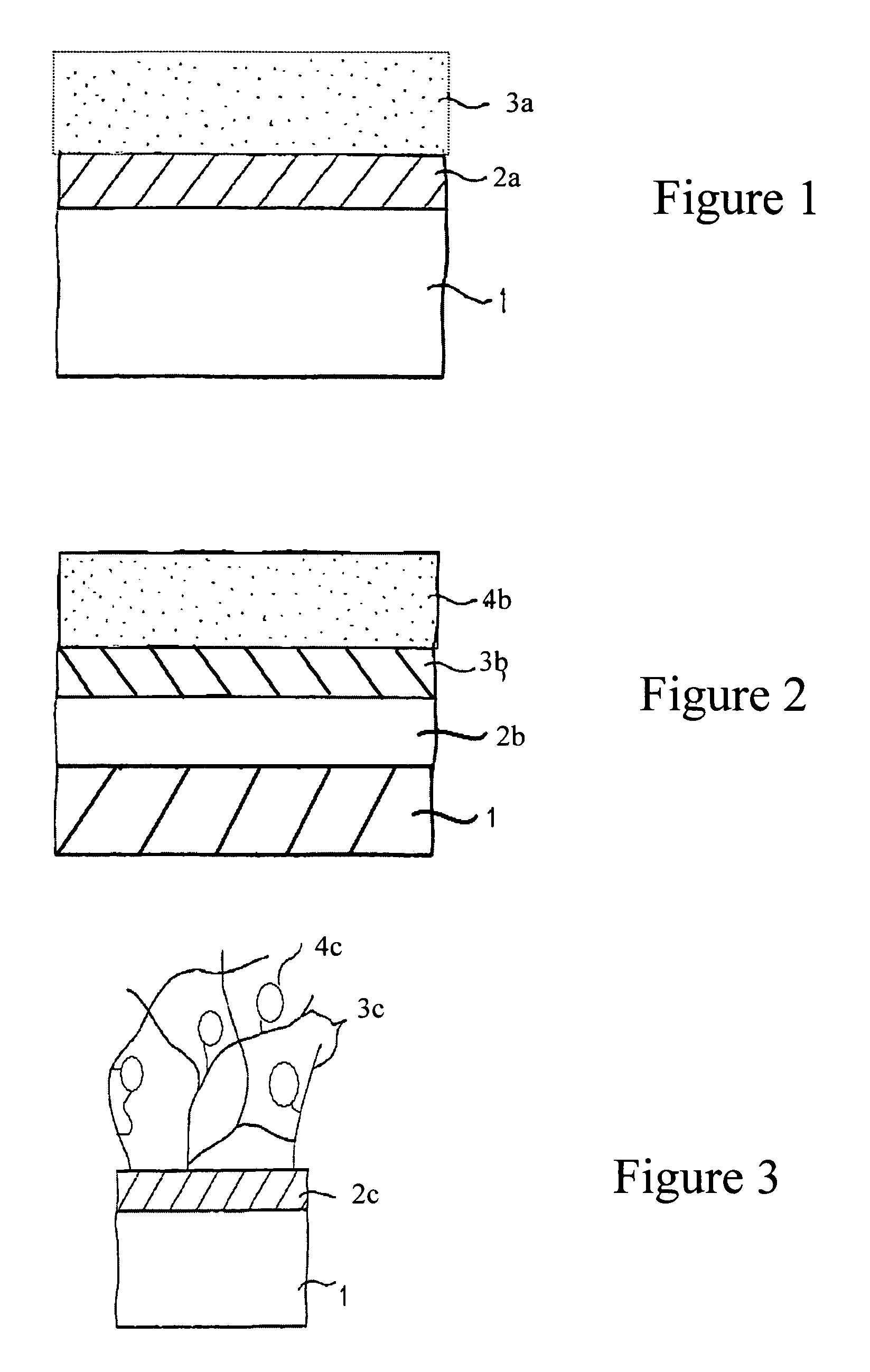

Electro-optic displays, and materials for use therein

A first electro-optic display comprises first and second substrates, and an adhesive layer and a layer of electro-optic material disposed between the first and second substrates, the adhesive layer comprising a mixture of a polymeric adhesive material and a hydroxyl containing polymer having a number average molecular weight not greater than about 5000. A second electro-optic display is similar to the first but has an adhesive layer comprising a thermally-activated cross-linking agent to reduce void growth when the display is subjected to temperature changes. A third electro-optic display, intended for writing with a stylus or similar instrument, is produced by forming a layer of an electro-optic material on an electrode; depositing a substantially solvent-free polymerizable liquid material over the electro-optic material; and polymerizing the polymerizable liquid material.

Owner:E INK CORPORATION

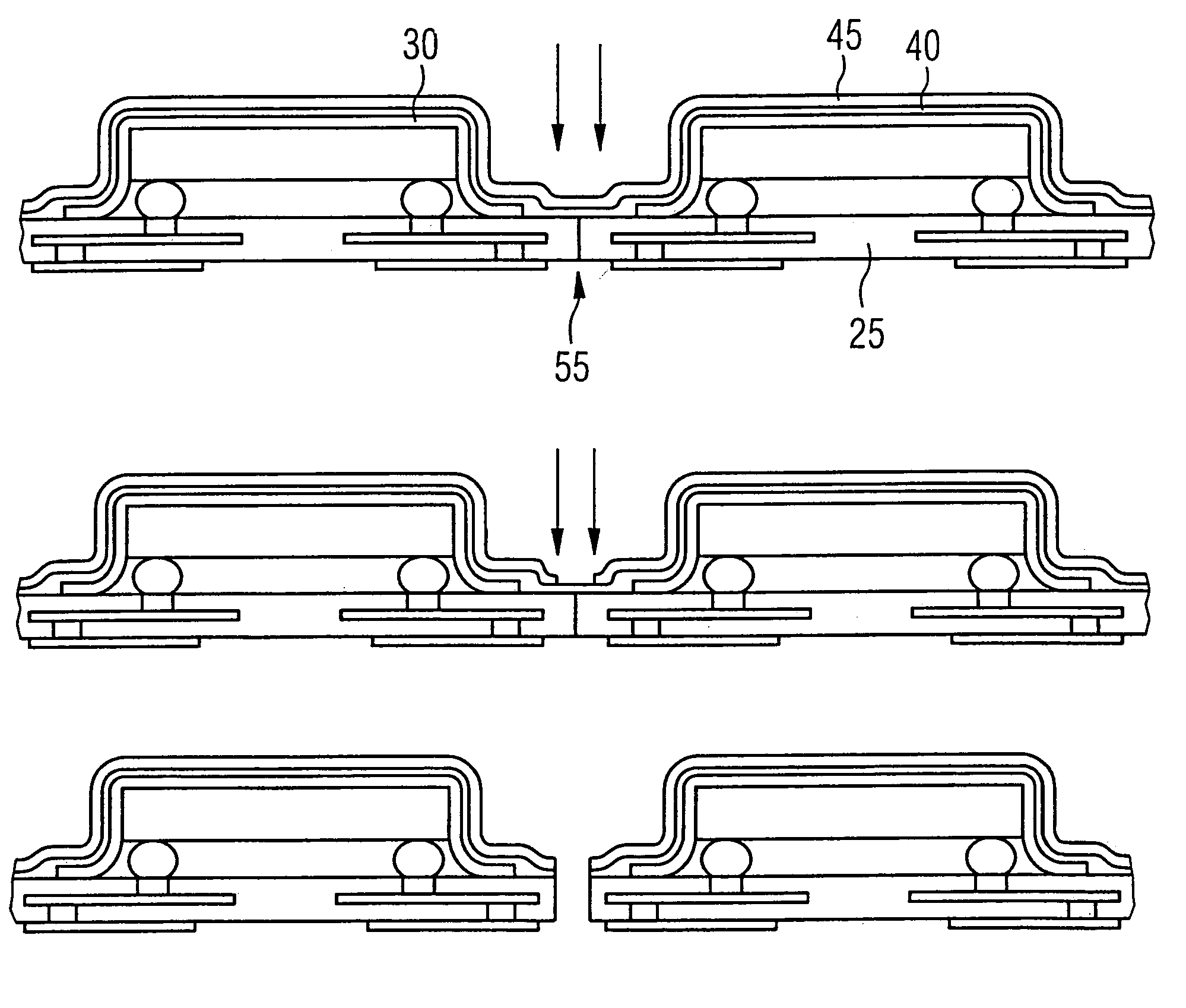

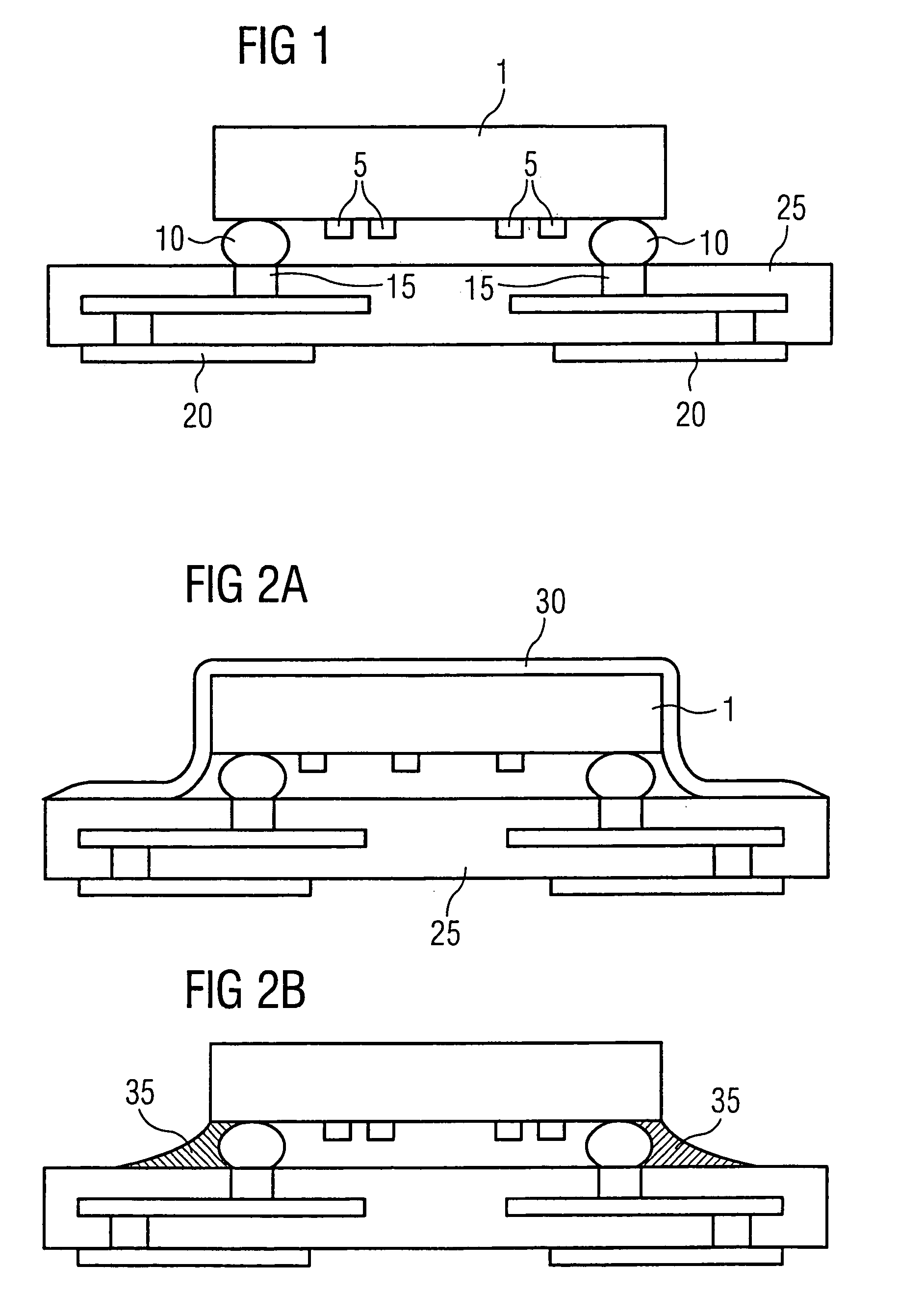

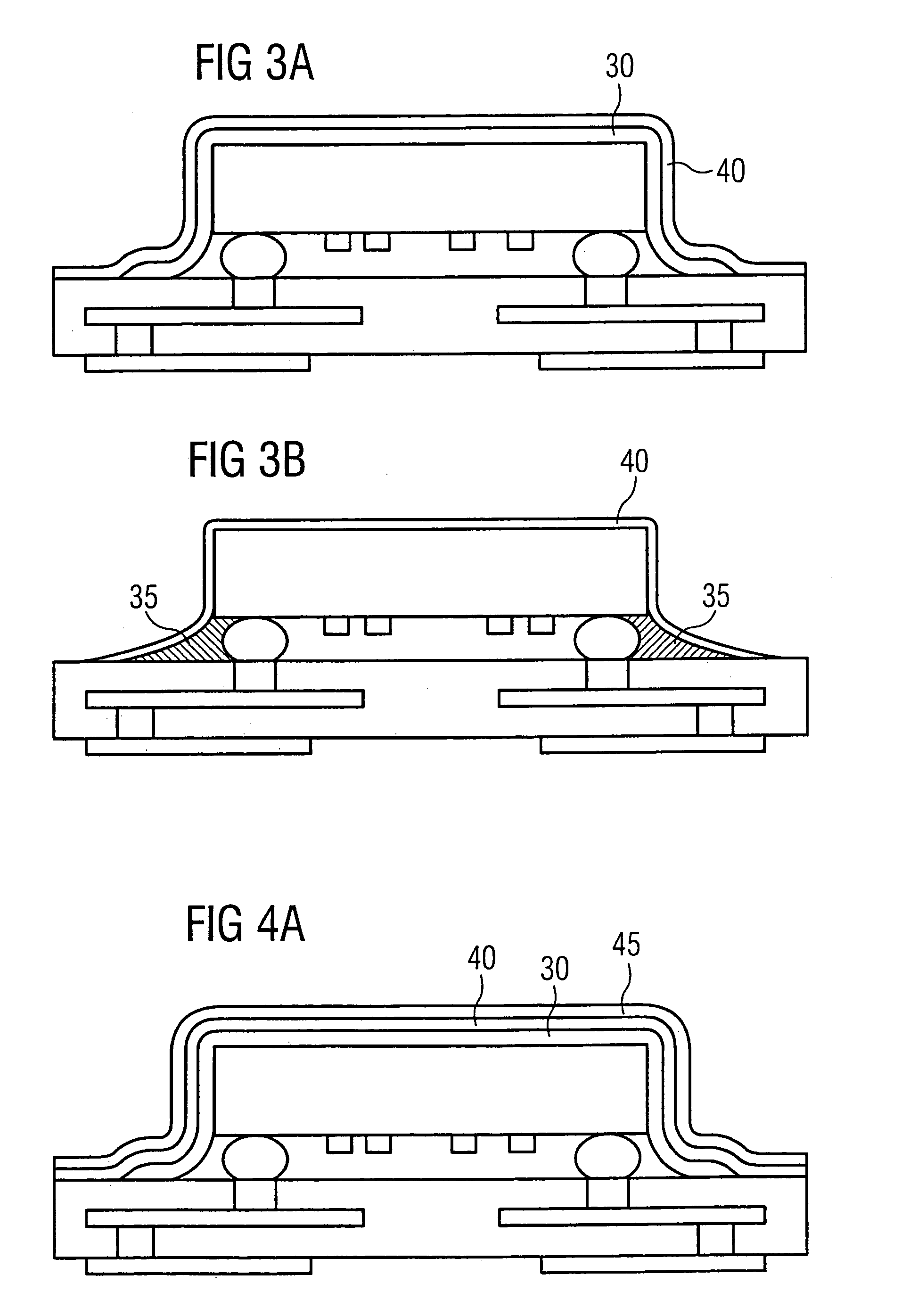

Method for the hermetic encapsulation of a component

InactiveUS7259041B2Easy to implementReduce metal consumptionImpedence networksSemiconductor/solid-state device detailsSolvent freeMaterials science

For hermetic encapsulation of a component, which includes a chip with component structures applied on a substrate in a flip-chip construction, a material is applied onto the lower edge of the chip and regions of the substrate abutting the chip, and then a first continuous metal layer is applied on the back side of the chip and on the material, as well as on edge regions of the substrate abutting the material. For hermetic encapsulation, a second sealing metal layer is subsequently applied by a solvent-free process at least on those regions of the first metal layer that cover the material.

Owner:SNAPTRACK

Radiation-curable coating composition

The present invention relates to a radiation-curable solvent-free coating composition for optical fiber having a radiation-curable urethane (meth)acrylate oligomer comprising an alkyd backbone,a reactive diluent, and a photoinitiator, and optionally an additive.

Owner:DSM IP ASSETS BV

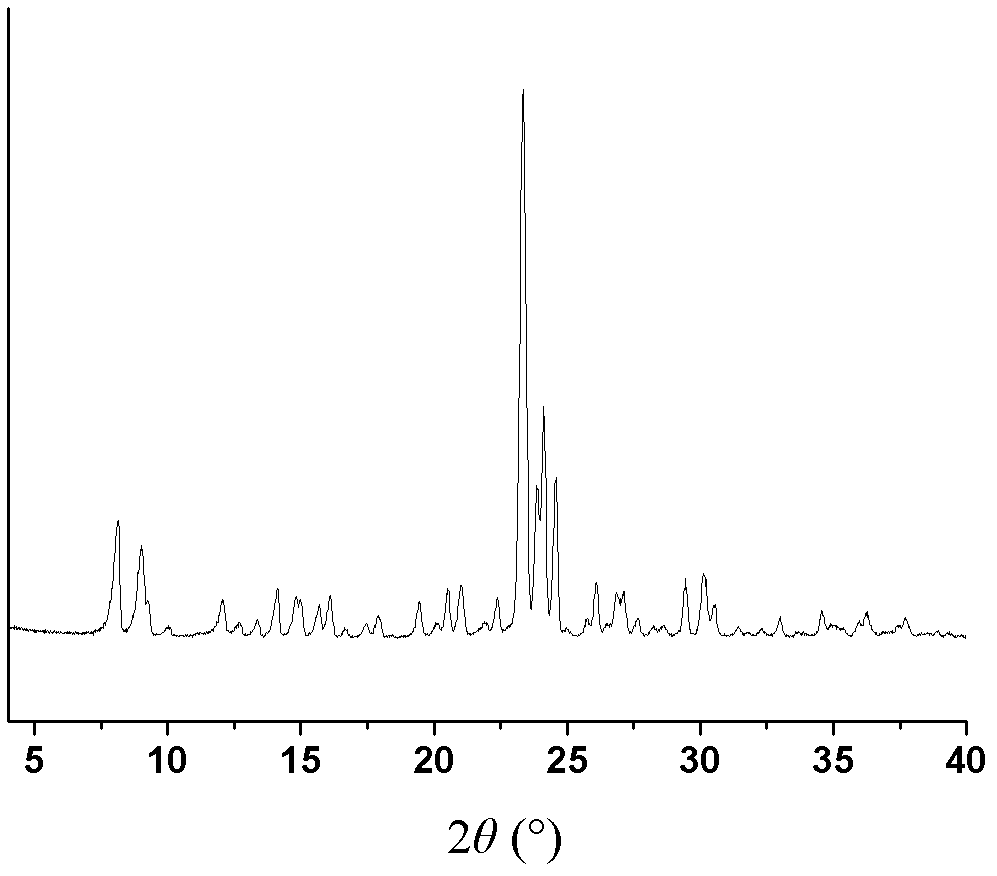

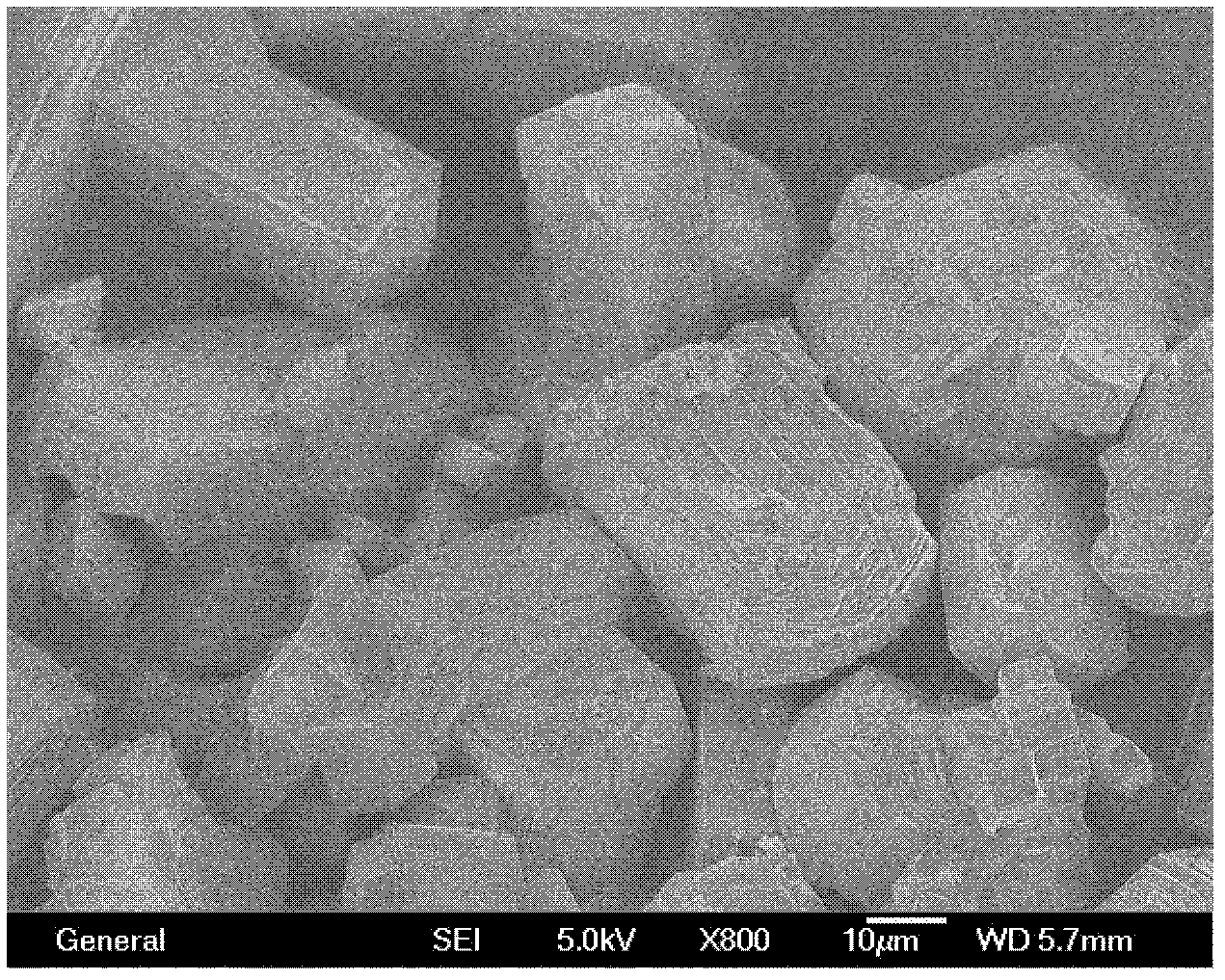

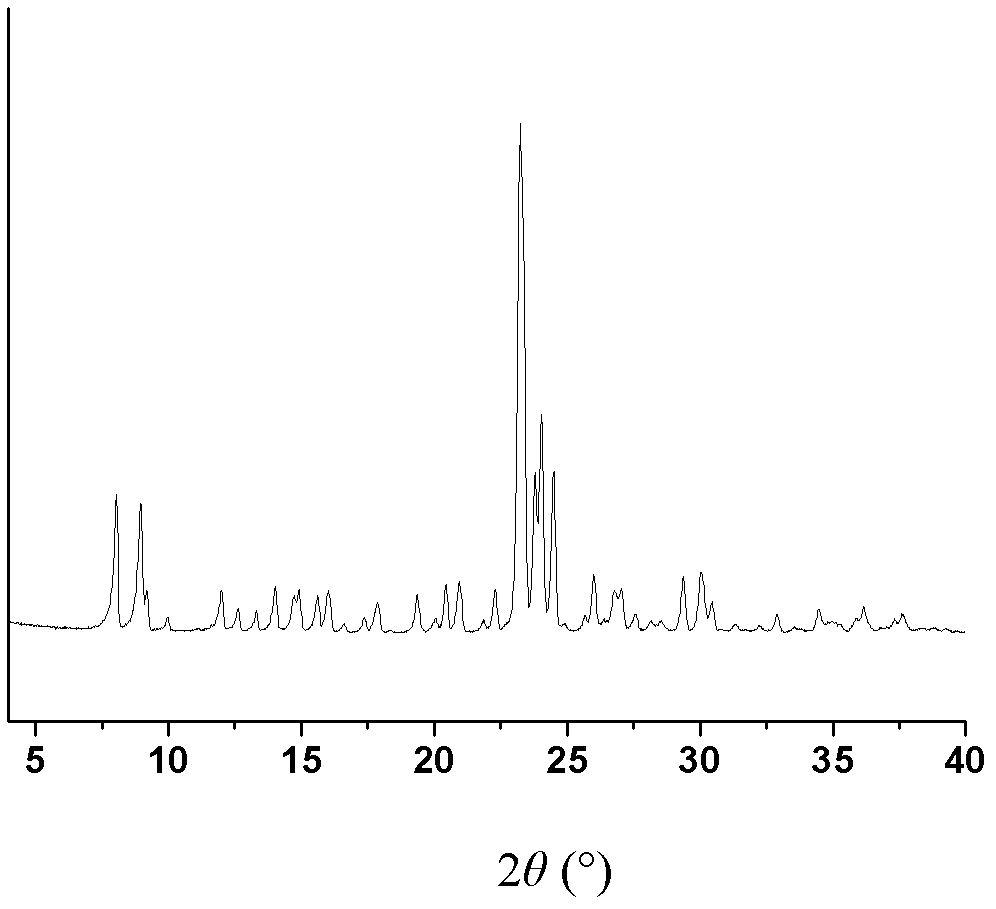

Method for synthesizing molecular sieve under solvent-free condition through grinding solid phase raw materials

ActiveCN102627287AHigh crystallinityThe synthesis steps are simplePentasil aluminosilicate zeoliteSolvent freeSolvent

The invention relates to a method for preparing a molecular sieve, aiming to provide a method for synthesizing a molecular sieve under a solvent-free condition through grinding solid phase raw materials. The method comprises the following steps of: grinding and mixing the pre-weighed solid raw materials which include silicon sources, metal atom sources, an organic template agent, and an alkalinity regulator, putting the grinded material into a reactor, and performing a crystallization reaction for 1-8 days at a temperature ranged from 80 DEG C to 180 DEG C; and drying for over 12 hours at a temperature of 80 DEG C after washing the reaction product thoroughly by using deionized water to obtain a final product. A ZSM-5 molecular sieve, a Beta molecular sieve, a ZSM-39 molecular sieve, and a SOD molecular sieve, which have a good crystallinity and a controllable silicon-aluminum ratio, can be prepared through the method provided by the invention. The synthetic route only involves a mixture of the raw materials without a use of any solvents, which simplifies the synthetic process compared to the traditional method, improves the yield rate and the single reactor utilization rate greatly, reduces the production cost greatly, saves energy and reduces emission, and has a wide industrial application prospect.

Owner:淮安六元环新材料有限公司

Integrated circuit chip carrier assembly comprising a stiffener attached to a dielectric substrate

InactiveUS6329713B1Eliminate needLayered productsSemiconductor/solid-state device detailsAdhesiveDielectric substrate

An integrated circuit chip carrier assembly is provided by joining a substrate having electrically conductive regions on at least one major surface thereof to a stiffener by a bonding film. The bonding film comprises a dielectric substrate having a thermoset adhesive on both of its major surfaces. The thermoset adhesive prior to the bonding is a B-stage adhesive, is tack-free at normal room temperatures and is solvent free.

Owner:IBM CORP

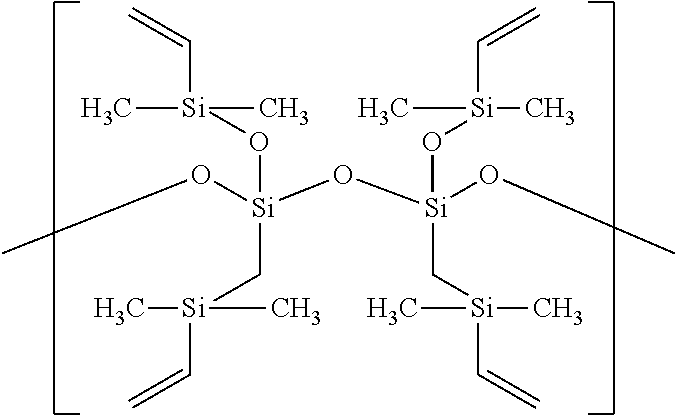

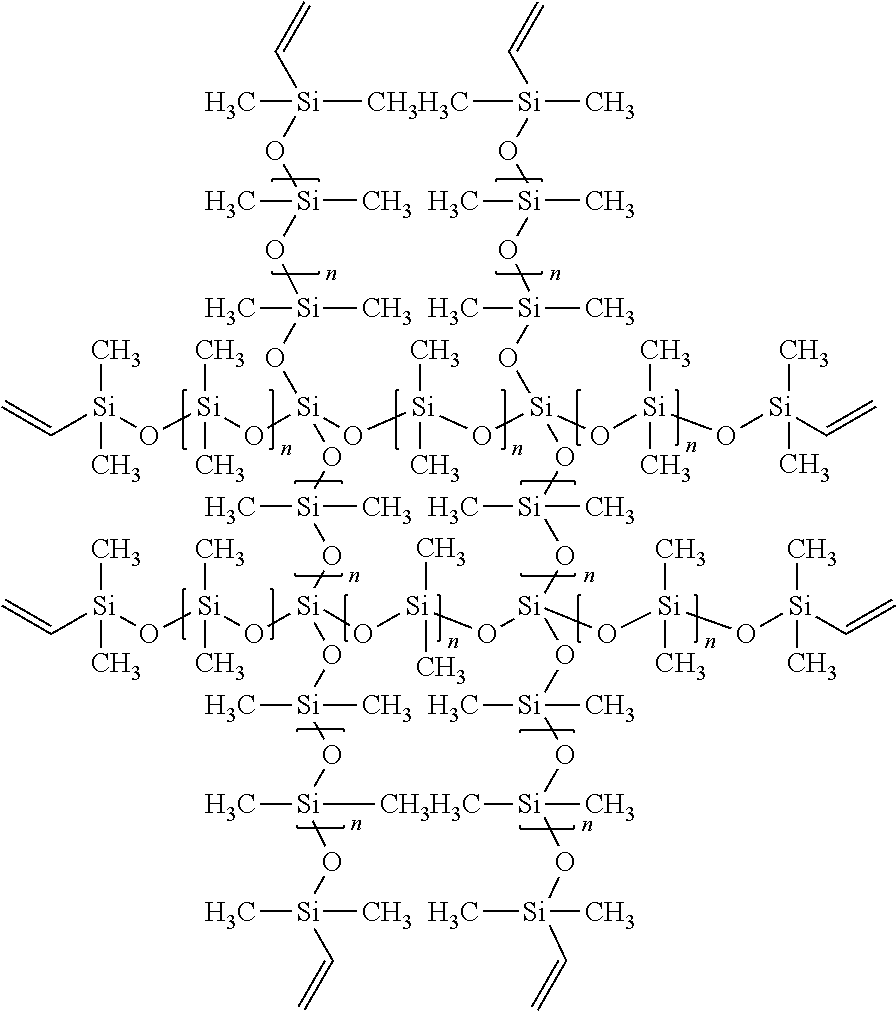

Solventless Cured Release Coating-Forming Organopolysiloxane Composition And Sheet-Form Substrate Having A Cured Release Coating

InactiveUS20110287267A1Good slipperinessGood release effectCoatingsThin material handlingPolymer sciencePtru catalyst

A solventless cured release coating-forming organopolysiloxane composition having a viscosity at 25° C. of 50 to 2,000 mPa·s comprising (A) 100 weight parts of an alkenyl-functional diorganopolysiloxane that has a viscosity of 25 to 1,000 mPa·s; (B) 0.5 to 15 weight parts of a diorganopolysiloxane that has a viscosity of at least 10,000 mPa·s and that has an aliphatically unsaturated group content of no more than 0.1 mole %; (C) 0.5 to 5 weight parts of a branched organopolysiloxane that has more than one SiO4 / 2 unit and that is a polymer product provided by an equilibration polymerization between a branched organosiloxane oligomer represented by the average siloxane unit formula (1) (SiO4 / 2)(RaRb2SiO1 / 2)x(1) and a diorganosiloxane oligomer; (D) a specific amount of an organohydrogenpolysiloxane that has a viscosity of 1 to 1,000 mPa·s; and (E) a hydrosilylation reaction catalyst in a catalytic quantity.

Owner:DOW CORNING TORAY CO LTD +1

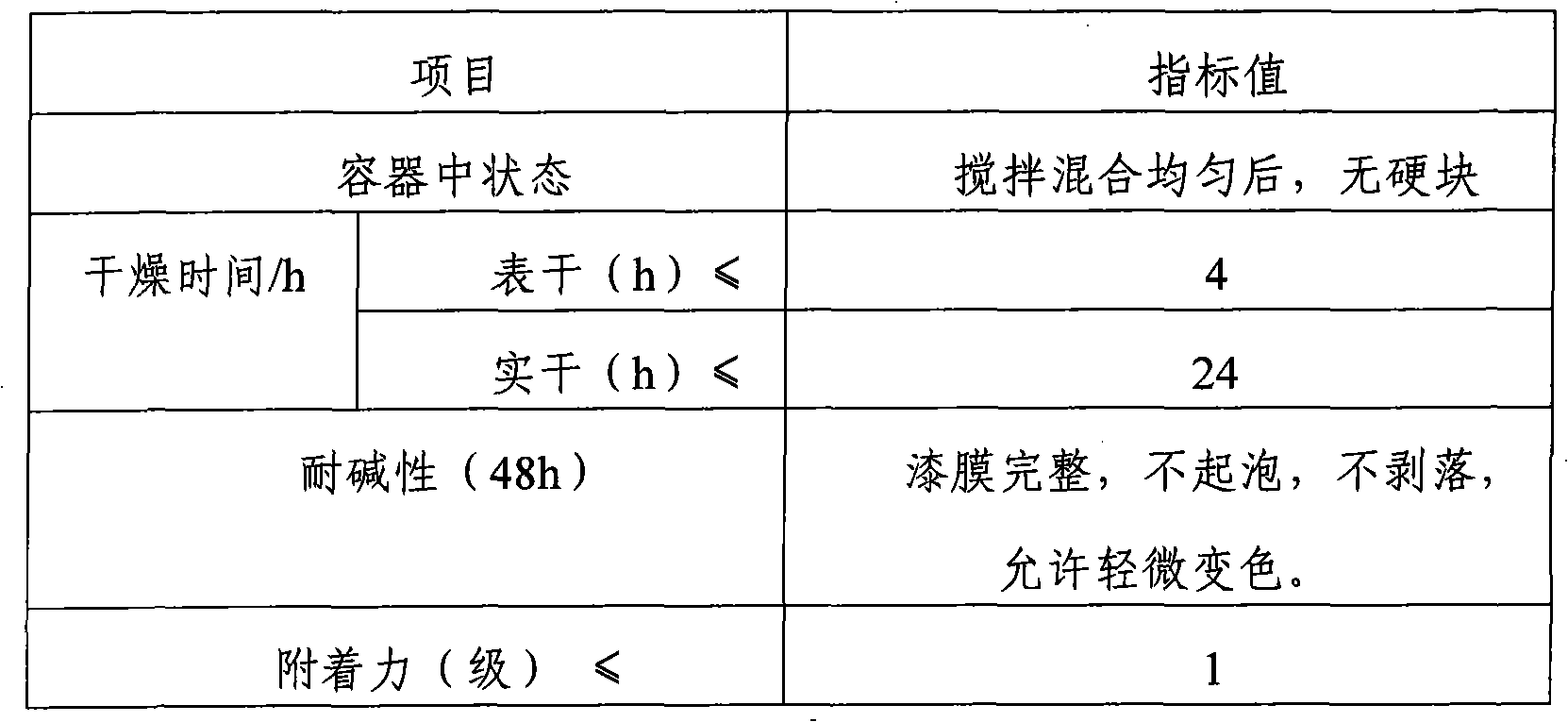

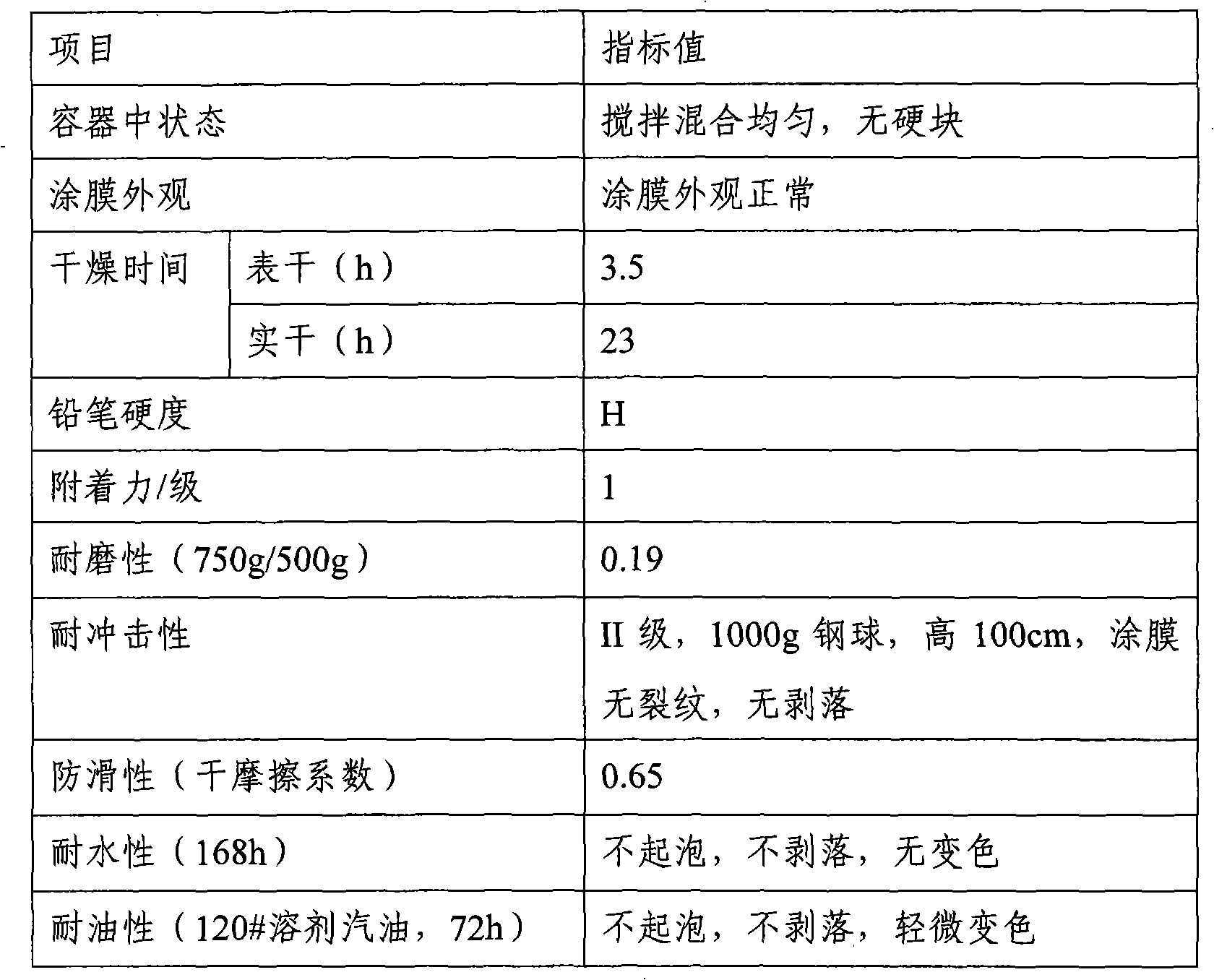

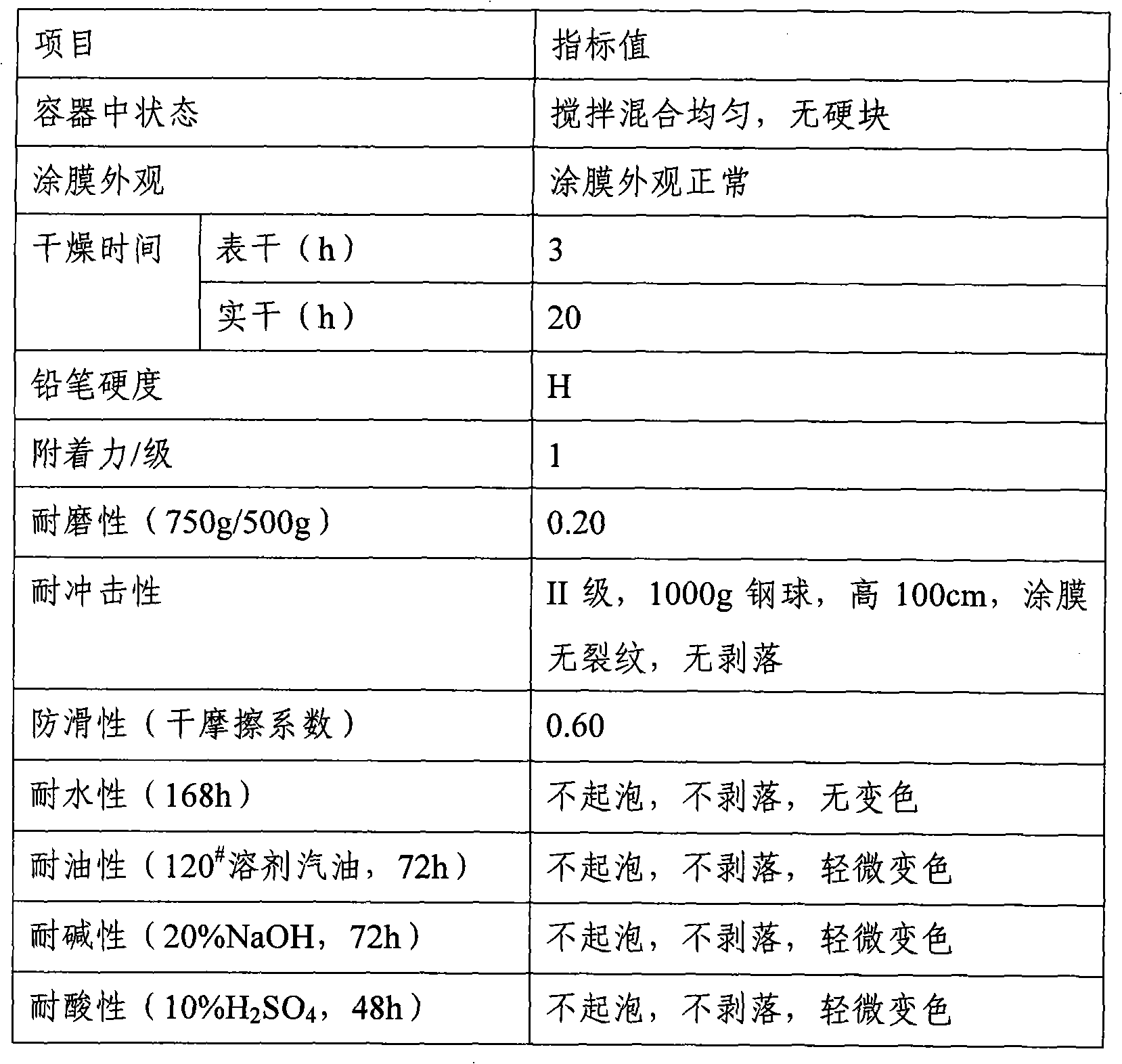

Compound epoxy flooring coating and preparation method thereof

InactiveCN101654583AHigh mechanical strengthImprove corrosion resistanceRosin coatingsEpoxy resin coatingsSolvent freeFirming agent

The invention relates to compound epoxy flooring coating adopting the mixture of epoxide resin and modified resin as a base material and further comprising organic solvent, dispersant, wetting agent, antifoaming agent, flatting agent, scratch resistance agent, pigment and stuffing as well as reactive diluent selected according to requirements. When in use, the coating is mixed and solidified withthe components of firming agent, accelerant, etc. By regulating the content of the components, the compound epoxy flooring coating of the invention can be used for manufacturing a solvent or solvent-free autolevelling epoxy floor. The compound epoxy flooring coating of the invention has favorable over-all properties, and not only has the characteristics of high mechanical strength, favorable anti-corrosion property, high adhesive force and good wear resistance property of the epoxide resin but also has the characteristics of good weather resistance, high decorative property and hardness and shock resistance of the modified resin; and the preparation method thereof is simple and practicable, is low-cost, and is suitable for mass preparation.

Owner:北京红狮科技发展有限公司

Water-in-oil bituminous dispersions and methods for producing paving compositions from the same

ActiveUS7297204B2Low viscosityHighly preventive effectProductsIn situ pavingsSolvent freeSURFACTANT BLEND

Owner:INGEVITY SOUTH CAROLINA

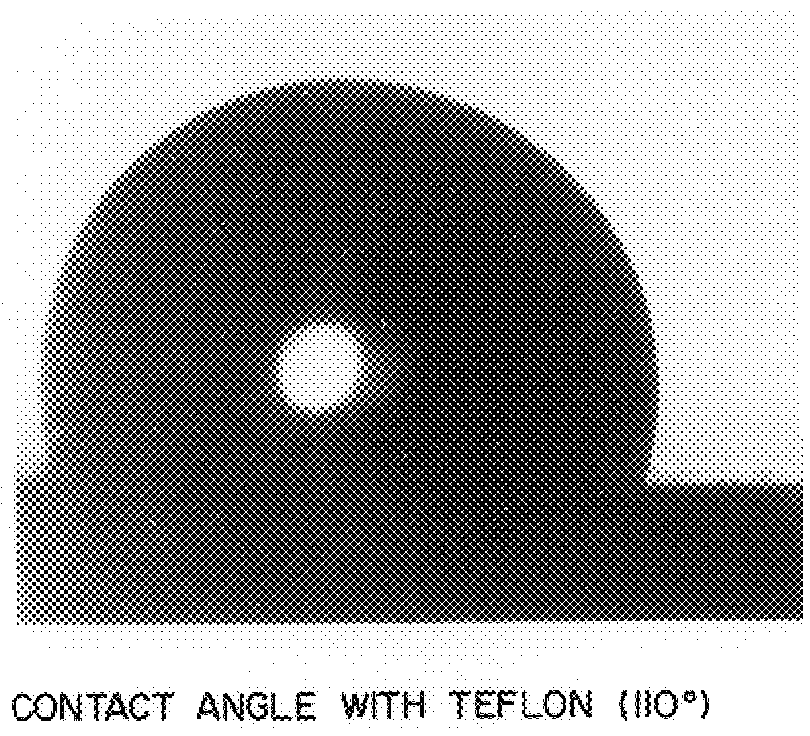

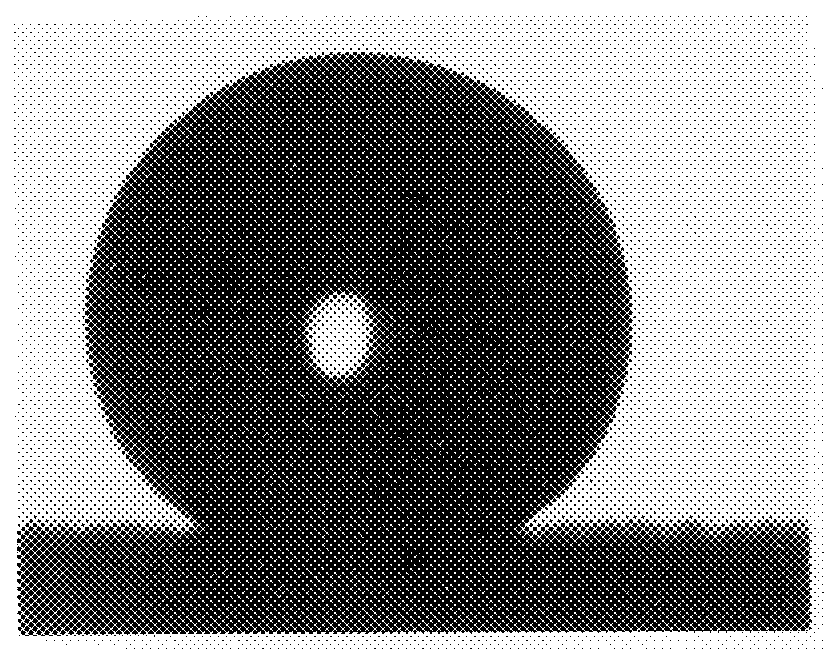

Solvent-free process for the preparation of mono-substituted fluorinated oxetane monomers

InactiveUS6037483AImprove hydrophobicityLower surface energyOrganic chemistry methodsPolyurea/polyurethane coatingsSide chainSolvent free

Owner:AMPAC FINE CHEM +1

Solvent free bi-component polyurethane adhesive and preparation method thereof

InactiveCN101597470ALow viscosityGood low temperature coatabilityPolyureas/polyurethane adhesivesPolyurethane adhesiveSolvent free

The invention discloses solvent free bi-component polyurethane adhesive and a preparation method thereof, wherein the solvent free bi-component polyurethane adhesive relates to a compound soft package adhesive in the fields of food, medicine, and the like. The adhesive comprises a component A and a component B, wherein the component A is an isocyanate compound, the component B is polyol, and the adhesive is obtained in such a way that the component A and the component B are mixed according to the weight percent of 2:1. The adhesive solves the problem that the use effect is influenced and the use range is limited because of poor properties of transparency, viscosity, low-temperature coating and stripping strength, and boiling resistance existing in the prior solvent free adhesive. The adhesive is environmental-friendly without solvent because the component A and the component B of the adhesive both are transparent liquid, has low viscosity as well as better low-temperature coating and stripping strength, and keeps better stripping strength after being boiled, thereby being environmental-friendly adhesive, wherein the viscosity of the component A is 2000-5000MPa.s and the viscosity of the component b is 400-2000MPa.s below 25 DEG C.

Owner:NANTONG GAOMENG NEW MATERIAL

Electro-optic displays, and materials for use therein

ActiveUS20150226986A1Polyureas/polyurethane adhesivesAdhesive processes with surface pretreatmentCross-linkDisplay device

A first electro-optic display comprises first and second substrates, and an adhesive layer and a layer of electro-optic material disposed between the first and second substrates, the adhesive layer comprising a mixture of a polymeric adhesive material and a hydroxyl containing polymer having a number average molecular weight not greater than about 5000. A second electro-optic display is similar to the first but has an adhesive layer comprising a thermally-activated cross-linking agent to reduce void growth when the display is subjected to temperature changes. A third electro-optic display, intended for writing with a stylus or similar instrument, is produced by forming a layer of an electro-optic material on an electrode; depositing a substantially solvent-free polymerizable liquid material over the electro-optic material; and polymerizing the polymerizable liquid material.

Owner:E INK CORPORATION

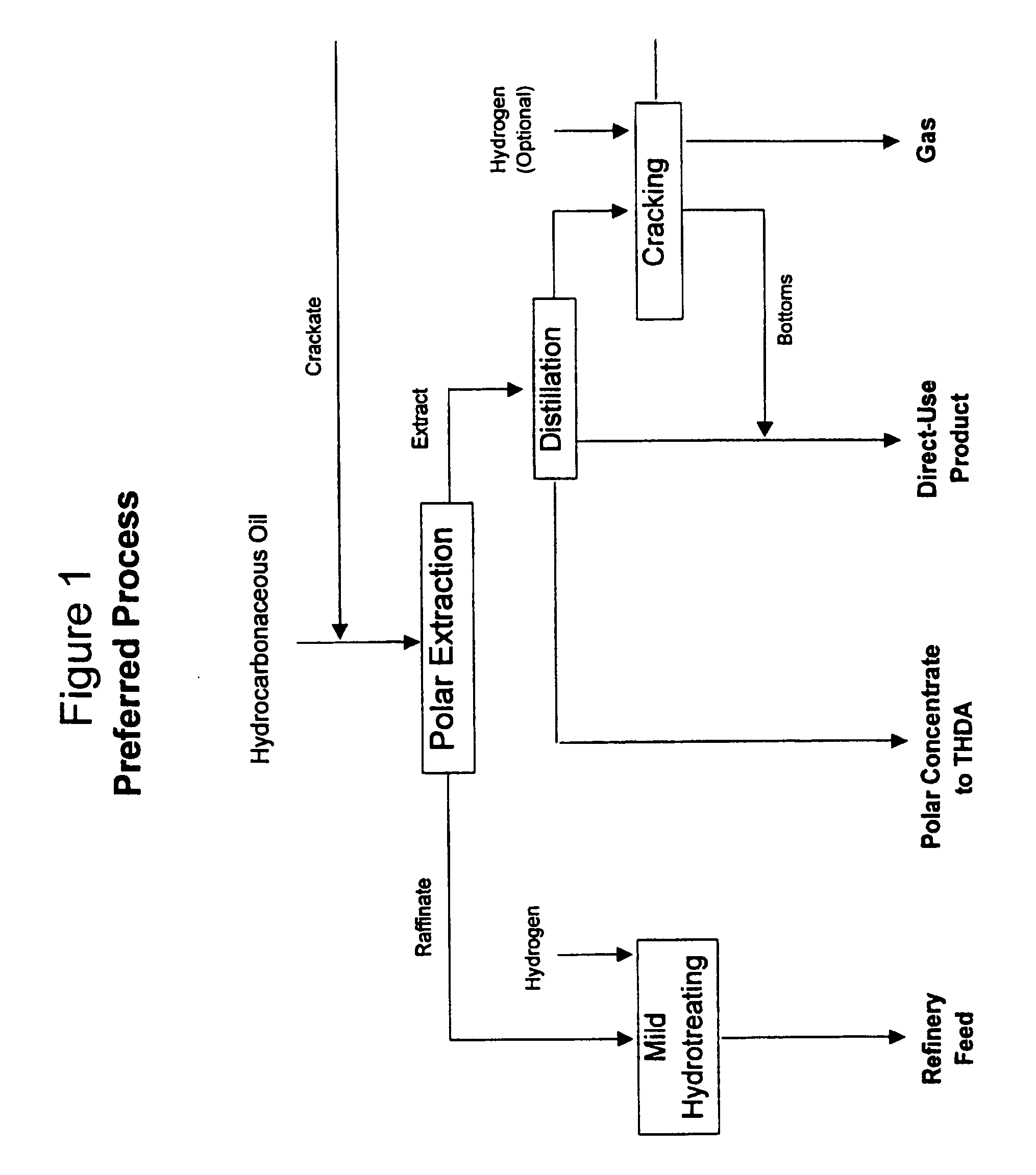

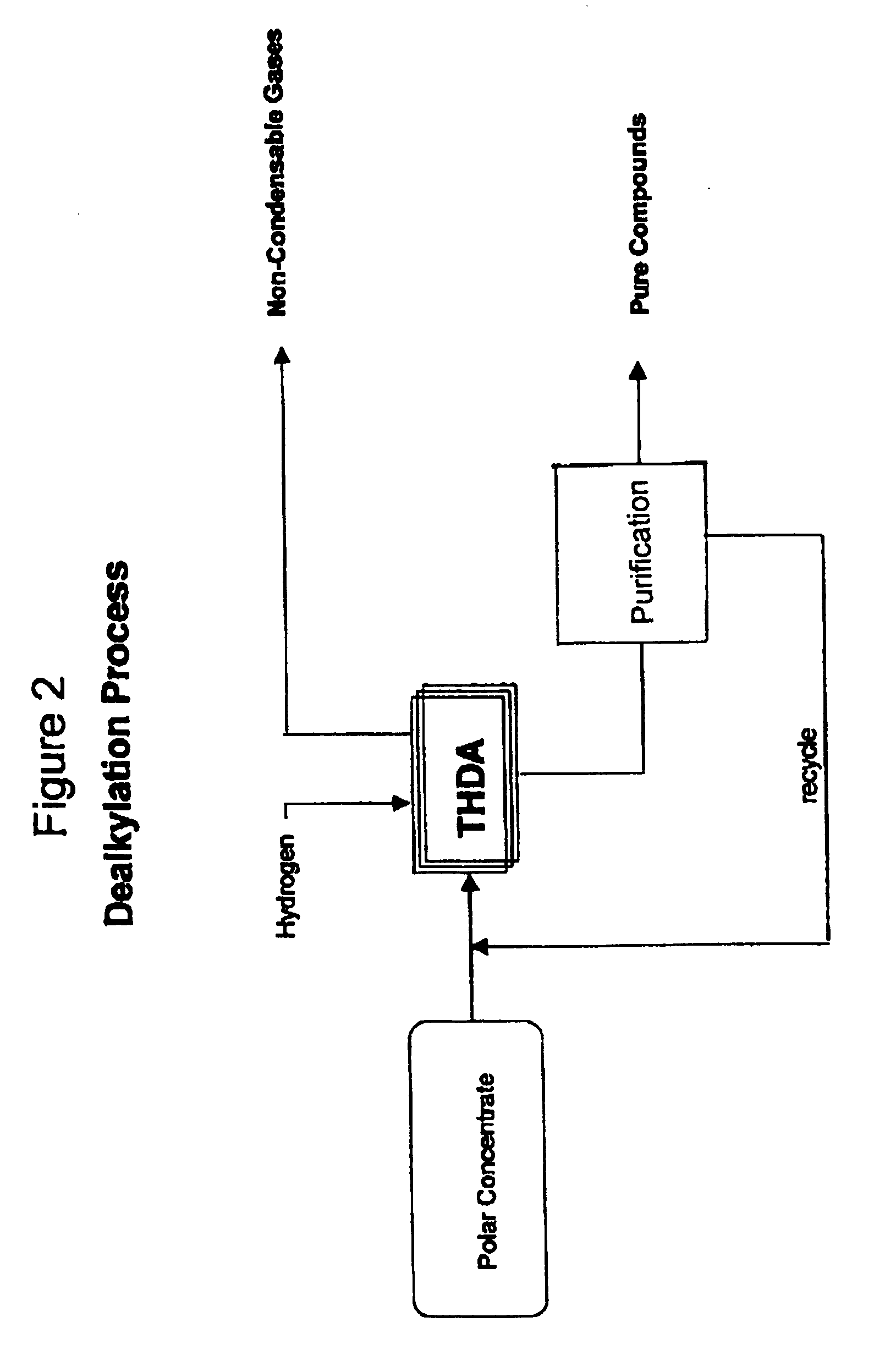

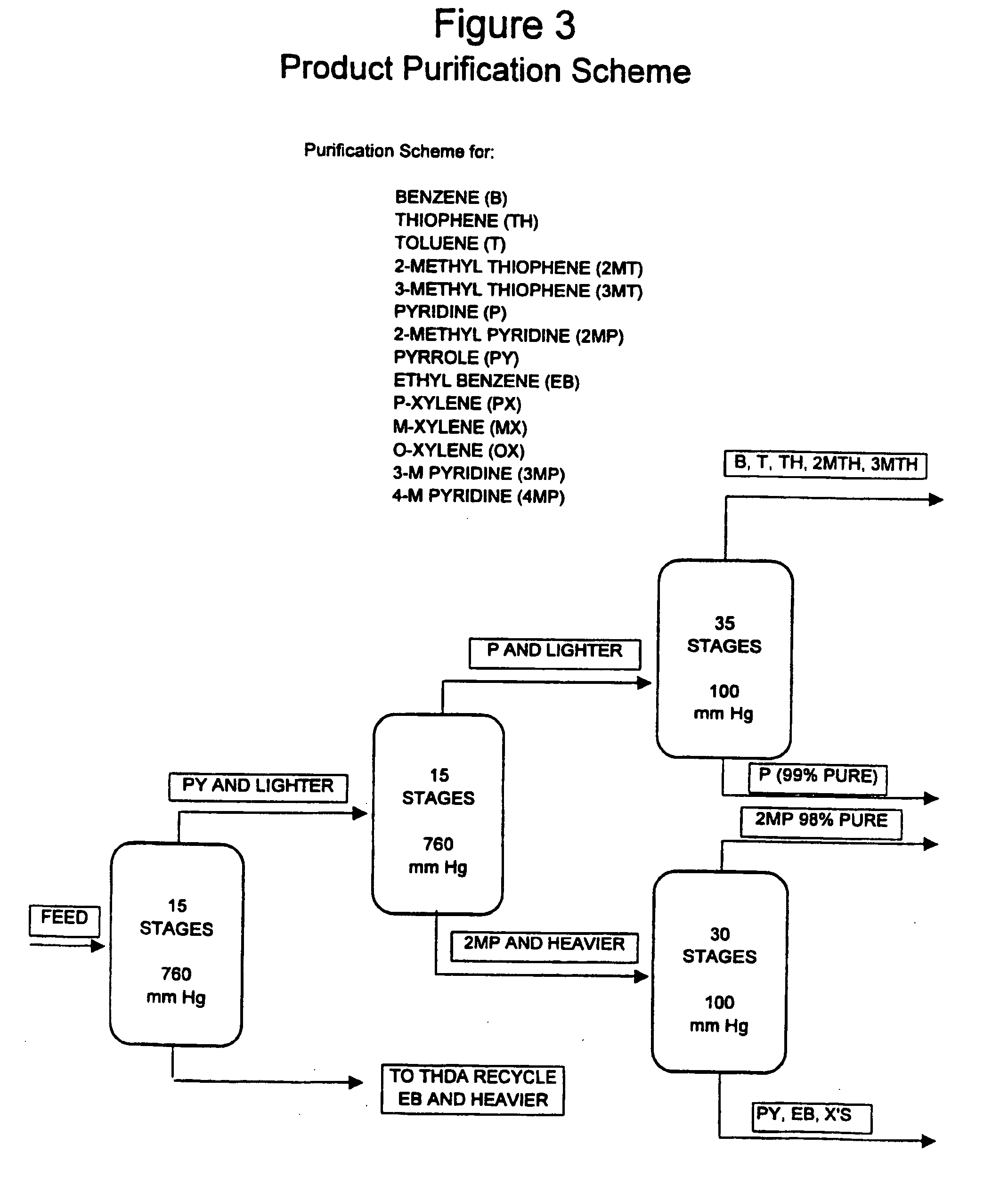

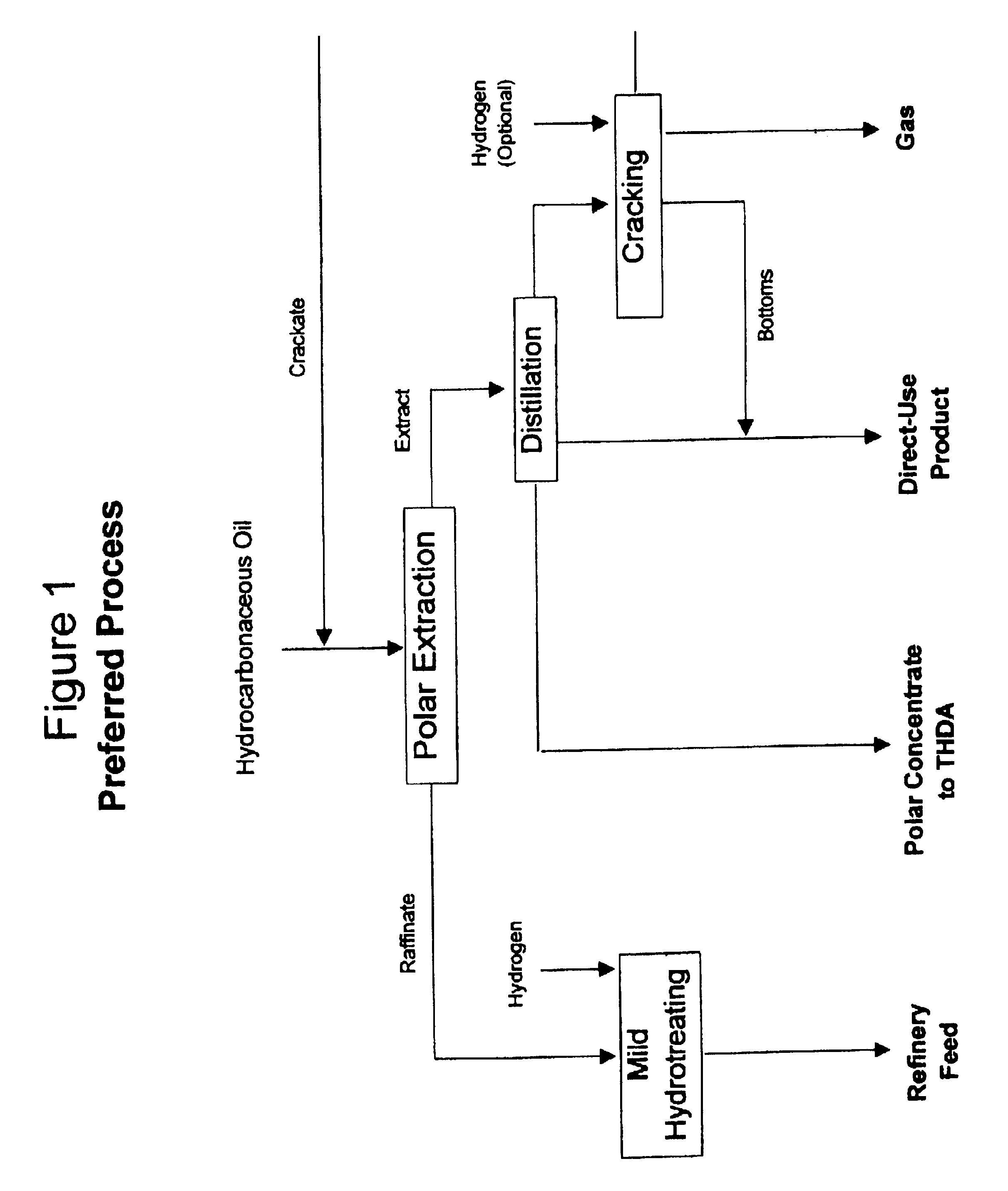

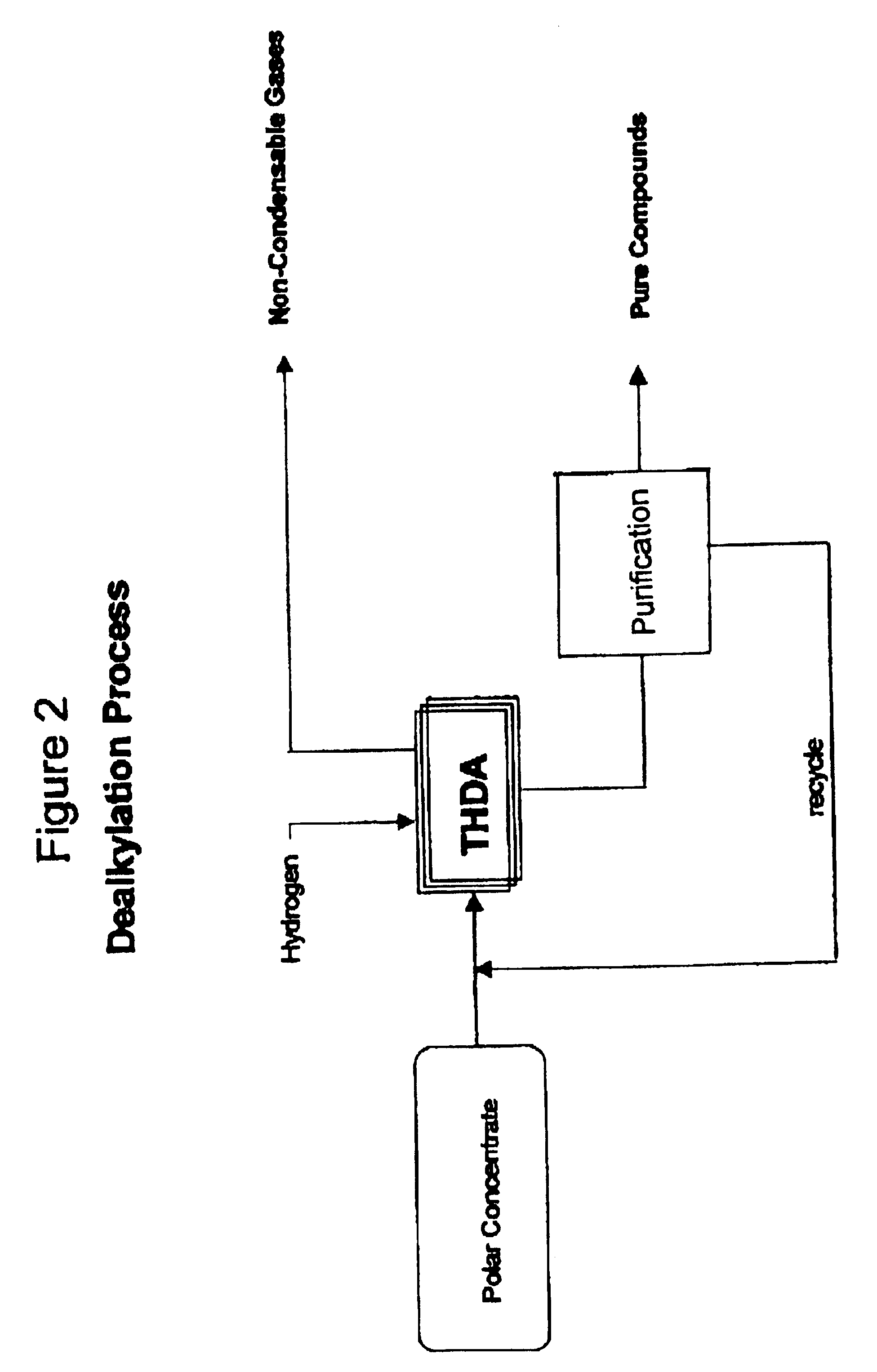

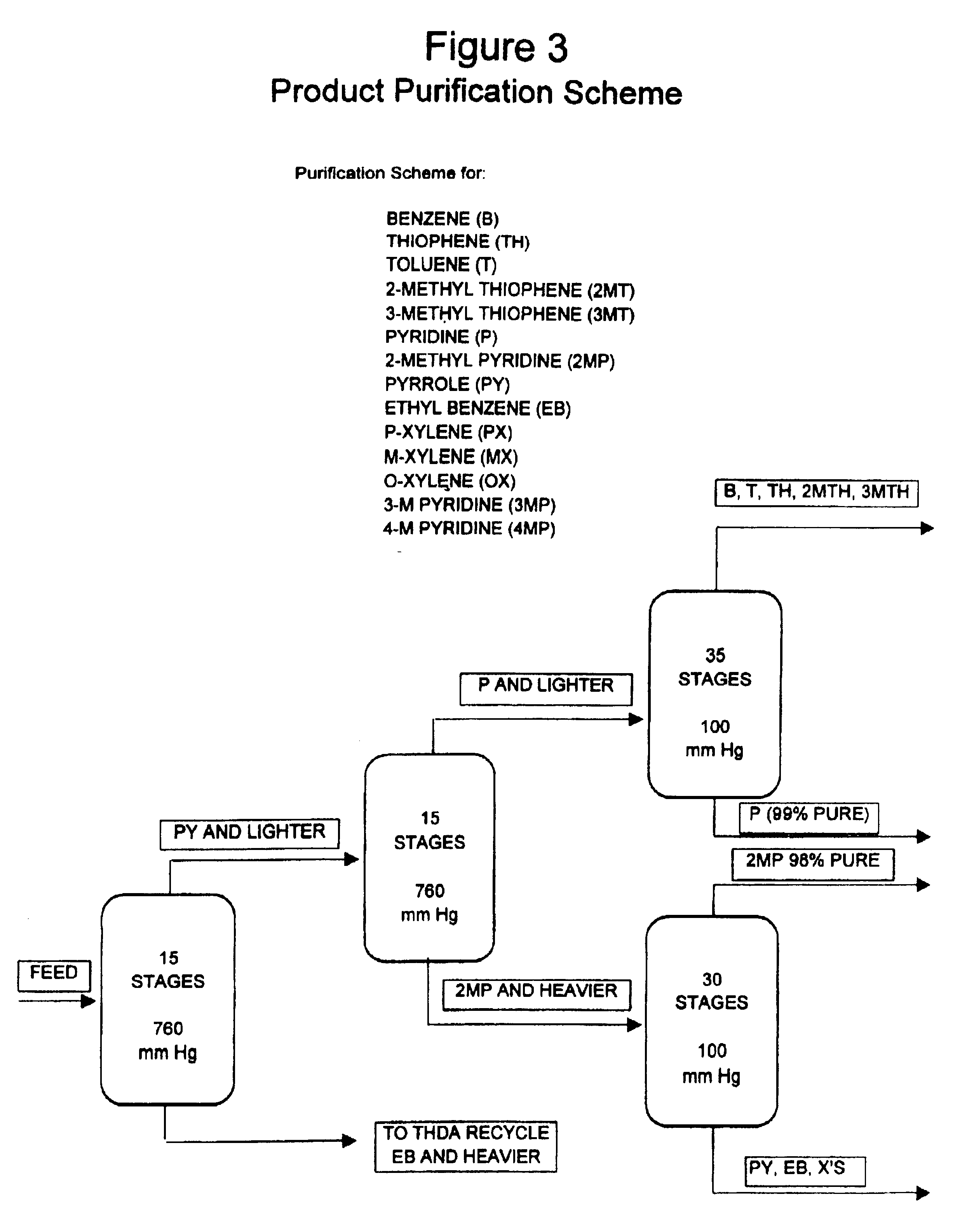

Process for enhancing the value of hydrocarbonaceous natural resources

InactiveUS20050167337A1Little and wasteLittle and valueHydrocarbon distillationTreatment with hydrotreatment processesSolubilityNatural resource

A process for upgrading hydrocarbonaceous oil containing heteroatom-containing compounds where the hydrocarbonaceous oil is contacted with a solvent system that is a mixture of a major portion of a polar solvent having a dipole moment greater than about 1 debye and a minor portion of water to selectively separate the constituents of the carbonaceous oil into a heteroatom-depleted raffinate fraction and heteroatom-enriched extract fraction. The polar solvent and the water-in-solvent system are formulated at a ratio where the water is an antisolvent in an amount to inhibit solubility of heteroatom-containing compounds and the polar solvent in the raffinate, and to inhibit solubility of non-heteroatom-containing compounds in the extract. The ratio of the hydrocarbonaceous oil to the solvent system is such that a coefficient of separation is at least 50%. The coefficient of separation is the mole percent of heteroatom-containing compounds from the carbonaceous oil that are recovered in the extract fraction minus the mole percent of non-heteroatom-containing compounds from the carbonaceous oil that are recovered in the extract fraction. The solvent-free extract and the raffinate concentrates may be used directly or processed to make valuable petroleum, chemical or industrial products.

Owner:JAMES W BUNGER & ASSOC

Process for enhancing the value of hydrocabonaceous natural recources

InactiveUS6875341B1Little and valueReduce total process throughputRefining with acid-containing liquidsHydrocarbonsSolubilitySolvent free

Owner:JWBA

Thermal interface adhesive and rework

InactiveUS20050256241A1Printed circuit assemblingNon-macromolecular adhesive additivesEpoxyDevice material

A reworkable conductive adhesive composition, and method of making such, comprising an epoxy based conductive adhesive containing conductive metal filler particles dispersed in a solvent-free hybrid epoxy polymer matrix. In an additional embodiment an improved method of removing cured conductive polymer adhesives, disclosed here as thermal interface materials, from electronic components for reclamation or recovery of usable parts of module assemblies, particularly high cost semiconductor devices, heat sinks and other module components.

Owner:IBM CORP

Solvent-free organic silicon pressure-sensitive adhesive and preparation method thereof

ActiveCN102174309AReduce or eliminate the generation ofGood compatibilityAdhesivesEnd-groupSolvent free

The invention relates to a solvent-free organic silicon pressure-sensitive adhesive. The organic silicon pressure-sensitive adhesive comprises the following components in part by mass: 100 parts of polydimethylsiloxane of which the end group is alkenyl; 1 to 300 parts of polydimethylsiloxane of which the end group is hydroxyl; 1 to 50 parts of MQ resin, 1 to 30 parts of polyisobutylene, 20 to 200 parts of diluting agent, 0.1 to 5 parts of crosslinking agent and a platinum catalyst capable of curing the organic silicon pressure-sensitive adhesive. The invention also relates to a preparation method of the organic silicon pressure-sensitive adhesive. The organic silicon pressure-sensitive adhesive has the characteristics of high initial tack, long residual action, proper peeling strength, drug penetration and the like, is nontoxic, environmentally-friendly and reusable, and can be prepared into pressure-sensitive adhesive tapes, medical pressure-sensitive adhesive strips and other functional materials requiring the pressure-sensitive performance.

Owner:SHENZHEN CITY SQUARE SILICONE MATERIALS

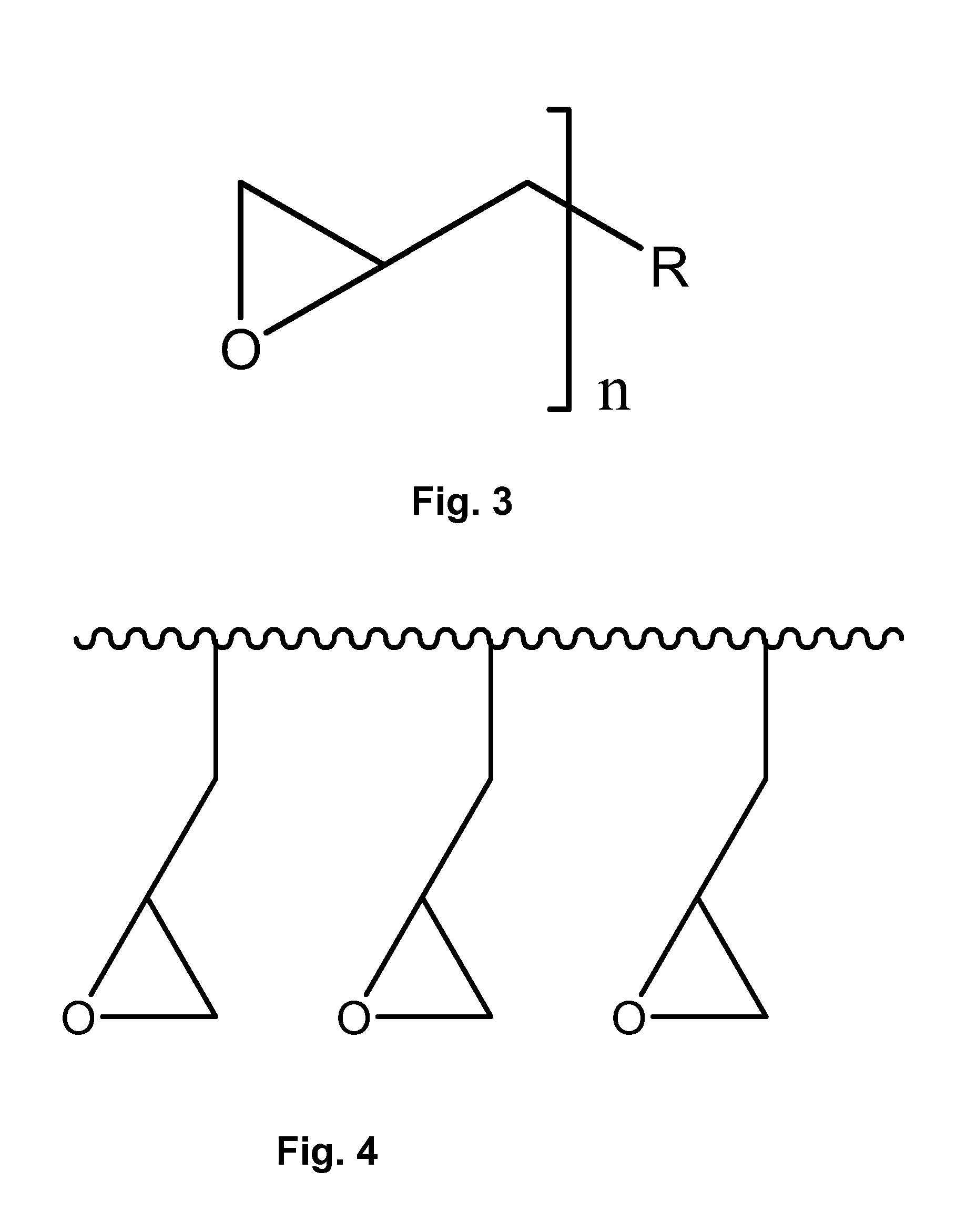

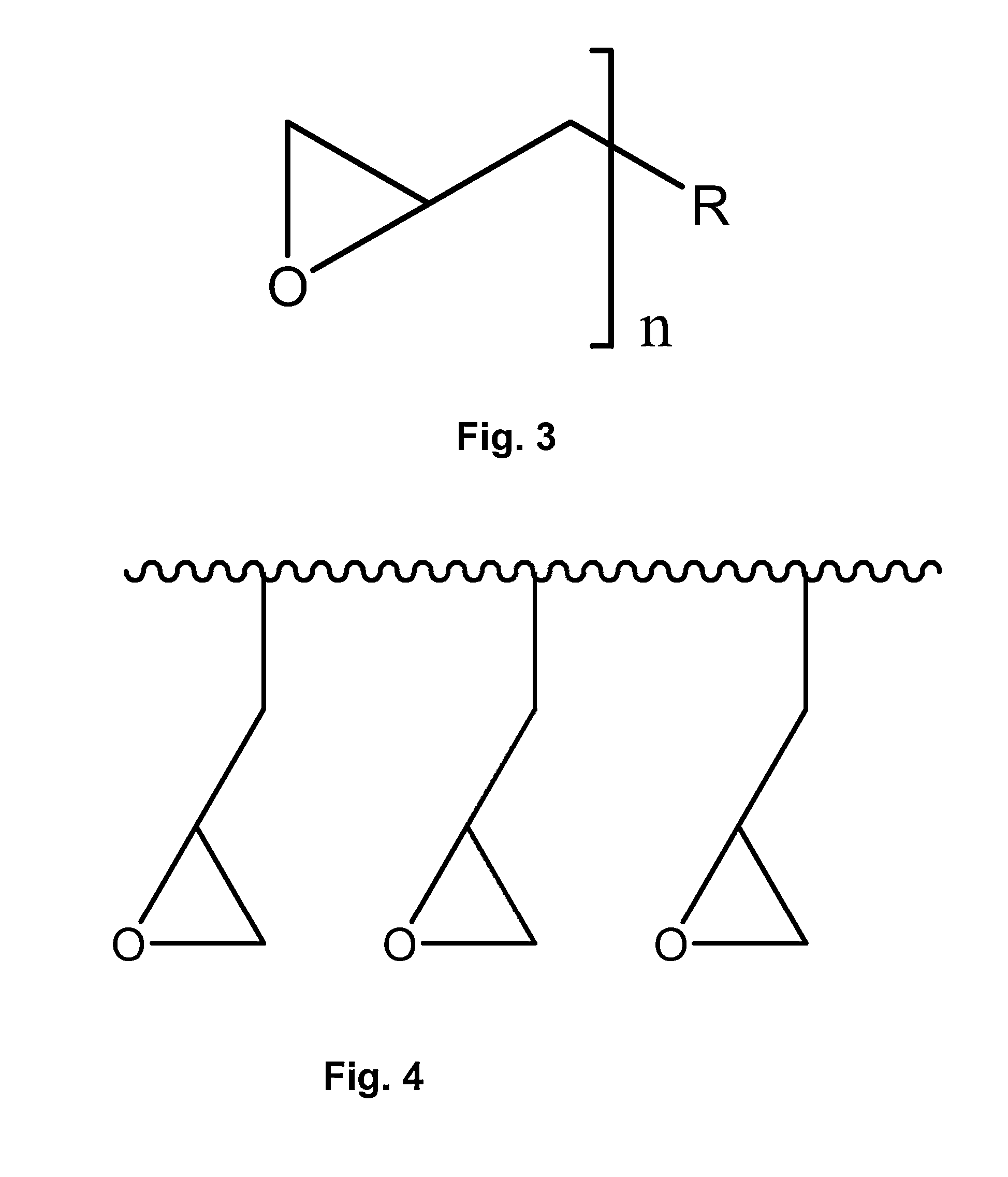

Elastomeric material compositions obtained from castor oil and epoxidized soybean oil

Elastomers are formed from castor oil and / or ricinoleic acid estolides and a polyester formed from an epoxidized vegetable oil such as ESO and a polycarboxylic acid such as sebacic acid, optionally in the presence of a peroxide initiator, or include crosslinked reaction products derived from ricinoleic acid or castor oil estolides, epoxy group-containing compounds such as epoxy resins and / or epoxidized vegetable oil, epoxy hardeners such as polyamine and polycarboxylic acid hardeners, thermally activated free radical initiators such as peroxides, and optionally but preferably include fillers such as limestone or wood flour. The elastomers can be prepared using a two-step, solvent-less procedure at elevated or ambient temperatures. These predominantly "all-natural" elastomers have physical properties comparable to conventional petroleum-based elastomers and composites and exhibit good flexibility, resiliency, abrasion resistance and inertness to hydrolysis. The resulting elastomers display good mechanical strength and resiliency, are resistant to abrasion and hydrolysis, and can be processed into sheet materials, which makes them attractive as floor covering components.

Owner:AFI LICENSING +1

Articles having bioactive surfaces and solvent-free methods of preparation thereof

Owner:BECTON DICKINSON & CO

Electro-optic displays, and materials for use therein

ActiveUS20150227018A1Lamination ancillary operationsPolyureas/polyurethane adhesivesCross-linkDisplay device

A first electro-optic display comprises first and second substrates, and an adhesive layer and a layer of electro-optic material disposed between the first and second substrates, the adhesive layer comprising a mixture of a polymeric adhesive material and a hydroxyl containing polymer having a number average molecular weight not greater than about 5000. A second electro-optic display is similar to the first but has an adhesive layer comprising a thermally-activated cross-linking agent to reduce void growth when the display is subjected to temperature changes. A third electro-optic display, intended for writing with a stylus or similar instrument, is produced by forming a layer of an electro-optic material on an electrode; depositing a substantially solvent-free polymerizable liquid material over the electro-optic material; and polymerizing the polymerizable liquid material.

Owner:E INK CORPORATION

Bicomponent high-strength sprayed polyurethane waterproof paint

InactiveCN101608094AHigh solid contentFast curingLiquid surface applicatorsAntifouling/underwater paintsAlcoholPolyol

The invention provides bicomponent high-strength sprayed polyurethane waterproof paint. The paint consists of a component A and a component B according to the volume ratio of 1 to 1, wherein the component A is a semi-prepolymer synthesized by polyisocyanate with low functionality and polyether glycol; according to weight portion, the component A comprises 50 to 80 portions of the polyisocyanate with functionality of between 2.0 and 2.4 and 20 to 50 portions of the polyether glycol with functionality of between 2 and 4; and the component B comprises 40 to 84 portions of the polyether polyol or amino-terminated polyether or mixture of the polyether polyol and the amino-terminated polyether, 10 to 40 portions of amine chain extender or alcohol chain extender or mixture of the amine chain extender or the alcohol chain extender and 0 to 20 portions of pigment filler and additive. The bicomponent high-strength sprayed polyurethane waterproof paint has mechanical performance close to or even higher than that of a waterproof coiled material, adopts a spraying construction method, is convenient and high-efficient and greatly prolongs the service life of the waterproof material; and a solvent-free system also greatly ensures the environment-friendly requirement of the material, so that the performance is more reliable, high efficient and environment-friendly. Compared with a conventional waterproof material, the bicomponent high-strength sprayed polyurethane waterproof paint has high strength and elongation rate.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP

Solvent free taste masked pharmaceutical compositions

A taste masked pharmaceutical composition comprising: (a) a core comprising a bitter tasting drug, such as cetirizine dihydrochloride; and (b) a coating comprising a pharmaceutically acceptable cationic co-polymer based on mono- or dialkylaminoalkyl methacrylate and neutral acrylic or methacrylic esters, wherein the alkyl group independently has 1 to 6 carbon atoms, wherein said coating is applied to the surface of said core. The taste masked pharmaceutical compositions of the invention may be prepared without using an organic solvent or a cyclodextrin.

Owner:KUMARAPERUMAL NATRAJAN +2

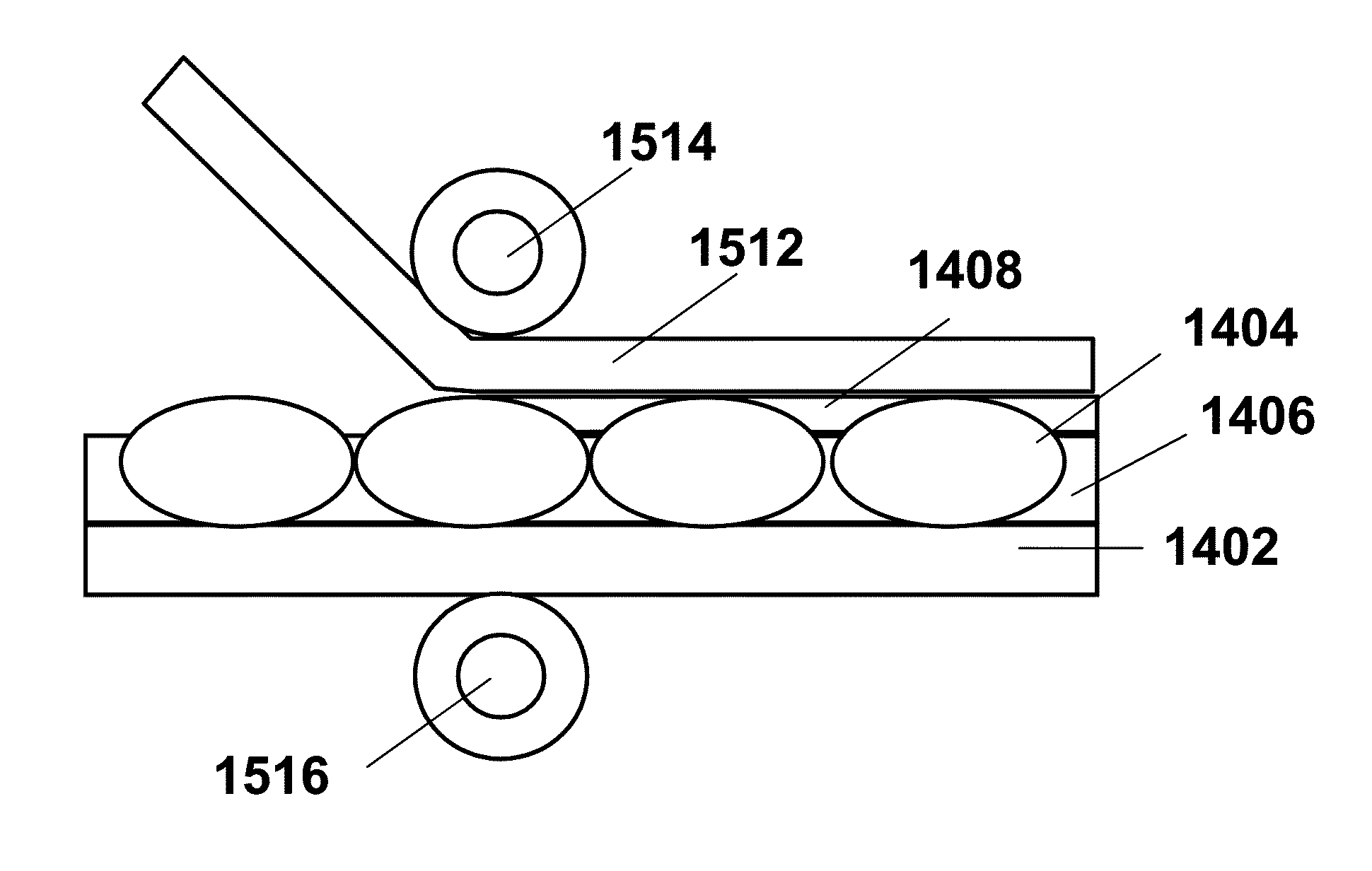

Preparation method of solvent-free environment-friendly polyurethane automobile leather

ActiveCN104088161AEliminate pollutionSmall investmentLamination ancillary operationsLaminationPolymer scienceSolvent free

The invention provides a preparation method of solvent-free environment-friendly polyurethane automobile leather. The automobile leather comprises a surface layer and a foaming layer, wherein both the surface layer and the foaming layer are made of double-component solvent-free polyurethane; each of solvent-free environment-friendly polyurethane surface layer rein and solvent-free environment-friendly polyurethane foaming layer resin respectively used in the surface layer and the foaming layer is composed of a solvent hydroxyl mixture component A and an isocyanate component B. The specific preparation method of the automobile leather comprises the following steps: blade coating a shell fabric, drying the shell fabric, blade coating the foaming layer resin, adhering base cloth when the foaming layer resin is half-dry, curing and rolling. The automobile leather is prepared from the solvent-free environment-friendly polyurethane resin by one-step molding on a dry-method production line; the preparation method gets rid of a wet-method process flow in the traditional production process of polyurethane automobile leather and the production procedure is shortened for one half; no organic solvent is discharged, and the production process and finished products are friendly to the environment.

Owner:XUCHUAN CHEM SUZHOU

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com